Highlead GK600 User Manual

Purchasing

Copy

Dept

HIGH

LEAD

GK600 SERIES

High-speed

Stretch

Sewing Machine

Instruction

Manual

Parts Catalog

SHANGHAI

HUIGONG

N0.3

SEWING

MACHINE

FACTORY

-INTRODUCTION-

Thank

This instruction manual describes daily routine maintenance and safety precautions to keep the machine

in the best possible conditions.

Please study this manual very carefully before operating the machine.

CHUTION

OBSERVE

Though Pegasus takes the utmost care to produce safe sewing machines and devices, operators

should follow these basic safety rules.

e To prevent accidents, do not remove safety devices

e Do not leave tools

you very much for purchasing

THESE

chine.

SAFETY

PRECAUTIONS

or

other unnecessary objects on the machine

600

Series

machine.

or

parts while

operating

table

the machine.

while operating the ma-

e Before maintenance, adjusting, cleaning, threading or replacing the needle, and to prevent acci-

dents, be sure the power is turned off,

pressed.

Check

that the machine will

not

operate when the pedal is

NOTE

In

case a crutch type motor

CD.

If

the machine pedal ®

unexpectedly. Keep

off power supply

e Turn the

e

In

the event

on

stepping on the machine pedal ® until the machine comes to a stop after turning

CD.

power

off

before leaving the machine table.

of

a power failure, be sure to turn the machine off.

e Check that the machine

is

used;' it will keep on rotating by inertia after turning

is

stepped on inadvertently, it

is

securely grounded.

off

power supply

is

dangerous because the machine will move

Ill

BEFORE

CONTENTS

OPERATING

1 . Lubrication

2.

Manual lubrication

3.

Filling

Threading

4.

5.

Threading

Ill

TEST

1.

Adjusting

2.

Adjusting

3.

Adjusting

4.

Adjusting

Ill

MAINTENANCE

1 .

Cleaning

2.

Replacing the needle

3.

Checking

Checking

4.

5.

Replacingtheoil

the

HR

.•.................•..•......•...............•.................•••••..

diagram (

SEWING

the presser foot pressure

the diff. feed ratio

the stitch length

the thread tension

the machine

the oil circulation

and replacing the oil filter

........•..............................•..........•...••

................

device with silicon oil

2-needle,

3-needle)

.•......................•..............................

...•..............•.•...........•.............•.........

...........•............................•..............

DURING

...........................................................

...................••.......................................

.......................................................

...............................................................

·

.....................................

.••........•.......•.......•................•••..

....................................••..•...•

.................................................•.

USE

................................................

·-

..........

-

..........

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Ill

PARTS CATALOG

...................................................................

15-20

Ill

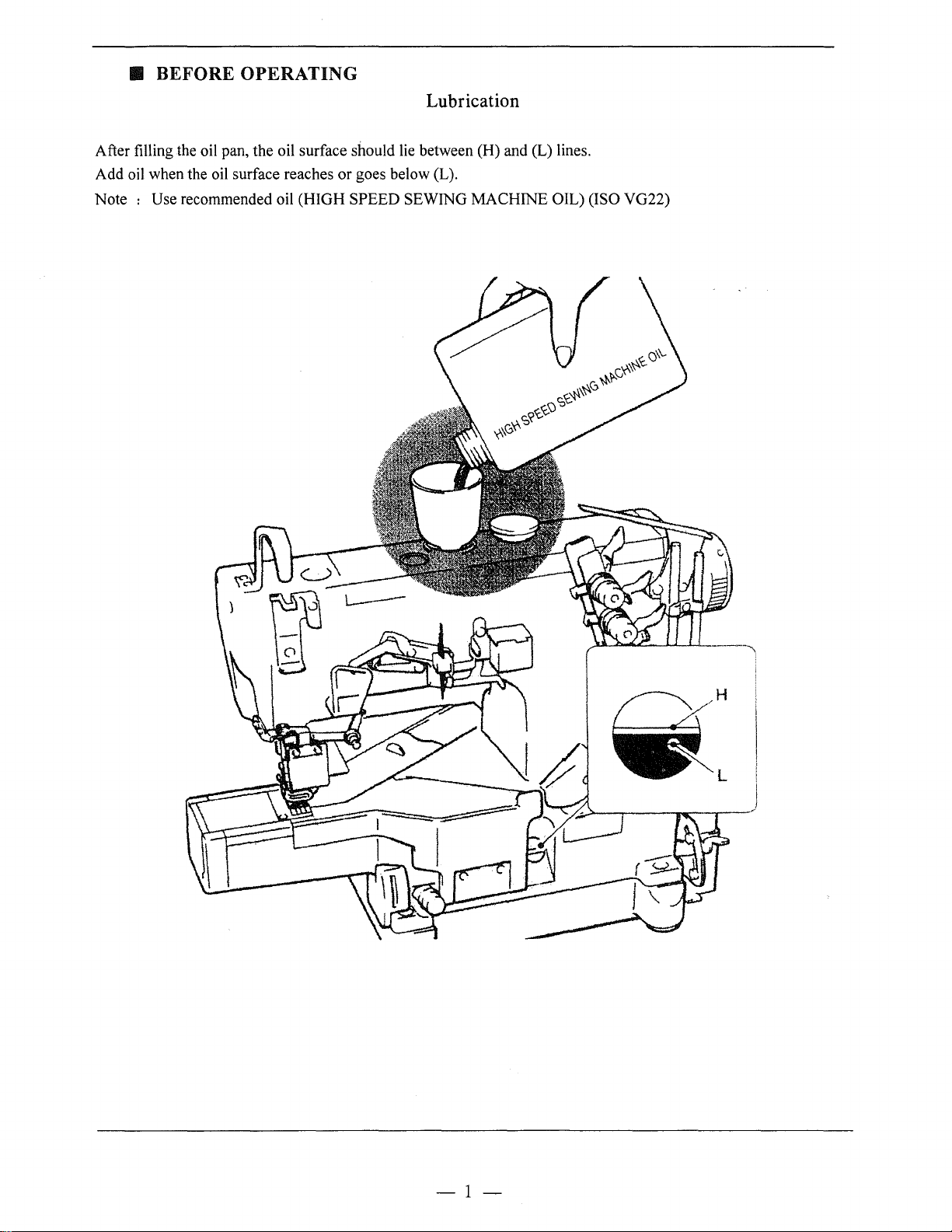

BEFORE

OPERATING

Lubrication

After filling the oil pan, the oil surface should lie between (H) and (L) lines.

Add oil when the oil surface reaches or goes below (L).

Note :

Use recommended oil (HIGH SPEED SEWING MACHINE OIL) (ISO VG22)

-1-

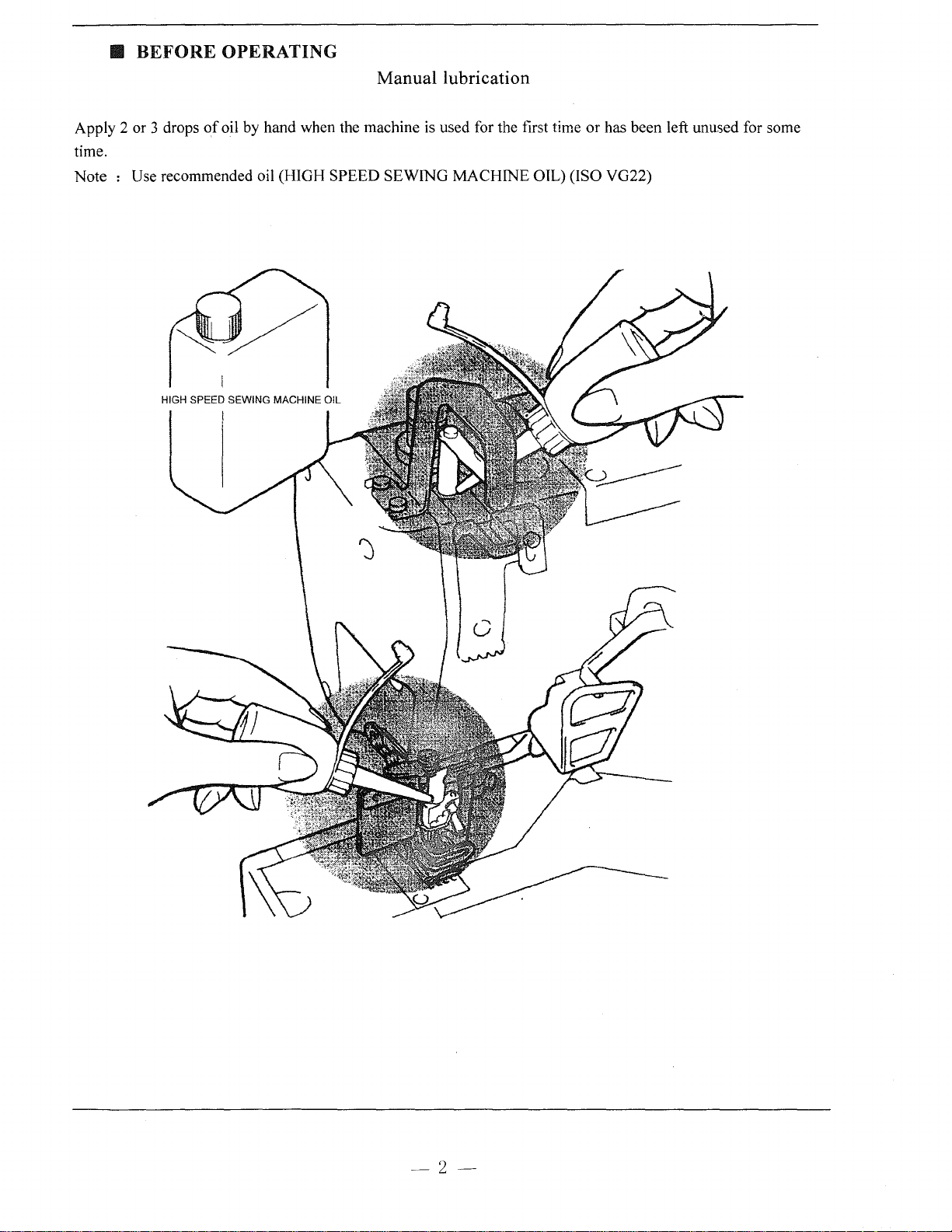

Ill

BEFORE

OPERATING

Manual lubrication

Apply 2 or 3 drops

time.

Note :

Use recommended oil (HIGH SPEED SEWING MACHINE OIL) (ISO VG22)

HIGH SPEED SEWING MACHINE OIL

of

oil by hand when the machine is used for the first time

!

or

has been left unused for some

-2-

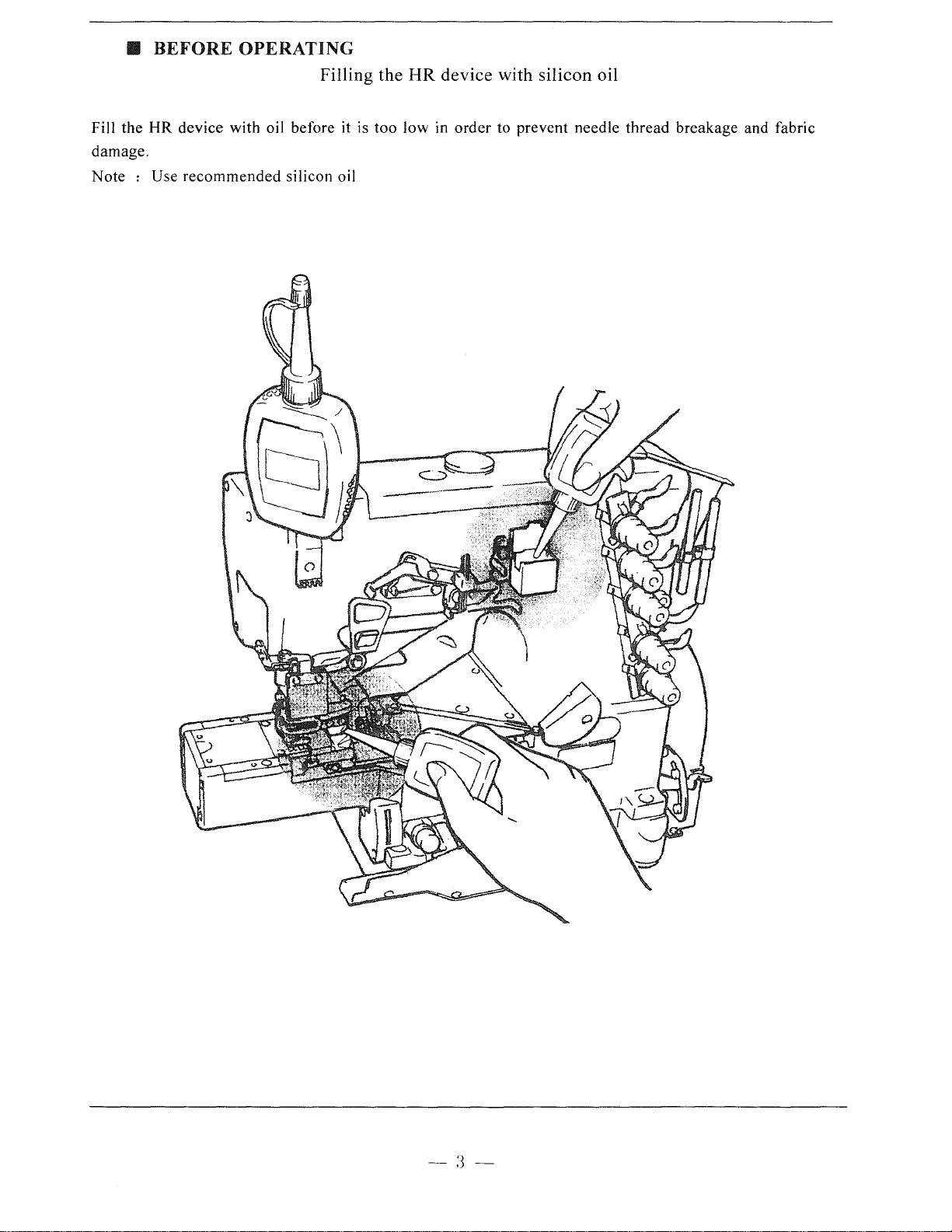

Ill

BEFORE

OPERATING

Filling the

Fill the HR device with oil before it is

damage.

Note :

Use

recommended

silicon oil

too

HR

device with silicon oil

low

in

order

to prevent needle thread breakage and fabric

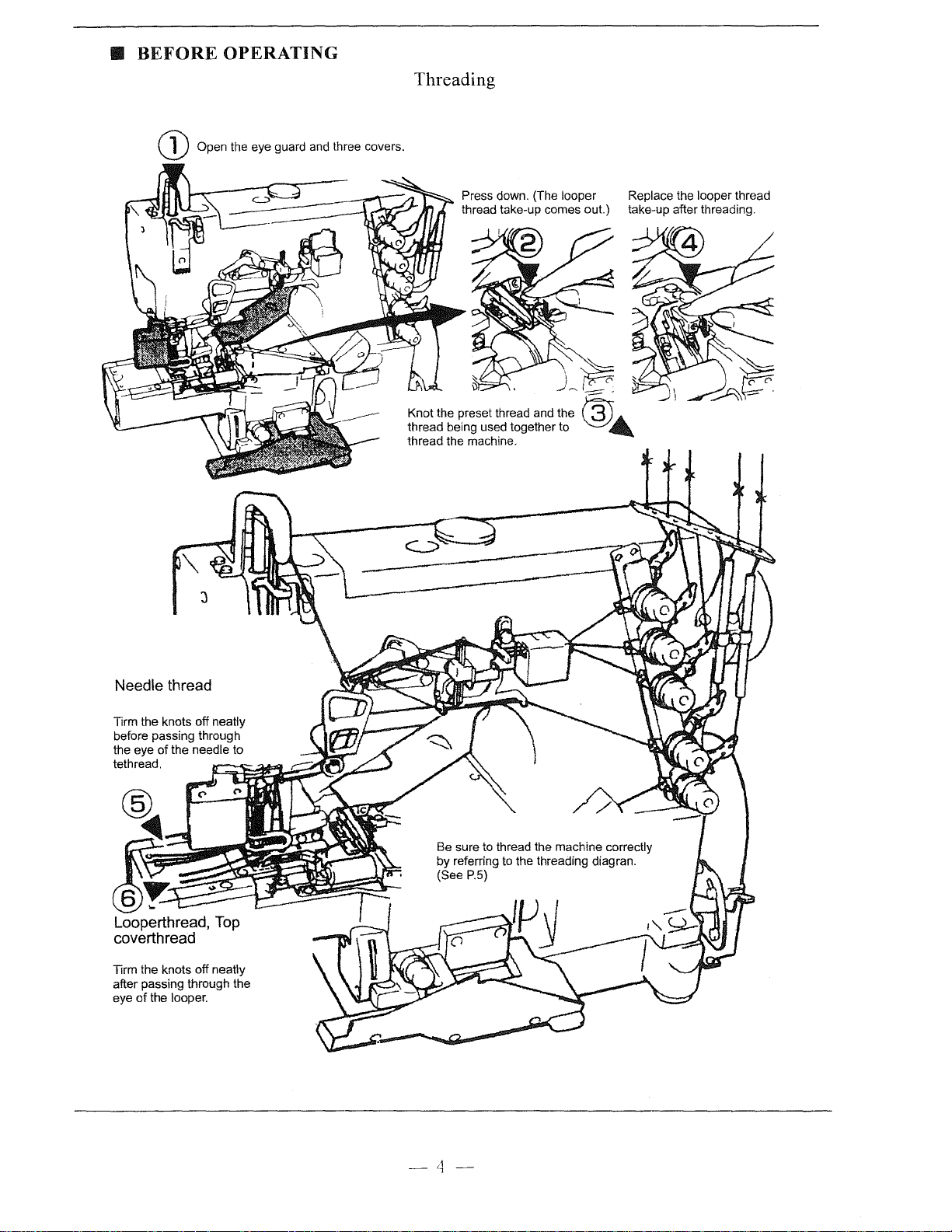

II

BEFORE

OPERATING

CD

Open the eye guard and three covers.

Threading

Replace the looper thread

take-up after threading.

Needle thread

Tirm the knots off neatly

befo~e

passing through

of

the eye

tethread.

Tirm the knots off

after passing through the

eye

the needle to

of

the looper.

neatly

Be sure to thread the machine

by referring to the threading diagran.

(See

P.5)

correctly

Loading...

Loading...