Page 1

GM288 Series

GM288-3

iiililr

® HIGHLEAD

Purchasing

Copy

Dept

1-Needle, Overedging Industrial

GM288-4

· 2-Needle, Overedging Industrial

GM288-5

Safety Stitch

Industrial

Sewing

Sewing

Sewing Machine

Machine

Machine

INSTRUCTION MANUAL

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Putting sewing systems into operation is prohibited until it has been ascertained that the

sewing systems in which these sewing machines will be built into, have conformed with the

safety regulations in your country. Technical service for those sewing systems is also prohibited.

1.

Observe the basic safety measures, including, but not limited to the following ones,

whenever you use the machine.

2.

Read all the instructions, including, but not limited to this instruction Manual before you use

the machine. In addition, keep this instruction Manual

necessary.

3.

Use the machine after it has been ascertained that it conforms with safety rules/standards

valid in your country.

4.

All safety devices must be in position when the machine is ready for work or in operation.

The operation without specified safety devices is not allowed.

5.

This machine shall be operated by appropriately-trained operators.

6.

For your personal protection, we recommend that you wear safety glasses.

7.

For the following, turn off the power switch or disconnect the power plug

from the receptacle.

1)

Threading needle(s), looper, spreader etc. and replacing bobbin.

2)

For replacing part(s)

needle guard, folder, cloth guide etc.

3)

For repair work.

4) When leaving the working place

5)

When Using clutch motors without applying brake,

stopped totally.

8.

If

you should allow oil, grease, etc. used with the machine and devices to come in contact

with your eyes or skin or swallow any

areas and consult a medical doctor.

9.

Tampering with the 1 ive parts and devices, regardless

prohibited.

10.

Repair, remodeling and adjustment works must only be done by appropriately trained

technicians or specially skilled personnel.

11.

General maintenance and inspection works have to be done by appropriately trained

personnel.

12.

Repair and maintenance works

electric technicians or under the audit and guidance

Whenever you find a failure

13.

Before making repair and maintenance works on the machine equipped with pneumatic

parts such as an air cylinder, the air compressor has to be detached from the machine and the

compressed air supply has

compressor from the machine has to be expelled. Exceptions to this are only adjustments and

performance checks done by appropriately trained technicians or specially skilled personnel.

14.

Periodically clean the machine throughout the period

15.

Grounding the machine is always necessary for the normal operation

machine has to be operated in an environment that is free from strong noise sources such

high-frequency welder.

of

needle, presser foot, throat plate, looper, spreader, feed dog,

or

when the working place is unattended.

of

such liquid

Only spare parts designated by can be used for repairs.

of

electrical components shall be conducted by qualified

of

any

of

electrical components, immediately stop the machine.

to

be cut off. Existing residual air pressure after disconnecting the air

so

that you may read it at anytime when

of

the machine

it

has to be waited until the motor

by

mistake, immediately wash the contacted

of

whether the machine is powered, is

of

specially skilled personnel.

of

use.

of

the machine. The

as

Page 3

16.

An

appropriate power plug has

Power plug has

7.

The machine is only allowed

1

allowed.

18.

Remodel or modify the machine in accordance with the safety rules/standards while taking

all the effective safety measures. Assumes

modification

to

be

connected to a grounded receptacle.

of

the machine.

to

be attached to the machine by electric technicians.

to

be used for the purpose intended. Other used are not

no

responsibility for damage caused by remodeling or

FOR SAFE OPERATION

1.

So

as

to

avoid electric shock hazards,

motor or touch any part inside the electrical box with the power to the machine turned

2.

To

prevent possible personal injury, never operate the machine with the belt cover and the

eye guard removed.

3.

To

protect against possible personal injury resulting from being caught in the motor, use a

is

motor that

4.

To

power supply removed.

5.

During operation, be careful not

to

come close to the hand wheel, V belt and motor so as to prevent possible personal injury that

may occur when your hands/fingers are caught in the machine. Also,

them.

6.

So

cloth cutting knife and the needle when turning the power to machine or while the machine

operation.

7.

To

guard while the machine is in operation.

8.

To

be

sure

9.

So

make sure to tum

10.

In the event

against possible personal injury resulting from abrupt start

11.

So

abrupt start

and the

confirming that the sewing machine will not run even by depressing

the start pedal.

12.

Before inspecting, adjusting or cleaning the machine, threading

the machine head or replacing the needle, so as to protect against

possible personal injury resulting from abrupt start

sure

to

and confirm that the sewing machine will not operate even when

depressing the foot pedal

13.

To

your machine by holding the cloth plate cover by hand. Doing

break resulting in drop hazards.

provided with a motor pulley cover.

avoid electric shock hazards, never operate the machine with the ground wire for the

to

as

to

avoid possible injury to your hands and fingers,

prevent possible injury to your hands and fingers,

avoid electric shock hazards and accidents arising from damaged electrical components,

to

turn OFF the power switch before inserting/detaching the power plug.

as

to

protect against possible personal injury resulting from abrupt start

OFF the power to the machine when you leave your machine.

of

a power failure,

as

to

protect against possible personal injury resulting from

of

the machine, remove the belt cover, motor pulley cover

V belt after turning OFF the power to the machine and

tum OFF the power to the machine

of

the sewing machine.

protect against personal injury resitting from possible drop

do

not open the cover

allow your or any other person's head, hands or fingers

do

not put any

be

sure to turn OFF the power

of

the machine.

of

the machine, be

so

as

to

prevent an accident

so

of

the electrical box

NO.

do

not plaything close

do

not put any

to

of

the machine,

may cause the cover to open or

of

them near the

of

them inside the eye

of

the machine,

the machine to protect

Cloth plate cover

do

not carry

of

is

the

to

in

-2-

Page 4

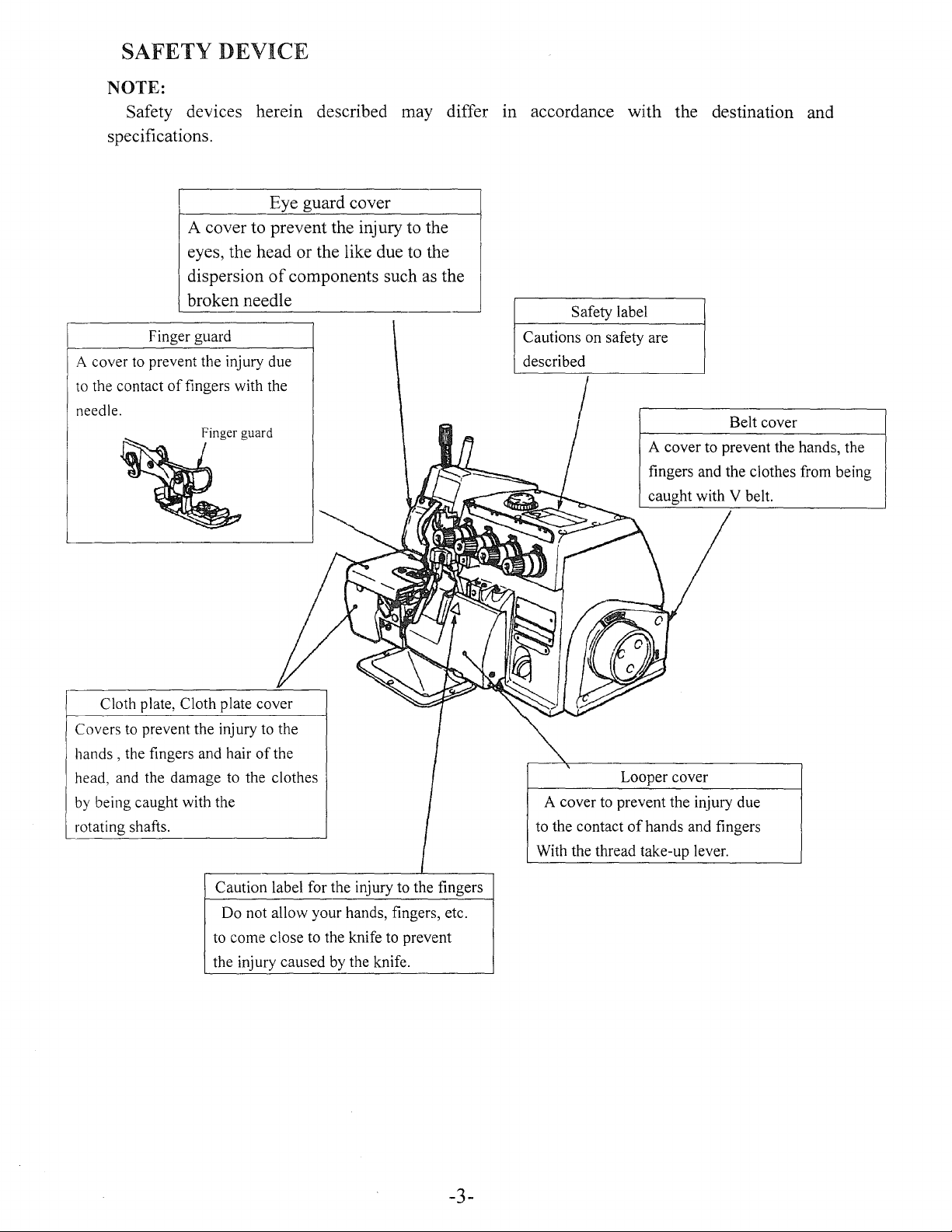

SAFETY

DEVICE

NOTE:

Safety devices herein described may differ m accordance with the destination and

specifications.

Eye guard cover

A cover to prevent the injury to the

eyes, the head or the like due

dispersion

broken needle

~-------------------------------

Finger guard

A cover to prevent the injury due

to the contact

needle.

of

fingers with the

Finger guard

of

to

components such

the

as

the

Safety label

Cautions on safety are

described

I

A cover to prevent the hands, the

fingers and the clothes from being

caught with V belt.

Belt cover

Cloth plate, Cloth plate cover

Covers to prevent the injury to the

hands , the fingers and hair

head, and the damage to the clothes

by

being caught with the

rotating shafts.

of

the

Caution label for the injury to the fingers

Do not allow your hands, fingers, etc.

to come close to the knife to prevent

the injury caused by the knife.

Looper cover

A cover to prevent the injury due

of

to the contact

With the thread take-up lever.

hands and fingers

-3-

Page 5

CONTENTS

I . SPECIFICATIONS

11.

INSTALLATION

1.

INSTALLING THE FRAME

2.

ATTACHING THE BELT COVER

3.

INSTALLING THE PEDALS

Ill.

PREPARATION AND OPERATION

1.

LUBRICATION

2.

CHECKING THE DIRECTION OF ROTATION

3.

THREADING THE MACHINE

4.

ATTACHING NEEDLES

5.

ADJUSTING THE PRESSUER OF THE PRESSER FOOT

ANE REMOVING THE PRESSER FOOT

6.

ADJUSTING THE STITCH LENGTH

7.

ADJUSTING THE DIFFERENTIAL FEED

IV.

MAINTENANCE

1.

ADJUSTING THE KNIVES AND OVEREDGE WIDTH

2.

CLEANING THE MACHINE HEAD

3.

CLEANING

4.

MOTOR PULLEY AND V BELT

5.

DIMENSIONS USED TO ADJUST THE LOOPER

AND THE NEEDLE GUARD

6.

DIMESIONS RELATED TO THE POSITION

OF

THE THREAD TAKE-UP AND THE LOOPER

THREAD

7.

CONVERSION TABLE OF THE NEEDLE NUMBER

CAM

........................................................................

...........................................................................

SUPPORf

.........................................................

...........................................................................

.......................................................

...............................................................

........................................................................

THE

FILTER

(STANDARD ADJUSTMENT)

AND

PUMP

....................................................

.......................................................

PLATE

...................................................

....................................................

...........................................

...............................................

........................................

................................................

NET

......................................

...................................

...................................

........................

.................................

..........................

5

5

5

6

6

6

7

7

7

8

9

9

9

10

1 0

.11

ll

11

11

13

14

-4-

Page 6

1 . SPECIFICATIONS

GM288-3

Sewing speed

(Excluding some subclass models)

Stitch length

Needle gauge

Overedge width

Differential feed ratio Gathering stitch 1:1.9 (Max. 1

Needle

Presser foot lift

Lubricating oil No.32 For special purposes Oil

Noise Workplace-related noise at sewing speed n=5,000 min-1

II.

INSTALLATION

1.

INSTALLING THE FRAME SUPPORT PLATE

(

1)

Semi-sunken type

1)

Attach rubber cushion®to frame support

2)

Attach support plate washer®, support plate bolt spacer@, frame support plateCDand

support plate

to the machine table with support plate bolt A@and

3)

Install waste chute opening(f)on the front side

waste chute(upper)@on the bottom face

4) Install waste chute (lower)®on waste chute(upper)@.

The installation

washer®in

of

the chutes can be adjusted within a length

the written order to the machine table . Then fix the frame support plate

1.0-3.6 mm 1.5-3.6 mm

4.0mm

DCX27

Noise measurement according to DIN 45635-48-A-1.

of

the

table.

GM288-4

I

Max. 6,500 rpm

I

( Standard

Excluding some subclass models

plateCD.

2.0mm

:2.

9) Stretching stitch 1:0.8 (Max. 1 :0.6)

6.5mm

nut®.

of

the upper surface

I

) DC X 1 may be used .

of

of

48 mm.

GM288-5

3.2, 4.8 mm

4.0, 4.8, 6.4 mm

:LPA::::;

the

table,

83

and install

dB(A)

r

b2

r-----1-----.

~~~:;;=~~

3

~/

(

2)

Fully-sunken type

1)

Attach frame support plate joint A@, frame support plate

frame support

2) Fix support plate bolt B@to the machine table .

3)

Put frame support plate joint A@and frame support plate joint B@between support plate

washers®respectively.

Install frame support plate

plateCD.

CD

so that the cloth plate is 5 mm higher than the upper surface

-5-

Table

joint®and

rubber cushion®to

Page 7

ofthe

machine table .

4) Install waste chute stopper

plate.

5)

Install waste chute(upper)(f)on waste chute stopper

®.

plate

6)

Install waste chute(lower)@on waste chute (upper)

(f).

The installation

a length

of

5

48 mm.

of

the chutes can be adjusted within

plate®on

frame support

2. ATTACHING

To

protect against possible personal injury due

of

the Machine,

power

off

and ascertaining that the motor is at rest.

Attach belt coverCDto the machine head .

3.

INSTALLING

To

protect against possible personal injury due to abrupt start

the following work after turning the power

1)

Install starting pedalCDon the left and presser lifter pedal@on the right as seen from the

operator.

2)

Use an S-shaped hook@to connect

the top end

of

presser lifting lever@.

THE

be

sure to start the following work after turning the

THE

BELT

COVER

PEDALS

to

abrupt start

off

and ascertaining that the motor is at rest.

chain®of

the presser lifter pedal to the hole located in

5

3

of

the machine, be sure to start

ill. PREPARATION AND OPERATION

To

avoid malfunction and damage

1)

Before you put the machine into operation for the first time after set-up, clean it

of

the machine, confirm the following:

-6-

Page 8

thoroughly.

2) Remove all dust gathering during transportatfon and oil it well.

3)

Confirm that the voltage has been correctly set.

4) Confirm that the voltage has been correctly connected to the power supply.

5) Never use the machine in the state where the voltage type is different from the designated one.

1.

LUBRICATION

To

protect against possible personal injury due to abrupt

of

start

turning the power off and ascertaining that the motor is at rest.

red marker lines when oil gauge®is observed from the side .

the machine, be sure to start the following work after

1)

Remove oil

2) Pour

3)

N0.32

Supply oil until the oil surface reaches between the two 2

capCD.

for special purposes oil reservoir.

.----6~....-i-..llf'l

Note:

1)

Be careful not to supply oil above the upper red marker

line, or else troubles due to excessive lubrication may result.

of

2) Change oil when one month has passed after the setup

change oil every six months.

3)

Supply oil

oil gauge from the side.

if

the oil surface comes down under the lower marker line when observing the

the sewing machine. Then,

Note:

Apply two or three drops

operating the machine for the first time after set-up or

of

oil

to

the needle bar and upper looper guide portion when

after a long period

2. CHECKING THE DIRECTION OF ROTATION

1)

The correct direction

clockwise when observing the machine from the handwheel side.

Never allow the machine to rotate in the reverse direction.

If

the machine rotates counterclockwise, the oil pump will fail to

function resulting in seizure.

of

rotation

of

the sewing machine is

3. THREADING THE MACHINE

To

protect against possible personal injury due to abrupt start

the following work after turning the power

Thread the machine

as

shown in the figure. (Threading diagram is pasted inside the looper

off

and ascertaining that the motor is at rest.

-7-

of

disuse.

of

the machine, be sure to start

Page 9

cover.)

GM288-4

GM288-5

Note:

Raise looper thread cam thread

guideCD

and perform threading . Return looper

thread cam thread guide

CD

to its home

position and securely fix it to thread guide

spring@.

Intermediate

Thread guide

Note:

Be sure to pass the needle thread for

double chainstitch through the needle

thread take-up lever.

(Pass the needle thread for overlocking

through the thread take-up lever located

outside.)

Note:

When using an untwisted thread such

wooly nylon thread or weak thread,

as

do

not wind it round the intermediate thread

guide.

4. ATTACHING NEEDLES

To

protect against possible personal injury due to abrupt start

the following work after turning the power off and ascertaining that the motor is at rest.

The standard needle is DC

X 27#11 .

You

can also use the DC X 1 needle . In

however, the clearance provided between the needle and the looper may be required to be

If

adjusted.

sewing needs to be carried out with a finely adjusted thread tension , use the DC X 27

needle.

1)

Bring needle clamp(Dup to the highest position .

2) Loosen needle clamp

screw®, and fully insert the needle into the needle clamp hole with the

needle recess facing backward as viewed from the operator's side .

of

the machine, be sure to start

thi~

case,

-8-

Page 10

3)

Tighten needle clamp screw@.

1

GM288-3

5.

ADJUSTING

PRESSER

To

start

of

turning the power

rest.

1)

presser foot adjust

When the adjust screw is turned clockwise, the pressure 3

will increase. When it

pressure will decrease.

2)

lower presser bar lifting lever@.

6.

ADJUSTING

FOOT

protect against possible personal injury due to abrupt

the machine, be sure to start the following work after

Adjust the pressure

To

open presser foot®sideward , raise the needle to the highest position

THE

PRESSURE

off

and ascertaining that the motor is at

of

screweD.

is

turned counterclockwise, the

THE

STITCH

Of'

THE

the presser foot by turning

PRESSER

LENGTH

FOOT

1

GM288-5

AND

REMOVING

of

its stroke and

THE

To

protect against possible personal injury due

to

abrupt start

following work after turning the power

ascertaining that the motor

1)

Slowly turn the hand wheel as you keep

depressing pushbuttonCD, and you will find a point

at which the pushbutton goes in farther .

2)

With the above condition maintained , align the desired scale mark on the handwheel with

mark@on the belt cover. Use the scale mark as reference.

3)

Reset pushbuttonCDafter setting the scale

?.ADJUSTING

To

protect against possible personal injury

due to abrupt

start the following work after turning the power

off

and ascertaining that the motor is at rest.

1)

Loosen differential feed lock

differential feed adjusting lever

stretching stitch or down for gathering stitch .

2)

When you want to move differential feed

adjusting leverCDonly slightly , use differential

of

the machine, be sure to start the

is

at rest.

THE

start

DIFFERENTIAL

of

the machine, be sure to

nut®.

CD

up for

Move

off

and

mark.

FEED

1

_j

-9-

Page 11

feed fine adjustment

3)

When

differential feed ratio

main feed dog and the differential feed dog will be 1:1.

4) The

depending

beyond

IV.

MAINTENANCE

1.

ADJUSTING

To

protect against possible personal injury due to

abrupt start

following

ascertaining that the motor is at rest.

1)

Height

Loosen

lower knifeCDso that its edge is flush with the throat

plate surface .

2) Height

Loosen

that upper knife

to 1

position.

3)

provided by changing the parts

models.

To

the lower knife comes in contact with the upper knife .

mm

Overedge

Overedge widths

(The overedge width will be slightly larger than the knife cut width.)

change the overedge width:

1)

Loosening setscrew@,

2) Loosen

3)

Lower

the scale

maximum

on

the adjustment

"0" are used as reference.

of

the machine, be sure to start the

work

of

the lower knife

setscrew®and

of

the upper knife

setscrew@and

when

width

setscrew@and

the upper knife to its lowest point and loosen setscrew@. Tighten setscrew@when

screw®.

mark

of

THE

after turning the power

@ overlaps lower knifeCDby 0.5

upper

of

is set to "-1 ", the machine will

1 :0.8, and

differential feed ratio for gathering is 1:1.9 (it can be set to 1:2.9

of

when

the internal mechanism

it is set to

KNIVES AND OVEREDGE

off

and

adjust the height

perform adjustment so

knife@

1.6 through 6.4

is at its lowest

mm

are

or

by

using subclass

push

lower knifeCDto the left and fix it .

move upper

knife®as

"0",

of

of

required,

the differential feed ratio between the

the sewing machine). The scale marks

then

perform

WIDTH

fix

it.

stretching stitch with a

4

Note:

1)

Be sure to tighten

2) After the completion

a thread to make sure

setscrew@

of

of

sharpness

before operating machine .

adjustment, make the knives cut

of

the knives.

4) Resharpening the lower knife

When

shown in the figure right.

the lower knife has become dull, resharpen it as

-10-

Page 12

2.

CLEANING

To

protect against possible personal injury due to abrupt start

the following work after turning the power

Clear lint from inside the looper cover and the needle bar and components about one or twice

a

day.

If

not, oil may leak or the sewing material will be soiled.

THE

MACHINE

HEAD

of

the machine, be sure to start

off

and ascertaining that the motor is at rest.

Note:

Do not wipe the coated surface

damage the coated surface.

3. CLEANING

1)

To

use the sewing machine for an extended period

time , clean filterCDand pump net®periodically twice or three

times a year .

the machine components may be seized or worn out

extraordinarily. So, carefully check the filter and pump net.

If

the lubricating oil in the machine is stained, change the

2)

oil also at the time

4.

MOTOR

Number

Revolutions

of

machine

(rpm)

of

Sewing

6,500 120

6,000

5,500 100

5,000 90

4,500 80

THE

If

the filter and pump net are clogged with dusts,

of

PULLEY

Outer V belt (inch) Outer

diameter

motor pulley

(mm)

110

FILTER

cleaning.

AND V BELT

50

of

Semi-sunken Fully-sunken

type

of

the machine head with lacquer thinner. Doing so will

AND PUMP NET

Hz

type

38

36

36

35

35

32

32

32

30 80

30 70 34 30

of

diameter

motor

pulley (mm)

100

95

85

60Hz

V belt (inch)

of

Semi-sunken Fully-sunken

type type

36

35

35

34

32

30

30

30

~

__

j

1)

Use a clutch motor

2)

Use an M type V belt.

3)

Relations among number

belt are as shown in the aforementioned table.

4)

Effective diameter

5.

DIMENSIONS USED

of

1/2 HP (400W).

of

ofthe

handwheel

TO

revolutions

of

sewing machine head is 50.6 mm.

ADJUST

of

sewing machine, motor pulley, and length

THE

LOOPER

GUARD

1)

To

protect against possible personal injury due to abrupt start

start the following work after turning the power

2)

To

avoid possible accidents due to unfamiliarity with the machine, get a maintenance man

of

who has a good knowledge

the machine or serviceman

off

and ascertaining that the motor is at rest.

of

our distributor to adjust the machine

-11-

AND

of

THE

the machine, be sure

NEEDLE

of

V

to

Page 13

or replace any

3)

To

avoid possible personal injury when the machine starts, it has to be ascertained in prior

to the actuation

one another.

of

its parts.

of

the machine that

no

screw are loosened and no components come in contact

Note:

The dimensions given in the table are standard ones to be used to adjust the looper. They are

intended to be used for reference and should be changed more or less in Accordance with the

sewing products and thread to be used.

GM288-3

GM288-305

A

GM288-4

F

G

A

GM288-5~

~

cf$$

A B

GM288-3

GM288-305

GM288-4

GM288-5

GM288-3B

GM288-5-60H 12.6 11.1

GM288-6

11

11

11

11

11

11

10.1

10.1 9.5

B

t

A

c

9.5

l

0.05-0.

D

11.8

11.8

11.8

11.8

10.5

12.8

11.8

Blade

e=ss=

2mm

E F

4.8

4.8

4.8

4.8

4.9

4.9

4.9

p~ln

0.05-0.

4

4

4

4

4

3

4

loopec

lmm

G

1.8

1.8

1.8

1)

Adjust the lower

so

looper

pushed by

this side by the blade point

of

lower lopper in the state

where the blade point

lower looper is aligned with

the center

that the needle is

0.05 to 0.1mm to

of

of

needle.

Push needle to this side.

-12-

Clearance provided between

Needle and blade point

Lower looper

of

CD

Page 14

2)

Then,

and the blade point

adjust traveling needle

of

lower looper should be 0 to 0.05mm in the state where the needle

guardCDso

that the clearance provided between the needle

pushed to this side by traveling needle guardeD.

For the 2-needle overlock machine, adjust both the left and

rig~1t

needles in the same manner.

is

Needle

6.

DIMENSIONS RELATED TO THE POSITION OF THE THREAD TAKE-UP

THE

(1) Position

guard

c1M:288-3i305i4

LOOPER

of

the looper

components

THREAD CAM (STANDARD ADJUSTMENT)

thread

take-up lever

(

'\

1288-3

(,\1288-4

CiM288-5

CM288-305 t

CM288-5-50H

GM288-5-60H

GM288-6

and

the looper

A B c

68 25 44.5

t t t t t

t

t t t

t

t

t t

t

t

t

t

t t t

thread

D E F G

22

t t t

t t

t t

t

t t

GM288-5

guide

37 26 9

24 8

26

t t

10

t

H

26 22

8

27 23.5

9

26

26

30 26.5

t

t t t t

27

8

23.5

I

22

19

AND

J K

12

t

t

15

18.5

12

t t

6

t

•t

6

(2) Position

take-up lever

To

protect against possible personal

injury due to abrupt start

be

sure to start the following work after

turnir:g the power

of

and

the

needle

needle

off

thread

of

the machine,

and ascertaining

that the motor is at rest.

A

(

\12XX-3B

1

68.5 24

Dimensions

when the upper looper

thread

Frame

guide

Throat plate surface

c D E

B

-

ofE

and G are adjustment values

Needle thread guide

F

G H l J

43

is

at its rightmost point.

take-up lever

~J/777?77777?

K

H

10

17

6.8

C11v1288-3B

Note:

The needle thread

take-up lever shall be

positioned at the upper

thread dead point

l

J K

20

23.5

35

-13-

Page 15

C

,:,

Needle

Needle thread

Position at which the lower end

of

thread hole

thread guide

edge line

take-up lever

of

IS

aligned with the

of

gu1ae

the needle

t:Jke-up lever

l::'SX-1

thread 1

~05

GM2R8-4

CiM288-5

GM288-6

o:l

..,

~

Chain looper needle

thread

0

e

00

"""

gmde

13mm

Chain looper needle

thread take-up lever

13

mm

Chain looper

needle thread

take-up lever

Note:

The needle thread take-up lever

shall be

positioned at the lower dead point.

(3)

Adjustment

Throat plate

Make sure that the looper thread cam releases the looper thread when

the needle tip

7.

CONVERSION TABLE

r

value for the looper

Interlock needle

is

positioned

±0.5

mm against the botton face

OF

thread

THE

cam (G!\1288-5)

NEEDLE NUMBER

JAPAN (ORGAN)

~--------------------------

DCX27

DCX27

DCX27

--

DCX27

DCX27

DCX27

DCX27

#9

#11

#14 B-27 Nm90

#16

#18

··----

#19

.,

_______

#21

Thread

of

the throat

plate.

GERMAN (SCHMETZ)

B-27 Nm65

B-27 Nm75

B-27

NmlOO

B-27

NmllO

B-27 Nm120

-

B-27 Nm130

--

--

-14--

Page 16

SHANGHAI HUIGONG SEWING MACHINE

ADD:

1418,

Yishan

Zip

Code:

201103

TEL:

(021)64061284

FAX:

(021)64462799

E-mail: Highlead@online.

http://highlead.

Road,

Shanghai, China

64654014

com.

en

sh.

en

N0.3

FACTORY

Loading...

Loading...