Highlead GK3088-2 User Manual

HIGH

LEAD

GK3088-2

2-Needle,Feed-off-the-arm Double Chainstitcher Machine

Instruction Manual

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

HIGH

LEAD

GK3088-2

2-Needle,Feed-off-the-arm Double Chainstitcher Machine

Instruction Manual

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

-----CONTENTS-----

1. PRECAUTIONS BEFORE STARTING OPERATION-------------------------------------------------- 1

1) Safety precautions------------------------------------------------------------------------------------------ 1

2) Precaution before Starting

3) Precaution for Operating Conditions------------------------------------------------------------------- 1

2.

SPECIFICATIONS--------------------------------------------------------------------------------------------- 2

3.

SETTING

4.

LUBRICATION------------------------------------------------------------------------------------------------- 3

5.

ATTACHING A NEEDLE ------------------------------------------------------------------------------------- 3

6.

THREADING

7.

THREAD TENTION ------------------------------------------------------------------------------------------- 5

8.

ADJUSTING

9.

ADJUSTING

10. HEIGHT OF

11.

TIMING

UP

THE

THE

THE

THE

THE

TO

RELEASE

SEWING

MACHINE HEAD--------------------------------------------------------------------- 4

STITCH LENGTH--------------------------------------------------------------------- 5

LOOPER

FEED DOG------------------------------------------------------------------------------- 6

Oper~tion

------------------------------------------------------------------ 1

MACHINE------------------------------------------------------------------ 2

CAM ------------------------------------------------------------------------- 6

THE

NEEDLE THREAD TENTION----------------------------------------- 7

12.

ADJUSTING

13.

MOTOR PULLEY

PARTS

CATALOG --------------------------------------------------------------------------------------------------- 8

THE

INTERMEDIATE THREAD GUIDE----------------------------------------------- 7

AND

BELT------------------------------------------------------------------------------- 7

1.

PRECAUTIONS BEFORE STARTING OPERATION

1)

Safety precautions

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

Power must be turned off when the machine

(2)

off

(3) The power must be turned

adjusting the machine, or when replacing.

(4) Avoid placing fingers, hairs bars etc. nears the pulley,

is

the machine

Do

(5)

(6)

2)

Precaution before Starting Operation

(I)

(2)

(3) When a new sewing machine

(4) Verify the voltage and (single or three) phase with those given on the motor nameplate.

not insert fingers into the thread take-up cover, .under/round the needle, or pulley when the

machine

If

a belt cover, finger guard, and/or eye guard are installed, do not operate the machine without these

safety devices.

Never operate the machine unless it has been properly lubricated.

If

a drop oiler lubricates the machine, never operate the machine before lubricating.

power on.(the pulley should rotate counterclockwise when viewed from the pulley.)

operation. Injury could result.

is

in

operation.

before tilting the machine head, installing or removing the "V" belt,

is

first turned on, verify the rotational direction

is

not used,.

"V" belt, bobbin winder pulley, or motor when

of

the pulley with the

3) Precaution for Operating Conditions

(1) Avoid using the machine at abnormally high temperature

lower). otherwise, machine failure may result.

Avoid

(2)

(3) Avoid using the machine in areas where too much electrical noise, resulted from the high-frequency

(4) For the first month after the installation ofyour machine, run it at a lower speed (approx.

using the machine in dusty conditions.

is

welder and others,

generated.

(3s·c

or higher) or low temperature (5.Cor

3,300rpm)

-I-

2.

SPECIFICATIONS

Application

Number

Sewing speed

Needle

Height

Stitch length

Needle gauge 4.8,

Circumference

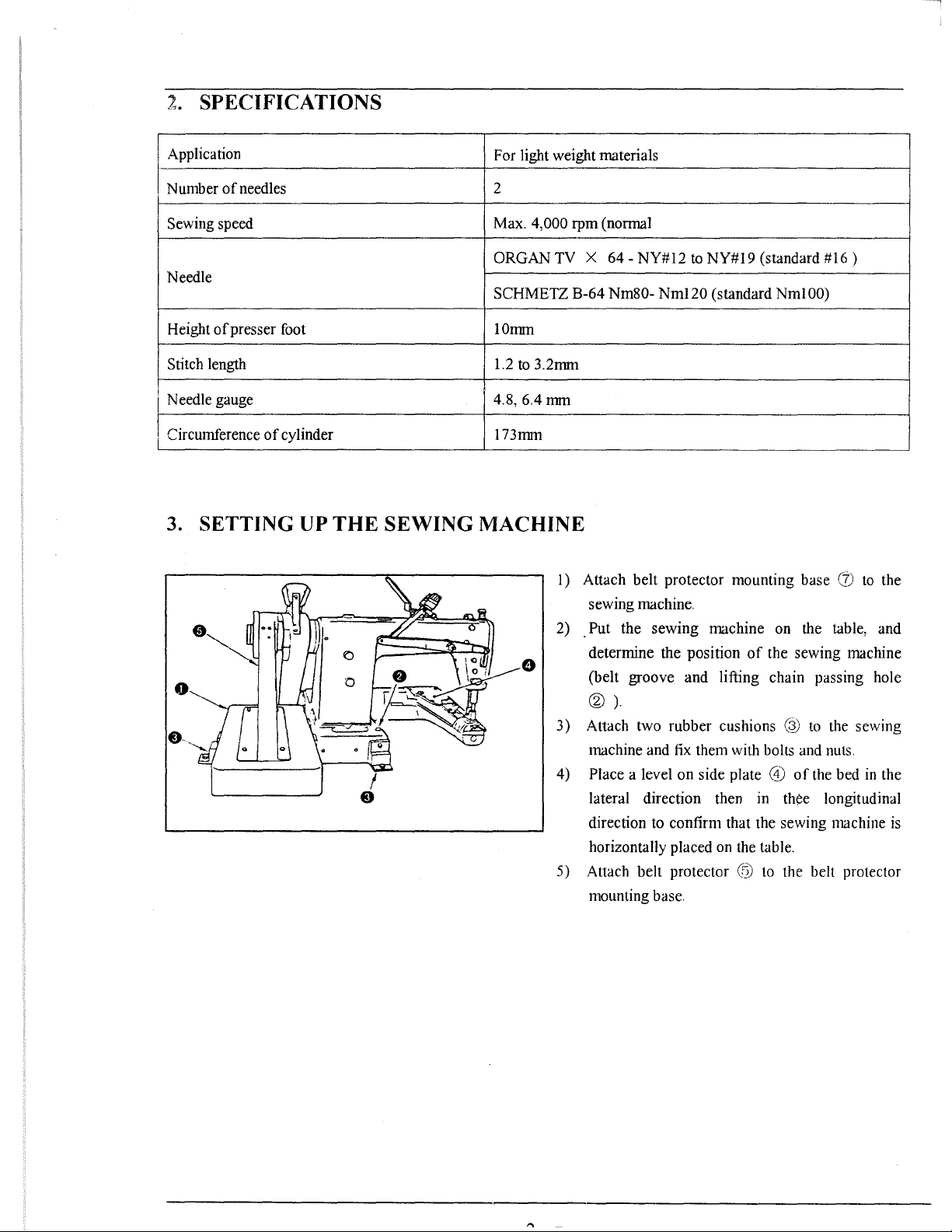

3. SETTING UP

of

needles 2

of

presser foot

of

cylinder 173mm

THE

SEWING MACHINE

For light weight materials

Max.

ORGAN TV X

SCHMETZ B-64

IOmm

1.2

4,000 rpm (normal

64-

NY#l2

Nm80-

to

3.2mm

6.4mm

I) Attach belt protector mounting base (j)

sewing machine.

Put the sewing machine on the table, and

2) .

determine the position

(belt groove and lifting chain passing hole

®

).

3) Attach two rubber cushions @

machine and

Place a level on side plate

4)

lateral direction then m

direction to confirm that the sewing machine

horizontally placed on the table.

5) Attach belt protector

mounting base.

to

NY#l9

Nml20

(standard NmlOO)

fix

them with bolts and nuts.

(standard

of

@

to

#16)

to

the

the sewing machine

to

the sewing

@)

of

the bed

thee longitudinal

the belt protector

in

the

is

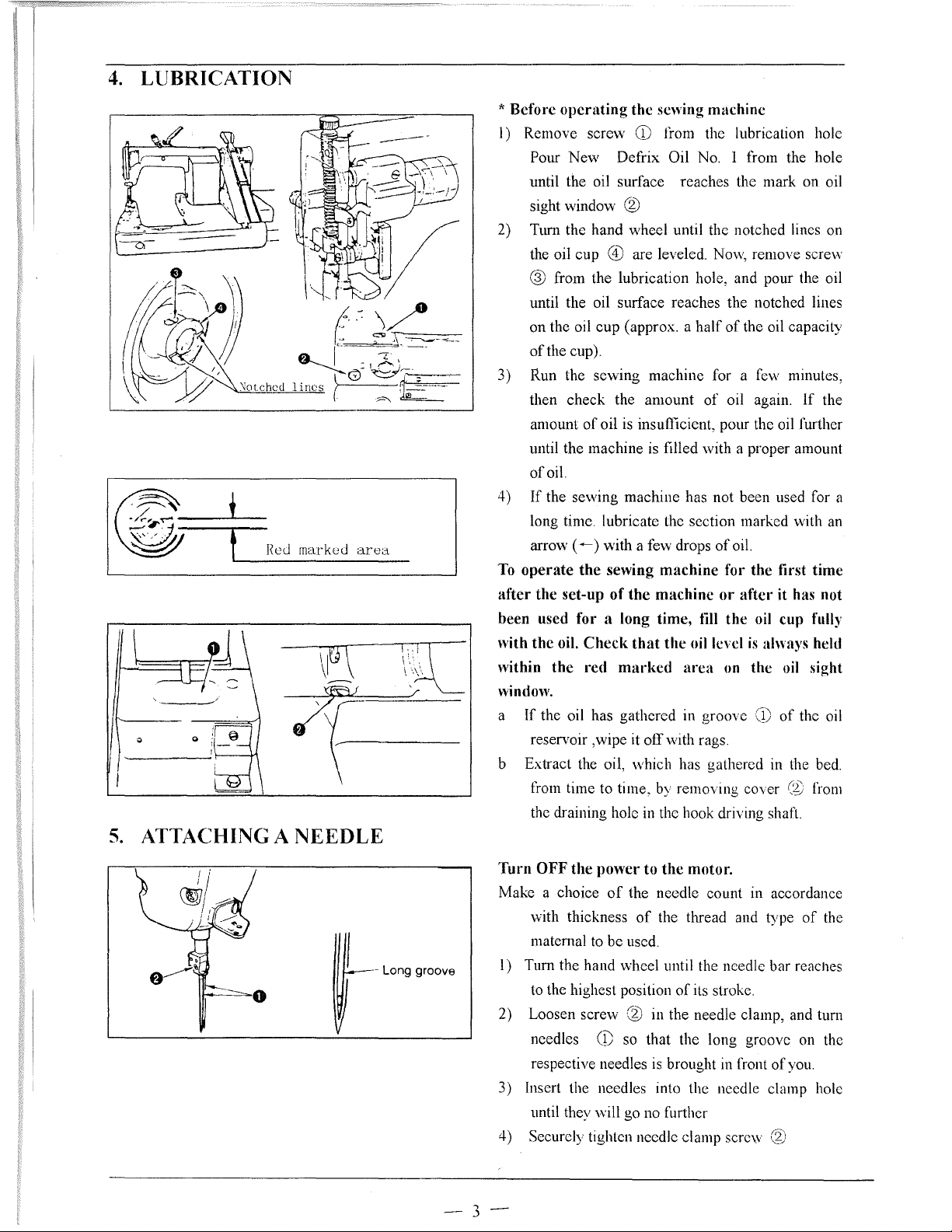

4.

LUBRICATION

5.

ATTACHING A

t

!(cJ

rnarkuJ

area

1-/

NEEDLE

*

Before

I) Remove screw

2) Tum the hand wheel until the notched lines on

3) Run the sewing machine for a few minutes,

4)

To

after

been used

with

within

window.

a

b Extract the oil, which has gathered in the bed.

operating

Pour New Defrix Oil

until the oil surface reaches the mark on oil

sight window

the oil cup

@ from the lubrication hole, and pour the oil

until the oil surface reaches the notched lines

on the oil cup (approx. a

of

the cup).

then check the amount

amount

until the machine

of

If

long time. lubricate the section marked with an

arrow (

operate

the

the

If

reservoir ,wipe it

from time to time, by removing cover

the draining hole

of

oil.

the sewing machine has not been used for a

.._) with a few drops

the

set-up

for

oil.

Check

the

red

the oil has gathered in groove

the

sewing

CD

@

@ are leveled. Now, remove screw

oil

is

insuftlcient, pour the oil further

is

sewing

of

a long

machine

the

machine

time,

that

marked

off

in

the hook driving shaft.

machine

from the lubrication hole

No.

1 from the hole

half

of

the oil capacity

of

oil again.

filled with a proper amount

of

oil.

for

the

or

after

till

the

oil cup full)'

the

oil level

area

on

is

the

CD

with rags.

If

tirst

time

it has not

always held

oil sight

of

the oil

(?:)

from

the

Turn

OFF

Make a choice

vvith

maternal

~-

Loog

gmo"

--

I) Tum the hand wheel until the needle bar

to

the highest position

2) Loosen screw

needles

respective needles

3) Insert the needles into the needle clamp hole

until they

4) Securely tighten needle clamp scre\v

3-

the

power

of

thickness

to

be used.

CD

\vill go

to

the

motor.

the needle count in accordance

of

the thread and type

of

its stroke.

of

the

reaches

@ in the needle clamp, and tum

so that the long groove on the

is

no

brought

further

in

front

of

@

you.

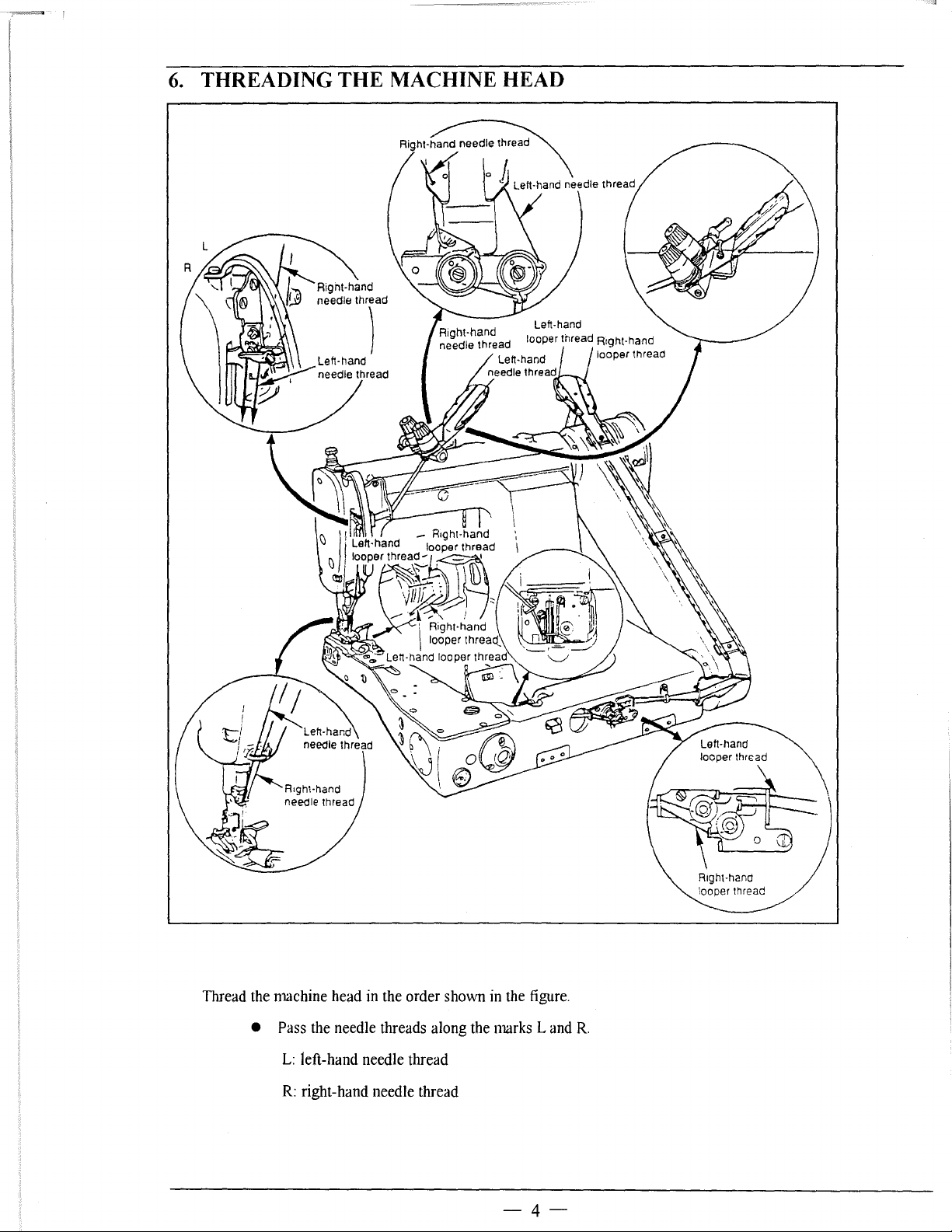

6.

THREADING THE MACHINE HEAD

Rignt-hand

"""'

'"'j"

Left-hand

needle thread

Rtght·hand

needle

thread

~~

~~

Thread the machine head in the order shown in the figure.

• Pass the needle threads along the marks L and

L:

left-hand needle thread

R:

right-hand needle thread

-4-

R.

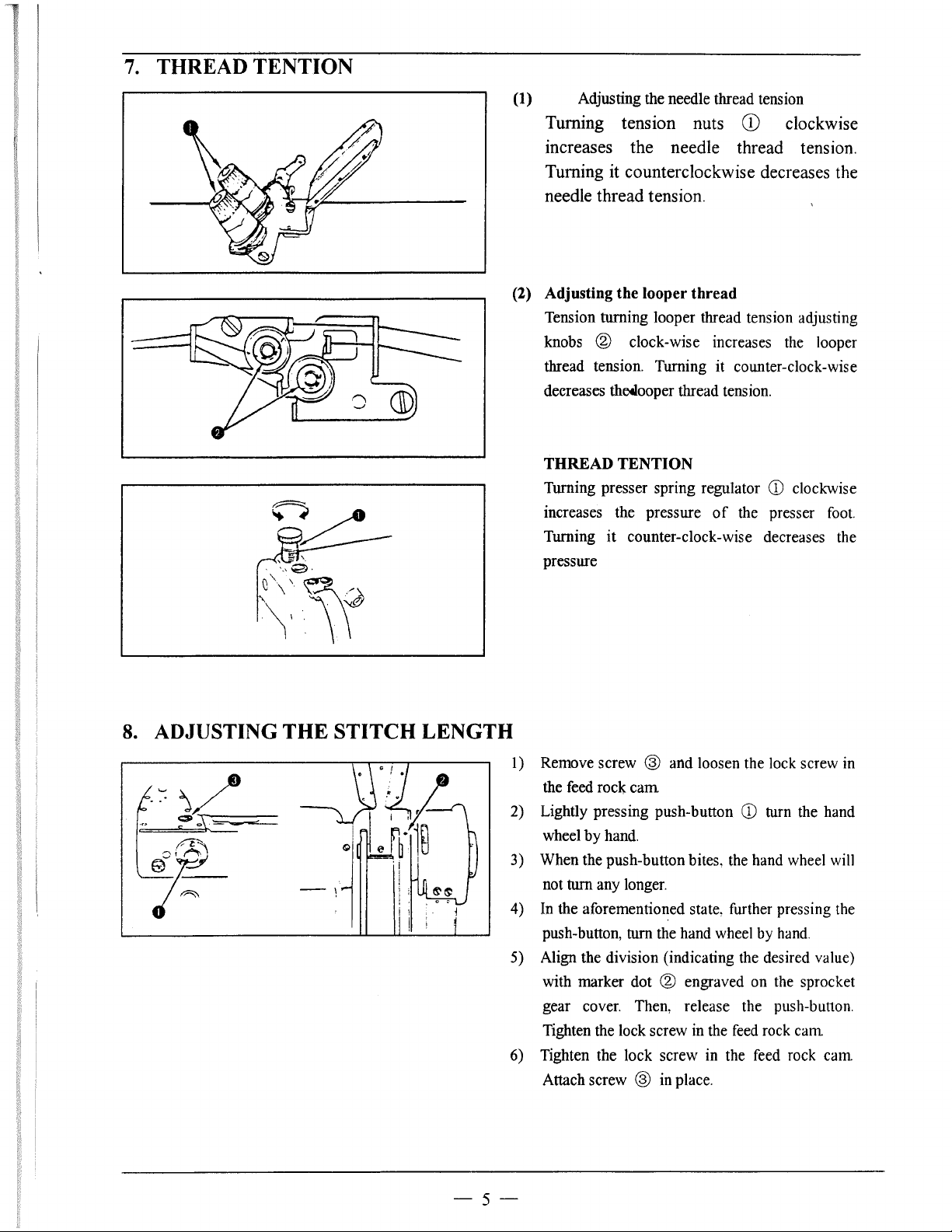

7.

THREAD TENTION

(1) Adjusting the needle thread tension

Turning tension nuts

increases the needle thread tension.

Turning it counterclockwise decreases the

needle thread tension.

(2) Adjusting the looper thread

Tension turning looper thread tension adjusting

knobs

thread tension. Turning it counter-clock-wise

decreases

THREAD TENTION

Turning presser spring regulator

increases the pressure

Turning

pressure

® clock-wise increases the looper

thetlooper thread tension.

it

counter-clock-wise decreases the

CD

clockwise

CD

clockwise

of

the presser foot.

8.

ADJUSTING THE STITCH LENGTH

-~~

1) Remove screw ® and loosen the lock screw in

by

cam

hand.

CD

turn the hand

® engraved on the sprocket

cam

cam

the feed rock

2) Lightly pressing push-button

wheel

3) When the push-button bites, the hand wheel will

turn any longer.

not

4) In the aforementioned state, further pressing the

push-button, tum the hand wheel by hand.

5) Align the division (indicating the desired value)

with marker dot

gear cover. Then, release the push-button.

Tighten the lock screw in the feed rock

6) Tighten the lock screw in the feed rock

Attach screw ® in place.

-5-

I 0

®

Lock

screw~

CID

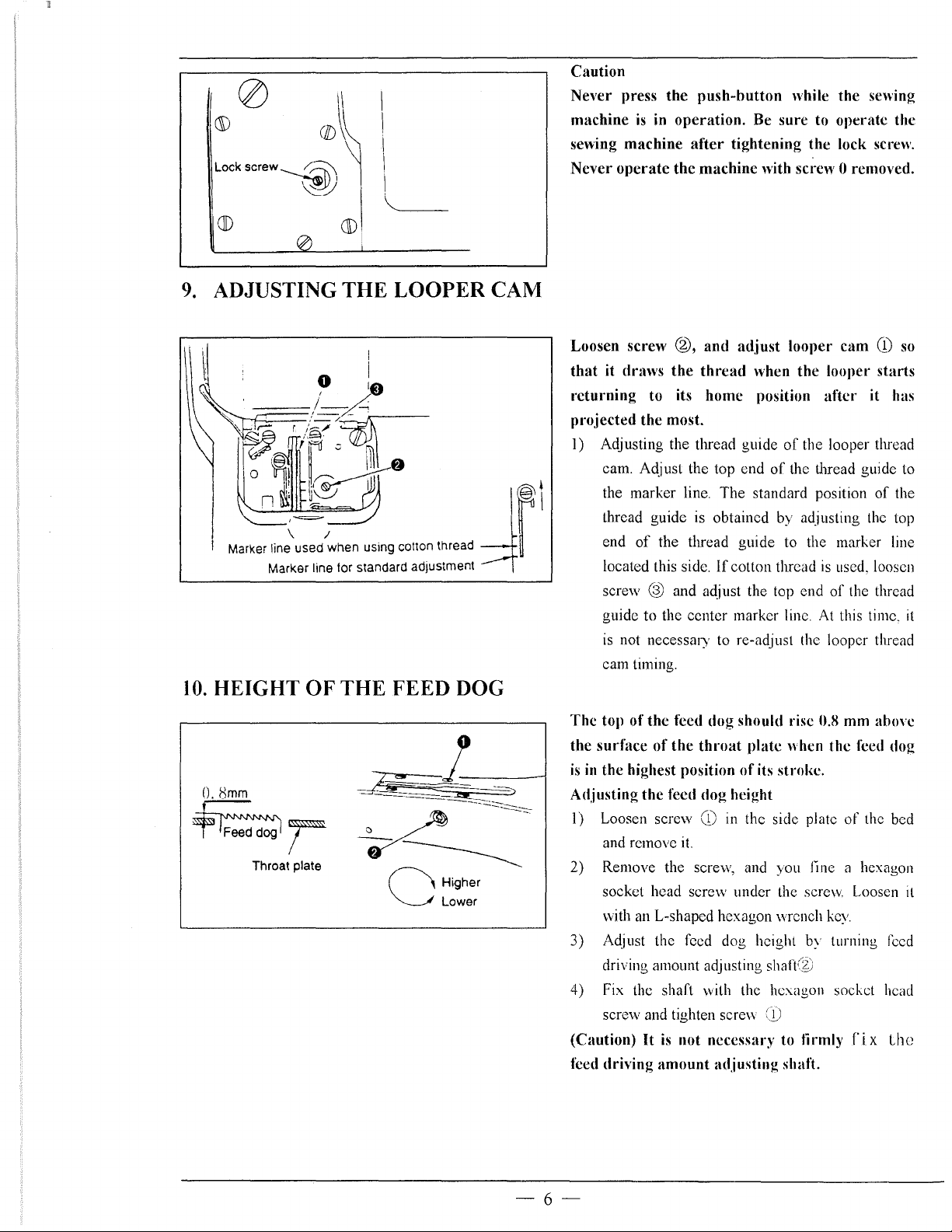

9.

ADJUSTING

10.

HEIGHT

11

(Jj)

~

~

~I

@,

0

THE

OF

THE FEED DOG

LOOPER

CAM

Caution

the

Never press

machine

sewing

Never

Loosen screw

that

returning

projected

I) Adjusting the thread guide

is

machine

operate

it draws

to its home position

the

cam. Adjust the top end

the marker line. The standard position

thread guide is obtained by adjusting the top

end

of

located this side.

screw

(:;£)

guide to the center marker line.

is

not necessary to re-adjust the looper thread

cam timing.

push-button

in operation. Be sure to operate the

after

tightening

the

machine with screw 0 removed.

®,

and

adjust

the

thread

most.

the thread guide to the marker line

If

cotton thread

and adjust the top end

while the sewing

the

looper cam

when

the

looper starts

after

of

the looper

of

the

tl1read

is

of

At

lock screw.

used. loosen

this time,

CD

so

it has

tlu·ead

guide to

of

the

the thread

it

0.

1-lmm

~r

Throat plate

_;_l;T<-;;-...-_-=--E'=-

"

~~

(~Higher

~Lower

The

top of

the

feed dog should rise 0.8 mm

the

surface

is

in

the highest position

Adjusting

1)

Loosen screw

and remove

2) Remove the screw, and you fine a hexagon

socket head screw under the screw. Loosen

vvith

3) Adjust the feed dog height by turning

driving amount adjusting shaft@

4) Fix the shaft with the hexagon socket head

screw and tighten screw

(Caution)

feed driving

of

the

throat

the

feed dog height

CD

it.

an

L-shapcd hexagon wrench

plate

of

its stroke.

in

the side plate

CD

It

is

not necessary to tirmly

amount

adjusting shaft.

when the feed dog

key.

of

the bed

f'

i x Lhc

abow

feed

it

-6-

Loading...

Loading...