Page 1

Design Guide

COM-C

Communication Module

Hilscher Gesellschaft für Systemautomation mbH

www.hilscher.com

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public

Page 2

Introduction 2/64

Table of Contents

1 Introduction.............................................................................................................................................4

1.1 About this Document......................................................................................................................4

1.2 List of Revisions .............................................................................................................................6

1.3 Technical Features.........................................................................................................................8

1.4 Legal Notes ..................................................................................................................................10

1.4.1 Copyright ......................................................................................................................................... 10

1.4.2 Important Notes............................................................................................................................... 10

1.4.3 Exclusion of Liability ........................................................................................................................ 11

1.4.4 Warranty.......................................................................................................................................... 11

1.4.5 Export Regulations .......................................................................................................................... 11

2 Type of COM-C Modules......................................................................................................................12

2.1 Mechanical Dimensions ...............................................................................................................13

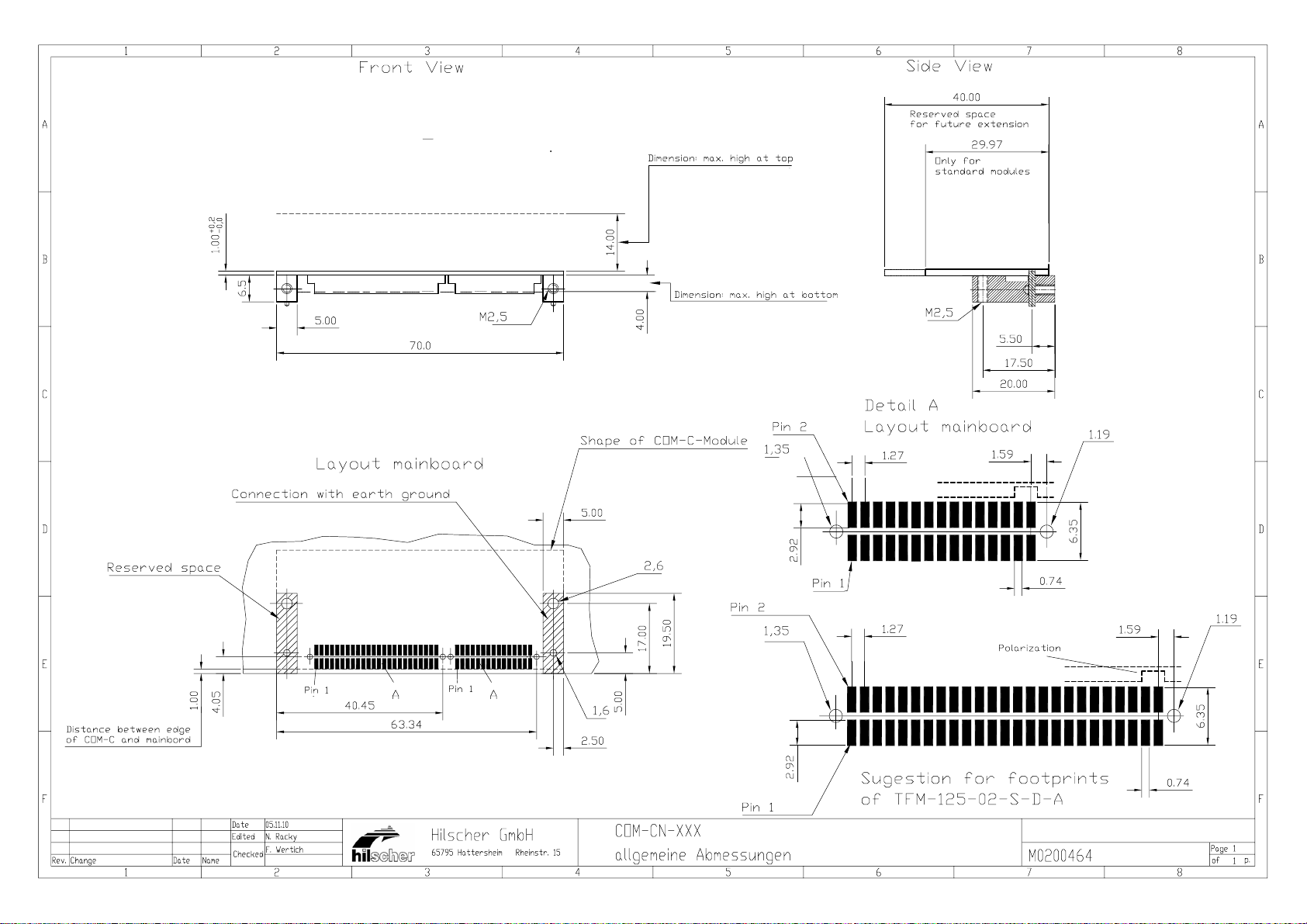

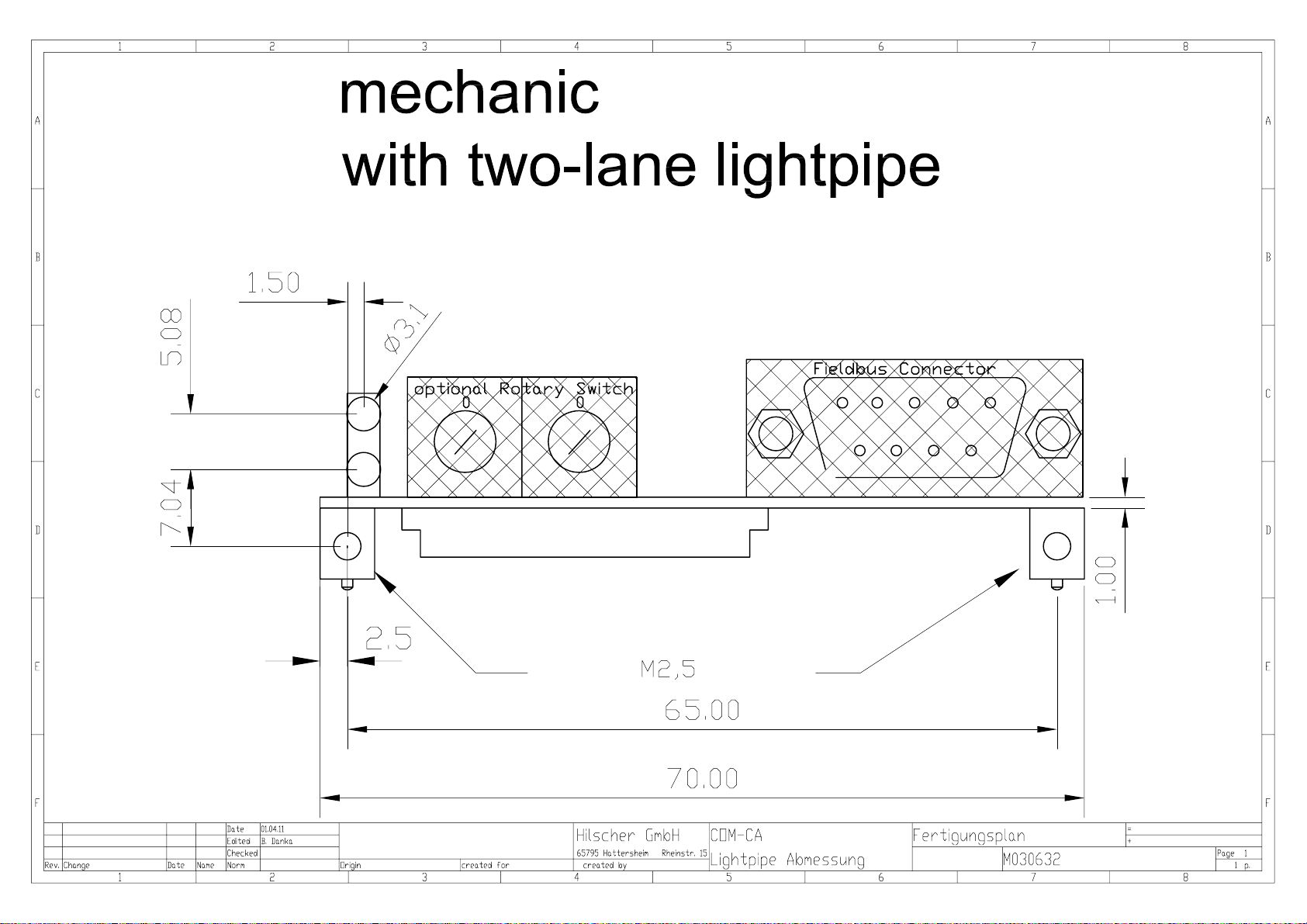

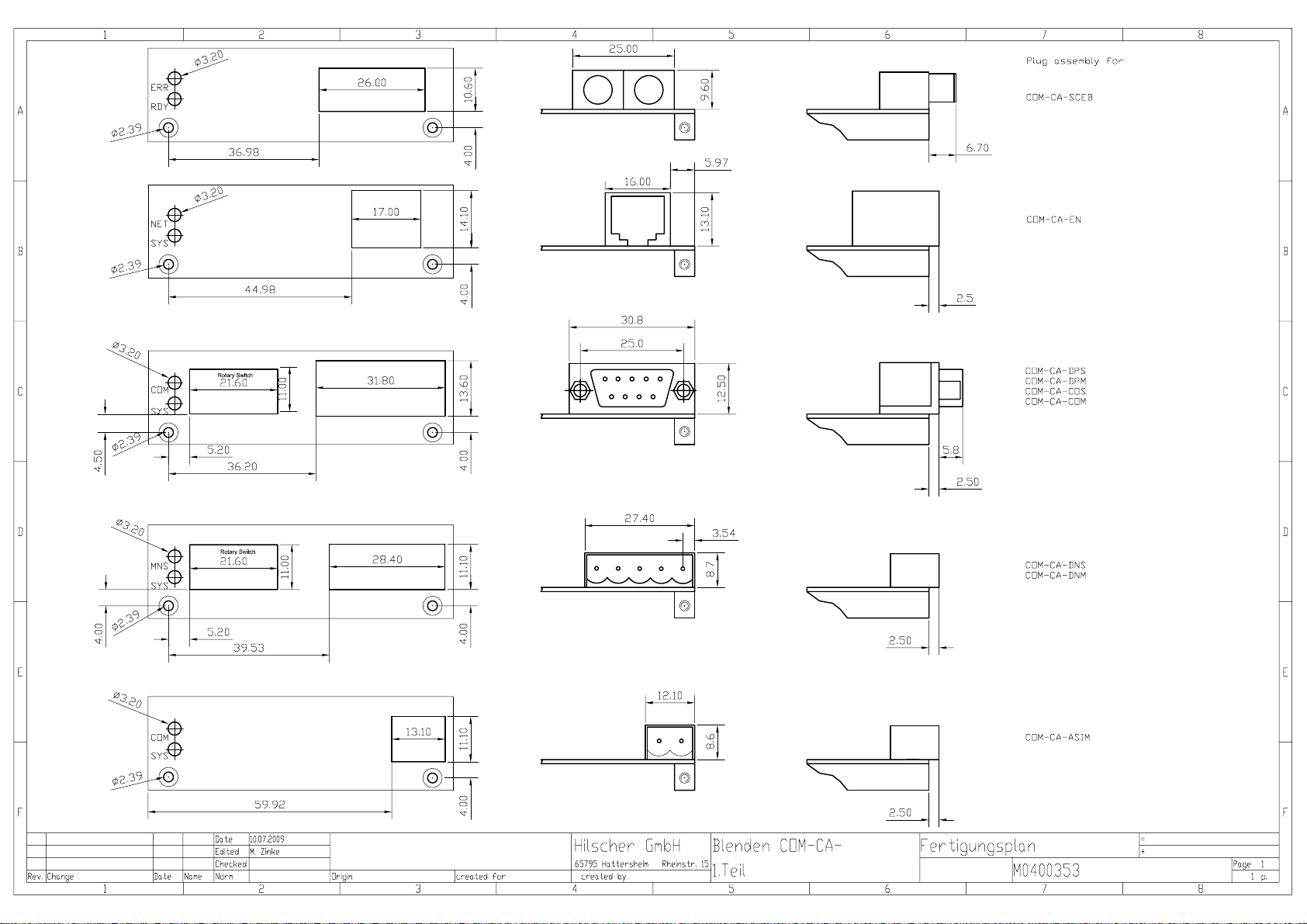

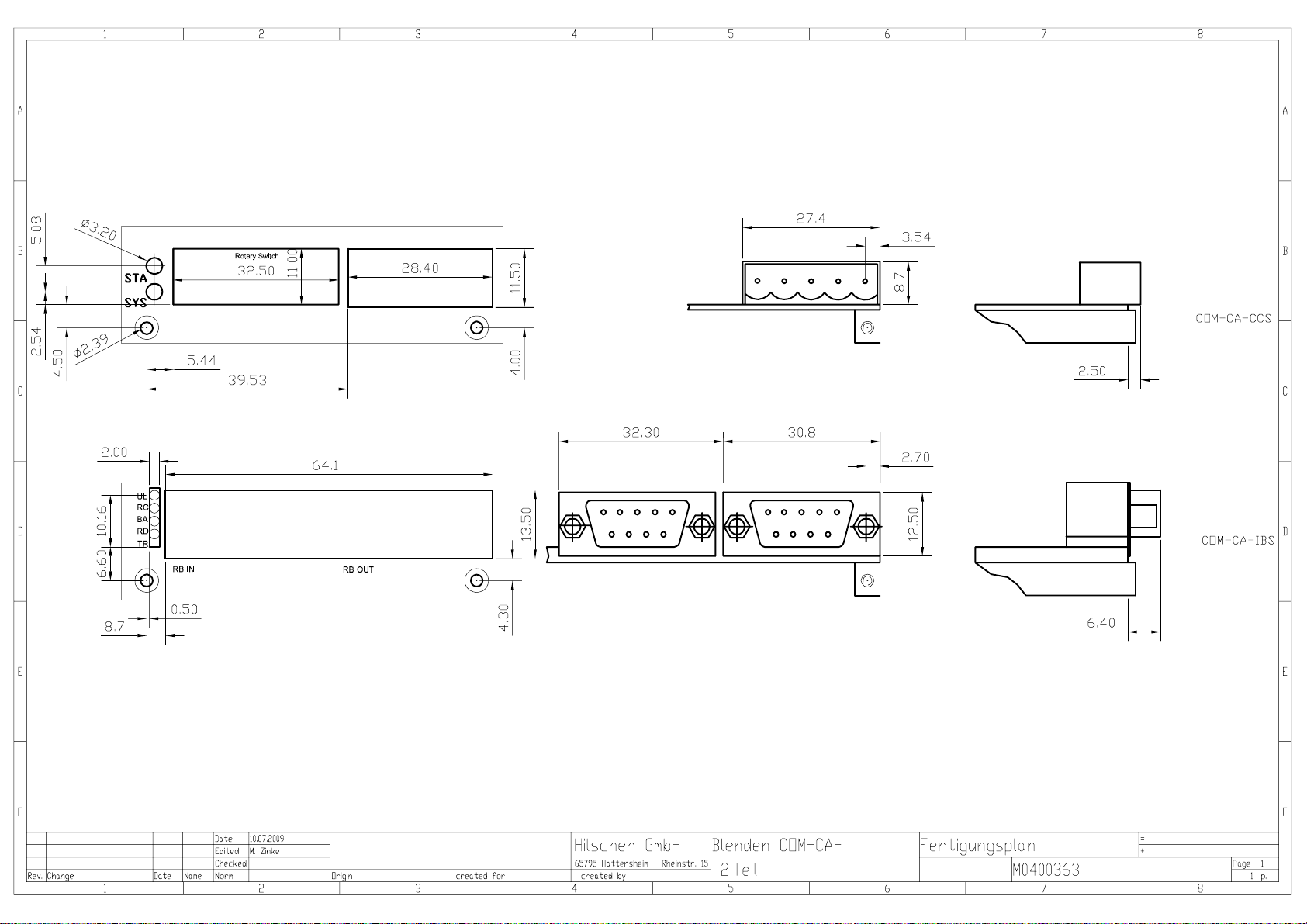

2.1.1 Common Mechanical Dimensions for COM-C Modules .................................................................. 13

2.1.2 Mechanical Dimensions of COM-C Modules ................................................................................... 14

2.2 Type of Connector........................................................................................................................20

2.3 Mounting of COM-C Modules ......................................................................................................22

2.4 Designation of the COM-C...........................................................................................................28

2.5 Meaning of the Rotary Switch ......................................................................................................29

3 Host Interface .......................................................................................................................................30

3.1 COM Pinning of the System Bus Connector X1 ..........................................................................31

3.2 COM-CA-SCEB Pinning of the System Bus Connector X1.........................................................33

3.3 Signal Overview and Pinning of the Fieldbus Connector X2 on COM-CN ..................................35

3.3.1 Fieldbus Connector X2 for AS-Interface-Master.............................................................................. 35

3.3.2 Fieldbus Connector X2 for CANopen-Master/-Slave ....................................................................... 36

3.3.3 Fieldbus Connector X2 for DeviceNet-Master/-Slave ...................................................................... 37

3.3.4 Fieldbus Connector X2 for PROFIBUS-Master/-Slave .................................................................... 38

3.3.5 Fieldbus Connector X2 for Ethernet ................................................................................................ 39

3.3.6 Fieldbus Connector X2 for CC-Link-Slave....................................................................................... 40

3.4 Signals of the Host Interface........................................................................................................41

3.4.1 Power Supply of the COM-C Modules............................................................................................. 41

3.4.2 RESET Signal ................................................................................................................................. 41

3.4.3 The Dual-port Memory Bus of COM ................................................................................................ 41

3.4.4 Address Bus and Data Bus ............................................................................................................. 42

3.4.5 Dual-Port Memory Control Lines ..................................................................................................... 42

3.4.6 Interrupt Line to the Host System .................................................................................................... 43

3.4.7 Busy Line to the Host System.......................................................................................................... 43

3.4.8 Interfacing to the Dual-Port Memory of COM-C............................................................................... 43

3.4.9 Timing Diagram of COM-C .............................................................................................................. 44

3.4.10 Interfacing to the Dual-Port Memory for COM-CA-SCEB ................................................................ 46

3.4.11 Timing Diagram of COM-CA-SCEB................................................................................................. 46

3.5 Integration a COM-C Module into a Host System........................................................................47

4 LEDs ......................................................................................................................................................48

4.1 LEDs for COM Modules ...............................................................................................................49

4.1.1 Ethernet........................................................................................................................................... 49

4.1.2 EtherNet/IP Adapter (Slave) ............................................................................................................ 49

4.1.3 AS-Interface Master......................................................................................................................... 50

4.1.4 CANopen Master............................................................................................................................. 51

4.1.5 CANopen Slave............................................................................................................................... 51

4.1.6 CC Link Slave.................................................................................................................................. 52

4.1.7 DeviceNet Master............................................................................................................................ 53

4.1.8 DeviceNet Slave.............................................................................................................................. 53

4.1.9 InterBus Slave ................................................................................................................................. 54

4.1.10 PROFIBUS DP Master .................................................................................................................... 55

4.1.11 PROFIBUS DP Slave ...................................................................................................................... 55

4.1.12 SERCOS (optical)............................................................................................................................ 56

5 Device Address ....................................................................................................................................57

6 Diagnostic Interface.............................................................................................................................58

6.1 Diagnostic Interface RS232C.......................................................................................................58

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 3

Introduction 3/64

7 Technical Data......................................................................................................................................59

7.1 Product Tests ...............................................................................................................................61

8 Appendix...............................................................................................................................................63

8.1 List of Tables................................................................................................................................63

8.2 List of Figures...............................................................................................................................63

8.2.1 Contacts .......................................................................................................................................... 64

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 4

Introduction 4/64

1 Introduction

1.1 About this Document

All OEM piggyback Modules of Hilscher GmbH are called COM (Communication Modules). These

Modules provide a universal and easy to use fieldbus interface for integration on various host systems. Through the set of standard application interfaces and the same board dimensions in each

COM family it is easy to switch between the different fieldbus systems, e.g. PROFIBUS DP, InterBus, CANopen, DeviceNet or Ethernet by changing the Module.

This manual describes only the hardware part of the Modules. The general application interface is

common to all our COM Modules and CIF PC cards described in our Toolkit-Manual and the fieldbus related details are defined in our Protocol Interface Manuals.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 5

Introduction 5/64

A new generation of communication Modules exists named COMX Modules and offer beside fieldbus communication also Real-Time Ethernet communication. The application interface is different

(not compatible) compared to COM Modules. The COMX Modules are described in an own manual

now. The following two tables give a comparison of both COM and COMX Modules.

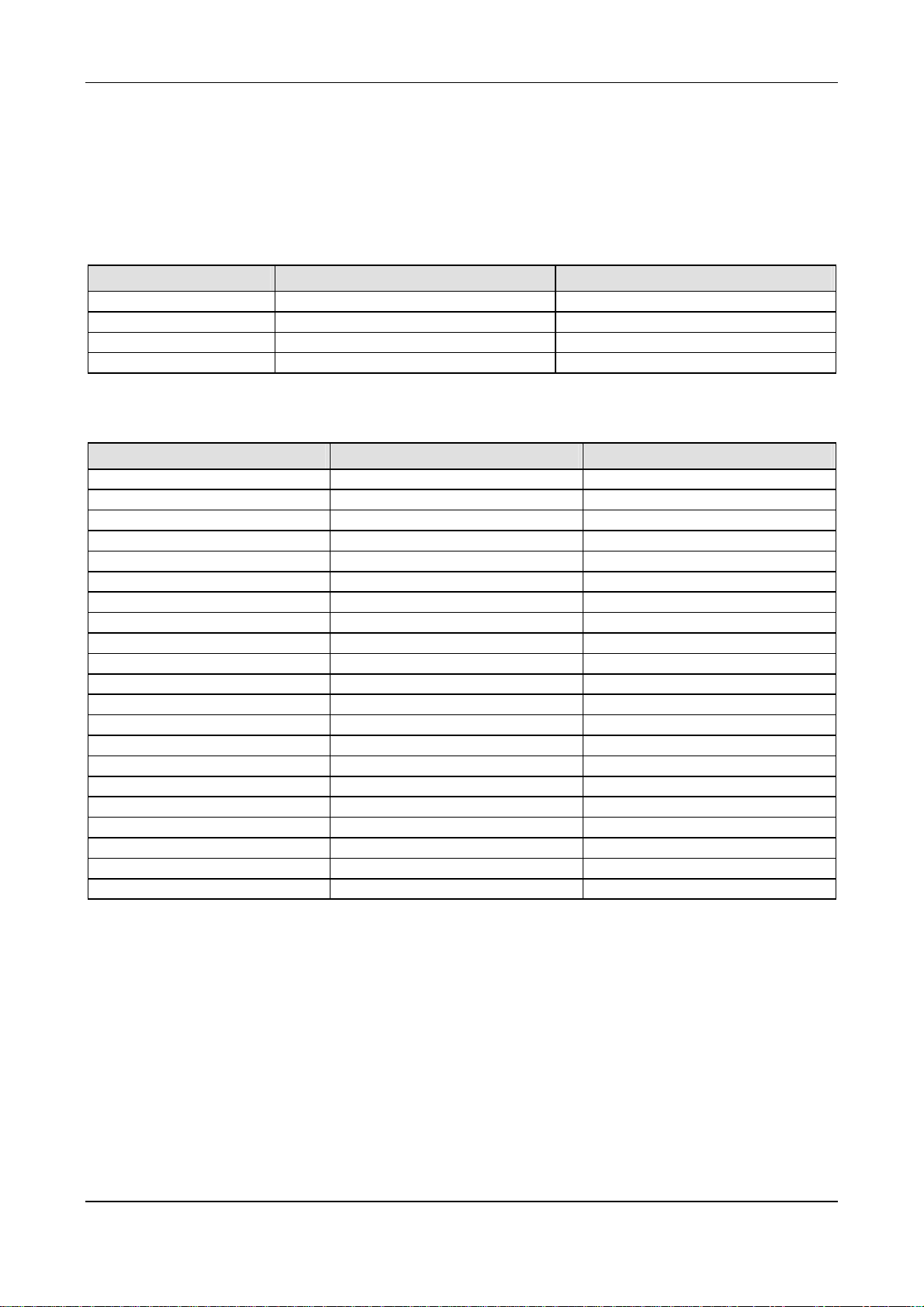

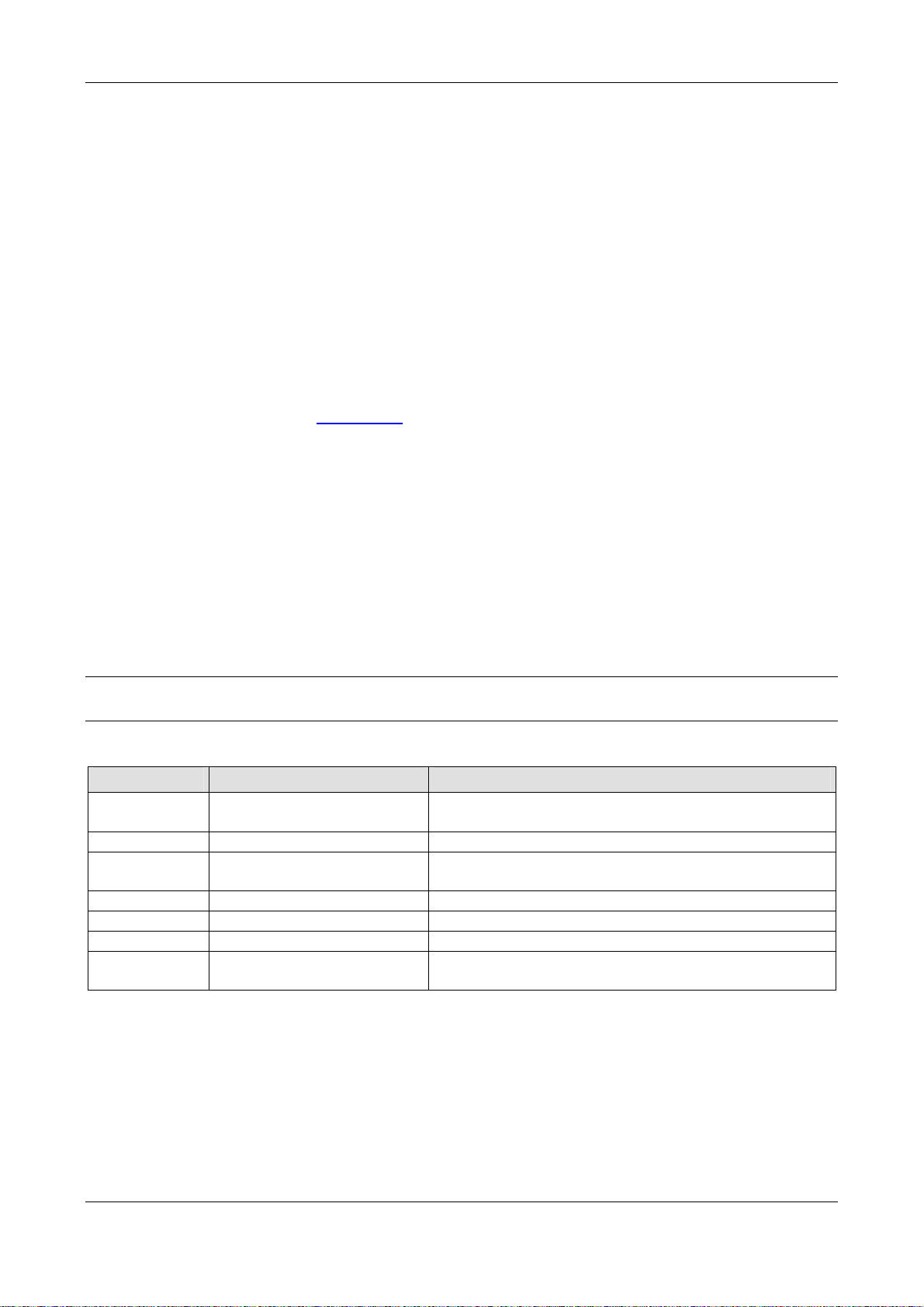

Comparison COM and COMX Modules

Basic differences between COM-C and COMX-C

COM-C COMX-C

Processor EC1 netX

Host Interface 8 Bit 8 / 16 Bit

Dual-Port Memory size 2 KByte or 8 KByte 16 KByte

USB Interface No Yes

Table 1: Basic differences between COM and COMX

Comparison of supported protocols for COM-C and COMX-C

COM-C COMX-C

AS-Interface Master supported in preparation

CANopen Master supported supported

CANopen Slave supported supported

CC-Link Slave supported supported

CompoNet Slave - in preparation

DeviceNet Master supported supported

DeviceNet Slave supported supported

InterBus Slave supported not supported by netX technology

PROFIBUS DP Master supported supported

PROFIBUS DP Slave supported supported

SERCOS II supported not supported by netX technology

EtherCAT Master - supported

EtherCAT Slave - supported

EtherNet/IP Scanner (Master) - supported

EtherNet/IP Adapter (Slave) supported supported

Open Modbus/TCP supported supported

POWERLINK Controlled Node - supported

PROFINET IO RT Controller - supported

PROFINET IO RT Device - supported

SERCOS III Master - supported

SERCOS III Slave - supported

Table 2: Comparison of supported protocols for COM and COMX

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 6

Introduction 6/64

1.2 List of Revisions

Rev Date Name Revision

7 2009-10-01 H. Hentsch COMX-CA-DP, COMX-CN-DP, COMX-CA-CO, COMX-CN-CO, COMX-CA-CO,

COMX-CN-CO, COMX-CA-CCS and COMX-CN-CCS added

Chapter 1 restructured

Table

Basic differences between COM and COMX and Comparison of supported

protocols for COM and COMX added.

Figure Block Diagram of the COMX-C Modules and explaining text added

Section Mechanical Dimensions of COM-A Modules: M0400272 (update),

M0900141 (new)

Section Mechanical Dimensions of COM-B Modules: M0400282 (update),

M0900151 (new), M0400291 (kept)

Section

M0200373 (update), M0200463 (kept), M0300632 (update), M0400353 (update),

M0400363 (update), M0600172 (update), M0900161 (new)

Section

M0600121 (new), M0900102 (new), M0200402 (kept)

Section

Section : SYNC Signals added

Section Signal Overview and Pinning of the Fieldbus Connector X2 on COM-CN:

Added that Pin 21 is used for isolation

Section Timing Diagram of the COMX-C: Both tables updated and notes ex-

panded

Section LEDs divided into LEDs for COM and LEDs for COMX

Subsections in LEDs for COMX Modules updated respectively added

Section

8 2009-10-27 H. Hentsch Section Diagnostic Interface USB:: USB interface circuit modified

Temperature range for COMX Modules. -20 … 65°C

9 2009-11-11 H. Hentsch Section Fieldbus Connector X2 for Real-Time Ethernet:

- LED names changed to COM0 and COM1

- Figure 6 with example added

Section LEDs:

- Figure 14: Example how to connect the LEDs COMX-CN Fieldbus and

- Figure 15: Example how to connect the LEDs COMX-CN-RE added

Section LEDs for COMX Modules with references to signal COM0 and COM1 for

all Real-Time Ethernet protocols

Table 3: List of Revisions (Part 1)

Mechanical Dimensions of COM-C Modules:

Mounting of COM-C Modules: M0500081 (new), M0100084 (update),

Mounting of COM-C Modules expanded (4 bolt types)

Technical Data: New modules added

Continued on next page.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 7

Introduction 7/64

Rev Date Name Revision

10 2010-07-13 H. Hentsch Table 2: Comparison of supported protocols for COM and COMX updated:

CANopen Slave, PROFIBUS DP Slave and DeviceNet Slave for COMX-C supported

Table 9: Available COMX-C Modules updated with COMX-C for Fieldbus Slaves

Table 7: Usage of Bolt for COM Modules updated

Designation of the COM-C expanded

Section Fieldbus Connector X2 for CANopen-Master/-Slave: COMX-CN-COS

added

Section

added

Section

added

Section

Section Fieldbus Connector X2 for PROFIBUS-Master/-Slave: Note 2 added

Section Diagnostic Interface USB: Note removed, because firmware now supports

USB

Table 74: Hardware Revision of COMX Modules with new USB Interface updated

Table 75: Hardware Revision of COMX Modules with old USB Interface updated

German text replaced by English text in the following drawings: M0500081,

M0500084, M0600121, M0900141, M0900151, M0400353

Section SERCOS III Slave, CANopen Slave, DeviceNet Slave and PROFIBUS

DP Slave added with LED Description

Table 38: Technical Data – Operating Condition: COMX-Cx-COS, COMX-Cx-DNS

and COMX-Cx-DPS added

11 2011-03-20 H. Hentsch Section Mechanical Dimensions of COM-C Modules:

M0200373 updated to M0200374, M0200463 updated to M0200464. Tolerance of

PCB thickness is 1.00 mm (-0,0 +0,2)

Section

12 2011-06-10 R. Göbel

H. Hentsch

Table 4: List of Revisions (Part 2)

Separation of documents for COM and COMX.

This manual contains the description for COM.

COM-A and COM-B removed as they are to be discontinued.

Section Mechanical Dimensions of COM-C Modules: Section updated, M0200374

updated, M0300632 updated

Table 5: COM-CA-EIS and COM-CN-EIS added

Section Meaning of the Rotary Switch added

Fieldbus Connector X2 for DeviceNet-Master/-Slave: COMX-CN-DNS

Fieldbus Connector X2 for PROFIBUS-Master/-Slave: COMX-CN-DPS

Fieldbus Connector X2 for CANopen-Master/-Slave: Note 2 added

Type of Connector: Headline ‘Cheaper version’ set to right position

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 8

Introduction 8/64

1.3 Technical Features

Common Technical Features for COM-C

Small footprint for the host connector with 50 mil grid

Solid mechanical assembly and a massive connection to earth ground by metal blocks spe-

cial design for the requirements of the Modules with fieldbus connector

Two dowels for exact mounting of the Module on the host board

Metal blocks can easily modified for special customer requirements

Front panel can be mounted on the metal blocks that the modules have always the same

front size and covers the fieldbus connector

Easy to use dual-port memory interface, with additional serial and diagnostic interface

Host interface is designed for 16 KByte address space of the dual-port memory with 8 bit bus

width.

3.3 V power supply reduce power consumption

Available in extended temperature specification

With the COM-C we have a much more compact form factor and additional technical features as

the already established COM Modules.

Extremely compact size 30 x 70 mm

Available with angled and without fieldbus connector

All fieldbus connectors are placed on one side, which is the edge side on the host board to

reserves space

2.5 mm space below the Module available for SMD components on the host board

Now you can have only one type of base board (for each COM family) on stock and you can mount

the requested fieldbus interface short before shipment to the customer. This gives much more

flexibility and saves money even if you have same mechanical constraints (for each COM family) in

comparison to our existing COM Modules. Therefore we have Modules with angled, straight and

without fieldbus connectors:

COM-CA COM-C Modules with angled fieldbus connector

COM-CN COM-C Modules without fieldbus connector

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 9

Introduction 9/64

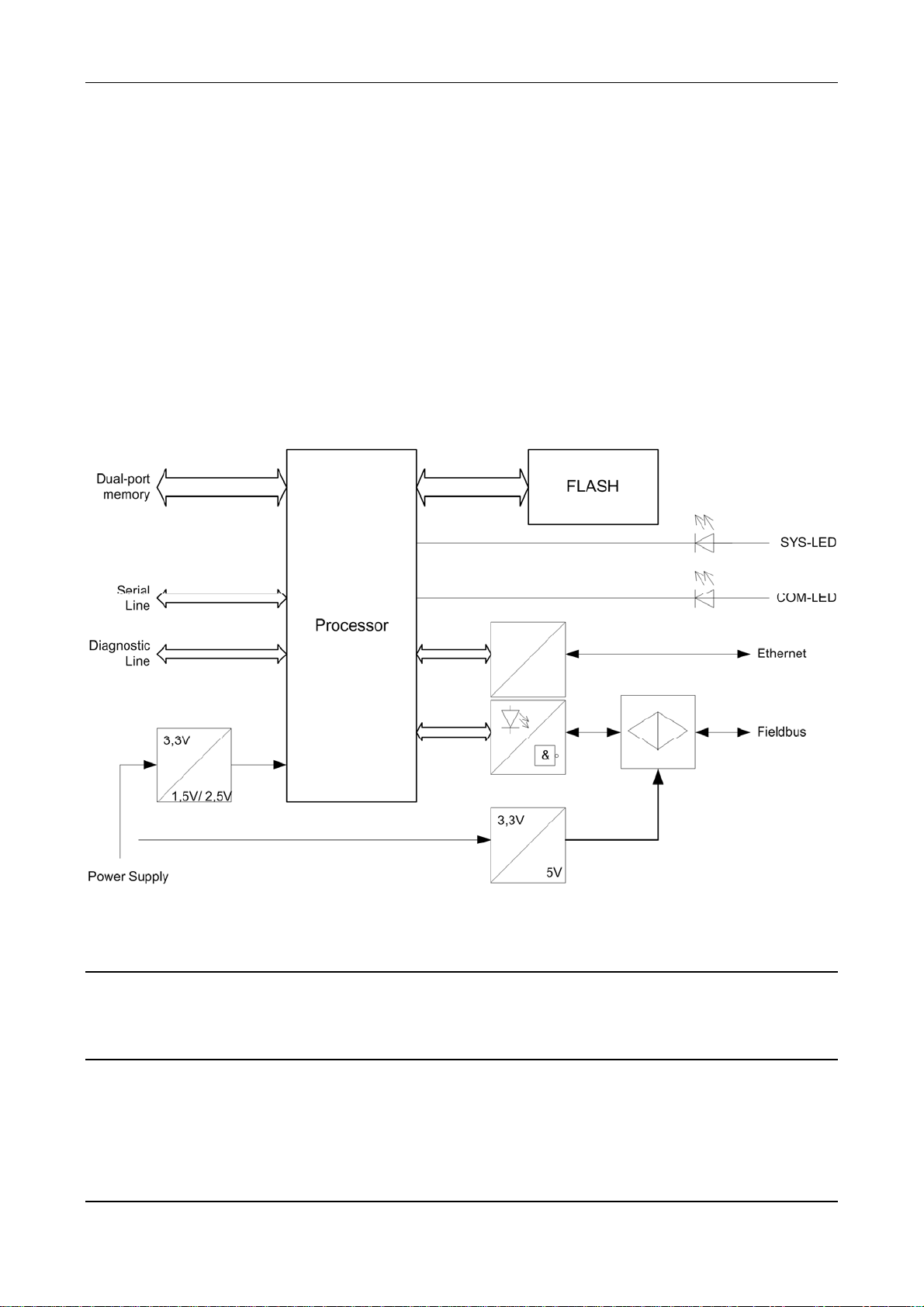

Description of COM Modules

All COM-C have a powerful processor and a complete fieldbus interface including isolated drivers

and the connector according to the standard. The slave modules have additional rotary switches to

set up the station address.

All boards require only a single stabilized 3.3 Voltage. All other voltages are created by DC/DC

converter on the COM-C Module.

The access to the COM-C Module is through the dual-port memory which can be easily integrated

as a static memory device. It has a non multiplexed 8 bit data bus with several control lines to the

host system. Between the COM-C Module and the host system it is possible to generate interrupts

for data handling.

Generally the firmware and the configuration data are stored permanently in FLASH memory by

loading the data through the dual port memory or the serial diagnostic line.

Figure 1: Block Diagram of the COM-C Modules

Note: The COM-CA-SCEB has only the special communication interface chip SERCON 816

on board. Programming of this chip must be done directly from the host application.

The description of the communication interface chip SERCON 816 can be get from the

‘SERCOS International’.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 10

Introduction 10/64

1.4 Legal Notes

1.4.1 Copyright

© Hilscher, 2002-2011, Hilscher Gesellschaft für Systemautomation mbH

All rights reserved.

The images, photographs and texts in the accompanying material (user manual, accompanying

texts, documentation, etc.) are protected by German and international copyright law as well as international trade and protection provisions. You are not authorized to duplicate these in whole or in

part using technical or mechanical methods (printing, photocopying or other methods), to manipulate or transfer using electronic systems without prior written consent. You are not permitted to

make changes to copyright notices, markings, trademarks or ownership declarations. The included

diagrams do not take the patent situation into account. The company names and product descriptions included in this document may be trademarks or brands of the respective owners and may be

trademarked or patented. Any form of further use requires the explicit consent of the respective

rights owner.

1.4.2 Important Notes

The user manual, accompanying texts and the documentation were created for the use of the

products by qualified experts, however, errors cannot be ruled out. For this reason, no guarantee

can be made and neither juristic responsibility for erroneous information nor any liability can be assumed. Descriptions, accompanying texts and documentation included in the user manual do not

present a guarantee nor any information about proper use as stipulated in the contract or a warranted feature. It cannot be ruled out that the user manual, the accompanying texts and the documentation do not correspond exactly to the described features, standards or other data of the delivered product. No warranty or guarantee regarding the correctness or accuracy of the information

is assumed.

We reserve the right to change our products and their specification as well as related user manuals, accompanying texts and documentation at all times and without advance notice, without obligation to report the change. Changes will be included in future manuals and do not constitute any

obligations. There is no entitlement to revisions of delivered documents. The manual delivered with

the product applies.

Hilscher Gesellschaft für Systemautomation mbH is not liable under any circumstances for direct,

indirect, incidental or follow-on damage or loss of earnings resulting from the use of the information

contained in this publication.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 11

Introduction 11/64

1.4.3 Exclusion of Liability

The software was produced and tested with utmost care by Hilscher Gesellschaft für Systemautomation mbH and is made available as is. No warranty can be assumed for the performance and

flawlessness of the software for all usage conditions and cases and for the results produced when

utilized by the user. Liability for any damages that may result from the use of the hardware or software or related documents, is limited to cases of intent or grossly negligent violation of significant

contractual obligations. Indemnity claims for the violation of significant contractual obligations are

limited to damages that are foreseeable and typical for this type of contract.

It is strictly prohibited to use the software in the following areas:

for military purposes or in weapon systems;

for the design, construction, maintenance or operation of nuclear facilities;

in air traffic control systems, air traffic or air traffic communication systems;

in life support systems;

in systems in which failures in the software could lead to personal injury or injuries leading to

death.

We inform you that the software was not developed for use in dangerous environments requiring

fail-proof control mechanisms. Use of the software in such an environment occurs at your own risk.

No liability is assumed for damages or losses due to unauthorized use.

1.4.4 Warranty

Although the hardware and software was developed with utmost care and tested intensively, Hilscher Gesellschaft für Systemautomation mbH does not guarantee its suitability for any purpose

not confirmed in writing. It cannot be guaranteed that the hardware and software will meet your requirements, that the use of the software operates without interruption and that the software is free

of errors. No guarantee is made regarding infringements, violations of patents, rights of ownership

or the freedom from interference by third parties. No additional guarantees or assurances are

made regarding marketability, freedom of defect of title, integration or usability for certain purposes

unless they are required in accordance with the law and cannot be limited. Warranty claims are

limited to the right to claim rectification.

1.4.5 Export Regulations

The delivered product (including the technical data) is subject to export or import laws as well as

the associated regulations of different counters, in particular those of Germany and the USA. The

software may not be exported to countries where this is prohibited by the United States Export

Administration Act and its additional provisions. You are obligated to comply with the regulations at

your personal responsibility. We wish to inform you that you may require permission from state authorities to export, re-export or import the product.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 12

Type of COM-C Modules 12/64

2 Type of COM-C Modules

The following table shows an overview about the availability of the different COM-C Modules.

Module Fieldbus / Protocol Type Connector

COM-CA-ASM AS-Interface Master angled

COM-CA-COS CANopen Slave angled

COM-CA-COM CANopen Master angled

COM-CA-CCS CC-Link Slave angled

COM-CA-DNS DeviceNet Slave angled

COM-CA-DNM DeviceNet Master angled

COM-CA-EN Ethernet angled

COM-CA-EIS EtherNet/IP Slave angled

COM-CA-IBS INTERBUS Slave angled

COM-CA-DPS PROFIBUS DP Slave angled

COM-CA-DPM PROFIBUS DP Master angled

COM-CA-SCEB SERCOS angled

COM-CN-ASM AS-Interface Master No

COM-CN-COS CANopen Slave No

COM-CN-COM CANopen Master No

COM-CN-CCS CC-Link Slave No

COM-CN-DNS DeviceNet Slave No

COM-CN-DNM DeviceNet Master No

COM-CN-EN Ethernet No

COM-CN-EIS EtherNet/IP Slave No

COM-CN-DPS PROFIBUS DP Slave No

COM-CN-DPS\NR

(NR = No Rotary switch)

COM-CN-DPM PROFIBUS DP Master No

Table 5: Available COM-C Modules

PROFIBUS DP Slave No

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 13

Type of COM-C Modules 13/64

2.1 Mechanical Dimensions

2.1.1 Common Mechanical Dimensions for COM-C Modules

After mounting the COM-CA Module parallel at a basis board the rotary switches, LEDs and the

fieldbus connector are on the top side and are angled to the basis board. The edge of all front elements are in one layer which is 2.5 mm ahead of the edge of printed circuit board of the COM

Module.

The COM-CN Module has to be used if the mechanical dimensions or order of the LEDs, switches

and fieldbus connector doesn't fit. In that case you have to place these components directly on the

motherboard and feed the signals to the connector X2 of the COM-CN Module.

Note Please take care on the isolation distance, because the optical isolation interface is on

the Module!

Especially for 12 MBit PROFIBUS the distance should as be less as possible.

For Ethernet, the signal traces should run parallel and should have the same length.

Please refer at the fieldbus standards for further information!

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 14

Type of COM-C Modules 14/64

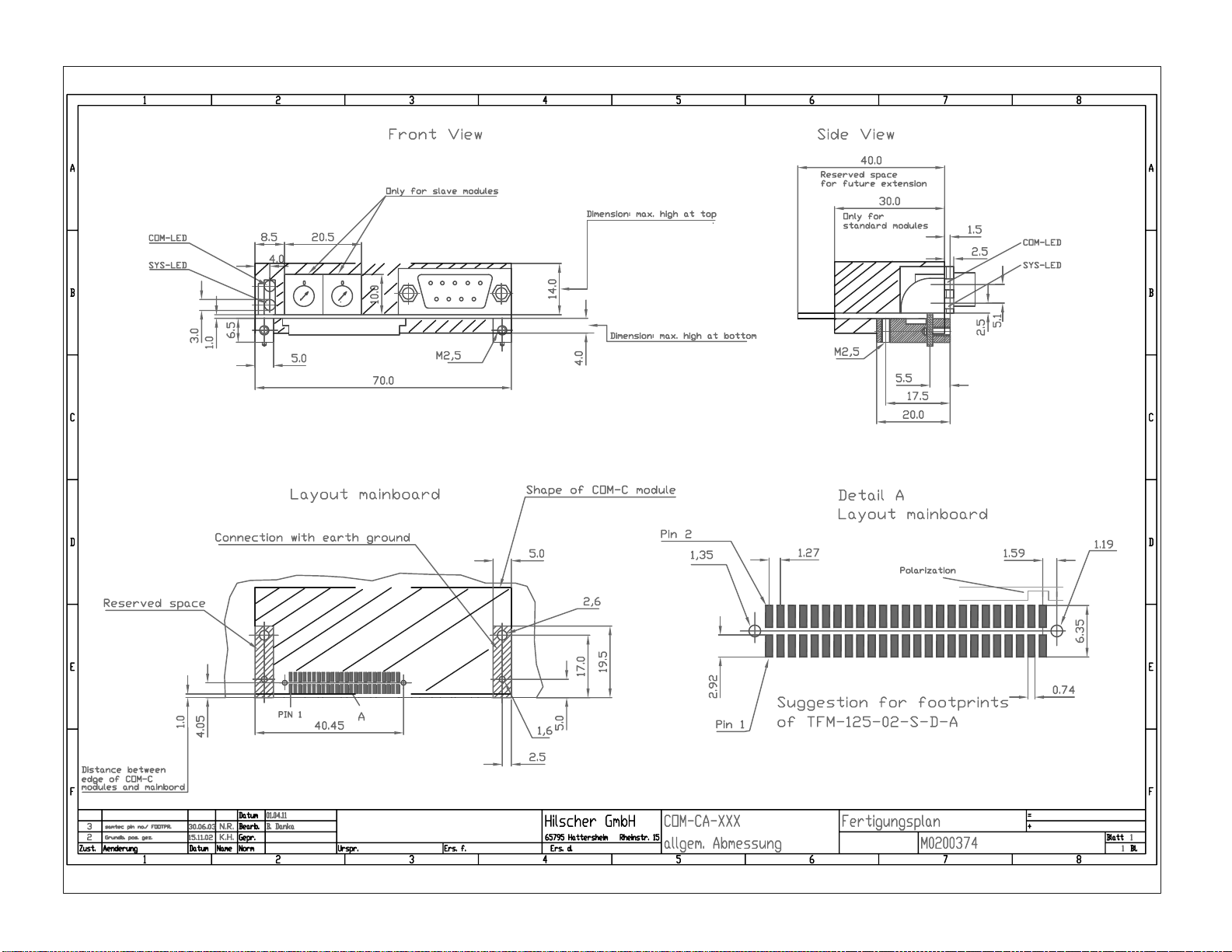

2.1.2 Mechanical Dimensions of COM-C Modules

The COM-C Module has a board size of 30 x 70 mm. The maximum height of the components at

the top side of the printed circuit board is 14.0 mm including the fieldbus connector. Keep the

space of 14.0 mm above the top side free.

At the bottom side the maximum height is 4.0 mm, therefore you have 2.5 mm space for components on the host board below the Module. The power dissipation in that area should be less than

330 maw!

For further Module development please reserve additional 10 mm space behind the Module. There

are a few larger fieldbus interfaces which do not fit on the small board space. In that case a second

printed circuit board will be mounted on top of the Module and the 10 mm space is necessary for

the connection with flex stripe between these boards.

The general dimensions of the COM-C Modules are shown on the following drawings:

M0200374 General Mechanical dimension of COM-CA-XXX

M0200464 Mechanical dimension of COM-CN-XXX

M0300632 Mechanical dimension of light pipe of COM-CA-XXX

M0400353 Mechanical dimension of Front Plate and Connector of COM-CA-XXX (part 1)

M0400363 Mechanical dimension of Front Plate and Connector of COM-CA-XXX (part 2)

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Type of COM-C Modules 20/64

2.2 Type of Connector

The connector X1 for the host interface is a 50 pins SMT female type with a grid of 1.27 mm. The

COM-CN Modules have an additional fieldbus connector X2 with 30 pins of the same family.

The connector of the motherboard is the corresponding male type and can be ordered as follows:

In Germany FJH die Steckverbinder GmbH

Hinter dem Turm 7

D-55286 Wörrstadt

Germany

Tel. +49 (0) 67 32 / 93 27 -0

Fax +49 (0) 67 32 / 93 27 -27

Web: www.fjh.de

Email:

info@fjh.de

50 pin. Box header 127 KA - 050 SB

30 pin. Box header 127 KA - 030 SB

World Wide SAMTEC

www.samtec.com

Cheaper version

50 pin. Connector TFM - 125 - 02 - S - D – A TFC - 125 - 02 - F - D – A

30 pin. Connector TFM - 115 - 02 - S - D – A TFC - 115 - 02 - F - D – A

Note: Datasheet of SAMTEC TFM connector see next page!

Please notice that the polarization of X1 and X2 is opposite to Pin 1!

The fieldbus connector on the Module is defined by the fieldbus standard as followed:

Fieldbus Connector Vendor

AS-Interface 2 pin, COMBICON, male

Grid 5.08 mm

CANopen 9 pin, DSub, male div. Vendor

DeviceNet 5 pin, COMBICON, male

Grid 5.08 mm

Ethernet 8 pin, RJ45, female div. Vendor

PROFIBUS 9 pin, DSub, female div. Vendor

InterBus 9 pin, DSub, male, female div. Vendor

CC-Link 5 pin, COMBICON, male

Grid 5.08 mm

Table 6: Connector Types

ie. PHOENIX Contact

MSTBA2,5/2-5,08-G

ie. PHOENIX Contact

MSTBA2,5/5-5,08G-AU

ie. PHOENIX Contact

MSTBA2,5/5-G-AU

Please use the same type of connector at the motherboard if you have chosen the COM-CN Module.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 21

Page 22

Type of COM-C Modules 22/64

2.3 Mounting of COM-C Modules

The COM-C Module has two metal blocks for mounting. This guaranties a robust mechanical construction and a solid connection to earth ground for the fieldbus connector. The metal blocks define

also the distance between the Module and host board. They are connected together with M2.5

screws.

On the front side of the metal blocks there are a M2.5 thread to mount a front panel directly on the

Module. This allows to have the same cutting in the device housing for all types of Modules.

Use fine technology that means six-mil-wide (150 μm) tracks

Note With this you have the possibility to get out between the pads.

For the power tracks you can insert a via straight in the pad.

To prevent a soldering problem please use a fine via (drill 0,2 mm).

Place a via between board edge and connector pad

Note There is 1 mm space between the connector and the board edge, where you can place

a 'normal' via (drill 0,3 mm) to feed the signals to the bottom side.

Figure 2: How to layout the Signals at the Connectors X1 and X2

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 23

Type of COM-C Modules 23/64

Four types of metal bolts are used. The following table lists the usage for each COM Module.

COM Type Left Side Right Side

COM-CA AS, CCS, CO, DN, DP, EN, IBS, SCEB COM-CA-B20X5 COM-CA-B20X5

COM-CN AS, CCS, CO, DN, DP, EN, IBS COM-CA-B20X5 COM-CA-B20X5

Table 7: Usage of Bolt for COM Modules

The drawings for the bolts are shown on the following drawings:

M0100084 Mechanical dimension of Bolt COM-CA-B20X5

M0600121 Mechanical dimension of Bolt COM-CA-B31,5X5

M0900102 Mechanical dimension of Bolt COM-CA-B24X5

M0200402 Mechanical dimension how to assemble COM-CA-XXX on the mother board

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 24

Page 25

Page 26

Page 27

Page 28

Type of COM-C Modules 28/64

2.4 Designation of the COM-C

Each COM-C Module has a matrix code label. A matrix label contains 3 items:

1. Part number

2. Hardware Revision

3. Serial number

The figure shows part number 1521.416, hardware revision 3 and serial number 00200.

Figure 3: Example Matrix Code label of COM-C Modules

The label is normally glued on top of the main processor.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 29

Type of COM-C Modules 29/64

2.5 Meaning of the Rotary Switch

The following figure shows the meaning of the rotary switch for COM-CA-DPS, COM-CA-COS and

COM-CA-DNS. The rotary switches are to set the bus address.

Figure 4: Meaning of the Rotary Switch

The following figure shows the meaning of the rotary switch for COM-CA-CCS and COM-CN-CCS.

The left and the middle rotary switch are to set the bus address.

Figure 5: Meaning of the Rotary Switch of COM-Cx-CCS

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 30

Host Interface 30/64

3 Host Interface

Attention! All COM modules have an operation voltage of 3.3 V which reduces the power con-

sumption. Therefore the voltage levels of the signals have to be not higher than 3.3 V

otherwise the module will be damaged.

The next sections show an overview of the signal pinning of the system connector.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 31

Host Interface 31/64

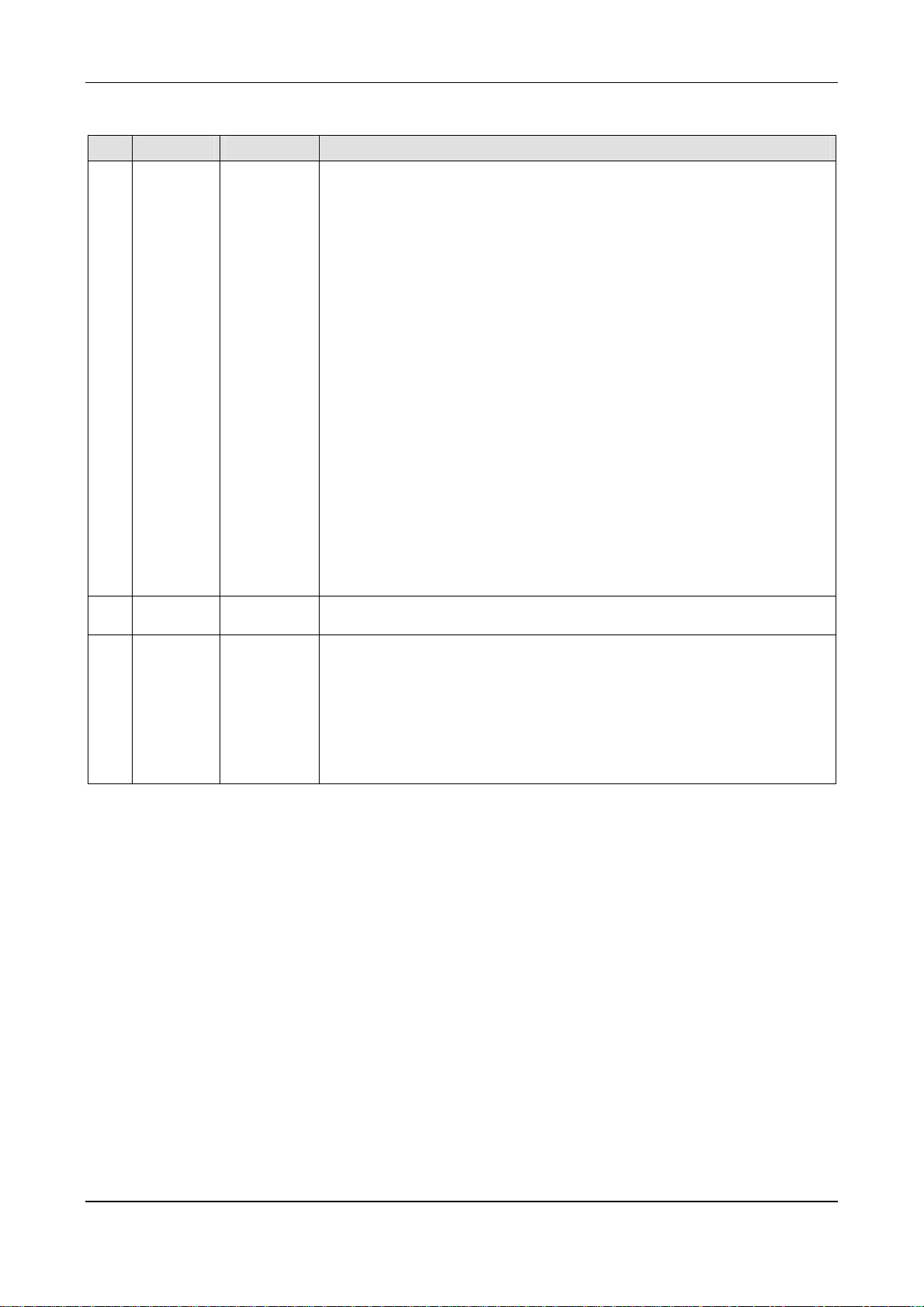

3.1 COM Pinning of the System Bus Connector X1

Pin Signal Symbol Type

1 Word Interface, active low WIF# GND if D8 - D15 is available (16 bit),

left unconnected if not (8 bit)

2 Bus high enable (future use), active low BHE# LVTTL Input

3 Data line 15 (future use) D15 LVTTL Input / Output

4 Data line 14 (future use) D14 LVTTL Input / Output

5 Data line 13 (future use) D13 LVTTL Input / Output

6 Data line 12 (future use) D12 LVTTL Input / Output

7 Data line 11 (future use) D11 LVTTL Input / Output

8 Data line 10 (future use) D10 LVTTL Input / Output

9 Data line 9 (future use) D9 LVTTL Input / Output

10 Data line 8 (future use) D8 LVTTL Input / Output

11 Ground GND

12 Power Supply +3.3 V

13 Transmit Data, Serial line TXD1 LVTTL Output

14 Receive Data, Serial line RXD1 LVTTL Input

15 Request to Send, Serial line RTS1 LVTTL Output

16 Clear to Send, Serial line CTS1 LVTTL Input

17 reserved for future - don't connect -

18 reserved for future - don't connect -

19 Receive Data, Diagnostic line RX0 LVTTL Input

20 Transmit Data, Diagnostic line TX0 LVTTL Output

21 Reset, active low RES# LVTTL Input; 10 k pull up

22 Busy, active low BUSY# LVTTL Output

23 Interrupt, active low INT# LVTTL Output

24 Read, active low RD# LVTTL Input

25 Write, active low WR# LVTTL Input

26 Chip select, active low CS# LVTTL Input

27 Address line 13 A13 LVTTL Input

28 Address line 12 A12 LVTTL Input

29 Address line 11 A11 LVTTL Input

30 Address line 10 A10 LVTTL Input

31 Address line 9 A9 LVTTL Input

32 Address line 8 A8 LVTTL Input

33 Address line 7 A7 LVTTL Input

34 Address line 6 A6 LVTTL Input

35 Address line 5 A5 LVTTL Input

36 Address line 4 A4 LVTTL Input

37 Address line 3 A3 LVTTL Input

38 Address line 2 A2 LVTTL Input

39 Address line 1 A1 LVTTL Input

40 Address line 0 A0 LVTTL Input

Table 8: COM Pinning of the System Bus Connector X1 (Part 1)

Continued on next page.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 32

Host Interface 32/64

Pin Signal Symbol Type

41 Data line 7 D7 LVTTL Input / Output

42 Data line 6 D6 LVTTL Input / Output

43 Data line 5 D5 LVTTL Input / Output

44 Data line 4 D4 LVTTL Input / Output

45 Data line 3 D3 LVTTL Input / Output

46 Data line 2 D2 LVTTL Input / Output

47 Data line 1 D1 LVTTL Input / Output

48 Data line 0 D0 LVTTL Input / Output

49 Ground GND

50 Power Supply +3.3 V

Table 9: COM Pinning of the System Bus Connector X1 (Part 2)

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 33

Host Interface 33/64

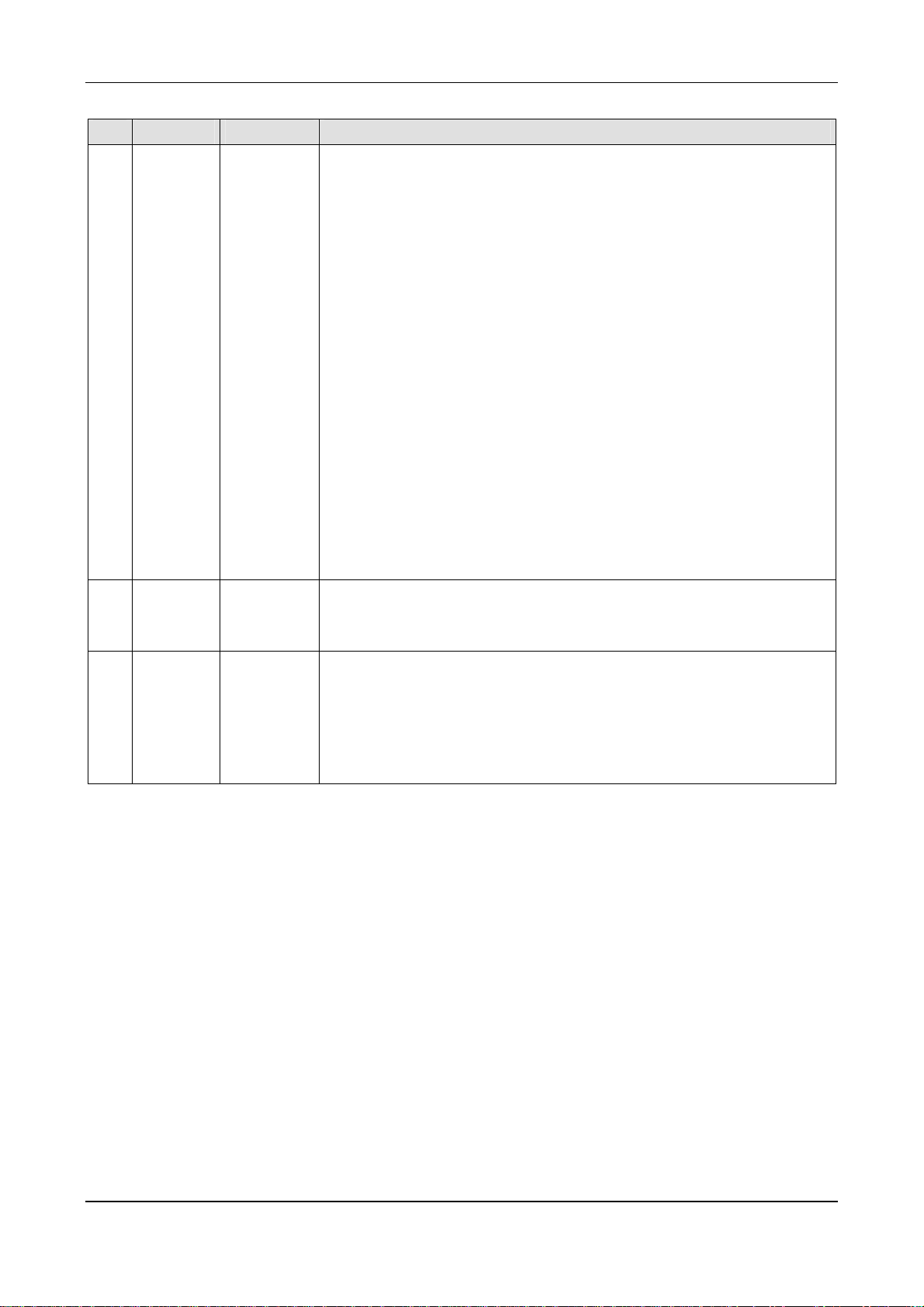

3.2 COM-CA-SCEB Pinning of the System Bus Connector X1

Pin Signal Symbol Type

1 Word Interface, active low WIF# GND if D8 - D15 is available (16 bit),

left unconnected if not (8 bit)

2 Bus high enable, active low BHE# LVTTL Input

3 Data line 15 D15 LVTTL Input / Output

4 Data line 14 D14 LVTTL Input / Output

5 Data line 13 D13 LVTTL Input / Output

6 Data line 12 D12 LVTTL Input / Output

7 Data line 11 D11 LVTTL Input / Output

8 Data line 10 D10 LVTTL Input / Output

9 Data line 9 D9 LVTTL Input / Output

10 Data line 8 D8 LVTTL Input / Output

11 Ground GND

12 Power Supply +3.3 V

13 reserved for future - don't connect -

14 reserved for future - don't connect -

15 reserved for future - don't connect -

16 reserved for future - don't connect -

17 Interrupt, active low INT1# LVTTL Output

18 reserved for future - don't connect -

19 reserved for future - don't connect -

20 reserved for future - don't connect -

21 Reset, active low RES# LVTTL Input; 10 k … 30 k pull up

22 Busy, active low BUSY# LVTTL Output

23 Interrupt, active low INT0# LVTTL Output

24 Read, active low RD# LVTTL Input

25 Write, active low WR# LVTTL Input

26 Chip select, active low CS# LVTTL Input

27 Address line 13 (reserved for future use) A13 LVTTL Input

28 Address line 12 A12 LVTTL Input

29 Address line 11 A11 LVTTL Input

30 Address line 10 A10 LVTTL Input

31 Address line 9 A9 LVTTL Input

32 Address line 8 A8 LVTTL Input

33 Address line 7 A7 LVTTL Input

34 Address line 6 A6 LVTTL Input

35 Address line 5 A5 LVTTL Input

36 Address line 4 A4 LVTTL Input

37 Address line 3 A3 LVTTL Input

38 Address line 2 A2 LVTTL Input

39 Address line 1 A1 LVTTL Input

40 Address line 0 A0 LVTTL Input

Table 10: COM-CA-SCEB Pinning of the System Bus Connector X1 (Part 1)

Continued on next page.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 34

Host Interface 34/64

Pin Signal Symbol Type

41 Data line 7 D7 LVTTL Input / Output

42 Data line 6 D6 LVTTL Input / Output

43 Data line 5 D5 LVTTL Input / Output

44 Data line 4 D4 LVTTL Input / Output

45 Data line 3 D3 LVTTL Input / Output

46 Data line 2 D2 LVTTL Input / Output

47 Data line 1 D1 LVTTL Input / Output

48 Data line 0 D0 LVTTL Input / Output

49 Ground GND

50 Power Supply +3.3 V

Table 11: COM-CA-SCEB Pinning of the System Bus Connector X1 (Part 2)

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 35

Host Interface 35/64

3.3 Signal Overview and Pinning of the Fieldbus Connector X2 on COM-CN

3.3.1 Fieldbus Connector X2 for AS-Interface-Master

Fieldbus connector X2 for COM-CN-ASM

Pin Signal Symbol Type Pin at Fieldbus

Connector

COMBICON

2pin

1

2

3

4

5

6

7

8

9

10 AS-i, Receive Data ASI_RX

11 AS-i, Power Fail ASI_PF LVTTL Output Note 1

12 AS-i, Transmit Data ASI_TX LVTTL Output Note 1

13 COM-LED, STA, Cathode yellow LED STA# 4 mA Output

14 SYS-LED, RUN, Cathode green LED RUN# 4 mA Output

15 COM-LED, ERR, Cathode red LED ERR# 4 mA Output

16 SYS-LED, RDY, Cathode yellow LED RDY# 4 mA Output

17 Ground GND

18 Power Supply +3.3 V

19 Peripheral IO PIO LVTTL Input / Output

20 Don't use - needed for isolation

21 Don't use - needed for isolation

22

23

24

25

26

27

28

29 AS-i + Bus line AS-i+ +24 V with AS-i 1

30 AS-i - Bus line AS-i- 0 V with AS-i 2

Table 12: Fieldbus Connector X2 for AS-Interface-Master

LVTTL Input Note 1

Note Information

1 LVTTL Signals could be only used without the hardware interface on the COM. Ask for special customer ver-

sion.

Table 13: Notes for Fieldbus Connector X2 for AS-Interface-Master

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 36

Host Interface 36/64

3.3.2 Fieldbus Connector X2 for CANopen-Master/-Slave

Fieldbus connector X2 for COM-CN-COM / COM-CN-COS

Pin Signal Symbol Type Pin at Fieldbus

Connector

DSub 9, male

1

2

3

4

5

6

7 CAN, Receive Data CAN_RX1 LVTTL Input Note 1

8

9 CAN, Transmit Data CAN_TX1 LVTTL Output Note 1

10

11

12

13 COM-LED, STA, Cathode yellow LED STA# 4 mA Output Note 2

14 SYS-LED, RUN, Cathode green LED RUN# 4 mA Output

15 COM-LED, ERR, Cathode red LED ERR# 4 mA Output

16 SYS-LED, RDY, Cathode yellow LED RDY# 4 mA Output

17 Ground GND

18 Power Supply +3.3 V

19 Peripheral IO PIO LVTTL Input / Output

20 Don't use - needed for isolation

21 Don't use - needed for isolation

22

23 CAN_H Bus line CAN_H ISO 11898 7

24

25

26 CAN Ground CAN_GND 3

27

28

29 CAN_L Bus line CAN_L ISO 11898 2

30

Table 14: Fieldbus Connector X2 for CANopen-Master/-Slave

Note Information

1 LVTTL Signals could be only used without the hardware interface on the COM. Ask for special customer ver-

sion.

2 Yellow LED for COM-CN-COM / COM-CN-COS

Table 15: Notes for Fieldbus Connector X2 for CANopen-Master/-Slave

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 37

Host Interface 37/64

3.3.3 Fieldbus Connector X2 for DeviceNet-Master/-Slave

Fieldbus connector X2 for COM-CN-DNM / COM-CN-DNS

Pin Signal Symbol Type Pin at Fieldbus

connector

COMBICON

5pin

1

2

3

4

5

6

7 CAN, Receive Data CAN_RX1 LVTTL Input Note 1

8

9 CAN, Transmit Data CAN_TX1 LVTTL Output Note 1

10

11 CAN, Power Fail CAN_PF1 LVTTL Input Note 1

12

13 MNS-LED, active low, Cathode green LED MNS_CG# 4 mA Output

14 RUN-LED, RUN, Cathode green LED RUN# 4 mA Output

15 MNS-LED, active low, Cathode red LED MNS_CR# 4 mA Output

16 SYS-LED, RDY, Cathode yellow LED RDY# 4 mA Output

17 Ground GND

18 Power Supply +3.3 V

19 Peripheral IO PIO LVTTL Input / Output

20 Don't use - needed for isolation

21 Don't use - needed for isolation

22

23

24

25

26 Reference potential DeviceNet V- 1

27 CAN Low-Signal CAN_L 2

28 Shield Drain 3

29 CAN High-Signal CAN_H 4

30 +24V Power Supply DeviceNet V+ 5

Table 16: Fieldbus Connector X2 for DeviceNet-Master/-Slave

Note Information

1 LVTTL Signals could be only used without the hardware interface on the COM. Ask for special customer ver-

sion.

Table 17: Notes for Fieldbus Connector X2 for DeviceNet-Master/-Slave

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 38

Host Interface 38/64

3.3.4 Fieldbus Connector X2 for PROFIBUS-Master/-Slave

Fieldbus connector X2 for COM-CN-DPM / COM-CN-DPS

Pin Signal Symbol Type Pin at Fieldbus

connector

DSub-9,

female

1 PROFIBUS, Receive Data PB_RX LVTTL Input Note 1

2

3 PROFIBUS, Transmit Data PB_TX LVTTL Output Note 1

4

5 PROFIBUS, Enable Bus Driver PB_ENB LVTTL Output Note 1

6

7

8

9

10

11

12

13 COM-LED, STA, Cathode yellow LED STA# 4 mA Output Note 2

14 SYS-LED, RUN, Cathode green LED RUN# 4 mA Output

15 COM-LED, ERR, Cathode red LED ERR# 4 mA Output

16 SYS-LED, RDY, Cathode yellow LED RDY# 4 mA Output

17 Ground GND

18 Power Supply +3.3 V

19 Peripheral IO PIO LVTTL Input / Output

20 Don't use - needed for isolation

21 Don't use - needed for isolation

22 Reference potential DGND 5

23 Control CNTR-P LVTTL 4

24

25 Receive / Send Data-N RXD/TXD-N RS 485 8

26 Receive / Send Data-P RXD/TXD-P RS 485 3

27

28

29 Positive power supply VP + 5V 6

30

Table 18: Fieldbus Connector X2 for PROFIBUS-Master/-Slave

Note Information

1 LVTTL Signals could be only used without the hardware interface on the COM. Ask for special customer ver-

sion.

2 Yellow LED for COM-CN-DPM / COM-CN-DPS

Table 19: Notes for Fieldbus Connector X2 for PROFIBUS-Master/-Slave

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 39

Host Interface 39/64

3.3.5 Fieldbus Connector X2 for Ethernet

Fieldbus connector X2 for COM-CN-EN

Pin Signal Symbol Type Pin at Fieldbus

connector

RJ45

1

2 Ethernet, Receive Data N EN_IN MAC Input neg. Note 1

3

4 Ethernet, Receive Data P EN_IP MAC Input pos. Note 1

5

6 Ethernet , Transmit Data N EN_ON MAC Output neg. Note 1

7

8 Ethernet, Transmit Data P EN_OP MAC Output pos. Note 1

9

10

11

12

13 LINK-LED, active low LNK# 4 mA Output

14 SYS-LED, RUN, Cathode green LED RUN# 4 mA Output

15 ERR-LED, active low ERR# 4 mA Output

16 SYS-LED, RDY, Cathode yellow LED RDY# 4 mA Output

17 Ground GND

18 Power Supply +3.3 V

19 Peripheral IO PIO LVTTL Input / Output

20 Don't use - needed for isolation

21 Don't use - needed for isolation

22

23 Transmit Data + TX+ 1

24 Transmit Data - TX- 2

25 Receive Data + RX+ 3

26

27

28 Receive Data - RX- 6

29

30

Table 20: Fieldbus Connector X2 for Ethernet

Note Information

1 Ethernet Signals could be only used without the hardware interface on the COM. Ask for special customer ver-

sion.

Table 21: Notes for Fieldbus Connector X2 for Ethernet

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 40

Host Interface 40/64

3.3.6 Fieldbus Connector X2 for CC-Link-Slave

Fieldbus connector X2 for COM-CN-CCS

Pin Signal Symbol Type Pin at Fieldbus

Connector

COMBICON

5pin

1

2 Receive Driver Enable RDENL# 8 mA Output Note 1

3

4 CC-Link, Transmission period signal SDGATEON 12 mA Output Note 1

5

6 CC-Link, Transmission Data SD 4 mA Output Note 1

7

8 CC-Link, Received Data (channel 1) RD1 TTL Input Note 1

9

10

11

12

13 COM-LED, STA, Cathode yellow LED STA# 4 mA Output

14 SYS-LED, RUN, Cathode green LED RUN# 4 mA Output

15 COM-LED, ERR, Cathode red LED ERR# 4 mA Output

16 SYS-LED, RDY, Cathode yellow LED RDY# 4 mA Output

17 Ground GND

18 Power Supply +3.3V

19

20 Don't use - needed for isolation

21 Don't use - needed for isolation

22

23

24

25

26 CC-Link, Data A DA 1

27 CC-Link, Data B DB 2

28 CC-Link, Data Ground DG 3

29 CC-Link, Function Ground FG 5

30 CC-Link, Shield SLD 4

Table 22: Fieldbus Connector X2 for CC-Link-Slave

Note Information

1 Signals could be only used without the hardware interface on the COM. Ask for a special customer version.

Table 23: Notes for Fieldbus Connector X2 for CC-Link-Slave

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 41

Host Interface 41/64

3.4 Signals of the Host Interface

3.4.1 Power Supply of the COM-C Modules

Only a single 3.3 V operation voltage is needed for the COM-C Module. The voltage must be regulated and can have a tolerance of ±5% (3.1 - 3.5 Volt) and must be connected twice to the system

bus connector X1. To avoid EMI problems we suggested using bypass capacitors in the power

supply path. All other special voltages required on the COM-C Module are generated by on board

DC/DC converter.

A watchdog circuit on all COM-C Modules supervises the voltage and the microprocessor. If the

voltage falls below the voltage reset level of typically 2.93 V (2.85 - 3.00 V) the COM-C are hold in

reset state. If the voltage increases over the reset voltage level the COM-C Module begin with the

power up sequence. To avoid problems with the power supply we recommended using a voltage of

3.3 V. So the operation will be in the safe range of voltage operation area and short voltage drops,

spikes and noise will not produce any reset conditions.

3.4.2 RESET Signal

It is possible to reset the COM-C Module by the extra reset signal RES#. For operation of the

COM-C Modules it is important to switch the signal RES# to high level. Then the COM-C Modules

begins with the program execution and initialization. This power up time is different for each COMC Module. Normally, the time is about less than two seconds. The COM-C Module is in reset state

when the signal RES# has a static low level. To reset the COM-C Module the RES# signal must be

low for more than 10 µs.

Note During Reset all signals of the Dual-port memory are configured as inputs! The output

level could be floating. If the host system needs a stable level a pull-up or pull-down resistor is required on the host board.

3.4.3 The Dual-port Memory Bus of COM

The communication for all input and output data and control commands between the COM-C Module and the host system are exchanged over the dual port memory with the same memory address

map. The highest 1 KByte is reserved for the communication mailboxes and some control and parameter values. The rest of the Dual-port memory is divided into two data areas, an input and output process data. Please refer at the special documents of the data model and communication

methods.

From host system side, the Dual-port memory looks like static RAM. The COM-C Modules have

always an 8 KByte Dual-port memory even if the firmware doesn't need so much memory. Only a

few signals are used to control the access to the Dual-port memory.

The maximum driving capability for the data lines is 4 mA.

To avoid data loss through simultaneous access at the same memory cell, it is necessary to use

the BUSY# signal.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 42

Host Interface 42/64

3.4.4 Address Bus and Data Bus

These signal lines contain the address bus lines A0 till A13 and data bus lines D0 up to D15 of the

Dual-port memory. The address and data lines are non-multiplexed. Generally the COM devices

use only an 8 Bit data bus (signals D0-D7) but the signals D8-D15, BHE# and WIF# are not connected.

The COM-CA-SCEB devices support additional data bus lines to drive a 16 Bit data interface. If

your host interface can support 16 Bit you should connect the WIF# signal to ground. If not please

let this uncommitted that 16 Bit modules will work in a compatible 8 Bit mode.

In case of a 16 Bit system you have to generate the BHE# and A0 signal according the following

table.

BHE# A0 Function

0 0 word access

0 1 access high byte

1 0 access low byte

1 1 no access

Table 24: Function Table of the 16 Bit Decode Logic

3.4.5 Dual-Port Memory Control Lines

The user has to integrate the Dual-port memory by mapping the memory space of the Dual-port

memory into the address range of the host system.

The access to the Dual-port memory is handled over the control lines write WR#, read RD# and

Chip select CS# and could be like standard static RAM. All signals are low active.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 43

Host Interface 43/64

3.4.6 Interrupt Line to the Host System

The signal INT# can be used to generate an interrupt at the host system when the COM-C Module

writes into the special handshake cells of the Dual-port memory. These cells are used for synchronization of the COM-C Module and the host system and have some handshake bits. For detailed

information see the special documentation for the Dual-port memory software protocol. The interrupt will be only cleared if the host reads a handshake cells.

3.4.7 Busy Line to the Host System

The signal BUSY# is used to insert wait states into an current access from host system to a COMC module. When the signal is active the host must hold on the current transfer.

3.4.8 Interfacing to the Dual-Port Memory of COM-C

If you connect the host system to the Dual-port memory you have to know some details of the functional working of the used microcontroller EC1. Generally it works like a standard SRAM. To ensure the proper operation of the Ethernet and the PROFIBUS when the host systems generates

very low speed accesses you have to consider the BUSY# signal.

To solve this problem, the external accesses to the EC1 Dual-port memory are internally synchronized to the EC1 memory cycle. This technique actually removes the possibility of the EC1 and the

external interface accessing the Dual-port memory at the same time. The internal memory bus arbitration logic insures that this cannot happen. The external interface may have to wait for several

EC1 memory cycles, but this is a short 80-145 ns compared to the 500 ns of the PC/ISA cycle.

When the PC/ISA interface starts its access to the Dual-port memory, the request is synchronized,

and the memory cycle to the Dual-port memory is completed during a normal EC1 memory cycle of

20.8 ns. The only additional requirement is that the write data has to be valid when the WR# strobe

for the external memory access becomes active. Fortunately, this is the normal case.

Note It is not possible to switch the address line with active CE# and WR# or RD# lines (no

burst access). The internal synchronization cycle is started only when CE# and WR' or

RD# is going low.

The EC1 does have a busy signal to synchronize the external accesses to the Dual port memory.

The BUSY# signal is a normally low signal that goes high once the Dual-port memory access has

completed. It will remain high until the external cycle completes. If the external memory cycle is

longer than 145 ns, then the BUSY# signal can just be ignored.

For further details please refer the following timing diagrams.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 44

Host Interface 44/64

3.4.9 Timing Diagram of COM-C

Figure 6: COM Timing Diagram of a Read Cycle at the Dual-Port Memory

Figure 7: COM Timing Diagram of a Write Cycle at the Dual-Port Memory

Continued on next page.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 45

Host Interface 45/64

No. Description Min. Max. Units

1 CS#, RD# low to BUSY# low 6 ns

2 Read Data available to BUSY# high 12 ns

4 BUSY# low width 0 3 - 7 CLK Cycle

5 CS#, WR# low to BUSY# low 6 ns

6 Write Data setup time to BUSY high 26 ns

8 BUSY# low width 0 3 - 7 CLK Cycle

CLK Cycle is 20.8 ns with 48 MHz CLK

Both CS# and RD# resp. CS# and WR# must be low to start a Dual-port memory cycle

If the CS# signal is going low or held low the BUSY# signal goes also low

Then after some clock cycle the BUSY# signal is released and going to high level

It's not possible to change the address lines with holding low the RD# or WR# signal low

The high level between two read and/or write cycles the RD# and WR# signals must be longer held at

Table 25: Symbols for COM Timing Diagram of a Read respectively Write Cycle at the Dual-Port Memory

Notes

high level than two CLK Cycle (41.6 ns)

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 46

Host Interface 46/64

3.4.10 Interfacing to the Dual-Port Memory for COM-CA-SCEB

The connection of the COM-CA-SCEB can be done like for the other COM-C. The timing is a little

bit different because of the used SERCON 816 protocol interface chip. Please ask for details of

timing and wiring if necessary.

3.4.11 Timing Diagram of COM-CA-SCEB

Ask for the special timing diagram of the COM-CA-SCEB Module if necessary.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 47

Host Interface 47/64

3.5 Integration a COM-C Module into a Host System

The following picture shows an example for a connection of a COM- C Module directly to a microprocessor. The signal lines of the COM-C Module are directly connected to the microprocessor

AM80C188ER which runs with 3.3 V. For other microprocessor families please check the bus timing and the control signals if additional glue logic is needed.

Figure 8: Connection Diagram of a COM-C Module with AM80C188ER Microprocessor

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 48

LEDs 48/64

4 LEDs

To get a fast overview about the status of the Module and the Communication two duo color LEDs

are placed on the Module respectively can be connected.

SYS defines the general status of the Module, means self test passed, firmware and configuration

loaded. On the Module we are using the colors yellow for hardware and basic function oriented information like self test passed, firmware loaded. Green is used for application oriented functions

like valid configuration loaded for that LED.

2nd Status LED shows communication errors or status and communication activities. If there is no

definition in the fieldbus standard we use red for error and yellow for status. If there is a definition

we use these for the functions and colors of that LED. For the Modules described in that revision of

the manual it is only for DeviceNet the case.

The outputs can drive max. 4 mA. If this is too less an external driver should be placed before the

LEDs.

The following schematic shows how to connect the LEDs.

In some cases the brightness of the LEDs of the duo color LEDs are so different that it makes

sense to use different resistors to make it equal. This is shown as an example for the LED COM.

The following figure shows the example how to connect the LED for COM-CN-ASM, COM-CNCOM, COM-CN-COS, COM-CN-DNM, COM-CN-DNS, COM-CN-DPM, COM-CN-DPS and COMCN-CCS.

Figure 9: Example how to connect the LEDs COM-CN

This design is possible for all current COM modules except COM-CN-RE.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 49

LEDs 49/64

4.1 LEDs for COM Modules

4.1.1 Ethernet

The LEDs for Ethernet depends on the used firmware.

LED Color State Meaning

SYS

NET

Table 26: LED Ethernet (COM)

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Communication is running, the device has established at least one

connection

green Flashing cyclic at 5Hz No error in the configuration found, communication is stopped or

ready for communication but no connection established.

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing.

- Off Device has no power supply or hardware defect

On depends on used firmware green

Flashing depends on used firmware

On depends on used firmware red

Flashing depends on used firmware

red/green Flashing depends on used firmware

- Off depends on used firmware

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

4.1.2 EtherNet/IP Adapter (Slave)

LED Color State Meaning

SYS

COM

Table 27: LED EtherNet/IP Adapter (COM)

(*) 3 times fast at 5 Hz, 8 times between 0.5 Hz and 1 Hz

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Slave in cyclic data exchange with the Master

green Flashing cyclic at 5Hz Slave has no cyclic data exchange with the Master

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

yellow On A connection to the Ethernet exists

yellow Flashing The device sends/receives Ethernet frames

red On not used

- Off The device has no connection to the Ethernet

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 50

LEDs 50/64

4.1.3 AS-Interface Master

LED Color State Meaning

SYS

CH1

Table 28: LED AS-Interface Master (COM)

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Communication is running, the device has established at least one

configured fieldbus connection

green Flashing cyclic at 5Hz No error in the configuration found, communication is stopped or

ready for communication but no connection to any Slave.

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

On No configuration error, data exchange active green

Flashing Configuration error, data exchange active

On Heavy system error or hardware failure red

Flashing AS-Interface power fail

red/green Flashing Project mode active

- Off No configuration found for the AS Interface channel

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 51

LEDs 51/64

4.1.4 CANopen Master

LED Color State Meaning

SYS

COM

Table 29: LED CANopen Master (COM)

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Communication is running, the device has established at least one

configured fieldbus connection

green Flashing cyclic at 5Hz No error in the configuration found, communication is stopped or ready

for communication but no connection to any CANopen Node

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defected

yellow On Device sends a telegram

red On Device has detected a communication problem to at least one

CANopen Node

- Off Device is ready to receive or is receiving telegrams

4.1.5 CANopen Slave

LED Color State Meaning

SYS

COM

Table 30: LED CANopen Slave (COM)

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Node is in state Operational

green Flashing cyclic at 5Hz Node is in state preoperational (respectively prepared)

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defected

yellow On Device sends a telegram

red On Node has left the state Operational

- Off Device is ready to receive or is receiving telegrams

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 52

LEDs 52/64

4.1.6 CC Link Slave

LED Color State Meaning

SYS

STA

Table 31: LED CC-Link Slave (COM)

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Slave in cyclic data exchange with CC-Link Master

green Flashing cyclic at 5Hz No error in the configuration found, communication is stopped or

ready for communication but the device has no cyclic data exchange

with the CC-Link Master

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

yellow On Connection to CC-Link Master established

red

- Off No connection to CC-Link Master

On CRC error detected or station address not valid (valid is 1 … 64) or

baud rate not valid (valid is 0 ... 4)

Flashing cyclic at 2.5Hz Station address or baud rate setting was changed since the last net-

work controller reset.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 53

LEDs 53/64

4.1.7 DeviceNet Master

LED Color State Meaning

SYS

MNS

Table 32: LED DeviceNet Master (COM)

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Communication is running, the device has established at least one

configured fieldbus connection

green Flashing cyclic at 5Hz No error in the configuration found, communication is stopped or

ready for communication but no connection to any Slave.

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

On Device is online and has at least one connection in established state green

Flashing Device is online and has no connection in established state

red

red/green Flashing Communication faulted state

- Off Not powered, not online.

On Critical link failure; Device has detected a network error (duplicate

MAC-ID or bus off)

Flashing Connection timeout

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

4.1.8 DeviceNet Slave

LED Color State Meaning

SYS

MNS

Table 33: LED DeviceNet Slave (COM)

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Communication is running, the device has established one connec-

tion

green Flashing cyclic at 5Hz No error in the configuration found, ready for communication but no

established connection

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

On Device is operational, online and connection is established green

Flashing Device is operational, online and connection is not established

On Critical fault red

Flashing Minor fault

red/green Flashing Communication faulted

- Off Not powered, not online

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 54

LEDs 54/64

4.1.9 InterBus Slave

LED Color State Meaning

On Protocol chip is supplied with power. UL green

Off Reset. Protocol chip is not supplied with power.

On Communication to the IBS Master is possible. RC green

Off Communication to the IBS Master is not possible.

BA green

Table 34: LED InterBus Slave (COM)

On Master active, user data is exchanged

Flashing irregular Communication is not possible,

system operation is being monitored.

Off No user data is exchanged.

On The outgoing interface is disabled. RD yellow

Off The outgoing interface is not disabled.

On PCP communication, send or receive TR green

Off No PCP data is exchanged.

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 55

LEDs 55/64

4.1.10 PROFIBUS DP Master

LED Color State Meaning

SYS

COM

Table 35: LED PROFIBUS DP Master (COM)

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Communication is running, the device has established at least one

configured fieldbus connection

green Flashing cyclic at 5Hz No error in the configuration found, communication is stopped or ready

for communication but no connection to any slave

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

yellow On Devise is holding the PROFIBUS Token and is able to transmit tele-

grams

yellow Flashing irregular (**) Devise is sharing the PROFIBUS Token with other Master devices in

the PROFIBUS network

red On Device has found a communication problem to at least one PROFIBUS

DP Slave or has detected a short circuit

- Off Device is not configured or has not received the Token permission on

the PROFIBUS network

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

(**) between 0,5 Hz and 1 Hz

4.1.11 PROFIBUS DP Slave

LED Color State Meaning

SYS

COM

Table 36: LED PROFIBUS DP Slave (COM)

(*) 3 times fast at 5 Hz, 8 times between 0,5 Hz und 1 Hz

yellow Flashing cyclic at 1Hz Device is in boot loader mode and is waiting for firmware download

yellow Flashing cyclic at 5Hz Firmware download is in progress

yellow Flashing irregular (*) Hardware or heavy runtime error detected

green On Slave in cyclic data exchange with DP Master

green Flashing cyclic at 5Hz Slave has no cyclic data exchange with DP Master

green Flashing irregular (*) Power Up: Configuration missing or faulty, device needs commission-

ing, Runtime: Host Watchdog timeout

- Off Device has no power supply or hardware defect

yellow On Slave has received parameter data / configuration data from DP Mas-

ter and has reached the state data exchange

red On Application program (communication mode: bus synchronous / device

controlled) not longer synchronous to bus cycle

- Off Slave has not reached the state data exchange

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 56

LEDs 56/64

4.1.12 SERCOS (optical)

LED Color State Meaning

On Device is powered and not in reset state RDY yellow

Off Device is not powered or in reset state

On or Flashing Communication errors detected ERR red

Off No communication errors

Table 37: LED SERCOS (COM)

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 57

Device Address 57/64

5 Device Address

The COM-CA Slave Modules have the rotary switch to set up the device address on board. If the

Module COM-CN is used for slave the address can be set by software over the dual-port memory.

Note: This feature is not available at the CC-Link Module COM-Cx-CCS, because the CC-

Link Communication Controller allows only a direct connection of the address switches.

Figure 10: Schematic to read in the device address for COM-CN Slave Modules

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 58

Diagnostic Interface 58/64

6 Diagnostic Interface

6.1 Diagnostic Interface RS232C

The signals TX0 and RX0 are transmit and receive signals to use with an RS232C interface for diagnostic purpose.

Over this diagnostic line you can download a new firmware, configuration files or make only diagnostic during running communication.

The following schematic shows an example for the RS232C interface necessary on the host board.

The module has not integrated drivers.

Figure 11: RS232C Interface Circuit for the Diagnostic Interface

COM-C | Communication Module

DOC021001DG12EN | Revision 12 | English | 2011-06 | Released | Public © Hilscher, 2002-2011

Page 59

Technical Data 59/64

7 Technical Data

Operating Condition Minimum Maximum

Operating temperature [° C]

COM-C

Storage temperature [° C] Standard

Operating voltage [V] U1