Page 1

Purchasing

Copy

Dept

HIGH

HIGH

GK22018

SPEED CYLINDRICAL BED

CHAIN

Instruction

LEAD

SERIES

STITCHER

Manual

INTERLOCK

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

Page 2

Page 3

CONTENTS

1 ,

In

traduction----------------------------------------------------------------------------------------------------------------- 1

, Mode and Specification --------------------------------------------------------------------------------------------------- 1

2

,

Ins

ta

3

4,

, Lubrication -----------------------------------------------------------------------------------------------------------------2

5

5-1

5-2 Feeding

5-3

5-4

5-5

6

, Proper Operation----------------------------------------------------------------------------------------------------------- 3

6-1

6-2

6-3

6-4 Thread

6-5

6-6 Adjusting

6-7 Adjusting

7,

7 -I Tension

7-2

7-3

7-4 Adjusting

7-5

7-6 Remove and Fitting

7-7 Relation

7-8

7-9

7-10 Adjusting

7

7-12 Relative Postioning ofNeedle and Looper

7-1

7-14 Adjusting o

7-15 Height

7-16 Paralleling

7-17 Fitting

7-18 Fitting

7-19 Fitting

7-20 Adjusting

7-21

8 , Parts book -----------------------------------------------------------------------------------------------------------------

lla tion ------------------------------------------------------------------------------------------------------------------ 1

Sewing Speed and Setting up

Oil

to

be Used------------------------------------------------------------------------------------------------------------- 2

of

Oil-------------------------------------------------------------------------------------------------------------2

Oil Sight Gauge and Check Procedure

Ex

change

Cleaning

Needles

Threading ------------------------------------------------------------------------------------------------------------------4

Operation

Pressure

Proper Adjusting

Adjusting ofNeedle Thread Upper Eyelet----------------------------------------------------------------------------- 6

Adjusting

Positioning

Fitting Angle and Height

Distance (M) Between Needle and Looper ----------------------------------------------------------------------------8

-II

Timing

3 Adjusting o

Exchange

of

Oil-----------------------------------------------------------------------------------------------------------3

of

Filter and Screen--------------------------------------------------------------------------------------------4

to

Be Used, Fitting

of

Spring-out Type Bobbin Thread Guide -----------------------------------------------------------------4

Tens

ion ------------------------------------------------------------------------------------------------------------4

of

Presser Foot and Its Adjustment--------------------------------------------------------------------------- 5

of

Stitch Length -----------------------------------------------------------------------------------------------5

of

Differential Feeding--------------------------------------------------------------------------------------- 6

of

Machine--------------------------------------------------------------------------------------------- 6

ofN

eedle Thread------------------------------------------------------------------------------------------------ 6

of

Ornamental Thread---------------------------------------------------------------------------------------- 6

of

Looper Thread --------------------------------------------------------------------------------------------- 7

of

Looper Thread Take-up Cam--------------------------------------------------------------------------- 7

of

ofN

eedle and stitch plate ------------------------------------------------------------------------------------- 8

ofN

eedle Bar------------------------------------------------------------------------------------------------ 8

ofN

eedle With Looper Moving Right/Left------------------------------------------------------------------ 8

fN

eedle Guard( Rear) ------------------------------------------------------------------------------------ 9

fN

eedle Guard(Front) ----------------------------------------------------------------------------------- 9

of

Feed Dog----------------------------------------------------------------------------------------------------- 9

ofF

eed Dog With Stitch Plate---------------------------------------------------------------------------- 9

of

Ornamental Looper and Its Adjusting-------------------------------------------------------------------

of

Ornamental Thread Guide--------------------------------------------------------------------------------

of

Ornamental Thread Eyelet ------------------------------------------------------------------------------

of

Swing Scope

of

Upper Shaft Driving Belt -----------------------------------------------------------------------------

of

Pulley --------------------------------------------------------------------------------- 2

of

Oil Cycling-------------------------------------------------------------- 3

ofN

eedles; Needle Thread and Needle Device--------------------------------------- 3

Presser Foot and

of

Looper ------------------------------------------------------------------------------------ 8

of

Ornamental Looper-----------------------------------------------------------------

Its

Height------------------------------------------------------------------- 7

in

Front/Rear----------------------------------------------------------- 8

10

10

10

10

10

12

Page 4

Page 5

1.

Introduction

Model GK31 058 Interlock stitch sewing machine

clothing, and underwear, etc. This series

stitch, loop type interlock stitch, fell interlock stitch, collar and band binding stitch, ornamental stitch which are even,

attractive, decorative, elastic and can

of

trousers waist, underclothes, underpants, front

be used

2.

as

different industrial sewing machines

Specifications

Dimensions:

Weight (Head):

Sewing Speed: Max. 6000 r.p.m Feed length: 1.2-4mm

Needle: Model UY128 GAS NM65-90, 128GAS 9-14

Needle Bar Stroke:31.2mm

Adjusting Form

Differential Ratio: Positive Ratio 1:1.3 Reverse 1 :0.5

Lubrication: With Oil Pump Automatic Oil Supply Lubricant: No.7 White Machine Oil

Oil Reserving Capacity: 1

Motor: Clutch motor: >400W,3phase,2pde.

585(L)X370

51

kg Type

of

Differential Feeding: Lever Type (It can also

(W)

OOOg

of

products is capable

be

met demands

of

to

sew zip, embroider and abut decorative lace and scallop lace etc.

X510

of

Presser Foot Raising

(H)

Stitch: 406,407,602,605( 401.408)

is

a Special equipment suitable for trades

of

sewing many stitches, fox example, plain interlock

of

sewing elastic trousers

garment etc. With proper attaching device and parts, it can also

Height:>

5mm

be

regulated

of

man and woman and elastic Cord

at

any time during operation)

of

kintwear,

3. Installation

Referring

l\...

to

the illustration install the machine correctly.

~

15

~

-

c;::::

B-B

SECTION

Unit::mm

Difference: ± 2

1.{')

'<t

'<t

.-

Ol

.-

V l n I

4-¢13

Ol

.-

.-

I

i

234

5-R1d~

I I

'\'

-=<~-l.....t~S

1200

·-·-4~

125

234

710

461

I___)

i B

I

.

90

400

302

245

'<t

<0

N N

210

-}-

Page 6

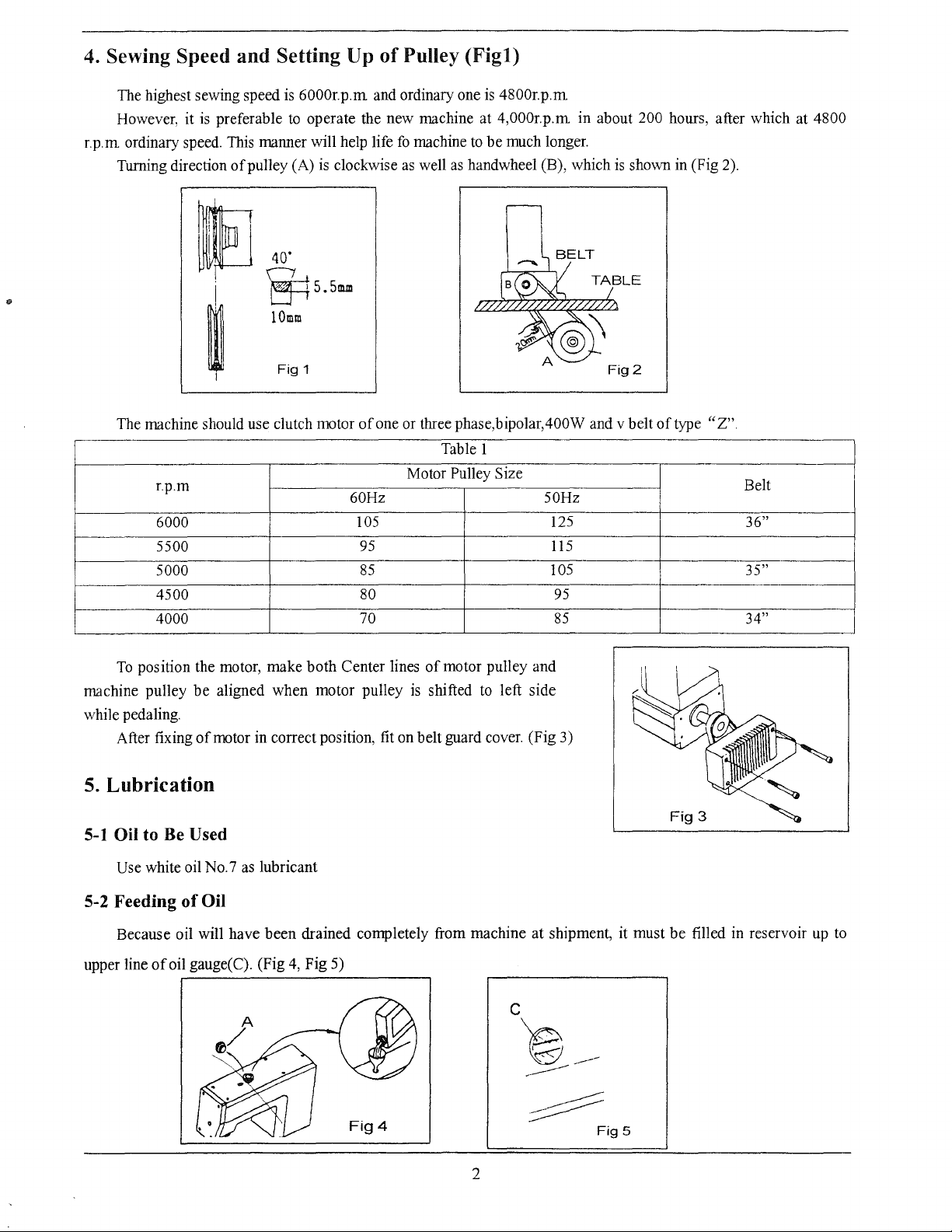

4. Sewing Speed

The highest sewing speed is 6000r.p.m and ordinary one is 4800r.p.m

However, it

r.p.m ordinary speed. This manner will help life

Turning direction

and

Setting Up

is

preferable to operate the new machine at 4,000r.p.m in about 200 hours, after which at 4800

of

pulley (A)

is

of

clockwise

Pulley

fo

machine

as

well

(Figl)

to

be

as

handwheel (B), which

much longer.

is

shown in (Fig 2).

..

fJ

40"

~5.5m.m

lOmm

~

The machine should use clutch motor

r.p.m

6000

5500

5000

4500

4000

To

position the motor, make

machine pulley

while pedaling.

After fixing

be

aligned when motor pulley

of

motor in correct position, fit on belt guard cover. (Fig 3)

Fig

1

both

of

one or three phase,bipolar,400W and v belt

Table 1

Motor Pulley Size

60Hz 50Hz

105

95

85

80

70

Center lines

of

motor pulley and

is

shifted

to

left side

125

115

105

95

85

of

type

"Z".

Belt

36"

35"

34"

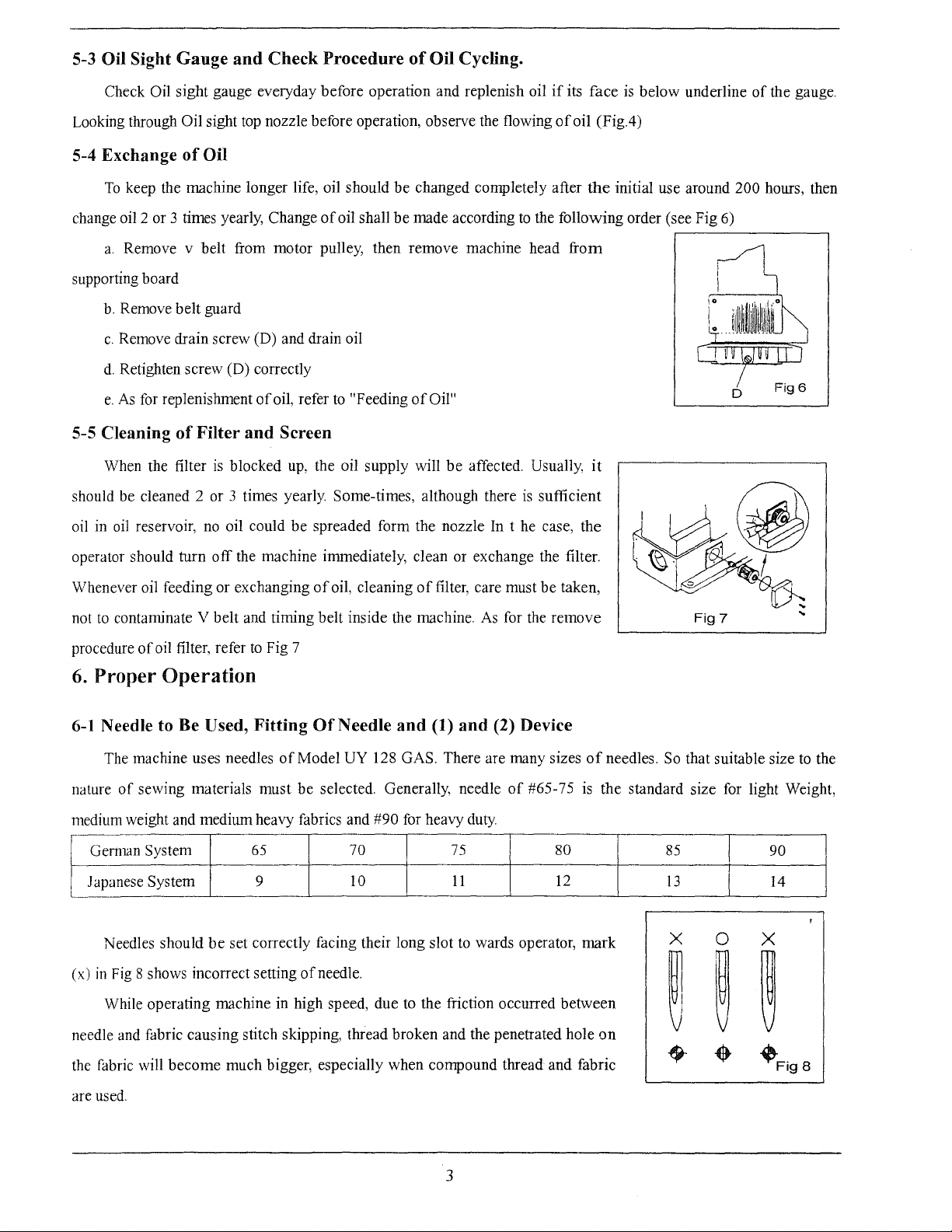

5.

Lubrication

5-1

Oil to Be Used

Use white oil No.7 as lubricant

5-2 Feeding

Because oil will have been drained completely from machine at shipment, it must

upper line

of

Oil

of

oil gauge( C). (Fig

4,

Fig 5)

~

2

Fig

Fig

3

be

filled in reservoir

5

up

to

Page 7

5-3 Oil Sight

Gauge

and

Check

Procedure

of

Oil

Cycling.

Check Oil sight gauge everyday before operation and replenish oil

Looking through Oil sight top nozzle before operation, observe the flowing

5-4 Exchange

To

keep the machine longer life, oil should

change oil 2 or 3 times yearly, Change

a.

Remove v belt from motor pulley, then remove machine head

supporting board

b.

Remove belt guard

c.

Remove drain screw (D) and drain oil

d.

Retighten screw (D) correctly

e.

As

5-5 Cleaning

When the filter

should be cleaned 2 or 3 times yearly Some-times, although there

oil

in

oil

of

Oil

for replenishment

of

Filter

is

blocked

reservoir,

no

oil could

of

and

be

changed completely after

of

oil, refer

oil shall

to

be

"Feeding

made according

of

Oil"

Screen

up,

the oil supply will

be

spreaded form the nozzle In t he case, the

be

affected. Usually,

to

the following order (see Fig

is

sufficient

if

its face

of

oil (Fig.4)

the

from

is

below underline

initial use around 200 hours, then

.--------------.

it

6)

of

the gauge.

operator should turn

Whenever oil feeding or exchanging

not

to

contanrinate V belt and rinring belt inside the machine.

procedure

6.

6-1

nCJture

medium weight

Genmm System

JCJpanese

(x)

needle and fabric causing stitch skipping, thread broken and the penetrated hole

of

oil filter, refer

Proper

Operation

Needle to Be Used,

The machine uses needles

of

sewing

System 9

Needles should

in

Fig 8 shows incorrect setting

While operating machine in high speed, due to the friction occurred between

off

the machine immediately, clean or exchange the filter.

of

oil, cleaning

to

Fig 7

Fitting

materiCJls

CJnd

medium heavy fabrics and #90 for heavy duty

be

must

65

set correctly facing their long slot

Of

Needle

of

Model UY 128 GAS. There are many sizes

be

selected. Generally, needle

70

10

of

needle.

of

and

(1)

filter, care must be taken,

As

for the remove

and

(2) Device

of

#65-75

75

11

to

wards operator, mark

is

80

12

Fig 7

of

needles.

the standard size for light Weight,

So

that suitable size

85

13

90

14

X 0 X

on

~ ~

~

...

to

the

the fabric will become much bigger, especially when compound thread and fabric

are used.

3

~Fig

8

Page 8

To

prevent from occurring above case, the machine

(l)

standardized

cooling (Fig.9)

To

achieve most efficient effect

Generally, we suggest

the,covers

If

these devices are not necessary,

tips

and thread

device-for needle thread lubrication and (2) device-for needle

of

them, check the oil amount and make feeding

to

touch them

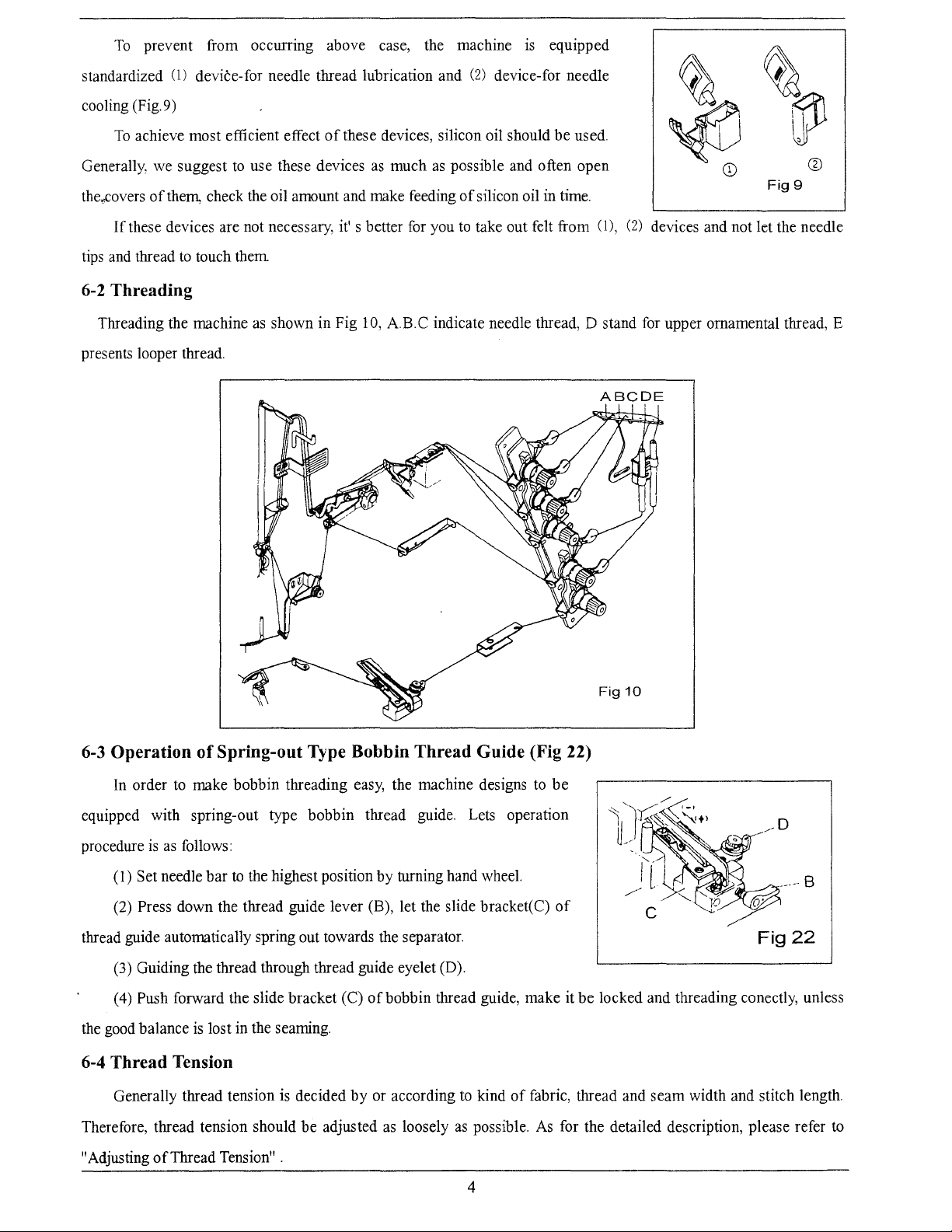

6-2 Threading

to

use these devices

is

equipped

of

these devices, silicon oil should be used.

as

much

as

possible and often open

of

silicon oil in time.

it's

better for you

to

take out felt from

~ ~

~w

CD

Fig

(l),

(2) devices and not let the needle

0

9

Threading the machine

presents looper thread.

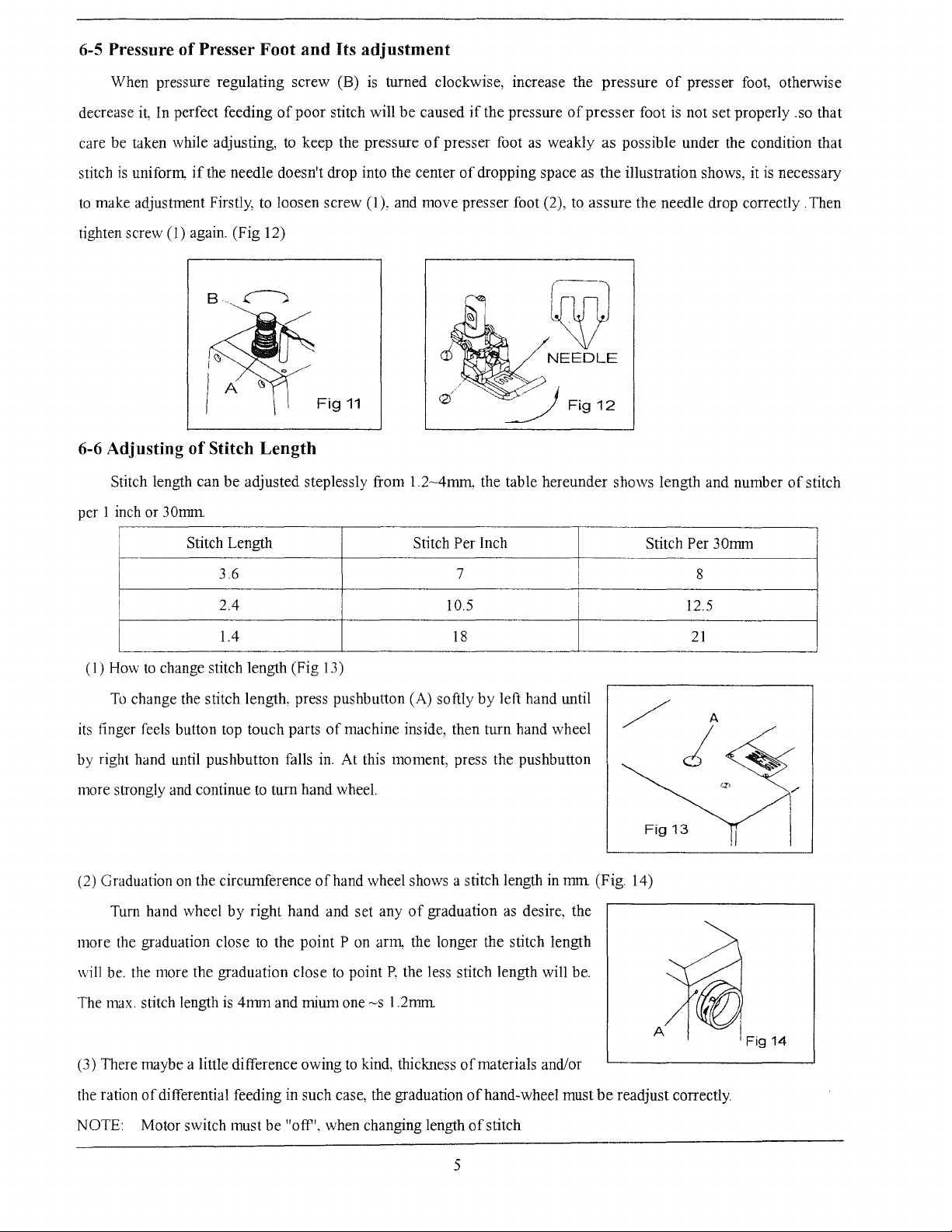

6-3 Operation

of

as

shown in Fig

10,

A

B.

C indicate needle thread, D stand for upper ornamental thread, E

Spring-out Type Bobbin Thread Guide (Fig 22)

ABC

Fig

DE

10

In

order

to

make bobbin threading easy, the machine designs

equipped with spring-out type bobbin thread guide. Lets operation

procedure

thread guide automatically spring out towards the separator.

the good balance

is

as

follows:

1)

Set needle bar

(

Press down the thread guide lever (B), let the slide bracket(C)

(2)

(3) Guiding the thread through thread guide eyelet (D).

(

4)

Push forward the slide bracket (C)

to

the highest position by turning hand wheel.

is

lost in the seaming.

of

bobbin thread guide, make it be locked and threading conectly, unless

to

be

of

6-4 Thread Tension

Generally thread tension is decided

Therefore, thread tension should be adjusted

"Adjusting

of

Thread Tension".

by

or according

as

loosely

to

kind

as

possible.

4

of

fabric, thread and seam width and stitch length.

As

for the detailed description, please refer

Fig22

to

Page 9

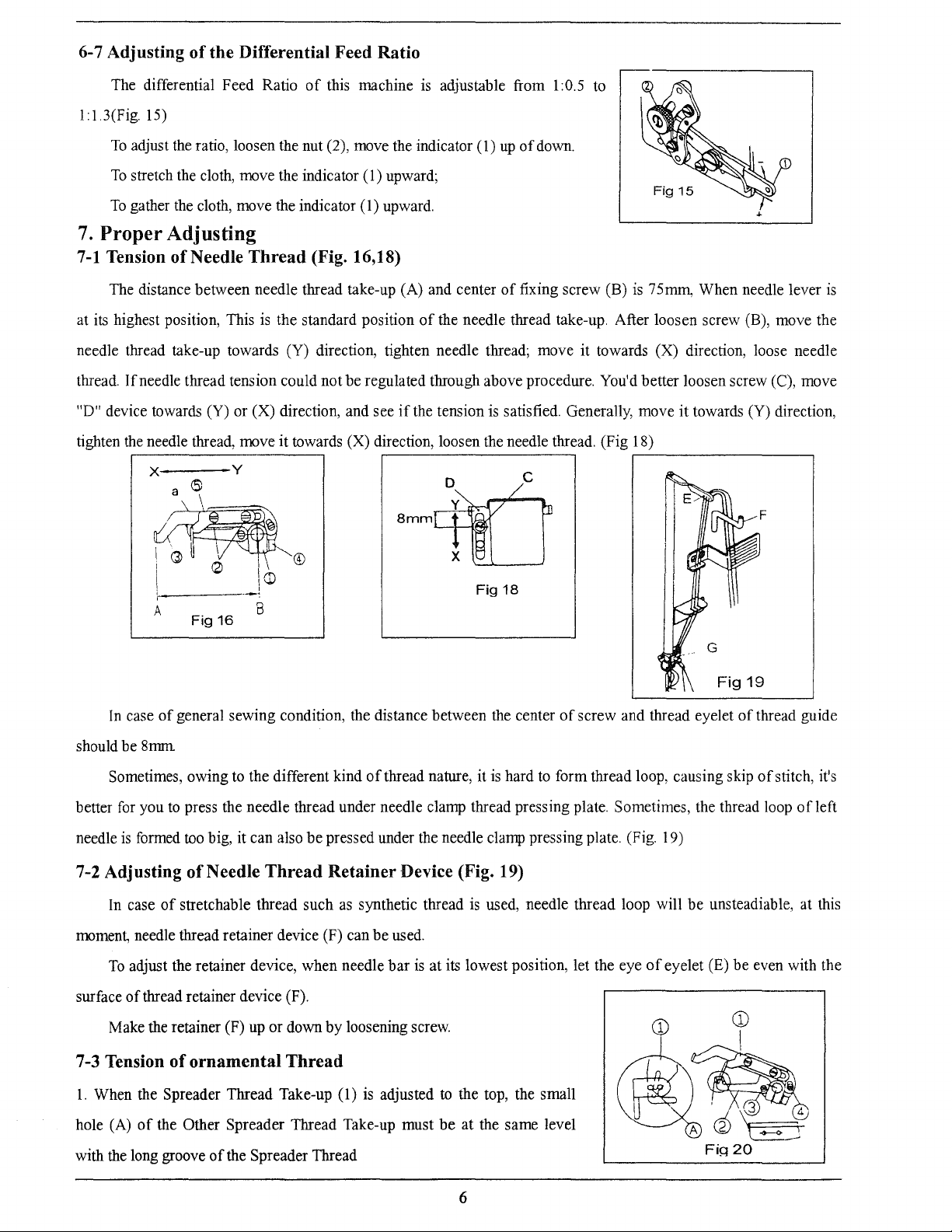

6-5 Pressure

of

Presser Foot and Its adjustment

When pressure regulating screw (B)

it,

decrease

care be taken while adjusting,

stitch

to

make adjustment Firstly, to loosen screw

tighten screw (1) again. (Fig 12)

6-6 Adjusting

per 1 inch or

In perfect feeding

is

uniform,

Stitch length can

if

the needle doesn't drop into the center

of

Stitch Length

30nnn

be

of

poor

to

keep the pressure

Fig

adjusted steplessly from

is

turned clockwise, increase the pressure

stitch will

(1

), and move presser foot (2), to

11

be

caused

1.2~4mm,

if

the pressure

of

presser foot as weakly

of

dropping space as

the table hereunder shows length and number

of

of

presser

assure

foot is not set properly .so that

as

possible under the condition that

the

illustration shows, it

the needle drop correctly . Then

[~

NEEDLE

presser foot, otherwise

is

necessary

of

stitch

Stitch Length

~

(I)

How

to

change stitch length (Fig 13)

To

change the stitch length, press pushbutton (A) softly

its finger feels button top touch parts

by right hand until pushbutton falls

more strongly and continue

(2) Graduation

Tum hand wheel

more the graduation close

will be. the more the graduation close

3.6

2.4

1.4

to

on

the circumference

by

right hand and set any

to

tum hand wheel.

ofhand

the point P on arm, the longer the stitch length

Stitch

Per Inch

7

10.5

18

by

left hand until

of

machine inside, then turn hand wheel

in.

At this moment, press the pushbutton

wheel shows a stitch length in

of

to

point

graduation

P,

the less stitch length will be.

as

desire, the

mm

Stitch

/ A

Fig

(Fig. 14)

Per 30mm

8

12.5

21

j

13

is

4mm

The max. stitch length

(3) There maybe a little difference owing

the ration

NOTE: Motor switch must

of

differential feeding in such case, the graduation ofhand-wheel must

and mium one

be

"off', when changing length

~s

1.2mm

to

kind, thickness

of

materials and/or

of

stitch

5

A

be

readjust correctly.

Page 10

6-7 Adjusting

of

the

Differential Feed Ratio

The differential Feed Ratio

1:1.3(Fig. 15)

To

adjust the ratio, loosen the nut (2), move the indicator (1)

To

stretch the cloth, move the indicator (1) upward;

To

gather the cloth, move the indicator (1) upward.

7.

Proper

7-1

Tension

The distance between needle thread take-up (A) and center

at its highest position, This is the standard position

needle thread take-up towards (Y) direction, tighten needle thread; move it towards (X) direction, loose needle

thread.

"D" device towards (Y) or (X) direction, and see

tighten the needle thread, move it towards (X) direction, loosen the needle thread. (Fig 18)

Adjusting

of

Needle

If

needle thread tension could not be regulated through above procedure. You'd better loosen screw (C), move

Thread

of

this machine is adjustable from 1:0.5 to

up

of

down.

(Fig. 16,18)

of

fixing screw (B) is 75mrn, When needle lever

of

the needle thread take-up. After loosen screw (B), move the

if

the tension is satisfied. Generally, move

it

towards (Y) direction,

is

.------------------,

X y

a

6:

D

c

~®

i

1 °

' '

A

Fig

In

case

of

general sewing condition, the distance between the center

should be 8nnn

Sometimes, owing to the different kind

better

for

you

to

press the needle thread under needle clamp thread pressing plate. Sometimes, the thread loop

needle

is

formed

7-2 Adjusting

In case

moment, needle thread retainer device (F) can

To

adjust the retainer device, when needle

surface

of

too

of

of

stretchable thread such

thread retainer device (F).

__

!

1m

8

16

big, it can also

Needle

Thread

be

pressed under the needle clamp pressing plate. (Fig. 19)

Retainer

as

X

Fig

of

thread nature, it is hard

Device (Fig. 19)

synthetic thread

be

used.

bar

is

is

at its lowest position, let the eye

18

of

screw and thread eyelet

to

form thread loop, causing skip

used, needle thread loop will

of

eyelet (E)

G

Fig

19

of

thread guide

of

stitch, it's

be

unsteadiable, at this

be

even with the

of

left

Make the retainer (F) up or down by loosening screw.

7-3 Tension

1.

When the Spreader Thread Take-up (1)

hole (A)

with the long groove

of

ornamental

of

the Other Spreader Thread Take-up must

of

the Spreader Thread

Thread

is

adjusted

to

the top, the small

be

at the same level

6

Page 11

2.

To

adjust, loosen Screw (3) and ( 4), and move the Spreader Thread Take-up (2) up or down, and then tighten

screw again. (Fig

7-4 Adjusting

The standard positioning is that eyes

supporting plate are aligned.

eyelets (F) and (G) move them towards direction (L), otherwise move them towards

direction (S) and retighten the fixing screws in time (Fig 21).

Please pay attention to that, too much plenty

stitch. In case

towards direction (L) and thread should not

plate (H) (Fig 21)

7-5 Positioning

The illustration shows thread take-up seen from side

position

looper thread take-up, let the looper thread cast

(J).little later. (Fig

by

20)

of

Tension

of

woly thread used, thread eyelets (F) and (G) must

of

Looper

mining hand wheel. When the needle

23

of

looper

To

get plenty

Thread

)

Thread

of

eyelet

F,

G,

of

casting thread, loosen fixing

of

casting thread will cause skip

be

pressed under small thread pressing

Take-up

bar

is

at the

off

from the top

and mark "0" on

of

needle bar. Lower the needle

half

position

of

cast

off

screw

be

set fully

of

looper, loosen screw (J), and move

looper take-up

of

of

cam

F

bar

from the highest

1,

then retighten screw

( i

r----ffi--

\ i /

\

1

/~

7-6 Removal

a.

Loosen regulating screw (B) and fixing screw (D)

b.

Push

the

To

fit

presser

a.

Press down presser foot lever (E), and fit on dresser foot.

b.

Keep a distance

and retighten presser foot stopper collar (C)

c.

Readjust stopper plate (A) and retighten the screw (B).

NOTE: The raising amount

necessary

and

presser foot lever (E) downwards, then presser foot can

foot:

of5mm

to

use the stopper collar (C).

_j

Fitting

between bottom face

of

~;

____

(

I~

__

_-

Fig

23

of

Presser Foot

as

show in the (Fig

presser foot

of

machines without ornamental thread looper

To

of

~@;~

<

"="

Fig24

remove presser foot:

of

toot stopper collar (C)(Fig 25)

be

removed.

presser foot and top face

25

Fig 26)

of

needle plate. Then fix the press foot

is

about 8mrn.and it

is

not

Fig25

Fig

26

\

Needle

7

>

Plate

5mm

Page 12

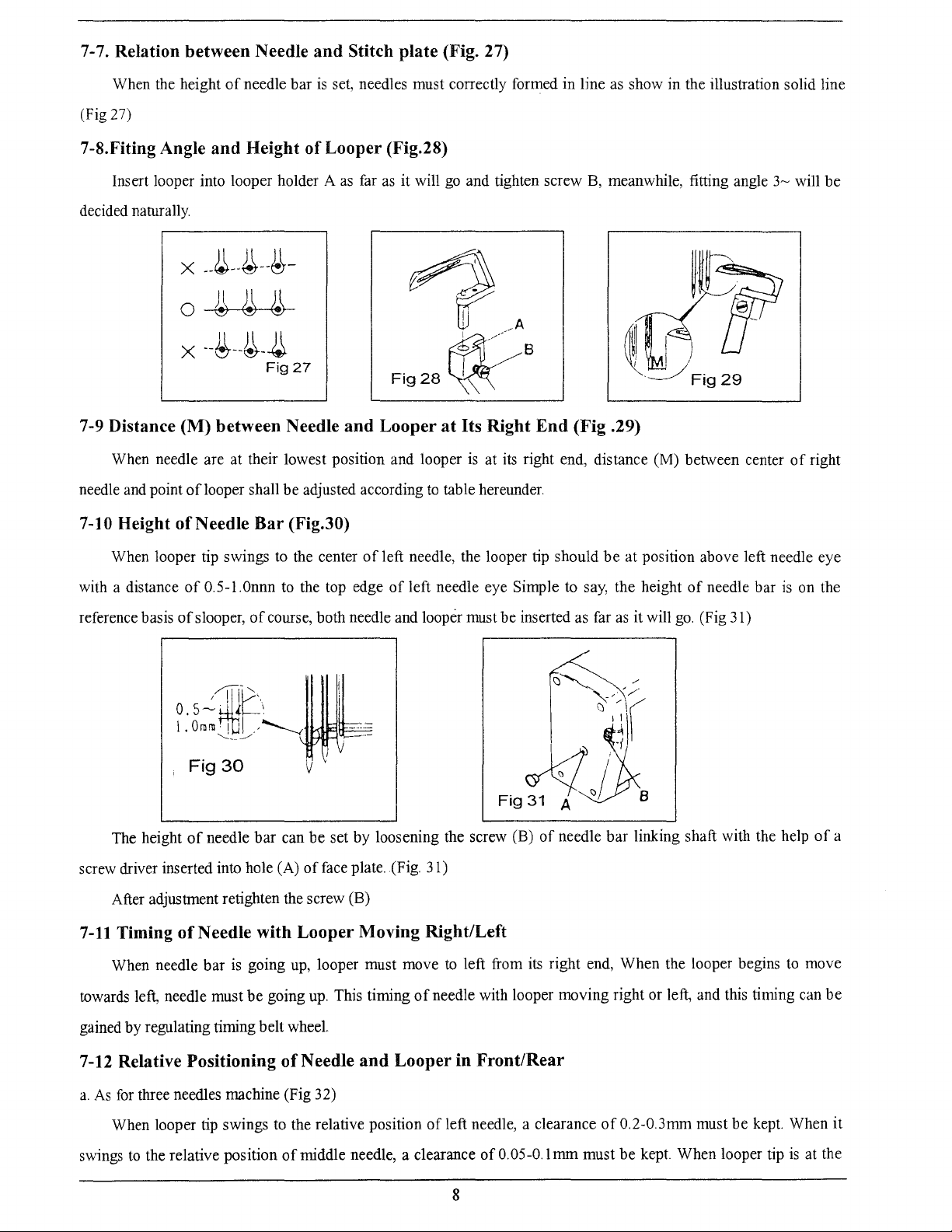

7-7. Relation between Needle

and

Stitch

plate

(Fig. 27)

When the height

(Fig 27)

7-8.Fiting Angle

Insert looper into looper holder A

decided naturally.

of

needle bar

and

Height

X

--~--4--~-

is

set, needles must correctly formed in hne

of

Looper (Fig.28)

as

far

as

it will go and tighten screw

~

0

~

~

~

. FA

X--~--~-~

Fig27

Fig28~

7-9 Distance (M) between Needle

When needle are at their lowest position and looper is at

needle and point oflooper shall be adjusted according

7-10 Height

ofNeedle

Bar

(Fig.30)

and

Looper

at

Its Right

to

table hereunder.

as

show in the illustration solid line

B,

meanwhile, fitting angle

8

End

(Fig .29)

its

right end, distance (M) between center

3~

will be

of

right

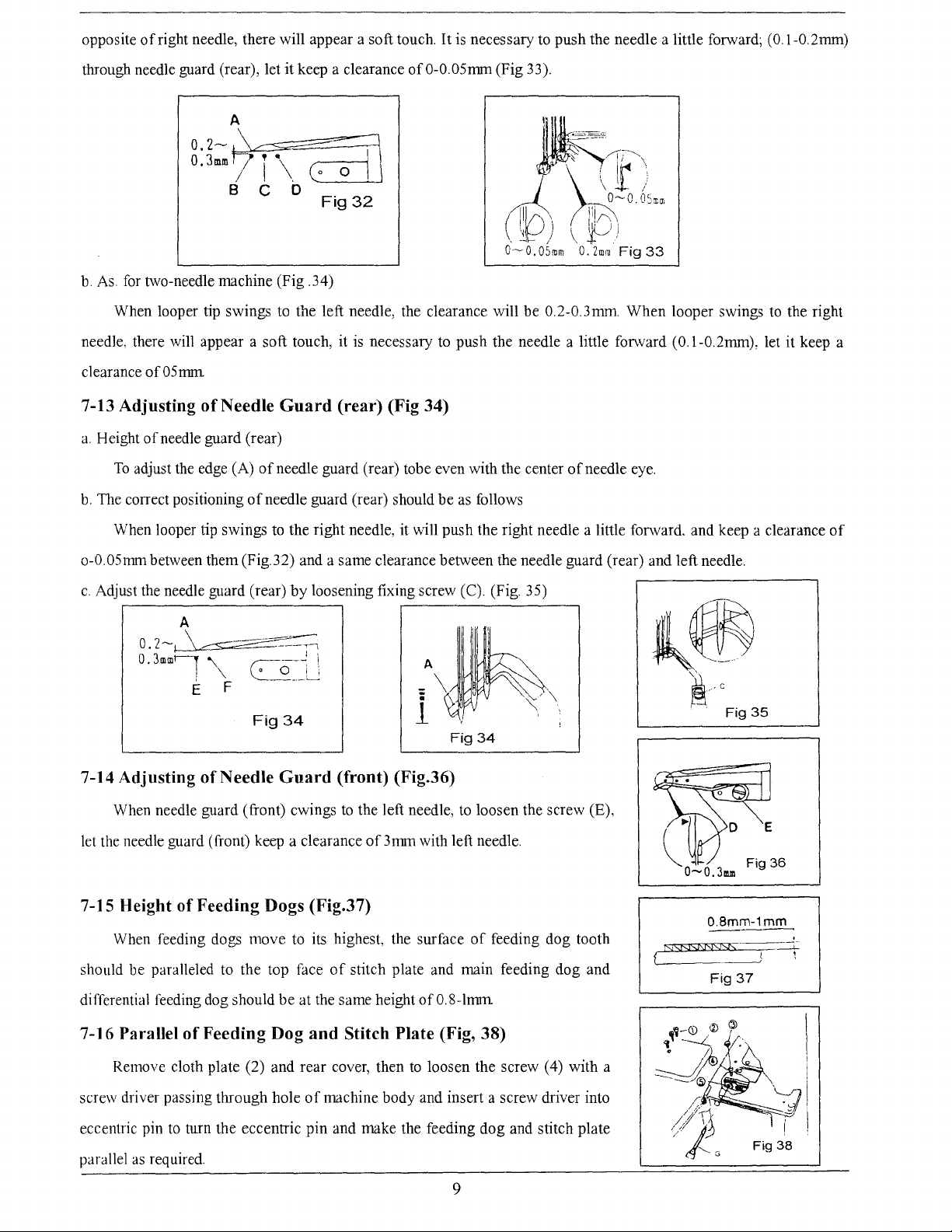

When looper tip swings

of

with a distance

reference basis

The height

screw driver inserted into hole (A)

After adjustment retighten the screw (B)

7-11

Timing

When needle bar

towards left, needle must

0.5-l.Onnn

of

slooper,

,

Fig30

of

needle bar can be set by loosening the screw (B)

of

Needle with

to

the center

to

of

course, both needle and looper must be inserted as far

is

going up, looper must move

be

going

of

left needle, the looper tip should

the top edge

of

face plate. (Fig. 31)

Looper

up.

This timing

of

Moving Right/Left

be

at position above left needle eye

left needle eye Simple to

to

left from its right end, When the looper begins

of

needle with looper moving right or left, and this timing can

say,

the height

as

it will

of

needle bar linking shaft with the help

of

go.

(Fig 31)

needle bar

is

to

on the

of

move

be

a

gained by regulating timing belt wheel.

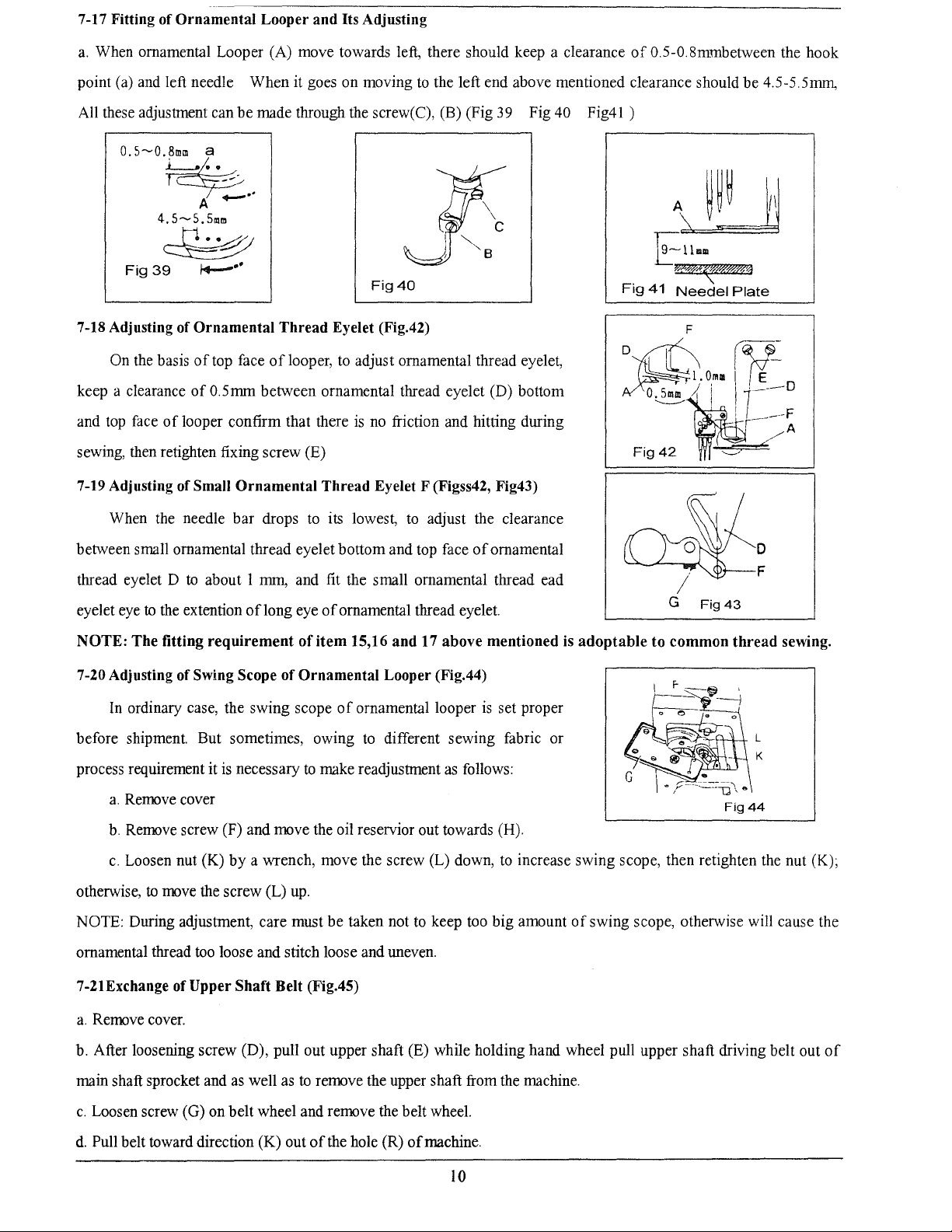

7-12 Relative Positioning

a.

As

for

three needles machine (Fig 32)

When looper tip swings

swings

to

the relative position

of

Needle

to

the relative position

of

middle needle, a clearance

and

Looper

in

Front/Rear

of

left needle, a clearance

of

0.05-0.1 mm must

8

of

0.2-0.3mm must be kept. When

be

kept

When looper tip

is

it

at the

Page 13

opposite

of

right needle, there will appear a soft touch.

It

is necessary to push the needle a little forward; (O.l-0.2mm)

through needle guard (rear), let it keep a clearance

A

of

0-0.05mm (Fig 33).

u:7f\7~ll

B C 0

b.

As

for

two-needle machine (Fig .34)

When looper tip swings to the left needle, the clearance will be 0.2-0.3mm. When looper swings

needle, there will appear a soft touch, it is necessary to push the needle a little forward (O.l-0.2mm), let it keep a

clearance

7-13 Adjusting

a.

Height

b.

The correct positioning

of05mm

ofNeedle

of

needle guard (rear)

To

adjust the edge (A)

of

of

needle guard (rear) should

Fig32

Guard (rear) (Fig 34)

needle guard (rear) tobe even with the center

be

as

follows

of

needle eye.

to

the right

When looper tip swings to the right needle, it will push the right needle a little forward, and keep a clearance

o-0.05nnn between them (Fig.32) and a same clearance between the needle guard (rear) and left needle.

c.

Adjust the needle guard (rear)

by

loosening fixing screw (C). (Fig. 35)

~~

Fig34

7-14 Adjusting

When needle guard (front) cwings

let the needle guard (front) keep a clearance

7-15 Height

When feeding dogs move to its highest, the surface

should be paralleled to the top face

differential feeding dog should

of

Needle Guard (front) (Fig.36)

to

the left needle,

of

Feeding Dogs (Fig.37)

of

stitch plate and main feeding dog and

be

at the same height ofO.S-lmm

of

3mm with left needle.

AJII~i

- \

- u

.

1

~

' '

Fig34

to

loosen the screw (E),

of

.

.

'\

~.

·,

feeding dog tooth

~.c

NSNSJSNSJSf>

L-----_j

Fig

O.Bmm-1mm

--

Fig

37

35

of

'

--L

~

7-16 Parallel

Remove cloth plate (2) and rear cover, then

screw driver passing through hole

eccentric pin

parallel

as

of

Feeding Dog and Stitch Plate (Fig, 38)

to

loosen the screw ( 4) with a

of

machine body and insert a screw driver into

to

turn the eccentric pin and make the feeding dog and stitch plate

required

9

Page 14

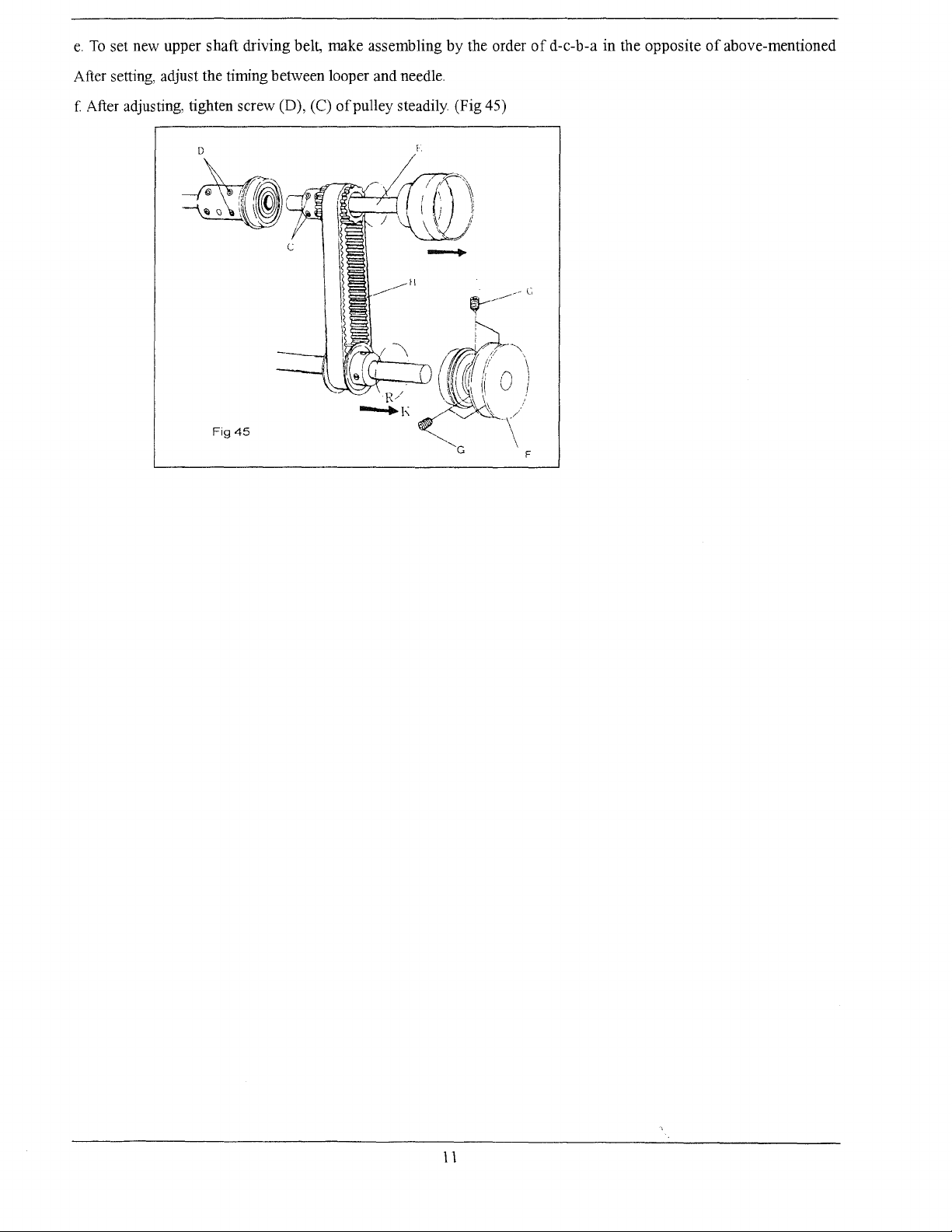

7-17 Fitting of Ornamental Looper and Its Adjusting

a.

When ornamental Looper (A) move towards left, there should keep a clearance

to

point (a) and left needle When it goes on moving

be

All these adjustment can

0.5~0.~

r~..--

A

4.5~5.51!lm

made through the screw( C), (B) (Fig

-··

the left end above mentioned clearance should be 4.5-5.5mm,

39

Fig 40 Fig41 )

of

0.5-0.Smmbetween the hook

A~

~

Fig

39

7-18 Adjusting of Ornamental

On the basis

keep a clearance

and top face

sewing, then retighten fixing screw (E)

7-19 Adjusting of Small

When the needle bar drops

between small ornamental thread eyelet bottom and top face

thread eyelet D

eyelet eye

NOTE:

7-20 Adjusting of Swing Scope of Ornamental Looper (Fig.44)

to

The

f.f-""

Fig40

Thread

of

top face oflooper,

of

0.5mm between ornamental thread eyelet (D) bottom

of

looper confirm that there

Ornamental Thread Eyelet F (Figss42, Fig43)

to

about 1 mm, and fit the small ornamental thread ead

the extention

fitting

oflong

requirement

Eyelet (Fig.42)

to

adjust ornamental thread eyelet,

is

no friction and hitting during

to

its lowest,

eye

of

ornamental thread eyelet.

of

item

15,16

and

to

adjust the clearance

17 above mentioned is

of

ornamental

Fig

D I

Fig

adoptable

E~llmm

*NM((W&&%'%1

41

Needel

Ll.O,u!

42

to common

F

'--'

Fig43

Plate

~

/E_~

0

/...-A

D

thread

sewing.

In

ordinary case, the swing scope

before shipment. But sometimes, owing

is

process requirement it

a.

Remove cover

b.

Remove screw (F) and move the oil reservior out towards (H).

c.

Loosen nut (K)

otherwise,

NOTE: During adjustment, care must

ornamental thread

7-21Exchange of

a.

Remove cover.

b. After loosening screw (D), pull out upper shaft (E) while holding hand wheel pull upper shaft driving belt out

main shaft sprocket and

c.

Loosen screw (G) on belt wheel and remove the belt wheel.

d.

Pull belt toward direction (K) out

to

move the screw (L)

Upper Shaft Belt (Fig.45)

necessary

by

a wrench, move the screw (L) down,

too

loose and stitch loose and uneven.

as

well

as

of

ornamental looper

to

different sewing fabric or

to

make readjustment

up.

be

taken not

to

remove the upper shaft from the machine.

of

the hole (R)

to

keep too big amount

of

machine.

as

follows:

is

set proper

to

increase swing scope, then retighten the nut (K);

Fig44

of

swing scope, otherwise will cause the

of

10

Page 15

e.

To

set new upper shaft driving belt, make assembling

After setting, adjust the timing between looper and needle.

by

the order

of

d-e-b-a in the opposite

of

above-mentioned

f After adjusting, tighten screw (D), (C)

0

of

pulley steadily (Fig 45)

11

Page 16

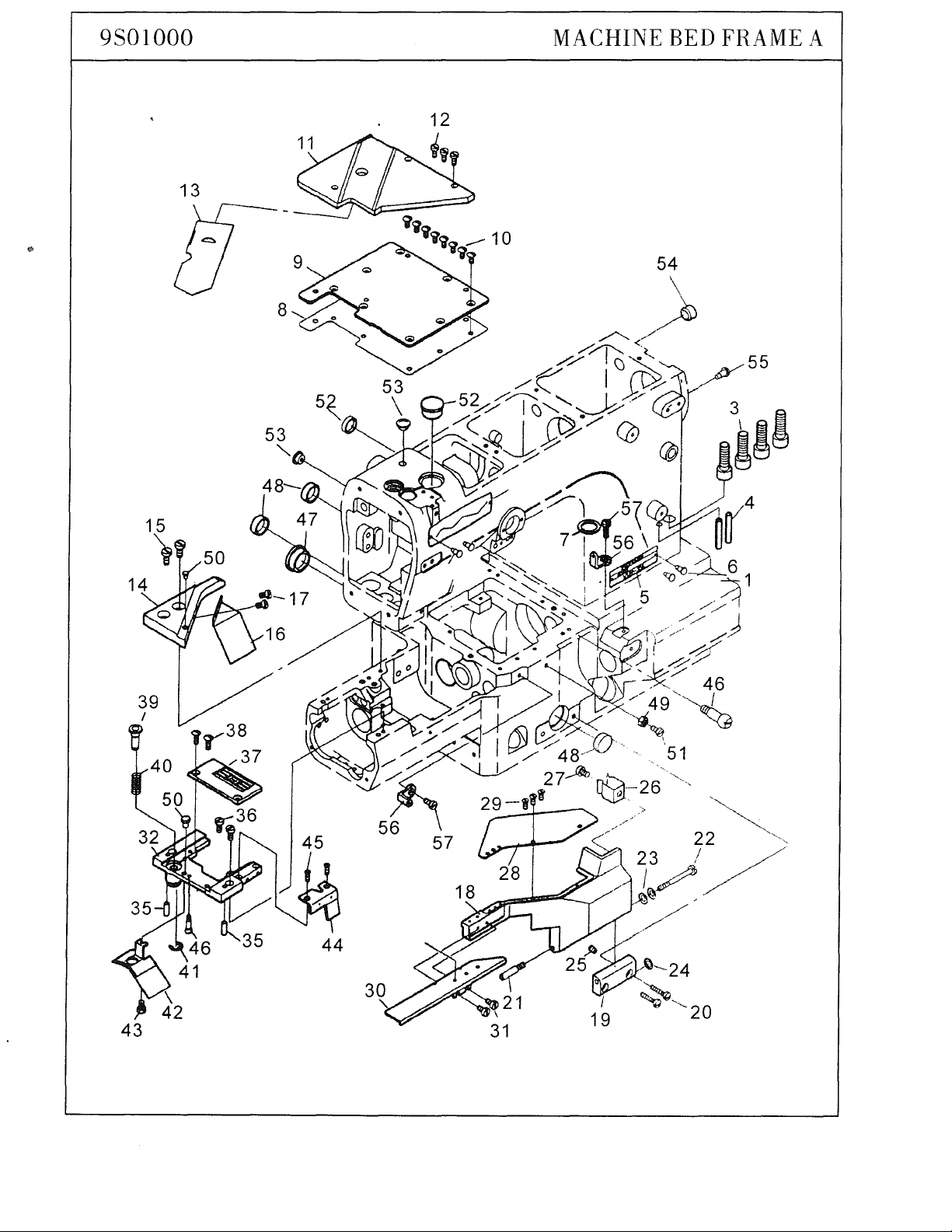

9S01000

13

53

"'

MACHINE

BED

FRAME

55

A

43

Page 17

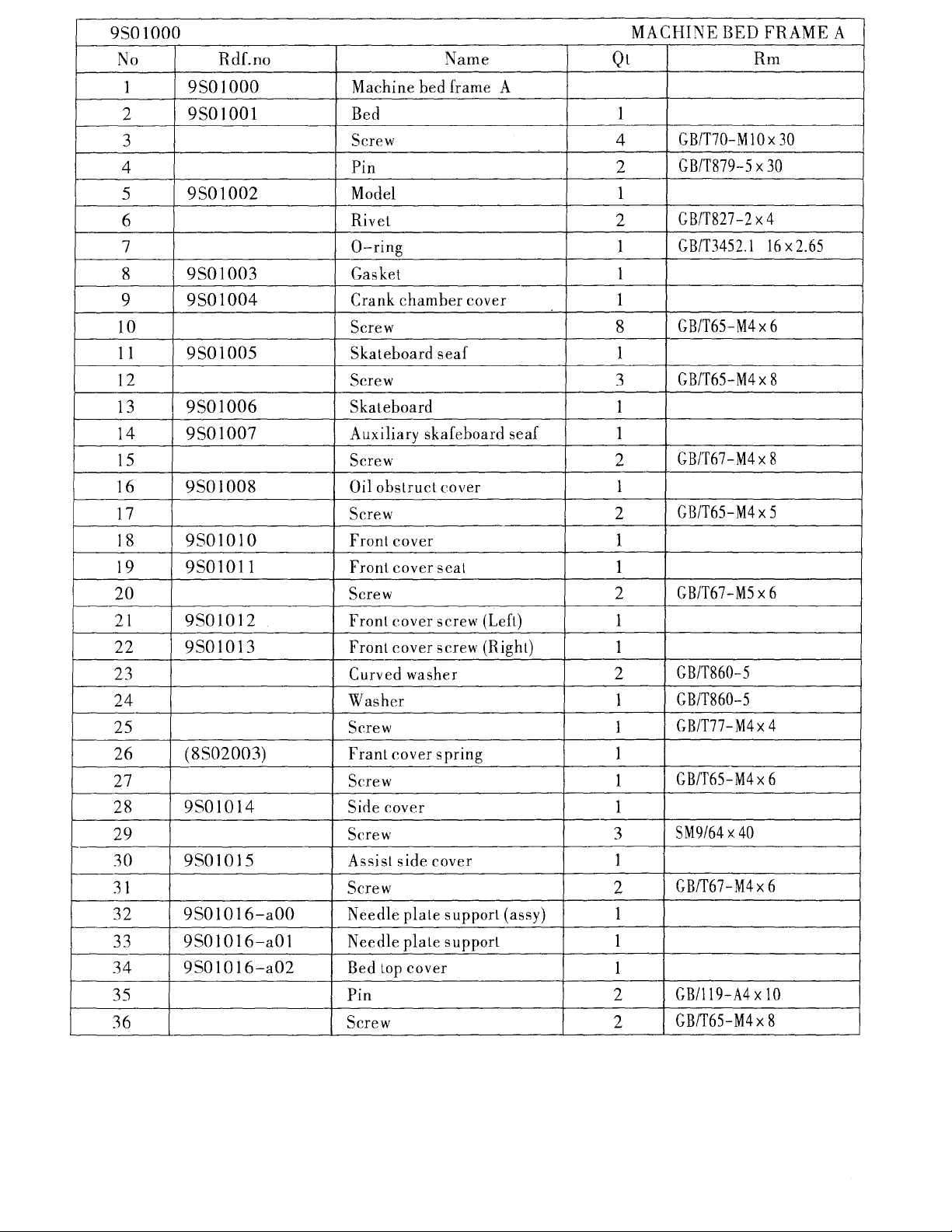

9S01000

No

Rdf.no

Name Qt

MACHINE BED FRAME A

Rm

Machine bed frame A

Screw 4

Pin 2

Model 1

Rivet

0-ring

Gasket 1

Crank chamber cover

7

9

4

5

6

8

1

2

3

9S01000

9S01001 Bed

9S01002

9S01003

9S01004

10 Screw 8

11

12

13

14

15

16

17

9S01005

9S01006

9S01007

9S01008

Skateboard seaf 1

Screw

Skateboard

Auxiliary skafeboard seaf 1

Screw

Oil obstruct cover

Screw

2

2

2

1

1

3

1

1

1

GB/T70-M10x30

GB/T879-5 X 30

GB/T827-2

GB/T3452.1

X 4

16x2.65

GB/T65-M4x6

GB/T65-M4x

GB/T67-M4

8

X 8

GB/T65-M4x5

18

19

20

21

22

23

9S01010

9S01011 Front cover seat

9S01012

9S01013

Front cover 1

Screw 2

Front cover screw

(Left)

Front cover screw (Right)

Curved washer

24 Washer 1

25

26

(8S02003) Franl cover spring 1

Screw

27 Screw 1

Sirle

28

29

30

31

32

33

34

35

36

9S01014

9501015

9501016-aOO Needle plate support (assy) 1

9S01016-a01

9S01016-a02

cover

Screw 3

Assist side cover 1

Screw 2

Needle plate support 1

Bed

Lop

cover

Pin

Screw 2

2

1

1

2

1

1

1

1

GB/T67-M5

X 6

GB/T860-5

GB/T860-5

GB/T77-M4x

GB/T65-M4x

SM9/64 X 40

GB/T67-M4x6

GB/119-A4x

10

GB/T65-M4x

4

6

8

Page 18

9501000

No Rdf.no

37

38

39

40

'9501017

(8510032)

9501018

9501019

41

42

9S01020-b00

43

44

9501021

45

46

47

48

9S01022

9501023

9S01024

49

50

(8510030)

51

52

53

54

(8S03009)

(8S0400

(8503001)

55

56

(8513004)

57

1)

Name Qt

Needle plate

Screw 2

Feed regulating pushbutt

Pushbutton spring

"E"ring

Oil protector plate

Screw

Stuff Obstruct cover

Screw

Screw

Seal plug

Seal plug

Nut

Cushiow rubber

2

2

1

3

1

2

Screw 1

2

2

2

Rivet

1

2

2

MACHINE BED

1

SM9/64 X 40

1

1

1

GB/T896-3.5

1

1

GB/T65-M4x4

1

GB/T68-M3

M4

<(>29.5

<f>20.1x7

GB/T6172-M4

GB/T65-M4x

<(>19

<(>7.5

<!>

10.8

GB/T827-2

GB/T67-M4

X 9

FRAME

Rm

X 9

X 6

16

X 8

X 5

A

Page 19

9S02000

47

1

44

-,

MACHINE

BED

FRAME B

r\?

45

48,~

~

I

:

I

5

15

19

I

1

13

i -

~/v

~

3

30

7~

Page 20

9S02000

No

Rdf.no Name

MACHINE BED FRAME B

Qt

Rm

1

2

9S02000

9S02001

3

4

9S02002

5

6 9S02003

7

8

9

10

9S02004

9S02005

9S02006

II

12

9S02007

I3

I4

9S02008

I5

I6

I7

9S02009

9S020IO

I8

I9

9S020II

20

Machine

Dust

proof

Screw

Pulley

Screw

Side

cover

Screw

Gasket

Side

cover

Side

cover

Screw

Side

cover

Screw

Smail

sewing

Screw

Side

cover

Oil

obstruct

Screw

Silicon

Screw

bed

plate

cover

seat

pin

upper

spring

oil

guide

frame

desk

cover

plate

rack

B

1

3

1

3

1

4

1

1

1

I

1

2

1

2

I

I

I

1

I

GB/T67-M4

X 5

GB/T67-M4 X 50

GB/T65-M4x

GB/T77-M4

GB/T67-M3

GB/T65-M4

GB/T65-M4

GB/T65-M4

10

x 5

X 5

X 5

X 5

X 8

2I

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

9S020I2

9S020I3-a00

9S02013-a01

9S020I4

9S020I5

9S02016

9S02017

(

8Sl4019)

(

8S14020)

(8S14021)

(

8S14022)

Silicon

Seal

plug

Lower

Lower

Lower

Screw

Screw

Oil

reservoir

Oil

reservoir

Screw

Washer

Press

plank

Screw

Magnet

Screw

Washer

oil

felt

silicone

silicone

silicone

oil

oil

oil

gasket

reservoir

reservoir

cover

inlaid

2

2

4

4

2

I

I

1

1

1

1

1

1

1

1

1

<!>2.5

GB/T65-M4

X 8

SM3/8 X 28

GB/T67-M4x

10

GB/T70-M8 X 25

GB/T848-8-140HV

Page 21

9S02000

No

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

Rdf.no Name

Spring washer

il

tube

9S02018

0

Screw

Oil

9S02019

( 9S02022)

9S02020

(8S01001)

(8S01

008)

sight gauge

Screw

Series

Top

cover

sight

Oit

plafe

Screw

Face plate

Screw

Screw

Screw

(8S01

002)

(8SOJ001-a01)

Shoulder

Needle bar take-up cover

Curved washer

(8S01015)

(8S01012)

(8S01

013)

(8S01016)

Needle thread

0-ring

0-ring

Arm

Pin

Washer

(8S01

009-h01) Silicone

Screw

Screw

(

8SO

1009-h03)

Upper

silicone oil reservoir

Screw

Silicone Lake-up bracket

(

8SO 1 009(8S01014)

(8S01

(8S01001-a04)

(8S01001-a03)

(8S0100I-a02)

006)

b04)

Thread guide

Take-up cover screw

Take-up cover

Shelter

Safety

Safety

cover

plate holder

plate support

Screw

(8S01019)

Seal

plug

Screw

Pin

part.i

tion plank

window

screw

oil

thread

guicle

MACHINE BED FRAME B

Qt

2

2

FB/T859-8

1

GB/T67-M4

Rm

X 5

1

1

M4

1

1

1

5

4

2

2

2

GB/T67-M4 X 20

GB/T67-M4 X 20

GB/T3452.1-15x

GB/T65-M4 X 20

GB/T65-M4 X 20

1.8

1

1

1

GB860-87-5

1

1

1

I

2

1

GB119-86

A2x6

GB848-85-4

1

2

2

GB65-M4 X 10

GB65-M4x10

I

2

2

GB67-M3

GB67-M3

X 5

X 5

3

2

1

I

1

I

3

1

1

1

GB80-M3

<!>

8.8

GB80-M4

X 4

X 6

Page 22

8S08000

UPPER SHAFT MECHANISM

/

/ 6

\

15

///

/

I

I

I

L

I

24

Page 23

8S08000

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

I9

20

21

22

23

24

25

26

Rdf.no

8S08001-a00

8S08001-a03

8S08001-a02

8S08002

8S08004

8S06018

8S08006

8S08012

8S08007-c00

8S08009

8S08005

8S08003-b00

8S080I1

8S080IO-d00

(9S03002)

Mction

Screw

Screw

Bsll

Upper

Screw

Upper

Balance

Screw

Joint

Screw

Upper

Ball

Upper

0-ring

Sqrocket

Take-up

Connecting

Screw

Upper

Hand

Washer

Screw

Screw

Screw

Timing

assem

bearing

shoft

shoft(front)

weight(upper)

shaft

bearing

shaft

ball

shaft(rear)

wheel(assy)

belt

Name

bly(assy)

front

middle

middle

wheel(lower)

rod(assy)

bushing

crank

UPPER

Qt

1

2

2

2

1

4

1

1

2

(1)

2

I

2

2

4

1

1

I

4

1

1

1

I

12

1

( 1 )

SHAFT

MECHANISM

Rm

GB/T67-M5X

M6X0.75X

600422

GB/T78-M6X

GB77-85-M5

M6X0.75X

620422

12

12

20X42X12

8

X5

15

20X47X

GB/T3452.1-36.5 X I.

GB/T70-M4X

14

GB/T95-5

GB/T67-M5X

14

GB/T77-M6X5

GB/T77-M6X

8

220XL-075

14

8

Page 24

8S09000

NEEDLE

SPREADER

THREAD

MECHANISM

I

21

23

012

Page 25

8Sll000

No

37

Rdf.no

8S11026

Screw

Name

PRESSER FOOT MECHANISM

Qt

3

SM11/64"X

Hexagon

Rm

40X5-

socket2

38

39

40

41

42

43

44

45

46

47

8S11030

8S

11031

8S11032

8Sl1025

8S

11

034-fOO

Screw

lifter

lever

Screw

Lever

Lever

Nut

Screw

Lever

Screw

Washer

seat

seat bushing

stop

2

2

1

1

1

1

1

1

1

1

SM11/64"X40X

Hexagon

GB/T5781-MSX20

GB/T6170-M5

GB/T70-MSX

GB/T65-M4X

GB/T848-10

12.5-

10

10

Page 26

8Sl2000

THREAD TENSION

\

20

MECHANISM

18

\

/('~

14

/~

16

(1)~

4

( 1 )

1

Page 27

8S12000

No

1

2

3

4

5

6 8512006

7

8512001-aOO

8512002

8512003

8512008

8512005

8512007

8 8512019

9

10

11

12

13

14

15

8512020

8512021

8512011

8512009

8512012

8512014

8512004

16

17

18

8512010

8512013

19

20

21

22

23

8512016

24 8512015

25

26

8512017

8512018

27

28

Rdf.no

Name

Post

nut

(assy)

Spring

Tension

Tension

Screw

bushing

spring

post

stud

Felt

Tension

Thread

Thread

dise

guide

eyelet

Latch

Thread

Tension

Tension

guide

dise

post

Repositioning

Cup

Screw

Tension

dise

Pin

Screw

Screw

Screw

Washer

Collar

Lever

Splashier

oil

Crank

Screw

Pin

collar

plate

pine

separtor

support

spring

eyelet

pipe

THREAD

Qt

5

5

5

5

5

5

10

I

2

2

5

1

I

I

5

2 GBff65-M4 X 8

5

1

2

2 GBff65-M4 X 5

1

I

I

I

I

I

I

I

TENSION

cpl

x3,

GBff65-M4

GBff65-M4

GBff97.1-8

GBff70-M5 X

GBff119-D5 X

MECHANISM

Rm

cp0.6x2

X 8

X

16

16

18

Page 28

9S03000

MAIN

SHAFT

22

AND

LOOPER

THREAD

MECHANISM

4

29

61

62

63

64

35

65

45

41

Page 29

9S03000

No

1

Rdf.no Name

Main

9S03000

shaft

and

looper

MAIN

thread

SHAFT

mechanism

AND

LOOPER

Qt

THREAD

MECHANISM

Rm

2

3

9S03001-a00

9S03001-a01

Sprocket wheel

Sprocket wheel

asm

4 Screw 1

5

6

7

8

9

10

11

12

9S03001-a02

9S03002

9S03003

9S03004

9S03005

9S03006

Ward slice

Upper Sprocket wheel

Screw 4

Timing belt

Balance weight

Screw

Lower shaft (Right) 1

Joint

13 Screw 2

14

15

9S03007 Lower shaft

16 9S03008

17

9S03009

18 9S03010 Oil wick

Screw 2

(Left)

Oil wick (Left)

Oil wick (Short)

(Long)

19 9S03011 Oil wick (Short)

20

21

22

23

24

25

26

9S03012

9S03013

9S02014-b00

9S02014-b01

9S02014-b02

9S02014-b03

Lower bushing (Center)

Large

ward

plate

Screw

Pulley wheel (assy)

Pulley wheel

Sprocket wheel

Sprocket wheel

key

1

1

2

1

1

1

2

1

1

1

5

2

1

1

1

2

1

1

1

1

GB/T80-

M6

GB/T80-M6

220XL-075

GB/T80-M5

GB/T80-M5

GB/T80-M5

4>2x3

4>2x

60

4>

2 X

15

GB/T67-M4

X 5

X 5

X 5

X 4

X 5

X 6

27

28

29

30

31

32

9S02014-h04

9S03015

9S03016-c00

9S03016-e01

9S03016-c02

Screw

Screw

Timing belt

Sprocket wheel (assy) 1

Cam

sproeket_wheel

Ward slice

33 Screw

34

35

36

9S03017

9S03018

9S03019

Cam

shaft

Wasket 2

Ball bearing

2

2

1

1

1

1

1

1

M6

GB/T80-M6

GB/T80-M5

6200ZE

4>30 X 4>

X 6

X 6

10

X 9

Page 30

9503000

No

MAIN

Rdf.no Name

SHAFT

AND

LOOPER

Qt

THREAD

MECHANISM

Rm

37 9S03020

38 9S03021

39

40

41

42

43

44

45

46

9S02022

( 8S07005)

9S03023

9S03024-d00

9S03024-d01

9S03024-d02

9S03025

9S03026

47 9S03027

48

49 9S03028

50

51

52

( 8S13005)

(8S13010)

53

54

55

56

57

58

(8S09010-c03)

(8S090 1 O-c04)

(8S090 1 O-c05)

(8S090 1 O-c02)

59

60

61

9S03029-e00

62 9S03029-e01

63

64

9S03029-e02

9S03029-e03

65

66

9S03030

67

68

( 9S05016)

69

70 (8S060

11-eOO)

71

72

0-ring

Cam

bushing

Collar

Screw

Lower thread guide

Left thread bracket

Thread guide pad guide

Lower

Screw

Wasket

Adjusting thread plate

Screw

Lock

Screw

Right thread guide

Left thread guide

Wasket

Screw

Screw

Nut

Tension spring

Tension disc

Screket

Wasket

Looper thread

Looper thread

PartiLing collar

Cam

Screw

Small

Screw

Oil Seal

Screw

Worm

Ball bearing

0-ring

thread bracket

spring

cam

cam

disc bushing

Guard

asm

(assy)

disc

2

2

1

2

1

1

2

1

1

2

1

2

1

1

1

1

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

cj>28.7 X cj>

SM1/8x44

M4

(GB/T955-6)

GB/T65-M4

GB/T65-M4

GB/T848-2.5

GB/T65-M2.5

GB/T67-M4

GB/T848-4

GB/T80-M5

GB/T67-M4

GB78-85-M6

6200ZZ

GB/T80-M6

1.3

X 4

X 4

X 8

X 6

X 6

20 X 52 X 15

X 5

X 4

x 6

Page 31

8S09000 NEEDLE SPREADER THREAD MECHANISM

No

1

2

3

4

5

6

7

8

9

10

1 1

12

13

14

15

16

17

18

19

20

21

22

23

Rdf.no

8S09004

8S09005

8S09006

8S09007

8S09008-b00

8S09002

8S09003

8S09001-a02

8S09001-a01

8S09001-a03

8S09010-c06

8S090

10-cO

8S09010-c03

8S09010-c02

8S09010-c05

8S09010-c04

8S09009

Driving

Rear

Collar

Front

Oil

seal

Thread

Screw

Thread

Washer

Screw

Washer

Screw

Thread

Thread

Bracket

Top

cover

Supplementary

1

Tension

Tension

Tension

Nut

Scrlew

Thread

bushing

Name

shaft

bushing

set

(assy)

guide

guide

take-up

take-up

thread

post

disc

spring

guide

guide

thread

guide

Qt

1

1

1

1

2

1

5

1

1

1

4

4

1

1

1

1

1

1

2

1

1

I

1

Rm

GB/T65-M4X6

GB/T93-5

GB/T70-

:\15 X 16

GB/T97.1-4

GB/T65-M4X

10

SM9/64"X40

GB/T65-M4X6

'

Page 32

8S10000

4

\.

NEEDLE

BAR

MECHANISM

/

16

19

/

\

22

\

24

52

\

2

Q

"---56

I

31

38

Page 33

8SIOOOO

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Rdf.no

8S

10011

8S10025

8S10003

8S10006

8S10007

8S10009

8S10010

8S10008

8SI0002

8S10023

8S10014

8S10038

8S10012

Driving shaft 1

Catch 1

Driving shaft bushing(left) 1

Screw

Oil wick

Screw

Screw

Adjusting lever

Driving

Collar

Screw

Screw

Nut

Washer

Rocking arm

Rocking

Screw

Thread

Needle

Crankshaft

Name

shaft bushing( right)

pin

guide

bar

8Sl0005 Connecting rod

8S10004

8S10027

8S10024

8S10022

8SI 0039

8S10028

8SI0029

8S10036

8S10034

Eccenting cam

Spreader

Oil seal

0-ring

Collar

Screw

Screw

Screw

Oil wick

Spieader

Spieader

Screw

Needle

Thread

Needle

Needle clamp

bushing

holder

guide

clamp eyelet

NEEDLE

Qt

2

1

1

1

I

1

I

1

2

1

1

1

1

2

2

1

1

1

1

1

1

I

1

2

1

1

1

1

1

1

3

1

1

1

BAR

MECHANISM

Rm

GB/T119-D5X14

GB/T80-M6X6

¢3X

15

GB/T67-M3

GB/T77-M5

M6

0.75X

X6

X4

15

GB/T6170-M5

GB/T95-5

GB/T65-M4X10

GB/T3452.1-10.6X

GB/T80-M4X4

SMII/64"

40X

10.5

GB/T70-M5X12

¢3X

15

SMI/8"44X4

UYI28GAS-11

4.8,5.6,6.4

1.8

Page 34

8S10000

NEEDLE

BAR

MECHANISM

No

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Rdf.no

8S10019

8S10018

8S10017

8S10016

8S10035

8S10021-a00

8S10020

8S10040

8S10046

8Sl0044

8Sl0042

8S10043-b00

8Sl0045

8S10013

8S10015

8S10026

ScrewApring

Latch

Thread

Screw

"E"ing

Oil

Needle

Needle

Needle

Connecting

Connecting

Needle

Needle

Oil

Screw

Needle

Ncrew

Sponge

Screw

Washer

guide

ring

bar

bar

bar

bdaring(assy)

bdearing

wick

plate

bar

Name

bushing

bracket

bushing(upper)

rod

rod

guide

(lower)

pin

washer

Qt

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

3

1

1

1

2

1

Rm

SMl/8"44-(1.58)

Hexagon

GB/T895.1-12

Kt8X

GB/T65-M4Xl2

GB/T65-M4X5

GB/T77-M5X5

GB/T861.2-3

socket1.58

12X

12

Page 35

8S11000

1

PRESSER

FOOT

MECHANISM

8

__

.-12

I

13""~

I

22

Page 36

8SIIOOO

PRESSER

FOOT

MECHANISM

1---·

No

IO

11

12

13

14

15

I6

I7

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

6

7

8

9

2

3

4

5

1

Rdf.no Name

8S

11001

8S

11002

8S

11

004-aOO

8Sll

005

8S11012

8S11003

8S11006

8S11011

8S110IO

8S11008

8S11009

8S1I013-h00

8S11014

8S11015

8S

I1

007

8S11016

8S1I017-cOI

8S

11017

-cOO

8S110I8-d00

8S11019

8SI1020

8S1I021

8S

11022

8SII023

8SI1029

8S

I1

024

8S

11

033

-eOO

8S

11

033

-e02

8S11028

8S11027

Adjusting

Lock

nut

Presser

Screw

Pin

Shouider

Outer

Presser

Lifter

Screw

Screw

Inner

Oil

Presser

Oil

Collar

Screw

Presser

Finger

Screw

Presser

Screw

Lifter

Pin

Spring

Collar

Screw

Rubber

Caller

Washer

Lifter

Lever

Interrupt

Screw

Correcting

Shouider

spring

link

spring

protector

seal

guard

shaft

lever

Screw

bar

guide

Screw

bar

clamp

ring

bar

bushing

bar

foot

complete(assy)

(assy)

washer

lump

plate

Screw

(assy)

Qt

1

1

1

1

1

2

1

1

I

2

1

1

1

1

I

I

2

1

1

I

1

1

1

1

1

1

2

2

I

2

2

1

1

1

I

2

Rm

M16XI

MI6XJ

SMI

J/64"X40

GB/T879-3X

SM3/16"X32

GB/T65-M4X20

GB/T70-M5X8

SM/8"

X 44-( I

Hexagon

SM9/64" X 40X8

GB/T65-M3X6

GB/T879-4X

SM9/64"X

GB/T97.

SMI

1/64"X40X8

SMII/64"X40

12

.58)

socketl.58

16

40X6

I -4

Page 37

9S03000

No

MAIN

SHAFT

AND

LOOPER

Rdf.no Name Qt

THREAD

MECHANISM

Rm

73

74

75

76

77

78

79

Screw

9S03031 Lower shaft bearing (Right)

0-ring

8S06014-h00

Lower shaft bearing (Rear)

Ball bearing

Thrust coller

Screw

4

1

2

1

2

1

1

GB/T80-M6

6004ZZ

X 5

20 X 42 X 12

GB/T4352.1-31.5 X 1.8

6304ZZ

GB/T80-M6

20 X 42 X 12

X 5

Page 38

9S04000

36

i

~

33

'

LOOPER

\

MECHANISM

26

-

11

9

~

~10

'

24

41

47

50

47

Page 39

9S04000

No

Rdf.no

Name

Qt

LOOPER

MECHANISM

Rm

5

6

7

8

9

IO

11

12

13

I4

15

16

17

18

I9

20

2I

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

2

3

4

1

9S04000

9S04001

9S04002

9S04003

9S04004

9S04005

9S04006

9S04007

9S04008

9S04009

9S04010

9S040

11

9S04012

9S040I2

9S04013

9S04014

9S04015

9S040I6

9S04017

9S04018

9S04019

Looper mechanism

Looper

Screw

Looper Seat

Screw

Gasket

Looper seat shaft

Bushing

Screw

Looper thread eyelet

Screw

Oil pipe

Oil wick

Washer

Looper front

rear

rocker

Slider holder

Screw

Slider

Screw

Screw gasket

Reduce gasket

Reduce

Reduce gasket

washer

holder

Screw

Bushing

Screw

Pin

Pin

Screw

Washer

Nut

Washer

Looper rocker

connecting

Needle bearing

Eccentric

Screw

roc

2

2

2

1

1

1

1

I

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

I

1

1

1

I

1

1

1

1

GB/T70-M4x

10

GB/T80-M6x6

GB/T67-M4x

GB/T879-

<j>

3 X

50

<P

5

4 X

GB/T67-M4 X 12

GB/T80-M4

GB/T67-M4x

X 4

12

GB/T80-M6x6

GB/T879-

<P

1.5

GB/T67-M5 X 30

GB/T6175-M5

GB/T972-5

26 X 30 X 12.5

GB/T80-M5

X 5

14

X 4

Page 40

9504000

No

Rdf.no

Name

Qt

LOOPER

MECHANISM

Rm

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

9504020

9504021

9S04022

9S04023

8S06006-b01

9S04024

9S04025

9S04026

9S04027

9S04028

9504029

9504030

9504028

( 9SOI

024)

Looper Connecting rod

Screw (upper)

Oil splasher

Screw (Lower)

"U" Guide fork

Screw

Looper ball crank

Screw

Looper rocker bar

Screw

Thrust roller bearing

Thrust plate

Looper shaft

Front bushing

Rear bushing

Oil wick

Oil plug

2

2

2

3

2

1

1

1

1

1

1

1

1

1

1

1

1

GB/T67-M3

GB/T70-M6x

X 6

0.75 x 10

GB/T70-M6 X 0.75 X 14

<j>4x

100

<j>20.1x7

Page 41

9S05000

DIFFERENTIAL

CONTROL

4

MACHANISM

~8

20 I ' 15

'I / /

!::J

~·

"""',

~'

/

J,

it19

(.,/

~

21

4>r

//

...

,,

/<

\J

-u-

16

-23

/

.

:v//13

/

/h/~

,'

_______

/

--·

/~

/

~r

14/

~

2

7

~~

~~

"

:e/

~//-

/J;q

--9

.··

-

is

1

>

4

44

47

~

46

Page 42

9S05000

No

Rdf.no

Name

DIFFERENTIAL CONTROL MACHANISM

Qt

Rm

1

2

3

4

5

6

7

8

9

10

I 1

12

13

I4

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

9S05000

9S05001

9S05002

9S05003

9S05004

9S05005

9S05006

9S05007

9S05008

9S05028

9S05009

9S050IO

9S05011

9S05012

9S05013

9S05014

9S05015

9S05016

9S05017

9S05018

9S05019

Differential control machanism

Differential feeddog

eccentric

Screw

Needle

Differential feed

bearing

link

"E"ring

Pin

Differential

feed

link

(Lever)

Screw

Differential feed

link

(short)

Pin

Differential

feed

crank

Screw

"E"ring

Connecting

Differential

rod guide

regulating

seat

Screw

Return

spring

Pin

Screw pin

Regulating

plate

Screw

Pin

Bushing

0-ring

Oil seal

set

Screw

Regulating

seat shaft

Washer

Differential

regulating

3

1

1

2

1

1

1

1

2

2

2

2

2

1

1

1

1

1

1

I

I

I

1

1

1

1

1

I

I

GB/T77-M5

X 6

25 X 29 X 10

GB/T894.1-25

GB/T80-M4

X 5

GB/T65-M5 X 12

GB/T80-M5

GB/T67-M4

GB/T879-3

X 5

X 6

X 4

GB/T3452.1-15 X 2.65

GB/T77-M6

X 8

31

32

33

34

35

36

9S05020-a00

9S05020-a01

9S05020-a02

8S04012-b00

(

8S04013)

Differential

Differential

Washer

Screw

Nut

Screw

regulating

regulating

craduations(assy)

craduations

2

2

1

1

1

1

GB/T67-M4x

12

Page 43

9S05000

No

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Rdf.no

(

8S040

9S05021

9S05022

9S05023

9S05024

9S05025

9S05026

9S05027

14)

Conical

Feed

spring

lift (Large)

Pin

Screw

Raise

Feed

crank

Screw

Screw

bushing

Nut

Screw (Lever)

Pin

Screw

Nut

Screw

Washer

Conical

spring

DIFFERENTIAL CONTROL MACHAl\ISM

Name Qt

washer

1

1

1

1

1

2

1

1

1

1

1

1

2

2

washer

1

Rm

GB/T80-M4

GB/T77-M5

GB/Tl19-D4 X 12

GB/T77-M3

GB/T67-M4x

GB/T97.1-4-140HV

X 5

x 5

X 6

10

Page 44

9S06000

FEED

REGVJIATING

58/'~

_/~-57

#-60

-59

MECHANISM

31

56

,19

/

50

18

Q-72

10

12

\

\

Page 45

9S06000

No

1

2

3

Rdf.no

9S06000

9S06001

9S06002

4

5 9S06003

6

9S06004

7

8

9

10

9S06005

11

12

13

14

15

9S06006

9S06007

9S06008

9S06009

16

17

18

19

9S06010

9S06011

20

21

22

9S06012

9S06013

23

24

25

26

27

28

9S06014

9S06015

9S06016

9S060I7

9S060I8

29

30

9S06019

3I

32

33

34

35

36

37

38

9S06020

9S06021

9S06022

9S06023

9S06024

9S06025

9S06026

Name

Feed

regvjiating

Right

Bushing

raise

collar

bushing

Screw

Left

raise

bushing

Raise

shaft

Oil wick

plug

Seal

Short oil wick

Feed

lift

block

Oil wick

Bushing

(Right)

Collar

Bushing

Differential

(Left)

feed shaft

Oil wick

Oil wick (short)

Differential

felL

Oil

small

Pin

Adjusting

eccentric

Lever Screw

Washer

Differential

Differential

Feed

dog key

feed

feed

Screw

Feed

bar

guide

Screw

Feed

bar

guide

Screw

Main feed

bar

Main feed dog

Feed

bar

guide

Feed

bar

black

Feed

small

link

Screw

Feed

small

link

mechanism

(Front)

link

bar

dog

(Lower)

(Left)

(Right)

(Rear)

bushing

FEED

REGVJIA TING MECHANISM

Qt

I

Rm

3

4

GB/T80-M5

X 4

1

I

I

<I>

2 X

320

1

I

<1>2 X 10

1

1

<1>2 X 15

1

1

I

1

2

2

<1>2 X 320

<1>2 X 10

1

1

2

GB/TI

19-AI X 5

1

1

2

1

SMII/64" x40x

GB/T97

.1-4-I

40HV

19

1

2

2

SM9/64" X 40

I

2

GB/T67-M4 X 10

1

2

GB/T77-M6

X 8

1

1

I

I

I

I

1

SM

I l/64 X

40

X I 7

Page 46

9S06000

No

Rdf.no Name

FEED

REGVJIATING

Qt

MECHANISM

Rm

39

40

41

9S06027

9S06028-a00

9S06028-a01

42

43 (

44

45

46

47

48

49

9S06028-b00

9S06028-b01

9S06028-b02

9S06028-c00

9S06028-c01

50

51

52

9S06028-b03

9S06028-b04

(

8S05009)

8S05008)

(

8S05007)

Oil felt

Feed

Regulator

Screw

Screw

Screw

Feed

Pin

Feed

Feed

Feed regulating eccentrc

Pin

Spring washer

Spring washer

53 Screw

54

55

9S06028-b05

Feed regulating restrict plafe

Res !ric t plafe pin

56 Screw

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

9S06029

9S06030

9S06031

9S06032

9S06033

9S06034

9S06035

9S06036

9S06037

9S06038

9S06039

Needle guard eccentrc (Front)

Screw

Needle guard forked (Front)

Screw

Needle guard forked (Rear)

Screw

Washer

Needle guard holder (Rear)

Needle· guard lover (Rear)

Screw

Needle guard (Rear)

Screw

Needle guard holder (Front)

Needle guard (Front)

Pin

Screw

Oil wick

Front shaft

Needle guard shaft

eccentric

eccentric

(assy)

(Small assy)

eccentric

regulating eccentrc (assy)

presser

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

I

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

M3x3

GB/T119-D2

SM3/32 X 56

GB/T879-Dl.5

SM9/64 X 40

GB/T77-M5

SM9/64 X 40 X 12

SM9/64 X 40 X 12

GB/T848-6-300HV

GB/T80-M4

SM9/64 X 40

GB/T80-M4

_<j)

3 X

15

X 9

X 4

x4

X 6

X 5

X 4

X 6

X 4

Page 47

8S14000

35

'\

9

/t'%'F

51

LUBRICATION

4

50

49

'JO

lf2

MECHANISM

/11

,..,..---1

_.,..---14

47

/

46

13

-~

\

20

43

Page 48

8S14000

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Rdf.no

8S14005-c07

8S14005-c06

8S14005-c04

8S

14005-cOl

8S14005-c05

8S14005-c08

8S14005-c03

(9S02018)

8S14023

8S14005-c02

8S

14021

8S14022

8S14019

8S

14020

8S14014

8S

14013

8S14012

8S14010

8S14009-e00

8S14008

8S14001-a02

8S14007

8S14025

8S14024

8S14002

8S14003

Pump

Pump

Pump

Pump

Screw

Screw

Worm

Screw

Bracket

Screw

Pump

Oil

Screw

Pump

Screw

Press

Magnet

Screw

Washer

Screw

Joint

Clamp

Oil

Screw

Nut

Screw

Qil

0-ring

Oil

Screw

Oil

Oil

Screw

Pipe

Ring fer

Oil

Latch

inner

gear

shaft

cover

body

tube

body

plank

tube

filter

filter

tube

guard

felt

gear

wheel

1

partition

2

spring

set (assy)

cap

press

hole

Name

plank

plank

LUBRICATION

MECHANISM

Qt

1

1

1

1

2 GB/T70-M4 X 42

2

1

2

1

2

1

( 1 )

( 2 )

1

2

1

1

1

1

3

5

7

1

3

1

1

1

1

I

3

2

1

1

1

( 1 )

1

1

GB/T70-M4X42

GB/T70-M4

GB/T80-M4X4

GB/T70-M6X 12

GB/T67-M4X5

GB/T65-M4X

SM3/8"X28

SM1/4"X40

¢6

X 1

X480

GB/T65-M4X

GB/T6170-M4

M10X 1

GB/T3452.1-38.7 X 2.65

GB/T65-M4X

GB/T77-M4X

¢8X1

GB/T895.1-16

Rm

X 25

10

6

16

16

Page 49

8Sl4000

No

38

39

40

41

42

43

44 8S14004-h02

45

46

47

48

49

50

51

52

Rdf.no

8S

14006-

8S14011-f00

8S14004-b00

8S14015

8S14001-a00

8S14026

8S14115-c09

8S14005-cl0

(

8503012)

9502019)

(

dOO

Name

Oil distributor(assy)

Oil tube

Non-return valve(assy)

Oil nozzle for

worm

gear(assy)

Oil tube

Screw

Nut

Looper oil distributor(assy)

Oil tube

Oil pipe

Looper oil tube

Latch

Oil filter screen

Oil filter

Oil sight Gauge

LUBRICATION

Qt

1

1

1

1

1

1

1

1

1

1 <j>4X0.5X80

1

1

1

( 1 )

( 1 )

<!>

6X 1 X340

<!>

6X 1 X340

SM1/4"X40

SM1/4"X40

<j>6X1X35

<j>6X 1 X260

GB73-85-M8X4

MECHANISM

Rm

Page 50

9S07000

SPECIAL

TABLE

COMPONENTS

-

---

.....--

---

.....--

.....--

---

-

-~

--

5~t

4-----

3------

0

0

0

0

Page 51

9S07000

No

Rdf.no

Name

SPECIAL

Qt

TABLE

COMPO!\El\TS

Rm

1

2

3

4

5

6

7

8

9

10

11

12

9S07000

9S07001

9S07002

(8S15004)

(8S15002)

Special table components

Oil reservoir screw

Oil reservoir nul

Spring washer

Washer

Pulley cover

Tapping screw

Block chain guard

Tapping screw

Vibration-proof rubber pad

Table

"L"machine stand (assy)