Rotary Mower

™

RCH Hydro

™

Radial Contouring Hitch

O P E R A T O R ' S M A N U A L

E14362V1

Rotary Mower

RCH Hydro

™

Radial Contouring Hitch ™

Operator’s

Manual

Printed in Canada Copyright © 2016 by Highline Manufacturing Ltd. All rights reserved.

The content of this manual was based on the most current information available as of the date of copyright. It is the policy of

Highline Manufacturing Limited to improve and develop our products continually. We reserve the right to make changes or add

improvements, at any time, without incurring any obligation to make changes or improvements on machines previously sold.

Changes may not be reflected in this manual.

Highline Manufacturing Limited

HWY #27, P.O. Box 307

Vonda, SK S0K 4N0

Canada

Phone: 306.258.2233

Fax: 306.258.2010

Toll Free: 1.800.665.2010

E14362V1

Highline Manufacturing Ltd. Rotary Mower - RCH Hydro

Highline Team Message

Congratulations on your purchase of the Rotary Mower RCH Hydro manufactured by

Highline Manufacturing Ltd. We are excited about your endeavor into cutting with the most

technically advanced rotary cutter known to date. You will find flexibility and maneuverability

of operation with this product that has never been experienced before. Welcome to the elite

group of Highline Rotary Mower owners.

This Operator's Manual has been prepared to provide information necessary for the safe and

efficient operation of your Rotary Mower. In the manual you will find safety procedures,

maintenance routines and detailed operational instructions.

If you find that you require information not covered in this manual, please feel free to consult

your local dealer. Your dealer is always able to contact Highline for this technical information.

Highline Manufacturing Ltd. thanks and congratulates you for selecting a Rotary Mower as your

machine of choice.

Highline Manufacturing Ltd.

Table of Contents

Section 1 - Safety

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Sign-off Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Decal Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 2 - Transporting the Mower

Tractor requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ensure correct PTO speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Adjust tractor drawbar length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lift the hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Connect the hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Connect the safety chain to the tractor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tractor wheel tread width settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Route the hydraulic hoses and wiring harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Attach the driveline to the PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Attach the hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connect the lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Place the hitch jack in the storage location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Check on the condition of all the tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Raise the wings until they rest in place. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install the wing transport lock pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lower the mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Height cylinder transport lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install the hitch transport locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Slow Moving Vehicle (SMV) sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

taillights and flashing warning lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Transport speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 3 - Mower Preparation

Park the tractor and mower on level ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ensure the lighting is working properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Optional joystick control, confirm that the hydraulic control block is configured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Check the condition of the blade pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Check the condition of the blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Lift the height control transport lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Remove the wing transport lock pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Remove the hitch transport locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Level the mower center section deck front to back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Verify the blade direction rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Determine the wing height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wing height adjustment procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Set the preferred cutting height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inspect all the hydraulic cylinders, pump, motors and hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Clear debris from the oil cooling tank, radiator and cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Check the oil level in the oil tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ensure the shutoff valves at the bottom of the tank are in the open position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Check the oil filter operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Check the oil level in the pump gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Check the condition of the chain guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspect the wheels and tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspect the wing skid plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inspect the center section skid plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

wing skid plate wheel is installed, check the condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Foot Models, inspect the center deck skid and counterweights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ensure the driveline is securely attached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ensure the driveline shields are lowered into place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lubricate all grease fittings and check the fluid level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 4 - Operating the Mower

Hydraulic Oil Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Move both wing transport lock pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Remove the hitch cylinder transport locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Lower the wings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Controlling the Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Box - 3 Remote Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Box - Joystick Control (1 Remote) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Joystick Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Swing the mower deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lower to the cutting height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust ground speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Move the wing blade pans switches on the control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operate the PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Allow the wings to float . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Avoid cutting into the ditch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Swing the mower deck away from obstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Check that the hydraulic oil cooling fan is operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Responding to a High Oil Temperature Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Do not drive or swing the mower into following or on-coming traffic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cross ditches and steep inclines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Making Turns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Recommended Practices for a Quality Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 5 - Maintaining the Mower

Check the oil level in the pump gearbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Check the oil level in the oil tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Check the oil filter operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Replacing the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Clear debris from the oil cooling tank, radiator and cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Oil Tank Oil Changing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Gearbox Oil Changing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Blade Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Removing and Replacing the Blade Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rear Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 6 - Storing the Mower

Clean all the debris off the mower decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lubricate all mower grease points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Park the mower on level ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lower the mower until the hydraulic height control cylinder is resting on the transport lock . . . . . . . . . . . . . . . . . . . . . . 1

Place the wing transport lock pins in place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

jack from the storage position and place it onto the hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Remove the driveline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Disconnect the safety chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Disconnect the hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

hydraulic hoses and disconnect them. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Disconnect the electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Secure the hydraulic hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Place the PTO driveline in the support bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Change the oil in the gear box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 7 - Troubleshooting

Operation .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Center Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mower Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fan Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hydraulic Manifold - Joystick Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tractor Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pump Gear Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Driveline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 8 - Specifications

Radial Contouring Hitch Hydro

RCH Hydro 15 Foot - has a center deck and

two wing decks. The cutting width is 15 feet

(4.6 m). This model can be configured for

Right Hand Slope (With Traffic) cutting and

Level Ground cutting.

Operating in Ditch

214064

RCH Hydro 10 Foot - has a center deck and

a right wing deck. The cutting width is 10 feet

(3.0 m). This model can be configured for

Right Hand Slope (With Traffic) cutting and

Level Ground cutting.

Winged Up

214106

Operating In Ditch

215069

Winged Up

215070

Section 1 - Safety

SERIAL NUMBER

Your serial number is found on the serial number plate (1) attached to a bracket on the oil

tank.

Serial Plate Location

It is important to record the serial number for proof of ownership and for any service or

maintenance assistance.

215071C

Serial Number

Owner

Model

Date of Purchase

Be Trained Before Operating Mowers!

Safety Training Makes a Difference.

The Association of Equipment Manufacturers offers the 22 minute video,

“Industrial and Agricultural Mower Safety Practices: A Safety Training

Program for Operators of Rotary-Type Mowing Equipment”.

This video reinforces the proper procedures to follow while operating rotary

mowing equipment.

To view the video on the Internet or to order a copy, please visit the Association of Equipment

Manufacturers website at www.aem.org and go the Safety & Training section.

The video does not replace the information contained in this Operator’s Manual. Please read

and understand this manual before operating the mower.

Page 1-1

Section 1 - Safety

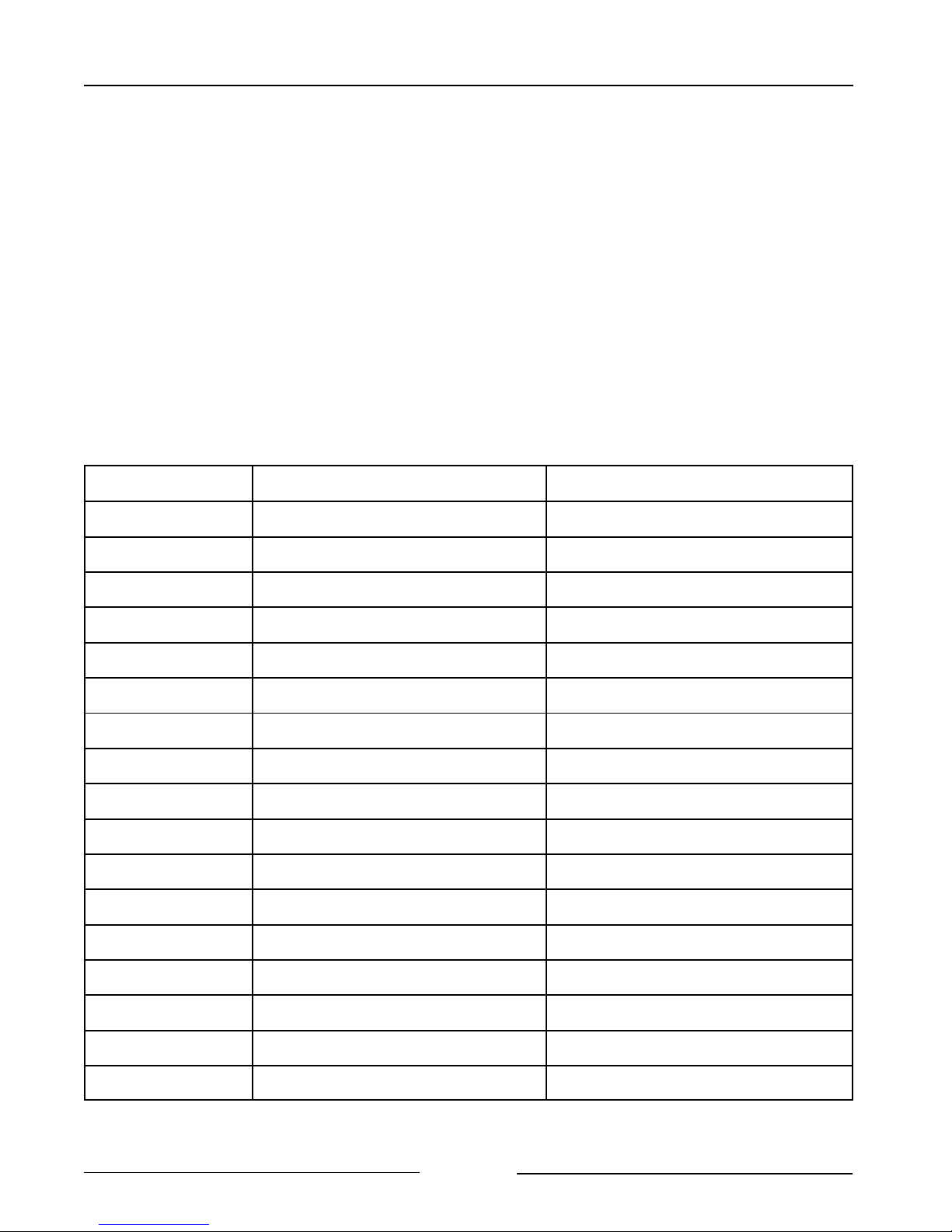

SAFETY SIGN-OFF FORM

Highline Manufacturing Ltd. follows the general Safety Standards specified by the American

Society of Agricultural and Biological Engineers (ASABE) and the Occupational Safety and

Health Administration (OSHA). Anyone who will be operating and/or maintaining the Highline

Rotary Mower should read and clearly understand all Safety, Operating and Maintenance

information presented in this manual.

Do not operate or allow someone to operate this equipment until this information has been

reviewed. This information should be reviewed by all operator’s before the season start-up.

This sign-off sheet is provided for record keeping to indicate that the person working with the

equipment has read and understood the information in the Operator’s Manual and has been

instructed in the safe operation of the equipment.

Date Employee’s Signature Employer’s Signature

Page 1-2

Section 1 - Safety

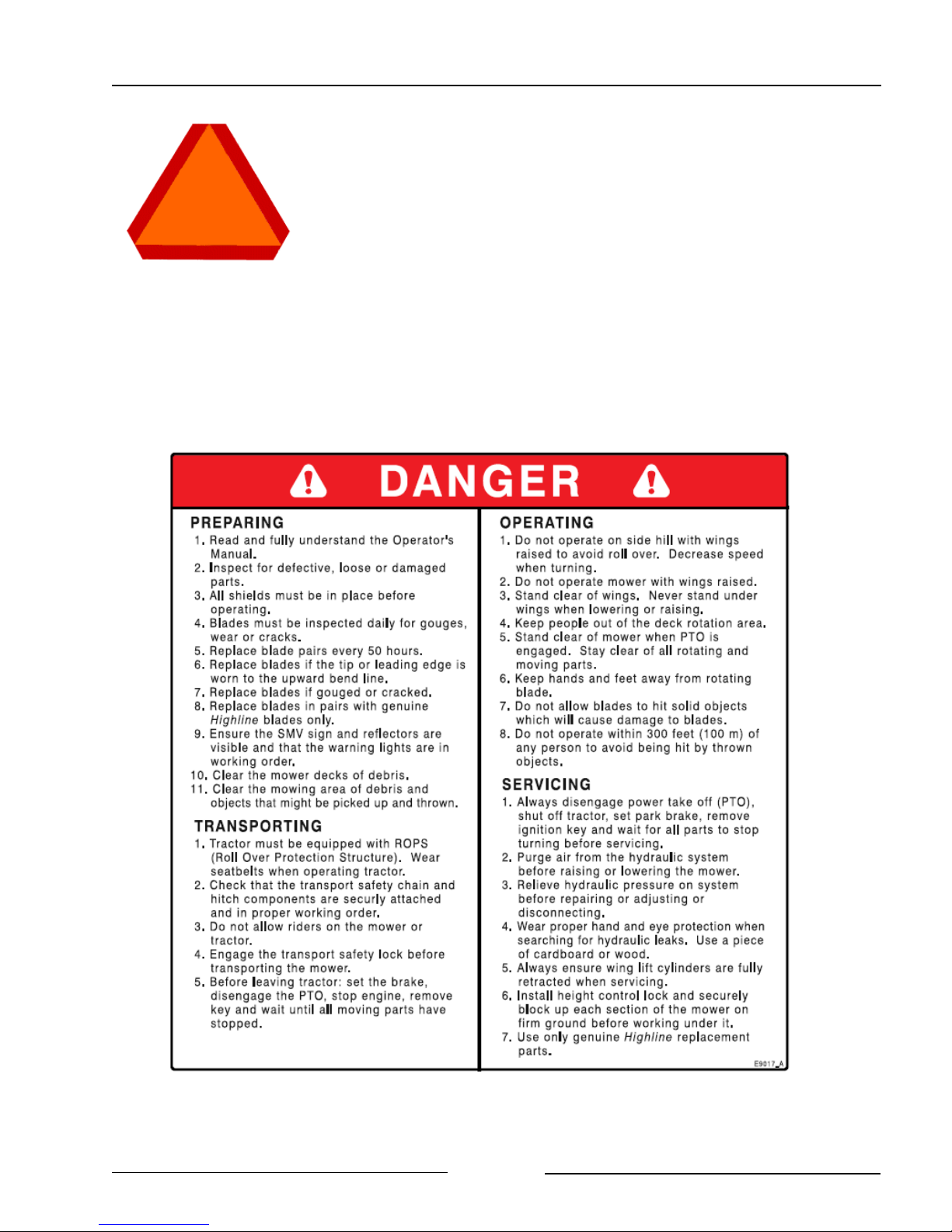

SAFETY ALERT SYMBOL

The Safety Alert Symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert Symbol combined with a Signal Word alert to the presence of a hazard and the

degree of possible injury.

Indicates an imminently hazardous situation that, if not

avoided, WILL result in DEATH OR SERIOUS INJURY.

The color is Red with White lettering.

Indicates a potentially hazardous situation that, if not

avoided, COULD result in DEATH OR SERIOUS

INJURY, and includes hazards that are exposed when

guards are removed or unsafe practices. The color is

Orange with Black lettering.

Indicates a potentially hazardous situation that, if not

avoided, MAY result in MINOR INJURY. The color is

Yellow with Black lettering.

Page 1-3

Section 1 - Safety

GENERAL SAFETY

1. Ensure that anyone who is going to operate, maintain or work near the Rotary Mower is

familiar with the recommended operating, maintenance procedures and safety information

contained in this manual and follows all the safety precautions.

2. “In addition to the design and configuration of the equipment, hazard control and accident

prevention are dependant upon the awareness, concern, prudence and proper training of

personnel involved in the operation, transport, maintenance and storage of the mower.”

3. The mower shall not be operated without all the guards in place.

SAFETY DECALS

1. Keep decals and signs clean and legible at all times.

2. Replace decals and signs that are damaged, missing or have become illegible.

3. Replaced parts that displayed a decal should also display the current decal.

4. Decals are available from the Highline Parts Department.

5. Be familiar with the decals, the type of warning and the area or function(s) related to the

area(s) that requires your awareness.

Page 1-4

Section 1 - Safety

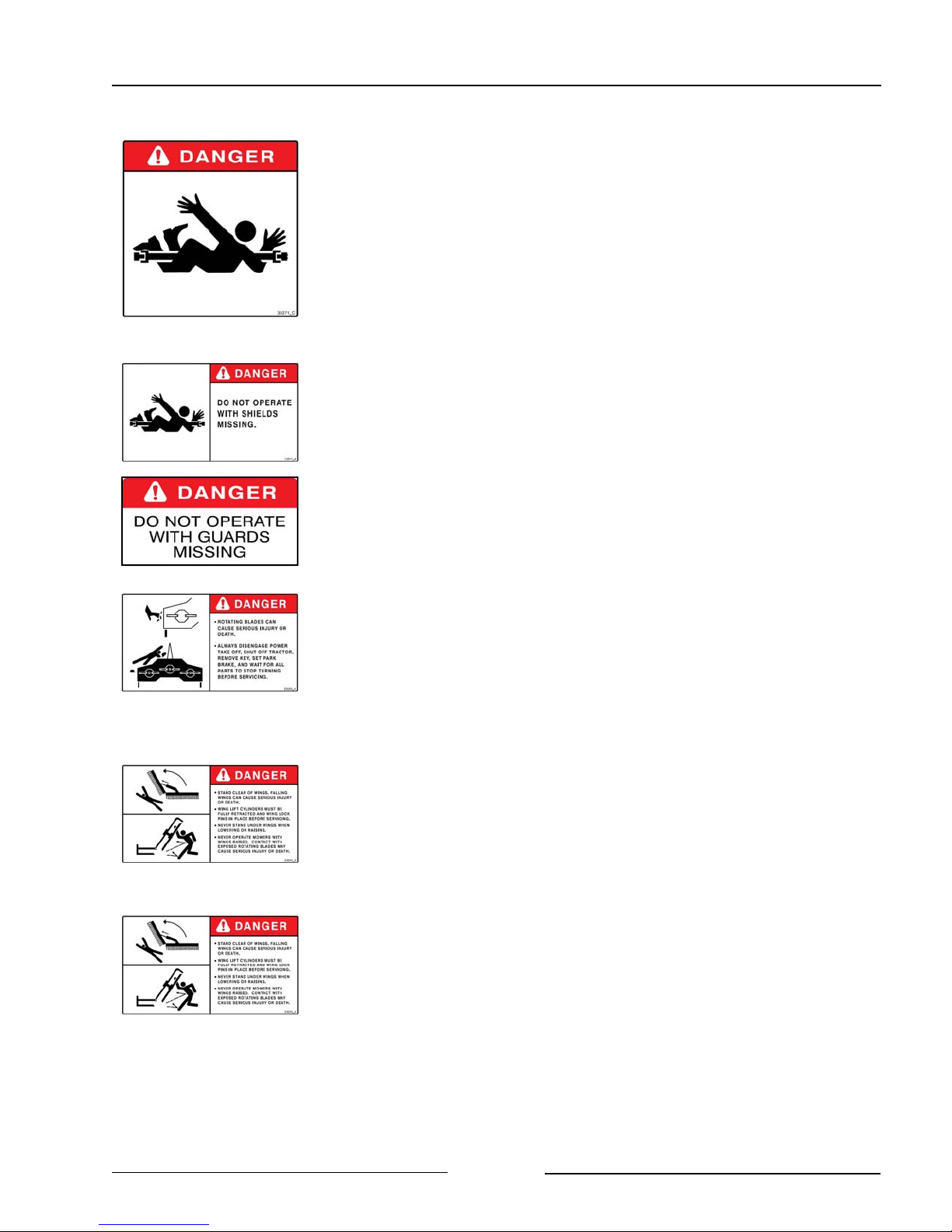

DO NOT CONTACT ROTATING DRIVELINE

Contact with rotating driveline will cause serious injury or death.

Keep all driveline guards in place.

Securely attach drivelines at both ends.

Check that the driveline guards turn freely on driveline.

DO NOT OPERATE WITH SHIELDS MISSING

DO NOT CONTACT ROTATING BLADES

Rotating blades can cause serious injury or death.

Always disengage power take off, shut off tractor, remove key, set

park brake and wait for all parts to stop turning before servicing.

Keep guards in place and in good condition.

DO NOT OPERATE MOWER WITH WINGS RAISED

Contact with exposed rotating blades may cause injury or death.

Rotating blades may throw objects, causing injury or death

STAND CLEAR OF WINGS

Falling wings can cause serious injury or death.

Wing cylinders must be fully retracted and wing lock pins in place

before servicing.

Never stand under wings when lowering or raising.

Page 1-5

Section 1 - Safety

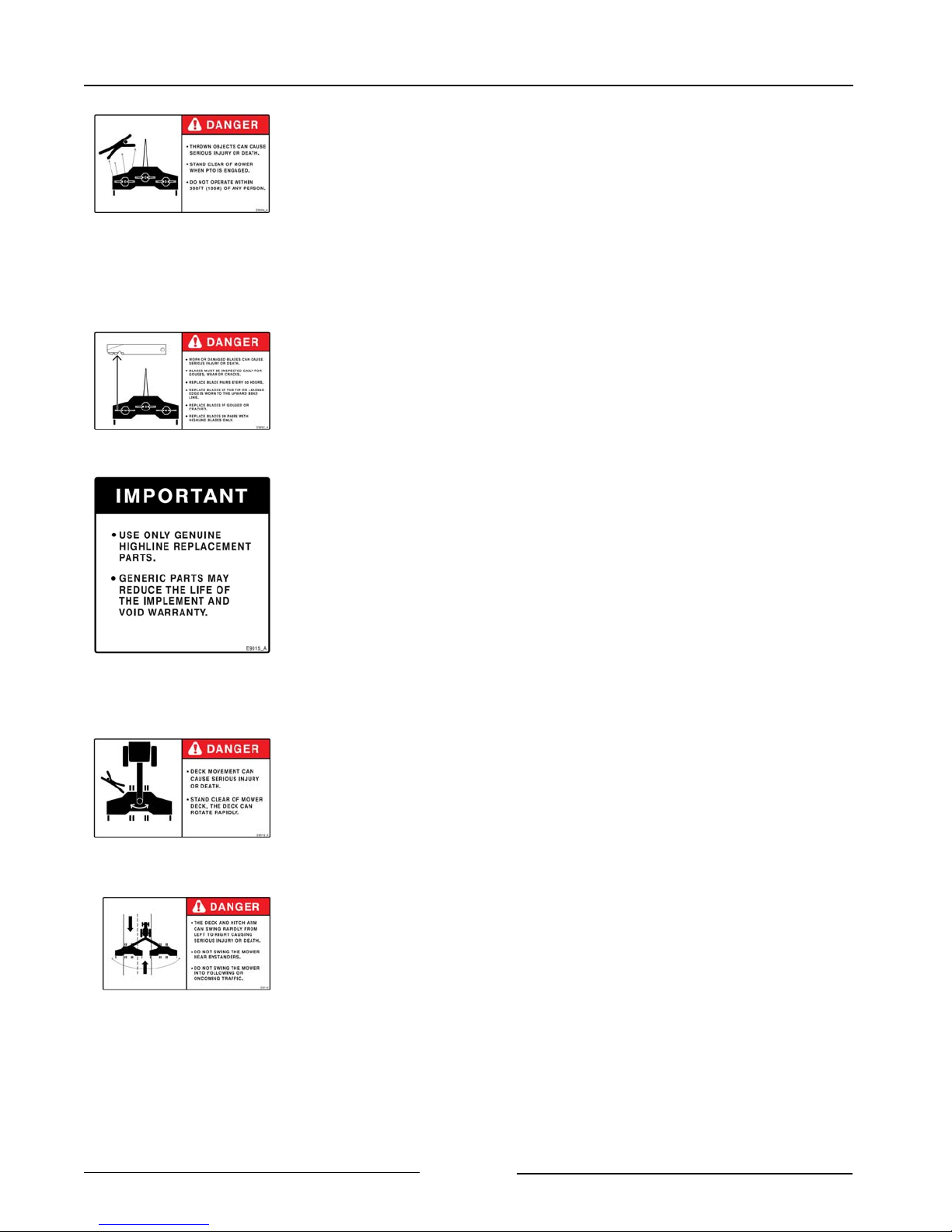

STAY BACK FROM MOWER IN OPERATION WHICH CAN

DISCHARGE OBJECTS SEVERAL HUNDREDS OF FEET

Thrown objects can cause serious injury or death.

Stand clear of mower when PTO is engaged.

Do not operate within 300 ft (100m) of any person.

Keep all shields and guards in place.

Clear mowing area of debris.

INSPECT BLADES FOR DAMAGE

Worn or damaged blades can cause serious injury or death.

Blades must be inspected daily for gouges, wear or cracks.

Replace blade pairs at maximum of 50 hours.

Replace the blade pair if the tip or leading edge is worn so that only

2" (51 mm) of the blade remains.

Replace blades if gouged or cracked.

Blades must be changed in sets.

Use only Highline replacement parts.

Do not repair blades.

STAND CLEAR OF ROTATING DECK

Contact with rotating deck can cause serious injury or death.

Stand clear of mower deck. Mower deck can rotate rapidly.

DO NOT SWING DECK AND HITCH ARM NEAR BYSTANDERS

OR INTO TRAFFIC

The deck and hitch arm can swing rapidly from left to right causing

serious injury or death.

Do not swing the mower near bystanders.

Do not swing the mower into following or oncoming traffic.

Page 1-6

Section 1 - Safety

ENSURE SLOW MOVING VEHICLE SIGN IS IN PLACE

Ensure the Slow Moving Vehicle sign is in place, clean and easily

visible.

Ensure the reflectors are in place, clean and easily visible.

READ AND FULLY UNDERSTAND THE INSTRUCTIONS ON THIS DECAL

Page 1-7

Section 1 - Safety

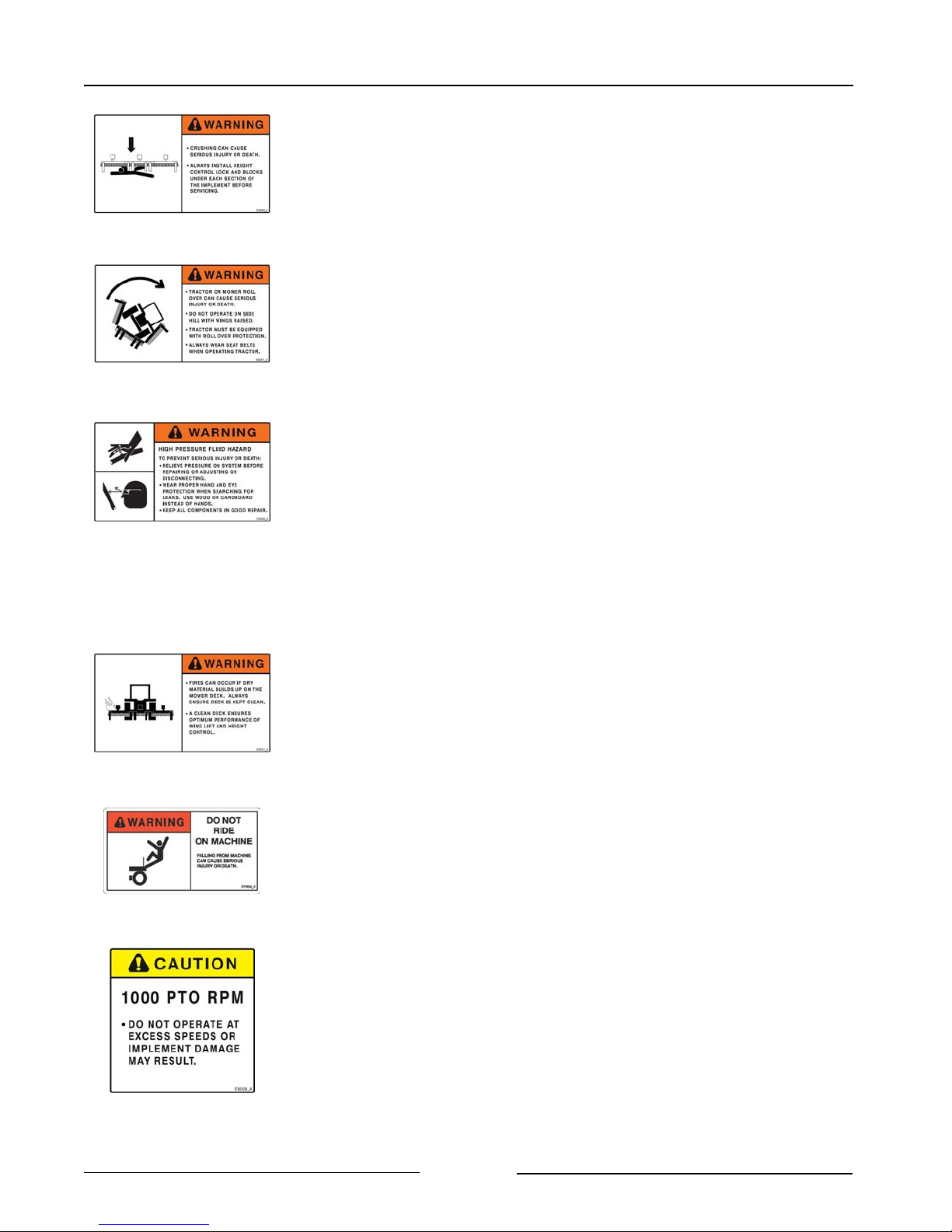

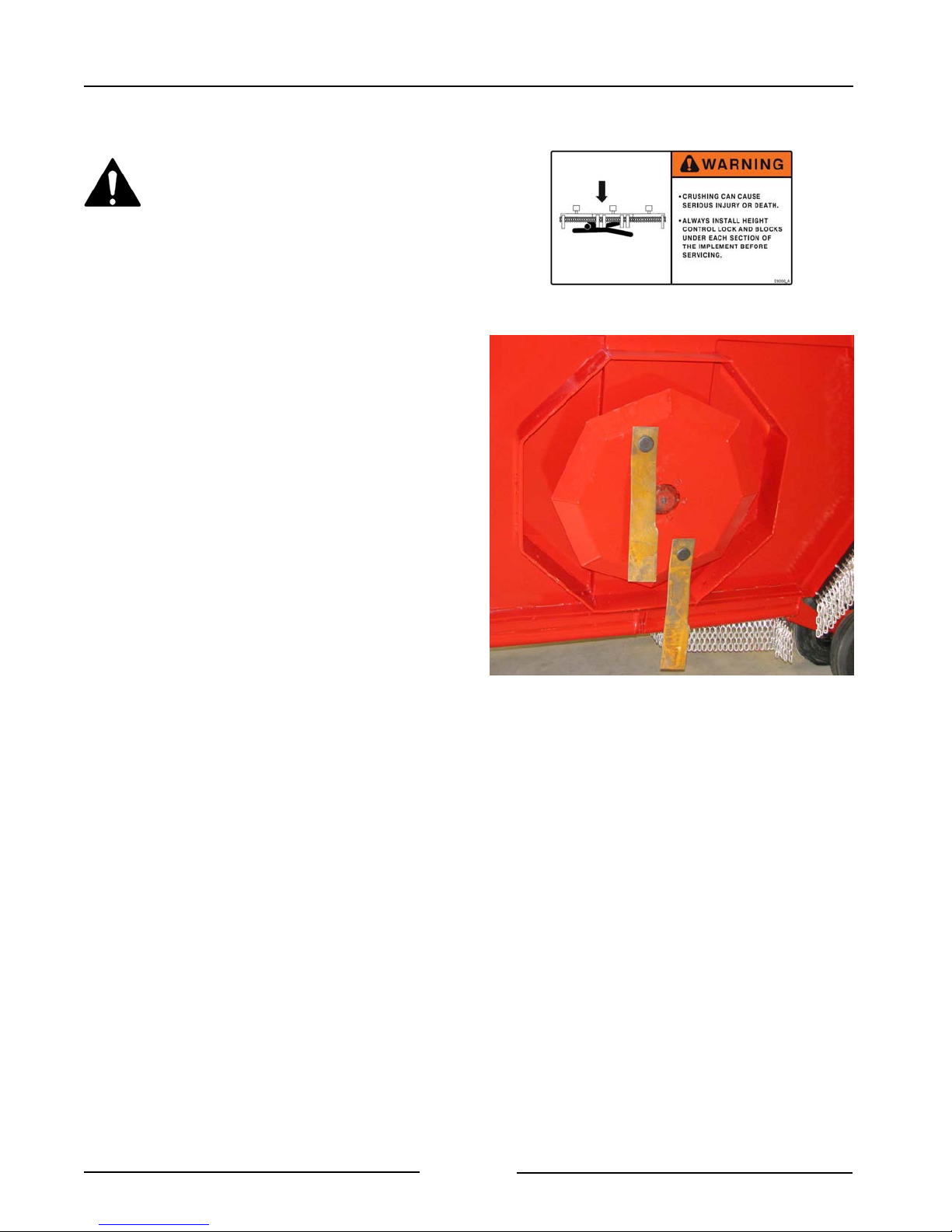

STAND CLEAR WHEN MOWER IS BEING RAISED OR

LOWERED

Crushing can cause serious injury or death.

Always install height control lock and blocks under each section of

the implement before servicing.

DO NOT OPERATE ON SIDE HILL WITH WINGS RAISED

Tractor or mower roll over can cause serious injury or death.

Tractor must be equipped with Roll Over Protection System.

(ROPS)

Always wear seat belts when operating tractor.

USE PAPER OR CARDBOARD TO CHECK FOR HYDRAULIC

LEAKS

To prevent serious injury or death:

Relieve pressure on hydraulic system before repairing, adjusting or

disconnecting.

Wear proper hand and eye protection when searching for leaks.

Use wood or cardboard instead of hands.

Keep all components in good repair.

KEEP MOWER DECK CLEAR OF DEBRIS

Fires can occur if dry material builds up on the mower deck.

Always ensure deck is kept clean.

A clean deck ensures optimum performance of wing lift and height

control.

DO NOT RIDE ON MACHINE

Falling from the moving machine can cause serious injury or

death.

Falling from the operating machine can cause being entangled

under the machine or being injured by the machine.

DO NOT EXCEED PTO SPEED

Do not operate at excess speeds or damage to the mower may

result.

Page 1-8

Section 1 - Safety

DO NOT TOUCH HOT SURFACES

Heat from the hydraulic oil causes surfaces to be hot.

Do not touch pump, motors, oil tank, oil cooler or hydraulic hoses

while using mower.

Allow a cool down time before touching or servicing these items.

Page 1-9

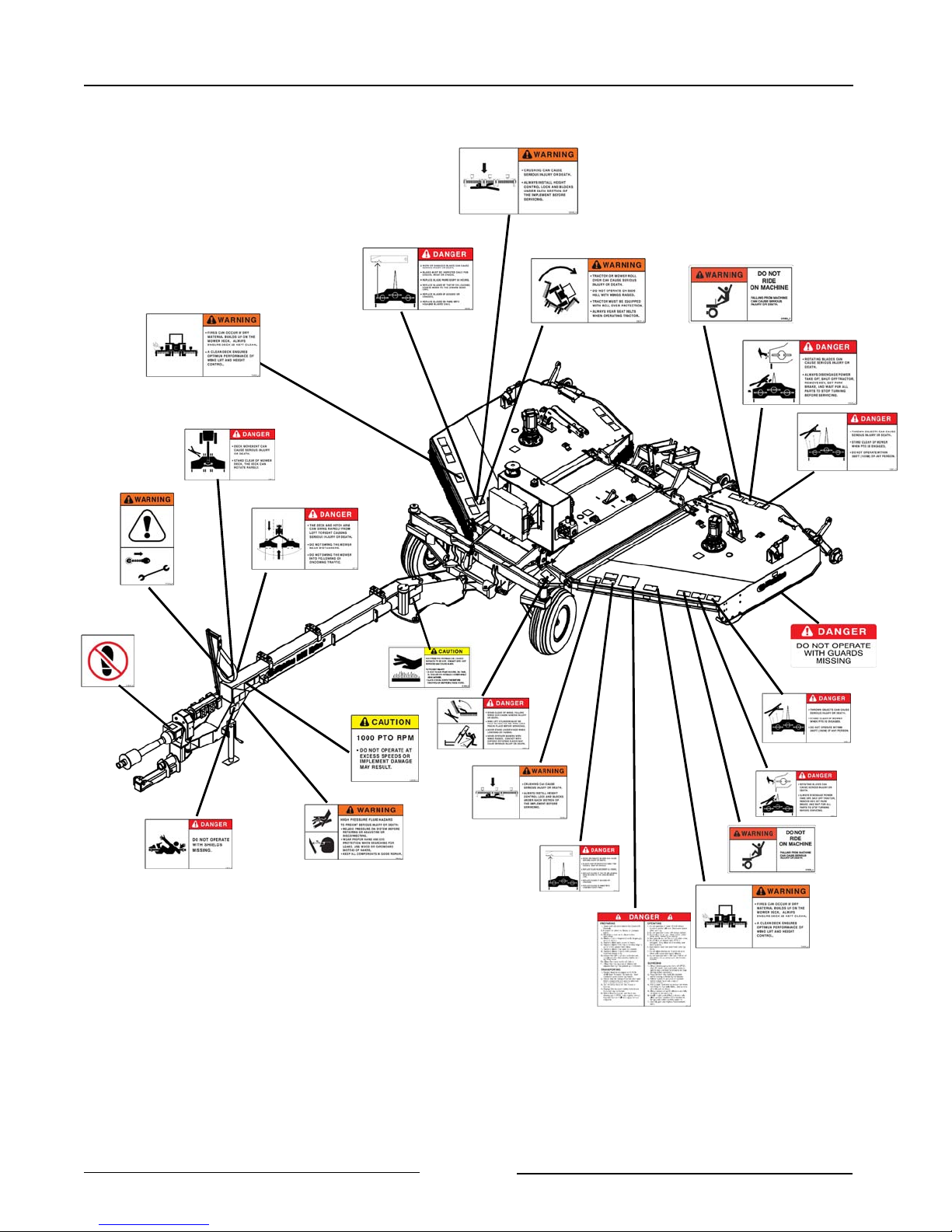

SAFETY DECAL LOCATIONS

Section 1 - Safety

Page 1-10

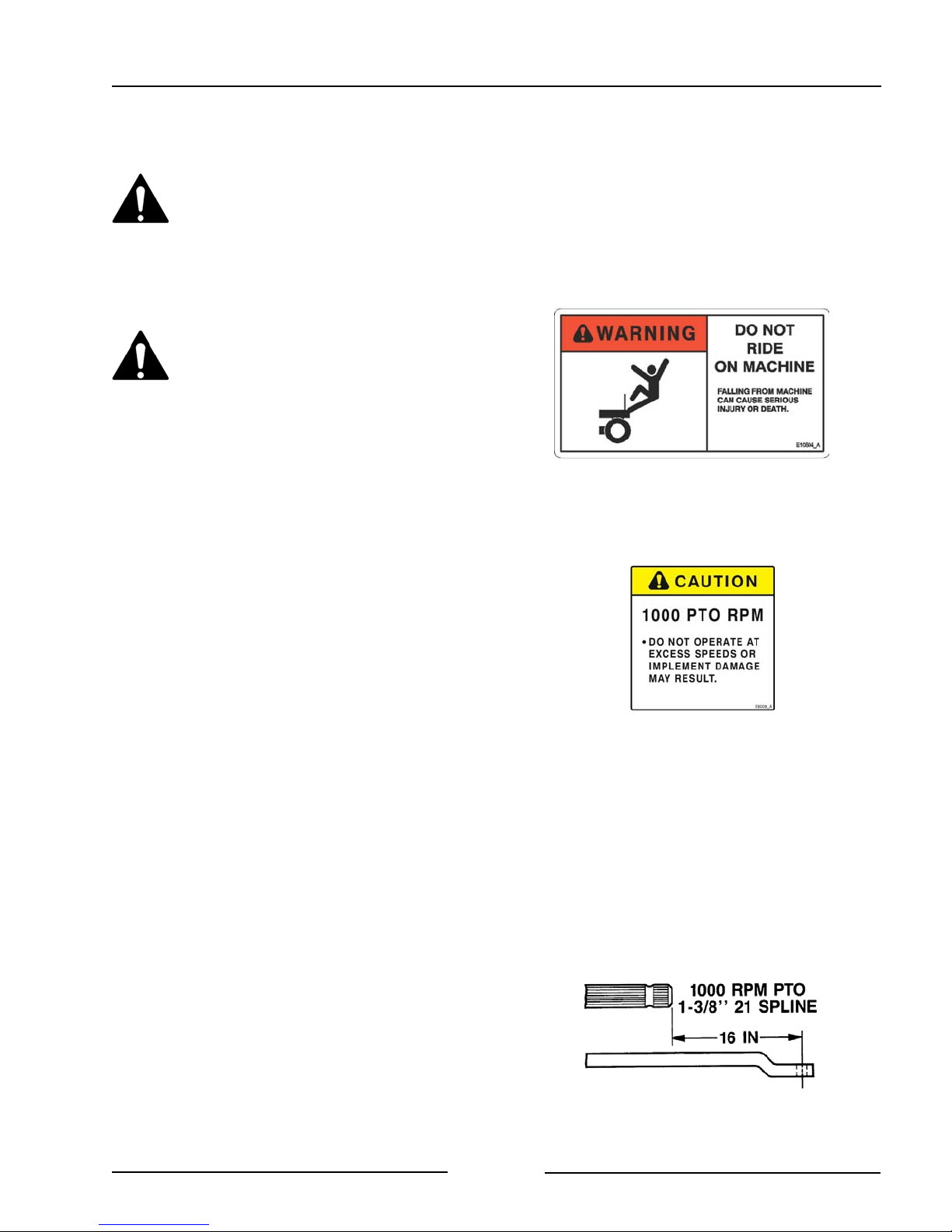

Section 2 - Transporting the Mower

2.0 TRANSPORTING THE MOWER

Only tow the mower behind a

properly sized and equipped

tractor which exceeds the weight

of the mower by 50%. Do not tow

the mower behind a truck or other

type of vehicle

Do not allow children or other

people to ride on the tractor or

mower. Falling off can result in

serious injury or death.

1. Tractor requirements.

- Roll Over Protection System (ROPS)

- Working seatbelts

- 1 3/8" 21 spline PTO

- Recommend 115 PTO HP

2. Ensure correct PTO speed.

- Ensure that the tractor PTO speed

matches the mower’s gearbox speed

of 1000 rpm.

- Do not attempt to operate the mower

at a different PTO speed.

3. Adjust tractor drawbar length.

- Set the drawbar length to 16" (406

mm) for a 1 3/8" 21 spline PTO.

- This length is measured from the tip of

the PTO shaft end to the center of the

drawbar hole. (Refer to your tractor’s

operator manual for drawbar

adjustment procedures.)

Note: To prevent damage to the tractor

drawbar, avoid traveling at high

speeds and over rough terrain.

Note: Do not use PTO adapters.

PTO adapters will cause a

driveline failure and possible

tractor damage. Your mower

warranty will also be invalid.

Tractor Drawbar Adjustment for 1000 RPM

108005

Page 2-1

Section 2 - Transporting the Mower

4. Lift the hitch.

- Lift the hitch arm with the jack (1).

- The hitch arm is very heavy. Do

not attempt to lift it without using

the jack.

- Adjust the hitch to connect the

drawbar.

5. Connect the hitch.

- Connect the tractor drawbar to the

drawbar connector with:

- 1 1/4" x 5" bolt, washer, locknut

and nut (1). Torque to 600 lbf (813

Nm)

- 3/4" x 3½" bolt,washer, lockwasher

and nut (2). Torque to 260 lbf (352

Nm).

- Place a ½" thick shim plate (1) on

each side of the drawbar and fasten in

place with 3/8" x 5" bolt and locknut

(2 ).

Lift Hitch with Jack

Connecting Drawbar Connector

213044C

107082C

Page 2-2

Drawbar Shims

107083C

Section 2 - Transporting the Mower

6. Connect the safety chain to the tractor.

- Ensure the safety chain rating is equal

or greater than the gross weight of the

mower.

- Route the safety chain (1) through the

large slot (2) in the drawbar

connector. Securely fasten the chain

to the tractor and lock in place with the

hook lock.

7. Tractor wheel tread width settings.

- Increase the tractor rear wheel widths

to maintain tractor stability when

working on inclines or rough ground.

Connect the Safety Chain

108167C

8. Route the hydraulic hoses and wiring

harness through the hose support arm.

Route Hoses Through Holder

214034

Page 2-3

Section 2 - Transporting the Mower

9. Attach the driveline to the PTO.

Shut off the tractor engine before

attaching PTO driveline.

Entanglement in the rotating

driveline can cause serious injury

or death.

The mower shall not be operated

without the driveline shields in

place.

- Shut off the tractor engine and

remove the key.

- Check that the driveline telescopes

easily and that the shields are in good

condition and rotate freely.

- Lift the tractor PTO shield.

- Support the driveline, pull back on the

yoke collar, align the splines by

rotating the mower driveline and push

the driveline into the tractor PTO shaft

until the collar snaps into place.

- Push and pull the yoke several times

to ensure the driveline is locked. Do

not pull on the collar as this will

release the lock.

- Lower the tractor & hitch PTO shields

into place.

Attach Driveline to PTO

108167

Page 2-4

Section 2 - Transporting the Mower

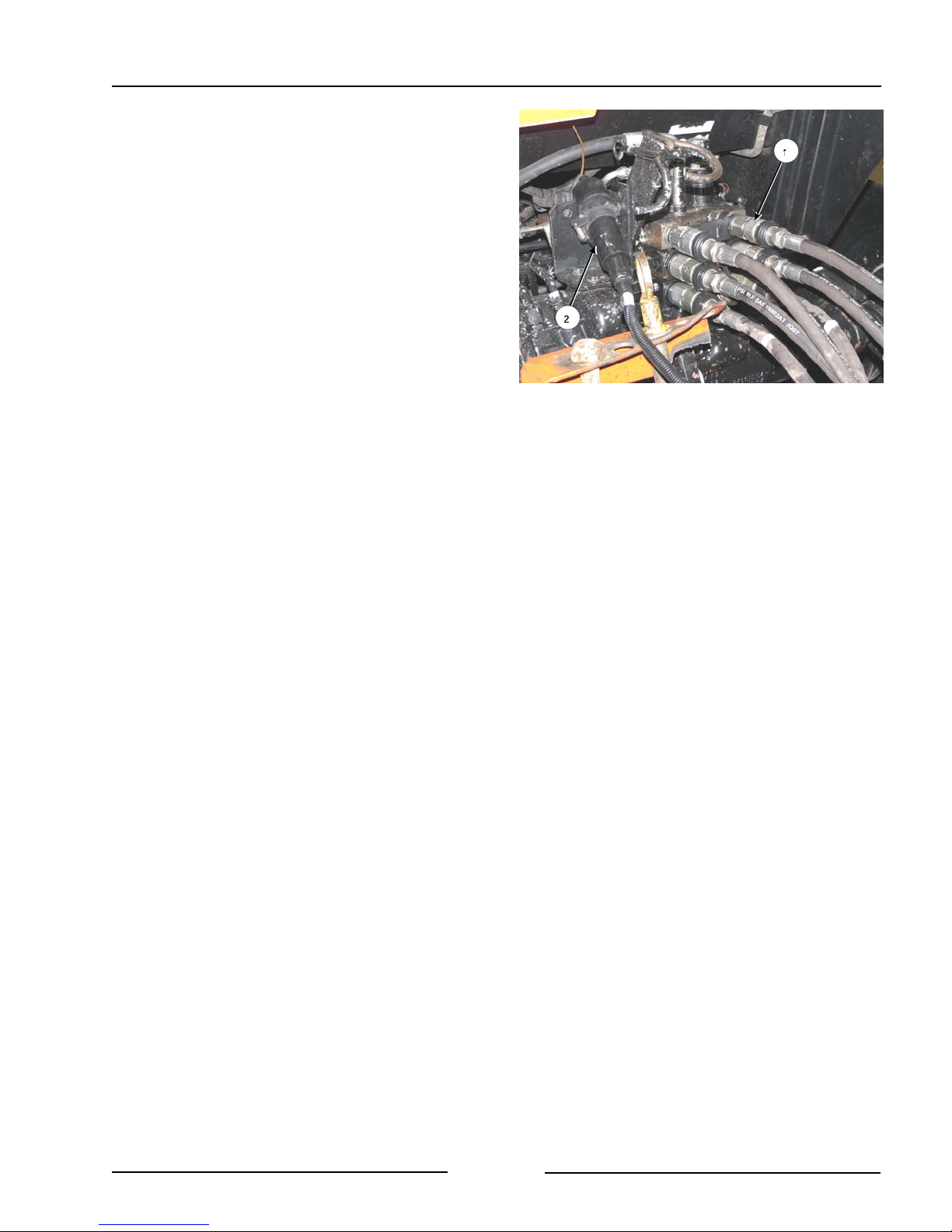

10. Attach the hydraulics.

The mower requires 3 remote connections.

- If the optional joystick is included, then

only 1 remote connection is required.

- For the joystick option, the

hydraulic lever will work in only

one direction. There is a check

valve on the valve manifold. If the

hydraulics are not working, move

the lever in the opposite direction.

- Clean the end of the hoses (1) and

the connection.

- Firmly push the hoses into the tractor

receptacle according to user

preference.

Attach Hydraulics and Lighting

108008C

- Route the hoses so they do not

interfere with moving parts.

11. Connect the lights.

- Connect the light plug (2) into the

appropriate tractor receptacle.

- Ensure the light cable does not

interfere with or contact moving parts.

12. If the optional joystick is on the

machine, route the joystick cable.

- Ensure the cable does not interfere

with or contact moving parts.

13. Place the hitch jack in the storage

location.

Page 2-5

Section 2 - Transporting the Mower

14. Check on the condition of all the tires.

- Ensure that the lug nuts have the flat

side of the lug nut against the wheel

rim.

- Torque the lug nuts to 75 lbf (101

Nm).

Laminated Tires:

! Do not transport the mower on

roadways for long distances with

laminated tires.

15. Raise the wings until they rest in

place.

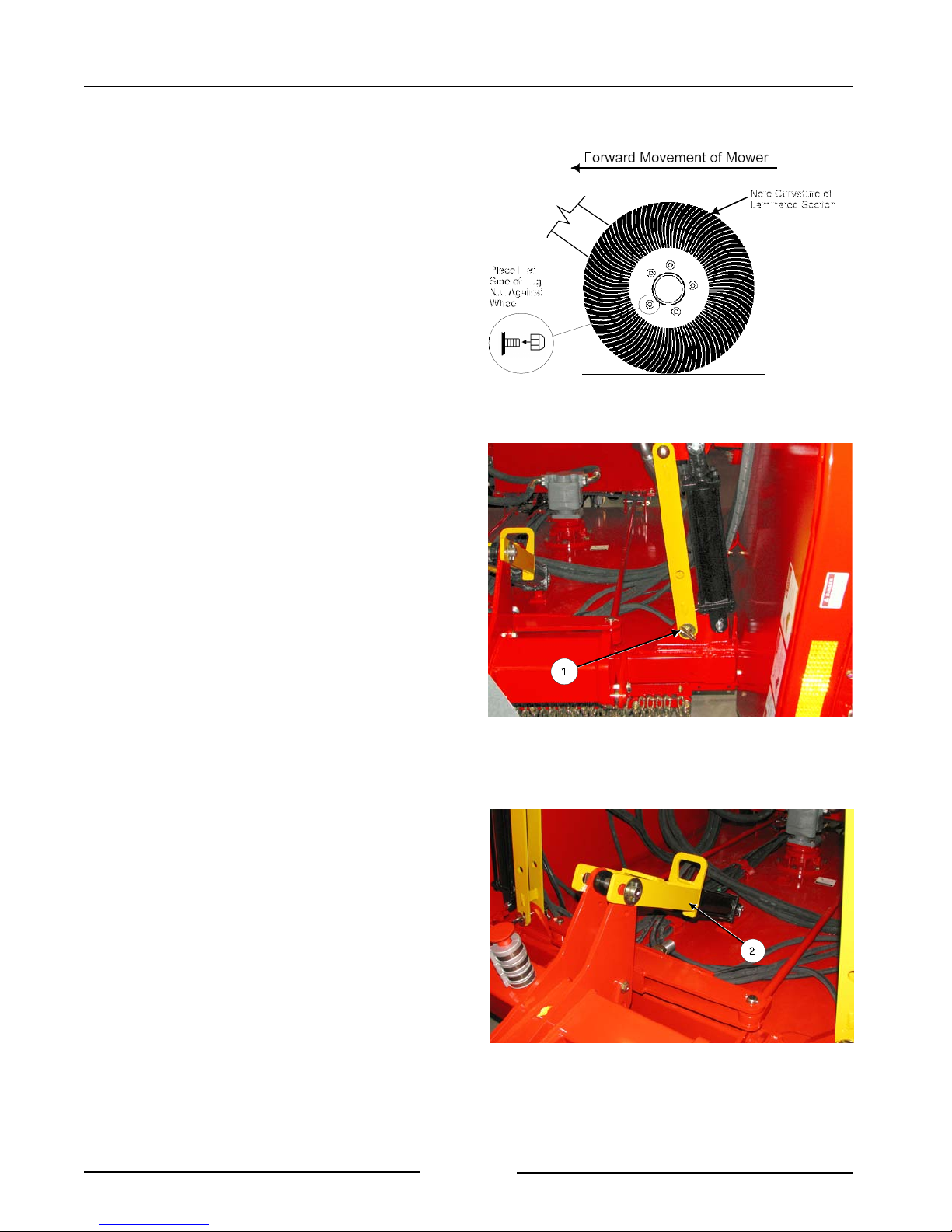

Laminated Tires

107074C

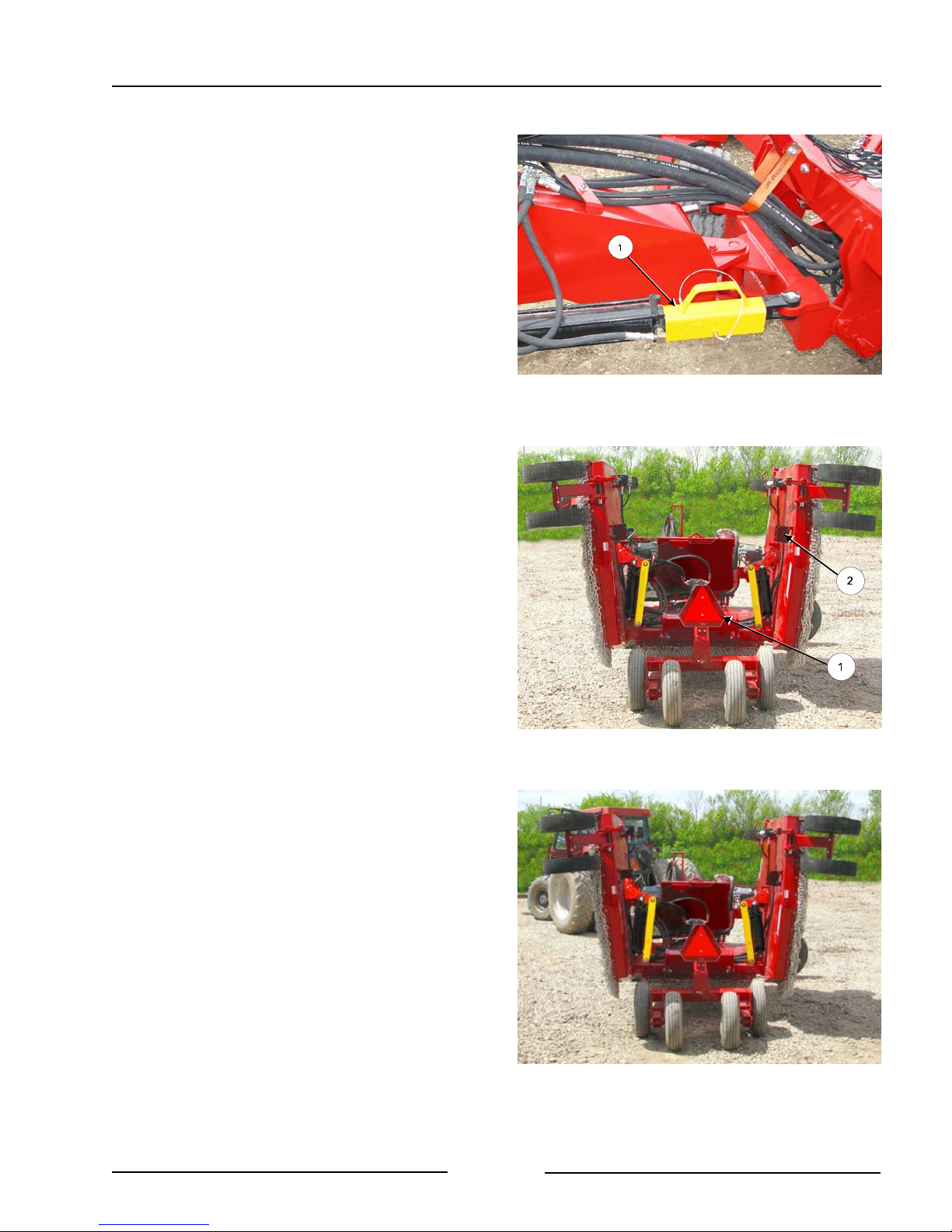

16. Install the wing transport lock pins (1)

on both wings and clip the pins into

place.

17. Lower the mower until the hydraulic

height control cylinder is resting on the

height cylinder transport lock (2).

Install the Wing Transport Lock Pins

216047C

Page 2-6

Height Cylinder Resting on Transport Lock

216048C

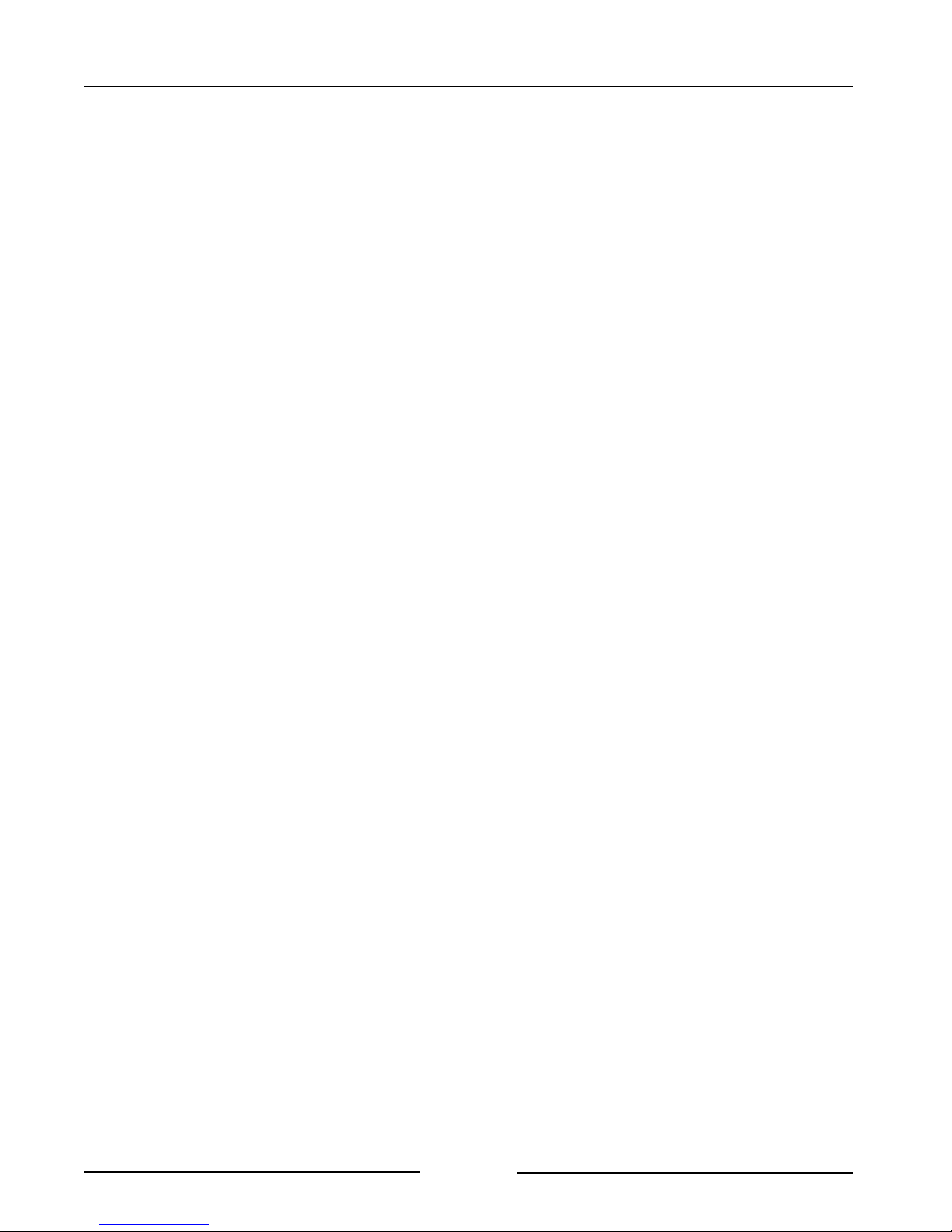

Section 2 - Transporting the Mower

18. Install the hitch transport locks (1)

over both hitch hydraulic cylinders and

pin into place.

19. Ensure that the Slow Moving Vehicle

(SMV) sign (1) is clean and visible.

20. Ensure that the taillights (2) are clean,

visible and in good working order.

21. Transport speed.

Hitch Transport Locks

Ensure SMV is Visible & Lights are Working

214067C

214107C

- Do not exceed 20 mph (32 km/h).

Page 2-7

Transport Speed

214106

Section 2 - Transporting the Mower

This Page Left Blank

Page 2-8

Section 3 - Mower Preparation

3.0 MOWER PREPARATION

1. Park the tractor and mower on level

ground.

- Engage the tractor parking brake.

2. Ensure that all decals are clean and in

place.

3. Ensure that the Slow Moving Vehicle

(SMV) sign is clean and visible.

4. Ensure the lighting is working properly.

5. Connect the electrical power for the

mower to an outlet that is rated for 30

amps or more to ensure sufficient power

for the cooling fan.

- The power can also be taken directly

from the tractor battery.

Clean SMV and Lights

214107

6. For mowers with the optional joystick

control, confirm that the hydraulic control

block is configured for the type of circuit

that is on the tractor.

- If the tractor has a Closed-loop circuit,

then the mower control block should

have a plug (1) in the last port.

- If tractor has an Open-loop circuit,

- Remove the plug from the mower

control block.

- Install the solenoid valve (2) that

came with the joystick.

- Connect the wiring harness

connector marked “F1".

If the mower will be used with both open-loop

system and closed-loop system tractors, then

run the control block with the solenoid valve

installed.

Block with Plug - Closed Loop Tractors

Block with Solenoid - Open Loop Tractors

214118C

214119C

Page 3-1

Section 3 - Mower Preparation

7. Check the condition of the blade pans.

Securely block-up the mower

before any work is done under the

mower when lifted up. This is to

prevent the mower from dropping

due to inadvertent operation of

controls, hydraulic leaking or

failure of any components.

- Clean debris and material buildup

from the blade pan area and from the

pans.

- Check that no wire or other materials

are wrapped around the shaft or pan.

- Inspect the pan for damage caused by

contact with an object.

- Inspect blade pan mounting hardware

for damage.

- Inspect blade mounting bolts for

damage.

Inspect Blades & Hardware

201059

Page 3-2

Section 3 - Mower Preparation

8. Check the condition of the blades.

- Inspect the blades daily.

- Check that the blades swing freely.

Note: Do not sharpen the blades.

Replace them with Highline

blades.

! Replace the blade pair at a maximum

of 50 hours regardless of the wear

because of the possibility of metal

fatigue and non-visible cracks in the

blades. Replace with Highline blades.

! Replace the blade pair if the tip or

leading edge is worn so that only 2"

(51 mm) of the blade remains.

Replace with Highline blades.

! Replace the blade pair if a blade is

gouged, has visible cracks or is bent.

Replace with Highline blades.

Replace blades in pairs with only

Highline blades.

-See “Blade Replacement

Procedure” in the Maintenance

Section.

Replace Blade When Tip/Leading Edge Worn

Replace Blade When Gouged

1070802C

107080

Page 3-3

Section 3 - Mower Preparation

6. Lift the height control transport lock.

- Raise the mower center section by

extending the lift cylinder.

- Shut off the tractor and remove the

ignition key.

- Lift the height control cylinder lock (1).

7. Remove the wing transport lock pins.

- Place the pins into the pin storage

position (1).

Lift the Height Control Transport Lock

216009C

8. Remove the hitch transport locks from the

hitch cylinders.

- Store the transport locks in the

toolbox.

Remove Hitch Cylinder Locks

Page 3-4

Remove Wing Transport Lock Pins

216049C

214039

Section 3 - Mower Preparation

9. Lower the wings on level ground.

10. Level the mower center section deck

front to back.

Note: Do this procedure on level ground.

- Raise the mower to full height by

extending the height cylinders.

Hold the lever for a few seconds to

ensure the phasing cylinders are

synchronized.

- Lower the mower to the preferred

cutting height.

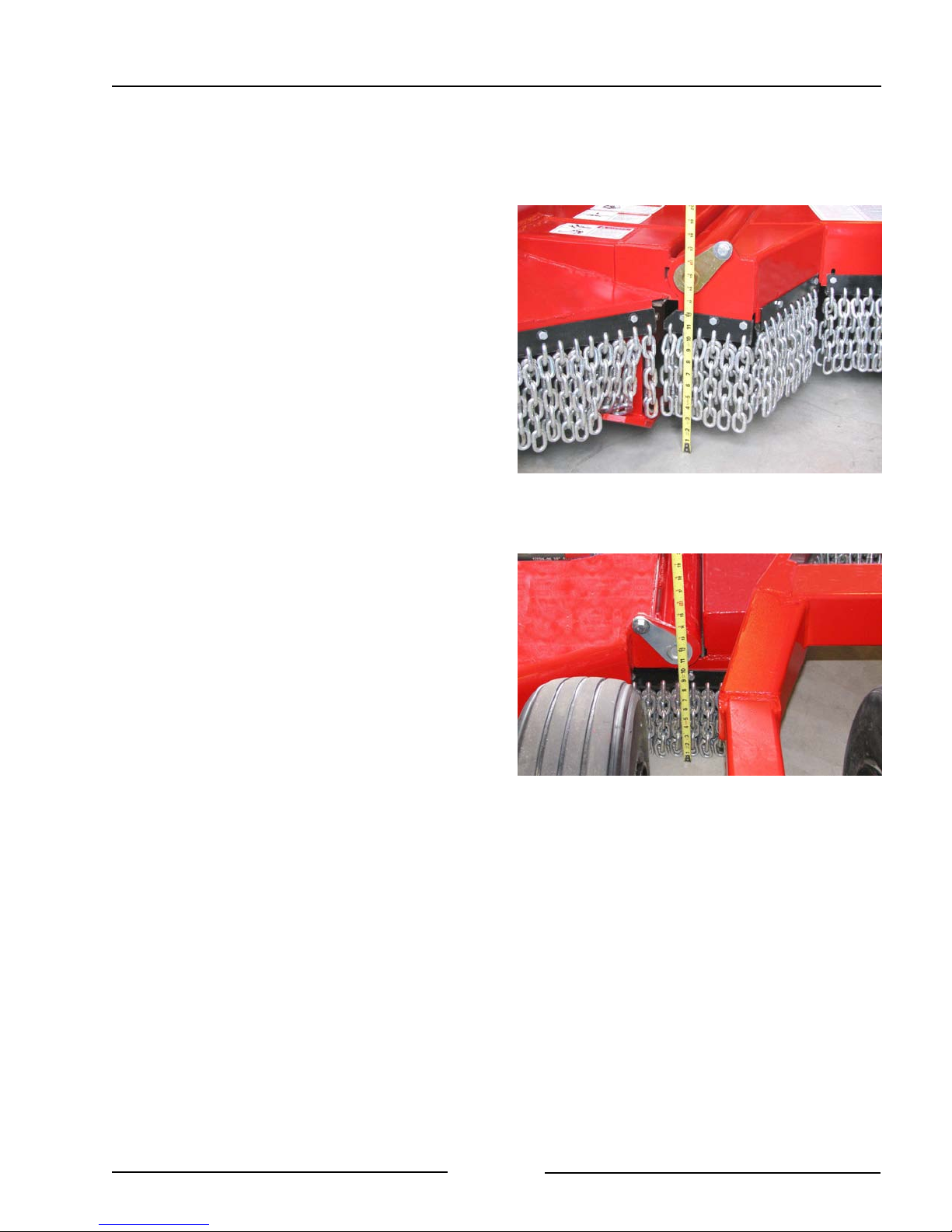

Height from Front Wing Pivot to Ground

201061

- Measure the left side from the

center of the front wing pivot to the

ground.

- Verify this measurement at the

left back wing pivot to the

ground.

- Compare this height to the right

front and the right back at the

center of the wing pivots to the

ground.

Height from Back Wing Pivot to Ground

201062

Page 3-5

Section 3 - Mower Preparation

- Use the level adjuster near the rear center lift cylinder to adjust the center section for

front to back level.

Note: The tie rod does not adjust for left to right leveling of the center deck. The rear

wheels are on pivot joints to allow for right to left self-levelling.

- Loosen the tie rod jam nut (1).

- Turn the adjuster nut (2) to raise or

lower the center rear wheels.

- To lower the mower, loosen the

adjuster nut.

- To raise the mower, tighten the

adjuster nut.

- Tighten the tie rod jam nut (1) to lock

in place.

- Measure and compare the level from

the front to back.

- Adjust further if required.

Level Adjuster & Jam Nut

214040C

Page 3-6

Section 3 - Mower Preparation

Primary Mowing Operating Conditions

There are 2 primary operating conditions:

- Mowing on Slopes such as roadway ditches when traveling with traffic.

- Mowing on Level Ground.

11. Verify the blade direction rotation.

! Direction of blade rotation is indicated by decals near the motor on the deck of the center

and wing sections.

- Verify that the blades turn in the direction of the decal.

- Verify that the leading edge of the blade moves into the direction of rotation.

! Compare the blade directions to the diagram below.

RCH Hydro 15 Foot RCH Hydro 10 Foot

Blade Direction for Right Hand Slope or

Level Ground

107106

Blade Direction for Right Hand Slope or

Level Ground

108225R

Page 3-7

Section 3 - Mower Preparation

13. Determine the wing height adjustment.

15 Foot Mower

! Slope Operation

- Confirm the Wing Height

according to the diagram.

- As needed, use the Wing

Adjustment Procedure (listed

below):

- Raise the outer edge of the left

wing (road side) ½" (12 mm) up

from the leveled center section.

- Lower the outer edge of the

right wing (ditch side) ½"

(12mm) down from the leveled

center section.

- This will enable the wings to

contour to the ditch.

|»Roadway

Wing Adjustment for Slopes- From Behind

107016

! Level Ground Operation

- Confirm the Wing Height

according to the diagram.

- As needed, use the Wing

Adjustment Procedure (listed

below) to level the left wing and

right wing with the leveled

center section.

Level Ground Wing Adjustment - From Behind

107101

Page 3-8

Section 3 - Mower Preparation

10 Foot Mower

! Slope Operation

- Confirm the Wing Height

according to the diagram.

- As needed, use the Wing

Adjustment Procedure (listed

below):

- Lower the outer edge of the

right wing (ditch side) ½"

(12mm) down from the leveled

center section.

- This will enable the wings to

contour to the ditch.

! Level Ground Operation

- Confirm the Wing Height

according to the diagram.

- Right Wing - level with the center

section.

- As needed, use the Wing

Adjustment Procedure(see below).

|»Roadway

Wing Adjustment for Slopes - From Behind

Level Ground Wing Adjustment - From Behind

108169

215072

Page 3-9

Section 3 - Mower Preparation

13. Wing height adjustment procedure.

Note: Level the center section before adjusting wing height.

- Fully raise the mower by extending the

lift cylinders. Hold the lever open for

30 seconds or until the phasing

cylinders are synchronized.

- On a level surface, lower the mower to

the preferred cutting height.

- On one wing, measure the height from

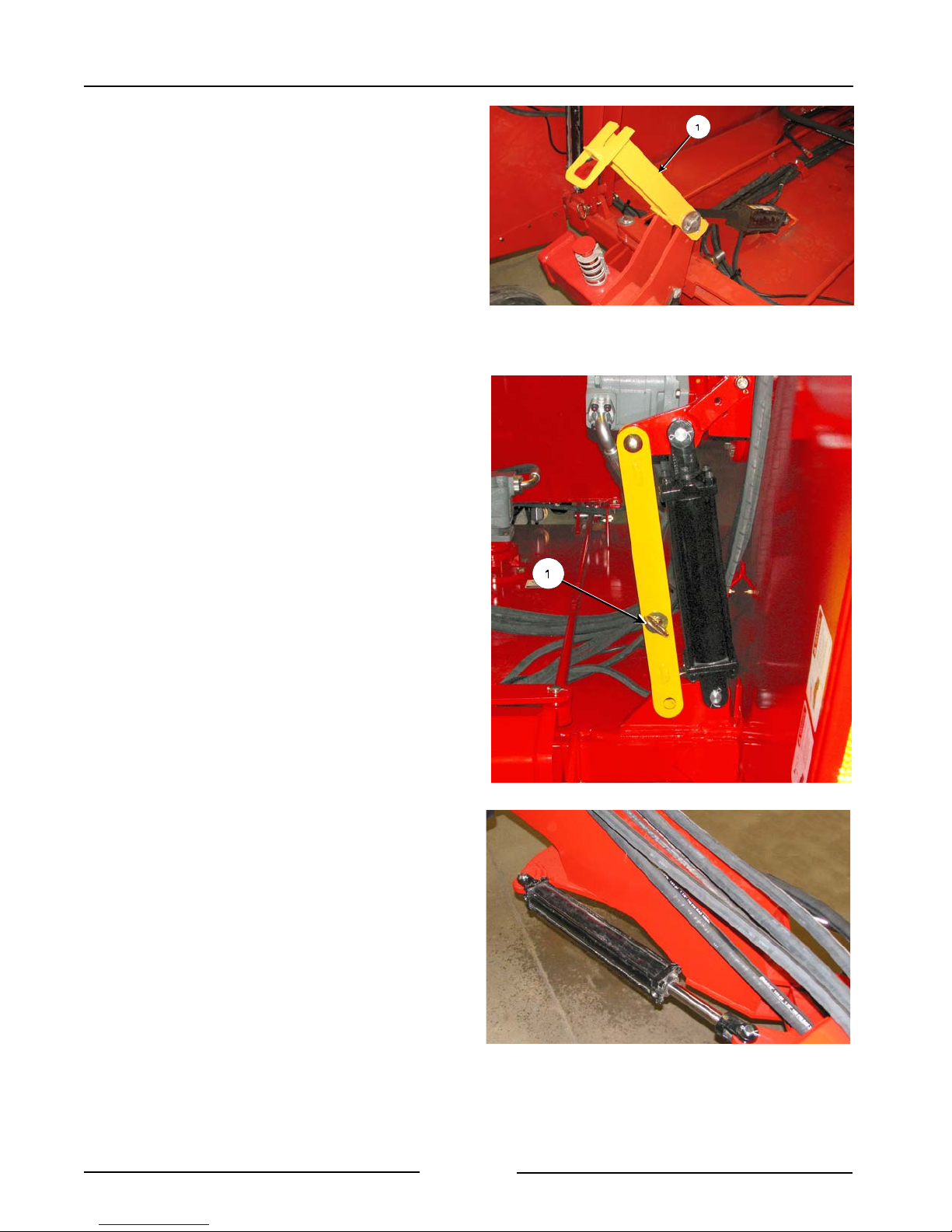

the top of the chain mount strap near

the center section (1) to level ground.

Compare the measurement to a

location on the outer wing section (2).

Measure Wing Heights

107032C

- Loosen the wing height adjustment

jam nut (1).

- Adjust the height of the wing using

the adjustment nut (2).

- Use the Wing Height Adjustment

diagram (shown above) for the

heights.

- Measure and compare.

- Tighten the jam nut (1).

- Repeat the procedure on the other

wing.

Adjust Wing Height

214137C

Page 3-10

Section 3 - Mower Preparation

14. Set the preferred cutting height.

- Lower the wings.

- Raise the mower to the preferred

cutting height.

- Install height stops (1) around the

cylinder rod to maintain the

preferred cutting height

15. Inspect all the hydraulic cylinders,

pump, motors and hoses.

Use a piece of cardboard or

heavy paper to check for leaks.

Do not use your hand. Wear

proper hand and eye protection

when searching for leaks.

Relieve pressure on the hydraulic

system before repairing, adjusting

or disconnecting.

Height Stops Installed

214041C

- Check for hydraulic leaks along the

hydraulic lines and at the tractor.

- Ensure the proper size pins are in

place and secured.

Page 3-11

Inspect Hydraulic Components and Hoses

214107

Section 3 - Mower Preparation

16. Clear debris from the removable chaff

screen.

- Remove the screen to clean the both

sides of the screen.

- Use a broom, low pressure air and

water to clean the screen.

17. With the chaff screen removed, clear

the debris from the oil cooling tank

and the radiator.

- Use a broom and a low pressure air

hose to remove the debris.

18. Clear debris from the fan on the

backside of the oil tank .

Clear Debris from the Chaff Screen

Clear Debris from Radiator

216050

216051

Note: When the fan initially starts up, the

fan will blow in reverse for a short

time to remove some of the debris

in the radiator.

- If additional material needs to be

removed, blow air through the fan and

through the radiator.

- If dirt is stuck in the fins or core of the

radiator, clean out with a low pressure

water hose.

Clear Debris from Fan

Page 3-12

216052

Section 3 - Mower Preparation

19. Check the oil level in the oil tank.

Maintaining a proper level of oil is very

important in the operation of the mower.

- When the oil is cold, check that the oil

level is showing in the middle of the

sight glass (1) which is on the side of

the oil tank.

Low Oil Level

Low oil level in the tank is caused by a

leakage of oil. Locate the leak at once. Loss

of oil can cause severe damage to the

hydraulic pump and motors.

- To fill the oil tank

- Clean the top of the tank to

prevent contamination of the oil.

- Remove the top breather cap (2)

and fill with hydraulic oil until the

oil level is showing in the middle of

the sight glass (1).

Check the Oil Level in the Tank

216053C

Note: Do not fill the tank to more than

the middle of the sight glass to

allow room for the oil to expand

as it heats up.

Note: It is important to only use clean

filtered oil when filling the oil.

Clean oil will assist the pump

and motors to work more

efficiently.

- Clean the breather cap (2) and

replace the cap on the tank.

Page 3-13

Section 3 - Mower Preparation

20. Ensure the shutoff valves (3) at the

bottom of the tank are in the open

position.

21. Check the oil filter operating pressure.

- When the oil is warm, with the pump

running, check the filter pressure

gauge (1).

Note: When the oil is cold, the gauge

may show that the filter needs

replacing. Allow the oil to warm

and check the filter gauge again.

- If the gauge is in the green zone, the

filter is okay.

- If the gauge is in the yellow zone, the

filter will need to be replaced soon.

- If the gauge is in the red zone, replace

the filter immediately.

Open Tank Shutoff Valves

Check Oil Filter Operating Pressure

214044C

216054C

Note: See Section 5 “Maintenance” for

information on “Replacing the

Filter”.

Page 3-14

Section 3 - Mower Preparation

22. Check the oil level in the pump

gearbox.

- Remove the breather vent (1) at the

top of the gearbox. The breather has

a dip stick attached to it.

- Check that the oil is at least to the

level of the line near the bottom of the

dip stick.

- If needed, add oil using 85W90 gear

oil.

- Replace the breather vent (1).

Check Oil Level in Pump Gearbox

214045C

Page 3-15

Section 3 - Mower Preparation

23. Check the condition of the chain

guards all around the machine.

The mower shall not be operated

without the chain guards in place

or in good condition.

- Replace worn, missing or broken

chain sections immediately.

24. Inspect the wheels and tires for

damage or foreign objects. Repair or

replace as necessary.

25. Inspect the wing skid plate for secure

mounting and wear.

The mower shall not be operated

without the skid plates in place.

- If the leading edge (1) of the wing skid

plate is worn excessively or is

damaged, it should be replaced.

Check Condition of the Chain Guards

Inspect Wing Skid Plates

214046

214047C

26. Inspect the center section skid plate

(behind the front chain guards) for

secure mounting and wear.

Inspect the Center Section Plates

Page 3-16

214048

Section 3 - Mower Preparation

27. If the wing skid plate wheel is

installed, check the condition of the

tire and that all fasteners are tight.

28. For 10 Foot Models, inspect the

center deck skid and counterweights

for secure mounting.

Inspect Wing Skid Plate Wheel

Inspect Center Skid & Counterweights (10 Foot)

214049

215073

Page 3-17

Section 3 - Mower Preparation

29. Ensure the driveline is securely

attached to the pump gearbox.

30. Ensure the driveline shields are

lowered into place and are in good

repair to prevent injuries.

The mower shall not be operated

without the driveline shields in

place.

31. Lubricate all grease fittings and check

the fluid level in the pump gearbox.

See the Maintenance Section.

32. Ensure all fasteners are tightened.

Driveline Fastened to Gearbox

214050

Page 3-18

Section 4 - Operating the Mower

4.0 OPERATING THE MOWER

Do not allow anyone to ride on the

mower.

- Falling from the machine can

cause injury

Do not operate mower blade pan on

the wings that are raised.

- Contact with exposed rotating

blades can cause serious injury or

death.

- Raised wings can throw objects

causing serious injury or death.

Hydraulic Oil Temperature

Cold Oil

When the oil temperature is low (ie. during

cool weather operation - below 32"F/0"C) it is

recommended to rotate the pump and motors

at a moderate speed (less than 1000 rpm) to

allow the oil to warm.

Cold oil may cause the filter to show that it

needs attention. When the oil warms, the oil

filter reading will return to normal.

Normal Oil Temperature

The typical temperature of the oil at the

motors is between 150 -160 "F (65 - 71 " C).

The fan at the radiator turns on at 150 "F (65

"

C).

Note: This is the factory setting but it

may be adjusted to another

temperature. See Section 7

“Troubleshooting” for more

information.

Note: An infrared heat sensor is a

valuable tool in knowing the

condition of the hydraulic system

and valuable for troubleshooting.

Page 4-1

Section 4 - Operating the Mower

Overheated Oil

If the oil temperature is too hot, damage to

the pump and motors may occur. It is

important to keep the oil cooler radiator clean

for heat to be removed from the oil.

When the “Oil Temp Warning” light comes on

at the switch box in the cab, it indicates the

oil temperature has reached 185" F (85" C).

When 185" F (85" C) oil temperature has

been reached, the wing motors will also stop

turning to indicate the high temperature

condition.

- Stop the mower immediately.

- Clean the radiator.

- Ensure the cooling fan is working.

Check the fuse that is located in the

power supply cable running to the

control box.

- Check that the electrical supply cable

is connected to an outlet that is rated

for 30 amps or more. The power can

also be taken directly from the tractor

battery.

Also check the “Troubleshooting” Section of

for additional directions.

Oil Temperature Warning Lamp

214052

1. Park on level ground.

2. Move both wing transport lock pins (1) to

the storage position on the wing lock

bars.

Page 4-2

Move the Wing Transport Lock Pins

216049C

Section 4 - Operating the Mower

3. Remove the hitch cylinder transport locks

from the cylinders.

- Store the locks in the toolbox.

4. Lower the wings.

Ensure all bystanders are well

clear of the wing movement area.

- Ensure the tractor PTO drive is

disengaged.

5. Remove debris from the cutting area.

- Mark areas where objects could cause

damage to the mower blades or pans.

Remove Hitch Cylinder Transport Locks

214039

Page 4-3

Section 4 - Operating the Mower

Controlling the Mower

The hydraulic pump on the hitch is driven by

the PTO driveline. The pump provides

hydraulic flow for the blade pan motors

mounted on the decks.

The flow for the hydraulic cylinders is

provided by the tractor hydraulics.

There are 2 types of controllers for the

mower:

- Control box requiring 3 tractor

hydraulic remotes.

- Control box with joystick requiring 1

tractor hydraulic remote.

Center Deck Blade Pan

When the hydraulic pump is being turned by

the PTO, the center deck blade pan will be

turning with both types of controllers.

Note: The wing deck blade pans will also

turn unless the RH Deck and LH

deck switches on the Control Box.

are in the “Off” position.

Control Box - 3 Remote Tractor

High Oil Temperature Warning

When the "Oil Temp Warning" light comes

on, it indicates the oil temperature has

reached the maximum temperature of 185" F

(85"C).

When 185" F (85"C) oil temperature has

been reached, the wing motors will also stop

turning to indicate the high temperature

condition.

Refer to “Responding to a High Oil

Temperature Warning” in this section.

Control Box for 3 Remote Tractor

42723_E

Also check the "Troubleshooting" Section

7 for additional directions regarding high

oil temperature.

Page 4-4

Section 4 - Operating the Mower

Wing Lift

This switch setting activates the wing lift

circuit.

Wing Lift LH or RH

When the Wing Lift switch is activated, this

switch allows the choice of which wing is to

be lifted when the hydraulic control lever is

moved.

Wing Deck Blade Pan Switches

To have the wing deck blade pans turning,

move the switches up.

Note: The deck blade pans will be

activated when the light on the

switch is on. If the light is off, the

deck blade pan is turned off.

Control Box for 3 Remote Tractor

42723_E

- To turn off one of the deck blade pans

move the switch down. This will

activate a solenoid valve that will cut

off the oil flow to the motor. The light

on the switch will be off.

Gradient Control (Steering Option)

If the mower has the optional Gradient

Control installed, the switch will activate the

hydraulic control lever to move the front

wheels so the mower tries to climbs the ditch.

This reduces the side force loads on the

tractor and also helps the mower to track

straight which improves the cutting.

- Turn on the switch on the control box.

- Activate the hydraulic control lever to

move the hydraulic cylinder to direct

the front wheels.

- Disengage the hydraulic cylinder when

wanting to turn or maneuver the

mower. This will allow the wheels to

castor.

Page 4-5

Section 4 - Operating the Mower

Control Box - Joystick Control (1 Remote)

High Oil Temperature Warning

When the "Oil Temp Warning" light comes

on, it indicates the oil temperature has

reached the maximum temperature of 185

F (85 C).

When this oil temperature has been reached,

the wing motors will also stop turning to

indicate the high temperature condition.

Refer to "Responding to a High Oil

Temperature Warning" in this section.

Also check the "Troubleshooting" Section

7 for additional directions regarding high

oil temperature.

"

Joystick Control Box

216010

Wing Deck Blade Pan Switches

To have the wing deck blade pans turning,

move the switches up (light on).

Note: The deck blade pans will be

activated when the light on the

switch is on. If the light is off, the

deck blade pan is turned off.

- To turn off one of the deck blade pans

move the switch down. This will

activate a solenoid valve that will cut

off the oil flow to the motor. The light

on the switch will be off.

Page 4-6

Section 4 - Operating the Mower

Joystick Control

The joystick has multifunction ability. These

functions are shown on the decal.

Mowing Height Control

The joystick controls the height of the decks

from the ground which controls the mowing

height. Refer to the decal on the joystick for

the desired height movement.

Deck Swing

The joystick controls the swing of the mowing

decks. Refer to the decal on the joystick for

the desired deck swing movement.

Raise Left Wing or Right Wing

To raise a wing so that it is not mowing,

- Use the control box switch to

disengage the wing motor.

- Use the joystick with the trigger

depressed to activate the wing

cylinder to raise that wing.

Joystick Control

214053A

Lower Left Wing or Right Wing

- Use the joystick with the trigger

depressed to activate the wing

cylinder to raise that wing.

Gradient Control (Steering Option)

The steering option move the front wheels so

the mower tries to climbs the ditch. This

reduces the side force loads on the tractor

and also makes the mower to track straight

which improves the cutting.

- Depress the rocker switch on the

joystick to move the cylinder to direct

the front wheels.

- Disengage the hydraulic cylinder when

wanting to turn or maneuver the

mower. This will allow the wheels to

castor.

Page 4-7

Section 4 - Operating the Mower

6. Swing the mower deck to move the

mower into the cutting area.

Ensure all bystanders are well

clear of the mower and hitch. The

deck and hitch can move rapidly.

The deck and hitch can swing

rapidly from left to right causing

serious injury or death.

Do not swing the mower into

following or oncoming traffic.

- Drive ahead slowly while operating the

hydraulic lever to swing the deck. This

will move the mower into the cutting

area.

- If using the optional joystick, drive

ahead slowly while operating the

joystick to swing the deck. This will

move the mower into the cutting area.

Swing Deck Into Cutting Area

The mower can be operated anywhere in the range of:

50 F left of the center of the tractor 50F right of the center of the tractor

F

50

50

214111

F

Range of Mower Operation

107098

Page 4-8

Section 4 - Operating the Mower

Recommended Setup to Obtain a Quality Mowing Cut

Level Ground Operation Slope Operation

107099

215074

1. Confirm that the blades rotate as indicated.

2. Adjust the wing heights for Level Ground

Operation (See Section 3).

107106

108225R

1. Confirm that the blades rotate as

indicated.

2. Adjust the wing heights for Slope

Operation. (See Section 3)

3. Set Gradient Control Option to full front

wheel movement.

3. Set Gradient Control Option to move the

front wheels to offset the effect of the

sloped ditch.

Page 4-9

Section 4 - Operating the Mower

7. Lower to the cutting height.

The mower shall not be operated

without the chain guards in place

or in good condition.

- Use the hydraulic lever (or joystick if

installed) to lower the deck to the

preferred cutting height.

- Operate at a sufficient height that

prevents the blades from striking the

ground or cutting the edge of the

ditch, which increases blade wear and

causes undue strain on the system.

- Install height stops around the height

cylinder rod to maintain the preferred

height.

Set the Cutting Height

214112

8. Adjust ground speed for the terrain, the

type, height and density of vegetation and

the cutting height.

The mower shall not be operated without

the side plate skid shoes in place.

- Recommended speed is between 2

and 5 mph (3 - 8 kmh)

- Decrease the ground speed as the

severity of the cutting condition's

increase and to permit grasses to

partially rebound from the tires.

- The mower can cut vegetation up to

3½" (89mm) in diameter for short

periods of time.

Note: If the mower is cutting too much

material, the hydraulic pressure

will exceed safe limits. At that point

a pressure relief valve will be

activated which will cause the

blade pan to stop turning.

Adjust Ground Speed

Once the pressure relief valve has been

activated (shown by blade pans not

turning), raise the mower decks to allow

the pressure relief valve to close and to

recover the blade pan RPM.

214113

Page 4-10

Section 4 - Operating the Mower

9. Move the wing blade pans switches up

(light on) on the control box to have the

wing blades operating.

10. Operate the PTO at the rated PTO

speed to engage the hydraulic pump

to turn the center and wing blade

pans.

Do not operate within 300 ft

(100m) of any person. Thrown

objects can cause serious injury

or death.

11. Allow the wings to float.

- Fully extend the wing lift cylinders.

This will allow the wings to follow the

contour of uneven ground.

Control Box (Joystick Option Shown)

216010

- If a wing seems to lower, re-phase the

wing height cylinders by fully raising

the mower. Hold the lever open for at

least 30 seconds or until the cylinders

are fully synchronized.

12. Avoid cutting into the ditch.

- On uneven areas, prevent the blades

from cutting into gravel or dirt by

positioning a support wheel near the

highest point.

Allow the Wings to Float

Page 4-11

Mower Deck On Uneven Area

214112

107075C

Section 4 - Operating the Mower

13. Swing the mower deck away from

obstructions.

- Swing the deck to move the mower

away from obstructions such as drive

approaches, culverts or large rocks.

- Swing the deck using the hydraulic

lever or the optional joystick control.

- If an object is hit, immediately stop

driving and disengage the PTO.

-Wait for all rotating parts to stop.

-Raise the mower and drive away

from the object.

-Check the mower for damage.

14. Check that the hydraulic oil cooling

fan is operating.

Swing Deck Away from Obstructions

214114

- Check that the electrical supply cable

is connected to an outlet that is rated

for 30 amps or more. The power can

also be taken directly from the tractor

battery.

- The factory setting is for the oil cooling

fan to come on when the hydraulic oil

reaches a temperature of 150" F

(65.5" C).

- Note: The temperature for the fan

to come on can be adjusted on the

fan controller module. See Section

7 “Troubleshooting” for more

information.

- A steady “on” status light on the fan

controller module means that the fan

is operating normally and will come on

as needed.

- A blinking status light on the fan

controller module indicates trouble

c o d e s . S e e S e c t i o n 7

"Troubleshooting" for information on

the trouble codes.

Page 4-12

Section 4 - Operating the Mower

Responding to a High Oil Temperature

Warning

Note: The wing motors will stop rotating

when there is a high oil temperature

warning.

1. Stop the mower PTO immediately.

Damage can occur to the pump and

motors if operated at high oil temperature

conditions.

2. Check the cleanliness of the oil cooling

radiator. It is important to keep the oil

cooler radiator clean for heat to be

removed from the oil.

- Use a broom and a low pressure air

hose to remove the debris.

- If additional material needs to be

removed, blow air through the fan and

through the radiator.

- If dirt is stuck in the fins or core of the

radiator, clean out with a low pressure

water hose.

3. Ensure the cooling fan is working.

- Check the main fuse located in the

power cable going to the control box.

4. Check the fan control module status light.

- If the status light is steady but the fan

does not start, remove the

temperature sensor lead wire.

- If the fan starts, replace the

temperature sensor.

- If the status light is blinking, check

Section 7 “Troubleshooting Fan

Control Module” for the Trouble

Codes.

- If there is no status light on the

module, check for power coming to

the module by using a volt meter.

- If there is power coming to the module

but the status light is not working,

replace the module.

- The fan can be made to run

continuously by taking power

around the module directly to the

fan until the module can be

replaced.

- Check the electrical supply to the fan.

The cable should be connected to an

outlet that is rated for 30 amps or

more. The power can also be taken

directly from the tractor battery.

5. Ensure all electrical connections are tight

including the grounding straps.

6. Check the Section 7 "Troubleshooting" for

additional directions.

Page 4-13

Section 4 - Operating the Mower

15. Do not drive or swing the mower into

following or on-coming traffic.

16. Cross ditches and steep inclines at

about a 30° approach angle.

- Maintain sufficient height to prevent

blades from hitting the ground.

- Do not approach a ditch or steep

incline straight on as this may collapse

the driveline to its shortest length,

causing damage by pushing the PTO

into the tractor or into the drivebox on

the hitch arm or downward onto the

PTO shaft, breaking it off.

Cross Ditch at 30° Angle

Hitch Driveline Collapsed in Steep Incline

107072

107089C

Page 4-14

Section 4 - Operating the Mower

17. Making Turns

- Do not make turns sharper than 110°.

- The hitch will contact itself if turns

greater than 110° are attempted.

Turns Less Than 110

Turns Less Than 110

" 214065

" 214066

Page 4-15

Section 4 - Operating the Mower

Recommended Practices for a Quality Cut

1. Use the correct tractor PTO speed for the

mower.

" Check the PTO speed decal on the

hitch of the mower.

2. Cut in the primary cutting conditions that

the mower is configured for. (See above)

" The rotation of the blades and the

wing height adjustment will influence

the quality of cut in the cutting area.

3. Verify the blades are mounted for the

cutting conditions.

" Check the rotation decals on the top

of the center and wing decks.

" Mount the blade so that when the bent

end of the blade is up toward the

underside of the deck, the leading

edge of the blade turns into the

rotation as indicated on the decal.

6. Set the cutting height according to the

vegetation being cut.

" Lower the height for short, dry or

sparse vegetation, but avoid hitting

the ground.

" Raise the height in tall, lush or dense

vegetation. Reduce the travel speed

to allow the cutting chamber to handle

the high volume of material.

4. Check that the blades are in good

condition.

" Replace blade pair at maximum of 50

hours use.

" Worn, bent or gouged blades will

cause uneven cutting height.

" Replace with new Highline blades.

5. Reduce the travel speed.

" In tall, wet or dense vegetation,

reduce the travel speed to handle the

higher volume of material in the

cutting chamber.

" Slower travel speed will reduce “uncut

tracks.”

- The mower wheels may bend over

the stalks of the vegetation and

debris may be distributed on top of

the bent over stalks.

- Reduce travel speed to allow more

time for the stalks to lift and to

allow more blade passes over the

vegetation.

Page 4-16

Section 5 - Maintaining the Mower

5.0 MAINTAINING THE MOWER

Shut down the tractor and remove

the key before repairing, servicing,

lubricating or cleaning the mower.

Relieve all hydraulic pressure in

the hoses. Disconnect the

hydraulic hoses from the tractor

before going near the machine.

! Check the oil level in the pump gearbox.

- Remove the breather vent (1) at the

top of the pump gearbox. The

breather has a dip stick attached to it.

- Check that the oil is at least to the

level of the line near the bottom of the

dip stick.

- If needed, add oil using 85W90 gear

oil.

- Replace the breather vent (1).

- Annually change the oil in the pump

gearbox. (See Gearbox Oil Changing

Procedures)

Check Oil Level in Pump Gearbox

214045C

Page 5-1

Section 5 - Maintaining the Mower

! Check the oil level in the oil tank.

- When the oil is cold, check that the oil

level is showing in the middle of the

sight glass (1) on the side of the oil

tank.

- To fill the oil tank

- Clean the top of the tank to

prevent contamination of the oil.

- Remove the top breather cap (2)

and fill with hydraulic oil until the

oil level is showing in the middle of

the sight glass (1).

Note: Do not fill the tank to more than

the middle of the sight glass to

allow room for the oil to expand as

it heats up.

Check the Oil Level in the Tank

216053C

Note: Only use clean filtered oil when

filling. Clean oil will assist the

pump and motors to work more

efficiently.

- Clean the breather cap (2) and

replace on the tank.

Page 5-2

Section 5 - Maintaining the Mower

! Check the oil filter operating pressure.

Change the oil filter after the first 25 hours of

operation.

Replace the filter every 500 hours or when

the filter condition gauge shows it needs to

be changed.

Note: When the oil is cold, the gauge

may show that the filter needs

replacing. Allow the oil to warm

and check the filter gauge again.

- When the oil is warm, with the pump

running, check the filter pressure

gauge.

Check Oil Filter Operating Pressure

216054

- If the gauge is in the green zone, the

filter is okay.

- If the gauge is in the yellow zone, the

filter will need to be replaced soon.

- If the gauge is in the red zone, replace

the filter immediately.

Replacing the Filter

- Loosen the bolts (1) that hold the top

of the filter cap.

- The bolts only need to be

loosened enough to rotate the cap.

- Remove the filter cap.

- Remove the o-ring seal under the cap.

The o-ring seal will be re-used.

- Remove the used filter and discard.

Remove Cap to Replace the Filter

216011C

- Install a new 5 micron oil filter.

- Replace the o-ring seal, cap and

fasteners. Tighten in place.

Page 5-3

Section 5 - Maintaining the Mower

! Clear debris from the removable chaff

screen.

- Remove the screen to clean the both

sides of the screen.

- Use a broom, low pressure air and

water to clean the screen.

! With the chaff screen removed, clear

the debris from the oil cooling tank

and the radiator.

- Use a broom and a low pressure air

hose to remove the debris.

! Clear debris from the fan on the

backside of the oil tank.

Clear Debris from the Chaff Screen

Clear Debris from Radiator

216050

216051

- Remove additional material by

blowing low pressure air through the

fan and through the radiator.

- If dirt is packed in the fins and core of

the radiator, use a low pressure water

source to clean the core.

Page 5-4

Clear Debris from Fan

216052

Section 5 - Maintaining the Mower

Lubrication

Lubricate all grease fittings with a quality

lithium soap compatible E.P. grease meeting

the N.L.G.I. #2 specifications and containing

no more than 1% molybdenum disulfide.

Every 10 Hours

! Lubricate 3 points on the hitch every 10

hours.

! PTO - Lubricate 5 points on the PTO

every 10 hours.

- 1 point at the constant velocity joint.

*Continued angled operation will

require lubrication every 4 hours.

- 1 point on each joint collar

- 1 point at the telescoping section

Note: If the grease point in the center

of the PTO (telescoping

section) is not accessible when

connected to the tractor,

disconnect from the tractor and

extend the PTO shaft to

access the grease point.

Every 50 Hours

! On the optional Steering Control, lubricate

2 points every 50 hours.

- on the left pivot pin