Page 1

User Manual

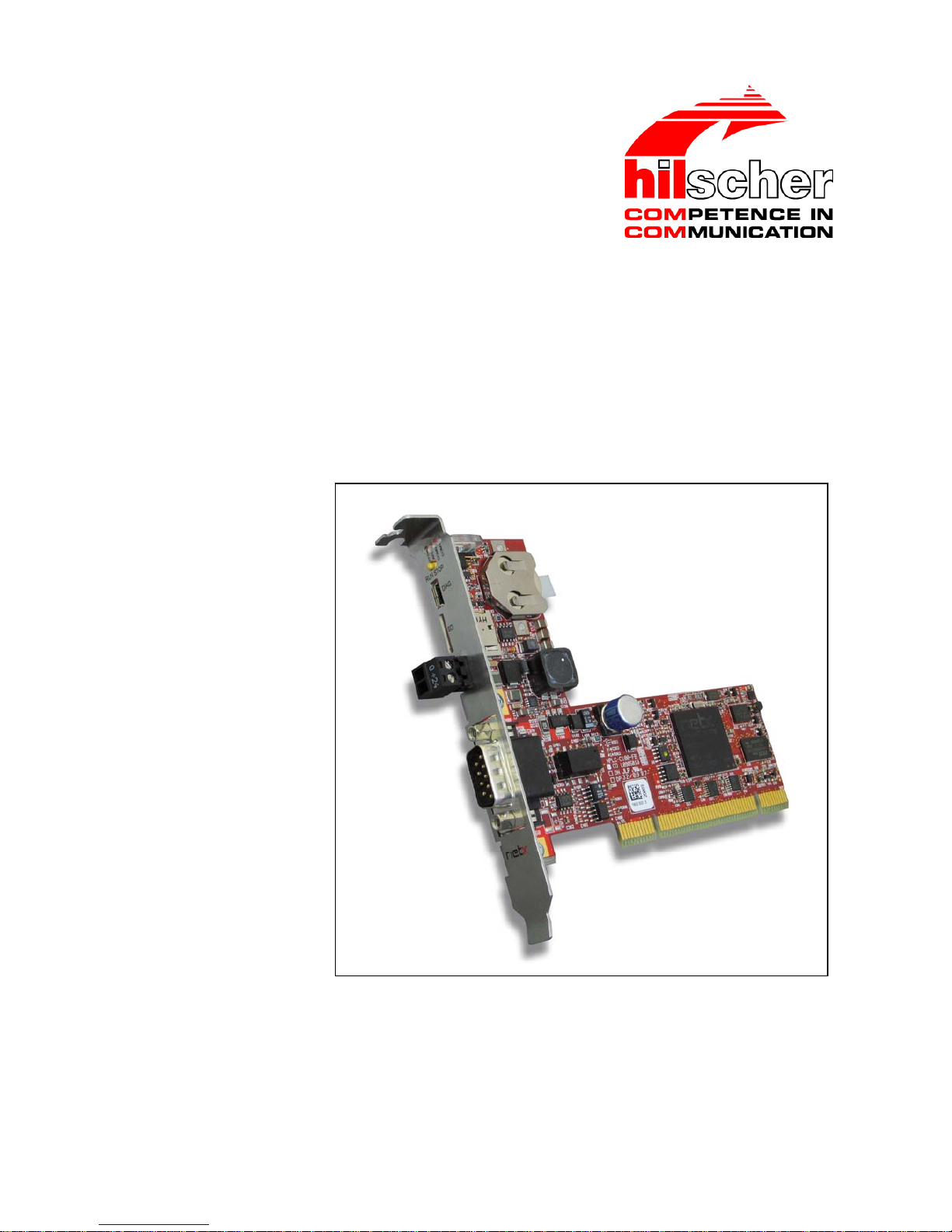

netPLC C100

Startup Guide

Hilscher Gesellschaft für Systemautomation mbH

www.hilscher.com

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public

Page 2

Introduction 2/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

Table of Contents

1 INTRODUCTION.........................................................................................................6

1.1 About the User Manual.............................................................................................6

1.1.1 List of Revisions ...................................................................................................6

1.1.2 Reference on Hardware, Firmware, Software and Driver ....................................7

1.1.3 Conventions in this Man ua l ..................................................................................8

1.2 Contents of the Product DV D...................................................................................9

1.2.1 Directory Structure of the DVD.............................................................................9

1.2.2 Documentations netPLC.....................................................................................10

1.3 Legal Notes............................................................................................................11

1.3.1 Copyright ............................................................................................................11

1.3.2 Important Notes..................................................................................................11

1.3.3 Exclusion of Liability...........................................................................................12

1.3.4 Warranty.............................................................................................................12

1.3.5 Export Regulations .............................................................................................13

1.3.6 Registered Trademarks......................................................................................13

1.4 Licenses.................................................................................................................13

2 SAFETY ....................................................................................................................14

2.1 Safety Instructions..................................................................................................14

2.2 Intended Use..........................................................................................................14

2.3 Personnel Qualification..........................................................................................14

2.4 Commitment to read and understand the Manual................................................... 14

2.5 Labeling of Safety Instructions ............................................................................... 15

2.6 Safety Instructions..................................................................................................16

2.6.1 Electrical Shock Hazard.....................................................................................16

2.7 Property Damage Messages..................................................................................16

2.7.1 Electrostatically sensitive Devices......................................................................16

2.8 Safety Instructions USA.........................................................................................17

2.8.1 Electrical Shock Hazard.....................................................................................17

2.9 Property Damage Messages USA.......................................................................... 17

2.9.1 Electrostatically sensitive Devices......................................................................17

3 DESCRIPTION AND REQUIREMENTS....................................................................18

3.1 Description.............................................................................................................18

3.2 System Requirements ............................................................................................ 19

3.2.1 System Requirements PC ..................................................................................19

3.2.2 System Requirements CoDeSys........................................................................19

3.3 Requiremen ts for Operation................................................................................... 20

3.3.1 Slot PLC .............................................................................................................20

4 DEVICE DRAWINGS................................................................................................21

Page 3

Introduction 3/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

4.1 Device Drawing NPLC-C100-DP............................................................................ 21

4.1.1 Cover NPLC-C100-DP .......................................................................................22

5 SYSTEM OVERVIEW...............................................................................................23

6 INSTALLING SOFTWARE........................................................................................27

6.1 Plug In SYCON.net Setup...................................................................................... 30

6.2 CoDeSys Programming System Setup...................................................................35

6.3 Device Driver Setup...............................................................................................42

6.4 netPLC CoDeSys Server Setup ............................................................................. 45

6.5 Installing the Device Driver..................................................................................... 47

6.6 Installing USB Driver..............................................................................................50

7 INSTALLING HARDWARE (SLOT PLC)...................................................................54

7.1 Safety Advices....................................................................................................... 54

7.1.1 Safety Advices USA ...........................................................................................54

7.2 Installing Battery.....................................................................................................55

7.3 Installing Slot PLC NPLC C100-DP........................................................................56

8 FIRST PROJECT......................................................................................................57

8.1 Overview................................................................................................................ 57

8.2 Preparation ............................................................................................................ 58

8.2.1 netPLC CoDeSys Server....................................................................................58

8.2.2 CoDeSys ............................................................................................................59

8.3 Create Control Program and Bus Configuration.....................................................61

8.3.1 Create Project.....................................................................................................61

8.3.2 Add PROFIBUS-DP Slave Device by use of a GSD File...................................66

8.3.3 Bus Configuration...............................................................................................67

8.3.4 Create PLC Program..........................................................................................73

8.3.5 Create Symbol Configuration ............................................................................. 77

8.3.6 Build Project .......................................................................................................81

8.4 Connect to the Slot PLC......................................................................................... 82

8.4.1 Define Gateway..................................................................................................82

8.4.2 Scan Network and set Active Path.....................................................................84

8.5 Download Control Program and Bus Configuration................................................ 86

8.5.1 Login and Download...........................................................................................86

8.5.2 Create Boot Application......................................................................................88

8.5.3 Remove Boot Application...................................................................................88

8.5.4 Start PLC Program.............................................................................................89

8.6 Disconnect from the Slot PLC................................................................................90

9 VISUALIZATION .......................................................................................................91

9.1 OPC Configurator...................................................................................................92

9.2 OPC Client.............................................................................................................96

Page 4

Introduction 4/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

10 FUNCTIONS .............................................................................................................97

10.1 Functions – CmpSysFunctions_netPLC.................................................................97

10.1.1 Battery Status – StatusOfBattery.......................................................................98

10.1.2 Status External Power Supply – StatusOfExt24VDC.........................................99

10.1.3 Status PCI Power Supply – StatusOfPCIPower...............................................100

11 HARDWARE ...........................................................................................................101

11.1 Block Diagram......................................................................................................101

11.2 Internal and External Power Supply ..................................................................... 102

11.3 Reset Behaviour................................................................................................... 102

11.4 RUN/STOP Switch............................................................................................... 102

12 BATTERY................................................................................................................103

12.1 Changing the Battery............................................................................................104

12.2 Battery Disposal................................................................................................... 106

12.3 Check the Battery Status with CoDeSys...............................................................106

13 BUS DIAGNOSTIC..................................................................................................107

13.1 Start up the Bus and Test.....................................................................................107

13.1.1 Login and Download.........................................................................................107

13.1.2 Device Assignment...........................................................................................109

13.1.3 Connect to the PROFIBUS-DP Master ............................................................112

13.1.4 Debug Bus Configuration .................................................................................114

13.1.5 Verify Input and Output Data............................................................................117

14 TROUBLESHOOTING............................................................................................119

15 LED.........................................................................................................................120

15.1 LED SYS.............................................................................................................. 120

15.2 LED APL.............................................................................................................. 121

15.3 LED PROFIBUS DP-Master.................................................................................121

16 ERROR NUMBERS ................................................................................................122

16.1 Error Numbers CmpSysFunctions_netPLC Functions..........................................122

17 TECHNICAL DATA .................................................................................................123

17.1 Technical Data Slot PLC...................................................................................... 123

17.1.1 NPLC C100-DP................................................................................................123

17.2 Protocols..............................................................................................................124

17.2.1 PROFIBUS DP Master .....................................................................................124

18 APPENDIX..............................................................................................................125

18.1 netPLC CoDeSys Server Program....................................................................... 125

18.1.1 Starting netPLC CoDeSys Server ....................................................................125

18.1.2 netPLC CoDeSys Server Window....................................................................126

Page 5

Introduction 5/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

18.1.3 Stopping netPLC CoDeSys Server ..................................................................127

18.2 Example Projects................................................................................................. 128

18.2.1 netPLC PROFIBUS Simple IO .........................................................................128

18.2.2 netPLC System Functions................................................................................ 128

18.2.3 netPLC Open Process Control (OPC)..............................................................129

18.2.4 netPLC Real Time Clock ..................................................................................130

18.3 Firmware Update.................................................................................................. 131

18.4 Memory Card.......................................................................................................135

18.5 PROFIBUS Interface............................................................................................136

18.5.1 PROFIBUS Interface Pinning...........................................................................136

18.5.2 PROFIBUS Wiring............................................................................................136

18.6 Mini-B USB Connector (5 Pin).............................................................................. 138

18.7 List of Figures ...................................................................................................... 139

18.8 List of Tables........................................................................................................140

18.9 Glossary...............................................................................................................141

18.10 Contacts............................................................................................................... 142

Page 6

Introduction 6/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1 Introduction

1.1 About the User Manual

This user manual is the startup guide for the use of the PLC programming

software CoDeSys in odrer to program a slot PLC card named “NPLC

C100-DP” for a PC with an example program.

This user manual describes the product

• NPLC-C100-DP/CDS-OPC

1.1.1 List of Revisions

Index Date Chapter Revisions

2 2009-10-01 all created

Table 1: List of Revisions

Page 7

Introduction 7/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1.1.2 Reference on Hardware, Firmware, Software and Driver

Note: The listed hardware revision, firmware and driver versions or

versions of the programming software CoDeSys including the

configuration software functionally belong together.

Hardware

Hardware Revision

NPLC-C100-DP 3, 4

Table 2: Reference on Hardware

Firmware

Firmware File Fieldbus System Firmware Version

NPC1CDPM.nxf PROFIBUS-DP Master 3.3.1.20

Table 3: Reference on Firmware

Driver

Driver Driver Version

cifX Device Driver

0.945

USB Driver 5.1.2600.2180

Table 4: Reference on Driver

Server

Software Software Version

netPLC CoDeSys Server

0.9.0.3

Table 5: Reference on Server

Software

Software Software Version

CoDeSys

V3.3 SP1 Patch 2

SYCONnet netX setup.exe

1.200.x.x

Table 6: Reference on Software

Page 8

Introduction 8/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1.1.3 Conventions in this Manual

Operation instructions, a result of an operation step or notes are marked as

follows:

Operation Instructions:

¾

<instruction>

Or

1. <instruction>

2. <instruction>

Results:

°

<result>

Notes:

Important: <important note>

Note: <note>

<note, were to find further information>

Page 9

Introduction 9/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1.2 Contents of the Product DVD

The Product DVD for the slot PLC contains:

• CoDeSys (PLC programming system) including bus configuration

software

• cifX Device Driver

• netPLC CoDeSys Server program

• Firmware with CoDeSys SP

• Documentation

• Examples

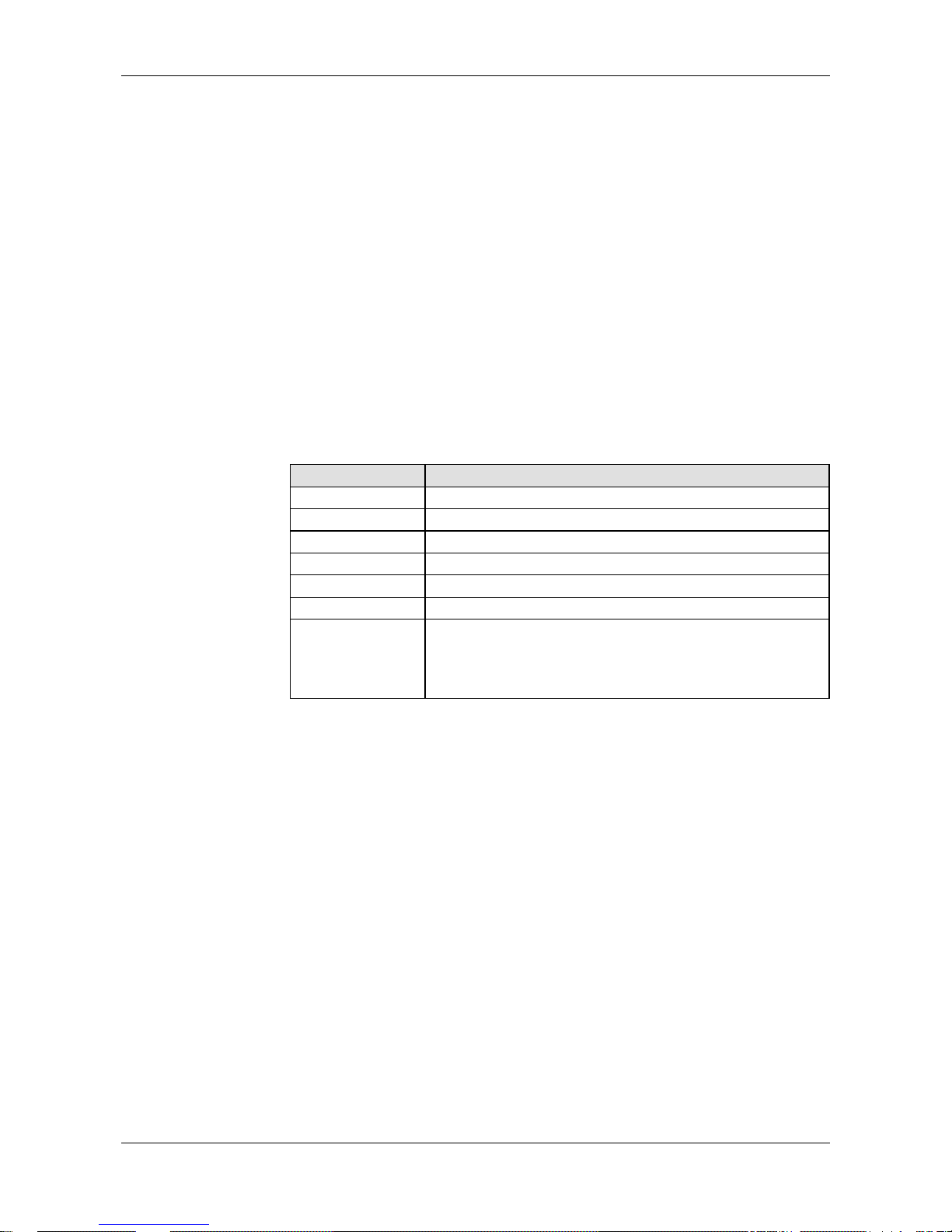

1.2.1 Directory Structure of the DVD

All manuals on this DVD are delivered in the Adobe Acrobat® Reader

format (PDF).

Directory Name Description

Adobe Flash Player Adobe Flash Player installation program

Documentation

Documentation in the Acrobat

®

Reader Format (PDF)

Drivers PCI device driver and USB driver

Example CoDeSys example programs

Firmware Loadable Firmware (contains CoDeSys SP)

Presentation netPLC presentation in Power Point format

Software Setup for CoDeSys programming software including configuration

software

Setup netPLC CoDeSys Server

Setup Device Driver

Table 7: Directory Structure of the CD

Page 10

Introduction 10/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

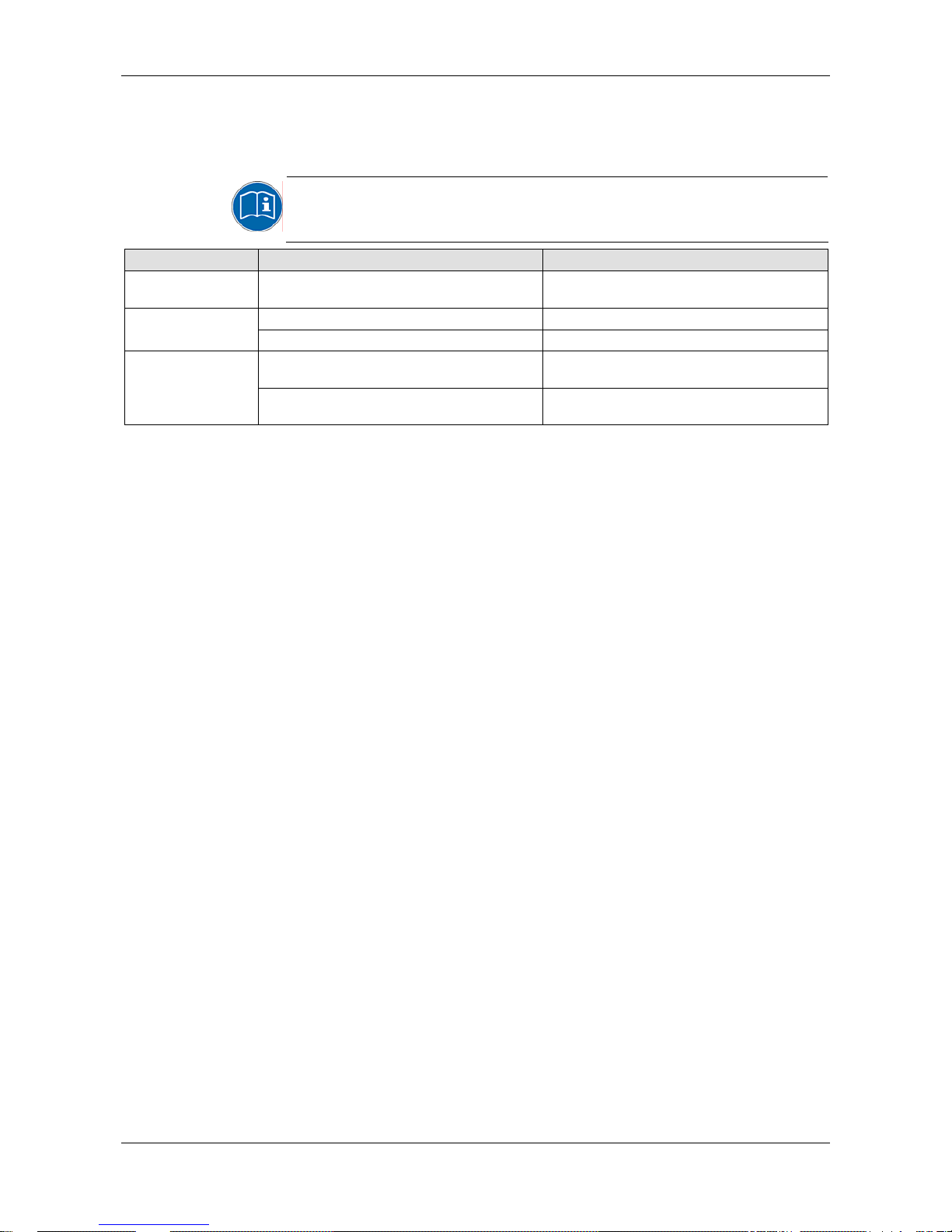

1.2.2 Documentations netPLC

The following documentation overview gives information about where to

find further information and refers the corresponding manual.

All manuals listed in the overview below can be found in the

Documentation directory on the CD delivered, in the Adobe Acrobat

®

Reader format (PDF).

Manual Contents Document name

User Manual

Slot PLC C100

Startup Guide including installation , operati on

and hardware description

netPLC C100 Startup Guide UM xx EN.pdf

CoDeSys Installation and first steps CoDesys Installation and Start.pdf CoDeSys

OPC Server V3 OPC_V3_how_to_use_E.pdf

DTM for Hilscher NETX PROFIBUS Master

Devices

PROFIBUS_Master_DTMx_en.pdf

Operating Instruction

Manual SYCON.net

Generic Slave DTM for PROFIBUS DP Slave

Devices

PROFIBUS_Slave_DTMx_en.pdf

Table 8: Documentations Slot PLC PROFIBUS-DP Master

Page 11

Introduction 11/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1.3 Legal Notes

1.3.1 Copyright

©

2008-2009 Hilscher Gesellschaft für Systemautomation mbH

All rights reserved.

The images, photographs and texts in the accompanying material (user

manual, accompanying texts, documentation, etc.) are protected by

German and international copyright law as well as international trade and

protection provisions. You are not authorized to duplicate these in whole or

in part using technical or mechanical methods (printing, photocopying or

other methods), to manipulate or transfer using electronic system s without

prior written consent. You are not permitted to make changes to copyright

notices, markings, trademarks or ownership declarations. The included

diagrams do not take the patent situation into account. The company

names and product descriptions included in this document may be

trademarks or brands of the respective owners and may be trademarked or

patented. Any form of further use requires the explicit consent of the

respective rights owner.

1.3.2 Important Notes

The user manual, accompanying texts and the documentation were created

for the use of the products by qualified experts, however, errors cannot be

ruled out. For this reason, no guarantee can be made and neither juristic

responsibility for erroneous information nor any liability can be assumed.

Descriptions, accompanying texts and documentation included in the user

manual do not present a guarantee nor any information about proper use

as stipulated in the contract or a warranted featur e. It cannot be ruled out

that the user manual, the accompanying texts and the documentation do

not correspond exactly to the described features, standards or other data of

the delivered product. No warranty or guarantee regarding the correct ness

or accuracy of the information is assumed.

We reserve the right to change our products and their specification as well

as related user manuals, accompanying texts and documentation at all

times and without advance notice, without obligation to report the change.

Changes will be included in future manuals and do not constitute any

obligations. There is no entitlement to revisions of delivered documents.

The manual delivered with the product applies.

Hilscher Gesellschaft für Systemautomation mbH is not liable under any

circumstances for direct, indirect, incidental or follow-on damage or loss of

earnings resulting from the use of the information contained in this

publication.

Page 12

Introduction 12/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1.3.3 Exclusion of Liability

The delivered product (including the technical data) is subject to export or

import laws as well as the associated reg ulations of different counters, in

particular those of Germany and the USA. The software may not be

exported to countries where this is prohibited by the United States Export

Administration Act and its additional provisions. You are obligated to

comply with the regulations at your personal responsibility. We wish to

inform you that you may require permission from state authorities to export,

re-export or import the product.

1.3.4 Warranty

Although the hardware and software was developed with utmost care and

tested intensively, Hilscher Gesellschaft für Systemautomation mbH does

not guarantee its suitability for any purpose not confirmed in writing. It

cannot be guaranteed that the hardware and software will meet your

requirements, that the use of the software operates without int err uption and

that the software is free of errors. No guarantee is made regarding

infringements, violations of patents, rights of ownership or t he f reedom from

interference by third parties. No additional guarantees or assurances are

made regarding marketability, freedom of defect of title, integration or

usability for certain purposes unless they are required in accordance with

the law and cannot be limited. Warranty claims are limited to the right to

claim rectification.

Page 13

Introduction 13/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

1.3.5 Export Regulations

The delivered product (including the technical data) is subject to export or

import laws as well as the associated reg ulations of different counters, in

particular those of Germany and the USA. The software may not be

exported to countries where this is prohibited by the United States Export

Administration Act and its additional provisions. You are obligated to

comply with the regulations at your personal responsibility. We wish to

inform you that you may require permission from state authorities to export,

re-export or import the product.

1.3.6 Registered Trademarks

Windows® XP are registered trademarks of the Microsoft Corporation.

Adobe-Acrobat

®

is an registered trademark of the Adobe Systems

Incorporated.

1.4 Licenses

Licenses are required for the operation of the slot PLC NPLC C100DP/CDS-OPC as a PROFIBUS-DP Master* as well as for CoDeSys SP.

These licenses are included in the scope of delivery.

* The master license includes operating of the slot PLC as master and the

license for the bus configuration software SYCON.net for the respective

card.

Page 14

Safety 14/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2 Safety

2.1 Safety Instructions

The user manual, the accompanying texts and the documentation are

written for the use of the products by educated personnel. W hen using the

products, all safety instructions and all valid legal regulations have to be

obeyed. Technical knowledge is presumed. The user has to assure that all

legal regulations are obeyed.

2.2 Intended Use

The slot PLC described in this user manual is a PC card with PLC

functionality and fieldbus communication. Depending from the loaded

firmware, the fieldbus systems listed in the following table can be r ealized

using the respective slot PLC.

Slot PLC Fieldbus System

NPLC-C100-DP/CDS-OPC PROFIBUS DP Master

Table 9: Slot PLC and Fieldbus Systems realized thereby

2.3 Personnel Qualification

The slot PLC must only be installed, configured and removed by qualif ied

personnel.

2.4 Commitment to read and understand the Manual

Important! Read and understand all instructions in this manual before

installation or use of your device to avoid injury.

Page 15

Safety 15/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

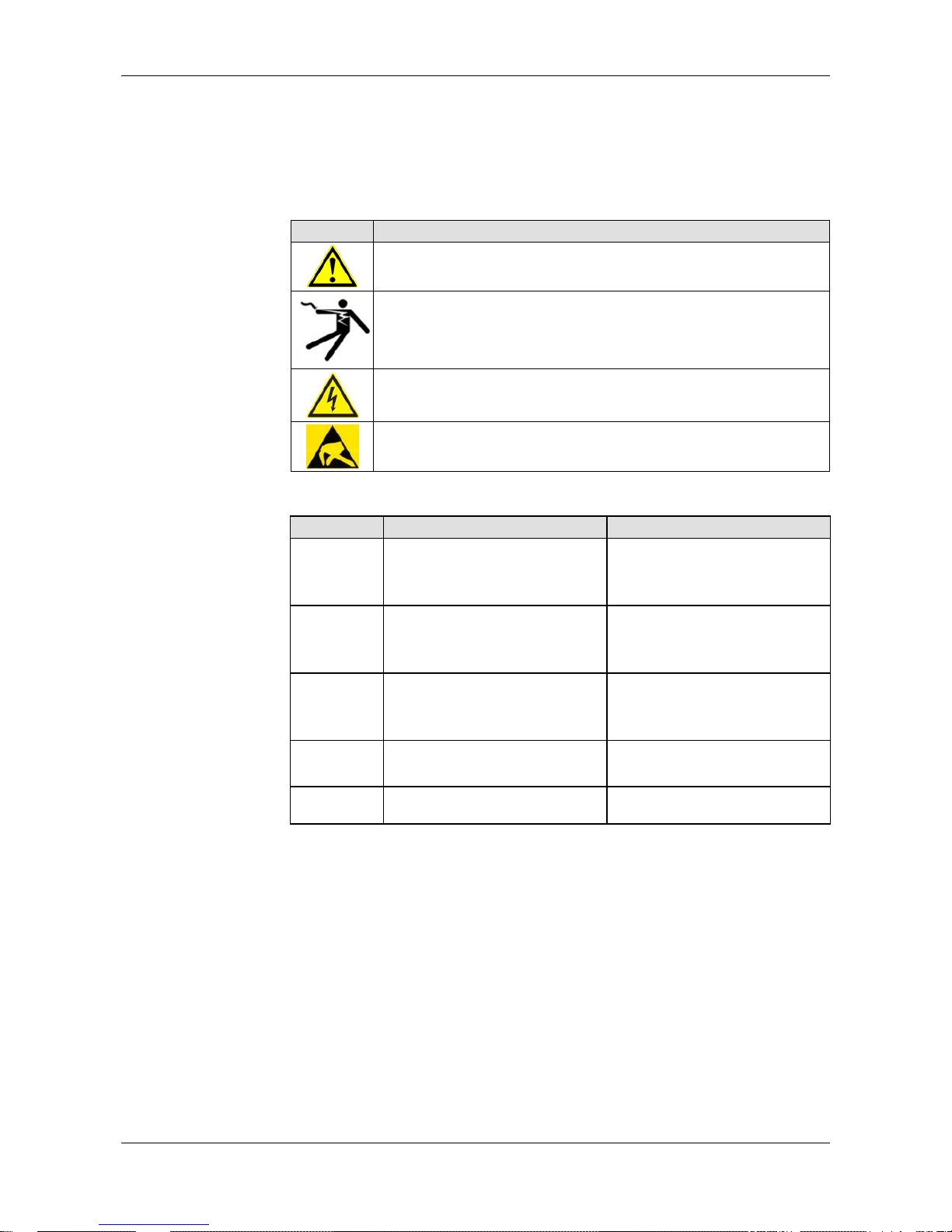

2.5 Labeling of Safety Instructions

The safety instructions are pinpointed particularly. The instructions are

highlighted with a specific safety symbol, a warning triangle and a signal

word according to the degree of endangerment. Inside the note the danger

is exactly named. Instructions to a property damage message do not

contain a warning triangle.

Symbol Sort of Warning or Principle

Safety symbol for the warning to personal injury

Warning for Electrical Shock Hazard

Warning of danger by electrical current

Warning of damages by electrostatic discharge

Table 10: Safety Symbols and Sort of Warning or Principle

Signal Word Meaning Meaning (ANSI)

DANGER

Indicates a direct hazard with high

risk, which will have as

consequence death or grievous

bodily harm if it isn't avoided.

Indicates a Hazardous Situation

Which, if not Avoided, will Result in

Death or Serious Injury.

WARNING

Indicates a possible hazard with

medium risk, which will have as

consequence death or (grievous)

bodily harm if it isn't avoided.

Indicates a Hazardous Situation

Which, if not Avoided, could Result

in Death or Serious Injury.

CAUTION

Indicates a minor hazard with

medium risk, which could have as

consequence simple battery if it isn't

avoided.

Indicates a Hazardous Situation

Which, if not Avoided, may Result in

Minor or Moderate Injury.

NOTICE

Indicates a Property Damage

Message.

Indicates a Property Damage

Message.

Note

Indicates an important note in the

manual.

Indicates an Important Note in the

Manual.

Table 11: Signal Words

Page 16

Safety 16/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2.6 Safety Instructions

This manual contains instructions which must be observed to ensure your

own personal safety and to avoid damage to devices.

2.6.1 Electrical Shock Hazard

Electrical Shock Hazard

HAZARDOUS VOLT AGE inside of the PC or of the connecting device.

Therefore f irst disconnect the power plug of the PC or of the connecting

device.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or remove the slot PLC only after

disconnecting power.

2.7 Property Damage Messages

This manual contains instructions which must must be red, understod and

observed to avoid damage to devices.

2.7.1 Electrostatically sensitive Devices

Adhere to the necessary safety precautions for components that are

vulnerable with electrostatic discharge (EN 61340-5-1 and EN 61340-5-2

as well as IEC 61340-5-1 and IEC 61340-5-2).

CAUTION!

Electrostatically sensitive Devices

This equipment is sensitive to electrostatic discharge, which cause

internal damage and affect normal operation. Follow guidelines when you

handle this equipment.

Observe the necessary safety precautions when handling components

that are vulnerable to electrostatic discharge.

Page 17

Safety 17/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2.8 Safety Instructi ons USA

This manual contains instructions which must be observed to ensure your

own personal safety and to avoid damage to devices.

2.8.1 Electrical Shock Hazard

Electrical Shock Hazard

HAZARDOUS VOLT AGE inside of the PC or of the connecting device.

Therefore f irst disconnect the power plug of the PC or of the connecting

device.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or remove the XXX card only after

disconnecting power.

2.9 Property Damage Messages USA

This manual contains instructions which must must be red, understod and

observed to avoid damage to devices.

2.9.1 Electrostatically sensitive Devices

Adhere to the necessary safety precautions for components that are

vulnerable with electrostatic discharge (EN 61340-5-1 and EN 61340-5-2

as well as IEC 61340-5-1 and IEC 61340-5-2).

Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which cause

internal damage and affect normal operation. Follow guidelines when you

handle this equipment.

Observe the necessary safety precautions when handling components

that are vulnerable to electrostatic discharge.

Page 18

Description and Requirements 18/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3 Description and Requirements

3.1 Description

The slot PLC described in this user manual is a PC card with PLC

functionality and fieldbus communication. Depending from the loaded

firmware, the fieldbus systems listed in the following table can be r ealized

using the respective slot PLC.

Slot PLC Fieldbus System

NPLC-C100-DP/CDS-OPC PROFIBUS-DP Master

Table 12: Slot PLC

These slot PLC device is a PC card for fieldbus communication and

handles the complete data exchange between the connected fieldbus

devices and CoDeSys.

In one PC a maximum of two slot PLC can be used.

Page 19

Description and Requirements 19/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3.2 System Requirements

3.2.1 System Requirements PC

• Windows® XP

• PC with PCI connector with 5 V for hardware revision 3 of “NPLC C100-

DP“

• PC with PCI connector with 3,3 V respectively 5 V for hardware revision

4 of “NPLC C100-DP“

• DVD ROM drive

• Graphic resolution: min. 1024 x 768 pixel or higher

• Keyboard and Mouse

3.2.2 System Requirements CoDeSys

System requirements for the programming system CoDeSys with

configuration software SYCON.net. The configuration software SYCON. net

is contained in CoDeSys as Plug In.

• Windows

®

XP

• Internet Explorer 5.5 or higher

• Free disk space: min. 400 MByte, recommended 1 GByte

• RAM: min. 512 MByte, recommended 1024 MByte

• Graphic resolution: min. 1024 x 768 pixel

• Keyboard and Mouse

Note: If the project file is saved and opened again or it is used on another

PC, the system requirements need to match. Particularly the DT Ms need

to be installed on the used PC.

Page 20

Description and Requirements 20/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

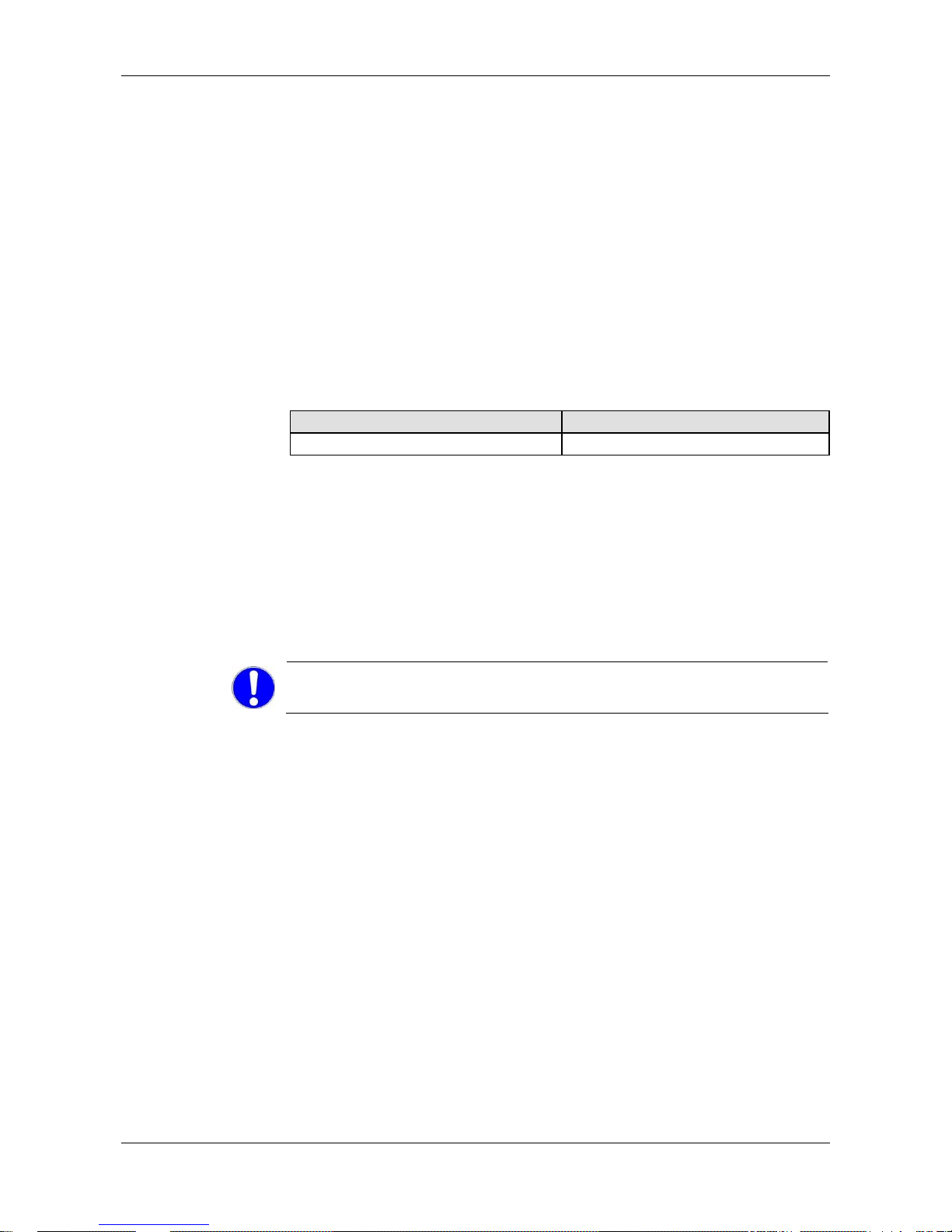

3.3 Requirements for Operation

Note: Upgrade older versions of the cifX Device Driver necessarily on

the version V0.945.

3.3.1 Slot PLC

For the slot PLC operation as a master the following requirements must be

fulfilled:

Protocol

PROFIBUS-DP Master

The device driver cifX Device Driver has to be installed (from

V0.945).

Software

Installation

The netPLC CoDeSys Server has to be installed and must run, if

communicating via PCI with the slot PLC.

Firmware

The firmware NPC1CDPM.NXF has to be loaded into the slot PLC.

License

Licenses are required for the operation of the slot PLC NPLC C100DP/CDS-OPC as a PROFIBUS-DP Master as well as for CoDeSys

SP. These licenses are included in the scope of delivery.

Configuration

Die slot PLC must be configured using the configuration software.

Programming

The PLC program must be created with CoDeSys and loaded into

the slot PLC.

Communication

For communication slave devices for the communication system

PROFIBUS-DP are required.

Table 13: Requirements for operation of the Slot PLC

Page 21

Device Drawings 21/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

4 Device Drawings

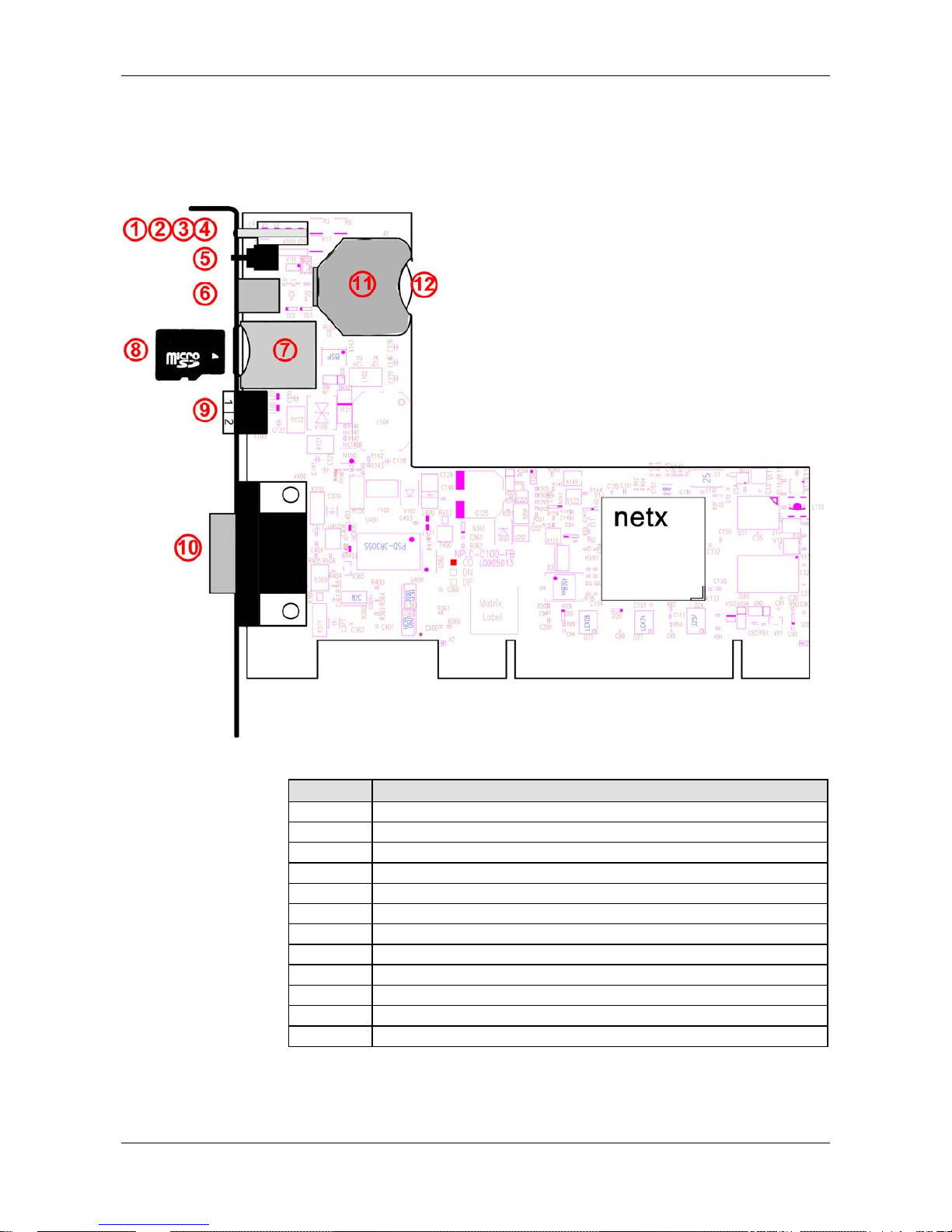

4.1 Device Drawing NPLC-C100-DP

Figure 1: Device Drawing NPLC-C100-DP

Number Designation

1 LED SYS

2 LED APL

3 LED COM0

4 LED COM1

5 RUN/STOP Switch

6 DIAG – USB Diagnostic Interface

7 Slot for Memory Card

8 MicroSD Memory Card

9 External Power Supply

10 PROFIBUS Interface

11 Battery holder

12 Battery

Table 14: Designation in the Device Drawing NPLC-C100-DP

Page 22

Device Drawings 22/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

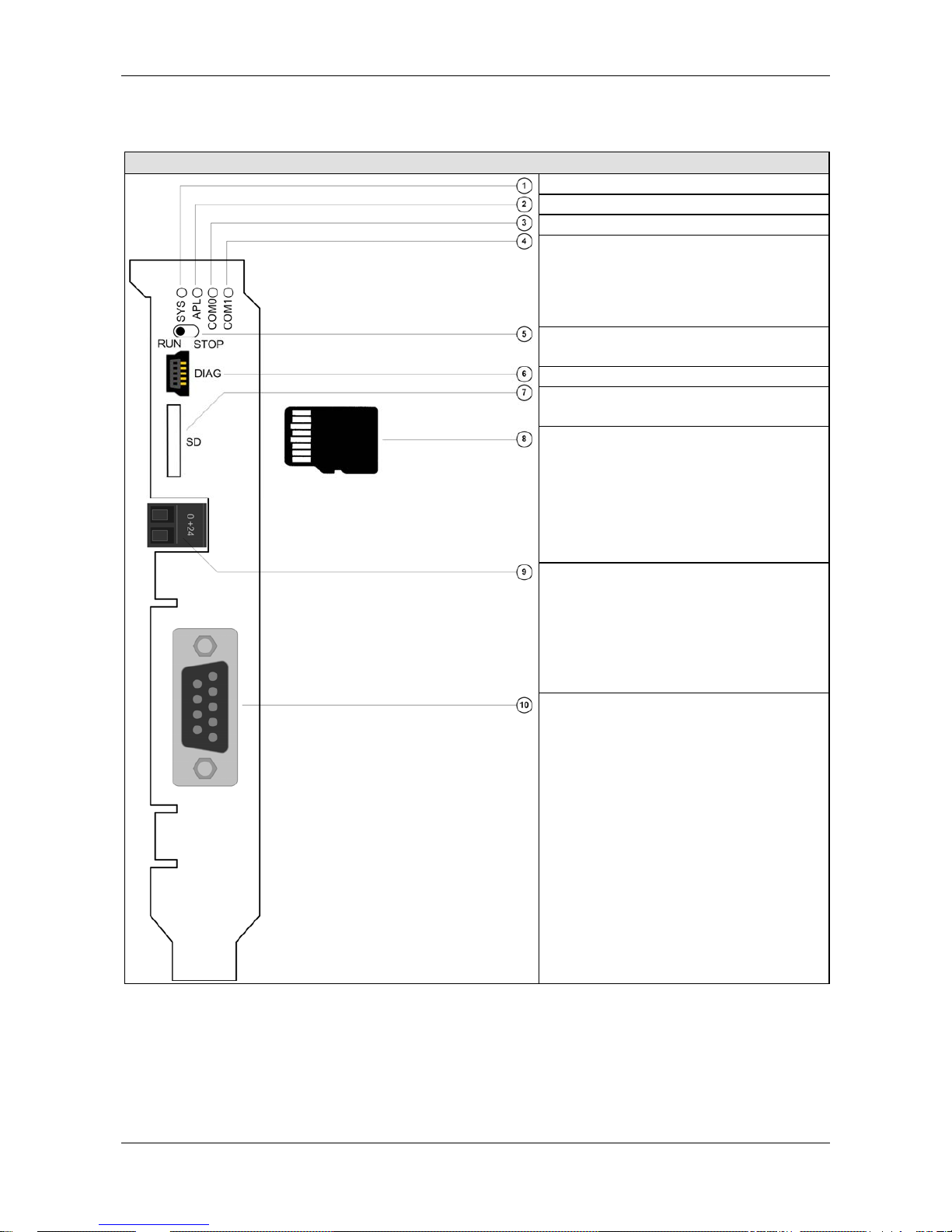

4.1.1 Cover NPLC-C100-DP

Designation

LED SYS

LED APL

LED COM0

LED COM1

RUN/STOP Switch

DIAG – USB Diagnostic Interface

Slot for Memory Card

MicroSD Memory Card

External Power Supply

PROFIBUS Interface

Table 15: Designation in the cover of NPLC-C100-DP

Page 23

System Overview 23/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

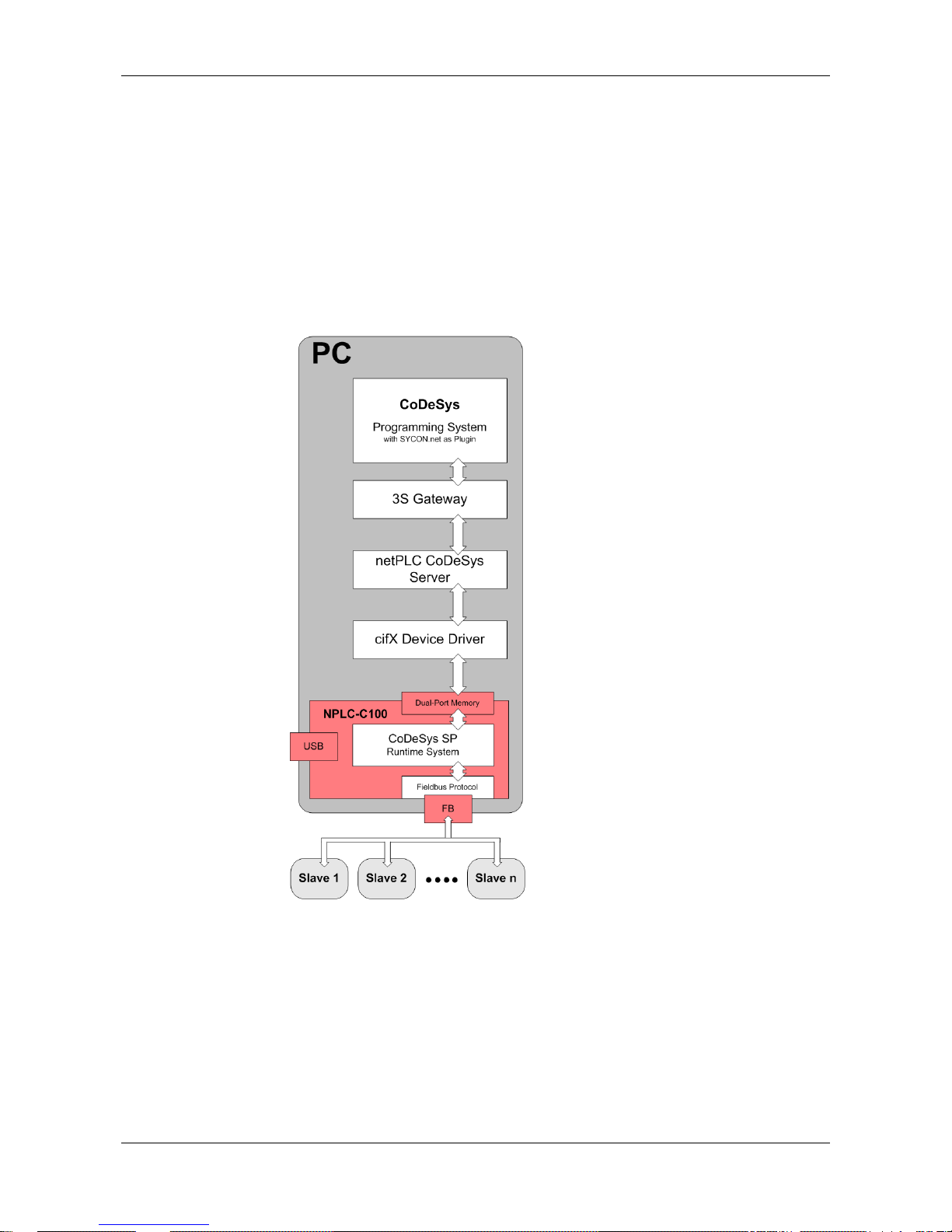

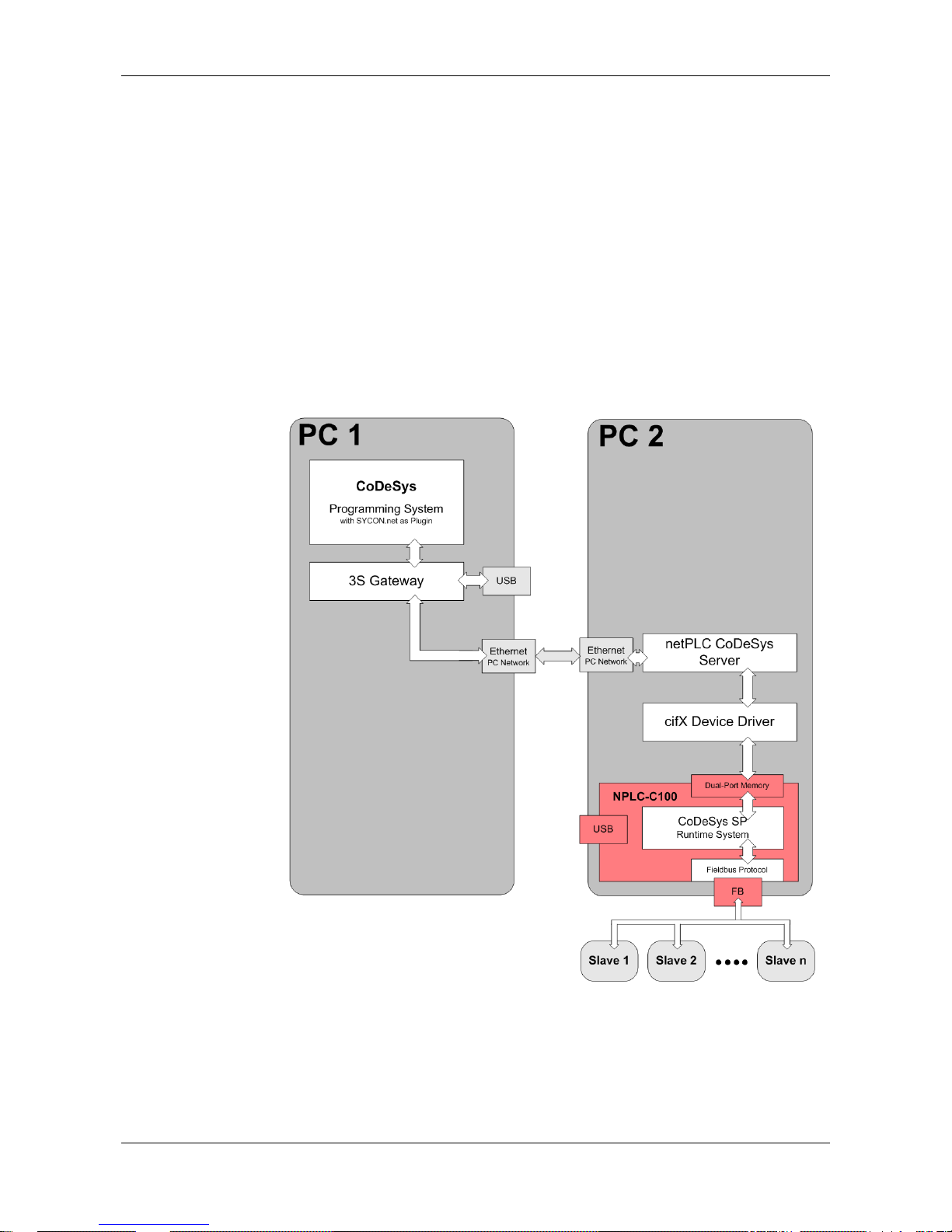

5 System Overview

The CoDeSys programming system and the slot PLC may be installed on

the same PC or on two separate PCs.

The following system overview shows beside the CoDeSys programming

system and the slot PLC additional components, how these communicate

together and which component needs to be installed on which PC.

The following components are important:

• CoDeSys programming system inclusive bus configuration software

• 3S Gateway

• netPLC CoDeSys Server and the

• Card’s Device Driver (cifX Device Driver).

Page 24

System Overview 24/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

Use Case 1:

The CoDeSys programming system and the slot PLC are installed on the

same PC as use case 1. The following software components are necessary

on this PC:

• CoDeSys programming system inclusive bus configuration software

• 3S Gateway

• netPLC CoDeSys Server and the

• Device Driver (cifX Device Driver) .

Figure 2: System Overview – Use Case 1 (One PC)

Page 25

System Overview 25/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

Use Case 2:

The CoDeSys programming system is installed on PC1 and the slot PLC is

installed in PC2 as use case 2. Both PC are connected via Ethernet (local

network).

The following software components are necessary for PC1:

• CoDeSys programming system inclusive bus configuration software

• 3S Gateway

The following software components are necessary for PC2:

• netPLC CoDeSys Server and the

• Device Driver (cifX Device Driver) .

Figure 3: System Overview – Use Case 2 (Two PCs with Ethernet Connection)

Page 26

System Overview 26/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

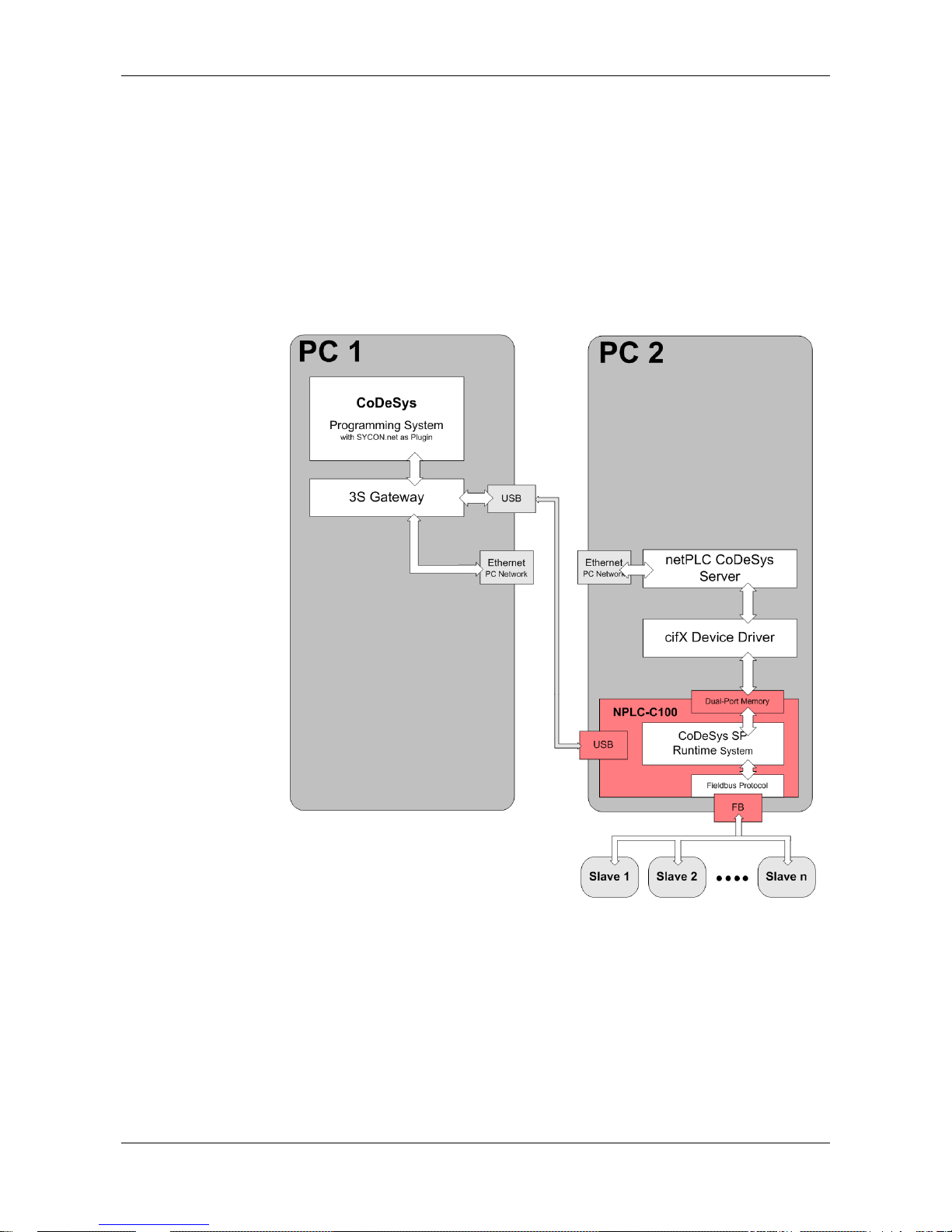

Use Case 3:

The CoDeSys programming system is installed on PC1 and the slot PLC is

installed in PC2 as use case 3. The USB port of PC1 is connected via an

USB cable to the USB port of the Slot PLC.

The following software components are necessary for PC1:

• CoDeSys programming system inclusive bus configuration software

• 3S Gateway

Figure 4: System Overview – Use Case 2 (Two PCs with USB Connection)

The following software components are necessary for PC2 to connect to a

visualization software:

• netPLC CoDeSys Server and the

• Device Driver (cifX Device Driver) .

Page 27

Installing Software 27/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

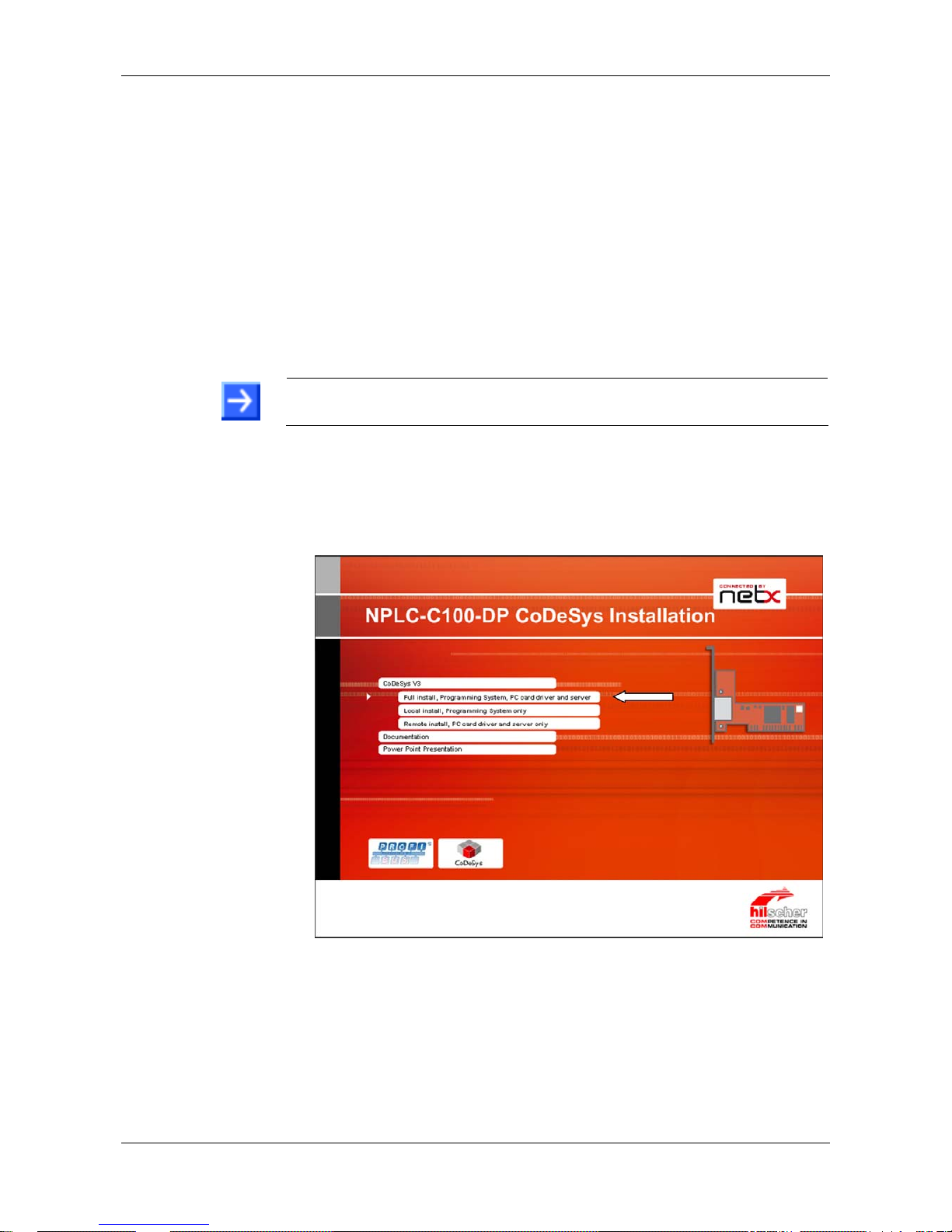

6 Installing Software

The software installation installs the following components:

• CoDeSys programming system (with 3S Gateway and bus configuration

software)

• Device Driver (cifX Device Driver) and the

• netPLC CoDeSys Server.

1. Insert the netPLC DVD into your local DVD ROM drive.

2.

Select CoDeSys V3 of the auto start menu.

Note: Administrator privileges are required on Windows

®

XP systems for

installation!

3. Select installation amount

Three selection are available:

¾

Select Full Install, Programming System, PC card driver and server,

when you want to install the programming system and the slot PLC in

the same PC.

Figure 5: netPLC auto start – Full Installation

°

The following setups are started one after the other:

bus configuration software

CoDeSys programming system

device driver (cifX Device Driver)

netPLC CoDeSys Server

Page 28

Installing Software 28/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

¾

Select Local Install, Programming System only, when you want to

install the programming system on one PC and the slot PLC in an othe

r

PC. The programming system can communicate via Ethernet with t he

PC with the slot PLC or via USB with the slot PLC.

Figure 6: netPLC auto start – Local Installation

°

The following setups are started one after the other:

bus configuration software

CoDeSys programming system

Page 29

Installing Software 29/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

¾

Select Remote Install, PC card driver and server only, when you

want to install the slot PLC device driver and server. This is the PC with

the slot PLC.

Figure 7: netPLC auto start – Remote Installation

°

The following setups are started one after the other:

device driver (cifX Device Driver)

netPLC CoDeSys Server

Page 30

Installing Software 30/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

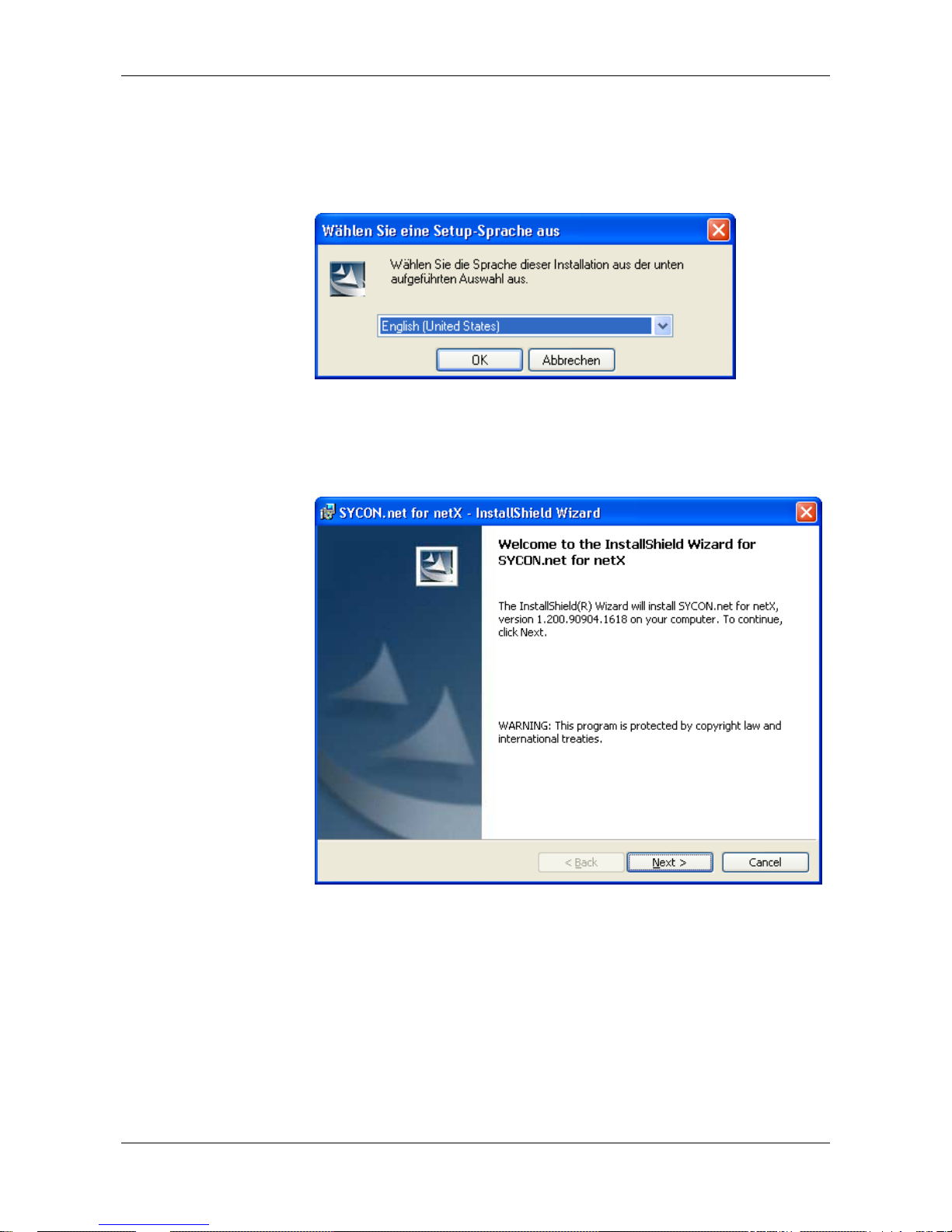

6.1 Plug In SYCON.net Setup

1. Language for the setup

¾

Select the language for the setup

¾

Click on OK.

2. Continue installation

¾

Click on Next > to continue the installation.

Page 31

Installing Software 31/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Accept license agreement

¾

Select I accept the terms in the license agreement, when you agree

to it.

¾

Click on Next > to continue the installation.

Page 32

Installing Software 32/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

4. Enter user information

¾

Enter the user name

¾

Enter the name of the organization

¾

Click on Next > to continue the installation.

Page 33

Installing Software 33/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

5. Select setup type

¾

Select Complete when you want to install the complete software.

¾

Click on Next > to continue the installation.

6. Installation

¾

Click on Install to do the installation now.

°

The components are installed. This will take several minutes.

Page 34

Installing Software 34/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

7. Finish installation

¾

Click on Finish

°

The software is installed.

Page 35

Installing Software 35/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

6.2 CoDeSys Progr amming System Setup

1. Accept installation

¾

Click on Next to start the installation.

2. License agreement

¾

Click on Yes when you accept the license agreement.

¾

When you want to print the license agreement then select Print.

Page 36

Installing Software 36/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Define destination folder

¾

Select Browse when you want to change the default destination folde

r

and enter the new destination folder then.

¾

Click on Next.

Page 37

Installing Software 37/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

4. Define installation amount

¾

Select as minimum

CoDeSys V3

CoDeSys Gateway

CoDeSys OPC Server 3

CoDeSys Gateway V2.3

°

¾

Click on Next.

Page 38

Installing Software 38/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

5. Define Program Folder

¾

The default program folder is 3S CoDeSys. If you want to use an othe

r

program folder then enter it now.

¾

Click on Next.

Page 39

Installing Software 39/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

6. Summary

°

¾

Click on Next.

7. Installation is processed

°

The components are installed. This will take several minutes.

°

Manufacturer specific components (Vendor AddOn) are installed.

Page 40

Installing Software 40/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8. Important information

°

¾

Read the information

¾

Select I read the information, when you have read the information.

¾

Click on Next.

Page 41

Installing Software 41/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

9. Finish installation

¾

Click on Finish.

Page 42

Installing Software 42/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

6.3 Device Driver Setup

1. Language for the setup

¾

Select the language for the setup

¾

Click on OK.

2. Continue installation

¾

Click on Next > to continue.

Page 43

Installing Software 43/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Installation

¾

Click on Install to start the installation now.

°

The device driver is (pre)installed.

4. Message: Device Driver is prepared

¾

Click on OK to confirm

Page 44

Installing Software 44/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

5. Finish installation

¾

Click on Finish.

°

The installation is completed.

Page 45

Installing Software 45/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

6.4 netPLC CoDeSys Server Setup

1. Continue installation

¾

Click on Next > (Weiter >) to continue

2. Installation

¾

Click on Install (Installieren) to start the installation now

°

The software is installed.

Page 46

Installing Software 46/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Finish installation

¾

Click on Finish (Fertigstellen) to finish

°

The software is installed.

Note: The netPLC CoDeSys Server starts automatically, when the PC is

started.

Page 47

Installing Software 47/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

6.5 Installing the Device Driver

Note: In case the Slot SPS was installed as described in section Installing

Slot PLC NPLC C100-DP on page 56 then the Windows

®

Hardware

Detection asks for a driver with the next start of the PC.

1. Switch on the PC

¾

After installing the slot PLC switch on your PC.

°

Windows

®

XP detects the slot PLC automatically.

°

The message Found New Hardware is displayed and the Found new

Hardware Wizard is started.

2. Windows Update

¾

Select No, not this time

¾

Click on Next > to continue

Page 48

Installing Software 48/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Install software automatically

¾

Select Install software automatically

¾

Click on Next > to continue.

°

The preinstalled device driver is found and installed then.

Page 49

Installing Software 49/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

4. Finish installation

¾

Click on Finish

°

The installation is completed.

5.

Check in the Device Manager if t he driver for the slot PLC is installed

properly.

¾

Open the Device Manager: Desktop symbol My Computer > right

mouse button Properties > Tab Hardware > button Device Manager.

¾

Check, if the display in the Device Manager shows

netPLC C100 PCI/PCIe Device

Page 50

Installing Software 50/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

6.6 Installing USB Driver

Note: If the slot PLC is connected via USB to your PC, then the Windows

®

Hardware detection asks for a driver.

1. Connect a USB cable

¾

Connect a USB cable your PC with the USB port of the slot PLC.

°

Windows

®

XP detects the slot PLC automatically.

°

The message Found New Hardware is displayed and the Found new

Hardware Wizard is started.

2. Windows update

¾

Select No, not this time

¾

Click on Next > to continue.

Page 51

Installing Software 51/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Install software automatically

¾

Select Install from a list or specific location

¾

Click on Next > to continue.

Page 52

Installing Software 52/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

4. Insert the netPLC-C100 DVD into your local DVD ROM drive

¾

Insert the netPLC-C100 DVD into your local DVD ROM drive

¾

Select Search for the best driver in these locations

¾

Select Include this location in the search

¾

Click on Browse

¾

Select the folder Drivers\USB\Windows .INF from the DVD

¾

Click on Next > to continue.

°

The USB driver is installed

Page 53

Installing Software 53/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

5. Finish installation

¾

Click on Finish

°

The Installation is completed.

6.

Check in the Device Manager if t he driver for the slot PLC is installed

properly.

¾

Open the Device Manager: Desktop symbol My Computer > right

mouse button Properties > Tab Hardware > button Device Manager.

¾

Check, if the display in the Device Manager shows

netPLC (COMx)

Page 54

Installing Hardware (Slot PLC) 54/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

7 Installing Hardware (Slot PLC)

7.1 Safety Advices

Obey to the following safety advices, when installing the slot PLC.

Electrical Shock Hazard

HAZARDOUS VOLT AGE inside of the PC or of the connecting device.

Therefore f irst disconnect the power plug of the PC or of the connecting

device.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or r emove the slot PLC car d only after

disconnecting power.

CAUTION!

Electrostatically sensitive Devices

To prevent damage to the PC and the slot PLC, make sure, that the slot

PLC is grounded via the endplate and the PC and make sure, that you

are discharged when you mount/demount the slot PLC.

7.1.1 Safety Advices USA

Obey to the following safety advices, when installing the slot PLC.

Electrical Shock Hazard

HAZARDOUS VOLT AGE inside of the PC or of the connecting device.

Therefore f irst disconnect the power plug of the PC or of the connecting

device.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or r emove the slot PLC card only after

disconnecting power.

Electrostatically sensitive Devices

To prevent damage to the PC and the slot PLC, make sure, that the slot

PLC is grounded via the endplate and the PC and make sure, that you

are discharged when you mount/demount the slot PLC.

Page 55

Installing Hardware (Slot PLC) 55/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

7.2 Installing Battery

With delivery a protection foil protects the battery against discharge.

Remove protection foil

¾

Remove the protection foil to activate the battery buffering.

°

Æ

Page 56

Installing Hardware (Slot PLC) 56/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

7.3 Installing Slot PLC NPLC C100-DP

For installation of the slot PLC handle as follows:

1. Disconnect the power plug of the PC.

2. Open the cabinet of the PC.

3. Plug in the slot PLC on a free PCI slot

4. Fix the slot PLC using the hole intended.

5. Close the PC casing.

6. Connect the external 24 V power supply.

7. Connect the PC to the power supply and switch on the PC.

Page 57

First Project 57/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8 First Project

8.1 Overview

This section describes how a project is created for the slot PLC. It is

assumed that the hardware (slot PLC) and software already is installed.

Additionally a PROFIBUS-DP slave device and a PROFIBUS cable are

needed.

If the project is loaded via USB into the slot PLC, then a USB cable with

type A to type mini B is needed.

An important note in advance:

Important: The name of the application has to be reduced. The name of

the application can have 7 characters as maximum. The target device

supports the MS-DOS file format 8.3 and no long file names. Application

names with more than 7 characters can not

be started in the target device.

The eights character is used internally and therefore is reserved.

Page 58

First Project 58/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.2 Preparation

8.2.1 netPLC CoDeSys Server

The netPLC CoDeSys server program is started automatically with each

start of the PC after the installation from DVD.

Note: Make sure that the server runs, if no USB is used.

Note: The netPLC CoDeSys server program must always be started

before CoDeSys is started.

1. Check if netPLC CoDeSys server is running

¾

Check, that the netPLC CoDeSys server is running, the symbol

has

to be shown in the system tray

¾

If the netPLC CoDeSys server is not running, then start it now: Start >

All Programs > Hilscher GmbH > netPLC CoDeSys Server.

°

The system tray shows the symbol

.

Page 59

First Project 59/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.2.2 CoDeSys

Note: Start CoDeSys always with the profile “for netPLC“

1. Start CoDeSys

¾

Select Start > All Programs > 3S CoDeSys > CoDeS ys > CoDeSys

V3.3 SPx Patch x for netPLC or

¾

Start CoDeSys by a double click on the desktop icon

°

CoDeSys is started.

Page 60

First Project 60/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

°

The CoDeSys GUI appears.

Page 61

First Project 61/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.3 Create Control Program and Bus Configuration

8.3.1 Create Project

1. Create a new project

¾

Select File > New Project

°

The window New Project appears.

Page 62

First Project 62/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2. Set up project-relevant information

¾

Select category (General) at Categories

¾

Select Standard project at Templates

¾

Fill in the project name FirstProject in the field Name

¾

Select a folder for storage of project data in t he field Location such as:

C:\Projekt

¾

Click at button OK with the left mouse button.

°

The window New Project is being closed and the selection window

Standard Project appears

3. Set up information regarding the standard project

¾

Select the device entry NPLC-C100-DP (Hilscher GmbH) at Device

¾

At PLC_PRG in select the programming mode Structured Text (ST)

¾

Click at button OK with the left mouse button.

Page 63

First Project 63/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

°

The window Standard Project is being closed and the project tree

appears:

4. Switch to the device view

¾

Check that the view is switched to

.

¾

If the view has been switched to POUs, then click onto the tab

using the left mouse button in order to switch to the device

view

°

Now the device view is activated.

5. Save project

¾

Save project using menu entry File > Save Project

°

The project is saved.

Page 64

First Project 64/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

Important: The name of the application has to be reduced. The name of

the application can have 7 characters as maximum. The target device

supports the MS-DOS file format 8.3 and no long file names. Application

names with more than 7 characters can not be executed in the target

device. The eights character is used internally and therefore is reserved.

6. Set name of application

¾

Single-click with the left mouse button at the name Application:

and change the name to App ( a nam e with less than 7 characters).

°

A security request appears

Page 65

First Project 65/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

7. Rename the application

¾

Answer with Yes to the security request

°

The name of the application is changed to App.

Page 66

First Project 66/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.3.2 Add PROFIBUS-DP Slave Device by use of a GSD File

1. Add PROFIBUS-DP slave device by use of a GSD file

¾

If you want to add PROFIBUS-DP slave devices to your device catalog ,

then copy the GSD file(s) of your slave device(s) into this folder:

E:\Documents and Settings\All Users\Application Data\

SYCONnet\PROFIBUS\GSD

2. Open window SYCON.net options

¾

Select menu Tools > Options

¾

Select option Sycon.net

°

3. Reload catalog

¾

Click on Reload Catalog to update the device catalog

°

The device catalog is reloaded

4. Close options window

¾

Click on OK to close the window.

Page 67

First Project 67/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.3.3 Bus Configuration

1. Opening the configuration window

¾

Open the configuration window with a double click a

t

NPLC_PROFIBUS (NPLC_PROFIBUS).

°

The configuration window NPLC_PROFIBUS with the tab Configurato

r

appears.

Page 68

First Project 68/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2. Insert PROFIBUS-DP Slave Device

¾

Select from the Device Catalog a PROFIBUS-DP Slave Device such as

the CB_AB32-DPS for instance and drag and drop the device icon to

the bus line.

°

The slave device appears at the PROFIBUS bus line.

Page 69

First Project 69/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Open the slave configuration window

¾

Open the configuration window of the slaves with a double click t he icon

of the slave device.

¾

Select the entry Module in the navigation area.

¾

The slave device used in this example already has selected modules at

Configured Modules. If you use an other slave then insert modules

from Available Modules to Configured Modules by using the insert

button.

°

In Configured Modules the information is displayed that the slave

device occupies 2 byte of input data and 2 byte of output data.

4. Close the configuration window

¾

Click on OK to close the windows and to apply the settings.

°

The window closes and the settings are applied.

Page 70

First Project 70/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

5. Open the window for Master configuration

¾

Open by a double click on the icon for the Master the configuration

window for the master.

¾

Select in the navigation area Bus Parameters.

°

6. Set Baud Rate

¾

Set at Baud Rate the Baud Rate, e. g. 1500 for 1, 5 MBit/s

Page 71

First Project 71/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

7. Set stations address of the PROFIBUS-DP slave(s)

¾

Select in the navigation area Station Table.

¾

Set in the column Station Address the address of the PROFIBUS-DP

slave device. The Master uses this address as slave identification to

communicate with the slave device.

°

8. Close the configuration window

¾

Click on OK to close the windows and to apply the settings.

°

The window closes and the settings are applied.

Page 72

First Project 72/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

9. Addressing of I/O data within the Fieldbus I/O image

¾

In the configuration window NPLC_PROFIBUS click at tab Fieldbus I/ O

Image in order to open the occupation of I/O data within the Fieldbus

I/O image.

¾

Open the variable tree.

°

The configuration window NPLC_PROFIBUS containing the tab

Fieldbus I/O Image appears.

The column Address shows the occupation of the I/O image. The input

addresses %IB0 und %IB1 and the output addresses %QB0 und %QB1

are occupied from the slave device CB_AB32-DPS. These addresses

are used in the PLC program.

10. Connect the PROFIBUS devices with a PROFIBUS cable

¾

Connect the Slot SPS with a PROFIBUS cable with the PROFIBUS-DP

slave device(s).

Page 73

First Project 73/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.3.4 Create PLC Program

1. Open Editor for function module PLC_PRG

¾

Open the Editor with a double click with the left mouse button a

t

PLC_PRG (PRG).

°

The editor window appears. The following picture shows the Edito

r

without any variables and PLC program.

Page 74

First Project 74/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2. Create a variable

¾

Create variable following variables:

var1 : BYTE;

opc_ib0 : BYTE;

opc_ib1 : BYTE;

opc_qb0 : BYTE;

°

Page 75

First Project 75/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Edit PLC Program

¾

Fill in the following PLC Program

var1 := var1 + 1;

%QB1 := var1;

opc_ib0 := %IB0;

opc_ib1 := %IB1;

%QB0 := opc_qb0;

°

A short explanation regarding the programming example

var1 := var1 + 1;

Variable var1 is incremented each PLC cycle.

%QB1 := var1;

The value of variable var1 is written to the output byte %QB1.

opc_ib0 := %IB0; und opc_ib1 := %IB1;

Input bytes %IB0 and %IB1 are copied to the variables opc_ib0 and

opc_ib1. This is the preparation, that the OPC server can access to the

input data.

%QB0 := opcqb0;

The value of variable opc_qb0 is copied to the output byte %QB0. This

is the preparation, that the OPC server can access to the output data.

Remark: Output byte %QB1 is used from the PLC program and

therefore can’t be accessed by the OPC server.

4. Save project

¾

Save project using menu entry File > Save Project

°

The project is saved.

Page 76

First Project 76/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

To create retain variables:

1. Create retain variables

¾

Create the section

VAR RETAIN

END_VAR

¾

Create a variable inside this section

VAR RETAIN

uiRemCount : UINT;

END_VAR

°

Page 77

First Project 77/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.3.5 Create Symbol Configuration

1. Add Object

¾

Select from the context menu on App t he entry Add Object.

°

The Object selection list appears.

Page 78

First Project 78/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2. Add object symbol configuration

¾

Select from the window Add Object the entry Symbol Configuration.

¾

Click on Open

°

In the project tree the entry Symbol configuration appears.

°

In the editor window the tab Symbol configuration appears.

Page 79

First Project 79/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

3. Refresh available variables

¾

Click at Available Variables on Refresh.

°

The Available Variables are updated.

4. Show available variables

¾

Open below Available Items the tree Variables > PLC_PRG.

°

The variables opc_ib0, opc_ib1 and opc_qb0 appear.

Page 80

First Project 80/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

5. Add symbols to selected variables

¾

Mark in the tree below Available Variabl es the variable opc_ib0.

¾

Add this variable by a click on “>“ to the Selected Variables.

¾

Mark in the tree below Available Variabl es the variable opc_ib1.

¾

Add this variable by a click on “>“ to the Selected Variables.

¾

ark in the tree below Available Variables the variable opc_qb0.

¾

Add this variable by a click on “>“ to the Selected Variables.

°

The variables opc_ib0, opc_ib1 and opc_qb0 appear at Selected

Variables.

Page 81

First Project 81/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.3.6 Build Project

1. Build Project

¾

Select Build > Build App [Device: PLC Logic] F11 in order to build

the project

°

The project is being built.

2. Check the message window.

¾

Check that the message

Compile complete -- 0 errors, 0 warnings

appears in the message window:

°

The project has successfully been built.

3. Save project

¾

Save project using menu entry File > Save Project

°

The project is saved.

Page 82

First Project 82/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.4 Connect to the Slot PLC

8.4.1 Define Gateway

1.

Open the window Communication Settings.

¾

Open by double clicking with the left mouse butt on onto Device (NPLC-

C100-DP) the tab Communication Settings of the window Device.

°

The window Device with the tab Communication Set t ings appears.

Page 83

First Project 83/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

If no gateway appears, the do step 2 and 3. If a gateway already shows up,

then skip step 2 and 3.

2. Add Gateway

¾

Click at button Add Gateway.

°

The window Gateway appears

3. Accept Gateway

¾

Click at OK in order to accept setting Gateway-1.

°

The window Gateway is being closed.

Page 84

First Project 84/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.4.2 Scan Network and set Active Path

Note: Make sure that the server runs, if no USB is used.

Note: If you use a USB connection then check now that the USB cable is

connected.

1. Scan the network

¾

Click on Scan Network to search for NPLC-C100 devices

°

Devices are searched over the USB connection, via the parallel system

bus of the slot PLC via the netPLC CoDeSys server as well as via

Ethernet.

°

Found devices are displayed below Gateway-1.

Page 85

First Project 85/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2 Set active path

¾

Click below Gateway-1 on the device NPLC-C100-DP to mark it.

¾

Click on Set active path to establish a connection to the device

°

Beside the device NPLC-C100-DP the text active appears.

Page 86

First Project 86/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.5 Download Control Program and Bus Configuration

8.5.1 Login and Download

1. Login to the slot PLC

¾

Select Online > Login to 'App [Device: PLC-Logic]'

°

The software verifies if the project in the slot PLC is the same as the

project on the PC. If no PLC program is in the slot PLC, then the

message “Application App does not exist on device. Do you want to

create it and proceed with download?“. If the projects are different then

the message “Unknown version of application App on taget. Do you

want to perform a download and replace the application?”.

Important: A download of the PLC program with login only stores the PLC

program not

zero voltage secure in the slot PLC. If the slot PLC is

disconnected from power supply then the downloaded PLC program and

bus configuration is deleted.

It is mandatory to create a boot application to store the PLC pr ogram and

the bus configuration permanently (zero voltage secure) in t he slot PLC.

This is described in section Create Boot Application on page 88.

Page 87

First Project 87/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

2. Start Download

¾

Answer the question “Application App does not exist on device. Do you

want to create it and proceed with download?“ with Yes.

°

The application is downloaded into the slot PLC.

°

With the start of the download the slot PLC goes into the stop mode.

°

The footer shows the progress of the download procedure: Sending

download info: Downloading … and shows the size of the alread

y

downloaded program and the complete size of the program.

Page 88

First Project 88/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.5.2 Create Boot Application

Important: It is mandatory to create a boot application t o store the PLC

program and the bus configuration permanently (zero voltage secure) in

the slot PLC.

1. Create boot application

¾

Select Online > Create Boot Application for ‚App [Device:PLC-

Logic]’.

°

The boot application is created and downloaded into the slot PLC.

8.5.3 Remove Boot Application

1. Remove boot application

¾

If an existing boot application should be removed, t hen select Online >

Reset > Origin.

°

The slot PLC is resetted and the existing boot application is removed.

Page 89

First Project 89/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.5.4 Start PLC Program

1. Start program

¾

Select Online > Start ‚App [Device:PLC-Logic]’ to start the PLC

program.

¾

Important: Check, that the switch on the slot PLC f or t he position RUN.

If the switch is in position STOP, the switch it to run.

°

The slot PLC goes in state RUN.

The PLC program increments in each PLC cycle the output byte %QB1 by

one. Check the PROFIBUS-DP Slave that the output data changes.

Change the input data of the PROFIBUS-DP Slave device and verify that

these appear in the slot PLC.

Page 90

First Project 90/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

8.6 Disconnect fr om the Slot PLC

1. Logging out

¾

Select

Online > Log out from 'Appl [Device: PLC Logic]' Ctrl+F8,

in order to log out.

°

The connection to the slot PLC is disconnected.

Page 91

Visualization 91/142

netPLC C100 | Startup Guide

DOC090701UM02EN | Revision 2 | English | 2009-10 | Released | Public © Hilscher, 2009

9 Visualization

Data can be read from and written to the slot PLC from a visualization

software with OPC interface (named OPC client in the following text) via the

OPC server.

Therefore a configuration is necessary. The following sections descr ibe the

configuration steps to connect a visualization software via OPC to the slot

PLC.

Requirements

Operational slot PLC, existing of

• installed hardware