Hills Rotary Clothesline 37, Rotary Clothesline 47 Product Manual

Rotary

Clothesline

37 and 47

Product Manual

Everyday

2

Introduction

Please retain this Product Manual. Record the following

information for future reference.

Product Number (printed on carton):

Date of purchase:

Name and location of store:

Made in China

®

Congratulations

Congratulations on the purchase of your Hills

Rotary Clothesline, which will bring you many

years of trouble free and ecient drying.

It’s important that you read this Product

Manual thoroughly before installation to

benefit from the design features and enjoy safe

use of this product.

Thank you for choosing Hills.

Patents and Registered Designs apply to

this product.

Warning

• Do not allow children or pets to swing on

the clothesline or items of laundry.

• Ensure when raising and lowering your

clothesline that bystanders (in particular

children) are standing well clear.

• Do not use for any purpose other than to

hang and dry washing.

• Do not use your clothesline if parts are worn

or damaged.

• Do not allow the frame to lower in an

uncontrolled manner as damage

or injury may result.

Carton Contents

Part name Qty.

Main standard 1

Head assembly 1

Ground socket with cover 1

Plastic spacers 3

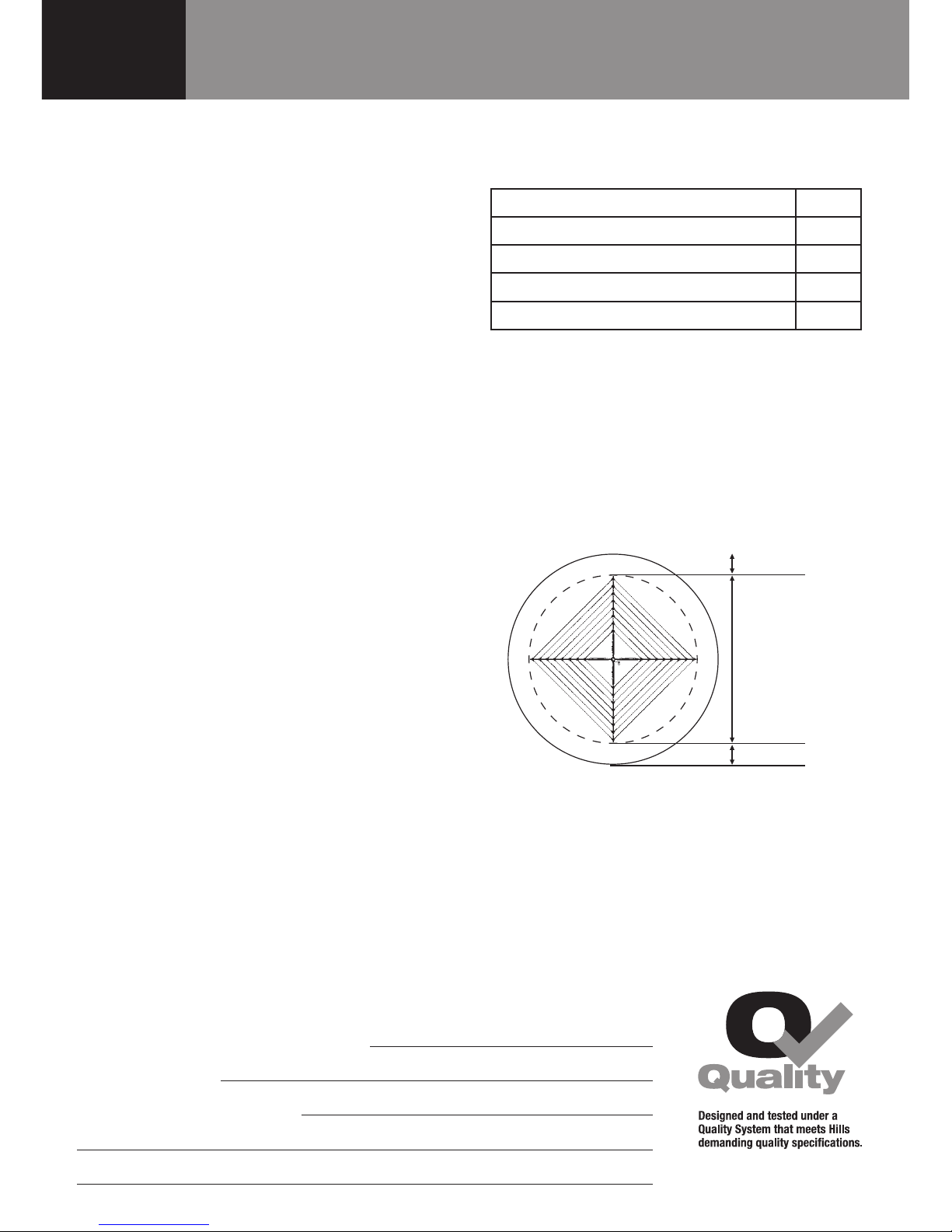

Step 1 – Select a suitable location

1.1 Select a suitable area for installation.

1.2 Allow a minimum of 500mm (1'7")

clearance around your Rotary Hoist (Fig. 1).

Fig. 1

500mm (1'7")

500mm (1'7")

3.2m (10'6")

Rotary 37

3.6m (11' 9")

Rotary 47

3

Installation

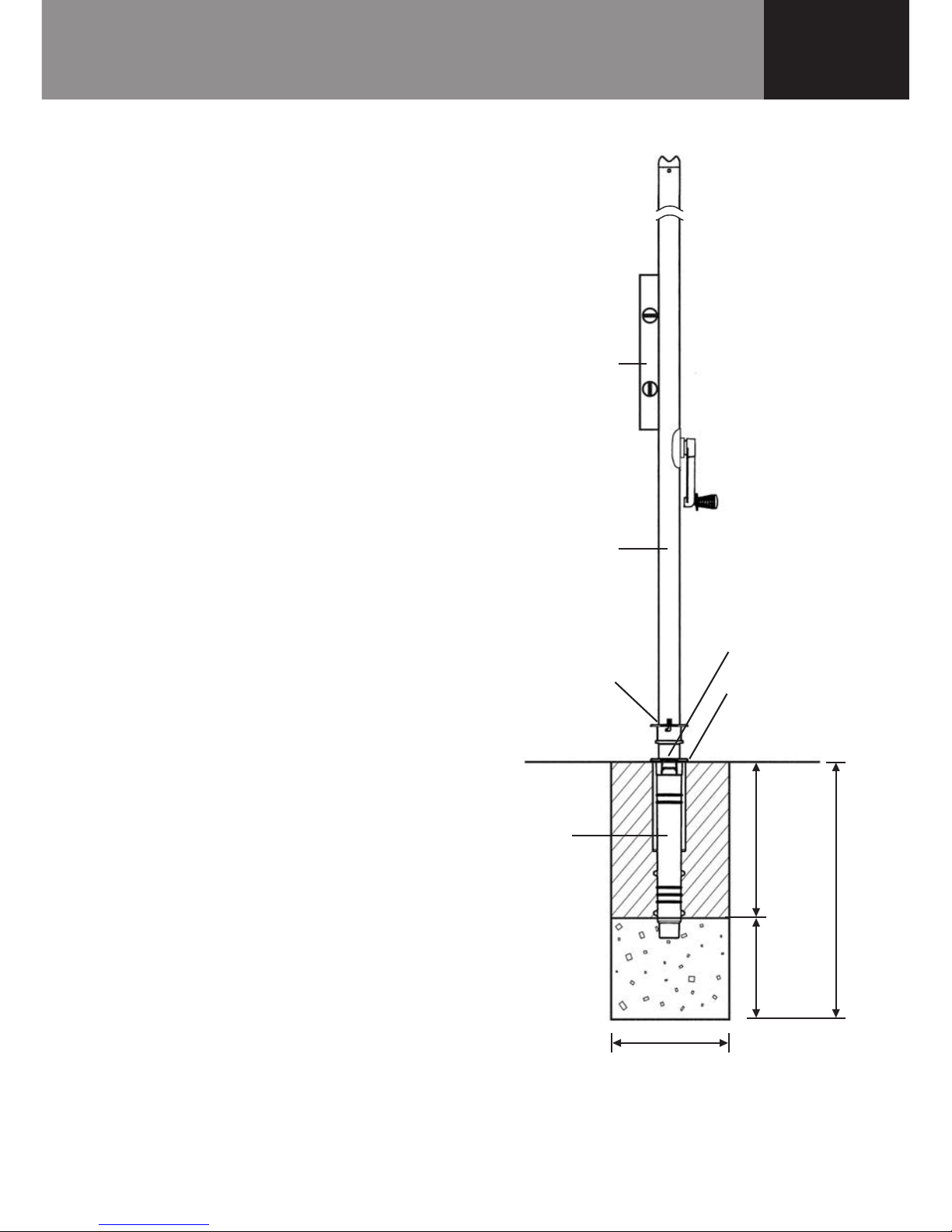

Step 2 – Install the Ground Socket

2.1 Dig a hole 250mm (10") diameter by

approximately 650mm (26") deep (Fig. 2).

2.2

Place approximately 200mm (8") of coarse

gravel into the hole.

2.3

Insert the main standard into the ground

socket. Engage the locking collar and lock

into position.

Make sure the tabs are closed to prevent

concrete entering the locking recess.

2.4

Place the ground socket and main standard

into the hole.

Push the base of the ground socket into

the gravel.

Check level vertically.

The top of the ground socket must sit

approximately 6-12mm (1/4"-1/2") above

ground level.

2.5

Support the main standard and concrete

into position.

Concrete should be damp enough to ‘hold

together’ when squeezed in your hand.

Settle concrete by pushing a thin stick into

the mix several times.

Leave the main standard in the ground

socket until the concrete has set.

Keep concrete out of the locking recess in

the ground socket.

2.6

Allow 24 hours for the concrete to set before

final assembly and use of your Rotary Hoist.

Check for level

Main standard

Locking collar

Engage into

ground socket.

Rotate to lock.

Close tabs to

prevent entry

of concrete

Ground

socket

450mm (18")

concrete

200mm (8")

gravel

650mm (26")

Fig. 2

Top of socket

approximately

6-12mm (1/4"-1/2")

above ground level

250mm (10")

4

Assembly

GENERAL ASSEMBLY DETAILS

ALL DIMENSIONS ARE EQUAL ABOUT UNLESS 1.

OTHERWISE STATED.

DIMENSIONS BOUNDED BY ARE CRITICAL FOR 2.

ASSEMBLY WITH OTHER COMPONENTS.

THE DIMENSIONS SHOWN ON THIS DRAWING PLUS 3.

THE 3D CAD DATA FULLY DEFINE THE FINISHED PART.

ALL COMPONENTS TO BE CLEAN AND FREE FROM 4.

SHARP EDGES, BURRS AND DEFECTS.

IF IN DOUBT ASK5.

GENERAL TOLERANCES:

Unless Otherwise Stated:

0 Dec. place 0.5mm

1 Dec. place 0.25mm

2 Dec. place 0.10mm

Holes: +0.25mm -0mm

Angles: 0.25

6

54321 211101987

1950432 (mm³)

Estimated Mass:

X. Xxxxxxxx

DO NOT SCALE DRAWING.

Projection.

:etaD:devorppA

Date:

XX.XX.XX

Checked:

24.09.10

P. Stevens

Date:

Drawn:

TM

Material:

Finish:

DIMENSIONS IN MILLIMETRES.

Third Angle

REFER TO INDIVIDUAL COMPONENTS

9187 (grams)

REFER TO DRAWING SPECIFICATION

Volume

Hills Industries Limited

ABN 35 007 573 417

Home & Hardware Products

Unit H, 5 Butler Boulevard

Burbridge Business Park

Adelaide Airport

South Australia 5950

Copyright

©

Additives:

ISSUEREF.REV ISIONDATERFC DWN. CHK. APP.

1 SP01.90.42KROWTRA ROF DESAELER

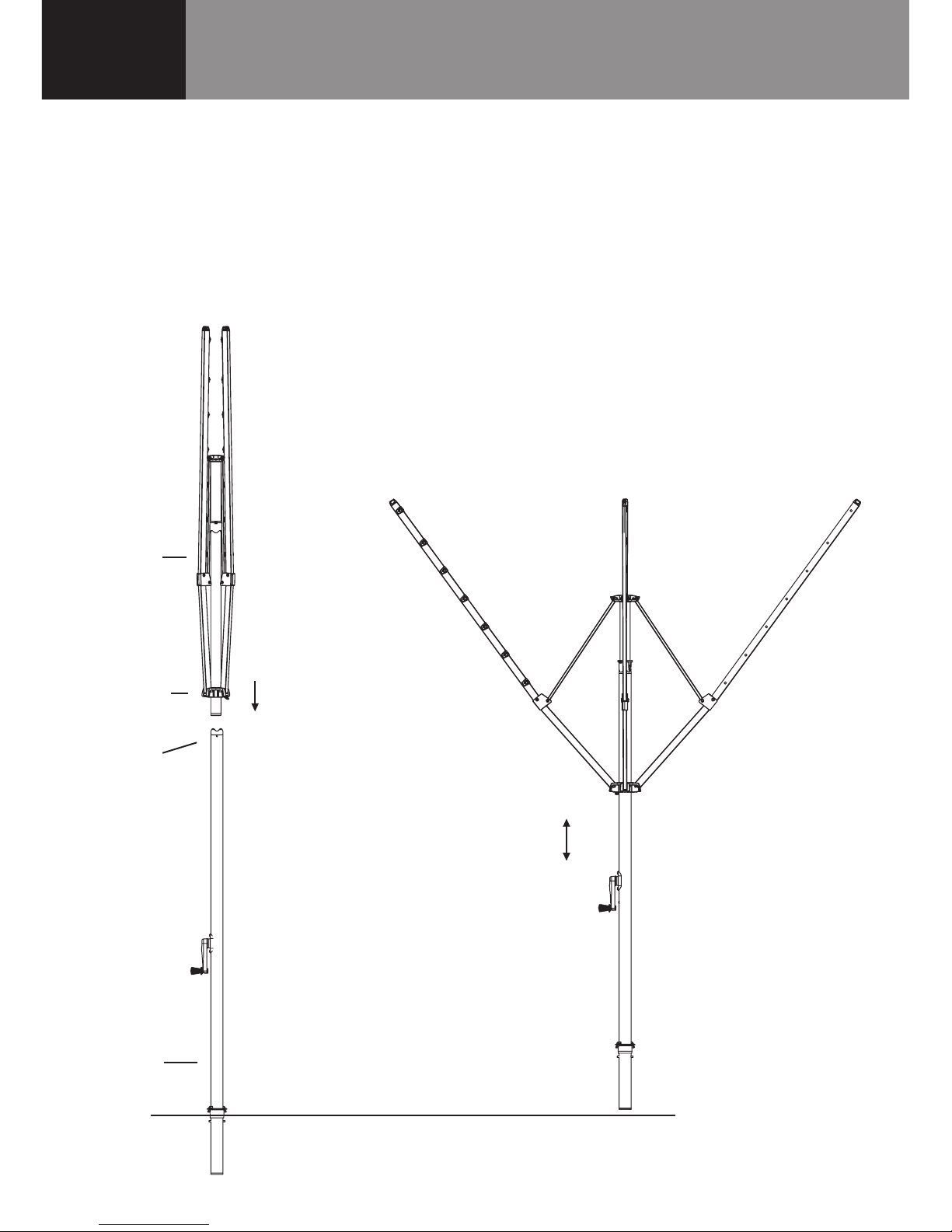

Step 3 – Assemble the Hoist

3.1 Place the main standard in the

ground socket.

3.2

Place the bottom of the head assembly

into the top of the main standard and

lower it gently until it stops (Fig. 3).

3.3

To engage, raise the head assembly by

approximately 100mm (4") and lower until

a ‘click’ is heard.

3.4

Check the head assembly is locked in

position by lifting upwards (it should

not move). If the head assembly is not

engaged, repeat Step 3.3.

Note: There is a small amount of rotational

movement between the wind brake and

the lower cross latch.

This is normal.

Note: Once the head is engaged into the

main standard it cannot be removed.

GENERAL ASSEMBLY DETAILS

ALL DIMENSIONS ARE EQUAL ABOUT

C

L

UNLESS

1.

OTHERWISE STATED.

DIMENSIONS BOUNDED BY ARE CRITICAL FOR

2.

ASSEMBLY WITH OTHER COMPONENTS.

THE DIMENSIONS SHOWN ON THIS DRAWING PLUS

3.

THE 3D CAD DATA FULLY DEFINE THE FINISHED PART.

6

E

A

B

C

D

5

7

8

9

10

11

12

GENERAL ASSEMBLY DETAILS

ALL DIMENSIONS ARE EQUAL ABOUT

C

L

UNLESS

1.

OTHERWISE STATED.

DIMENSIONS BOUNDED BY ARE CRITICAL FOR

2.

ASSEMBLY WITH OTHER COMPONENTS.

THE DIMENSIONS SHOWN ON THIS DRAWING PLUS

3.

THE 3D CAD DATA FULLY DEFINE THE FINISHED PART.

ALL COMPONENTS TO BE CLEAN AND FREE FROM

4.

SHARP EDGES, BURRS AND DEFECTS.

IF IN DOUBT ASK

5.

GENERAL TOLERANCES:

Unless Otherwise Stated:

0 Dec. place

0.5mm

1 Dec. place

0.25mm

2 Dec. place

0.10mm

Holes: +0.25mm -0mm

Angles:

0.25

6

E

A

B

C

D

F

7

8

9

10

11

12

G

Project:

X. Xxxxxxxx

DO NOT SCALE DRAWING.

DIMENSIONS IN MILLIMETRES.

Third Angle

Projection.

Approved:

Date:

Date:

XX.XX.XX

Checked:

22.09.10

P. Stevens

Date:

Drawn:

TM

Colour:

Material:

Finish:

Estimated Mass:

REFER TO INDIVIDUAL COMPONENTS

9534 (grams)

REFER TO DRAWING SPECIFICATION

REFER TO COLOUR TABLE

Volume

2215249 (mm³)

Hills Industries Limited

ABN 35 007 573 417

Home & Hardware Products

Unit H, 5 Butler Boulevard

Burbridge Business Park

Adelaide Airport

South Australia 5950

Copyright

©

2010

Additives:

Insert head

assembly

Main

standard

Head

assembly

Ground level

Lower

cross

Wind

brake

Engage by

raising and

lowering head

assembly until a

‘click’ is heard

Fig. 3

Loading...

Loading...