Hillyard TRIDENT R30SC Use And Maintenance Manual

Scrubbing machine

Use and Maintenance manual

Original instructions - DOC. 10075358- Ver. AA - 11-2017

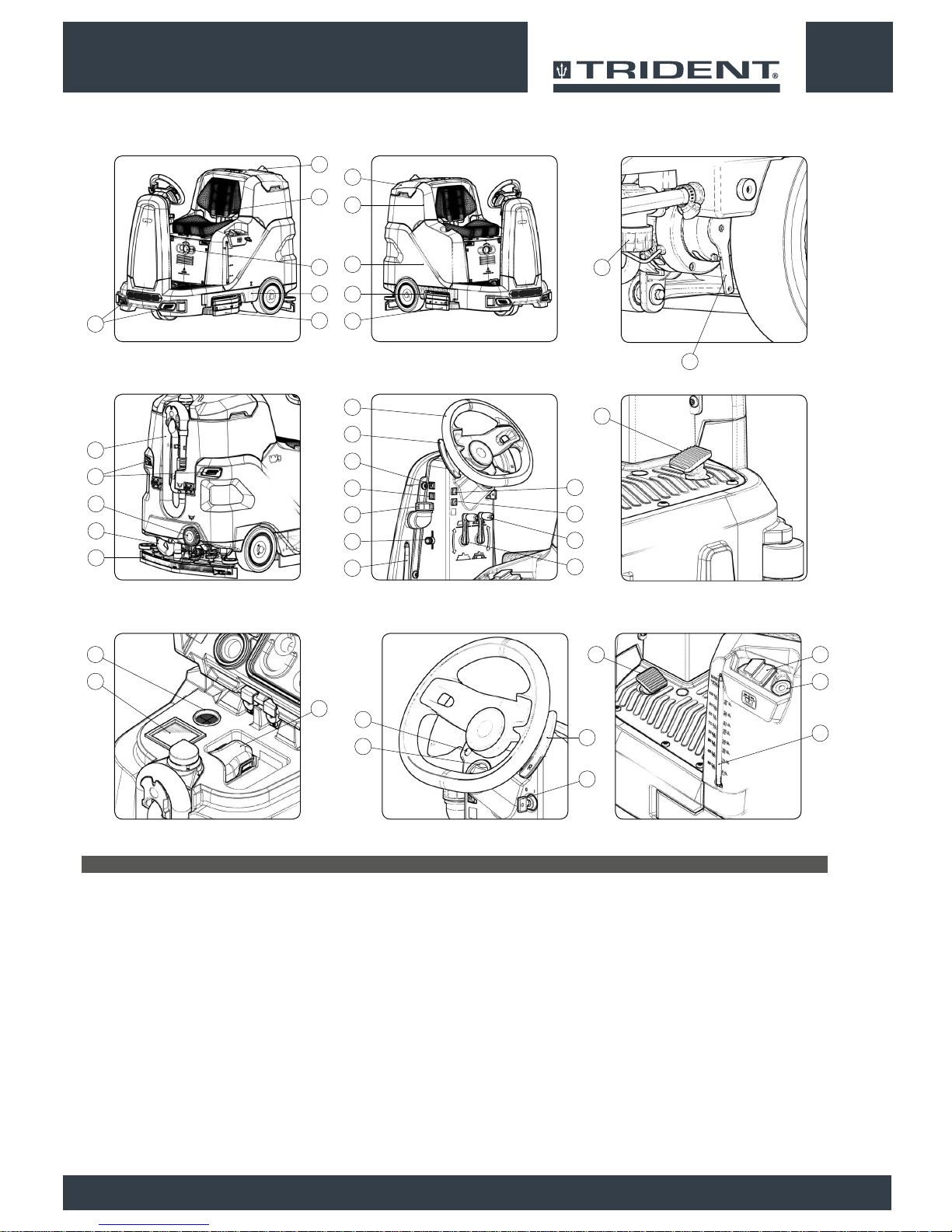

The machine's main components are the following:

1. Right-hand splash guard pre-assembly.

2. Scrubbing brush head.

3. Squeegee body.

4. Hour meter display – battery charge level.

5. Headlights (optional).

6. Tail lights (optional).

7. Vacuum motor air intake lter.

8. Vacuum motor air duct lter.

9. Recovery tank lter.

10. Detergent solution lter.

11. Main key switch.

12. Blinking light (optional).

13. Brush head extra pressure LED indicator.

14. Brush head control lever.

15. Electric brake control lever.

16. Detergent solution tap control lever.

17. Squeegee control lever.

18. Brush head extra pressure selection lever.

19. Reverse gear selection lever.

20. Service brake pedal.

21. Drive pedal.

22. Horn button.

23. Adjustment button for HDC system detergent solution (optional).

24. HDC system activation button (optional).

25. Emergency button.

26. Operator seat

27. Recovery tank lid.

28. Recovery tank.

29. Solution tank.

30. Right hatch.

31. Left hatch.

32. Squeegee support.

33. Solution tank drainage shaft cap.

34. Solution tank cap.

35. Squeegee vacuum hose.

36. Solution tank rapid lling hose.

37. Solution tank level hose.

38. Recovery tank drainage hose.

39. Steering wheel.

40. Left-hand splash guard pre-assembly.

41. Detergent tank cap.

42. Detergent level tube.

43. Activation button for tank cleaning kit (optional).

MAIN MACHINE COMPONENTS

3

17

43

14

22

1

30

29

28

27

12

26

40

31

25

3

35

33

5

6

38

42

24

23

13

39

41

16

9

19

11

34

36

37

20

13

4

15

21

10

8

7

CONTENTS

MAIN MACHINE COMPONENTS .......................................... 3

CONTENTS ............................................................................ 4

1. GENERAL SAFETY REGULATIONS ................................ 5

1. RECHARGING THE BATTERIES ...............................................5

2. USING THE MACHINE ............................................................... 6

3. DEACTIVATION OF THE MACHINE ...........................................8

4. MAINTENANCE .......................................................................... 8

5. TRANSPORT .............................................................................. 9

2. SYMBOLS USED IN THE MANUAL ...............................10

3. PURPOSE AND CONTENT OF THE MANUAL ..............10

4. TARGET GROUP ............................................................. 10

5. STORING THE USE AND MAINTENANCE MANUAL ....10

6. ON CONSIGNMENT OF THE MACHINE ........................ 10

7. INTRODUCTORY COMMENT .........................................10

8. IDENTIFICATION DATA ...................................................10

9. TECHNICAL DESCRIPTION ...........................................10

10. INTENDED USE ............................................................. 10

11. SAFETY .......................................................................... 10

12. SERIAL NUMBER PLATE ............................................. 10

13. TECHNICAL DATA ........................................................ 11

14. SYMBOLS USED ON THE MACHINE ..........................12

15. SYMBOLS USED ON THE SERIAL NUMBER

PLATE ..................................................................................12

16. MACHINE PREPARATION ............................................13

1. HANDLING THE PACKAGED MACHINE .................................13

2. HOW TO UNPACK THE MACHINE ..........................................13

3. HOW TO MOVE THE MACHINE .............................................. 13

4. SECURING THE MACHINE ...................................................... 14

5. TYPE OF BATTERY TO BE USED ...........................................14

6. BATTERY MAINTENANCE AND DISPOSAL ............................14

7. INSERTING THE BATTERIES INTO THE MACHINE ............... 14

8. CONNECTING BATTERIES TO THE SYSTEM

OF THE APPLIANCE .................................................................... 14

9. RECHARGING THE BATTERIES .............................................14

10. ASSEMBLING THE BRUSH HEAD BRUSHES

(SCRUBBING VERSION) ............................................................. 15

11. ASSEMBLING THE SQUEEGEE BODY ................................. 15

12. FILLING THE SOLUTION TANK .............................................15

12. DETERGENT SOLUTION ....................................................... 15

17. PREPARING TO WORK ................................................ 16

18. WORK ............................................................................ 16

1. SCRUBBING WITH DRYING .................................................... 16

2. SCRUBBING WITHOUT DRYING ............................................16

3. DRYING ..................................................................................... 17

4. ADJUSTING THE DETERGENT SOLUTION

(VERSIONS WITHOUT HDC) ....................................................... 17

5. AUTOMATIC DETERGENT MEASURING SYSTEM

(HDC VERSION) ........................................................................... 17

6. REVERSE GEAR ...................................................................... 17

7. EXTRA BRUSH HEAD PRESSURE ......................................... 17

8. ACOUSTIC SIGNALLING DEVICE ........................................... 17

9. WORKING HEADLIGHTS (OPTIONAL) ................................... 18

10. EMERGENCY BUTTON .......................................................... 18

11. HOUR METER.........................................................................18

12. BATTERY CHARGE LEVEL INDICATOR ............................... 18

13. OVERFLOW DEVICE ............................................................. 18

19. AT THE END OF THE WORK ........................................ 18

20. RECOMMENDED MAINTENANCE OPERATIONS ......19

1. EMPTYING THE RECOVERY TANK ........................................ 19

2. CLEANING THE SQUEEGEE BODY........................................ 19

3. CLEANING THE BRUSH HEAD BRUSHES

(SCRUBBING VERSION) ............................................................. 19

4. CLEANING THE RECOVERY TANK FILTERS .........................19

5. CLEANING THE RECOVERY TANK......................................... 20

6. EMPTYING THE SOLUTION TANK ..........................................20

7. CLEANING THE WATER SYSTEM FILTER .............................21

8. CLEANING THE VACUUM TUBE .............................................21

21. EXTRAORDINARY MAINTENANCE WORK ................21

1. REPLACING THE BRUSH HEAD BRUSHES

(SCRUBBING VERSION) ............................................................. 21

2. REPLACING THE SQUEEGEE BODY RUBBER BLADES ...... 21

3. REPLACING THE SIDE SPLASH GUARD

RUBBER BLADES ........................................................................ 21

22. ADJUSTMENT INTERVENTIONS ................................. 22

ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES ....... 22

23. DISPOSAL .....................................................................22

24. CHOOSING AND USING BRUSHES ............................22

25. TROUBLESHOOTING ................................................... 23

4

The following symbols are used to indicate any potentially hazardous situations. Always read this information carefully

and take the necessary precautions to protect any people and/or objects that may be present.

Operator cooperation is paramount for accident prevention. No accident prevention programme can be eective

without the full cooperation of the person directly responsible for the machine's operation. Most accidents that occur

at the workplace, during work activities, or while in transit, are caused by the failure to respect the most basic safety

regulations. An attentive, careful operator is most eective guarantee against accidents and is fundamental in order

to implement any prevention programme.

DANGER: Indicates an imminent danger that could cause serious injury or death.

WARNING: Indicates a probable dangerous situation that could cause serious injury or death.

CAUTION: Indicates a probable dangerous situation that could cause minor injuries.

ATTENTION: Indicates a probable dangerous situation that could damage objects.

DANGER:

• If the battery charger power cable is damaged or broken, it should be replaced by the

manufacturer, by authorised service personnel or else by a qualied person, in order to protect

against hazards.

• The socket for the battery charger cable must have a prescribed earth connection.

• Keep sparks, ames, and incandescent materials at a safe distance from the batteries.

Explosive gases are emitted during normal use.

• highly explosive hydrogen gas is generated while charging the batteries. Keep the recovery

tank unit in a maintenance position during the entire battery recharging cycle, and only perform

the procedure in well-ventilated areas at a safe distance from any open ames.

• Before charging check that the electric cable that connects the battery charger to the batteries

is not damaged, and if it is damaged do not use it and contact technical assistance.

• Before starting to charge the batteries, check that there is no standing water or dampness in

the on-board battery charger socket.

• Before charging check that the electric cable that connects the battery charger to the mains is

not damaged, and if it is damaged do not use it and contact technical assistance.

• Do not disconnect the direct current cable of the battery charger from the socket of the machine

when the battery charger is operating. This is necessary in order to avoid electric arcs forming.

To disconnect the battery charger when it is charging, rst disconnect the alternating current

power cable.

WARNING:

• Do not use an incompatible battery charger since it could damage the batteries and potentially

cause a re.

• The batteries emit hydrogen gas. This gas can cause explosions or res. Keep a safe distance

from ames or sparks. keep the covers open when charging the batteries.

• Before using the battery charger, make sure that the frequency and the voltage values

indicated on the machine's data plate coincide with the network's values.

• Keep the battery charger's cable at a safe distance from any hot surfaces.

• Never smoke in the machine's vicinity while the batteries are charging.

• Carefully read the user manual of the battery charger that you want to use before starting the

charging operation.

1. GENERAL SAFETY REGULATIONS

1. RECHARGING THE BATTERIES

5

DANGER:

• In the event of danger, quickly press the emergency button in the electrical system panel near

the operator's seat.

• Never collect gases, explosive/inammable liquids or powders, nor acids and solvents! These

include gasoline, paint thinners and fuel oil (which, when mixed with the vacuum air, can form

explosive vapours or mixtures), and also non-diluted acids and solvents, acetones, aluminium

and magnesium powders. These substances may also corrode the materials used to construct

the machine.

• If the machine is used in dangerous areas (e.g. petrol stations), the relative safety standards

must be observed. It is forbidden to use the machine in environments with a potentially

explosive atmosphere.

WARNING:

• The machine can be used by children over the age of 8 and by people with limited physical,

sensorial or mental capacity, or people without experience or the required knowledge, as long

as they are supervised or have been instructed about safe machine use and the inherent

dangers. Children must not play with the machine. The cleaning and maintenance that should

be carried out by the user should not be done by unsupervised children.

• The machine must be exclusively used by authorised, trained personnel.

• Do not use the machine on surfaces with a slope greater than the one indicated on the serial

number plate.

• The machine is not suitable for cleaning rough or uneven oors. Do not use the machine on

slopes.

• In the event of a re, use a powder extinguisher. Do not use water.

• Adapt the speed to the adhesion conditions.

• In order to prevent the unauthorised use of the machine, the power supply must be

disconnected: switch the machine o using the main switch (by removing the key from the

block) and disconnect the battery's connector from the electrical system's connector.

• Do not use the machine if you do not have the requisite knowledge or authorisation.

• Do not use the machine if you have not read and understood the following user manual.

• Do not use the machine under the inuence of alcohol or drugs.

• Do not use the machine when using a mobile phone or other electronic devices.

• Do not use the machine if it is not working correctly.

• Do not use the machine in areas where there are inammable vapours or liquids or combustible

powders.

• Do not use the machine in areas that are too dark to see the controls or operate the machine

safely, unless the work lights or the front headlights are on.

• Do not use the machine in areas where there is a risk of falling objects, unless the machine is

equipped with an overhead guard (optional).

CAUTION:

• Children must be supervised to ensure they do not play with the machine.

• During the working of the machine, pay attention to other people and especially to children.

• The machine must only be powered with a voltage equal to that shown on the serial number

plate.

2. USING THE MACHINE

6

• Read the labels on the machine carefully. Do not cover them for any reason, and replace them

immediately if they become damaged.

• The machine must only be used and stored in an enclosed or covered environment.

• The machine must not be used or stored outdoors in damp conditions or directly exposed to

rain.

• The machine does not cause harmful vibrations.

• Use the machine only in the way described in this manual.

• Do not pick up anything that is burning or smouldering, like cigarettes, matches or glowing

embers.

• Reduce speed on slopes and dangerous corners.

• Reduce speed before making a turn.

• Keep all parts of your body inside when the machine is moving.

• Be careful when reversing.

• Do not transport passengers.

• Always follow the instructions for mixing, use and disposal on the containers of the chemical

substances.

ATTENTION:

• If the machine is to be used in the presence of other individuals, aside from the operator, the

beacon light must be utilized.

• Always take appropriate measures to protect any individuals and/or objects that may be

present while using this machine.

• Be careful to avoid collisions with shelving or scaolding, above all if there is a risk of objects

falling from heights.

• Do not place any liquid containers on the machine.

• The machine must only be used under temperature conditions ranging from 32 °F to +104 °F.

• When using detergents to clean the ooring, always follow the instructions and respect the

warnings indicated on the containers' labels.

• Always use appropriate gloves and protective equipment when handling the detergents used

to clean the oor.

• Do not use the machine as a means of transport.

• Avoid working with the brushes when the machine is standing still, so as not to damage the oor.

• In the event of a re, use a powder re extinguisher if possible, and avoid the use of water.

• Do not allow any objects to penetrate into the machine's openings. Do not use the machine is

the openings are obstructed.

• Keep the machine's openings free of any dust, lint, hairs, or any other foreign materials that

could reduce the airow.

• Do not remove or alter any labels axed to the machine.

• This machine has not been approved for use on public streets or roadways.

• Only use the brushes and pad holders that have been supplied with the machine or those

specied in the Use and Maintenance Manual. The use of other brushes or felt pads could

compromise the machine's safety conditions.

• Before starting to work check that there are no leaks.

• Before starting to work check that all the safety devices have been installed and are working

correctly.

• Before starting work check that the brakes and steering are working correctly.

• Before starting work adjust the seat and steering wheel, and also the seat belt if there is one.

7

WARNING:

• Always protect the machine against sunlight, rain, and other atmospheric agents, both while it is

stationary and while it is in function. Store the machine in a dry, sheltered place: this machine is only

designed for use under dry conditions, and must not be used or stored outdoors under humid conditions.

• Do not park the machine near combustible materials, powders, gases or liquids.

• Stop the machine on a at surface.

• Check that the electric brake is engaged, switch o the machine and remove the key from the

instrument panel, disconnect the battery connector from the electrical system connector.

• If the machine is left unattended, it must be protected from any accidental movements

ATTENTION:

• The machine must only be stored under temperature conditions ranging from 32 °F to

+104 °F. The humidity level must be between 30% and 95%.

3. DEACTIVATION OF THE MACHINE

DANGER:

• In order to avoid short-circuits when working in the vicinity of electrical components, do the

following: avoid the use of non-insulated tools; do not place or allow metallic objects to fall

upon the electrically powered components; remove any rings, watches and/or clothing with

metallic parts that might come into contact with the electrically powered components.

• do not work underneath the raised machine without adequate xed safety supports.

WARNING:

• Read all the relevant instructions carefully before performing any maintenance/repair

operations.

• If the machine does not work properly, check this is not caused by failure to carry out routine

maintenance. Otherwise, ask for intervention of the authorised technical assistance centre.

• Restore all electrical connections after any maintenance interventions.

CAUTION:

• When doing maintenance work, switch o the machine using the main switch. Remove the

key from the instrument panel and remove the battery connector from the electrical system

connector.

• Avoid contact with moving parts. Do not wear loose clothing or jewellery and tie long hair back.

• Block the wheels before lifting the machine.

• Lift the machine with equipment that can sustain the weight to be lifted.

ATTENTION:

• Never tamper with the machine's protection devices for any reason; always follow the supplied

routine maintenance instructions scrupulously.

• If the machine needs to be pushed for maintenance purposes (batteries absent; discharged

batteries; etc.), never exceed 2.49 mph.

• If any issues are encountered while using the machine, check to make sure that these are

4. MAINTENANCE

8

not due to a lack of proper maintenance. Otherwise, request the intervention of authorized

personnel or an Authorized service centre.

• If any parts need to be replaced, always request ORIGINAL spare parts from an authorized

Dealer or Retailer.

• In order to ensure the machine's safety and proper functionality, always have the scheduled

maintenance interventions (specied in the appropriate section of this Manual) performed by

authorized personnel or by an authorized Service Centre.

• Do not clean the machine with direct or pressurized jets of water, or with corrosive substances.

• If lead batteries (WET) have been installed on the machine, avoid tilting the machine beyond

30° with respect to the horizontal plane, as this could cause the highly corrosive liquid to leak

out of the batteries.

• Avoid contact with the battery acid.

• Keep all metal objects away from the batteries.

• Use a non-conductive device for removing the battery.

• Use a hoist and suitable equipment when lifting the batteries.

• The battery must be installed by qualied personnel.

• Always observe the safety measures of the site regarding removing the battery.

• Remove the batteries if the machine needs to be tilted in order to perform maintenance

procedures.

• Have the machine checked by an authorised technical assistance centre every year.

• When disposing of consumable materials, observe the laws and regulations in force. Once

the machine has reached the end of its service life, the materials contained within it must be

disposed of in an appropriate manner, keeping in mind that the machine itself has been built

using fully recyclable materials.

• Do not push or tow the machine without an operator on the seat who can control the machine.

• Do not wash the machine with pressurised water or wet the machine near electrical components.

• All repairs must be carried out by qualied personnel.

• Do not physically change the design characteristics of the machine.

• Use spare parts supplied by Hillyard or by Hillyard service centres.

• Wear personal protective equipment as required and as suggested in the manual.

WARNING:

• Drain both tanks before transport.

• Bring both the squeegee and the brushes to a working position before securing the machine

to the transport vehicle.

• Use a ramp, a truck or a trailer that can support the weight of the machine and the operator.

• To place the machine on the transport vehicle use a pulley. Do not drive the machine on or o

a truck or trailer.

• The ramp for placing the machine on the transport vehicle should have such a slope that the

machine does not get damaged.

• Check that the electric brake is correctly engaged after loading the machine onto the transport

vehicle.

ATTENTION:

• The machine must only be stored under temperature conditions ranging from 32 °F to

+104 °F. The humidity level must be between 30% and 95%.

5. TRANSPORT

9

Loading...

Loading...