Page 1

MODEL

DH 24PM

ROTARY HAMMER

DH 24PM

Hitachi

Power Tools

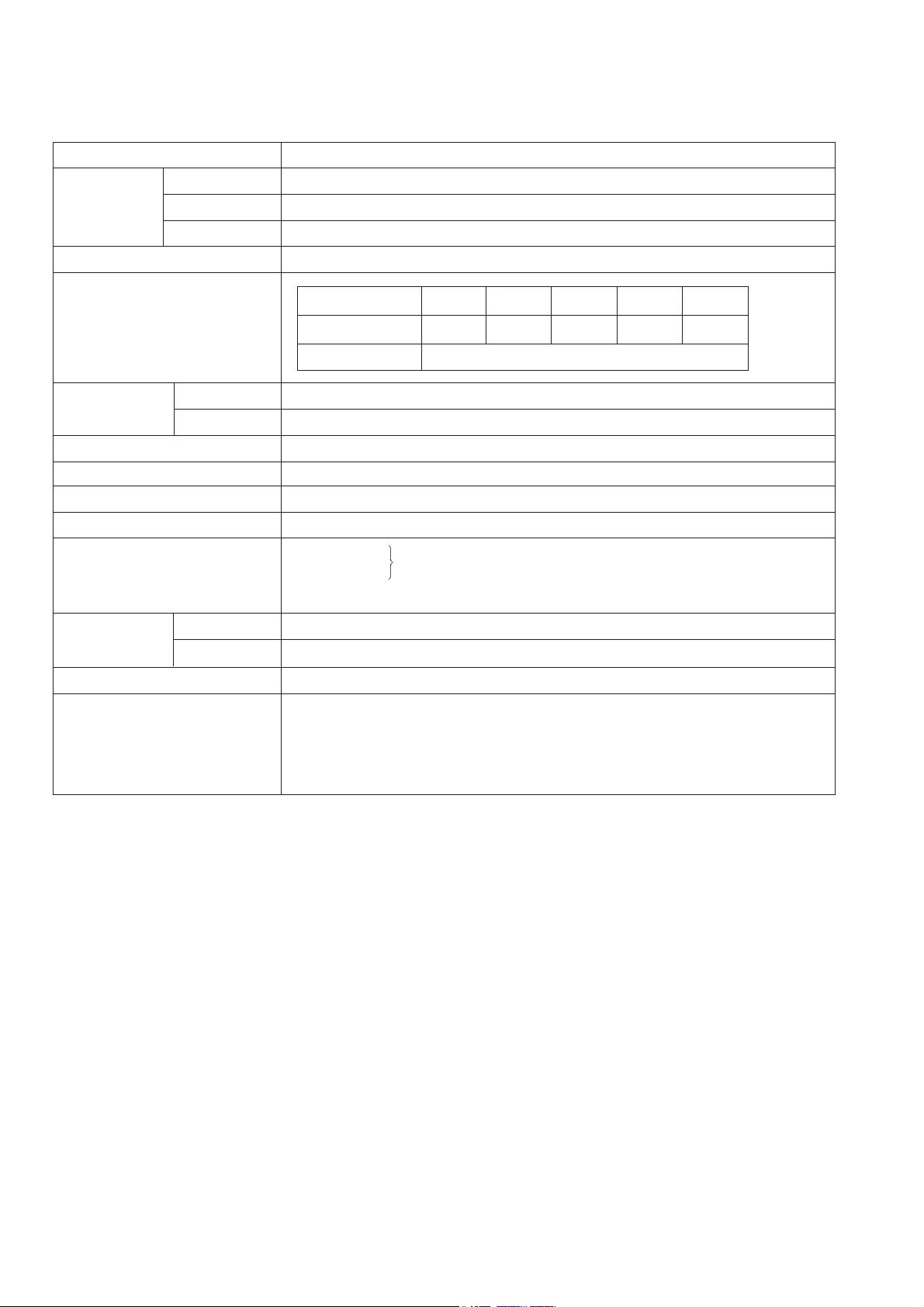

TECHNICAL DATA

AND

SERVICE MANUAL

D

LIST No. E496 Sep. 2006

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Page 2

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, symbols

are used in the place of company names and model names of our

competitors. The symbols utilized here are as follows:

Competitors

Symbols Utilized

Company Name

Model Name

B

C

BOSCH

MAKITA

GBH2-26DFR

HR2450T

Page 3

CONTENTS

Page

1. PRODUCT NAME ........................................................................................................................... 1

2. MARKETING OBJECTIVE ............................................................................................................. 1

3. APPLICATIONS .............................................................................................................................. 1

4. SELLING POINTS .......................................................................................................................... 2

4-1. Selling Point Descriptions ............................................................................................................... 2

5. SPECIFICATIONS .......................................................................................................................... 4

5-1. Specifications .................................................................................................................................. 4

5-2. Optional Accessories ...................................................................................................................... 5

6. COMPARISONS WITH SIMILAR PRODUCTS .............................................................................. 9

6-1. Specification Comparisons ............................................................................................................. 9

6-2. Drilling Speed Comparison ........................................................................................................... 10

6-3. Chiseling Performance Comparison .............................................................................................. 11

7. PRECAUTIONS IN SALES PROMOTION ................................................................................... 12

7-1. Handling Instructions .................................................................................................................... 12

7-2. Caution Plate ................................................................................................................................ 12

8. REFERENCE MATERIAL ............................................................................................................. 13

8-1. Lubrication .................................................................................................................................... 13

8-2. Tool Structure ................................................................................................................................ 13

8-3. "Three-mode" Changeover Mechanism ........................................................................................ 18

8-4. Caution when Using "Rotation Only" (No Hammering) Function .................................................. 20

8-5. Drill Bits ......................................................................................................................................... 21

8-6. Chuck Section ............................................................................................................................... 22

8-7. Dust Collector (B) ......................................................................................................................... 22

9. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY .......................................................... 24

9-1. Disassembly ................................................................................................................................. 24

9-2. Reassembly .................................................................................................................................. 30

9-3. Tightening Torque ......................................................................................................................... 33

9-4. Wiring Diagrams ........................................................................................................................... 34

9-5. Internal Wire Arrangement and Wiring Work ................................................................................ 35

9-6. Insulation Tests ............................................................................................................................. 37

9-7. No-load Current Values ................................................................................................................. 37

10. STANDARD REPAIR TIME (UNIT) SCHEDULES ..................................................................... 38

Assembly Diagram for DH 24PM

Page 4

1. PRODUCT NAME

Hitachi Rotary Hammer, Model DH 24PM

2. MARKETING OBJECTIVE

The new Model DH 24PM is a 3-mode type rotary hammer based on the Model DH 24PC3 rotary hammer drill. It

can provide 3 modes of operation, "Rotation and hammering," "Rotation only" and "Hammering only."

In addition, the Model DH 24PM is equipped with a quick-release tool retainer that requires only two steps to

switch between the drill bit holder for use with SDS-plus bits and the drill chuck holder for drilling holes in steel

and wood easily and safely.

The main features of the Model DH 24PM are as follows:

(1) The tool retainer requires only two steps to switch between the drill bit holder for use with SDS-plus bits and

the drill chuck holder for drilling holes in steel and wood easily and safely.

(2) Class-top drilling speed

(3) More comfortable and frisky drilling

(4) Long service life and high durability thanks to the internal pressure adjustment mechanism

(5) Non-slip double-layer molded handle and gear cover

3. APPLICATIONS

(1) Rotation and hammering function (When the drill bit holder is mounted)

Drilling anchor holes

Drilling holes in concrete, tile, brick and similar materials

(2) Rotation only function (When the drill chuck holder is mounted)

Drilling holes in steel and wood

Tightening and loosening machine screws and wood screws

(3) Hammering only function (When the drill bit holder is mounted)

Light-duty chiselling of concrete

Groove digging and edging

[Typical applications]

Air conditioning ................................... Installation of air conditioners, water coolers and heaters, and air ducts

Piping and plumbing ........................... Installation of gas, water, and sanitary facilities

Electrical work ..................................... Installation of light fixtures and various electric appliances

Interior decoration ............................... Installation of seating, display stands and partitions

Other civil engineering, construction and repair work

--- 1 ---

Page 5

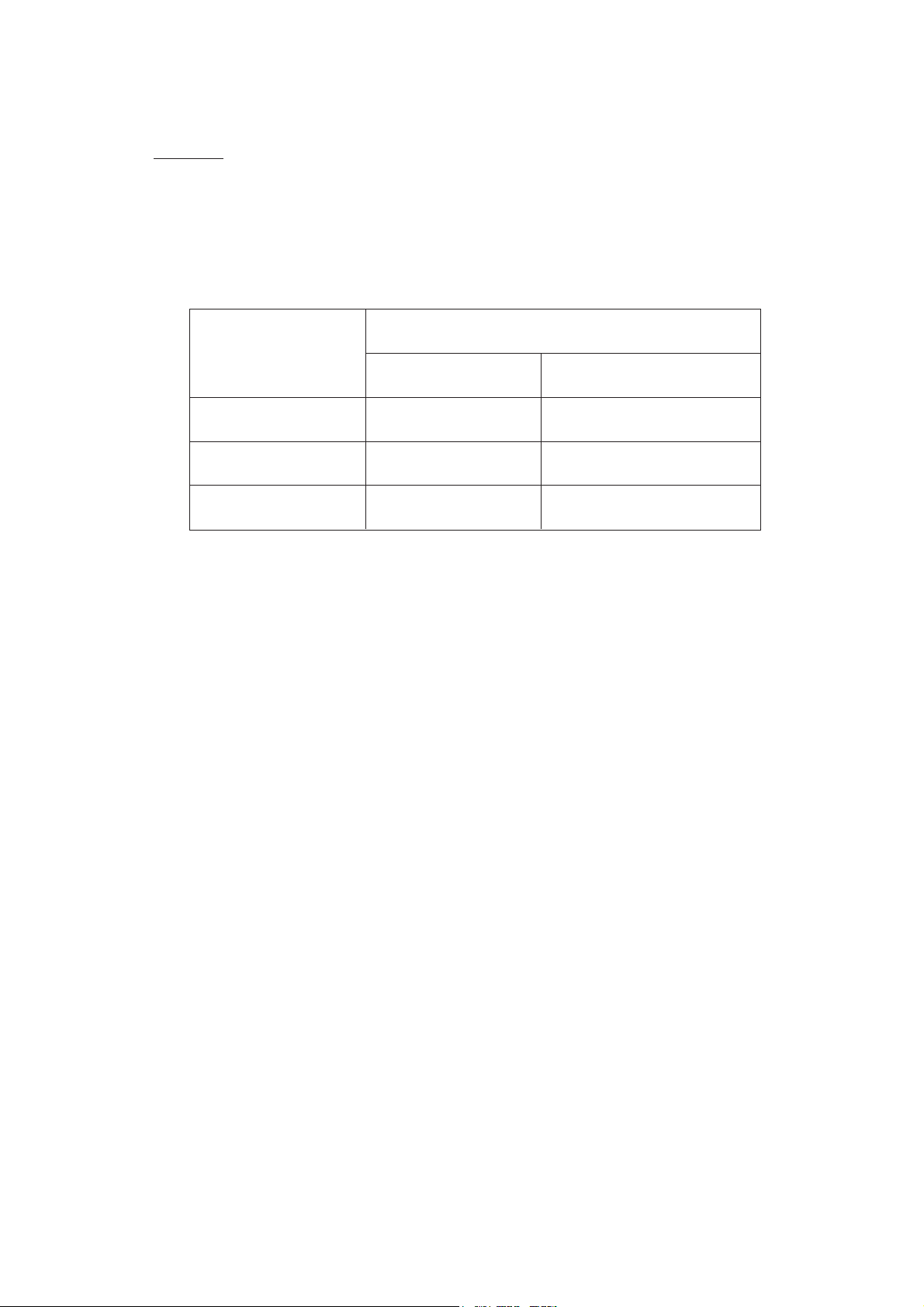

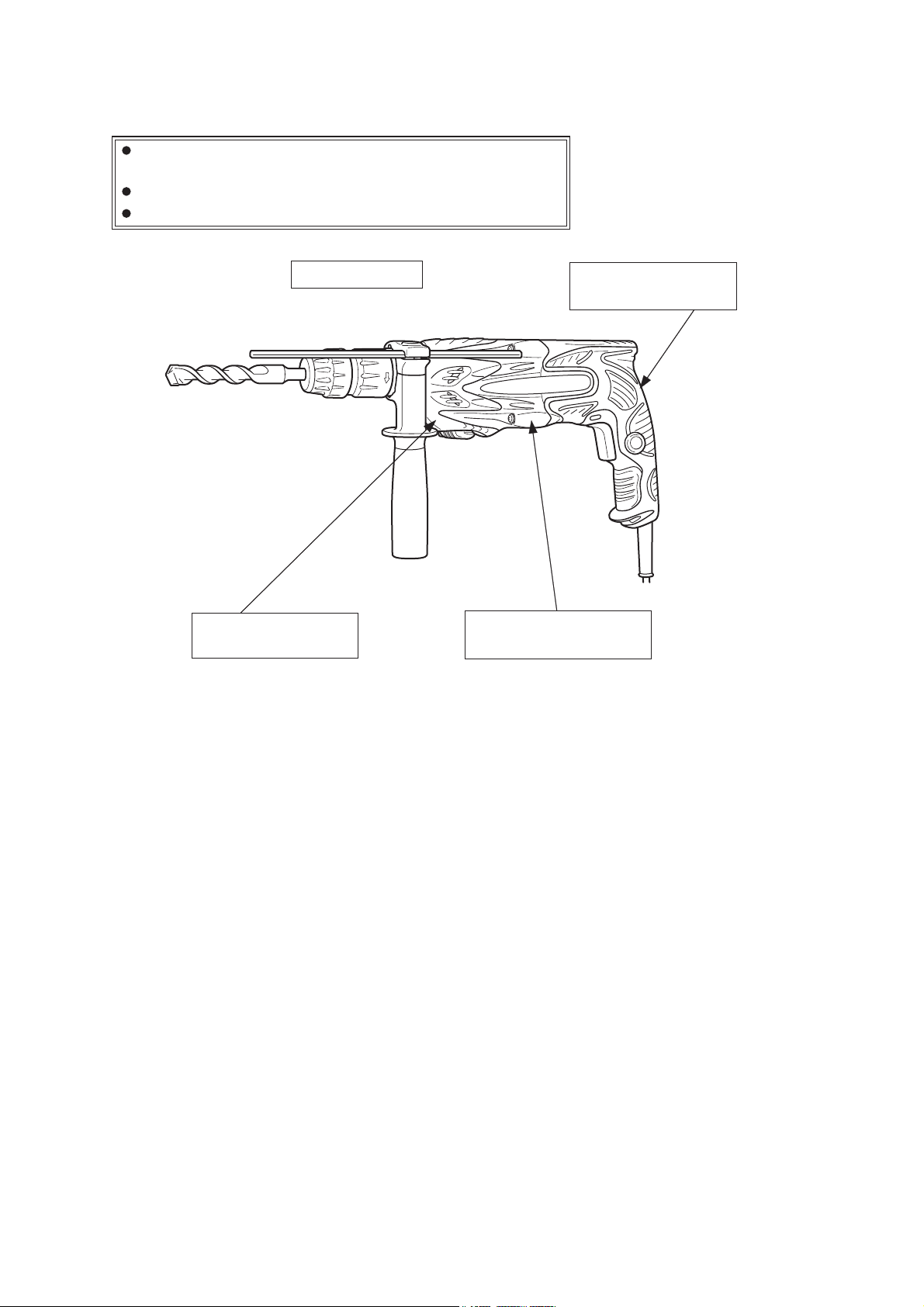

4. SELLING POINTS

Quick-release tool retainer requires only two steps to switch

between the drill bit holder and the drill chuck holder

Class-top drilling speed

More comfortable and frisky drilling

Non-slip double-layer

molded gear cover

4-1. Selling Point Descriptions

Compact body

Non-slip double-layer

molded handle

Internal pressure

adjustment mechanism

4-1-1. Quick-release tool retainer requires only two steps to switch between the drill bit holder and the drill

chuck holder

The Model DH 24PM is equipped with a quick-release tool retainer that requires only two steps to switch between

the drill bit holder for use with SDS-plus bits and the drill chuck holder for drilling holes in steel and wood. To

remove the drill bit holder or the drill chuck holder, turn the lock grip to unlock then pull for prevention of

inadvertent dropping. To mount the drill bit holder or the drill chuck holder, simply turn and push the lock grip in.

4-1-2. Selectable from 3 modes, "Rotation and hammering", "Rotation only" and "Hammering only"

The new Model DH 24PM is a 3-mode type rotary hammer based on the Model DH 24PC3 rotary hammer drill. It

features the "Hammering only" mode in addition to the "Rotation and hammering" mode and the "Rotation only"

mode. The "Hammering only" mode is available not only for light-duty chipping by means of bull points but also

for groove digging and edging by means of cold chisels and cutters for various applications.

4-1-3. Variable lock mechanism

With the variable lock mechanism, the tip angle of a tool such as a cold chisel or a cutter is selectable from

36 levels and can be locked in the "hammering only" mode. Thus the tip of a tool can be properly positioned

according to the application.

--- 2 ---

Page 6

4-1-4. Class-top drilling speed

The drilling speed of the Model DH 24PM is 1.1 times higher than B thanks to the efficient transmission of the

hammering energy.

4-1-5. More comfortable and frisky drilling

The Model DH 24PM can drill holes more comfortably and friskily with a light pushing force because the quantity

of body jumping is 20% less than B.

4-1-6. Internal pressure adjustment mechanism

By minimizing variations in the internal pressure during operation, hammering operation is stabilized. In addition,

idling and grease leakage can be prevented.

4-1-7. Non-slip double-layer molded gear cover

The double-layer molded gear cover consists of a plastic resin base covered with a soft resin to ensure ease of

operation and a non-slip grip during chipping.

4-1-8. Non-slip double-layer molded handle

The double-layer molded handle consists of a plastic resin base covered with a soft resin to ensure a soft-touch

and non-slip grip.

4-1-9. Compact body: Entire length 351 mm

The Model DH 24PM has the same helical driving structure as the Model DH 24PC3 to make the entire length as

short as possible to 384 mm. The Model DH 24PM has the shortest body in the class.

Maker/Model

HITACHI DH 24PM

B

C

Entire length when mounting

the drill bit holder

384 mm (15-1/8")

407 mm (16")

384 mm (15-1/8")

Entire length when mounting

the drill chuck holder

430 mm (16-15/16")

440 mm (17-5/16")

430 mm (16-15/16")

--- 3 ---

Page 7

5. SPECIFICATIONS

5-1. Specifications

Model

Capacity

Power source

Concrete

Steel

Wood

DH 24PM

3.4 --- 24 mm (1/8" --- 15/16")

13 mm (1/2")

32 mm (1-1/4")

AC single phase 50 Hz or 60 Hz

Voltage, current and

power input

Voltage (V)

Current (A)

110

7.6

120

7.0

Power input (W)

Rotation speed

No-load

Full-load

Full-load blow rate

Type of motor

Forward: 0 to 1,150 min-1, Reverse: 0 to 550 min

0 to 890 min

0 to 4,600 min

-1

-1

AC single-phase commutator motor

Type of switch Speed control switch with reversing switch

Type of handle

Enclosure

Gun-type handle of main body and side handle

Housing

•••

Glassfiber reinforced polyamide resin (green and black)

Handle cover

Gear cover

•••••••••••

Glassfiber reinforced polyamide resin (cool gray and black)

220

3.8

800

230

3.6

-1

240

3.5

Weight

Packaging

Standard accessories

Net*

Gross

2.6 kg (5.7 lbs.)

4.7 kg (10.4 lbs.)

Plastic case

(1) Plastic case

(2) Side handle

(3) Depth gauge

(4) Drill chuck holder

*: Weight excludes cord and side handle.

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

1

1

1

--- 4 ---

Page 8

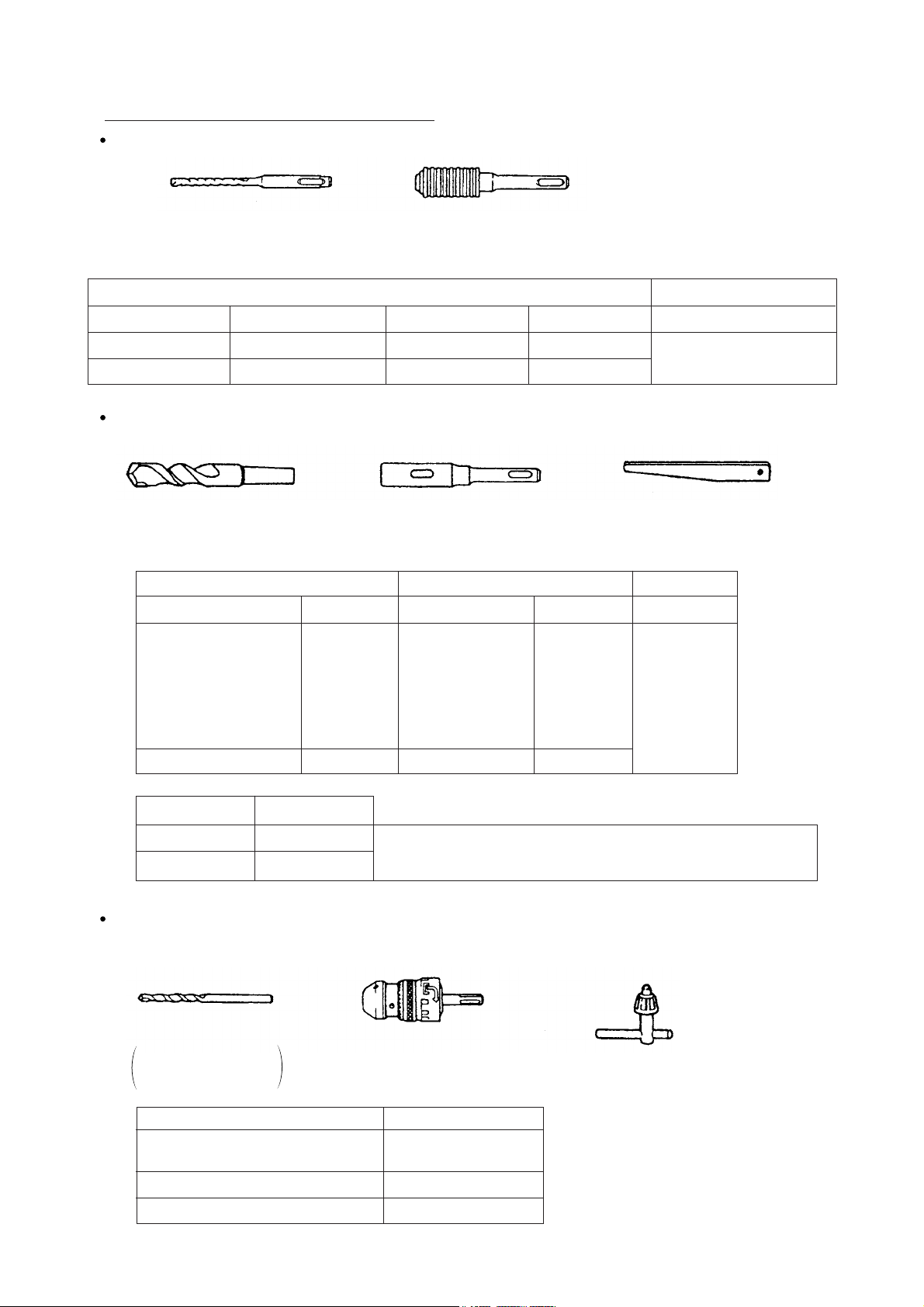

5-2. Optional Accessories

A. Drilling anchor holes (Rotation and hammering)

Drill bit (slender shaft)

+

(1) Drill bit (slender shaft)

Outer dia. (mm)

3.4 (1/8")

3.5 (9/64")

Drill bit (taper shank)

(1) Drill bit (taper shank)

(1) Drill bit (Taper shank)

Outer dia. (mm)

11 (7/16")

12.3 (31/64")

12.7 (1/2")

14.3 (9/16")

14.5 (73/128")

17.5 (11/16")

21.5 (27/32")

Effective length (mm)

Drill bit (slender shaft)

45 (1-25/32")

45 (1-25/32")

+

Code No.

944460

944461

993038

944462

944500

944463

944464

(2) Adapter for slender shaft

(SDS-plus shank)

Overall length (mm)

90 (3-17/32")

90 (3-17/32")

(2) Taper shank adapter

(SDS-plus shank)

(2) Taper shank adapter

Type

Morse taper

No. 1

Morse taper No. 2 303618

Code No.

Code No.

303617

306369

306368

Adapter for slender shaft

Code No.

306370

(3) Cotter

(3) Cotter

Code No.

944477

Code No.Part name

A-taper

B-taper

13 mm hammer drill chuck

For drilling operations when using a straight shank bit for impact drilling with a rotary hammer

303619

303620

Taper shank adapters (A-taper or B-taper) is provided as an

optional accessory, but drill bit is not provided.

+

Straight-shank bit

for impact drills

Part name

13 mm (1/2") hammer drill chuck

(Including chuck wrench)

Chuck wrench

Rubber cap

13 mm (1/2") hammer drill

chuck (SDS-plus shank)

Code No.

303332

303334

303335

--- 5 ---

Chuck wrench

Page 9

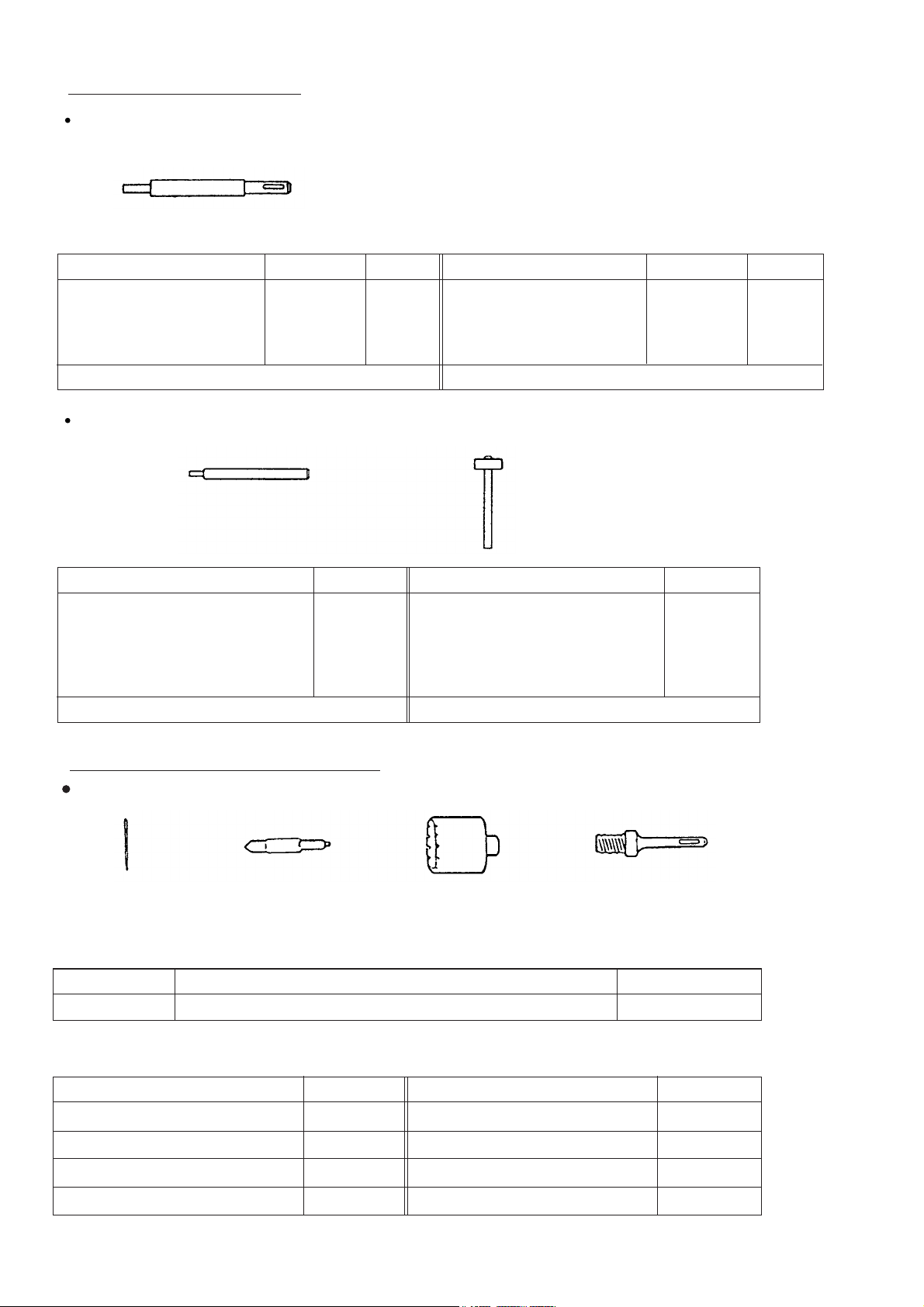

B. Anchor setting (Hammering only)

Anchor setting bar to permit anchor setting operation with the rotary hammer

Anchor setting bar

Anchor setting adapter (SDS-plus shank)

Part name

W-1/4 Anchor setting adapter-A

W-5/16 Anchor setting adapter-A

W-3/8 Anchor setting adapter-A

W-3/8 Anchor setting adapter-A

Internal cone type

Anchor setting bar for manual anchor setting

Anchor setting adapter

Part name

W-1/4 Anchor setting adapter-A

W-5/16 Anchor setting adapter-A

W-3/8 Anchor setting adapter-A

W-1/2 Anchor setting adapter-A

W-5/8 Anchor setting adapter-A

Internal cone type

Overall length

260

260

160

260

Code No.

971794

971795

971796

971797

971798

Code No.

302976

302975

303621

302974

+

W-1/4 Anchor setting adapter-B

W-5/16 Anchor setting adapter-B

W-3/8 Anchor setting adapter-B

W-1/2 Anchor setting adapter-B

W-5/8 Anchor setting adapter-B

Part name

W-1/4 Anchor setting adapter-B

W-5/16 Anchor setting adapter-B

W-3/8 Anchor setting adapter-B

W-3/8 Anchor setting adapter-B

External cone type

Part name

External cone type

Overall length

260

260

160

260

Code No.

971799

971800

971801

971802

971803

Code No.

302979

302978

303622

302977

C. Large hole boring (Rotation and hammering)

Center pin, core bit, core bit shank and guide plate

+

(Guide plate) Center pin Core bit Core bit shank

(1) Center pin (Do not use bit with outer diameter of 25 mm (31/32") and 29 mm (1-5/32")

Center pin (A) Core bit (outer diameter) 32, 35, 38 mm (1-1/4", 1-3/8", 1-1/2") Code No. 982684

Center pin (B) Core bit (outer diameter) 45, 50 mm (1-25/32", 2") Code No. 982685

(2) Guide plate

Core bit (outer diameter ) (mm)

32 (1-1/4")

35 (1-3/8")

38 (1-1/2")

45 (1-25/32")

Code No.

++

(SDS-plus shank)

Core bit (outer diameter ) (mm)

982686

982687

982688

982689

50 (2")

Code No.

982690

--- 6 ---

Page 10

(3) Core bit with guide plate (The guide plate is not supplied with 25 mm (31/32") and 29 mm (1-5/32") outer

diameter core bits.)

Outer diameter (mm)

25 (31/32")

29 (5/32")

32 (1-1/4")

35 (1-3/8")

38 (1-1/2")

(4) Core bit shank (SDS-plus shank)

Core bit shank (A)

Core bit shank (B)

D. Bolt placing operations with chemical anchor (Rotation and hammering)

Core bit (outer diameter) 25 --- 38 mm

Core bit (outer diameter) 45 --- 50 mm

Code No.

982672

982673

982674

982675

982676

(31/32" --- 1-1/2")

(1-25/32" --- 2")

Outer diameter (mm)

45 (1-25/32")

50 (2")

Overall length 105 mm (4-1/8")

Overall length 300 mm (11-52/64")

Overall length 300 mm (11-52/64") Code No. 303627

+

Code No.

982677

982678

Code No. 303625

Code No. 303626

(Standard sockets available on the market)

Part name

12.7 mm (1/2") Chemical anchor adapter

19 mm (3/4") Chemical anchor adapter

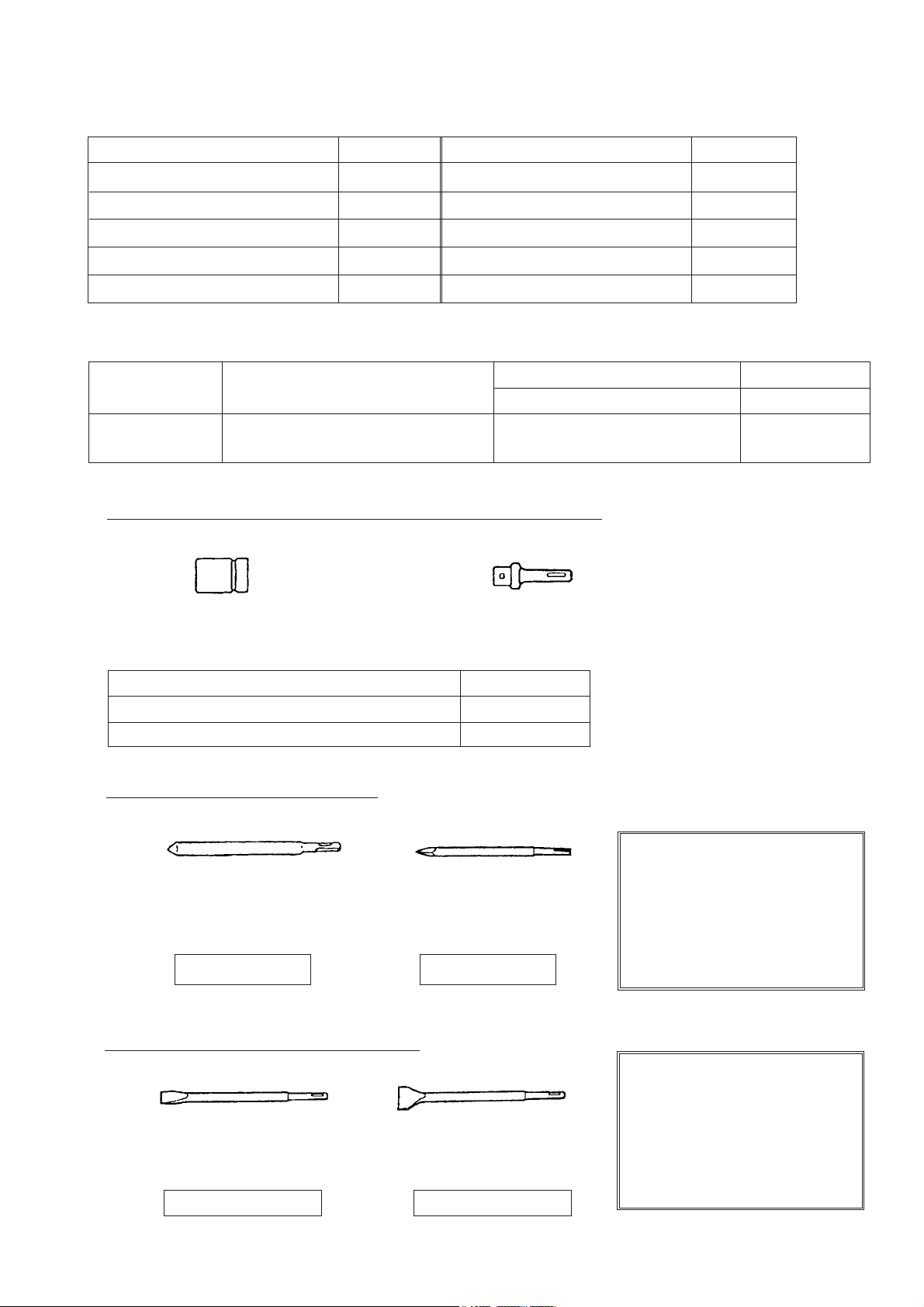

E. Crushing operations (Hammering only)

Bull point (round type)

(SDS-plus shank)

Code No. 303046 Code No. 316656

F. Groove digging and edging (Hammering only)

Cold chisel

(SDS-plus shank)

Code No. 316657 Code No. 316658

12.7 mm (1/2") Chemical anchor adapter (SDS-plus shank)

19 mm (3/4") Chemical anchor adapter (SDS-plus shank)

Code No.

303044

303045

Continuous chipping operation

can cause temperature rise of the

Square bull point

(SDS-plus shank)

Cutter

(SDS-plus shank)

main body, resulting in failure.

Rest the Model DH 24PM about

30 minutes after continuous

operation for 15 minutes.

Continuous chipping operation

can cause temperature rise of the

main body, resulting in failure.

Rest the Model DH 24PM about

30 minutes after continuous

operation for 15 minutes.

--- 7 ---

Page 11

G. Grooving (Hammering only)

Grooving chisel

(SDS-plus shank)

Code No. 316659

H. Driving screws (Rotation only)

(1) Cross-recessed head (Phillips) bit

[Overall length: 70 mm]

(For use with cross-recessed head (Phillips) screw)

Stamped bit No.

Bit No.

No. 2

No. 3

I. Grease for electric impact drill

Containing 500 g (17.64 oz): Code No. 980927

Code No.

955654

955655

Applicable screw dia. (mm)

4 --- 5

6 --- 8

(2) Slotted-head (minus) bit

[Overall length: 50 mm]

(For use with slotted-head (minus) screw)

Tip thickness

Bit tip thickness

0.8

1

Code No.

955658

955673

Applicable screw dia. (mm)

4

5 --- 6

Containing 30 g (1.06 oz): Code No. 981840

70 g (2.5 oz): Code No. 308471

J. Dust cup, dust collector (B)

Dust cup Dust collector (B) ass'y

Code No. 971787 Code No. 306885

--- 8 ---

Page 12

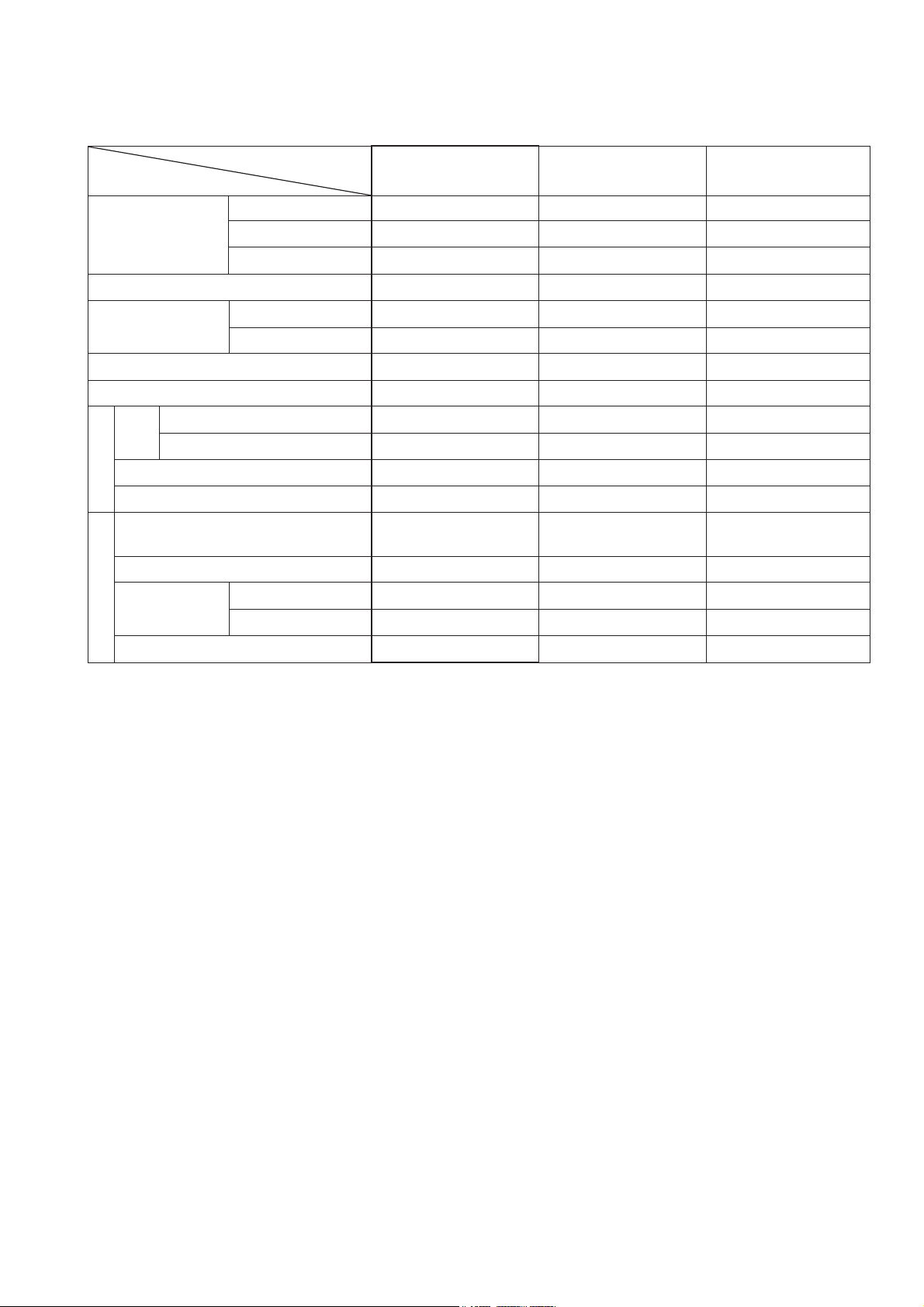

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons

Maker • Model

Item

Concrete

Nominal capacity

Steel

Wood

Power consumption

Forward

No-load speed

Reverse

Full-load speed

Weight

When mounting the drill bit holder

When mounting the drill chuck holder

Entire

length

Height

Dimensions

Width

Forward/reverse changeover switch

Tool retainer

Double-layer

Function

molding

Gear cover

Handle

Changeover mode

HITACHI

DH 24PM

24 mm

13 mm

32 mm

800 W

0 --- 1,150 min

0 --- 550 min

0 --- 4,600 min

-1

(rpm)

-1

(rpm)

-1

(rpm)

2.6 kg (5.7 lbs.)

384 mm (15-1/8")

430 mm (16-15/16")

198 mm (7-51/64")

78 mm (3-1/16")

Provided

(Push-button type)

One-push type

Provided

Provided

3 modes

B

26 mm

13 mm

30 mm

800 W

0 --- 900 min-1 (rpm)

0 --- 900 min

0 --- 4,000 min

-1

(rpm)

-1

(rpm)

2.9 kg (6.4 lbs.)

407 mm (16")

2.6 kg (5.7 lbs.)

384 mm (15-1/8")

C

24 mm

13 mm

32 mm

780 W

0 --- 1,100 min

0 --- 600 min

0 --- 4,500 min

-1

440 mm (17-5/16") 430 mm (16-15/16")

210 mm (8-1/4")

84 mm (3-5/16")

Provided

(CB rotary type)

One-push type

Not provided

204 mm (8-1/32")

72 mm (2-27/32")

Provided

(Lever type)

One-push type

Not provided

Provided Provided

3 modes3 modes

-1

-1

* Weight excludes cord and side handle.

--- 9 ---

Page 13

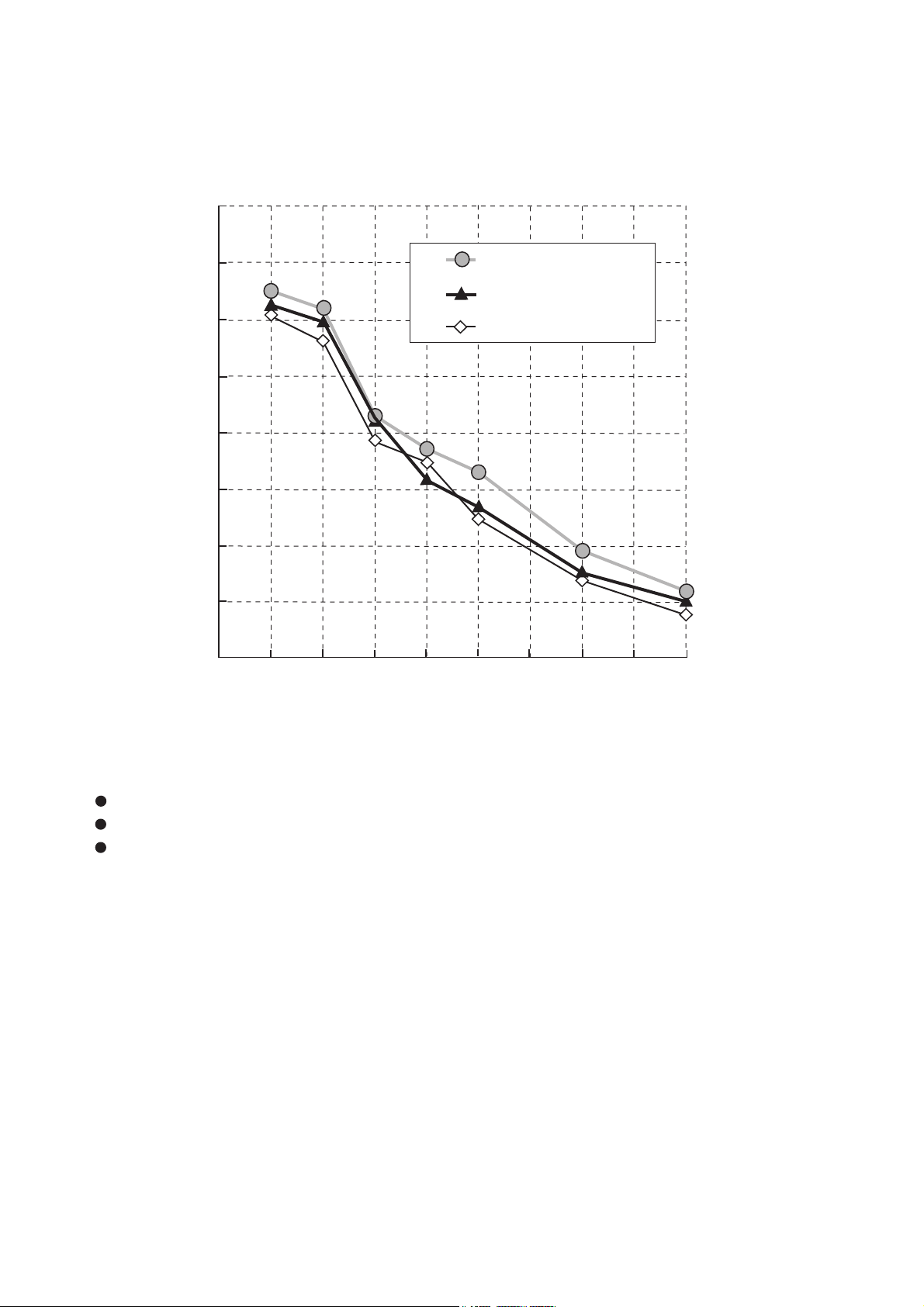

6-2. Drilling Speed Comparison

Drilling speed varies considerably depending on the work conditions. Use the factory test results shown in Fig. 1

for comparison purpose only.

800

700

600

500

400

300

Drilling speed (mm/min.)

200

100

6

HITACHI DH 24PM

B

C

108

18161412

20

22

24

Drilling bit diameter (mm)

Fig. 1

[Test conditions]

Direction : Downward drilling

Pushing force : 98 N (10 kgf)

Test material : Concrete panel with a compression strength of 2,352 N/cm2 (240 kgf/cm2)

--- 10 ---

Page 14

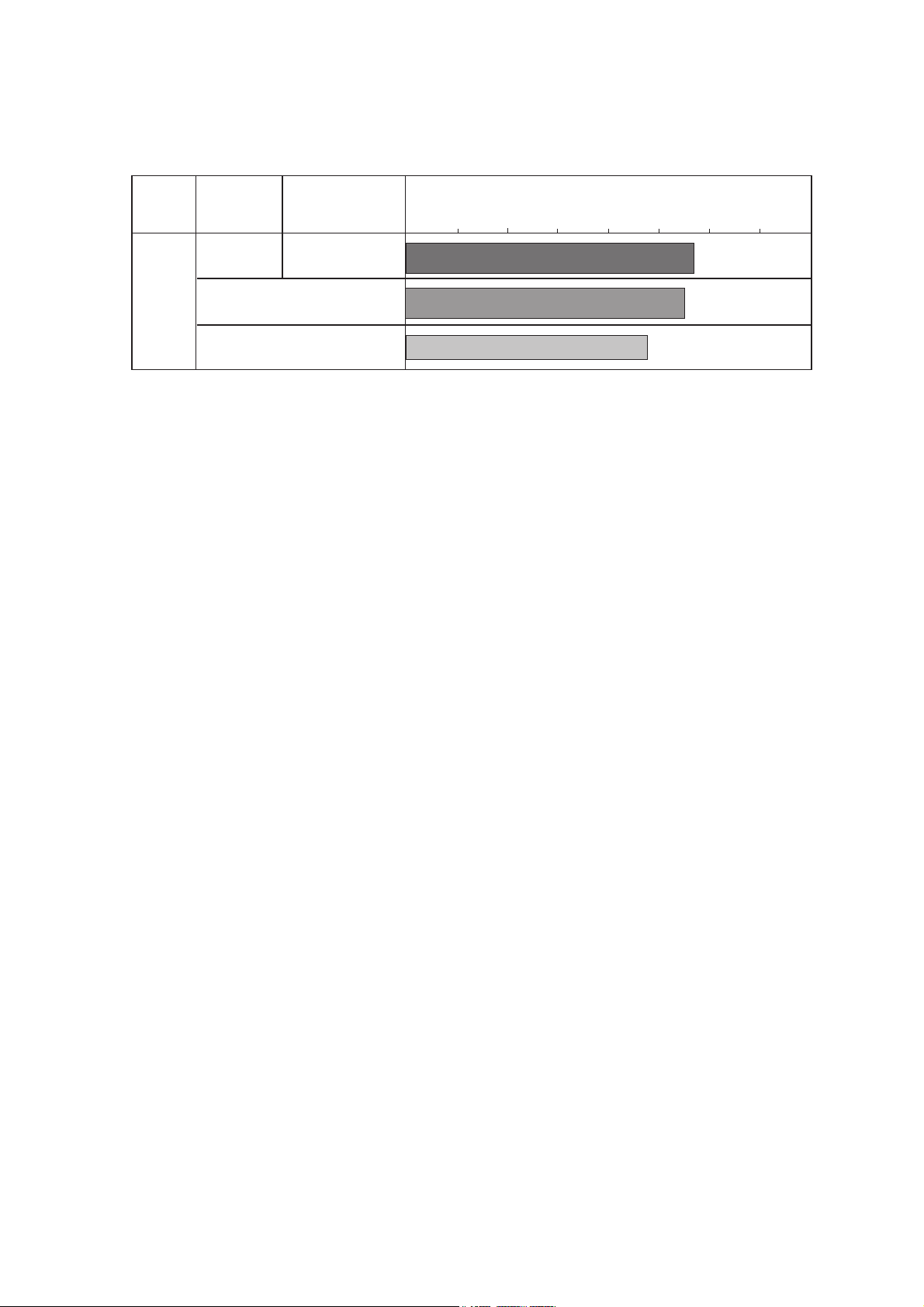

6-3. Chiseling Performance Comparison

Chiseling performance varies considerably depending on the work conditions. Use the factory test results shown

in Fig. 2 for comparison purposes only.

Voltage

supply

230 V

Maker

HITACHI

Model

DH 24PM

B

C

Chiseling amount (kg/30 min.)

0

105

15

20

25

30

24

35

28

27

Fig. 2

--- 11 ---

Page 15

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Model DH 24PM Rotary Hammer by all of our

customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously

recognizes the importance of the contents of the Handling Instructions, and fully understands the meaning of the

precautions listed on the Caution Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric power tool cannot be completely eliminated.

Accordingly, general precautions and suggestions for the use of electric power tools, and specific precautions and

suggestions for the use of the Rotary Hammer are listed in the Handling Instructions to enhance the safe, efficient

use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling

Instructions to be able to offer appropriate guidance to the customer during sales promotion.

7-2. Caution Plate

The Model DH 24PM unit is provided with a Caution Plate (illustrated below) which lists basic safety precautions

in use. Carefully ensure that the customer fully understands and follows these precautions before using tool.

For Australia and New Zealand

For the U.S.A. and Canada

--- 12 ---

Page 16

8. REFERENCE MATERIAL

8-1. Lubrication

It is not necessary to replenish the grease lubricant unless the tool is disassembled or there is grease leakage

due to a defective seal. Special grease is used in the striking section. Should the striking section (within the gear

cover) be disassembled, carefully remove the old grease from all parts and, on reassembly, inject 45 g (1.6 oz) of

new grease into the gear cover and 5 g (0.2 oz) into the groove of the inner cover. Be careful not to exceed the

designated amount of grease. Excessive grease will reduce striking efficiency. Apply Molub Alloy No. 777-1

grease to the pin portion of the change lever.

8-2. Tool Structure

Transmission of rotation

Unlike conventional hammer drills, the armature shaft in the Model DH 24PM is in parallel with the tool shaft -

the same structure that is employed in most impact drills. This structure was adopted in order to make the

Model DH 24PM more compact for easier handling and operation. Thus, the appearance of the Model

DH 24PM is similar to that of an impact drill. The rotation of the armature is transmitted to the second shaft via

the first gear, and causes it to rotate. The second pinion provided on the second shaft engages the second

gear mounted on the outer circumference of the cylinder. The cylinder is coupled to the second gear by

means of a slip mechanism, and they rotate together. The tip of the cylinder is fit in the bit holder. It is coupled

to the drill bit inserted in the bit holder by means of two key rails and one steel ball to transmit rotation.

--- 13 ---

Page 17

Piston reciprocating mechanism

In conventional rotary hammers, a piston is caused to reciprocate by a connecting rod and crank shaft, and

the crank shaft and the cylinder axes are at right angles to each other. Accordingly, the armature shaft and the

cylinder axes are also at right angles to each other. In the Model DH 24PM, through adoption of a spiral drive

system (a mechanism using a reciprocating bearing), a more compact design has been achieved by arranging

the armature shaft in parallel with the cylinder axis. Referring to Fig. 3, the armature's rotation is transmitted to

the second shaft via the first gear. The second shaft's rotation is then transmitted through a spline to the

clutch, which engages with a reciprocating bearing and causes it to rotate. However, as illustrated, circular

grooves on the inner race of the reciprocating bearing are positioned on an angle of inclination with relation to

the second shaft. The rotation of the inner race and the shaft causes the angle of inclination to change

regularly forward and back with relation to the second shaft, and produces a rocking motion in the outer race

of the reciprocating bearing. Finally, a rod extending from the outer race of the reciprocating bearing is

connected to the piston by a piston pin, and causes the reciprocating motion of the piston.

Armature

Motor shaft

Reciprocating bearing

Hammering function

The piston reciprocates within the cylinder to move the striker in the same manner as in conventional rotary

Piston pin

First gear

Annular groove

Piston

Fig. 3

Second gear

Clutch

Bit holder

Second shaft

Cylinder

Steel ball

Key rail (2 pcs.)

hammers. As the piston reciprocates, the changing air pressure inside the air chamber between the piston

and the striker causes the striker to move and repeatedly strike against the end of the second hammer.

At the same time, the changing air pressure within the air chamber which moves the striker also provides an

"air cushion" which absorbs the impact of the hammering action. As any air leakage from the air chamber

weakens the air-cushion effect and reduces impact absorption, the O-ring (mounted on the striker) is

extremely important to seal the air. Although a special rubber material is utilized in construction of the O-ring

to make its effective service life as long as possible, wear cannot be fully avoided. Accordingly, it is

recommended that the O-ring be replaced approximately once a year, depending on the frequency of usage of

the tool.

--- 14 ---

Page 18

Idle hammering prevention mechanism

The idle hammering prevention mechanism in the Model DH 24PM is different from that of conventional rotary

hammers. When the drill bit is lifted from the work surface on completion of drilling, the second hammer

moves to the position indicated by the continuous lines in Fig. 4 and the protruding (lip) portion at the tip of the

striker is gripped by O-ring (C) mounted between the hammer holder and the damper holder. In this state,

should the piston continue to move so that the small piston vent hole is blocked by the inner wall of the

cylinder, the air in the air chamber will pass through the large piston vent hole and be released through the air-

escape slot and large cylinder vent hole provided on the inner wall of the cylinder. Accordingly, there is no

change in the air pressure within the air chamber, and movement of the striker (idle hammering operation) is

prevented. The gripping force of O-ring (C) on the striker is so small in comparison with the conventional

mouth system that practically no pressing force at all is required to restart the hammering operation.

Striker

Small piston vent hole

Gear cover

Air escape slot

Piston

Large piston vent hole

Second gear

Claw

Moving

distance

Front cap

Air

chamber

Bit holder

Second hammer

First gear

Cylinder

O-ring (C)

Coil spring

Reciprocating bearing

Clutch claw

Fig. 4

Slip mechanism

The slip mechanism in the Model DH 24PM consists of a coil spring which applies a pre-set amount of

pressure to ensure the interlocking of three claws provided on the flange of the cylinder (the final rotating

shaft) and six matching claws provided on the face of the second gear, by which rotation is transmitted to the

cylinder. The second gear is fitted to the cylinder with a certain amount of play.

If an excessively large torque is applied to the tool shaft (cylinder), the force of the torque will exceed the

pressure of the coil spring and cause the claws on the second gear to disengage from and ride over the claws

on the cylinder so that the second gear idles and does not transmit rotation. Even if the drill bit comes in

contact with a reinforcing bar within the concrete, causing sudden excessive torque, the slip mechanism

functions to prevent damage to the gears, and possible loss of control of the tool by the operator.

--- 15 ---

Page 19

Sealed and dustproof construction

The gear cover is totally enclosed by oil seals, O-rings and other devices to prevent leakage of lubricating

grease, and to keep dust and dirt out of the internal mechanisms. The drill bit chuck portion is protected by a

rubber front cap to keep out dust and chips which could cause improper fitting of the drill bit and/or other faulty

operation of the chuck portion. The speed control switch is also a fully dust-proofed type to prevent dust and

chips from entering the handle section and causing possible operational trouble or a break down of the

insulation.

Speed control

The Model DH 24PM is equipped with a variable speed control switch which permits free change of the

rotation speed and hammering force. When drilling in fragile materials, pull the switch trigger gently for low

rotation speed (hammering force) to achieve optimum results.

Note that the switch trigger cannot be pulled to the full but up to the half in the reverse drilling, and the speed

is about half of the forward drilling. In addition, the switch stopper cannot be used in the reverse drilling.

Internal pressure adjustment mechanism

An air passage is provided as shown in Fig. 5 to let out air inside the gear cover and let outside air in the gear

cover. This passage is sandwiched between felt packings to pass only air (pressure). Thus variations in the

internal pressure are minimized for stable hammering operation and prevention of idling and grease leakage.

A-A (2:1)

Air passage

(Outside the

gear cover)

(Inside the gear cover)

Felt packing (A)

Felt packing (B)

Valve

Inner cover

Fig. 5

--- 16 ---

Page 20

Switching the tool retainer between the drill chuck holder and the drill bit holder

<Removing>

Turning the lock grip in the direction indicated with an arrow on the

lock grip, pull out the lock grip. If it is hard to pull out the lock grip,

put the Model DH 24PM in "Hammering only" mode then turn and

pull out the lock grip. The above two steps are required to remove

the lock grip for prevention of inadvertent dropping.

<Mounting>

Turn the drill chuck holder or the drill bit holder in the direction indicated with an

arrow on the lock grip until the spline is engaged. Then push in the lock grip turning

further. Thus the drill chuck holder or the drill bit holder can be easily mounted

without position adjustment. After mounting, pull the drill chuck holder or the drill bit

holder to check for secure mounting.

Lock grip

Drill chuck holder

or drill bit holder

Lock grip

Spline

--- 17 ---

Page 21

8-3. "Three-mode" Changeover Mechanism

The change lever of the Model DH 24PM permits quick and easy changeover among the "Rotation and

hammering", "Rotation only" and "Hammering only" functions. Each function mode is explained below. When

operating the change lever, be sure to continue pressing the pushing button.

(1) Rotation and hammering (Fig. 6)

Adjust the change lever to "Rotation and hammering" ( marks). Armature rotation is transmitted to the first

gear and second shaft, and then to the clutch via the spline of the second shaft. Claws on the end surface of

the clutch engage with matching claws of the reciprocating bearing ( A portion in the figure) to convert the

rotation into reciprocating motion. Three claws on the tip of the second shaft engage with matching three

claws of the pinion sleeve all the time, and the second shaft rotation is transmitted to the pinion sleeve. Then

claws on the large-dia. portion of pinion sleeve engage with the second pinion ( B portion in the figure), and

the rotation is transmitted to the second gear and the cylinder.

Armature

First gear

Reciprocating bearing

Second shaft

A portion is meshed.

(Hammering transmitted.)

Second gear

Change lever

Spline of the second shaft

Clutch

Cylinder

Pinion sleeve

Three claws of second shaft

B portion is engaged.

(Rotation transmitted.)

Second pinion

Fig. 6

--- 18 ---

Page 22

(2) Rotation only (Fig. 7)

Adjust the change lever to "Rotation only" ( mark). The lock plate is moved forward by the pin of the change

lever, and the clutch is moved forward at the back end of the lock plate. Engagement between the clutch and

the claws of the reciprocating bearing is released ( A portion in the figure). Thus no rotation is transmitted to

the reciprocating bearing and hammering is stopped. On the other hand, the pinion sleeve engages with the

second pinion ( B portion in the figure), and so the rotation is transmitted to the pinion sleeve for "rotation

only" function.

Claw of reciprocating bearing

A portion is separated. (Hammering stopped.)

Clutch claw

Lock plate

(Rear end portion)

Reciprocating

bearing

(3) Hammering only (Fig. 8)

Adjust the change lever to "Hammering only" ( mark). The second pinion is moved to the motor side by the

pin of the change lever. Engagement between the pinion sleeve and the second pinion is released and no

rotation is transmitted ( B portion in the figure). The lock plate is moved to the motor side by spring (B) and

Washer (D)

Change lever pin

Lock plate (Front end portion)

Fig. 7

Second pinion

B portion is meshed.

(Rotation transmitted.)

Pinion sleeve

engaged with the locking claw of the second pinion to lock the cylinder rotation ( C portion in the figure).

On the other hand, the clutch engages with the reciprocating bearing for "hammering only" function ( A portion

in the figure).

Lock plate

Second pinion

Second gear

Cylinder

Pinion sleeve

B portion is separated.

(Rotation stopped.)

Spring (B)

A portion is meshed.

(Rotation transmitted.)

Reciprocating

bearing

C portion meshed. (Tool locked.)

Locking claw of the second pinion

Clutch

Change lever pin

Fig. 8

--- 19 ---

Page 23

(4) Neutral (Fig. 9)

The Model DH 24PM has a neutral mode used for positioning a tool such as a flat chisel. Adjust the change

lever to a position halfway between "Hammering only" ( mark) and "Rotation and hammering" ( marks).

Engagement between the pinion sleeve and the second pinion ( B portion in the figure), and between the lock

plate and the locking claw of the second pinion ( C portion in the figure) is released and the cylinder rotates

freely. Simply turn the grip to adjust the tool to the desired position.

C portion is separated. (Tool turns free.)

Locking claw of second pinion

Fig. 9

Lock plate

Second pinion

Second gear

Cylinder

Pinion sleeve

B portion is separated.

(Rotation stopped.)

8-4. Caution when Using "Rotation Only"(No Hammering) Function

The drill chuck holder (standard accessory) is required for drilling holes in wood or metal materials. The change

lever of the Model DH 24PM permits changeover among "Rotation only," "Rotation and hammering" and

"Hammering only" functions. Be sure to adjust the change lever to "Rotation only" for drilling holes in wood or

metal materials by means of the drill chuck holder. If the change lever is adjusted to "Rotation and hammering" or

"Hammering only" for such operation, no hammering force will be transmitted but the drill chuck may be damaged.

Please caution the customers about the above.

--- 20 ---

Page 24

8-5. Drill Bits

The chuck section is designed exclusively for the popular and widely available SDS-plus shank bits, as shown in

Fig. 10. Rotating torque is transmitted to the drill bit by two key rails provided in the tool holding section. A steel

ball is used to prevent the bit from coming off.

Key slot (two pieces)

Section A - A'

Shape of SDS-plus shank bit

Cylinder

Key rail (2 pcs.)

Ball holder

Chuck section

Fig. 10

The service life of a drill bit with a diameter of 8 mm is approximately 300 holes when drilling into concrete to a

depth of 30 mm. If reground before the end of its service life, the drill bit will continue to provide efficient drilling.

Figure 11 shows the regrinding angle.

Regrinding angle of drill bit

a:b = 1:2

Steel ball

Rotation

direction

Section A - B

130û

Fig. 11

--- 21 ---

Page 25

8-6. Chuck Section

The tool retainer is structured as shown in Fig. 12.

The tip of the tool retainer is covered with the front cap (made of rubber) to prevent dust and chips from getting

inside. The steel ball falls into the round groove of the bit to prevent the tool from coming off and the two key rails

transmit the rotation torque.

To mount the bit, push the bit in the tool retainer as far as it will go. Pushing lightly, turn the bit until it is caught.

At this position, push the bit in as far as it will go (sliding the grip is not required for mounting the bit). To remove

the bit, slide the grip backward to the full and remove the bit.

Grip

Holder spring

Washer (B)

Ball holder

Steel ball

Front cap

Bit holder

Holder plate

Fig. 12

8-7. Dust Collector (B)

When drilling holes overhead, dust collector (B) can be mounted on the Model DH 24PM to prevent dust and

chips from falling downward. Dust collector (B) is intended solely for use when drilling holes in concrete, and

cannot be used for drilling holes in steel or wood. It is designed for use with drill bits with overall lengths of

110 mm, 160 mm and 166 mm, and cannot be used with any longer bits. When using a drill bit with an overall

length of 166 mm with dust collector (B), drilling up to a depth of approximately 72 mm is possible. When using

dust collector (B), ensure it is securely fastened to the grip on the main body with socket adapter (B). Although

the socket and socket adapter (B) rotate together with the tool shank, there is a steel ball between the outer race

and the socket which serves as a ball bearing. Should the dust cover be forced against the concrete surface, it

will not rotate even though the tool shank continues to rotate. Should the tool be operated when the dust cover is

not being held against a concrete surface, inertia may cause dust collector (B) to become disconnected from the

grip. Accordingly, caution the customer to press dust collector (B) and drill bit firmly against the concrete surface

Stopper ring

Key rail (2 pcs.)

before turning on the switch to start drilling.

When dust collector (B) is used, almost no dust and chips are scattered about. However, since the chips and dust

remaining in the collector may scatter after completion of the drilling operation, the customer should be advised to

always wear protective glasses.

When dust collector (B) is disassembled for repair of maintenance, be very careful to prevent oil or grease from

adhering to the steel balls. Grease or oil on the steel balls may cause concrete dust to enter the unit and cause

defective rotation.

--- 22 ---

Page 26

Approx. 72 mm (2-27/32")

Approx. 16 mm (5/8")

Drill bit

length = 166 mm

Drill bit

length = 110 mm

Grip (on the main body side)

Socket adapter (B)

Dust cover

Seal cover

Retaining ring for D30 shaft

Fig. 13 Dust collector (B) structure

Washer

Socket

Outer race

Steel Ball D6.35

--- 23 ---

Page 27

9. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [Bold] numbers in the descriptions below correspond to the item numbers in the Parts List and exploded

assembly diagram.

9-1. Disassembly

(1) Disassembly of the striking mechanism section

Push the Second Hammer [43] in the main body with a drill bit or screwdriver to release the Striker [51] from

O-ring (C) [48].

Pressing the Pushing Button [31], move the Change Lever [34] to the "Hammering only" mode ( mark).

(Be sure to keep pressing the Pushing Button [31] when operating the Change Lever [34].)

Loosen the four Tapping Screws (W/Flange) D5 x 35 [19], and remove the Gear Cover Ass'y [18]. The Inner

Cover Ass'y [56] and the Housing [83] are loosely fitted together. Attempting to pull them out first could cause

the Armature [77] to be pulled out at the same time, causing damage to the Carbon Brushes (1 Pair) [89].

Remove Spring (B) [35] from the rails in the Gear Cover Ass'y [18] as shown in Fig. 14.

Pull out the Second Pinion [59], Clutch Spring [60], Clutch [61], Washer (D) [62] and the Lock Plate [58]

(these parts are sandwiched by means of the Lock Plate [58] as a unit as shown in Fig. 15) from the end of

the Second Shaft [63]. Turn the Reciprocating Bearing [65] so that the Piston [53] is moved to its maximum

upper position (Inner Cover Ass'y [56] side). The arm of the Reciprocating Bearing [65] can then be

disconnected from the Piston Pin [64], and the Second Shaft [63] and the components mounted on it can be

removed from the Inner Cover Ass'y [56] as a unit.

Remove the First Gear [66] from the Second Shaft [63] with a bearing puller. Then take off the Reciprocating

Bearing [65]. At this time, take care not to damage the end surface of the Second Shaft [63] because the First

Gear [66] is press-fitted in alignment with the 9 mm diameter end surface of the Second Shaft [63].

Clutch [61]

Washer (D) [62]

Clutch Spring [60]

Pinion Sleeve [57]

Spring (B) [35]

Gear Cover Ass'y [18]

Fig. 14

Rails

Lock Plate [58]

Second Pinion [59]

Fig. 15

--- 24 ---

Page 28

(2) Removal of the Change Lever

As shown in Fig. 16, pressing the Pushing Button [31] hard, turn the Change Lever [34] 45û counterclockwise

from the "Hammering only" position ( mark). Pry out the Change Lever [34] at this position.

Change Lever [34] Pushing Button [31]

Fig. 16

(3) Disassembly of the tool retainer

Slide the Grip [4] fully in the arrow direction as shown in Fig. 17 and remove the Front Cap [2]. Pulling the

Grip [4] as shown in Fig. 18, remove the Stopper Ring [3] with a retaining ring puller. Then the Grip [4], Ball

Holder [5], Steel Ball D7.0 [14], Holder Plate [6] and Holder Spring [7] can be removed from the Bit Holder

[13].

Grip [4]

Front Cap [2]

Fig. 17

Holder Plate [6]

Holder Spring [7]

Ball Holder [5]

Steel Ball D7.0 [14]

Stopper Ring [3]

Grip [4]

Fig. 18

--- 25 ---

Page 29

Remove the parts around the grip and the Retaining Ring for D25 Shaft [8] as shown in Fig. 19. Then Washer

(B) [9], Spring [10], Lock Grip [11], Lock Ring [12], Steel Ball D7.0 [14], Washer (A) [15] and Retaining Ring

for D28 Shaft [16] can be removed in this order.

Bit Holder [13]

< Removal of the chuck holder >

Engage the chuck holder jig (J-345) with the spline as shown in Fig. 20. Hold the width across flats in a vise

and remove Flat Hd. Screw (A) (Left Hand) M6 x 25 [26]. Put a hexagonal bar in the Drill Chuck 13VLRH-N

(W/O Chuck Wrench) [27] then loosen and remove it using a torque wrench. Remove the Stopper [28]. Then

Lock Ring [12]

Lock Grip [11]

Fig. 19

the chuck holder can be removed in the same manner as the bit holder.

Chuck holder jig (J-345)

Chuck Holder [29]

Stopper [28]

Fig. 20

Drill Chuck 13VLRH-N

(W/O Chuck Wrench) [27]

Flat Hd. Screw (A)

(Left Hand) M6 x 25 [26]

--- 26 ---

Page 30

(4) Removal of the Cylinder [38] from the Gear Cover Ass'y [18]

To remove the Cylinder [38] from the Gear

Cover Ass'y [18], remove the Retaining

Ring [17] from the Cylinder [38] first. Then

support the end face of the gear cover on

the gear cover jig (J-344) and press the tip

of the Cylinder [38] by tapping with a hand

press as shown in Fig. 21. If the Cylinder

[38] is pressed excessively, the gear cover

will be deformed and the Cylinder [38]

cannot be removed. Be sure to tap with a

hand press in order to remove the

Cylinder [38].

Hand press

Cylinder [38]

Gear Cover Ass'y [18]

Gear cover jig (J-344)

Fig. 21

--- 27 ---

Page 31

(5) Removal of the cylinder and the second gear (slip mechanism section)

Remove the Retaining Ring D30 [42] from the Cylinder [38] with a retaining ring puller. Then the Second Gear

[39], Spring (A) [40] and Washer (A) [41] can be removed from the Cylinder [38].

(6) Removal of the cylinder and the second hammer

Remove the Stopper Ring [50] from the inside diameter portion of the Cylinder [38]. Then the Second

Hammer [43], O-ring (1AP-20) [44], Hammer Holder [45], O-ring (B) [46], Damper (A) [47], O-ring (C) [48]

and Damper Holder [49] can be removed from the Cylinder [38]. As shown in Fig. 22, insert the no-hole side

of stopper ring jig (A) (J-341) into the Cylinder [38] until it contacts the end surface of the Damper Holder [49].

Hold the Cylinder [38] and the end surface of stopper ring jig (A) (J-341) with a vise, and compress Damper

(A) [47] (it moves a little when the Stopper Ring [50] is pressed with punch (C) (J-341)). Insert punch (C)

(J-341) into the 5-mm diameter hole (2 places) in the Cylinder [38] and tap the outside of the Stopper Ring

[50] until the Stopper Ring [50] cannot be seen from the 5-mm diameter hole (2 places) to remove the Stopper

Ring [50] from the groove of the inside diameter portion of the Cylinder [38]. Then remove the Cylinder [38]

from the vise and pull out the Stopper Ring [50] from the inside diameter portion of the Cylinder [38] with ring

puller jig (B) (J-341) being careful not to pop out the Stopper Ring [50]. At reassembly, replace the Stopper

Ring [50] with new one as the removed Stopper Ring [50] is deformed. To prevent idle hammering, also

replace O-ring (C) [48] with new one at reassembly.

Tap with a hammer.

O-ring (1AP-20) [44]

Hammer Holder [45]

Second Hammer [43]

Vise

O-ring (B) [46]

Damper (A) [47]

Punch (C) (J-341)

5-mm diameter hole (2 pcs.)

Damper Holder [49]

O-ring (C) [48]

Vise

Stopper Ring [50]

Stopper ring jig (A) (J-341)

Fig. 22

--- 28 ---

Page 32

(7) Removal of the gear cover and the pinion sleeve

Pinch the Pinion Sleeve [57] with the pinion sleeve puller (J-302, No. 319265) and fix the pinion sleeve puller

to a vise. Pull the Gear Cover Ass'y [18] to remove the Pinion Sleeve [57] from the Gear Cover Ass'y [18]

(Figs. 23 and 24).

Hold with a vise.

Gear Cover Ass'y [18] Pinion Sleeve [57]

Claws of pinion sleeve puller

Pinion Sleeve [57]

Pinion sleeve puller (J-302)

Fig. 23

Adjuster

Pinion sleeve puller (J-302)

Fig. 24

--- 29 ---

Page 33

9-2. Reassembly

Reassembly can be accomplished by following the disassembly procedure in reverse. However, special attention

should be given to the following items.

(1) Application of lubricant

Apply special grease (for hammer and hammer drill) to the O-ring (1AP-20) [44] and O-ring (B) [46] for the

Hammer Holder [45], Damper (A) [47], O-ring (C) [48], O-ring (I.D. 16) [52] for the Striker [51], outer

circumference of the Striker [51], inner and outer circumference of the Piston Pin [64], outer circumference of

the Piston [53], Reciprocating Bearing [65], Reciprocating Bearing [65] rotary shaft of the Second Shaft [63],

Second Pinion [59] rotary shaft, clutch claw of the Cylinder [38], inner circumference of the metal of the Inner

Cover Ass'y [56], Second Hammer [43], and the lip portion of the Oil Seal [21]. Fill 45 g of the special grease

in the gear cover and 5 g in the inner cover groove. Apply Molub Alloy No. 777-1 grease to the pin portion of

the Change Lever [34]. Apply Molub Alloy No. 777-1 grease to the contact portion between the Clutch [61],

Washer (D) [62] and the Lock Plate [58]. Fill Molub Alloy No. 777-1 grease in the ball portion of the

Reciprocating Bearing [65]. Apply Hitachi Motor Grease No. 29 to the O-ring (S-18) [33] for the Change Lever

[34] and the Steel Ball D7.0 [14].

(2) Mounting the Cylinder [38]

Mount the Second Hammer [43], O-ring (1AP-20) [44], Hammer Holder [45], O-ring (B) [46], Damper (A) [47],

new O-ring (C) [48] and Damper Holder [49] in the Cylinder [38]. Push the new Stopper Ring [50] in the

Cylinder [38] then push in the hole side of stopper ring jig (A) (J-341) on it as shown in Fig. 25. Push the

upper end surface of stopper ring jig (A) (J-341) with a hand press to fit the Stopper Ring [50] in the groove of

the inside diameter portion of the Cylinder [38]. Check that the Stopper Ring [50] is securely fitted in the

groove of the inside diameter portion of the Cylinder [38] viewing from the 5-mm diameter hole (2 pcs.) on the

Cylinder [38].

5-mm diameter hole (2 pcs.)

O-ring (1AP-20) [44]

Hammer Holder [45]

Second Hammer [43]

O-ring (B) [46]

Damper (A) [47]

Damper Holder [49]

O-ring (C) [48]

Hand press

Stopper Ring [50]

Stopper ring jig (A) (J-341)

Fig. 25

--- 30 ---

Page 34

(3) Mounting the change lever

Press the Pushing Button [31] deeply into the hole of the Change Lever [34]. Adjust the Change Lever [34] to

the position shown in Fig. 26 of the Gear Cover Ass'y [18] and press it hard. Then move the Change Lever

[34] to the "Hammering only" position ( mark).

Change Lever [34]

Fig. 26

(4) Press-fitting the first gear

Press-fit the First Gear [66] aligning with the shaft end surface of the Second Shaft [63]. After press-fitting the

First Gear [66], check that the inside ring of the Reciprocating Bearing [65] turns smoothly.

(5) Mounting the oil seal

Prior to reassembly, apply grease to the inner circumference of the Oil Seal [21]. However, do not apply

grease to its outer circumference. Also, when press-fitting the Oil Seal [21], ensure that it is straight and level.

(6) Reassembly of the internal pressure adjustment mechanism

Push Felt Packing (A) [69], Valve [70] and Felt Packing (B) [71] in the Inner Cover Ass'y [56] as far as they

will go in this order.

Pushing Button [31]

Felt Packing (A) [69]

Felt Packing (B) [71]

Valve [70]

Inner Cover Ass'y [56]

Fig. 27

--- 31 ---

Page 35

(7) Mounting the bit holder or the chuck holder

The bit holder or the chuck holder can be mounted by the disassembly procedure in reverse. How to mount

the Lock Grip [11] is as follows. Mount the Spring [10] and the Lock Ring [12] to the Lock Grip [11] and align

the Spring [10] with the notch of the Bit Holder [13]. At this time, place the Bit Holder [13] on a suitably-sized

support for easy mounting. Mount Washer (B) [9]. Push in the Lock Grip [11] turning in the arrow direction on

the Lock Grip [11] as shown in Fig. 29 and fix it with the Retaining Ring for D25 Shaft [8]. If it is impossible to

mount Washer (B) [9] to the fixing position of the Retaining Ring for D25 Shaft [8], remove Washer (B) [9] and

check that the Sping [10] is inserted to the proper position. (Fig. 19)

Lock Grip [11]

Notch

Spring [10]

Lock Grip [11]

Lock Ring [12]

Spring [10]

Fig. 28

(8) Mounting the piston

Mount the Piston [53] as shown in Fig. 30.

Bit Holder [13] or

Chuck Holder [29]

Inner Cover Ass'y [56]

Support

Fig. 29

Piston [53]

Striker [51]

First Gear [66]

Second Shaft [63]

Reciprocating Bearing [65]

Fig. 30

--- 32 ---

Page 36

(9) Mounting the gear cover

After reassembly as shown in Fig. 31, ensure that the Change Lever [34] is adjusted to the "Hammering only"

position. Engage the claws of the Clutch [61] and the Reciprocating Bearing [65] each other. Align the wing

portion of the Lock Plate [58] horizontally and reinstall the Gear Cover Ass'y [18] so that the wing portion of

the Lock Plate [58] is contained in the rail inside of the Gear Cover Ass'y [18]. When the Second Shaft [63]

contacts the Pinion Sleeve [57] inside the Gear Cover Ass'y [18], move the Change Lever [34] to the "Rotation

and hammering" mode and rotate the Grip [4]. Then the Second Shaft [63] and the Pinion Sleeve [57] are

engaged and the end surface of the Gear Cover Ass'y [18] contacts that of the Housing [83]. At this time,

rotate the Grip [4] to check that the rotation of the Cylinder [38] is transmitted to the armature shaft.

Move the Piston [53] to the top dead center.

Housing [83]

End surface of the

Housing [83]

End surface of the Gear Cover Ass'y [18]

Rail in the Gear Cover Ass'y [18]

Engage the claws of the Clutch [61]

and the Reciprocating Bearing [65].

Position the wing portion of the

Lock Plate [58] horizontally.

9-3. Tightening Torque

Tapping Screws D4 [79] [97] [99] ............................................... 2.0 0.5 N•m (20 5 kgf•cm, 17.4 4.3 in-lbs.)

Tapping Screw (W/Flange) D5 X 35 [19] .................................... 2.9 0.5 N•m (30 5 kgf•cm, 26.0 4.3 in-lbs.)

Drill Chuck 13VLRH-N (W/O Chuck Wrench) [27] ...................... 34.3 5 N•m (350 50 kgf•cm, 305 44 in-lbs.)

Flat Hd. Screw (A) (Left Hand) M6 x 25 [26]............................... 4.9 0.5 N•m (50 5 kgf•cm, 44 4.3 in-lbs.)

Spring (B) [35]

Fig. 31

Gear Cover Ass'y [18]

Move the Change Lever [34] to the

"Hammering only" ( mark) position.

--- 33 ---

Page 37

9-4. Wiring Diagrams

(1) Product with noise suppressor

Black or brown

Cord ass'y

White or blue

Speed control SW

(2) Product without noise suppressor

Black or brown

Gray

Red

Gray

Stator

Noise

suppressor

Stator

Fig. 32

Stator

White

Black

White

Choke coil

Brown

Blue

Choke coil

Reversing SW

Brown

Cord ass'y

White or blue

Speed control SW

Red

Stator

Fig. 33

Blue

Black

Reversing SW

--- 34 ---

Page 38

9-5. Internal Wire Arrangement and Wiring Work

A. Internal wire arrangement

(1) Product with noise suppressor

Brown (Choke coil) Black (Stator)

Choke Coil (A) Blue [87]

Choke Coil (A) Brown [84]

White (Stator)

Gray (Stator)

White (Stator)

White or blue

Red (Stator)

Blue (Choke coil)

Noise Suppressor [93]

Black or brown

Fig. 34

--- 35 ---

Page 39

(2) Product without noise suppressor

White (Stator)

Brown (CB)

Black (Stator)

Gray (Stator)

White (Stator)

Red (Stator)

Blue (CB)

White or blue

Black or brown

Fig. 35

--- 36 ---

Page 40

B. Additional wiring work

General internal wiring can be accomplished by referring to

paragraphs 9-4 and 9-5-A. The following are special

instructions for switch connection.

(1) Wiring of reversing switch

Insert the lead wire (black) coming from the stator into

the terminal (4) of the reversing switch, and the lead wire

(white) into the terminal (3) as shown in Fig. 36.

Insert the lead wire (brown) coming from the carbon

brush or choke coil into the terminal (2) and the lead wire

(blue) into the terminal (1). After insertion, pull each lead

wire slightly to check that the lead wires do not come off.

To disconnect the lead wires, insert a small flat-blade

screwdriver into the windows near the terminals and pull

out the lead wires.

(2) Wiring of speed control switch

Insert each cord into the terminal 1 and terminal 2 of

the speed control switch as shown in Fig. 37 and tighten

Blue (CB)

White (Stator)

Black (Stator)

Fig. 36 Wiring of reversing switch

Brown (CB)

Black (Cord)

White (Cord)

the screw [tightening torque: 0.6 0.2 N•m (6 2 kgf•cm,

5.2 1.7 in-lbs.)]. Insert the lead wire (gray) coming

from the stator into the terminal M1 and the lead wire

(red) into the terminal M2. Insert each lead wire (white)

coming from the noise suppressor into the terminal C1

and C2.

After insertion, pull each lead wire slightly to check the

lead wires do not come off. To disconnect the lead wires,

insert a small flat-blade screwdriver into the windows

near the terminals and pull out the lead wires.

Fig. 37 Wiring of reversing switch

9-6. Insulation Tests

On completion of disassembly and repair, measure the insulation resistance and conduct the dielectric strength

test.

Insulation resistance: 7 M Ω or more with DC 500 V megohm tester

Dielectric strength: AC 4,000 V/1 minute, with no abnormalities 220 V --- 240 V (and 110 V for U.K. products)

Red (Stator)

Gray (Stator)

White

(Noise suppressor)

White

(Noise suppressor)

AC 2,500 V/1 minute, with no abnormalities 110 V --- 120 V (except U.K. products)

9-7. No-load Current Values

After no-load operation for 30 minutes, the no-load current value should be as follows:

Voltage (V)

Current (A) max. 3.6

110

120

3.3

220

1.8

--- 37 ---

230

1.7

240

1.6

Page 41

10. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

DH 24PM

General Assembly

Variable

Work Flow

Handle Cover

Cord Armor

Switch

Cord

Housing

Stator

Armature Ass'y

O-ring (P-22)

Ball Bearing

(608DD)

Ball Bearing

(608VV)

Second Hammer

O-ring (1AP-20)

Hammer Holder

O-ring (B)

Damper (A)

O-ring (C)

Damper Holder

50

Cylinder

Second Gear

Spring (A)

60 min.

Change Lever

O-ring (S-18)

Pushing Button

Striker

O-ring

Piston

O-ring

Piston Pin

Washer (C) x 2

Gear Cover

Ass'y

Oil Seal

Ball Bearing

(6904DD)

Sleeve (A)

Inner Cover

Ass'y

Spring (B)

Second Shaft

Clutch Spring

Clutch

Reciprocating

Bearing

First Gear

Ball Bearing

(626VV)

Lock Plate

Second Pinion

--- 38 ---

Page 42

Hitachi Power Tools

ELECTRIC TOOL PARTS LIST

LIST NO. E496

ROTARY HAMMER

Model DH 24PM

2

3

4

5

26

27

28

36

37

38

39

72

73

74

75

76

77

1

6

7

8

9

25

8

9

10

11

40

41

42

43

57

58

59

78

79

2006 • 9 •15

(E1)

501

10

11

12

13

14

15

12

29

30

15

16

44

45

46

47

48

49

60

61

62

63

80

76

81

17

16

50

51

64

65

18

31

32

52

53

66

502

19

33

34

54

55

67

68

503

20

21

22

23

24

35

56

90

89

88

87

86

85

84

83

82

93

91

92

90

97

96

94

95

69

70

71

98

99

100

Page 43

PARTS

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

1 326-516 BIT HOLDER ASS’Y 1 INCLUD. 2-16

2 306-345 FRONT CAP 1

3 306-340 STOPPER RING 1

4 324-527 GRIP 1

5 324-528 BALL HOLDER 1

6 324-526 HOLDER PLATE 1

7 322-812 HOLDER SPRING 1

8 965-469 RETAINING RING FOR D25 SHAFT 2

9 326-520 WASHER (B) 2

10 326-519 SPRING 2

11 326-387 LOCK GRIP 2

12 326-661 LOCK RING 2

13 326-517 BIT HOLDER 1

14 959-156 STEEL BALL D7.0 (10 PCS.) 3

15 326-518 WASHER (A) 2

16 962-553 RETAINING RING FOR D28 SHAFT 2

17 306-993 RETAINING RING 1

18 324-605 GEAR COVER ASS’Y 1 INCLUD. 57

19 301-654 TAPPING SCREW (W/FLANGE) D5X35 4

20 NAME PLATE 1

21 307-688 OIL SEAL 1

22 322-815 SLEEVE 1

23 323-232 FELT PACKING (B) 1

24 690-4DD BALL BEARING 6904DDPS2L 1

25 326-271 CHUCK HOLDER ASS’Y 1 INCLUD. 8-12, 15, 16, 26-30

26 995-344

27 322-357

FLAT HD. SCREW (A) (LEFT HAND) M6X25

DRILL CHUCK 13VLRH-N (W/O CHUCK WRENCH)

28 326-527 STOPPER 1

29 326-526 CHUCK HOLDER 1

30 959-156 STEEL BALL D7.0 (10 PCS.) 2

31 324-530 PUSHING BUTTON 1

32 317-223 PUSHING SPRING 1

33 878-885 O-RING (S-18) 1

34 325-059 CHANGE LEVER 1

35 317-238 SPRING (B) 2

36 324-522 SLEEVE (A) 1

37 322-813 RETAINING RING 37MM 1

38 326-521 CYLINDER 1

39 323-185 SECOND GEAR 1

40 317-233 SPRING (A) 1

41 317-234 WASHER (A) 1

42 317-235 RETAINING RING D30 1

43 326-522 SECOND HAMMER 1

44 944-486 O-RING (1AP-20) 1

45 324-523 HAMMER HOLDER 1

46 322-802 O-RING (B) 1

47 322-805 DAMPER (A) 1

48 322-808 O-RING (C) 1

49 324-524 DAMPER HOLDER 1

50 322-807 STOPPER RING 1

51 324-535 STRIKER 1

ALTERNATIVE PARTS--- 2 ---

*

NO.

USED

1

1

DH 24PM

9 -- 06

Page 44

PARTS

ITEM

NO.

CODE NO.

DESCRIPTION

52 322-834 O-RING (I.D. 16) 1

53 324-534 PISTON 1

54 322-799 WASHER (C) 2

55 322-793 O-RING (I.D. 66.5) 1

56 324-542 INNER COVER ASS’Y 1 INCLUD. 69-71

57 323-249 PINION SLEEVE 1

58 318-522 LOCK PLATE 1

59 323-181 SECOND PINION 1

60 323-182 CLUTCH SPRING 1

61 324-606 CLUTCH 1

62 326-524 WASHER (D) 1

63 323-180 SECOND SHAFT 1

64 322-798 PISTON PIN 1

65 324-533 RECIPROCATING BEARING 1

66 322-797 FIRST GEAR 1

67 322-795 SPACER 1

68 626-VVM BALL BEARING 626VVC2PS2L 1

69 324-543 FELT PACKING (A) 1

70 324-545 VALVE 1

71 324-544 FELT PACKING (B) 1

72 322-816 FELT PACKING 1

73 876-796 O-RING (P-22) 1

74 322-818 PACKING WASHER 1

75 608-DDM BALL BEARING 608DDC2PS2L 1

76 982-631 WASHER (A) 2

*77 360-720U ARMATURE ASS’Y 110V-120V 1 INCLUD. 75, 76, 81

*77 360-720E ARMATURE 220V-230V 1

*77 360-720F ARMATURE 240V 1

78 324-531 FAN GUIDE 1

79 961-672 HEX. HD. TAPPING SCREW D4X50 2

*80 340-635C STATOR 110V-120V 1

*80 340-635E STATOR 220V-230V 1

*80 340-635F STATOR 240V 1

81 608-VVM BALL BEARING 608VVC2PS2L 1

82 326-523 HITACHI PLATE 1

83 324-553 HOUSING 1

*84 324-549 CHOKE COIL (A) BROWN 1

*84 324-550 CHOKE COIL (A) BROWN 1 FOR GBR (110V)

85 324-536 SWITCH (1P PILLAR TYPE) 1

86 322-853 PUSHING BUTTON 1

*87 324-551 CHOKE COIL (A) BLUE 1

*87 324-552 CHOKE COIL (A) BLUE 1 FOR GBR (110V)

*88 324-538 INTERNAL WIRE (A) (BLUE) 1 FOR USA, CAN

89 999-041 CARBON BRUSH (1 PAIR) 1

90 955-203 BRUSH HOLDER 2

*91 324-537 INTERNAL WIRE (A) (BROWN) 1 FOR USA, CAN

92 999-072

CARBON BRUSH (AUTO STOP TYPE) (1 PAIR) 1

*93 930-039 NOISE SUPPRESSOR 1 EXCEPT FOR USA, CAN

*94 981-373 TUBE (D) 2 FOR CORD

95 953-327 CORD ARMOR D8.8 1

96 937-631 CORD CLIP 1

9 -- 06

ALTERNATIVE PARTS --- 3 ---

*

NO.

USED

REMARKS

DH 24PM

Page 45

PARTS

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

97 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

98 324-554 HANDLE COVER 1

99 301-653

TAPPING SCREW (W/FLANGE) D4X20 (BLACK)

* 100 500-390Z CORD 1

* 100 500-249Z CORD 1 FOR USA, CAN

* 100 500-446Z CORD 1 FOR GBR (230V)

* 100 500-454Z CORD 1 FOR GBR (110V)

* 100 500-391Z CORD 1 FOR SUI

* 100 500-408Z CORD 1 FOR AUS, NZL

NO.

USED

3

DH 24PM

ALTERNATIVE PARTS--- 4 ---

*

9 -- 06

Page 46

STANDARD ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

501 324-548 SIDE HANDLE 1

* 502 303-709 DEPTH GAUGE 1

* 502 310-331 DEPTH GAUGE 1 FOR USA, CAN

503 326-525 CASE 1

NO.

USED

OPTIONAL ACCESSORIES

ITEM

CODE NO.

NO.

601 981-840

602 308-471

603 980-927

DESCRIPTION REMARKS

GREASE (A) FOR HAMMER. HAMMER DRILL (30G)

GREASE FOR HAMMER. HAMMER DRILL (70G) 1

GREASE FOR HAMMER. HAMMER DRILL (500G)

604 306-885 DUST COLLECTOR (B) ASS’Y 1 INCLUD. 605, 613

605 986-802 DUST COLLECTOR ASS’Y 1 INCLUD. 606-612

606 986-803 DUST COVER 1

607 986-804 SEAL COVER 1

608 948-310 RETAINING RING FOR D30 SHAFT 1

609 958-063 WASHER 1

610 959-150 STEEL BALL D6.35 (10 PCS.) 19

611 986-805 OUTER RACE 1

612 986-806 SOCKET 1

613 306-910 SOCKET ADAPTER (B) 1

614 971-787 DUST CUP 1

615 931-844 STOPPER 1

616 321-814 DRILL CHUCK 13VLRB-D 1 INCLUD. 617

617 995-344 FLAT HD. SCREW (A) (LEFT HAND) M6X25 1

618 321-813 DRILL CHUCK 13VLD-D 1

619 971-511Z + DRIVER BIT (A) NO. 2 25L 1

620 971-512Z + DRIVER BIT (A) NO. 3 25L 1

621 944-477 COTTER 1

622 982-684

CENTER PIN (A) 109L FOR CORE BIT D32-38 1

623 982-685 CENTER PIN (B) 104L FOR CORE BIT D45-90 1

624 982-672 CORE BIT (A) 25MM 1

625 982-673 CORE BIT (A) 29MM 1

626 982-674 CORE BIT (A) 32MM 1 INCLUD. 627

627 982-686 GUIDE PLATE (FOR CORE BIT 32MM) 1

628 982-675 CORE BIT (A) 35MM 1 INCLUD. 629

629 982-687 GUIDE PLATE (FOR CORE BIT 35MM) 1

630 982-676 CORE BIT (A) 38MM 1 INCLUD. 631

631 982-688 GUIDE PLATE (FOR CORE BIT 38MM) 1

632 982-677 CORE BIT (B) 45MM 1 INCLUD. 633

633 982-689 GUIDE PLATE (FOR CORE BIT 45MM) 1

634 982-678 CORE BIT (B) 50MM 1 INCLUD. 635

635 982-690 GUIDE PLATE (FOR CORE BIT 50MM) 1

636 971-794

637 971-795

638 971-796

639 971-797

640 971-798

641 971-799

ANCHOR SETTING ADAPTER A W1/4” (MANUAL)

ANCHOR SETTING ADAPTER A W5/16” (MANUAL)

ANCHOR SETTING ADAPTER A W3/8” (MANUAL)

ANCHOR SETTING ADAPTER A W1/2” (MANUAL)

ANCHOR SETTING ADAPTER A W5/8” (MANUAL)

ANCHOR SETTING ADAPTER B W1/4” (MANUAL)

ALTERNATIVE PARTS --- 5 ---9 -- 06

*

NO.

USED

1

1

1

1

1

1

1

1

DH 24PM

Page 47

OPTIONAL ACCESSORIES

ITEM

CODE NO.

NO.

642 971-800

643 971-801

644 971-802

645 971-803

DESCRIPTION REMARKS

ANCHOR SETTING ADAPTER B W5/16” (MANUAL)

ANCHOR SETTING ADAPTER B W3/8” (MANUAL)

ANCHOR SETTING ADAPTER B W1/2” (MANUAL)

ANCHOR SETTING ADAPTER B W5/8” (MANUAL)

646 944-460 TAPER SHANK DRILL BIT D11X100 1

647 944-461 TAPER SHANK DRILL BIT D12.3X110 1

648 993-038 TAPER SHANK DRILL BIT D12.7X110 1

649 944-462 TAPER SHANK DRILL BIT D14.3X110 1

650 944-500 TAPER SHANK DRILL BIT D14.5X110 1

651 944-463 TAPER SHANK DRILL BIT D17.5X120 1

652 944-464 TAPER SHANK DRILL BIT D21.5X140 1

653 320-859 SYRINGE (BLOW-OUT BULB TYPE) 1

654 326-305 SERVICE KIT (DH 24PB3, ETC.) 1 INCLUD. 33, 44, 46-48, 53, 55, 92, 601

655 303-046

656 303-044

657 303-045

BULL POINT (SDS+) 250MM (ROUND SHANK TYPE)

CHEMICAL ANCHOR ADAPTER (SDS+) 12.7MMX90L

CHEMICAL ANCHOR ADAPTER (SDS+) 19.0MMX100L

658 930-515 CHUCK WRENCH 10G 1

659 302-976

660 302-975

661 303-621

662 302-974

663 302-979

664 302-978

665 303-622

666 302-977

ANCHOR SETTING ADAPTER A (SDS+) W1/4X260L

ANCHOR SETTING ADAPTER A(SDS+) W5/16X260L

ANCHOR SETTING ADAPTER A (SDS+) W3/8X160L

ANCHOR SETTING ADAPTER A (SDS+) W3/8X260L

ANCHOR SETTING ADAPTER B (SDS+) W1/4X260L

ANCHOR SETTING ADAPTER B (SDS+) W5/16X260L

ANCHOR SETTING ADAPTER B (SDS+) W3/8X160L

ANCHOR SETTING ADAPTER B (SDS+) W3/8X260L

667 303-332 HAMMER DRILL CHUCK SET 13MM 1 INCLUD. 668, 669

668 303-334 CHUCK HANDLE 1

669 303-335 RUBBER CAP 1

670 303-617

671 303-618

TAPER SHANK ADAPTER (SDS PLUS) NO. 1

TAPER SHANK ADAPTER (SDS PLUS) NO. 2

672 303-619 A-TAPER SHANK ADAPTER (SDS PLUS) 1

673 303-620 B-TAPER SHANK ADAPTER (SDS PLUS) 1

674 981-122 SPECIAL SCREW M6X22 1

675 303-625

676 303-626

677 303-627

CORE BIT SHANK (SDS PLUS) 25-38MM 105L

CORE BIT SHANK (SDS PLUS) 25-38MM 300L

CORE BIT SHANK (SDS PLUS) 45-90MM 300L

678 303-624 CHUCK ADAPTER (D) (SDS PLUS) 1

679 321-825 DRILL CHUCK AND ADAPTER SET 1 INCLUD. 680

680 303-623 CHUCK ADAPTER (G) (SDS PLUS) 1

681 306-369 DRILL BIT (SLENDER SHAFT) D3.4X90 1

682 306-368 DRILL BIT (SLENDER SHAFT) D3.5X90 1

683 306-370

ADAPTER FOR SLENDER SHAFT (SDS PLUS)

NO.

USED

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

DH 24PM

ALTERNATIVE PARTS--- 6 ---

*

Printed in Japan

(060915N)

9 -- 06

Page 48

Loading...

Loading...