Page 1

Operation Manual

Predator SS

SIMPLIFIED STRETCH

LOW PROFILE

SERIAL NUMBER

Please refer to the serial number in all correspondence with Highlight or

any Highlight Distributor. This identifies your machine and will help in

our ability to quickly and efficiently respond to your needs.

OPERATION MANUAL NUMBER: PREDSS_LP / DEC-2017

Page 2

Predator SS Turntable Stretch Wrapper Operation Manual

Table of Contents

Table of Contents ............................................................................................................. 1

Table of Figures ................................................................................................................ 2

General Information ........................................................................................ 3

Safety Messages .............................................................................................................. 4

Introduction and Warranty ................................................................................................ 6

Revision History ................................................................................................................ 8

Specifications.................................................................................................. 9

Specifications ................................................................................................................. 10

System Overview Prints .................................................................................................. 11

System Description ......................................................................................................... 12

Installation & Adjustments ............................................................................. 13

Machine Placement ........................................................................................................ 14

Machine Set-Up .............................................................................................................. 15

Microprocessor Card ...................................................................................................... 18

Optional Scale Package ................................................................................................. 20

Operation Instructions ................................................................................... 23

Operator Controls ........................................................................................................... 24

Film Loading ................................................................................................................... 27

Machine Operating Instructions ...................................................................................... 29

Maintenance ................................................................................................. 30

Preventative Maintenance .............................................................................................. 31

Maintenance Schedule ................................................................................................... 34

Trouble-shooting ........................................................................................... 35

Self Test Troubleshooting ............................................................................................... 36

Troubleshooting Guide ................................................................................................... 39

Power Problems ............................................................................................................. 40

Turntable Problems ........................................................................................................ 41

Film Carriage Problems .................................................................................................. 42

Technical References ................................................................................... 43

Recommended Spare Parts ........................................................................................... 44

Electrical Drawings ......................................................................................................... 45

Mechanical Drawings...................................................................................................... 50

Notes ............................................................................................................ 64

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 1

Page 3

Predator SS Turntable Stretch Wrapper Operation Manual

Table of Figures

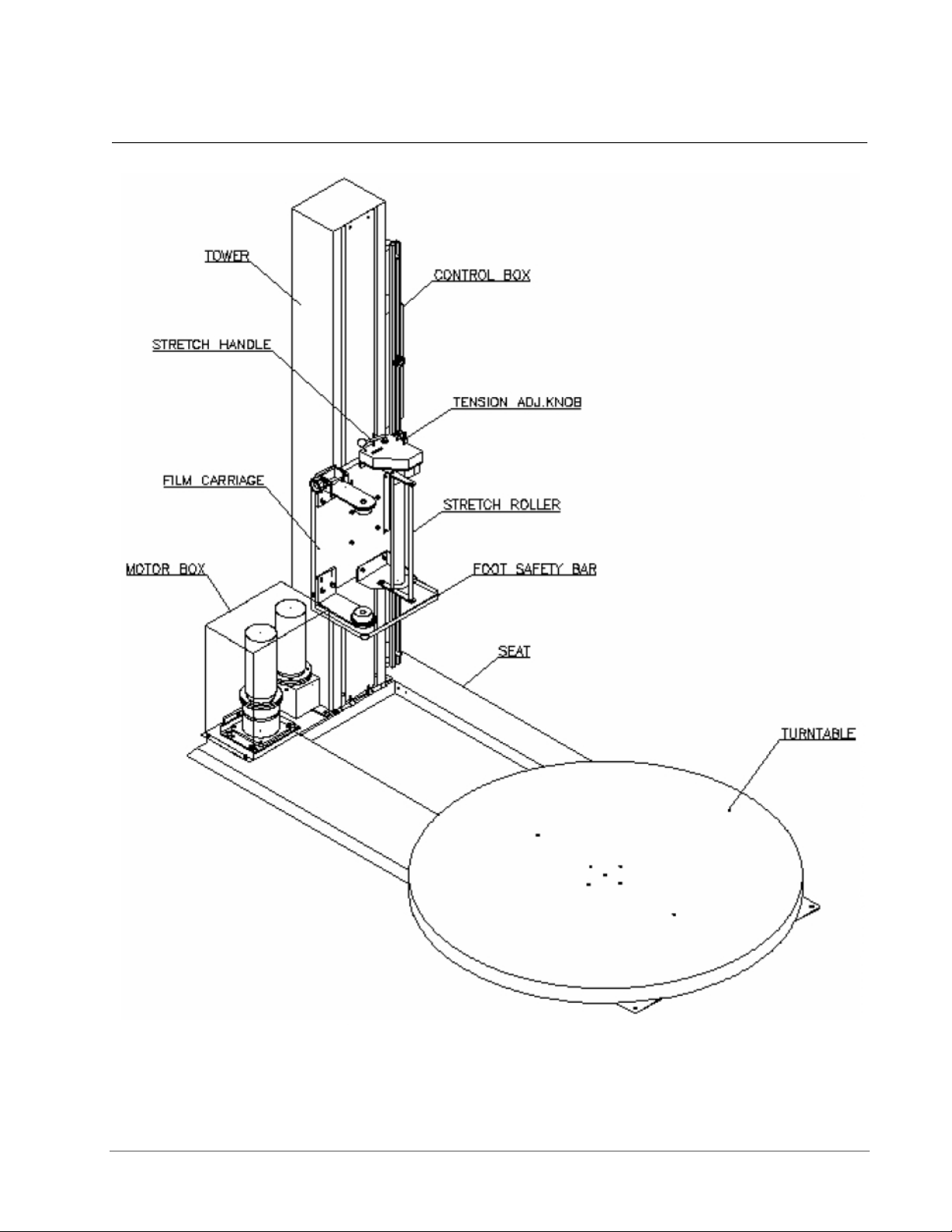

Figure 1: Predator SS Low Profile Overview Layout .......................................................... 11

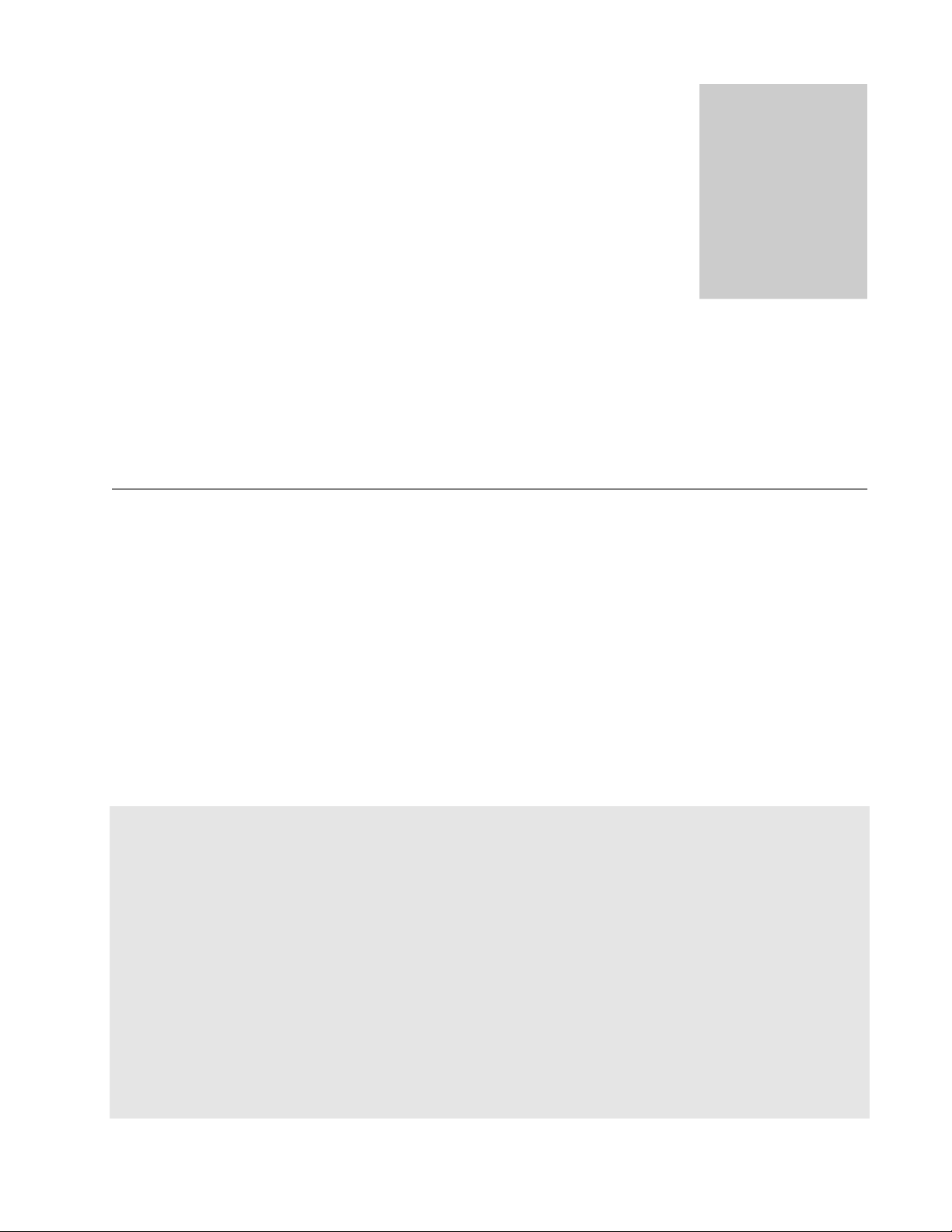

Figure 2: Predator SS Low Profile Machine Description..................................................... 12

Figure 3: Bracket in the Shipping Position .......................................................................... 16

Figure 4: Bracket in its Operating Position ......................................................................... 16

Figure 5: Microprocessor Card for the Predator SS ........................................................... 18

Figure 6: Operator Controls Diagram for the Predator SS .................................................. 24

Figure 7: Film Loading/Threading Diagram ........................................................................ 27

Figure 8: Turntable Belt Adjustment ................................................................................... 32

Figure 9: Film Carriage Lift Chain Adjustment .................................................................... 33

Figure 10: Self Test Error Display ...................................................................................... 37

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 2

Page 4

1

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

General

Information

Page 5

General

Safety Messages

Information Predator SS Turntable Stretch Wrapper Operation Manual

For the best result with the Predator Turntable Stretch Wrapper, carefully read this manual

and all of the warning labels attached to the equipment before installing and operating it,

and follow instructions exactly. Keep this manual for machine reference.

Definitions and Symbols

High Voltage!

This symbol indicates high voltage. It calls your attention to items or

operations that could be dangerous to you or other persons operating

the equipment. Read the message and follow the instructions carefully.

Warning!

This symbol indicates a potentially hazardous situation which, if not

avoided, can result to bodily injury, or serious damage to the product.

Notes

This symbol indicates an area or subject of special merit, emphasizing

the equipment’s capabilities, common errors in operation or

maintenance, or other special instructions that can provide benefits to

users.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 4

Page 6

General

Information Predator SS Turntable Stretch Wrapper Operation Manual

General Precautions – Read These First!

High Voltage!

Disconnect AC input power before checking components, performing

maintenance, cleaning up, and when the machine is not in use. Do NOT

connect or disconnect wires and connectors while power is applied to circuit.

High Voltage!

Wiring work should be carried out only by qualified personnel. Otherwise, there

is a danger of electric shock or fire.

High Voltage!

The user is responsible for conforming to all applicable code requirements with

respect to grounding all requirements. Do NOT use extension cords to operate

the equipment.

High Voltage!

Motor control equipment and electronic controllers are connected to hazardous

line voltages. When servicing drives and controllers, there may be exposed

components with housings or protrusions at or above line potential. Extreme

care should be taken to protect against shock.

Warning!

Loose clothing must NOT be worn while the machine is in operation. Stay clear

of moving parts while the machine is running.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 5

Page 7

General

Introduction and Warranty

Information Predator SS Turntable Stretch Wrapper Operation Manual

Introduction

Thank you for your purchase of a Predator SS Turntable Stretch Wrapper! Designed for the

high volume industrial user the Predator SS will stretch wrap any load to the maximum

stretch level of any film with full independent control of the film force. This allows even light

unstable loads to be wrapped at the lowest possible cost and the maximum load holding

force.

Limited Warranty

Highlight Industries, Inc. warrants its Predator manufactured by it, and sold pursuant to this

order, will be of merchantable quality, free from defects in material and workmanship as

determined at the date of shipment, by generally recognized, applicable and accepted

practices and procedures in the industry, for a period of three (3) years from the Highlight

invoice date, under normal use and service.

When the Purchaser gives Highlight written notice of any alleged defect within the

applicable warranty period, Highlight will, at its option repair or replace the same free of

charge F.O.B. its manufacturing plant, installation not included. Equipment replaced under

the warranty shall have the same warranty as new equipment but does not extend the

warranty of the original equipment.

Satisfaction of this warranty, consistent with other provisions herein, will be limited to the

replacement or repair or modification of, or issuance of a credit for, the equipment involved,

at Highlight’s option.

Highlight neither assumes nor authorizes any person to assume for it any other obligation

in connection with the sale of Highlight’s equipment.

This warranty shall not apply to any equipment which has been repaired or altered by unauthorized personnel in any way so as to, in the judgment of Highlight, affect serviceability,

or which has been subjected to misuse, negligence, accident, or to equipment made by

Highlight which has been operated in a manner contrary to Highlight’s instructions.

In no event regardless of the cause, shall Highlight be liable for penalties or penalty clauses

of any description or any damages resulting from loss of profits, use of products or for any

incidental indirect or consequential damages, even if advised of the possibility of such

damages. This limitation of Highlight’s liability will apply regardless of the form of action,

whether in contract or tort, including negligence. Any action against Highlight must be

brought within twelve (12) months after cause of action accrues.

“This warranty in lieu of all other warranties whether expressed, implied or statutory

including implied warranties of merchantability of fitness or extends only to the buyer or

customer purchasing from Highlight Industries, Inc or an authorized distributor.”

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 6

Page 8

General

Information Predator SS Turntable Stretch Wrapper Operation Manual

About This Document

The purpose of this manual is to provide you with information necessary to install, operate,

troubleshoot, and maintain the Predator SS Turntable Stretch Wrapper. The audience for

this manual should have basic knowledge of mechanical and electronic components,

standard electrical wiring practices, and schematics symbols.

To guarantee safe operation of the equipment, carefully observe the safety messages

throughout this manual. Keep this operating manual and distribute it to all users for

reference.

Application Assistance

If any assistance is desired, contact the distributor from whom you have purchased the unit,

or call the number listed on the bottom of each page of this manual. To receive quick and

proper technical support for the equipment you have purchased, please be prepared to

provide the following information:

1. Machine Serial Number

2. Date of Purchase

3. Symptoms of any problems

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 7

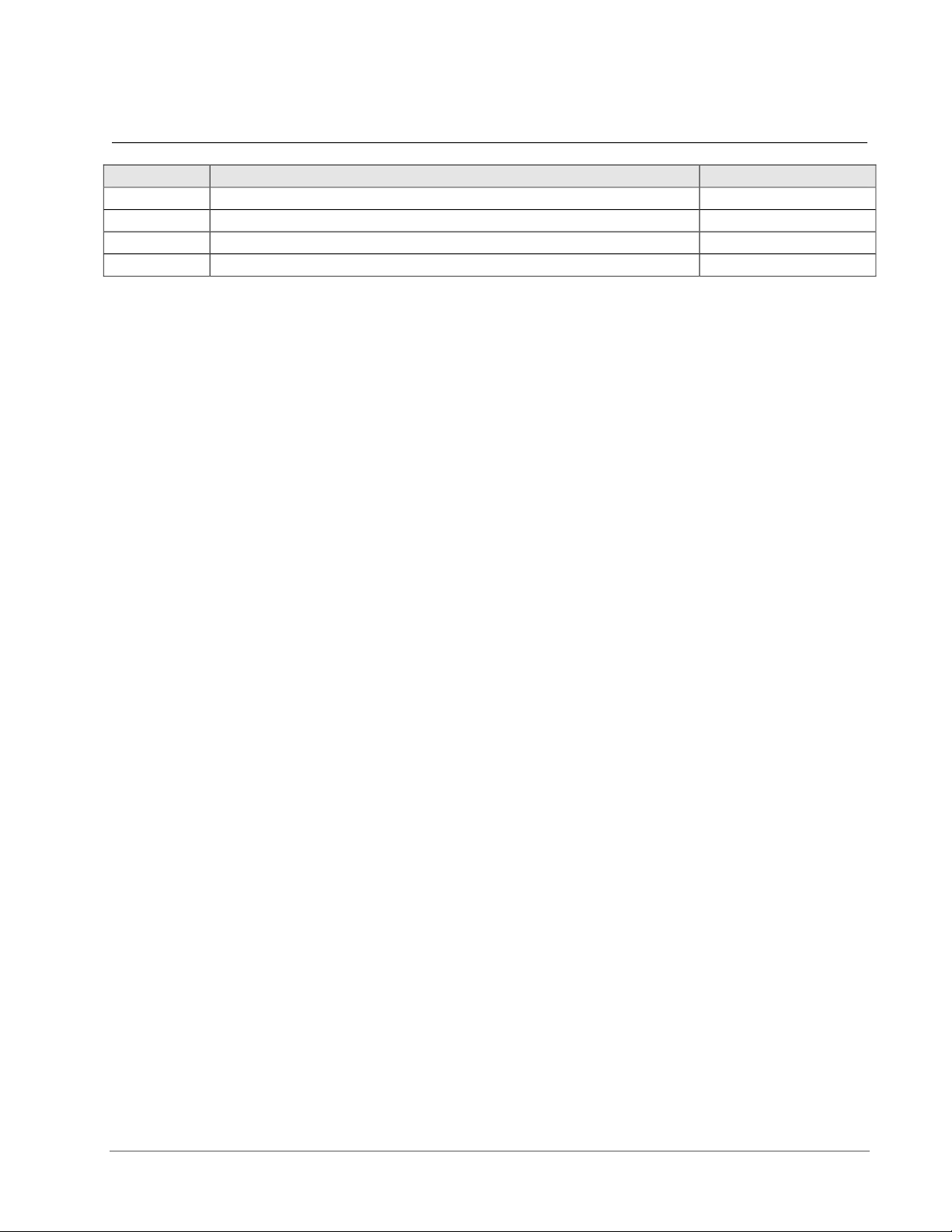

Page 9

General

Revision

Revision Comment

Date of Revision

Initial Release

October 2014

Updated load cell part number

Feb 2015-RDU

Updated 110” part numbers

April 2015-RDU

Added summing board cover to scale TT

Jan 2018-RDU

Revision History

Information Predator SS Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 8

Page 10

2

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Specifications

Page 11

Specifications Predator SS Turntable Stretch Wrapper Operation Manual

LOW PROFILE

80” Wrap Height

110” Wrap Height

Length (inch)

98

98

Width (inch)

60

60

Height (inch)

91

132

Turntable Diameter (inch)

60

60

Turntable Height from Floor (inch)

3.25

3.25

Operation Space (inch)

105 x 75 x 120

105 x 75 x 132

Maximum Pallet Size (inch)

52 x 52 x 80

52 x 52 x 110

Shipping Weight (lbs)

1500

1700

Specifications

Machine Dimensions

Electrical Specifications

120VAC, 60Hz, Single Phase, 15Amp

Turntable

4,000 lbs Maximum Turntable Load Capacity

12 RPM Maximum Turntable Speed

20-30 Loads Per Hour

Optional Integrated Scale

Film Carriage

Adjustable Raise and Lower Speeds

Automatic Package Height Detection

Film Delivery

Infinite/Manual Film Force Adjustment

10 Inch Diameter Roll Capacity

20 Inch Height Roll Capacity (30 Inch Optional)

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 10

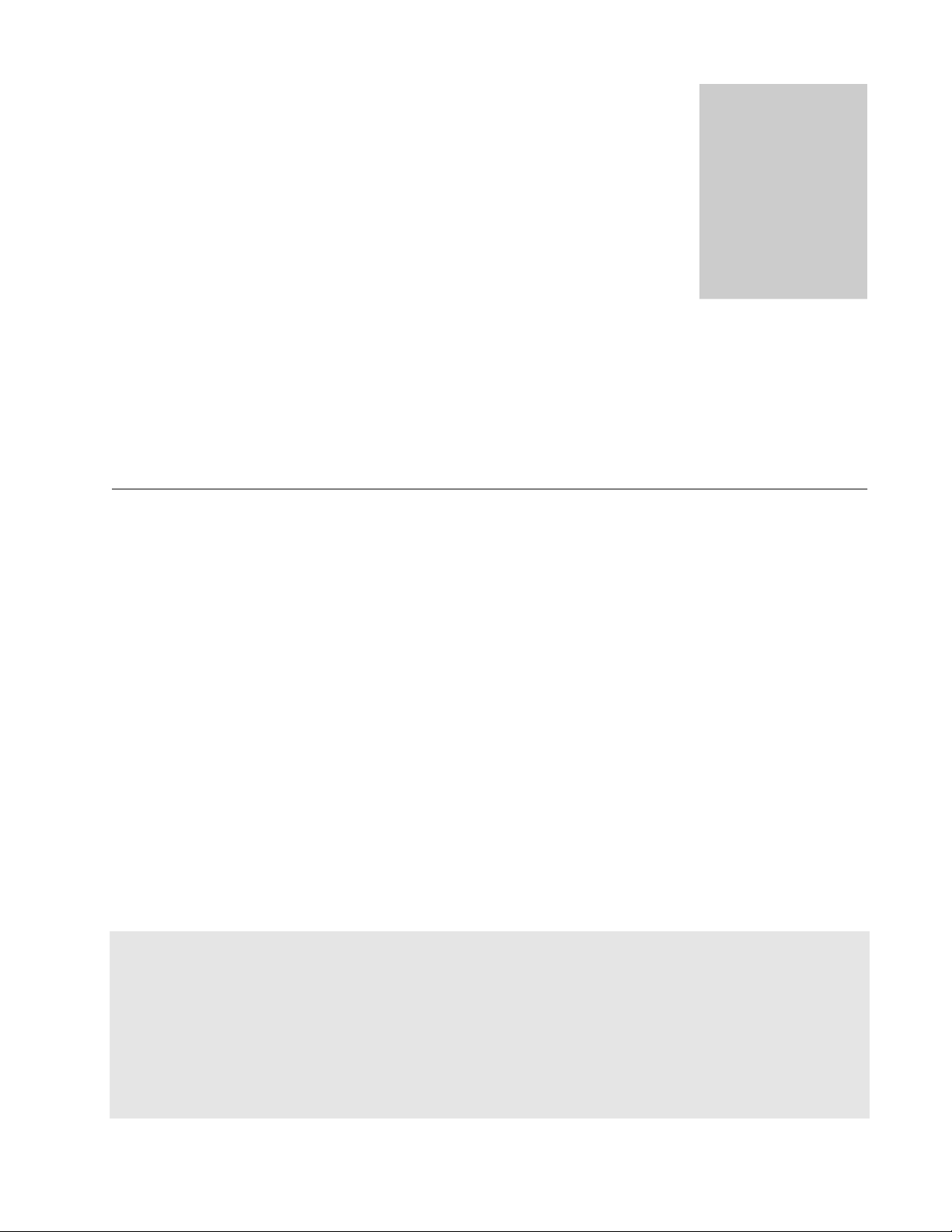

Page 12

Specifications Predator SS Turntable Stretch Wrapper Operation Manual

System Overview Prints

Note

Shown below are STANDARD assembly drawings. It may not reflect your

purchased system, especially when optional items are added. Refer to the

Technical References section of the manual for more detailed information.

Figure 1: Predator SS Low Profile Overview Layout

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 11

Page 13

Specifications Predator SS Turntable Stretch Wrapper Operation Manual

System Description

Figure 2: Predator SS Low Profile Machine Description

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 12

Page 14

3

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Installation &

Adjustments

Page 15

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Machine Placement

Receiving and Inspections

The Predator Turntable Stretch Wrapper has gone through quality control tests at the

factory before shipment. Upon receiving, please do the following:

1. Inspect the entire machine for visual damage during shipment. If found, immediately

report this damage to the trucking line. Highlight Industries, Inc. has taken every

precaution during the packaging and loading of this equipment, however, it is YOUR

RESPONSIBILITY to inspect for damage before installation.

2. Make sure the part or serial number indicated on the machine corresponds with the

part number of your order.

Positioning of the Machine

Place the Predator Turntable Stretch Wrapper close to an area where you will be wrapping

your loads. Make sure that there is sufficient room to load/unload the machine and that you

do not stretch the power cable. Remember, you will need to plug the machine in to a

120VAC, 15-Amp outlet.

Floor Weight Bearing/Stress Tolerance

The floor must be able to bear the weight of the machine, the weight of the maximum load,

plus a safety factor. The floor must also be able to tolerate the stress of the machine’s

operation. If the fork trucks will operate on the same weight bearing area, add the weight of

the trucks to the weight bearing stress tolerance requirements.

The Predator can be installed on any type of floor constructions that meets the weight

bearing and stress tolerance requirements.

Warning!

The Predator must be anchored securely to the floor, using the type of anchor

recommended for your floor.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 14

Page 16

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Machine Set-Up

Unpacking and Moving the Machine

It is very important to read all instructions before undertaking any of these steps. The

following steps should help achieving a safe and quick machine set-up.

1. Place the skidded machine close to the designated wrap area. Remove all shipping

fasteners holding the machine to the pallet. The machine may be crated with the

tower tilted down with the motor cover and carriage removed for shipping purposes.

1.1. Stand up tower, pivoting about the pivot bracket at the base of the tower. Once

upright align 5 bolts at tower base to frame and tighten.

1.2. Remove 4 lower bolts from carriage mount bracket – leave the top 2 bolts loose but

in place. Align keyholes on carriage back over top 2 bolts in carriage mount bracket

and hang carriage. Install and tighten all 6 mounting bolts.

1.3. The carriage photo eye bracket may need to be unbolted from its shipping position

(Figure 3) to its operating position (Figure 4).

1.4. Mount motor cover in place over turntable and carriage lift motors with provided

fasteners.

1.5. Re-connect wiring to carriage if removed for shipping.

2. Place the forks of the forklift through the tubes provided on the base of the machine,

remove the machine from the shipping skids, and place it in the designated wrap

area.

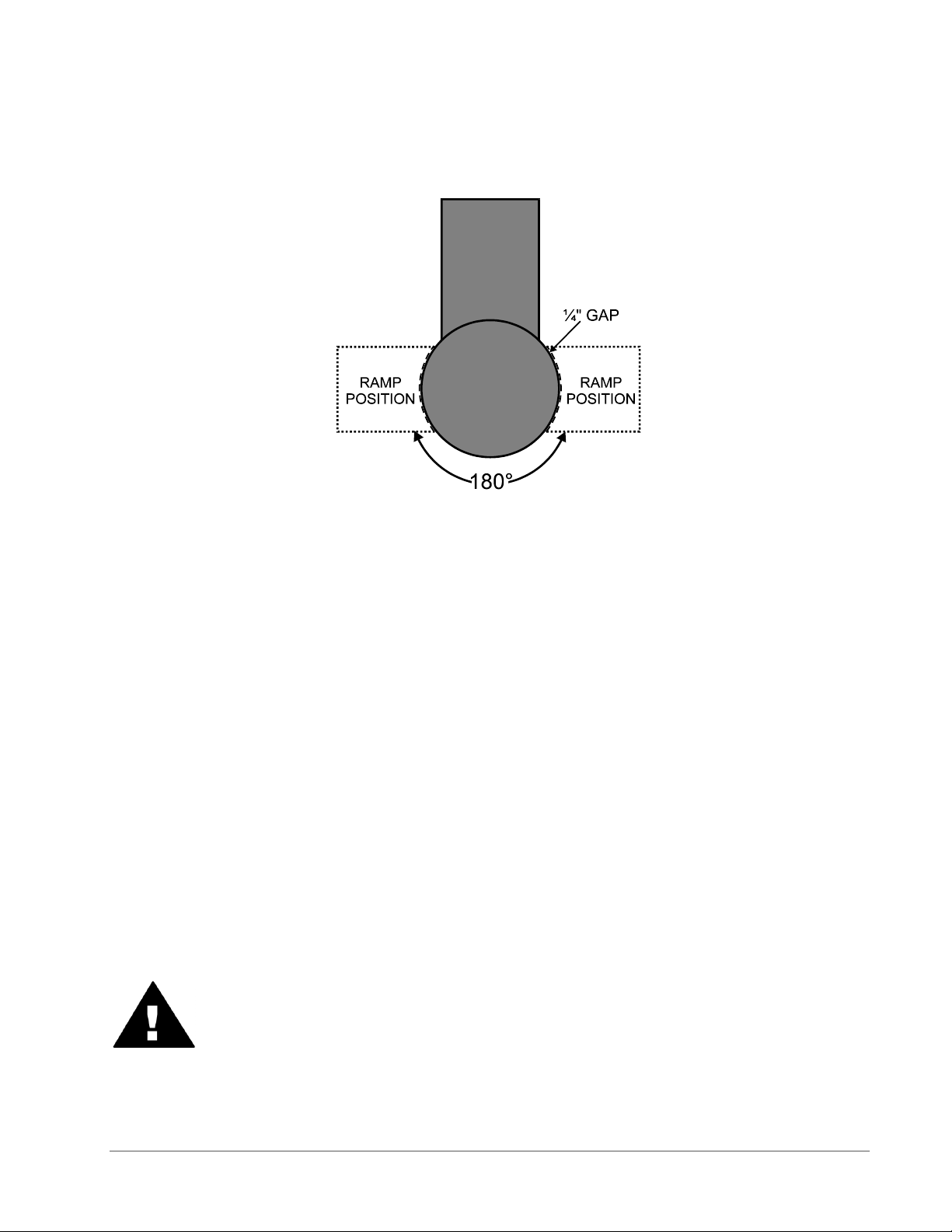

3. If the OPTIONAL ramp (Part Number #600086) is purchased:

Select a ramp position as illustrated below. The ramp can be positioned anywhere in

a 180° rotation around the front of the turntable. There should be ¼” gap between

the turntable and the ramp. The ramp should be fully supported by the floor. Both the

ramp and the machine should be lagged to the floor.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 15

Page 17

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

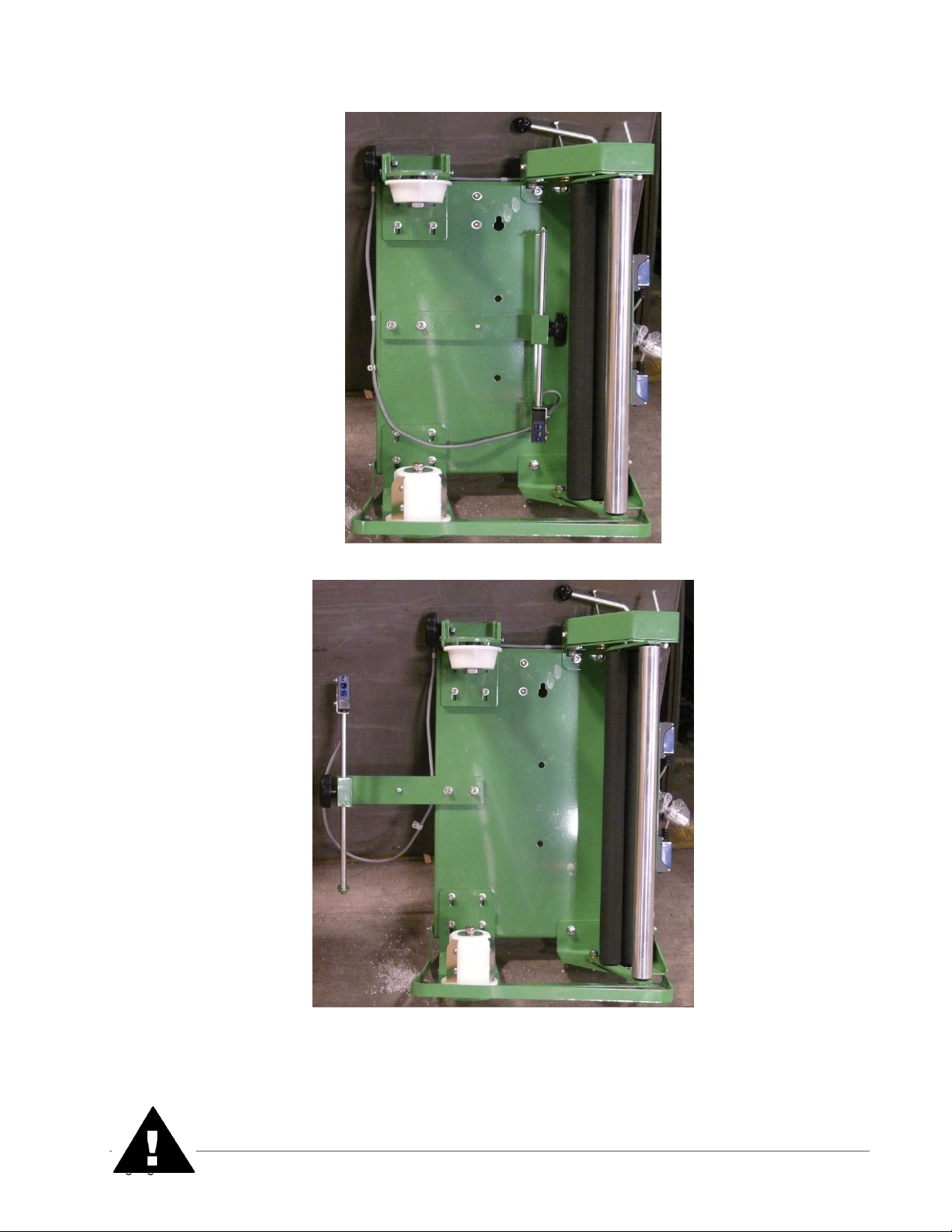

Figure 3: Bracket in the Shipping Position

Figure 4: Bracket in its Operating Position

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 16

Page 18

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Warning!

It is very important that the machine be leveled. Uneven floors will cause premature

turntable support roller failure.

Figure 5: Ramp Position for the Predator SS Low Profile

Power and Control Wiring Checks

1. Using a volt meter, check the AC voltage coming to the machine and insure the

proper voltage is present.

2. Make sure the Emergency Stop button on the operator panel is fully pressed in. Turn

the disconnect switch to the ON position. Power should be applied to the drive

board, operating touch-panel, photoelectric sensors, switches, and LED’s.

3. Press the Emergency Stop button. Make sure all machine power is completely

removed when the Emergency Stop button is depressed. Pull the Emergency Stop

button out to resume.

4. Open the electric control box. Make sure all machine power is completely removed

when the electrical control box is open. Close the electrical control box to resume.

5. Trip the carriage foot security bar. Make sure all machine power is completely

removed when the carriage foot security bar is tripped. Clear the bar to resume.

Warning!

Ensure that the Emergency Stop button light is ON when the button is pushed

in and OFF when the button is pulled out.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 17

Page 19

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

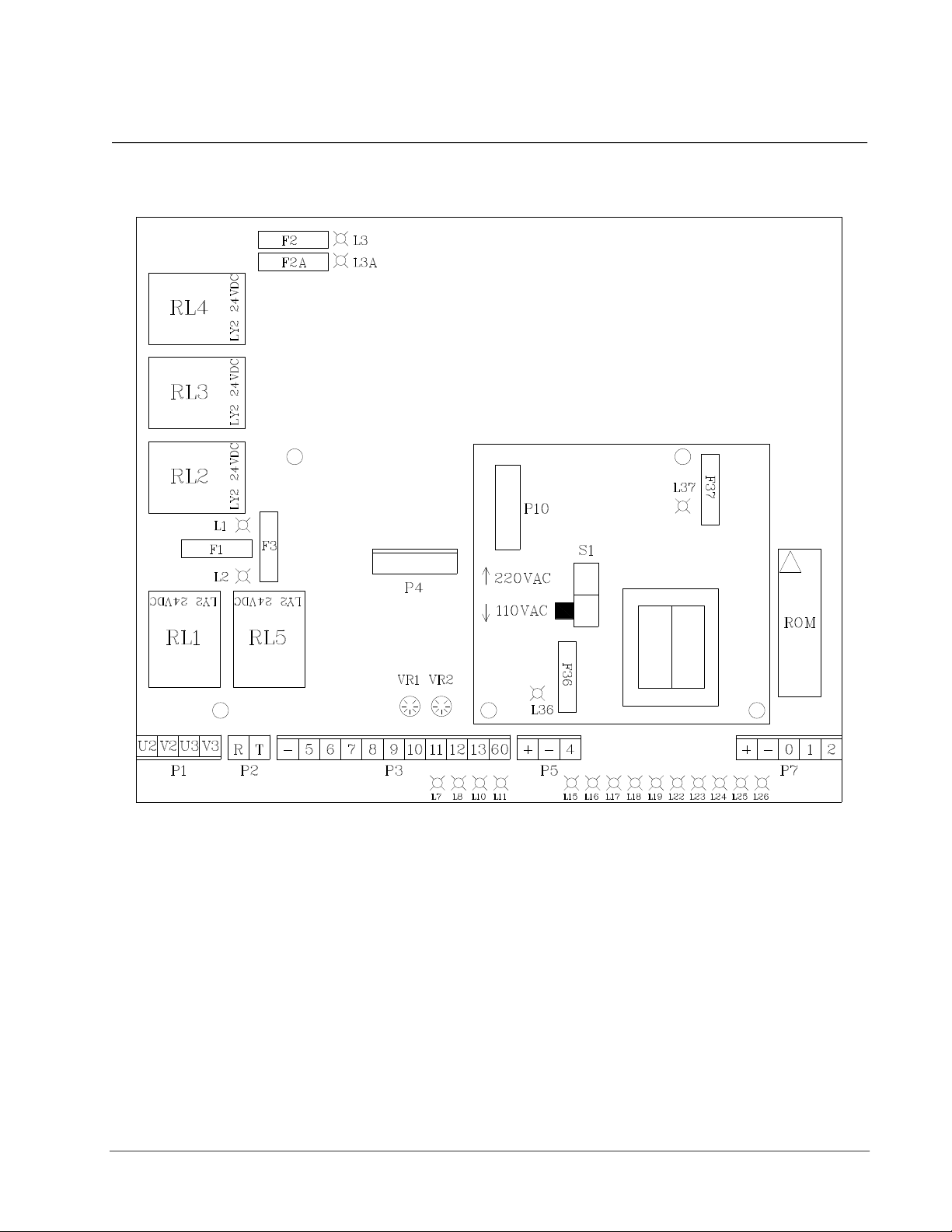

Microprocessor Card

Microprocessor Card Description

Figure 5: Microprocessor Card for the Predator SS

S1: Operating voltage selector (220 VAC or 110 VAC)

Connector P1: Turntable/Film Carriage Relay Output

Connector P2: Power Input

Connector P3: Operator Panel Input

Connector P4/P10: Transformer Input/Output

Connector P5: Turntable Proximity Sensor Input

Connector P7: Film Carriage Limit Switches Input

Relay 1: Film Carriage Down

Relay 2: Film Carriage Up

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 18

Page 20

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Relay 3: Turntable/Film Carriage Stop

Relay 4: Power Input

Relay 5: Turntable Running

Fuse 1: Carriage Motor (5 Amp)

Fuse 2/2A: Power Input (10 Amp)

Fuse 3: Turntable Motor (5 Amp)

Fuse 6: Transformer Input (1 Amp)

Fuse 7: Transformer Output (1 Amp)

LED 1 is ON: Film Carriage Motor fuse is blown

LED 2 is ON: Turntable Motor fuse is blown

LED 3/3A is ON: Power Input fuse is blown

LED 7 is ON: Cycle starts

LED 8 is ON: Film Carriage is moving up

LED 10 is ON: Film Carriage is moving down

LED 11 is ON: Turntable is rotating

LED 15 is ON: Start Button is pushed

LED 16 is ON: Pause Button is pushed

LED 19 is ON: Package Height Photo Sensor is unblocked

LED 23 is ON: Carriage Max Up Limit Switch is not tripped

LED 24 is ON: Carriage Max Down Limit Switch is tripped

LED 25 is ON: Emergency Stop Button is not pushed

LED 26 is ON: Turntable Home/Count proximity switch is blocked

LED 36 is ON: Transformer Input/Output is blown

VR1: Film Carriage Max Speed setting

VR2: Turntable Max Speed setting

Replacing Microprocessor Card

1. Turn the disconnect switch to OFF position.

2. Removed the old microprocessor card by pulling all connectors off and loosening the

four mounting screws.

3. Install the new microprocessor card; connect all connectors and tighten the

mounting screws.

4. Turn the disconnect switch to ON position. The display should show “- -“. If not,

check all connectors and fuses again.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 19

Page 21

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Optional Scale Package

The optional scale package allows the user to quickly measure the weight of the package

placed on the machine. To operate correctly and efficiently the scale needs to be

configured with the correct settings. Below are the instructions on how to re-configure the

scale and the settings that have been pre-programmed. Re-configuring the scale is not

required unless there is a problem with the existing scale or a new scale is added to the

machine. Refer to the scale manual for more information.

Note

Changing the scale parameters to values other than the Highlight

recommended values may result in poor scale operation.

Navigating the Scale Menu

Step 1: Turn the scale display over so you are looking from above down at the back side of

the scale and turn off the scale power.

Step 2: Remove the two small screws holding a small plate on the back of the scale.

Step 3: Looking down at the scale, move the switch under the plate to the right.

Step 4: Turn the scale power back on.

Step 5: Press the “PRINT / >>” button until the desired setting appears on the screen.

Step 6: Press the “ZERO” button to enter the parameter set-up.

Step 7: Press the “PRINT / >>” button until the display reads the correct setting and press

the “SET / NET” button.

Step 8: Turn the power back off, move the switch under the plate to the left, and turn the

power back on.

Step 9: Replace the screws on the back cover and retighten the scale swivel grips on the

side.

Step 10: The scale is now ready to use.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 20

Page 22

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Name/Code

Description

Highlight

Recommended

Value

F1:

Graduations

Specifies the number of full-scale graduations. Value

should be consistent with legal requirements and

environmental limits on the useful system resolution.

5000

F2: Span

Gain

Span Gain is related to A/D integration time. The larger the

span gain, the higher the internal resolution, but the slower

the update speed. Note that the scale must be recalibrated whenever this parameter is altered. See

Appendix C in the scales manual for more information.

100

F3: Zero

Track Band

Selects the range within which the scale will automatically

zero. Note that the scale must be in a standstill to zero the

scale.

3

F4: Zero

Range

Selects the range within which the scale may be zeroed.

Note that the indicator must be in standstill to zero the

scale.

100

F5: Motion

Band

Sets the level at which motion is detected by comparing

the present display update with the previous one. If motion

is not detected for two seconds or more, scale is in

standstill and can process a Print or Zero command.

Maximum value varies depending on local regulations

1

F6: Digital

Filter

Averages weight readings to produce higher stability but

the slower the indicator’s response time. Choose 8 unless

a very fast response is needed.

8

F7: Overload

Limit

Selects the desired formula which determines the point at

which the indicator shows overload. All selections are

based on the primary unit selected in F8.

2%

F8:

Calibration

Unit

Selects the primary base unit to be used in the calibration

process. Also the default unit for normal operation. 1 =

pounds, 2 = kilograms.

1

F9: Display

Divisions

Determines the desired weight increments. Value should

be consistent with legal requirements.

1

F10: Decimal

Point

Determines the location of the decimal point.

0

F16: Zero

Calibration

Places the scale in a Zero Calibration routine.

See below.

F17: Span

Calibration

Places the scale in a Span Calibration routine. See below.

See below.

Highlight Recommended Configuration Values:

Note

Changing the scale parameters to values other than the Highlight recommended

values may result in poor scale operation.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 21

Page 23

Installation & Adjustments Predator SS Turntable Stretch Wrapper Operation Manual

Scale Calibration Procedure

Note

Highlight Industries, Inc calibrates the scale before shipment using known

weights. The values stored in theses settings are custom per scale and

machine. Do not change these values unless directed to do so by Highlight

personnel.

Step 1: Navigate the scale menu to parameter “F 16.”

Step 2: Press the “ZERO” button ONCE. This enters the Zero Calibration Menu. The

display will momentarily show “C 0” followed by a value.

Step 3: After making sure that there are no test weights on the machine press the “ZERO”

button again. The display will zero.

Step 4: Press the “SET / NET” button to save the zero point value. The display will show

“EndC0” momentarily then revert to parameter F16.

Step 5: Navigate to parameter “F 17.”

Step 6: Press the “ZERO” button ONCE. This enters the Span Calibration Menu. The

display will momentarily show “C 1” followed by a value with one flashing digit. This value

will be zero with the decimal point parameter selected in F10.

Step 7: Place a known weight on the machine. Ensure that the test weight is below the

maximum capacity of the scale and above 1% of the maximum capacity of the scale.

Step 8: Key in the weight of the test weight using the buttons on the screen. Press the

“TARE / <<” button to select the digit to the left of the current position. Press “PRINT / >>”

to select the digit to the right of the current position. Press “UNITS” to increase the value of

the digit and press “ZERO” to decrease the value of a digit.

Step 9: Once the weight of the test weight is keyed in exactly, press the “SET / NET” button

to save the value. If the calibration was successful the display will read “EndC1”

momentarily, and then revert back to “F17”. If “Err0” is displayed the test weight is larger

than the full capacity of the scale. If “Err1” is displayed the test weight is below 1% of the

full capacity of the scale. If “Err2” is displayed the internal resolution of the scale is not high

enough to accept the calibration value.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 22

Page 24

4

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Operation

Instructions

Page 25

Operation Instructions Predator SS Turntable Stretch Wrapper Operation Manual

Operator Controls

The operator panel for the Predator SS is shown and described as follows:

Figure 6: Operator Controls Diagram for the Predator SS

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 24

Page 26

Operation Instructions Predator SS Turntable Stretch Wrapper Operation Manual

FUNCTION

This displays the system information:

EO = Emergency Stop condition

- - = System is normal

- - Blinking = PWS is bad or both carriage up and down are on

A = Mode A is selected

B = Mode B is selected

CO = Continue operation by pushing START button

S = System is in Manual

This displays the selected wrapping mode:

Mode A = The LED light on the button’s upper left is on. In Mode A,

the bottom wrap is applied first, and then the top wrap follows. The

film carriage comes down to its home position after wrapping cycle

is finished.

Mode B = The LED light on the button’s upper right is on. In Mode

B, after a bottom to top wrapping is completed, the carriage stays on

the top. The START button flashes at this point. To resume the

operation, push START. When the carriage reaches the bottom, the

START button goes off. Push START button again to begin a new

cycle.

The TURNTABLE JOG button allows you to manually operate the

turntable. When this button is pushed, the light on the button’s upper

left is on. Push START button to run the table. Pushing the button

again will stop the turntable, and the light will turn off. This button

may be used in conjunction with the CARRIAGE JOG button.

The CARRIAGE JOG button allows you to manually operate the

carriage. When this button is pushed, one of the lights on the

button’s upper right or left is on. The upper left light indicates that

the carriage will go up when the START button is pushed.

Conversely, the upper right light indicates the carriage will go down

when the START button is pushed. To pause the operation, simply

push this button again. Both indicator lights will go off. This button

may be used in conjunction with the TURNTABLE JOG button.

Push this RESET button, followed by a START button, to reset the

system. The turntable will return to its home position, and the

carriage will lower all the down.

Push this TOP WRAPS button to select the number of top wraps

desired (0 to 9).

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 25

Page 27

Operation Instructions Predator SS Turntable Stretch Wrapper Operation Manual

Push this BOTTOM WRAPS button to select the number of bottom

wraps desired (0 to 9).

Turn the CARRIAGE SPEED adjustment knob clockwise to

increase, and counterclockwise to decrease the carriage speed.

Turn the TURNTABLE SPEED adjustment knob clockwise to

increase, and counterclockwise to decrease the turntable speed.

The BANDING button is used for applying multi-layer reinforcing

wraps in automatic or manual mode. Push and hold this button: the

carriage will stop raising/lowering. When released, the carriage will

resume its movement.

The EMERGENCY STOP button stops the turntable in the event of

emergency. This will NOT stop the turntable instantly. The turntable

will coast to a stop, depending on the load’s weight, after this button

is pushed.

This switches the main power ON or OFF.

WARNING!

The FOOT SAFETY BAR, located underneath the film carriage, works only

when the machine is ON. When the bar is activated, the main power will shut

OFF. Releasing the bar will re-activate the main power. Push START button to

resume the operation.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 26

Page 28

Operation Instructions Predator SS Turntable Stretch Wrapper Operation Manual

Film Loading

Stretch Tension

Adjustment Knob

Stretch Tension

Indicator

Film Feed

Diagram

Stretch Handle

(in off position)

Follow the procedure below to thread the film onto the Film Carriage.

Warning!

Be sure the Emergency Stop button is pressed before threading the film and

while the film is being threaded.

1. Place the film on the film mandrel.

2. Set the Stretch Handel to the OFF position to release the tension. (See figure below)

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 27

Figure 7: Film Loading/Threading Diagram

3. Follow the Film Feed Diagram and thread the 6-foot film tail ALL THE WAY though

the rollers.

4. After threading, rotate the Stretch Tension Knob clockwise to increase film tension;

or counterclockwise to decrease film tension.

Page 29

Operation Instructions Predator SS Turntable Stretch Wrapper Operation Manual

5. Attach the film securely to the pallet. Tying the end of the film in a knot often helps

secure the film to the pallet.

Note

The Stretch Tension numbers (0 to 100) DO NOT indicate the stretch

percentage of your film. The numbers are used for reference only.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 28

Page 30

Operation Instructions Predator SS Turntable Stretch Wrapper Operation Manual

Machine Operating Instructions

Normal System Start-Up

After the machine has been positioned and supplied with proper voltage, you are ready to

begin operating. Read thoroughly and follow these steps to operate your system:

1. Place product on the turntable

2. Make sure the film carriage is situated at the max down position.

3. Thread the film as instructed, and attach it to the product.

4. Set the desired number for top and bottom wrap counts.

5. Select wrapping made “A”, “B”, or “C”.

6. Press the “Start button to initiate cycle.

Stop Condition

Follow the procedure below in the event of an emergency.

1. Press the “STOP” button. This cancels the current wrapping cycle and immediately

stops the system.

2. Correct the problem.

3. Pull the “STOP” button out, and then perform normal system start-up procedure.

Note

After pressing the “E-STOP” button, wait for at least 60 (sixty) seconds before

pulling the button back out. This will allow the microcontroller card to completely

turn off.

Applying Reinforcement Wraps

Automatic operation can be paused in order to apply reinforcement wraps to an additional

top sheet or corner boards on the product. Follow he procedure below.

1. Press the “START” button as normal to initiate cycle.

2. As the carriage travels up, press the “Banding” button. The carriage will stop and

reinforcing wraps will be applied.

3. Letting go of the “Banding” button will resume the cycle.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 29

Page 31

5

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Maintenance

Page 32

Maintenance Predator SS Turntable Stretch Wrapper Operation Manual

Preventative Maintenance

As with all machinery, proper attention and maintenance is the key to long component life,

maximum performance, and safe operation. By spending a few minutes reading and

following these preventive measures, you should reduce the downtime and prolong the life

of your system.

It is important to understand that these maintenance schedules are minimum

recommendations. Highlight Industries, Inc. cannot possibly know, evaluate, or advise the

various trades in all schedules of periodic maintenance. Accordingly, anyone who

maintains or services a stretch wrap machine must first satisfy himself/herself as to the

schedules of preventive maintenance based on cycling operation and environmental

locations.

Warning!

All maintenance operations require the equipment to be powered down and

locked out for personnel safety.

Lock-out/ Tag-out Procedures

Be sure that anyone performing any type of maintenance on this equipment is familiar with

and is adhering to the lock-out/tag-out procedures set forth by the General OSHA or the

State OSHA guidelines.

Visual Checks

Visual checks should be conducted daily before operating equipment:

1. Keep the machine and surrounding area as clean as possible, especially near

moving components.

2. Check for loose hardware, especially set screws located in: sprocket hubs, bearing

hubs, and flanges.

3. Check for oil leaks around the speed reducers.

4. Check for dry seals at the bearings.

5. Check for chain wear and proper tension on the power roller stretch sprockets. The

correct amount of chain tension can be checked by pulling the chain taut and having

3/8” slack.

6. Check for loose electrical connections and for frayed cords and cables. Replace

immediately any damaged cords and cables.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 31

Page 33

Maintenance Predator SS Turntable Stretch Wrapper Operation Manual

Turntable Belt Adjustment

Refer to the figure below to adjust the turntable belt. First, loosen the four motor flange

(M10) screws. Turn the (M10) bolt on the adjuster tab until the belt is tensioned. Retighten

the four motor flange screws.

Figure 8: Turntable Belt Adjustment

Film Carriage Lift Chain Adjustment

Refer to the figure below to adjust the film carriage lift chain. First, loosen nut (M12) on the

adjustment bracket. Turn the bottom bolt until desired tension is achieved. Retighten nut

(M12). Note that the driving chain and adjustment bracket should be parallel with the

movable pulley base.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 32

Page 34

Maintenance Predator SS Turntable Stretch Wrapper Operation Manual

Film carriage raise/lower chain

Threaded rod

Tensioning nuts

Bracket attached to backside

of carriage receiver

Bracket attached to backside

of carriage receiver

Tensioning nut

Threaded rod

Film Carriage raise/lower

chain

Sprockets and Chains

All sprockets should be inspected for wear, and chains should be checked for proper

tension and lubrication on a periodic basis. Failure to do so will lead to premature sprocket

failure. Any general-purpose chain lube should be sufficient for lubrication. Replace chain

guards when preventative maintenance is complete.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 33

Figure 9: Film Carriage Lift Chain Adjustment

Page 35

Maintenance Predator SS Turntable Stretch Wrapper Operation Manual

Maintenance Schedule

Part

Schedule

Service With

Carriage Lift Belt

Check and tighten every six months.

All pivot bearings

Initially first 1,000 cycles; every 10,000 cycles

thereafter.

Mobil EP-2 grease

Note

For additional maintenance information about specific components on the

machine, refer to the components operation manuals shipped inside the main

enclosure.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 34

Page 36

6

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Trouble-

shooting

Page 37

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

Display

Possible Problem Location(s)

E1

Film carriage max upper limit switch

E2

Film carriage max down limit switch

E3

Turntable count/home proximity switch

E4

Package height photo sensor

Self Test Troubleshooting

Warning!

Make sure that only qualified personnel will perform inspection, troubleshooting,

and part replacement.

An operator may check the status of the machine by running one of the self-tests. If the

procedures are carried out of properly, the INFO screen will display the location of the

problem.

To run Self-test A, follow the procedure below:

1. Turn the turntable and carriage speed adjustment knobs to maximum (clockwise)

position.

2. Put a load on the turntable (about 3-feet tall).

3. While holding down the TURNTABLE JOG and CARRIAGE JOG buttons, turn the

main disconnect switch ON.

4. Release the buttons after the screen shows “EE”

5. Push the START button. The machine will run the test, which takes approximately

two minutes.

6. The screen will display the alarm code. Refer to the table below for code information.

To run self-test B, follow the procedure below:

1. Turn the turntable and carriage speed adjustment knobs to maximum (clockwise)

position.

2. Put a load on the turntable (about 3-feet tall).

3. While holding down the TOP WRAPS and BOTTOM WRAPS buttons, turn the main

disconnect switch ON.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 36

Page 38

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

Display

Possible Problem Location(s)

A1

Film Carriage Safety Bar

EMERGENCY STOP button

Electrical enclosure safety switch

B1

Film carriage max upper limit switch

C1

Film carriage max down limit switch

D1

Turntable count/home proximity switch

E1

BANDING push button

F1

START push button

G1

Package height photo sensor

A2

START light

B2

Turntable motor

C2

Carriage motor

4. Release the buttons after the screen shows “99”

5. The limit switches and sensors should be on during operation. The screen will

display the alarm code that gives information about alarm code.

Figure 10: Self Test Error Display

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 37

Page 39

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

During normal machine operation, the following messages might be

displayed:

EO = Emergency Stop condition

- - = System is normal

- - = Blinking = Power supply is bad or both carriage up and down

limit switch inputs are on

A = Mode A is selected

B = Mode B is selected

CO = Continue operation by pushing START button

S = System is in Manual

Additional INFO Messages

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 38

Page 40

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

Troubleshooting Guide

Warning!

Make sure that only qualifies personnel will perform inspection, troubleshooting,

and part replacement.

High Voltage!

Disconnect all power including external control power that may be present before

servicing the machine. Wait 3 (three) minutes for the microcontroller card to fully

discharge. The machine INFO and/or LED’s are not accurate indicators of the

absence of voltage.

The diagrams in this section will guide you in identifying typical problems while operating

the Predator Turntable Stretch Wrapper, and provide you with corresponding solution(s).

Problems are divided in reference to the machine functions: power, turntable, and film

carriage.

If further assistance is required, contact the distributor from whom you have purchased the

equipment, or call the number listed on the bottom page of this manual. To receive quick

and proper technical support, please be prepared to provide the following information:

1. Machine serial number

2. Date of purchase

3. Symptoms of any problem

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 39

Page 41

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

Problem

Possible Cause

Possible Solution

The machine

does not power

up. (INFO

screen is blank)

The machine is not plugged in.

Plug the machine into a 120VAC,

20A outlet.

The Main Disconnect is turned

off.

Turn the Main Disconnect on.

A fuse is blown.

Replace the fuse(s).

The power supply has

malfunctioned.

Ensure fuses F6 and F7 are not

blown. Replace the power supply

(transformer card).

Power to the machine is not

correct

Use a voltmeter to check that the

machine is receiving 120VAC.

The INFO

display shows

E0

The Emergency Stop button is

pressed.

Turn the breaker back on, or

replace if necessary.

The film carriage foot safety

switch is tripped.

Remove any obstructions and

check that the switch is working

properly.

The electrical enclosure door

switch is open.

Ensure the door is closed and

that the safety switch is made.

The INFO

display is

flashing ‘- -‘

The power supply has

malfunctioned.

Ensure fuses F6 and F7 are not

blown. Replace the power supply

(transformer card).

The carriage raised/lowered limit

switches are both tripped.

Ensure there are no obstructions

and that the switches are working

properly.

Power Problems

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 40

Page 42

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

Problem

Possible Cause

Possible Solution

The turntable

does not rotate

manually.

The Start Button was not pressed.

The Start button needs to be

pressed at the same time as the

turntable job button to activate

manual mode.

The Turntable speed

potentiometer is not set high

enough.

Adjust the turntable speed

towards 100%.

The turntable is mechanically

restricted.

Check the condition of the motor,

chain, and rollers under the

turntable. Replace as necessary.

The turntable speed

potentiometer has failed.

Use a multi-meter to check the

resistance of the potentiometer.

A fuse on the microcontroller card

has blown.

Check fuses and replace as

needed.

The motor is not wired correctly.

Check wiring to the motor and

replace as necessary.

The turntable

does not stop at

home.

The Turntable Home proximity

switch is malfunctioning.

Check the wiring to the proximity

switch and that it is adjusted

properly (only 8mm sensing

range). Replace as necessary.

Turntable Problems

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 41

Page 43

Trouble-shooting Predator SS Turntable Stretch Wrapper Operation Manual

Problem

Possible Cause

Possible Solution

The Film

Carriage does

not Raise or

Lower manually

or in the wrap

cycle.

The Start Button was not

pressed.

The Start button needs to be

pressed at the same time as the

carriage raise/lower button to

activate manual mode.

The Carriage Banding button is

tripped.

Ensure the banding button is not

tripped and that the button is

working properly.

The Film Carriage

Raised/Lowered limit switch is

malfunctioning.

Ensure that the carriage limit

switch is clear of any obstruction

and moves smoothly. Check

wiring to the limit switch and

replace as necessary.

The film carriage speed

potentiometer is not set high

enough.

Adjust the speed potentiometer

towards 100%.

The film carriage speed

potentiometer has failed.

Use a multi-meter to check the

resistance of the potentiometer.

A fuse on the microcontroller card

has blown.

Check fuses and replace as

needed.

The motor is not wired correctly.

Check wiring to the motor and

replace as necessary.

The Film

Carriage rises

some, but does

not rise to the

top of the

package.

The Product Height Detection

photo eye is positioned too high.

Slide the Product Height

Detection photo eye lower.

The Product Height Detection

photo eye does not see the load.

Black or clear loads may require

an optional advanced sensor

instead of the standard diffuse

sensor.

Check wiring to the sensor.

Replace the sensor as

necessary.

The Product Height Detection

photo eye is not adjusted

properly.

Adjust position or sensitivity of

the sensor.

The Film

Carriage rises

too far above the

package.

The Product Height Detection

photo eye is positioned too low.

Slide the Product Height

Detection photo eye higher.

The Product Height Detection

photo eye is not adjusted properly

and always sees a ’package’.

Adjust the sensitivity of the

sensor (see the Photo Sensor

Adjustments and/or PreOperation Adjustments section).

Film Carriage Problems

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 42

Page 44

7

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Technical

References

Page 45

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Machine

Section

HLI Part

Number

Item Description

Qty

Turntable

300013

BELT B-172

1

Turntable

500010

PLASTIC SUPPORT WHEEL

6

Turntable

300037

TURNTABLE DRIVE MOTOR – 1/4HP (60” dia turntable)

1

Turntable

300040

TURNTABLE DRIVE MOTOR – 1/2HP (72” dia turntable)

1

Turntable

300031

TURNTABLE DRIVE REDUCER (60” dia turntable)

1

Turntable

300032

TURNTABLE DRIVE REDUCER (72” dia turntable)

1

Scale

306275

LOAD CELL

1

Scale

306276

LOAD CELL FOOT

1

Tower

300038

CARRIAGE LIFT MOTOR – 1/4HP

1

Tower

300030

CARRIAGE LIFT REDUCER

1

Recommended Spare Parts

The table below provides the recommended spare parts list for the Predator SS Turntable

Stretch Wrapper.

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 44

Page 46

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Electrical Drawings

Electrical Schematics

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 45

Page 47

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Electrical Schematics (continued)

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 46

Page 48

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Enclosure Layout

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 47

Page 49

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Sensor Layout

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 48

Page 50

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Machine

Section

HLI Part

Number

Item Description

Qty

1

401495

MICROPROCESSOR CARD

1 2 401361

TRANSFORMER CARD

1 3 401362

FUSE, 250 VAC, 1 AMP, GMA

2 4 401363

EPROM 1 5

403261

FUSE, 250 VAC, 10 AMP, GMA

2 6 401365

FUSE, 250 VAC, 5 AMP, GMA

2 7 401366

RELAY LY2 DC24V

5

11

401367

BUTTON WHITE

1

12

401368

BUTTON SEAT CONTACTOR Nox1

1

13

400609

400610

400611

AUTO RUN GREEN LAMP: COVER

SEAT

LIGHT

1

1

1

14

401371

KNOB RN-99F,ø6.4

2

15

400649

VARIOUS RESISTOR 5K

2

16

401372

EMG. SWITCH

1

17

401373

BUTTON SEAT CONTACTOR NCx1

1

18

401374

MAIN POWER SWITCH

1

21

400639

LIMIT SWITCH TZ-8108

2

22

400636

LIMIT SWITCH TM-1307

1

23

400641

PROXIMITY SWITCH PS-05N-3M

1

24

400637

LIMIT SWITCH TZ-7110

1

25

400643

PHOTO SENSOR A3R-2MX(OPTION)

1

26

404261

FAN, 80MM, 110-120VAC

1

27

404262

FUSE HOLDER

1

28

404263

FUSE, 0.2A, 30MM

1

N/S

310008

BUTTON MEMBRANE LABEL FOR CONTROL PANEL

1

N/S

403409

CARRIAGE CONTROL CABLE

1

Electrical Parts List

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 49

Page 51

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Mechanical Drawings

Turntable Frame Assembly

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 50

Page 52

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Machine

Section

HLI Part

Number

Item Description

Qty

1

300037

300040

MOTOR VP3310D 1/4HP 1.5M

MOTOR VP3330D 1/2HP 1.8M

1

1 2 200091

SCREW M8X20L & W.

3 200092

SCREW M10x20L & S.W. & W.

4

4

300031

300032

SPEED REDUCER 1/4HP 1.5M

SPEED REDUCER 1/2HP 1.8M

1

1 5 300002

KEY 5X20L

1

6

200093

SCREW M10x25L & S.W. & W.

4

7

500034

500035

MOTOR ADJUST SEAT 1.5M

MOTOR ADJUST SEAT 1.8M

1

1

8

500014

500015

MOTOR PULLEY 4”22 1.5M

MOTOR PULLEY 4”28 1.8M

1

1 9 207303

SET SCREW, M8 x 10L

2

10

200095

SCREW M10x70L

1

11

200077

SCREW M6x12L & W.

1

12

500083

MOTOR BOX FIX PLATE

1

13

500087

PIN 2 14

300006

RING STW-10

2

15

600000

600001

TURNTABLE SEAT 1.5M

TURNTABLE SEAT 1.8M

1

1

16

300009

RING STW-17

48

17

305300

305300

BEARING 6203ZZ 1.5M

BEARING 6203ZZ 1.8M

24

28

18

500010

500010

SUPPORTING PLASTIC WHEEL 1.5M

SUPPORTING PLASTIC WHEEL 1.8M

12

14

19

500009

500009

SUPPORTING PLASTIC WHEEL SHAFT 1.5M

SUPPORTING PLASTIC WHEEL SHAFT 1.8M

12

14

20

300009

RING STW-17

1

21

305300

BEARING 6203ZZ

2

22

500011

BELT LOCK PULLEY

1

23

500012

BELT LOCK PULLEY SHAFT

1

24

200078

SCREW M6x16L

3

25

200098

SCREW M3x25L & W.

2

26

400641

PROXIMITY SWITCH PS-05N-3M

1

Turntable Parts List

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 51

Page 53

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

27

500013

PROXIMITY SWITCH FIX SEAT

1

28

200103

SCREW M4x20L

2

29

200128

NUT M5

6

30

300013

300014

BELT B-172 1.5M

BELT B-183 1.8M

1

1

31

200113

SCREW M8x25L

4

32

500004

500005

TURNTABLE PLATE 1.5M

TURNTABLE PLATE 1.8M

1

1

33

200084

SCREW M8x20L

4

34

500007

WHEEL 22”

1

35

500006

LOCATING PLATE

1

36

200108

SCREW M5x10L & W.

4

37

500008

PULLEY FIXING PLATE

1

38

500085

BELT PULLEY SEAT RING

1

39

300012

RING RTW-42

1

40

500084

BELT PULLEY SHAFT

1

41

300018

BEARING 6004ZZ

2

42

300010

RING STW-20

1

43

500086

BELT PULLEY BEARING SEAT

1

44

200088

SCREW M10x16L

4

45

200100

SCREW M4x8L & W.

4

46

500081

500082

MOTOR COVER 1.5M

MOTOR COVER 1.8M

1

1

47

600028

600029

TURNTABLE MOTOR BOX 1.5M

TURNTABLE MOTOR BOX 1.8M

1

1

48

200100

SCREW M4x8L & W.

2

49

600038

RAMP (FOR 60” TURNTABLE - NOT SHOWN)

OPT

50

600039

RAMP PORCH – 24” (FOR 60” TURNTABLE - NOT SHOWN)

OPT

51

602297

RAMP PORCH – 48” (FOR 60” TURNTABLE - NOT SHOWN)

OPT

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 52

Page 54

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Turntable Scale Frame Assembly (optional)

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 53

Page 55

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Machine

Section

HLI Part

Number

Item Description

Qty

1

300037

MOTOR VP3310D 1/4HP 1.5M

1 2 200091

SCREW M8X20L & W.

3 200092

SCREW M10x20L & S.W. & W.

4 4 300031

SPEED REDUCER 1/4HP 1.5M

1 5 300002

KEY 5X20L

1 6 200093

SCREW M10x25L & S.W. & W.

4

7

500034

MOTOR ADJUST SEAT 1.5M

1

8

500014

MOTOR PULLEY 4”22 1.5M

1

9

207303

SET SCREW, M8 x 10L

2

10

200095

SCREW M10x70L

1

11

200077

SCREW M6x12L & W.

1

12

500083

MOTOR BOX FIX PLATE

1

13

500087

PIN 2 14

300006

RING STW-10

2

15

600424

TURNTABLE SEAT WITH INTEGRAL SCALE - 1.5M

1

16

300009

RING STW-17

48

17

300021

BEARING 6203ZZ 1.5M

24

18

500010

SUPPORTING PLASTIC WHEEL 1.5M

12

19

500009

SUPPORTING PLASTIC WHEEL SHAFT 1.5M

12

20

300009

RING STW-17

1

21

300021

BEARING 6203ZZ

2

22

500011

BELT LOCK PULLEY

1

23

500012

BELT LOCK PULLEY SHAFT

1

24

200078

SCREW M6x16L

3

25

200098

SCREW M3x25L & W.

2

26

400641

PROXIMITY SWITCH PS-05N-3M

1

27

504280

PROXIMITY SWITCH FIX SEAT

1

28

200103

SCREW M4x20L

2

29

200128

NUT M5 6 30

300013

BELT B-172 1.5M

1

31

200113

SCREW M8x25L

4

32

500004

TURNTABLE TOP 1.5M

1

Turntable Parts List

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 54

Page 56

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

33

200084

SCREW M8x20L

4

34

500007

WHEEL 22”

1

35

504281

LOCATING PLATE

1

36

200108

SCREW M5x10L & W.

4

37

500008

PULLEY FIXING PLATE

1

38

500085

BELT PULLEY SEAT RING

1

39

300012

RING RTW-42

1

40

500084

BELT PULLEY SHAFT

1

41

300018

BEARING 6004ZZ

2

42

300010

RING STW-20

1

43

500086

BELT PULLEY BEARING SEAT

1

44

200088

SCREW M10x16L

4

45

200100

SCREW M4x8L & W.

4

46

500081

MOTOR COVER 1.5M

1

47

600028

TURNTABLE MOTOR BOX 1.5M

1

48

200100

SCREW M4x8L & W.

2

49

200140

JAM NUT – M12

REF

50

306276

LOAD CELL FOOT

4

51

306275

LOAD CELL

4

52

300353

SCALE DISPLAY (NOT SHOWN)

1

53

600947

RAMP – INTEGRATED SCALE (NOT SHOWN)

OPT

54

510287

SUMMING BOARD COVER (NOT SHOWN)

1

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 55

Page 57

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Tower Assembly

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 56

Page 58

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Machine

Section

HLI Part

Number

Item Description

Qty

1

500133

500317

TOWER - STD

TOWER - 110

1

1 2 300038

ELEVATOR UNIT MOTOR VP3310D

1 3 200091

SCREW M8x20L & S.W.

4 4 200090

SCREW M10x25L & S.W. & W.

5 5 300030

ELEVATOR UNIT SPEED REDUCER VTM-40

1 6 200085

SCREW M8x25L & S.W. & W.

4 7 500135

CHANNEL SUPPORT

2

8

200078

SCREW M6x16L & S.W. & W.

4

9

500136

500290

CHAIN WHEEL COVER - STD

CHAIN WHEEL COVER - 110

1

1

10

500041

UP & DOWN CHAIN WHEEL (LOWER) 11 TEETH

1

11

200802

SHCS, M6 x 16L & S.W & W

1

12

300020

BEARING 6202-2NR

1

13

500102

SPEED REDUCER BEARING SEAT

1

14

200099

SCREW M4x6L & W.

2

15

200120

SCREW M6x8L

1

16

300000

PIN ø4X8

1

17

200082

SCREW M8x12L

2

18

500103

BEARING ADJUST SEAT

1

19

200077

SCREW M6x12L & W.

4

20

500003

UPPER CHAIN WHEEL SHAFT

1

21

300017

BEARING 6002ZZ

2

22

500118

UPPER CHAIN WHEEL

1

23

500093

RING 2 24

300008

RING STW-15

2

25

500104

ADJUST BAR WASHER

1

26

200140

NUT M12

1

27

300049

500488

CHAIN - STD

CHAIN - 110

1

1

28

500025

ELEVATOR UNIT CHAIN SCREW SHAFT

2

29

200147

WASHER M12

4

30

500092

CHAIN ADJUST SEAT

1

Tower Parts List

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 57

Page 59

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

31

200133

NUT M12

3

32

300007

RING STW-12

6

33

300016

BEARING 6001ZZ

8

34

500090

UP & DOWN DRIVING WHEEL

4

35

500091

UP & DOWN DRIVING WHEEL SHAFT

4

36

500040

CHAIN WHEEL SEAT

1

37

200131

NUT M10 & S.W. & W.

6

38

600008

ELEVATOR UNIT SEAT (INNER)

1

39

200084

SCREW M8x20L & S.W. & W.

2

40

200083

SCREW M8x16L & S.W. & W.

6

41

500138

LIMIT PLATE

2

42

200125

SCREW M6x16L & S.W & NUT

4

43

500139

500140

CHANNEL - STD

CHANNEL - 110

1

1

44

200078

SCREW M6x16L

1

45

500141

FIX PIECE

1

46

500142

HANDEL WHEEL

1

47

400637

LIMIT SWITCH TZ-7110

1

48

200105

SCREW M4x30L & W

2

49

300041

LOCK w/ KEY

2

50

500143

CONTROL BOX

1

50a

310008

BUTTON MEMBRANE LABEL FOR CONTROL PANEL

1

51

200076

SCREW M6x10L & S.W.

1

52

300048

LOCK LATCH PLATE

2

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 58

Page 60

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Film Carriage Assembly

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 59

Page 61

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Machine

Section

HLI Part

Number

Item Description

Qty

1a

500000

KNOB

1

1b

204908

KNOB THREADED ROD STUD

1 2 500144

FILM FIX SEAT(UPPER)

1 3 500145

SHAFT

1 4 300006

RING STW-10

2 5 200079

SCREW M6x20L & S.W. & W.

4 6 200627

FLAT HEAD SCREW M10x20L

1

7

500146

FILM MOVING SHAFT

1

8

500147

FILM SEAT SPRING

1 9 500148

FILM SEAT(UPPER)

1

10

500101

FILM SEAT SHAFT

1

11

500149

504260

ELEVATOR UNIT SEAT(OUTER)-20”

ELEVATOR UNIT SEAT(OUTER)-30”

1

1

12

500150

PEDAL

1

13

200079

SCREW M6x20L & S.W. & W.

4

14

700072

LOWER CORE HOLDER ASSEMBLY

1 W

FILM SEAT SHAFT

1* X

SPRING

1* Y

BEARING NTB/A51730

1* Z – 500107

FILM CORE HOLDER

1*

Za – 500111

FILM BRAKE PLATE

2*

Zb – 500694

FILM BRAKE DISC

1*

Zd – 500112

WASHER

1*

18

500151

FILM FIX SEAT(LOWER)

1

19

200089

SCREW M10x20L

1

23

200079

SCREW M6x20L & S.W. & W.

2

24

500152

LIMIT SWITCH SEAT

1

25

400639

LIMIT SWITCH TZ-8108

2

26

200101

SCREW M4x12L

2

27

500130

TERMINAL COVER

1

28

200102

SCREW M4x16L

4

29

200101

SCREW M4x12L

4

31

200077

SCREW M6x12L & S.W. & W.

2

Film Carriage Parts List

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 60

Page 62

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

32

200137

NUT M6

2

33

200103

SCREW M4x20L

1

34

200079

SCREW M6x20L

2

35

500016

SPRING

1

36

200127

NUT M4

2

37

500913

HANDLE KNOB

1

38

500153

HANDLE

1

39

200077

SCREW M6x12L & S.W. & W.

2

40

300006

RING STW-10

1

41

500154

RING

1

42

200157

SCREW M6x100L

2

43

200129

NUT M6

4

44

500155

STRETCH SEAT COVER(UPPER)

1

45

500156

WHEEL

1

46

200121

SCREW M6x10L

1

47

200130

NUT M8 & S.W.

2

48

500157

STRETCH SEAT SHAFT

1

49

200130

NUT M8 & W.

1

50

500158

RING

1

51

500159

UPPER STRETCH SEAT

1

52

500160

TENSION ADJUST SEAT

1

53

500161

STRETCH SPRING

1

54

500162

BRAKE PLATE

1

55

500163

TENSION ADJUST SCREW

1

56

500164

GEAR SCREW FIX SEAT

1

57

500154

RING

1

58

500000

HANDLE

1

59

200077

SCREW M6x12L & S.W. & W.

2

60

500165

BREAK PLATE SHAFT

1

61

200129

NUT M6 & S.W.

2

62

500166

BREAK WHEEL FIX SHAFT

1

63

500167

BRAKE WHEEL

1

64

300002

PIN 5x5x20L

1

65

200084

SCREW M8x20L & S.W. & W.

2

66

300051

BEARING 6004ZZ-NR

2

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 61

Page 63

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

67

500168

504261

PRE-STRETCH SHAFT-20”

PRE-STRETCH SHAFT-30”

1

1

68

400640

WIRE PROTECTOR

1

69

400636

LIMIT SWITCH TM-1307

1

70

200104

SCREW M4x25L

2

71

500169

LOWER STRETCH SEAT

1

72

200084

SCREW M8x20L & S.W. & W.

2

73

300010

RING STW-20

1

74

500158

RING

2

75

500170

MOVING SHAFT PIN

2

76

200833

SCREW M6x12L

4

77

500171

500172

MOVING SHAFT

MOVING SHAFT

1

1

78

300052

RING STW-22

4

79

300006

RING STW-10

4

80

300015

BEARING 6000ZZ

4

81

500173

504262

IDLER ROLLER-20”

IDLER ROLLER-30”

1

1

82

500174

504263

IDLER ROLLER SHAFT-20”

IDLER ROLLER SHAFT-30”

2

2

83

500175

504264

IDLER ROLLER-20”

IDLER ROLLER-30”

1

1

85

200127

NUT M4 (OPTION)

2

86

400643

PHOTO SENSOR A3R-2MX

1

87

200101

SCREW M4x12L & W.

2

88

200110

SCREW M6x12L

2

89

500094

FIX PIECE

1

90

200079

SCREW M6x20L & S.W. & W.

2

91

500176

PHOTO SENSOR ADJUST SEAT

1

92

500000

HANDLER

1

93

500095

PHOTO SENSOR ADJUST BAR

2

94

500096

CONNECTING PLATE

1

95

200077

SCREW M6x12L & S.W. & W.

2

96

304629

SPACER, ANTI-SQUEAK

1

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 62

Page 64

Technical References Predator SS Turntable Stretch Wrapper Operation Manual

Advanced Infrared Eye - Optional

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 63

Page 65

8

Highlight Industries, Inc.

Predator SS Turntable Stretch Wrapper Operation Manual

Notes

Page 66

Notes Predator SS Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 65

Page 67

Notes Predator SS Turntable Stretch Wrapper Operation Manual

Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465 66

Loading...

Loading...