S I N G L E - D E C K I S L A N D M E R C H A N D I S E R I N S TA L L AT I O N & O P E R AT I O N S M A N U A L

O W I Z - O W E Z

O W I Z V - O W E Z V

TABLE OF CONTENTS

GENERAL INFORMATION ...................................... 2

INSTALLATION & TRIM OUT .............................. 3–4

CONNECTIONS & PIPING ...................................... 5

PRE-POWER CHECKLIST ....................................... 6

To ensure proper functionality and optimum performance, it is strongly recommended that Hillphoenix display cases be installed/serviced by

qualied technicians who have experience working with commercial refrigerated display merchandisers and storage cabinets. For a list of

Hillphoenix-authorized installation/service contractors, please visit our Web site at www.hillphoenix.com.

COMPONENT

LIGHTING SYSTEMS .......................................... 7–8

AIR QUALITY CONTROL ........................................ 9

FANS & CASE CLEANING .................................... 10

APPENDIX ............................................................. 11

P080658A

V1.07

03/14

ii REVISION HISTORY

REV. DATE CHANGE DESCRIPTION AUTHOR

V1.00 02/21/12 Initial manual release (new format) B. Moody

V1.01 04/30/12 Removed Dual Temp (Fans Off) wiring diagram (Appendix E) B. Moody

V1.02 07/02/12 Correct TOC errors B. Moody

V1.03 08/03/12 Updated Wiring Diagrams (Appendix E) B. Moody

V1.04 10/15/12 Updated Electrical Data (Appendices A–D) B. Moody

V1.05 12/19/12 Updated Electrical Data (Appendices A–D) B. Moody

V1.06 07/03/13 Added Glycol notice to Important Notices section

Added Parts List (Appendix H)

V1.07 03/14/14 Added Clearvoyent logos to cover page

Updated page headers

Added Parts logo to General Information page

Updated Important Notices section

Updated Connections & Piping section

Added Lighting Systems section

Updated Air Quality Control page

Added Fresh Thinking/Responsible Solutions logo to back page

B. Moody

B. Moody

Copyright © 2014 by Hill PHOENIX

All rights reserved. No part of this document may reproduced or transmitted in any form or by any means—electronic or

mechanical, including photocopying or recording; or any other information storage and retrieval system—without express

written permission from Hill PHOENIX.

IMPORTANT NOTICES iii

PRECAUTIONARY NOTICES

At Hillphoenix®, the safety of our customers and employees—as well as the ongoing performance of our

products—are top priorities. To that end, we designate

important information in all Hillphoenix installation and operations handbooks with an accompanying alert symbol.

All of these notices are meant to provide information about

potential dangers to personal health and safety—as well as

risks of case damage—if the instructions are not carefully

followed.

ATTENTION!

Indicates important information that is critical to proper case performance.

CAUTION!

Indicates the potential threat of injury if all

instructions are not followed carefully.

DANGER!

Indicates an immediate threat of serious

injury or death if all instructions are not followed carefully.

used on a display case with a shelf lighting system, then

Hillphoenix shall not be subject to any obligations or liabilities (whether arising out of breach of contract, warranty,

tort [including negligence], strict liability or other theories

of law) directly or indirectly resulting from, arising out of or

related to such installation or use, including, without limitation, any personal injury, death or property damage resulting from an electrical failure, re, electric shock, or mold.

P079211M, REVO

R-744 (CO2) NOTICE

For Systems Utilizing R-744 (CO2) Refrigerant

For refrigeration units that utilize R-744 (CO2), pressure relief and pressure-regulating relief valves may need to be

installed based on the system capacity. The valves need

to be located such that no stop valve is positioned between

the relief valves and the parts or section of the system being protected.

When de-energizing refrigeration units containing R-744

(CO2), venting of the R-744 (CO2) refrigerant may occur

through the pressure regulating relief valves. These valves

are located on the refrigeration system and not on the case

model. If venting does occur, the valve must not be defeated, capped, or altered by any means.

SERVICE NOTICE

To ensure optimum case performance, we strongly recommended that Hillphoenix display cases be installed and

serviced by qualied technicians who have experience

working with commercial refrigerated display merchandisers and storage cabinets. For a list of Hillphoenix-authorized installation and service contractors, please visit our

Web site: www.hillphoenix.com

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix shelf lighting systems—as well as display cases with shelf lighting systems—are not designed to withstand direct or indirect exposure to water or other liquids.

The use of a misting system or water hose on a display

case with a shelf lighting system, resulting in the direct or

indirect exposure of the lighting system to water, can lead

to a number of serious issues (including, without limitation,

electrical failures, re, electric shock, and mold) in turn resulting in personal injury, death, sickness, and/or serious

property damage (including, without limitation, to the display itself, to the location where the display is situated [e.g.,

store] and to any surrounding property).

Do not use misting systems, water hoses or other devices

that spray liquids in Hillphoenix display cases with lighted

shelves. If a misting system or water hose is installed or

GLYCOL NOTICE

For Systems Utilizing Glycol Refrigerant

Use of glycol as a secondary refrigerant must be carried

out in accordance with the instructions and procedures set

forth in the Hillphoenix Second Nature Medium Temperature Secondary Refrigeration Installation Manual, available

online for download here: http://goo.gl/JIWd77

Additionally, Hillphoenix uses and recommends Dow glycol-based coolants, which contain specially formulated

industrial inhibitors that help to prevent corrosion in our

display cases. Over time, the effectiveness of these inhibitors deteriorates, increasing the chance for corrosion.

We recommend testing of glycol solutions annually through

the Dow lab. The service is free for systems containing

over 250 gallons of glycol coolants, while the cost is approximately $100 for smaller systems. For more information, see Dow’s DOWFROST and DOWFROST HD Guide,

available online for download here: http://goo.gl/v6i1iQ

CAUTION!

Under no circumstance should any component be replaced or added without

consulting Hillphoenix Field Service Engineering. Utilizing improper components

may result in serious injury to persons or

damage to the refrigeration system.

2 GENERAL INFORMATION

Thank you for choosing Hillphoenix display cases for your food merchandising needs. This handbook contains important

technical information and will assist you with the installation and operation of your new display cases. By closely following

the instructions, you can expect attractive fit and finish, peak performance, and long case life.

We are always interested in your suggestions for improvements to Hillphoenix products and accessories—case design,

technical documents, etc. Please feel free to contact our Marketing Services group at the toll-free number listed below.

Thank you for choosing Hillphoenix, and we wish you the very best in outstanding food merchandising.

CASE MODELS

OWIZ, OWEZ, OWIZV, OWEZV single-deck island merchandisers.

OPERATING DATA & DIMENSIONAL DRAWINGS

Operating data and dimensional drawings for the cases

listed in this manual can be found in Appendices A–D.

STORE CONDITIONS

Hillphoenix cases are designed to operate in an air-conditioned store that maintains a 75°F (24°C) store temperature and 55% (max) relative humidity (CRMA conditions).

Case operation will be adversely affected by exposure to

excessively high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation

for efficient performance. Machine-room temperatures

must be maintained at a minimum of 65°F in winter and a

maximum of 95°F in summer. Minimum condensing temperatures should be no less than 70°F.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping

damage and/or shortages, please contact the Service

Parts Department at 1-800-283-1109.

SERVICE/TECHNICAL SUPPORT

For service or technical questions, please contact our

Case Division Customer Service Department at 1-800283-1109. For questions regarding our refrigeration systems or electrical distribution centers, please contact our

Systems Division Customer Service Department at 1-770-

388-0706.

PARTS ORDERING

If you need to contact Hillphoenix regarding specific fixtures or parts, please call 1-800-283-1109 and ask for a

Service Parts Representative. Provide the following information about the part you are ordering:

• Model number and serial number* of the case for which

the part is intended.

• Length of the part (if applicable).

• Color of part (if painted) or color of polymer part.

• Whether part is for left- or right-hand application.

• Quantity

*Serial plate is located inside the case on the bottom-right side.

If the parts are to be returned for credit, ask the Parts

Department to furnish you with a Return Material

Authorization Number.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carrier's agent; otherwise, the carrier may refuse the claim. If

damage becomes apparent after the equipment is

unpacked, retain all packing materials and submit a written

request to the carrier for inspection within 14 days of

receipt of the equipment.

LOST/MISSING ITEMS

Hillphoenix equipment is carefully inspected before shipping to insure the highest level of quality. Any claim for

lost/missing items must be made to Hillphoenix within 48

hours of receipt of the equipment.

See Appendix H for a detailed parts list and illustration.

Hillphoenix

1925 Ruffin Mill Rd.

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m. to 5 p.m. EST)

Tel: 1-800-283-1109

Fax: 804-526-7450

Web site: www.hillphoenix.com

INSTALLATION & TRIM OUT 3

FLOOR PREP

1. Ask the general contractor if your current copy of the

building dimensions are the most recently issued. Also,

ask for the points of reference from which you should

take dimensions to locate the cases.

2. Using chalk lines or a laser transit, mark the oor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

case feet.

3. Leveling is necessary to ensure proper case alignment

and to avoid potential case damage. Locate the highest point on the positioning lines as a reference for

determining the proper height of the shim-pack levelers. A laser transit is recommended for precision and

requires just one person.

4. Locate basehorse positions along the chalk lines. Spot

properly leveled shim packs at each basehorse location.

LINE-UP & INSTALLATION

Single Case

1. Roll the case into position, leaving a minimum of 2” between the wall and back of case. Using a “J” bar, raise

the end of the case (under cross support), remove the

caster assembly (Fig. 1) and lower the basehorse on to

the shim packs. Repeat on the other end of the case.

2. Once the basehorse is properly placed on the shim

packs, check the vertical plumb of the case by placing

a bubble level on the shelf standard. Add/remove shim

packs as needed. For the horizontal level, repeat this

process after placing the bubble level on the front sill.

Multi-Case

1. Remove any shelves (discard the shelf clips) and/or

loose items (e.g. shipping braces, mirror assemblies,

etc) from the cases that may interfere with case joining. Keep all loose items as they will be used later in

the installation process.

2. Follow the single-case installation instructions for the

rst case, then position the next case in the line-up approximately 3’ away. Remove the casters on the end

that is closest to the rst case.

3. Apply the foam tape gasket (supplied) and a bead of

butyl or silicone sealant to the end of the rst case (Fig.

2). From the opposite end, push the second case to

a position that is approximately 6” from the rst case,

then remove the remaining casters and position case

on the shim packs.

4. Push the cases tightly together, then lightly bolt them

together through the holes that are provided (Fig. 2).

Tighten all the joining bolts until all margins are equal.

Be careful not to over tighten.

5. Repeat steps 3-6 of this sequence for all remaining

cases. Be certain to properly level all cases.

6. See Appendix G for seismic bracket installation instructions.

TRIM OUT

COTTER

PIN

CASTER

Fig. 1 Removing the casters is an easy process. Simply flatten and

remove the cotter pins that are holding the casters in place. Then

lift the case with a “J” bar and slide the caster assemblies out. The

dismantled casters can now be discarded.

CAUTION!

Be certain that your hands and feet are

out of the way before lowering the case

after the removal of the casters. Failure

to do so may result in serious injury.

1.

If master bumpers are included, slide master bumper

joint trim in between adjoining master bumpers.

2. Slide the master bumpers left or right (after loosening

or removing screws) to close the seams as required,

working outwards from the center of the line-up to the

ends.

3. Close the seam where the bumper joins the case end.

The bumper joint closes the seam that may develop

if the master bumper is moved away from the end to

close the case-to-case joint seam.

4. Install top sill covers over case-to-case joint seams.

The top sill joint is shipped loose with the case. Secure

with fasteners (supplied).

5. Seal the case-to-case joints with caulk (supplied), then

apply acrylic tape (supplied) over the pipe-chase seam

(Fig. 4). The tape acts as a watershed preventing water from settling in the case joint.

6. Install the front panel joint trim (ships loose).

4 INSTALLATION & TRIM OUT

ACRYLIC

TAPE

PIPE

CHASE

Fig. 2 Sealing the pipe chase

7. Attach the “J” rail with the supplied screws (Fig. 2).

8. Insert top of kickplate into the kickplate retainer. Slide

the kickplate up into the retainer, then down onto the

“J” rail (Fig. 3). Be certain that the bottom of the kickplate is tted over extruding "lip" of the "J" rail.

9. If the case is outtted with a polymer bumper, insert

the nose bumper into the open bumper channel, up

to 96 feet. Hillphoenix recommends leaving an additional 6 inches of nose bumper at the ends to allow for

shrinkage during the rst 24–48 hours following case

start-up—after sufcient time has passed, cut away the

excess bumper for nal t and nish. Be certain to use

an appropriate cutting tool (tubing- or PVC-cutter) to

ensure a smooth cut.

1. Slide kickplate UP into

kickplate retainer recess.

2. Drop the kickplate

DOWN onto the "J" rail lip.

1

KICKPLATE

2

"J" RAIL

Fig. 3 Kickplate installation

XXXX

X

XXX

X

X

X

7

XXXXX

o oooooooo

XX

XXXX

X

X

o

X

oooooooooooooooooooooooooooooooooooooooooo

o

X

o

o

X

o

X

o

X

o

X

o

X

X

X

X

X

3

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

X

X

X

X

X

X

X

X

X

X

o

o

o

o

o

o

o

o

o

X

X

X

X

X

X

X

X

X

1 2

o

o

o

o

o

o

o

o

o

o

X

X

X

X

X

X

X

X

5

o

o

o

o

o

o

o

o

o

o

o

o

o

X

XX

X

X

X

X

X

X

X

X

X

XX

X

ooo oooooo

XXXX

o

o

o

o

o

X

o

XX

o

o

X

o

XXXX

o

o

o

o

X

o

o

o

o

XX

o

o

o

o

o

X

o

o

X

o

o

X

o

o

X

o

XX

X

X

X

XXXX

Fig. 4 Bolt holes locations; foam gasket and sealant

= bolt holes

X

= foam tape gasket

O

= butyl or silicone sealant

NOTE: It is recommended that cases

be bolted together in the numbered

order that is indicated in the diagram.

X

ooo oooooo

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

X

XXXX

X

X

X

XX

X

X

6

8

4

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

X

X

X

X

X

X

X

XX

X

XXXXXX

XX

X

X

XX

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

X

o

o

o

o

o

o

o

o

X

X

X

X

X

X

X

X

X

X

XX

o oooooooo

XXX

X

X

XXX

X

XX

o

X

oooooooooooooooooooooooooooooooooooooooooo

o

X

o

X

o

X

o

X

o

X

o

o

X

o

X

o

o

X

X

X

X

X

X

ATTENTION!

Connections are illustrated in dimensional

drawings found in Appendices

REFRIGERATION

The refrigeration piping penetration is located beneath the

case in the front-right area, fully visible in front of the fan

plenum.

A–D.

CONNECTIONS & PIPING 5

If hot gas defrost is used, suction lines to each case in the

circuit should be of equal distance from the main suction

line. Expansion valves and other controls—located on the

left-hand side of the cases (both sides for the OWIZ and

OWIZV)—are accessed by lifting the two left-hand deck

pans (lifting the fan plenum is not required).

REMOVE

Fig. 5 Remove the shipping blocks

DRAIN

"P"

TRAP

Fig. 6 “P” trap; drain line

pull the bottom out, away from the case—see Trim Out

instructions on pages 4–5.

LINE

ELECTRICAL

Electrical connections are made in the continuous raceway (Fig. 7) that is located at the bottom-front of OWIZ

and OWIZV cases and all sides of the OWEZ and

OWEZV end caps. This continuous raceway helps to

easily facilitate case-to-case wiring.

Before operating the case, be certain to remove the

shipping blocks that protect the refrigeration lines during

shipping (Fig. 5). If it becomes necessary to penetrate the

case tank in any area, be certain to seal any open gaps

afterwards with canned-foam sealant and white RTV.

PLUMBING

The drain outlet is specially molded out of PVC material

and is located in the front-center of the case for convenient access. The “P” trap, furnished with the case, is

constructed of schedule 40 PVC pipe (Fig. 6). Care

should be given to ensure that all connections are watertight and sealed with the appropriate PVC or ABS cement.

The drain lines can be run left or right of the tee, with the

proper pitch to satisfy local drainage requirements. Since

the kickplate is shipped loose with the case, you should

have open access to the drain line area during installation.

If the kickplate has been installed, you will nd it easy to

remove: simply lift the kickplate up from the “J” rail and

Fig. 7 Raceway electrical wiring

For case-to-case wiring, run conduit between the junction

boxes or run wiring through the raceway. When connecting to the junction box on the bottom-left side of the case,

eld wiring should exit box from the right side (furthest

away from case wiring) to allow more room inside for

wiring connections. For more detailed electrical wiring

information, see Appendix E.

ATTENTION!

If brazing is necessary, place wet rags

around the area to avoid tank damage.

6 PRE-POWER CHECKLIST

Before powering-up the case, be certain that all of the steps listed below

have been completed to ensure proper case functionality, safety and compliance with warranty terms.

Have you thoroughly examined the case for shipping damage? (see

pg. 2)

Have you removed and discarded the casters? (see pg. 3)

Have you checked the vertical plumb of the case? The horizontal

level? (see pg. 3)

Have you applied the foam tape gasket and sealant between adjoining

cases? (see pg. 3)

Have you sealed the case-to-case joints by applying caulk and acrylic

tape to the pipe-chase seam? (see pg. 4)

Have you removed the shipping blocks from the refrigeration lines?

(see pg. 5)

Have you sealed any tank penetrations? (see pg. 5)

ATTENTION!

Be certain to clear the case of any loose

packaging or case materials before energizing the case. Failure to do so may result in case damage or malfunction.

ATTENTION!

Be certain that all piping and electrical

connections comply with local codes.

ATTENTION!

Installation of 3rd-party materials may

result in diminished case performance.

LIGHTING SYSTEMS 7

DANGER!

SHOCK HAZARD

Always disconnect power to case when

servicing or cleaning. Failure to do so

may result in serious injury or death.

Hillphoenix cases may be equipped with either T-8 lights or

LED luminaires. Depending on case configuration, T-8

electronic ballasts or LED power supplies operate both the

canopy lights and shelf lights and are located in the cornice

area, above the light reflectors.

CAUTION!

During replacement of ballasts/power

supplies, always confirm that the new ballasts/power supplies are the correct

replacement parts. Failure to do so may

result in damage to the LED system or

the luminaires, leading to poor performance and increased risk of safety issues.

Both lighting systems have an ON/OFF switch that is

located in the upper left-hand corner of the lighting assembly. Once cases have been properly positioned in the

store and an electrician has connected the lighting circuit,

the lights may be turned on to verify that they are connected and functioning properly.

To ensure peak performance, it is advisable to run the

lighting systems only when the store climate control is on

and case refrigeration is started. NOTE: it is highly recommended that the ambient store temperature not exceed

80°F.

2. Attach the lamp caps and plastic shield to the new T-8

lamp.

3. Push the new T-8 lamp into place on the lamp holder. When the T-8 is properly seated, the lamp button

- which secures the T-8 to the lamp holder - will be

clearly visible through the lamp button hole (Fig. 9).

LAMP

BUTTON

Fig. 9 Align new T-8 with plug button to secure

REPLACING SHELF LED LUMINAIRES

1. Unplug the LED luminaire (Fig. 10).

2. Pinching the latching clips inward at the ends of the luminaire, rotate luminaire down at each end until hooks

are free, then remove (Fig. 11).

3. To install the new luminaire, place hook into shelf roll at

shelf front and rotate rear of luminaire toward the shelf.

4. Depress the rear clip so that luminaire can finish rotation and until clip engages the shelf bracket.

REPLACING T-8 LIGHTS

1. Simultaneously pull down at both ends of the old T-8

light to remove from the lamp holder (Fig. 8). Remove

the lamp caps and plastic shield from the old light, then

discard the light.

LAMP

HOLDER

LAMP

CAP

Fig. 8 Remove old T-8

LAMP

BUTTON

LAMP

BUTTON

HOLE

Fig. 10 Unplug the LED luminaire

8 LIGHTING SYSTEMS

Fig. 11 Remove the old LED luminaire

REPLACING NON-SHELF LED LUMINAIRES

1. Squeeze plastic clips on the four-pin connector at the

end of the luminaire, then pull free of the receptacle

(Fig. 12).

3. To install the new luminaire, simply reverse the previous steps.

ACCESSING BALLASTS/POWER SUPPLIES

Ballasts or power supplies are housed beneath the case in

the slide-out electrical tray and may be removed easily by

following these instructions:

4. Remove the lower front panel (if necessary for access

to raceway).

5. Unscrew the kickplate and lift up from the "J" rail. Pull

the bottom edge of the kickplate out and away from the

case to remove.

6. Pull out the slide-out electrical tray that is visible in the

raceway. Ballasts/power supplies will now be visible

(Fig. 14).

2. At the other end, slide the luminaire to the opening and

disengage from the metal housing slot (Fig. 13).

Fig. 12 Squeeze the latching clips and pull the luminaire free

Fig. 14 Power supply in the slide-out tray beneath the case.

Fig. 13 Slide the other end to the opening in the sheet metal

and disengage

AIR QUALITY CONTROL 9

AIR FLOW & PRODUCT LOAD

Do not overload the food product display so that it impinges

on the air ow pattern—doing so will result in diminished

performance and loss of proper temperature levels, particularly when the discharge honeycomb and return air grille

are covered. Please keep products within the load limit line

shown on the diagram below (Fig. 15).

DEFROST & TEMPERATURE CONTROLS

Hillphoenix cases utilize electric, hot gas, or timed-off

defrost. The primary components used for the defrost

cycle are the various defrost termination sensors, which

work to terminate the defrost cycle in the case. These

controls may include 1) a Klixon® thermostat, 2) a sensor

probe, or 3) a dial-type thermostat with sensor bulb (the

thermostat will always be mounted with the electrical controls of the case, either in an electrical junction box or in the

electrical raceway, etc.

If electric defrost is used, the defrost termination sensor

will be located either behind the rear baffle or mounted to

the coil. If hot gas defrost is used, the defrost termination

sensor will be mounted to the dump line—the sensor

should always be mounted on the coil-side of the check

valve or solenoid valve. Finally, if timed-off defrost is used,

the refrigeration cycle is simply turned off by the case controls for a specified amount of time; therefore, there are

generally no active defrost components utilized.

The discharge air probe monitors the temperature of the

discharge air and may be used as the defrost termination

sensor. The probe can generally be found behind the rear

baffle, in the upper baffle, or in front of the honeycomb.

NOTE: if the discharge air probe is used for defrost termination, none of the termination sensors listed earlier will be

installed in the case.

For more detailed information on suggested defrost times

and settings, see Appendices A–D. Further adjustment

may be required depending on store conditions.

DETERMINING SUPERHEAT

To identify the correct superheat settings, complete the following steps:

1. Obtain suction pressure from the access port. Obtain

the suction line temperature from the area near the

TXV bulb at the outlet of the evaporator coil (Fig. 16).

2. Using the suction pressure reading and the Sporlan®

temperature-pressure chart (see Appendix F), convert pressure-to-temperature.

3. Finally, subtract the converted temperature reading

from the actual temperature reading. The resulting

number is the superheat setting—once this has been

determined, adjust the TXV as needed to obtain the

proper setting.

1. DISCHARGE AIR

2. LOAD LIMIT

OWIZV shown. Airflow is similar for other case models.

3. AIR CURTAIN

4. RETURN AIR

1

MODEL

2

Fig. 15 Airflow

OWIZV

SUCTION

LINE TEMP

READING

3

TXV

BULB

Fig. 16 Obtain pressure and temperature readings

SUCTION

PRESSURE

READING

4

10 FANS & CASE CLEANING

DANGER!

SHOCK HAZARD

Always disconnect power to case when

servicing or cleaning. Failure to do so

may result in serious injury or death.

CAUTION!

Exercise extreme caution when working in

a case with the coil cover removed. The

coil contains many sharp edges that can

cause severe cuts to the hands and arms.

FANS

Fan blade pitch is set during manufacturing. It is important

that the blade pitch be maintained as specified. Do not

attempt a field modification by altering the blades.

Fan assemblies may be changed with an easy two-step

process without lifting up the plenum, thereby avoiding

the necessity to unload the entire product display to

change the fan assembly:

1. Unplug the fan motor (Fig. 17), easily accessible outside the plenum. Be certain to push the power cord

back through the plenum opening to avoid damage to

the power cord.

2. Remove fasteners, then lift out the entire fan basket.

Reverse procedure when re-installing fan basket.

CLEANING PROCEDURES

A periodic cleaning schedule should be established to

maintain proper sanitation, insure maximum operating efficiency, and avoid the corrosive action of food fluids on

metal parts that are left on for long periods of time. We

recommend cleaning once a week.

• Be certain that all electricity to the case is turned off

before servicing or cleaning to avoid electrical shock.

In some cases, more than one switch may need to be

turned off to completely de-energize the case.

• All surfaces pitch downward to a deep-drawn drain

trough, funneling liquids and other debris to the waste

outlet. Check waste outlet before starting the cleaning

process to insure it is unclogged. Avoid introducing

water faster than the case drain can carry it away.

• Lift the fan plenum to gain access to the coil for clean-

ing and maintenance (Fig. 18).

SINGLE PIECE FAN

PLENUM SWINGS

UP FOR EASY

CLEANING

FAN

PLENUM

COIL

2

1

Fig. 17 Fan basket

Power cord must be pushed back through

the plenum opening before removing the

fan basket. Failure to do so may result in

damage to the power cord.

ATTENTION!

Fig. 18 Single-piece fan plenum and coil cover

• To clean the lights, shut off the lights in the case, then

wipe them down with a soft, damp cloth. Avoid using

harsh or abrasive cleaners as they may damage the

lights. Be certain that the lights are completely dry before re-energizing.

• If any potentially harmful cleaners are used, be cer-

tain to provide a temporary separator (e.g., cardboard,

plastic wrap, etc.) between those cases that are being

cleaned and those that may still contain product.

• Avoid spraying cleaning solutions directly on electrical

connections.

• Allow cases to be turned off long enough to clean any

frost or ice from coil and pans.

• Remove kickplate and clean underneath the case with

a broom and a long-handled mop. Use warm water

and a disinfecting cleaning solution when cleaning underneath the cases.

APPENDIX 11

A .................................................................................................................................. OWIZ OPERATING DATA & CASE DIMENSIONS

B ................................................................................................................................ OWEZ OPERATING DATA & CASE DIMENSIONS

C ............................................................................................................................... OWIZV OPERATING DATA & CASE DIMENSIONS

D .............................................................................................................................. OWEZV OPERATING DATA & CASE DIMENSIONS

E ............................................................................................................................................................................. ELECTRICAL WIRING

F .................................................................................................................................. SPORLAN PRESSURE-TEMPERATURE CHART

G ............................................................................................................................................................................... SEISMIC BRACKETS

H .............................................................................................................................................................................................. PARTS LIST

A.1 OPERATING DATA

OWIZ

Electrical Data

High Efciency

Fans

Defrost

Heaters

1

Case

Length

Fans

Per Case

Open

Case

Sliding

Doors

Drain

Heaters

120 Volts 120 Volts 120 Volts 208 Volts 240 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

8' 4 0.29 16 0.18 11 0.26 30 11.54 2400 13.31 3195

12' 6 0.44 24 0.28 17 0.26 30 17.31 3600 19.98 4795

Anti-Condensate Heater Data

Case

Length

2

Solid

Front

120 Volts 120 Volts 120 Volts 120 Volts 120 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

Glass

Front

8' 2.62 314 3.02 362 0.50 60 0.68 82 0.50 60

12' 3.96 475 4.38 526 0.74 89 0.68 82 0.76 91

Glass

Cap

3

Glass Wrap

End

4

Super

Structure

Lighting Data

Clearvoyant LED Lighting

(Per Light Row)

Standard Power

(Cornice or Shelf)

Case

Length

Shelf

Depth

Lights

Per Row

Light

Length

120 Volts 120 Volts

Amps Watts Amps Watts

8' Super Structure/All Shelves 4 4ft 0.40 47.6 0.72 86.0

12' Super Structure/All Shelves 6 4ft 0.60 71.4 1.08 129.0

High Power

(Cornice)

Guidelines & Control Settings

5

(FPM)Conventional Parallel

Application

Case

Type

4

BTUH/ft

Superheat

Set Point @ Bulb

(°F)

Evaporator

(°F)

Discharge

Air

(°F)

Discharge

Air Velocity

Frozen Food Open 610 587 3 - 5 -12 -6 180

Doors 339 326 3 - 5 -10 -4 106

Ice Cream Open 719 692 3 - 5 -22 -16 180

Doors 399 384 3 - 5 -20 -14 106

Medium Temp. Open 456 450 6 - 8 17 27 180

Defrost Controls

Application

Frozen Food

Ice Cream

Defrosts

Type

Per Day

Open 1 13-15 60 49 - - -

Doors 1 13-15 30 49 - - - - - - 10 60

Time

(min)

Case

Medium Temp. Open 1 13-15 35 49 - - - - - - 20 60

1 Defrost data for one side °F case only.

2 Solid wraparound ends have no anti-condensate heaters.

3 Glass cap heater for stainless steel glass cap option only.

4 Data given is for one glass wraparound end.

5 Standard fans (see Appendix C) increase refrigeration load by 96 BTUH/fan.

6 Average discharge air velocity at peak of defrost.

7 NOTE: "- - -" indicates that feature is not an option on this case model.

Run-Off

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (°F)

Fail-Safe

(min)

7

Termination

Temp (°F)

Fail-Safe

(min)

- - - 20 60

Termination

Temp (°F)

SUPERSTRUCTURE

(OPTIONAL)

SECOND SHELF FOR 60"

SUPERSTRUCTURE OPTION

ONLY

CASE DIMENSIONS A.2

62 5/8 in

[159.0 cm]

(60" OPTION)

77 9/16 in

[196.9 cm]

54 5/8 in

[148.9 cm]

(52" OPTION)

50 5/8 in

[128.5 cm]

(48" OPTION)

5 in [12.7 cm]

PLENUM

REFRIGERATION

15 in

[38.1 cm]

COIL

6 7/16 in [16.3 cm]*

C

L

77 9/16 in [196.9 cm]

LOAD LIMIT

LINE

30 13/16 in [78.2 cm]

COIL

26 in [66.0 cm]

33 11/16 in [85.6 cm]

38 3/4 in [98.5 cm]

PLENUM

ELECTRICAL

SOLID FRONT

35 1/2 in

[90.2 cm]

26 9/16 in

[67.4 cm]

13" THERMOPANE

GLASS FRONT

12 3/8 in

[31.4 cm]

35 1/2 in

[90.2 cm]

18 3/8 in

[46.7 cm]

C

L

33 11/16 in

38 3/4 in

[98.5 cm]

26 in

[66.0 cm]

[85.6 cm]

1 1/2 in [3.8 cm]

{FLAT END}

29 1/4 in

[74.3 cm]**

ELECTRICAL

WIRING TO RACEWAY

(STANDARD)

1 1/2" PVC DRAIN

CONNECTION

96 in [243.8 cm] {8' case}

144 in [365.8 cm] {12' case}

NOTES:

* STUB-UP AREA

** RECOMMENDED STUB-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

L

C

30 1/2 in

[77.5 cm]

[64.8 cm]

3 11/16 in [9.4 cm]

{SOLID WRAP END}

6 1/4 in [15.9 cm]

{GLASS WRAP END}

6 1/2 in [16.5 cm]

25 1/2 in

REFRIGERATION

C

L

B.1 OPERATING DATA

OWEZ

Electrical Data

High Efciency

Fans

Open

Case

Fans

Per Case

2 0.30 17 0.19 12 0.13 15 8.65 1800 9.98 2394

120 Volts 120 Volts 120 Volts 208 Volts 240 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

Sliding

Doors

Drain

Heaters

Defrost

Heaters

Anti-Condensate Heater Data

Solid

Front

120 Volts 120 Volts 120 Volts

Amps Watts Amps Watts Amps Watts

0.42 51 1.96 235 0.51 61

Glass

Front

Glass

Cap

1

Guidelines & Control Settings

2

BTUH/ft

Application

Frozen Food Open 1726 1689 2769 2663 3 - 5 -10 -12 -6 -6 110 200

Ice Cream Open 1956 1900 3429 3298 3 - 5 -22 -22 -17 -16 110 200

Medium Temp. N/A 1038 1008 2196 2150 6 - 8 28 27 31 27 110 200

Case

Type

Doors 959 938 1538 1479 3 - 5 -8 -10 -4 -4 65 118

Doors 1087 1056 1905 1832 3 - 5 -20 -20 -15 -14 65 118

Solid Front Glass Front

Superheat

Set Point @ Bulb

(°F)

Evaporator

(°F)

Solid

Front

Glass

Front

Discharge

Air

(°F)

Solid

Front

Glass

Front

Discharge

Air Velocity

(FPM)

Solid

Glass

Front

3

FrontConventional Parallel Conventional Parallel

Defrost Controls

Run-Off

Application

Frozen Food

Ice Cream

Medium Temp. Open 1 5 13 - 15 35 48 35 42 20 60

1 Glass cap heater for stainless steel glass cap option only.

2 Standard fans (see Appendix C) increase refrigeration load by 96 BTUH/fan.

3 Average discharge air velocity at peak of defrost.v

4 NOTE: "- - -" indicates that feature is not an option on this case model.

Case

Open 1 5 13 - 15 60 48 - - -

Doors 1 5 13 - 15 30 48 - - - - - - 10 60

Type

Defrosts

Per Day

Time (min)

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (°F)

Fail-Safe

(min)

4

Termination

Temp (°F)

- - - 20 60

Fail-Safe

(min)

Termination

Temp (°F)Electric Hot Gas

CASE DIMENSIONS B.2

35 in

[88.9 cm]

5 in [12.7 cm]

REAR REFRIGERATION

FOR PIPING TO OWIZ

(14 1/2" off of floor)

12 13/16 in [32.5 cm]

5 1/8 in [13.0 cm]

27 1/4 in

[69.3 cm]

37 11/16 in

[95.8 cm]

SOLID FRONT

14 13/16 in

[37.6 cm]

33 9/16 in [85.3 cm]

COIL

PLENUM

9 1/2 in [24.1 cm]*

27 1/4 in [69.3 cm]

37 11/16 in [95.8 cm]

42 3/4 in [108.6 cm]

ELECTRICAL

WIRING TO RACEWAY

(STANDARD)

78 3/4 in [200.0 cm]

ELECTRICAL

13" THERMOPANE

GLASS FRONT

35 1/2 in

[90.2 cm]

26 9/16 in

[67.5 cm]

9 7/8 in [25.1 cm]

12 3/8 in

[31.4 cm]

35 1/2 in

[90.2 cm]

18 3/8 in

[46.6 cm]

REAR REFRIGERATION

FOR PIPING TO OWIZ

(14 1/2" off of floor)

1 1/2 in [3.8 cm] {FLAT END}

34 1/4 in

[87.1 cm]

42 3/4 in

[108.6 cm]

REFRIGERATION

1 1/2" PVC DRAIN

CONNECTION

C

L

FRONT OF CASE

77 9/16 in [196.9 cm]

NOTES:

* STUB-UP AREA

** RECOMMENDED STUB-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

• SUCTION LINE - 7/8", LIQUID LINE - 3/8"

• DASHED LINES SIGNIFY AREA INSIDE BASE RAIL BEHIND KICK-PLATE

10 13/16 in [27.5 cm]

C.1 OPERATING DATA

OWIZV

Electrical Data

High Efciency Fans

Case

Length

Open

Fans

per

Case

Case

120 Volts 120 Volts 120 Volts 120 Volts 120 Volts 120 Volts 208 Volts 240 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

Sliding

Doors

Drain

Heaters

6’ 4 0.29 16 0.17 11 0.26 30 1.08 129 1.93 232 0.68 82 8.70 1800 10.00 2400

8’ 4 0.29 16 0.17 11 0.26 30 1.82 218 2.55 306 0.68 82 11.54 2400 13.31 3195

10’ 6 0.44 24 0.26 17 0.26 30 2.40 288 3.31 397 0.68 82 14.42 3000 16.64 3994

12’ 6 0.44 24 0.26 17 0.26 30 2.85 343 4.06 487 0.68 82 17.31 3600 19.98 4795

Anti-Condensate Heaters

1

Solid

Front

Glass

Front

Glass Wrap

End

2

Defrost

3

Heaters

Lighting Data (Superstructure)

Clearvoyant LED Lighting

Fluorescent

Case

Length

4

Lights

Per Row

Light

Length

Lighting

(Per Light Row)

120 Volts 120 Volts 120 Volts

Amps Watts Amps Watts Amps Watts

Standard Power

(Cornice or Shelf)

6’ 4 3’ 0.74 88 0.28 33.2 0.50 59.6

8’ 4 4’ 0.94 112 0.40 47.6 0.72 86.0

10’ 6 3’(4) / 4’ (2) 1.20 144 0.48 57 0.86 102.6

12’ 6 4’ 1.44 168 0.60 71 1.08 129.0

(Per Light Row)

High Power

(Cornice)

Guidelines & Control Settings

5

(FPM)Conventional Parallel

Application

Frozen

Food

Ice

Cream

Case

Type

BTUH/ft

Superheat

Set Point @ Bulb

(°F)

Evaporator

(°F)

Open 610 587 3 - 5 -12 -6 180

Doors 335 322 3 - 5 -11 -8 70

Open 719 692 3 - 5 -22 -16 180

Doors 345 332 3 - 5 -20 -15 70

Discharge

Air

(°F)

Discharge

Air Velocity

Med. Temp. Open 458 450 6 - 8 17 27 180

Defrost Controls

Run-Off

Time

(min)

Application

Frozen/

Ice Cream

Case

Type

Defrosts

Per Day

Open 1 13 - 15 60 49 - - -

Doors 1 13 - 15 30 49 - - - - - - 10 60

Med. Temp Open 1 13 - 15 35 49 - - - - - - 20 60

1 Solid wraparound ends have no anti-condensate heaters.

2 Data given is for one glass wraparound end.

3 Defrost data for one side °F case only.

4 Light values represent both sides °F superstructure.

5 Average discharge air velocity at peak of defrost.

6 NOTE: “- - -” indicates that feature is not an option on this case model.

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (°F)

Fail-Safe

(min)

6

Termination

Temp (°F)

Fail-Safe

(min)

- - - 20 60

Termination

Temp (°F)

CASE DIMENSIONS C.2

63 1/8 in

[160.2 cm]

(60" OPTION)

[139.9 cm]

(52" OPTION)

1 1/2 in [3.8 cm]

55 1/8 in

51 1/8 in

[129.7 cm]

(48" OPTION)

(SLIDING DOOR

5 1/8 in [13.1 cm]

SOLID END PANEL

6 7/8 in

[17.6 cm]

43 1/4 in

[109.9 cm]

OPTION)

29 7/8 in

15 5/8 in

[39.7 cm]

33 in [83.8 cm]

[75.8 cm]

COIL

6 3/8 in [16.1 cm] *

29 7/8 in [75.9 cm]

31 1/4 in [79.3 cm]

82 1/2 in [209.6 cm]

SUPERSTRUCTURE

(OPTIONAL)

SECOND SHELF FOR 60"

SUPERSTRUCTURE OPTION

ONLY

LOAD LIMIT LINE

COIL

PLENUMPLENUM

37 5/8 in [95.4 cm]

41 1/4 in [104.8 cm]

SLIDING DOORS

(OPTIONAL)

12" GLASS FRONT

11 1/2 in

[29.2 cm]

24 5/8 in

[62.6 cm]

36 1/8 in

[91.8 cm]

12" GLASS W/T

FLAT METAL

FRONT

36 1/8 in

[91.8 cm]

7" GLASS

FRONT

36 1/8 in

[91.6 cm]

CLASSIC 2

FRONT

36 1/8 in

[91.6 cm]

SOLID

FRONT

36 in

[91.4 cm]

82 1/2 in

[209.6 cm]

41 1/4 in

[104.8 cm]

13 5/8 in

[34.7 cm]

[75.9 cm]

37 5/8 in

[95.4 cm]

29 7/8 in

REFRIGERATION

(OPTIONAL)

8 5/8 in [22.0 cm]

27 1/2 in

[69.9 cm]

34 3/8 in

[87.4 cm]

**

WIRING TO RACEWAY

(STANDARD)

ELECTRICAL

4 1/2 in [11.3 cm] ( ALL CASES )

45 1/2 in [115.6 cm] { 8' CASE }

42 7/8 in [108.7 cm] { 10' CASE }

50 in [127.0 cm] { 12' CASE }

81 1/4 in [206.2 cm] { 10' CASE }

98 in [248.9 cm] { 12' CASE }

NOTES:

* STUB-UP AREA

** RECOMMENDED STUP-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

SUCTION LINE - 7/8", LIQUID LINE - 1/2"

1 1/2" PVC

DRAIN

CONNECTION

C

L

FRONT OF CASE

72 in [182.9 cm] { 6' CASE }

96 in [243.8 cm] { 8' CASE }

120 in [304.8 cm] { 10' CASE }

144 in [365.8 cm] { 12' CASE }

ELECTRICAL

BASE FRAME

HORSE LEG

31 1/4 in

[79.3 cm]

REFRIGERATION

KICK PLATE

4 1/2 in [11.3 cm] ( ALL CASES )

8 5/8 in

[22.0 cm]

13 5/8 in

[34.7 cm]

3 in [7.6 cm]

WRAP END

D.1 OPERATING DATA

OWEZV

Electrical Data

High Efciency Fans

Open

Fans

per

Case

Case

120 Volts 120 Volts 120 Volts 120 Volts 120 Volts 208 Volts 240 Volts

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

Sliding

Doors

Drain

Heaters

Anti-Condensate Heaters

Solid

Front

Glass

Front

1

Defrost

Heaters

2 0.15 8 0.09 6 0.13 15 0.81 98 1.48 178 8.65 1800 9.98 2394

Guidelines & Control Settings

BTUH/case

Application

Frozen

Food

Ice

Cream

Case

Type

Solid Front Glass Front

Conventional Parallel Conventional Parallel

Superheat

Set Point @ Bulb

(°F)

Evaporator

(°F)

Open 1726 1689 2769 2663 3 - 5 -12 -6 200

Doors 959 938 1538 1479 3 - 5 -10 -4 118

Open 1956 1900 3429 3298 3 - 5 -22 -16 200

Doors 1087 1056 1905 1832 3 - 5 -20 -14 118

Discharge

Air

(°F)

Discharge

Air Velocity

(FPM)

Medium Temp. Open 1038 1008 2196 2150 6 - 8 17 27 200

Defrost Controls

Electric Defrost Timed-Off Defrost Hot Gas Defrost

Fail-Safe

(min)

Termination

Temp (°F)

Fail-Safe

(min)

4

Termination

Temp (°F)

Fail-Safe

(min)

- - - 20 60

Termination

Temp (°F)

Application

Frozen Food

Ice Cream

Med. Temp

Case

Type

Defrosts

Per Day

Run-Off

Time

(min)

Open 1 13 - 15 60 49 - - -

Doors 1 13 - 15 30 49 - - - - - - 10 60

Open 1 13 - 15 35 49 - - - - - - 20 60

3

1 Data applies to both 7” & 12” glass fronts.

2 NOTE: “TBD” = "to be determined".

3 Average discharge air velocity at peak of defrost.

4 NOTE: “- - -” indicates that feature is not an option on this case model.

CASE DIMENSIONS D.2

15 7/8 in

[40.4 cm]

36 in

[91.6 cm]

REAR REFRIGERATION

FOR PIPING TO OWIZV

(14 1/2" OFF OF FLOOR)

28 3/4 in [72.9 cm]

LOAD

LIMIT LINE

33 in [83.8 cm]

COIL

PLENUM

30 1/2 in [77.6 cm]

34 1/2 in [87.7 cm]

38 5/8 in [98.2 cm]

42 1/4 in [107.4 cm]

7 in

[17.7 cm]

SLIDING DOORS

(OPTIONAL)

12" GLASS FRONT

11 1/2 in

[29.1 cm]

24 5/8 in

[62.5 cm]

4 1/8 in [10.5 cm]

14 in [35.5 cm]

7 1/2 in [19.0 cm]

36 1/8 in

[91.7 cm]

82 1/2 in [209.6 cm]

11 1/8 in

[28.4 cm]

12" GLASS WITH

FLAT METAL FRONT

36 1/8 in

[91.8 cm]

7" GLASS FRONT

36 1/8 in

[91.6 cm]

CLASSIC 2

FRONT

36 1/8 in

[91.6 cm]

SOLID FRONT

36 in

[91.4 cm]

REAR REFRIGERATION

FOR PIPING TO OWIZV

(14 1/2" OFF OF FLOOR)

1 1/2 in [3.8 cm]

{FLAT END-PANEL}

38 5/8 in

[98.0 cm]

42 1/4 in

[107.4 cm]

3 5/8 in [9.2 cm]

34 1/2 in

[87.7 cm]

ELECTRICAL

WIRING TO RACEWAY

(STANDARD)

1 1/2" PVC DRAIN

CONNECTION

NOTES:

* STUB-UP AREA

** RECOMMENDED STUP-UP CENTERLINE FOR ELECTRICAL AND HUB DRAINS

- SUCTION LINE - 7/8", LIQUID LINE - 1/2"

- FLAT END-PANEL REQUIRED WHEN CASE IS STANDALONE

29 3/4 in

[75.6 cm]

C

L

FRONT OF CASE

82 1/2 in [209.6 cm]

[67.0 cm]

KICK PLATE

BASE FRAME

HORSE LEG

26 3/8 in

REFRIGERATION

3 3/4 in

[9.4 cm]

12 in [30.4 cm]

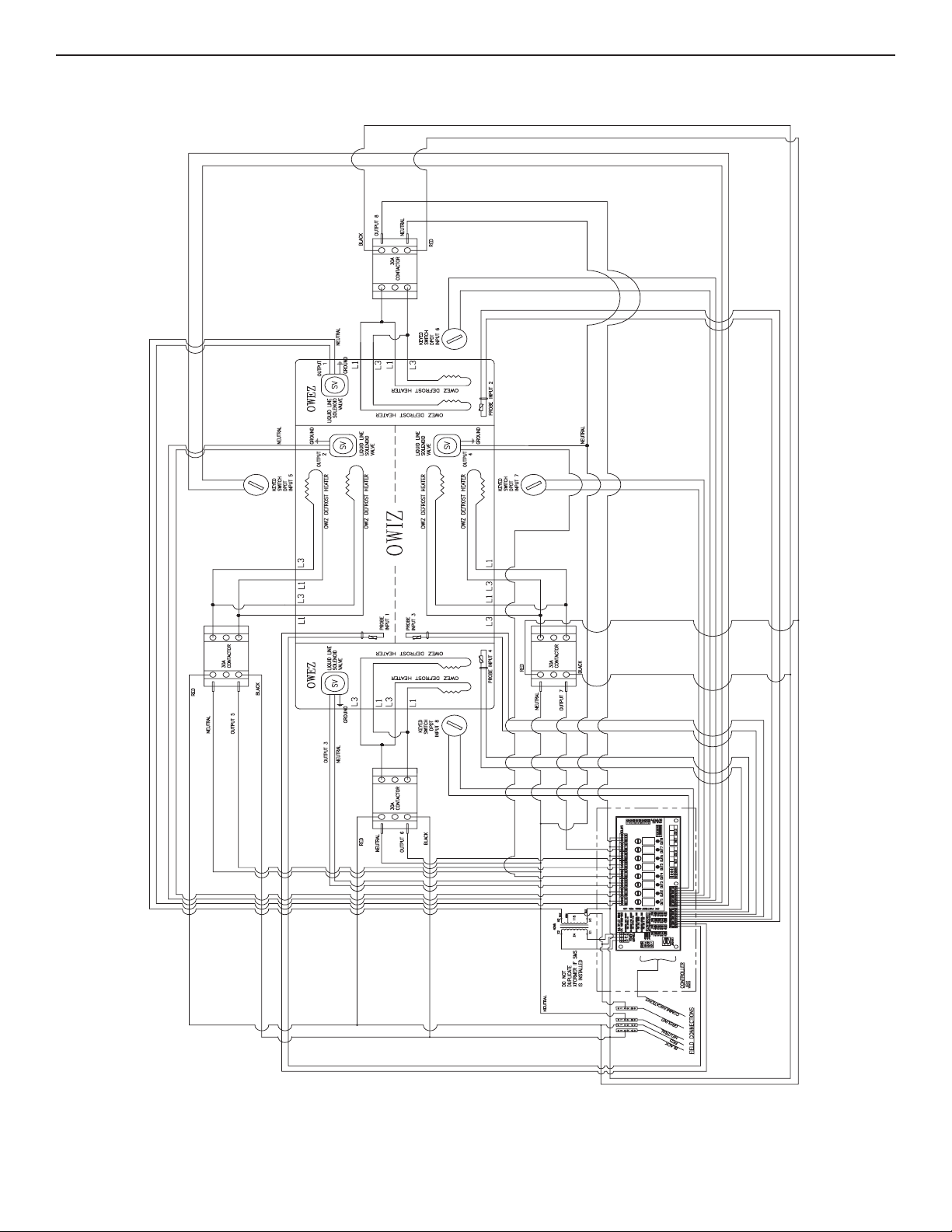

E.1 ELECTRICAL WIRING

WIRE IDENTIFICATION

WIRE IDENTIFICATION

DEFROST HEATERS (1-PHASE)

DEFROST HEATERS (3-PHASE)

ANTI-CONDENSATE HEATERS

AISLE WARMER

DRAIN HEATER

PRIMARY FANS

SECONDARY FANS

AMBIENT FANS

LIGHTS

TEMPERATURE CONTROL

DEFROST TERMINATION CONTROL

DEFROST SAFETY CUT-OUT CONTROL

LIQUID LINE SOLENOID

SUCTION LINE SOLENOID

CASE/CONTROLLER POWER

SYSTEM NEUTRAL (3-PHASE)

POWER CORD (SELF-CONTAINED)

SERVICE LIGHT (HI-PRESSURE)

HIGH PRESSURE SWITCH

DUAL PRESSURE SWITCH

CONDENSING UNIT POWER

CONDENSING UNIT FAN

REFRIGERATED PAN SOLENOID

REFRIGERATED PAN BYPASS SOLENOID

AIR HEATER DEFROST SOLENOID

MAIN SECONDARY FLUID SOLENOID

AIR DEFROST FAN

SECONDARY COOLANT PUMP

TANK FLUSH SOLENOID

REAR STORAGE BOX FANS

GROUND TO EXTERIOR/FRAME

GROUND TO INTERIOR LINER

GROUND TO JUNCTION BOX

GROUND TO LIGHTS

BELL

TRANSFORMER

CAPACITOR

RECEPTACLE

IG RECEPTACLE

GFI RECEPTACLE

HUMIDIFIER

MISTING SOLENOID

DRIP DOWN TIMER

BLACK WHITE BLUE RED YELLOW PURPLE ORANGE

1,2

16 15

18 17

10 9

36 37

4 3 40

12 11

60,62

24 25

58 57

53,54

51,52

26 43

56 55

70 71

65 220V

67 220V

69 220V

73 220V

74 59

76 61

87 220V

89 220V

94

1314

56

78

4142

3332

N

4748

45 46

73

87

89

95

5343

49,50

6667

2L3L1L

19,20

3130

3938

44 220V

6465

72

88

90

GREEN

321222

927282

75

77

79

6869

86

81

83

85

97

ATTENTION: ELECTRICIAN

For safety and code compliance, ground fixture at the time

of installation.

CAUTION

Risk of electric shock. More than one power supply.

Disconnect all power supplies before servicing.

P901598E - R4

OWIZ/OWIZV WIRING

SOLID END PANEL

82 1/2 in

[209.6 cm]

37 5/8 in

[95.4 cm]

41 1/4 in

ELECTRICAL

REFRIGERATION

(OPTIONAL)

REFRIGERATION

29 7/8 in

[75.9 cm]

BASE FRAME

HORSE LEG

31 1/4 in

[79.3 cm]

8 5/8 in

[22.0 cm]

27 1/2 in

[69.9 cm]

34 3/8 in

[87.4 cm]

**

13 5/8 in

[34.7 cm]

8 5/8 in [22.0 cm]

1 1/2 in [3.8 cm]

ELECTRICAL WIRING E.2

CLASSIC 2

FRONT

12" GLASS W/T

FLAT METAL

FRONT

SECOND SHELF FOR 60"

(OPTIONAL)

SUPERSTRUCTURE

36 1/8 in

SUPERSTRUCTURE OPTION

ONLY

36 1/8 in

[91.6 cm]

[91.8 cm]

12" GLASS FRONT

SLIDING DOORS

(OPTIONAL)

SOLID

7" GLASS

36 1/8 in

[91.8 cm]

11 1/2 in

[29.2 cm]

LOAD LIMIT LINE

FRONT

FRONT

24 5/8 in

PLENUMPLENUM

COIL

[62.6 cm]

36 in

[91.4 cm]

36 1/8 in

[91.6 cm]

41 1/4 in [104.8 cm]

37 5/8 in [95.4 cm]

29 7/8 in [75.9 cm]

6 3/8 in [16.1 cm] *

31 1/4 in [79.3 cm]

63 1/8 in

[160.2 cm]

(60" OPTION)

[75.8 cm]

29 7/8 in

55 1/8 in

[139.9 cm]

(52" OPTION)

15 5/8 in

[39.7 cm]

6 7/8 in

[17.6 cm]

51 1/8 in

[129.7 cm]

COIL

33 in [83.8 cm]

43 1/4 in

OPTION)

[109.9 cm]

(SLIDING DOOR

(48" OPTION)

82 1/2 in [209.6 cm]

5 1/8 in [13.1 cm]

E.3 ELECTRICAL WIRING

OWIZV LIGHTING

26 3/8 in

[67.0 cm]

29 3/4 in

[75.6 cm]

3 3/4 in

[9.4 cm]

42 1/4 in

34 1/2 in

[87.7 cm]

38 5/8 in

[98.0 cm]

REFRIGERATION

ELECTRICAL

WIRING TO RACEWAY

(STANDARD)

CLASSIC 2

FRONT

12" GLASS WITH

FLAT METAL FRONT

36 1/8 in

36 1/8 in

[91.8 cm]

[91.6 cm]

OWIZ/OWIZV WIRING

36 in

SOLID FRONT

7" GLASS FRONT

[91.4 cm]

36 1/8 in

[91.6 cm]

ELECTRICAL WIRING E.4

{FLAT END-PANEL}

1 1/2 in [3.8 cm]

(14 1/2" OFF OF FLOOR)

REAR REFRIGERATION

FOR PIPING TO OWIZV

SLIDING DOORS

12" GLASS FRONT

(OPTIONAL)

LOAD

28 3/4 in [72.9 cm]

11 1/2 in

[29.1 cm]

7 in

[17.7 cm]

LIMIT LINE

33 in [83.8 cm]

15 7/8 in

[40.4 cm]

36 1/8 in

[91.7 cm]

24 5/8 in

[62.5 cm]

PLENUM

COIL

4 1/8 in [10.5 cm]

30 1/2 in [77.6 cm]

34 1/2 in [87.7 cm]

42 1/4 in [107.4 cm]

38 5/8 in [98.2 cm]

11 1/8 in

[28.4 cm]

82 1/2 in [209.6 cm]

14 in [35.5 cm]

7 1/2 in [19.0 cm]

36 in

[91.6 cm]

FOR PIPING TO OWIZV

REAR REFRIGERATION

(14 1/2" OFF OF FLOOR)

E.5 ELECTRICAL WIRING

DUAL TEMP WIRING

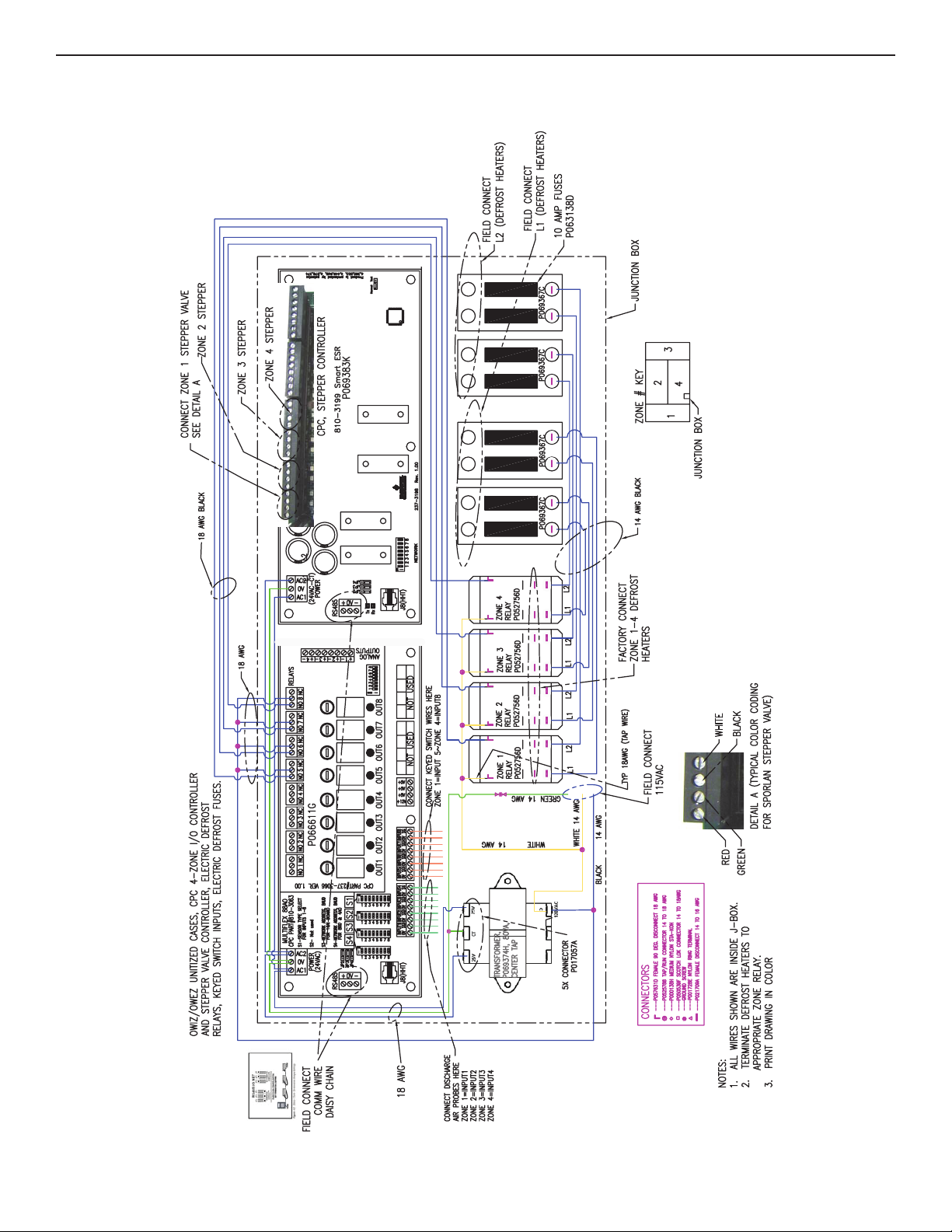

CPC CONTROLLER W/ MULTI-FLEX BOARD

ELECTRICAL WIRING E.6

E.7 ELECTRICAL WIRING

CPC CONTROLLER W/ STEPPER CONTROL (DX)

DANFOSS (CO2)

ELECTRICAL WIRING E.7

E.9 ELECTRICAL WIRING

DANFOSS (DX)

DANFOSS (5-8 ZONE)

ELECTRICAL WIRING E.10

F.1 SPORLAN PRESSURE-TEMPERATURE CHART

Square Inch Gauge

Pressure-Pounds Per

(°F) (°C) 134a (J ) 404A (S) 507 (P) 717 (A) 744 - CO2

TEMPERATURE REFRIGERANT (SPORLAN CODE)

43 6.1 38.0 90.6 94.6 63.1 577.6

42 5.6 37.0 88.8 92.8 61.6 569.3

44 6.7 39.0 92.4 96.5 64.7 586.0

46 7.8 41.1 96.0 100.2 67.9 603.1

45 7.2 40.1 94.2 98.3 66.3 594.5

48 8.9 43.2 99.8 104.1 71.1 620.5

47 8.3 42.2 97.9 102.1 69.5 611.7

50 10.0 45.4 103.6 108.0 74.5 638.3

49 9.4 44.3 101.7 106.0 72.8 629.3

60 15.6 57.4 126.0 129.2 92.9 733.1

65 18.3 64.0 137.3 140.7 103.2 784.2

70 21.1 71.1 149.3 153.0 114.2 838.1

55 12.8 51.2 115.3 118.3 83.4 684.4

75 23.9 78.7 162.0 165.9 125.9 894.9

80 26.7 86.7 175.4 179.6 138.4 954.9

85 29.4 95.2 189.5 194.1 151.8 1018

90 32.2 104.3 204.5 209.3 166.1 **

95 35.0 113.9 220.2 225.4 181.2 **

100 37.8 124.2 236.8 242.3 197.3 **

105 40.6 135.0 254.2 260.1 214.4 **

110 43.3 146.4 272.5 278.8 232.5 **

115 46.1 158.4 291.8 298.5 251.6 **

120 48.9 171.2 312.1 319.2 271.9 **

125 51.7 184.6 333.3 340.9 293.3 **

130 54.4 198.7 355.6 363.8 315.8 **

135 57.2 213.6 379.1 387.8 339.6 **

140 60.0 229.2 403.7 413.0 364.7 **

145 62.8 245.7 429.6 439.5 391.0 **

150 65.6 262.9 456.8 467.4 418.7 **

155 68.3 281.0 485.5 497.0 447.8 **

TEMPERATURE PRESSURE CHART - at sea level

Vacuum-Inches of Mercury

Bold Italic Figures

FORM IC-11-09 COPYRIGHT 2009 BY SPORLAN VALVE COMPANY, WASHINGTON, MO 63090 Printed in U.S.A.

(°F) (°C) 134a (J ) 404A (S) 507 (P) 717 (A) 744 - CO2

TEMPERATURE REFRIGERANT (SPORLAN CODE)

13 -10.6 13.8 46.6 49.3 26.5 363.4

12 -11.1 13.1 45.4 48.1 25.6 357.4

79.9

91.1

15 -9.4 15.0 49.0 51.8 28.4 375.6

14 -10.0 14.4 47.8 50.5 27.5 369.5

103.4

14.3

17 -8.3 16.4 51.5 54.3 30.4 388.0

16 -8.9 15.7 50.2 53.0 29.4 381.8

131.0

8.8

19 -7.2 17.7 54.0 56.9 32.4 400.7

18 -7.8 17.0 52.7 55.6 31.4 394.3

163.1

1.6

21 -6.1 19.1 56.6 59.6 34.6 413.8

20 -6.7 18.4 55.3 58.3 33.5 407.2

23 -5.0 20.6 59.3 62.4 36.8 427.1

22 -5.6 19.9 58.0 61.0 35.7 420.4

25 -3.9 22.1 62.1 65.3 39.0 440.7

24 -4.4 21.3 60.7 63.8 37.9 433.8

27 -2.8 23.7 64.9 68.2 41.4 454.6

26 -3.3 22.9 63.5 66.7 40.2 447.6

29 -1.7 25.3 67.8 71.2 43.8 468.8

28 -2.2 24.5 66.4 69.7 42.6 461.7

31 -0.6 26.9 70.8 74.3 46.3 483.4

30 -1.1 26.1 69.3 72.7 45.0 476.1

33 0.6 28.6 73.9 77.5 48.9 498.3

32 0.0 27.8 72.4 75.9 47.6 490.8

35 1.7 30.4 77.1 80.7 51.6 513.4

34 1.1 29.5 75.5 79.1 50.2 505.8

37 2.8 32.2 80.3 84.1 54.3 529.0

36 2.2 31.3 78.7 82.4 52.9 521.2

39 3.9 34.1 83.7 87.5 57.2 544.8

38 3.3 33.1 82.0 85.8 55.7 536.9

41 5.0 36.0 87.1 91.0 60.1 561.0

40 4.4 35.0 85.4 89.2 58.6 552.9

0.9

4.3 5.4

9.6 11.0

12.7 14.1 1.3 181.0

16.0 17.6 3.6 200.2

9.8

6.9

-35 -37.2 12.5 6.8 8.1 5.4 146.5

-30 -34.4

-25 -31.7

3.7

-20 -28.9

-18 -27.8 2.3 17.4 19.1 4.6 208.3

To determine subcooling for R-404A use BUBBLE POINT values (Temperatures above 50°F — Gray Background); to determine superheat for R-404A, use DEW POINT values (Temperatures 50°F and below).

** = exceeds critical temperature

-16 -26.7 0.8 18.9 20.6 5.6 216.5

-14 -25.6 0.4 20.4 22.2 6.7 225.0

-12 -24.4 1.1 22.0 23.8 7.8 233.8

-10 -23.3 1.9 23.6 25.5 9.0 242.7

-8 -22.2 2.8 25.3 27.3 10.3 251.9

-6 -21.1 3.6 27.0 29.1 11.5 261.3

-4 -20.0 4.6 28.8 30.9 12.9 271.0

-2 -18.9 5.5 30.7 32.8 14.3 280.9

0 -17.8 6.5 32.6 34.8 15.7 291.0

1 -17.2 7.0 33.6 35.8 16.4 296.2

2 -16.7 7.5 34.6 36.9 17.2 301.5

3 -16.1 8.0 35.6 37.9 18.0 306.8

4 -15.6 8.5 36.6 39.0 18.8 312.1

5 -15.0 9.1 37.7 40.1 19.6 317.6

6 -14.4 9.6 38.7 41.1 20.4 323.1

7 -13.9 10.2 39.8 42.3 21.2 328.6

11 -11.7 12.5 44.3 46.9 24.7 351.5

8 -13.3 10.8 40.9 43.4 22.1 334.2

9 -12.8 11.3 42.0 44.5 22.9 339.9

10 -12.2 11.9 43.1 45.7 23.8 345.7

21.8 7.3 5.8 18.6

20.3 3.9 2.2 16.6

18.7 0.1

14.8

(°F) (°C) 134a (J ) 404A (S) 507 (P) 717 (A) 744 - CO2

TEMPERATURE REFRIGERANT (SPORLAN CODE)

-60 -51.1

-55 -48.3

-50 -45.6

-45 -42.8 16.9 2.0 3.0 11.7 116.6

-40 -40.0

CONSTRAINT BRACKET INSTALLATION

The case constraint brackets can be installed

BASE FRAME CONSTRAINT BRACKET - 2 PER CASE

(BRACKET SHOWN HERE IS FOR A 5" TALL BASE FRAME,

CONSTRAINT BRACKETS ARE ALSO AVAILABLE

FOR ALL BASE FRAME HEIGHTS

USE (3) #10 SELF DRILLING / SELF TAPPING SCREWS

FOR ATTACHMENT TO THE BASE FRAME

ALTERNATE LOCATION

(BACK OF CASE)

USE (1) 0.5" OR (2) 0.375"

ANCHOR(S) FOR ATTACHMENT

TO THE STORE FLOOR

in 2 ways. Option 1 can be used on multi-deck cases

and uses an “L” bracket to attach the case to a vertical

wall, as shown below. Option 2 can be used on multideck cases or on cases that do not have a canopy.

Attach the “L” brackets to the base frames in either of

the locations shown below. Brackets are available for

all base frame heights.

ATTACK BRACKET TO WALL

USE (1) 0.5"

OR (2) 0.375" ANCHORS

CONSTRAINT BRACKET

ATTACH TO TOP OF CASE

USE (3) #10 SELF TAPPING

SCREWS

SEISMIC BRACKETS G.1

OPTION 1

OPTION 2

11/05

BRACKET CAN BE POSITIONED

ON EITHER SIDE OF THE

BASE FRAME

G.2 SEISMIC BRACKETS

5” BRACKETS

7” BRACKETS

SEISMIC BRACKETS G.3

G.4 SEISMIC BRACKETS

11” BRACKETS

15” BRACKETS

SEISMIC BRACKETS G.5

H.1 PARTS LIST

PARTS ORDERING

82

12

30

31

59

87

11

36

16

15

83

9

81

37

7

14

6

5

73

72

18

23

69

E01

E11

E10

2

17

74

26

4

3

1

24

77

E20

E09

MODEL

OWIZ

MODEL OWIZ

PARTS LIST H.2

Location Part Descriptions

Number

1 Kickplate, Storm Grey

2 Master Bumper, Featherstone, Smoke, White, French Vanilla, Black

3 Lower Front Panel, Painted

4 Color Band, Painted

5 Thermopane, Front Sill Glass

6 Flue Glass

7 Flue Glass Bracket

9 Deck Pan, Painted, Unpainted

11 Front Baffle, Painted

12 Honeycomb

14 Glass Cap, for Solid Panel and Glass Front Extensions

15 Rear Baffle

16 Sill Cap, Center

17 Nose Bumper, Polymer Custom Color

18 Pedestal, Painted

23 Electrical Junction Box

24 “J” Rail, for Kickplate

26 Front Panel, Painted

30 Corner Bumper, Featherstone, Smoke, White, French Vanilla, Black

31 Corner Casting, for Solid Panel and Glass Front Extensions

36 Plug Button

37 Corner Glass Support

59 Upper Front Extension Panel, Painted

69 Coil

72 Color Band Corner

73 Front Panel Corner

74 Glass Joint Trim

77 P-Trap

81 Wire Rack

82 Tag Moulding

83 Thermometer, and Bracket

87 End Assembly, Wraparound (Shown), Solid Flat End

E01 Defrost Heater

E02 Anti-Condensate Heater (Not Shown)

E03 Thermostats, Temperature and Defrost Termination Control, (Not Shown)

E09 Fan Motor - STATE HIGH EFFICIENCY OR STANDARD

E10 Fan Blade

E11 Fan Basket, 6”

E20 Fan Cord-Set - High Efficiency or Standard (Not Shown)

NOTES

NOTES

NOTES

WARRANTY

HEREINAFTER REFERRED TO AS MANUFACTURER

FOURTEEN MONTH WARRANTY. MANUFACTURER’S PRODUCT IS WARRANTED TO BE FREE FROM DEFECTS

IN MATERIAL AND WORKMANSHIP UNDER NORMAL USE AND MAINTENANCE FOR A PERIOD OF FOURTEEN

MONTHS FROM THE DATE OF ORIGINAL SHIPMENT. A NEW OR REBUILT PART TO REPLACE ANY DEFECTIVE

PART WILL BE PROVIDED WITHOUT CHARGE, PROVIDED THE DEFECTIVE PART IS RETURNED TO

MANUFACTURER. THE REPLACEMENT PART ASSUMES THE UNUSED PORTION OF THE WARRANTY.

This warranty does not include labor or other costs incurred for repairing, removing, installing, shipping, servicing, or handling of either defective parts or replacement parts.

The fourteen month warranty shall not apply:

1. To any unit or any part thereof which has been subject to accident, alteration, negligence, misuse or abuse, operation

on improper voltage, or which has not been operated in accordance with the manufacturer’s recommendation, or if the

serial number of the unit has been altered, defaced, or removed.

2. When the unit, or any part thereof, is damaged by fire, flood, or other act of God.

3. Outside the continental United States.

4. To labor cost for replacement of parts, or for freight, shipping expenses, sales tax or upgrading.

5. When the operation is impaired due to improper installation.

6. When installation and startup forms are not properly complete or returned within two weeks after startup.

THIS PLAN DOES NOT COVER CONSEQUENTIAL DAMAGES. Manufacturer shall not be liable under any circumstances for

any consequential damages, including loss of profit, additional labor cost, loss of refrigerant or food products, or injury to

personnel or property caused by defective material or parts or for any delay in its performance hereunder due to causes

beyond its control. The foregoing shall constitute the sole and exclusive remedy of any purchases and the sole and exclusive liability of Manufacturer in connection with this product.

The Warranties are Expressly in Lieu of All Other Warranties, Express or Implied and All Other Obligations or Liabilities

on Our Part. The Obligation to Repair or Replace Parts or Components Judged to be Defective in Material or

Workmanship States Our Entire Liability Whether Based on Tort, Contract or Warranty. We Neither Assume Nor

Authorize Any Other Person to Assume for Us Any Other Liability in Connection with Our Product.

MAIL CLAIM TO:

Hillphoenix

Display Merchandisers

1925 Ruffin Mill Road

Colonial Heights, VA 23834

1-800-283-1109

Refrigeration Systems &

Electrical Distribution Products

Hillphoenix

709 Sigman Road

Conyers, GA 30013

770-285-3200

06/00

Warning

Servicing & Case Care

When servicing or cleaning cases, observe the following

procedures to avoid case damage or injury:

Be certain that all electricity to the case is turned off before

servicing or cleaning to avoid electrical shock. In some

cases, more than one switch may need to be turned off to

completely de-energize the case.

Do not spray cleaning solution or water directly on fan

motors or any electrical connections.

All lighting components must be dried thoroughly before

installation and before re-energizing the lighting circuit.

Please refer to the Case Cleaning section of this installation manual.

Hillphoenix

1925 Ruffin Mill Rd.

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m. to 5 p.m. EST)

Tel: 1-800-283-1109

Fax: 804-526-7450

Web site: www.hillphoenix.com

Due to our commitment to continuous improvement, all specifications are subject to change without notice.

Hillphoenix is a Sustaining Member of the American Society of Quality.

Loading...

Loading...