Page 1

English

Model

Модель

C 10RD

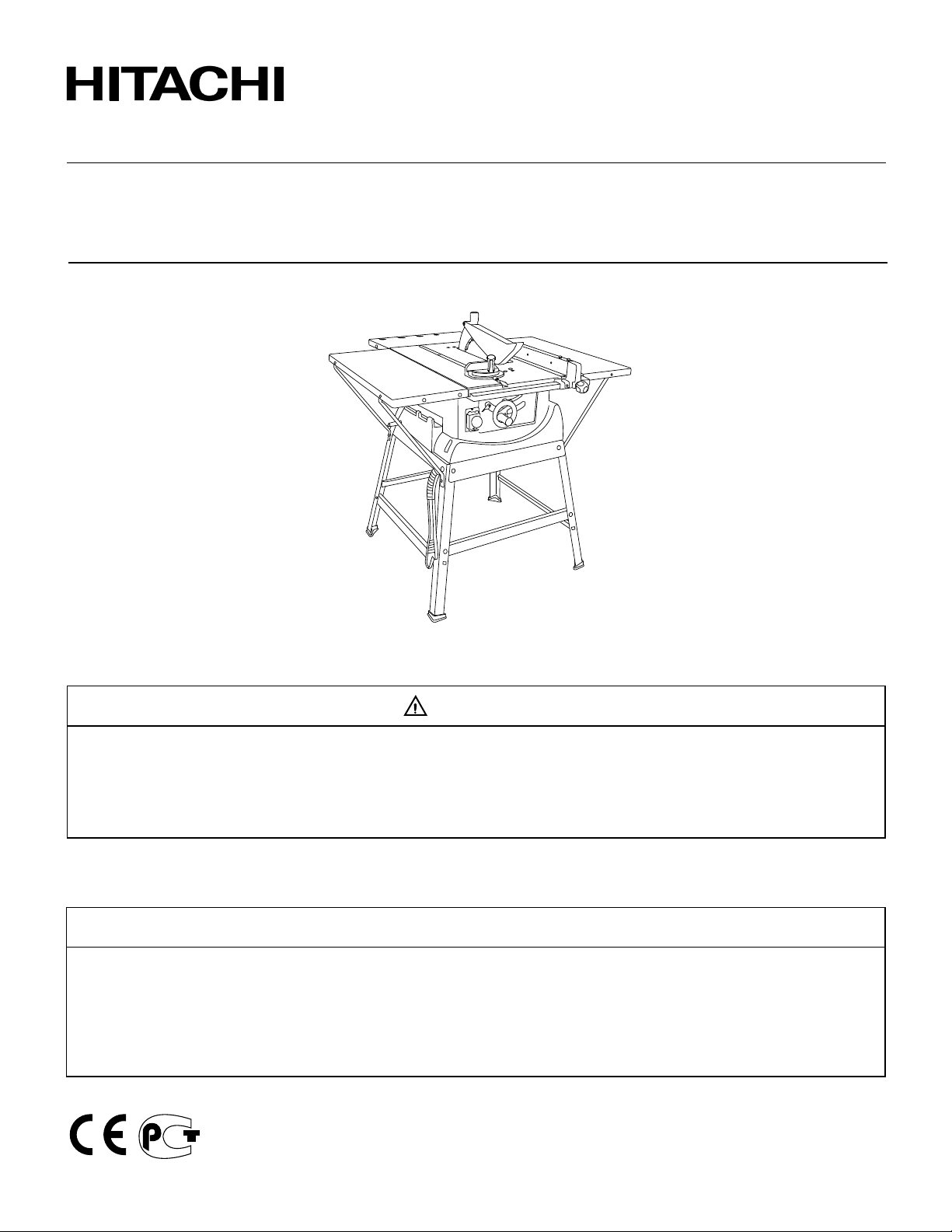

Jobsite Table Saw

Настольная дисковая пила

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

WARNING

Improper and unsafe use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual

before operating the power tool. Please keep this manual available for others before they use the power

tool.

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ И ТЕХНИКЕ БЕЗОПАСНОСТИ

Ненадлежащее использование данного механизированного инструмента и несоблюдение техники безопасности могут

привести к серьезным травмам!

В данной инструкции содержится важная информация относительно техники безопасности. Перед эксплуатацией

инструмента следует прочесть и полностью понять данную инструкцию. Обеспечьте свободный доступ к данной

инструкции всем, кто будет использовать инструмент.

Hitachi Koki

AЯ46

– 1 –

Page 2

English

English

CONTENTS

SECTION PAGE

Product Specifications ................................................................................................................ 3

Power Tool Safety ...................................................................................................................... 4

Table Saw Safety ........................................................................................................................ 5

Electrical Requirements and Safety ........................................................................................... 6

Accessories and Attachments .................................................................................................... 7

Tools Needed for Assembly ....................................................................................................... 7

Carton Contents ......................................................................................................................... 7

Know Your Table Saw ................................................................................................................ 9

Assembly and Adjustments ........................................................................................................ 10

Operation .................................................................................................................................... 15

Maintenance ............................................................................................................................... 18

Troubleshooting Guide ............................................................................................................... 19

Push Stick Pattern ...................................................................................................................... 20

Parts List ..................................................................................................................................... 39

СОДЕРЖАНИЕ

Russian

РАЗДЕЛ СТР.

Спецификации инструмента......................................................................................................... 21

Техника безопасности механизма................................................................................................. 22

Техника безопасности станка

Требования к электрике и техника безопасности........................................................................... 24

Аксессуары и дополнительное оборудование................................................................................ 25

Инструменты, необходимые для сборки........................................................................................ 25

Содержимое коробки.................................................................................................................... 25

Знайте конструкцию станка........................................................................................................... 27

Сборка и настройка...................................................................................................................... 28

Эксплуатация............................................................................................................................... 33

........................................................................................................

23

Обслуживание.............................................................................................................................. 36

Устранение неполадок.................................................................................................................. 37

Шаблон толкателя........................................................................................................................ 38

Перечень деталей........................................................................................................................ 39

– 2 –

Page 3

English

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety equipment, such as

dust masks that are specially designed to filter out microscopic particles.

PRODUCT SPECIFICATIONS

MOTOR SAW

Type ........................................ Universal Table Size with Extension................. 970mm x 890mm

Amps ....................................... 6.5A Table Extension ................................ Left, Right, Rear

Voltage .................................... 230V/50Hz Rip Capacity with Extension.............. 130mm R x 185mm L

Watts ....................................... 1600W (S6, 25%,10min) Blade Size......................................... 250mm

No load speed ......................... 4800min

Overload Protection ................ YES Rip Fence ......................................... YES

SYMBOLS

V........... Volts A............ amperes

Hz......... hertz W........... watts

min....... minutes ~............ alternating current

h........... hours ........... class II Construction

I............ ON O........... OFF

min-1..... revolutions per minute

-1

Rip Scale .......................................... YES

Mitre Gauge ...................................... YES

Maximum Cut Depth @ 90º .............. 73mm

Maximum Cut Depth @ 45º .............. 63mm

Net Weight ........................................ 21.65kg

Wear safety goggles

Wear ear protection

Wear a breathing mask

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, hoses and packaging should be

sorted, taken to the local recycling center and disposed of in an environmentally safe way.

WARNING

Noise can be a health hazard. When the noise level exceeds 85dB(A), be sure to wear ear protection.

WARNING

To avoid electrical hazards, fire hazards or damage to the table saw, use proper circuit protection.

This table saw is wired at the factory for 230 Volt operation. It must be connected to a 230 Volt / 6.5 Ampere

time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is worn, cut or

damaged in any way. Before using your table saw, it is critical that you read and understand these safety rules.

Failure to follow these rules could result in serious injury to you or damage to the table saw.

WARNING

Through poor conditions of the electrical MAINS, shortly voltage drops can appear when starting the

EQUIPMENT. This can influence other equipment (e.g. blinking of a lamp). If the MAINS-IMPEDANCE Zmax <

0.3 OHM, such disturbances are not expected. (In case of need, you may contact your local supply authority

for further information).

– 3 –

Page 4

English

POWER TOOL SAFETY

WARNING

Before using your table saw, it is critical that you read and understand these safety rules. Failure to follow

these rules could result in serious injury or damage to the table saw.

Good safety practices are a combination of common

sense, staying alert and understanding how to use your

power tool. To avoid mistakes that could cause serious

injury, do not plug in your power tool until you have read

and understood the following safety rules:

1. READ and become familiar with this entire

Operator’s Manual. LEARN the tool’s applications,

limitations and possible hazards.

2.

Look for this symbol that identifies important

3. NEVER OPERATE THIS MACHINE WITHOUT THE

4. DO NOT USE IN A DANGEROUS ENVIRONMENT

5. DO NOT use power tools in the presence of

6. KEEP WORK AREA CLEAN. Cluttered areas and

7. KEEP CHILDREN AWAY. All visitors should be

8. DO NOT FORCE THE TOOL. It will do the job

9. USE THE RIGHT TOOL. Don’t force the tool or

10. WEAR PROPER APPAREL. DO NOT wear loose

Non-slip footwear is recommended. Wear protective

11. WEAR A FACE MASK OR DUST MASK. Sawing,

12. DISCONNECT TOOLS before servicing and when

13. REDUCE THE RISK OF UNINTENTIONAL

14. USE ONLY RECOMMENDED ACCESSORIES.

WARNING

safety precautions. It means BE ALERT! YOUR

SAFETY IS INVOLVED!

SAFETY GUARD IN PLACE FOR ALL THROUGH

–SAWING OPERATIONS.

such as damp or wet locations or in the rain. Keep

work area well lighted.

flammable liquids or gases.

benches invite accidents.

kept at a safe distance from the work area.

better and safer if used at the rate for which it was

designed.

attachment to do a job for which it is not designed.

clothing, gloves, neckties, rings, bracelets or other

jewelry that may get caught in moving parts.

hair covering to contain long hair.

cutting and sanding operations produce dust.

changing accessories, such as blades, cutters, etc.

STARTING. Make sure the switch is in the OFF

position before plugging tool into the power supply.

Consult the Operator’s Manual for recommended

accessories. The use of improper accessories may

cause injury to you or damage to the tool.

15. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool

before turning ON.

16. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Do not leave the tool

before the blade comes to a complete stop.

17. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

18. DO NOT OVERREACH. Keep proper footing and

balance at all times.

19. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for most efficient and safest performance.

Follow instructions for lubricating and changing

accessories.

20. CHECK FOR DAMAGED OR LOOSE PARTS.

Check for alignment of moving parts, binding

of moving parts, loose mounting and any other

conditions that may affect its safe operation. A

guard or other part that is loose or damaged should

be properly adjusted, repaired or replaced.

21. MAKE WORKSHOP CHILDPROOF with padlocks,

master switches or by removing starter keys.

22. DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medication that

could impair your ability to use the tool safely.

23. USE A DUST COLLECTION SYSTEM whenever

possible. Dust generated from certain materials can

be hazardous to your health and, in some cases,

a fire hazard. Always operate the power tool in a

well-ventilated area with adequate dust removal.

24. ALWAYS WEAR EYE PROTECTION. Any power

tool can throw debris into your eyes that could

cause permanent eye damage. ALWAYS wear

safety goggles (not glasses) that comply with ANSI

safety standard Z87.1. Everyday glasses have only

impact resistant lenses. They ARE NOT safety

glasses.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could cause serious injury when they

break.

25. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or

cutter only.

– 4 –

Page 5

TABLE SAW SAFETY

English

1. ALWAYS USE SAW BLADE GUARD, splitter

and antikickback pawls for every operation for

which they can be used, including through sawing.

Through sawing operations are those in which the

blade cuts completely through the workpiece when

ripping or crosscutting.

2. ALWAYS HOLD WORK FIRMLY against the mitre

gauge or rip fence.

3. ALWAYS USE a push stick, especially when ripping

narrow stock. Refer to ripping instructions in this

Operator’s Manual where the push stick is covered

in detail. A pattern for making your own push stick is

included on page 20.

4. NEVER PERFORM ANY OPERATION

FREEHAND, which means using only your

hands to support or guide the workpiece.

Always use either the fence or the mitre gauge

to position and guide the work.

WARNING: FREEHAND CUTTING IS THE MAJOR

CAUSE OF KICKBACK AND FINGER/HAND

AMPUTATIONS.

5. NEVER STAND or have any part of your body in

line with the path of the saw blade. Keep your hands

out of the saw blade path.

12. PROVIDE ADEQUATE SUPPORT to the rear

and the sides of the saw table for long or wide

workpieces.

13. AVOID KICKBACKS (work thrown back towards

you) by keeping the blade sharp, the rip fence

parallel to the saw blade and by keeping the splitter,

anti-kickback pawls and guards in place, aligned

and functioning. Do not release work before passing

it completely beyond the saw blade. Do not rip work

that is twisted, warped or does not have a straight

edge to guide it along the fence.

14. AVOID AWKWARD OPERATIONS and hand

positions where a sudden slip could cause your

hand to move into the saw blade.

15. NEVER USE SOLVENTS to clean plastic parts.

Solvents could possibly dissolve or otherwise

damage the material. Only a soft damp cloth should

be used to clean plastic parts.

16. MOUNT your table saw on a bench or stand

before performing any cutting operations. Refer to

ASSEMBLY AND ADJUSTMENTS on page 10.

17. NEVER CUT METALS or materials that may make

hazardous dust.

6. NEVER REACH behind or over the cutting tool for

any reason.

7. REMOVE the rip fence when crosscutting.

8. DO NOT USE a molding head with this saw.

9. FEED WORK INTO THE BLADE against the

direction of rotation only.

10. NEVER use the rip fence as a cut-off gauge when

crosscutting.

11. NEVER ATTEMPT TO FREE A STALLED SAW

BLADE without first turning the saw OFF. Turn

power switch OFF immediately to prevent motor

damage.

18. ALWAYS USE IN A WELL-VENTILATED AREA.

Remove sawdust frequently. Clean out sawdust

from the interior of the saw to prevent a potential

fire hazard. Attach a vacuum to the dust port for

additional sawdust removal.

19. NEVER LEAVE THE SAW RUNNING

UNATTENDED. Do not leave the saw until the blade

comes to a complete stop.

20. For proper operation follow the instructions in this

Operator’s Manual entitled ASSEMBLY AND

ADJUSTMENTS (Page 10). Failure to provide

sawdust fall-through and removal hole will allow

sawdust to build up in the motor area resulting in a

fire hazard and potential motor damage.

– 5 –

Page 6

English

ELECTRICAL REQUIREMENTS AND SAFETY

CONNECTING TO THE POWER SUPPLY

Check that the power supply and plug used is in accordance with your table saw. Have a look at the rating plate of the

motor or the rating on the table saw. Any changes should always be carried out by a qualified electrician.

WARNING

This machine must be earthed.

If not properly earthed this machine can cause an electrical shock. Be sure that the power supply outlet is earthed. If

there is any doubt, have it checked by a qualified electrician.

WARNING

Avoid contact with the terminals on the plug when installing (removing) the plug to (from) the power supply

outlet. Contact will cause a severe electrical shock.

USING AN EXTENSION LEAD

The use of any extension lead will cause some loss of power. To keep this to a minimum and to prevent overheating

and motor burn-out, ask advice from a qualified electrician to determine the minimum wire size of the extension lead.

The extension lead should be equipped with an earthed type plug that fits the power supply outlet at one end, and with

an earthed type socket that fits the plug of this machine at the other end.

– 6 –

Page 7

ACCESSORIES AND ATTACHMENTS

RECOMMENDED ACCESSORIES

WARNING

Visit your Hardware Department or see the Power

and Hand Tools Catalog to purchase recommended

accessories for this power tool.

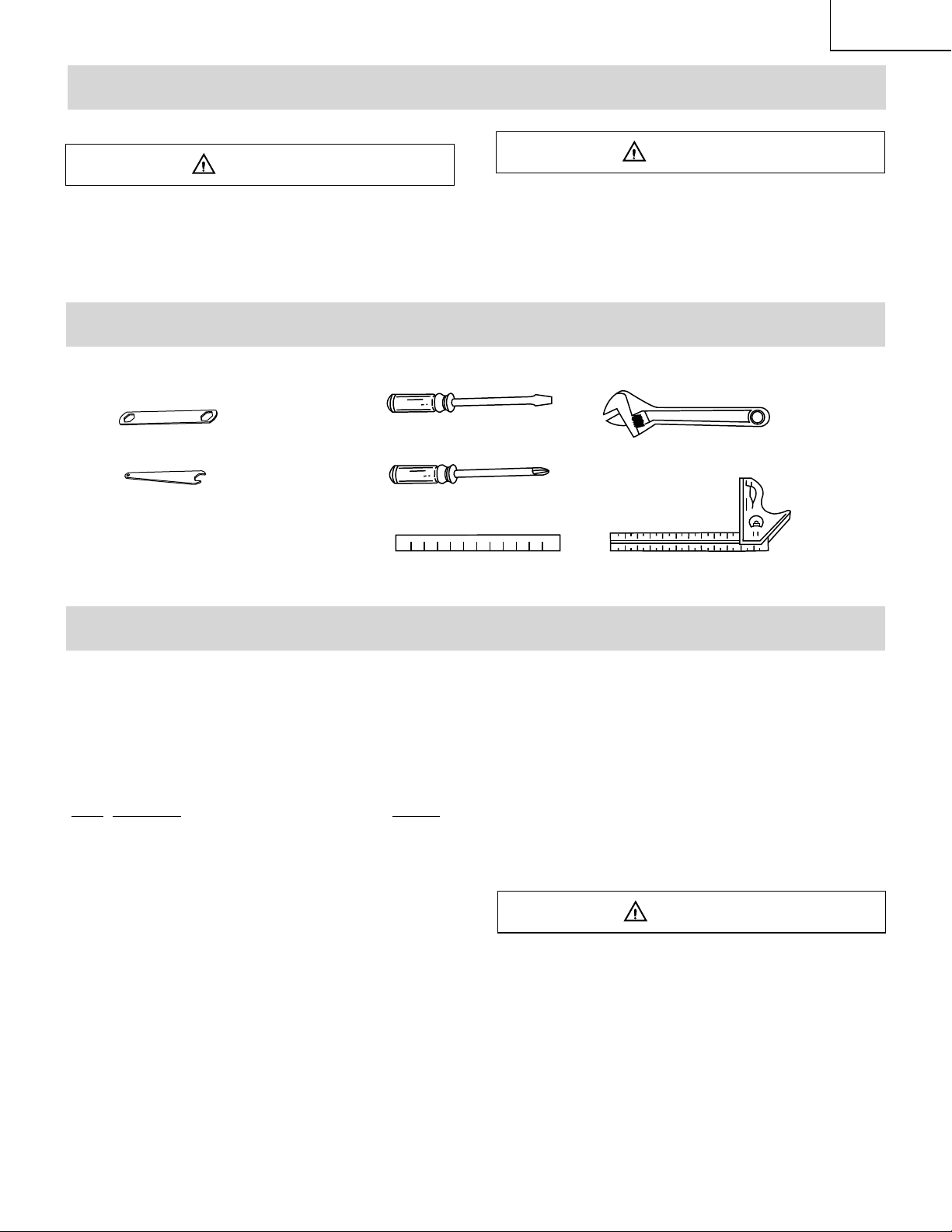

TOOLS NEEDED FOR ASSEMBLY

English

WARNING

To avoid the risk of personal injury:

• Do not use molding head set with this saw.

• Do not modify this power tool or use accessories

not recommended by Store.

Supplied

Wrench

Wrench

Not Supplied

Medium Screwdriver

#2 Phillips Screwdriver

Straight Edge

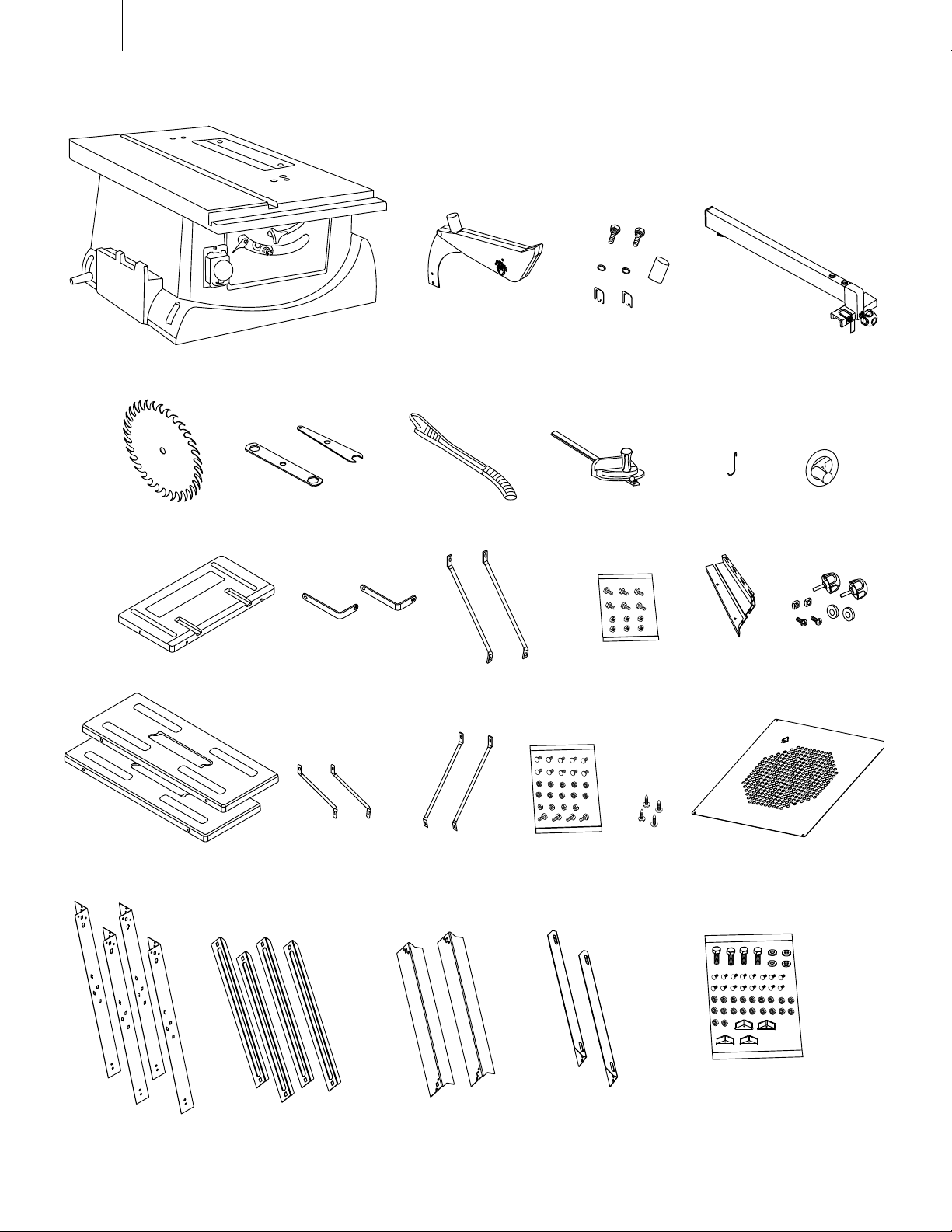

CARTON CONTENTS

UNPACKING AND CHECKING CONTENTS

Separate all parts from packing materials. Check each

part with the illustration on the next page and the “Table

of Loose Parts” to make certain all items are accounted

for before discarding any packing material.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

A

Table saw assembly 1

B Riving knife assembly

C Riving knife hardware bag 1

D Rip fence

E Blade

F Blade wrench 2

G Push stick

H Mitre gauge

I Push stick storage

J Handwheel 1

K Rear table extension 1

L Rear table extension bracket 2

M Rear table extension support 2

N Rear table extension hardware bag 1

O Auxiliary fence 1

P Auxiliary fence hardware bag 1

Q Table side extension 2

1

1

1

1

1

1

Adjustable Wrench

Combination Square

R Left side table extension support 2

S Right side table extension support 2

T Table side extension hardware bag 1

U Screw 4

V Base cover 1

STAND:

W Leg 4

X Bottom support bracket 4

Y Long upper support 2

Z Short upper support 2

AA Stand hardware bag 1

WARNING

If any part is missing or damaged, do not attempt

to assemble the table saw, plug in the power cord,

or turn the switch ON until the missing or damaged

part is obtained and is installed correctly.

NOTE: To make assembly easier, keep contents of box

together. Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean dry cloth. This will

reduce friction when pushing the workpiece.

– 7 –

Page 8

English

UNPACKING YOUR TABLE SAW

A

E

K

F

L

B

G

M

C

H

N

I

D

J

O

P

W

Q

X

R

S

Y

– 8 –

T

Z

U

V

AA

Page 9

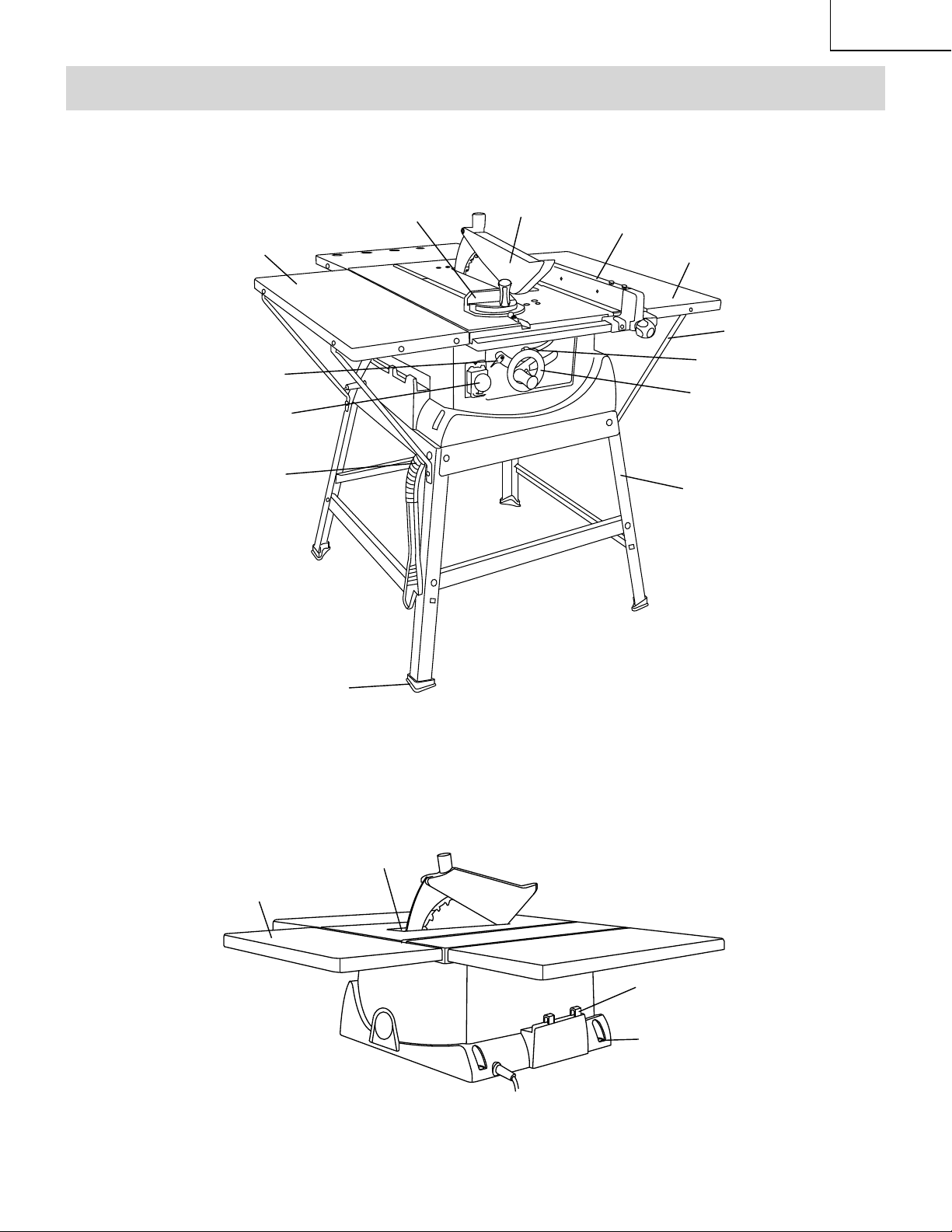

KNOW YOUR TABLE SAW

The Front of Table Saw

English

Left side table extension

Bevel angle pointer & scale

No-Volt-Release (NVR) switch

Push stick storage

Mitre gauge

OFF

ON

Upper blade guard

Rip fence

Right side table extension

Extension support

Blade bevel lock knob

Blade tilting handwheel

Stand assembly

Rear table extension

Foot pad

The Rear of Table Saw

Table Insert

Rip fence & Mitre gauge storage

Mounting hole

– 9 –

Page 10

English

ASSEMBLY AND ADJUSTMENTS

WARNING

For your own safety, never connect the plug to

power source outlet until all assembly steps are

completed and you have read and understood the

safety and operational instructions.

ESTIMATED ASSEMBLY TIME 25~35 MINUTES

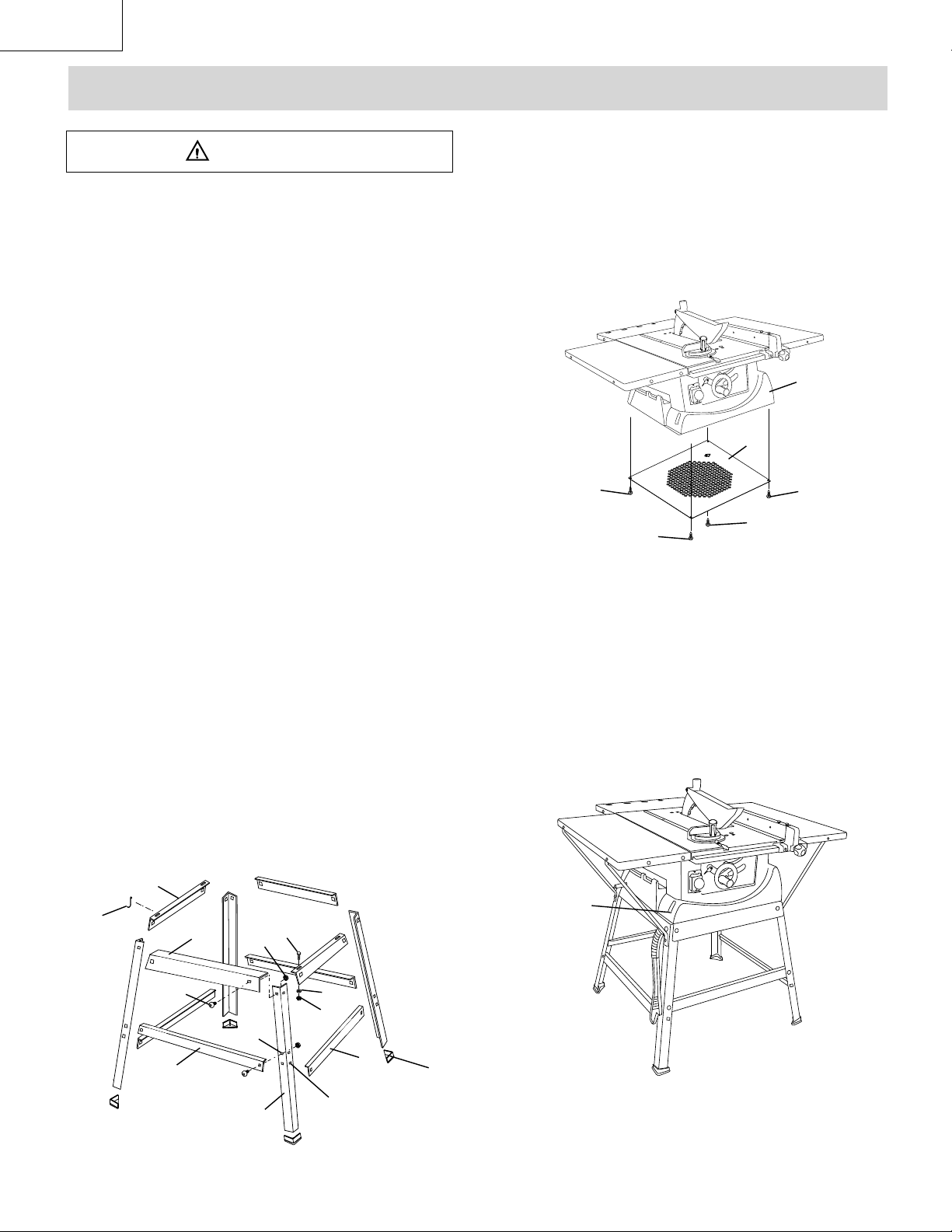

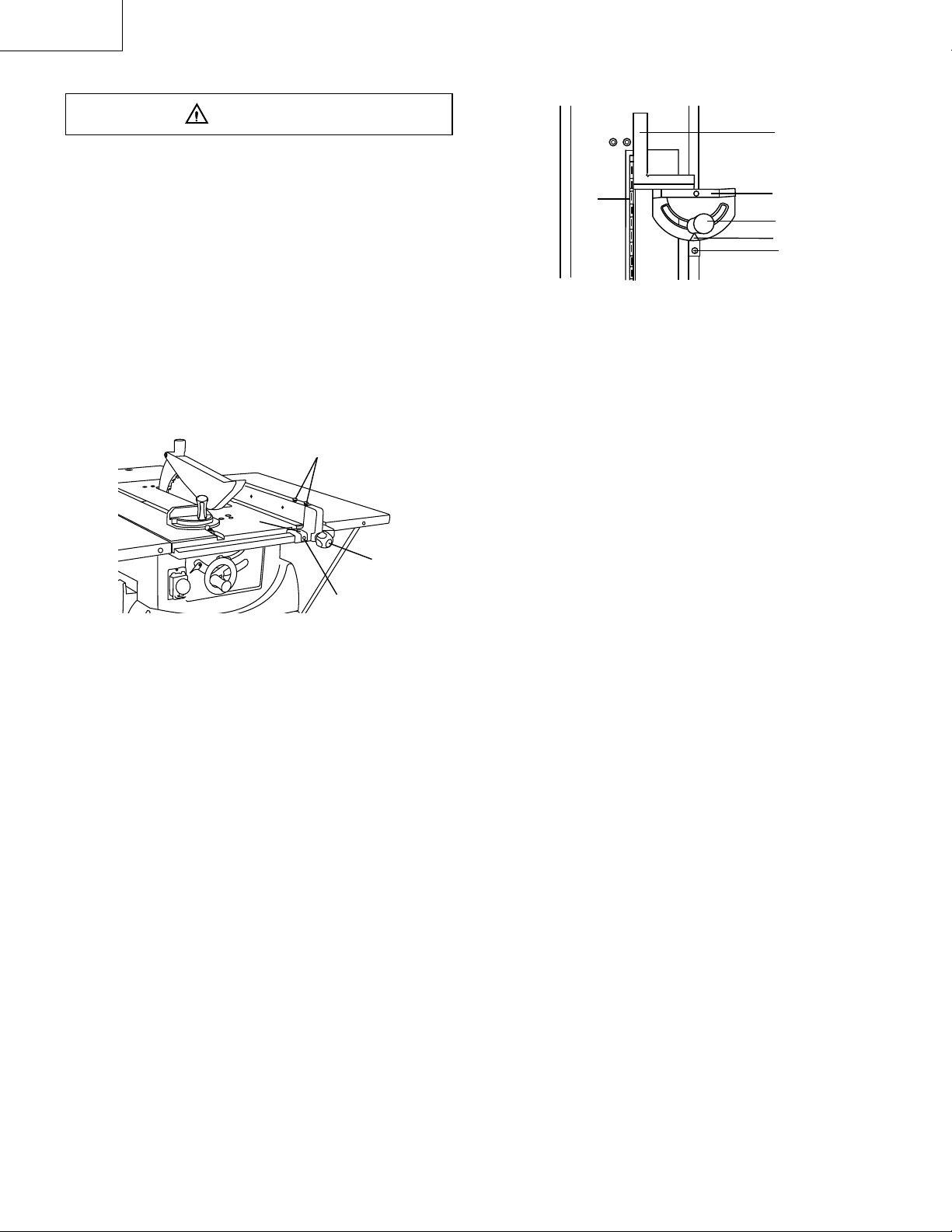

STAND ASSEMBLY (FIG. A)

1. Unpack all parts and group by type and size. Refer to

the parts list for correct quantities.

2. Attach one long upper support (1) to top of leg (2)

using one bolt (3) and nut (4).

NOTE:

●

Align detents in stand leg with support brackets to

ensure proper fit.

●

Do not tighten bolts until stand is properly

aligned (see step #8 before tightening).

3. Attach other end of long upper support to top of

another leg using one bolt and nut.

4. Attach one bottom support (5) to the higher hole (13)

of the leg using bolt (3) and nut (4). This completes

the front frame section.

5. Assemble rear frame section in exactly the same

manner.

6. Join front and rear frame assemblies using two short

upper supports (6), two bottom supports (7), bolts

and nuts.

NOTE: Place the two bottom supports (7) to the

lower holes (14) of the leg.

7. Insert foot pad (8) into bottom of leg. Repeat for each

leg.

8. Place stand on level surface and adjust so all legs

are contacting the floor and are at similar angles to

the floor, and detents in stand leg align with support

brackets, then tighten all bolts.

NOTE: To avoid rocking, tighten all bolts.

ASSEMBLE BASE COVER TO TABLE SAW (FIG. B)

NOTE:

Your saw is supplied with the base cover

unassembled.

1. Assemble the base cover (1) to the saw base (2) by

using the 4 screws (3) in the loose parts bag supplied .

2. Tighten the 4 screws (3) before mounting the saw on

the stand.

Fig. B

2

1

3

3

3

ASSEMBLE TABLE SAW TO STAND (FIG. A & C)

1. Position the saw base on the leg set and match the

holes (1) of the saw base to the holes of the stand.

(Fig. C)

2. Secure the saw base to the leg set using bolts (12),

washers (10) and nuts (11). (Fig. A)

Fig. C

3

Fig. A

9

6

1

1

3

12

4

10

11

13

5

7

8

14

2

– 10 –

Page 11

English

INSTALLING THE PUSH-STICK STORAGE (FIG. A)

Attach the hook (9-Fig. A) into the left short upper

support (6) for push stick storage.

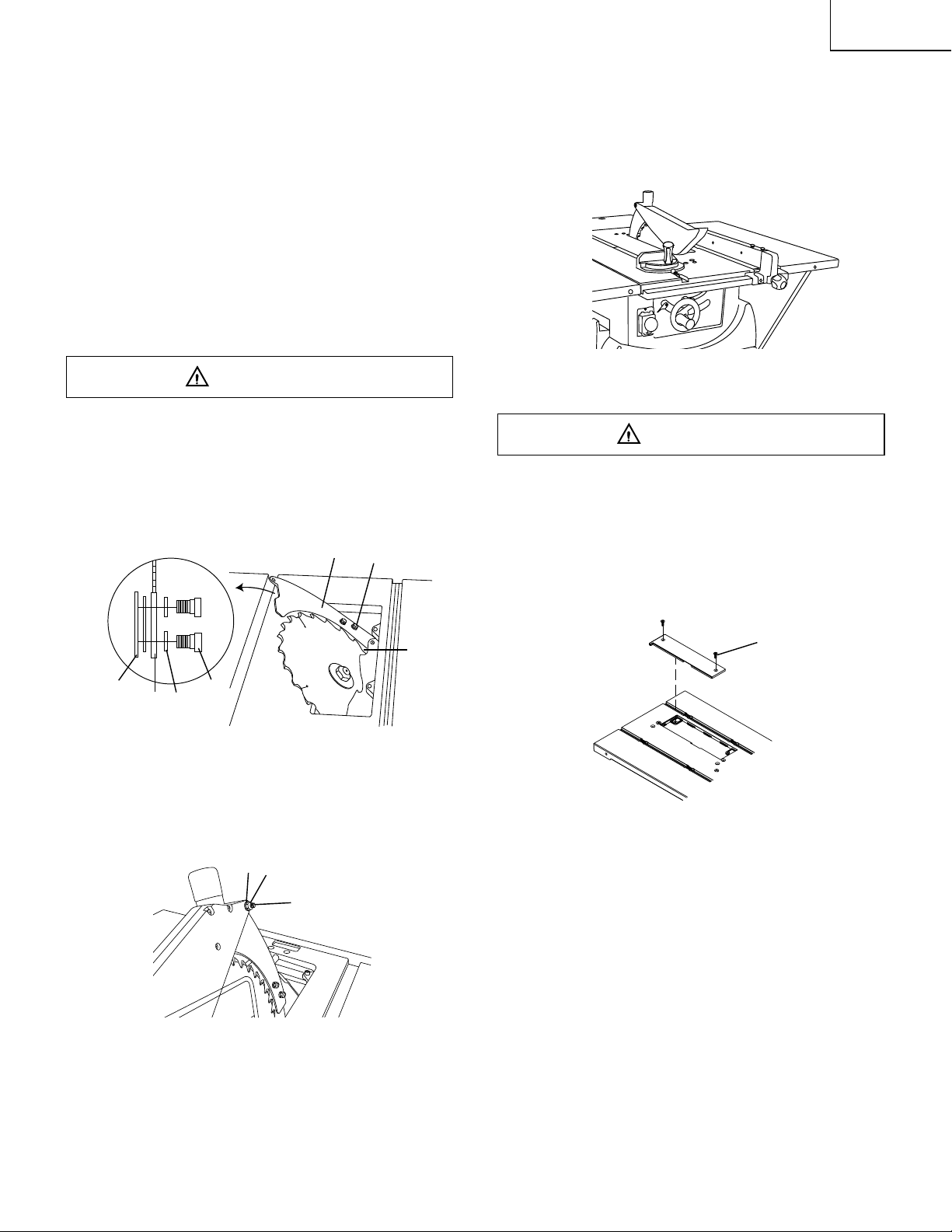

INSTALLING THE RIVING KNIFE (FIG. D)

1. Rise the blade to its highest position by turning the

handwheel and tilt the blade to 45° bevel angle.

2. Loosen the screws on the table insert and remove the

table insert.

3. Place the knob bolts (3), and flat washers (4) on the

riving knife bracket (5) and the riving knife (6).

4. Tighten the knob bolts (3).

5. Replace the table insert and tighten the screw.

WARNING

The riving knife thickness of 2.5 mm. Make sure the

blade and riving knife are aligned on the same line.

If not, adjust the riving knife by loosening the knob

bolts. It should be less than 5 mm at all positions.

Fig. D

INSTALLING THE RIP FENCE (FIG. F)

Slide in the rip fence assembly from the end of the table

with aligning the groove in the front of the table and the

tongue on the fence bracket.

Fig. F

INSTALLING AND CHANGING THE BLADE (

FIG. G, H)

WARNING

To avoid injury from accidental starting, always turn

the switch off (“0”) and remove the power plug from

the power source before changing the blades.

6

3

5

5

6

Blade Guard Assembly (Fig. E)

Place the blade guard on the riving knife and secure it

with the bolt (1), flat washer (2), and nut (3).

Fig. E

3

4

2

3

1

1. Loosen the screws (3) on the table insert by a

screwdriver and remove the table insert.

Fig. G

3

2. Raise the saw blade to its maximum height.

3. Use the supplied open end wrench (1) to keep the

arbor from turning and the supplied box-end wrench

(2) to loosen the arbor nut. (Fig. H)

4. Remove the arbor nut and flange.

5. Replace the saw blade. Make sure the teeth of the

blade point down at the front of the table.

6. Assemble the arbor flange and arbor nut back to the

saw arbor and tighten the arbor nut.

7. Replace the table insert and retighten the two screws.

– 11 –

Page 12

English

Fig. H

1

2

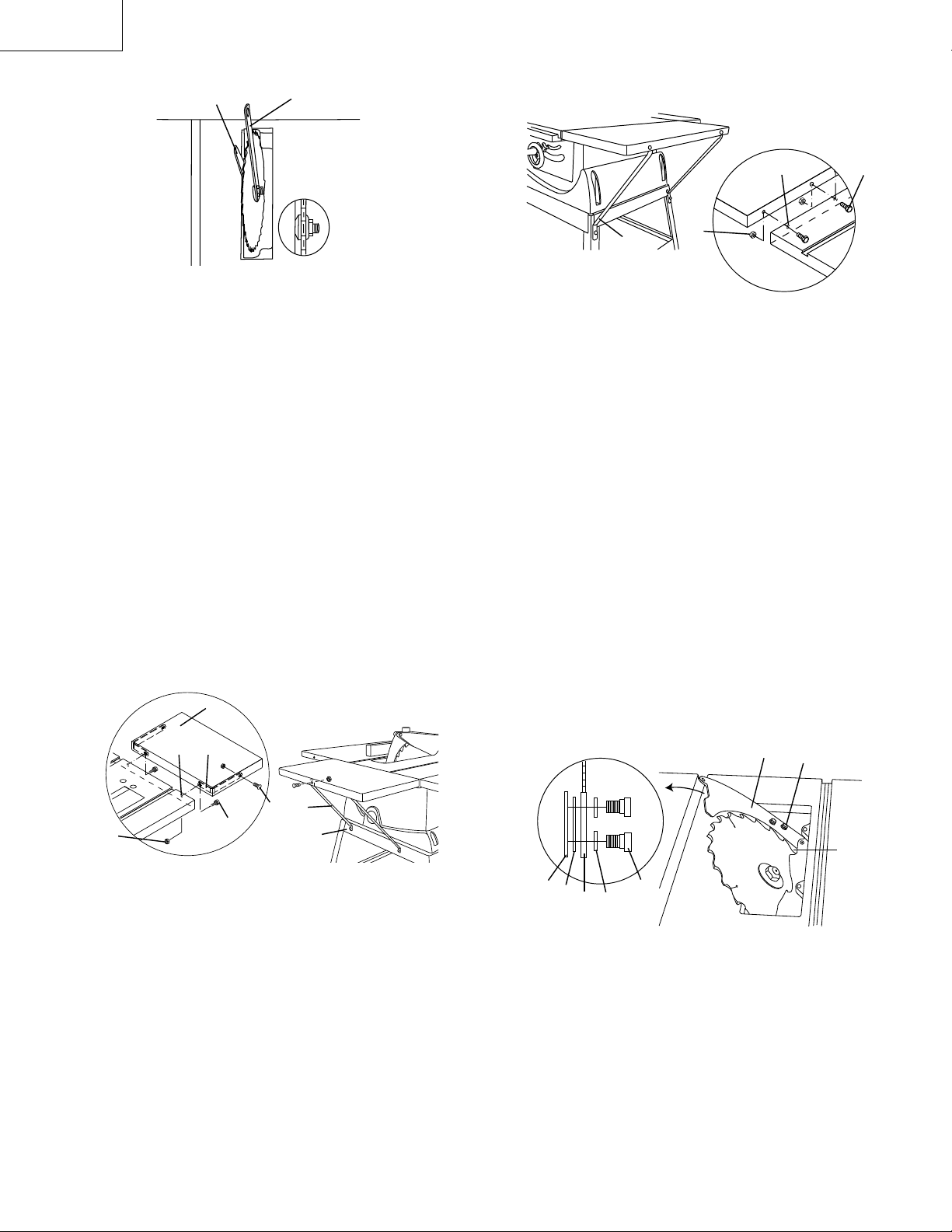

INSTALLING REAR TABLE EXTENSION (FIG. I )

1. Place the rear table extension (3) next to the table

saw, aligning the mounting holes (1).

2. Insert the bolt (2) through the bracket (5), rear table

extension (3) into the mounting hole (1).

3. Place the nut (6) and tighten.

4. Insert the bolt (2) and through the table extension (3)

into the other end of the bracket (5) and tighten the nut.

5. Attach the other end of the rear table extension to the

table saw using bolts and nuts.

6. Place a straight edge or combination square on the

saw table, across the rear table extension (3).

7. Adjust the bolts (2) until the extension is flush with the

saw table. Tighten the nuts (6).

8. Place the extension supports (7) to the rear table

extension and secure them on the stand (4) with bolts

and nuts.

Fig. I

Fig. J

1

3

2

4

ALIGNING THE RIVING KNIFE (FIG. K)

1. If the blade and riving knife are not correctly aligned:

a. Remove the table insert by removing the screws.

b. Remove the blade guard by removing the bolt, flat

washer and nut that lock the guard in place.

c. Loosen the two bolts (3) from the riving knife

bracket (5).

2. Insert the spacers (7) between the riving knife (6)

and bracket (5).

3. Retighten the two mounting bolts (3) securely.

4. Replace the blade guard assembly using the bolt, flat

washer and nut.

5. Check the riving knife and blade alignment again at

both 90° and 45°.

6. Add or remove the spacers until the alignment is

correct.

7. Replace the table insert.

3

1

5

7

8

6

2

4

INSTALLING TABLE SIDE EXTENSION (FIG. J)

1. Place the left table extension next to the saw table,

aligning the mounting holes (1).

2. Insert the bolts (4) through the mounting holes and

attach the nuts (2).

3. Place a straight edge or combination square on the

saw table, across the table extension.

4. Adjust the nut (2) until the extension is flush with the

saw table. Tighten.

5. Place the extension supports (3) to the left table

extension and secure them on the stand with bolts

and nuts.

6. Repeat these procedures for the right extension table.

Fig. K

6

3

5

5

7

6

NOTE: This tool is accurately adjusted before shipping

3

4

from the factory. Check the following accuracy and

readjust them if necessary in order to obtain the best

results in operation.

– 12 –

Page 13

English

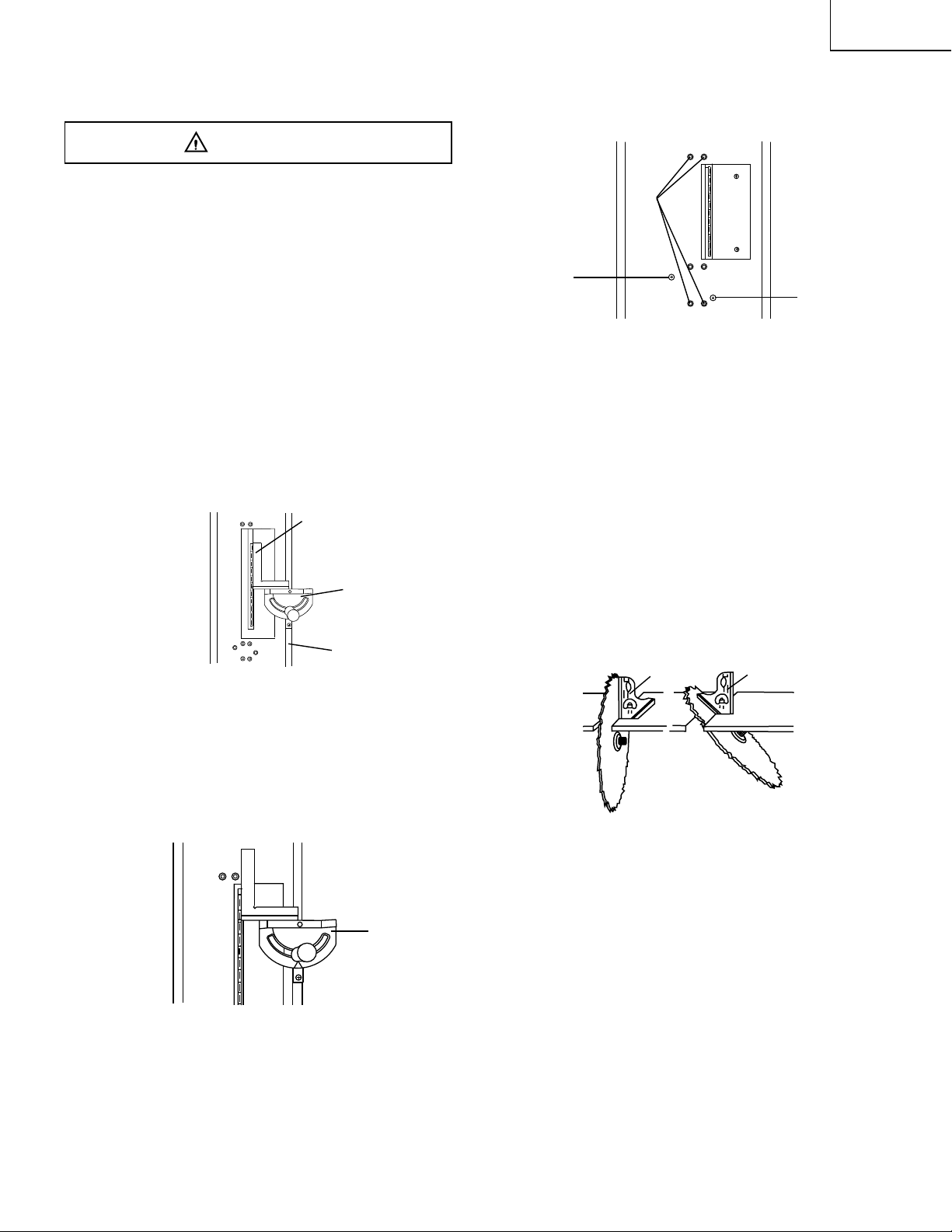

ADJUSTING THE BLADE PARALLEL TO THE MITRE

GAUGE GROOVE (FIG. L, M, N)

WARNING

This adjustment must be correct or kickback could

result and accurate cuts cannot be made.

1. Raise the blade to its highest position and set it to 0°

bevel angle.

2. Select a tooth on the saw blade which is bent to

the right. Mark that tooth with a pencil or permanent

marker.

3. Place the mitre gauge (1) in the right hand groove

(2) on the table top. Set the mitre gauge to 90° and

tighten the gauge handle to lock it in that position.

4. Rotate the blade to bring the marked tooth in the front

and about 13 mm above the table top. Place the bar

of square (3) flat against the mitre gauge and move

the bar toward the saw blade until it just touches the

tip of the marked saw blade tooth. (Fig. L)

Fig. L

5. Without disturbing the bar clamped to the mitre gauge

(1), move the mitre gauge to the centre of the saw

blade. Rotate the blade so the marked tooth is at the

rear and about 13 mm above the table top.

6. Slide the mitre gauge rearward until the clamped bar

is closest to the tip of the marked tooth. (Fig. M)

3

1

2

measurements taken at the front and rear are identical.

Tighten the four screws (1). (Fig. N)

Fig. N

1

2

3

ADJUSTING 90° POSITIVE STOP OF BLADE

1. Raise the saw blade to its maximum height.

2. Loosen the saw blade tilt lock handle and move the

saw blade tilting mechanism to the left until it hits

against the stopper. Then tighten the saw blade tilt

lock handle.

3. Use a square (1) to check the saw blade is at 90°.

(Fig. O)

4. If the saw blade is not at 90°, loosen the saw blade

tilt lock handle. Adjust the screws (2-Fig. N) a few

turns and move the saw blade tilting mechanism until

the blade is at 90° to the table.

5. Tighten the saw blade tilt lock handle after adjustment.

6. Loosen the screw of the tilt pointer and set the

pointer to 0°.

Fig. O

1

2

Fig. M

1

7. If the bar just touches the tooth when the gauge was

in the front position, it should touch the tooth in the

rear position.

8. If the front and rear clearance are not identical, remove

the mitre gauge, loosen four screws (1) and carefully

grasp the saw blade. Make necessary correction until

ADJUSTING 45° POSITIVE STOP OF BLADE

1. Raise the saw blade to its maximum height.

2. Loosen the saw blade tilt lock handle and move the

saw blade tilting mechanism to the right until it hits

against the stopper. Then tighten the saw blade tilt

lock handle.

3. Use a 45° gauge (2) to check the saw blade is at 45°.

(Fig. O)

4. If the saw blade is not at 45°, loosen the saw blade

tilt lock handle. Adjust the screws (3-Fig. N) a few

turns and move the saw blade tilting mechanism until

the blade is at 45° to the table.

5. Tighten the saw blade tilt lock handle after adjustment.

6. Loosen the screw of the tilt pointer and set the

pointer to 45°.

– 13 –

Page 14

English

ADJUSTING RIP FENCE (FIG. P)

WARNING

This adjustment must be correct or kickback could

result and accurate cuts cannot be made.

1. Loosen the clamp handle (1).

2. Position the rip fence at one edge of the mitre gauge

groove.

3. Lock the rip fence to the table using the clamp

handle. The edge of the rip fence should then line up

parallel with the mitre gauge groove.

4. If the edge of the rip fence is not parallel with the

mitre gauge groove, loosen the bolts (2) on the

femce, adjust the fence until it is parallel with the

mitre gauge groove, then tighten the bolts (2).

Fig. P

2

4

Fig. Q

2

3

4

1

5

6

1

5

ADJUSTING THE POINTER OF RIP FENCE (FIG. P)

NOTE: The pointer will need to be readjusted whenever

a different thickness saw blade is installed.

1. To adjust pointer 0 setting, loosen the clamp handle

(1) and move the rip fence to bring it into tight contact

with the side of the saw blade.

2. Make sure that the pointer (4) points to 0 on the scale

in the front of table.

3. If the pointer does not point to 0 on the scale, tighten

the clamp handle, loosen the pointer screw (5) and

adjust the pointer to the 0 position and retighten the

pointer screw.

ADJUSTING THE MITRE GAUGE (FIG. Q)

1. To adjust pointer 90° setting, loosen the clamp

handle (1) and place a square (2) against both the

saw blade (3) and mitre gauge (4). The pointer (5)

should indicate 90° on the mitre gauge.

2. If the pointer does not point to 90° on the mitre

gauge, tighten the clamp handle, loosen the pointer

screw (6) on the bar, adjust the pointer to the 90°

position and retighten the pointer screw.

– 14 –

Page 15

OPERATION

English

SWITCHES OF THE TABLE SAW (FIG. R)

The main switch (3-Fig. R), No Volt Release (NVR)

switch, is on the front of saw base. Press “ I “ to turn on

the power; press “O” to turn off the power.

WARNING

Never connect the plug to the power source outlet

until all installations and adjustments are completed

and you have read and understood the safety and

operational instructions.

RAISING AND LOWERING THE SAW BLADE (FIG. R)

WARNING

Never operate while saw blade rotating.

1. To raise the saw blade, rotate the handwheel (1)

anticlockwise.

2. To lower the saw blade, rotate the handwheel (1)

clockwise.

NOTE: The saw blade height is recommended about 3.2

mm above the top of the workpiece.

Fig. R

3

2

1

OPERATING THE MITRE GAUGE

NOTE:

1. The mitre gauge can be used on either side of the

saw blade.

2. Because the mitre gauge groove is a T-type slot, to

install the mitre gauge, insert the gauge bar from the

end of the groove.

3. To set the mitre cut angle, loosen the clamp handle,

turn the mitre gauge to the desired angle, retighten

the clamp handle.

RIPPING (FIG. S)

NOTE:

1. Generally ripping is cutting with the grain.

2. Do not perform ripping “free hand”. Use the rip fence

for ripping and remove the mitre gauge from the table.

WARNING

1. Before ripping, confirm the following items:

a. Rip fence is securely fixed and parallel to the

saw blade.

b. Riving knife is properly aligned with the saw

blade.

c. The workpiece must have a straight edge

against the rip fence and must not be warped,

twisted or bowed.

2. Keep both hands away from the saw blade and

away from the path of the saw blade.

TILTING THE SAW BLADE (FIG. R)

WARNING

Always lock the saw blade tilt lock handle during

operations.

Loosen the saw blade tilt lock handle (2), move the hand

wheel until the saw blade is at the desired angle and

tighten the saw blade tilt lock handle.

MOVING THE RIP FENCE

NOTE:

1. The rip fence can be used on either side of the saw

blade.

2. The pointer on the rip fence indicates the distance

between the saw blade and rip fence.

3. To move the rip fence, loosen the clamp handle while

pressing the fence bracket against the table surface

and set the desired distance from the saw blade,

retighten the clamp handle.

1. Adjust the saw blade height so it is about 3.2 mm

above the top of the workpiece.

2. Hold the workpiece flat on the table and against the

rip fence. Keep the workpiece about 25 mm away

from the saw blade.

3. Turn on the switch and allow the saw blade to come

up to speed.

4. Keep the workpiece against the table and rip fence,

slowly feed the workpiece rearward all the way

through the saw blade. Continuously push the

workpiece until it passes the blade guard and clears

the rear of the table.

5. When ripping long boards or large panels, always

use an adequate support.

6. When the width of rip is more than 150 mm, feed the

workpiece with one or both hands continuously until

it is beyond the saw blade and riving knife

– 15 –

Page 16

English

WARNING

Never operate while saw blade rotating.

7. When the width of rip 50 mm to 150 mm wide, use

the supplied push stick to feed the workpiece.

8. When perform bevel ripping, only work with the work

piece and rip fence on the right side of the saw blade.

Fig. S

CROSSCUTTING (FIG. T)

NOTE:

1. Generally cross cutting is cutting across the grain.

2. Do not perform cross cutting “free hand”. Use the

mitre gauge for cross cutting and remove the rip

fence from the table.

WARNING

1. Before cross cutting, confirm the following items:

a. Riving knife is properly aligned with the saw

blade.

b. The workpiece must have a straight edge

against the mitre gauge and must not be

warped, twisted or bowed.

2. Keep both hands away from the saw blade and

away from the path of the saw blade.

5. When performing bevel cross cutting, only work with

the workpiece and mitre gauge on the right side of

the saw blade.

Fig. T

3

BEVEL CROSSCUTING (FIG. U)

This cutting operation is the same as crosscutting except

the blade is at bevel angle other than 0°.

2

1

WARNING

Always work to the right side of the blade during this

type of cut. The mitre gauge (3) must be in the right

side groove (2) because the bevel angle may cause

the blade guard to interfere with the cut if used on

the left side groove.

1. Adjust the blade (1) to the desired angle, and tighten

the blade bevel lock knob.

2. Tighten mitre lock handle at 90°.

3. Hold workpiece firmly against the face of the mitre

gauge (3) throughout the cutting operation.

NOTE: When tilting the blade to 45°, the mitre gauge

handle will hit the blade guard.

Fig. U

1

3

2

1. Adjust the saw blade height so it is about 3.2 mm

above the top of the workpiece.

2. Hold the workpiece flat on the table and against the

mitre gauge. Keep the workpiece about 25 mm away

from the saw blade.

3. Turn on the switch and allow the saw blade (1) to

come up to full speed.

4. Keep the workpiece (2) against the table and mitre

gauge (3), slowly feed the workpiece rearward all the

way through the saw blade. Continuously push the

workpiece until it is clear of the blade guard and it

falls off the rear of the table.

– 16 –

Page 17

English

COMPOUND MITRE CROSSCUTTING (FIG. V)

This sawing operation is combining a mitre angle with a

bevel angle.

WARNING

Always work to the right side of the blade during

this type of cut. The mitre gauge (3) must be in the

right side groove because the bevel angle may

cause the blade guard to interfere with the cut

if used on the left side groove. When tilting the

workpiece to 45° and push it toward the blade, the

blade guard may hit the blade. To avoid injury, stop

the work at that time.

1. Set the mitre gauge (3) to the desired angle.

2. Place the mitre gauge (3) in the right side groove (2)

of the table.

3. Set the blade (1) bevel to the desired bevel angle

and tighten the blade bevel lock knob.

4. Hold workpiece firmly against the face of the mitre

gauge (3) throughout the cutting operation.

Fig. V

1

3

2

USING AUXILIARY FENCE ON THE RIP FENCE

(FIG. X)

A auxiliary fence should be used when ripping material

such as thin paneling to prevent the material from

catching between the bottom of the fence and the table.

When performimg some special cutting operations, you

can add a auxiliary fence (3) to the either side of the rip

fence (4).

Fig. X

2

3

1. Place the square nuts (2) to the slot of the auxiliary

fence (3).

2. Attach the auxiliary fence to the rip fence with the

clamp handles (1) through the washers (5) and holes

in the rip fence.

3. Tighten the clamp handles.

5

1

4

MITRE CUTS (FIG. W)

This sawing operation is the same as crosscutting except

the mitre gauge is locked at an angle other than 90°.

1. Set the blade (1) to 0° bevel angle and tighten the

blade bevel lock knob.

2. Set the mitre gauge (3) at the desired mitre angle

and lock in position by tightening the mitre gauge

locking handle.

3. Hold the workpiece (2) firmly against the face of the

mitre gauge throughout the cutting operation.

Fig. W

2

3

1

USING AUXILIARY FENCE ON THE MITRE GAUGE

(FIG. Y)

When performimg some special cutting operations, you

can add a auxiliary fence (2) to the mitre gauge (1).

1. Place the square nuts (5) to the slot of the auxiliary

fence (2).

2. Attach the auxiliary fence to the mitre gauge with the

washers (3) and screws (4).

3. Tighten the screws.

Fig. Y

5

2

1

3

4

– 17 –

Page 18

English

MAINTENANCE

MAINTAINING YOUR TABLE SAW

WARNING

To avoid injury from accidental starting, always turn the switch off (“0”) and remove the power plug from the

power source before changing the blades.

GENERAL MAINTENANCE

Occasionally use a cloth to wipe off chips and dust from the machine. And oil the rotary parts once a month to extend

the tool life. Do not oil the motor.

BRUSH INSPECTION

Check the motor brushes after the first 50 hours of use for a new machine or after a new set of brushes have been

installed. After the first check, examine them every 10 hours of use.

When the carbon is worn to 6 mm in length or if the spring or shunt wire is burned or damaged, replace both brushes. If

the brushes are found serviceable after removing, reinstall them.

EC-Declaration of Conformity

Rexon Industrial Corp., Ltd. declares this Table Saw,

Model C10RD, is in conformity with the Low Voltage

Directive 73/23/EEC and the Amendment Directive

93/68/EEC and the Machinery Directive Annex 1

of 98/37/EC and EMC Directive 89/336/EEC. The

conformity is certified by TÜV Rheinland Product Safety

GmbH, Am Grauen Stein, D-51105 Köln, Germany.

George Ku, Marketing manager

Date: 24, August, 2006

Rexon Industrial Corp., Ltd.,

261 Jen Hwa Road,

Tali, Taichung 412

Taiwan, R.O.C.

– 18 –

Page 19

TROUBLESHOOTING GUIDE

WARNING

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power

source before making any adjustments.

• Consult Hitachi Authorized Service Centre if for any reason the motor will not run.

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

English

Saw will not start. 1. Saw not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord damaged.

Does not make accurate 45°

and 90° rip cuts.

Material pinched blade when

ripping.

Material binds on splitter. 1. Splitter not aligned correctly with blade. 1. Check and align splitter with blade.

Saw makes unsatisfactory

cuts.

Material kicked back from

blade.

Blade does not raise or tilt

freely.

Blade does not come up to

speed.

Machine vibrates excessively. 1. Saw not mounted securely to workbench.

Does not make accurate 45°

and 90° crosscuts.

1. Positive stop not adjusted correctly.

2. Tilt angle pointer not set accurately.

1. Rip fence not aligned with blade.

2. Warped wood, edge against fence is not

straight.

1. Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

4. Incorrect blade for work being done.

5. Gum or pitch on blade causing erratic

feed.

1. Rip fence out of adjustment.

2. Splitter not aligned with blade.

3. Feeding stock without rip fence.

4. Splitter not in place.

5. Dull blade.

6. The operator letting go of material before

it is past saw blade.

7. Mitre angle lock knob is not tight.

1. Sawdust and dirt in raising/tilting

mechanisms.

1. Extension cord too light or too long.

2. Low house voltage.

2. Bench on uneven floor.

3. Damaged saw blade.

1. Mitre gauge out of adjustment. 1. Adjust mitre gauge.

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced by Hitachi

Authorized Service Centre.

1. Check blade with square and adjust

positive stop.

2. Check blade with square and adjust to

zero.

1. Check and adjust rip fence.

2. Select another piece of wood.

1. Replace blade.

2. Turn the blade around.

3. Remove blade and clean with

turpentine and coarse steel wool.

4. Change the blade.

5. Clean table with turpentine and steel

wool.

1. Align rip fence with mitre gauge slot.

2. Align splitter with blade.

3. Install and use rip fence.

4. Install and use splitter. (with guard)

5. Replace blade.

6. Push material all the way past saw

blade before releasing work.

7. Tighten knob.

1. Brush or blow out loose dust and dirt.

1. Replace with adequate size cord.

2. Contact your electric company.

1. Tighten all mounting hardware.

2. Reposition on flat level surface. Fasten

to floor if necessary.

3. Replace blade.

– 19 –

Page 20

English

PUSH STICK CONSTRUCTION

●

This is a full-size drawing (actual size)

●

Use good quality plywood or solid wood

●

Use 1/2 in. or 3/4 in. material

●

Push stick MUST be thinner than the width

of material being cut

Drill Hole For

Hanging

Notch To Prevent

Hand From

Slipping

Cut Here To

Push 1/2 in.

Wood

– 20 –

Cut Here To

Push 3/4 in.

Wood

Page 21

Russian

ВНИМАНИЕ

Некоторые виды пыли, образующиеся при шлифовании, пилении, полировке, сверлении и других строительных

работах, содержат химические вещества, которые, как считается в штате Калифорния, вызывают раковые

заболевания, врожденные пороки и наносят другой вред репродуктивной системе. Среди этих химических

веществ:

• Краски на основе свинца

• Кристаллический кремнезем от кирпича, цемента и других кладочных материалов

• Мышьяк и хром от химически обработанной древесины

Степень риска для здоровья, связанного с этими веществами, зависит от частоты выполнения данного вида

работ. Чтобы снизить контакт с этими веществами, следует работать в хорошо вентилируемом помещении с

использованием одобренных средств безопасности, таких как противопылевые респираторы, предназначенные

специально для задержки микроскопических частиц.

ТЕХНИЧЕСКАЯ ХАРАКТЕРИСТИКИ СТАНКА

ЭЛЕКТРОДВИГАТЕЛЬ ПИЛА

Тип..................................... Универсальный Размер стола с удлинением.................. 970mm x 890mm

Сила тока.......................... 6.5A Удлинение стола.................................... слева, справа, сзади

Напряжение...................... 230 В / 50 Гц Ширина реза с удлинениями................. 130 мм справа х 185 мм слева

Мощность......................... 1600 Вт (S6, 25%, 10 мин.) Диаметр диска........................................ 250mm

Холостой ход................... 4800 мин1. Масштабная линейка............................. ЕСТЬ

Защита от перегрузки..... ЕСТЬ Направляющая планка.......................... ЕСТЬ

ОБОЗНАЧЕНИЯ

В............ Вольт А............ Ампер

Гц.......... Герц Вт........... Ватт

мин........ минут ~............ переменный ток

ч............ часов ........... Конструкция класса II

i............. включен O........... выключен

мин1....... оборотов в минуту

ЗАЩИТА ОКРУЖАЮЩЕЙ СРЕДЫ

Угловой упор........................................... ЕСТЬ

Макс. глубина пропила под углом 90º.. 73mm

Макс. глубина пропила под углом 45º.. 63mm

Масса нетто............................................ 24,65 кг

Носите защитные очки

Носите защиту слуха

Носите респиратор

Отправляйте отходы материалов на вторичную переработку, не выбрасывайте их с обычным мусором. Все

инструменты, трубки, материалы упаковки должны быть отсортированы и переданы в ближайший центр

вторичной переработки для их безопасной утилизации.

ВНИМАНИЕ

Высокий уровень шума может негативно сказаться на здоровье. Когда уровень шума превышает 85 дБ,

обязательно носите защиту слуха.

ВНИМАНИЕ

Чтобы избежать поражения электрически током или порчи инструмента, используйте надлежащие средства

защиты электрической цепи.

Данный станок поставляется производителем с проводкой, рассчитанной на работу от сети 230 В. Он должен быть

оснащен предохранителем с задержкой на срабатывание или автоматическим выключателем. Чтобы избежать

поражения током и пожара при износе, разрыве или любом другом виде повреждения провода питания, следует

немедленно его заменить. Очень важно полностью прочитать и понять технику безопасности, прежде чем начинать

работу со станком. Нарушение техники безопасности может привести к серьезным травмам или порче станка.

ВНИМАНИЕ

В случае плохого состояния электрической СЕТИ, возможны кратковременные скачки напряжения при включении

СТАНКА. Это может оказать влияние на другое оборудование (например, мигание лампы). Если полное

сопротивление электрической СЕТИ Zmax < 0,3 Ом, подобный эффект не наблюдается. (При необходимости

обратитесь в местную энергоснабжающую организацию).

– 21 –

Page 22

Russian

ТЕХНИКА БЕЗОПАСНОСТИ МЕХАНИЗМА

ВНИМАНИЕ

Перед использованием станка необходимо прочесть и полностью понять правила техники безопасности.

Нарушение техники безопасности может привести к серьезным травмам или порче станка.

Техника безопасности складывается из здравого

смысла, внимательности и понимания того, как работает

инструмент. Во избежание совершения ошибок, не

подключайте станок к сети, без прочтения и понимания

следующих правил:

1. ПРОЧТИТЕ и изучите всю данную инструкцию.

ЗНАЙТЕ область применения станка, ограничения и

потенциальные опасности.

2.

Обращайте внимание на этот символ,

ВНИМАНИЕ

обозначающий важную информацию

по безопасности. Он предупреждает:

БУДЬТЕ ВНИМАТЕЛЬНЫ! ВОПРОС ВАШЕЙ

БЕЗОПАСНОСТИ!

3. НЕ ИСПОЛЬЗУЙТЕ СТАНОК БЕЗ ЗАЩИТНОГО

КОЖУХА ПРИ СКВОЗНОМ ПРОПИЛИВАНИИ.

4. НЕ ИСПОЛЬЗУЙТЕ СТАНОК В ОПАСНОЙ СРЕДЕ,

например во влажных, мокрых помещениях и под

дождем. Обеспечьте хорошее освещение рабочей

зоны.

5. НЕ используйте станок вблизи

легковоспламеняющихся жидкостей или газов.

6. СОДЕРЖИТЕ РАБОЧУЮ ЗОНУ В ЧИСТОТЕ.

Загроможденное пространство и лишние верстаки

повышают вероятность несчастных случаев.

7. НЕ ДОПУСКАЙТЕ ДЕТЕЙ к станку. Все, кто

не работает на станке, должны находиться на

безопасном расстоянии от него.

8. НЕ ПРИЛАГАЙТЕ ИЗЛИШНЮЮ СИЛУ. Работа

выполняется лучше и безопасней на установленной

производителем скорости.

9. ПРАВИЛЬНО ИСПОЛЬЗУЙТЕ ИНСТРУМЕНТ.

Не пытайтесь при помощи инструментов или

приспособлений выполнить операцию, для которой

они не предназначены.

10. НОСИТЕ НАДЛЕЖАЩУЮ ОДЕЖДУ. НЕ носите

свободную одежду, перчатки, галстуки, кольца,

браслеты и другие украшения, которые могут

зацепиться за движущиеся части станка.

Рекомендуется носить нескользящую обувь. Длинные

волосы следует собрать под специальный убор.

11. НОСИТЕ ЛИЦЕВУЮ МАСКУ ИЛИ РЕСПИРАТОР. При

пилении, резке и полировке образуется пыль.

12. ОТКЛЮЧАЙТЕ ИНСТРУМЕНТ перед обслуживанием

станка и заменой приспособлений, таких как диски,

резцы и т.п.

13. СНИЖАЙТЕ РИСК СЛУЧАЙНОГО ЗАПУСКА.

Убедитесь, что переключатель находится в

выключенном положении (OFF) перед подключением

станка к сети.

14. ПОЛЬЗУЙТЕСЬ ТОЛЬКО РЕКОМЕНДОВАННЫМИ

АКСЕССУАРАМИ. Список рекомендованных

аксессуаров ищите в инструкции по эксплуатации.

Использование иных аксессуаров может привести к

травмам или порче оборудования.

15. УБИРАЙТЕ ГАЕЧНЫЕ КЛЮЧИ СО СТАНКА.

Выработайте привычку проверять станок на

отсутствие на нем гаечных ключей перед включением.

16. НЕ ОСТАВЛЯЙТЕ СТАНОК РАБОТАТЬ БЕЗ

ПРИСМОТРА. ВЫКЛЮЧАЙТЕ ЕГО. Не отходите от

станка, пока диск полностью не остановится.

17. НЕ ВСТАВАЙТЕ НА СТАНОК. Если станок

перевернется или произойдет контакт с режущим

инструментом, это повлечет серьезные травмы.

18. НЕ ТЯНИТЕСЬ К СТАНКУ. Всегда крепко держитесь

на ногах и сохраняйте равновесие.

19. ОСТОРОЖНО ОБРАЩАЙТЕСЬ С ИНСТРУМЕНТОМ.

Для эффективной и безопасной работы всегда

держите инструмент чистым и хорошо заточенным.

Следуйте инструкции при замене и смазке

компонентов.

20. ПРОВЕРЯЙТЕ НАЛИЧИЕ НЕИСПРАВНЫХ И ПЛОХО

ЗАКРЕПЛЕННЫХ ДЕТАЛЕЙ. Проверяйте движущиеся

части на выравнивание и деформации; все детали

на надежность крепления и другие факторы, которые

могут повлиять на безопасность работы. Защитное

устройство или любые другие детали, которые не

закреплены или деформированы, должны быть

закреплены, отремонтированы или заменены.

21. ЗАЩИТИТЕ РАБОЧУЮ ЗОНУ ОТ ДЕТЕЙ при

помощи навесных замков, главных выключателей или

вынимая пусковой ключ.

22. НЕ пользуйтесь станком под действием наркотиков,

алкоголя или лекарств, которые могут сказаться на

вашей способности к работе со станком.

23. ПОЛЬЗУЙТЕСЬ СИСТЕМОЙ СБОРА ПЫЛИ, где

это возможно. Пыль, образующаяся при работе,

может содержать небезопасные для здоровья

вещества, также она может стать причиной пожара.

Всегда используйте станок в хорошо вентилируемых

помещениях с эффективной системой сбора пыли.

24. ВСЕГДА НОСИТЕ ЗАЩИТНЫЕ ОЧКИ. Любой

механический инструмент может выбрасывать

осколки, которые могут нанести непоправимый

вред глазам. ВСЕГДА носите закрытые защитные

очки (а не обычные очки), которые соответствуют

требованиям стандарта ANSI по безопасности Z87.1.

Очки для повседневного ношения – открытые. Они НЕ

являются средством защиты.

ПРИМЕЧАНИЕ: Защитные очки, не соответствующие

стандарту ANSI Z87.1 могут разбиться и нанести

травмы.

25. НАПРАВЛЕНИЕ ПОДАЧИ. Подавайте заготовку на

диск или резец только против направления вращения

диска или резца.

– 22 –

Page 23

ТЕХНИКА БЕЗОПАСНОСТИ СТАНКА

Russian

1. ВСЕГДА ИСПОЛЬЗУЙТЕ ЗАЩИТУ ДИСКА,

расклиниватель и противоударное устройство, когда

их использование возможно, в том числе при сквозном

пропиливании. При сквозном пропиливании диск

полностью проходит через заготовку при продольной

или поперечной резке.

2. ВСЕГДА КРЕПКО ПРИЖИМАЙТЕ ЗАГОТОВКУ к

угловому упору или направляющей планке.

3. ВСЕГДА ПОЛЬЗУЙТЕСЬ толкателем, особенно при

резке тонкой заготовки. Подробней об этом читайте

в соответствующем разделе данного руководства.

На стр. 20 приведен чертеж для изготовления

собственного толкателя.

4. НИКОГДА НЕ ВЫПОЛНЯЙТЕ РАБОТУ ГОЛЫМИ

РУКАМИ без использования углового упора или

направляющей планки для ведения заготовки по

столу.

ВНИМАНИЕ: РЕЗКА ГОЛЫМИ РУКАМИ – НАИБОЛЕЕ

ЧАСТАЯ ПРИЧИНА ОТДАЧИ И ПОСЛЕДУЮЩЕЙ

АМПУТАЦИИ ПАЛЬЦЕВ И КИСТЕЙ РУК.

5. НЕ СТОЙТЕ и не располагайте любые части своего

тела прямо по направлению резки диска. Не кладите

руки по направлению резки диска.

6. НЕ ПЕРЕГИБАЙТЕСЬ и не наклоняйтесь над

режущим инструментом ни при каких обстоятельствах.

7. СНИМАЙТЕ направляющую планку при поперечной

резке.

8. НЕ ИСПОЛЬЗУЙТЕ инструмент для изготовления

фигурного профиля с данным станком.

13. ИЗБЕГАЙТЕ ОТДАЧИ, поддерживая диск

заточенным, направляющую планку параллельной

диску и используя установленные должным образом

расклиниватель и противоударные устройства. Не

отпускайте заготовку до самого конца прохода диска.

Не режьте скрученные, искривленные заготовки, а

также заготовки, не имеющие ровной грани для упора

о направляющую планку.

14. ИЗБЕГАЙТЕ НЕУДОБНЫХ ПОЗ и положений рук,

при которых неожиданное проскальзывание может

отбросить руку на диск.

15. НЕ ПОЛЬЗУЙТЕСЬ РАСТВОРИТЕЛЯМИ при очистке

пластиковых деталей. Они могут впитаться или

иным образом повредить материал. Для очистки

пластиковых деталей пользуйтесь только чистой

влажной тряпкой.

16. ЗАКРЕПИТЕ пилу на верстаке или подставке перед

началом работы. См. раздел СБОРКА И НАСТРОЙКА

на стр. 10.

17. НЕ РЕЖЬТЕ МЕТАЛЛ и материалы, дающие опасную

для здоровья пыль.

18. ВСЕГДА РАБОТАЙТЕ В ХОРОШО

ВЕНТИЛИРУЕМОМ ПОМЕЩЕНИИ. Часто убирайте

опилки. Очищайте от опилок внутренние части

пилы во избежание возгорания. Подсоедините

насос к отверстию для стружки, чтобы повысить

эффективность уборки стружки.

19. НЕ ОСТАВЛЯЙТЕ РАБОТАЮЩИЙ СТАНОК БЕЗ

ПРИСМОТРА. Не отходите от станка, пока диск

полностью не остановится.

9. ПОДАВАЙТЕ ЗАГОТОВКУ только против

направления вращения диска.

10. НИКОГДА не используйте направляющую планку при

поперечной резке.

11. НИКОГДА НЕ ПЫТАЙТЕСЬ ВЫСВОБОДИТЬ

ЗАСТРЯВШИЙ ДИСК, не выключив станок (OFF).

Немедленно выключите станок во избежание поломки

электродвигателя.

12. ОБЕСПЕЧЬТЕ НАДЕЖНУЮ ПОДДЕРЖКУ задних и

боковых частей стола при резке длинных или широких

заготовок.

20. Для правильного начала работы следуйте

инструкциям в разделе СБОРКА И НАСТРОЙКА на

стр. 10. Если не обеспечить отвод стружки, она будет

скапливаться у электродвигателя, что может привести

к возгоранию и порче электродвигателя.

– 23 –

Page 24

Russian

ТРЕБОВАНИЯ К ЭЛЕКТРИКЕ И ТЕХНИКА БЕЗОПАСНОСТИ

ПОДКЛЮЧЕНИЕ К ИСТОЧНИКУ ПИТАНИЯ

Убедитесь, что источник питания и розетка соответствуют станку. Обратите внимание на информационную табличку на

электродвигателе или на корпусе станка. Все изменения должны вноситься только квалифицированным электриком.

ВНИМАНИЕ

Станок должен быть заземлен.

При отсутствии надлежащего заземления станок может стать причиной поражения электрическим током. Убедитесь, что

розетка источника питания заземлена. Если Вы сомневаетесь в этом, следует вызвать квалифицированного электрика для

проверки.

ВНИМАНИЕ

Избегайте контакта с выводами вилки при включении и выключении вилки из розетки. Контакт с выводом

приведет к поражению электрическим током.

ИСПОЛЬЗОВАНИЕ УДЛИНИТЕЛЯ

При использовании удлинителя наблюдается некоторая потеря мощности. Чтобы свести потери к минимуму и

предотвратить перегрев и отключение двигателя, посоветуйтесь с квалифицированным электриком и определите

минимальный размер провода удлинителя.

Удлинитель должен быть снабжен вилкой с заземлением на одном конце, подходящем к розетке, и розетку с заземлением

на другом, подходящем к вилке станка.

– 24 –

Page 25

АКСЕССУАРЫ И ДОПОЛНИТЕЛЬНОЕ ОБОРУДОВАНИЕ

РЕКОМЕНДУЕМЫЕ АКСЕССУАРЫ

Russian

ВНИМАНИЕ

Для приобретения необходимых для данного станка

аксессуаров обратитесь в хозяйственный магазин или

к каталогу автоматического и ручного инструмента.

ИНСТРУМЕНТЫ, НЕОБХОДИМЫЕ ДЛЯ СБОРКИ

Входят в комплект

Ключ

Ключ

Не входят в комплект

Средняя отвертка

Крестообразная отвертка N02

Линейка

ВНИМАНИЕ

Чтобы избежать травм:

• Не используйте инструмент для изготовления

фигурного профиля с данным станком

• Не вносите изменения в конструкцию станка и не

пользуйтесь аксессуарами, не рекомендованными

продавцом.

Разводной ключ

Комбинированный угольник

СОДЕРЖИМОЕ КОРОБКИ

ОСВОБОДИТЕ ВСЕ ДЕТАЛИ ОТ УПАКОВОЧНОГО

МАТЕРИАЛА.

Сверьте содержимое с иллюстрациями на следующей

странице и с “Таблицей отдельных деталей”, чтобы

убедиться, что все детали присутствуют, прежде чем

избавляться от упаковки.

ТАБЛИЦА ОТДЕЛЬНЫХ ДЕТАЛЕЙ

ДЕТ. Описание Кол-во

A

Узел настольной дисковой пилы

B

Узел предохранительного клина

C

Пакет с креплениями клина

D

Направляющая планка

E

Диск

F

Ключ для диска

G

Толкатель

H

Угловой упор

I Крючок толкателя 1

J Рулевое колесо 1

K Заднее удлинение стола 1

L Скобы для заднего удлинения стола 2

M Суппорты для заднего удлинения стола 2

N Крепеж для заднего удлинения стола 1

O Дополнительная планка 1

P Крепеж для дополнительной планки 1

Q

Боковое удлинение стола

1

1

1

1

1

2

1

1

2

R

Суппорт левого удлинения стола

S

Суппорт правого удлинения стола

T

Крепеж для бокового удлинения стола

U

Болт

V

Крышка

СТОЙКА:

W Ножка 4

X Нижняя поддерживающая скоба 4

Y Длинный верхний суппорт 2

Z Короткий верхний суппорт 2

AA Крепеж для стойки 1

2

2

1

4

1

ВНИМАНИЕ

Если какая-либо из деталей отсутствует или

повреждена, не пытайтесь собирать станок,

включать провод питания в розетку или переводить

переключатель в положение Вкл. (ON), до тех пор,

пока не будет получена и установлена исправная

деталь.

ПРИМЕЧАНИЕ: Для облегчения сборки, держите

содержимое коробки вместе. Нанесите немного восковой

пасты для полировки автомобилей на стол станка.

Тщательно протрите все детали чистой сухой тряпкой. Это

снизит трение при проходе заготовок.

– 25 –

Page 26

Russian

РАСПАКОВКА НАСТОЛЬНОЙ ДИСКОВОЙ ПИЛЫ

A

E

K

F

L

B

G

M

C

H

N

I

D

J

O

P

W

Q

X

R

S

Y

– 26 –

T

Z

U

AA

V

Page 27

ЗНАЙТЕ КОНСТРУКЦИЮ СТАНКА

Вид спереди

Russian

ЛeBOe yдлиHeHиe CTOлa

УKa3aTeлb yrлa HaKлOHa диcKa

и MacшTaбHaя лиHeйKa

BbIKлючaTeлb HyлeBOrO

HanpяжeHия

KpючOK для TOлKaTeля

УrлOBOй ynop

OFF

ON

Защитный кожух

HanpaBляющaя ллaHKa

ПpaBoe yдлиHeHиe CTOлa

CyппopT yдлиHeHия

ФиKCaTop диCKa

KoлeCO HaKлoHa диCKa

CTOйKa

резиновая накладка

3aдHee yдлиHeHиe CTOлa

Вид сзади

BcTaBKa CTOлa

ДepжaTeлb yглoBOгO ynopa и

HanpaBляющeй плaHKи

KpeпeжHOe oTBepcTиe

– 27 –

Page 28

Russian

СБОРКА И НАСТРОЙКА

ВНИМАНИЕ

Для обеспечения Вашей собственной безопасности,

не включайте вилку в розетку до тех пор, пока

все процедуры сборки не будут окончены, и Вы

полностью прочтете и поймете правила техники

безопасности и эксплуатации.

ПРИМЕРНОЕ ВРЕМЯ НА СБОРКУ 30-40 МИНУТ

СБОРКА СТОЙКИ (РИС. А)

1. Распакуйте все детали и отсортируйте их по типу и

размеру. Необходимое количество деталей указано в

списке деталей.

2. Прикрепите верхний суппорт (1) к верхней части ножки

(2) при помощи одного болта (3) и гайки (4).

ПРИМЕЧАНИЕ:

● Чтобы обеспечить надежное крепление совместите

стопоры на ножку со скобами суппорта

● Не затягивайте болты, пока стойка полностью не

выровнена (см. пункт 8. перед затяжкой болтов)

3. Прикрепите другой конец длинного верхнего суппорта к

верхней части другой ножки при помощи болта и гайки.

4. Закрепите один нижний суппорт (5) на верхних

отверстиях (13) ножки при помощи болта (3) и гайки (4).

Передняя часть стойки собрана.

5. Аналогично соберите заднюю часть стойки.

6. Соедините переднюю и заднюю часть стойки при

помощи двух коротких верхних суппортов (6) и двух

нижних суппортов (7), болтов и гаек.

ПРИМЕЧАНИЕ: Прикрепите два нижних суппорта (7) к

нижним отверстиям (14) ножки.

7. вставьте резиновую накладку (8) в ножки станины.

Повторите процедуру для каждой ножки.

8. Поместите стойку на горизонтальную поверхность

и добейтесь того, чтобы все ножки касались пола

под одинаковым углом, и чтобы стопоры ножек

совмещались со скобами суппортов. Затяните болты.

ПРИМЕЧАНИЕ: Чтобы избежать раскачивания стойки,

затяните все болты.

КРЕПЛЕНИЕ КРЫШКИ К СТОЛУ (РИС. B)

ПРИМЕЧАНИЕ:

Крышка основания поставляется не в сборе.

1. Прикрепите крышку основания (1) к основанию стола

(2) при помощи 4 болтов (3) из набора отдельных

частей.

2. Затяните 4 болта (3) перед креплением стола к стойке.

Рис. B

2

1

3

3

3

КРЕПЛЕНИЕ СТОЛА К СТОЙКЕ (РИС. A И C)

1. Поместите основание стола на стойку, совместив

отверстия (1) (Рис. С).

2. Закрепите стол на стойке при помощи болтов (28),

шайб (24) и гаек (25) (Рис. А).

Рис. С

3

Рис. A

9

1

6

1

3

12

4

10

11

5

7

8

2

– 28 –

Page 29

Russian

УСТАНОВКА КРЮЧКА ДЛЯ ТОЛКАТЕЛЯ (РИС. А)

Прикрепите крючок для хранения толкателя (9-Рис. А) к

левому короткому суппорту (6).

УСТАНОВКА РАСКЛИНИВАТЕЛЯ (РИС. D)

1. Поднимите диск в его верхнее положение, повернув

колесо и наклонив диск под углом 45º.

2. Ослабьте болты на вставке стола и выньте ее.

3. Вставьте болты (3) и плоские шайбы (4) в скобу

расклинивателя (5) и сам расклиниватель (6).

4. Затяните болты (3).

5. Верните вставку стола на место и затяните болты.

ВНИМАНИЕ

Толщина расклинивателя – 2,5 мм. Убедитесь, что диск

и расклиниватель располагаются на одной прямой.

В противном случае скорректируйте положение

расклинивателя, ослабив болты. Расстояние должно

быть менее 5 мм в любом положении.

Рис. D

6

3

УСТАНОВКА НАПРАВЛЯЮЩЕЙ ПЛАНКИ (РИС. F)

Установите направляющую планку, задвинув ее с края

стола, ровняясь по желобку в передней части стола и

выступу на скобе планки.

Рис. F

УСТАНОВКА И ЗАМЕНА ДИСКА (РИС. G, H).

ВНИМАНИЕ

Во избежание случайного запуска, всегда переводите

переключатель в положение Выкл. (OFF, 0) и

вынимайте провод питания из розетки перед сменой

диска.

1. Ослабьте болты (3) на вставке стола при помощи

отвертки и снимите вставку.

5

5

6

3

4

Сборка защитного кожуха (Рис. Е)

Поместите защитный кожух на расклиниватель и

закрепите его при помощи болта (1), плоской шайбы (2) и

гайки (3).

Рис. Е

2

3

1

Рис. G

3

2. Поднимите диск в его верхнее положение.

3. при помощи поставляемого рожкового ключа (1)

удерживайте оправку от вращения, а накидным ключом

(2) ослабьте гайку на оправке. (Рис. H)

4. Снимите гайку на оправке и фланец.

5. Замените диск. Убедитесь, что зубцы диска

направлены вниз к передней части стола.

6. Верните на место фланец и гайку оправки и затяните

гайку.

7. Верните вставку стола и затяните два болта.

– 29 –

Page 30

Russian

Рис. H

1

2

УСТАНОВКА ЗАДНЕГО УДЛИНЕНИЯ СТОЛА (РИС. I)

1. Поднесите заднее удлинение (3) к столу, совместив

крепежные отверстия (1).

2. Вставьте болты (2) в крепежные отверстия (1) через

скобу (5) и заднее удлинение (3).

3. Наденьте гайку (6) и затяните ее.

4. Вставьте болт (2) через удлинение (3) в другую часть

скобы (5) и затяните гайку.

5. Прикрепите другой конец удлинения к столу при помощи

болтов и гаек.

6. Поместите линейку или комбинированный угольник на

стол и заднее удлинение (3).

7. При помощи болтов (2) добейтесь, чтобы удлинение

плотно и ровно прилегло к столу. Затяните гайки (6).

8. Прикрепите суппорты удлинения (7) к заднему

удлинению и закрепите их на стойке (4) при помощи

болтов и гаек.

Рис. J

1

3

2

ВЫРАВНИВАНИЕ РАСКЛИНИВАТЕЛЯ (РИС. К)

1. Если диск и расклиниватель не выровнены:

а. Снимите вставку стола, отвернув болты.

b. Снимите защитный кожух, сняв болт, плоскую шайбу

и гайку, которыми крепится кожух.

с. Ослабьте два болта (3) на скобе расклинивателя (5).

2. Вставьте шайбы (7) между расклинивателем (6) и

скобой (5).

3. Надежно затяните два крепежных болта (3).

4. Верните на место защитный кожух, закрепив его при

помощи болта, шайбы и гайки.

5. Проверьте выравнивание расклинивателя и диска в

положении 90° и 45°.

6. Добавляйте или снимайте шайбы, пока не будет

достигнуто выравнивание.

7. Верните на место вставку стола.

4

Рис. I

3

1

5

7

8

6

2

4

УСТАНОВКА БОКОВЫХ УДЛИНЕНИЙ СТОЛА (РИС. J)

1. Поднесите левое удлинение к столу, совместив

крепежные отверстия (1).

2. Вставьте болты (4) в крепежные отверстия и наденьте

гайки.

3. Поместите линейку или комбинированный угольник на

стол и удлинение (3).

4. При помощи гайки (2) добейтесь, чтобы удлинение

плотно и ровно прилегло к столу. Затяните.

5. Прикрепите суппорты удлинения (3) к левому

удлинению и закрепите их на стойке при помощи

болтов и гаек.

6. Повторите эти операции для крепления правого

удлинения.

– 30 –

Рис. К

6

3

5

5

7

6

3

4

ПРИМЕЧАНИЕ: Точное выравнивание производится

на заводе производителя. Проверьте его точность и

проведите настройку, если необходимо, чтобы добиться

наилучших результатов.

Page 31

Russian

ВЫРАВНИВАНИЕ ДИСКА ПАРАЛЛЕЛЬНО КАНАВКЕ

УГЛОВОГО УПОРА (РИС. L, M, N)

ВНИМАНИЕ

Выравнивание необходимо произвести точно, иначе

возможна отдача и затруднение точной резки.

1. Поднимите диск в его верхнее положение. И

установите угол 0°.

2. Выберите зубец диска, отогнутый вправо. Отметьте его

карандашом или маркером.

3. Поместите угловой упор (1) в правую канавку (2) на

крышке стола. Поверните угловой упор в положение

90° и поверните ручку, чтобы зафиксировать это

положение.

4. Вращайте диск, чтобы помеченный зубец находился

впереди на расстоянии 13 мм над поверхностью стола.

Поместите угольник (3) вплотную к угловому упору

и двигайте угольник к диску до тех пор, пока он едва

коснется кончика отмеченного зубца. (Рис. L)

Рис. L

3

Рис. N

1

2

3

УСТАНОВКА ЖЕСТКОГО УПОРА ДИСКА ПОД УГЛОМ 90°.

1. Поднимите диск в его верхнее положение.

2. Освободите ручку фиксатора наклона диска и двигайте

поворотный механизм влево, пока он не упрется в

стопор. Затяните ручку фиксатора наклона.

3. При помощи угольника проверьте, равен ли угол

наклона 90°. (Рис. О)

4. Если угол не равен 90°, ослабьте ручку фиксатора

наклона. При помощи нескольких поворотов болтов

(2-рис N) проведите настройку и приведите поворотный

механизм в положение 90° относительно стола.

5. После настройки затяните ручку фиксатора наклона.

6. Ослабьте болт указателя наклона и установите

указатель в положение 0°.

1

2

5. Не меняя положение угольника, приложенного к упору

(1) двигайте упор к центру диска. Поворачивайте

диск так, чтобы отмеченный зубец оказался сзади на

расстоянии 13 мм над поверхностью стола.

6. Двигайте угловой упор назад до тех пор, пока угольник

не приблизится к кончику отмеченного зубца. (Рис. М)

Рис. М

1

7. Если угольник едва касался зубца, когда упор был

впереди, он должен касаться зубца и в этом положении.

8. Если зазор впереди и сзади неодинаков, снимите

угловой упор, ослабьте четыре болта (1) и осторожно

возьмите диск. Проведите необходимые манипуляции,

чтобы зазор впереди и сзади был одинаков. Затяните

четыре болта (1). (Рис. N)

– 31 –

Рис. О

1

2

УСТАНОВКА ЖЕСТКОГО УПОРА ДИСКА ПОД УГЛОМ 45°.

1. Поднимите диск в его верхнее положение.

2. Освободите ручку фиксатора наклона диска и двигайте

поворотный механизм влево, пока он не упрется в

стопор. Затяните ручку фиксатора наклона.

3. При помощи угольника в 45° (2) проверьте, равен ли

угол наклона 45°. (Рис. О)

4. Если угол не равен 45°, ослабьте ручку фиксатора

наклона. При помощи нескольких поворотов болтов

(3-рис N) проведите настройку и приведите поворотный

механизм в положение 45° относительно стола.

5. После настройки затяните ручку фиксатора наклона.

6. Ослабьте болт указателя наклона и установите

указатель в положение 45°.

Page 32

Russian

НАСТРОЙКА НАПРАВЛЯЮЩЕЙ ПЛАНКИ (РИС. Р)

ВНИМАНИЕ

Настройку необходимо произвести точно, иначе

возможна отдача и затруднение точной резки.

1. Ослабьте ручку зажима (1).

2. Поместите направляющую планку на один из краев

канавки углового упора.

3. Зафиксируйте планку на столе при помощи ручки

зажима. Края планки должны стать параллельны

канавке углового упора.

4. Если край планки не параллелен канавке углового

упора, ослабьте болты (2) на планке, установите ее

параллельно канавке и затяните болты (2).

Рис. Р

2

4

Рис. O

2

3

4

1

5

6

1

5

НАСТРОЙКА УКАЗАТЕЛЯ НАПРАВЛЯЮЩЕЙ ПЛАНКИ

(РИС. Р)

ПРИМЕЧАНИЕ: настройку указателя необходимо

проводить заново при установке диска другой толщины.

1. Чтобы установить нулевое положение указателя,

ослабьте ручку зажима (1) и двигайте планку до

плотного контакта с боковой плоскостью диска.

2. Убедитесь, что указатель (4) расположен на отметке 0

на линейке в передней части стола.

3. Если указатель не находится на отметке 0, затяните

ручку зажима, ослабьте болт указателя (5) и

переведите указатель в положение 0. Затяните болт

указателя.

НАСТРОЙКА УГЛОВОГО УПОРА (РИС. Q)

1. Чтобы провести настройку положения 90°, ослабьте

ручку зажима (1) и поместите угольник (2) вплотную

одновременно к диску (3) и угловому упору (4).

Указатель упора (5) должен находиться у отметки 90°.

2. Если указатель не находится у отметки 90° на упоре,

затяните ручку зажима, ослабьте болт указателя (6),

переведите его к отметке 90°, затяните болт указателя.

– 32 –

Page 33

ЭКСПЛУАТАЦИЯ

Russian

ПЕРЕКЛЮЧАТЕЛИ НАСТОЛЬНОЙ ДИСКОВОЙ ПИЛЫ

(РИС. R)

Главный переключатель (3-Рис. R), выключатель нулевого

напряжения в передней части у основания станка. Для

подачи питания следует нажать «I», для выключения – «0».

ВНИМАНИЕ

Не включайте станок в электрическую сеть, пока

не будут завершены все работы по установке и

настройке, и пока Вы полностью не прочтете и

поймете инструкции по технике безопасности и

эксплуатации.

ПОДЪЕМ И ОПУСКАНИЕ ДИСКА (РИС. R)

ВНИМАНИЕ

Не проводите операцию при вращающемся диске.

1. Чтобы поднять диск, вращайте колесо (1) против часовой

стрелки.

2. Чтобы опустить диск, вращайте колесо (1) по часовой

стрелке.

ПРИМЕЧАНИЕ: Рекомендуемая высота диска составляет 3,2

мм над поверхностью заготовки.

Рис. R

3

2

1

РАБОТА С УГЛОВЫМ УПОРОМ

ПРИМЕЧАНИЕ:

1. Угловой упор можно устанавливать справа или слева от

диска.

2. Поскольку канавка углового упора Т-образная, для

установки упора следует вставлять его с конца канавки.

3. Для установки угла резки ослабьте ручку зажима,

поверните угловой упор на нужный угол, затяните ручку

зажима.

ПРОДОЛЬНАЯ РЕЗКА (РИС. S)

ПРИМЕЧАНИЕ:

1. Под продольной резкой обычно понимают резку вдоль

волокна.

2. Не выполняйте продольную резку “голыми руками”.

Пользуйтесь направляющей планкой, снимите угловой

упор со стола.

ВНИМАНИЕ

1. Перед продольной резкой убедитесь, что:

а. Направляющая планка надежно закреплена

параллельно диску.