INSTRUCTION MANUAL

PROFESSIONAL

DIGITAL CONTROL UNIT CEM7

CONTENTS

3 1. Introduction

6 2. Front of the display module

10 3. Operating modes

12 4. Operation

22 5. CEM7 control unit inputs and outputs

31 6. CEM7 control unit alarms

47 7. Maintenance

51 8. Options (expansions)

56 9. Appendix I: parameters table

66 10. Appendix II. CEM7 control unit screens

79 11. Appendix III: dimensions, wiring and mechanical parts

92 12. Appendix IV: CAN communications

95 13. Appendix V: calibration of the control unit

97 14. Appendix VI: expanding inputs

97 15. Appendix VII: communications failure

GENERATOR HS355 | PAGE 2

1. INTRODUCTION

The CEM7 control unit is a generator set power supervision and control device.

The control unit consists of 2 different modules:

• Display module. The display module is responsible for carrying out

the information tasks regarding the status of the device and allows

actions to be performed by the user; through the display module

the user is able to control the control unit, as well as program and

congure the functions. Through the display module, access is given

to a record of the last 10 errors registered by the control unit.

• Measurements module. The measurements module is responsible

for performing the tasks of monitoring and control of the control unit.

This module is located in the rear panel to reduce wiring and increase

the control unit's immunity against electromagnetic noise. All the

signal, sensor and actuators are connected to the measurements

module. (See illustrations in Appendix III)

NOTE

A Timer module can be added as an option to the measurements module and

allows the functions of start up, blocking and scheduled maintenance to be

performed. Also, the Timer module allows the capacity of the error records to be

increased.

INTRODUCTION | PAGE 3

1.1 MEASUREMENTS MODULE

The measurements module provides the following electrical signal characteristics,

both those generated and those from the network itself:

• Phase-neutral voltage

• Phase-to-phase voltage

• Current phase

• Frequency

• Active, apparent and reactive power

• Power factor and cosine of FI

• Instant energy (kWh) and accumulated power (day, month, year) with

the timer option

• THD (total harmonic distortion) of voltages and currents

• Calculation of harmonics up to order 20

The measurements module provides the following engine characteristics:

1. Engine alarm inputs:

• Fuel reserve

• Oil pressure

• Water temperature

• Water level

• Emergency stop (mushroom head stop button)

2. Analogue inputs of the engine:

• Fuel level

• Pressure

• Temperature

• Congurable input (Oil temperature)

• Charge-battery alternator voltage

3. Congurable inputs; the measurements plate has 5 inputs that can be

programmed to perform the following functions:

• Tariff change warning

• Tariff change (CEM7 + CEA7CC2)

• Start up disabling

• External start

• Test (CEM7 + CEA7CC2)

• Forced operation

• Programmable alarms

• Genset contactor conrmation

• Parameter set selection

4. Engine statistics:

• Operating hours

• Number of starts

5. The measurements module commands the following engine functions:

• Preheating

• Stopping

• Starting

• Heating resistor

• Fuel transfer pump

• Battery charging alternator excitation

The measurements module has outputs which allow the status of the control unit

to be monitored:

• Motor started

• Control unit alarm

• 3 programmable outputs that monitor the status of the control unit

alarms or the engine status inputs

The measurements module commands relay outputs for activation of the genset

contactor and the electronic protection that trips the genset's general circuit

breaker.

The connection of the measurements module and display module is performed

via a CAN communications bus, enabling the interconnection between additional

modules which ensures the scalability of the control unit.

The following additional modules can be added as options via the CAN bus:

INTRODUCTION | PAGE 4

• Timer device

• Telesignal device

• CCJ1939 device

• Repetitive display

• Telecontrol device

• Announcement panel device

• CAN/USB

• CAN/232 + MODEM LINE

• CAN/232 + MODEM GSM

• CAN/232 + MODEM GSM/GPS POSITIONING

• CAN/232 + MODEM GPRS HG FLEET MANAGER

• CAN/232 + MODEM GPRS/GPS HG FLEET MANAGER

• CAN/485 (MODBus)

• CAN/LAN

• CAN/LAN (MODBUS IP)

• CAN/LAN HG FLEET MANAGER

• Second Zero Suppressor

• PT100 temperature probes expansion

• ATS panel with CEC7 control unit.

• Precision gauge

INTRODUCTION | PAGE 5

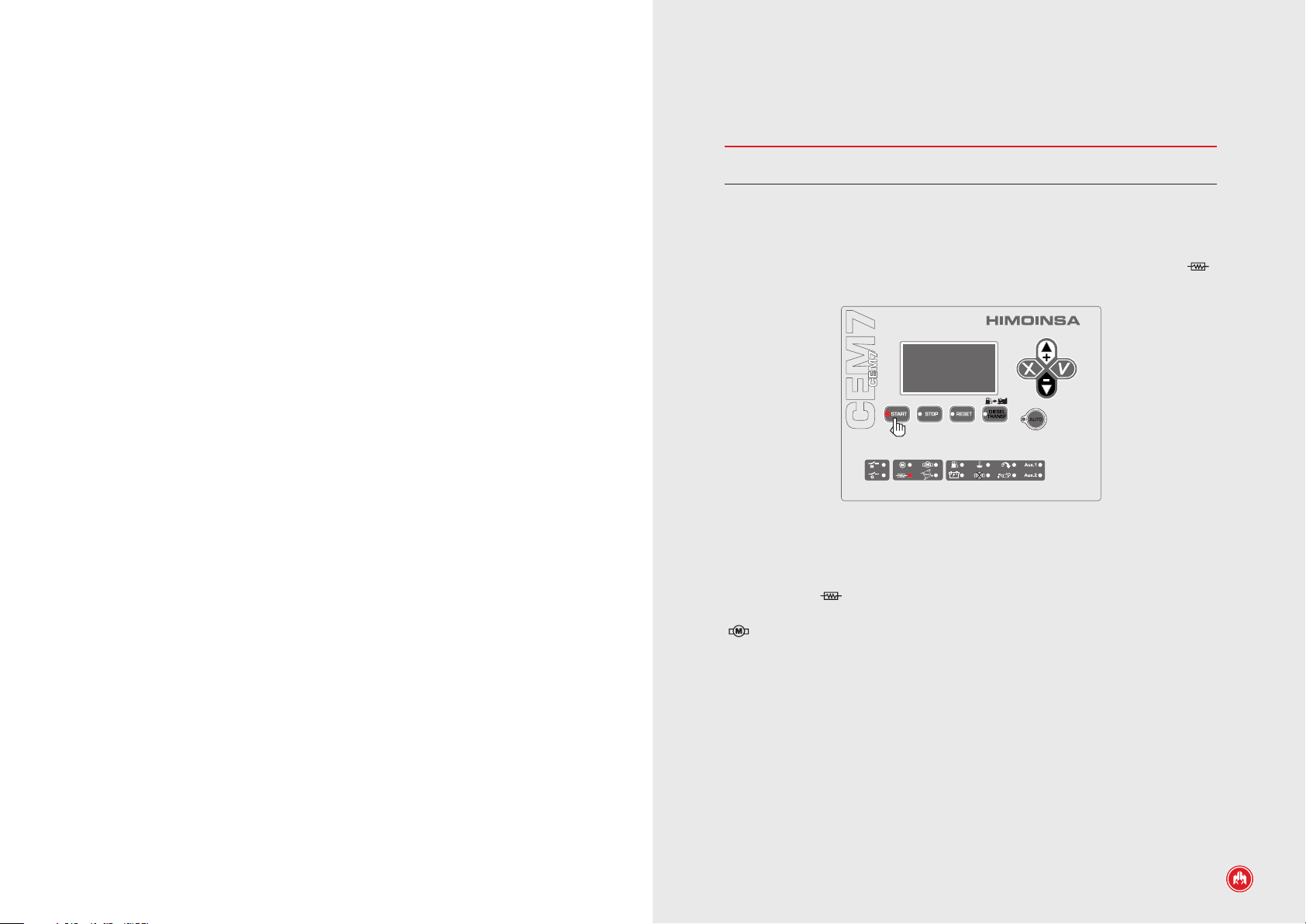

2. FRONT OF THE DISPLAY MODULE

The display module has a backlit display and various LEDs for monitoring the

status of the control unit. It also has keys that allow the user to control and

program the control unit.

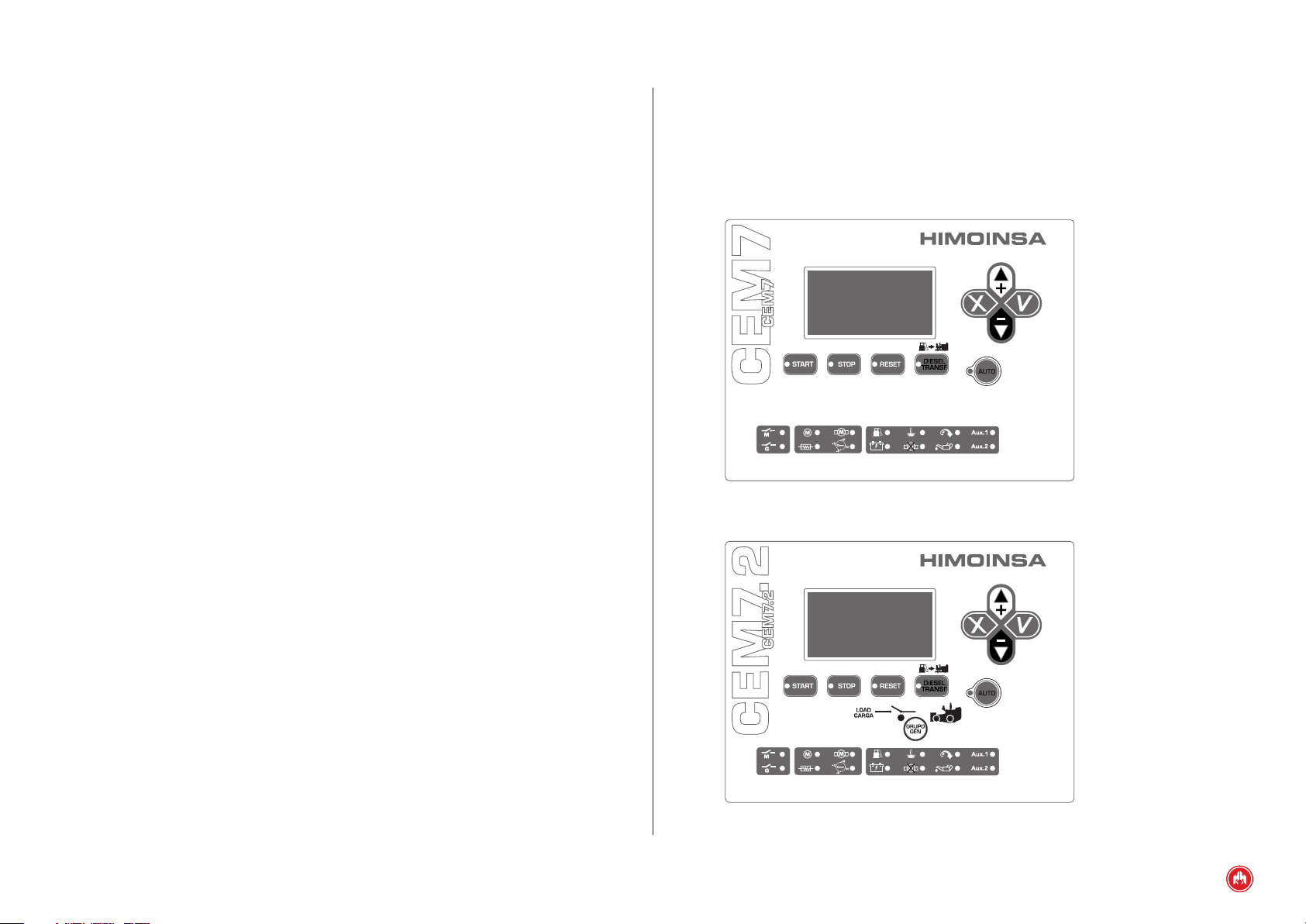

CEM7 display module

CEM7P display module

FRONT OF THE DISPLAY MODULE | PAGE 6

Fig.1

Fig.2

1. Backlit display 4 lines by 20 digits.

2.1.2 CONTROL UNIT COMMAND BUTTONS

NOTE

The display goes into low power mode (backlight off) after 10 minutes have

passed without any keystroke.

2. Control unit buttons

• Buttons for control unit operating mode

• Control unit command buttons

• Display buttons

• Genset contactor activation button (only CEM7P module)

3. Status LEDs

• ENGINE status LEDs

• ALARMS LEDs

• CONTACTORS status LEDs

2.1 CONTROL UNIT BUTTONS

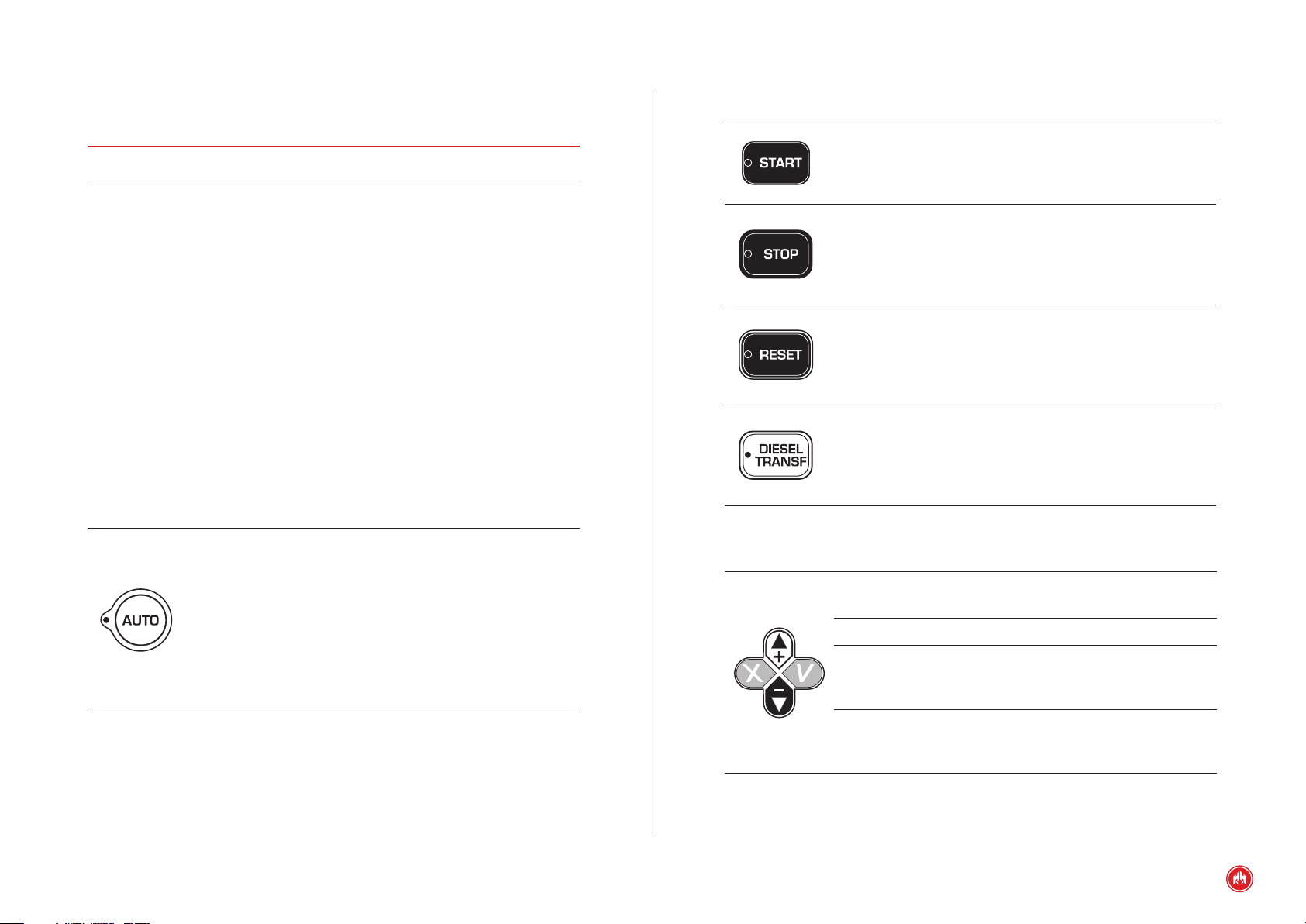

2.1.1 BUTTONS FOR CONTROL UNIT OPERATING MODES

Lit LED: Automatic

Automatic mode: The control unit

mode active

monitors the status of the genset and

manages its operation and the

programmable inputs.

LED flashing:

Automatic mode

blocked

Manual mode: The control unit is

commanded by the user.

LED off: Manual

mode active

Engine start button (only in manual mode)

Controls the start up with a single push.

Lit LED: Engine started.

Engine stop button (only in manual mode)

The rst press stops the engine following a cooling cycle. The

second press stops the engine immediately.

Lit LED: Engine stopping (with or without cooling)

Alarms reset button. Allows acoustic signals to be eliminated

and the user to report the alarms.

LED flashing: Pending notication alarms.

Lit LED: Alarms active.

Fuel transfer pump button.

In manual mode, this button activates the fuel transfer pump

if the fuel level is below the programmed limit.

Lit LED: Fuel transfer pump active.

2.1.3 DISPLAY BUTTONS

Confirm (V). Enter the menus and conrm the data

entered.

Cancel (X). Leave the menus and cancel the data entered.

Up (+). Advance through the selection on display screens,

the selection in maintenance menus and increase the

programming settings.

Down (-). Go back through the selection on display screens,

the selection in maintenance menus and decrease the

programming settings.

FRONT OF THE DISPLAY MODULE | PAGE 7

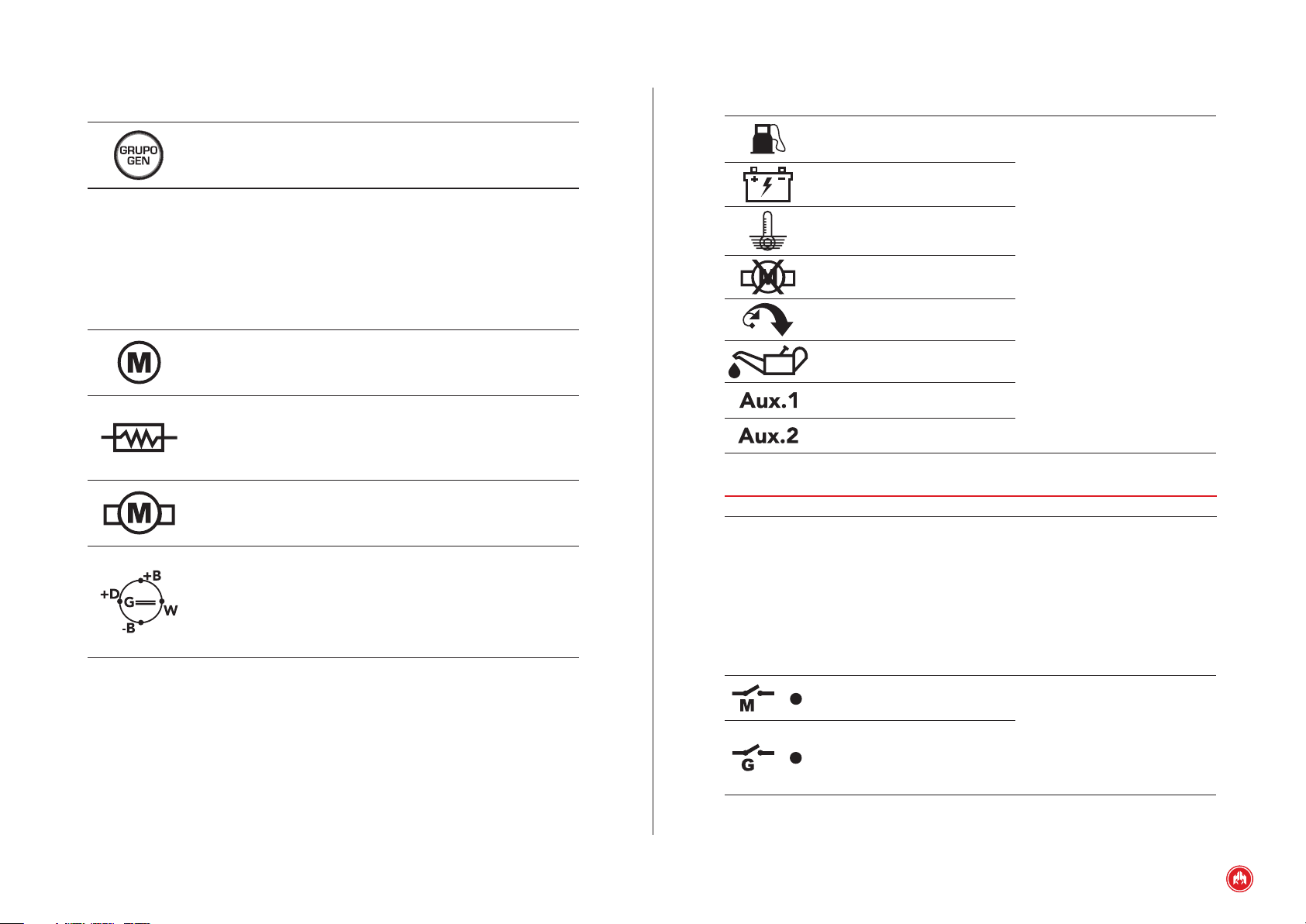

2.1.4 CONTACTOR BUTTONS (ONLY CEM7P MODULE)

2.2.2 ALARMS LEDS

Genset contactor. Enable/disable genset contactor (manual

mode only).

2.2 STATUS LEDS

2.2.1 ENGINE STATUS LEDS

Motor started

Preheating

Start engine

Alternator status

battery charging

Lit: Engine running detected

Off: Motor stopped

Lit: Engine preheating activated

Off: Engine preheating deactivated

Lit: Engine started

Off: Engine start deactivated

Lit: With engine running, voltage in the

battery charging alternator is detected

Off: Stopped engine or engine running

without voltage in the battery charging

alternator

Fuel reserve

Battery level

High temperature

Lit: Analogue sensor alarm

Engine start up failure

Overspeeding

Flashing: Digital sensor alarm

Off: Without alarm

Low oil pressure

Auxiliary 1 (freely

programmable)

Auxiliary 2 (freely

programmable)

NOTE

For more details see the Alarms section

2.2.3 CONTACTORS STATUS LEDS (CEM7 + CEA7CC2).

These LEDs only appear active when the switching control unit is connected.

Start up option due to Network Voltage Failure (CEM7 + CEA7CC2)

The M and G symbols on the front of the control unit only appear activated when

the switching control unit is connected.

Network contactor status

Genset contactor status

Lit: Contactor active

Flashing: Contactor in the

connection/disconnection

phase.

Off: Contactor disconnected.

FRONT OF THE DISPLAY MODULE | PAGE 8

2.3 PASSWORDS

The CEM7 control unit has 2 levels of 4-digit password to protect against

unauthorized access. The different levels of access are as follows:

• User (default password: 1111). User level access allows the operator

to access the main menu of the CEM7 control unit.

• Maintenance (default password: 1911). Maintenance level access

allows the operator to access the Parameters programming option

from the main menu.

The CEM7 control unit's passwords are customizable by the user from the main

menu. A user can congure both passwords for their access level and lower-level

passwords.

NOTE

To enter a password see Appendix II: password entry

FRONT OF THE DISPLAY MODULE | PAGE 9

3. OPERATING MODES

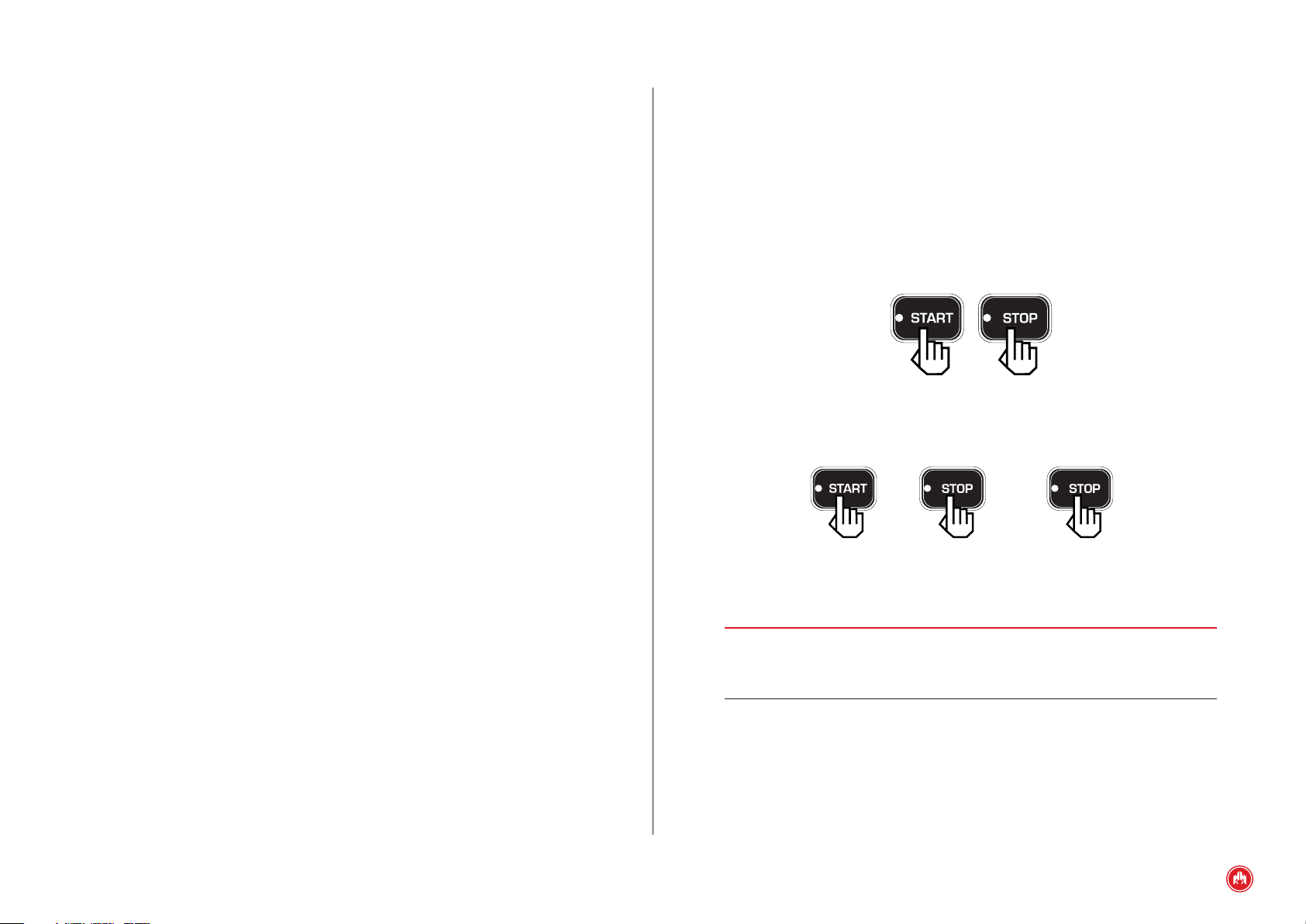

3.1 MANUAL MODE

In manual mode, the control unit is commanded by the user via the front panel of

the display module. The user can start and stop the engine by pressing the

START and STOP keys respectively.

Pressing the START key initiates the engine starting procedure (without

deactivating the network contactor CEM7 + CEA7CC2). Pressing the STOP key

initiates the engine stopping procedure with cooling; a second press of the STOP

key causes the engine to stop immediately without waiting for the cooling time.

x 1 click

WITH cooling

NOTE

In manual mode, the control unit's protection devices remain active, being able

to produce alarms that cause the motor to stop.

In manual mode, the control unit does not take into consideration the start

conditions (programmed, by external signal) that can be programmed.

Activation of the genset contactor on the CEM7P display module is performed by

pressing the GENSET key.

x 2 (double click)

WITHOUT cooling

OPERATING MODES | PAGE 10

In order to achieve activation of the genset contactor, the engine has to be

running and provide a stabilised electrical signal.

3.2 AUTOMATIC MODE

In automatic mode supervision of the installation is managed by the control

unit. Under certain conditions which can be programmed, the control unit starts

the genset to power the installation.

Programmable conditions for genset starting and activation of the genset

contactor include:

• External start (Settings table, parameter 10)

• Start programmed by schedule

• Forced operation signal (Settings table, parameter 12 and

Regulations table, parameter 25)

• Starting via the switching panel (CEA7CC2)

3.3 MODE LOCKING FUNCTION

Pressing the Auto or Man keys for 5 seconds activates the locking of the mode.

This control unit state is indicated by the ashing of the mode key currently

active. To deactivate the mode lock and allow normal operation of the control

unit, press the key associated to the active mode for 5 seconds.

5 ’’ Locked 5 ’’ Unlocked

Programmable conditions for genset starting without activation of the genset

contactor include:

• Tariff warning (Settings table, parameter 7)

• Engine test (Settings table, parameter 11)

Also in automatic mode it is possible to manage start ups by using external

devices (PC, modem, display modules or switching control units).

OPERATING MODES | PAGE 11

4. OPERATION

4.1 STARTING THE ENGINE

Under the conditions for activating the control unit, proceed to perform the

following engine start procedure:

4.1.1 DIESEL ENGINE

1. Start delay. Once activation conditions are detected, it is possible to program

a time delay (Times table, parameter 3) before continuing the engine start up

procedure only in automatic (CEM7 + CEA7CC2 or CEM7 + AE)

2. Preheating of the motor (PR). The control unit activates preheating output

(PR) for the programmed time (Times table, parameter 4). The control unit allows

programming of a temperature threshold (Thresholds table, parameter 48) of the

coolant sensor that interrupts the preheating process, before proceeding with

the engine start up.

3. Enabling the starting of the motor (positive contact activation). Enabling the

starting of the motor (positive contact activation) is performed via the

measurements module PC output. The output supports a Stop by De-energisation

conguration (output activation during engine operation) or Stop by Excitation

(engine stop pulse -Table times, - parameter 12). The operating mode of the

enabled output can be set (Times table, parameter 18).

OPERATION | PAGE 12

4. Starting the motor (ARR). For a maximum time (Times table, parameter 5),

the start output of the measurements module is activated while waiting to detect

at least one of the programmed start conditions. The possible engine starting

conditions are:

• Generator voltage (Regulations table, parameter 19). The motor is

considered started when a certain generator voltage is exceeded

(Threshold table, parameter 20).

• Alternator voltage (Regulations table, parameter 20). The motor is

considered started when a certain battery charging alternator voltage

is exceeded (Threshold table, parameter 21).

• Pickup frequency (Regulations table, parameter 21). The motor is

considered started when a certain pickup frequency is exceeded

(Threshold table, parameter 22). To activate the pickup calculation

via the engine ring gear, it is necessary to enter the number of teeth

on the engine's ywheel ring gear (Threshold table, parameter 24);

if the number of teeth for the ywheel ring gear is zero, the pickup

frequency is calculated via the generator frequency according to the

ratio 50 Hz / 1500 rpm, 50 Hz / 3000 rpm or 60 Hz /1800 rpm

(Regulations table, parameter 26).

• Low Oil Pressure Signal (Regulations table, parameter 22). Due to

its characteristics, it is not advisable to use the low oil pressure

signal to detect if the engine is running, but its use is recommended

as protection against a restart, as the engine is already running.

Exceptions to this engine start detection are SCANIA engines and

sensors that have their own power source.

4.1.2 GAS ENGINE

1. Checking the engine gas train (PR). The process of checking the gas train

begins with the activation of the PR output and lasts for a programmable

maximum time (Times table, parameter 4). If the control unit has a programmable

input (Settings table, parameter 25) assigned to the verication of the gas train,

the process checking the gas train shall end when activation of the gas train

verication input is detected; if gas train activation time ends without having

detected gas train verication, the control unit shall attempt the start again. If

the control unit has no input assigned to gas train verication (Settings table,

parameter 25, value 0), the control unit shall carry out the engine start after the

time set for checking the gas train. The gas train output PR will remain active

from the engine's start and running process until the engine stop is carried out.

2. Starting the motor (ARR). For a maximum time (Times table, parameter 5),

the start output of the measurements module is activated while waiting to detect

at least one of the programmed start conditions (Regulations table, parameters

19 to 22).

3. Gas Ignition (PC). Some time after (Times table, parameter 30) activating the

start signal, the PC output is activated to enable engine ignition once the residual

gas has been purged.

4. Gas valve. Some time after (Times table, parameter 31) activating the Gas

Ignition signal, the output congured as gas valve is activated (Settings table,

parameters 1 to 3, value 25).

5. If during the set time no motor starting is detected, the control unit waits for a

period of time (Times table, parameter 2) before retrying the start. Once a certain

number of starts has been exceeded without detecting any start condition (Times

table, parameter 1), the control unit activates the Starting Failure alarm.

6. During motor starting, the excitation of the battery charging alternator is

carried out through the D+ output for a period of time (Times table, parameter 8).

Once the excitation of the alternator has been completed, the measurement

module monitors the correct functioning of the battery charging alternator. In the

event a battery charging alternator failure is detected, the Alternator Failure

alarm is activated (Alarms table, parameter 10).

OPERATION | PAGE 13

7. Generator stabilisation. Once any start condition is detected, the control unit

waits for a xed time for stabilization of the generator signal before monitoring

the quality of the generator signal.

8. Nominal condition. After achieving engine stabilisation, verication of the

generator signal is performed. In this state, the quality of the signal produced by

the genset is evaluated (voltage levels, frequency,...).

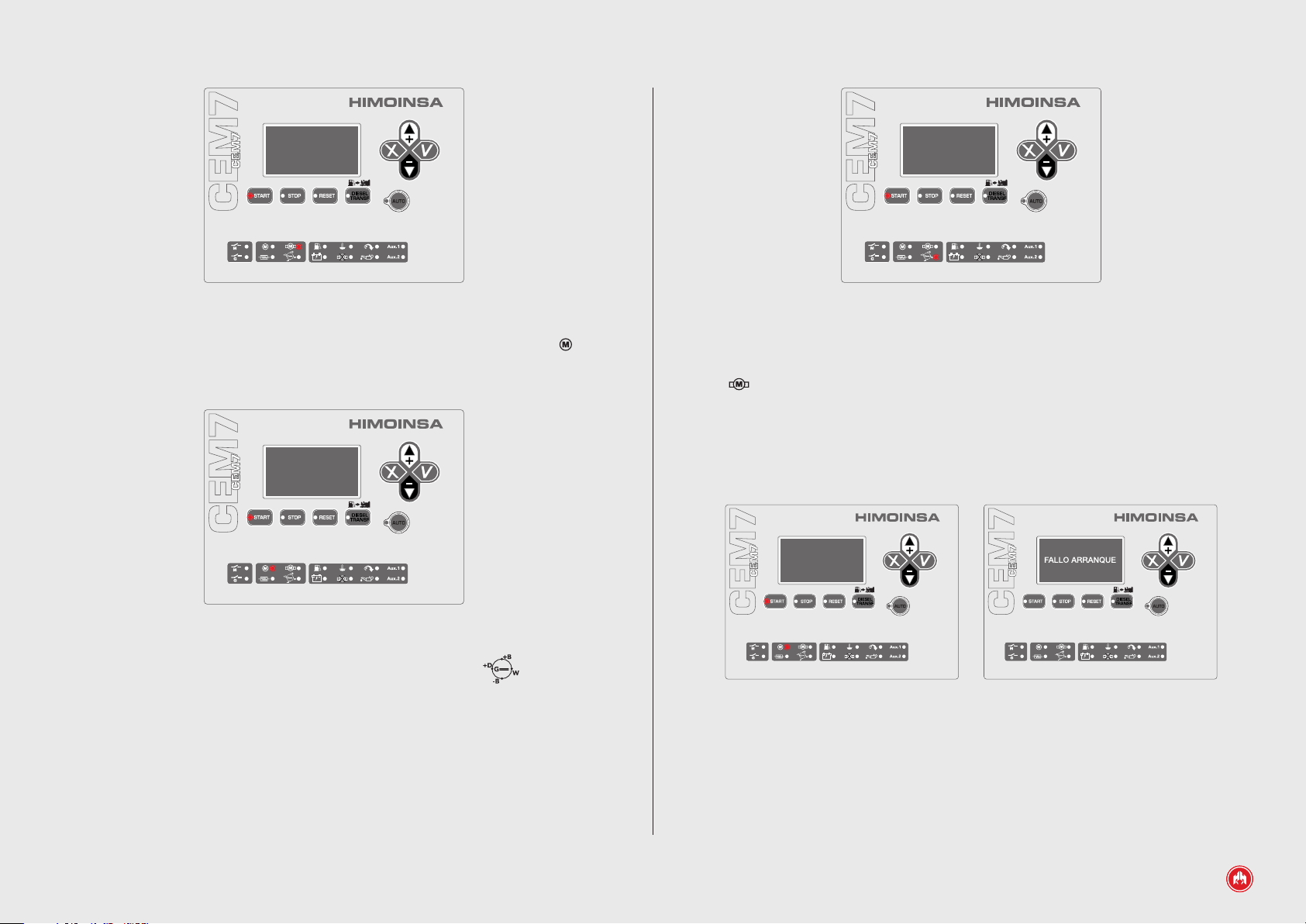

PRACTICAL EXAMPLE OF A START OPERATION

NOTE

Before starting the start cycle it is advisable to ensure the genset's main circuit

breaker is in the off position (OFF).

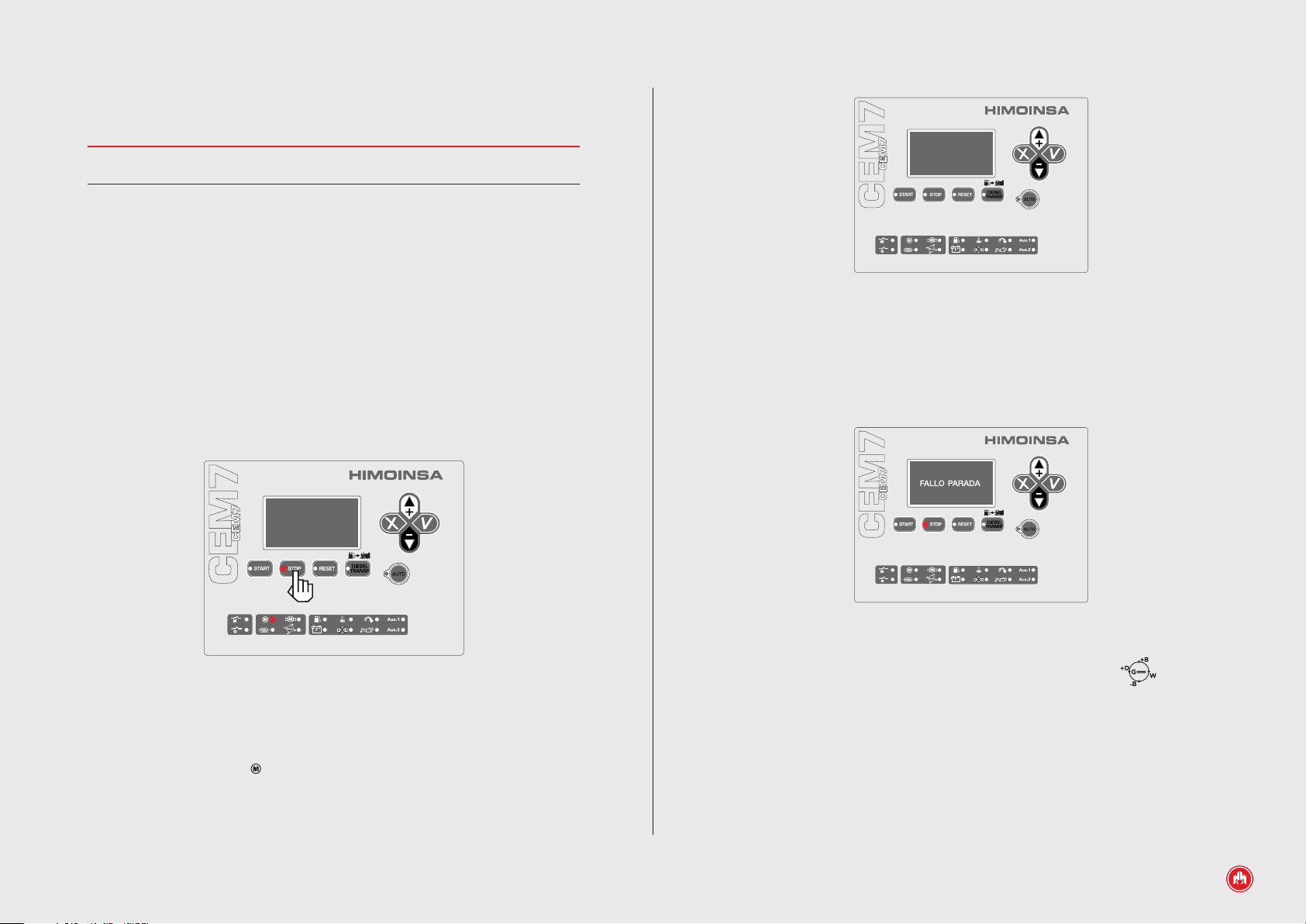

OPERATION

By pressing the START button the start cycle is initiated and is indicated by the

START button's LED switching on. At the same time if the motor has a preheating

plug the PR output is activated, with the corresponding LED switching on ( ),

for the programmed time. (1)

Fig.1

Once this time has elapsed the PR output is deactivated, and the corresponding

LED turns off ( ) and immediately the positive contact of the PC output is

activated and 0.5 seconds later the ARR output with the switching on of the LED

( ), this output remains activated until any engine running condition is

detected. (2)

OPERATION | PAGE 14

Fig.2

Fig.4

Once it has been detected that the engine is running the LED switches on ( ),

this indicates the end of the start cycle and the START button turns off. (3)

Fig.3

The LED corresponding to the battery charging alternator voltage ( ) switches

on when the voltage provided by the alternator exceeds the voltage threshold set

by default. (4)

If during the start cycle, the engine started condition is not detected after 5

seconds, the ARR output deactivates and the corresponding LED turns off

( ). Subsequently the control unit automatically attempts a new start, repeating

a new cycle without the need to press START (4 cycles by default). After

exhausting the attempts to start the engine without success, the control unit

display shows the alarm (START FAILURE). (5)

To interrupt the start cycle just press the STOP button.

x4

Fig.5

OPERATION | PAGE 15

NOTE

The display shows the engine status screen, where the engine status is displayed

during the start up operation. This sequence is:

Genset: Stopped

Genset: Starting

Genset: Started

Genset: Stabilised

Genset: Charging

NOTE

The start an automatic system using a timer, external signal, etc. is carried out

following the same process as when starting manually.

• Pickup frequency (Regulations table, parameter 21). The engine is

considered stopped when the pickup frequency is below the start

up threshold (Threshold table, parameter 22). To activate the pickup

calculation via the engine ring gear, it is necessary to enter the

number of teeth on the engine's ywheel ring gear (Threshold table,

parameter 24); if the number of teeth for the ywheel ring gear is

zero, the pickup frequency is calculated via the generator frequency

according to the ratio 50 Hz / 1500 rpm, 50 Hz / 3000 rpm or 60 Hz

/1800 rpm (Regulations table, parameter 26).

• Low Oil Pressure Signal (Regulations table, parameter 22). The

low oil pressure condition is used for detecting a stop, by which the

engine is considered stopped when it is detected that the sensor is

closed. Exceptions to this engine stop detection are SCANIA engines

and sensors that have their own power source.

4.2 ENGINE STOP

The engine stopping process in automatic mode is carried out as follows:

4.2.1 DIESEL ENGINE

1. Cooling the motor. Once free of charging, the engine will continue running for

a cooling time (Times table, parameter 11). In certain situations, it is possible to

set the alarms (Alarms table, parameters 3, 6, 9...) of the control unit to perform

a stop without engine cooling

2. Engine stop. After the engine cooling time has elapsed, the PC output of the

measurements module is enabled or disabled according to the programmed

conguration (Regulations table, parameter 18). As an engine stop condition it is

possible to select:

• Generator voltage (Regulations table, parameter 19). The engine is

considered stopped when the generator voltage is below the start up

threshold (Threshold table, parameter 20).

• Alternator voltage (Regulations table, parameter 20). The engine is

considered stopped when the battery charging alternator voltage is

below the start up threshold (Threshold table, parameter 21).

4.2.2 GAS ENGINE

1. Checking the engine gas train (PR) and gas valve. The control unit

deactivates the gas supply outputs to the engine.

2. Gas Ignition (PC). Some time after (Times table, parameter 32) closing the

gas supply, the Gas Ignition output is deactivated to stop the engine. If the

engine stop is triggered by an emergency stop alarm, the Gas Ignition output is

deactivated simultaneously to cutting the gas supply.

To conrm the engine has stopped, all the programmed stop conditions must be

detected for a set period of time (Alarms table, parameter 71). If after 90

seconds an engine running condition continues to be detected, the Stop Failure

alarm is triggered.

OPERATION | PAGE 16

PRACTICAL EXAMPLE OF A STOP OPERATION

NOTE

Before starting the stop cycle it is advisable to ensure the genset's main circuit

breaker is in the off position (OFF).

The genset stop can be performed in various ways:

1. Manual: Pressing the STOP button once. To perform a stop with cooling cycle.

2. Manual: Pressing the STOP button twice. To perform a stop without cooling

cycle.

3. Turning the panel's activation key to the “O” position. To perform a stop

without cooling cycle.

4. Automatic: After cancelling the order which leads to the automatic start and

in this way performing a stop with cooling.

Sequence: We press the STOP button once and begin the stop cycle with engine

cooling. This is indicated with the STOP1 button lighting up.

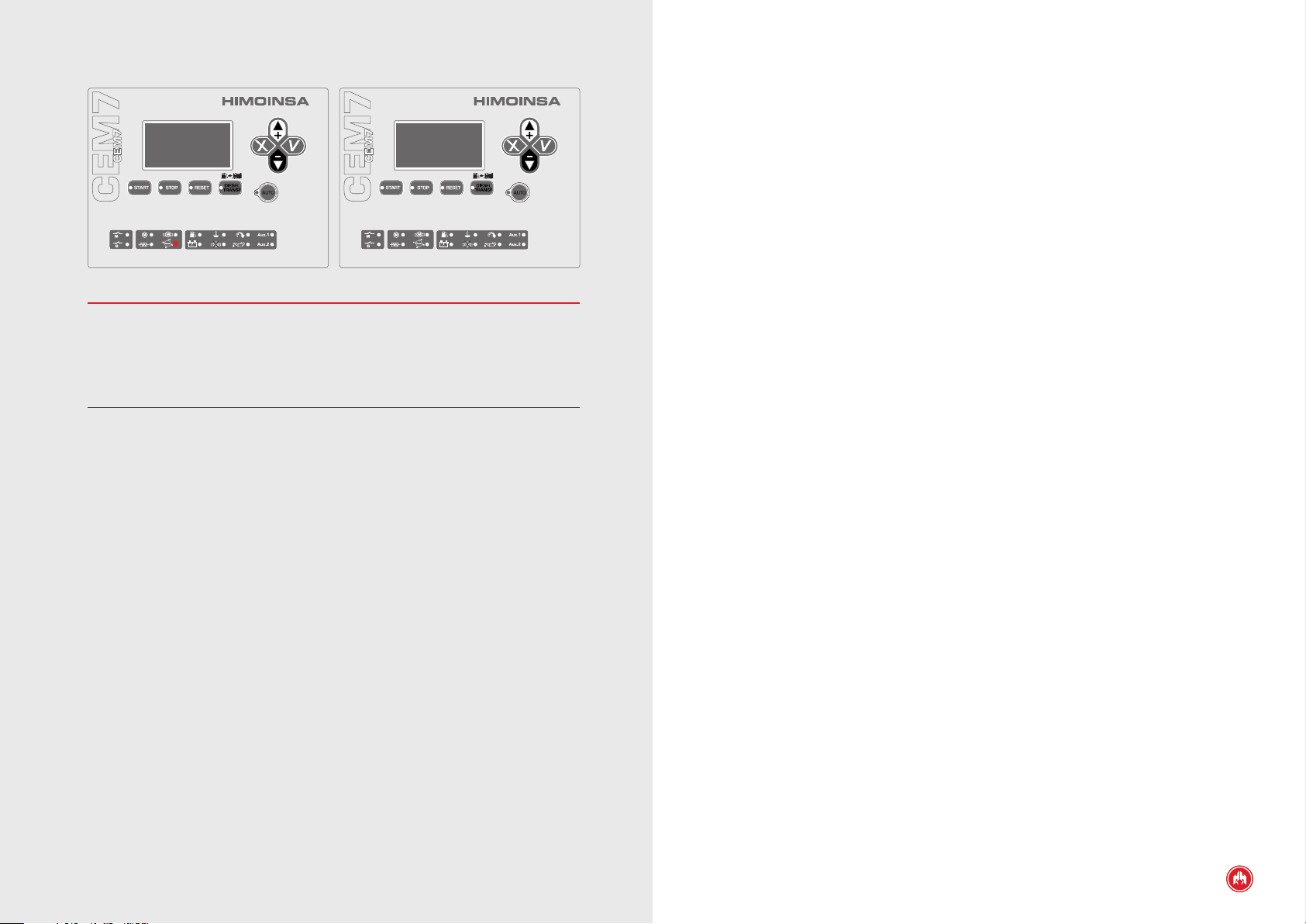

Fig.2

If after a period of time any engine running condition is detected, the control unit

shows on the display the STOP FAILURE alarm and the LED of the STOP button

remains lit (3).

Fig.1

After concluding the cooling time (120 seconds by default), the PC output is

disabled or enabled according to the type of engine to carry out the stop, the

STOP button and the LED ( ) for the started engine switch off (2).

Fig.3

The LED corresponding to the battery charging alternator voltage ( ) switches

off when the voltage provided by the alternator falls below the programmed

voltage threshold (4).

OPERATION | PAGE 17

NOTE

The display shows the engine status screen, where the engine status is displayed

during the stop operation. This sequence is:

Genset: Stabilised

Genset: Cooling

Genset: Stopping

Genset: Stopped.

4.3 FUEL TRANSFER PUMP

It is possible to activate the fuel transfer pump of the CEM7 control unit by

associating its operation with the BT relay of the measurements module

(Regulations table, parameter 4). Once the fuel transfer pump option is enabled,

the operating mode is then set (Regulations table, parameter 1):

1. Inhibited mode. The fuel transfer pump is not managed.

2. Manual mode. The fuel transfer pump is activated by pressing the DIESEL

TRANSF key provided that the fuel level is below the maximum deactivation

threshold (Threshold table, parameter 19)

3. Automatic mode. Managing the fuel transfer pump works by monitoring the

minimum activation threshold (Threshold table, parameter 18) below which the

BT relay is connected and a maximum deactivation threshold (Threshold table,

parameter 19) above which the BT relay disconnects.

4. Combined mode. The combined mode of the fuel transfer pump manages the

fuel transfer pump according to the Automatic mode, but also allows activation of

the BT relay by pressing the diesel Transf. key. Manual activation of the BT relay

is limited by the maximum deactivation threshold (Threshold table, parameter

19). The combined mode of the fuel transfer pump is available for control units

with rmware versions 2.56 and above.

5. Control unit mode. Managing the fuel transfer pump is performed as follows:

• When the control unit is in automatic mode or test mode, the

operation of the fuel transfer pump is managed in automatic mode.

• When the control unit is in manual mode, the operation of the fuel

transfer pump is managed manually.

• When the control unit is in locked mode, the operation of the fuel

transfer pump is inhibited (CEM7 + CEA7CC2).

The control unit mode of the fuel transfer pump is available for control units with

rmware versions 2.54 and below.

OPERATION | PAGE 18

Calibration of the gauge: For correct fuel level measurements (required for

managing the fuel transfer pump and fuel level alarm) a calibration of the tank

gauge should be performed. This requires access to the minimum and maximum

gauge level parameters (Measurements table, parameters 12 and 13). To adjust

the minimum level of fuel in the tank validation of parameter 12 of the

Measurements table should be performed with the gauge in the minimum

position. To adjust the maximum level of fuel in the tank validation of parameter

13 of the Measurements table should be performed with the gauge in the

maximum position.

In the event the gauge response is not linear, it is possible to program a gauge

response curve with up to 8 points from the option MenuParametersSensors.

4.5 BATTERY CHARGING ALTERNATOR

The battery charging alternator is connected to the CEM7 control unit via the

digital output D + and the DI analogue input of the measurements module.

The CEM7 control unit can be congured to produce an Alternator Voltage alarm

(Alarms table, parameters 10 to 12) if a low voltage supplied by the battery

charging alternator is detected through the DI analogue input of the

measurements module.

It is possible to select (Regulations table, parameter 3) between 2 modes of

operation of the battery charging alternator:

4.5.1 ALTERNATOR MODE

4.4 HEATING

Management of engine heating allows 2 modes of activation:

• Assigning the heating function to BT relay of the measurements

module (Regulations table, parameter 4).

• Assigning the heating function to one of the 3 programmable outputs

of the measurements module (Settings table, parameters 1-3)

provided that the BT relay of the measurements module is assigned

to the management of the fuel transfer pump (Regulations table,

parameter 4).

Management of engine heating provides the following function:

• Below a certain engine temperature threshold (Threshold table,

parameter 29), the heating resistor is activated.

• Below a certain engine temperature threshold (Threshold table,

parameter 28), activation of the genset contactor is controlled

and the Low Engine Temperature Alarm is managed (Alarms table,

parameters 73 to 74) .

• Above a certain engine temperature threshold (Threshold table,

parameter 30), the heating resistor is deactivated.

Operation of the CEM7 control unit's battery charging alternator congured to

alternator mode, excites the alternator via a pulse with a congurable duration

(Times table, parameter 8) during engine start process through the D+ output of

the measurements module. At the end of the pulse, the control unit tests the

voltage generated by the battery charging alternator.

The voltage generated by the battery charging alternator can be used as an

engine running condition (Regulations table, parameter 20). For this purpose, the

control unit waits to measure voltage, via the DI analogue input, which is above

an alternator voltage detection threshold (Threshold table, parameter 21).

The CEM7 control unit can be congured to produce an Alternator Voltage alarm

(Alarms table, parameters 10 to 12) if a low voltage supplied by the battery

charging alternator is detected through the DI analogue input of the

measurements module if it is set to alternator mode.

OPERATION | PAGE 19

4.5.2 DYNAMO MODE

PROGRAMMING

Operation of the CEM7 control unit's battery charging alternator congured in

dynamo mode, excites the alternator via a continuous pulse through the D+

output of the measurements module while the engine is in start up phase or is

running.

The control unit congured in dynamo mode cannot use the voltage measured via

the DI analogue input for detecting an engine running condition.

The CEM7 control unit can be congured to produce an Alternator Voltage alarm

(Alarms table, parameters 10 to 12) if a low voltage supplied by the battery

charging alternator is detected through the DI analogue input of the

measurements module if it is set to alternator mode.

4.6 START/STOP KEY

The start/stop key in the ON position causes power to be supplied to the CEM7

control unit's electronic devices (measurements module and display module).

The start/stop key in the OFF position causes a controlled stop if it is running;

once the engine has stopped, power to the CEM7 control unit is disconnected.

4.7 START DUE TO LOAD DEMAND (ONLY CEA7CC2 EXPANSION)

The generator set will start operating, acquiring this load, when network power

consumption is detected which more than the limit set by parameter (Threshold

table, parameter 34). The genset will continue to operate until the genset power

consumption measured falls below a limit set by parameter (Thresholds table,

parameter 35). Both with the start and stop of the genset due to load demand,

the conditions must be validated for a programmable time (Times table,

parameter 27). The function of start up due to load demand is only enabled in

Automatic mode of the CEM7 control unit associated to a switching control unit

CEA7CC2.

NOTE

From the rmware versions of control units: Display 3.20 / Measurements 2.50

4.8 ELECTRONIC PROTECTION

DESCRIPTION

The electronic protection is a feature that permits a control unit output to be

activated in the event of an overload and short circuit alarm. This function allows

the genset's main circuit breaker to be disabled via the trip coil. While any of

these alarms that causes the engine to stop (immediate or cooling) remains

active or pending notication, the output assigned to electronic protection

remains active.

DESCRIPTION

This function enables automatic start up and activation of generator set charging

depending on the power consumption of the network.

The start up is performed according to the programming, considering the

maximum power (Threshold table, parameter 34) the network can consume for a

period of time (Times table, parameter 27). Once the generator set is started,

the system changes genset power leaving the network free of load.

When the load in the installation is below the programmed threshold (Threshold

table, parameter 35) for deactivation and the programmed period of time (Times

table, parameter 27) has elapsed, the system returns to charging the installation

via the network and the genset begins its stopping cycle.

PROGRAMMING

The possible outputs that can be assigned to this function are:

• The SC relay is assigned by default to this function. Furthermore, the

SC relay is also activated when any alarm is generated which causes

the engine to stop.

• The BT relay of the measurements module (Regulations table,

parameter 4).

• Any of the programmable outputs of the measurements module

(Settings table, parameters 1 to 3).

OPERATION | PAGE 20

4.9 MOTORPUMP MODE

4.10 GENSET IN RESERVE

DESCRIPTION

The motorpump mode congures the CEM 7 control unit to display only engine

measurements, hiding generator set voltage measurements. This conguration

must only be used for control units installed in motorpump type systems where

there is no electrical power generation. They must also disable all alarms

associated with the electrical measurements of the control unit and the detection

of the engine start up via generator voltage.

PROGRAMMING:

Enabling the motorpump mode is carried out through programming of a control

unit parameter (Screen table, parameter 6).

DESCRIPTION

The genset in reserve function allows the operation of several generator sets in

the same installation. In order to balance out the hours that all the gensets are

operational, this function lets the control units specify which generator set should

start up. They select the genset whose engine has been running for the least

length of time. This running mode only affects the control unit’s automatic

working mode. For safety reasons, a generator set can not start-up if any other

genset is detected to be starting-up with the functionality of the genset in reserve

enabled.

It is possible to combine the functionality of the genset in reserve with the

programmed weekly schedules (a timer switch expansion is required) in order to

establish priorities during specic periods of time. To do this, you have to

programme time slots in one of the gensets (the master genset) in the facility,

for:

• Forced start-up. During this period, the master genset will have

priority start-up and the facility’s genset in reserve will stop running,

once the master genset has started running.

• Star t-up inhibited. During this period, the master genset will not have

priority and therefore, the genset in reserve will start up. Once the

genset in reserve has started running, the master genset will stop.

PROGRAMMING

Enabling the genset in reserve function is performed by programming a control

unit parameter (Regulations table, parameter 31, values 4 to 7).

OPERATION | PAGE 21

5. CEM7 CONTROL UNIT INPUTS AND

IN: Input

OUT: Outputs

OUTPUTS

The CEM7 control unit's digital inputs, both those with a specic purpose as well

as those which are programmable, have a debounce time associated (Times table,

parameters 15-24) which requires that the value of the input is stable over a time

interval. Also, all of the CEM7 control unit's inputs can be congured to be active

with contact closed to earth or be inactive with contact closed to earth (Regulations

table parameters 5 to 15).

The status of the CEM7 control unit's inputs and outputs can be monitored from

the Main menu1.Inputs/Outputs. From that position, a screen displays the

status of the control unit's digital inputs and outputs:

* INPUTS/OUTPUTS *

IN:

OUT:

Index of the input/output. Ordered from 13 to 1

Detection of an active input is indicated by the following characters:

• IN 1. R: Fuel reserve (RC)

• IN 2. B: Low oil pressure (BPA)

• IN 3. A: High temperature (ATA)

• IN 4. N: Water level (NA)

• IN 5. X: Programmable input 4 (default value, external start)

(AE)

• IN 6. I: Programmable input 5 (default value, disabling start

up) (IA)

• IN 7. P: Emergency stop (PEM)

• IN 8. 1: Programmable input 1

• IN 9. 2: Programmable input 2

• IN 10. 3: Programmable input 3

• IN 11. S: Mushroom head emergency stop

• IN 12. M: Ignition key (MAN)

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 22

Detection of an active output is indicated by the following characters:

• OUT 1. A: Alarm active (AL)

• OUT 2. M: Motor started (MA)

• OUT 3. 1: Programmable output 1 (SAL 1)

• OUT 4. +: Battery charging alternator (D+)

• OUT 5. 2: Programmable output 2 (SAL 2)

• OUT 6. 3: Programmable output 3 (SAL 3)

• OUT 7. r: Network contactor (CRC, CRNA, CRNC)

• OUT 8. g: Genset contactor (CGC, CGNA, CGNC)

• OUT 9. B: Fuel transfer pump/heating resistor

(BTNA, BTA)

• OUT 10. 4: Electronic protection

• OUT 11. R: Preheating/Powered stop (PR)

• OUT 12. P: Unpowered stop/Powered stop (PC)

• OUT 13. C: Enabling control unit

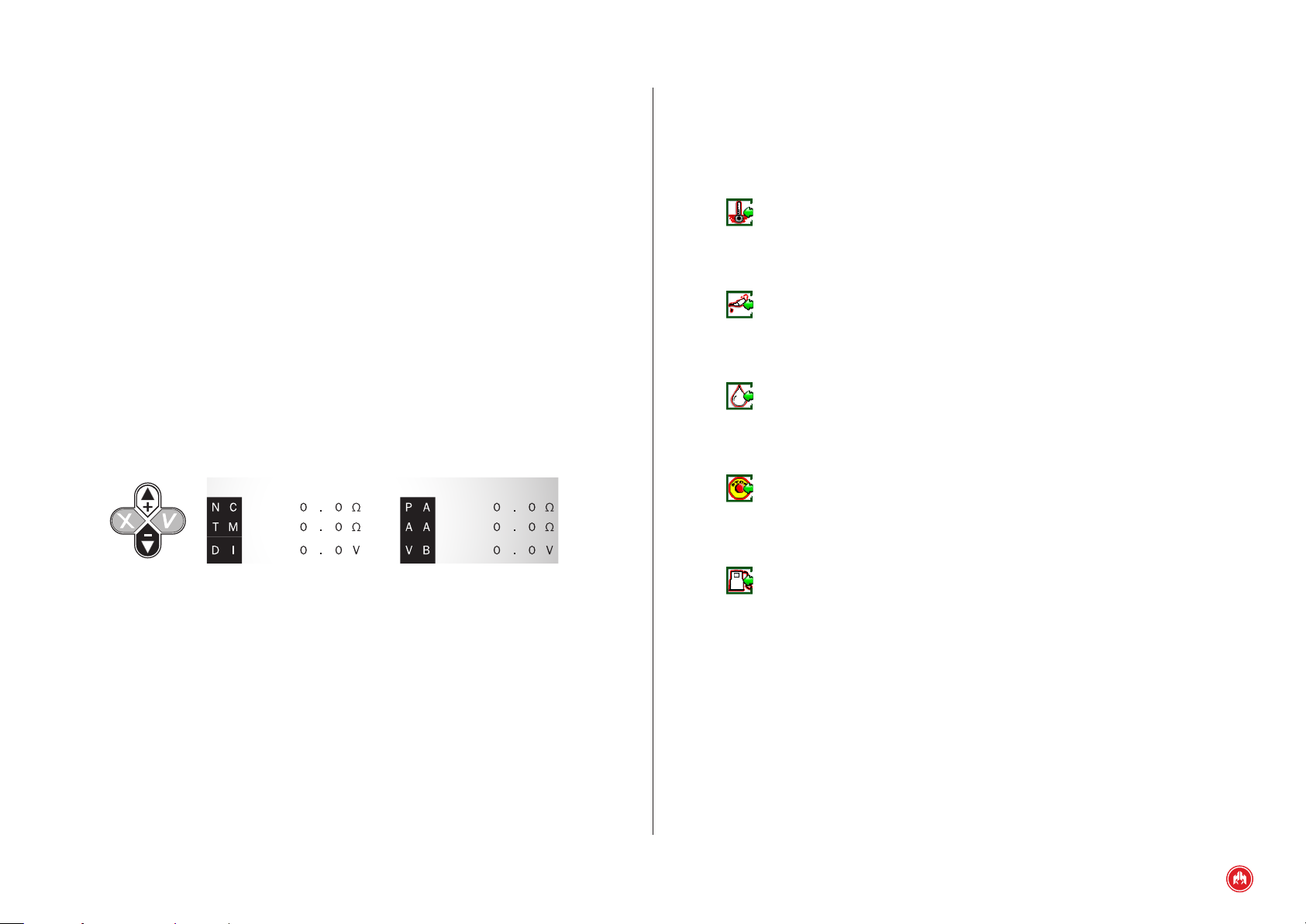

By pressing the up or down scroll keys it is possible to display the analogue

inputs.

5.1 DIGITAL INPUTS

The CEM7 control unit's measurements module has 5 digital inputs with

operation that is already preset.

The xed purpose inputs have the following behaviour:

HIGH TEMPERATURE (ATA)

Digital signal indicating to the control unit that an alarm has been generated due

to high engine temperature (Table Alarms, parameters 1-3).

LOW OIL PRESSURE (BPA)

Digital signal indicating to the control unit that an alarm has been generated due

to low oil pressure (Table Alarms, parameters 4 to 6).

WATER LEVEL (NA)

Digital signal indicating to the control unit that an alarm has been generated due

to low water level (Table Alarms, parameters 16 to 18).

ANALOGUE INPUTS

The value of the resistance analogue inputs is shown in ohms and the voltage

analogue inputs in volts. The various inputs displayed are:

• NC: Fuel level

• PA: Oil pressure

• TM: Engine temperature

• AA: Auxiliary analogue

• DI: Alternator voltage

• VB: Battery voltage

EMERGENCY STOP (PEM + SETA)

Digital signal indicating to the control unit that an immediate stop of the engine

must be performed without cooling

FUEL RESERVE (RC)

Digital signal indicating to the control unit that an alarm has been generated due

to the fuel reserve (Table Alarms, parameters 19 to 21).

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 23

5.2 PROGRAMMABLE INPUTS

The CEM7 control unit's measurements module has 5 digital inputs with

operation that can be programmed. The programmable inputs can be congured

to have the following behaviour:

TARIFF WARNING SIGNAL (EJP1)

This function is only managed in automatic mode of the control unit CEM7 +

CEA7CC2. The input congured as tariff warning (Settings table, parameter 7)

starts the genset after activating the corresponding input and after a set time

(Times table, parameter 9). Completion of the tariff ends when the input EJP1 is

disabled, stopping the engine with cooling.

TARIFF CHANGE SIGNAL (EJP2)

This function is only managed in automatic mode of the control unit CEM7 +

CEA7CC2. The input congured as tariff change (Settings table, parameter 8)

activates the genset contactor provided that no fault is found in the genset.

DISABLING START UP SIGNAL (IA + ENT5)

This function is only managed in automatic mode of the CEM7 control unit. The

input congured as disabling start up (Settings table, parameter 9) prevents the

genset from starting under any starting condition except in the case of forced start

up operation (Settings table, parameter 12) congured as high priority (Regulations

table, parameter 25).

EXTERNAL START SIGNAL (AE + ENT4)

This function is only managed in automatic mode of the CEM7 control unit. The

input congured as external start (Settings table, parameter 10) forces the start

up of the genset if it is in automatic mode, provided none of the following

conditions are present disabling start up:

• the control unit does not manage the disabling start up input (IA) or it

is not active.

• the control unit is not in lock mode programmed by time.

TEST SIGNAL (TEST)

This function is only managed in automatic mode of the CEM7 control unit with

the motorised circuit breaker option.

The input congured as test (Settings table, parameter 11) allows a check of the

genset to be performed without activation of the load.

FORCED OPERATION (MFOR)

This function is only managed in automatic mode of the CEM7 control unit.

The input congured as forced operation (Settings table, parameter 12) complies

with anti-re regulations according to which it should not stop the operation of

the genset under any condition except overspeeding and emergency stop

(whether this is alarm, external start up disabling input or programmed block). It

is possible to congure 3 modes of forced operation (Regulations table,

parameter 25):

• 0: Forced operation not enabled. The process of forced operation is

not managed despite having an associated programmable input.

• 1: Star ting due to network failure. Before activating the forced

operation input, the system waits for the start to occur due to a

programmed condition (alarms related to network signal, network

contactor failure, external start up...) needed to start the genset. To

stop the genset it is not sufcient that the start condition disappears,

but the input associated with the forced operation must be disabled.

• 2: Star ting due to forced operation. Before activating the forced

operation input, the genset starts immediately without the need to

wait for any other start condition to occur. To stop the genset, it is

necessary to switch to manual operating mode and in this mode

perform the stop using the control unit keyboard. Predominating the

stop button.

A delay in starting the genset can be congured through an external input via a

parameter (Regulations table, parameter 31).

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 24

PROGRAMMABLE ALARMS (AL1, AL2 AND AL3)

VERIFICATION OF GAS RAMP (S1 AND S2)

There are 3 programmable alarms available (Settings table, parameters 13, 14

and 15) that can be associated with any of the programmable inputs and which

serve the purpose of providing the control unit with additional alarms with

congurable operation (Alarms table, parameters 79 to 87). These alarms can be

programmed both with regards the mode of action as well as the text shown on

the display when activated.

PROGRAMMABLE ALARMS (AL4 AND AL5)

There are 2 additional programmable alarms available (Settings table, parameters

22 and 23) that can be associated with any of the programmable inputs and

which serve the purpose of providing the control unit with additional alarms with

congurable operation (Alarms table, parameters 111 to 116). These alarms can

be programmed both with regards the mode of action as well as the text shown

on the display when activated.

NOTE

From the rmware versions of control units: Display 3.20 / Measurements 2.50

SELECTION OF SET OF PARAMETERS (S1 AND S2)

There are 2 sets of additional parameters that can be enabled via any of the

programmable inputs (Settings table, parameters 16 and 17). Activating the

parameter set selection input enables the values with which the control unit

operates (Selector table).

GENSET CONTACTOR CONFIRMATION (CKG) (PHG7 REV 4.14 AND HIGHER)

The input congured as genset contactor conrmation (Settings table,

parameter 6) is used to verify the correct activation of the contactor. Upon

activation of the genset contactor, a time interval begins (Times table,

parameter 13) for verication of the contactor through the activation of the

genset contactor conrmation input. If after this time has elapsed there is no

conrmation of the activation of the genset contactor, a genset contactor alarm

is generated (Alarms table, parameter 101). If the control unit is operating in

automatic mode, a stop occurs with engine cooling. Similarly, if the genset

contactor conrmation input is detected as being active when the contactor is

not active, the start up of the generator set is inhibited.

The input congured to perform the gas train verication function (Settings table,

parameter 25) is used in gas engines (Regulations table, parameter 18, value 4)

to complete the testing process of the gas ramp and start the engine start up

process.

5.3 ANALOGUE INPUTS

The CEM7 control unit has 5 analogue inputs for measuring the engine operation

values. These analogue inputs characterize the operation of the engine to display

its status and produce alarms if necessary. By default, the alarms produced by

the analogue inputs do not stop the control unit (engine warnings), but can be

congured to perform this stop with or without cooling.

The CEM7 control unit performs a continuous check on the presence of the

analogue sensors installed, with the readings taken appearing on the display

module screen.

FUEL LEVEL INPUT (NC)

The fuel level analogue input indicates the amount of fuel remaining in the tank.

To adapt its operation it is necessary to adjust the maximum fuel tank value

(Measurements table, parameter 13) and the minimum fuel tank value

(Measurements table, parameter 12). To adjust go to section 4.3.

Also, it is possible to set a minimum fuel threshold in the tank (Thresholds table,

parameter 25) to cause an alarm warning (Alarms table, parameters 55-57) when

the fuel level is detected to be below this limit.

When the BT relay of the measurements module is programmed for managing the

fuel transfer pump, if the fuel level is detected to be below a lower limit

(Thresholds table, parameter 18) the fuel transfer pump is activated to provide

the tank with fuel. The deactivation of the fuel transfer pump occurs when fuel

level is detected to be above the programmable threshold (Thresholds table,

parameter 19). When the fuel transfer pump is in manual operation mode, this

upper threshold leads to the activation of the fuel transfer pump after the user

presses the relative button.

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 25

OIL PRESSURE INPUT (P)

AUXILIARY ANALOGUE INPUT (AA)

The oil pressure analogue input allows the engine oil pressure value to be

monitored. The control unit allows connection of VDO type sensors to the

analogue input. By setting a threshold a minimum oil pressure limit can be

established (Thresholds table, parameter 26) causing an alarm warning (Alarms

table, parameters 52 to 54) when the fuel level is detected to be below this limit.

ENGINE INPUT TEMPERATURE (T)

The engine temperature analogue input allows the engine water temperature

value to be monitored. The control unit allows connection of VDO type sensors to

the analogue input. By setting a threshold a maximum engine temperature limit

can be established (Thresholds table, parameter 27) causing an alarm warning

(Alarms table, parameters 49 to 51) when the temperature is detected to be

below this limit.

Also, provided heating management is programmed (either through the BT relay

or through any programmable output, provided that the BT relay is assigned to

the management of the fuel transfer pump), the engine temperature analogue

input is used to regulate the activation of the heating resistor.

The control unit allows a temperature threshold to be programmed (Thresholds

table, parameter 48) for the coolant sensor that interrupts the preheating

process during the start up of the engine.

ALTERNATOR VOLTAGE INPUT (DI)

The alternator voltage analogue input allows the voltage generated by the battery

charging alternator to be monitored. This input is used to diagnose possible

malfunctioning of the alternator if it detects a low voltage while the engine is

running; under these conditions, a battery alternator alarm (Alarms table,

parameters 10 to 12) is generated.

Also, this voltage can be programmed for detecting genset start up conditions

(Regulations table, parameter 20) via an alternator voltage threshold for the engine

when running (Thresholds table, parameter 21), provided it is not set in dynamo mode

(Regulations table, parameter 3).

The auxiliary analogue input is assigned by default to the supervision of the oil

temperature and can be programmed to be allocated to any other measurement

through a programmable curve (Analogue Sensors table).

ANALOGUE INPUTS EXPANSION

The CEM7 control unit allows you to add 8 analogue temperature inputs to the

PT100 sensor through the expansion of up to 2 CCPT100 devices. 2 maximum

temperature alarms can be added to each of these 4 analogue temperature

inputs with a P100 sensor.

The CEM7 control unit allows you to add 4 congurable analogue inputs (voltage

0 to 10 V, current 4 to 20 mA or resistive) through the expansion of the CCPT100

device. A congurable response curve, a descriptive text and the units displayed

in the user interface of the control unit can be associated to each of these 4

congurable analogue inputs.

5.4 PICKUP INPUT (PKC1, PKC2)

The measurements module pickup input measures the engine speed in

revolutions per minute (rpm). To calculate the speed it is necessary to enter the

number of teeth on the ywheel ring gear (Thresholds table, parameter 24). If

zero is entered as the number of teeth for the ywheel ring gear parameter, the

control unit is congured to not have a pickup sensor and calculate the rotational

speed from the frequency generated by the genset according to the ratio

50Hz/1500rmp, 50Hz/3000rpm or 60Hz/1800rmp or 60Hz/3600rpm

(Regulations table, parameter 26).

The CEM7 control unit can be congured to produce an overspeeding alarm

(Alarms table, parameters 22 to 24) as well as a under speed alarm (Alarms

table, parameters 25 to 27) depending on the mechanical speed provided by the

pickup.

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 26

5.5 PROGRAMMED DIGITAL OUTPUTS

The CEM7 control unit has 8 specic purpose outputs (2 relay outputs, 3 power

outputs and 3 digital outputs).

The functioning of these outputs is preset but can be congured.

PREHEATING OUTPUT. (PR). POWER OUTPUT

The preheating output (PR) of the CEM7 control unit is an output connected to a

high power shortable driver (70 A) which regulates the heating process of the

engine's spark plugs during the starting process. The activation time of the

preheating output can be set (Times table, parameter 4). The preheating output

can also be used to control stopping via the excitation of engines which use this

type of stop (Regulations table, parameter 18).

ENGINE STARTING OUTPUT. (ARR). POWER OUTPUT

The engine starting output (ARR) of the CEM7 control unit is an output connected

to a high power shortable driver (70 A) which activates the starter. The engine

starting output remains active until a programmed motor running condition is

detected (Regulations table, parameters 19 to 22) for a programmable maximum

time (Times table, parameter 5).

• Control PULL/HOLD. The engine start control set in PULL/HOLD

mode uses the PC engine stop output as a PULL signal which is

activated for a xed time of 1 second during starting. Any of the

programmable outputs (SAL1, SAL2 or SAL3) can be used as a HOLD

signal (Settings table, parameters 1 to 3, value 25) which remains

active during the time the engine is running.

FUEL TRANSFER PUMP/HEATING/ELECTRONIC PROTECTION OUTPUT (BT).

RELAY OUTPUT

The fuel transfer pump/heating output (BT) of the CEM7 control unit is a relay

output that can be congured (Regulations table, parameter 4) to manage the

fuel tank relling function through the fuel transfer pump or control the engine

heating process or electronic protection output for overload or short circuit.

The fuel transfer pump/heating output (BT) congured as electronic protection is

activated when the control unit detects excessive consumption (Thresholds

table, parameters 7 and 8) and activates an overload (Alarms table, parameters

28 to 30) or short circuit alarm (Alarms table, parameters 58 to 60).

EXCITATION OUTPUT OF THE BATTERY CHARGE ALTERNATOR (D+). DIGITAL

OUTPUT

ENGINE STOP OUTPUT. (PC). POWER OUTPUT

The engine stop output (ARR) of the CEM7 control unit is an output connected to

a high power shortable driver (70 A) which activates the stopping of the engine.

The congurable engine stop output (PC) can be congured so that it controls

engines with four different stop modes (Regulations table, parameter 18):

• Stop via de-energisation. The engine stop output congured as

a stop via de-energisation is activated 500 minutes after the

preheating output has been deactivated, which occurs when the

engine stop command has been given.

• Stop by excitation. The engine stop output congured as a stop by

excitation is activated for a programmable time interval (Times table,

parameter12) the engine stop command has been given.

• Stop by excitation/de-energisation. The engine stop output congured

as a stop by excitation/de-energisation is activated 500 minutes

after the preheating output has been deactivated, and is deactivated

when the engine stop command has been given. This output is used

to enable the engine sensors, with the preheating output involved in

performing the engine stop via the process of stopping by excitation.

The D+ output of the CEM7 control unit is responsible for exciting the battery

charging alternator during the starting process. This output can be congured

(Regulations table, parameter 3) to provide a start pulse (alternator mode) for a

programmable time interval (Times table, parameter 8) or keep the alternator

continuously energized (dynamo mode).

GENSET CONTACTOR OUTPUT (CG). RELAY OUTPUT

The genset contactor output (CG) of the CEM7 control unit is a relay output that

manages the closing and opening of the contactor. The activation of the genset

contactor can be congured to be continuous or via a pulse (Times table,

parameter 29)

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 27

ALARM OUTPUT (AL). DIGITAL OUTPUT

STARTED ENGINE OUTPUT (MA). DIGITAL OUTPUT

The alarm output (AL) is responsible for communicating the different states of

the CEM7 control unit. The AL output simultaneously activates the ashing of the

Reset key LED and display module buzzer of the CEM7 control unit. This output

monitors the following states of the CEM7 control unit:

• External start of the control unit. Before starting the control unit

when commanded by a programmable input associated with AE

mode, the control unit's alarm output (AL) is activated for 5 seconds.

The activation of the alarm output (AL) due to an external start of the

control unit can be inhibited (Regulations table, parameter31).

• Control unit errors. Given an error which is active or pending

notication by the user, control unit alarm output is activated for

a maximum programmable time (Times table, parameter 14). The

errors that activate the AL output are both alarms that cause the

engine to stop and warnings that do not cause the engine to stop.

Depending on how the AL output has been programmed (Regulations

table, parameter 31, acoustic alarm eld):

For an AL outlet that has been programmed as an acoustic signal (Regulations

table, parameter 31, acoustic alarm, eld value 0), when the user presses the

RESET key:

• Continuous activation of the AL output (value 0 in Times table,

parameter 14): the AL output is disabled, providing there is no active

error or warning.

• Timed activation (value in seconds of the activation of the output in

the Times table, parameter 14): the AL output is disabled the rst

time the RESET key is pressed or once the output activation time is

exceeded.

The started engine output (MA) of the CEM7 control unit is activated when any

started engine condition is detected and remains active while the engine is

running. The started engine output (MA) is deactivated as soon as the engine

stopping process begins; said process includes the engine cooling interval

(Times table, parameter 11) during the stopping process.

ELECTRONIC PROTECTION OUTPUT (SC). DIGITAL OUTPUT

The electronic protection output (SC) is activated when any alarm that stops the

engine is detected. The output remains activated until all the alarms that cause

the engine to stop disappear and are reported.

5.6 PROGRAMMABLE OUTPUTS

The CEM7 control unit has 3 programmable outputs with operation which can be

congured to indicate certain states (Settings table, parameters 1 to 3) and a

relay output (Settings table, parameter 4). The possible congurations that are

permitted with the programmable outputs are:

INHIBITED OUTPUT

The programmable outputs congured as inhibited output do not respond to any

action or state as they are permanently disabled.

When the AL output is programmed to signal errors (Regulations table, parameter 31, acoustic alarm eld, value 1), when the user presses the RESET key, the

buzzer of the interface is disabled but the AL output activation is maintained as

long as any active genset alarm remains in effect or pending notication.

OUTPUT PROGRAMMED ACCORDING TO THE STATE OF AN INPUT

The programmable outputs (associated with a programmable input) are activated

when an associated input is detected.

Possible congurations of associated inputs include the following values:

• Fuel reserve input

• Water level input

• Programmable input 1

• Programmable input 2

• Programmable input 3

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 28

• Programmable input 4

• Programmable input 5

PROGRAMMED OUTPUT FOR ALARM

parameter 26). The programmable output congured as programmed output for

dummy load is deactivated when higher genset power consumption than the

programmed threshold is detected (Thresholds table, parameter 33) during a set

time (Times table, parameter 26). As a condition for enabling the dummy load

output, the engine must be in a stabilized state.

The programmable outputs congured as a programmed output for alarm is

activated when the control unit detects an active alarm associated to a

programmable output or has not still not been notied by the user.

PROGRAMMED OUTPUT FOR FUNCTION

The programmable outputs congured as programmed output for function are

congured to allow a functionality associated to an output already used. Possible

congurations of functions include the following values:

• Heating resistor. The output programmed to function as heating

resistor activation if the BT relay is programmed to manage the fuel

transfer pump.

PROGRAMMED OUTPUT FOR MODE

The programmable outputs congured as a programmed output for mode is

congured to indicate the mode of operation of the control unit. Possible mode

congurations include the following values:

• Control unit in manual mode.

• Control unit in auto mode.

PROGRAMMED OUTPUT FOR DUMMY LOAD

DESCRIPTION

This function allows the activation of a loading bank which is separate to the

installation load, to avoid the generator set operating with low-load, in order to

prevent excessive oil consumption in the engine and allow it to run with an

optimal load.

PROGRAMMING

The programmable outputs congured as programmed output for dummy load is

activated when lower genset power consumption than the programmed threshold

is detected (Thresholds table, parameter 32) during a set time (Times table,

NOTE

From the rmware versions of control units: Display 3.20 / Measurements 2.50

PROGRAMMED OUTPUT FOR ENGINE HOLD CONTROL MODE

DESCRIPTION

This functionality activates for one second the PC output, simultaneously with the

programmed output in HOLD mode, in engines controlled in PULL/HOLD mode

(Regulations table, parameter 18, value 3). The programmed output in HOLD

mode remains active during engine operation.

For GAS engines (Regulations table, parameter 18, value 4), this functionality

allows the activation of the gas train at the installation.

PROGRAMMING

To activate the engine's PULL/HOLD control mode, a programmable output must

be assigned to the HOLD control function (Settings table, parameters 1 to 3,

value 25).

PROGRAMMED OUTPUT FOR STARTING DUE TO LOAD DEMAND

DESCRIPTION

This functionality allows the activation of an output when the power generated by

the generator set exceeds a programmable threshold for power generated by the

genset.

PROGRAMMING

With the generator set in operation, an output programmed with the load demand

start function will be activated (Settings table, parameters 1-4) when it is

detected that power consumption exceeds a programmed parameter limit

(Thresholds table, parameter 34). The output will remain active until the genset

power consumption falls below a programmed parameter limit (Thresholds table,

parameter 35). Both with the activation and deactivation of the load demand

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 29

output, the conditions must be validated for a programmable time (Times table,

parameter 27).

NOTE

From the rmware versions of control units: Display 4.49 / Measurements 4.01

DESCRIPTION

Programmable outputs can be congured to open the genset contactor for use

with motorized thermal-magnetic circuit breakers (Settings table, parameter 1 to

4, value 27). The output can be congured so that it is activated continuously or

in a timed mode via a pulse (Times table, parameter 29).

PROGRAMMED OUTPUT FOR GENSET/NETWORK CONTACTOR STATE (ONLY CEA7)

DESCRIPTION

The programmable outputs can be congured to monitor both the genset

contactor status and the network contactor status (only CEA control unit).

WATCHDOG PROGRAMMED OUTPUT

DESCRIPTION

The programmable outputs can be congured to monitor the status of the

electronics. The output remains active if the correct operation of the generator

set's control system is veried.

STABILIZED ENGINE PROGRAMMED OUTPUT

DESCRIPTION

Programmable outputs can be congured to monitor the stabilized engine status

(Settings table, parameters 1 to 4 or 24, value 96). The output remains active

once it detects the stabilized running condition of the engine after start-up (Times

table, parameter 7) including the cooling time during the stopping cycle.

NOTE:

Activation of the genset contactor is performed with a programmable time after

detecting that the engine is in operation (Times table, parameter 6), it being

possible to dephase the activation of the genset contactor and programmed

output in STABILIZED ENGINE mode.

PROGRAMMED FUMES CONTROL OUTPUT

DESCRIPTION

Programmable outputs can be congured to initiate the engine start-up process

with fumes control. This requires assigning a programmable output (Settings

table, parameters 1 to 4, value 97) that will be enabled during the start-up

process and will remain active for a programmable length of time (Times table,

parameter 33) once the engine is running.

5.7 EXPANSION PROGRAMMABLE OUTPUTS

The CEM7 control unit has 4 additional programmable outputs installed in the

Second Zero Suppression expansion, the operation of which can be congured to

indicate certain states (Settings table, parameters 18 to 21). Of the 4 outputs

available, 2 (Programmable outputs 4 and 5) of them are directly connected at

the terminal and the other 2 (programmable outputs 6 and 7) must be requested

as a special function. The possible congurations permitted by the programmable

outputs are the same as those explained in section 5.6 Programmable outputs.

PROGRAMMED GENSET CONTACTOR OPENING OUTPUT

CEM7 CONTROL UNIT INPUTS AND OUTPUTS | PAGE 30

6. CEM7 CONTROL UNIT ALARMS

1:

3: Total number of errors in the list

The CEM7 control unit has a list of alarms, the operation of which can be

congured so that actions are performed or so that they are shown on the display

module screen.

The CEM7 control unit distinguishes between errors that cause the engine to

stop (alarms) and errors do not cause the engine to stop (warnings).

Upon detection of an alarm or warning, the control unit produces an acoustic

signal, which activates the alarm digital output (AL) and the LED of the RESET

button and the display ashes; this condition will remain as long as the error

condition continues for a programmable maximum period of time (Times table,

parameter 14).

When there is an alarm, active warning or pending notication, the LED of the

RESET button remains illuminated. Pressing the RESET button allows the user to

view a list of alarms, active warnings and pending notication. To scroll through

the list of errors use the buttons on the display, the up button and down button.

Pressing the RESET button a second time noties the alarm.

The list of alarms, active warnings and pending notication has the following

format:

* ALARM *

MIN. GENSET FREQUENCY

E: Alarm / A: Warning

N: Pending notication

Position of the error in the list of errors

On the front of the control unit there are LEDs which indicate alarms detected by

digital sensors (digital inputs) or by analogue sensors (analogue inputs).

CEM7 CONTROL UNIT ALARMS | PAGE 31

NOTE

Alarms that cause the engine to stop are not auto-resettable, they must be

notied and reset so that the engine can be restarted, provided that the alarm

does not remain active.

The alarms produced by the analogue inputs do not cause the engine to stop,

just provide a warning in the default setting. They need to be reset to disappear

from the display, provided that the warning does not remain active, except for

the fuel level warning which is auto-resettable.

EXAMPLES OF ALARM OPERATIONS

• “EN” Alarm with engine stopped

• “AN” Warning that needs to be reset

• “A” Auto-resettable warning

“EN” ALARM WITH ENGINE STOPPED

1. Upon detection of an alarm or warning, the control unit produces an acoustic

signal, the LED of the RESET button and the display ashes and the alarm digital

output (AL) is activated. In this case the engine stops.

Fig.1

2. Pressing the RESET button eliminates the acoustic warning. The RESET LED

remains lit and the type of alarm is shown on the display (which stops ashing).

Ex: Alarm active “EN” High Water Temperature.

CEM7 CONTROL UNIT ALARMS | PAGE 32

ALARM

HIGH WATER

TEMPERATURE

Fig.2

3. We provide solutions for the alarm. In this case the temperature of the engine

when stopped must be lowered. We check the water level of the engine to detect

the cause of the anomaly. Once the alarm is no longer active "N", it can be reset

by pressing the RESET button and the engine can be put into operation again.

“AN” WARNING THAT NEEDS TO BE RESET, DOES NOT CAUSE THE ENGINE TO

STOP

1. Upon detection of an alarm or warning, the control unit produces an acoustic

signal, the LED of the RESET button and the display ashes and the alarm digital

output (AL) is activated.

ALARM

HIGH WATER

TEMPERATURE

Fig.1

2. Pressing the RESET button eliminates the acoustic warning. The RESET LED

remains LIT and the type of warning is shown on the display (which stops

ashing). Active warning “AN”.

NOTICE

HIGH WATER

TEMPERATURE

Fig.3

Fig.2

CEM7 CONTROL UNIT ALARMS | PAGE 33

3. We provide solutions for the warning. In this case, we stop the engine if we

believe this is necessary to detect the cause of the anomaly. Once the warning is

no longer active, "N" appears on the display and it can be reset by pressing the

RESET button.

NOTICE

HIGH WATER

TEMPERATURE

Fig.3

“A” AUTO-RESETTABLE WARNING

2. Pressing the RESET button eliminates the acoustic warning. The RESET LED

remains LIT and the type of warning is shown on the display (which stops

ashing). Warning “A”.

3. This type of warning is auto reset automatically whenever normal operating

conditions are restored. It focuses on the alarms related to the fuel level as part

of the default programming and the alarm corresponding to the network

thresholds.

WARNING

FUEL RESERVE

1. Upon detection of an alarm or warning, the control unit produces an acoustic

signal, the LED of the RESET button and the display ashes and the alarm digital

output (AL) is activated.

Fig.4

Fig.5

CEM7 CONTROL UNIT ALARMS | PAGE 34

6.1 LIST OF ALARMS

The list of active alarms and warnings can be grouped as follows (according to

the MANUFACTURER'S DEFAULT SETTINGS)

6.1.1 ENGINE ALARMS

Table 1

Description of the engine alarms

Description Front LED Type Action

Low engine temperature Notice Not for engine

Unit signal failure Alarm

Engine communication

(only CEM7J option)

Temperature Warning

(only expansion PT100)

Notice Not for engine

Engine stops with

cooling

Description Front LED Type Action

High water temperature Flashing LED alarm

Low oil pressure Flashing LED alarm

Emergency Stop alarm

Battery charging alternator

failure (with engine

running)

Starting failure Flashing LED

Low water level Flashing LED alarm

Fuel reserve Flashing LED warning Not for engine

Overspeeding Lit LED alarm

Under Speed alarm

Low battery voltage Notice Not for engine

High water temperature by

sensor

Low oil pressure by sensor Lit LED Notice Not for engine

LED off warning Not for engine

Lit LED Notice Not for engine

Engine stops immediately without cooling

Engine stops immediately without cooling

Engine stops immediately without cooling

Engine stops immediately without cooling

Engine stops immediately without cooling

Engine stops with

cooling

6.1.2 GENERATOR ALARMS

Table 2

Description of the generator alarms

Description Type Action

Overload Alarm Genset stops with cooling

Genset voltage asymmetry Alarm Genset stops with cooling

Maximum genset voltage Alarm Genset stops immediately without cooling

Maximum genset frequency Alarm Genset stops immediately without cooling

Incorrect genset phases sequence Alarm Genset stops with cooling

Reverse Power Alarm Genset stops with cooling

Short Circuit Alarm Genset stops with cooling

Minimum genset voltage Alarm Genset stops with cooling

Minimum genset frequency Alarm Genset stops with cooling

6.1.3 ALARMS ASSOCIATED WITH PROGRAMMABLE INPUTS

There are three free programmable alarms that can be associated with engine

alarms and they can be reected on the display via LEDS Aux1 and Aux2.

Low fuel level by sensor Lit LED Notice

Unexpected stop

Stop failure

Not for engine

CEM7 CONTROL UNIT ALARMS | PAGE 35

6.2 DESCRIPTION OF THE ALARMS

Table 3

Description of the alarms associated with programmable inputs

Description Type Action

Associated with programmable inputs Alarm According to conguration

Conrmation of Contactor Alarm Engine stopped

The high water temperature alarm is set by default (Alarms table, parameter 3) to

always perform an immediate stop of the engine.

NOTE

In the CEM7J option the ATA input can be assigned to a programmable alarm. In

this case, the alarm detection is performed by the engine's CIU and transmitted

by the communication bus J1939.

All alarms except those which are non-programmable, can be congured as

follows:

To be activated:

• Never

• Always

• During the start up of the engine

• From detection that the engine has started

• From the nominal condition of the engine

To perform one of the following actions:

• Not perform any actions (warning)

• Stop the engine with cooling of the engine

• Perform an immediate stop of the engine

The default conguration of each of the alarms will be highlighted.

HIGH WATER TEMPERATURE

The CEM7 control unit's high water temperature alarm is associated with the

digital input specically for the high water temperature (ATA) or errors detected by

the engine's CIU (only CEM7J option). The status of this input must be validated

during a time interval (Times table, parameter 17) for stabilisation (debounce)

before generating the high water temperature alarm.

It can be congured as normally open or normally closed (Regulations table,

parameter 7). Detection of the high water temperature alarm is set by default

(Alarms table, parameter 1) to always be active.

LOW OIL PRESSURE

The CEM7 control unit's low oil pressure alarm is associated with the digital

input specically for the low oil pressure (BPA) or errors detected by the engine's

CIU (only CEM7J option). The status of this input must be validated during a time

interval (Times table, parameter 16) for stabilisation (debounce) before

generating the low oil pressure alarm.

It can be congured as normally open or normally closed (Regulations table,

parameter 6).

The low oil pressure alarm is set by default (Alarms table, parameter 4) to be

activated when it is detected that the engine has been started.

A low oil pressure alarm can be associated with a time (Alarms table,

parameter 5) to delay the moment at which the alarm begins to conrm the alarm

conditions.

The low oil pressure alarm is set by default (Alarms table, parameter 6) to always

perform an immediate stop of the engine.

NOTE

In the CEM7J option the BPA input can be assigned to a programmable alarm. In

this case, the alarm detection is performed by the engine's CIU and transmitted

by the communication bus J1939.

A high water temperature alarm can be associated with a time (Alarms table,

parameter 2) to delay the moment at which the alarm begins to conrm the alarm

conditions.

CEM7 CONTROL UNIT ALARMS | PAGE 36

EMERGENCY STOP (ACTION NOT PROGRAMMABLE)

The CEM7 control unit's emergency stop alarm is associated with the digital

input specically provided for emergency stops (PEM).

It can be congured as normally open or normally closed (Regulations table,

parameter 11).

Similarly, the emergency stop alarm is also associated with the SETA input of the

measurements module; said input cuts power to the power outputs of the