Page 1

Mixer

UM 22VYST • UM 16VST2 • UM 12VST2

Handling instructions

UM 22VYST UM 16VST2 UM 12VST2

Read through carefully and understand these instructions before use.

Page 2

1

1

6

1

4

3

9

7

〈UM 22VYST〉

8

0

2

4

3

6

5

〈UM 16VST2〉

〈UM 12VST2〉

2

2

4

3

2

2

1

1

8

7

!

2

1

5

2

1

〈UM 22VYST〉

〈UM 16VST2〉

%

$

〈UM 22VYST〉

2

$

%

#

$

or

〈UM 16VST2 / UM 12VST2〉

!

@

or

〈UM 12VST2〉

$

5

Page 3

3

6

4

4

4

Lock

+ 2 =

1

3

2

1

4

2

1

1

+ 2 =

56

2

3

Page 4

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and

specifi cations provided with this power tool.

Failure to follow all instructions listed below may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as a dust mask, non-skid

safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off -position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your fi nger on the switch or

energising power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away from

moving parts.

Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles.

A careless action can cause severe injury within a

fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may aff ect the power toolʼs operation. If

damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

Use of the power tool for operations diff erent from

those intended could result in a hazardous situation.

4

Page 5

English

h) Keep handles and grasping surfaces dry, clean

and free from oil and grease.

Slippery handles and grasping surfaces do not allow

for safe handling and control of the tool in unexpected

situations.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach of

children and infi rm persons.

MIXER SAFETY INSTRUCTIONS

a) Hold the tool with both hands at the intended

handles. (Fig. 6)

Loss of control can cause personal injury.

b) Ensure suffi cient ventilation when mixing fl ammable

materials to avoid a hazardous atmosphere.

Developing vapour may be inhaled or be ignited by the

sparks the power tool produces.

c) Do not mix food.

Power tools and their accessories are not designed for

processing food.

d) Keep the cord away from the working area.

The cord may be entangled by the mixer basket.

e) Ensure that the mixing container is placed in a fi rm

and secure position.

A container that is not properly secured may move

unexpectedly.

f) Ensure that no liquid splashes against the housing

of the power tool.

Liquid that has penetrated the power tool can cause

damage and lead to electric shock.

g) Follow the instructions and warnings for the

material to be mixed.

Material to be mixed may be harmful.

h) If the power tool falls into the material to be mixed,

unplug the tool immediately and have the power

tool checked by a qualifi ed repair person.

Reaching into the bucket with the tool still plugged in can

lead to electric shock.

i) Do not reach into the mixing container with your

hands or insert any other objects into it while

mixing.

Contact with the mixer basket may lead to serious

personal injury.

j) Start up and run down the tool in the mixing

container only.

The mixer basket may bend or spin in an uncontrolled

manner.

PRECAUTIONS ON USING THE MACHINE

1. Do not use the power tool for explosive materials

(e. g., easily infl ammable solvents).

Power tools produce sparks which could ignite

developing vapours.

2. In case the power tool should fall into the material

to be stirred, pull the plug immediately and have the

power tool checked by an after-sales service agent.

Material that has penetrated the power tool can cause

damage and lead to an electric shock.

3. When working with the machine, always hold it

fi rmly with both hands and provide for a secure

stance.

The power tool is guided more secure with both hands.

4. Do not work materials containing asbestos.

Asbestos is considered carcinogenic.

5. Take protective measures when dust can develop

during working that is harmful to one's health,

combustible or explosive.

Example: Some dusts are regarded as carcinogenic.

Wear a dust mask and work with dust/chip extraction

when connectable.

6. Always wait until the machine has come to a

complete stop before placing it down.

The tool insert can jam and lead to loss of control over the

power tool.

7. Never use the machine with a damaged cable. Do

not touch the damaged cable and pull the mains

plug when the cable is damaged while working.

Damaged cables increase the risk of an electric shock.

8. When operating a mixer with wet material avoid

splashes up to the motor part.

9. Connect machines that are used in the open via a

residual current device (RCD).

NAMES OF PARTS (Fig. 1 – Fig. 6)

Brush cap

1

Speed control dial

2

Lock for ON

3

Trigger

4

Stirrer paddle

5

Gear shift dial

6

Stirrer (L)

7

Stirrer (R)

8

Nut (L)

9

Nut (R)

0

Extension bar

!

(18.5 mm)

Spindle

@

Wrench (19 mm)

#

Wrench (22 mm)

$

Wrench (28 mm)

%

5

Page 6

English

SYMBOLS

WARNING

The following show symbols used for the machine.

Be sure that you understand their meaning before

use.

UM 22VYST / UM 16VST2 / UM 12VST2:

Mixer

To reduce the risk of injury, user must read

instruction manual.

Switching ON

Switching OFF

Disconnect mains plug from electrical outlet

Class II tool (Double insulation)

SPECIFICATIONS

Model UM 22VYST UM 16VST2 UM 12VST2

Voltage (by areas)* 230 V

Power input* 1800 W 1600 W 1200 W

Speed change 121212

No load speed 150 – 300 /min 300 – 650 /min 150 – 300 /min 300 – 650 /min 150 – 300 /min 300 – 650 /min

Stirrer paddle 220 mm (135 mm × 2) 160 mm 120 mm

Weight 6.4 kg 5.7 kg 5.4 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

Electronic control

○ Soft start

Reduces recoil against the operator by managing the number of rotations during startup.

○ 0 Voltage Re-start Protection

The 0 voltage restart protection feature prevents the power tool from restarting after the power has been temporarily cut

off during operation.

○ Variable speed

○ Overload protection

This protection feature cuts off the power to the motor in the event of overloading of motor or a conspicuous reduction in

rotational speed during operation.

When the overload protection feature has been activated, the motor may stop.

In this case, release the tool switch and eliminate causes of overloading.

After that you can use it again.

NOTE

Due to HiKOKI’s continuing program of research and development, the specifi cations herein are subject to change

without prior notice.

STANDARD ACCESSORIES

UM 22VYST UM 16VST2 UM 12VST2

Stirrer

paddle (mm)

Extension

bar (mm)

Standard accessories are subject to change without notice.

∅ 135 × 2 ∅ 160 × 1 ∅ 120 × 1

— L185 —

APPLICATIONS

Mixing pulverised building materials such as mortar,

plaster, adhesives, as well as solvent-free paint, varnish

and similar substances.

6

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Trigger

Ensure that the trigger is in the OFF position. If the plug

is connected to a receptacle while the trigger is in the ON

position, the power tool will start operating immediately,

inviting serious accident.

3. Extension cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

Page 7

English

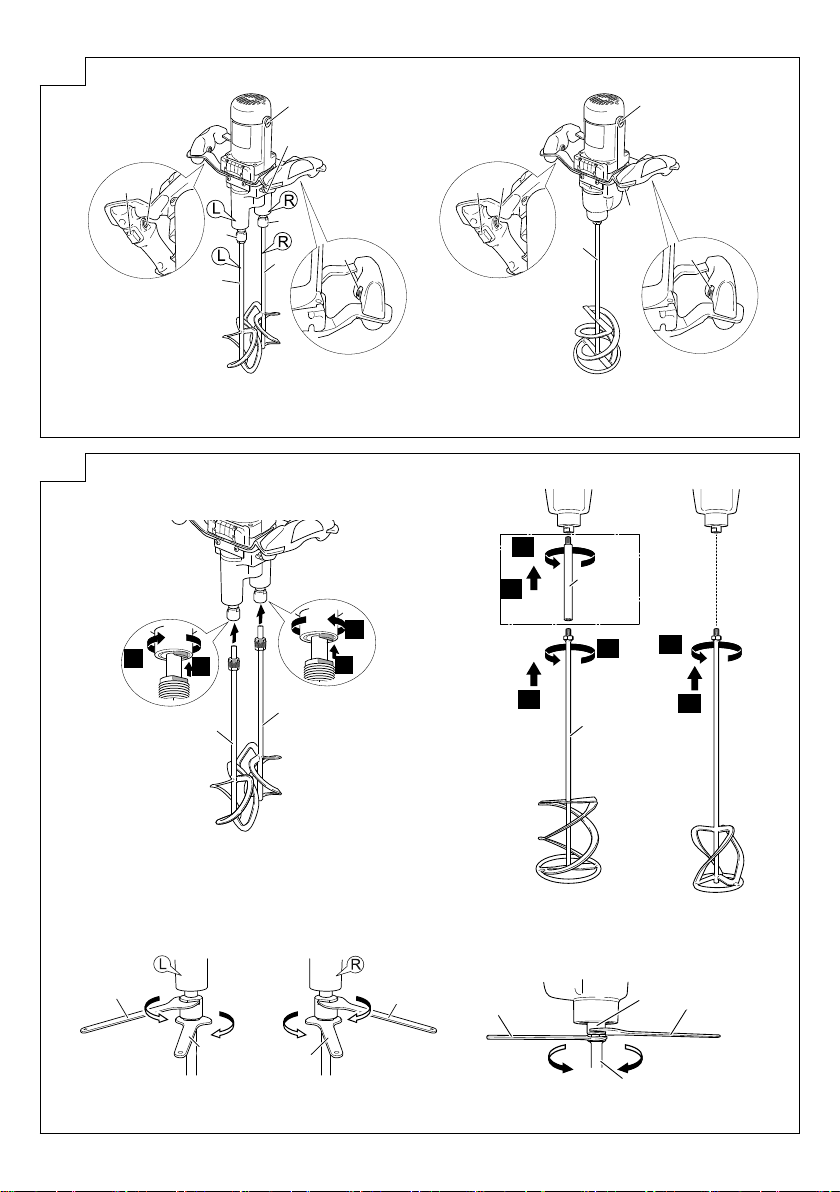

4. Mounting and dismounting of the stirrer paddle

(Fig. 2)

CAUTION

To avoid serious accident, ensure the trigger is in the

OFF position, and the power source is disconnected.

Disconnect the mains plug!

(1) Screw the stirrer paddle onto the spindle. Hold the

spindle in place with wrench and turn the stirrer paddle

with another wrench in the clockwise direction (viewed

from the front side). Tighten securely.

A wrench with the measurements below is required.

⎡UM 22VYST: 22 mm, 28 mm ⎤

⎢UM 16VST2: 22 mm × 2, 19 mm (for extension bar) ⎥

⎣UM 12VST2: 22 mm × 2 ⎦

(2) The stirrer paddle is disassembled in reverse order.

5. High-speed/Low-speed changeover

Prior to changing speed, ensure that the trigger is in the

OFF position, and the machine has come to a complete

stop.

To change speed, rotate the gear shift dial as indicated

by the arrow in Fig. 3. The numeral “1” engraved on

the machine body denotes low speed, the numeral “2”

denotes high speed.

If it is hard to turn the gear shift dial, turn the spindle

slightly in either direction and then turn the gear shift dial

again.

HOW TO USE

1. Switch operation (Fig. 4)

○ When the trigger is depressed, the tool rotates. When the

trigger is released, the tool stops.

○ Pulling the trigger and pushing the Lock for ON, it keeps

the switched-on condition which is convenient for

continuous running. When switching off , the Lock for ON

can be disconnected by pulling the trigger again.

2. Adjusting the speed (Fig. 5)

The desired rotation speed can be pre-selected with the

speed control dial.

CAUTION

When replacing the new carbon brushes, always use

genuine HiKOKI carbon brushes with the number

specifi ed in the drawing.

5. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed. Contact the HiKOKI Authorized Service Center

when repurchasing carbon brushes.

6. Replacing supply cord

If the supply cord of Tool is damaged, the Tool must be

returned to HiKOKI Authorized Service Center for the

cord to be replaced.

If it becomes necessary to replace the connecting cable,

then this is to be undertaken by the manufacturer or his

representative in order to avoid any safety risks.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MAINTENANCE AND INSPECTION

The plug must be fi rst pulled out before maintenance and

cleaning.

1. Storage and cleaning

When a mixer is not in use store it in dry locations the

motor part upwards.

When cleaning a mixer avoid entrance of any water or

liquid to the motor part.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brushes with new ones having the same carbon brush

No.. In addition, always keep carbon brushes clean and

ensue that they slide freely within the brush holders.

7

Page 8

ﺔﻴﺑﺮﻌﻟا

ﺹﺣﻔﻟﺍﻭ ﺔﻧﺎﻳﺻﻟﺍ

.ﻑﻳﻅﻧﺗﻟﺍﻭ ﺔﻧﺎﻳﺻﻟﺍ ﻝﺑﻗ ًﻻﻭﺃ ﺱﺑﺎﻘﻟﺍ ﺏﺣﺳ ﺏﺟﻳ

ﻑﻳﻅﻧﺗﻟﺍﻭ ﻥﻳﺯﺧﺗﻟﺍ

ﺔﻓﺎﺟ ﻊﻗﺍﻭﻣ ﻲﻓ ﻪﻧﻳﺯﺧﺗﺑ ﻡﻘﻓ ﻡﺍﺩﺧﺗﺳﻻﺍ ﺩﻳﻗ ﻁﻼﺧﻟﺍ ﻥﻭﻛﻳ ﻻ ﺎﻣﺩﻧﻋ

.ﻙﺭﺣﻣﻟﺍ ءﺯﺟﻟ ﻝﺋﺍﻭﺳ ﻭﺃ ﻩﺎﻳﻣ ﻱﺃ ﻝﻭﺧﺩ ﺏﻧﺟﺗ ﻁﻼﺧﻟﺍ ﻑﻳﻅﻧﺗ ﺩﻧﻋ

ﺎﻬﻁﺑﺭ ﻡﺎﻛﺣﺇ ﻥﻣ ﺩﻛﺄﺗﻟﺍﻭ ﺕﻳﺑﺛﺗﻟﺍ ﺭﻳﻣﺎﺳﻣ ﺔﻓﺎﻛﻟ ﻱﺭﻭﺩﻟﺍ ﺹﺣﻔﻟﺎﺑ ﻡﻗ

.ﺭﻭﻔﻟﺍ ﻰﻠﻋ ﺎﻬﻁﺑﺭ ﻡﺎﻛﺣﺈﺑ ﻡﻗ ،ﺭﻳﻣﺎﺳﻣ ﺔﻳﺃ ﻙﻓ ﺔﻟﺎﺣ ﻲﻓ .ﺢﻳﺣﺻ ﻝﻛﺷﺑ

.ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻥﻣ "ﻁﺳﻭﻷﺍ ءﺯﺟﻟﺍ" ﻭﻫ ﻙﺭﺣﻣﻟﺍ ﺓﺩﺣﻭ ﻑﻠﻣ

.ءﺎﻣﻟﺍ ﻭﺃ ﺕﻳﺯﻟﺍ ﺔﻁﺳﺍﻭﺑ ﻪﻠﻠﺑ ﻭﺃ/ﻭ ﻑﻠﻣﻟﺍ ﻑﻠﺗ ﻡﺩﻋ ﻥﻣ ﺭﺍﺭﻣﺗﺳﺎﺑ ﺩﻛﺄﺗ

.ﺓﺭﻣﻌﻣ ﺭﻳﻏ ءﺍﺯﺟﻷﺍ ﻥﻣ ﻲﻫﻭ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻙﺭﺣﻣﻟﺍ ﻡﺩﺧﺗﺳﻳ

ﻲﻓ ﻝﻁﻋ ﻰﻟﺇ ﻱﺩﺅﺗ ﺩﻗ ﺓﺩﺷﺑ ﺔﻠﻛﺂﺗﻣﻟﺍ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻥﺍ ﺙﻳﺣﻭ

ﻡﻗﺭ ﺱﻔﻧ ﺎﻬﻟ ﺓﺩﻳﺩﺟ ﻯﺭﺧﺄﺑ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺎﺑ ﻡﻘﻓ ،ﻙﺭﺣﻣﻟﺍ

ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻑﻳﻅﻧﺗﺑ ﻡﻗ ،ﻙﻟﺫ ﻰﻟﺇ ﺔﻓﺎﺿﻹﺎﺑ .ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ

.ﺓﺎﺷﺭﻔﻟﺍ ﺽﺑﺎﻘﻣ ﻝﺧﺍﺩ ﺔﺳﻼﺳﺑ ﺎﻬﻗﻻﺯﻧﺍ ﻥﻣ ﺩﻛﺄﺗﻟﺍﻭ ﺭﺍﺭﻣﺗﺳﺎﺑ

HiKOKI ﺓﺎﺷﺭﻓ ﺎًﻣﺋﺍﺩ ﻡﺩﺧﺗﺳﺍ ،ﺓﺩﻳﺩﺟﻟﺍ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺍ ﺩﻧﻋ

ﺩﻌﺑﻭ .ﺕﺎﺣﺗﻓ ﻭﺫ ﺱﺃﺭﺑ ﺭﻳﻐﺻ ﻙﻔﻣ ﻡﺍﺩﺧﺗﺳﺎﺑ ﺓﺎﺷﺭﻔﻟﺍ ﺔﻳﻁﻏﺃ ﻙﻔﺑ ﻡﻗ

ﺔﻣﺩﺧﻟﺍ ﺯﻛﺭﻣ ﻊﻣ ﻝﺻﺍﻭﺗ .ﺔﻟﻭﻬﺳﺑ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺵﺭﻔﻟﺍ ﻉﺯﻧ ﻥﻛﻣﻳ ﻙﻟﺫ

ﺔﻣﺩﺧ ﺯﻛﺭﻣﻟ ﺓﺍﺩﻻﺍ ﻉﺎﺟﺭﺇ ﺏﺟﻳ ،ﺓﺍﺩﻸﻟ ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻟﺍ ﻙﻠﺳ ﻑﻠﺗ ﺍﺫﺇ

ﺔﻳﻟﻭﺅﺳﻣ ﻥﻭﻛﺗ ،ﻝﻳﺻﻭﺗﻟﺍ ﻝﺑﺎﻛ ﻝﺍﺩﺑﺗﺳﺍ ﻱﺭﻭﺭﺿﻟﺍ ﻥﻣ ﺢﺑﺻﺃ ﺍﺫﺇ

ﺏﻧﺟﺗ ﻝﺟﺃ ﻥﻣ ﻪﺑ ﺹﺎﺧﻟﺍ ﺏﻭﺩﻧﻣﻟﺍ ﻭﺃ ﻊﻧﺻُﻣﻟﺍ ﻰﻠﻋ ﻊﻘﺗ ﻙﻟﺫﺑ ﻡﺎﻳﻘﻟﺍ

.ﻰﻠﻋﻷ ﺎًﻬﺟﺗﻣ ﻙﺭﺣﻣﻟﺍ ءﺯﺟ ﻥﻭﻛﻳ ﺙﻳﺣﺑ

ﺕﻳﺑﺛﺗﻟﺍ ﺭﻳﻣﺎﺳﻣ ﺹﺣﻓ

.ﺭﻁﺎﺧﻣ ﻰﻟﺇ ﻙﻟﺫﺑ ﻡﺎﻳﻘﻟﺍ ﻲﻓ ﻝﺷﻔﻟﺍ ﺽﺭﻌﻳ ﺩﻘﻓ

ﻙﺭﺣﻣﻟﺍ ﺔﻧﺎﻳﺻ

ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﺹﺣﻓ

ﺭــﻳﺫـﺣـﺗ

.ﻡﺳﺭﻟﺍ ﻲﻓ ﺩﺩﺣﻣﻟﺍ ﻡﻗﺭﻟﺎﺑ ﺓﺩﻣﺗﻌﻣﻟﺍ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ

ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺍ

.ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺵﺭﻔﻟﺍ ءﺍﺭﺷ ﺩﻧﻋ HiKOKI ﻥﻣ ﺓﺩﻣﺗﻌﻣﻟﺍ

ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻟﺍ ﻙﻠﺳ ﻝﺍﺩﺑﺗﺳﺍ

.ﻙﻠﺳﻟﺍ ﻝﺍﺩﺑﺗﺳﻻ ﺩﻣﺗﻌﻣﻟﺍ

HiKOKI

.ﺔﻣﻼﺳﻟﺎﺑ ﺔﺻﺎﺧ ﺭﻁﺎﺧﻣ ﻱﺃ

1

2

3

4

5

6

ﺕﺎﻣﻳﻠﻌﺗ ﻉﺎﺑﺗﺍ ﺏﺟﻳ ،ﺎﻬﺗﻧﺎﻳﺻ ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﺔﻟﺎﺣ ﻲﻓ

ﻪﻳﺑﻧﺗ

.ﺔﻟﻭﺩ ﻝﻛﺑ ﺔﺻﺎﺧﻟﺍ ﺭﻳﻳﺎﻌﻣﻟﺍﻭ ﻥﺎﻣﻷﺍ

8

٤

Page 9

ﺔﻴﺑﺮﻌﻟا

ﺕﺎﻔﺻﺍﻭﻣﻟﺍ

.ﺔﻘﻁﻧﻣﻟﺍ ﺏﺳﺣ ﺭﻳﻳﻐﺗﻠﻟ ﺔﺿﺭُﻋ ﺎﻬﻧﺃ ﺙﻳﺣ ﺞﺗﻧﻣﻟﺍ ﻰﻠﻋ ﺓﺩﻭﺟﻭﻣﻟﺍ ﻡﺳﻻﺍ ﺔﺣﻭﻟ ﺹﺣﻓ ﻥﻣ ﺩﻛﺄﺗ *

.ﻝﻳﻐﺷﺗﻟﺍ ءﺩﺑ ءﺎﻧﺛﺃ ﺕﺍﺭﻭﺩﻟﺍ ﺩﺩﻋ ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﻕﻳﺭﻁ ﻥﻋ ﻝﻐﺷﻣﻟﺍ ﻩﺎﺟﺗ ﺩﺍﺩﺗﺭﻻﺍ ﻥﻣ ﺩﺣﻳ

.ﺔﻳﻠﻣﻌﻟﺍ ءﺎﻧﺛﺃ ﺔﻗﺎﻁﻠﻟ ﺕﻗﺅﻣﻟﺍ ﻉﺎﻁﻘﻧﻻﺍ ﺩﻌﺑ ﻝﻳﻐﺷﺗﻟﺍ ﺓﺩﺎﻋﺇ ﻥﻣ ﺔﻟﻵﺍ 0 ﻲﺑﺭﻬﻛﻟﺍ ﺩﻬﺟﻟﺍ ﺩﻧﻋ ﻝﻳﻐﺷﺗﻟﺍ ﺓﺩﺎﻋﺇ ﺔﻳﺎﻣﺣ ﺔﻳﺻﺎﺧ ﻊﻧﻣﺗ

.ﻝﻳﻐﺷﺗﻟﺍ ءﺎﻧﺛﺃ ﻥﺍﺭﻭﺩﻟﺍ ﺔﻋﺭﺳ ﻲﻓ ﻅﻭﺣﻠﻣﻟﺍ ﻝﻳﻠﻘﺗﻟﺍ ﻭﺃ ﻙﺭﺣﻣﻠﻟ ﺩﺋﺍﺯﻟﺍ ﻝﻣﺣﻟﺍ ﺔﻟﺎﺣ ﻲﻓ ﻙﺭﺣﻣﻟﺍ ﻥﻋ ﺔﻗﺎﻁﻟﺍ ﺓﺯﻳﻣﻟﺍ ﻩﺫﻫ ﻊﻁﻘﺗ

.ﻕﺑﺳﻣ ﻡﻼﻋﺇ ﻥﻭﺩ ﺎﻧﻫ ﺓﺭﻭﻛﺫﻣﻟﺍ ﺕﺎﻔﺻﺍﻭﻣﻟﺍ ﺭﻳﻐﺗﺗ ،ﺭﻣﺗﺳﻣﻟﺍ ﺭﻳﻭﻁﺗﻟﺍﻭ ﺙﺣﺑﻠﻟ

(2 ﻝﻛﺷﻟﺍ) ﻪﻛﻓﻭ ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ ﻑﺍﺫﻘﻣ ﺏﻳﻛﺭﺗ 4

ﺭــﻳﺫـﺣـﺗ

ﻑﺎﻘﻳﺇ" ﻊﺿﻭ ﻲﻓ ﺡﺍﺩﻘﻣﻟﺍ ﻥﺃ ﺩﻛﺄﺗ ،ﺓﺭﻳﻁﺧﻟﺍ ﺙﺩﺍﻭﺣﻟﺍ ﺏﻧﺟﺗﻟ

!ﺔﻳﺳﻳﺋﺭﻟﺍ ﺕﻼﺑﺎﻛﻟﺍ ﺱﺑﺎﻗ ﻝﺻﻓﺍ .ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻝﺻﻓﻭ ،"ﻝﻳﻐﺷﺗﻟﺍ

ﻥﺍﺭﻭﺩﻟﺍ ﺩﺍﻭﻣﻋ ﻙﺳﻣﺍ .ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻌﺑ ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ ﻑﺍﺫﻘﻣ ﺕﻳﺑﺛﺗﺑ ﻡﻗ (1)

ﻩﺎﺟﺗﺍ ﻲﻓ ﺭﺧﺁ ﺡﺎﺗﻔﻣﺑ ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ ﻑﺍﺫﻘﻣ ﻑﻟﻭ ﺡﺎﺗﻔﻣﻟﺍ ﻊﻣ ﻪﻧﺎﻛﻣ ﻲﻓ

.ﻡﺎﻛﺣﺈﺑ ﻪﻁﺑﺭﺍ .(ﻲﻣﺎﻣﻷﺍ ﺏﻧﺎﺟﻟﺍ ﻲﻓ ﺢﺿﻭﻣ ﻭﻫ ﺎﻣﻛ) ﺔﻋﺎﺳﻟﺍ ﺏﺭﺎﻘﻋ

.ﻩﺎﻧﺩﺃ ﺱﻳﻳﺎﻘﻣﻟﺍ ﻪﻳﻠﻋ ﺢﺿﻭﻣ ﺡﺎﺗﻔﻣ ﺩﻭﺟﻭ ﻥﻣ ﺩﺑﻻ

(ﺩﻳﺩﻣﺗﻟﺍ ﻉﺍﺭﺫﻟ) ﻡﻣ 19 ،2 × ﻡﻣ 22 : UM 16VST2

ﻡﻣ

28 ،ﻡﻣ 22 : UM 22VYST

ﻡﻣ 22 : UM 12VST2

2 ×

.ﻲﺳﻛﻌﻟﺍ ﻩﺎﺟﺗﻻﺍ ﻲﻓ ﺏﻳﻠﻘﺗﻟﺍ ﺓﺩﺃ ﻑﺍﺫﻘﻣ ﻙﻓ ﻡﺗﻳ (2)

ﺔﺿﻔﺧﻧﻣﻟﺍ ﺔﻋﺭﺳﻟﺍ/ﺔﻌﻔﺗﺭﻣﻟﺍ ﺔﻋﺭﺳﻟﺍ ﺭﻳﻳﻐﺗ 5

ﻥﺃﻭ ،"ﻝﻳﻐﺷﺗﻟﺍ ﻑﺎﻘﻳﺇ" ﻊﺿﻭ ﻲﻓ ﺡﺍﺩﻘﻣﻟﺍ ﻥﺃ ﺩﻛﺄﺗ ،ﺔﻋﺭﺳﻟﺍ ﺭﻳﻳﻐﺗ ﻝﺑﻗ

.ﺎًﻣﺎﻣﺗ ﻑﻗﻭﺗ ﺯﺎﻬﺟﻟﺍ

ﺢﺿﻭﻣ ﻭﻫ ﺎﻣﻛ ﻲﻔﻠﺧﻟﺍ ﻥﺍﺭﻭﺩﻟﺍ ﺹﺭﻗ ﺭﻳﻭﺩﺗﺑ ﻡﻗ ،ﺔﻋﺭﺳﻟﺍ ﺭﻳﻳﻐﺗﻟ

ﻡﺳﺟ ﻲﻓ ﺎﻫﺭﻔﺣ ﻡﺗ "1" ﺔﻳﺩﺩﻌﻟﺍ ﺔﻣﻳﻘﻟﺍ .3 ﻝﻛﺷﻟﺍ ﻲﻓ ﻡﻬﺳﻟﺍ ﺔﻁﺳﺍﻭﺑ

ﺭﻳﺷﺗ "2" ﺔﻳﺩﺩﻌﻟﺍ ﺔﻣﻳﻘﻟﺍﻭ /ﺔﺿﻔﺧﻧﻣﻟﺍ ﺔﻋﺭﺳﻟﺍ ﻰﻟﺇ ﺭﻳﺷﺗ ﻲﺗﻟﺍﻭ ﺯﺎﻬﺟﻟﺍ

.ﺔﻌﻔﺗﺭﻣﻟﺍ ﺔﻋﺭﺳﻟﺍ ﻰﻟﺇ

ﺩﻭﻣﻋ ﻑﻠﺑ ﻡﻘﻓ ،ﻲﻔﻠﺧﻟﺍ ﻥﺍﺭﻭﺩﻟﺍ ﺹﺭﻗ ﻑﻟ ﺏﻌﺻﻟﺍ ﻥﻣ ﻥﺎﻛ ﺍﺫﺇ

.ﻯﺭﺧﺃ ﺓﺭﻣ ﻲﻔﻠﺧﻟﺍ ﻥﺍﺭﻭﺩﻟﺍ ﺹﺭﻗ ﻑﻟ ﻡﺛ ﻩﺎﺟﺗﺍ ﻱﺃ ﻲﻓ ﻥﺍﺭﻭﺩﻟﺍ

ﻡﺍﺩﺧﺗﺳﻻﺍ ﺔﻳﻔﻳﻛ

،ﺡﺍﺩﻘﻣﻟﺍ ﺭﻳﺭﺣﺗ ﺩﻧﻋ .ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻑﻗﻭﺗﺗ ،ﺡﺍﺩﻘﻣﻟﺍ ﻁﻐﺿ ﺩﻧﻋ ○

ﻙﻟﺫ ﻝﻣﻌﻳ ،"ﻝﻳﻐﺷﺗﻟﺍ" ﻝﺟﺃ ﻥﻣ ﻝﻔﻘﻟﺍ ﻰﻠﻋ ﻁﻐﺿﻟﺍﻭ ﺡﺍﺩﻘﻣﻟﺍ ﺏﺣﺳ ○

ﻝﻳﻐﺷﺗﻟﺍ ﻊﻣ ﺏﺳﺎﻧﺗﻳ ﺍﺫﻫﻭ ﻝﻳﻐﺷﺗﻟﺍ ﻊﺿﻭ ﻲﻓ ﺯﺎﻬﺟﻟﺍ ءﺎﻘﺑﺇ ﻰﻠﻋ

"ﻝﻳﻐﺷﺗﻟﺍ" ﻝﺟﺃ ﻥﻣ ﻝﻔﻘﻟﺍ ﻝﺻﻓ ﻥﻛﻣﻳ ،ﻝﻳﻐﺷﺗﻟﺍ ﻑﺎﻘﻳﺇ ﺩﻧﻋ .ﻝﺻﺍﻭﺗﻣﻟﺍ

ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﺹﺭﻗ ﻊﻣ ﺔﺑﻭﻏﺭﻣﻟﺍ ﻥﺍﺭﻭﺩﻟﺍ ﺔﻋﺭﺳﻟ ﻕﺑﺳﻣﻟﺍ ﺩﻳﺩﺣﺗﻟﺍ ﻡﺗﻳ ﺩﻗ

(4 ﻝﻛﺷﻟﺍ) ﺡﺎﺗﻔﻣﻟﺍ ﻝﻳﻐﺷﺗ 1

.ﺓﺍﺩﻷﺍ ﻑﻗﻭﺗﺗ

.ﻯﺭﺧﺃ ﺓﺭﻣ ﺡﺍﺩﻘﻣﻟﺍ ﺏﺣﺳﺑ

5 ﻝﻛﺷﻟﺍ) ﺔﻋﺭﺳﻟﺍ ﻁﺑﺿ 2

(

.ﺔﻋﺭﺳﻟﺍ

UM 22VYSTUM 16VST2UM 12VST2

*(ﻕﻁﺎﻧﻣﻟﺍ ﺏﺳﺣ) ﻲﺑﺭﻬﻛﻟﺍ ﺩﻬﺟﻟﺍ ﺕﻟﻭﻓ 230

121212

ﺔﻘﻳﻗﺩ/ 300 - 150ﺔﻘﻳﻗﺩ /650 - 300ﺔﻘﻳﻗﺩ/ 300 - 150ﺔﻘﻳﻗﺩ /650 - 300ﺔﻘﻳﻗﺩ/ 300 - 150ﺔﻘﻳﻗﺩ/ 650 - 300

ﻝﻣﺣ ﻥﻭﺩﺑ ﺔﻋﺭﺳﻟﺍ

ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ ﻑﺍﺫﻘﻣ(2 × ﻡﻣ 135) ﻡﻣ 220ﻡﻣ 160ﻡﻣ 120

(ﻙﻠﺳﻟﺍ ﻥﻭﺩﺑ) ﻥﺯﻭﻟﺍﻡﺟﻛ 6.4ﻡﺟﻛ 5.7ﻡﺟﻛ 5.4

ﻲﻧﻭﺭﺗﻛﻟﻹﺍ ﻡﻛﺣﺗﻟﺍ

0

ﻲﺑﺭﻬﻛﻟﺍ ﺩﻬﺟﻟﺍ ﺩﻧﻋ ﻝﻳﻐﺷﺗﻟﺍ ﺓﺩﺎﻋﺇ ﺔﻳﺎﻣﺣ ○

ﺓﺭﻳﻐﺗﻣ ﺔﻋﺭﺳ ○

ﺩﺋﺍﺯﻟﺍ ﻝﻣﺣﻟﺍ ﻥﻣ ﺔﻳﺎﻣﺣﻟﺍ ○

.ﻙﺭﺣﻣﻟﺍ ﻑﻗﻭﺗﻳ ﺩﻗ ،ﺩﺋﺍﺯﻟﺍ ﻝﻣﺣﻟﺍ ﻥﻣ ﺔﻳﺎﻣﺣﻟﺍ ﺓﺯﻳﻣ ﻁﻳﺷﻧﺗ ﻡﺗﻳ ﺎﻣﺩﻧﻋ

.ﺩﺋﺍﺯﻟﺍ ﻝﻣﺣﻟﺍ ﺏﺎﺑﺳﺃ ﻥﻣ ﻑﻔﺧﻭ ﺓﺍﺩﻷﺍ ﺡﺎﺗﻔﻣ ﺭﺭﺣ ،ﺔﻟﺎﺣﻟﺍ ﻩﺫﻫ ﻲﻓ

.ﻯﺭﺧﺃ ﺓﺭﻣ ﻪﻣﺍﺩﺧﺗﺳﺍ ﻙﻧﻛﻣﻳ ﻙﻟﺫ ﺩﻌﺑﻭ

HiKOKI

ﺞﻣﺎﻧﺭﺑﻟ ﺎًﻌﺑﺗ

ﺔﻳﺳﺎﻳﻗ ﺕﺎﻘﺣﻠﻣ

UM 22VYSTUM 16VST2UM 12VST2

∅ 135 × 2∅ 160 × 1∅ 120 × 1

—L185—

(ﻡﻣ) ﺩﺷﻟﺍ ﻉﺍﺭﺫ

ﺕﺎﻘﺻﻼﻟﺍﻭ ﻁﻼﻣﻟﺍ ﻝﺎﺛﻣﻟﺍ ﻝﻳﺑﺳ ﻰﻠﻋ ءﺎﻧﺑﻟﺍ ﺩﺍﻭﻣ ﻕﻭﺣﺳﻣ ﻥﺣﻁ

ﺩﺍﻭﻣﻟﺍﻭ ﺵﻳﻧﺭﻭﻟﺍﻭ ﺕﺎﺑﻳﺫﻣﻟﺍ ﻥﻣ ﻲﻟﺎﺧﻟﺍ ﻥﺎﻫﺩﻟﺍ ﺎًﺿﻳﺃﻭ ﺕﺎﺟﺯﻼﻟﺍﻭ

ﺕﺎﺑﻠﻁﺗﻣﻟ ﻕﺑﺎﻁﻣ ﻪﻣﺍﺩﺧﺗﺳﺍ ﻡﺗﻳﺳ ﻱﺫﻟﺍ ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ

.ﺞﺗﻧﻣﻟﺍ ﻰﻠﻋ ﺓﺩﻭﺟﻭﻣﻟﺍ ﻡﺳﻻﺍ ﺔﺣﻭﻟ ﻰﻠﻋ ﺓﺩﺩﺣﻣﻟﺍ ﺔﻗﺎﻁﻟﺍ

ﺱﺑﺎﻘﻟﺍ ﻝﻳﺻﻭﺗ ﺔﻟﺎﺣ ﻲﻓ ."ﻑﺎﻘﻳﺇ" ﻊﺿﻭﻟﺍ ﻰﻠﻋ ﺡﺍﺩﻘﻣﻟﺍ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ

ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻡﺗﻳﺳﻓ ،"ﻝﻳﻐﺷﺗ" ﻊﺿﻭﻟﺍ ﻰﻠﻋ ﺡﺍﺩﻘﻣﻟﺍ ﻥﺎﻛﻭ ﺱﺑﻘﻣﻟﺎﺑ

.ﺭﻳﻁﺧ ﺙﺩﺎﺣ ﻉﻭﻗﻭ ﻰﻟﺇ ﻱﺩﺅﻳ ﺎﻣﻣ ،ﺭﻭﻔﻟﺍ ﻰﻠﻋ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﻝﻳﺻﻭﺗ ﻙﻠﺳ ﻡﺩﺧﺗﺳﺍ ،ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻥﻣ ﻝﻣﻌﻟﺍ ﺔﻘﻁﻧﻣ ﺔﻟﺍﺯﺇ ﺩﻧﻋ

ﻝﻳﺻﻭﺗﻟﺍ ﻙﻠﺳ ﻝﻅﻳ ﻥﺃ ﺏﺟﻳ .ﺔﻧﻧﻘﻣ ﺔﻌﺳﻭ ٍﻑﺎﻛ ﻙﻣﺳ ﻭﺫ ﻲﻓﺎﺿﺇ

.ﺭﺎﻁﺧﺇ ﻥﻭﺩ ﺔﻳﺳﺎﻳﻘﻟﺍ ﺕﺎﻘﻠﺣﻣﻟﺍ ﺭﻳﻳﻐﺗ ﻥﻛﻣﻳ

ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ 1

ﻲﻓﺎﺿﻹﺍ ﻝﻳﺻﻭﺗﻟﺍ ﻙﻠﺳ

.ﻉﺎﻁﺗﺳﻣﻟﺍ ﺭﺩﻘﺑ ﺍًﺭﻳﺻﻗ ﻲﻓﺎﺿﻹﺍ

ﺯﺍﺭﻁﻟﺍ

*ﺔﻗﺎﻁﻟﺍ ﻝﺎﺧﺩﺇﺕﺍﻭ 1800ﺕﺍﻭ 1600ﺕﺍﻭ 1200

ﺔﻋﺭﺳﻟﺍ ﺭﻳﻳﻐﺗ

ﻡﻋﺎﻧﻟﺍ ءﺩﺑﻟﺍ ○

ﺔﻅﺣﻼﻣ

ﺓﺍﺩﺃ ﻑﺍﺫﻘﻣ

(ﻡﻣ) ﺏﻳﻠﻘﺗﻟﺍ

ﺕﺎﻘﻳﺑﻁﺗ

ﺔﻬﺑﺎﺷﻣﻟﺍ

ﻝﻳﻐﺷﺗﻟﺍ ﻝﺑﻗ

ﻝﻐﺷﻣﻟﺍ

2

3

٣

9

Page 10

ﺔﻴﺑﺮﻌﻟا

ﺭﺎﺿ ﻪﻧﻷ ﻝﻣﻌﻟﺍ ءﺎﻧﺛﺃ ﺭﺎﺑﻐﻟﺍ ﻥﻭﻛﺗﻳ ﺎﻣﺩﻧﻋ ﺔﻳﺋﺎﻗﻭﻟﺍ ﺭﻳﻳﺎﻌﻣﻟﺍ ﺫﺎﺧﺗﺎﺑ ﻡﻗ 5

.ﺭﺎﺟﻔﻧﻻﺍ ﻭﺃ ﻕﺍﺭﺗﺣﻼﻟ ﻝﺑﺎﻗ ﻪﻧﺃ ﺎﻣﻛ ،ﺹﺧﺷﻟﺍ ﺔﺣﺻ ﻰﻠﻋ

ﻉﺎﻧﻗ ءﺍﺩﺗﺭﺎﺑ ﻡﻗ .ﻕﺍﺭﺗﺣﻼﻟ ﺔﻠﺑﺎﻗ ﻥﻭﻛﺗ ﺔﺑﺭﺗﻷﺍ ﻉﺍﻭﻧﺃ ﺽﻌﺑ :ﻝﺎﺛﻣ

ﺩﻧﻋ ﺔﺣﻳﺭﺷﻟﺍ/ﺭﺎﺑﻐﻟﺍ ﺹﻼﺧﺗﺳﺍ ﻊﻣ ﻝﻣﺎﻌﺗﻭ ﺭﺎﺑﻐﻟﺍ ﻥﻣ ﺔﻳﺎﻗﻭﻟﺍ

.ﻝﺎﺻﺗﻻﺍ

.ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﻥﺍﺩﻘﻓﻭ ﻡﺎﺣﺩﺯﻻﺍ ﻲﻓ ﺏﺑﺳﺗﻳ ﺩﻗ ﺓﺩﻌﻟﺍ ﻝﺎﺧﺩﺇ

ﺔﻔﻟﺎﺗﻟﺍ ﺕﻼﺑﺎﻛﻟﺍ ﺱﻣﻠﺗ ﻻ .ﺔﻔﻟﺎﺗﻟﺍ ﺕﻼﺑﺎﻛﻟﺍ ﻊﻣ ﺯﺎﻬﺟﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ

.ﻪﻌﺿﻭ ﻝﺑﻗ ﺎًﻣﺎﻣﺗ ﺯﺎﻬﺟﻟﺍ ﻑﻗﻭﺗﻳ ﻰﺗﺣ ﺎًﻣﺋﺍﺩ ﺭﻅﺗﻧﺍ

.ﻝﻣﻌﻟﺍ ءﺎﻧﺛﺃ ﻝﺑﺎﻛﻟﺍ ﻑﻠﺗﻳ ﺎﻣﺩﻧﻋ ﺔﻳﺳﻳﺋﺭﻟﺍ ﺕﻼﺑﺎﻛﻟﺍ ﺏﺣﺳﺍﻭ

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻﻟ ﺽﺭﻌﺗﻟﺍ ﺓﺭﻭﻁﺧ ﻥﻣ ﺔﻔﻟﺎﺗﻟﺍ ﺕﻼﺑﺎﻛﻟﺍ ﺩﻳﺯﺗ

.ﻙﺭﺣﻣﻟﺍ ءﺯﺟ ﻰﺗﺣ ﺫﺍﺫﺭﻟﺍ ﺏﻧﺟﺗ ﺔﻠﻠﺑﻣ ﺩﺍﻭﻣ ﻊﻣ ﻁﻼﺧﻟﺍ ﻝﻳﻐﺷﺗ ﺩﻧﻋ

ﺯﺎﻬﺟ ﻡﺍﺩﺧﺗﺳﺎﺑ ﻕﻠﻁﻟﺍ ءﺍﻭﻬﻟﺍ ﻲﻓ ﺔﻣﺩﺧﺗﺳﻣﻟﺍ ﺓﺯﻬﺟﻷﺍ ﻝﻳﺻﻭﺗﺑ ﻡﻗ 9

.(RCD) ﻲﻘﺑﺗﻣ ﺭﺎﻳﺗ

(6 ﻝﻛﺷﻟﺍ - 1 ﻝﻛﺷﻟﺍ) ءﺍﺯﺟﻷﺍ ءﺎﻣﺳﺃ

ﺩﺎﻧﺯﻟﺍ

1

2

3

4

5

6

7

8

(L) ﺔﻟﻭﻣﺻ

(R) ﺔﻟﻭﻣﺻ

(ﻡﻣ 18.5) ﺩﺷﻟﺍ ﻉﺍﺭﺫ

ﻥﺍﺭﻭﺩ ﺩﻭﻣﻋ

(ﻡﻣ 19) ﻁﺑﺭ ﺡﺎﺗﻔﻣ

(ﻡﻣ 22) ﻁﺑﺭ ﺡﺎﺗﻔﻣ

(ﻡﻣ 28) ﻁﺑﺭ ﺡﺎﺗﻔﻣ

9

0

ﺔﻋﺭﺳﻟﺍ ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﺡﺎﺗﻔﻣ

!

@

#

$

ﻲﻔﻠﺧﻟﺍ ﻝﻳﻭﺣﺗﻟﺍ ﺹﺭﻗ

%

ﺓﺎﺷﺭﻔﻟﺍ ءﺎﻁﻏ

ﻝﻳﻐﺷﺗﻟﺍ ﻝﻔﻗ

ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ ﻑﺍﺫﻘﻣ

(L) ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ

(R) ﺏﻳﻠﻘﺗﻟﺍ ﺓﺍﺩﺃ

ﺯﻭﻣﺭﻟﺍ

ﺎﻫﺎﻧﻌﻣ ﻡﻬﻔﺗ ﻙﻧﺃ ﻥﻣ ﺩﻛﺄﺗ .ﺔﻧﻳﻛﺎﻣﻠﻟ ﺔﻣﺩﺧﺗﺳﻣﻟﺍ ﺯﻭﻣﺭﻟﺍ ﻲﻠﻳ ﺎﻣ ﻥﻳﺑﻳ

.ﻡﺍﺩﺧﺗﺳﻻﺍ ﻝﺑﻗ

:UM 12VST2 / UM 16VST2 / UM 22VYST

ﻁﻼﺧ

ﻝﻳﻟﺩ ﺓءﺍﺭﻗ ﻡﺩﺧﺗﺳﻣﻟﺍ ﻰﻠﻋ ﺏﺟﻳ ،ﺔﺑﺎﺻﻹﺍ ﺭﻁﺧ ﻝﻳﻠﻘﺗﻟ

ﺕﺎﻣﻳﻠﻌﺗﻟﺍ

(ON) ﻝﻳﻐﺷﺗﻟﺍ ﺡﺎﺗﻔﻣ

ﺭﻳﺫﺣﺗ

ﺕﻭﻳﺯﻟﺍ ﻥﻣ ﺔﻳﻟﺎﺧﻭ ،ﺔﻓﺎﺟ ﺽﺑﻘﻣﻟﺍ ﺢﻁﺳﺃﻭ ﺽﺑﺎﻘﻣﻟﺍ ﻰﻠﻋ ﻅﻓﺎﺣ (ﺩ

.ﻡﻭﺣﺷﻟﺍ ﻭﺃ

ﻥﻣﻵﺍ ﻝﻣﺎﻌﺗﻟﺎﺑ ﺔﻘﻟﺯﻧﻣﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺢﻁﺳﺃﻭ ﺽﺑﺎﻘﻣﻟﺍ ﺢﻣﺳﺗ ﻻ

.ﺔﻌﻗﻭﺗﻣﻟﺍ ﺭﻳﻏ ﻑﻗﺍﻭﻣﻟﺍ ﻲﻓ ﺓﺍﺩﻷﺍ ﻲﻓ ﻡﻛﺣﺗﻟﺍﻭ

6

ﻁﻘﻓﻭ ﻥﻳﺻﺻﺧﺗﻣﻟﺍ ﻝﺑﻗ ﻥﻣ ﻁﻘﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﻙﺗﺩﻋ ﺢﻳﻠﺻﺗﺑ ﺢﻣﺳﺍ (ﺃ

7

8

.ﻥﺳﻟﺍ ﺭﺎﺑﻛﻭ ﻝﺎﻔﻁﻷﺍ ﻝﻭﺎﻧﺗﻣ ﻥﻋ ًﺍﺩﻳﻌﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻊﺿﻭ ﻰﺟﺭﻳ

. ﻁﻘﻓ ﺔﻳﻠﺻﻷﺍ ﺭﺎﻳﻐﻟﺍ ﻊﻁﻗ ﻝﺎﻣﻌﺗﺳﺈﺑ

.ﺯﺎﻬﺟﻟﺍ ﻥﺎﻣﺃ ﻰﻠﻋ ﺔﻅﻓﺎﺣﻣﻟﺍ ﻙﻟﺫ ﻥﻣﺅﻳ

ﻥﻋ ﺓﺩﻳﻌﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻰﻠﻋ ﻅﺎﻔﺣﻟﺍ ﺏﺟﻳ ﻡﺍﺩﺧﺗﺳﻻﺍ ﻡﺩﻋ ﺔﻟﺎﺣ ﻲﻓ

.ﻥﺳﻟﺍ ﺭﺎﺑﻛﻭ ﻝﺎﻔﻁﻷﺍ ﻝﻭﺎﻧﺗﻣ

ﻁﻼﺧﻟﺎﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻣﻼﺳﻟﺍ ﺕﺎﻣﻳﻠﻌﺗ

(6 ﻝﻛﺷﻟﺍ) .ﺹﺻﺧﻣﻟﺍ ﺽﺑﻘﻣﻟﺍ ﻥﻣ ﻥﻳﺗﻧﺛﻻﺍ ﻙﻳﺩﻳﺑ ﺓﺍﺩﻷﺍ ﻝﻣﺣﺍ (ﺃ

ﺏﻧﺟﺗﻟ ﻝﺎﻌﺗﺷﻼﻟ ﺔﻠﺑﺎﻘﻟﺍ ﺩﺍﻭﻣﻟﺍ ﻁﻠﺧ ءﺎﻧﺛﺃ ﺔﻳﻓﺎﻛ ﺔﻳﻭﻬﺗ ﺩﻭﺟﻭ ﻥﻣ ﺩﻛﺄﺗ (ﺏ

ﻩﺩﻟﻭﺗ ﻱﺫﻟﺍ ﺭﺭﺷﻟﺍ ﺔﻁﺳﺍﻭﺑ ﻝﻌﺗﺷﺗ ﻭﺃ ﺓﺩﻋﺎﺻﺗﻣﻟﺍ ﺓﺭﺧﺑﻷﺍ ﻕﺷﻧﺗﺳُﺗ ﺩﻗ

ﻱﺩﺅﻳ ﺩﻗﻭ ﺎﻬﻔﻠﺗ ﻲﻓ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻕﺭﺗﺧﺍ ﻱﺫﻟﺍ ﻝﺋﺎﺳﻟﺍ ﺏﺑﺳﺗﻳ ﻥﺃ ﻥﻛﻣﻳ

ﺔﻳﻠﻣﻋ ءﺎﻧﺛﺃ ﺎﻬﻠﺧﺍﺩ ءﻲﺷ ﻱﺃ ﻝﺧﺩﺗ ﻻﻭ ﻙﻳﺩﻳﺑ ﻁﻠﺧﻟﺍ ﺔﻳﻭﺎﺣ ﺱﻣﻠﺗ ﻻ (ﺫ

.ﺔﻳﺻﺧﺷ ﺔﺑﺎﺻﺇ ﻉﻭﻗﻭ ﻲﻓ ﺏﺑﺳﺗﻳ ﺩﻗ ﻡﻛﺣﺗﻟﺍ ﻥﺍﺩﻘﻓ ﻥﺈﻓ

.ﺓﺭﻁﺧ ﺔﺋﻳﺑ ﻥﻳﻭﻛﺗ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

.ﻡﺎﻌﻁﻟﺍ ﻁﻠﺧﺗ ﻻ (ﺕ

.ﻡﺎﻌﻁﻟﺍ ﺔﺟﻟﺎﻌﻣﻟ ﺎﻬﺗﺎﻘﺣﻠﻣﻭ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﻳﻣﺻﺗ ﻡﺗﻳ ﻡﻟ

.ﻝﻣﻌﻟﺍ ﺔﻘﻁﻧﻣ ﻥﻋ ﺩﻳﻌﺑ ﻥﺎﻛﻣ ﻲﻓ ﻙﻠﺳﻟﺍ ﻊﺿ (ﺙ

.ﻁﻼﺧﻟﺍ ﺔﻠﺳ ﻊﻣ ﻙﻠﺳﻟﺍ ﻙﺑﺎﺷﺗﻳ ﺩﻗ

.ﺔﻧﻣﺁﻭ ﺔﻣﻛﺣﻣ ﺔﻳﻌﺿﻭ ﻲﻓ ﻁﻠﺧﻟﺍ ﺔﻳﻭﺎﺣ ﻥﺃ ﺩﻛﺄﺗ (ﺝ

.ﻥﻣﺁ ﺭﻳﻏ ﻝﻛﺷﺑ ﺔﻋﻭﺿﻭﻣ ﺕﻧﺎﻛ ﺍﺫﺇ ،ﺓﺄﺟﻓ ﺔﻳﻭﺎﺣﻟﺍ ﻙﺭﺣﺗﺗ ﺩﻗ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺕﻳﺑﺛﺗ ﺭﺎﻁﺇ ﻰﻠﻋ ﻝﺋﺎﺳ ﺫﺍﺫﺭ ﺩﻭﺟﻭ ﻡﺩﻋ ﻥﻣ ﺩﻛﺄﺗ (ﺡ

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻ ﻉﻭﻗﻭ ﻰﻟﺇ

.ﺎﻬﻁﻠﺧ ﺩﺍﺭﻣﻟﺍ ﺓﺩﺎﻣﻟﺎﺑ ﺔﺻﺎﺧﻟﺍ ﺕﺍﺭﻳﺫﺣﺗﻟﺍﻭ ﺕﺎﻣﻳﻠﻌﺗﻟﺍ ﻊﺑﺗﺍ (ﺥ

.ﺓﺭﺎﺿ ﺓﺩﺎﻣ ﺎﻬﻁﻠﺧ ﺩﺍﺭﻣﻟﺍ ﺓﺩﺎﻣﻟﺎﺑ ﻥﻭﻛﺗ ﺩﻗ

ﻝﺻﻔﺑ ﻡﻘﻓ ،ﺎﻬﻁﻠﺧ ﺩﺍﺭﻣﻟﺍ ﺩﺍﻭﻣﻟﺍ ﻝﺧﺍﺩ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺕﻁﻘﺳ ﺍﺫﺇ (ﺩ

ﻝﻫﺅﻣ ﺹﺧﺷ ﺔﻁﺳﺍﻭﺑ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺹﺣﻓﺍﻭ ﻝﺎﺣﻟﺍ ﻲﻓ ﺓﺍﺩﻷﺍ

.ﺡﻼﺻﻹﺍ ﺔﻳﻠﻣﻌﻟ

ﻉﻭﻗﻭ ﺱﺑﻘﻣﻟﺎﺑ ﺔﻠﺻﻭﻣ ﺓﺍﺩﻷﺍ ﻝﺍﺯﺗ ﻻ ﺎﻣﻧﻳﺑ ﻭﻟﺩﻟﺍ ﺱﻣﻟ ﻥﻋ ﺞﺗﻧﻳ ﺩﻗ

.ﺔﻳﺋﺎﺑﺭﻬﻛ ﺔﻣﺩﺻ

.ﺓﺭﻁﺧ ﺔﻳﺻﺧﺷ ﺕﺎﺑﺎﺻﺇ ﻰﻟﺇ ﻁﻼﺧﻟﺍ ﺔﻠﺳﺑ ﻝﺎﺻﺗﻻﺍ ﻱﺩﺅﻳ ﺩﻗ

.ﻁﻘﻓ ﻁﻠﺧﻟﺍ ﺔﻳﻭﺎﺣ ﻲﻓ ﺎﻬﻛﻳﺭﺣﺗﻭ ﺓﺍﺩﻷﺍ ﻝﻳﻐﺷﺗﺑ ﻡﻗ (ﺭ

.ﻪﻳﻓ ﻡﻛﺣﺗﻟﺍ ﻥﻛﻣﻳ ﻻ ﻝﻛﺷﺑ ﺭﻭﺩﺗ ﻭﺃ ﻁﻼﺧﻟﺍ ﺔﻠﺳ ﻲﻧﺣﻧﺗ ﺩﻗ

ﺔﻣﺩﺧﻟﺍ (

ﺕﺎﻁﺎﻳﺗﺣﻻﺍ

.ﻁﻠﺧﻟﺍ

5

(OFF) ﻝﻳﻐﺷﺗﻟﺍ ﻑﺎﻘﻳﺇ ﺡﺎﺗﻔﻣ

ﻲﺋﺎﺑﺭﻬﻛﻟﺍ ﺫﻔﻧﻣﻟﺍ ﻥﻣ ﺫﺧﺄﻣﻟﺍ ﺱﺑﺎﻗ ﻝﺻﻓﺍ

.ﺭﺎﺟﻔﻧﻼﻟ ﺔﻠﺑﺎﻗ ﺩﺍﻭﻣ ﻥﻣ ﺏﺭﻘﻟﺎﺑ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ 1

ﺯﺎﻬﺟﻟﺍ ﻡﺍﺩﺧﺗﺳﺍ ﺩﻧﻋ ﺔﻣﺯﻼﻟﺍ ﺕﺎﻁﺎﻳﺗﺣﻻﺍ

.(ﻝﺎﻌﺗﺷﻼﻟ ﺔﻠﺑﺎﻗ ﺭﻳﻏ ﺕﺎﺑﻳﺫﻣﻟﺍ ،ﻝﺎﺛﻣﻟﺍ ﻝﻳﺑﺳ ﻰﻠﻋ)

.ﺓﺩﻋﺎﺻﺗﻣﻟﺍ ﺓﺭﺧﺑﻷﺍ ﻝﻌﺷﻳ ﺩﻗ ﻱﺫﻟﺍﻭ ﺭﺭﺷﻟﺍ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺞﺗﻧﺗ

(ﺝﻭﺩﺯﻣﻟﺍ ﻝﺯﻌﻟﺍ) II ﺔﺋﻓ ﺓﺩﻋ

ﺩﺍﺭﻣﻟﺍ ﺩﺍﻭﻣﻟﺍ ﻝﺧﺍﺩ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻁﻘﺳﺗ ﻥﺃ ﻱﺭﻭﺭﺿﻟﺍ ﻥﻣ ﻥﺎﻛ ﺍﺫﺇ

ﻝﻳﻛﻭﺑ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺹﺣﻓﺍﻭ ﻝﺎﺣﻟﺍ ﻲﻓ ﺱﺑﺎﻘﻟﺍ ﺏﺣﺳﺍ ،ﺎﻬﺟﺯﻣ

2

.ﻊﻳﺑﻟﺍ ﺩﻌﺑ ﺎﻣ ﺔﻣﺩﺧ

ﻱﺩﺅﺗ ﺩﻗﻭ ﺎﻬﻔﻠﺗ ﻲﻓ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺕﻗﺭﺗﺧﺍ ﻲﺗﻟﺍ ﺓﺩﺎﻣﻟﺍ ﺏﺑﺳﺗﺗ ﻥﺃ ﻥﻛﻣﻳ

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻ ﻉﻭﻗﻭ ﻰﻟﺇ

ﻊﺿﻭ ﺭﻳﻓﻭﺗﺑ ﻡﻗﻭ ﻥﻳﺩﻳﻟﺍ ﺎﺗﻠﻛﺑ ﺕﺎﺑﺛﺑ ﻪﻛﺳﻣﺍ ،ﺯﺎﻬﺟﻟﺍ ﻊﻣ ﻝﻣﻌﻟﺍ ﺩﻧﻋ

3

.ﻥﻣﺁ

.ﻥﻳﺩﻳﻟﺍ ﺎﺗﻠﻛﺑ ﺎﻬﺑ ﻙﺎﺳﻣﻹﺍ ﺩﻧﻋ ﻥﻣﺁ ﻊﺿﻭ ﻲﻓ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻥﻭﻛﺗ

.ﺱْﻭُﺗﺳَﺑْﺳﻷﺍ ﻰﻠﻋ ﻱﻭﺗﺣﺗ ﻲﺗﻟﺍ ﺩﺍﻭﻣﻟﺍ ﻊﻣ ﻝﻣﻌﺗ ﻻ

.ﺔﻧﻁﺭﺳﻣﻟﺍ ﺩﺍﻭﻣﻟﺍ ﻥﻣ ﺱْﻭُﺗﺳَﺑْﺳﻷﺍ ﺭﺑﺗﻌﻳ

10

٢

4

Page 11

ﺔﻴﺑﺮﻌﻟا

.ﻥﻳﻌﻠﻟ ﻲﻗﺍﻭﻟﺍ ﻉﺎﻧﻘﻟﺍ ءﺍﺩﺗﺭﺎﺑ ﺎًﻣﺋﺍﺩ ﻡﻗ .ﻥﺎﻣﻷﺍ ﺕﺍﻭﺩﺃ ﻡﺩﺧﺗﺳﺍ (ﺏ

ﺔﻳﺫﺣﺃ ﻭﺃ ﺭﺎﺑﻐﻟﺍ ﻥﻣ ﻲﻗﺍﻭﻟﺍ ﻉﺎﻧﻘﻟﺍ ﻝﺛﻣ ﺔﻳﺎﻣﺣﻟﺍ ﺕﺍﻭﺩﺃ ﻝﻣﻌﺗﺳ

ﻊﻣﺳﻟﺍ ﺔﻳﺎﻣﺣ ﺓﺯﻬﺟﺃ ﻭﺃ ﺔﺑﻠﺻ ﺔﻌﺑﻗ ﻭﺃ ﻕﻻﺯﻧﻼﻟ ﺓﺩﺎﺿﻣﻟﺍ ﻥﺎﻣﻷﺍ

ﺕﻻﺎﻣﺗﺣﺍ ﻝﻳﻠﻘﺗ ﻰﻠﻋ ﺔﻧﻳﻌﻣ ﻑﻭﺭﻅ ﻲﻓ ﺎﻬﻣﺍﺩﺧﺗﺳﺍ ﻡﺗﻳ ﻲﺗﻟﺍﻭ

.ﺔﻳﺻﺧﺷ ﺕﺎﺑﺎﺻﻹ ﺽﺭﻌﺗﻟﺍ

ﻊﺿﻭﻟﺍ ﻲﻓ ﺡﺎﺗﻔﻣﻟﺍ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ .ﺩﻭﺻﻘﻣﻟﺍ ﺭﻳﻏ ﻝﻳﻐﺷﺗﻟﺍ ﻊﻧﻣ (ﺕ

ﺔﻣﺯﺣ ﻭﺃ/ﻭ ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣﺑ ﻝﻳﺻﻭﺗﻟﺍ ﻝﺑﻗ ﻝﻳﻐﺷﺗﻟﺍ ﻑﺎﻘﻳﺇ

.ﺓﺍﺩﻷﺍ ﻝﻣﺣ ﻭﺃ ﻁﺎﻘﺗﻟﻻﺍﻭ ،ﺔﻳﺭﺎﻁﺑﻟﺍ

ﻭﺃ ﺡﺎﺗﻔﻣﻟﺍ ﻲﻓ ﻙﻌﺑﺻﺇ ﺩﻭﺟﻭ ﻊﻣ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻣﺣ ﻱﺩﺅﻳ

ﻝﻳﻐﺷﺗﻟﺍ ﻊﺿﻭ ﻲﻓ ﺡﺎﺗﻔﻣﻟﺍ ﺎﻬﻳﻓ ﻥﻭﻛﻳ ﻲﺗﻟﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ

.ﺙﺩﺍﻭﺣ ﻉﻭﻗﻭ ﻝﺎﻣﺗﺣﺍ ﻰﻟﺇ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻝﺑﻗ ﻁﺑﺭﻟﺍ ﺡﺎﺗﻔﻣ ﻭﺃ ﻁﺑﺿﻟﺍ ﺩﺩﻋ ﻉﺯﻧﺍ (ﺙ

ﻥﻣ ﻙﺭﺣﺗﻣﻟﺍ ءﺯﺟﻟﺍ ﺭﺎﺳﻳ ﻰﻠﻋ ﻁﺑﺿ ﺡﺎﺗﻔﻣ ﻭﺃ ﻁﺑﺭ ﺡﺎﺗﻔﻣ ﺩﻭﺟﻭ

.ﺔﻳﺻﺧﺷ ﺔﺑﺎﺻﺇ ﺙﻭﺩﺣ ﻰﻟﺇ ﻱﺩﺅﻳ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

ﻥﻳﺑﻭ ﻙﻧﻳﺑ ﺔﺑﺳﺎﻧﻣ ﺔﻓﺎﺳﻣ ﻙﺭﺗﺍ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻥﻣ ﺏﺭﺗﻘﺗ ﻻ (ﺝ

.ﺕﺎﻗﻭﻷﺍ ﻊﻳﻣﺟ ﻲﻓ ﻙﻧﺯﺍﻭﺗ ﻰﻠﻋ ﻅﻓﺎﺣﻭ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

ﻲﻓ ﻝﺿﻓﺃ ﻝﻛﺷﺑ ﺯﺎﻬﺟﻟﺍ ﻰﻠﻋ ﺓﺭﻁﻳﺳﻟﺍ ﻥﻣ ﻙﻟﺫ ﻙﻟ ﺢﻣﺳﻳﺳ

.ﺔﻌﻗﻭﺗﻣﻟﺍ ﺭﻳﻏ ﻑﻗﺍﻭﻣﻟﺍ

ﺎﻬﺑ ﻭﺃ ﺔﺿﺎﻔﺿﻓ ﺱﺑﻼﻣ ﻱﺩﺗﺭﺗ ﻻ .ﺔﺑﺳﺎﻧﻣ ﺱﺑﻼﻣ ءﺍﺩﺗﺭﺎﺑ ﻡﻗ (ﺡ

ءﺍﺯﺟﻷﺍ ﻥﻋ ﻙﺳﺑﻼﻣﻭ ﻙﺭﻌﺷ ﺩﻌﺑﺍ .ﻲﻠﺣ ﻭﺃ ﺔﺑﺋﺎﺳ ﻑﺍﺭﻁﺃ

.ﺔﻛﺭﺣﺗﻣﻟﺍ

ﻲﻠﺣﻟﺍ ﻭﺃ ﻑﺍﺭﻁﺃ ﺎﻬﺑ ﻲﺗﻟﺍ ﻭﺃ ﺔﺿﺎﻔﺿﻔﻟﺍ ﺱﺑﻼﻣﻟﺍ ﻙﺑﺷﺎﺗﺗ ﺩﻗ

.ﺏﺎﻘﺛﻣﻠﻟ ﺔﻛﺭﺣﺗﻣﻟﺍ ءﺍﺯﺟﻷﺎﺑ ﻝﻳﻭﻁﻟﺍ ﺭﻌﺷﻟﺍﻭﺃ

ﻡﺗﻳﻭ ﺔﻠﺻﺗﻣ ﻥﻣ ﺩﻛﺄﺗﻓ .ﺭﺎﺑﻐﻟﺍ ﻊﻳﻣﺟﺗﻭ ﻁﻔﺷ ﺯﺎﻬﺟ ﺏﻳﻛﺭﺗ ﺯﺎﺟ ﻥﺇ (ﺥ

.ﻡﻳﻠﺳ ﻝﻛﺷﺑ ﺎﻬﻣﺍﺩﺧﺗﺳﺍ

ﻥﻋ ﺔﻣﺟﺎﻧﻟﺍ ﺭﻁﺎﺧﻣﻟﺍ ﻝﻳﻠﻘﺗ ﻰﻟﺇ ﺭﺎﺑﻐﻟﺍ ﻊﻳﻣﺟﺗ ﻡﺍﺩﺧﺗﺳﺍ ﻱﺩﺅﻳ ﺩﻗ

.ﺭﺎﺑﻐﻟﺍ

ﻥﺃ ﺕﺍﻭﺩﻸﻟ ﺭﺭﻛﺗﻣﻟﺍ ﻡﺍﺩﺧﺗﺳﻻﺍ ﺔﺟﻳﺗﻧ ﺔﺑﺳﺗﻛﻣﻟﺍ ﺔﻔﻟُﻷﺍ ﻉﺩﺗ ﻻ (ﺩ

.ﺓﺍﺩﻷﺎﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻣﻼﺳﻟﺍ ﺉﺩﺎﺑﻣﻟ ﻝﻫﺎﺟﺗﻣﻭ ٍﻝﺎﺑﻣ ﺭﻳﻏ ﻙﻠﻌﺟﺗ

.ﺔﻳﻧﺎﺛﻟﺍ ﻥﻣ ءﺯﺟ ﻝﻼﺧ ﺭﻳﻁﺧ ﺡﺭﺟ ﻲﻓ ﻝﺎﻣﻫﻹﺍ ﺏﺑﺳﺗﻳ ﺩﻗ

:ﺎﻬﺑ ﺔﻳﺎﻧﻌﻟﺍﻭ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﺍ ﺔﻘﻳﺭﻁ (

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺍﻭ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﺍ ﻲﻓ ﻁﺭﻔﺗ ﻻ (ﺃ

.ﻪﺑ ﻡﻭﻘﺗ ﻱﺫﻟﺍ ﻝﻣﻌﻠﻟ ﺔﺑﺳﺎﻧﻣﻟﺍ

ﻙﺩﻋﺎﺳﻳ ﺍﺫﻫ ﻥﺈﻓ ﻙﻟﺫﻟ ﺔﺻﺻﺧﻣﻟﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻙﻣﺍﺩﺧﺗﺳﺍ ﺩﻧﻋ

ﻡﺗ ﻲﺗﻟﺍ ﺔﻣﻬﻣﻠﻟ ًﺎﻌﺑﺗ ًﺎﻧﻣﺃ ﺭﺛﻛﺃﻭ ﻝﺿﻓﺃ ﺔﺟﻳﺗﻧ ﻰﻠﻋ ﻝﻭﺻﺣﻟﺍ ﻰﻠﻋ

.ﺎﻬﻟ ﺏﺎﻘﺛﻣﻟﺍ ﻡﻳﻣﺻﺗ

ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ ﻝﻣﻌﻟﺍ ﻥﻋ ﻝﻳﻐﺷﺗﻟﺍ ﺡﺎﺗﻔﻣ ﻝﻁﻌﺗ ﺔﻟﺎﺣ ﻲﻓ (ﺏ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﺎﻬﺑ ﺹﺎﺧﻟﺍ ﻝﻳﻐﺷﺗﻟﺍ ﺡﺎﺗﻔﻣ ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﻥﻛﻣﻳ ﻻ ﺔﻳﺋﺎﺑﺭﻬﻛ ﺓﺩﻋ ﻱﺃ

.ﺡﺎﺗﻔﻣﻟﺍ ﺍﺫﻫ ﺡﻼﺻﺇ ﺏﺟﻳﻭ ﺎﻬﻣﺍﺩﺧﺗﺳﺍ ﺩﻧﻋ ًﺍﺭﻁﺧ ﻝﻛﺷﺗ ﺎﻬﻧﺈﻓ

ﺔﻳﺭﺎﻁﺑﻟﺍ ﺔﻣﺯﺣ ﺔﻟﺍﺯﺇ ﻭﺃ/ﻭ ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻥﻣ ﺱﺑﺎﻘﻟﺍ ﻝﺻﻔﺑ ﻡﻗ (ﺕ

ﺕﻼﻳﺩﻌﺗ ﻱﺃ ﻝﻣﻋ ﻝﺑﻗ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻥﻣ (ﻙﻔﻠﻟ ﺔﻠﺑﺎﻗ ﺕﻧﺎﻛ ﺍﺫﺇ)

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻥﻳﺯﺧﺗ ﻭﺃ ﺕﺎﻘﺣﻠﻣﻟﺍ ﺭﻳﻳﻐﺗ ﻭﺃ

ﺭﻳﻏ ﻝﻛﺷﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻩﺫﻫ ﻁﺎﻳﺗﺣﻻﺍ ﺕﺍءﺍﺭﺟﺇ ﻊﻧﻣﺗ

.ﺩﻭﺻﻘﻣ

ﻝﻭﺎﻧﺗﻣ ﻥﻋ ًﺃﺩﻳﻌﺑ ﺔﻣﺩﺧﺗﺳﻣ ﺭﻳﻐﻟﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻥﻳﺯﺧﺗﺑ ﻡﻗ (ﺙ

ﻝﻳﻐﺷﺗ ﻥﻋ ﺓﺭﻛﻓ ﻪﻳﺩﻟ ﺱﻳﻟ ﺹﺧﺷ ﻱﻷ ﺢﻣﺳﺗ ﻻﻭ ﻝﺎﻔﻁﻷﺍ

.ﺎﻬﻠﻳﻐﺷﺗ ﻭﺃ ﺕﺍﻭﺩﻷﺍ ﻩﺫﻫ ﻥﻣ ﺏﺍﺭﺗﻗﻻﺎﺑ ﺏﺎﻘﺛﻣﻟﺍ

ﻥﻳﺑﺭﺩﻣ ﺭﻳﻐﻟﺍ ﺹﺎﺧﺷﻷﺍ ﻱﺩﻳﺃ ﻲﻓ ﺓﺭﻭﻁﺧ ﻝﺛﻣﺗ ﻝﻳﻐﺷﺗﻟﺍ ﺕﺍﻭﺩﺃ

.ﺎﻬﻳﻠﻋ

ﺔﻳﺣﺎﻧ ﻥﻣ ًﺍﺩﻳﺟ ﺎﻬﺻﺣﻔﺑ ﻡﻗ .ﺕﺎﻘﺣﻠﻣﻟﺍﻭ ﺔﻳﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺔﻧﺎﻳﺻ (ﺝ

ءﺯﺟ ﻱﺃ ﻲﻓ ﺭﺳﻛ ﻱﺃ ﺩﻭﺟﻭ ﻭﺃ ﺔﻛﺭﺣﺗﻣﻟﺍ ءﺍﺯﺟﻷﺍ ﻁﺑﺍﺭﺗ ﻯﺩﻣ

ﺕﺍﻭﺩﺄﺑ ﻑﻠﺗ ﺙﻭﺩﺣ ﺔﻟﺎﺣ ﻲﻓ .ﺎﻬﻠﻳﻐﺷﺗ ﻰﻠﻋ ﺭﺛﺅﻳ ﺎﻣﺑ ﺎﻬﺋﺍﺯﺟﺃ ﻥﻣ

.ﻡﺍﺩﺧﺗﺳﻻﺍ ﻝﺑﻗ ﺎﻬﺣﻼﺻﺇ ﺏﺟﻳ ﻝﻳﻐﺷﺗﻟﺍ

ﺭﻳﻏ ﻝﻛﺷﺑ ﺔﻧﺎﻳﺻﻟﺍ ﺔﻳﻠﻣﻌﺑ ﻡﺎﻳﻘﻟﺍ ﻭﺃ ﻝﻳﻐﺷﺗﻟﺍ ﺕﺍﻭﺩﺃ ﺔﻧﺎﻳﺻ ﻡﺩﻋ

.ﺙﺩﺍﻭﺣﻟﺍ ﻥﻣ ﺭﻳﺛﻛﻟﺍ ﺙﻭﺩﺣ ﻰﻟﺇ ﻱﺩﺅﻳ ﺢﻳﺣﺻ

ﺔﻔﻳﻅﻧﻭ ﺓﺩﺎﺣ ﻊﻳﻁﻘﺗﻟﺍ ﺕﺍﻭﺩﺃ ﻰﻠﻋ ﻅﺎﻔﺣﻟﺍ ﻰﺟﺭﻳ (ﺡ

ﻝﻬﺳﻳ ﺙﻳﺣﺑ ﻑﺍﻭﺣﻟﺍ ﺓﺩﺎﺣ ﻊﻳﻁﻘﺗﻟﺍ ﺕﺍﻭﺩﺃ ﻰﻠﻋ ﻅﺎﻔﺣﻟﺍ ﻰﺟﺭﻳ

.ﺎﻬﻳﻓ ﻡﻛﺣﺗﻟﺍ

ﻙﻟﺫ ﺭﻳﻏﻭ ﺓﺩﻌﻟﺍ ءﺍﺯﺟﺃﻭ ،ﺕﺎﻘﺣﻠﻣﻟﺍﻭ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺍ (ﺥ

ﻑﻭﺭﻅ ﺭﺎﺑﺗﻋﻻﺍ ﻲﻓ ﻊﺿﻭﻟﺍ ﻊﻣ ،ﺕﺎﻣﻳﻠﻌﺗﻟﺍ ﻩﺫﻫ ﻊﻣ ﻕﻓﺍﻭﺗﻳ ﺎﻣﻳﻓ

.ﺎﻬﻘﻳﻘﺣﺗ ﺏﻭﻠﻁﻣﻟﺍ ﻝﺎﻣﻋﻷﺍﻭ ﻝﻣﻌﻟﺍ

ﻰﻟﺇ ﺎﻬﻟ ﺔﺻﺻﺧﻣﻟﺍ ﺭﻳﻏ ﺽﺍﺭﻏﻸﻟ ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻡﺩﺧﺗﺳﺍ ﻱﺩﺅﻳ ﺩﻗ

.ﺭﻳﻁﺧ ﻑﻗﻭﻣ ﺩﻭﺟﻭ

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺔﻣﻼﺳﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻣﺎﻌﻟﺍ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ

ﺕﺎﻔﺻﺍﻭﻣﻟﺍﻭ ،ﺕﺎﺣﻳﺿﻭﺗﻟﺍﻭ ،ﺕﺎﻣﻳﻠﻌﺗﻟﺍﻭ ،ﻥﺎﻣﻷﺍ ﺕﺍﺭﻳﺫﺣﺗ ﻝﻛ ﺓءﺍﺭﻘﺑ ﻡﻗ

ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛ ﺔﻣﺩﺻ ﻲﻓ ﻩﺎﻧﺩﺃ ﺓﺩﺭﺳﻣﻟﺍ ﺕﺎﻣﻳﻠﻌﺗﻟﺍ ﻉﺎﺑﺗﺍ ﻲﻓ ﻝﺷﻔﻟﺍ ﺏﺑﺳﺗﻳ ﺩﻗ

.ًﻼﺑﻘﺗﺳﻣ ﺎﻬﻳﻟﺇ ﻉﻭﺟﺭﻠﻟ ﺕﺎﻣﻳﻠﻌﺗﻟﺍﻭ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ ﺔﻓﺎﻛ ﻅﻔﺣﺍ

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻰﻟﺇ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ ﻲﻓ "ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ" ﺢﻠﻁﺻﻣ ﺭﻳﺷﻳ

ﺓﺩﻌﻟﺍ ﻭﺃ ﻙﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻳﺳﻳﺋﺭﻟﺍ ﻝﻳﻐﺷﺗﻟﺍ ﺕﻼﺻﻭﻣ ﻝﻣﻌﺗ ﻲﺗﻟﺍ (ﺔﻳﻛﻠﺳﻟﺍ)

.ﺔﻳﺭﺎﻁﺑﻟﺎﺑ ﻝﻣﻌﺗ ﻲﺗﻟﺍ (ﺔﻳﻛﻠﺳﻼﻟﺍ) ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﺏﺑﺳﺗﺗ ﺓءﺎﺿﻣ ﺭﻳﻐﻟﺍ ﻝﻣﻌﻟﺍ ﺕﻻﺎﺟﻣﻭ ﻝﻣﻌﻟﺍ ﻥﺎﻛﻣ ﻲﻓ ﻰﺿﻭﻔﻟﺎﻓ

.ﻙﻠﻐﺷ ﻥﺎﻛﻣ ﺓءﺎﺿﺇ ﻥﺳﺣﻭ ﺔﻓﺎﻅﻧ ﻰﻠﻋ ﻅﻓﺎﺣ (ﺃ

ﺩﻭﺟﻭ ﻲﻓ ﻱﺃ ﺔﻳﺭﺎﺟﻔﻧﺍ ءﺍﻭﺟﺃ ﻲﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗﺑ ﻡﻘﺗ ﻻ (ﺏ

.ﺭﺎﺑﻏ ﻭﺃ ﻝﺎﻌﺗﺷﻼﻟ ﺔﻠﺑﺎﻗ ﺕﺍﺯﺎﻏ ﻭﺃ ﻝﺋﺍﻭﺳ

.ﺔﻧﺧﺩﻷﺍ ﺭﺎﺑﻏ ﻝﺎﻌﺷﺇ ﻰﻠﻋ ﻝﻣﻌﺗ ﺓﺭﺍﺭﺷ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺙﺩﺣﺗ

ﻝﺎﻔﻁﻷﺍ ﻝﻭﺎﻧﺗﻣ ﻥﻋ ﺓﺩﻳﻌﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻥﻭﻛﺗ ﻥﺃ ﻰﻠﻋ ﻅﻓﺎﺣ (ﺕ

ﻙﺩﻘﻓ ﻰﻟﺇ ﻱﺩﺅﺗ ﻥﺃ ﻥﻛﻣﻣﻟﺍ ﻥﻣ ﺕﻳﺗﺷﺗﻟﺍ ﻝﺎﻛﺷﺃ ﻥﻣ ﻝﻛﺷ ﻱﺃ

ﺱﺑﺎﻘﻟﺍ ﻝﻳﺩﻌﺗ ﺭﻅﺣﻳ ،ءﺎﺑﺭﻬﻛﻟﺍ ﺫﻔﻧﻣﺑ ﺱﺑﺎﻘﻟﺍ ﻝﻳﺻﻭﺗ ﺏﺟﻳ (ﺃ

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻊﻣ ﺊﻳﺎﻬﻣ ﺱﺑﺎﻗ ﻱﺃ ﻡﺩﺧﺗﺳﺗ ﻻ .ﺔﻘﻳﺭﻁ ﻱﺎﺑ

4

ﺭﻁﺧ ﻥﻣ ﺔﻣﺋﻼﻣﻟﺍ ﺱﺑﺎﻘﻣﻟﺍﻭ ﺎﻫﺭﻳﻳﻐﺗ ﻡﺗﻳ ﻡﻟ ﻲﺗﻟﺍ ﺱﺑﺍﻭﻘﻟﺍ ﺽﻔﺧﺗ

. ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺕﺎﻣﺩﺻﻟﺍ ﺙﻭﺩﺣ

ﺏﻳﺑﺎﻧﻷﺍ ﻝﺛﻣ ﺔﻳﺿﺭﻷﺍ ﺢﻁﺳﻷﺍ ﻊﻣ ﻱﺩﺳﺟﻟﺍ ﺱﻣﻼﺗﻟﺍ ﺏﻧﺟﺗ (ﺏ

.ﺩﻗﺍﻭﻣﻟﺍﻭ ﺕﺎﺟﻼﺛﻟﺍﻭ ﺔﻳﺭﺍﺭﺣﻟﺍ ﺕﻻﺩﺎﺑﻣﻟﺍﻭ

ﻙﺎﻧﻫ ﺔﻳﺿﺭﻷﺍ ﺢﻁﺳﻷﺍ ﻙﻠﺗ ﻥﻣ ﻱﻷ ﻙﻣﺳﺟ ﺔﺳﻣﻼﻣ ﺔﻟﺎﺣ ﻲﻓ

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻﻟ ﻙﺿﺭﻌﺗﻟ ﺓﺭﻭﻁﺧ

ﺓﺩﻌﻟﺍ ﻝﺧﺍﺩ ﻰﻟﺇ ءﺎﻣﻟﺍ ﺏﺭﺳﺗ ﻥﺇ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺕﺎﻣﺩﺻﻟﺍ ﺭﻁﺧ ﺩﺍﺩﺯﻳ

.ﺔﺑﻭﻁﺭﻟﺍ ﻭﺃ ﺭﻁﻣﻠﻟ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺽﺭﻌﺗ ﻻ (ﺕ

ﻭﺃ ﻝﻣﺣﻟ ًﺎﻘﻠﻁﻣ ﻪﻠﻣﻌﺗﺳﺗ ﻻ ،(ﻙﻠﺳﻟﺍ) ﻝﺑﺎﻛﻟﺍ ﻝﺎﻣﻌﺗﺳﺍ ءﻲﺳﺗ ﻻ (ﺙ

.ﺱﺑﻘﻣﻟﺍ ﻥﻣ ﺱﺑﺎﻘﻟﺍ ﺏﺣﺳﻟ ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻊﻓﺩ ﻭﺃ ﺩﺷ

ﻑﺍﻭﺣﻟﺍ ﻭﺃ ﺕﻳﺯﻟﺍ ﻭﺃ ﺓﺭﺍﺭﺣﻟﺍ ﺭﺩﺎﺻﻣ ﻥﻋ ًﺍﺩﻳﻌﺑ ﻪﻳﻠﻋ ﻅﻓﺎﺣﻭ

.ﺔﻛﺭﺣﺗﻣﻟﺍ ﺯﺎﻬﺟﻟﺍ ءﺍﺯﺟﺃ ﻭﺃ ﺓﺩﺎﺣﻟﺍ

ﺕﺎﻣﺩﺻﻟﺍ ﺭﻁﺧ ﻥﻣ ﺔﻛﺑﺎﺷﺗﻣﻟﺍ ﻭﺃ ﺔﻔﻟﺎﺗﻟﺍ (ﻙﻼﺳﻷﺍ) ﺕﻼﺑﺎﻛﻟﺍ ﺩﻳﺯﺗ

ﻙﻠﺳ ﻡﺍﺩﺧﺗﺳﺎﺑ ﺢﺻﻧﻳ ،ﺝﺭﺎﺧﻟﺎﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﺔﻟﺎﺣ ﻲﻓ (ﺝ

.ﻲﺟﺭﺎﺧﻟﺍ ﻝﺎﻣﻌﺗﺳﻻﺍ ﻊﻣ ﺏﺳﺎﻧﺗﻳ (ﻝﺑﺎﻛ)

ﻥﻣ ﻝﻳﻠﻘﺗﻠﻟ ﻲﺟﺭﺎﺧﻟﺍ ﻝﺎﻣﻌﺗﺳﻻﺍ ﻊﻣ ﺏﺳﺎﻧﻣ ﻙﻠﺳ ﻡﺍﺩﺧﺗﺳﺎﺑ ﻡﻗ

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻﻟ ﺽﺭﻌﺗﻟﺍ ﺓﺭﻭﻁﺧ

ﺭﻔﻣ ﻻ ﺭﻣﺃ ﺏﻁﺭ ﻥﺎﻛﻣ ﻲﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻥﻭﻛﻳ ﺎﻣﺩﻧﻋ (ﺡ

(RCD)

.

ﻲﻘﺑﺗﻣﻟﺍ ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻠﻟ ﻲﻣﺣﻣﻟﺍ ﺩﻭﺯﻣﻟﺍ ﻡﺩﺧﺗﺳﺎﻓ ،ﻪﻧﻣ

ﺕﺎﻣﺩﺻﺑ ﺔﺑﺎﺻﻹﺍ ﺭﻁﺎﺧﻣ ﻝﻳﻠﻘﺗ ﻰﻠﻋ

ﺓﺩﻌﻟﺍ ﺔﻁﺳﺍﻭﺑ ﻝﻣﻌﻟﺎﺑ ﻡﻗﻭ ﻪﻠﻌﻔﺗ ﺎﻣ ﻰﻟﺇ ﻪﺑﺗﻧﺃﻭ ﺎًﻅﻘﻳ ﻥﻛ (ﺃ

ﻙﺭﻭﻌﺷ ﺔﻟﺎﺣ ﻲﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ .ﻝﻘﻌﺗﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﺩﺍﻭﻣ ﻭﺃ ﺔﻳﻭﺩﺃ ﻭﺃ ﺓﺭﺩﺧﻣ ﺩﺍﻭﻣ ﺭﻳﺛﺄﺗ ﺕﺣﺗ ﺕﻧﻛ ﺍﺫﺇ ﻭﺃ ﺏﻌﺗﻟﺎﺑ

ﻱﺩﺅﻳ ﺩﻗ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﺇ ﺩﻧﻋ ﺓﺩﺣﺍﻭ ﺔﻅﺣﻠﻟ ﻩﺎﺑﺗﻧﻹﺍ ﻡﺩﻋ

.ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻊﻣ ﺔﻣﺩﻘﻣﻟﺍ

.ﺔﺑﺎﺻﺇ ﻭﺃ ،ﻕﻳﺭﺣ

ﻝﻣﻌﻟﺍ ﺔﻘﻁﻧﻣ ﺔﻣﻼﺳ (

.ﺙﺩﺍﻭﺣ ﻉﻭﻗﻭ ﻲﻓ

.ﻙﺑ ﻥﻳﻁﻳﺣﻣﻟﺍ ﻭﺃ

.ﺓﺭﻁﻳﺳﻟﺍ

ﺔﻳﺑﺭﻬﻛﻟﺍ ﺕﺎﻣﺩﺻﻟﺍ ﻥﻣ ﺔﻳﺎﻗﻭﻟﺍ (

.ﺔﻳﺿﺭﻷﺍ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

.ﺔﻳﺑﺭﻬﻛﻟﺍ

RCD

ﻡﺍﺩﺧﺗﺳﺍ ﻝﻣﻌﻳ

ﺔﻳﺻﺧﺷﻟﺍ ﺔﻣﻼﺳﻟﺍ (

.ﺔﻳﻟﻭﺣﻛ

.ﺓﺭﻳﻁﺧ ﺔﺑﺎﺻﺇ ﻰﻟﺇ

ﺭﻳﺫﺣﺗ

1

2

.ﺔﻳﺑﺭﻬﻛ

3

١

11

Page 12

906

Code No. C99254751 Ō

Printed in China

Loading...

Loading...