HighLine spray gun Operation Manual

SPRAY GUN OPERATIONS

MANUAL

HighLine Spray Gun

Table of Contents

Page

Safety and Handling 2

Important Safety Information 3

Characteristics 5

Technical Specifications 5

General Description 6

Installation and Start-Up 8

Shutdown Procedures 10

Loss of Air Pressure/Emergency Shut-Off 11

Maintenance 12

Mixing Chamber Maintenance or Replacement 13

Screen Screw and Component Maintenance 15

Gun Block Removal 17

Gun Block Reversal 19

Trigger and Trigger Valve Maintenance 21

Air Cylinder Maintenance 23

Troubleshooting Guide 25

Gun Operation 27

Page 1 of 27

HighLine Spray Gun

Safety and Handling

This chapter contains important information on the safety, handling, and use of

your HighLine spray gun.

Before installing the spray gun and start-up, carefully read all the

technical and safety documentation included in this manual. Pay

special attention to the information to know a nd understand the

operation and conditions of use of the unit. All of the information

is aimed at enhancing user safety and avoiding possible

breakdowns derived from the incorrect use of the gun.

presents information to alert of a situation that might cause

serious injuries if the instructions are not followed.

presents information that indicates how to avoid damage to the

spray gun, or how to avoid a situation that could cause minor

injuries.

is relevant information of a procedure being carried out.

Careful study of this manual will enable the operator to know the characteristics of

the spray gun and the operating procedures. By following the instructions and

recommendations contained, you will reduce the potential risk of accidents in the

installation, use, or maintenance of the spray gun. You will provide a better

opportunity for incident-free operations for a longer time, greater output, and the

possibility of detecting and resolving problems fast and simply.

Keep this operations manual handy for future reference to useful information. If you

lose the manual, contact ArmorThane for a new copy.

Page 2 of 27

HighLine Spray Gun

Important Safety Information

The HighLine spray gun has been designed and built for the application of

polyurethane and polyurea chemical systems, and polyurethane foam chemical

systems.

The design and configuration of the HighLine spray gun does not

allow its use in potentially explosive atmospheres or exceeding

the pressure and temperature limits described in the technical

specification of this manual to be exceeded.

Always use liquids and solvents that are compatible with the spray gun. If in doubt,

contact the ArmorThane Technical Department.

When working with the spray gun, it is recommended that the operator wear

suitable clothing and personal protection, including, without limitation, gloves,

protective goggles, safety footwear, and face masks. Use breathing equipment

when working with the spray gun in enclosed areas or in areas with insufficient

ventilation. The introduction and follow up of safety measures must not be limited

to those described in this manual. Before beginning to work with the spray gun, a

comprehensive analysis must be made of the risks derived from the products to be

dispensed, the type of application and the working environment.

To prevent possible injury caused by incorrect handling of

the materials and solvents used in the process, carefully read

the Material Safety Data Sheets (MSDS) provided by

ArmorThane.

Deal with the waste according to current regulations.

To avoid damage caused by the impact of pressurized fluids,

do not open an y connection or perform ma intenance work on

components subject to pressure until the pressure has been

completely eliminated.

Use suitable protection when opera ting, maintaining, or be ing

present in the area where the equipment is functioning. This

includes, but is not limited to, the use of protective goggles,

gloves, shoes, and safety clothing and breathing equipment.

Page 3 of 27

HighLine Spray Gun

The equipment includes components that reach high

temperatures and can cause burns. Hot parts of the

equipment must not be handled or touched until they are

completely cool.

To prevent serious injury through crushing or a mputation, do

not work with the equipment without the safety guards

installed on the moving parts. Ensure that all the safety

guards are correctly reinstalled at the end of the repair or

maintenance work of the equipment.

Page 4 of 27

HighLine Spray Gun

Maximum Working Pressure:

3500 psi

Maximum Air Pressure:

125 psi

Maximum Output (1:1 ratio):

40 lb/min

Minimum Output (1:1 ratio):

3.3 lb/min

Opening Force @ 110 psi:

200 lb

Closing Force @ 110 psi:

205 lb

Approximate Air Consumption @ 110 psi:

10 cfm

Characteristics

Internal mixing from high pressure impingement

Automatic cleaning with air pressure

No solvents required

Exterior lubrication of the mix chamber

Weight: 2.8 lbs

Dimensions: 7” x 4” x 8” (L x W x H)

Technical Specifications

Page 5 of 27

HighLine Spray Gun

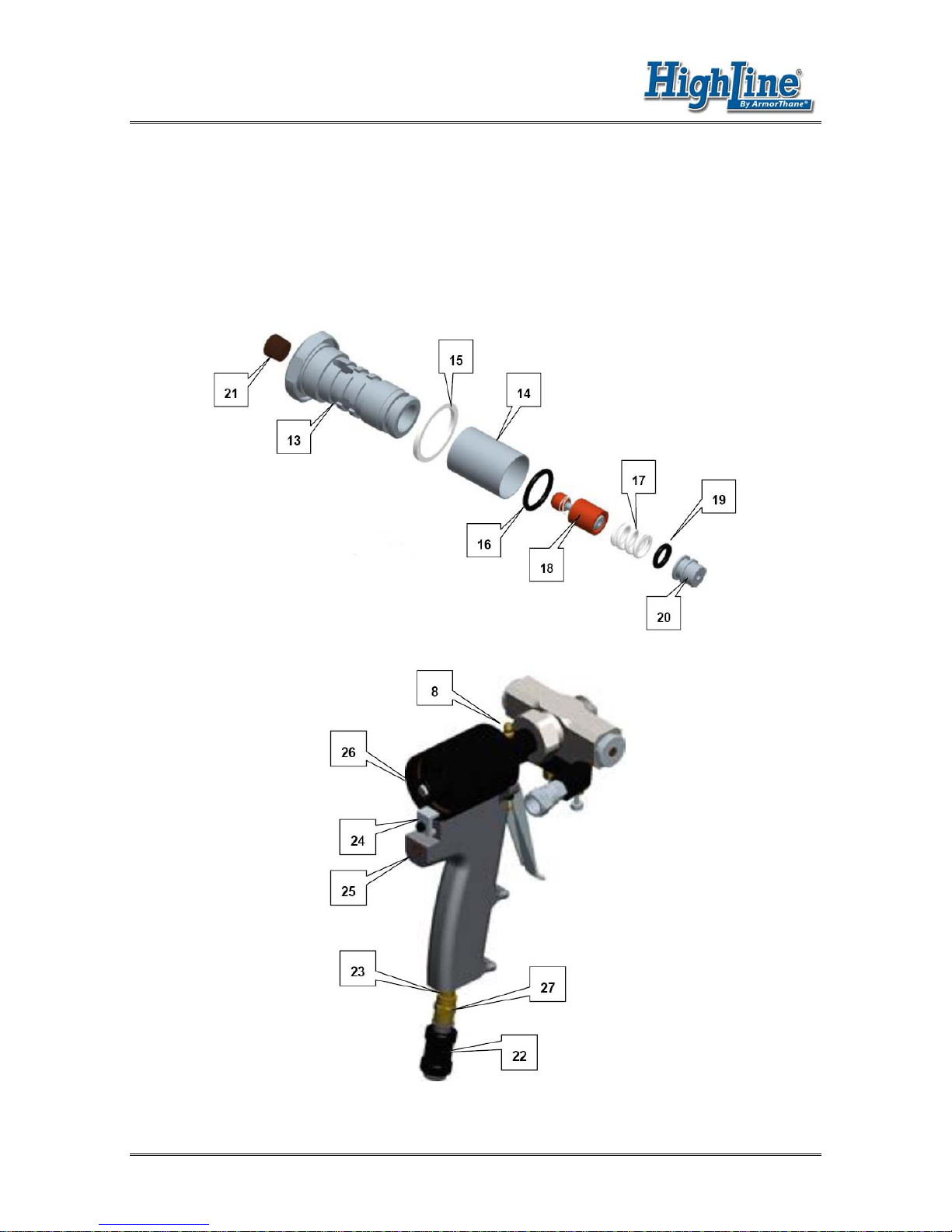

1. Gun Block

6. Coupling Block Gasket

2. Coupling Block

7. Coupling Block Mounting Screw

3. Mixing Chamber & Seal

8. Grease Fitting

3a. Air Seal

9. Trigger Handle

4. Air Cap

10. Gun Handle with screws

5. Manual Valve

11. Air Cylinder with screw and nut

General Description

For better knowledge of the HighLine spray gun, the main components and their

description are shown. For a more precise identification, see the parts identification

section.

Page 6 of 27

HighLine Spray Gun

13. Iso (A) Screen Screw

20. Side Seal

13a. Resin (B) Screen Screw (not shown)

21. Cleanout Plug

14. Screen

22. Air Safety Slide Valve

15. Screen Screw Seal

23. Pipe Nipple

16. O-Ring

24. Air Cylinder Mtg. Clamp

17. Spring

25. Pipe Plug

18. Check Valve Assembly

26. Piston Shaft (not shown)

19. O-Ring

27. Air Coupling

Page 7 of 27

HighLine Spray Gun

Installation & Start-Up

When working with the HighLine spray gun, or performing

maintenance work, wear suitable safety protection in accordance

with the recommendations and specifications provided by

ArmorThane.

1. Ensure the coupling block manual valves (5) are closed by turning them to the

full clockwise position.

Excessive force closing or opening the manual valves may result

in damage to the manual valves and/or coupling block.

2. CLOSE the air safety slide valve (22) (downward/rearward position)

3. Connect the spray gun to the coupling block using the supplied hex key wrench.

Ensure coupling block gaskets (6) are in place.

4. Connect the air supply to the air safety slide valve.

The material delivery hoses are color-coded red and blue,

allowing the user to recognize them. The red corresponds to

the isocyanate (A) and the blue to the resin (B). To avoid

connection errors, the coupling connections of the

isocyanate (A) and resin (B) hoses are also different sizes,

which makes it difficult to swap connections.

Page 8 of 27

Loading...

Loading...