Hilti AG 100-7S, AG 100-8S, AG 115-7S, AG 115-8S, AG 100-7D Operating Instructions Manual

...Page 1

AG 100-7/-8 (S/D),

AG 115-7/-8 (S/D)

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Istruzioni d’uso it

Manual de instrucciones es

Használati utasítás hu

Instrukcja obsługi pl

Инструкция по зксплуатации ru

Návod k obsluze cs

Návod na obsluhu sk

Ръководство за обслужване bg

ar

Пайдалану бойынша басшылы

қ kk

ja

ko

zh

Printed: 02.04.2014 | Doc-Nr: PUB / 5169257 / 000 / 01

Page 2

ꙣ ꙥ

Ꙧ

ꙩ

ꙫ

Ꙫ

Ꙩ

ꙧ

Ꙭ

ꙭ

꙯

꙰

꙱

Ꙥ Ꙥ

ꙮ

1

Printed: 02.04.2014 | Doc-Nr: PUB / 5169257 / 000 / 01

Page 3

2

3

Printed: 02.04.2014 | Doc-Nr: PUB / 5169257 / 000 / 01

Page 4

5

6

PP

PP

7

4

8

Printed: 02.04.2014 | Doc-Nr: PUB / 5169257 / 000 / 01

Page 5

ORIGINAL OPERATING INSTRUCTIONS

AG 100‑7(S/D), AG 100‑8(S/D), AG 115‑7(S/D), AG 115‑8(S/D)

angle grinder

It is essential that the operating instructions

are read before the power tool is operated for

the first time.

Always keep these operating instructions together with the power tool.

Ensure that the operating instructions are

with the power tool when it is given to other

persons.

Contents Page

1 General information 15

2Description 16

3Consumables 18

4 Technical data 18

5 Safety instructions 19

6Beforeuse 23

7 Operation 24

8 Care and maintenance 25

9 Troubleshooting 26

10 Disposal 26

11 Manufacturer’s warranty - tools 26

12 EC declaration of conformity (original) 27

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover

pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the designation “power

tool” always refers to the AG 100‑7S, AG 100‑7D,

AG 100‑8S, AG 100‑8D, AG 115‑7S, AG 115‑7D,

AG 115‑8S or AG 115‑8D angle grinder.

Operating controls and parts 1

Spindle lockbutton

@

Steadying rib

;

On / off switch

=

Side handle

%

Threaded bushing for grip

&

Keyed locating lug

(

Spindle

)

Adjusting screw

+

Clamping lever

§

Clamping flange

/

Clamping nut

:

Switch-on interlock

·

Guard

$

Abrasive cutting disc / abrasive grinding disc

£

Wrench

|

en

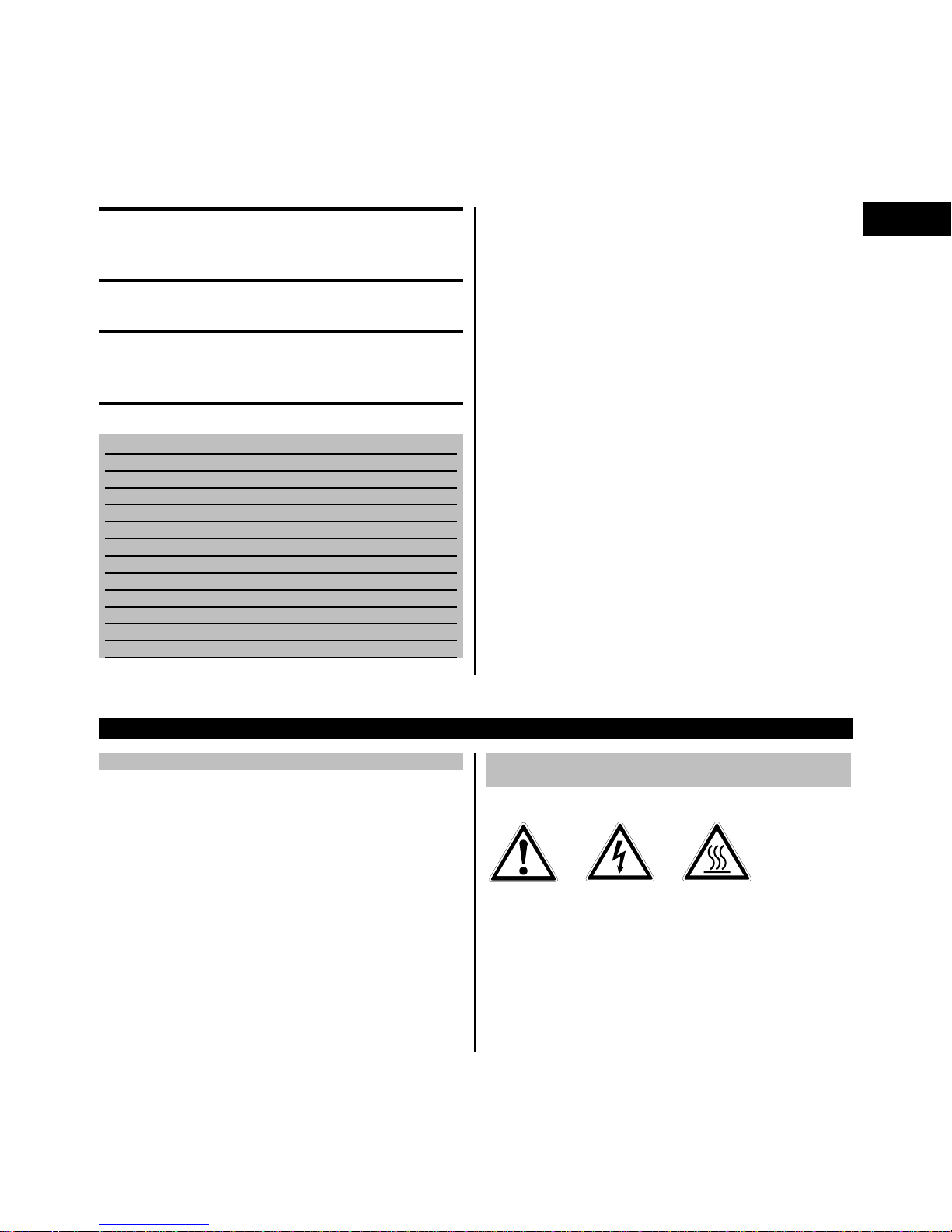

1 General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that will lead to

seriousbodilyinjuryorfatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

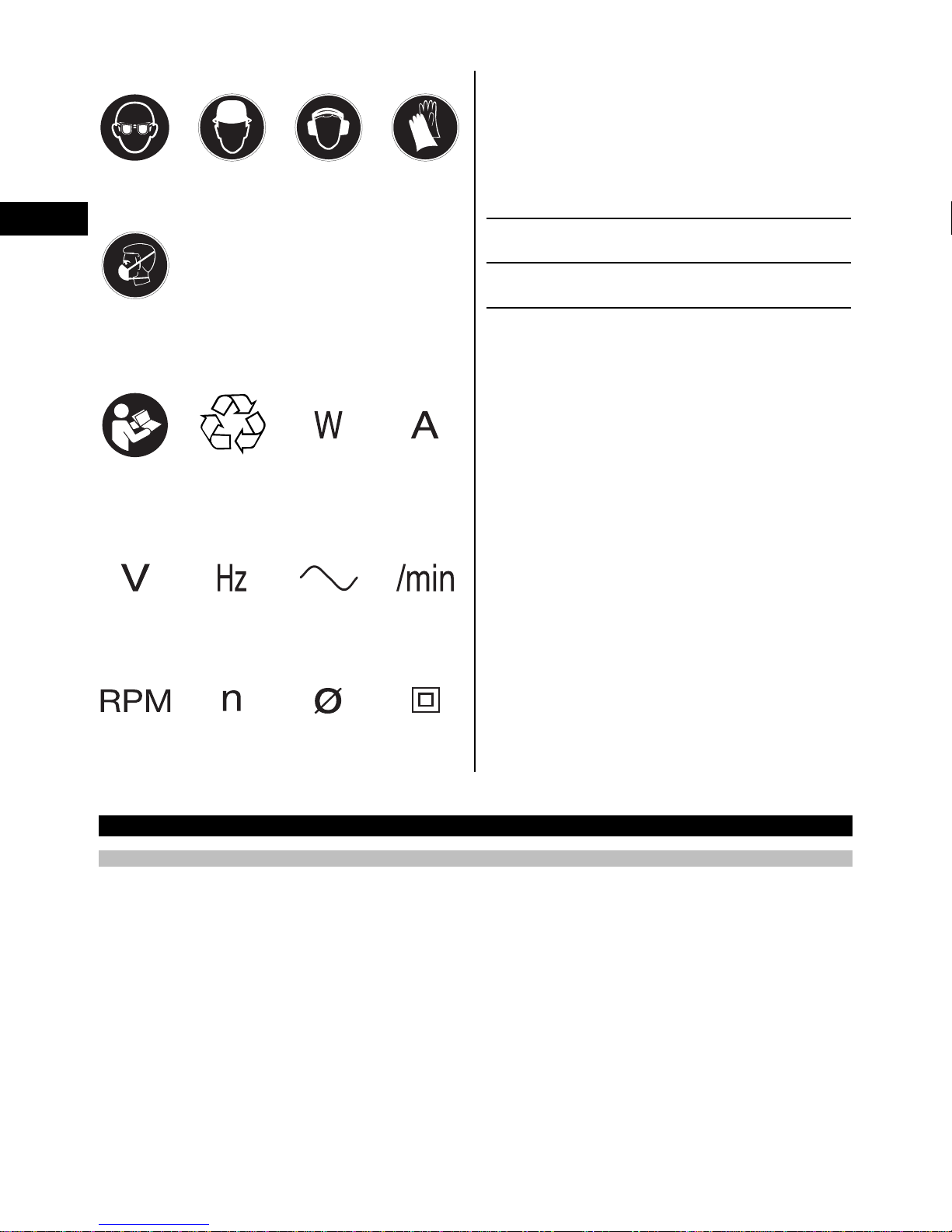

1.2 Explanation of the pictograms and other

information

Warning signs

General

warning

Warning:

electricity

Warning: hot

surface

15

Page 6

Obligation signs

protective

glasses

en

breathing

protection

Symbols

Wear

Wear

Wear a hard

hat

Wear ear

protection

Wear

protective

gloves

Location of identification data on the power tool

The type designation and serial number can be found

on the type identification plate on the machine or tool.

Makeanoteofthisdatainyouroperatinginstructions

and always refer to it when making an enquiry to your

Hilti representative or service department.

Type:

Generation: 03

Serial no.:

Read the

operating

instructions

before use

Volts Hertz Alternating

Revolutions

per minute

Returning

materials for

recycling

Rated speed Diameter Double

Watts Amps

current

Revolutions

per minute

insulated

2 Description

2.1 Use of the product as directed

The power tool is designed for cutting and grinding metal and mineral materials without use of water.

The working environment may be as follows: construction site, workshop, renovation, conversion or new construction.

The power tool may be operated only when connected to a power supply providing a voltage and frequency in

compliance with the information given on its type identification plate.

Working with metals: Cutting, grinding.

Working with mineral materials: Cutting, slitting and grinding.

Use only discs (abrasive grinding discs, abrasive cutting discs, etc.) that are approved for use at a speed of at least

11500/min, with a maximum thickness of 6.4 mm (grinding discs) or 2.5 mm (cutting discs) and a diameter of max.100

mm or, respectively, 115 mm.

Use only synthetic resin-bonded, fiber-reinforced grinding discs or cutting discs approved for use at a permissible

peripheral speed of at least 80 m/sec.

The power tool may be used only for dry cutting or grinding.

Working on materials hazardous to the health (e.g. asbestos) is not permissible.

Take the influences of the surrounding area into account. Do not use the power tool or appliance where there is a risk

of fire or explosion.

Observe national health and safety requirements.

16

Page 7

To avoid the risk of injury, use only genuine Hilti accessories and insert tools.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

The power tool is designed for professional use and may be operated, serviced and maintained only by trained,

authorized personnel. This personnel must be informed of any special hazards that may be encountered. The power

tool and its ancillary equipment may present hazards when used incorrectlybyuntrainedpersonnelorwhenusednot

as directed.

Modification of the power tool or tampering with its parts is not permissible.

2.2 Switches

Lockable on/off switch (AG 100‑7S, AG 100‑8S, AG 115‑7S, AG 115‑8S)

On/off switch with switch-on safety interlock (AG 100‑7D, AG 100‑8D, AG 115‑7D, AG 115‑8D)

2.3 The items supplied in the cardboard box are:

1 Power tool

1Guard

1 Front cover for the disc guard

1Sidehandle

1 Clamping flange

1Clampingnut

1Wrench

1 Operating instructions

1 Cardboard box

2.4 Using extension cords

Use only extension cords of a type approved for the application and with conductors of adequate cross section. The

power tool may otherwise loose performance and the extension cord may overheat. Check the extension cord for

damage at regular intervals. Replace damaged extension cords.

Recommended minimum conductor cross section and max. cord lengths

Conductor cross section

Mains voltage 100V 35 m 65 m

Mains voltage 110-120 V 30 m 45 m

Mains voltage 220-240 V 85 m 145 m

1.5 mm² 2.0 mm² 2.5 mm² 3.5 mm²

en

Do not use extension cords with 1.25 mm² conductor cross section.

2.5 Using extension cords outdoors

When working outdoors, use only extension cords that are approved and correspondingly marked for this application.

2.6 Using a generator or transformer

This power tool may be powered by a generator or transformer when the following conditions are fulfilled: The unit

must provide a power output in watts of at least twice the value printed on the type identification plate on the power

tool. The operating voltage must remain within +5% and -15% of the rated voltage at all times, frequency must be in

the 50 - 60 Hz range and never above 65 Hz, and the unit must be equipped with automatic voltage regulation and

starting boost.

Never operate other power tools or appliances from the generator or transformer at the same time. Switching other

power tools or appliances on and off may cause undervoltage and / or overvoltage peaks, resulting in damage to the

power tool.

2.7 Front cover for the disc guard 2

CAUTION

When grinding with straight grinding discs and cutting with cutting discs in metalworking applications, use the

guard with front cover.

17

Page 8

3Consumables

Discs with a max. diameter of 100 mm or, respectively, 115 mm, designed for a speed of 11500/min and a

peripheral speed of 80 m/sec, and with a maximum thickness of 6.4 mm (abrasive grinding discs) or 2.5 mm

(abrasive cutting discs).

Discs Application Designation Material

Abrasive cutting disc Cutting, slitting AC‑D metal

en

Diamond cutting disc Cutting, slitting DC‑D mineral

Abrasive grinding disc Rough grinding AG‑D, AF‑D, AN‑D metal

Assignment of discs to the equipment used

Equipment Equipment

A Guard XXXXX

BFrontcover(incombin-

ation with A)

C Sidehandle XXXXX

D Clampingnut XXXXX

E Clamping flange X X X X X

AC‑D AG-D

X

---

AF-D AN-D

DC‑D

X

4 Technical data

Right of technical changes reserved.

Power tool

Rated power input 100 V: 700 W

Rated current input 6.4…7 A 3.4 A 6.4…7 A 3.4 A

Rated speed 11,500/min 11,500/min 11,500/min 11,500/min

Rated frequency 50…60 Hz 50…60 Hz 50…60 Hz 50…60 Hz

Dimensions (L x H x

W) without hood

AG 100‑7S/

AG 115‑7S

110 V: 700 W

284 mm x 79 mm x

103 mm

AG 100‑8S/

AG 115‑8S

220…240 V: 850 W 100 V: 700 W

284 mm x 79 mm x

103 mm

AG 100‑7D/

AG 115‑7D

110 V: 700 W

279 mm x 79 mm x

103 mm

AG 100‑8D/

AG 115‑8D

220…240 V: 850 W

279 mm x 79 mm x

103 mm

Power tool

Abrasive cutting discs / abrasive

grinding discs

Thread diameter M10 M14

Thread length 11 mm 15 mm

Protection class Protection class II (double insu-

Weight in accordance with EPTA

procedure 01/2003

NOTE

The vibration emission level given in this information sheet has been measured in accordance with a standardised test

giveninEN60745andmaybeusedtocompareonetoolwithanother.Itmaybeused for a preliminary assessment

of exposure. The declared vibration emission level represents the main applications of the tool. However if the tool is

used for different applications, with different accessories or poorly maintained, the vibration emission may differ. This

may significantly increase the exposure level over the total working period. An estimation of the level of exposure to

vibration should also take into account the times when the tool is switched off or when it is running but not actually

doing the job. This may significantly reduce the exposure level over the total working period. Identify additional safety

measures to protect the operator from the effects of vibration such as: maintain the tool and the accessories, keep

the hands warm, organisation of work patterns.

18

AG 100‑7S/D; AG 100‑8S/D AG 115‑7S/D; AG 115‑8S/D

Max. 100 mm Max. 115 mm

Protection class II (double insu-

lated)

1.9 kg 2.0 kg

lated)

Page 9

Noise and vibration information (in accordance with EN 60745‑1):

Typical A-weighted sound power level for the

AG 100‑7S/D; AG 100‑8S/D; AG 115‑7S/D;

AG 115‑8S/D

Typical A-weighted emission sound pressure level

for the AG 100‑7S/D; AG 100‑8S/D; AG 115‑7S/D;

AG 115‑8S/D

Uncertainty for the given sound level 3 dB (A)

Triaxial vibration values (vibration vector sum) Measured in accordance with EN 60745‑2‑3

Surface grinding with the AG 100‑7S/D; AG 100‑8S/D;

AG 115‑7S/D; AG 115‑8S/D, a

Uncertainty (K) 1.5 m/s²

Additional information Other applications may produce vibration values that

h,AG

96 dB (A)

85 dB (A)

6.5 m/s²

deviate from the given values.

5 Safety instructions

en

5.1 General Power Tool Safety Warnings

a)

5.1.1Workareasafety

a) Keep work area clean and well lit. Cluttered or dark

b) Do not operate power tools in explosive atmo-

c) Keep children and bystanders away while operat-

5.1.2 Electrical safety

a) Power tool plugs must match the outlet. Never

b) Avoid body contact with earthed or grounded

c) Do not expose power tools to rain or wet condi-

d) Do not abuse the cord. Never use the cord for

WARNING

Read all safety warnings and all instructions. Fail-

ure to follow the warnings and instructions may result

in electric shock, fire and/or serious injury. Save all

warnings and instructions for future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

areas invite accidents.

spheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

ing a power tool. Distractions can cause you to lose

control.

modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

tions. Water entering a power tool will increase the

risk of electric shock.

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangledcords increase

theriskofelectricshock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

5.1.3 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protectionused for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch

is in the off‐position before connecting to power

source and/or battery pack, pickingup or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

d) Remove any adjusting key or wrench before turn-

ing the power tool on. A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

e) Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

19

Page 10

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

5.1.4 Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the switch does not

en

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for opera-

tions different from those intended could result in a

hazardous situation.

5.1.5 Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

5.2 Safety warnings for abrasive cutting-off

operations

a) This power tool is intended to function as a cut-

off tool. Read all safety warnings, instructions,

illustrations and specifications provided with this

power tool. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious

injury.

b) Operations such as sanding, wire brushing or

polishing are not recommended to be performed

with this power tool Operations for which the power

tool was not designed may create a hazard and cause

personal injury.

c) Do not use accessories which are not specifically

designed and recommended by the tool manufac-

turer. Just because the accessory can be attached

to your power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at

least equal to the maximum speed marked on the

power tool. Accessories running faster than their

rated speed can break and fly apart.

e) The outside diameter and the thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories can-

not be adequately guarded or controlled.

f) Threaded mounting of accessories must match

the grinder spindle thread. Foraccessoriesmounted by flanges, the arbour hole of the accessory

must fit the locating diameter of the flange. Ac-

cessories that do not match the mounting hardware

of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

g) Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for loose

or cracked wires. If power tool or accessory

is dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged

accessories will normally break apart during this test

time.

h) Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable of

stopping flying debris generated by various operations. The dust mask or respirator must be capable of

filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area must

wear personal protective equipment. Fragments

of workpiece or of a broken accessory may fly

away and cause injury beyond immediate area of

operation.

j) Hold the power tool by insulatedgripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or

its own cord. Cutting accessory contacting a "live"

wire may make exposed metal parts of the power tool

"live" and could give the operator an electric shock.

k) Position the cord clear of the spinning accessory.

If you lose control, the cord may be cut or snagged

andyourhandorarmmaybepulledintothespinning

accessory.

l) Never lay the power tool down until the access-

ory has come to a complete stop. The spinning

20

Page 11

accessory may grab the surface and pull the power

tool out of your control.

m) Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into

your body.

n) Regularly clean the power tool’s air vents. The

motor’sfanwilldrawthedustinsidethehousing

and excessive accumulation of powdered metal may

cause electrical hazards.

o) Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

5.3 Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the

rotating accessory which in turn causes the uncontrolled

power tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel that is entering

into the pinch point can dig intothe surface of the material

causing the wheel to climb out or kick out. The wheel may

either jump toward or away from the operator, depending

on direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and po-

sition your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if

provided, for maximum control over kickback or

torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper

precautions are taken.

b) Never place your hand near the rotating access-

ory. Accessory may kickback over your hand.

c) Do not positionyour body in the areawhere power

tool will move if kickback occurs. Kickback will

propel the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or bouncing have a

tendency to snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

5.4 Safety warnings specific for grinding and

abrasive cutting-off operations

a) Use only wheel types that are recommended for

your power tool and the specific guard designed

for the selected wheel. Wheels for which the power

tool was not designed cannot be adequately guarded

and are unsafe.

b) The grinding surface of centre depressed wheels

must be mountedbelow the plane of the guard lip.

An improperly mounted wheel that projects through

the plane of the guard lip cannot be adequately

protected.

c) The guard must be securelyattachedto the power

tool and positioned for maximum safety, so the

least amount of wheel is exposed towards the operator. The guard helps to protect operator from

broken wheel fragments, accidental contact with

wheel and sparks that could ignite clothing.

d) Wheels must be used only for recommended ap-

plications. For example: do not grind with the side

of cut-off wheel. Abrasive cut-off wheels are inten-

ded for peripheral grinding, side forces applied to

these wheels may cause them to shatter.

e)

Always use undamaged wheel flanges that are of

correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for

cut-off wheels may be different from grinding wheel

flanges.

f) Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and

may burst.

5.5 Additional safety warnings specific for abrasive

cutting-off operations

a) Do not "jam" the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases the

loading and susceptibility to twisting or binding of

the wheel in the cut and the possibility of kickback or

wheel breakage.

b) Do not position your body in line with and behind

the rotating wheel. When the wheel, at the point

of operation, is moving away from your body, the

possible kickback may propel the spinning wheel

and the power tool directly at you.

c) When wheel is binding or when interrupting a cut

for any reason, switch off the power tool and hold

the power tool motionless until the wheel comes

to a complete stop. Never attempt to remove the

cut-off wheel from the cut while the wheel is in

motion otherwise kickback may occur.Investigate

and take corrective action to eliminate the cause of

wheel binding.

d) Do not restart the cutting operation in the work-

piece. Let the wheel reach full speed and carefully

re-enter the cut. The wheel may bind, walk up or

kickback if the power tool is restarted in the workpiece.

e) Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback.

Large workpiecestend to sag under their own weight.

Supports must be placed under the workpiece near

en

21

Page 12

the line of cut and near the edge of the workpiece on

both sides of the wheel.

f) Use extra caution when making a "pocket cut"

into existing walls or other blind areas. The protruding wheel may cut gas or water pipes, electrical

wiring or objects that can cause kickback.

5.6 Additional safety instructions

en

5.6.1 Personal safety

a) Wear ear protectors. Exposure to noise can cause

hearing loss.

b) Always hold the power tool securely with both

hands on the grips provided. Keep the grips dry,

clean and free from oil and grease.

c) Breathing protection must be worn if the power

tool is used without a dust removal system for

work that creates dust.

d) Improve the blood circulation in your fingers by

relaxing your hands and exercising your fingers

during breaks between working.

e) Avoid touching rotating parts. Switch the power

tool on only after bringing it into position at the

workpiece. Touching rotating parts, especially rotat-

ing insert tools, may lead to injury.

f) Always lead the supply cord and extension cord

away from the power tool to the rear while working. This helps to avoid tripping over the cord while

working.

g) Children must be instructed not to play with the

power tool.

h) The power tool is not intended for use by children,

by debilitated persons or those whohavereceived

no instruction or training.

i) Before beginning the work, check the hazardclas-

sification of the dust that will be produced. Use

an industrial vacuum cleaner with an officially

approved protection classification in compliance

with locally applicable dust protection regulations.

j) Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory diseases

to the operator or bystanders. Certain kinds of dust

are classified as carcinogenic such as oak and beech

dust especially in conjunctionwith additives for wood

conditioning (chromate, wood preservative). Material

containing asbestos must only be treated by specialists. Where the use of a dust extraction device is

possible it shall be used. To achieve a high level

of dust collection, use a suitable vacuum cleaner

of the type recommended by Hilti for wood dust

and/or mineral dust together with this tool.Ensure

that the workplace is well ventilated. The use of a

dust mask of filter class P2 is recommended. Follow national requirements for the materials you

want to work with.

5.6.2 Power tool use and care

a) Grinding discs must be stored and handled care-

fully in accordance with the manufacturer’s instructions.

b) Check that the grinding disc is fitted in accord-

ance with the manufacturer’s instructions.

c) If use of a spacer ring or other intermediate part is

specifiedand the part is supplied withthe grinding

disc, check to ensure that the part is fitted.

d) Before use, check that the cutting disc has been

fitted correctly and the clamping nut tightened.

Then allow the power tool to run for 60 seconds

under no load while holding it securely. Switch off

the power tool immediately if significant vibration

or any other faults are noticed. Should this occur,

examine the power tool in order to determine the

cause.

e) Never use the power tool without the guard.

f) The workpiece must be fixed securely in place.

g) Do not use cutting discs for grinding.

h) After disc breakage, or if the power tool is

dropped, falls or suffers other mechanical

damage, it must be checked at a Hilti Service

Center.

i) Take steps to ensure that flying sparks from the

power tool do not present a hazard, i.e. by striking

yourself, other persons or inflammable materials.

Adjust the position of the guard accordingly.

j) In case of an interruption in the electric supply:

Switch the power tool off and unplug the supply

cord. This will prevent accidental restarting when the

electric power returns.

5.6.3 Electrical safety

a) Before beginning work, check the working area

(e.g. using a metal detector) to ensure that no

concealed electric cables or gas and water pipes

are present. External metal parts of the power tool

may become live, for example, when an electric cable

is damaged accidentally. This presents a serious risk

of electric shock.

b) Check the power tool’s supply cord at regular

intervals and have it replaced by a qualified specialist if found to be damaged. If the machine’s

supply cord is damaged it must be replaced with

a specially-prepared and approved supply cord

available from Hilti Customer Service. Check extension cords at regular intervals and replace

them if found to be damaged. Do not touch the

supply cord or extension cord if it is damaged

while working. Disconnect the mains plug from

the power outlet. Damaged supply cords or exten-

sion cords present a risk of electric shock.

22

Page 13

c) Dirty or dusty power tools which have been used

frequently for work on conductive materials

should be checked at regular intervals at a Hilti

Service Center. Under unfavorable circumstances,

dampness or dust adhering to the surface of

the power tool, especially dust from conductive

materials, may present a risk of electric shock.

d) When working outdoors with an electric tool

check to ensure that the tool is connected to the

electric supply by way of a ground fault circuit

interrupter (RCD) with a rating of max. 30 mA

(tripping current). Use of a ground fault circuit

interrupter reduces the risk of electric shock.

e) Use of a ground fault circuit interrupter (RCD

residual current device) with a maximum tripping

current of 30 mA is recommended.

5.6.4 Work area

a) Ensure that the workplace is well lit.

6Beforeuse

WARNING

Never use the power tool without the guard.

DANGER

Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

6.1 Fitting the side handle

WARNING

The side handle must be fitted for all types of work.

The side handle may be screwed onto the power tool on

the right or left.

6.2 Guard

CAUTION

Wear gloves when fitting or removing parts, when

making adjustments or when remedying malfunctions.

CAUTION

Adjust the position of the guard to suit the requirements of the work being done.

CAUTION

Theclosedsideoftheguardmustalwaysfacethe

operator.

b) Ensure that the workplace is well ventilated. Ex-

posure to dust at a poorly ventilated workplace may

result in damage to the health.

5.6.5 Personal protective equipment

en

The user and any other persons in the vicinity must

wear suitable eye protection, a hard hat, ear protection, protective gloves and breathing protection while

the tool is in use.

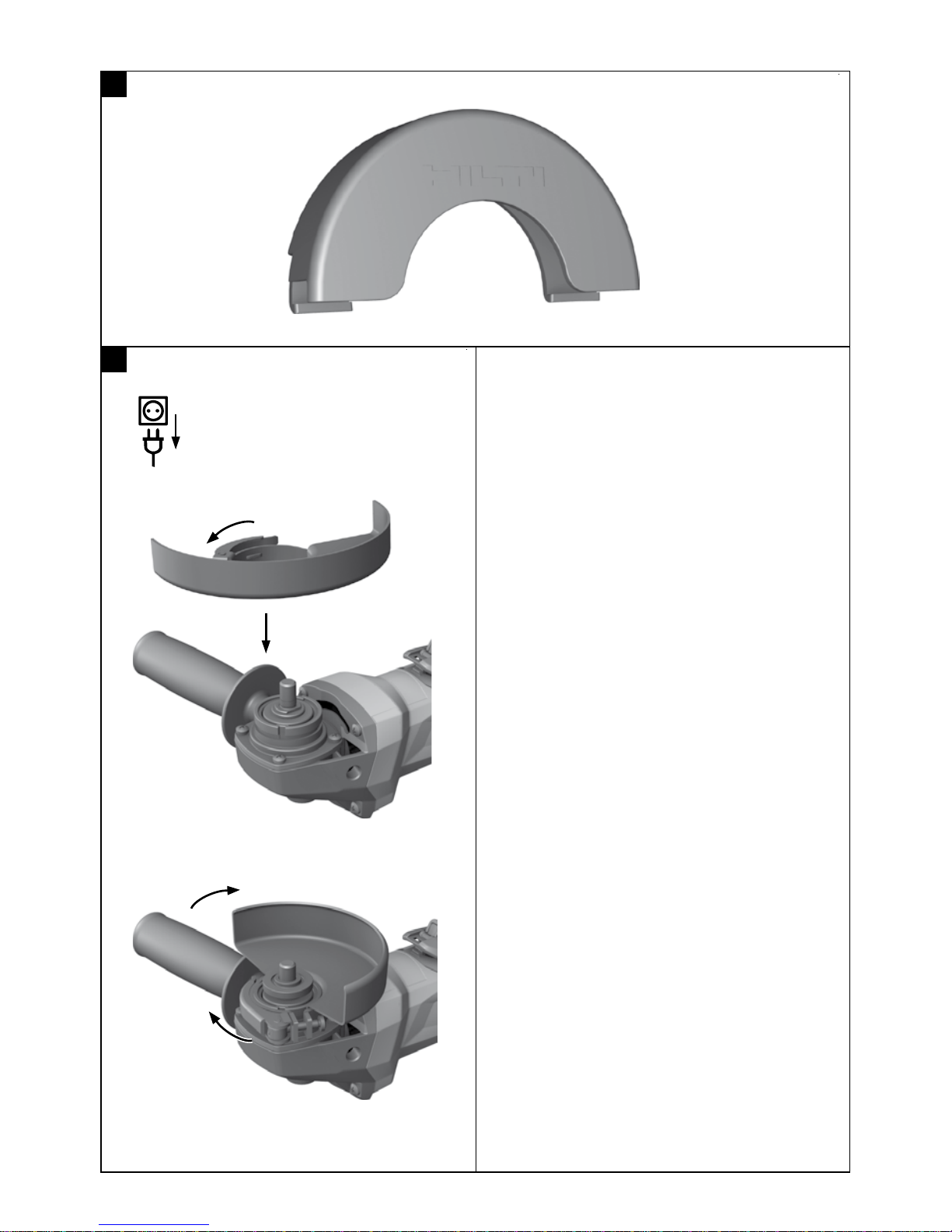

6.2.1 Fitting and removing the guard 3

NOTE

The guard is already set to the correct tension by way

of the adjusting screw. If the tension is too low when

the guard is fitted, the adjusting screw can be tightened

slightly to increase the tension.

NOTE

The keyed locating lug on the guard ensures that only

a guard designed for use with the power tool can be

fitted. The keyed locating lug also prevents the guard

from coming into contact with the disc.

1. Release the clamping lever.

2. Fit the guard onto the spindle collar so that the

keyed locating lug engages in the recess provided.

3. Rotate the guard to the required position.

4. CAUTION The closed side of the guard must

always face the operator.

Secure the guard by closing the clamping lever.

5. To remove the guard from the power tool, follow the

instructions for fitting the guard but carry out the

steps in the reverse order.

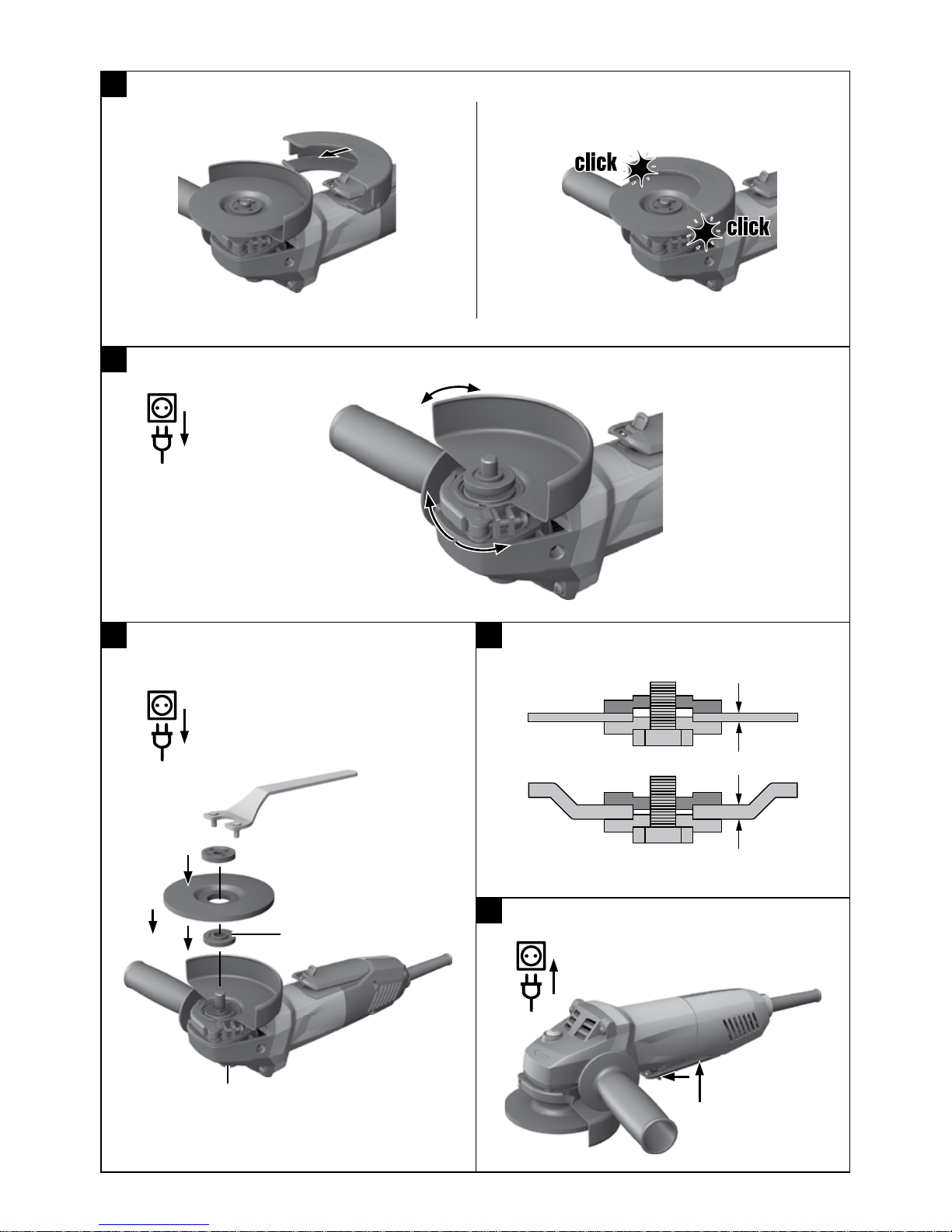

6.2.2 Fitting the front cover 4

1. Press the front cover onto the standard guard, with

the closed side positioned as shown in the illustration, until it engages.

6.2.3 Adjusting the guard 5

1. Release the clamping lever.

2. Rotate the guard to the desired position.

3. Close the clamping lever.

23

Page 14

6.3 Fitting and removing the disc 67

CAUTION

Wear gloves when fitting or removing parts, when

making adjustments or when remedying malfunctions.

DANGER

Check that the speed rating printed on the cutting

en

or grinding disc is equal to or higher than the rated

speed of the power tool.

DANGER

Check the condition of the disc before using it. Do

not use discs that are broken, cracked or damaged in

any way.

NOTE

Diamond discs must be replaced when the cutting or

grinding performance drops significantly. This generally

is the case when the segments reach a height of less

7Operation

than 2 mm. Other discs must be replaced when the

cutting performance drops significantly or other parts of

the angle grinder (not the disc) come into contact with

the material you are working on. Abrasive discs generally

have to be replaced when the durability date has been

reached.

1. Clean the clamping flange.

2. Fit the clamping flange onto the drive spindle.

3. Fit the disc.

4. Screw on the clamping nut corresponding to the

type of disc fitted7.

5. CAUTION Do not press the spindle lockbutton

before the drive spindle has stopped rotating.

Press the spindle lockbutton and hold it in this

position.

6. Use the wrench to tighten the clamping nut securely

and then release the spindle lockbutton.

7. To remove the disc from the power tool, follow the

instructionsfor fitting the disc but carry out the steps

in the reverse order.

CAUTION

Use clamps or a vice to hold the workpiece securely.

NOTE

Adjust the position of the guard to suit the requirements

of the work being done.

DANGER

Wear ear protectors.Exposure to noise can cause hear-

ing loss.

WARNING

Test new cutting or grinding discs by allowing them

to run at maximum speed in a protected area for at

least 60 seconds.

WARNING

Slits cut in loadbearing walls of buildings or other structures may influence the statics of the structure, especially

when steel reinforcing bars or load-bearing components

are cut through. Consult the structural engineer, ar-

chitect, or person in charge of the building project

before beginning the work.

WARNING

The electric supply voltage must comply with the information given on the type identification plate on the

power tool. 230 V power tools may also be connected

to a 220 V supply.

WARNING

Always use the side handle with the power tool.

WARNING

Cutting or grinding may cause splintering of the material.

Wear eye protection.

DANGER

The operator and bystanders must wear breathing

protection if the work causes dust.

WARNING

Avoid touching rotating parts. Switch the power tool

on only after bringing it into position at the workpiece.

Touching rotating parts, especially rotating insert tools,

may lead to injury.

CAUTION

The insert tool may get hot during use. Wear protective

gloves when changing insert tools.

WARNING

Reduce the load on the power tool by avoiding tilting the disc in the kerf when cutting. Thediscmay

otherwise break, or the power tool may kick back or stall.

CAUTION

Improve the blood circulation in your fingers by relaxing your hands and exercising your fingers during

breaks between working.

WARNING

Keep inflammable materials away from the working

area.

WARNING

Never use the power tool without the guard.

24

Page 15

CAUTION

In accordance with the applications for which it is designed, the power tool produces a high torque. Always

use the side handle and hold the power tool with both

hands. The user must be prepared for sudden sticking

and stalling of the insert tool.

CAUTION

Working on the material may cause it to splinter. Wear

eye protection and protective gloves. Wear breathing

protection if no dust removal system is used. Splin-

tering material presents a risk of injury to the eyes and

body.

7.1 Rough grinding

CAUTION

Never use abrasive cutting discs for grinding.

Best results are obtained when the disc maintains an

angle of 5° to 30° with the working surface when grinding.

Move the power tool to and fro while applying moderate

pressure. This will avoid overheating and discoloration of

the workpiece and ensure an even surface finish.

7.2 Cutting

When cutting, apply moderate feed pressure and do not

tilt the power tool or, respectively, the cutting disc (hold

at approx. 90° to the surface being cut). For best results,

start cutting at the smallest cross section when cutting

profiles and square tube.

7.3 Switching on / off

In the event of motor overload due to application of

excessive pressure to the disc, performance will drop

noticeably or the power tool may stop running (avoid

stalling the power tool in this way). Permissible tool

overload cannot begiven as a specific value as it depends

on the temperature of the motor. If the power tool has

been overloaded, release the pressure applied and then

allow it to run under no load for approx. 30 seconds.

7.3.1 Switching on (AG 100‑7S, AG 100‑8S,

AG 115‑7S, AG 115‑8S)

1. Plug the supply cord into the power outlet.

2. Press the rear section of the on / off switch.

3. Slide the on / off switch forward.

4. Lock the on / off switch.

7.3.2 Switching off (AG 100‑7S, AG 100‑8S,

AG 115‑7S, AG 115‑8S)

Press the rear section of the on / off switch. The on / off

switch jumps back to the off-position.

7.3.3 Switching on (AG 100‑7D, AG 100‑8D,

AG 115‑7D, AG 115‑8D) 8

The hold-to-run switch with built-in safety interlock enables the user to check the switch function and prevents

inadvertent starting of the power tool.

1. Plug the supply cord into the power outlet.

2. Press the safety interlock to unlock the hold-to-run

switch.

3. Press the hold-to-run switch fully.

en

8 Care and maintenance

CAUTION

Disconnect the mains plug from the power outlet.

8.1 Care of the power tool

DANGER

When working on metal under extreme conditions, conductive dust may accumulate inside the power tool. This

may negatively affect the power tool’s protective insulation. Under such conditions, the tool should be

plugged into a ground fault circuit interrupter (RCD)

and use of a stationary dust removal system and

frequent cleaning of the tool’s cooling air slots is

recommended.

The outer casing of the power tool is made from impactresistant plastic.

Never operate the power tool when the air vents are

blocked. Regularly clean the power tool’s air vents carefully with a dry brush. Do not permit foreign objects to

enter the interior of the tool. The motor’s fan will draw

7.3.4 Switching off (AG 100‑7D, AG 100‑8D,

AG 115‑7D, AG 115‑8D)

When the hold-to-run switch is released, the safety interlock returns automatically to the locked position.

dust into the casing and an excessive accumulation of

conductive dust (e.g. metal, carbon fiber) may cause

electrical hazards. Clean the outside of the power tool at

regular intervals with a slightly damp cloth. Do not use

a spray, steam pressure cleaning equipment or running

water for cleaning. This may negatively affect the electrical safety of the tool. Always keep the grip surfaces

of the tool free from oil and grease. Do not use cleaning

agents which contain silicone.

NOTE

Frequent work on conductive materials (e.g. metal, carbon fiber) may make shorter maintenance intervals necessary. Take your individual work place risk assessment

into account.

25

Page 16

8.2 Maintenance

WARNING

Do not operate the tool if parts are damaged or when

the controls do not function faultlessly. If necessary,

the power tool should be repaired by Hilti Service.

WARNING

Repairs to the electrical section of the power tool may

en

be carried out only by trained electrical specialists.

9 Troubleshooting

Fault Possible cause Remedy

The power tool doesn’t start. Interruption in the electric supply. Plug in another electric appliance and

The supply cord or plug is defective. Have the parts checked by a trained

The carbon brushes are worn. Have it checked by a trained electrical

The power tool doesn’t achieve

full power.

The extension cord’s conductor cross

section is inadequate.

Check all external parts of the power tool for damage

at regular intervals and check that all controls operate

faultlessly.

8.3 Checking the power tool after care and

maintenance

After carrying out care and maintenance work on the

power tool, check that all protective and safety devices

are fitted and that they function faultlessly.

check whether it works.

electrical specialist and replaced if

necessary.

specialist and replaced if necessary.

Use an extension cord with an ad-

equate conductor cross section.

10 Disposal

Most of the materials from which Hilti power tools or appliances are manufactured can be recycled. The materials

must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for

taking back your old power tools or appliances for recycling. Please ask your Hilti customer service department or

Hilti representative for further information.

For EC countries only

Disposal of electric tools together with household waste is not permissible.

In observance of the European Directive on waste electrical and electronic equipment and its imple-

mentation in accordance with national law, electrical appliances that have reached the end of their life

must be collected separately and returned to an environmentally compatible recycling facility.

11 Manufacturer’s warranty - tools

Please contact your local Hilti representative if you have

questions about the warranty conditions.

26

Page 17

12 EC declaration of conformity (original)

Designation: angle grinder

Type: AG 100‑7(S/D),

AG 100‑8(S/D),

AG 115‑7(S/D),

AG 115‑8(S/D)

Generation: 03

Year of design: 2013

We declare, on our sole responsibility, that this product

complies with the following directives and standards:

2006/42/EC, 2004/108/EC, 2011/65/EU, EN 60745‑1,

EN 60745‑2‑3, EN ISO 12100.

Hilti Corporation, Feldkircherstrasse 100,

FL‑9494 Schaan

Paolo Luccini TassiloDeinzer

Head of BA Quality and Process Management

Business Area Electric Tools & Accessories

01/2014 01/2014

Executive Vice President

Business Unit Power

Tools & Accessories

Technical documentation filed at:

Hilti Entwicklungsgesellschaft mbH

Zulassung Elektrowerkzeuge

Hiltistrasse 6

86916 Kaufering

Deutschland

en

27

Page 18

*2075365*

2075365

Hilti Corporation

LI-9494 Schaan

Tel.: +423/234 21 11

Fax: +423/234 29 65

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan

W 4328 | 0314 | 00-Pos. 1 | 1

Printed in China © 2014

Right of technical and programme changes reserved S. E. & O.

2075365 / A3

Printed: 02.04.2014 | Doc-Nr: PUB / 5169257 / 000 / 01

Loading...

Loading...