Page 1

en

es

CM 75EAP・CM 75EBP

pt

en

Handling instructions

es

Instrucciones de manejo

pt

Instruções de uso

Page 2

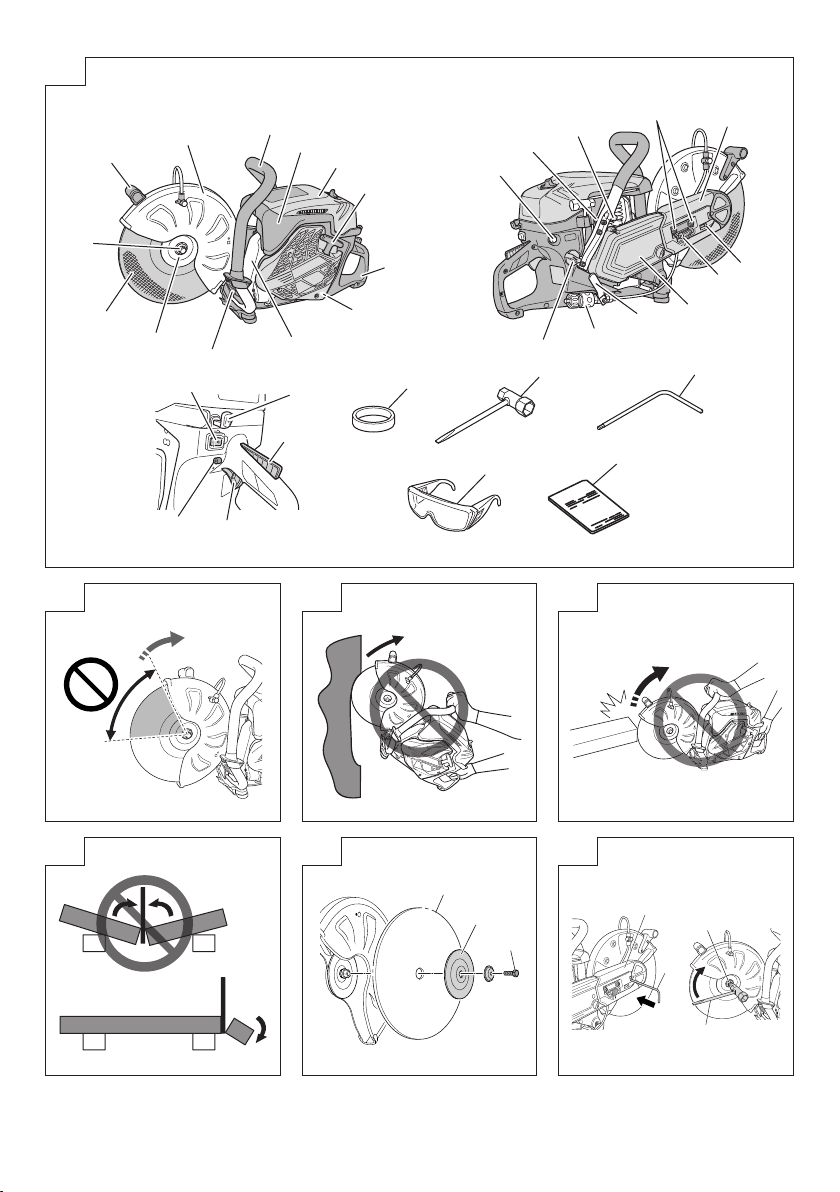

1

R

a

V

O

Z

Q

A

D

G

L

K

F

H

Q

Y

I

C

B

b

J

e

S

Q

E

c

P

X

W

f

N

T

U

M

d

234

567

1

2

3

2

5

3

4

6

Page 3

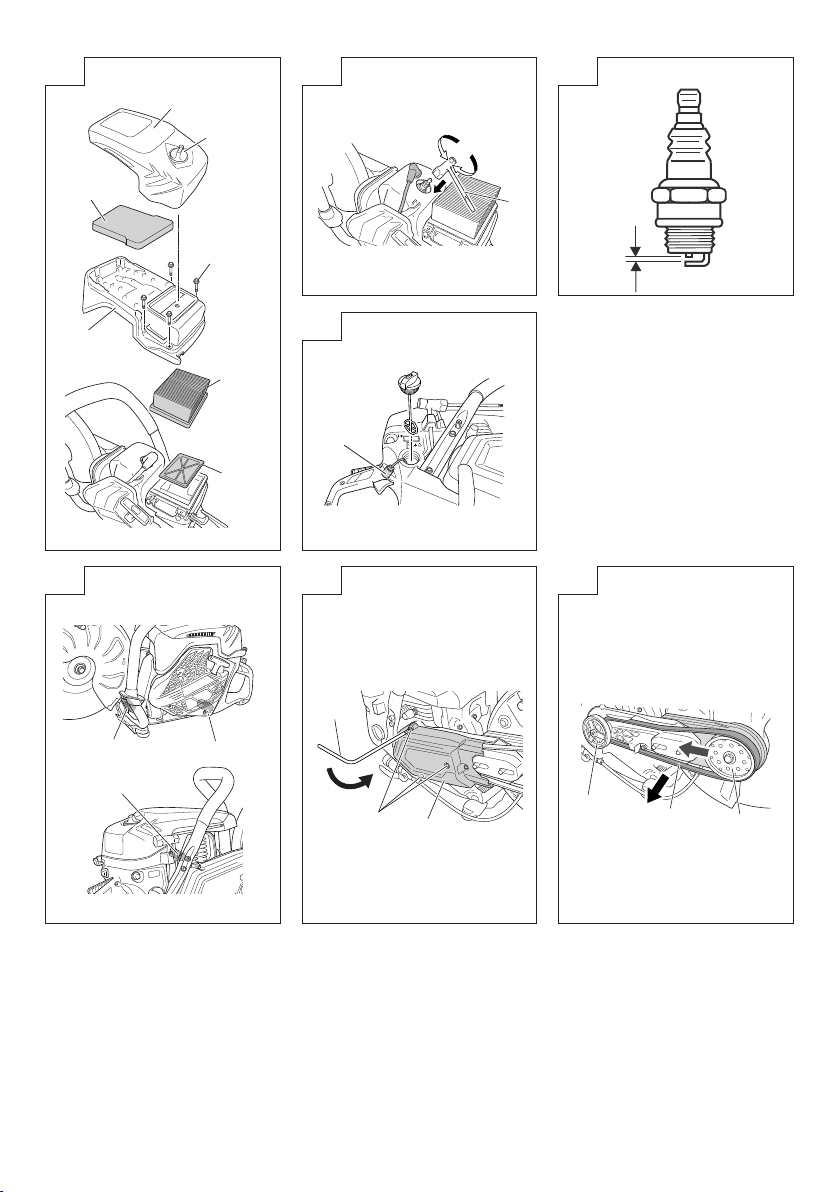

8910

2

3

7

8

11 12 13

9

4

10

6

11

12

13

12

11

14 15 16

15

14

14

17 18 19

17

18

19

3

16

4

6

Page 4

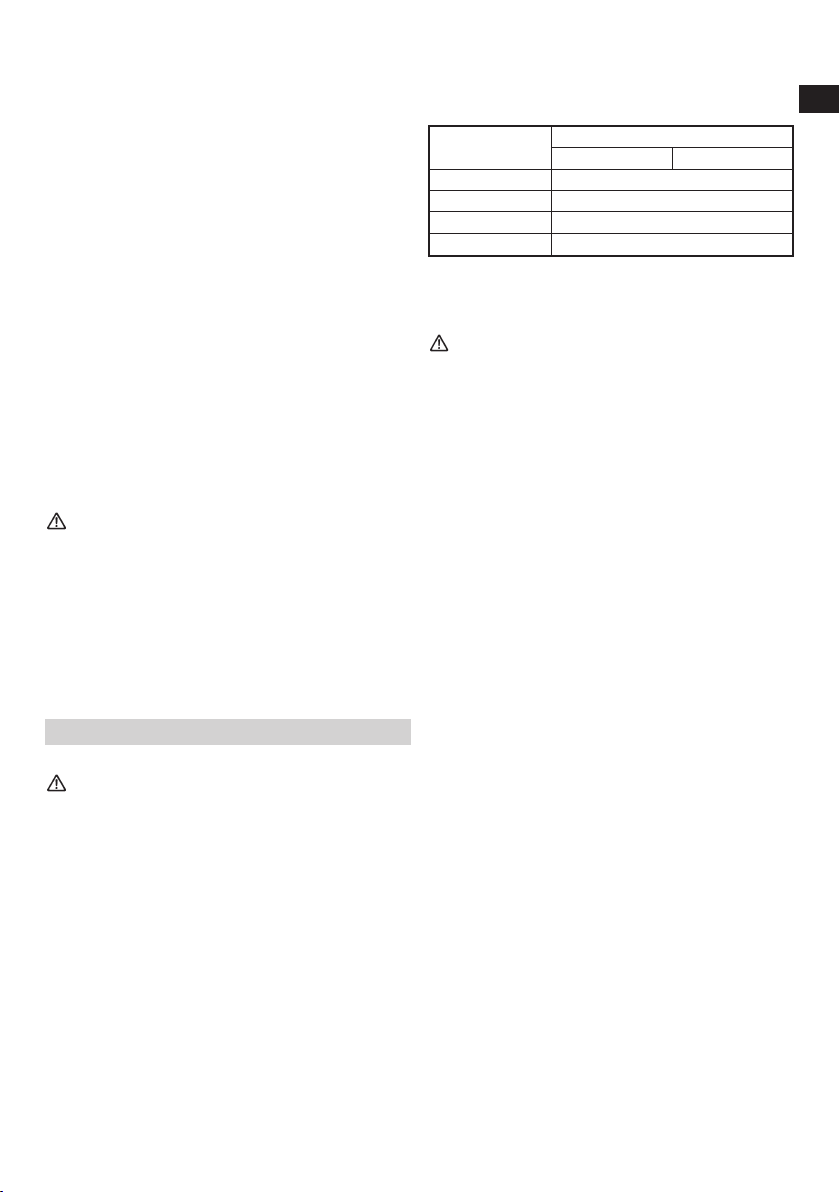

20 21 22

21

25-50

1

20

23 24 25

22

23

26

26 27 28

28

22

21

27

25

24

30

29

29 30

31

4

Page 5

31 32 33

32

33

37

34

38

34

35

39

36

6

0.6 mm

35 36 37

4

40 40

40

41

44

42

5

43

45

Page 6

38 39

40

44

43

43

45

0 mm

10

11

6

Page 7

Pay special attention to statements preceded by the

following words:

WARNING

Indicates a strong possibility of severe personal injury or

loss of life if instructions are not followed.

CAUTION

Indicates a possibility of personal injury or equipment

damage if instructions are not followed.

NOTE

Helpful information for correct function and use.

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the

machine. Be sure that you understand their

meaning before use.

Cutter: Portable cut-off machine

CM75EAP / CM75EBP

It is important that you read, fully understand

and observe the following safety precautions

and warnings. Careless or improper use of

the unit may cause serious or fatal injury.

Read, understand and follow all warnings and

instructions in this manual and on the unit.

Always wear eye, head and ear protectors,

and also dust protection, when using this unit

Choke

On / Start

Off / Stop

Emergency stop

Maximum spindle speed of the machine.

Warning: Do not use wheels that are rated for

speeds lower than the indicated maximum

spindle speed of the machine.

Fire warning! This tool generates sparks when

cutting metal.

Warning! Do not use damaged cut-off wheel.

Rotation direction of cut-off wheel

Cut-off wheel dimensions

English

Fuel and oil mixture

Carburetor adjustment - Idle speed

Carburetor adjustment - Low speed mixture

Carburetor adjustment - High speed mixture

Priming pump

Guaranteed sound power level

8

Decompression valve

Hazardous dust and gas emission warning

Kickback warning

Warning! Never use blades designed for

cutting wood.

WHAT IS WHAT? (Fig. 1)

A: Stop switch: Device for allowing the engine to be started

or stopped.

B: Throttle lever: Device activated by the operatorʼs fi nger,

for controlling the engine speed.

C: Throttle lever lockout: Device that prevents the

accidental operation of the throttle lever until manually

released.

D: Throttle lock: Device for setting the throttle in partially

open position to aid starting.

E: Fuel tank cap: For closing the fuel tank.

F: Starter knob: Pull handle to start the engine.

G: Front handle: Support handle located at or towards the

front of the engine housing.

H: Rear handle: Support handle located at or towards the

rear of the engine housing.

I: Choke lever: Device for enriching the fuel/air mixture in

the carburetor, to aid starting.

J: Priming pump: Device for supplying extra fuel, to aid

starting.

K: Cleaner box (B): Cover for pre-fi lter

L: Cleaner box (A): Cover for paper-fi lter and carburetor.

M: Clutch cover: Device between the engine and the cutting

equipment designed to prevent unintentional contact

with the transmission.

N: Arm cover: Device between the engine and the cutting

equipment designed to prevent unintentional contact

with the transmission.

O: Wheel guard: Cover which is intended to protect the

operator from wheel contact, and also directs debris

away from the operator.

P: Nut: Secures the wheel guard to engine.

7

Page 8

English

Q: Anti-vibration spring: Reduce the transmission of

vibrations to the operator’s hands.

R: Handle(W): Handle for rotating the wheel guard.

S: Decompression valve: Device for reducing the

compression pressure of engine to aid starting.

T: Tensioner bolt: Device to increase and release belt

tension.

U: Tension nut: Mark for indicating the state of tension of

the belt.

V: Cut-off wheel: Bonded abrasive with reinforced resinoid

wheel for cutting, with blotter.

W: Coupler: Device for attaching the hose

X: Valve: Device for adjusting water fl ow rate.

Y: Muffl er: Reduces engine exhaust noise and directs the

exhaust gases.

Z: Wheel washer: Flange provided to clamp and drive the

cut-off wheel.

a: Bolt: Secures the cut-off wheel

b: Adapter collar: Spindle attachment for using arbor hole

25.4mm cut-off wheels.

c: Combi box spanner: Maintenance tool for removing or

installing a spark plug

d: Hex. wrench: Maintenance tool for removing cover and

tensioning the belt.

e: Protective glasses: Eye protection.

f: Handling instructions: Included with unit. Read before

operation and keep for future reference to learn proper,

safe techniques.

WARNINGS AND SAFETY

INSTRUCTIONS

Operator safety

○ Always wear a proper face shield or protective glasses.

○ Gloves should always be worn when operating this

machine and also when touching the cut-off wheel.

○ When using this machine, always wear proper protective

attire such as jacket, trousers, helmet, boots with steel

toe-caps and non-slip soles, and eye, ear, leg protection

equipment whenever you use this machine.

Do not wear loose clothing, jewelry, short pants and/or

sandals, or go barefoot.

○ Never let a child or inexperienced person operate the

machine.

A fi rst-time operator should obtain practical instruction

before using the machine.

○ When you wear hearing protection, pay attention to your

surroundings. Be aware of any bystanders who may be

signaling a problem.

○ Cutting operations can expose you to respiratory

hazards such as silica and other harmful dust particles.

Please wear a protective mask when operating this

machine.

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not grab or hold the machine by the cutting

equipment.

○ Do not smoke or allow smoking near fuel or the machine,

or while using the machine.

○ When the unit is shut off , make sure the cutting

attachment has stopped before setting down the unit.

○ When operation is prolonged, take a break periodically

so that you may avoid possible Hand-Arm Vibration

Syndrome (HAVS) which is caused by vibration.

○ National regulation can restrict the use of machine.

And the operator must obey the local regulations of

working area.

WARNING

○ The machine produces exhaust fumes, which include

hydrocarbons and benzene. When using this machine,

suffi cient ventilation is needed, not only if used indoors

but also when working in trenches, hollows or other

confi ned locations. Breathing exhaust fumes can be

fatal.

○ Do not operate this machine when you are tired, ill or

under the infl uence of alcohol, drugs or medication.

○ Antivibration systems do not guarantee that you will not

sustain Hand-Arm Vibration Syndrome or carpal tunnel

syndrome.

Therefore, continual end regular users should monitor

closely the condition of their hands and fi ngers. If any

of the above symptoms appear, seek medical advice

immediately.

○ Long or continuous exposure to high noise levels may

cause permanent hearing impairment. Always wear

approved hearing protection when operating a machine.

○ If you are using any medical electric/electronic devices

such as a pacemaker, consult your physician as well as

the device manufacturer prior to operating any power

equipment.

Unit / machine safety

○ Inspect the entire machine for any damage before each

use. Check for fuel leaks and make sure all fasteners are

in place and securely tightened.

○ Keep others away when making carburetor adjustments.

○ Use only accessories as recommended for this machine

by the manufacturer.

○ Select and mount the correct cut-off wheel for the type of

work to be carried out.

○ All items, other than the items listed in the operator’s/

owner’s manual, should be performed by HiKOKI

Authorized Service Centers. (For example, if improper

tools are used to remove the fl ywheel or if an improper

tool is used to hold the fl ywheel in order to remove the

clutch, structural damage to the fl ywheel could occur

and could subsequently cause the fl ywheel to burst.)

WARNING

○ Never modify the machine in any way. Do not use your

machine for any job except that for which it is intended.

○ Never use wheels that are rated for speeds lower than

the maximum spindle speed indicated on the machine.

A wheel running faster than its rated speed can break

and fl y apart.

○ The arbor size of wheels and fl anges must properly fi t

the spindle of the machine.

Wheels and fl anges with arbor holes that do not match

the mounting hardware of the machine will run off -

balance, vibrate excessively and may cause loss of

control.

○ It is important to use only cut-off wheels designed for use

on hand-held cut-off machines. It is dangerous to use a

cut-off wheel that is not intended for a hand-held cut-off

machine.

Fuel safety

○ Mix and pour fuel outdoors and where there are no

sparks or fl ames.

○ Use a container approved for fuel.

○ Wipe off all fuel spills and allow any remaining fuel to

evaporate before starting engine.

○ Move at least 3 m away from fueling site before starting

engine.

○ Stop engine and let it cool for a few minutes before

opening fuel tank cap.

○ Store the machine and fuel in area where fuel vapors

cannot reach sparks or open fl ames from water heaters,

electric motors or switches, furnaces, etc.

8

Page 9

WARNING

Fuel is highly fl ammable and its fumes should not be

inhaled. Be particularly careful when handling the

machine as the sparks produced when cutting metal can

easily ignite any fuel spillage.

Cutting safety

○ Keep bystanders at a safe distance, away from the

work area. Anyone entering the work area must wear

personal protective equipment. Flying fragments from

the workpiece or the cut-off wheel may cause injury.

Children, other unauthorized persons and animals must

remain well away from the work area.

○ Hold the machine fi rmly with the right hand on the rear

handle and the left hand on the front handle.

○ Keep fi rm footing and balance. Do not over-reach.

○ Keep all parts of your body away from the muffl er and

cutting attachment when the engine is running.

○ Make sure to check the work area for any hidden

hazards such as water or gas pipes, electrical cables

and fl ammable substances.

○ Never place the machine on the ground when running.

○ Always ensure that the engine is shut off and any cutting

attachments have completely stopped before clearing

debris from the cutting attachment.

○ Always carry a fi rst-aid kit when operating any power

equipment.

○ The muffl er gets very hot during and after use. This also

applies during idling.

Be aware of the fi re hazard, especially when working

near fl ammable substances and/or vapours.

WARNING

○ Exhaust gases from the engine are hot and may contain

sparks which can cause a fi re.

Also, sparks are generated when cutting metal with this

machine.

Never use the machine where fl ammable substances

and gases are present.

○ Sparks generated from cutting operations can cause

fi res. Always have adequate fi re extinguishing equipment

available.

○ When relocating to a new work area, be sure to shut off

the machine and ensure that all cutting attachments are

stopped.

○ Always ensure that the engine is shut off and any cutting

attachments have completely stopped before moving.

Gyroscopic forces occur when moving while the engine

is operating and the cut-off wheel is rotating. This may

cause you to lose control of the machine.

○ Never cut materials that consist of asbestos.

○ Never leave the engine running while unattended

(e.g. on the ground).

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel. Pinching or snagging causes sudden stalling

of the rotating wheel which in turn causes the machine to

be forced in the direction opposite of the wheel's rotation at

the point of the binding. For example, if an abrasive wheel is

snagged or pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the surface of

the material causing the wheel to climb out or kick out. The

wheel may either jump toward or away from the operator,

depending on the direction of the wheel's movement at the

point of pinching. Abrasive wheels may also break under

these conditions.

Either of these reactions may cause you to lose control of the

machine which could result in serious personal injury.

Kickback is the result of cut-off machine misuse and/or

incorrect operating procedures or conditions that can be

avoided by taking proper precautions as given below.

English

○ Kickback occurs when the upper angle of the cut-off

wheel is used or touches an object when the cut-off

wheel is running. Pay special attention not to touch the

upper angle of the cut-off wheel to any object. (Fig. 2,

Fig. 3)

○ Use special care when working corners, sharp edges

etc. Avoid bouncing and snagging the cut-off wheel.

Corners, sharp edges or bouncing have a tendency to

snag the rotating wheel and cause loss of control or

kickback. (Fig. 4)

○ Do not use cut-off wheels other than those approved or

recommended by the manufacturer. Never use blades

designed for cutting wood. Failure to comply could result

in personal accidents or injury.

○ Do not jam the wheel or apply excessive pressure. Do

not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the cut

and the possibility of kickback or wheel breakage.

○ If the wheel binds or a cut is interrupted for any reason,

stop the engine and hold the machine motionless until

the wheel comes to a complete stop. Never attempt

to remove the wheel from the cut while the wheel is in

motion otherwise kickback may occur. Investigate and

take corrective action to eliminate the cause of wheel

binding.

○ Do not restart the cutting operation with the wheel in the

workpiece. After allowing the wheel to reach full speed,

carefully re-enter the cut. The wheel may bind, walk up or

kickback if the power tool is restarted in the workpiece.

○ Provide supports for panels or any oversized workpiece

to minimize risk of wheel pinching and kickback.

Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece so that

the cutting surface to open. (Fig. 5)

Maintenance safety

○ Maintain the machine according to recommended

procedures.

○ Disconnect the spark plug before performing

maintenance except for carburetor adjustments.

○ Keep others away when making carburetor adjustments.

○ Use only genuine HiKOKI replacement parts as

recommended by the manufacturer.

CAUTION

Do not disassemble the recoil starter. There is a

possibility of personal injury with recoil spring.

WARNING

Improper maintenance could result in serious engine

damage or in serious personal injury.

Transport and storage

○ Carry the machine by hand with the engine stopped and

the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank and

carburetor, and secure the machine before storing or

transporting.

○ Store machine out of the reach of children.

○ Clean and maintain the machine carefully and store it in

a dry place.

○ Make sure stop switch is off when transporting or storing.

○ Do not store the cut-off wheels in a wet or frost condition.

Pay special attention about the abrasive wheel.

There is a risk of bursting to using the abrasive wheel

wetted.

If situations occur which are not covered in this manual, take

care and use common sense. Contact HiKOKI Authorized

Service Centers if you need assistance.

9

Page 10

English

SPECIFICATIONS

3

Engine displacement (cm

) 75.0

Spark Plug NGK BPMR-7A

Max. engine power by ISO 7293 (kW) 3.9

Model CM75EAP CM75EBP

-1

Rated engine speed by ISO 7293 (min

-1

Max. engine speed (min

Idle engine speed (min

) 9800

-1

) 2500

) 9200

Fuel Tank Capacity (L) 1.1

Dry weight (kg)

Without fuel, wheel and accessories

10.4 10.6

Wheel type Type 41

Outer diameter (mm) 305 (12") 355 (14")

Abrasive wheel

Arbor hole diameter (mm) 20 (25.4 with Adapter collar)

-1

Max. speed (min

) 5100 or more

Max. Thickness (mm) 3.5 4.0

Outer diameter (mm) 305 (12") 355 (14")

Diamond wheel

Arbor hole diameter (mm) 20 (25.4 with Adapter collar)

-1

Max. speed (min

) 5100 or more

Max. Thickness (mm) 3.5 4.0

Minimum fl ange outside diameter (mm) 101.7

Wheel-fastener tightening torque (N·m) 20

Spindle diameter (mm) 20 (25.4 with Adapter collar)

-1

Spindle max. speed (min

Sound pressure level LpA

Sound power level LwA*2 (dB(A)) by ISO 19432

Vibration level (m/s

NOTE

Noise level/vibration levels are calculated as the time-

weighted energy total for noise / vibration levels under

various working conditions with the following time

distribution:

*1:1/7 idle, 6/7 full load.

*2: Full load.

All data subject to change without notice.

ASSEMBLY PROCEDURES

Assembly of cut-off wheel

1. Place the wheel (1) between the two fl anges (2), and

tighten the bolt (3) by hand. (Fig. 6)

2.

Insert the hex. wrench (4) into the hole of arm cover (5)

and lock the spindle in place while tightening the bolt (3)

securely using the combi box spanner (6). (Fig. 7)

3. Make sure the rotation direction of the diamond wheel

conforms to the direction indicated on the clutch cover

and install the diamond wheel. (Fig. 8)

NOTE

○

When using a wheel with an arbor hole of 25.4mm, securely

attach the adapter collar (7) to the spindle. (Fig. 9)

○ Select and mount the correct cut-off wheel for the type of

work to be carried out.

) 4200

*1

(dB(A)) by ISO 19432

Measured / Uncertainty 99.5 / 3.0

Measured / Uncertainty 115 / 3.0

2

) by ISO 19432

Front handle

*1

/ Rear handle

Uncertainty

*1

2.2 / 2.7

1.0

Abrasive wheels Diamond wheels

Plastic

(Special wheel) —

Masonry

Metal (Special wheels)

Cast iron

WARNING

○ Do not use damaged wheels. Before each use, inspect

the wheels for chips, cracks, distortion of shape or

imbalance and reject any such wheel.

○ When you use the abrasive cut-off wheel check the

expiration year marked (8) on the wheel before attaching.

(Fig. 10)

There is a risk of bursting when using a wheel that it past

its expiration year.

○ Before tightening the bolt, check that the direction of the

two fl anges is correct. Also check that the fl anges are

securely installed in the fl ats of the spindle.

○ The correct tightening torque is 20 N·m. Do not tighten

more than 20 N·m.

○ Check the wheel by running it for 1 minutes at full throttle

before applying it to a workpiece.

2.4 / 2.9

1.0

(Special wheels)

10

Page 11

Adjustment of belt

1. Loosen the nut (9) with the combi box spanner (6) so that

the arm cover can (10) move. (Fig. 11)

2. Use the hex. wrench (4) to rotate the tensioner bolt (11)

so that the position of the tension nut (12) matches with

the marking (13) on the arm cover (10). (Fig. 12, Fig. 13)

3. Tighten the nut again.

NOTE

Suffi cient power is not transmitted to the wheel when the

belt is loose. Appropriately adjust the belt as necessary.

Adjustment of wheel guard

1. Wheel guard (14) can be moved by hand without using

a tool. To adjust the wheel guard (14), use handle(W)

(15), or press the end of wheel guard (14) against the

workpiece. (Fig. 14)

Make sure to adjust the wheel guard (14) to shield you

from any fl ying debris. (Fig. 15)

Wet cutting with water

This machine can be set up for wet cutting which can

suppress dust emission during cutting.

1. Remove coupler (16) by pulling the coupler from the

machine. (Fig. 16)

2. Remove the ring (17) from the coupler, slide the ring over

the hose and insert the hose to the coupler. (Fig. 17)

3. Re-tighten the ring to the coupler securely.

4. Reattach the coupler to the machine until it locks into

position.

5. Running water into the hose, turn the lever (18) of valve

(19). (Fig. 18) This will supply to the cut-off wheel.

Warning

The cut-off wheel that is included with this machine is an

abrasive cut-off wheel for concrete, stone, or masonry.

When cutting with water supplied to this cut-off wheel,

use the wheel up on the same day. There is a risk of

bursting when using the abrasive wheel wetted in this

manner on the following day.

For other cut-off wheels, follow the instructions provided

with those cut-off wheels.

Mounting the tools to the machine (Fig. 19)

This machine is designed to store the combi box spanner (6)

and hex. wrench (4).

OPERATING PROCEDURES

Fuel

WARNING

○ The machine is equipped with a two-stroke engine.

Always run the engine on fuel, which is mixed with oil.

Provide good ventilation, when fueling or handling fuel.

○ Fuel is highly fl ammable and it is possible to get seriously

injured when inhaling or spilling on your body.

Always pay attention when handling fuel. Always have

good ventilation when handling fuel.

Fuel (Fig. 20)

○ Always use branded 89 octane unleaded gasoline.

○ Use genuine two-cycle oil or use a mix between 25:1 to

50:1, please consult about the oil mixture ratio to HiKOKI

Authorized Service Centers.

○ If genuine oil is not available, use an anti-oxidant added

quality oil expressly labeled for air-cooled 2-cycle engine

use (JASO FC GRADE OIL or ISO EGC GRADE). Do not

use BIA or TCW (2-stroke water-cooling type) mixed oil.

○ Never use multi-grade oil (10 W/30) or waste oil.

○ Never mix fuel and oil in machine’s fuel tank. Always mix

fuel and oil in a separate clean container.

Fuel mixing method

Always start by fi lling half the amount of gasoline, which is to

be used into container.

English

Then add the whole amount of oil. Mix (shake) the fuel

mixture. Add the remaining amount of gasoline.

Mix (shake) the fuel-mix thoroughly before fi lling the fuel tank.

Mixing amount of two-cycle oil and gasoline

Gasoline (Liter)

0.5 10 ——— 20

1 20 ——— 40

2 40 ——— 80

4 80 ——— 160

Fueling (Fig. 21)

Before fueling, clean fuel tank cap (20) area carefully to

ensure that no dirt falls into the tank. Make sure that the fuel

is well mixed by shaking the container before adding fuel.

WARNING

○ Always shut off the engine and let it cool for a few

minutes before refueling.

Do not smoke or bring fl ames or sparks near the fuel.

○ Slowly open the fuel tank cap (20), when fi lling up with

fuel, so that possible overpressure disappears.

○ Tighten the fuel tank cap carefully, after fueling.

○ Always move the unit at least 3 m from the fueling area

before starting.

○ Always wash any spilled fuel from clothing immediately

with soap.

○ Be sure to check any fuel leaking after refueling.

○ Before fueling, in order to remove static electricity from

the main body, the fuel container and the operator,

please touch the ground that is slightly damp.

Starting the cold engine (Fig. 22-27)

CAUTION

Before starting, make sure that the cut-off wheel does

not touch anything.

1. Set stop switch (21) to ON position. (Fig. 22)

2. Pull choke lever (22) fully to set it in the START position.

(Fig. 23)

3. Push the priming pump (23) approximately ten times so

that fuel fl ows into carburetor. (Fig. 24)

4. Fully pull the throttle lever (24) while pressing the throttle

lever lockout (25). Then press the throttle lock (27).

This will automatically lock to half throttle, to aid in

starting the engine. (Fig. 22)

5. Push the decompression valve (26). The valve will

automatically return to the original position once the

engine has started. (Fig. 25)

6. Holding the tool in position with the left hand on the front

handle (29) and the right foot pressing down on the rear

handle (30), rapidly pull the starter knob (28). (Fig. 26)

7. When you hear fi rst ignition, push the choke lever (22)

fully to set it in the run position. (Fig. 27)

8. Push decompression valve (26) again.

9. Pull starter knob (28) rapidly again in the aforementioned

manner.

10. As soon as the engine starts, pull throttle lever (24)

full once with throttle lever lockout (25) pressed and

immediately release throttle lock (27). Then half throttle

is disengaged.

11. Allow the engine to warm up for about 2 to 3 minutes

before cutting.

NOTE

To avoid reducing engine life, do not run the engine at

high speeds without any load over a long period of time.

Starting the warm engine

Use only 1, 5, and 6 of the starting procedure for a cold

engine.

If the engine does not start, use the same starting procedure

as for a cold engine.

11

Two-cycle oil (ml)

Ratio 50:1 Ratio 25:1

Page 12

English

Stopping (Fig. 28)

Decrease engine speed, and push stop switch (21) to stop

position.

WARNING

Do not put the machine where there are fl ammable

materials such as dried grass, since the muffl er is still

hot after the engine has stopped.

Basic cutting techniques

1. Adjust the wheel guard to shield you from fl ying debris.

2. Cut a straight shallow line (31) to the range to be cut.

(

Fig. 29

3. Cut straight along the line to the required depth.

○ Do not overreach or cut above shoulder height.

○

○

○

NOTE

○ When cutting, move the machine back and forward along

If you cut the same position in long time, the cut-off wheel

○ Always cut at full speed at all times with pressing lightly.

○ Do not cut a deep groove at one time. To make deep

)

WARNING

Operator and bystanders must not stand in the line of

rotation of the cut-off wheel. Doing so may result in serious

injury or death should the wheel burst.

Never apply lateral pressure (side force) to the cut-off

wheel during cutting. Doing so will damage the cut-off

wheel.

Do not cut in a curved line.

the line in order to be not overheat the cut-off wheel.

may get hot and be weakened.

This is the way to get best effi cient for cutting.

groove, cut several times a shallow groove.

MAINTENANCE

Carburetor adjustment

In the carburetor, fuel is mixed with air. When the engine is

test run at the factory, the carburetor is adjusted. A further

adjustment may be required, according to climate and

altitude. The carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T) (Fig. 30)

Check that the pre-fi lter and paper fi lter are clean. When the

idle speed is correct, the cutting attachment will not rotate.

If adjustment is required, close (clockwise) the T-screw, with

the engine running, until the cutting attachment starts to

rotate. Open (counter-clockwise) the screw until the cutting

attachment stops. You have reached the correct idle speed

when the engine runs smoothly in all positions well below the

rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed

adjustment, contact HiKOKI Authorized Service Centers.

WARNING

When the engine is idling, the cutting attachment must

not rotate under any circumstances.

NOTE

○ Please use combi box spanner for adjusting the T-screw.

○ Do not touch the High speed adjustment (H) and the

Low speed adjustment (L) screws on the carburetor.

Those are only for HiKOKI Authorized Service Centers.

If you rotate them, it will cause a serious damage to the

machine.

Air fi lter (Fig. 31)

If the engine power seems to have decreased, it is likely

because the air fi lter needs to be cleaned.

1. Before cleaning the air fi lter, pull the choke lever (22) to

prevent dust from entering into the engine.

2. Open cleaner box (B) (32) by loosening cleaner knob

(33) to expose the pre-fi lter (sponge form) (34) inside the

cleaner box (B) (32).

12

3. Clean the pre-fi lter by tapping or blowing it gently. If the

pre-fi lter is still dirty, rinse it in warm soap suds.

If the inside of cleaner box (B) (32) that is closed off by the

pre-fi lter is dirty with dust, clean the paper-fi lter (35) in the

following manner.

4. In order to take out of paper-fi lter (35) and nylon-fi lter

(36), open the cleaner box (A) (37) by loosening the M5

set bolt (38).

5. Clean the nylon-fi lter by tapping or blowing it gently. If

the nylon-fi lter is still dirty, rinse it in warm soap suds.

6. Clean the paper-fi lter by tapping. If you use compressed

air to blow out the dust, apply the air gently from inside.

7. Reassemble the parts to their original positions by

following the aforementioned steps in reverse.

NOTE

○ When you remove paper-fi lter and nylon-fi lter, please

take care so that dust does not get inside the engine.

○ After rinsing in warm soap suds. Check to make sure that

the fi lter is dry before reassembly. An air fi lter that has

been used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new one.

A damaged fi lter must always be replaced.

Spark plug (Fig. 31, 32, 33)

1. Remove cleaner box (B) (32) and cleaner box (A) (37).

(Fig. 31)

2. Remove the spark plug by turning it counterclockwise

with the combi box spanner. (Fig. 32)

3. Clean the spark plug if it is dirty. Check the electrode

gap. The correct gap is 0.6 mm. (Fig. 33)

NOTE

○ When you remove the spark plug, please take care so

that dust does not get inside the engine.

○ The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly

eroded.

Fuel fi lter (Fig. 34)

Remove the fuel fi lter (39) from the fuel tank and thoroughly

wash it in solvent. After that, push the fuel fi

completely.

NOTE

If the fuel fi lter (39) is hard due to dust and dirt, it must be

replaced.

Anti-vibration systems (Fig. 35)

Check the springs (40) for any loosening or damage. If you

fi nd any failure in those parts, please contact a HiKOKI

Authorized Service Center.

Replacing of belt

1. Remove nut (9) using the combi box spanner (6)

and loosen the tensioner bolt (11) by rotating it

counterclockwise with the hex. wrench (4). Then,

remove the arm cover (10). (Fig. 11, 12)

2. Loosen the three bolts (41) on the clutch cover (42) and

remove clutch cover (42). (Fig. 36)

3. Remove the belt (43) and set a new one in the grooves of

the pulleys (44)(45) securely. (Fig. 37, 38)

4. Before assembling, turn the tensioner bolt (11) and

adjust the length protrusion of the tensioner bolt (11)

from the arm cover (10) to 0 mm. (Fig. 39)

5. Assemble clutch cover and arm cover by following the

aforementioned steps in reverse.

6. Readjust the tension of the belt. Please refer to

“Adjustment of belt”.

lter into the tank

Page 13

Maintenance schedule

Daily maintenance

○ Clean the exterior of the machine.

○

Check that the nut on the arm cover is suffi ciently tightened.

○

Check that the bolts for the cut-off wheel are suffi ciently

tightened.

○

Check that the cut-off wheel does not rotate when the

engine is idling

○ Clean the air fi lter.

Weekly maintenance

○ Check the recoil starter, especially rope.

○ Clean the exterior of the spark plug.

○ Remove the spark plug and check the electrode gap.

Adjust it to 0.6 mm or change the spark plug.

○

Check that the air intake at the recoil starter is not clogged.

TROUBLESHOOTING

Condition Probable Cause Remedy

No fuel or low fuel Supply fuel

Fuel is not in the carburetor

Old fuel Supply new fuel

Spark plug is wet

Engine does not start

Engine starts but immediately stalls

Abnormal vibration

Engine starts, but the cut-off wheel

does not rotate

Engine does not stop Electrical system failure

The fuel pipe is bent or detached

Carburetor failure

Spark plug failure Replace spark plug or correct the gap

Electrical system failure

No fuel or low fuel Supply fuel

Fuel is not in the carburetor

The choke is closed Push choke lever securely

Carburetor failure

Spark plug failure Replace spark plug or correct the gap

Clogged air fi lter Clean the air fi lter

Faulty mounting of the cut-off wheel

Deformation of the cut-off wheel Replace the cut-off wheel

Anti-vibration system failure

Belt is loose

Belt is too tight

Belt is out of pulleys Please refer to “Replacing of belt”

English

Monthly maintenance

○ Rinse the fuel tank with gasoline, and clean fuel fi lter.

○ Clean the exterior of the carburetor and the space

around it.

Quarterly maintenance

○ Clean the cooling fi ns on the cylinder.

○ Clean the fan and the space around it.

○ Clean the carbon of muffl er.

CAUTION

Cleaning of cylinder fi ns, fan and muffl er shall be done

by HiKOKI Authorized Service Centers.

Supply fuel and push priming pump a

few times.

1. Remove spark plug and dry it

2. Pull starter and dry the fuel inside

the engine

Consult a HiKOKI Authorized Service

Center

Consult a HiKOKI Authorized Service

Center

Consult a HiKOKI Authorized Service

Center

Supply fuel and push priming pump a

few times.

Consult a HiKOKI Authorized Service

Center

Please refer to “Assembly of cut-off

wheel”

Consult a HiKOKI Authorized Service

Center

Please refer to “Adjustment of belt”

Consult a HiKOKI Authorized Service

Center

13

Page 14

English

SPECIAL ACCESSORIES

Diamond wheel

HiKOKI off ers a diamond wheel for a variety of applications

which are listed below.

Diamond wheels (12") for CM75EAP

Type Category Outer Dia. (mm) Arbor hole (mm) Code No.

Universal 300 20

Diamond wheel

Diamond wheels (14") for CM75EBP

Type Category Outer Dia. (mm) Arbor hole (mm) Code No.

Diamond wheel

Water pressure tank (Fig. 40)

HiKOKI water pressure tank is a portable and manual

pressured tank. This tank allows wet cutting where

there is no immediately available water supply.

(Code No.: 712630)

Brick and asphalt 300 20

Concrete and hard

stone

Universal 350 20

Brick and asphalt 350 20

Concrete and hard

stone

300 20

350 20

773000

773004

773137

773018

773008

773012

773002

773006

773016

773020

773010

773014

REPLACEMENT PARTS

6699872 6699868 6699867 6699877

14

Page 15

Dedique especial atención a los apartados introducidos por

las siguientes palabras:

ADVERTENCIA

Indica un riesgo signifi cativo de que se produzcan daños

personales graves e incluso la muerte si no se siguen las

instrucciones.

PRECAUCIÓN

Indica la posibilidad de que se produzcan daños

personales o materiales si no se siguen las instrucciones.

NOTA

Indica información útil para el uso y funcionamiento

correctos de la máquina.

Español

Dimensiones del disco de corte

Mezcla de combustible y aceite

Ajuste del carburador: velocidad a ralentí

Ajuste del carburador: mezcla a baja velocidad

SIGNIFICADO DE LOS SÍMBOLOS

NOTA: Algunas unidades no están provistos de ellos.

Símbolos

ADVERTENCIA

A continuación se muestran los símbolos

utilizados para la máquina. Asegúrese de

comprender su signifi cado antes de utilizar el

dispositivo.

Cuchilla: Máquina de corte portátil

CM75EAP / CM75EBP

Es importante que lea, entienda totalmente

y respete las siguientes precauciones

y advertencias de seguridad. El uso

descuidado o incorrecto de la unidad podría

provocarle lesiones graves o fatales.

Lea, comprenda y siga todas las advertencias

y demás instrucciones de este manual y las

que se muestran en el aparato.

Cuando utilice esta unidad, use siempre

protecciones para los ojos, la cabeza, los

oídos y protecciones antipolvo

Estárter

Encendido / Arranque

Apagado / Parada

Parada de emergencia

Velocidad máxima del husillo de la máquina.

Advertencia: No utilice discos con una

capacidad de velocidad inferior a la velocidad

máxima indicada del husillo de la máquina.

¡Advertencia de incendios! Esta herramienta

genera chispas al cortar metal.

¡Advertencia! No utilice discos de corte

dañados.

Dirección de giro del disco de corte

Ajuste del carburador: mezcla a alta velocidad

Bomba de cebado

Nivel de potencia acústica garantizado

8

Válvula de descompresión

Advertencia de polvo y emisiones de gas

dañinos

¡Advertencia de retroceso

¡Advertencia! Nunca utilice cuchillas

diseñadas para cortar madera.

DESCRIPCIÓN DE LAS PARTES (Fig. 1)

A: Interruptor de parada: Dispositivo que permite arrancar y

detener el motor.

B: Palanca del acelerador: Dispositivo activado mediante el

dedo del operario para controlar la velocidad del motor.

C: Bloqueo de la palanca del acelerador: Dispositivo que

evita el funcionamiento accidental de la palanca del

acelerador hasta que se libera manualmente.

D: Bloqueo del acelerador: Dispositivo de confi guración

del acelerador en la posición parcialmente abierta para

ayudar al arranque.

E: Tapa del depósito de combustible: Para cerrar el

depósito de combustible.

F: Mando del arrancador: Tire del asidero para arrancar el

motor.

G: Asidero frontal: Asidero de apoyo situado en la parte

frontal de la carcasa del motor u orientado hacia ella.

H: Asidero trasero: Asidero de apoyo situado en la parte

trasera de la carcasa del motor u orientado hacia ella.

I: Palanca del estárter: Dispositivo para enriquecer la

mezcla de combustible/aire, para ayudar al arranque.

J: Bomba de cebado: Dispositivo para suministrar

combustible adicional para ayudar al arranque.

K: Caja del fi ltro (B): Cubierta del prefi ltro

L: Caja del fi ltro (A): Cubierta del fi ltro de papel y del

carburador.

M: Tapa del embrague: Dispositivo entre el motor y el

equipo de corte diseñado para evitar el contacto no

intencionado con la transmisión.

15

Page 16

Español

N: Cubierta del brazo: Dispositivo entre el motor y el

equipo de corte diseñado para evitar el contacto no

intencionado con la transmisión.

O: Protección del disco: Cubierta diseñada para proteger al

operario del contacto del disco y para alejar los residuos

del operario.

P: Tuerca: Fija la protección del disco al motor.

Q: Resorte antivibración: Reduce la transmisión de

vibraciones a las manos del operario.

R: Asidero (W): Asidero para girar la protección del disco.

S:

Válvula de descompresión: Dispositivo para reducir la

presión de compresión del motor para ayudar al arranque.

T: Perno tensor: Dispositivo para aumentar y liberar tensión

de la correa.

U: Tuerca de tensión: Marca para indicar el estado de la

tensión de la correa.

V: Disco de corte: Disco abrasivo adherido con resina

sintética reforzada para el corte con papel secante.

W: Acoplador: Dispositivo para instalar la manguera

X: Válvula: Dispositivo para ajustar la tasa del fl ujo de agua.

Y: Silenciador: Reduce el ruido de salida de escape del

motor y dirige los gases de escape.

Z: Arandela del disco: Brida suministrada para fi jar y dirigir

el disco de corte.

a: Perno: Fija el disco de corte

b: Anillo adaptador: Accesorio del husillo para el uso de

discos de corte de 25,4 mm de orifi cio de eje.

c:

Llave combinada de cubo: Herramienta de mantenimiento

para extraer o instalar una bujía

d: Llave hexagonal: Herramienta de mantenimiento para

extraer cubiertas y tensar la correa.

e: Gafas protectoras: Protección para los ojos.

f: Instrucciones de manejo: Incluidas con la unidad. Lea las

instrucciones para aprender a utilizar apropiadamente

y con seguridad la unidad, y guárdelas para futuras

referencias.

ADVERTENCIAS E INSTRUCCIONES

DE SEGURIDAD

Seguridad del usuario

○ Use siempre protección facial o gafas protectoras

adecuadas.

○ Al operar esta máquina y tocar el disco de corte, debe

usar siempre guantes.

○ Utilice siempre indumentaria protectora adecuada tal

como chaqueta, pantalones, casco, botas con puntera

de acero y suelas antideslizantes, así como equipo de

protección ocular, auditivo y para las piernas, cuando

utilice esta máquina.

No utilice prendas sueltas, joyas, pantalones cortos y/o

sandalias, y nunca trabaje descalzo.

○ No deje que niños o personas inexpertas utilicen esta

máquina.

El operario primerizo deberá obtener instrucciones

prácticas antes de usar la máquina.

○ Cuando use protección auditiva, preste atención a los

alrededores. Esté atento a personas que pudieran estar

avisándole de un problema.

○ Las operaciones de corte pueden exponerlo a peligros

respiratorios tales como sílice y otras partículas de

polvo perjudiciales. Al utilizar esta máquina, utilice una

máscara protectora.

○ Mantenga los asideros libres de aceite y combustible.

○ Mantenga las manos alejadas del mecanismo de corte.

○ No agarre ni sostenga la máquina por el mecanismo de

corte.

○ No fume ni deje fumar a otras personas en las

proximidades del combustible o de la máquina ni cuando

utilice la misma.

○ Cuando apague la unidad, asegúrese de que el

mecanismo de corte se ha detenido antes de apoyar la

unidad sobre el suelo.

○ Si utiliza este dispositivo durante un periodo de tiempo

prolongado, se recomienda descansar de vez en cuando

para evitar el posible Síndrome por vibración en manos y

brazos (HAVS), causado por las vibraciones.

○ Las normativas nacionales pueden restringir el uso de la

máquina.

El operario deberá respetar los reglamentos locales del

área de trabajo.

ADVERTENCIA

○ La máquina genera gases de escape, que incluyen

hidrocarburos y benceno. Al utilizar esta máquina,

necesitará la ventilación adecuada no solamente al

usarse en interiores, sino también al usarse en zanjas,

cavidades y otras ubicaciones confi nadas. La inhalación

de los humos de escape puede ser fatal.

○ No utilice esta máquina cuando esté cansado, enfermo o

bajo la infl uencia del alcohol, drogas o medicamentos.

○ Los sistemas antivibración no garantizan que no se

vaya a padecer del Síndrome por vibración en manos y

brazos o el síndrome del túnel carpiano.

Por lo tanto, aquellas personas que utilicen este dispositivo

de forma continua y regular deberán mantener vigilado en

todo momento el estado de sus manos y dedos. Si aparece

cualquiera de los síntomas citados, deberá solicitarse

inmediatamente atención médica.

○ La exposición prolongada o continua a niveles altos de

ruido puede causar discapacidad auditiva permanente.

Al utilizar una máquina que genere ruidos, utilice

siempre protección auditiva aprobada.

○ Si utiliza algún dispositivo médico eléctrico o electrónico

tal como marcapasos, consulte a su médico y al

fabricante del dispositivo antes de utilizar cualquier

equipo motorizado.

Seguridad de la máquina

○ Inspeccione toda la máquina en busca de daños

antes de cada uso. Compruebe que no haya fugas de

combustible y asegúrese de que todas las piezas se

encuentren en su sitio y estén correctamente apretadas.

○ No permita que se acerquen otras personas mientras

esté ajustando el carburador.

○ Utilice únicamente los accesorios para esta máquina

que hayan sido recomendados por el fabricante.

○ Seleccione y monte el disco de corte correcto para el

tipo de trabajo que se vaya a llevar a cabo.

○ Todos los artículos deberán efectuarse en los centros de

servicio autorizado de HiKOKI, a excepción de aquellos

indicados en el manual del propietario/operario. (Por

ejemplo, si se emplean herramientas incorrectas para

quitar el volante o si se utiliza una herramienta incorrecta

para sujetar el volante con el propósito de quitar el

embrague, podría ocasionar daños estructurales al

volante y provocar que se rompa).

ADVERTENCIA

○ Nunca intente modifi car la máquina de ninguna manera.

No utilice esta máquina para tareas distintas para las

que ha sido diseñada.

○ Nunca utilice discos con una capacidad de velocidad

inferior a la velocidad máxima indicada del husillo de la

máquina.

Un disco funcionando más rápido que su velocidad

nominal puede romperse y saltar en pedazos.

○ El diámetro del eje de los discos y bridas ha de encajar

correctamente en el husillo de la máquina.

Los discos y bridas que posean diámetros de eje que

no coincidan con el hardware de montaje de la máquina

se desequilibrarán, vibrarán excesivamente y podrían

causar una pérdida del control.

16

Page 17

○ Es importante utilizar únicamente discos de corte

diseñados para su uso en máquinas de corte portátiles.

Es peligroso utilizar un disco de corte no diseñado para

una máquina de corte portátil.

Seguridad del combustible

○ Mezcle y llene el combustible al aire libre, en lugares

donde no se produzcan chispas ni haya fuego.

○ Utilice un recipiente adecuado para el combustible.

○ Limpie los derrames de combustible y permita que

cualquier combustible restante se evapore antes de

arrancar el motor.

○ Antes de poner en marcha el motor, apártese como

mínimo 3 metros del lugar en el que se ha repostado el

combustible.

○ Detenga el motor y deje que se enfríe durante unos

minutos antes de abrir el tapón del depósito de

combustible.

○ Guarde la máquina y el combustible en un lugar donde

los vapores del combustible no puedan llegar a chispas

ni llamas de calentadores de agua, motores eléctricos,

interruptores, hornos, etc.

ADVERTENCIA

El combustible es altamente infl amable y sus vapores

no deben ser inhalados. Tenga especial cuidado al

manipular la máquina, ya que las chispas producidas

durante el proceso de corte de metal pueden infl amar

fácilmente cualquier derrame de combustible.

Seguridad durante el corte

○ Mantenga a los viandantes a una distancia segura del

área de trabajo. Cualquier persona que acceda a la zona

de trabajo deberá usar equipo protector personal. Los

fragmentos despedidos de las piezas de trabajo o del

disco de corte podrían causar lesiones.

Los niños, el resto de personal no autorizado y los

animales deberán permanecer alejados de la zona de

trabajo.

○ Agarre la máquina fi rmemente con la mano derecha

en el asidero trasero y la mano izquierda en el asidero

delantero.

○ Mantenga estable el cuerpo, con los pies bien apoyados

sobre el suelo. No estire demasiado el cuerpo.

○ Mantenga su cuerpo apartado del silenciador de escape

y del mecanismo de corte mientras esté en marcha el

motor.

○ Asegúrese de comprobar la zona de trabajo en busca

de peligros ocultos tales como tuberías de agua o gas,

cables eléctricos y sustancias infl amables.

○ Jamás coloque la máquina sobre el suelo cuando esté

en marcha.

○ Asegúrese siempre de que el motor esté apagado y de

que todos los accesorios de corte estén completamente

parados antes de limpiar los residuos del accesorio de

corte.

○ Cuando utilice cualquier equipo motorizado, lleve

siempre un botiquín de primeros auxilios consigo.

○ El silenciador alcanza temperaturas muy elevadas

durante y después de su uso. Esta situación también se

da durante su inactividad.

Tenga presente el riesgo de incendio, especialmente al

trabajar cerca de sustancias o vapores infl amables.

ADVERTENCIA

○ Los gases de escape del motor alcanzan temperaturas

muy elevadas y podrían contener chispas que podrían

provocar un incendio.

Además, al cortar metal con esta máquina se generan

chispas.

No utilice nunca la máquina en lugares en los que

existan substancias y gases infl amables.

○ Las chispas generadas por las operaciones de corte

podrían causar incendios. Tenga disponible en todo

momento un equipo de extinción de incendios adecuado.

Español

○ Cuando cambie para situarse en una nueva área de

trabajo, asegúrese de detener la máquina y de que

todos los accesorios de corte estén detenidos.

○ Asegúrese siempre de que el motor esté apagado y de

que todos los accesorios de corte estén completamente

parados antes de desplazarse.

Durante el transporte del motor mientras éste está

funcionando y el disco de corte está girando se producen

fuerzas giroscópicas. Esto podría provocar la pérdida de

control de la máquina.

○ Nunca corte materiales con amianto.

○ Nunca deje el motor en marcha desatendido

(por ejemplo, sobre el suelo).

Retroceso y advertencias relacionadas

Retroceso es una reacción repentina en un disco giratorio

enganchado o atrapado. El enganche o agarre causa el

estancamiento repentino del disco giratorio, el cual a su

vez, causa que la máquina salga disparada en dirección

opuesta al giro del disco en el punto de unión. Por ejemplo,

si un disco abrasivo queda atrapado o atascado a causa

de una pieza de trabajo, el borde del disco que pasa por el

punto de agarre puede penetrar en la superfi cie del material,

causando que el disco se monte o retroceda. El disco podría

entonces salir disparado hacia el operario o alejarse del

mismo, en función de la dirección del movimiento del disco

en el momento del atasco. Los discos abrasivos podrían,

igualmente, romperse en estas condiciones.

Cualquiera de estas reacciones podría hacer perder el

control de la máquina, pudiendo causar serias lesiones

personales.

Retroceso es el resultado un uso incorrecto de la máquina

de corte y/o los procedimientos de operación o condiciones

incorrectos que puede evitarse tomando las precauciones

necesarias, tal y como se indica a continuación.

○ El retroceso se produce cuando el ángulo superior del

disco de corte se usa o toca un objeto cuando el disco

de corte está en marcha. Preste especial atención para

no tocar el ángulo superior del disco de corte con ningún

objeto. (Fig. 2, Fig. 3)

○ Preste especial atención al trabajar en esquinas, bordes

afi lados, etc. Evite que el disco de corte rebote o se

quede atrapado.

Las esquinas, los bordes afi lados o el rebote tienden

a causar atascos en el disco giratorio y la pérdida de

control o el retroceso del mismo. (Fig. 4)

○ No utilice discos de corte distintos a los aprobados o

recomendados por el fabricante. Nunca utilice cuchillas

diseñadas para cortar madera. De lo contrario podría

causar accidentes personales o lesiones.

○ No atasque el disco ni aplique una presión excesiva. No

intente lograr una profundidad de corte excesiva.

Sobrecargar el disco aumenta la carga y la

susceptibilidad a giros o adhesiones del disco en el

corte, y la posibilidad de retroceso o rotura del disco.

○ Si el disco se atasca o se interrumpe un corte por cualquier

motivo, detenga el motor y mantenga la máquina inerte

hasta que el disco se detenga completamente. Nunca

intente extraer el disco del corte mientras el disco

está en movimiento, de lo contrario podría retroceder.

Averigüe el motivo y tome la acción correctiva necesaria

para eliminar la causa del atascamiento del disco.

○ No reinicie la operación de corte con el disco en la pieza

de trabajo. Una vez que el disco alcance la velocidad

máxima, vuelva a introducirlo en el corte con cuidado.

El disco podría atascarse, levantarse o retroceder si la

herramienta de alimentación es reiniciada en la pieza de

trabajo.

○ Proporcione soportes para paneles o cualquier pieza de

trabajo de gran tamaño para reducir el riesgo de que el

disco se atasque o retroceda.

17

Page 18

Español

Las piezas de trabajo grandes tienden a deslizarse por

su propio peso. Los soportes deben colocarse debajo de

la pieza de trabajo de forma que la superfi cie de corte se

abra. (Fig. 5)

Seguridad durante el mantenimiento

○ Realice el mantenimiento de la máquina siguiendo los

procedimientos recomendados.

○ Antes de iniciar el mantenimiento, desconecte la bujía,

excepto si hay que ajustar el carburador.

○ No permita que se acerquen otras personas mientras

esté ajustando el carburador.

○ Utilice únicamente repuestos y accesorios originales de

HiKOKI recomendados por el fabricante.

PRECAUCIÓN

No desmonte el arrancador de retroceso. El resorte

del arrancador puede ocasionarle lesiones personales

graves.

ADVERTENCIA

El mantenimiento incorrecto podría conducir a una

avería seria del motor o a heridas graves.

Transporte y almacenamiento

○ Transporte la máquina a mano con el motor detenido y el

silenciador alejado del cuerpo.

○ Antes de almacenar o transportar la máquina, espere

a que se haya enfriado el motor, vacíe el depósito de

combustible y el carburador y sujete bien la máquina.

○ Guarde la máquina fuera del alcance de niños.

○ Limpie y lleve a cabo el mantenimiento de la máquina

cuidadosamente, y guárdela en un lugar seco.

○ Asegúrese de que esté desconectado el interruptor de

parada al transportar o almacenar el aparato.

○ No guarde los discos de corte en lugares húmedos o

congelados. Preste especial atención al disco abrasivo.

Existe el riesgo de explosión si usa el disco abrasivo

humedecido.

Si se producen situaciones no previstas en este manual,

utilice el sentido común. Si necesita ayuda, póngase en

contacto con un centro de servicio autorizado HiKOKI.

ESPECIFICACIONES

3

Desplazamiento del motor (cm

) 75,0

Bujía NGK BPMR-7A

Potencia máx. del motor según ISO 7293 (kW) 3,9

Velocidad nominal del motor según ISO 7293 (min

-1

Velocidad máxima del motor (min

Velocidad de ralentí del motor (min

) 9800

-1

) 2500

Capacidad del depósito de combustible (L) 1,1

Peso en seco (kg)

Sin combustible, disco ni accesorios

Tipo de disco Tipo 41

Diámetro exterior (mm) 305 (12") 355 (14")

Disco abrasivo

Diámetro del orifi cio del eje (mm) 20 (25,4 con anillo adaptador)

Velocidad máx. (min

Grosor máximo (mm) 3,5 4,0

Diámetro exterior (mm) 305 (12") 355 (14")

Disco de diamante

Diámetro del orifi cio del eje (mm) 20 (25,4 con anillo adaptador)

Velocidad máx. (min

Grosor máximo (mm) 3,5 4,0

Diámetro exterior mínimo de la brida (mm) 101,7

Par de apriete del fi jador del disco (N·m) 20

Diámetro del husillo (mm) 20 (25,4 con anillo adaptador)

-1

Velocidad máx. del husillo (min

Nivel de presión acústica LpA

Nivel de potencia acústica LwA

Nivel de vibración (m/s

NOTA

Los niveles de ruido / vibración se calculan como la

energía ponderada en tiempo total para los niveles de

ruido/vibración en varias condiciones de trabajo con la

distribución de tiempo siguiente:

Medición / Incertidumbre

Medición / Incertidumbre

Asidero delantero

) 4200

*1

(dB(A)) según ISO 19432

*2

(dB(A)) según ISO 19432

2

) según ISO 19432

*1

/ Asidero trasero

Modelo CM75EAP CM75EBP

-1

) 9200

10,4 10,6

-1

) 5100 o más

-1

) 5100 o más

99,5 / 3,0

115 / 3,0

Incertidumbre

*1

2,2 / 2,7

1,0

*1: 1/7 ralentí, 6/7 carga completa.

*2: Carga completa.

Todos los datos están sujetos a cambios sin previo aviso.

18

2,4 / 2,9

1,0

Page 19

PROCEDIMIENTOS DE MONTAJE

Conjunto del disco de corte

1. Coloque el disco (1) entre las dos bridas (2), y apriete

manualmente el perno (3). (Fig. 6)

2. Introduzca la llave hexagonal (4) en el orifi cio de la

cubierta del brazo (5) y bloquee el husillo en su lugar

mientras aprieta el perno (3) fi rmemente utilizando la

llave combinada de tubo (6). (Fig. 7)

3. Asegúrese de que la dirección de rotación de la rueda de

diamante se encuentra en conformidad con la dirección

indicada en la cubierta del embrague e instale la rueda

de diamante. (Fig. 8)

NOTA

○ Al usar un disco con un orifi cio del eje de 25,4 mm,

coloque fi rmemente el anillo adaptador (7) en el husillo.

(Fig. 9)

○ Seleccione y monte el disco de corte correcto para el

tipo de trabajo que se vaya a llevar a cabo.

Discos abrasivos Discos de

Plástico (disco especial) —

Mampostería

Metal

Hierro fundido

ADVERTENCIA

○ No use discos dañados. Antes de cada uso, inspeccione

los discos en busca de virutas, grietas, pérdida de la

forma o desequilibrio y rechace tal tipo de discos.

○ Al usar el disco de corte abrasivo, compruebe la fecha

(8) de expiración indicada en el disco antes de instalarlo.

(Fig. 10)

Cuando se usa un disco cuyo año de caducidad ha

terminado, pueden producirse riesgos de explosión.

○ Antes de apretar el perno, compruebe que la dirección

de las dos bridas sea correcta. Compruebe también que

las bridas están fi rmemente instaladas en las bases del

husillo.

○ El par de apriete correcto es 20 N·m. No apriete por

encima de 20 N·m.

○ Compruebe el disco dejándolo en marcha durante 1

minuto a máxima aceleración antes de aplicarlo a una

pieza de trabajo.

Ajuste de la correa

1. Afl oje la tuerca (9) con la llave combinada de cubo (6)

de modo que la cubierta del brazo (10) pueda moverse.

(Fig. 11)

2. Utilice la llave hexagonal (4) para girar el perno tensor

(11) de modo que la posición de la tuerca de tensión (12)

coincida con la marca (13) de la cubierta del brazo (10).

(Fig. 12, Fig. 13)

3. Apriete la tuerca de nuevo.

NOTA

Si la correa está fl oja, no transmitirá sufi ciente energía al

disco. Debe ajustar adecuadamente la correa según sea

necesario.

Ajuste de la protección del disco

1. La protección del disco (14) puede extraerse

manualmente sin usar herramientas. Para ajustar la

protección del disco (14), use el asidero (W) (15) o

presione el extremo de la protección del disco (14)

contra la pieza de trabajo. (Fig. 14)

Asegúrese de ajustar la protección del disco (14) para

protegerse de cualquier resto que salga despedido. (Fig.

15)

diamante

(discos especiales)

(discos especiales)

Español

Corte en mojado con agua

Esta máquina se puede confi gurar para el corte en mojado,

lo cual puede suprimir la emisión de polvo durante el corte.

1. Extraiga el acoplador (16) tirando del acoplador de la

máquina. (

2.

Extraiga el aro (17) del acoplador, deslice el aro sobre

la manguera e introduzca la manguera en el acoplador.

(Fig. 17)

3. Vuelva a apretar el aro en el acoplador fi rmemente.

4. Vuelva a instalar el acoplador en la máquina hasta que se

bloquee en su posición.

5.

Haciendo correr agua por la manguera, gire la palanca

(18) de la válvula (19). (Fig. 18) Esto suministrará al

disco de corte.

Advertencia

El disco de corte incluido en esta máquina es un disco de

corte abrasivo para hormigón, piedra o mampostería.

Al cortar usando de agua suministrada a este disco de

corte, desgaste el disco ese mismo día. Existe el riesgo

de explosión cuando usa el disco abrasivo humedecido de

esta manera al día siguiente.

Para el resto de discos de corte, siga las instrucciones

proporcionadas con los mismos.

Montaje de las herramientas en la máquina (Fig. 19)

Esta máquina está diseñada para almacenar la llave

combinada de cubo (6) y la llave hexagonal (4).

Fig. 16

)

PROCEDIMIENTOS DE

FUNCIONAMIENTO

Combustible

ADVERTENCIA

○ La máquina está equipada con un motor de dos tiempos.

El motor debe funcionar siempre con combustible

mezclado con aceite. Asegúrese de que existe una

buena ventilación en los lugares de manipulación o

repostaje de combustible.

○

El combustible contiene sustancias altamente infl amables,

por lo que existe la posibilidad de sufrir lesiones graves por

inhalación o por derrames sobre su cuerpo.

Preste siempre atención cuando manipule el combustible.

Cuando manipule el combustible, asegúrese de que haya

una buena ventilación en todo momento.

Combustible (Fig. 20)

○

Utilice siempre gasolina sin plomo de marca de 89 octanos.

○

Utilice aceite de dos tiempos genuino o utilice una mezcla

de 25:1 a 50:1. Consulte la proporción de la mezcla de

aceite a un centro de servicio autorizado HiKOKI.

○ Si no hay aceite genuino disponible, utilice un aceite

con antioxidante de calidad que esté etiquetado

expresamente para motores de dos tiempos refrigerados

por aire (JASO FC GRADE OIL o ISO EGC GRADEC).

No utilice aceite mezclado BIA o TCW (para motores de

2 tiempos refrigerados por agua).

○ No utilice nunca aceites multigrado (10 W/30) ni

residuales.

○ Nunca mezcle el combustible y el aceite en el depósito

de combustible de la máquina. Mezcle siempre el

combustible y el aceite en un recipiente limpio y

destinado a este fi n.

Método de mezcla de combustible

Comience siempre llenando la mitad del combustible que va

a utilizar en el contenedor.

Luego, agregue todo el aceite. Agite la mezcla de

combustible. Añada el resto de gasolina.

Antes de llenar el depósito de combustible, agite bien la mezcla.

19

Page 20

Español

Cantidad de mezcla de aceite de dos tiempos y gasolina

Gasolina (litros)

0,5 10 ——— 20

1 20 ——— 40

2 40 ——— 80

4 80 ——— 160

Repostaje (Fig. 21)

Antes de repostar, limpie cuidadosamente la zona de la

tapa del depósito de combustible (20) para asegurarse de

que no entra suciedad en el depósito. Asegúrese de que

el combustible está bien mezclado agitando el recipiente

antes de añadir combustible.

ADVERTENCIA

○ Antes de repostar el combustible, apague el motor y

deje que se enfríe durante unos minutos.

No fume ni acerque llamas o chispas cerca del combustible.

○ Al repostar combustible en el depósito, abra lentamente

la tapa del depósito de combustible (20) para drenar el

exceso de presión que pueda contener.

○ Después del repostaje, cierre y apriete bien la tapa del

depósito de combustible.

○ Antes de arrancar la máquina, debe alejarse un mínimo

de 3 m del área de repostaje.

○ Lave siempre inmediatamente con jabón cualquier

combustible vertido sobre la ropa.

○ Asegúrese de verifi car si existe alguna fuga de

combustible después del repostaje.

○ Antes de repostar, y con el fi n de descargar la

electricidad estática del cuerpo principal, del recipiente

y del operario, toque una superfi cie de suelo ligeramente

humedecida.

Arranque del motor en frío (Fig. 22-27)

PRECAUCIÓN

Antes de arrancar, asegúrese de que el disco de corte

no entre en contacto con nada.

1. Coloque el interruptor de parada (21) en la posición de

encendido (Fig. 22).

2. Tire de la palanca del estárter (22) en todo su recorrido

para colocarla en la posición de arranque START (Fig.

23)

3. Pulse la bomba de cebado (23) aproximadamente

diez veces, de forma que el combustible fl uya hacia el

carburador. (Fig. 24)

4. Tire completamente de la palanca del acelerador

(24) mientras presiona el bloqueo de la palanca del

acelerador (25). A continuación, presione el bloqueo del

acelerador (27).

Con ello se bloqueará automáticamente en medio

acelerador para ayudar en el arranque del motor. (Fig.

22)

5. Pulse la válvula de descompresión (26). La válvula

volverá automáticamente a la posición original una vez

que el motor haya arrancado. (Fig. 25)

6. Mientras sostiene la herramienta en posición con la

mano izquierda en el mango delantero (29) y el pie

derecho presiona hacia abajo el mango trasero (30), tire

rápidamente del mando del estárter (28). (Fig. 26)

7. Cuando escuche la primera ignición, empuje la palanca

del estárter (22) en todo su recorrido para colocarla en la

posición de marcha. (Fig. 27)

8. Vuelva a pulsar la válvula de descompresión (26).

9. Tire de nuevo rápidamente del mando del arrancador

(28) de la forma antes mencionada.

Aceite de dos tiempos (ml)

Proporción 50:1 Proporción 25:1

10. En cuanto el motor se ponga en marcha, tire de la palanca

del acelerador (24) una vez en todo su recorrido con el

bloqueo de la palanca del acelerador (25) presionado, y

libere inmediatamente el bloqueo del acelerador (27). A

continuación se desacopla medio acelerador.

11. Deje que el motor se caliente durante unos 2–3 minutos

antes de cortar.

NOTA

Para evitar reducir la vida útil del motor, no haga

funcionar el motor a altas velocidades sin carga durante

un largo período de tiempo.

Puesta en marcha del motor en caliente

Utilice únicamente los puntos 1, 5 y 6 para el procedimiento

de arranque de un motor en frío.

Si el motor no arranca, realice el mismo procedimiento que

para un motor en frío.

Parada (Fig. 28)

Reduzca la velocidad del motor y coloque el interruptor de

parada (21) en la posición de parada.

ADVERTENCIA

No coloque la máquina en lugares en los que haya

materiales infl amables, como hierba seca, ya que

el silenciador sigue estando caliente después de

detenerse el motor.

Técnicas de corte básicas

1.

Ajuste la protección del disco para protegerse de restos

despedidos.

2.

Corte una línea recta superfi cial (31) hasta el rango de corte.

(Fig. 29)

3. Corte a lo largo de la línea recta hasta la profundidad

deseada.

ADVERTENCIA

○ No extienda excesivamente la mano ni corte sobre la

altura de los hombros.

○

Ni el operador ni viandantes deben estar en la línea de

giro del disco de corte. De lo contrario, podrían producirse

lesiones de gravedad o la muerte en caso de que el disco

reviente.

○

Nunca aplique presión lateral (fuerza lateral) sobre el disco

de corte durante el corte. Hacerlo dañará el disco de corte.

○

No corte en línea curvada.

NOTA

○ Durante el corte, mueva la máquina hacia delante y

hacia atrás junto con la línea para no sobrecalentar el

disco de corte.

Si corta en la misma posición durante mucho tiempo, el

disco podría calentarse y debilitarse.

○ Corte siempre a la máxima velocidad presionando

ligeramente. Esta es la mejor manera de lograr un corte

efi ciente.

○

No realice un corte profundo de golpe. Para realizar cortes

profundos, corte varias veces una ranura superfi cial.

MANTENIMIENTO

Ajuste del carburador

En el carburador, el combustible se mezcla con aire. Cuando

se realiza la prueba de funcionamiento en la fábrica, se

ajusta el carburador. Sin embargo, puede que sea necesario

reajustarlo según el clima y la altitud. El carburador tiene una

opción de ajuste:

T = Tornillo de ajuste de la velocidad de ralentí.

20

Page 21

Ajuste de la velocidad de ralentí (T) (Fig. 30)

Compruebe que el prefi ltro y el fi ltro de papel están limpios.

Cuando la velocidad de ralentí sea la correcta, el mecanismo

de corte no girará. Si es necesario realizar ajustes, cierre el

tornillo T (hacia la derecha) con el motor en marcha hasta

que el accesorio de corte empiece a girar. Abra el tornillo

T (hacia la izquierda) hasta que el mecanismo de corte se

detenga. Habrá obtenido la velocidad de ralentí correcta

cuando el motor funcione con suavidad en cualquier posición

encontrándose muy por debajo de las rpm necesarias para

que el accesorio de corte empiece a girar.

Si el accesorio de corte sigue girando después del ajuste de

la velocidad de ralentí, póngase en contacto con un centro

de servicio autorizado HiKOKI.

ADVERTENCIA

Cuando el motor está al ralentí, el accesorio de corte no

debe girar bajo ninguna circunstancia.

NOTA

○ Use la llave combinada de cubo para ajustar el tornillo T.

○ No toque los tornillos de ajuste de alta velocidad (H)

ni los de ajuste de baja velocidad (L) en el carburador.

Estos ajustes están destinados únicamente a los centros

de servicio autorizados HiKOKI. Si los gira, provocará

daños de gravedad a la máquina.

Filtro de aire (Fig. 31)

Si la potencia del motor parece haber disminuido, es posible

que sea debido a que el fi ltro de aire necesita ser limpiado.

1. Antes de limpiar el fi ltro de aire, tire de la palanca del

estárter (22) para evitar que el polvo entre en el motor.

2. Abra la caja del fi ltro (B) (32) afl ojando el mando del

fi ltro (33) para dejar al descubierto el prefi ltro (forma de

esponja) (34) dentro de la caja del fi ltro (B) (32).

3. Limpie el prefi ltro golpeándolo o soplándolo suavemente.

Si el prefi ltro sigue sucio, aclárelo con agua tibia

jabonosa.

Si el interior de la caja del fi ltro (B) (32) cerrada por el

prefi ltro está sucio, limpie el fi ltro de papel (35) de la

siguiente manera.

4. Para poder extraer el fi ltro de papel (35) y el fi ltro de nilón

(36), abra la caja del fi ltro (A) (37) afl ojando el perno de

ajuste M5 (38).

5. Limpie el fi ltro de nilón golpeándolo o soplándolo

suavemente. Si el fi ltro de nilón sigue sucio, aclárelo con

agua tibia jabonosa.

6. Limpie el fi ltro de papel golpeándolo. Si utiliza aire

comprimido para limpiar el polvo, aplique el aire

suavemente desde el interior.

7. Vuelva a ensamblar las piezas en las posiciones

originales siguiendo los pasos mencionados a la inversa.

NOTA

○ Al extraer el fi ltro de papel y el fi ltro de nilón, tenga

cuidado para evitar que el polvo entre en el interior del

motor.

○ Después de lavar los fi ltros con agua jabonosa caliente.

Antes de volver a montar el fi ltro, compruebe para

asegurarse de que éste esté seco. Un fi ltro de aire que

ha sido utilizado durante mucho tiempo nunca podrá

quedar completamente limpio. Por tanto, los fi ltros deben

cambiarse por otros nuevos cada cierto tiempo.

Cambie los fi ltros que estén dañados.

Bujía (Fig. 31, 32, 33)

1. Extraiga la caja del fi ltro (B) (32) y la caja del fi ltro (A)

(37). (Fig. 31)

2. Extraiga la bujía girándola hacia la izquierda con la llave

combinada de cubo. (Fig. 32)

3. Limpie la bujía si está sucia. Compruebe el huelgo del

electrodo. El huelgo correcto debe ser de 0,6 mm. (Fig.

33)

Español

NOTA

○ Al extraer la bujía, tenga cuidado de que no penetre

suciedad en el motor.

○ Se debe reemplazar la bujía después de unas 100 horas

de funcionamiento o antes si los electrodos están muy

gastados.

Filtro de combustible (Fig. 34)

Desmonte el fi ltro de combustible (39) del depósito de

combustible y lávelo completamente con disolvente.

Posteriormente, empuje el fi ltro de combustible en todo su

recorrido para colocarlo en el depósito.

NOTA

Si el fi ltro de combustible (39) está obstruido debido al

polvo y la suciedad, deberá ser sustituido.

Sistemas antivibración (Fig. 35)

Compruebe que los resortes (40) no estén sueltos ni

dañados. Si encuentra algún fallo en dichas piezas, póngase

en contacto con un centro de servicio autorizado de HiKOKI.

Sustitución de la correa

1. Extraiga la tuerca (9) usando la llave combinada de cubo

(6) y afl oje el perno tensor (11) girándolo en sentido

antihorario con la llave hexagonal (4). A continuación,

extraiga la cubierta del brazo (10). (Fig. 11, 12)

2. Afl oje los tres pernos (41) de la cubierta del embrague

(42) y retire la cubierta del embrague (42). (Fig. 36)

3. Retire la correa (43) y coloque una nueva fi rmemente en

las ranuras de las poleas (44)(45). (Fig. 37, 38)