HighLine RCH Mower Operator's Manual

RCH™ Mower

Radial Contouring

Hitch Mower

Operator’s

Manual

E9145V1

RCH™ Mower

Radial Contouring

Hitch Mower

Operator’s

Manual

Printed in Canada Copyright © 2008 by Highline Manufacturing Ltd. All rights reserved.

The content of this manual was based on the most current information available as of the date of copyright. It is the policy of

Highline Manufacturing Limited to improve and develop our products continually. We reserve the right to make changes or add

improvements, at any time, without incurring any obligation to make changes or improvements on machines previously sold.

Highline Manufacturing Limited

HWY #27, P.O. Box 307

Vonda, SK S0K 4N0

Canada

Phone: 306.258.2233

Fax: 306.258.2010

Toll Free: 1.800.665.2010

E9145V1

Highline Manufacturing Ltd. RCH Mower

Highline Team Message

Congratulations on your purchase of the RCH Mower manufactured by Highline

Manufacturing Ltd. We are excited about your endeavor into cutting with the most technically

advanced rotary cutter known to date. You will find flexibility and maneuverability of operation

with this product that has never been experienced before. Welcome to the elite group of

Highline RCH mower owners.

This operator's manual has been prepared to provide information necessary for the safe and

efficient operation of your RCH Mower. In the manual you will find safety procedures,

maintenance routines and detailed operational instructions.

If you find that you require information not covered in this manual, please feel free to consult

your local dealer. Your dealer is always able to contact Highline for this technical information.

Highline Manufacturing Ltd. thanks and congratulates you for selecting a RCH Mower as your

machine of choice.

Highline Manufacturing Ltd.

Table of Contents

Section 1 - Safety

Serial Number

Safety Sign-off Form

Safety Alert Symbol

Section 2 - Transporting the Mower

Tractor Requirements

Ensure Correct PTO Speed

Adjust Single Point Drawbar Length

Connect Single Point Hitch

Connect the Safety Chain to Tractor

Connect the 2 Point Hitch

Tractor Wheel Tread Width Settings

Attach Driveline to PTO

Attach Hydraulics

Section 3 - Mower Preparation

Park On Level Ground

Ensure Safety Decals Are in Place

Ensure the SMV is Clean and Visible

Ensure Lighting is Working Properly

Check the Condition of the Blade Pans

Check the Condition of the Blades

Remove the Height Control Transport Lock

Remove the Wing Transport Lock Pins

Remove the Hitch Transport Lock Pin

Lower the Wings on Level Ground

General Safety

Safety Decals

Safety Decal Locations

Connect Lights

Place Hitch Jack in Storage Location

Check on the Condition of the Tires

Raise Wings and Lock in Place

Lower Mower Onto Height Control Lock

Install Hitch Transport Lock Pin

Verify SMV & Lights In Place and Working

Transport Speed

Level the Mower Center Section Deck

Determine the Primary Mowing Operating Conditions

Wing Adjustment Procedure

Set the Preferred Cutting Height

Inspect All the Hydraulic Cylinders

Check Condition of the Chain Guards

Inspect the Wheels and Tires

Inspect the Wing Skid Shoe

Ensure Driveline Clutches Will Slip

Ensure Driveline Shields Are in Place

Section 4 - Operating the Mower

Do Not Operate with the Wings Raised

Park on Level Ground

Remove the Wing Lock Pins

Remove the Hitch Lock Pin

Lower the Wings

Remove Debris from the Cutting Area

Rotate the Mower Deck to Move into the Cutting Area

Recommended Setup for a Quality Cut

Lower to the Cutting Height

Section 5 - Maintaining the Mower

Check Fluid Level in Gearboxes Daily

Lubrication

Gearbox Oil Changing Procedures

Run-In of the Friction Clutch

Section 6 - Storing the Mower

Clean Debris off the Mower Decks

Lubricate Grease Points

Tighten All Bolts to Torque

Touch-up the Paint to Prevent Rusting

Park the Mower on Level Ground

Lower the Mower

Support the Hitch with the Jack

Adjust Ground Speed

Operate the PTO at the Rated Speed

Allow the Wings to Float

Avoid Cutting into the Ditch

Rotate the Deck to Swing Away from Obstructions

Crossing Ditches and Steep Inclines

Wing Cutting Angles

Making Turns

Recommended Practices for A Quality Cut

Replacing the Clutch Friction Discs

Blade Replacement Procedure

Removing and Replacing the Blade Pan

Tires

Remove the Driveline from Tractor

Disconnect Safety Chain

Disconnect Hitch from Tractor

Relieve/Disconnect Hydraulic Hoses

Secure Hydraulic Hoses

Support Driveline in Holder

Change Oil in all Gearboxes

Section 7 - Troubleshooting

Operation

Wings

Wheels

Hitch

Section 8 - Mower Specifications

Options

Blades

Driveline Clutches

Drive Boxes

Drivelines

This Page Left Blank

Section 1 - Safety

SERIAL NUMBER

Your serial number is found on the serial number plate attached to the RCHTM Mower on the

left side of the fifth wheel hitch support tower.

It is important to record the serial number for proof of ownership and for any service or

maintenance assistance.

Serial Number

Owner

Model

Date of Purchase

Be Trained Before Operating Mowers!

Safety Training Makes a Difference.

The Association of Equipment Manufacturers offers the 22 minute video,

“Industrial and Agricultural Mower Safety Practices: A Safety Training

Program for Operators of Rotary-Type Mowing Equipment”.

This video reinforces the proper procedures to follow while operating rotary

mowing equipment.

To view the video on the Internet or to order a copy, please visit the Association of Equipment

Manufacturers website at www.aem.org and go the Safety & Training section.

The video does not replace the information contained in this Operator’s Manual. Please read and

understand this manual before operating the mower.

Page 1-1

Section 1 - Safety

SAFETY SIGN-OFF FORM

Highline Manufacturing Ltd. follows the general Safety Standards specified by the American

Society of Agricultural Engineers (ASAE) and the Occupational Safety and Health Administration

(OSHA). Anyone who will be operating and/or maintaining the Highline RCH Mower should read

and clearly understand all Safety, Operating and Maintenance information presented in this

manual.

Do not operate or allow someone to operate this equipment until this information has been

reviewed. This information should be reviewed by all operator’s before the season start-up.

This sign-off sheet is provided for record keeping to indicate that the person working with the

equipment has read and understood the information in the Operator’s Manual and has been

instructed in the safe operation of the equipment.

Date Employee’s Signature Employer’s Signature

Page 1-2

Section 1 - Safety

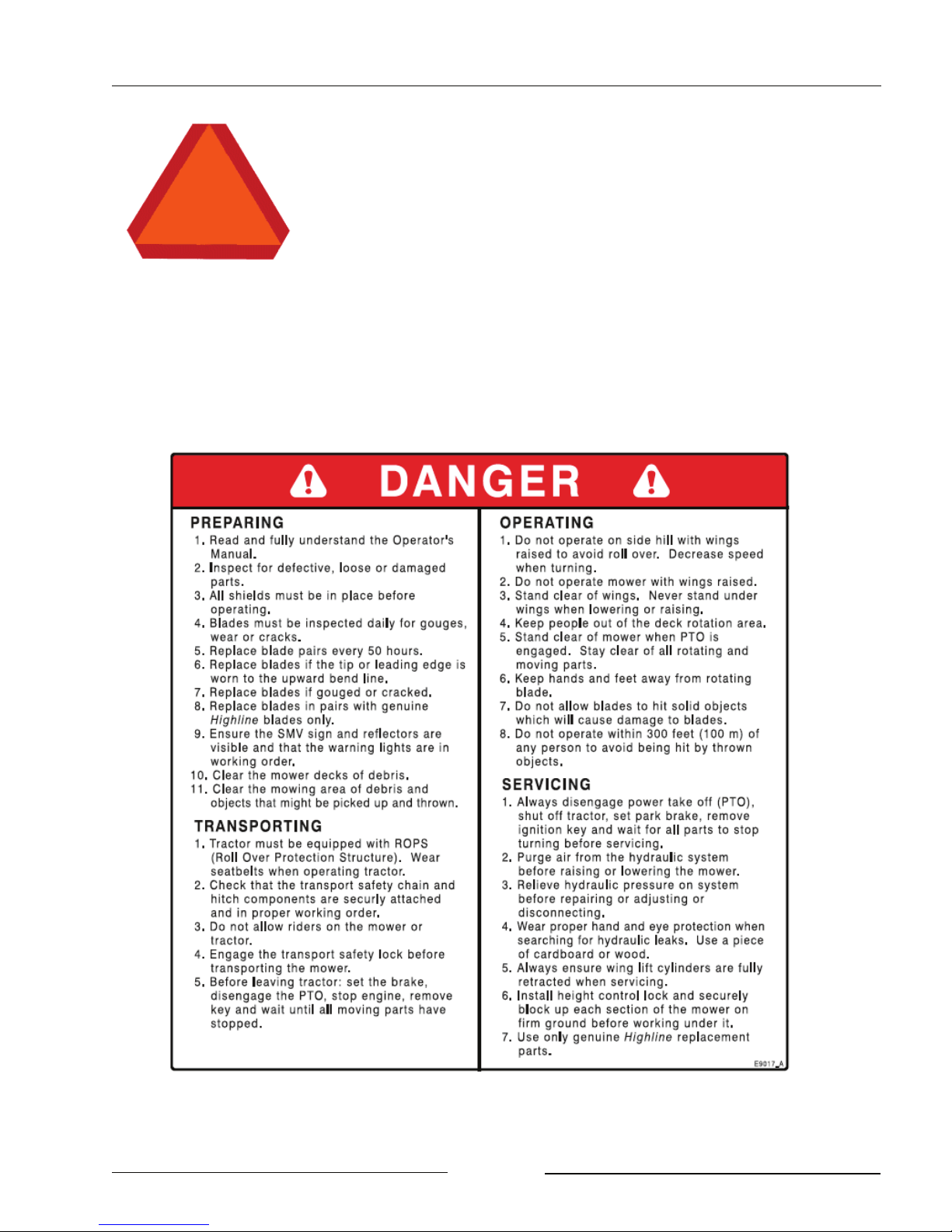

SAFETY ALERT SYMBOL

The Safety Alert Symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert Symbol combined with a Signal Word alert to the presence of a hazard and the

degree of possible injury.

Indicates an imminently hazardous situation that, if not

avoided, WILL result in DEATH OR SERIOUS INJURY.

The color is Red with White lettering.

Indicates a potentially hazardous situation that, if not

avoided, COULD result in DEATH OR SERIOUS

INJURY, and includes hazards that are exposed when

guards are removed or unsafe practices. The color is

Orange with Black lettering.

Indicates a potentially hazardous situation that, if not

avoided, MAY result in MINOR INJURY. The color is

Yellow with Black lettering.

Page 1-3

Section 1 - Safety

GENERAL SAFETY

1. Ensure that anyone who is going to operate, maintain or work near the RCH Mower is

familiar with the recommended operating, maintenance procedures and safety information

contained in this manual and follows all the safety precautions.

2. “In addition to the design and configuration of the equipment, hazard control and accident

prevention are dependant upon the awareness, concern, prudence and proper training of

personnel involved in the operation, transport, maintenance and storage of the mower.” (Taken

from ASAE S474.1 Feb 04 - 5.2.5.1)

3. The mower shall not be operated without all the guards in place.

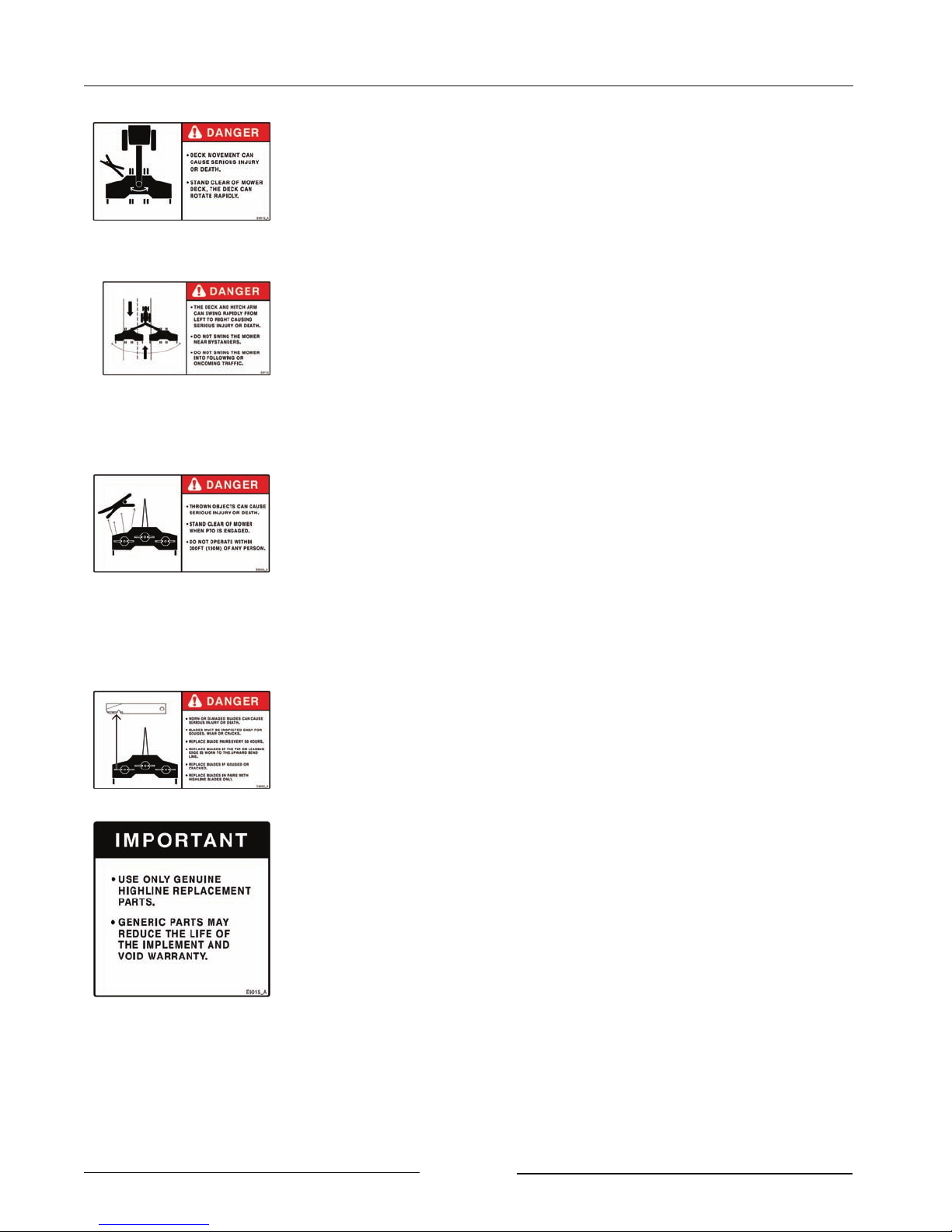

SAFETY DECALS

1. Keep decals and signs clean and legible at all times.

2. Replace decals and signs that are damaged, missing or have become illegible.

3. Replaced parts that displayed a decal should also display the current decal.

4. Decals are available from the Highline Parts Department.

5. Be familiar with the decals, the type of warning and the area or function(s) related to the

area(s) that requires your awareness.

Page 1-4

Section 1 - Safety

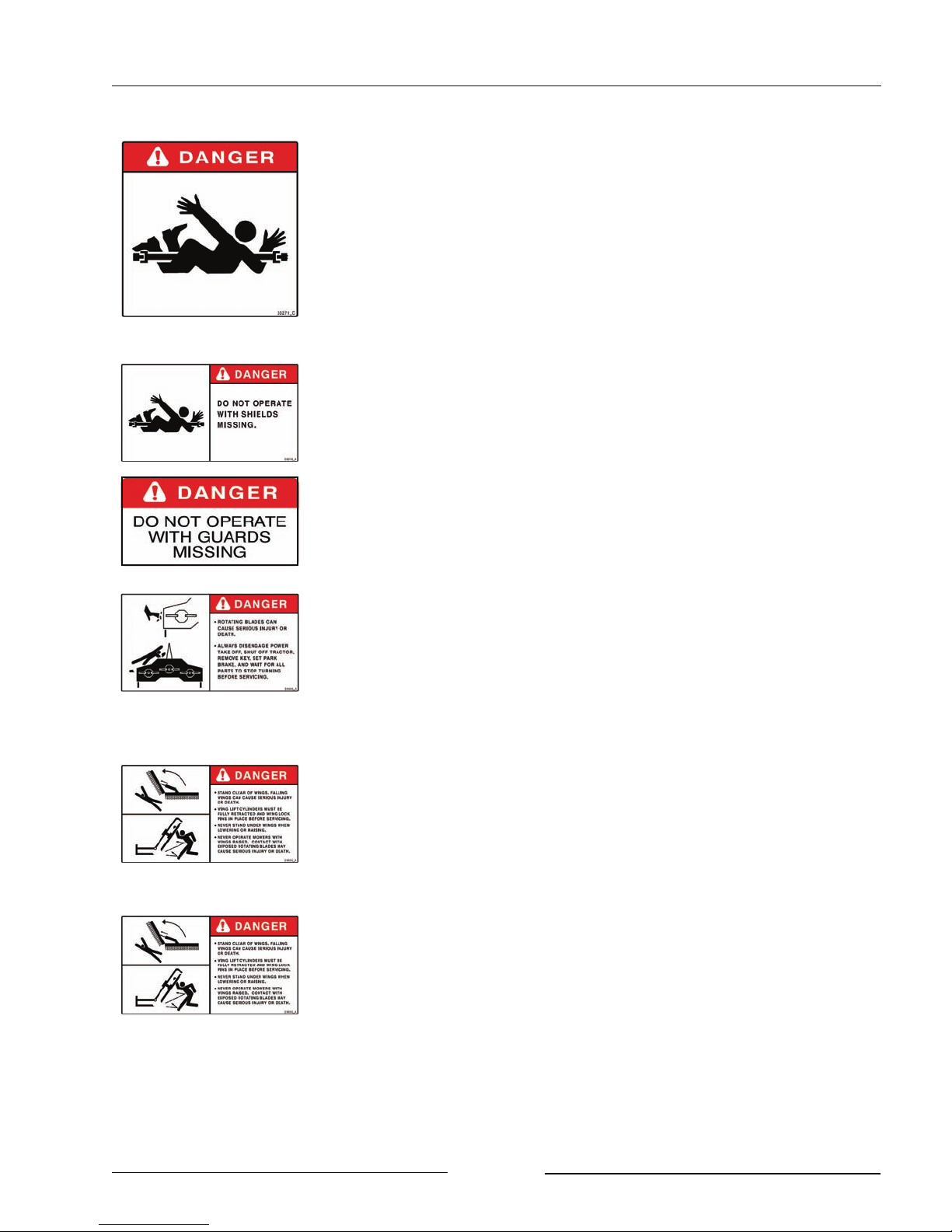

DO NOT CONTACT ROTATING DRIVELINE

Contact with rotating driveline will cause serious injury or death.

Keep all driveline guards in place.

Securely attach drivelines at both ends.

Check that the driveline guards turn freely on driveline.

DO NOT OPERATE WITH SHIELDS MISSING

DO NOT CONTACT ROTATING BLADES

Rotating blades can cause serious injury or death.

Always disengage power take off, shut off tractor, remove key, set

park brake and wait for all parts to stop turning before servicing.

Keep guards in place and in good condition.

DO NOT OPERATE MOWER WITH WINGS RAISED

Contact with exposed rotating blades may cause injury or death.

Rotating blades may throw objects, causing injury or death

STAND CLEAR OF WINGS

Falling wings can cause serious injury or death.

Wing cylinders must be fully retracted and wing lock pins in place

before servicing.

Never stand under wings when lowering or raising.

Page 1-5

Section 1 - Safety

STAND CLEAR OF ROTATING DECK

Contact with rotating deck can cause serious injury or death.

Stand clear of mower deck. Mower deck can rotate rapidly.

DO NOT SWING DECK AND HITCH ARM NEAR BYSTANDERS

OR INTO TRAFFIC

The deck and hitch arm can swing rapidly from left to right causing

serious injury or death.

Do not swing the mower near bystanders.

Do not swing the mower into following or oncoming traffic.

STAY BACK FROM MOWER IN OPERATION WHICH CAN

DISCHARGE OBJECTS SEVERAL HUNDREDS OF FEET

Thrown objects can cause serious injury or death.

Stand clear of mower when PTO is engaged.

Do not operate within 300 ft (100m) of any person.

Keep all shields and guards in place.

Clear mowing area of debris.

INSPECT BLADES FOR DAMAGE

Worn or damaged blades can cause serious injury or death.

Blades must be inspected daily for gouges, wear or cracks.

Replace blade pairs at maximum of 50 hours.

Replace blades if the tip or leading edge is worn to the upward bend

line. (The bend line is 2" (51mm) from the leading edge of a 4" (102

mm blade.)

Replace blades if gouged or cracked.

Blades must be changed in sets.

Use only Highline replacement parts.

Do not repair blades.

Page 1-6

Section 1 - Safety

ENSURE SLOW MOVING VEHICLE SIGN IS IN PLACE

Ensure the Slow Moving Vehicle sign is in place, clean and easily

visible.

Ensure the reflectors are in place, clean and easily visible.

READ AND FULLY UNDERSTAND THE INSTRUCTIONS ON THIS DECAL

Page 1-7

Section 1 - Safety

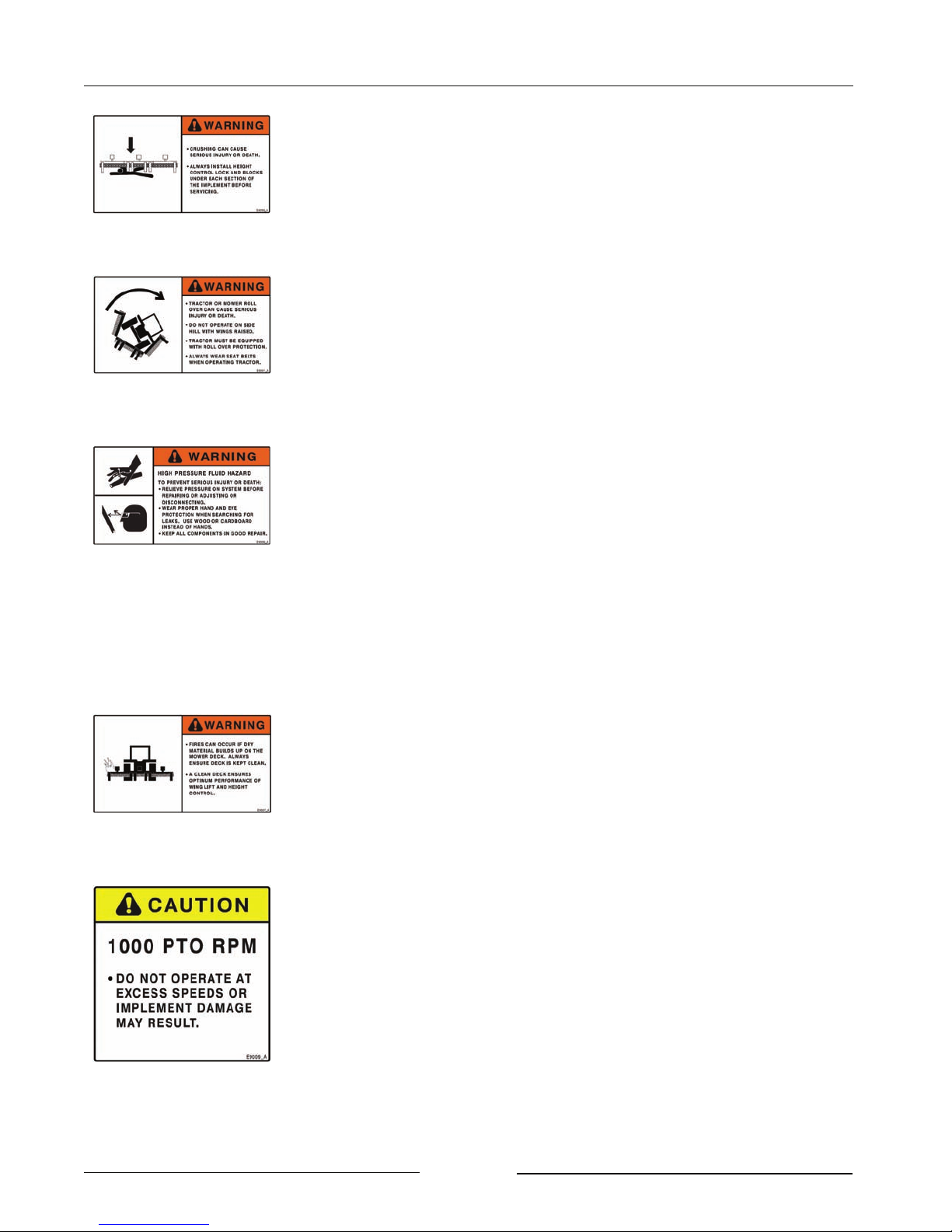

STAND CLEAR WHEN MOWER IS BEING RAISED OR

LOWERED

Crushing can cause serious injury or death.

Always install height control lock and blocks under each section of

the implement before servicing.

DO NOT OPERATE ON SIDE HILL WITH WINGS RAISED

Tractor or mower roll over can cause serious injury or death.

Tractor must be equipped with Roll Over Protection System.

(ROPS)

Always wear seat belts when operating tractor.

USE PAPER OR CARDBOARD TO CHECK FOR HYDRAULIC

LEAKS

To prevent serious injury or death:

Relieve pressure on hydraulic system before repairing, adjusting or

disconnecting.

Wear proper hand and eye protection when searching for leaks. Use

wood or cardboard instead of hands.

Keep all components in good repair.

KEEP MOWER DECK CLEAR OF DEBRIS

Fires can occur if dry material builds up on the mower deck.

Always ensure deck is kept clean.

A clean deck ensures optimum performance of wing lift and height

control.

DO NOT EXCEED PTO SPEED

Do not operate at excess speeds or damage to the mower may result.

Page 1-8

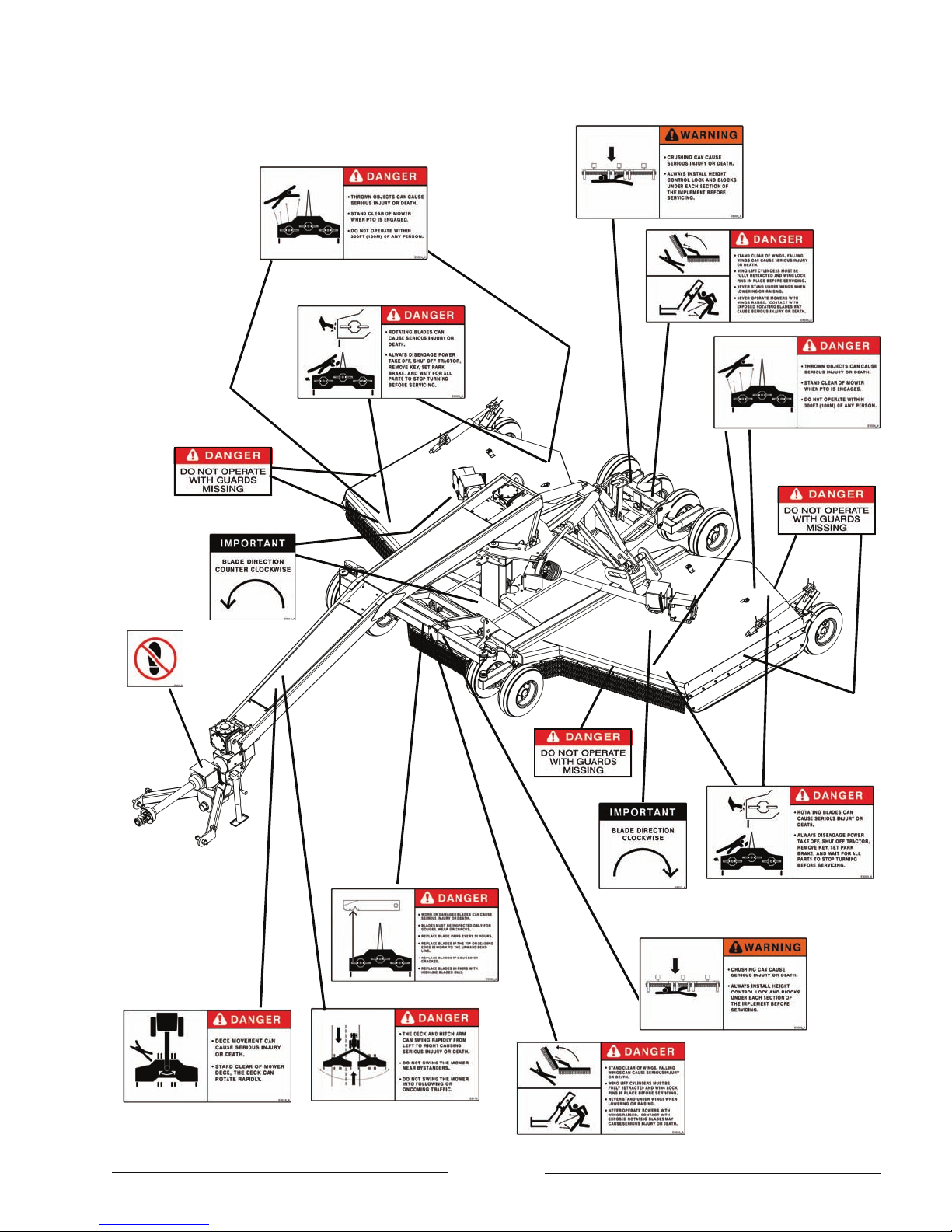

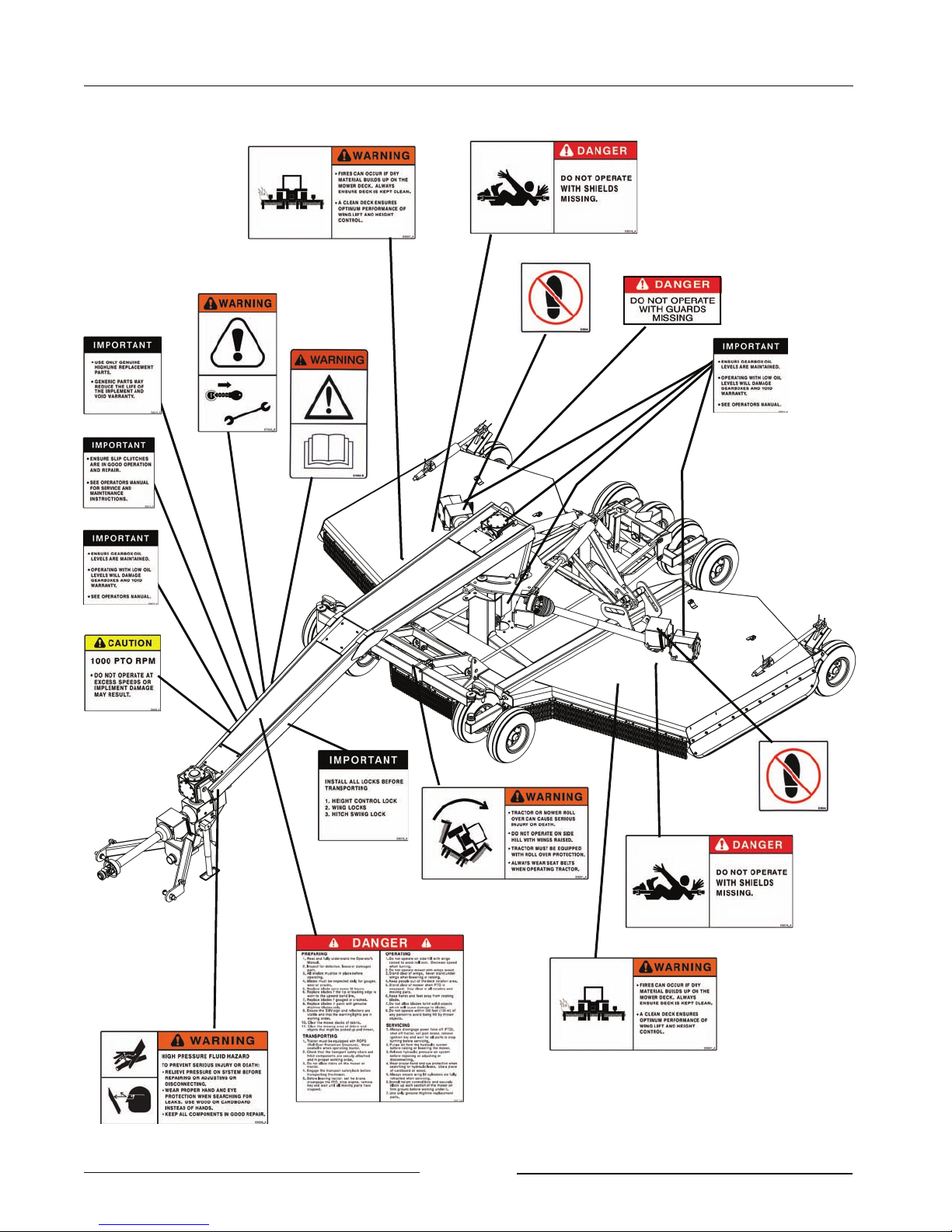

SAFETY DECAL LOCATIONS

Section 1 - Safety

Page 1-9

Section 1 - Safety

SAFETY DECAL LOCATIONS CONTINUED

Page 1-10

Section 2 - Transporting the Mower

2.0 TRANSPORTING THE MOWER

Only tow the mower behind a

properly sized and equipped

tractor which exceeds the weight

of the mower by 20%. Do not tow

the mower behind a truck or other

type of vehicle

Do not allow children or other

people to ride on the tractor or

mower. Falling off can result in

serious injury or death.

1. Tractor Requirements

- Minimum tractor weight of 9360 lbs

(4246 kg).

- Roll Over Protection System (ROPS)

- Working seatbelts

- 1 3/8" 21 spline PTO

- Minimum 80 PTO HP

Recommended is 100 PTO HP.

- 3 Spool Control Valves (SCV)

2. Ensure correct PTO speed

- Ensure that the tractor PTO speed

matches the mower’s gearbox speed

of 1000 rpm.

- Do not attempt to operate the mower

at a different PTO speed.

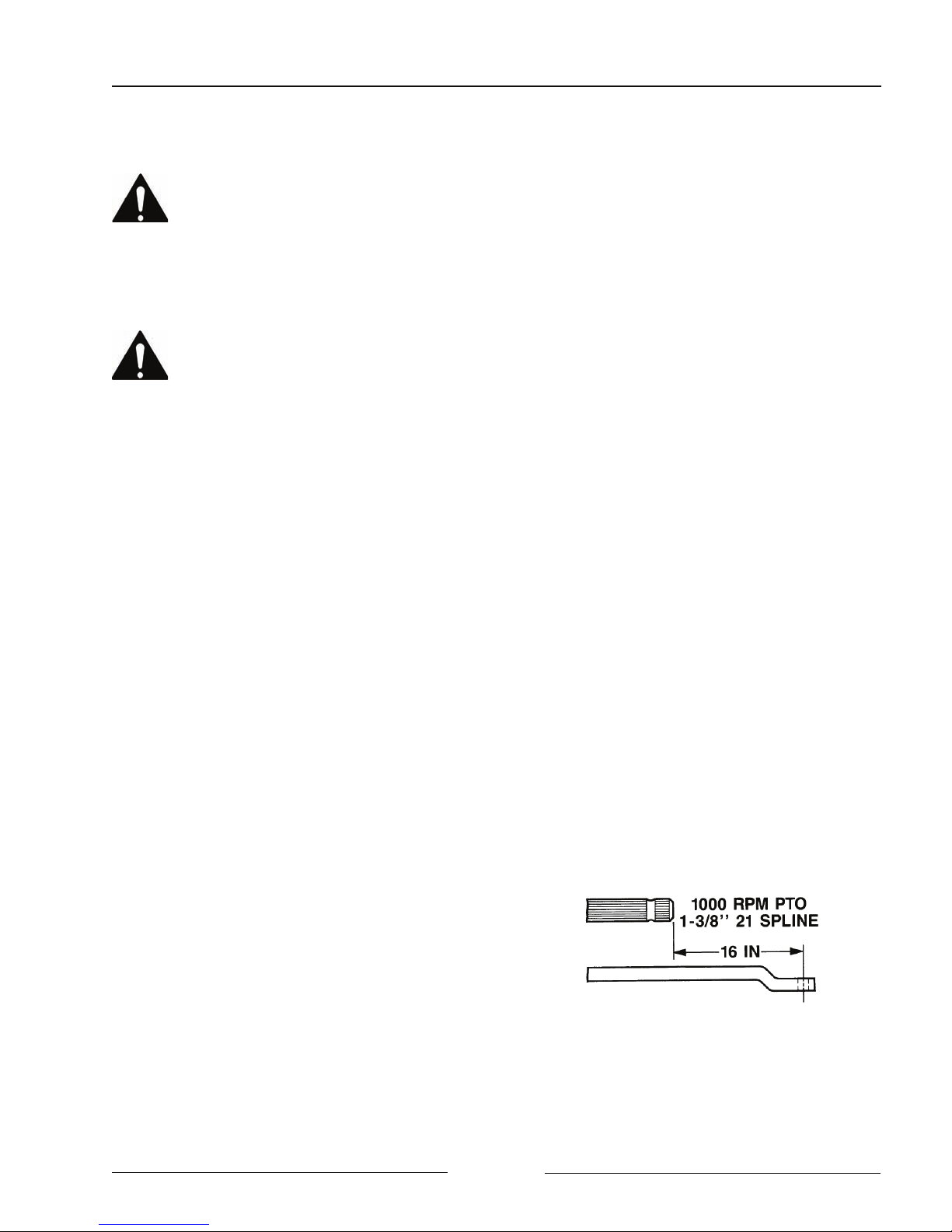

3. Adjust Single Point Hitch Drawbar Length

- Set the drawbar length to 16" (406

mm) for a 1 3/8" 21 spline PTO.

- This length is measured from the tip of

the PTO shaft end to the center of the

drawbar hole. (Refer to your tractor’s

operator manual for drawbar

adjustment procedures.)

Note: To prevent damage to the tractor

drawbar, avoid traveling at high

speeds and over rough terrain.

Note: Do not use PTO adapters. PTO

adapters will cause a driveline

failure and possible tractor

damage. Your mower warranty

will also be invalid.

Tractor Drawbar Adjustment for 1000 RPM

108005

Page 2-1

Section 2 - Transporting the Mower

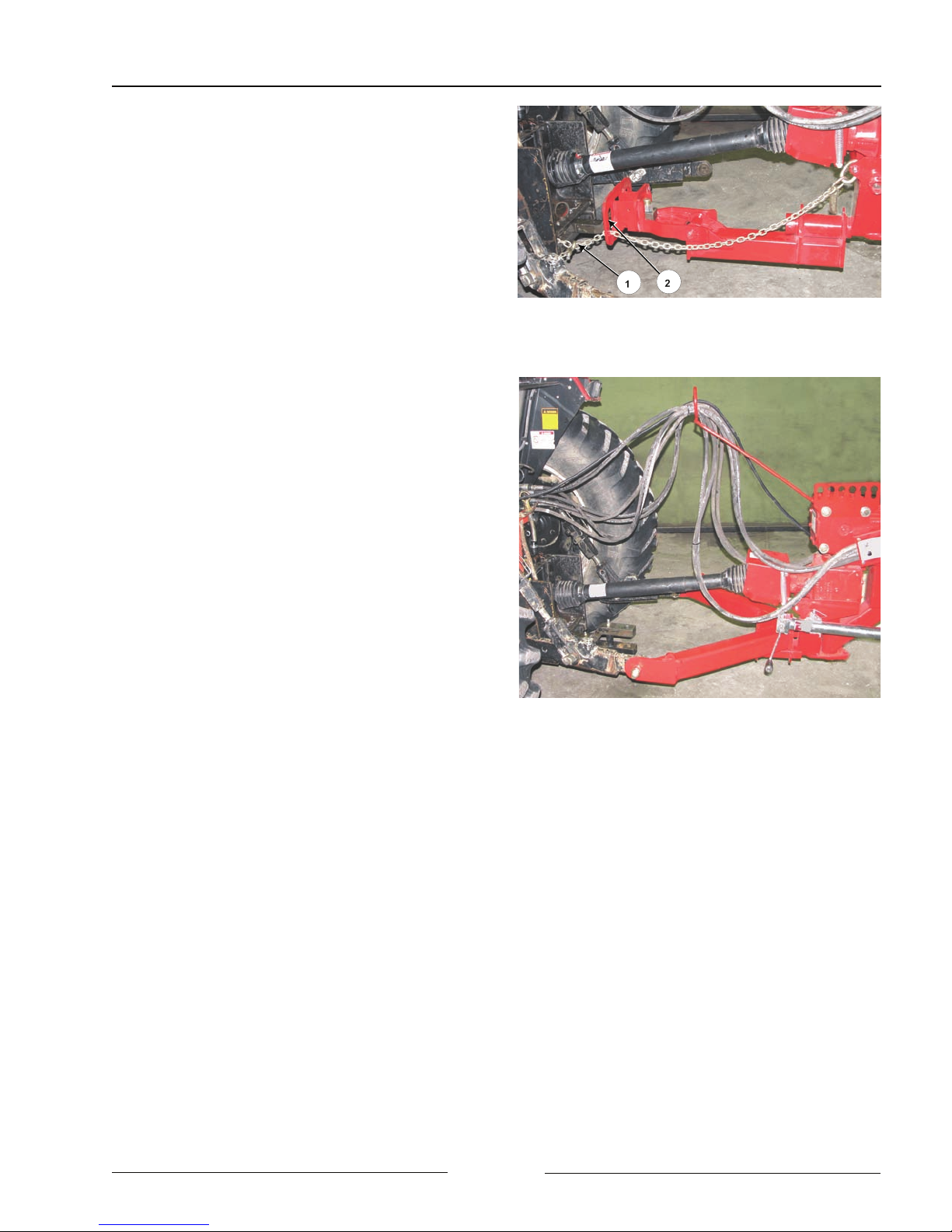

4. Connect Single Point Hitch (if applicable)

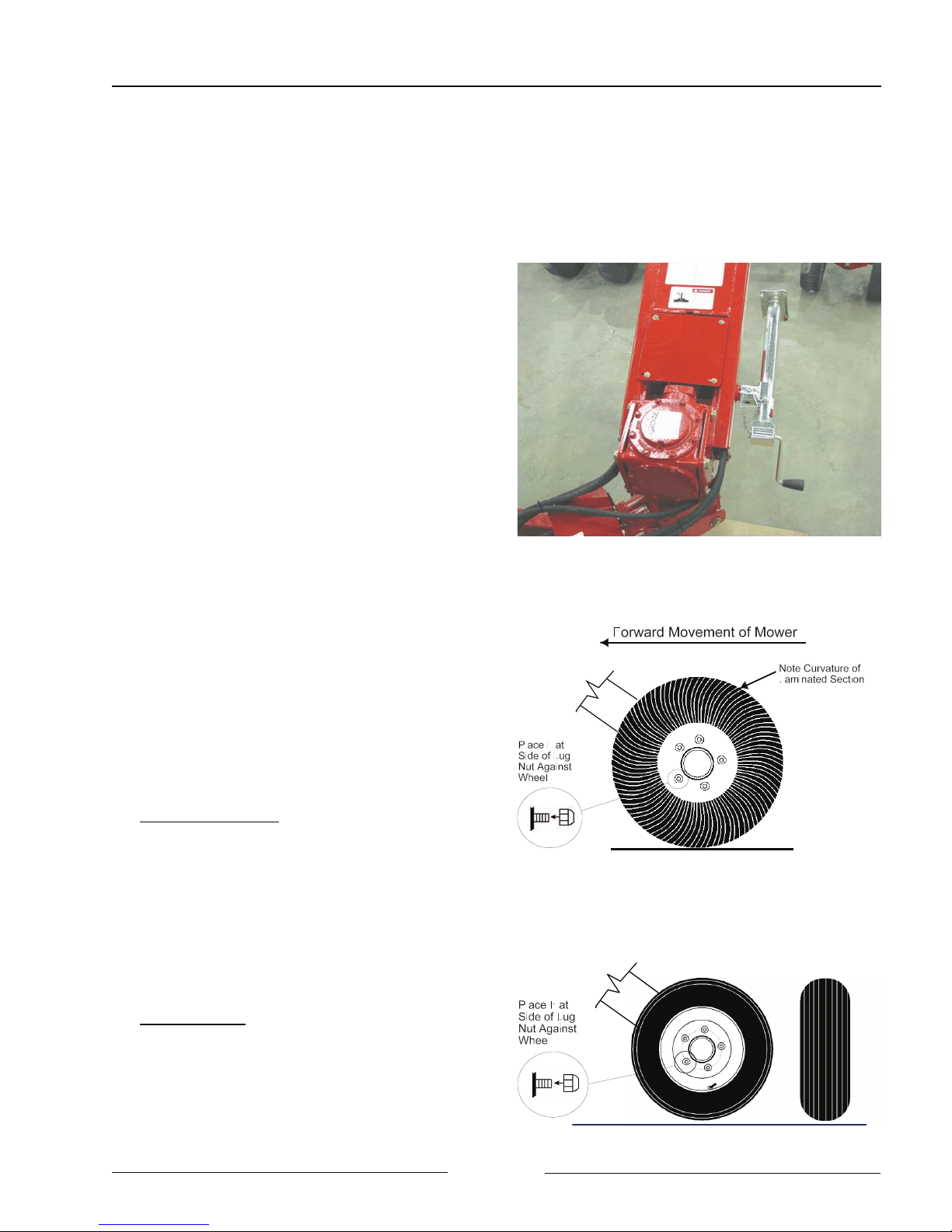

- Lift the Hitch Arm with the jack (1)

- The hitch arm is very heavy. Do

not attempt to lift it without using

the jack. - Adjust the hitch to

connect the drawbar.

- Connect the tractor drawbar to the

drawbar connector with:

- 1 1/4" x 5" bolt, washer and

locknut (1). Torque to 600 lbf (813

Nm)

- 3/4" x 3 ½" bolt, washer and

locknut (2). Torque to 260 lbf (352

Nm).

- Place a ½" thick shim plate (1) on

each side of the drawbar and fasten in

place with 3/8" x 5" bolt and locknut

(2 ).

Single Point Hitch on Jack

Connecting Drawbar Connector

107081C

107082C

Page 2-2

Drawbar Shims

107083C

Section 2 - Transporting the Mower

5. Connect the Safety Chain to the tractor.

- Ensure the safety chain rating is equal

or greater than the gross weight of the

mower.

- Route the safety chain (1) through the

large slot (2) in the drawbar connector.

Securely fasten the chain to the tractor

and lock in place with the hook lock.

6. Connect the 2 Point Hitch (if applicable)

- Adjust the lift links so that the PTO is

relatively level.

- Insert the 2 point hitch pins into the

hitch member and fasten in place with

D-ring pins.

Connect the Safety Chain

108006C

7. Tractor Wheel Tread Width Settings

- Increase the tractor rear wheel widths

to maintain tractor stability when

working on inclines or rough ground.

8. Route the hydraulic hoses and wiring

harness through the hose support arm.

2 Point Hitch Connection

108007

Page 2-3

Section 2 - Transporting the Mower

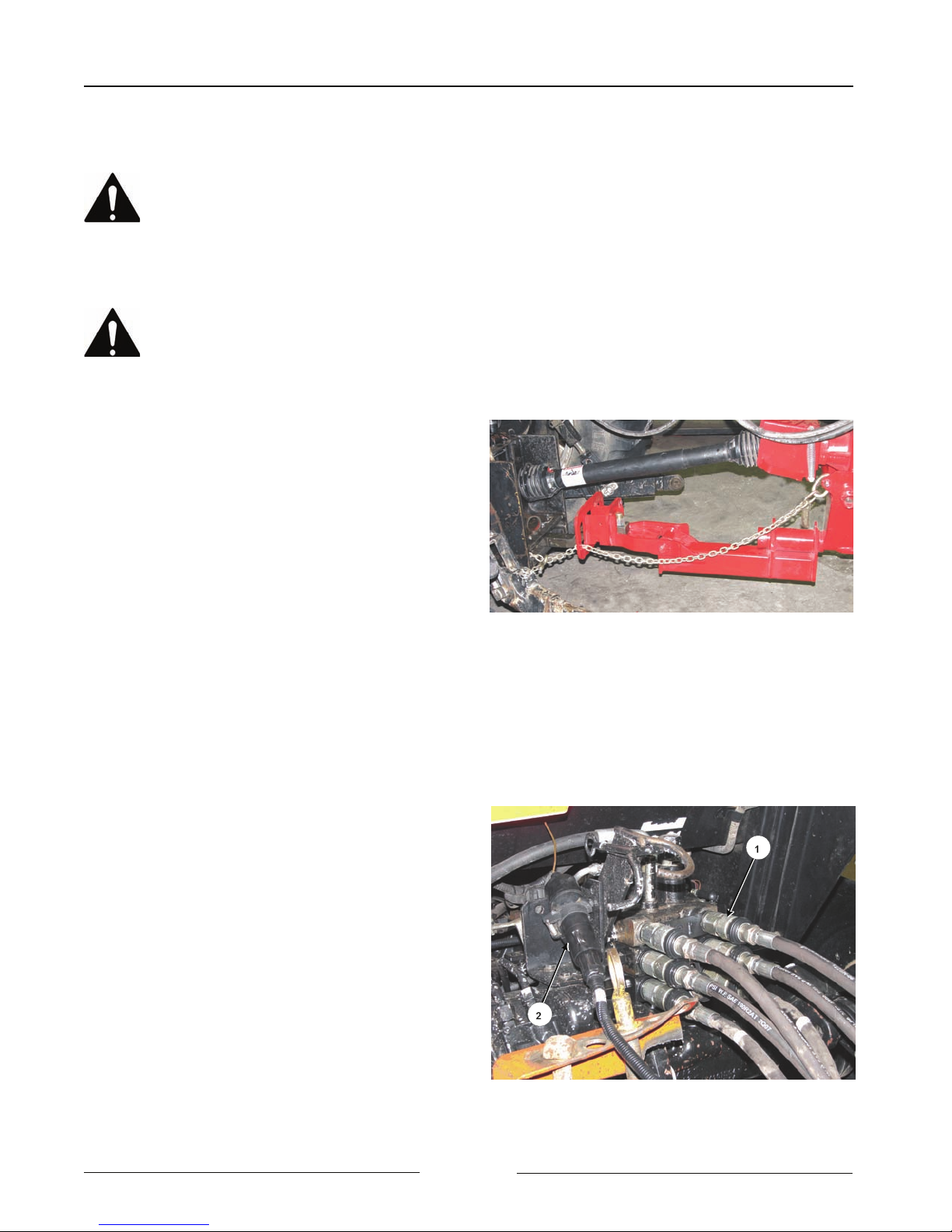

9. Attach Driveline to PTO

Shut off the tractor engine before

attaching PTO driveline.

Entanglement in the rotating

driveline can cause serious injury

or death.

The mower shall not be operated

without the driveline shields in

place.

1) Shut off the tractor engine and remove

the key.

2) Check that the driveline telescopes

easily and that the shields are in good

condition and rotate freely.

3) Lift the tractor PTO shield.

4) Support the driveline, pull back on the

yoke collar, align the splines by

rotating the mower driveline and push

the driveline into the tractor PTO shaft

until the collar snaps into place.

5) Push and pull the yoke several times

to ensure the driveline is locked. Do

not pull on the collar as this will

release the lock.

6) Lower the tractor & hitch PTO shields

into place.

Attach Driveline to PTO

108006

10. Attach Hydraulics

- The tractor must be equipped with 3

spool control valves (SCV) to control

the deck rotation, winging up and

down and height control.

- Clean the end of the hoses (1) and the

connection.

- Firmly push the hoses into the tractor

receptacle according to user

preference.

- Route the hoses so they do not

interfere with moving parts.

Page 2-4

Attach Hydraulics and Lighting

108008C

Section 2 - Transporting the Mower

11. Connect Lights

- Connect the light plug (2) into the

appropriate tractor receptacle.

- Ensure the light cable does not

interfere with or contact moving parts.

12. Place the Hitch Jack in the Storage

Location.

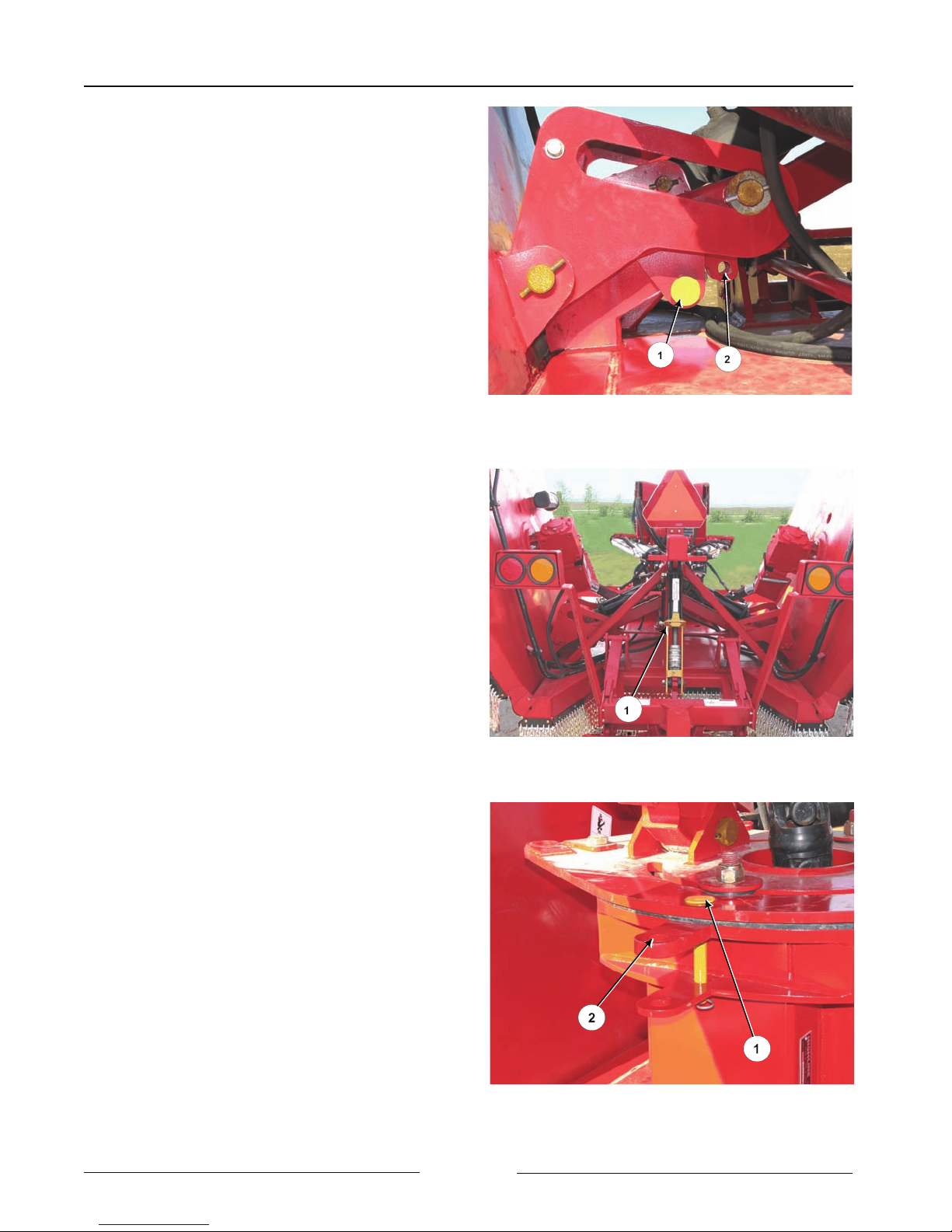

13. Check on the condition of all the tires.

- Verify that the lug nuts have the flat

side of the lug nut against the wheel

rim.

- Torque the lug nuts to 75 lbf (101

Nm).

Laminated Tires:

! Do not transport the mower on

roadways for long distances with

laminated tires.

Hitch Jack in Storage Location

Laminated Tires

107043

107074C

Aircraft Tires

! Air Filled Tire Pressure - Fill the tires

to 30 psi (207 Kpa).

Page 2-5

Aircraft Tires

107094C

Section 2 - Transporting the Mower

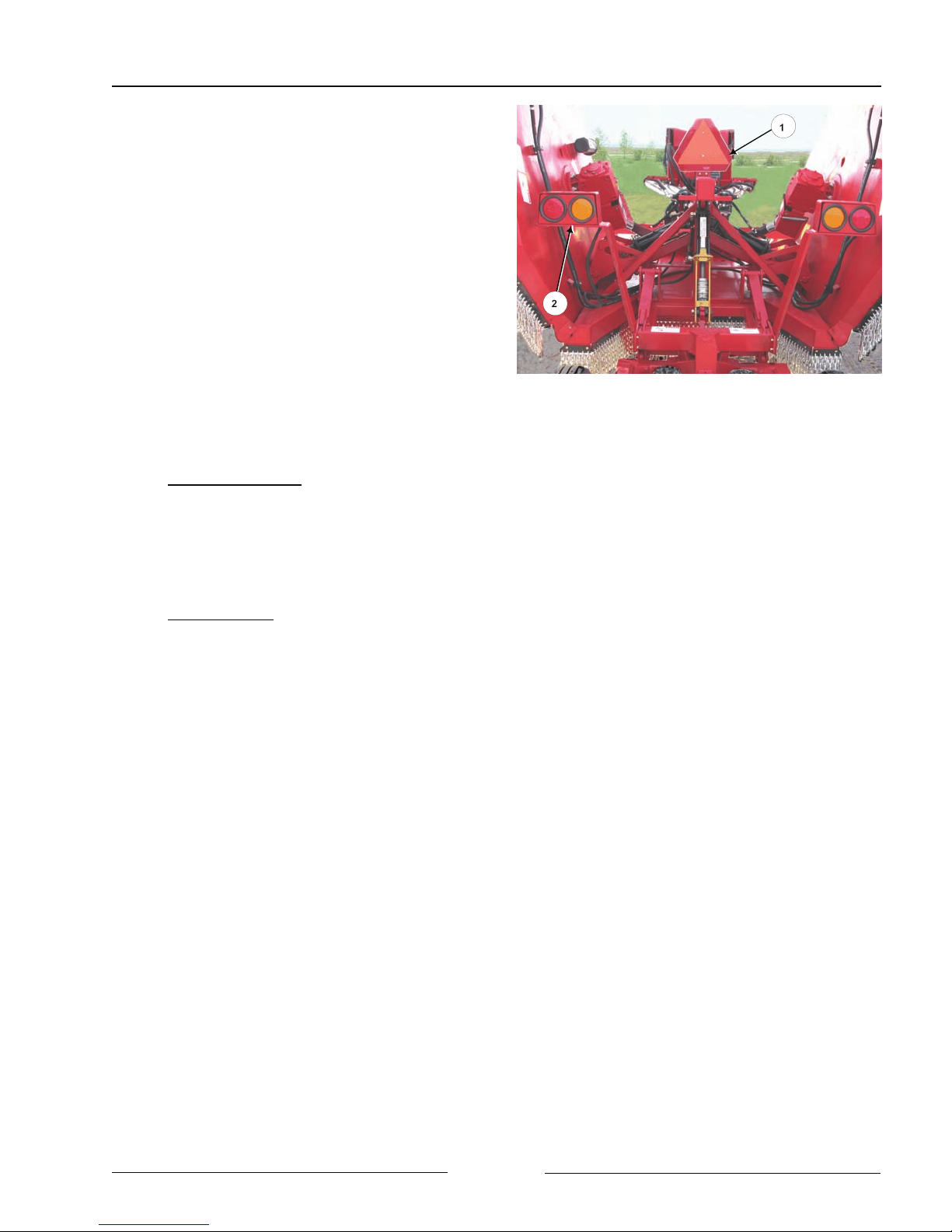

14. Raise the wings until they rest in

place.

- Install the Wing Lock Pins (1) from the

lock pin carrier (2) position. Clip the

pin into place.

15. Lower the mower until the hydraulic

height control cylinder is resting on the

height cylinder lock (1).

16. Install the Hitch Transport Lock Pin (1)

from the lock pin carrier (2) position.

Clip the pin into place.

Install the Wing Transport Lock Pins

Height Cylinder Resting on Lock

107085C

108077C

Page 2-6

Install the Hitch Transport Lock Pin

107086C

Section 2 - Transporting the Mower

17. Verify that the Slow Moving Vehicle

(SMV) sign (1) is clean and visible.

18. Verify that the taillights and flashing

warning lights (2) are clean, visible

and in good working order.

19. Transport Speed

Laminated Tires

- Do not exceed 15 mph (24 km/h).

Excessive speed can cause

damage to the machine and tire

sections.

Aircraft Tires (Air or Foam Filled)

- Do not exceed 20 mph (32 km/h).

Verify the SMV is Visible & Lights are Working

108077C2

Page 2-7

Section 2 - Transporting the Mower

This Page Left Blank

Page 2-8

Section 3 - Mower Preparation

3.0 MOWER PREPARATION

1. Park the tractor and mower on level

ground.

- Engage the tractor parking brake.

2. Ensure that all Decals are clean and in

place.

3. Ensure that the Slow Moving Vehicle

(SMV) sign is clean and visible.

4. Ensure the Lighting is working properly.

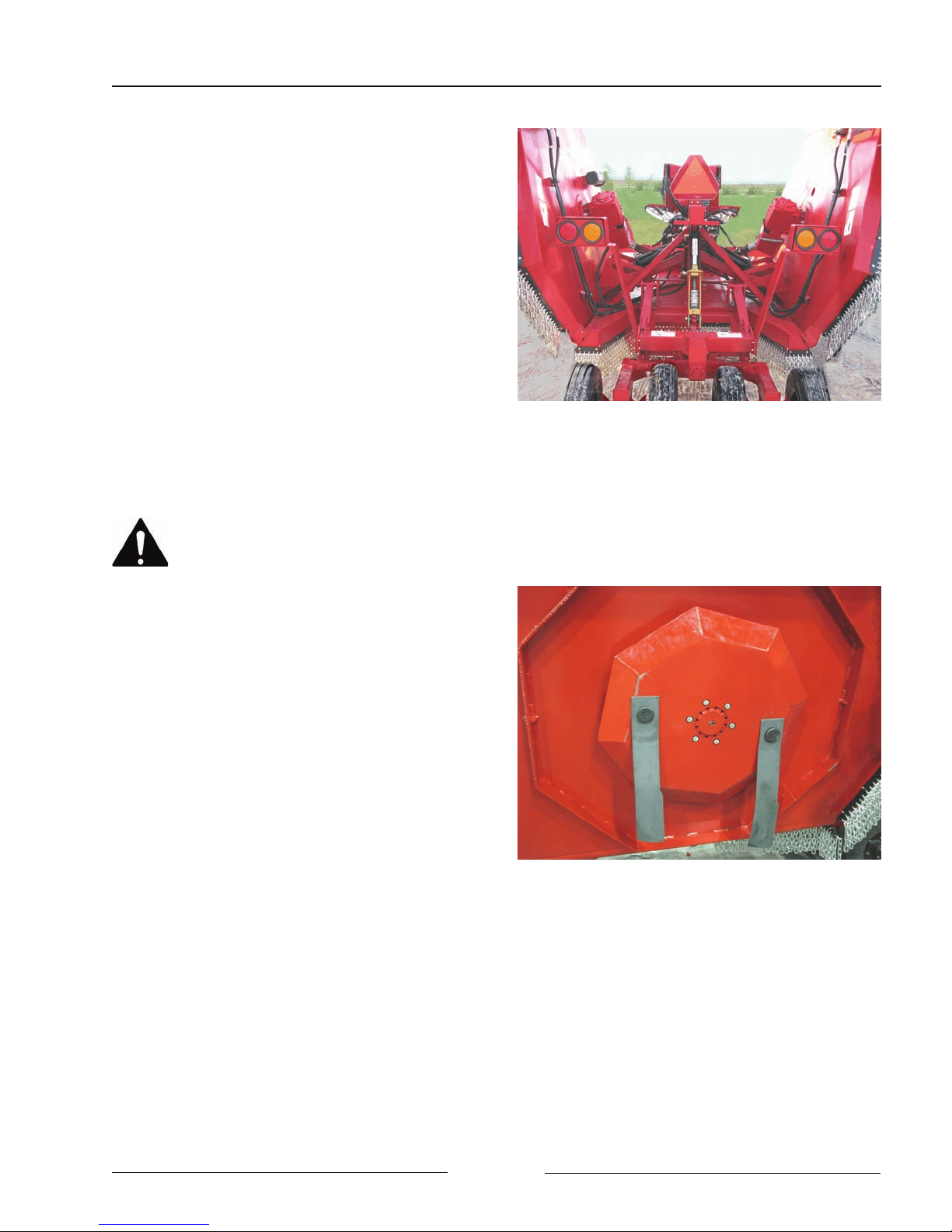

5. Check the Condition of the Blade Pans

Securely block-up the mower

before any work is done under the

mower when lifted up. This is to

prevent the mower from dropping

due to inadvertent operation of

controls, hydraulic leaking or

failure of any components.

- Clean debris and material buildup

from the blade pan area and from the

pans.

- Check that no wire or other materials

are wrapped around the driveshaft or

pan.

- Inspect the pan for damage caused by

contact with an immovable object.

Park On Level Ground

Inspect Blades & Hardware

108084

107034

- Inspect blade pan mounting hardware

for damage.

- Inspect blade mounting bolts for

damage.

Page 3-1

Section 3 - Mower Preparation

6. Check the Condition of the Blades

- Inspect the blades daily.

- Check that the blades swing freely.

Note: Do not sharpen the blades.

Replace them with Highline

blades.

! Replace the blade pair at a maximum

of 50 hours regardless of the wear

because of the possibility of metal

fatigue and non-visible cracks in the

blades. Replace with Highline blades.

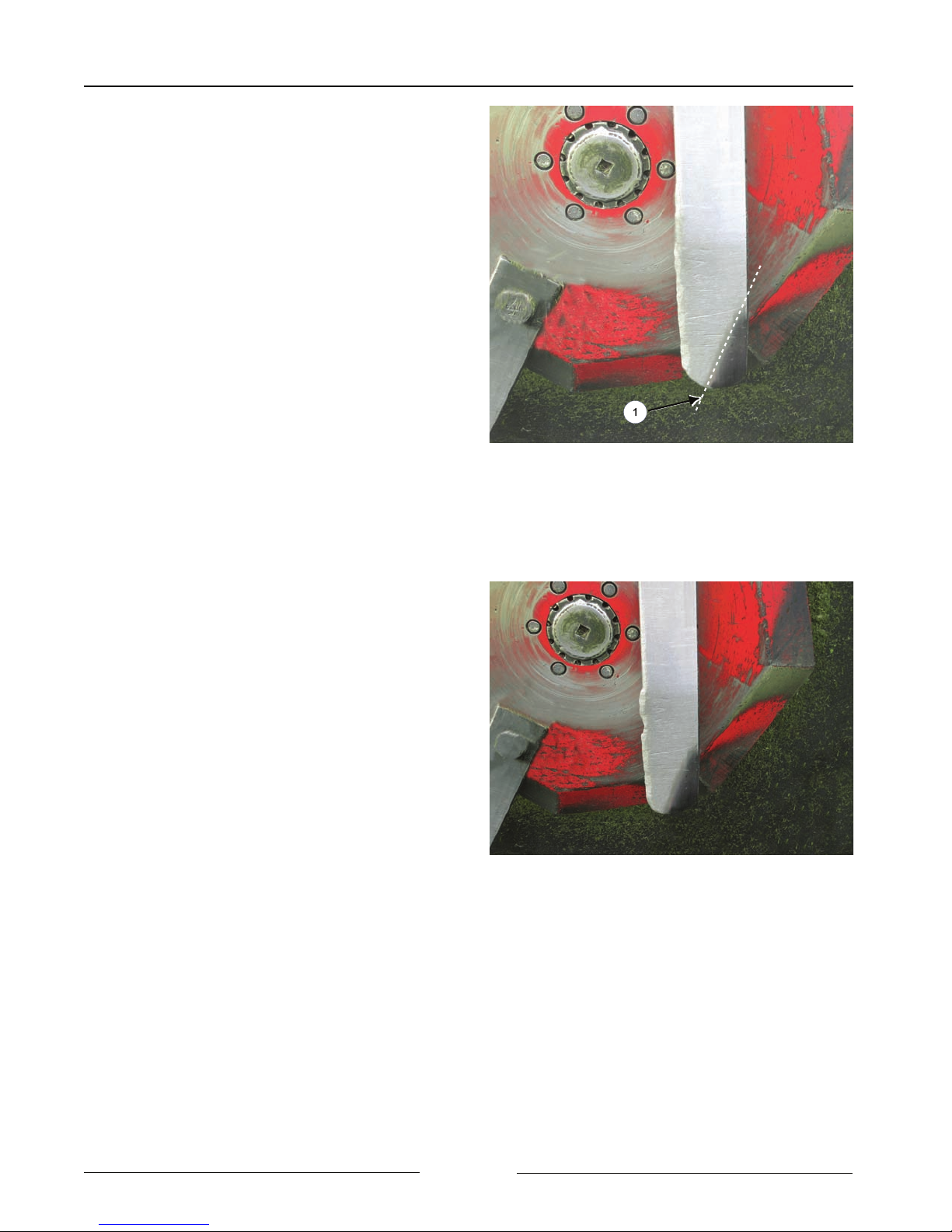

! Replace the blade pair if the tip or

leading edge is worn to the upward

bend line (1). Replace with Highline

blades.

- The bend line is 2" (51mm)

from the leading edge of a 4"

(102mm) blade.

! Replace the blade pair if a blade is

gouged, has visible cracks or is bent.

Replace with Highline blades.

Replace blades in pairs with only

Highline blades.

-See “Blade Replacement

Procedure” in the Maintenance

Section.

Replace Blade When Tip Worn to Bend Line

Replace Blade When Gouged

1070802C

107080

Page 3-2

Loading...

Loading...