Page 1

AG 4S-A22

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

English 1

Dansk 17

Svenska 33

Norsk 49

Suomi 65

Eesti 81

Latviešu 97

Lietuvių 114

Русский 130

Українська 149

Қазақ 167

Türkçe 185

ﻋﺮﺑﻲ 201

Page 2

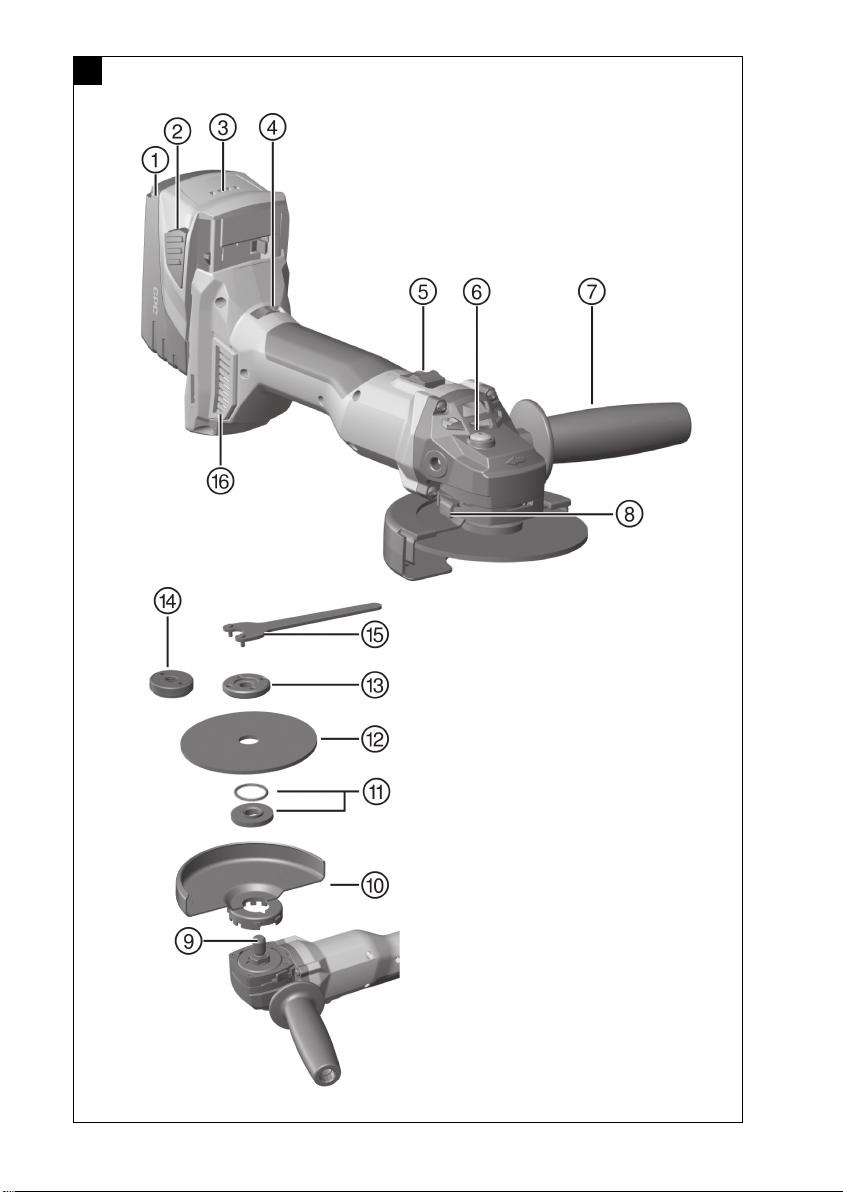

1

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 3

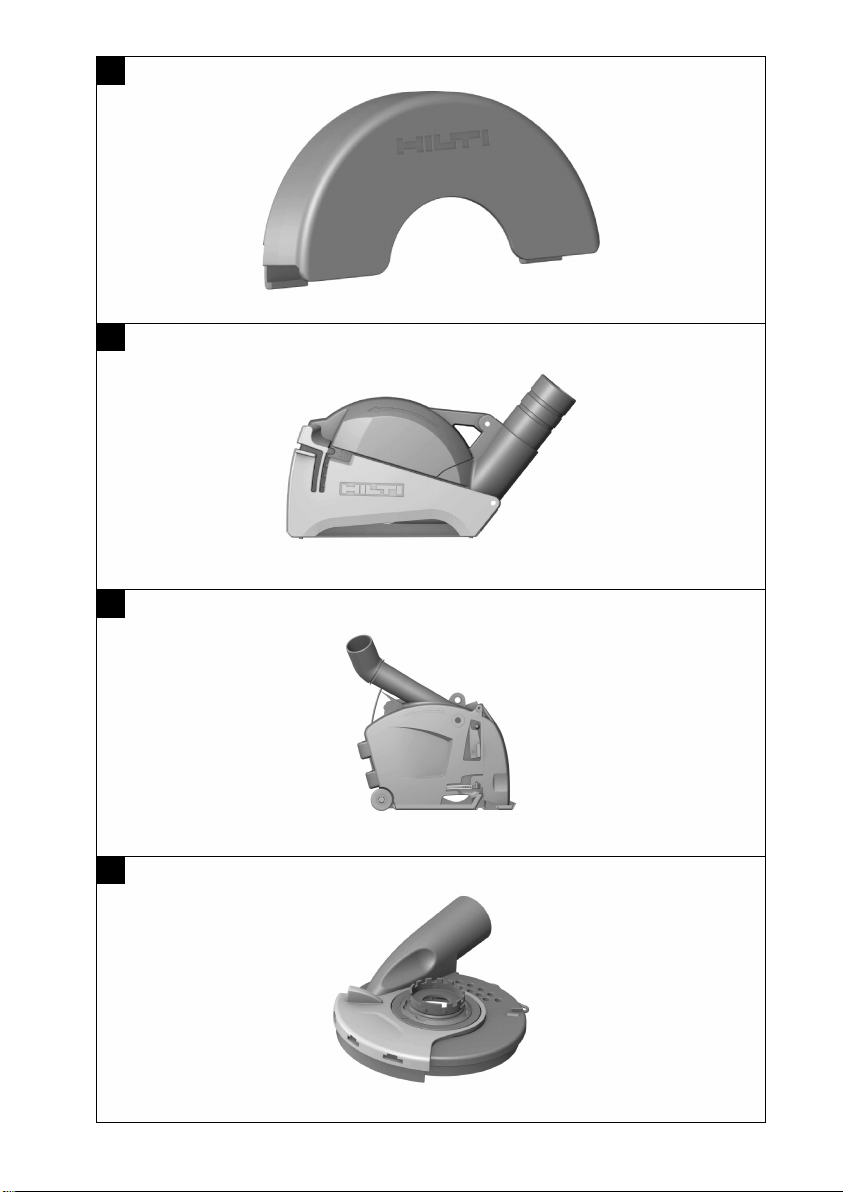

2

3

4

5

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 4

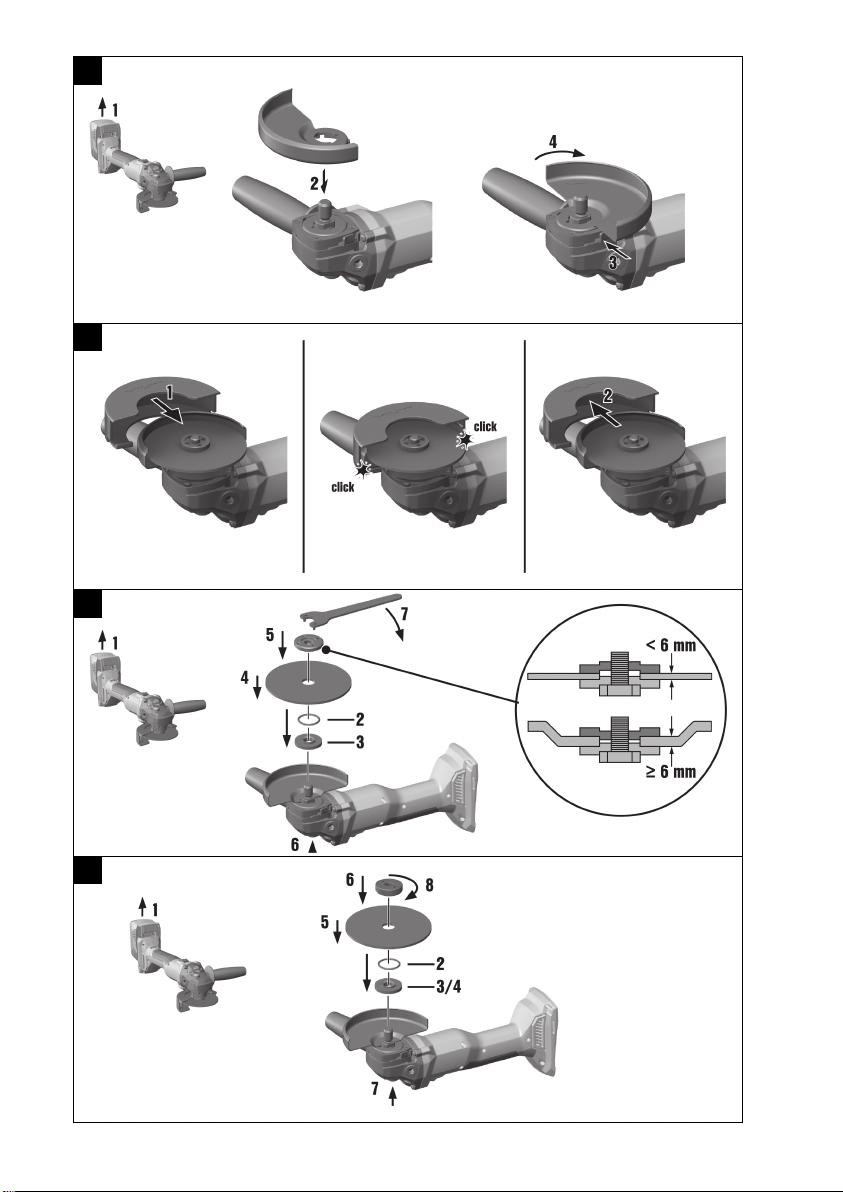

6

7

8

9

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 5

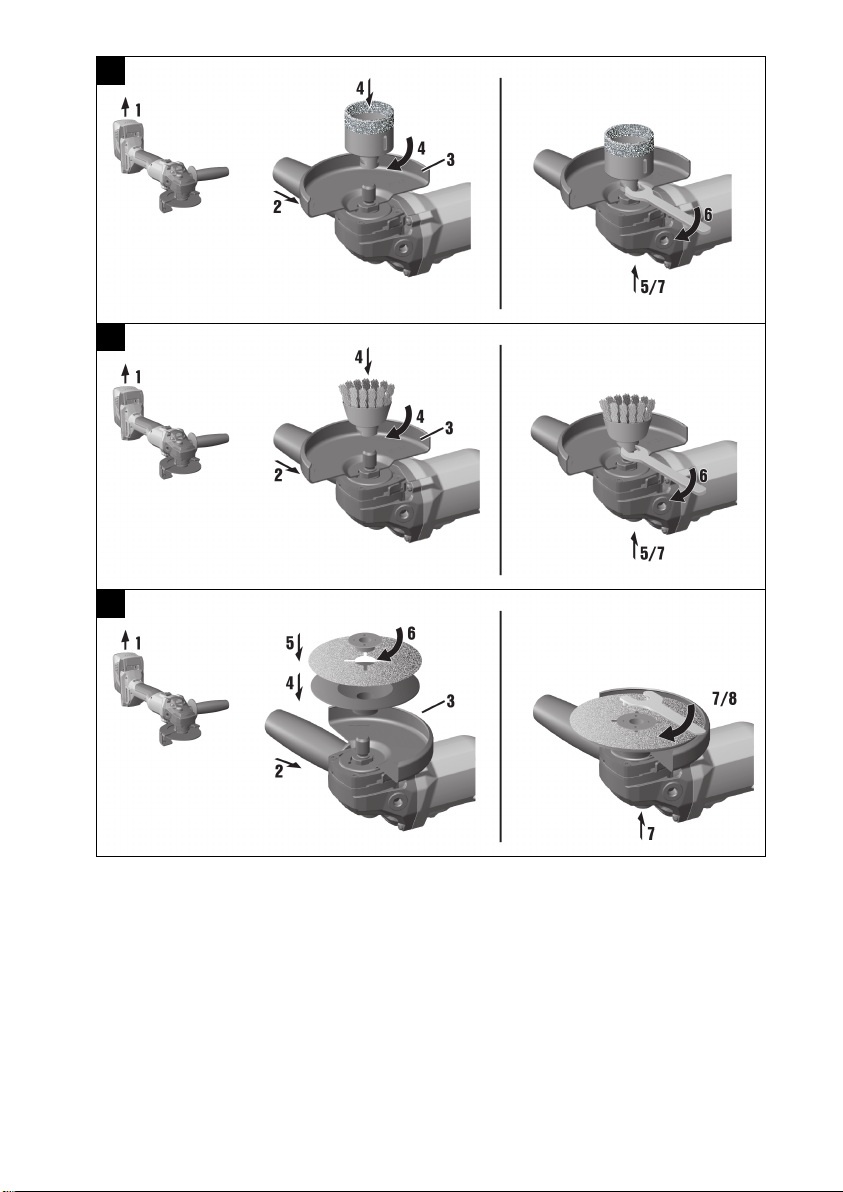

10

11

12

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 6

AG 4S-A22

en Original operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

da Original brugsanvisning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

sv Originalbruksanvisning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

no Original bruksanvisning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

fi Alkuperäiset ohjeet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

et Originaalkasutusjuhend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

lv Oriģinālā lietošanas instrukcija . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

lt Originali naudojimo instrukcija . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

ru Перевод оригинального руководства по эксплуатации . . . . . . . . . . . . . . . . . . . . 130

uk Оригінальна інструкція з експлуатації . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

kk Түпнұсқа пайдалану бойынша нұсқаулық . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

tr Orijinal kullanım kılavuzu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

ar ﺩﻟﻴﻞﺍﻻﺳﺘﻌﻤﺎﻝﺍﻷﺻﻠﻲ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 7

1 Information about the documentation

1.1 About this documentation

• Read this documentation before initial operation or use. This is a prerequisite for safe, trouble-free

handling and use of the product.

• Observe the safety instructions and warnings in this documentation and on the product.

• Always keep the operating instructions with the product and make sure that the operating instructions

are with the product when it is given to other persons.

1.2 Explanation of symbols used

1.2.1 Warnings

Warnings alertpersons to hazards that occur when handling or using the product. The following signal words

are used:

DANGER

DANGER !

▶ Draws attention to imminent danger that will lead to serious personal injury or fatality.

WARNING

WARNING !

▶ Draws attention to a potential threat of danger that can lead to serious injury or fatality.

CAUTION

CAUTION !

▶

Draws attention to a potentially dangerous situation that could lead to slight personal injury or damage

to the equipment or other property.

1.2.2 Symbols in the documentation

The following symbols are used in this document:

Read the operating instructions before use.

Instructions for use and other useful information

Dealing with recyclable materials

Do not dispose of electric equipment and batteries as household waste

1.2.3 Symbols in the illustrations

The following symbols are used in illustrations:

These numbers refer to the corresponding illustrations found at the beginning of these operating

instructions

The numbering reflects the sequence of operations shown in the illustrations and may deviate

from the steps described in the text

Item reference numbers are used in the overview illustrations and refer to the numbers used in

the product overview section

This symbol is intended to draw special attention to certain points when handling the product.

1.3 Product-dependent symbols

1.3.1 Symbols on the product

The following symbols are used on the product:

2233926 English 1

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 8

Wear eye protection

Rated speed

Revolutions per minute

Revolutions per minute

Diameter

Wireless data transfer

Hilti Li-ion battery type series used. Observe the information given in the section headed Intended use.

1.4 Product information

permitted to operate, service and maintain the products. This personnel must be specifically informed about

the possible hazards. The product and its ancillary equipment can present hazards if used incorrectly by

untrained personnel or if used not in accordance with the intended use.

The type designation and serial number are printed on the rating plate.

▶ Write down the serial number in the table below. You will be required to state the product details when

1.5 Declaration of conformity

We declare, on our sole responsibility, that the product described here complies with the applicable directives

and standards. A copy of the declaration of conformity can be found at the end of this documentation.

The technical documentation is filed here:

Hilti Entwicklungsgesellschaft mbH | Tool Certification | Hiltistrasse 6 | 86916 Kaufering, Germany

products are designed for professional users and only trained, authorized personnel are

contacting Hilti Service or your local Hilti organization to inquire about the product.

Product information

Angle grinder AG 4S-A22

Generation 01

Serial no.

2 Safety

2.1 Safety instructions

2.1.1 General power tool safety warnings

WARNING Read all safety warnings, instructions, illustrations and specifications provided with this

power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

▶ Keep work area clean and well lit. Cluttered or dark areas invite accidents.

▶ Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

▶ Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

Electrical safety

▶ Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

▶ Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

2 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 9

▶ Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

▶ Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

▶ When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

▶ If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety

▶ Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

▶ Use personal protective equipment. Always wear eye protection. Protective equipment such as a

dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will

reduce personal injuries.

▶ Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on

the switch or energising power tools that have the switch on invites accidents.

▶ Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

▶ Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

▶ Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

▶ If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

▶ Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore

tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

▶ Do not force the power tool. Use the correct power tool for your application. The correct power tool

will do the job better and safer at the rate for which it was designed.

▶ Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

▶ Disconnect the plug from the power source and/or remove the battery pack, if detachable, from

the power tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

▶ Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

▶ Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained power

tools.

▶ Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

▶ Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous situation.

▶ Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Battery tool use and care

▶ Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with another battery pack.

▶ Use power tools only with specifically designated battery packs. Use of any other battery packs may

create a risk of injury and fire.

▶ When battery pack is not in use, keep it away from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects, that can make a connection from one terminal to

another. Shorting the battery terminals together may cause burns or a fire.

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

2233926 English 3

Page 10

▶ Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

▶ Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may

exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

▶ Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature

above 130° C (265 °F) may cause explosion.

▶ Follow all charging instructions and do not charge the battery pack or tool outside the temperature

range specified in the instructions. Charging improperly or at temperatures outside the specified range

may damage the battery and increase the risk of fire.

Service

▶ Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

▶ Never service damaged battery packs. Service of battery packs should only be performed by the

manufacturer or authorized service providers.

2.1.2 Safety warnings common for grinding, sanding, wire brushing, polishing or abrasive cutting-

off operations:

▶ This power tool is intended to function as a grinder, sander, wire brush or cut-off tool. Read all

safety warnings, instructions, illustrations and specifications provided with this power tool. Failure

to follow all instructions listed below may result in electric shock, fire and/or serious injury.

▶ Operations such as polishing are not recommended to be performed with this power tool.

Operations for which the power tool was not designed may create a hazard and cause personal injury.

▶ Do not use accessories which are not specifically designed and recommended by the tool

manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe

operation.

▶ The rated speed of the accessory must be at least equal to the maximum speed marked on the

power tool. Accessories running faster than their rated speed can break and fly apart.

▶ The outside diameter and the thickness of your accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

▶ Threaded mounting of accessories must match the grinder spindle thread. For accessories

mounted by flanges, the arbour hole of the accessory must fit the locating diameter of the flange.

Accessories that do not match the mounting hardware of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

▶ Do not use a damaged accessory. Before each use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or

cracked wires. If power tool or accessory is dropped, inspect for damage or install an undamaged

accessory. After inspecting and installing an accessory, position yourself and bystanders away

from the plane of the rotating accessory and run the power tool at maximum no-load speed for

one minute. Damaged accessories will normally break apart during this test time.

▶ Wear personal protective equipment. Depending on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of

stopping flying debris generated by various operations. The dust mask or respirator must be capable of

filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

▶ Keep bystanders a safe distance away from work area. Anyone entering the work area must wear

personal protective equipment. Fragments of workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

▶ Hold the power tool by insulated gripping surfaces only, when performing an operation where the

cutting tool may contact hidden wiring. Contact with a "live" wire will also make exposed metal parts

of the power tool "live" and could give the operator an electric shock.

▶ Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged

and your hand or arm may be pulled into the spinning accessory.

▶ Never lay the power tool down until the accessory has come to a complete stop. The spinning

accessory may grab the surface and pull the power tool out of your control.

▶ Do not run the power tool while carrying it at your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the accessory into your body.

▶ Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause electrical hazards.

4 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 11

▶ Do not operate the power tool near flammable materials. Sparks could ignite these materials.

▶ Do not use accessories that require liquid coolants. Using water or other liquid coolants may result

in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other

accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is

entering into the pinch point can dig into the surface of the material causing the wheel to climb out or kick

out. The wheel may either jump toward or away from the operator, depending on direction of the wheel’s

movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

▶ Maintain a firm grip on the power tool and position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback or

torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper

precautions are taken.

▶ Never place your hand near the rotating accessory. Accessory may kickback over your hand.

▶ Do not position your body in the area where power tool will move if kickback occurs. Kickback will

propel the tool in direction opposite to the wheel’s movement at the point of snagging.

▶ Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and

cause loss of control or kickback.

▶ Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety warnings specific for grinding and abrasive cutting-off operations:

▶ Use only wheel types that are recommended for your power tool and the specific guard designed

for the selected wheel. Wheels for which the power tool was not designed cannot be adequately

guarded and are unsafe.

▶ The grinding surface of centre depressed wheels must be mounted below the plane of the guard

lip. An improperly mounted wheel that projects through the plane of the guard lip cannot be adequately

protected.

▶ The guard must be securely attached to the power tool and positioned for maximum safety, so the

least amount of wheel is exposed towards the operator. The guard helps to protect the operator from

broken wheel fragments, accidental contact with wheel and sparks that could ignite clothing.

▶ Wheels must be used only for recommended applications. For example: do not grind with the side

of cut-off wheel. Abrasive cut-off wheels are intended for peripheral grinding, side forces applied to

these wheels may cause them to shatter.

▶ Always use undamaged wheel flanges that are of correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for

cut-off wheels may be different from grinding wheel flanges.

▶ Do not use worn down wheels from larger power tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and may burst.

Additional safety warnings specific for abrasive cutting-off operations:

▶ Do not "jam" the cut-off wheel or apply excessive pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases the loading and susceptibility to twisting or binding of

the wheel in the cut and the possibility of kickback or wheel breakage.

▶ Do not position your body in line with and behind the rotating wheel. When the wheel, at the point of

operation, is moving away from your body, the possible kickback may propel the spinning wheel and the

power tool directly at you.

▶ When wheel is binding or when interrupting a cut for any reason, switch off the power tool and hold

the power tool motionless until the wheel comes to a complete stop. Never attempt to remove the

cut-off wheel from the cut while the wheel is in motion otherwise kickback may occur. Investigate

and take corrective action to eliminate the cause of wheel binding.

▶ Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully

re-enter the cut. The wheel may bind, walk up or kickback if the power tool is restarted in the workpiece.

▶ Support panels or any oversized workpiece to minimize the risk of wheel pinching and kickback.

Large workpieces tend to sag under their own weight. Supports must be placed under the workpiece

near the line of cut and near the edge of the workpiece on both sides of the wheel.

2233926 English 5

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 12

▶ Use extra caution when making a "pocket cut" into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

Safety warnings specific for sanding operations:

▶ Do not use excessively oversized sanding disc paper. Follow manufacturers recommendations,

when selecting sanding paper. Larger sanding paper extending beyond the sanding pad presents a

laceration hazard and may cause snagging, tearing of the disc or kickback.

Safety warnings specific for wire brushing operations:

▶ Be aware that wire bristles are thrown by the brush even during ordinary operation. Do not

overstress the wires by applying excessive load to the brush. The wire bristles can easily penetrate

light clothing and/or skin.

▶ If the use of a guard is recommended for wire brushing, do not allow any interference of the wire

wheel or brush with the guard. Wire wheel or brush may expand in diameter due to work load and

centrifugal forces.

2.1.3 Additional safety instructions

Personal safety

▶ Only use the product if it is in perfect working order.

▶ Never tamper with or modify the tool in any way.

▶ Avoid touching rotating parts – risk of injury!

▶ Wear protective gloves also when changing the accessory tool. Touching the accessory tool presents a

risk of injury (cuts or burns).

▶ Before starting work, check the hazard class of the dust that will be produced when working. Use

an industrial vacuum cleaner with an officially approved protection class in compliance with the locally

applicable dust protection regulations. Dust from materials such as lead-based paint, certain types of

wood and concrete/masonry/stone containing quartz, minerals or metal may be harmful to health.

▶ Make sure that the workplace is well ventilated and, where necessary, wear a respirator appropriate for

the type of dust generated. Contact with or inhalation of the dust may cause allergic reactions and/or

respiratory or other diseases among operators or bystanders. Certain kinds of dust are classified as

carcinogenic such as oak and beech dust, especially in conjunction with additives for wood conditioning

(chromate, wood preservative). Material containing asbestos may be handled only by specialists.

▶ Take breaks between working and do physical exercises to improve the blood circulation in your fingers.

Exposure to vibration during long periods of work can lead to disorders of the blood vessels and nervous

system in the fingers, hands and wrists.

Electrical safety

▶ Before beginning work, check the working area for concealed electric cables or gas and water pipes.

External metal parts of the power tool may give you an electric shock if you damage an electric cable

accidentally.

Using and handling power tools with care

▶ Do not use cutting discs for grinding.

▶ Tighten the accessory tool and flange securely. If the accessory tool and flange are not tightened

securely, the accessory tool may work loose from the spindle due to the braking effect of the motor after

switching off.

▶ Comply with the manufacturer's instructions for handling and storing grinding discs.

2.1.4 Battery use and care

▶ Observe the special regulations and instructions applicable to the transport, storage and use of Li-ion

batteries.

▶ Do not expose batteries to high temperatures, direct sunlight or fire.

▶ Do not disassemble, crush or incinerate batteries and do not subject them to temperatures over 80 °C.

▶ Do not use or charge batteries that have suffered mechanical impact, have been dropped from a height

or show signs of damage. In this case, always contact your Hilti Service.

▶ If the battery is too hot to touch it may be defective. In this case, place the product in a non-flammable

location, well away from flammable materials, where it can be kept under observation and allowed to

cool down. In this case, always contact your Hilti Service.

6 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 13

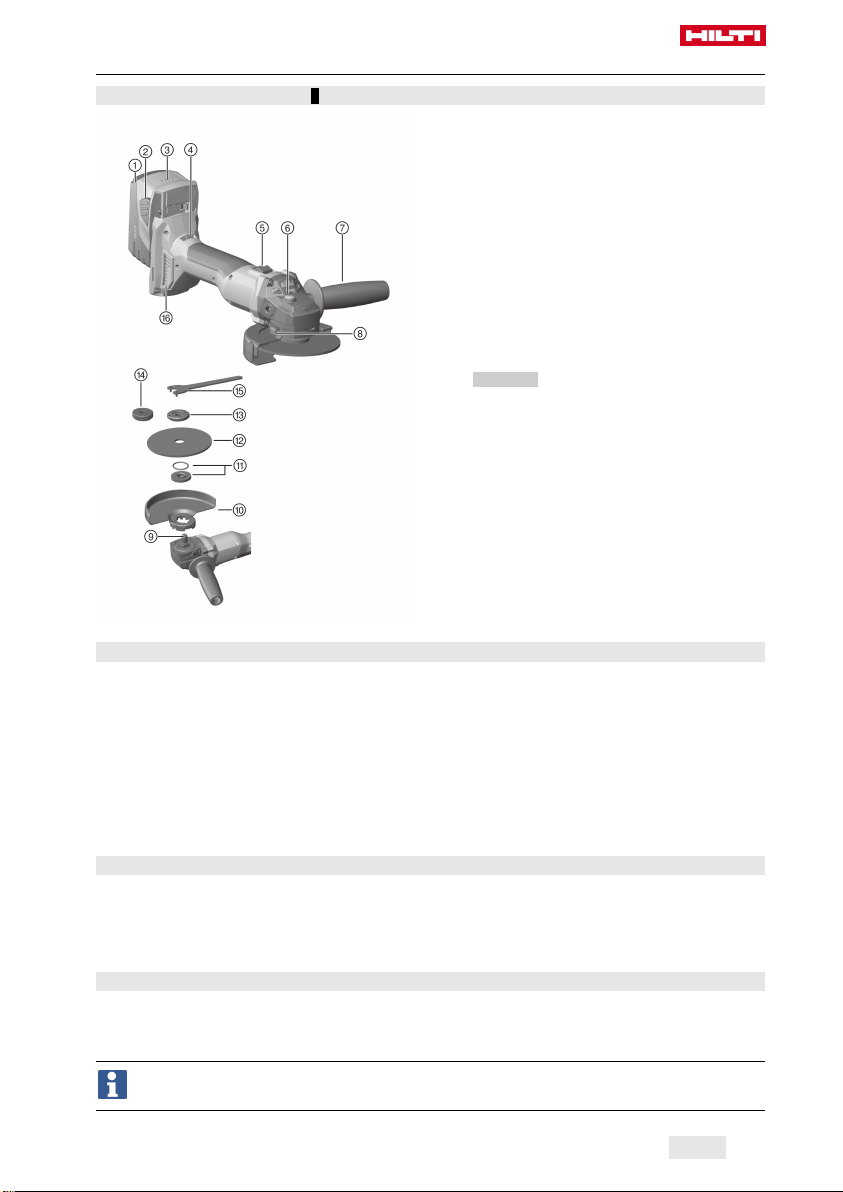

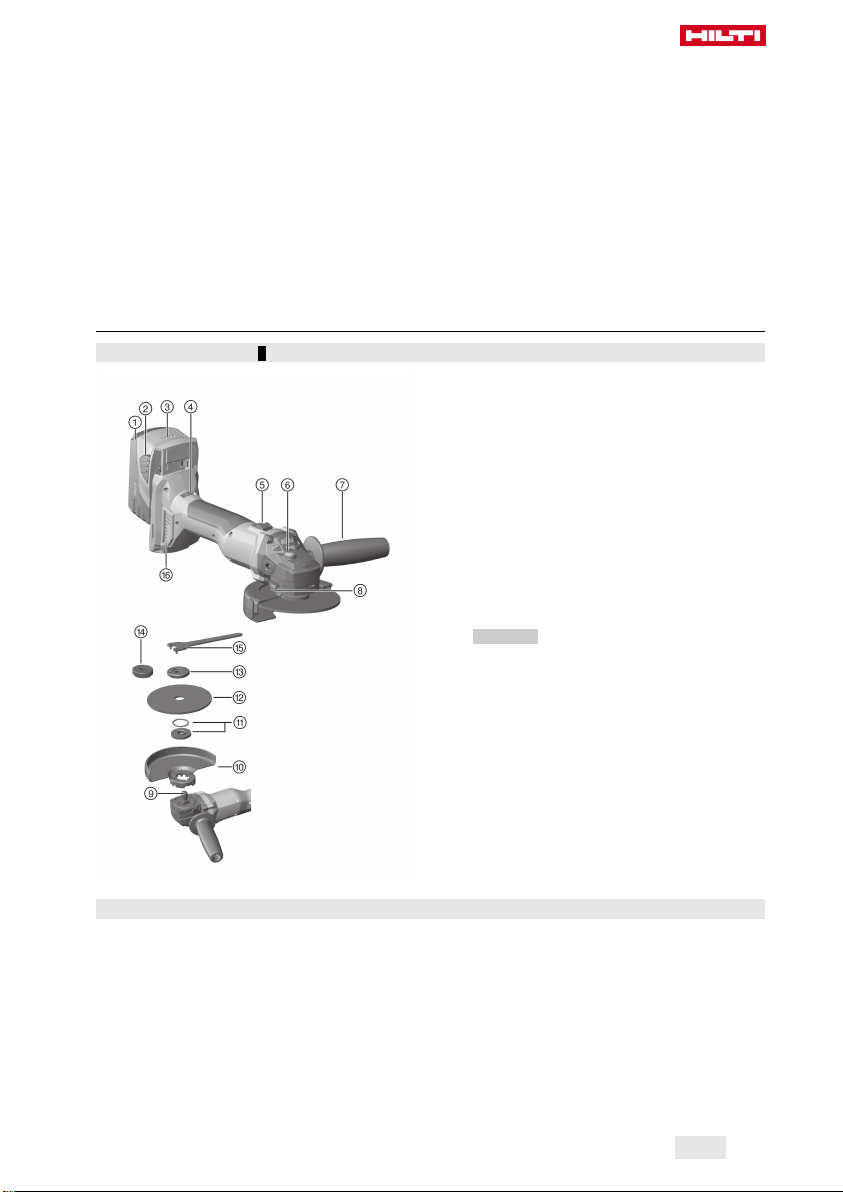

3 Description

3.1 Overview of the product 1

Battery

@

Battery release button

;

Charge state indicator

=

Speed regulation

%

On/off switch

&

Spindle lock button

(

Side handle

)

Guard release button

+

Spindle

§

Standard guard

/

Clamping flange with O-ring

:

Abrasive cutting disc / abrasive grinding disc

∙

Clamping nut

$

Kwik lock clamping nut (optional)

£

Pin wrench

|

Dust filter

¡

3.2 Intended use

The product described is a hand-held cordless angle grinder. It is designed for cutting and grinding metal

and mineral materials, brushing, sanding and for hole cutting in tiles, all without use of water. It can be used

only for dry grinding / cutting.

• The power tool may be used for cutting, slitting and grinding mineral materials only when equipped with

the corresponding guard (optional accessory).

• A dust removal hood together with a suitable Hilti vacuum cleaner must be used for working on mineral

materials such as concrete or stone.

▶ Use only Hilti Liion batteries of the B 22 series with this product.

▶ Use only Hilti battery chargers of the C4/36 series for charging these batteries.

3.3 Items supplied

Angle grinder, side handle, standard guard, front cover, clamping flange, clamping nut, pin wrench, dust

filter, operating instructions.

Other system products approved for use with this product can be found at your local Hilti Store or online at:

www.hilti.group.

3.4 ATC

The power tool is equipped with the ATC (Active Torque Control) quick-acting electronic cut-out.

If the accessory tool sticks or stalls, the power tool will suddenly pivot about its own axis in the opposite

direction. ATC detects this suddenpivotingmovementof the power tool and switches the tool off immediately.

For ATC to function correctly, the power tool must be free to pivot.

After an ATC cut-out, switch the power tool off and then on again.

2233926 English 7

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 14

3.5 Temperature-dependent motor protection

The temperature-dependent motor protection system monitors current input and motor temperature and

thus prevents the power tool overheating.

If the motor is overloaded through application of excessive working pressure, the power tool’s performance

drops noticeably or it may stall completely.

If the power tool stalls or slows significantly due to overloading, release the pressure applied to the tool and

then allow it to run under no load for approx. 30 seconds.

3.6 Guard with front cover 2

When grinding with straight grinding discs and cutting with cutting discs in metalworking applications, use

the standard guard with front cover.

3.7 DC-EX 125/5" C compact dust hood for cutting (accessory) 3

When cutting mineral materials with diamond cutting discs, use the DC-EX 125/5" C compact hood.

Use of this guard for working on metal is not permissible.

3.8 DC-EX 125/5"M dust hood for grinding (accessory) 4

The power tool must be equipped with a dust hood when mineral materials are cut or slit with diamond

cutting discs.

CAUTION Use of this hood for working on metal is prohibited.

3.9 DG-EX 125/5" dust hood for grinding (accessory) 5

The grinding system is suitable only for occasional use with diamond cup wheels for grinding mineral

materials.

Use of this guard for working on metal is not permissible.

3.10 Li-ion battery charge status display

The charge status of the Liion battery is displayed after one of the two battery release buttons is pressed.

Status Meaning

4 LEDs light. Charge status: 75 % to 100 %

3 LEDs light. Charge status: 50 % to 75 %

2 LEDs light. Charge status: 25 % to 50 %

1 LED lights up. Charge status: 10 % to 25 %

1 LED flashes. Charge status: < 10 %

Indication of the charge status is not possible while the power tool is in operation or immediately

after operation. If the battery charge status LEDs flash, please refer to the information given in the

Troubleshooting section.

4 Consumables

Only synthetic resin-bonded, fiber-reinforced discs with maximum Ø 125 mm which are approved for use at

a rotational speed of at least 11,000/min and a peripheral speed of 80 m/s may be used.

The maximum permissible grinding disc thickness is 6.4 mm and the maximum cutting disc thickness is

3.0 mm.

ATTENTION! When cutting or slitting with abrasive cutting discs always use the standard guard with

the additional front cover, or a fully enclosing dust hood.

Discs

Type Application Designation Material

Abrasive cutting disc Cutting, slitting ACD Metal

Diamond cutting disc Cutting, slitting DC-TP, DCD (SPX,

SP, P)

8 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Mineral

*2233926*

Page 15

Type Application Designation Material

Abrasive grinding disc Rough grinding AGD, AFD, AND Metal

Diamond grinding disc Rough grinding DGCW (SPX, SP,P)Mineral

Wire brushes Wire brushes 3CS, 4CS, 3SS,

Diamond core bit Drilling in tiles DDM14 Mineral

Abrasive resin-fiber disc Rough grinding AP-D Metal

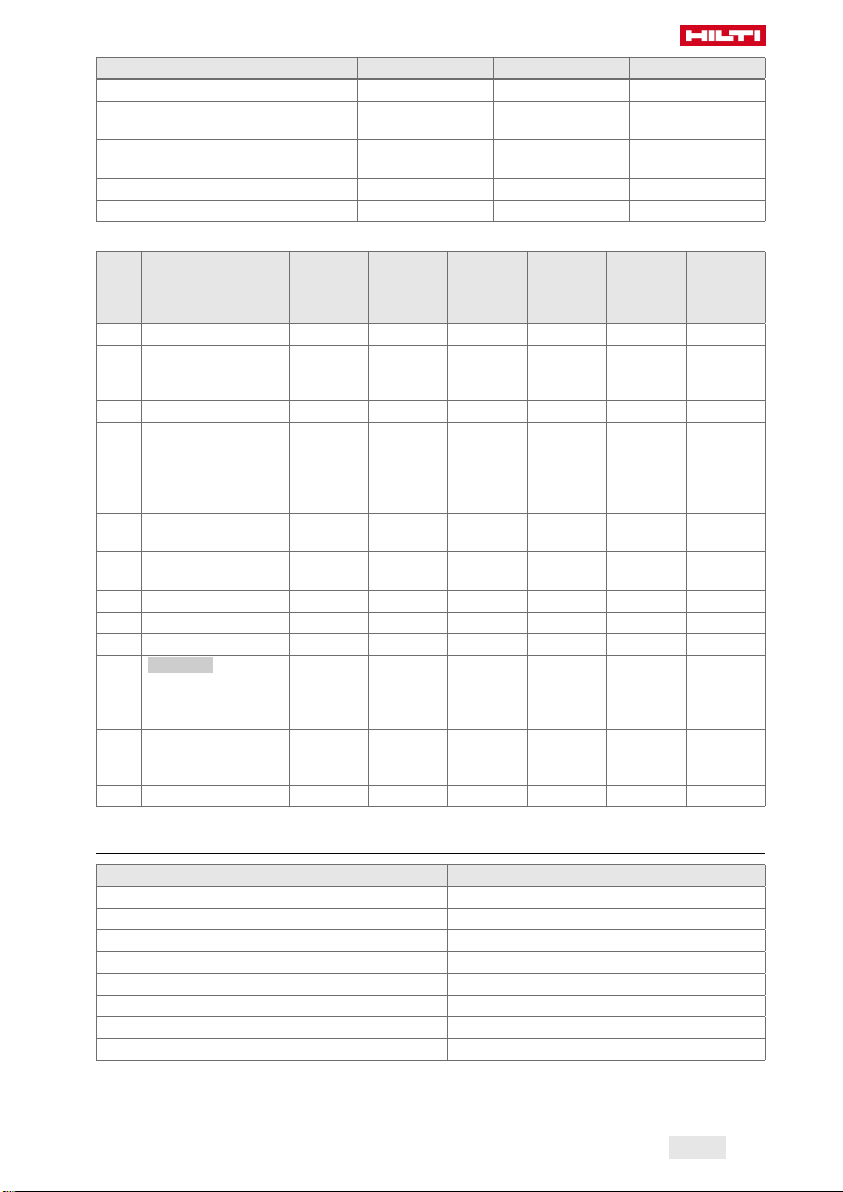

Suitability of discs for the equipment used

Item Equipment ACD AGD,

A Guard X X X X X X

B Front cover (in

combination with

A)

C Dust hood (grinding) — — X — — —

D Dust hood (cutting)

DCEX 125⁄5"C (in

combination with A)

only for AG 4S-

A22125

E DC-EX 125/5"M dust

hood for slitting

F DCEX SL adapter (in

combination with E)

G Side handle X X X X X X

H Clamping nut X X X X — —

I Clamping flange X X X X — —

J

Kwik lock (optional

instead of H)

only for AG 4S-

A22125

K Clamping nut for

abrasive resin-fiber

disc

L Support plate — — — — X —

X — — X — —

— — — X — —

— — — X — —

— — — X — —

X X — X — —

— — — — X —

AFD,

AND

4SS

DG-CW

(SPX, SP,

P)

DC-TP,

DC-D

(SPX, SP,

P)

Metal

AP-D 3CS, 4CS,

3SS, 4SS,

DD-M14

5 Technical data

Rated voltage

Rated speed

Maximum disc diameter

Weight in accordance with EPTA procedure 01

Drive spindle thread

Spindle length

Ambient temperature for operation

Storage temperature

2233926 English 9

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

AG 4S-A22125

21.6 V

8,500 /min

125 mm

3.1 kg

M14

22 mm

−17 ℃ … 60 ℃

−20 ℃ … 70 ℃

Page 16

5.1 Technical data

Spindle length

Ambient temperature for operation

Storage temperature

5.2 Battery

Battery operating voltage

Ambient temperature for operation

Storage temperature

Battery charging starting temperature

5.3 Noise information and vibration values in accordance with EN 60745

The sound pressure and vibration values given in these instructions have been measured in accordance with

a standardized test and may be used to compare one power tool with another. They may be used for a

preliminary assessment of exposure.

The data given represents the main applications of the power tool. However, if the power tool is used for

different applications, with different accessory tools or is poorly maintained, the data may vary. This may

significantly increase exposure over the total working period.

An accurate estimation of exposure should also take into account the times when the power tool is switched

off, or when it is running but not actually being used for a job. This may significantly reduce exposure over

the total working period.

Identify additional safety measures to protect the operator from the effects of noise and/or vibration, for

example: Maintaining the power tool and accessory tools, keeping the hands warm, organization of work

patterns.

AG 4S-A22125

Noise information

Emission sound pressure level (LpA)

Uncertainty for the sound pressure level (KpA)

Sound power level (LWA)

Uncertainty for the sound power level (KWA)

Vibration information

Other applications, such as cutting, may produce vibration values that deviate from the given values.

Surface grinding with the vibration-absorbing side handle (a

Sanding with sandpaper with the vibration-absorbing side handle (a

Uncertainty (K)

22 mm

−17 ℃ … 60 ℃

−20 ℃ … 70 ℃

)

h,AG

h,DS

)

21.6 V

−17 ℃ … 60 ℃

−20 ℃ … 40 ℃

−10 ℃ … 45 ℃

81.5 dB(A)

3 dB(A)

92.5 dB(A)

3 dB(A)

4.7 m/s²

5.3 m/s²

1.5 m/s²

6 Before use

6.1 Charging the battery

1. Before charging the battery, read the operating instructions for the charger.

2. Make sure that the contacts on the battery and the contacts on the charger are clean and dry.

3. Use an approved charger to charge the battery.

6.2 Inserting the battery

CAUTION

Risk of injury by short circuit or falling battery!

▶ Before inserting the battery, make sure that the contacts on the battery and the contacts on the product

are free of foreign matter.

▶ Make sure that the battery always engages correctly.

1. Charge the battery fully before using it for the first time.

10 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 17

2. Push the battery into the battery holder until it engages with an audible click.

3. Check that the battery is seated securely.

6.3 Removing the battery

1. Press the release buttons on the battery.

2. Pull the battery out of its holder in the device.

6.4 Fitting the side handle

▶ Screw the side handle into one of the threaded bushings provided.

6.5 Fitting or removing the guard

CAUTION

Risk of injury. The accessory tool may be hot or have sharp edges.

▶ Wear protective gloves when fitting, removing or adjusting the accessory tool or other parts and when

troubleshooting.

▶ Observe the instructions for fitting the applicable guard.

6.5.1 Installing standard guard 6

The guard is equipped with locating lugs that ensure only guards of a type suitable for use with the

power tool can be fitted. The locating lugs of the guard fit into the guard mount on the power tool.

1. Fit the guard onto the drive spindle collar so that the two triangular marks on the guard and on the power

tool are in alignment.

2. Press the guard onto the drive spindle collar.

3. Press the guard release button and then rotate the guard until it engages in the desired position.

➥ The guard release button jumps back.

6.5.2 Adjusting standard guard

▶ Press the guard release button and then rotate the guard until it engages in the desired position.

6.5.3 Removing standard guard

1. Press the guard release button and then rotate the guard until the triangular marks on the guard and the

power tool are in alignment.

2. Remove the guard.

6.6 Fitting or removing the front cover 7

The front cover, when used, is clipped onto the guard.

1. Position the front cover with the closed side on the standard guard and push it on until it engages.

2. To remove it, release the catch for the front cover and then lift the front cover away from the standard

guard.

6.7 Fitting and removing accessory tools

WARNING

Risk of injury. The accessory tool may work loose due to the braking effect of the motor.

▶ Wait until the accessory tool has come to a standstill before touching or gripping the accessory tool or

the clamping nut.

▶ Secure the accessory tool by tightening the clamping flange and clamping nut firmly so that no parts

work loose from the spindle due to the braking effect of the motor.

2233926 English 11

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 18

CAUTION

Risk of injury. The accessory tool may be hot.

▶ Wear protective gloves when changing the accessory tool.

Diamond discs must be replaced when their cutting or grinding performance drops significantly. This

generally is the case when the segments reach a height of less than 2 mm.

Other discs must be replaced when their cutting performance drops significantly or other parts of the

angle grinder (not the disc) come into contact with the material you are working on.

Abrasive discs must be replaced when their expiry date has been reached.

6.7.1 Fitting an accessory tool 8

1. Remove the battery. → page 11

2. Check that the O-ring is in place in the clamping flange and that it is undamaged.

Result

The O-ring is damaged.

There is no O-ring in the clamping flange.

▶ Fit a new clamping flange with O-ring.

3. Fit the clamping flange onto the drive spindle (keyed fit to prevent slipping/rotation).

4. Fit the accessory tool.

5. Screw on the clamping nut corresponding to the type of accessory tool fitted.

6. Press the spindle lockbutton and hold it in this position.

7. Use the pin wrench to tighten the clamping nut securely, then release the spindle lockbutton and remove

the wrench.

6.7.2 Removing the accessory tool

1. Remove the battery. → page 11

CAUTION

Risk of breakage and irreparable damage. If the spindle lockbutton is pressed while the spindle is rotating,

the accessory tool can detach from the power tool.

▶ Press the spindle lockbutton only when the spindle has stopped rotating.

2. Press the spindle lockbutton and hold it in this position.

3. Release the clamping nut by gripping it with the wrench and turning the nut counterclockwise.

4. Release the spindle lockbutton and remove the accessory tool.

6.7.3 Fitting an accessory tool secured with a Kwik lock nut 9

CAUTION

Risk of breakage. Heavy wear (abrasion) may cause the Kwik lock nut to break.

▶

When working with the power tool, make sure that the Kwik lock nut doesn’t come into contact with the

working surface.

▶

Do not use a damaged Kwik lock nut.

The optional Kwik lock nut can be used instead of the standard clamping nut. Accessory tools (discs

etc.) can then be changed without need for additional tools (keyless system).

1. Remove the battery. → page 11

2. Check that the O-ring is in place in the clamping flange and that it is undamaged.

Result

The O-ring is damaged.

There is no O-ring in the clamping flange.

▶ Fit a new clamping flange with O-ring.

3. Clean the clamping flange and the quick-release clamping nut.

4. Fit the clamping flange onto the drive spindle.

5. Fit the accessory tool.

12 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 19

6.

Screw on the Kwik lock nut until it is seated against the accessory tool.

➥

The name Kwik lock should be visible when the nut is screwed on.

7. Press the spindle lock button and hold it in this position.

8.

Turn the accessory tool firmly by hand in a clockwise direction until the Kwik lock nut is tightened

securely and then release the spindle lock button.

6.7.4 Removing an accessory tool secured with a Kwik lock nut

1. Remove the battery. → page 11

CAUTION

Risk of breakage and irreparable damage. If the spindle lockbutton is pressed while the spindle is rotating,

the accessory tool can detach from the power tool.

▶ Press the spindle lockbutton only when the spindle has stopped rotating.

2. Press the spindle lockbutton and hold it in this position.

3.

Release the Kwik lock nut by turning it counterclockwise by hand.

4.

If the Kwik lock nut cannot be released by turning it by hand, use a pin wrench to turn the nut in a

counterclockwise direction.

Never use a pipe wrench! A pipe wrench could damage the Kwik lock nut.

5. Release the spindle lockbutton and remove the accessory tool.

6.7.5 Fitting the core bit 10

1. Remove the battery. → page 11

2. Fit the side handle. → page 11

3. Install the standard guard.

4. Place the core bit in position and tighten it hand-tight.

5. Press and hold down the spindle lock button.

6. Tighten the core bit with a suitable open-end wrench.

7. Then release the spindle lock button and remove the open-end wrench.

6.7.6 Fitting the wire brush 11

1. Remove the battery. → page 11

2. Fit the side handle. → page 11

3. Install the standard guard.

4. Place the wire brush in position and tighten it hand-tight.

5. Press and hold down the spindle lock button.

6. Tighten the wire brush with a suitable open-end wrench.

7. Then release the spindle lock button and remove the open-end wrench.

6.7.7 Fitting the abrasive resin-fiber disc 12

1. Remove the battery. → page 11

2. Fit the side handle. → page 11

3. Install the standard guard.

4. Fit the support plate and the abrasive resin-fiber disc, screw on the clamping nut and tighten it securely.

5. Press the spindle lock button and hold it in this position.

6. Use the pin wrench to tighten the clamping nut.

7. Release the spindle lock button and remove the pin wrench.

7 Operation

7.1 Switching on

1. Press the rear section of the on/off switch.

2. Slide the on/off switch forward.

➥ The motor runs.

3. Lock the on/off switch.

2233926 English 13

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 20

7.2 Grinding

CAUTION

Risk of injury. The accessory tool may suddenly stick or stall.

▶ Use the power tool with the side handle fitted and always hold it securely with both hands.

7.3 Cutting

▶ When cutting, apply moderate feed pressure and do not tilt the power tool or the cutting disc (when

working, hold at approx. 90° to the surface being cut).

For best results when cutting profiles and square tube, start cutting at the smallest cross section.

7.4 Rough grinding

CAUTION

Risk of injury. The abrasive cutting disc could shatter and flying fragments may cause injury.

▶ Never use abrasive cutting discs for grinding.

▶ Move the power tool to and fro while maintaining a 5° to 30° angle of attack and applying moderate

pressure.

➥ This will avoid overheating and discoloration of the workpiece and help ensure an even surface finish.

7.5 Switching off

▶ Press the rear section of the on/off switch.

➥ The on/off switch jumps into the off position and the motor stops.

8 Care and maintenance

WARNING

Risk of injury with battery inserted !

▶ Always remove the battery before carrying out care and maintenance tasks!

Care and maintenance of the tool

• Carefully remove any dirt that may be adhering to parts.

• Remove the dust filter and clean it and the air vents carefully, using a dry brush.

• Use only a slightly damp cloth to clean the casing. Do not use cleaning agents containing silicone as

these can attack the plastic parts.

Care of the lithiumion batteries

• Keep the battery free from oil and grease.

• Use only a slightly damp cloth to clean the casing. Do not use cleaning agents containing silicone as

these may attack the plastic parts.

• Avoid ingress of moisture.

Maintenance

• Check all visible parts and controls for signs of damage at regular intervals and make sure that they all

function correctly.

• Do not operate the product if signs of damage are found or if parts malfunction. Have it repaired

immediately by Hilti Service.

• After cleaning and maintenance, fit all guards or protective devices and check that they function correctly.

To help ensure safe and reliable operation, use only genuine Hilti spare parts and consumables. Spare

parts, consumables and accessories approved by Hilti for use with the product can be found at your

local Hilti Store or online at: www.hilti.group.

14 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 21

9 Transport and storage of cordless tools

Transport

CAUTION

Accidental starting during transport !

▶ Always transport your products with the batteries removed!

▶ Remove the battery.

▶ Never transport batteries in bulk form (loose, unprotected).

▶ Check the tool and batteries for damage before use after long periods of transport.

Storage

CAUTION

Accidental damage caused by defective or leaking batteries !

▶ Always store your products with the batteries removed!

▶ Store the tool and batteries in a place that is as cool and dry as possible.

▶ Never store batteries in direct sunlight, on heating units or behind a window pane.

▶ Store the tool and batteries in a place where they cannot be accessed by children or unauthorized

persons.

▶ Check the tool and batteries for damage before use after long periods of storage.

10 Troubleshooting

If the trouble you are experiencing is not listed in this table or you are unable to remedy the problem by

yourself, please contact Hilti Service.

10.1 Troubleshooting

Trouble or fault Possible cause Action to be taken

The battery runs down more

quickly than usual.

The battery doesn’t engage

with an audible click.

1 LED flashes.

The device does not work.

All 4 LEDs flash.

The device does not work.

The angle grinder or battery

gets very hot.

The tool does not achieve full

power.

The motor has no braking

effect.

Very low ambient temperature. ▶ Allow the battery to warm up

The retaining lugs on the battery

are dirty.

Low battery. ▶ Change the battery and charge

The battery is too hot or too cold. ▶ Allow the battery to cool down

The tool has been overloaded. ▶ Release the control switch and

Electrical fault ▶ Switch the power tool off im-

A battery with inadequate capacity

was used.

Low battery. ▶ Change the battery and charge

The power tool was overloaded

briefly.

slowly to room temperature.

▶ Clean the retaining lugs and refit

the battery.

the empty battery.

or warm up slowly to room

temperature.

then press it again. Then allow

the power tool to run under no

load for approx. 30 seconds.

mediately, remove the battery,

keep it under observation, allow

it to cool down and contact Hilti

Service.

▶ Use a battery with adequate

capacity.

the empty battery.

▶ Switch the power tool off and

then on again.

11 RoHS (Restriction of Hazardous Substances)

Click on the link to go to the table of hazardous substances: qr.hilti.com/r9884540.

There is a link to the RoHS table, in the form of a QR code, at the end of this document.

2233926 English 15

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 22

12 Disposal

Most of the materials from which Hilti tools and appliances are manufactured can be recycled. The

materials must be correctly separated before they can be recycled. In many countries, your old tools,

machines or appliances can be returned to Hilti for recycling. Ask Hilti Service or your Hilti representative

for further information.

Battery disposal

Improper disposal of batteries can result in health hazards from leaking gases or fluids.

▶ DO NOT send batteries through the mail!

▶ Cover the terminals with a non-conductive material (such as electrical tape) to prevent short circuiting.

▶ Dispose of your battery out of the reach of children.

▶ Dispose of the battery at your Hilti Store, or consult your local governmental garbage disposal or public

health and safety resources for disposal instructions.

▶ Do not dispose of power tools, electronic equipment or batteries as household waste!

13 Manufacturer’s warranty

▶ Please contact your local Hilti representative if you have questions about the warranty conditions.

16 English 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 23

1 Oplysninger vedrørende dokumentationen

1.1 Vedrørende denne dokumentation

• Læs denne dokumentation igennem før ibrugtagning. Det er en forudsætning for sikkert arbejde og

korrekt håndtering.

• Følg sikkerheds- og advarselshenvisningerne i denne dokumentation og på produktet.

• Opbevar altid brugsanvisningen sammen med produktet, og overdrag det kun til andre personer sammen

med denne anvisning.

1.2 Tegnforklaring

1.2.1 Advarsler

Advarsler advarer mod farer ved håndtering af produktet. Følgende signalord anvendes:

FARE

FARE !

▶ Betegner en umiddelbart truende fare, der kan medføre alvorlige kvæstelser eller døden.

ADVARSEL

ADVARSEL !

▶ Står ved en potentielt truende fare, der kan medføre alvorlige kvæstelser eller døden.

FORSIGTIG

FORSIGTIG !

▶ Betegner en potentielt farlig situation, der kan forårsage lettere personskader eller materielle skader.

1.2.2 Symboler i denne dokumentation

Følgende symboler anvendes i denne dokumentation:

Læs brugsanvisningen før brug

Anvisninger for anvendelse og andre nyttige oplysninger

Håndtering af genvindbare materialer

Elektriske maskiner og batterier må ikke bortskaffes som almindeligt husholdningsaffald

1.2.3 Symboler i illustrationer

Følgende symboler anvendes på illustrationer:

Disse tal henviser til de forskellige illustrationer i begyndelsen af brugsanvisningen

Nummereringen udtrykker arbejdstrinnenes rækkefølge på illustrationen og kan afvige fra arbejds-

trinnene i teksten

Positionsnumre anvendes i illustrationen Oversigt og refererer til tallene i symbolforklaringen i

afsnittet Produktoversigt

Dette symbol skal sikre skærpet opmærksomhed ved omgang med produktet.

1.3 Produktspecifikke symboler

1.3.1 Symboler på produktet

Følgende symboler anvendes på produktet:

Brug beskyttelsesbriller

2233926 Dansk 17

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

Page 24

Nominelt omdrejningstal

Omdrejninger pr. minut

Omdrejninger pr. minut

Diameter

Trådløs dataoverførsel

Anvendt Hilti lithium-ion-batteritypeserie. Overhold oplysningerne i kapitlet Bestemmelsesmæs-

sig anvendelse.

1.4 Produktoplysninger

autoriseret og instrueret personale. Dette personale skal i særdeleshed informeres om de potentielle farer,

der er forbundet med anvendelsen af denne maskine. Der kan opstå farlige situationer ved anvendelse af

produktet og det tilhørende udstyr, hvis det anvendes af personer, der ikke er blevet undervist i dens brug,

eller hvis det ikke anvendes korrekt i henhold til forskrifterne i denne brugsanvisning.

Typebetegnelse og serienummer fremgår af typeskiltet.

▶ Notér serienummeret i den efterfølgende tabel. Du skal bruge produktoplysningerne ved henvendelser til

1.5 Overensstemmelseserklæring

Vi erklærer som eneansvarlige, at det beskrevne produkt er i overensstemmelse med gældende direktiver og

standarder. Sidst i dette dokument finder du et bilede af overensstemmelseserklæringen.

Den tekniske dokumentation er arkiveret her:

Hilti Entwicklungsgesellschaft mbH | Zulassung Geräte | Hiltistraße 6 | 86916 Kaufering, DE

-produkter er beregnet til professionel brug og må kun betjenes, efterses og vedligeholdes af

vores lokale afdeling eller vores serviceværksted.

Produktoplysninger

Vinkelsliber AG 4S-A22

Generation 01

Serienummer

2 Sikkerhed

2.1 Sikkerhedsanvisninger

2.1.1 Generelle sikkerhedsanvisninger for elværktøj

ADVARSEL Læs alle sikkerhedsanvisninger, henvisninger, billedtekster og tekniske data på

elværktøjet. Hvis følgende anvisninger ikke overholdes, er der risiko for elektrisk stød, brand og/eller

alvorlige personskader.

Opbevar alle sikkerhedsanvisninger og instruktioner til senere brug.

Det benyttede begreb "elværktøj" i sikkerhedsanvisningerne refererer til elektriske maskiner (med netledning)

eller batteridrevne maskiner (uden netledning).

Arbejdspladssikkerhed

▶ Sørg for at holde arbejdsområdet ryddeligt og godt oplyst. Uorden eller uoplyste arbejdsområder

øger faren for uheld.

▶ Brug ikke elværktøj i eksplosionstruede omgivelser, hvor der er brændbare væsker, gasser eller

støv. Elværktøj kan slå gnister, der kan antænde støv eller dampe.

▶ Sørg for, at andre personer og ikke mindst børn holdes væk fra arbejdsområdet, når elværktøjet

er i brug. Hvis man distraheres, kan man miste kontrollen over maskinen.

Elektrisk sikkerhed

▶ Elværktøjets stik skal passe til kontakten. Stikket må under ingen omstændigheder ændres. Brug

ikke adapterstik sammen med jordforbundne elværktøj. Uændrede stik, der passer til kontakterne,

nedsætter risikoen for elektrisk stød.

18 Dansk 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 25

▶ Undgå kropskontakt med jordforbundne overflader som f.eks. rør, radiatorer, komfurer og

køleskabe. Hvis din krop er jordforbundet, øges risikoen for elektrisk stød.

▶ Elværktøj må ikke udsættes for regn eller fugt. Indtrængning af vand i elværktøj øger risikoen for

elektrisk stød.

▶ Brug ikke ledningen til formål, den ikke er beregnet til (f.eks. må man aldrig bære elværktøjet i

ledningen, hænge det op i ledningen eller rykke i ledningen for at trække stikket ud af kontakten).

Beskyt ledningen mod varme, olie, skarpe kanter eller dele, der er i bevægelse. Beskadigede eller

sammenviklede ledninger øger risikoen for elektrisk stød.

▶ Hvis elværktøjet benyttes i det fri, må der kun benyttes en forlængerledning, der er egnet til

udendørs brug. Brug af forlængerledning til udendørs brug nedsætter risikoen for elektrisk stød.

▶ Hvis det ikke kan undgås at anvende elværktøjet i fugtige omgivelser, skal du anvende et

fejlstrømsrelæ. Anvendelsen af et fejlstrømsrelæ nedsætter risikoen for et elektrisk stød.

Personlig sikkerhed

▶ Det er vigtigt at være opmærksom, se, hvad man laver, og bruge maskinen fornuftigt. Anvend aldrig

elværktøj, hvis du er træt eller påvirket af stoffer, alkohol eller medicin. Et øjebliks uopmærksomhed

under brugen af elværktøjet kan medføre alvorlige personskader.

▶ Brug beskyttelsesudstyr, og hav altid beskyttelsesbriller på. Brug af sikkerhedsudstyr som f.eks.

støvmaske, skridsikkert fodtøj, beskyttelseshjelm eller høreværn afhængigt af elværktøjets type og

anvendelse nedsætter risikoen for personskader.

▶ Undgå utilsigtet igangsætning. Kontrollér, at elværktøjet er frakoblet, før du slutter det til

strømforsyningen og/eller batteriet, tager det op eller transporterer det. Undgå at bære elværktøjet

med fingeren på afbryderen, og sørg for, at det ikke er tændt, når det sluttes til nettet, da dette øger

risikoen for personskader.

▶ Fjern indstillingsværktøj eller skruenøgler, inden elværktøjet tændes. Hvis et stykke værktøj eller en

nøgle sidder i en roterende maskindel, er der risiko for personskader.

▶ Undgå at arbejde i unormale kropsstillinger. Sørg for at stå sikkert, mens der arbejdes, og kom

ikke ud af balance. Det er derved nemmere at kontrollere elværktøjet, hvis der skulle opstå uventede

situationer.

▶ Brug egnet arbejdstøj. Undgå løse beklædningsgenstande eller smykker. Hold hår, tøj og handsker

væk fra dele, der bevæger sig. Dele, der er i bevægelse, kan gribe fat i løstsiddende tøj, smykker eller

langt hår.

▶ Hvis støvudsugnings- og opsamlingsudstyr kan monteres, er det vigtigt, at dette tilsluttes og

benyttes korrekt. Ved at anvende en støvudsugning er det muligt at nedsætte risiciene som følge af

støv.

▶ Man må ikke ignorere sikkerhedsreglerne for elværktøj, heller ikke selvom man er fortrolig med

brugen af elværktøjet. Uagtsomhed kan medføre alvorlig tilskadekomst inden for få sekunder.

Anvendelse og pleje af elværktøjet

▶ Undgå at overbelaste maskinen. Brug altid en maskine, der er beregnet til det stykke arbejde,

der skal udføres. Med det rigtige værktøj arbejder man bedst og mest sikkert inden for det angivne

effektområde.

▶ Brug ikke elværktøj, hvis afbryderen er defekt. En maskine, der ikke kan startes og stoppes, er farlig

og skal repareres.

▶ Træk stikket ud af stikkontakten, og/eller fjern batteriet fra maskinen, inden du foretager

indstillinger på den, skifter tilbehør og dele eller lægger den til side. Disse sikkerhedsforanstaltninger

forhindrer utilsigtet start af elværktøjet.

▶ Opbevar ubenyttede elværktøjer uden for børns rækkevidde. Lad aldrig personer, der ikke er

fortrolige med maskinen eller ikke har gennemlæst sikkerhedsanvisningerne, benytte denne.

Elværktøj er farligt, hvis det benyttes af ukyndige personer.

▶ Sørg for at pleje elværktøj omhyggeligt. Kontrollér, om bevægelige dele fungerer korrekt og

ikke sidder fast, og om delene er brækket eller beskadiget, således at elværktøjets funktion

påvirkes. Få beskadigede dele repareret, inden elværktøjet tages i brug. Mange uheld skyldes

dårligt vedligeholdte elværktøjer.

▶ Sørg for, at skæreværktøjer er skarpe og rene. Omhyggeligt vedligeholdte skæreværktøjer med

skarpe skærekanter sætter sig ikke så hurtigt fast og er nemmere at føre.

▶ Anvend elværktøj, tilbehør, indsatsværktøj osv. i overensstemmelse med disse anvisninger. Tag

hensyn til arbejdsforholdene og det arbejde, der skal udføres. I tilfælde af anvendelse af maskinen til

formål, som ligger uden for det fastsatte anvendelsesområde, kan der opstå farlige situationer.

▶ Sørg for, at greb og gribeflader er tørre, rene og fri for olie og fedt. Glatte greb og gribeflader gør

betjeningen usikker, og det kan være svært at styre elværktøjet i uforudsete situationer.

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

2233926 Dansk 19

Page 26

Anvendelse og pleje af batteridrevet elværktøj

▶ Oplad kun batterier i ladere, der er anbefalet af fabrikanten. Der er risiko for brand, hvis en lader, der

er beregnet til et bestemt batteri, anvendes til opladning af en anden batteritype.

▶ Brug kun de batterier, der er beregnet til elværktøjet. Brug af andre batterier øger risikoen for

personskader og er forbundet med brandfare.

▶ Ikke benyttede batterier må ikke komme i berøring med kontorclips, mønter, nøgler, søm, skruer

eller andre små metalgenstande, da disse kan kortslutte kontakterne. En kortslutning mellem

batterikontakterne øger risikoen for personskader i form af forbrændinger.

▶ Hvis batteriet anvendes forkert, kan der løbe væske ud af batteriet. Undgå at komme i kontakt

med denne væske. Hvis det alligevel skulle ske, skylles med vand. Søg læge, hvis væsken kommer

i øjnene. Batterivæske kan give hudirritation eller forbrændinger.

▶ Brug aldrig et beskadiget eller ændret batteri. Beskadigede eller ændrede batterier kan virke utilsigtet

og medføre brand, eksplosion eller risiko for tilskadekomst.

▶ Batterier må ikke udsættes for åben ild eller høje temperaturer. Ild eller temperaturer over 130 °C

(265 °F) kan medføre eksplosion.

▶ Følg alle anvisninger vedrørende opladning, og oplad aldrig batteriet eller det batteridrevne

værktøj uden for det temperaturområde, der er anført i betjeningsvejledningen. Forkert opladning

eller opladning uden for det tilladte temperaturområde kan ødelægge batteriet og øge risikoen for brand.

Service

▶ Sørg for, at elværktøjet kun repareres af kvalificerede fagfolk, og at der altid benyttes originale

reservedele. Dermed sikres størst mulig elværktøjssikkerhed.

▶ Forsøg aldrig at reparere beskadigede batterier. Al vedligeholdelse af batterier skal foretages af

producenten eller af autoriserede forhandlere.

2.1.2 Generelle sikkerhedsanvisninger for slibning, sandpapirslibning, arbejde med trådbørster,

polering og skæring:

▶ Dette elværktøj kan anvendes som sliber, sandpapirsliber, trådbørste og skære-/slibemaskine.

Overhold alle de sikkerhedsanvisninger, anvisninger, diagrammer og data, som følger med

maskinen. Hvis du ikke overholder følgende anvisninger, kan det medføre elektrisk stød, brand

og/eller alvorlige personskader.

▶ Dette elværktøj egner sig ikke til polering. Anvendelsesformål, som elværktøjet ikke er beregnet til,

kan indebære risici og personskader.

▶ Anvend ikke tilbehør, som ikke er specielt beregnet til dette elværktøj og anbefalet af producenten.

Kun hvis du kan montere tilbehøret på elværktøjet, er maskinen sikker at bruge.

▶ Indsatsværktøjets tilladte omdrejningstal skal være mindst lige så højt som det maksimale

omdrejningstal angivet på elværktøjet. Tilbehør, der roterer hurtigere end det tilladte omdrejningstal,

kan gå i stykker og slynge dele ud.

▶ Indsatsværktøjets udvendige diameter og tykkelse skal svare til de mål, der er angivet for elværk-

tøjet. Forkert dimensionerede indsatsværktøjer kan ikke afskærmes eller kontrolleres tilstrækkeligt.

▶ Indsatsværktøjer med gevindindsats skal passe præcist på slibespindelens gevind. Ved indsats-

værktøjer, som er monteret med flange, skal indsatsværktøjets huldiameter passe til flangens

holdediameter. Indsatsværktøjer, som ikke fastgøres præcist på elværktøjet, roterer ujævnt, vibrerer

utrolig kraftigt og kan medføre, at man mister kontrollen over værktøjet.

▶ Anvend aldrig beskadigede indsatsværktøjer. Kontrollér hver gang før brug indsatsværktøjer

såsom slibeskiver for slagmærker og revner, slibetallerkner for revner, slid eller alvorlige skader,

samt trådbørster for løse eller brækkede tråde. Hvis elværktøjet eller indsatsværktøjet falder på

gulvet, skal du kontrollere, om det er blevet beskadiget, eller anvende et intakt indsatsværktøj.

Når du har kontrolleret og isat indsatsværktøjet, skal du og personer i nærheden blive uden for det

roterende indsatsværktøjs fareområde og lade elværktøjet køre med maksimalt omdrejningstal i

ét minut. Beskadigede indsatsværktøjer brækker for det meste i løbet af denne testperiode.

▶ Brug personligt beskyttelsesudstyr. Brug ansigtsmaske, øjenværn eller beskyttelsesbriller af-

hængigt af opgaven. Brug så vidt muligt støvmaske, høreværn, beskyttelseshandsker eller

specialforklæde, som beskytter dig imod små slibe- og materialepartikler. Øjnene skal beskyttes

imod flyvende fremmedlegemer, som opstår i forbindelse med forskellige opgaver. Støvmaske og åndedrætsværn skal bortfiltrere det støv, der opstår i forbindelse af den konkrete opgave. Hvis du udsættes

for et højt støjniveau igennem længere tid, kan det medføre nedsat hørelse.

▶ Sørg for, at andre personer opholder sig isikker afstand af dit arbejdsområde. Alle, som befinder sig

i arbejdsområdet, skal bære personligt beskyttelsesudstyr. Brudstykker fra emnet eller beskadigede

indsatsværktøjer kan slynges ud og medføre personskader også uden for det direkte arbejdsområde.

20 Dansk 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 27

▶ Hold kun elværktøjet på de isolerede grebsflader, når du udfører opgaver, hvor indsatsværktøjet

kan ramme skjulte strømledninger. Ved kontakt med en spændingsførende ledning kan også metalliske

værktøjsdele sættes under spænding, hvilket kan medføre elektrisk stød.

▶ Hold netkablet væk fra roterende indsatsværktøjer. Hvis du mister kontrollen over elværktøjet, kan

netkablet blive skåret over eller fanges af værktøjet, så din hånd eller arm kommer ind i det roterende

indsatsværktøj.

▶ Læg aldrig elværktøjet fra dig, før indsatsværktøjet er standset helt. Det roterende indsatsværktøj

kan komme i kontakt med overfladen på fralægningsstedet, hvilket kan medføre, at du mister kontrollen

over elværktøjet.

▶ Lad ikke elværktøjet køre, mens du bærer det fra et sted til et andet. Dit tøj kan ved en tilfældig

kontakt med det roterende indsatsværktøj blive grebet, hvorved indsatsværktøjet kan bore sig ind i din

krop.

▶ Rengør regelmæssigt elværktøjets ventilationsåbninger. Motorblæseren trækker støv ind i huset, og

en stor ophobning af metalstøv kan indebære elektriske risici.

▶ Anvend ikke elværktøjet i nærheden af brændbare materialer. Gnister kan antænde disse materialer.

▶ Anvend ikke indsatsværktøjer, der kræver flydende kølemidler. Anvendelse af vand eller andre

flydende kølemidler kan medføre elektrisk stød.

Tilbageslag og tilhørende sikkerhedsanvisninger

Tilbageslag er en pludselig reaktion som følge af et fastsiddende eller blokeret roterende indsatsværktøj,

f.eks. slibeskive, slibetallerken, trådbørste etc. Fastklemning ellerblokering medfører et omgående stop af det

roterende værktøj. Derved accelereres et ukontrolleret elværktøj modsat indsatsværktøjets rotationsretning

ved blokeringsstedet.

Når eksempelvis en slibeskive sætter sig fast i et emne eller blokeres, kan den kant af slibeskiven, som

arbejder sig ned i emnet, blive hængende og derved brække slibeskiven eller forårsage et tilbageslag.

Slibeskiven bevæger sig derefter hen imod brugeren eller væk fra denne, alt efter skivens rotationsretning

ved blokeringsstedet. Slibeskiven kan også brække i den forbindelse.

Et tilbageslag er resultatet af ukorrekt eller fejlagtig brug af elværktøjet. Det kan forhindres ved at træffe

passende forholdsregler som beskrevet i det følgende.

▶ Hold elværktøjet godt fast, og indtag en position med krop og arme, hvor du kan absorbere

eventuelle tilbageslag. Anvend altid det ekstra håndtag, hvis et sådant findes, for at have den

størst mulige kontrol over tilbageslag eller reaktionsmomenter ved opstart. Brugeren kan ved at

træffe egnede forholdsregler absorbere tilbageslag og reaktionsmomenter.

▶ Anbring aldrig dine hænder i nærheden af roterende indsatsværktøjer. Indsatsværktøjet kan i tilfælde

af et tilbageslag bevæge sige hen over din hånd.

▶ Undgå at anbringe din krop i det område, hvor elværktøjet bevæges ved tilbageslag. Tilbageslaget

bevæger elværktøjet i den modsatte retning af slibeskivens bevægelse ved blokeringsstedet.

▶ Vær særlig forsigtig ved hjørner, skarpe kanter osv. Undgå, at indsatsværktøj slår tilbage fra

emnet og sætter sig fast. Det roterende indsatsværktøj har en tendens til at sætte sig fast ved hjørner,

skarpe kanter eller hvis det preller af. Dette medfører, at du mister kontrollen eller oplever tilbageslag.

▶ Anvend ikke savkæde eller fortandet savklinge. Sådanne indsatsværktøjer forårsager ofte tilbageslag

eller er ofte skyld i, at brugeren mister kontrollen over elværktøjet.

Særlige sikkerhedsanvisninger for slibning og skæring:

▶ Anvend altid de slibeskiver, der er godkendt til elværktøjet, og den beskyttelsesafskærmning, der

er beregnet til den pågældende slibeskive. Slibeskiver, som ikke er beregnet til elværktøjet, kan ikke

afskærmes tilstrækkeligt og er ikke sikre.

▶ Forkrøppede slibeskiver skal monteres, så deres slibeflade ikke rager ud over kanten af beskyttel-

sesafskærmningen. En forkert monteret slibeskive, som rager ud over kanten af beskyttelsesafskærm-

ningen, kan ikke afskærmes på tilstrækkelig vis.

▶ Beskyttelsesafskærmningen skal være monteret på elværktøjet på sikker vis og af hensyn til en

optimal sikkerhed være indstillet på en sådan måde, at brugeren har mindst mulig adgang til

slibeskiven. Beskyttelsesafskærmningen er med til at beskytte brugeren mod brudstykker, tilfældig

kontakt med slibeskiven samt gnister, som kan antænde brugerens tøj.

▶ Slibeskiver må kun anvendes til de anbefalede formål. For eksempel: Slib aldrig med den flade

side på en skæreskive. Skæreskiver er beregnet til at fjerne materiale med kanten af skiven. Hvis en

skive påvirkes på siden, kan det medføre, at den brækker.

▶ Anvend altid intakte spændeflanger i korrekt størrelse og form til den valgte slibeskive. Egnede

flanger støtter slibeskiven og nedsætter dermed risikoen for at brække slibeskiven. Flanger til skæreskiver

kan adskille sig fra flanger til andre slibeskiver.

*2233926*

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

2233926 Dansk 21

Page 28

▶ Anvend aldrig slidte slibeskiver fra større elværktøjer. Slibeskiver til større elværktøjer er ikke

dimensioneret til de højere omdrejningstal, der kendetegner mindre elværktøjer, og kan brække som

følge deraf.

Yderligere særlige sikkerhedsanvisninger for skæring:

▶ Undgå blokering af skæreskiven eller et for stort tryk på skiven. Foretag ikke for dybe snit. En

overbelastning af skæreskiven forøger spændingen og tendensen til at sætte sig fast eller blokere og

øger dermed risikoen for tilbageslag eller et brud på slibeskiven.

▶ Hold dig i sikker afstand af området foran og bag ved den roterende skæreskive. Hvis du bevæger

skæreskiven i emnet væk fra dig, kan elværktøjet med den roterende skæreskive i tilfælde af et tilbageslag

blive kastet direkte tilbage på dig.

▶ Hvis skæreskiven sætter sig fast, eller du afbryder arbejdet, skal du slukke elværktøjet og holde

det stille, indtil skiven er standset. Forsøg aldrig at trække den roterende skæreskive ud af sporet,

da dette kan medføre tilbageslag. Find og afhjælp årsagen til fastklemningen.

▶ Tænd ikke elværktøjet, så længe det befinder sig i emnet. Lad skæreskiven komme op på

maksimalt omdrejningstal, før du fortsætter skæringen forsigtigt. I modsat fald kan skiven sætte sig

fast, springe op fra emnet eller medføre tilbageslag.

▶ Sørg for at understøtte plader eller store emner for at nedsætte risikoen for tilbageslag som

følge af en fastklemt skæreskive. Store emner kan bøje meget som følge af egen vægt. Emnet skal

understøttes på begge sider, og det både i nærheden af snittet og ved kanten.

▶ Vær især forsigtig ved "dyksavning" i eksisterende vægge eller andre områder, hvor du ikke kan

se, hvad der befinder sig bag overfladen. Skæreskiven, der sænkes ned i emnet, kan, hvis den skærer

gas- og vandrør, elektriske ledninger eller andre genstande over, medføre tilbageslag.

Særlige sikkerhedsanvisninger for slibning med sandpapir:

▶ Anvend ikke overdimensionerede slibeblade, men følg producentens anvisninger vedrørende

størrelse af slibeblade. Slibeblade, som rager ud over slibetallerknen, kan medføre personskader og

forårsage blokering, iturivning af slibebladene eller tilbageslag.

Særlige sikkerhedsanvisninger for arbejde med trådbørster:

▶ Vær opmærksom på, at trådbørsten også under almindelig brug mister trådstykker. Undgå at

overbelaste trådene ved at trykke for hårdt ned. Trådstykker, der slynges væk, kan meget let trænge

igennem tyndt tøj og/eller hud.

▶ Hvis en beskyttelsesafskærmning anbefales, skal du sørge for, at beskyttelsesafskærmning og

trådbørste ikke kommer i berøring med hinanden. Tallerken- og kopbørster kan forøge deres diameter,

hvis de trykkes ned, eller hvis de udsættes for centrifugalkræfter.

2.1.3 Yderligere sikkerhedsanvisninger

Personlig sikkerhed

▶ Anvend kun produktet i teknisk fejlfri stand.

▶ Foretag aldrig manipulationer eller ændringer på maskinen.

▶ Undgå berøring af roterende dele - fare for personskader!

▶ Brug også beskyttelseshandsker, når du skifter værktøj. Berøring af indsatsværktøjet kan medføre snitsår

og forbrændinger.

▶ Find ud af, hvilken fareklasse det støv, der opstår ved arbejdet, har, inden du går i gang med arbejdet.

Anvend en industristøvsuger med en officielt tilladt beskyttelsesklassificering, som opfylder de lokale

støvbeskyttelsesbestemmelser. Støv fra materialer såsom blyholdig maling, visse træsorter, beton /

murværk / natursten, som indeholder kvarts, og mineraler samt metal kan være sundhedsfarlige.

▶ Sørg for en god ventilation af arbejdspladsen, og brug om nødvendigt et åndedrætsværn, som egner sig

til den pågældende støvtype. Berøring eller indånding af støv kan medføre allergiske reaktioner og/eller

luftvejssygdomme hos brugeren eller personer, der opholder sig i nærheden. Bestemte støvtyper,

f.eks. støv fra ege- og bøgetræ, er kræftfremkaldende, især i forbindelse med tilsætningsstoffer til

træbehandling (kromat, træbeskyttelsesmidler). Asbestholdige materialer må kun håndteres af fagfolk.

▶ Hold pauser under arbejdet, og lav øvelser, så dine fingre får en bedre blodgennemstrømning. Ved

længerevarende arbejde kan vibrationer medføre forstyrrelser af fingrenes, hændernes eller håndleddenes

blodkar og nervesystem.

Elektrisk sikkerhed

▶ Kontrollér før påbegyndelse af arbejdet arbejdsområdet for skjulte elektriske ledninger, gas- og vandrør,

f.eks. med en metaldetektor. Udvendige metaldele på maskinen kan medføre elektrisk stød, hvis du ved

en fejl kommer til at beskadige en elledning.

Omhyggelig omgang med og brug af elværktøj

▶ Anvend ikke skæreskiver til skrubning.

22 Dansk 2233926

Printed: 11.02.2019 | Doc-Nr: PUB / 5476814 / 000 / 00

*2233926*

Page 29

▶ Spænd indsatsværktøjet og flangen. Hvis indsatsværktøjet og flangen ikke spændes godt fast, er der

efter slukning mulighed for, at indsatsværktøjet løsner sig fra spindlen ved bremsning via motoren.

▶ Overhold producentens anvisninger for håndtering og opbevaring af slibeskiver.