Highlead GC2698-2 User Manual

Purchasing

Copy

Dept

HIGH

LEAD

GC2698-2

CYLINDER-BED UNISON FEED

Instruction

Manual

SEWING

MACHINE

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING

MACHINE

FACTORY

CONTENTS

INSTRUCTION MANUAL

1,

SAFETY .......................................................................................................................................................... 1

1)

GENERAL SAFETY TIPS ............................................................................................................................... 1

2)

IMPORTANT POINTS

3)

SERVICE AND TECHNICAL PERSONNEL ................................................................................................. 1

4)

DANGER TIPS ............................................................................................................................................... 2

2,

TESTING, TRANSPORT & STORAGE .......................................................................................................... 3

1)

TIPS ON TESTING ........................................................................................................................................ 3

. .

2)

TRANSPORT WITHIN THE CUSTOMER SITE ........................................................................................... 3

3)

STORAGE ........................................................................................................................................................ 3

3,

INSTALLATION & FIRST OPERATION ....................................................................................................... 3

1)

ASSEMBLING THE BOBBIN STANDS ........................................................................................................ 3

2)

FIRSTOPERATION ......................................................................................................................................... 3

FOR

THE EMPLOYER ............................................................................................. 1

4,

SPECIFICATIONS ........................................................................................................................................... 3

5,

PREPARATION ................................................................................................................................................ 4

1)

ATTACHING THE NEEDLE ........................................................................................................................... 4

2)

WINDING THE

3)

TAKING OUT THE BOBBIN CAPSULE ....................................................................................................... 5

4)

ROUTING THE UPPER THREAD ................................................................................................................. 6

5)

REGULATING THE TENSION OF THE THREAD ....................................................................................... 6

6,

STITCH LENGTH ADJUSTING LEVER I REVERSE SEWING .................................................................. 7

7,

MAINTENANCE & CARE .............................................................................................................................. 7

1)

MAINTENANCE AND CARE INTERVALS .................................................................................................. 7

2)

CLEANING ...................................................................................................................................................... 7

3)

GENERAL OILING ......................................................................................................................................... 8

4)

OILING THE HEAD ...................................................................................................................................... 8

5)

OILINGTHEROTATINGHOOK

8,

ADJUSTMENT ................................................................................................................................................ 8

LOWER

THREAD, REGULATING THE TENSION OF

................................................................................................................... 8

THE

THREAD ......................... .4

1)

TIPS FOR ADJUSTMENT ............................................................................................................................... 8

2)

ABBREVIATIONS ........................................................................................................................................... 9

3)

POSITION OF THE FEED

DOG

..................................................................................................................... 9

-1-

4)

NEEDLE HEIGHT (PRE-ADruSTMENT) ..................................................................................................... 9

5)

NEEDLE

6)

PRESSER FOOT, WALKING FOOT AND FEED DOG SLIDING MOVEMENT ......................................

7)

HOOK POSITIONER, GRAB DISTANCE AND NEEDLE HEIGHT ..........................................................

8)

HYDRAULIC MOVEMENT OF THE WALKING FOOT AND PRESSER FOOT .....................................

9)

PRESSER FOOT ............................................................................................................................................

IN

THE MIDDLE OF THE STITCHING HOLE .................................... , ..................................... 1 0

11

11

12

12

10) UPPER THREAD TENSION REGULATION ...............................................................................................

11)

THREAD TAKE-UP SPRING ........................................................................................................................

12)

BOBBIN WINDER. ......................................................................................................................................

13)

ADJUSTMENT OF PRESSER PRESSURE ................................................................................................

13

13

14

14

CATALOG

A,

ARM BED AND ITS ACCESSORIES (

A,

ARM BED AND ITS ACCESSORIES

B,

FEEDING AND FEED LIFTING & ROTATING HOOK SHAFT MECHANISM ......................................

C ARM SHAFTMECHANISM ........................................................................................................................ 22

D,

STITCH REGULATOR MECHANISM ........................................................................................................ 24

E,

PRESSER FOOT MECHANISM ...................................................................................................................

F,

NEEDLE BAR FEEDING MECHANISM (

F,

NEEDLEBARFEEDINGMECHANISM

G,

ACCESSORIES .............................................................................................................................................

1)

................................................................................................

(2)

................................................................................................

1)

..........................................................................................

(2)

.......................................................................................... 29

15

16

19

26

28

32

-2-

1.

SAFETY

1)

GENERAL SAFETY TIPS

CD

The machine should only be used after studying the accompanying instruction manual and only by

specially instructed operating staff

® Before bringing the machine into service read the safety tips and the instruction manual

manufacturer.

® The machine may only be used according to their regulations and

protective

threading up, when leaving the work place

unplugged or switched off at the main switch.

specially trained personnel.

spare parts and accessories that are not supplied

use

fittings.

@ When changing sewing tools (for example needle, presser foot, needle

@ Daily maintenance work should only

@ Repair work as well

(j) Working on the electrical equipment should only be carried out

@ Working on active parts and equipment are not permitted.

® Only the spare parts provided

of

such products can

All relevant safety regulations should also be observed.

as

well

as

during maintenance work the machine should be

be

carried out by specially trained

as

special maintenance work should only

by

by

us

should

in

certain circumstances reduce the predetermined

be

used during repairs.

by

us are also not tested or

qualified electricians.

personnel

be

carried

passed

quality

not

without the accompanying

plate

and bobbin winder),when

out

We

explicitly point out that the

by

of

your machine.

of

by

skilled workers or

us.

The installation or

the engine

We

take

no

responsibility for damage caused

2)

IMPORTANT POINTS

CD

This

instruction manual

machine operators.

It

is

necessary

® Operation and maintenance personnel must

working methods.

® The employer must ensure that the machine

@ The employer should make sure that only authorised persons are permitted to work on the machine.

@ Further information can be obtained from the responsible sales office.

3) SERVICE AND

TECHNICAL

by

the use

FOR

is

a component

to

read the manual before using the machine

of

non-original parts.

THE

EMPLOYER

of

be

is

only used

the machine and must

instructed on safety features

if

it

is

PERSONNEL

always

for

in perfect condition.

be at the disposal

the first

of

time.

the machine and safe

(1) Service Personnel

Service personnel are responsible for the preparing, running and cleaning

of

elimination

CD

®

faults in the sewing. Service personnel must observe the following points:

to

follow the safety guidelines in the instruction manual

to

avoid any type

of

work which may reduces the safety

of

the

machine

of

the machine

as

well

of

as

the

'

the

-1-

® to wear tight-fitting clothes and avoid wearing jewellery, like necklaces and rings

@ to

repo~t

immediately changes in the machine which may reduce safety to the employer.

(2) Technical Personnel

Technical personnel are responsible for the lubrication, maintenance, repair and adjustments to the machine.

Technical personnel must observe the following points:

CD

To

follow safety guidelines in the instruction manual

® Before beginning maintenance work the main switch must be switched off and it must be ensured that it

will not be switched on again.

® Working on active parts and equipment

@

Mter

repair and maintenance work the protective covering must be put back and the electric control box

must be closed.

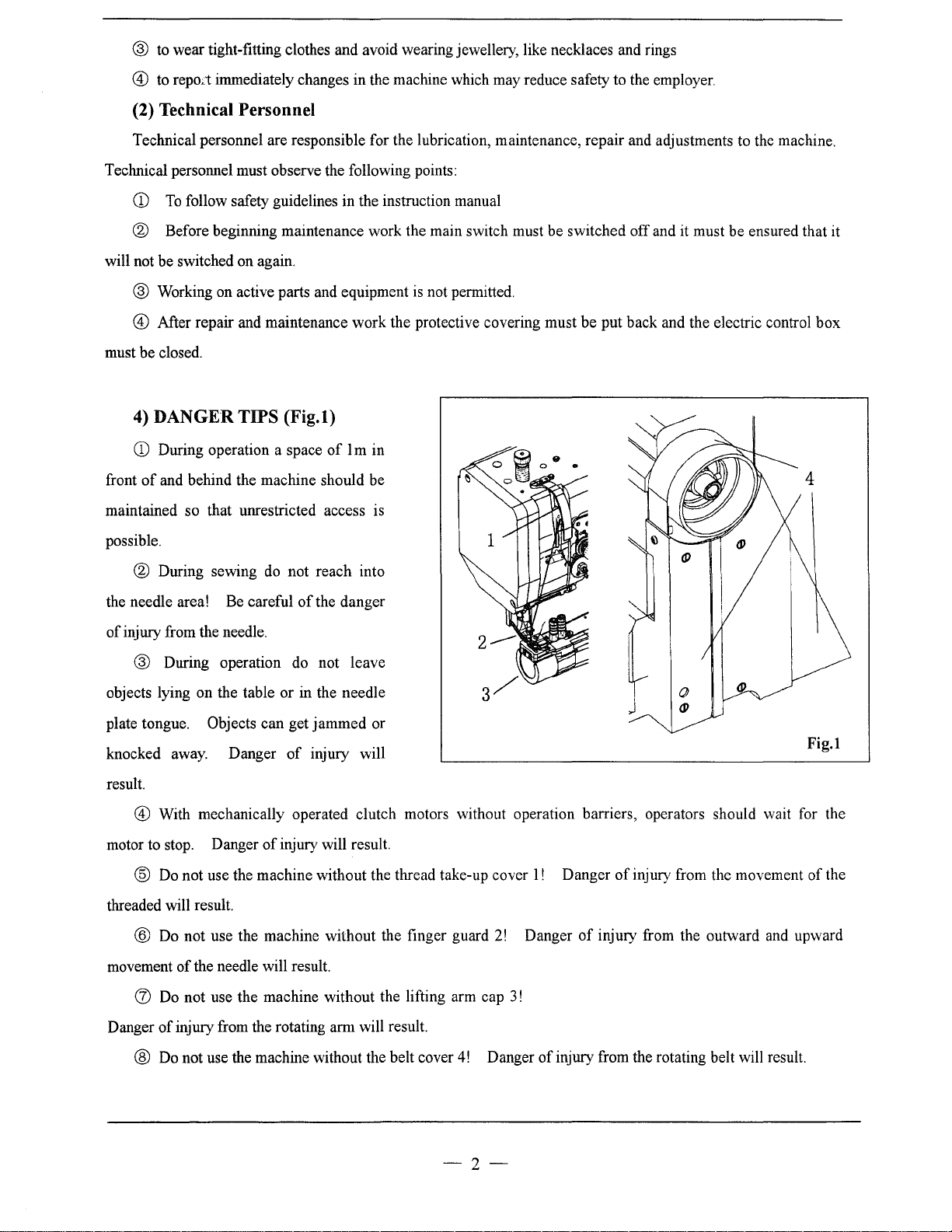

4) DANGER TIPS

CD

During operation a space

of

front

maintained so that umestricted access

possible.

and behind the machine should be

® During sewing

the needle area! Be careful

of

injury from the needle.

(Fig.l)

of

do

not reach into

of

the danger

I m in

® During operation do not leave

objects lying on the table or in the needle

plate tongue.

knocked away. Danger

Objects can get jammed or

of

injury will

ts

is

not permitted.

Fig.l

result.

@ With mechanically operated clutch motors without operation barriers, operators should wait for the

of

motor to stop. Danger

@

Do

not use the machine without the thread take-up cover

threaded will result.

@ Do not use the machine without the finger guard

of

movement

(J)

Danger

the needle will result.

Do not use the machine without the lifting arm cap

of

injury from the rotating arm will result.

® Do not use the machine without the belt cover

injury will result.

4!

2!

Danger

3!

Danger

1!

Danger

of

injury from the rotating belt will result.

-2-

of

injury from the movement

of

injury from the outward

and

of

the

upward

2.

TESTING, TRANSPORT & STORAGE

1)

TIPS ON TESTING

The machine was tested before delivery according

2) TRANSPORT WITHIN

Transport within the customer site is not the responsibility

the machine

3)

The machine can be stored unused for up

If

the machine is

against corrosion, with an oil film for example.

is

correctly transported.

STORAGE

to

be

stored longer the individual parts, in particular the sliding plates, should

3. INSTALLATION &

The machine should only

regulations should be observed. Suitable electricity supply must

technical data). It must

the installation site.

l)ASSEMBLINGTHE

be

be

ensured that there

THE

CUSTOMER SITE

FIRST

installed and started by qualified technical personnel. All the relevant safety

OPERATION

is

BOBBIN STANDS

to

the EN60204-3-1 editionl/86.

of

the manufacturer.

to

6 months.

an even and solid ground surface

It

should

It

should be ensured that

be

protected against dirt and moisture.

be

available

at

the installation site (see

as

well as sufficient lighting at

be

protected

Place the bobbin stands in the drill hole in the table plate and

2)

FIRST OPERATION

Before the first operation check the electric cables in case

CD

Clean and oil the machine thoroughly

® Allow technical specialists to check whether the machine's motor may

main supply and whether it is properly plugged

@ When the machine is running the balance wheel should be turned towards the operator. Otherwise let

technical specialists adjust the motor.

4.

SPECIFICATIONS

Max. Sewing Speed 2200rpm

Max. Stitch Length 6mm

Thread Take-up Lever Stroke 59.55mm

Needle

Bar Stroke 33.4mm

Presser Foot Stroke

Needle

Lubrication System

in.

If

there

By Hand

fix

them into

of

any possible damage.

is

any deviation,

l8mm

DPX35LR

Manual

place

with the enclosed nuts.

be

connected

do

not start the machine.

I

ByKnee

18#-21#

IBmm

to

the available

-3-

5.

PREPARATION

CD

All

regulations and guidelines in this manual should

safety regulations.

®

All

preparation work may only be carried out

work the machine should

be

observed, with special attention being paid

by

specially instructed personnel. Before all preparation

be

disconnected from the main electricity supply

by

switching

off

the main switch or

to

unplugging

The choice

used.

CD

it.

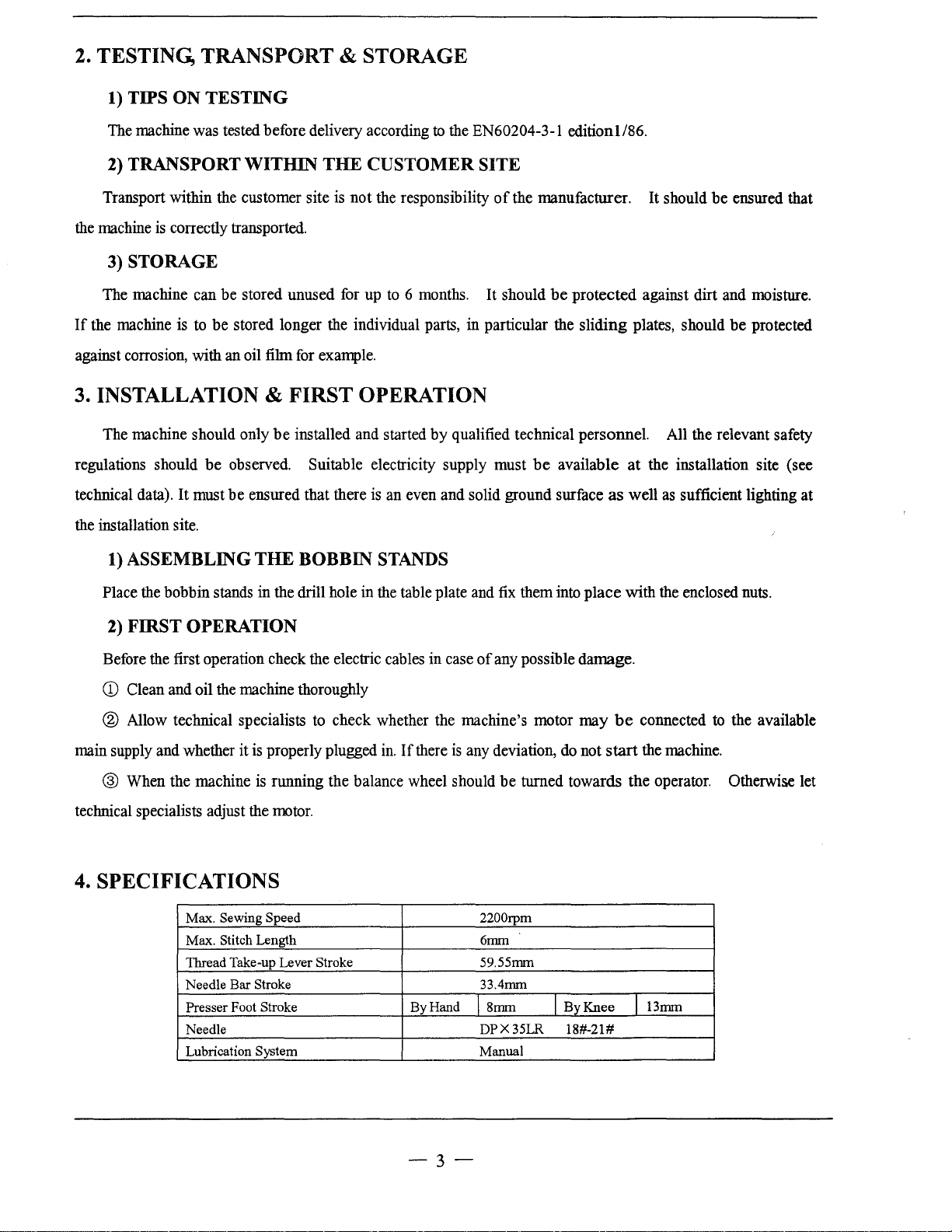

1) ATTACHING

of

the right needle depends on the model

Switch off the machine!

THE

® Loosen needle-holding screw

@ Put the needle in

@ Tighten needle-holding screw 1

as

far

Insert the needle until it bottoms, and

tighten the screw keeping the

in the needle facing

groove

Long groove

facing to the

left

NEEDLE (Fig.2)

as

it will

go

(the long needle groove should point

long

to

the left.

.

of

the machine

Insufficient

as

well

as

the thread and material

to

the left)

insertion Wrong direction

X X

to

be

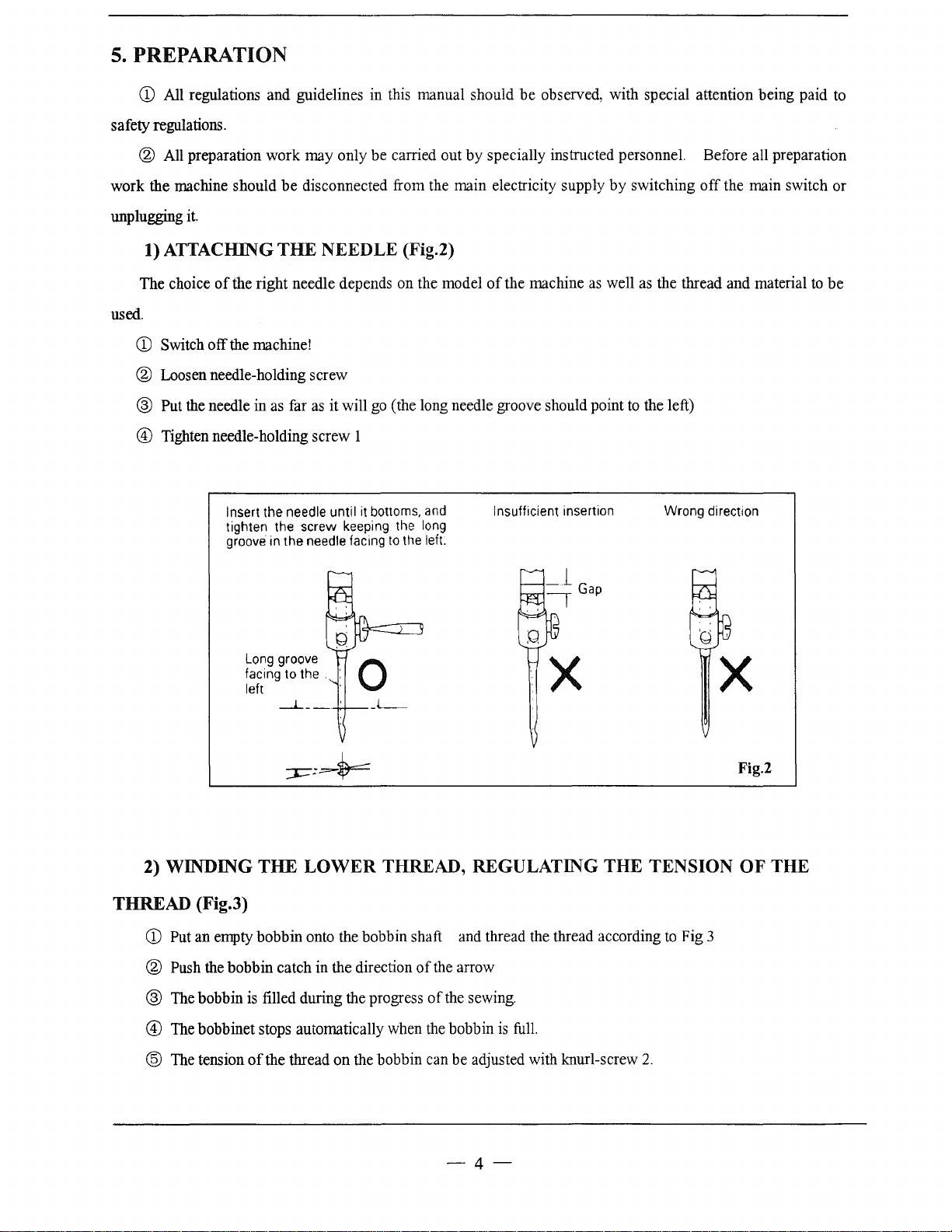

2) WINDING

THE

LOWER

THREAD, REGULATING THE TENSION

THREAD (Fig.3)

CD

Put an empty bobbin onto the bobbin shaft and thread the thread according

® Push the bobbin catch in the direction

@ The bobbin is filled during the progress

@ The bobbinet stops automatically when the bobbin

® The tension

of

the thread on the bobbin can be adjusted with knurl-screw

of

the arrow

of

the sewing.

-4-

is

full.

2.

to

Fig 3

Fig.2

OF

THE

2

Fig.3

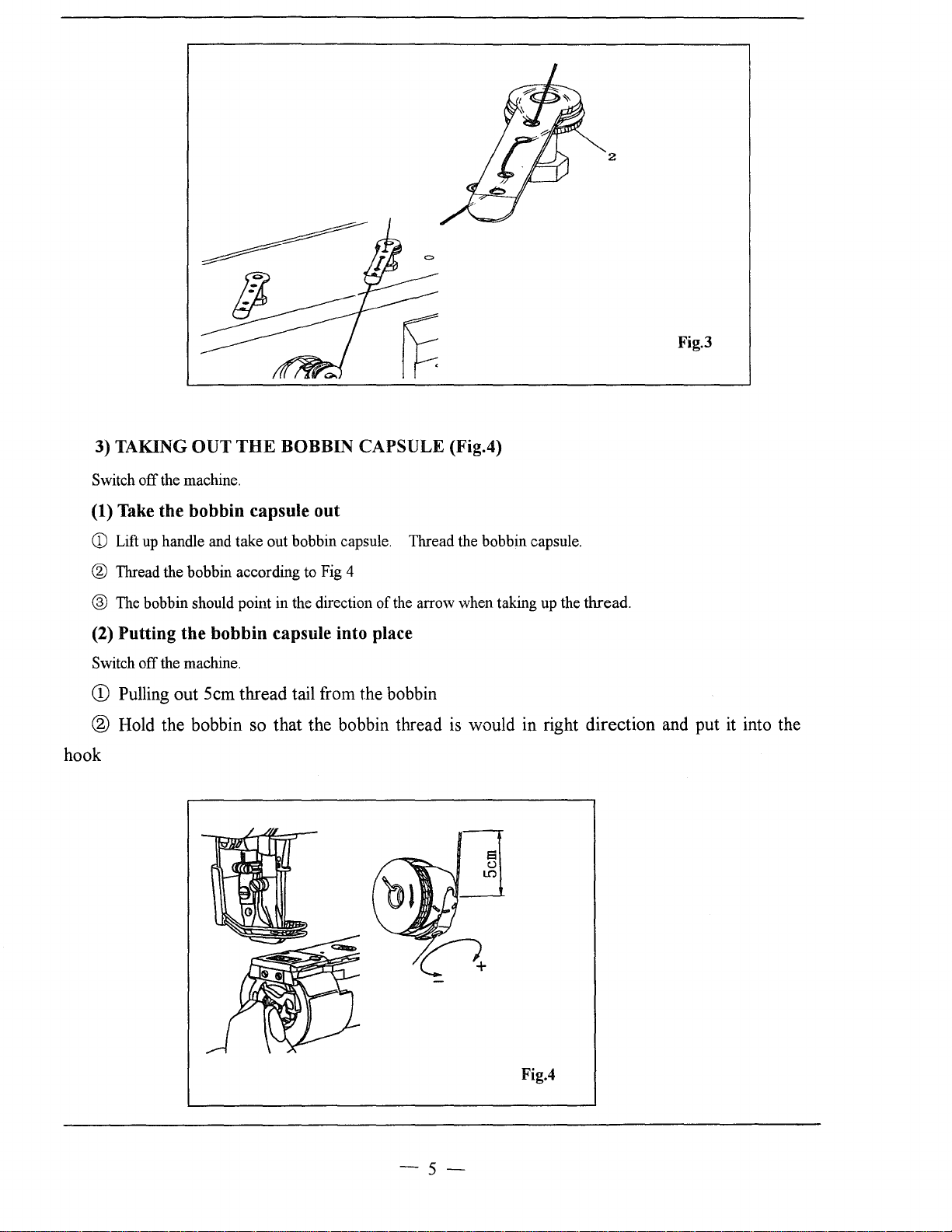

3) TAKING

Switch off the machine.

(1) Take the bobbin capsule

CD

Lift up handle and take out bobbin capsule. Thread the bobbin capsule.

OUT

THE

BOBBIN CAPSULE (Fig.4)

out

® Thread the bobbin according to Fig 4

® The bobbin should point in the direction

(2) Putting

Switch off the machine.

CD

Pulling out Scm thread tail from the bobbin

the

bobbin capsule into place

of

® Hold the bobbin so that the bobbin thread

hook

the arrow when taking up the thread.

is

would in right direction and put it into the

Fig.4

-s-

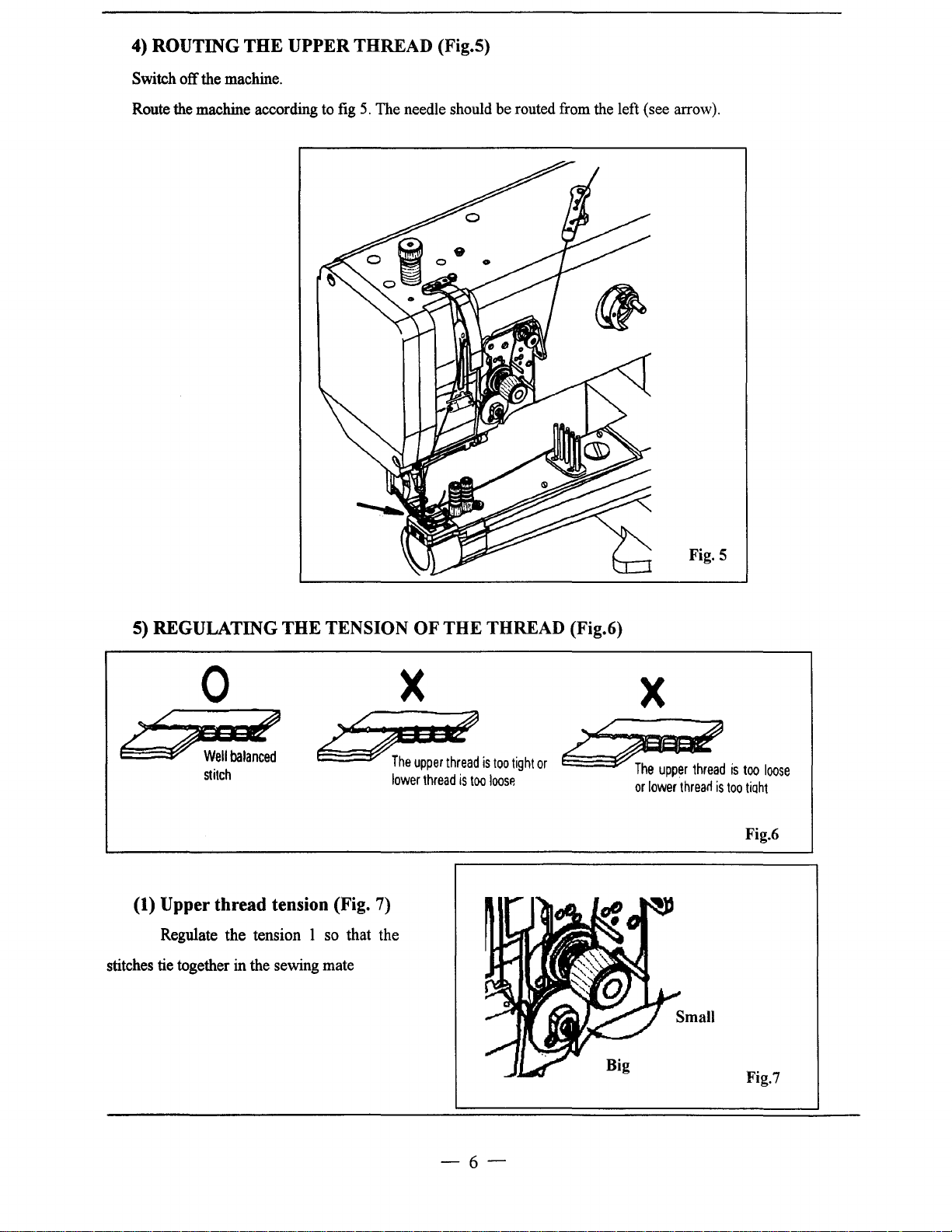

4) ROUTING

Switch off the machine.

Route the machine according to fig

THE

UPPER THREAD (Fig.S)

5.

The needle should be routed from the left (see arrow).

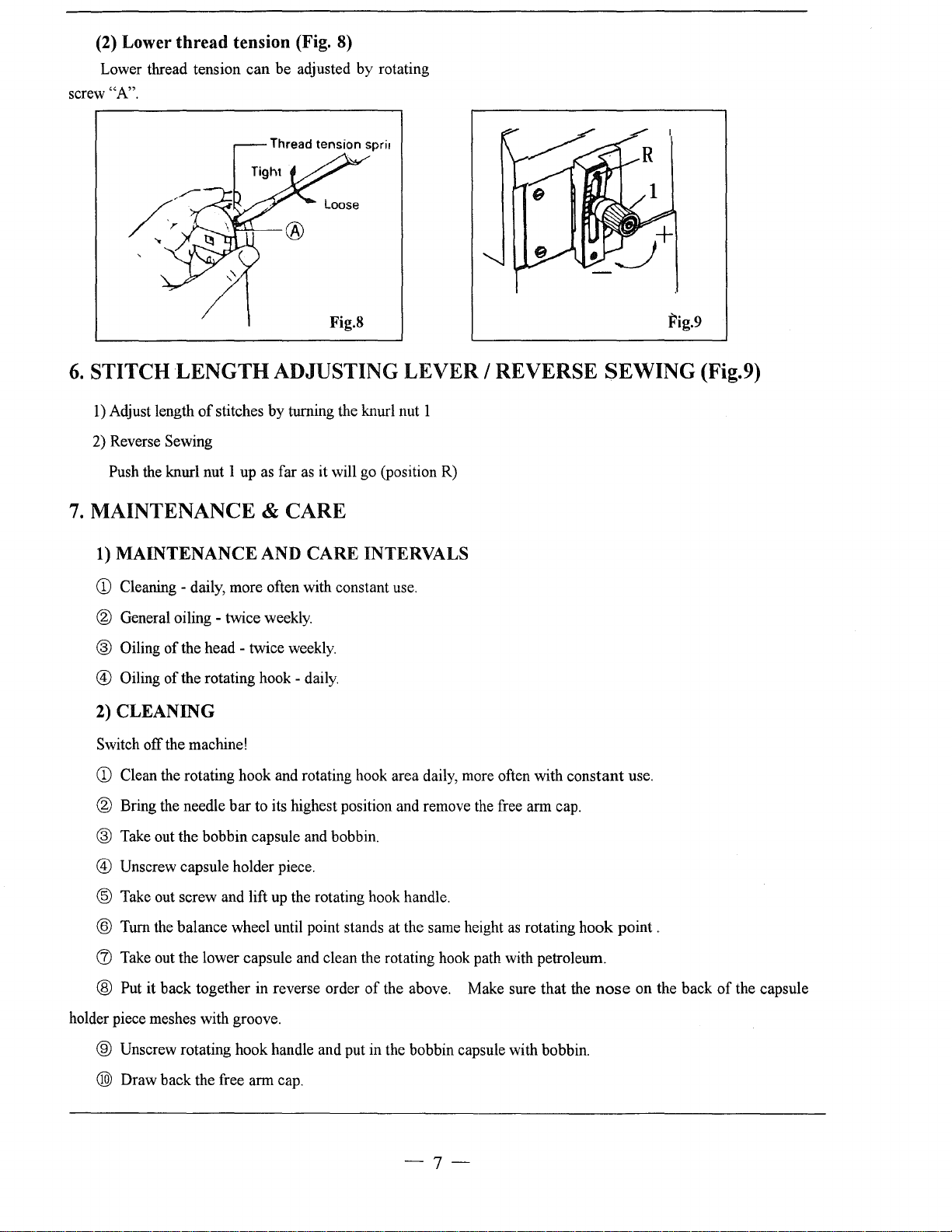

5)

REGULATING

THE

TENSION

0

2.~

~

(1) Upper thread tension (Fig.

stitches tie together in the sewing mate

Well

stitch

Regulate

balanced

the

tension 1 so that the

/~II~

r§-:s

7)

OF

X

The

upper

lower

THE THREAD (Fig.6)

thread

is

too

tight

or

thread

is

too

loosf!

~is tool"''

X

or

lower

Fig. 5

threarf

is

too

tioht

Fig.6

-6-

Fig.7

(2) Lower

Lower thread tension

"A".

screw

thread

tension (Fig.

can

be adjusted

8)

by

rotating

6.

STITCH

1)

Adjust length

2) Reverse Sewing

Push the knurl nut 1 up as far

7.

MAINTENANCE & CARE

1)

MAINTENANCE AND CARE INTERVALS

CD

Cleaning - daily, more often with constant use.

LENGTH

of

stitches

ADJUSTING LEVER I REVERSE

by

turning the knurl nut 1

® General oiling - twice weekly.

® Oiling

® Oiling

2)

CLEANING

Switch off the machine!

of

the head - twice weekly.

of

the rotating hook - daily.

Fig.8

as

it will go (position R)

Fig.9

SEWING

(Fig.9)

CD

Clean the rotating hook and rotating hook area daily, more often with

® Bring the needle

bar

to its highest position and remove the free arm cap.

® Take out the bobbin capsule and bobbin.

® Unscrew capsule holder piece.

@ Take out screw and lift up the rotating hook handle.

@ Turn the balance wheel until point stands at the same height

CD

Take out the lower capsule and clean the rotating hook path with petroleum.

@ Put it back together in reverse order

holder piece meshes with groove.

of

the above. Make sure that the

as

rotating

® Unscrew rotating hook handle and put in the bobbin capsule with bobbin.

@)

Draw back the free arm cap.

-7-

constant

hook

nose

use.

point .

on the back

of

the capsule

3) GENERAL OILING (Fig.lO,

Use white spindle oil.

Fig.ll)

Oil all the bearing positions shown in Fig 10 and

Danger ofbeing crushed between the top part and the base!

11

twice weekly.

Fig.ll

Fii!. 10

4)

OILING

Switch

CD

Take

positions shown in fig 12 twice weekly.

® Then screw the cover back

Use white spindle oil.

5)

OILING

Switch

CD

Take the bobbin capsule out and drip one or two

of

drops

oil into the rotating hook path (fig 13) once daily.

THE

HEAD (Fig.12)

off

the machine!

off

the cover and oil all the bearing and sliding

on.

THE

ROTATING

off

the machine!

® Then put the bobbin capsule back in.

8.

ADJUSTMENT

1)

TIPS

FOR

ADJUSTMENT

CD

All adjustments in this manual apply to a completely assembled machine. Covers, which have to be

HOOK

Fig.l2

(Fig.13)

Fig.13

unscrewed and screwed on again for adjustment work are not mentioned in the text.

® The screws or nuts mentioned in brackets are to be loosened before adjustments and tightened again

afterwards.

-8-

Loading...

Loading...