Page 1

HLK-1510

SHANGHAI HUIGONG NO.3 SEWING MACHINE FACTORY

ELECTRONIC PATTERN SEWING MACHINE

Instruction Manual

Parts Catalog

Page 2

Thistechnicalmanualexplainstheinstructionshowtooperateandmaintainthesewing

machine.AllinformationinthistechnicalManualaresubjecttochangewithoutnotice

.

ShangHai

ShangHai

ShangHai

ShangHaiHuiGong

Hui Gong

HuiGong

HuiGongCORPROTATION

COR PROTA TION

CORPROT A TION

CORPROT A TIONhas

all

thecopyrightsonthistechnicalmanual

.

Reprintingthepartsor

all

ofthistechnicalmanualisnotallowedwithoutpermission.

FOR

NO

Warningsign

Meaningsofwarningsign

1

2

3

Cautionforsewingmachineoperation:

Warningtooperatethesewingmachine

withoutsafetyguardsandtoprohibitdoing

anyoperationexceptsewingwhilethe

poweristurnedon.

<Interpretationofsign>

·Donotoperatewithoutfingerguard,eye

guard,beltcoverandothersafetydevices

.

·Beforethreading,changingneedleand

bobbinclearing,oilingetc.switchoffmain

switch.

Cautionforawoundonthefingers:

Warningtoapossibledangertocausea

woundonthefingersunderthespecified

operation.

Cautionforthefingers:

Warningtoapossibledangertobecaught

thefingersinthemachineunderthe

specifiedoperation.

FOR

FOR

FORYOUR

Ifyouoperatethesewingmachinefirsttime,pleasemakesuretoreadthefollowing

instructionsforyoursafetyandproperoperation.

CAUTION

Inthistechnicalmanual。thenoticeCAUTION

attentionforthesafety.Pleasekeepitinmindwheneveryouworkwiththesewingmachine.

CAUTION

CAUTION

CAUTION

CAUTIONisusedasthenoticetowarnapossibledangertocauseawound

CAUTION

CAUTIONismentionedatsomeparagraphtoattractyour

YOUR

YO UR

YOURSAFETY!

SAF ETY!

SAFETY!

SAFETY!

Explanations

Explanations

Explanations

Explanationsfor

for

the

f or

th e

forthe

thewarning

war ning

warning

warningsigns

sig ns

signs

signs

Page 3

Caution

★ For avoiding the sewing machine from the troubles,please do not operate the sewing

machine under the following conditions.

1. T emperature and humidity

During operating:

The atmosphere temperature should not exceeded more 350 ℃( 9 5° F ) or less 5°C(41°F).

During transportation:

The atmosphere temperature should not exceeded more 55°C(131°F) or less -10°C(18°F).

The relative humidity in the atmosphere should not exceeded more 85%or less 45%.

2. Atmosphere for the machine operation

In the atmosphere filled with dust or corrosive gas.

In the atmosphere filled with flammable or explosive gas.

3. Power source voltage

In the place where the power fluctuation exceeds more or less 10%of the fixed power voltage.

In the place where the power source cannot supply enough voltage to keep the motor running.

4. Power source voltage

In the place where the power fluctuation exceeds more or less 10%of the fixed power voltage.

In the place where the power source cannot supply enough voltage to keep the motor running.

5. Noise

In the place near a high frequency transmitter or a high frequency welder.

In the place filled with strong electromagnetic radiation or magnetic field.

Page 4

----- CONTENTS -----

1 STRUCTURE OF THE SEWING MAC HI NE ............................................................................................... 1

2 SPECI FICATION ........................................................................................................................................... 2

3 INSTALLATION ............................................................................................................................................. 3

3-1 Installation of the control box ........................................................................................................................... 3

3-2 Installation of the power switch ........................................................................................................................ 3

3-3 Installation of the oil pan .................................................................................................................................. 3

3-4 Installation of the sewing machine head ........................................................................................................... 4

3-5 Installation of the spindle motor ....................................................................................................................... 4

3-6 Connection of the operation panel .................................................................................................................... 5

3-7 Connection of the electric cables ...................................................................................................................... 5

3-8 Installation of the thread stand .......................................................................................................................... 6

4 LUBRICATION ............................................................................................................................................... 7

4-1 Filling the oil tank ............................................................................................................................................ 7

4-2 Oiling ............................................................................................................................................................... 7

5 PROPER O PER ATION ................................................................................................................................... 7

5-1 Installation of the needle .................................................................................................................................. 7

5-2 Threading the upper thread ............................................................................................................................... 8

5-3 Winding the bobbin thread

5-4 Settling the bobbin ........................................................................................................................................... 9

5-5 Setting the bobbin case ................................................................................................................................... 10

6 PROPER SEWING ........................................................................................................................................ 10

6-1 Operation of the halt switch ........................................................................................................................... 10

6-2 The sewing operation ..................................................................................................................................... 11

6-3 Adjustment of the thread tension .................................................................................................................... 12

7 ST ANDARD ADJ USTMENT ....................................................................................................................... 13

7-1 Adjustment of the needle bar position ............................................................................................................ 13

7-2 Adjustment of the position between the needle and the shuttle hook .............................................................. 14

...............................................................................................................................

8

7-3 Adjustment of the clearance between the shuttle hook and the needle

7-

4 Adjustment of the clearance between the driver and the needle ...................................................................... 15

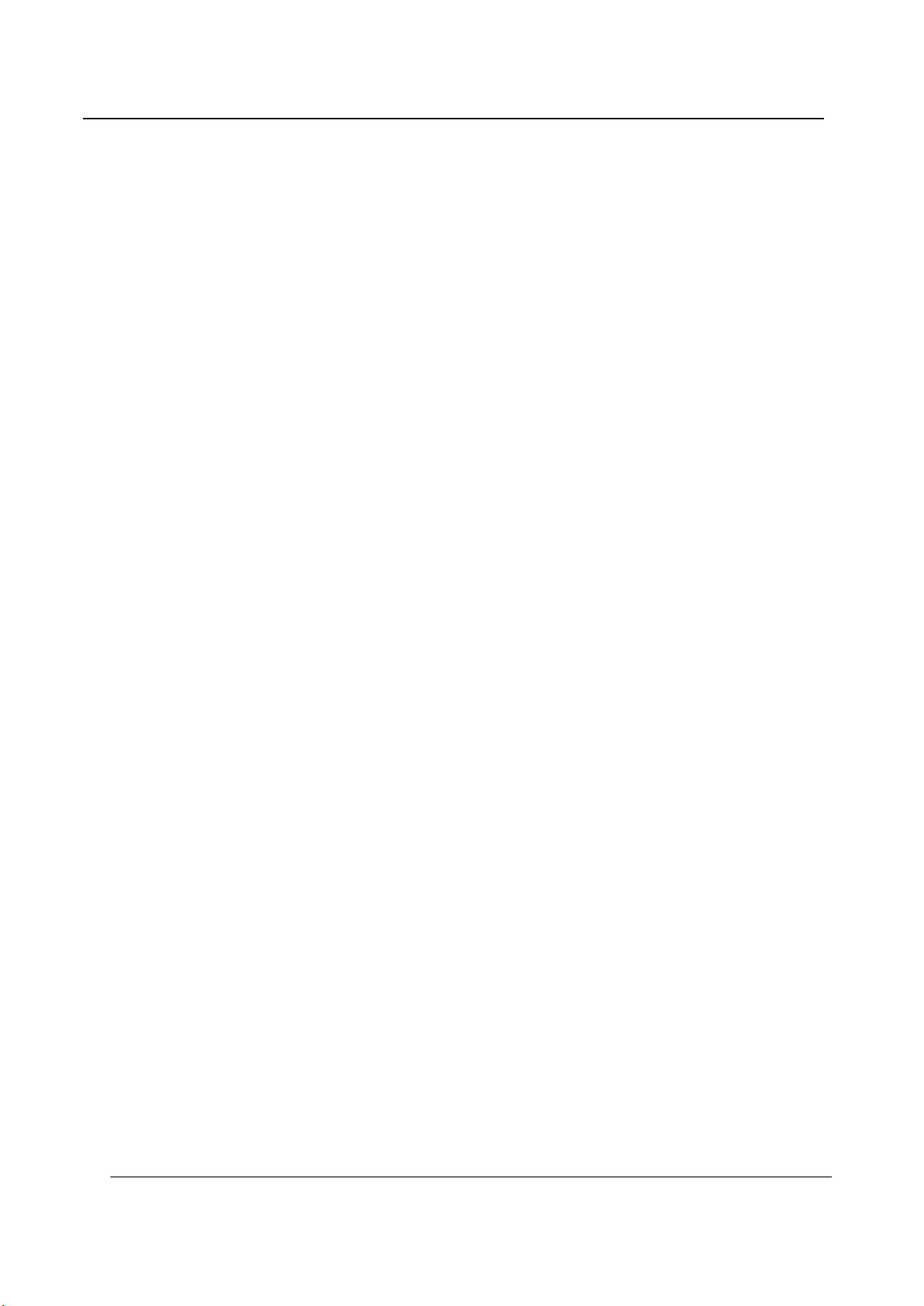

7-5 Adjustment of the thread guide ...................................................................................................................... 15

7-6 Adjustment of the presser foot ....................................................................................................................... 16

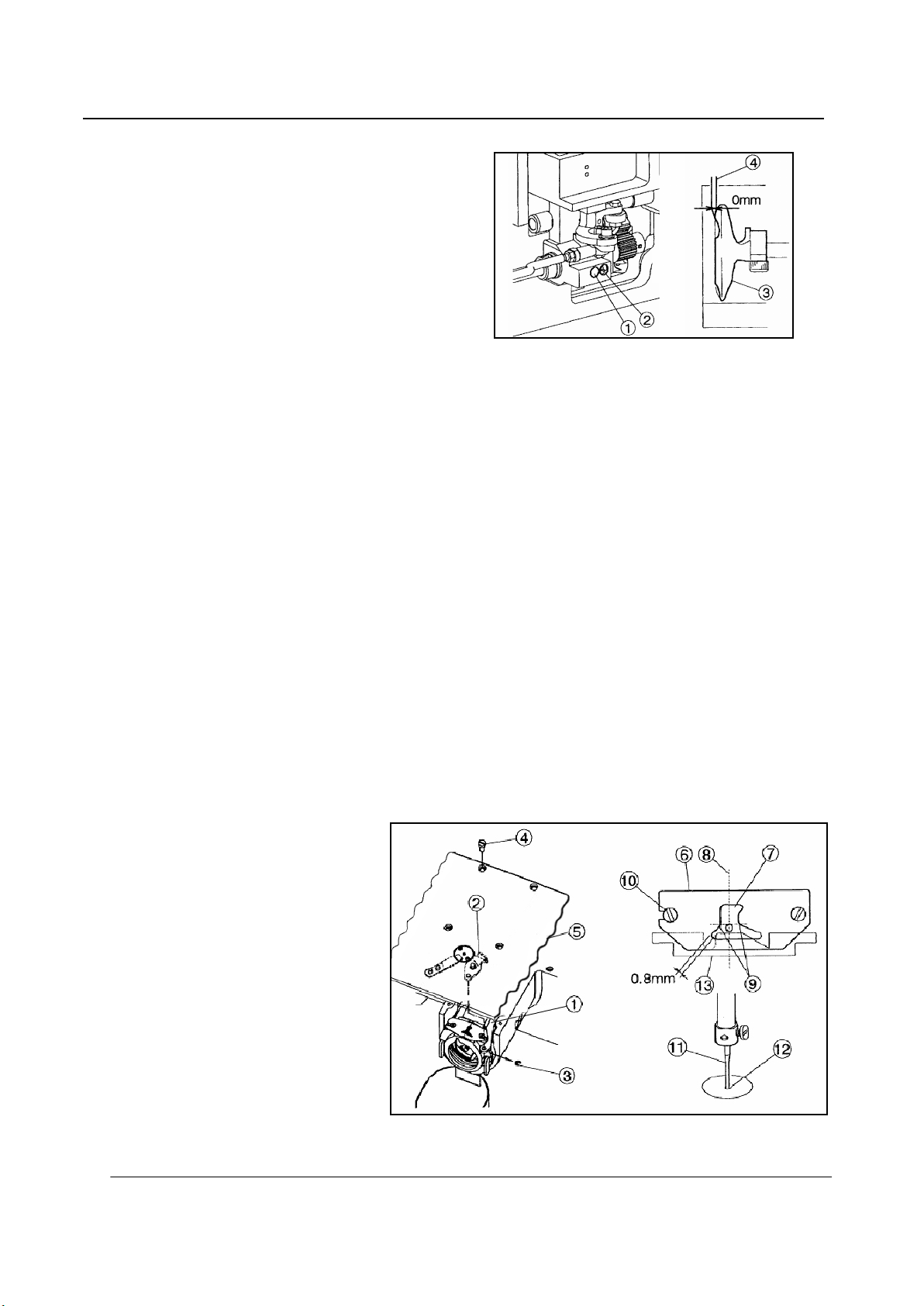

7-7 Adjustment of the wiper ................................................................................................................................. 19

7-8 Adjustment of the bobbin winder ................................................................................................................... 19

............................................................ 14

Page 5

7-9 Adjustment of the work holder ....................................................................................................................... 20

7-10 Adjustment of the trimmer cam follower ....................................................................................................... 20

7-11 Adjustment of the position for the movable knife point .................................................................................. 21

7-12 Adjustment of the fixed knife position ........................................................................................................... 21

7-13 Adjustment of the thread take up spring swing stroke .................................................................................... 22

7-14 Adjustment of the thread take up spring tension ............................................................................................. 22

7-15 Adjustment of the thread tail after the trimming ............................................................................................. 22

7-16 Cancellation of the trimming function ............................................................................................................ 22

7-17 Adjustment of the upper thread tension release .............................................................................................. 23

7-18 Adjustment of the mechanical home position ................................................................................................. 23

7-19 Adjustment of the X-Y table contact pressure ................................................................................................ 25

7-20 Adjustment of the X timing belt tension ......................................................................................................... 25

7-21 Adjustment of Y stepping motor position ....................................................................................................... 25

8 MAINTENANCE .......................................................................................................................................... 26

8-1 Cleaning ......................................................................................................................................................... 26

8-2 Disposing of oil waste .................................................................................................................................... 26

9 BAD SEWING CONDI TI O N&ITS CAUSE AND REM EDY .................................................................... 27

PARTS CATALOG

A. ARM BED &IT'S ACCESSORIES(一) .................................................................................................... 31

B. ARM BED &IT'S ACCESSORIES(二) .................................................................................................... 34

C. SEWING MECHANISM(一) ................................................................................................................... 37

D. SEWING MECHANIS M(二) ................................................................................................................... 40

E. X-Y TABLE MECHANISM(一) ............................................................................................................... 42

F. X-Y TABLE MECHANISM(二) ............................................................................................................... 44

G. CABLE COMPONENT & DETECT O R M EC HA NI S M ............................................................................... 46

H. WORK HOLDER MECH A NI SM ( AIR OPERATED) ................................................................................... 48

J. PRESSER FOOT MECHANI SM ................................................................................................................... 51

K. PRESSER BAR LIFTING ME CH ANISM ..................................................................................................... 53

L. THREAD TRIMMING MECHANI SM ......................................................................................................... 55

M. WIPER MECHANISM .................................................................................................................................. 58

N. OIL LUBRI CATION MECHANISM ............................................................................................................. 60

R. ACCESSORIES ............................................................................................................................................. 62

Page 6

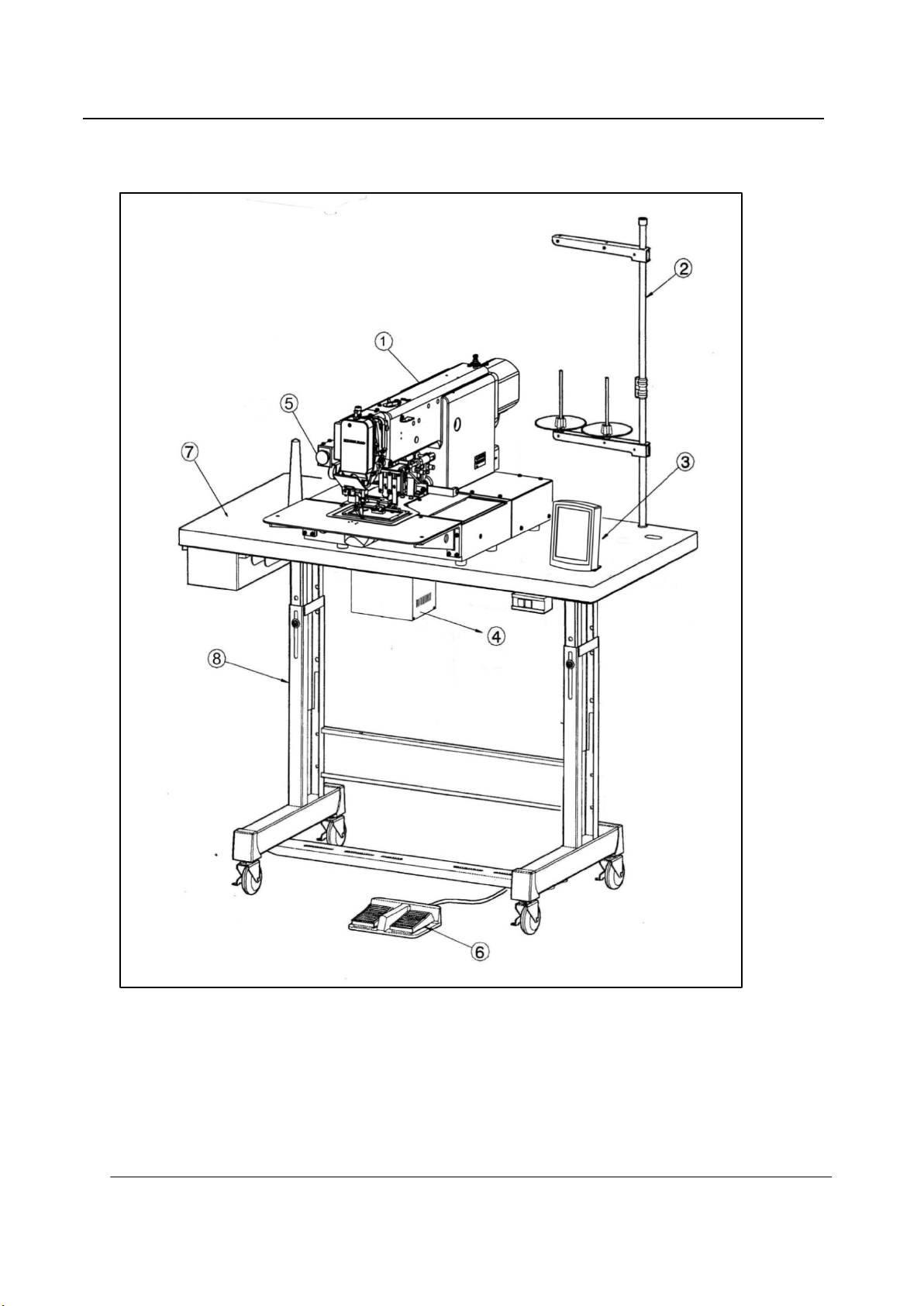

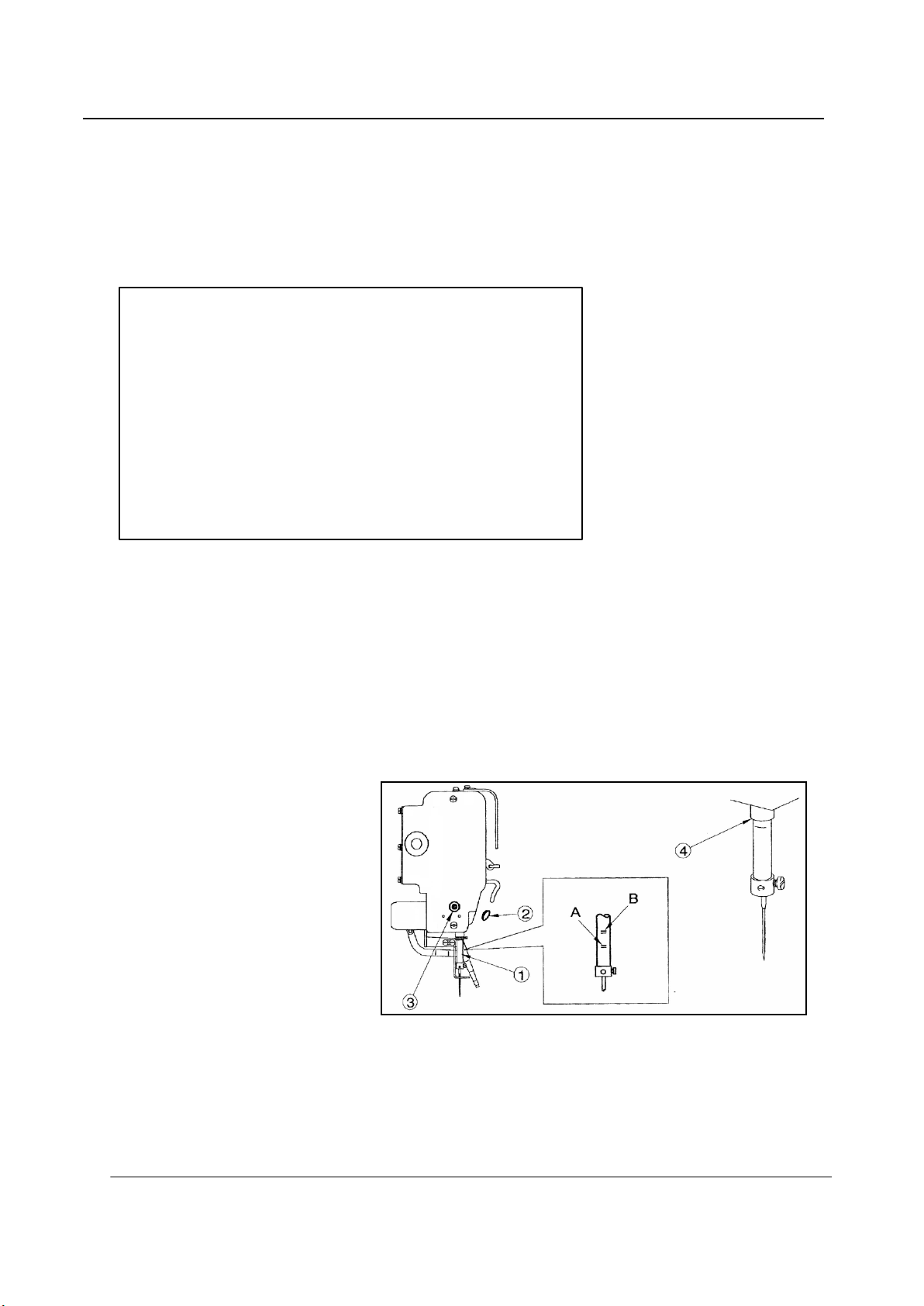

1 STRUCTURE OF THE SEWING MACHINE

HLK-1510 electronic pattern sewing machine is constructed with the following main parts

1 Sewing machine head ②T hread stand ③O peration P anel ④C ontrol U nit

○

⑤H a lt s w itc h ⑥W ork holder foot switch ⑦Wooden Table ⑧Steel stand

— 1 —

Page 7

2 SPECI FICATION

Sewing area: X-Direction(left/right) 100mm

Y-Direction(forward/backward) 100mm

Maximum sewing speed: 2500 rpm

Sewing speed: 10 steps variable from 200 to 2500 rpm

Stitch length: 0.1 to 12.7mm

Stitch type: Single needle lock stitch

Needle bar stroke : 41.2 mm

Thread take up lever stroke: 68mm

Class of needle: DP × 17#16(the standard specification)

Wiper system : Back to forward wiping system(the standard specification)

Presser foot lift: 15 mm(18mm max)

Presser foot stroke: Variable from 4mm to 10mm(4mm is standard)

Work holder lift: 25 mm

Hook: Large size shuttle hook

Bobbin case: With non racing spring

Bobbin: Large size aluminum bobbin

Thread trimmer system: Horizontal engagement with fixed knife and movable knife

Lubrication system: Manual oiling and replenishment with the oil braids from the oil tanks

Lubrication oil: White machining oil

X—Y drive system: Stepping motor and X-Direction timing belt drive

Y-Direction gear Intermittent or continuous feeding

Machine dimension: 1,200mm (W)× 740mm (L)×1,220mm (H)

main motor: 450W

— 2 —

Page 8

3 INSTALLATION

Caution

★ The machine should be installed by the specialists who have enough expe rience for the sewing machine

installations.

★ All the necessary electric wiring should be d one by electric engineers who are qualifi ed for the electric

wiring.

★ If any damage or fault is found on the machine at the installation,please do not operate until it is

repaired.

★ Please do not operate the sewing machine with excessive modifications from the standard specification.

3-1 Installation of the control box

If the control box is purchased without

assembling to th e table, the control box has

to be installed underneath the table. Please

install the control box with the in struc tion in

the paragraph

3-2 Installation of the power switch

If the power switch is purchased

without assembling to the table,the

power switch has to be attached with

the following procedure.

(1) Mount the power switch

2 underneath the table as shown on

screw

○

the figure.

(2) Fix the electric cords with the staples

underneath the table.

(3) Hook up the connector

switch

1 to the control box○7

○

1 with the wood

○

8 of the power

○

.

3

○

(4) Attach the power plug

Connect the foot switch

3-3 Installation of the oil pan

(1) Fix the oil pan

5 to another end of the power switch cord○4 . Connection of the foot switch

○

6 to the control box

○

1 at its four corners on the table top with four.

○

7 .The foot switch is enclosed in the accessory box.

○

— 3 —

Page 9

3-4 Installation of the sewing machine he ad

Caution

★ For the safety,please make sure to ca rr y the

sewing machine head by more than two

people.

(1) Make sure to hold the machine table

with the caster stopper.

(2) Fit the rubber cushion pads

each hole

rubber cushion pads are enclosed in the

accessory box.

(3) Put the sewing machine head on the

table top and set the each leg

each rubber cushion pad

(4) Attach two hinge s

machine bed .

(5) At this time,take notice that the E-shaped snap ring on the front side hinge must be come to the backside,

and E-shaped snap ring on the backside hinge must be come to the front.

(6) These parts are all enclosed in the accessory box.

(7) Fit the screw holes

through these holes and fasten the bolt

washers

(8) Fasten firmly hexagonal socket head set screws

hinges

(9) Insert the headrest

4 on the tabletop. The

○

6 temporarily,make the setting screw

○

9 of the hinges○6 to the bolt setting holes○8 ong the table top then,pass the bolt○10

○

12 and the nuts ○13

○

6

perfectly.

○

14 into the hole

○

3 into the

○

○5 to the

○3

.

10 to fix the hinges○6 with the flat washers○11 ,the spring

○

7 ,which se t the hi nges○6 temporar ily then,fix the

○

15 on the tabletop.

○

7 fastening on the left side surface of the

○

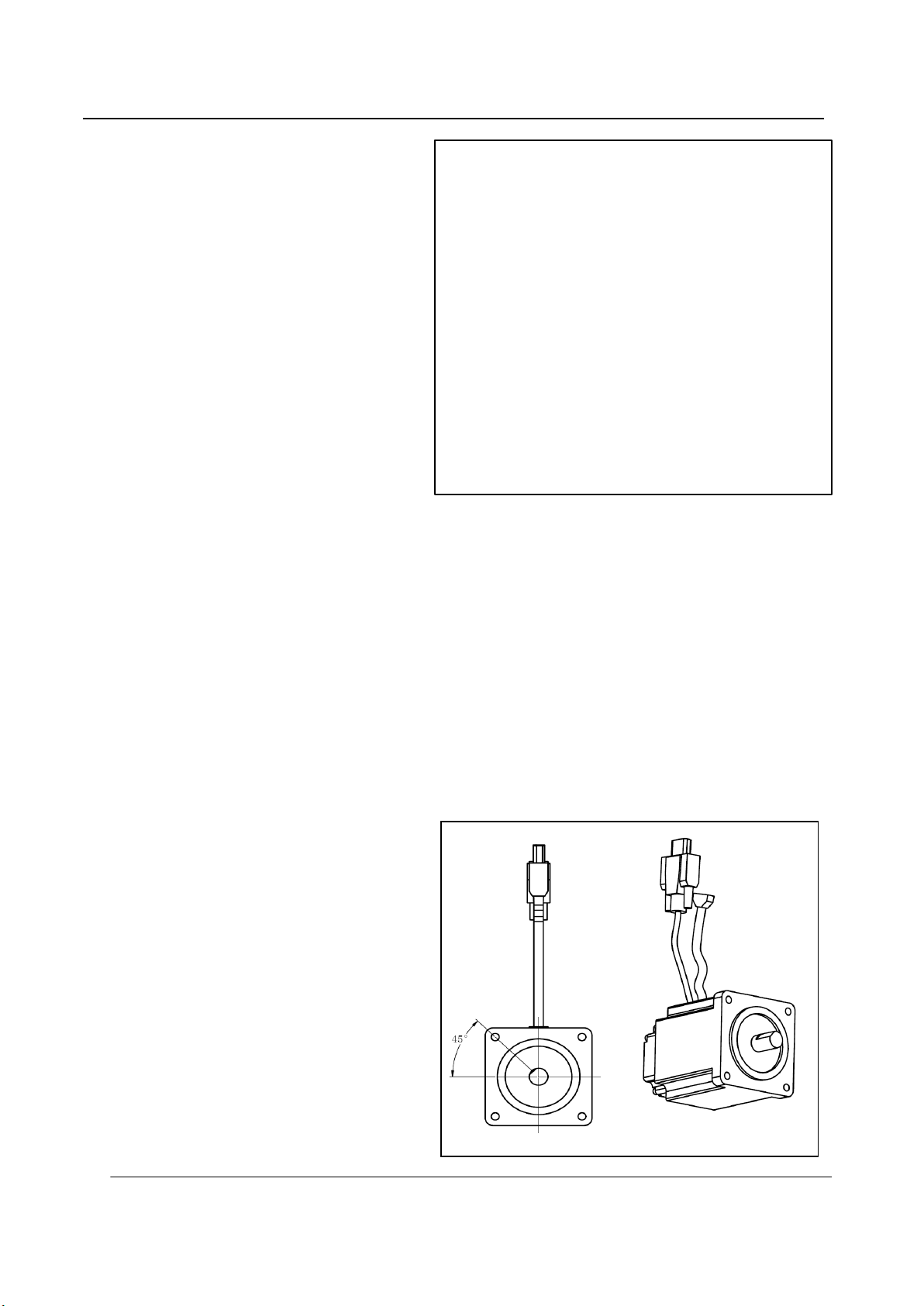

3-5 Install ati on of the spindle m ot or

If the spindle motor has been removed from

the machine for the adjustment or the like,

fix the spindle motor as the procedure

described right.

(1) Spindle motor according to right: put

the signal cord upward.

(2) Adjust the plane of the motor shaft

alignment of the left on the motor

mounting holes, 45 ° Angle adjustment.

— 4 —

Page 10

3-6 Connection of the operation panel

Please connect the operation panel with the instructions of operation panel manual enclosed in the packing.

3-7 Connection of the electric cables

Please make sure to

ground the place

where there is a

mark. Failure to do so

may cause electric

shock and/or

malfunction.

(1) Connect the machine head and the control

box with cables as shown on the figure.

(2) Hold the dangling cables under the table

with accessory tie holders and cord ties.

(3) At this time, please check whether the

cables are not pulled when tilting the

sewing machine.

(4) Control box back and socket as shown on

the below figure

(5) Printed circuit board wiring as shown on the top of next page

X4: Spindle motor power X5: Spindle motor signal X6: RS-232C(selection)

X7: Operation panel X8: Foot switch X9: Electromagnet output

X10:RS-232C(selection) X11: Control signal one X12: Expand I /0

X13: Control signal two X14: X spindle stepping motor X15: Y spindle stepping motor

G: Grounding wires

— 5 —

Page 11

3-8 Installation of the thr ea d st and

(1) Assemble the

thread stand with the

instructions enclosed in

the packing.

(2) Fit the thread

stand

1

in the thread

○

stand holeg on the

tabletop.

(3) Fix the thread

stand

○1 firmly from the

rear side of the table

with tightening the

nut

washers

4 and the

○

2 ,○3 .

○

— 6 —

Page 12

4 LUBRICATION

Caution

★Please make sure to turn power switch off before oiling.

★Please make sure to put some oil before starting the operation of the brand new machine or

NOTE : Please use high quality white machining oil.

4-1 Filling the oil tank

Pour the oil through the oil

hole

1 to the oil tank○2 on the

○

machine arm . Move the work

holder by hand to the right end

then,machine bed.Please Pour the

oil through the oil hole

oil tank,fill with the oil over level

mark

5 of the oil tank.

○

4-2 Oiling

Put some oil to red marked oil

holes(NO.

7 ~

○

10 ).

○

4 to the

○

5 PROPER OPERA TION

5-1 Installation of the needl e

Caution

★Please make sure to turn the power switch OFF before installing or replacing the needle.

★Please pay attention for the fingers not to be wounded by the needlepoint.

(1) Loosen the needle set screw

Insert the new needle

head is reached the end of the hole of the

3

needle bar

(2) Fasten the setting screw

the needle groove

○

.

2 until the needle

○

4 to the front

○

1 then,

○

1 with facing

○

— 7 —

Page 13

5-2 Threading the up per t hr e ad

★ Please make sure to turn the power switch off before threading the upper thread.

★ Please thread the upper thread with referring to the below figures.

5-3 Winding the bobbin thread

★Please make sure to pull the upper thread out of the needle before winding the bobbin thread

(1) Turn the power switch ON.

(2) Press the READY key on the

operation panel twice slowly. Firstly

Press, the work holder moves to home

position.Secondly, the interface for data

input will be shown.

(3) Press the SELECTION key on the

operation panel to select the

BOBBIN-WIND key , then press

the ENTER key ,at this time, work

holder goes down.

(4) Then , Wind mode window will be

appeared.(the background color is blue)

— 8 —

Page 14

(5) Pass through the thread from the thread

stand

4 as shown on the right figure .

○

then , wind the thread to the empty

bobbin

direction couple times and insert the

bobbin

(6) Push the adjust lever

“b” direction.

(7) Step on the gra y color star t foot switch

. The thread is kept winding to the

Bobbin

switch is stepping on.

(8) When the bobbin becomes full of the

thread,the adjust lever

the original position.

(9) Step the gray foot switc h to exit winding mode, and press the Escape key to back to the standard

operation interface.

(10) To wind the bobbin thread during the sewing operation,carry out above (2) to (7) procedure,then,the

5 in the arrow mark “a”

○

5 into the bobbin winder

○

7

in the arrow mark

○

5 while the gray color start

○

6

○

6 .

○

is returned to

○8

bobbin winding is performed automatically.

5-4 Settling the bobbi n

(1) Set the bobbin

(2) Pull the bobbin thread

thread through the thread hole

(3) At this time,pull the bobbin thread

the bobbin

not,set the bobbin

to get the proper rotation.

2 into the bobbin case

○

○

2 if it is rotaled to the arrow direction.if it is

○

2 into the bobbin case○1 over again

○

1 .

○

3 into the slit○4 and pass the

5

.

○

3 then,check with

○

— 9 —

Page 15

5-5 Setting the bobbin case

1

(1) Set the needle bar to its highest position then,open the cylinder cover

(2) Open the bobbin case latch lever

[NOTE]Please pull the bobbin thread about 2.5mm out of the thread hole(NO.4)of the bobbin case.

2 fully then,fit it securely in the inner hook

○

○

.

3 .

○

6 PROPER SEWING

6-1 Operation of the halt switch

If an incident such as a thread breakage,needle breakage and any other incidents are happened during the

sewing operation,please hit immediately the halt switch.The sewing machine running is stopped instantly.

Caution

★ B efore start the sew ing operation,please make sure the location of the halt switch and keep it in mind the

function and how to use it.

★ Please keep away the hands and the face from the needle during the sewing operation.

1

(1) Press the HALT switch

operations will stop,and the sewing

machine will stop at the needle UP state

without trimming the thread.

(2) Remove the cause of the abnormality.

(3) To continue sewing,turn the HALT

switch to the right. The switch will be

unlocked.Next,press the Escape key

○

, All

on the operation panel,then press

key to select the key or other

key. in the end ,press key,and

work holder will go up and return to the

— 10 —

Page 16

home position.

(4) When the start switch

Caution

★ Dependi ng on the shape of the work holder,the collision may be happened with the work holder and the

presser foot while the work holder is on the way back to the home position.For avoidance of this accident,

before starting the sewing operation . program the work hol der returning home with the operation panel of

the control box to trace the sewing pattern.

6-2 The sewing operation

Caution

★ It is very dangerous to operate the sewing machine without the safety guards(Eye guard:belt cover,Link cover,

Finger guard etc.).

★ Please make sure to always operate the sewing machine with the safety guards.

★ Please do not put unnecessary articles except for the sewing operation on the tabletop.

★ Please keep the hands and the face away from the needle.

(1) Turn the power switch○1

The collision may be happened with

the work holder and the presser foot

depending on the work holder shape

when the work holder is moved to

original position.

(2) In sewing interface, press to

return to the interface of data input.

(3) In the interface of data input, press to

2

(left)is pressed again,the operation will start .

○

ON.

select the ,then press to

enter the interface for selecting the

mode(as shown in the figure righe)

(4) After mode selecting end , back

to the inte rface of data input, pres s

to select ,then enter the the

interface for selecting pattern number ,

— 11 —

Page 17

(5) Back to the interface of data input,

press ,then enter the Sewing

Interface(the background color is blue)

(6) When the start switch

pressed,the work holder

down ,the operation will start .

For the deta ils ,please

refer to the

instructions on the

technical manual

[Operation Panel].

6-3 Adjustment of the thread tension

2 (left) is

○

3 will go

○

The thread tension between the upper and bosom thread should be balanced in the best condition.

When the upper thread tension is well balanced with the bobbin thread tension,both threads are interlocked

along the centerline of fabric layers as shown on the below figures.

NOTE Normally weaker bobbin thread tension brings better sewing quality.

So it is prefer to set bobbin thread tension first and then set upper thread tension.

(1) Bobbin thread tension

Adjust the bobbin thread tension with the thread tension adjusting screw

thread tension becomes loose if turn the thread tension adjusting screw

2 on the bobbin case○1 .The

○

2 to the counte r clockwise,and the

○

— 12 —

Page 18

thread tension becomes tight if turn it to the clockwise.

(2) Upper thread tension

Adjust the upper thread tension based on the bobbin thread tension.For this adjus tment,turn the thread

tension adjusting nut○3 .The upper tread tension becomes tight if turn the thread tension adjus ting nut

the clockwise,and the upper thread tension becomes loose if turns it to the counter clock wise.

3 to

○

7 ST ANDARD ADJUSTMENT

Caution

★Please make sure to turn the power switch OFF before adjust the sewing machine.

★If the adjustment is required under the power switch is ON,keep the start foot switch away from the foot.

★Be careful not to be wounded by the needle or the inner hook point.

★Please make sure to put the safety guards(Eye guard,Belt guard,Link cover and finger guard etc.)back on the

original location after the sewing machine adjustment.

7-1 Adjustment of the needle bar position

(1) Turn the power switch OFF.

(2) Turn the sewing machine

pulley by hand then,stop the

1

3 .

○

4 .

○

○

at the lowest

2

○

○1 to the position where the needle ba r timing mark A is matched to the needle bar

4 then,tighten the needle bar holder setscrew ○3

○

— 13 —

.

needle bar

position.

(3) Remove the rubber plug

from the face plate then,

loosen the needle bar holder

setscrew

(4) Move the needle bar

bushing bottom line

NOTE: If the needle class is DP×5,match the needle bar timing mark B to the needle ba r bushing bottom

line

Page 19

7-2 Adjustment of the position between the needle and the shuttle hook

(1) Turn the power switch OFF.

(2) Turn the sewing machine pulley by

hand then,move up the needle bar

from the lowest position and stop it at

the position

timing mark C is matched to the needle

bar bushing bottom line.

NOTE:If the needle cla ss is DP×5,

match the ne edle bar timing mark D to

the needle bar bushing bottom line

(3) Open the cylinder cover

(4) Remove the bobbin case

(5) Turn the hook retainer lever

remove the hook retainer

(6) Loosen the driver setscrew

move the driver(No.10)and adjust the

shuttle hook point

with the center line

(7) After the adjustment,tighten the driver setscrew

2 where the needle bar

○

2

.

○

3

.

○

○

6 .

○

○9 then,

7 to be matched

○

8

of the needle.

○

1

○

2

○

5 then,

.

9 and put the bobbin case○4 ,the hook retainer○6 and

○

the hook retainer lever

7-3 Adjustment of the clearance between the shuttle hook and the needle

(1) Please take the same procedures as above paragraph 7-2.from(1) to(5).

(2) Loosen the outer hook setscrew

hook point and the needle becomes 0.05~0.1 mm.

(3) After the adjustment,securely tighten the outer hook setscrew

bobbin case back to the original location then,close the cylinder cover

5 back to the original location then close the cylinder cover○9

○

3 and turn the eccentric pin

○

4 so that the clearance between the shuttle

○

.

3 and put the hook retainer and the

○

5 .

○

— 14 —

Page 20

7-4 Adjustment of the clearance between the driver and the needle

(1) Please take the same procedures as above

paragraph 7-2.from(1)to(5).

(2) Please make sure the clearance between

the shuttle hook point and the needle has

been adjusted 0.05~0.1 mm at above

procedure 7-3 Adjustment of the

clearance between the shuttle hook and

the needle.

(3) Loosen the driver setscrew

and the needle

(4) After the adjustment,securely tighten the driver setscrew

back to the original location then,close the cylinder cover

7-5 Adjustment of the thread guide

(1) Remov e t h e E-shaped snap ring

the setscrews

(2) Loosen the setscrews

divides the needle groove

shoulder

hook retainer and the thread guide

it(standard clearance is 0. 8mm).If this clearance is too wide,it causes the trimming fai lure and if thi s

clearance is too narrow,it causes the sewing condition disturbance,the trimmed upper thread tail uneven

and the locking up the hook with the upper thread.

4 can become 0.

○

4 and remove the sliding plate(S) ○5

○

9 of the thread guide○6 .At this time,make sure that there is some clearance between the

○

1 and turn the eccentric pin○2 so that the clearance between the driver○3

○

3 which is engaging the movable knife○2 and the link ○1 then,loosen

○

10 and move the thread guide○6 to the pos ition where the needle center line○8

○

7 evenly and the rear side line ○9 of the needle is aligned with the

○

6 at least the upper thread can be passed smoothly through

○

○1 and put the hook retainer and the bobbin case

5 .

○

.

(3) After the adjustment,engage the

1 of th e trimmer mechanism

link

○

with the movable knife

the E shaped snap ring

the sliding plate(S)

original loca tion then,tighten the

setscrews

sliding plate(S)

needle

center

needle plate.

4 .At this time,set the

○

11 can come down to the

○

12 of the needle hole of the

○

○

5 back on the

○

5 so that the

○

2 with

○

3 and put

— 15 —

Page 21

7-6 Adjustment of the presser foot

[NOTE]The presser foot is a very important part to form the fine stitches.

It moves simultaneously with the needle and s tabilize the needle penetrating area of the sewing material with

pressing down it,when the needle sticks into or pulls out the sewing material and prevent the skip stitch or the

over penetration happening.Please adj us t th e pr e s se r foot properl y to the sewing ma te rials with the following

instructions.

7.6.1 Adjustment of the presser foot position

[NOTE]Please always adjust the presser foot position when the thickness of the sewing material is changed.

(1) Turn the power switch OFF.

(2) Remov e t h e face plat e○1 and the link cover

(3) Turn the sewing machine pulley by hand and stop the needle bar

make sure the se tscrew

shaft.This is the standard position of the eccentric cam

position , set it back to the standard position with the instructions on the paragraph[7-6-3.Adjustment of

the presser foot timing]in the following page.

(4) Turn the sewing machine pulley by hand and stop the needle at the highest position(this is also the thread

take up lever's highest posi tion).At this time,loosen the setscrew

8 and adjust the center line of the bell crank○6 to be parallel with the presser foot bar

shaft

○

(5) Insert the sewing material

stop the presser foot

(6) Loose n t h e p r es ser foot b ar s etscrew

position to be become the clearance bet ween the bot tom surface of the presser foot

the sewing material 0~0.5mm.At t he same time,rotate the presser foot ba r

come down to the center of the needle hole of the presser foot

5 of the eccentric cam○4 is positioned r ight beside the center line of the upper

○

10 under the work holder○11 and turn the sewing machine pulley by hand then,

○

12

at the lowest position.

○

14 and move the presser foot bar○7 then,adjust the presser foo○12

○

2 .

○

3 at the lowest position.At this time,

○

4 .If the eccentric cam○4

○

9 of the upper feed lock crank

○

○

12

.

○

is off from this

12 and the surface of

○

7 for the needle○15 to

7 .

○

(7) After the adjustment,put the face plate

[NOTE]The lower position of the presser foot,the more effective for the skip stitches. However,if the

presser foot becomes to Press the sewing material,the movement of the presser foot mechanism

generates a slight noise.And also,the presser foot stays longer to hold the sewing material,so

the upper thread tension becomes loose or the sewing pattern forming gets out of shape because

the presser foot catches the surface of the sewing material.For avoiding these troubles,please

lower the presser foot as small as possible.

1 and the link cover

○

— 16 —

2 back on the original location.

○

Page 22

[NOTE]If the thickness of the sewing material changes very often,it is recommended to takethe easy

way for the adjustment of the presser foot position with the method thatchange only the fixed

position of the presser foot after fixed the presser foot bar at higher position. For this

adjustment,loosen the setscrew

7.6.2 Adjustment of the presser foot lift during the sewing

[NOTE]The presser foot lift during the sewing can be adjusted 0 and 2~10mm.

(1) The presser foot lift during the sewing becomes 4~10mm at the condition which the connection of the

link

2 and the lever○3 with the shoulder screw○1

○

if the connection is made with A hole,and it becomes 0 mm if the connection is made with B hole.

(2) The stepping lift is adjusted 4mm when the sewing machine is shipped from the factory.

(3) For the adjus t ment at the each ran ge of the p re sser foot li ft,remov e the link cov er

move the adjust bolt

(4) If the link

presser foot position with adjusting the position of the presser foot bar or the presser foot itself with

loosing their setscrews

(5) Regarding the running noise and the vibration,the higher lift effects worse.So adjust the presser foot lift

2 connection is changed to A or B hole,the presser foot position is also changed.So reset the

○

5 .

○

○

6 or○7

.

16 then,move the presser foot

○

is as shown on the figure and it becomes 2 to 4 mm

12 up and down.

○

4 then,loosen and

○

during the sewing as small as possible.

(6) After the adjustment,put the link cover

4 and the face plate○8 back on the original location.

○

— 17 —

Page 23

7.6.3 Adjustment of the presser foot timing

[NOTE] The presser foot up and down movement during the sewing synchronizes with the needle up

and down movement. With changing this synchronized timing to the sewing materials,the skip

stitches can be prevented or the seam tightness can be improved.

For example,the delay of the presser foot timing against the needle movement prevents the skip

stitches especially to the thin materials,and the advance of the presser foot timing can improve

the seam tightness especially to the thick materials.

1

(1) Remove the link cover

(2) Loosen the setscrew “C” of the eccentric cam

(3) Turn the sewing machine pulley by hand and stop the needle bar

the setscrew “A” of the eccentric cam

is the standard position for the eccentric cam

(4) Loosen the setscrew “A” of the eccentric cam

(5) Hold the eccentric cam

machine pulley to the arrow direction “D”,the presser foot timing against the needle movement is

delayed,and if turn the pulley to the opposite direction,the timing of the presser foot is advanced.

.

○

2

.

○

3 at the lowest position.At this stage,

○

2 is positioned right beside the center line of the upper shaft.This

○

2

.

○

2

.

○

2

and turn the sewing machine pulley slowly by hand. If turn the sewing

○

(6) After the adjustment,tighten the setscrew “A” and “C” in turn with slightly pushing the eccentric

2

cam

(7) Put the link cover

to the arrow direction “E”.

○

1 back on the original location.

○

— 18 —

Page 24

7-7 Adjustment of the wiper

(1) Loosen the wiper setscrew

adjust the wiper

where the wiper

needle point

clearances right after the sewing

machine is stopped running at the

needle upper position (the thread take

up lever's highest position).

[NOTE] When the presser foot position or the presser foot lift is changed, the wiper

presser foot

function with operation

7-8 Adjustment of the bobbin winder

(1) Adjustment of the winding volume

Loosen the setscrew

4 .in that case , please do not use the wiper○1 .If do not use the wiper

○

1 to be positioned

○

1 passes under the

○

2 with about 2 mm

○

2 of the adjusting lever○1 and adjust the position of the adjusting lever○1 .If

○

3 and

○

1 may collide with the

○

1 ,cancel the wiper

○

move the adjus ting leve r

the adjusting lever

volume is adjusted 80%of the full volume when the sewing machine is shipped from the factory.

(2) Adjustment of the proper position of the bobbin winde r Firstly . loosen the setscrews

○

1 to th e arrow dire ction “a” the Winding volume is reduced,and if mov e

○

1

to the arrow direction “b”, the winding volume is increas ed .The winding

— 19 —

3 and○4 of

○

Page 25

the bobbin winder and put the empty bobbin○5 on the rotating shaft○6 then,push the adjusting

lever

1 to the arrow direction “a”.Secondary.move the whole bobbin winder to the arrow direction

○

“C” and stop it at the position where the empty bobbin is rotated then,tighten the setscrews

4

and

7-9 Adjustment of the work holder

If the sewing material is thick

and the work holder does not

press it strong enough,adjust

the work holder presser as

follow.

(1) Insert the sewing

material

work holder

(2) Turn the power switch

ON and lower the work

of the bobbin winder.This is the proper position of the bobbin winder.

○

1 under the

○

2 .

○

3

○

holder

holder foot switch

(3) Loosen the 2 of the setscrews

tighten the 2 of the setscrews

7-10 Adjustment of the trimmer cam follower

(1) Turn the power switch OFF and remove the top cover.

2

with the work

○

3 and move adjusting plate○4 unt il it touches the material○1 then,

○

3 .

○

— 20 —

Page 26

(2) Under the sewing machine regular stop condition(the needle stop position is upper and the take up lever

stop position is highest),loosen the setscrew

follower

about 1 mm clearance between the cam follower

tighten the setscrew

(3) Push the cam follower lever

engaged into the cam groove

(4) lf the cam follower

follower

the stopper screw

stopper screw

7-11 Adjustment of the position for the mova ble knife poi nt

(1) Tilt the sewing machine head to

the left to be able to see the

bottom component parts.

2 to be positioned to contact with the shoulder portion○3 of th e trimmer cam○1 with having

○

5 of the cam follower lever ○4

○

4 by hand to the arrow d i rec tio n an d ma ke sur e tha t th e c a m fol lower○2 is

○

3

smoothly.

○

2 is not engaged s moothly,under confirming with the condition which the cam

○

2 cont acts with the sho ulder port ion○3 of the tr immer cam ○1 , loosen the nut○7 and tighten

○

8 until it touche s with the stopper○9 of the ca m follower lever○4 then,loosen the

○

8 back about 1/3 turn and fix the nut

○

5 of the cam follower lever ○4 and adjust the cam

○

○

2 and the tri mmer cam○1 .After this adjustment,

.

7 firmly.

○

(2) Open the cylinder cover

(3) Check with the point

movable knife whether it is located

at the position apart 0.5mm fromthe front face of the hook retainer

(4) For the adjustment of the movable knife point

4

end

(5) After the adjustment,tighten the adjusting screw nut

7-12 Adjustment of the fixe d kni fe po siti o n

(1) Open the cylinder cover

(2) Remove the E-shaped snap

ring

movable knife

(3) Loosen the setscrews

remove the sliding plate

right and left then,adjust the position of the movable knife point.

○

4 , which engages the

○

○

1 of the

○

1

.

○

2 and the link○3

5 then,

○

6 .

○

.

2 .

○

1 ,loosen the adjusting screw○3 and move the rod

○

3

securely.

○

(4) Turn the sliding plate

position to be positioned for the blade edge

6 upside down and loosen two setscrews○9 then,adjust the fixed knife○10

○

7 to have the clearance 0.5m m from the edge of the needle

○

— 21 —

Page 27

plate○8

(5) After the adjustment,tighten the setscrews

(6) Put all the parts for this adjustment back to the original locations.

7-13 Adjustment of the t hread take up sprin g s wi ng s t roke

Loosen the setscre w

swing stroke to be become 9 to 10mm.

After the adjustment,tighten the setscrew

7-14 Adjustment of the thread t a ke up sprin g tension

Insert the screw driver

slit

○

regulator

up spring

driver to the clockwise,the thread take

.

2 and turn the whole thread tension regulator○3 then,adjust the thread take up spring

○

2

○

5 into the

○

4 of the thread tension

3 and adjust the thread take

○

1 tension.If turn the screw

○

9

○

securely.

securely.

up spring tension becomes tight.and if

turn the screw driver to the counter

clockwise.the thread take up spring

tension becomes loose.

7-15 Adjustment of the thread tail after the trimming

Adjust the thread tail

needle after the trimming with

turning the nut

pre-tension

If turn the nut

the thread tail becomes shorter

and if turn the nut

counter-clockwise,the tread tail

becomes longer.

1 .

○

2 to the clockwise,

○

3 from the

○

2 of the

○

2

to the

○

7-16 Cancellation of the trimming function

If the automatic trimming is not required during the sewing operation ,cancel the Trimming function with the

setting panel of the control box .

— 22 —

Page 28

7-17 Adjustment of the upper thread te nsi on r el ea se

[NOTE] (a) The upper thread tension release works when the upper thread is trimmed automatically or the

presser foot is lifted during the work holder feeding.

(b) If the upper thread tension release does not work properly when the upper thread is t rimmed

automatica lly, the thread tail fr om the needle becomes shorter then, it induces the ski p stitch

happening or pulling the thread tail out of the needle at the start of the sewing.

(c) During the sewing operation, the discs

presser foot is moving up and down.

If the discs

loose and the proper stitch condition can not be obtained.

(d) When the upper thread tension release is activated, the discs

regulator opens 0.8~1.0mm. This is the normal conduction of the discs

adjustment, take the following procedure.

1 of the thread tension regulator is not closed, the upper thread tension becomes

○

1 of the thread tension regulator is closed while the

○

1 the upper thread tension

○

1 opening. For this

○

(1) Remove the top motor cover.

(2) Fully turn the crank

(3) adjust the upper thread tension release for the di scs to be opened 0.8 to 1.0 mm. For this adjustment,

loosen the nut A then,if tighten the nut B,the discs opening becomes wider and if loosen the nut B,it

becomes narrower.

(4) lf the normal opening of the discs can not be obtained with the nut adjustment,loosen the wire fix

screws

(5) The wire

thread tension release again.

7-18 Adjustment of the mechanical home pos iti on

[NOTE]The mechanical home position is fixed at the center of the sewing area when the sewing machine is

shipped from the factory.However,it can be moved within the area covered with diagonal lines.

5 and adjust the tension of the wire

○

6

may be got longer over a long period machine operation.At that time, adjust the upper

○

3 of the rotary solenoid

○

2 in the arrow direction.At this time,

○

6 .

○

— 23 —

Page 29

(1) Turn the power switch ON and cancel the sewing area limit with the operation panel.

(2) After the cancellation of the sewing area limit, once. Turn the power switch OFF.

7-18-1. Shifting the mechanical home position to the X direction

(1) Remov e t h e X-Y cover (right),(left) and X cover.

(2) Loosen the detector plate fix screws(2 pieces)

mechanical home position is shifted to the left and if it is moved to the left, the mechanical home

position is shifted to the right.

(3) After the mechanical home position setting,tighten the detector plate fix screws

[NOTE] When the original mechanical home position is shifted.Please check the clearance between the X detector

plate and the X detector.This clearance should be set within the range of 1.0—1.5 mm.

1 . if move the detector plate

○

2 to the right, the

○

1

securely.

○

— 24 —

Page 30

7-18-2.Shifting the mechanical home position to the Y dir ection

(1) Loosen the Y-detector setscrew○5

4

(2) lf move the Y-detector

moved to the backward.the mechanical home position is shifted to the front.

(3) After the mechanical home position setting,tighten the screw

7-19 Adjustment of the X-Y table contact pr e ssure

[NOTE] When take the X -Y table apart or the X-Y table became weak in the joint s,adjust the X-Y table contact

pressure.The adjustment should be made the X-Y t able movement as smooth as possible without having

play.If the X·Y table cont ac t pres sure is too tigh t ,the over pressure induces the out of control on the

X-Y table movement.

(1) Remove the right and left X-Y cover and the right X cover plate.

(2) Loosen the setscrew(2 pieces)

(3) If tight en the both right and left contact presser adj usting screws

increased.

to the front,the mechanical home posi tion is shifted to the backward.If it is

○

.

2 so that the X fixed race

○

5

securely.

○

1 can be moved slightly.

○

3

,the X table contact pressure is

○

(4) Loosen the setscrews(2 pieces)

(5) If tighten the contact pressure adjusting screws

(6) After adjustment,tighten the setscrews

7-20 Adjustment of the X timing belt tensi on

[NOTE] The proper condition of the X

timing belt tens ion is standing that

they will not be got any yield even

it is slightly pushed by hand.

(1) Remove the right X cover and the

right X cover plate.

(2) Loosen the nut○8 and the

setscrew

(3) If the tighten the tension adjust screw

(4) After adjustment,tighten the nut

9 of the bracket○7

○

5 so that the Y fixed race

○

.

8 and the setscrew

○

4 can be moved slightly.

○

6

,the Y table contact pressure is increased.

○

2 and

○

10

,the X timing belt tension will be increased.

○

5 securely.

○

9 .

○

7-21 Adjustment of Y stepping motor position

(1) Remov e t h e motor cov e r.

— 25 —

Page 31

(2) Loosen four setscrews ○1 of the

Y-stepping motor adapter

(3) Press the Y-motor adapter

direction lightly.

(4) Fasten the sets crews

the motor cover to original position.

NOTE After the adjustment, please make sure

that there is no gap in the gear

mechanism. Please grease gear

periodically for reduction of noise or

abrasion

2 .

○

2

to arrow

○

securely, and put

1

○

8 MAINTENANCE

Caution

★Please make sure to turn the power switch always OFF when clean up the sewing machine.

★Before or after the sewing operation,clean up the sewing machine and check the Oil level in the oil tank.

8-1 Cleaning

(1) Turn the power switch OFF.

(2) Remove the dust and the

thread waste sticking

around the threading parts or

the shuttle hook area.

(3) Check the oil level in the

oil tank.1f the oil is under

the red mark level supply the

oil to be over the red mark

level.

8-2 Disposing of oil waste

7. lf the waste oil is full, please remove the oil .

— 26 —

Page 32

1.

2.

Adjust thread take up spring’s swing

Adjust fixed knife and needle plate

9 BAD SEWING CONDITION&ITS CAUSE AND REM EDY

[NOTE]Please fix the troubles during the sewing machine operation with referring to the following

instructions.Beside,if the trouble conditions are not coming under these classification,please contact the

sewing machine dealers nearby.

Bad

condition

Upper thread

breakage after

happens

Upper thread is

pilled out from

needle

Cause Remedy Ref. page &

item

Poor thread tension Use better quality thread —

Tight upper thread tension Adjust thread tension 6-3

Strong thread take up spring Adjust thread take up spring properly 7-14

Upper thread is thicker than

needle size

Damages on shuttle hook or

drive

Damages inside presser foot

needle hole

Needle touches with presser

foot needle hole

Needle and shuttle hook are

not in proper timing

Thread melts with needle heat Slow down sewing speed —

Thread tension discs are not

opened at trimming

Thread take up spring swings

too much

Upper thread is broken before

regular trimming

Needle size is bigger than

thread size

Pre–tension is too tig ht Adjust pre-tension 7-16

Thread guide is in wrong

position

Needle and shuttle hook are

in bad timing

Trimmer timing is not correct Adjust trimmer cam position 7-10

Change needle to suitable size —

Change them new ones or gr ind them with

buffing wheel or grind stone

Change it new one or grind it with buffing

wheel

Move presser foot position 7-6-1(6)

Adjust the timing 7-2

Use silicon oil —

Use needle cooler —

Adjust thread tension release 7-17

stroke

position

Change needle to suitable size

Adjust thread guide position properly 7-5

Adjust the timing properly 7-2

Adjust movable knife position 7-11

Adjust synchronizer position —

—

—

7-14

7-12

— 27 —

Page 33

3.

4.

5.

6.

Bad

condition

Skip stitch

happens at

start sewing

Thread tail

from needle is

too long after

trimming

Trimming is

not functioned

Skip stitching

often happens

Cause Remedy Ref. page &

item

Too short bobbin thread by

Use non racing spring with bobbin

—

bobbin spinning after

trimming

Bobbin thread tension is too

Loosen bobbin thread tension spring 6-3

tight

Thread tail from needle is

very short after tr im m in g

Decrease pre-tension 7-16

Adjust trimmer cam position 7-10

Adjust synchronizer position

—

Make thread take up swing stroke smaller 7-13

Advance thread tension release timing Control unit

Adjust thread guide position properly 7-5

Pre-tension is too loose Make pre-tension tighter 7-14

Trimmer timing is delayed Adjust trimmer cam position 7-10

—

Upper thread tension release

Adjust synchronizer position

Delay tension release timing Control unit

timing is too fast

Tread guide is in wrong

Adjust thread guide position properly 7-5

position

Trimmer function is canceled Resume trimmer function Control unit

Fixed knife is dull Change it new knife 7-11

Movable Knife is in wrong

Adjust movable knife position properly 7-11

position

Skip stitching happens at

Fix skip stitching

7-6

trimming

Trimmer timing is wrong Adjust trimmer cam position

Adjust synchronizer position

Needle and shuttle hook

clearance is too big

Needle and shuttle hook

timing is not correct

Adjust needle and shuttle hook timing

properly

Adjust needle and shuttle hook timing

properly

Needle is bent Change it new needle

Needle is bent by driver Adjust needle and diver clearance

7-10

—

7-2

7-2

—

7-4

properly

Needle is in wrong position Amend needle position 7-2

Presser foot position is not

Adjust presser foot position properly 7-6

correct

— 28 —

Page 34

7.

8.

9.

10.

11.

Bad

Cause Remedy Ref.page &

condition

Upper thread tension is not

tight enough

Thread tension regulator’s

discs are opened during

sewing

Stitch forming

is loose

Presser foot position is not

correct

Driver and shuttle hook

clearance is very small

Presser foot up and down

timing is not proper

Cables wiring is

Sewing

machine does

not work even

start switch is

turned ON

disconnected

System softwa re is no t

loaded

Emergency stop switch is

kept ON

Synchronizer cable is

Sewing

machine runs

disconnected

Synchronizer is out of order Change it new synchronizer

idle at high

speed when

power switch is

turned ON

Work holder activate cable

is disconnected

Work holder

does not work

Work holder activate cable

is not strong enough

Work holder switch is out of

order

Work holder switch is not

strong enough

Sewing pattern

is distorted

sewing material weight is

very heavy

X timing belt is loose Adjust X timing belt tension properly 7-21

item

Increase upper thread tension 6-3

Adjust tension regulator position

7-17

properly

Adjust upper tension release position

7-17

properly

Adjust presser foot position properly 7-6

Change shuttle hook

—

Adjust presser foot timing properly 7-6

Connect all cables precisely 3

Load system software to control box 5-1

Release emergency stop switch lock 6-1

Connect synchronizer cable precisely control unit

—

Connect the cable precisely control unit

Increase work holder pressure 7-9

Change it new work holder switch

—

Increase work holder pressure 7-9

Slow down sewing speed 6-2

Slow down feeding speed control unit

Select sewing material weight level at

control unit

feeding

— 29 —

Page 35

12.

Y detectors cable are

Y detectors cable are

Detector and detector

13.

Detector and detector

Detector and detector

plate clearance is bigger

Bad

condition

Work holder does

no stop at home

position

Work holder

stops at not

original home

position

Cause Remedy Ref. page & item

X-

Connect X-Y cables precisely

—

disconnected

X-

Change them new detectors

—

out of order

Adjust the clearance properly 7-19

plate clearance is too big

Check setscrews and tighten them

plate mounting is loose

than standard

securely

Adjust detector and detector plate

clearance properly

7-19

7-19

— 30 —

Page 36

A.ARM BED &IT'S ACCESSORIES(一)

— 31 —

Page 37

Fig.

A.ARM BED &IT'S ACCESSORIES(一)

No.

A01 HK41B88001 Type plate 1

A02 H924025050 Pin 2 Ф2.5×5

A03 HK42C58001 Motor cover 1

A04 HK41B98001 Plate 1

A05 H6642B8001 Screw 4 M4×8

A06 HM019B8001 Arm plate 1

A07 HA307B0674 Rubber plug 1

A08 HM015B8001 Bracket 1

A09 HA104G0654 Screw 4 1/8(44)×6

A10 H6671B8001 Hinge 2

A11 HA100C2190 Screw 2 11/64(40)×8

A12 HM014B8001 Plate 1

A13 H6675B8001 Plate 1

A14 HA106B0676 Screw 2 9/64(40)×6

A15 HZ11040250 Screw 1 M4×25

A16 H6609I8001 Screw 1 M4×20

A17 H6642B8001 Screw 5 M4×8

A18 H6648I8001 Nylon clip 5 AB-6N

A19 HK42B48001 Bed cover 1

A20 HK42B68001 Middle cover 2

A21 H415030120 Screw 10 M3×12

A23 HK42B88001 Front guide 2

A24 HK43B08001 Back guide 2

A25 H6698B8001 Screw 2 M3×6

A26 HK43B27101 Cylinder cover 1

A26 H663FB7101 Cylinder cover 1

A27 H6692B8001 Screw 2 9/64(40)×3.2

A28 H6691B8001 Spring 1

A29 H431050080 Screw 1

A30 H661EB8001 Screw 3 M4×6

A31 HA106B0675 Thread guide 1

A32 H3000B2130 Thread guide 1

A33 H415040080 Screw 2 M4×8

A34 HK44B88001 Plate 1

A35 HA600B2050 Thread guide 1

A36 HA700B2050 Thread guide 1

A37 H4715B8001 Rubber 5

A38 H431040060 Screw 1 M4×6

A39 H6689B8001 Thread take-up lever guard 1

A40 H6642B8001 Screw 1 M4×8

A41 HA307B0673 Rubber plug 1

A42 HK44B68001 Bed cover 1

A43 H6642B8001 Screw 4 M4×8

Part No. Description Pcs. Remarks

M5×8

— 32 —

Page 38

Fig.

A.ARM BED &IT'S ACCESSORIES(一)

No.

A44 H6665B8001 Screw 2 M4×30

A45 H6664B8001 Ball bushing 2

A46 H415050180 Screw 4 M5×18

A47 HK42B58001 Cover 1

A49 HK45B18001 Cover 1

A50 H661EB8001 Screw 2 M4×6

A51 H6613I7102 Connector panel 1

A52 H6642B8001 Screw 8 M4×8

A53 HK44B38001 Cover 1

Part No. Description Pcs. Remarks

— 33 —

Page 39

B. ARM BED &IT'S ACCESSORIES(二)

18

4

1~

------,

::

~

1

9

~

44

~

22

— 34 —

Page 40

Fig.

B.ARM BED &IT'S ACCESSORIES(二)

No.

B01 HA115B0709 Pin 1

B02 HA115B0708 Screw 1

B03 HA310B0703 Regulator casing 1

B04 HA115B0701 Screw 1

B05 HA115B0706 Thread take-up spring 1

B06 HA310B0705 Thread tension discs 2

B07 HA310B0702 Disc retaining plate 1

B08 H6675C8001 Thread tension spring 1

B09 HA115B7010 Thumb nut revolution stopper 1

B10 HA310B0701 Thumb nut 1

B11 H660GB8001 Thumb nut 1

B12 H660FB8001 Spring guide 1

B13 H660EB8001 Thread tension spring 1

B14 H660HB8001 Thread tension stud 1

B15 H6662B8001 Thread guide 1

B16 H6663B8001 Spacer 1

B17 HK45B08001 Top cover 1

B18 H6656B8001 Spacer 1

B19 H6651B8001 Lever 1

B20 H6648B8001 Driven shaft 1

B21 H431030040 Screw M3×4 2 M3×4

B22 H6649B8001 shaft 1

B23 H6682D8001 Screw M4×10 2 M4×10

B24 H431040040 Screw M4×4 2 M4×4

B25 H6645B7101 Lever 1

B26 H6650B8001 Pin 1

B27 H6657B8001 Wheel 1

B28 H6644B8001 Bracket 1

B29 H4921K8001 Pin φ2.5×8 1

B30 H6652B8001 Cam 1

B31 H4917K8001 Pin φ2.5×12 2

B32 H6653B8001 Spring 1

B33 H6655B8001 Pin φ5×56 1

B34 H6658B8001 Tire 1

B35 HA710B0674 Thread guide 1

B36 HA710B0673 Thread tension stud 1

B37 HA112B0693 Thread tension discs 2

B38 HA710B0672 Thread tension spring 1

B39 HA710B0671 Thumb nut 1

B40 H662EB8001 Plate 1

B41 H3200B2100 Screw 1 9/64(40)×6.5

B42 HA100H2150 Screw 1 9/64(40)×11

B43 H662IB8001 Spacer 1

Part No. Description Pcs. Remarks

— 35 —

Page 41

Fig.

B.ARM BED &IT'S ACCESSORIES(二)

No.

B44 HE121B8001 Spacer 1

B45 H6756B8001 Knife 1

B46 H6698B8001 Screw 2 M3×6

B47 HA310B0705 Thread tension discs 2

Part No. Description Pcs. Remarks

— 36 —

Page 42

C. SEWING MECHANISM(一)

40

50

45

~

""

37

\

38

11

~

4

43

58

13 14

26

19

~~~\\

25

0

C)

0

17

~0

29

'

— 37 —

27

Page 43

Fig.

C. SEWING MECHANISM(一)

No.

C01 H2009B0743 Felt 3

C02 H2009B0742 Felt 1

C03 H6616B8001 Felt 1

C04 H6617B8001 Bushing 1

C05 H2009B0731 Felt 1

C06 H6616B8001 Felt 1

C07 H6620B8001 Bushing 1

C08 H431050100 Screw 1 M5×10

C09 H3208H0661 Ball bearing 1

C10 H3416D0692 Screw 2 15/64(28)×8

C11 H6612B8001 Needle bar bushing(upper) 1

C12 H6613B8001 Needle bar bushing(lower) 1

C13 HK40C58001 Drive shaft 1

C14 H6607C8001 Crank 1

C15 HA105D0662 Screw 1 1/4(40)×4

C16 HA307C0662 Screw 2 1/4(40)×6

C17 HA100C2070 Screw 1 9/32(28)

C18 H6612C7101 Thread take-up lever assy 1

C19 H6613C8001 shaft 1

C20 H6614C8001 Crank 1

C21 H2004H0067 Screw 1

C22 H6616C8001 Crank 1

C23 HA104C0658 Needle bar joint 1

C24 HA104C0659 Screw 1

C25 H6619C8001 Crank 1

C26 H431050120 Screw 1 M5×12

C27 HM005C7101 Guide bracket assy 1

C28 H6623C8001 Screw 2 M4×8

C29 HA100C2200 Square block 1

C30

C31 HA300C2070 Thread guide 1

C32 H6625C8001 Thread guide 1

C33 HA100C2170 Screw 1 1/8(44)×4.5

C34 HM010C8001 needle 1 DP×17-18

C35 HA108G0661 Collar 1

C36 HA105D0662 Screw 2 1/4(40)×4

C37 H6608C8001 Pulley 1

C38 H431040060 Screw 2 M4×6

C39 HK42C38001 Main shaft motor 1

C40 H415050140 Screw 4 M5×14

C41 H8827O8001 Coupling 1

C42 H415030120 Screw 2 M3×12

C43 HA113D2112 Gear 1

Part No. Description Pcs. Remarks

H6624C8001 Needle bar 1

— 38 —

Page 44

Fig.

C. SEWING MECHANISM(一)

No.

C44 HA108C0663 Screw 2 SM1/4(40)×7

C45 HK42C98001 Hand wheel 1

C46 H609030120 Pin 1

C47 HK43C18001 Shaft 1

C48 H4767E8001 Spring 1

C49 HK43C08001 Bushing 1

C50 H5311F8001 Screw 1 11/64(40)×6.1

C51 H415030100 Screw 1 M3×10

C52 HF15401014 Bearing 1

C53 HF15401012 Washer 1

C54 HA108C0662 Screw 2 1/4(40)×5

C55 HA113D2122 Gear 1

C56 H431050080 Screw 1 M5×8

C57 H3205J0661 Bushing 1

C58 H6606F8001 Thread trimmer cam 1

C59 HA105D0662 Screw 2 1/4(40)×4

Part No. Description Pcs. Remarks

— 39 —

Page 45

D. SEWING MECHANISM(二)

4

6\

5~

16

17

18

19

22

23\

24

~

~~

~36

r \

30

31

28

~

32

29

35

37

— 40 —

Page 46

Fig.

D. SEWING MECHANISM(二)

No.

D01 HA304G0656 Screw 2 3/16(28)×15

D02 H6634C8001 Felt 1

D03 H6628C7101 Connecting rod assy 1

D04 H6628B8001 Bushing 1

D05 H2010J0066 Nut 1 9/32(28)

D06 H431050050 Screw 1

D07 H6630C8001 Screw 1 9/32(28)

D08 H6635C8001 Rock shaft 1

D09 H431050080 Screw 1 M5×8

D10 H6670C8001 Collor 1

D11 HA305E0662 Screw 2 SM15/64(28)×4.5

D12 H6631C8001 Sector gear 1

D13 H6627B8001 Oil braid 1

D14 H2009B0743 Felt 2

D15 H431060100 Screw 2

D16 H6684C8001 Bobbin case 1

D17 H6685C8001 Bobbin 1

D18 H6674C8001 Hook retaine 1

D19 H6683C8001 Inner hook 1

D20 H6654C8001 Hook driver 1

D21 H415050160 Bolt M5×16 1 M5×16

D22 H6646C8001 Hook clamp 2

D23 H6658C8001 Screw 2 1/8(40)×4

D24 H6657C8001 Thread guide 1

D25 H431060120 Screw 1 M6×12

D26 HC01048019 O ring 1

D27 H6648C8001 Eccentric shaft 1

D28 H6625B8001 Bushing 1

D29 HK44C87101 Hook shaft assy 1

D30 H6642C8001 Outer hook 1

D31 H6648C8001 Eccentric shaft 1

D32 H431060120 Screw 1 M6×12

D33 H6651C8001 Pin 1

D34 H6643C8001 Screw 2 1/8(44)×4.5

D35 H6644C8001 Washer 2

D36 H6645C8001 Spring 2

D37 HC01048019 O ring 1

Part No. Description Pcs. Remarks

— 41 —

Page 47

E. X-Y TABLE MECHANISM(一)

9

24~

21

20

28

— 42 —

Page 48

Fig.

E.X-Y TABLE MECHANISM(一)

No.

E01 HK42D38001 Cover 1

E02 HA70264C06 Screw 4 9/64(40)×8

E03 H7351C8001 Washer 4

E04 H415040080 Screw 2 M4×8

E05 HK42D18001 Cover 1

E06 HK42D08001 Screw 2 M3×6

E07 HK41D78001 Rear stopper Y 1

E08 HK42D48001 Cover 1

E09 H103040080 Bolt 6 M4×8

E10 H431030060 Screw 1 M3×6

E11 H416040100 Screw 4 M4×10

E12 HK41D18001 Fixed race Y 2

E13 HK41D08001 Retainer Y 2

E14 H6618D8001 Ball 80

E15 HK41D58001 Movable race Y 1

E16 HK41D38001 Front stopper Y 1

E17 HK41D98001 Connceting plate 1

E18 HA70264C06 Screw 2 9/64(40)×8

E19 H6623D8001 Cover 1

E20 HK40D68001 Movable race X 2

E21 H416040160 Screw 8 M4×16

E22 HK40D98001 Fixed race X 2

E23 H6610D8001 Stopper 2

E24 H6611D8001 Stopper 2

E25 H415040140 Screw 2 M4×14

E26 H415040400 Screw 2 M4×40

E27 H003002040 Nut 2 M4

E28 HK40D88001 Retainer X 2

Part No. Description Pcs. Remarks

— 43 —

Page 49

F.X - Y TABLE MECHANISM ( 二 )

— 44 —

13

·

~

27

32

33

~

Page 50

Fig.

F.X-Y TABLE MECHANISM(二)

No.

F01 H415050100 Screw 4 M5×10

F02 H6686D8001 Washer 4

F03 H6646D8001 Motor mounting plate Y 1

F04 H6632D8001 Screw 2 M4×6

F05 H6631D8001 Gear 1

F06 HK43D08001 Stepping motor 1

F06 HK43D08001 Stepping motor 1

F07 H415040120 Screw 4 M4×12

F08 HK46D68001 Rack Y 1

F09 H415050160 Screw 2

F10 H6649D8001 Rack adapter Y 1

F11 H6623B8001 Ball bushing 10 2

F12 H6693D8001 Screw 2 M4×14

F13 HK47E18001 Linear shaft Y 1

F14 HK41B58001 Bearing 2

F15 HK44D68001 Driving pulley B 1

F16 H6632D8001 Screw 2 M4×6

F17 HK43D48001 Shaft 1

F18 HK43D38001 Screw 4 M5×6

F19 HK43D28001 Coupling 1

F20 H415040160 Screw 4 M4×16

F21 HK42D58001 Pulley shaft 1

F22 HK42D68001 Pulley shaft 1

F23 HK45D58001 Cog belt 1

F24 HK45D38001 Driving pulley A 1

F25 H6632D8001 Screw 2 M4×6

F26 HK45D48001 Shaft 1

F27 HK41B58001 Bearing 2

F28 H007013060 E-type retaining ring 2

F29 H415050160 Screw 4

F30 H6686D8001 Washer 4

F31 H005008050 Spring washing 4

F32 HK45D08001 Bracket 1

F33 HK42D88001 Screw 1

F34 H3100E2180 Nut 1 M4

Part No. Description Pcs. Remarks

M5×16

— 45 —

Page 51

G. CABLE COMPONENT & DETECTOR MECHANISM

16

~17

7

~

4

19

8

·~

— 46 —

Page 52

Fig.

G. CABLE COMPONENT & DETECTOR MECHANISM

No.

G01 H6656D8001 Detector X mounting plate 1

G02 H6657D8001 Bracket 1

G03 H6677D8001 Pin 2

G04 H6694D8001 Detector X 1

G05 H6695D8001 Screw 2

G06 H415040080 Screw 2 M4×8

G07 H415040080 Screw 2 M4×8

G08 H6642B8001 Screw 1 M4×8

G09 H6679D8001 Nylon clip 1 AB-3N

G10 H6665D8001 Detector bracket Y 1

G11 H6676D7101 Holder plate assy 1

G12 H415030100 Screw 1 M3×10

G13 H6679D8001 Nylon clip 1 AB-3N

G14 H6642B8001 Screw 1 M4×8

G15 H6670D8001 Detector Y 1

G16 H6666D8001 Detector cover Y 1

G17 H661AB8001 Screw 2 M4×6

G18 H415040100 Screw 4 M4×10

G19 Print circuit board 1

G20 H6609I8001 Screw 4 M4×20

Part No. Description Pcs. Remarks

— 47 —

Page 53

H. WORK HOLDER MECHANISM(AIR OPERATED)

18

20 15

22

~~

— 48 —

Page 54

Fig.

H. WORK HOLDER MECHANISM(AIR OPERATED)

No.

H01 HM012E8001 Work holder guide base 1

H02 Pin 1

H03 H005001080 Washer 2

H04 H007013060 E-type retaining ring 2

H05 Link 1

H06 HA719B7010 Washer 1

H07 HA700F2100 Screw 1 SM11/64(40)×7

H08 Link 1

H09 Link 1

H10 HA719B7010 Washer 1

H11 HA700F2100 Screw 1 SM11/64(40)×7

H12 Link 1

H13 HF15404017 Bracket 1

H14 H415040080 Screw 4 M4×8

H15 HF15404016 Pin 1

H16 retaining ring 2

H17 HF997J8001 Screw 4 M3×4

H18 HEE4108001 air cylinder 2

H19 H415050140 Screw 2 M5×14

H20 HEE4218001 Joint 4

H21 HEE4708001 Bolt 2

H22 HF15404014 Bracket 2

H23 H007013040 E-type retaining ring 4

H24 HK40E68001 Clamp foot 1

H25 HM007E8001 Bracket 1

H26 H416040080 Screw 2 M4×8

H27 HM008E8001 Guide bracket 1

H28 H660JB8001 Screw 2 M4×8

H29 HM011E8001 Bracket 1

H30 H415040160 Screw 4 M4×16

H31 H415040120 Screw 2 M4×12

H32

H33 HK42E78001 Bracket 1

H34 H431040060 Screw 2 M4×6

H35 H6623B8001 Bearing 1

H36 H6682E8001 Bearing housing 1

H37 HK46E88001 Shaft 1

H38 H415050080 Screw 2 M5×8

H39 HK46E98001 Feed plate 1

H40 H666GE8001 Positioning block 1

H41 H415040050 Screw 1 M4×5

H42 H6685D8001 Washer 3

H43 H6684D8001 Washer 2

Part No. Description Pcs. Remarks

H6686D8001 Washer 4

— 49 —

Page 55

Fig.

H. WORK HOLDER MECHANISM(AIR OPERATED)

No.

H44 H415050140 Screw 2 M5×14

H45 H6686D8001 Washer 4

Part No. Description Pcs. Remarks

— 50 —

Page 56

J. PRESSER FOOT MECHANISM

21

25

17

;;!

·~

5

6

20

18

30

]

31

32

22

43

24

— 51 —

Page 57

Fig.

J. PRESSER FOOT MECHANISM

No.

J01 H2010J0065 Screw 1 9/32(28)×35

J02 H2010J0066 Nut 1 9/32(28)

J03 HM018F8001 Bracket 1

J04 H6682D8001 Screw 2 M4×10

J05 HM022F8001 Presser spring 1

J06 H2000J2040 Presser bar 1

J07 HM016F8002 Screw 1 1/4(40)

J08 HM015F8001 Positioning block 1

J09 HM016F8001 Screw 4 1/4(40)

J10 HM014F8001 Link 1

J11 HM011F8001 Link 1

J12 HM013F8001 Link 1

J13 H431040100 Screw 2 M4×10

J14 H6650B8001 Pin 1

J15 HA106B0676 Screw 1 9/64(40)×6

J16 H3200K0190 Holder 1

J17 H2000M0080 Felt 1

J18 HM012F8001 Link 1

J19 HM007F7101 Shaft 1

J20 HM006B8001 Bushing 2

J21 H2012N0652 Screw 1 1/4(40)×16

J22 Nut 1 M6

J23 H005001060 Washer 1

J24 HM005F8001 Link 1

J25 H2000J2100 Screw 1 M6

J26 H20111C106 Holder 1

J27 H2014J0068 Felt 1

J28 H007009250 retaining ring 1

J29 HA307C0662 Screw 2 1/4(40)×6

J30 HA309H0681 Screw 1 1/2(28)×43

J31 HA117H0692 Nut 1 1/2(28)

J32 HM025F8001 Presser bar guide 1

J33 H662IB8001 Washer 1

J34 HM026F8001 Presser spring 1

J35 H6027H8001 Presser bar holder 1

J36 HA3411D308 Screw 1 15/64(28)×7

J37 HA100H2090 Bushing 1

J38 HM029F8001 Presser bar 1

J39 H2000I2050 Screw 1 9/64(40)×8

J40 H431040100 Screw 1 M4×10

J41 HM027F8001 Presser foot 1

J42 H2014J0652 Eccentric cam 1

J43 H2100I2010 Link 1

Part No. Description Pcs. Remarks

— 52 —

Page 58

K. PRESSER BAR LIFTING MECHANISM

— 53 —

Page 59

Fig.

K. PRESSER BAR LIFTING MECHANISM

No.

K01 HA700I2070 Pin 1

K02 HA100H2050 Screw 1 15/64(28)

K03 HA107H1012 Cam 1

K04 HM036F8001 Link 1

K05 HA107H1013 Screw 1

K06 HA107H0662 Screw 2 3/16(28)

K07 HK43F48001 Lever 1

K08 HK44F17101 Solenoid 1

K09 H007013040 E-type retaining ring 4

K10 HK44F68001 Link 2

K11 HM048F8001 Bushing 2

K12 HK44F88001 Link 1

K13 H431050080 Screw 1 M5×8

K14 HK45F38001 Pin 1

K15 HM037F8001 Pin 2

K16 H415050200 Screw 2 M5×20

K17 H6608E8001 Bracket 1

K18 H663FE8001 Washer 4

K19 HA700B2060 Screw 4 11/64(40)×8

K20 H104040160 Bolt 1 M4×16

K21 H003002040 Nut 1 M4

K22 HD412J8001 Spring 1

K23 HK44F98001 Bearing 2

Part No. Description Pcs. Remarks

— 54 —

Page 60

L. THREAD TRIMMING MECHANISM

~1

/

~

3 6

/;7

89

10

11

\

•

, . ,)

13

··.·~

20

..