Page 1

User Manual

SmartWire-DT Gateway

EU5C-SWD-POWERLINK

Hilscher Gesellschaft für Systemautomation mbH

www.hilscher.com

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public

Page 2

Table of Contents 2/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

Table of Contents

1 INTRODUCTION.........................................................................................................5

1.1 About This Manual......................................................................................................5

1.1.1 List of Revisions ...................................................................................................5

1.1.2 Conventions in this Manual ..................................................................................6

1.2 Versions of Devices, Firmware, Software Tools, Drivers and Device Description File

....................................................................................................................................7

1.3 Software Package.......................................................................................................8

1.3.1 Contents of the Product DVD ...............................................................................8

1.3.2 How to Use the Product DVD.............................................................................10

1.3.3 Notes on Installing the USB Driver.....................................................................11

1.4 Documentation Overview..........................................................................................12

1.5 Legal Notes...............................................................................................................13

1.5.1 Copyright ............................................................................................................13

1.5.2 Important Notes ..................................................................................................13

1.5.3 Exclusion of Liability ...........................................................................................14

1.5.4 Warranty .............................................................................................................14

1.5.5 Export Regulations .............................................................................................15

1.5.6 Trademarks ........................................................................................................15

2 SAFETY ....................................................................................................................16

2.1 General Note ............................................................................................................16

2.2 Intended Use ............................................................................................................16

2.3 Personnel Qualification.............................................................................................16

2.4 References Safety ....................................................................................................16

2.5 Safety Instructions to Avoid Personal Injury .............................................................17

2.5.1 Electrical Shock Hazard .....................................................................................17

2.5.2 Danger of Unintended Starting Up of Machines.................................................17

2.6 Safety Instructions to Avoid Property Damage .........................................................18

2.6.1 General Safety Instructions Concerning Supply Voltage ...................................18

2.6.2 Device Destruction by Exceeding Allowed Supply Voltage................................18

2.6.3 Electrostatic Sensitive Device ............................................................................19

2.7 Labeling of Safety Messages....................................................................................20

3 DESCRIPTIONS AND REQUIREMENTS .................................................................21

3.1 Device Description EU5C-SWD-POWERLINK Gateway..........................................21

3.1.1 Function..............................................................................................................21

3.1.2 Configuration ......................................................................................................22

3.1.3 Interfaces............................................................................................................24

3.1.4 Diagnosis............................................................................................................24

3.1.5 Firmware and Device Description File................................................................24

3.2 Prerequisites for Operation.......................................................................................25

Page 3

Table of Contents 3/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

3.2.1 Network Systems................................................................................................25

3.2.2 Power Supply .....................................................................................................25

4 DEVICE PICTURE, CONNECTORS AND LEDS ......................................................27

4.1 Device Picture...........................................................................................................27

4.2 Positions and Meaning of the LEDs..........................................................................28

4.2.1 Positions of the LEDs .........................................................................................28

4.2.2 Descriptions of the LEDs....................................................................................29

4.3 Pinning POWERLINK Interface ................................................................................31

4.4 Device Type Label ....................................................................................................32

5 GETTING STARTED................................................................................................. 33

6 INSTALLING GATEW

AY...........................................................................................34

6.1 Safety Messages ......................................................................................................34

6.2 Mounting Gateway....................................................................................................35

6.2.1 Mounting Gateway onto Top Hat Rail ................................................................35

6.2.2 Removing Gateway from Top Hat Rail...............................................................37

6.3 Connecting Gateway to Power Supply .....................................................................38

6.4 Connecting SmartWire-DT........................................................................................40

6.5 Connecting POWERLINK .........................................................................................41

6.6 EMC-Conformant Wiring of the Network ..................................................................41

7 CONFIGURING GATEWAY ...................................................................................... 42

7.1 Configuring SmartWire-DT network in Gateway (Creating Target Configuration) ....42

7.2 Installing SWD-Assist and USB Driver on Configuration PC ....................................44

7.3 Connecting Gateway to Configuration PC via USB ..................................................46

7.4 Configuring Gateway in SWD-Assist (Creating Project Configuration).....................47

8 CONFIGURING GATEWAY IN POWERLINK ........................................................... 53

9 POWERLINK DATA COMMUNICATION

..................................................................58

9.1 Acyclical Communication..........................................................................................58

9.1.1 SDO Write (Acyclic Output)................................................................................58

9.1.2 SDO Read (Acyclic Input) ..................................................................................60

9.2 Diagnosis/Status Response......................................................................................61

10 UPDATING FIRMWARE ...........................................................................................62

10.1 Overview...................................................................................................................62

10.2 IP Address of Gateway.............................................................................................62

10.3 Prerequisites.............................................................................................................64

10.4 Step-by-Step Instructions for Updating Firmware.....................................................64

10.5 Resetting Gateway ...................................................................................................66

Page 4

Table of Contents 4/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

11 TECHNICAL DATA ...................................................................................................67

11.1 Technical Data EU5C-SWD-POWERLINK Gateway................................................67

11.2 Technical Data POWERLINK Controlled Node ........................................................69

12 ANNEX......................................................................................................................70

12.1 List of Figures ...........................................................................................................70

12.2 List of Tables ............................................................................................................71

12.3 Contacts....................................................................................................................72

Page 5

Introduction 5/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1 Introduction

1.1 About This Manual

This manual describes the Hilscher EU5C-SWD-POWERLINK

SmartWire-DT Gateway. Here you will find information on how to install,

configure and operate the gateway.

This manual is intended for automation technicians and engineers. Detailed

knowledge of Ethernet POWERLINK is presumed. In addition, readers

should also be familiar with the handling of the SmartWire-DT system.

IMPORTANT!

To avoid personal injuries or damage of electrical devices, please read

this manual carefully before installing and using the EU5C-SWDPOWERLINK Gateway.

Please first read the Safety chapter on page 16 ff.

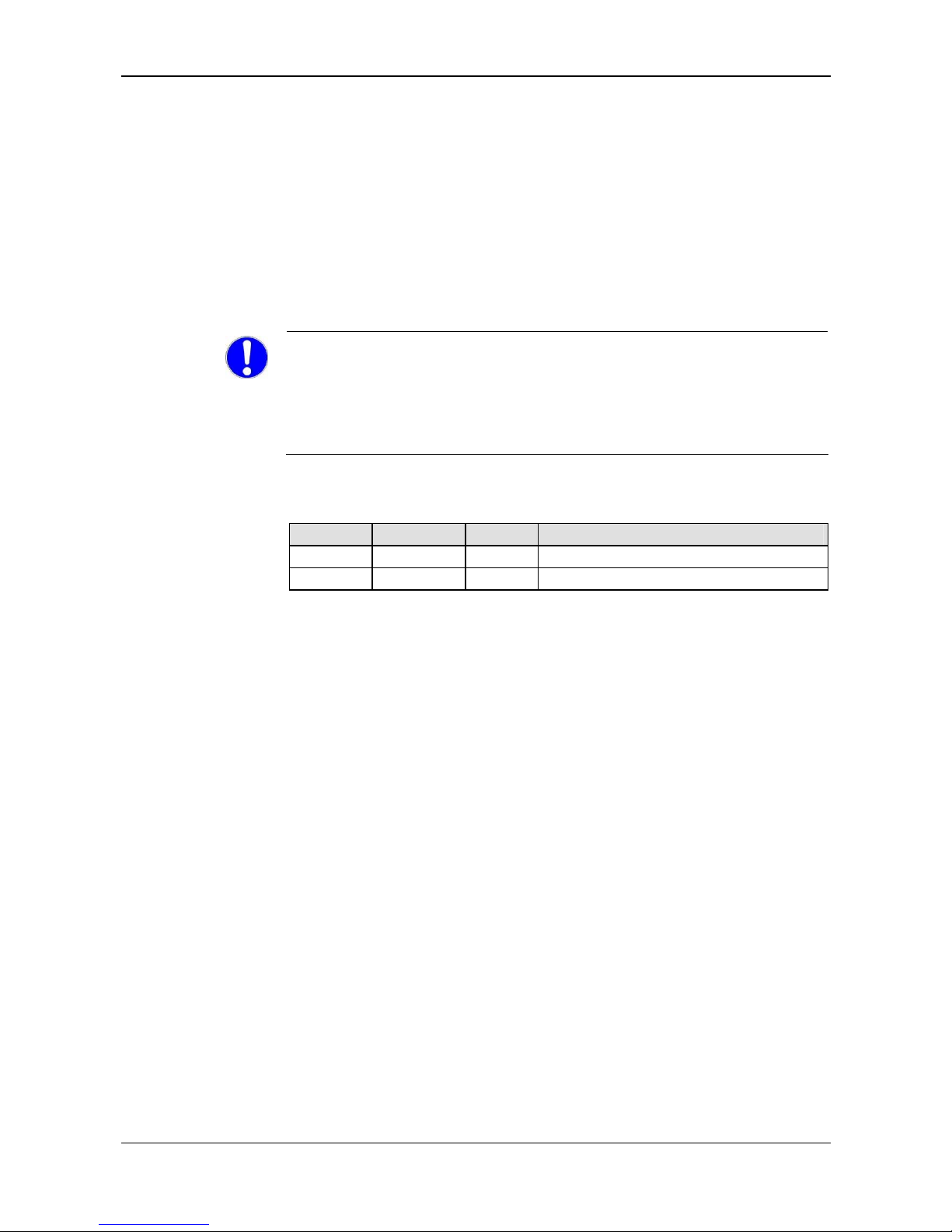

1.1.1 List of Revisions

Revision Date Chapter Revisions

1 2013-10-15 All Created

2 2013-12-09 9.2 Section Diagnosis/Status Response revised.

Table 1: List of Revisions

Page 6

Introduction 6/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.1.2 Conventions in this Manual

Notes, operation instructions and results of operation steps are marked as

follows:

Notes

Important: <important note>

Note: <note>

<note, where to find further information>

Operation Instructions

1. <instruction>

2. <instruction>

or

<instruction>

Results

<result>

For a description of the labeling of Safety Messages, see Labeling of

Safety Messages sect

ion on page 20.

Page 7

Introduction 7/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.2 Versions of Devices, Firmware, Software Tools, Drivers

and Device Description File

The hardware revisions and software versions functionally belong together.

This means that certain revisions of the hardware of the gateway need

certain versions of firmware, software and drivers, in order to function

properly.

This section lists the hardware revisions and the versions of the firmware,

the configuration software and the drivers which functionally belong

together and to which all instructions in this manual refer.

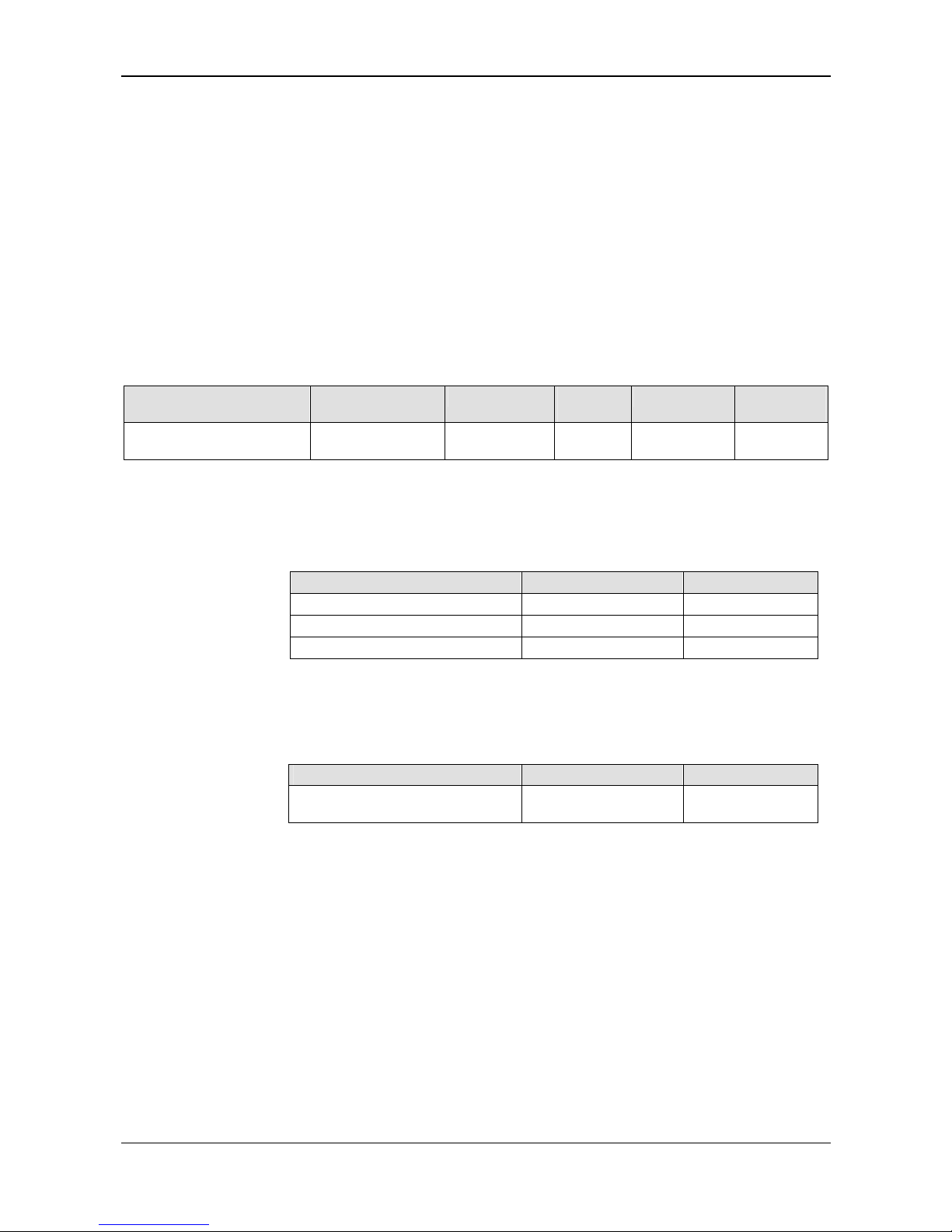

Device and Firmware

This manual refers to the following hardware revision and firmware version

of the EU5C-SWD-POWERLINK Gateway:

Device type name Protocol Part number

Hardware

revision

Firmware

Firmware

version

EU5C-SWD-POWERLINK

POWERLINK

Controlled Node

9233.921 3 E030K0U0.nxf 1.0.x.x

Table 2: Reference to Hardware and Firmware

Software Tools

This manual refers to the following software versions:

Software Manufacturer Version

Ethernet Device Configuration Tool Hilscher 1.501

Automation Studio Bernecker + Rainer 3.0.90

SWD-Assist Eaton 1.90

Table 3: Reference to Software Tools

Drivers

This manual refers to the following driver versions:

Driver File name Version

Windows USB Driver usbser.sys

Depending on

Windows version

Table 4: Reference to Drivers

Page 8

Introduction 8/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.3 Software Package

You need the SWD-Assist software in order to configure the EU5C-SWDPOWERLINK gateway.

The software can be ordered separately from Hilscher under the product

name EU5C-SWD-SW (order number 3233.920). The package contains the

SmartWire-DT Gateway Solutions product DVD and a Mini-USB cable.

You can download the contents of the product DVD as ZIP file free of

charge from our website www.hilscher.com

under Products > Gateways or

under Support > Downloads.

1.3.1 Contents of the Product DVD

There is one product DVD, which can be used for several types of

gateways.

The SmartWire-DT Gateway Solutions product DVD includes:

Device description files

Note: A device description file for the EU5C-SWD-POWERLINK Gateway

is not provided on the product DVD. The project-specific XDD device

description file for the POWERLINK-Gateway has to be generated by the

SWD-Assist software.

Firmware

Eaton SWD-Assist software

Wizard for installing the software available on the DVD and for

downloading the latest version of the SWD-Assist software from the

internet

Installation program for USB driver (USB driver is needed for connecting

the gateway to a PC in order to use the Eaton SWD-Assist software)

Installation program for the Hilscher Ethernet Device Configuration Tool

Documentation in PDF format

Installation program for Adobe Reader

Page 9

Introduction 9/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

The product DVD has the following directories:

Directory Contents

Documentation PDF manuals in German and English and installation program for Adobe Reader

Driver

Folder containing installation program (setup.exe) and .INF- and .CAT- files for

Windows USB driver.

EDS

Electronic device description files and bitmaps, to be imported directly into

Master/Controller configuration software.

Note: The device description file for the EU5C-SWD-POWERLINK Gateway has to be

generated by the SWD-Assist software.

Firmware Loadable gateway firmware

fscommand Files for start screen of product DVD

Software

SWD-Assist software

Folder: Software\SWD-Assist

Wizard for installing the software available on the DVD and for downloading the latest

version of the SWD-Assist software from the internet

Folder: Software\Setup

Installation program for Ethernet Device Configuration Tool

Folder: Software\EnDeviceCfg

Table 5: Directory of DVD

Note: You can use the wizard on the product DVD to download updates of

the Eaton SWD-Assist software, or you can download SWD-Assist directly

from the www.moeller.net website under Support > Download Center.

Direct link:

http://downloadcenter.moeller.net/en/software.a487d8b7-da91-486f-b3ba-a7ca2035db99

You can download other content stored on the DVD from the Hilscher

website

www.hilscher.com under Support > Downloads.

Page 10

Introduction 10/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.3.2 How to Use the Product DVD

Insert the SmartWire-DT Gateway Solutions product DVD into the DVD

drive of your configuration PC.

If the auto start function of your DVD drive is enabled, the start screen of

the DVD automatically opens. You can also start the DVD by doubleclicking the SmartWire.exe file in the root directory of the DVD.

In the menu of the start screen of the DVD, click Install Planning and

Configuration Tools to open a wizard for installing the software programs

stored on the DVD. The wizard also helps you to download the latest

version of the Eaton planning software SWD-Assist from the internet. It

automatically checks for already installed software components (which e. g.

might have been installed for an earlier project), and lists the missing

components accordingly. The following options might be offered:

USB driver: installs USB driver for Windows on your PC.

SWD Planning Software SWD-Assist V1.90: installs version 1.90 of

the SWD-Assist software (provided on the DVD) on your PC.

Download Center SWD-Assist, manual update check: connects your

browser to a web page where you can download the latest version of the

SWD-Assist software.

Ethernet Device Scanner/Configuration Tool: installs the Hilscher

Ethernet Device Configuration Tool on your PC.

PROFINET GSDML File: opens a link to the device description file of

the EU5C-SWD-PROFINET gateway.

Note: A device description file for the EU5C-SWD-POWERLINK Gateway

is not provided on the product DVD. The device description file for the

POWERLINK gateway has to be generated by the SWD-Assist software

specifically for the project.

In the menu of the start screen of the DVD, you can also open folders

(directories) in which the documentation, the USB driver and the GSDML

file are stored.

Page 11

Introduction 11/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.3.3 Notes on Installing the USB Driver

Before you connect the EU5C-SWD-POWERLINK Gateway via USB to

your configuration PC (in order to use the SWD-Assist software), you

should first install the USB driver on your PC.

To install the USB driver from the DVD, choose Install Planning and

Configuration Tools in the DVD menu to open the installation wizard, and

then select the USB driver option. As an alternative, you can use the

Windows Explorer to open the Driver\USB\Windows folder on the DVD,

and then double-click the setup.exe file. Just follow the instructions of the

installation routine afterwards.

Note: Under Windows XP, the installation process is not yet finished by

the setup. The installation process has to be completed in the Found new

Hardware Wizard, which automatically opens when you connect the

gateway to a PC via USB cable for the first time (see below).

Windows XP

When you connect the gateway via USB for the first time to a PC running

under Windows XP, the Found New Hardware Wizard opens:

Answer the question Can Windows connect to Windows Update…?,

with No, not this time. Then click Next button.

If you have already carried out the setup of the USB driver (as

recommended), you can ignore the wizard’s request to insert a CD or

floppy disk. Answer the What do you want the wizard to do? question

by selecting the Install the software automatically option, then click

Next button.

After the installation is complete, click Finish button.

Windows 7 and 8

If you have carried out the setup of the USB driver before first connecting

the USB cable (as recommended), then the USB connection is instantly

operative under Windows 7 and 8.

Uninstall USB Driver

If you want to remove the USB driver from a PC running under Windows

XP, choose Start menu > Control Panel > Add or Remove Programs,

then select:

Windows Driver Package – Hilscher GmbH (hilusbser) Ports entry.

Click Change/Remove button to uninstall the driver.

Under Windows 7 and 8, choose Start menu > Control Panel > Uninstall

a program, then select:

Windows Driver Package – Hilscher GmbH (hilusbser) Ports entry.

Click Uninstall/Change button to uninstall the driver.

Page 12

Introduction 12/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.4 Documentation Overview

Besides this user manual at hand (path on product DVD:

Documentation\english\2. Hardware\EU5C-SWD-POWERLINK UM

01 EN.pdf), the following documents are also relevant for the user of the

EU5C-SWD-POWERLINK Gateway:

Title Contents Publisher Document ID Path on product DVD

SmartWire-DT

Units

Information on engineering,

installation and

programming of the

individual SmartWire-DT

slaves.

Eaton

05/11

MN05006001Z-EN

Documentation\english\

3.SmartWireDT\SmartWire-DT – Units\

MN05006001Z_EN.pdf

SmartWire-DT

The System

Information on function,

installation, commissioning

and diagnostics of the

SmartWire-DT system.

Eaton

02/11

MN05006002Z-EN

Documentation\english\

3.SmartWireDT\SmartWire-DT - The

System\

MN05006002Z_EN.pdf

Ethernet Device

Configuration

Operating Instruction

Manual of Hilscher Ethernet

Device Configuration Tool.

Hilscher

DOC050402OIxxEN Documentation\english\

1.Software\Ethernet

Device Setup Utility\

Ethernet Device

Configuration OI xx

EN.pdf

SWD-Assist

Online help

Online help for SWD-Assist

planning software

Eaton - Included in SWD-Assist software

B&R Help

Explorer –

Automation

Studio

Online help for Automation

Studio software

Bernecker

+ Rainer

-

Included in Automation Studio

software

Table 6: Documentation Overview

Page 13

Introduction 13/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.5 Legal Notes

1.5.1 Copyright

© Hilscher 2013, Hilscher Gesellschaft für Systemautomation mbH

All rights reserved.

The images, photographs and texts in the accompanying material (user

manual, accompanying texts, documentation, etc.) are protected by

German and international copyright law as well as international trade and

protection provisions. You are not authorized to duplicate these in whole or

in part using technical or mechanical methods (printing, photocopying or

other methods), to manipulate or transfer using electronic systems without

prior written consent. You are not permitted to make changes to copyright

notices, markings, trademarks or ownership declarations. The included

diagrams do not take the patent situation into account. The company

names and product descriptions included in this document may be

trademarks or brands of the respective owners and may be trademarked or

patented. Any form of further use requires the explicit consent of the

respective rights owner.

1.5.2 Important Notes

The user manual, accompanying texts and the documentation were created

for the use of the products by qualified experts, however, errors cannot be

ruled out. For this reason, no guarantee can be made and neither juristic

responsibility for erroneous information nor any liability can be assumed.

Descriptions, accompanying texts and documentation included in the user

manual do not present a guarantee nor any information about proper use

as stipulated in the contract or a warranted feature. It cannot be ruled out

that the user manual, the accompanying texts and the documentation do

not correspond exactly to the described features, standards or other data of

the delivered product. No warranty or guarantee regarding the correctness

or accuracy of the information is assumed.

We reserve the right to change our products and their specification as well

as related user manuals, accompanying texts and documentation at all

times and without advance notice, without obligation to report the change.

Changes will be included in future manuals and do not constitute any

obligations. There is no entitlement to revisions of delivered documents.

The manual delivered with the product applies.

Hilscher Gesellschaft für Systemautomation mbH is not liable under any

circumstances for direct, indirect, incidental or follow-on damage or loss of

earnings resulting from the use of the information contained in this

publication.

Page 14

Introduction 14/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.5.3 Exclusion of Liability

The software was produced and tested with utmost care by Hilscher

Gesellschaft für Systemautomation mbH and is made available as is. No

warranty can be assumed for the performance and flawlessness of the

software for all usage conditions and cases and for the results produced

when utilized by the user. Liability for any damages that may result from the

use of the hardware or software or related documents, is limited to cases of

intent or grossly negligent violation of significant contractual obligations.

Indemnity claims for the violation of significant contractual obligations are

limited to damages that are foreseeable and typical for this type of contract.

It is strictly prohibited to use the software in the following areas:

for military purposes or in weapon systems;

for the design, construction, maintenance or operation of nuclear

facilities;

in air traffic control systems, air traffic or air traffic communication

systems;

in life support systems;

in systems in which failures in the software could lead to personal injury

or injuries leading to death.

We inform you that the software was not developed for use in dangerous

environments requiring fail-proof control mechanisms. Use of the software

in such an environment occurs at your own risk. No liability is assumed for

damages or losses due to unauthorized use.

1.5.4 Warranty

Although the hardware and software was developed with utmost care and

tested intensively, Hilscher Gesellschaft für Systemautomation mbH does

not guarantee its suitability for any purpose not confirmed in writing. It

cannot be guaranteed that the hardware and software will meet your

requirements, that the use of the software operates without interruption and

that the software is free of errors. No guarantee is made regarding

infringements, violations of patents, rights of ownership or the freedom from

interference by third parties. No additional guarantees or assurances are

made regarding marketability, freedom of defect of title, integration or

usability for certain purposes unless they are required in accordance with

the law and cannot be limited. Warranty claims are limited to the right to

claim rectification.

Page 15

Introduction 15/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

1.5.5 Export Regulations

The delivered product (including the technical data) is subject to export or

import laws as well as the associated regulations of different counters, in

particular those of Germany and the USA. The software may not be

exported to countries where this is prohibited by the United States Export

Administration Act and its additional provisions. You are obligated to

comply with the regulations at your personal responsibility. We wish to

inform you that you may require permission from state authorities to export,

re-export or import the product.

1.5.6 Trademarks

SmartWire-DT® is a registered trademark of Eaton Corporation.

Windows

®

XP, Windows® 7 and Windows® 8 are registered trademarks of

the Microsoft Corporation.

Adobe-Acrobat

®

is a registered trademark of Adobe Systems Incorporated.

Ethernet POWERLINK and B & R Automation Studio are trademarks of

B&R, Bernecker + Rainer Industrie-Elektronik Ges.m.b.H, Eggelsberg,

Austria.

All other mentioned trademarks are property of their respective legal

owners.

Page 16

Safety 16/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

2 Safety

2.1 General Note

The user manual, all accompanying texts and the documentation are

written for the use of the products by educated personnel. When using the

products, all safety instructions, property damage messages and all valid

legal regulations have to be observed. Technical knowledge is presumed.

The user has to assure that all legal regulations are obeyed.

2.2 Intended Use

The purpose of the EU5C-SWD-POWERLINK Gateway described in this

user manual is to create a connection between SmartWire-DT slaves and

an overriding Managing Node (master device) in an Ethernet POWERLINK

network.

2.3 Personnel Qualification

The EU5C-SWD-POWERLINK Gateway must be installed, configured and

removed by qualified personnel only. Job-specific technical skills for people

professionally working with electricity must be present concerning the

following issues:

Safety and health at work

Mounting and connecting of electrical equipment

Measurement and analysis of electrical functions and systems

Evaluation of the safety of electrical systems and equipment

Installing and configuring IT systems

2.4 References Safety

[S1]

ANSI Z535.6-2006 American National Standard for Product Safety Information in

Product Manuals, Instructions, and Other Collateral Materials

[S2]

IEC 60950-1, Information technology equipment - Safety -

Part 1: General requirements,

(IEC 60950-1:2005, modified); German Edition EN 60950-1:2006

[S3] EN 61340-5-1 and EN 61340-5-2 as well as IEC 61340-5-1 and IEC 61340-5-2

Page 17

Safety 17/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

2.5 Safety Instructions to Avoid Personal Injury

To ensure your own personal safety and to avoid personal injury, you must

read, understand and follow the following safety instructions in this manual

and all warning messages before you install and operate the EU5C-SWDPOWERLINK Gateway.

2.5.1 Electrical Shock Hazard

Take care of the following safety measures before installing or uninstalling

the gateway:

First disconnect the power plug of the device.

Make sure that the device is disconnected from the power supply.

Cover or enclose neighboring units that are live.

Devices that are designed for mounting in housings or control cabinets

must only be operated and controlled after they have been installed with

the housing closed. Desktop or portable units must only be operated and

controlled in enclosed housings.

2.5.2 Danger of Unintended Starting Up of Machines

Install automation devices and related operating elements in such a way

that they are well protected against unintentional operation.

Emergency stop devices complying with IEC/EN 60204-1 must be

effective in all operating modes of the automation devices. Unlatching

the emergency-stop devices must not cause restart.

You must take safety precautions (emergency switching off) in the

external circuitry of the EU5C-SWD-POWERLINK and any power

modules type EU5C-SWD-PF1-1 or EU5C-SWDPF2-1 that are used. To

do so, plan to switch off the power supply to the contactor coils AUX.

Measures should be taken to ensure the proper restart of programs

interrupted after a voltage dip or failure. This should not cause

dangerous operating states even for a short time. If necessary,

emergency stop devices should be implemented.

Wherever faults in the automation system may cause damage to

persons or property, external measures must be implemented to ensure

a safe operating state in the event of a fault or malfunction (for example,

by means of separate limit switches, mechanical interlocks etc.).

Page 18

Safety 18/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

2.6 Safety Instructions to Avoid Property Damage

To avoid damage to your EU5C-SWD-POWERLINK Gateway or your

communication system, you must read, understand and follow the following

safety instructions and all safety instructions and warnings in this manual

concerning property damage, before you install and operate the gateway.

2.6.1 General Safety Instructions Concerning Supply Voltage

In safety-relevant applications the power supply providing power to the

SmartWire-DT system must feature a PELV power feed module

(protective extra low voltage).

Switch off the power supply if you are reconnecting slaves in the

SmartWire-DT system or reconnecting the ribbon cable connection.

Otherwise the SmartWire-DT slaves can be destroyed!

The gateway has protection against polarity reversal for the 24-V-DC-

POW supply. However, if the gateway is connected via the serial

interface to an earthed device (for example to a PC), the gateway can be

destroyed, if the polarity of the power supply is reversed!

The functional earth (FE) must be connected to the protective earth (PE)

or to the potential equalization. The system installer is responsible for

implementing this connection.

Connecting cables and signal lines should be installed so that inductive

or capacitive interference does not impair the automation functions.

Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire breakage on the

signal side does not result in undefined states in the automation devices.

2.6.2 Device Destruction by Exceeding Allowed Supply Voltage

The EU5C-SWD-POWERLINK Gateway must only be operated with the

specified supply voltage.

Make sure that the limits of the allowed range for the supply voltage are

not exceeded. A supply voltage above the upper limit can cause severe

damage of the gateway!

A supply voltage below the lower limit can cause malfunction of the

gateway!

Ensure a reliable electrical isolation of the low voltage for the 24 volt

supply. Only use power supply units complying with IEC 60364-4-41

(VDE 0100 Part 410) or HD 384.4.41 S2.

The allowed range for the supply voltage is indicated in the Technical Data

EU5C-SW

D-POWERLINK Gateway section on page 67.

Page 19

Safety 19/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

2.6.3 Electrostatic Sensitive Device

The EU5C-SWD-POWERLINK Gateway is sensitive to electrostatic

discharge, which can cause internal damage and affect its normal

operation. Therefore adhere to the necessary safety precautions for

components that are vulnerable to electrostatic discharge when you install

or remove the gateway. Follow the guidelines listed hereafter when you

handle the gateway:

Touch a grounded object to discharge potential static before you handle

the gateway.

Wear an approved grounding wrist strap.

If possible, use a static-safe workstation.

When not in use, store the device in appropriate static-safe packaging.

Page 20

Safety 20/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

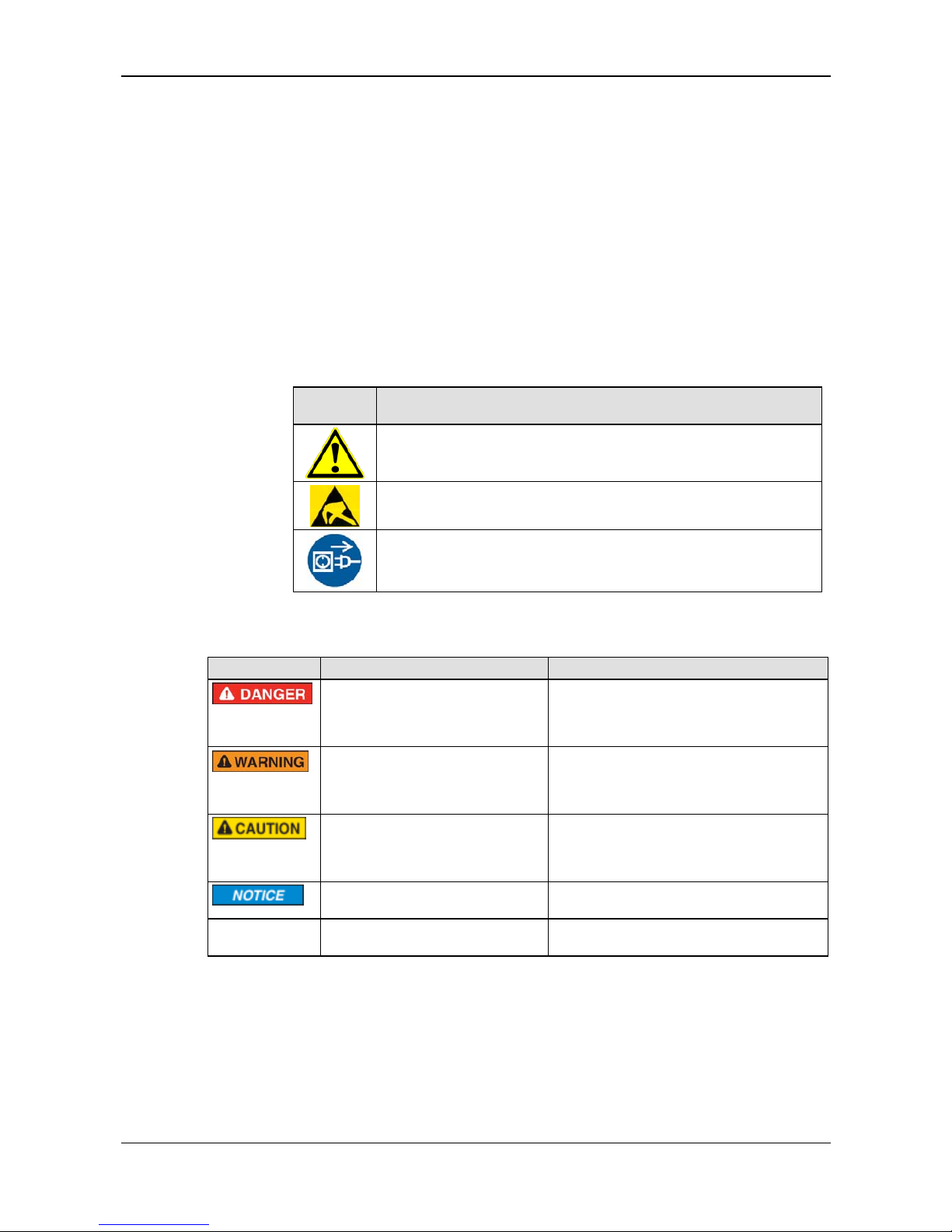

2.7 Labeling of Safety Messages

In this document, the safety instructions and property damage messages

are designed according both to the internationally used safety conventions

as well as to the ANSI Z535 standard.

The Section Safety Messages at the beginning of a chapter are

pinpointed particularly. They are highlighted by a specific safety symbol

and a signal word according to the degree of endangerment. In the

safety message, the nature of the hazard is indicated.

The Integrated Safety Messages embedded in operating instructions

are highlighted by a signal word according to the degree of

endangerment and possibly by a safety symbol. In the safety message,

the nature of the hazard is indicated.

Safety

symbol

Sort of warning or principle

Warning of personal injury or property damage

Warning of damages by electrostatic discharge

Principle: Disconnect the power plug

Table 7: Safety Symbols and Sort of Warning or Principle

Signal word Meaning Meaning USA

Indicates a direct hazard with high

risk, which will have as consequence

death or grievous bodily harm if it is

not avoided.

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a possible hazard with

medium risk, which will have as

consequence death or (grievous)

bodily harm if it is not avoided.

Indicates a hazardous situation which, if not

avoided, could result in death or serious

injury.

Indicates a minor hazard with

medium risk, which could have as

consequence personal injury, if it is

not avoided.

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate

injury.

Indicates a property damage

message.

Indicates a property damage message.

Note Indicates an important note in the

manual.

Indicates an important note in the manual.

Table 8: Signal Words

Page 21

Descriptions and Requirements 21/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

3 Descriptions and Requirements

3.1 Device Description EU5C-SWD-POWERLINK Gateway

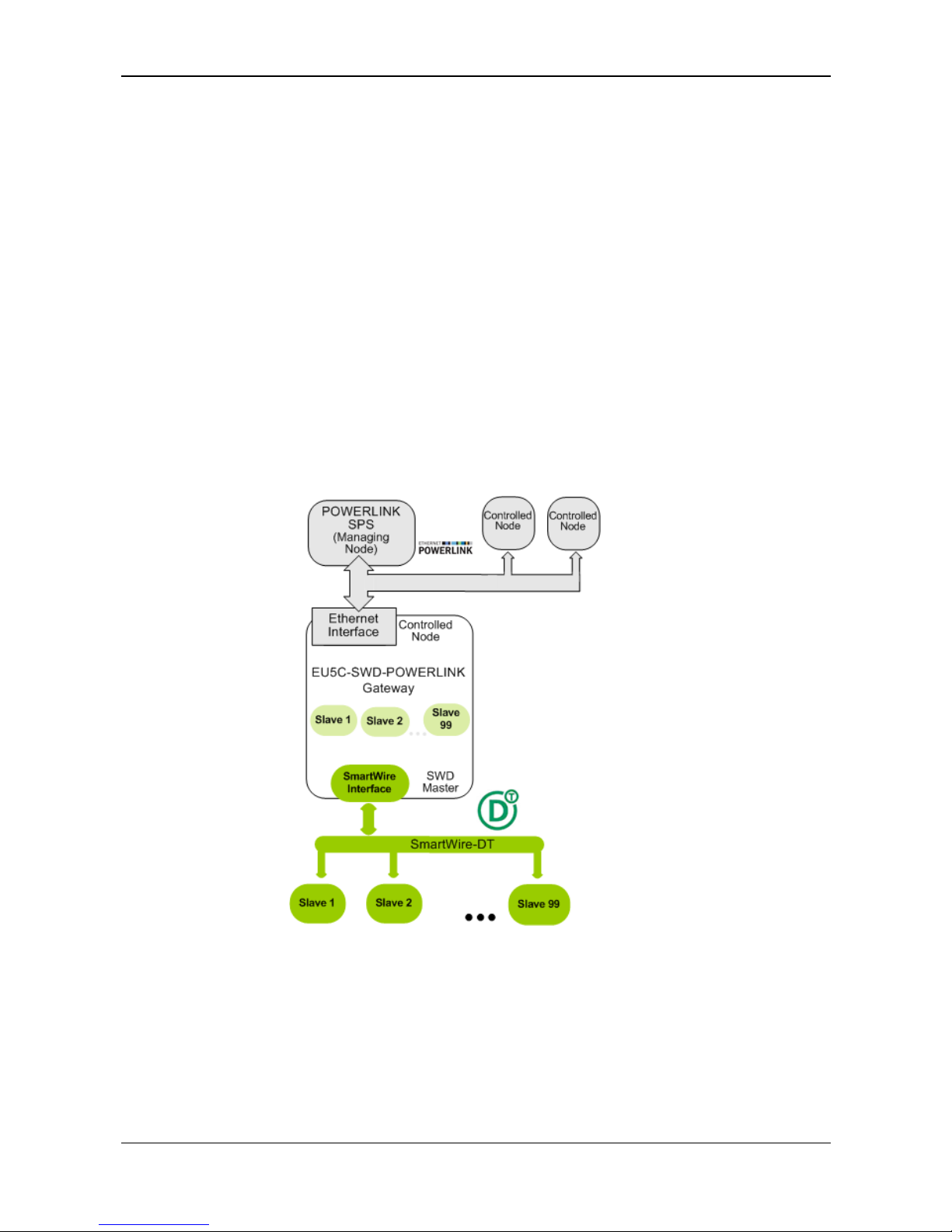

3.1.1 Function

The EU5C-SWD-POWERLINK Gateway integrates a SmartWire-DT

network into an Ethernet POWERLINK network. The Gateway creates a

data connection between the participants (the slave devices) of the

subordinate SmartWire-DT network and the Managing Node (the master

device or PLC) of the super ordinate POWERLINK network.

The gateway acts as master in the SmartWire-DT network on the one hand,

and on the other hand as modular Controlled Node (slave device) in the

POWERLINK network. It thereby presents each connected SmartWire-DT

participant as individual module to the POWERLINK Managing Node.

The cyclic process data is exchanged transparently between both

networks. 1000 Bytes of process input/output data can in sum be

exchanged with up to 99 SmartWire-DT participants (slaves).

Figure 1: Data Flow EU5C-SWD-POWERLINK Gateway

Page 22

Descriptions and Requirements 22/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

3.1.2 Configuration

There are three types of configurations that are relevant for commissioning

and operating the EU5C-SWD-POWERLINK gateway.

The actual configuration is the current actual constellation of the devices

at the SmartWire-DT bus connected to the SmartWire-DT interface of the

gateway. It is always scanned after each restart of the gateway. This

procedure can not be influenced.

In case the actual configuration complies with the configuration envisaged

for operation, the actual configuration can be captured as target

configuration and stored zero-voltage safe in the device. This capturing

and storing of the actual configuration as target configuration can be

achieved either by pressing the configuration button located at the front

panel of the gateway or by using the SWD-Assist software (for the position

of the configuration button, see Device Picture se

ction on page 27).

This target configuration is then available within the gateway even after

power-off or restart of the device. If a target configuration has been stored,

the gateway checks on each restart whether the actual configuration

complies with the target configuration. In case the gateway detects

inadmissible deviations, it will not go into operation. If the actual

configuration deviates from the target configuration because of a device

failure or removal on the SWD bus, the SWD LED on the gateway starts to

blink red (for the position of the SWD LED, see Positions of the LEDs

section on p

age 28).

If no errors are detected

, the gateway is in principle ready for operation, but

remains in waiting until the so-called planned configuration is downloaded

to the gateway via the SWD-Assist software.

Without a target configuration, the gateway will not go into operation. The

target configuration therefore has to be generated

when you commission the gateway for the first time,

after replacing a SmartWire-DT slave or

after deliberately changing the setup of the SmartWire-DT network in

any other way.

The third configuration is the planned configuration (in this document also

called project configuration). It is created by using the SWD-Assist

software and contains the desired configuration and the parameters of the

SmartWire-DT network. It can be manually created in SWD-Assist by

adding the individual device symbols in the “workbench” window, or it can

be automatically created by taking over (i. e. reading-in) the target

configuration from the gateway. The latter method is less prone to errors

and therefore recommended.

The project configuration has to be complemented in SWD-Assist with the

device-specific parameters of the SWD slaves and the POWERLINKspecific parameters (i. e. the node ID of the gateway). It then has to be

downloaded from the configuration PC to the gateway via USB, where it is

stored (like the target configuration) zero voltage-safe in the flash memory

of the device.

Page 23

Descriptions and Requirements 23/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

The gateway checks the project configuration against the target

configuration after each restart. SWD-Assist lets you define individual SWD

slaves in the project configuration as being “non-mandatory” (which means

that these slaves are allowed to be missing in the target configuration).

Thus project configuration and target configuration must not necessarily

comply with each other, but must be compatible. The result of this checking

is indicated by the Config LED on the gateway (for the position of the

Config LED, see Positions of the LEDs section o

n page 28).

In order to acquaint the gateway with the POWERLINK Managing Node

within its POWERLINK configuration, you have to generate an XDD device

description file out of the project configuration in SWD-Assist, and then and

export it. This file contains the projected/planned configuration of the

gateway in a standardized description format, which complies with general

POWERLINK specifications. The XDD file then has to be imported into your

POWERLINK engineering tool (e. g. Automation Studio by B & R).

Afterwards, you can add the gateway in the engineering tool to an already

existing POWERLINK project as Controlled Node and perform a data

mapping for the contained I/O modules (i. e. the SmartWire-DT slaves).

Finally, you can load the project onto your POWERLINK Managing Node.

Page 24

Descriptions and Requirements 24/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

3.1.3 Interfaces

The gateway features a SmartWire-DT interface (plug, 8-pole), a 2-port

switch Ethernet interface (RJ45) and a Mini-USB interface. Via the MiniUSB interface, the gateway can be accessed, configured and diagnosed

with the SWD-Assist software.

3.1.4 Diagnosis

The gateway can be diagnosed by connecting the SWD-Assist software to

the Mini-USB interface. For further information, please refer to the SWDAssist online help.

The POWERLINK protocol also provides diagnostic functions. For further

information, see Diagnosis/Status Response se

ction on page 61.

3.1.5 Firmware and Device Description File

The EU5C-SWD-POWERLINK Gateway is shipped with its most recent

firmware already loaded. Which firmware version is loaded in the gateway

at the time of delivery can be inferred from the device type label (see

Device Type Label sect

ion on page 32).

You can update the firmware from your configuration PC by using an

ordinary web browser.

A web server embedded in the gateway provides a special web page for

updating the firmware. This web server can be accessed via the Ethernet

interface of the Gateway. For more details on this, please refer to the

Updating Firmware chap

ter on page 62 ff.

A device description file in XDD format can be generated by the SWDAssist software. It can then be imported into a POWERLINK engineering

tool (like e. g. Automation Studio by B & R).

Page 25

Descriptions and Requirements 25/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

3.2 Prerequisites for Operation

The following prerequisites must be fulfilled to operate the EU5C-SWDPOWERLINK Gateway:

3.2.1 Network Systems

SmartWire-DT network with maximum number of up to 99

participants/stations/slaves and maximum extension of up to 600

meters.

Ethernet POWERLINK network with POWERLINK PLC (Managing

Node). Maximum cable length for one segment (i. e. cable between two

devices or hubs) is 100 meters.

3.2.2 Power Supply

In safety-relevant applications the power supply providing power for the

SmartWire-DT system must feature a PELV power feed module

(protective extra low voltage).

Ensure a reliable electrical isolation of the low voltage for the 24 volt

supply. Only use power supply units complying with IEC 60364-4-41

(VDE 0100 Part 410) or HD 384.4.41 S2.

You must take safety precautions (emergency switching off) in the

external circuitry of the EU5C-SWD-POWERLINK and any power

modules type EU5C-SWD-PF1-1 or EU5C-SWDPF2-1 that are used. To

do so, plan to switch off the power supply to the contactor coils AUX.

Important!

Please take into consideration the total power consumption of your

SmartWire-DT network and, if necessary, plan for an additional feeder

module EU5C-SWD-PF2.

You can find information on the power consumption in the operating

manuals of the SmartWire-DT devices.

Page 26

Descriptions and Requirements 26/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

3.2.2.1 POW Power Connection

A Power supply of 24 V DC for the coupling unit and for the Smart-Wire-DT

slave electronics is needed at the connection POW.

On the SmartWire-DT gateway, connect the POW and AUX supply

voltages via separate miniature circuit-breakers or fuses:

Miniature circuit-breaker 24 V DC for POW

Cable protection in accordance with DIN VDE 0641 Part 11, IEC/EN

60898:

Miniature circuit-breaker 24 V DC rated operational current 3 A; trip

types C or Fuse 3 A, utilization class gL/gG

Cable protection for cable AWG 24 in accordance with UL 508 und CSA-

22.2 No. 14:

Miniature circuit-breaker 24 V DC rated operational current 3 A; Tripping

characteristics C or Fuse 3 A

3.2.2.2 AUX Power Connection

If any switching devices are also to be connected, for example via the DILSWD-32-001/002 SmartWire-DT slaves, a 24 V DC supply will also be

required at the AUX power connection. This provides the supply for

activating the contactor coils. This supply must be protected by an

automatic circuit-breaker (3A gG/gl or 3 A miniature circuit-breaker with a Z

characteristic).

If switching devices with an activation power greater than 3 A are

connected, an additional feeder module EU5C-SWD-PF1 or EU5C-SWDPF2 must be used.

On the SmartWire-DT gateway, connect the POW and AUX supply

voltages via separate miniature circuit-breakers or fuses:

Miniature circuit-breaker 24 V DC for AUX

Cable protection in accordance with DIN VDE 0641 Part 11, IEC/EN

60898:

Miniature circuit-breaker 24 V DC rated operational current 3 A; trip type

Z or Fuse 3 A, utilization class gL/gG

Cable protection for cable AWG 24 in accordance with UL 508 und CSA-

22.2 No. 14:

Miniature circuit-breaker 24 V DC rated operational current 2 A; Tripping

characteristics Z or Fuse 2 A

Page 27

Device Picture, Connectors and LEDs 27/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

4 Device Picture, Connectors and LEDs

4.1 Device Picture

24 V power supply POW

Ethernet POWERLINK interface

(RJ45)

LEDs communication status

POWERLINK

(see subsequent section for details)

Mini-USB interface

Configuration button

LEDs Gateway functions

(see subsequent section for details)

24 V power supply AUX

SmartWire-DT connection

(plug, 8-pole)

Figure 2: Front View EU5C-SWD-POWERLINK Gateway

Page 28

Device Picture, Connectors and LEDs 28/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

4.2 Positions and Meaning of the LEDs

4.2.1 Positions of the LEDs

POW: System status

APL: Application status

Config.: Configuration status

SWD: SmartWire-DT status

BS: POWERLINK bus status

BE: POWERLINK bus error

L/A: LINK/Activity for channel 0

Receive/Transmit (RX/TX) for channel 0

L/A: LINK/Activity for channel 1

Receive/Transmit (RX/TX) for channel 1

Figure 3: LEDs EU5C-SWD-POWERLINK Gateway

Page 29

Device Picture, Connectors and LEDs 29/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

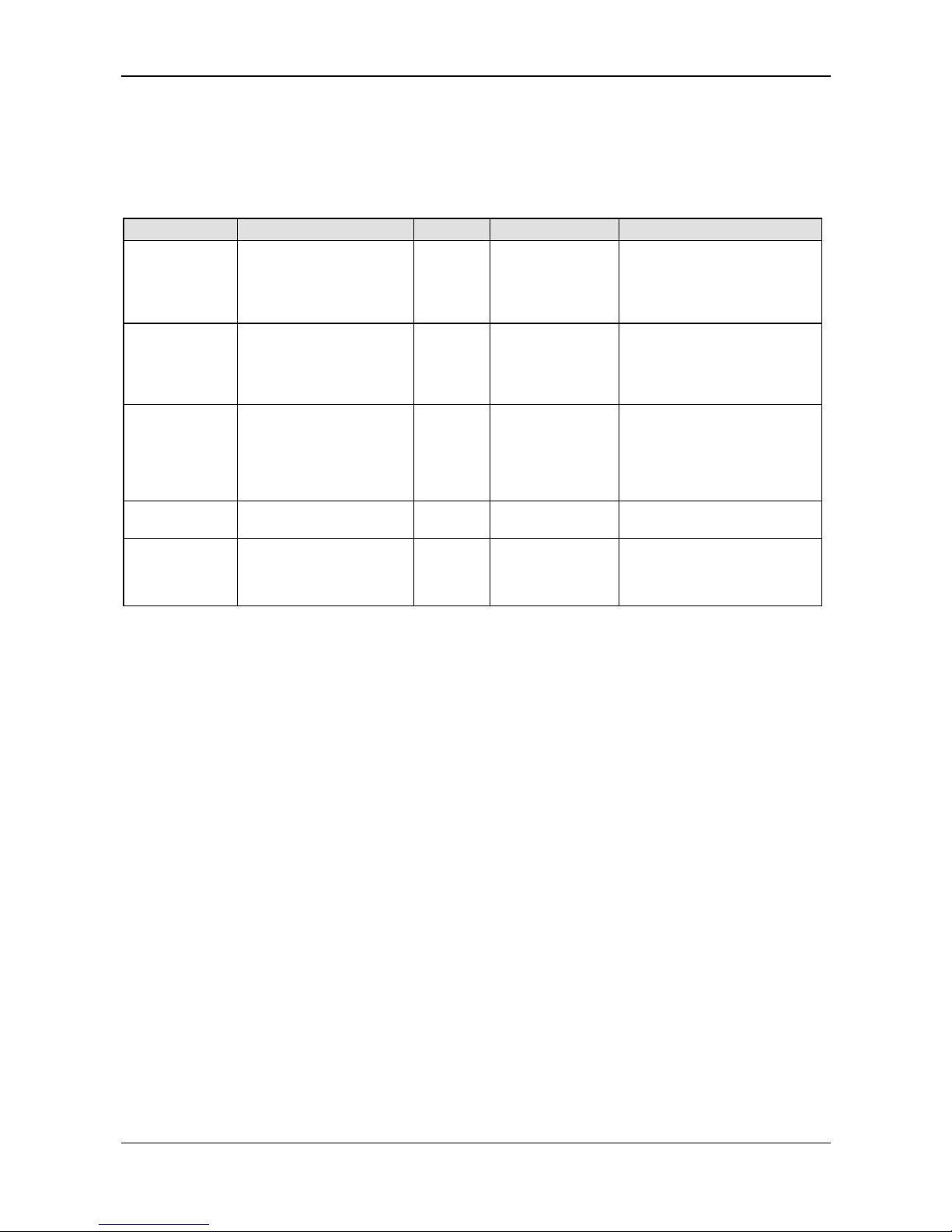

4.2.2 Descriptions of the LEDs

LED Color State Meaning

Duo-LED yellow/green

(yellow)

On

Bootloader netX (= rom loader) is waiting for Second Stage

Bootloader.

(green/yellow)

Flashing

green/yellow

Second Stage Bootloader is waiting for firmware.

(green)

On Operating system running, firmware is started.

POW

System

status

Number in

picture:

(off)

Off Power supply for device is missing or hardware is defect.

Duo-LED red/green

(green)

On

Communication on POWERLINK and SmartWire-DT is in cyclic data

exchange and the gateway function is executed.

(green)

Flashing

1 s off,

1 s on

Gateway is initialized, but the communication on POWERLINK and

SmartWire-DT is not in cyclic data exchange.

(red)

Flashing

1 s off,

1 s on

Gateway is initialized, but the SmartWire-DT configuration is

missing or in error.

APL

Application

status

Number in

picture:

(red)

On

Gateway has detected an error during the initialization: Missing

configuration, error in configuration or internal error.

Duo-LED red/green

(green)

On

The project configuration complies with the target configuration.

Data exchange between gateway and PLC via POWERLINK is

possible.

(green)

Flashing

The project configuration does not comply with the target

configuration, but is compatible with it.

Data exchange between gateway and PLC via POWERLINK is

possible.

(red)

On

The project configuration and the target configuration are not

compatible.

Data exchange between gateway and PLC via POWERLINK is not

possible.

Config.

Configuration

status

Number in

picture:

(off)

Off

No communication with the POWERLINK PLC, or the gateway does

not have a project configuration.

Table 9: Description of the LEDs (1)

Page 30

Device Picture, Connectors and LEDs 30/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

LED Color State Meaning

Duo-LED red/green/orange (orange = red/green at same time)

(green)

On

The actual configuration complies with the target configuration.

Data exchange between gateway and SmartWire-DT slaves takes

place.

(red)

Flashing

The gateway misses its target configuration

or a necessary SmartWire-DT slave is missing

or the target configuration does not comply with the actual

configuration.

No data exchange between gateway and SmartWire-DT slaves.

(green)

Flashing

Slave addressing is active (after power-on or download of a project

configuration containing empty modules).

No data exchange between gateway and SmartWire-DT slaves.

(red)

On

Short-circuit on the 15 V power supply or no SmartWire-DT slave is

connected.

No data exchange between gateway and SmartWire-DT slaves.

SWD

Status

SmartWire-DT

Number in

picture:

(orange)

Flashing

After having pressed the configuration button: The gateway reads

the actual configuration and stores it as target configuration.

Duo-LED red/green

(off)

Off Controlled Node (gateway) is initialized

Flickering Controlled Node (gateway) is in basic Ethernet state

Single Flash Controlled Node (gateway) is in state “Pre-Operational 1”

Double Flash Controlled Node (gateway) is in state “Pre-Operational 2”

Triple Flash Controlled Node (gateway) is in state “ReadyToOperate”

On Controlled Node (gateway) is in state “Operational”

BS

POWERLINK

Bus Status

Number in

picture:

(green)

Blinking Controlled Node (gateway) is in state “Stopped”

Duo-LED red/green

(off)

Off No error

BE

POWERLINK

Bus Error

Number in

picture:

(red)

On Controlled Node (gateway) has detected an error

LED green

(green)

On Link: Gateway has connection to Ethernet

(green)

Flashing Activity: Gateway sends/receives Ethernet frames

L/A (RJ45)

Ch0 & Ch1

Numbers in

picture:

&

(off)

Off

Gateway has no connection to Ethernet

LED yellow (RJ45)

Ch0 & Ch1

Numbers in

picture:

&

(yellow)

- This LED is not used

Table 10: Description of the LEDs (2)

Page 31

Device Picture, Connectors and LEDs 31/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

4.3 Pinning POWERLINK Interface

The following picture shows the pinning of the Real-Time Ethernet interface

of the Gateway:

Figure 4: Pinning of the Ethernet Interface (RJ45)

Pin Signal Description

1 TX + Transmit Data +

2 TX – Transmit Data –

3 RX + Receive Data +

4 TERM

5 TERM

Bob Smith Termination

6 RX – Receive Data –

7 TERM

8 TERM

Bob Smith-Termination

Table 11: Ethernet Interface Channel 0 and Channel 1 Pin Assignment (RJ45)

Note: The Ethernet interface supports Auto-Crossover.

Page 32

Device Picture, Connectors and LEDs 32/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

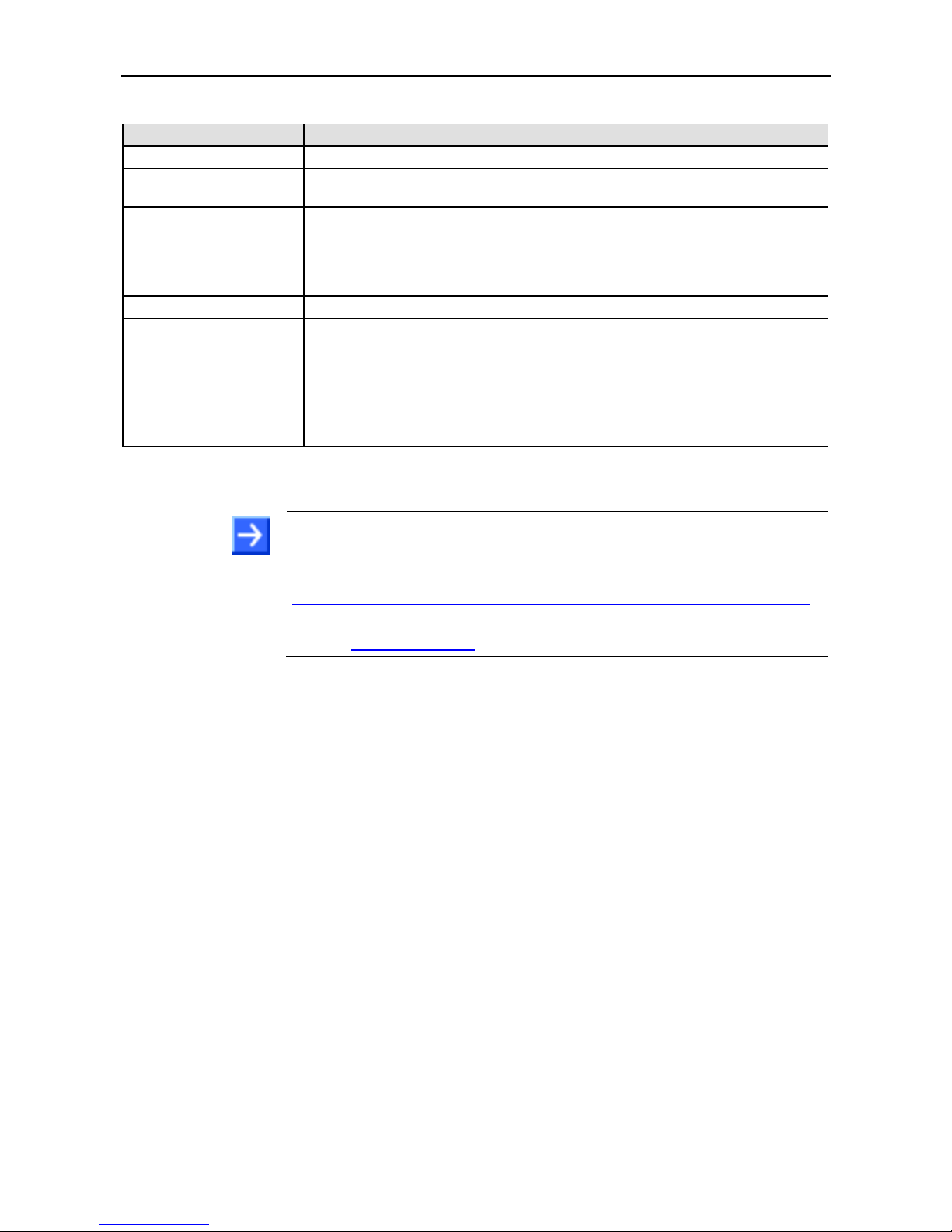

4.4 Device Type Label

The EU5C-SWD-POWERLINK Gateway is equipped with a device type

label, which provides the following information:

Version of firmware (at time of

delivery)

Information on power supply for

switching devices (AUX)

Information on power supply for

Gateway and Smart-Wire-DT

slaves (POW)

Information on wire gauge of

power supplies

Operating ambient temperature

Device type name

Part number

Hardware revision number

Serial number

Figure 5:Device Type Label EU5C-SWD-POWERLINK Gateway

Page 33

Getting Started 33/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

5 Getting Started

The following table provides an overview of the steps necessary for

installing and commissioning the EU5C-SWD-POWERLINK Gateway.

# Step For details see

1 Install gateway

Chapter Installing Gateway on page 34

1.1 Take safety precautions Section Safety Messages on page 34

1.2 Mount gateway onto top hat rail

Section Mounting Gateway onto Top

Hat Rail on page 35

1.3 Connect gateway to power supply

Section Connecting Gateway to Power

Supply on page 38

1.4 Connect gateway to SmartWire-DT network

Section Connecting SmartWire-DT on

page 40

2 Configure gateway Chapter Configuring Gateway on page

42

2.1 Configure SmartWire-DT network in gateway

Section Configuring SmartWire-DT

network in Gateway on page 42

2.2

Install SWD-Assist and USB driver on configuration

PC

Section Installing SWD-Assist and USB

Driver on Configuration PC on page 44

2.3 Connect configuration PC to gateway via USB

Section Connecting Gateway to

Configuration PC via USB on page 46

2.4 Configure gateway project in SWD-Assist

2.5 Download project configuration to gateway

Section Configuring Gateway in SWD-

Assist (Creating Project Configuration)

on page 47

3 Configure gateway in POWERLINK Chapter Configuring Gateway in

POWERLINK on page 53

3.1

Create XDD device description file for gateway in

SWD-Assist

3.2

Import XDD device description file in POWERLINK

engineering tool

3.3

Configure gateway in POWERLINK engineering

tool

3.4 Download POWERLINK configuration to PLC

Chapter Configuring Gateway in

POWERLINK on page 53

3.5 Connect gateway to POWERLINK network

Section Connecting POWERLINK on

page 41

Table 12: Getting Started

Page 34

Installing Gateway 34/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

6 Installing Gateway

6.1 Safety Messages

Please observe the following safety messages when you install and

handle the gateway!

First disconnect the power plug of the device.

Make sure that the power supply is off at the device.

Cover or enclose neighboring units that are live.

Electrostatic Sensitive Device

The gateway is sensitive to electrostatic discharge, which can cause

internal damage and affect its normal operation. Therefore adhere to the

necessary safety precautions for components that are vulnerable to

electrostatic discharge, when you install or handle the gateway.

Do not touch the metal pins of the connectors of the gateway.

Touch a grounded object to discharge potential static.

Wear an approved grounding wrist strap.

If available, use a static-safe workstation.

When not in use, store the device in an appropriate static-safe

packaging.

Page 35

Installing Gateway 35/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

6.2 Mounting Gateway

No tools are required for mounting the EU5C-SWD-POWERLINK Gateway

onto a top hat rail. The back of the gateway

carries a spring-fitted bolt ,

by which the gateway can be clamped to the rail

.

Figure 6: Mounting Principle of the Gateway

6.2.1 Mounting Gateway onto Top Hat Rail

To mount the gateway onto the top hat rail, proceed as follows:

Make sure that the gateway is disconnected from any power supply.

Cover or enclose neighboring units that are live.

Tilt the gateway slightly and hook it

into the upper railing from above,

thereby pushing down the gateway

with slight force, in order to

overcome the resistance of the

spring in the bolt.

Figure 7: Hook Gateway to Upper

Railing

Page 36

Installing Gateway 36/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

Keep on pushing the gateway

downwards and tilt it back into

vertical position, thereby hooking

the gateway into the lower railing.

Figure 8: Hook Gateway to Lower

Railing

Let go of the gateway. The spring

inside the bolt automatically pushes

the gateway upwards into the

railings, thereby fixing the gateway

to the top hat rail.

Figure 9: Gateway is Clamped to

Top Hat Rail

Page 37

Installing Gateway 37/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

6.2.2 Removing Gateway from Top Hat Rail

To remove the gateway from the top hat rail, proceed as follows:

First disconnect the power plugs from the gateway.

Make sure that the power supply is off at the gateway.

Cover or enclose neighboring units that are live.

Push down the gateway with slight

force (to overcome the resistance of

the spring in the bolt), then unhook

the gateway first from the lower

railing and then from the upper

railing.

Figure 10: Unhook Gateway

Page 38

Installing Gateway 38/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

6.3 Connecting Gateway to Power Supply

Danger of lethal injuries by unexpected starting up of motors or

machinery!

If you have already integrated devices into a system, secure the operating

range of any connected parts of the system against access, so that

nobody is endangered by motors or machinery starting up unexpectedly.

In safety-relevant applications, the power supply providing power to the

SmartWire-DT system must feature a PELV power feed module

(protective extra low voltage).

You must take safety precautions (emergency switching off) in the

external circuitry of the EU5C-SWD-POWERLINK Gateway and any

power modules type EU5C-SWD-PF1-1 or EU5C-SWDPF2-1 that are

used. To do so, plan to switch off the power supply to the contactor coils

AUX.

Important!

Please take into consideration the total power consumption of your

SmartWire-DT network and, if necessary, plan for an additional feeder

module EU5C-SWD-PF2.

You can find information on the power consumption in the operating

manuals of the SmartWire-DT devices.

Connect the 24 V DC voltage to the POW terminals on the front side of

the gateway. The POW connection provides the voltage for the gateway

itself and for the SmartWire-DT slave electronics.

Note: For the 15 V supply of the SmartWire-DT slaves, the gateway

contains an additional power feed module with an amperage of 0.7 A.

Page 39

Installing Gateway 39/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

If necessary, connect the 24 V DC voltage for the contactor coils to the

AUX terminals on the front side of the gateway.

Figure 11: Gateway Power Supply

Note: The AUX supply is required if any switching devices are also to be

connected, for example, via the DIL-SWD-32-001/002 SmartWire-DT

slaves. The AUX connection provides the supply for activating the

contactor coils.

This supply must be protected by an automatic circuit-breaker (3A gG/gl or

3 A miniature circuit-breaker with a Z characteristic).

If switching devices with an activation power greater than 3 A are

connected, an additional feeder module EU5C-SWD-PF1 or EU5C-SWDPF2 must be used.

Potential conditions between the components

The entire SmartWire-DT system operates on a common supply voltage.

Provide a common star point for the earth wiring. In this way, the various

slaves in the SmartWire-DT system will not be electrically isolated from one

another.

The POWERLINK network and the SmartWire-DT system are electrically

isolated from one another.

Page 40

Installing Gateway 40/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

6.4 Connecting SmartWire-DT

Connect the SmartWire-DT network to the gateway. To do so, use the

SmartWire-DT cable SWD4-100LF8-24 and the SWD4-8MF2 relevant

blade terminal or prefabricated cables of type SWD4-(3/5/10)F8-24-2S.

Figure 12: Connecting SmartWire-DT to Gateway

Switch off the power supply, if you are reconnecting slaves in the

SmartWire-DT system or reconnecting the ribbon cable connection.

Otherwise the SmartWire-DT slaves can be destroyed!

Note: Detailed instructions on adapting the SmartWire-DT external device

plug (SWD4-8SF2-5) to the 8 pole Smart-Wire-DT cable are provided in

chapter Fitting external device plugs SWD4-8SF2-5 of the manual

SmartWire-DT – The System, MN05006002Z-EN (previously AWB27231617en).

Page 41

Installing Gateway 41/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

6.5 Connecting POWERLINK

Connect the RJ45 plug of the POWERLINK cable to one of the Ethernet

connectors on the gateway.

Figure 13: Connecting POWERLINK to Gateway

Important!

Please observe the following notes on POWERLINK cabling:

Use only hubs, no switches.

Maximum cable length in a segment (allowed space between

individual devices/hub) is 100 meters.

6.6 EMC-Conformant Wiring of the Network

Undesired faults can occur on the bus due to electromagnetic interference.

This can be minimized beforehand by the implementation of suitable EMC

measures. These include:

EMC-conformant system configuration,

EMC compliant cable routing,

Measures that do not allow the occurrence of large differences in

potential and

correct installation of the POWERLINK system (cables, connection of

the bus connectors, etc.)

The effects of electromagnetic interference can be significantly reduced by

fitting a shield.

For more detailed information on this, please refer to the IAONA Industrial

Ethernet -Planning and Installation Guide by IAONA e.V. Magdeburg,

Germany.

Page 42

Configuring Gateway 42/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

7 Configuring Gateway

For data exchange between the gateway and the POWERLINK Managing

Node, the gateway needs valid target and project configurations of the

SmartWire-DT network. This chapter describes how to create and store

these configurations in the gateway.

7.1 Configuring SmartWire-DT network in Gateway (Creating

Target Configuration)

When you commission the gateway, you have to read-in the actual

configuration of the SmartWire-DT network (i. e. the line-up of the

participants/devices connected to the SWD bus) and store it as target

configuration.

Reading and storing the SmartWire-DT network configuration takes place

by pressing the configuration button on the gateway (for the position of the

configuration button, see figure Front View EU5C-SWD-POWERLINK

Gateway o

n page 27). All SmartWire-DT slaves are re-addressed in

ascending o

rder by this process. As an alternative, you can generate and

store the target configuration by using the SWD-Assist software (the

gateway must be connected to SWD-Assist via USB).

This process should only take place in the case of:

initial commissioning,

replacement of a defective slave or

deliberate change to the configuration.

Important!

If there is a faulty configuration and the configuration button is pressed,

only the slaves up to the failed device are addressed and stored. Use of

the remaining slaves is not possible until the defective slave has been

replaced and the configuration has been read-in again by pressing the

configuration button.

The remanently stored target configuration is compared with the current

configuration (actual configuration) each time the gateway is restarted and

during bus operation. If the gateway recognizes that a required SmartWireDT slave cannot be reached or a wrong slave type is determined, the

gateway will not go into operation or stops operating. This depends in each

case on the setup of the network which has been defined in the

planned/project configuration. In case of error, the SmartWire-DT status

LED (SWD LED) starts to blink in red (for the position of the SWD LED, see

Positions of the LEDs section on pag

e 28).

If a SmartWire-DT slave has failed, the SmartWire-DT network can still be

operated with the remaining slaves, depending on the settings in the

planned/project configuration (even after a repeated power up of the

gateway). The failure is reported to the application.

Page 43

Configuring Gateway 43/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

Prerequisites for reading-in the SmartWire-DT configuration are:

All SmartWire-DT slaves are connected to the SmartWire-DT line.

The SmartWire-DT network is connected to the gateway.

The voltage POW is applied to the gateway and the power LED POW is

on.

The voltage AUX is applied (if necessary).

The SmartWire-DT status LEDs of the individual SmartWire-DT slaves

are on or are flashing.

The POWERLINK network is disconnected from the gateway by

removing the RJ45 plug from the Ethernet interface of the gateway.

To read-in the SmartWire-DT configuration proceed as follows:

Make sure that POWERLINK is disconnected from the gateway.

Press the configuration button on the gateway for at least two seconds

(for the position of the configuration button, see figure Front View

EU5C-SW

D-POWERLINK Gateway on page 27).

Note: Take care to push-in the button properly. You have to feel and

overcome a slight resistance at the end when pushing the button into the

gateway, otherwise the button won’t trigger.

The SmartWire-DT status LED (SWD LED) on the gateway begins to

flash orange. The SmartWire-DT status LEDs on the SmartWire-DT

slaves also flash. All slaves are addressed in sequence, the complete

configuration is stored retentively as gateway target configuration.

The SmartWire-DT status LED (SWD LED) on the gateway shows

steady green.

Page 44

Configuring Gateway 44/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

7.2 Installing SWD-Assist and USB Driver on Configuration

PC

You need the SWD-Assist software on your configuration PC in order to

create, parameterize and download a project configuration to the gateway.

With SWD-Assist, you can also perform a diagnosis of the SmartWire-DT

network and create an XDD device description file, which can imported into

your POWERLINK engineering tool for the purpose of configuring the

POWERLINK Managing Node.

In the installation wizard of the SmartWire-DT Gateway Solutions DVD, you

can install the version of the SWD-Assist software delivered on the DVD, or

you can choose to be directed to an internet website from which you can

download the latest version of SWD-Assist (if available).

In order to establish an USB connection between SWD-Assist and the

gateway, you also need to install the USB driver on your configuration PC.

An installation program for the USB driver is delivered on the SmartWire-DT

Gateway Solutions DVD. It contains all components needed for the

installation of the driver under Windows XP, Windows Vista, Windows 7

and Windows 8. It detects whether the 32 bit or the 64 bit version of the

driver needs to be installed.

It is recommended to use the installation program to install the USB driver.

It is also recommended to install the USB driver before you connect the

gateway to your configuration PC via USB for the first time (“software first”

principle).

Step-by-step Instructions

To install the software on your configuration PC, proceed as follows:

Insert the SmartWire-DT Gateway Solutions DVD into your local DVD-

ROM drive.

If the “Auto Play” function of your Windows PC is enabled, the start

screen of the DVD is displayed.

Note: As an alternative, you can also open the start screen of the DVD by

double-clicking the SmartWire.exe file in the root directory of the DVD.

In the menu of the start screen, click Install Planning and

Configuration Tools.

Page 45

Configuring Gateway 45/72

SmartWire-DT Gateway | EU5C-SWD-POWERLINK

DOC130802UM02EN | Revision 2 | English | 2013-12 | Released | Public © Hilscher 2013

The SmartWire-DT Installation Wizard opens:

Figure 14: SmartWire-DT Installation Wizard

Note: The wizard automatically checks for already installed software

components (which e. g. might have been installed for an earlier project),

and lists the missing components accordingly.

Select the appropriate installation options.

Read the license agreement, then select License agreement read and

accepted.

Click Execute, then follow the instructions of the installation program.

Note: Under Windows XP, the installation process of the USB driver is not

yet finished after having executed the driver setup.

The installation process has to be completed in the Found New

Hardware Wizard, which automatically opens when you connect the

gateway to your configuration PC via USB cable for the first time (see

following section).

Page 46

Configuring Gateway 46/72