Hinds-Bock 2P-160 User Manual

The Hinds-Bock standard single and twin gallon fillers/depositors are especially designed

for the institutional packer. Easy to clean and operate, versatile and gentle on all

products, they provide immediate cost-saving results. Large port openings permit filling

of chunky ingredients without crushing. USDA and AG Canada approved.

PARTIAL PRODUCT LIST:

HOT AND COLD PRODUCTS

Improve Payback

2122 – 222

ND

Street S.E. | Bothell, WA 98021 | USA

Jams & Jellies

Pie Fillings

Cake Batters

Flowable Dough’s

Fruit Cake Batters

Fruit Puree

Mayonnaise

Salad Dressings

Potato Salad

Macaroni Salad

Cole Slaw

Burrito Fillings

Meat Pie Fillings

Stews

Soups & Sauces

Relish

Mustard

Ketchup

Caramel

Cream Topping

Salsa

Chili

Baked Beans

Dips & Spreads

Shampoo

Creams & Lotions

Increase Yield

Reduce Cost

Toll Free: 877.292.5715 | Tel: 425.885.1183 | Fax: 425.885.1492

Improve Quality

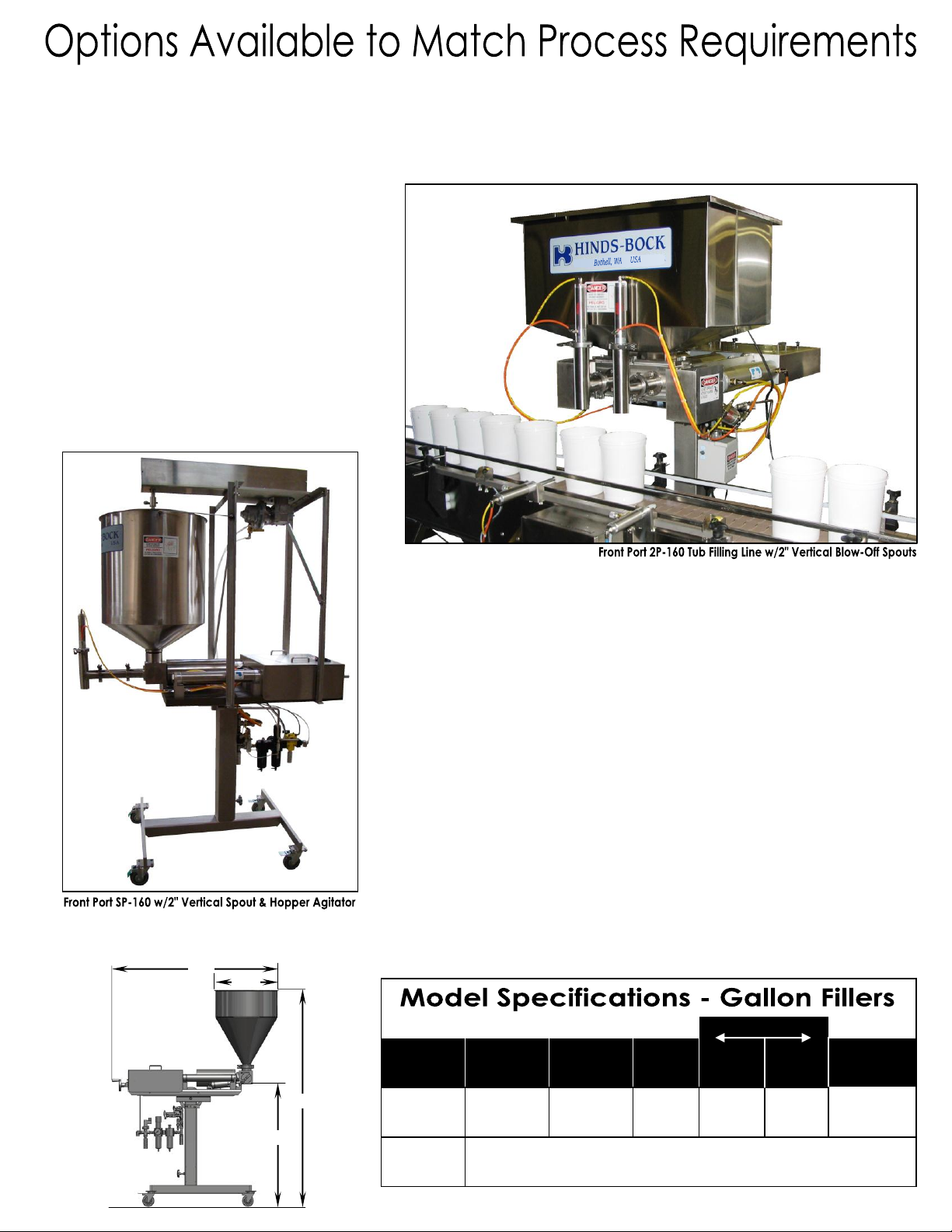

Options Include: Conical (20, 40 gallon) hoppers, rectangular and divided hopper (on 2P-160),

“U” shaped agitated hoppers on both models, change cylinders, wide variety of spouting

including traveling and diving spouts, automatic & semi-automatic controls, level probes,

agitators… all matched to customers’ applications

SPECIAL ADAPTATIONS

Depositing and filling on conveyors into containers of

glass, metal, plastic and paper.

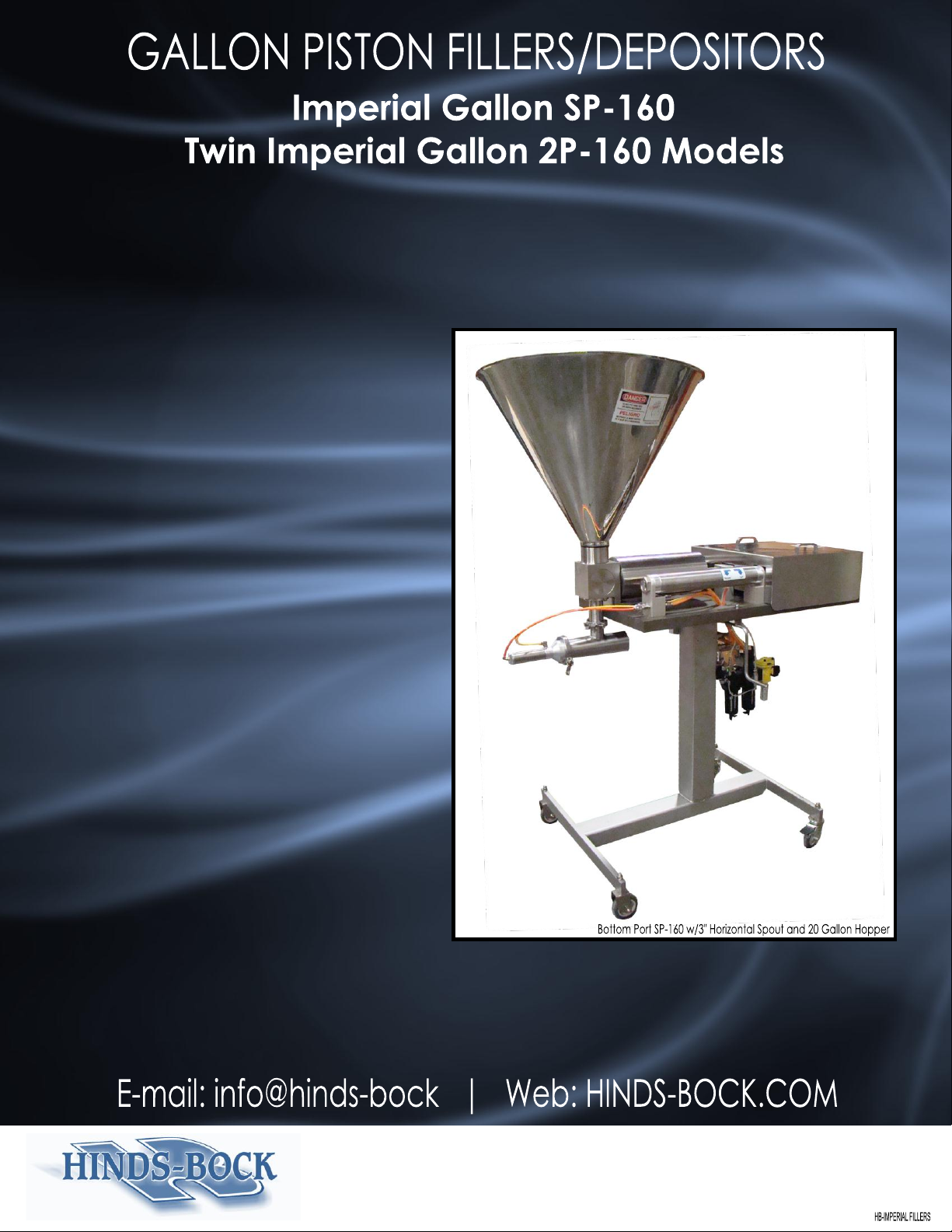

20-gallon hopper is standard on single gallon (SP-160).

40-gallon is standard on the twin (2P-160)

filler/depositor. Various shapes and sizes available on

both single and twin models.

Special centering mechanisms are available to cleanly

fill containers with narrow openings.

Infinite speed controls are available. Repeat-stroke

mechanism can be provided to automatically fill multigallon containers.

Fully automatic, semi-automatic or hand filling. No

container/no fill built into automatic system

HOPPER WIDTH

MODEL

A B D

SP-160

SINGLE

PISTON

59”-74”

33.5” 47.5”

8-10

*

E

REQ’D

CFM

C

N/A

30.25”

57”

A

D & E

C

B

STANDARD FEATURES

Air powered

8 inches of height adjustment

Locking swivel casters

All stainless steel construction,

including stand. Contact parts all

food-approved materials.

Fills form one ounce to 160 ounces

from each spout with change

cylinders

2P-160

TWIN

PISTON

Check with factory. Hopper variations affect dimensions

Loading...

Loading...