Hills Reliance 8, Reliance 12, Reliance 128 Installation & Programming Manual

Reliance

TM

8, 12, 128 Zone Control Panel

Installation & Programming Manual

(Australian and New Zealand Version)

Hills Reliance Control Panel

Thank-you for choosing the Hills Reliance Control Panel!

The Hills Reliance security control panel from Hills Industries represents a new approach to security system design.

Drawing on experience from the world market, Hills has develo ped the most flexible, dur able, and user-friend ly control ever

seen in our industry. Featuring sophisticated software that allo ws up to 9 9 users to i nterface with 128 z ones, 8 areas, and a

host of integrated fire, access, verification, and input/output modules, all reported with the Contact I.D. formats. The

modular design establishes a logical solution for ease of expansion. Up to 32 modules can be added to expand the

capabilities of the Hills Reliance.

NZ Telepermit Notice

Warnings

The equipment should be installed by

qualified SERVICE PERSONNEL only

The equipment should only be operated with

an approved power adapter with insulated live pins

CAUTION – RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT

TYPE. DISPOSE OF BATTERIES ACCORDING TO THE INSTRUCTIONS.

CONTACT YOUR INSTALLER FOR REPLACEMENT BATTERIES.

When installed as directed, this product conforms to the standards set by

Standards Australia on behalf of the Australian Communications Authority (ACA)

N4131

Disclaimer

The content of this document has been prepared to the best of our knowledge, provided “as is” and is subject to change

without notice. Hills Industries does not guarantee technical accuracy beyond the date of publishing. For the latest

information please enquire about attending one of our Hills Reliance training courses.

Copyright Notice

This work is copyright Hills Industries 2006. Apart from any use as permitted under the Copyright Act 1968, no part may be

reproduced by any process, including photocopying, scanni ng or other means, without prior written permission from Hills

Industries. Creation of derivative work unless agreed to in writing by the copyright owner is forbidden.

© Hills Industries 2006 Page 1

Hills Reliance Control Panel

Installation Manual

Page

Warnings...............................................................................................................................................................................1

Compliance Notices.............................................................................................................................................................2

Updated Features.................................................................................................................................................................3

Ordering Information............................................................................................................................................................4

Installation & Programming Flowchart...............................................................................................................................5

Board Installation.................................................................................................................................................................6

Control Panel Comparison..................................................................................................................................................6

Hills Reliance 128 Wiring Diagram......................................................................................................................................7

Hills Reliance 128 Terminal Descriptions...........................................................................................................................8

Hills Reliance 12 Wiring Diagram........................................................................................................................................9

Hills Reliance 12 Terminal Descriptions...........................................................................................................................10

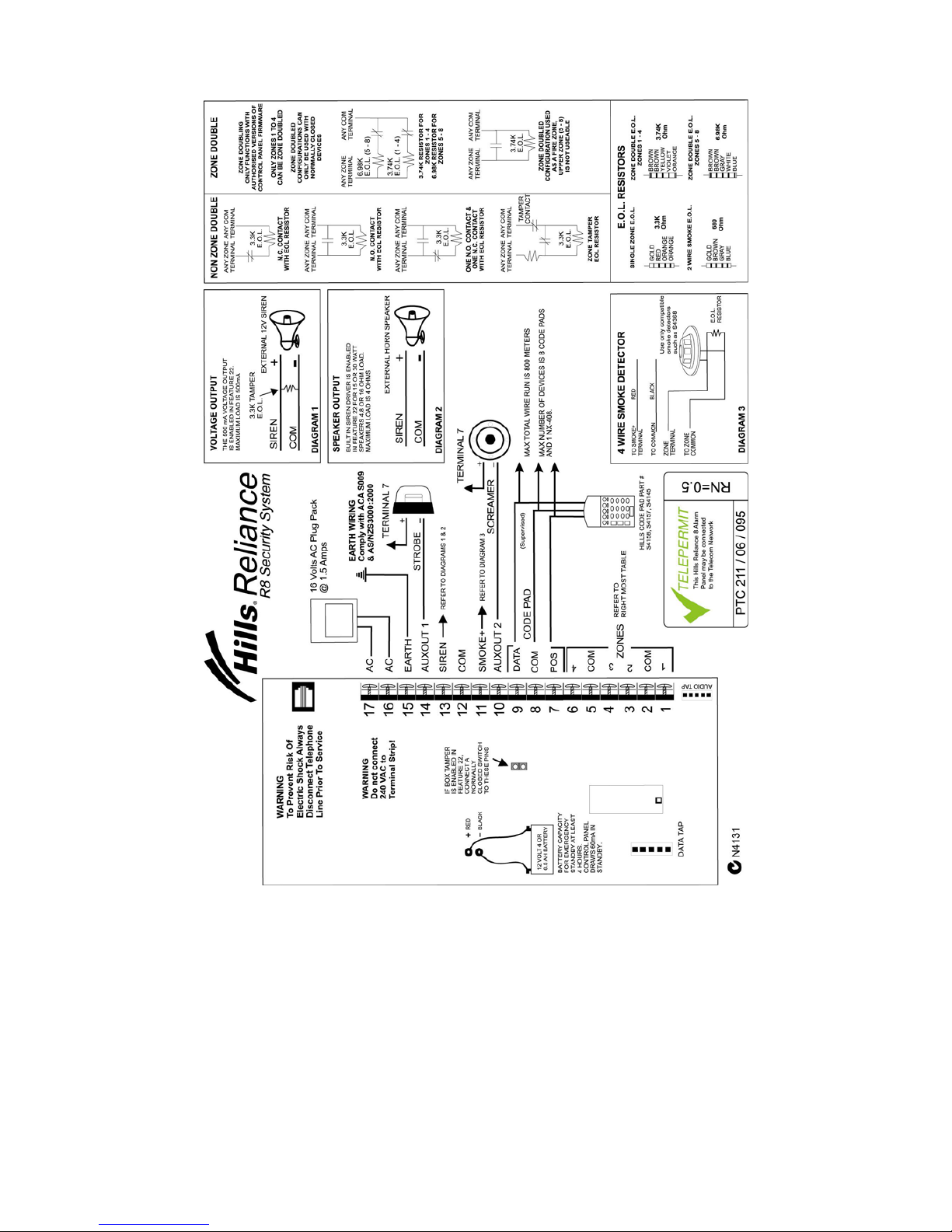

Hills Reliance 8 Wiring Diagram........................................................................................................................................11

Hills Reliance 8 Terminal Descriptions.............................................................................................................................12

Main Options.......................................................................................................................................................................13

Programming The LED Code Pads...................................................................................................................................15

1. Setting The LED Code Pad Starting Zone - Function [9] [2]...............................................................................15

2. Setting The LED Code Pad Options - Function [9] [3]........................................................................................15

3. Setting The LED Code Pad Number And Area Options - Function [9] [4] ..........................................................16

4. Set Elapsed Hours Since Last Auto Test - Function [9] [5] ................................................................................16

5. Set System Date - Function [9] [6] .....................................................................................................................16

6. Setting The System Clock - Function [9] [7].......................................................................................................16

7. Service Menu - Function [2] ...............................................................................................................................17

8. Changing User Codes - Function [5]..................................................................................................................17

9. Assigning User Code Authority Levels - Function [6].........................................................................................18

10. Walk Test Mode - Function [Á] [Chime]...........................................................................................................19

11. Call Back Download [Á] [9] [8] and Answer Call [Á] [9] [9]..............................................................................19

Programming The Hills Reliance Control Panel ..............................................................................................................20

Features, Segments and Options...........................................................................................................................20

Navigating Program Mode .....................................................................................................................................20

Programming Data.................................................................................................................................................21

Loading Factory Defaults .......................................................................................................................................21

Enrolling Modules & Code Pads.............................................................................................................................21

Programming Example Figure1 - Numerical Data (Binary)....................................................................................22

Programming Example Figure 2 - Option Selection Data.......................................................................................22

Programming Feature Descriptions..................................................................................................................................23

System Codes........................................................................................................................................................23

Dialer Options (Features 4 – 11)............................................................................................................................24

Download Options (Features 12 – 15) ...................................................................................................................26

Area 1 – Option and Report Selections..................................................................................................................27

Zones 1 – 8 Configuration......................................................................................................................................29

Default Zone Configurations ..................................................................................................................................29

Zones 9 – 16 Configuration....................................................................................................................................31

System Options

new

................................................................................................................................................32

Siren / Communicator Attempt Counter .................................................................................................................35

Code Pad Sounder Control....................................................................................................................................35

System Timer Configuration...................................................................................................................................35

Auxiliary Output 1 – 4 Configuration.......................................................................................................................36

Auxiliary Output 1 – 4 Logic

new

..............................................................................................................................37

Auxiliary Output Logic Selection

new

........................................................................................................................38

Auxiliary Output Event Selection............................................................................................................................38

Areas 2 – 8 Programming Options.........................................................................................................................40

Zones 17 – 48 Configuration..................................................................................................................................44

Configuration Groups 1 – 20..................................................................................................................................45

Zones 49 – 128 Configuration

new

...........................................................................................................................51

Appendix 1: Reporting Zone Codes in Contact I.D..........................................................................................................55

Appendix 2: Reporting Fixed Codes in Contact I.D.........................................................................................................56

Appendix 3: Expander Numbers for Reporting Expander Trouble................................................................................57

Appendix 4: Troubleshooting System Problems.............................................................................................................59

Installation Floor Plan........................................................................................................................................................62

Program Planning Sheets..................................................................................................................................................63

© Hills Industries 2006 Page 2

Compliance Notices

Information to the Installer - Changes and modifications not expressly approved by Hill s can void the user’s authority to

operate the equipment.

Australia & New Zealand Compliances

This equipment has been tested and found to compli ant with the ACA A-T ick and (NZ) T elepermit standards. T hese limits

are designed to provide reasonable protection against interference in a re sidential installation.

Hills Reliance systems fitted with the 433 MHz wireless receiver module receives radio frequency energ y from wireless

transmitters and, if not installed and used in accordance with the instructions, may cause harmful interference to radi o

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the wireless transmitter units or receiver module to reduce interference.

• Increase the separation between the transmitting units and receiver.

• Connect the affected equipment and the panel receiver to separate power outlets, on different branch circuits.

• Consult the dealer or an experienced radio/TV technician for help.

A 230-240VAC mains power outlet (GPO) with protective earthing connection must be provided within reach of the

supplied plug pack power lead and be easily accessible. Only licensed electrical workers should install n ew GPOs. GPO

installation must comply with AS/NZS 3000:2000 and national or state electrical regulations. Co nnect this product to a

compliant 611, Mode3 or switched 8P4C socket. A RJ1 1p ho ne lead is required to connect this product to a compliant 611,

Mode3 or switched 8P4C socket. A compliant RJ11 lead is supplied with this product.

Alarm dialing equipment must be able to seize the telephone line a nd place a call in an emergency situation. It must be

able to do this even if other equipment (te lephone, answering system, computer m odem, etc.) already has the telep hone

line in use. To do so, alarm dialing equipment must be connected t o a ACA (Aust.) or Telepermit (NZ) compliant Mode -3

socket that is electrically in series and ahead of all other telecommunication equipment attached to the same telephone

line. In Australia, only ACA certified technicians are permitted to install or modify telephone sockets.

Security Installation License

Australia installers - In New South Wales and the ACT the installer m ust hold a Security Installer License to install this

product.

New Zealand - All people involved in the s elling, installation and servicing of security equipment must hold a Securit y

Guards Licence. Refer to the NZ Government Justice Department for further updates.

Note: Other national/state regulations may also apply. Enquire at the p lace of purchase if specific installation regulation s

demand the Hills Reliance control panel installation requires a licensed installation technician.

Automatic Dialing Devices (Australia and New Zealand)

This equipment shall not be set to make automatic calls to the ‘000’ (Aust) or the Telecom ‘111’ (NZ) Emergency Service.

Series Connected Equipment (Australia & New Zealand)

The equipment may be set up to carry out test calls at pre-determined times. Such test c alls will interrupt any other calls

that may be set up on the line at the same time. The timing set for such test calls should be discussed with the installer.

The timing set for such test calls from this equipment may be subject to “drift”. If this proves to be inconvenient and your

calls are interrupted, then the problem of timing should be discussed with the equipm ent installer. T he matter should NOT

be reported as a fault to your telephone service provider faults service.

Automatic Re-attempts to the Same Number (New Zealand only)

Some parameters required for compliance with Telecom’s Telepermit requirements are dependent on the equipment

associated with this device. The associated equipment shall be set to operate within the following limits for compliance

with Telecom’s specification:

(a) There shall be no more than 10 call attempts to the same number within any 30 minute period for any single

manual call initiation.

(b) The equipment shall go on-hook for a period of not less than 30 seconds between the end of one attempt and the

beginning of the next attempt.

Automatic Call to Different Numbers (New Zealand only)

Some parameters required for compliance with Telecom’s Telepermit requirements are dependent on the equipment

associated with this device. In order to operate within the limits for compliance with Telecom Specifications, the

associated equipment shall be set to ensure that automatic calls to different numbers are spaced such that there is no

less than 5 seconds between the end of one attempt and the beginning of another.

Fault Clearance (New Zealand only)

In the event of any problem with this device, the telephone lead should be disconnect ed from the LINE connection at the

rear of the unit. The user is then to arrange with the supplier of the dev ice to make necessary repairs. Shou ld the matter

be reported to Telecom as a wiring fault and the fault is proven to this device, a call-out charge will be incurred.

© Hills Industries 2006 Page 3

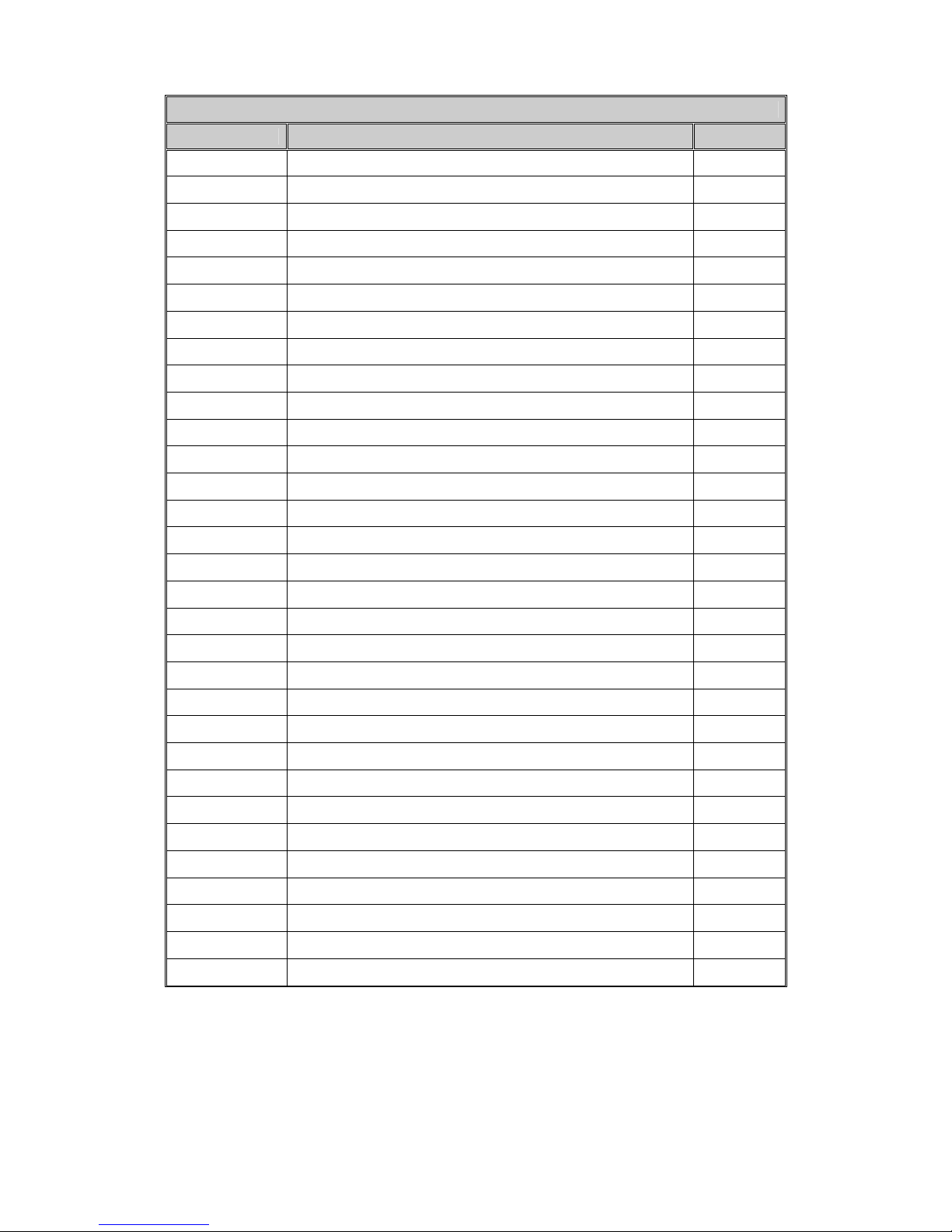

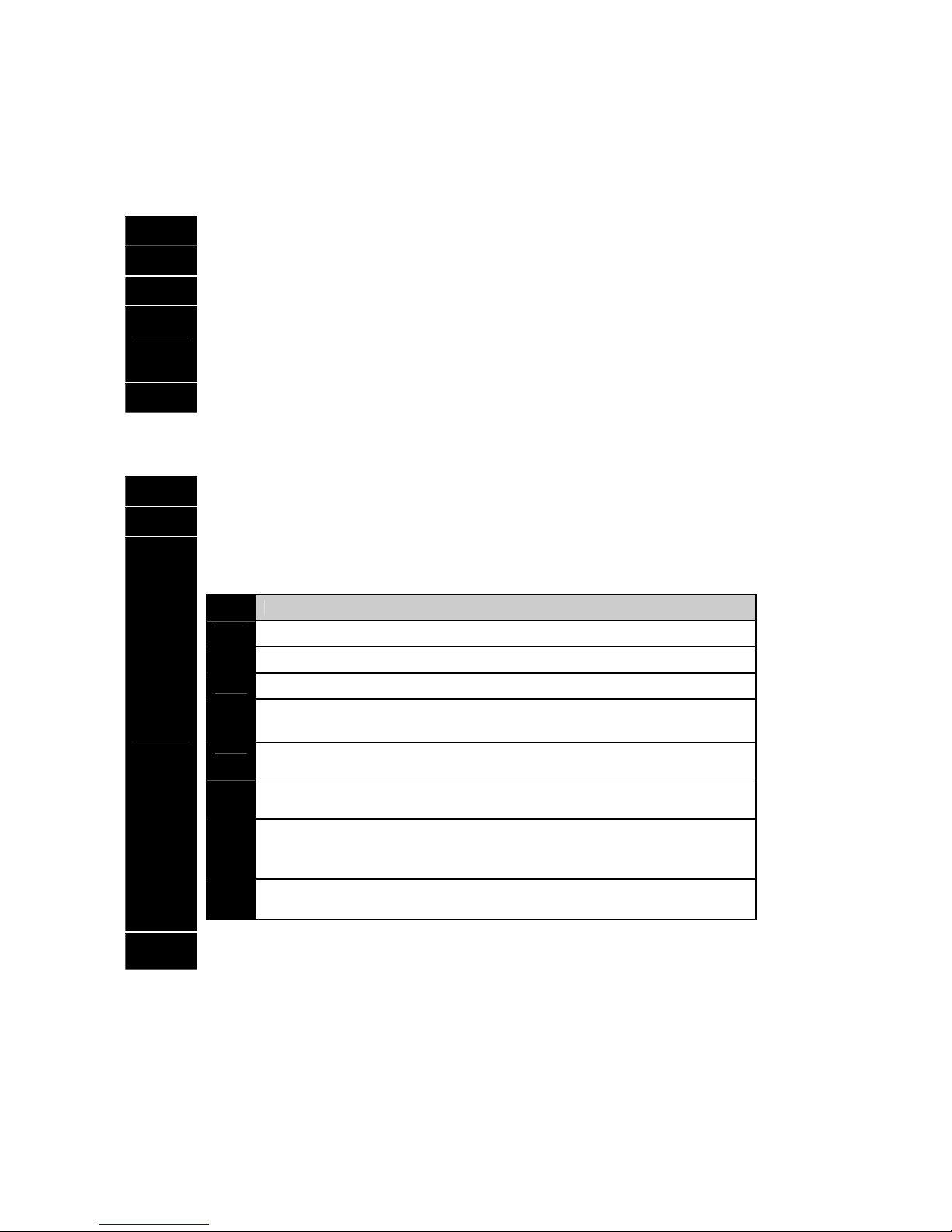

Updated Features

There are new features on the Hills Reliance product, and some which have been changed

from the previous version.

These have the text “

new

” next to the relevant sections in this manual. A summary of key updates is presented below.

Feature

Location

Description

Feature

Location

Description

F5, 37, 38,

41, 44, 47,

50, 53, 56

Account Codes – expanded for future use F33 Auto Disarm Time – added

F16, 39,

42, 45, 48,

51, 54, 57

Area Options – added Late To Close, Auto

Arm in Partial, Disable Bypass For Force

Arm Zones

F36

Days of the Week for Auto Arm – added

Retry Timer

F17, 40,

43, 46, 49,

52, 55, 58

Entry / Exit Timers – expanded for future use

F22

System Options – added Two Wire Smoke,

Zone Inactivity Monitor, Steady/Evac Siren

F22 Disable hardwire zones req power cycle

F68, 70,

72, 74, 76,

78, 80, 82,

84, 86, 88,

90, 92, 94,

96, 98,

100, 102,

104, 106

Configuration Groups – added Zone

Activity Monitor, EOL Defeat, REX

event, DOTL and Forced Door events

F25

System Timers – added Chime Option, Zone

Inactivity Monitor

F119 - 138 Zones 49-128 – added

F27 Auxiliary Output – changed on Reliance 8 F155

Days of the Week for Auto Disarm –

added

F28 - 31 Auxiliary Output Logic – enhanced F162 EOL Resistor Value Select – added

Sales & Distribution

For Service / Technical Support call

(02) 9717 5222 or 1800 252 213

SA

Edwardstown:(08) 8375 9900

NSW

Granville: (02) 9897 7722

Chatswood: (02) 8467 1467

Rosebery: (02) 9698 9698

VIC

Rowville: (03) 9755 6922

Coburg: (03) 9383 2066

WA

Balcatta: (08) 8240 4420

ACT

Fyshwick: (02) 6280 9630

QLD

Bowen Hills: (07) 3852 5512

Ashmore: (07) 5597 7203

TAS

Hobart: (03) 6234 9455

Auckland

Penrose: (09) 525 8007

Christchurch

Sydenham: (03) 374 6277

Wellington

Lower Hutt: (04) 939 9355

© Hills Industries 2006 Page 4

Ordering Information

Hills Reliance System Modules & Equipment

Part # Description DAS Code

NX-8-v2-HILLS Hills Reliance 128 Control Panel S4133

NX-6-v2-HILLS Hills Reliance 12 Control Panel S4142

NX-4-v2-HILLS Hills Reliance 8 Control Panel S4697

NX-1508-HILLS Vertex 8 Zone LED Code Pad S4158

NX-1516-HILLS Vertex 16 Zone LED Code Pad S4157

NX-108-HILLS 8 Zone LED Code Pad S4127

NX-116-HILLS 16 Zone LED Code Pad S4132

NX-124-HILLS 24 Zone LED Code Pad S4131

NX-148-HILLS Alphanumeric LCD Code Pad S1241A

NX-1448-HILLS Icon LCD Code Pad S2284

NX-216E 16 Zone Expander Module S4387

NX-507E 7 Relay Expander Module S4164

NX-508E 8 Output Expander Module S4128

NX-408EI 8 Zone Wireless Expansion Module S4135

NX-416EI 16 Zone Wireless Expansion Module S4134

NX-448EI 48 Zone Wireless Expansion Module S4136

NX-320E Smart Power Supply and Bus Extender S4137

NX-536E DTMF Communicator Module (only for Reliance) S1204A

- DTMF Monitor Module (for commissioning & testing) S3079

NX-583 STU Interface S4143

NX-584E RS232 Serial Interface Automation S4703

NX-586E Direct Connect Lead S4714

NX-588E USB Flash Programming Lead S1221A

NX-590E Ethernet TCP/IP Interface S3159

60-707-43-EUR ITI 2 Button Keyfob Transmitter S5735

60-659-43-EUR ITI 4 Button Keyfob Transmitter S5753

60-705-43-ENG ITI Pendant Panic Transmitter S5744

DL900 NX/Hills Reliance Downloader Software -

NX-1701E Proximity Card Reader S1845

NX-002 Metal Box Small (for Hills Reliance 8) S4146

NX-003 Metal Box Large (for Hills Reliance 12 and 128) S4700

© Hills Industries 2006 Page 5

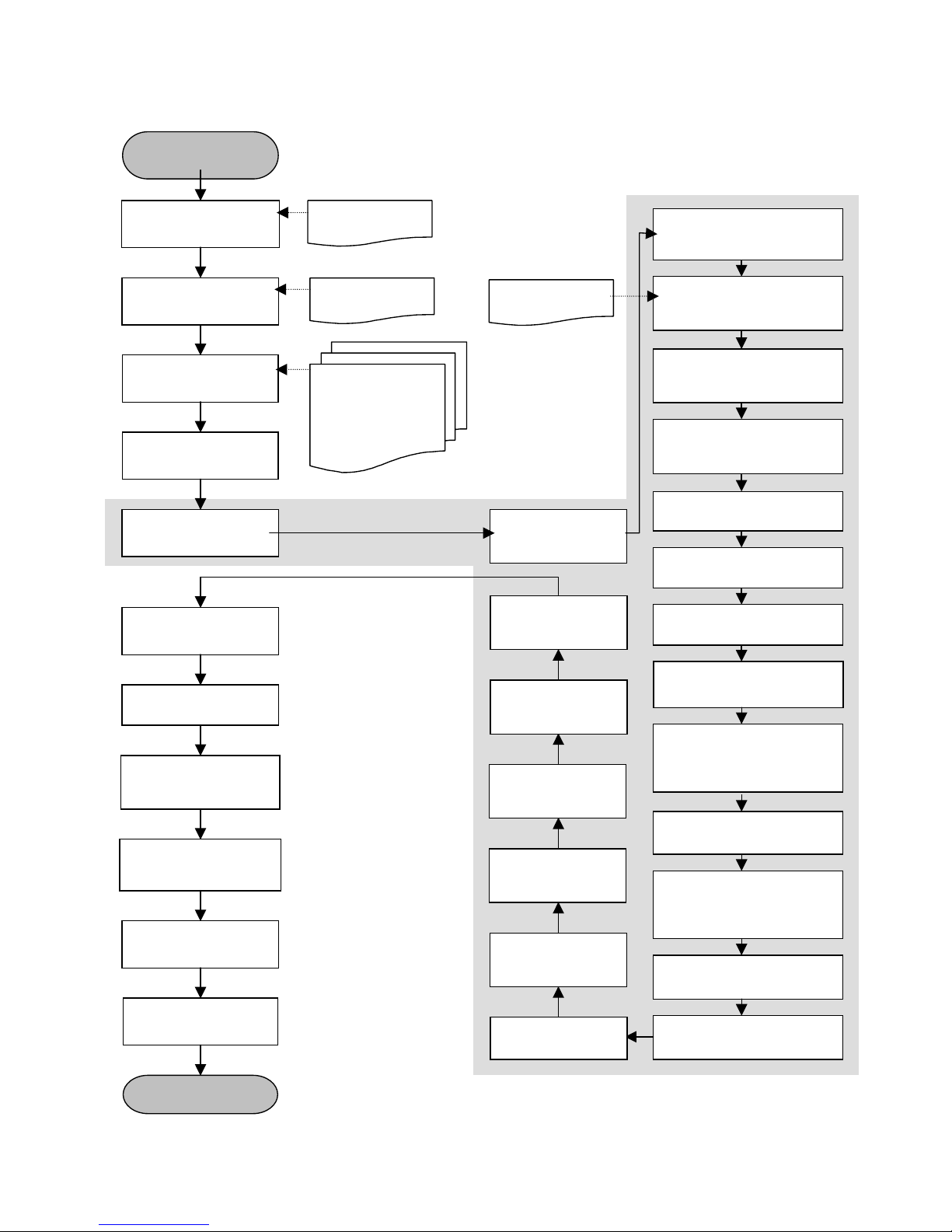

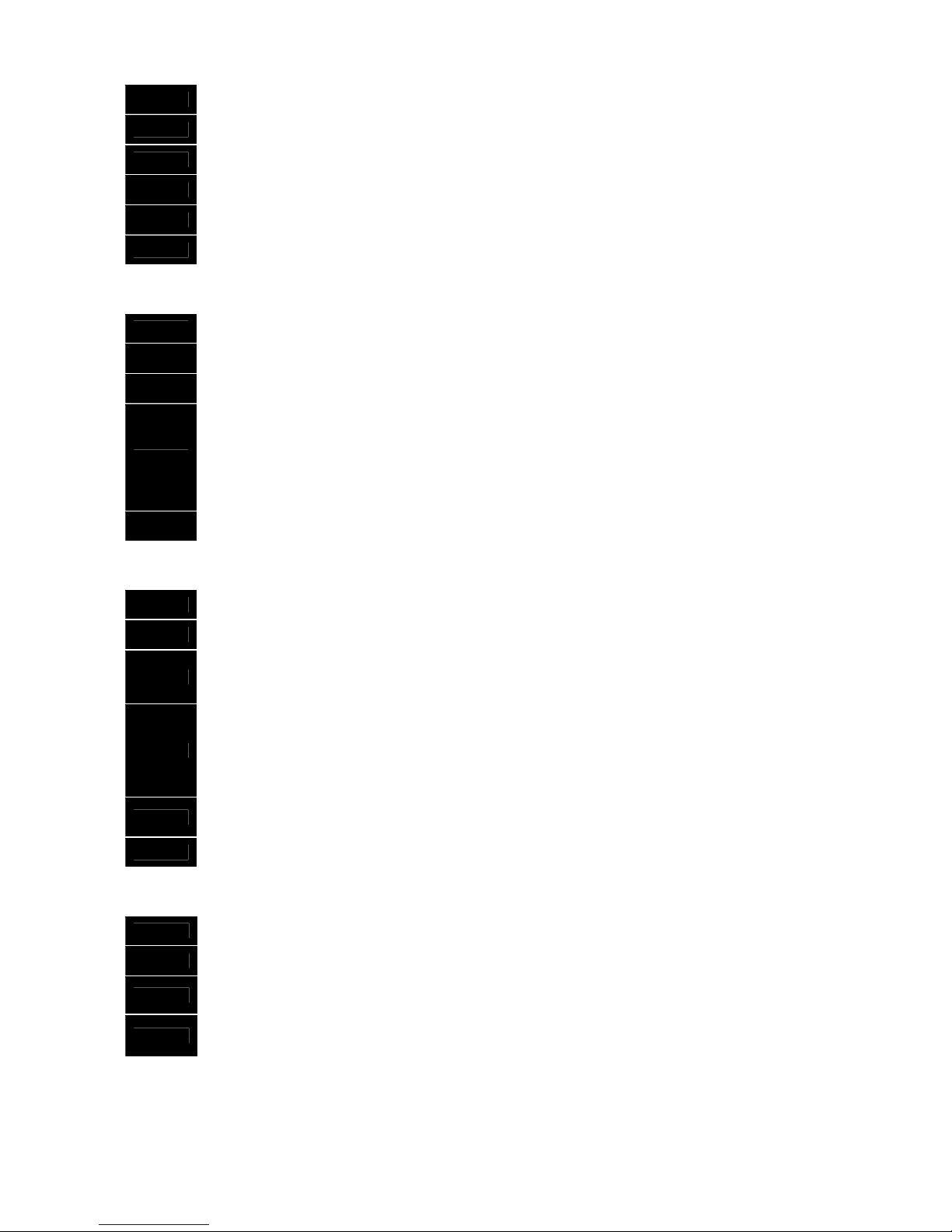

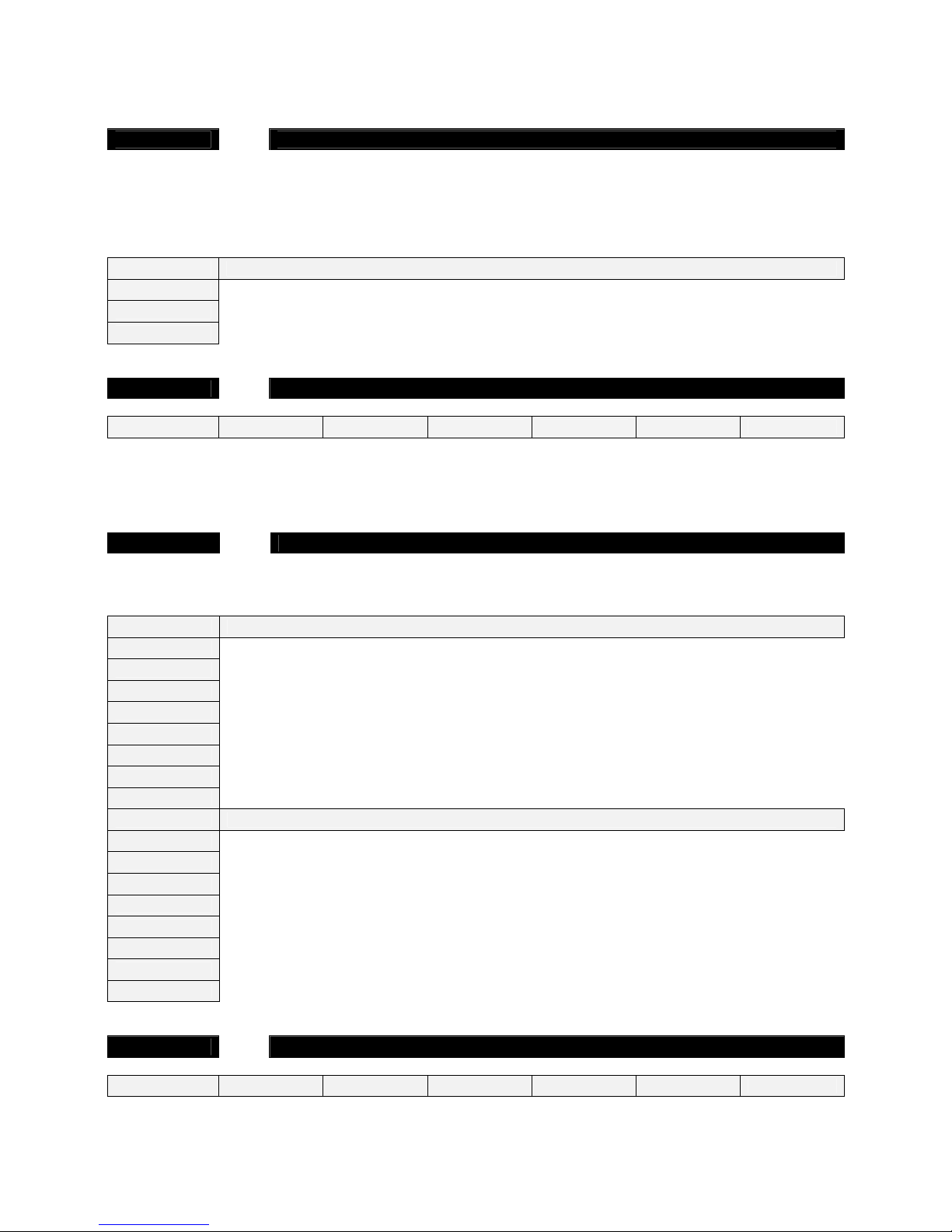

Note –This diagram is a guide for basic system programming only.

Configuration depends upon customer requirements

Installation & Programming Flowchart

Program Phone 1 (4#)

Account code (5#)

Report Format (6#) p 24

Program Event Reports (9#)

& No. Dial Attempts (10#)

p 25

Set Phone Line Cut

Delay (11#) p 25

Program Area 1 Options (16#)

& Entry/Exit Time (17#) p 27

Change Installer Code (1#) &

Duress Code (3#)

p

23

Program Zones 1-8 (18#)

& Area allocation (19#) p 29

Default System

Programming

p 21

Customer

User Details p 63

via code pad (or DL900 software)

Program System Options

(22#) p 32

For Multiple Area Systems

see F37-58 p 40-44

Program Phone 2 (7#)

& Phone 3 (8#)

if required p 25

Program Zones 9-16

(20#, 21#) p 31

Zones 17-48

(59# - 66#) p 44 -45

Program Siren/

Communication Attempts

(23#) & Code Pad Sound

Options (24#) p 35

Program System Timers (25#)

p 35

Program Autotest Time &

Freq. (32#) p 39

Plan & quote

installation p 62

Order modules and

hardware p 4

Install cabling

p 7

Mount equipment

Program system

p 20

Customer

Re

q

uirements

Train customer to use

system

Test user codes

Walk test sensors

(¹ Chime) p 19

Test timers

(siren, entry, exit, etc)

(¹44)

Test phone numbers

(Cent Stn. & mobiles)

(

¹44)

Test battery back up

(¹44)

System Handover

Planning Sheet

see p 63

DAS order form/s

ACA Cab ler

Electrical Contractor

Security License

(NSW)

or other local

re

q

uirements

Program System

Date (¹96)

p 16

Program Code Pad

No. & Areas (¹94)

p 16

Program Code Pad

Options (¹93)

p 15

Program System

Time (¹97)

p 16

Exit Program Mode

p 20

Program User

Codes (¹5)

p 17

© Hills Industries 2006 Page 6

Board Installation

The metal enclosure should be installed with the door opening from the top to bottom. It

should be installed away from damp areas (e.g. bathrooms, kitchens), away from sources of

heat, dust or interference (e.g. air conditioners, washing machines, dryers, refrigerators) and

away from external walls.

Inside the enclosure there are four slots for board inserti on, two on the top and two on the

bottom of the enclosure. These allow the PC board to be positioned vertically as shown in the

diagram. When you slide the board between the grooves of the slots, make sure the terminal

strip is toward the front opening (toward you) to allow for the wire connections.

Inside the enclosure several 2-holed insertion points have been construc ted. This allows for

either vertical or horizontal placement of the modules. Notice that each insertion point has

two sizes of holes - a larger hole and a smaller hole.

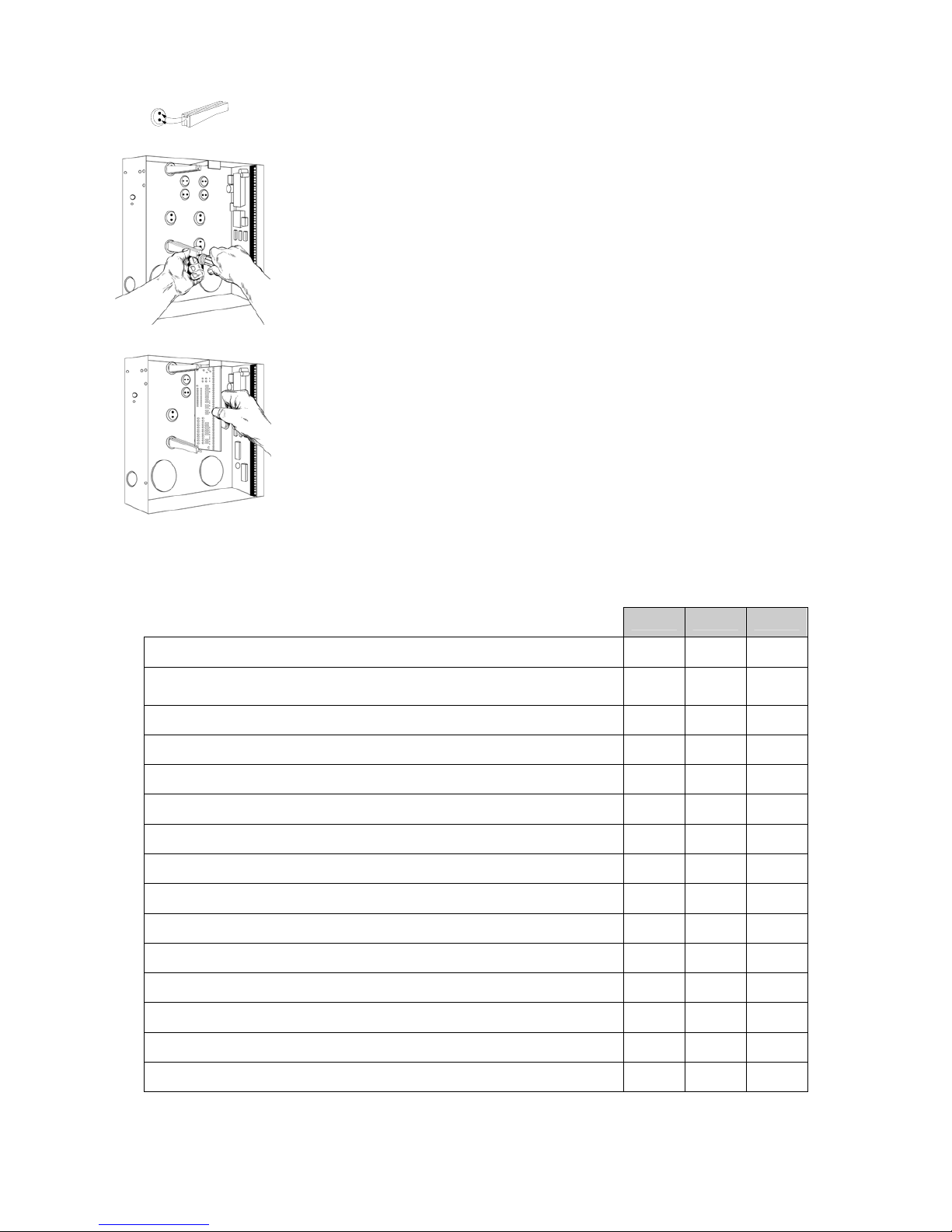

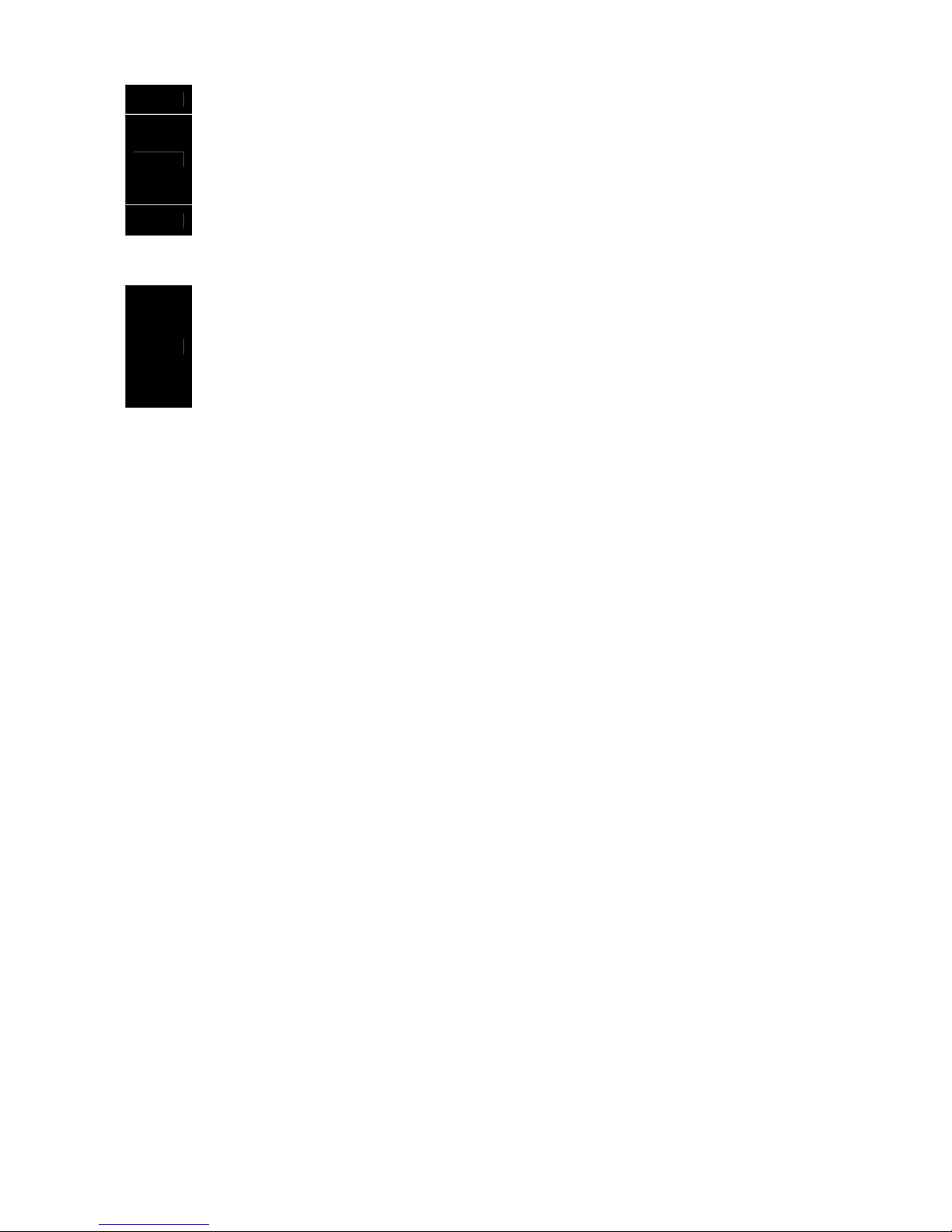

Diagram 1: The black plastic PCB guides are grooved on one edge where the PC board will

be seated. The end with the half-moon protrusion fits into the larger hole. T he smaller hole is

for the screw.

Diagram 2: Place the first black plastic PCB guide in the top insertion point, grooved edge

downward. The half-moon protrusion will be in the large hole. It does not require force to

insert. Insert one of the provided screw into the smaller hole (from inside the enclosure) to

secure it in place. A screwdriver should reach through the notch that run s the length of the

guide to tighten the screw. The second PBC guide should be positioned opposite the first

(grooved edge up) and placed in the lower insertion point, using the same procedures

described above. Once mounted, screw it in securely.

Diagram 3: The PC Board should slide freely in the grooves of both guides.

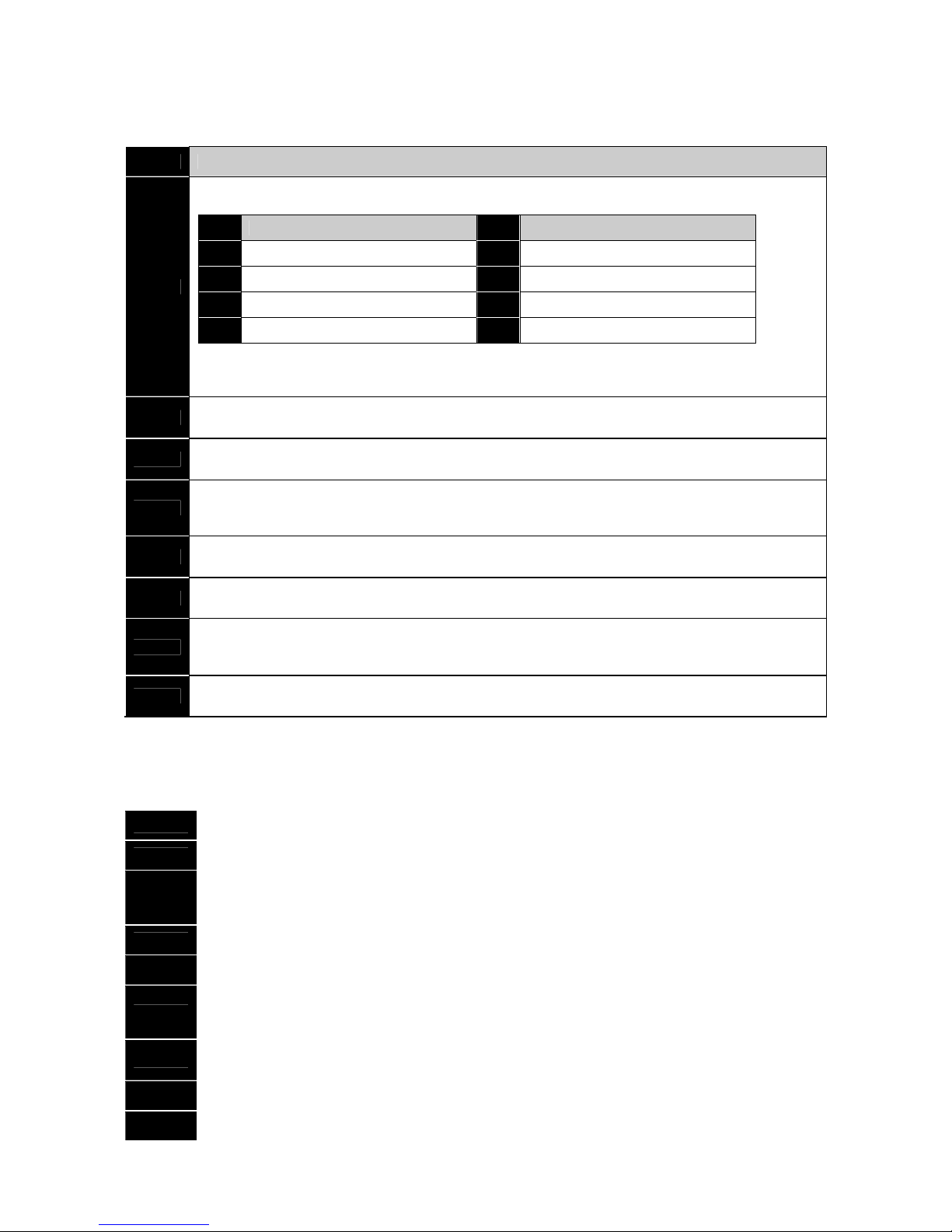

Control Panel Comparison

R8 R12 R128

Independent number of zones 8 12 16

Expandable to a maximum number of zones

(a combination of hardwired and/or wireless)

8 16 128

Anti-tamper supervision of all zones (hardwired and wireless) Yes Yes Yes

Full supervision of all expansion module and codepads Yes Yes Yes

Individual areas/partitions 1 2 8

Total number of user PIN codes (4 digit) 8 40 99

Maximum number of codepads 8 16 24

Codepad tampers Yes Yes Yes

Uni Arming (single button arming for full or partial mode) Yes Yes Yes

Home mode/Partial mode arming Yes Yes Yes

Automatic arming (and auto partial mode arming) Yes Yes Yes

Re-exit Yes Yes Yes

Real-time event history (maximum events) 185 185 185

Phone line monitor No Yes Yes

Fire alarm verification Yes Yes Yes

© Hills Industries 2006 Page 7

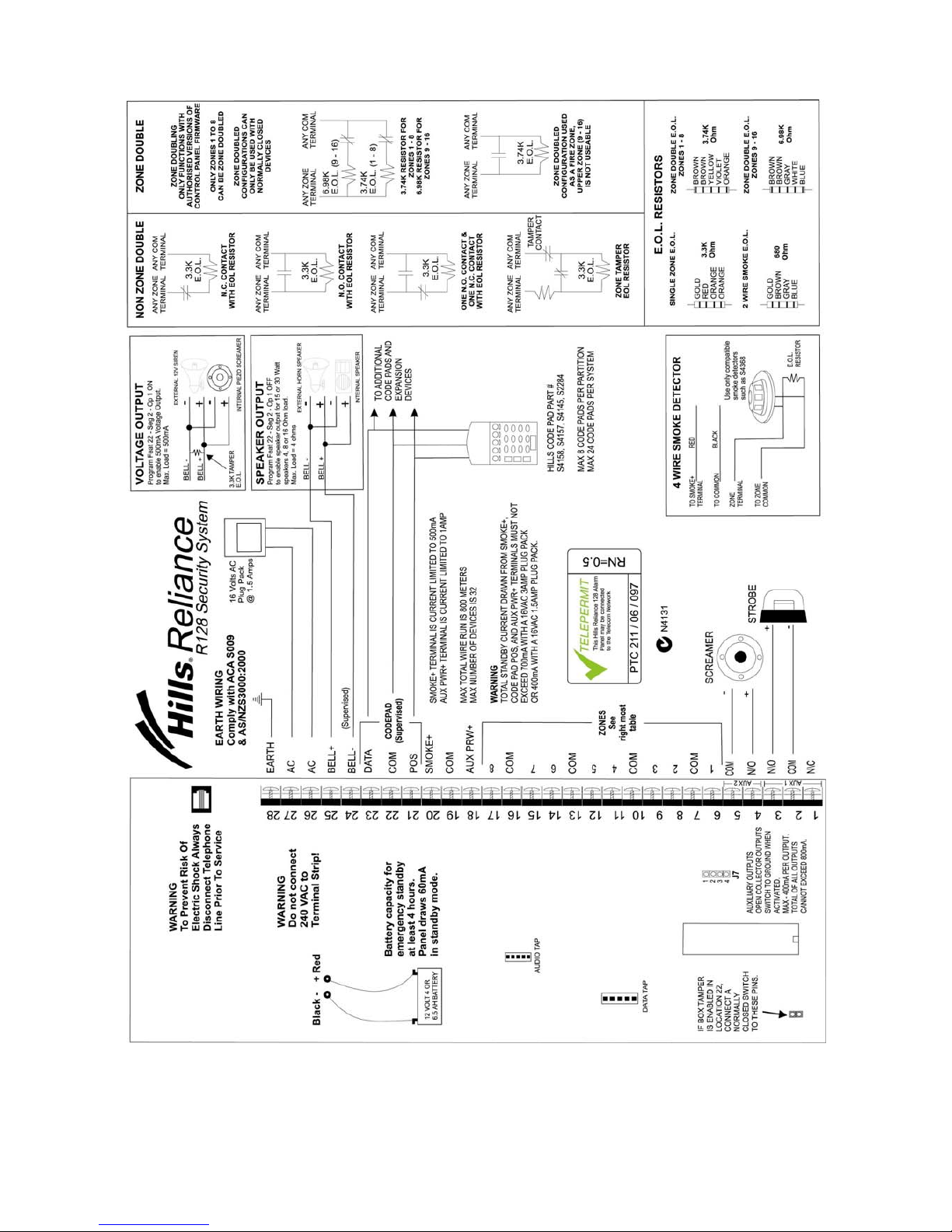

Hills Reliance 128 Wiring Diagram

© Hills Industries 2006 Page 8

Hills Reliance 128 Terminal Descriptions

Terminal Description

EARTH

Earth / Ground.

To comply with ACA S009 & AS/NZS3000:2000. Connect to the 16.5V AC plug pack earth wire.

AC

AC input. Connect a 16.5V, 25 VA, 40 VA or 50 VA approved transformer.

BELL + &

BELL -

Built in siren driver, if used as a siren output (default), the speaker rating should be

15 Watt at 8 or 16 Ohm, or 30/40 Watt at 4, 8, or 16 Ohm, 250mA maximum load.

If voltage output is selected in Feature 22 - Segment 2 - Option 1, this output becomes voltage

output, 12 VDC, 1 Amp maximum load.

Note: A 3.3K

Ω

resistor may be required across the bell terminals when a 12 VDC siren is used.

If no resistor is used, you may experience voltage leakage into the siren that will cause thes e devices

to output a small signal.

KP DATA

Connect the to the KP data terminal on the code pads and the expanders (usually blue or green

wire). Maximum total wire run is 800 metres using 14/020 cable. These numb ers are for one code

pad at the end of the wire. When connecting more than one code pad to the system bus wire, a

higher gauge wire will be required, or there will be a re duction in maximum wire distance. Maximum

32 devices.

KP COM

Connect to the Common terminal on the code pads and the expanders (usually the black wire).

KP POS

Connect to the Positive terminal on the code pads and the expanders (usually the red wire).

The KP POS and AUX PWR + terminals are limited to 1 Amp total current when added together.

SMOKE+

Smoke detector power 12VDC, 500mA maximum.

COM

Connect negative wire of powered devices such as motion detectors and smoke detectors.

AUX PWR+

Connect positive wire of all powered devices except smoke detectors and code pads.

This terminal and KP POS are limited to 1 Amp total current when added together.

ZONE 8

Connect to one side of zone 8 loop. Connect the other side to a COM termi nal. Open or short cause s

alarm. Zone 8 may be used f or a two- wire smoke detector using a 680Ω E.O.L. resistor. See Featur e

22.

COM

Common (-) terminal for zones 7 & 8. (See the wiring diagram for examples)

ZONE 7 -

ZONE 1

Connect to one side of zone loop. Connect the other side to a COM terminal. Open or short causes

alarm. Only zone 8 can be a two-wire smoke zone. (See the wiring diagram for examples)

AUX

RELAY

OUT 1-2

Relays one and two switch a 12 volts output on their N/C and N/O terminals. This me ans that you

connect the positive lead of your device to these terminals, and connect the negativ e lead to a COM

terminal. Ensure your device does not exceed the ratings of these relays, max 400 mA per output,

max 800 mA total output.

AUX

OUT 3-4

Auxiliary outputs 3 and 4 (in addition to 1 & 2) are located on a pin header J7, see wiring diagram for

details.

Battery

Leads

Connect black (-) and red (+) leads to a 12VDC sealed lead acid rechargeable battery.

Do not connect to a dry cell battery.

Warning: Total standby current drawn from SMOKE +, KP POS and AUX PWR +, must not exceed

700 mA with 16 VAC 3 Amp Plug Pack or 400 mA with 16 VAC 1.5 Amp Plug Pack.

© Hills Industries 2006 Page 9

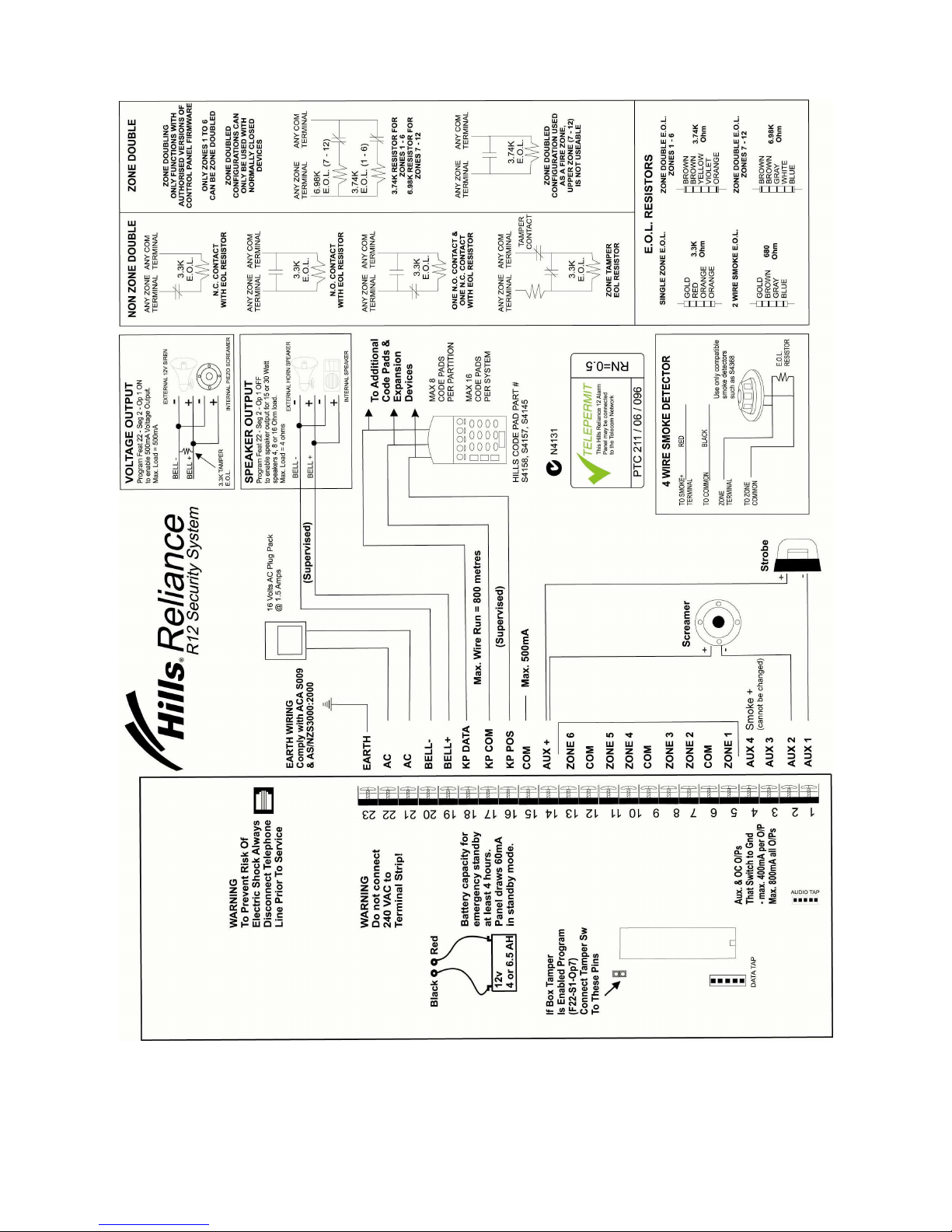

Hills Reliance 12 Wiring Diagram

© Hills Industries 2006 Page 10

Hills Reliance 12 Terminal Descriptions

Terminal Description

EARTH

Earth / Ground.

To comply with ACA S009 & AS/NZS3000:2000. Connect to the 16.5V AC plug pack earth wire.

AC

AC input. Connect a 16.5V, 25 VA, 40 VA or 50 VA approved transformer.

BELL + &

BELL -

Built in siren driver, if used as a siren output (default), the speaker rating should be

15 Watt at 8 or 16 Ohm, or 30/40 Watt at 4, 8, or 16 Ohm, 250mA maximum load.

If voltage output is selected in Feature 22 - Segment 2 - Option 1, this output becomes voltage

output, 12 VDC, 1 Amp maximum load.

Note: A 3.3K

Ω

resistor may be required across the bell terminals when a 12 VDC siren is used.

If no resistor is used, you may experience voltage leakage into the siren that will cause these devices

to output a small signal.

KP DATA

Connect the to the KP data terminal on the code pads and the expanders (usually blue or green

wire). Maximum total wire run is 800 metres using 14/020 cable. These numbers are for one code

pad at the end of the wire. When connecting more than one code pad to the system bus wire, a

higher gauge wire will be required, or there will be a reduction in maximum wire distance. Maximum

16 devices.

KP COM

Connect to the Common terminal on the code pads and the expanders (usually the black wire).

KP POS

Connect to the Positive terminal on the code pads and the expanders (usually the red wire).

The KP POS and AUX PWR + terminals are limited to 1 Amp total current when added together.

COM

Connect negative wire of powered devices such as motion detectors and smoke detectors.

AUX PWR+

Connect positive wire of all powered devices except smoke detectors and code pads.

This terminal and KP POS are limited to 1 Amp total current when added together.

ZONE 6

Connect to one side of zone 6 loop. Connect the other side to a COM terminal. Open or short causes

alarm.

COM

Common (-) terminal for zones 5 & 6. (See the wiring diagram for examples)

ZONE 5 -

ZONE 1

Connect to one side of zone loop. Connect the other side to a COM terminal. Open or short causes

alarm. Only zone 7 can be a two-wire smoke zone. (See the wiring diagram for examples)

AUX

OUT 4

(or Zone 7

/Smoke +)

Aux 4 defaults to 12VDC smoke power for a four-wire smoke detector.

Alternatively this output can be programmed in Feature 22 as Zone 7 two-wire smoke detector. Use a

680Ω E.O.L. resistor with the two-wire smoke detector. Current is limited to 250mA when output is

negative and 250 microamps maximum when output is positive.

Note: The 2-wire smoke loop cannot be enabled if Zone Doubling is used.

AUX

OUT 1-3

Connect negative lead of low current device (e.g. relay, LED [install 1K resistor in series with LED],

etc). Connect positive lead of device to AUX PWR +. Current is limited to 250mA when output is

negative and 250 microamps maximum when output is positive.

Battery

Leads

Connect black (-) and red (+) leads to a 12VDC sealed lead acid rechargeable battery.

Do not connect to a dry cell battery.

Warning: Total standby current drawn from SMOKE +, KP POS and AUX PWR +,

must not exceed 700 mA with 16 VAC 3 Amp Plug Pack or 400 mA with 16 VAC 1.5 Amp Plug Pack.

© Hills Industries 2006 Page 11

Hills Reliance 8 Wiring Diagram

© Hills Industries 2006 Page 12

Hills Reliance 8 Terminal Descriptions

Terminal Description

AC

AC input. Connect a 16.5V 1.5A approved plug pack.

EARTH

Earth / Ground.

To comply with ACA S009 & AS/NZS3000:2000. Connect to the 16.5V AC plug pack earth wire.

AUX

OUT 1

Auxiliary Output Terminal, normally used to conn ect the n egative lead of the strob e. T he positive lead

of the strobe can be connected to any of the positive terminals e.g. KP POS. Current is limited to

250mA when output is negative and 250 microamps maximum when output is positive.

SIREN

Built in siren driver, if used as a siren output (default), the speaker rating should be

15 Watt at 8 or 16 Ohm, or 30/40 Watt at 4, 8, or 16 Ohm, 250mA maximum load.

If voltage output is selected in Feature 22 - Segment 2 - Option 1, this output becomes voltage

output, 12 VDC, 500mA maximum load.

Note: A 3.3K

Ω

resistor may be required across the bell terminals when a 12 VDC siren is used.

If no resistor is used, you may experience voltage leakage into the siren that will cause thes e devices

to output a small signal.

COM

Common (-) Terminal

SMOKE+

Smoke detector power 12VDC, 100mA maximum.

At default output is 0V, to enable 12V set F27 - Seg 3 - Op 6 (invert output) to off. See Feature 27.

AUX

OUT 2

Auxiliary Output Terminal, normally used to connect the ne gative lead of the screamer. The positive

lead of the screamer can be connected to any of the positive terminals e.g. KP POS. Current is

limited to 250mA when output is negative and 250 microamps maximum when output is positive.

KP DATA

Connect the to the KP data terminal on the code pads and the expanders (usually blue or green

wire). Maximum total wire run is 800 metres using 14/020 cable. These numb ers are for one code

pad at the end of the wire. When connecting more than one code pad to the system bus wire, a

higher gauge wire will be required, or there will be a r eduction in m aximu m wire distanc e. Maximum 8

devices.

KP COM

Connect to the Common terminal on the code pads and the expanders (usually the black wire).

KP POS

Connect to the Positive terminal on the code pads and the expanders (usually the red wire).

The KP POS and AUX PWR + terminals are limited to 1 Amp total current when added together.

COM

Connect negative wire of powered devices such as motion detectors and smoke detectors.

ZONE 4

Connect to one side of zone 4 loop. Connect the other side to a COM termi nal. Open or short cause s

alarm.

COM

Common (-) terminal for zones 5 & 6. (See the wiring diagram for examples)

ZONE 3 -

ZONE 1

Connect to one side of zone loop. Connect the other side to a COM terminal. Open or short causes

alarm.

Battery

Leads

Connect black (-) and red (+) leads to a 12VDC sealed lead acid rechargeable battery.

Do not connect to a dry cell battery.

Warning: Total standby current drawn from SMO KE +, KP POS and AUX PWR +, must not exceed 700 mA with

16 VAC 3 Amp Plug Pack or 400 mA with 16 VAC 1.5 Amp Plug Pack.

© Hills Industries 2006 Page 13

Main Options

Areas

The Hills Reliance 128 can have up to a maximum of eight separate systems (areas) with distinct reportin g codes,

user codes, and operating options for each system (see Features 16-21 and 37-58). T he Hills Reliance 12 has up to

two areas, and the Hills Reliance 8 has one area.

Arm / Disarm Codes

The Hills Reliance 128 can have 99 four-digit codes or 66 six-digit codes to arm/disarm the control. All codes must

have the same number of digits. User codes are programmed and vie wed from the code pad functio ns [*] 5 and [*] 6.

The factory default for user 1 is [1]-[2]-[3]-[4] when using a 4-digit code, or [1]-[2]-[3]-[4]-[5]-[6] for a 6-digit code.

This code can then be used to enter the new arm/disarm codes (see Feature 0). The Hills Reliance 12 can have up to

40 users, the Hills Reliance 8 up to 8 users.

Auto Arm in Partial

The Hills Reliance can be armed automatic ally in the partial m ode. T his option can on ly be us ed for area one. If Auto

Arm in Partial is enabled, area one cannot have full mode Auto Arming selected. (See Feature 22)

Automatic Arming

If programmed, the Hills Reliance will Auto Arm at a specified time. At this time, the code pad will beep for 50

seconds before the panel arms. The auto arming proces s can be stopped by a valid code entry. The Auto Arming of

an area can be programmed to be silent. If closing reports are sent, the user cod e will be 97. (See Features 16, an d

33-36)

Auxiliary Outputs

The Hills Reliance 128 has two (2) programmable rela y outputs and two (2) programmable open collector outputs that

can be used to activate a strobe and two internal sirens. (See the terminal description Features 26-29). The Hills

Reliance 12 has 4 programmable open collector outputs, and the Hills Reliance 8 has two.

Auxiliary Power Over Current

The Hills Reliance will illuminate the ‘Service’ LED on th e code pad whenever too much current is drawn from any

device powered by the system. This condition can be reported to the central station. (See Features 9 and 22)

Box Tamper

The Hills Reliance has an input for a normally closed tamper switch (see wiring diagrams on p7, p9, p11). T he Box

Tamper can be programmed to report and/or sound the siren and/or the Code P ad. These terminals can be e nabled

or disabled in programming. (See Features 22 and 23)

Code Pad Start Zone

The Hills Reliance LED Code Pads can be programmed with a starting zone from 1 to 64. The starting zone

programmed into the LED Code Pad via function [*][9][2] will tie the system zone to zone one (1) of the Code Pad.

I.e. If you wish to start displaying zone 25 as the zone on e (1) on a LED Code Pad, pro gram a 25 as the start zone

into the Code Pad that will function in this manner. When system zone 25 is faulted, zone LED one (1) will illuminate

on the programmed Code Pads. Zone bypasses will be tied to the Code Pad LED number; however reporting will

follow the system zone number.

Configuration Group

The Hills Reliance has 20 programmable and 10 fixed zon e configurati on groups (i.e. zo ne types) that determi ne ho w

each zone will function and report. The first 20 groups can be reprogrammed.

Dual End of Line

All Hills Reliance zones can be enabled for tamper monitoring if the Dual End of Line option is enabled. Zone

Doubling cannot be used if the option is enabled. (See Feature 22)

Dynamic Battery Test

The Hills Reliance can be programmed to perform a dynamic battery test to verify the condition of the battery for a

selected duration the first time the panel is armed or disarmed every day. T he Hills Reliance can also be programmed

to perform a missing battery test every 12 seconds. (See Features 22 and 25)

© Hills Industries 2006 Page 14

Exit Error

If enabled, the Hills Reliance will send an ‘E xit Err or Rep ort’ if an entr y/e xit zone is fau lted at the inst ant t he e xit del ay

expires. This report will be sent along with the user number that armed the system, if the panel is not disarmed

before the entry delay expires. The alarm report will also be sent. Even if this option is not enabled, the siren will

sound if any entry/exit zone is faulted at the instant the exit delay expires. (See Feature 9 and 16)

Expander Trouble

The Hills Reliance will report expander trouble to the central station if enabled. This condition will illuminate the

‘Service’ LED on the code pad even if not reported. N ote: The code pads are considered ex panders. The number of

the expansion devices reported can be found in Appendix 3. (See also Feature 9 an d 22)

Fire Alarm Verification

When enabled, the Hills Reliance will verify a fire alarm by waiting for a second trip on a smoke detector within a

specified time before creating an alarm (see Feature 25). To interrupt the smoke detector power (when in the

disarmed state) each time the [*] 7 keys are pressed, the corresponding LE D(s) for zones designated as ‘Fire’ must

be on steady for alarm or blinking for trouble. When the ‘Fire Alarm Verification’ o ption is enabled, a smoke detecto r

will be powered down and reset automatically after the first trip, waiting for a second trip within a specified time before

creating an alarm. The communicator will delay for a specified time b efore reporting the alarm, if a valid code is

entered, the report will be aborted, and the smoke alarm ve rification option will be reset if enabled. If no valid code is

entered the alarm report will be reported to the base station. (See Zone Configuration Group Table and Feature 2 5)

Group Bypass

A designated group of zones can be programmed to bypass by pressing [Bypass]-[0]-[0]-[Bypass] prior to arming.

(See Zone Configuration Group Table)

Internal Event Log

Up to 185 events can be stored in memory along with the date and time of the event. These events can later b e

viewed through downloading or the LCD code pad. All reportable events report to the log.

Number of Calls and Rings to Answer

The Hills Reliance can count the number of calls and rings that must be met for automatic download ans wering.

(See Feature 13)

On Board Zone Disable

The zones on the main Hills Reliance control panel can be disabled in order to have a completely wireless alarm

system. (See Feature 22)

Partial Mode

Partial mode allows system owners to arm only designated partial zones (e.g. downstairs, front doors, garage),

bypassing all non-partial zones (e.g. upstairs bedroom). Part ial mode encourages system owners to use their alarm

system more frequently when the premise is occupied. When armed in the ‘Partial’ mode, the openin g of any zones

designated as ‘Partial Mode zone’ will initiate the code p ad sounder and start the Partial Mode entry delay before

creating an alarm. All other zones will function as normal. (See Zon e configuration Group Table and Features 16

and 25)

Siren Supervision

The Hills Reliance has a siren supervision circuit (B ell + and Bell -) that will consta ntly monitor the siren on the Hills

Reliance and can be programmed to report if the wires are cut. (See Feature 22)

Telephone Line Monitor

The Hills Reliance 128 and Hills Reliance 12 have a telephon e line monitor that monitors the voltage and current of

the telephone line to detect a cut phone line. This condition can als o be reported to the central statio n after the line is

restored. Not available on the Hills Reliance 8.

Twin Trip

This option requires two or more trips on a zone or zones programmed as ‘Twin Trip’ within a specified time before

reporting an alarm. During the time between trips, the Hills Reliance can be programmed to sound the code pad

and/or the siren. The Hills Reliance will als o see an al arm ac tivation if any Twin Trip zone that is continuously faulted

for longer than 10 seconds. (See Zone configuration Group Table and Features 22, 24, and 25)

© Hills Industries 2006 Page 15

Programming The LED Code Pads

This section describes how to program the address and area of each code p ad as well as the options that are available.

The code pad address allows the panel to monitor and supervise the connected code pads and report code pad

communication faults.

The factory default for the Master code is [1]-[2]-[3]-[4] when using a 4-digit code or [1]-[2]-[3]-[4]-[5]-[6] for a 6-digit code.

The factory default for the ‘Go To Program’ code is [9]-[7]-[1]-[3] for a 4-digit code or [9]-[7]-[1]-[3]-[0]-[0] for a 6-digit code.

1. Setting The LED Code Pad Starting Zone - Function [9] [2]

Step 1

Your system must be in the Disarmed state to program the code pad settings

Step 2 Press the [Á]-[9]-[2] keys

Step 3 Enter the [Program Code]

Step 4

Enter the Starting zone number from 1 to 128.

Note that older code pads only support up to 48 zones (i.e. non “E” versions”). Keep this in mind when

expanding a site by replacing the panel – some code pads may also need replacing. O n sites with >48

zones it is recommended to use an LCD code pad.

Step 5 Press [Á] to save changes and exit this function

2. Setting The LED Code Pad Options - Function [9] [3]

Step 1

Your system must be in the disarmed state to program the code pad settings

Step 2 Press the [Á]-[9]-[3] keys

Step 3

Enter the [Program Code]. The ‘Service’ LED will flash

LEDs 1-8 can now be toggled on/off to enable/disable the functions listed in the table below:

LED Code Pad Option Enabled

1 Enable Code Pad tamper switch

2 Enable Silent Code Pad option

3 Enable Ding Dong sound for Chime – If off, chime will be a single tone.

4

Enable Key-press Silence option (silences the pu lsing code pad sounder for 5

seconds when a key is pressed)

5

Enable Armed Status Suppression (faulted or bypassed zones will n ot display

on code pad when system armed)

6

Enable Panic, Fire, Medical Beep-tone (will sound a short beep to verif y that the

key-press was accepted)

7

Suppresses the ‘Service’ LED (will not allow the ‘Service’ LED to illuminate for

any reason. If there is a system trouble, pressing [Á]-[2] will still show the service

menu.)

8

Enable multi-area viewing (enables temporary viewing of all areas by pressing

[Á]-[1]-[Area Number])

Step 4 After enabling/disabling the desired functions press [r] to save changes and exit this function.

© Hills Industries 2006 Page 16

3. Setting The LED Code Pad Number And Area Options - Function [9] [4]

Step 1

Your system must be in the disarmed state to program the code pad settings

Step 2 Press the [Á]-[9]-[4] key

Step 3 Enter the [Program Code] – The ‘Service’ LED will flash

Step 4 Enter the code pad number [1-8]

Step 5 Press [Á] - The ‘Instant’ LED will illuminate steady and the ‘Service’ LED will remain flashing

Step 6 Enter the [Area Number] for the code pad (the code pad will automatically exit this mode at this time)

4. Set Elapsed Hours Since Last Auto Test - Function [9] [5]

Step 1

Your system must be in the disarmed state to program the code pad settings

Step 2 Press the [Á]-[9]-[5] keys

Step 3 Enter the [Program Code] – The ‘Service’ LED will flash

Step 4

Enter [100's digit] - [10's digit] - [1's digit] for the elapsed hours

Example: if you have programmed the Auto-Test intervals to report every 72 hours, the value in this

function will determine the first time the auto test report is made, so to have the first test occur in 12

hours and then every 72 hours, simply subtract the 12 fro m 72 which give s you a value of 60 hours. The

value in this function would be [6][0].

Step 5 Press the [#] key to exit this function

5. Set System Date - Function [9] [6]

Step 1 Press the [Á]-[9]-[6] keys

Step 2 Enter the [Master Code]

Step 3

Enter the ‘Day of Week Code’:

1 = Sunday 3 = Tuesday 5 = Thursday 7 = Saturday

2 = Monday 4 = Wednesday 6 = F rid ay

Step 4

Enter the ‘Month Code’ – this must be two (2) digits:

01 = January 05 = May 09 = September

02 = February 06 = June 10 = October

03 = March 07 = July 11 = November

04 = April 08 = August 12 = December

Step 5

Enter the ‘Day Code’ – this must always be two (2) digits.

Example: The 5th would be entered as [0][5]

Step 6

Enter the last two digits of the ‘Year Code’. Example: For 2006 enter [0][6].

6. Setting The System Clock - Function [9] [7]

Step 1 Press the [Á]-[9]-[7] keys.

Step 2 Enter the [Master Code]

Step 3

Enter the ‘Hour Code’, which must be two (2) digits. Note: The clock is a 24-hour clock.

Example: Enter 12:00 am as [0]-[0], 7.00 AM as [0]-[7], and 5:00 PM as [1]-[7].

Step 4

Enter the ‘Minutes Code’, which must be two (2) digits.

Example: 7 minutes after the hour would be entered [0] [7].

© Hills Industries 2006 Page 17

7. Service Menu - Function [2]

The service light will be “on” if the security system requires service. If the service LED is “on”, press the [r] key followed by

the [2] key to determine the service condition. One or mor e zone LEDs will illumin ate indicating what service(s) is requi red.

Call your service provider immediately for these problems. Below is a listing of what each LED means in a service

condition

:

LED

Problem

1

SYSTEM FAULT – Press the [1] key. The zone LED(s) illuminated corresponds to the s ystem fault(s)

below:

LED System Fault LED System Fault

1

Over Current Fault

5

Expander Low Battery

2

Siren Trouble

6

Expander Box Tamper

3

Box Tamper

7

Expander Trouble

4

Expander Power

8

Reserved

Note: Faults 1 & 2 are global in nature and will affect all areas of a multi-area system.

Press the [#] key to return to the 1 of 8 service LEDs.

2

ZONE TAMPER – Press the [2] key and the zone LED(s) will illuminat e showing the zone(s) that are

tampered. Press the [#] key to return to the 1 of 8 service LEDs.

3

ZONE LOW BATTERY – Press the [3] key. The zone LED(s) will illuminate showing which zone(s) has a

low battery. This only applies to wireless zones. Press the [#] key to return to the 1 of 8 service LEDs.

4

ZONE LOSS OF SUPERVISION – Press the [4] key and the zone LED(s) will illuminate showing which

zone(s) has loss of supervision. This only applies to wireless zones. Press [#] key to return to the 1 of 8

service LEDs.

5

ZONE TROUBLE – Press the [5] key and the zone LED(s) will illuminate showing which zone(s) has a

trouble condition. Press the [#] key to return to the 1 of 8 service LEDs.

6

TELEPHONE LINE TROUBLE/LINE CUT – This light will illuminate when the panel senses loss of ph one

line.

7

FAILURE TO COMMUNICATE – This LED illuminates when there is a failure to co mmunicate between

your system and the central station. Note: This fault is global i n nature affecting all areas of a multi-area

system.

8

LOSS OF SYSTEM TIME – This LED illuminates when there has been a loss of power and your s ystem

clock needs to be reset. See steps 5 and 6 above to program system date and time.

To exit the Service LED Mode - press the [#] key.

8. Changing User Codes - Function [5]

Step 1

Your system must be in the disarmed state to change user codes.

Step 2 Press the [Á]-[5] keys

Step 3

Enter a [Master Arm/Disarm Code]

Note: Multi area systems: A user changing another user’s code must have access to all or more areas

than the user being changed.

Step 4

The ready light will flash

Step 5 Enter the 2 digit ‘user number’ (always enter 2 digit such as [0]-[3] for user 3)

Step 6

Enter the new four (4) or six (6) digit ‘user code’.

Note: To delete a user code, enter [Chime]-[Chime]-[Chime]-[Chime] for a 4-digit code,

or [Chime]-[Chime]-[Chime]-[Chime]-[Chime]-[Chime] for a 6-digit code.

Step 7

The ready light will flash indicating you are back at Step 5 above. If the code is rejected, the sound er

beeps 3 times.

Step 8

If another ‘user code’ needs to be programmed, return to Step 6

Step 9 Press the [#] key while the ready light is flashing to exit the user code programming mode.

© Hills Industries 2006 Page 18

9. Assigning User Code Authority Levels - Function [6]

Step 1

Assign user codes before assigning authority levels

Step 2 Press the [Á]-[6] key

Step 3

Enter a [Master Arm/Disarm Code]

Note: a user changing the authority of another user can only add or remove area authorization for areas

to which they have access.

Step 4

The ready light will flash

Step 5

Enter the 2 digit ‘user number’ to be assigned authority.

(The ready light is constant and the partial light will flash).

Step 6

Lights illuminated indicate the authority levels assigned to this code. You may toggle (turn on/off) the

authority level by pressing the number for that authority level. An explanation of the lights is listed below:

LED Attributes if LED 8 is off LED Attributes if LED 8 is on

1

Reserved

1

Activate output 1

2

Arm Only

2

Activate output 2

3

Arm Only After Close Window

3

Activate output 3

4

Master arm/disarm (can program

other codes)

4

Activate output 4

5

Arm/disarm code

5

Arm/disarm

6

Allowed to bypass zones (see F23)

6

Bypass zones

7

Code will send open / close reports

7

Open / Close reporting

8

If LED 8 is off, LEDs 1-7 will use the

details in this column

8

If LED 8 is on, LEDs 1-7 will use the

details in this column

Note you cannot set attributes on both sides of the table above (e.g. Arm Only and Activate output 3).

Step 7

Press the [Á] key. The ready light will flash. This moves you to the area enab le.

(The user has access to areas that are illuminated by the LEDs.)

Step 8

The illuminated numbers indicate each area where the user has access. To change any of the areas

where the user has access, press numbers corresponding to areas where you want to give the user

access or deny access. Refer to chart shown below:

LED Areas Assigned LED Areas Assigned

1

Area 1

5

Area 5

2

Area 2

6

Area 6

3

Area 3

7

Area 7

4

Area 4

8

Area 8

Example: If zone LED 2 is lit, then the user is assigned access to area 2. By pressing the [2] key, the

light will go off, denying access to area 2.

Step 9

When the areas are assigned, press the [Á] key, returning you to Step 4. You may then enter another

user number to assign authority level. Repeat Steps 4 - 8 until you have assigned authority levels to all

user numbers.

Step 10 Press the [#] key to exit the Assigning Authority Level Program.

Note: Any master arm/disarm code can add or change a user code if the master code has access to the sa me areas as the

code being added/changed. Consequently, when programming the user codes for such a system, leave at least one code

(can be ‘Go To Program Code’ if enabled in Feature 2) access to all areas or you w ill not be able to add new users. If you

desire the end user to be able to add new codes, you must remove the area authority from all blank codes.

© Hills Industries 2006 Page 19

10. Walk Test Mode - Function [Á] [Chime]

Step 1 Press the [Á]-[Chime] keys

Step 2

Enter a [Master Arm/Disarm Code]

Now all zones become 24 hour, silent and local (non r epo rting zo nes). By faulting a ny zone, that zone will

latch its zone light on the LED code pad, and sound the Chime. The Chime will continue to sound each

time a zone is faulted. Once all zone are tested (zone lights lit on the LED code pad) go to step 3.

Step 3 Enter a [Master Arm/Disarm Code]

11. Call Back Download [Á] [9] [8] and Answer Call [Á] [9] [9]

Step 1

Pressing [Á]-[9]-[8] while the system is disarmed will cause the control p anel to initiate a call back for a

download connection (remote access). Note: a valid user code may be required after [Á]-[9]-[8] if

enabled in Feature 0.

Pressing [Á]-[9]-[9] while the system is disarmed will cause the control panel to seize the pho ne line for

a download connection (remote access). Note: a valid user code may be required after [Á]-[9]-[9] if

enabled in Feature 0.

© Hills Industries 2006 Page 20

Programming The Hills Reliance Control Panel

Features, Segments and Options

The Hills Reliance programming structure consists of Features, Segments, and Options.

Features or Feature numbers are used to locate an option or group of options.

Example: Feature 6 contains the communicator format selection and Feature 16 co ntains area one options.

Segments are contained within each feature, there are two types of segments.

The first segment type is referred to as an option select segment. This segment type contains up to eight options that can

be toggled On or Off like dip switches.

The second segment type is referred to as a numeric segment. This segment type requires a value from ‘0’ to ‘255’ to be

entered.

Options are contained within segments. An option select segment can have up to eight options. A numeric segment can

have a value of ‘0’ to ‘255’.

Example: Feature 6 contains the communicator format that has one segment with one option; and Feature 16 contains area

one options that has 5 segments with 40 options in total.

Navigating Program Mode

Entering The Program Mode: To enter the program Mode, press [r]-[8]. At this time, the five function LEDs (On, Partial,

Exit, Bypass, & Chime) will begin to flash. Next, enter the ‘Go To Program Code’ (factory default is [9]-[7]-[1]-[3]). If the ‘Go

To Program Code’ is valid, the ‘Service’ LED will flash and the five fu nction LEDs will illumin ate steady. You are no w in the

Program Mode and ready to select the module to program.

Selecting The Module To Program: Since all modules connected to the Hills Reliance are programmed throug h the code

pad, the module you are programming should be the first entr y. To program the Hills Reliance control panel, e nter [0]-[#].

[0] is the module number of the control and the [#] is the enter key. Other module e ntry numbers can be found in their

corresponding manuals.

Programming A Feature: Once the number of the module to be programmed has been entered, the ‘Armed’ LED will

illuminate, indicating it is waiting for a programming feature to be entered. Any feature can be accessed by directly entering

the desired programming feature followed by the hash [#] k ey. If the feature entered is a valid feat ure, the ‘Armed’ LED will

extinguish, the ‘Ready’ LED will illuminate a nd the bi nary data for the first s egment of this feature will be sho wn by the zone

LED's. While entering new data, the ‘Ready’ LED will begin flashing to indicate a data c hange in proc ess. The flashing will

continue until the new data is stored by pressing the [Á] key. Upon pressing the [Á] key, the code pad will adva nce to the

next segment and display its data. This procedure is repeated until the last segme nt is reached. Pressing the [#] key will

exit from this feature, and the ‘Armed’ LED will illuminate again waiting for a ne w programming feature to be entered. If the

desired feature is the next sequential feature, press the [POLICE] key. If the previous feature is desired press the [FIRE]

key. If the same feature is desired press the [MEDICAL] key. To review the data in a feature, repeat the a bove procedure,

pressing the [#] key without any numeric data entry. Each time the [r] key is pressed, the programming data of the next

segment will be displayed for review.

Exiting A Feature: After the last segment of a feature is programmed, pressing the [Á] key will exit that feature, turn the

‘Ready’ LED off and the ‘Armed’ LED on. You are now ready to enter another programmi ng feature as before. If an attempt

is made to program an invalid entry for a particular segment, the code pad sounder will emit a triple error beep (b eep, beep,

beep), and remain in that segment awaiting a valid entry.

Exiting The Program Mode: When all the desired changes in programming have been made, it is time to exit the progr am

mode. Pressing the [Exit] key will exit this programming level, and go to the ‘Select a Module to Program’ level. If no

additional modules are to be programmed, pressing th e [Exit] key agai n will e xit the program mo de. If there is a module t o

be programmed, it may be selected by entering its address followed by the [#] key (see ‘Selecting the Module T o Program’

above). The procedure for programming these devices is the same as for the control panel, except the features will be for

the module selected.

© Hills Industries 2006 Page 21

Programming Data

Programming Data: Programming data is always one of two types. One type of d ata is numerical and can tak e on values

from 0-15 or 0-255 depending on the feature's segment. The other type of data is a O ption selection type. Option selection

data is used to turn options on or off. Use the following procedures when working with these two data types:

Numerical Data: Numerical data is programmed by entering a number from 0-255 on the numeric keys of the system code

pad. To view the data in a feature, a binary process is used. W ith this process, the LED’s for zones 1 through 8 are

utilized, and the numeric equivalents of their illuminated LE D’s are added together to determine the data in a pr ogramming

feature. The numeric equivalents of these LED’s are as follows:

Zone 1 LED = 1 Zone 2 LED = 2 Zone 3 LED = 4 Zone 4 LED = 8

Zone 5 LED = 16 Zone 6 LED = 32 Zone 7 LED = 64 Zone 8 LED = 128

Example: If the numerical data to be programmed in a feature is ‘ 66’, press [6]-[6] on the code pa d. The LED’s for zone 2

and Zone 7 will become illuminated indicating 66 is in that feature (2 + 64 = 66). See this example on page 22.

Once the data is programmed, press the [r] key to enter the data and advance to the next segment of that feature. After

the last segment of a feature is programmed, pressing the [r] key will exit that feature, turn the ‘Ready’ LED off and the

‘Armed’ LED on. As before, you are now ready to enter another programming feature. If an attempt is made to program a

number too large for a particular segment, the code pad sounder will emit a triple beep, indicating an error, and remain in

that segment awaiting a valid entry.

Option Selection Data: Option selection data will display the current conditio n (on or off) of eight options associated with

the programming feature and segment selected. Pressing a button on the touch-pad (1 thru 8) that corresponds to the

‘option number’ within a segment, will toggle (on/off) that opt ion. Press ing a ny num eric key between [1] and [8] for selection

of a option, will make the corresponding LED illuminate (opt ion ON). Press the number again and the LED will extinguish

(option OFF). You will see that numerous options can be selected from within one segment. For instance, if all eight

options of a segment are desired, pressing [1]-[2]-[3]-[4]-[5]-[6]-[7]-[8] will turn on LED's 1 thru 8 as you press the keys,

indicating that those options are enabled. After the desired setting of options is selected for this segment, press the [Á] key.

This will enter the data and automatically advance to the next segment of the feature. When yo u are in the last segment of a

feature and press the [Á] to enter the data, you will exit that feature. This will now turn the ‘ Ready’ LE D off and the ‘ Armed’

LED on. As before, you are now ready to enter another programming feature.

Loading Factory Defaults

There are two methods of loading the factory defaults:

Method 1 - Enter the program mode using the procedure on page 9, then type [9]-[1]-[0]-[#]. The code pad will beep 3

times indicating that the loading is in progress. The loading takes about 6 seconds.

Method 2 - Enter [9]-[7]-[1]-[3]-[0]-[0] within 10 seconds of power up at any code pad which is not programmed for

master mode. The procedure will default the Hills Reliance control panel even if it is armed.

Enrolling Modules & Code Pads

For supervision purposes, the Hills Reliance has the ability to automatically find and store in its memor y, the presence of all

code pads, zone expanders, wireless receivers, and any other module connected to the data termina l (KP DATA) whenever

exiting the program mode. The enrolling process takes about 12 seconds, during which time the ‘Service’ LED will

illuminate. Once a module is enrolled, if it is not detected by the control panel, the ‘Service’ LED will illuminate on that code

pad.

To force module and keypad enrolment, whilst in program mode enter [9]-[1]-[5]-[#]-[Exit]-[Exit], and wait 12 seconds.

© Hills Industries 2006 Page 22

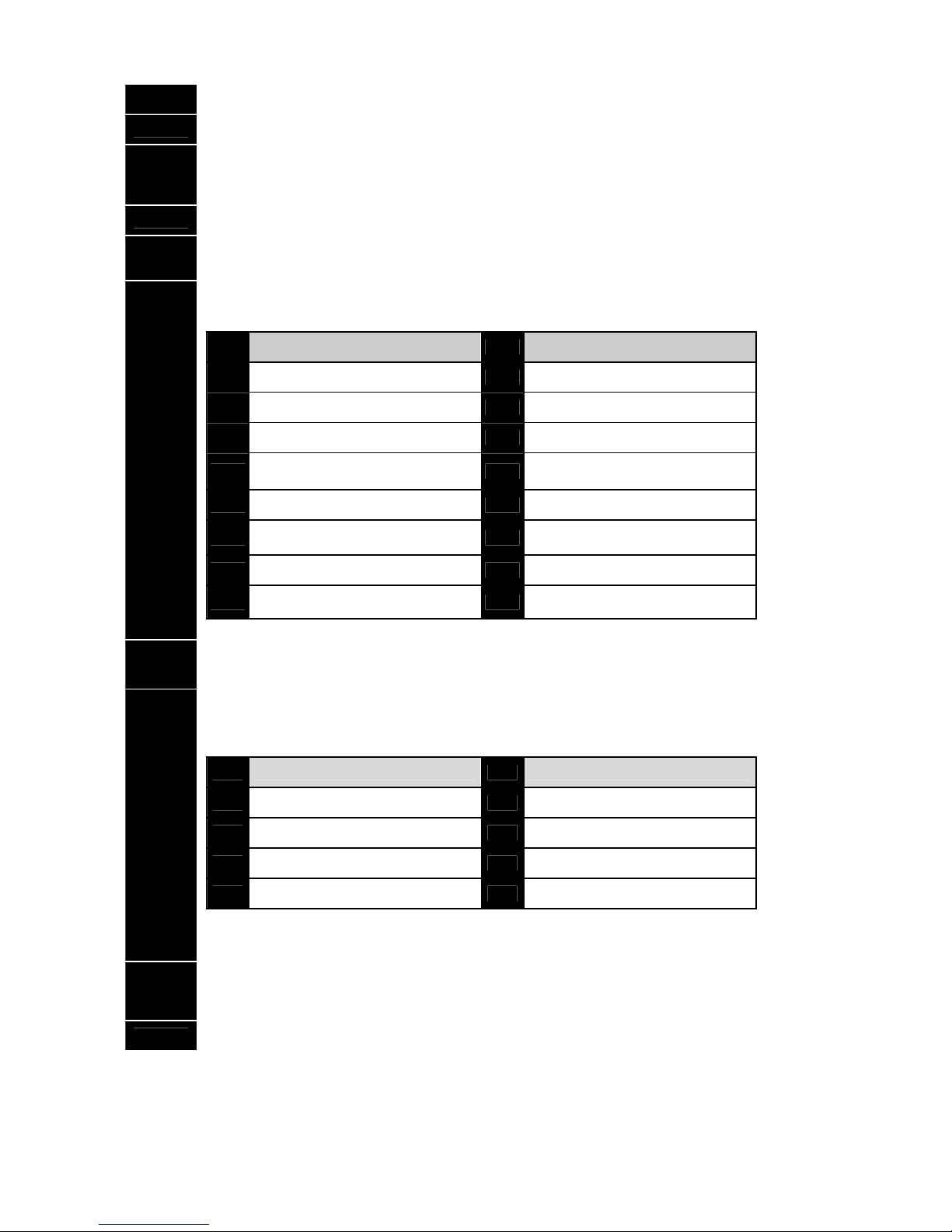

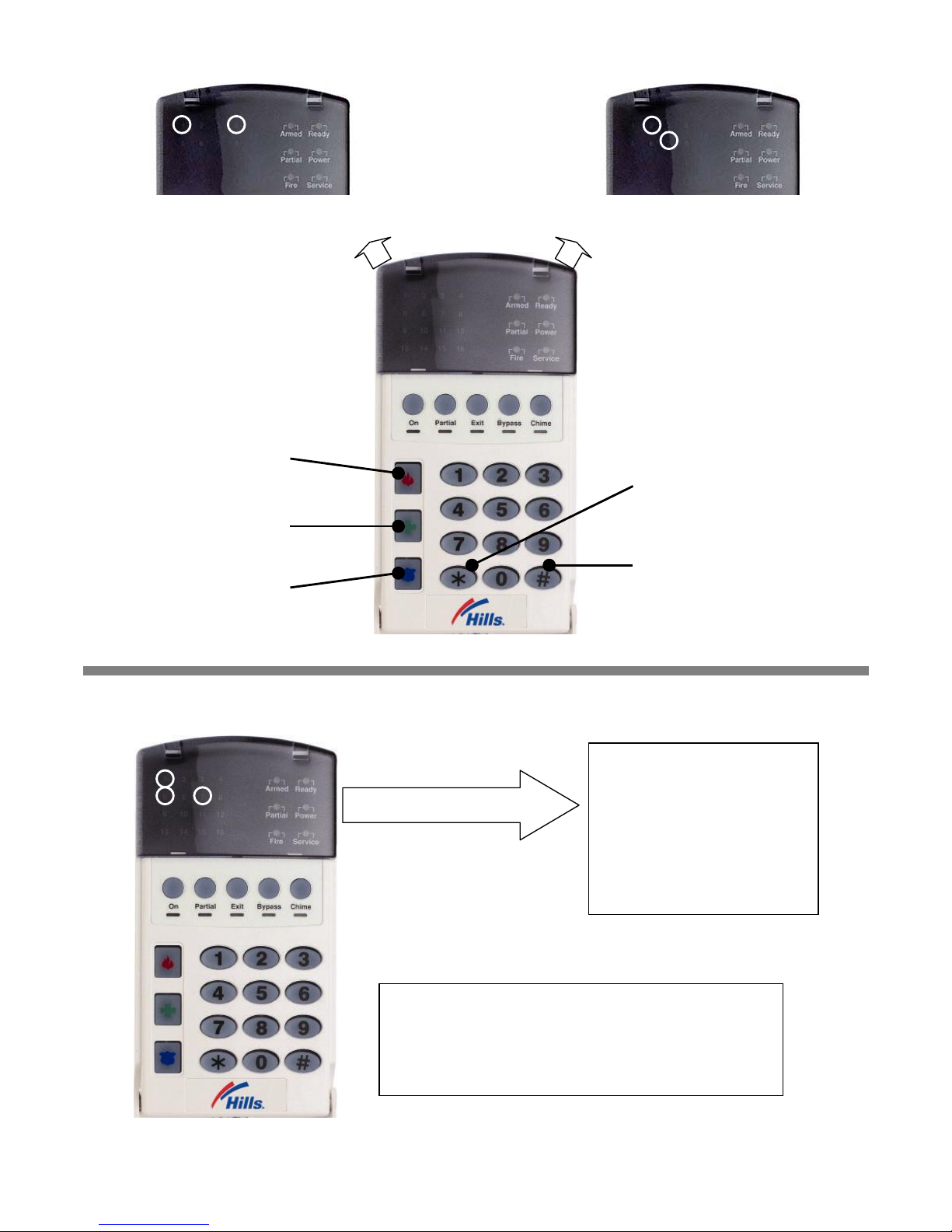

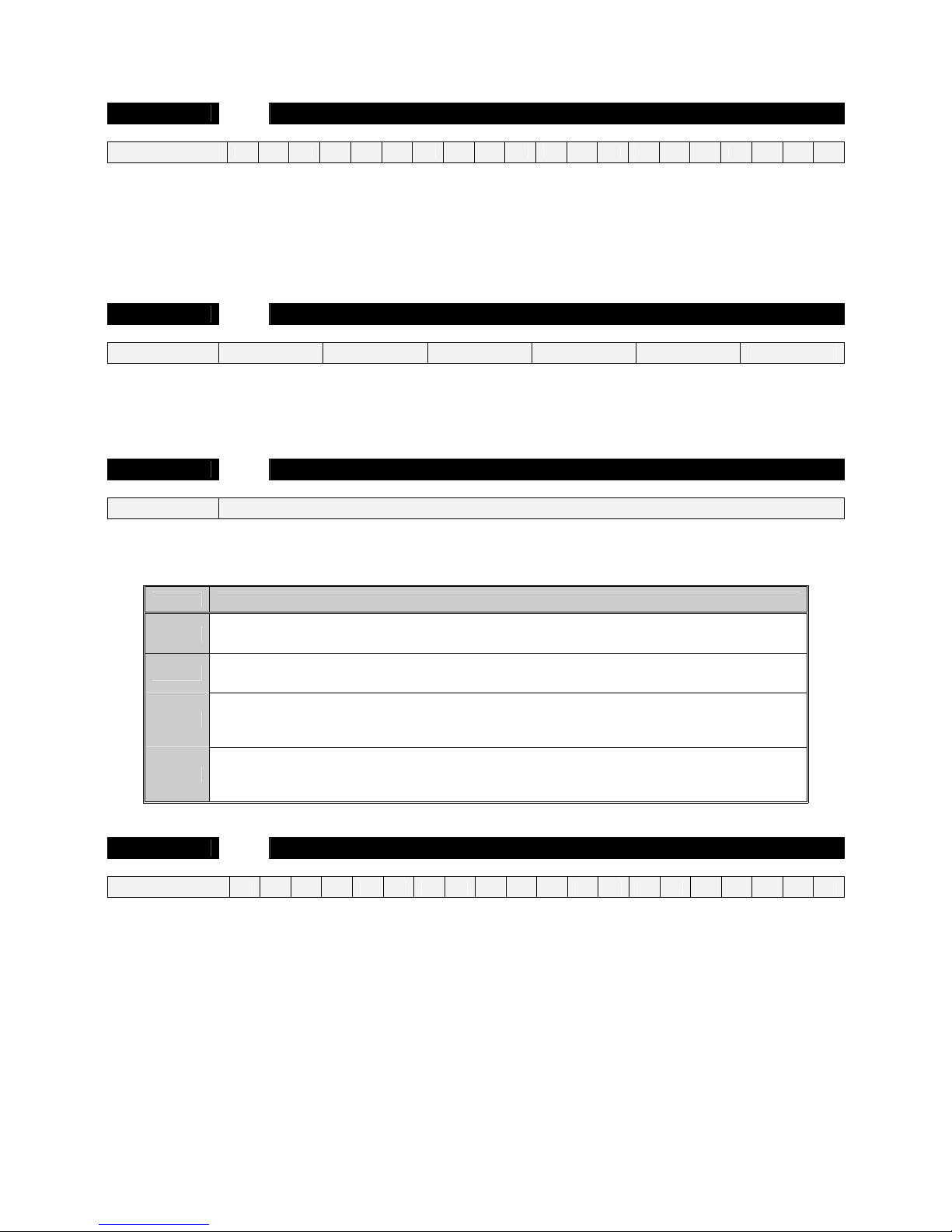

Programming Example Figure1 - Numerical Data (Binary)

Programming Example Figure 2 - Option Selection Data

Enters the previous

programming “feature”

Returns to the “feature”

j

ust programmed.

Advances to the next

programming “feature”

To change data in a segment,

enter the data followed by [À]

Pressing [#] will exit a feature

without changing the data in

the current segment

Zone 1 LED = 1

Zone 4 LED = 8

}

Data = 9

Zone 2 LED = 2

Zone 7 LED = 64

}

Data = 66

Feature 16 - Segment 1

1 = Quick Arm

2 = Re-Exit

3 = Force Arm

4 = Silent Code Pad Panic

5 = Audible Code Pad Panic

6 = Code Pad Fire

7 = Code Pad Medical

8 = Code Pad Multiple

9 = Code Attempt Tamper

LEDs show Options enabled

Press the key on the numeric Code Pad that corresponds

to the option you wish to enable/disable. When an LED is

“on”, an option is enabled; when “off” the option is

disabled. For example: With the 1, 5, & 7 LEDs “on”,

Quick Arm, Audible Code Pad Panic and Code Pad

Medical are enabled.

1 4

2

7

1

5 7

© Hills Industries 2006 Page 23

Programming Feature Descriptions

System Codes

Feature 0 Code Requirements

Feature 0, segment 1 is used to enable the 6 digit user code option. If 6-digit o ption is enabled, all arm/disarm codes, the

‘Go To Program Code’ and duress code are 6 digits. If this option is e nabled, the default user 1 code is [1]-[2]-[3]-[4]-[5]-

[6]. The Hills Reliance 128 has 99 four (4) digit user codes or 66 six (6) digit user codes, the Hills Reliance 12 has 40

codes, the Hills Reliance 8 has 8 codes. Segment 2 is used to enable user code requirement for functions [Á]-[9]-[8]

(perform call back download) and [Á]-[9]-[9] (answer incoming call for download).

Segment 1

1

On enables the 6-digit code option. Its original off state is a 4-digit code.

2 On requires code entry for [Á]-[9]-[8] and [Á]-[9]-[9] functions

3 –8

Reserved

Feature 1 Go to Program Code

Segments 1-6

9 7 1 3 0 0

Feature 1 contains the ‘Go To Program Code’. This featur e contains either a 4 or 6-di git code. If the 6-digit code option is

enabled in Feature 0, this code must contain six (6) digits. If this option is not enabled i n Feature 0, the last 2 segments

(digits) will be ignored. With the panel disarmed, the ‘Go To Program Code’ can be used to enter the program mode.

Feature 2 Go To Program Code Area and Authorisation

The ‘Go To Program Code’ can be used as a standard arm/disarm code. W hen using the code to arm or disarm, the user

I.D. is 255. (This code may not be changed in the run mode.)

Segment 1

1

Reserved

2

On enables ‘Go To Program Code’ as an arm only code

3

On enables ‘Go To Program Code’ as an arm only after closing

(4)

On enables ‘Go To Program Code’ as a master code (can change user codes)

5

On enables ‘Go To Program Code’ as an arm/disarm code

6

On enables ‘Go To Program Code’ to bypass zones

7

On enables ‘Go To Program Code’ opening and closing reports

8

Reserved

Segment 2

(1)

On enables the ‘Go To Program Code’ for area #1

(2)

On enables the ‘Go To Program Code’ for area #2

(3)

On enables the ‘Go To Program Code’ for area #3

(4)

On enables the ‘Go To Program Code’ for area #4

(5)

On enables the ‘Go To Program Code’ for area #5

(6)

On enables the ‘Go To Program Code’ for area #6

(7)

On enables the ‘Go To Program Code’ for area #7

(8)

On enables the ‘Go To Program Code’ for area #8

Feature 3 Duress Code

Segments 1-6

15 15 15 15 15 15

Feature 3 contains the ‘Duress’ code. This feature contains either 4 or 6 digits. If the 6-digit code option is enabled in

Feature 0, This code must contain six (6) digits. If the 6-digit option is not enabled in Feature 0, the last 2 digits will be

ignored. If the duress code is programmed, it will work for all areas.

© Hills Industries 2006 Page 24

Dialer Options (Features 4 – 11)

Feature 4 Phone Number One (1)

Segments 1-20

14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

The first telephone number is programmed in Feature 4.

’15’ = pulse dialling - in the segment where pulse dialling should begin

’14’ indicates the end of the phone number. Fill all empty segments after end of dialling with ‘14’

’13’ = four second delay - in the segment where a delay is required

’12’ = a ‘#’ - in the segment as required

‘11’ = for a ‘Á’ - in the segment as required

Feature 5

new

System Account Code

Segments 1-6

10 10 10 10 Reserved

new

Reserved

new

This is the account code sent for any area event (open/close and zone related alar ms) that does not have its account code

programmed. System events (siren/box tampers, expander troubles, etc.) will use the system account unless area one

account is programmed.

Feature 6 Communicator Format

Segment 1

0

Feature 6 contains the communicator format used. Select a format from the format selection table. If this feature contains a

‘0’, the built-in communicator will be disabled, and the panel will function as a local onl y control.

Data Communicator Format

0

Local

Communicator is disabled

1

Contact I.D.

DTMF format for control rooms

2

Pager

Reports in 4 + 2 DTMF format. Phone numbers can be programmed via code pad in normal

operation.

3

Domestic Siren

Domestic dialling via a siren tone format. Call can be kissed off via the star (Á) key on a DTMF

phone. Phone numbers can be programmed via code pad in the run mode.

Feature 7 Phone Number Two (2)

Segments 1-20

14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

The second telephone number is programmed in Feature 7.

’15’ = pulse dialling - in the segment where pulse dialling should begin

’14’ indicates the end of the phone number. Fill all empty segments after end of dialling with ‘14’

’13’ = four second delay - in the segment where a delay is required

’12’ = a ‘#’ - in the segment as required

‘11’ = for a ‘Á’ - in the segment as required

Loading...

Loading...