Page 1

Drill

D13

Handling instructions

Read through carefully and understand these instructions before use.

Page 2

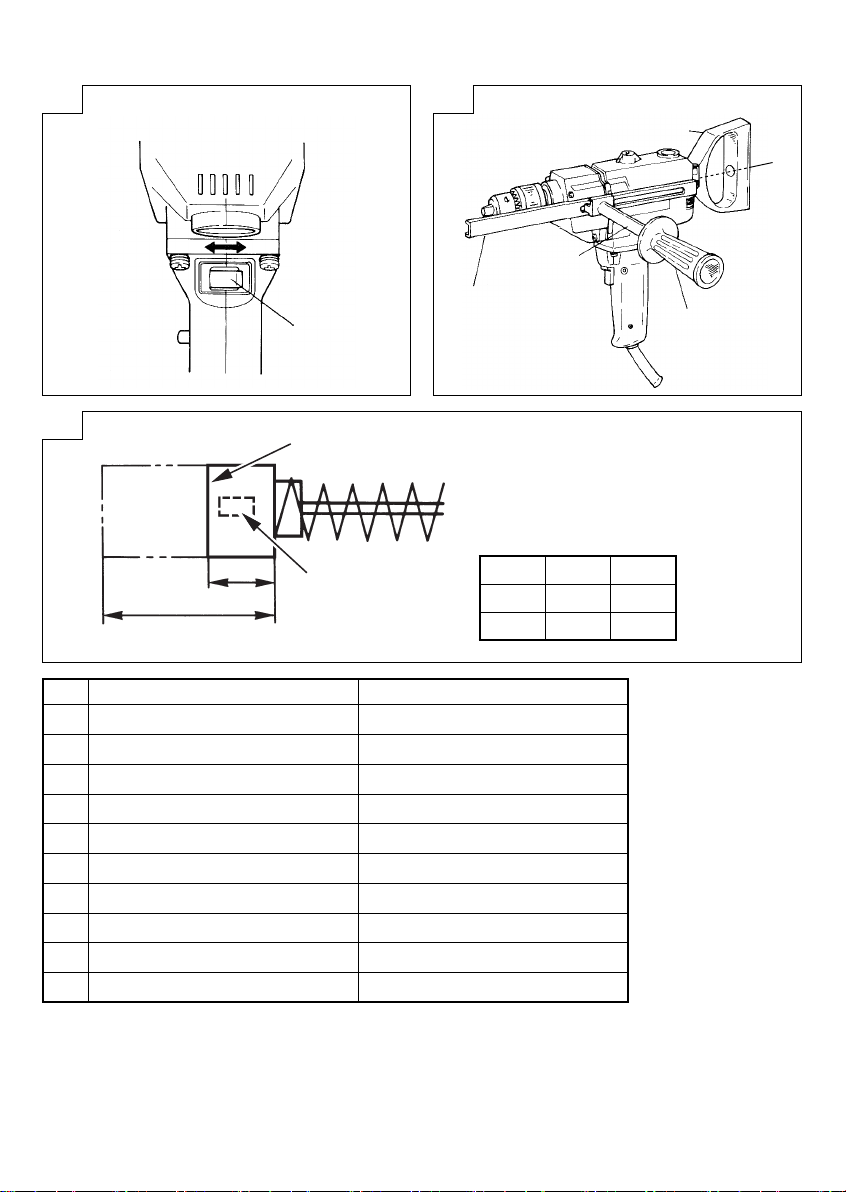

12

5

6

(L) (R)

3

17 m m

English

Lever

1

Depth stopper

2

Handle joint

3

Side handle

4

Spade handle

5

Bolt

6

Wear li mit

7

No. of carbon brush

8

Usual carbon brush

9

Auto-stop carbon brush

0

3

2

1

4

7

a

8

9

0

ﺔﻳﺑﺭﻌﻟﺍ

ﺔﻳﺩﺎﻌﻟﺍ ﻥﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻓ

ﻑﻗﻭﺗﻟﺍ ﺔﻳﺋﺎﻘﻠﺗ ﻥﻭﺑﺭﻛﻟﺎﺑ ﻝﻘﺻ ﺓﺎﺷﺭﻓ

a

6 mm 43

7 mm 73

ﻉﺍﺭﺫ

ﻕﻣﻌﻟﺍ ﺩﺍﺩﺳ

ﺽﺑﻘﻣﻟﺍ ﺔﻠﺻﻭ

ﻲﺑﻧﺎﺟ ﺽﺑﻘﻣ

ﻑﺍﺭﺟﻣﻟﺍ ﺽﺑﻘﻣ

ﺭﺎﻣﺳﻣ

ﻝﻛﺂﺗﻟﺍ ﺩﺣ

ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺵﺭﻔﻟﺍ ﺩﺩﻋ

8

2

Page 3

English

GENERAL POWER TOOL SAFET Y WARNINGS

WARNING

Read all safet y warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fi re and/or serious injur y.

Save all wa rnings and ins tructions f or future ref erence.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work ar e a s a fe t y

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet .

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

c) Prevent unintentional star ting. Ensure the

switch is in the off -position before connecting

to power source and/or batter y pack , picking

up or carrying the tool.

Carr ying power tools with your fi nger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the bat tery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power to ols are dangero us in the hands of untrained

users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may aff ect the

power toolsʼ operation.

If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cut ting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

Use of the power tool for operations diff erent from

those i ntended coul d result in a haza rdous situati on.

3

Page 4

English

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach

of children and infi rm persons.

DRILL SAFETY WARNINGS

1. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

Hold power tool by insulated gripping sur faces,

2.

when performing an operation where the cutting

accessory m ay contact hidden wiring or its own cord.

Cutting accessory contacting a "live" wire may make

exposed metal parts of the power tool "live" and could

give the operator an electric shock.

3. Never wear gloves during operation.

Gloves are sometimes caught by rotating parts,

resulting in serious injury. Do not use gloves during

operation.

4. Install the side handle and hold the tool fi rmly with both

hands.

One-hand operation is very dangerous. Always install

the side handle and hold the tool with both hands.

Holding the tool insuffi ciently can result in serious

damage during operation.

5. Hold the main handle by your right hand.

Holding the main handle by your left hand may make

the switch be unintentionally locked.

SPECIFICATIONS

Voltage (by areas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Power Input* 720 W

No-load speed* 650 /min

Capacity

Weight (without cord) 3 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

(1) Chuck Wrench ..............................................................1

(2) Side handle ..................................................................1

Stand ard accessor ies are subje ct to change wit hout notice.

OPTIONAL ACCESSORIES (sold separately)

(1) Handle joint

(2) Depth Stopper

Optional accessories are subject to change without notice.

APPLICATIONS

Drilling in metal, lumber and plastics.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will star t

operating immediately, inviting serious accident.

3. Extension cord

When the work area is removed from the power source.

Use an extension cord of suffi cient thickness and rated

capaci ty. The extension cord sho uld be kept as shor t as

practicable.

Steel 13 mm

Wood 40 mm

4. Confi rm the direction of bit rotation

The drill bit rotates clock wise (when viewed from the

rear) when the lever of the reversing switch is set to the

“R” position, and rotates in the reverse direction when

the lever of the reversing switch is set to the “L” position.

5. Fitting the drill bit

Fit the drill bit into the chuck and use the chuck key

to secure it, tightening the chuck by each of the three

holes in turn.

6. Selecting the appropriate drill bit

○ When boring metal or plastic

Use ordinary metalworking drill bits.

Sizes range from a minimum of 1.2 mm to chuck

maximum capacity.

○ When boring wood

Use ordinary woodworking drill bits.

However, when drilling 6.5 mm or smaller holes, use a

metalworking drill bit.

7. Installing spade handle

The spade handle can be installed on the back of

the drill. Insert the bolt through the hole in the spade

handle, locate the spade handle in the desired position

and tighten the bolt fi rmly.

8. Installing the side handle

The side handle screws into the housing on either side

of the gear cover. For safe operation, use of the side

handle is necessary. Especially in heavy duty drilling,

use handle joint and side handle.

9. Installing the depth stopper (optional accessory)

The depth stopper which is useful for adjusting the

drilling depth is available. Install the depth stopper to

the gear cover using the side handle or set screw.

4

Page 5

English

10. RCD

Th e use of a residu al current dev ice with a rate d residual

current of 30mA or less at all times is recommended.

PRACTICAL HANDLING PROCEDURES

1. Pressure

Drilling will NOT be accelerated by placing heavy

pressure on the drill. Such action will only result in a

damaged drill bit, decreased drilling effi ciency, and/or

shortened service life of the drill.

2. Using a large diameter drill bit

The larger the drill bit diameter, the larger the reactive

force on your arm. Be careful not to lose control of the

drill because of this reactive force. To maintain fi rm

control, establish a good foothold, hold the drill tightly

with both hands, and ensure that the drill is vertical to

the material being drilled.

3. When drilling completely through the material

When the drill bit bores completely through the

material, careless handing often results in broken drill

bit or damage to the drill body itself due to the sudden

movement of the drill.

Always be alert and ready to release pushing force

when drilling through the material.

4. Switch operation

(1) Trigger switch

By pulling the trigger switch and depressing the

stopper, the switch is held in the ON position for

continuous drilling. To turn the drill OFF, pull the trigger

switch again and release.

(2) Reversing switch

This drill can rotate both clockwise (for drilling)

and counterclockwise (for releasing the drill bit) by

operating the reversing switch.

CAUTION

Never change the direc tion of rotation while th e motor is

rotating. Turn the power switch off before changing the

direction of rotation.

5. Precautions on boring

The drill bit may become overheated during operation;

however, it is suffi ciently operable. Do not cool the drill

bit in water or oil.

6. Caution concerning immediately after use

Immediately after use, while it is still revolving, if

the Drill is placed on a location where considerable

ground chips and dust have accumulated, dust may

occasionally be absorbed into the drill mechanism.

Always pay at tention to this undesirable possibility.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of an abraded drill bits will cause motor

malfunctioning and degraded effi ciency, replace the

drill bits with a new one or resharpening without delay

when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, retighten them immediately. Failure to do so

could result in serious hazard.

3. Inspecting the carbon brushes

The motor employs carbon brushes which are

consumable parts.

When the brushes are worn down, motor trouble may

result . When the brush es are worn down to th e limit line,

replace the brushes with new ones. Keep the brushes

clean, so that they smoothly slide into the brush holders.

When replacing the brushes with new ones, be sure to

use a pair o f brushes for HiKOK I ELECTRIC DRILL Type

D13 corresponding to the illustrated number. Auto-stop

carbon brushes automatically cut off the electric circuit,

when it is worn down to the wear limit.

This indicates the replacement time of the brush and

prevents damage of the commutator.

4. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

5. Maintenance of the motor

The motor unit winding is the very “heart ” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

6. Replacing supply cord

If the replacement of the supply cord is necessar y, it

has to be don e by H iKOKI Authorized Ser vice Center to

avoid a safet y hazard.

7. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modifi cation and inspection of HiKOKI Power

Tools must be carried out by a HiKOKI Authorized

Service Center.

Thi s Par ts Li st will be hel pful if pr esen ted w ith t he to ol to

the HiKOKI Au thorized Ser vice Center when requ esting

repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

countr y must be observed.

MODIFICATION

HiKOKI Power Tools are constantly being improved

and modifi ed to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE

Due to HiKOKI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

5

Page 6

ﺔﻴﺑﺮﻌﻟا

ﺔﻣﺩﺧﻟﺍ ءﺍﺯﺟﺃ ﺔﻣﺋﺎﻗ

ﺭﺻﻧﻌﻟﺍ ﻡﻗﺭ :A

ﺯﻣﺭﻟﺍ ﻡﻗﺭ :B

ﻡﺩﺧﺗﺳﻣﻟﺍ ﻡﻗﺭﻟﺍ :C

ﺕﺎﻣﻼﻌﻟﺍ :D

HiKOKI

ﺕﺍﻭﺩﻷ ﺹﺣﻔﻟﺍﻭ ،ﻝﻳﺩﻌﺗﻟﺍﻭ ،ﺡﻼﺻﻹﺍ ﻝﺎﻣﻋﺃ ﺫﻳﻔﻧﺗ ﺏﺟﻳ

HiKOKI

ﺔﻣﺩﺧ ﺯﻛﺭﻣﻟ ﺓﺍﺩﻷﺍ ﻊﻣ ﺎﻬﻣﻳﺩﻘﺗ ﺩﻧﻋ ﺓﺩﻳﻔﻣ ﻩﺫﻫ ءﺍﺯﺟﻷﺍ ﺔﻣﺋﺎﻗ

.ﺩﻣﺗﻌﻣﻟﺍ ﺔﻣﺩﺧﻟﺍ ﺯﻛﺭﻣ ﻝﺑﻗ ﻥﻣ

ﻪﻳﺑﻧﺗ

.ﺔﻧﺎﻳﺻﻟﺍ ﻝﺎﻣﻋﺃ ﻥﻣ ﺎﻫﺭﻳﻏ ﻭﺃ ﺡﻼﺻﻹﺍ ﺏﻠﻁ ﺩﻧﻋ ﺩﻣﺗﻌﻣ

ﺕﺎﻣﻳﻠﻌﺗ ﻉﺎﺑﺗﺍ ﺏﺟﻳ ،ﺎﻬﺗﻧﺎﻳﺻ ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﺔﻟﺎﺣ ﻲﻓ

.ﺔﻟﻭﺩ ﻝﻛﺑ ﺔﺻﺎﺧﻟﺍ ﺭﻳﻳﺎﻌﻣﻟﺍﻭ ﻥﺎﻣﻷﺍ

ﺕﺎﻳﻧﻘﺗﻟﺍ ﺙﺩﺣﻷ ﺎًﻌﺑﺗ ﺎﻬﻠﻳﺩﻌﺗﻭ ﺭﺍﺭﻣﺗﺳﺎﺑ

HiKOKI

ﺕﺍﻭﺩﺃ ﻥﻳﺳﺣﺗ ﻡﺗﻳ

ﺕﻼﻳﺩﻌﺗﻟﺍ

.ﺔﻣﺩﻘﺗﻣﻟﺍ

(ﻡﻳﻣﺻﺗﻟﺍ ﻭﺃ/ﻭ ﺯﻭﻣﺭﻟﺍ ﻡﺎﻗﺭﺃ ﻝﺛﻣ) ءﺍﺯﺟﻷﺍ ﺽﻌﺑ ﺭﻳﻳﻐﺗ ﻡﺗﻳ ﺩﻗ ،ﻙﻟﺫﻟﻭ

.ﻕﺑﺳﻣ ﻡﻼﻋﺇ ﻥﻭﺩ

ﺕﺎﻔﺻﺍﻭﻣﻟﺍ ﺭﻳﻐﺗﺗ ،ﺭﻣﺗﺳﻣﻟﺍ ﺭﻳﻭﻁﺗﻟﺍﻭ ﺙﺣﺑﻠﻟ

HiKOKI

ﺔﻅﺣﻼﻣ

ﺞﻣﺎﻧﺭﺑﻟ ﺎًﻌﺑﺗ

.ﻕﺑﺳﻣ ﻡﻼﻋﺇ ﻥﻭﺩ ﺎﻧﻫ ﺓﺭﻭﻛﺫﻣﻟﺍ

7

.ﻙﻋﺍﺭﺫ ﻰﻠﻋ ﺔﻳﻠﻋﺎﻔﺗﻟﺍ ﺓﻭﻘﻟﺍ ﺕﺩﺍﺯ ﺎﻣﻠﻛ ،ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺭﻁﻗ ﺩﺍﺯ ﺎﻣﻠﻛ

ﺭﻳﺑﻛ ﺭﻁﻗ ﻱﺫ ﺭﻔﺣ ﺏﻘﺛﻣ ﻡﺍﺩﺧﺗﺳﺍ 2

ﻅﺎﻔﺣﻠﻟ .ﺔﻳﻠﻋﺎﻔﺗﻟﺍ ﺓﻭﻘﻟﺍ ﺏﺑﺳﺑ ﺏﻘﺛﻣﻟﺍ ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﺩﻘﻓ ﻡﺩﻋ ﻰﻠﻋ ﺹﺭﺣﺍ

ﻙﻳﺩﻳﺑ ﻡﺎﻛﺣﺈﺑ ﺏﻘﺛﻣﻟﺍ ﻙﺳﻣﺃﻭ ،ﻡﺩﻗ ﺊﻁﻭﻣ ﻊﺿ ،ﺕﺑﺎﺛﻟﺍ ﻡﻛﺣﺗﻟﺍ ﻰﻠﻋ

.ﺎﻬﻳﻓ ﺏﻘﺛﻟﺍ ﻡﺗﻳ ﻲﺗﻟﺍ ﺓﺩﺎﻣﻟﺍ ﻰﻠﻋ ﻱﺩﻭﻣﻋ ﻝﻛﺷﺑ ﻥﻳﺗﻧﺛﻻﺍ

ﺎًﺑﻟﺎﻏ ﻝﺎﻣﻫﺈﺑ ﻝﻣﺎﻌﺗﻟﺍ ﻱﺩﺅﻳ ﺩﻗ ،ﺓﺩﺎﻣﻟﺍ ﺭﺑﻋ ﺎًﻣﺎﻣﺗ ﺏﻘﺛﻣﻟﺍ ﻕﺭﺗﺧﻳ ﺎﻣﺩﻧﻋ

ﺓﺩﺎﻣﻟﺍ ﺭﺑﻋ ﻝﻣﺎﻛ ﻝﻛﺷﺑ ﺏﻘﺛﻟﺍ ﺩﻧﻋ

ﺔﺋﺟﺎﻔﻣﻟﺍ ﺔﻛﺭﺣﻟﺍ ﺏﺑﺳﺑ ﻪﺗﺍﺫ ﺏﻘﺛﻣﻟﺍ ﻝﻛﻳﻫ ﻑﻠﺗ ﻭﺃ ﺏﻘﺛﻣﻟﺍ ﺭﺳﻛ ﻰﻟﺇ

.ﺓﺩﺎﻣﻟﺍ ﻝﺧﺍﺩ ﺏﻘﺛﻟﺍ ﺩﻧﻋ ﻊﻓﺩﻟﺍ ﺓﻭﻗ ﺭﻳﺭﺣﺗﻟ ﺍًﺩﻌﺗﺳﻣﻭ ﺎﻣﺋﺍﺩ ﺎًﻬﺑﺗﻧﻣ ﻥﻛ

ﺡﺎﺗﻔﻣﻟﺍ ﻝﻳﻐﺷﺗ

ﺩﺎﻧﺯﻟﺍ ﺡﺎﺗﻔﻣ (1)

ﻙﺎﺳﻣﻹﺍ ﻡﺗﻳ ،ﻑﺎﻘﻳﻹﺍ ﺓﺍﺩﺃ ﻰﻠﻋ ﻁﻐﺿﻟﺍﻭ ﻝﻳﻐﺷﺗﻟﺍ ﺡﺎﺗﻔﻣ ﺏﺣﺳ ﺔﻁﺳﺍﻭﺑ

ﺏﺣﺳﺍ ،ﺏﻘﺛﻣﻟﺍ ﻝﻳﻐﺷﺗ ﻑﺎﻘﻳﻹ .ﺭﻣﺗﺳﻣﻟﺍ ﺏﻘﺛﻠﻟ ﻝﻳﻐﺷﺗﻟﺍ ﻊﺿﻭ ﻲﻓ

.ﻩﺭﺭﺣ ﻡﺛ ﻯﺭﺧﺃ ﺓﺭﻣ ﺡﺩﻘﻣﻟﺍ ﺡﺎﺗﻔﻣ

ﺱﻛﻌﻟﺍ ﺡﺎﺗﻔﻣ (2)

(ﺏﻘﺛﻠﻟ) ﺔﻋﺎﺳﻟﺍ ﺏﺭﺎﻘﻋ ﻩﺎﺟﺗﺍ ﻲﻓ ﺏﻘﺛﻣﻟﺍ ﺍﺫﻫ ﺭﻭﺩﻳ ﻥﺃ ﻥﻛﻣﻣﻟﺍ ﻥﻣ

ﺡﺎﺗﻔﻣ ﻝﻳﻐﺷﺗ ﺔﻁﺳﺍﻭﺑ (ﺭﻔﺣﻟﺍ ﺏﺎﻘﺛﻣ ﺭﻳﺭﺣﺗﻟ) ﺔﻋﺎﺳﻟﺍ ﺏﺭﺎﻘﻋ ﺱﻛﻋﻭ

.ﺱﻛﻌﻟﺍ

ﻝﻳﻐﺷﺗ ﻑﺎﻘﻳﺈﺑ ﻡﻗ .ﻙﺭﺣﻣﻟﺍ ﻥﺍﺭﻭﺩ ﺩﻧﻋ ﺭﻳﻭﺩﺗﻟﺍ ﻩﺎﺟﺗﺍ ﺭﻳﻳﻐﺗﺑ ﻡﻘﺗ ﻻ

.ﻥﺍﺭﻭﺩﻟﺍ ﻩﺎﺟﺗﺍ ﺭﻳﻳﻐﺗ ﻝﺑﻗ ﺔﻗﺎﻁﻟﺍ

ﻝﺑﺎﻗ ﻭﻬﻓ ﻙﻟﺫ ﻊﻣﻭ ،ﻝﻳﻐﺷﺗﻟﺍ ءﺎﻧﺛﺃ ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺓﺭﺍﺭﺣ ﺩﺍﺩﺯﺗ ﺩﻗ

ﺭﻔﺣﻟﺍ ءﺎﻧﺛﺃ ﺕﺎﻁﺎﻳﺗﺣﻻﺍ

.ٍﻑﺎﻛ ﻝﻛﺷﺑ ﻝﻳﻐﺷﺗﻠﻟ

.ﺕﻳﺯﻟﺍ ﻭﺃ ءﺎﻣﻟﺎﺑ ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺩﻳﺭﺑﺗﺑ ﻡﻘﺗ ﻻ

ﻥﺎﻛ ﺍﺫﺇ ،ﻥﺍﺭﻭﺩﻟﺍ ﻲﻓ ﻩﺭﺍﺭﻣﺗﺳﺍ ءﺎﻧﺛﺃﻭ ،ًﺓﺭﺷﺎﺑﻣ ﺏﻘﺛﻣﻟﺍ ﻡﺍﺩﺧﺗﺳﺍ ﺩﻌﺑ

ﺓﺭﺷﺎﺑﻣ ﻡﺍﺩﺧﺗﺳﻻﺍ ﺩﻌﺑ ﺎﻣﺑ ﻕﻠﻌﺗﻳ ﺎﻣﻳﻓ ﻪﻳﺑﻧﺗ

ﻡﺗﻳ ﺩﻘﻓ ،ﺭﺎﺑﻏﻭ ﺓﺭﻳﺑﻛ ﺔﻳﺿﺭﺃ ﺢﺋﺍﺭﺷ ﻪﻳﻓ ﻡﻛﺍﺭﺗﺗ ﻥﺎﻛﻣ ﻰﻠﻋ ﺎًﻋﻭﺿﻭﻣ

.ﺏﻘﺛﻣﻟﺍ ﺔﻟﺁ ﻝﺧﺍﺩ ﺭﺎﺑﻐﻟﺍ ﺹﺎﺻﺗﻣﺍ ﺎًﻧﺎﻳﺣﺃ

.ﺏﻭﻏﺭﻣﻟﺍ ﺭﻳﻏ ﻝﺎﻣﺗﺣﻻﺍ ﺍﺫﻬﻟ ﺎًﻣﺋﺍﺩ ﻪﺑﺗﻧﺍ

ﺹﺣﻔﻟﺍﻭ ﺔﻧﺎﻳﺻﻟﺍ

ﻝﻳﻠﻘﺗﻟﺍﻭ ﻙﺭﺣﻣﻟﺍ ﻑﻠﺗ ﻰﻟﺇ ﻱﺩﺅﺗ ﺔﻠﻛﺂﺗﻣﻟﺍ ﺭﻔﺣﻟﺍ ﺏﻗﺎﺛﻣ ﻥﺃ ﻰﻟﺇ ﺍًﺭﻅﻧ

ﻱﻷ ﻙﺗﻅﺣﻼﻣ ﺭﻭﻓ ﺎﻫﺫﺣﺷﺑ ﻡﻗ ﻭﺃ ﺭﻔﺣﻟﺍ ﺏﻗﺎﺛﻣ ﻝﺩﺑﺗﺳﺍ ،ﺓءﺎﻔﻛﻟﺍ ﻥﻣ

ﺎﻬﻁﺑﺭ ﻡﺎﻛﺣﺇ ﻥﻣ ﺩﻛﺄﺗﻟﺍﻭ ﺕﻳﺑﺛﺗﻟﺍ ﺭﻳﻣﺎﺳﻣ ﺔﻓﺎﻛﻟ ﻱﺭﻭﺩﻟﺍ ﺹﺣﻔﻟﺎﺑ ﻡﻗ

.ﺭﻭﻔﻟﺍ ﻰﻠﻋ ﺎﻬﻁﺑﺭ ﻡﺎﻛﺣﺈﺑ ﻡﻗ ،ﺭﻳﻣﺎﺳﻣ ﺔﻳﺃ ﻙﻓ ﺔﻟﺎﺣ ﻲﻓ .ﺢﻳﺣﺻ ﻝﻛﺷﺑ

.ﺭﻁﺎﺧﻣ ﻰﻟﺇ ﻙﻟﺫﺑ ﻡﺎﻳﻘﻟﺍ ﻲﻓ ﻝﺷﻔﻟﺍ ﺽﺭﻌﻳ ﺩﻘﻓ

.ﺓﺭﻣﻌﻣ ﺭﻳﻏ ءﺍﺯﺟﻷﺍ ﻥﻣ ﻲﻫﻭ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻙﺭﺣﻣﻟﺍ ﻡﺩﺧﺗﺳﻳ

ﺓﺎﺷﺭﻔﻟﺍ ﻝﻛﺂﺗ ﺩﻧﻋ .ﻙﺭﺣﻣﻟﺎﺑ ﻝﻁﻋ ﻙﻟﺫ ﻥﻋ ﺄﺷﻧﻳ ﺩﻗ ،ﺓﺎﺷﺭﻔﻟﺍ ﻝﻛﺂﺗ ﺩﻧﻋ

ﻰﻠﻋ ﻅﻓﺎﺣ .ﺓﺩﻳﺩﺟ ﻯﺭﺧﺄﺑ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺎﺑ ﻡﻗ ،ﻪﺑ ﺡﻭﻣﺳﻣﻟﺍ ﺩﺣﻠﻟ

.ﺓﺎﺷﺭﻔﻟﺍ ﺕﻼﻣﺎﺣ ﻝﺧﺍﺩ ﺔﻧﻭﺭﻣﺑ ﺓﺎﺷﺭﻔﻟﺍ ﻙﺭﺣﺗﺗ ﻙﻟﺫﻟ ،ﺓﺎﺷﺭﻔﻟﺍ ﺔﻓﺎﻅﻧ

ﻥﻣ ﺝﻭﺯ ﻡﺍﺩﺧﺗﺳﺍ ﻥﻣ ﺩﻛﺄﺗ ،ﺓﺩﻳﺩﺟ ﻯﺭﺧﺄﺑ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺍ ﺩﻧﻋ

ﻊﻣ ﻕﻓﺍﻭﺗﻣﻟﺍﻭ D13 ﻉﻭﻧﻟﺍ HiKOKI ﻥﻣ ﻲﺑﺭﻬﻛﻟﺍ ﺏﻘﺛﻣﻠﻟ ﺓﺎﺷﺭﻔﻟﺍ

ﺓﺭﺋﺍﺩﻟﺍ ﺎًﻳﺋﺎﻘﻠﺗ ﻑﻗﻭﺗﻟﺍ ﺔﻳﺗﺍﺫ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻊﻁﻘﺗ .ﺢﺿﻭﻣﻟﺍ ﺩﺩﻌﻟﺍ

.ﻪﺑ ﺡﻭﻣﺳﻣﻟﺍ ﻝﻛﺂﺗﻟﺍ ﺩﺣﻟ ﻝﺻﺗ ﺎﻣﺩﻧﻋ ،ﺔﻳﺑﺭﻬﻛﻟﺍ

ﺭﺎﻳﺗﻟﺍ ﺱﻛﺎﻋ ﻑﻠﺗ ﻊﻧﻣﻭ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺍ ﺩﻋﻭﻣ ﻡﻭﺩﻗ ﻰﻟﺇ ﻙﻟﺫ ﺭﻳﺷﻳ

ﺵﺭﻔﻟﺍ ﺔﻟﺍﺯﺇ ﻥﻛﻣﻳ .ﺕﺎﺣﺗﻓ ﻭﺫ ﻙﻔﻣ ﻝﻼﺧ ﻥﻣ ﺓﺎﺷﺭﻔﻟﺍ ﺔﻳﻁﻏﺃ ﻙﻔﺑ ﻡﻗ

ﺩﻛﺄﺗ .ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻥﻣ "ﻁﺳﻭﻷﺍ ءﺯﺟﻟﺍ" ﻭﻫ ﻙﺭﺣﻣﻟﺍ ﺓﺩﺣﻭ ﻑﻠﻣ

.ءﺎﻣﻟﺍ ﻭﺃ ﺕﻳﺯﻟﺍ ﺔﻁﺳﺍﻭﺑ ﻪﻠﻠﺑ ﻭﺃ/ﻭ ﻑﻠﻣﻟﺍ ﻑﻠﺗ ﻡﺩﻋ ﻥﻣ ﺭﺍﺭﻣﺗﺳﺎﺑ

ﻡﺗﻳ ﻥﺃ ﺏﺟﻳﻓ ،ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻟﺍ ﺱﺑﺎﻗ ﻙﻠﺳ ﻝﺍﺩﺑﺗﺳﺍ ﻰﻟﺇ ﺔﺟﺎﺣﻟﺍ ﺕﻋﺩ ﺍﺫﺇ

.ﺔﻣﻼﺳﻟﺍ ﺭﻁﺎﺧﻣ ﺏﻧﺟﺗﻟ ﺩﻣﺗﻌﻣﻟﺍ HiKOKI ﺔﻣﺩﺧ ﺯﻛﺭﻣ ﻝﻼﺧ ﻥﻣ ﻙﻟﺫ

ﺭﻔﺣﻟﺍ ﺏﻗﺎﺛﻣ ﺹﺣﻓ 1

ﺕﻳﺑﺛﺗﻟﺍ ﺭﻳﻣﺎﺳﻣ ﺹﺣﻓ

ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﺹﺣﻓ

.ﻲﺑﺭﻬﻛﻟﺍ

ﺔﻳﻧﻭﺑﺭﻛﻟﺍ ﺓﺎﺷﺭﻔﻟﺍ ﻝﺍﺩﺑﺗﺳﺍ 4

.ﺔﻟﻭﻬﺳﺑ ﺔﻳﻧﻭﺑﺭﻛﻟﺍ

ﻙﺭﺣﻣﻟﺍ ﺔﻧﺎﻳﺻ 5

ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻟﺍ ﻙﻠﺳ ﻝﺍﺩﺑﺗﺳﺍ 6

3

.ﺏﻘﺛﻣﻠﻟ

4

ﻪﻳﺑﻧﺗ

5

6

.ﻝﻛﺂﺗ

2

3

6

٣

Page 7

ﺔﻴﺑﺮﻌﻟا

ﺩﻗ ﺔﻳﻠﻣﻋ ءﺍﺩﺃ ﺩﻧﻋ ﺔﻟﻭﺯﻌﻣﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺢﻁﺳﺄﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻙﺳﻣﺃ

.ﺎﻬﺑ ﺹﺎﺧﻟﺍ ﻙﻠﺳﻟﺎﺑ ﻭﺃ ﺔﻳﻔﺧﻣ ﻙﻼﺳﺄﺑ ﻊﻳﻁﻘﺗﻟﺍ ﺕﺎﻘﺣﻠﻣ ﺎﻬﻳﻓ ﻝﺻﺗ

ﺔﻳﻧﺩﻌﻣﻟﺍ ءﺍﺯﺟﻸﻟ ﺽﺭﻌﺗﺗ ﺩﻗ "ﺭﺷﺎﺑﻣ" ﻙﻠﺳﺑ ﺔﻠﺻﺗﻣﻟﺍ ﻊﻳﻁﻘﺗﻟﺍ ﺕﺎﻘﺣﻠﻣ

.ﺔﻳﺋﺎﺑﺭﻬﻛ ﺔﻣﺩﺻﺑ ﺔﻳﻠﻣﻌﻟﺍ ﺏﻳﺻﺗ ﺩﻗﻭ "ﺓﺭﺷﺎﺑﻣﻟﺍ" ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

.ﻝﻳﻐﺷﺗﻟﺍ ءﺎﻧﺛﺃ ﺕﺍﺯﺎﻔﻗ ﺩﺗﺭﺗ ﻻ 3

ﺕﺎﺑﺎﺻﺇ ﺙﻭﺩﺣ ﻰﻟﺇ ﻱﺩﺅﺗﻭ ،ﺓﺭﺍﻭﺩﻟﺍ ءﺍﺯﺟﻷﺎﺑ ﺕﺍﺯﺎﻔﻘﻟﺍ ﻕﻠﻌﺗ ﺩﻗ

.ﻝﻳﻐﺷﺗﻟﺍ ءﺎﻧﺛﺃ ﺕﺍﺯﺎﻔﻘﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ .ﺓﺭﻳﻁﺧ

.ﻥﻳﺩﻳﻟﺍ ﺎﺗﻠﻛﺑ ﺕﺎﺑﺛﺑ ﺓﺩﻌﻟﺍ ﻙﺳﻣﺍﻭ ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺏﻳﻛﺭﺗﺑ ﻡﻗ 4

ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺏﻳﻛﺭﺗﺑ ﺎًﻣﺋﺍﺩ ﻡﻗ .ﺍًﺩﺟ ﺭﻳﻁﺧ ﺭﻣﺃ ﺓﺩﺣﺍﻭ ﺩﻳﺑ ﻝﻳﻐﺷﺗﻟﺍ

ﻥﻣ ﻑﺎﻛ ﺭﻳﻏ ﻝﻛﺷﺑ ﺓﺩﻌﻟﺍ ﻝﻣﺣ .ﻥﻳﺩﻳﻟﺍ ﺎﺗﻠﻛﺑ ﺕﺎﺑﺛﺑ ﺓﺩﻌﻟﺍ ﻙﺳﻣﺍﻭ

.ﻝﻳﻐﺷﺗﻟﺍ ءﺎﻧﺛﺃ ﺭﻳﻁﺧ ﺭﺭﺿ ﻰﻟﺇ ﻱﺩﺅﻳ ﻥﺃ ﻥﻛﻣﻣﻟﺍ

.ﻰﻧﻣﻳﻟﺍ ﻙﺩﻳﺑ ﻲﺳﻳﺋﺭﻟﺍ ﺽﺑﻘﻣﻟﺍ ﻙﺳﻣﺍ 5

ﺭﻳﻏ ﻝﻛﺷﺑ ﺡﺎﺗﻔﻣﻟﺍ ﻝﻔﻘﻳ ﺩﻗ ﻯﺭﺳﻳﻟﺍ ﺩﻳﻟﺎﺑ ﻲﺳﻳﺋﺭﻟﺍ ﺽﺑﻘﻣﻟﺎﺑ ﻙﺎﺳﻣﻹﺍ

.ﺩﻭﺻﻘﻣ

(ﺕﻟﻭﻓ

240

،ﺕﻟﻭﻓ

230

،ﺕﻟﻭﻓ

220

،ﺕﻟﻭﻓ

40

127

720

650

13

3

،ﺕﻟﻭﻓ

120

،ﺕﻟﻭﻓ

.ﺔﻘﻁﻧﻣﻟﺍ ﺏﺳﺣ ﺭﻳﻳﻐﺗﻠﻟ ﺔﺿﺭُﻋ ﺎﻬﻧﺃ ﺙﻳﺣ ﺞﺗﻧﻣﻟﺍ ﻰﻠﻋ ﺓﺩﻭﺟﻭﻣﻟﺍ ﻡﺳﻻﺍ ﺔﺣﻭﻟ ﺹﺣﻓ ﻥﻣ ﺩﻛﺄﺗ *

ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺏﻳﻛﺭﺗ 5

ﺽﺑﻘﻣﻟﺍ ﺡﺎﺗﻔﻣ ﻡﺩﺧﺗﺳﺍﻭ ﺽﺑﻘﻣﻟﺍ ﻝﺧﺍﺩ ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺔﻣءﺍﻭﻣﺑ ﻡﻗ

.ﺎًﻋﺎﺑﺗ ﺕﺎﺣﺗﻓ ﺙﻼﺛﻟﺍ ﻥﻣ ﻝﻛﺑ ﺽﺑﻘﻣﻟﺍ ﻁﺑﺭ ﻡﺎﻛﺣﺇ ،ﻪﻧﻳﻣﺄﺗﻟ

ﺏﺳﺎﻧﻣﻟﺍ ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺩﻳﺩﺣﺗ

:ﻙﻳﺗﺳﻼﺑﻟﺍ ﻭﺃ ﻥﺩﺎﻌﻣﻟﺍ ﻲﻓ ﺏﻘﺛﻟﺍ ﺩﻧﻋ ○

.ﺽﺑﻘﻣﻠﻟ ﻯﻭﺻﻘﻟﺍ ﺔﻌﺳﻠﻟ ﻰﻧﺩﺃ ﺩﺣﻛ ﻡﻣ

ﻝﺎﻐﺷﺃ ﺭﻔﺣ ﺏﻘﺛﻣ ﻡﺩﺧﺗﺳﺍ ،ﺭﻐﺻﺃ ﻭﺃ ﻡﻣ

.ﺔﻳﻧﺩﻌﻣﻟﺍ ﺩﺍﻭﻣﻠﻟ ﻱﺩﺎﻋ ﺭﻔﺣ ﺏﺎﻘﺛﻣ ﻡﺩﺧﺗﺳﺍ

1.2 ﻥﻣ ﻡﺎﺟﺣﻷﺍ ﺡﻭﺍﺭﺗﺗ

.ﻱﺩﺎﻋ ﺔﻳﺑﺷﺧ ﻝﺎﻐﺷﺃ ﺭﻔﺣ ﺏﻘﺛﻣ ﻡﺩﺧﺗﺳﺍ

:ﺏﺷﺧﻟﺍ ﻲﻓ ﺏﻘﺛﻟﺍ ﺩﻧﻋ ○

6.5

ﺕﺎﺣﺗﻓ ﻝﻣﻌﻟ ﺏﻘﺛﻟﺍ ﺩﻧﻋﻭ

.ﺔﻳﻧﺩﻌﻣ

ﻝﺧﺩﺃ .ﺏﻘﺛﻣﻟﺍ ﻥﻣ ﻲﻔﻠﺧﻟﺍ ءﺯﺟﻟﺍ ﻰﻠﻋ ﻑﺍﺭﺟﻣﻟﺍ ﺽﺑﻘﻣ ﺏﻳﻛﺭﺗ ﻥﻛﻣﻳ

ﻑﺍﺭﺟﻣﻟﺍ ﺽﺑﻘﻣ ﺏﻳﻛﺭﺗ

ﺽﺑﻘﻣ ﻥﺎﻛﻣ ﺩﺩﺣﻭ ﻑﺍﺭﺟﻣﻟﺍ ﺽﺑﻘﻣ ﻲﻓ ﺔﺣﺗﻔﻟﺍ ﻝﻼﺧ ﻥﻣ ﺭﺎﻣﺳﻣﻟﺍ

.ﺭﺎﻣﺳﻣﻟﺍ ﻁﺑﺭ ﻡﻛﺣﺃﻭ ﺏﻭﻏﺭﻣﻟﺍ ﻥﺎﻛﻣﻟﺍ ﻲﻓ ﻑﺍﺭﺟﻣﻟﺍ

ءﺎﻁﻐﻟﺍ ﻥﻣ ﺏﻧﺎﺟ ﻝﻛ ﻰﻠﻋ ﺕﻳﺑﻣﻟﺍ ﻝﺧﺍﺩ ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺕﺑﺛﻳ

ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﺏﻳﻛﺭﺗ

ﺏﻘﺛ ﻲﻓ ﺍًﺩﻳﺩﺣﺗ .ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﻡﺩﺧﺗﺳﺍ ﻡﺯﻠﻳ ،ﻥﻣﻵﺍ ﻝﻳﻐﺷﺗﻠﻟ .ﻲﻔﻠﺧﻟﺍ

.ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍﻭ ﺽﺑﻘﻣﻟﺍ ﺔﻠﺻﻭ ﻡﺩﺧﺗﺳﺍ ،ﻝﻳﻘﺛﻟﺍ ﻝﻣﺣﻟﺍ

ﻑﺎﻘﻳﺇ ﺓﺍﺩﺃ ﺏﻳﻛﺭﺗﺑ ﻡﻗ .ﺏﻘﺛﻟﺍ ﻕﻣﻋ ﻁﺑﺿ ﻲﻓ ﻕﻣﻌﻟﺍ ﻑﺎﻘﻳﺇ ﺓﺍﺩﺃ ﺩﻳﻔﺗ

(ﻱﺭﺎﻳﺗﺧﺍ ﻕﺣﻠﻣ) ﻕﻣﻌﻟﺍ ﻑﺎﻘﻳﺇ ﺓﺍﺩﺃ ﺏﻳﻛﺭﺗ

ﺔﻋﻭﻣﺟﻣ ﻭﺃ ﻲﺑﻧﺎﺟﻟﺍ ﺽﺑﻘﻣﻟﺍ ﻡﺍﺩﺧﺗﺳﺎﺑ ﻲﻔﻠﺧﻟﺍ ءﺎﻁﻐﻟﺎﺑ ﻕﻣﻌﻟﺍ

.ﺭﻳﻣﺎﺳﻣﻟﺍ

10

ﺭﺎﻳﺗ ﻰﻠﻋ ﻱﻭﺗﺣﻳ ﻱﺫﻟﺍ ﻲﻘﺑﺗﻣﻟﺍ ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻟﺍ ﻡﺍﺩﺧﺗﺳﺎﺑ ﻰﺻﻭﻳ

.ﺕﺎﻗﻭﻷﺍ ﻊﻳﻣﺟ ﻲﻓ ﻝﻗﺃ ﻭﺃ ﺭﻳﺑﻣﺃ

30 ﻥﻣ ﻥﻧﻘﻣ ﻲﺑﺭﻬﻛ

RCD

ﺔﻳﻠﻣﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﻻﺍ ﺕﺍءﺍﺭﺟﺇ

ءﺍﺭﺟﻹﺍ ﺍﺫﻫ ﻱﺩﺅﻳ .ﺏﻘﺛﻣﻟﺍ ﻰﻠﻋ ﺩﻳﺩﺷﻟﺍ ﻁﻐﺿﻟﺎﺑ ﺏﻘﺛﻟﺍ ﻊﻳﺭﺳﺗ ﻡﺗﻳ ﻥﻟ

ﺭﻣﻋ ﻝﻳﻠﻘﺗ ﻭﺃ/ﻭ ،ﺏﻘﺛﻟﺍ ﺓءﺎﻔﻛ ﻥﻣ ﺩﺣﻟﺍ ﻭﺃ/ﻭ ،ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﻑﻠﺗ ﻰﻟﺇ

ﻁﻐﺿﻟﺍ 1

.ﺏﻘﺛﻣﻟﺍ

2

ﻁﻘﻓﻭ ﻥﻳﺻﺻﺧﺗﻣﻟﺍ ﻝﺑﻗ ﻥﻣ ﻁﻘﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﻙﺗﺩﻋ ﺢﻳﻠﺻﺗﺑ ﺢﻣﺳﺍ (ﺃ

. ﻁﻘﻓ ﺔﻳﻠﺻﻷﺍ ﺭﺎﻳﻐﻟﺍ ﻊﻁﻗ ﻝﺎﻣﻌﺗﺳﺈﺑ

.ﺯﺎﻬﺟﻟﺍ ﻥﺎﻣﺃ ﻰﻠﻋ ﺔﻅﻓﺎﺣﻣﻟﺍ ﻙﻟﺫ ﻥﻣﺅﻳ

.ﻥﺳﻟﺍ ﺭﺎﺑﻛﻭ ﻝﺎﻔﻁﻷﺍ ﻝﻭﺎﻧﺗﻣ ﻥﻋ ًﺍﺩﻳﻌﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻊﺿﻭ ﻰﺟﺭﻳ

ﻥﻋ ﺓﺩﻳﻌﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻰﻠﻋ ﻅﺎﻔﺣﻟﺍ ﺏﺟﻳ ﻡﺍﺩﺧﺗﺳﻻﺍ ﻡﺩﻋ ﺔﻟﺎﺣ ﻲﻓ

.ﻥﺳﻟﺍ ﺭﺎﺑﻛﻭ ﻝﺎﻔﻁﻷﺍ ﻝﻭﺎﻧﺗﻣ

ﺏﺎﻘﺛﻣﻟﺎﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻣﻼﺳﻟﺍ ﺕﺍﺭﻳﺫﺣﺗ

.ﺓﺍﺩﻷﺎﺑ ﺍًﺩﻭﺯﻣ ﻥﺎﻛ ﺍﺫﺇ ﻲﻓﺎﺿﻹﺍ (ﺽﺑﺎﻘﻣﻟﺍ) ﺽﺑﻘﻣﻟﺍ ﻡﺩﺧﺗﺳﺍ 1

.ﺔﻳﺻﺧﺷﻟﺍ ﺔﺑﺎﺻﻹﺍ ﻲﻓ ﺏﺑﺳﺗﻳ ﺩﻗ ﻡﻛﺣﺗﻟﺍ ﻥﺍﺩﻘﻓ ﻥﺈﻓ

115

،ﺕﻟﻭﻓ

110

)

*(ﻕﻁﺎﻧﻣﻟﺍ ﺏﺳﺣ) ﻲﺑﺭﻬﻛﻟﺍ ﺩﻬﺟﻟﺍ

*ﺔﻗﺎﻁﻟﺍ ﻝﺎﺧﺩﺇﺕﺍﻭ

*ﻝﻣﺣ ﻥﻭﺩﺑ ﺔﻋﺭﺳﻟﺍﺔﻘﻳﻗﺩ/

ﺏﻠﺻﻟﺍﻡﻣ

ﺏﺷﺧﻟﺍﻡﻣ

(ﻙﻠﺳﻟﺍ ﻥﻭﺩﺑ) ﻥﺯﻭﻟﺍﻡﺟﻛ

ﺔﻳﺳﺎﻳﻗ ﺕﺎﻘﺣﻠﻣ

1

.........................................................ﻑﺭﻅﻟﺍ ﺡﺎﺗﻔﻣ

6

1

......................................................... ﻲﺑﻧﺎﺟ ﺽﺑﻘﻣ

.ﺭﺎﻁﺧﺇ ﻥﻭﺩ ﺔﻳﺳﺎﻳﻘﻟﺍ ﺕﺎﻘﻠﺣﻣﻟﺍ ﺭﻳﻳﻐﺗ ﻥﻛﻣﻳ

(ﺔﻠﺻﻔﻧﻣ ﻉﺎﺑُﺗ) ﺔﻳﺭﺎﻳﺗﺧﺍ ﺕﺎﻘﺣﻠﻣ

ﺽﺑﻘﻣﻟﺍ ﺔﻠﺻﻭ

7

8

.ﺭﺎﻁﺧﺇ ﻥﻭﺩ ﺔﻳﺭﺎﻳﺗﺧﻻﺍ ﺕﺎﻘﻠﺣﻣﻟﺍ ﺭﻳﻳﻐﺗ ﻥﻛﻣﻳ

.ﺔﻳﻛﻳﺗﺳﻼﺑﻟﺍ ﺩﺍﻭﻣﻟﺍﻭ ﻥﺩﺎﻌﻣﻟﺍ ﻲﻓ ﺏﻘﺛﻟﺍ

9

ﺕﺎﺑﻠﻁﺗﻣﻟ ﻕﺑﺎﻁﻣ ﻪﻣﺍﺩﺧﺗﺳﺍ ﻡﺗﻳﺳ ﻱﺫﻟﺍ ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ

.ﺞﺗﻧﻣﻟﺍ ﻰﻠﻋ ﺓﺩﻭﺟﻭﻣﻟﺍ ﻡﺳﻻﺍ ﺔﺣﻭﻟ ﻰﻠﻋ ﺓﺩﺩﺣﻣﻟﺍ ﺔﻗﺎﻁﻟﺍ

ﺱﺑﺎﻘﻟﺍ ﻝﻳﺻﻭﺗ ﺔﻟﺎﺣ ﻲﻓ .ﻑﺎﻘﻳﺇ ﻊﺿﻭﻟﺍ ﻰﻠﻋ ﺔﻗﺎﻁﻟﺍ ﺡﺎﺗﻔﻣ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ

ﺓﺍﺩﺃ ﻝﻳﻐﺷﺗ ﻡﺗﻳﺳﻓ ،ﻝﻳﻐﺷﺗ ﻊﺿﻭﻟﺍ ﻰﻠﻋ ﺔﻗﺎﻁﻟﺍ ﺡﺎﺗﻔﻣ ﻥﺎﻛﻭ ﺱﺑﻘﻣﻟﺎﺑ

.ﺭﻳﻁﺧ ﺙﺩﺎﺣ ﻉﻭﻗﻭ ﻰﻟﺇ ﻱﺩﺅﻳ ﺩﻗ ﺎﻣﻣ ،ﺭﻭﻔﻟﺍ ﻰﻠﻋ ﺔﻗﺎﻁﻟﺍ

ﻝﻳﺻﻭﺗ ﻙﻠﺳ ﻡﺩﺧﺗﺳﺍ ،ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻥﻣ ﻝﻣﻌﻟﺍ ﺔﻘﻁﻧﻣ ﺔﻟﺍﺯﺇ ﺩﻧﻋ

ﻲﻓﺎﺿﻹﺍ ﻝﻳﺻﻭﺗﻟﺍ ﻙﻠﺳ

ﻝﻳﺻﻭﺗﻟﺍ ﻙﻠﺳ ﻝﻅﻳ ﻥﺃ ﺏﺟﻳ .ﺔﻧﻧﻘﻣ ﺔﻌﺳﻭ ٍﻑﺎﻛ ﻙﻣﺳ ﻭﺫ ﻲﻓﺎﺿﺇ

.ﻉﺎﻁﺗﺳﻣﻟﺍ ﺭﺩﻘﺑ ﺍًﺭﻳﺻﻗ ﻲﻓﺎﺿﻹﺍ

(ﻑﻠﺧﻟﺍ ﻥﻣ ﺎﻬﺿﺭﻋ ﺩﻧﻋ) ﺔﻋﺎﺳﻟﺍ ﺏﺭﺎﻘﻋ ﻩﺎﺟﺗﺍ ﻲﻓ ﺭﻔﺣﻟﺍ ﺏﻘﺛﻣ ﺭﻭﺩﻳ

ﺭﻭﺩﻳﻭ ،"R" ﻊﺿﻭﻟﺍ ﻰﻠﻋ ﺱﻭﻛﻌﻣﻟﺍ ﺡﺎﺗﻔﻣﻠﻟ ﻉﺍﺭﺫﻟﺍ ﻁﺑﺿ ﻡﺗﻳ ﺎﻣﺩﻧﻋ

ﺔﻣﻘﻠﻟﺍ ﻥﺍﺭﻭﺩ ﻩﺎﺟﺗﺍ ﻥﻣ ﺩﻛﺄﺗﻟﺍ

ﻊﺿﻭﻟﺍ ﻰﻠﻋ ﺱﻭﻛﻌﻣﻟﺍ ﺡﺎﺗﻔﻣﻟﺍ ﻁﺑﺿ ﻡﺗﻳ ﺎﻣﺩﻧﻋ ﺱﻭﻛﻌﻣﻟﺍ ﻩﺎﺟﺗﻻﺍ ﻲﻓ

٢

ﻕﻣﻌﻟﺍ ﺩﺍﺩﺳ

ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ

ﺔﻗﺎﻁﻟﺍ ﺡﺎﺗﻔﻣ

ﺔﻣﺩﺧﻟﺍ (

ﺕﺎﻁﺎﻳﺗﺣﻻﺍ

ﺕﺎﻔﺻﺍﻭﻣﻟﺍ

ﺔﻌﺳﻟﺍ

(1)

(2)

(1)

(2)

ﺕﺎﻘﻳﺑﻁﺗ

ﻝﻳﻐﺷﺗﻟﺍ ﻝﺑﻗ

."L"

5

1

2

3

4

7

Page 8

ﺔﻴﺑﺮﻌﻟا

.ﻥﻳﻌﻠﻟ ﻲﻗﺍﻭﻟﺍ ﻉﺎﻧﻘﻟﺍ ءﺍﺩﺗﺭﺎﺑ ﺎًﻣﺋﺍﺩ ﻡﻗ .ﻥﺎﻣﻷﺍ ﺕﺍﻭﺩﺃ ﻡﺩﺧﺗﺳﺍ (ﺏ

ﺔﻳﺫﺣﺃ ﻭﺃ ﺭﺎﺑﻐﻟﺍ ﻥﻣ ﻲﻗﺍﻭﻟﺍ ﻉﺎﻧﻘﻟﺍ ﻝﺛﻣ ﺔﻳﺎﻣﺣﻟﺍ ﺕﺍﻭﺩﺃ ﻝﻣﻌﺗﺳ

ﻊﻣﺳﻟﺍ ﺔﻳﺎﻣﺣ ﺓﺯﻬﺟﺃ ﻭﺃ ﺔﺑﻠﺻ ﺔﻌﺑﻗ ﻭﺃ ﻕﻻﺯﻧﻼﻟ ﺓﺩﺎﺿﻣﻟﺍ ﻥﺎﻣﻷﺍ

ﺕﻻﺎﻣﺗﺣﺍ ﻝﻳﻠﻘﺗ ﻰﻠﻋ ﺔﻧﻳﻌﻣ ﻑﻭﺭﻅ ﻲﻓ ﺎﻬﻣﺍﺩﺧﺗﺳﺍ ﻡﺗﻳ ﻲﺗﻟﺍﻭ

.ﺔﻳﺻﺧﺷ ﺕﺎﺑﺎﺻﻹ ﺽﺭﻌﺗﻟﺍ

ﻊﺿﻭﻟﺍ ﻲﻓ ﺡﺎﺗﻔﻣﻟﺍ ﻥﺃ ﻥﻣ ﺩﻛﺄﺗ .ﺩﻭﺻﻘﻣﻟﺍ ﺭﻳﻏ ﻝﻳﻐﺷﺗﻟﺍ ﻊﻧﻣ (ﺕ

ﺔﻣﺯﺣ ﻭﺃ/ﻭ ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣﺑ ﻝﻳﺻﻭﺗﻟﺍ ﻝﺑﻗ ﻝﻳﻐﺷﺗﻟﺍ ﻑﺎﻘﻳﺇ

.ﺓﺍﺩﻷﺍ ﻝﻣﺣ ﻭﺃ ﻁﺎﻘﺗﻟﻻﺍﻭ ،ﺔﻳﺭﺎﻁﺑﻟﺍ

ﻭﺃ ﺡﺎﺗﻔﻣﻟﺍ ﻲﻓ ﻙﻌﺑﺻﺇ ﺩﻭﺟﻭ ﻊﻣ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻣﺣ ﻱﺩﺅﻳ

ﻝﻳﻐﺷﺗﻟﺍ ﻊﺿﻭ ﻲﻓ ﺡﺎﺗﻔﻣﻟﺍ ﺎﻬﻳﻓ ﻥﻭﻛﻳ ﻲﺗﻟﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ

.ﺙﺩﺍﻭﺣ ﻉﻭﻗﻭ ﻝﺎﻣﺗﺣﺍ ﻰﻟﺇ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻝﺑﻗ ﻁﺑﺭﻟﺍ ﺡﺎﺗﻔﻣ ﻭﺃ ﻁﺑﺿﻟﺍ ﺩﺩﻋ ﻉﺯﻧﺍ (ﺙ

ﻥﻣ ﻙﺭﺣﺗﻣﻟﺍ ءﺯﺟﻟﺍ ﺭﺎﺳﻳ ﻰﻠﻋ ﻁﺑﺿ ﺡﺎﺗﻔﻣ ﻭﺃ ﻁﺑﺭ ﺡﺎﺗﻔﻣ ﺩﻭﺟﻭ

.ﺔﻳﺻﺧﺷ ﺔﺑﺎﺻﺇ ﺙﻭﺩﺣ ﻰﻟﺇ ﻱﺩﺅﻳ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

ﻥﻳﺑﻭ ﻙﻧﻳﺑ ﺔﺑﺳﺎﻧﻣ ﺔﻓﺎﺳﻣ ﻙﺭﺗﺍ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻥﻣ ﺏﺭﺗﻘﺗ ﻻ (ﺝ

.ﺕﺎﻗﻭﻷﺍ ﻊﻳﻣﺟ ﻲﻓ ﻙﻧﺯﺍﻭﺗ ﻰﻠﻋ ﻅﻓﺎﺣﻭ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

ﻲﻓ ﻝﺿﻓﺃ ﻝﻛﺷﺑ ﺯﺎﻬﺟﻟﺍ ﻰﻠﻋ ﺓﺭﻁﻳﺳﻟﺍ ﻥﻣ ﻙﻟﺫ ﻙﻟ ﺢﻣﺳﻳﺳ

.ﺔﻌﻗﻭﺗﻣﻟﺍ ﺭﻳﻏ ﻑﻗﺍﻭﻣﻟﺍ

ﺎﻬﺑ ﻭﺃ ﺔﺿﺎﻔﺿﻓ ﺱﺑﻼﻣ ﻱﺩﺗﺭﺗ ﻻ ،ﺔﺑﺳﺎﻧﻣ ﺱﺑﻼﻣ ءﺍﺩﺗﺭﺎﺑ ﻡﻗ (ﺡ

ﺱﺑﻼﻣﻟﺍﻭ ﻙﺭﻌﺷ ﺩﺎﻌﺑﺇ ﻰﻠﻋ ًﺎﻣﺋﺍﺩ ﻅﻓﺎﺣﻭ ،ﻲﻠﺣ ﻭﺃ ﺔﺑﺋﺎﺳ ﻑﺍﺭﻁﺃ

ﺓﺩﻌﻟﺍ ﻥﻣ ﺔﻛﺭﺣﺗﻣﻟﺍ ءﺍﺯﺟﻷﺍ ﻥﻋ ًﺍﺩﻳﻌﺑ ﺯﺎﻔﻘﻟﺍﻭ ﺎﻬﻳﺩﺗﺭﺗ ﻲﺗﻟﺍ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﻲﻠﺣﻟﺍ ﻭﺃ ﻑﺍﺭﻁﺃ ﺎﻬﺑ ﻲﺗﻟﺍ ﻭﺃ ﺔﺿﺎﻔﺿﻔﻟﺍ ﺱﺑﻼﻣﻟﺍ ﻙﺑﺷﺎﺗﺗ ﺩﻗ

.ﺏﺎﻘﺛﻣﻠﻟ ﺔﻛﺭﺣﺗﻣﻟﺍ ءﺍﺯﺟﻷﺎﺑ ﻝﻳﻭﻁﻟﺍ ﺭﻌﺷﻟﺍﻭﺃ

ﻡﺗﻳﻭ ﺔﻠﺻﺗﻣ ﻥﻣ ﺩﻛﺄﺗﻓ .ﺭﺎﺑﻐﻟﺍ ﻊﻳﻣﺟﺗﻭ ﻁﻔﺷ ﺯﺎﻬﺟ ﺏﻳﻛﺭﺗ ﺯﺎﺟ ﻥﺇ (ﺥ

.ﻡﻳﻠﺳ ﻝﻛﺷﺑ ﺎﻬﻣﺍﺩﺧﺗﺳﺍ

ﻥﻋ ﺔﻣﺟﺎﻧﻟﺍ ﺭﻁﺎﺧﻣﻟﺍ ﻝﻳﻠﻘﺗ ﻰﻟﺇ ﺭﺎﺑﻐﻟﺍ ﻊﻳﻣﺟﺗ ﻡﺍﺩﺧﺗﺳﺍ ﻱﺩﺅﻳ ﺩﻗ

.ﺭﺎﺑﻐﻟﺍ

ﺎﻬﺑ ﺔﻳﺎﻧﻌﻟﺍﻭ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﺍ ﺔﻘﻳﺭﻁ (

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺍﻭ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﺍ ﻲﻓ ﻁﺭﻔﺗ ﻻ (ﺃ

.ﻪﺑ ﻡﻭﻘﺗ ﻱﺫﻟﺍ ﻝﻣﻌﻠﻟ ﺔﺑﺳﺎﻧﻣﻟﺍ

ﻙﺩﻋﺎﺳﻳ ﺍﺫﻫ ﻥﺈﻓ ﻙﻟﺫﻟ ﺔﺻﺻﺧﻣﻟﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻙﻣﺍﺩﺧﺗﺳﺍ ﺩﻧﻋ

ﻡﺗ ﻲﺗﻟﺍ ﺔﻣﻬﻣﻠﻟ ًﺎﻌﺑﺗ ًﺎﻧﻣﺃ ﺭﺛﻛﺃﻭ ﻝﺿﻓﺃ ﺔﺟﻳﺗﻧ ﻰﻠﻋ ﻝﻭﺻﺣﻟﺍ ﻰﻠﻋ

.ﺎﻬﻟ ﺏﺎﻘﺛﻣﻟﺍ ﻡﻳﻣﺻﺗ

ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ ﻝﻣﻌﻟﺍ ﻥﻋ ﻝﻳﻐﺷﺗﻟﺍ ﺡﺎﺗﻔﻣ ﻝﻁﻌﺗ ﺔﻟﺎﺣ ﻲﻓ (ﺏ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﺎﻬﺑ ﺹﺎﺧﻟﺍ ﻝﻳﻐﺷﺗﻟﺍ ﺡﺎﺗﻔﻣ ﻲﻓ ﻡﻛﺣﺗﻟﺍ ﻥﻛﻣﻳ ﻻ ﺔﻳﺋﺎﺑﺭﻬﻛ ﺓﺩﻋ ﻱﺃ

.ﺡﺎﺗﻔﻣﻟﺍ ﺍﺫﻫ ﺡﻼﺻﺇ ﺏﺟﻳﻭ ﺎﻬﻣﺍﺩﺧﺗﺳﺍ ﺩﻧﻋ ًﺍﺭﻁﺧ ﻝﻛﺷﺗ ﺎﻬﻧﺈﻓ

ﻥﻣ ﺔﻳﺭﺎﻁﺑﻟﺍ ﺔﻣﺯﺣ ﻭﺃ/ﻭ ﺔﻗﺎﻁﻟﺍ ﺭﺩﺻﻣ ﻥﻣ ﺱﺑﺎﻘﻟﺍ ﻝﺻﻔﺑ ﻡﻗ (ﺕ

ﻭﺃ ﺕﺎﻘﺣﻠﻣﻟﺍ ﺭﻳﻳﻐﺗ ﻭﺃ ﺕﻼﻳﺩﻌﺗ ﻱﺃ ﻝﻣﻋ ﻝﺑﻗ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻥﻳﺯﺧﺗ

ﺭﻳﻏ ﻝﻛﺷﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻩﺫﻫ ﻁﺎﻳﺗﺣﻻﺍ ﺕﺍءﺍﺭﺟﺇ ﻊﻧﻣﺗ

.ﺩﻭﺻﻘﻣ

ﻝﻭﺎﻧﺗﻣ ﻥﻋ ًﺃﺩﻳﻌﺑ ﺔﻣﺩﺧﺗﺳﻣ ﺭﻳﻐﻟﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻥﻳﺯﺧﺗﺑ ﻡﻗ (ﺙ

ﻝﻳﻐﺷﺗ ﻥﻋ ﺓﺭﻛﻓ ﻪﻳﺩﻟ ﺱﻳﻟ ﺹﺧﺷ ﻱﻷ ﺢﻣﺳﺗ ﻻﻭ ﻝﺎﻔﻁﻷﺍ

.ﺎﻬﻠﻳﻐﺷﺗ ﻭﺃ ﺕﺍﻭﺩﻷﺍ ﻩﺫﻫ ﻥﻣ ﺏﺍﺭﺗﻗﻻﺎﺑ ﺏﺎﻘﺛﻣﻟﺍ

ﻥﻳﺑﺭﺩﻣ ﺭﻳﻐﻟﺍ ﺹﺎﺧﺷﻷﺍ ﻱﺩﻳﺃ ﻲﻓ ﺓﺭﻭﻁﺧ ﻝﺛﻣﺗ ﻝﻳﻐﺷﺗﻟﺍ ﺕﺍﻭﺩﺃ

.ﺎﻬﻳﻠﻋ

ﺔﻳﺣﺎﻧ ﻥﻣ ًﺍﺩﻳﺟ ﺎﻬﺻﺣﻔﺑ ﻡﻗ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺔﻣﻼﺳ ﻥﻣ ﺩﻛﺄﺗ (ﺝ

ءﺯﺟ ﻱﺃ ﻲﻓ ﺭﺳﻛ ﻱﺃ ﺩﻭﺟﻭ ﻭﺃ ﺔﻛﺭﺣﺗﻣﻟﺍ ءﺍﺯﺟﻷﺍ ﻁﺑﺍﺭﺗ ﻯﺩﻣ

.ﺎﻬﻠﻳﻐﺷﺗ ﻰﻠﻋ ﺭﺛﺅﻳ ﺎﻣﺑ ﺎﻬﺋﺍﺯﺟﺃ ﻥﻣ

ﻝﺑﻗ ﺎﻬﺣﻼﺻﺇ ﺏﺟﻳ ﻝﻳﻐﺷﺗﻟﺍ ﺕﺍﻭﺩﺄﺑ ﻑﻠﺗ ﺙﻭﺩﺣ ﺔﻟﺎﺣ ﻲﻓ

.ﻡﺍﺩﺧﺗﺳﻻﺍ

ﺭﻳﻏ ﻝﻛﺷﺑ ﺔﻧﺎﻳﺻﻟﺍ ﺔﻳﻠﻣﻌﺑ ﻡﺎﻳﻘﻟﺍ ﻭﺃ ﻝﻳﻐﺷﺗﻟﺍ ﺕﺍﻭﺩﺃ ﺔﻧﺎﻳﺻ ﻡﺩﻋ

.ﺙﺩﺍﻭﺣﻟﺍ ﻥﻣ ﺭﻳﺛﻛﻟﺍ ﺙﻭﺩﺣ ﻰﻟﺇ ﻱﺩﺅﻳ ﺢﻳﺣﺻ

ﺔﻔﻳﻅﻧﻭ ﺓﺩﺎﺣ ﻊﻳﻁﻘﺗﻟﺍ ﺕﺍﻭﺩﺃ ﻰﻠﻋ ﻅﺎﻔﺣﻟﺍ ﻰﺟﺭﻳ (ﺡ

ﻝﻬﺳﻳ ﺙﻳﺣﺑ ﻑﺍﻭﺣﻟﺍ ﺓﺩﺎﺣ ﻊﻳﻁﻘﺗﻟﺍ ﺕﺍﻭﺩﺃ ﻰﻠﻋ ﻅﺎﻔﺣﻟﺍ ﻰﺟﺭﻳ

.ﺎﻬﻳﻓ ﻡﻛﺣﺗﻟﺍ

ﻙﻟﺫ ﺭﻳﻏﻭ ﺓﺩﻌﻟﺍ ءﺍﺯﺟﺃﻭ ،ﺕﺎﻘﺣﻠﻣﻟﺍﻭ ،ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺍ (ﺥ

ﻑﻭﺭﻅ ﺭﺎﺑﺗﻋﻻﺍ ﻲﻓ ﻊﺿﻭﻟﺍ ﻊﻣ ،ﺕﺎﻣﻳﻠﻌﺗﻟﺍ ﻩﺫﻫ ﻊﻣ ﻕﻓﺍﻭﺗﻳ ﺎﻣﻳﻓ

.ﺎﻬﻘﻳﻘﺣﺗ ﺏﻭﻠﻁﻣﻟﺍ ﻝﺎﻣﻋﻷﺍﻭ ﻝﻣﻌﻟﺍ

ﻰﻟﺇ ﺎﻬﻟ ﺔﺻﺻﺧﻣﻟﺍ ﺭﻳﻏ ﺽﺍﺭﻏﻸﻟ ﺔﻗﺎﻁﻟﺍ ﺓﺍﺩﺃ ﻡﺩﺧﺗﺳﺍ ﻱﺩﺅﻳ ﺩﻗ

.ﺭﻳﻁﺧ ﻑﻗﻭﻣ ﺩﻭﺟﻭ

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﺔﻣﻼﺳﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻣﺎﻌﻟﺍ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ

ﺔﻣﺩﺻ ﻲﻓ ﻩﺎﻧﺩﺃ ﺓﺩﺭﺳﻣﻟﺍ ﺕﺎﻣﻳﻠﻌﺗﻟﺍﻭ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ ﻉﺎﺑﺗﺍ ﻲﻓ ﻝﺷﻔﻟﺍ ﺏﺑﺳﺗﻳ ﺩﻗ

ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻰﻟﺇ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ ﻲﻓ "ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ" ﺢﻠﻁﺻﻣ ﺭﻳﺷﻳ

ﺓﺩﻌﻟﺍ ﻭﺃ ﻙﺑ ﺔﺻﺎﺧﻟﺍ ﺔﻳﺳﻳﺋﺭﻟﺍ ﻝﻳﻐﺷﺗﻟﺍ ﺕﻼﺻﻭﻣ ﻝﻣﻌﺗ ﻲﺗﻟﺍ (ﺔﻳﻛﻠﺳﻟﺍ)

ﺏﺑﺳﺗﺗ ﺓءﺎﺿﻣ ﺭﻳﻐﻟﺍ ﻝﻣﻌﻟﺍ ﺕﻻﺎﺟﻣﻭ ﻝﻣﻌﻟﺍ ﻥﺎﻛﻣ ﻲﻓ ﻰﺿﻭﻔﻟﺎﻓ

ﺩﻭﺟﻭ ﻲﻓ ﻱﺃ ﺔﻳﺭﺎﺟﻔﻧﺍ ءﺍﻭﺟﺃ ﻲﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻝﻳﻐﺷﺗﺑ ﻡﻘﺗ ﻻ (ﺏ

.ﺔﻧﺧﺩﻷﺍ ﺭﺎﺑﻏ ﻝﺎﻌﺷﺇ ﻰﻠﻋ ﻝﻣﻌﺗ ﺓﺭﺍﺭﺷ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺙﺩﺣﺗ

ﻝﺎﻔﻁﻷﺍ ﻝﻭﺎﻧﺗﻣ ﻥﻋ ﺓﺩﻳﻌﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻥﻭﻛﺗ ﻥﺃ ﻰﻠﻋ ﻅﻓﺎﺣ (ﺕ

ﻙﺩﻘﻓ ﻰﻟﺇ ﻱﺩﺅﺗ ﻥﺃ ﻥﻛﻣﻣﻟﺍ ﻥﻣ ﺕﻳﺗﺷﺗﻟﺍ ﻝﺎﻛﺷﺃ ﻥﻣ ﻝﻛﺷ ﻱﺃ

ﻱﺎﺑ ﺱﺑﺎﻘﻟﺍ ﻝﻳﺩﻌﺗ ﺭﻅﺣﻳ ،ءﺎﺑﺭﻬﻛﻟﺍ ﺫﻔﻧﻣﺑ ﺱﺑﺎﻘﻟﺍ ﻝﻳﺻﻭﺗ ﺏﺟﻳ (ﺃ

.ﺔﻳﺿﺭﻷﺍ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﻊﻣ ﺊﻳﺎﻬﻣ ﺱﺑﺎﻗ ﻱﺃ ﻡﺩﺧﺗﺳﺗ ﻻ

4

ﺭﻁﺧ ﻥﻣ ﺔﻣﺋﻼﻣﻟﺍ ﺱﺑﺎﻘﻣﻟﺍﻭ ﺎﻫﺭﻳﻳﻐﺗ ﻡﺗﻳ ﻡﻟ ﻲﺗﻟﺍ ﺱﺑﺍﻭﻘﻟﺍ ﺽﻔﺧﺗ

ﺏﻳﺑﺎﻧﻷﺍ ﻝﺛﻣ ﺔﻳﺿﺭﻷﺍ ﺢﻁﺳﻷﺍ ﻊﻣ ﻱﺩﺳﺟﻟﺍ ﺱﻣﻼﺗﻟﺍ ﺏﻧﺟﺗ (ﺏ

ﻙﺎﻧﻫ ﺔﻳﺿﺭﻷﺍ ﺢﻁﺳﻷﺍ ﻙﻠﺗ ﻥﻣ ﻱﻷ ﻙﻣﺳﺟ ﺔﺳﻣﻼﻣ ﺔﻟﺎﺣ ﻲﻓ

ﺓﺩﻌﻟﺍ ﻝﺧﺍﺩ ﻰﻟﺇ ءﺎﻣﻟﺍ ﺏﺭﺳﺗ ﻥﺇ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺕﺎﻣﺩﺻﻟﺍ ﺭﻁﺧ ﺩﺍﺩﺯﻳ

ﻭﺃ ﻝﻣﺣﻟ ًﺎﻘﻠﻁﻣ ﻪﻠﻣﻌﺗﺳﺗ ﻻ ،(ﻙﻠﺳﻟﺍ) ﻝﺑﺎﻛﻟﺍ ﻝﺎﻣﻌﺗﺳﺍ ءﻲﺳﺗ ﻻ (ﺙ

.ﺱﺑﻘﻣﻟﺍ ﻥﻣ ﺱﺑﺎﻘﻟﺍ ﺏﺣﺳﻟ ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻊﻓﺩ ﻭﺃ ﺩﺷ

ﻑﺍﻭﺣﻟﺍ ﻭﺃ ﺕﻳﺯﻟﺍ ﻭﺃ ﺓﺭﺍﺭﺣﻟﺍ ﺭﺩﺎﺻﻣ ﻥﻋ ًﺍﺩﻳﻌﺑ ﻪﻳﻠﻋ ﻅﻓﺎﺣﻭ

ﺕﺎﻣﺩﺻﻟﺍ ﺭﻁﺧ ﻥﻣ ﺔﻛﺑﺎﺷﺗﻣﻟﺍ ﻭﺃ ﺔﻔﻟﺎﺗﻟﺍ (ﻙﻼﺳﻷﺍ) ﺕﻼﺑﺎﻛﻟﺍ ﺩﻳﺯﺗ

ﻙﻠﺳ ﻡﺍﺩﺧﺗﺳﺎﺑ ﺢﺻﻧﻳ ،ﺝﺭﺎﺧﻟﺎﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﺔﻟﺎﺣ ﻲﻓ (ﺝ

ﻥﻣ ﻝﻳﻠﻘﺗﻠﻟ ﻲﺟﺭﺎﺧﻟﺍ ﻝﺎﻣﻌﺗﺳﻻﺍ ﻊﻣ ﺏﺳﺎﻧﻣ ﻙﻠﺳ ﻡﺍﺩﺧﺗﺳﺎﺑ ﻡﻗ

ﺭﻔﻣ ﻻ ﺭﻣﺃ ﺏﻁﺭ ﻥﺎﻛﻣ ﻲﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻝﻳﻐﺷﺗ ﻥﻭﻛﻳ ﺎﻣﺩﻧﻋ (ﺡ

(RCD)

.

ﻲﻘﺑﺗﻣﻟﺍ ﻲﺑﺭﻬﻛﻟﺍ ﺭﺎﻳﺗﻠﻟ ﻲﻣﺣﻣﻟﺍ ﺩﻭﺯﻣﻟﺍ ﻡﺩﺧﺗﺳﺎﻓ ،ﻪﻧﻣ

ﺕﺎﻣﺩﺻﺑ ﺔﺑﺎﺻﻹﺍ ﺭﻁﺎﺧﻣ ﻝﻳﻠﻘﺗ ﻰﻠﻋ

ﺓﺩﻌﻟﺍ ﺔﻁﺳﺍﻭﺑ ﻝﻣﻌﻟﺎﺑ ﻡﻗﻭ ﻪﻠﻌﻔﺗ ﺎﻣ ﻰﻟﺇ ﻪﺑﺗﻧﺃﻭ ﺎًﻅﻘﻳ ﻥﻛ (ﺃ

ﻙﺭﻭﻌﺷ ﺔﻟﺎﺣ ﻲﻓ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺩﺧﺗﺳﺗ ﻻ .ﻝﻘﻌﺗﺑ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﺩﺍﻭﻣ ﻭﺃ ﺔﻳﻭﺩﺃ ﻭﺃ ﺓﺭﺩﺧﻣ ﺩﺍﻭﻣ ﺭﻳﺛﺄﺗ ﺕﺣﺗ ﺕﻧﻛ ﺍﺫﺇ ﻭﺃ ﺏﻌﺗﻟﺎﺑ

ﻱﺩﺅﻳ ﺩﻗ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺓﺩﻌﻟﺍ ﻡﺍﺩﺧﺗﺳﺇ ﺩﻧﻋ ﺓﺩﺣﺍﻭ ﺔﻅﺣﻠﻟ ﻩﺎﺑﺗﻧﻹﺍ ﻡﺩﻋ

.ﺕﺎﻣﻳﻠﻌﺗﻟﺍ ﺔﻓﺎﻛﻭ ﺔﻣﻼﺳﻟﺍ ﺕﺍﺭﻳﺫﺣﺗ ﺔﻓﺎﻛ ﺓءﺍﺭﻘﺑ ﻡﻗ

.ﺔﺑﺎﺻﺇ ﻭﺃ/ﻭ ،ﻕﻳﺭﺣ ﻭﺃ ﺔﻳﺋﺎﺑﺭﻬﻛ

.ًﻼﺑﻘﺗﺳﻣ ﺎﻬﻳﻟﺇ ﻉﻭﺟﺭﻠﻟ ﺕﺎﻣﻳﻠﻌﺗﻟﺍﻭ ﺕﺍﺭﻳﺫﺣﺗﻟﺍ ﺔﻓﺎﻛ ﻅﻔﺣﺍ

.ﺔﻳﺭﺎﻁﺑﻟﺎﺑ ﻝﻣﻌﺗ ﻲﺗﻟﺍ (ﺔﻳﻛﻠﺳﻼﻟﺍ) ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

ﻝﻣﻌﻟﺍ ﺔﻘﻁﻧﻣ ﺔﻣﻼﺳ (

.ﻙﻠﻐﺷ ﻥﺎﻛﻣ ﺓءﺎﺿﺇ ﻥﺳﺣﻭ ﺔﻓﺎﻅﻧ ﻰﻠﻋ ﻅﻓﺎﺣ (ﺃ

.ﺙﺩﺍﻭﺣ ﻉﻭﻗﻭ ﻲﻓ

.ﺭﺎﺑﻏ ﻭﺃ ﻝﺎﻌﺗﺷﻼﻟ ﺔﻠﺑﺎﻗ ﺕﺍﺯﺎﻏ ﻭﺃ ﻝﺋﺍﻭﺳ

.ﻙﺑ ﻥﻳﻁﻳﺣﻣﻟﺍ ﻭﺃ

.ﺓﺭﻁﻳﺳﻟﺍ

ﺔﻳﺑﺭﻬﻛﻟﺍ ﺕﺎﻣﺩﺻﻟﺍ ﻥﻣ ﺔﻳﺎﻗﻭﻟﺍ (

. ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺕﺎﻣﺩﺻﻟﺍ ﺙﻭﺩﺣ

.ﺩﻗﺍﻭﻣﻟﺍﻭ ﺕﺎﺟﻼﺛﻟﺍﻭ ﺔﻳﺭﺍﺭﺣﻟﺍ ﺕﻻﺩﺎﺑﻣﻟﺍﻭ

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻﻟ ﻙﺿﺭﻌﺗﻟ ﺓﺭﻭﻁﺧ

.ﺔﺑﻭﻁﺭﻟﺍ ﻭﺃ ﺭﻁﻣﻠﻟ ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ ﺩﺩﻌﻟﺍ ﺽﺭﻌﺗ ﻻ (ﺕ

.ﺔﻳﺋﺎﺑﺭﻬﻛﻟﺍ

.ﺔﻛﺭﺣﺗﻣﻟﺍ ﺯﺎﻬﺟﻟﺍ ءﺍﺯﺟﺃ ﻭﺃ ﺓﺩﺎﺣﻟﺍ

.ﺔﻳﺑﺭﻬﻛﻟﺍ

.ﻲﺟﺭﺎﺧﻟﺍ ﻝﺎﻣﻌﺗﺳﻻﺍ ﻊﻣ ﺏﺳﺎﻧﺗﻳ (ﻝﺑﺎﻛ)

.ﺔﻳﺑﺭﻬﻛ ﺔﻣﺩﺻﻟ ﺽﺭﻌﺗﻟﺍ ﺓﺭﻭﻁﺧ

RCD

ﻡﺍﺩﺧﺗﺳﺍ ﻝﻣﻌﻳ

ﺔﻳﺻﺧﺷﻟﺍ ﺔﻣﻼﺳﻟﺍ (

.ﺔﻳﻟﻭﺣﻛ

.ﺓﺭﻳﻁﺧ ﺔﺑﺎﺻﺇ ﻰﻟﺇ

ﺭﻳﺫﺣﺗ

1

2

.ﺔﻘﻳﺭﻁ

.ﺔﻳﺑﺭﻬﻛ

3

8

١

Page 9

ABC D

33 981-586 2

37 982-796Z 1 M10

38 937-807 4 D5 × 25

39 949-424 4 M5

40 984-361 1

41 980-060 2 M3.5 × 5

42 971-667Z 1

43 981-373 2

44 982-804Z 1

46 982-802Z 1 "44"

47 984-360 1

48 982-095 1 D4 × 20

49 930-153 1

50 994-273 1

51 930-446 2 D4 × 16

52 981-373 2

53 961-419Z 1

54 960-266 1

34A 985-114 2

36A 982-794Z 1

55 957-561 1

56-1 953-327 1 D8.8

56-2 938-051 1 D10.1

5 7 ––––––––––– 1

58 981-122 1 M6 × 22

1 930-515 1

ABC D

6202VVCMPS2S

4 939-556 1

5 620-2VV 1

3B 981-667 1

2C 950-275 1 13VLR "1, 58"

6 939-544 1

7 957-725 2 D5 × 70

9 981-650 1

627VVMC2EPS2S

10 983-448 1

11 627-VVM 1

608VVMC2EPS2L

12 981-652Z 1

13 949-426 1 M8

14 608-VVM 2

609VVMC2PS2S

15 982-791 1 "14, 16, 17"

16 984-357 1

17 609-VVM 1

18 981-657E 1 220V-230V

19 981-562 1

21 931-875 2 D5 × 35

22A 991-007 2 D5 × 60

23A 982-797L 1 220V-230V

24 984-367 1

25 946-362 1

26 982-800Z 1

27 982-801Z 1

29 981-205 1

30 961-781 2

28A 982-790 1 "33, 34A"

3 2 ––––––––––– 1

31A 999-073 2

9

Page 10

10

Page 11

11

Page 12

806

Code No. 99456751 F

Printed in China

Loading...

Loading...