Page 1

Reciprocating Saw

Sierra sable

水平式線鋸機

CR 13VC

Handling instructions

Instrucciones de manejo

使用說明書

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

使用前務請詳加閱讀

Page 2

12

1 2

1

34

3

3

4

4

56

1

3

1

78

5

1

6

1

7

4

910

1

9

3

8

1

Page 3

11 12

0

0

2

13 14

0

15 16

17 18

^

^

!

$

@

#

%

19 20

2

Page 4

21 22

23 24

25 26

27

&

43

6 mm

17 mm

3

*

Page 5

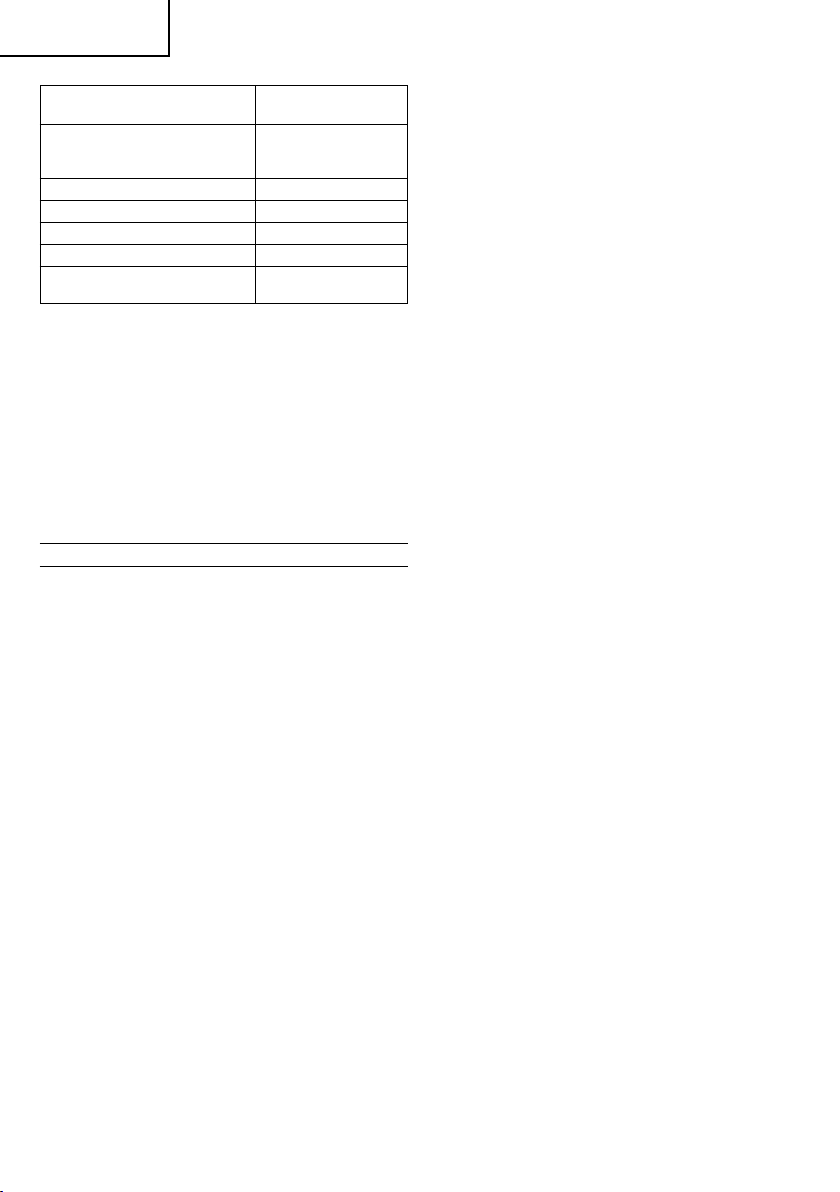

English

Lever Palanca

1

Front cover Cubierta delantera

2

Blade Hoja

3

Plunger slit Ranura del émbolo

4

Another blade Otra hoja

5

Blade holder Sujetador de cuchilla

6

Machine oil Aceite para máquinas

7

Rubber cap Gummikappe

8

Blade hole Orifi cio de la hoja

9

Base Base

0

Set screw 12 mm Tornillo de ajuste de 12 mm

!

Hexagonal bar wrenh Llave macho hexagonal

@

#

Switch trigger Interruptor de gatillo

Dial Cuadrante

$

Graduation Graduación

%

Stroke Carrera

^

Wear limit Límite de uso

&

No. of carbon brush N° de escobilla de carbón

*

Español

中國語

手柄

前罩

刀刃

柱塞縫

其他刀刃

刀刃座

機油

橡皮蓋

刀刃孔

底座

固定 12 mm 的螺絲

六角桿扳手

扳機開關

數字轉盤

刻度

行程

磨損極限

碳刷號

4

Page 6

English

GENERAL SAFETY RULES

WARNING!

Read all instructions

Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or

battery operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks which may ignite the

dust of fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

c) Avoid accidental starting. Ensure the switch is in

the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have the

switch on invites accidents.

5

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed.

Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of

children and infirm persons.

Page 7

PRECAUTIONS ON USING RECIPROCATING

SAW

Prior to cutting into walls, ceillings or floors, ensure

there are no electric cables or conduits inside.

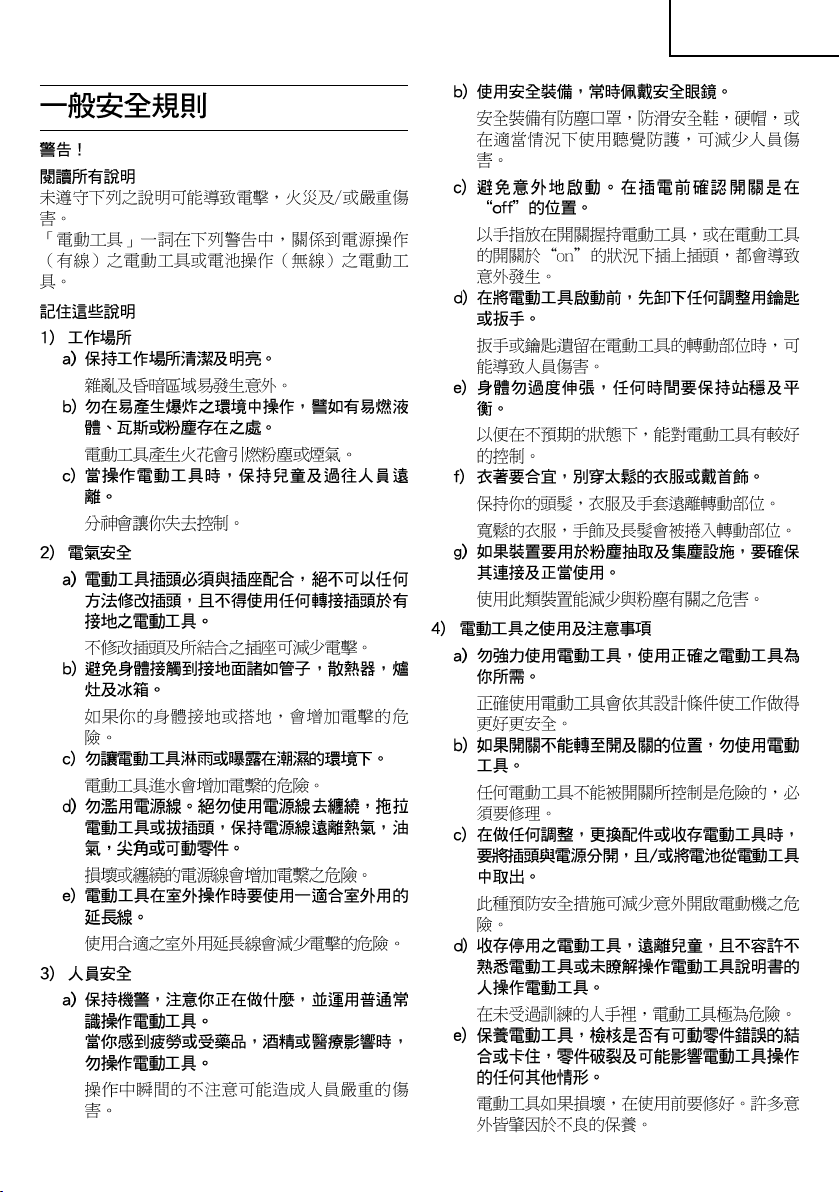

SPECIFICATIONS

Voltage (by areas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Power Input 1010 W*

Capacity Mild Steel Pipe: O.D. 130 mm

Vinyl Chloride Pipe: O.D. 130 mm

Wood: Depth 300 mm

Mild Steel Plate: Thickness 19 mm

No-Load Speed 0 – 2800 /min

Stroke 29 mm

Weight (without cord) 3.3 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

English

STANDARD ACCESSORIES

(1) Blade (No. 103) .........................................................1

(2) Case ............................................................................. 1

(3) Hexagonal bar wrench ............................................. 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

(1) No. 1 Blade (12) No. 103 Blade

(2) No. 2 Blade (13) No. 104 Blade

(3) No. 3 Blade (14) No. 105 Blade

(4) No. 4 Blade (15) No. 106 Blade

(5) No. 5 Blade (16) No. 107 Blade

(6) No. 8 Blade (17) No. 108 Blade

(7) No. 9 Blade (18) No. 121 Blade

(8) No. 95 Blade (19) No. 131 Blade

(9) No. 96 Blade (20) No. 132 Blade

(10) No. 101 Blade (21) Cut-off guide for pipe

(11) No. 102 Blade

䡬 (1) – (9) : HCS Blades (HCS : Highspeed Carbon

Steel)

䡬 (10) – (20) : Bl-METAL Blades

Refer to Table 1, 2 and 3 for use of the blades.

Optional accessories are subject to change without notice.

APPLICATIONS

䡬 Cutting pipe and angle steel.

䡬 Cutting various lumbers.

䡬 Cutting mild steel plates, aluminum plates, and

copper plates.

䡬 Cutting synthetic resins, such as phenol resin and

vinyl chloride.

For details refer to the section entitled “SELECTION OF

BLADES”.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirement specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Mounting the blade

This unit employs a detachable mechanism that

enables mounting and removal of saw blades

without the use of a wrench or other tools.

(1) Turn on and off the switching trigger several times

so that the lever can jump out of the front cover

completely. Thereafter, turn off the switch and

unplug the power cord. (Fig. 1)

CAUTION

Be absolutely sure to keep the switch turned off

and the power cord unplugged to prevent any

accident.

(2) Push the lever in the direction of the arrow mark

shown in Fig. 2 marked on the lever. (Fig. 2)

(3) Insert the saw blade all the way into the small slit

of the plunger tip with the lever pushing. You can

mount this blade either in the upward or downward

direction. (Fig. 3, Fig. 4)

(4) When you release the lever, the spring force will

return the holder sleeve to the correct position

automatically. (Fig. 5)

(5) Pull the back of the saw blade two or three times

by hand and check that the blade is securely

mounted. When pulling the blade, you will know

it is properly mounted if it clicks and the lever

moves slightly. (Fig. 6)

6

Page 8

English

CAUTION

When pulling the saw blade, be absolutely sure to

pull it from the back. Pulling other parts of the blade

will result in an injury.

5. Dismounting the blade

(1) Turn on and off the switching trigger several times

so that the lever can jump out of the front cover

completely. Thereafter, turn off the switch and

unplug the power cord. (Fig. 1)

CAUTION

Be absolutely sure to keep the switch turned off

and the power cord unplugged to prevent any

accident.

(2) After you have pushed the lever in the direction

of the arrow mark shown in Fig. 2, turn the blade

so it faces downward. The blade should fall out by

itself. If the blade doesn’t fall out, pull it out by

hand.

CAUTION

Never touch the saw blade immediately after use.

The metal is hot and can easily burn your skin.

WHEN THE BLADE IS BROKEN

Even when the saw blade is broken and remains

inside the small slit of the plunger, it should fall

out if you push the lever in the direction of the

arrow mark, and face the blade downward. If it

doesn’t fall out itself, take it out using the procedures

explained below.

(1) If a part of the broken saw blade is sticking out

of the small slit of the plunger, pull out the protruding

part and take the blade out.

(2) If the broken saw blade is hidden inside the small

slit, hook the broken blade using a tip of another

saw blade and take it out. (Fig. 7)

MAINTENANCE AND INSPECTION OF SAW BLADE

MOUNT

(1) After use, blow away sawdust, earth, sand, moisture,

etc., with air or brush them away with a brush, etc.,

to ensure that the blade mount can function

smoothly.

(2) As shown in Fig. 8, carry out lubrication around the

blade holder on a periodic basis by use of cutting

fluid, etc.

NOTE

Continued use of the tool without cleaning and

lubricating the area where the saw blade is installed

can result in some slack movement of the lever due

to accumulated sawdust and chips. Under the

circumstances, pull a rubber cap provided on the

lever in the direction of an arrow mark as shown

in Fig. 9 and remove the rubber cap from the lever.

Then, clean up the inside of the blade holder with

air and the like and carry out sufficient lubrication.

The rubber cap can be fitted on if it is pressed firmly

onto the lever. At this time, make certain that there

exists no clearance between the blade holder and

the rubber cap, and furthermore ensure that the

saw-blade-installed area can function smoothly.

CAUTION

Do not use any saw blade with a worn-out blade

hole. Otherwise, the saw blade can come off,

resulting in personal injury. (Fig. 10)

6. Adjusting the base

(1) Lift the front cover up as illustrated in Fig. 11.

7

(2) If a base setting screw is loosened with an attached

hexagonal bar wrench, you can adjust a base

installing position. (Fig. 12, Fig. 13)

(3) After adjusting the base installing position, tighten

the base setting screw with the attached hexagonal

bar wrench completely.

7. Adjusting the blade reciprocating speed

This unit has a built-in electronic control circuit that

makes it possible to adjust the variable speed of

the saw blade either both by pulling a switching

trigger or turning a dial. (Fig. 14)

(1) If you pull the trigger further in, the speed of the

blade accelerates. Begin cutting at a low speed to

ensure the accuracy of your target cut position.

Once you’ve obtained a sufficient cutting depth,

increase the cutting speed.

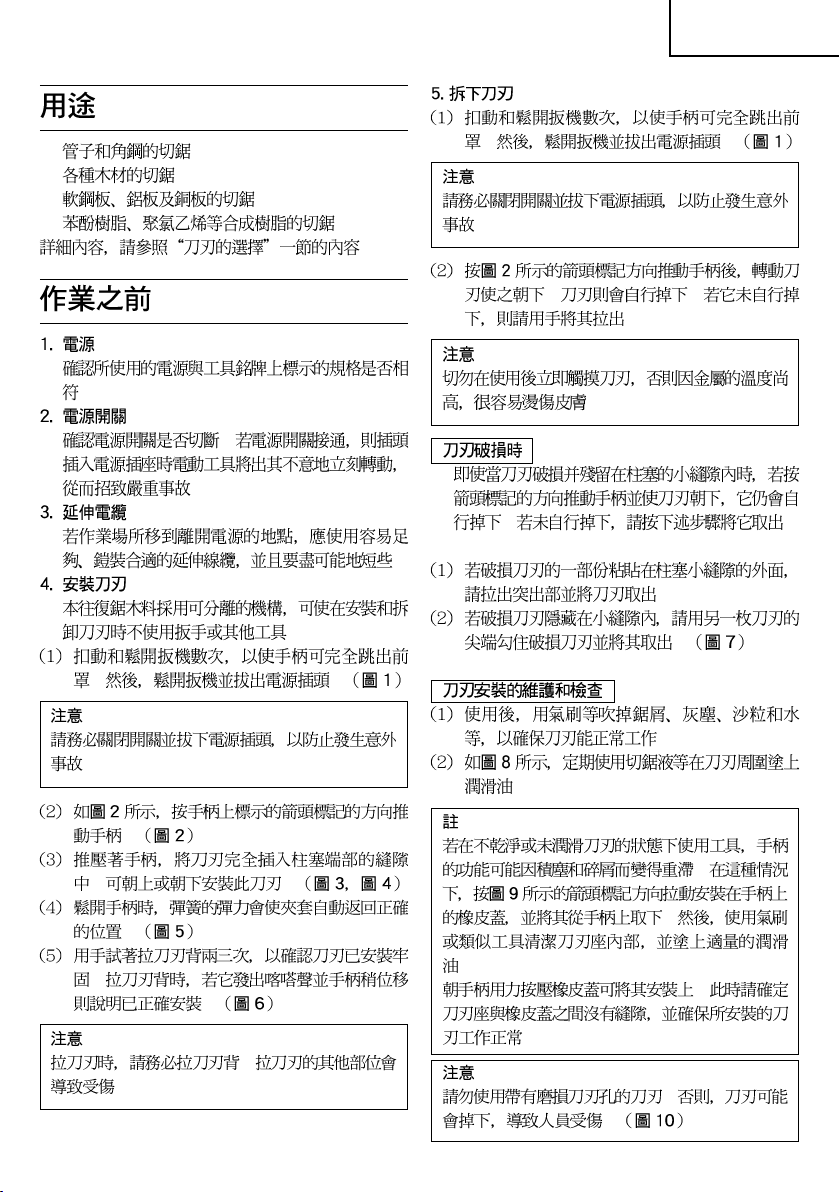

(2) On the dial scale, “5” is the maximum speed and

“1” the minimum. The high speed is generally

suitable for soft materials such as wood, and the

low speed is suitable for hard materials such as

metal. We recommend that you use the following

as a rough guide in selecting the suitable speed

for the materials you are cutting.

Example of materials Recommended

to be cut dial scale

Mild steel pipes /

cast-iron tubes / 2 – 4

L-shaped angle steel

Wood / wood with nails

driven in

Stainless steel 1 – 3

Aluminum / brass / copper 2 – 4

Plaster board 4 – 5

Plastic / fiber board 1 – 3

CAUTION

䡬 When cutting at low speed (scale of 1 – 2), never

cut a wooden board more than 10 mm thick or a

mild steel plate more than 2 mm thick. The load

on the motor can result in overheating and damage.

䡬 Although this unit employs a powerful motor,

prolonged use at a low speed will increase the load

unduly and may lead to overheating. Properly adjust

the saw blade to allow steady, smooth cutting

operation, avoiding any unreasonable use such as

sudden stops during cutting operation.

5

HOW TO USE

CAUTION

䡬 Avoid carrying it plugged to the outlet with your

finger on the switch. A sudden startup can result

in an unexpected injury.

䡬 Be careful not to let sawdust, earth, moisture, etc.,

enter the inside of the machine through the plunger

section during operation. If sawdust and the like

accumulate in the plunger section, always clean it

before use.

䡬 Do not remove the front cover (refer to Fig. 1).

Be sure to hold the body from the top of the front

cover.

䡬 During use, press the base against the material

while cutting.

Page 9

English

Vibration can damage the saw blade if the base is

not pressed firmly against the workpiece.

Furthermore, a tip of the saw blade can sometimes

contact the inner wall of the pipe, damaging the

saw blade.

䡬 Select a saw blade of the most appropriate length.

Ideally, the length protruding from the base of the

saw blade after subtracting the stroke quantity should

be larger than the material (see Fig. 15 and

Fig. 17).

If you cut a large pipe, large block of wood, etc.,

that exceeds the cutting capacity of a blade; there

is a risk that the blade may contact with the inner

wall of the pipe, wood, etc., resulting in damage.

(Fig. 16, Fig. 18)

䡬 To maximize cutting efficiency for the materials you

are using and working conditions, adjust the speed

of the saw blade.

1. Cutting metallic materials

CAUTION

䡬 Press the base firmly against the workpiece.

䡬 Never apply any unreasonable force to the saw

blade when cutting. Doing so can easily break the

blade.

(1) Fasten a workpiece firmly before operation. (Fig. 19)

(2) When cutting metallic materials, use proper machine

oil (turbine oil, etc.). When not using liquid machine

oil, apply grease over the workpiece.

CAUTION

The service life of the saw blade will be drastically

shortened if you don’t use machine oil.

(3) Use the dial to adjust the speed of the saw blade

to suit your working conditions and materials.

2. Cutting lumber

(1) When cutting lumber, make sure that the workpiece

is fastened firmly before beginning. (Fig. 20)

(2) You can cut efficiently if the speed of the saw blade

is set to dial scale “5”.

CAUTION

Never apply any unreasonable force to the saw

blade when cutting. Also remember to press the

base against the lumber firmly.

3. Sawing curved lines

We recommend that you use the BI-METAL blade

mentioned in Table 2 (Page 9) for the saw blade

since it is tough and hardly breaks.

CAUTION

Delay the feed speed when cutting the material into

small circular arcs. An unreasonably fast feed may

break the blade.

4. Plunge cutting

With this tool, you can perform plunge cutting on

plywood panels and thin board materials. You can

carry out pocket cutting quite easily with the saw

blade installed in reverse as illustrated in Fig. 22,

Fig. 24, and Fig. 26. Use the saw blade that is as

short and thick as possible. We recommend for this

purpose that you use BI-METAL Blade No. 132

mentioned in Page 9, Table 2. Be sure to use

caution during the cutting operation and observe

the following procedures.

(1) Press the lower part (or the upper part) of the base

against the material. Pull the switch trigger while

keeping the tip of the saw blade apart from the

material. (Fig. 21, Fig. 22)

(2) Raise the handle slowly and cut in with the saw

blade little by little. (Fig. 23, Fig. 24)

(3) Hold the body firmly until the saw blade completely

cuts into the material. (Fig. 25, Fig. 26)

CAUTION

䡬 Avoid plunge cutting for metallic materials. This can

easily damage the blade.

䡬

Never pull the switch trigger while the tip of the

saw blade tip is pressed against the material. If you

do so, the blade can easily be damaged when it

collides with the material.

䡬 Make absolutely sure that you cut slowly while

holding the body firmly. If you apply any

unreasonable force to the saw blade during the

cutting operation, the blade can easily be damaged.

5. Cut off guide for cutting pipe (optional accessory)

Product

Cut-off Outer diameter

guide (L) 75mm – 165mm

NOTE

Please refer to the cut off guide user’s manual for

details on how to use it correctly.

Cutting Blade

application used

No. 9 321113

Code No.

SELECTION OF BLADES

To ensure maximum operating efficiency and results, it

is very important to select the appropriate blade best

suited to the type and thickness of the material to be cut.

NOTE

Dimensions of the workpiece mentioned in the table

represent the dimensions when the mounting

position of the base is set nearest to the body of

the saber saw. Caution must be exercised since

dimensions of the workpiece will become smaller

if the base is mounted far away from the body of

the saber saw.

1. Selection of HCS blades

The blade number of HCS blades in Table 1 is

engraved in the vicinity of the mounting position

of each blade. Select appropriate blades by referring

to Tables 1 and 3 below.

Table 1: HCS blades

Blade Thickness

No.

No. 1 For cutting steel pipe less than

105 mm in diameter

No. 2 For cutting steel pipe less than

30 mm in diameter

No. 3 For cutting steel pipe less than

30 mm in diameter

No. 4 For cutting and roughing lumber 50 – 70

No. 5 For cutting and roughing lumber Below 30

No. 8 For cutting vinyl chloride pipe less

than 105 mm in diameter

For cutting and roughing lumber Below 105

No. 9 For cutting mild steel pipe less

than 165 mm in diameter when 2.5 – 6

used with cut off guide

Uses

(mm)

2.5 – 6

2.5 – 6

Below 3.5

2.5 – 15

8

Page 10

English

Blade Thickness

No.

No. 95 For cutting stainless steel pipe

less than 105 mm in diameter

No. 96 For cutting stainless steel pipe

less than 30 mm in diameter

NOTE

No. 1 – No. 96 HCS blades are sold separately as optional

accessories.

2. Selection of BI-METAL blades

The BI-METAL blade numbers in Table 2 are

described on the packages of special accessories.

Select appropriate blades by referring to Table 2

and 3 below.

Table 2: Bl-METAL blades

Blade Thickness

No.

No. 101

For cutting steel and stainless pipes

less than 60 mm in outer diameter

No. 102

For cutting steel and stainless pipes

less than 130 mm in outer diameter

No. 103

For cutting steel and stainless pipes

less than 60 mm in outer diameter

No. 104

For cutting steel and stainless pipes

less than 130 mm in outer diameter

No. 105

For cutting steel and stainless pipes

less than 60 mm in outer diameter

No. 106

For cutting steel and stainless pipes

less than 130 mm in outer diameter

No. 107

For cutting steel and stainless pipes

less than 60 mm in outer diameter

No. 108

For cutting steel and stainless pipes

less than 130 mm in outer diameter

No. 121

For cutting and roughing lumber 300

No. 131

All purposes —

No. 132

All purposes —

NOTE

Nos. 101 – No. 132 Bl-METAL blades are sold separately

as optional accessories.

3. Selection of blades for other materials

Table 3

Material Material Thickness

to be cut quality (mm)

Iron plate Mild steel 2.5 – 19 No. 1, 2, 101,

Nonferrous Aluminium, 5 – 20 No. 1, 2, 101,

metal Copper and 102, 103, 104,

9

plate 102, 103, 104,

Brass 105, 106, 131,

Uses

Uses

Below 3.5 No. 3, 107,

Below 5 No. 3, 107,

(mm)

Below 2.5

Below 2.5

(mm)

2.5 – 6

2.5 – 6

2.5 – 6

2.5 – 6

2.5 – 6

2.5 – 6

Below 3.5

Below 3.5

Blade No.

105, 106, 131,

132

108

132

108

Material Material Thickness

to be cut quality (mm)

Synthetic Phenol resin, 10 – 50 No. 1, 2, 4,

resin Melamine 101, 102, 103,

resin, etc. 104, 131, 132

5 – 30 No. 3, 5, 8,

Vinyl chloride,

Acrylic resin, 101, 102, 103,

etc. 104, 131, 132

10 – 60 No. 1, 2, 4,

5 – 30 No. 3, 5, 8,

Blade No.

105, 106, 107,

108

105, 106, 107,

108

MAINTENANCE AND INSPECTION

1. Inspecting the blade

Continued use of a dull or damaged blade will

result in reduced cutting efficiency and may cause

overloading of the motor. Replace the blade with

a new one as soon as excessive abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Inspecting the carbon brushes (Fig. 27)

The Motor employs carbon brushes which are

consumable parts. When they become worn to or

near the “wear limit”, it could result in motor trouble.

When an auto-stop carbon brush is equipped, the

motor will stop automatically.

At that time, replace both carbon brushes with new

ones which have the same carbon brush Numbers

shown in the figure. In addition, always keep carbon

brushes clean and ensure that they slide freely

within the brush holders.

5. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

NOTE

Due to HITACHI’s continuing program of research and

HiKOKI's

development, the specifications herein are subject to

change without prior notice.

Page 11

Español

NORMAS GENERALES DE SEGURIDAD

¡ADVERTENCIA!

Lea todas las instrucciones

Si no se siguen las instrucciones de abajo podría producirse

una descarga eléctrica, un incendio y/o daños graves.

El término “herramienta eléctrica” en todas las

advertencias indicadas a continuación hace referencia a

la herramienta eléctrica que funciona con la red de

suministro (con cable) o a la herramienta eléctrica que

funciona con pilas (sin cable).

CONSERVE ESTAS INSTRUCCIONES

1) Área de trabajo

a) Mantenga la zona de trabajo limpia y bien

iluminada.

Las zonas desordenadas y oscuras pueden

provocar accidentes.

b) No utilice las herramientas eléctricas en entornos

explosivos como, por ejemplo, en presencia de

líquidos inflamables, gases o polvo.

Las herramientas eléctricas crean chispas que

pueden hacer que el polvo desprenda humo.

c) Mantenga a los niños y transeúntes alejados

cuando utilice una herramienta eléctrica.

Las distracciones pueden hacer que pierda el control.

2) Seguridad eléctrica

a) Los enchufes de las herramientas eléctricas tienen

que ser adecuados a la toma de corriente.

No modifique el enchufe.

No utilice enchufes adaptadores con herramientas

eléctricas conectadas a tierra.

Si no se modifican los enchufes y se utilizan tomas

de corriente adecuadas se reducirá el riesgo de

descarga eléctrica.

b) Evite el contacto corporal con superficies conectadas

a tierra como tuberías, radiadores y frigoríficos.

Hay mayor riesgo de descarga eléctrica si su

cuerpo está en contacto con el suelo.

c) No exponga las herramientas eléctricas a la lluvia

o a la humedad.

La entrada de agua en una herramienta eléctrica

aumentará el riesgo de descarga eléctrica.

d) No utilice el cable incorrectamente. No utilice el

cable para transportar, tirar de la herramienta

eléctrica o desenchufarla.

Mantenga el cable alejado del calor, del aceite, de

bordes afilados o piezas móviles.

Los cables dañados o enredados aumentan el

riesgo de descarga eléctrica.

e) Cuando utilice una herramienta eléctrica al aire

libre, utilice un cable prolongador adecuado para

utilizarse al aire libre.

La utilización de un cable adecuado para usarse

al aire libre reduce el riesgo de descarga eléctrica.

3) Seguridad personal

a) Esté atento, preste atención a lo que hace y utilice

el sentido común cuando utilice una herramienta

eléctrica.

No utilice una herramienta eléctrica cuando esté

cansado o esté bajo la influencia de drogas,

alcohol o medicación.

La distracción momentánea cuando utiliza

herramientas eléctricas puede dar lugar a

importantes daños personales.

b) Utilice equipo de seguridad. Utilice siempre una

protección ocular.

El equipo de seguridad como máscara para el

polvo, zapatos de seguridad antideslizantes, casco

o protección para oídos utilizado para condiciones

adecuadas reducirá los daños personales.

c) Evite un inicio accidental. Asegúrese de que el

interruptor está en “off” antes de enchufarlo.

El transporte de herramientas eléctricas con el

dedo en el interruptor o el enchufe de

herramientas eléctricas con el interruptor

encendido puede provocar accidentes.

d) Retire las llaves de ajuste antes de encender la

herramienta eléctrica.

Si se deja una llave en una pieza giratoria de la

herramienta eléctrica podrían producirse daños

personales.

e) No se extralimite. Mantenga un equilibrio

adecuado en todo momento.

Esto permite un mayor control de la herramienta

eléctrica en situaciones inesperadas.

f) Vístase adecuadamente. No lleve prendas sueltas

o joyas. Mantenga el pelo, la ropa y los guantes

alejados de las piezas móviles.

La ropa suelta, las joyas y el pelo largo pueden

pillarse en las piezas móviles.

g) Si se proporcionan dispositivos para la conexión

de extracción de polvo e instalaciones de recogida,

asegúrese de que están conectados y se utilizan

adecuadamente.

La utilización de estos dispositivos puede reducir

los riesgos relacionados con el polvo.

4) Utilización y mantenimiento de las herramientas

eléctricas

a) No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación.

La herramienta eléctrica correcta trabajará mejor

y de forma más segura si se utiliza a la velocidad

para la que fue diseñada.

b) No utilice la herramienta eléctrica si el interruptor

no la enciende y apaga.

Las herramientas eléctricas que no pueden

controlarse con el interruptor son peligrosas y

deben repararse.

c) Desconecte el enchufe de la fuente eléctrica antes

de hacer ajustes, cambiar accesorios o almacenar

herramientas eléctricas.

Estas medidas de seguridad preventivas reducen

el riesgo de que la herramienta eléctrica se ponga

en marcha accidentalmente.

d) Guarde las herramientas eléctricas que no se

utilicen para que no las cojan los niños y no

permita que utilicen las herramientas eléctricas

personas no familiarizadas con las mismas o con

estas instrucciones.

Las herramientas eléctricas son peligrosas si son

utilizadas por usuarios sin formación.

e) Mantenimiento de las herramientas eléctricas.

Compruebe si las piezas móviles están mal

alineadas o unidas, si hay alguna pieza rota u

otra condición que pudiera afectar al

funcionamiento de las herramientas eléctricas.

Si la herramienta eléctrica está dañada, llévela a

reparar antes de utilizarla.

10

Page 12

Español

Se producen muchos accidentes por no realizar

un mantenimiento correcto de las herramientas

eléctricas.

f) Mantenga las herramientas de corte afiladas y

limpias.

Las herramientas de corte correctamente

mantenidas con los bordes de corte afilados son

más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las

brocas de la herramienta, etc., de acuerdo con estas

instrucciones y de la manera adecuada para el tipo

de herramienta eléctrica, teniendo en cuenta las

condiciones laborales y el trabajo que se va a realizar.

La utilización de la herramienta eléctrica para

operaciones diferentes a pretendidas podría dar

lugar a una situación peligrosa.

5) Revisión

a) Lleve su herramienta a que la revise un experto

cualificado que utilice sólo piezas de repuesto

idénticas.

Esto garantizará el mantenimiento de la seguridad

de la herramienta eléctrica.

PRECAUCIÓN

Mantenga a los niños y a las personas enfermas alejadas.

Cuando no se utilicen, las herramientas deben almacenarse

fuera del alcance de los niños y de las personas enfermas.

PRECAUCIONES EN EL EMPLEO DE LA

SIERRA DE SABLE

Antes de cortar en paredes, techos o suelos, asegurarse

de que no hayan empotrados cables o conducciones

eléctricas.

ESPECIFICACIONES

Voltaje (por áreas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Acometida 1010 W*

Capacidad Tubo de acero dulce: D.E. 130 mm

Velocidad de marcha en vacío 0 – 2800 /min

Carrera 29 mm

Peso (sin cable) 3,3 kg

* Verificar indefectiblemente los datos de la placa de características de la máquina, pues varían de acuerdo

al país de destino.

Tubo de cloruro de vinilo: D.E. 130 mm

Madera: Profundidad 300 mm

Chapa de acero dulce: Espesor 19 mm

ACCESORIOS ESTANDAR

(1) Hoja (Nº103) .............................................................. 1

(2) Caja ............................................................................. 1

(3) Llave macho hexagonal ........................................... 1

Los accesorios estandar están sujetos a cambio sin

pviso aviso.

ACCESORIOS FACULTATIVOS

(de venta por separado)

(1) Nº 1 Hoja (12) Nº 103 Hoja

(2) Nº 2 Hoja (13) Nº 104 Hoja

(3) Nº 3 Hoja (14) Nº 105 Hoja

(4) Nº 4 Hoja (15) Nº 106 Hoja

(5) Nº 5 Hoja (16) Nº 107 Hoja

(6) Nº 8 Hoja (17) Nº 108 Hoja

(7) Nº 9 Hoja (18) Nº 121 Hoja

(8) Nº 95 Hoja (19) Nº 131 Hoja

(9) Nº 96 Hoja (20) Nº 132 Hoja

(10) Nº 101 Hoja (21) Guía de cortes para tubos

(11) Nº 102 Hoja

䡬 (1) – (9) : Hojas HCS (HCS : Acero al carbono de

gran velocidad de corte)

䡬 (10) – (20) : Hojas BIMETÁLICAS

Para el uso de las hojas, consulte las tablas 1, 2 y 3.

Los accesorios facultativos están sujetos a cambio sin

previos aviso.

11

APLICACIONES

䡬 Corte de acero angular y de tubo

䡬 Cortes de diversas maderas útiles

䡬 Corte de placa de acero dulce, de aluminio y de

cobre.

䡬 Corte de resina sintética, tal como resina de fenol

y cloruro de vinilo.

Para más detalles dirigirse a la sección titulada

“SELECCION DE HOJAS”.

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegurarse de que la alimentación de red que ha

de ser utilizada responda a las exigencias de

corriente especificadas en la placa de características

del producto.

2. Interruptor de alimentación

Asegurarse de que el interruptor de alimentación

esté en la posición OFF (desconectado). Si el enchufe

está conectado en el receptáculo mientras el

interruptor de alimentación está en posición ON

(conectado) las herramientas eléctricas empezarán

a funcionar inesperadamente, provocando un serio

accidente.

3. Cable de prolongación

Cuando el área de trabajo está alejada de la red

de acometida, usar un cable de prolongación

suficiente grueso y potente. El cable de prolongación

debe ser mantenido lo más corto posible.

Page 13

Español

4. Montaje de la hoja

Esta unidad emplea un mecanismo desmontable

que permite montar y desmontar las hojas de sierra

sin necesidad de llave u otras herramientas.

(1) Conecte y desconecte el gatillo conmutador varias

veces de manera que la palanca del sujetador salte

completamente de la cubierta delantera.

Seguidamente, desconecte el interruptor y

desenchufe el cable de alimentación. (Fig. 1)

PRECAUCIÓN

Para evitar accidentes, asegúrese de mantener el

interruptor desconectado y el cable de alimentación

desenchufado.

(2) Empuje la palanca en la dirección de la flecha

indicada en la Fig. 2 y marcada en la misma. Si

gira el manguito del sujetador hasta la mitad

conseguirá asegurarlo automáticamente. (Fig. 2)

(3) Inserte completamente la hoja de sierra en la

hendidura pequeña de la punta del émbolo mediante

el empuje de la palanca. Esta hoja puede montarse

tanto en dirección ascendente como descendente.

(Fig. 3, Fig. 4)

(4) Cuando suelte la palanca, la fuerza del resorte hará

que el manguito del sujetador vuelva

automáticamente a la posición correcta. No hay

necesidad de asegurar el manguito del sujetador

en este momento. (Fig. 5)

(5) Con la mano, tire de la hoja de sierra hacia atrás

dos o tres veces y verifique que la hoja esté

firmemente instalada. Si al tirar de la hoja ésta

produce un chasquido y la palanca se mueve

ligeramente, significa que se encuentra

correctamente instalada. (Fig. 6)

PRECAUCIÓN

Cuando tire de la hoja de sierra, asegúrese de

hacerlo desde atrás. Si intenta tirar de la misma

desde alguna otra parte, podrá sufrir lesiones.

5. Desmontaje de la hoja

(1) Conecte y desconecte el gatillo conmutador varias

veces de manera que la palanca salte completamente

de la cubierta delantera. Seguidamente, desconecte

el interruptor y desenchufe el cable de alimentación.

(Fig. 1)

PRECAUCIÓN

Para evitar accidentes, asegúrese de mantener el

interruptor desconectado y el cable de alimentación

desenchufado.

(2) Después de haber empujado la palanca en la

dirección de la flecha mostrada en la Fig. 2, gire

la hoja de manera que quede dirigida hacia abajo.

La hoja debe caer por su propio peso. Si la hoja

no cae, extráigala con la mano.

PRECAUCIÓN

Nunca toque la hoja de sierra inmediatamente

después de haberla utilizado. El metal estará caliente

y podrá quemarse.

CUANDO SE ROMPA LA HOJA

Aun cuando la hoja de sierra se rompa y permanezca

dentro de la pequeña hendidura del émbolo, la

misma saldrá si empuja la palanca en la dirección

de la flecha. Por lo tanto, dirija la hoja hacia abajo.

Si no sale por sí misma, extráigala de la siguiente

manera.

(1) Si una parte de la hoja de sierra rota sobresale de

la pequeña hendidura del émbolo, extraiga la parte

saliente y extraiga la hoja.

(2) Si la hoja de sierra rota se encuentra oculta dentro

de la pequeña hendidura, enganche la hoja rota

utilizando la punta de otra hoja de sierra y extráigala.

(Fig. 7)

MANTENIMIENTO E INSPECCION DE LA MONTURA

DE LA HOJA DE SIERRA

(1) Después de utilizar la sierra, elimine el aserrín, el

polvo, la arena, la humedad, etc. con aire o con

un cepillo, etc. para asegurarse de que la montura

de la hoja funciona suavemente.

(2) Tal como se muestra en la Fig.8, lubrique

periódicamente alrededor del sujetador de la hoja

con lubricante para cuchillas.

NOTA

Si utilizara la herramienta sin haber realizado la

limpieza y la lubricación del área en que se instala

la hoja de sierra, el movimiento de la palanca

podría volverse lento debido a la acumulación de

partículas de polvo y aserrín. En tal caso, tire de

la tapa de goma provista en la palanca en la dirección

de la flecha tal como se muestra en la Fig. 9 y

extraiga la tapa de goma de la palanca. Luego,

limpie el interior del sujetador de la hoja con aire,

etc., y lubrique suficientemente.

Compruebe que la tapa de goma esté correctamente

instalada y que esté presionada firmemente sobre

la palanca. En este momento, asegúrese de que no

haya ninguna holgura entre el sujetador de la hoja

y la tapa de goma, y compruebe que el área de

instalación de la hoja de sierra pueda funcionar

suavemente.

PRECAUCIÓN

No utilice ninguna hoja de sierra con el orificio de

la hoja gastado. De lo contrario, la hoja podría

soltarse y provocar lesiones personales. (Fig.10)

6. Ajuste de la base

(1) Levante la cubierta hacia arriba, tal como se indica

en la Fig.11.

(2) Afloje el tornillo de ajuste de la base con la llave

de barra hexagonal suministrada para ajustar la

posición de instalación de la base. (Fig.12, Fig.13)

(3) Después de ajustar la posición de instalación de

la base, apriete completamente el tornillo de ajuste

de la base con la llave de barra hexagonal.

7. Ajuste de la velocidad alternativa de la hoja

Esta unidad está provista de un circuito de control

electrónico incorporado que hace posible controlar

la velocidad variable de la hoja de sierra tirando

del gatillo conmutador o bien girando un cuadrante.

(Fig. 12)

(1) Si continúa tirando del gatillo, la velocidad de la

hoja aumentará. Comience el corte a baja velocidad

para asegurar con exactitud la posición de corte

objetivo. Una vez que alcance una profundidad de

corte suficiente, aumente la velocidad de corte.

(2) En la escala del cuadrante, “5” corresponde a la

velocidad máxima, y “1” a la mínima. La velocidad

alta por lo general es adecuada para materiales

blandos como la madera, y la velocidad baja para

materiales duros, como el metal. Se recomienda

utilizar lo siguiente como guía aproximada al

seleccionar la velocidad adecuada para los materiales

que se están cortando.

12

Page 14

Español

Ejemplo de materiales Escala recomendada

a cortar del cuadrante

Tubos de acero dulce /

tubos de hierro fundido / 2 – 4

Angulos de acero en L

Madera / madera clavada 5

Acero inoxidable 1 – 3

Aluminio / latón / cobre 2 – 4

Cartón-yeso 4 – 5

Plástico /

cartón de pasta de madera

PRECAUCIÓN

䡬 A bajas velocidades de corte (escala de 1 – 2),

nunca corte una tabla de madera de un espesor

de más de 10 mm o una chapa de acero dulce de

un espesor de más de 2 mm. La carga aplicada al

motor podría producir recalentamientos y daños.

䡬 Aunque esta unidad emplea un motor potente, el

uso prolongado a baja velocidad aumentará la carga

indebidamente y podría producir recalentamientos.

Ajuste la hoja de sierra correctamente para permitir

una operación de corte suave y estable, y evitar

operaciones innecesarias como paros repentinos

durante la operación de corte.

1 – 3

MODO DE EMPLEO

PRECAUCIÓN

䡬 Evite transportar la herramienta conectada al

tomacorriente con su dedo sobre el interruptor.

Podría arrancar imprevistamente y producir lesiones.

䡬 Durante la operación, tenga cuidado de no permitir

la infiltración de aserrín, polvo, humedad, etc., a

través de la sección del émbolo. Si llegara a haber

aserrín y otras impurezas acumulados en la sección

del émbolo, límpielo antes del uso.

䡬 No desmonte la cubierta delantera (consulte la Fig.1).

Asegúrese de sujetar el cuerpo desde la parte

superior de la cubierta delantera.

䡬 Mientras realiza el corte, presione la base contra

el material.

La hoja de sierra podría dañarse debido a la vibración

si la base no está firmemente presionada contra la

pieza de trabajo.

Además, la punta de la hoja de sierra a veces puede

entrar en contacto con la pared interior del tubo,

y dañarse la hoja de sierra.

䡬 Seleccione una hoja de sierra del largo más

apropiado. Lo ideal sería que el largo que sobresale

de la base de la hoja de sierra después de restar

la carrera sea mayor que el del material (consulte

las Fig. 15 y 17).

Si corte un tubo grande, una pieza de madera

grande, etc., que exceda la capacidad de corte de

la hoja, existiría el riesgo de que la misma no haga

contacto con la pared interior del tubo, madera,

etc., y podrían producirse daños. (Fig. 16, Fig. 18)

䡬 Para aumentar al máximo la eficiencia de operación

y de los materiales que está usando, ajuste la

velocidad de la hoja de sierra.

13

1. Corte de materiales metálicos

PRECAUCIÓN

䡬 Presione la base firmemente contra la pieza de

trabajo.

䡬 No aplique nunca ninguna fuerza indebida a la hoja

de sierra durante el corte. De lo contrario, la hoja

podrá romperse fácilmente.

(1) Sujete firmemente una pieza de trabajo antes de

la operación. (Fig. 19)

(2) Cuando corte materiales metálicos, utilice un aceite

para máquinas apropiado (aceite para turbinas, etc.).

Si no emplea aceite para máquinas líquido, aplique

grasa sobre la pieza de trabajo.

PRECAUCIÓN

La vida de servicio de la hoja de sierra se acortará

de manera drástica si no utiliza aceite para máquinas.

(3) Utilice el cuadrante para ajustar la velocidad de la

hoja de sierra a los materiales y a otras condiciones

de trabajo.

2. Corte de madera

(1) Cuando corte madera, cerciórese de asegurar

firmemente la pieza de trabajo antes de comenzar.

(Fig. 20)

(2) Podrá cortar con eficiencia si ajusta la velocidad de

la hoja de sierra a “5” de la escala del cuadrante.

PRECAUCIÓN

No aplique nunca ninguna fuerza indebida a la hoja

de sierra durante el corte. Asimismo, no olvide de

presionar firmemente la base contra la madera.

3. Corte de líneas curvadas

Recomendamos utilizar la hoja BIMETÁLICA

mencionada en la Tabla 2 (Página 15) debido a su

resistencia y a sus características de robustez.

PRECAUCIÓN

Disminuya la velocidad de alimentación cuando corte

material en pequeños arcos circulares, pues una

velocidad innecesariamente alta podría romper la

hoja.

4. Corte por penetración

Con esta herramienta, podrá realizar cortes de

cavidad en madera laminada y en tablas de material

delgado. El corte de cavidad se puede realizar con

toda facilidad con la hoja de sierra instalada en

sentido inverso, tal como se observa en las Figs.

22, 24, y 26. Utilice una hoja de sierra lo más corta

y gruesa posible. Para este fin, se recomienda la

hoja BIMETÁLICA Nº 132 mencionada en la Tabla

2 de la página 15. Asegúrese de prestar atención

durante la operación de corte y de proceder de la

siguiente manera.

(1) Presione la parte inferior (o la parte superior) de

la base contra el material. Tire del gatillo mientras

mantiene la punta de la hoja de sierra separada del

material. (Fig. 21, Fig. 22)

(2) Levante el mango lentamente y corte con la hoja

de sierra poco a poco. (Fig. 23, Fig. 24)

(3) Sujete el cuerpo firmemente hasta que la hoja de

sierra penetre completamente dentro del material

(Fig. 25, Fig. 26)

PRECAUCIÓN

䡬 Evite el corte por penetración de materiales

metálicos, pues se dañará la hoja.

䡬 No tire nunca del gatillo conmutador mientras la

punta de la hoja de sierra está presionada contra

el material. De hacerlo, la hoja podría dañarse al

chocar contra el material.

Page 15

Español

䡬 Asegúrese de cortar lentamente mientras sostiene

el cuerpo con firmeza. Si aplica una fuerza irracional

a la hoja de sierra durante la operación de corte,

la hoja quedará dañada.

5. Guía de corte para tubos (accesorio facultativo)

Producto

Guía de Diámetro exterior

corte (L) 75mm – 165mm

NOTA

Con respecto a los detalles sobre el manejo correcto

de la guía de corte, consulte el manual de

instrucciones de la misma.

Aplicación Hoja Nº de

de corte empleada modelo

Nº 9 321113

SELECCION DE HOJAS

Para asegurar una máxima eficiencia operativa y buenos

resultados, es muy importante seleccionar la hoja

apropiada y más adecuada al tipo y al espesor del

material a cortar.

NOTA

Las dimensiones de la pieza de trabajo mencionadas

en la tabla se refieren a aquellas que se obtienen

cuando la posición de montaje de la base está

ajustada cerca del cuerpo de la sierra de sable.

Preste atención a este punto, ya que las dimensiones

de la pieza de trabajo podrían resultar menores si

montara la base alejada del cuerpo de la sierra de

sable.

1. Selección de las hojas HCS

El número de hoja de las hojas HCS de la Tabla

1 se encuentra grabado cerca de la posición de

montaje de cada hoja. Seleccione las hojas

apropiadas refiriéndose a las Tablas 1 y 3 de abajo.

Tabla 1: Hojas HCS

Hoja Usos

Nº 1 Para cortar tubos de acero de

menos de 105 mm. de diámetro.

Nº 2 Para cortar tubos de acero de

menos de 30 mm. de diámetro.

Nº 3 Para cortar tubos de acero menos

de 30 mm. de diámetro.

Nº 4 Para cortar y desbastar madera útil. 50 – 70

Nº 5 Para cortar y desbastar madera útil. Bajo 30

Nº 8 Para cortar tubos de cloruro vinilo

de menos de 105 mm. de diámetro.

Para cortar y desbastar madera útil. Bajo 105

Nº 9 Para cortar tubos de acero dulce

menos de 165 mm de diámetro

cuando se emplee con la guía de

corte.

Nº 95 Para cortar tubos de acero

inoxidable menos de 105 mm de Bajo 2,5

diámetro.

Nº 96 Para cortar tubos de acero

inoxidable menos de 30 mm de Bajo 2,5

diámetro.

Grosor

(mm)

2,5 – 6

2,5 – 6

Bajo 3,5

2,5 – 15

2,5 – 6

NOTA

Las hojas Nº 1 – Nº 96 se venden separadamente como

accesorios opcionales.

2. Selección de las hojas BIMETÁLICAS

Los números de las hojas BIMETÁLICAS de la Tabla

2 están indicados en los paquetes de los accesorios

especiales. Seleccione las hojas apropiadas

consultando las Tablas 2 y 3 de abajo.

Tabla 2: Hojas BIMETÁLICAS

Nº de

hojas (mm)

Nº 101 Para cortar tubos de acero y

Nº 102 Para cortar tubos de acero y

Nº 103 Para cortar tubos de acero y

Nº 104 Para cortar tubos de acero y

Nº 105 Para cortar tubos de acero y

Nº 106 Para cortar tubos de acero y

Nº 107 Para cortar tubos de acero y

Nº 108 Para cortar tubos de acero y

Nº 121 Para cortar y desbastar madera 300

Nº 131 Para todo —

Nº 132 Para todo —

NOTA

Las hojas BIMETÁLICAS Nº 101 – Nº 132 se venden

separadamente como accesorios opcionales.

3. Selección de las hojas para otros materiales

Tabla 3

Chapa de Chapa de 2,5 – 19 Nº 1, 2, 101,

hierro acero dulce 102, 103, 104,

Metales no Aluminio, 5 – 20 Nº 1, 2, 101,

ferrosos cobre y latón 102, 103, 104,

de acero inoxidable de menos de 2,5 – 6

60 mm de diámetro exterior

de acero inoxidable de menos de 2,5 – 6

130 mm de diámetro exterior

de acero inoxidable de menos de 2,5 – 6

60 mm de diámetro exterior

de acero inoxidable de menos de 2,5 – 6

130 mm de diámetro exterior

de acero inoxidable de menos de 2,5 – 6

60 mm de diámetro exterior

de acero inoxidable de menos de 2,5 – 6

130 mm de diámetro exterior

de acero inoxidable de menos de

60 mm de diámetro exterior

de acero inoxidable de menos de

130 mm de diámetro exterior

Material Calidad del Espesor

a cortar material (mm)

Usos

Inferior Nº 3, 107,

a 3,5 108

Inferior Nº 3, 107,

a 5 108

Espesor

Inferior

a 3,5

Inferior

a 3,5

Nº de hoja

105, 106, 131,

132

105, 106, 131,

132

14

Page 16

Español

Material Calidad del Espesor

a cortar material (mm)

Resina Resina fenólica, 10 – 50 Nº 1, 2, 4,

sintética resina 101, 102, 103,

melamínica, 104, 131, 132

etc.

Cloruro de 10 – 60 Nº 1, 2, 4,

vinilo, resina 101, 102, 103,

acrílica, etc. 104, 131, 132

5 – 30 Nº 3, 5, 8,

5 – 30 Nº 3, 5, 8,

Nº de hoja

105, 106, 107,

108

105, 106, 107,

108

MANTENIMIENTO E INSPECCION

1. Inspeccionar la cuchilla

El uso continuo de una cuchilla desgastada y dañada

podría resultar deficiencia de corte y además

causando un recalentamiento al motor. Reemplazar

la cuchilla por una nueva tan pronto como se note

un excesivo desgaste.

2. Inspeccionar los tornillos de montaje

Regularmente inspeccionar todos los tornillos de

montaje y asegurarse de que estén apretados

firmemente. Si cualquier tornillo estuviera suelto,

volver a apretarlo inmediatamente. El no hacer esto

provocaría un riesgo serio.

3. Mantenimiento de motor

La unidad de bobinado del motor es el verdadero

“corazón” de las herramientas eléctricas. Prestar el

mayor cuidado y asegurarse de que el bobinado

no se dañe y/o se humedezca con aceite o agua.

4. Inspección de escobillas de carbón (Fig. 27)

El motor emplea escobillas de carbón que son

partes consumibles. Cuando se gastan o están cerca

del “limite de desgaste” pueden causar problemas

al motor. Al equiparse la escobilla de carbón de

parada automática, el. motor se detendrá

automáticamente en ese momento hay que proceder

a cambiar ambas escobillas de carbón por la nuevas,

que tienen los mismos números de escobillas de

carbón como se muestra en la figura. Además

siempre hay que mantener las escobillas de carbón

limpias y asegurarse de que se muevan libremente

en sus portaescobillas.

5. Reemplazar el carbón de contacto

Quitar la cápsula de carbón con un destornillador

con cabeza pequeña. El carbón de contacto se deja

luego se quita con facilidad.

OBSERVACION

Debido al programa continuo de investigación y

desarrollo de HITACHI estas especificaciones están

sujetas a cambio sin previo aviso.

15

HiKOKI

Page 17

中國語

16

Page 18

中國語

-

-

-

17

䡬

䡬

-

-

Page 19

中國語

䡬 -

䡬 -

䡬 -

䡬 -

-

-

-

-

- -

- -

-

-

- -

-

-

- -

-

-

-

-

-

- -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

18

Page 20

中國語

-

-

-

-

-

-

-

-

-

-

䡬

-

-

䡬 -

-

䡬

-

-

-

䡬 -

-

-

䡬

-

䡬 -

䡬 -

-

䡬

-

-

䡬

-

-

䡬

-

19

-

-

-

-

-

-

-

Page 21

中國語

-

-

-

-

-

-

-

-

-

-

-

-

-

䡬

-

䡬 -

-

䡬 -

-

-

-

-

-

-

-

- -

20

Page 22

中國語

-

-

-

-

-

-

-

-

-

-

-

21

-

-

Page 23

ΕΎϔλϮϤϟ ήϴϐΘΗ ˬήϤΘδϤϟ ήϳϮτΘϟϭ ΚΤΒϠϟ

.ϖΒδϣ ϡϼϋ· ϥϭΩ ΎϨϫ ΓέϮϛάϤϟ

HiKOKI

ΔψΣϼϣ

ΞϣΎϧήΒϟ Ύ˱όΒΗ

ΎϬϧ ϰϠϋ ΓΪΣ ϰϠϋ

Γήϔθϟ Ϣϗέ

101ϭ 2ϭ 1

104ϭ 103ϭ 102

131ϭ 106ϭ 105

108ϭ 107ϭ 3

101ϭ 2ϭ 1

104ϭ 103ϭ 102

131ϭ 106ϭ 105

108ϭ 107ϭ 3

103ϭ 102ϭ 101

132ϭ 131ϭ 104

107ϭ 106ϭ 105

103ϭ 102ϭ 101

132ϭ 131ϭ 104

107ϭ 106ϭ 105

Ϣϗέ

132

Ϣϗέ

Ϣϗέ

132

Ϣϗέ

4ϭ 2ϭ 1 Ϣϗέ

8ϭ 5ϭ 3 Ϣϗέ

108

4ϭ 2ϭ 1 Ϣϗέ

8ϭ 5ϭ 3 Ϣϗέ

108

ϭ

ϭ

ϭ

3.5

ϭ

ϭ

ϭ

ϭ

ϭ

ϭ

ϭ

ϭ

ϭ

ϭ

ϭ

132 – 101

ϚϤδϟ

(Ϣϣ)

19 – 2.5

Ϧϣ Ϟϗ

20 – 5

5

Ϧϣ Ϟϗ

50 – 10

30 – 5

60 – 10

30 – 5

Ϣϗέ

Bl-METAL

ΔψΣϼϣ

Εήϔη ωΎΒΗ

.ΔϳέΎϴΘΧ ΕΎϘΤϠϣ

ϯήΧ ΩϮϣ ϊτϘϟ Εήϔη ΪϳΪΤΗ

3

ϝϭΪΠϟ

ΩϮϤϟ ΓΩϮΟ

ΩήϤϟ ΩϮϤϟ

ΎϬότϗ

ϱΪϳΪΣ ΡϮϟ ΐϠλ ΡϮϟ

ωϭΎτϣ

ϡϮϴϨϣϮϟϷ

αΎΤϨϟ αΎΤϨϟϭ

ήϴϏ ϥΩΎόϣ

ΔϳΪϳΪΣ

ήϔλϷ

ϝϮϨϴϔϟ ϦΪϟ

ϦϴϣϼϴϤϟ ϦΪϟϭ

ϦΪϠϟ

ΔϴϋΎϨτλϻ

ϚϟΫ ϰϟ· Ύϣϭ

ϞϴϨϴϔϟ ΪϳέϮϠϛ

ϚϴϠϳήϛϷ ϦΪϟϭ

ϪΑΎη Ύϣϭ

3

κΤϔϟϭ ΔϧΎϴμϟ

κϘϧ ϰϟ· ΔϔϟΎΘϟ ϭ ΓΩΎΤϟ ήϴϏ ΓήϔθϠϟ ήϤΘδϤϟ ϡΪΨΘγϻ ϱΩΆϳ ϑϮγ

Γήϔθϟ ϝΪΒΘγ .ϙήΤϤϟ ϰϠϋ ϞϤΤϟ ΓΩΎϳί ϲϓ ΐΒδΘϳ Ϊϗϭ ϊτϘϟ Γ˯Ύϔϛ

.ΎϬΗΪΣ ϒόο ΩήΠϤΑ ΓΪϳΪΟ ΓήϔθΑ

ΎϬτΑέ ϡΎϜΣ· Ϧϣ Ϊϛ΄Θϟϭ ΖϴΒΜΘϟ ήϴϣΎδϣ ΔϓΎϜϟ ϱέϭΪϟ κΤϔϟΎΑ Ϣϗ

.έϮϔϟ ϰϠϋ ΎϬτΑέ ϡΎϜΣΈΑ Ϣϗ ˬήϴϣΎδϣ Δϳ Ϛϓ ΔϟΎΣ ϲϓ .ϴΤλ ϞϜθΑ

.ήσΎΨϣ ϰϟ· ϚϟάΑ ϡΎϴϘϟ ϲϓ Ϟθϔϟ νήόϳ ΪϘϓ

.ΔϗΎτϟ ΓΩ Ϧϣ "ςγϭϷ ˯ΰΠϟ" Ϯϫ ϙήΤϤϟ ΓΪΣϭ ϒϠϣ

.˯ΎϤϟ ϭ Ζϳΰϟ ΔτγϮΑ ϪϠϠΑ ϭ/ϭ ϒϠϤϟ ϒϠΗ ϡΪϋ Ϧϣ έήϤΘγΎΑ ΪϛΎΗ

27

ϞϜθϟ) ΔϴϧϮΑήϜϟ ΓΎηήϔϟ κΤϓ

ΪϨϋ .ΓήϤόϣ ήϴϏ ˯ΰΟϷ Ϧϣ ϲϫϭ ΔϴϧϮΑήϜϟ ΓΎηήϔϟ ϙήΤϤϟ ϚϠϬΘδϳ

(

ΕϼϜθϣ ΙϭΪΣ ϲϓ ΐΒδΘΗ ϥ ϦϜϤϳ ˬ"ϞϛΘϟ ΪΣ" Ϧϣ ΎϬΑήΘϗϭ ΎϬϠϛΗ

ˬϒϗϮΘϟ ΔϴΎϘϠΗ ϥϮΑήϜϟΎΑ ϞϘλ ΓΎηήϓ ήϴϓϮΗ ΔϟΎΣ ϲϓ .ϙήΤϤϟΎΑ

ϥϮϜϳϭ ΔϤϳΪϘϟ Ϧϣ ˱ϻΪΑ ΓΪϳΪΟ ϞϘλ ΓΎηήϓ ϡΪΨΘγ ˬΔϠΣήϤϟ ϩάϫ ϲϓ

Ϣϗ ˬϚϟΫ ϰϟ· ΔϓΎοϹΎΑ .ϞϜθϟ ϲϓ ΔΤοϮϤϟ ϡΎϗέϷ βϔϧ ΎϬϴϠϋ

ΔγϼδΑ ΎϬϗϻΰϧ Ϧϣ Ϊϛ΄Θϟϭ έήϤΘγΎΑ ϥϮΑήϜϟΎΑ ϞϘμϟ ΓΎηήϓ ϒϴψϨΘΑ

ΓΎηήϔϟ Δϟί· .ΕΎΤΘϓ ϭΫ Ϛϔϣ ϝϼΧ Ϧϣ ΓΎηήϔϟ ΔϴτϏ ϚϔΑ Ϣϗ

۱

Εήϔθϟ κΤϓ

ΖϴΒΜΘϟ ήϴϣΎδϣ κΤϓ

ϙήΤϤϟ ΔϧΎϴλ

.Ύ˱ϴΎϘϠΗ ϙήΤϤϟ ϒϗϮΘϴγ

.ΓΎηήϔϟ ξΑΎϘϣ ϞΧΩ

ΔϴϧϮΑήϜϟ ΓΎηήϔϟ ϝΪΒΘγ

.ΔϟϮϬδΑ ΔϴϧϮΑήϜϟ

1

2

3

4

5

22

Page 24

HCS

Εήϔη :1 ϝϭΪΠϟ

ϚϤδϟ

(Ϣϣ)

6 – 2.5

6 – 2.5

3.5

Ϧϣ Ϟϗ

70 – 50

30

Ϧϣ Ϟϗ

15 – 2.5

105

Ϧϣ Ϟϗ

6 – 2.5

2.5

Ϧϣ Ϟϗ

2.5

Ϧϣ Ϟϗ

.ΔϳέΎϴΘΧ ΕΎϘΤϠϣ ΎϬϧ ϰϠϋ ΓΪΣ ϰϠϋ

ΕϮΒϋ ϰϠϋ 2 ϝϭΪΠϟ ϲϓ ΓΩέϮϟ

ϰϟ· ωϮΟήϟ ϝϼΧ Ϧϣ ΔϤϼϤϟ Εήϔθϟ ΩΪΣ .ΔλΎΨϟ ΕΎϘΤϠϤϟ

ϚϤδϟ

(Ϣϣ)

6 – 2.5

6 – 2.5

6 – 2.5

6 – 2.5

6 – 2.5

6 – 2.5

3.5

Ϧϣ Ϟϗ

3.5

Ϧϣ Ϟϗ

300

–

–

ϡΪΨΘγϻ νήϏ

Ϣϣ

Ϣϣ

Ϣϣ

105

Ϣϣ

ΔϨθΧ ΓέϮθϨϣ ΔϴΒθΧ ϊτϗ ϊτϘϟ

165

Ϣϣ

105

Ϧϋ ϩήτϗ

ϊτϘϟ Ϫ˷ΟϮϣ

Ϧϋ ϩήτϗ

ϊϣ ϪϣΪΨΘγ ΪϨϋ Ϣϣ

Ϣϣ 30 Ϧϋ ϩήτϗ

96 – 1

BI-METAL

.ϩΎϧΩ ϦϴΤοϮϤϟ

HCS

Ϣϗέ

BI-METAL

Εήϔη ϡΎϗέ οϮΗ

3ϭ 2

Bl-METAL

ϡΪΨΘγϻ νήϏ

Ϣϣ 60 Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

130

Ϣϣ

Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

Ϣϣ 60 Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

130

Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

Ϣϣ

Ϣϣ 60 Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

130

Ϣϣ

Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

60

Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

Ϣϣ

130

Ϣϣ

Ϧϋ ϲΟέΎΨϟ Ύϫήτϗ ϝϮσ ϞϘϳ

105

Εήϔη ΪϳΪΤΗ

Εήϔη :2 ϝϭΪΠϟ

Ϣϗέ

Γήϔθϟ

1

Ϣϗέ Ϧϋ ϩήτϗ ϝϮσ ϞϘϳ ΐϠλ ΏϮΒϧ ϊτϘϟ

2

Ϣϗέ Ϧϋ ϩήτϗ ϝϮσ ϞϘϳ ΐϠλ ΏϮΒϧ ϊτϘϟ

30

3

Ϣϗέ Ϧϋ ϩήτϗ ϝϮσ ϞϘϳ ΐϠλ ΏϮΒϧ ϊτϘϟ

30

4

ϢϗέΔϨθΧ ΓέϮθϨϣ ΔϴΒθΧ ϊτϗ ϊτϘϟ

5

ϢϗέΔϨθΧ ΓέϮθϨϣ ΔϴΒθΧ ϊτϗ ϊτϘϟ

8

Ϣϗέ ϩήτϗ ϝϮσ ϞϘϳ ϞϴϨϴϔϟ ΪϳέϮϠϛ ΏϮΒϧ ϊτϘϟ

Ϧϋ

9

Ϣϗέ ϝϮσ ϞϘϳ ωϭΎτϣ ΐϠλ ΏϮΒϧ ϊτϘϟ

95

Ϣϗέ ϝϮσ ϞϘϳ Ϊμϳ ϻ ΐϠλ ΏϮΒϧ ϊτϘϟ

96

Ϣϗέ ϝϮσ ϞϘϳ Ϊμϳ ϻ ΐϠλ ΏϮΒϧ ϊτϘϟ

ΔψΣϼϣ

Εήϔη ωΎΒΗ

ϦϴϟϭΪΠϟ

Ϣϗέ

Γήϔθϟ

101

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

102

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

103

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

104

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

105

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

106

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

107

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

108

Ϣϗέ ϲΘϟ ΪμϠϟ ΔϣϭΎϘϤϟϭ ΐϠμϟ ΐϴΑΎϧ ϊτϘϟ

121

ϢϗέΔϨθΧ ΓέϮθϨϣ ΔϴΒθΧ ϊτϗ ϊτϘϟ

131

ϢϗένήϏϷ ΔϓΎϛ

132

ϢϗένήϏϷ ΔϓΎϛ

ΎϬότϗ ΩήϤϟ ΔότϘϟ ΖϴΒΜΗ Ϧϣ Ϊϛ΄Η ˬέϮθϨϤϟ ΐθΨϟ ϊτϗ ΪϨϋ

έϮθϨϤϟ ΐθΨϟ ϊτϗ

"5"

.

αΎϴϘϤϟ ϰϠϋ έΎθϨϤϟ Γήϔη Δϋήγ ΖϧΎϛ Ϋ· Γ˯ΎϔϜΑ ϊτϘϟ ϚϨϜϤϳ

.(20 ϞϜθϟ) ϊτϘϟ ϞΒϗ ϡΎϜΣΈΑ

ήϛάΗ .ϊτϘϟ ΪϨϋ έΎθϨϤϟ Γήϔη ϊϣ Δϣίϼϟ ήϴϏ ΓϮϘϟ ϡΪΨΘγ ΐϨΠΗ

.ϡΎϜΣΈΑ ϪΘϴΒΜΘϟ έϮθϨϤϟ ΐθΨϟ ϰϠϋ ΓΪϋΎϘϟΎΑ ςϐπϟ Ϛϟάϛ

2 ϝϭΪΠϟ ϲϓ ΓέϮϛάϤϟ

BI-METAL

ΔϴϨΤϨϤϟ ϱέΎΠϤϟ ήθϧ

Γήϔη ϡΪΨΘγΎΑ ϲλϮϧ

.Ύϫήδϛ ΐόμϳϭ ΔΒϠλ ΎϬϧϷ έΎθϨϤϟ ΓήϔθΑ ιΎΨϟ (˽ ΔΤϔλ)

ΔϳήΪϟ αϮϗϷ ϞΧΩ ΓΩΎϤϟ ϊτϗ ΪϨϋ ϢϴϘϠΘϟ Δϋήγ ϲϓ ϞΠόΘΗ ϻ

.Γήϔθϟ ήδϛ ϰϟ· ϡίϼϟ ήϴϏ ϊϳήδϟ ϢϴϘϠΘϟ ϱΩΆϳ ΪϘϓ .Γήϴϐμϟ

ΔϘϴϗέ ΔϴΒθΧ ΕΎΣϮϟ ϰϠϋ βΒϜϤϟΎΑ ϊτϘϟ ϚϨϜϤϳ ˬΓΩϷ ϩάϫ ϡΪΨΘγΎΑ

ΔτγϮΑ ΔϟϮϬδΑ ϲΒϴΠϟ ϊτϘϟ ˯ήΟ· ϚϨϜϤϳ .Δόϴϓέ ΔϳϮϘϣ ΡϮϟϭ

24

ˬ

ϞϜθϟϭ 22 ϞϜθϟ ϲϓ οϮϣ Ϯϫ ΎϤϛ ΐϴϛήΘϟ ΔγϮϜόϣ Γήϔθϟ

.ϚϤδϟϭ ήμϘϟ ΔϴϫΎϨΘϣ ϥϮϜΗ έΎθϨϣ Γήϔη ϡΪΨΘγ .26 ϞϜθϟϭ

132

Ϣϗέ BI-METAL Γήϔη ϡΪΨΘγΎΑ ϲλϮϧ ˬνήϐϟ άϬϟϭ

βΒϜϤϟΎΑ ϊτϘϟ

ϊτϘϟ ΔϴϠϤϋ ˯ΎϨΛ έάΤϟ ΥϮΗ .2 ϝϭΪΠϟ ˬ˽ ΔΤϔλ ϲϓ ΓέϮϛάϤϟ

.ΔϴϟΎΘϟ Ε˯ήΟϹ ϊΒΗϭ

ΓΩΎϤϟ ϰϠϋ ΓΪϋΎϘϟ Ϧϣ (ϱϮϠόϟ ˯ΰΠϟ ϭ) ϲϠϔδϟ ˯ΰΠϟΎΑ ςϐο

Γήϔη ϑήσ ΩΎόΑ· ϊϣ ϞϐθϤϟ ΡΎΘϔϣ ΐΤγ .ΎϬΘϴΒΜΘϟ ΎϬότϗ ΩήϤϟ

.(22 ϞϜθϟϭ 21 ϞϜθϟ) ΎϬότϗ ΩήϤϟ ΓΩΎϤϟ Ϧϋ έΎθϨϤϟ

23 ϞϜθϟ) Ύ˱ϴΠϳέΪΗ έΎθϨϤϟ ΓήϔθΑ ϊτϘϟΎΑ Ϣϗ ϢΛ ϖϓήΑ ξΒϘϤϟ ϊϓέ

.(24 ϞϜθϟϭ

ϞϣΎϜϟΎΑ ΓΩΎϤϟ ϊτϗ Ϧϣ έΎθϨϤϟ Γήϔη ϦϜϤΘΗ ϰΘΣ ϡΎϜΣΈΑ ίΎϬΠϟ ϞϤΣ

.(26 ϞϜθϟϭ 25 ϞϜθϟ)

ϒϠΗ ϰϟ· ϚϟΫ ϱΩΆϳ ΪϘϓ .ΔϴϧΪόϤϟ ΩϮϤϟ ϊϣ βΒϜϤϟΎΑ ϊτϘϟ ΐϨΠΗ

2

έΎθϨϤϟ Γήϔη ϑήτΑ ςϐπϟ ˯ΎϨΛ ϞϐθϤϟ ΡΎΘϔϣ ΐΤγ Ύ˱ϣΎϤΗ ΐϨΠΗ

.ΔϟϮϬδΑ Γήϔθϟ

ϰϠϋ Γήϔθϟ ϒϠΗ ϰϟ· ϚϟάΑ ϡΎϴϘϟ ϱΩΆϳ ΪϘϓ .ΎϬότϗ ΩήϤϟ ΓΩΎϤϟ ϰϠϋ

.ΎϬότϗ ΩήϤϟ ΓΩΎϤϟ ϊϣ ΎϬϣΩΎμΗ ΪϨϋ έϮϔϟ

ϱΩΆϳ ΪϘϓ .ϡΎϜΣΈΑ ίΎϬΠϟ ϞϤΣ ˯ΎϨΛ ϖϓήΑ ϊτϘϟ ϰϠϋ Ύ˱ϣϭΩ ιήΣ

ϊτϘϟ ΔϴϠϤϋ ˯ΎϨΛ έΎθϨϤϟ Γήϔη ϊϣ Δϣίϼϟ ήϴϏ ΓϮϘϠϟ ϡΪΨΘγ ϱ

.έϮϔϟ ϰϠϋ ΎϬϔϠΗ ϰϟ·

(ΔϳέΎϴΘΧ ΕΎϘΤϠϣ) ΐϴΑΎϧϷ ϊτϘϟ ϊτϘϟ ϞϴϟΩ

ΰϣήϟ Ϣϗέ

321113

ϢΗ Γήϔη

ΎϬϣΪΨΘγ

9

Ϣϗέ

ϲΟέΎΨϟ ήτϘϟ

165 –

Ϣϣ

Ϣϣ

75

ϰϠϋ ϝϮμΤϠϟ ϊτϘϟ ϞϴϟΪΑ ιΎΨϟ ϡΪΨΘδϤϟ ϞϴϟΩ ϰϟ· ωϮΟήϟ ϰΟήϳ

.ϢϴϠγ ϞϜθΑ ϪϣΪΨΘγ Δϴϔϴϛ ϝϮΣ ϞϴλΎϔΘϟ

Εήϔθϟ ΪϳΪΤΗ

Ϧϣ ˬΞΎΘϨϟ Ϟπϓ ϰϠϋ ϝϮμΤϟϭ ϞϴϐθΘϟ Γ˯ΎϔϜϟ ΪΣ ϰμϗ ϥΎϤπϟ

ΩήϤϟ ΓΩΎϤϟ ωϮϧ ϊϣ ΐγΎϨΘΗ ϲΘϟ ΔϤϼϤϟ Γήϔθϟ ΪϳΪΤΗ ϱέϭήπϟ

ϊοϭ ΎϬόϣ ϥϮϜϳ ϲΘϟ ΩΎόΑϷ ϝϭΪΠϟ ϲϓ ΓέϮϛάϤϟ ΔότϘϟ ΩΎόΑ ϞΜϤΗ

ΥϮΗ ϲϐΒϨϳ .έΎθϨϤϟ ϝΩΎΒΘϳ ϞϜϴϬϟ ϥϮϜϳ Ύϣ Ώήϗ ΓΪϋΎϘϟ ΐϴϛήΗ

˱ΪϴόΑ ΓΪϋΎϘϟ ΐϴϛήΗ ΔϟΎΣ ϲϓ

ΏήϘϟΎΑ έϮϔΤϣ 1 ϝϭΪΠϟ ϲϓ

Γήϴμϗ ΔότϘϟ ΩΎόΑ ΒμΗ ΎϣΪϨϋ έάΤϟ

.έΎθϨϤϟ ϝΩΎΒΘϳ ϞϜϴϫ Ϧϋ

HCS

ΕήϔθΑ ΔλΎΨϟ Γήϔθϟ Ϣϗέ ϥ·

ϝϼΧ Ϧϣ ΔϤϼϤϟ Εήϔθϟ ΩΪΣ .Γήϔη ϞϜϟ ΐϴϛήΘϟ ϊοϭ Ϧϣ

.ϩΎϧΩ ϦϴΤοϮϤϟ 3ϭ 1 ϦϴϟϭΪΠϟ ϰϟ· ωϮΟήϟ

.ΎϬϜϤγϭ ΎϬότϗ

HCS

Εήϔη ΪϳΪΤΗ

ΞΘϨϤϟϊτϘϟ ϖϴΒτΗ

ϞϴϟΪϟ ϊτϗ

(ϝ)

ΔψΣϼϣ

ΔψΣϼϣ

(1)

(2)

ϪϴΒϨΗ

ϪϴΒϨΗ

(1)

(2)

(3)

ϪϴΒϨΗ

2

3

4

○

○

○

5

1

23

۰

Page 25

ΎϬότϘΑ ϰλϮϤϟ ΩϮϤϟ ϰϠϋ ϝΎΜϣϪΑ ϰλϮϤϟ ιήϘϟ αΎϴϘϣ

4 – 2

3 – 1

4 – 2

5 – 4

3 – 1

ϊτϘΑ ϢϘΗ ϻ ˬ(

5

2 – 1

αΎϘϣ) ΔπϔΨϨϣ Δϋήγ ϡΪΨΘγΎΑ ϊτϘϟ ΪϨϋ

/ ωϭΎτϣ ΐϠλ ΐϴΑΎϧ

/ήϫί ΪϳΪΣ ΐϴΑΎϧ

L

ϑήΣ ϞϜη ϰϠϋ ΔϳϭΰΑ ΐϠλ

ήϴϣΎδϤΑ ΐθΧ / ΐθΧ

ΪμϠϟ ϡϭΎϘϣ ΐϠλ

αΎΤϨϟ / ήϔλϷ αΎΤϨϟ / ϡϮϴϨϣϮϟϷ

κμΠϣ ΡϮϟ

ϲϔϴϟ ΡϮϟ / ϚϴΘγϼΒϟ

ωϭΎτϤϟ ΐϠμϟ ΡϮϟϷ ϭ ˬϢϣ 10 Ϧϣ ήΜϛ ϚϤδΑ ΐθΨϟ ΡϮϟ

ωΎϔΗέ ϰϟ· ϙήΤϤϟ ϰϠϋ ϞϤΤϟ ϱΩΆϳ ΪϘϓ .Ϣϣ 2 Ϧϣ ήΜϛ ϚϤδΑ

.ίΎϬΠϟ ϒϠΗϭ ΓέήΤϟ ΔΟέΩ

ΔϠϳϮσ ΕήΘϔϟ ϡΪΨΘγϻ ΐΒδΘϳ Ϊϗ ˬΎ˱ϳϮϗ Ύ˱ϛήΤϣ ΓΪΣϮϟ ϩάϫ ϡΪΨΘδΗ

ϰϟ· ϱΩΆϳ Ϊϗϭ Ϣϼϣ ήϴϏ ϮΤϧ ϰϠϋ ϞϴϤΤΘϟ ϲϓ ΔπϔΨϨϣ ΕΎϋήδΑ

ΔϴϠϤϋ ϰϠϋ ϝϮμΤϠϟ έΎθϨϤϟ Γήϔη ςΒπΑ Ϣϗ .ΓέήΤϟ ΔΟέΩ ωΎϔΗέ

ϞϴΒγ ϰϠϋ ΏϮϠτϤϟ ήϴϏ ϡΪΨΘγϻ ΐϨΠΗ ϊϣ ˬΔΘΑΎΛϭ ΔτϴδΑ ϊτϗ

.ϊτϘϟ ΔϴϠϤϋ ˯ΎϨΛ ΔΌΟΎϔϤϟ ΕΎϔϗϮΘϟ ϝΎΜϤϟ

ϡΪΨΘγϻ Δϴϔϴϛ

ϰϠϋ ϚόΑΎλ ϝϼΧ Ϧϣ έΎϴΘϟ άϔϨϤΑ ϞμΘϣ ϥϮϜϳ ΎϣΪϨϋ ϪϠϤΣ ΐϨΠΗ

Ύ˱ϣϭΩ ιήΣϭ .ϞϴϐθΘϟ ˯ΎϨΛ βΒϜϤϟ ˯ΰΟ ϝϼΧ ίΎϬΠϟ ϰϟ· ϝϮΧΪϠϟ

Ύϣϭ ΔΑήΗϷ ϢϛήΗ ΔϟΎΣ ϲϓ ˬϡΪΨΘγϻ ϞΒϗ βΒϜϤϟ ˯ΰΟ ϒϴψϨΗ ϰϠϋ

ίέΎΒϟ ˯ΰΠϠϟ ϲϟΎΜϤϟ ϝϮτϟ ϥϮϜϳϭ .ΐγΎϨϣ ϝϮτΑ έΎθϨϣ Γήϔη ήΘΧ

ΩήϤϟ ΓΩΎϤϟ ϝϮσ Ϧϣ ήΒϛ ϕϮϘθϟ ΩΪϋ Ρήσ ΪόΑ Γήϔθϟ ΓΪϋΎϗ Ϧϣ

έΪΠϟΎΑ Γήϔθϟ βϣϼΗ ϝΎϤΘΣ ϰϟ· Γήϔθϟ ϊτϗ ΓέΪϗ ίϭΎΠΘΗ ΖϧΎϛϭ

ΎϬϔϠΗ ϰϟ· ϱΩΆϳ ΎϤϣ ˬϪΑΎη Ύϣ ϭ ΔϴΒθΨϟ ΔότϘϟ ϭ ΏϮΒϧϸϟ ϲϠΧΪϟ

ςΒπΑ Ϣϗ ˬϞϤόϟ ϑϭήχϭ ΎϬϣΪΨΘδΗ ϲΘϟ ΩϮϤϟ ϊτϗ Γ˯Ύϔϛ ΓΩΎϳΰϟ

ΪϘϓ .ϊτϘϟ ΪϨϋ έΎθϨϤϟ Γήϔη ϊϣ Δϣίϼϟ ήϴϏ ΓϮϘϟ ϡΪΨΘγ ΐϨΠΗ

ϊο ˬϞΎδϟ ίΎϬΠϟ Ζϳί ϡΪΨΘγ ΪϨϋ .(ϚϟΫ ϰϟ· Ύϣϭ ˬΕΎϨϴΑέϮΘϟ

Ζϳί ϡΪΨΘδΗ Ϣϟ Ύϣ ΓΰϴΟϭ ΓήΘϓ ϲϓ έΎθϨϤϟ Γήϔη ΔϣΪΧ ήϤϋ ήμϘϳ

ϞϤόϟ ϑϭήχ Δϣ˯ϼϤϟ έΎθϨϤϟ Γήϔη Δϋήγ ςΒπϟ ιήϘϟ ϡΪΨΘγ

.ΓήϴτΧ ΔΑΎλ· ϰϟ· ΊΟΎϔϤϟ ϞϴϐθΘϟ ϱΩΆϳ ΪϘϓ .ΡΎΘϔϤϟ

ϚϟΫ ϰϟ· Ύϣϭ ΔΑϮσήϟϭ έΎΒϐϟϭ ΔΑήΗϸϟ ΡΎϤδϟ ϡΪϋ ϰϠϋ ιήΣ

.ϪϠΧΩ ϪΑΎη

.ϲϣΎϣϷ ˯Ύτϐϟ Ϧϣ ϱϮϠόϟ ˯ΰΠϟ Ϧϣ ίΎϬΠϟ ϞϤΣ ϰϠϋ ιήΣ

.(1 ϞϜθϟ ϊΟέ) ϲϣΎϣϷ ˯Ύτϐϟ ΝήΧ· ΐϨΠΗ

.ϊτϘϟ ˯ΎϨΛ ΔϋϮτϘϤϟ ΓΩΎϤϟ ϰϠϋ ΓΪϋΎϘϟΎΑ ςϐο ˬϡΪΨΘγϻ ˯ΎϨΛ

ϰϠϋ ςϐπϟ ϢΘϳ Ϣϟ Ύϣ έΎθϨϤϟ Γήϔη ϒϠΗ ϰϟ· ίΰΘϫϻ ϱΩΆϳ ΪϘϓ

.ΎϬϴϠϋ ΓΪϋΎϘϟ ΖϴΒΜΗϭ ΔϋϮτϘϤϟ ΓΩΎϤϟ

ϊϣ ϥΎϴΣϷ ξόΑ ϲϓ έΎθϨϤϟ Γήϔη βϣϼΘΗ Ϊϗ ˬϚϟΫ ϰϠϋ Γϭϼϋ

.Γήϔθϟ ϒϠΗ ϰϟ· ϱΩΆϳ ΎϤϣ ˬΏϮΒϧϸϟ ϲϠΧΪϟ έΪΠϟ

17

ϞϜθϟϭ 15 ϞϜθϟ ήψϧ) ΎϬότϗ

ϪΑΎη Ύϣ ϭ ΓήϴΒϛ ΔϴΒθΧ Δότϗ ϭ ϢΨο ΏϮΒϧ ϊτϗ ϱΩΆϳ Ϊϗ

.(

18

.(

ϞϜθϟϭ 16 ϞϜθϟ)

.έΎθϨϤϟ Γήϔη Δϋήγ

ΔϴϧΪόϤϟ ΩϮϤϟ ϊτϗ

.ϡΎϜΣΈΑ ΎϬότϗ ΩήϤϟ ΔότϘϟ ϰϠϋ ΓΪϋΎϘϟΎΑ ςϐο

19

ϞϜθϟ) ϞϴϐθΘϟ ϞΒϗ ϡΎϜΣΈΑ ΎϬότϗ ΩήϤϟ ΓΩΎϤϟ ςΑέ

.(

.έϮϔϟ ϰϠϋ Γήϔθϟ ήδϛ ϰϟ· ϚϟΫ ϱΩΆϳ

ΕϮϳί) ϢϼϤϟ ίΎϬΠϟ Ζϳί ϡΪΨΘγ ˬΔϴϧΪόϤϟ ΩϮϤϟ ϊτϗ ΪϨϋ

.ΎϬότϗ ΩήϤϟ ΔότϘϟ ϕϮϓ ϢΤθϟ

.ίΎϬΠϟ

.ΎϬϣΪΨΘδΗ ϲΘϟ ΩϮϤϟϭ

Ϣϗϭ ΡΎΘϔϤϟ ϞϴϐθΗ ϑΎϘϳ· Ϧϣ Ϊϛ΄Θϟ ϰϠϋ ιήΣ ˬΙΩϮΣ ϱϷ Ύ˱ϳΩΎϔΗ

.ΔϴΎΑήϬϜϟ ΔϗΎτϟ ϚϠγ ωΰϨΑ

ϲϓ ΔΤοϮϤϟ ϢϬδϟ Δϣϼϋ ϩΎΠΗ ϲϓ ωέάϟ ϰϠϋ ςϐπϟ ΪόΑ

ΎϫΪόΑ Γήϔθϟ ςϘδΗ .ϞϔγϷ ΔϬΟϮϣ ϥϮϜΗ ϰΘΣ Γήϔθϟ έΩ ˬ2 ϞϜθϟ

.ϙΪϴΑ ΎϬΒΤγ ˬΓήϔθϟ ρϮϘγ ϡΪϋ ΔϟΎΣ ϲϓϭ .Ύ˱ϴΎϘϠΗ

ϥϮϜΗ ΚϴΣ .ΓήηΎΒϣ ϡΪΨΘγϻ ΪόΑ έΎθϨϤϟ Γήϔη βϤϟ Ύ˱ϣΎϤΗ ΐϨΠΗ

.ϕϭήΤΑ ϚΒϴμΗ Ϊϗϭ ΓέήΤϟ ΔόϔΗήϣ

Γήϔθϟ ήδϜϨΗ ΎϣΪϨϋ

ϲϓ ήϴϐμϟ ϖθϟ ϞΧΩ ΖϠχϭ ήδϜϠϟ Γήϔθϟ ΖοήόΗ Ϯϟ ϰΘΣ

Δϣϼϋ ϩΎΠΗ ϲϓ ωέάϟ ϰϠϋ Ζτϐο ϥ· Ύϣ ςϘδΗ ΎϬϧΈϓ ˬβΒϜϤϟ

Γήϔθϟ ρϮϘγ ϡΪϋ ΔϟΎΣ ϲϓϭ .ϞϔγϷ Γήϔθϟ ϪϴΟϮΘΑ ΖϤϗϭ ˬϢϬδϟ

ϪϴΒϨΗ

○

.ϩΎϧΩ ΔΤοϮϤϟ Ε˯ήΟϹ ωΎΒΗΎΑ ΎϬΟήΧΈΑ Ϣϗ ˬΎ˱ϴΎϘϠΗ

Ϧϣ ήϴϐμϟ ϖθϟ ϲϓ ΓέϮδϜϤϟ Γήϔθϟ Ϧϣ ˯ΰΟ

.βΒϜϤϟ Ϧϣ Γήϔθϟ ΝήΨΘϟ ίέΎΒϟ ˯ΰΠϟ ΐΤγ ˬβΒϜϤϟ

έΎθΤϧ ΔϟΎΣ ϲϓ

ΖϴΒΜΘΑ Ϣϗ ˬήϴϐμϟ ϖθϟ ϞΧΩ ΓέϮδϜϤϟ Γήϔθϟ ˯ΎϔΘΧ ΔϟΎΣ ϲϓ

ΝέΎΨϠϟ ΎϬΒΤγϭ ϯήΧϷ Γήϔθϟ ϑήσ ϡΪΨΘγΎΑ ΓέϮδϜϤϟ Γήϔθϟ

○

έΎθϨϤϟ Γήϔη ΔϣΎϋΩ κΤϓϭ ΔϧΎϴλ

ϰϟ· Ύϣϭ ΔΑϮσήϟϭ ϝΎϣήϟϭ έΎΒϐϟϭ ΔΑήΗϷ έΎΛ ϝί ˬϡΪΨΘγϻ ΪόΑ

Δγϼγ ϦϤπΘϟ ˬϪΑΎη Ύϣϭ ΓΎηήϔΑ ϪΤδϤΑ ϭ ϪΘϳϮϬΘΑ έΎθϨϤϟ Ϧϋ ϚϟΫ

.Γήϔθϟ ΔϣΎϋΩ ϞϤϋ

Γήϔθϟ ξΒϘϣ ϝϮΣ ϢϴΤθΘϟ ˯ήΟΈΑ Ϣϗ ˬ

.ϚϟΫ ϰϟ· Ύϣϭ ˬϊτϘϟ ϞΎγ ϡΪΨΘγΎΑ ΔϳέϭΩ βγ ϰϠϋ

ϪϴΒϨΗ

○

○

○

○

ϲΘϟ ΔϘτϨϤϟ ϢϴΤθΗϭ ϒϴψϨΗ ϥϭΩ ΓΩϷ ϡΪΨΘγ έήϤΘγ ϱΩΆϳ

ΔΠϴΘϧ Ίθϟ ξόΑ ωέάϟ ΔϛήΣ ˯ΎΨΗέ ϰϟ· ΎϬϴϓ Γήϔθϟ ΐϴϛήΗ ϢΘϳ

ϩάϫ ϲϓ .έΎθϨϤϟ ϡΪΨΘγ ΪόΑ ΔϋϮτϘϤϟ ϖΎϗήϟϭ ΔΑήΗϷ ϢϛήΘϟ

Δϣϼϋ ϩΎΠΗ ϲϓ ωέάϟ ϰϠϋ ΩϮΟϮϤϟ ϲσΎτϤϟ ˯Ύτϐϟ ΐΤγ ˬΔϟΎΤϟ

ωέάϟ Ϧϣ ˯Ύτϐϟ ΝήΧ ϢΛ 9 ϞϜθϟ ϲϓ οϮϣ Ϯϫ ΎϤϛ ϢϬδϟ

ΪόΑ .

ϪΑΎη Ύϣ ϭ ϪΘϳϮϬΘΑ Γήϔθϟ ξΒϘϣ Ϧϣ ϲϠΧΪϟ ˯ΰΠϟ ϒϴψϨΘΑ Ϣϗ ˬϚϟΫ

ϞΧΪϳ ϰΘΣ ϡΎϜΣΈΑ ϪϴϠϋ ςϐπϟ ϢΗ ϥ· Ύϣ ϲσΎτϤϟ ˯Ύτϐϟ ΖϴΒΜΗ ϦϜϤϳ

ξΒϘϣ ϦϴΑ ιϮϠΧ ΩϮΟϭ ϡΪϋ Ϧϣ Ϊϛ΄Η ˬΔψΤϠϟ ϩάϫ ϲϓ .ωέάϟ ϲϓ

ΔϘτϨϤϟ ϞϤϋ

Δγϼγ Ϧϣ Ϛϟάϛ Ϊϛ΄Η ϢΛ ˬϲσΎτϤϟ ˯Ύτϐϟϭ Γήϔθϟ

8

ϞϜθϟ ϲϓ οϮϣ Ϯϫ ΎϤϛ

.ΔΒγΎϨϤϟ ϢϴΤθΘϟ ΕϮτΧ ˯ήΟΈΑ Ϣϗ ϢΛ

.έΎθϨϤϟ Γήϔη ΎϬΑ ΐϛήϤϟ

ϰϟ· ϚϟΫ ϱΩΆϴγ ϻ·ϭ .ΔϠϛΘϣ ΔΤΘϔΑ έΎθϨϣ Γήϔη Δϳ ϡΪΨΘγ ΐϨΠΗ

○

10

ϞϜθϟ) ΔϴμΨθϟ ΔΑΎλϹ ϲϓ ΐΒδΘϳ ΎϤϣ Γήϔθϟ ΖϴΒΜΗ ϡΪϋ

.(

.11 ϞϜθϟ ϲϓ οϮϣ Ϯϫ ΎϤϛ ϰϠϋϷ ϲϣΎϣϷ ˯Ύτϐϟ ϊϓέ

ˬϲγΪγ ςϳήη ςΑέ ΡΎΘϔϣ ϝϼΧ Ϧϣ ΓΪϋΎϘϟ ΩΪϋ· έΎϤδϣ ˯ΎΧέ· ϢΗ Ϋ·

.(13 ϞϜθϟϭ ˬ12 ϞϜθϟ) ΓΪϋΎϘϟ ΐϴϛήΗ ϊοϭ ςΒο ϚϨϜϤϴϓ

ΓΪϋΎϘϟ ΩΪϋ· έΎϤδϣ ςΑέ ϡΎϜΣΈΑ ϢϘϓ ˬΓΪϋΎϘϟ ΐϴϛήΗ ϊοϭ ςΒο ΪόΑ

○

ςΒο Ϧϣ ϞόΠΗ ΔΠϣΪϣ ΔϴΑήϬϛ ϢϜΤΗ ΓήΩ ΓΪΣϮϟ ϩάϬΑ ΪΟϮϳ

ϞϳϮΤΗ ϭ ΡΎΘϔϤϟ ΡΪϘϣ ΐΤδΑ έΎθϨϤϟ Γήϔθϟ ΓΩΪόΘϤϟ ΕΎϋήδϟ

ΪΑ .Γήϔθϟ Δϋήγ ΩΩΰΗ ϑϮδϓ ˬϞΧΪϠϟ ΡΎΘϔϤϟ ΐΤδΑ ΖϤϗ Ϋ·

ιΎΨϟ ϑΪϬΘδϤϟ ϊτϘϟ ϊοϭ ΔϗΩ ϥΎϤπϟ ΔπϔΨϨϣ ΕΎϋήδΑ ϊτϘϟ

ϪϴΒϨΗ

1

○

○

.ϊτϘϟ Δϋήγ ΓΩΎϳΰΑ ϢϘϓ ˬ˳ϑΎϛ ϊτϗ ϖϤϋ ϰϠϋ ϞμΤΗ ϥ ΩήΠϤΑ .ϚΑ

.Δϋήγ Ϟϗ ϲϫ

(1)

ΐγΎϨΗ ΎϤϨϴΑ ˬΐθΨϟ ϞΜϣ ΔϤϋΎϨϟ ΩϮϤϠϟ ΓΩΎϋ ΔΒγΎϨϣ ΔϴϟΎόϟ Δϋήδϟ

(2)

ϡΪΨΘγΎΑ ϚϴλϮϧ .ϥΪόϤϟ ϞΜϣ ΔΒϠμϟ ΩϮϤϟ ΔπϔΨϨϤϟ Δϋήδϟ

.ϲγΪγ ςϳήη ςΑέ ΡΎΘϔϣ ϝϼΧ Ϧϣ Ύ˱ϣΎϤΗ

Γήϔθϟ ΩΩήΗ Δϋήγ ςΒο

(14 ϞϜθϟ) .ιήϘϟ

"1"

ϭ ˬΔϋήγ ϰμϗ ϲϫ

"5"

ˬιήϘϟ αΎϴϘϣ ϰϠϋ

ϡϮϘΗ ϲΘϟ ΩϮϤϠϟ ΔΒγΎϨϤϟ Δϋήδϟ ΪϳΪΤΗ ΪϨϋ ϲΒϳήϘΗ ϞϴϟΪϛ ϲϠϳ Ύϣ

ϪϴΒϨΗ

(3)

ۯ

ϪϴΒϨΗ

ϪϴΒϨΗ

.(7 ϞϜθϟ)

ΔψΣϼϣ

ϪϴΒϨΗ

ΓΪϋΎϘϟ ςΒο

.ΎϬότϘΑ

(2)

(1)

(2)

(1)

(2)

(1)

(2)

(3)

(1)

(2)

6

7

24

Page 26

έΎθϨϤϟ ϝΩΎΒΘϳ ϡΪΨΘγ ΪϨϋ Δϣίϼϟ ΕΎσΎϴΘΣϻ

Ϧϣ Ϊϛ΄Η ˬΕΎϴοέϷ ϭ ϒϘγϷϭ ˬςΎΤϟ ϲϓ ήϔΤϟ ΕΎϴϠϤόΑ ϡϮϘΗ ϥ ϞΒϗ

.ϞΧΪϟΎΑ ΕϼλϮϣ ϭ ΔϴΎΑήϬϛ ΕϼΑΎϛ ΩϮΟϭ ϡΪϋ

ΕΎϔλϮϤϟ

240

ˬΖϟϮϓ

230

220

ˬΖϟϮϓ

130

ϲΟέΎΧ ήτϗ : ωϭΎτϣ ΐϠλ ΏϮΒϧ

Ϣϣ

130

Ϣϣ

ϲΟέΎΧ ήτϗ : ϞϴϨϴϔϟ ΪϳέϮϠϛ ΏϮΒϧ

Ϣϣ

Ϣϣ

127

ˬΖϟϮϓ

1010

300

ϖϤόϟ :ΐθΨϟ

19

ϚϤγ : ωϭΎτϣ ΐϠλ ΡϮϟ

2800 – 0

29

3.3

ϢΠϛ

ˬΖϟϮϓ

120

ˬΖϟϮϓ

.ΔϘτϨϤϟ ΐδΣ ήϴϴϐΘϠϟ Δοή˵ϋ ΎϬϧ ΚϴΣ ΞΘϨϤϟ ϰϠϋ ΓΩϮΟϮϤϟ Ϣγϻ ΔΣϮϟ κΤϓ Ϧϣ Ϊϛ΄Η *

ϞϴϐθΘϟ ϞΒϗ

ΕΎΒϠτΘϤϟ ϖΑΎτϣ ϪϣΪΨΘγ ϢΘϴγ ϱάϟ ΔϗΎτϟ έΪμϣ ϥ Ϧϣ Ϊϛ΄Η

.ΞΘϨϤϟ ϰϠϋ ΓΩϮΟϮϤϟ Ϣγϻ ΔΣϮϟ ϰϠϋ ΓΩΪΤϤϟ ΔϗΎτϟ

βΑΎϘϟ ϞϴλϮΗ ΔϟΎΣ ϲϓ .ϑΎϘϳ· ϊοϮϟ ϰϠϋ ΔϗΎτϟ ΡΎΘϔϣ ϥ Ϧϣ Ϊϛ΄Η

ΓΩ ϞϴϐθΗ ϢΘϴδϓ ˬϞϴϐθΗ ϊοϮϟ ϰϠϋ ΔϗΎτϟ ΡΎΘϔϣ ϥΎϛϭ βΒϘϤϟΎΑ

.ήϴτΧ ΙΩΎΣ ωϮϗϭ ϰϟ· ϱΩΆϳ Ϊϗ ΎϤϣ ˬέϮϔϟ ϰϠϋ ΔϗΎτϟ

ϞϴλϮΗ ϚϠγ ϡΪΨΘγ ˬΔϗΎτϟ έΪμϣ Ϧϣ ϞϤόϟ ΔϘτϨϣ Δϟί· ΪϨϋ

ϞϴλϮΘϟ ϚϠγ Ϟψϳ ϥ ΐΠϳ .ΔϨϨϘϣ Δόγϭ ˳ϑΎϛ ϚϤγ ϭΫ ϲϓΎο·

.ωΎτΘδϤϟ έΪϘΑ ˱ήϴμϗ ϲϓΎοϹ

έΎθϨϤϟ Εήϔη ΐϴϛήΗ Ϧϣ ϦϜ˷ϤΗ ϚϔϠϟ ΔϠΑΎϗ Δϴϟ ΓΪΣϮϟ ϩάϫ ϡΪΨΘδΗ

.ΕϭΩϷ Ϧϣ ϩήϴϏ ϭ ςΑέ ΡΎΘϔϤΑ ΔϧΎόΘγϻ ϥϭΩ ΎϬΟήΧ·ϭ

ωέάϟ ΝήΨϳ ϰΘΣ Εήϣ ΓΪϋ ϞϳΪΒΘϟ ΡΎΘϔϣ ϞϴϐθΗ ϑΎϘϳ·ϭ ϞϴϐθΘΑ Ϣϗ

Ϣϗϭ ΡΎΘϔϤϟ ϞϴϐθΗ ϑΎϘϳΈΑ Ϣϗ ˬϚϟΫ ΪόΑ .ϞϣΎϜϟΎΑ ϲϣΎϣϷ ˯Ύτϐϟ Ϧϣ

.(1 ϞϜθϟ) ΔϴΎΑήϬϜϟ ΔϗΎτϟ ϚϠγ ωΰϨΑ

Ϣϗϭ ΡΎΘϔϤϟ ϞϴϐθΗ ϑΎϘϳ· Ϧϣ Ϊϛ΄Θϟ ϰϠϋ ιήΣ ˬΙΩϮΣ ϱϷ Ύ˱ϳΩΎϔΗ

2

ϞϜθϟ ϲϓ ΔΤοϮϤϟ ϢϬδϟ Δϣϼϋ ϩΎΠΗ ϲϓ ωέάϟ ϰϠϋ ςϐο

βΒϜϤϟ ϑήσ Ϧϣ ήϴϐμϟ ϖθϟ ϲϓ ϞϣΎϜϟΎΑ έΎθϨϤϟ Γήϔη ϞΧΩ

ϭ ϰϠϋϷ ˱˯Ϯγ Γήϔθϟ ϩάϫ ΐϴϛήΗ ϚϨϜϤϳ .ωέάϟ ϰϠϋ ςϐπϟΎΑ

.ΔϴΎΑήϬϜϟ ΔϗΎτϟ ϚϠγ ωΰϨΑ

.(2 ϞϜθϟ) ωέάϟ ϰϠϋ ΓΩϮΟϮϤϟ

4

.(

ϞϜθϟϭ 3 ϞϜθϟ) ϞϔγϷ

ϊοϮϟ ϰϟ· ϞϣΎΤϟ ΔΒϠΟ ξΑΎϨϟ ΓϮϗ ΩήΗ ˬωέάϟ ήϳήΤΘΑ ϡϮϘΗ ΎϣΪϨϋ

.(5 ϞϜθϟ) Ύ˱ϴΎϘϠΗ ϴΤμϟ

ϡΎϜΣ· Ϧϣ ϖϘΤΗϭ ΙϼΛ ϭ ϦϴΗήϣ ϒϠΨϠϟ έΎθϨϤϟ Γήϔη ϙΪϴΑ ΐΤγ

ΔϟΎΣ ϲϓ ΎϬΒϴϛήΗ Δϣϼγ Ϧϣ ϖϘΤΘΘγ ˬΓήϔθϟ ΐΤγ ΪϨϋ .ΎϬΒϴϛήΗ

6

.(

ϞϜθϟ) ϒτϠΑ ωέάϟ ϙήΤΗϭ ήϘϧ ΕϮλ ωΎϤγ

.ϒϠΨϟ Ϧϣ ΎϬΒΤγ Ϧϣ Ϊϛ΄Θϟ ϰϠϋ ιήΣ ˬέΎθϨϤϟ Γήϔη ΐΤγ ΪϨϋ

.ΔΑΎλϺϟ ιήόΘϟ ϰϟ· ϯήΧ ˯ΰΟ Ϧϣ ΎϬΒΤγ ϱΩΆϳ ΪϘϓ

ωέάϟ ΝήΨϳ ϰΘΣ Εήϣ ΓΪϋ ϞϳΪΒΘϟ ΡΎΘϔϣ ϞϴϐθΗ ϑΎϘϳ·ϭ ϞϴϐθΘΑ Ϣϗ

Ϣϗϭ ΡΎΘϔϤϟ ϞϴϐθΗ ϑΎϘϳΈΑ Ϣϗ ˬϚϟΫ ΪόΑ .ϞϣΎϜϟΎΑ ϲϣΎϣϷ ˯Ύτϐϟ Ϧϣ

1

.(

ϞϜθϟ) ΔϴΎΑήϬϜϟ ΔϗΎτϟ ϚϠγ ωΰϨΑ

ΔϗΎτϟ έΪμϣ

ΔϗΎτϟ ΡΎΘϔϣ

ϲϓΎοϹ ϞϴλϮΘϟ ϚϠγ

Γήϔθϟ ΐϴϛήΗ

ϪϴΒϨΗ

ϪϴΒϨΗ

Γήϔθϟ Ϛϓ

(1)

(2)

(3)

(4)

(5)

(1)

115

ˬΖϟϮϓ

110

)

*(ϖσΎϨϤϟ ΐδΣ) ϲΑήϬϜϟ ΪϬΠϟ (ΖϟϮϓ

ϞϤΣ ϥϭΪΑ ΔϋήδϟΔϘϴϗΩ /

(ϚϠδϟ ϥϭΪΑ) ϥίϮϟ

ΔϴγΎϴϗ ΕΎϘΤϠϣ

1

1

....................................................... (

1

.................................................................... ΔΒϠόϟ

1

..............................................ϲγΪγ ςϳήη ςΑέ ΡΎΘϔϣ

2

3

4

ΐϴΑΎϧϸϟ ϊτϘϟ ϞϴϟΩ

(Δϋήδϟ ϲϟΎϋ ϲϧϮΑήϛ ΐϠλ :

.έΎτΧ· ϥϭΩ ΔϴγΎϴϘϟ ΕΎϘϠΤϤϟ ήϴϴϐΗ ϦϜϤϳ

(ΔϠμϔϨϣ ωΎΒ˵Η) ΔϳέΎϴΘΧ ΕΎϘΤϠϣ

103

104

105

106

107

108

121

131

132

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Bl-METAL

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21) 101

HCS) HCS

.Εήϔθϟ ϡΪΨΘγΎΑ ΔλΎΨϟ 3ϭ

.έΎτΧ· ϥϭΩ ΔϳέΎϴΘΧϻ ΕΎϘϠΤϤϟ ήϴϴϐΗ ϦϜϤϳ

.ΔΒϠμϟ ΐϧϮΠϟϭ ΐϴΑΎϧϷ ϊτϗ

.αΎΤϨϟ ΡϮϟϭ ϡϮϴϨϣϮϟϷ ΡϮϟϭ ωϭΎτϤϟ ΐϠμϟ ΡϮϟ ϊτϗ

.ΓέϮθϨϤϟ ΏΎθΧϷ ωϮϧ ϰΘη ϊτϗ

.ϞϴϨϴϔϟ ΪϳέϮϠϛϭ ϝϮϨϴϔϟ ϦΪϟ ϞΜϣ ˬΔϴϋΎϨτλϻ ϦΪϠϟ ϊτϗ

."Εήϔθϟ ΪϳΪΤΗ" ϥϮϨϋ ϞϤΤϳ ϱάϟ ϢδϘϟ ϊΟέ ˬϞϴλΎϔΘϟ ϰϠϋ ωϼσϼϟ

5

95 Ϣϗέ Γήϔη

96 Ϣϗέ Γήϔη

102

Εήϔη :

Εήϔη :

103

1 Ϣϗέ Γήϔη

2 Ϣϗέ Γήϔη

3 Ϣϗέ Γήϔη

4 Ϣϗέ Γήϔη

5 Ϣϗέ Γήϔη

8 Ϣϗέ Γήϔη

9 Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

Ϣϗέ Γήϔη

(20) – (10)

2 ˬ1

ΔϗΎτϟ ϝΎΧΩ·*Εϭ

Δόδϟ

ρϮηϢϣ

Ϣϗέ) Γήϔη

Εήϔθϟ

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(9) – (1)

ϝϭΪΠϟ ϊΟέ

ΕΎϘϴΒτΗ

(1)

(2)

(3)

○

○

○

○

○

○

25

ۮ

Page 27

.ΔϴΎΑήϬϜϟ ΓΪόϟ ϞϴϐθΗ ϞΒϗ ςΑήϟ ΡΎΘϔϣ ϭ ςΒπϟ ΩΪϋ ωΰϧ (Ι

Ϧϣ ϙήΤΘϤϟ ˯ΰΠϟ έΎδϳ ϰϠϋ ςΒο ΡΎΘϔϣ ϭ ςΑέ ΡΎΘϔϣ ΩϮΟϭ

.ΔϴμΨη ΔΑΎλ· ΙϭΪΣ ϰϟ· ϱΩΆϳ ΔϴΎΑήϬϜϟ ΓΪόϟ

ϦϴΑϭ ϚϨϴΑ ΔΒγΎϨϣ ΔϓΎδϣ ϙήΗ ˬΔϴΎΑήϬϜϟ ΓΪόϟ Ϧϣ ΏήΘϘΗ ϻ (Ν

.ΕΎϗϭϷ ϊϴϤΟ ϲϓ ϚϧίϮΗ ϰϠϋ φϓΎΣϭ ΔϴΎΑήϬϜϟ ΓΪόϟ

ϲϓ Ϟπϓ ϞϜθΑ ίΎϬΠϟ ϰϠϋ Γήτϴδϟ Ϧϣ ϚϟΫ Ϛϟ Ϥδϴγ

.ΔόϗϮΘϤϟ ήϴϏ ϒϗϮϤϟ

ΎϬΑ ϭ ΔοΎϔπϓ βΑϼϣ ϱΪΗήΗ ϻ ˬΔΒγΎϨϣ βΑϼϣ ˯ΪΗέΎΑ Ϣϗ (Ρ

βΑϼϤϟϭ ϙήόη ΩΎόΑ· ϰϠϋ ˱ΎϤΩ φϓΎΣϭ ˬϲϠΣ ϭ ΔΒΎγ ϑήσ

ΓΪόϟ Ϧϣ ΔϛήΤΘϤϟ ˯ΰΟϷ Ϧϋ ˱ΪϴόΑ ίΎϔϘϟϭ ΎϬϳΪΗήΗ ϲΘϟ

ϲϠΤϟ ϭ ϑήσ ΎϬΑ ϲΘϟ ϭ ΔοΎϔπϔϟ βΑϼϤϟ ϚΒηΎΘΗ Ϊϗ

.ΔϴΎΑήϬϜϟ

.ΏΎϘΜϤϠϟ ΔϛήΤΘϤϟ ˯ΰΟϷΎΑ ϞϳϮτϟ ήόθϟϭ

ϢΘϳϭ ΔϠμΘϣ Ϧϣ Ϊϛ΄Θϓ .έΎΒϐϟ ϊϴϤΠΗϭ ςϔη ίΎϬΟ ΐϴϛήΗ ίΎΟ ϥ· (Υ

ǍŶƾƥȚ ǚƸƴƲů ǟŽȘ ȜǎƷűLjȚ ȵnjƀ ȳȚNjƈƄŴȚ ȸȢƻƁ ȴȖ ǜƳƵƓȚ ǜž

.ϢϴϠγ ϞϜθΑ ΎϬϣΪΨΘγ

.ȤƾƃưŽƾŮ ǀƲƴƯƄƓȚ

:ΎϬΑ ΔϳΎϨόϟϭ ΔϴΎΑήϬϜϟ ΓΪόϟ ϡΪΨΘγ ΔϘϳήσ (

ΔϴΎΑήϬϜϟ ΓΪόϟ ϡΪΨΘγϭ ˬΔϴΎΑήϬϜϟ ΓΪόϟ ϡΪΨΘγ ϲϓ ρήϔΗ ϻ (

ϙΪϋΎδϳ άϫ ϥΈϓ Ϛϟάϟ ΔμμΨϤϟ ΔϴΎΑήϬϜϟ ΓΪόϟ ϚϣΪΨΘγ ΪϨϋ

.ϪΑ ϡϮϘΗ ϱάϟ ϞϤόϠϟ ΔΒγΎϨϤϟ

ϢΗ ϲΘϟ ΔϤϬϤϠϟ ˱ΎόΒΗ ˱ΎϨϣ ήΜϛϭ Ϟπϓ ΔΠϴΘϧ ϰϠϋ ϝϮμΤϟ ϰϠϋ

.ΎϬϟ ΏΎϘΜϤϟ ϢϴϤμΗ

ΓΪόϟ ϡΪΨΘδΗ ϻ ϞϤόϟ Ϧϋ ϞϴϐθΘϟ ΡΎΘϔϣ ϞτόΗ ΔϟΎΣ ϲϓ (Ώ

.ΔϴΎΑήϬϜϟ

ΎϬΑ ιΎΨϟ ϞϴϐθΘϟ ΡΎΘϔϣ ϲϓ ϢϜΤΘϟ ϦϜϤϳ ϻ ΔϴΎΑήϬϛ ΓΪϋ ϱ

.ΡΎΘϔϤϟ άϫ Ρϼλ· ΐΠϳϭ ΎϬϣΪΨΘγ ΪϨϋ ˱ήτΧ ϞϜθΗ ΎϬϧΈϓ

ϭ ΕϼϳΪόΗ ϱ ˯ήΟ· ϞΒϗ ΔϗΎτϟ έΪμϣ Ϧϋ βΑΎϘϟ ϞμϔΑ Ϣϗ (Ε

.ΔϗΎτϟ ΕϭΩ ϦϳΰΨΗ ϭ ΕΎϘΤϠϤϟ ήϴϴϐΗ

ήϴϏ ϞϜθΑ ΔϴΎΑήϬϜϟ ΓΪόϟ ϞϴϐθΗ ϩάϫ ρΎϴΘΣϻ Ε˯ήΟ· ϊϨϤΗ

.ΩϮμϘϣ

ϝϭΎϨΘϣ Ϧϋ ˱ΪϴόΑ ΔϣΪΨΘδϣ ήϴϐϟ ΔϴΎΑήϬϜϟ ΩΪόϟ ϦϳΰΨΘΑ Ϣϗ (Ι

ϞϴϐθΗ Ϧϋ ΓήϜϓ ϪϳΪϟ βϴϟ κΨη ϱϷ ϤδΗ ϻϭ ϝΎϔσϷ

.ΎϬϠϴϐθΗ ϭ ΕϭΩϷ ϩάϫ Ϧϣ ΏήΘϗϻΎΑ ΏΎϘΜϤϟ

ϦϴΑέΪϣ ήϴϐϟ ιΎΨηϷ ϱΪϳ ϲϓ ΓέϮτΧ ϞΜϤΗ ϞϴϐθΘϟ ΕϭΩ

.ΎϬϴϠϋ

ΔϴΣΎϧ Ϧϣ ˱ΪϴΟ ΎϬμΤϔΑ Ϣϗ ˬΔϴΎΑήϬϜϟ ΩΪόϟ Δϣϼγ Ϧϣ Ϊϛ΄Η (Ν

˯ΰΟ ϱ ϲϓ ήδϛ ϱ ΩϮΟϭ ϭ ΔϛήΤΘϤϟ ˯ΰΟϷ ςΑήΗ ϯΪϣ

ϞΒϗ ΎϬΣϼλ· ΐΠϳ ϞϴϐθΘϟ ΕϭΩ΄Α ϒϠΗ ΙϭΪΣ ΔϟΎΣ ϲϓ

.ΎϬϠϴϐθΗ ϰϠϋ ήΛΆϳ ΎϤΑ ΎϬΰΟ Ϧϣ

.ϡΪΨΘγϻ

ήϴϏ ϞϜθΑ ΔϧΎϴμϟ ΔϴϠϤόΑ ϡΎϴϘϟ ϭ ϞϴϐθΘϟ ΕϭΩ ΔϧΎϴλ ϡΪϋ

.ΙΩϮΤϟ Ϧϣ ήϴΜϜϟ ΙϭΪΣ ϰϟ· ϱΩΆϳ ϴΤλ

ϞϬδϳ ΚϴΤΑ ϑϮΤϟ ΓΩΎΣ ϊϴτϘΘϟ ΕϭΩ ϰϠϋ υΎϔΤϟ ϰΟήϳ

Δϔϴψϧϭ ΓΩΎΣ ϊϴτϘΘϟ ΕϭΩ ϰϠϋ υΎϔΤϟ ϰΟήϳ (Ρ

.ΎϬϴϓ ϢϜΤΘϟ

ϖϓϮΘϳ ΎϤΑ ˬΦϟ· ϊτϘϟ ϡϼϗϭ ΕΎϘΤϠϤϟϭ ˬΔϗΎτϟ ΓΩ ϡΪΨΘγ (Υ

ΔϗΎτϟ ΓΩ ωϮϨϟ ΔμμΨϤϟ ΔϘϳήτϟΎΑϭ ΕΎϤϴϠόΘϟ ϩάϫ ϊϣ

ΏϮϠτϤϟ ϞϤόϟϭ ϞϤόϟ ϑϭήχ έΎΒΘϋϻ ϲϓ ϊοϮϟ ϊϣ ˬΩΪΤϤϟ

.ϪΑ ϡΎϴϘϟ

ϰϟ· ΎϬϟ ΔμμΨϤϟ ήϴϏ νήϏϸϟ ΔϗΎτϟ ΓΩ ϡΪΨΘγ ϱΩΆϳ Ϊϗ

.ήϴτΧ ϒϗϮϣ ΩϮΟϭ

ΔϣΪΨϟ (

ςϘϓϭ ϦϴμμΨΘϤϟ ϞΒϗ Ϧϣ ςϘϓ ΔϴΎΑήϬϜϟ ϚΗΪϋ ϴϠμΘΑ Ϥγ (

. ςϘϓ ΔϴϠλϷ έΎϴϐϟ ϊτϗ ϝΎϤόΘγΈΑ

.ίΎϬΠϟ ϥΎϣ ϰϠϋ ΔψϓΎΤϤϟ ϚϟΫ ϦϣΆϳ

ΕΎσΎϴΘΣϻ

.Ϧδϟ έΎΒϛϭ ϝΎϔσϷ ϝϭΎϨΘϣ Ϧϋ ˱ΪϴόΑ ΔϴΎΑήϬϜϟ ΓΪόϟ ϊοϭ ϰΟήϳ

Ϧϋ ΓΪϴόΑ ΔϴΎΑήϬϜϟ ΓΪόϟ ϰϠϋ υΎϔΤϟ ΐΠϳ ϡΪΨΘγϻ ϡΪϋ ΔϟΎΣ ϲϓ

.Ϧδϟ έΎΒϛϭ ϝΎϔσϷ ϝϭΎϨΘϣ

ΔϣΎόϟ Δϣϼδϟ ΕΎϤϴϠόΗ

ΔϣΪλ ΙϭΪΣ ϰϟ· ϩΎϧΩ ΔΤοϮϤϟ ΕΎϤϴϠόΘϟ ϩάϬΑ ϡΰΘϟϻ ϡΪϋ ϱΩΆϳ Ϊϗ

.ΓήϴτΧ ΔΑΎλ· ϭ ϖϳήΣ ΏϮθϧ ϭ ΔϴΑήϬϛ

ΔΤοϮϤϟ ΕήϳάΤΘϟ ϊϴϤΟ ϲϓ ΩέϮϟ "ΔϴΎΑήϬϜϟ ΓΪόϟ" ϠτμϤϟ

ΓΪόϟ ϭ ϚΑ ΔλΎΨϟ (ΔϴϜϠδϟ) Δϴδϴήϟ ΔϴΎΑήϬϜϟ ΓΪόϟ ϰϟ· ήϴθϳ ϩΎϧΩ

ΐΒδΘΗ Γ˯Ύπϣ ήϴϐϟ ϞϤόϟ ΕϻΎΠϣϭ ϞϤόϟ ϥΎϜϣ ϲϓ ϰοϮϔϟΎϓ

.ϚϠϐη ϥΎϜϣ Γ˯Ύο· ϦδΣϭ ΔϓΎψϧ ϰϠϋ φϓΎΣ (

ΩϮΟϭ ϲϓ ϱ ΔϳέΎΠϔϧ ˯ϮΟ ϲϓ ΔϴΎΑήϬϜϟ ΩΪόϟ ϞϴϐθΘΑ ϢϘΗ ϻ (Ώ

4

.έΎΒϏ ϭ ϝΎόΘηϼϟ ΔϠΑΎϗ ΕίΎϏ ϭ ϞϮγ