Page 1

User Manual

Slot PLC NPLC-C100

Hardware Installation

Hilscher Gesellschaft für Systemautomation mbH

www.hilscher.com

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public

Page 2

Introduction 2/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

Table of Contents

1 INTRODUCTION.........................................................................................................4

1.1 About the User Manual...............................................................................................4

1.1.1 List of Revisions ...................................................................................................4

1.1.2 Reference to Hardware, Firmware, Driver and Software.....................................5

1.1.3 Conventions in this Manual..................................................................................6

1.2 Legal Notes.................................................................................................................7

1.2.1 Copyright..............................................................................................................7

1.2.2 Important Notes....................................................................................................7

1.2.3 Exclusion of Liability.............................................................................................8

1.2.4 Warranty...............................................................................................................8

1.2.5 Export Regulations...............................................................................................9

1.2.6 Registered Trademarks........................................................................................9

1.3 Licenses......................................................................................................................9

2 SAFETY ....................................................................................................................10

2.1 Safety Instructions....................................................................................................10

2.2 Intended Use ............................................................................................................10

2.3 Personnel Qualification.............................................................................................10

2.4 References Safety....................................................................................................10

2.5 Commitment to read and understand the Manual ....................................................11

2.6 Safety Instructions to avoid Personal Injury..............................................................11

2.6.1 Electrical Shock Hazard .....................................................................................11

2.7 Labeling of Safety Instructions..................................................................................12

2.8 Safety Instructions....................................................................................................13

2.8.1 Electrical Shock Hazard .....................................................................................13

2.9 Property Damage Messages ....................................................................................13

2.9.1 Electrostatically sensitive Devices......................................................................13

3 DESCRIPTION AND REQUIREMENTS ...................................................................14

3.1 Description................................................................................................................14

3.2 System Requirements ..............................................................................................15

3.2.1 System Requirements PC..................................................................................15

3.3 Requirements for Operation .....................................................................................15

3.3.1 Slot PLC NPLC-C100-XX...................................................................................15

4 DEVICE DRAWINGS................................................................................................16

4.1 Device Drawing NPLC-C100-DP..............................................................................16

4.1.1 Cover NPLC-C100-xx.........................................................................................17

5 INSTALLING HARDWARE (SLOT PLC)...................................................................18

5.1 Safety Messages on Personal Injury........................................................................18

Page 3

Introduction 3/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

5.2 Safety Advices..........................................................................................................18

5.3 Property Damage Messages ....................................................................................19

5.3.1 Device Destruction by exceeding allowed Supply Voltage ................................19

5.3.2 Device Destruction by exceeding allowed Signaling Voltage ............................19

5.3.3 Electrostatically sensitive Devices......................................................................19

5.4 Installing Battery.......................................................................................................20

5.5 Installing Slot PLC NPLC-C100-xx ...........................................................................20

6 HARDWARE .............................................................................................................21

6.1 Block Diagram ..........................................................................................................21

6.2 Internal and External Power Supply .........................................................................22

6.3 Reset Behaviour.......................................................................................................22

6.4 RUN/STOP Switch....................................................................................................22

6.5 LEDs.........................................................................................................................22

6.6 Interfaces..................................................................................................................23

6.6.1 CANopen Interface.............................................................................................23

6.6.2 DeviceNet Interface............................................................................................23

6.6.3 PROFIBUS Interface..........................................................................................24

6.6.4 Mini-B USB Connector (5 Pin)............................................................................24

7 BATTERY..................................................................................................................25

7.1 Preparation for changing Battery..............................................................................26

7.1.1 Safety Messages on Personal Injury..................................................................26

7.2 Changing the Battery................................................................................................26

8 TROUBLESHOOTING..............................................................................................28

9 TECHNICAL DATA SLOT PLC NPLC-C100-XX.......................................................29

10 APPENDIX

................................................................................................................30

10.1 Memory Card............................................................................................................30

10.2 Update Firmware......................................................................................................31

10.3 Battery Disposal........................................................................................................34

10.4 Disposal of Waste Electronic Equipment..................................................................34

10.5 List of Figures...........................................................................................................35

10.6 List of Tables............................................................................................................35

10.7 Contacts....................................................................................................................36

Page 4

Introduction 4/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

1 Introduction

1.1 About the User Manual

This user manual contains the description for the slot PLC NPLC-C100-xx.

NPLC-C100-xx are PC cards with PLC functionality.

This user manual describes the slot PLCs

NPLC-C100-DP

NPLC-C100-CO

NPLC-C100-DN

1.1.1 List of Revisions

Index Date Chapter Revisions

1 2012-05-22 all Created.

2 2014-01-23 10.4 Section Disposal of Waste Electronic Equipment updated.

Table 1: List of Revisions

Page 5

Introduction 5/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

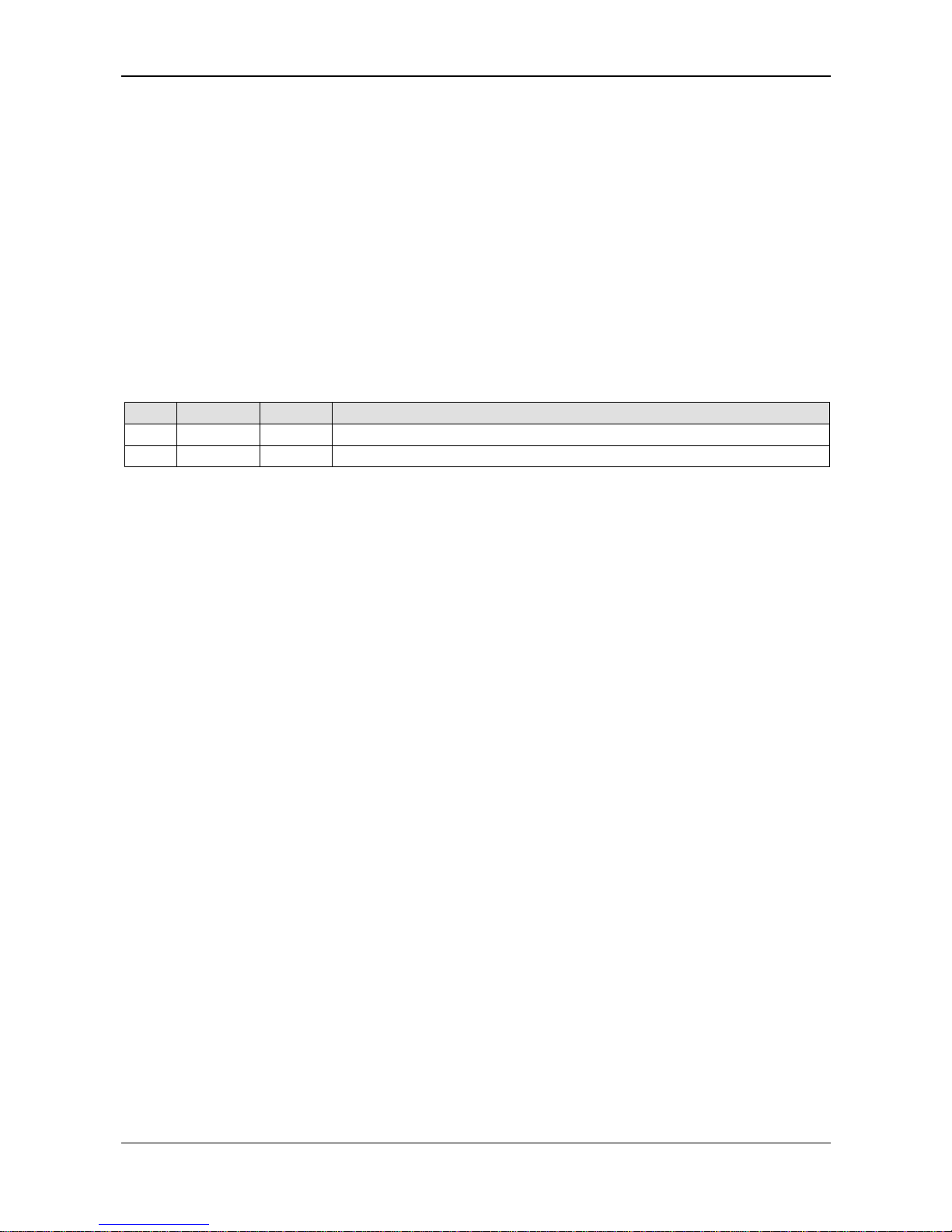

1.1.2 Reference to Hardware, Firmware, Driver and Software

Note: The listed hardware revision, firmware and driver versions

respectively versions of the programming software CoDeSys functionally

belong together.

Hardware

Hardware Part Number Bus Type Revision

NPLC-C100-DP 1800.410 PROFIBUS DP 4

NPLC-C100-CO 1800.500 CANopen 4

NPLC-C100-DN 1800.510 DeviceNet 4

Table 2: Reference to Hardware

The part number only is not enough to order the slot PLC. The product

variant must also be specified (which is the part after the slash “/”) to get a

slot PLC with the preloaded firmware containing the embedded PLC type.

Product Variant

Product PLC Type

Including PLC

Programming Software

NPLC-C100-DP/S7

S7 compatible PLC from

IBH Softec

-

NPLC-C100-DP/CDS-OPC

NPLC-C100-CO/CDS-OPC

NPLC-C100-DN/CDS-OPC

CoDeSys PLC from 3S CoDeSys

NPLC-C100-DP/CLR

ProConOS eCLR from

KW-Software

MULTIPROG Express

Table 3: Reference to Product Variant

Firmware

Each slot PLC of the product variants listed above is delivered with

preloaded firmware.

Driver

Driver Driver Type Driver Version

cifX Device Driver PC card driver for Windows 1.1.1.0

USB Driver USB driver for Windows 5.1.2600.2180

Table 4: Reference to Driver

Page 6

Introduction 6/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

1.1.3 Conventions in this Manual

Operation instructions, a result of an operation step or notes are marked as

follows:

Operation Instructions:

<instruction>

or

1. <instruction>

2. <instruction>

Results:

<result>

Notes:

Important: <important note>

Note: <note>

<note, where to find further information>

Positions in Figures

The Positions

, , ... or , , ... or , , ... refer to the

figure used in that section. If the numbers reference to a section outside the

current section then a cross reference to that section and figure is

indicated.

Page 7

Introduction 7/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

1.2 Legal Notes

1.2.1 Copyright

© Hilscher, 2009-2014, Hilscher Gesellschaft für Systemautomation mbH

All rights reserved.

The images, photographs and texts in the accompanying material (user

manual, accompanying texts, documentation, etc.) are protected by

German and international copyright law as well as international trade and

protection provisions. You are not authorized to duplicate these in whole or

in part using technical or mechanical methods (printing, photocopying or

other methods), to manipulate or transfer using electronic systems without

prior written consent. You are not permitted to make changes to copyright

notices, markings, trademarks or ownership declarations. The included

diagrams do not take the patent situation into account. The company

names and product descriptions included in this document may be

trademarks or brands of the respective owners and may be trademarked or

patented. Any form of further use requires the explicit consent of the

respective rights owner.

1.2.2 Important Notes

The user manual, accompanying texts and the documentation were created

for the use of the products by qualified experts, however, errors cannot be

ruled out. For this reason, no guarantee can be made and neither juristic

responsibility for erroneous information nor any liability can be assumed.

Descriptions, accompanying texts and documentation included in the user

manual do not present a guarantee nor any information about proper use

as stipulated in the contract or a warranted feature. It cannot be ruled out

that the user manual, the accompanying texts and the documentation do

not correspond exactly to the described features, standards or other data of

the delivered product. No warranty or guarantee regarding the correctness

or accuracy of the information is assumed.

We reserve the right to change our products and their specification as well

as related user manuals, accompanying texts and documentation at all

times and without advance notice, without obligation to report the change.

Changes will be included in future manuals and do not constitute any

obligations. There is no entitlement to revisions of delivered documents.

The manual delivered with the product applies.

Hilscher Gesellschaft für Systemautomation mbH is not liable under any

circumstances for direct, indirect, incidental or follow-on damage or loss of

earnings resulting from the use of the information contained in this

publication.

Page 8

Introduction 8/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

1.2.3 Exclusion of Liability

The delivered product (including the technical data) is subject to export or

import laws as well as the associated regulations of different counters, in

particular those of Germany and the USA. The software may not be

exported to countries where this is prohibited by the United States Export

Administration Act and its additional provisions. You are obligated to

comply with the regulations at your personal responsibility. We wish to

inform you that you may require permission from state authorities to export,

re-export or import the product.

1.2.4 Warranty

Although the hardware and software was developed with utmost care and

tested intensively, Hilscher Gesellschaft für Systemautomation mbH does

not guarantee its suitability for any purpose not confirmed in writing. It

cannot be guaranteed that the hardware and software will meet your

requirements, that the use of the software operates without interruption and

that the software is free of errors. No guarantee is made regarding

infringements, violations of patents, rights of ownership or the freedom from

interference by third parties. No additional guarantees or assurances are

made regarding marketability, freedom of defect of title, integration or

usability for certain purposes unless they are required in accordance with

the law and cannot be limited. Warranty claims are limited to the right to

claim rectification.

Page 9

Introduction 9/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

1.2.5 Export Regulations

The delivered product (including the technical data) is subject to export or

import laws as well as the associated regulations of different counters, in

particular those of Germany and the USA. The software may not be

exported to countries where this is prohibited by the United States Export

Administration Act and its additional provisions. You are obligated to

comply with the regulations at your personal responsibility. We wish to

inform you that you may require permission from state authorities to export,

re-export or import the product.

1.2.6 Registered Trademarks

Windows® XP, Windows® Vista, Windows® 7 are registered trademarks of

the Microsoft Corporation.

Adobe-Acrobat

®

is an registered trademark of the Adobe Systems

Incorporated.

1.3 Licenses

A license for the used PLC runtime (PLC type) is necessary to operate the

PLC runtime. This license is stored in the slot PLC hardware and included

in the scope of delivery of the ordered product variant. The license permits

the use and operation of the respective PLC runtime in the hardware.

A slot PLC is delivered with exactly one license which is stored in the

hardware. A license can’t be converted into another license. The license

can’t be used for another PLC type.

A license for fieldbus master functionality is necessary in the slot PLC to

operate on the fieldbus as master.

Page 10

Safety 10/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

2 Safety

2.1 Safety Instructions

The user manual, the accompanying texts and the documentation are

written for the use of the products by educated personnel. When using the

products, all Safety Messages, Safety Messages, Property Damage

Messages and all valid legal regulations have to be obeyed. Technical

knowledge is presumed. The user has to assure that all legal regulations

are obeyed.

2.2 Intended Use

The slot PLC described in this user manual is a PC card with PLC

functionality and fieldbus communication. Depending from the loaded

firmware, the fieldbus systems listed in the following table can be realized

using the respective slot PLC.

Slot PLC Fieldbus System

NPLC-C100-DP PROFIBUS DP Master

NPLC-C100-CO CANopen Master

NPLC-C100-DN DeviceNet Master

Table 5: Slot PLC NPLC-C100 and Fieldbus Systems realized thereby

2.3 Personnel Qualification

The PC Card NPLC-C100 must only be installed, configured and removed

by qualified personnel. Job-specific technical skills for people professionally

working with electricity must be present concerning the following topics:

Safety and health at work

Mounting and connecting of electrical equipment

Measurement and Analysis of electrical functions and systems

Evaluation of the safety of electrical systems and equipment

Installing and Configuring IT systems

2.4 References Safety

[S1]

ANSI Z535.6-2006 American National Standard for Product Safety Information in

Product Manuals, Instructions, and Other Collateral Materials

[S2]

IEC 60950-1, Information technology equipment - Safety - Part 1: General

requirements, (IEC 60950-1:2005, modified); German Edition EN 60950-1:2006

[S3] EN 61340-5-1 and EN 61340-5-2 as well as IEC 61340-5-1 and IEC 61340-5-2

Page 11

Safety 11/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

2.5 Commitment to read and understand the Manual

Important!

To avoid personal injury and to avoid property damage to your system

or to your device, you must read and understand all instructions in the

manual and all accompanying texts to your device, before installing and

operating your device.

First read the Safety Instructions in the safety chapter.

Obey to all Safety Messages in the manual.

Keep the product DVD providing the product manuals.

2.6 Safety Instructions to avoid Personal Injury

To ensure your own personal safety and to avoid personal injury, you

necessarily must read, understand and follow the following safety

instructions and safety messages in this manual about danger causing

personal injury, before you install and operate your NPLC-C100.

2.6.1 Electrical Shock Hazard

The danger of a lethal electrical shock caused by parts with more than 50V

may occur, if you open the PC cabinet to install the PC Card NPLC-C100.

HAZARDOUS VOLTAGE is present inside of the PC or of the connec-

ting device, into which the PC Card cifX is integrated. Strictly obey to all

safety rules provided by the device’s manufacturer in the documentation!

First disconnect the power plug of the PC or of the connecting device,

before you open the cabinet.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or remove the PC Card NPLC-C100

only after disconnecting power.

An electrical shock is the result of a current flowing through the human

body. The resulting effect depends on the intensity and duration of the

current and on its path through the body. Currents in the range of

approximately ½ mA can cause effects in persons with good health, and

indirectly cause injuries resulting from startle responses. Higher currents

can cause more direct effects, such as burns, muscle spasms, or

ventricular fibrillation.

In dry conditions permanent voltages up to approximately 42.4 V peak or

60 V DC are not considered as dangerous, if the contact area is equivalent

to a human hand.

Reference Safety [S2]

Page 12

Safety 12/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

2.7 Labeling of Safety Instructions

The Section Safety Messages at the beginning of a chapter are

pinpointed particularly. They are highlighted with a specific safety

symbol and a signal word according to the degree of endangerment.

Inside the safety message the danger is exactly named.

The Integrated Safety Messages within an instruction description are

highlighted with a signal word according to the degree of endangerment

and possibly by a principle symbol. Inside the safety message the

danger is exactly named.

Safety

Symbol

USA Sort of Warning or Principle

Warning of Personal Injury and Property Damage Message

USA: Warning of Personal Injury

As in the scope of the ANSI Z535 Standard (for USA) instructions to a property damage

message may not contain a warning triangle, this property damage messages are listed

separately for the USA.

Warning of Lethal Electrical Shock

Warning of Damages by Electrostatic Discharge

Principle: Disconnect the Power Plug

Table 6: Safety Symbols and Sort of Warning or Principle

Signal

Word

Meaning Meaning (USA)

Indicates a direct hazard with high risk, which

will have as consequence death or grievous

bodily harm if it isn't avoided.

Indicates a Hazardous Situation Which if not

Avoided, will Result in Death or Serious Injury.

Indicates a possible hazard with medium risk,

which will have as consequence death or

(grievous) bodily harm if it isn't avoided.

Indicates a Hazardous Situation Which if not

Avoided, could Result in Death or Serious

Injury.

Indicates a minor hazard with medium risk,

which could have as consequence simple

battery if it isn't avoided.

Indicates a Hazardous Situation Which if not

Avoided, may Result in Minor or Moderate

Injury.

Indicates a Property Damage Message. Indicates a Property Damage Message.

Note

Indicates an important note in the manual. Indicates an Important Note in the Manual.

Table 7: Signal Words

In this document all Safety Instructions and Safety Messages are designed

according both to the international used safety conventions as well as to

the ANSI Z535 standard, refer to reference safety [S1].

Page 13

Safety 13/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

2.8 Safety Instructions

This manual contains instructions which must be observed to ensure your

own personal safety and to avoid damage to devices.

2.8.1 Electrical Shock Hazard

Electrical Shock Hazard

HAZARDOUS VOLTAGE inside of the PC or of the connecting device.

Therefore first disconnect the power plug of the PC or of the connecting

device.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or remove the slot PLC only after

disconnecting power.

2.9 Property Damage Messages

This manual contains instructions which must must be red, understod and

observed to avoid damage to devices.

2.9.1 Electrostatically sensitive Devices

Adhere to the necessary safety precautions for components that are

vulnerable with electrostatic discharge (EN 61340-5-1 and EN 61340-5-2

as well as IEC 61340-5-1 and IEC 61340-5-2).

Electrostatically sensitive Devices

This equipment is sensitive to electrostatic discharge, which cause

internal damage and affect normal operation. Follow guidelines when you

handle this equipment.

Observe the necessary safety precautions when handling components

that are vulnerable to electrostatic discharge.

Page 14

Description and Requirements 14/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

3 Description and Requirements

3.1 Description

The slot PLC NPLC-C100 described in this user manual is a PC card with

PLC functionality and fieldbus communication. Depending from the loaded

firmware, the fieldbus systems listed in Table 5: Slot PLC NPLC-C100 and

Fieldbus Systems realized thereby on page 10 can be realized.

Pow

er Supply

The slot PLC NPLC-C100 can be supplied by 5 V or 3.3 V (via the PCI bus)

or by an external supply voltage of 24 V DC. By that a redundant power

supply is achieved.

Additionally the slot PLC NPLC-C100 can be used with a battery that in

case of loss of power supplies power to the real time clock and to the

SRAM circuit (for remanent data of the PLC) of the PLC.

The supply voltage of the slot PLC and the battery charge condition can be

monitored within the PLC program by monitoring functions.

This slot PLC is a PC card for fieldbus communication and handles the

complete data exchange between the connected fieldbus devices and the

PLC program.

In one PC a maximum of two slot PLCs can be used.

Page 15

Description and Requirements 15/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

3.2 System Requirements

3.2.1 System Requirements PC

Windows® XP, Windows® 7

PC with PCI connector with 3,3 V or 5 V for hardware revision 4 of

“NPLC C100-xx“

DVD ROM drive

Graphic resolution: min. 1024 x 768 pixel or higher

Keyboard and Mouse

3.3 Requirements for Operation

Note: For operating a slot PLC NPLC-C100-xx

Update older versions of the cifX Device Driver to V1.1.1.0.

3.3.1 Slot PLC NPLC-C100-XX

The following requirements must be fulfilled for operation of the slot PLC

with a master functionality:

Firmware

A suitable firmware (for the PLC type) has to be loaded.

License

The slot PLC was ordered with the right and necessary licenses.

Configuration

Die slot PLC must be configured using the configuration software.

Programming The PLC program must be created with the PLC programming

software and loaded into the slot PLC.

Communication For communication slave devices for the used communication

system are required.

Table 8: Requirements for Operation of the Slot PLC

Page 16

Device Drawings 16/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

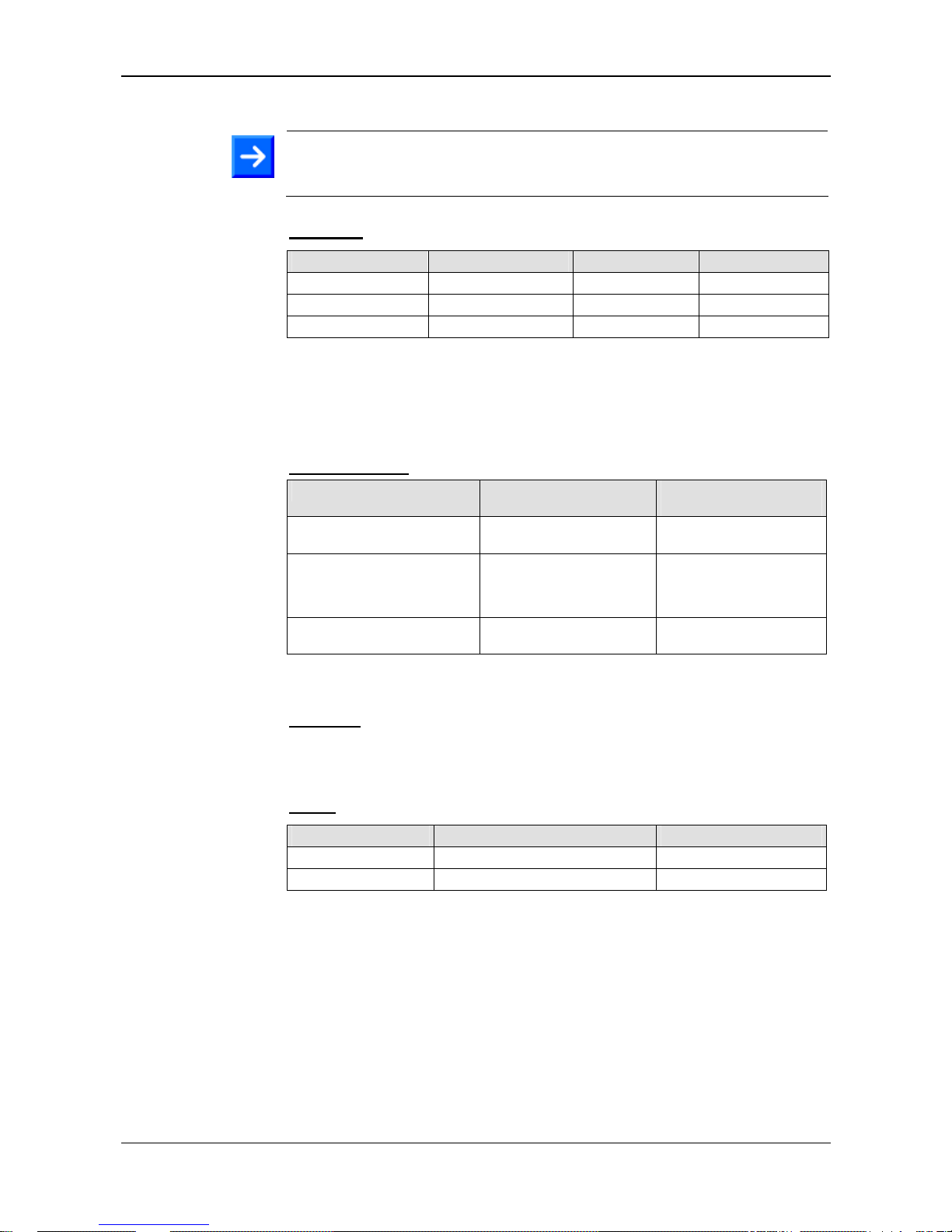

4 Device Drawings

4.1 Device Drawing NPLC-C100-DP

Figure 1: Device Drawing NPLC-C100-xx

Number Designation

1 LED SYS

2 LED APL

3 LED COM0

4 LED COM1

5 RUN/STOP Switch

6 DIAG – USB Diagnostic Interface

7 Slot for Memory Card

8 MicroSD Memory Card

9 External Power Supply

10 Fieldbus interface

NPLC-C100-DP: PROFIBUS interface

NPLC-C100-CO: CANopen interface

NPLC-C100-DN: DeviceNet interface

11 Battery holder

12 Battery

Table 9: Designation in the Device Drawing NPLC-C100-xx

Page 17

Device Drawings 17/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

4.1.1 Cover NPLC-C100-xx

NPLC-C100-DN NPLC-C100-DP / NPLC-C100-CO No. Designation

LED SYS

LED APL

LED COM0

LED COM1

RUN/STOP Switch

DIAG – USB Diagnostic

Interface

Slot for Memory Card

MicroSD Memory Card

External Power Supply

Fieldbus interface

-DP – D-Sub female, 9 pin

-CO – D-Sub male, 9 pin

-DN – COMBICON, 5 pin

Table 10: Designation for the Cover of NPLC-C100-xx

Page 18

Installing Hardware (Slot PLC) 18/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

5 Installing Hardware (Slot PLC)

5.1 Safety Messages on Personal Injury

Obey to the following safety messages on personal injury, when installing,

uninstalling or replacing the slot PLC NPLC-C100.

5.2 Safety Advices

Obey to the following safety advices, when installing the slot PLC.

Lethal Electrical Shock caused by parts with more than 50V!

HAZARDOUS VOLTAGE inside of the PC or of the connecting device.

Strictly obey to all safety rules provided by the device’s manufacturer in

the documentation!

First disconnect the power plug of the PC or of the connecting device,

before you open the cabinet.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or remove the slot PLC NPLC-C100

only after disconnecting power

Page 19

Installing Hardware (Slot PLC) 19/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

5.3 Property Damage Messages

Obey to the following property damage messages, when installing,

uninstalling or replacing the slot PLC NPLC-C100.

5.3.1 Device Destruction by exceeding allowed Supply Voltage

Adhere for all slot PLC NPLC-C100 described in this manual the instruction

hereafter:

Device Destruction!

Use only the permissible supply voltage to operate the slot PLC NPLC-

C100.

Operating the slot PLC NPLC-C100 with a supply voltage above of the

specified range leads to device destruction.

5.3.2 Device Destruction by exceeding allowed Signaling Voltage

Adhere for all slot PLC NPLC-C100 described in this manual the instruction

hereafter:

Device Destruction!

All I/O signal pins at the slot PLC NPLC-C100 tolerate only a specified

signaling voltage!

Operation the slot PLC NPLC-C100 with a signaling voltage other than

the specified signaling voltage may lead to severe damage to the slot

PLC NPLC-C100!

For detailed information on the supply and signaling voltage of the slot PLC

NPLC-C100 described in this manual, refer to section Technical Data Slot

PLC NPL

C-C100-xx on page 29.

5.3.3 Electrostatically sensitive Devices

Adhere to the necessary safety precautions for components that are

vulnerable with electrostatic discharge.

Electrostatically sensitive Devices

To prevent damage to the PC and the slot PLC NPLC-C100, make sure,

that the slot PLC NPLC-C100 is grounded via the endplate and the PC

and make sure, that you are discharged when you install/uninstall the

slot PLC NPLC-C100.

Page 20

Installing Hardware (Slot PLC) 20/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

5.4 Installing Battery

With delivery a protection foil protects the battery against discharge.

Remove protection foil

Remove the protection foil to activate the battery buffering.

5.5 Installing Slot PLC NPLC-C100-xx

Note: Install all software components, before you install the hardware, to

prevent problems due to missing drivers after rebooting the PC.

For installation of the slot PLC NPLC-C100 handle as follows:

1. Disconnect the power plug of the PC.

2. Open the cabinet of the PC.

3. Plug in the slot PLC on a free PCI slot

4. Fix the slot PLC using the hole intended.

5. Close the PC casing.

6. Connect the external 24 V power supply, if needed.

7. Connect the PC to the power supply and switch on the PC.

Page 21

Hardware 21/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

6 Hardware

6.1 Block Diagram

Figure 2: NPLC-C100-xx Block Diagram

Page 22

Hardware 22/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

6.2 Internal and External Power Supply

Note: Hardware revision 3 of the slot PLC NPLC-C100 can be supplied

via the PCI bus only with 5 V. Hardware revision 4 of the slot PLC NPLCC100 can be supplied via the PCI bus with 3.3 V respectively 5 V.

The slot PLC can be supplied by 5 V or 3.3 V (via PCI) or by an additional

external supply voltage of 24 VDC. The permitted voltage range for external

powering is 18 … 30 V. If the external supply voltage reaches a level below

13 V, then the supply of the slot PLC from the external supply voltage is

switched off.

6.3 Reset Behaviour

The slot PLC has no connection via the PCI bus to the PC reset signal.

This means that a reset of the PC for example when using the front panel

reset button of the computer does not influence the slot PLC behavior.

The PowerOn reset will be served from both power sources (internal und

external).

6.4 RUN/STOP Switch

The PLC program’s operating condition in the slot PLC can be changed

using the switch at the front of the slot PLC and may get the status.

Position Function

RUN

The loaded PLC program is executed cyclically.

STOP The cyclic execution of the PLC program is stopped. Loa ding a new PLC

program or a firmware update is possible in this state.

Table 11: RUN/STOP Switch

6.5 LEDs

The meaning of the LED signals depends on the used firmware and the

embedded PLC type.

For a firmware with CoDeSys: The meaning of the LED is described in the

manual ‚netPLC with CoDeSys, commissioning’.

Page 23

Hardware 23/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

6.6 Interfaces

6.6.1 CANopen Interface

Slot PLC NPLC-C100-CO:

CANopen Pin Assignment

CANopen Pin Signal Description

2 CAN L CAN Low bus line

3

ISO

GND

CAN ground

7 CAN H CAN High bus line

1, 4, 5,

6, 8, 9

Important note and strongly

recommended: Leave these pins

unconnected! Otherwise there is

a high risk of a device damage.

9-pole

sub-D male.

Shield PE Metal shell on PE

Table 12: CANopen Pin Assignment

Position in Figure 1 on page 16.

6.6.2 DeviceNet Interface

Slot PLC NPLC-C100-DN:

DeviceNet Pin Assignment

DeviceNet Pin Signal Description

1 ISO GND Common ground

DeviceNet-power supply.

2 CAN L CAN Low signal

3 Drain Shield

4 CAN H CAN High signal

COMBICON

Socket, female

5 V+ +24 V DeviceNet-power supply

Table 13: DeviceNet Pin Assignment

Position in Figure 1 on page 16.

Page 24

Hardware 24/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

6.6.3 PROFIBUS Interface

Slot PLC NPLC-C100-DP:

RS-485 PROFIBUS Pin Assignment

PROFIBUS Pin Signal Description

3 Rx/Tx + Receive- / Transmit data positive

4 CNTR-P Control signal for repeater (direction control)

5 ISO GND Data ground

6 VP Power supply positive

9-pole sub-D

socket,

female

8 Rx/Tx - Receive- / Transmit data negative

Table 14: PROFIBUS RS-485 Pin Assignment

Position in Figure 1 on page 16.

6.6.4 Mini-B USB Connector (5 Pin)

USB Buchse Pin Signal Beschreibung

1 -

2 D- Data 3 D+ Data +

4 ID

5 GND Ground

Schirm PE Metallschutzkragen auf PE

Tabelle 1: Mini-B USB Anschluss Pinbelegung (5-polig)

Position in Figure 1 on page 16.

Page 25

Battery 25/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

7 Battery

The battery has the type CR2032.

Using the Battery is optional.

The battery is used for

buffering the real time clock and

buffering of remanent data.

The PLC program is normally not buffered by the battery. The PLC program

is stored remanently in the FLASH memory of the slot PLC. The operation

to store the PLC program remanently has to be activated manually.

A fully charged battery has a life time of 1 year.

If the slot PLC is powered then the battery is not discharged.

Important: Recommendation: Change the battery every 12 month.

Page 26

Battery 26/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

7.1 Preparation for changing Battery

7.1.1 Safety Messages on Personal Injury

Obey to the following safety messages on personal injury, when installing,

uninstalling or replacing the slot PLC NPLC-C100.

7.1.1.1 Electrical Shock Hazard

Lethal Electrical Shock caused by parts with more than 50V!

HAZARDOUS VOLTAGE inside of the PC or of the connecting device.

Strictly obey to all safety rules provided by the device’s manufacturer in

the documentation!

First disconnect the power plug of the PC or of the connecting device,

before you open the cabinet.

Make sure, that the power supply is off at the PC or at the connecting

device.

Open the PC cabinet and install or remove the slot PLC NPLC-C100 only

after disconnecting power.

7.2 Changing the Battery

1. Pull off the power plug of your PC.

2. Open the housing of your PC.

3. Unmount the slot PLC

4. Pull out the slot PLC from the card slot of your PC.

5. Remove battery

To remove the battery from its battery holder move it sidewards

Page 27

Battery 27/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

6. Insert Battery

Use a fully charged battery.

Pay attention to the polarity of the battery. In the picture below the

positive pole is on top.

To insert the battery shift it under control of the correct polarity into the

battery holder.

7. Plug in the slot PLC into a free PCI card slot.

8. Fix the slot PLC at the designated drilling hole.

9. Close the PC housing.

10. Reconnect the PC to the mains power and switch it on.

For battery disposal see section Battery Disposal on page 34.

Page 28

Troubleshooting 28/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

8 Troubleshooting

General

Check, if the requirements for slot PLC operation are fulfilled.

Further information to this you find in section System Requirements on

page 15.

Cable

Check that the pin assignment of the used cable is correct.

Configuration

Check the configuration in the Master and the Slave device. The

configuration has to match.

Page 29

Technical Data Slot PLC NPLC-C100-xx 29/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

9 Technical Data Slot PLC NPLC-C100-xx

Number of Slot PLCs

Max. 2 slot PLC in one PC

Table 15: Technical Data Slot PLC

Item

NPLC-C100-DP, NPLC-C100-CO, NPLC-C100-DN

System Interface

PCI V2.3, 33 MHz

Dual-Port Memory Size

64 KByte

Protocols

NPLC-C100-DP, PROFIBUS DP Master

NPLC-C100-CO, CANopen Master

NPLC-C100-DN, DeviceNet Master

Processor

netX 100

Memory

8 MByte SDRAM,

128 KByte SRAM (Battery buffering),

4 MByte serial Flash

LED

SYS, APL, COM0, COM1

Operating Elements

RUN/STOP switch

Battery Type

CR 2032

Memory Card

microSD

PROFIBUS Interface

NPLC-C100-DP

D-Sub female connector, 9 pin;

optically isolated RS-485 interface for PROFIBUS DP

NPLC-C100-CO

D-Sub male connector, 9 pin for CANopen

NPLC-C100-DN

COMBICON, 5 pin for DeviceNet

Connection for

external Power Supply

COMBICON 2-pin

Diagnostic Interface

Mini USB

Power Supply Rev 3:

5 V (4,5 … 5,5 V), 500 mA

Rev 4:

PCI-Bus 3,3 V (3,1 … 3,5 V), 700 mA or

5 V (4,5 … 5,5 V), 500 mA or

External: 18 … 30 VDC

Current consumption at 18 V approx. 120 mA,

at 30 V approx. 80 mA.

The current is taken from the highest supply voltage.

External Power Supply

18 … 30 VDC

Dimensions (L x W x D)

120 x 90 x 20 mm

(130 x 121 x 22 mm over all)

Operating Temperatur

0 … 55 °C

Table 16: Technical Data NPLC-C100-xx

Page 30

Appendix 30/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

10 Appendix

10.1 Memory Card

The slot PLC “NPLC-C100” device can be set back to factory settings with

a micro SD card and the base firmware on it.

Requirements

The memory card can have up to 4 GB storage capacity.

The memory card must be formatted in the FAT16 format (no FAT32).

The HDSC format is not supported.

Preparation

Copy all files from the directory

"Firmware\...\Memory Card Image"

including the file STARTUP.INI and the directory BACKUP and all

subdirectories onto an empty micro SD card to the card's root directory.

Procedure

1. Have the SD card ready with the copied image

2. Power down the PC with the slot PLC inserted. If used, switch off the

external power supply.

3. Insert the card into the SD card slot till it clicks into place

4. Re-Power the PC

The device loads the base firmware and indicates this by the following

states of the SYS LED: Fast change between green and yellow (fo

r

appr. 8 s), then yellow on (for appr. 10 s), then off for a short moment

and finally it turns to green on.

The device then has factory settings.

5. Remove the SD card from the SD card slot

Page 31

Appendix 31/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

10.2 Update Firmware

This section describes how the firmware of the slot PLC is updated.

1. Exit programs

Exit all programs that access to the slot PLC.

2. Open from the control panel the cifX Setup Program

Open the Control Panel with Start > Control Panel

open the program cifX Setup with a double click on the cifX Setup

symbol

The cifx Driver Setup Program is started

Page 32

Appendix 32/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

3. Select CH#0

Select in the Device List tree under Active Devices at cifX (cifX0,

cifX1, …) entry CH#0.

4. Select firmware file

Open in the area Assigned Module/Firmware Files

with a click on

Add

the windows for the firmware file selection

Select the firmware file for the NPLC-C100 as listed in the document

“software installation” of the used PLC type.

Page 33

Appendix 33/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

5. Provide firmware file for download

Click on Open

The firmware file is shown below Assigned Module/Firmware Files

6. Start firmware download

Click on Apply.

Answer the question

with Yes to start the firmware download.

The firmware file is loaded into the slot PLC

7 Reset of the slot PLC NPLC-C100

The slot PLC NPLC-C100 requires a reset.

Therefore shut down and power down the PC

If the external power supply is used, then switch off or disconnect the

external power supply from the slot PLC NPLC-C100.

Switch on the PC and if required switch on the external power supply.

The slot PLC NPLC-C100 does a reset.

Page 34

Appendix 34/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

10.3 Battery Disposal

Important note from the European Directive 2006/66/EC on waste

accumulators and batteries:

Important: Batteries are not allowed to be thrown into the domestic

refuse. As a end user you are legally bound to return batteries to collecting

points or back to their origin.

Products containing batteries are marked with a crossed wheelie bin

symbol:

Figure 3: Labeling Batteries

Beneath the symbol you will find also a chemical symbol added for a

particular metal if the battery contains more than a specific percentage of it.

The chemical symbols Cd stands for Cadmium, Hg for mercury and Pb for

lead. Those are pollutants the environment never shall be contaminated

with.

10.4 Disposal of Waste Electronic Equipment

According to the European Directive 2002/96/EG “Waste Electrical and

Electronic Equipment (WEEE)”, waste electronic equipment may not be

disposed of as household waste. As a consumer, you are legally obliged to

dispose of all waste electronic equipment according to national and local

regulations.

Waste Electronic Equipment

This product must not be treated as household waste.

This product must be disposed of at a designated waste electronic

equipment collecting point.

Page 35

Appendix 35/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

10.5 List of Figures

Figure 1: Device Drawing NPLC-C100-xx 16

Figure 2: NPLC-C100-xx Block Diagram 21

Figure 3: Labeling Batteries 34

10.6 List of Tables

Table 1: List of Revisions 4

Table 2: Reference to Hardware 5

Table 3: Reference to Product Variant 5

Table 4: Reference to Driver 5

Table 5: Slot PLC NPLC-C100 and Fieldbus Systems realized thereby 10

Table 6: Safety Symbols and Sort of Warning or Principle 12

Table 7: Signal Words 12

Table 8: Requirements for Operation of the Slot PLC 15

Table 9: Designation in the Device Drawing NPLC-C100-xx 16

Table 10: Designation for the Cover of NPLC-C100-xx 17

Table 11: RUN/STOP Switch 22

Table 12: CANopen Pin Assignment 23

Table 13: DeviceNet Pin Assignment 23

Table 14: PROFIBUS RS-485 Pin Assignment 24

Table 15: Technical Data Slot PLC 29

Table 16: Technical Data NPLC-C100-xx 29

Page 36

Appendix 36/36

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

10.7 Contacts

Headquarters

Germany

Hilscher Gesellschaft für

Systemautomation mbH

Rheinstrasse 15

65795 Hattersheim

Phone: +49 (0) 6190 9907-0

Fax: +49 (0) 6190 9907-50

E-Mail: info@hilscher.com

Support

Phone: +49 (0) 6190 9907-99

E-Mail: de.support@hilscher.com

Subsidiaries

China

Hilscher Systemautomation (Shanghai) Co. Ltd.

200010 Shanghai

Phone: +86 (0) 21-6355-5161

E-Mail: info@hilscher.cn

Support

Phone: +86 (0) 21-6355-5161

E-Mail: cn.support@hilscher.com

France

Hilscher France S.a.r.l.

69500 Bron

Phone: +33 (0) 4 72 37 98 40

E-Mail: info@hilscher.fr

Support

Phone: +33 (0) 4 72 37 98 40

E-Mail: fr.support@hilscher.com

India

Hilscher India Pvt. Ltd.

New Delhi - 110 065

Phone: +91 11 26915430

E-Mail: info@hilscher.in

Italy

Hilscher Italia S.r.l.

20090 Vimodrone (MI)

Phone: +39 02 25007068

E-Mail: info@hilscher.it

Support

Phone: +39 02 25007068

E-Mail: it.support@hilscher.com

Japan

Hilscher Japan KK

Tokyo, 160-0022

Phone: +81 (0) 3-5362-0521

E-Mail: info@hilscher.jp

Support

Phone: +81 (0) 3-5362-0521

E-Mail: jp.support@hilscher.com

Korea

Hilscher Korea Inc.

Seongnam, Gyeonggi, 463-400

Phone: +82 (0) 31-789-3715

E-Mail: info@hilscher.kr

Switzerland

Hilscher Swiss GmbH

4500 Solothurn

Phone: +41 (0) 32 623 6633

E-Mail: info@hilscher.ch

Support

Phone: +49 (0) 6190 9907-99

E-Mail: ch.support@hilscher.com

USA

Hilscher North America, Inc.

Lisle, IL 60532

Phone: +1 630-505-5301

E-Mail: info@hilscher.us

Support

Phone: +1 630-505-5301

E-Mail: us.support@hilscher.com

Loading...

Loading...