Highlead GL13138-1 User Manual

Purchasing

Copy

Dept

HIGH

GL13138-1

Industrial

LEAD

Blindstitch

Machine

Instruction Manual

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

CONTENTS

INSTRUCTION MANUAL

1.

Part Name .......................................................................................................................................................... 1

2.

Safety Precautions ............................................................................................................................................... 1

Precautions before starting operation .......................................................................................................... I

2.01

2.

02 General Safety Tips ..................................................................................................................................... 1

3.

Specification ....................................................................................................................................................... 2

4.

Assembling .......................................................................................................................................................... 2

of

4.01 Assembly

the Clamp

seL

Lift

bar,

Motor ......................................................................................... 2

)

4.01.01 Assembly

4.01.02 Assembly

4.01.03 Assembly

4.02 Threading .................................................................................................................................................... 3

4.02.01 Thread Guide Pole ............................................................................................................................. 3

4.02.02 Threading ........................................................................................................................................... 3

4.03 Regulating the

4.04 Adjustment

4.05 Adjustment

4.06 Regulating

4.07 Removal

4.08 Assembly

4.

09 Replacing

4.10 Take

4.11

Out Stitch ............................................................................................................................................ 8

Skip Stitch ................................................................................................................................................... 8

ofthe

Clamp Set ................................................................................................................ 2

of

the Lifter Bar ................................................................................................................. 2

ofMotor.

Sewing Range ..................................................................................................................... 4

ofThread

ofNeedle

Stitch Length ............................................................................................................................. 5

ofthe

Material From the Machine and Break the Thread ............................................................ 6

of

Auxiliary Plate .................................................................................................. , ..................... 6

theN

eedle .................................................................................................................................. 7

............................................................................................................................ 2

Tension .................................................................................................................... 4

Penetration .............................................................................................................. 5

4.12 Lubrication .................................................................................................................................................. 8

5.

Eventual Trouble Shooting .................................................................................................................................. 9

Sewing Machine

5.01

5.02 No sewing ................................................................................................................................................... 9

5.

03

No break the thread ..................................................................................................................................... 9

5.

04 Stitch skipping ............................................................................................................................................. 9

5.

05

Uneven stitch .............................................................................................................................................. 9

5.06 Unstable needle penetration ........................................................................................................................ 9

doesn't

work .................................................................................................................. 9

-1-

CATALOG

A. Arm Bed and Its Accessories ........................... .

B. Needle Plate Mechanism ........................

C. Presser Foot Me::hanism .......... .

D. Arm Shaft Mechanism ............ .

E. Needle Rocking Motion Mechanism .............. .

F. Skipping Stitch Mechanism ..........

..

··················

. ...................

. ...........

. ........................... 16

..

G. Lifting Mechanism ................. . .

...

. ....

...

..1

12

14

18

20

22

H. Feeding Mechanism ................................... . . ....... 24

I.

Looper Mechanism .................................

..

. ...

26

J. Auxiliary Plate Mechanism .......................... . . ............................................. 28

K. Thread Stand Mechanism. ................................................ . . ............................ 30

L. Knee Lifter Mechanism ............

M. Motor Mechanism.

N. Accessories .............................................. .

..

. .............................. 32

. ...................................... 34

..

36

0

-2-

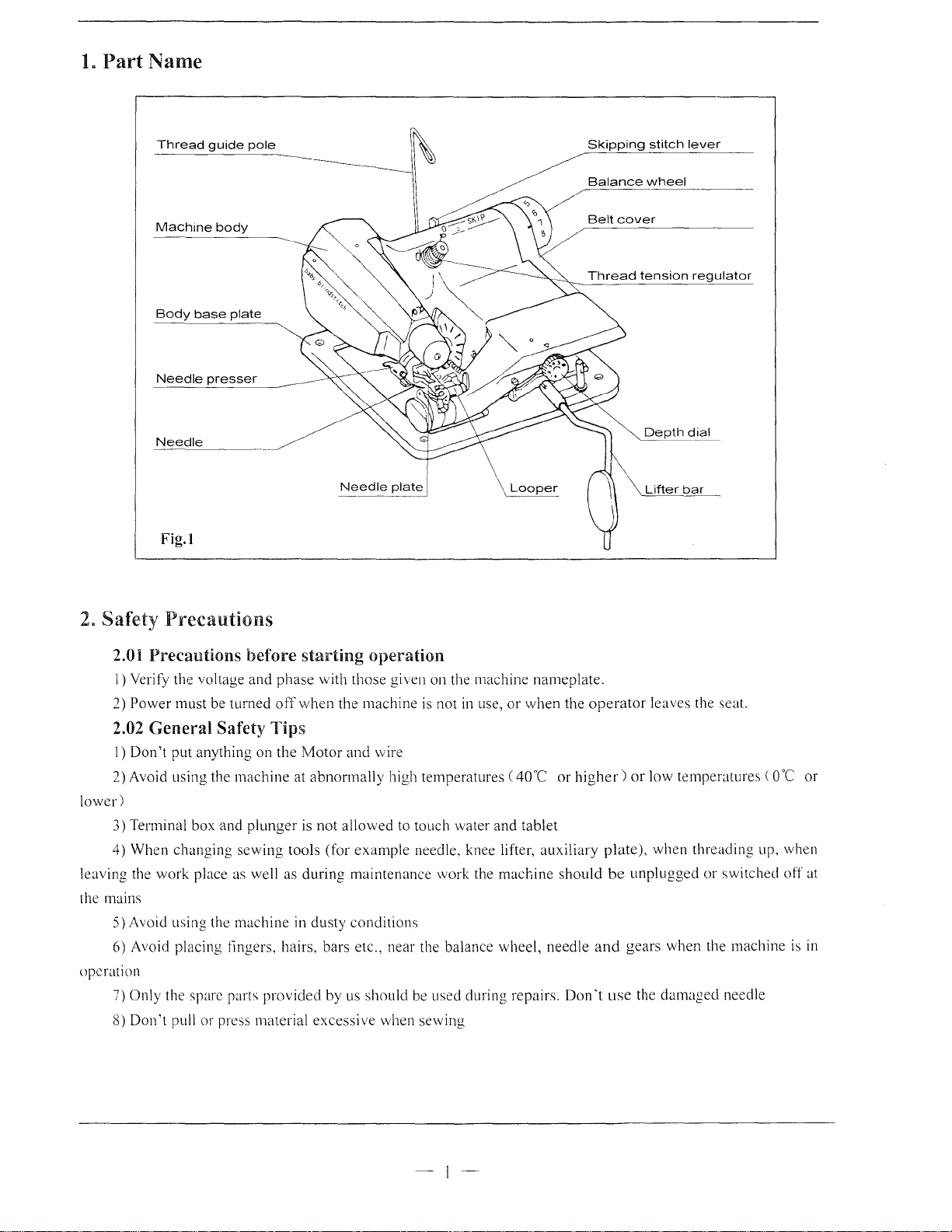

1.

Part

Name

Thread

Machine

Body

base

Needle

Needle

Fig.l

guide

body

plate

presser

pole

Skipping

stitch

lever

~wheel

Thread

Looper

tension

Lifter

regulator

bar

2.

Safety Precautions

2.01

Precautions before

1)

Verify the voltage

2)

Power

must

be turned

2.02

General

l)

Don't

2) Avoid

lower)

3) Terminal box

4)

When

leaving the

the mains

5) Avoid using the

6) Avoid

operation

Only the spare parts

7)

Don't

8)

work

Safety Tips

put anything

using

the

and

changing

place as well as

placing

pull or press material

starting

and

phase

with

off

when

on

the

Motor

machine

sewing

machine

fingers, hairs, bars etc., near the balance

plunger

tools

provided

at

abnormally

is

not

during

in

dusty

excessive

operation

those

the

machine

and

allowed

(for

example

maintenance

conditions

by

us

should

given on the

is

not

wire

high

temperatures

to

touch

needle. knee lifter,

work

be

used

when

sewing

machine

in use,

water

the

during repairs.

nameplate.

or

when

(

4o·c

and

tablet

machine

wheel,

the

operator

or

higher)

auxiliary

should

needle

Don't

plate),

be

and

use

leaves the seat.

or

low

temperatures

when

unplugged

gears

when

the

damaged

threading

or

switched

the

machine

needle

(

o·c

or

up, when

off

at

is

in

-1-

3. Specification

Max.

Stitch Length 3-8mm

Needle

Skip stitch

Stitch spec.

Lubrication Manual

4.

Assembling

Speed

1200rpm

LWX6T

With skip (1: 1,2:1)

-

Single thread. Blindstitch

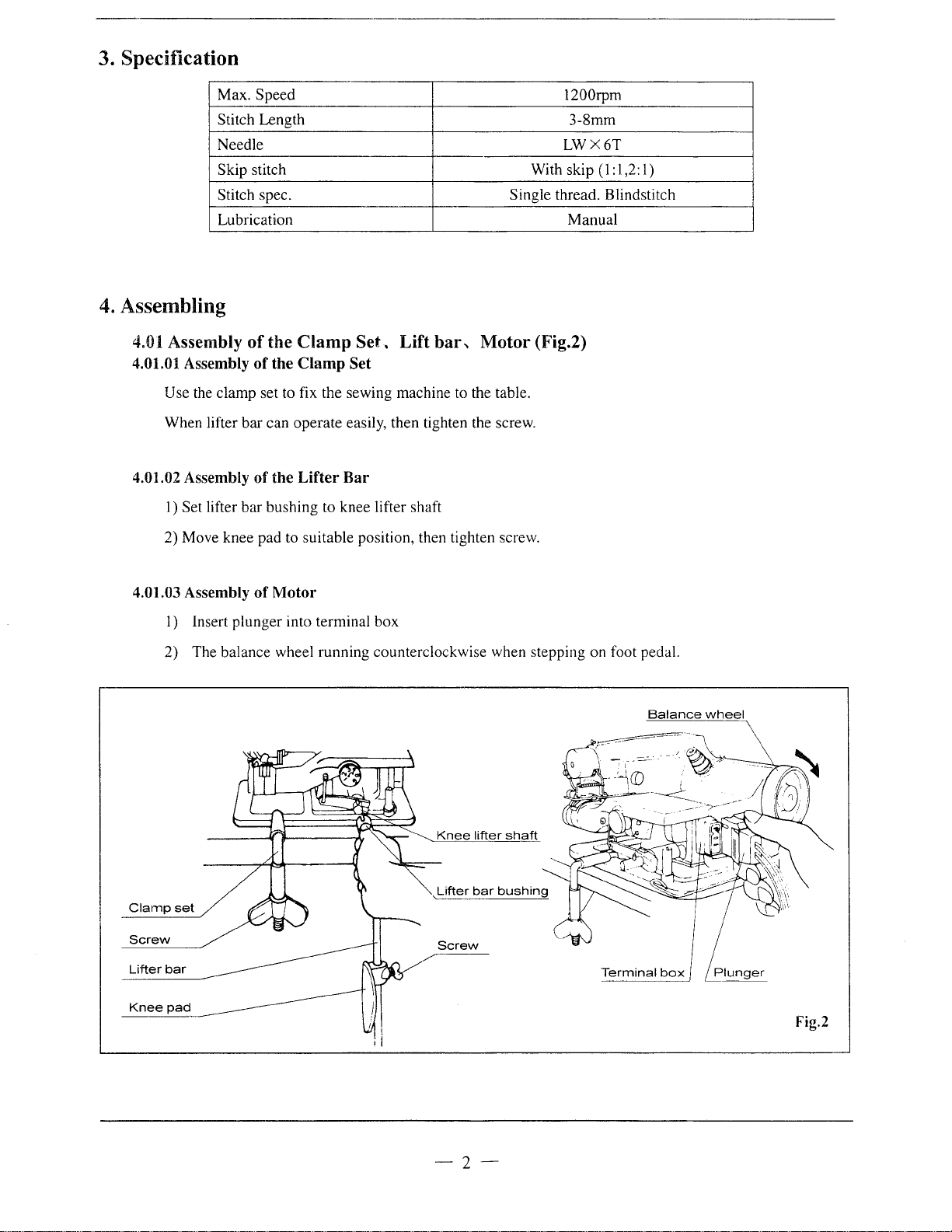

4JH Assembly

4.01.01 Assembly

Use the clamp set to fix the sewing machine to the table.

When lifter bar can operate easily, then tighten the screw.

4.01.02 Assembly

1)

Set lifter bar bushing to knee lifter shaft

2) Move knee pad to suitable position, then tighten screw.

4.01.03 Assembly

1)

Insert plunger into terminal box

2) The balance wheel running counterclockwise when stepping on foot pedal.

of

of

of

of

the

the

the

Motor

Clamp

Clamp

Lifter

Bar

Set.

Set

Lift

bar,

Motor

(Fig.2)

Knee

lifter

shaft

Lifter

bar

bushing

Clarnp

set

Screw

Lifter

Knee

bar

pad

Screw

-2-

Terminal

box

Fig.2

4.02 Threading

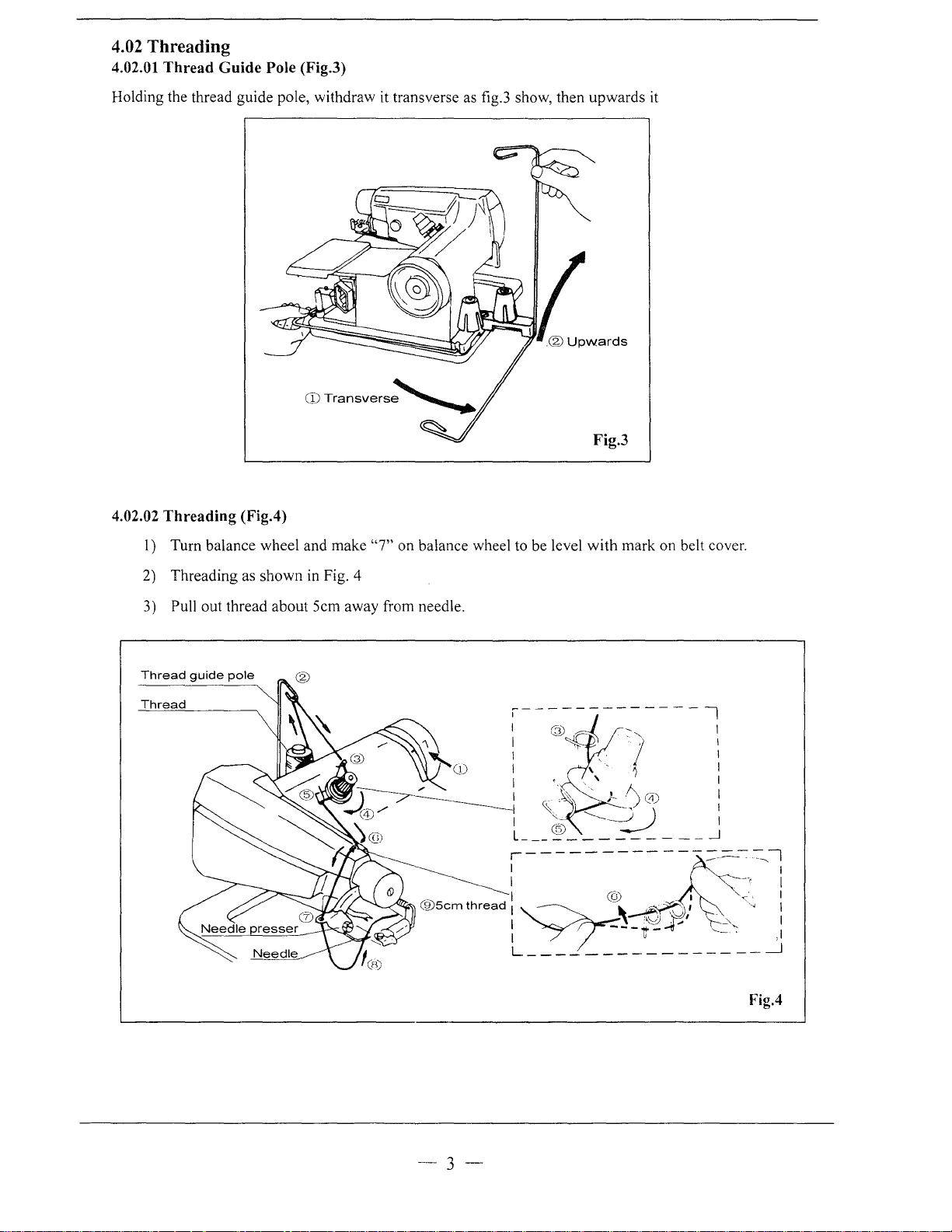

4.02.01 Thread Guide Pole (Fig.3)

Holding the thread guide pole, withdraw it transverse as fig.3 show, then upwards

Fig.3

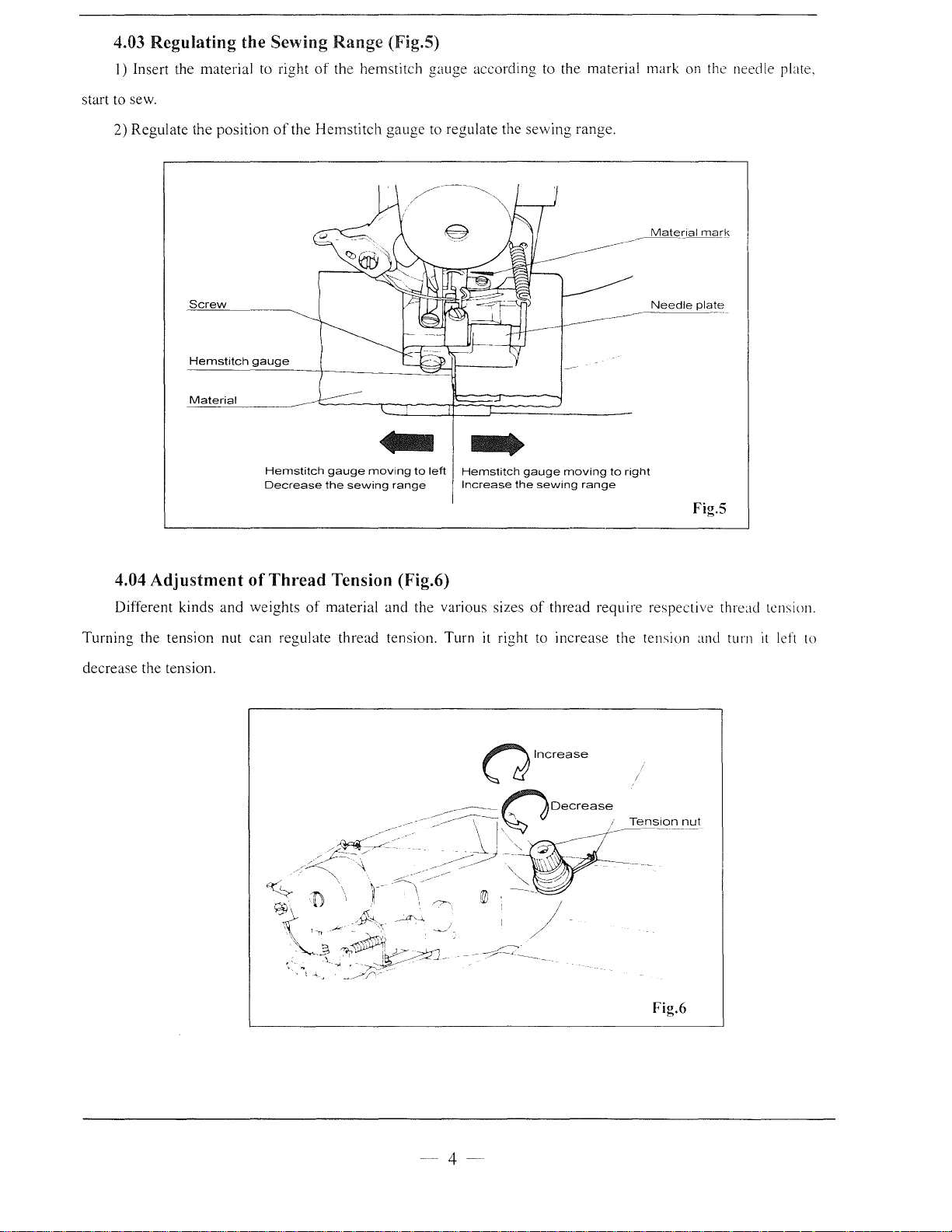

4.02.02 Threading (Fig.4)

1)

Turn balance wheel and make

"7"

on balance wheel to be level

with

mark on belt cover.

it

2) Threading as shown in Fig. 4

3)

Pull out thread about Scm away from needle.

Thread

guide

pole

(gJ5cm

i-----

I _

thread

I

~111.~~}1cvo-

I

1 u - ·

----

((;)

"

---

-

r:::--

~)

."';I

....

-

::--

1

1 .

~

L----------------~

-----

'-

-:.

-::-,;

--,

-~·.

--,

Fig.4

I

I

I

I

,I

-3-

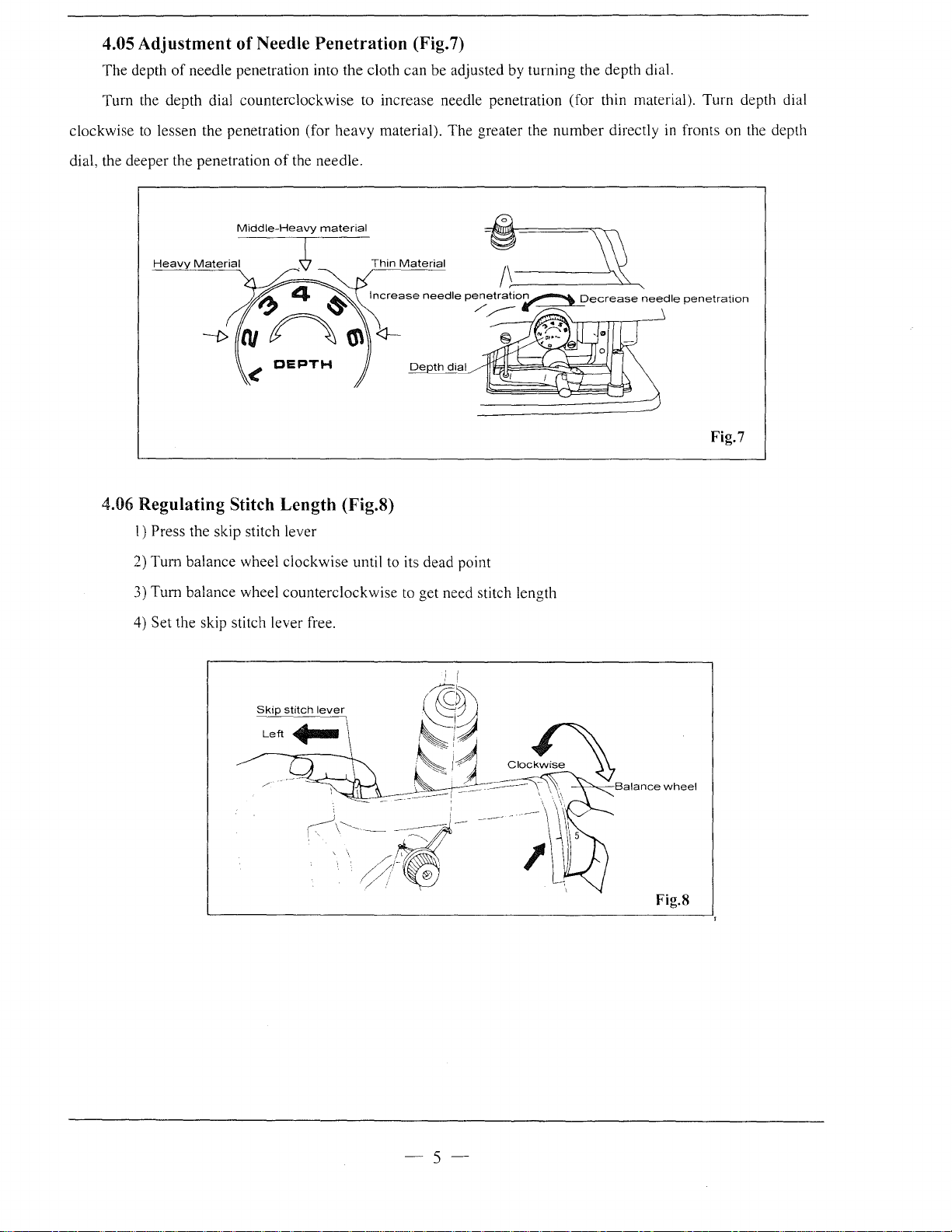

4.03 Regulating the Sewing

I)

Insert the material to right

start to sew.

2)

Regulate

the

position

of

of

the

Hemstitch

Range

the

hemstitch

(Fig.5)

gauge

gauge

according

to regulate the

to the material mark on the needle plate.

sewing

range.

Screw

Hemstitch

Material

4.04 Adjustment

Different

Turning

decrease the tension.

kinds

the tension nut

and

gauge

Hemstitch

Decrease

of

Thread Tension (Fig.6)

weights

can

regulate thread tension. Turn

gauge

moving

the

sewing

range

of

material and the various sizes

to

left

Hemstitch

Increase

it

right to

gauge

the

sewing

of

thread

moving

range

require

increase

to

~~-------~~

right

Material

Needle

mark

pia!"'

Fig.S

respective thread tension.

the tension and turn

it

left to

-4-

Fig.6

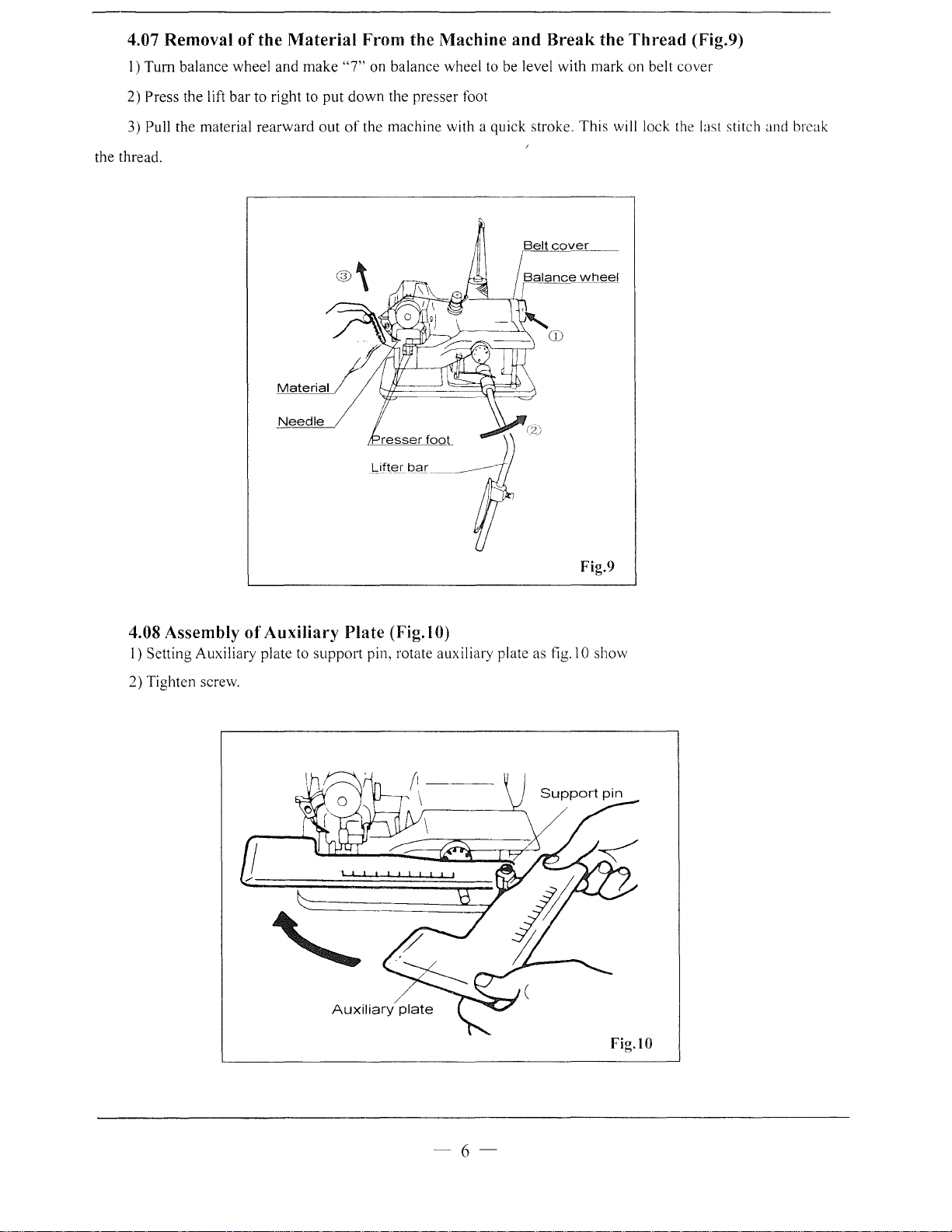

4.05 Adjustment

The depth

Turn the depth dial counterclockwise to increase needle penetration (for thin material). Turn depth dial

of

needle penetration into the cloth can be adjusted by turning the depth dial.

of

Needle Penetration (Fig.7)

clockwise

dial, the deeper the penetration

to

lessen the penetration (for heavy material). The greater the

of

the needle.

DEPTH

4.06 Regulating Stitch Length (Fig.8)

I) Press the skip stitch lever

2) Turn balance wheel clockwise until to its dead point

Thin

Material

Increase

needle

Depth

number

directly

in

fronts on the depth

~~o~-~

!\~----------~~,

penetration~

./

~

lr-=""'

dial

Decrease

needle

penetration

Fig.7

3) Turn balance wheel counterclockwise to get need stitch length

Set the skip stitch lever free.

4)

Fig.8

--5-

4.07 Removal

I)

Tum

2)

Press

3)

Pull the material

the thread.

balance

the lift

of

the

wheel

bar

to right to

rearward

Material

and

make

out

Material

Needle

From

"7"

put

down

of

the machine with a quick stroke.

the Machine

on

balance wheel to be level

the presser foot

and

Belt

Break

with

This

cover

the

Thread

mark

on

will lock the last stitch and break

belt

(Fig.9)

cover

4.08 Assembly

I) Setting Auxiliary plate to

2) Tighten screw.

of

Auxiliary

Plate

support

Auxiliary

Fig.9

(Fig.l

0)

pin, rotate auxiliary plate as fig. I 0

(1

__

_

\

,--------->-.,

\

plate

show

-6-

Fig.IO

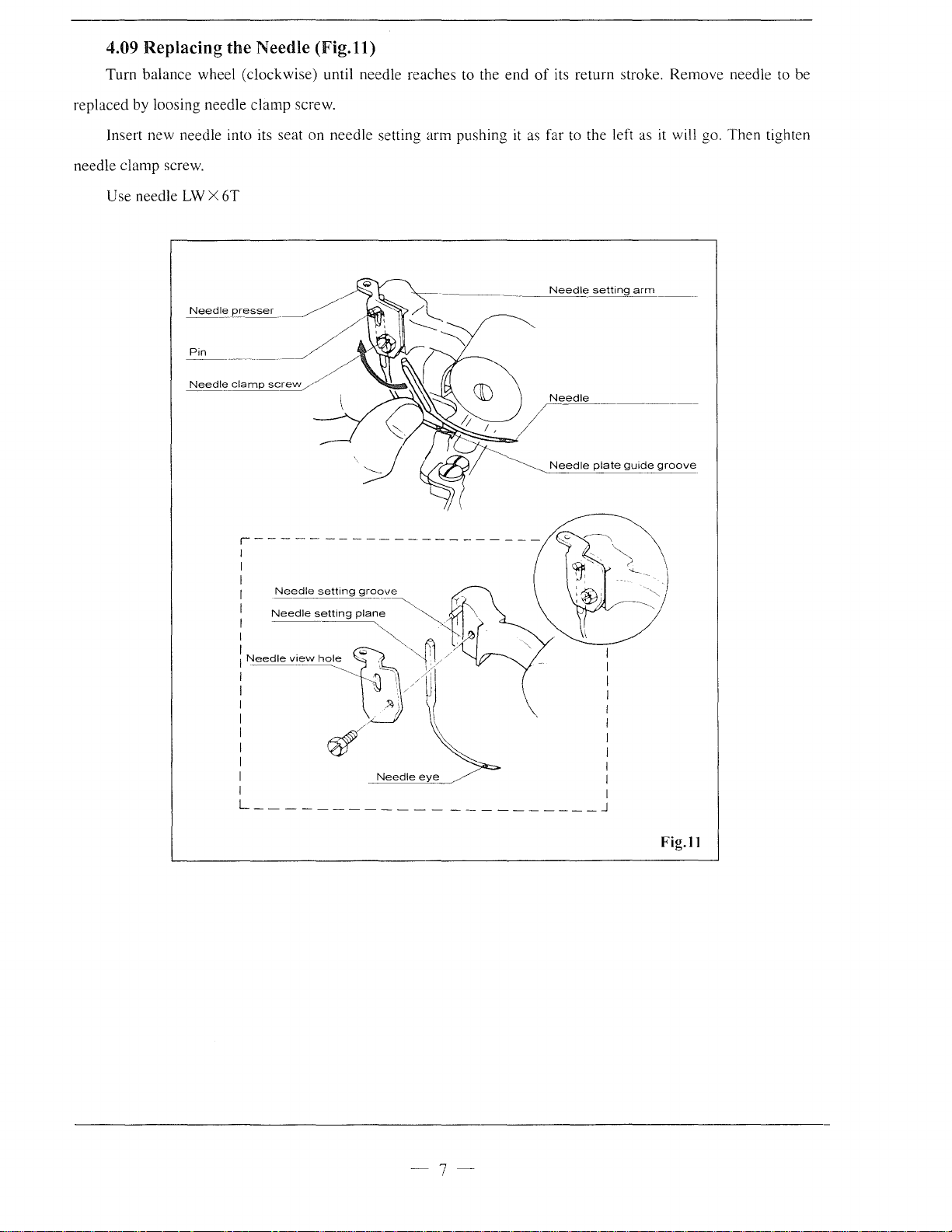

4.09 Replacing the Needle

Turn balance wheel (clockwise) until needle reaches to the

replaced by loosing needle clamp screw.

(Fig.ll)

end

of

its return stroke. Remove needle to be

Insert new needle into its seat on needle setting arm pushing

needle clamp screw.

Use needle

LW

X 6T

,-----

1

I

I

1

Needl~setting_£J_C_O()\/e

I

Needle

------------

setting

plane

it

as far to the left as

Needle

setting

Needle

Needle

~----~~-

plate

arm

guide

it

will go. Then tighten

groove

,

___

_

~

)

"

:

!

Need'e

~

"~eo';~

1!J/1

1

:

I

I

I I

L

______________________

if

Needle

eye

J

Fig.

II

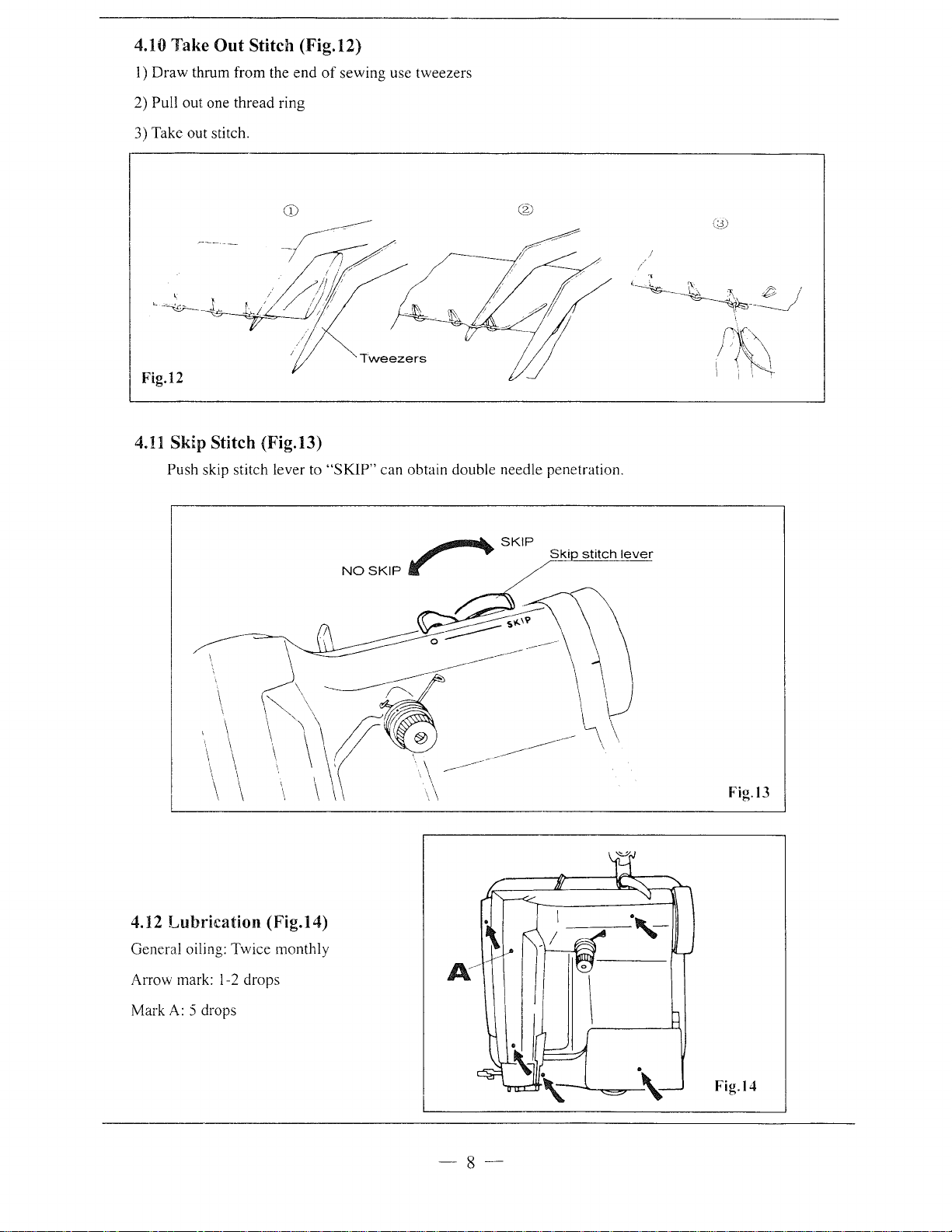

4.10 Take

1)

Draw

2) Pull out one thread ring

3) Take out stitch.

Out

Stitch (Fig.12)

thrum from the

end

of

sewing use tweezers

(3)

~

'~--~_)

Fig.12

4.11

Sktp Stitch (Fig.l3)

Push skip stitch lever to

\

\ '

\ \

\ \

\ I

Tweezers

"SKIP"

can obtain double needle penetration.

~'\

( <N

I ! '

Fig.l3

4.12 Lubrication (Fig.14)

General oiling: Twice monthly

1-2

Arrow mark:

Mark A: 5 drops

drops

-8-

Fig.I4

5.

Eventual Trouble Shooting

5.01

Sewing

1)

Terminal box and

2) Too loose belt

3)

Sewing machine does not lubrication.

5.02

No

I)

Inconect

Machine

sewing

plunger

threading.

doesn't

(According

work

are not connect. (According to 4.01)

(According

to 4.02)

to 4.12)

2) Needle incorrectly inserted

5.03

No

break

1)

Incorrect threading.

2) Excessive

3) Needle incorrectly inserted

4) Incorrect thread size.

5.04 Stitch

I) Needle incorrectly inserted

2) Unsuited needle penetration and material. (According to 4.05)

3) Incorrect threading.

4) Excessively elastic material

the

thread

thread

skipping

(According

tension. (According to 4.04)

(According

or

damaged.

to 4.02)

or

damaged.

or

damaged.

to 4.02)

or

excessively elastic thread.

(According

(According

(According

5.05 Uneven stitch

1)

Ensure thread

2) Unsuited stitch length and thread tension. (According to 4.04)

3) Incorrect threading.

5.06 Unstable needle

and

tension. (According to 4.04)

(According

to 4.02)

penetration

to 4.09)

to 4.09)

to 4.09)

(According

to 4.01)

1)

Unsuited needle penetration and material. (According to 4.05)

2) Incorrect position

3) Uneven position

4) Needle incorrectly inserted

of

material. (According to 4.03)

of

material and hemstitch gauge. (According

or

damaged.

(According

--

9-

to 4.09)

to

4.03)

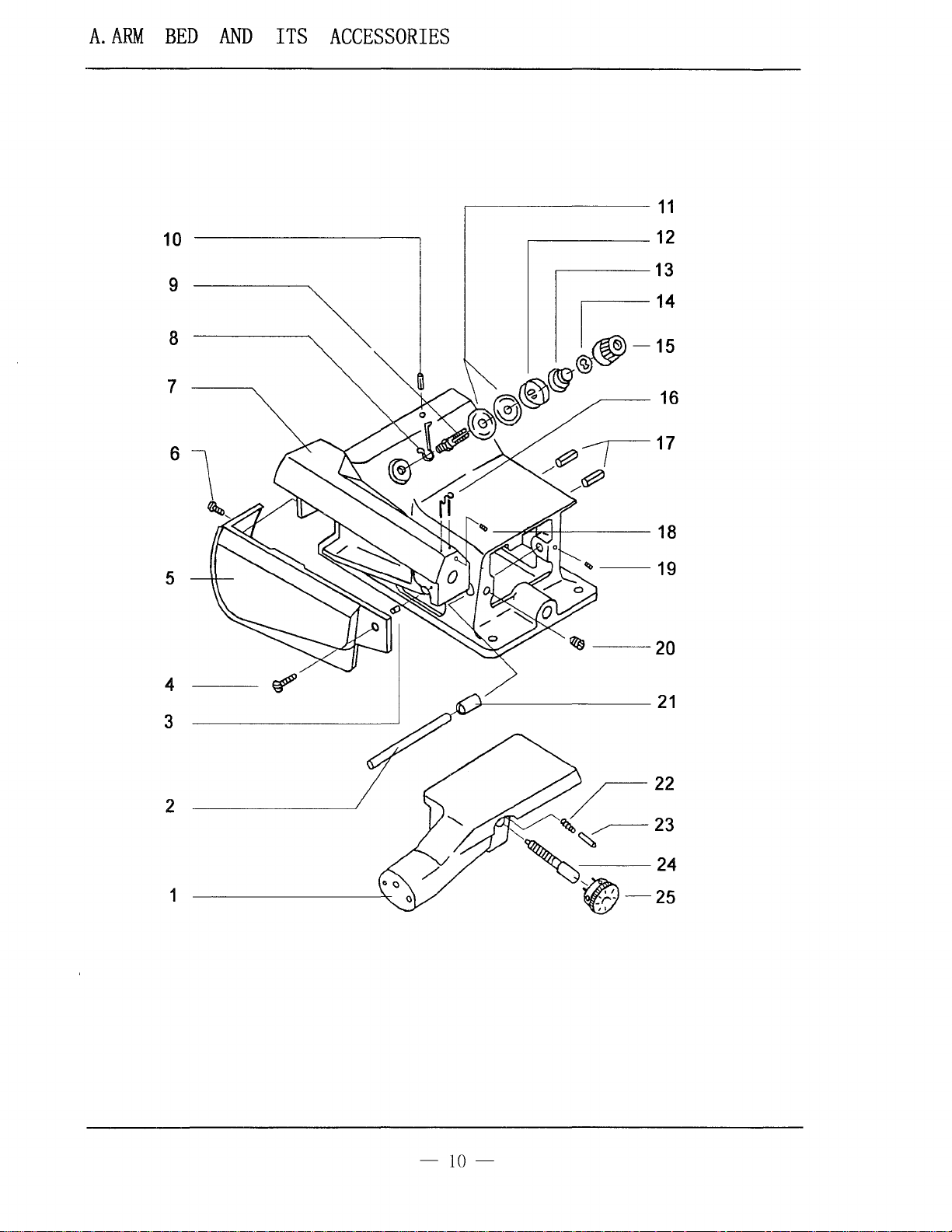

A.ARM

BED

AND

ITS

ACCESSORIES

11

10

9

8

7

5

4

~::

~~

~rgj

(

...J

~----y-----17

/

~

/

--20

12

16

18

19

3

2

1

-10-

,,

/

r--22

<

~

~-25

w

23

24

Loading...

Loading...