Purchasing

Copy

Dept

HIGH

GM700 Series

HIGH-SPEED

Instruction

LEAD

OVERLOCK

SEWING MACHINE

Manual

Parts

SHANGHAI

HlliGONG

N0.3

Catalog

SE,VING

MACHINE

FACTORY

-INTRODUCTION-

Thank

This

in

Please

you

instruction

the

best

study

very

much

manual

possible

this

manual very

conditions.

CHUTION

OBSERVE

Though

should

• To

• Do not leave tools

machine.

8

Before

accidents,

pedal is

THESE

Pegasus

follow

prevent

maintenance,

pressed.

SAFETY

takes

these

basic

accidents,

be sure the

for

purchasing

describes

the

utmost

safety

do

or

other

adjusting,

power

700

Series

daily

routine

carefully

PRECAUTIONS

rules.

not

remove

before

care

to

safety

unnecessary

cleaning,

is

turned

machine.

maintenance

operating

produce

devices

objects

threading

off,

Check

safe

or

on the

that

the

machine.

sewing

parts

or

the

and

safety

machines

while

machine

replacing

machine

precautions

and

operating

table

the needle,

will

devices,

the

while

not

to keep

machine.

operating

and

operate

the

operators

to

prevent

when

machine

the

the

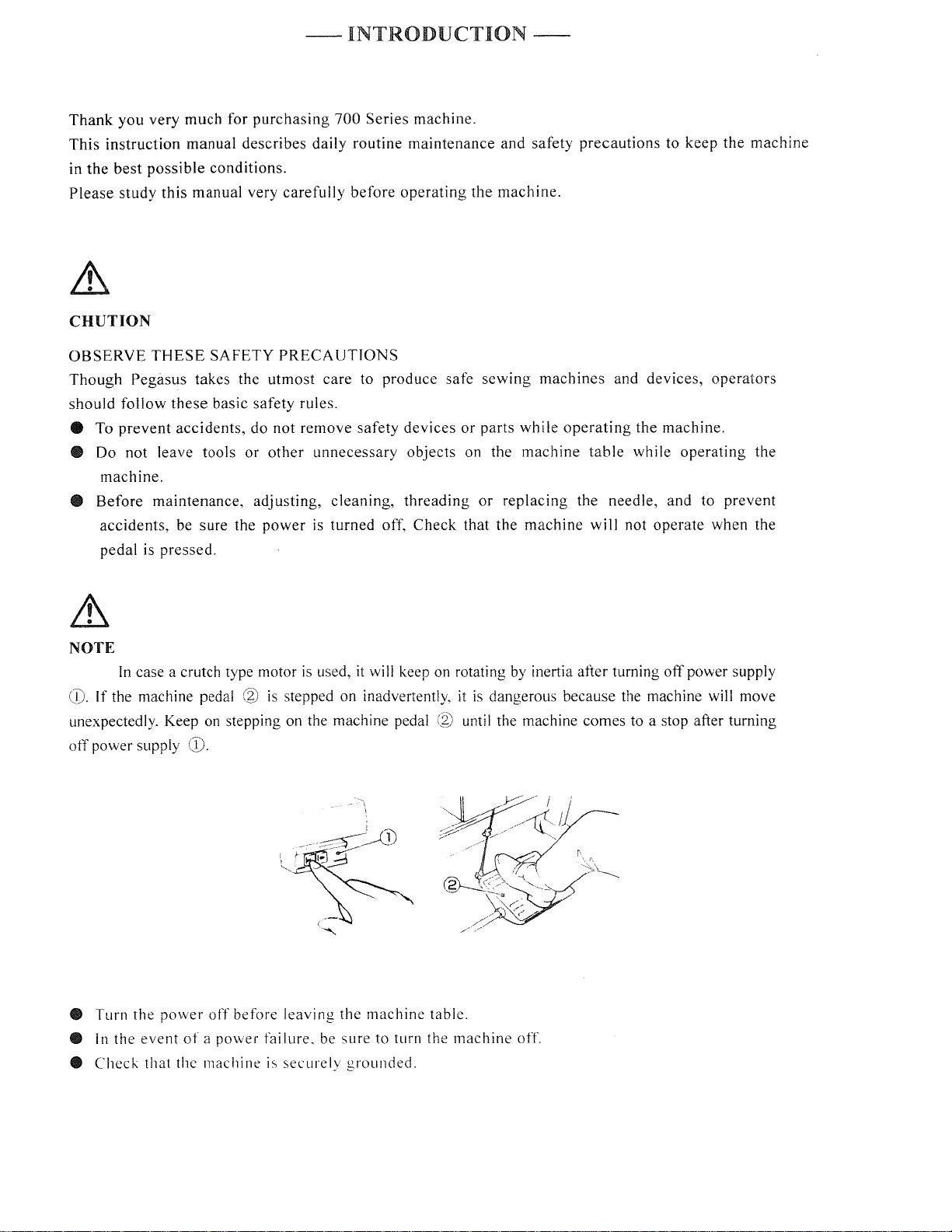

NOTE

In

case a crutch type motor

0). If the machine pedal ®

on

unexpectedly. Keep

otf

power supply

• Turn

8

8

In

the

Check

the

power

event

that the machine

stepping on the machine pedal

CD.

off

before

of a power

is

used,

it

will keep on rotating by inertia after turning

is

stepped on inadvertently,

',

~·--~~~~)

',

.,

'

leaving

failure. be

is

securely

the

machine

sure

to turn the

grounded.

it

is

dangerous because the machine will move

(2.)

until the machine comes to a stop after turning

table.

machine

off.

off

power supply

•

BEFORE

CONTENTS

OPERATING

1 . Schematic diagram

2.

Installing the machine head

3.

The machine speed and the turning direction

4. Lubrication

5.

Manual lubrication

6. Filling the HR device with silicon oil

7. Threading

•

TEST

1 . Adjusting the presser foot pressure

2.

Adjusting the diff. feed ratio

3.

Adjusting the stitch length

4. Adjusting the thread tension

.•...................................................................

.....•.........................................

SEWING

of

the machine table

..••.••........••....•.•......•............•.....•......

••........•.......••....................•....................•.

...................................................

.......................................................

......•.................................................

.......................................................

• MAINTENANCE DURING USE

1 . Cleaning the machine

2.

Replacing the needle

3.

Checking the oil circulation

4. Replacing the oil

5. Replacing the lower knife

6. Adjusting dimensions

7. Standard needle Comparison table

...•.......................................................

...............•............................................

...................

...............................................................

........................................................

............................................................

of

.....•••....•.•.............•••.....•..........

..........•................................

.....................................••.........

;

...................................

equivalent sizes

.................................

~

......................

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

17

• PARTS CATALOG

...................................................................

18-25

Ill

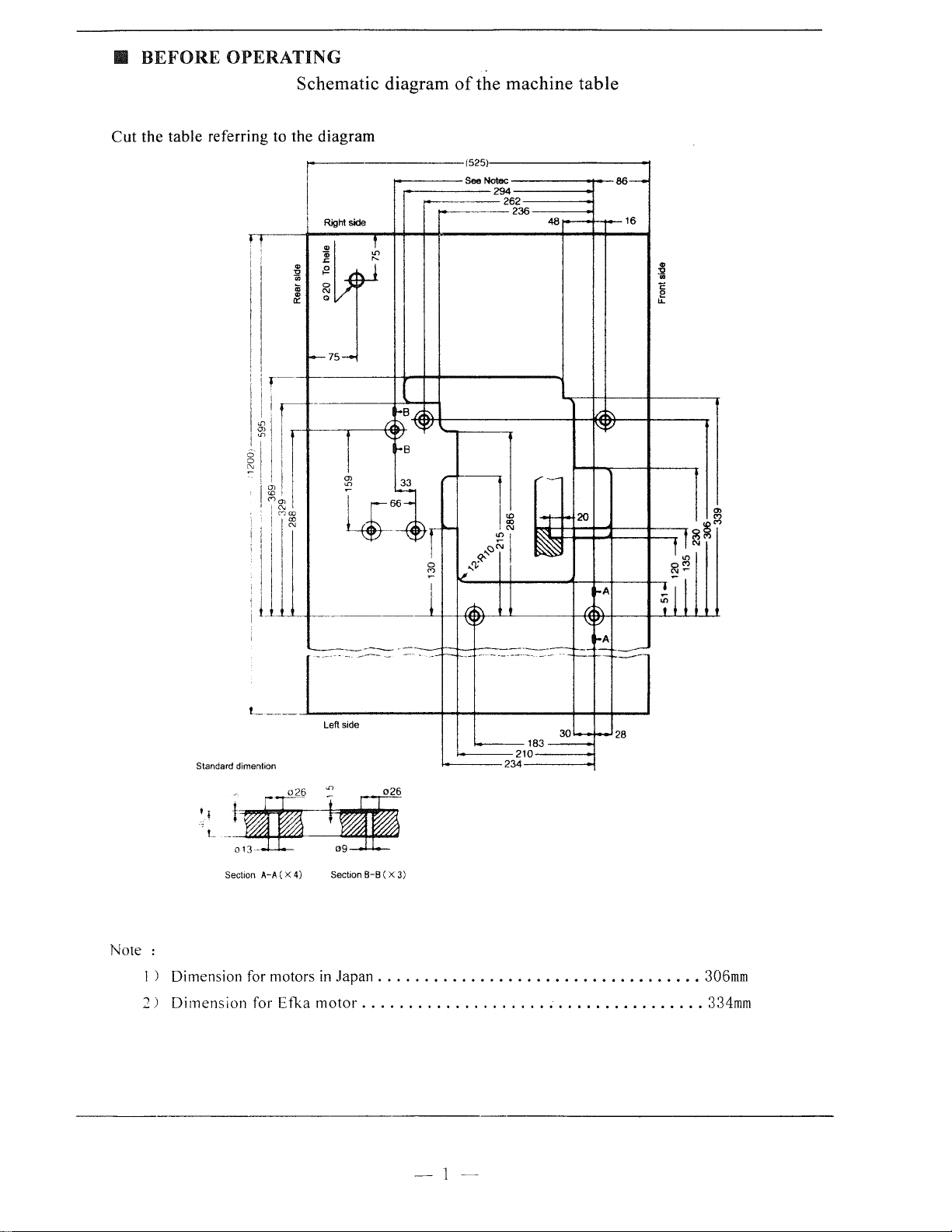

BEFORE

OPERATING

Schematic diagram

Cut

the table referring to the diagram

of

the machine

table

I!

"0

"'

u;

a;

ct:

"'

r-

I

(J)

"'

"'

6

0

~

lJ)

<D

7~co

co

N

i

I

I

I

See

Notec

236

Right

side

48

j J

;}

1--

75_,.

r.;~Br.~

"~

-..:

':/

~B

r

~

~

'---

33

[~"~~~~

cC\i

<!,;«-"'

0

(')

i.t"

;;

1

~

-..:

~

------

----

~

-

~

---

--

-··

---

"'

--

<D

co

"'

,_

~20

_T

~

---

;;

-..:

,_

16

v,~

I\::~

I-A

~

':/

I-A

:2

"'

..

E

e

u..

f t

;g"'

0

"'

!!1

"'

"'

Standard dim ention

Section A-A

Note :

I l Dimension for motors

2)

Dimension for Efka motor

L~----

(X

4)

Left side

Section

8-8

(X

3)

in

Japan

............................•......

.....................................

234

183

30-

-28

306mm

334mm

-

l-

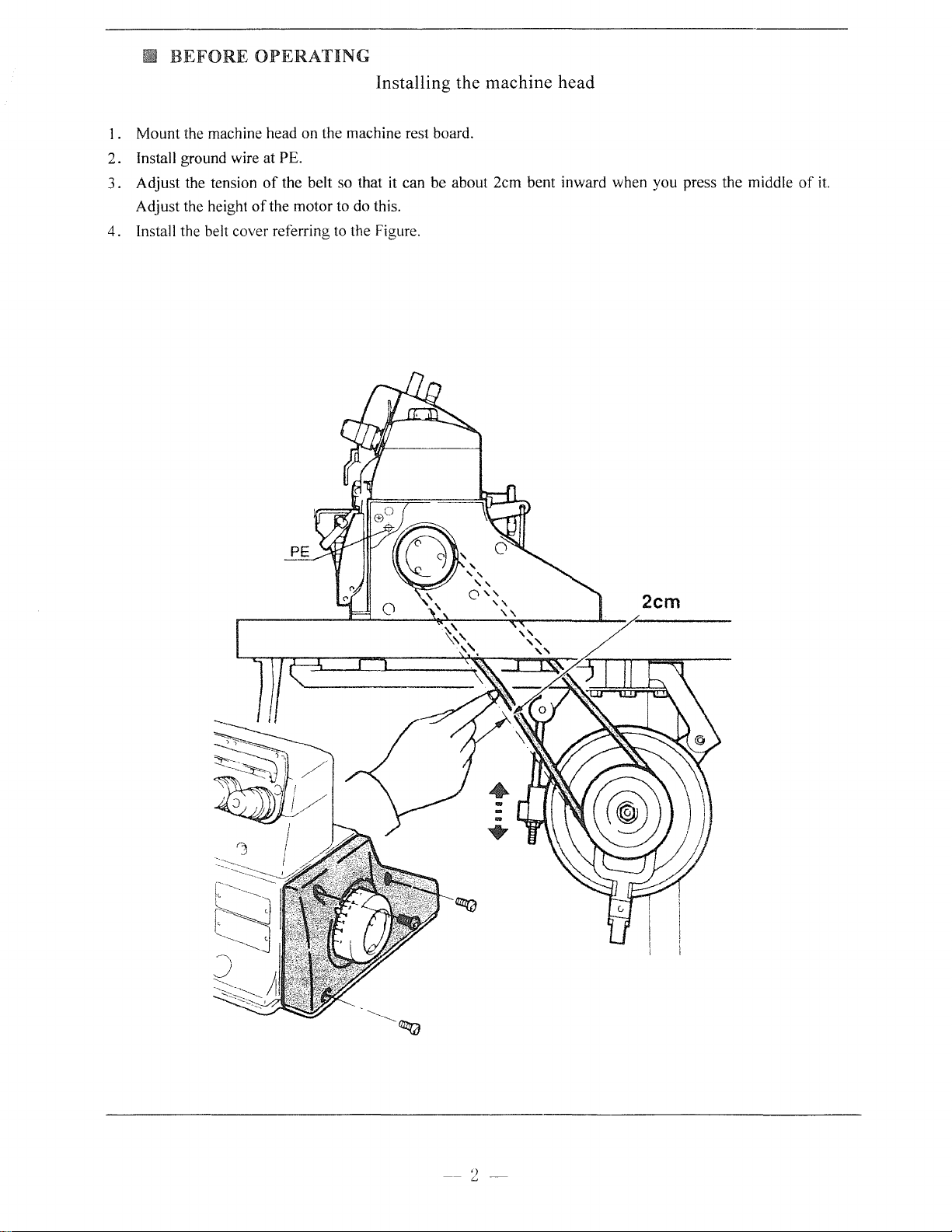

BEFORE

OPERATING

Installing the machine head

1 . Mount the machine head on the machine rest board.

2. Install ground wire at

3.

Adjust the tension

Adjust the height

4. Install the belt cover referring to the Figure.

PE.

of

the belt so that it can be about 2cm bent inward when you press the middle

of

the motor to do this.

of

it.

2cm

--

2-

1111

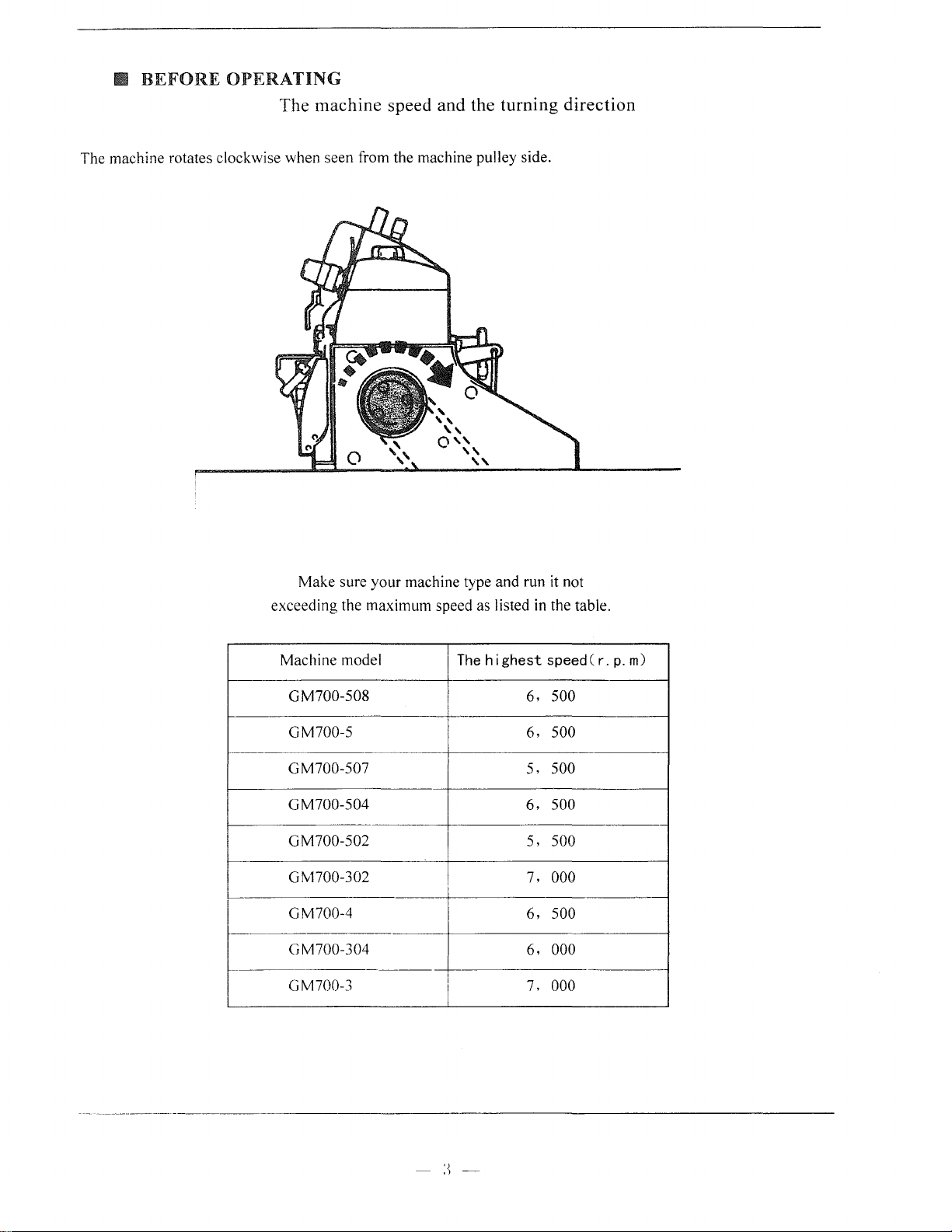

BEFORE

OPERATING

The machine speed and the turning direction

The machine rotates clockwise when seen from the machine pulley side.

Make sure your machine type and run it not

exceeding the maximum speed as listed

Machine model

r---

GM700-508

GM700-5

GM700-507

GM700-504

GM700-502

GM700-302

GM700-4

GM700-304

GM700-3

I

The

highest

6,

6,

5,

6,

5,

7,

6,

6,

7,

in

the table.

speed(r.

500

500

500

500

500

000

500

000

000

p.

m)

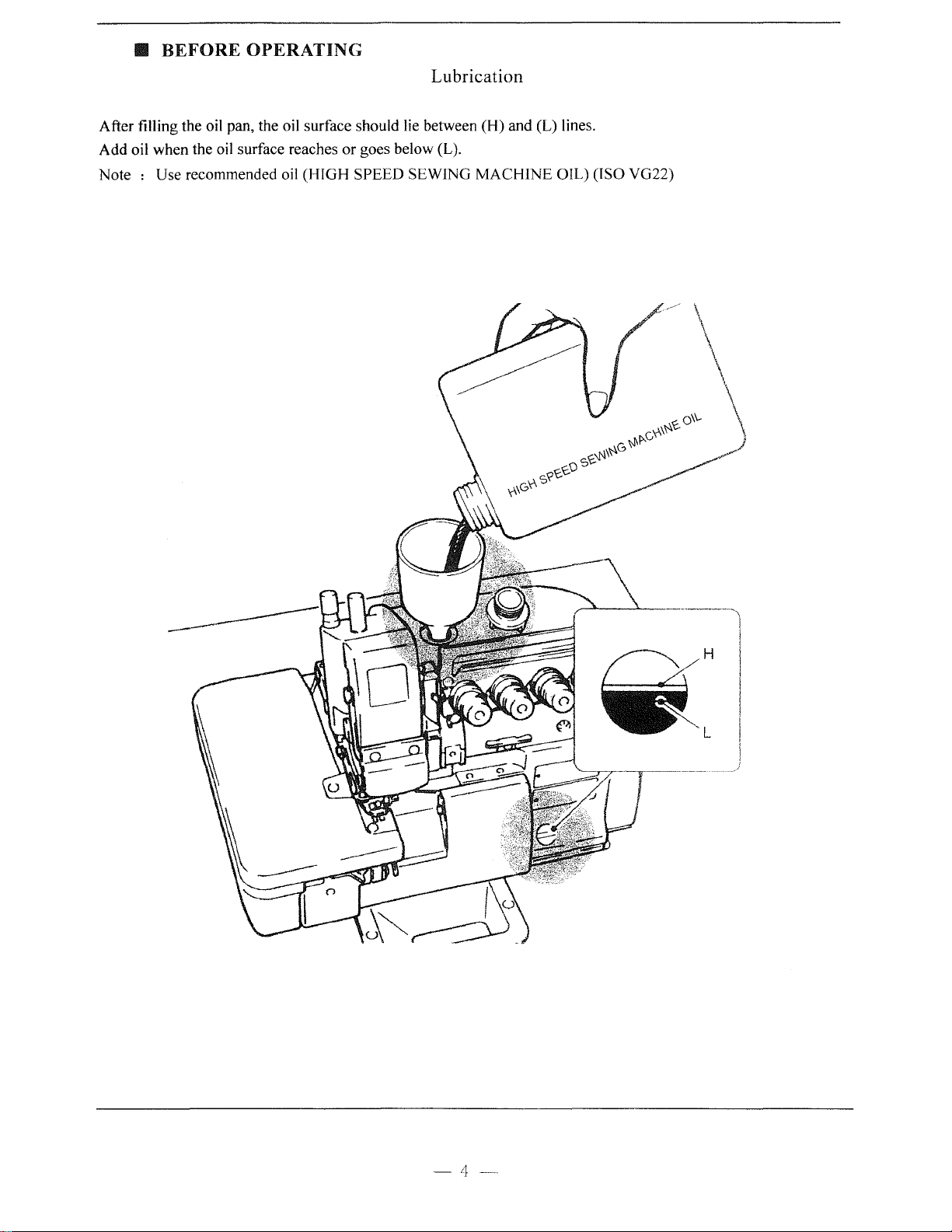

II

BEFORE

OPERATING

Lubrication

After filling the oil pan, the oil surface should lie between (H) and (L) lines.

Add oil when the oil surface reaches or goes below (L).

Note :

Use recommended oil (HIGH SPEED SEWING MACHINE OIL) (ISO VG22)

-4-

Ill

BEFORE

OPERATING

Manual lubrication

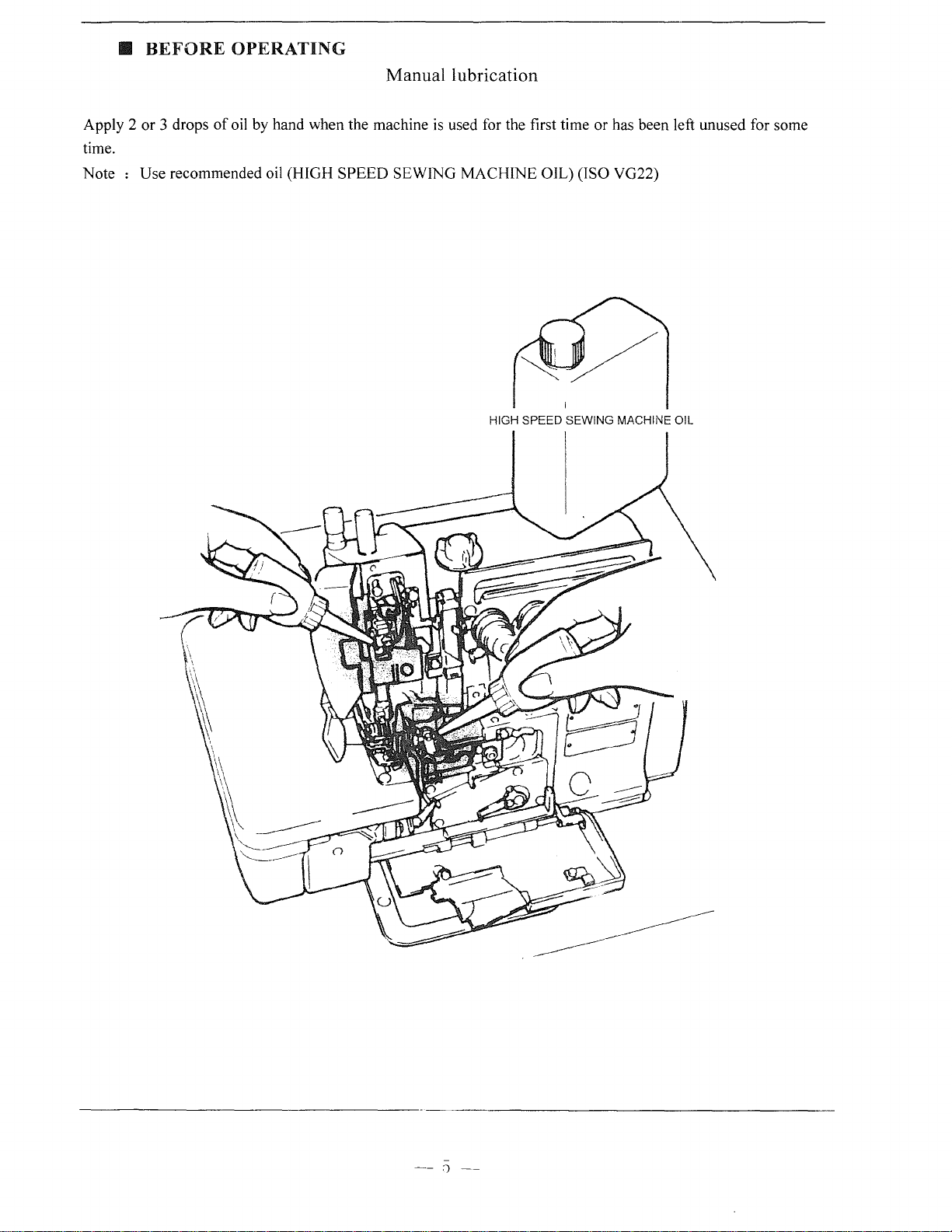

Apply 2 or 3 drops

of

oil by hand when the machine

is

used for the first time

or

has been left unused for some

time.

Note : Use recommended oil (HIGH SPEED SEWING MACHINE OIL) (ISO VG22)

I

HIGH SPEED SEWING MACHINE OIL

-

:)

• BEFORE

OPERATING

Filling the HR device. with silicon oil

Fill the HR device with oil before it is too low in order to prevent needle thread breakage and fabric

damage.

Note :

Use recommended silicon oil

-6-

Loading...

Loading...