MODEL AR-2000

30 FT. FLAIL SHREDDER

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 79203563

Table of Contents 1

Section 1

TABLE OF CONTENTS

79203563 2/13 Manual/79203563

ASSEMBLY ..........................................................................................................................................33-39

Skid Shoes ........................................................................................................................................38

Grass Divider .....................................................................................................................................39

Basic Machine ..............................................................................................................................33-38

Off-loading ......................................................................................................................................... 33

FIELD PREPARATION .........................................................................................................................10-13

End Transport Towing ........................................................................................................................ 12

PTO’s .................................................................................................................................................10

Rockshaft & Wheels ...........................................................................................................................11

Trailing Hitch ......................................................................................................................................10

Tractor ............................................................................................................................................... 10

TITLE

GENERAL

Specications .......................................................................................................................40

To Purchaser .......................................................................................................................... 2

Storage .................................................................................................................................16

LUBRICATION .............................................................................................................................18

OPERATION ...........................................................................................................................14-17

End Transport Towing ...........................................................................................................15

General.................................................................................................................................14

Trailing Hold Height Adjustment ........................................................................................... 15

SAFETY

......................................................................................................................................... 9

Before Operation .................................................................................................................... 4

Decal Location........................................................................................................................6

During Operation .................................................................................................................... 4

General...................................................................................................................................3

Service ................................................................................................................................... 5

Towing .................................................................................................................................... 5

SERVICE ................................................................................................................................23-32

Belts ..................................................................................................................................... 25

Drive Shaft Bearings ............................................................................................................ 29

Gearbox................................................................................................................................30

Hardware .............................................................................................................................. 23

Knives...................................................................................................................................23

Rotor Bearings ..................................................................................................................... 25

Sheaves ............................................................................................................................... 28

Wheel Bearings .................................................................................................................... 29

TROUBLESHOOTING ................................................................................................................22

WARRANTY ................................................................................................................................ 41

2 Section

2 To The Purchaser

TO THE PURCHASER

This product is designed and manufactured to

give years of dependable service, when properly

maintained and used for the purpose for which

it is intended. Never allow anyone to operate

this equipment until they fully understand the

complete contents of this manual. It is the responsibility of owner’s, who do not operate this

equipment, to insure the operator is properly instructed and is fully aware, and understands, the

contents of this manual. It is also the owner’s responsibility to insure that anyone operating this

equipment is mentally and physically capable of

so doing.

Important information is contained in this manual

tohelpinsuresafeandefcientoperation.

If you have any questions about this manual, or

the equipment discussed therein, contact your

HINIKER dealer.

TITLE

ONE COPY IS TO BE GIVEN TO YOU. DO NOT

ACCEPT THIS EQUIPMENT UNTIL YOU ARE

SATISFIED ALL ITEMS THEREON HAVE BEEN

CHECKED, AND YOU UNDERSTAND THEM.

Check that your dealer has forwarded the

HINIKER delivery report copy, along with the

machine serial number, because it helps main-

tain maximum service and warranty benets.

This does not put you on any mailing list and

information thereon is not available to others.

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED,

THESE INSTRUCTIONS, OTHERWISE DEATH,

OR SERIOUS INJURY CAN RESULT!

All references to LEFT or RIGHT means viewing the equipment from the rear and facing the

tractor.

Additional copies of this manual are available

from your Hiniker Dealer

ALWAYS OBTAIN ORIGINAL HINIKER SERVICE PARTS BECAUSE SUBSTITUTE PARTS

COULD ADVERSELY AFFECT EQUIPMENT

PERFORMANCE AND WARRANTY.

All photos in this manual refer to paragraph(s)

preceding the photo.

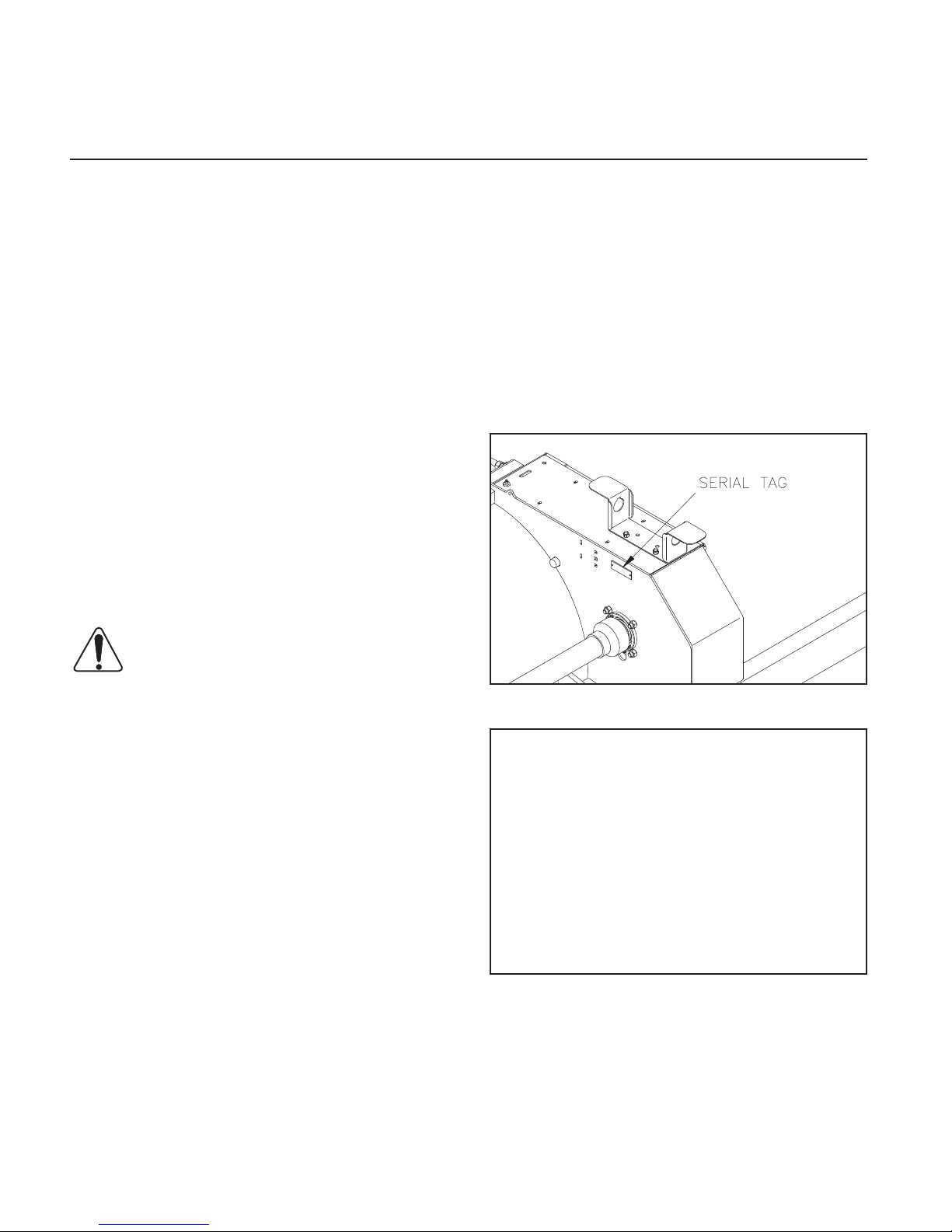

FIGURE 1 DWG NO. 6864

Record the following information for later

reference when obtaining service parts:

Purchase Date:________________________

Purchaser’s Name:_____________________

Dealer’s Name:________________________

Machine Serial #:_______________________

3 COPIES OF THE DELIVERY REPORT ARE

TO BE FILLED OUT BY YOUR HINIKER DEALER WHEN YOU ACCEPT THIS EQUIPMENT.

TITLE

SAFETY

Safety 3

Section 3

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED,

THESE SYMBOLS AND INSTRUCTIONS, OTHERWISE DEATH, OR SERIOUS INJURY CAN

RESULT!

Operator safety is a principle concern in equipment

design and distribution. However, many accidents

occur because a few seconds of thought, and a

more careful approach to handling, were ignored.

ACCIDENTS CAN BE AVOIDED BY KNOWING,

AND, FOLLOWING, THE PRECAUTIONS CITED

IN THIS MANUAL.

For better viewing, certain photos may show a

safety shield open or removed. This equipment

should never be operated without factory installed

shields in place.

Replace any decals that are not readable, or missing. Their ordering numbers and proper location

are shown in the DECAL LOCATION section of

this manual. Keep decals free of dirt, grease, etc.

Throughout this manual, and on all safety related

decals, a safety alert symbol, along with the signal

word CAUTION, WARNING or DANGER will be

found.Thesearedenedasfollows:

CAUTION: A reminder for proper safety

practices and directs attention to fol-

lowing them. Decals of this class are

yellow and black.

WARNING: A reminder for proper safety

practices and what can happen if they

are ignored. This has a more serious

consequence than CAUTION. Decals of this

class are orange and black.

There are other decals, and copy, in this manual

that pertain to protecting the equipment. They are

not directly related to operator safety. These have

black letters on a white background to distinguish

them from safety decals. They lack the safety alert

symbol, but carry the words NOTICE or IMPOR-

TANTdenedasfollows:

NOTICE: INFORMS THE READER OF SOMETHING THAT CAN CAUSE MINOR MACHINE

DAMAGE, OR POOR PERFORMANCE, IF IGNORED.

IMPORTANT: WARNS THE READER OF POTENTIALLY MORE SERIOUS MACHINE DAMAGE, OR POOR PERFORMANCE IF IGNORED.

GENERAL

1. Additional copies of this operator’s manual

are available from your HINIKER dealer. If you

sell this equipment, insure the new owner acknowledges receipt of this manual.

2. Read this manual thoroughly. Make sure the

operator understands it and knows how to operate this equipment safely. Farm equipment

can kill or injure an untrained, or careless, operator.

3. Do not attempt to handle and service this

equipment, or direct others to do the same,

unless you know how to do it safely.

4. Keep all shields and guards in place.

5. Keep hands, feet, hair and clothing away from

moving parts.

6. Disengage PTO, stop tractor engine, set

brakes and wait for all motion to stop before

adjusting, or servicing, this equipment.

DANGER: Denotes a most serious safety hazard. It is a reminder for observing

the stated precautions and what can

happen if they are ignored. Decals of this class

are red and white.

7. Keep off, keep others off, and insure everyone

is clear before starting, actuating hydraulics,

and during equipment operation.

4 Safety

8. Do not service, or otherwise handle, a

shredder in a raised position unless it is

securely blocked against unexpected falling.

9. Keepallfrontippershieldsinplaceandfree

swinging.

10. Never shred in areas littered with glass, rocks,

metal, etc. Use cab tractor if operating in

unfamiliar areas. Keep cab windows clean to

maintain good visibility.

11. Escapinghydraulic/dieseluidunderpressure

can penetrate the skin causing serious injury.

DO NOT use your hand to check for leaks. Use a

piece of cardboard.

Stop tractor and relieve pressure before connecting/

disconnecting lines.

Tighten all connections before pressurizing

hydraulic lines.

Ifuidisinjectedintotheskin,getmedicalattention

to prevent serious infection.

12. Discipline yourself to always visually inspect

this equipment for any excessively worn,

damaged, or cracked parts before starting

use. Replace these with genuine HINIKER

parts.

13. Stalk shredding often involves a combustible

environment. Carry a re extinguisher and

rstaidkitwithtractor.

BEFORE OPERATION

1. Insure unit’s PTO assembly is fully engaged

with gearbox and tractor shafts and SLIDING

COLLARS ARE RETURNED TO THEIR

LOCKED POSITIONS.

2. NEVER allow improperly supervised minors,

or anyone else, to operate this equipment. It is

your responsibility to insure that any operator

is mentally and physically capable of so doing.

3. Do not operate a 1000 RPM shredder with a

540 RPM tractor.

4. Do not “jump start” the tractor from along side

it. Start tractor only from seat.

5. Lock any swinging tractor drawbar before

hooking up. Use a cross retainer in end of the

hitch pin.

6. Disengage PTO, stop tractor engine, and

remove key before hooking up shredder PTO.

7. Clear area of people, and debris, before

engaging tractor PTO Be alert for blind areas

of operator. Slow down PTO and “feather” into

engagement to prevent unnecessary stress

on shredder’s driveline.

8. DO NOT OPEN MACHINE SHIELDS WITH

TRACTOR ENGINE RUNNING.

9. Do not stand close to, immediately behind or

in front of, a running shredder.

14. OSHA requires farm employers to meet certain

safety standards. Become familiar with, and

comply with them.

15. Do not alter this equipment to the extent of

compromising safety and performance.

16. Do not substantially operate tractor in a closed

building.

17. Ag chemicals can be dangerous. Always follow

the manufacturer’s label safety precautions

when using them.

18. Do not assume everyone is as safety

conscious as yourself.

DURING OPERATION

1. Gradually bring unit up to operating speed

and check for any abnormal vibration, or

performance. IF ABNORMAL VIBRATION

IS PRESENT AT ANY TIME, IMMEDIATELY

DISENGAGE PTO, STOP TRACTOR

ENGINE, REMOVE KEY AND DETERMINE/

CORRECT CAUSE BEFORE PROCEEDING.

2. Disengage PTO, stop tractor engine, remove

key and allow EQUIPMENT TO COME TO A

COMPLETE STOP before:

- Cleaning, unclogging, lubricating, inspecting,

or otherwise servicing, any part of this

equipment.

Safety 5

- Connecting or disconnecting the shredder

from the tractor.

- Allowing anyone else near the equipment.

- Dismounting from the tractor seat and parking

the equipment.

- Placing any part of your body in dangerous

proximity to shredder.

3. When parking this equipment, lower it to full

“down” position. Set the tractor brakes and

block wheels if on an extreme slope.

TOWING

1. When towing on public highways:

- Use a safety chain between the shredder hitch

and the towing vehicle (The 10,000# safety

chain is part number 85501539).

- Be sure end transport hydraulic cylinder locks

are in place.

- Use a tractor of sufcient size, and weight,

requiredforeldoperation.

- Do not tow faster than 25 MPH (40 kph).

- BE AWARE THE TRAIL HITCH WIDTH, WITH

END TRANSPORT KIT, IS 138” (11 1/2’)

WIDE. THESE WIDTHS ARE WITH THE PTO

REMOVED. If these widths are not permitted,

or advisable, under your circumstances, the

hitch must be removed.

SERVICE

1. Service information herein is intended

for dealers and others correspondingly

competent. If you are not experienced and/

or capable of handling such service, do not

attempt it.

2. Disengage PTO, stop tractor engine, remove key and allow EQUIPMENT TO COME

TO A COMPLETE STOP before:

- Cleaning, unclogging, lubricating,

inspecting, or otherwise servicing, any part

of this equipment.

- Connecting or disconnecting the shredder

from the tractor.

- Allowing anyone else near the equipment.

- Placing any part of your body in dangerous

proximity to shredder.

3. Do not service, or otherwise handle, a

shredder in a raised position unless it is

securely blocked against unexpected falling.

4. Stalk shredders operate in a naturally

vibratory environment. Discipline yourself

to always visually inspect this equipment for

any excessively worn, damaged, or cracked

parts before starting use. Replace these

with genuine HINIKER parts.

5. DO NOT SERVICE END DRIVE BELTS

WHEN TRACTOR IS RUNNING!

- Check local regulations on towing width and

warning lights.

2. Never tow trailing shredders in eld mode

with the PTO detached from the tractor and

hooked to the gearbox.

3. Ensure ASAE SMV (slow moving vehicle) is

visible when towing down public roadways.

4. At sundry locations, RED (rear facing) and

AMBER (forward facing) reectors are

provided. Insure these do not become defaced

or covered with debris.

6. Replace all shields removed for service, and

check PTO shield for free rotation, before

operating this equipment.

REMEMBER - ACCIDENT PREVENTION IS

PART OF YOUR JOB!

6 Decal Location

6 Section

DECAL LOCATION

TITLE

It is an owner’s and dealer’s responsibility to

ensure clear, complete decals are maintained

on equipment, whether operating or offered for

sale.

Information herein is provided for proper decal

ordering and placement.

Decal surfaces should be free of dirt, grease,

etc. Temperatures should be above 50° F. To apply, remove the smaller part of the decal backing

paper and apply this part of the exposed adhesive to the desired location. Peel the other part

of the backing paper slowly off and smooth out

the entire decal.

3

15

7

2

17

3

2

2

20

14

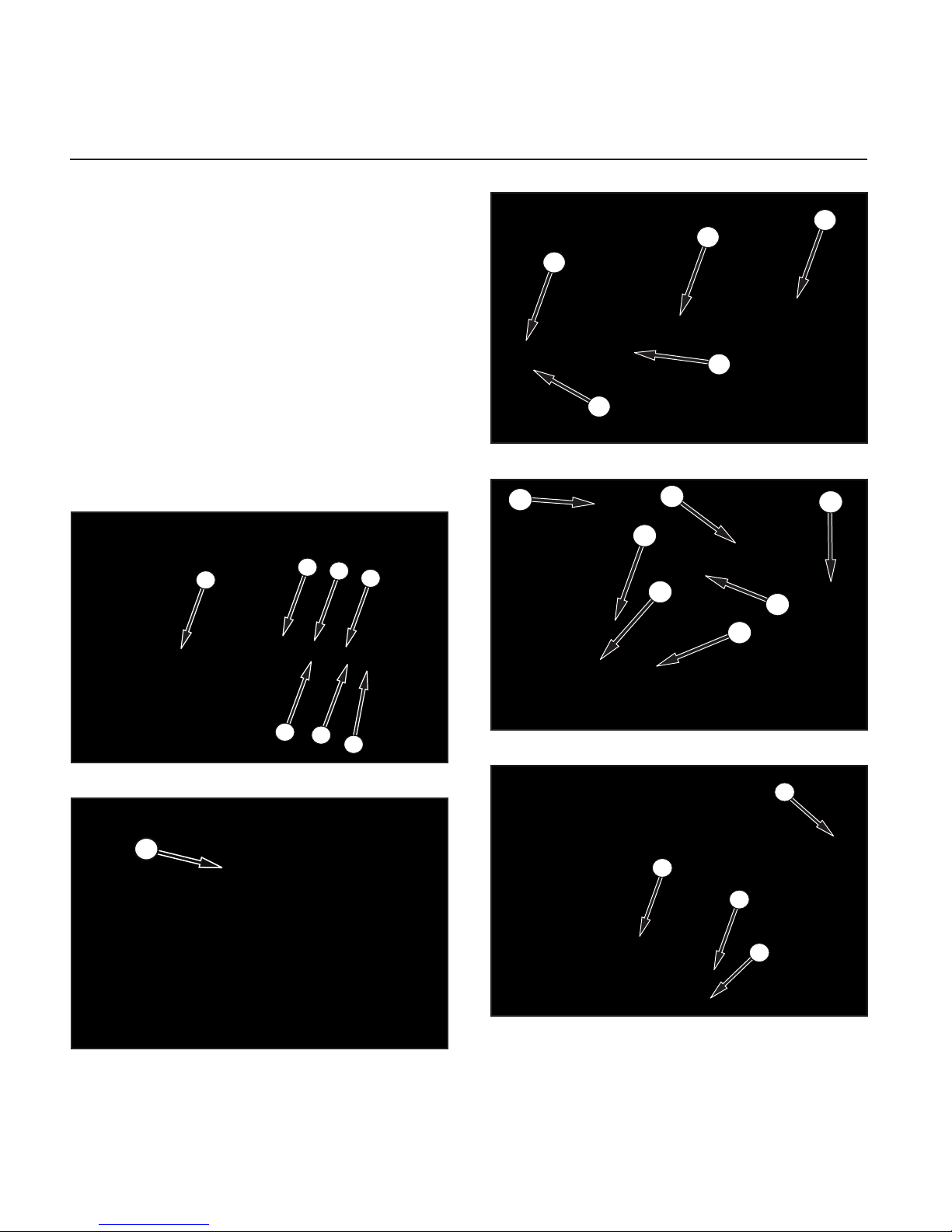

PHOTO NO. ARS004A

19

10

12

21

5

11

8

1

14

PHOTO NO. ARS040A

PHOTO NO. DSCN4637B

6

PHOTO NO. 100-4282A

13

18

9

8

PHOTO NO. 100-4283A

DWG NO. 6865

AR-2000

Decal Location 7

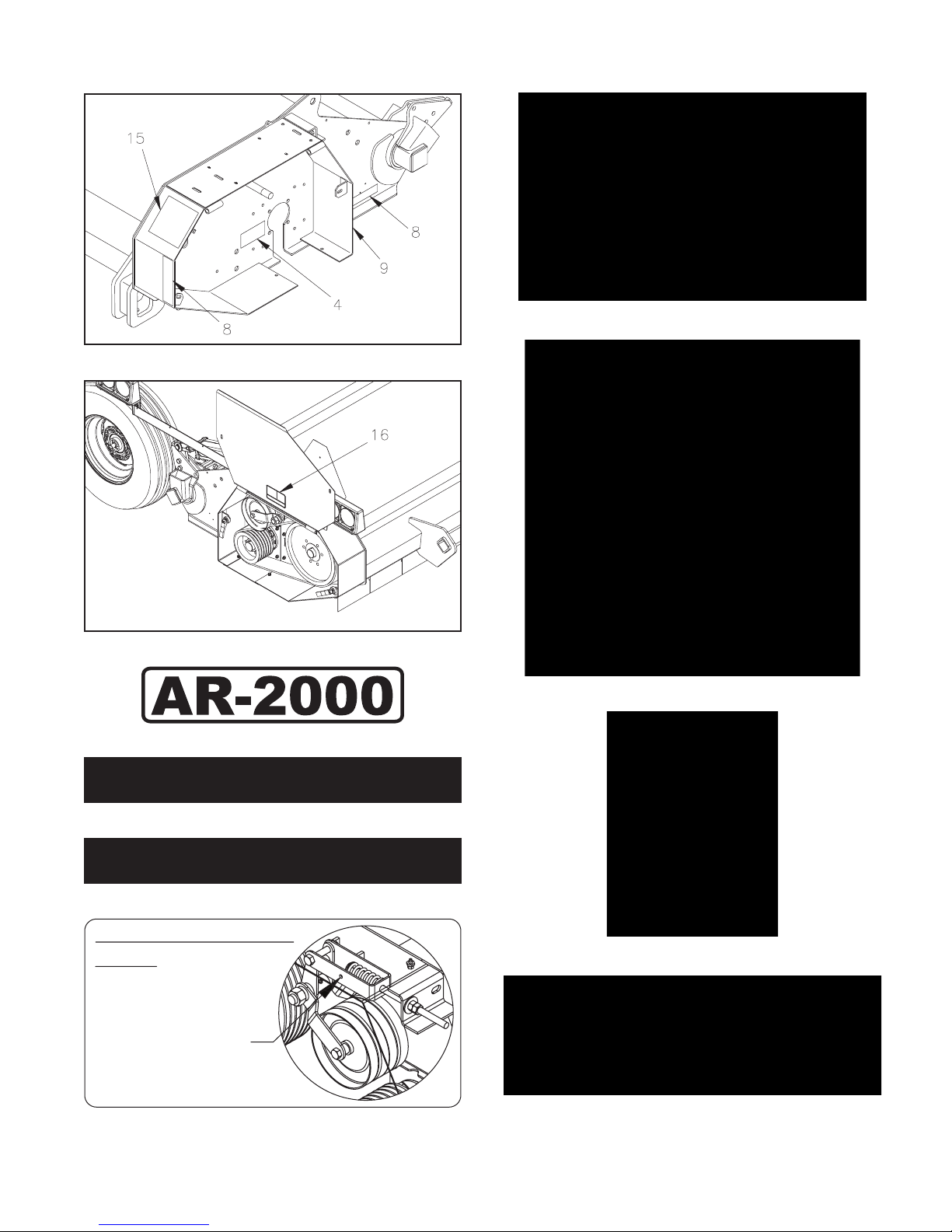

FIGURE 5 71504126 IMPORTANT: OPERATE MACHINE...

Section 7

DWG NO. 6866

FIGURE 1 79202299 LOGO AR-2000

FIGURE 2 71505168 LOGO HINIKER

FIGURE 3 79202337 LOGO AR-2000

IMPORTANT: Maintain Belt Tension

Stop unit completely for maintenance.

No Rotation. Read Operators Manual.

Compress spring until

washer can be seen

through sight hole

PART NO. 79203548

FIGURE 4 79203548 IMPORTANT: MAINTAIN BELTS...

FIGURE 6 71504133 IMPORTANT: HITCH...

FIGURE 7 715-03174 IMPORTANT: LIFT...

FIGURE 8 850-001-285 TAPE YELLOW REFLECTOR

8 Decal Location

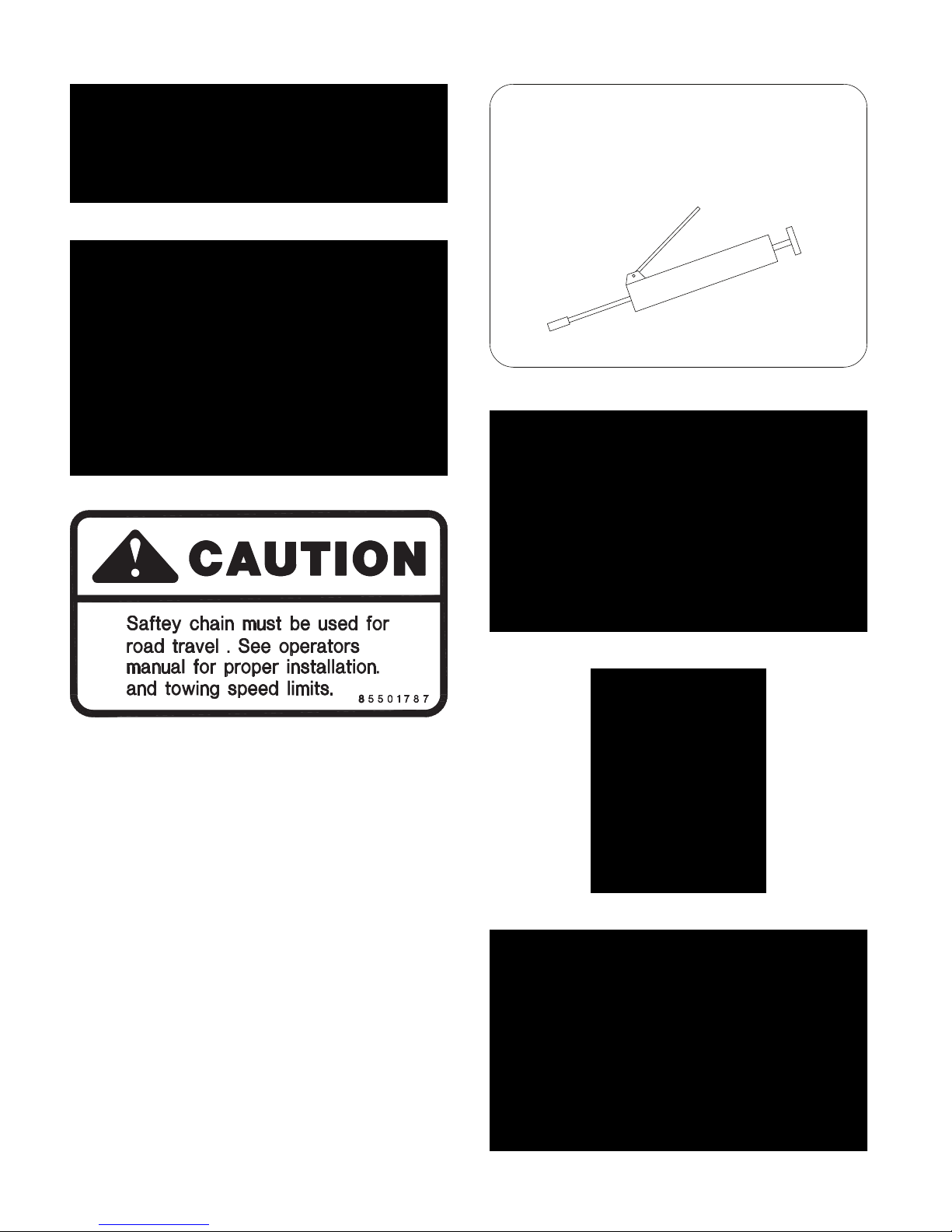

FIGURE 9 850-001-305 TAPE RED REFLECTOR

FIGURE 10 715-04132 CAUTION: READ MANUAL...

GREASE

FIGURE 13 79203259 GREASE:

FIGURE 11 85501787 CAUTION: SAFETY CHAIN...

FIGURE 12 71504129 CAUTION: 1000 RPM

FIGURE 14 71505169 WARNING: LOOK AND LISTEN...

FIGURE 15 71505171 WARNING: KEEP HANDS, ETC...

FIGURE 16 71505170 WARNING: DO NOT OPERATE...

Decal Location 9

FIGURE 17 520-03138 DANGER: ROTATING DRIVE...

FIGURE 18 520-03139 DANGER: SHIELD MISSING...

FIGURE 21 520-03138 WARNING: DO NOT EXCEED...

FIGURE 19 71504131 DANGER: KEEP FLIPPERS...

IMPORTANT

Maintain tires at 15-20 psi

on level land.

See operator's manual for

ridged operation.

FIGURE 20 71504136 IMPORTANT: MAINTAIN TIRES...

71504136

10 Field Preparation

10 Section

FIELD PREPARATION

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. BEFORE FIELD

PREPARATION, READ SAFETY-GENERAL, BEFORE OPERATION, DURING OPERATION AND TOWING AT FRONT OF THIS

MANUAL.

TRACTOR-GENERAL

IMPORTANT: IT IS CRITICAL TO KNOW WHAT

SHREDDER CONFIGURATION IS INVOLVED

BEFORE TRACTOR HOOKUP. TRACTOR

MUST HAVE 1 3/4-20 SPLINE OUTPUT SHAFT.

Hiniker shredders are only available with a PTO

output option of: 1000 RPM 1 3/4”-20 spline

Part# 79202277

TITLE

Raise the shredder with hitch jack until the hitch

yoke corresponds with the tractor’s drawbar and

insert hitch pin. Always store the hitch jack (arrow 1) as shown in Photo DCP0603.

1

PHOTO NO. DCP0603

All units use ONLY CV (constant velocity) PTO’s.

These are identied by extended front yokes

separated by a large guide hub between them.

SHREDDER-TRAILING HITCH

Trailing shredders have an adjustable hitch

height adjustment (Item 1) to match various tractor drawbar heights. Refer to Photo 100-4282B.

1

PHOTO NO. 100-4282B

IMPORTANT: ALWAYS USE A 1” DIAMETER

HITCH PIN.

CAUTION: DEATH OR SERIOUS INJURY CAN RESULT. ALWAYS INSERT

THE HITCH PIN POINT DOWN WITH A

CROSS LOCKING PIN THROUGH ITS LOWER

END.

SHREDDER-PTO’s

IMPORTANT: IT IS CRITICAL TO KNOW WHAT

TRACTOR CONFIGURATION IS INVOLVED

BEFORE HOOKUP. THE PROPER SHREDDER

PTO MUST BE USED, OTHERWISE UNSATISFACTORY PERFORMANCE WILL RESULT.

TRACTOR MUST HAVE 1 3/4-20 SPLINE OUTPUT SHAFT.

All shredder PTO’s have similar sliding yoke

couplers at the tractor and gearbox ends. GEARBOX ENDS ARE IDENTIFIED BY AN OVERRUNNING CLUTCH (Item 1).

IMPORTANT: CORRECT TRAILING HITCH

DRAFT LINK LENGTH ADJUSTMENT CANNOT BE MADE UNTIL AFTER THE SHREDDER IS INITIALLY FIELDED.

Clean gearbox spline of any encrusted dirt or

grease and lightly oil it. Slide outer PTO collar

(Item 2) toward its adjacent yoke (Item 3) and

slide PTO over the gearbox spline. Reverse the

sliding collar to lock the assemblies together.

PHOTO NO. 2969A

NOTICE: TO FACILITATE PTO HOOK UPS, CHECK

TRACTOR SPLINE FOR BURRS, OR OTHER DAMAGE. IF SHREDDER’S LOCKING COLLAR IS DIFFICULT TO PROPERLY ENGAGE, CLEAN AND

LIGHTLY OIL SPLINE.

Field Preparation 11

DWG. NO. 71504129

DANGER: DEATH OR SERIOUS INJURY CAN RESULT. KEEP AWAY AND

KEEP OTHERS AWAY FROM AN OPERATING PTO. DO NOT OPERATE WITHOUT ALL SHIELDS IN PLACE. INSURE PTO

SHIELDS FREE WHEEL AND BOTH PTO’S

ENDS ARE SECURELY ATTACHED.

The tractor PTO spline engages similar to above.

Slide outer collar (Item 1) toward its adjacent yoke

(Item 2) and slide PTO over the tractor spline. Reverse the sliding collar to lock the assemblies together.

PHOTO NO. 2966A

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. NEVER OPERATE

A SHREDDER UNLESS BOTH ENDS

OF THE PTO ARE PROPERLY LOCKED TO

THEIR INTENDED SPLINES.

Check the decal on gearbox shield to insure

proper tractor/shredder RPM matching.

IMPORTANT: NEVER TOW A TRAILING

SHREDDER UNLESS THE PTO IS PROPERLY HOOKED UP TO BOTH TRACTOR AND

SHREDDER. OTHERWISE, IT CAN BE DAMAGED. IF NECESSARY TO OTHERWISE TOW,

DETACH ENTIRE PTO ASSEMBLY (1) FROM

GEARBOX AND SECURE IT BEHIND A DRIVE

SHAFT SHIELD (2).

PHOTO NO. 3547

SHREDDER ROCKSHAFT & WHEELS

Toadjust therockshafteldwheelspacingthe

end transport wheels can be used. Insert tractor quick couplers to give machine a downward movement when tractor hydraulic lever is

pushed forward.

12 Field Preparation

DWG NO. 6668

To adjust wheel spacing on rear rock shaft wheels,

attach a tractor of adequate size to operate unit

totheeldhitch.Slideendtransporthitchoutand

pin in position (arrow 1). Attach jack to spud on

hitch. Using tractor hydraulics lower end transport

wheels(arrow2)andraiseeldwheels(arrow3).

Rotate locking channels (arrow 4) over end transport hydraulic cylinder shafts to prevent cylinder

contracting.

Once correct spacing is set up unlock end

transport cylinder locks. Lower eld wheels all

the way down. Raise end transport cylinders and

slide end transport hitch in and re-pin in position.

Store jack in its storage position.

1

PHOTO NO. 1000-4284A

Hydraulic cylinder control segments (arrow 1)

are provided to hold machine at desired cutting

height.

Loosen wheel bolt clamps and slide wheels into

correct dimensionsforeld operation.The correct spacing for 30” and 36” row and is provided

in the table below.

Dimns. 30” Rows 36” Rows

30 foot units

(outer) (1) 180” 180”

(inner) (2) 30” 36”

DWG NO. 6667

SHREDDER TIRES

Recommended tires are 9.5L x 15 8 ply

(implement) tires with 8” rims. The shredder

will perform better, especially under ridged

conditions, if tire pressures are kept no greater

than recommended. (If the shredder tends to

“yaw”, or climb ridged rows, decrease pressure

in the outside tires to the lower range cited and

recheck that tire centerlines are running in the

row middles.

SHREDDER-END TRANSPORT TOWING

Hiniker 30 Ft. shredders are designed for end

transport only down public roadways. Implement

lights (arrow 1) and SMV sign (arrow 2) are

standard equipment and mounted on rear of

machine.

For other row spacings, adjust the above settings accordingly. Torque up each wheel leg

clamping bolts by uniformly tightening the lower

boltsto a snug t.Then,torque, andre-torque

top bolts to 146-206 Ft/lbs.

Field Preparation 13

2

1

PHOTO NO. ARS048A

CAUTION: DEATH OR SERIOUS INJU-

RY CAN RESULT. WHEN TOWING ON

PUBLIC HIGHWAYS:

USE A TRACTOR OF SUFFICIENT SIZE, AND

WEIGHT, REQUIRED FOR FIELD OPERATION.

DO NOT TOW AT SPEEDS IN EXCESS OF 25

MPH (40 KMH).

USE A TOWING CHAIN BETWEEN TOWING

VEHICLE AND SHREDDER.

THE SMV’S REFLECTIVE SURFACE MUST

BE VISIBLE FROM THE REAR OF UNIT.

CHECK LOCAL REGULATIONS ON TOWING

WIDTH AND WARNING LIGHTS.

THE FRONT HITCH, PTO AND PTO HOLDER

MAY BE REMOVED TO REDUCE THE END

TRANSPORT WIDTH IF REQUIRED.

PHOTO NO. 3550

Check the lights to be sure they are connected prop-

erlysothatturnsignalashersoperatecorrectly.

Use a safety towing chain (Item 1) between the

shredder and towing vehicle. Hook chain around

bracket (Item 2) and pass forward through aftermarket clevis (Item 3). Fix chain’s forward end

(Item 4) to tractor.

14 Section

14 Operation

TITLE

OPERATION

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. BEFORE OPER-

ATING, READ SAFETY-GENERAL,

BEFORE OPERATION, DURING OPERATING

AND TOWING AT FRONT OF THIS MANUAL.

GENERAL

DWG. NO. 71504131

IMPORTANT: FOR TRAILING HITCH END

TURNS ACROSS RIDGED ROWS, SLOW

FORWARD SPEED AND RAISE MACHINE

TO MINIMIZE EXCESSIVE BOUNCING AND

SCALPING.

CAUTION: DEATH OR SERIOUS INJURY CAN

RESULT. FOR TRAILING UNITS, SOME

TRACTOR MASTER PTO SHIELD’S

MAY CONTACT SHREDDER’S FRONT

PTO SHIELD ON TURNS. BE ALERT FOR

THIS AND MAXIMIZE TURNING RADII. REPLACE SHREDDER FRONT PTO SHIELD IF IT

BECOMES DAMAGED.

IMPORTANT: INITIALLY START SHREDDING

WITH UNIT SET SUBSTANTIALLY HIGHER

THAN THE RECOMMENDED MINIMUM KNIFE/

ROW CLEARANCE OF 3”.

Shred a short distance and check performance.

The higher knife/row clearance may not give satisfactory results; therefore, lower unit and check

again. Progressively lower unit until good results

are obtained. DO NOT OPERATE WITH LESS

THAN 3” KNIFE CLEARANCE TO HIGHEST

GROUND POINT WITHIN SHREDDED WIDTH.

DWG. NO. 71504132

Always operate tractor at standard 1000 RPM

PTO. Use transmission up, or down, shift to

vary forward speed. CONSISTENTLY OVERSPEEDING THE PTO WASTES FUEL AND AGGRAVATES KNIFE WEAR.

Avoid “jackrabbit” PTO engagement at full speed

because it overstresses the shredder’s driveline.

Engage PTO at slow speed and throttle up to

operating speed.

Insert quick couplers to give shredder a DOWNWARD movement when tractor hydraulic lever is

shoved FORWARD and vice versa.

Once optimum height is set, insert equal amount

of hydraulic cylinder stop segments over the

rods of the lift cylinders to hold machine at desired height.

IMPORTANT: “SCALPING” ROWS WASTES

FUEL AND RAPIDLY AGGRAVATES KNIFE

WEAR. THIS IS PARTICULARLY TRUE IN

ROCKY FIELDS. IF YOUR FIELD HAS PROTRUDING ROCKS, KEEP UNIT’S HEIGHT

SUFFICIENT FOR KNIVES TO CLEAR THEM.

STALK SHREDDERS ARE NOT INTENDED TO

BE USED AS A “ROCK PICKER”, OR A “ROTOTILLER”.

Operate the shredder approximately LEVEL.

That is, front (Item 1) of main frame should clear

ground about the same as the rear (Item 2).

Operation 15

CAUTION: DEATH OR SERIOUS

INJURY CAN RESULT. EXCESSIVE

FRONT FRAME/GROUND CLEARANCE

CAUSES MORE DEBRIS TO THROW

FORWARD UNDER THE TRASH SHIELDS.

NEVER STAND NEAR, AND AHEAD OF, A

RUNNING MACHINE.

DWG NO. 6869

TRAILING HITCH HEIGHT ADJUSTMENT

1. Position unit astraddle rows and insure

wheels are centered in row middles before

making any adjustments. Rotate

rockshaft/wheels until knives clear rows by

GREATER than 3”.

3. Shred a short distance, stop and check

stubble to insure knives are properly clearing rows and satisfactory performance is obtained. If necessary, reset rockshaft/wheels

and drawbar’s underneath draft link.

4. Ensure cylinder stop collars, are of equal

height on lift cylinders.

END TRANSPORT TOWING

The 30 Ft. AR shredder can only be towed down

public highways in end transport mode. Towing

theshredderineldmodedownpublichighways

will violate local regulations and is prohibited.

CAUTION: DEATH OR SERIOUS INJURY CAN RESULT. WHEN TOWING ON

PUBLIC HIGHWAYS:

USE A TRACTOR OF SUFFICIENT SIZE, AND

WEIGHT, REQUIRED FOR FIELD OPERATION.

DO NOT TOW AT SPEEDS IN EXCESS OF 25

MPH (40 KMH).

USE THE PROVIDED SAFETY TOWING

CHAIN BETWEEN TOWING VEHICLE AND

SHREDDER/WINDROWER.

1

PHOTO NO. 100-4277A

With unit attached to tractor, adjust turn-

buckle (arrow 1) to raise machine front up

or down to desired height.

2. Recheck knives/row clearance and readjust rockshaft/wheels, as well as draft link

length, if necessary.

USE THE SMV EMBLEM AS SPECIFIED AND

STORE PTO SHAFT IN PTO HOLDER.

CHECK LOCAL REGULATIONS ON TOWING

WIDTH AND WARNING LIGHTS.

DWG NO. 6868

To put the machine in end transport. With tractor

attachedtotheeldhitchSlideoutendtransport

tongue (arrow 1) and pin in position.

16 Operation

Rotate jack into position. Lower end transport

wheels all theway down(arrow 2). Raise eld

wheels all the way up (arrow 3). Rotate hydraulic

cylinder channel locks (arrow 4) into position to

hold cylinders in the fully extended position. Using jack raise front end of tractor until the cast

hitch on shredder comes off the draw bar of the

tractor.

DWG NO. 6870

Disconnect hydraulic lines and store in hydraulic tip holder (arrow 5). Flip up PTO holder (arrow 6). Disconnect PTO and lay in PTO holder.

Raise or lower end transport hitch so it can be

attached to tractor drawbar. Attach tractor of suf-

cientsizeforoperationtoendtransporttongue.

Storejackoneldhitchstoragelocation.

1

2

PHOTO NO. 3550B

Attach safety chain on end transport hitch to

tractor.

Insert electrical connector into tractor. Verify

warning lights and turn indicators all work correctly. Verify SMV sign is visible from rear of machine.

STORAGE

CAUTION: DEATH OR SERIOUS

INJURY CAN RESULT. DISENGAGE

PTO, STOP TRACTOR ENGINE,

SET BRAKES, REMOVE KEY AND ALLOW

EQUIPMENT TO COME TO A COMPLETE

STOP BEFORE:

DWG NO. 6871

Wrap safety Chain around hitch tube and pass

through the large chain end loop and welded on

c-channel.

CLEANING, UNCLOGGING, LUBRICATING,

INSPECTING, OR OTHERWISE SERVICING,

ANY PART OF THIS EQUIPMENT.

The following will insure equipment is in top

operating condition at start of next season.

1. Open end shields and thoroughly clean

out dirt and trash. Clean out any other

trash hanging on unit. Check drive shaft

and gearbox bearing seals for trash

entanglement.

2. Back off backwrap belt idlers to relax tension

on “V” belts. Inspect belts for wear.

3. Clean debris from PTO ends and insure

safety shield freely rotates.

4. Relube machine and check gearbox lube

level.

5. Clean rust off exposed surfaces and repaint

any surface requiring it. Also check for any

loose hardware.

6. Inspect both rotor assemblies for lost,

broken, or worn out knives. Replace

these as required. Also, replace any other

deteriorated parts, especially decals and

reectors.

Operation 17

18 Section

18 Lubrication

LUBRICATION

TITLE

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. BEFORE LUBRICATING, READ SAFETY-GENERAL AND

SERVICE AT FRONT OF THIS MANUAL.

CAUTION: DEATH OR SERIOUS INJURY CAN RESULT. DISENGAGE PTO,

STOP TRACTOR ENGINE, REMOVE

KEY AND ALLOW EQUIPMENT TO COME TO

A COMPLETE STOP BEFORE: CLEANING,

UNCLOGGING, LUBRICATING, INSPECTING,

OR OTHERWISE SERVICING, ANY PART OF

THIS EQUIPMENT. SECURELY BLOCK UNIT

BEFORE SERVICING TO PREVENT UNEXPECTED FALLING.

HINIKER shredders have been factory checked

and lubricated. However, re-check and relubri-

cateaunitpriortorsteldoperation.

Lubrication Chart

Ref.

No. Description Interval

1. Front Cross & Bearing Daily

2. Front Shield Bearing Daily

3. Sliding Tube Daily

4. Rear Shield Bearing Daily

5. Rear Cross & Bearing Daily

6. Overrunning Clutch Daily

7. Front Shield Bearing Daily

8. CV Cross Daily

9. CV Cone Shield & Bearing Daily

10. Front Cross & Bearing Daily

Shredders operate in an extremely dirty (ne

dust) environment. Proper maintenance attention to the anti-friction bearings will save money!

IMPORTANT: WIPE ALL ZERKS AND GUN

TIPS BEFORE LUBRICATING.

IMPORTANT: WHEN LUBRICATING BEARINGS ADHERE TO 1 PUMP PER FITTING ON

A DAILY INTERVAL.

When lubricating, couplers, pivots, and PTO lubricate until you see grease. Items (8 & 15) CV

double yoke needs 15 to 20 pumps.

IMPORTANT: INNER ROTOR COUPLER (ITEM

29) NEEDS 20-25 PUMPS DAILY FOR PROPER OPERATION.

Replace anydamaged ttings andusea good

grade of lithium base grease.

Gearbox should be checked at least seasonally.

After300hoursoperation,drainandrell.

11. End Transport Pivot Daily

12. Overrunning Clutch Daily

13. Rear Cross & Bearing Daily

14. Rear Shield Bearing Daily

15. CV Flange (15-20 Pumps) Daily

16. Line Shaft Coupler (15-20 Pumps) Daily

17. Outer Rotor Bearing Daily

18. Rockshaft Bearing Weekly

19. Center Bearings Daily

20. Wheel Hub Weekly

21. Ratchet Jack

22. Gearbox Drain

23. Center Rotor Bearings Daily

24. Outer Lineshaft Bearing Daily

25. Mid Lineshaft Bearing Daily

26. Idler Pivot Weekly

Seasonal

300 Hours

A 1000 rpm gearbox is checked by measuring

3 7/8” to 4” depth to lube level below ll hole

thread top or use check plug at rear. Clean plug

before removing. Use a.P.I. 80W90 synthetic extreme pressure lubricant.

27. Gearbox Breather

28. Gearbox Oil Level Check Plug

29. Rotor Coupler (20-25 Pumps)

-----------

----------Daily

11

Lubrication 19

PHOTO NO. 2964

PHOTO NO. 2968B

PHOTO NO. 100-1334

14

13

12

PHOTO NO. DCP0569

15

8

7

8

PHOTO NO. DCP0560

7

10

9

PHOTO NO. DCP0571

20 Lubrication

DWG NO. 6877

DWG NO. 6878

PHOTO NO. 2976

DWG NO. 6872

DWG NO. 6876

DWG NO. 6875

25

Lubrication 21

29

19

PHOTO NO. 100-4281A

DWG NO. 6873

27

PHOTO NO. DSCN4609A

PHOTO NO. DCP0647

28

22 Section

22 Trouble Shooting

TROUBLE SHOOTING

TITLE

CONDITION POSSIBLE CAUSE CORRECTION

Poor shredding. 1. Missing, or broken knives. 1. Inspect and replace.

See SERVICE section.

2. Knives worn out. 2. Same as above.

3. Under speed PTO. 3. Check tractor for 1000 PTO RPM.

4. Slipping belts. 4. Check belts backwrap idler adjustment.

See SERVICE Section

5. Worn out belts. 5. Inspect belts for wear or mismatching.

Replace only in banded sets.

6. Shredder bouncing. 6. Deate tires to 15-20 psi. Slow down

ground speed.

7. Operating too high. 7. Decrease knives operating height to

approximately 3” above rows.

8. Excessive ground speed. 8. Slowdown.

Excessive row knife wear. 1. Operating too low. 1. Raise knives operating height to

approximately 3” above rows.

Excessive knife stone damage 1. Running too low. 1. Raise knives operating height to

approximately 3” above rows, or to clear

rocks.

Entire shredder crosswise “yawing”. 1. Wheel not exactly centered on middles. 1. Readjust wheel spacings.

2. Different tire sizes on same unit. 2. Correct.

Excessive shredder vibration. 1. Missing or broken knives. 1. Inspect and replace.

See SERVICE section.

2. Rock damaged rotor. 2. Replace.

3. Worn or loose rotor bearings. 3. Inspect and maintain.

See SERVICE section.

4. Loose or misaligned end sheaves. 4. Inspect and maintain.

See SERVICE section.

5. Deteriorated belts. 5. Replace belts.

6. High tire air pressure. 6. Bleed to 15-20 PSI.

Too rapid belt wear. 1. Belts too loose or too tight. 1. Backwrap idler tension not properly

maintained. See SERVICE section.

Crossways tilted operation. 1. Unequalized ratchet jacks or hydraulic

Excessive power required for available

tractor.

1. Equalize ratchet jacks or hydraulic cylinder

cylinder stops.

1. Cutting to low. 1. Raise knives operating height to

2. Excessive ground speed. 2. Slow Down.

stops.

approximately 3” above rows.

TITLE

SERVICE

Section 23

Service 23

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. BEFORE SER-

VICING, READ SAFETY-GENERAL,

BEFORE OPERATION, DURING OPERATION

AND SERVICE AT FRONT OF THIS MANUAL.

CAUTION: DEATH OR SERIOUS IN-

JURY CAN RESULT. DISENGAGE

PTO, STOP TRACTOR ENGINE, SET

BRAKES, REMOVE KEY AND ALLOW EQUIPMENT TO COME TO A COMPLETE STOP BEFORE:

CLEANING, UNCLOGGING, LUBRICATING,

INSPECTING, OR OTHERWISE SERVICING,

ANY PART OF THIS EQUIPMENT.

DO NOT SERVICE OR OTHERWISE HANDLE

A MACHINE, IN A RAISED POSITION UNLESS

IT IS SECURELY BLOCKED AGAINST UNEXPECTED FALLING.

DO NOT SERVICE END DRIVE BELTS WHEN

TRACTOR IS RUNNING.

REPLACE ALL SHIELDS REMOVED FOR

SERVICE BEFORE OPERATING THIS EQUIPMENT.

HARDWARE

Shredders operate in an inherently vibratory environment. Discipline yourself to regularly check

suspect bolt torques and lost, warn out, or broken parts. Replace these promptly.

HINIKER shredders are EQUIPPED ONLY

WITH GRADE 5 BOLTS (3 marks on heads) and

retained with TYPE B or F LOCKNUTS (except

on wheel legs, sheaves, backwrap idler inside

nut, and the gearbox which have lock washers).

Type B locknuts are PLAIN hex. Type F locknuts

are FLANGED hex.

IMPORTANT: DO NOT REPLACE HARDWARE

WITH LOWER GRADE ITEMS. EXCEPT ON

SHEAVES, ALL BOLT TORQUE VALUES ARE

FOR GRADE 5. HARDWARE OVER, OR UNDER, TORQUING, CAN RESULT IN UNSATISFACTORY DURABILITY.

Diameter Ft/lbs. N/m.

5/16” 13-18 17-25

3/8” 23-33 31-44

7/16” 38-54 51-73

1/2” 58-82 79-112

5/8” 117-165 158-223

3/4” 206-292 280-396

1” 500-708 678-960

GRADE 5 TYPE B & F LOCKNUT

TORQUE VALUES

Diameter Ft/lbs. N/m.

3/8” 29-41 39-56

1/2” 73-103 99-140

5/8” 146-206 198-279

* applications without locknuts

GRADE 5 BOLT TORQUE VALUES*

It is a good idea to recheck critical bolt torque

valuesaftertherst2or3hoursofoperation.

KNIVES

HINIKER shredder rotors are factory dynamically balanced.

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. SHOULD ABNOR-

MAL ROTOR VIBRATION OCCUR AT

ANY TIME, IMMEDIATELY DISENGAGE PTO,

STOP TRACTOR ENGINE, SET BRAKES,

REMOVE KEY AND DETERMINE/CORRECT

CAUSE BEFORE PROCEEDING.

24 Service

Periodically inspect rotor assemblies for broken

or missing knives. Immediately replace those

so indicated because they will cause the rotor

to run out of balance. Partially worn out SIDE

SLICER knives may be removed and reversed

to give a fresher cutting edge. HINIKER knives

are marketed singularly; however,

IMPORTANT: REPLACE KNIVES IN OPPOSITE (180° APART) SETS. ALSO, REPLACE

CORRESPONDING IDENTICAL KNIVES AT

OTHER END OF SAME ROTOR HALF.

Shredders are factory shipped with SIDE SLICER knives, per Photo 1575A.

Rotate the knives so that the edge of the side

slicer knives that is not worn is facing in the

direction of travel. Put the knives and bushing

back between the same ears that they came

from on the shredder rotor. Secure them by

torquing the 5/8 x 2 3/4” Gr. 8 bolt and lock nut

to 95 -110 lb. ft.

To replace side slicer knives loosen the 5/8” x

2 3/4” Gr. 8 bolt and lock nut.

Remove the bolt from the ears on the shredder rotor and pull out the two side slicer knives

and the bushing. See Photo DCP0594.

Examine the side slicer knives (Item 1), bushing (Item 2), 5/8 x 2 3/4” Gr. 8 bolt (Item 3) and

the 5/8” lock nut (Item 4). Replace the worn

knives and the bushings if worn or cracked.

Always replace knives in opposite (180 degree apart) sets. Also, replace corresponding

knives at the other end of the same rotor. This

will help to keep the rotors balanced. See Photo DCP0597.

PHOTO NO. 1575A

Shredder side slicer knife Service

To rotate side slicer knives loosen the 5/8” x 2 3/4”

Gr. 8 bolt and lock nut. Remove the bolt from the

ears on the shredder rotor and pull out the two

side slicer knives and the bushing. See Photo

DCP0594.

1

PHOTO NO. DCP0597

4

2

3

Knives hardware should be torqued to 95-110 ft/

lbs (128-149 N/m).

PHOTO NO. DCP0594

Service 25

BELTS

HINIKER shredders are EQUIPPED ONLY WITH

PREMIUM GRADE BANDED BELTS. Do not replace these with “garden variety” belts because

their power transmission capability, and durability, will be degraded.

NOTICE: ADEQUATE TENSION IS NECESSARY FOR FULL POWER TRANSMISSION

AND SATISFACTORY BELT PERFORMANCE.

1. Belt tension is obtained by following instructions on decal located on endplates inside

each end shield.

IMPORTANT: Maintain Belt Tension

Stop unit completely for maintenance.

No Rotation. Read Operators Manual.

Compress spring until

washer can be seen

through sight hole

OUTER ROTOR BEARINGS

All rotor bearings are flange mounted and piloted. They have no eccentric locking collars and

are loosened from their shafts by removing (2)

3/8” Allen set screws from their inner races. Because of high vibration associated with shredders, these set screws are retained with an anaerobic threadlock (eg. Locktite 242 (blue) or

Perma-Lok HM 118 (red). Important: Use only

grade 5 bolts and type B lock nuts with thread

lock when replacing.

PART NO. 79203548

DWG. NO. 3543

2. Recheck initial belt tension after rst hour

and rstday of operation. Loose beltscan

“glaze” and contribute to slippage. DO NOT

USE BELT DRESSING ON “V” BELTS. This

will aggravate poor belt function.

If evidence exists of belts overheating and/or

excessive side wrapper wear, check sheave

alignment. See Photo DCP0618, page 28.

3. Replacement belts should only be ordered

by specic HINIKERpart number.The correct belt part numbers are:

(6/5VL794 banded belt) Part No. 79203528

4. Install new belts as follows:

a. Loosen double nut on outside of drive shield

to remove tension on belt idler.

b. Remove old belts.

c. Roll (DO NOT PRY) the new belt into the

pulley grooves working back and forth between the large and small pulley.

DWG NO. 6879

2

3

4

PHOTO NO. 100-1311A

1. Loosen spring tension (Item 1) and remove

belt (Item 2) and driveN sheave (Item 3).

See Photo 110-1311A.

CAUTION: DEATH OR SERIOUS INJURY CAN RESULT. ROTORS ARE

HEAVY AND SUBJECT TO UNEXPECTED MOVEMENT. SECURELY UNDERNEATH

BLOCK ROTOR END BEING SERVICED

AGAINST DROPPING OR SHIFTING BEFORE

THE END BEARING IS REMOVED FROM ITS

PILOT HOLE.

26 Service

2. Remove (4) 3/8” bolts (Item 4) and the

(2) inside anti-wrap shields. This allows

wrench access to the bearing mounting bolt

heads. See Photo 100-1311A and Photo

DCP0659B.

3. Loosen outer end zerk hex nut of lube

tube and detach tube from bearing.

Circumferentially polish shaft (Item 5).

Remove (3) 3/8 bolts (Item 6) securing the

bearing support plate to the shredder end

panel. See Photo DCP0659B.

4. Remove (2) 3/8” Allen set screws from the

inner race of the outer rotor bearing which

are factory retained with anaerobic thread

lock Perma-Lok HM118 (red) or Locktite 242

(blue).

8

4

4

Washer Part Number

1/16” Thick 79202329

1/8” Thick 79202328

7. After the washers have been checked, torque

bearing mounting bolts and Allen set screws.

Torque the Allen screws once, loosen and

torque a second time. Reinstall anti-wrap

shields and torque support plate bolts.

Commercial anaerobic threadlocks have

installation instructions, and SAFETY CAUTIONS, on their containers. These should

be adhered to.

8. Reinstall and realign previously removed

sheave and belt.

INNER ROTOR BEARINGS

1. To remove the rotor the shredder must be

turned upside down.

7

6

PHOTO NO. DCP0659B

5. Remove (4) 1/2” locknuts (Item 7) which are

factory retained with anaerobic threadlock

(eg. Lock-tite 242 (blue) or Perma-Lok HM

118 (red). Modestly pry plate (Item 8) outward to start bearing off shaft.

6. A varying quantity of 2 3/16” nominal. I.D.

washers are factory installed between the

inner end of bearing and the shoulder on

shaft. Because replacement bearings vary

in axial dimensions, care must be exercised

to FULLY WASHER THE SPACE BETWEEN

THE BEARING AND SHAFT SHOULDER.

Reinstall plate (Item 8) and bearing by temporarily snugging up (2) each of their bolts

(without anti-wrap shields). Visually check

above cited washers to insure no looseness, or substantial axial preload, exists. 2

3/16 inch nominal I.D. washers are available

as part numbers:

6

5

2. Raise front and securely block front corners.

Remove SMV, PTO, and trailing hitch.

3. Remove belt and sheave or rotor. Fully retract cylinder(s). Loosen both inner and outer

bearing’s lube tube zerk nuts and detach lube

tubes from their supports. Remove lights and

light brackets.

4. Temporarily insure end panel shields are

latched shut. Reinstall hitch pins and their

cotters.

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. DO NOT ATTEMPT

TO REMOVE A ROTOR FROM UNDER

NEATH A SHREDDER IN ITS OPERATING POSITION.

NEVER ATTEMPT TO REMOVE A ROTOR

WITH THE UNIT UPENDED IN A VERTICAL

POSITION.

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. USE HOISTING

EQUIPMENT CAPABLE OF SAFELY

HANDLING NO LESS THAN 4 TON (8000#).

Service 27

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. CLEAR PEOPLE

FROM WORK AREA WHEN TIPPING

SHREDDER OVER. DO NOT WORK ON SOFT,

OR UNEVEN, GROUND. LIFT ONLY FROM

MAIN FRAME 1 INCH DIAMETER HITCH PINS.

5. Securely block rear (Item 1) of each wheel

and approach shredder from REAR. Use a

chain sling (Item 2) approximately 5’ long

on each run. Fix EACH sling chain hook

SECURELY around both 1” diameter hitch

pins (Item 3) where shown by decal (Item 4).

Lift unit until wheels are about to clear the

ground.

2

4

3

Unless this bearing is also being serviced, it

is not necessary to remove it from the rotor

at this time.

8. Remove center anti-wrap shields. This allows access, through the rotor’s inner end

notches to bearing’s inner race Allen set

screws. Detach shield and lube tube.

9. Loosen (2) 3/8” Allen set screws (Item 1)

from center bearing (Item 2). These are retained with anaerobic threadlock (eg. Locktite 242 (blue) or Perma-lok HM 118 (red).

See Photo DCP0591.

1

2

1

PHOTO NO. 2990B

6. Move wheel blocks previously installed to

opposite side of wheels (Item 1). Swing unit

rearward and overcenter, then slowly lower the unit to the ground. Open end shield

(Item 3) and detach bottom enclosure plate

(Item 4).

PHOTO NO. DCP0591

Commercial anaerobic threadlocks have installation instructions, and SAFETY CAUTIONS, on

their containers. These should be adhered to.

10. Attach chain sling around rotor. Outer end

of rotor is lifted above frame to obtain clearance.

Axially pry rotor free of its inner bearing and

swing it clear of working area. NOTE: Carefully lift both split rotors together on units

with four rotors. Sling should be from center

of rotors to reduce stress on coupling.

7. Loosen outer bearing from its mounting as

shown in Photo DCP0659B on page 26.

PHOTO NO. 3014

28 Service

Check that all previously removed and/or

loosened parts are properly reinstalled. Remove hoist and reverse above tipping procedure to return the unit to operating position

and reinstall previously removed hitch, etc.

SHEAVES ALIGNMENT

It is unnecessary to realign sheaves unless they

have been damaged, removed or loosened. Do

not realign sheaves unless they are more than +

or - 1/16” misaligned. See Photo DCP0618.

DWG. NO. 6384

11. Circumferentially polish rotor center stub

shaft and reinstall it in replaced bearing. Insure stub shaft shoulder is against bearing

inner race. Torque (2) Allen set screws once,

loosen and torque them a second time.

IMPORTANT: WHENEVER THESE LOCK

NUTS/BOLTS ARE DISCARDED, ONLY

GRADE 5 BOLTS AND TYPE B LOCKNUTS SHOULD BE REINSTALLED. THE

ABOVE CITED (OR SIMILAR) ANAEROBIC

THREADLOCK SHOULD BE USED IN REASSEMBLY OF BEARING MOUNTING BOLTS

AND ALLEN SET SCREWS. TORQUE ALL

BEARING MOUNTING BOLTS TO 58-82 Ft/

lbs. (79-112 N/m.).

12. Temporarily reinstall (4) 3/8” bolts through

outer bearing mounting plate and snug them

up. Do not reinstall outer anti-wrap shields

at this time. Check varying quantity of 2

3/16” nominal I.D. washers between outer

bearing’s inner race and shoulder of rotor

shaft. If these are axially SNUG WITH NO

PRE-LOAD, proceed to completely reinstall

outer bearing and anti-wrap shields.

1

2

3

PHOTO NO. DCP0618

1. It is generally best to align driveR (Item 1)

to driveN sheave (Item 2); thus, only (1)

sheave need be loosened.

2. Determine misalignment by placing a steel

straight edge (Item 3) across sheaves as

shown. Move sheave in or out to align.

SHEAVES REMOVAL/INSTALLATION

1. Loosen belt’s backwrap idler and remove

belts.

13. If washers are not as stated above, it will

be necessary to remove outer bearing. See

Photo DCP0659B, page 26 and add, or subtract, washers. 2 3/16” nominal I.D. washers

are available as part numbers:

Washer Part Number

1/16” Thick 79202329

1/8” Thick 79202328

1

5

3

4

6

PHOTO NO. 100-1311B

2

Service 29

2. Loosen and remove bolts from (3) UNTHREADED holes (Item 1).

3. Insert these bolts in the (3) THREADED

holes (Item 2). Start with the bolt furthest

from the inner bushing’s slot (Item 3) and

gradually alternately torque bolts in a uniform pattern. Continue torquing in small increments until the tapered surfaces disengage. The same procedure is used if driveN

sheave (Item 4) is to be removed.

NOTICE: EXCESSIVE AND/OR UNEQUAL

BOLT TORQUES CAN BREAK THE INNER

BUSHING’S FLANGE.

4. The inner bushings are retained with 3/8” Allen set screws (Item 1) over their keyways

(Item 2). Remove the set screw to enable

removal of the inner bushing.

7. Align (3) UNTHREADED bolt holes with

THREADED bolt holes in mating sheave

or bushing. Inset bolts and lockwashers

in these UNTHREADED holes and tighten

about (2) turns each.

8. Alternately torque these bolts , in a uniform

pattern, until the tapers are seated (approximately 1/2 bolt torque). Check for sheave

alignment and possible wobble. Correct if

necessary.

IMPORTANT: SHEAVE BOLTS ARE ONLY

TORQUED TO VALUES:

Dia. Ft/lbs. N/m.

3/8” 30 41

1/2” 75 102

9. Continue bolt torquing until above values occur, or NO LESS THAN 1/8” HUB FLANGE

TO SHEAVE CLEARANCE EXISTS. There

will always be a gap in the inner bushing

hub when proper procedure is followed.

1

2

PHOTO NO. DCP0656

5. For installation, insure the tapered mating

surfaces of the inner bushing (Item 5) and

sheave (Item 6) are free of dirt, paint, rust,

metal chips and LUBRICANT.

IMPORTANT: DO NOT USE LUBRICANTS,

ANTISEIZE, AND/OR EXCESSIVE BOLT

TORQUES WHEN ASSEMBLING Q.D.

SHEAVES. THESE CAN BREAK THE ASSEMBLY.

6. Insure woodruff key is in place before sliding inner bushing on shaft. Align (in/out) the

Allen set screw hole of the bushing being

installed with existing witness marks on its

shaft and torque the set screw.

NOTICE: INDIVIDUAL BOLT TORQUES

SHOULD BE ACHIEVED NO MORE THAN (2)

TIMES IN THE TIGHTENING CYCLE.

10. Reinstall belts and reposition backwrap

idler.

DRIVE SHAFTS BEARINGS

The front drive shafts bearings have set screw

lock collars. To loosen these, loosen 3/8” Allen

set screw therein.

Servicing these bearings requires removing

the driven sheave, See page 28-29 and extract

the drive shaft. Paint must be polished off drive

shaft to permit stripping it through the bearings.

WHEEL BEARINGS & SEALS

HINIKER shredders are equipped with O.D. riding triplex (3 labyrinths) seals. They also have

a replaceable seal riding ring (Item 6) and zerk

relube in the hub. This system is highly effective

when properly installed and maintained. See

Photo 3011 on page 30.

30 Service

IMPORTANT: WHEEL SEAL AND RIDING RING

MUST BE INSTALLED IN THE RIGHT DIRECTION, PROPERLY PRE LUBED AND THE HUB

FULLY PACKED WITH LUBE. IGNORING PROCEDURES BELOW WILL RESULT IN PREMATURE CONTAMINATION AND FAILURE.

1. Remove hub, inboard bearing cone (Item

1), outboard bearing cone (Item 2) and seal

(Item 3) from spindle. Thoroughly clean

hub’s interior grease cavity, both bearing

cups (Item 4), cones (Item 1 and Item 2),

hub cap (Item 5) and pre load hardware.

PHOTO NO. 3011

2. Discard old seal (Item 3) and inspect bearings for deterioration. Replace both cups

and cones if necessary. Generally, seal riding ring (Item 6) should be replaced when

doing wheel hub maintenance.

IMPORTANT: PRESS SEAL RIDING RING

INTO HUB WITH INTERIOR EDGE FLANGE

TOWARD INBOARD BEARING CUP. MANUALLY WORK LUBE INWARD BETWEEN (3)

SEAL LABYRINTHS BEFORE INSTALLING.

CAREFULLY START NEW SEAL (ITEM 3)

ONTO SPINDLE WITH BEARING CONE (ITEM

1) WHICH CAN BE SEATED WITH A 3/16”

PUNCH OR 1 1/2” I.D. DRIVER. INSURE SEAL

IS NOT CROOKED AND IS INSTALLED WITH

ITS SHARP EDGED INSIDE FLANGE TOWARD THE OUTBOARD SPINDLE END. THE

OPPOSITE (SMOOTH) SEAL FACE IS USUALLY MARKED “OUTSIDE”. THIS MUST ALWAYS FACE THE SPINDLE’S INBOARD END,

OTHERWISE THE SEAL WILL NOT FUNCTION CORRECTLY.

GEARBOX

All Hiniker 1000 RPM shredders are equipped

with a common 1.00:1.00 ratio gearbox. Refer to

Photo 3008A and DWG. 6088 on page 32.

PHOTO NO. 3008A

Gearbox can best be worked on as follows:

1. Detach tractor PTO at gearbox input spline.

3. Install hub, outboard bearing cone (Item 2),

end washer and adjusting nut. Adjust nut

with a HAND WRENCH ONLY. Tighten until seal is seated and bearings substantially

drag, then back nut off 1/6 turn to insert and

spread cotter.

4. Use zerk to fully lube hub cavity and bearings, while rotating hub, and until lube

emerges through outboard bearing. Pack

hub cap (Item 5) with lube and drive it home.

Continue lubing hub until lube emerges

around seal’s outside diameter.

2. Remove the left cross drive shaft shield.

Loosen and remove left outboard drive shaft

bearingangebolts.Thiscanbedonewithout removing the driveR sheave by slacking

off the backwrap idler and removing belts.

This permits sliding the entire left drive shaft

assembly leftward; thus, allowing room to

slide the gearbox loose from its R.H. spline

coupling.

3. Remove the (2) right 3/8” bolts nearest the

gearbox holding the right cross shaft shield.

Service 31

4. Remove the top (4) 1/2” bolts holding the

gearbox/PTO input shield and remove this

shield.

5. Remove the bottom (4) 1/2” gearbox mounting bolts and slide the gearbox leftward suf-

cient to uncouple it from its right splined

coupler. Then slide the gearbox forward to

remove it for placing on a workbench.

6. Remove the gearbox drain plug and discard

the lube.

The gearbox has no shims because preload and

backlash are factory set. To service this box proceed as follows:

1. Remove (12) 3/8” socket head bolts (Item

1) holding the 2 halves together. Tap input

shaft (Item 2) with a soft hammer, while

holding the output shaft (Item 3) off the work

table. Be careful to not damage the case’s

mating surfaces by prying them apart.

5. Whenever shafts are disassembled, make

sure the same thickness snap ring (Item 5)

are used to maintain backlash and preload.

There is (1) external snap ring used. For reassembly, capture bearings and seals in appropriate machined areas. Tap gently with

a soft hammer to seat, being careful to not

damage seals.

6. After both shafts have been reseated, apply

anaerobic sealant (eg. Locktite 518 (red) or

Perma-Lok HH 190 (dark purple) or Permatex silicone sealant 765-1344/1485) to

housing top half and reseat it on bottom

half. Apply pressure, or tap lightly, until top

halfisrmlyinplace.Replace,andretorque

the (12) previously removed socket head

bolts.

Commercial anaerobic sealants have installation and SAFETY CAUTIONS on their containers. These should be adhered to.

2. The input and output shafts and gears are

precision tted. Do not separate them by

prying on an individual set. Lift them apart

together.

3. Remove old anaerobic sealant and complete necessary maintenance. Whenever a

gearbox is opened, all 3 oil seals (Item 4)

should be replaced. Lube the seal’s inside

diameters before reinstalling and insure

their spring garters are toward the gearbox’s

inside.

4. Clean gearbox of all dirt and metal particles.

Inspect all removed parts for wear. Replace

any bearing showing signs of pitting, inability to rotate freely and discoloration. Clean

any bearings to be reused and coat with

gear lube. Replace gears showing pitting,

breaks or de-formation. Replace input and

through shafts having spline wear or deformation.

32 Service

1000 RPM GEARBOX ASSEMBLY

REF.

NO.

1

400-17205

2

400-17206

3

50106488

4

50106489

5

601-05002

6

601-02075

7

601-05001

8

601-03003

PART

NUMBER

DESCRIPTION QTY.

Casting (Tapped Holes)

Casting (Thru Holes)

Pinion Shaft/Gear

Cross Shaft/Gear

Bearing Cup (Large)

Bearing Cone (Large)

Bearing Cup (Small)

Bearing Cone (Small)

DWG. NO. 6088Gearbox Assembly 51700216

REF.

NO.

1

1

1

1

1

1

3

2

9

650-06056

10

702-05093

11

950-011-032

12

203-51156

13

203-51074

14

203-50308

15

601-02001

16

79201412

PART

NUMBER

DESCRIPTION QTY.

Seal (1 3/4 Shaft)

Retaining Ring (1 3/4 Shaft)

Socket Head Cap Screw 3/8-16 x 2 1/4

Plug, 1/2 NPT Sock Head Hex

Bushing, 1/2 NPT - 1/8 NPT

Pressure Relief

Bearing Cone 625580

Plain Plug 1/4 NPT #200300

3

1

12

1

1

1

1

1

TITLE

ASSEMBLY

Service 33

Assembly 33

Section 33

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. BEFORE ASSEMBLING, READ SAFETY-GENERAL AT

FRONT OF THIS MANUAL.

OFFLOADING

Warning: Death Or Serious Injury Can

Result. Use Equipment Capable Of

Safely Handling No Less Than: 4 Ton

(8000#).

WARNING: DEATH OR SERIOUS INJURY CAN RESULT. CLEAR PEOPLE

FROM CARRIER AND OFFLOADING

AREA. DO NOT OFFLOAD ON SOFT, OR UNEVEN GROUND. AVOID HIGH WORK SPEEDS

AND “JACKRABBIT” MANEUVERING.

HINIKER shredders are shipped vertical with

self contained storage and handling dunnage.

They may be off-loaded with a forklift or an overhead chain sling.

For forklift off-loading, (2) fork pockets (Item 1),

spaced 32” apart, are provided. The forklift may

approach the shredder from either the knives, or

hood, face. Set forks centerlines 32” apart and

position forklift as close as possible to shipping

package. Lift off carrier and deposit on a rm,

clear and level work area. See Photo 2980.

For overhead chain sling off-loading, use a chain

sling (Item 1) approximately 5’ long on each run.

Fix EACH sling chain hook SECURELY around

both 1” diameter hitch pins (Item 2) where shown

by decal (Item 3). Lift off carrier and deposit on

a rm, clear and level work area. See drawing

6800.

DWG NO. 6880

Shredder hitches are shipped separately along

with tires and end transport package.

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. CLEAR PEOPLE

FROM ERECTING AREA BEFORE TIPPING

SKIDDED UNIT DOWN.

Prepare to tilt the unit down by hooking an approximately 5’ long sling chain (Item 1) securely

around both 1” diameter hitch pins (Item 2) the

same as in Photo 3137. Securely place solid (do

not use hollow concrete) blocks under rear corners of each end of the unit as shown at (Item 3).

Blocks should be approximately 8” square.

PHOTO NO. 2980

With either an overhead crane, or forklift, allow

a SMALL AMOUNT of slack in the sling chain

and slowly tip the unit forward until its downward

force is being supported by the sling chain.

IMPORTANT: GROSSLY LOOSE SLING

CHAIN SLACK CAN ALLOW THE SHREDDER

TO FALL WITH EXCESSIVE FORCE ON THE

SUPPORTING EQUIPMENT.

34 Assembly

34 Section

Slowly lower unit onto the rear corner blocks

(Item 3) until its front (Item 4) is approximately

18” above the ground.

DWG NO. 6881

ROCKSHAFT AND WHEEL LEGS

PHOTO NO. 3137

Place blocks under each front corner as at (Item

1). These blocks should be approximately 8”-10”

high and wide enough for stability. Insure they

clear thefrontipper shields. Continuelowering

the unit onto these blocks. Loosen and remove

the sling chains. See Photo 2984A.

PHOTO NO. 2984A

Remove shipping brace from outside rock shaft

brackets. Insert 3 x 8 hydraulic cylinder (arrow

1) as shown. The base end will be assembled on

the base machine and the rod end attached to

the bolt-in bracket on the rockshaft. Insert an extended pin (arrow 2) in the hole on the shredder

weld and base of cylinder. Insert washer over

shaft and secure with cotter pins. Insert hydraulic cylinder stops (arrow 3) over extended pin.

Attach (4) rock shaft wheel leg welds (arrow 4)

using the provided 5/8 hardware at the correct

row spacing needed. Make sure to insert the

5/8 spacer (arrow 5) on the (4) rear rock shaft

wheels on the back of the machine.

Note: There are (8) 9.5L tires with the machine

(6) are 8 ply and (2) are 12 ply. The (8) ply are

eld wheels and the 12 ply are end transport

wheels. Attach the 9.5L x 15 (8) ply tires (arrow

6) to the rock shaft wheel leg hubs.

Remove (6) wheels from rockshaft. Discard all

dunnage associated with these.

DWG NO. 6882

Attach (2) front gauge wheels (arrow 1) to front

rigid rock shaft. These will be attached the same

Assembly 35

as the rear but with out 5/8 spacers. Attach 9.5L

x 15 (8) ply tires to hubs on front gauge wheels.

The shredder will perform better, especially under ridged conditions, if tire pressures are kept

no greater than recommended.

Contract cylinders to rotate wheel legs sufciently upward to permit installation of wheels

and tires.

The wheels are offset, that is, the wheel “dish”

is greater on one side than the other. Install the

wheels and tires with the deepest dish TOWARD

the wheel leg. This places its loaded centerline

between the hub bearings. Torque up the (6)

1/2” wheel bolts on each wheel.

Transversely slide the entire wheel leg and tire

assemblies to these recommended tire centerlines (as applicable). Tire centerline spacings

should be EQUALIZED on each side of the

shredder’s centerline.

30” rows 36” rows

(2 outboard wheels)

(2 inboard wheels)

360”

60”

360”

72”

For other row spacings, adjust above settings accordingly. Torque up each wheel leg’s (6) clamping bolts by uniformly tightening the lower (3) to

snugt.

Subsequently, torque, and retorque, top 3 to 146206 Ft/lbs. (198-279 N/m.).

TRAILING HITCH

Attach the trailing hitch to the machine by removing the hitch pins (arrow 1) at the center of

the machine. Insert the hitches rear brackets

between both sets of ears on the base of the

machine. Insure both pairs of cotter pins are

spread. Locate the turnbuckle from the pallet

of additional components. Install the turnbuckle

(arrow 2) at the location shown. Locate the handle extension (arrow 3) from the shipping pallet. Remove old handle and install new longer

handle onto turnbuckle using the provided cotter

pin. Locate screw jack and attach to its storage

location on the hitch (arrow 4).

PTO’s

It is easiest to install the trailing PTO AFTER

completing the trailing hitch installation.

Hiniker shredders are only available with:

1 3/4” (1000) 20 spline trailing all widths.

(55” Telescoped O.A. length)

Whole goods item 79202277

All shredder PTO’s have C.V. (constant velocity) yokes as standard equipment and have similar sliding yoke couplers at tractor and gearbox

ends. GEARBOX ENDS ARE IDENTIFIED BY

AN OVERRUNNING CLUTCH (Item 1). See

Photo 2969A.

Clean gearbox spline of any encrusted dirt or

grease and lightly oil it. Slide outer PTO collar

(Item 2) toward its adjacent yoke (Item 3) and

slide PTO over the gearbox spline. Reverse the

sliding collar to lock the assemblies together.

IMPORTANT: NEVER TOW A TRAILED

SHREDDER IN FIELD MODE UNLESS THE

PTO IS PROPERLY HOOKED UP TO BOTH

TRACTOR AND SHREDDER. OTHERWISE,

IT CAN BE DAMAGED. IF TOWED WITHOUT

FULL HOOKUP, DETACH ENTIRE PTO FROM

GEARBOX AND SECURE IT BEHIND CROSS

DRIVE SHAFT SHIELD.

DWG NO. 6883

36 Assembly

PHOTO NO. 2969A

LIGHTS

DWG NO. 6884

From the pallet of shipping components locate

the light bar, (2) lights, wiring, and (2) light brackets. Attach the light bracket (arrow 1) to the base

machine using the 3/8 carriage bolts and lock

nuts.

DWG NO. 6885

Wind up excess wiring onto the wire holder (arrow 5) on top of drive shield by end transport

hitch.

END TRANSPORT

Attach a tractor to the A-Frame hitch for stability.

DWG NO. 6886

Attach each light (arrow 2) to a light bracket using the provided 1/4” hardware. Attach the light

brackets (arrow 3) to each side of the light bar

using the provided 5/16 carriage bolts and hardware. The lights need to be installed so at the

rear of the machine the yellow and red light are

facing rearward and the single yellow light is facing forward. Run the wiring along the hydraulic

cylinder towards rear of machine and inside the

formed bar (Arrow 4) at the rear of the machine.

From the shipping pallet Attach the front frame

weld (arrow 1) to the machine using the provided

5/8 hardware and lock nuts.

IMPORTANT: FRONT WELDMENT BRACKETS

WITH 4 HOLES (ARROW 1) MUST BE BELOW

BRACKETS WELDED ON SHREDDER BODY.

Attach tire and rim assembly to the front wheel

leg (item 2) and then to front frame bracket with

1 1/4 diameter pin (arrow 3) and hardware. Secure pin in position using 5/16 hardware. Tighten

all bolts.

Assembly 37

Install hydraulic cylinder (arrow 4) and cylinder

stop (arrow 5) on wheel assembly with rod end

towards tire and ports pointing towards main

shredder body. Rod end will use longer 1” diameter x 5 1/2” pin (arrow 6). Install cylinder latch

(arrow 7) with compression spring (arrow 8) and

secure with 5/16 hardware.

DWG NO. 6890

On the rock shaft lift cylinders unscrew the port

plugs. Insert a 90 degree ORB fitting into both

ports on the cylinder. In the front end transport

cylinder unscrew the port plugs and insert a 90

degree ORB fitting into both ports.

On the rear end transport cylinder unscrew port

plugs and insert ORB tee fitting into both ports.

Install (4) 90 degree male to female elbows onto

both ends of each tee fitting.

From the hydraulic fitting box locate (2) bulkhead tee fittings and (2) bulkhead 90 elbow fittings. Install these into the (4) holes located in

the center panel at the rear of the machine.

Attach rear transport pivot (arrow 1) to rear center plate with 3/4 x 2 bolts and lock nuts. Install

two pivot clamp brackets (arrow 2) with 1/2 x 1

1/2 bolts and lock nuts.

Slide rockshaft bearing segments (arrow 3) into

pivot brackets (from previous step). NOTE: Middle segments are turned 90 degrees. Thread

grease zerks (arrow 4) into bearing cap (Arrow

5).

Secure (arrow 5 and arrow 3) with 3/8 bolts as

illustrated NOTE: Turn one set of (arrow 3) 90

degrees. Tighten all bolts.

Attach tire and rim assembly to rear wheel leg

(arrow 6) hub. Assemble rear wheel leg and tire

assembly to rear transport pivot (arrow 1) using

a 1 1/4“ pivot pin (arrow 7) and 5/16 hardware.

Install hydraulic cylinder (arrow 8) and cylinder stop (Arrow 9) on wheel assembly with rod

end towards tire and ports toward main shredder body. Install cylinder latch (arrow 10) with

compression spring in the same way as front

cylinder lock.

DWG NO. 6887

From the hose box locate (4) 3/8 x 186” long

hydraulic hose assemblies. Attach matching colored zip ties to both ends of each hose assembly.

Attach one hose assembly to each elbow (arrow

1) of the rear rock shaft lift cylinders. Run hydraulic lines together and underneath welded in

bar (arrow 2) on shredder machine. Run hydraulic lines on other lift cylinder in a similar fashion.

Attach the hydraulic lines from both base ends

intooneteettingatthecenterofthemachine.

Attach the hydraulic lines from the rod ends of

bothcylindersontotheteettingatthecenterof

the machine.

38 Assembly

DWG NO. 6888

From the hose box locate the (4) 3/8 x 72” long

hydraulic hose assemblies. Attach matching

colored zip ties to both ends of each hose assembly. Attach one end (arrow A) to the rod end

port of the front end transport cylinder. Attach

theotherendtoonesideoftheteetting(arrow

A) on the rod end port of the rear end transport

cylinder. Attach another hose assembly onto the

90 degree elbow (arrow B) on base end port of

the front end transport cylinder. Attach the other

endtoonesideoftheteetting(arrowB)onthe

base end of the rear end transport cylinder.

Assemble the next hose assembly to the 90 el-

bowontheteetting(arrowC)ontherodendof

the rear end transport cylinder. Run the hose assembly to the center of the machine under neath

the welded in bar on the hood of the shredder.

Attach the other end of the hose assembly to 90

bulkhead elbow (arrow C) at the center of the

machine. Attach the last hose similarly between

the base end of the end transport cylinder and

thelast90bulkheadelbowtting(arrowD).Colored zip ties will help to keep rod and base ends

apart.

Locate the (4) 3/8 x 150” long hydraulic hose

lines. Attach matching colored zip ties to both

ends of each hose assembly. Attach one end

ofeachhosetothebulkheadttingsattherear

center of the machine. Make sure to keep the

lift and end transport functions together. Run the

lines along the front center of the machine thru

the loop at the top of the hitch. Attach the tractor

couplers to the ends of the hydraulic lines. Insert

the hydraulic couplers into the hydraulic coupler

holder.

Attachtractortoeldhitch.Inserthydrauliccouplers into tractor. Cycle the end transport and

lift wheels to purge all air out of system. Check

the hydraulic level on the tractor and rell as

needed.

MISCELLANEOUS

The SMV (slow moving vehicle) emblem and

spade bracket are shipped inside an end enclosure.

DWG NO. 6889

Insert spade connector into socket (arrow 1) located on RH side of machine. Make sure SMV

emblem will be facing machine rear in end

transport mode.

Check the gearbox lube level. See LUBRICATION SECTION.

PREDELIVERY RUN IN

Refer to delivery check list and routinely preform

relevant checks. Verify hitch, PTO, and wheel

settings are conguredto customersstated requirements. Refer to machine operation to con-

guremachineinendtransportmode.

OPTIONAL SKID SHOES

Hiniker offers an optional skid shoe package that

will help with keeping the shredder knives from

contacting the ground. The skid plates extend

approximately 1/2” below the shredder knives.

1. Break the bands securing the skid shoes

with hardware together.

Assembly 39

2. Remove the (4) 3/4 x 1 3/4” long bolts and

3/4 inch lock nuts in each skid shoe and

save them for assembly to the shredder.

3. Raise the shredder as high as the hydraulic

lift will allow it while attached to tractor and

block it in this position with stands.

4. The Skid shoes are mounted to the inside of

the shredder end panels.

2

2

2

2

1

OPTIONAL CENTER GRASS

DIVIDER ASSEMBLY

This is used to reduce center “streaking” when

shredding/clipping grass, etc. Remove the (2)

1/2” bolts and Mac-lock nuts from the grass divider assembly(Item 1). Insert the atbarbetween the base unit ears and secure in the front

5/8” hole with 1/2 x 2 1/4” bolt and 1/2” Mac-lock