Page 1

ATevo SERIES BATTERY CHARGER

AT SERIES BATTERY CHARGER

PRODUCT

OPERATING & SERVICE

INSTRUCTIONS

Microprocessor-Controlled Float Battery Charger

SINGLE PHASE INPUT - GROUP I (6-25 Adc)

JA5011-51

Page 2

User Notes

Page 3

Manufacturer's Warranty

FIVE-YEAR

WARRANTY

[applies only to product(s) delivered within United States and Canada]

Product Details:

Battery Charger Model:

Factory Ordering Code:

Battery Charger Serial Number:

Date Shipped:

Date Energized:

Standard Warranty

This product is warranted to be free from defects in material and

workmanship for a period of five (5) years from date of manufacture.

During the term of the warranty period: parts, assemblies, or

components deemed to be defective will be repaired or replaced at the

manufacturer’s option, free of charge. All costs related to removal,

reinstallation and transportation will be paid by the purchaser/

customer and/or operator of the product. Evaluation, repair and/or

replacement of any defective part(s) are FOB manufacturer’s factory.

This warranty does not cover products or parts that are damaged from

improper use or abuse, as determined by the manufacturer. Accessory

items or additional items carry only their respective manufacturer’s

warranty. Consumable items (such as fuses and electrolytic

capacitors), which wear out under normal use are specifically not

covered by this standard warranty. Any consequential damage due

to diagnosis or repair by any party other than the manufacturer’s

authorized personnel is not covered under this warranty.

ATevo

iii

Page 4

Manufacturer's Warranty

Extended Spare Parts Warranty

The manufacturer’s extended warranty includes all items as mentioned

in the ‘Standard Warranty’ as previously listed, plus reasonable in/

out freight costs related to a warranty claim for parts. Said freight

cost is based on either standard UPS rates or common carrier only, as

appropriate. Contact your sales representative for more information

& pricing regarding the extended spare parts warranty.

Magnetic Parts 25-Year Extended Warranty

(equal to 5% of the original purchase price)

Lifetime warranty (limited to 25 years from date of shipment) covers

battery charger major electromagnetic components (T1 transformer,

L1 inductor & L2 inductor) as applicable. Coverage is for 100%

replacement of any covered magnetic component that fails during

normal use. Abuse, neglect, and damage from outside sources

or improper application will make this warranty null and void. The

manufacturer reserves the right to make final determination regarding

the application of this warranty. The manufacturer will be responsible

for costs related to inbound and outbound freight of warranted

magnetic components (T1, L1 & L2).

Freight cost is based on standard UPS rates or common carrier only,

as appropriate. Costs related to removal and/or reinstallation of

warranted magnetic components will be the responsibility of the

purchaser/customer and/or operator of the product. Contact your

sales representative for more information & pricing regarding the

magnetic parts extended warranty.

NOTICE Requests for returns or warranty claims

via manufacturer’s Return Material Authorization (RMA) instructions and

assignment. Contact your sales representative for more information &

pricing regarding returns or warranty claims. Returns that do not follow

this procedure will not be honored.

Election to any of the above offered extended warranties must be done

within the terms of the initial standard warranty.

iv

ATevo

must

be made

Page 5

SAFETY INSTRUCTIONS

PLEASE READ AND FOLLOW TO AVOID

SERIOUS INJURY OR DEATH

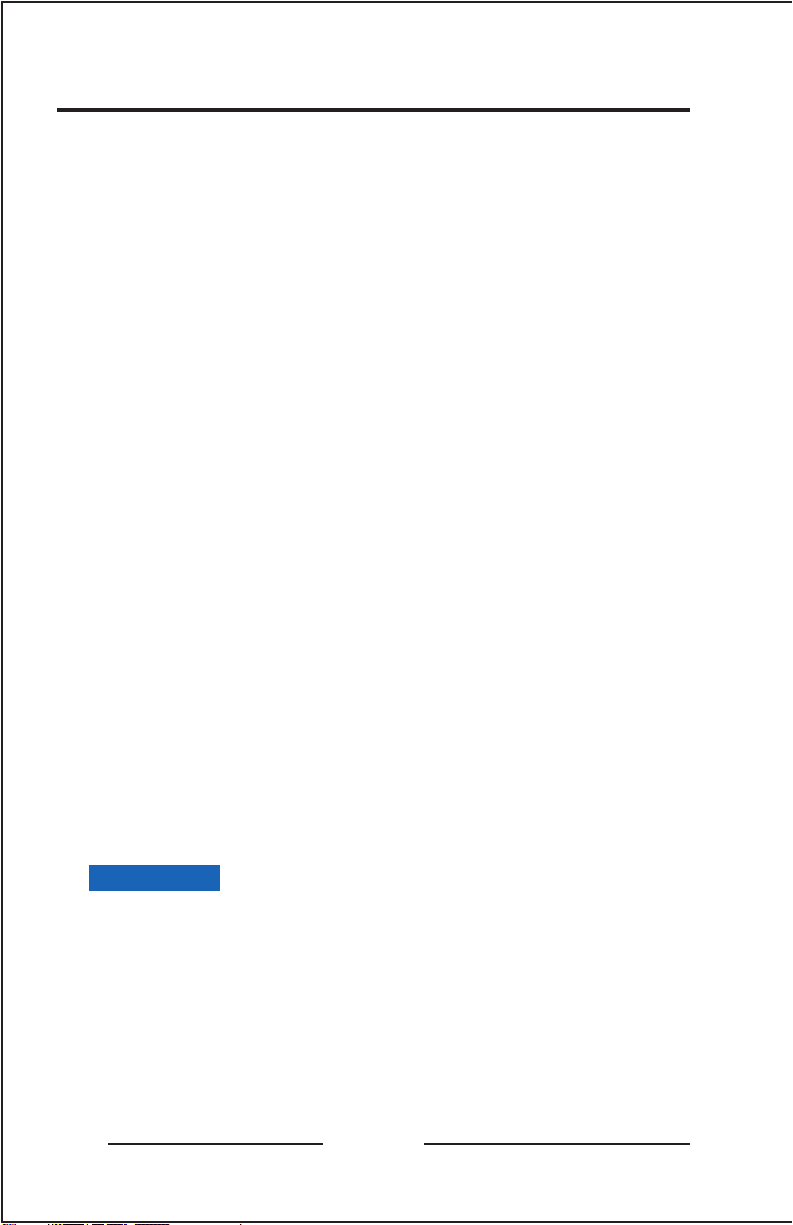

EQUIPMENT/MANUAL SAFETY WARNINGS

WARNING MEANING

Imminently hazardous situation,

which if not avoided, WILL

result in death or serious injury.

Potentially hazardous situation,

which if not avoided, could

result in death or serious injury.

Potentially hazardous situation,

which if not avoided, could

result in minor or moderate

injury (e.g. minor burns,

bruising from pinch points,

minor chemical irritation).

May also be used to alert

against unsafe practices.

ATevo

Important information not

related to personal injury (e.g.

messages related to equipment

or property damage).

LOCKOUT TAGOUT is required

before servicing.

VENTILATION MANDATORY.

Maintain at least 6in / 152mm

of free air on all vented surfaces

for cooling. Allow sufficient

clearance to open front panel

for servicing.

v

Page 6

SAFETY INSTRUCTIONS

PLEASE READ AND FOLLOW TO AVOID

SERIOUS INJURY OR DEATH

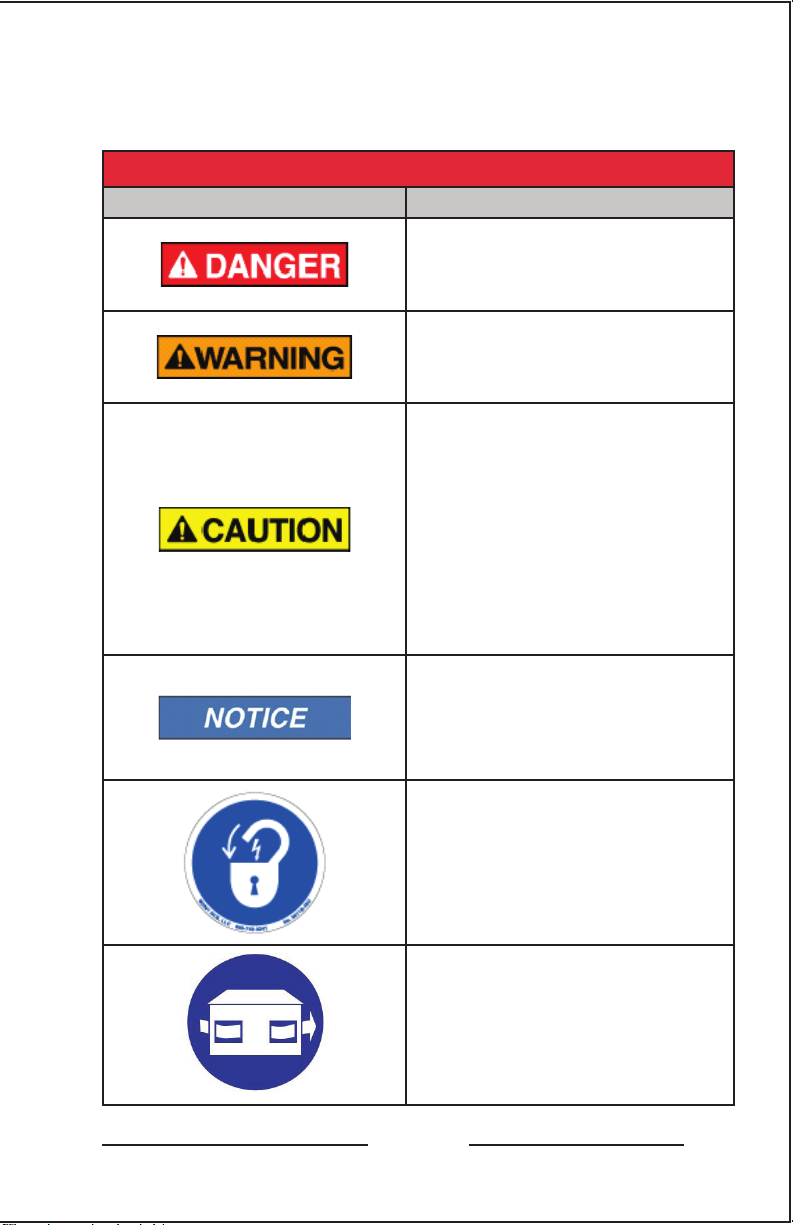

EQUIPMENT/MANUAL SAFETY WARNINGS

WARNING MEANING

Refer to manual.

SAFETY ALERT. Indicates that a

hazardous situation exists. TO

REDUCE RISK OF INJURY OR

DEATH, refer to accompanying

documents, and follow all steps

or procedures as instructed.

DANGEROUS HIGH VOLTAGE

inside product enclosure.

TO REDUCE RISK OF FIRE

OR ELECTRIC SHOCK, do not

attempt to open enclosure or

gain access to areas where you

are not instructed to do so.

SERVICING IS TO BE DONE

ONLY BY QUALIFIED SERVICE

PERSONNEL.

vi

Allow at least 3 minutes

for internal components to

discharge to a safe level

after performing lockout

tagout to prevent exposure to

DANGEROUS HIGH VOLTAGE.

ATevo

Page 7

SAFETY INSTRUCTIONS

PLEASE READ AND FOLLOW TO AVOID

SERIOUS INJURY OR DEATH

EQUIPMENT/MANUAL SAFETY WARNINGS

WARNING MEANING

DANGER! Risk of Arc Flash

(only for ATevo units with input

voltage over 416 Vac)

EXPLOSIVE GAS can be

produced from batteries during

normal operation.

Never smoke, use an open

flame, or create arcs in the

vicinity of the ATevo or the

battery.

Do not operate equipment

without all guards and/or

covers in place.

ATevo

vii

Page 8

SAFETY INSTRUCTIONS

PLEASE READ AND FOLLOW TO AVOID

SERIOUS INJURY OR DEATH

Use of equipment in a manner not specified by

manufacturer may impair protection provided by ATevo.

EXAMPLES OF EQUIPMENT MISUSE

SYMBOL EXAMPLE

Do not use the equipment for

any purpose not described in

this manual.

Do not operate this equipment

without all guards and covers in

place.

Do not operate this equipment

from any power source that

does not match voltage rating

stamped on equipment.

Refer to Manufacturer’s

Identification Label for

operational requirements.

1. Do not touch any uninsulated parts of ATevo, especially the

input and output connections, as there is the possibility of

electrical shock.

2. During normal operation, batteries may produce EXPLOSIVE

GAS! Never smoke, use an open flame, or create arcs in the

vicinity of ATevo, or the battery.

viii

ATevo

Page 9

SAFETY INSTRUCTIONS

PLEASE READ AND FOLLOW TO AVOID

SERIOUS INJURY OR DEATH

1. Before using ATevo, read all instructions and cautionary

markings on: a) this equipment, b) battery, and c) any other

equipment to be used in conjunction with ATevo

2. Do not use ATevo for ANY purpose not described in this manual.

3. Do not install ATevo outdoors, or in wet or damp locations,

unless specifically equipped for that environment.

4. Do not operate ATevo with any power source that does not

match the specified ac and dc voltage ratings. Refer to the data

nameplate decal affixed to the outside panel for operational

requirements.

5. Turn OFF ATevo before connecting or disconnecting the battery

to avoid electrical shock hazards, arcing, burning, and/or

equipment damage.

6. Do not operate ATevo with the safety shield or any other

supplied guards removed or improperly installed.

7. Do not operate ATevo if it has been damaged in any way. Refer

to qualified service personnel.

8. De-energize and lock out all ac and dc power sources to ATevo

before servicing.

9. Do not disassemble ATevo. Only qualified service personnel

should attempt repairs. Incorrect reassembly could result in

explosion, electrical shock or fire.

10. Remove all jewelry, watches, rings, etc. before proceeding with

installation or servicing to avoid electrical shock hazards.

1. This manual contains important safety and operating

instructions, and therefore should be filed for easy access.

2. Maintain at least 6in / 152mm of free air on all vented surfaces

for cooling. Allow sufficient clearance to open the front panel

for servicing.

ATevo

ix

Page 10

Table of Contents - ATevo

TABLE OF

CONTENTS (1PH 6-25 Adc - Group I)

MANUFACTURER’S WARRANTY � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � iii

SAFETY INSTRUCTIONS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � v

1. RECEIVING & MOUNTING � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �2

1.1 Storing ATevo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Receiving ATevo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Unpacking and Inspecting ATevo . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Inspection Checklist

1.4 Reporting Damage or Shortage . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Returning Damaged Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6 Moving ATevo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6.1 ATevo Weight Table

1.7 Mounting ATevo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7.1 Wall-Mounting

1.7.2 Floor-Mounting

1.7.3 Rack-Mounting

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

2

3

4

6

8

2. WIRING � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �10

2.1 Mechanical Diagram and Component Location . . . . . . . . . . 10

2.1.1 Main Control Board (A1)

2.1.2 Power Board (A2)

2.1.3 Auxiliary I/O Board (A4) - optional

2.1.4 Filter Capacitor Board (A7)

2.1.5 AC Surge Suppressor MOV Board (A9)

2.1.6 Serial Communications Adapter (A12) - optional

2.1.7 Forced Loasd Shating Adapter (A13) - optional

2.1.8 Ethernet Communications Adapter (A22) - optional

2.1.9 Eliminator Capacitor (C2) - optional

2.1.10 AC Input Circuit Breaker (CB1)

2.1.11 DC Output Circuit Breaker (CB2)

2.1.12 Main Filter Inductor (L1)

2.1.13 Secondary Filter Inductor (L2)

2.1.14 Power Isolation Transformer (T1)

x

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

� � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

ATevo

12

12

12

12

12

12

13

13

13

13

13

13

13

13

Page 11

Table of Contents - ATevo

2.2 Removing Safety Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 ATevo with Selectable Input Voltage - optional . . . . . . . . . . . . 14

2.3.1 Determining if Multi-Tap Option is Present

2.3.2 Verifying Multi-Tap AC Input Voltage Setting

2.3.3 Modifying Multi-Tap AC Input Voltage Setting

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

14

15

15

2.4 Making AC Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 Making DC Output Connections . . . . . . . . . . . . . . . . . . . . . . . 18

2.6 Remote Voltage Sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7 Wiring ATevo Common Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.8 Wiring Relays on Auxiliary I/O Board . . . . . . . . . . . . . . . . . . . 21

2.9 Wiring Temperature Compensation Probe . . . . . . . . . . . . . . . 21

2.10 Wiring Serial Communications Adapters . . . . . . . . . . . . . . . 22

2.11 Wiring Ethernet Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3. CONTROLS & NAVIGATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

3.1 Front Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . . 23

3.1.1 Main ATevo Display

3.1.2 Navigation and Control Button Group

3.1.3 Operation Modes and Methods Button Group

3.1.4 Alarm Section

3.1.5 Hindle Health System (HHS) Section

3.1.6 AC Input and DC Output Circuit Breakers

3.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Home Screen

3.2.2 Configuration Screens

3.2.3 Status Screens

3.2.4 Hindle Health System Screens

3.3 Main Menu and Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.1 MENU and ARROW Buttons

3.3.2 EDIT/ENTER Button

3.3.3 Navigation Conventions in This Manual

3.3.4 Escape (ESC) Button

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

24

24

24

24

24

24

25

26

26

26

27

28

29

30

4. STARTUP & CONFIGURATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �31

4.1 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 Understanding Startup Sequence

4.1.2 Factory Settings Tables

4.1.3 Checking Installation

4.1.4 Starting Up

4.1.5 Home Screen

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

ATevo

� � � � � � � � � � � � � � � � � � � � � � � � � � �

31

31

36

36

36

xi

Page 12

Table of Contents - ATevo

4.2 Configuring Basic Set Points and Alarms . . . . . . . . . . . . . . . . 37

4.2.1. How to Configure General Parameter Settings

4.2.2 Setting Float Voltage

4.2.3 Setting Equalize Voltage

4.2.4 Setting Equalize Timer

4.2.5 Setting High DC Alarm Voltage

4.2.6 Setting Low DC Alarm Voltage

4.2.7 Setting Current Limit Level

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

4.3 Configuring Advanced Set Points and Alarms . . . . . . . . . . . . 41

4.3.1 How to Configure Advanced Settings

4.3.2 Setting High Voltage Shutdown

4.3.3 Setting High Level Detect

4.3.4 Setting End of Discharge (EOD) Alarm

4.3.5 Setting Low Voltage Level Detect

4.3.6 Setting AC Ripple Alarm

4.3.7 Setting Positive (+) Ground Fault Sensitivity Level

4.3.8 Setting Negative (-) Ground Fault Sensitivity Level

4.3.9 Setting Battery Temperature Compensation

4.3.10 Setting Battery Type for Temperature Compensation

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � �

� � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � �

4.4 Configuring System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.1 How to Configure System Settings

4.4.2 Setting System Time

4.4.3 Setting System Date

4.4.4 Setting Display Backlight Control

4.4.5 Setting Display Contrast

4.4.6 Setting Display Backlight Intensity

4.4.7 Setting Display Reverse Image Control

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

4.5 Configuring Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.5.1 Configuring Common Alarm Relay

4.5.2 Configuring Auxiliary I/O Board Relays

� � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

4.6 Disabling Alarms in Common Alarm List . . . . . . . . . . . . . . . . 49

4.7 Configuring Serial Communications Adapter . . . . . . . . . . . . . 50

4.8 Configuring Ethernet Communications Adapter . . . . . . . . . . 50

4.9 Enabling/Disabling High Level Detect . . . . . . . . . . . . . . . . . . . 51

37

38

38

39

39

39

40

41

41

42

42

42

43

43

43

44

44

45

45

46

46

46

47

47

47

49

5. BASIC OPERATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 52

5.1 ATevo Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.1.1 Changing Display Mode

5.1.2 Changing Charge Mode

5.1.3 Changing Equalize Method

5.1.4 Lamp Test & Display of Firmware Versions

5.1.5 Resetting Latched Relays (legacy method)

xii

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

ATevo

52

53

54

55

55

Page 13

Table of Contents - ATevo

5.2 High Voltage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3 Low Level Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.4 High Level Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6. ADVANCED OPERATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 58

6.1 ATevo Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.1.1 Basic Settings Icon

6.1.2 Advanced Settings Icon

6.1.3 Save|Reset Configuration Icon

6.1.4 Event Logs Icon

6.1.5 Common Alarm Icon

6.1.6 Relays Icon

6.1.7 AUX Inputs Icon

6.1.8 Testing Icon

6.1.9 Communication Icon

6.1.10 Security Icon

6.1.11 System Settings Icon

6.1.12 System Information Icon

6.2 Alarms Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3 Health Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.4 Security and Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.4.1 Three (3) Levels of Password Protection

6.4.2 How to Access Security Features and Password Configuration

6.4.3 Setting Passwords

6.4.4 Setting Default Access

6.4.5 Logging In to a Password Authorization Level

6.4.6 Logging Out

6.5 Optional SD Memory Card Features . . . . . . . . . . . . . . . . . . . . 65

6.5.1 Installing SD Memory Card

6.5.2 Storing Event Log File to Memory Card

6.5.3 Storing/Recalling Settings to/from Memory Card

6.5.4 Upgrading Firmware via SD Memory Card

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

� � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � �

59

59

59

59

59

60

60

60

60

61

61

61

62

62

63

63

64

64

65

66

67

68

7. ALARMS & INDICATORS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �70

7.1 Legacy AT10.1 Alarms and Indicators . . . . . . . . . . . . . . . . . . . 70

7.2 Common Alarm Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.2.1 Configuring Common Alarm

7.3 Alarm LED Summary Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.4 Active Alarm Bar, Alarm View, and Alarm Log . . . . . . . . . . . . 74

7.4.1 Active Alarm Bar

7.4.2 Active Alarm List

7.4.3 Alarm Logs

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

ATevo

71

74

74

74

xiii

Page 14

Table of Contents - ATevo

7.5 Advanced Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.5.1 High Voltage Shutdown Alarm

7.5.2 Low Level Detect Alarm

7.5.3 End of Discharge (EOD) Alarm

7.5.4 High AC Ripple Alarm

7.5.5 Battery Temperature Probe Failure Alarm

7.5.6 Rectifier Over Temperature Alarm

7.5.7 External Feedback Failure Alarm

7.5.8 Internal Feedback Failure Alarm

7.5.9 Open DC Circuit Breaker Alarm

7.5.10 Open AC Circuit Breaker Alarm - optional

7.5.11 DC Power Supply Failure Alarm

7.5.12 SCR Failure Alarm

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � �

75

75

76

76

76

76

76

77

77

77

77

77

7.6 Resetting Latched Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . 77

7.7 Battery Open Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.7.1 Battery Open Test Settings

7.7.2 Running Battery Open Test Periodically

7.7.3 Running Battery Open Test Manually

7.7.4 Resetting Battery Open Alarm

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

79

80

81

81

8. HINDLE HEALTH SYSTEM � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 82

8.1 Hindle Health System - Overview . . . . . . . . . . . . . . . . . . . . . . . 82

8.2 Hindle Health System - Components . . . . . . . . . . . . . . . . . . . . 82

8.2.1 Self-Diagnostics

8.2.2 Hindle Health Button

8.2.3 Hindle Health LED Indicators

8.3 Hindle Health System - Screens . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3.1 Introduction and Warning Screens

8.3.2 Test Selection

8.3.3 Test Screens

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

82

82

83

83

84

84

9. EVENT LOGS� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 85

9.1 Event Log Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.2 Viewing Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3 Viewing Hindle Health Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.4 Clearing Event Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.5 Copying Event Logs to SD Memory Card . . . . . . . . . . . . . . . . 87

xiv

ATevo

Page 15

Table of Contents - ATevo

10. BATTERY TEMPERATURE COMPENSATION � � � � � � � � � � � � � � � � � � � � � � � � 88

10.1 ATevo Battery Temperature Compensation . . . . . . . . . . . . . . 88

10.2 Installing the TempCo Option . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.2.1 Configuring the TempCo Option

� � � � � � � � � � � � � � � � � � � � � � � � � �

91

10.3 Using the TempCo Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.3.1 Home Screen with TempCo Option

� � � � � � � � � � � � � � � � � � � � � � � �

92

10.4 Temperature Compensation Curves . . . . . . . . . . . . . . . . . . . 93

11. REMOTE SENSE � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 94

11.1 ATevo Remote Voltage Sense . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.2 Remote Sense Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.3 Procedure for Wiring Remote Sense . . . . . . . . . . . . . . . . . . . 95

11.4 Configuring Remote Sense Jumpers . . . . . . . . . . . . . . . . . . . 97

11.4.1 Locating Remote Sense Configuration Jumpers

11.4.2 Enabling Remote Sense

11.4.3 Enabling Local Sense

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � �

97

97

97

11.5 Disabling Remote Sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

12. AUXILIARY INPUTS/OUTPUTS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 99

12.1 Auxiliary Input/Output (I/O) Board . . . . . . . . . . . . . . . . . . . . 99

12.1.1 Relays

12.1.2 Binary Inputs

12.1.3 Analog Inputs

12.2 Connections to Auxiliary I/O Board . . . . . . . . . . . . . . . . . . . 101

12.2.1 System Connections

12.2.2 Wiring Relays Connections

12.2.3 Wiring Binary Input Connections

12.2.4 Wiring Analog Input Connections

12.3 Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

12.3.1 Auxiliary I/O Board Address

12.3.2 Binary Input Voltage Configuration

12.4 Software Configuration for Relays . . . . . . . . . . . . . . . . . . . . 106

12.4.1 Auxiliary I/O Board Relay Configuration

12.4.2 Auxiliary I/O Board Relay Alarm Configuration

12.4.3 Auxiliary I/O Board Relay Latch Configuration

12.4.4 Auxiliary I/O Board Relay Time Delay Configuration

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � �

� � � � � � � � � � � � � � �

� � � � � � � � � � �

99

100

100

101

101

102

104

105

106

107

108

108

109

ATevo

xv

Page 16

Table of Contents - ATevo

12.5 Software Configuration for Binary Inputs . . . . . . . . . . . . . . 110

12.5.1 Binary Input Configuration

12.5.2 Binary Input Name Assignment

12.5.3 Binary Active State Assignment

12.5.4 Binary Input Alarm Enable

12.5.5 Binary Input Action Assignment

12.5.6 Factory Default Binary Input Configuration

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

110

111

111

112

112

113

12.6 Software Configuration for Analog Inputs . . . . . . . . . . . . . 113

12.6.1 Analog Input Configuration

12.6.2 Analog Input Name Assignment

12.6.3 Analog Input Primary Unit Assignment

12.6.4 Analog Input Scaling Assignment

12.6.5 Analog Input Alarm and Trigger Assignment

12.6.6 Analog Input Alarm Threshold Assignment

12.6.7 Analog Input Action Assignment

12.6.8 Factory Default Analog Input Configuration

� � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

114

114

115

115

116

117

119

119

13. FORCED LOAD SHARING � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 120

13.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

13.2 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

13.3 Forced Load Sharing Configuration . . . . . . . . . . . . . . . . . . . 120

13.3.1 Installing Serial Communications Adapter (A13)

13.3.2 Configuring Serial Communications Hardware

13.4 Wiring ATevo Chargers for Forced Load Sharing . . . . . . . . 122

13.4.1 Configuring ATevo for Forced Load Sharing

13.5 Forced Load Sharing Operation . . . . . . . . . . . . . . . . . . . . . . 125

13.5.1 Requirements to Maintain Forced Load Sharing

13.5.2 Virtual Independent Mode

13.5.3 Forced Load Sharing Alarms

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � �

13.6 Temperature Compensation with Forced Load Sharing . . 127

13.7 Battery Open Alarm for Forced Load Sharing . . . . . . . . . . 127

13.8 Timed Equalize with Forced Load Sharing . . . . . . . . . . . . . 127

13.9 Auto-Equalize with Forced Load Sharing . . . . . . . . . . . . . . . 128

13.10 Firmware Updates with Forced Load Sharing . . . . . . . . . . 12 8

13.11 Troubleshooting Forced Load Sharing ATevos . . . . . . . . . . 128

� � � � � � � � � � �

� � � � � � � � � � � �

� � � � � � � � � � � � � � �

� � � � � � � � � � � �

121

121

123

126

126

127

14. MAINTENANCE � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 129

14.1 Performing Routine Maintenance . . . . . . . . . . . . . . . . . . . . 129

14.1.1 Keeping ATevo Clean

14.1.2 Checking Power and Signal Connections

14.1.3 Checking Remote Sense Wiring - optional

14.1.4 Checking Temperature Compensation Probe - optional

14.1.5 Measuring Output Ripple Voltage

xvi

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � �

� � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � �

ATevo

129

129

129

130

130

Page 17

Table of Contents - ATevo

14.2 Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . 130

14.3 Replacing Defective Components . . . . . . . . . . . . . . . . . . . . 130

14.3.1 Removing Safety Shield

14.3.2 Replacing Main Control Board (A1)

14.3.3 Replacing Serial Communications Adapter Board (A12/A13)

14.3.4 Replacing Ethernet Communications Adapter Board (A22)

14.3.5 Replacing Rectifier / Heat Sink Assembly (A6)

14.3.6 Replacing Power Board (A2)

14.3.7 Replacing DC Power Supply (P/S-9V)

14.3.8 Replacing Auxiliary I/O Board (A4)

14.3.9 Replacing Filter Capacitor Baord (A7 w/C1x)

14.3.10 Replacing AC Surge Suppressor MOV Board (A9)

14.3.11 Replacing Eliminator Filter Capacitor (C2) - optional

14.3.12 Replacing Circuit Breakers (CB1/CB2)

14.3.13 Replacing Power Isolation Transformer (T1)

14.3.14 Replacing Filtering Inductors (L1/L2)

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � �

� � � � �

� � � � � �

� � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � �

� � � � � � � � � � � �

� � � � � � � � � �

� � � � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � � � � �

131

131

132

132

132

133

133

134

135

135

136

136

137

139

15. APPENDICES & DRAWINGS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 140

Appendix A - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Appendix B - Standard Drawings . . . . . . . . . . . . . . . . . . . . . . . . . 142

ATevo Batt Chgr Outline: NEMA-1 Style-5054 Encl (JE5251-00)

ATevo Batt Chgr Internal Comp Layout: Style-5054 (JE5252-00)

Appendix C - Document Control Information . . . . . . . . . . . . . . . 146

� � � � � � � �

� � � � � � �

142

144

ATevo

xvii

Page 18

1 Receiving & Mounting

1.1 Storing ATevo

If you store ATevo for more than a few days before installation, store

it in its original shipping container, in a temperature-controlled,

dry climate. Ambient temperatures of 0 to 122 °F / -18 to 50 °C are

acceptable. Storage should not exceed two (2) years due to limited

shelf life of dc filter capacitors when they are not in service.

1.2 Receiving ATevo

The manufacturer does not assume any liability for damage during

transportation or handling. Therefore, upon receipt of ATevo (or

related products) immediately unpack, inspect for damage or

shortage (per Section 1.3), and report issues found (per Section 1.4).

1.3 Unpacking and Inspecting ATevo

Carefully remove all shipping materials from ATevo, and save until

you are sure ATevo is undamaged. Remove ATevo from shipping

pallet. Inspect for possible damage, using checklist below. If

damage found, see Section 1.4 for proper reporting.

1.3.1 Inspection Checklist

□ Enclosure exterior and interior are not marred or dented.

□ No visible damage to exterior or interior components.

□ Internal components are secure.

□ Printed circuit boards are firmly seated on their standoffs.

□ Hardware is tight.

□ Wire terminations are secure.

□ User’s Manual is included.

□ Includes all items on packing list.

1.4 Reporting Damage or Shortage

If damage or shortage is found, notify the delivery person and make

notation on all copies of carrier’s receipt before signing. If such is

discovered after delivery, notify carrier immediately and request an

inspection. Should the products require an inspection by (or return

to) the manufacturer, please contact your sales representative for

further instructions.

2

ATevo

Page 19

1 Receiving & Mounting

1.5 Returning Damaged Equipment

Returned material must be packed in compliance with shipping

regulations. It is preferable to use original shipping materials

if possible. Mark the outside of the shipping container with

manufacturer’s Return Material Authorization (RMA) number.

1.6 Moving ATevo

Once you have established that ATevo is undamaged, identify the

weight of the unit using the table below.

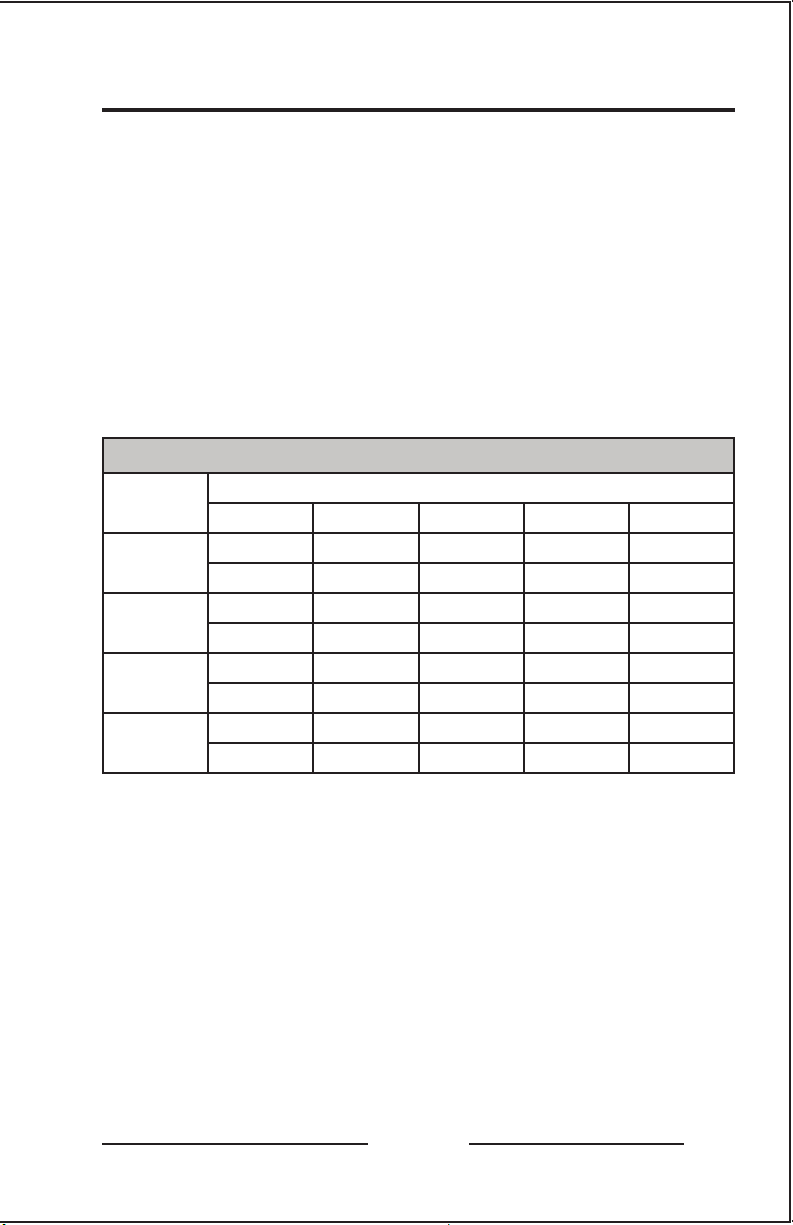

1.6.1 ATevo Weight Table

ATevo Weight by Model

Output

Voltage

24 Vdc

48 Vdc

130 Vdc

260 Vdc

6 Adc 12 Adc 16 Adc 20 Adc 25 Adc

33 lb 33 lb 88 lb 101 lb 101 lb

15 kg 15 kg 40 kg 46 kg 46 kg

83 lb 96 lb 112 lb 108 lb 108 lb

38 kg 44 kg 51 kg 48 kg 48 kg

97 lb 125 lb 125 lb 193 lb 193 lb

44 kg 57 kg 57 kg 88 kg 88 kg

128 lb 193 lb n/a n/a n/a

58 kg 88 kg n/a n/a n/a

Ampere Rating

ATevo’s Style-5054 enclosure does not feature top-lifting eyes for

moving. Move ATevo with a forklift using the supplied shipping

pallet. Lift ATevo into a wall-mount or rack-mount installation, using

a heavy-duty sling or a scissor lift.

ATevo

3

Page 20

1 Receiving & Mounting

1.7 Mounting ATevo

Mount the ATevo Style-5054 enclosure to easily access the front

panel AC Input (CB1) and DC Output (CB2) Circuit Breakers. Choose

from the following mounting methods:

1.7.1 Wall-Mounting

Wall-mounting is the standard method. When wall-mounting ATevo,

consider the following:

1. Refer to the Style-5054 enclosure outline drawing in Appendix B.

2. The wall must be strong enough to properly support ATevo’s

weight, plus a safety factor. Refer to Weight Table in Section

1.6.1. The weight of ATevo may be different, depending on the

features, options, and accessories ordered with the unit.

3. Select conduit entrances with planned ac input and dc output

wiring in mind. By using pre-fab knockouts on enclosure sides

or bottom, the cabinet shroud can be removed for internal

servicing without removing ATevo from the wall.

4. Location requirements:

» Free of drips and splatter. If falling particles and liquids are

a problem, install a NEMA Type 2 drip shield accessory.

» Between 0 and 122 °F / -18 and 50 °C, with relative humidity

between 0% and 95% non-condensing.

» Must be free of flammable or explosive materials.

5. Maintain at least 6in / 152mm of free air on all vented surfaces

for cooling.

6. Allow at least 36in / 914mm front clearance for operation and

maintenance.

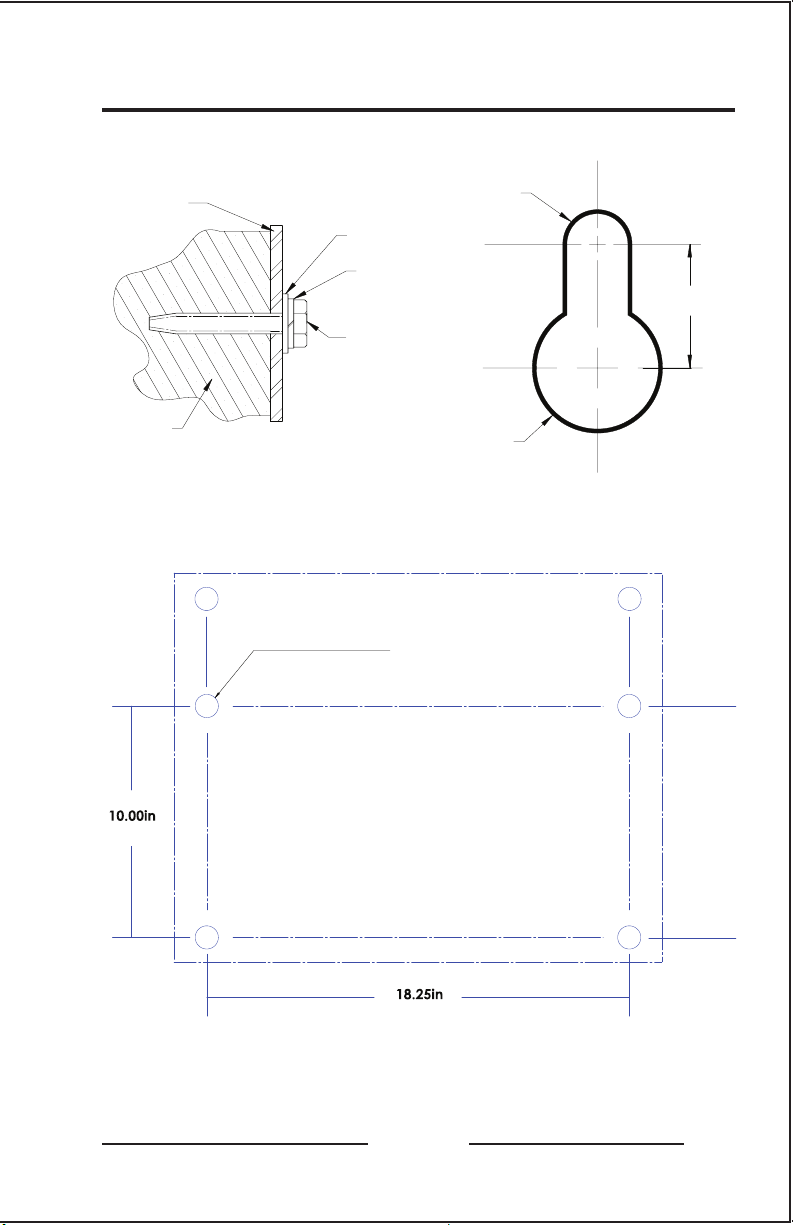

PROCEDURE

Install four (4) 0.25in / 6.4mm anchor bolts (not supplied) rated

to support ATevo’s weight plus a minimum safety factor of two (2)

times, into the wall. Place ATevo onto anchor bolts, add appropriate

mounting hardware, and tighten securely. Refer to the following

graphics for ATevo wall-mounting pattern and specification.

4

ATevo

Page 21

GRAPHICS

ENCLOSURE

MOUNTING

FLANGE

FLAT WASHER

LOCKWASHER

0.25in / 6.4mm

DIA BOLT

1 Receiving & Mounting

0.312in

[8.00mm]

DIA

0.750in

[19.00mm]

WALL

0.750in

[19.00mm]

DIA

RECOMMENDED MOUNTING KEYHOLE SLOT USED ON

HARDWARE LOADING STYLE-5054 MOUNTING FLANGE

USE 0.25in / 6.4mm DIA

BOLTS - FOUR (4) PLACES

254mm

464mm

ATevo STYLE-5054 ENCLOSURE

WALL-MOUNTING PATTERN

ATevo

5

Page 22

1 Receiving & Mounting

1.7.2 Floor-Mounting

To install ATevo onto a horizontal surface, the standard enclosure

does not need to be modified, but a special floor mounting accessory

is required. The kit includes a set of mounting brackets that elevate

the top of ATevo approximately 47in /1194mm above floor level,

with provisions for floor anchoring. The kit also includes appropriate

hardware and installation instructions for the floor-mounting

procedure.

When floor-mounting ATevo, consider the following:

1. Locate anchor bolt holes at least 4.25in /108mm from any wall,

to allow clearance behind the mounting brackets.

2. Select conduit entrances with planned ac input and dc output

wiring in mind. By using pre-fab knockouts on enclosure sides

or bottom, the cabinet shroud can be removed for internal

servicing without removing ATevo from the floor stand.

3. Location requirements:

» Free of drips and splatter. If falling particles and liquids are

a problem, install a NEMA Type 2 drip shield accessory.

» Between 0 and 122 °F / -18 and 50 °C, with relative humidity

between 0% and 95% non-condensing.

» Must be free of flammable or explosive materials.

4. Maintain at least 6in /152mm of free air on all vented surfaces

for cooling.

5. Allow 36in /914mm front clearance for operation and

maintenance.

PROCEDURE

Install four (4) 0.25in / 6.4mm anchor bolts (not supplied) rated

to support the unit weight plus a minimum safety factor of two (2)

times, into floor.

Assemble the floor-mounting accessory on to the anchor bolts as

shown. Place ATevo onto vertical posts, add appropriate mounting

hardware, and tighten.

Refer to the following graphics for floor mounting patterns and

enclosure footprints.

6

ATevo

Page 23

GRAPHICS

19.75in

502mm

1 Receiving & Mounting

47.75in

1213mm

0.437in / 11mm

FLOOR MTG HOLE

FOUR (4) PLACES

10.00in

ATevo STYLE-5054 ENCLOSURE

FLOOR-MOUNTNG PATTERN

WALL

4.25in

min.

108mm

18.25in

463mm

0.375in / 9.5mm

FLOOR-MOUNTING

HARDWARE

FOUR (4) PLACES

ATevo

10.00in

254mm

7

Page 24

1 Receiving & Mounting

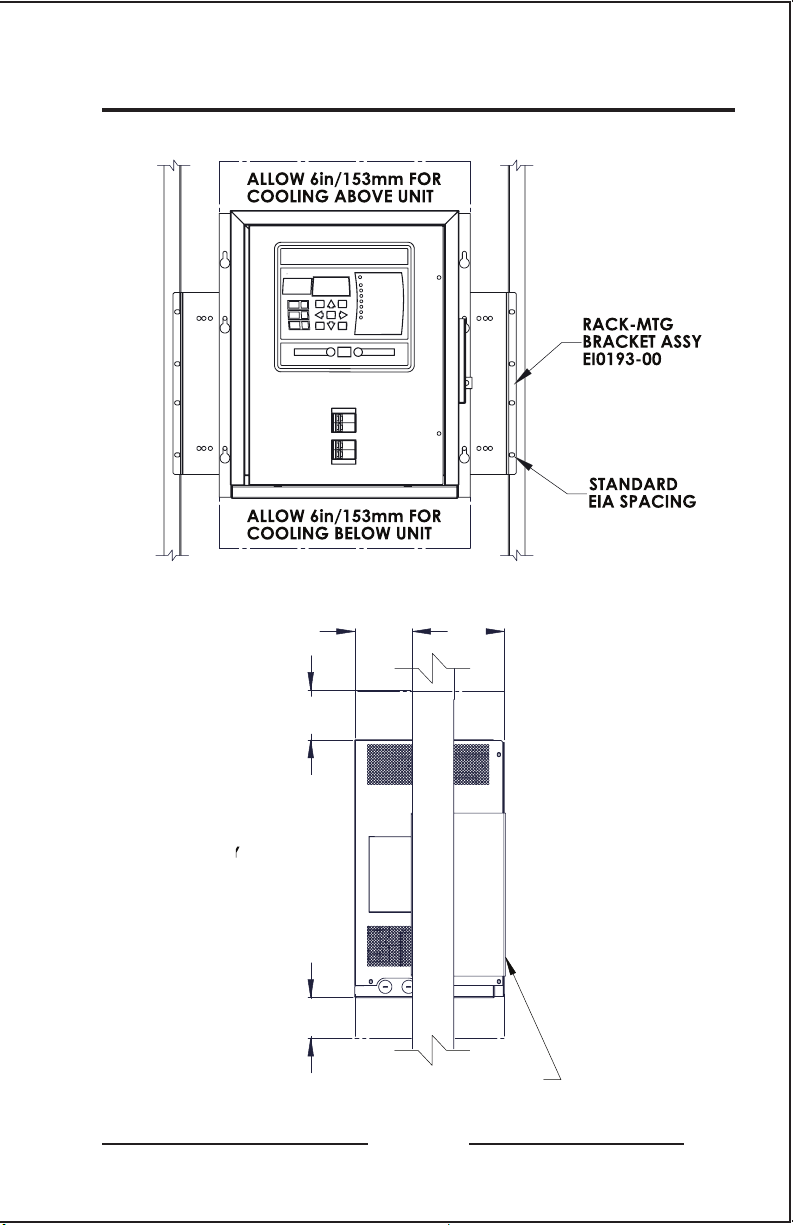

1.7.3 Rack-Mounting

ATevo can be installed into most 23in/584mm and 24in/610mm relay

racks with standard EIA hole spacing. ATevo’s enclosure does not

need to be modified for rack mounting, but a special kit is required.

The kit includes two (2) mounting brackets, appropriate hardware,

and Installation Instructions for the rack-mounting procedure.

When rack-mounting ATevo, consider the following:

1. Rack must be strong enough to properly support the unit’s

weight. Refer to Weight Table in Section 1.6.1.

2. Select conduit entrances such that planned ac input and dc

output conduit is accessible after rack-mounting. Note the

standard pre-fab conduit knockouts located on the sides, top,

and bottom of the enclosures.

3. Location requirements:

» Free of drips and splatter. If falling particles and liquids are

a problem, install a NEMA Type 2 drip shield accessory.

» Between 0 and 122 °F / -18 and 50 °C, with relative humidity

between 0% and 95% non-condensing.

» Must be free of flammable or explosive materials.

4. Maintain at least 6in /152mm of free air on all vented surfaces

for cooling.

5. Allow at least 36in /914mm front clearance for operation and

maintenance.

PROCEDURE

To rack mount ATevo, first install mounting brackets into rack using

proper hardware (not supplied). Second, mount ATevo onto installed

brackets, using supplied kit hardware. Provide at least 6in /152mm

of free air above and below ATevo for cooling. Refer to the following

graphics for rack-mounting configurations.

8

ATevo

Page 25

GRAPHICS

6in/153mm

COOLING

6in/153mm

COOLING

8.50in

216mm

4.00in

57mm

R

A

C

K

1 Receiving & Mounting

ATevo STYLE-5054 RACK-MOUNTING

4.00in

57mm

8.50in

216mm

6in/153mm

COOLING

6in/153mm

COOLING

R

A

C

K

ATevo

0.25in/6.4mm

MTG. BOLTS

9

Page 26

2 Wiring

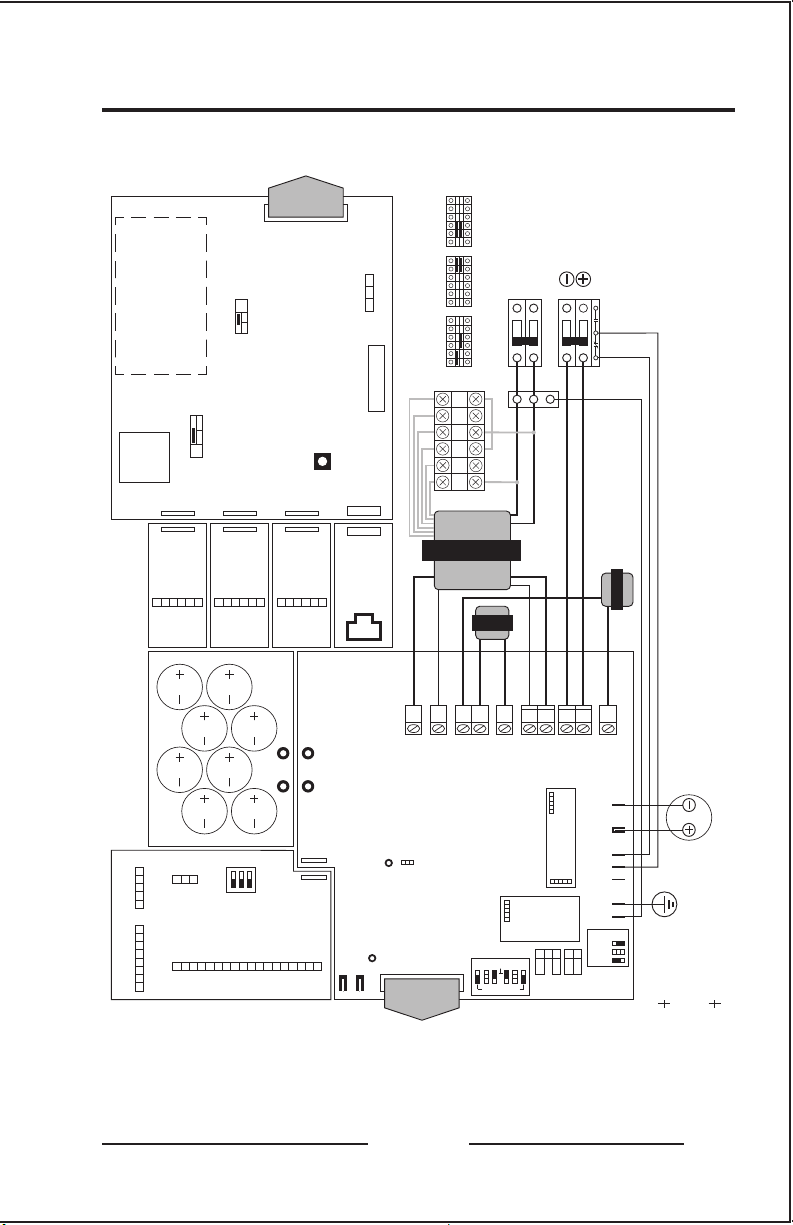

2.1 Mechanical Diagram and Component Location

ATevo has the following mechanical layout and wiring diagram

screen-printed onto its patented, internal acrylic safety shield.

ATevo is composed of these components and subsections:

• A1 - Main Control PC Board

• A2 - Power Board

• A4 - Auxiliary I/O Board - optional

• A7 - Filter Capacitor (C1x) Board

• A9 - AC Surge Suppressor MOV Board

• A10 - Remote Temperature Probe - optional

• A12 - Serial Communications Adapter(s) - optional

• A13 - Forced Load Sharing Communications Adapter - optional

• A22 - Ethernet Communications Adapter - optional

• C2 - Eliminator Filter Capacitor - optional

• CB1 - AC Input Circuit Breaker (and input terminals L1/L2)

• CB2 - DC Output Circuit Breaker (and output terminals +/-)

• L1 - Main Filter Inductor

• L2 - Secondary Filter Inductor

• T1 - Power Isolation Transformer

10

ATevo

Page 27

PUSH CARD IN

TO EJECT

SD MEMORY

CARD

PORT 1

RXD/RA (-)

P1

TXD/TA (-)

JP4

RE-FLASH

A12 Serial

Adapter

GND

RTS/TB (+)

CTS/RB (+)

ATevo Silkscreen (1PH 6-25 Adc)

RIBBON CABLE TO

PRGM

NORM

ENABLE

PORT 2

P10

(EN5034-##)

SHIELD

RXD/RA (-)

P1

A12 Serial

TXD/TA (-)

CTS/RB (+)

A2 POWER BOARD

HIGH LEVEL

DETECT SHUTDOWN

DIS

EN

J1

A1 Main Control Board

PORT 3

P11

P1

(EN5034-##)

Adapter

GND

SHIELD

TXD/TA (-)

RXD/RA (-)

RTS/TB (+)

(EN5031-##)

PUSH TO

RESET

P12

(EN5034-##)

A12/13 Serial

Adapter

GND

SHIELD

RTS/TB (+)

CTS/RB (+)

P1

SW13

ETHERNET

P1

ALARM

1 2 3

C NC NO

TB6 COMMON

P2

P13

(EN5035-##)

A22 Ethernet

Adapter

J1

AC INPUT VOLTAGE SELECTION

(OPTION NOT AVAILABLE ON SINGLE INPUT UNITS)

USE BOTH JUMPERS WHEN MAKING SELECTIONS

H1 H3 H2 H5 H4 H2 H1 H3 H2 H5 H4 H2 H1 H3 H2 H5 H4 H2

H2

MAIN CONTROL CARD VIEWED FROM BACK OF DOOR

H4

H2 H5

H3

H1

T1 Transformer

120 Vac INPUT 208 Vac INPUT 240 Vac INPUT

L1 Inductor

AC INPUT

L1 / Line

L2 / Neutral

INPUT BREAKER CB1

Negative

Positive

DC OUTPUT

OUTPUT BREAKER CB2

AUX-CB2

(EN5039-##)

A9 MOV BOARD

CONTACTS

STRIP WIRE INSULATION 1/2in

USE COPPER CONDUCTOR ONLY

L2 Inductor

2 Wiring

TORQUE SCREWS TO 31 in-lb

DANGER

ATevo Series

Component Layout (6-25 Adc)

A7 Filter

Board

1 NA

2 NA

3 NA

4 NA

MOC

TB1 TB3

)+( 1B

)-( 1B

)+( 2B

)-( 2B

)+( 3B

)-( 3B

)+( 4B

)-( 4B

S1

(EN5040-##)

A4 Aux I/O Board

TB4 TB2

1YALER

NC

NC

NO

COM

4YALER

3YALER

2YALER

NC

NC

NO

NO

NO

COM

COM

HIGH VOLTAGE

COM

(EN5038-##)

NEG

POS

NC

NO

X4

X1

L2-1

L1-2

DANGER

TBS1 TBS2

HIGH VOLTAGE

J105

P1

6YALER

5YALER

NC

NO

COM

COM

TP4 Output (+)

TP3 Output (-)

TP2 (+)

TP1 (-)

P1

RIBBON CABLE TO

A1 MAIN CONTROL

JP101

(EN5037-##)

A2 Power Board

JP103 LOCAL

REMOTE SENSE

ATevo

L1-1

J104

JP104

Y2

Y1

J102

POS 1

REMOTE SENSE

TB1

CB2 POS

CB2 NEG

C2 (-)

EN5042-XX

C2 (+)

COMM

A24 DC POWER

SUPPLY

J101

EARTH

AC MOV

GROUND DETECT

ENABLED

DISABLED

SIG 1

NEG 3

GND 2

BATT TEMP

TB8

L2-2

C2 Eliminator

Capacitor

CB2

CB1

GROUND

JP102

TP4

OUTPUT

POS

TP3

OUTPUT

NEG

11

Page 28

2 Wiring

2.1.1 Main Control Board (A1)

Shown on top-right of silkscreen. Mounted on the ATevo front panel

door. Contains display, buttons, alarm indicators, and is responsible

for battery charger controls.

2.1.2 Power Board (A2)

Shown on bottom-left of silkscreen. Mounted on heat sink along

left side of ATevo. Contains most power electronic connections,

and terminal blocks for remote sense and battery temperature

compensation options.

2.1.3 Auxiliary I/O Board (A4) - optional

Shown at top-left of silkscreen. Bolted to heat sink on the left side,

above the Power Board. Plugs directly into Power Board (A2).

• six (6) relays, four (4) Binary Inputs, and four (4) Analog Inputs

• relays can be configured to indicate status of six (6) different alarms

or status points

• independently-isolated Binary Inputs can be configured to report ON/

OFF status of four (4) controls

• Analog Inputs include input scaling and can report the status of four

(4) analog controls referenced to the dc bus

2.1.4 Filter Capacitor Board (A7)

Shown near top-left of silkscreen. Bolted to top of the Power Board

(A2). The capacitors (C1x) filter ‘ripple’ from the dc output.

2.1.5 AC Surge Suppressor MOV Board (A9)

Shown to left of AC Circuit Breaker (CB1) on silkscreen. Mounted to

top-left side of breaker bracket. Contains ac input surge suppression

and filtering. It is located for easy access, examination, and

replacement in case an input transient event should occur.

2.1.6 Serial Communications Adapter (A12) - optional

Shown above Ethernet Comm. Adapter (A22) on silkscreen. Up

to three (3) Serial Communications Adapter boards (A12) can be

plugged into the Main Control Board (A1) at locations P10, P11, and

P12. This option supports DNP3 and Modbus protocols, and can be

configured to support 2-wire or 4-wire RS-232 connections, or 2-wire

or 4-wire RS-485 connections.

12

ATevo

Page 29

2 Wiring

2.1.7 Forced Load Sharing Comm Adapter (A13) - optional

Mounted similarly to Serial Communications Adapter (A12).

2.1.8 Ethernet Communications Adapter (A22) - optional

Shown directly to bottom-left of Main Control Board (A1) on

silkscreen. Plugs into Main Board at P13. Supports DNP3 and

Modbus protocols via 10/100 copper Ethernet connection.

2.1.9 Eliminator Filter Capacitor (C2) - optional

Shown below Power Board on silkscreen. Mounted on bottom-left

under Power Board. Provides the additional ripple filtering, required

for the ‘filtered eliminator’ option.

2.1.10 AC Input Circuit Breaker (CB1)

Located in center of ATevo, about one third from bottom. Protects

ATevo ac wiring, and can be used to disconnect from ac source.

2.1.11 DC Output Circuit Breaker (CB2)

Located at bottom-center of ATevo. Protects ATevo dc wiring, and can

be used to disconnect ATevo from battery and system dc load(s).

2.1.12 Main Filter Inductor (L1)

Shown in center of silkscreen. Located on bottom-left of back wall. It

is part of the dc filter, lowering ripple.

2.1.13 Secondary Filter Inductor (L2)

Shown bottom-center of silkscreen. Located on bottom of back wall

to right of Filter Inductor (L1). It is also part of the dc filter.

2.1.14 Power Isolation Transformer (T1)

Shown at center of silkscreen. Located on back wall above the filter

inductors (L1/L2). Provides isolation and converts ac input voltage to

appropriate potential, prior to rectification.

NOTICE ATevos with the multi-tap ac input option (smart part

code ‘MT1/2’), feature a terminal block (TB-H#) mounted above

the AC Input Circuit Breaker (CB1) for voltage selection. Jumper

positions are shown on silkscreen to right of Power Isolation

Transformer (T1). See Section 2.3.

ATevo

13

Page 30

2 Wiring

2.2 Removing Protective Safety Shield

! WARNING To prevent injuries, the ATevo safety shield

must always be installed when charger is in operation and/or

energized.

STEPS

• A standard flat blade screwdriver is required.

• Open the ATevo front panel door to access safety shield.

• Remove the two (2) screws that attach the safety shield to the

ATevo, one above AC Input Breaker (CB1), the other below the

DC Output Breaker (CB2).

• Grab the safety shield on both left and right sides, and gently lift

up and off of AC Input and DC Output Circuit Breakers.

• Reverse procedure for reinstalling the safety shield.

2.3 ATevo with Selectable Input Voltage - optional

ATevo may be equipped with a multi-tap ac input voltage, in two (2)

options for field configuration:

• 120, 208 or 240 Vac 60Hz - ‘MT1’ in smart part number

• 115, 220, or 240 Vac 50/60Hz - ‘MT2’ in smart part number

2.3.1 Determining if Multi-Tap Option is Present

Check the ATevo nameplate. If the ac input voltage is listed as

120/208/240 or 115/220/240 Vac, the ATevo is equipped with the

multi-tap option. If the nameplate is not visible:

• Open the ATevo front panel door.

• Behind the safety shield, look for a gray terminal block directly

above the AC Input Circuit Breaker (CB1).

» Reference the input voltage selection silk-screened on the

center-right of the safety shield.

» If this terminal block is present, the ATevo is equipped with

the multi-tap ac input voltage option.

14

ATevo

Page 31

2.3.2 Verifying Multi-Tap AC Input Voltage Setting

Before you connect ac power to ATevo, inspect

the present ac input voltage setting, and

confirm the correct jumper positions for the

desired ac input supply voltage. The multi-tap

ac input voltage setting can be verified without

removing the safety shield.

• Open ATevo’s front door and locate

the Multi-Tap terminal block above

the AC Input Breaker (CB1).

• Observe the relative locations of the

RED jumpers in the Multi-Tap terminal

block (TB-H#).

• Refer to the adjacent diagram to

confirm the present ac input voltage

setting is correct.

2.3.3 Modifying Multi-Tap AC Input Voltage Setting

! WARNING Before changing the voltage selection

jumper, shut down ATevo and lock out ac and dc power supplies.

Turning off (opening) the ATevo internal circuit breakers does not

eliminate live voltages inside the enclosure.

• Standard flat blade screwdriver is required.

• Remove the ATevo safety shield per Section 2.2.

• Locate the multi-tap terminal block.

• Set locations of RED jumpers for desired ac input voltage, per

Section 2.3.2.

» Carefully pry out jumpers in existing locations.

» Re-install jumpers into new (correct) locations.

• Re-check jumper locations and confirm jumpers are properly

seated.

2 Wiring

ATevo

15

Page 32

2 Wiring

2.4 Making AC Input Connections

ATevo is a commercial product. It is not intended for use at

any time in a residential environment or to be powered by lowvoltage public mains.

It is the responsibility of the installer to provide ac supply wiring

approved for use in the country where installed. When selecting

wire sizes, consult the data nameplate decal affixed to ATevo for

voltage and current requirements.

Follow these steps to supply proper ac power to ATevo:

1. Confirm that the ATevo nameplate voltage rating is correct for

the ac input supply voltage. If ATevo has the Multi-Tap ac input

voltage option, make sure the setting matches the ac input

supply voltage per Section 2.3.2.

2. Use a branch circuit breaker or fused disconnect switch

upstream from ATevo. This device should have lockout

capabilities so that the ac input supply to ATevo can be deenergized for unit maintenance. A time-delay circuit breaker or

slow-blow fuse is recommended.

3. Size the branch circuit breaker or fused disconnect switch

for ATevo’s maximum ac input current as listed on the data

nameplate decal.

4. Size the ac input wiring per the National Electric Code (NEC),

Canadian Electrical Code, local and site codes for the trip rating

of the branch circuit breaker or fused disconnect switch.

5. Do not run external ac input power wiring through the same

conduit as external dc wiring.

6. All site requirements of the facility take precedence over these

instructions.

16

ATevo

Page 33

2 Wiring

NOTES

• Conduit must be properly grounded, and in compliance with the

national wiring rules of the country where installed.

• Use copper or aluminum conductors only.

• For 120 Vac, connect the neutral leg to input terminal (CB1-L2).

PROCEDURE

1. Remove safety shield per Section 2.2.

2. Run ac input supply wiring into ATevo, ending at the AC Input

Circuit Breaker (CB1) and ground stud.

3. Connect wires to appropriate locations on AC Input Circuit

Breaker (CB1-L1/L2) and system ground stud, as indicated on

drawing.

4. Using a flat-blade screwdriver, securely tighten the compression

screws on AC Breaker (CB1-L1/L2).

5. Securely tighten ground wire on system ground stud.

6. Check all connections and reinstall safety shield.

ATevo

17

Page 34

2 Wiring

2.5 Making DC Output Connections

Installer is responsible to provide suitable dc output, battery, and dc

load wiring.

Follow these steps to connect the battery to ATevo:

1. Size the dc wiring to minimize voltage drop. Acceptable wire

size depends on the installation. As a guideline, voltage

drop should not exceed 1% of nominal output voltage at

full current. Refer to the following table to determine the

voltage drops for various wire sizes, currents and distances.

Wire Sizing Chart

Voltage Drop per 100ft / 30.5m of Wire

(for copper at 68 °F / 20 °C)

Wire

Size

(AWG)

#16

#14

#12

#10

#8

#6

#4

EXAMPLE: 100ft / 30.5m of #8 AWG wire at 16A has a 1.1V drop.

6 12 16 20 25

2.5V 5.0V 6.7V 8.2V 10.5V

1.6V 3.2V 4.2V 5.3V 6.6V

1.0V 2.0V 2.6V 3.3V 4.2V

0.63V 1.3V 1.7V 2.1V 2.6V

0.40V 0.80V 1.1 V 1.3V 1.7V

0.25V 0.50V 0.66V 0.83V 1.1 V

0.16V 0.32V 0.42V 0.52V 0.65V

DC Current (Amperes)

2. ATevo is factory wired to regulate output voltage at the

output terminals. If total voltage drop is greater than 1%

(e.g. 1.3V for a 130 Vdc system), remote sense wiring is

recommended (see Section 11).

3. Do not run external ac and dc power wiring through the

same conduit.

4. Facility-specific installation requirements take precedence.

18

ATevo

Page 35

2 Wiring

PROCEDURE

1. Use a dc disconnect switch or circuit breaker between ATevo and

the dc bus. This device should have lockout capability to allow

ATevo to be disconnected from the dc bus for maintenance.

2. Remove safety shield (see Section 2.2).

3. Run dc wiring to Output Circuit Breaker (CB2).

4. Connect wires to appropriate locations on the DC Output

Breaker (CB2+/-) as indicated on drawing above.

5. Using a flat-blade screwdriver, securely tighten compression

screws on DC Output Breaker Terminals (CB2+/-).

6. Reinstall safety shield after you have made and checked all

connections.

ATevo

19

Page 36

2 Wiring

2.6 Remote Voltage Sense

You can wire ATevo to regulate output voltage at the battery

terminals instead of at the battery charger dc output terminals

(CB2+/-). See Section 11 for information and wiring instructions.

2.7 Wiring ATevo Common Alarm

ATevo Main Control Board (A1) is equipped with a ‘summary’

Common Alarm relay. This relay contact transfers when any one (1)

or more of the standard ATevo alarm(s) become active. One (1) set

of form-C alarm contacts is provided, and are accessible via terminal

block (A1-TB6) on the Main Control Board. Refer to figure below.

20

ATevo

Page 37

PROCEDURE

1. Allow 30in / 762mm of wire inside enclosure, and trim

excess.

2. Route annunciator wires to ATevo front panel door by

following existing harness past door hinge.

3. Use two (2) wire ties and allow a 4-6in / 102-153mm

loop for the hinge.

4. Trim wires to length to connect to alarm terminal block

(A1-TB6), and strip 0.25in / 6.4mm of insulation.

5. Make connections at A1-TB6 and tighten compression

screws.

NOTES

1. Alarm contacts are rated at 0.5A / 125 Vac or Vdc.

2. Common Alarm relay terminal block (A1-TB6) is

compression type, accepting wire sizes #22-14 AWG.

3. Terminals are labeled in non-alarm condition.

4. If user alarm contacts (A1-TB6) are to drive inductive dc

loads (e.g. a larger dc relay) an external protective diode

must be installed at the dc relay to avoid equipment

damage. Refer to Application Note (JD5011-00).

2 Wiring

2.8 Wiring Relays on Auxiliary I/O Board

When provided, the optional Auxiliary Alarm I/O Board (A4) is

mounted to the heat sink, above the Power Board (A2) on the

left side of the ATevo. See Section 12 for more information and

wiring instructions.

2.9 Wiring Temperature Compensation Probe

The battery temperature compensation, or ‘TempCo’, probe

(A10) contains a temperature-dependent resistor in an epoxy

module. When used, this probe is installed on the battery. See

Section 11 for more information and wiring instructions.

ATevo

21

Page 38

2 Wiring

2.10 Wiring Serial Communications Adapters

ATevo will support up to three (3) optional Serial Communications

Adapter pc boards. They mount on the ATevo’s front panel door,

by pluging directly into the Main Control Board (A1) via connection

points P10, P11, and P12. Refer to the supplementary ATevo

Communications Manual (JA0102-54) for more information and

wiring instructions.

2.11 Wiring Ethernet Adapter Board

ATevo will support an optional Ethernet Adapter Board (A22). It

mounts on the ATevo’s front panel door, by pluging directly into

the Main Control Board (A1) via connection point P13. Refer to the

supplementary ATevo Communications Manual (JA0102-54) for

more information and wiring instructions.

22

ATevo

Page 39

MODES &

METHODS

MAIN

DISPLAY

NAVIGATION

& CONTROLS

HINDLE

HEALTH

ALARM

SECTION

AC INPUT &

DC OUTPUT

BREAKERS

3 Controls & Navigation

3.1 Front Panel Controls and Indicators

ATevo front panel controls and indicators are organized into six (6)

major groups or sections.

ATevo

23

Page 40

3 Controls & Navigation

3.1.1 ATevo Main Display

A back-lit Liquid Crystal Display (LCD) shows all charger status and

configuration information. The display is discussed in Section 3.2.

3.1.2 Navigation and Control Button Group

This group of buttons (MENU, ESC, EDIT/ENTER, LEFT, RIGHT, UP, and

DOWN) is used to navigate through ATevo display screens, and user

interface menus. Use of these controls is discussed in Section 3.3,

Main Menu and Navigation.

3.1.3 Operation Modes and Methods Button Group

This group of buttons (DISPLAY MODE, CHARGE MODE, and

EQUALIZE METHOD) is used to select the mode of operation. Use of

these controls is discussed in Section 5.1.

3.1.4 Alarm Section

The alarm section consists of the discrete alarm indication LEDs, the

AC ON indicator (LED), and the ALARMS button. An alarm indicator

will light when its associated alarm is activated. The AC ON

indicator is lit when ac power is detected by the Main Control Board

(A1). The ALARMS button is used to enter screens which display

alarm statuses. Alarms and indicators are discussed in Section 7.

3.1.5 Hindle Health System (HHS) Section

The Hindle Health System section consists of the HEALTH BUTTON

(HH) and the RED and GREEN health indication LEDs at the bottom

of the panel. The Hindle Health System is discussed in Section 8.

3.1.6 AC Input and DC Output Breakers

The AC Input Circuit Breaker (CB1) is directly below the front control

panel. When opened, the Input Breaker disconnects all internal

ATevo connections from the ac source except for the breaker terminal

(CB1-L1/L2), where the ac input feed is connected.

The DC Output Circuit Breaker (CB2) is below the AC Breaker. When

opened, the DC Breaker disconnects ATevo output from the dc bus.

! WARNING There still may be live dc power connected to some

of ATevo’s internal boards (this will include any relays wetted by the

battery voltage).

24

ATevo

Page 41

3 Controls & Navigation

3.2 Display

The ATevo front panel features a back-lit Liquid Crystal Display (LCD)

that is capable of displaying various fonts, text sizes, and graphical

objects. The graphical display, in combination with the front panel

control buttons, provides an easy-to-use, powerful interface. The

various ATevo screens include user prompts and navigation icons to

provide an intuitive and hedonic experience.

ATevo screens can be grouped, by function, into four (4) basic types:

• HOME Screen

• Configuration Screens

• Status Screens

• Hindle Health Screens (HHS)

3.2.1 Home Screen

The HOME screen is the primary ATevo display, and is active most

of the time ATevo is energized. Other screens are displayed during

configuration changes, during testing, when the user requests more

detailed status than what is provided on the HOME screen, or when

the user wishes to utilize one of the advanced ATevo features.

• The Factory Default HOME Screen displays the output voltage

(Vdc) and output current (Adc) in a large font for easy reading.

• ‘Float’ or ‘Equalize’ will appear on the left side of the top of the

display to indicate that the charger is actively in either FLOAT or

EQUALIZE CHARGE MODE.

ATevo

25

Page 42

3 Controls & Navigation

• ‘Eqlz Mthd: Man’ or ‘Eqlz Mthd: Auto’ will appear on the right

side of the top of the display to indicate that the EQUALIZE

METHOD is presently configured for MANUAL TIMER or

AUTOMATIC TIMER mode.

• If a Temperature Compensation (TempCo) Probe option is

installed and enabled, the present battery temperature and

normalized voltage set point will also appear on the display (see

Section 10 for more details on the TempCo option and display).

3.2.2 Conguration Screens

These screens are used for changing ATevo set points and

configuration. Many of these screens will be described in Startup

and Configuration, Section 4. Other configuration screens for

installed options will be described later in their respective installed

option sections.

3.2.3 Status Screens

ATevo Status screens do not permit any system changes, and are

used only for viewing information. Most of the status screens (e.g.

Event Log and Active Alarm List) are covered in Advanced Operation,

Section 6. The HOME screen can be thought of as a ‘special’ Status

Screen in that it can indicate dc output voltage (Vdc), dc output

current (Adc), and status of Equalize/Float mode and method.

3.2.4 Hindle Health System Screens

Hindle Health System screens are associated with the Hindle Health

button (HH). When (HH) is pressed, ATevo enters a user-assisted selfdiagnostic mode. Screens prompt the user to participate in a series

of tests that confirm that ATevo is operating correctly. For more

information on the Hindle Health System, see Section 8.

26

ATevo

Page 43

3 Controls & Navigation

3.3 Main Menu and Navigation

The navigation control buttons (MENU, ESC, EDIT/ENTER, LEFT,

RIGHT, UP and DOWN) are used to navigate through ATevo screens

and menus. This system is intuitive to most people as it is similar to

universally-adopted televison remote control navigation buttons.

3.3.1 MENU and ARROW Buttons

Press the MENU button to access the Main Menu. The first six (6)

menu selection icons appear. Use the UP, DOWN, LEFT, or RIGHT

arrow buttons to navigate. Icons appear in inverse video when

selected. In the screenshot below, the user has already pressed the

DOWN arrow to select ‘Event Logs’.

The top-left of the screen indicates the Main Menu is displayed. The

top-right displays an up and/or down arrow icon that indicates that

more menu selection icons are available if you continue to navigate

in the direction of the arrow(s). In the screenshot above, both up and

down arrow icons appear in the top right corner. This indicates that

menu icons can be accessed by navigating either up or down from

the presently selected icon.

ATevo

27

Page 44

3 Controls & Navigation

3.3.2 EDIT/ENTER Button

Pressing the EDIT/ENTER button will activate the feature or function

selected onscreen. As an example, in the prior screenshot, ‘Event

Logs’ was selected. Pressing EDIT/ENTER with this selection causes

the following screen to open.

Pressing EDIT/ENTER with ‘View event log’ selected, as shown above,

takes the user to an event log entry as seen below.

The screenshot above is an example where a left and right arrow icon

appear in the top right of the display. This indicates that pressing

either LEFT or RIGHT arrow buttons will show additional screens.

LEFT and RIGHT arrow buttons are also used when moving between

numbers when setting parameters or between characters when

setting passwords.

28

ATevo

Page 45

3 Controls & Navigation

3.3.3 Navigation Conventions in this Manual

In the previous two (2) pages, a sequence of commands executed

a sequence of screens to display. That example was provided to

illustrate the use of the UP, DOWN, LEFT, RIGHT arrow buttons, and

the EDIT/ENTER button for navigation.

The full command sequence shown was:

1. Press MENU to open the Main Menu screen.

2. Press DOWN to select EVENT LOGS.

3. Press EDIT/ENTER to open ‘Event Logs’ screen.

4. Press UP OR DOWN arrows to navigate to ‘View event log’.

5. Press EDIT/ENTER to open an event log screen.

Using a full command sequence with every command in this manual

would lead to needless repetition and tedious document length. As

the above example illustrates, most of the repetition comes from

listing every navigation button push.

ATevo uses a simple, nearly universal navigation system that is used

by most tv remote controls. It is not necessary to list the following

navigation button pushes: UP, DOWN, RIGHT, LEFT or EDIT/ENTER.

This convention results in a streamlined sequence of ATevo-specific

commands.

For our example, this is:

1. Press MENU to open the Main Menu screen.

2. Execute the EVENT LOGS command on the Main Menu.

3. Execute the ‘View event log’ command on the Events Logs screen.

ATevo

29

Page 46

3 Controls & Navigation

To simplify further, we use a shorthand convention that makes use of

the ‘>’ character between commands.

Navigation Convention: Command > Command > Command

With this convention, the previous example’s command sequence is:

MENU > EVENT LOGS > ‘View event log’.

Screen Convention: