Hi-G-Tek Ltd. Microelectronics and Asset Tracking Technology

User’s Manual

Ver. A 61 UM4710

INTRODUCTION....................................................................... 10

1

1.1 W

1.2 A

1.3 S

HAT PRODUCTS ARE COVERED BY THIS MANUAL

BOUT TH E PRO DUCT

YSTEM COMPO NENTS

............................................................... 10

.............................................................. 14

.................. 10

1.3.1 The Mounting Fixture............................................................ 14

1.3.2 The Dat aSeal ........................................................................ 14

1.3.3 Sealing Wire......................................................................... 15

1.3.4 Outdoor DataReader.............................................................. 15

1.3.5 Indoor DataReader ................................................................ 17

2 Q UICK-START .......................................................................... 20

2.1 B

2.2 S

2.3 I

2.4 C

2.5 P

2.6 E

2.7 A B

EFOR E YOU BEGIN

ETTING UP TH E DATAREADERS

NSTALLING THE EVALUATION SOFTWARE

ONF IGURING TH E SYSTEM

REPARING TH E DATASEAL/DATATAG

XECUTING A VERIFY COMMAND

RIEF TUTORIAL THROUGH THE STATES O F TH E DATASEAL

................................................................... 20

............................................... 21

............................... 21

...................................................... 22

..................................... 24

.............................................. 27

29

3 DATAS EAL INSTALLATIO N................................................... 34

4 DATA TAG INSTA LLA TION..................................................... 38

4.1 P

LACING TH E DATATAG O N A VEHICLE

.................................... 38

4.1.1 Horizontal Orientation:.......................................................... 39

- 2 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

4.1.2 Vert ical Orientation............................................................... 39

5 DATAREADER INSTALLA TION ............................................. 42

5.1 O

UTDOOR DATAREADER INSTALLATIO N

.................................. 42

5.1.1 Ceiling Installat ion................................................................ 42

5.1.2 Connecting the Outdoor Unit ................................................. 43

5.1.3 Wiring the Outdoor DataReader............................................. 44

5.1.4 RS-232 Wiring Diagram........................................................ 45

5.1.5 RS-485 Full Duplex Wiring Diagram...................................... 46

5.1.6 RS-485 Half Duplex Wiring Diagram..................................... 46

5.1.7 DataReader Configuration Switches ....................................... 46

5.2 I

NDOOR DATAREADER INSTALLATION

...................................... 47

5.2.1 Connecting the Indoor Unit.................................................... 47

5.2.2 Wiring the Indoor DataReader................................................ 48

5.2.3 RS-232 Wiring Diagram........................................................ 49

5.2.4 RS-485 Full Duplex Wiring Diagram...................................... 50

5.2.5 RS-485 Half Duplex Wiring Diagram..................................... 51

5.3 C

5.4 RS -232/RS - 48 5 A

HA INING DATAREADERS TO G E TH ER

DAPTER

.......................................................... 54

...................................... 51

5.4.1 Connecting the RS-232/RS-485 Adapter to the First DataReader

54

5.4.2 Connecting the RS-232/RS-485 Adapter to the Controlling

Computer 56

5.5 P

OWER SUPPLY REQUIREMENTS

............................................... 56

5.5.1 General................................................................................. 56

5.5.2 Indoor Installation................................................................. 57

5.5.3 Outdoor Installation............................................................... 57

5.6 C

5.7 I

5.8 D

ABLE SELECTION

NSTALLATIO N NOTES

ATAREADER OPERATION INSTRUCTIONS

.................................................................... 58

............................................................... 59

................................ 60

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 3 -

5.8.1 Power Indicators:.................................................................. 60

5.8.2 Channel 1 SD/RD Indicator:.................................................. 60

5.8.3 Channel 2 SD/RD Indicator:.................................................. 61

6 SYSTEM O VERVIEW................................................................ 64

6.1 S

6.2 D

YSTEM DESCRIPTION

ATASEAL A ND DATAREADER MODES O F OPERATION

............................................................... 64

............. 66

6.2.1 DataSeal Modes of Operation................................................. 66

6.2.2 DataReader Modes of Operation............................................. 68

6.3 M

OST COMMON COMMANDS AND SEA L STATU S

....................... 69

6.3.1 Most Commonly Used Commands......................................... 69

6.3.2 DataSeal's Status................................................................... 70

6.4 S

YSTEM PLANNING

................................................................... 71

6.4.1 Electromagnetic Environment ................................................ 72

6.4.2 System Layout ...................................................................... 72

6.4.2.1 Radio Frequency Communication Layout............................. 73

6.4.2.2 Line Communication RS-485 Layout.................................... 74

6.5 S

YSTEM S SEGREGATION

........................................................... 75

6.5.1 Companies Segregation by OrgID .......................................... 76

6.5.2 Department Isolation............................................................. 76

6.5.3 Services to Several Companies by a Service Provider.............. 77

6.5.4 Subgroups of DataSeals......................................................... 77

6.5.5 OrgID, Department, Global and ADI Impact on DataSeal’s

Response 78

6.6 D

ATASEAL'S MEMOR Y

.............................................................. 79

6.6.1 Events Memory..................................................................... 79

6.6.2 User Dat a.............................................................................. 80

6.6.2.1 The User Data portion used by the DataT erminal................... 81

6.7 S

YSTEM COMMANDS

................................................................. 82

- 4 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

7 EVALUATIO N SO FTWARE...................................................... 88

7.1 S

7.2 C

W

OFTWARE INSTALLATIO N

OMMUN ICATION SETUP

INDOW

............................................................................................ 89

........................................................ 88

HE READERS ADM INISTRA TION

– T

7.2.1 Defining the Connected DataReaders...................................... 89

7.2.2 Setting Up the Communication Port........................................ 90

7.3 R

7.4 T

EADER SETUP

HE VERIFY AND SET WINDOW

......................................................................... 90

................................................. 91

7.4.1 Executing Broadcast Verify Command................................... 94

7.4.2 Executing Addressed Verify Command.................................. 96

7.4.3 Executing Set Command........................................................ 98

7.4.4 Cyclical Interrogations Options.............................................. 99

7.5 E

W

XECUTING ANY COMMAND USING THE ALL COMMANDS

INDOW

.......................................................................................... 100

7.5.1 Executing an RF Command ................................................. 101

7.6 S

PECIFIC COMMAND STRUCTURES

.......................................... 102

7.6.1 Verify................................................................................. 103

7.6.2 T ampered (T amper)............................................................. 105

7.6.3 Addressed Verify ................................................................ 105

7.6.4 Set 106

7.6.5 Soft Set............................................................................... 107

7.6.6 Suspended Set..................................................................... 107

7.6.7 Read Data........................................................................... 108

7.6.8 Write Dat a.......................................................................... 110

7.6.9 Read Parameters.................................................................. 112

7.6.10 Write Parameters................................................................. 113

7.6.11 Reset Data.......................................................................... 115

7.6.12 Deep Sleep.......................................................................... 116

7.6.13 Hard Wakeup...................................................................... 117

7.6.14 Start Alert Burst Mode......................................................... 118

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 5 -

7.6.15 Start Alert Burst Mode (all).................................................. 119

7.6.16 Stop Alert Burst Mode......................................................... 120

7.6.17 Stop Alert Burst Mode (all).................................................. 120

7.6.18 Acknowledge Alert Burst..................................................... 121

7.6.19 Read Events........................................................................ 122

7.7 A

DVANCED FEATURES

............................................................. 124

7.7.1 Built-In Test....................................................................... 124

7.7.2 Authorization Levels and Passwords..................................... 125

7.7.2.1 Logging-in Using the Desired Authorization Level.............. 126

7.7.2.2 Changing Passwords.......................................................... 126

7.7.3 Updating the DataReader's Internal Software......................... 127

7.7.3.1 The MCU Download Utility............................................... 128

7.7.3.2 RF Modem Download Utility............................................. 129

8 S YSTEM PARAMETERS AND CO MMANDS ........................ 132

8.1 T

HE HIGH FREQ UENCY

RF P

ROTOCOL

................................... 132

8.1.1 The Basics.......................................................................... 132

8.1.2 Addressing Types................................................................ 134

8.1.3 The Slotted Aloha Concept .................................................. 135

8.2 D

ATASEAL PARAMETERS

........................................................ 136

8.2.1 The Dat aSeal Status Flags.................................................... 167

8.3 E

VENTS

................................................................................... 179

8.3.1 General Structure of an Event Record................................... 180

8.4 H

IGH-FREQUENCY

OMMANDS SUMMA RY

RF C

........................ 186

8.4.1 Broadcast Commands.......................................................... 187

8.4.2 Addressed Commands......................................................... 195

8.4.3 Multi Addressed Commands................................................ 204

8.4.3.1 Multi Addressed Commands With Parameters..................... 204

8.4.3.2 Multi Addressed Commands Without Parameters................ 205

8.5 B

- 6 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

URST MESSAGES

................................................................... 210

8.6 D

8.7 C

ATAREADER PAR AMETERS

OMMAND CHAIN

................................................................... 230

................................................... 215

9 TRO UBLE S HOO TING AND PROBLEM SO LVING ............. 234

9.1 G

9.2 RS-232/485 C

9.3 G

9.4 S

ENERAL DATAREADER PROBLEM S

OMMUNICATION PROBLEM S

ENERAL

PECIFIC

OMMUN ICATION PRO BLEM S

RF C

CO MMANDS TROUBLESHOOTING

RF

....................................... 234

.............................. 234

........................... 234

:....................... 235

10 TECHNIC AL SPECIFICATIONS............................................ 238

10.1 24V O

10.2 12V O

10.3 48V O

10.4 24V I

10.5 12V I

10.6 48V I

10.7 D

10.8 M

10.9 FC C

UTDOOR DATAREADER

UTDOOR DATAREADER

UTDOOR DATAREADER

NDOOR DATAREADER

NDOOR DATAREADER

NDOOR DATAREADER

ATASEAL

AGNETICDATASEAL

.............................................................................. 244

APPROVED PRODUCTS

.................................................. 238

.................................................. 239

.................................................. 241

..................................................... 242

..................................................... 243

..................................................... 243

............................................................. 245

:.................................................... 246

11 INDEX....................................................................................... 250

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 7 -

This User’s Manual includes all the information required for installing

and operating Hi-G-T ek Electronic DataSeals and DataReaders.

Software License Agreement

Information in this do cument is subject to change without notice and does not

represent a commitment on the part of the manu facturer. The software described in

this document is furnished under licens e agreement or nondisclosure agreement. It

is against the law to copy the software on any medium except as speci fi cally

allowed in the license or nondisclosure agreem ent. T he purchaser may make one

copy of the softw are for backup purposes. No part o f this manual may be

reproduced or transmitted in any form or by any means, electronic or m echanical,

including photocopying, recording, or in fo rmation storage and retrieval, for any

purpose other than fo r the purchaser’s personal use, without written permission.

© Copyright 2001 Hi-G-Tek Ltd.

All rights reserved.

DataSeal

Pentium

Microsoft Windows 98

TM

is a trademark of Hi-G-T ek.

TM

is a trademark of Intel Corporation.

®

and Microsoft Windows NT® are trademarks of

Microsoft Corporation.

Moxa is a trademark of Moxa Technologies.

- 8 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 1 Introduction

1

Introduction

1.1 What Products are Covered by this Manual

This manual covers the DataReader (both Indoor and Outdoor versions),

Dat aSeal, Dat aT ag and th e Magnet icDat a Seal p roduct s.

The DataTerminal, DataPort, MicroDataReader, T rackingDataReader and

Smart DataReader are Hi-G-T ek products that are referred to in some places

in the manual, but are not covered by it.

1.2 About the Product

Thank you for choosing Hi-G-T ek quality product s. The Hi-G-T ek range of

product s provides a h igh ly reliable and secure car go an d asse t monitoring

system utilizing stat e-of-the-art RFID technologies.

Cost-effective, more reliable and more secure than their mechanical

counterparts, the Hi-G-Tek product range will const ant ly monitor your

assets and alert you to any potential problems at all times.

The Hi-G-Tek syst em was developed in order to fill the requirement for

fast, automatic processing of secured cargoes and to provide real t ime

mon ito r ing and im pr ov ed managem ent of cargoes bot h in t ransit an d in

storage.

The basis of the system is a family of reusable electronic seals named

DataSeal. Th is family of p ro duct s in cludes t he DataSeal, DataT ag and t he

MagneticDataSeal.

- 10 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 1 Introduction

Note: T his manual uses the t erm DataSeal to refer to any member of this

fam ily o f p ro duct s, unless oth erwise sp ecified.

The most significant purposes of the Dat aSeal are:

Track any attempts of opening, bypassing or tampering.

Record events when tamper occurs.

Write and read user data.

The reusable electronic seal automates the processing of secured cargoes

enabling the organization to effectively and economically process t he

increasing numbers of containers’ traffic in the ports and between inland

destinations.

The DataSeal includes a transmitter / receiver unit, real-time clock,

processor, memory and sensing circuitry for sealing verification. The

Sealing Wire

1

prevents any attempt of opening, bypassing or tampering

with the seal without alert ing the syst em and recording of the event. The

system combines t he technological and operat ional advantages of both low

frequency close-range AND high frequency (UHF) long range for sealing

verification and other communications with the DataSeal.

The low frequency (short range) communication protocol is used by the

DataTerminal, t he DataPort and t he MicroDataReader. This channel of

communication is useful for writing the electronic manifest of the sealed

cargo into the DataSeal's memory. For example: this information can

1

In t he case o f DataT ag, there's a “ S ensor Plate” instead o f t he Sealing Wire, and

in the case of the MagneticD ataS eal , there's a “ Magnet Element”.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 11 -

Chapter 1 Introduction

include the vehicle ID, container and invoice numbers, cargo description,

etc. It is also useful for reading the DataSeal's event records, and t o reset

the DataSeal for a new use (an operation called "Set").

Note:

The low frequency protocol, the DataTerminal, DataPort and

MicroDataReader devices are not covered by this manual.

The high frequency protocol is used by devices of the DataReader family of

products. This family includes the DataReader it self, which connects to a

controlling computer (normally a PC) t hrough an RS-232/485 interface; the

TrackingDataReader which cont ains a GPS and GSM modules and is

usually installed on a truck; and t he SmartDat aReader which contains an

embedded PC and connects to an Ethernet network. This manual covers

only th e DataReade r device itself. The high frequen cy pr otocol is use f ul for

monitoring the presence and status of one or more DataSeals constantly or

periodically. It is capable of communicating with multiple DataSeals

simultaneously and even with DataSeals in high speed motion, for

example: on a train.

The DataSeal and DataReader devices are capable of communicating in

distances of up to 30 meters, and in some cases even more.

The use of the high frequency/long range protocol enables applications

such as: tracking and sealing verification of containers in transit; protection

of containers in storage; remote automatic data collection from secured

cargoes as they pass through check points, etc.

The DataReader is able t o detect which DataSeals are present in its area,

and their statuses (open/close, tampered, etc). It can also receive messages

from DataSeals in real-time, for example when the DataSeal is tampered.

These types of messages that the Dat aSeal transmit s are called "Burst

Messages" .

- 12 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 1 Introduction

Multiple DataReaders can be connect ed to a single controlling computer

using the RS-485 interface. This allows to maximize the coverage area of

the DataReaders while keeping them synchronized. The Dat aReader is

av ailable in both in doo r and o utdoor mo dels.

A set of Mount ing Fix t ures has been de v eloped for t he Dat aSeal syst em

which allow convenient mounting and removal of the DataSeal from a

co ntainer when ev er r equir e d. Th e v ario us Mount ing Fix t ures differ in the

level of protection they provide to the DataSeal as may be required in

various environments.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 13 -

Chapter 1 Introduction

1.3 System Compone nts

1.3.1 The Mounting

Fixt u re

The Dat aSeal Mount in g Fixt ure

is used to mount the DataSeal on

the cont ainer’s keeper bar or

other surface.

1.3.2 The DataSeal

The DataSeal unit contains t he

DataSeal electronics, a battery, a

transceiver, a processor and

m e mo ry t o r eco r d an d stor e t h e

events and the relevant

information about the cargo.

- 14 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 1 Introduction

1.3.3 Sealing Wire

The Sealing Wire serves t o seal

the cargo. Any tampering with the

Sealing Wire at any p o int during

transport is recorded and can be

reported at once.

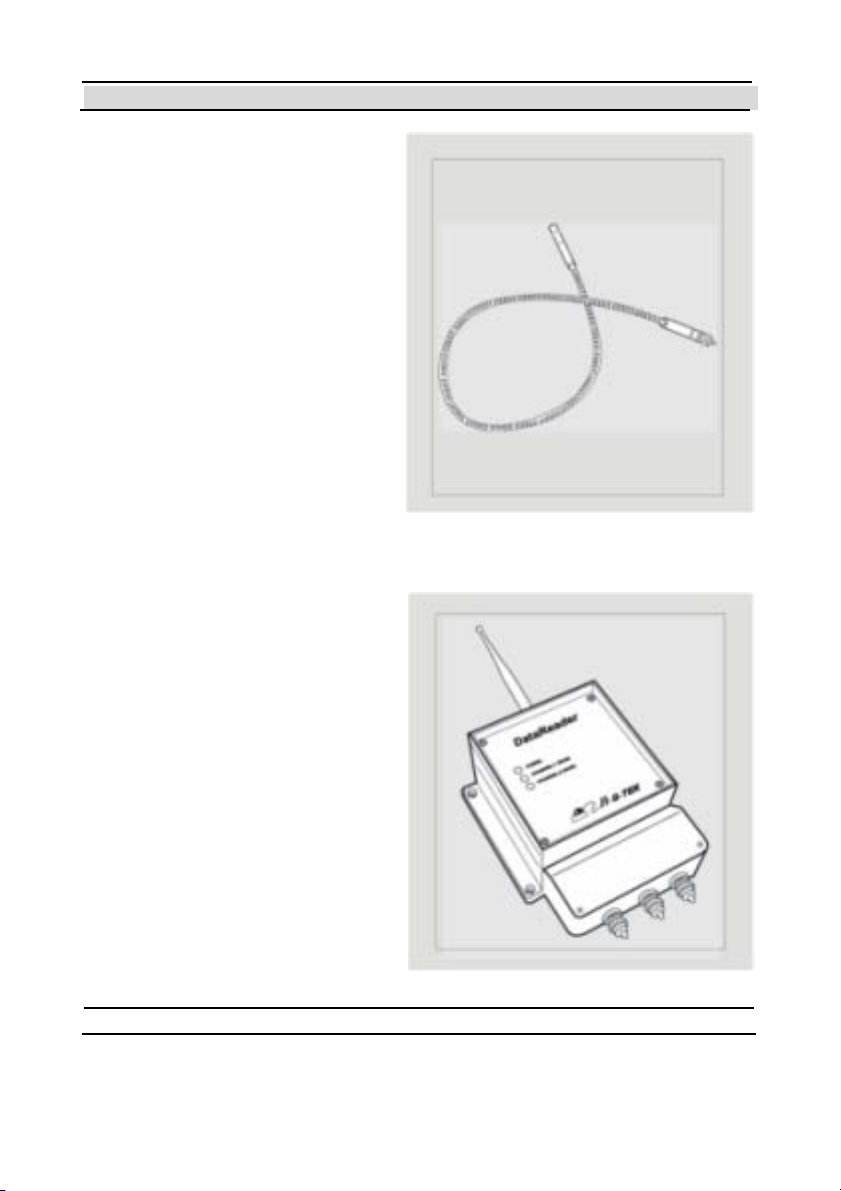

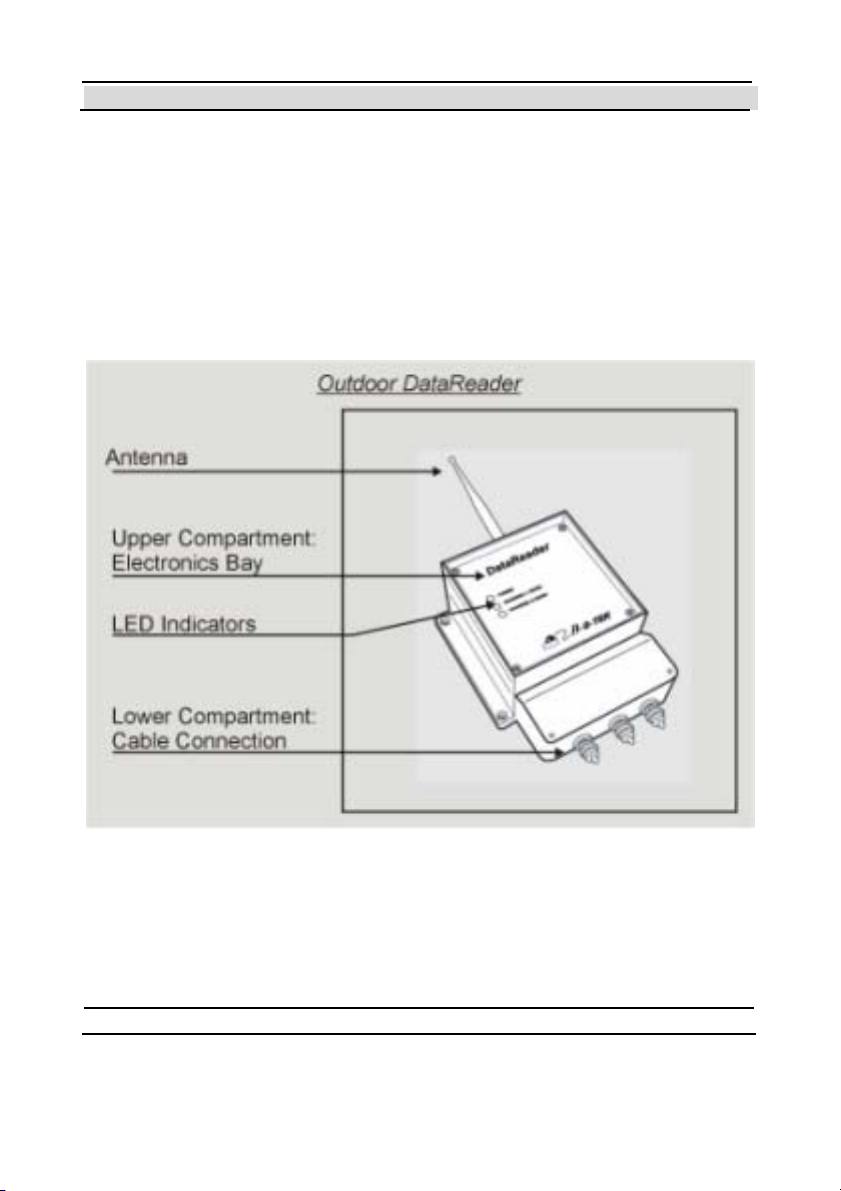

1.3.4 Outdoor DataReader

The Hi-G-Tek DataSeal System

uses st at e-of-t he-art t echnology to

secure and monit or secured

cargoes in storage and during

transport.

The DataReader is comprised of

two compartments. The upper

compart ment is the heart of the

unit and co nt ains the

DataReader’s electronics sect ion.

The lower compart ment cont ains

the terminal glands which connect

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 15 -

Chapter 1 Introduction

the unit to the RS-232/485 networking cable.

The Dat aReade r may be used in bo th station ary and mobile configurat ions.

In the st ationary configuration, the unit is mounted on a flat surface such as

a wall or pole. A typical installation of this configuration is at the point of

exit from ports, customs t erminals, warehouses, etc. This operation mode

allows monitoring of the Dat aSeal at predetermined sites and checkpoints.

In the mobile configur at ion, t he unit is mount ed in t he t ruck cabin . T he

DataReader monitors the seal during t he entire journey, and reports its

status via the vehicle’s communication system to the control center in realtime. T his configurat ion requires an addit ional 3rd party controlling device

to cont rol the Dat aReader, or to use the T rackingDataReader which is not

covered by this manual.

- 16 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 1 Introduction

The DataReader is mast ered by a controlling computer. Once installed, the

unit waits for commands coming from the controlling computer.

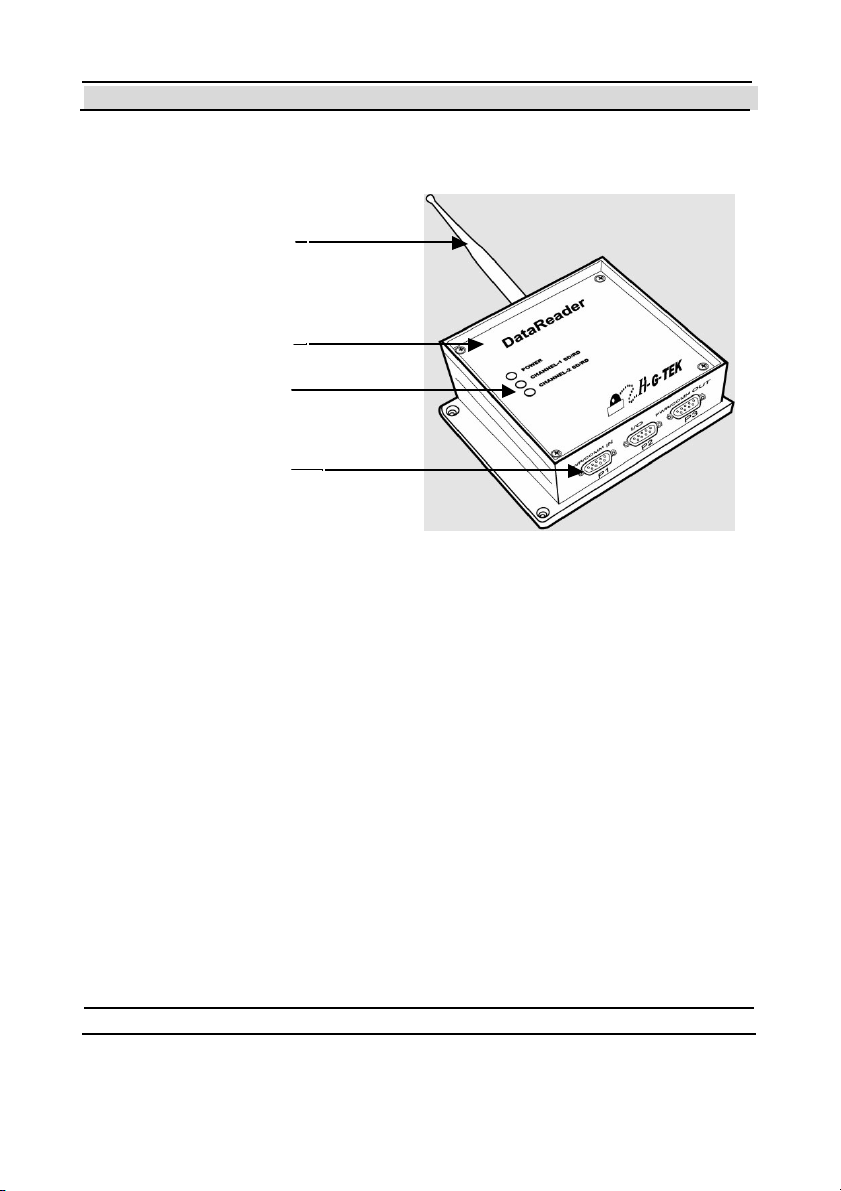

1.3.5 Indoor

Data Re ader

Similar to the outdoor

version, the Indoor

DataReader uses state-of-the-

art technology to secure and

monitor secured cargoes in

an indoor environment.

The Indoor DataReader may

be use d in st at io n ary

configuration only.

The unit is mounted on a flat

surface such as a wall or

pole. A typical installation of

this configuration is at the

point of closed warehouses, offices, etc.

Unlike the Outdoor DataReader, the Indoor version does not have the lower

compart ment. Instead it has 3 connectors.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 17 -

Chapter 1 Introduction

Indo or Data Reade r

Antenna

Electronics Bay

Led I n dicat or

Cable Connection

- 18 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

2

Quick-Start

The aim of this chapter is to lead you step-by-step in the quickest way to

the stage where you can verify that the Demo System is working properly,

an d that yo u h ave a simp le sy stem that yo u can p lay with , in o r der t o

ev aluat e the p otent ial of th e pro duct s. Th is guide a ssum es t hat t he

parameters of the DataReader and DataSeal are the factory defaults, and it

refers only to the Demo System. For installation instructions for a

DataReader that is not a Demo System, see chapter 5.

2.1 Be fore you begin

Before you begin, make sure that you have the following items available:

1. The Hi-G-Tek DataReader

device.

2. DataReader Antenna.

3. At least one Hi-G-Tek DataSeal device.

4. The Seal ID of the DataSeal (printed on t he sticker on the bottom side

of the DataSeal).

5. Sealing W ire( s) (accordin g to the number of DataSeals. I f yo u are usin g

DataTags you need Sensor Plate(s) instead of the Sealing Wires)

6. P C runnin g one o f the following op erat ing sy st ems:

• Windows 98 or above.

• Windows NT 4.0 or above.

- 20 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

This computer must have at least one available serial communication

port, a CD-ROM drive, and at least 20MB of free hard disk space. T he

computer must use an Intel Pentium

TM

or compatible processor.

7. CD-ROM with Evaluation Software.

2.2 Setting up the DataReaders

First, connect the antenna to the DataReader. The antenna connects to the

TNC connector at the top side of the Dat aReader.

Then, connect the DB9 female connector to a serial communication port in

t he PC. T ake not e of which p ort you ar e using (for examp le COM2). It is

good practice to connect and disconnect cables only when the computer is

off.

Plug the power chord of the Dat aReader into a power outlet. You should

see the POWER LED blinking red and green. Aft er about 30 seconds it

should remain green. If it remains red, or isn't lit at all, there is a problem

with the DataReader. Refer to the chapter 0 for troubleshooting.

2.3 Installing the Evaluation Software

If the computer is not turned on, turn it on now, and wait until the operating

system is loaded completely.

Insert the CD-ROM labeled "Hi-G-T ek" into t he CD-ROM drive.

From the Start menu, choose "Run". Assuming your CD-ROM drive is

drive E, type "E:\DataSeal Evaluation Software\Setup.EXE" in the "Run"

dialog box. If your CD-ROM drive lett er is not E, replace t he fir st E wit h

your CD-ROM drive letter. Click OK to st art installing t he DataSeal

Evaluation Software.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 21 -

Chapter 2 Quick Start

Follow t he instructions on the screen until it says that the software is

successfully installed.

If you're using Windows 98, restart your computer (even if you're not

requested to by t he installation soft ware).

The Evaluat ion Soft war e is now in st alled. A new short cut icon "

Dat aSeal E v aluat ion" is added t o yo ur St art - >Pro gr ams m enu.

2.4 Configuring the System

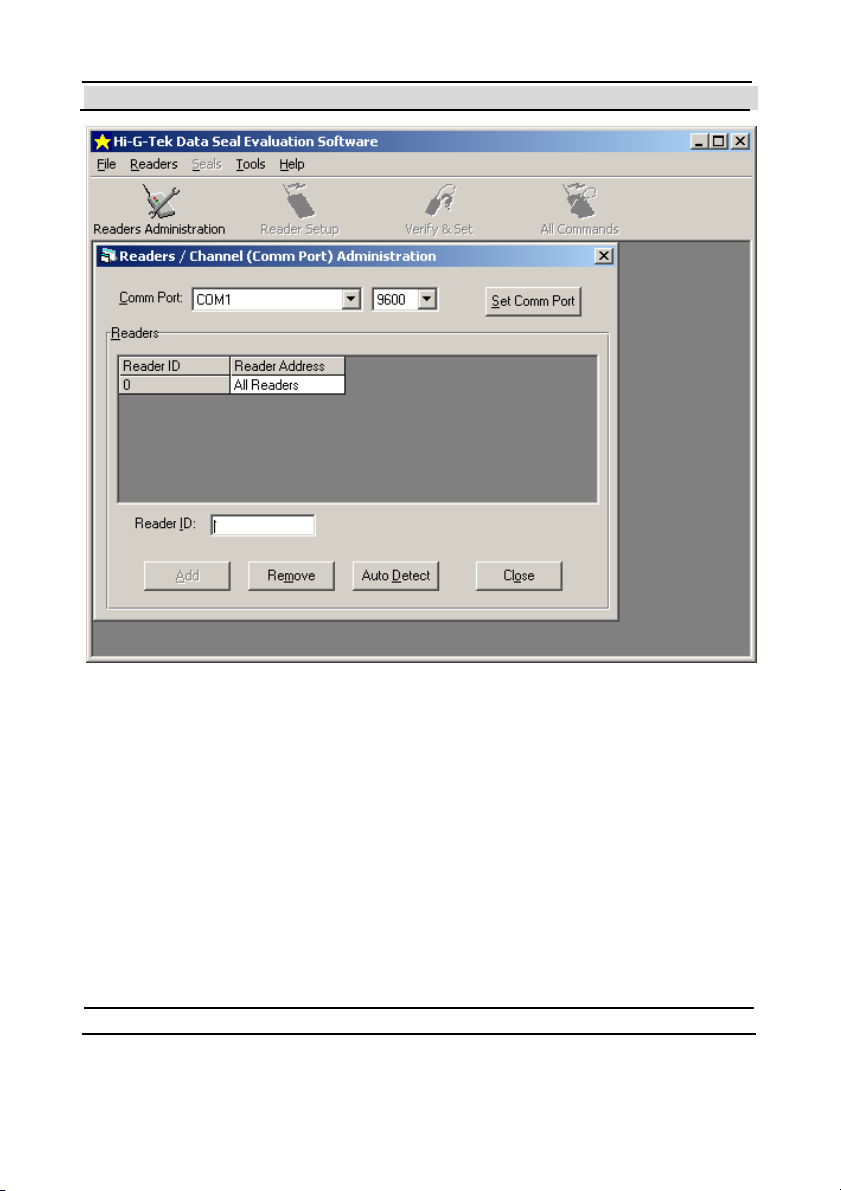

Run the Evaluation Software by clicking on that icon. The Rea de rs

Admini stration Window shown in Figure 2-1 will be displayed.

- 22 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

Figure 2-1 - The Readers Administration Window.

If you connect ed the Reader to a serial port other than COM1, choose the

appropriate COM port from the Comm Port drop do wn list , an d t hen click

on the Se t Comm Port butt on. Click OK to close t he message window that

says "Comm port was set successfully".

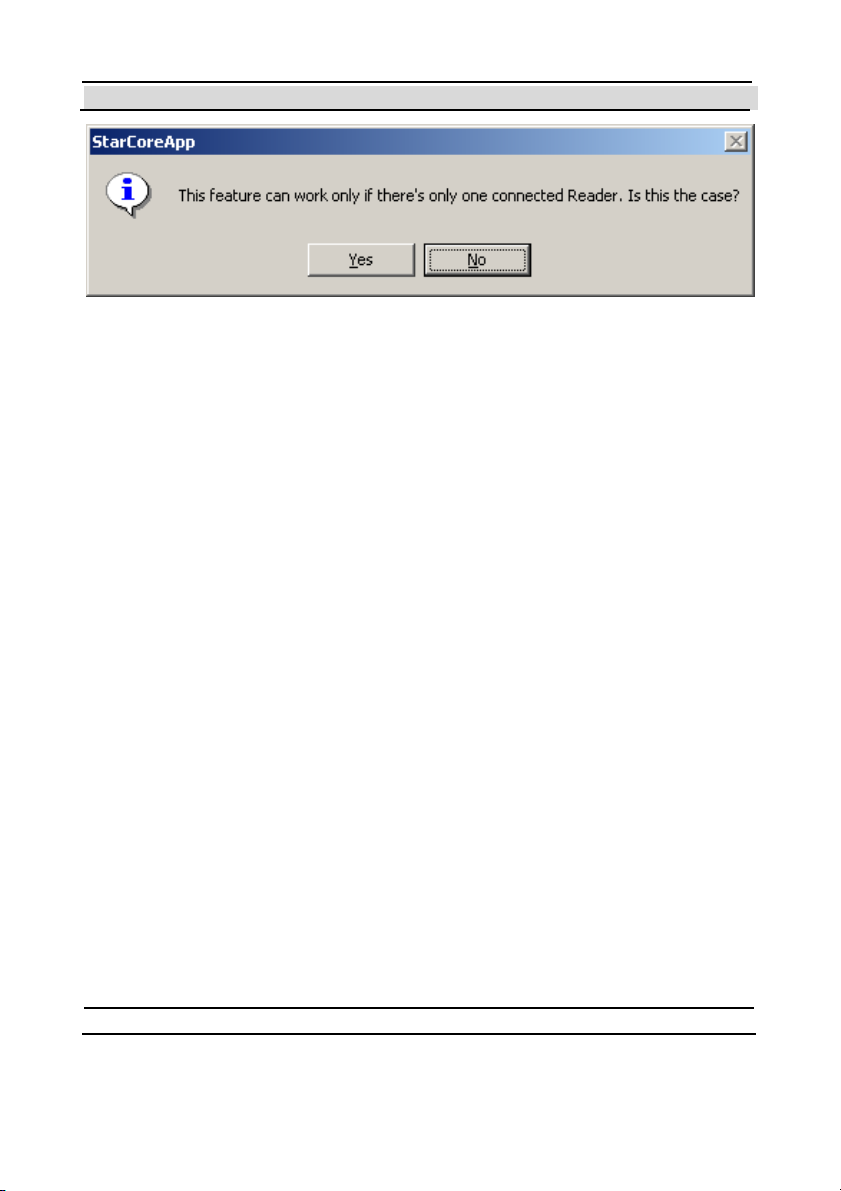

Click on the Au to De tec t button on the bottom of the window, to

automatically find the Reader ID of t he DataReader. The message shown in

Figure 2-2 will be displayed.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 23 -

Chapter 2 Quick Start

Figure 2-2 - Auto Detect Warning Message.

Because you're using the Demo System that includes only one DataReader,

click Ye s .

If everything is connect ed appropriately, a message window will appear

saying "Reader was added successfully". Click OK to close this message.

If inst ead of this message, a "T imeout " message appears, check your

connections and verify that the communication port setting corresponds to

t he on e yo u're usin g. Remember t o click on Set Comm Port each t ime you

change the communication port setting.

If a different message appears, refer to chapter 9 for troubleshooting.

The DataReader's ID is now added to the list with a Reader Address of 1.

Click on the Close button to close the Re a de rs A dmini str ati on win do w.

2.5 Preparing the DataSeal/DataTag

DataSeals provided by Hi-G-T ek leave the factory in a special power

saving mode called "Deep Sleep Mode". Before you can communicate

normally with a DataSeal, you must send it a special command called

"Hard Wakeup" that returns the DataSeal into its normal mode of

operation. You will t hen have t o close the Sealing Wire (as will be

- 24 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

explained below), and send another command called "Set" that prepares t he

DataSeal for normal operation.

This section describes how to prepare a single DataSeal. If you have more

than one DataSeal, repeat all the instructions in this section for each

Dat aSeal yo u have.

In order to send the Hard Wakeup command to the DataSeal or DataSeals

do the following:

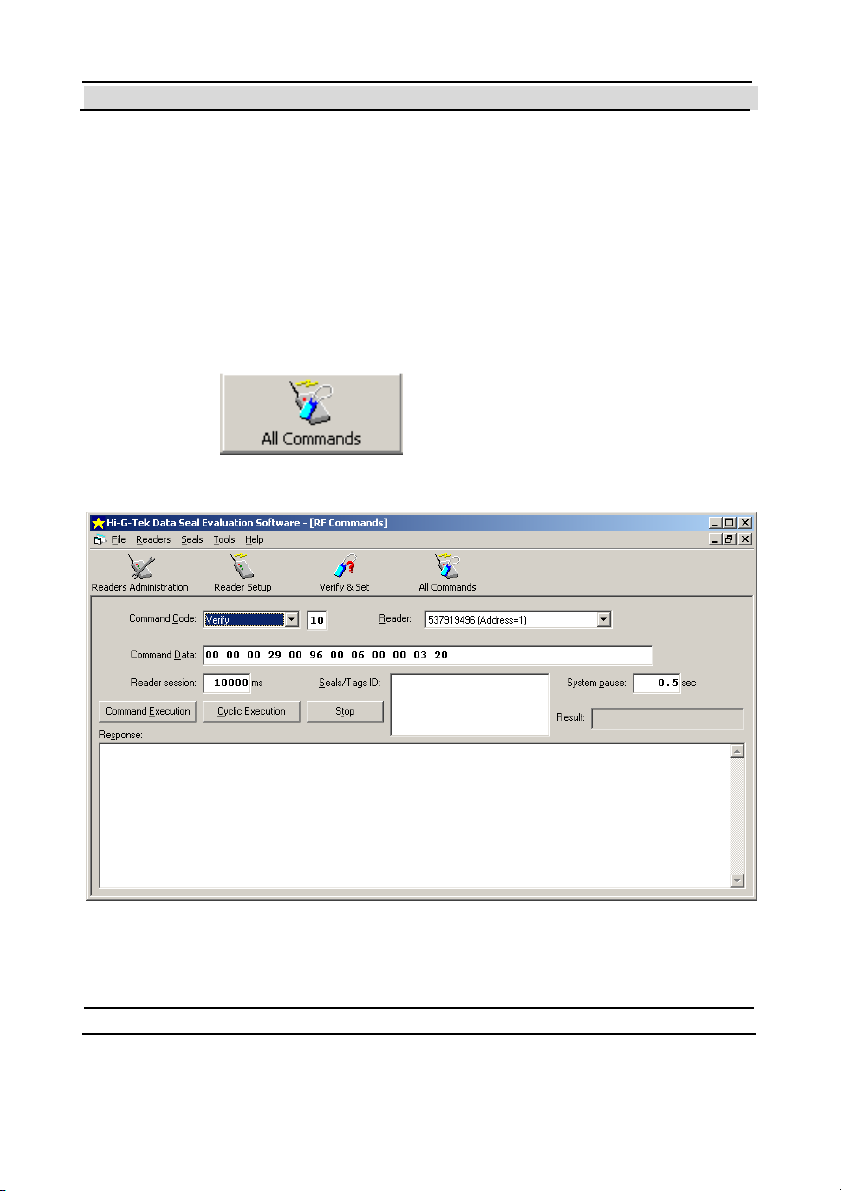

Click on the

button on the tool bar to open the

window shown in Figure 2-3.

Figure 2-3 - All Commands Window.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 25 -

Chapter 2 Quick Start

From the Command Code dr op do wn list , select Har d Wakeu p.

Copy the Seal ID of the DataSeal you want to wake up into the Seals/Tags

ID t ext box. The Seal ID is pr int ed o n the st icker on the bottom o f t he

DataSeal.

Click the Command Execution button. The mouse cursor will change to

an hourglass icon for about 11.5 seconds and then return to a normal

pointer cursor.

If the DataSeal received the message, The Res ult box will show the

message "Command OK" in green letters. If not, verify that you typed the

Seal ID correctly in the Seals/Tags ID box, and that the DataSeal is nearby,

and try again. If you still don't get the green "Command OK" message, or

you see a different r ed m essage in th e Re su l t box, refer to chapter 9 for

troubleshooting.

If yo u're usin g a DataSeal (as op po sed to a Dat aTag), y o u no w h ave t o

close the Sealing Wire by inserting its 2 ends t o the 2 socket s in the

DataSeal. Push the ends inside the sockets as far as you can. (You should

hear a 'Click' when the wire end is fully inserted). If you're using a

DataTag, you should place the Sensor Plate in its appropriate place at the

bott om of the Dat aT ag.

From the Command Code drop down list , select Set and then click the

Command Execution button. After about 4 seconds, a green "Command

OK" message should appear in the Re sul t box.

Congratulations! Now your DataSeal is prepared for normal operation!

- 26 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

2.6 Executing a Verify command

As a m att er of fact, if everyt h ing worked fine up to th is point , yo u can be

sure t hat your Demo System is workin g. Nevertheless, yo u pro bably wan t

to know how to perform some basic operations.

The most commonly used command is the Verify command. The main

purpose of this command is to detect which DataSeals are currently around,

and their status (opened/closed, tampered/not tampered).

In order to execute a Verify command, open the Ve ri fy & S e t window, by

clicking on the

button on the tool bar. The window shown

in Figure 2-4 will be displayed.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 27 -

Chapter 2 Quick Start

F igure 2-4 - The Ve rify & Se t W indow .

Note that there are 2 buttons labeled "Single Interrogation": the upper one

resides in a rectangle labeled "Broadcast Verify", and the lower one in a

rect angle labeled "Address Verify and Set ". In this guide, we'll on ly use t he

upper one (Broadcast Verify). Click this button now. After about 5 seconds,

one or more lines will be added to the list, according to the number of

DataSeals that were detect ed.

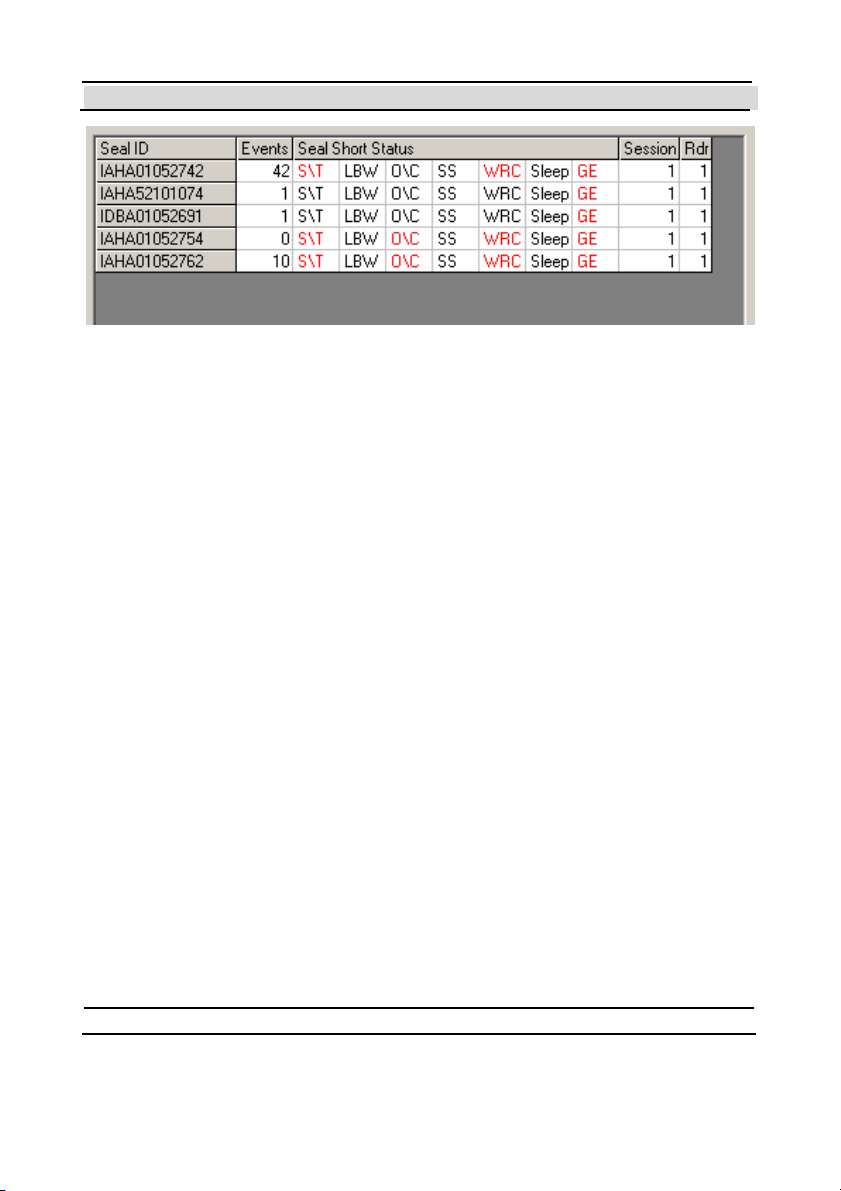

Figure 2-5 shows an example of a list with 5 detect ed DataSeals.

- 28 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

Figure 2-5 - 5 DataSeals Detected.

Clicking the Single Interrogation button again will add another one or

more lines to the list. To clear the list, click on the Rese t butto n at t he

bottom of the window.

A complete explanation about the results you see is out of the scope of this

Quick-Start chapter. Nevertheless, t here are 2 flags in t he DataSeal's Short

Status that are worth a brief explanation here.

2.7 A Brief Tutorial Through the States of the DataSeal

The DataSeal has many flags that determine its state, as well as Parameters,

Event Records and User Data. Even though most of these feat ures are out

of the scope of this chapter, 2 of the flags represent the most fundamental

concepts of the DataSeal. T hese flags are the Tampered flag (shown in

Figure 2-5 as "S/T"), and t he Opened flag (shown in Figure 2-5 as "O/C").

Note that in the Evaluation Soft ware, flags that are set appear in red, while

unset flags appear in black.

If you have followed t his guide st ep by step up to t his po int, y ou should

have both flags off (black). If you cleared the list, click Single

Interrogation (the upper one) again to see the flags.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 29 -

Chapter 2 Quick Start

The Opened flag is set (on) whenever the Sealing Wire is open, and unset

(off) whenever it is closed. That explains why the O/C flag appears black.

Now, open the Sealing Wire by pulling one of its ends out of the socket.

Click t he Single Interrogation button again to see that the O/C flag has

turned red (on).

You may have not iced that also the S/T flag has become red. This indicat es

that the DataSeal was Tam pered. If you now close the Sealing Wire, this

flag will remain on, even t hough the Opened flag will turn off again. Try it

now: close the wire, and click the Single interrogation once more. You

should see the O/C flag black again, but the S/T remains red.

No matter how many times you would open and close the wire now, the

Tampered flag remains set, to indicate that it was opened at least once.

Yo u can try it if yo u want.

Yo u may be won derin g by now, whet her this tutorial led y o u to a st at e

where the DataSeal is irreversibly tampered, meaning t hat the DataSeal is

no longer usable! Well, you can relax because the Hi-G-Tek Dat aSeal is a

reusable seal, meaning that you can c l ea r th at Tampered flag. The

Tampered flag can be cleared only when the Sealing Wire is closed, and it

is done by sending a Set command to the DataSeal. That’s right, that's the

same command you sent aft er the Hard Wakeup in the "Preparing the

Seal/T ag" sect ion.

You can send this command from the Ve ri fy & S e t windows too. After

performing a Single In te rrogation, click on the line in the list that shows

the Seal ID of the DataSeal you want to Set. Notice that the Seal ID now

appears in the Seal ID box at the top part of the window. You may also

type the Seal ID there manually if you prefer. Make sure that the Sealing

Wire is closed, and then click on the Set button (inside the Addresse d

Ve rify and Set frame).

- 30 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 2 Quick Start

After about 5 seconds, you should see a green "Set OK" message in the

Result box (in the upper left side of the window). If you see a "Set Failed"

message instead, it means t hat the Sealing Wire is not properly closed. If

you see a different message, refer to chapter 0 for troubleshooting.

P erform anoth er Verify interrogation (click the Single Interrogation

button). You should see now that both the Tampered (S/T) and Opened

(O/C) flags are clear (black), just as they were in the beginning.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 31 -

Chapter 3 DataSeal Installation

3

DataSeal Installation

To inst all t he DataSeal Mo unt in g Fixt ure,

att ach t he f ixt ure t o t h e k eep er bar at th e

back of the container (Fig.1). A click

indicates that the fixture is in place.

The two side holes may be used to secure

t he Mo unt in g Fixt ure to t he container, usin g

a 3-5mm width by 180-250 mm length

plastic strap (Fig. 2).

- 34 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 3 DataSeal Installation

To inst a l l th e Dat a Se a l, ho ld t he un it at a

45° angle as illustrated and snap it into

place in its cradle on the DataSeal

Mount in g Fixt ure . (Fig. 3)

To connect the Sealing Wire, simply attach

one end of the Sealing Wire connectors to

either of the sockets at the base of the

DataSeal (Fig. 4).

Loop t he wir e t hro ugh the cont ainer lockin g

ring and the keeper bar, then insert the end

into the other socket (Fig. 5).

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 35 -

Chapter 3 DataSeal Installation

Alt ernatively , yo u may loop t he wir e t hrough

both keeper bars then insert the end into the

other socket (Fig. 6).

FCC ID: OB6- IGRS40916

This device complies with Part 15 of FCC rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful

interference, and (2) This device must accept any interference that may

cause undesired operation.

- 36 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 4 DataTag Installation

4

DataTag Installation

The Dat aTag is de liv ered wit h a set of do uble-sided

tapes that are used for placing the DataTag on the

t agged object .

The Sensor Plate (item #1) is supplied separately

from the Dat aTag. To place the Sensor Plate peel

t he p ap er from t he do uble- sided t ap e (item #2) and

place the Sensor P lat e in its place.

2

3

1

5

4

Press the Sensor Plate to the DataTag such that the

double-sided tape will hold t he Sensor Plat e in place.

Make sure the contacts at the bott om part of the plate are

aligned with the pins in the DataTag.

Peel the paper from the three pieces of double-sided

tape: The two larger pieces (items #3 & #4) are used for holding t he

DataTag to the tagged object, while the smaller piece in the middle (item

#5) is used for pulling the Sensor Plate off

the DataTag when the DataTag is removed

from th e t agged object, in o r der to det ect the

T am p er ev ent .

4.1 Placing the DataTag on a Vehicle

Note

: The Installation inst ructions refer to

the case when the DataReader is installed

Vertically.

- 38 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 4 DataTag Installation

There are two preferred orientations for placing the DataTag on a vehicle:

Horizontal and Vertical. These 2 options are described in the following

sections:

4.1.1 Horizontal Orientation:

Place the tag on a flat surface t hat is completely

horizont al an d press f irmly to create good co ntact

between the DataTag and the tagged object.

4.1.2 Vertical Orientation

Place the DataT ag on a flat surface that is complet ely vertical, and press

firmly to create good contact between the

DataTag and the vehicle. It is recommended

t hat the height of the DataT ag above t he

ground will be above 3’, and the optimal

height is 5’ above ground.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 39 -

Chapter 4 DataTag Installation

FCC ID: OB6-IGRS40T916

This device complies with P art 15 of FCC rules. Operat ion is subject to the

following two conditions: (1) This device may not cause harmful

interference, and (2) This device must accept any interference that may

cause un desired operation.

No te: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reason able protection against harm ful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequ ency en ergy and, i f not installed and us ed in acco rdan ce with t he instructions,

may caus e harm ful interference to radio communications. However, there is no

guarantee that interferen ce will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can b e determined by turning the equipment o ff and on, the user is encou rag ed to

try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Incr ease the sepa ration bet ween the equi pment and re ceiver.

Connect the equipment into an outlet on a circuit different from that to which

t he receiv er i s connect ed.

C onsul t t he dealer or an experi en ced r adio/T V technician for hel p.

Changes or modifications to this equipment not expressly approved by Hi-G-Tek

Ltd. could void the user’s authority to operate the equipment.

- 40 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

5

DataReader Installation

5.1 Outdoor DataReader Installation

The DataReader should be mounted on a smooth, flat surface.

To mount the unit, insert 4 screws into the holes on the unit and fix to

the surface.

A 6mm plastic anchor and 35mm pan head tapping screw is

recommended.

5.1.1 Ce iling Installation

The DataReader can be mounted on the ceiling. In such cases it is requested

to mount the antenna perpendicular to the ceiling using a 90° connector.

The figure below shows the DataReader installed on a ceiling, with t he

- 42 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

antenna perpendicular to the ceiling.

5.1.2 Connecting the Outdoor Unit

Not e : The electronics compartment panel should only be

opened by an authorized repair person. Unauthorized use may

result in loss of warranty.

Remove the cover of the bottom portion

of the DataReader unit by

removing the screws holding it in place.

Remove t he covers from t he glan ds being used.

Expose t he wires in the cable and insert them t hrough t he glands into the

terminal blocks. Use a small screwdriver to push the lever of the connector

in order to let the wires in. Ensure t hat the wires are inserted in the slots in

accordance with the color scheme. Wiring information for specific

configurations are given further on in the chapter.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 43 -

Chapter 5 DataReader Installation and Oper ating Instructions

5.1.3 Wiring the Outdoor DataRe ader

The DataReader can be communicated with via one of three types of serial

communication modes:

1. RS-485 Full Duplex

2. RS-485 Half duplex.

3. RS-232 (different model number)

According to the Dat aReader model in use, t he serial connect ion can be

either RS-232 or RS-485 (see chapter 10 for technical specifications).

When the DataReader is connected using RS485, it can be set by the user to

full duplex m ode o r half duplex mo de by altering a configurat ion swit ch .

For further information see sections 5.1.4 5.1.5 - 5.1.7.

- 44 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

5.1.4 RS-232 Wiring Diagram

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 45 -

Chapter 5 DataReader Installation and Oper ating Instructions

5.1.5 RS-485 Full Duplex Wiring Diagram

5.1.6 RS-485 Half Duple x Wir ing Diagram

5.1.7 DataReader Configuration Sw itches

S1: Reserved for future use. Must be OFF.

- 46 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

S2: Termination ON/OFF swit ch.

In RS-232 mode this switch does not exist. In RS-485 mode, set

this switch to ON if this is the last DataReader in the RS-485

chain. When this switch is ON, it connects an internal 120 Ohm

termination resistor to the RS485 chain.

S3, S6: Full/Half duplex switches.

In RS-232 mode this switch does not exist. In RS-485 Full

Duplex mode this switch must be ON. In RS-485 Half Duplex

mode this switch must be OFF.

S4: DataReader shut-down switch.

While OFF: DataReader is active. While ON: DataReader is not

powered. Default position: OFF

5.2 Indoor DataReader Installation

The DataReader should be mounted on a smooth, flat surface.

To mount the unit, insert 4 screws into the holes on the unit and fix to

the surface. A 6mm plastic anchor and 35mm pan head tapping screw

is recommended.

5.2.1 Connecting the Indoor Unit

Not e

: The electronics compartment panel should only be

opened by an authorized repair person. Unauthorized use may

result in loss of warranty.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 47 -

Chapter 5 DataReader Installation and Oper ating Instructions

The indoor unit has three connector sockets at its base. Connector socket P1

is for incoming communications and power-in. Socket P3 is used to transfer

power and to connect the unit to the next unit in a daisy chain.

5.2.2 Wiring the Indoor DataRe ader

The DataReader may be connected to the network via three types of serial

communication:

1. RS-485 Full Duplex

2. RS-485 Half duplex.

3. RS-232.

Note

: RS-485 and RS-232 are different models.

According to the Dat aReader model in use, t he serial connect ion can be

either RS232 or RS485 (see Technical Specifications). The RS485

connector is always opt ically isolated.

- 48 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

1

6

9

5

10

5

DB9 MALE

9

6

PIN ARRAGEMEN T

15

DB9 FEMALE

PIN ARRAGEMEN T

1

DB15 FEMALE

6

PIN ARRAGEMEN T

1115

5.2.3 RS-232 Wiring Diagram

4. P in assignment f or PWR/COM IN (P 1) & PW R/COM OUT (P 3)

Funct ion Pin Number

Positive Power 1

Positive Power 2

Signal GND 3

Negative Power 4

Negative Power 5

TX 6

RX 7

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 49 -

Chapter 5 DataReader Installation and Oper ating Instructions

5.2.4 RS-485 Full Duplex Wiring Diagram

Pin assignment for PWR/ COM IN (P1) & PWR/COM OUT (P3)

Funct ion Pin Number

Positive Power 1

Positive Power 2

Signal GND 3

Negative Power 4

Negative Power 5

RX-A 6

RX-B 7

TX-A 8

TX-B 9

- 50 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

5.2.5 RS-485 Half Duple x Wir ing Diagram

Pin assignment for PWR/ COM IN (P1) & PWR/COM OUT (P3)

Funct ion Pin Number

Positive Power 1

Positive Power 2

Signal GND 3

Negative Power 4

Negative Power 5

TX/RX-A 6

TX/RX-B 7

5.3 Chaining DataReaders Together

Up to 32 DataReaders can be connected in a daisy chain using RS-485. The

last DataReader in the chain should be terminated by a 120 Ohm resistor

between the RXA and the RXB.

For the Outdoor version, the user can decide to create either an internal or

external termination switch. The internal termination switch is creat ed by

setting t o ON the t ermination switch (S2) of the last DataReader in t he

daisy chain.

An external termination is relevant for the Indoor version only. An RS-485

to RS-232 adapter termination should be provided for the adapter receive

channel.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 51 -

Chapter 5 DataReader Installation and Oper ating Instructions

The diagram in the next page shows the connections of a system with 4

DataReaders using an RS-485 chain.

- 52 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 53 -

Chapter 5 DataReader Installation and Oper ating Instructions

5.4 RS-232/ RS-485 Adapter

To connect one or more DataReaders that use RS-485 to a controlling

computer you need an RS-232 to RS-485 adapter.

Adapter’s requirements:

Full/Half duplex operat ion mode.

Isolated communication lines.

Recommended adapter: Moxa T echnologies, model A53.

Adapter configuration: (refer to adapter’s User Manual)

1. Communication mode, either half or full duplex – according to the

DataReader configuration.

2. Txd: always enabled.

3. Rxd: always enabled.

Default configuration of the Moxa A53:

Full Duplex mode

Txd always enabled.

Rxd always enabled.

5.4.1 Connecting the RS-232/RS-485 Adapter to the First

Data Re ader

The Rx and Tx lines should be crossed between the adapter and the first

DataReader as follows:

- 54 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

Dat aReader

RXA

RXB

TXA

TXB

SIG-GND

Moxa A53 Wiring:

Reader TB1

1 PWR+

2 PWR3 RXB

4 RX A

5 GND

6 TXB

7 TXA

RXA

Dat aReader

RXB

TXA

TXB

SIG-GND

MOXA

TXB 1

TXA 2

RXB 3

RXA 4

GND 5

PWR- 6

PWR+ 7

Terminal

Block

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 55 -

Chapter 5 DataReader Installation and Oper ating Instructions

5.4.2 Connecting the RS-232/RS-485 Adapter to the

Controlling Com puter

RS-232 3-wire connection should be performed between the Adapter and

the controlling computer. (Other control signals beside the Rx, Tx and

GND ar e not required).

Rx and Tx should be crossed as follows:

Adapter

Rx

Tx

GND

Contr. Computer

Rx

Tx

GND

The Moxa A51 is connected to the controlling computer wit h RJ45/DB25

cable supplied wit h the adapter. If the controlling computer has a DB9

connector, a DB25/DB9 adapter should be used.

5.5 Power Supply Requirements

5.5.1 General

The DataReader supply voltage is chosen according to the model, either

12v, 2 4v or 48 v ( see the specificat ions of the different models in chapt e r

10.

Power supply wattage: each DataReader consumes maximum 1.7W, so the

power should tolerate the number of Dat aReaders in the chain multiplied by

each Dat aReader’s power consumption.

- 56 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

Example: 10 DataReaders connected in a daisy chain require 10x1.7=17W

of power supply.

Note that if the power supply is inst alled in a high t emperature area (usually

above 40° C), there is a derate in power supply wattage. (Refer to your

power supply manual).

For safety reasons, power supply current should be limited to 3A. Current

limitation should be done internally in the power supply, or externally with

a 3A fuse.

Both in the Out door an d In do or sy st ems, the power sup p ly should be

inst alled indoor.

When power supply cable ends are connect ed direct ly to system cable, a

proper iso lation should be m ade. Using h eat shrink tube is r e comm ended.

5.5.2 Indoor Installation

When the Dat aReader is inst alled indoor, the power supply used should be

UL1950 approved. A desktop style with IEC320 inlet is recommended.

5.5.3 Outdoor Ins tallation

For safety reasons, the DataReader shall be used with the following power

supply only:

HI-G-TEK

P/N

Manu fa cture r Manu fa cture r

P/N

Supply

Vo ltage

[V]

Supply

Wattage

[W]

HGT5291A EDAC EA1050D-240 24 24

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 57 -

Chapter 5 DataReader Installation and Oper ating Instructions

5.6 Cable Selection

The cable is used for power supply to DataReaders in a chain and for RS485 serial communication.

For most applications, 3 or 4 pairs of 24AWG shielded cable is adequate.

The serial communication requires shielded twisted pair cable, t he power

supply requires low ohmic resistance of the conductors.

Cable connection:

1 pair for RXA an d RXB signals.

1 pair for TXA and TXB signals.

SIGNAL GND may be connected to shield or to a pair of wires (shield

co nnect ion is recomm e n ded, t hough it depe n ds on t he no ise level of the

specific environment).

For the power supply: two main issues should be considered: max current

carrying capacity and wire resistance.

Max current capacity: For 24AWG cable, the jacket is heated at 1°C at

0.1A current, max temperat ure is 80°C. So, this cable can carry a max of

2A at 60°C. ( (80°-60°)*0.1 ).

This calculation should be done for the application specific requirements.

Wire resistance: The voltage drop across the cable may cause insufficient

voltage to the last DataReaders in the chain. Calculation of voltage drop for

the certain setup should be done, in order to avoid this.

In most cases, the solution for such problems can be connecting a pair of

wires for the supply (2 for supply and 2 for return), using thicker cable, or

- 58 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

using higher temperature rated cable. Environmental considerations: In an

outdoor installation, the cable should withstand all outdoor conditions,

in cludin g wat er p ro of , temp erat ur e, r uggedn ess et c.

Example:

A setup of 10 DataReaders with 20 meter 24AWG cable between

DataReaders and 24v supply to the first DataReader.

The ohmic resistance between Dat aReaders is 3.4 Ohms (20 meter of

supp ly and 20 m et ers of ret urn ) . Calc ulat ing the vo lt age drop acro ss t he

lines gives 5v only, left t o the last DataReader in t he chain. T his is below

DataReader specificat ion of DataReader minimum supply voltage. If two

co nductors are used f o r supp ly and return , t he ohm ic resist an ce would be

3.4/2=1.7 ohm. The voltage to the last DataReader in the chain would then

be 17v, well above the minimum voltage required.

If you experience difficulty calculating the voltage drop across t he supply

line, cont act y our dist ribut or for assist an ce.

5.7 Ins tallation Notes

The DataReader is dist ribut ed to a commercial/industrial use only, and

should only be sold to the professional customers.

When installed outdoors, the unit shall be installed in accordance with t he

NEC or CEC.

Installation must be performed according to this user manual, and by a

professional personnel only.

It is the responsibility of the installer to ensure that when using the out door

antenna kits in the United States (or where FCC rules apply), only t hose

antennas certified with the product are used. The use of any antenna other

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 59 -

Chapter 5 DataReader Installation and Oper ating Instructions

than those certified with the product is expressly forbidden in accordance

with FCC rules CFR47 part 15.204.

5.8 DataRe ader Operation Instructions

Three LED indicators are located on the lefthand side of the electronics compartment.

5.8.1 Power Indicators:

The DataReader is activated by connect ing it

t o a power supply. At power ON an d self-

test the power indicator's color alternates

between green and red for several seconds.

If the check result is OK, the indicator

rem ain s green. If a problem was det ect ed, the in dicato r remains r e d.

This LED also has a special meaning when performing firmware download:

On MCU firmware download, the indicator alternates between green

an d red.

On RF Modem firmware download - the indicator remains off.

5.8.2 Channel 1 SD/RD Indicator :

Wh en t his indicator is red, the unit is in SD ( sen ding RF dat a) mo de.

When the indicator is green, the unit is in RD (receiving RF dat a)

mode.

When t he indicator is off, it is in stand-by mode.

- 60 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 5 DataReader Installation and Oper ating Instructions

5.8.3 Channel 2 SD/RD Indicator :

This indicat or is not in use.

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 61 -

Chapter 6 System Overview

6

System Overview

6.1 System description

The Hi-G-Tek syst em consists of the following components:

1. DataSeal

The DataSeal is a sophisticated device, which includes 2

transmitter/receiver units (one for high frequency/long range and another

one for low frequency/short range communications), real-time clock,

processor, memory and sensing circuitry for sealing verification. The

Sealing Wire prevents any attempt of opening, bypassing, or tampering

with the DataSeal without alerting t he syst em and recording the event.

Data may also be written into and read from the DataSeal to store and

retrieve general information. The DataSeal can communicate both in low

frequency with short range devices, such as the DataTerminal and

MicroDataReader, and in high frequency for long ranges with the

DataReader, together allowing a broad range of applications.

2. DataTag

The DataTag is a variant of the DataSeal device. Instead of t he Sealing

Wire it has a removal sensing mechanism. T his makes it more suitable for

cases where you want to tag goods, but you don't have to seal them. Other

than that, it is identical t o the DataSeal device.

3. MagneticDataSeal

The MagneticDataSeal is a variant of the Dat aSeal device. Instead of the

Sealing Wire it has a Magnet element. This makes it more suitable for cases

- 64 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 6 System Overview

where you want to sense if the door is open but you can’t seal it. Other than

that, it is identical to the DataSeal device.

4. DataReader

The DataReader uses in high frequency (long range) RF communication to

communicate with the Dat aSeals mainly for reading their IDs and their

Statuses. The DataReader can also be used for reading and writ ing

information to and from the Dat aSeal and retrieving logged events from the

DataSeal. Each Dat aReader can communicate with numerous DataSeals

simultaneously and verify their presence and stat us. The DataReaders can

also be chained together to allow a longer and wi der range of coverage.

Dat aReaders must be connect ed t o a controlling computer that control

them.

5. DataTe rmin al (previously known as Hand Held Terminal or HHT)

This is a mobile handheld device which includes a keypad, a small LCD

screen, a low frequency receiver/transmitter, and an RS-232 interface.

The main things that you can do with the DataTerminal are: Reading a

DataSeal's ID and Stat us; Reset the DataSeal for a new use ("Set"

command); reading and writ ing data to and from the DataSeal – for

example: manifest number, truck number, driver name etc.; reading the

events that were logged in the Dat aSeal; T ransferring this information t o

and from a PC.

6. DataPort (Previously known as Low Frequency Terminal, or LFT)

The Dat aPo rt is a simp le lo w frequen cy m o dem. It includes a low

frequency t ransmitter/receiver and an RS-232 interface that connects to a

PC. In other words, it enables a PC to communicate almost directly with a

DataSeal. In general, the DataPort enables the P C to perform t he same

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 65 -

Chapter 6 System Overview

operations as the DataTerminal, given that an appropriate software exists in

the PC.

7. Mi cr oDa ta Re a de r

The MicroDataReader is a key ring size mobile device that includes a low

frequency t ransmitter/receiver, 1 or 2 buttons and a LED indicat or. Using

the MicroDataReader you can perform the following functions:

1. Verify – The LED will turn green if the DataSeal's St at us is OK, or

to red if it's Tampered.

2. Set (Optional) – prepares the DataSeal for a new use. The type of

t he Set c om m an d ( no rm al, So ft Se t or Susp en de d Se t ) is m o de l

specific. Hi-G-T ek can provide MicroDataReaders with different

co mmands if required.

6.2 DataSeal and DataRe ader M odes of Operation

6.2.1 DataSeal Modes of Ope r ation

Generally speaking, a Dat aSeal can be used in any of the following ways:

1. O pera tion Mode (Normal Mode)

This is the normal and most basic mo de of operation. In th is mode, t he

DataSeal is on standby most of the time. Once every predetermined period,

called Tw , the DataSeal samples the HF (high frequency) channel

searching for a transmission from a DataReader. If it det ects such

transmission, it listens and answers as needed. The default value of T w is 3

seconds, which is the most appropriate for most applications. In the

Operation Mode, the DataSeal also listens const antly to the low frequency

channel and responds as needed. During the Operation Mode the DataSeal

- 66 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 6 System Overview

logs events (like opened, closed, tampered, etc.) and stores them internally

in t h e Ev ent s M em ory .

2. D ee p Sl ee p Mo de

This mode should be used when the DataSeal is not in use in order to

conserve energy. DataSeals always leave the fact ory in this mode. It is

possible to ent er a DataSeal t o this mode also by usin g h igh frequency o r

low frequency command. To exit this mode, interrogat e the DataSeal using

low frequency (for example, using a DataTerminal), or send a Hard

Wakeup command in high frequency using a DataReader.

Note

: While in Deep Sleep mode, no Events are recorded. Events aren't

recorded also after waking up the DataSeal, until a Set command is

performed. In other words, after waking up a DataSeal, you must also

perform a Set command in order for the Dat aSeal to start record events.

3. Alert Burst Mode

This mode is similar to the Operation Mode. In addition, whenever t he

DataSeal is opened, it transmits an Alert Burst message in the high

frequency channel. The DataReader and the applicat ion should both be

configured to receive and handle t he alert message. A DataSeal can be

configured also to t ransmit Burst messages on ot her event s.

4. Footprint Events Mode

This mode is a way of using the DataSeal, rather than a configuration of t he

DataSeal. When t he DataSeal receives a special variant of the Ve ri fy

command in low frequency or in high frequency, it records a certain Event

called "Read", that includes the DataReader's ID or the low frequency

device's ID. To use this special command in the Dat aReader, the

DataReader has to be configured accordingly. This mode is useful to

determine t he DataSeal's track if there are several DataReaders, or check

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 67 -

Chapter 6 System Overview

points with DataT erminals along the way. In this scenario, you can know

the DataSeal's track by reading its Events, without having to have these

DataReaders connected to any central syst em.

6.2.2 DataReader Modes of Operation

There are several aspects that determine the DataReader's mode of

operat ion. These aspects are det ermined by the Mode parameter, which is a

bit orient ed param ete r .

5. Carrie r Sense Collision Prevention

Just like you can't understand what two people are saying when the speak

simultaneously, that way a DataSeal can't understand two DataReaders that

transmit simultaneously. When t wo (or more) close DataReaders aren't

controlled by t he same controlling computer (or by controlling computers

that are synchronized among t hem), there's a chance that they will try to

transmit simultaneously. In order t o prevent that, the DataReaders can be

configured to sense for a carrier (transmission of another DataReader or

DataSeal) before they start transmitt ing. When a DataReader is configured

for Carrier Sense, each time before it transmits something it listens to the

frequency, and only if it's clear (no one else is transmitting), it start

transmitting it s own message.

6. Bu rst Recei ving Mo de

When DataSeals are operating in Alert Burst mode, the DataReader’s

receiver must be ON at all times in order to receive the Burst messages.

The controlling computer has to query the DataReader periodically t o

receive the Burst messages that the DataReader received.

- 68 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 6 System Overview

6.3 Most Comm on Commands and Se al Status

6.3.1 Most Comm only Use d Comm ands

There are a number of key commands that are used in most applicat ions, as

they enable t he basic operation of the system. These commands are:

7. Verify

The Ve ri fy command is use d to detect DataSeals which are located within

the Dat aReaders Receiving Zone and also verify their state. The DataSeals

which respond may be in one of two states. The DataSeals may be in either

the normal stat e, meaning the have not been tampered with, or in the

tampered stat e, meaning they have been tampered with. Additional

information can also be queried from the DataSeal. T his is the most useful

and commonly used command in the system.

8. Tampered

The Tampered command is used to communicate with tampered

DataSeals. The command operat es the same as the Ve ri fy com man d on ly

DataSeals which are in t he T ampered state respond. The aim of the

command is to provide high priority to tampered DataSeals in a crowded

DataSeals environment.

9. Se t

The Set command is used to set a Dat aSeal for a new use. T he Sealing

Wire must be connected and closed in order for a DataSeal to be set. T he

Se t command deletes all Events stored in the Events Memory and is the

first new Event recorded in the DataSeal. T he DataReader can send the Se t

command to up t o 8 DataSeals simultaneously.

10. Suspen de d Set

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 69 -

Chapter 6 System Overview

Similar to the Set co mma n d, Suspende d Se t is used to set a DataSeal for

new use. Unlike the Set command, when performing a Suspen ded Set

command, the Sealing Wire Must be opened (or complet ely disconnected

from the Dat aSeal). T he DataSeal will become armed (Set) once the

Sealing Wire has been connected to the Dat aSeal and closed.

11. Approve Open

The Approve Open command allows a Sealing Wire to be opened after t he

DataSeal has been set in a way that the application can determine that the

Dat aSeal was opened with an approval. When the Sealing Wire will be

opened after receiving this command, the application will be able to

det er m ine that t he ope n ing is ap prov ed by ex amining the Appr ov ed Open

flag in the Dat aSeal's St at us.

6.3.2 DataSeal's Status

The DataSeal's Status consists of 4 bytes. A DataReader may be used to

request t he DataSeal's Status. The DataSeal's Status is used to indicate the

DataSeal's current state and is a bitwise value. Each bit in the Status

represents a specific st atus flag. The DataSeal's Status is divided into t he

Short Status and Long Status pa r ameters as explained below:

The DataSeal's Sh ort Status parameter consists of 1 byte (8 bits) which is

a subset of the Long S tatus parameter. The Short S tatus contains the most

important flags. These flags are:

1. Tampered – The Tampered flag gets set if the Sealing Wire was

opened or t ampered with. It remains set even if the Sealing Wire is

closed again. It can only be unset by performing on of the Set

commands.

2. Low Ba t tery Warnin g – Battery is low, replace the DataSeal.

3. Opened – Indicates that t he Sealing Wire is open.

- 70 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 6 System Overview

4. Suspended Set – A Suspended Set command was performed, and t he

Sealing Wire wasn't closed yet.

5. Se aling Wi re Ch ange d – Indicates that the Sealing Wire's elect ronic

characteristics have changed since the DataSeal was Set.

6. Dee p Sleep – Indicates t hat the DataSeal is in Deep Sleep mode.

7. General Error – Indicates an error with the Dat aSeal that is not

represented in the Dat aSeal's Short Sta tus.

8. Approved O pen – If t he DataSeal Opened flag is on, the Approve d

Open flag means that the opening is approved. If the DataSeal's

Opened flag is off, it means that the next open will be approved, if

performed during a certain period.

The DataSeal's Long Status contains the Short S tatus flags as well as 3

additional bytes that together represents the complete DataSeal's status. For

a det ailed descript ion of the Long S tatus, see chapter 8.

6.4 System Planning

When planning an application, attention should be paid to both system

operatio n and topolo gy. Application requir ement s and elect ro m agnet ic

environment characteristics should also be taken into account.

2 basic types of applicat ions are possible: Fixed DataReader applicat ions

and Mobile Dat aReader applications. A complex application that combines

DataReaders in both configurations is also possible.

The Fixed DataReader applications are applicat ions where the DataReaders

are mounted at a fixed site. The Mobile applications are situations where

the DataReaders are mounted on vehicles for monit oring DataSeals in

transit. Mobile applicat ions are normally implement ed using the

TrackingDataReader, but may also be implemented using a Dat aReader

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 71 -

Chapter 6 System Overview

connected to any mobile controller (E.g. laptop, palmtop, etc), that has a

serial communications port.

6.4.1 Electromagnetic Environment

Radio Frequen cy Co m mun icat io n is t he basic t ech no logy used by the

system. While this is a very robust method for communicating with remote

devices, several issues should be considered when planning a site.

Met al walls should not be used to shield the remot e devices.

Communication distance between remote devices may vary due to

atmospheric conditions and other electromagnetic interferences.

Communication distance may also vary according to one or more of the

following:

• Line of sight between devices – existence and clearance.

• P roximity to metal objects.

• Indoor or Outdoor environment.

• Antenn a orient at io n bet ween the devices.

It is recommended to map the site with actual devices for proper coverage.

When planning the site layout, safe margins should be taken into account to

ensure proper operation at all times. Possible environmental changes

should also be considered.

6.4.2 System Layout

Two aspects should be considered when dealing with system layout:

1. Radio Fr equency Co mm un icat ion Layo ut.

2. Line Communication RS-485 or RS-232 Layout.

- 72 - Hi-G-Tek Ltd. Micro el ec tro nic s & A sset Tra ck ing Te ch no logy

Chapter 6 System Overview

6.4.2.1 Radio Fre quency Communication Layout.

When only one DataReader is in use, the previously ment ioned

environmental considerations are all that need be taken into account.

When more than one DataReader is in use, it should be understood that in

the same area only one

DataReader can communicate with the DataSeals at

the same time. Interference will be cause d by more than one DataReader

Trying to communicate with the DataSeals in the same period of time. Th e

DataReaders should be synchronized using the application software or

using the Carrier Sense mode . Several DataReaders may operate

sim ult an eously p ro v ided that it has pr ev iously been confirm ed t hat they

will not interfere with each other.

6.4.2.1.1 Cellular Layout

Cellular topology should be used to ensure efficient coverage of a large

area. The following diagram illustrates the concept:

Hi-G-Tek Ltd. Micro electro nics & Asset Tracking Technology - 73 -

Chapter 6 System Overview

Reade r Zone

DataReaders must be properly placed to ensure there are no dead zones

within the defined area. Overlaps should be as shown in the above drawing.

DataReader's Receiving Zone is t he t erm used to describe the area of

reliable communication covered by a DataReader. T he DataReader's

Receiving Zone is also called a Cell. As the drawing illust rates, it is

extremely import ant that the application software controls and synchronizes

the DataReader’s operation in order to avoid RF collisions. In other words,

the application software has to make sure that no two DataReaders with

overlapping Receiving Zones transmit at the same time.

6.4.2.2 Line Comm unication RS-485 Layout

The connection of many DataReaders to a cont rolling computer is done via