HighLine Bale Pro CFR651 Operator's Manual

®

Bale Pro

Complete Feed Ration

CFR651

O p e r a t o r s M a n u a l

E12033V3_A

®

BalePro

Complete Feed Ration 651

Bale Processor

Operator’s

Manual

Printed in Canada Copyright © 2018 by Highline Manufacturing Ltd. All rights reserved.

The content of this manual was based on the most current information available as of the date of copyright. It is the policy of

Highline Manufacturing Limited to improve and develop our products continually. We reserve the right to make changes or add

improvements, at any time, without incurring any obligation to make changes or improvements on machines previously sold.

Changes may not be reflected in this manual.

Starting at Serial Number CFR6510009

Highline Manufacturing Limited

HWY #27, P.O. Box 307

Vonda, SK S0K 4N0

Canada

Phone: 306.258.2233

Fax: 306.258.2010

Toll Free: 1.800.665.2010

E12033V3_A

103116

Highline Manufacturing Ltd. Complete Feed Ration 651 (CFR 651)

Highline Team Message

Congratulations on your purchase of the Complete Feed Ration 651 manufactured by Highline

Manufacturing Ltd.

This Operator's Manual has been prepared to provide information necessary for the safe and

efficient operation of your Complete Feed Ration 651 (CFR 651). In the manual you will find

safety procedures, maintenance routines and detailed operational instructions.

If you find that you require information not covered in this manual, please feel free to consult

your local dealer. Your dealer is always able to contact Highline for this technical information.

Highline Manufacturing Ltd. thanks and congratulates you for selecting a Complete Feed Ration

651 as your machine of choice.

Highline Manufacturing Ltd.

Table of Contents

Section 1 - Safety

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Sign-off Form . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 2 - Transporting the CFR 651

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . . 2

Ensure the correct PTO speed . . . . . . . . . . . . . . . . 2

Adjust the tractor drawbar length . . . . . . . . . . . . . . 2

Lift the hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Connect the hitch to tractor drawbar . . . . . . . . . . . . 3

Connect the safety chain . . . . . . . . . . . . . . . . . . . . 3

Hoses and wiring harness through the support arm 3

Attach driveline to PTO . . . . . . . . . . . . . . . . . . . . . . 4

Attach hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connect the lights . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Jack in the storage location . . . . . . . . . . . . . . . . . . 5

Section 3 - Preparing the CFR 651

Park on level ground. . . . . . . . . . . . . . . . . . . . . . . . 1

Ensure all decals are clean & in place. . . . . . . . . . . 1

Slow Moving Vehicle (SMV) clean and visible . . . . . 1

Check the condition of the flail drum . . . . . . . . . . . . 1

Clean debris from the flail drum and processor tub . 2

Check the condition of the flails . . . . . . . . . . . . . . . . 2

Remove twine, netwrap around flail drum/bearings. 2

Check the condition of the feeder chain . . . . . . . . . 3

Check the tension of the feeder chain . . . . . . . . . . . 3

Adjust the height of the hitch tongue . . . . . . . . . . . . 4

Set the level of the lower discharge door. . . . . . . . . 4

Verify the position of the lower discharge door . . . 5

Remove material around the feeder chain bearings 5

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Decal Locations . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust wheel stance settings . . . . . . . . . . . . . . . . . . . . . . 6

Check the condition of the tires . . . . . . . . . . . . . . . . . . . . 6

Raise the bale loading forks . . . . . . . . . . . . . . . . . . . . . . 7

Install the cylinder lock on the bale loading forks . . . . . . 7

Raise the discharge deflector door ................. 7

Install the discharge deflector door transport lock . . . . . . 7

Secure the rubber panel on door . . . . . . . . . . . . . . . . . . . 7

Slow Moving Vehicle (SMV) clean and visible . . . . . . . . . 8

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Transport Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Check condition and tension of flail drum drive belt. . . . . 6

Adjust the bale loader forks width . . . . . . . . . . . . . . . . . 7

Inspect all hydraulic motors, cylinders and hoses . . . . . . 8

Inspect the wheels and tires . . . . . . . . . . . . . . . . . . . . . . 8

Check that the axle u-bolts are tight. . . . . . . . . . . . . . . . . 9

Remove twine built up around spindle and hub . . . . . . . 9

Driveline shields in place and in good repair . . . . . . . . . 9

Remove the flail drum lock pin . . . . . . . . . . . . . . . . . . . 10

Remove the fork cylinder lock . . . . . . . . . . . . . . . . . . . 10

Remove the nuts and washers from rubber panel . . . . . 11

Remove lock pin on the discharge deflector door . . . . 12

Lubricate grease fittings and check the fluid level . . . . 12

NetWrap or Twine Removal Procedure . . . . . . . . . . . . . 13

Section 4 - Operating the CFR 651

Unlock the flail drum . . . . . . . . . . . . . . . . . . . . . . . . 1

Set the aggression level of the flails . . . . . . . . . . . . 2

Set the speed of the feeder chain . . . . . . . . . . . . . . 3

Set the upper deflector door . . . . . . . . . . . . . . . . . . 4

Set the level of lower discharge door . . . . . . . . . . . 5

Load the bale into the processor tub . . . . . . . . . . . . 6

Load a second bale . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 5 - Maintaining the CFR 651

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Visually Inspect Hydraulic Hoses/Fittings . . . . . . . . 3

Adjust the Feeder Chain Tension . . . . . . . . . . . . . . 4

Adjust the Belt Tension for the Flail Drum Drive . . . 5

Changing the Gearbox to Flail Drum Belt . . . . . . . . 7

Start PTO to engage the flail drum . . . . . . . . . . . . . . . . . 7

Begin processing material. . . . . . . . . . . . . . . . . . . . . . . . 8

Adjust the feeder chain speed . . . . . . . . . . . . . . . . . . . . . 8

Adjust the aggression level . . . . . . . . . . . . . . . . . . . . . . 9

Re-adjust the lower discharge door . . . . . . . . . . . . . . . . 9

Crossing ditches and steep inclines . . . . . . . . . . . . . . . 10

Making turns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Check the Fluid Level in the Gearbox . . . . . . . . . . . . . . . 8

Gearbox Oil Changing Procedures . . . . . . . . . . . . . . . . . 9

Flail Replacement Procedure . . . . . . . . . . . . . . . . . . . . 10

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 6 - Storing the CFR 651

Clean all the debris from the tub area . . . . . . . . . . . 1

Park the CFR 651 on level ground . . . . . . . . . . . . . . 1

Lubricate all CFR 651 grease points . . . . . . . . . . . . 1

Oil the feeder chains with a rust inhibiting oil . . . . . 1

Lock the CFR 651 flail drum . . . . . . . . . . . . . . . . . . . 2

Lower the forks to the ground . . . . . . . . . . . . . . . . . . 3

Raise the discharge deflector door . . . . . . . . . . . . . . 3

Install the discharge deflector door transport lock . . 3

Place the rubber into the tabs and fasten . . . . . . . . . 3

Place the jack onto the hitch . . . . . . . . . . . . . . . . . . 4

Remove the driveline from the tractor PTO shaft . . . 4

Section 7 - Troubleshooting

Section 8 - CFR 651 Specifications

Disconnect the safety chain . . . . . . . . . . . . . . . . . . . . . . 4

Disconnect the hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Relieve the pressure on the hydraulic hoses and

disconnect them. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disconnect the electrical connection . . . . . . . . . . . . . . . 4

Secure the hydraulic hoses and electrical connector to the

hose holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Place the driveline into the driveline support . . . . . . . . . 5

Change the oil in the gearbox . . . . . . . . . . . . . . . . . . . . . 5

Check for worn and damaged parts . . . . . . . . . . . . . . . . 5

Touch-up the p

aint to prevent rusting . . . . . . . . . . . . 5

GENERAL DESCRIPTION OF THE COMPLETE FEED RATION 651 (CFR 651)

The Complete Feed Ration 651 (CFR 651) is a machine to process round bales of hay or other

animal feed materials. When the CFR 651 is engaged, it uses power from the tractor PTO to

rotate a flail drum. The flails strike the round bale and process it into feed size materials or

animal bedding sized materials. The bale is rotated against the flails by a feeder chain.

The Complete Feed Ration (CFR 651) has forks on the rear of the machine that allow the CFR

651 to pick up and self-load a round bale into the processing tub. An additional bale may be

carried on the forks while the bale in the tub is being processed.

The amount of processing and chopping of material in the processing tub is adjusted by setting

the height of the guard rods. The height of the guard rods determine the level of aggression of

the flails acting on the round bale. The round bale is rotated by a feeder chain while the flail

drum turns to process the material. The rotation of the bale assists in the bale being processed

in an even manner.

The processed material is discharged from the CFR 651 on the right side of the machine. The

height and distance of discharge is adjusted by moving the lower discharge door. A top

discharge deflector door allows the processed material to be laid down into a feed bunk,

windrow or spread to different distances.

The Complete Feed Ration 651 has the option of adding a Feed Chopper for additional

processing of the feed materials. There is also the option of adding a Grain Tank to add feed

grains in a measured amount to the feed mix to achieve the feed ration needed for the animals.

The operator of the CFR 651 is located in the tractor cab to control the speed of driving and the

speed of operation of the CFR 651.

INTENDED USE OF THE COMPLETE FEED RATION 651 (CFR 651)

- The CFR 651 is designed to process animal feed and bedding materials from a

round bale.

- The CFR 651 is intended for use in farming applications.

- The CFR 651 is intended for off road use only.

- The CFR 651 is intended for use in locations away from people who could be

harmed by the discharged materials.

Any uses of the CFR 651 other than the above stated Intended Uses shall be considered

misuse of the CFR 651. This misuse shall include (but not limited to):

- Using the CFR 651 in non-farming applications

- Using the CFR 651 on public roads

- Using the CFR 651 around people or in public places

- Processing materials other than animal feed materials

Always use the CFR 651 according to the instructions contained in this Operator's Manual and

the safety and instruction decals on the machine.

Perform regular maintenance and repair to ensure that the CFR 651 operates safely and

efficiently.

This Page Left Blank

Section 1 - Safety

SERIAL NUMBER

Your serial number is found on the serial number plate attached to the tub wall of the Complete

Feed Ration 651.

Serial Plate Location

It is important to record the serial number for proof of ownership and for any service or

maintenance assistance.

215120C

Serial Number

Owner

Model

Date of Purchase

Page 1-1

Section 1 - Safety

SAFETY SIGN-OFF FORM

Highline Manufacturing Ltd. follows the general Safety Standards specified by the American

Society of Agricultural Engineers (ASAE) and the Occupational Safety and Health Administration

(OSHA). Anyone who will be operating and/or maintaining this equipment should read and

clearly understand all Safety, Operating and Maintenance information presented in this manual.

Do not operate or allow someone to operate this equipment until this information has been

reviewed. This information should be reviewed by all operators before the season start-up.

This sign-off sheet is provided for record keeping to indicate that the person working with the

equipment has read and understood the information in the Operator’s Manual and has been

instructed in the safe operation of the equipment.

Date Employee’s Signature Employer’s Signature

Page 1-2

Section 1 - Safety

SAFETY ALERT SYMBOL

The Safety Alert Symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert Symbol combined with a Signal Word alert to the presence of a hazard and the

degree of possible injury.

Indicates an imminently hazardous situation that, if not

avoided, WILL result in DEATH OR SERIOUS INJURY.

The color is Red with White lettering.

Indicates a potentially hazardous situation that, if not

avoided, COULD result in DEATH OR SERIOUS

INJURY, and includes hazards that are exposed when

guards are removed or unsafe practices. The color is

Orange with Black lettering.

Indicates a potentially hazardous situation that, if not

avoided, MAY result in MINOR INJURY. The color is

Yellow with Black lettering.

Page 1-3

Section 1 - Safety

GENERAL SAFETY

1. Ensure that anyone who is going to operate, maintain or work near the Complete Feed

Ration 651 is familiar with the recommended operating, maintenance procedures and safety

information contained in this manual and follows all the safety precautions.

2. In addition to the design and configuration of the equipment, hazard control and accident

prevention are dependent upon the awareness, concern, prudence and proper training of

personnel involved in the operation, transport, maintenance and storage of the machine.

3. The CFR 651 shall not be operated without all the guards in place.

SAFETY DECALS

1. Keep decals and signs clean and legible at all times.

2. Replace decals and signs that are damaged, missing or have become illegible.

3. Replaced parts that displayed a decal should also display the current decal.

4. Decals are available from the Highline Parts Department.

5. Be familiar with the decals, the type of warning and the area or function(s) related to the

area(s) that requires your awareness.

Page 1-4

Section 1 - Safety

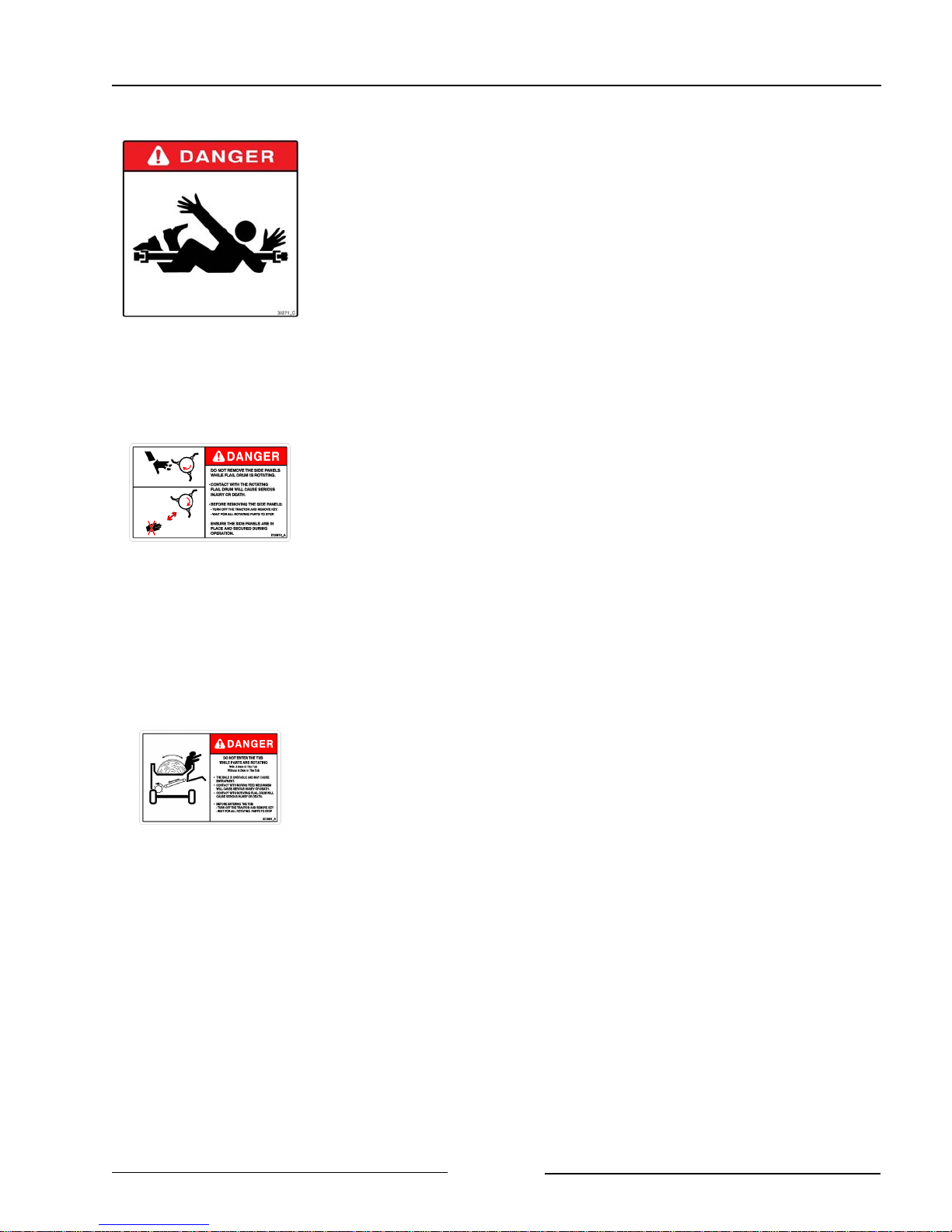

DO NOT CONTACT ROTATING DRIVELINE

Contact with rotating driveline will cause serious injury or death.

Keep all driveline guards in place.

Securely attach drivelines at both ends.

Check that the driveline guards turn freely on the driveline.

DO NOT OPERATE WITH SHIELDS MISSING

Stop engine and ensure the PTO driveline is stopped before

working on driveline

DO NOT REMOVE SIDE PANELS WHILE FLAIL DRUM IS

ROTATING

Contact with rotating parts can cause serious injury or death.

Before removing the side panels:

- Turn off the tractor and remove key.

- Wait for all rotating parts to stop.

Ensure the side panels are in place and secured during operation.

DO NOT ENTER TUB WHILE PARTS ARE ROTATING

- With a bale in the tub

- Without a bale in the tub

Before entering the tub

- Turn off the tractor and remove the key.

- Wait for rotating parts to stop

The bale is unstable and may cause entrapment.

Contact with the moving feed mechanism or rotating flail drum will

cause serious injury or death.

Page 1-5

Section 1 - Safety

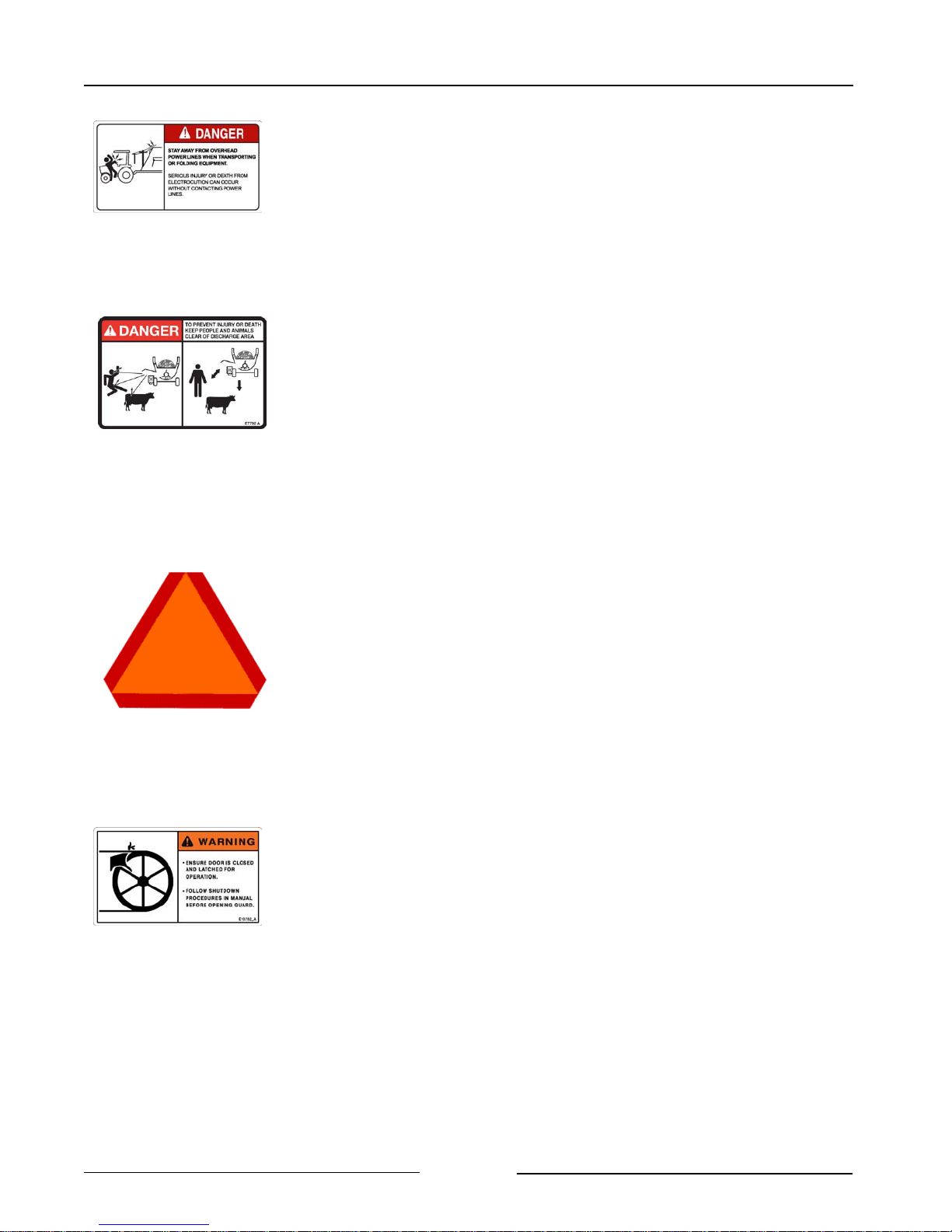

STAY AWAY FROM OVERHEAD POWER LINES

Stay away from overhead power lines when transporting

equipment.

Serious injury or death from electrocution can occur without

contacting power lines.

STAY BACK FROM AN OPERATING MACHINE WHICH CAN

DISCHARGE OBJECTS SEVERAL FEET

Stay clear from discharge side when PTO is engaged.

Thrown material or objects leaving the discharge area can cause

serious injury or death.

Do not operate within 100 ft (30m) of any person.

Keep all shields and guards in place.

ENSURE SLOW MOVING VEHICLE SIGN IS IN PLACE

Ensure the Slow Moving Vehicle sign is in place, clean and easily

visible.

Ensure the reflectors are in place, clean and easily visible.

DO NOT OPERATE WITH SHIELDS MISSING

Contact with the moving belt/sheaves or moving chain/sprockets

may cause serious injury or death.

Keep shields fastened in place.

Keep away from moving parts.

Do not stand or climb on the machine when operating.

Page 1-6

Section 1 - Safety

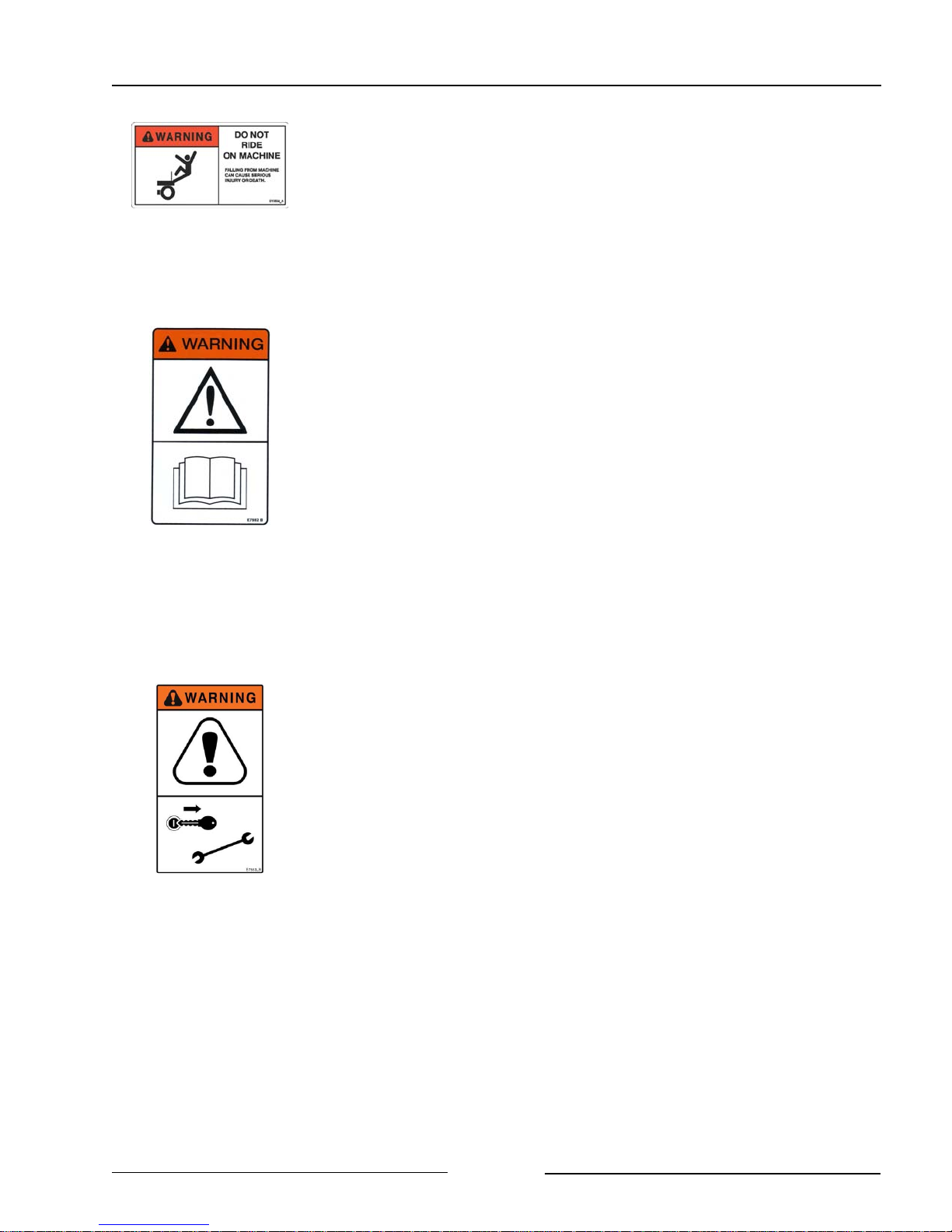

DO NOT RIDE ON MACHINE

Falling from the moving machine can cause serious injury or

death.

Falling from the operating machine can cause being entangled

under the machine or being injured by the machine.

READ, UNDERSTAND, AND FOLLOW SAFETY INSTRUCTIONS

Read, understand and follow all instructions and safety messages

included in this manual and on decals attached to the machine.

These instructions and safety messages contain important

information.

Allow only responsible, properly instructed individuals to operate

and service the machine.

Failure to follow the instructions and safety messages in this

manual and on the decals attached to the machine could result in

serious injury or death.

Keep all safety and instruction decals in good condition. Replace

any missing or damaged decals

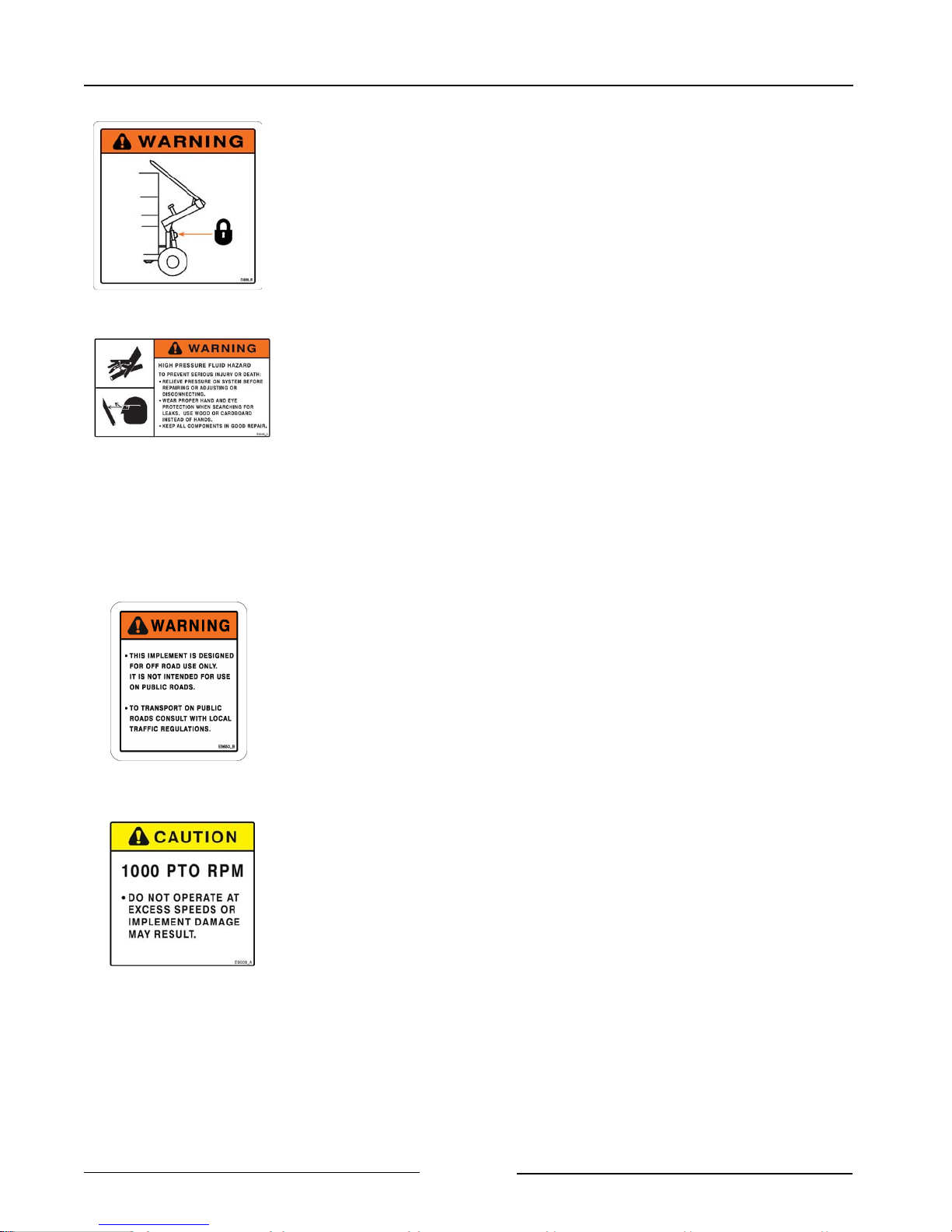

SHUT DOWN THE TRACTOR BEFORE DISMOUNTING

TRACTOR

Shut down the tractor and remove the key before repairing,

servicing, lubricating or cleaning the machine.

Relieve all hydraulic pressure in the hoses before going near the

machine. Leave the hydraulics in the “float” position.

Page 1-7

Section 1 - Safety

INSTALL CYLINDER LOCK BEFORE GOING UNDER RAISED

BALE FORKS

Install and secure the cylinder lock before going under raised bale

forks.

Install and secure cylinder lock before using the twine cutter.

USE PAPER OR CARDBOARD TO CHECK FOR HYDRAULIC

LEAKS

To prevent serious injury or death:

Relieve pressure on hydraulic system before repairing, adjusting or

disconnecting.

Wear proper hand and eye protection when searching for leaks.

Use wood or cardboard instead of hands.

Keep all components in good repair.

IMPLEMENT IS DESIGNED FOR OFF ROAD USE ONLY.

Do not transport with bales in the processor tub.

Do not transport with a bale loaded on the forks.

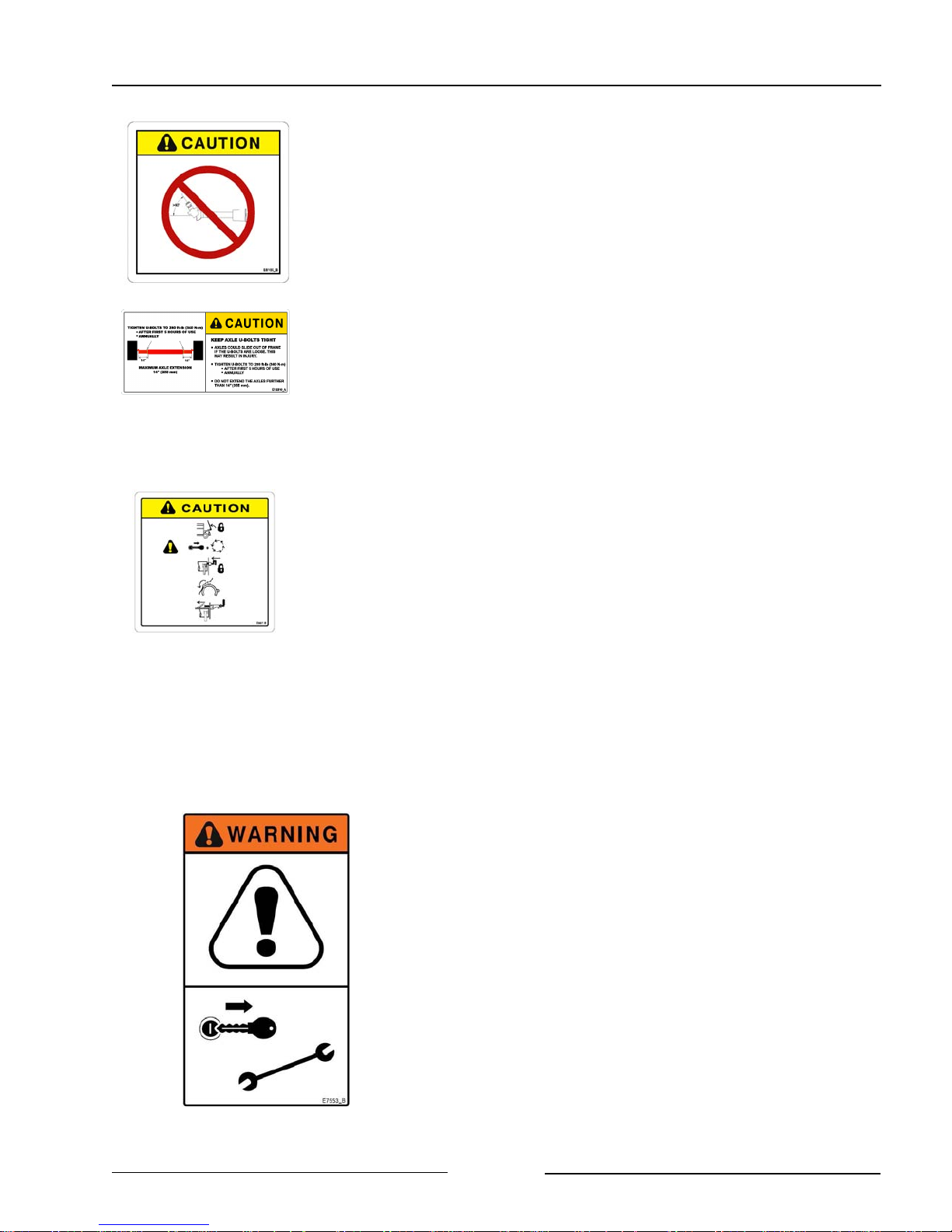

DO NOT EXCEED PTO SPEED

Do not operate at excess speeds or damage to the machine may

result.

Page 1-8

Section 1 - Safety

DO NOT EXCEED 80F TURNS IN OPERATION

Do not operate the Constant Velocity (CV) driveline at greater than

80F to prevent damage to the driveline.

KEEP AXLE U-BOLTS TIGHT

axles could slide out of the frame if the u-bolts are loose. This may

result in injury/

Tighten u-bolts after first 5 hours of use.

Tighten u-bolts annually.

SHUT DOWN TRACTOR BEFORE USING TWINE CUTTER

Use the shutdown procedure to ensure no movement of the flail

drum will occur while cutting twine or netwrap.

LOCK FORKS AND FLAIL DRUM BEFORE USING TWINE

CUTTER

Lock forks in the upright position before going under the raised

forks.

Lock the flail drum to ensure no movement of the flail drum will

occur while cutting twine or netwrap.

SHUTDOWN PROCEDURE

For your safety and the safety of others, this shutdown

procedure mzust be followed before dismounting from

the tractor for inspecting, repairing, servicing, cleaning,

or lubricating the machine.

Step 1: Reduce the engine speed to idle.

Step 2: Disengage tractor power takeoff.

Step 3: Set tractor park brake.

Step 4: Lower bale loader forks to the ground.

Step 5: Shut off tractor engine and remove key.

Step 6: Cycle tractor controls to relieve any residual

circuit pressure.

Step 7: Wait for drum to stop turning.

Page 1-9

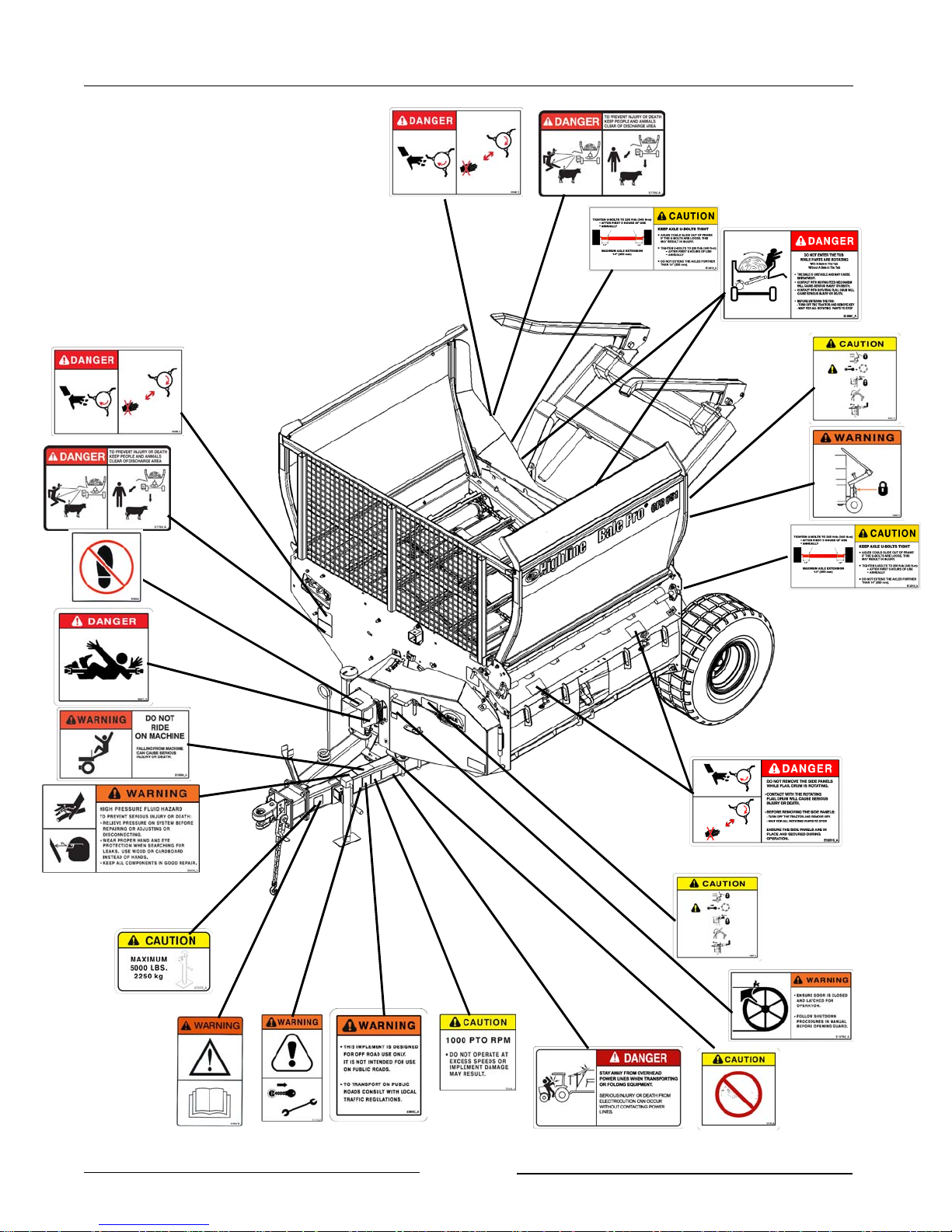

SAFETY DECAL LOCATIONS

Section 1 - Safety

216197

Page 1-10

Section 2 - Transporting the CFR 651

2.0 TRANSPORTING THE CFR 651

Only tow the CFR 651 behind a

properly sized and equipped

tractor which exceeds the loaded

weight of the CFR 651 by 50%.

Do not tow behind a truck or other

type of vehicle.

The CFR 651 is designed for off

road use only.

Do not transport on public roads

with bales in the processor tub.

Do not transport on public roads

with a bale loaded on the forks.

Check with local traffic regulations

to transport on public roads.

Stay away from overhead power

lines when transporting

equipment. Electrocution can

occur without contacting power

lines.

Do not allow any person to ride

on the tractor or CFR 651. Falling

off can result in serious injury or

death.

Keep the Axle U-Bolts Tight. Injury

could result if axles come out.

Page 2-1

Section 2 - Transporting the CFR 651

1. Tractor Requirements

- Roll Over Protection System (ROPS)

- Working seatbelts

- 1 3/8" 21 spline PTO

- PTO requirement

- refer to the "Specifications"

Section for the PTO requirements.

- 3 Selective Control Valves (SCV)

- An optional solenoid valve is

available for tractors with 2 SCV.

2. Ensure the correct PTO speed.

- Ensure that the tractor PTO speed

matches the CFR 651’s gearbox

speed of 1000 rpm.

- Do not attempt to operate the CFR

651 at a different PTO speed.

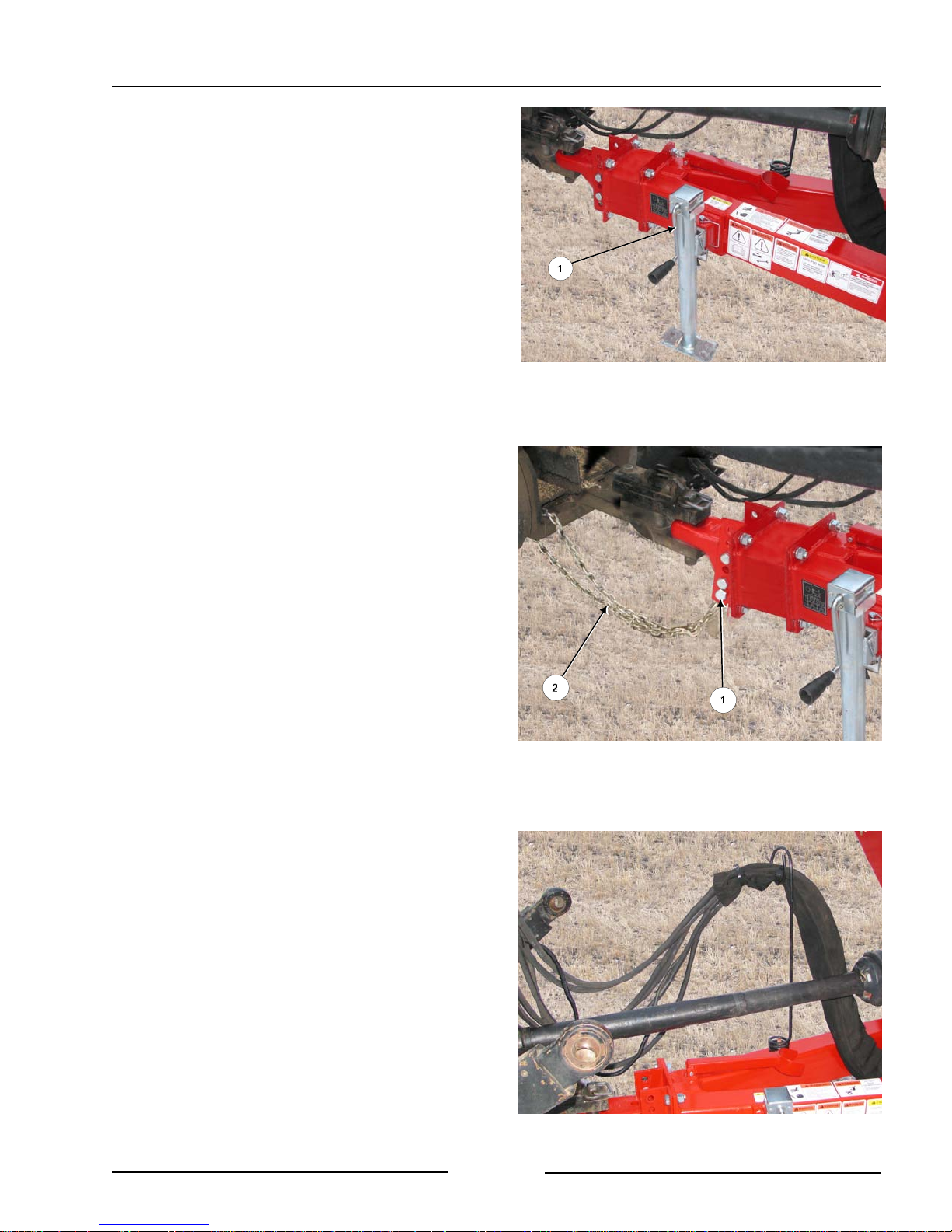

3. Adjust the tractor drawbar length.

- Set the drawbar length to 16" (406

mm) for a 1 3/8" 21 spline PTO.

- This length is measured from the tip of

the PTO shaft end to the center of the

drawbar hole. (Refer to your tractor’s

operator manual for drawbar

adjustment procedures.)

Note: To prevent damage to the tractor

drawbar, avoid traveling at high

speeds and over rough terrain.

Note: Do not use PTO adapters.

PTO adapters will cause a

driveline failure and possible

tractor damage. Your CFR 651

warranty will also be invalid.

Tractor Drawbar Adjustment

PTO Dimensions

Page 2-2

Section 2 - Transporting the CFR 651

4. Lift the hitch.

- Lift the Hitch with the jack (1).

- The hitch is heavy. Do not attempt

to lift it without using the jack.

5. Connect the hitch to the tractor clevis

drawbar.

- Use a 1" (25 mm) pin.

- Secure with a hitch pin clip.

Lift Hitch with the Jack

213174C

6. Connect the safety chain

.

- Ensure the safety chain rating is equal

or greater than the gross weight of the

loaded CFR 651.

- Route the safety chain around the

lower safety chain bolt (1).

- Attach the chain to a secure location

on the tractor (2).

- Fasten the chain hook with the hook

lock.

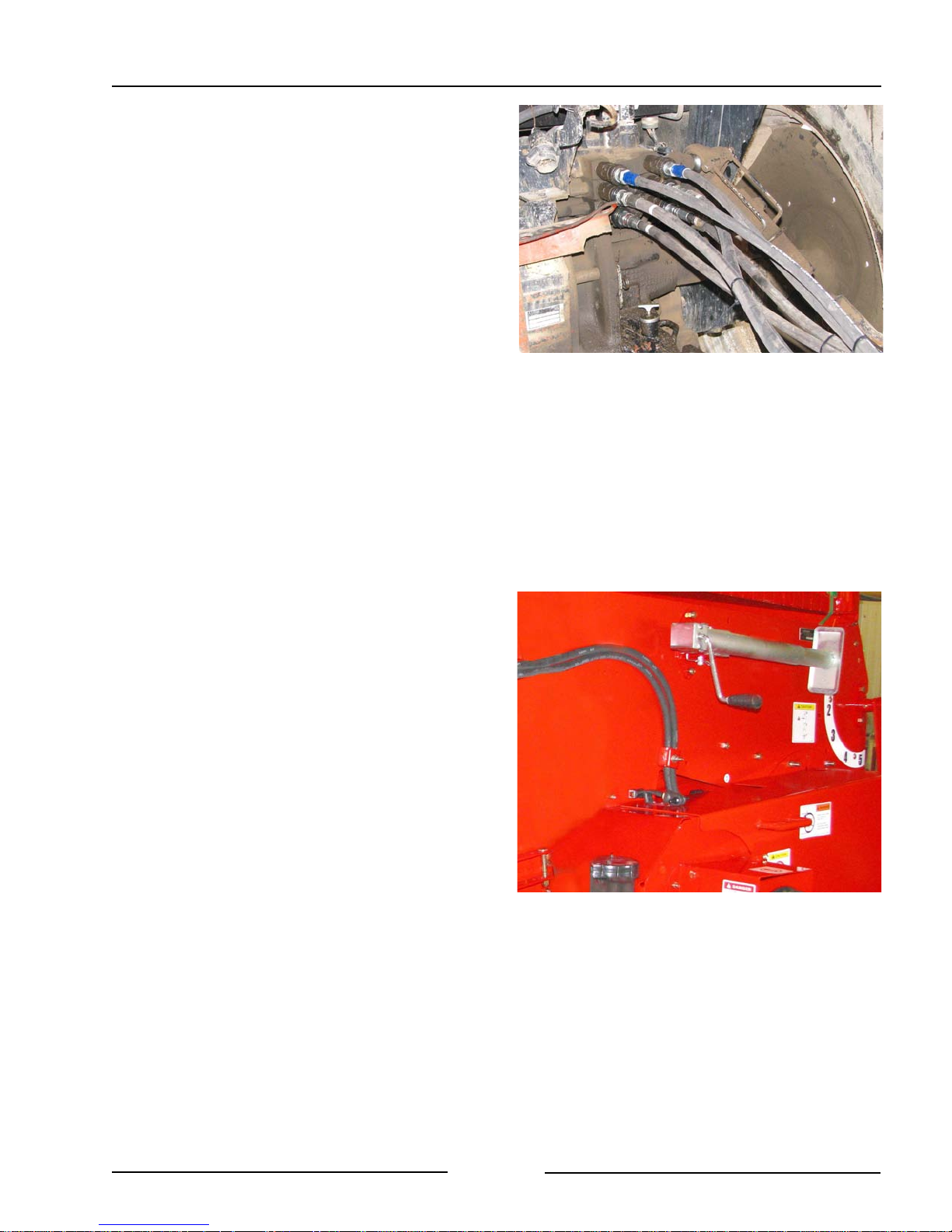

7. Route the hydraulic hoses and wiring

harness through the hose support arm.

Connect Hitch & Safety Chain to Tractor

213175C

Page 2-3

Hoses and Electrical in Support Arm

211217

Section 2 - Transporting the CFR 651

8. Attach driveline to PTO.

Note: Use the Category 6 drive line with the

Feed Chopper Option.

Shut off the tractor engine before

attaching PTO driveline.

Entanglement in the rotating

driveline can cause serious injury

or death.

The CFR 651 shall not be operated

without the driveline shields in

place.

- Shut off the tractor engine and

remove the key.

- Check that the driveline telescopes

easily and that the shields are in good

condition and rotate freely.

- Lift the tractor PTO shield.

- Support the driveline, pull back on the

yoke collar, align the splines by

rotating the CFR 651 driveline and

push the driveline into the tractor PTO

shaft until the collar snaps into place.

- Push and pull the yoke several times

to ensure the driveline is locked. Do

not pull on the collar as this will

release the lock.

- Lower the tractor & hitch PTO shields

into place.

- Fold down the PTO support holder (1).

- Failure to fold down the support

may result in damage to the

driveline.

Connect Driveline to PTO

213176C

Page 2-4

Section 2 - Transporting the CFR 651

9. Attach hydraulics.

- Clean the end of the hoses and the

connection.

- Firmly push the hoses into the tractor

receptacle according to user

preference.

- Route the hoses so they do not

interfere with moving parts.

10. Connect the lights.

- Connect the light plug into the

appropriate tractor receptacle.

- Ensure the light cable does not

interfere with or contact moving parts.

11. Place the hitch jack in the storage

location on the front tub wall.

Attach Hydraulics

201199

Page 2-5

Hitch Jack in Storage Location

213014

Section 2 - Transporting the CFR 651

12. Adjust wheel stance settings.

- Increase the wheel stance to maintain

stability when working on hilly terrain

or rough ground.

Note: Ensure the bale processing tub is

empty before adjusting wheel

stance.

- Jack up the main axle under the

cylinder mount and support.

- Loosen the u-bolts (1) that hold the

axle tubes in place.

- Slide the axle to achieve the desired

wheel stance setting.

Wheel Stance Adjustment

212017C

Note: Maximum axle extension is 14"

(355 mm). Axles may bend if

extended beyond this amount.

- Tighten the u-bolts (1) to 250 lbf (339

Nm).

13. Check the condition of the tires.

- Ensure that the lug nuts have the

cone side of the lug nut against the

wheel rim.

- Torque the lug nuts to 121 lbf (164

Nm).

- Fill the tires to 24 psi (165 kPa).

Check the Tires

215126

Page 2-6

Section 2 - Transporting the CFR 651

14. Raise the bale loading forks to the

highest position.

15. Install the cylinder lock (1) on the

cylinder of the bale loading forks.

- Fasten the cylinder lock in place

with the pin (2).

16. Raise the discharge deflector door to

the transport position.

- The discharge deflector door is

operated by a hydraulic cylinder.

Note: If the 2 remote option is

installed, the door cylinder will be

linked to the bale lift hydraulic circuit

through an electric solenoid

- Move the electric selector valve so

the hydraulic flow goes to the door

cylinder.

17. Install the discharge deflector door

transport lock.

- Rotate the short link (1) toward the

cylinder.

- Join the flats by inserting the pin of

the short flat into the longer flat (2).

Fork Cylinder Resting on Lock

Deflector Door Lock

216193C

212040C

- Install the clip pin (3).

18. Secure the rubber panel on door.

- Place the rubber panel into the tabs

(1) and fasten with a washer and nut

(2) to prevent the wind from blowing

the rubber panel from the tabs during

transport.

Page 2-7

Discharge Door Raised - Rubber Secured

212019C

Loading...

Loading...