Page 1

.,

..

HIGH

LEAD

GG0028-L

Customer

Copy

Service

I

SINGLE NEEDLE FLAT BED ZIGZAG INDUSTRAIAL

SEWING MACHINE

Instruction Manual

Parts

Catalog

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

Page 2

SINGLE NEEDLE FLAT BED ZIGZAG INDUSTRIAL

SEWING

MACHINE

Use

of

Mach

ine

The machine is used chiefiy for stitching upper clothing such as attaching top collar to the under collar tack,

stitching

heavy materials.

collar comers, attaching collar to neck opening, and for other operations consisting

..

1

in

joining rather

Page 3

Specifications

Machine

Stitch type

Stitch length

Stitch windth

Zigzag stitch width position

Needle

Hook

Thickness of

Threads

Presser foot stroke

speed

sewn

n:taterial

2200tpm

two-thread zigzag lockstitch

up

to 5

mm.

up

to

10

median

Schmelz

forward

mm

134-

35

and

Nos.

110-

R251

up

to 8

mm

cotton threads: 14,5 tex x

+ synthetic threads:

8

mm

with

10

mm

.witt\

hand

knee

PES

lever

lever

reverse

130

3-

25

tex x 1 x 2

25

tex x 1 x 3

35,5 tex·x 3

Clear

work

space

fMachine

+With synthetic threads,

Technical description

The

hook.

to

the

with

1.

It

for setting the stitch length

presser

increased

automatic lubrication of the

with

stand

be

sure

adequately

machine GG0028-L

situated

direction

a gear

is

adapted

a screw attachment for fixing a suspension-type lighting

foot.

strain

in

the

of

feed

ratio

of 2

for forward

by a hand

are

bed

seated

to

plate

of

sewn

1.

lever

is

designed

and

equipped

work.

And

from

and

reverse

and

stitch

or

by

in

antifriction bearings. The machine

hook.

In

750 x 120

standard steel profile

to

reduce

as

a flat-bed zigzag two-thread lockstitch

with

positive bobbin

The

drive

is

transmitted, from

the

upper shaft

sewing,

width.The

the

its

and

the

rever-Se

left-side treadle. The most important

basic

version.

mm

stand

the

machine

to

the

lower

front part ofthe machine

stitching is

the

machine

..

case

the

one,

has

speed.

opening,

lower

by

endless

actuated

a group

is

supplied

sewing

rotates

shaft

to

the

belt

column

by a hand

parts

of

wick

lubrication

without

machine.

in a plane

hook,

with

holds

lever,

mechanisms

lighting.

perpendicular

by

a gear ratio

control elements

the

and

but

The

rotary

gearwheels

of 1 to

lifting of

subject

separate

it

is

frtted

the

to

2

Page 4

Machine Equipments and

their

Use

Ordering No.

791

522

522

522

522

522 794 222

The Equipments are

124 027

791149

791

995 014 00

792112

35

001

00

010 00

01

0 00

Name

Stitching set - throat plate with needle aperture 1.8 mm;

needle Schmetz

Overedging equipment

Plug for the

Built-in

Suspension-type lighting

supplied on special order only.

hole overedging operations

fridional bobbin winder

of

work area

134-

35"No. 120

3

Page 5

I.

INST~UCTIONS

A.

GENERACINSTRUCTIONS

FOR SERVICING OF MACHINE

1. Read the instructions

2. During transport and while unpacking the machine, proceed

marks on the packing.

3. Report any damage which may have occurred during transport

forwarding agents at once.

report any discrepancies to

4. Having transported the machine to its work

Make sure that no machine part has become loose and that its mechanism is free

5.

Lubricate the machine daily!

Before lubrication. always check whether the lubrication places are clean. It is advisable to lubricate

frequentJy in

strain should be lubricated several times a day

6. Clean the machine

material. During the cleaning,

7.

Once a week, during through cleaning, carefully check the whole machine to see that no parts are

damaged and that

immediately.

be dismantled, thoroughly cleaned. all individual pieces and parts

and faulty

small quantities. Those parts

Once a year. a general overhaul

or

worn

of

the manual carefully and adhere to them.

in

accordance with the instructions and

to

the railway authorities

Immediately after unpacking, check the contents against the order and

us.

We

cannot recognise delayed claims.

site, remove the preserving grease coating and all dirt.

of

any foreign bodies.

of

the machine which are subjected to increased friction

as

needed. Top up the oil tank

daily, especially the parts which become choked by impurities from the sewn

carefully check that the machine parts have not become loose.

all machin.e machanisms operate correctly. Any faults ascertained must

-out

pieces repaired

or

replaced.

sho.uld

be carried out, i.e., the whole machine should

of

electrical equipment inspected,

ofthe

hook as needed.

be

or

to the

repaired

or

8.

Adhere to the safety

operation. Do

9.

Electrical equipment

electrotechnical and safety regulations.

plugging in that all switches are off. Never try to repair any defects

yourself but

10.

We

cannot assume any responsiblity

riot

call in

reg~lations.

remove covers

of

the machine should be kept in a good and safe state in accordance with the

an

expert electrician.

Never clean the machine or repair defects while the machine is in

or

other safety devices.

If

the machine is provided with a plug always make sure before

for

faults resulting from non-observance

of

the electrical equipment by

of

these instructions.

4

Page 6

B.

PACKING,

1.

2.

3.

4.

UNPACKING,

Packing

The

severe climate

Unpacking

When

arrived

authorities or to

to

prevent

and

To set the machine on stand

After

seated

stand

To

Fix

is

designed

of

me)chine

machine

of

taking

in

good

damage

report

any

the

machine

properly, a gap

plate

on

set and

the

fix

machine

as a stable

head

over

the

CLEANING

is

seated

conditions).

machine

the

machine

order.

Report

the

foiWarding

to

machine

discrepancy

has

been

of

approximately

whole

the machine

using

the

unit

of its

levelling

in a separate

immediately,

brought

with

AND

LUBRICATION

case,

from

the

railway

any

damage

agents

parts.

Futher check

to

cireumference.

foot

the

stand

which

immediately.

as

its

work

1.5

mm

oft

he

stand

requiring

the

authorities

we

cannot

site,

will

OF

stand

has

occurred

Unpacking

the

accessories

consider

set

it

on

appear

fitted

with

no

fixing

MACHINE

either

in

or

in

the

during

should

belated

the

rubber

between

adjusting

to

the

crating

works

the

be

of the

washers

the

bed

screw.

floor.

or

in a separate

ascertain

transport

carried

machine

daims.

of

plate

Otherwise,

whether

to

out

carefully

against

the

stand.

and

the

case

the

the

rim

the

machine

(for

it

has

railway

so

as

order

When

of

the

5.

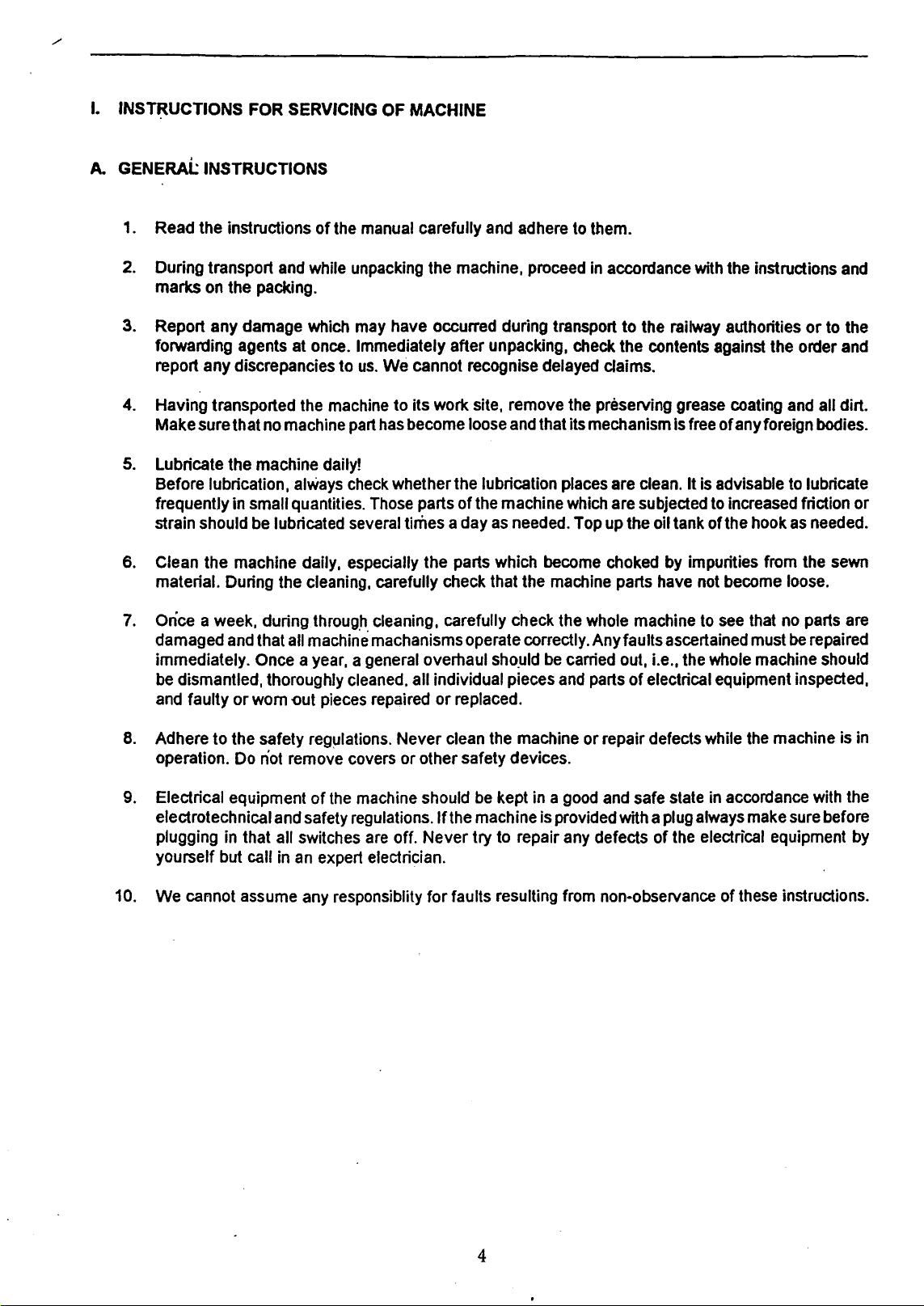

To clean and lubricate the machine (Fig. 1; Tabs. 16,

Before putting

coating and clean

hook is recommended heavy white

an oilcan. drip

beginning

tank. The

zear

box bottom. The hook and

Apply two

surrounding mechanism,

out

dirt, and

out

daily, especially

on

the

hook and

of

the

gear

or

oil

the

unpacked machine into operation, remove

the

machine thoroqghly. For oiling

vase

line

oil

into

the

marked holes

work shift.

wheels

three

the

of

drops

hook with

after

its

mechanism. From time

the

let

the

Check

hook

of

the

also

the

gear

box

its

mechanism should be

kerosene

machine run

its

mechanism with oil. This cleaning should

end

of

the

work

(7, Tab. 16) and (6, Tab. 17) with lubrication

machine,

hook bobbin

thread

out

and

of

take

the

the

hook.

Once a week, The machine

should be thoroughly

settled

oil

and

of

all

impurities.

freed

of

oil

with viscosity

of

the

machine arm

level

of

receive

to

all

soiled

at

high

shift

to

time.

grease.

17)

the

all

machine

of

50

once

oil

at

the

indicator

oil

from

the

felt

cleaned

speed,

in

order

use

grease

parts

of

then

to

prevent

nipple

the

stop

Before proceeding

@

1

•

protective

mechanisms

mm2.s

_,at

and

20 .With

a day, before

of

the

hook

inlay

situated

several

times

hook and

it wipe off flushed

be

dirt

from drying

to

refill

the

~o

cle~n

grease

the

the

oil

on

the

a day.

of

the

carried

shafts

the

5

·Fig.

Page 7

WarninJJ

Before proceeding to clean and lubricate the machine,

switch and hold your feet away from the machine stand treadles in order to avoid accidental

machine start by treadle actuation.

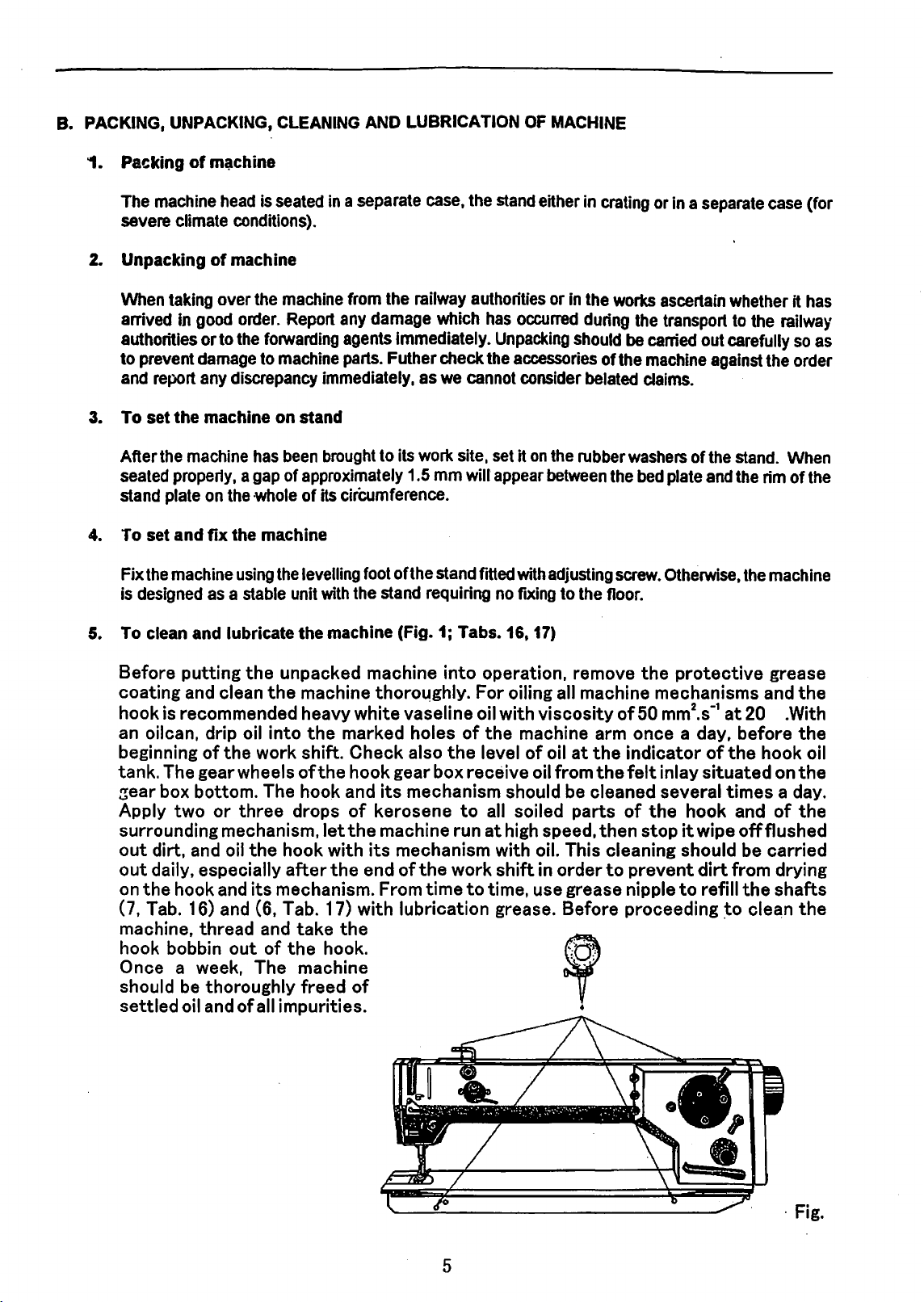

6.

To

adjust

To

adjust the oil flow to the hook, tum

screwdriver the adjusting pin

the front side

plate,

anticlockwise). Adjusted at zero, the regula-

tion

hook preventing

machine has been put into service, check at

regular-intervals the oil level both in the hook

oil tank and in the

machine ann.

the

from

zero

still provides

I ·

hook

lubrication

of

the oil tank under the bed

to

maximum (to

for

a minimum oil flow to the

it

from seizing.

oil· tank situated on the

(Fig. 2)

(1

), located on

with

the

After

left,

the

a

be

sure to switch

·

off

the main

Caution

At

interval, e.g., at the beginning

shift,

the gathered superfluous

the machine run idly

by prod.ucing a few stitches (20 em apprQxi-

mately) on a test material, to prevent the

threads and,

from getting soiled by oil.

C.

TO PREPARE THE MACHINE

I

the beginning

it

is advisable to remove.from the hooks

of

consequently, the sewn work

1. General insJ.!ection

Inspect the machine thoroughly for loose parts

the hand wheel by hand,

correctly. Further check the correct working

presser foot by means

the left treadle. ·

work after a relatively long

of

the morning

oil, either by letting

for

a short period time

FOR

SEWING

·check first whether it revolves freely and whether the machine is adjusted

of

the knee lever, and the reverse stitching by means of the hand lever or

or

as

well as for the presence

of

the mechanism controlling the lifting and sinking

of

foreign bodies. Rotating

Fig. 2

of

the

of

2.

Sense

The handwhee.l must turn in the direction

3.

Electrical equipment

An electrician connects the machine to the mains. Switch

pulley turns

must must

the electric motor. An incorrect sense

of

rotation

be

of

the red arrow on the belt guard.

in

the correct direction, i.e.,

taken out and the cable must be switched over

to

the left. It this is not the case, the plug

of

rotation

of

the pulley is inadmissible.

on

the electric motor

Warning I .

Avoid any intervention into the electrical equipment

·Unqualified intervention involves the risk

of

accident by electric shock.

6

and

check whether the

of

the lead-in cable

on

the plug or

of

the machine but call in an electrician.

on

the tenninal board

of

Page 8

7

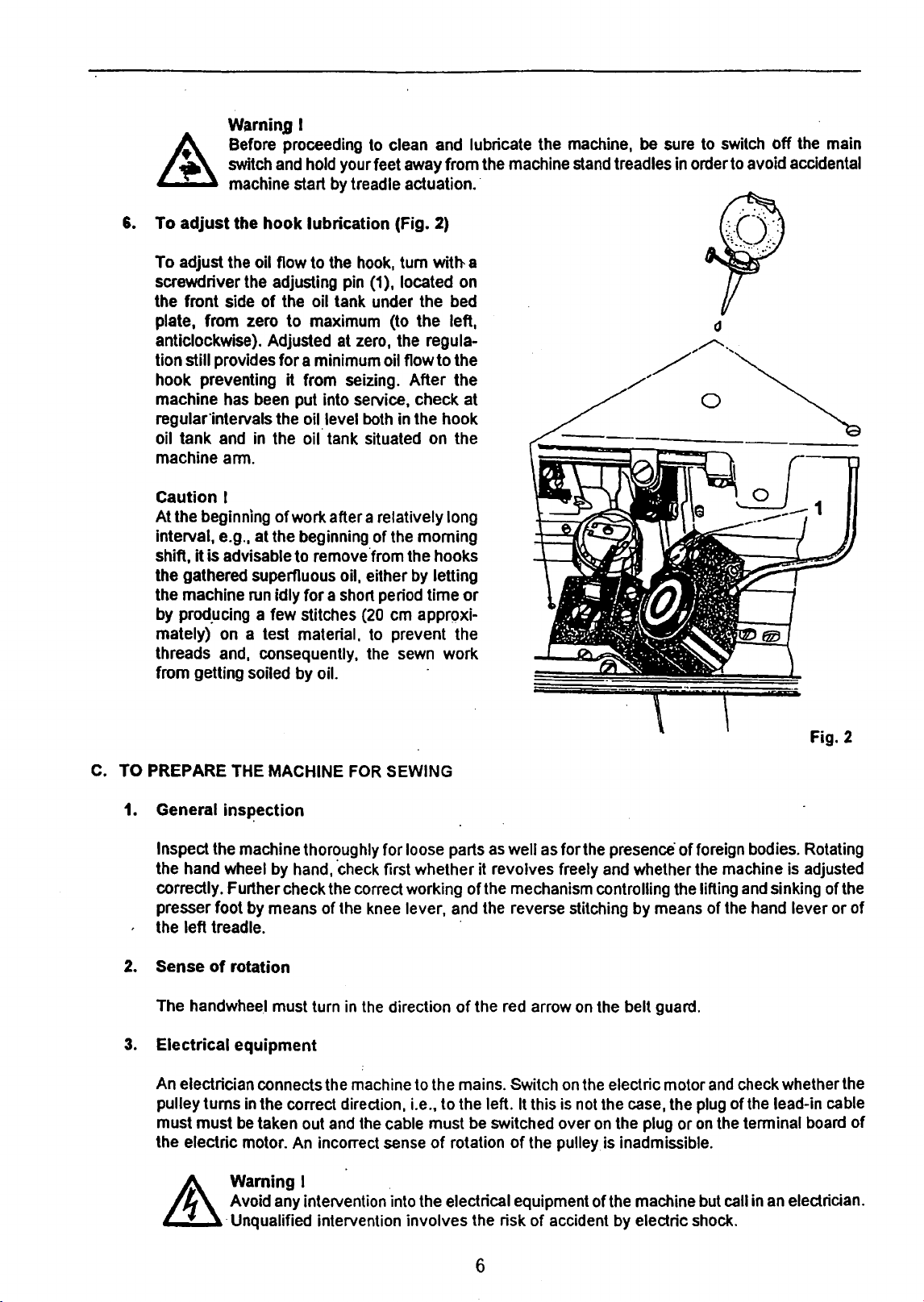

4.

V-belt

The

of

power with losses reduced to minimum.

middle

will

increases both the power consumption and the wear

follows:

the lower belt guard the sheet piece fixed by screws to

falling out the groove

electromotor, fix

insert

correct tension, and mount the upper

and

its

tension

V-belt can

be

its holder after the loosening

part between the hand wheel and

yield some

Tilt

it

into the hand wheel groove. Lift the machine to its operational position, check the V-belt for

20

the machine head, screw out the screws (4), remove the upper belt guard (1), and from

(Fig.

3)

easily tensioned by means

of

two screws. The correct belt tension ensures transmission

To

the

mm sideways. Excessive tension

of

the pulley, remove the V-belt, mount a new one onto the pulley

it

by attaching back the sheet piece, pass it between the tank

belt guard.

1

I

4

...

Fig. 3

of

the electromotor that can be displaced in the guiding

check the tension

pulley;

if

the belt tension is correct, the pressed-on part

of

the V-belt reduces the machine output and

of

bearings. To remove the V-belt, ·proceed

the, stand plate and protecting the V-belt from

of

the V-belt, depress

it

lightly in the

and

stand plate, and

of

of

full

as

the

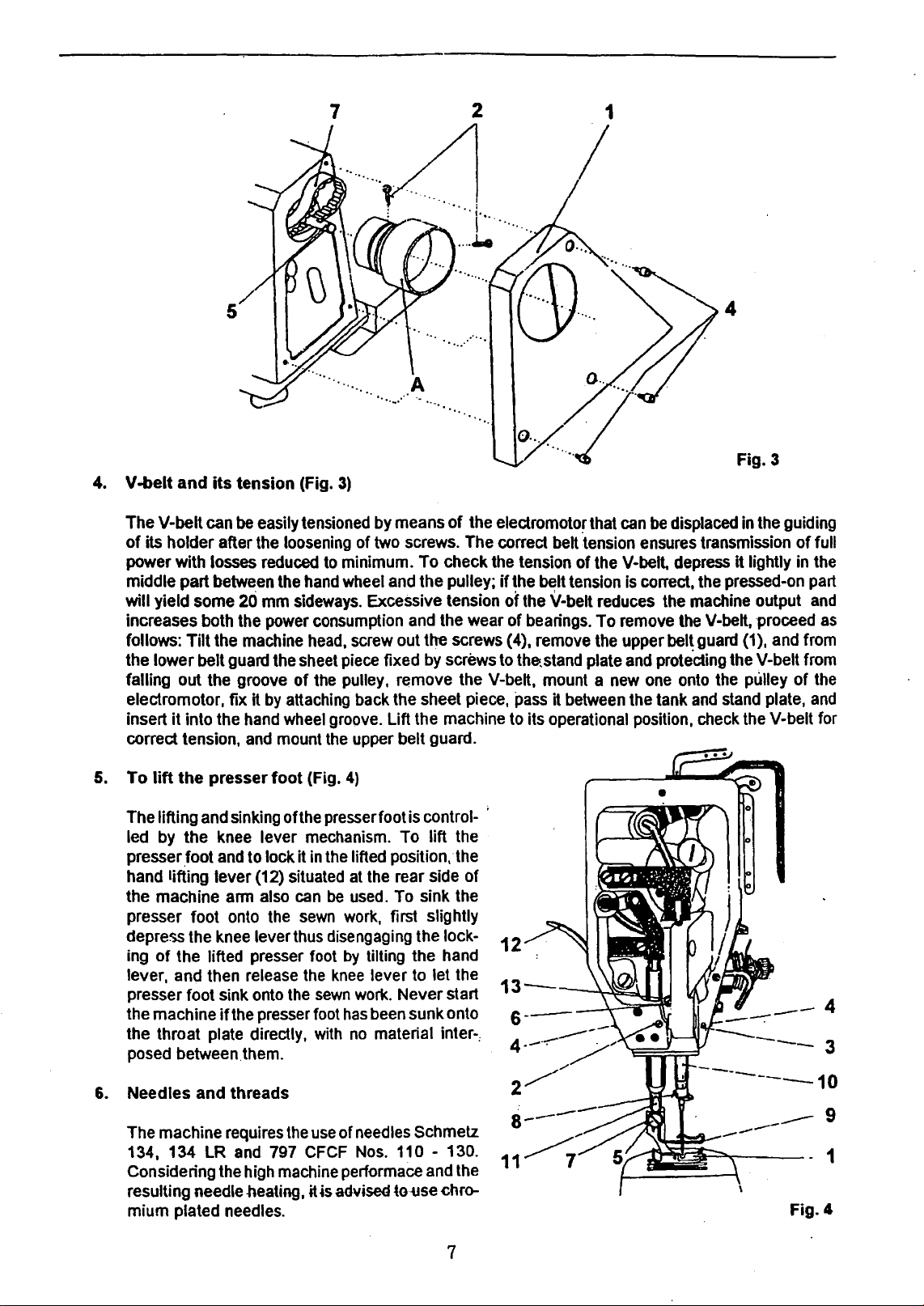

5.

To

lift

the

presser

The lifting and sinking ofthe presser foot is control- '

led by

presser.foot and to lock it

hand lifting lever (12) situated at the rear side

the machine arm also can

presser foot onto the

depress the knee lever thus disengaging the lock-

ing

lever, and then release the

presser foot sink onto the

the machine

the throat plate directly, with

posed between.them.

6.

Needles

The machine requires the use

134, 134

Considering the high machine performaee and the

resulting needle

mium plated needles.

the

knee lever mechanism. To lift the

of

the lifted presser foot

if

and

LR

foot

(Fig.

4)

in

the lifted position,·the

be

used. To sink the

sewn

work,

first

by

tilting the hand

knee

lever to let the

sewn

work. Never start

the presser foot

threads

and 797 CFCF Nos. 110 - 130.

-heating, it

has

been sunk onto

no

material inter-;

of

needles Schmelz

~s

advised to-use chro-

of

slightly

12

2

11

Fig.

4

7

Page 9

The

size of

ear.lt is

the needle ear

the beginning of stitching after

the

thickness of

excessive strain (impacts

by

friction

correct needle

stitches. Only high-class threads should

S-twist threads

thread.

the

needle ear

threads, the

7.

To insert the needle (Fig.

the

m~edle

advisabl~

but

between

course

should

A

coarse

reduces

sewing

depends

to

choose

·helping

sewn

work.

the

needle

follwed

be

thread or

speed

the

a rather thin needle, just permitting

to prevent the upper

A needle too thin

at

the

used

one

machine performance

should

4)

on

the size of

the

previous thread trimming.

needle punches into the

and

the

sewn

by

irregular formation ofthe

for the needle. white

which

has

be

reduced accordingly,

the

thread,

thread

with

work, etc.}

be

used.

Especially suitable

to overcome

and

since

from

respect.to

work,

and

upper

both

S-twist

considerable

incerases

it

must

pass

freely through

the

free

passage

being

threaded

The

needle

the

thickness of

upper

thread

exposed

to

to

the

thread

loops

are

conical

and

Z-twist

resistance

its trouble incidence. With synthetic

prevent

the

ofthe thread

out

of

the

needl~

size

should

sewn

tension, heat

risk of deviations

and

thread

threads

be

work

resulting

cross--wound

is suitable

when

passing

from melting.

adequate

is

the

needle

through

ear

subject

generated

from

the

in

skipped

bobbins.

as

lower

through

at

to

to

To facilitate

toward

between

of

the needle bar

directed

I

the

needle shaft

screw.

the centre ofthe

but choose it

switch and

stand treadles

chine start

8.

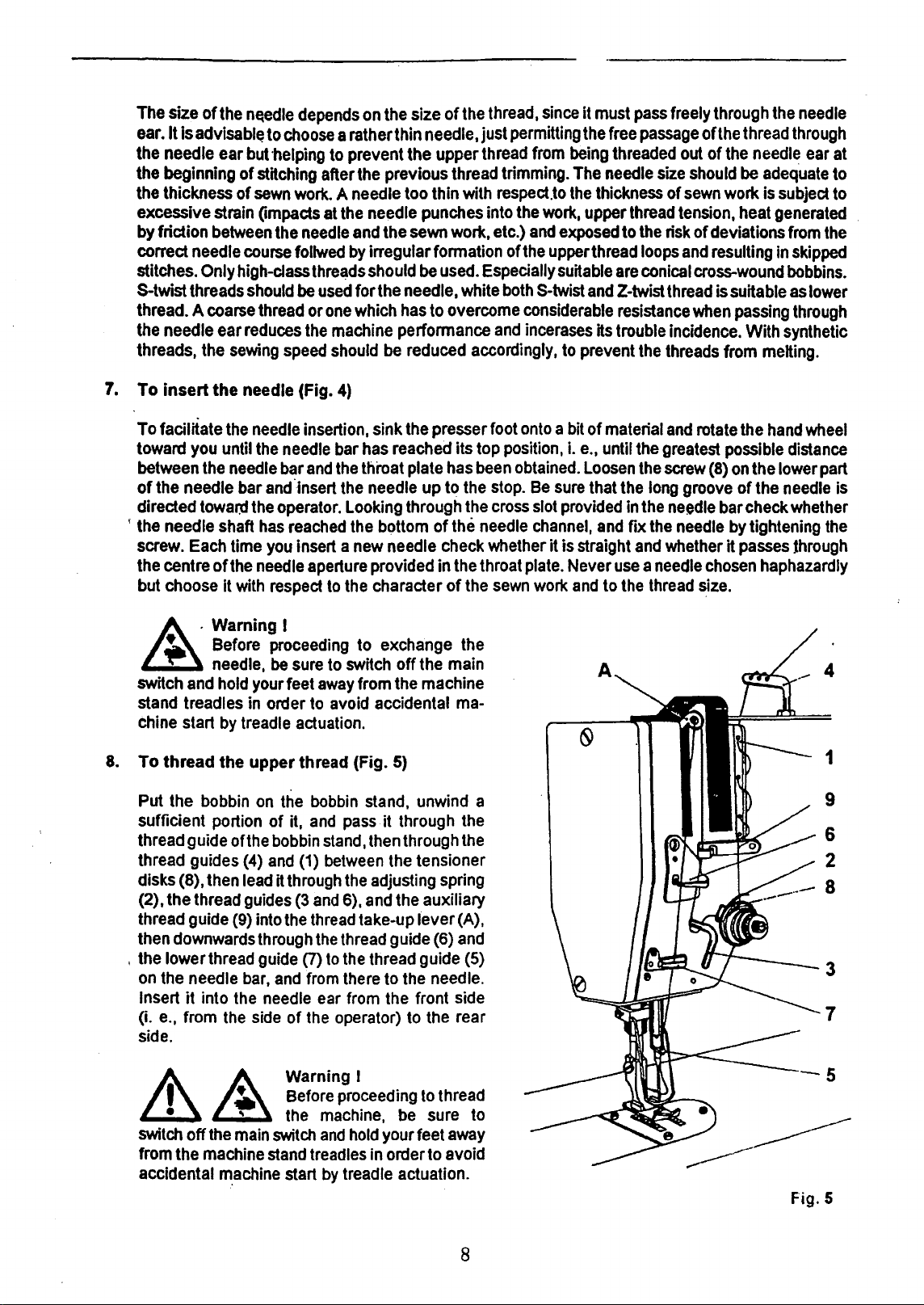

To thread the upper thread (Fig.

Put

the

sufficient portion of

thread guide ofthe

thread guides

disks (8), then

(2), the thread

thread guide

then downwards

, the lower thread

on

the needle

Insert

(i.

e.,

side.

you

until

the

towar:d

Each

Warning I

Before

needle,

hold

by

bobbin

it into

from

the

the

needle

the

needle

the

has

time

needle

with

your feet

in

treadle

on

(4)

lead

guides

(9)

into

through

guide

bar,

the

side

insertion, sink

needle

bar

and

and

·insert

operator.

reached

you

insert a

aperture provided in

respect

proceeding

be

sure

order

to

actuation.

the

bobbin

it,

and

bobbin

and

(1)

it

through

(3

and

the

thread

(7)

and

from

needle

of

the

the

bar

has

reached its top position, i.e., until the greatest

the

throat plate

the

needle

Looking through the

the

bottom of

new

needle

to

the

character

to exchange the

to

switch

away

avoid accidental

pass

stand,

between

the

6),

the

thread

to

the

there

ear

from

operator)

off the main

from

the

5)

stand, unwind a

it through

then

through

the

tensioner

adjusting spring

and

the auxiliary

take-up

thread guide

l·ever

guide (6)

to

the

the

front side

to

presser foot

has

been

up

to

the

the

needle

check

whether it is straight

the

throat

of

the

machine

ma-

the

the

(A),

and

(5)

needle.

the

rear

onto a bit

obtained.

stop.

cross

sewn

Be

sure

slot

provided

channel,

plate.

Never

work

of material

Loosen

that the

and

use a needle

and

to

the

the

in

fix

and

long

the

the

thread

and

rotate

possible

screw

(8}

on

groove of the

needle

whether it

needle

chosen

size.

bar

by

the

hand

wheel

distance

the lower

check whether

tightening

passes

haphazardly

part

needle

the

through

4

1

9

6

2

3

7

is

Warning!

..

&~

switch

off

the

main

from the machine

accidental

~achine

Before proceeding

"

the

switch

stand

treadles

start

machine,

and

hold

by

treadle actuation.

be

your feet

in

order

to

thread

sure

to

to

away

avoid

8

Fig. 5

Page 10

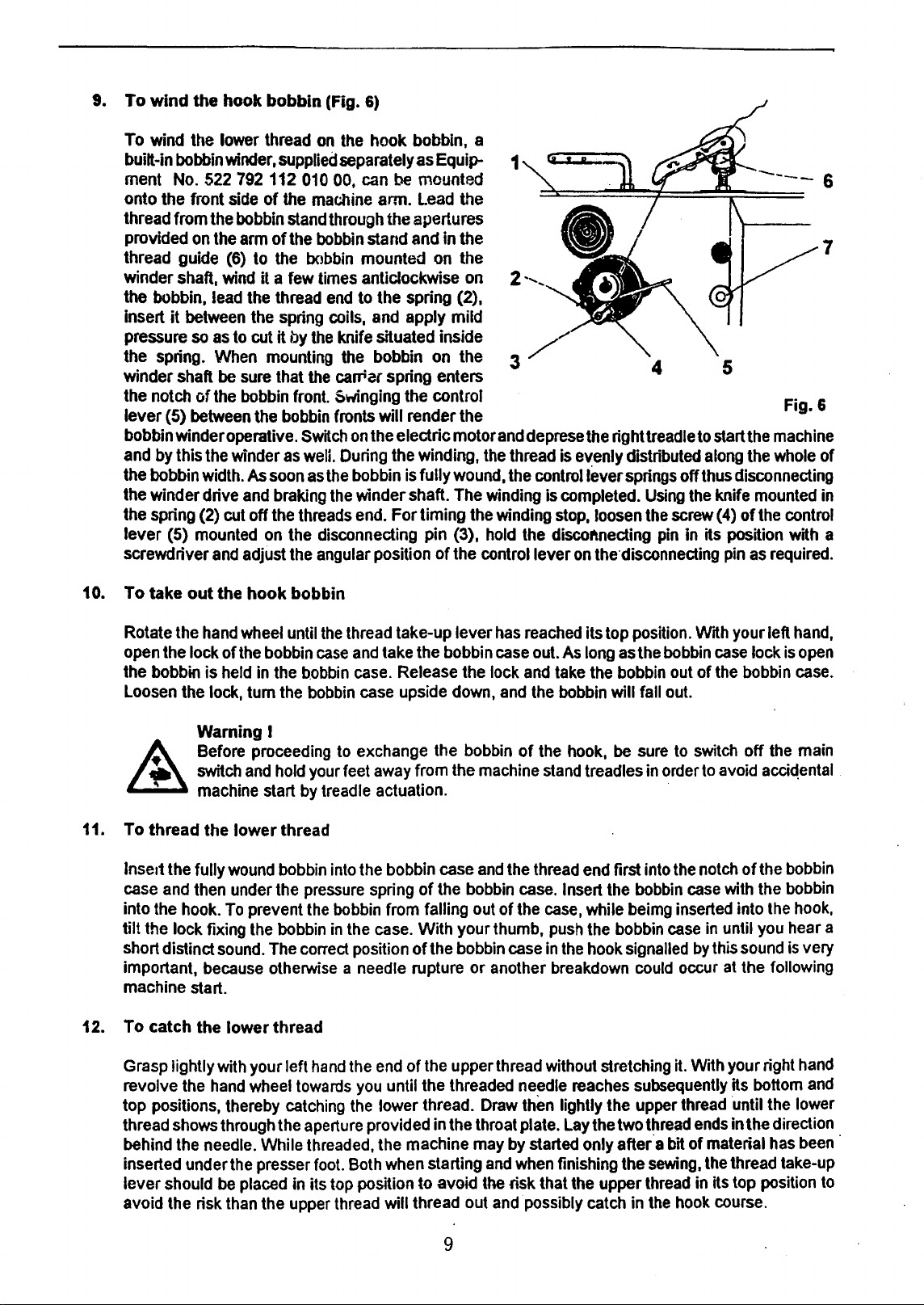

9.

To

wind

the hook bobbin (Fig.

To

wind

the

lower thread

built-in

ment

onto the front

thread from

provided

thread guide

winder

the bobbin, lead

insert

pressure so

the spring.

winder shaft

the notch of

lever (5)

bobbin winder operative.

and

the bobbin

the winder drive

the spring

lever (5)

screwdriver

bobbin

No.

it

by

shaft,

this

winder,

522 792 112 010 00,

the

on

the

(6}

wind

between

as

When

be

the

between

the

width.

(2}

cut

mounted

and

side

of

bobbin

arm

to

it a

the

the

to

cut

sure

bobbin

the

winder

As

and

off

on

adjust

6)

on

the

hook bobbin, a

supplied

the

stand

of

the

the

few

thread

spring coils,

it

by

mounting

that

bobbin

as

soon

braking

the

the disconnecting pin (3),

the

separately

can

machine

through the apertures

bobbin

bobbin

times

the

the

front. Swinging the control

Switch

welL

as

threads

angular position of the control lever

stand and in the

mounted on the

anticlockwise

end

to

knife situated inside

the bobbin

carriar spring enters

fronts will render the

on

During

the

bobbin

the

winder shaft. The

end.

as

be

mounted

arm.

Lead

the spring

and

apply mild

the

electric motor

the winding,

is

fully

For timing

Equip- 1

the

on

(2},

on

the 3

and

the

wound.

winding

the

winding

hold

2

deprese

thread

the

controiiEwer

the discoftnecting

the

right

is

evenly distributed

is

completed.

stop,

loosen

on

the'disconneding

4 5

treadle

springs

Using

the

pin

Fig. 6

to

start

the

machine

along

the

whole

off thus disconnecting

the

knife

mounted

screw

( 4) of

the

control

in

its position with a

pin

as

required.

7

of

in

10. To take

Rotate the

open

the bobbin is

Loosen

11. To thread the lower thread

Insert the fully

case

into

tilt the lock fixing

short distind

important,

machine start.

12. To catch the

out

hand

the lock of

the

lock, tum

Warning I

Before

switch

machine

and

then

the

hook.

because

the hook bobbin

wheel

until

the

the

bobbin

held

in

proceeding

and

start

wound

under the

To

prevent

the

sound.

lower thread

case

the

bobbin

the

bobbin

hold

your

by

treadle actuation. ·

bobbin

pressure

the

bobbin

The

correct

otherwise a needle

thread

to

feet

into

bobbin

in

take-up lever

and

take

case.

case

exchange the

away

the

bobbin

spring

from falling

the

case.

position of the

has

the

bobbin

Release

upside

from

case

of

the

With your thumb,

rupture or another

the

down,

bobbin

the

machine

and

bobbin

out

bobbin

case

lock

and

the

of

case

reached

out.

and

take

the

bobbin

of

the

stand

thread

case.

the

case,

push

in

breakdown

its top position.

As

long

as

the

bobbin

will fall

hook,

be

treadles

end

first into

Insert

the

while

beimg

the

bobbin

the

hook

signalled

the

bobbin

out

out.

sure

to

in

order

the

bobbin

case

could

Wrth

case

of

the

switch

to

avoid

notch

case

with

inserted

in

until

by

this

occur

at

your left

bobbin

off

of

into

sound

the following

hand,

lock

is

open

case.

the

main

acciqental

the

bobbin

the

bobbin

the

hook,

you

hear a

is

very

.

Grasp

revolve

top positions, thereby

thread

behind the

inserted under

lever should

avoid the risk

lightly

the

shows

needle.

with

hand

through

the

be

placed

than

your left

wheel

towards

catching

the

While

presser

in its

the

upper

hand

the

you

the

aperture

threaded,

foot.

Both

top

position to avoid

thread

end

of

the

upper thread without stretching it. With your right

until the threaded

lower thread.

provided

the machine

in

the

when

starting

will thread out

needle

Draw

thEm

throat plate.

may

by

started only after a

and

when

the

risk that

and

possibly

reaches

lightly the upper

Lay

finishing the

the

9

the two

upper

catch

subsequently

thread

thread

thread

in

bit

of material

sewing,

the

hook

ends

the

in

Hs

course.

hand

its

bottom

·until

in

the direction

thread take-up

top position

the

has

and

lower

been

to

·

Page 11

13.

Sewing-

Insert

gradually depressing the right treadle.

by

with the treadle has reached its lowest position.

is disengaged,

the material but guide it only. By pulling

it

in

collisions

machine

it, and cut the

To

Having

or

four

per

lubrication.

machine

II

..

INSTRUCTIONS

work

P.roper

the

material

case

of

of

stop,

observe:

put the

weeks. when the machine is running-in, increase its speed gradually from about 3 000 stitches

min. and check carefully its running. Throughout this time. pay'special attention

even

to

be sewn under the presser foot and switch on the electro motor. Start the machine

The

sewing speed increases up

By

releasing the treadle, the clutch

the

electromotor braked, and

a collisions with the edge

this kind burr the needle aperture which, in its

set

the needle

two

threads with scissors.

new

machine in use do not charge

By

keeping to these rules you will obtain a long service

at

its full perfonnance.

FOR

ADJUSTMENT

to

its top position,

OF

the

machine stopped. During the sewing, avoid pulling

the

material, you. bend the needle with the risk

of

the

needle aperture provided

lift

the presser foot, remove the sewn

After

that.

the

machine

it

fully from the very beginning. During

MACHINE

MECHANISMS

to

the

in

the throat plate. Repeated

tum,

causes thread ruptures.

is

ready

for

stitching

life

and perfect precision

maximum

ofthe

electromotor

of

work

from

another

the

to

the

obtained

breaking

After

machine

under

seam.

first

of

the

two

the

This

section

adjustments. requiring more time, should be carried out by a

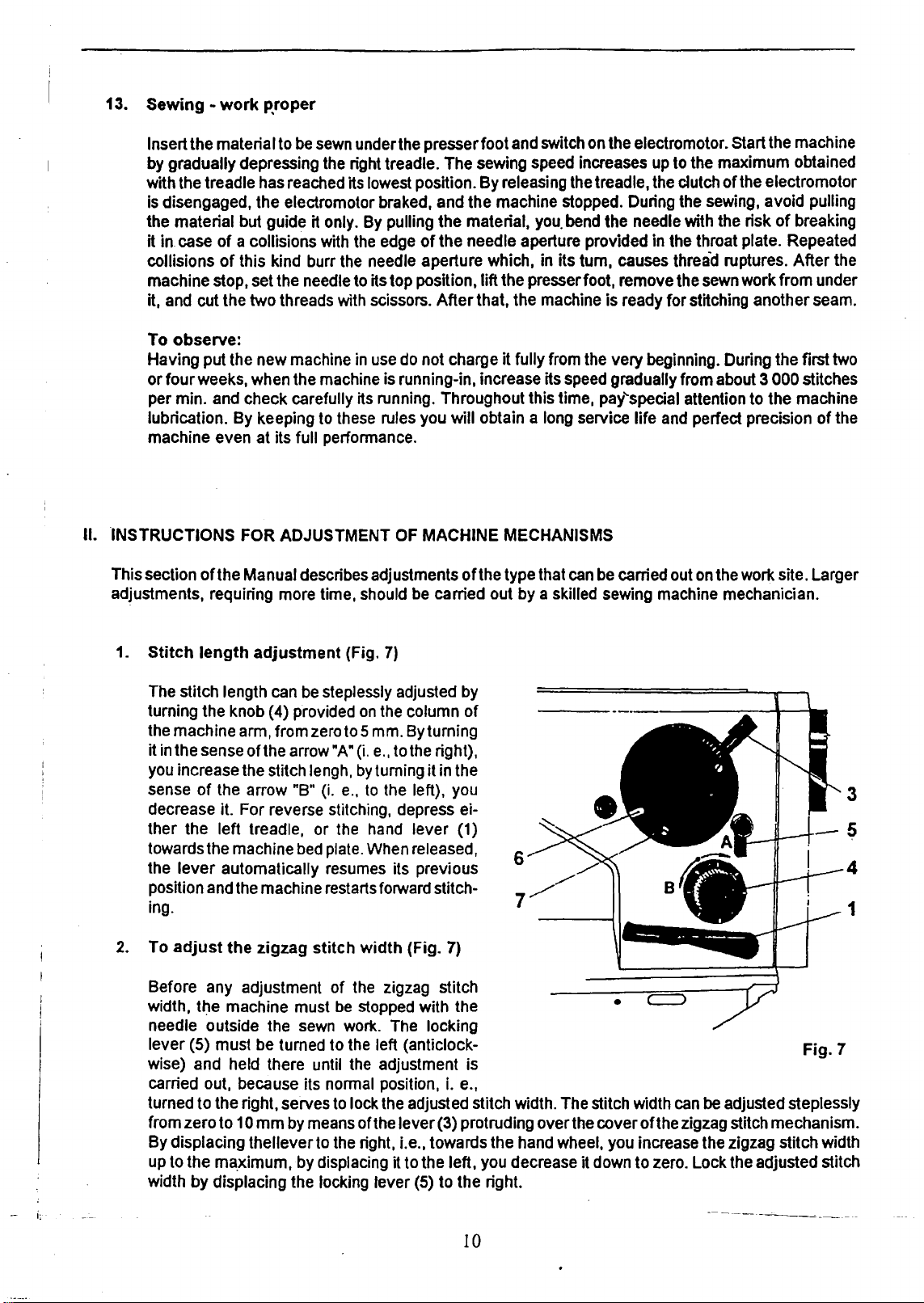

1.

Stitch

The stitch length can be steplessly adjusted by

turning the knob

the

it in the sense

you increase the stitch lengh,

sense

decrease

ther

towards the machine bed plate. When released,

the

position and the machine restarts forward stitch-

in g.

2.

To

Before any adjustment

width,

needle outside the sewn work. The locking

lever

wise) and held there until the adjustment is

carried out. because its normal position, i. e.,

turned

from

By

up

width

ofthe

Manual describes adjustments

length

adjustment

(4) provided

machine

arm, from zero to 5 mm. By turning

ofthe

arrow "A" (i.e.,

of

the arrow "B"

it. For reverse stitching, depress ei-

the

left

treadle, or the hand

lever

automatically resumes its previous

adjust

displacing

to

the

zigzag

t~e

machine must be stopped with the

(5)

must

be turned

to

the

right, serves to lock the adjusted stitch width. The stitch width can

zero

to

1 0

mm

by means

thelleverto

the

ma_ximum, by displacing it

by

displacing the locking

(Fig.

7)

on

the column

to

the right),

by

turning it in the

(i.

e.,

to

the left), you

lever

stitch

width

(Fig. 7)

of

the zigzag stitch

to

the left (anticlock-

of

the

lever

(3) protruding

the right, i.e., towards

to

the

lever

(5)

to

of

the type that can be carried out on the work site. Larger

of

(1)

6

7

over

the

hand wheel, you increase the zigzag stitch width

left, you decrease it down

the

right.

skilled sewing machine mechanician.

•

Fig.

be

adjusted steplessly

the

cover

oft

he zigzag stitch mechanism.

to

zero. Lock the adjusted stitch

3

5

4

1

7

10

------

-~----

Page 12

3.

Thread tension adjustment

The

tension

the middle layer ofthe

to the

thread tension,

By

turning

consequently.

inversely .lfthe

thread

of stitching.

of

right, i.e.,

the

the

tension

the

upper

clockwise,

use

screw

tension

lower

by

means

sewn

the

screw

to

thread

and

the

lower thread

material. To adjust the upper

to

increase the tension,

the

of

of

situated

right

the

lower thread that

tension

the

tensioner

you

has

in

increase

the

been

nut

must

middle

the

originally

will

be

or

part

pressure

passes

adjusted

be

sufficient,

so

Interrelated that

thread

inversely,

of

between

tension,

to

ttle

pressure

of

the

the

correctly'

as a rule,

the

tum

decrease

spring

spring

on

spring

and

the

to

resorte

stitch

binding

the

tensioner nut either

it.

To

adjust

the lower

on

the

bobbin

the

bobbin

the

bobbin

adjustment

the

case

.case

oft

he

desired

place

case.

and,

•.

and

upper

quality

in

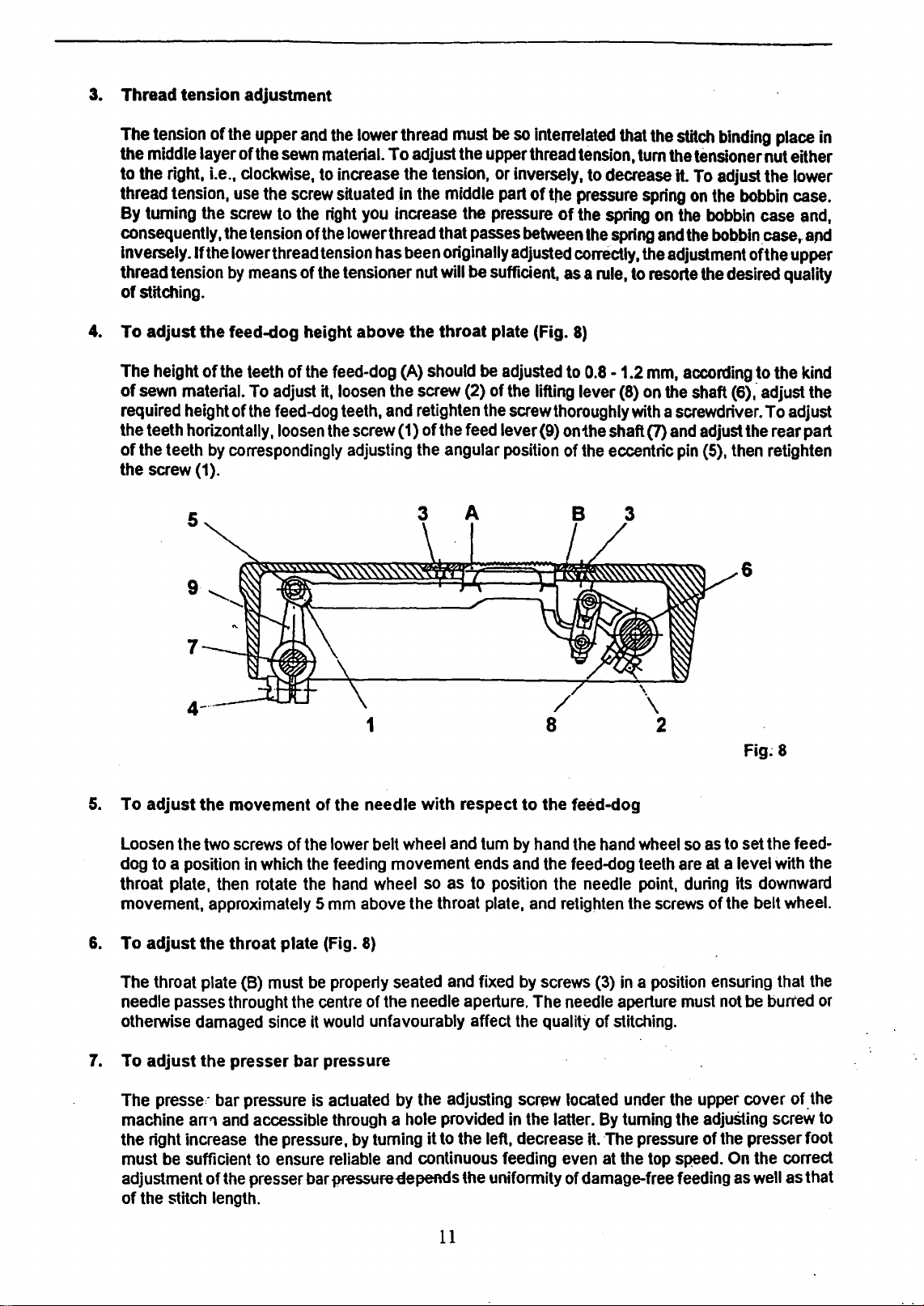

4. To adjust the feed-dog height above the throat plate (Fig.

The

height of

of

sewn

required

the

teeth horizontally,

the

teeth

of

screw

the

the

material.

height of

by

correspondingly

(1}.

teeth

To

adjust

the

feed-dog

of

the

loosen

feed-dog

it,

loosen

teeth,

the

screw

adjusting

(A)

the

and

(1) of

should

screw

(2) of

retighten

the

feed

the

angular

be

adjusted

the

the

screw

lever (9)

position

lifting lever (8)

thoroughly

5

9

7

4

1

8

8)

to

0.8 - 1.2

on

the shaft (7)

of

the

eccentric

mm,

according

on

the

shaft (6); adjust

with a screwdriver.

and

adjust

the

pin

(5),

then

6

Fig~

to the

To

adjust

rear part

retighten

8

kind

the

5.

To adjust the movement of the needle with respect

Loosen

dog

throat plate,

movement, approximately 5

6.

To adjust the throat plate (Fig.

The

needle

otherwise

7.

To adjust the presser bar pressure

The

machine

the right

must

adjustment of

of

the

to a position

throat

plate

passes

damaged

presse,-

arr'l

increase

be

sufficient

the

stitch

two

then

throught

bar

and

the

length.

screws

in

which

rotate

(B)

must

since

pressure

accessible

the

to

ensure

presser

of

the

lower

the

feeding

the

hand

mm

be

property

the

centre

it

would

is

actuated

through a hole

pressure,

reliable

bar

pr~ssur~-depends

belt

wheel

movement

wheel

above

8)

of

unfavourably affect

by

turning

the

seated

the

needle

by

the

and

continuous

so

throat

provided

it

to

11

to

and

tum

by

hand

ends

and

as

to

position

plate,

and

and

fixed

by

aperture.

adjusting

the left,

the uniformity of

The

the

screw

in

the

decrease

feeding

the feed-dog

the

hand

the

feed-dog

the

needle

retighten

screws

needle

quality of

located

latter.

even

the

(3)

in a position

aperture

stitching.

under

By

turning

it. The

at

the

damage-free

wheel

so

teeth

are

point,

during

screws

must

the

the

pressure

top

speed.

feeding

as

to

set

at

a level

its

of

the

ensuring

not

be

upper

cover of.the

adjuSting

of

the

presser foot

On

as

the

feed-

with

the

downward

belt

wheel.

that

the

burred

screw

the

correct

well

as

that

or

to

Page 13

8.

To

adjust

The hook must be so interrelated with the needle that at the moment when the hook point begins to

take

hook point, at

is not adequate

screw (6)

plate.

9.

To

adjust

up

in

height

the

upper

th~

maximum stitch width and in the left position

to

of

the carrier (13)

the·hook

the

needle

thread loop, the upper edge

this requirement, loosen the respective screws, remove the front plate, loosen the

course

bar

of

the needle

(Fig.

bar

4)

of

the needle ear is approximately 0.6

oft

he needle

(1

0), adjust the needle

bar

correctly, and mount the front

bar.lfthe

mm

needle bar height

under the

Adjust the stitch width to zero and tum the hand wheel towards you until the needle

bottom position and reascends by 2.8

axis, and the distance between the needle and hook must be

the throat plate, loosen the screws, adjust the angular position

the screws, and mount the throat plate.

10.

To

adjust

After

a gap

11.

To

adjust

If

the machine is adjusted correctly the feed-dog describes

reverse stitching. The adjustable eccentric is positioned by means

shaft

adjustable

Tt•e

eccentric

height adjustment

eccentricity

dog holder with the feed-dog to the centre

the screw(4)

the middle

the

hook

holder

the hook course adjustment, loosen the fixing screw and adjust the hook holder(2) so as

of

approximately

the

elliptical

a~d

commands the length

one, commands the corre,:;t interrelation between the

stationary eccentric is secured by two screws located in its collar. The eccentricity

!s constant so that the height

of

the feed-dog teeth. The adjustment should be carried out

of

the adjustable eccentric equals zero (so that

of

the lever(9) on the feed shaft (7). Ensure that the feed-dog reaches its top height about

of

the feed-dog movement.

(Fig.

0.

7 mm between the holder lug and the bottom

path

of

+ 0.2 mm. In this position the hook point must lie in the needle

0.1

mm

or

less.

of

the hook on the hook shaft, retighten

2)

of

the

feed-dog

of

feeding. Another eccentric, stationary and situated in front

of

the height

movement

of

of

the slot provided in the throat plate, having first loosened

(Fig.

8)

an

elliptical path both with forward and with

of

a pin in the aperture

major

and the minor axe

the ellipse remains the same regardless

no

feeding takes place) adjust the feed-

bar

reaches its

If

it is not the case remove

to

obtain

the inner part

as

of

the hook.

ofthe

of

the ellipse.

oft

he stationary

follows: When the

lower

of

the

of

the

12.

To

adjust

Loosen the screw

regulation knob to its zero position, adjust the traversable sleeve

position corresponding to zero, retighten the screw

equally long at forward and reverse stitching.

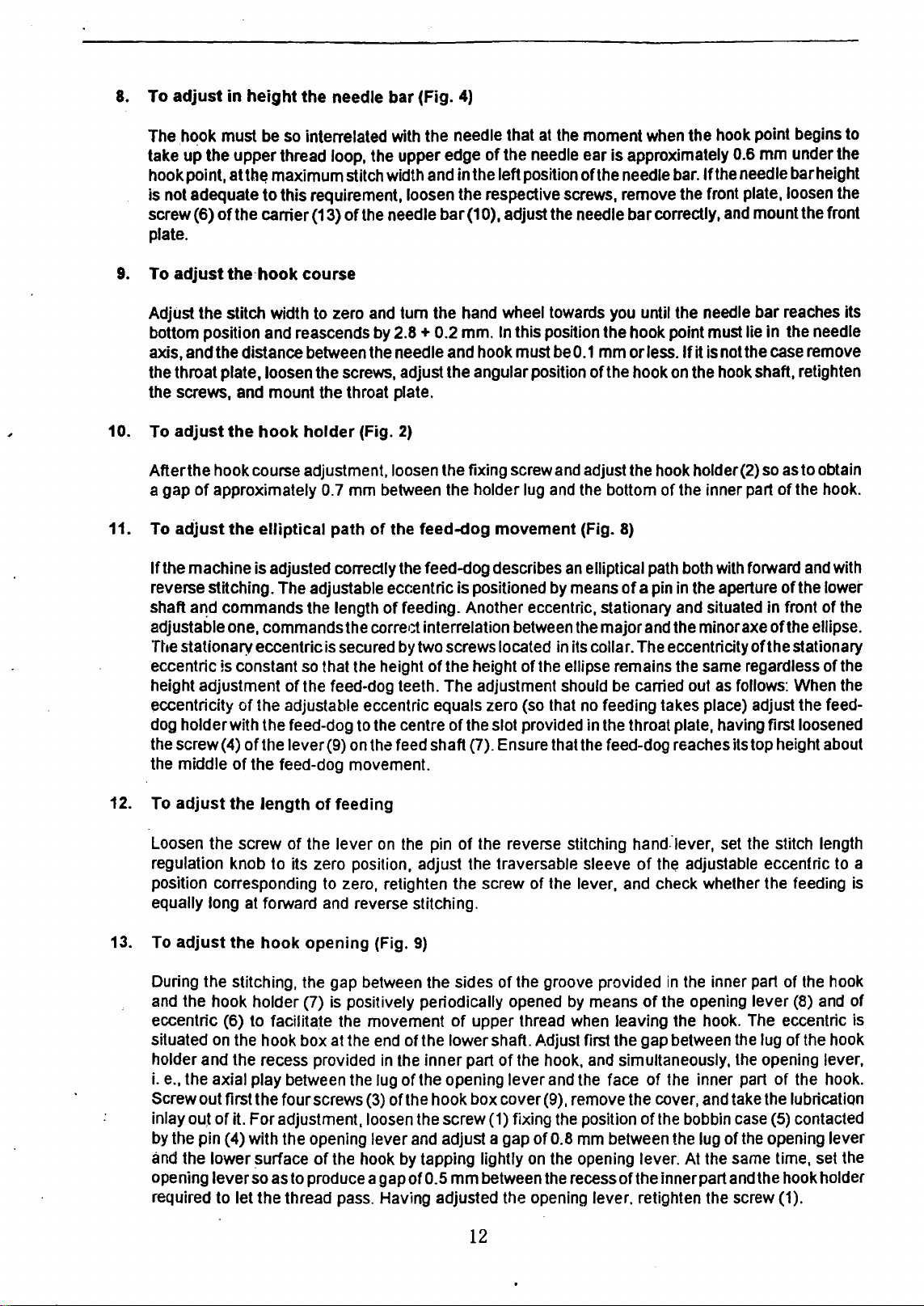

13. To

adjust

During the stitching, the gap between the sides

and the hook holder (7) is positively periodically opened by means

eccentric (6) to facilitate the movement

situated on the hook box at the end

holder and the recess provided

i.e.,

Screw out first the four screws (3)

inlay

by the pin (4) with the opening lever and adjust a gap

and the

opening

required to let

the

length

the

hook

the axial play between the

ou,t

of

it.

For

lower

~urface

lever

so as to produce a gap

the

of

feeding

of

the lever

opening

adjustment, loosen the screw (1) fixing the position

of

the hook by tapping lightly on the opening lever. At the same time, set the

thread pass. Having adjusted the opening lever. retighten the screw (1).

on

the pin

(Fig.

of

in

the inner part

Jug

of

of

the hook box cover(9), remove the cover, and take the lubrication

of

of

the reverse stitching hand.'lever, set the stitch length

of

9)

of

the groove provided

of

upper thread when leaving the hook. The eccentric is

the lower shaft. Adjust

of

the hook, and simultaneously, the opening lever,

the opening

0.5

mm

lever

of

between the recess

12

of

the adjustable eccentric to a

the lever, and check whether the feeding is

in

the inner part of the hook

of

the opening

first

the gap between the lug

and the face

0.8 mm between the lug

of

the inner part

of

the bobbin case (5) contacted

of

the inner part and the hook holder

lever

(8) and of

of

the hook

of

the hook.

of

the opening lever

Page 14

Before

remove

opening

carried

sewn

eccentric (6)

lower shaft

inner part of

moment

across

and

correct

hook

proaches

around

thread.

on

move

adjustment

insert the lubrication inlay,

cover of

14.

To exchange the presser foot (Fig.

proceeding

the

lever

uot

off.

when

the

the

lug

passage

bottom,

the

The

the

adjusting

while

the

throat

with

only

Loosen

and

so

as

the

the

recess

of

the

when

the

opening

inner

correct

the

thread

ofthe

hook

to

cany

plate.

respeCt

while

the

the

two

set

Hs

angular

to

time

hook

upper

of

the

hook

holder.

ofthe

upper

the

lug

part

of

the

adjustment

spring

that

passes

eccentric,

box.

to

thread

inner

out

the

The

timing of

to

the

machine

screws

position

the

opening

begin

begins

part

Check

thread

opening

to

open

hook

is

must

freely.

retighten

and

adjustment,

the

looper is

prior to the

of the hook

the

for the upper

best

only slightly

Is

being

(2) of

on

of

to

also

around

lever

passage

checked

After

its

screws,

mount

4)

best

the

the

the

pass

the

the

ap-

the

the

7

8

1

5

6

2

9

3

Fig. 9

To

exchange

lifting lever (12). Lift

presser

foot

from

foot

check,

presser

15.

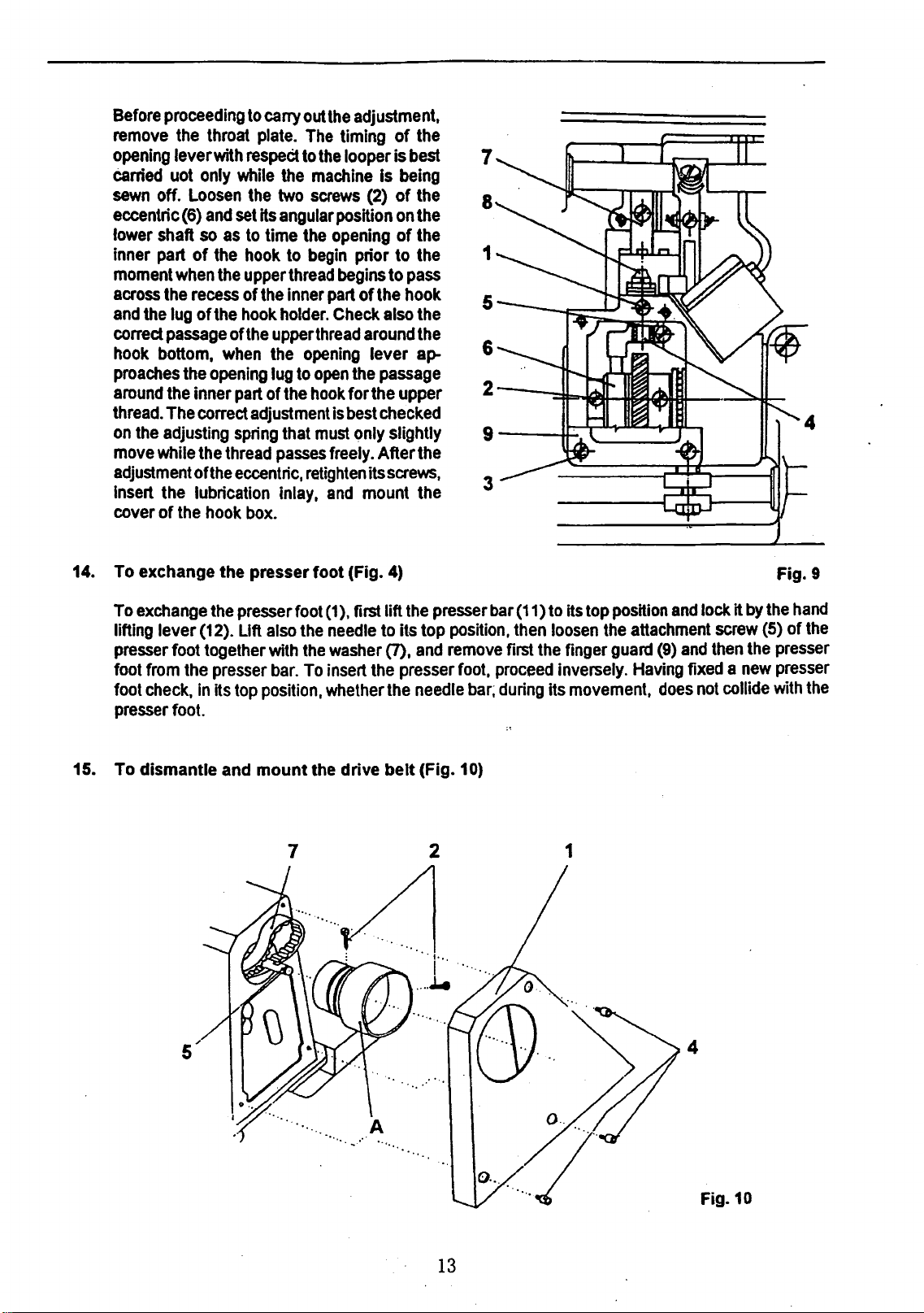

To dismantle and mount the drive belt (Fig.

the

presser

foot together

the

presser

in

its

top

foot.

foot (1), first lift

also

the

with

the

bar.

To

insert

position,

whether

needle

washer

to

(7),

the

the

the

presser

its top

and

presser

needle

bar

position.

remove

foot,

proceed

bar;

10)

(11)

then

first

during

to

its

loosen

the

finger

inversely.

its

movement,

top

the

position

guard

and

lock it

attachment

(9)

and

Having

fixed a new

does

not

4

screw

then

collide

by

(5}

the

the

hand

of

presser

presser

with

the

the

13

Fig.10

Page 15

Screw out the three screws

onto the suppoting

tbe two screws

Pass the drive belt (7) through the aperture thus created in the machine ann, set it

wheels,

screw

the upper shaft,

its operational position, i.e., into

and

(2), considered

.pin

(2),

and

mount the complete

when

(4),

remove the belt guad (1) from the machine ann, tilt

situated

remove the hand wheel from the machine arm and from

in

tightened. Retighten the screws (2) of the

the

on

the bed plate, take the V-belt out of the

hand

sense

of rotation of the

the

rim of the stand plate,

wheel back

on

the upper shaft

hand

wheel, comes to sit

hand

and

mount the belt

hand

in

such

wheel, tilt the machine

the

wheel

the

a position that the first

on

the

guard.

machine

groove, loosen

upper shaft (5).

on

small surface of

the

two

back

head

belt

to

16. To

17. To

adjust

(Fig.

Adjust the zigzag stitch

reaches

longitudinally

work) screw out the two

3).

and

machine

screws

To observe:

When tightening the adjustment screws

completely but leave a minimum play between ihem

the transverse movement of

Absence

damages to the needle bar mechanism.

adjust

(Tabs.1,

Adjust the zigzag stitch

reaches its bottom position.

the transverse

the cover

part. Then loosen

holder (4)

the plug. Check the needle

between the needle

adjusted at zero, the needle

wheel rotation.

adjusted

the needle punches longitudinally

4)

to

the

zero

width

Hs

bottom position.

and

transversely.

screws

finely adjust the angular position of the screws (4)

arm

so

as

to

set

(2

and

3) and mount

of

play

between

the needle punches transversely into the centre

3)

to

and

in

the

(25, Tab. 1)

so

as

If

by

an

experienced

out

with

a screwdriver the two

to

set

the

and

it

does

The

needle should

In

case

of

the

front plate, remove

the

needle longitudinally into

the

front plate.

the

needle bar holder required for the

the adjusting screws (4)

the

zero

width

In

this position, the needle should

longitudinal direction. If this

of

the

front part of

needle

the

react,

punch

slot

bar

the

sewing

at

the

position

side

in

with

the needle should

basic zero position of

machine mechanician since

into

the centre

and

tum the

of

longitudinal deviation (i.e.,

(4) for adjusting the needle position,

and

turn

the

screws

centre of

at

the maximum stitch width

each lateral position of

handwheel

be

in the centre of the throat plate slot

the

latter, loosen the securing screws (2

both

the

centre of

and

the

needle bar holder

and

the needle bar holder involves the risk of

the

hand

wheel

is

not

the

machine arm,

(27, Tab. 3)

the

throat plate groove,

react

the

zigzag stitcfl tjrive

until

on

the front

until

be

case,

and

and

the

with

such

at

of

the

the

.needle

in

the

and

the

front plate slot. Retighten the

zigz.ag

of

the

slot

the

needle bar with

the

centre of

screw

out the screw {26)

the opposite

adjust the complete needle

and

and

be.sure

needle.

no

lateral

adjustment

slot

of

the

throat

bar

with·

feed

direction of

on

the

rear side of

do

not

tighten them

in

order not to obstruct

stitch.

of

the

throat

the

groove

plug,

out of

reinsert the cover

that

there

V'iiti1

zigzag slitch

movt:i•lf:iit

mec:nanisrr;

is

rather extensive.

plate

the needle

both

sewn

and

the

plate

the

needle

both

and

take

its

rear

bar

and

is a play

width

k ihe

hand

.>hould

in

be

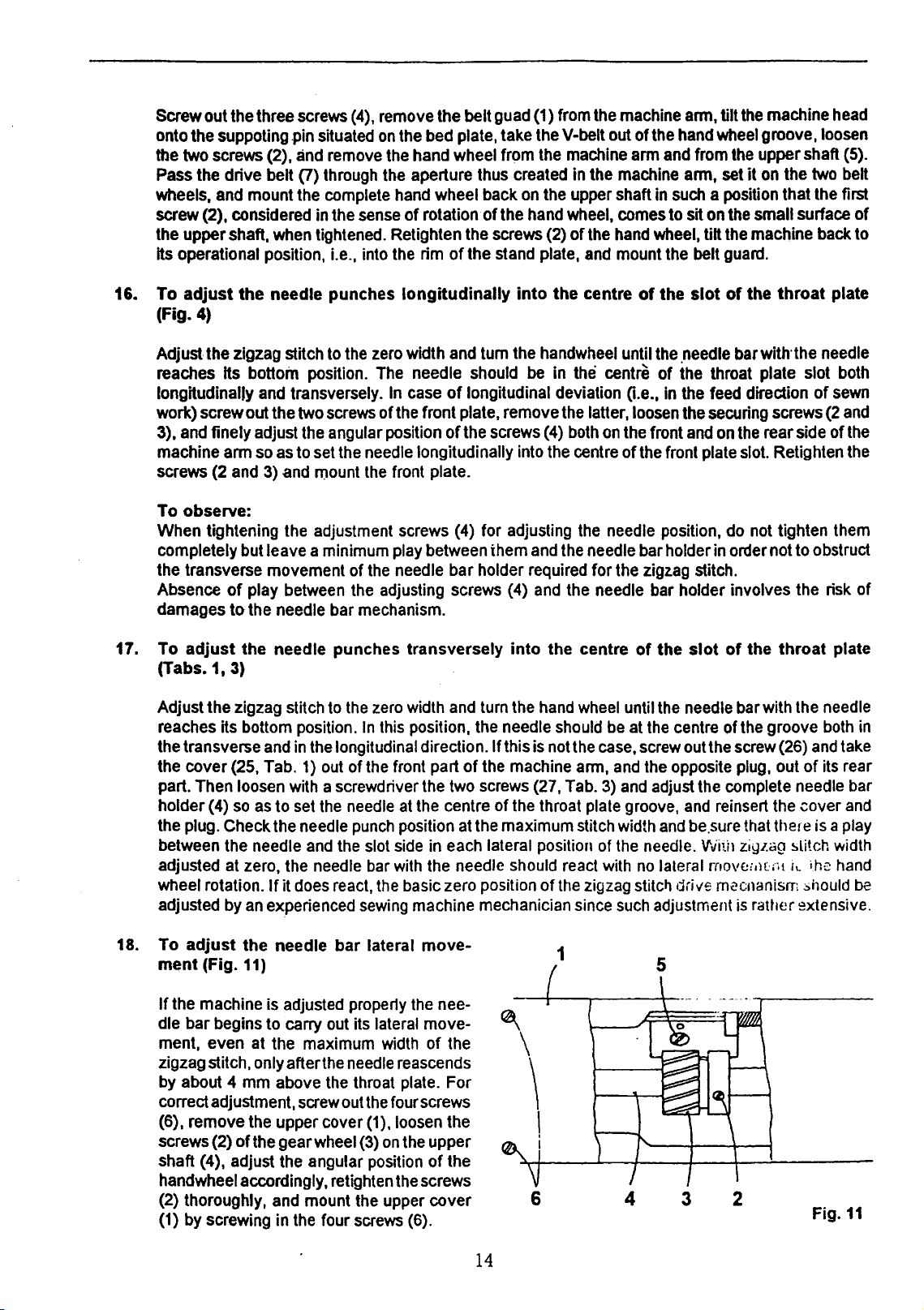

18. To

adjust

ment (Fig.

If

the machine

dle bar begins to carry

ment. even at the maximum

zigzag stitch. only after

by

about 4

correct adjustment,

(6), remove the upper cover

screws (2) of the gear

shaft (4), adjust the angular position of the

handwheel accordingly, retighten

thoroughly, and mount the upper cover

(2)

{1)

by

the needle bar lateral move-

11)

is

mm

screwing

adjusted

above

screw

in

the

property

out

its lateral move-

width

the

needle

the

throat plate. For

out

the

(1),1oosen

wheel

(3)

on

four

screws

the

nee-

of

the

reascends

four screws

the

the upper

the

screws

{6).

\

\

\

I

6

1

14

4 3 2

Fig.11

Page 16

19. To adjust the control force required

(Figs. 12, 13)

for

stepless adjustment

of

the zigzag stitch width

For the stepless tilting of

stitch mechanism contains

Turning the

required to

stitch width

by

out

that

can

cover (1, Fig. 13)

control force, first take the

purpose, screw

out

the three attachment

out

the

lever

stitch mechanism that

screw

adjust

must

the lever (2)

be increased

securing

(7, Fig. 12}

to the right

the

stitch

be tomed

whose

up

shows

out

the

screw

{3,

and

take

can

two

screws

3 2

the

zigzag

the

increases

windth.

to

the

extreme

to

1 0

the

approximative stitch

complete

screws

Fig.

the

pin

be

then

stitch bracket,

braking

mm

13}

roller (1) with

the

A mechanism actuated

left prior

left position, defined

by

displacing

zigzag stitch

(2}

from the

(3,

Fig.

12) from

on

the

pin

(6, Fig.

taken

13)

outofthe

pressure

to

proceeding to

the

width

mechanism

body

the

(5},

remove

out

of

engagement,

machine

the

inlay

the

spring

exerted

the

by a stop,

lever

value

of

the

body

ofthe

the

5

(1

0,

Fig.

(5)

and

on

the

roller

by

the

lever (7)

stitch width

produces

to

the

right.

at

each

out

of

the

mechanism,

zigzag

pin

from

the

thus

releasing

arm.

For

the

12)

of

the

body

of

the zigzag

with

the

adjustment screw (8}.

and,

consequently,

serving

adjustment

the

The

lever position. To adjust

machine

remove

stitch

guiding

assembly,

to

zero

zigzag

number marking

ann

column.

the

cover (1),

mechanism,

(4),

loosen

the

body

proceed

fix

the

which

stitch

then

ofthe

the force

adjusted

is

the fixing

inversely.

carried

width

on

the

the

For this

screw

screw

zigzag

5~~

'(8

20. To adjust the tooth play

The

tooth play of

12}.

To

cover

(1

pin

(6,

Fig.

cam

and

by

throughly tightening the

21.

To adjust the position

adjust

),

and

12)

the gear

1

the

the

toqth

loosen

adjust

wheel

zigzag

play,

the

the

9

4

3

:

•

7

Fig.

12

of

the zigzag transmission mechanism (Figs.

stitch

transmission

first

screw

outthe four attachment

screw

(5)

tooth

play

(3,

Fig.

screw

of

the needle

located

of

11)

(5).

in

the

the

zigzag transmission

mounted

on

barwith

3~

mechanism

lug

oft

the

upper:shaft (4),

respect to that

he

machine

is

mechanism,

actuated

screws

11,

12)

by

the

eccentric

(6,

Fig.

11},

remove

arm.

By

turning

i.

e.,

then

lock

of

the hook shaft (Figs.

then

between

the

adjusted

pin

the

the

eccentric

the

complete

1

Fig.

13

(6,

Fig.

upper

position

14,

15)

After a substantial adjustment of machine mechanism

bar position

needle bar

the

bed

lug

of

plate

the

with

axis.

and

bed

plate. Lock

respect

For

adjustment.

the

hook

to that of

gear

the

the

loosen

box.

gear box .position

hook

shaft.

the

two

In

correct position,

The

screws

by

tightening

should

hook

(1,

Fig.

the

be

shaft

14)

hook

the

checked

15

the

axis

is

ensuring

gear box

two

screws

median

displaced

the

is

indired contact

(vertical)

to

locking joint

(1).

the

needle

left of

between

with

the

the

Page 17

0

To

observe:

If

the

gear

box

of

the hook has been removed be sure to reinstall it so as to ensure the parallelism

the hook shaft axis with the bed plate plane. Check

laid onto the upper surface

the value

(B, Fig. 15).

of

the bed plate and onto the worked surface

Fig. 14

the·

parallelism for instance by means

of

the gear box, and measure

oftwo

of

shafts

To

22.

adjust

spring

Loosen the screw (1) and take the complete

upper thread tensioner out

arm.

spring (2), loosen the screw (3)

(4) and adjust the angular position

(5). Turning the pin to the left

spring

ment is adjusted the spring arm stroke as

Displace the right-side sliding plate, sew a few

stitches, and check the adjustment

adjusting spring. With correct

thread passing around the hook bottom

produce a slight movement of the adjusting

spring without being stretched.

the

operation

(Fig.

16)

To

adjust the tension of the adjusting

tension, and inversely. By this adjust-

of

the

of

the machine

on

will decrease the

adjustment, the

adjusting

the bushing

of

the pin

well.

of

the

shall

Fig.15

Fig.16

16

Page 18

23.

Electrical equipment

of

machine

The machine is fitted

of

the machine should

To change the

or at the terminal

lead-in cable out of

Ill.

MAINTENANCE

1. Machine cleaning

Plain machine lines help

remove the

daily.

with

an

sense

board

of

the

be

kept

rotation

of

socket.

electromotor mounted

in

good

state according

of

the electromotor cllange over

the

electromotor.

In

in

the

to

the

the latter case,

Warning I

Avoid

any

intervention

Unqualified intervention involves the risk

waste

between

to

the

keep

into

the

clean

feed-dog

electrical

outer machine

and

equipment

the throat

of

accident

parts.

plate.

Warning I .

Before

switch

machiAe

proceeding

and

hold

your

start

by

to

clean

feet

treadle

and

away

from tile

actuation.

lubricate

machine

the

machine

electrotechnicaland

Otherwise.

machine,

stand

the

do

not omit

ofthe

by

From

treadles

stand.

lead-in

first

machine

electric

time

to

the

machine

be

sure

in

The

shock.

order

electrical equipment

security

cable

to take the

but

call

time.

to

switch

to

either

in

an

it

is

necessary

sould

avoid

regulations.

at

the

plug

electrician.

be

cleaned

off

the

accidental

plug

of

the

main

to

2.

General overhaul and repair

Should

faulty pieces

tested. The electromotor

overhaul of

major defects for another

3.

To store the machine

After the machine

exchanged,

all the tools

be

carried

out

exchanged

the

machine

has

if

any.

The

and

accessories.

of

once a year.

and

due

and

the

should

been

machine

year.

set

be

out

should

the machine

The

machine

repairs cerried

electrical equipment

carried

of operation, it

be

should

out.

out

so

thoroughly

should

then tested,

be

set

The

machine

should

be

coated

out

of

be

inspected

as

to

enable

cleaned,

with

operation.

should

the

inspeded,

protective

cle~~ed,

be

then

and

tested.

machine

grease,

dismantled,

assembled

The

to

r:un

·and

faulty

and

stored

an~

general

without

pieces

with

17

Page 19

IV.

FAULTS AND HOW TO REMOVE THEM

Fault

a)

Heavy machine run

b)

Slow

machine

c)

Upper

thread

start

breakage

Cause

The machine has been out

for considerable time, dried

and impurities deposited in the

bearings.

Insufficient belt tension.

of

use

oil

1. Slashed thread guides.

2.

Too sharp hook point.

3. Faulty feeding.

".

Faulty

or

5.

lncorrectupperthreadtension.

6. Bad needle quality

needle.

upper

needle threading.

thread guiding

or

bent

7. Thread size is inadequate to

of

the thickness

rial.

8.

Machine considerably

9. Thread wound

10. Thread is too thin

enough.

sewn mate-

~oiled.

on

the hook.

or

not strong

Removal

Inject some drops

into all lubrication holes and

sliding surfaces and let the machine run rapidly so

lubrication holes in the bearings.

Then

oil the machine carefully

(see par.

Increase the belt tension by tilting

the electromotor.

1. Ascertain

5, page 6).

and

of

kerosene

on

as

to clean the

exchange them.

2. Repair it.

3. Adjust it see par. 5, page 12.

4.

Thread the upper thread correctly see par.

5.

Adjust it see par. 3, page 12.

6.

Exchange

8, page 9.

the

needle see par.

7, page 9.

7. Use adequate threaa.

8. Unscrew the throat plate, clean

the mechanism, and set the

throat plate see par.

6, page

12.

9. Remove the thread.

10. Use adequate thread.

d)

Lower

thread

breakage

1. The thread is incorrectly threa-

ded into the bobbin case.

.

2.

Thread is too thin

stroung enough.

3.

Thread is wound incorre-::tly

on the bobbin.

or

not

4. Damaged bobbin.

5.

e)

Skipped

stitches

Too sharp pressure sp:-ing

the bobbin case.

1.

Needle inserted inr.orrectly

2.

Blunt

or

bent needle.

3. Slashed

4.

Excessiv~=.;

the throat plate.

or

broken

needie apeiiure in

hoo~.

on

point

18

1 . Thread it correctly see par.

11, page 10.

2. Use adequate thread. ·

3.

Wind it

rectly.

4.

Exchange it.

on

the bobbin cor-

5. Exchange the spring.

1 .

Insert

it

correctly see par.

page 9.

2.

Exchange it see par. 7, page

7,

9.

Exchange the hook.

3.

4. Exchange the throat plate and

correctly.

set it

Page 20

Fault

f)

Needle breakage

Cause

5.

Broken adjusting spring for

upper thread tension.

6. Needlebarpositionedtoo

or too low.

7.

Overturned hook, incorrect

hook course.

8.

Soiled hook mechanism.

1.

Feed-dog positioned

2. F

au

tty

attendance-pulling the

material.

3. Needle too thin with respect

to material.

too

high.

4. Needle inserted incorrectly.

5. Loosened throat

6. Excesive upper· thread ten-

sion.

plate.

high

Removal

5. Exchange the spring

just the upper thread tension

see

par.

6. Adjust it

3, page

see

12.

par. 8, page 13.

7. Adjust the hook course

par. 9,

8.

Clean

page

13.

it

with kerosene

it with oil.

1. Adjust it

page

2. Let the material

3.

Exchange

7,

4. Insert

page

5.

Set the throat plate correctly

see

by

6. Adjust it

12.

page

9.

it

9.

par.

screws.

in

height

the

needle

correctly

6,

page

see

par.

see

pass

see

12

3,

and

page

and

and

par.

freely.

see

par.

par. 7,

fix

ad-

see

oil

4,

it

12.

g)

Heavy and irregular feeding

h)

Stitch

material

forming

below

sewn

1.

Feed-dog positioned

2. Worn-out feed-dog.

3.

Clogged or blunt teeth offeeddog.

4. Insufficient pressure of

er foot.

1. Tensioner discks

upper thread.

2.

The

thread does

smoothly around the looper

or catches the bobin

3.

The upper thread

between the tensioner disc.

4.

Thread broken

tween the tensioner disks.

5.

Incorrect proportion

the

upper

tensions.

and

too

press-

slashed

not

case.

is

not

thread

and

caught

between

lower thread

low.

by

pass

be-

1. Adjust it

page

2.

Exchange

Clean

3.

dog.

4.

Increase

7.

1.

Exchange

upper thread tension

3,

2.

Clean

bobbin

3.

Thread

4.

Clean

adjust it

5.

Correct

3,

time to time.

in

height

12.

it.

or exchange the feed-

the

pressure

page

12.

them and adjust

page

12.

the

hook

case.

it correctly.

the

thread

see

par.

the

proportion

page

12

and

see

par. 4,

see

par.

the

see

par.

and

adjust

the

tensioner

3,

check it from

page

see

and

12.

par.

i) Stitch

material

fonning

above sewn

Damaged spring

bin

case, the lower thread

braked insufficiently.

on

the

bob-

is

1.

19

1.

Exchange the spring.

Page 21

Fault

Cause

2.

Lower thread is not threaded

under the spring

case.

3.

Lower thread broken

caught under the spring

bobbin case.

4.

Incorrect proportion between

the upper and

tensions.

5.

Premature feeding.

ofthe

lower thread

bobbin

and

of

the

Removal

2. Tread it correctly.

3.

Remove the thread.

4. Correct the proportion see par.

3.

page 12.

5.

Adjust it see par.

5.

page 12.

j)

Locked

hook

Thread rests caught in the hook.

Rotate the hand

diresction regardless

siderable resistance until the

caught

pieces. Remove them and start

the unthreaded machine. Let

run

three drops

in

thre~~

for a period. then drip two or

par.

5,

page 6 onto the hook.

wheel in each

of

the con-

rests are cut to

of

oil recommended

it

20

Page 22

TABLES

OF

PARTS

Page 23

tab.

1

2

522980

522080

3

4 321161

5

522080

6

522080

7

522080

9

522080

10

522080

11

522080

522080

12

13

522080

522080

14

15

522080

16

522080

17

522080

18

522080

19

522080

20

522080

21

522080

22 722923

23

522080

25

522080

522080

26

831348

123117

001000

840073

313204

161138

815007

120248

7211.73

827180

123122

111227

271184

821115

821on

821113

190368

120361

823115

126063

132112

831494

123166

Page 24

I

I

~-~

i

I

!

I

l

i

I

/

I

i

-

3

4

5

--·

522080 2

522080

52208

522080

--

- -

tab.

--··,.

2

-

0

·-

-

111

227

945100

945188

272039

I

80

080

080

822424

131027

310428

120350

025

244

264294

828079

828080

262074

1950-1'1

171

037

I

l

I

i

I

I

I

I

I

. I

II

10

11

12

13

14

1•~

18

19

20

21

22

522080

522080

522080

5220130

522980

315231

522 0

522

522

522 080

522080

..

fJ

I

I

L __

---

I

I I

I I

I

i

-

__

_)

\.__

_·--·

···

--

)

Page 25

tab.3

x··

..

··

..

~

.•'

..

·

..

·

...

··········

27

...

...

..

·

.

·.

..

...

·

..

·······

··

......

...

·······

...

:

:

:

:

:

:

:

:

~

··.;

·:x

. .

: · .

...

·

273111

1

2 522080

522080 190593

3

4

522080 264281

522980 035654

5

6 522080

7

522080

8 522080 613468

522080 343074

9

10

522080

11

321861 953200

12

522080

13

522080 945296

14

522080 111094

15

522080 672174

16

311732

17

522080 124050

18

522080 111230

19

522080 260483

20

522080 870170

21

522980

22

522980 025249

23

522080 827194

24

522080

25

522080 1631'06

26 522080

27 311515

28

522980 036122