Page 1

GG0028-1/-1D

MEDIUM HEAVY DUTY

MACIDNE

Instruction

Parts

Catalog

ZIGZAG

SEWING

Manual

Page 2

CONTENT

1 Operating instruction

1,

Safety operating guide .................... : ........................................................

2,

Operating notice ........................................................................... _ ........... 1

3,

Operating condition ................................................................................. 1

4,

Chief specification ................................................................................... 1

5,

~ower cable connection ........................................................................... 2

6,

Control box connection .................................................... .-....................... 2

7,

Install belt .............................................................................................. 2

8,

Install belt cover ...................................................................................... 2

9,

The needle bar

1

O,

Operation guide (motor and control box) .................................................. 3

11,

To

lubricate the machine ......................................................................... 3

12,

The hook lubricating condition adjustment .............................................. 3

13,

Time machine cleaning .......................................................................... 3

14,

Wind the

15,

Insert the needle .......................................... ; .......... , ............................. 4

16,

Put bobbin in hook assembly .................................................................. 5

17,

To

thread upper thread .......................................... : ... .-............................ 5

18,

To

catch lower thread ............................................................................. 5

19,

The stitch length and backstitch adjustment.. ........................................... 5

20,

The stitch width adjustment.. .................................................. · ................ 6

21,

The thread tension adjustment. .............................................................. 6

22,

The thread take up spring tension adjustment.. ........................................ 7

23,

The presser.

24,

The gap between hook assembly and needle adjustment.. ......................... 7

25,

The feed dog height adjustment. ......... : ................................................... 7

stop

bobbin

foot

..................................................................................... 4

pressure adjustment.. ................................................... 7

manual

-1

position adjustment.. .................................................. 2

26,

The feed dog obUquity adjustment.. ......................................................... 7

27,

Th

..

e needle

adjustment

28,

The needle base point offset adjustment.. ................................................ 9

29,

Install synchronous belt...~ ...................................................................... 9

30,

Timing between needle and feed dog motion ............................................ 9

31,

The forward/backward stitch length

32,

The position between

~3,

The thread trimming

punches

.................................................................. · .....................

into

the

hook

devics

center

and opener motion adjustment._ ....................... 9

adjustment..

of

the

slot

of

error

adjustment ............................... 9

..

!·::············ ............................... 10

the

throat

plate

position

8

Page 3

2 Pa-rts

A,

B,

C, Needle bar vibrating parts .....................................................................

D, Presser foot parts .................................................................................

E, Stitch length ~djustment and backstitch parts .......................................... 23

F, Lower shaft, feed dog parts ....................................................................

G,

H, Thread trimming parts ........................................................................... 32

I,

J,

list

Arm bed

Arm shaft and needle bar thread take

Hook assembly .....................................................................................

Oil lubrication parts ................................................................................

Accessories ...........................................................................................

and

its accessories ..................................................................

up

parts .........................................

12

14

17

20

26

29

35

37

Page 4

1,

Safety operating

1) When turning the power on, keep your hands and fingers away from the area under

guide

.

the needle and around the pulley.

2) Power must be turned

when the machine

is

not used or when the operator leaves

off

his/her seat.

3) Power must be turned off when incline the machine head, install/remove the belt or

move machine.

·4)

Don't place finger, hair, shaft etc. near pulley, belt, wheel and motor

in

order to avoid

injury.

5) Don't insert finger into the thread take up lever guard cover, keep your hands and

fingers away from the area under the needle and around the pulley when the machine

in

operation.

is

if

6) Don't operate the machine without the safety devices

the belt cover or eye guard

are installed.

2,

Operating notice

1)

Don't operate the machine

if

the oil tank without full oil.

2) The machine adopt semi-automatic lubricating mode. Don't operate the machine

before lubricating.

of

3) Check the rotation direction

pulley when firstly start new machine. (The pulley

should rotate in counterclockwise when viewed from pulley)

4) Check the voltage and phase. (Single or three whether is corresponds with the data

in motor nameplate)

3,

Operating condition

1) Avoid using machine at abnormally high temperature

(5

°C

temperature

or lower). Otherwise machine failure may result.

(40°C

or higher) or low

2) Avoid using machine in dusty condition.

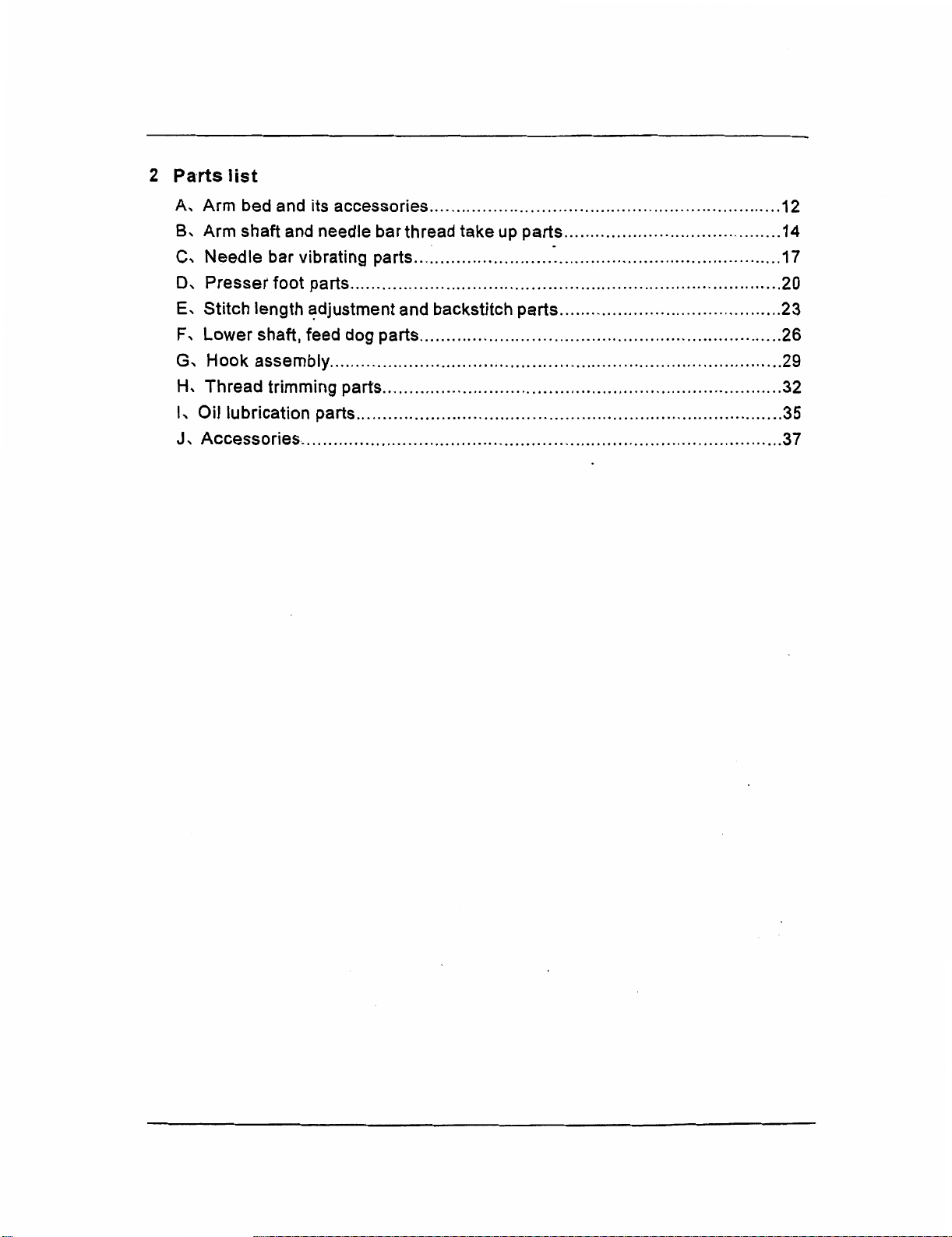

4

..

Chief specification

p

~

Max

Needle

Take-up

Feed dog height (mm)

Presser root

sewing

speed

(rmp)

Stitch length (mm)

Stitch width (mm)

bar

stroke

(mm)

lever

stroke

(mm)

Needle

height

lift

Lubricating mode

Trimming device

Hook

Motor

By

hand

(mm)

(mm)

GG0028-1

2800

0-5

0-10

36

82

DPxl 7 Nm90-120

1.2

8

10

Semi-lubricating

Semi-automatic

Without With

Clutch

motor

- 1 -

and

370W

trinal

lubricating

Servo

GG0028-1D

thread

capacity

motor

550W

Page 5

5, Power cable

1)

When con_necting the power cable to control box, it should confirm the connector

type and machine direction firstly and then plug

completely.

2) Rotary direction: Please refer the instruction

change the rotary direction

connection

of

motor.

the

connector into proper receptacle

book

-of

confected motor if it needs

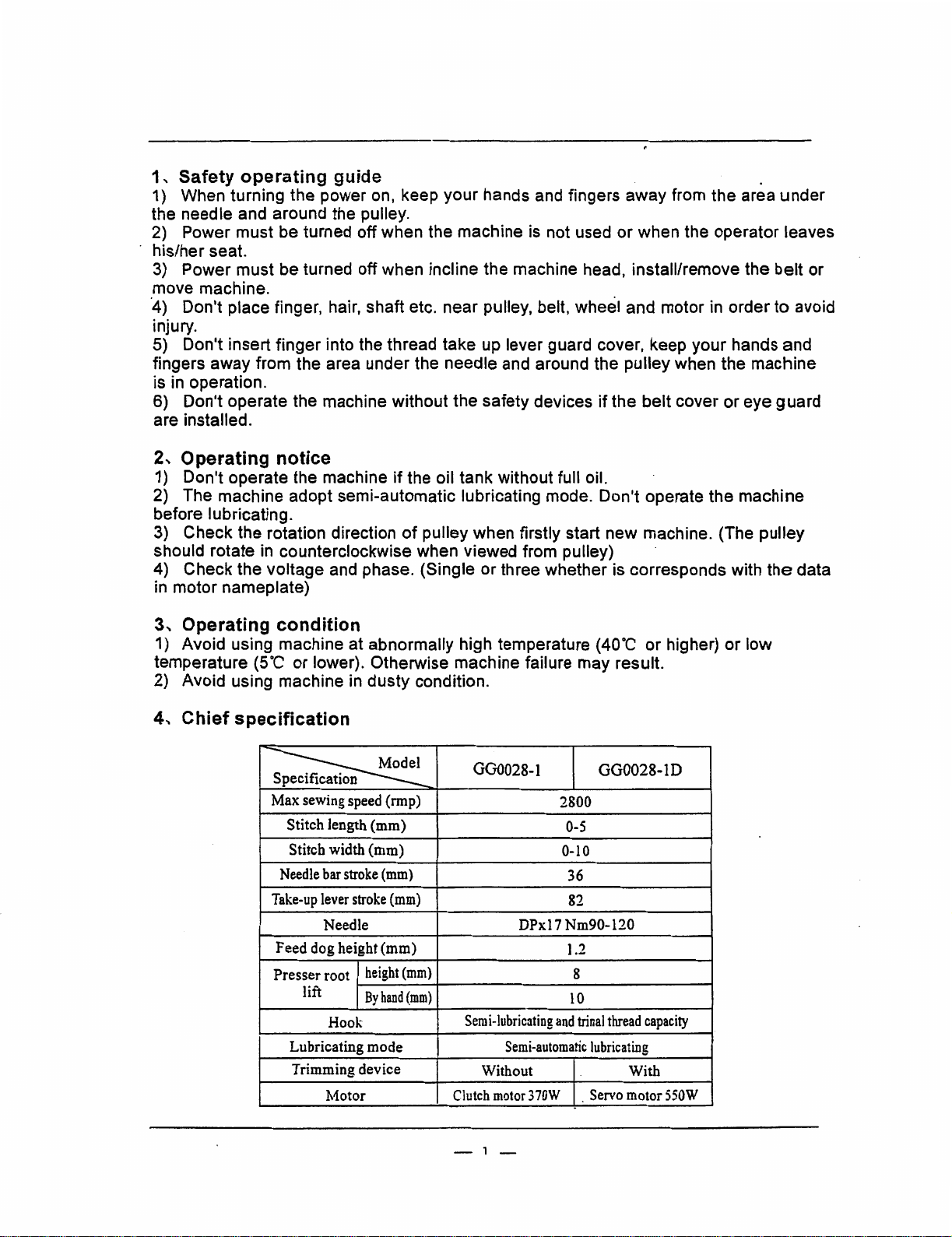

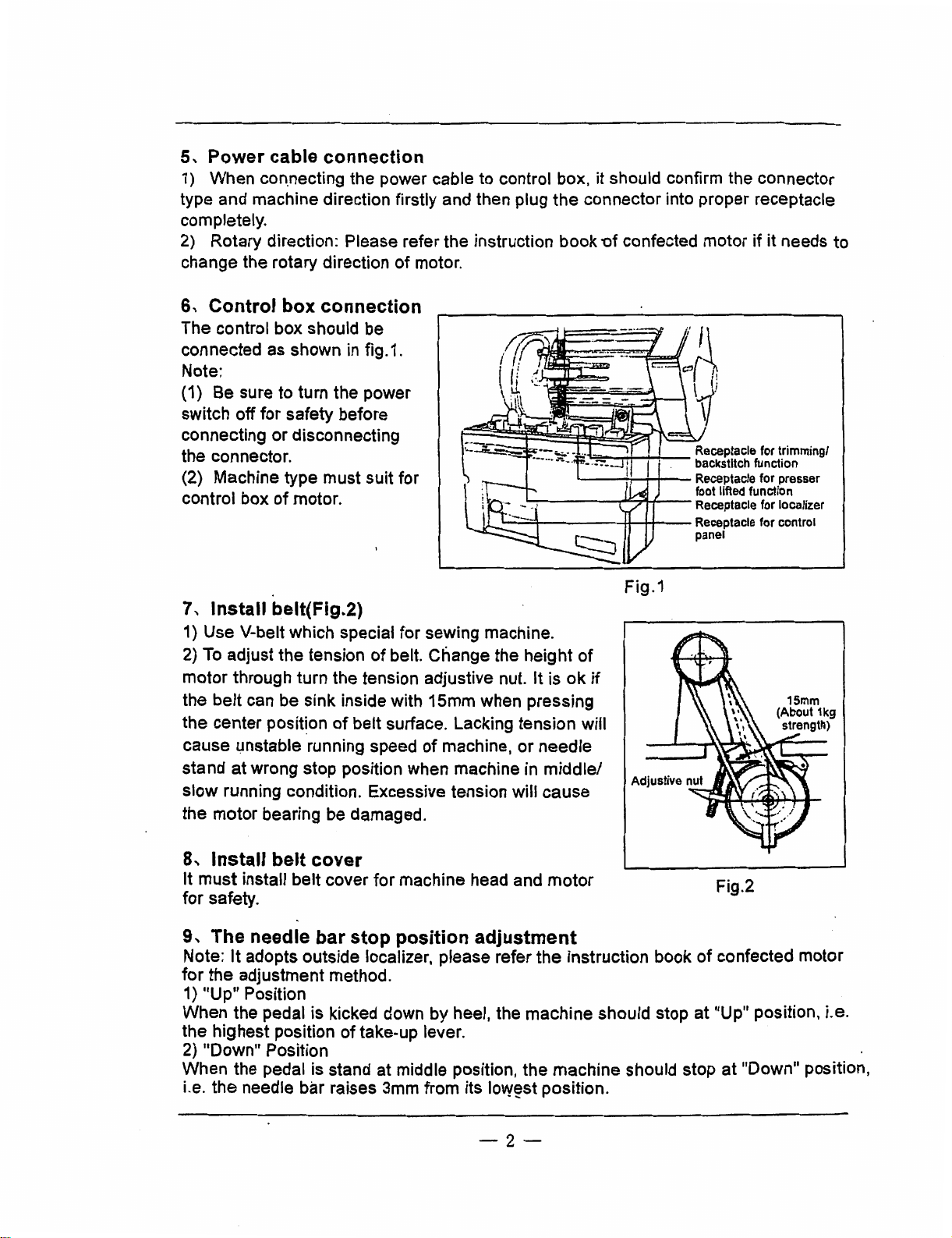

6, Control box connection

The control box should be

connected as shown in fig.1.

Note:

(1) Be sure to turn the power

switch off for safety before

connecting or disconnecting

the connector.

(2) Machine type

control box

7,

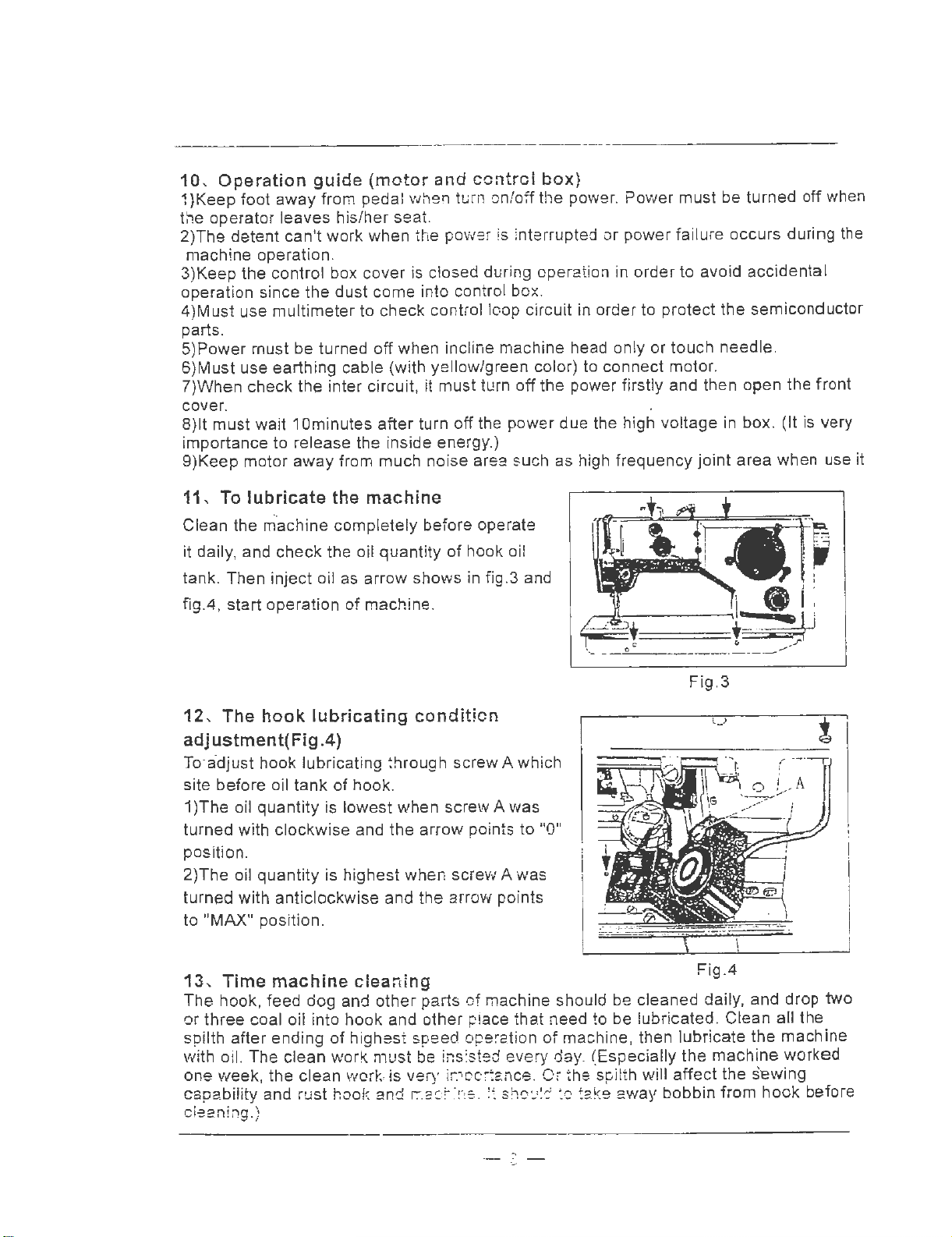

Install belt(Fig.2)

1)

Use

of

V-belt which special

2) To adjust the tension

motor

the

the center posit~on

cause unstable running speed

stand

slow

the motor bearing be damaged.

through turn the tension adjustive nut.

belt

can be sink inside with 15mm when pressing

at

wrong stop position when machine in

running condition. Excessive tension will

must

motor.

of

suit for

for

sewing machine.

of

belt. Change the

belt surface. Lacking tension will

of

machine, or needle

L....-----,.w::...,-1-+--

"-~-------1,-+--1~-

height

It

·~-....,_..,.__

L...------~---

Fig.1

of

is

ok

if

middle/

cause

Receptacle for trimming/

backstitch function

Receptacle for presser

foot lifted function

Receptacle for localizer

Receptacle for control

panel

to

8,

Install belt cover

It

must

install

for

safety.

9,

The needle bar stop position adjustment

Note:

for

1)

When the pedal is kicked down by heel, the

the highest position

2) "Down" Position

When the pedal is stand at middle position, the

i.e.

It

the

adjustment method.

"Up"

Position

the

needle bar raises 3mm from its low~st position.

belt

cover for machine head and

adopts outside localizer, please refer

of

take-up lever.

motor

the

machine

machine

-2-

instruction book

should stop

should stop

Fig.2

of

confected motor

at

"Up" position, i.e.

at

"Down"

position,

Page 6

10, Operation

1 )Keep foot away from pedal when tu

the operator leaves his/her seat.

2)The detent can't work when the power is interrupted or power fa ilu

machine operation.

3)Keep the control box cover is closed during operation in order to avoid accidental

operation since the

4)Must use multimeter to check control loop circuit in order to protect the semiconductor

parts .

5)Power must be turned off when incline machine head only

6)Must use earthing cable (with yellow/green color) to connect motor.

?)When check the inter circuit, it must turn

cover.

8)1t

must wait 1 Ominutes after turn

importance to release the inside energy.)

9)Keep motor away from much noise area

guide

dust

(motor

come into control box.

and

control

rn

onto~ the power. Power must be turned off when

off

off

the power due the high voltage in box. (It

$UCh

box}

re

occurs during the

or

touch needle.

the power firstly and then open the front

is

very

as high frequency

joint

area when use it

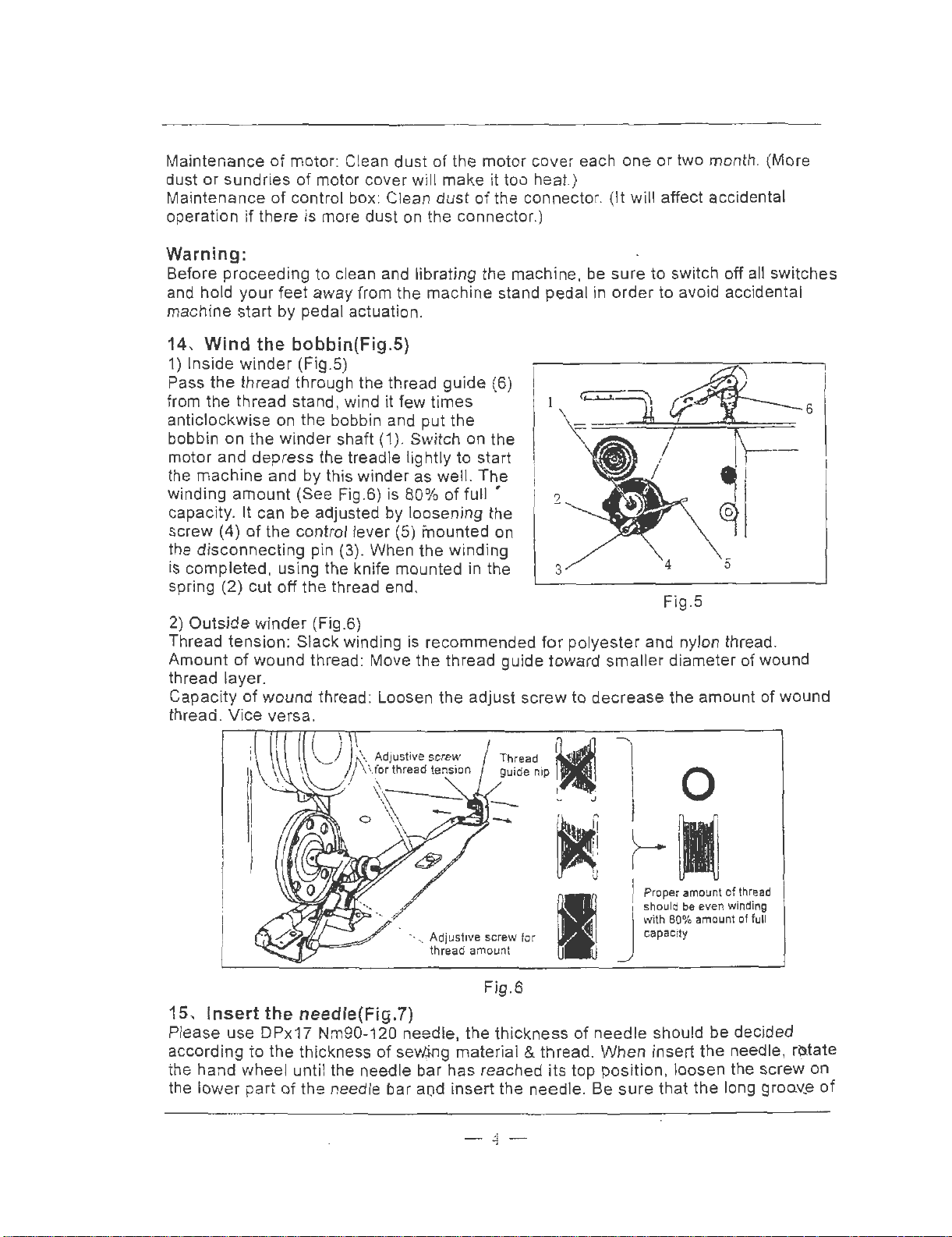

11- To

Clean the m·achine completely before operate

it daily, and check the oil quantity

tank. Then inject oil as arrow shows in fig.3 and

fig.4, start operation

12,

lubricate

the

of

machine

machine.

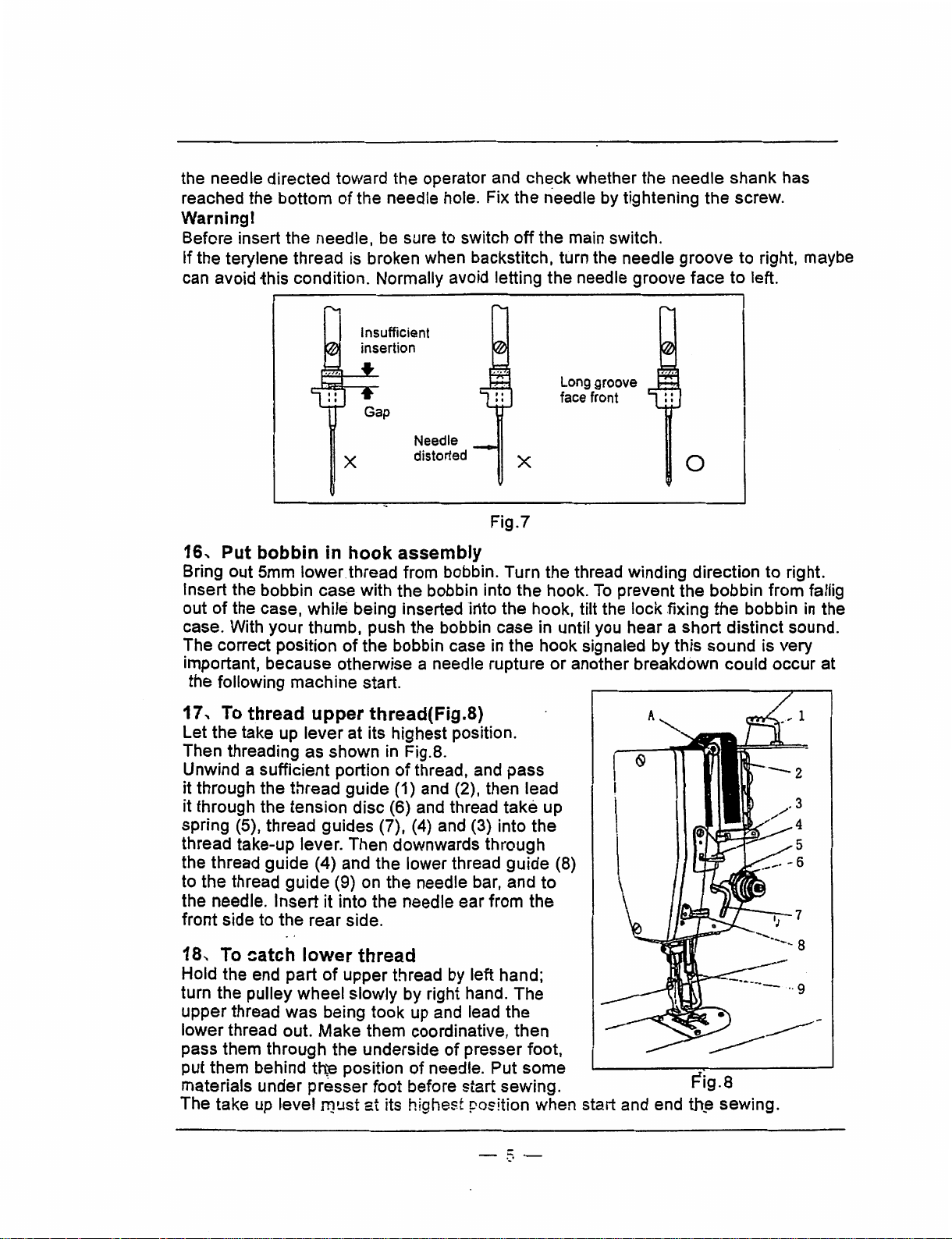

The hook lubricating

of

hook oil

condition

adjustment(Fig.4)

.To

·adjust hook lubricating !hrough screw A which

tank

of

hook

site before oil

.

1 )The oil quantity is lowest when screw A was

turned with clockwise and the arrow points to "

position.

2)The oil quantity is highest when screw A was

turned with anticlockwise and the arrow points

"MAX"

to

position.

Fig.3

O"

13

,

Time

The

hook, feed dog and

or three coal oil into hook

spilth after ending

with oil. The clean work

one week , the clean work,is very ir.ioc,tance.

capability and rust hook and r.:ae;~:ne. !t sh0u!d

ea

ning.)

cl

machine

of

cleardng

other

parts

of

machine should be cleaned dai

an

d other piace that need to be lubricated. Clean all the

highest speed ope ~ation

must

be ins'.sted every day. (Especially the machine

of

machine, then lubricate

Oi

the spilth will affect

:c

.3

Fig.4

ly,

and drop two

the

machine

worked

the

s'ewing

take away bobbin from hook before

Page 7

Maintenance

dust or sundries

Maintenance

operation

of

motor: Clean dust

of

motor cover will make it too heat.)

of

control box: Clean

if

there is more dust on the connector

of

the motor cover each one or two month . (More

dust

of

the connector. (

.)

Warning:

Before proceeding to clean and librating the machine, be

and hold your feet away from the machine stand pedal in

machine start by pedal actuation.

14,

Wind

1) Insi

the

Pass

the

from

anticlockwise on the bobbin and put

bobbin on the winder shaft (1

motor and depress the treadle lightly

the machine and by this winder as well. The

winding amount (See Fig.6) is 80%

capacit

screw (4)

the disconnecting pin (3). When the winding

is completed, using the knife mounted

spring (2) cut

2) Outside

Thread tension : Slack winding is recommended

Amount

thread

Capacity

thread. Vice versa.

the

bobbin(Fig.5)

de

winder (Fig.5)

thread through the thread guide (6)

thread stand, wind it few times

the

).

Switch on the

to

start

of

full •

y.

It can be adjusted by loosening the

of

the control lever (5) mounted

off

the thread end.

winder

of

wound thread: Move the thread guide toward

layer

.

of

wound thread: Loosen the adjust screw to

(Fig.6)

in

on

the

2

3

for

polyester and nylon thread.

decrease

It

will affect accidental

sure

to switch off a

order

to avo

smaller

id

accidental

5

Fig.5

diameter

the amount

ll

switches

of

wound

of

wound

',

Adjustive

thread amount

15,

In

sert

the

needle(Fig.7)

Please use DPx17 Nm90-120 needle, the thickness

of

according to the thickness

the hand wheel until the needle bar has reached its top position, loosen the screw on

of

the lower part

the needle bar aod insert the needle . Be

sew,i.ng

screw

for

I

Fig.6

material & thread.

-

4-

0

Proper amount

should

80

with

capacity

of

needle should be decided

When

insert the needle, r~tate

sure

that

be

even winding

% amou

the

of

thread

nt

of

long groQv_e

full

of

Page 8

the needle directed toward the operator and ch~ck whether the needle

reached the bottom

of

the needle hole. Fix

the

needle by tightening

the

Warning!

Before insert the needle. be sure to switch

if

the terylene

can avoid -this condition. Normally avoid letting

thread

is broken when backstitch. turn the needle

Needle

X

distorted

off

X

Fig.7

the main switch.

the

needle groove face

Long groove

face front

groove

0

shank

screw.

to

has

to

right. maybe

left.

16, Put bobbin

Bring out 5mm lower. thread from bobbin. Turn

Insert the bobbin case with

out

of

the case,

case. With

The correct position

important,

the following machine start.

17,

To

Let

the

Then threading

Unwind a sufficient portion

it through

it through the

spring (5), thread

thread take-up lever. Then downwards

the thread

the

to

the needle. Insert

front

18,

To

Hold the end

turn the pulley

upper

lower

pass them

put them behind

materials under

The

take up level

your

because

thread upper thread(Fig.8)

take up

the

guide

thread

side to

the

catch lower thread

thread

thread out.

through

in

hook assembly

the

bobbin into

while

being inserted into

thumb, push the bobbin case in until you hear a

of

the

bobbin case in

otherwise a needle rupture

lever

at its highest position.

as

shown in Fig.8.

of

thread, and

thread

tension

guide

part

wheel

was

guide

guides

(4) and the lower thread

(9) on the needle bar,

it

into the needle ear from

rear

side.

of

upper

being took

Make

the

th,'e

position

presser

must

(1) and (2), then lead

disc

(6) and thread

(7), (4) and (3) into

thread by left hand;

slowly

by

right hand.

up

and lead

them coordinative, then

underside

foot before start sewing. F1g.8

at

its highest position when start and end th~

of

presser foot,

of

needle. Put

the

the

the

pass

take

through

guide

and

The

the

some

the

thread winding direction

hook.

hook, tilt the lock .fixing

hook signaled by this

up

the

to

the

To

prevent

or

another breakdown could occur at

(8)

'------..-.

the

bobbin

short

sound

the

bobbin

distinct

_____

sewing.

to

right.

from fallig

in

sound.

is very

the

_.

-::.-

Page 9

19,

The sti

1) The stitch length can be adjusted by turning

of

the machine arm, from O

in

crease

2)

Depress the backstitch hand lever (

3) Depress the

tch

length

the

stitch length. By turning it in the

backst

and

backstit

to

5mm. By turning it in

itch button

as

ch

adjustment

1)

can

shown in

(Fig

.9iFig.10)

the

knob (4) provided on the

the

sense

proceed

Fig.10

of

sense

the arrow "B", you d_ecrease it.

backstitch.

can proceed backstitch.

of

column

the arrow "A",

Ba

ckstitch

button

you

Fig.9

20,

The

stitch width adjustm

Before

outside

ad

increa

locking spanner (2) afte r

21

The

in

(Fig.12)

1) To

lower

clo

decrease

2) To

screw A in Fig.14.

3)

tension for special

adjustment

the

sewn work. Release the locking

just sti

,

terrel

ckwise

It can adjust

tch width

se

the

The

thread tension ad justm

tension

ated that

adjust

thread

to

it.

adjust

of

the stitch width, the machi ne

through

zigzag stitch width. By displacing it

of

upper

the

tension. Turn

increase

the

and

the

stitch forming and l:he sewn m

upper

lower

the

thread tension according

the tension, or inversely, to

threa

take

sewn

ent

(Fig.9)

the

spanner (3). By

the

adju~tment is well.

ent

(Fig.11 ,

the

lower thread

the

tension adjustive

d tension by turning

up spring to adjust

material and thread.

must

X

spanner

displacing

to

12,

be

ateria

to

nut

adjust

upper

thread

Fig.10

must

be stopped and the

(2) (anticlockwise) and

the

lever to the right can

the left

can decrease i

14)

l.

the

in

ive

Tension

adjustive

X

needle

then

t. Lock the

Tighten

nut

Fig

.11

Balance tem;i

or-

Tight upper thread tension Tight lower thread tension

::r loose lower thread tens

Fig.12

-6

io

n

-

or loose upper thread te.nsion

Page 10

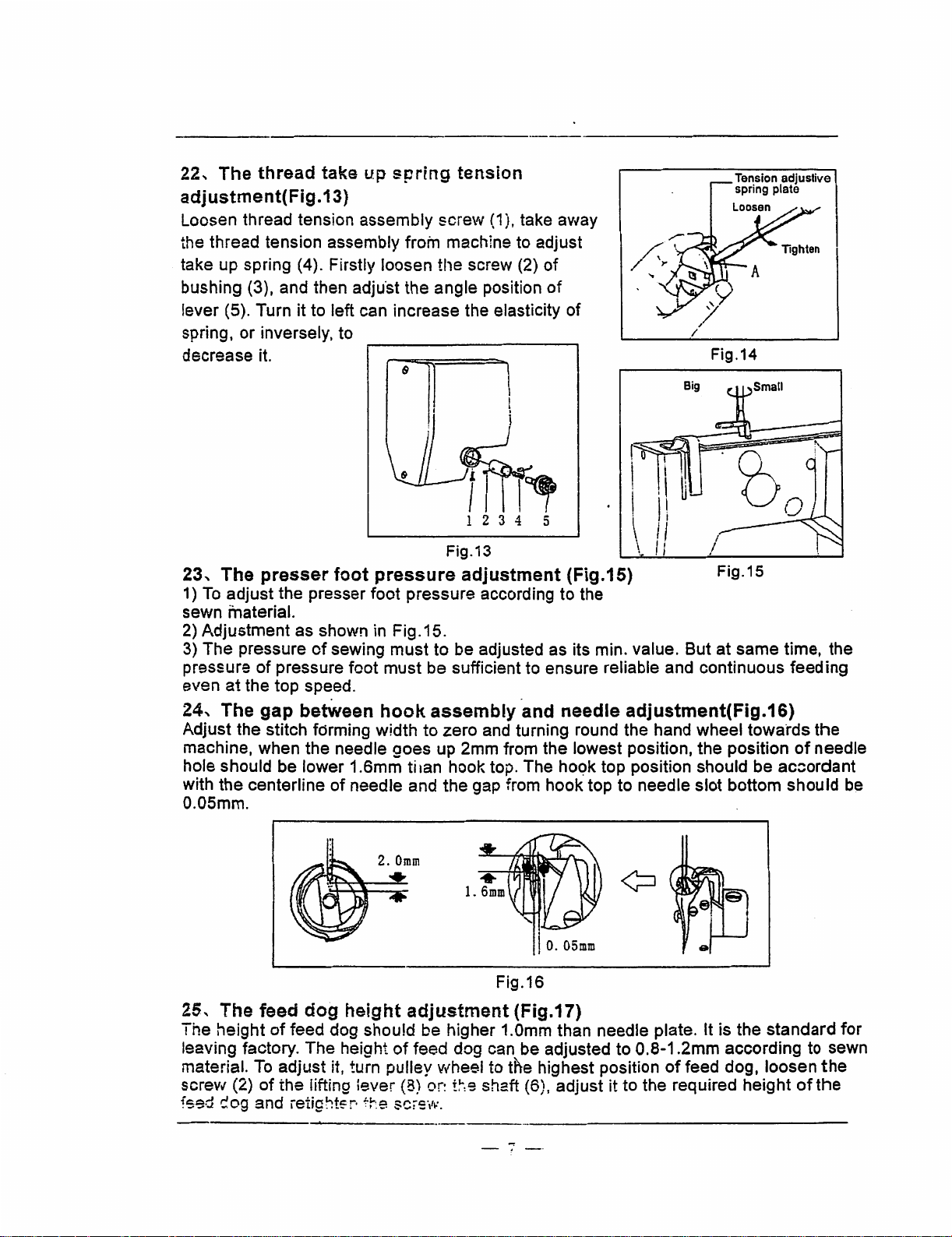

22, The thread take

adjustment(Fig.13}

Loosen thread tension assembly screw

the thread tension assembly from machine to adjust

take up spring

bushing (3), and then adju·st the angle position

lever (5). Turn it to left can increase the elasticity of

spring, or inversely, to

decrease it.

(4). Firstly loosen

up

sprfng

tl1e

&

tension

{1

),

screw (2)

I

take away

of

of

Big

Tension

spring

Fig.14

adjustive

plate

~mr~

1 2 3 4 5

Fig.13

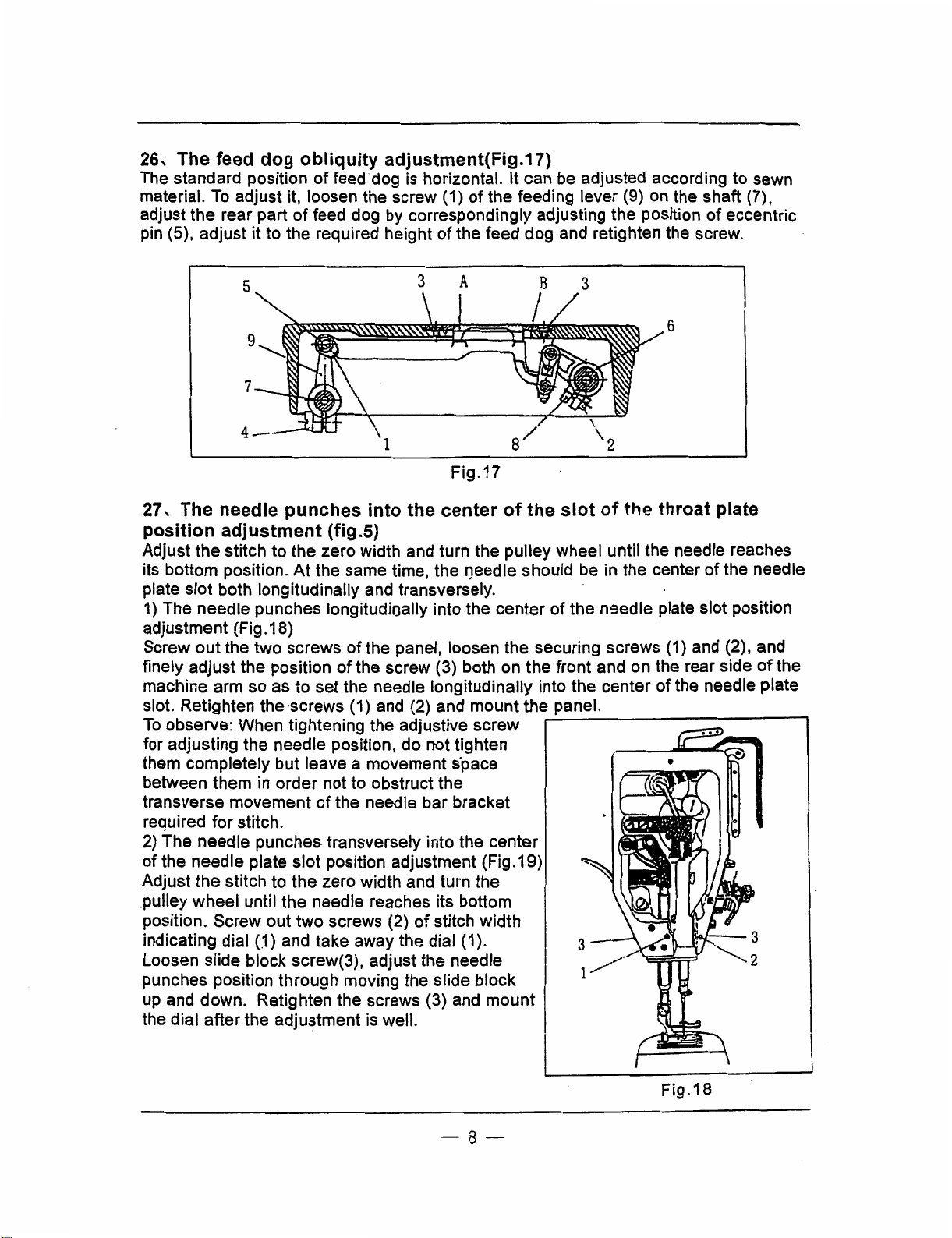

23, The

1)

To

sewn material.

2) Adjustment as shown in Fig.15.

3) The pressure

pressure

even

24, The gap between

Adjust the stitch forming width to zero and turning round the hand wheel towards the

machine, when the needle goes up 2mm from the lowest position, the position

hole should be lower 1.6mm

with

0.05mm.

presser

adjust the presser foot pressure according to the

of

pressure foot

at the top speed.

the

centerline

foot

pressure

of

sewing

. .

must

must

hook

ti

of

needle and the gap from hook top to needle slot bottom should be

adjustment {Fig.15)

to be adjusted as its min. value. But at same time, the

be sufficient to ensure reliable and continuous feeding

assembly

1an

hook top. The

and needle adjustment(Fig.16)

hoc;>k

top position should be ac::ordant

Fig.15

of

needle

I

0.

05mm

Fig.16

25, The feed

The height

leaving factory. The height

material.

screw (2)

fs9d cog and ietight~r·

To

dog

height

of

feed dog should be higher 1.0mm than needle plate. It is the standard for

adjust it, turn pulley wheel to the highest position

of

the lifting lever (8) or:

adjustment

of

f-r:e

scrsvi:.

(Fig.17)

feed dog can be adjusted to 0.8-1.2mm according

t~:s

shaft

(6), adjust it to the required height

- 7

-·

of

feed dog, loosen

of

to

the

sewn

the

Page 11

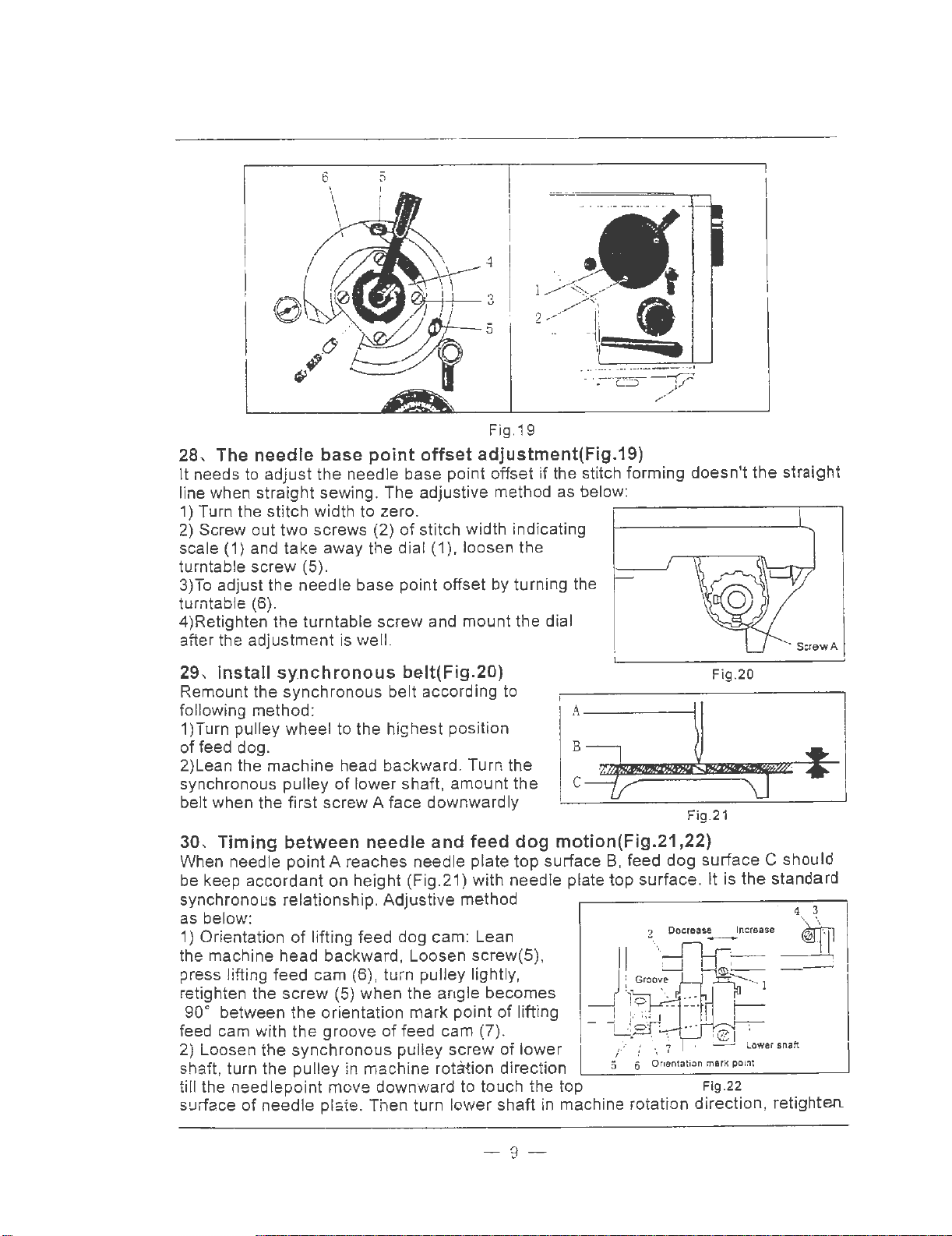

26, The feed

The standard position

material.

adjust the rear part

pin

To

(5), adjust it to the required height

dog

obliquity

of

feed dog is horizontal. It can

adjust it, loosen the screw (1) of the feeding lever (9) on the shaft (7),

of

feed dog

adjustment(Fig.17)

be

adjusted according to sewn

by

correspondingly adjusting the position of eccentric

of

the feed dog and retighten the screw.

6

Fig.17

27, The needle punches into the center of the slot of the throat plate

position adjustment (fig.5)

Adjust the stitch to the zero width and turn the pulley wheel until the needle reaches

its bottom position.

plate slot both longitudinally and transversely.

1)

The needle punches longitudinally into the center

adjustment (Fig .18)

Screw out the two screws of the panel, loosen the securing screws

finely adjust the position

machine arm so as to set the needle longitudinally into the center of the needle plate

slot. Retighten the ·screws (1) and (2) and mount the panel.

To

observe: When tightening the adjustive screw

for adjusting the needle position, do not tighten

them completely but leave a movement

between them

transverse movement

required for stitch.

2)

The needle punches transversely into the center

of the needle plate slot position adjustment (Fig.19)

Adjust

pulley wheel until the needle reaches its bottom

position. Screw out two screws (2)

indicating dial

Loosen slide block screw(3), adjust the needle

punches position through moving the slide block

up

the dial after the adju~tment

the

stitch to the zero width and turn the

and down. Retighten the screws (3) and mount

At

the same time, the f)eedle should be

of

the screw (3) both on the ·front and on the rear side

in

order not to obstruct the

of

the needle bar bracket

of

(.1)

and take away the dial (1).

is

well.

s·pace

stitch width

in

the center of the needle

of

the n9edle plate slot position

(1)

and (2), and

-------------,

of

the

-8-

Fig.18

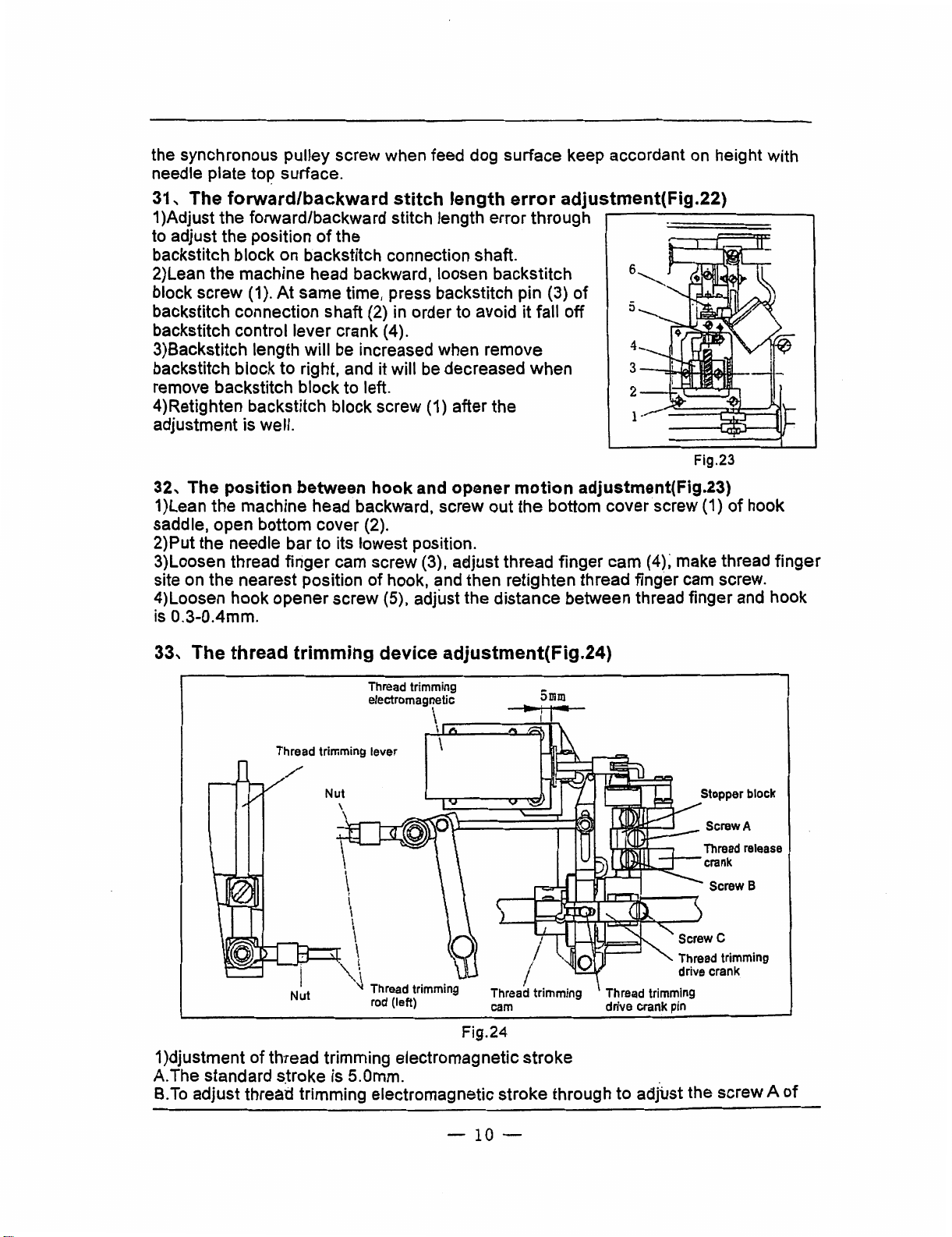

Page 12

5

4

0

5

Fig.19

28

, The needle base point offset adjustment(Fig.19)

It needs to adjust the needle base point offs

sew

line when straigh t

ing. The adjust ive method as below:

et

if the stitch forming doesn't

1) Turn the stitch width to zero .

2) Screw out

(1

scale

two screws (2)

of

stitch width indicating

) and take away the di al (1), loosen the

turntable screw (5).

3)

To

adjust the needl

e base point offset by turn i

ng

the

turntable (6).

Re

4)

tighten

the

turntable screw and mount the dial

after the adjustment is well.

29, Install sy.nchronous belt(Fig.20)

Remount the synchronous belt acco rding to

ng

followi

method:

1 )Turn pulley wheel to the highest posi tion

of

feed dog.

2)Lean the

synchronous pulley

machine

head backward. Turn the

of

lower shaft, amount t

belt when the first screw A face downwardly

he

A-

B

C

---

----

-----~

~

Fig.21

F

ig.20

the

straight

-

----..

30, Timing between needle and feed dog motion(Fig.21 ,22)

When needle point A reaches needle plate top surface B, feed dog surface C should

be keep acco

on height (Fig.21)

wit

h needle plate top surface. It is the stand

rd

ant

synchronous relationship. Adjustive method

be

low:

as

1)

Orientation

the machine head backward, Loosen

press lifting feed cam (6) , turn pulley lightl

re

tighten the

90

° between

feed cam with

2) Loosen the synchronous pulley screw

shaft, turn

ti

ll the need

surface

of

of

lifting feed dog cam: Lean

sc

screw

the

lepoint

(5) whe n the angle becomes

the

orientation mark point

the

groove

pulley

of

feed cam (7).

in

machine rotation

move down ward to tou

needle piste. Then turn lower

-

rew(5),

y,

of

lifting

of

lower

direc

tion

ch

the top Fi

shaf

t in machine rotation direction, retighten.

9-

g.2

2

Lower

ard

shaft

Page 13

the synchronous pulley screw when feed dog surface keep accordant on height with

needle plate top surface.

31, The

forward/backward

stitch

length

error

adjustment(Fig.22)

1 )Adjust the forward/backward stitch length error through

to adjust the position

of

the

backstitch block on backstitch connection shaft.

2)Lean the machine head backward, loosen backstitch

(1

).

At

block screw

same time, press backstitch pin (3)

backstitch connection shaft (2) in order to avoid

it

of

fall off

5

backstitch control lever crank (4).

3)Backstitch length will be increased when remove

backstitch block to right, and it will be decreased

when

remove backstitch block to left.

4)Retighten backstitch block screw

(1) after the

4-

3

-~21H!~jil--.---lll-

2

---b~~~

_:__..,uj,,..h,

adjustment is well.

Fig.23

32, The position between hook and opener motion adjustment(Fig.23)

1)Lean the machine head backward, screw out

saddle, open bottom cover

2)Put the needle bar

to

3)Loosen thread finger cam screw

site on the nearest position

4)Loosen hook

opener

(2).

its lowest position.

(3), adjust thread finger cam

of

hook, and then retighten thread finger cam screw.

screw (5), adjust the distance between thread finger and hook

the

bottom cover screw (1)

(4)~

of

hook

make thread

finger

is 0.3-0.4mm.

33, The thread trimming device adjustment(Fig.24)

Thread trimming

electromagnetic

Thread trimming lever

Nut

\

\

\.-----._...M.

\

5mm

\

\

\

\

\

. \

~\

~

Nut

Thread trimming

rod

(left)

Fig.24

Thread trimming

drive crank pin

1 )djustment of thread trimming electromagnetic stroke

A.The standard stroke is 5.0mm.

B.To

adjust thread trimming electromagnetic stroke through to adjust the screw A

Thread trimming

drive crank

Stopper block

Screw A

Thread

release

crank

Screw

B

of

-10-

Page 14

stopper block.

2)Adjustment

A.

Turn pulley till the needle to its lowest position.

B.

Press the thread trimming drive crank, put the thread trimming drive crank pin into

of

thread trimming cam

groove of thread trimming cam.

C.

Turn pulley, adjust thread trimming cam till the movable knife start to move and the

take up lever start to lift from its lowest position.

3)Adjustment

cam

(Fig.25)

A.

Turn pulley till the needle to its lowest

of

gap between thread trimming drive crank pin and thre~d trimming

po.sition.

B.

Loosen screw C of thread trimming

drive crank, put the thread trimming drive

crank

pin into groove

C.

Adjust the distance between the

surface

of

pin with the bottom

cam

groove is 0.5mm, retighten screwC

of

thread trimming cam.

thread trimming drive crank

of

thread trimming

of Thread trimming drive crank.

4)Adjustment

A.

Loosen two nuts

of

movable knife position (Fig.26)

of

thread trimming rod

(left). .

B.

To

·adjust the thread trimming rod (left),

......,.,.-·......_.~

1

0.5mm

' ScrewO

Thread

drive

crank

Screw

C

Fig.25

Thread trimming ·

pressure

~

trimming

-$-

Screw 8 release

adjustive

nut

Thread

0-0.

make the distance between the acclivitous

forepart surface

forepart

of

retighten nut.

of

movable knife.with the

fixed knife is 0-0.Smm, then

Slide plate Movable knife Fixed knife

crank

5mm

Fig.26

5)Adjustment

A.

Turn the thread trimming pressure adjustive

of

pressure

of

movable knife and fixed knife (Fig.26)

nut

of slide plate to adjust the mesh

power

of

movable knife and fixed knife.

B.

To

confirm the thread trimming whether is sharp by moving the movable knife after

ending adjustment. .

To

observe: The more mesh power will bring large operation moment and failure

trimming, so it should to be adjusted to its minimum.

6)Adjustment

A.

Turn pulley till the needle to its lowest position.

B

..

Press the thread trimming drive crank, put the thread trimming drive crank pin into

of

releasing gap

of

thread tension disc (Fig.25)

groove of thread trimming cam.

C.

Turn pulley till the take

up

lever to its lowest position. Here the releasing gap

tension disc should be its maximal.

D.

The ringent degree can

shaft connection. During adjustment, loosen the screw D

and shrink the flexible

~e

wire.-.

adjusted through thread release crank and

of

release soft-shaft connection

rel(:3.ase

- 11 -

of

thread

soft-

Page 15

A,

Arm

29

bed

and its

accessories

'

28

21

(20)

26

(2)--__;~~~~~

25

(12)~

23~

24-

22----

··

....

·

,··...

~--

··~

... ~ ..

_,

'•,

,:-::

..

,,::~---·····

..........

. .

········...

· . •

· ·

•.

<e,(J)·~ . ·.

··.~~

,,r~.::~~-

~~

_ .

.,

~-·~

·

..

_·. · ..

......

.

~

·.

'"

·

...

-.

··

...

•:-~-~

·

...

~~.

- 12 -

Page 16

A,

Arm

bed

and

its

accessories

No.

A0l

A02

A03 7.02.16.-058

A04

A0S 7.02.11.060

A06

A07

A08

A09 7.02.14.032

AI0

All

Al2

Al3

Al4

Al5

Al6

A17

Al8

Al9

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

PartNo.

7.02.11.059

7.02.15.388

7 .02.16.032

~-~

7.02.16.078

7.02.14.031

7.02. 15.393

7.02.11.063

7.02.15.006

7.02.15.391

7 .02.14.029

7.02.15.392

7.02.18.070

7 .02.14.028

7.02.14.027

7.02.14.025

7 .02.15 .390

7.02.14.026

7.02.01.044

7.02.10.088

7.02.01.038

7.02.02.085

7.02.02.086

7.02.11.062

7.02.15.389

7.02.l 1.061

7.01.02.013

--

Name

up

Thread take

Thread take

plug

Plastic

Felt

Top

cover

Aluminium oil spite

Nut

Thread guide lever(upper)

Winder

cover

Round

cover

Round

Winder fixed screw

guide

Thread

Thread guide lever (middle)

guide

Thread

washer

Screw

guide

Thread

Thread guide plate

Thread guide lever(lower)

Lower thread guide platcfscrew

Lower

thread

Winder assy.

Release

Thread tension assy.

Slide plate

Needle plate

Felt splint

screw

Panel

Panel

Machine frame

lever guard cover

up

lever guard cover screw

thread

clip small assy.

screw

lever (middle) screw

plate screw

plate

guide plate

pin

Qty.

GG0028-I

1 1

12

5

1 I

1 1

I

1

1 1

1

I I

I 1

3

I

1

1 1

1

1

1 1

1 1

3 3

1

1 1

1 I

1 I

1

1 I

1

2 2

1

1 I

GG0028-1D

10

4

l

1

1

3

1

1

~

1

1

1

l

Remark

M4X8

JII.

M3X12

M4X8

M4X5

M3X6

GB/T97.1 3

M3X8

M5X14

-#;

A07

to

...__...._

____

be ordered

---,1~--------------'---···---'----------

with

A08

-13-

Page 17

B,

Arm

shaft

and

needle

bar

thread

33

take

35

up

36 37

parts

38

11

12

13----.J

14----lil-.A

l

6------11

44 45

-

14-

46

17

49

(32)

50

51

Page 18

B.

I

!

l

Arm

No.

BO!

B02

B03

B04

B05

B06

B07

B08

B09

BIO

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

33,

shaft

PartNo.

7.02.10.091

7.02.15.411

7.02.05.066

7 .02.06.036

7 .02.04.025

• 7.02.05.067

7.02.15.395

7.02.15.413

7.02.15.408

7.02.02.088

7.02.03.071

7.02.15.409

7 .02. l O .090

7.02.15.412

7.02.14.030

7.02.21.140

7.02.16.219

~

~~

~-

7.02.05.065

7 .02.15 .056

7.02.15.400

7.02.15.401

7.02.15.037

7.02.15.404

7.02.15.403

7.02.10.089

7.02.05.064

7.02.15.396

7.02.15.397

7.02.16.035

7.02. 15.398

7.02.16.090

7.02.15.399

7.02.04.024

7.02.08.095

7.02.07.059

7.02.17.094

7.02.09.032

and

Thread

Thread

Thread

Libra

Bearing

Needle

Libra

Thread

Needle

Needle

Needle

Needle

Needle

Screw

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Tighten

Needle

Needle

Needle

Felt

Arm

Arm

Arm

Winder

Replacement

\\-:nder

needle

take

up

take

up

take

up

crank

bar

link

crank

screw

take

up

bar

joint

bar

joint

bar

clamp

clamp

clamp

bar

joint

bar

connection

bar

connection

bar

connecti9n

bar

connection

bar

connection

bar

connection

bar

connection

bar

connection

bar

connection

screw

bar

crank

bar

crank

bar

crank

shaft

bushing

shaft

bearing

shaft

bushing

drive

spring

drive

bar

lever

lever

lever

rod

crank

screw

shaft

shaft

washer

oil

tighten

orientation

pulley

pulley.

thread

Name

support

support

assy.

screw

screw

wick

holder

bracket

bracket

bracket

bracket

bracket

bracket

bracket

bracket

screw

epllar

screw

screw

stud

stud

tighten

screw

screw

shaft

screw

screw

shaft

take

screw

(back)

(left)

screw

(front)

(right)

screw

up

parts

GG0028-l

I

I

I

I

2

I

I

1

I

1

1

1

I

I

1

1

1

1

I

1

I

1

I

1

1

1

1

1

I

1

I

I

2

I

I

I

1

Qty.

GG0028-1D

1

1

1

I

2

1

1

l

I

I

I

I

1

1

I

I

1

1

I

l

1

l

1

1

1

I

I

1

I

I

I

1

2

1

1

I

I

Remark

M6(0.75)X8

HK.0810

M6(0.75)X7.5

9/64(40)X

M4X8

M2.SX5

M3X5.8

19•

!l>2X25mm

M5X5

M4Xl2

M6(0.7S)X30

M3X6

M4Xl6

M6(0.

MSXJO

M6(0.7S)X

M6(0.75)X

M6Xl4

6003

5.S(left)

75) X 11

15

17.5

-15-

Page 19

B,

Arm shaft and needle bar thread take up parts

No.

B38

B39

B40

B41

B42

B43

B44 7.02.07.053

B45

B46

B47

B48

B49

BSO

BSl

PartNo.

7.02.15.407

7.02.15.428

7 .02.08.102

7.02.07.051

7.02.15.126

7.02.03.070

7.02.15.431

7 .02.18.076

7.02.18.078

7 .02.04.027

7.02.07.054

7 .02.11.064

7.02.15.432

Name

Drive pulley orientation screw

Collar screw

Arm

shaft bearing collar

Vibrating needle drive gear

Small gear screw

Arm shaft

Synchronous pulley (upper)

Synchronous pulley screw 2

Elasticity stop

Elasticity stop ring

Arm shaft bearing(right) 1 1

Pulley

Pulley cover 1 1

Pulley cover

ring

screw

Qty.

GG0028-l

1

3

1

1

3

1

1

1 1

1

1 l

3

GG0028-1D

~

3

I

1

3

1

1

~

1

3

Remark

M6(0.75)X7

M6(0.75)XS

l/4(40)X7

M6(0.7S)X

10

GB/T893.1-1986-62

GB/T894.l-1986-30

6206

M3X8

'

-16-

Page 20

C,

Needle

1 2 3

\J~

4----f

bar

vibrating parts

26

27

I I

28

fl

I I

;J---30

&J--31

10

1!-·

--·12

-.

17 -

Page 21

C,

Needle bar vibrating parts

No.

COI

CO2

Co3

C04

cos

C06

C07

cos

C09

ClO

Cll

C12

C13

Cl4

ClS

C16

Cl7

C18

C19

C20

C21

C22

C23

C24

C25

C26 7.02.06.037

C27

C28

C29

C30 · 7.02.03.074

C31

C32 7.02.08.100

C33

C34 7.02.15.426

C35

C36 7.02.15.449

j

C37

PartNo.

7.02.15.405

7.02.18.071

7.02.13.043

7.02.01.039

1.02.15.407

7.02.15.391

7.02.15.406

7.02.08.096

7.02.15.410

7 .02.08.097

7.02.08.101

7.02.17.091

7.02.15.443

7.02.16.219

7.02.15.049

7 .02.03.075

7 .02. l 6.059

7.02.10.093

7.02.05.076

7.02.15.428

7.02.09.030

7.02.16.067

7.02.04.026

7 .02.16.064

7 .02.07 .050

7.02.18.075

7.02.05.077

7.02.16.056

7 .02.08 .099

7.02.15.427

7.02.15.446

7.02.16.0S6

Fixed

bracket

Washer

Needle

bar

Needle

bar

Needle

bar

Tighten

screw

Tighten

screw

Needle

bar

Needle

bar

Needle

bar

Connection

Connection

·

Connection

Felt

Needle

feeding

Needle

feeding

Oil

spile

Connection

Link

lever

·Collar

screw

Needle

feeding

Coppery

Bearing

Aluminium

Vibrating

Vibrating

Coppery

Vibrating

Felt

Vibrating

Vibrating

Connection

Connection

Vibrating

Vibrating

Vibrating

Vibrating

screw

vibrating

vibrating

vibrating

vibrating

vibrating

vibrating

bushing

plate

screw

shaft

oil

spile

oil

needle

needle

washer

needle

range

bushing

bushing

bushing

needle

needle

needle

needle

Name

bracket

crank

crank

crank

plug

driven

cam

link

shaft

screw

eccentric

link

rod

link

rod

eccentric

fixed

bracket

shaft

bushing

shaft

bushing

shaft

bushing

shaft

shaft

shaft

gear

lever

shaft

screw

screw

shaft

bracket

screw

tighten

collar

screw

locklMg

o-ring

(left)

screw

(right)

screw

nut

(small)

Qty.

GG0028-l

5

2

l

1

2

1

1

1

2

1

2

2

2

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

I

GG0028-1D

s

2

1

1

2

1

1

1

2

1

2

2

~

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

Remark

M4X14

GB/T97.1

M6(0.75)X7

M4X5

M3X4

M6X8

MS(O.S)X

MSXB

M6(0.7S)X5

51101

M2X4

M6Xl2

M6(0.75)X34

M6(0.75)

4

14

-18-

Page 22

C,

Needle

bar

vibrating

parts

No.

C38

C39

C40

C41

C42

C43

C44

C45

C46

C47

C48

C49

cso

CSl

C52

C53

C54

css

C56

C57

C58

C59

C60

C61

C62

C63

C64

C65

C66

C67

PartNo.

7.02.16.219

--~---

7 .02. l 0.094

7 .02.16.066

7.02.01.04102

7.02.01.04103

7.02.01.04104

7.02.01.04105

7.02.01.04106

7.02.01.04107

7.02.15.425

7.02.01.04101

7.02.13.044

7.02. 15.416

7.02.18.016

7.02.13.045

7.02.i7.089

7 .02.16 .063

7.02.17.090

7.02.15.423

7.02.12.046

7.02.15.424

7.02.15.451

7.02.15.450

7 .02.04.036

-

7.02.05.071

7.02.15.421

7.02.05.070

7.02.15.417

7.02.16.062

7.02.15.422

Name

Oil wick

Vibrating needle eccentric shaft

0-ring

(big)

Vibrating needle bracket connector

Vibrating needle bracket nut

Vibrating needle bracket holder

Nut

Vibrating needle locking spanner

Vibrating needle locking spanner screw

Vibrating needle bracket link rod screw

vibrating needle bracket link rod

Vibrating bracket

Vibrating range shaft screw

Vibrating range shaft screw washer

Turntable

Vibrating needle spanner stop block

Plug

Plug spring

Plug spring screw

Slide block

Slide block screw

nut

Round

Hexagonal

Vibrating needle spanner orientation pin

Vibrating needle spanner

Vibrating needle spanner handel screw

Vibrating needle spanner handle

Vibrating needle spanner screw

Scale

Scale screw

nut

GG0028-l

1

1

l

1

1

1

1

1

1

1

1

1

1

1

1

1

I

1

1

1

5

1

1 1

1

1

2

1

1

1 1

2

Qty.

GG0028-1D

1

1

1

1

1

1

1

1

1

1

1

I

1

1

1

1

1

1

1 M8(0.75)XS

1

5

1

1

1

2

1

1

2

Remark

Cl>2X80mm

'

M5X12

GBff97.l

M4Xl2

M4X12

M4Xl8

I

I

I

I

I

5

-19-

-

Page 23

D'

Presser foot parts

1----------s

26

32

\

33

(9)

20

Page 24

D,

Presser

foot

parts

I

No.

D01

D02

D03

D04

D05

D06

D07

D08

D09

D10

D11

D12

D13

D14

D15

D16

D17

D18

D19

D20

D21

D22

D23

D24

D25

D26

D27

D28

D29

D30

D31

D32

D""

~~

D34

D35

D36

D37

PartNo.

7.02.15.414

7.02.15.415

7.02.17.085

7.02.18.072

7.02.10.092

7.02.16.033

7 .02.12.045

7.02.1S.417

7 .02.18.031

7 .02.17 .087

7.02.05.068

7.02.15.418

7.02.08.098

7.02.15.411

7.02.03.072

7.02.18.0S7

7.02.15.419

7.02.02.089

7.02.17.088

7.02.15.394

7.02.05.063

7 .02.03.073

7 .02.17 .086

7.02.18.060

7 .02.08.040

7.02.19.035

7.02.15.053

7 .02.11.09S

7.02.15.105

7.02.06.081

7.02.15.048

7.02.10.146

7.02.12.081

7.02.18.016

7.02.15.068

·.7.02.15.416

, J.02.05.069

Presser

Presser

Presser

E·ring

Presser

Felt

·-

Presser

Presser

E·ring

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

~

Spring

Release

Release

Presser

Replacement.

Washer

Presser

presser

Fixed

Lifting

Lifting

Presser

Presser

Presser

Slide

Washer

Presser

Knee

Knee

foot

bar

bar

bar

bar

bar

foot

bar

bar

bar

bar

bar

foot

foot

foot

lever

lever

foot

foot

foot

plate

presser

presser

foot

foot

foot

pole

foot

lifting

lifting

pressure

sprtng

spring

pin

slide

block

slide

block

lifting

spanner

spanner

bushing

bushing

screw

screw

screw

lifting

spring

lifting

Lifting

screw

foot

foot

lifting

lifting

lifting

lifting

crank

crank

Name

adjustive

support

connection

screw

tighten

washer

sh~ft

.

shaft

electromagnetic

electromagnetic

electromagnetic

crank

crank

crank

crank

screw

screw

screw

screw

bushing

screw

pin

pin

screw

plate

nut

fixed

screw

plate

Qty.

GG0028-l

GG0028-1D

1

1

1

1

1

1

1

1

1

1 1

1

1

1 1

1

1

1

1

1

1

1

1

1

I

1

1

1

1

1

1

1

1

2

1

1

1 M6(0.75)X8

1

1

1

1

1

1

1

1

1

1

1

I

4

1

3 M6X8

1

1 M6X15

1

1

1

1

1 MSX12

I

Remark

GB/T896-l 986·6

M4X12

GB/T896-l 986-4

M3.SX10

GB/T97.1 8

MSX12

GB/T97.l

GB/T6170

5

MS

-21-

Page 25

D,

Presser foot parts

No.

D38

D39

D40

D41

D42

D43

D44

PartNo.

7.02.17.041

7.02.01.04001

7.02.01.04002

7.02.15.420

7.02.01.04003

7.02.01.04004

7.02.01.04005

I

Name

Pin

Presser

:

Link lever fixed plate

foot

lifting link lever

Link h:\er

Link lever collar

Nut

Knee lifting connection nut

f~\.

.. ~ p!!:e screw

Qty.

GG0028-l

1

1

1

3

1

1

1

1

1

GG0028-1D

!

Remark

M4X6

-22-

Page 26

E~

St

itch

length

a

JU

d. stm

ent

d

backstitch

an

parts

---

,~t~

! / i

iL

~?GD~

I /

I i i '

I I I I '

_~

_3

~'r°

_ "

__

56--

;\

, .

~

/

"-9:JtJ

i·

f1

·

I

I

I

- 23 -

! I

71 72 73

Page 27

E,

Stitch length adjustment and backstitch parts

No.

EOl

E02

E03

E04

E05 7.02.12.048 ·

E06 7.02.12.047.04

E07

E08 7 .02.15.428

E09

ElO

Ell

E12 7.02.13.186

El3

E14

El5

El6

El7

EIS

E19

E20

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E32

E33

E34

E35

E36

E37

PartNo.

7.02.12.047.01

7.02.12.047.02

7 .02.12.047 .03

7.02.15.006

7.02.16.068

7.02.12.135

7.02.05.217

· 7.02.13.185

7.02.15.017

7.02.16.212

7.02.05.216

7 .02.05.079

7.02.03.077

7 .02.10.078

--~~-

7 .02 .12.049

7 .02.05.078

7.02.05.080

7.02.15.416

7.02.17.092

7 .02.03 .076

7.02.18.021

7.02.12.050

7 .02.15.424

7.02.15.447

7 .02.06.039

7.02.15.436

7 .02.04.024

7.02.01.04201

7.02.01.04202

7.02.01.04203

7.02.01.04204

7.02.05.175

7.02.17.033

Qty.

GG0028-l

Stitch length indication holder nut

Washer

Stitch length indication holder

Stitch length indication holder screw

Stitch length adjustive block

Stitch length indication holder shaft 1

Stitch length indication dial

Stitch length indication dial screw 2

Stitch length adjustive tighten block

Stitch length adjustive lever 1

Stitch length adjustive block 1

Stitch length indication holder 1

Stitch length indication holder screw

Stitch length indication dial

Stitch length dial lbcking screw

Backstitch control lever spanner

Backstitch control lever

Pin

B~ckstitch stop lever block

Stitch length adjustive crank

Backstitch control lever crank 1

-

-Backstitch control lever crank screw

Replacement spring

Backstitch conection shaft

E-ring

Backstitch block

Backstitch block screw

Backstitch block tighten screw

Backstitch cam crank 1

Backstitch cam crank screw 1

Backstitch cam crank bearing 1

Feed

backstitch cam

Feed

backstitch cam bushing

Orientation pin 1

Orientation pin screw

Backstitch link lever

Backs.!itch link lever replacement

spring

2

1

1

2

1

1

1

1

1 1

1

1

2

1

l

1

1

1

1

1

1

I 1

GG0028-10

~

1

2 .

1

1

l

1

1

1

1

2

.

l

1

1

l

3

1

1

1

I

I

1

1

1

1

Remark Name

M4X8

M6(0.75)XS

M4X10

MSX12

GBff896· 1986-7

M4Xl2

M4X6

M5X30

6003

-24-

Page 28

E,

Stitch length adjustment and backstitch parts

No.

E38

E39

E40

E41

E42

E43

E44

E45

E46

E47

E48

E49

E50

E51

E52

E53

E54

ES5

E56

E57

E58

E59

E60

E61

E62

E63

E64

E65

E66

E67

E68

E69

E70

E71

E72

E73

PartNo.

7.02.15.268

7.02.18.031

7.02.10.149

7 .02.06.083

7.02.15.053

7.02.18.055

7 .02.15 .068

7.02.21.176

7 .02.07

.071

7.02.15.107

7.02.15.108

7.02.05.176

7.02.03.112

7.02.10.148

7.02.21.173

7.02.15.1>89

7.02.15.088

7.02.15.106

7.02.10.147

7.02. 19.036

7.02.21.033

7.02.11.104

7.02.18.058

7.02.15.007

7.02.19.030

7.02.19.027

7.02.15.420

7.02.16.166

7.02.15.101

7.02.13.072

7.02. 15.005

7.02.11.079

7.02.01.059

7.02.19.113

7.

02.

I 9 .104

7.02.16.16i

Name

......

Replacement

E-ring

Backstitch

Backstitch

Backstitch link lever

Spring

Backstitch

Knee

Foot

control shaft link

Foot

control shaft

Foot

control

Foot

control shaft link

Foot

control backstitch shaft

Foot

control backstitch

Foot

control backstitch

Stop

screw/nut

Stop

screw

Foot

control shaft nut

Backstitch electromagnetic

Backstitch electromagnetic

Backstitch electromagnetic

Backstitch electromagnetic

Spring

Backstitch electromagnetic

Jacket

Socket

Wire

clip

Nylon

Switch

Switch

Switch

Switch

Backstitch

Earthing

Earfrin~

Nyi:-,

j

spring

link

lever

link lever

washer

link

lever

lifting

Lever

shaft

washer

screw

clip

AB-3N

·

box

fixed

bracket

box

fixed

bracket

box

screw

box cover plate

switch

assy.

wire

plug

c-:ip

ABM8N

nut

assy,

link

link

crank

crank

crank

crank

lever

lever

lever

lever

crank

crank

pin

screw

pin

screw

screw

nut

pin

fixed

fixed

screw

screw

pin

nut

roller

plate

plate

screw

GG0028-l

2

4

l

1

2

1

1

1

t

I

2

l

1

1

1

1

1

1

1

1

4

l

3

3

1

1

3

2

2

1

2

1

I

I

1

1

Qty.

GG0028-1D

-

GBff

GBff896-1986-4

M5X12

GB/T93.

GBff6170

GBff6172

GBfT6172

M6Xl2

MB

GBIT99

GBIT93.

M6X10

M4X6

M3X4

M4X8

Remark

6170

S

MS

MS

M6

Cle)

4.5 X 20

6

M4

-25-

Page 29

F,

Lower

shaft,

feed dog

1 2 3 4 5

\ \ l I

i \ •

\ I I

parts

,1

28

29

~~·

-~~II

30

31

32

(30)

(1)

37

44

-

26-

I

54

Page 30

F"

Lower

shaft,

feed dog

parts

No.

FOi

F02

PartNo.

7.02.16.067

7.02.03.079

F03 7.02.08. 103

F04

7.02.15.428

F05 7.02.15.448

F06

7 .02.05. 081

F07

7.02.15.408

F0S

7.02.08.104

7.02.15.430

f

..

·~

FIO

7.02.06.038

Fll

7.02.15.391

Fl2

7 .02.09

.030

F13

7 .02.08.105

Fl4

7.02.16.072

~

7

.).,

:,:,

7.02.16.219

~~-

-

7.02.10.097

7.02.02.090

7.02.02.087

7.02.15.433

7.02.04.028

7.02.18.079

7.02.18.080

7.02.04.030

7.02.05.082

7.02.16.219

-

~

~

7.02.15.050

7.02.07.055

7.02.16.219

-

-

-

7.02.10.096

7.02.U.082

7.02.04.029

7 . .02.05 .083

7 .02.18.031

7.02.11.065

7.02.10.095

7.02.16.219

~

7 .02.Q~.:080

-

~

FIS

Fl6

Fl

FIS

Fl9

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F"'.,

F"'"'

F34

F35

F36

FJ"'

Oil

Feed

Feed

Bushing

Feed

Feed

Feed

Feed

Feed

Feed

Feed

Collar

Feed

Oil

Feed

--

Feed

Feed

~

Feed

Feed

Lifting

Elasticity stop

Washer

Lifting

Lifting

.

Lifting

Lifting

Lifting

Backsti~h

-

Feed

Gear

Backstitch

Backstitch

E-ring

Connection

Lifting

Lifting

Lifting

Name

spile

shaft

shaft

bm:hing (left)

screw

crank (left) screw

crank (left)

dog holder adjustive

shaft

bushing (middle)

crank (right) screw

crank (right)

crank

pin screw

shaft

bushing (right)

spile (big)

dog

holder

adjustive

dog

holder

adjustive

dog holder

dog

dog

screw

feed

dog

cam bearing

riJ?.g

feed

dog

cam link

feed

dog

cam link

feed

dog

cam

feed

dog

cam screw

feed dog cam

cam link lever oil

crank

pin

washer

cam

link lever bearing

cam link lever

plate

feed dog link lever

feed dog link lever

feed dog shaft

pin

screw

pin

oil

pin

lever

bearing

lever

link lever oil

wick

pin

pin

oil

wick

wick

wick

Qty.

GG0028-l

2

1

I

12

1

1

1

I

3

1

4

3

1

1

2

1

GG0028-1D

2

1

1

14

. l

l

1

I

3

1

4 M4X5

4

1

1

2

1

1 I

1 1

2

2

2 2

1

1

1

1

l 1

l

1

1 I <l>2X350mm

2

I

2 M6(0.7S)X8

1

1 1

2

2

2

2

I I

1

4

2

2

1

4

2

2

1 I

I

1

Remark

M6(0.75)X5

M6Xl4

M4X8

M5XI0

<l>2X

M4X6

6002

GB/T894.1-1986-18

<l>2X200mm

GB/T896-1986-4

<l>2X60mm

160mm

-27-

Page 31

F,

Lower

shaft, feed dog parts

No.

F38

F39

F40

F41

F42

F43

F44

F45

F46

F47

F48

F49

FSO

FSl

F52

F53

F54

PartNo.

7.02.08.i08

7.02.05.084

7.02.18.109

7.02.15.389

7 .02.06.040

7.02.16.219

--

~

7.02.03.078

7.02.08.107

7.02.15.058

7.02.06.080

7.02.1S.437

7.02.08

..

106

7.02.04.024

7 .02.18.08

7.02.07.056

7.02.15.431-

7.02.07.052

Name

feed

Lifting

Lifting

Lifting

Lifting

Lifting

Lifting

-

Lower shaft

Lower shaft bearing bushing

Thread trimming

Thread trimming

Lower shaft bearing bushing screw

Lower sbaft bearing bushing 1 1

Lower shaft bearing

l

Synchr9nous pulley (lower) washer 1

Synchronous pulley (lower)

Synchronous pulley

Synchronous belt

dog shaft bushing (left)

feed

dog crank (left)

feed

dog shaft bushing (right)

feed

dog crank (right) screw

feed

dog crank (right)

feed

dog crank pin oil wick

cam

screw

cam

screw

-

GG0028-1

1

1 1

1 1

2

1

l 1

l

1 1

1

I

1 1

2

1

Qty.

GG0028-1D

Remark

1.

2

1

1

2 M5X16

. I

M5X14

<1>2X30mm

1

1

1

1

2

M6(0.75) X 14

6003

M6(0.75)X 10

.

-28-

Page 32

G,

Hook

assembly

1.4

1~

. '

1.6

17

27

I

5

35 36

\ \ 3 ~ 38 39

\ \ \ I /

\

41.

---....___

42

~~~~-

~

·--J----1

~

~

\\

~

-~

~

...._

c.

'

I

\

45

46

\~

//

I

I /

~i

~

i°

;

-

29-

Page 33

G,

Hook assembly

No.

G0l

G02

G03

004

GOS

006

G07

GOS

009

010

011

012

013

__Z:~2.16~0~

014

015

016

G17

018

019

020

021

022

023

024.

025

026

027

028

029

030

031

032

033

034

035

036

037

PartNo.

7.02.18.083

7 .02.04.031

7.02.06.041

7.02.15.434

7.02.04.033

7 .02.08.112

7 .02.08.111

7.02.15.017

7.02.07.058

7.02.15.126

7.02.04.026

7 .02.15.439

7.02.09.031

7 .02.04.032

7 .02.15.438

7.02.13.046

7.02.15.445

7.02.16.074

~~---~~

7 .02.10.098

7 .02.07 .057

7 .02.18.027

7 .02.02.092

7 .02.21.144

7 .02.02.095

~~

--

-

7 .02.02.094

7.02.15.006

7.02.02.091

7.02.10.099

7.02.08.110

7.02.15.440

7.02.18.084

7 .02.16.094

--

7 .02.13.047

7.02.16.075

7.02.16.219

~:02.15.441

Name

Elasticity stop ring

Bearing

Opener

cam

Opener

cam

screw

Opener

cam

bearing

Opener

cam

bushing

Hook

opener

Hook

opener screw

Hook

drive

gear

Drive

gear

screw

Bearing

Felt

fixed

screw

Felt

Hook

saddle bearing cover

Bearing

Bearing cover screw

Hook

saddle

Hook

sa4dle

fixed

screw

Felt

Elasticity pin

Hook

gear

Elasticity stop ring

Hook

Bobbin

case

Bobbin

Hook

orientation claw

Hook

orientation claw

Hook

thread distributing claw 1

Hook

thread distributing bracket

Hook

thread distributing bracket bushing

screw

Bushing tighten screw 1

Hook

saddle bottom cover

washer

Felt

Hook

saddle

bottom cover

Hook

coopery oil tube 1

Hook

oil

w1~k

r Oil seals~rew

Qty.

GG0028-l

1

1

1 1

2

1

1

1 1

1

1 1

2

1 1

1 1

1

1

2

2

1

2

1

1

1

I 1

1

1

1

1

s

l

1

1 1

1

1

1

1 1

GG0028-1D

1

1

2

1

1

t

2

1

1

l

2

I

2

1

1

1

1

1

1

1

5

1

1

1

1

1

1

1

1

Remark

GB/T893.

6292

M6(0.7S)X7

HK1412

M4Xl0

l/4(40)X7

51101

MSXB

l-1986-

608

M4(0.5)><7

M6X25

GB/T893.l-1986-

M4X8

M6(0.7S)X3.5

M6X5

26

22

-30-

Page 34

G,

Hook

assembly

No.

G38

G39

G40

G4I

G42

G43

G44

G45

G46

PartNo.

7.02.16.904

-~-

7 .02.15 .406

7.02.13.048

7.02.15.442

7.02.16.069

.

7.02.16.071

Name

Oil box felt

--

-

Coppery oil tube tighten screw

Hook saddle oil box

box

...

screw

Sold with

-

-

washer

G40

Oil

Oil quantity adjustive valve felt

Oil quantity adjustive valve o-ring

Oil quantity adjustive valve

Oil window cover

Oil window cover

GG0028-l

1

1

1

1

I

1

1

I

I

GG0028-1D

1

1

1

1

I

1

l

I

1

Remark

M3X4

M4X25

-M

*

~

..

Qty.

'

I

I

-31--

Page 35

I •

I

!

t

H,

Thread trimming parts

16 15

14

13

12

·-t/

(17)

44

45

..

• .

...,5-

,•

4 3 2

____

_

46_

,,>

1

·~69

V

66---m~

- 32 -

67

r=:ss

---10

Page 36

I No. I PartNo.

! !

7.02.19.032

!{()l

I

3J2

I

7.02.15.037

:i.

..

_,..,

:>..,

1

I

i

7.02.18.123

I

i.02.17.125

7.02.15.032

7.02.05.163

7.02.10.136

7.02.18.024

7.02.15.096

7.02.13.073

7.02.15.268

7 .02.06.075

7.02.10.137

7.02.15.097

7.02.17.018

7.02.10.144

7.02. 15.006

7.02.11.101

7.02.11.100

7.02.05.172

7 .02.06.076

7.02.15.416

7.02.12.073

7.02.15.430

7.02.06.077

7.02.16.122

7.02.06.078

7.02.03.111

7.02.18.039

7.02.06.079

7.02.10.139

7.02.10.138

7 .02.18.031

7.C2.i8.0!6

7.02.17..019

i.Q2.l8.07l

-

,,~

1

r:

.. v ...

·-.

r,o:·

-·-·.

H03

?.04

H05

H06

H07

HOS

H09

HlO

Hll

Hl2

H13

Hl4

Hl5

H16

E17

i

;{iB

l

319

I

t.~--o

...

I

:.;·:

I;~~

I

H23

H24

H2~

P..26

H27

H28

P"29

H30

H31

..

H''~

E33

:B4

t.r.,,

••

I

~3':'

---.-

Thread

trimming

Th.read

trimming

Thread

trimming

Thread

trin~ming

Thread

trimming

'fhread

trimming

Thread

trimming

E-ring

Thread

trimming

Thread

trimming

Crank

connection

Link

lever

Link

lever

Crank

connection

Replacement

Replacement

Link

lever

Release

Relwe

Link

lever

Link

lever

Link

lever

Stopper

Stopper

block

Release

Release

soft-shaft

Thread

trimming

Thread

trimming

E-:ring

Thread

trimming

Thread

trimming

n.:.read

tdmr.-Jz:g

E-ring

Washer

Replacemeut

WesLer

;

7;.~~c.:=

~b,;~,ir~g

!

crank

crank

spring

spring

crank

soft-shaft

soft-shaft

crank

crank

bloc,

scre"1

crank

sp;:-ir.:g

·---·----··

Name

eiectromagnetic

electro:nagnetic

electromagnetic

electromagnetic

electromagnetic

eleciromagr.etk

electromagnetic

parts

setting

bracket

parts

setting

bracket

screw/nut

(upper)

pin

screw

~

pin

pin

screw

fixed

press

plate

fixed

plate

(lower)

'.iower)

screw

connection

drive

crank

crank

shaft

vibrating

drive

vibrating

:;~J.:

crank

crank

rrnnk

~.'! . .,~,.

:-~}1~:;t:-:,t

pin

...

·--

screw

screw

fixed

fixed

link

iink

pin

washer

plate

plate

lever

lever

screw

sc1°,•,

screw

pin

---L

Qty.

GG0028-1

GGOOZS-10

1

4

4

l

Remark

M3X6

GB/T97.l

2 M4X8

1

1

3

GB/T896-l 986-3

M5X16

3

1

3 GB/T6170

1

1

2 M4X6.5

2

1

11

M4X8

1

I

1

1

MSX12

2

1

3 MSXlO

1

1

1

1

1 GB/T896-l 986-5

I

1

1

GB/T896-l 986-4

6

1 GB/T97.1

1

GB/T97.1 4

1

1

I

3

M4

t

5

-33-

Page 37

H,

Thread trimming parts

No.

H38

H39

H40

H41

H42

H43

H44

H45

H46

H47

H48

H49

HS0

HSI

HS2

HS3

H54

HSS

H56

H57

H58

HS9

H60

H61

H62

H63

H64

H65

H66

H67

H68

H69

H70

H71

H72

H73

H74

PartNo.

7.02.15.098

7.02.05.173

7.02.10.140

7.02.10.141

· 7.02.08.039

7 .02.05.177

7.02.05.093

7.02.10.193

7.02.15.622

7.02.05.171

7 .02.15.068

7.02.05.174

7.02.10.143

7.02.15.056

7.02.15.053

7.02.13.074

7.02.10.142

7 .02.18.059

7.02.21.085

7.02.15.102

7.02.11.103