Page 1

en

de

C 8FSHG

fr

it

nl

es

pt

sv

da

no

fi

el

pl

hu

cs

tr

ro

sl

en

Handling instructions

de

Bedienungsanleitung

fr

Mode d’emploi

it

Istruzioni per l’uso

nl

Gebruiksaanwijzing

es

Instrucciones de manejo

pt

Instruções de uso

sv

Bruksanvisning

da

Brugsanvisning

no

Bruksanvisning

fi

Käyttöohjeet

el

Οδηγίες χειρισμού

sk

bg

sr

hr

Page 2

1

2

3

7

$

8

9

0

@

#

!

%

6

5

^

4

&

y

*

t

e

r

1

(

w

q

;

)

l

u

i

o

p

a

k

j

h

s

d

2

f

g

Page 3

23

2

h

4 – ø9 mm

214 mm

4

^

214 mm

v

230 mm

n

b

c

z

x

m

5

6

/

.

,

j

*

8

3

¡

Page 4

7

8

j

¢

£

&

o

11

™

9

10

l

¶

∞

s

a

(

i

q

a

§

l

∞

¶

s

b

!

12

i

q

b

@

6

#

4

Page 5

13 14

)

(

o

15 16

⁄

•

i

ª

•

º

ª

17 18

¤

‹

e

e

‹

¤

e

›

5

e

e

›

Page 6

19

fi

20 21

t

fl

y

‡

$

0

#

fl

fi

°

·

‚

22

ⓐ

ⓐ

„

i

ⓑ

ⓑ

ŒŒ

ⓐⓑ

´

6

Page 7

23

1

‰

2

Ü

j

24

3

Á

2

ˇ

º

25

27

*

î

l

§

Ø

(

∞

)

o

s

26

∏

ⓐ

ⓑ

ⓑ

Å

*

28

0

#

Ï

0

Î

Í

Î

a

7

Î

b

Î

Í

Page 8

29

u

1

30

p

17 mm

¸

6 mm

a

c

˛

110V 463

230V C

Ô

˛

Ò

Ô

Ò

˝

Ó

b

i

Ú

d

◊

Ç

a

31

;

ı

1

8

Page 9

English Deutsch Français Italiano

Lower guard Unterer Schutz Carénage inférieur Protezione inferiore

1

Switch handle Schaltergriff Poignée de contacteur Manico di commutazione

2

Motor head Motorkopf Tête du moteur Testa del motore

3

Gear case Getriebegehäuse Carter d'engrenage Cassa ingranaggi

4

Dust bag Staubbeutel Sac à poussière Sacca per la polvere

5

Slide securing knob Führungssicherungsknopf

6

Slide carriage Führungsträger Chariot coulissant Carrello slitta

7

Bevel pointer Schrägschnittanzeiger Pointe de biseau Puntatore smussatura

8

Holder (A) Halter (A) Support (A) Supporto (A)

9

Vise assembly Schraubstocksatz Ensemble de l'étau Gruppo morsa

0

Sub fence Hilfsgitter Butée secondaire Guida secondaria

!

Lock knob Sperrknopf Bouton de verrouillage Manopola di blocco

@

Fence (A) Gitter (A) Butée (A) Guida di appoggio (A)

#

Vise lock knob Schraubstocksperrknopf

$

Left extention table Linker Anbautisch

%

Base Basis Base Base

^

Miter pointer Gehrungsanzeiger Pointe d'onglet Puntatore quartabuono

&

Turntable Drehscheibe Plateau tournant Piatto girevole

*

Positive stop locking lever

(

Miter handle Gehrungsgriff Poignée d'onglet Manico per quartabuono

)

Table insert Tischeinsatz Plaque d'insertion Inserimento tavola

q

Fence (B) Gitter (B) Butée (B) Guida di appoggio (B)

w

Laser marker Lasermarker Marqueur laser Marcatore laser

e

Rotation direction Drehrichtung Sens de rotation Direzione di rotazione

r

Laser marker switch Schalter für Lasermarker

t

Trigger switch Auslöseschalter Interrupteur à détente Interruttore a grilletto

y

Blade guard locking lever

u

Blade Sägeblatt Lame Lama

i

Quick-cam locking lever Schnellspannhebel

o

Spindle lock Spindelsperre Verrouillage de broche Blocco dell’alberino

p

Motor Motor Moteur Motore

a

Anchor plate Ankerplatte Plaque d'ancrage Piastra di ancoraggio

s

Extention wing lock knob

d

Right extention table Rechter Anbautisch Plateau de rallonge droit

f

Mounting hole Montagebohrung Trou de montage Foro di montaggio

g

Locking pin Sicherungsstift Goupille de verrouillage Perno di bloccaggio

h

Bevel lock knob

j

Hinge Scharnier Charnière Cardine

k

Sperrhebel für den

Festanschlag

Sperrhebel für den

Sägeblattschutz

Verriegelungsknopf für den

Anbaufl ügel

SchrägschnittVerriegelungsknopf

Bouton de fi xation

coulissant

Bouton de verrouillage de

l'étau

Plateau de rallonge

gauche

Levier de verrouillage

d'arrêt positif

Contacteur de marqueur

laser

Levier de verrouillage du

protège-lame

Levier de verrouillage à

came rapide

Bouton de blocage de la

rallonge

Bouton de blocage de

biseau

Manopola di fi ssaggio slitta

Manopola di blocco morsa

Tavola di estensione

sinistra

Leva di blocco arresto

positivo

Interruttore marcatore laser

Leva di blocco protezione

lama

Leva di blocco camma

rapida

Manopola di blocco ala di

estensione

Tavola di estensione

destra

Manopola di blocco

smussatura

9

Page 10

English Deutsch Français Italiano

Stop knob Anschlagknopf Bouton d'arrêt Manopola di arresto

l

Dust port

;

Work bench Werkbank Établi Banco di lavoro

z

8 mm nut 8-mm-Mutter Écrou de 8 mm Dado da 8 mm

x

25 mm thick work bench 25 mm dicke Werkbank

c

8 mm nut 8-mm-Mutter Écrou de 8 mm Dado da 8 mm

v

Holder Halter Support Supporto

b

Hole Loch Trou Foro

n

Screw Schraube Vis Vite

m

Combination square Kombi-Winkelmaß Équerre combinée Squadra universale

,

Lock nut Sicherungsmutter Contre-écrou Controdado

.

Adjustment bolt Einstellschraube Boulon de réglage Bullone di regolazione

/

Bevel pointer screw

¡

Lock nut Sicherungsmutter Contre-écrou Controdado

™

Bolt Schraube Boulon Bullone

£

Screw Schraube Vis Vite

¢

Stop block Anschlagblock Bloc d'arrêt Blocco di arresto

∞

Stop seat Anschlagsitz Butée du siège Sede di arresto

§

4 mm machine screw 4-mm-Maschinenschraube Vis à métaux de 4 mm Vite da macchina da 4 mm

¶

Laser line Laserlinie Ligne de laser Linea laser

•

Cutting line Schnittlinie Ligne de coupe Linea di taglio

ª

Workpiece Werkstück Pièce à usiner Pezzo da lavorare

º

Top view Draufsicht Vue de dessus Vista superiore

⁄

Rivet Stift Rivet Rivet

¤

Laser housing Lasergehäuse Boîtier laser Alloggiamento laser

‹

Set screw Einstellschraube Vis de réglage Vite di fi ssaggio

›

Line Linie Ligne Linea

fi

Warning sign Warnschild Signe d'avertissement Segnale di avvertenza

fl

Hole Loch Trou Foro

‡

Knob Knopf Bouton Manopola

°

Vise plate Schraubstockplatte Plaque d'étau Piastra della morsa

·

Workpiece Werkstück Pièce à usiner Pezzo da lavorare

‚

Marking (pre-marked) Markierung (vormarkiert) Marquage (pré-marqué) Marcatura (pre-marcata)

Œ

(Front view) (Vorderansicht) (vue de face) (Vista anteriore)

„

Adjusting line Einstelllinie Ligne de réglage Linea di regolazione

´

Pull forward Nach vorn ziehen Tirer vers l'avant Tirare in avanti

‰

Press down Herunterdrücken Appuyer vers le bas Premere in basso

ˇ

Push backward Nach hinten drücken Pousser en arrière Spingere indietro

Á

Bevel scale Schrägschnittskala Échelle de biseau Scala di smussatura

¨

Miter scale Gehrungsskala Échelle à onglets Scala di quartabuono

î

Turn the turntable

Ø

Cut grooves with saw

∏

blade

Anschluss für

Staubabsaugung

Schrägschnittzeigerschraube

Drehen Sie die

Drehscheibe

Nuten mit dem Sägeblatt

schneiden

Sortie d'évacuation de

poussière

Établi de 25 mm

d'épaisseur

Vis à pointe biseautée Vite puntatore smussatura

Tourner le plateau tournant Ruotare il piatto girevole

Couper les rainures avec

une lame de scie

10

Porta per la polvere

Banco di lavoro da 25 mm

di spessore

Tagliare le scanalature con

la lama sega

Page 11

English Deutsch Français Italiano

Bottom line of the groove Untere Linie der Nut

Å

Aluminum sash Aluminiumrahmen Cadre en aluminium Telaio in alluminio

Í

Wood plate Holzplatte Plaque en bois Piastra di legno

Î

Clamp Klemme Dispositif de serrage Morsetto

Ï

Cover plate screw

˝

Cover plate Abdeckplatte Couvercle Piastra coperchio

Ó

8 mm bolt 8-mm-Schraube Boulon de 8 mm Bullone da 8 mm

Ô

Blade spanner Sägeblattschlüssel Clé à lame Chiave per lama

Washer (B) Unterlegscheibe (B) Rondelle (B) Rondella (B)

Ò

Washer (A) Unterlegscheibe (A) Rondelle (A) Rondella (A)

Ú

Wear limit line Verschleißgrenzlinie Ligne de limite d'usure Linea limite di usura

¸

No. of carbon brush Nr. der Kohlebürste

˛

Brush cap Bürstenkappe Capuchon de la brosse Tappo spazzola

Ç

Carbon brush Kohlebürste Brosse en carbone Spazzola al carbonio

◊

Air gun Druckluftpistole Pistolet à air Pistola ad aria compressa

ı

Schraube für die

Abdeckplatte

Ligne inférieure de la

rainure

Vis de couvercle Vite piastra coperchio

N° de brosse en fi bres de

carbone

Linea inferiore della

scanalatura

N. di spazzola di carbone

11

Page 12

Nederlands Español Português Svenska

Onderste afscherming Protección inferior Guarda inferior Undre skydd

1

Schakelaarhendel Manecilla del interruptor Punho de comutação Brytarhandtag

2

Motorkop Cabezal del motor Cabeça do motor Motorhuvud

3

Versnellingsbak Caja de engranajes Caixa de engrenagens Växellåda

4

Stofzak Bolsa para el polvo Saco de pó Dammpåse

5

Schuifvastzetknop

6

Schuifwagen Carro deslizante Carro da corrediça Glidvagn

7

Schuine wijzer Puntero del bisel Ponteiro do bisel Faspekare

8

Houder (A) Soporte (A) Suporte (A) Hållare (A)

9

Bankschroefmontage

0

Geleider Guía secundaria Guia secundária Subanslag

!

Vergrendelknop Perilla de bloqueo Botão de bloqueio Låsvred

@

Geleider (A) Guía (A) Guia (A) Anslag (A)

#

Bankschroef

$

vergrendelknop

Linker verlengingstafel

%

Basis Base Base Bas

^

Verstekwijzer Puntero del inglete Ponteiro de esquadria Geringspekare

&

Draaischijf Mesa giratoria Plataforma giratória Vridplatta

*

Vergrendelhendel

(

positieve stop

Verstekhandvat Mango del inglete Pega de esquadria Geringshandtag

)

Tafelinzetstuk Inserto de mesa Calço da mesa Bordinsats

q

Geleider (B) Guía (B) Guia (B) Anslag (B)

w

Lasermarkering Marcador láser Marcador a laser Lasermarkör

e

Rotatierichting Dirección de rotación Direção de rotação Rotationsriktning

r

Lasermarkerschakelaar

t

Trekschakelaar Interruptor de disparo Gatilho Avtryckare

y

Vergrendelingshendel

u

mesbeschermer

Blad Hoja Lâmina Blad

i

Snelle-

o

nokvergrendelingshendel

Spil vergrendelen Bloqueo del husillo Bloqueio do fuso Spindellås

p

Motor Motor Motor Motor

a

Ankerplaat Placa de anclaje Placa de ancoragem Förankringsplatta

s

Uitbreidingsvleugel

d

vergrendelknop

Rechter verlengingstafel

f

Bevestigingsgat Orifi cio de montaje Orifício de montagem Monteringshål

g

Borgpen Pasador de bloqueo Pino de bloqueio Låsstift

h

Schuine

j

vergrendelingsknop

Scharnier Bisagra Dobradiça Gångjärn

k

Perilla de fi jación del

pasador

Conjunto del tornillo de

carpintero

Perilla de bloqueo del

tornillo de carpintero

Mesa de extensión

izquierda

Palanca de bloqueo de

parada positiva

Interruptor del marcador

láser

Palanca de bloqueo del

protector de la cuchilla

Palanca de bloqueo de la

leva rápida

Perilla de bloqueo del ala

de extensión

Mesa de extensión

derecha

Perilla de bloqueo del bisel Botão de bloqueio do bisel Faslåsratt

Botão de segurança da

corrediça

Conjunto do torno Skruvstäd

Botão de bloqueio de torno Skruvstädslåsknapp

Mesa de extensão

esquerda

Alavanca de bloqueio de

paragem positiva

Interruptor de marcador

a laser

Alavanca de bloqueio da

proteção da lâmina

Alavanca de bloqueio de

came rápida

Botão de bloqueio da asa

de extensão

Mesa de extensão direita Höger förlängningsbord

12

Glidande säkringsratt

Vänster förlängningsbord

Positiva stoppets låsspak

Lasermarkörbrytare

Klingskyddets låsspak

Snabbkam-låsspak

Förlängningsvingens

låsratt

Page 13

Nederlands Español Português Svenska

Stopknop Perilla de parada Botão de paragem Stoppvred

l

Stofpoort Puerto del polvo Orifício do pó Dammutsläpp

;

Werkbank Banco de trabajo Bancada de trabalho Arbetsbänk

z

8 mm moer Tuerca de 8 mm Porca de 8 mm 8 mm mutter

x

25 mm dikke werkbank

c

8 mm moer Tuerca de 8 mm Porca de 8 mm 8 mm mutter

v

Houder Soporte Suporte Hållare

b

Gat Agujero Orifício Hål

n

Schroef Tornillo Parafuso Skruv

m

Combinatievierkant Cuadrado de combinación Quadrado de combinação Kombinationsvinkel

,

Borgmoer Tuerca de bloqueo Contraporca Låsmutter

.

Stelbout Perno de ajuste Parafuso de ajuste Justerbult

/

Schuine aanwijzerschroef

¡

Borgmoer Tuerca de bloqueo Contraporca Låsmutter

™

Bout Perno Perno Bult

£

Schroef Tornillo Parafuso Skruv

¢

Stopblok Bloque de parada Bloco de paragem Stoppblock

∞

Stopknop Asiento de parada Assento de paragem Stoppsäte

§

4 mm machineschroef

¶

Laserlijn Línea láser Linha de laser Laserlinje

•

Zaaglijn Línea de corte Linha de corte Skärlinje

ª

Werkstuk Pieza de trabajo Peça de trabalho Arbetsstycke

º

Bovenaanzicht Vista superior Vista do topo Sedd uppifrån

⁄

Klinknagel Remache Rebite Nitarna

¤

Laserbehuizing Carcasa del láser Carcaça do laser Laserhus

‹

Stelschroef Tornillo de ajuste Parafuso de ajuste Inställningsskruven

›

Lijn Línea Linha Linje

fi

Waarschuwingsbord Señal de advertencia Sinal de aviso Varningsskylt

fl

Gat Agujero Orifício Hål

‡

Knop Perilla Alavanca Knapp

°

Bankschroefplaat

·

Werkstuk Pieza de trabajo Peça de trabalho Arbetsstycke

‚

Markering (vooraf

Œ

gemarkeerd)

(Vooraanzicht) (Vista frontal) (Vista frontal) (Vy framifrån)

„

Stellijn Línea de ajuste Linha de ajuste Justeringslinje

´

Vooruit trekken Empujar hacia delante Puxar para a frente Dra framåt

‰

Duw naar beneden Presionar Pressionar para baixo Tryck ned

ˇ

Duw naar achteren Empujar hacia atrás Empurrar para trás Tryck bakåt

Á

Schuine schaal Escala del bisel Escala do bisel Fasskala

¨

Verstekschaal Escala del inglete Escala de esquadria Geringsskala

î

Draai aan de draaitafel Gire la mesa giratoria Rode a plataforma giratória Vrid vridplattan

Ø

Banco de trabajo de 25

mm de grosor

Tornillo del puntero

biselado

Tornillo de la máquina de

4 mm

Placa del tornillo de

carpintero

Marcado (marcado

previamente)

Bancada com 25 mm de

espessura

Parafuso de ponteiro de

inclinação

Parafuso de 4 mm para

máquina

Placa de torno Skruvstädsplatta

Marcação (pré-marcada) Märkning (förkodad)

25 mm tjock arbetsbänk

Fasningsskruv

4 mm maskinskruv

13

Page 14

Nederlands Español Português Svenska

Snijd groeven met

∏

zaagblad

Onderste lijn van de groef Línea inferior de la ranura Linha de fundo do entalhe Spårets bottenlinje

Å

Aluminium raamwerk Marco de aluminio Faixa de alumínio Lösramar av aluminium

Í

Houten plaat Placa de madera Placa de madeira Träplatta

Î

Klem Abrazadera Grampo Tving

Ï

Afdekplaatschroef

˝

Afdekplaat Placa de cubierta Placa de cobertura Täckplatta

Ó

8 mm bout Perno de 8 mm Perno de 8 mm 8 mm bult

Ô

Steekringsleutel Llave de la cuchilla Chave de lâmina Bladnyckel

Tussenring (B) Arandela (B) Anilha (B) Bricka (B)

Ò

Tussenring (A) Arandela (A) Anilha (A) Bricka (A)

Ú

Lijn slijtagelimiet Línea límite de desgaste Linha limite de desgaste Slitagegränslinje

¸

Aantal koolborstels Núm. de cepillo de carbón N.º da escova de carvão Antal kolborstar

˛

Borstelkap Tapa del cepillo Tampa da escova Borstskydd

Ç

Koolborstel Escobilla de carbón Escova de carbono Kolborste

◊

Persluchtspuit Pistola de aire Pistola de ar Tryckluftspistol

ı

Corte surcos con la

cuchilla de la sierra

Tornillo de la placa de

cubierta

Cortar entalhes com

lâmina de serra

Parafuso da placa de

cobertura

Skära spår med sågblad

Täckplattskruv

14

Page 15

Dansk Norsk Suomi Ελληνικά

Nedre afskærmning Nedre vern Alasuojus Κάτω προφυλακτήρας

1

Skiftehåndtag Bytt håndtak Kytkinkahva Λαβή διακόπτη

2

Motorhoved Motorhode Moottoripää Κεφαλή μοτέρ

3

Gearkasse Girkasse Vaihdelaatikko Θήκη ταχυτήτων

4

Støvpose Støvpose Pölypussi Σακούλα σκόνης

5

Glidesikringsgreb Skyv sikringsbryteren Liukukiinnitysnuppi

6

Skydervogn Skyvevogn Liukuteräkelkka Φορείο ολίσθησης

7

Skråmarkør Skråviser Kaltevuudenosoitin Δείκτης κλίσης

8

Holder (A) Holder (A) Pidike (A) Στήριγμα (A)

9

Skruestik Skrustikkemontering Ruuvipenkkiyhdistelmä

0

Under-anlægsfl ade Føringshjelp Apusuojus Δευτερεύων οδηγός

!

Låsegreb Låseknapp Lukitusnuppi Λαβή ασφάλισης

@

Hegn (A) Fører (A) Suojus (A) Οδηγός (A)

#

Låsegreb til skruestik Låseknapp for skrustikke

$

Venstre forlængerplade Venstre forlengelsesbord

%

Base Base Jalusta Βάση

^

Geringsmarkør Gjæringsviser Viistekulman osoitin Δείκτης λοξοτομής

&

Drejeplade Dreieskive Tasauspöytä

*

Låsehåndtag for positivt

(

stop

Geringshåndtag Gjæringshåndtak Viistekulman lukituskahva Λαβή λοξοτομής

)

Maskinbordsindsats Bordinnsats Pöydän pisto-osa Τεμάχιο τροφοδοσίας

q

Hegn (B) Fører (B) Suojus (B) Οδηγός (B)

w

Laserindikator Lasermarkør Lasermerkitsijä Δείκτης λέιζερ

e

Rotationsretning Rotasjonsretning Pyörimissuunta Κατεύθυνση περιστροφής

r

Laserindikatorkontakt Lasermarkørbryter Lasermerkitsimen kytkin Διακόπτης δείκτη λέιζερ

t

Aftrækker-kontakt Bryterknapp Liipaisukytkin Πληκτροδιακόπτης

y

Låsehåndtag til

u

klingeafskærmning

Klinge Blad Terä Λεπίδα

i

Låsehåndtag for hurtig

o

knast

Spindellås Spindellås Karan lukitus Ασφάλεια άξονα

p

Motor Motor Moottori Μοτέρ

a

Ankerplade Ankerplate Ankkurilevy Πλάκα αγκύρωσης

s

Låseknap til

d

forlængelsesvinge

Højre forlængerplade Høyre forlengelsesbord Oikeanpuoleinen jatkotaso

f

Monteringshul Monteringshull Kiinnitysreikä Οπή συναρμολόγησης

g

Låsestift Låsestift Lukitustappi Περόνη ασφαλείας

h

Skrålåseknap Skrålåseknapp

j

Hængsel Hengsel Sarana Μεντεσές

k

Positiv stopp-låsespak

Sperrehåndtak til

sagbladvern

Hurtiglåsespak Pikalukitusvipu

Vingelåseknapp til

forlengelse

Ruuvipuristimen

lukitusnuppi

Vasemmanpuoleinen

jatkotaso

Positiivisen pysähdyksen

lukitusvipu

Teränsuojuksen lukitusvipu

Jatkotason lukitusnuppi

Kaltevuuskulman

lukitusnuppi

Λαβή ασφάλισης

ολίσθησης

Μέγγενη

συναρμολόγησης

Κουμπί ασφάλισης

μέγγενης

Επιφάνεια εργασίας

επέκτασης στα αριστερά

Περιστροφική πλάκα

Μοχλός ασφάλισης

θετικού στοπ

Μοχλός ασφάλισης

προστατευτικού λεπίδας

Μοχλός ασφάλισης

quick-cam

Κουμπί ασφάλισης

πτερυγίου επέκτασης

Επιφάνεια εργασίας

επέκτασης στα δεξιά

Κουμπί ασφάλισης κλίσης

15

Page 16

Dansk Norsk Suomi Ελληνικά

Stophåndtag Stoppeknott Pysäytysnuppi Λαβή τερματισμού

l

Støvport Støvåpning Pölyportti Θύρα σκόνης

;

Arbejdsbænk Arbeidsbenk Työstöpöytä Πάγκος εργασίας

z

8 mm-møtrik 8 mm mutter 8 mm:n mutteri Παξιμάδι 8 mm

x

25 mm tyk arbejdsbænk 25 mm tykk arbeidsbenk 25 mm paksu työstöpenkki

c

8 mm-møtrik 8 mm mutter 8 mm:n mutteri Παξιμάδι 8 mm

v

Holder Holder Pidike Στήριγμα

b

Hul Hull Reikä Οπή

n

Skrue Skrue Ruuvi Βίδα

m

Kombinationsfi rkant Kombinasjonsfi rkant Yhdistelmäkulmamittain Γνώμονας συνδυασμού

,

Låsemøtrik Låsemutter Lukkomutteri Παξιμάδι ασφάλισης

.

Justeringsbolt Justeringsbolt Säätöpultti Μπουλόνι ρύθμισης

/

Skråindikatorskrue Skråskrue Kaltevuuden osoitinruuvi Βίδα δείκτη κλίσης

¡

Låsemøtrik Låsemutter Lukkomutteri Παξιμάδι ασφάλισης

™

Bolt Bolt Pultti Μπουλόνι

£

Skrue Skrue Ruuvi Βίδα

¢

Stopblok Stoppeblokk Pysäytyslohko Μπλοκ τερματισμού

∞

Stopsæde Stoppesete Pysäytyspaikka Έδρα τερματισμού

§

4 mm-maskinskrue 4 mm maskinskrue 4 mm:n koneruuvi Μηχανική βίδα 4 mm

¶

Laserlinje Laserlinje Laserlinja Γραμμή λέιζερ

•

Skærelinje Skjærelinje Leikkauslinja Γραμμή κοπής

ª

Arbejdsstykke Arbeidsstykke Työkappale Προς κατεργασία κομμάτι

º

Set ovenfra Grunnriss Ylhäältä Κατοψη

⁄

Nitte Nagle Niitti Πριτσίνι

¤

Laserkabinet Laserhus Laserkotelo Περίβλημα λέιζερ

‹

Indstillingsskrue Setteskrue Kiristysruuvi Σετ βιδών

›

Linje Linje Linja Γραμμή

fi

Advarselsskilt Varselskilt Varoitusmerkki Προειδοποιητική πινακίδα

fl

Hul Hull Reikä Οπή

‡

Greb Knapp Nuppi Λαβή

°

Skruetvingeplade Skrustikkplate Ruuvipuristin levy Πλάκα διάταξης

·

Arbejdsstykke Arbeidsstykke Työkappale Προς κατεργασία κομμάτι

‚

Mærkning

Œ

(forhåndsmærket)

(Set forfra) (Forfra) (Edestä) (Μπροστινή όψη)

„

Justeringslinje Justeringslinje Säätölinja Γραμμή ρύθμισης

´

Træk fremad Dra fremover Vedä eteenpäin Τραβήξτε προς τα εμπρός

‰

Tryk ned Trykk ned Paina alas Πιέστε προς τα κάτω

ˇ

Skub baglæns Skyv bakover Työnnä taaksepäin Σπρώξτε προς τα πίσω

Á

Skråningsskala Skråskala Kaltevuusasteikko Κλίμακα κλίσης

¨

Geringsskala Gjæringsskala Viistekulman asteikko Κλίμακα λοξοτομής

î

Drej drejebordet Drei på dreieskiven Käännä tasauspöytää

Ø

Skær riller med savklinge Kutte riller med sagblad Leikkaa urat sahanterällä

∏

Merking (pre-merket) Merkintä (ennalta merkitty) Σημάδι (προσημειωμένο)

16

Πάγκος εργασίας πάχους

25 mm

Γυρίστε την περιστροφική

πλάκα

Κόψτε αυλακώσεις με την

οδοντωτή λεπίδα

Page 17

Dansk Norsk Suomi Ελληνικά

Bundlinje for rillen Bunnlinjen av sporet Uran alalinja

Å

Aluminiumsramme Aluminiumramme Alumiinikehys Αψίδα αλουμινίου

Í

Træplade Treplate Puulevy Πλάκα ξύλου

Î

Låseanordning Klemme Kiinnike Σφιγκτήρας

Ï

Skrue til dækselplade Dekkplateskrue Suojalevyn ruuvi Βίδα πλάκας κάλυψης

˝

Dækselplade Dekkplate Suojalevy Πλάκα κάλυψης

Ó

8 mm-bolt 8 mm bolt 8 mm:n pultti Μπουλόνι 8 mm

Ô

Klingeskive Bladnøkkel Terän avain Κλειδί λεπίδας

Spændeskive (B) Skive (B) Aluslevy (B) Ροδέλα (B)

Ò

Spændeskive (A) Skive (A) Aluslevy (A) Ροδέλα (A)

Ú

Linje for slidgrænse Linje for slitasjegrense Kulumisrajan merkki Γραμμή ορίου φθοράς

¸

Antal kulstofbørster Antall kullbørster Hiiliharjan nro Αρ. ανθρακικής ψήκτρας

˛

Børstehætte Børstehette Harjan suojus Καπάκι βούρτσας

Ç

Kulstofbørste Kullbørste Hiiliharja Ανθρακική ψήκτρα

◊

Trykluftpistol Luftpistol Ilmapyssy Αεροπίστολο

ı

Κάτω γραμμή της

αυλάκωσης

17

Page 18

English

(Original instructions)

GENERAL POWER TOOL SAFETY

WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and

specifi cations provided with this power tool.

Failure to follow all instructions listed below may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as a dust mask, non-skid

safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off -position before connecting

to power source and/or battery pack, picking up

or carrying the tool.

Carrying power tools with your fi nger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away

from moving parts.

Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles.

A careless action can cause severe injury within a

fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may aff ect the power toolʼs operation. If

damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

Use of the power tool for operations diff erent from

those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean

and free from oil and grease.

18

Page 19

English

Slippery handles and grasping surfaces do not

allow for safe handling and control of the tool in

unexpected situations.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach of

children and infi rm persons.

SAFETY INSTRUCTIONS FOR MITER

SAW

a) Miter saws are intended to cut wood or wood-like

products, they cannot be used with abrasive cutoff wheels for cutting ferrous material such as bars,

rods, studs, etc.

Abrasive dust causes moving parts such as the lower

guard to jam. Sparks from abrasive cutting will burn the

lower guard, the kerf insert and other plastic parts.

b) Use clamps to support the workpiece whenever

possible. If supporting the workpiece by hand, you

must always keep your hand at least 100 mm from

either side of the saw blade. Do not use this saw to

cut pieces that are too small to be securely clamped

or held by hand.

If your hand is placed too close to the saw blade, there is

an increased risk of injury from blade contact.

c) The workpiece must be stationary and clamped or

held against both the fence and the table. Do not

feed the workpiece into the blade or cut "freehand"

in any way.

Unrestrained or moving workpieces could be thrown at

high speeds, causing injury.

d) Push the saw through the workpiece. Do not pull

the saw through the workpiece. To make a cut, raise

the saw head and pull it out over the workpiece

without cutting, start the motor, press the saw head

down and push the saw through the workpiece.

Cutting on the pull stroke is likely to cause the saw blade

to climb on top of the workpiece and violently throw the

blade assembly towards the operator.

e) Never cross your hand over the intended line of

cutting either in front or behind the saw blade.

Supporting the workpiece “cross handed” i.e. holding

the workpiece to the right of the saw blade with your left

hand or vice versa is very dangerous.

f) Do not reach behind the fence with either hand

closer than 100 mm from either side of the saw

blade, to remove wood scraps, or for any other

reason while the blade is spinning.

The proximity of the spinning saw blade to your hand

may not be obvious and you may be seriously injured.

g) Inspect your workpiece before cutting. If the

workpiece is bowed or warped, clamp it with the

outside bowed face toward the fence. Always make

certain that there is no gap between the workpiece,

fence and table along the line of the cut.

Bent or warped workpieces can twist or shift and may

cause binding on tile spinning saw blade while cutting.

There should be no nails or foreign objects in the

workpiece.

h) Do not use the saw until the table is clear of all

tools, wood scraps, etc., except for the workpiece.

Small debris or loose pieces of wood or other objects

that contact the revolving blade can be thrown with high

speed.

i) Cut only one workpiece at a time.

Stacked multiple workpieces cannot be adequately

clamped or braced and may bind on the blade or shift

during cutting.

j) Ensure the miter saw is mounted or placed on a

level, fi rm work surface before use.

A level and fi rm work surface reduces the risk of the miter

saw becoming unstable.

k) Plan your work. Every time you change the bevel or

miter angle setting, make sure the adjustable fence

is set correctly to support the workpiece and will

not interfere with the blade or the guarding system.

Without turning the tool “ON” and with no workpiece

on the table, move the saw blade through a complete

simulated cut to assure there will be no interference or

danger of cutting the fence.

I) Provide adequate support such as table extensions,

saw horses, etc. for a workpiece that is wider or

longer than the table top.

Workpieces longer or wider than the miter saw table

can tip if not securely supported. If the cut-off piece or

workpiece tips, it can lift the lower guard or be thrown by

the spinning blade.

m) Do not use another person as a substitute for a

table extension or as additional support.

Unstable support for the workpiece can cause the

blade to bind or the workpiece to shift during the cutting

operation pulling you and the helper into the spinning

blade.

n) The cut-off piece must not be jammed or pressed

by any means against the spinning saw blade.

If confi ned, i.e. using length stops, the cut-off piece could

get wedged against the blade and thrown violently.

o) Always use a clamp or a fi xture designed to properly

support round material such as rods or tubing.

Rods have a tendency to roll while being cut, causing the

blade to "bite" and pull the work with your hand into the

blade.

p) Let the blade reach full speed before contacting the

workpiece.

This will reduce the risk of the workpiece being thrown.

q) If the workpiece or blade becomes jammed, turn the

miter saw off . Wait for all moving parts to stop and

disconnect the plug from the power source and/

or remove the battery pack. Then work to free the

jammed material.

Continued sawing with a jammed workpiece could cause

lass of control or damage to the miter saw.

r) After fi nishing the cut, release the switch, hold

the saw head down and wait for the blade to stop

before removing the cut-off piece.

Reaching with your hand near the coasting blade is

dangerous.

s) Hold the handle fi rmly when making an incomplete

cut or when releasing the switch before the saw

head is completely in the down position.

The braking action of the saw may cause the saw head

to be suddenly pulled downward, causing a risk of injury.

19

Page 20

English

PRECAUTIONS ON USING SLIDE

COMPOUND MITER SAW

1. Keep the fl oor area around the machine level. Well

maintained and free of loose materials e.g. chips and

cut-off s.

2. Provide adequate general or localized lighting.

3. Do not use power tools for applications other than those

specifi ed in the handling instructions.

4. Repairing must be done only by authorized service

facility. Manufacturer is not responsible for any damages

and injuries due to the repair by the unauthorized

persons as well as the mishandling of the tool.

5. To ensure the designed operational integrity of power

tools, do not remove installed covers or screws.

6. Do not touch movable parts or accessories unless the

power source has been disconnected.

7. Use your tool at lower input than specifi ed on the

nameplate; otherwise, the fi nish may be spoiled and

working effi ciency reduced due to motor overload.

8. Do not wipe plastic parts with solvent. Solvents such as

gasoline, thinner, benzine, carbon tetrachloride, alcohol,

may damage and crack plastic parts. Do not wipe them

with such solvent. Clean plastic parts with a soft cloth

lightly dampened with soapy water.

9. Use only original HiKOKI replacement parts.

10. This tool should only be disassembled for replacement

of carbon brushes.

11. The exploded assembly drawing on this handling

instructions should be used only for authorized service

facility.

12. Never cut ferrous metals or masonry.

13. Adequate general or localized lighting is provided.

Stock and fi nished workpieces are located close to the

operators normal working position.

14. Wear suitable personal protective equipment when

necessary, this could include:

Hearing protection to reduce the risk of induced hearing

loss.

Eye protection to reduce the risk of injuring an eye.

Respiratory protection to reduce the risk of inhalation of

harmful dust.

Gloves for handling saw blades (saw blades shall be

carried in a holder wherever practicable) and rough

material.

15. The operator is adequately trained in the use, adjustment

and operation of the machine.

16. Refrain from removing any cut-off s or other parts of the

workpiece from the cutting area whilst the machine is

running and the saw head is not in the rest position.

17. Never use the slide compound miter saw with its lower

guard locked in the open position.

18. Ensure that the lower guard moves smoothly.

19. Do not use the saw without guards in position, in good

working order and properly maintained.

20. Use correctly sharpened saw blades. Observe the

maximum speed marked on the saw blade.

21. Do not use saw blades which are damaged or deformed.

22. Do not use saw blades manufactured from high speed

steel.

23. Use only saw blades recommended by HiKOKI.

Use of saw blade comply with EN847-1.

24. The saw blades should be from 210 mm to 216 mm

external diameter ranges.

25. Select the correct saw blade for the material to be cut.

26. Never operate the slide compound miter saw with the

saw blade turned upward or to the side.

27. Ensure that the workpiece is free of foreign matter such

as nails.

28. Replace the table insert when worn.

29. Do not use the saw to cut other than aluminium, wood or

similar materials.

30. Do not use the saw to cut other materials than those

recommended by the manufacturer.

31. Blade replacement procedure, including the method for

repositioning and a warning that this must be carried out

correctly.

32. Connect the slide compound miter saw to a dust

collecting device when sawing wood.

33. Take care when slotting.

34. When transporting or carrying the tool, do not grasp the

holder. Grasp the handle instead of the holder.

35. There is the danger of the holder slipping out of the base.

Grasp the handle instead of the holder.

36. Start cutting only after motor revolution reaches

maximum speed.

37. Promptly cut OFF the switch when abnormality observed.

38. Shut off power and wait for saw blade to stop before

servicing or adjusting tool.

39. During a miter or bevel cut the blade should not be lifted

until it has stopped rotation completely.

40. During slide cutting operation, the saw must be pushed

and slided away from the operator.

41. Take all the possibility of residual risks in cutting

operation into your consideration, such as the laser

radiation to your eyes, the inadvertent access to moving

parts on slide mechanical parts on machine and so on.

42. Ensure before each cut that the machine is stable.

Use only saw blades whose maximum permitted speed

is higher than the no-load speed of the power tool.

Do not replace the laser with a diff erent type.

43. Do not stand in a line with the saw blade In front of the

machine. Always stand aside of the saw blade. This

protects your body against possible kickback. Keep

hands, fi ngers and arms away from the rotating saw

blade.

Do not cross your arms when operating the tool arm.

44. If the saw blade should become jammed, switch the

machine o

comes to a complete stop. To prevent kickback, the

workpiece may not be moved until after the machine has

come to a complete stop.

Correct the cause for the jamming of the saw blade

before restarting the machine.

ff and hold the workpiece until the saw blade

20

Page 21

SYMBOLS

WARNING

The following show symbols used for the machine.

Be sure that you understand their meaning before

use.

C 8FSHG: Slide Compound Miter Saw

To reduce the risk of injury, user must read

instruction manual.

Always wear eye protection.

Always wear hearing protection.

Only for EU countries

Do not dispose of electric tools together with

household waste material!

In observance of European Directive 2012/19/

EU on waste electrical and electronic equipment

and its implementation in accordance with

national law, electric tools that have reached

the end of their life must be collected separately

and returned to an environmentally compatible

recycling facility.

V volts

Hz hertz

A amperes

no load speed

no

Class II Construction

---/min revolutions per minute

alternating current

English

STANDARD ACCESSORIES

○ 216 mm TCT Saw blade (mounted on tool) ...................1

○ Dust bag .......................................................................1

○ 13 mm Box wrench .......................................................1

○ Vise Assembly ..............................................................1

○ Holder ...........................................................................1

○ Miter Handle .................................................................1

Standard accessories are subject to change without notice.

APPLICATION

Cutting various types of aluminium sash and wood.

21

Page 22

English

SPECIFICATIONS

1. Slide Compound Miter Saw

Item Model C 8FSHG

Motor Series commutator motor

Maximum output <0.39mW CLASS 1M Laser Product

Laser Marker

Applicable saw blade

Voltage (by areas)*

Power Input* 1030 W 1100 W

No load speed 5300 min

Max.

sawing

dimension

Max.

sawing

dimension

Miter sawing range Left 0° – 48° Right 0° – 48°

Bevel sawing range Left 0° – 47° Right 0° – 2°

Compound sawing range

Machine Dimensions (Width × Depth × Height) 528 mm × 725 mm × 495 mm

Weight (Net)** 13.8 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

** According to EPTA-Procedure 01/2014

Wave length 400 – 700 nm

Laser medium Laser Diode

Outside Dia. 216 mm

Hole Dia. 30 mm

110 V

-1

Head Turntable Max. sawing dimension

(With anchor plate)

Max. Height

00

Miter

Bevel Left 45° 0

Compound Left 45°

0

0

Left 45°

Right 45°

Left 48°

Right 48°

Left 45°

Right 45°

Max. Width

(Without anchor plate)

Max. Height

Max. Width

(With anchor plate)

Max. Height

Max. Width

or

(Without anchor plate)

Max. Height

Max. Width

(With anchor plate)

Max.Height

Max.Width

or

(Without anchor plate)

Max.Height

Max.Width

(With anchor plate)

Max. Height

Max. Width

(Without anchor plate)

Max. Height

Max. Width

(With anchor plate)

Max. Height

Max. Width

or

(Without anchor plate)

Max. Height

Max. Width

Left (Bevel) 0° – 45°, Left (Miter) 0° – 45°

Right (Bevel) 0° – 45°, Right (Miter) 0° – 45°

230 V

65 mm

280 mm

54 mm

305 mm

65 mm

203 mm

54 mm

210 mm

65 mm

192 mm

54 mm

199 mm

38 mm

280 mm

26 mm

305 mm

38 mm

203 mm

26 mm

210 mm

22

Page 23

English

PRIOR TO OPERATION

CAUTION

Make all necessary adjustments before inserting the

plug in the power source.

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

Do not use with direct current, or transformers such as

boosters. Doing so may result in damage or accidents.

2. Power switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a receptacle while the trigger switch

is in the ON position, the power tool will start operating

immediately, inviting serious accident.

3. Extention cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Remove all packing materials attached or

connected to the tool before attempting to operate

it.

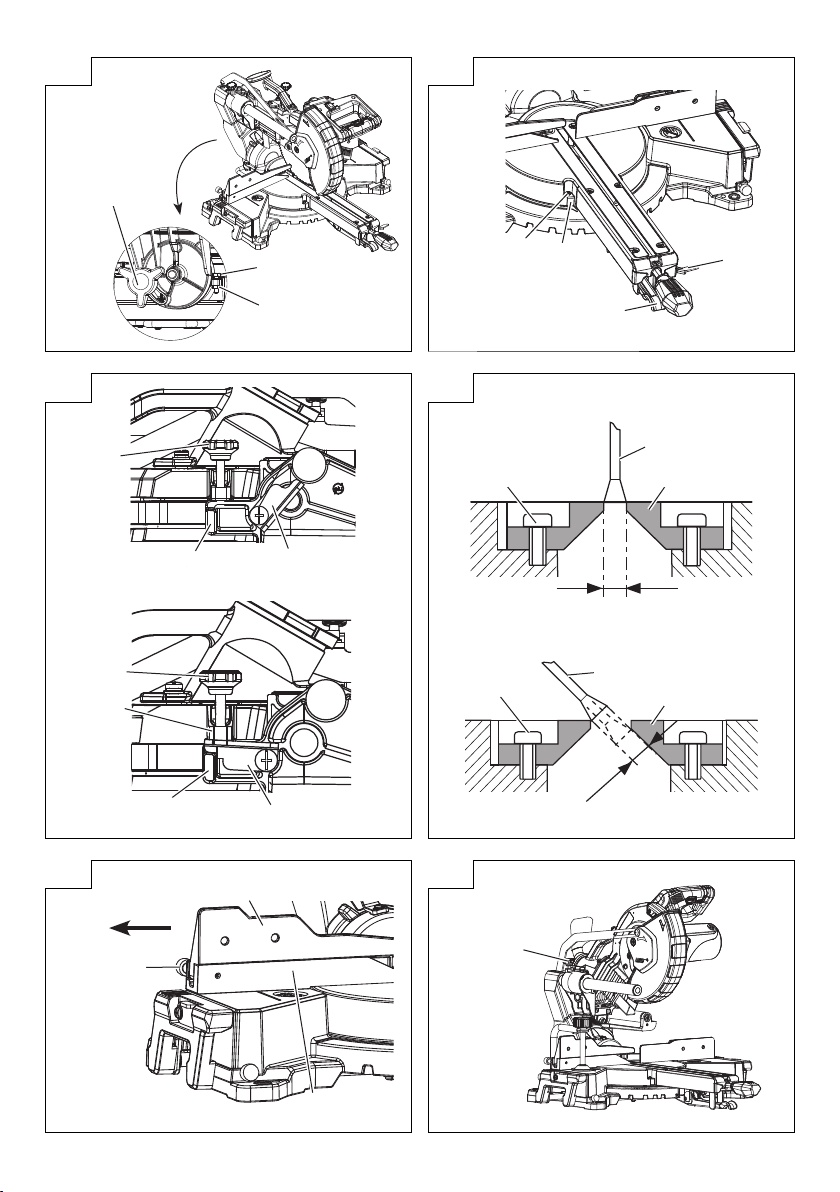

5. Releasing the locking pin (Fig. 2)

When the power tool is prepared for shipping, its main

parts are secured by a locking pin.

Press the handle slightly down and pull out the locking

pin to disengag the cutting head.

NOTE

Lowering the handle slightly will enable you to disengage

the locking pin more easily and safely. The lock position

of the locking pin is for carrying and storage only.

6. Installing the dust bag and vise (Fig. 1)

Install the dust bag onto the dust port on the miter saw.

Fit the connecting tube of dust bag and the dust port

together.

To empty the dust bag, pull out the dust bag assembly

from dust port. Open zipper on underside of bag and

empty into waste container. Check frequently and

empty the dust bag before it gets full.

NOTE

The dust bag should be angled toward the right side

of the saw for best results. This will also avoid any

interference during the saw operation.

CAUTION

Empty the dust bag frequently to prevent the duct and

the lower guard from becoming clogged.

Sawdust will accumulate more quickly than normal

during bevel cutting.

WARNING

Do not use this saw to cut and/or sand metals. the

hot chips or sparks may ignite saw dust from the bag

material.

(Attach the vise assembly as shown in Fig. 1 and Fig. 28.)

7. Installation (Fig. 3)

Ensure that the machine is always fi xed to bench.

Attach the power tool to a level, horizontal work bench.

Select 8 mm diameter bolts suitable in length for the

thickness of the work bench.

Bolt length should be at least 40 mm plus the thickness

of the work bench.

For example, use 8 mm × 65 mm bolts for a 25 mm thick

work bench.

8. Installing the holder (Fig. 4)

The holder attached to the rear of the base helps

stabilize the power tool.

Align the holder with the two holes under the rear of the

base, and tighten two screws with a Philip screwdriver.

23

9. Check the lower guard for proper operation

Lower guard is designed to protect the operator from

coming into contact with the saw blade during operation

of the tool.

Always check that the lower guard moves smoothly after

releasing the blade guard locking lever, and covers the

saw blade properly.

WARNING

NEVER OPERATE THE POWER TOOL if the lower

guard does not function smoothly.

10. 90° (0°) Bevel adjustment (Fig. 5)

WARNING

To ensure accurate cuts, alignment should be checked

and adjustments made prior to use.

(1) Loosen bevel lock knob and tilt the cutting arm

completely to the right. Tighten the bevel lock knob.

(2) Place a combination square on the miter table with the

ruler against the table and the heel of the square against

the saw blade as show in Fig. 5.

(3) If the blade is not 90° square with the miter table, loosen

the bevel lock knob, tilt the cutting head to the left, loosen

the lock nut on the bevel angle adjustment bolt and use a

10 mm spanner to adjust the bevel angle adjustment bolt

depth in or out to increase or decrease the bevel angle.

(4) Tilt the cutting arm back to the right at 90° bevel and

recheck for alignment.

(5) Repeat steps 1 through 4 if further adjustment is needed.

(6) Tighten bevel lock knob and lock nut when alignment is

achieved.

11. 90° Bevel pointer adjustment (Fig. 6)

(1) When the blade is exactly 90° (0°) to the table, loosen

the bevel pointer screw using a #2 Phillips screwdriver.

(2) Adjust bevel pointer to the “0” mark on the bevel scale

and retighten the screw.

12. 45° Left bevel adjustment (Fig. 7)

(1) Loosen the bevel lock knob and tilt the cutting head

completely to the left.

(2) Using a combination square, check to see if the blade is

45° to the table.

(3) If the blade is not at 45° to the miter table, tilt the cutting

arm to the right, loosen the lock nut and use a 10 mm

spanner to adjust the stop bolt depth in or out to increase

or decrease the bevel angle.

(4) Tilt the cutting arm to the left to 45° bevel and recheck for

alignment.

(5) Repeat steps 1 through 4 until the blade at 45° to the

miter table.

(6) Tighten bevel lock knob and lock nut when alignment is

achieved.

13. Miter angle adjustment

The slide compound miter saw scale can be easily read,

showing miter angles from 0° to 48° to the left and right.

The miter saw table has nine of the most common angle

settings with positive stops at 0°, 15°, 22.5°, 31.6°,

and 45°. These positive stops position the blade at the

desired angle quickly and accurately. Follow the process

below for quickest and most accurate adjustments.

Adjusting miter angles: (Fig. 8)

(1) Lift up the quick-cam locking lever to unlock the

table.

(2) Move the table while lifting up on the positive stop

locking lever to align the pointer to the desired

degree measurement.

(3) Lock the table into position by pressing down the

quick-cam locking lever.

Miter pointer adjustment:

(1) Move the table to the 0° positive stop.

(2) Loosen the screw that holds the miter pointer with a

Phillips screwdriver.

(3) Adjust the pointer to the 0° mark and retighten the

screw.

Page 24

English

14. Adjusting cutting depth

The maximum depth travel of the cutting head was set at

the factory.

(1) Setting the maximum width travel of the cutting head,

follow the below steps: (Fig. 9-a)

Turn the stop knob counterclockwise until the stop knob

is not protruding out of the stop seat while moving the

cutting head upward.

Rotate the anchor plate clockwise.

Recheck the blade depth by moving the cutting head

front to back through the full motion of a typical cut along

the control arm.

(2) Setting the maximum height travel of the cutting head,

follow the below steps: (Fig. 9-b)

Turn the stop knob counterclockwise until the stop knob

is not protruding out of the stop seat while moving the

cutting head upward.

Rotate the anchor plate counterclockwise to touch the

stop block.

Make sure the stop seat touches the anchor plate

completely.

15. Setting the cutting depth (Fig. 9-b)

The depth of cut can be preset for even and repetitive

shallow cuts.

(1) Adjust the cutting head down until the teeth of the blade

are at the desired depth.

(2) While holding the upper arm in that position, turn the stop

knob until it touches the anchor plate.

(3) Recheck the blade depth by moving the cutting head

front to back through the full motion of a typical cut along

the control arm.

NOTE

If the anchor plate becomes loose, it can interfere with

raising and lowering the cutting head. The anchor plate

must be tightened in horizontal position as shown in

Fig. 9-b.

PRIOR TO CUTTING

1. Positioning the table insert

Table inserts are installed on the turntable. When

shipping the tool from the factory, the table inserts are

so fi xed that the saw blade does not contact them. The

burr of the bottom surface of the workpiece is remarkably

reduced, if the table insert is fi xed so that the gap

between the side surface of the table insert and the saw

blade will be minimum. Before using the tool, eliminate

this gap in accordance with the following procedure.

(1) Right angle cutting

Loosen the three 4 mm machine screws, then secure

the left side table insert and temporarily tighten the 4 mm

machine screws of both ends. Then fi x a workpiece (about

200 mm wide) with the vise assembly and cut it off . After

aligning the cutting surface with the edge of the table

insert, securely tighten the 4 mm machine screws of both

ends. Remove the workpiece and securely tighten the

4 mm center machine screw. Adjust the right hand table

insert in the same way.

(2) Left bevel angle cutting

Adjust the table insert in the manner shown in Fig. 10-b

following the same procedure for right angle cutting.

CAUTION

After adjusting the table insert for right angle cutting, the

table insert will be cut to some extent if it is used for bevel

angle cutting.

When bevel cutting operation is required, adjust the

table insert for bevel angle cutting.

2. Use of sub fence

WARNING

The sub fence must be extended when making any left

angle bevel cut. Failure to extend the sub fence will not

allow enough space for the blade to pass through which

could result in serious injury. At extreme miter or bevel

angles the saw blade may also contact the fence.

This power tool is equipped with a sub fence.

In the case of direct angle cutting use the sub fence.

Then, you can realize stable cutting of the material with a

wide back face.

When left angle cutting, loosen the lock knob, then slide

the sub fence outward, as shown in Fig. 11.

NOTE

When transporting the saw, always secure the sub fence

in the collapsed position and lock it.

3. Securing the workpiece

WARNING

Always clamp or vise to secure the workpiece to the

fence; otherwise the workpiece might be thrust from the

table and cause bodily harm.

4. Slide carriage system (Fig. 12)

WARNING

To reduce the risk of injury, return slide carriage to the

full rear position after each crosscut operation.

For chop cutting operations on small workpieces, slide

the cutting head assembly completely toward the rear of

the unit and tighten the slide securing knob.

To cut wide boards up to 305 mm, the slide securing

knob must be loosened to allow the cutting head slide

freely.

5. Quick-cam locking lever operation (Fig. 13)

If miter angles required are NOT one of the nine positive

stops, the miter table can be locked at any angle

between these positive stops by using the quick-cam

locking lever.

Unlock the miter table by lifting up on the quick-cam

locking lever. While holding the positive stop locking

lever up, grasp the miter handle and move the table left

or right to the desired angle. Release the positive stop

locking lever. Press down on the quick-cam locking lever

until it locks the table in place.

6. The laser guide

WARNING

● For your own safety, never connect the plug to power

source outlet until the adjustment steps are complete

and you have read and understood the safety and

operational instructions.

● Your tool is equipped with a laser guide using a Class

1M laser guide. The laser guide allows you to preview

the saw blade path on the workpiece to be cut before

starting the miter saw. The saw must be connected to the

power source and the laser on/off switch must be turned

on for the laser line to show.

(1) Avoid direct eye contact (Fig. 14)

WARNING

* AVOID EXPOSURE

Laser radiation is emitted from this aperture.

CAUTION

● Use of controls or adjustments or performance of

procedures may result in hazardous radiation exposure.

● The use of optical instruments with this product will

increase eye hazard.

WARNING

Do not attempt to repair or disassemble the laser. If

unqualifi ed persons attempt to repair this laser product,

serious injury may result. Any repair required on this

laser product should be performed by a qualifi ed service

dealer.

24

Page 25

English

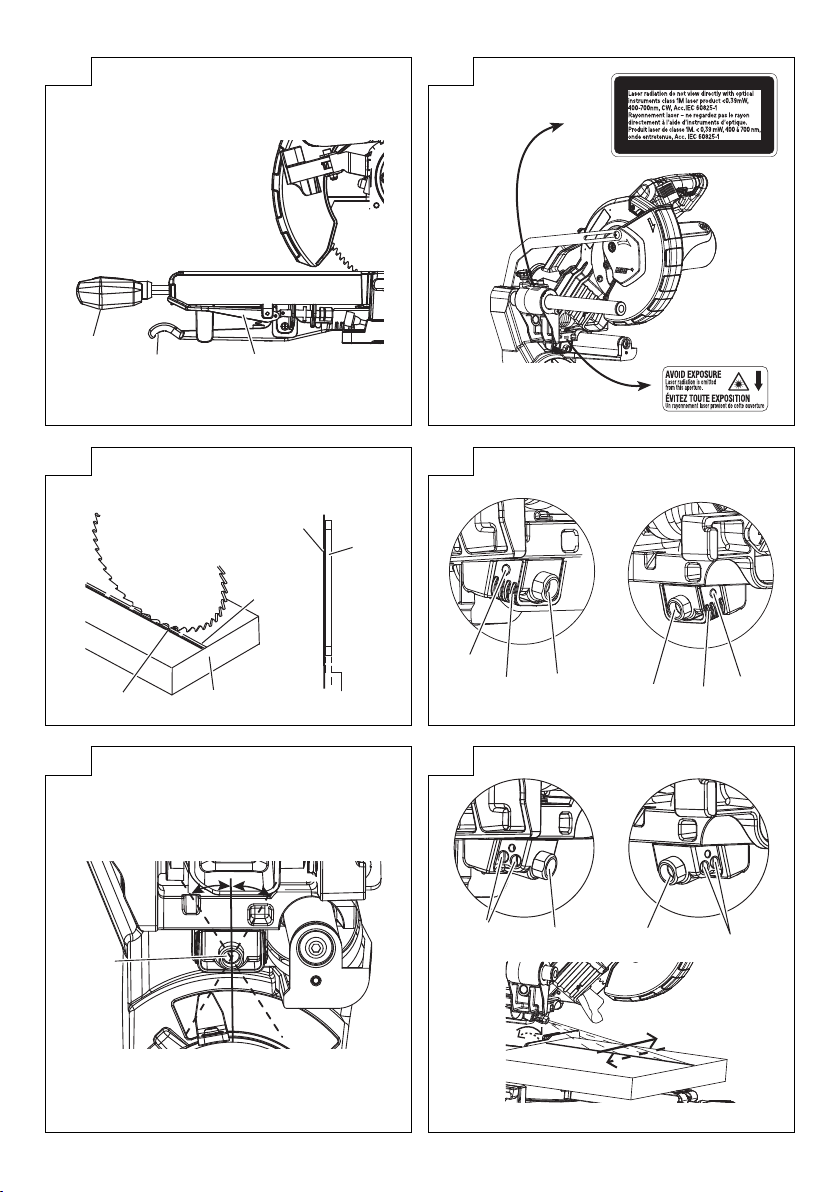

(2) Checking laser line alignment (Fig. 15)

(a) Set the saw to a 0° miter and 0° bevel setting.

(b) Use a combination square to mark a 90° angled running

across the top of a board. This line will serve as the

pattern line to adjust the laser. Place the board on the

saw table.

(c) Carefully lower the saw head down to align the saw blade

with the pattern line. Position the saw blade to the left,

side of the “pattern line” depending on your preference

for the laser line location. Lock the board in place with

the hold-down clamp.

(d) With the saw plugged in, turn on the laser guide. Your

saw has been preset with the laser line to the left side of

the blade.

(e) Lower saw blade to pattern line and if blade is not fl ush

with the pattern line, adjust as follow the instructions

listed below under “Adjusting the angle of the laser line”

paragraph and “Aligning the laser line” paragraph.

(3) Adjusting the angle of the laser line (Fig. 16, 17)

(a) After sliding the motor head forward, remove two rivets

on two sides of the laser housing and take the laser

housing off to reveal the laser marker. (Fig. 16)

(b) Turn the laser marker in the desired direction to adjust

the laser angle. (Fig. 17)

NOTE

Do not adjust the laser more than ¼ turn in either

direction as this may damage the laser.

(4) Aligning the laser line. (Fig. 16, 18)

(a) Loosen only ½ turn at a time the four set screws.

(Fig. 18)

(b) Adjust laser marker by turning the left side set screws

clockwise to shift the laser line to the right. To shift the

laser line to the left, turn the right side set screws ½ turn

at a time.

(c) Once alignment of the laser is achieved, tighten only ½

turn at a time the four set screws.

(d) After fi nishing the laser adjustment, replace the laser

housing on the laser marker and then tighten the two

rivets. (Fig. 16)

PRACTICAL APPLICATIONS

WARNING

○ To avoid personal injury, never remove or place a

workpiece on the table while the tool is being operated.

○ Never place your limbs inside of the line next to warning

sign while the tool is being operated (see Fig. 19). This

may cause hazardous conditions.

CAUTION

○ It is dangerous to remove or install the workpiece while

the saw blade is turning.

○ When sawing, clean off the shavings from the turntable.

○ If the shavings accumulate too much, the saw blade from

the cutting material will be exposed. Never subject your

hand or anything else to go near the exposed blade.

NOTE

Prior to operating the switch, make sure to check the

stability of the tool by setting the angle and turn to

conduct a trial cutting run without using a workpiece.

1. Switch operation (Fig. 20)

(1) Turning the saw on

This miter saw is equipped with a trigger switch. Squeeze

the trigger switch to turn the miter saw ON. Release the

trigger switch to turn the saw OFF.

(2) Turning the laser guide on

Press the laser switch to turn it ON, and press again to

turn it OFF.

WARNING

Make the ON/OFF switch childproof. Insert a padlock,

or chain with padlock, through the hole in the trigger

and lock the tool’s switch, preventing children and other

unqualifi ed users from turning the machine on.

2. Using the Vise Assembly (Standard accessory)

(1) The vise assembly can be mounted on the base.

(2) Turn the vise lock knob and securely fi x the vise

assembly.

(3) Turn the upper knob and securely fi x the workpiece in

position (Fig. 21).

NOTE

When using the vise, make sure that the tool is free of

any excessive contact when the unit is swing or slide.

WARNING

Always fi rmly clamp or vise to secure the workpiece to

the fence; otherwise the workpiece might be thrust from

the table and cause bodily harm.

3. Cutting Operation

(1) As shown in Fig. 22 the width of the saw blade is the

width of the cut. Therefore, slide the workpiece to the

right (viewed from the operator’s position) when length

ⓑ is desired, or to the left when length ⓐ is desired.

If a laser marker is used, align the laser line with the left

side of the saw blade, and then align the ink line with the

laser line.

(2) Once the saw blade reaches maximum speed, push the

handle down carefully until the saw blade approaches

the workpiece.

(3) Once the saw blade contacts the workpiece, push the

handle down gradually to cut into the workpiece.

(4) After cutting the workpiece to the desired depth, turn the

power tool OFF and let the saw blade stop completely

before raising the handle from the workpiece to return it

to the full retract position.

CAUTION

Increased pressure on the handle will not increase the

cutting speed.

On the contrary, too much pressure may result in

overload of the motor and/or decreased cutting

effi ciency.

WARNING

● Confi rm that the trigger switch is turned OFF and the

power plug has been removed from the receptacle

whenever the tool is not in use.

● Always turn the power off and let the saw blade stop

completely before raising the handle from the workpiece.

If the handle is raised while the saw blade is still rotating,

the cut-off piece may become jammed against the saw

blade causing fragments to scatter about dangerously.

● Every time one cutting or deep-cutting operation is

fi nished, turn the trigger switch off , and check that the

saw blade has stopped. Then raise the handle, and

return it to the full retract position.

● Be absolutely sure to remove the cut material from the

top of the turntable, and then proceed to the next step.

● Continued cutting operation can result in overload of the

motor. Touch the motor and if it's hot, stop your cutting

operation at once and rest for 10 minutes or so, and then

restart your cutting operation.

4. Cutting wide workpieces (Slide cutting)

(1) Workpieces up to 65 mm high and 280 mm wide:

Loosen the slide securing knob (see

handle and slide the saw blade forward.

Then press down on the handle and slide the saw blade

backward to cut the workpiece as indicated in Fig. 23.

This facilitates cutting of workpieces of up to 65 mm in

height and 280 mm in width.

(2) Workpieces up to 54 mm high and 305 mm wide:

Workpieces of up to 54 mm in height and up to 305 mm

in width can be cut in the same manner as described in

paragraph 4-(1) above on page 25.

25

Fig. 1), grip the

Page 26

English

CAUTION

● If the handle is pressed down with excessive or lateral

force, the saw blade may vibrate during the cutting

operation and cause unwanted cutting marks on the

workpiece, thus reducing the quality of the cut.

Accordingly, press the handle down gently and carefully.

● In slide cutting, gently push the handle back (rearwards)

in a single, smooth operation.

Stopping the handle movement during the cut will cause

unwanted cutting marks on the workpiece.

WARNING

● For slide cutting, follow the procedures indicated above

in Fig. 23.

Forward slide cutting (toward the operator) is very

dangerous because the saw blade could kick upward

from the workpiece. Therefore, always slide the handle

away from the operator.

● Always return the carriage to the full rear position after

each crosscut operation in order to reduce the risk of

injury.

● Never put your hand on the miter handle during the

cutting operation because the saw blade comes close to

the miter handle when the motor head is lowered.

5. Bevel cutting procedures

WARNING

The sub fence must be extended when making any

bevel cut. Failure to extend the sub fence will not allow

enough space for the blade to pass through which could

result in serious injury. At extreme miter or bevel angles

the saw blade may also contact the fence.

(1) When a bevel cut is required, loosen the bevel lock knob

by turning it clockwise. (Fig. 24)

(2) Tilt the cutting head to the desired angle, as shown on

the bevel scale.

(3) The blade can be positioned at any angle, from a 90°

straight cut (0° on the scale) to a 45°. Tighten the bevel

lock knob to lock the cutting head in position. Positive

stops are provided at 0° and 45°.

(4) Turn the laser guide on and position the workpiece on

the table for pre-alignment of your cut.

WARNING

When the workpiece is secured on the left or right side

of the blade, the short cut-off portion will come to rest

on the right or left side of the saw blade. Always turn the

power off and let the saw blade stop completely before

raising the handle from the workpiece.

If the handle is raised while the saw blade is still rotating,

the cut-off piece may become jammed against the saw

blade causing fragments to scatter about dangerously.

When stopping the bevel cutting operation halfway, start

cutting after pulling back the motor head to the initial

position.

Starting from halfway, without pulling back, causes the

lower guard to be caught in the cutting groove of the

workpiece and to contact the saw blade.

CAUTION

● If not tightened fi rmly enough the motor head might

suddenly move or slip, causing injuries. Be sure to

tighten the motor head section enough so it will not

move.

● Always check that the bevel lock knob is secured and

the motor head is clamped. If you attempt angle cutting

without clamping the motor head, then the motor head

might shift unexpectedly causing injuries.

6. Miter cutting procedures (Fig. 25)

(1) Unlock the miter table by lifting up on the quick-cam

locking lever.

(2) While raising the positive stop locking lever up, grasp

the miter handle and rotate the table left or right to the

desired angle.

(3) Release the positive stop locking lever and set the table

at the desired angle, making sure the lever snaps into

place.

(4) Once the desired miter angle is achieved, press down

on the quick-cam locking lever to secure the table into

position.

(5) If the desired miter angle is NOT one of the nine positive

stops noted above, simply lock the table at the desired

angle by pressing down on the quick-cam locking lever.

(6) Turn the laser guide on and position the workpiece on

the table for pre-alignment of your cut.

CAUTION

Always check that the miter handle is secured and the

turntable is clamped.

If you attempt angle cutting without clamping the

turntable, then the turntable might shift unexpectedly

causing injuries.

NOTE

○ Positive stops are provided at the right and left of the 0°

center setting, at 15°, 22.5°, 31.6° and 45° settings.

Check that the miter scale and the tip of the indicator are

properly aligned.

○ Operation of the saw with the miter scale and indicator

out of alignment will result in poor cutting precision.

7. Compound cutting procedures

Compound cutting can be performed by following the

instructions in 4 to 6 above. For maximum dimensions

for compound cutting, refer to “SPECIFICATIONS” table

on page 22.

CAUTION

Always secure the workpiece with the right or left

hand and cut it by sliding the round portion of the saw

backwards with the other hand.

It is very dangerous to rotate the turntable to the left

during compound cutting because the saw blade may

come into contact with the hand that is securing the

workpiece.

In case of compound cutting (angle + bevel) by left bevel,

extend the sub fence fully before cutting operation.

Please confi rm that sub fence does not interfere with

other parts before attempting compound cutting.

8. Groove cutting procedures

Grooves in the workpiece can be cut as indicated in

Fig. 26 by adjusting the stop knob.

Cutting depth adjustment procedure:

(1) Turn the anchor plate on the direction shown in

Fig. 27.

Lower the motor head, and turn the stop knob by

hand. (where the head of the stop knob contacts the

anchor plate.)

(2) Adjust to the desired cutting depth by setting the

distance between the saw blade and the surface of

the turntable (see ⓑ in Fig. 27).

NOTE

When cutting a single groove at either end of the

workpiece, remove the unneeded portion with a chisel.

9. Cutting easily-deformed materials, such as

aluminum sash

Materials such as aluminum sash can easily deform

when tightened too much in a vise assembly. This will

cause ineffi cient cutting and possible overload of the

motor.

When cutting such materials, use a wood plate to protect

the workpiece as shown in Fig. 28-a. Set the wood plate

near the cutting section.

When cutting aluminum materials, coat the saw blade

with cutting oil (non-combustible) to achieve smooth

cutting and a fi ne fi nish.

In addition, in case of a U-shaped workpiece, use the

wood plate as shown in Fig. 28-b to ensure stability in

the lateral direction, and clamp it near the cutting section

of the workpiece and tighten it using both the vise

assembly and the clamp available in the market.

26

Page 27

English

SAW BLADE MOUNTING AND

DISMOUNTING

WARNING

● To prevent an accident or personal injury, always turn off

the trigger switch and disconnect the power plug from

the receptacle before removing or installing a saw blade.

If cutting work is done in a state where the 8 mm bolt is

not suffi ciently tightened, the 8 mm bolt can get loose,

the blade can come off , and the lower guard can get

damaged, resulting in injuries.

Also, check that the 8 mm bolts are properly tightened

before plugging the power plug into the receptacle.

● If the 8 mm bolts are attached or detached using tools

other than the 13 mm wrench (standard accessory),

excessive or improperly tightening occurs, resulting in

injury.

1. Dismounting the blade (Fig. 29-a, Fig. 29-b, Fig. 29-c

and Fig. 29-d)

(1) Unplug the power cord from the outlet.

(2) Raise the cutting head to the upright position and slide

the cutting head completely toward the rear of the unit

and tighten the slide securing knob.

(3) Push slightly on the blade guard locking lever and then

raise the lower guard to the uppermost position.

(4) While holding the lower guard, remove the cover plate

screw with a Phillips screwdriver.

(5) Rotate the cover plate to expose the 8 mm bolt.

(6) Place the blade end spanner over the 8 mm bolt.

(7) Locate the spindle lock on the motor.

(8) Press the spindle lock, holding it in fi rmly while turning

the blade clockwise. The spindle lock will then engage

and lock the arbor. Continue to hold the spindle lock,

while turning the spanner clockwise to loosen the

8 mm bolt.

(9) Remove the 8 mm bolt, washer (B) and the blade. Do not

remove the washer (A).

NOTE

○ If the spindle lock cannot be easily pressed in to lock the

spindle, turn the 8 mm bolt with 13 mm wrench (standard

accessory) while applying pressure on the spindle lock.

The saw blade spindle is locked when the spindle lock is

pressed inward.

○ Pay attention to the pieces removed, noting their position

and direction they face. Wipe the washer (B) clean from

any sawdust before installing a new blade.

WARNING

When mounting the saw blade, confi rm that the rotation

indicator mark on the saw blade and the rotation direction

of the lower guard (see Fig. 1) are properly matched.

CAUTION

● Confi rm that the spindle lock has returned to the retract

position after installing or removing the saw blade.

● Tighten the 8 mm bolt so it does not come loose during