Page 1

..

Purchasing

HIGHLEAD

GG0068

-1

Dept

Copy

High-Speed,1-Needle,Lockstitch, Zigzag Stitching Machine

In struction Manual

Pa

rt

s

Catal

og

•

SHANGHAI HUIGONG

N0.3

SEWING

MACHINE FACTORY

Page 2

CONTENTS

CONTENTS •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1

1,

PRECAUTIONS

2,

MAIN SPECIFICATIONS

3,

PREPARATION AND LUBRICATION ••••••••••••••••••••••••••••••••••••••••••••••••••••.••••••••••••••••••••••••••• 2

4,

REPLACE NEEDLES

5,

WINDING

6,

THREADING

.._

ADJUSTING

7

8,

ADJUSTING

9,

ADJUSTING

10

...

ADJUSTING

11,

ADJUSTING

12

...

ADJUAT

THE

THE

THE

THE

THE

BEFORE

BOBBIN

THE

MACHINE

STITCH

HEIGHT

PRESSURE

THE

THE

BOBBINTHREADTENSION

ZIGZAG

STARTING

..................................................................................................

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••.••••••••••••••••••

THREAD

LENGTH

OF

THREAD

WIDTH

•••••••••••••.....•••••••.••••••••••••••••••.•.•.•••••••••••••..•.•••••••••••••••.•....•.•••••••••.••...•••••

HEAD

THE

OF

THE

TENSION

••••••••••.•.••••....••.••..•••••••••••••••••••••.•......••••••••••••.•..•••••.••......••.•••.....••••••••••••••

OPERATION

••••••••.••..••••••••••••••••••••••••••••••••••••••••••••••••.•••••••••••••.•...•..•••••••••••••••••••.•

.••••••••••••••••••••.•••••••••••••••••••••••••••••••••••••.••.•••••••••••••••••.....••••••••••••••••..••

PRESSER

PRESSER

.•.•••...•....•.•••••••••••.•.•.........••••••••••••..••••••••••••••••••••••••••.•••••••••••

..... , .......................................................

3

3

4

5

....................................................................................... 5

FOOT

................................................................

......................................................

5

5

6

6

2

2

13,

ADJUSTING

14

...

ATTACHING/REMOVINGTHEHOOK

15

...

ADJUST

16

...

ADJUSTING

17,

ADJUSTING

18,

ADJUSTING

19

...

CHANGEOVER

20,

PLACING A BOBBIN

PARTS CATALOG .•...•...•..•..••••••••••••••.••••.••.••••••••••.•.•••••••••.•..•..••.•.•••••••.••••••••••....•.•••••••.••. 10

THE

THE

HEIGHT

THE

THE

DENSER

POSITION

OF

NEEDLE

AMOUNT

OF

STANDARD

INTO

STITCHING

OF

FEED

THE

NEEDLE BAR

TO

HOOK

OF

OIL

ZIGZAG

THE

BOBBIN

.............................................................................................. 7

.•.•.••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••.•••••••••••••

DOG

•.•.••••••••••••••••••••••••.••..••••••••••••••••••••••••••••••••••.••••••••.•••••.•••••••••••

••••••••••••••...••••••••••••••••••.•..•..••••••••....••••••••••••••.•.••••••••••••••

TIMING

IN

THE

AND

THE

NEEDLE

HOOK

.•••..•••••••••••••••••••••••••••..••••••••.••••••.•••••••••••••.•...•.•..•••••.•.•••.••••••

CASE

............................................................................ 8

................................................................................... 9

GUARD

.............................. 8

7

7

8

9

-1

Page 3

1.

PRECAUTIONS

1)

Safety Precautions

(I)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the balance wheel.

(2) Power must be turned

(3) Power must be turned

the machine,

(4) Avoid placing fingers, hairs, bars etc., near the balance wheel,

or motor when the machine

(5) Do not insert fingers into the thread take-up cover, under/around the needle,

machine

If a belt cover, finger guard, eye guard are installed, do not operate the machine without these safety

(6)

devices.

2) Precautions before Starting Operation:

(I)

If the machine's oil pan has an oil sump, never operate the machine before filling it.

(2) If the machine

(3) When a new sewing machine is first turned ·on, verify the rotational direction

the power on. (The balance wheel should rotate counter-clockwise when viewed from the balance wheel)

(4)

Verify

is

in

the voltage and (single

BEFORE

off

when the machine

off

when tilting the machine head, installing or removing the

or

when replacing.

operation.

is

lubricated by a drop oiler, never operate the machine before lubricating.

STARTING

is

is

in operation.

or

three) phase with those given on the machine nameplate.

OPERATION

not in use,

or

when the operator leaves the seat.

"V"

belt, bobbin winder balance wheel,

or

of

balance wheel when the

"V"

belt, adjusting

the balance wheel with

3)

Precautions for Operating Conditions:

(I)

Avoid using the machine at abnormally high temperature (

lower) .

(2) Avoid using the machine in dusty conditions.

2.

MAIN

SPECIFICATIONS

s

~

Max.sewing speed

Feed pitch

Zigzag width 5mm

By

Presser

Needle

Rotating hook Auto lubricated hook

Lubrication Auto lubricated

Motor 370W clutch motor

hand 5.5mm

By knee 10mm

2-step

2.5mm

4500rpm

DPX5

35"C

or

higher)

10 mm ( Standard 8

9#-14#

or

4-step

2mm

low temperature (

mm)

s·c

or

3.

PREPARATION

AND

LUBRICATION

-2-

Page 4

1)

Cleaning the machine

Before leaving the factory, the machine

parts are coated with rust-preventive grease,

be

which may

dust during storage and shipment. This grease

be

must

2) Examination

strict inspection and test before leaving the

factory, the machine parts may

deformed after long distance transportation with

jolt. A thorough examination must be performed

after cleaning the machine. Turn the balance

wheel

parts collision, uneven resistance or abnormal

noise. If these exist, adjustment must

accordingly before run-in operation.

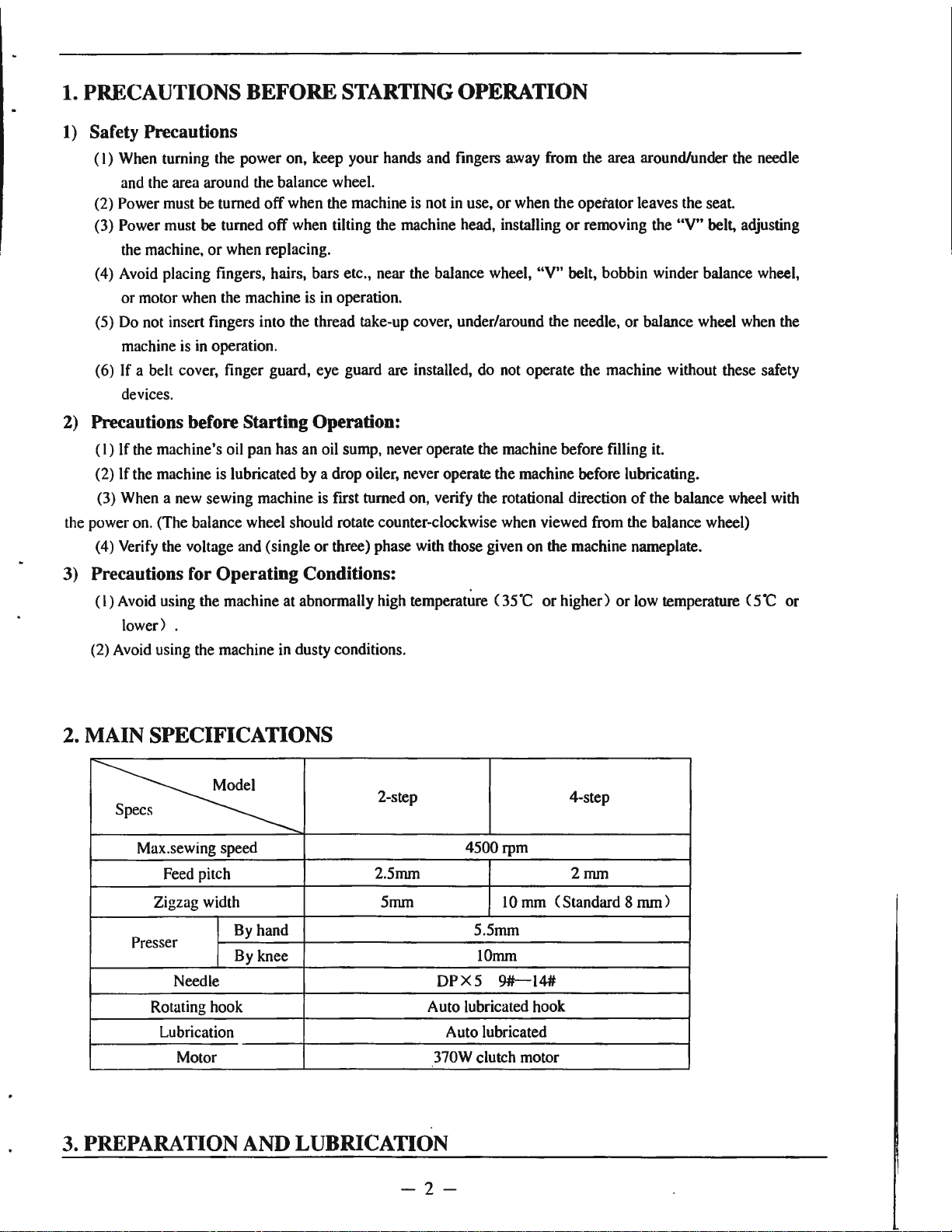

3) Oiling (Fig.I)

removed with gasoline.

Though every machine is confirmed by

to

(I)

Line (A) on the oil reservoir: Max. Oil level

Line (B) on the oil reservoir: Min. Oil level

If oil level goes down under line

distributed

parts a seizure.

(2) Replenishing

hardened and contaminated by

see

if

there is running obstruction,

Required amount

to

each part

of

oil

of

the machine, thus causing the

be

loose or

be

B,

oil cannot be

made

A

,t

I

!

I

I

I

I

I

,.,

2

B

18

Always use only No.

for high speed sewing. Be sure to replenish oil to

line A before starting operation.

(3) Replacing oil

To

replace oil, remove screw (C) to drain oil.

After completely draining off oil, clean the oil

reservoir and securely tighten screw (C), then fill

the reservoir with fresh oil.

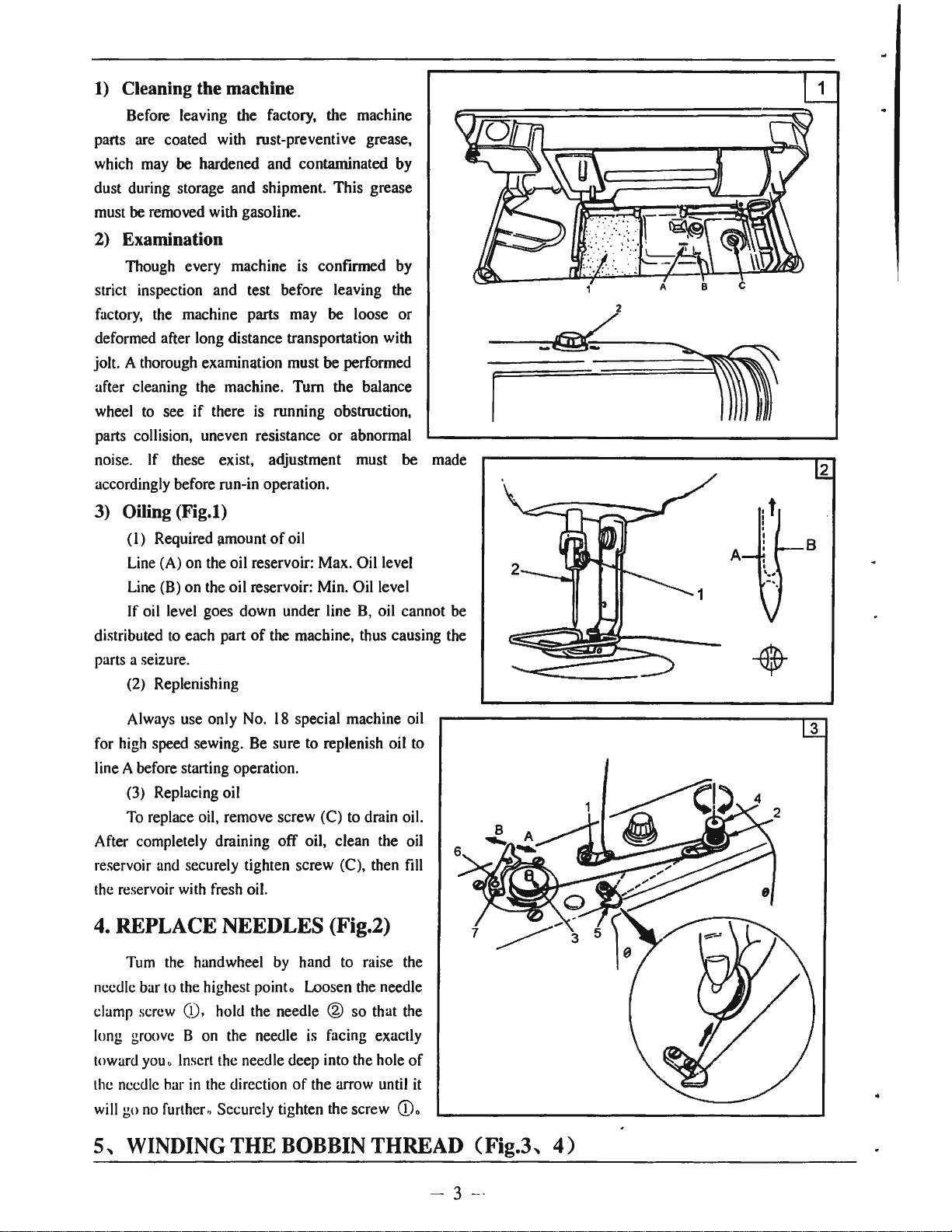

4.

REPLACE

Tum the handwheel by hand to raise the

needle bar

damp

long groove B on the needle is facing exactly

toward

the needle har

will go

5,

to

screw (!), hold the needle ® s·o that the

you

" Insert the needle deep into the hole

no

further., Securely tighten the screw (i).

WINDING

NEEDLES

the highest point. Loosen the needle

in

the direction

THE

special machine oil

(Fig.2)

of

the arrow until it

BOBBIN

THREAD

of

. (Fig.3,

3

4)

- 3 -

Page 5

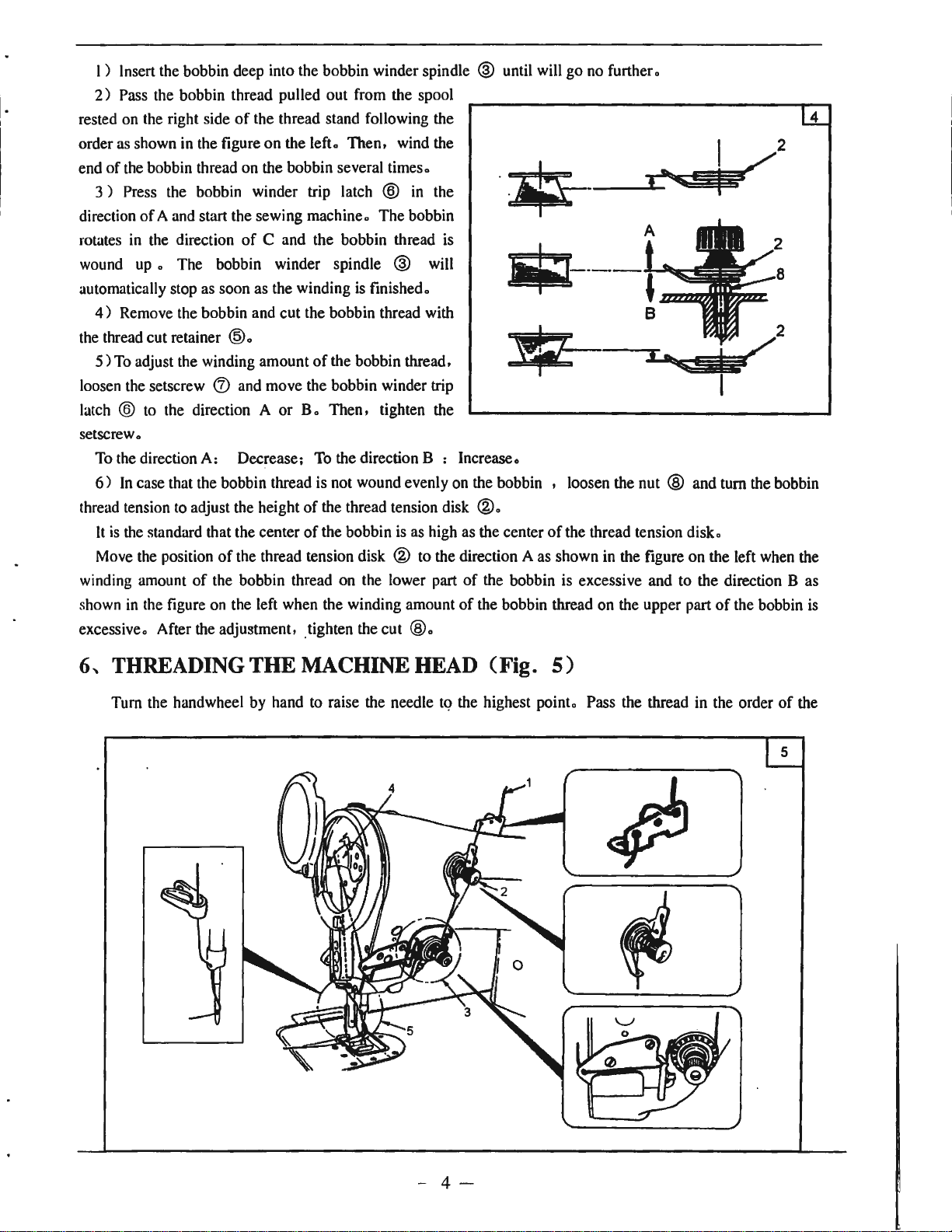

I ) Insert the bobbin deep into the bobbin winder spindle @ until will

2)

Pass the bobbin thread pulled out from the spool

rested on the right side

order as shown in the figure on the left. Then, wind the

end

of

the bobbin thread on the bobbin several times.

3 ) Press the bobbin winder trip latch @ in the

direction

rotates

wound up • The bobbin winder spindle @ will

automatically stop as soon as the winding is finished.

the thread cut retainer

loosen the setscrew

latch @ to the direction A

setscrew.

thread tension to adjust the height

winding amount

shown

excessive. After the adjustment, _tighten the cut

of

A and start the sewing machine. The bobbin

in

the direction

4)

Remove the bobbin and cut the bobbin thread with

5)

To adjust the winding amount

To the direction A: Decrease; To the direction B : Increase.

6)

In

case that the bobbin thread is not wound evenly on the bobbin , loosen the nut ® and turn the bobbin

It

is

the standard that the center

Move the position

in

the figure on the left when the winding amount

of

the thread stand following the

of

C and the bobbin thread

is

®·

of

the bobbin thread,

(J)

and move the bobbin winder trip

or

B.

Then, tighten the

of

the thread tension disk

of

the bobbin is as high as the center

of

the thread tension disk @ to the direction A as shown in the figure on the left when the

of

the bobbin thread on the lower part

®·

of

the bobbin is excessive and to the direction B as

of

the bobbin thread on the upper part

®·

go

no further.

of

the thread tension

disk.

of

the bobbin is

4

6,

THREADING THE MACHINE HEAD (Fig.

Turn the handwheel by hand to raise the needle tq the highest point. Pass the thread in the order

5)

of

the

- 4 -

Page 6

numbers

as

illustrated.

7

..

ADJUSTING THE STITCH

"mm".

6)

)

7)

of

the arrow so that

in

the normal stitching direction

OF

THE

LENGTH (Fig.

I) Adjusting the stitch , turn the stitch

in

length dial A

the number corresponding to the desired stitch

length meets the marker dot B engraved on the

machine arm. (Nimber on the stitch length dial

are calibrated

2)

down the feed lever C • The sewing machine

performs reverse feed stitching as long as you keep the feed lever

held pressed. The feed lever will return to its home position and

the sewing machine will run

you

when

the direction

in

To

perform reverse feed stitching, press

release the feed lever.

8.. ADJUSTING THE HEIGHT

PRESSER (Fig.

0

A ("')

0

'-------

6

C o

7

To change the height

the presser foot, loosen the presser bar connection screw

perform the adjustment properly. After the adjustment, securely

tighten

the

screw.

9,

ADJUSTING THE PRESSURE

of

the presser bar or the inclination of

CD

OF

and

THE

PRESSER FOOT (Fig.8)

Pressure of presser foot

thickness of materials to

presser spring regulator 2 clockwise A

by

the presser foot; turn the presser spring regulator counterclockwise

to

decrease

B

The pressure

normal feeding

it.

Then tighten lock nut

of

presser foot is recommended

is

ensured.

is

to be adjusted

be

sewn.. First loosen lock nut l , turn the

to

increase the pressure given

I.

in

accordance with

to

be less as long as

10, ADJUSTING THE THREAD TENSION

(Fig.9,

10)

8

9

1) Adjusting the needle thread tension (Fig.9)

Adjust the needle thread tension using the tension nut

the tension nat clockwise increases the needle thread tension , or

crn,atecclackwise

decreases

iln

4.

Turning

-5-

Page 7

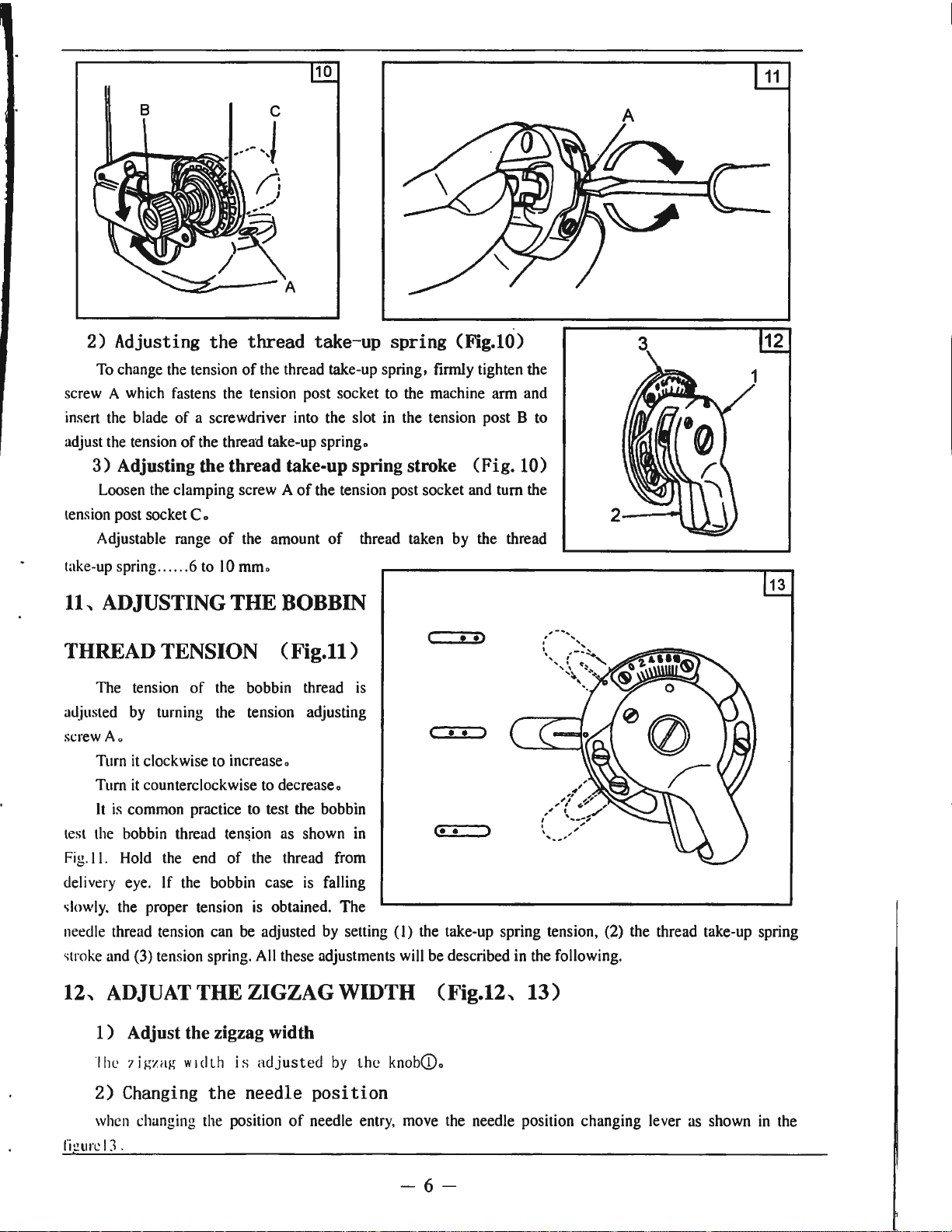

10

2) Adjusting the thread take-up spring (Fig.IO)

To change the tension

screw A which fastens the tension post socket to the machine arm and

insert the blade

adjust the tension

3)

Adjusting the thread take-up spring stroke (Fig. 10)

Loosen the clamping screw A

tension post socket

Adjustable range

take-up spring

of

a screwdriver into the slot in the tension post B to

of

C.

......

6 to

of

the thread take-up spring, firmly tighten the

the thread take-up

of

of

the amount

IO

mm.

spring.

the tension post socket and

of

thread taken by the thread

tum

the

11, ADJUSTING THE BOBBIN

c •

• •

<•

•>

• >

THREAD TENSION (Fig.11)

The tension

adjusted by turning the tension adjusting

A.

screw

Turn

it

clockwise to increase.

it

Turn

test the bobbin thread

Fig. I I. Hold the end

delivery eye. If the bobbin case is falling

slowly. the proper tension is obtained.

needle thread tension can be adjusted by setting

stroke and

counterclockwise to decrease.

It

is

common practice to test the bobbin

(3) tension spring. All these adjustments will be described in the following.

of

the bobbin thread

ten&ion

of

as shown in

the thread from

is

The

(I)

the take-up spring tension, (2) the thread take-up spring

12

13

12,

ADJUAT

THE ZIGZAG WIDTH (Fig.12,

13)

1 ) Adjust the zigzag width

The

7 i g

:rng width

2)

Changing

when changing the position

l'i!.?.ure

I J"

is

adjusted

the needle

of

by

the

knob(D.

position

needle entry, move the needle position changing lever as shown in the

-6-

Page 8

13, ADJUSTING THE DENSER STITClllNG

(Fig.14)

14

Stitch

This

feature

I ) If you turn the dial with the feed lever held pressed down, the

feed lever will move. Adjust the stitch length for denser stitching

the graduation which meets the top surface

reference:

2)

stitch length. "+2"means "normal feed stitch length is 2mm" and "-2"

means "reverse feed stitch length is

Advert: The graduations on the dial are mere reference. So adjust

the denser stitching while actually observing the finished seam.

length

is

used

Turn the dial

can

in

be

for

the

reduced

fastening

"+"

at

the

star

or

end

of

stitch.

of

the feed lever as

direction to reduce the reverse feed

2mm".

sewing.

talcing

14, ATTACHING I REMOVING THE HOOK

(Fig.15)

When

you

replace the sewing hook, remove it

procedures:

I ) Turn the handwheel until the needle reaches to its highest

position :

2)

Remove the needle, presser foot, throat

plate, feed dog and bobbin case from the machine:

3 ) Remove the setscrew I and take out the

bobbi"n

sewing hook.

the sewing hook. Advert: At this time, make sure

that top end A

is

Never

case positioning finger 2:

4)

Loosen the two screws 4 and remove the

Reverse the above procedures when inserting

of

the bobbin case positioning finger

aligned with line

let

A protrude from line B.

B.

as shown in the figure 15.

in

the following

15

4

16

15,

ADJUST THE POSITION OF

FEED

link

1.2mm.

DOG

To

adjust

I ) Loosen the screw I and turn the feed driving

pin

2 using a screwdriver:

2 ) The standard height

(Fig.16)

the

height

of

the

feed

of

the feed dog

dog

is

t=

--,

-~----~

-7-

Page 9

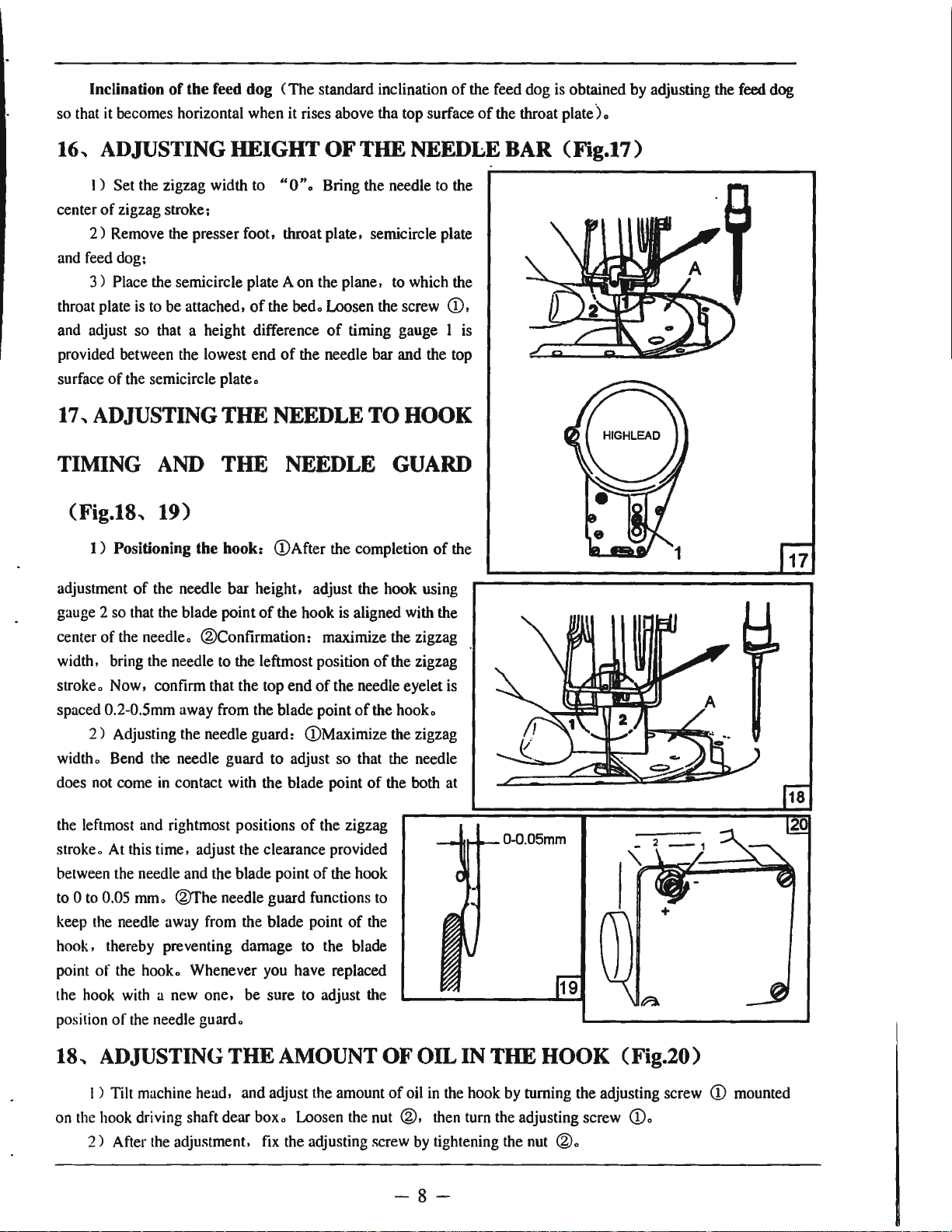

Inclination

it

so that

16,

center

and feed dog:

throat plate

and adjust so that a height difference

provided between the lowest end

·surface

becomes horizontal when it rises above tha top surface

ADJUSTING HEIGHT OF THE NEEDLE BAR (Fig.17)

I)

Set the zigzag width to

of

zigzag stroke;

2)

Remove the presser foot, throat plate, semicircle plate

3)

Place the semicircle plate A on the plane, to which the

of

of

the feed dog

is

to be attached,

the semicircle plate.

of

(The

standard inclination

"O".

Bring the needle to the

the

bed.

Loosen the screw

of

timing gauge l

of

the needle bar and the top

of

the feed dog

of

the throat

CD,

is

17, ADJUSTING THE NEEDLE TO HOOK

TIMING AND THE NEEDLE GUARD

is

obtained by adjusting the feed dog

plate).

(Fig.18,

1 ) Positioning the hook: (!)After the completion

adjustment

gauge 2 so that the blade point

of

center

width, bring the needle to the leftmost position

stroke o Now, confirm that the top end

spaced 0.2-0.5mm away from the blade point

2)

Adjusting the needle guard: (!)Maximize the zigzag

widtho Bend the needle guard to adjust so that the needle

does not come

the leftmost and rightmost positions

strokeo At this time, adjust the clearance provided

between the needle and the blade point

to

Oto 0.05

keep the needle away from the blade point

hook, thereby preventing damage to the blade

point

of

the hook with a new one, be sure to adjust the

position

of

19)

of

of

the needle bar height, adjust the hook using

of

the hook

the needle. ®Confirmation: maximize the zigzag

in

contact with the blade point

mmo

@The needle guard functions

the hooko Whenever you have replaced

the needle guardo

is

aligned with the

of

the needle eyelet

of

of

of

the zigzag

of

the hook

of

the

of

the zigzag

the hooko

the both at

to

is

the

r

+

18,

ADJUSTING THE AMOUNT OF OIL IN THE HOOK (Fig.20)

I ) Tilt machine head, and adjust the amount

on the hook driving shaft dear boxo Loosen the nut

2)

After the adjustment, fix the adjusting screw by tightening the nut

of

oil in the hook by turning the adjusting screw

®,

then tum the adjusting screw (D.

®o

-8-

CD

mounted

Page 10

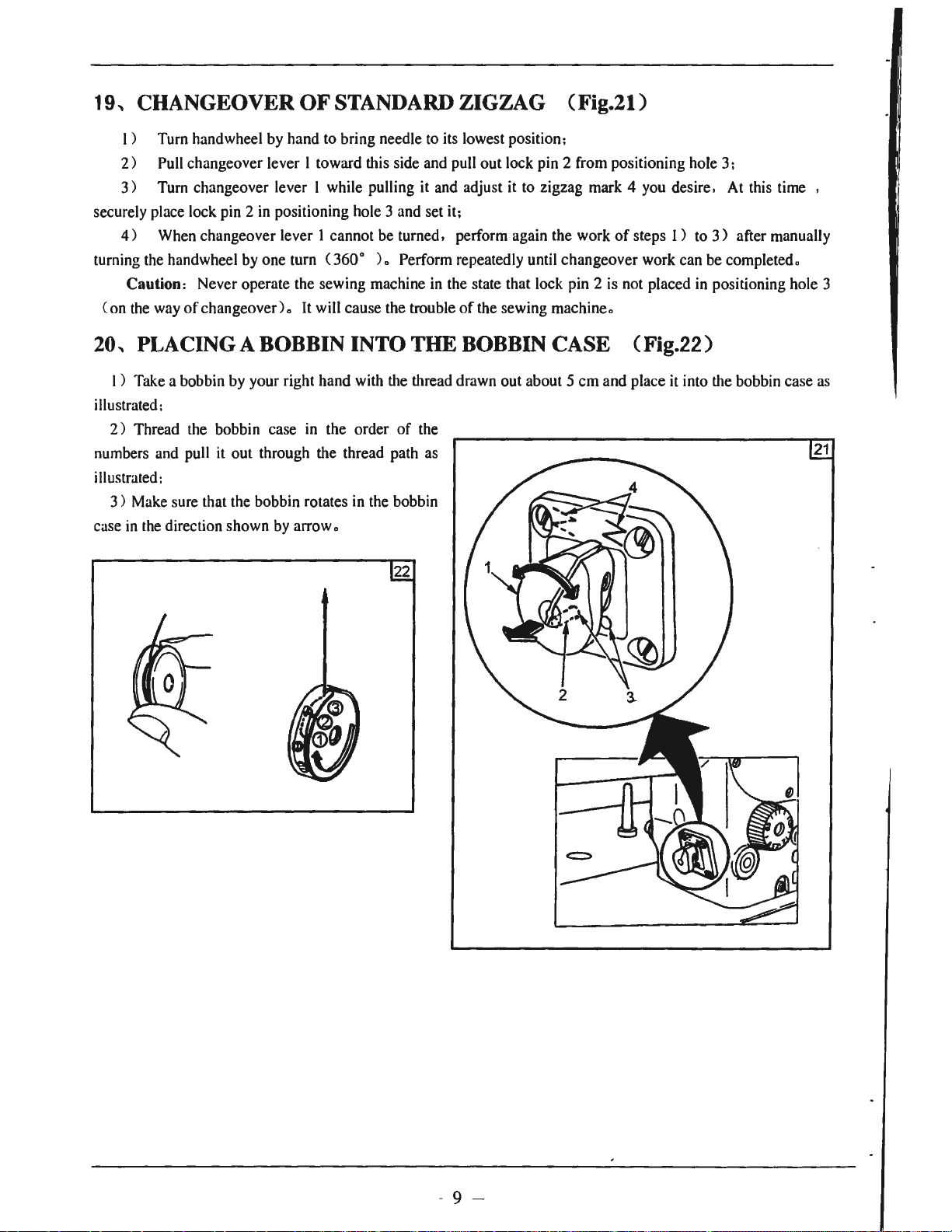

19, CHANGEOVER OF STANDARD ZIGZAG (Fig.21)

I)

Turn handwheel by hand to bring needle to its lowest position;

2)

Pull changeover lever l toward this side and pull out lock pin 2 from positioning hole 3;

3)

Turn changeover lever 1 while pulling it and adjust it to zigzag mark 4 you desire, At this time ,

securely place lock pin 2 in positioning hole 3 and set it;

4)

When changeover lever l cannot be turned, perform again the work

turning the handwheel by one turn

Caution: Never operate the sewing machine in the state that lock pin 2 is not placed

of

( on the way

changeover). It will cause the trouble

060°

).

Perform repeatedly until changeover work can be completed.

of

the sewing machine a

of

steps

I)

to

in

20, PLACING A BOBBIN INTO THE BOBBIN CASE (Fig.22)

3)

after manually

positioning hole 3

1 ) Take a bobbin by your right hand with the thread drawn out about 5 cm and place it into the bobbin case

illustrated:

2)

Thread the bobbin case

it

numbers and pull

illustrated:

3)

Make sure that the bobbin rotates in the bobbin

in

case

the direction shown by arrow.

out through the thread path as

in

the order

of

the

22

as

21

- 9 -

Page 11

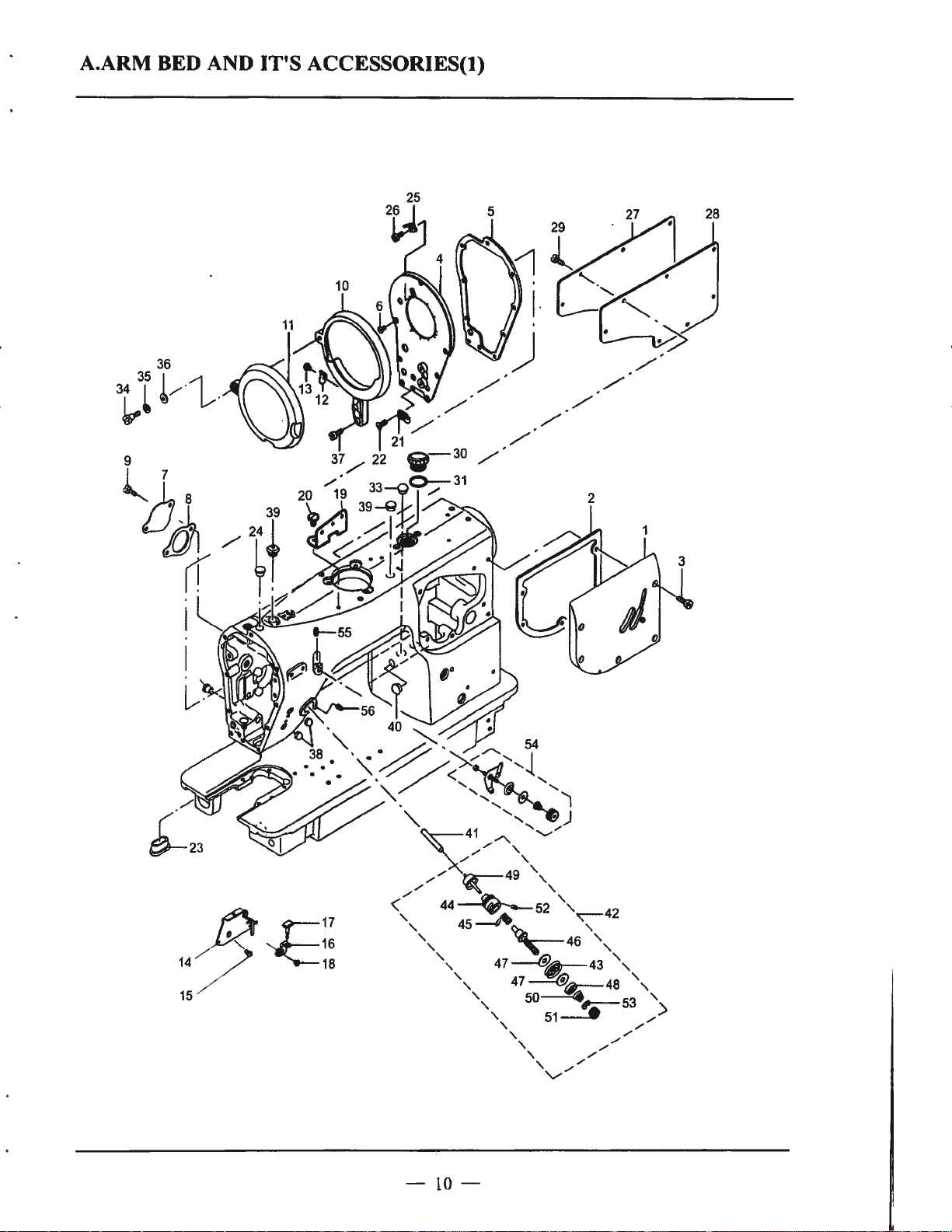

A.ARM BED AND IT'S ACCESSORIES(t)

-

10-

Page 12

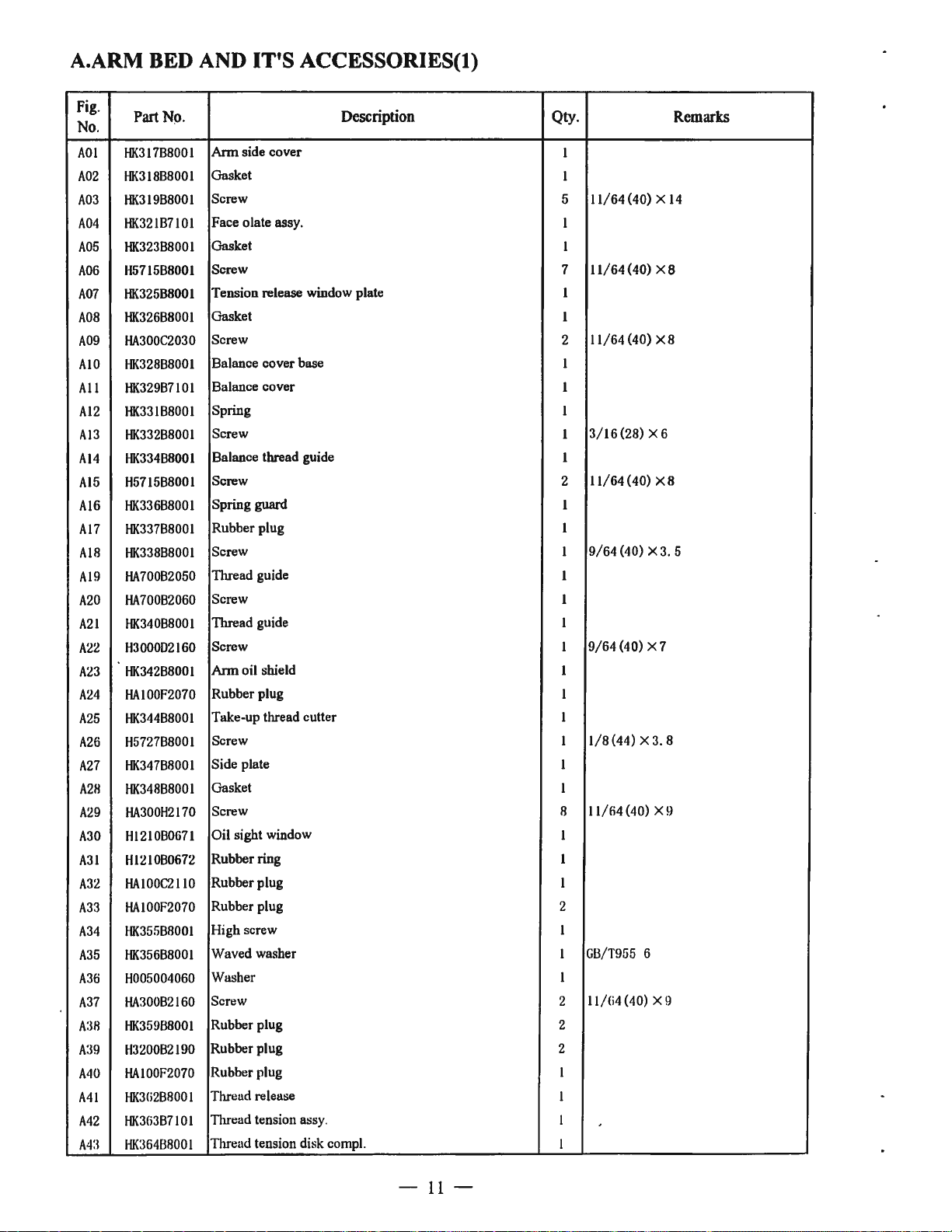

A.ARM BED AND IT'S ACCESSORIES(t)

Fig.

No.

AO!

A02

A03

A04

A05

A06

A07

A08

A09

AIO

All

Al2

Al3

Al4

Al5

Al6

Al7

AIR

Al9

A20

A21

A22

A23

A24

A25

A26

A27

A211

A29

A30

A31

A32

A33

A34

A35

A36

A37

A:!8

A:!9

A40

Ml

A42

A4:l

Part

N9.

HK317B8001

HK.318B8001

HK.319B8001

HK321B7101

HK.323B8001

H5715B8001

HK.325B8001

HK.326B8001

HA300C2030

HK328B8001

HK329B7101

HK331B8001

HK332B8001

HK334B8001

H5715B8001

HK336B8001

HK337B8001

HK338B8001

HA70082050

HA700B2060

HK340B8001

H3000D2160

HK342B8001

HAIOOF2070

HK344B8001

H5727B8001

HK347B8001

HK348B8001

HA300H2170

Hl210B0671

Hl210B0672

HAIOOC2110

HAIOOF2070

HK355B8001

HK356B8001

H005004060

HA300B2160

HK35988001

H3200B2190

HAIOOF2070

HK3G2B8001

HK363B7101

HK36488001

Description

Arm

side cover

Gasket

Screw

Face olate assy.

Gasket

Screw

Tension release window plate

Gasket

Screw

Balance cover base

Balance cover

Spring

Screw

Balance thread guide

Screw

Spring guard

Rubber plug

Screw

Thread guide

Screw I

Thread guide

Screw

Arm

oil shield

Rubber plug

Take-up thread cutter

Screw

Side plate

Gasket

Screw 8

Qty.

Oil sight window

Rubber ring

Rubber plug

Rubber plug

High screw I

Waved washer

Washer

Screw

Rubber plug

Rubber plug 2

Rubber plug

Thread release

Thread tension ass

Thread tension disk compl.

y.

I

I

11/64

5

I

I

7

11/64

I

I

11/64 (40) X 8

2

I

I

I

3/16(28)

I

I

11/64(40)

2

I

I

9/64

I

I

I

9/64

I

I

I

I

1/8

I

I

I

11/64

I

I

I

2

I

GB/T955

I

ll/Ci4 (40) X 9

2

2

I

I

I

I

(40) X

(40) X 8

X6

X8

(40) X 3. 5

(40) X 7

(44) X 3. 8

(40) X 9

6

Remarks

14

-

11

-

Page 13

A.ARM BED AND IT'S ACCESSORIES(t)

Fig.

No.

A44

A45

A46

A47

A48

A49

A50

A51

A52

A53

A54

A55

A56

Part

No.

HK33BB8001

HAI

15B0706

HAI

15B0701

HK368B8001

HA310B0702

HK33CB7101

HAI

15B0703

HAI

15B0702

HA711B0681

HAll5B7010

HK33HB7101

HA100B2110

HA300B2080

Description

Thread

Take-up spring

Screw

Felt

Tension disc holder

Tension release pin assy.

Tension spring

Tension nut

Screw

Rotating stopper

Pre-tension controller assy.

Screw

Screw

tension

rod assy.

Qty.

1

I

I

2

I

I

1

1

1

I

1

1

1

9/64

15/64

(40) X

(28)

Remarks

4.

5

X6.

5

-

12

-

Page 14

B.ARM BED

AND

IT'S

ACCESSORIES(2)

-

13

-

Page 15

B.ARM BED AND IT'S ACCESSORIES(2)

Fig.

No.

BO!

B02

B03

B04

B05

B06

B07

BOB

B09

BIO

Bil

Bl2 H200000360

Bl3

Bl4

Bl5

B16

Bl7

BIS

Bl9

820

B21

822

823

B24

825

826

827

828

82~)

B30

B:Jl

8:J2

8:

8:!4

IHfi

B:

l{:17

B:l8

IH!l

IWl

B,J I

Bl2

B•I

HK374B8001

HA300B2160

HK376B7101

HK377B8001

HK37BB8001

HK380B8001

HAI00B2060

HK383B8001

HK384B7101

HK388B8001

HK38988001

HA300B2190

HK359B8001

HK391B7101

HA30082160

HK395B8001

HK397B8001

HK398B7101

HK399B7101

HK30BB7101

HK30EB8001

HK30FB8001

HK33AB8001

H6720N8001

HAI00H2150

H6721N8001

H3200B2100

Hfi722N8001

H7214J8001

H733ID8001

H6717N8001

l3

H6724N8001

H0070!3050

H4:II050050

114:l

l!i

HK:l l GB800

I-IK31HB8001

Hfi312D8001

HJ(:! I JB800

HK:!

IICi7iifiB8001

1-1Ci7

:l

Part

No.

I 030040

I JB800 I

Ci2B800

Description Qty.

Support plate

Screw

Helical gear box cover assy.

Helical

gear

box

cover

Bed screw stud

Connecting screw

Screw

Bed plate

Bed slide assy.

Oil shield plate

Oil shield rubber

Screw

Screw 4

Rubber plug 1

Helical bevel gear box cover assy.

Screw 3

Nylon cap 1

Needle plate 1

Bobbin device assy. I

Bobbin fitting basis assy. 1

Bobbin brace assy. 1

Bobbin shaft 1

Bobbin cam shaft I

Bobbin cam

Bobbin lever

Screw 1

Adjust plate 1

Scrw

Washer

Bobbin winder wheel

Rubber ring 1

.

Cushion I

Spring

E-ring

Screw

Screw 2

Gasket 1

J..

Bobbin winder wheel

Screw

Tirrentl guide 1

I

Screw 1

Tirread cutter 1

Screw 2

I

I

2

1

1

2

1

4

1

1

1

1

2

I

I

1

1

2

1

I

2

1

I

2

11/64(40)

11/64

(40)

11/64

(40)

11/64

(40)

(40)

11/64

M5X5

M3X4

1/4

(40)

11/64

(40)

Remarks

XI0

X 9

X5

X4. 5

X9

X6

X5

-14-

Page 16

B.ARM BED AND IT'S ACCESSORIES(?)

Fig.

No

844

845

B46

847

B48

849

850

851

Part No.

.

HK32AB7101

HA71080671

HK33IB8001

HA11280693

H420680661

HK31188001

H5729F8001

H3107G0662

Description

Bobbin thread tension assy.

Bobbin thread nut

Bobbin thread soring 1

Bobbin winder thread disc

Bobbin thread screw 1

Thread guide 1

Nut 1

Screw 3

Qty.

2

Remarks

1

1

11/64 (40)

-

15

-

Page 17

C. UP SHAFT MECHANISM

- 16 _ .

Page 18

C.UP SHAFT MECHANISM

Fig.

No.

COi

CO2

C03

C04

cos

C06

C07

COB

C09

CI0

Cl!

Cl2

C13

C14

Ci5

Ci6

Cl7

ClB

C

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C3I

C32

C:

C34

C

35

C36

C37 HK341C8001

C38

C39

C:

40

(4

C42

C43

i9

13

1

Part

No.

HK305CB00I

HK307C8001

HAI

11

IE204

028018

HK309C7101

HK310CB00I

H3205J0662

HA307C0662

HK312C8001

HA306D0066

HK314C8001

HA307C0662

HK316C8001

H2405D0664

HK317C8001

HK318CII001

HK320C8001

HK322CII001

HK323C8001

HK325C7101

HK329C8001

HK330C7101

HAI00C2020

-HAI00C2020

HA100C2070

HA705C0662

HA307C0662

H4100B2180

HA105D0066

HK333C7101

HA104C0655

HK

336C

8001

HK337CII00I

HK338CII00I

HK339C8001

HK340C8001

HAI00C2170

H3211

ID604

HA300B2160

HA300C2030

HK343C7101

HK344C8001

Description Qty. Remarks

Up

shaft I

Oil adjust pin

Oil wick

Rubber ring

lbrust

collar assy.

Pushing I

Bearing

Screw

Oil seal coller

Oil seal I

Sprocket (up) I

Screw

Hand wheel

Screw 2

Balance l

Up

shaft

bushing(left)

Up

shaft

bushing(middle)

Counterweight l

Counterweight plate l

Take-up counterweight assy.

Timing belt

Needle bar crank

Screw l

Screw I

Screw

Rubber ring

Screw 2

Screw 3

lbrust

collar assy. l

Needle bar crank assy. l

Bearing

Needle bar connection

Thread rack

Needle b

Needle bar connection

Needle bar connection

Needle

Screw I

Screw

Screw

Screw 2

Needle bar yoke assy.

Needle bar yoke l

ar

guid

e l

guide

2 I

I

I

I

I

I

6204ZNR

1/4(40)

2

I

l/4(40)X6

2

I

15/64

l

l

l

l

I

15/64

15/64

l

l

9/64

l

l

l

l

l

DPX5 10#

l

1/8

9/64

l

I 1/64 (40) X

2

l 1/64 (40) X 8

l

X6

(211) X 14

(28)

(28)

(40) X

(44) X

4.

(40) X 8. 5

8.

5

10

X

X

10

10

6

-

17

-

Page 19

C.UP SHAFT MECHANISM

Fig.

No

C44

C45

C46

C47

C48

C49

C50

C51

C52

C53

C54

C56

C57

Part

.

HK345C8001

HK346C8001

HK347C8001

HK349C8001

HK350C8001

HK352C8001

HC04050019

HK354C8001

HK355C8001

HA100B2110

HK358C8001

HD409H8001

No.

40200

Description

Shaft

Shaft bushing (up)

Shaft bushing (down)

Spring pin

Shaft bushing (left)

Guide pin

Screw

O-ring

Needle bar yoke presser

Shaft bushing (ringht)

Screw

Screw

Bearing

Qty.

I

I

I

1

I

I

I

1

I

1

1 11/64 (40) X

9/32 (28) X

1

1

Remarks

5.

5

6.

3

18

Page 20

D.NEEDLE VIBRATOR & ADJUSTMENT COMPONENTS(l)

49

~

{}-24

~

20

~55

-

19

-

Page 21

D.NEEDLE VIBRATOR & ADJUSTMENT COMPONENTS(t)

Fig

No

DOI

002

D03

D04

005

006

D07

008

009

D10

011

D12

01:1

D14

D15

DJG

017

DIil

Ol!l

D20

1)21

1)22

02

:1

D24

()2!i

1)2(;

027

()211

02!1

n:

10

IJ:11

D:l2

0:

1:1

IJ:14

l):l!i

IJ:Hi

1):17

IJ:lll

11:1!)

()'(()

D•I I

ll-1:l

II

1:1

.

Part

.

HK304D7101

HK305D8001

HK306D8001

HK307D7101

HK308D8001

HA104G0012

HK31

HK312D8001

HK313D7101

H3207F0672

HA7311CC06

HK317D8001

HK318D8001

H421l050040

HK320D8001

HK322D8001

HK324D8001

H428050060

H3210F0682

HK32fiDll001

H421l050040

HK328Dll001

HAIOOF2070

11007009100

HK332D7101

HK:133D1100

H0070

1-10070 l :lOfiO

HC

HK3:HD8001

HJ<:l38Dll001

HK3

HIC140Dll001

HK34!Dll001

1-12,io

HK:M

HK:

HE!l2!)1)1l00

I

UtM!JDllOO

I IK:1 I

I

lK:!:lCDllOO

l

lK:15201100

lK:1:i:IDllOO

I

No.

ID8001

J :!040

0404001!>

:l!

>D710

,1 r 003,i

:lDllOO

l4

IDllOOJ

!IBllOO

Drive link assy.

Drive link

Shall

Shall connection assy.

Shall connection

Screw

Link 1

Pin 1

Collar 1

Screw

Screw

Pin 1

Needle driving rod

Screw

Shall

Needle cam

Needle driving

Screw

Screw

Shall 1

Screw

Bushing 2

Plug 1

C-ring

Change over basis assy. 1

Roller I

I

E-ring 4 2

E-ring 5

Rubber ring I

Spring

Change over slide shall l

Change over lever assy. I

I

Change over lever

Pin

Screw

Change over basis

I

Gasket I

Screw 4

I

Needle cam

1

Screw

I

Rubber plug

I

Needle cam shall

I

Needle cam roller

I

ann

Description Qty.

ann

I

1

1

1

1

3/16(28) X 12

1

70. 1

8. 5

X6. 5

M5 X 14

11/64 (40) X

2

9/64(40)

2

1

M5X4

2

1

1

1

M5X6

2

GB/T

1

M5X4

4

'

1

2

·I

l

l

9/64

I

1

1

3 l

l

2

2

(40) X 8. 5

I/64

(40) X

14

Remarks

-

20-

Page 22

D.NEEDLE VIBRATOR & ADJUSTMENT COMPONENTS(t)

Fig

.

Part

No

044

045

046

047

048

049

050

051

052

053

054

055

056

057

058

059

060

061

062

.

HK35508001

HK35608001

HAIOOC2190

HA307C0662

HK35908001

HK36008001

..

HK36108001

HK36208001

HK36408001

HK36508001

HK36608001

H4707I8001

HC04070019

HK36907101

HK371D7101

HA34110308

HA10500662

HA108C0663

H007009100

No.

Worm

wheel

shaft

Worm

wheel

Screw

Screw

Worm

Rubber plug

Camshaft

Bushing

Drive link guide 1

Pin

Drive link guide 2

Screw

O-ring

Thrust collar assy.(back)

Thrust collar assy.(front)

Screw

Screw l

Screw l

Snap spring 1

Description Qty.

1

1

3 11/64

4

1

1

1

1

1

1

l

1

1

l

1

1

(40) X 10

1/4(40) X6

1/4(40) X6. 5

(28)

15/64

1/4(40) X4

l/4(40)X7

X 7

Remarks

-

21

-

Page 23

E.NEEDLE VIBRATOR & ADJUSTMENT COMPONENTS(2)

0

0

rhr-

..

-5fi-

~

(~J~,,,,,......

\ 46 I

\ I

\

___

-

22-

/

ll-··

------

............

...,

45

__

J

·

41

47

r·

"l

'

.-J

51

"f@

24

Page 24

E.NEEDLE VIDRA T

OR

& ADJUSTMENT COMPONENTS(2)

Fig.

No.

EOI

E02

E03

E04

E05

E06

E07

E08

E09

EIO

Ell

E12

El3

El4

El5

El6

El7

EIS

El9

E20

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E32

E33

E34

E35

E36

E37

E38

E39

E40

E41

E42

E43

Part

No.

HK373D7101

HK374D7101

HK377D8001

HK378D8001

HK385D7101

HK386D8001

H42'('040050

HK388D7101

HK389D8001

HK390D8001

H3406C8001

HK39ID8001

HK392D8001

HK393D7101

HK394D8001

HK395D8001

HK396D8001

HA104J6510

HK398D8001

HK399D8001

HK30AD8001

HA104C0659

HK30CD8001

HK30DD8001

H007009100

HK30FD8001

HA104J6510

HK30HD7101

H007013020

HK318D8001

HK31CD8001

HK31DD7101

H007013040

HE01040

HK31HD8001

HK31ID8001

HK31JD8001

HK32AD8001

HK328D8001

HK32CD8001

HK32ED8001

HK391D8001

H32481BC21

Description

Scale plate assy.

Scale mounting base assy.

Scale plate 1

Screw 2

Adjusting pick-up assy.

Adjusting pick-up

Screw 2

Lever assy. 1

Lever 1

Screw

Washer 2

Nut 2

Knob 1

Base assy.

Needle position adjusting base 1

Highe screw 1

Waved washer 1

Nut

Base mounting plate 1

Arm

Shaft 1

Screw

Washer

Waved washer

Snap ring

Shaft 2

Nut

Stopper assy. 1

E-ring

Nut 1

Nut stopper

Lever assy. 1

E-ring

Hand

stop

crank

shaft

ball

ct>

4

Spring

Oil shield

Screw

Packing

Roller

Adjusting pick-up screw

Knob

Nut

Screw

Qty.

2

2

1

1

(44)

1/8

1

1

M4X5

9/64

2

(40)

3.

7X7.5X0.8

1

12.

8. 5X

15/64

1

I

1

9/64(40) X6

3

3

10.

2X

3

10.5Xl4.5X0.3

1

1

15/64(28)

1

1

1

1

1

I

I

9/64(40)

1

1

1

1

I

9/64

(40)

X 2. 5

(28)

18XO

X 3. 5

5XO.

. 5

X5

X (i

Remarks

3

-

23

-

Page 25

E.NEEDLE VIBRATOR & ADJUSTMENT COMPONENTS(2)

Fig.

No.

E44

E45

E46

E47

E4H

E49

E50

E51

E52

Part

No.

H3406C8001

HK32FD7101

HK32GD8001

HK32HD8001

HK32IDB00I

HA30082160

H2404I0034

HK338D8001

H7353G8001

Washer

Lever

assy.

Lever

Key

Spring

Screw

Screw

Screw

Washer 1

Description

Qty.

2

1

1

1

1

4

1

1

1

11/64

9/64

3/16

10.

2X 18X 1

Remarks

(40) X 10

(40)

X8. 5

(32)

X6. 5

- 24 -

Page 26

F.PRESSER FOOT MECHANISM

20

,-L-1

:

21-i

I I

I I

I

122~

l:_

_____

23

J

l

27

I

26

24

0 /

<

t}--14

33

25

16

~

[__..

~

-0---L

____-- I I

I O I

I I

I I

I I

I I

I I

I I

I I

I

______

__

_ I

I

I

I

I

I

I

I

L

_____

30

J

-

25

-

Page 27

F.PRESSER FOOT MECHANISM

Fig.

No.

FOi

F02

F03

F04

F05

F0!i

F07

FOB

F09

FI0

Fil

Fl2

Fl3

Fl4

Fl5

Fl6

Fl7

FIR

Fl!l

F20

F2l

F22

F23

F24

F2fi

F26

F27

F2R

F2!l

r:10

F31

F:12

F:l:l

F:M

r:1ri

F:lli

P.art

No.

HK304E7101

HK312E7101

HK313E8001

HA300H2080

HK316E8001

HK317E8001

HK318E8001

HK319E8001

HK320E8001

HK32IE7101

HK322E8001

HK323E8001

HK324E8001

HK325E8001

HA107H0662

H3200E2010

HK328E7101

HK329E8001

HAI l 1G0683

H5404F7101

H5405F8001

H5406F8001

HAIO0H2120

IID511Q8001

HK335E8001

HN705FR001

HA:3008217

HK339E8001

HK340E8001

HK342E8001

HK343E800l

H3200E2020

li4!ll 4

H0070130!i0

HK346Ell001

HA305E0662

0

IH00

Description Qty.

Presser foot assy.

Hand lifter cam comp!.

Hand lifter cam

O-ring

Lifting lever

Screw

Lifting lever link (left)

Screw

Lifting lever connecting rod

Litling lever link (right) assy.

Lifting lever link (right)

Screw

Spring

Swivel

Hinge screw

Presser bar

Presser bar guide bracket assy.

Presser bar guide bracket

Screw

Presser spring regulator assy.

Presser spring regulator

Nut

Presser guide bar

Spring

Bushing

Hand lefter

Screw

Lifting lever gasket

Hinge screw

Connecting rod, vertical

Screw

Screw

Nut 1

1

Snap ring 2

Screw

Screw

1

1

1

1

1

1

1

2

1

1

1

l

1

1

1

l

1

1

11/64

1

1

1

1

1

1

1

1

11/64

1

1

1

1

3/

16

1

1

1

1

(32)

1/8

(44)

3/16

(28)

15/64(28)

15/64 (28) X 4. 5

Remarks

(40) X 12

(40) X 10

-

26

-

Page 28

G.STITCH

LENGTH

REGULATOR MECHANISM

24

l 23

19

'~

27

-

27

-

Page 29

G.STITCH LENGTH REGULATOR MECHANISM

Fig.

No.

GOl

G02

G03

G04

G05

G06

G07

GOH

G09

GIO

GI

Gl2

Gl3

Gl4

Gl5

G

(;(7

GIB

Gl9

G20

G21

G2:l

G2'.l

G:l4

1:2

G:l!i

HK305F8001

HK338D8001

HK306F8001

HK307F7101

HK309F7101

HA104G0012

HK312F8001

HK313F7101

HK314F8001

H6039G8001

HK315F8001

I

HK331F8001

HK319F8001

HK316F8001

HA300C2030

ICi

HK317F8001

HK318F8001

HK30DD8001

HK320F8001

HK321F8001

HK322F8001

HA109F0674

HAIOOF2080

HAIOOF2090

r,

HK326F8001

HK327F8001

Part No.

G27 H4!Jl418001

G28

HK329F8001

(;'.,!!)

HK330P8001

G:IO

HK33:lF8001

c;:31

HK333F8001

c::1:l

HK:l:l4F800

c:3:1

HK335F8001

c;:34

HK3:l6F8001

G:15

HK338F8001

i;

:w

I

c::l7

IA I 04GOO

HK:l40F7

l:l

IO

Description

Lever

Screw

Shaft

Thrust

colter assy.

Condense stopper

Screw

Feed driving

Knobassy.

Knob

Screw

Adjusting screw

Screw

Adjusting screw

Stopper

Screw

Adusting bushing

Stopper dial plate

Waved

washer 1

Feed dial

Screw

Adjusting screw

O-ring 1

Pin

Spring

Link

Screw 2

Nut

Pin

Scale plate

Spring

suspension I 1

Torsion

Spring suspension 2

I

Slipper 1

Screw

Feed variable arm

Screw

Bushing assy.

I

spring

arm

adjuster

base

assy.

Qty.

1

3/16(32) X6. 5

1

1

1

1

3/16(28) X 12

2

1

1

1

11/64 (40) X 3. 5

1

I

4 3/16(28) X6

1

1

11/64

1

(40) X 8

1

I

10.5Xl4.5X0.3

1

1 3/16(28) X

1

GB1235

14X2. 4

1

1

1

I

1

1

1

1

1

1

3/16(28) X

I

1

Remarks

18

12

-

28-

Page 30

H.

FEED

MECHANISM COMPONENTS

28

1

17

43~

40

44~

8

-

29

-

Page 31

ff.FEED MECHANISM COMPONENTS

Fig.

No

HO!

H02

H03

H04

HOS

H06

H07

HOR

HO!l

HIO

HI!

H

1-113

Hl4

Hlfi

HlCi

1-117

HI

H19

H20

1121

1122

112:1

H21I

112fi

112(i

11

H2H

112!)

11:!0

11:11

ll:l2

11:1:1

11:14

11:l

ll:lli

11:17 HK:1:l4G

11:!/l

11:1!1

IMO I IK:1:lHGHOO

1

14

IM

II

.

12

H

27

!i

1

2

1:1

Part No.

HK305G8001

HK306G8001

H491418001

HK307G8001

HAIOOE2150

H720918001

HK310G8001

HA305E0662

HK31

IG800l

HK312G8001

HK3l3G7101

HE929D800l

HK316G8001

H3221

IG205

HK3l7G8001

HK3l8G8001

HK319G8001

HK320G8001

HK321G8001

HA104GOOl2

H007013035

HK322G7101

HK:123G800

HA:I07C0662

I

IA I 08C06Ci3

HEIO(iF8001

HK:124G800

H20l0JOOfili

HK:12fiGROOI

HK321iG800

I-IK3

27G

ROO

HA

:l4 I ID:l08

HK330GHOOI

HK331G8001

HK:1:12G800I

Hltl:l:IGHOO

HOO

IIK

:l:HiG

HOO

l11\:l04G0Cifili

IIK

:1:l!

lGHOO

IIA700F2l00

HK:1-IOGHOO

Description

Feed reversal link

Hinge screw

Nut 2

Tension spring back

Screw l

Spring

Feed base l

Screw

Felt

Link

Balance weight comp!. l

Screw

Feed dog

Screw

Shatl

Feed rocker

Spacer

Link shaft

Screw 2

Screw

E-ring

Collar assy. 1

Collar

I

Screw 2

Screw

Screw 2

Screw 2

I

Nut

Shall

Bushing (letl) l

I

Bushing (right)

I

Screw

Eccentric

Rod

Side disc plate l

Bearing

I

Connecting rod

I

Feed rocker shatl crmtk

I

Screw

Fe

I

Plate (!ell)

I

Screw 4

Stopp

I

cam

ed

driving rocker 1

er

plate

Qty.

l

2

3/

l

11/64

l

15/64

l

l

l

11/64

2

l

2

l

1

2

l

3/16(28)X9

4

3/16(28) X 14

3. 5

1

l

1/4(40)

2

9/32

2

l

I

15/64

l

l

l

K22X26X

l

l

l

3/16(

l

l

11/64

l

16

(28)

(40) X 10

(28) X 4. 5

(40) X 7. 5

1/8

(40) X

l/4(40)X7

X8

l/8(44)X6

(28)

(28) X 7

28) X 15.

(40) X 8. 5

Remarks

6.

3

. 4

10

(NTN)

-

:30

-

Page 32

ff.FEED

MECHANISM

COMPONENTS

Fig.

No.

H44

H45

H46

H47

H48

H49

H50

H51

H52

Part

No

.

H2400l2080

HK342G8001

HK343G8001

HK344G8001

HK346G8001

HK347G8001

HK348G8001

HK349G8001

HA100E2150

Description

Screw

Plate (right)

Shaft

Bushing

Feed variable

Feed driving rocker block

Pin

Reverse feed limiter

Screw l

ann

Qty.

11/64(40) X7

1

l

1

l

1

2

l

1

11/64

Remarks

(40) X 11

-

31

-

Page 33

I.LOWER

SHAFf

MECHANISM

12--{i

~~

_ft ..

-<l/

17

18

--~

~~

-

32

-

Page 34

I.LOWER SHAFT MECHANISM

Fig.

No.

IOI

I02

I03

I04

I05

I06

I07

I08

I09

110

Ill

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

Part

No.

HK304H7101

HK308H8001

HK309H8001

HK310H8001

HA3411D308

HK312H8001

HK313H8001

..

HE106F8001

HK314H8001

HA300C2030

i-lA34 l lD308

HAI08C0663

HK315H8001

HA104E0011

HAll

llEI04

HAll

llE204

HK319H8001

HK320H8001

HK321H8001

HK322H8001

HK324H8001

HK325H8001

HK326H8001

HK327H8001

HK328H8001

HK329H7101

HK331H8001

HK333H8001

HK334H7101

HK335H8001

HA307C0662

Description Qty. Remarks

Hook comp!.

Hook shaft

Hook shaft bushing

Hook shaft bushing

Screw

Bushing cap

Gasket

Screw

Inner hook stopper

Screw

Screw

Screw

Bearing

Oil seal screw assy.

Oil seal screw

Oil wick

Gear

Gear

Bobbin case assy.

Bobbin

Bushing l

Helical gear

..

Helical gear

Bushing l

Shaft l

Hook driving shaft l

Bushing l

Bushing

Sprocket assy.

Sprocket

Screw

DP2-57(3LP2R)

l

l

l

l

15/64

l

l

l

1/8(44) X6

2

l

11/64

l

15/64

4

1/4(40) X8

8

l

9.

525 X 22.

l

l

l

l

l

225-24169

l

225-96704

l

l

l

l

l

I

1/4(40)

2

(28)

(40)

(28)

X 7

X 9

X 7

225

X7

-

33

-

Page 35

J.OIL LUBRICATION MECHANISM

50

~51

~

, I

) :

·4

1

-

34

-

Page 36

J.OIL LUBRICATION MECHANISM

Fig.

No.

JOI

J02

J03

J04

J05

J06

J07

JOB

J09

JlO

Jll

Jl2

J13

J14

J15

J16

Jl7

Jl8

Jl9

J20

J21

·

J22

J23

J24

J26

J27

J28

J29

J30

J31

J32

J33

J34

J35

J36

J37

J38

J39

J40

J41

J42

J43

J44

Part

No.

HK304l7101

HK30918001

HK31018001

H3000D2030

HK31118001

HK313l8001

HA300C2030

HK314l7101

HK315l8001

HK316l8001

HK31718001

HK319B8001

HK380B8001

HK319l8001

HK320l8001

H200000360

HK32118001

HA3411D308

HK32218001

HK323l8001

HK32418001

HA105D0662

HK325l7101

HK32618001

HK32918001

HA104J6510

HK33018001

HK33118001

HK33218001

HK33418001

HK335l8001

HC04060019

HA100E2150

HK340l7101

HK34218001

HK343l8001

HA700M0070

HK35318001

!{1{35417101

HK355l8001

HK35618001

HK31918002

HK319l8003

Description Qty. Remarks

Oil supplypipe assy.

Oil supplypipe

Distributor

Screw 1

Connecting screw

Felt presser

Screw

Oil tank assy.

Gasket

Oil tank

Oil tube

Screw

Connecting screw

Oil tube

Oil felt guide

Screw 1

Bushing

Screw 1

Shaft 1

Pump

driving gear

Pump

driving gear

$crew 4

Thrust collar assy. 1

Thrust collar

Screw

Nut

Plunger thrust plate

Spring

Plunger

Screw

Spring

0-ring

Screw

Lubricating oil pump assy.

Rubber joint

Rubber joint l

Cable band

Oil wick

Oil regulating valve assy. 1

Oil regulating valve l

Wiper link joint 1

Oil tube

Oil tube

l

1

1

3

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

l

1

I

l

l

l

11/64

(40) X 4.

11/64

(40)

11/64

(40) X 14

11/64(40)

15/64

(28)

1/4(40)

X4

•

5

X 8

.

X7

X 7

•

-

35

-

Page 37

J.OIL LUBRICATION MECHANISM

..

Fig.

No.

J45

J46

J47

J48

J49

J50

J51

J52

Part

No.

HK35918001

H5729F8001

H3406C8001

HK319B8001

HA300C2030

H5733F8001

HK364l8001

HK365l7101

Description Qty. ·

Oil adjusting screw

Nut

Washer

Screw

Screw

Screw

Oil shield

Felt assy. l

l

11/64 (40)

l

2

11/64 (40) X

l

11/64(40) XB

I

11/64 (40) X 8

l

l

Remarks

14

•

•

- 36 -

Page 38

K.ACCESSORIES

r------------7

•

1

I

22

23

21

:o.q

! -.. ,

I

I

L--------~~

,,,,,,

/

(

I

l..

'

'

45

°'

.

~

24

/

/

/./

///

......

......

26

1

I • u I ,

I

r !

25

..._J,,,,

~:;,,,

~

/

' /

,,,,

30

20 ~;----~~----L

,,,,,,,/

/

1

32

'-.._

33

V

____

_

\ij\

?

47

36...-a,

35--fil

34

~

~

~

28

27

~::

~:

/-41

- 37 -

Page 39

K.ACCESSORIES

•

Fig

.

No.

KOi

K02

K03

K05

K06

K07

KOH

K09

KIO

Kil

Kl2

Kl3

Kl4

Kl5

Klfi

Kl7

Kl8

Kl!)

K20

K21

K22

K2

:l

K24

K2!i

K2!i

K27

K28

K2!1

!O

K:

K:

ll

K:12

K:l

:l

K:l4

K:

l!i

:w

K

K:l7

:l

l!

K

K:l!l

K40

K-

11

1

12

K

1

K

1:1 HA:

K11,1

Part

No

.

HK304J7101

HA104J0655

HK306J8001

HA104J0658

HA106J0663

HA300J2160

HK308J8001

HK309J8001

HA104J0653

HA104J0652

HA104J6510

HA104J0659

HA110D0672

HA300J2180

H007013090

HK310J8001

HAI06J0661

HA100J2120

HAI06J0066

HA106J0665

HA106J0668

HA106J0662

IIAI

06J0666

HAI06J0667

HA200J2030

HK341C8001

HK322H8001

HK:ll4J8001

HA313.l7101

HA30082l!i0

Hl!O(i045250

50

HAI

!OJ0070

HAIOOJ2090

HAIOOJ2100

HBOI020

HB01030

liA300J2070

HA300J2200

HA300J2210

HD!iO(iS800

I

I05EOCi(i2

IIA:IOOJ:l

170

Description

Oil reservoir assy.

Oil reservoir gasket

Oil reservoir gasket

Connecting rot.

Bracket

Knee press rod

Spring

Rubber pluge

Rubber ring

Screw

Nut

Screw

Screw

Screw

E-ring

Tinuninggaug

Knee press lifter rod

Magnet

Knee press plate assy.

Knee press plate

Knee press plate cover

Knee ligter plate rod

Knee press plate holder

Screw

lbread

stand assy.

Needle

Bobbin

Belt cover

Belt cover assy.

Screw

Wood screw

Washer

Hinge with rubber cushion

Head cushion(large)

Head cushion(small)

Hexagon socket screw key 2mm

Hexagon socket screw key

Screw driv

Screw driver (M)

Screw driver (S) 1

Collar

Screw

Oil tank I

er

(L)

3mm

Qty.

1

1

730

1

210

1

1

I

1

1

l

1 5/16 "

(28) X 10

2

2

1

2

1

l

1

1

1

1

1

1

I

1

1

DPX5

4

10#

3

I

I

3 11/64(40) X

4.

5X25

2

2

<1>5

2

2

2

1

1

1

I

1

15/64(28) X4. 5

2

Remarks

10

.

-

38

-

Page 40

K.ACCESSORIES

Fig.

No.

K45

K47

Part

No.

HK317J8001

HAIOOJ2180

Oil reservoir base

Head cover

Description Qty.

I

I

Remarks

•

"

. -

39

-

Loading...

Loading...