Page 1

Customer

Copy

Service

HIGH

GM747series

HIGH-SPEED

MACHING

Instruction Manual

LEAD

OVERLOCK

SEWING

Parts

SHANGHAI HUIGONG

N0.3

Catalog

SEWING MACHINE FACTORY

Page 2

To

the

Operators

.......

......

..........

.........................................

Contents

......................................................

.............................

l

Ho\\' to install the

Ho\V

to

operate

Lubrication

I . Lubrication .................................................................................................................................................... 1

2. Drainage ........................................................................................................................................................ I

3.

Needle Cooling

Threading

Thread

I.

..,

3.

4. Chain Looper Thread Cmn Control ............................................................................................................. 3

the

tension ..........................................

Tension Nuts Adjustment ............................................................................................................................. 2

Needle Thread Control ············· .................................................................................................................... 2

Looper Thread Control ................................................................................................................................. 2

Stitch Length

Need le

replacement

Differential feed

machine···········

the

ne\v machine

and

drainage

Lubrication-Silicon

machine .............

Adjustment

...........................................................................................

ratio

adjustment

........................

...............

...........................................................................................

...

.................................

....

.........................

.......

................................................

.....................................................................................................

......

....

.............................

oil ................................................................................................... I

...

................................................................................... 1

.......................................................................

.................................. 2

............................................................................................................................... 3

....

............................................... 3

.................................................................................................................. 4

.............

1

1

I

Parts

relation

I.

Needle and Needle Plate .............................................................................................................................. 4

2. Upper Looper and Needle ............................................................................................................................ 4

3. Lo\vcr Looper and Needle ............................................................................................................................ 5

4. Upper Looper and Lower Lopper ................................................................................................................ 5

5. Needle and Needle Guard ............................................................................................................................ 5

6. Chain Looper and Needle ............................................................................................................................. 5

Problem

Parts

catalog .................................................................................................

and

settlement

timing ...................................................................................................................................

............................................. : ..............................................

.....................

....................

...

.......

...

..............

......

.....

...

...............

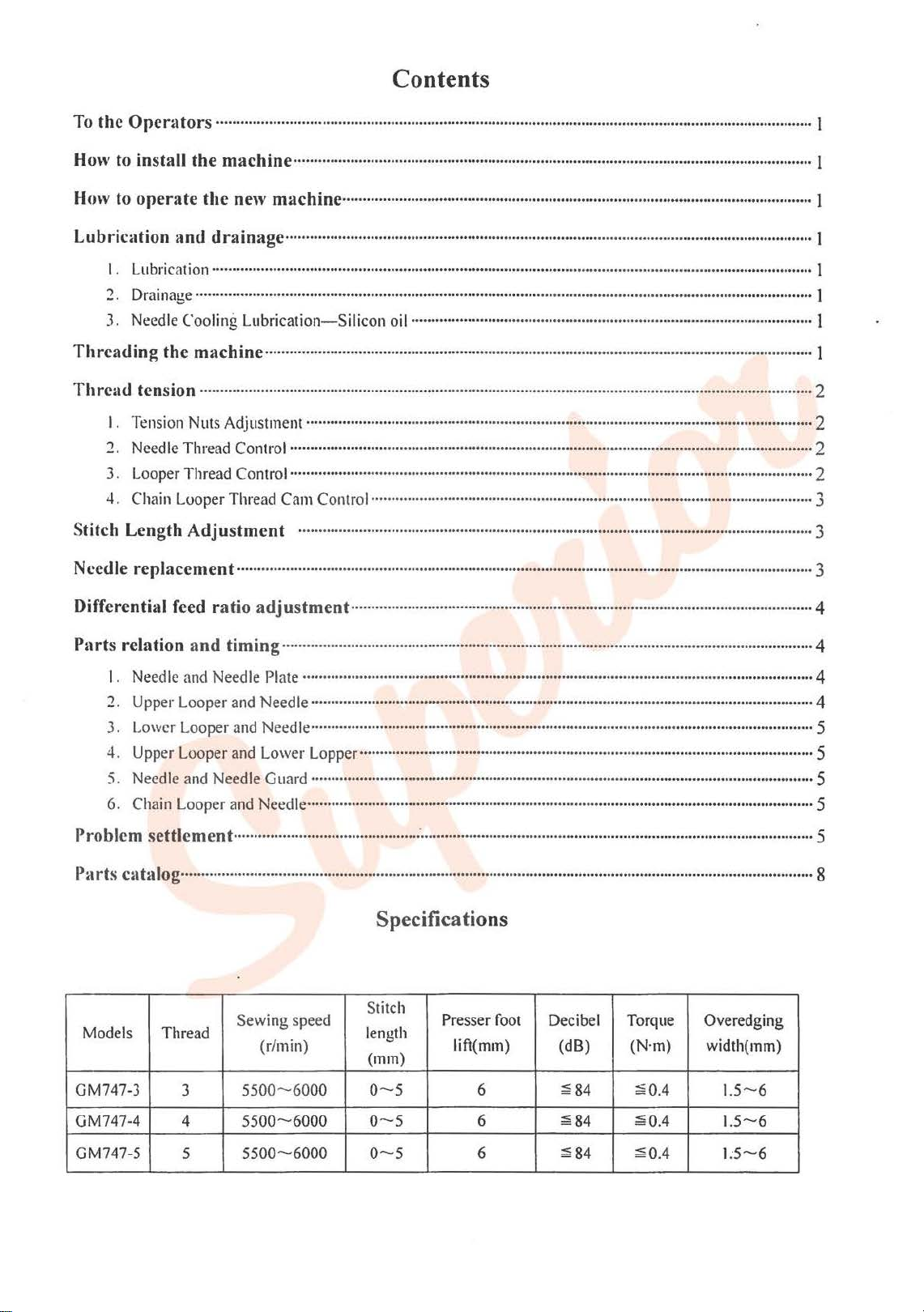

Specifications

Models

GM747-3 3 5500- 6000

Thread

Sewing speed

(r/min)

Stitch

length

(mm)

0-5

Presser foot Decibel Torque

lift(mm) (dB) (N·m)

6

~84

~0.4

Overedging

width(mm)

1.5--6

4

...

....

......

5

8

;;a

GM747-4

GM747-5

4

5

5500-6000

5500-6000

0-5

0--5

6

6

84

~84

~0.4

~0.4

1.5-6

1:5-6

Page 3

To the operator

Thank

you

very

much

for

using our High speed, Straight Needle, Overlock Safety Stitch Machine.

operating

machine.

correct direction

this

machine. please study this book thoroughly. understand the functions

Then

it

ATTENTION:

of

will

help

Because this

motor.

you

to

increase your sewing efficiency

is

an

high speed machine.

How to install the machine

1.

Install

the

enclosed.

IOOmm,and

2. Setting the

3 .

Install

Be

4.

NOTE:

machine according

In

case

of

semi-submerged, the distance between Needle plate top surface

for

fully-submerged

pedal

the

cloth waste chute. thread stand

sure the motor turning direction

The dimensions

is

of

clutch motor

of

motor pulley

about

to

the table

5mm.

to

the

is

How to operate the new machine

Please

run

thereafter

the new machine

the

machine

may

be

operated

in

the ftrst four at 20%less

up

to

left

side

as

parts list.

c.Jockwise.

and

sewing

maximum

cut-out

and

And

speed

speed.

and

quality.

Do

not

run

it

before

filling

diagram, Cushion Rubber

the

pedal

of

the belt can

are

speed

than

presser

shown

maximum.

be

pressed

in

Table I.

foot

Then replace

oil

and

lift

at

inward

and

features

and

making

and

Rest

Table

Top

right ride.

about

the

Before

of

sure

Board

is

about

JOmm.

new

oil

the

the

as

and

Lubrication and drainage

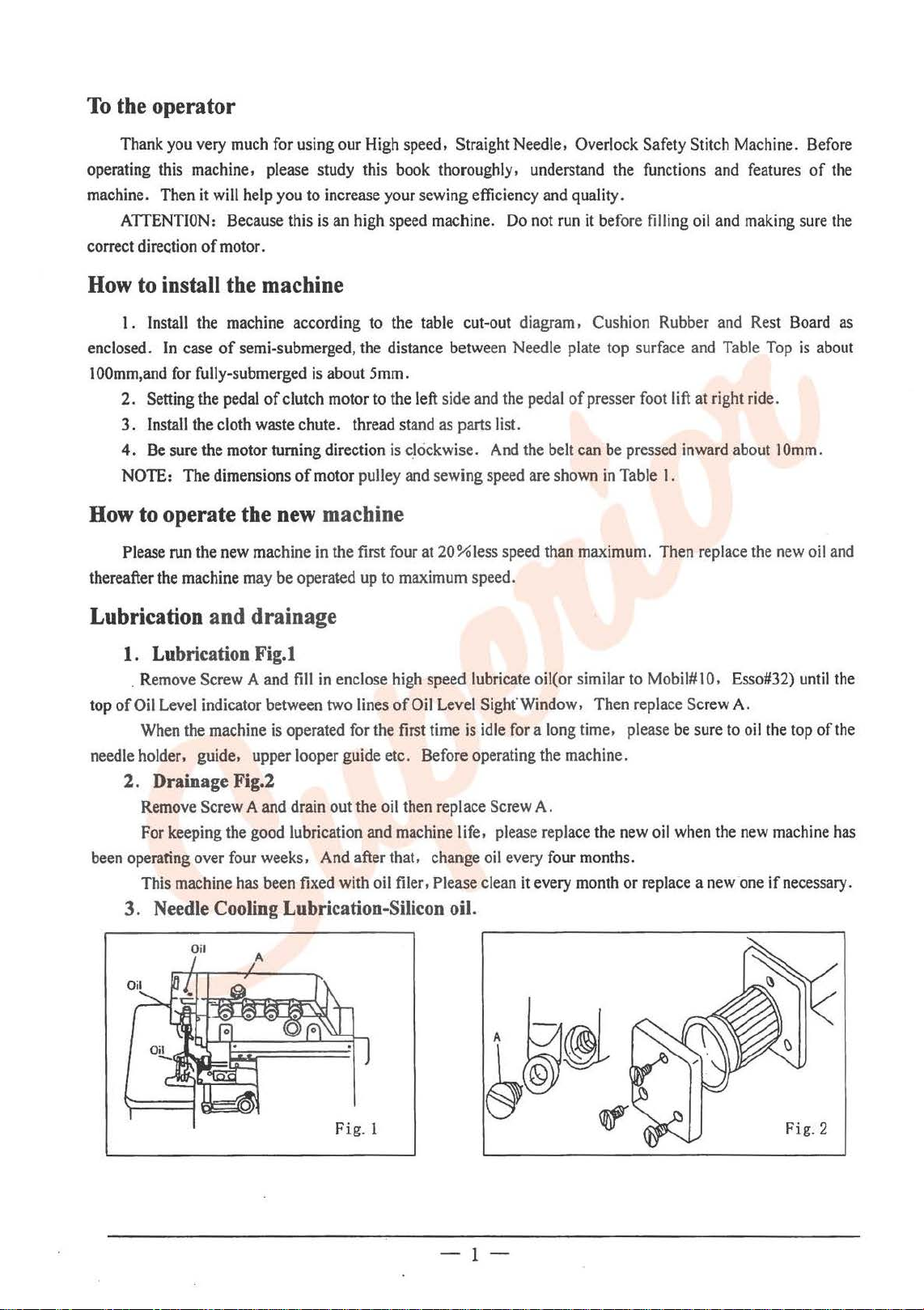

1. Lubrication Fig.l

.

Remove

top

of

Oil

When

needle

holder. guide, upper looper guide etc. Before operating the machine.

2.

Remove

For

been

operating over

This

3.

Screw A

Level

indicator between

the

machine

Drainage

Screw A and

keeping

machine

Fig.l

the

good

four

has

and

ftll

in

enclose

two

is

operated for the ftrst time

drain

out the

lubrication

weeks,

been

And

ftxed

with

high

lines

of

oil

and

machine

after that, change

oil

ftler

speed lubricate oil( or similar

Oil

Level

is

then

replace

life,

, Please clean

Needle Cooling Lubrication-Silicon oil.

Oil

A

Sight'Window. Then replace Screw A.

idle

for a long

Screw

please

oil

every

A.

replace the

four

it

every

time,

months.

month

to

Mobil# I 0,

please

be

new

oil

when

or replace a

sure

to

the

new ·one

Esso#32)

oil

the

new

machine

if

necessary.

until

top

of

the

the

has

Fig. 1 Fig.2

-1-

Page 4

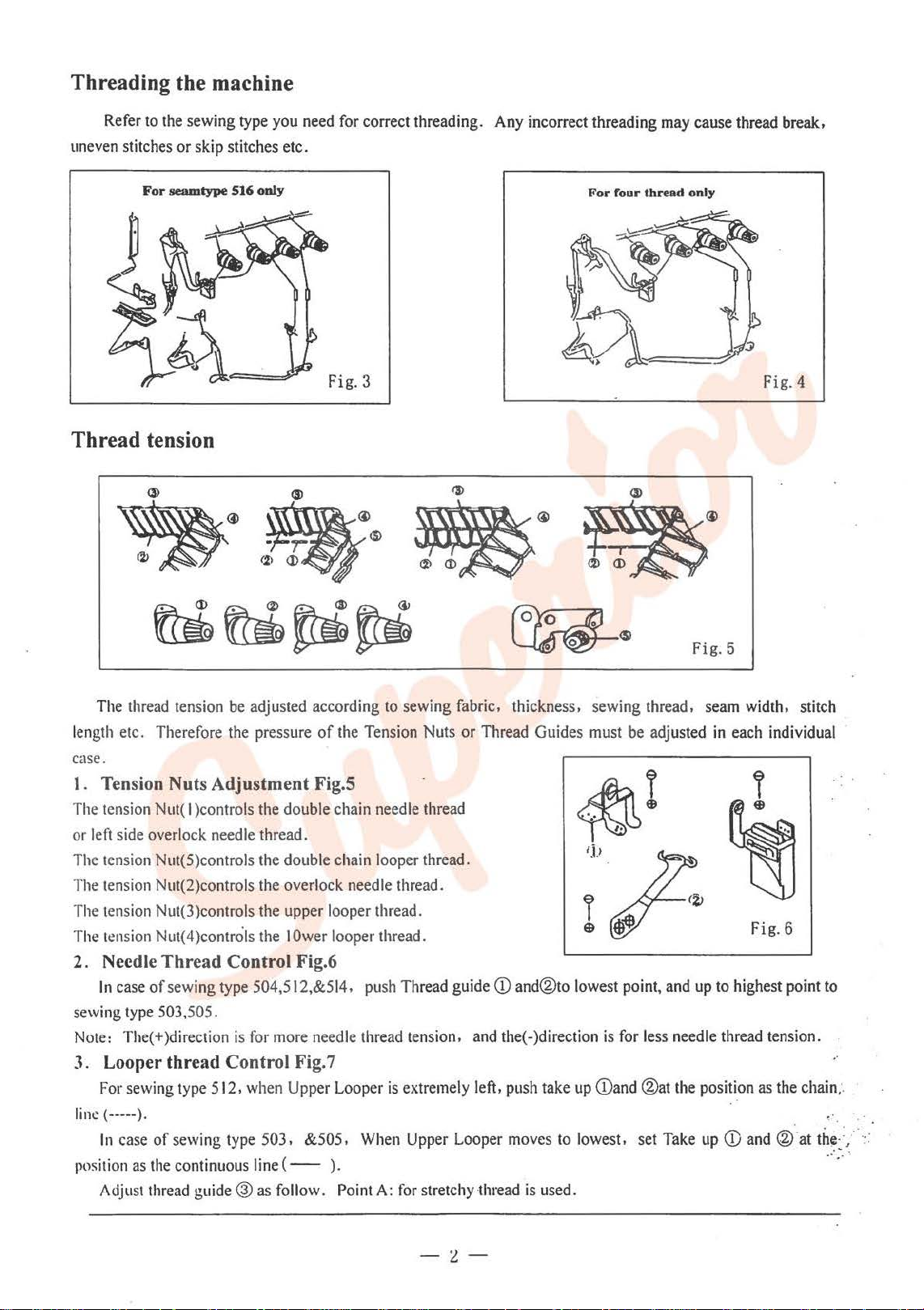

Threading the machine

Refer

to

the

uneven

sewing type

stitches or skip stitches etc.

For

seamtype

516

you

only

Thread tension

need

for

correct threading.

Any

incorrect threading

For

four

may

thread

cause thread break,

only

Fig. 3 Fig.4

The

thread

tension

length etc. Therefore

case.

l.

Tension Nuts Adjustment Fig.S

The

tension

or

left

The

tension Nut(5)controls the double chain looper thread.

The

tension Nut(2)controls

The

tension Nut(3)controls

The

tension

2. Needle

In

sewing

Note:

Nut(

side overlock needle thread.

Nut(

Thread

case

of

sewing

type

503,505.

The(+)direction

be

the

I )controls

4 )controls

Control Fig.6

type

is

adjusted according to sewing fabric, thickness, sewing thread,

pressure

the

the

the

the I Ower

504,512,&514.

for

of

the

Tension Nuts or Thread Guides

double chain

overlock needle thread.

upper looper thread.

more

needle

needle

looper thread.

push

Thread guide

thread tension ,

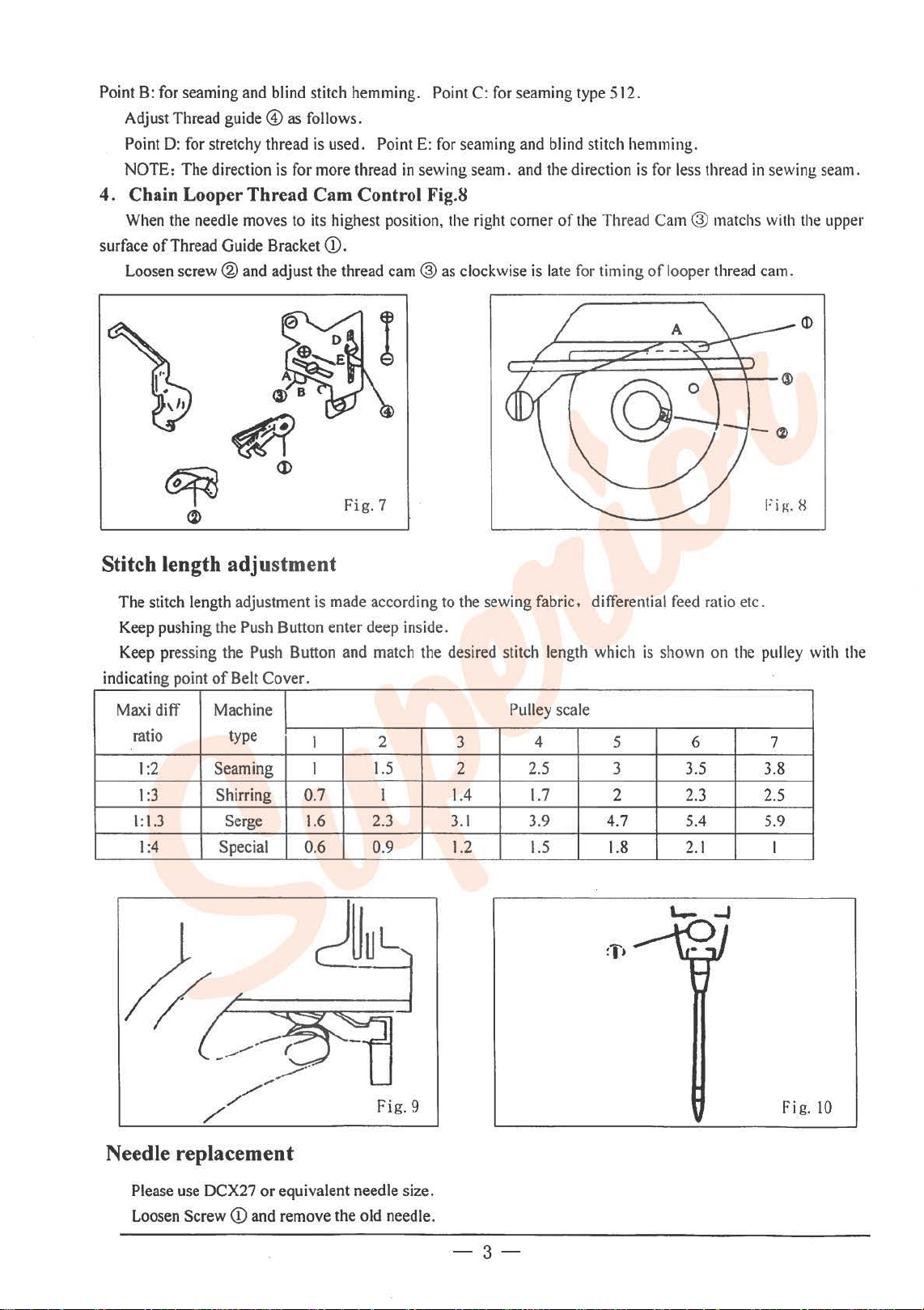

3. Looper thread Control Fig. 7

For

line ( -----

In

case of sewing

position

Adjust

sewing type 5

).

as

the

thread guide@ as follow.

12,

when Upper Looper

type

503. &505.

continuous line (

--

).

Point

is

When

A:

for

thread

and

extremely left,

Upper

Looper

stretchy thread

must

be

CD

and®to lowest point, and

the(-)direction

push

take

moves

is

used.

is

up

<Dand

to

lowest. set

for

Fig.

5

seam

width. stitch

adjusted

less

®at

Take

in

each individual

Fig.6

up

to

highest point to

needle thread tension. .

the

position as

up

CD

and

the

chain;.

@)"at

th~·:/

..

'- '

-:l-

Page 5

Point

B:

for seaming and blind stitch hemming. Point

Adjust Thread

Point D: for stretchy thread

NOTE: The direction

guide@

as follows.

is

used. PointE: for seaming and blind stitch

is

for more thread

in

sewing seam.

4. Chain Looper Thread Cam Control Fig.S

When

the needle moves to

surface ofThread Guide Bracket Q).

Loosen

screw®

and

its

highest position,

adjust the thread

cam@

the

as

Fig. 7 Fig. H

C:

for

seaming type 512.

right corner

clockwise

and

the direction

of

is

late for

hemm

ing.

is

for

less thread

the

Thread Cam ® matchs

timing

of

looper thread cam.

in

sewing seam.

with

the

upper

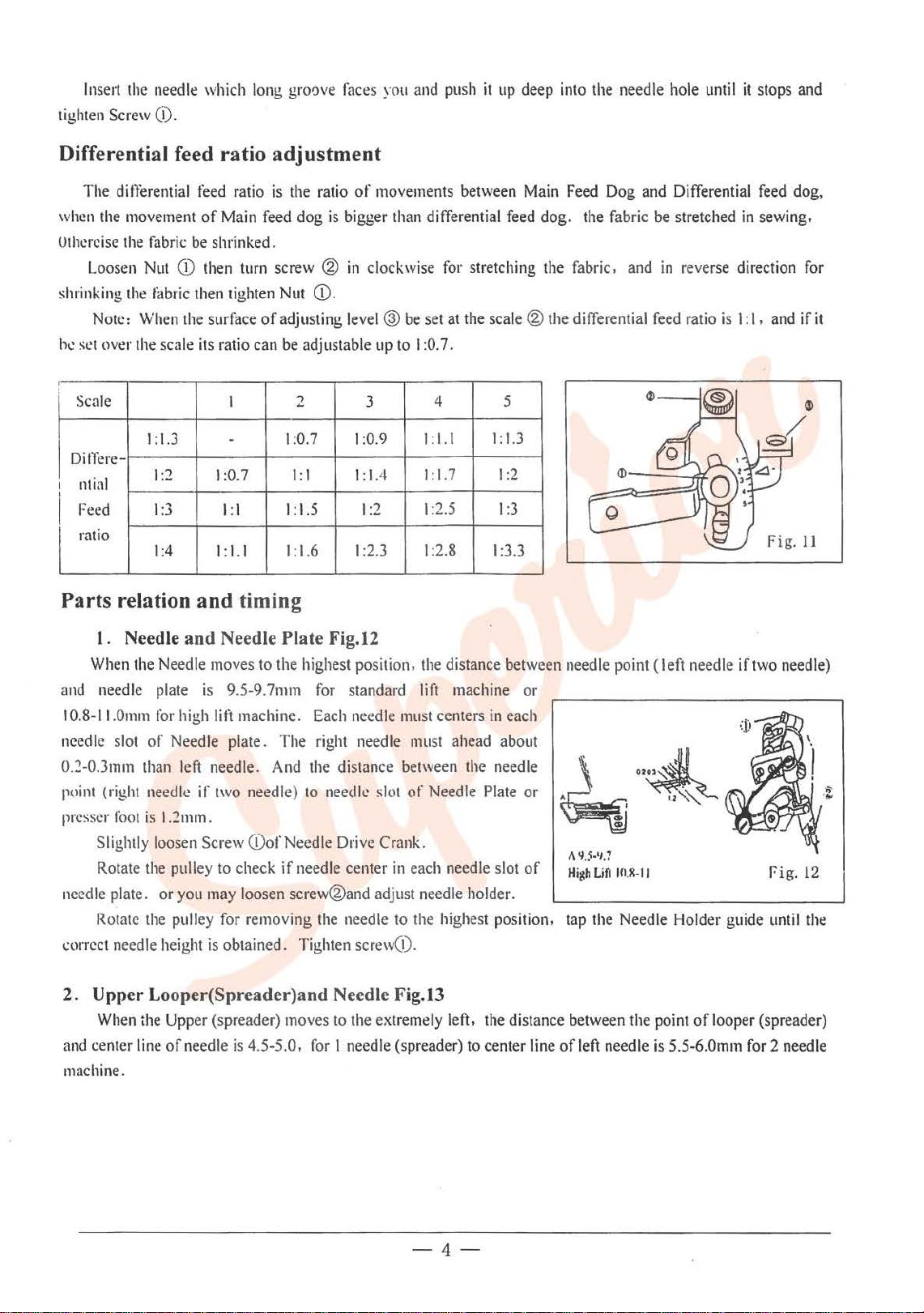

Stitch length adjustment

The stitch length adjustment

Keep

pushing the Push Button enter deep inside.

Keep

pressing the Push Button and

indicating point

Maxi

diff Machine

ratio type

1

:2

I :3

1:1.3 Serge

1:4

of

Belt

Cover.

Seaming I

Shirring

Special

is

made according

I

0.7

1.6

0.6 0.9

match

2

1.5

I

2.3

to

the sewing fabric. differential

the desired stitch length which

Pulley scale

3

2 2.5 3

1.4

3.1

1.2 1.5 1.8

4

1.7

3.9

5 6 7

2

4.7

is

shown

feed

3.5

2.3

5.4

2.1

ratio etc.

on

the pulley

3.8

2.5

5.9

I

with

the

Fig. 9

Needle replacement

Please

use

DCX27 or equivalent needle size.

Loosen

Screw

Q)

and

remove the old needle.

-3-

Fig.

10

Page 6

Insert

the needle which long gro0ve

faces

tighten Screw (i).

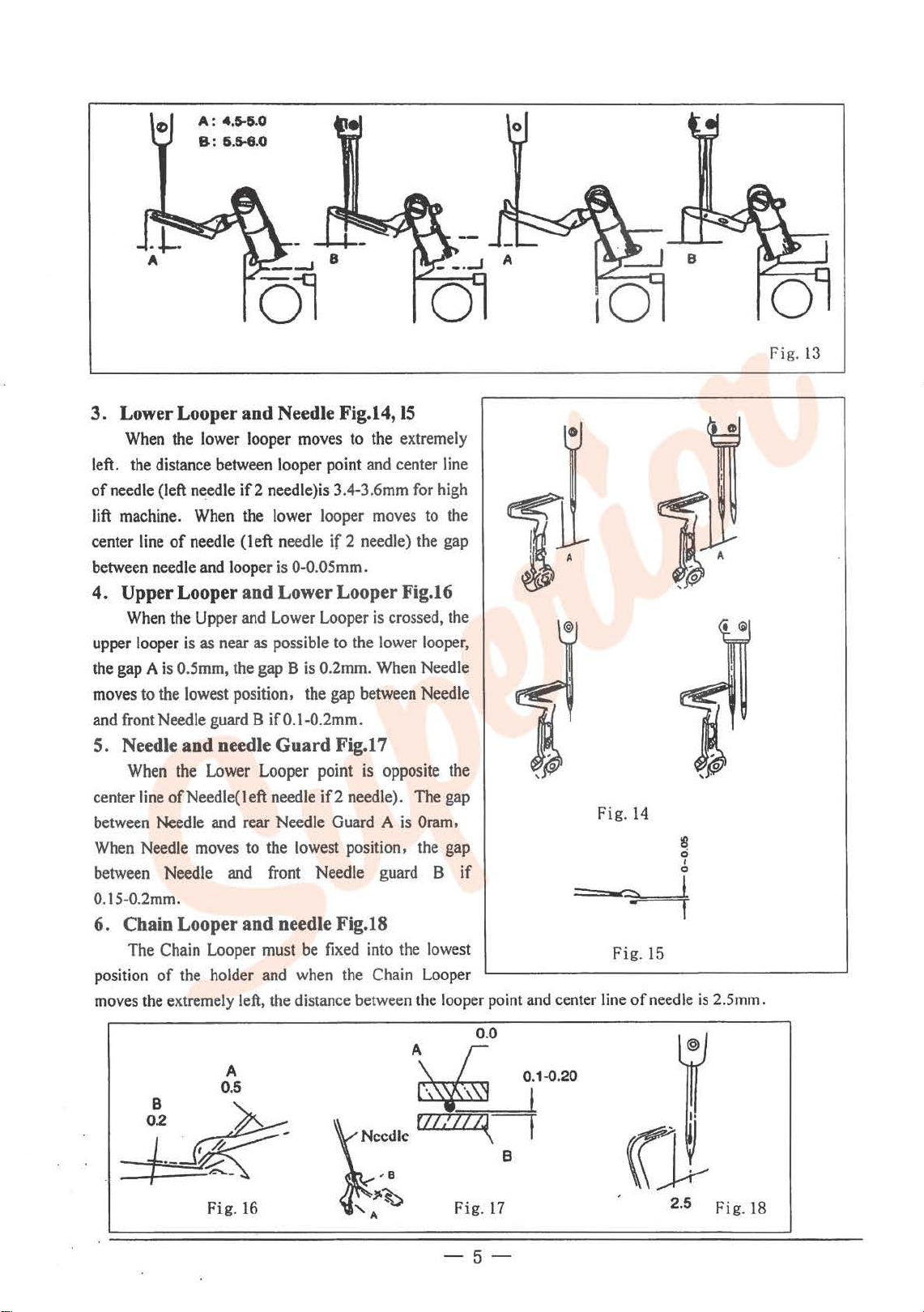

Differential feed ratio adjustment

you

and

push

it

up

deep into the needle hole until

it

stops

and

The ditlerential teed ratio

when

the

Uthcrcise

Loosen

shrinking

Note:

b~

set

over

I

I

movement

the

fabric

Nut

the

fabric

When

the

of

be

Q)

then turn screw ®

then tighten Nut (D.

the surface

scale

its

Main

shrinked.

ratio can

is

the ratio

feed

of

adjusting level@

be

Scale I 2

1:1.3

-

1:0.7 1:0.9

Ditlere-

I

tHial

Feed

1:2

I

:3

1:0

.7 I :I

1:1

I:

ratio

1:4

I:

1.1

1:1

I

Parts relation and timing

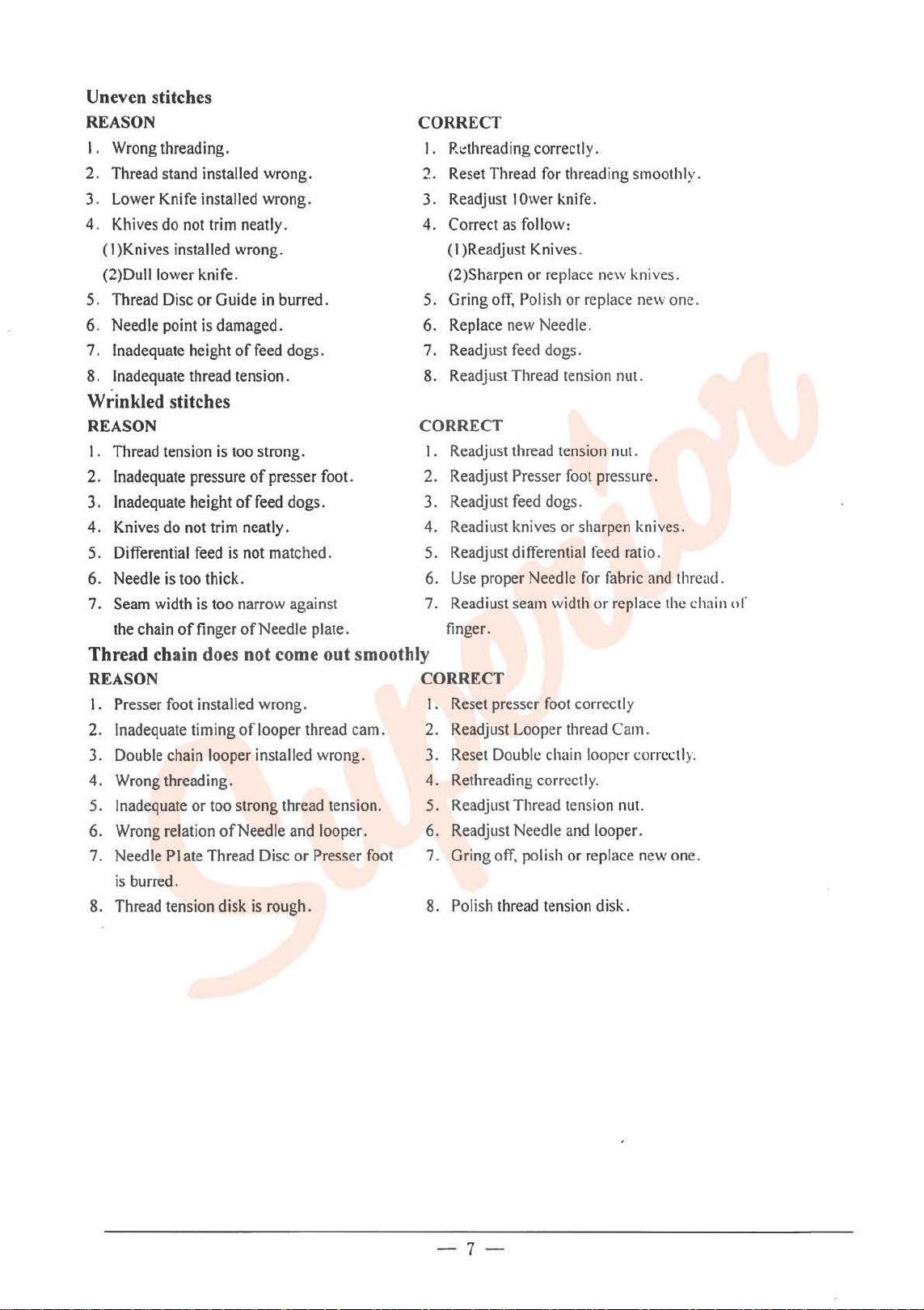

1. Needle and Needle Plate Fig.12

When

the

Needle moves to the highest position.

and

needle plate

10.8-II.Omm

needl

e slot

of

0.::!-0.3mm

point

presser

than left needle.

(right needle if two needle)

foot

is

Slightly loosen Screw

Rotate

the pulley

needle plate. or you

Rotate

~:orrcct

the

needle height

is

9.5-9.7mm

for

high

lift machine.

Needle plate. The right needle must ahead about

And

1.2mm

.

Q)of Needle Drive Crank.

to

check

if

may

loosen screw®and adjust needle holder.

pulley for removing

is

obtained. Tighten screw(!).

of

movements between

dog

is

bigger than differential feed dog. the fabric

in

adjustable

1.5

.6

for

standard

Each

needle

clockwise

up

3

I:

1.4

1:2

I

:2.3

be

to

must

set

I :0.7.

I :I. I

I:

1:2

1:2.8

the

lift

for

stretching the fabric,

at

the

4 5

1.7

.5

distance between needle point (left needle iftwo needle)

machine or

centers

Main

scale®

1:1.3

1:2

I

:3

1:3.3

in

each

the distance between the needle

to

needle slot

needle center

the

needle

of

Needle

in

each

to

the highest position, tap the Needle Holder guide

needl

Plate

e slot

or

of

Feed

Dog and Differential

and

the differential

t\

'15-'1.1

High

Lifl

IOJ~·II

be

stretched

in

reverse direction

feed

ratio

is

feed

in

sewing.

I:

1.

and

Fig.

J7ig.

until

dog,

for

if

ll

12

the

it

2. Upper Looper(Spreader)and Needle Fig.l3

When

the

and

center

Upper (spreader) moves to

line

of

needle

is

4.5-5.0,

the

extremely left, the distance between the point

for

I needle (spreader) to center line

of

left needle

machine.

-4-

of

looper (spreader)

is

5.5-6.0mm for 2 needle

Page 7

A: 4.5-5.0

8:

5.6-6.0

3.

Lower Looper and Needle Fig.14,

When

the

lower

looper

left.

the

distance

of

needle

(left

lift

machine.

center

line

between

4.

upper

the gap A

moves

and

5.

center

between

When

between

0.15-0.2mm.

6.

position

moves

needle

Upper Looper and Lower Looper Fig.16

When

looper

is

to

the

front

Needle

Needle and needle Guard Fig.17

When

line

ofNeedle(Ieft needle

Needle

Needle

Needle

Chain Looper and needle Fig.18

The

Chain

of

the

extremely

needle

When

of

needle

and

the

Upper

is

as

O.Smm,

lowest

the

Lower

moves

the

between

if2

the

(left needle if 2 needle) the

looper

and

near

the

position. the gap

guard

and

rear Needle

to the

and

Looper

holder

left,

moves

looper

needle)is 3.4-3.6mm

lower

is

0-0.0Smm.

Lower

as

possible

gap B

point

looper

Looper

is

0.2mm.

to

to

and

the

between

B if 0.1-0.2mm.

Looper point

lowest

front Needle

must

be

and

when

the distance

is

if2

needle).

Guard A is

position, the

fixed

into

the

between

the

moves

is

lower

When

opposite the

guard

Chain

15

extremely

center

for

to

crossed,

looper,

Needle

Needle

The

Oram,

B if

the

lowest

Looper

the

line

high

the

gap

the

gap

gap

looper

point

and

~

center

Fig.

Fig.

line

14

8

0

I

0

• I

15

of

needle

0

is

2.Smm.

Fig. 13

0.0

A

0.5

Fig.

16

A\

r 0.1..().20

~

ccdlc

f///lZ"\~

-a

~b

A

Fig.

f

17

-5-

2.5

Fig.

18

Page 8

Problem settlement:

Needle

break

REASON

I . Needle installed wrong.

2. Wrong needle size.

3.

Needle is bended.

4.

Wrong relation with Needle Guard.

5.

Wrong relation with looper.

6.

Needle does not center the needle.

Slot

of

Thread

Needle

break

Plate

or

Presser Foot.

REASON

I.

Inferior quality

2. Thread thicker than Needle hole.

3.

Wrong threading.

4.

Thread tension is too strong.

5.

Needle installed wrong.

6. Thread Stand installed wrong.

7. Over heat

(2 )Wrong setting

8.

Thread Disc

9.

Wrong relation

10. Needle . Looper needle Plate and guide

is burred.

of

thread.

ofNeedle:

of

Needle Guard

or

Guide is burred.

of

Needle

(J)NO silicon oil

and

Looper.

Skip stitches

REASON

1. Wrong relation

2.

Wrong threading.

3.

Needle installed wrong.

4. Inadequate thread tension

too strong.

5.

Looper point is damaged.

6.

Needle is bended.

7. Wrong installed needle Guard .

ofNeedle

and Looper.

or

tension

Loosen stitches

REASON

I . Wrong threading

2. Thread is thicker than Needle

hole.

3.

Tension Disc do not press thread

properly.

4.

Needle thread is not 1 ubricated.

5. Wrong setting

Loopers.

ofNeedle

and

CORRECT

1. Reset needle correctly.

2.

Use properly needle for fabric and thread.

3.

Replace new needle.

4.

Readjust Needle guard.

5.

Readjust looper.

6.

Readjust the Needle Plate and Presser Foot.

CORRECT

I. Use good quality thread.

2.

Use proper Needle for fabric and thread.

3.

Rethreading correctly.

4.

Readjust thread tension nut.

5. Reset needle correctly.

6. Reset thread stand for threading smoothly.

7.

(l)FillinSiliconeoil.

(2)Readjust Needle Guard.

8.

Gring

off

polish

or

replace new one.

9. Readjust Needle and Looper.

10. Grind .

off

, polish

or

replace new one.

CORRECT

I.

Readjust Needle and Looper.

2. Rethreading correctly.

3.

Reset Needle correctly.

4.

Readjust Thread Tension Nut.

5. Replace new

6.

Replace new one.

7.

Readjust Needle guard.

one.

CORRECT

I.

Rethreading correctly.

2.

Use proper Needle.

3.

Reset Tension Disc properly.

4.

Fill silicon oil.

5.

Readjust needle and loopers.

Page 9

Uneven stitches

REASON

I.

Wrong

2. Thread stand installed wrong.

Lower

3.

Khives

4.

(I

(2)Dull

5. Thread Disc or Guide

6. Needle point

7.

8. Inadequate thread tension.

threading.

Knife

installed wrong.

do

not

trim

)Knives

Inadequate height

installed wrong.

lower

knife.

is

damaged.

neatly.

in

of

feed dogs.

burred.

CORRECT

Wrinkled stitches

REASON

I . Thread tension

2. Inadequate pressure

3. Inadequate height

Knives

4.

5. Differential

6. Needle

Seam

7.

the

do

is

width

chain

is

too

strong.

of

of

feed

not

trim

neatly.

feed

is

not matched.

too

thick.

is

too narrow against

of

finger

of

Needle plate.

presser foot.

dogs.

Thread chain does not come out smoothly

REASON

I.

Pre

sser

foot

installed wrong.

2. Inadequate timing

3.

Double

4.

Wrong

5.

Inadequate or

6.

Wrong

7. Needle Plate Thread Disc or Presser

is

8.

Thread tension disk

chain looper installed wrong. 3.

threading. 4. Rethreading correctly.

relation ofNeedle

burred.

of

looper thread cam.

too

strong thread tension.

and

is

rough.

looper.

foot

I .

R.:thread

2. Reset Thread

3. Readjust

4. Correct

(I

(2)Sharpen or replace

5. Gring

6. Replace

Readj

7.

8. Readjust Thread tension nut.

ing correctly.

for

threading smoothly.

!Ower

knife.

as

follow

:

)Readjust Knives.

off,

Polish or replace

new

Needle.

ust

feed

dogs.

new

knives.

new

CORRECT

I . Readjust thread tension nut.

2. Readjust

3. Readjust

4. Readiust knives or sharpen knives.

Readjust

5.

Use

6.

7. Readiust

finger.

Presser foot pressure.

feed

dogs.

differential

proper Needle

seam

for

width

feed

ratio.

fabric

and

or replace the chain

CORRECT

Reset

I.

2.

5. Readjust Thread tension

presser

Readjust

Reset

Double

6. Readjust Needle

7.

Gring

off,

8.

Polish thread tension disk.

foot

correctly

Looper thread Cam.

chain looper co

nut.

and

looper.

polish or replace

rrectl

new

one.

thread.

or

y.

one.

-7-

Page 10

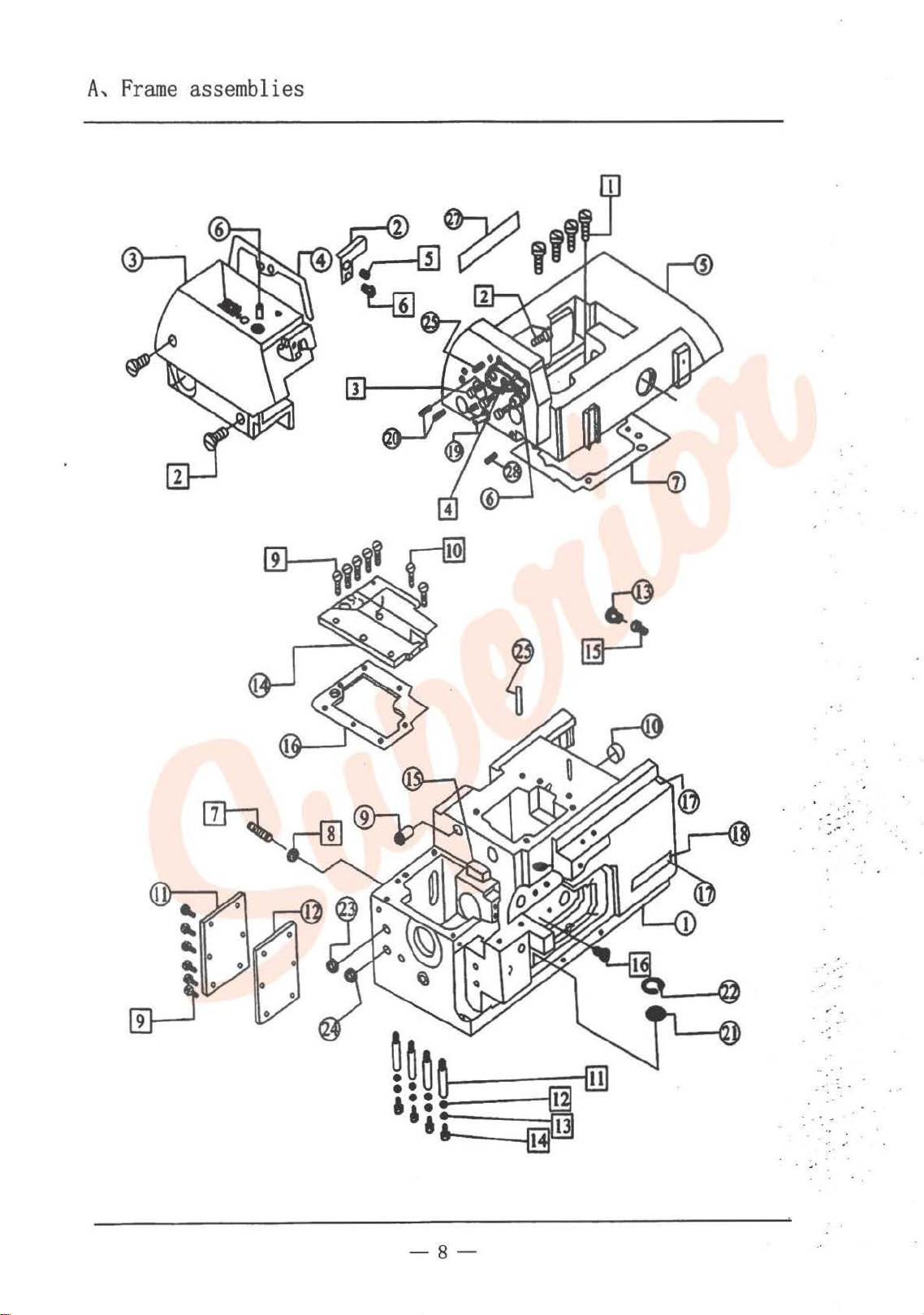

A,

Frame

assemblies

_______

-8-

. . .

_____..

. . .'

. .

.. -

. -·

~

-

...

' ..

~·

-

.

.

·

·~

.,.

. -

~

. .

..

. -

Page 11

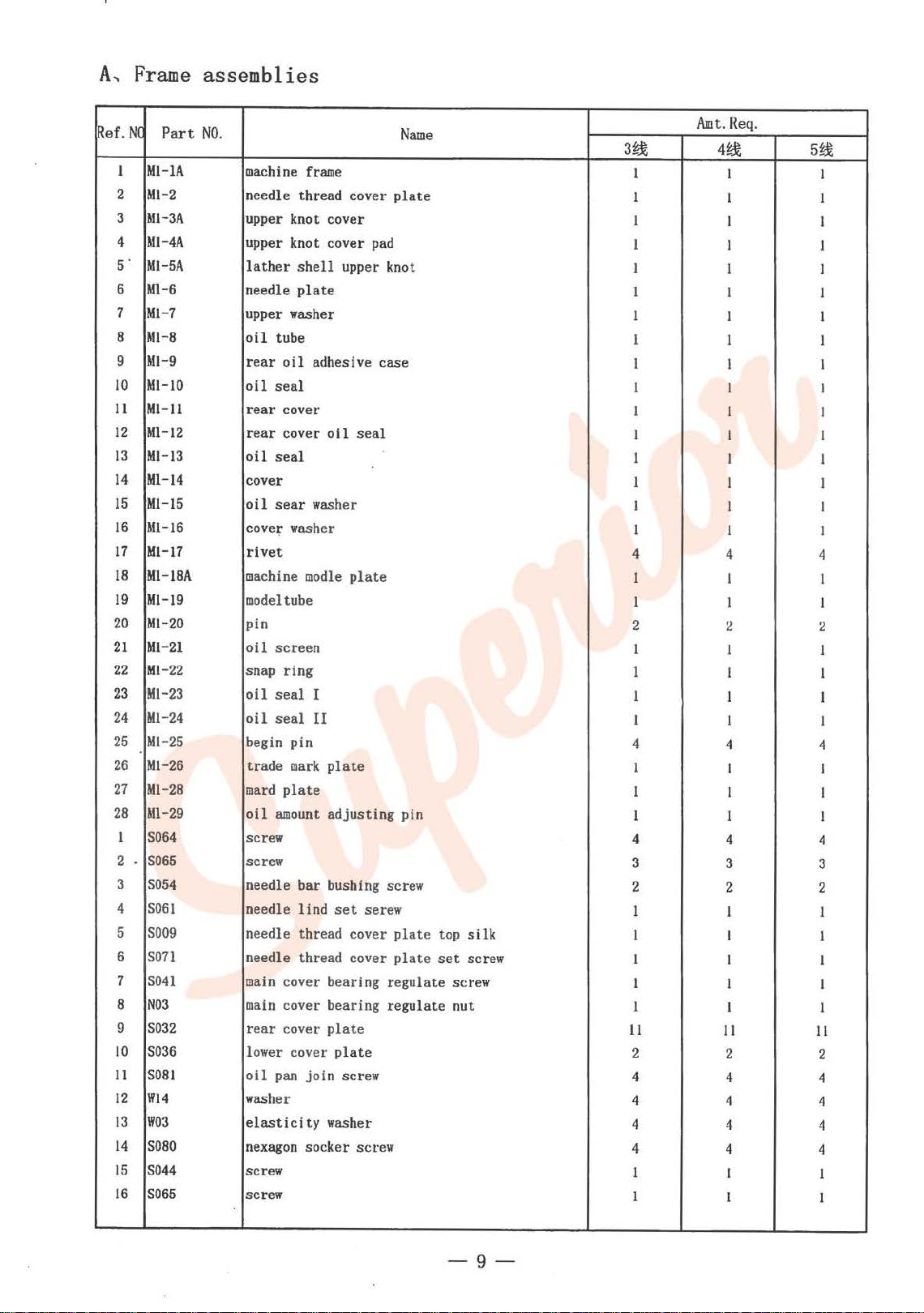

A,

Frame

Ref.NC

1

2

3

4

5'

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22 Ml-22

23

24

25

26

27

28

1

2

.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Part

MI-lA

M1-2

Ml-3A

Ml-4A

M1-5A

Ml-6

Ml-7

Ml-8

M1-9

Ml-10

MI-ll

Ml-12

Ml-13

Ml-14

Ml-15

Ml-16

M1-17

M1-18A

M1-19

M1-20

Ml-21

Ml-23

Ml-24

Ml-25

M1-26

M1-28

All-29

S064

S065

S0

54

S061

S009

son

S04l

N03

S032

S036

S081

Wl4

W03

S080

S044

S065

assemblies

NO.

machine

needle thread cover

upper knot cover

upper knot cover

lather

needle

upper washer

oil

rear

oil

rear

rear

oil

cover

oil

cove~

rivet

machine

model

pin

oil

snap ring

oil

oil

begin pin

trade

mard

oil

screw

screw

needle bar bushing screw

needle

needle thread cover

needle thread cover

main

main

rear

lower cover

oil

washer

elasticity

nexagon

screw

screw

frame

shell

plate

tube

oil

adhesive case

seal

cover

cover

seal

sear

washer

washer

modle

tube

screen

seal

I

seal

II

mark

plate

amount

lind

cover bearing regulate screw

cover bearing reg

cover

pan

join

socker screw

Name

plate

pad

upper knot

oil

seal

plate

plate

adjusting pin

set

serew

plate

plate

ulat

plate

plate

screw

washer

top

set

e nut

silk

screw

A.mt.

Req.

3~

1

1

1

4~

I I

I 1

I I

1 I

1 1

1

1

1

I I I

I

1

I I

1

1

I I

1

4

I

1

2

1

1

1

I

I I

1

I I

I

1 I

I I

I I

4

1 I

1

2 2

I

I 1

1 1

1 1

4

1

1 I

1

4

3

2

1

1

I I

1

1 1

11

4

I I

I I

4

3 3

2 2

I I

I I

I

II

2 2

4

4

4

4

I

1

4 4

4

4

4 4

I

I I

5~

I

I

I

1

I

I

I

4

I

1

1

4

I

4

I

I

I

11

2

4

4

I

-9-

Page 12

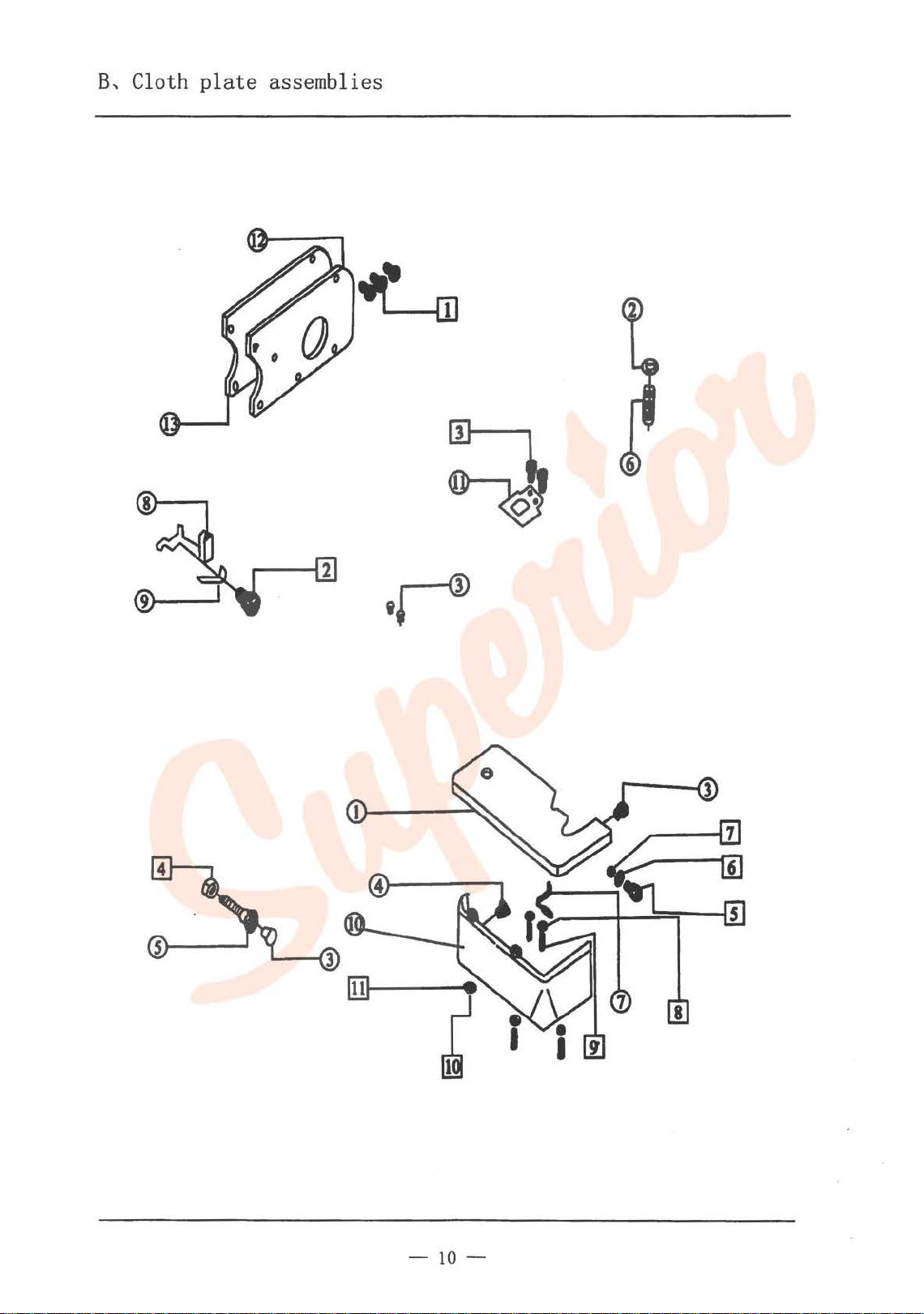

B,

Cloth

8,__...,

plate

assemblies

-10-

Page 13

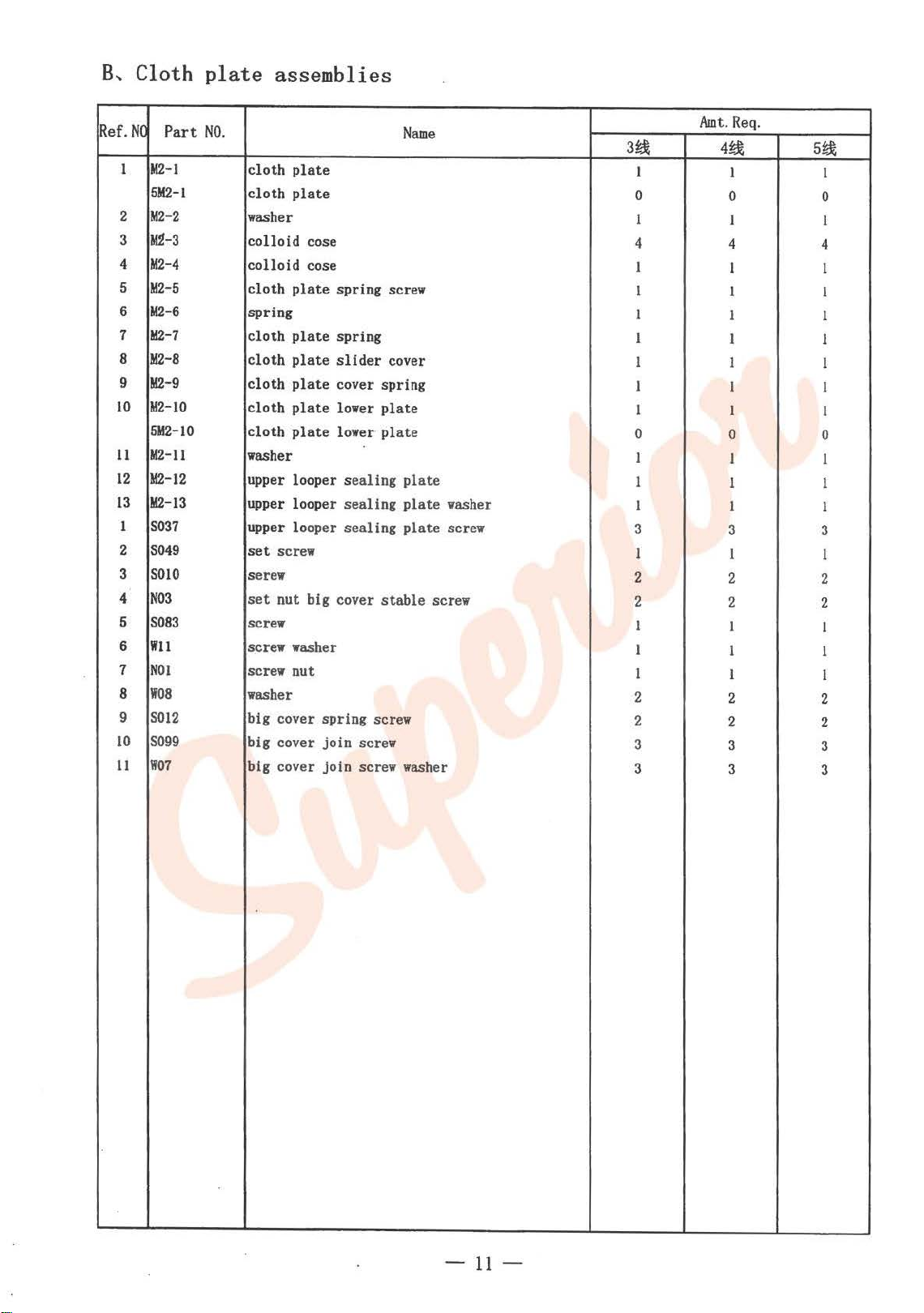

B,

Ref.

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

6

6

7

8

9

10

11

Cloth

NO

M2-l

1

5M2-I

M2-2

111-3

M2-4

M2-5

M2-6

M2-7

M2-8

M2-9

M2-10

5M2-10

M2-11

M2-12

M2-13

S037

S049

SOlO

N03

S083

Wll

N01

W08

S012

S099

W07

plate

Part NO.

assemblies

Name

cloth

plate

cloth

plate

washer

colloid

colloid

cloth

spring

cloth

cloth

cloth

cloth

cloth

washer

upper looper

upper looper

upper looper

set

serew

set

screw

screw washer

screw nut

washer

big cover spring screw

big cover

big cover join screw washer

cose

cose

plate

spring screw

plate

spring

plate

slider

plate

cover spring

plate

lower

plate

lower·

sealing

sealing

sealing

screw

nut big cover

join

screw

cover

plate

plate

plate

plate

plate

stable

screw

washer

screw

Amt.

3~

1

0

1

4

1

1

1

1

1 1

1

1

0

I

1

1

3

I

2

2

1

I I

1

2 2

2

3 3

3

Req.

4~

1

0 0

1

4

1 1

1

1

I 1

1 1

1

0

1 1

1 1

1

3 3

l 1

2 2

2

1

1

2

3

5~

1

1

4

1

1

1

1

0

1

2

1

1

1

2

2

3

3

-11-

Page 14

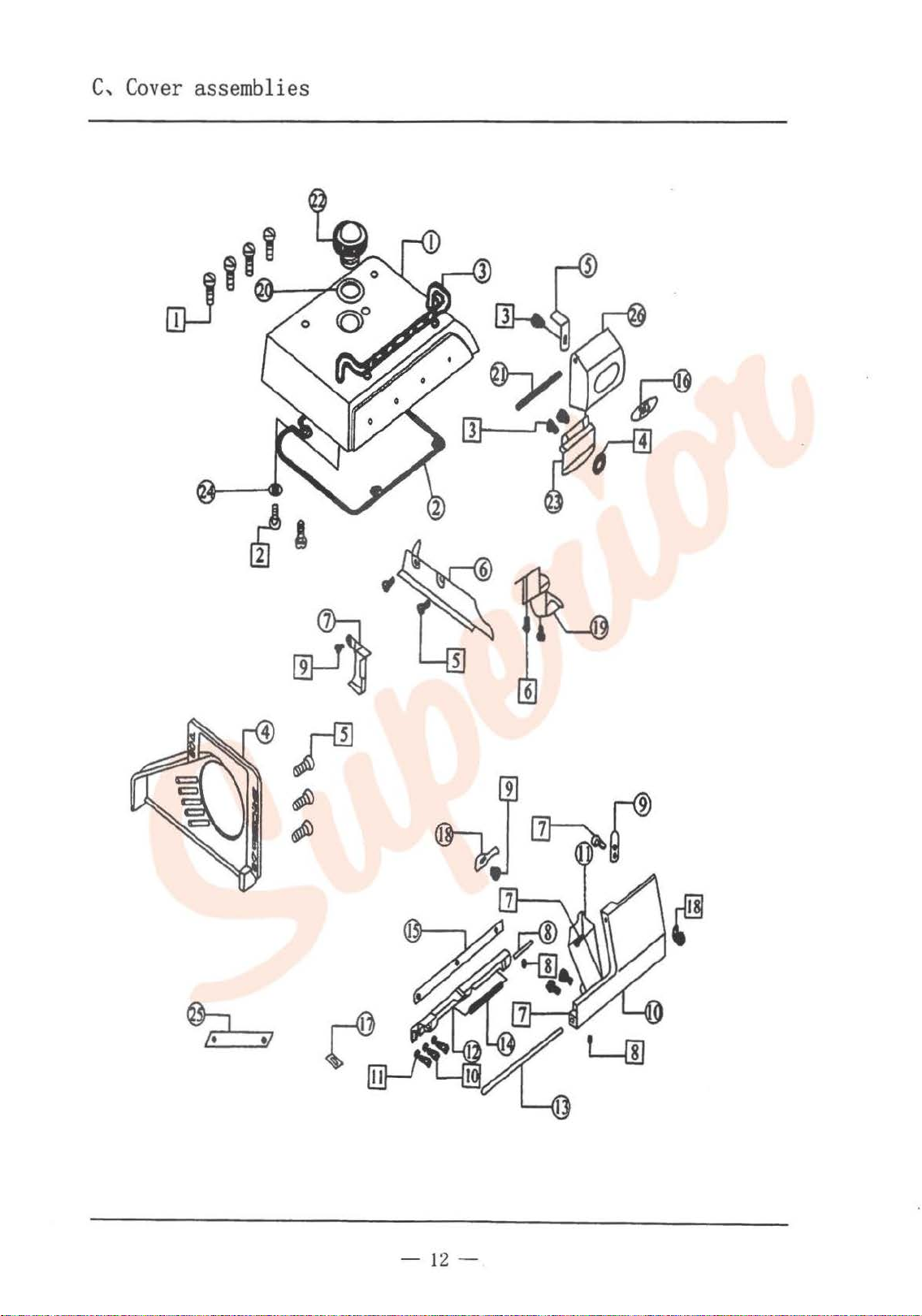

c,

Cover

asse

mblies

=----

-1

2-

Page 15

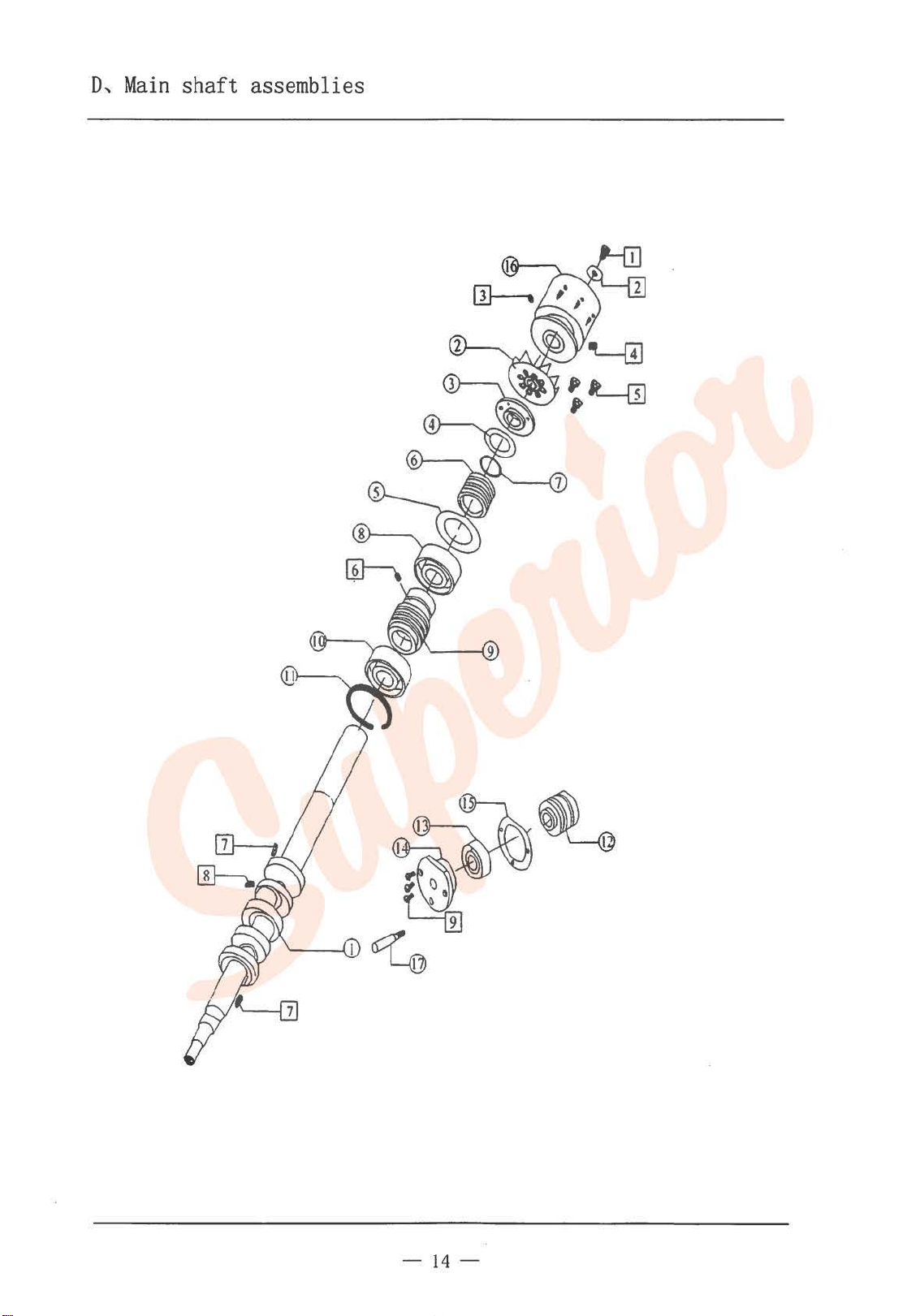

C,

Cover assemblies

Ref.

NC

Part

NO.

1

M3-l

2

M3-2

M3-3

3

4

jM3

-4A

5

M3-5

M3-6

6

7

M3-7

M3-8

8

9

M3-9

10

M3-10

11

M3-11

5M3-ll

12

M3-12

13

M3-13

14

M3-14

M3-15

15

16

M3-16A

17

M3-17

M3-18

18

M3-19

19

20

M3-20

21

M3-21

22

M3-22A

23

M3-23A

24

M3-24

25

M3-25

26

M3-26A

1

S098

2

~091

S017

3

Wl7

4

S032

5

6

S020

S090

7

R

S082

9

S027

10

S024

Wll

11

12

E02

Name

upper cover

upper cover washer

thread guide supporter

belt

cover

thread covet· spring

cloth

guide

plate

oil

guide

II

pin

front

spring

frong cover

front

cover guard

front

cover guard

front

cover hinge

hinge pin

front

cover hinge spring

front

cover hinge washer

trade

mark

plate

oil

flow

window

front

cover snap guard

oil

guard I

oil

sight

gauge

washer

pin

oil

cover

gauge

cover

oil

sight

washer

trade

mark

plate

upper cover

upper cover screw

thread guard screw

upper cover spring screw

washer

cloth

guide

plate

screw

oil

guard screw I

snap

plate

screw

front

cover

plate

block

front

cover hinge screw

front

cover hinge washer

snap uing

spring

screw

Amt.

3~

1 1

I 1

I

I

I I

1 I

1 I

1

1

I

I

0

I

1 1

I I

I

I

2 2

I

1

I

1 I

I I

1

1

1 1

1 1

4

2

3

2

5 5

2

4

3 3

2

3 3

3 3

1 1

Req.

4~

I I

I 1

1

I I

I I

I 0

0 I

1 I

I

1 I

1 1

I 1

1 I

1

1

4

2

3

2

2

4

2

5~

I

I

I

I

I

I

I

I

I

2

I

1

I

I

I

I

4

2

3

2

5

2

4

3

2

:l

3

I

-13-

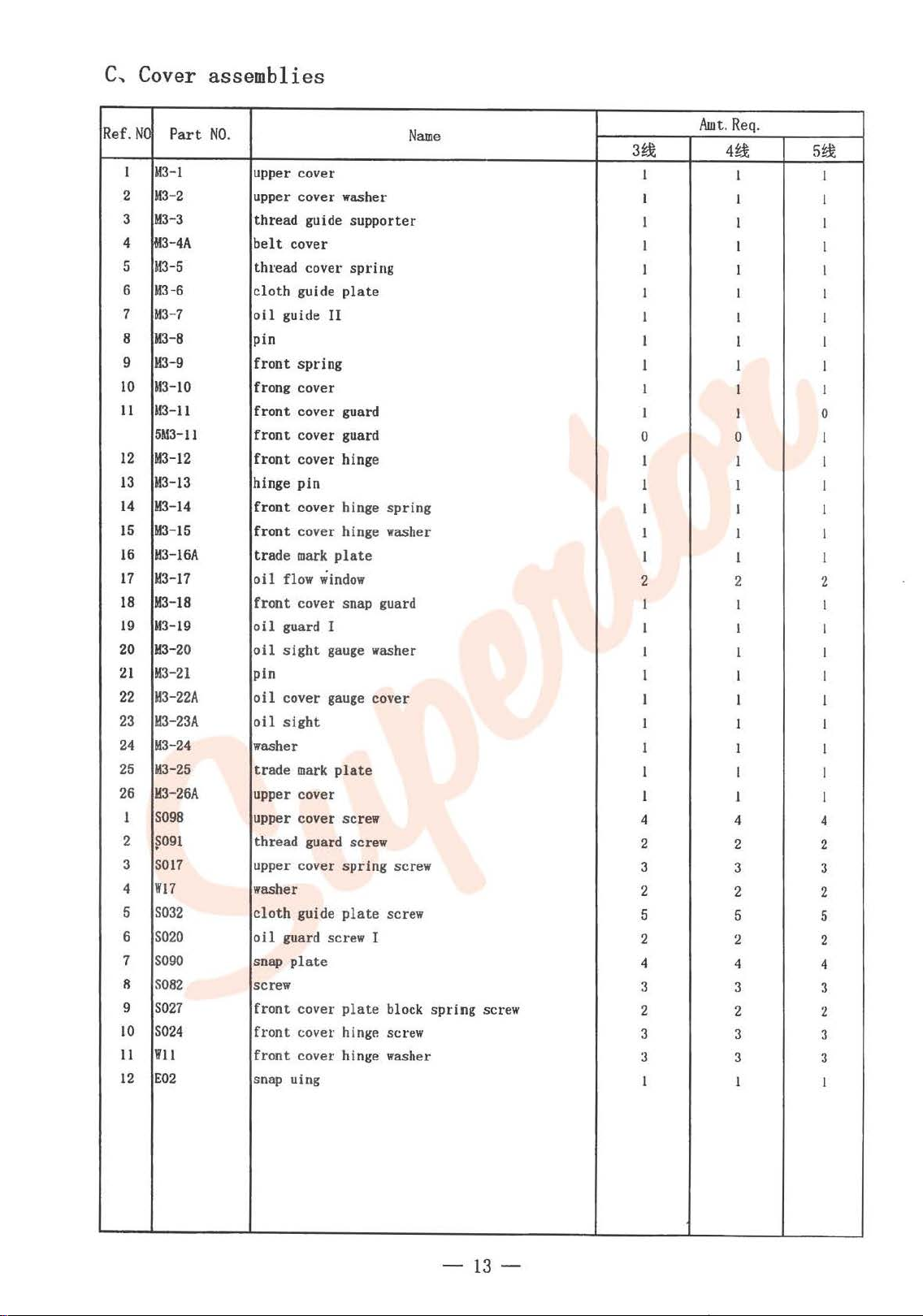

Page 16

D,

Main

shaft

assembl.

1es

-14-

Page 17

..

D,

Main

!Ref.NC

1

2

3

4

5

6

7

..

8

9

10

11

12

13

14

15

16

17

I

2

3

4

5

6

1

8

9

shaft

Part

NO.

M4-l

M4-2

M4-3

M4-4

M4-5

M4-6

M4-7

M4-8

M4-9

M4-10

M4-ll

M4-12

M4-13

. bearing

M4-14

5M4-14

M4-15

M4-16

5M4-17

S073

W03

S070

S085

S032

S043

S078

S0l9

S022

assemblies

Name

main

shaft

wheel

rear

shaft

bearing cover

rear

shaft

bearing cover

main

shaft

main

shaft

spring

busing

washer

Seal ring

main

shaft

queen

shaft

oil

pump

worm

main

shaft

bearing

shaft

end bushing washer

main

shaft

light

bushing

80200

bearing cover

beari.

ng

cover

bearing cover washer

pulley

bulgy pulley bearing

pulley screw

pulley screw washer

pulley

pulley

set

set

screw

screw

rear shafting bearing cover screw

oil

pump

worm

screw

screw

screw

bearing cover screw

washer

bearing

Amt.

Req.

3~

1

1 I

1

1

1 1 I

1 1

1 1

1

4~

I 1

1

I

1 I

1 I I

1 I I

l

I

l

1 I 0

0

1 I

1

0

1 I

1 1 I

1

1

1

1 I

l

0 I

1 1

0

l I

1 1

3 3

1 I 1

2

1

3

2 2

1

3 3

5~

1

1

1

I

1

I

1

1

0

1

3

I

.·

·

•·

..

~~·~

..

-.~.

0

,-;

••

-15-

Page 18

E,

Needle b

ar

asseml·

1es

-16-

Page 19

E,

Needle bar

Ref.

NO

Part

MS

-1

1

2

&15-2

3

MS-3

4

M5-4

M5-5

5

6

M5

-6

M5-7

7

8

M5-8

9

M5-9

10

M5-10

11

M5-ll

12

M5&1

5-13

13

14

M5-14

15

M5-

16

MS-16

17

MS51115-17

&15-18

18

19

M5-

20

MS-20

21 MS-21

22

MS-22

M5-23

23

24

M5-24

25

M5-25

26

MS-26

27

4M5-27

31115-27

5M5-27

28

M5-58

29

M5-59

I

S0

57

2

S102

3

S055

S043

4

5

S074

S053

6

7

SOOl

8

S006

S012

9

10

S009

I I

E0

1

12

15

17

19

assemlies

NO.

needle bur d

eccentric

needle bar

sn

ap

throat

oil

needle bearing

washer

th

roat

oil

throat

needle driving

seal

needle bar

ap ring

sn

balance block

needle bar flame

throa~

needle bar connecting rod

connecting

washer

throat

needle bar

oil

oi 1

plasties

oil

needle

needle

needle

needle

oil

snap ring screw

hexagon

balance block

frame rock

shaft

screw

screw

screw

screw

screw

snap ring

shaft

shaft

ring

driving crank

wick

ring

cli

p guide pin

wick

bar rock crank

ring

rear

bar

shaft

link

clip

felt

wick

tube

wick

clamp

clamp

clamp

seal

socket screw

shaft

position

Name

riving

guide bushing

frame

ro.:k

bush

ing

back

shaft

bearing

driving copper bearing

shaft

rock

crank

crank

pin

position

set

screw

screw

screw

shaft

Awr..

3~

1 1

1

1

I

1

1

I

I

I I

I

1

I

2

1

2

1

0

I 0

I

I

1

1

I

I 1

I

1

2 2

0

I

0

1

I

4

I 1

2 2

3

2 2

1

1

1

I I

5 5

I

Req.

4~

1 1

1 1

1

I I

I I

1

I I

1

I I

I I

2 2

1 1

2

1 1

I 0

I

I I

1 I

1 I

1 I

1

1

I 0

0

0

I

2

4

3

1

I

1

I

5~

1

I

1

I

1

2

I

I

I

1

I

2

0

1

I

2

4

1

2

3

2

1

1

1

1

5

I

-17-

Page 20

F,

Thread guide assemblies

-

lH

Page 21

F,

Thread guide assemblies

Ref. NO

10*

11

12

13

14

1

2

3

4

5

6

7

8

9

Part

M6-1

M6-2

M6-3A

M6-4

M6-57\

M6-6

M6-7

M6-8A

M6-9

5M6-9

M6-10

M6-ll

M6-12

M6-13

M6-14

NO.

thread tension spring

thread tension screw

thread ·tension nut

thread tension spring

thread tension spring

thread tension

thread tension

thread guide

upper thread take-up

upper thread take-up

oil

box

oil

felt

thread guide

o

11

box

oil

feet

washer

15 M6-15 tension spring

16

M6-16

17

M6-17

18

M6-18

19

M6-19

20

M6-20

21

M6-21

5M6-21

22

M6-22

23

M6-23

4M6-24

24

3M6-24

5M6-24

25

4M6-25

3M6-25

5M6-25

26

M6-26A

27

5&16-27

28

5H6-28

29

5616-29

30

M6-30

5&16-30

31 M6-31

32

M6-32

1

S099

S035

2

S016

3

4

S061

5

SOI5

S033

6

thread

controller

spring

thread

thread

thread

thread

thread

teat

controller

plate

plate

mark

mark

needle guard

thread tension

front

needle guard

front

needle guard

front

needle guard

throat

throat

throat

plate

plate

plate

thread guide

thread guide

needle guard I

needle guide

needle guard barcket

needle guard barcket

snap

plate

snap

plate

screw

throat

front

throat

plate

needle snap screw

plat

thread guide bolder screw

.

oil

box

set

Name

retainer

disc

disc

washer

disc holder

disc guide bushing

positionign rod

barcket

guide

guide

spring

II

washer

screw

barcket screw

screw

house

Amt.

Req.

3~

4~

1 2

3

4 4

3 4

3

4

3 4

6 8

3

2

4 4

2 2

I 1 0

0

0

1 1

I I

I 1

1 1

1

1

1

1

I 1 I

1

I

2

1

1

0

I

2

0

1

0

0

1 I

1 1

2

1 I

1

0

1 I

2

1

0 0

0

1

1 0

0

I 2

0

0

0

0

0

0 0

I

0

1

1

I I

2

I

2

2

1

I 0

0

I

I I

2

1

2

2

I

5~

2

4

4

4

8

I

I

I

I

I

1

I

2

0

I

2

0

1

0

0

I

I

I

1

1

1

1

I

2

1

2

2

I

-19-

Page 22

F,

Ref.

7

8

9

10

11

12

13

14

15

Thread

NO

Part

S072

S005

S023

W07

S017

Sl03

S019

S104

S045

guide assemblies

NO.

oil

box

washer

rear

needle guard screw

needle guard screw

needle guard washer

thread take

snap

plate

snap

plate

snap

plate

screw

set

up

screw

screw I

screw

set

screw

screw

II

Name

Amt.

Req.

3~

1

2 2

1

1 1 1

2 2 2

2 2

1

1 1

2

4~

1 1

1 1

1 1

2

5~

2

2

1

2

-20-

Page 23

G,

Upper

oper assembl '

lo

1es

-21

-

Page 24

G,

Upper

Ref.

NC

I

:t

3

-1

!i

7

ll

!l

10

II M7-II

12

13 M714

Iii

J(i

17

Ill

I!J

20 M7-20

21

22

2:1

24

2:i

:w

27

21! M7-28

2!l

:!()

:n

:12

:l:l M7-

I

2

:1

I

:1

li

7

H

!I

10

Part.

M7-l

M7-2

M7-3

5M7

-3

M7

·4

M7-

G

M7-7

M7-ll

M7

-9

M7-IO

M7-l2

l3

M7-14

M7-15

M7

-Hi

M7-17

M?-18

Mi-

l!l

M7-21

M7-22

M7-23

Ml-24

M7

·2:i

M7-2!i

M7

-27

m29

ll7-:30

m-

:H

iiMi

-

:11

M7

-n

:1:1

SOi:J

SO:lH4

SO!iH

11'1::!

SOO!l

Sl!ll

sn:w

W0-1

so:12

so:n

looper

NO.

looper

looper

thickness

thickness

upper

hig

upper

upper looper

upper

upper

upper

connecting

washer

oil

upper

oi 1 felt

oi 1 felt

oi

lwick

s<:rceu

t'el

thread

upper

oil

oi

1 t.uhe

oi I tuhe

thread

upper

upper looper

shaft.

lower

Loop<:r

IIJ>JH!r

upper

t.h

reading

two

shat't.

SCI'I!\1'

upper

IIJIIWI' I

I

ink

lll'Xfi!(OII

upper

washer

upper

thn

assemblies

link

link

holder

washer

washer

looper

washer

looper

looper

looper

looper

wick

looper

t.

plate

looper

seal

Looper t.hreud

hearing

loopet·

looper

looper

fo

I'

serew

looper

pin st:t

looper

looper

:ad

shaft

shaft

shaft

shaft

shaft

shaft

rod

shaft

shaft

oil

plate

hold

er

snap

shaft

amount

ooper shaft

amount.

regulating

shaft.

guaicl

holder

crank

crank

t.uhe

l.h

t·eacl gn i dt'

shaft.

scrPw

SOtkl!t.

shaft.

shaft. thread

regulating

SPI"P.\1'

Name

rear

foot

oil

seal

cnmk

har

pin

slide

plate

slide

guide

tht·ead

c:oppt'r

heariug

heariug

c:rauk

waslu·

:r

sc:n:w

bashing

bushing

bar

block

har

bracket

plate

plut.e

st·n:w

guide!

platt•

screw

3~

2

2

0

1

I

1

1

1

1

1

I

1

1

l

I

2

I

2

I

I

I

I

2

I

I

I

I

I

2

I

I

0

I

2

I

8

2

I

I

I

I

I

I

2

2

Amt.

Req.

2

2

I

0

I

I

I

I

I

I

l

1

l

l

1

2

I

2

I

I

I

I

2

I

I

I

I

I

2

I

I

I

0

2

I

H

I

I

I

I

I

I

2

2

5~

2

2

0

1

I

1

1

I

1

1

1

1

1

1

I

2

I

2

I

1

I

I

2

I

I

I

I

1

2

I

I

0

l

2

I

8

. 2

1

I

I

I

I

I

2

2

-22-

Page 25

G~

Upper

Ref.NC

11

12

13

14

15

16

17

18

Part

S037

S014

\fOB

S097

S062

S012

S095

S015

looper

NO.

screw

loopet·

looper

upper looper

upper looper

thread holder snap

thread holder snap

upper looper

assemblies

shaft

thread guide screw

shaft

thread guide washer

shaft

thread

shaft

thread

plate

plate

set

screw

Name

plate

plate

sctew

screw

screw

screw

Awt.

Req.

3~

I I

2

2

l I

I I I

I I

1

1

4~

2 2

2 2

I I

I

5~

I

I

I

I

-23-

.

Page 26

H,

Lower

looper assemblies

-24-

Page 27

H,

Lower

Ref.NC

1

2

3

4

5 MS-5

6

7

8

9

10

11 MS-11

12

13

14

1

2

3

4

5

6

7

R

9

10

Part

MS-1

!iMR

-1

MS-2

MS-3

MS-4

MS-6

MS-7

MS-8

M8-9

MS-10

AIS-12

MS-13

5M8-13

MS-14

5&18-14

S036

W04

SI01

S060

W12

W07

S022

S032

S067

SOlS

looper

assemblies

NO.

Lower

looper

washer

lower looper

oil

seal

lower looper

lower

looper

lower looper holder

lower looper crank

lower looper

cop

per washer

thread guide

lower looper thread guide

lower looper 3-tht·ead guide

lower looper

lower looper

lower

looper crank

lower looper crank

lo

wer

looper

elastic

crank screw

lower looper holder screw

lower looper holder washer

lower looper holder washer

lower looper screw

lower looper thread guide screw

crank screw

crank screw

shaft

shaft

front

rear

shaft

shaft

shaft

washer

Name

copp

er

washer

bushing

bushing

washer

screw

bushing

Amt.

3~

I

0

1

I I

I

I

1 I

2

I I

I I

1

1

I

I

0

I

0

I

1

I

1

1

l

I

I

0

0

Req.

4tt

I

0

I

I

I I

2

I

1

I I

1 0

0

I 0

0

I

I I

1

I I

I

I I

1 I

I

0

0

!)~

0

I

I

2

I

I

5

0

I

I

I

I

I

I

I

I

I

2

2

-25-

Page 28

I,

Front lower looper

assemblies

-26-

Page 29

l,

Front lower

Ref.

NO

Part

I

5M9-l

2

5M9-2

3

5M9-3

4

5M9-4

5

5M9-5

6

5M9-6

7

5M9

-7

8

5M9-8

9

5M9-9

10

5M9-IO

11

5M9-11

12

5M9-12

13

5M9-13

II

S005

2

SOI6

3

S060

4

Wl2

5

S028

6

SIOI

7

S04:l

8

S094

9

S093

10

E03

NO.

looper

Front looper

front

looper

front

looper

front

looper crank

regulating

regulating

oil

thread

front

looper

front

looper

frong looper

driving

driving

front

looper

front

looper thread guide screw

front

looper guide

front

loop

front

looper holder screw washer

front

looper crank screw

front

looper crank holder

nexagon

drivi

ng

driving

snap

ring

assemblies

shaft

shaft

plate

plate

shaft

shaft

shaft

lever

crank

slide

er

holder

socket

lever

lever

set

set

set

pin

Name

holder

regulding washer

front

bushing

rear

bushing

block

set

screw

set

screw

set

screw

screw

screw

screw

Amt.

Req.

3~

0 0

0

0

0

0 0

0 0

0

0

0

0

0

0 0 1

0

0

0 0

0

0 0

0

0

0

0

0

0

4~ 5~

0

0 I

0 I

0 2

0 I

0 I

0 I

0 I

0 I

0 1

0 I

0

0 1

0 I

0

0 I

0

I

I

l

2

I

2

2

I

I

-27-

Page 30

J,

Cam

assembli=es~

---------

2

-28-

Page 31

1~

Cam

Ref.NC

I 5

MIO-I

2 5MI0-2

5&110-3

3

4 5M10-4

!i

5MI0-5

5MI0-6

6

i

5MI0-7

5MJ0-8

8

9 5Ml0-9

10

5~110-10

11

5MIO-

!iMI0-12

12

13

5Ml0-13

5MI0-14

14

15

5MI0-15

16 5Ml0-16

17

5MI0-17

18

5MI0-18

5MI0-19

19

20

5MI0-20 tht·ead

21

5Ml0-21

5M10-22

22

23

5MJ0-23

24

5MJ'0-24

25

5MI0-25

26 5Ml0-26

I S002

S009

2

3 S!Ol

:I

Wl2

wor.

ii

li

N02

7

N03

H

S032

9 S003

S017

10

I I

SO:lR

12

S027

I

:1

lVII

14

S020

asse

Part

NO.

ll

mblies

link

bear

bearing

pin

shaft

s

haft

bushing

bushing(left)

oil

seal

cam

thread

thread

holder

washer

stopper

thread

2-thread

rear

thread

thread

thread

holder

holder

holder

presser

bearing

cam

set

crank

erank

crank

crank

thread

thread

thread

thread

thread

thread

washer

threud

snap

crank

(right)

guide

guide

bracket

guide

thread

thread

guide

guide

guide

tension

spool

disc

spool

nut

sna1>

screw

set

screw

washer

adjusting

adjusting

tensiou

t:eusion

guide

guide

guide

gui1le

guide

Name

ring

finger

plate

hook

gu i

de

guide

finger

tube

bushing

tube

tube

clamp

plate

spring

ring

screw

pin

washer

pin

nut

screw

screw

plate

screw

plate

scn~w

fiuger

Sill.

for 2-thread

hook SCl"I:IV

holder

ttlll

screw

sc:rew

Awt..

Req.

3~ 4~

0 0 I

0

0 I

0 0 I

0 0 I

0 0 I

0 0 I

0 0 I

0 0

0 0 I

0 0 I

0 0 I

0

0 2

0 0 I

0

0

0

()

0

()

0 0

0 0 I

0

0 0

0

0

()

0 0 I

0

0

0

0

0

()

0 0 I

0 0

0 0

0 0

0

0

0

0

0

0

0

0

0

0

()

()

0

()

()

()

()

()

II

()

0 II

5~

I

I

I

I

I

2

I

2

I

2

I

2

'L

I

I

I

I

I

I

2

I

I

:I

I

I

-29-

Page 32

K,

Differential

feed assemblies

-30

-

Page 33

K,

Dil'l'erential

. lll'f'.

\0

I

mt

'!.

~II

:l

~II

.(

lll I

,,

~Ill

(i

~Ill

-

~II

'

H

m1

!J

~11

tO

~Ill

~Ill

II

l'l.

~II

1:\

~Ill

1-1

~II

Iii

~Ill-Iii

l(i

~Ill

17

~Ill

IH

~Ill

I

!J

mt··t!J

:w

Mll

'l.l

m1-21

'l.'l.

Mll -

'/.:1

.

\II

'l.l

~Ill

'l.£i

}Ill

'l.ti .\II

'l.i

Mil 'l.i

'l.H

~Ill

'l.!J

Mil

:10

M

:\I

::iMII

SO!l!i

I

'l.

SJOI

:l

SO'l.H

:(

\fl!j

ii

SOl

fi

so:l7

7

SOI'l.

H

so:H

!)

S07!J

10

S0'/.7

II

SO:l2

l'l.

sv<1:1

1:3

SOOH

I.J

SOil

(:j

S040 set·ew

((j

S036

\0.

I'

HI'

I

I

I

'l.

I :\

:(

·

:i

(i

-

I

I

H

!J

I

10

II

I

1'1.

1:1

(.(

I·

I()

Jj

IH

..

:.W

'l.'l.

I ·

'l.:l

'l.·l

..

'l.:i

I

'l.li

'l.H

:w

:!0

II

:!I ('!';)Ilk

reed assemhl1es

st

itdt

lt>llgtlt

spring

oi

I washt•r

st

.i

tch

I ('Ill: I

stitdt

st

st

stitdt

ft•Ptl

l't•t•tl

t't•t•cl

l't•t'd

l't•t'tl

ft•t•tl

rl

Iii

IPIIgtlt

itdt

l<~ngt

i ll'lt

!Pugth

lt•Jiglh rcgu

tit· i \'('

1'<1111

('illll

I iuk

rod

l'l'illlk

i r fp

1'1'111 i al

f'fpn~nt

pill

cl

i J'fp

n·nl i al

oi

I SPill

Sllap

riug

sp

ring

wash1•r

l't!galat

i11g

waslll'r

t'PI'd

1'11111

washt•r

di

l'l'<·n·ut

n•gula

t ing

r<!glllat ittg

Iii t'l't•n•nt

I

i

di

ITt•t·put

d

i

ITt~ n~11

Sllap

riug

wnslwr

waslwr

di

l'l't!l't'lll

SIH'i ng St:rcw

di

fl't~rcut.inl

screw

di

fl't·

'n:tt

eli

ft'et·cutial

st.i

tch

lt:Jtgt.h

fc~~~~~

<:illll

t:am

reed

stitch

length

I'PI:Iat jIll:

It

I'Pgulat i

n•gulat

h rt•gul

t·am

('Hill

1-:l>rilll{

pill

rolling

pill

I iuk I

ial

t:rauk

shal't

hlo1·k

ial

t'l'gttlat

S<:l't!W

spriug

St'l'l'll'

ial

rcgulatiug

!'HOI

uk

ial

I ink St'l't'\1'

I i

al

t•t·auk

St'I'!!W

ial

posit

set

SCI'I'W

t.ial

posi

top

(>OS

i

I.Op

t·eg

ulat.illg

screw

SCI'f!W

\ilttll'

shaft

111:

('ilfll

asm

ing

hlot·k

at i ng

lat

ing

lwa

I'

spring

hlo<·k

pi

a I t' I

i

111:

hPariug

ittJ.:

holdt•r

I iuk I

St'l't'W

ou

SI'I'PW

st·rP.w

Sl:

1'1~

11'

st:n:w

:\mt.

Req

.

3~ 4~ 5~

I I

I

I I

I

I I I

I I I

I

'l.

I I

I I

'!.

2

I

I I

I

I

I

I

I

I

I

I

I

I I

I I

I I

I I

I I

I

I

I I

I I

I

I

I

I

I I I

I

I

I

I

'l.

I

I

I

I

I

I

I I

I

I

'l.

I 0

I I

I I

I I

I I

I

I

I

'l.

I I

0

I

'l.

I

I

'l.

I

I

I

l

I

I

4

I

I

I

I

()

I

'l.

I I

I

'!.

I I

I

I

I

I I

I

4 4

I I

I

I

I I

I

I

2

I

'l.

I

I

I

I

I

I

-31

-

Page 34

L,

Feed

dog

assemblies

-32-

Page 35

L~

Feed

Ref.

NO

1

Ml2-l

2 Ml2-2

3

MI2-3A

Ml2

4

5 Ml2-5

6

Ml2

Ml2

7

Ml2

8

9

All:1

10 MI2--

Ml

11

Ml2-12

12

13

Ml2-13

14

Ml2

Ml2-15

IS

16 Ml2-16

17

Ml2-17

IR

MI2-IR

19

Ml2

20

Ml2

21

M1

22 M12-22

23 M12-23

24

Ml2

25

Ml2

26

Ml2-26

Ml2-27

27

28 Ml2-28

29

Ml2-29

30

Ml2-30

31

Ml2-31

5M12-31

32

Ml2-32

5MI2-32

33

Ml2-33

5M12-33

I

S028

2

soos

3

S024

4

SIOO

5 S029

(j

S006

7

SIOI

8

SOI2 cr ank

9

S069

10

S034

11

S04fi

12

S03l

13

N02

Part

- 4

-6

-7

-8

-9

IO

2-ll

- 14

- 19

-20

2-21

-24

-25

5M12-30

dog

assemblies

NO

.

dog

feed

differential

feed

feed

s n

differential

slide block

differential

slide

feed

feed

feed shaft bushing(righ

feed

washer

feed

feed

diffet·eti

crank

crank slide block

feed

differential

diffet·ential

differential

screw

feed

sealing

adjustable

sealing

feed

feed

differential

differential

assist

assist feed dog

main

main

regulating

feed

screw

main

dog

feed

f

eed

crank

tooth

tooth

screw

feed crank

link

dog

dog

dog

ap

ring

blo

shaft

shaft

regulating

dog

dog h

slide

regulating

o i 1

dog

dog

dog

feed

feed

dog

feed

hloder

dog I i

shaft

sct·ew(left)

slide

rorks

rorks

plate

holder

feed

lift

slide

lift slide

feed

eccentric

feed

ck

ecce

bushing(left)

hold

er link

older

al

feed

block

feed

feed

feed

plate

carrier

connecting

oil

connecting

link

ecentric

link

ecentric

dog

clog

feed

dog

dog

dog

bushing

hushing

dog

screw

link

ft

slide

crank

block

screw

screw

pin

Name

dog

holder

block

block

slide

shaft

slide

ntric shaft

crank

link

bushing

dog

holder 1 ink

cover

crank

dog

holder

dog

holder

dog

holder

connection

ring

seal

rod

shaft

shaft

screw

!Jlo<:k

screw(right.)

cover

shaft

nut.

shaft

block

block

t)

screw

screw

bearing

eccentric

hus

hing

1 ink

link

link

rod

bashing

bushing

bushing

washer

washet

Amt..

R

eq.

3~

4~

I I I

1

I

I

1 I

I

I I

I

1 I

I I

I I

I I

I

I

I

1 I

I I

I

I

I I

I

2 2

1

I

I

1

I

I

I

I

I

2

I

I

0

I

0

I

I I

I

I I

I

I I

1

I I

I

1

I

I

I I

I

I

I

2

I

I

0

I

0

I

0 0

I

0

I

I I

I I

2 2

I

0

I I

2 2

I J

2 2

5

2 2

I

4 4

I

I I

5

I

I

5~

I

I

I

I

I

I

I

I

I

I

2

I

I

I

I

I

I

I

2

I

0

I

()

I

0

I

()

I

I

I

2

2

I

2

5

2

I

4

I

I

-33-

Page 36

M,

Frimming

assemblies

-34-

Page 37

M,

Frimming

Ref.

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

l

2

3

4

5

6

7

8

9

10

11

Part

M13-1

M13-2

5M13-2

!113-3

Ml3-4

Ml3-5

Ml3-6

Ml3-7

Ml3-8

5Ml3-8

Ml3-9

Ml3-10

Ml3-ll

&113-12

Ml3-13

5Ml3-13

M13-14

Ml3-15

Ml3-16

M13-17

M13-18

S057

SOlO

S043

S074

S046

S025

S036

S033

S045

S022

NO!

assemblies

NO.

upper

knife

driving

upper

knife

crank

upper

knife

crank

crank pin

upper

knife

frame rock

upper

knife

frame

rock

upper

knife

frame

rock

washer

upper

knife

holder

upper

knife

holder

snap

ring

upper

knife

holder pin

upper

knife

washer

lower knife holder

lower knife holder

lower knife holder bushing

lower knife holder

lower

knife

holder

lower knife

lower

knife

holder locking

snapring screw

upper

knife

crank

set

upper

knife

crank pin screw

upper knife conneting link screw

upper

knife

holdet· screw

upper knife screw

lower knife holder locking

lower

knife

holdet· locking

lower

knife

snap

plate

lower

knife

snap

plate

lower

knife

snap

plate

Name

connecting link

shaft

shaft

bushing

shaft

bushing

spring

plate

screw

plate

plate

screw

screw

screw

screw

screw

left

right

Amt.

3~

1

1

0

1

1

I

I I

1

I

0

1

1 I

1

I

I

0

I

1

I

I

1

2

I

1

2

I

I

I

I

I

1

I

Req.

4~

1

1

0

1 1

I I

1 I

I I

1 0

0 I

l 1

1 1

1 I

I

0 I

I I

1

1 I

1 I

1 I

2 2

I

1 1

2

I I

I I

I

I I

I

I

I

5~

I

0

1

1

1

0

I

I

2

I

I

I

I

·-

-35-

Page 38

N,

Presser

foot

assemblies

~

'

-36-

Page 39

N,

Ref.

27

28

29

30

31

32

NC

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

I

2

3

4

5

(j

7

8

!)

10

I I

12

13

Presser

Part

NO.

Al14-l

Ml4-2

M14

-3

Ml4-4

Ml4

-5

Ml4-6

M14

-7

M14

-8

M14

-9

M14

-10

Ml4-ll

Ml4-12

Ml4-13

Ml4-14

Ml4-15

Ml4-16

M14-17

M14

-18

&114-19

Ml4-20

5M14-21

M14-22

Ml4

-23

Ml4-24

M14-25

Ml4

-26

Ml4-27

M14-28

MJ4

-29

Ml4-30

5Ml4-31

Ml4-32

S0

59

S030

SOli

SJ6

S004

Sl3

S068

N03

SOlO

SOt.l9

S043

S071

S007

foot

assemblies

presser

presser

presser

presser

presser

presser

lever

presser

presser

foot holder

foot

foot

foot

foot

foot

spring

foot

foot

hook

spring

thread

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

presser

lifter

presser

presser

presser

cutting

bar

bar

regulating

foot

foot

foot

bar bushing

foot

foot

foot

foot

foot

foot base spring

foot

foot

foot base

presser

form

form

foot

screw

set

screw

presser

presser

foot holclet connecting

foot.

screw

screw

presser

nut

presser

foot

foot crank

pt·esser foot shaft.

screw

thrad

cutting

presser

foot

Name

shaft

bushing

holder pin

holder

shaft

shaft

shaft

bushing

snap ring

crank

lifting

lever

knife

spring

screw

lifting

lifting

lifting

lifting

handle

pin

handle bracket

spring

spring

holder conneting

holder

spring

holder cover

form

foot

lifting

holder

crank

handle pin

screw

sc:rew

screw

snap washer

knife screw

lifting

handle screw

plate

plate

s1:rew

screw

Amt..

Req.

3~

1

1

4;~

I I

0 I

1 1

1 I I

I I I

I I I

I

I

I

I

I

1 I I

I I I

I I

I I

I I

I I

I I

4 4 4

1

1

I 1

1

1

I

I

I

I

1 I I

0

I I I

I

1 I I

1 I

I

()

I I

I I

0 I 0

0 I

0

I 0

I 0

0 0

I I

1 I

I

2 2 2

I

I

I I

I I I

I I

I

3 :!

I

2

I

I I

I I

I

I

I I

2 2

I

5~

0

I

I

I

I

I

I

I

()

0

I

I

I

I

I

I

I

:J

I

-37-

Page 40

0, L

ubrication

assemblies

-38-

Page 41

0,

Lubrication a

Ref.

NO

Part

I

Ml

5- 1

2

Ml

5-2

3 All 5-3

4

M

15-4

5 M15-5

6 Ali 5-6

7 Ml5-7

MIS-8

8

9 M15-9

10 Ml5-10

11

M15-l

l

12 M15-12

13 M15-13

14

Ml5-14

15

Ml5-15

16

All

5-16

17 MIS-

17

18 MIS-18

19 Ml5-19

20

&115-20

21

M1

5-21

22

MIS-22

23

All5-23

24

MIS

-24·

25 Ml5-25

26

Ml5-26

27

M15-27

28

Ml5-28

29

M15-29

30

Mj5-30

31

M15-3l

32

Ml5-32

:!:3

Ml!i- 33

34

AIIS-34

S057

I

2

S24

3

S086

4

S063

5

S052

6

S039

7

S042

8

S037

9

S066

10

S048

II

S065

NO.

oil

oi l

oil

oil pump rotator

oil

oil

oil cleaner

o

il

oil

indicati

o

il tube

oil

oil tube

oi

l tu

lubricate

up

per

lower screen

regulat ing pin

oil

oil

oilshow

oil

oil

self-adhesive

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

oil

o i 1 p

o

il pump

o

il pum

sse

mbli

es

Name

pump

worm

gear

pump

rotator

pump

rotator shaft

pump cover p

bus

late

hing

cleaner

joi

nt

cleaner

cle

cover

rner cover

ng pl

ate

seal

tube joint

join

t

be

snap r i

ng

bushing

screen

show

bracket

show

cleaner

cleaner

link

guard

pan

pan

washer

paper

dial

seal

pan

magnet

pan

magn

et

cover

screen holder

screen

sight

pump

pump

cleaner

tube

tube

felt

gauge

asm

worm

screw

joint

joint

gear screw

screw

screw

screen screw

scteen cover screw

body

pan

ump

finger

magnet

screw

scre

w

cover screw

screw

ps

asm

screw

ring

Amt..

Req.

3f&

4

f&

1 1

I I

1

1

I

I 1

1 1 I

1 1 I

1 I

I I I

I I I

I

1

1

I 1

1 I 1

I I I

4 4 4

I I 1

l 1 I

I

I I I

I I

I I I