Page 1

Disc Grinder

Amoladora angular

手提圓盤電磨機

G18MR • G23MR

Handling instructions

Instrucciones de manejo

使用說明書

G23MR

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

使用前務請詳加閱讀。

Page 2

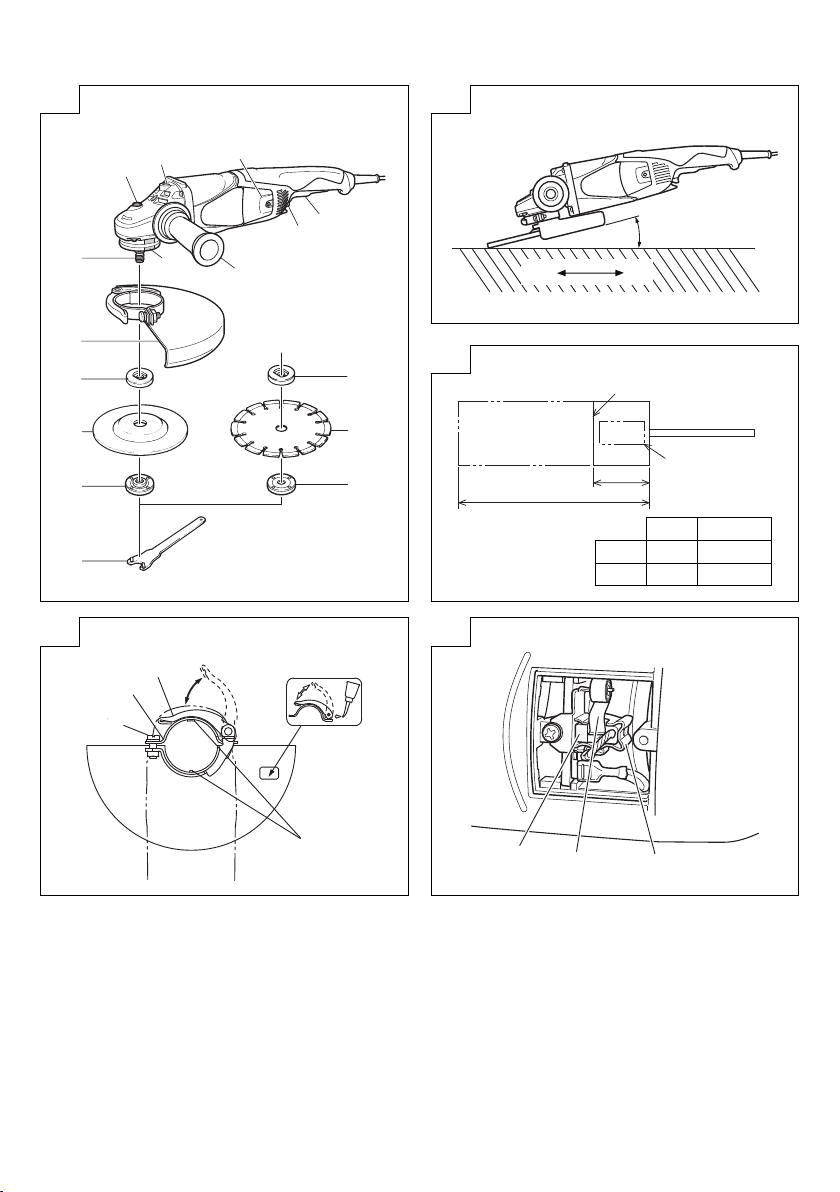

13

1

@

#

$

15 – 30o

AB

4

3

2

5

6

7

8

9

0

7

!

9

4

(

)

22.5 mm

a

q

w

)

61 6.5 mm

89 8.5 mm

a

25

%

^

&

*

2

q

w

e

r

Page 3

English Español

Brush cover Cubierta de la escobilla

1

Socket for side handle Rosca para el asa lateral

2

Push button (Spindle lock)

3

Spindle Eje

4

Across fl ats Distancia entre caras

5

Wheel guard

6

Wheel washer Arandela molar

7

Depressed center wheel Muela de alisado

8

Wheel nut Contratuerca molar

9

Wrench Llave para tuercas

0

Diamond wheel Adiamantado

!

Side handle Asidero lateral

@

Lock button Botón de seguridad

#

Switch Conmutador

$

Lever Palanca

%

Set piece Pieza de ajuste

^

Screw Tornillo

&

Locating pin

*

Wear limit Límite de uso

(

No. of carbon brush No. de carbón de contacto

)

Usual carbon brush Escobilla de carbón usual

q

Auto-stop carbon brush

w

Spring Resorte

e

Brush holder Portaescobilla

r

Botón pulsador

(bloqueo del eje)

Cubierta protectora de

muela

Pasador de

posicionamiento

Escobilla de carbón de

parada

中國語

碳刷蓋

側柄插座

鎖定銷(主軸鎖)

主軸

對邊寬度

輪罩

輪墊圈

砂輪

砂輪螺帽

扳手

金剛石輪

側柄

開關鎖

開關

手柄

設定片

螺絲釘

定位銷

磨損極限

碳刷號

通常碳刷

自動停止碳刷

彈簧

刷握

ﺔﻳﺑﺭﻌﻟﺍ

ﺓﺎﺷﺭﻔﻟﺍ ءﺎﻁﻏ

ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺫﺧﺄﻣ

(ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻋ ﻝﻔﻗ) ﻁﻐﺿﻟﺍ ﺭﺯ

ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻋ

ﺔﻠﺧﺍﺩﺗﻣﻟﺍ ﺢﻁﺳﻷﺍ

ﺔﻠﺟﻌﻟﺍ ءﺎﻗﻭ

ﺔﻠﺟﻌﻟﺍ ﺔﻘﻠﺣ

ﺯﻛﺭﻣﻟﺍ ﺔﻁﻭﻐﺿﻣ ﺔﻠﺟﻋ

ﺔﻠﺟﻌﻟﺍ ﺔﻟﻭﻣﺻ

ﻁﺑﺭﻟﺍ ﺡﺎﺗﻔﻣ

ﺱﺎﻣﻟﺍ ﺓﺭﺎﺳﻛﺑ ﺦﻳﻠﺟﺗ ﺔﻠﺟﻋ

ﻲﺑﻧﺎﺟ ﺽﺑﻘﻣ

ﻝﻔﻘﻟﺍ ﺭﺯ

ﺡﺎﺗﻔﻣ

ﻉﺍﺭﺫ

ﻁﺑﺿﻟﺍ ﺔﻌﻁﻗ

ﺭﺎﻣﺳﻣ

ﺭﺎﻣﺳﻣ ﻊﻗﻭﻣ ﺩﻳﺩﺣﺗ

ﻝﻛﺂﺗﻟﺍ ﺩﺣ

ﻥﻭﺑﺭﻛﻟﺎﺑ ﻝﻘﺻﻟﺍ ﺓﺎﺷﺭﻓ ﻡﻗﺭ

ﺔﻳﺩﺎﻌﻟﺍ ﻥﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻓ

ﺔﻳﺋﺎﻘﻠﺗ ﻥﻭﺑﺭﻛﻟﺎﺑ ﻝﻘﺻ ﺓﺎﺷﺭﻓ

ﻑﻗﻭﺗﻟﺍ

ﺽﺑﺎﻧﻟﺍ

ﺓﺎﺷﺭﻔﻟﺍ ﻝﻣﺎﺣ

3

Page 4

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fi re and/or serious injury.

Save all wa rnings and ins tructions f or future ref erence.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work ar ea s afe ty

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a p ower tool whil e you are tired o r under

the infl uence of drugs, alcohol or medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as dust mask, non-skid

safety shoes , hard h at, or hear ing pro tection u sed for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off position before connecting

to power source and/or battery pack, picking

up or carrying the tool.

4

Carr ying power tools with your fi nger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power to ols are dangero us in the hands of untrained

users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may aff ect the

power toolʼs operation.

If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges a re less likely to bi nd and are easie r to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

Use of the power tool for operations diff erent from

those i ntended coul d result in a haza rdous situati on.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach

of children and infi rm persons.

Page 5

English

SAFETY WARNINGS COMMON FOR GRINDING

OR ABRASIVE CUTTING-OFF OPERATIONS

a) This power tool is intended to function as a grinder

or cut-off tool. Read all safety warnings, instructions,

illustrations and specifi cations provided with this

power tool.

Failure to follow all instructions listed below may result

in electric shock, fi re and/or serious injury.

b) Operations such as sanding, wire brushing or

polishing are not recommended to be performed

with this power tool.

Operations for which the power tool was not designed

may create a hazard and cause personal injury.

c)

D

o not use accessories which are not specifi cally

desi

gned and recommended by the tool manufacturer.

Just because the accessory can be attached to your

power tool, it does not assure safe operation.

d) T

he rated speed of the accessory must be at least

equal to th

Accessories running faster than their rated speed can

break and fl y apart.

e) The outside diameter and the thickness of your

accessory must be within the capacity rating of your

power tool.

Incorrectly sized accessories cannot be adequately

guarded or controlled.

f) Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

fl anges, the arbour hole of accessory must fi t the

locating diameter of the fl ange.

A

ccessories that do not match the mounting hardware

of the power tool will run out of balance, vibrate

excessively an

g) Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheels for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the plane of

the rotating accessory and run the power tool at

maximum no-load speed for one minute.

Damaged accessories will normally break apar t during

this test time.

h)

Wear

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capabl

fragments.

The eye protection must be capable of stopping fl ying

debris generated by various operations. The dust mask

or respirator must be capable of fi ltrating particles

generated by your operation. Prolonged exposure to

high intensit y noise may cause hearing loss.

i) Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment.

Fragments of workpiece or of a broken accessory may

fl y away and cause injur y beyond immediate area of

operation.

j)

Hol

only, when performing an operation where the

cutting accessory may contact hidden wiring or its

own

Cutting accessory contacting a “live” wire may make

exposed metal par ts of the power tool “ live” and could

give the operator an electric shock.

e maximum speed marked on the power tool.

d may cause loss of control.

personal protective equipment. Depending

e of stopping small abrasive or workpiece

d the power tool by insulated gripping surfaces

cord.

k) Position the cord clear of the spinning accessory.

If you lose c ontrol, the co rd may be cut or sna gged and your

hand or arm may be pulled into the spinning accessory.

l) Never lay the power tool down until the accessory

has come to a complete stop.

The spinning accessor y may grab the surface and pull

the power tool out of your control.

m)

Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could

snag your clothing, pulling the accessory into your body.

n) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal may

cause electrical hazards.

o)

Do n

ot operate the power tool near fl ammable

mate

rials.

Sparks could ignite these materials.

p) Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in

electrocution or shock.

KICKBACK AND RELATED WARNINGS

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power tool

to be forced in the direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel that is entering

into the pinch point can dig into the surface of the material

causing the wheel to climb out or kick out. The wheel may

either jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these conditions.

Kickback is the result of po wer tool misuse and/or inc orrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below.

a) Maintain a fi rm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start-up.

The operator can control torque reactions or kickback

forces, if proper precautions are taken.

b) N

ever

Accessory may kickback over your hand.

c) D

Kickback will propel the tool in direction opposite to the

d) Us

Corners, sharp edges or bouncing have a tendency to

e) Do no

place your hand near the rotating accessory.

o not position your body in the area where power to

will move if kickback occurs.

wheel’s movement at the point of snagging.

e special care when working corners, sharp edges

etc. Avoid bouncing and snagging the acc

snag the rotating acces sory and caus e loss of control o r

kickback.

t attach a saw chain woodcarving blade or tooth

saw blade.

Such

bl ad es c re ate fre qu en t ki ck bac k a nd l os s of co ntr o

essory.

ed

ol

l.

SAFETY WARNINGS SPECIFIC FOR GRINDING

AND ABRASIVE CUTTING-OFF OPERATIONS

a) Use only wheel types that are recommended for

your power tool and the specifi c guard designed

for the selected wheel.

Wheels for which the power tool was not designed

cannot be adequately guarded and are unsafe.

5

Page 6

English

b) The grinding surface of centre depressed wheels

must be mounted below the plane of the guard lip.

An improperly mounted wheel that projects through the

plane of the guard lip cannot be adequately protected.

c)

The

guard must be securely attached to the power

tool and positioned for maximum safety, so the

least a

mount of wheel is exposed towards the

operator.

The guard helps to protect the operator from broken

wheel fragments, accidental contact with wheel and

sparks that could ignite clothing.

d) Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel.

Abrasive cut-off wheels are intended for peripheral

grinding, side forces applied to these wheels may

cause them to shatter.

e) Always use undamaged wheel fl anges that are of

correct size and shape for your selected wheel.

Proper wheel fl anges support the wheel thus reducing

the possibility of wheel breakage. Flanges for cut-off

wheels may be diff erent from grinding wheel fl anges.

f) Do not use worn down wheels from larger power

tools.

Wheel intended for larger power tool is not suitable for

the higher speed of a smaller tool and may burst.

ADDITIONAL SAFETY WARNINGS SPECIFIC

FOR ABRASIVE CUTTING-OFF OPERATIONS

a) Do not “jam” the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut.

Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the

cut and the possibility of kickback or wheel breakage.

b) Do not position your body in line with and behind

the rotating wheel.

When the wheel, at the point of operation, is moving

away from your body, the possible kickback may propel

the spinning wheel and the power tool directly at you.

c) When wheel is binding or when interrupting a cut

for any reason, switch off the power tool and hold

the power tool motionless until the wheel comes to

a complete stop. Never attempt to remove the cutoff wheel from the cut while the wheel is in motion

otherwise kickback may occur.

Investigate and take corrective action to eliminate the

cause of wheel binding.

d) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut.

The wheel may bind, walk up or kickback if the power

tool is restarted in the workpiece.

e) Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback.

Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near the

line of cut and near the edge of the workpiece on both

sides of the wheel.

f) Use extra caution when making a “pocket cut” into

existing walls or other blind areas.

The protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

PRECAUTIONS ON USING DISC GRINDER

1. Never operate these power tools without Wheel

Guards.

2. Check that speed marked on the wheel is equal to or

greater than the rated speed of the grinder.

Use only depressed center wheels rated at 80 m/s or

more.

3. Ensure that the wheel dimensions are compatible with

the grinder and that the wheel fi ts the spindle.

4. Abrasive wheels shall be stored and handled with care

in accordance with manufacturer’s instructions.

5. Inspect the depressed center wheel before use, do not

use chipped, cracked or otherwise defective products.

6. Always hold the body handle and side handle of the

power tool fi rmly. Otherwise the counterforce produced

may result in inac curate and even dangerous opera tion.

7. Do not use cutting-off wheels for side grinding.

8. Do not use of separate reducing bushings or adapters

to adapt large hole abrasive wheels.

9. The wheel continues to rotate after the tool is switched

off .

SPECIFICATIONS

Model G18MR G23MR

Voltage (by areas)

*1

Input

No-load speed 8500 min

Wheel

*2

Weight

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 Weight: Only main body

6

*1

Outer dia. 180 mm 230 mm

Inner dia. 22.23 mm

Peripheral speed 80 m/s

(110 V, 220 V, 230 V, 240 V)

2400 W

-1

5.4 kg

6600 min

-1

Page 7

English

STANDARD ACCESSORIES

(1) Wrench ........................................................................1

(2) Side handle ................................................................1

Depressed center wheels are not provided as standard

accessories.

Standard accessories are subject to change without

notice.

APPLICATIONS

○ Removal of casting fi n and fi nishing of various types of

steel, bronze and aluminum materials and castings.

○ G rind ing of we lde d se ctio ns o r se cti ons cut by me ans of

a cutting torch.

○ Grinding of synthetic resins, slate, brick, marble, etc.

○ Cutting of synthetic concrete, stone, brick, marble and

similar materials.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will star t

operating immediately, which could cause a serious

accident.

3. Extension cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capaci ty. The extension cord sho uld be kept as shor t as

practicable.

4. Fitting and adjusting the wheel guard

The wheel guard is a protective device to prevent injury

should the depressed center wheel shatter during

operation. Ensure that the guard is properly fi tted and

fastened before commencing grinding operation.

[Installing and adjusting the wheel guard]

○ Open the lever and insert the locating pin of wheel

guard, bringing it into line with the across fl ats of

packing ground.

○ Then, turn the wheel guard to a desired position (for

use).

○ Close the lever and fi x it. If and when required, carry out

adjustments by tightening or loosening the screw.

○ If the lever does not move smoothly, apply some

lubricating oil to the sliding section between the set

piece and the lever.

○ Fasten the wheel guard at the position where the across

fl ats of the wheel guard positioning pin and packing

ground are aligned (the position where the wheel guard

is inserted), but do not use it.

5. Ensure that the depressed center wheel to be utilized is

the correct type and free of cracks or surface defects.

Also ensure that the depressed center wheel is properly

mounted and the wheel nut is securely tightened. Refer

to the section on “Assembling and Disassembling the

Depressed Center Wheel”.

6. Conducting a trial run

Ensure that the abrasive products is correctly mounted

and tightened before use and run the tool at no-load

for 30 seconds in a safe position, stop immediately if

there is considerable vibration or if other defects are

detected.

If th is condition occur s, check the mac hine to determi ne

the cause.

7. C o nfi rm the spindle lock mechanism

Confi rm that the spindle lock is disengaged by pushing

push button two or three times before switching the

power tool on (See Fig. 1).

8. Fixing the side handle

Screw the side handle into the gear cover.

PRACTICAL GRINDER APPLICATION

1. Pressure

To prolong the life of the machine and ensure a fi rst

class fi nish, it is important that the machine should not

be overloaded by applying too much pressure. In most

appli cations, the we ight of the mach ine alone is su ffi cient

for eff ective grinding. Too much pressure will result in

reduced rotational speed, inferior surface fi nish, and

overloading which could reduce the life of the machine.

2. Grinding angle

Do not apply the entire surface of the depressed center

wheel to the material to be ground. As shown in Fig. 3,

the machine should be held at an angle of 15° – 30° so

that the external edge of the depressed center wheel

contacts the material at an optimum angle.

3. To prevent a new depressed center wheel from digging

into the workpiece, initial grinding should be performed

by drawing the grinder across the workpiece toward the

operator (Fig. 3 direction B). Once the leading edge

of the depressed center wheel is properly abraded,

grinding may be conducted in either direction.

4. Switch operation

Switch ON: Push the locking button forward and then

* For c ontinuous use, press th e switch lever.

Switch OFF: Press and release the switch lever.

5. Precautions immediately after fi nishing operation

Af ter switching off the machine, do not put it down until

the depressed center wheel has come to a complete

stop. Apar t from avoiding serious accidents, this

precaution will reduce the amount of dust and swarf

sucked into the machine.

CAUTION

○ Check that the work piece is properly supported.

○ Ensure that ventilation openings are kept clear when

working in dust y conditions.

If it should become necessary to clear dust, fi rst

disconnect the tool from the mains supply (use nonmetallic objects) and avoid damaging internal par ts.

○ Ensure that sparks resulting from use do not create

a hazard e.g. do not hit persons, or ignite fl ammable

substances.

○ Always use eye and ear protection.

Other personal protective equipment such as dust

mask, gloves, helmet and apron should be worn when

necessary.

If in doubt, wear the protective equipment.

○ When the machine is not use, the power source should

be disconnected.

press the switch lever.

The switch lever is locked by pushing

the locking button forward once again.

(*Subject to change depending on area.)

ASSEMBLING AND DISASSEMBLING THE

DEPRESSED CENTER WHEEL

CAUTION

Be sure to switch OFF and disconnect the attachment

plug from the receptacle to avoid a serious accident.

1. Assembling (Fig. 1)

(1) Turn the machine upside down so that the spindle is

facing upward.

7

Page 8

English

(2) Mount the wheel washer onto the spindle.

(3) Fit the protruding part of the depressed center wheel or

diamond wheel onto the wheel washer.

(4) Screw the wheel nut onto the spindle.

(For diamond wheel assembling, use the wheel nut with

the convex side against the diamond wheel.)

(5) Insert the push button to prevent rotation of the spindle,

and tighten the wheel nut with the accessory wrench,

as shown in Fig.1.

2. Disassembling

Follow the above procedures in reverse.

CAUTION

○ Comfi rm that the depressed center wheel is mounted

fi rmly.

○ Confi rm that the push button is disengaged by pushing

push button two or three times before switching the

power tool on.

MAINTENANCE AND INSPECTION

1. Inspecting the depressed center wheel

Ensure that the depressed center wheel is free of

cracks and surface defects.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, retighten them immediately. Failure to do so

could result in serious hazard.

3. Inspecting the carbon brushes (Fig. 4)

The motor employs carbon brushes which are

consumable parts.

When they become worn to or near the “wear limit”, it

could re sult in motor trouble. Whe n an auto-stop c arbon

brush is equipped, the motor will stop automatically.

At that time, replace both carbon brushes with new

ones which have the same carbon brush numbers

shown in the fi gure. In addition, always keep carbon

brushes clean and ensure that they slide freely within

the brush holders.

4. Replacing carbon brushes (Fig. 5)

<Disassembly>

(1) Loosen the D4 tapping screw retaining the brush cover

and remove the brush cover.

(2) Use the a uxiliar y hexagonal w rench or sm all screwdr iver

to pull up the edge of the spring that is holding down the

carbon brush. Remove the edge of the spring toward

the outside of the brush holder.

(3) Remove the end of the pig-tail on the carbon br ush from

the terminal section of brush holder and then remove

the carbon brush form the brush holder.

<Assembly>

(1) Insert the end of the pig-tail of the carbon brush in the

terminal section of brush holder.

(2) Insert the carbon brush in the brush holder.

(3) Use the a uxiliar y hexagonal w rench or sm all screwdr iver

to return the edge of the spr ing to the head of th e carbon

brush.

(4) Mount the tail cover and tighten the D4 tapping screw.

5. Maintenance of the motor

The motor unit winding is the very “heart ” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

6. Service parts list

CAUTION

Repair, modifi cation and inspection of HiKOKI Power

Tools must be carried out by an HiKOKI Authorized

Service Center.

Thi s Par ts Li st will be hel pful if pr esen ted w ith t he to ol to

the HiKOKI Au thorized Ser vice Center when requ esting

repair or other maintenance.

8

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

countr y must be observed.

MODIFICATIONS

HiKOKI Power Tools are constantly being improved

and modifi ed to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without prior

notice.

NOTE

Due to HiKOKI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

Page 9

Español

ADVERTENCIAS DE SEGURIDAD GENERAL DE

LA HERRAMIENTA ELÉCTRICA

ADVERTENCIA

Lea todas las instrucciones y advertencias de

seguridad.

Si no se siguen las advertencias e instrucciones, podría

producirse una descarga eléctrica, un incendio o daños

graves.

Guarde todas las advertencias e instrucciones para

futura referencia.

El término “herramienta eléctrica” en las advertencias hace

referencia a la herramienta eléctrica que funciona con la

red de suministro (con cable) o a la herramienta eléctrica

que funciona con pilas (sin cable).

1) Seguridad del área de trabajo

a) Mantenga la zona de trabajo limpia y bien

iluminada.

Las zonas desordenadas u oscuras pueden

provocar accidentes.

b) No utilice las herramientas eléctricas en

entornos explosivos como, por ejemplo, en

presencia de líquidos infl amables, gases o

polvo.

Las herramientas eléctricas crean chispas que

pueden infl amar el polvo o los gases.

c) Mantenga a los niños y transeúntes alejados

cuando utilice una herramienta eléctrica.

Las distracciones pueden hacer que pierda el

control.

2) Seguridad eléctrica

a) Los enchufes de las herramientas eléctricas

tienen que ser adecuados a la toma de

corriente.

No modifi que el enchufe.

No utilice enchufes adaptadores con

herramientas eléctricas conectadas a tierra.

Si no se modifi can los enchufes y se utilizan tomas

de corriente adecuadas se reducirá el riesgo de

descarga eléctrica.

b) Evite el contacto corporal con superfi cies

conectadas a tierra como tuberías, radiadores

y frigorífi cos.

Hay mayor riesgo de descarga eléctrica si su

cuerpo está en contacto con el suelo.

c) No exponga las herramientas eléctricas a la

lluvia o a la humedad.

La entrada de agua en una herramienta eléctrica

aumentará el riesgo de descarga eléctrica.

d) No utilice el cable incorrectamente. No utilice el

cable para transportar, tirar de la herramienta

eléctrica o desenchufarla.

Mantenga el cable alejado del calor, del aceite,

de bordes afi lados o piezas móviles.

Los cables dañados o enredados aumentan el

riesgo de descarga eléctrica.

e) Cuando utilice una herramienta eléctrica al aire

libre, utilice un cable prolongador adecuado

para utilizarse al aire libre.

La utilización de un cable adecuado para usarse al

aire libre reduce el riesgo de descarga eléctrica.

f) Si no se puede evitar el uso de una herramienta

eléctrica en un lugar húmedo, utilice un

suministro protegido mediante un dispositivo

de corriente residual (RCD).

El uso de un RCD reduce el riesgo de descarga

eléctrica.

3) Seguridad personal

a) Esté atento, preste atención a lo que hace y

utilice el sentido común cuando utilice una

herramienta eléctrica.

No utilice una herramienta eléctrica cuando

esté cansado o esté bajo la infl uencia de

drogas, alcohol o medicación.

La distracción momentánea cuando utiliza

herramientas eléctricas puede dar lugar a lesiones

personales graves.

b) Utilice un equipo de protección. Utilice siempre

una protección ocular.

El equipo de protección como máscara para el

polvo, zapatos de seguridad antideslizantes, casco

o protección auditiva utilizado en las situaciones

adecuadas reducirá las lesiones personales.

c) Evite un inicio involuntario. Asegúrese de que

el interruptor está en “off ” antes de conectar

la herramienta a una fuente de alimentación o

batería, cogerla o transportarla.

E l t ran sp or te de her ra mi en ta s el éc tr ic as c on el de do

en el interruptor o el encendido de herramientas

eléctricas con el interruptor encendido puede

provocar accidentes.

d) Retire las llaves de ajuste antes de encender la

herramienta eléctrica.

Si se deja una llave en una pieza giratoria de la

herramienta eléctrica podrían producirse lesiones

personales.

e) No se extralimite. Mantenga un equilibrio

adecuado en todo momento.

Esto permite un mayor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase adecuadamente. No lleve prendas

sueltas o joyas. Mantenga el pelo, la ropa y los

guantes alejados de las piezas móviles.

La ropa suelta, las joyas y el pelo largo pueden

quedar atrapados en las piezas móviles.

g) Si se proporcionan dispositivos para

la conexión de extracción de polvo e

instalaciones de recogida, asegúrese de que

están conec tados y se util izan adecu adamente.

La utilización de un sistema de recogida de polvo

puede reducir los riesgos relacionados con el polvo.

4) Utilización y mantenimiento de las herramientas

eléctricas

a)

No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación.

La herramienta eléctrica correcta trabajará mejor y

de forma más segura si se util iza a la velocidad para

la que fue diseñada.

b) No utilice la herramienta eléctrica si el

interruptor no la enciende y apaga.

Las herramientas eléctricas que no pueden

controlarse con el interruptor son peligrosas y

deben repararse.

c) Desconecte el enchufe de la fuente eléctrica o

la batería de la herramienta eléctrica antes de

hacer ajustes, cambiar accesorios o almacenar

herramientas eléctricas.

Estas m edidas de seguridad preventivas reducen el

riesgo de que la herramienta eléctrica se ponga en

marcha accidentalmente.

d) Guarde las herramientas eléctricas que no

se utilicen fuera del alcance de los niños,

y no permita que utilicen las herramientas

eléctricas personas no familiarizadas con las

mismas o con estas instrucciones.

Las herramientas eléctricas son peligrosas si son

utilizadas por usuarios sin formación.

9

Page 10

Español

e)

Realice el mantenimiento de las herramientas

eléctricas. Compruebe si las piezas móviles

están mal alineadas o unidas, si hay alguna

pieza rota u otra condición que pudiera afe ctar al

funcionamiento de las herramientas eléctricas.

Si la herramienta eléctrica está dañada, llévela

a reparar antes de utilizarla.

Se producen muchos accidentes por no realizar un

mantenimiento correcto de las herramientas eléctricas.

f) Mantenga las herramientas de corte afi ladas y

limpias.

Las herramientas de corte correctamente

mantenidas con los bordes de cor te afi lados son

más fáciles de controlar, y existe menor riesgo de

que se atasquen.

g) Utilice la herramienta eléctrica, los accesorios

y las brocas de la herramienta, etc. de acuerdo

con estas instrucciones, teniendo en cuenta

las condiciones laborales y el trabajo que se va

a realizar.

La utilización de la herramienta eléctrica para

operaciones diferentes a las previstas podría dar

lugar a una situación peligrosa.

5) Revisión

a) Solicite a un experto cualifi cado que revise la

herramienta eléctrica y que utilice solo piezas

de repuesto idénticas.

Esto garantizará el mantenimiento de la seguridad

de la herramienta eléctrica.

PRECAUCIÓN

Mante nga a los niños y a l as persona s enfermas al ejadas.

Cuando no se utilicen, las herramientas deben

almacenarse fuera del alcance de los niños y de las

personas enfermas.

ADVERTENCIAS COMUNES DE SEGURIDAD

PARA LAS OPERACIONES DE MOLIDO O

CORTE ABRASIVO

a) Esta herramienta eléctrica está diseñada para

utilizarse como amoladora o herramienta de

corte. Lea todas las advertencias de seguridad,

instrucciones, ilustraciones y especifi caciones

incluidas con esta herramienta.

Si no se siguen las instrucciones indicadas a

continuación podría producirse una descarga eléctrica,

un incendio o daños graves.

b) No se recomienda realizar operaciones como lijado,

cepillado metálico o pulido con esta herramienta

eléctrica.

Las operaciones para las que no se diseñó la

herramienta eléctrica podrían producir un riesgo y

causar daños personales.

c) No utilice accesorios que no estén diseñados

y estén recomendados específi camente por el

fabricante de la herramienta.

El hecho de que el accesorio pueda acoplarse en la

herramienta eléctrica no garantiza un funcionamiento

seguro.

d) La velocidad nominal del accesorio debe ser al

menos igual a la velocidad máxima marcada en la

herramienta eléctrica.

La utilización de accesorios a una velocidad superior a

su veloci dad nominal po dría provocar que se r ompieran

o se descompusieran.

e) El diámetro exterior y el grosor de su accesorio

deben estar dentro de la clasifi cación de capacidad

de su herramienta eléctrica.

10

Los accesorios de tamaño incorrecto no pueden

supervisarse o controlarse adecuadamente.

f) El montaje roscado de accesorios debe coincidir

con la rosca del husillo de la amoladora. Para los

accesorios instalados por medio de bridas, el

orifi cio del mandril del accesorio debe coincidir

con el diámetro de posicionamiento de la brida.

Los accesorios que no coincidan con la estructura de

montaje de la herramienta eléctrica se desequilibrarán,

vibrar án en exceso y pueden c ausar una pérd ida de control.

g)

No utilice accesorios dañados. Antes de cada uso, revise

el accesorio, comprobando aspectos tales como si las

ruedas abrasivas tienen grietas o roturas, las almohadillas

de respaldo tienen grietas, rasgaduras o desgaste

excesivo o el cepillo metálico está suelto o con el metal

roto. Si se cae la herramienta eléctrica o el accesorio,

compruebe si está dañado o instale un accesorio sin

dañar. Tras inspeccionar e instalar un accesorio, tanto

usted como los viandantes deben alejarse del plano del

accesorio giratorio y utilizar la herramienta eléctrica a

máxima velocidad sin carga durante un minuto.

Los accesorios dañados se romperán durante este

periodo de prueba.

h)

Utilice

un equipo de protección personal.

Dependiendo de la aplicación, utilice protector

facial, gafas protectoras o gafas de seguridad. Si

procede, utilice máscara para polvo, protectores

auditivos, guantes y mono capaz de detener

pequeños fragmentos abrasivos o piezas de trabaj

El protec tor ocula r debe ser ca paz de deten er los desec hos

que salen desprendidos generados por las diferentes

operaciones. La máscara para polvo o respirador debe

ser capaz de fi ltrar par tículas generadas por su operación.

Una exposición prolongada a un ruido de intensidad

elevada podría producir pérdida de audición.

i) Mantenga a los viandantes alejados del área de

trabajo. Toda persona que entre en la zona de

trabajo debe utilizar equipo de protección personal.

Los fragmentos de un trabajo o un accesorio roto

pueden salir despedidos y causar daños más allá del

área de operación inmediata.

j)

Suje

te la herramienta eléctrica solo por las

superfi cies de agarre aisladas cuando realice una

ope

ración en la que el accesorio de corte pueda entrar

en contacto con el cableado oculto o su propio cable.

Si el accesorio de corte entra en contacto con un cable

con corriente, las partes metálicas expuestas de la

herramienta eléctrica pueden transmitir esa corriente y

provocar una descarga eléctrica al operador.

k) Coloque el cable cerca del accesorio giratorio.

Si pierde el control, el cable podría cortarse o engancharse

y la mano o el brazo podrían entrar en el accesorio giratorio.

l)

No c

oloque boca abajo la herramienta eléctrica hasta

que el accesorio se haya parado comple

El accesorio giratorio podría agarrar la superfi cie y

descontrolar la herramienta eléctrica.

m) No ponga en marcha la herramienta eléctrica

cuando la lleve al lado.

Un contacto accidental con el accesorio giratorio podría

enganc har la ropa y el acce sorio podría pr ovocarle lesion es.

n) Limpie regularmente las ranuras de ventilación de

aire de la herramienta eléctrica.

El ventilador del motor extraerá el polvo del interior

de la carcasa, y la acumulación excesiva de metal en

polvo podría producir peligros eléctricos.

o) No utilice la herramienta eléctrica cerca de

materiales infl amables.

Las chispas podrían quemar dichos materiales.

p) No utilice accesorios que requieran refrigerantes

líquidos.

tamente.

o.

Page 11

Español

El uso de agua u otros refrigerantes líquidos podría

provocar electrocución o descargas eléctricas.

RETROCESO Y ADVERTENCIAS

RELACIONADAS

El retroc eso es una reac ción repent ina a una rueda g iratoria,

almohadilla de soporte, cepillo u otro accesorio atrapado

o enganchado. El bloqueo o enganche causa una parada

rápida del accesorio giratorio que, a su vez, hace que la

herramienta eléctrica no controlada vaya en la dirección

opuesta del giro del accesorio en el punto de atasco.

Por ejemplo, si una rueda de abrasión se engancha o

queda atrapada en la pieza de trabajo, el borde de la rueda

que entra en el punto de bloqueo puede hundirse en la

superfi cie del material, provocando que la rueda se salga

o rebote. La rueda puede saltar en dirección al operario

o en sentido contrario, dependiendo de la dirección del

movimiento de la rueda en el punto de bloqueo.

Estas sit uaciones tamb ién pueden provoc ar que las ruedas

abrasivas se rompan.

El retroceso es el resultado de un uso incorrecto o

procedimientos/condiciones de funcionamiento incorrectos

de la herramienta eléctrica, y puede evitarse tomando las

precauciones adecuadas indicadas a continuación.

a) Agarre la herramienta eléctrica con fi rmeza y

coloque el cuerpo y el brazo de forma que le

permitan resistir las fuerzas de retroceso de

la herramienta. Utilice siempre una agarradera

auxiliar, si se incluye, para tener el máximo control

posible sobre el rebote o la reacción del par durante

la puesta en marcha.

El operario puede controlar las reacciones del par o

las fuerzas de retroceso si se toman las precauciones

adecuadas.

b) No coloque nunca la mano cerca del accesorio

giratorio.

Su mano podría recibir el retroceso del accesorio.

c)

No coloque el cuerpo en la zona en la que la herramienta

eléctrica se moverá en caso de producirse retroceso.

El retroceso impulsará la herramienta en dirección

op ue sta al m ovi mie nt o de l a r ued a en el p unt o de blo qu eo.

d) Tenga especial cuidado cuando trabaje con

esquinas, bordes afi lados, etc. Evite que el

accesorio rebote y se bloqueo.

Las esquinas, bordes afi lados o el rebote tienden a

enganchar el ac cesorio giratorio y causan la pérdida de

control y retroceso.

e) No coloque una cuchilla talladora de madera o

cuchilla dentada en la sierra.

Dichas cuchillas suelen provocar retroceso y pérdida

de control.

ADVERTENCIAS DE SEGURIDAD ESPECÍFICAS

PARA LAS OPERACIONES DE MOLIDO Y

CORTE ABRASIVO

a) Utilice solo tipos de ruedas recomendados para

su herramienta eléctrica y el protector específi co

diseñado para la rueda seleccionada.

Las ruedas para las que no se diseñó la herramienta

eléctrica no pueden protegerse adecuadamente y no

son seguras.

b) La superfi cie de molienda de las ruedas presionadas

debe estar montada debajo del plano del labio

protector.

Una rueda mal montada que se proyecta a través del plano

del labi o protector n o puede ser prot egida adecu adamente.

c) La protección debe colocarse con fi rmeza en el

herramienta eléctrica y colocarse para máxima

seguridad, de forma que se exponga al operario a

la cantidad mínima de rueda.

El protector ayuda a proteger al operario de fragmentos

de rueda rota, de un contacto accidental con la rueda y

de las chispas que podrían encender la ropa.

d) Las ruedas deben utilizarse solo para las

aplicaciones recomendadas. Por ejemplo, no

muela con el lado de la rueda de corte.

Las ruedas de corte abrasivas están diseñadas para un

molido periférico. Las fuerzas periféricas aplicadas a

estas ruedas podrían provocar que se rompan.

e)

Uti

lice siempre bridas de ruedas sin dañar con

el tamaño y la forma correctos para la rueda

sel

eccionada.

Las bridas de rueda adecuadas soportan la rueda,

reduciendo la posibilidad de rotura de rueda. Las

bridas para ruedas de corte pueden ser diferentes de

las bridas de rueda de molido.

f) No utilice ruedas gastadas de herramientas

eléctricas más grandes.

La rueda diseñada para una herramienta eléctrica más

grande no es adecuada para la velocidad superior de

una herramienta inferior y podría estallar.

ADVERTENCIAS DE SEGURIDAD

ADICIONALES ESPECÍFICAS PARA LAS

OPERACIONES DE CORTE ABRASIVO

a) No atasque la rueda de corte ni aplique una

presión excesiva. No intente realizar un corte

excesivamente profundo.

Aplicar una tensión excesiva a la rueda provoca el

aumento de la carga y aumenta la susceptibilidad

de que se tuerza o adhiera la rueda en el corte y el

retroceso o la rotura de la rueda.

b) No col oque el cuerpo alineado con la rueda giratoria

ni detrás de ella.

Si la rueda se desplaza en sentido a contrario a su

cuerpo en el punto de operación, el posible retroceso

podría ex pulsar la rued a giratoria y dir igir la herram ienta

eléctrica en su dirección.

c)

Cuando la rueda se atasque o se interrumpa un corte

por algún motivo, apague la herramienta eléctrica y

no mueva la herramienta eléctrica hasta que la rueda

se detenga completamente. No trate de extraer la

rueda de corte del corte mientras la rueda esté en

movimiento, ya que podría producirse retroceso.

Investigue y tome medidas correctivas para eliminar la

causa de atasco de la rueda.

d) No reinicie la operación de corte en la pieza de

trabajo. Deje que la rueda alcance la velocidad

máxima y acceda de nuevo al corte con cuidado.

La rueda puede atascarse, desplazarse o retroceder si

la herramienta eléctrica se pone en marcha de nuevo

sobre la pieza de trabajo.

e) Sostenga los paneles o las piezas con un tamaño

excesivamente grande para minimizar el riesgo de

bloqueo o retroceso de la muela.

Las piezas de trabajo grandes tienden a combarse por

su propio peso. Deben colocarse soportes debajo de la

pieza cerca de la línea de cor te y cerca del borde de la

pieza a ambos lados de la muela.

f) Tenga especial cuidado cuando realice un “corte de

bolsa” en las paredes existentes o en otras áreas

ciegas.

La muela que sobresale podría cortar tuberías de gas o

agua, cables eléctricos u objetos que pueden provocar

retroceso.

11

Page 12

Español

PRECAUCIONES AL UTILIZAR LA

AMOLADORA ANGULAR

1. Nunca trabajar con estas herramientas eléctricas sin

cubiertas protectoras de la muela.

2. Compruebe que la velocidad marcada en la muela sea

igual o mayor que la vel ocidad nomina l de la amoladora .

Emplee sólo muelas de centro hundido con una

velocidad nominal de 80 m /s o más.

3. Compruebe que las dimensiones de la muela sean

compatibles con la amoladora y que la muela encaja en

el husillo.

4. Las muelas abrasivas se deben almacenar y tratar

con cuidado, de conformidad con las instrucciones del

fabricante.

5. Inspeccione la muela rectifi cadora antes del uso, y

no utilice productos descascarados, agrietados o

defectuosos de cualquier otro manera.

6. Sujetar siempre fi rmemente el asidero del cuerpo y

el asidero lateral de la herramienta. De lo contrario

la contrafuerza producida podría causar un

funcionamiento impreciso e incluso peligroso.

7. No utilice las muelas de tallado para el amolado lateral.

8. No utilice los bujes o adaptadores de reducción

separados para adaptar muelas abrasivas de orifi cio

grande.

9. La muela continúa girando aún después de apagar la

herramienta.

ESPECIFICACIONES

Modelos G18MR G23MR

Voltaje (por áreas)

Acometida

Velocidad marcha en vacio 8500 min

Muela

*2

Peso

*1 Verifi car indefectiblemente los datos de la placa de características de la máquina, pues varían de acuerdo al país

de destino.

*2 Peso: Cuerpo principal solamente

*1

*1

Diámetro exterior 180 mm 230 mm

Diámetro interior 22,23 mm

Velocidad periférica 80 m/s

(110 V, 220 V, 230 V, 240 V)

2400 W

-1

5,4 kg

6600 min

-1

ACCESORIOS ESTANDAR

(1) Llave para tuercas .....................................................1

(2) Asidero lateral ............................................................1

Las ruedas centrales abombadas no se proveen como

accesorios estándar.

Los accesorios estándar están sujetos a cambio sin previo

aviso.

APLICACIONES

○ Eliminación de rebabas de juntas y acabado de

diversos tipos de acero, bronce y aluminio, materiales

y fundiciones.

○ Alisado de secciones soldadas o secciones cortadas

por medio de soldadura.

○ Alisado de resina sintética, pizarra,ladrillo, mármol,

etc.

○ Cor te de hormigón sintético, piedra, ladrillos, mármol y

materiales similares.

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegurarse de que la alimentación de red que ha de

ser utilizada responda a las exigencias de corriente

especifi cadas en la placa de características del

producto.

12

2. Conmutador de alimentación

Asegurarse de que el conmutador de alimentación esté

en la posición OFF (desconectado). Si la clavija está

conec tada en la caj a del enchufe m ientras el c onmutador

de alimentación está en posición ON (conectado)

las herramientas eléctricas empezarán a trabajar

inmediatamente, provocando un serio accidente.

3. Cable de prolongación

Cuando está alejada el área de trabajo de la red de

alimentación, usar un cable de prolongación de un

grosor y potencia nominal sufi ciente. El cable de

prolongación debe ser mantenido lo más corto posible.

4. Montar y ajustar la cubierta protectora de muela

La cubierta protectora de muela es un dispositivo

pr ot ec to r p ar a ev it ar he ri da s, en ca so d e q ue la mu el a de

alisado se quiebre durante la operación. Asegurarse de

que la cubierta protectora esté bién montada y apretada

antes de comenzar con la operación de alisado.

[Instalación y ajuste del protector de la rueda]

○ Instalación y ajuste del protector de la rueda Abra la

palanca e inserte el pasador de posicionamiento del

protector de la rueda, alineándolo con la distancia

entre caras del prensaestopas.

○ Luego, gire el protector de la rueda hasta la posición

deseada (de uso).

○ Cierre la palanca y fíjela. De requerirse, realice el

ajuste apretando o afl ojando el tornillo.

○ Si la palanca no se mueve con suavidad, aplique una

li ge ra cap a d e ac ei te lub ri ca nt e en la s ec ci ón des li za nte

entre la pieza de ajuste y la palanca.

Page 13

Español

○ Sujete el protector de la muela en una posición

que permita que las entre caras del pasador de

posicionamiento del protector de la muela y del

prensaestopas se encuentren alineados (la posición

en que se inserta el protector de la muela), pero no lo

utilice.

5. Asegurarse de que la muela de alisado a utilizar sea de

tipo correcto y libre de rajas o defectos de super fi cie.

También asegurarse de que la muela de alisado esté

montada debidamente y que la contratuerca de muela

esté apretada fi rmemente. Dirigirse a la sección de

“montaje y desmontaje de la muela alisado”.

6. Realizar una prueba

Asegúrese de que los productos abrasivos estén

correctamente montados y apretados antes del uso,

y haga funcionar la herramienta sin carga durante

30 segundos en una posición segura. Apáguela

inmediatamente si nota una vibración considerable u

otros defectos.

Si se produce esta condición, inspeccione la

herramienta para determinar la causa.

7. C o nfi rmar el mechanismo de bloqueo del eje

Confi rmar que el mechanismo del bloqueo del eje esté

desconectado, apretando el botón pulsador de cierre

dos o tres veces, antes de conectar el aparato eléctrico

(véase en la Fig. 1).

8. Instalación del asidero lateral

Atornille el asidero lateral en la cubierta de engranaje.

APLICACION PRACTICA DEL ALISADOR

1. Presión

Para prolongar la vida da la máquina y asegurar

un acabado de primera clase, es importante que la

máquina no sea recalentada aplicando demasiada

presión. En la mayoría de las aplicaciones el sólo

peso de la máquina, es sufi ciente para un alisado

efectivo. Demasiada presión ocasionaría una reducida

velocidad rotacional, inferior acabado de super fi cie y

recalentamiento que reduciría la vida de la máquina.

2. Angulo de alisado

No aplicar toda la superfi cie de la muela de alisado al

material a alisar. Como muestra en Fig. 3, la máquina

deberá ser mantenida en un ángulo de 15° – 30° de tal

manera que el canto externo de la muela de alisado

contacte la pieza de trabajo en un ángulo óptimo.

3. Para prevenir que una nueva muela de alisado cave la

pieza de trabajo, el alisado inicial debe ser llevado a

cabo tirando de la amoladora por encima de la pieza de

trabajo hacia el operario (Fig. 3 dirección B). Una véz

que el canto directriz de la muela de alisado esté bién

raspado, el alisado puede ser realizado en cualquier

dirección.

4. Operación del conmutador

Puesta en funcionamento:

Presione el botón de seguridad hacia adelante

* Para una utilización continua, presione

Parada: Presione y suelte la palanca del interruptor.

5. Precauciones inmediatamente después de haber

Después de desconectar la máquina no posarla

y depués presione la palanca del interruptor.

la palanca del interruptor. Esta palanca

quedará trabada al volver a presionar

el botón de seguridad hacia adelante.

(*Sujeto a cambios dependiendo de la zona.)

acabado la operación

antes de que la muela de alisado se haya parado

completamente. Aparte de evitar serios accidentes,

esta precaución reduciría la cantidad de polvo y

limaduras absorbidos por la máquina.

PRECAUCIÓN

○ Compruebe que la pieza de trabajo esté correctamente

soportada.

○ Cuando trabaje en ambientes polvorientos, asegúrese

de que las aberturas de ventilación se mantengan

libres de obstrucciones.

Si llegara a ser necesario eliminar el polvo, primero

desconecte la herramienta del tomacorriente de la red

(use objetos no metálicos) y evite que se dañen las

piezas internas.

○ Asegúrese de que las chispas resultantes del uso

no representen peligro alguno, por ejemplo, que no

alcancen a las personas, ni que incendien sustancias

infl amables.

○ Utilice siempre protectores oculares y auriculares.

Otros equipos de protección personal, como máscara

contra el polvo, guantes, casco y delantal se deben

usar según se requiera.

En caso de dudas, utilice el equipo de protección.

○ C ua n d o n o s e u s a la m á qu i n a, d e b e e s t ar d e sc o n e ct a d a

la acometida de red.

MONTAJE Y DESMONTAJE DE LA MUELA

ALISADO

PRECAUCIÓN

Cerciórese de desconectar la alimentación y

desenchufe el enchufe de la toma de alimentación de

la red para evitar averías serias.

1. Montaje (Fig. 1)

(1) Volver la máquina boca abajo de tal manera que el eje

esté mirando hacia arriba.

(2) Montar la arandela molar en el eje.

(3) Montar la protuberancia de la muela de alisado o la

muela adiamantada en la arandela molar.

(4) Atornillar la contratuerca molar en el eje.

(Para instalar la muela adiamantada, emplee la

contratuerca molar con el lado convexo hacia la muela

adiamantada.)

(5) Insertar el pulsador para prevenir la rotación del eje y

apretar la contratuerca molar con llave accesoria como

muestra en la Fig. 1.

2. Desmontaje

Seguir los procedimientos antedichos a la inversa.

PRECAUCIÓN

○ Confi rme que la muela de alisado esté fi rmemente

montada.

○ Confi rmar que el botón esté desactivado presionando

el botón dos o tres veces antes de conectar la

alimentación de la herramienta eléctrica.

MANTENIMIENTO E INSPECCION

1. Inspeccionar la muela de alisado

Asegurarse de que la muela de alisado esté libre de

rajas y defectos en la superfi cie.

2. Inspeccionar los tornillos de montaje

Regularmente inspeccionar todos los tornillos de

montaje y asegurarse de que estén apretados

fi rmemente. Si cualquier tornillo estuviera suelto,

volver a apretarlo inmediatamente. El no hacer esto

provocaría un riesgo serio.

3. Inspeccionar los carbones de contacto (Fig. 4)

El motor emplea escobillas de carbón que son par tes

consumibles.

Cu ando se gast an o están cer ca del “limi te de desgast e”

pueden causar problemas al motor.

Al equiparse la escobilla de carbón de parada

automática, el motor se detendrá automáticamente

en ese momento hay que proceder a cambiar ambas

13

Page 14

Español

escobillas de carbón por la nuevas, que tengan los

mismos números de escobillas de carbón como

se muestra en la fi gura. Además siempre hay que

manten er las escobi llas de carbó n limpias y aseg urarse

de que se muevan libremente en sus porta- escobillas.

4. Reemplazar el carbón de contacto (Fig. 5)

<Desmontaje>

(1) Afl oje el tornillo autorroscante D4 que retiene a la

cubierta de la escobilla y retire esta cubierta.

(2) Emplee la llave mach o hexagonal auxi liar o un pequeño

destornillador para tirar del borde del resorte helicoidal

que emp uja hacia abajo e l carbón de con tacto. Extra iga

el dorde del resorte hacia afuera el soporte del carbón

de contacto.

(3) Extraiga la sección del soporte carbón de contacto

en la sección del terminal del soporte del carbón de

contacto y después extraiga el carbón de contacto de

su soporte.

<Montaje>

(1) Inserte el extremo del conductor helicoidal del carbón

de contacto en la sección del terminal del soporte del

carbón de contacto.

(2) Inserte el carbón de contacto en el soporte del mismo.

(3) Emplee la llave mach o hexahonal auxi liar o un pequeño

destornillador para devolver el borde del resorte

helicoidal hasta la cabeza del carbón de contacto.

(4) Cierre la cubier ta de la cola y apriete el tornillo

autorroscante D4.

5. Mantenimiento de motor

La unidad de bobinado del motor es el verdadero

“corazón” de las herramientas eléctricas. Prestar el

mayor cuidado a asegurarse de que el bobinado no se

dañe y/o se humedezca con aceite o agua.

6. Lista de repuestos

PRECAUCIÓN

La reparación, modifi cación e inspección de las

herramientas eléctricas HiKOKI deben ser realizadas

por un Centro de Servicio Autorizado de HiKOKI.

Est a lista de repue stos será de uti lidad si es prese ntada

junto con la herramienta al Centro de Ser vicio

Autorizado de HiKOKI, para solicitar la reparación o

cualquier otro tipo de mantenimiento.

En el manejo y el mantenimiento de las herramientas

eléctricas, se deberán observar las normas y

reglamentos vigentes en cada país.

MODIFICACIONES

HiKOKI Power Tools introduce constantemente

mejoras y modifi caciones para incorporar los últimos

avances tecnológicos.

Por consiguiente, algunas partes pueden ser

modifi cadas sin previo aviso.

OBSERVACION

Debido al programa continuo de investigación y desarrollo

de HiKOKI éstas especifi caciones están sujetas a cambio

sin previo aviso.

14

Page 15

中國語

一般安全規則

警告

閱讀所有安全警告說明

未遵守警告與說明可能導致電擊、火災及或其他嚴

重傷害。

請妥善保存所有警告與說明,以供未來參考之用。

「電動工具」一詞在警告中,係指電源操作(有線)

之電動工具或電池操作(無線)之電動工具。

1) 工作場所安全

a) 保持工作場所清潔及明亮。

雜亂或昏暗的區域容易發生意外。

b) 勿在易產生爆炸之環境中操作,譬如有易燃液

體、瓦斯或粉塵存在之處。

電動工具產生火花會引燃粉塵或煙氣。

c) 當操作電動工具時,保持兒童及過往人員遠離。

分神會讓你失去控制。

2) 電氣安全

a) 電動工具插頭必須與插座配合,絕不可以任何

方法修改插頭,且不得使用任何轉接插頭於有

接地之電動工具。

不修改插頭及所結合之插座可減少電擊。

b) 避免身體接觸到接地面諸如管子、散熱器、爐

灶及冰箱。

如果你的身體接地或搭地,會增加電擊的危險。

c) 勿讓電動工具淋雨或曝露在潮濕的環境下。

電動工具進水會增加電繫的危險。

d) 勿濫用電源線。絕勿使用電源線去纏繞、拖拉

電動工具或拔插頭,保持電源線遠離熱氣、油

氣、尖角或可動零件。

損壞或纏繞的電源線會增加電繫之危險。

e) 電動工具在室外操作時要使用一適合室外用的

延長線。

使用合適之室外用延長線會減少電擊的危險。

f) 若無法避免在潮濕地區操作電動工具,請使用

以殘餘電流裝置 (RCD) 保護的電源。

使用 RCD 可降低觸電危險。

3) 人員安全

a) 保持機警,注意你正在做什麼,並運用普通常

識操作電動工具。

當你感到疲勞或受藥品、酒精或醫療影響時,

勿操作電動工具。

操作中瞬間的不注意可能造成人員嚴重的傷

害。

b) 使用個人防護裝備,經常配戴安全眼鏡。

配戴防塵口罩、防滑安全鞋、硬帽等防護裝

備,或在適當情況下使用聽覺防護,可減少人

員傷害。

c) 防止意外啟動。在連接電源及或電池組、拿

起或攜帶工具前,請確認開關是在「off」(關

閉)的位置。

以手指放在開關握持電動工具,或在電動工具

的開關於“on”的狀況下插上插頭,都會導致

意外發生。

d) 在將電動工具啟動前,先卸下任何調整用鑰匙

或扳手。

扳手或鑰匙遺留在電動工具的轉動部位時,可

能導致人員傷害。

e) 身體勿過度伸張,任何時間要保持站穩及平

衡。

以便在不預期的狀態下,能對電動工具有較好

的控制。

f) 衣著要合宜,別穿太鬆的衣服或戴首飾。

保持你的頭髮、衣服及手套遠離轉動部位。

寬鬆的衣服、手飾及長髮會被捲入轉動部位。

g) 如果裝置要用於粉塵抽取及集塵設施,要確保

其連接及正當使用。

使用集塵裝置可減少與灰塵相關的危險。

4) 電動工具之使用及注意事項

a) 勿強力使用電動工具,使用正確之電動工具為

你所需。

正確使用電動工具會依其設計條件使工作做得

更好更安全。

b) 如果開關不能轉至開及關的位置,勿使用電動

工具。

任何電動工具不能被開關所控制是危險的,必

須要修理。

c) 進行任何調整、更換配件或收存電動工具時,

必須將插頭與電源分開,且或將電池組從電

動工具中取出。

此種預防安全措施可減少意外開啟電動機之危

險。

d) 收存停用之電動工具,遠離兒童,且不容許不

熟悉電動工具或未瞭解操作電動工具說明書的

人操作電動工具。

在未受過訓練的人手裡,電動工具極為危險。

e) 保養電動工具,檢核是否有可動零件錯誤的結

合或卡住、零件破裂及可能影響電動工具操作

的任何其他情形。

電動工具如果損壞,在使用前要修好。

許多意外皆肇因於不良的保養。

f) 保持切割工具銳利清潔。

適當的保養切割工具,保持銳利之切削鋒口,

可減少卡住並容易控制。

15

Page 16

中國語

g) 按照說明書使用電動工具、配件及刀具時,必

須考量工作條件及所執行之工作。

若未依照這些使用說明操作電動工具時,可能

造成相關之危害情況。

5) 維修

a) 讓你的電動工具由合格修理人員僅使用相同的

維修零件更換。

如此可確保電動工具的安全得以維持。

注意事項

不可讓孩童和體弱人士靠近工作場所。

應將不使用的工具存放在孩童和體弱人士伸手不及的

地方。

砂磨或砂磨切割操作的通用安

全警告

a) 該電動工具是用於實現砂輪機或切斷工具功能

的。閱讀隨該電動工具提供的所有安全警告、說

明、圖解和規定。

不瞭解以下所列所有說明將導致電擊、著火和 /

或嚴重傷害。

b) 不推薦用該電動工具進行諸如砂光、刷光、拋光

或切斷等操作。

電動工具不按指定的功能去操作,可能會發生危

險和引起人身傷害。

c) 不使用非工具製造商推薦和專門設計的附件。

否則該附件可能被裝到你的電動工具上,而它不

能保證安全操作。

d) 附件的額定速度必須至少等於電動工具上標出的

最大速度。

附件以比其額定速度大的速度運轉會發生爆裂和

飛濺。

e) 附件的外徑和厚度必須在電動工具額定能力範圍

之內。

不正確的附件尺寸不能得到充分防護或控制。

f) 安裝配件的螺紋必須與電磨機主軸螺紋相配。對

於以法蘭安裝的配件,配件的軸孔必須符合法蘭

的定位直徑。

與電動工具的安裝硬體不相配的配件會失去平

衡,劇烈振動,並可能導致失去控制。

g) 不要使用損壞的附。在每次使用前要檢查附件,

例如砂輪是否有碎片和裂縫,靠背墊是否有的裂

縫、撕裂或過度磨損,鋼絲刷是否鬆動或金屬絲

是否斷裂。如果電動工具或附件跌落了,檢查是

否有損壞或安裝沒有損壞的附件。檢查和安裝附

件後,讓自己和旁觀者的位置遠離旋轉附件的平

面,並以電動工具最大空載速度運行 1min。

損壞的附件通常在該試驗時會碎裂。

16

h) 戴上防護用品。根據適用情況,使用面罩、安全

護目鏡或安全眼鏡。適用時,戴上防塵面具、聽

力保護器、手套和能擋小磨料或工件碎片的工作

圍裙。

眼防護罩必須擋住各種操作產生的飛屑。防塵面

具或口罩必須能過濾操作產生的顆粒。長期暴露

在高強度雜訊中會引起失聰。

i) 讓旁觀者與工作區域保持一安全距離。任何進入

工作區域的人必須戴上防護用品。

工件或破損附件的碎片可能會飛出並引起緊靠著

操作區域的旁觀者的傷害。

j) 進行操作時若切割配件可能接觸到暗線或其自身

的電線,請握著電動工具的絕緣手柄表面。

接觸到「通電」電線的切割配件可能使電動工具

的金屬零件「通電」,而造成操作人員觸電。

k) 使軟線遠離旋轉的附件。

如果控制不當,軟線可能被切斷或纏繞,並使得

你的手或手臂可能被捲入旋轉附件中。

l) 直到附件完全停止運動才放下電動工具。

旋轉的附件可能會抓住表面並拉動電動工具而讓

你失去對工具的控制。

m) 當攜帶電動工具時不要開動它。

意外地觸及旋轉附件可能會纏繞你的衣服而使附

件傷害身體。

n) 經常清理電動工具的通風口。

電動機風扇會將灰塵吸進機殼,過多的金屬粉末

沈積會導致電氣危險。

o) 不要在易燃材料附件操作電動工具。

火星可能會點燃這些材料。

p) 不要使用需用冷卻液的附件。

用水或其他冷卻液可能會導致電腐蝕或電擊。

反彈和相關警告

反彈是因卡住或纏繞住的旋轉砂輪、靠背墊、鋼絲刷

或其他附件而產生的突然反作用力。卡住或纏繞會引

起旋轉附件的迅速堵轉,隨之使失控的電動工具在卡

住點產生與附件旋轉方向相反的運動。

例如,如果砂輪被工件纏繞或卡住,伸入卡住點的砂

輪邊緣可能會進入材料表面而引起砂輪爬出或反彈。

砂輪可能飛向或飛離操作者,這取決於砂輪在卡住點

的運動方向。

在此條件下砂輪也可能碎裂。

反彈是電動工具誤用和 / 或不正確操作工序或條件的結

果,可以通過採取以下給出的適當預防措施得以避免。

a) 保持緊握電動工具,使你的身體和手臂處於正確

狀態以抵抗反彈力。如有輔助手柄,則要一直使用,

以便最大限度控制住起動時的反彈力或反力矩。

如採取合適的預防措施,操作者就可以控制反力

矩或反彈力。

Page 17

中國語

b) 絕不能將手靠近旋轉附件。

附件可能會反彈碰到手。

c) 不要站在發生反彈時電動工具可能移動到的地

方。

反彈將在纏繞點驅使工具逆砂輪運動方向運動。

d) 當在尖角、銳邊等處作業時要特別小心。避免附

件的彈跳和纏繞。

尖角、銳邊和彈跳具有纏繞旋轉附件的趨勢並引

起反彈的失控。

e) 不要附裝上鋸鏈、木雕刀片或帶齒鋸片。

這些鋸片會產生頻繁的反彈和失控。

對磨削和砂磨切割操作的專用

安全警告

a) 只使用所推薦的砂輪型號和為選用砂輪專門設計

的護罩。

不是為電動工具設計的砂輪不能充分得到防護,

是不安全的。

b) 去壓中心輪的磨削表面必須安裝在護刃器唇的平

面下方。

突出護刃器唇平面,未妥善安裝的砂輪,無法得

到適當的保護。

c) 護罩必須牢固地裝在電動工具上,且放置得最具

安全性,只有最小的砂輪部分暴露在操作人面前。

護罩有助於保護操作者免於碰觸到損壞的砂輪碎

片,可能點燃衣物的火花,以及與砂輪的意外接觸。

d) 砂輪只用作推薦的用途。例如:不要用切割砂輪

的側面進行磨削。

施加到砂輪側面的力可能會使其碎裂。

e) 始終為所選砂輪選用未損壞的、有恰當規格和形

狀的砂輪法蘭盤。

合適的砂輪法蘭盤支承砂輪可以減小砂輪破裂的

可能性。切割砂輪的法蘭盤可以不同於砂輪法蘭

盤。

f) 不要使用從大規格電動工具上用剩的磨損砂輪。

用於大規格電動工具上的砂輪不適於較小規格工

具的高速工況並可能會爆裂。

c) 當砂輪被卡住或無論任何原因而中斷切割時,關

掉電動工具並握住工具不要動,直到砂輪完全停

止。決不要試圖當砂輪仍然運轉時使切割砂輪脫

離切割,否則會發生反彈。

調查並採取校正措施以消除砂輪卡住的原因。

d) 不能在工件上重新起動切割操作。讓砂輪達到全

速後再小心地重新進入切割。

如果電動工具在工件上重新起動,砂輪可能會卡

住、爬出或反彈。

e) 支撐面板或過大工件,使砂輪受夾住或產生反衝

作用力的風險降到最低。

大工件由於其自身重量,容易趨於下陷。支撐座

必須置於工件下方的砂輪兩側,靠近鋸切路徑與

工件邊緣。

f) 在進行牆壁或其他隱蔽區域之局部鋸切時請格外

小心。

凸出的砂輪可能會鋸切到瓦斯管、水管、電線或

足以產生反衝作用力的物體。

使用手提圓盤電磨機時應注意

事項

1. 沒有砂輪防護裝置千萬不要使用圓盤電磨機這種

動力工具。

2. 確認砂輪上所標示的轉速等於或大於電磨機的額

定轉速只能使用額定轉速為 80 m秒 以上的砂

輪。

3. 確保砂輪尺寸與電磨機相符、砂輪與主軸相配。

4. 須按照廠家的使用說明書小心存放和使用磨輪。

5. 使用前檢查砂輪,不要使用破損、有裂縫的或有

其他缺陷的產品

6. 始終抓緊電動工具的機身手柄和側柄。否則,所

產生的反作用力可能會導致錯誤的、甚至是危險

的操作。

7. 請勿使用切斷砂輪進行側面研磨。

8. 請勿將獨立的減速軸襯或接頭用於大孔砂輪。

9. 在切斷本電動工具的電源之後,砂輪仍會繼續旋

轉一段時間。

對砂輪切割操作的附加專用安

全警告

a) 不要“夾”住切割砂輪或施加過大的壓力。不要

試圖做過深的切割。

給砂輪施加過應力增加了砂輪在切割時的負載,容

易纏繞或卡住,增加了反彈或砂輪爆裂的可能性。

b) 身體不要對著旋轉砂輪,也不要站在其後。

當把砂輪從操作者身邊的操作點移開時,可能的

反彈會使旋轉砂輪和電動工具朝你推來。

17

Page 18

中國語

規 格

型式 G18MR 台灣 G18MR G23MR

電壓(按地區)

輸入功率

額定輸出功率 1000 W 1600 W

無負荷速度 8500 轉分 6600 轉分

砂輪

*2

重量

*1 當須改變地區時應檢查產品上的銘牌。

*2 僅限於本體

*1

*1

外徑 180 mm 230 mm

穴徑 22.23 mm

外緣速度 80 m秒

110 V (110 V, 220 V, 230 V, 240 V)

1560 W 2400 W

5.4 kg

標 準 附 件

(1) 扳手 ................................................................... 1

(2) 側柄 ................................................................... 1

砂輪不作為標準附件附送。

標準附件可能不預先通告而徑予更改。

用 途

○ 用於去除鑄品毛刺,飛邊等物及拋光各種型號的

鋼,青銅,鋁及鑄造品。

○ 研磨焊接部分或研磨用焊接切割的部分。

○ 合成樹脂、石板、磚、大理石等的研磨。

○ 混凝土、石頭、磚、大理石等的切削。

作 業 之 前

1 電源

確認所使用的電源與工具銘牌上標示的規格是否

相符。

2. 電源開關

確認電源開關是否切斷。若電源開關接通,則插

頭插入電源插座時電動工具將出其不意地立刻轉

動,從而招致嚴重事故。

3. 延伸線纜

若作業場所移到離開電源的地點,應使用厚度足

夠、額定電容的延伸線纜,並且要盡可能地短些。

4. 安裝並調整輪罩

輪罩是一種保護裝置,用來防止作業中因砂輪破

裂而受傷。開始研磨作業之前,請確認輪罩裝好

緊固。

18

〔安裝和調整輪罩的方法〕

○ 打開手柄,對準墊座的對邊寬度並插入輪罩的定

位鎖。

○ 然後將輪罩轉動到所需的位置(使用位置)。

○ 關閉手柄使之固定。若有必要,擰緊或擰鬆螺絲

進行調整。

○ 手柄移動不暢時,請給設定鎖與手柄的連接部分

加注潤滑油。

○ 請勿在輪罩的定位銷與墊座的對邊寬度一致的位

置(輪罩的插入位置)固定輪罩並使用。

5. 確認要使用的砂輪屬於正確類型、沒有裂紋或表

面缺陷。同時也要確認砂輪裝好,輪螺母緊固。

參照“砂輪的裝卸”一節。

6. 試行運轉

在使用前確保已正確安裝並擰緊研磨產品,並在

安全場所在空載狀態下運轉 30 秒鐘,若有較大

的振動或察覺到其他缺陷,則應立即停止試運

轉。

遇此情況時,檢查電動工具以究明原因。

7. 檢查主軸鎖的裝置

在打開電源開關之前,撳兩、三下鎖定銷檢查鎖

定銷是否被釋放(圖 1)。

8. 固定側柄

把側柄旋進齒輪罩。

實用手提圓盤電磨機的應用

1. 壓力

本機不可施加過大壓力使其過載,以延長使用壽

命並確保加工品質。在大部份的用法中,機器本

身的重量即夠研磨。加壓過大將導致轉速降低、

表面加工不良以及過載,從而縮短機器壽命。

Page 19

中國語

2. 研磨角度

切勿將砂輪之全表面施加於要研磨的材料上。如

圖 3 所示,機器應保持 15°—30°,使砂輪的外緣

以最佳角度與工件相接觸。

3. 用新砂輪首次進行研磨,應將手提圓盤電磨機由

對面橫過工件往操作人員這邊拉,以免挖入工作

(圖 3 的 B 方向)。等砂輪的前緣適當磨損,就

可往任何方向進行研磨。

4. 手提圓盤電磨機的開關

接通: 將開關鎖往前推,接著按開關的手柄開關

就被接通。

* 長時間使用時,只須再度將開關徑前推,

開關將上鎖。

(* 依地區而異。)

斷開: 按緊開關的手柄,然後釋放,開關就會斷

開。

5. 收工後的注意事項

關掉機器之後,需等手提圓盤電磨機完全停止才

能放下,以免造成嚴重事故,而且還可減少吸入

機器的塵埃與切削量。

注意

○ 檢查工件已被正確固定。

○ 在多塵的條件下工作時,確保通風口暢通無堵

塞現象。

如果需要清除灰塵,首先使電動工具斷開電源

(使用非金屬物品)並避免損壞內部零件。

○ 確保使用時產生的火花不會引起危險:例如,

不要濺在身體上或點燃易燃物。

○ 始終採用視力和聽力保護。

必要時應使用其他個人保護裝置,如口罩、手

套、頭盔和圍裙等。

拿不準時,請使用保護裝置。

○ 未使用本電動工具時,請斷開電源。

砂輪的裝卸

注意

確認開關已斷開並且從電源插座中拔去電源插頭

以避免嚴重事故。

1. 裝配(圖 1)

(1) 將機器翻過去,使主軸朝上。

(2) 將砂輪墊圈裝於主軸上。

(3) 將砂輪或金剛輪的突出部裝入砂輪墊圈。

(4) 將砂輪螺帽旋入主軸。

(使用金剛輪時,請把砂輪螺帽的凸面裝到金剛

輪的相反方向上,並且把螺帽擰到主軸上。)

(5) 按下鎖定銷以防止主軸轉動,並如圖 1 所示用附

送的扳手擰緊砂輪螺帽。

2. 拆卸

按照上述步驟相反的順序進行拆卸。

注意

○ 確認砂輪安裝是否牢固。

○ 確認鎖定銷被解除鎖定。可在打開電源開關之

前通過撳兩、三次鎖定銷進行檢查。

維 護 和 檢 查

1. 檢查砂輪

檢查砂輪確無破裂和表面缺隱。

2. 檢查安裝螺絲

要經常檢查安裝螺絲是否緊固妥善。若發現螺絲鬆

了,應立即重新扭緊,否則會導致嚴重的事故。

3. 檢查碳刷(圖 4)

電動機裏的碳刷是一種消耗品。

碳刷一旦使用到磨損極限,電動機就會出現各種

障礙;如果所使用的碳刷是“自停式”,電動機

將自動地停止轉動。

遇到上述情況,應立即換上與圖上代號一致的新

碳刷。此外,碳刷應經常保持乾淨狀態,以保證

能在刷握裏自由滑動。

4. 更換碳刷(圖 5)

〈拆卸〉

(1) 擰鬆固定碳刷蓋的 D4 自攻螺絲釘,拆下碳刷

蓋。

(2) 使用六角形扳手或小螺絲刀拔起固定碳刷的彈簧

邊緣。朝刷握的外側方拆下彈簧邊緣。

(3) 從刷握的端部取下碳刷上的引出端,然後從刷握

裡拆下碳刷。

〈安裝〉

(1) 將碳刷的引線端插入刷握的端部。

(2) 將碳刷裝入刷握。

(3) 使用六角形扳手或小螺絲刀使彈簧邊緣回到碳刷

頭處。

(4) 安上尾部蓋並擰緊 D4 自攻螺絲釘。

5. 電動機的維護

電動機繞線是電動工具的“心臟部”。應仔細檢

查有無損傷,是否被油液或水沾濕。

6. 維修部件目錄

注意

HiKOKI電動工具的修理、維護和檢查必須由HiKOKI

所認可的維修中心進行。

當尋求修理或其他維護時,將本部件目錄與工具

一起提交給HiKOKI所認可的維修中心會對您有所

幫助。

在操作和維護電動工具中,必須遵守各國的安全

規則和標准規定。

19

Page 20

中國語

改進

HiKOKI電動工具隨時都在進行改進以適應最新的技

術進步。

因此,有些部件可能未預先通知而進行改進。

註

為求改進,本手冊所載規格可能不預先通知而徑

予更改。

20

Page 21

ﺔﻳﺑﺭﻌﻟﺍ

.ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻥﻣ "ﻁﺳﻭﻷﺍ ءﺯﺟﻟﺍ" ﻭﻫ ﻙﺭﺣﻣﻟﺍ ﺓﺩﺣﻭ ﻑﻠﻣ

ﻙﺭﺣﻣﻟﺍ ﺔﻧﺎﻳﺻ

.ءﺎﻣﻟﺍ ﻭﺃ ﺕﻳﺯﻟﺍ ﺔﻁﺳﺍﻭﺑ ﻪﻠﻠﺑ ﻭﺃ/ﻭ ﻑﻠﻣﻟﺍ ﻑﻠﺗ ﻡﺩﻋ ﻥﻣ ﺭﺍﺭﻣﺗﺳﺎﺑ ﺩﻛﺎﺗ

ﺔﻣﺩﺧﻟﺍ ءﺍﺯﺟﺃ ﺔﻣﺋﺎﻗ

HiKOKI

ﺕﺍﻭﺩﻷ ﺹﺣﻔﻟﺍﻭ ،ﻝﻳﺩﻌﺗﻟﺍﻭ ،ﺡﻼﺻﻹﺍ ﻝﺎﻣﻋﺃ ﺫﻳﻔﻧﺗ ﺏﺟﻳ

HiKOKI

ﺔﻣﺩﺧ ﺯﻛﺭﻣﻟ ﺓﺍﺩﻷﺍ ﻊﻣ ﺎﻬﻣﻳﺩﻘﺗ ﺩﻧﻋ ﺓﺩﻳﻔﻣ ﻩﺫﻫ ءﺍﺯﺟﻷﺍ ﺔﻣﺋﺎﻗ

.ﺩﻣﺗﻌﻣﻟﺍ ﺔﻣﺩﺧﻟﺍ ﺯﻛﺭﻣ ﻝﺑﻗ ﻥﻣ

.ﺔﻧﺎﻳﺻﻟﺍ ﻝﺎﻣﻋﺃ ﻥﻣ ﺎﻫﺭﻳﻏ ﻭﺃ ﺡﻼﺻﻹﺍ ﺏﻠﻁ ﺩﻧﻋ ﺩﻣﺗﻌﻣ

ﺕﺎﻣﻳﻠﻌﺗ ﻉﺎﺑﺗﺍ ﺏﺟﻳ ،ﺎﻬﺗﻧﺎﻳﺻ ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﺔﻟﺎﺣ ﻲﻓ

.ﺔﻟﻭﺩ ﻝﻛﺑ ﺔﺻﺎﺧﻟﺍ ﺭﻳﻳﺎﻌﻣﻟﺍﻭ ﻥﺎﻣﻷﺍ

ﺕﺎﻳﻧﻘﺗﻟﺍ ﺙﺩﺣﻷ ﺎ

ً

ﻌﺑﺗ ﺎﻬﻠﻳﺩﻌﺗﻭ ﺭﺍﺭﻣﺗﺳﺎﺑ

HiKOKI

ﺕﺍﻭﺩﺃ ﻥﻳﺳﺣﺗ ﻡﺗﻳ

ﺕﻼﻳﺩﻌﺗﻟﺍ

.ﺔﻣﺩﻘﺗﻣﻟﺍ

.ﻕﺑﺳﻣ ﻡﻼﻋﺇ ﻥﻭﺩ ءﺍﺯﺟﻷﺍ ﺽﻌﺑ ﺭﻳﻳﻐﺗ ﻡﺗﻳ ﺩﻗ ،ﻙﻟﺫﻟﻭ

ﺕﺎﻔﺻﺍﻭﻣﻟﺍ ﺭﻳﻐﺗﺗ ،ﺭﻣﺗﺳﻣﻟﺍ ﺭﻳﻭﻁﺗﻟﺍﻭ ﺙﺣﺑﻠﻟ

HiKOKI

ﺔﻅﺣﻼﻣ

ﺞﻣﺎﻧﺭﺑﻟ ﺎًﻌﺑﺗ

.ﻕﺑﺳﻣ ﻡﻼﻋﺇ ﻥﻭﺩ ﺎﻧﻫ ﺓﺭﻭﻛﺫﻣﻟﺍ

5

6

ﻪﻳﺑﻧﺗ

٥

21

Page 22

ﺔﻳﺑﺭﻌﻟﺍ

ﻻ ًﻼﺛﻣﻓ ﺍًﺭﻁﺧ ﺏﺑﺳﺗ ﻻ ﻡﺍﺩﺧﺗﺳﻻﺍ ﻥﻋ ﺔﺟﺗﺎﻧﻟﺍ ﺕﺍﺭﺍﺭﺷﻟﺍ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ

.ﻝﺎﻌﺗﺷﻼﻟ ﺔﻠﺑﺎﻗ ﺩﺍﻭﻣ ﺏﻧﺎﺟﺑ ﺎﻬﻠﻌﺷﺗ ﻭﺃ ﺹﺎﺧﺷﺄﺑ ﻡﺩﻁﺻﺗ

.ﻥﺫﻷﺍﻭ ﻥﻳﻌﻟﺍ ﻲﻗﺍﻭ ﺎًﻣﺋﺍﺩ ﻡﺩﺧﺗﺳﺍ

ﺔﺑﺭﺗﻷﺍ ﻥﻣ ﻲﻗﺍﻭﻟﺍ ﻉﺎﻧﻘﻟﺍ ﻝﺛﻣ ﻯﺭﺧﻷﺍ ﺔﻳﺋﺎﻗﻭﻟﺍ ﺕﺍﺩﻌﻣﻟﺍ ءﺍﺩﺗﺭﺍ ﺏﺟﻳ

.ﺓﺭﻭﺭﺿﻟﺍ ﺩﻧﻋ ﺭﺯﺋﻣﻟﺍﻭ ﺓﺫﻭﺧﻟﺍﻭ ﺕﺍﺯﺎﻔﻘﻟﺍﻭ

.ﺔﻳﺎﻗﻭﻟﺍ ﺕﺍﺩﻌﻣ ءﺍﺩﺗﺭﺎﺑ ﻡﻗ ،ﺩﻛﺄﺗﻟﺍ ﻡﺩﻋ ﺔﻟﺎﺣ ﻲﻓ

.ﺔﻳﺭﺎﻁﺑﻟﺍ ﻝﺻﻓ ﺏﺟﻳ ،ﺔﻟﻵﺍ ﻡﺍﺩﺧﺗﺳﺍ ﻡﺩﻋ ﺩﻧﻋ

ﺯﻛﺭﻣﻟﺍ ﺔﻁﻭﻐﺿﻣ ﺔﺟﻠﻌﻟﺍ ﻙﻓﻭ ﻊﻳﻣﺟﺗ

ﺏﻧﺟﺗﻟ ﺱﺑﻘﻣﻟﺍ ﻥﻣ ﺕﺎﻘﺣﻠﻣﻟﺍ ﺱﺑﺎﻗ ﻝﺻﻔﺑ ﻡﻗﻭ ﻝﻳﻐﺷﺗﻟﺍ ﻑﺎﻘﻳﺇ ﻥﻣ ﺩﻛﺄﺗ

.ﺓﺭﻁﺧﻟﺍ ﺙﺩﺍﻭﺣﻟﺍ

1

ﻝﻛﺷﻟﺍ) ﻊﻳﻣﺟﺗﻟﺍ

ﺎًﻬﺟﺍﻭﻣ ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻋ ﺢﺑﺻﻳ ﻙﻟﺫﻟ ﺏﻘﻋ ﻰﻠﻋ ﺎًﺳﺃﺭ ﺔﻟﻵﺍ ﺏﻠﻘﺑ ﻡﻗ

(

.ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻋ ﻲﻓ ﻝﺧﺍﺩ ﺔﻠﺟﻌﻟﺍ ﺔﻘﻠﺣ ﺏﻳﻛﺭﺗ

ﺓﺭﺎﺳﻛﺑ ﺦﻳﻠﺟﺗﻟﺍ ﺔﻠﺟﻋ ﻭﺃ ﺔﻁﻭﻐﺿﻣﻟﺍ ﺯﻛﺭﻣﻟﺍ ﺔﻠﺟﻋ ءﻭﺗﻧ ﺔﻣءﺍﻭﻣﺑ ﻡﻗ

.ﺔﻠﺟﻌﻟﺍ ﺔﻘﻠﺣﻟ ﺱﺎﻣﻟﺍ

.ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻌﺑ ﺔﻠﺟﻌﻟﺍ ﺔﻟﻭﻣﺎﺻ ﺕﻳﺑﺛﺗﺑ ﻡﻗ

ﻊﻣ ﺔﻠﺟﻌﻟﺍ ﺔﻟﻭﻣﺎﺻ ﻡﺩﺧﺗﺳﺍ ،ﺱﺎﻣﻟﺍ ﺓﺭﺎﺳﻛﺑ ﺦﻳﻠﺟﺗﻟﺍ ﺔﻠﺟﻋ ﺏﻳﻛﺭﺗﻟ)

.(ﺱﺎﻣﻟﺍ ﺓﺭﺎﺳﻛﺑ ﺦﻳﻠﺟﺗﻟﺍ ﺔﻠﺟﻌﻟ ﻪﺟﺍﻭﻣﻟﺍ ﺏﺩﺣﻣﻟﺍ ﺏﻧﺎﺟﻟﺍ

ﺔﻟﻭﻣﺎﺻ ﻡﺎﻛﺣﺇﻭ ،ﻥﺍﺭﻭﺩﻟﺍ ﺩﻭﻣﻋ ﺭﻳﻭﺩﺗ ﻊﻧﻣﻟ ﻊﻓﺩﻟﺍ ﺭﺯ ﻝﺎﺧﺩﺈﺑ ﻡﻗ

.1 ﻝﻛﺷﻟﺍ ﻲﻓ ﺽﻭﺭﻌﻣ ﻭﻫ ﺎﻣﻛ ،ﺕﺎﻘﺣﻠﻣﻟﺍ ﺡﺎﺗﻔﻣ ﻊﻣ ﺔﻠﺟﻌﻟﺍ

.ﻩﻼﻋﺃ ﺕﺍءﺍﺭﺟﻹﺍ ﺱﻛﻋﺍ

ﺕﺍﺭﻣ ﺙﻼﺛ ﻭﺃ ﻥﻳﺗﺭﻣ ﻪﻳﻠﻋ ﻁﻐﺿﻟﺎﺑ ﻁﻐﺿﻟﺍ ﺭﺯ ﻑﻗﻭﺗ ﻡﺩﻋ ﻥﻣ ﺩﻛﺄﺗ

.ﺍًﺩﻳﺟ ﺯﻛﺭﻣﻟﺍ ﺔﻁﻭﻐﺿﻣ ﺔﻠﺟﻌﻟﺍ ﺕﻳﺑﺛﺗ ﻥﻣ ﺩﻛﺄﺗ

.ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻝﻳﻐﺷﺗ ﻝﺑﻗ

ﻪﻳﺑﻧﺗ

.ﻝﻔﺳﻷ

ﻙﻔﻟﺍ

ﻪﻳﺑﻧﺗ

ﺹﺣﻔﻟﺍﻭ ﺔﻧﺎﻳﺻﻟﺍ

ﺏﻭﻳﻌﻟﺍﻭ ﻕﻘﺷﺗﻟﺍ ﻥﻣ ﺔﻳﻟﺎﺧ ﺯﻛﺭﻣﻟﺍ ﺔﻁﻭﻐﺿﻣ ﺔﻠﺟﻌﻟﺍ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ

ﺎﻬﻁﺑﺭ ﻡﺎﻛﺣﺇ ﻥﻣ ﺩﻛﺄﺗﻟﺍﻭ ﺕﻳﺑﺛﺗﻟﺍ ﺭﻳﻣﺎﺳﻣ ﺔﻓﺎﻛﻟ ﻱﺭﻭﺩﻟﺍ ﺹﺣﻔﻟﺎﺑ ﻡﻗ

.ﺭﻭﻔﻟﺍ ﻰﻠﻋ ﺎﻬﻁﺑﺭ ﻡﺎﻛﺣﺈﺑ ﻡﻗ ،ﺭﻳﻣﺎﺳﻣ ﺔﻳﺃ ﻙﻓ ﺔﻟﺎﺣ ﻲﻓ .ﺢﻳﺣﺻ ﻝﻛﺷﺑ

.ﺭﻁﺎﺧﻣ ﻰﻟﺇ ﻙﻟﺫﺑ ﻡﺎﻳﻘﻟﺍ ﻲﻓ ﻝﺷﻔﻟﺍ ﺽﺭﻌﻳ ﺩﻘﻓ

.ﺓﺭﻣﻌﻣ ﺭﻳﻏ ءﺍﺯﺟﻷﺍ ﻥﻣ ﻲﻫﻭ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻙﺭﺣﻣﻟﺍ ﻙﻠﻬﺗﺳﻳ

ﺙﻭﺩﺣ ﻲﻓ ﺏﺑﺳﺗﺗ ﻥﺃ ﻥﻛﻣﻳ ،"ﻝﻛﺂﺗﻟﺍ ﺩﺣ" ﻥﻣ ﺎﻬﺑﺍﺭﺗﻗﺍﻭ ﺎﻬﻠﻛﺂﺗ ﺩﻧﻋ

ﺔﻳﺋﺎﻘﻠﺗ ﻥﻭﺑﺭﻛﻟﺎﺑ ﻝﻘﺻ ﺓﺎﺷﺭﻓ ﺭﻳﻓﻭﺗ ﺔﻟﺎﺣ ﻲﻓ .ﻙﺭﺣﻣﻟﺎﺑ ﺕﻼﻛﺷﻣ

ﻥﻭﻛﻳﻭ ﺔﻣﻳﺩﻘﻟﺍ ﻥﻣ ًﻻﺩﺑ ﺓﺩﻳﺩﺟ ﻝﻘﺻ ﺓﺎﺷﺭﻓ ﻡﺩﺧﺗﺳﺍ ،ﺔﻠﺣﺭﻣﻟﺍ ﻩﺫﻫ ﻲﻓ

ﻡﻗ ،ﻙﻟﺫ ﻰﻟﺇ ﺔﻓﺎﺿﻹﺎﺑ .ﻝﻛﺷﻟﺍ ﻲﻓ ﺔﺣﺿﻭﻣﻟﺍ ﻡﺎﻗﺭﻷﺍ ﺱﻔﻧ ﺎﻬﻳﻠﻋ

ﺔﺳﻼﺳﺑ ﺎﻬﻗﻻﺯﻧﺍ ﻥﻣ ﺩﻛﺄﺗﻟﺍﻭ ﺭﺍﺭﻣﺗﺳﺎﺑ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻑﻳﻅﻧﺗﺑ

ﻡﻗﻭ ﺓﺎﺷﺭﻔﻟﺍ ءﺎﻁﻏ ﻰﻠﻋ ﺔﻅﻓﺎﺣﻣﻟﺍ ﻊﻣ D4 ﻁﻐﺿﻟﺍ ﺭﻳﻣﺎﺳﻣ ءﺎﺧﺭﺈﺑ ﻡﻗ

ﺏﺣﺳﻟ ﺭﻳﻐﺻﻟﺍ ﻙﻔﻣﻟﺍ ﻭﺃ ﻲﻓﺎﺿﻹﺍ ﻲﺳﺍﺩﺳﻟﺍ ﻁﺑﺭﻟﺍ ﺡﺎﺗﻔﻣ ﻡﺩﺧﺗﺳﺍ

ﺩﻭﻣﻋ ﺔﻓﺎﺣ ﺔﻟﺍﺯﺈﺑ ﻡﻗ .ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻝﻣﺣﺑ ﻡﻭﻘﺗ ﻲﺗﻟﺍ ﺽﺑﺎﻧﻟﺍ ﺔﻓﺎﺣ

.ﺓﺎﺷﺭﻔﻟﺍ ﻝﻣﺎﺣ ﻥﻣ ﻲﺟﺭﺎﺧﻟﺍ ءﺯﺟﻟﺍ ﻰﺗﺣ ﻥﺍﺭﻭﺩﻟﺍ

ﻝﻣﺎﺣﻟ ﻑﺭﻁﻟﺍ ﻡﺳﻗ ﻥﻣ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﺔﻠﻳﺩﺟ ﻑﺭﻁ ﺔﻟﺍﺯﺈﺑ ﻡﻗ

.ﺓﺎﺷﺭﻔﻟﺍ ﻝﻣﺎﺣ ﻥﻣ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﺔﻟﺍﺯﺈﺑ ﻡﻗ ﻡﺛ ﺓﺎﺷﺭﻔﻟﺍ

ﻝﻣﺎﺣﻟ ﻑﺭﻁﻟﺍ ﻡﺳﻗ ﻲﻓ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻠﻟ ﺔﻠﻳﺩﺟﻟﺍ ﻑﺭﻁ ﻝﺎﺧﺩﺈﺑ ﻡﻗ

.ﺓﺎﺷﺭﻔﻟﺍ ﻝﻣﺎﺣ ﻲﻓ ﻥﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻓ ﻝﺎﺧﺩﺈﺑ ﻡﻗ

ﺔﻓﺎﺣ ﺓﺩﺎﻋﻹ ﺭﻳﻐﺻﻟﺍ ﻙﻔﻣﻟﺍ ﻭﺃ ﻲﻓﺎﺿﻹﺍ ﻲﺳﺍﺩﺳﻟﺍ ﻁﺑﺭﻟﺍ ﺡﺎﺗﻔﻣ ﻡﺩﺧﺗﺳﺍ

.D4 ﻁﻐﺿﻟﺍ ﺭﻳﻣﺎﺳﻣ ﻡﺎﻛﺣﺈﺑ ﻡﻗﻭ ﻑﺭﻁﻟﺍ ءﺎﻁﻏ ﺏﻳﻛﺭﺗﺑ ﻡﻗ

22

ﺯﻛﺭﻣﻟﺍ ﺔﻁﻭﻐﺿﻣ ﺔﻠﺟﻌﻟﺍ ﺹﺣﻓ

.ﺔﻳﺣﻁﺳﻟﺍ

ﺕﻳﺑﺛﺗﻟﺍ ﺭﻳﻣﺎﺳﻣ ﺹﺣﻓ

4

ﻝﻛﺷﻟﺍ) ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﺹﺣﻓ

(

.ﺎًﻳﺋﺎﻘﻠﺗ ﻙﺭﺣﻣﻟﺍ ﻑﻗﻭﺗﻳﺳ ،ﻑﻗﻭﺗﻟﺍ

.ﺓﺎﺷﺭﻔﻟﺍ ﺽﺑﺎﻘﻣ ﻝﺧﺍﺩ

5

ﻝﻛﺷﻟﺍ) ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺍ

(

<ﻙﻔﻟﺍ>

.ﺓﺎﺷﺭﻔﻟﺍ ءﺎﻁﻏ ﺔﻟﺍﺯﺈﺑ

<ﺏﻳﻛﺭﺗﻟﺍ>