Page 1

DH 36DMA

Handling instructions

Page 2

1

2

3

4

5

1

6

^

$

%

#

@

!

0

9

8

7

23

5

&

1

2

*

0

4

2

0

3

1

(

5

0

3

)q

2

1

w

2

Page 3

5

1

e

1

2

67

1

1

^

4

3

1

33

2

%

2

%

89

3

2

2 3

r

1

3

Page 4

10

11

4

12

Ls

n

Bpm 1420 1850 2240 2860

260 340 410 590

0

9 8

Hs

t y t

4

Page 5

13

14

o

u

i

ty

15 16

p

a

s

o

17

d

f

5

Page 6

18

19

0

ab

20

j

j

g

g

1

2

1

h

2

h

6

Page 7

GENERAL POWER TOOL SAFETY

WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your fi nger on the switch or

energising power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may aff ect the power

toolʼs operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

Use of the power tool for operations diff erent from

those intended could result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specifi ed by the

manufacturer.

A charger that is suitable for one type of battery pack

may create a risk of fi re when used with another

battery pack.

b) Use power tools only with specifi cally

designated battery packs.

Use of any other battery packs may create a risk of

injury and fi re.

7

Page 8

c) When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal to

another.

Shorting the battery terminals together may cause

burns or a fi re.

d) Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, fl ush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or

burns.

6) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach of

children and infi rm persons.

CORDLESS ROTARY HAMMER

SAFETY WARNINGS

1. Wear ear protectors

Exposure to noise can cause hearing loss.

2. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring.

Cutting accessory contacting a "live" wire may make

exposed metal parts of the power tool "live" and could

give the operator an electric shock.

ADDITIONAL SAFETY WARNINGS

1. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

2. Never disassemble the rechargeable battery and

charger.

3. Never short-circuit the rechargeable battery.

Shortcircuiting the battery will cause a great electric

current and overheat. It results in burn or damage to the

battery.

4. Do not dispose of the battery in fi re. If the battery is burnt,

it may explode.

5. When using this unit continuously, the unit may overheat,

leading to damage in the motor and switch. Please leave

it without using it for approximately 15 minutes.

6. Do not insert object into the air ventilation slots of the

charger. Inserting metal objects or infl ammables into the

charger air ventilation slots will result in electrical shock

hazard or damaged charger.

7. Bring the battery to the shop from which it was purchased

as soon as the post-charging battery life becomes too

short for practical use. Do not dispose of the exhausted

battery.

8. Before starting to break, chip or drill into a wall, fl oor or

ceiling, thoroughly confi rm that such items as electric

cables or conduits are not buried inside.

9. Ensure that the power switch is in the OFF position. If the

battery is installed while the power switch is in the ON

position, the power tool will start operating immediately,

which could cause a serious accident.

10. Do not touch the bit during or immediately after operation.

The bit becomes very hot during operation and could

cause serious burns.

11. Always hold the body handle and side handle of the

power tool fi rmly. Otherwise the counterforce produced

may result in inaccurate and even dangerous operation.

12. Wear a dust mask

Do not inhale the harmful dusts generated in drilling or

chiseling operation. The dust can endanger the health of

yourself and bystanders.

13. Make sure that the battery is installed fi rmly. If it is at all

loose it could come off and cause an accident.

14. To prevent accidents, make sure to turn the switch off

and pull out the battery before changing accessories,

storing, carrying or when not using the tools.

15. Mounting the tool

○ To prevent accidents, make sure to turn the switch off

and pull out the battery.

○ When using tools such as bull points, drill bits, etc.,

make sure to use the genuine parts designated by our

company.

○ Clean the shank portion of the drill bit. Then smear the

shank portion with the grease or machine oil.

○ Check the latching by pulling on the drill bit.

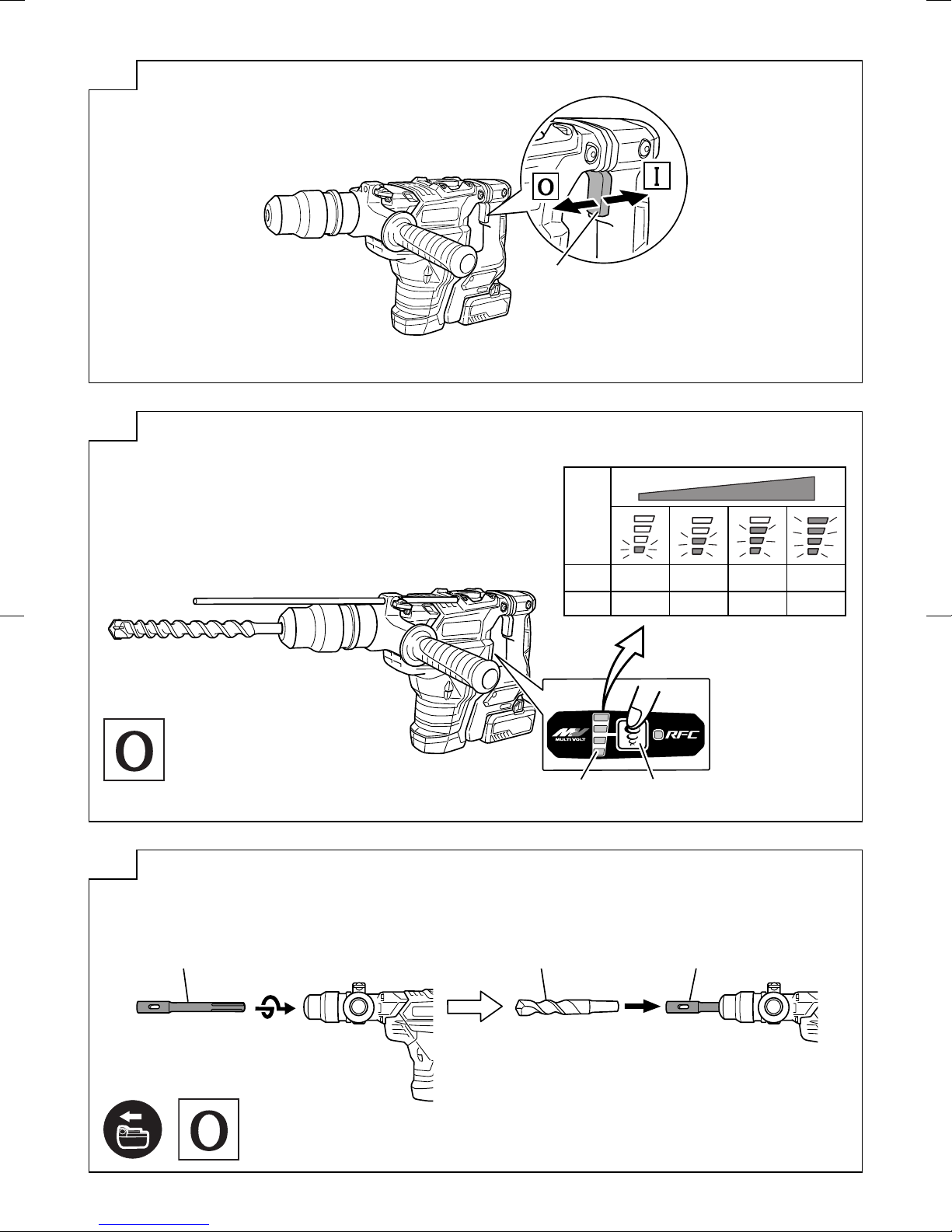

16. Operate the change lever only when the motor is at a

full stop. Operating the change lever while the motor is

running may cause the tip tool to unexpectedly rotate

and result in an accident. (Fig. 8)

17. Rotation + hammering

When the drill bit touches construction iron bar, the bit

will stop immediately and the rotary hammer will react to

revolve. Therefore fi rmly tighten the side handle, hold the

body handle and side handles.

18. Do not use the product if the tool or the battery terminals

(battery mount) are deformed.

Installing the battery could cause a short circuit that

could result in smoke emission or ignition.

19. Keep the tool’s terminals (battery mount) free of swarf

and dust.

○ Prior to use, make sure that swarf and dust have not

collected in the area of the terminals.

○ During use, try to avoid swarf or dust on the tool from

falling on the battery.

○ When suspending operation or after use, do not leave

the tool in an area where it may be exposed to falling

swarf or dust.

Doing so could cause a short circuit that could result in

smoke emission or ignition.

CAUTION ON LITHIUM-ION BATTERY

To extend the lifetime, the lithium-ion battery equips with the

protection function to stop the output.

In the cases of 1 to 3 described below, when using this

product, even if you are pulling the switch, the motor may

stop. This is not the trouble but the result of protection

function.

1. When the battery power remaining runs out, the motor

stops.

In such a case, charge it up immediately.

2. If the tool is overloaded, the motor may stop. In this

case, release the switch of tool and eliminate causes of

overloading. After that, you can use it again.

3. If the battery is overheated under overload work, the

battery power may stop.

In this case, stop using the battery and let the battery

cool. After that, you can use it again.

Furthermore, please heed the following warning and caution.

WARNING

In order to prevent any battery leakage, heat generation,

smoke emission, explosion and ignition beforehand, please

be sure to heed the following precautions.

8

Page 9

1. Make sure that swarf and dust do not collect on the

battery.

○ During work make sure that swarf and dust do not fall on

the battery.

○ Make sure that any swarf and dust falling on the power

tool during work do not collect on the battery.

○ Do not store an unused battery in a location exposed to

swarf and dust.

○ Before storing a battery, remove any swarf and dust that

may adhere to it and do not store it together with metal

parts (screws, nails, etc.).

2. Do not pierce battery with a sharp object such as a

nail, strike with a hammer, step on, throw or subject the

battery to severe physical shock.

3. Do not use an apparently damaged or deformed battery.

4. Do not use the battery in reverse polarity.

5. Do not connect directly to an electrical outlets or car

cigarette lighter sockets.

6. Do not use the battery for a purpose other than those

specifi ed.

7. If the battery charging fails to complete even when a

specifi ed recharging time has elapsed, immediately stop

further recharging.

8. Do not put or subject the battery to high temperatures or

high pressure such as into a microwave oven, dryer, or

high pressure container.

9. Keep away from fi re immediately when leakage or foul

odor are detected.

10. Do not use in a location where strong static electricity

generates.

11. If there is battery leakage, foul odor, heat generated,

discolored or deformed, or in any way appears abnormal

during use, recharging or storage, immediately remove it

from the equipment or battery charger, and stop use.

12. Do not immerse the battery or allow any fl uids to fl ow

inside. Conductive liquid ingress, such as water, can

cause damage resulting in fi re or explosion. Store your

battery in a cool, dry place, away from combustible and

fl ammable items. Corrosive gas atmospheres must be

avoided.

CAUTION

1. If liquid leaking from the battery gets into your eyes,

do not rub your eyes and wash them well with fresh

clean water such as tap water and contact a doctor

immediately.

If left untreated, the liquid may cause eye-problems.

2. If liquid leaks onto your skin or clothes, wash well with

clean water such as tap water immediately.

There is a possibility that this can cause skin irritation.

3. If you fi nd rust, foul odor, overheating, discolor,

deformation, and/or other irregularities when using the

battery for the fi rst time, do not use and return it to your

supplier or vendor.

WARNING

If a conductive foreign matter enters in the terminal of

lithium ion battery, the battery may be shorted, causing fi re.

When storing the lithium ion battery, obey surely the rules of

following contents.

○ Do not place conductive debris, nail and wires such as

iron wire and copper wire in the storage case.

○ To prevent shorting from occurring, load the battery in

the tool or insert securely the battery cover for storing

until the ventilator is not seen.

REGARDING LITHIUM-ION BATTERY

TRANSPORTATION

When transporting a lithium-ion battery, please observe the

following precautions.

WARNING

Notify the transporting company that a package contains a

lithium-ion battery, inform the company of its power output

and follow the instructions of the transportation company

when arranging transport.

○ Lithium-ion batteries that exceed a power output of

100Wh are considered to be in the freight classifi cation

of Dangerous Goods and will require special application

procedures.

○ For transportation abroad, you must comply with

international law and the rules and regulations of the

destination country.

○ If the BSL36B18 is installed in the power tool, the power

output will exceed 100 Wh and the unit will be classifi ed

as Dangerous Goods for freight classifi cation.

Power Output

Wh

2 to 3 digit number

USB DEVICE CONNECTION

PRECAUTIONS (UC18YSL3)

When an unexpected problem occurs, the data in a USB

device connected to this product may be corrupted or lost.

Always make sure to back up any data contained in the USB

device prior to use with this product.

Please be aware that our company accepts absolutely no

responsibility for any data stored in a USB device that is

corrupted or lost, nor for any damage that may occur to a

connected device.

WARNING

○ Prior to use, check the connecting USB cable for any

defect or damage.

Using a defective or damaged USB cable can cause

smoke emission or ignition.

○ When the product is not being used, cover the USB port

with the rubber cover.

Buildup of dust etc. in the USB port can cause smoke

emission or ignition.

NOTE

○ There may be an occasional pause during USB

recharging.

○ When a USB device is not being charged, remove the

USB device from the charger.

Failure to do so may not only reduce the battery life

of a USB device, but may also result in unexpected

accidents.

○ It may not be possible to charge some USB devices,

depending on the type of device.

9

Page 10

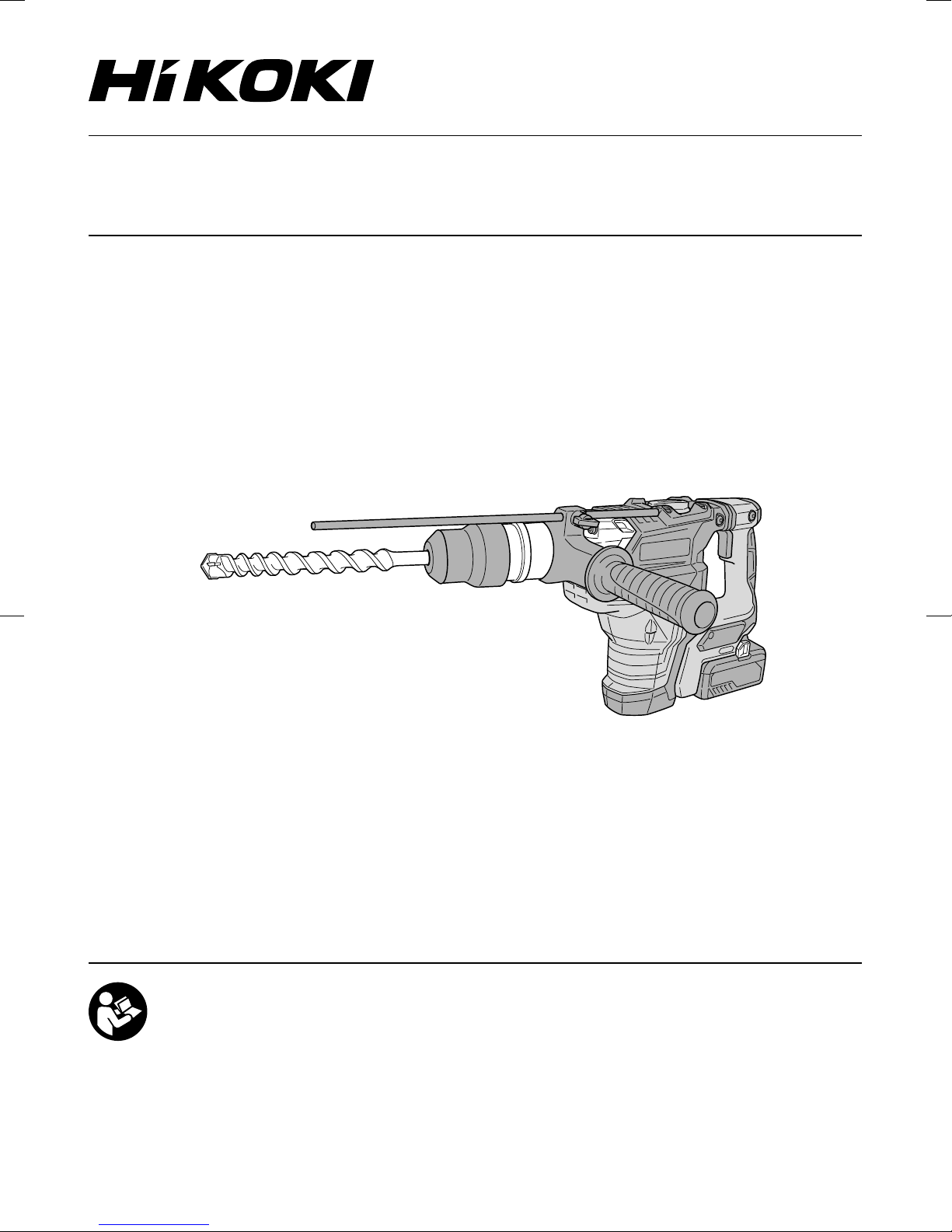

NAMES OF PARTS (Fig. 1 – Fig. 20)

Switching ON

Drill bit

1

Stopper

2

Selector lever

3

Switch trigger

4

Handle

5

Nameplate

6

RFC indicator lamp

7

Rotation speed

8

selector switch

Display lamp

9

Battery

0

Tail cover

!

Housing

@

Motor

#

Side handle

$

Grip

%

Front cap

^

Stopper lever

&

Latch

*

Charge indicator lamp

(

Remaining battery

)

indicator switch

Remaining battery

q

indicator lamp

Display panel

w

Grease

e

Wing bolt

r

Taper shank adapter

t

Drill bit (Taper shank)

y

Cotter

u

Core bit shank

i

Core bit

o

Guide plate

p

Center pin

a

Core bit tip

s

Battery sliding

d

grooves

Terminal

f

Rubber cover

g

USB port

h

USB cable

j

SYMBOLS

WARNING

The following show symbols used for the machine.

Be sure that you understand their meaning before

use.

Ls

Hs

Switching OFF

Rotation speed selector switch

Display lamp

Low speed / impact rate

High speed / impact rate

Disconnect the battery

Lights ;

The battery remaining power is over 75%

Lights ;

The battery remaining power is 50% – 75%.

Lights ;

The battery remaining power is 25% – 50%.

Lights ;

The battery remaining power is less than 25%

Blinks ;

The battery remaining power is nearly empty.

Recharge the battery soonest possible.

Blinks ;

Output suspended due to high temperature.

Remove the battery from the tool and allow it to

fully cool down.

Blinks ;

Output suspended due to failure or malfunction.

The problem may be the battery so please

contact your dealer.

Warning

DH36DMA: Cordless Rotary Hammer

To reduce the risk of injury, user must read

instruction manual.

Direct current

V Rated voltage

No-load speed

n

0

/min Oscillation per minute

Bpm Full-load impact rate

φ

max

Drilling diameter, max.

Weight

kg

(According to EPTA-Procedure 01/2003)

Drill bit

Core bit

Adjustment of the tool position function

Hammering only function

Rotation and hammering function

STANDARD ACCESSORIES

In addition to the main unit (1 unit), the package contains the

accessories listed on page 16.

Standard accessories are subject to change without notice.

APPLICATIONS

Rotation and hammering function

○ Drilling anchor holes

○ Drilling holes in concrete

Hammering only function

○ Crushing concrete, chipping, digging, and squaring

(Some applications need optional accessories)

SPECIFICATIONS

The specifi cations of this machine are listed in the Table on

page 16.

NOTE

○ Existing batteries (BSL3660/3626X/3626/3625/3620,

BSL18xx and BSL14xx series) cannot be used with this

tool.

○ Due to HiKOKI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

10

Page 11

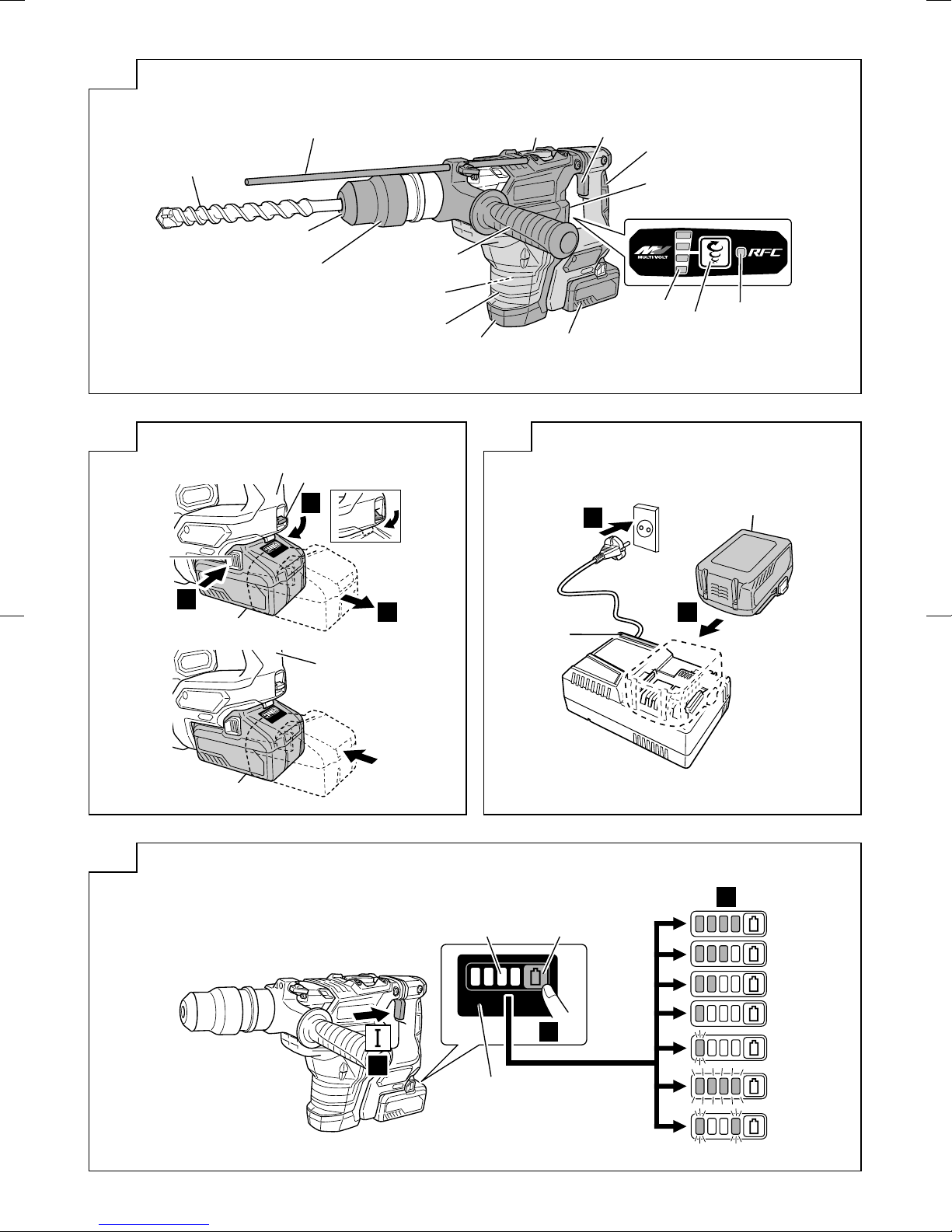

CHARGING

Before using the power tool, charge the battery as follows.

1. Connect the charger’s power cord to the receptacle.

When connecting the plug of the charger to a receptacle,

the charge indicator lamp will blink in red (At 1- second

intervals).

2. Insert the battery into the charger.

Firmly insert the battery into the charger as shown in

Fig. 3 (on page 2).

Table 1

Indications of the charge indicator lamp

Before

charging

Blinks

(RED)

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

3. Charging

When inserting a battery in the charger, the charge

indicator lamp will blink in blue.

When the battery becomes fully recharged, the charge

indicator lamp will light up in green. (See Table 1)

(1) Charge indicator lamp indication

The indications of the charge indicator lamp will be

as shown in Table 1, according to the condition of the

charger or the rechargeable battery.

Plugged into power source

Blinks

(BLUE)

While

charging

Charge

indicator

lamp

(RED /

BLUE /

GREEN /

PURPLE)

(2) Regarding the temperatures and charging time of the rechargeable battery

The temperatures and charging time will become as shown in Table 2.

Charging

complete

Overheat

standby

Charging

impossible

Blinks

(BLUE)

Lights

(BLUE)

Lights

(GREEN)

Blinks

(RED)

Flickers

(PURPLE)

Charger

Lights for 0.5 seconds. Does not light for

1 second. (off for 1 second)

Lights for 1 second. Does not light

for 0.5 seconds. (off for 0.5 seconds)

Lights continuously

Lights continuously

(Continuous buzzer sound: about 6

seconds)

Lights for 0.3 seconds. Does not light for

0.3 seconds. (off for 0.3 seconds)

Lights for 0.1 seconds. Does not light for

0.1 seconds. (off for 0.1 seconds)

(Intermittent buzzer sound: about 2

seconds)

Table 2

UC18YSL3

Battery capacity at less than 50%

Battery capacity at less than 80%

Battery capacity at more than 80%

Battery overheated. Unable to

charge. (Charging will commence

when battery cools)

Malfunction in the battery or the

charger

Type of battery Li-ion

Temperatures at which the

battery can be recharged

Charging voltage V 14.4 18

Battery

Charging time,

approx. (At 20°C)

min.

USB

NOTE

The recharging time may vary according to the ambient temperature and power source voltage.

Charging voltage V 5

Charging current A 2

-10°C – 50°C

BSL14xx series BSL18xx series

(4 cells) (8 cells) (5 cells) (10 cells) (10 cells)

BSL1415S : 15

BSL1415

BSL1415X

BSL1420

BSL1425

BSL1430C

:

:

:

15

:

15

20

25

:

30

BSL1430

BSL1440

BSL1450

BSL1460

11

:

:

:

:

BSL1815S : 15

BSL1815 : 15

20

BSL1815X : 15

26

BSL1820 : 20

32

BSL1825 : 25

38

BSL1830C : 30

BSL1830 : 20

BSL1840 : 26

BSL1850 : 32

BSL1860 : 38

Multi volt

BSL36A18 : 32

BSL36B18 : 52

series

Page 12

4. Disconnect the charger’s power cord from the

receptacle.

5. Hold the charger fi rmly and pull out the battery.

NOTE

Be sure to pull out the battery from the charger after use,

and then keep it.

Regarding electric discharge in case of new batteries,

etc.

As the internal chemical substance of new batteries and

batteries that have not been used for an extended period

is not activated, the electric discharge might be low when

using them the fi rst and second time. This is a temporary

phenomenon, and normal time required for recharging

will be restored by recharging the batteries 2 – 3 times.

How to make the batteries perform longer.

(1) Recharge the batteries before they become completely

exhausted.

When you feel that the power of the tool becomes

weaker, stop using the tool and recharge its battery.

If you continue to use the tool and exhaust the electric

current, the battery may be damaged and its life will

become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after

use. If such a battery is recharged immediately after

use, its internal chemical substance will deteriorate, and

the battery life will be shortened. Leave the battery and

recharge it after it has cooled for a while.

CAUTION

○ If the battery is charged while it is heated because

it has been left for a long time in a location subject to

direct sunlight or because the battery has just been

used, the charge indicator lamp of the charger lights

for 0.3 seconds, does not light for 0.3 seconds (off for

0.3 seconds). In such a case, fi rst let the battery cool,

then start charging.

○ When the charge indicator lamp fl ickers (at 0.2-second

intervals), check for and take out any foreign objects in

the charger’s battery connector. If there are no foreign

objects, it is probable that the battery or charger is

malfunctioning. Take it to your authorized Service Center.

○ Since the built-in micro computer takes about 3 seconds

to confi rm that the battery being charged with

UC18YSL3 is taken out, wait for a minimum of 3 seconds

before reinserting it to continue charging. If the battery

is reinserted within 3 seconds, the battery may not be

properly charged.

MOUNTING AND OPERATION

Action Figure Page

Removing and inserting the battery 2 2

Charging 3 2

Remaining battery indicator 4 2

Inserting SDS-max tools 5 3

Removing SDS-max tools 6 3

Changing tool direction 7 3

Selecting the operating mode 8 3

Install the stopper 9 3

Switching on and off 10 4

Speed change*

1

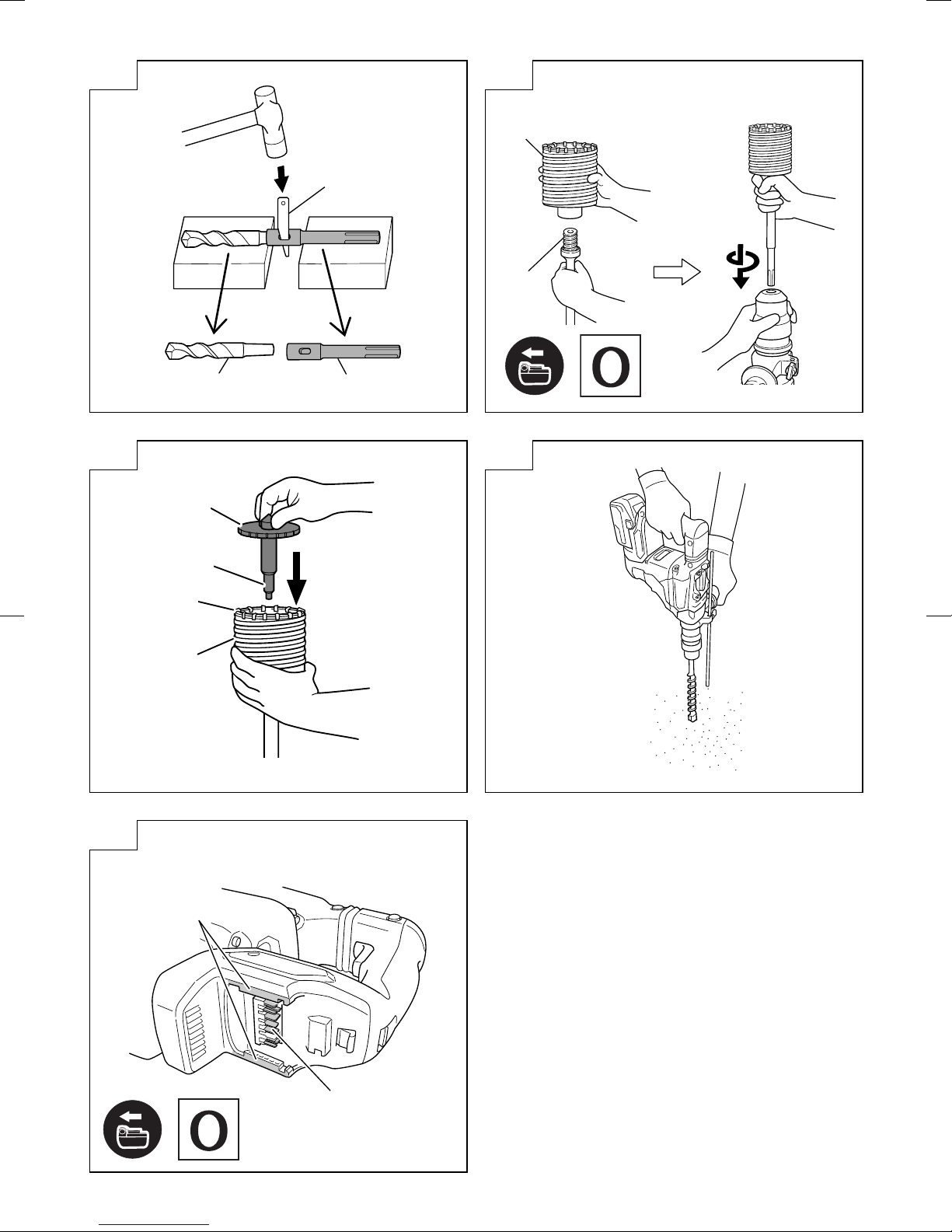

Using taper shank adapter 12 4

11 4

Removing taper shank adapter 13 5

Mounting core bit 14 5

Mounting guide plate and center pin 15 5

Cleaning of the battery installation

compartment

Charging a USB device from a

electrical outlet

Charging a USB device and battery

from a electrical outlet

17 5

18-a 6

18-b 6

How to recharge USB device 19 6

When charging of USB device is

completed

Selecting accessories*

2

20 6

― 17 – 19

*1 When drilling fragile materials, or when conducting

chipping operations or alignment operations, change the

tool’s rotation speed in accordance with the task by using

the rotation speed selector switch.

NOTE

○ Rotation speed cannot be adjusted until a battery is

installed to the power tool and the switch has been

triggered once.

○ While the tool’s motor is operating, rotation speed cannot

be adjusted by pressing the rotation speed selector

switch.

To adjust rotation speed, switch off the tool. Once the

motor has stopped, press the rotation speed selector

switch to adjust the speed.

*2 For detailed information regarding each tool, contact a

HiKOKI authorized service center.

Operate this Rotary Hammer by utilizing its own weight. The

performance will not be better even if it is pressed or thrust

forcibly against the work surface.

Hold this Rotary Hammer with a force just suffi cient to

counteract the reaction.

CAUTION

After long time of use, the cylinder case becomes hot.

Therefore, be careful not to burn your hands.

Warming up (Fig. 16)

The grease lubrication system in this unit may require

warming up in cold regions.

Position the end of the bit so makes contact with the

concrete, turn on the switch and perform the warming

up operation. Make sure that a hitting sound is produced

and then use the unit.

CAUTION

When the warming up operation is performed, hold the

side handle and the main body securely with both hands

to maintain a secure grip and be careful not to twist your

body by the jammed drill bit.

12

Page 13

ABOUT THE PROTECTION

FUNCTIONS

This product features functions that are designed to protect

the tool itself as well as the battery. While the switch is

pulled, if any of the safeguard functions are triggered

during operation, the display lamp will blink as described in

Table 3. When any of the safeguard functions are triggered,

immediately remove your fi nger from the switch and follow

the instructions described under corrective action.

Table 3

Display

lamp

fl ashing

Flash

Flash

Flash

Cause Solution

Internal temperature

has risen beyond

the unit’s specifi ed

temperature.

(Temperature

increase protection

function)

Excessive pressure

applied to the tool

has resulted in an

overload.

(Overload

protection function)

Sensor signal read

error.

(Control monitoring

function)

Turn off the unit and

allow it to cool down

for about 15 minutes.

When the temperature

goes down, the unit is

ready for use.

Remove the cause of

the overburdening.

Repair may be

required.

REACTIVE FORCE CONTROL

This product is equipped with a Reactive Force Control

(RFC) feature that reduces jerking of the tool body.

If the tool bit is suddenly overburdened, any jerking of the

tool body is reduced by activation of the slip clutch or by

stopping of the motor by the sensor built into the tool body.

If the motor is stopped because of overburdening detection

by the controller, the RFC indicator lamp will blink while the

switch is pulled. In addition, the lamp will continue blinking

for approximately three seconds after the switch is released.

The motor will remain stopped while the lamp is blinking.

(Fig. 21)

Because the RFC feature may not activate or its performance

may be insuffi cient depending on the working environment

and conditions, be careful not to suddenly overburden the

tool bit while operating.

● Possible causes of sudden overburdening

1 Tool bit biting into material

2 Impact against nails, metal or other hard objects

3 Tasks involving prying or any excess application of

pressure, etc.

Also, other causes include any combination of the

aforementioned.

● When the reactive force control (RFC) is triggered

When the RFC is triggered and the motor stops, turn

off the tool’s switch and remove the cause of the

overburdening before continuing operation.

Fig. 21

GREASE REPLACEMENT

This Rotary Hammer is of full air-tight construction to protect

against dust and to prevent lubricant leakage.

Therefore, this Rotary Hammer can be used without

lubrication for long periods. Replace the grease as described

below.

Grease Replacement Period

After purchase, replace grease after every 6 months of

usage. Ask for grease replacement at the nearest authorized

Service Center.

MAINTENANCE AND INSPECTION

CAUTION

Be sure to turned off the switch and remove the battery

before maintenance and inspection.

1. Inspecting the tool

Since use of as dull tool will degrade effi ciency and

cause possible motor malfunction, sharpen or replace

the tool as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspection of terminals (tool and battery)

Check to make sure that swarf and dust have not

collected on the terminals.

On occasion check prior, during and after operation.

CAUTION

Remove any swarf or dust which may have collected on

the terminals.

Failure to do so may result in malfunction.

5. Cleaning on the outside

When the power tool is stained, wipe with a soft dry cloth

or a cloth moistened with soapy water. Do not use chloric

solvents, gasoline or paint thinner, for they melt plastics.

6. Cleaning of the battery installation compartment

After drilling concrete, if concrete dust has accumulated

on the terminals or the area where the battery slides

within the battery installation compartment, clean off the

accumulated concrete dust with a dry cloth before using

the tool. (Fig. 17)

Also, after cleaning, ensure that the battery can be

installed and removed smoothly from the tool.

13

Page 14

CAUTION

Using the tool when the battery is covered with concrete

dust may lead to accidents such as the battery falling

during use.

Furthermore, such use may cause a malfunction or

contact failure between the battery and the terminals.

7. Storage

Store the power tool in a place in which the temperature

is less than 40°C and out of reach of children.

NOTE

Storing lithium-ion batteries.

Make sure the lithium-ion batteries have been fully

charged before storing them.

Prolonged storage (3 months or more) of batteries with

a low charge may result in performance deterioration,

signifi cantly reducing battery usage time or rendering

the batteries incapable of holding a charge.

However, signifi cantly reduced battery usage time may

be recovered by repeatedly charging and using the

batteries two to fi ve times.

If the battery usage time is extremely short despite

repeated charging and use, consider the batteries dead

and purchase new batteries.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

Important notice on the batteries for the HiKOKI

cordless power tools

Please always use one of our designated genuine

batteries. We cannot guarantee the safety and

performance of our cordless power tool when used with

batteries other than these designated by us, or when

the battery is disassembled and modifi ed (such as

disassembly and replacement of cells or other internal

parts).

NOTE

Due to HiKOKI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

TROUBLESHOOTING

Use the inspections in the table below if the tool does not operate normally. If this does not remedy the problem, consult your

dealer or the HiKOKI Authorized Service Center.

1. Power tool

Symptom Possible cause Remedy

Tool doesn’t run No remaining battery power Charge the battery.

Battery isn’t securely attached. Push in the battery until a click is heard.

Concrete dust has accumulated on

the terminals of the battery installation

compartment as well as on the battery

sliding grooves.

The battery was attached while the switch

trigger was ON.

Tool suddenly stopped Tool was overburdened Get rid of the problem causing the

Reactive force control was activated

The battery is overheated. Let the battery cool down.

Tool bits

-can’t be attached

-fall off

Holes can’t be smoothly

drilled.

Battery cannot be installed. Attempting to install a battery other than that

The shape of the attachment portion doesn’t

match

The drill is worn Replace with a new drill.

specifi ed for the tool.

Clean off the accumulated concrete dust

with a dry cloth.

Attach the battery when the switch trigger

is OFF.

overburden.

For the SDS-max shank type, use a bit with

a diameter that is within the designated

range.

Please install a multi volt type battery.

14

Page 15

2. Charger

Symptom Possible cause Remedy

The charge indicator lamp

rapidly fl ickers purple, and

battery charging doesn’t

begin.

The charge indicator lamp

blinks red, and battery

charging doesn’t begin.

Battery usage time is short

even though the battery is

fully charged.

The battery takes a long

time to charge.

The USB power lamp

has switched off and the

USB device has stopped

charging.

USB power lamp does not

switch off even though the

USB device has fi nished

charging.

It is unclear what the

charging status of a USB

device is, or whether its

charging is complete.

Charging of a USB device

pauses midway.

Charging of the USB device

pauses midway when the

battery and the USB device

are being charged at the

same time.

Charging of the USB device

doesn’t start when the

battery and the USB device

are being charged at the

same time.

The battery is not inserted all the way. Insert the battery fi rmly.

There is foreign matter in the battery

Remove the foreign matter.

terminal or where the battery is attached.

The battery is not inserted all the way. Insert the battery fi rmly.

The battery is overheated. If left alone, the battery will automatically

begin charging if its temperature decreases,

but this may reduce battery life. It is

recommended that the battery be cooled in

a well-ventilated location away from direct

sunlight before charging it.

The battery’s life is depleted. Replace the battery with a new one.

The temperature of the battery, the charger,

or the surrounding environment is extremely

Charge the battery indoors or in another

warmer environment.

low.

The charger’s vents are blocked, causing its

Avoid blocking the vents.

internal components to overheat.

The cooling fan is not running. Contact a HiKOKI Authorized Service

Center for repairs.

The battery’s capacity has become low. Replace the battery with one that has

capacity remaining.

Plug the charger’s power plug into an

electric socket.

The USB power lamp lights up green to

This is not a malfunction.

indicate that USB charging is possible.

The USB power lamp does not switch off

even when charging is complete.

The charger was plugged into an electrical

socket while the USB device was being

charged using the battery as the power

source.

Examine the USB device that is charging to

confi rm its charging status.

This is not a malfunction.

The charger pauses USB charging for about

5 seconds when it is diff erentiating between

power sources.

A battery was inserted into the charger while

the USB device was being charged using a

power socket as the power source.

The battery has become fully charged. This is not a malfunction.

The charger pauses USB charging for

about 5 seconds while it checks whether

the battery has successfully completed

charging.

The remaining battery capacity is extremely

low.

This is not a malfunction.

When the battery capacity reaches a certain

level, USB charging automatically begins.

15

Page 16

V

36V

n

0

Bpm

φ

max

φ

max

kg

BSL36B18

260 – 590 /min

1420 – 2860 /min

40 mm

105 mm

7.9 kg

DH36DMA

(2WC) (NNK)

2 ―

1 ―

UC18YSL3

2 ―

11

11

11

11

16

Page 17

BSL36B18

329897

30g: 981840

UC18YSL3 (14.4V – 18V)

337577

330209

949556

949859

331246

331247

371135

971786

17

Page 18

D

956009 (D < 35)

955165 (D > 38)

300 mm : 313466 (D < 35)

313467 (D > 38)

944477

313465

321813 313468

930515

12.7 mm : 313469

19.0 mm : 313470

18

Page 19

400 mm : 313472

400 mm : 313474

W50 × 400 mm : 313475

400 mm : 313476

150 mm

313477

313478

320859

313479

318085

19

Page 20

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

Code No. C99724711 G

806

Printed in China

Loading...

Loading...