Page 1

Purchasing

Copy

Dept

HIGH

GC2698-1/GC2698-1B

CYLINDER-BED UNISON

Instruction Manual

LEAD

FEED

SEWING

MACHINE

Parts

SHANGHAI

HUIGONG

N0.3

Catalog

SEWING MACHINE FACTORY

Page 2

----~

Page 3

The Machine Conforms to the Following European Regulations:

EN60204-31:

19.96-.

98/37/EC-. DIN5310-. DIN5318-. 73/23/EEC

(93/68/EEC)

CONTENTS

INSTRUCTION

1, SAFETY .......................................................................................................................................................... 1

1)

GENERAL SAFETY TIPS ............................................................................................................................... 1

2)

IMPORTANT POINTS FOR THE EMPLOYER ............................................................................................. 1

3)

SERVICE AND TECHNICAL PERSONNEL ................................................................................................ 1

4)

DANGER TIPS ............................................................................................................................................... 2

2,

TESTING, TRANSPORT& STORAGE .......................................................................................................... 3

1)

TIPS ON TESTING ........................................................................................................................................ 3

2)

TRANSPORT WITHIN THE CUSTOMER SITE ........................................................................................... 3

3)

STORAGE ........................................................................................................................................................ 3

3,

INSTALLATION & FIRST OPERATION ....................................................................................................... 3

MANUAL

1)

ASSEMBLING THE BOBBIN STANDS ........................................................................................................ 3

2)

FIRST OPERATION ........................................................ : ................................................................................ 3

4,

SPECIFICATIONS ........................................................................................................................................... 3

5,

PREPARATION ................................................................................................................................................ 4

1)

ATTACHING THE NEEDLE ........................................................................................................................... 4

2)

WINDING THE LOWER THREAD, REGULATING THE TENSION OF THE THREAD ......................... .4

3)

TAKING OUT THE BOBBIN CAPSULE ....................................................................................................... 5

4)

ROUTING THE UPPER THREAD ................................................................................................................. 6

5)

REGULATING THE TENSION OF THE THREAD ....................................................................................... 6

6,

STITCH LENGTH ADJUSTING LEVER I REVERSE SEWING .................................................................. 7

7,

MAINTENANCE & CARE .............................................................................................................................. 7

1)

MAINTENANCE AND CARE INTERVALS .................................................................................................. 7

2)

CLEANING ...................................................................................................................................................... 7

3)

GENERAL OILING ......................................................................................................................................... 8

4)

OILING THE HEAD ...................................................................................................................................... 8

5)

OILING THE ROTATING HOOK ................................................................................................................... 8

8,

ADJUSTMENT ................................................................................................................................................ 8

1)

TIPS FORADJUSTMENT ............................................................................................................................... 8

-I-

Page 4

2)

ABBREVIATIONS ........................................................................................................................................... 9

3)

POSITION OF THE FEED DOG ..................................................................................................................... 9

4)

NEEDLE

5)

NEEDLE IN THE MIDDLE OF THE STITCHING HOLE .......................................................................... 1 0

6)

PRESSER FOOT, WALKING FOOT AND FEED DOG SLIDING MOVEMENT ......................................

7)

HOOK POSITIONER, GRAB DISTANCE AND NEEDLE HEIGHT ..........................................................

8)

HYDRAULIC MOVEMENT OF THE WALKING FOOT AND PRESSER FOOT .....................................

9)

PRESSER FOOT ............................................................................................................................................

HEIGHT(PRE-ADJUSTMENn

................................................................................................... 10

ll

11

12

12

10) UPPER THREAD TENSION REGULATION ...............................................................................................

11) THREAD TAKE-UP SPRING ........................................................................................................................

12)

BOBBINWINDER

13)

ADJUSTMENT OF PRESSER PRESSURE ................................................................................................

......................................................................................................................................

CATALOG

A,

ARM BED AND ITS ACCESSORIES ( 1 ) ................................................................................................

A,

ARM BED AND ITS ACCESSORIES

B,

FEEDING AND FEED LIFTING & LOWER SHAFT MECHANISM ........................................................

C,

ARM SHAFTMECHANISM ........................................................................................................................

D,

STITCH REGULATOR MECHANISM ........................................................................................................ 24

E,

PRESSER FOOT MECHANISM ...................................................................................................................

F

'·

NEEDLE BAR FEEDING MECHANISM (

F,

NEEDLEBARFEEDINGMECHANISM

G,

ACCESSORIES ............................................................................................................................................. 32

(2)

................................................................................................

1)

..........................................................................................

(2)

.......................................................................................... 29

13

13

13

14

15

16

19

22

26

28

-2-

Page 5

1.

SAFETY

1) GENERAL SAFETY TIPS

CD

The machine should only be used after studying the accompanying instruction manual and only

specially instructed operating staff

by

@ Before bringing the machine into service read the safety tips and the instruction manual

manufacturer.

@ The machine may only

protective fittings. All relevant safety regulations should also

@ When changing sewing tools (for example needle, presser foot, needle plate and bobbin winder),when

up,

threading

unplugged or switched off at the main switch.

@ Daily maintenance work should only be carried out

® Repair work

specially trained personnel

(])

@ Working

when leaving the work place

as

well

Working on the electrical equipment should only be carried out by qualified electricians.

on

active parts and equipment are not permitted.

® Only the spare parts provided

spare parts and accessories that are not supplied

use

of

such products can in certain circumstances reduce the predetermined quality

be

used according

as

special maintenance work should only

by

us

should be used during repairs.

as

to

their regulations and not without the accompanying

be

observed.

well

as

during maintenance work the machine should

by

specially trained personnel.

by

us

are also not tested or passed

be

carried out

We

by

explicitly point out that the

by

us. The installation or

of

your machine.

of

the engine

skilled workers or

We

be

take

no

responsibility

2)

IMPORTANT POINTS

CD

This

machine operators. It

@ Operation and maintenance personnel must be instructed

working methods.

@

The

@

The

@ Further information can

3)

SERVICE AND

(1) Service

Service personnel are responsible for the preparing, running and cleaning

elimination

CD

to

®

to

for

damage caused

instruction manual

is

necessary

employer must ensure that the machine

employer should make sure that only authorised persons are permitted

TECHNICAL

by

the use

FOR

is

a component

to

read the manual before using the machine for the first time.

be

obtained from the responsible sales office.

of

non-original parts.

THE

EMPLOYER

of

is

only used

the machine and must always

on

if

it

is

in perfect condition.

PERSONNEL

Personnel

of

faults in the sewing. Service personnel must observe the following points:

follow the safety guidelines in the instruction manual

avoid any type

of

work which may reduces the safety

of

the machine

safety features

to

work on the machine.

of

the machine

be

at the disposal

of

the machine and safe

as

well

of

as

the

the

-1-

Page 6

@ to wear tight-fitting clothes and avoid wearing jewellery, like necklaces and rings

@ to report immediately changes in the machine which may reduce safety to the employer.

(2) Technical

Technical personnel are responsible for the lubrication, maintenance, repair and adjustments

CD

p"ersonnel

To

follow safety guidelines in the instruction manual

Technical

® Before beginning maintenance work the main switch must

will not be switched on again.

Personnel

must observe the following points:

be

switched

off

and

@ Working on active parts and equipment is not permitted.

@ After repair and maintenance work the protective covering must

must be closed.

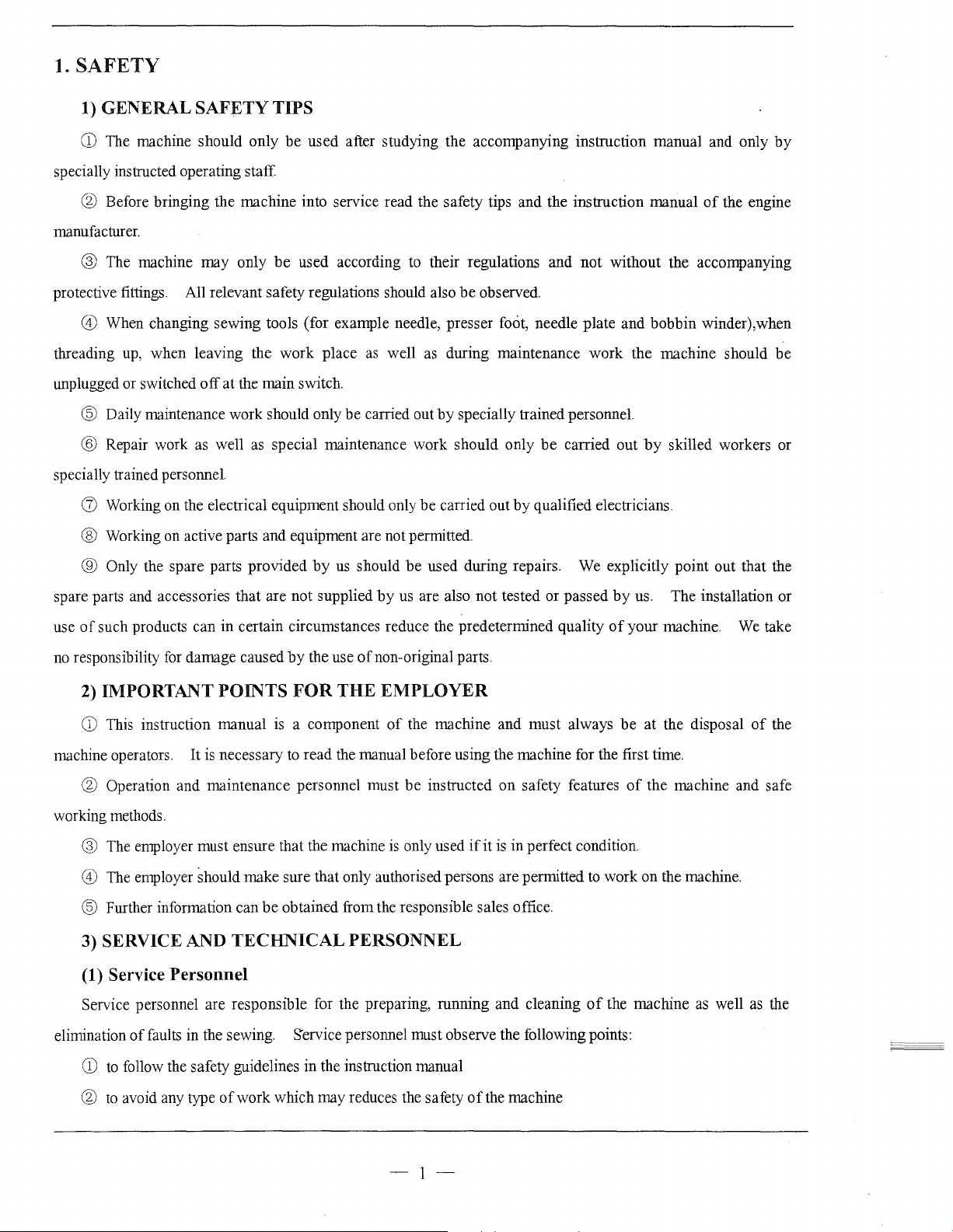

4)

DANGER

CD

During operation a space

of

front

maintained so that umestricted access

possible.

and behind the machine should be

TIPS

(Fig.l)

of

lm

in

IS

be

put

back and the electric control box

it

must

to

the machine.

be

ensured that it

® During sewing do not reach into

of

the needle area! Be careful

of

injury from the needle.

@ During operation

objects lying on the table or in the needle

plate tongue. Objects can get jammed or

knocked

result.

away.

Danger

the danger

do

not leave

of

injury will

Fig. I

® With mechanically operated clutch motors without operation barriers, operators should wait

to

motor

threaded will result.

movement

stop. Danger

@

Do

@

Do

:

(J)

Do

not use the machine without the thread take-up cover

not use the machine without the finger guard

of

the needle will result.

not use the machine without the lifting arm cap

of

injury will result.

2!

1!

Danger

3!

Danger

of

injury from the movement

of

injury from the outward and upward

for

of

the

the

Danger

of

injury from the rotating

@

Do

not use the machine without the belt cover

an:n

will result.

4!

Danger

of

injury from the rotating belt will result.

-2-

Page 7

2.

TESTING,

1)

TIPS ON

TRANSPORT

TESTING

& STORAGE

The machine was tested before delivery according

2)

TRANSPORT

Transport within the customer site is

is

the machine

correctly transported.

WITHIN

THE

not

3) STORAGE

The machine can

If

the machine is

against corrosion, with an oil film for example.

3. INSTALLATION &

The machine should only

regulations should

technical data).

the installation site.

l)ASSEMBLINGTHE

It

be

stored unused for up

to

be

stored longer the individual parts,

FIRST

be

installed and started

be

observed. Suitable electricity supply must

must

be

ensured that there is an even and solid ground surface

OPERATION

BOBBIN STANDS

to

the EN60204-3-1 editionl/86.

CUSTOMER SITE

the responsibility

to

6 months.

by

of

the manufacturer.

It

should

in

particular the sliding plates, should

qualified technical personnel. All the relevant safety

It

should

be

protected against dirt and moisture.

be

available at the installation site (see

as

well

as

be

ensured that

be

protected

sufficient lighting at

Place the bobbin stands in the drill hole in the table plate and fix them into place with the enclosed nuts.

2)

FIRST OPERATION

Before the first operation check the electric cables in case

CD

Clean and oil the machine thoroughly

@ Allow technical specialists

main supply and whether

it

is properly plugged

to

check whether the machine's motor may

in.

If

there is any deviation,

® When the machine is running the balance wheel should

technical specialists adjust the motor.

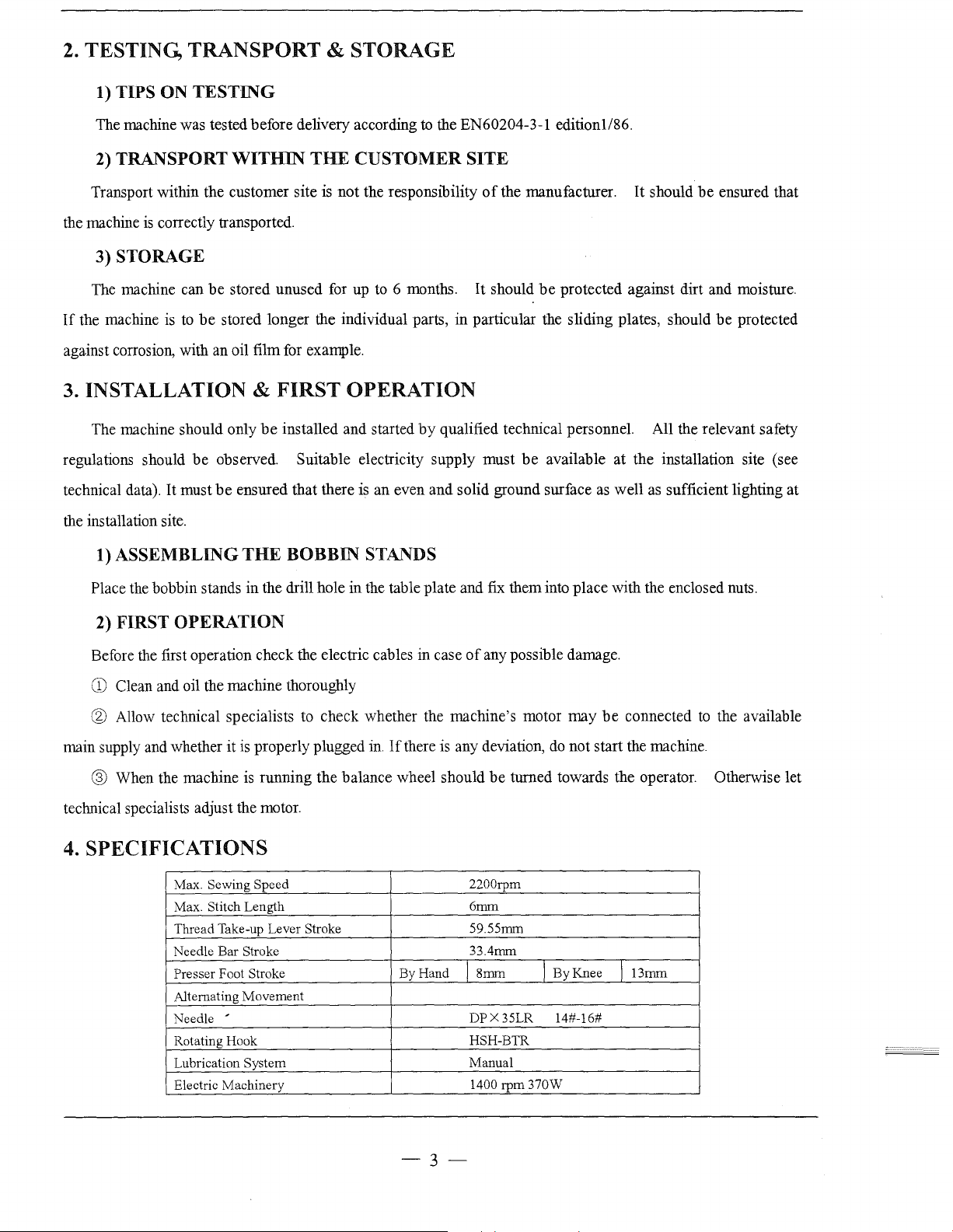

4.

SPECIFICATIONS

Max. Sewing Speed

Max. Stitch Length

Thread Take-up Lever Stroke

Needle Bar Stroke

Presser Foot Stroke

Alternating Movement

Needle

Rotating Hook HSH-BTR

Lubrication System

Electric Machinery

-

By Hand

of

any possible damage.

be

connected

do

not start the machine.

be

turned towards the operator. Otherwise let

2200rpm

6mm

59.55mm

33.4mm

I

lsmm

DPX35LR

Manual

1400 rpm 370W

ByKnee

14#-16#

113mm

to

the available

-3-

Page 8

5

..

Preparation

CD

All regulations and guidelines in this manual should

safety regulations.

be

observed,

with

special attention being paid to

® All preparation

work the machine should

unplugging it.

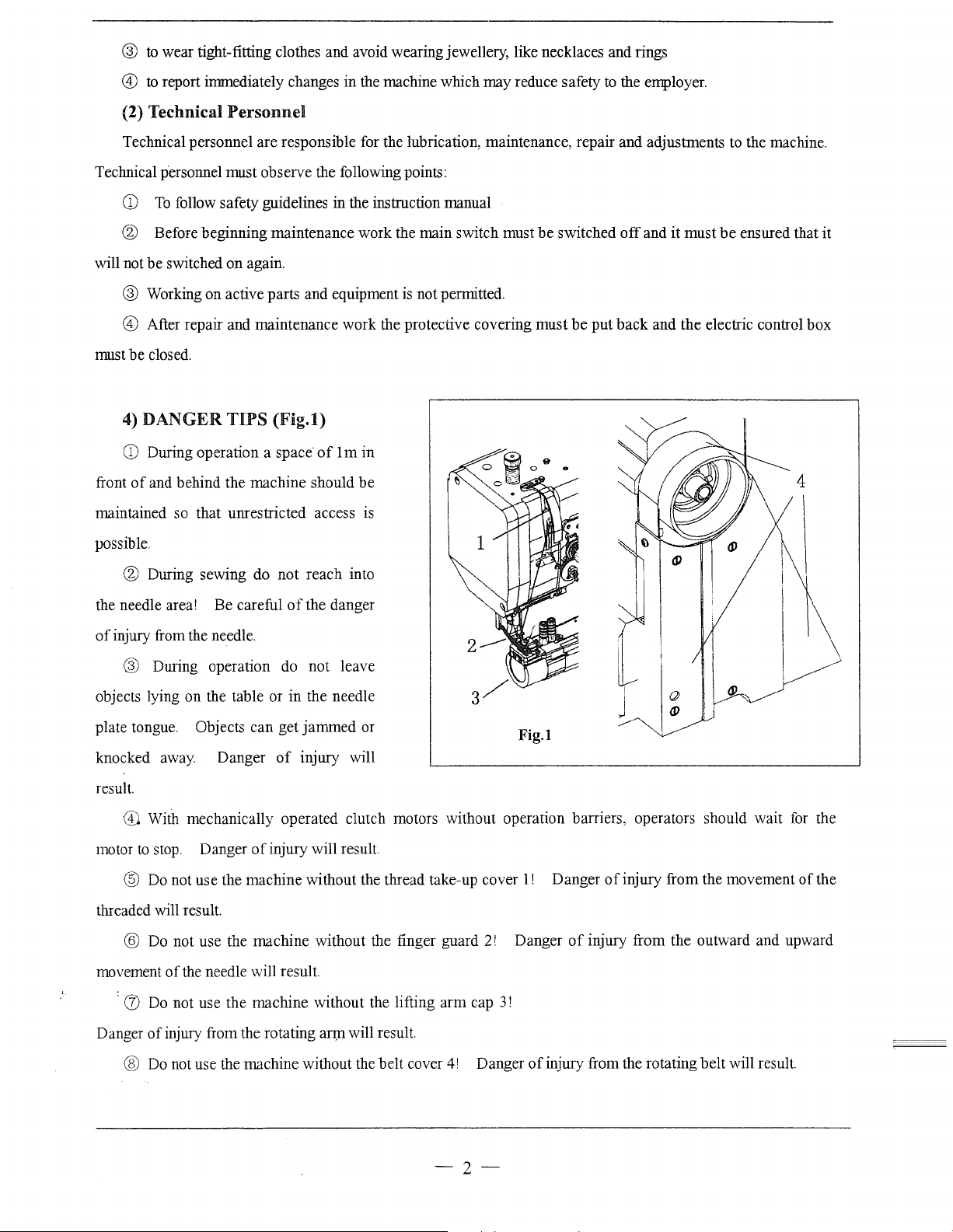

1)

ATTACHING

The choice

used.

CD

Switch

of

off

work

may

only

be

carried out

be

disconnected from the main electricity supply

THE

NEEDLE (Fig.2)

the right needle depends on the model

the machine!

by

specially instructed personnel. Before all preparation

of

the machine as well as the thread and material

® Loosen needle-holding screw

® Put the needle in as far as it will go (the long needle groove should point

@)

Tighten needle-holding screw 1

nsuff1cient insertion

Insert the needle until it bottoms, and

t1ghten

groove m the needle facing to the left.

the screw keeping the long

I

by

switching

to

off

the left)

Wrong direction

the main switch or

to

be

Long

groove

facing to the .

left

I

=r-==-$==

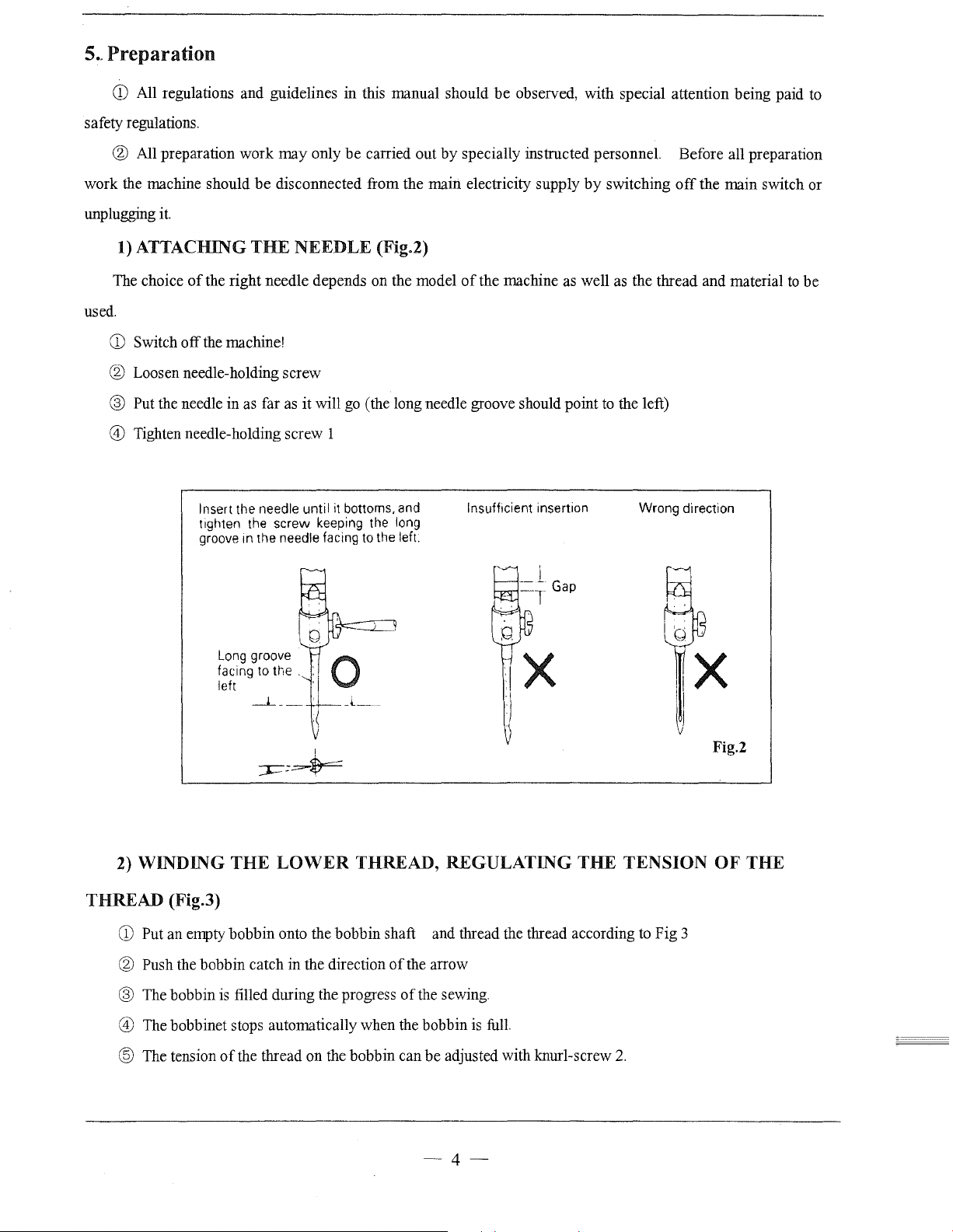

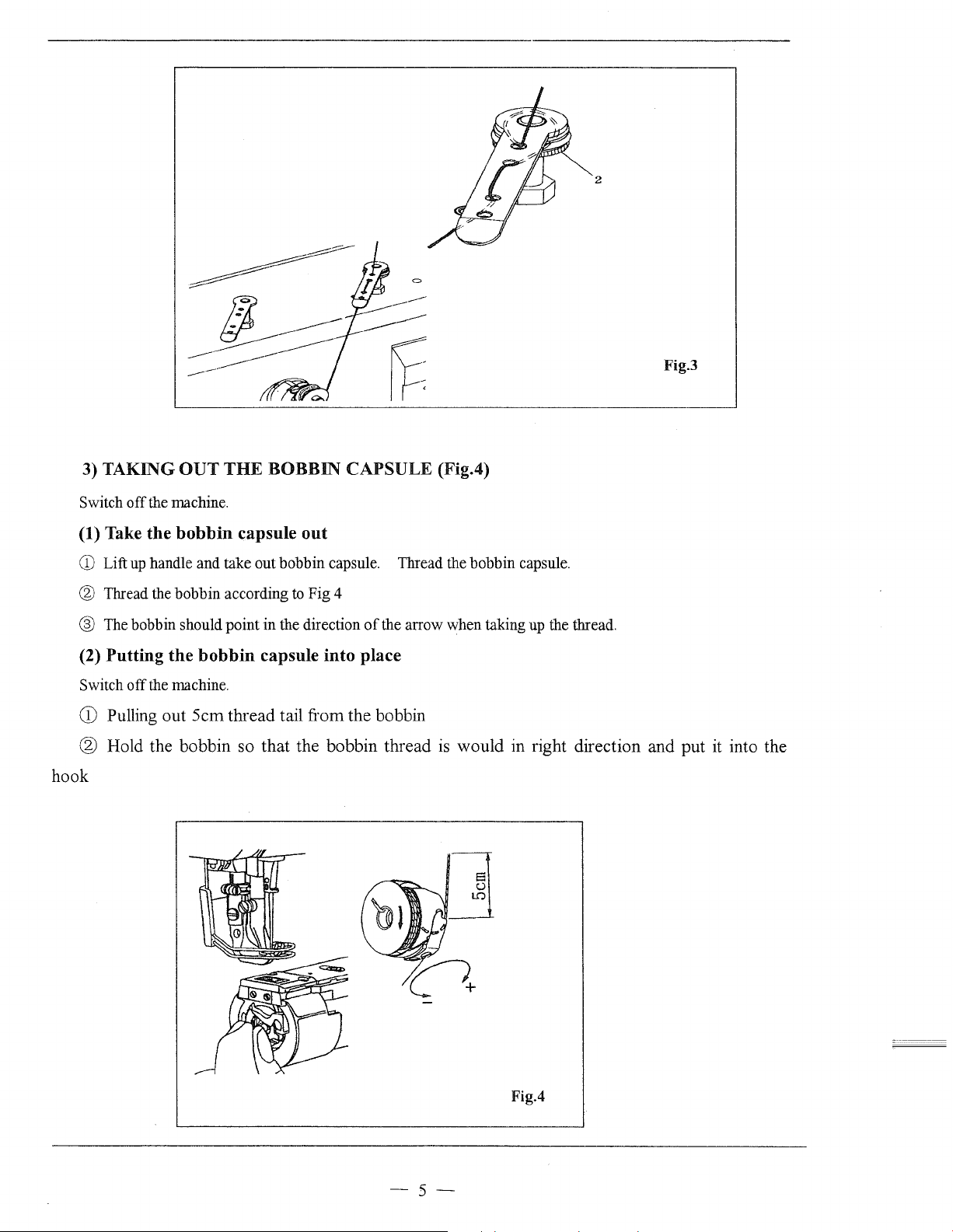

2)

WINDING

THREAD (Fig.3)

CD

Put an empty

® Push the bobbin catch

® The bobbin is filled during the progress

@)

The bobbinet stops automatically when the bobbin

® The tension

THE

LOWER

bobbin

of

onto the bobbin shaft and thread the thread according to Fig 3

in

the direction

the thread on the bobbin can

THREAD, REGULATING

of

the arrow

of

the sewing.

is

full.

be

adjusted with knurl-screw

THE

TENSION

2.

Fig.2

OF

THE

-4-

Page 9

2

Fig.3

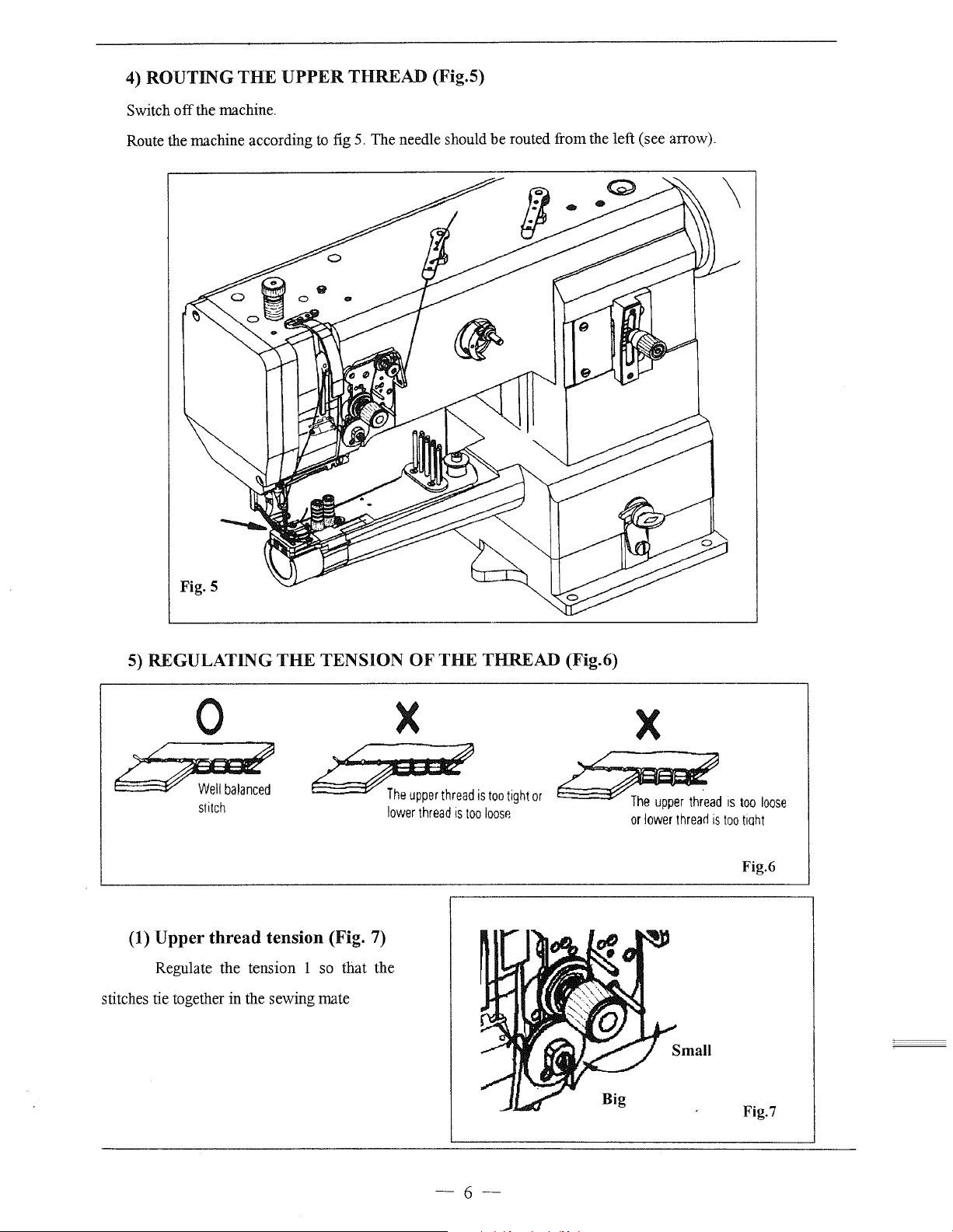

3) TAKING

Switch

off

(1) Take

CD

Lift

up

® Thread the bobbin according

® The bobbin should point

(2) Putting

Switch off the machine.

CD

Pulling out

OUT

THE

BOBBIN

the machine.

the

bobbin

handle and take out bobbin capsule. Thread the bobbin capsule.

the

capsule

to

in

the direction

bobbin

Scm

capsule into place

thread tail from the bobbin

CAPSULE (Fig.4)

out

Fig 4

of

® Hold the bobbin so that the bobbin thread

hook

the arrow when taking up the thread.

is

would in right direction and put

it

into the

Fig.4

-5-

-·---~

---------------

Page 10

4)

ROUTJNG

Switch

off

THE

the machine.

UPPER

THREAD

(Fig.5)

Route the machine according to fig 5. The needle should

be

routed

from

the

left

(see

arrow).

5)

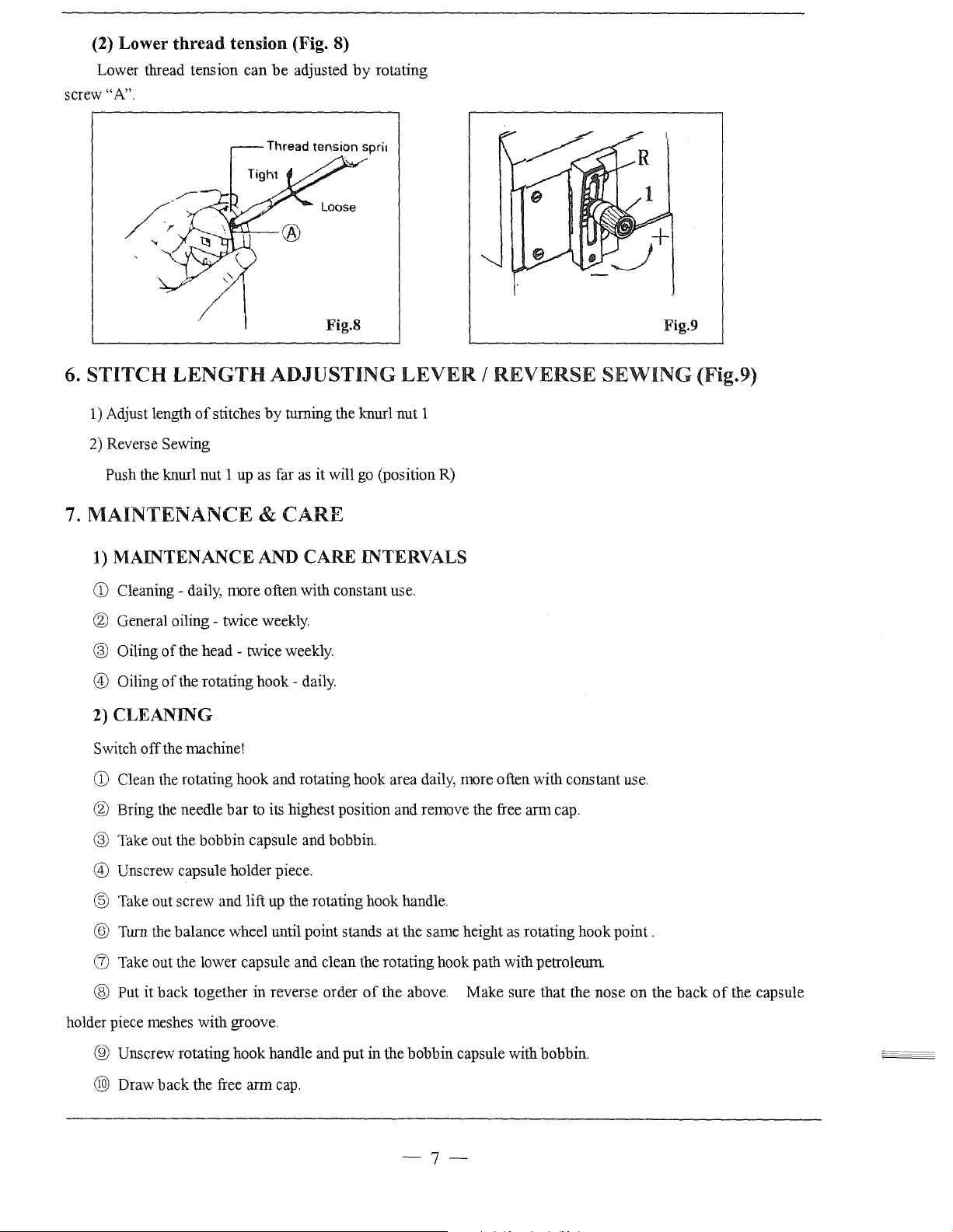

REGULATJNG

0

6~

stitch

(1)

Upper

Regulate

stitches tie together

thread

the

in

THE

TENSION

Qn~

tension (Fig. 7)

tension

the

1 so

sewing

mate

that

OF

X

n:;er

lovverthread

the

THE

THREAD (Fig.6)

thread

is

too

tight

is

too

loosr.

X

or

~;stoolaos<

or

lovver

threarl

is

too

tiqht

Fig.6

-~--

---

---------

-----

Fig.7

-6-

Page 11

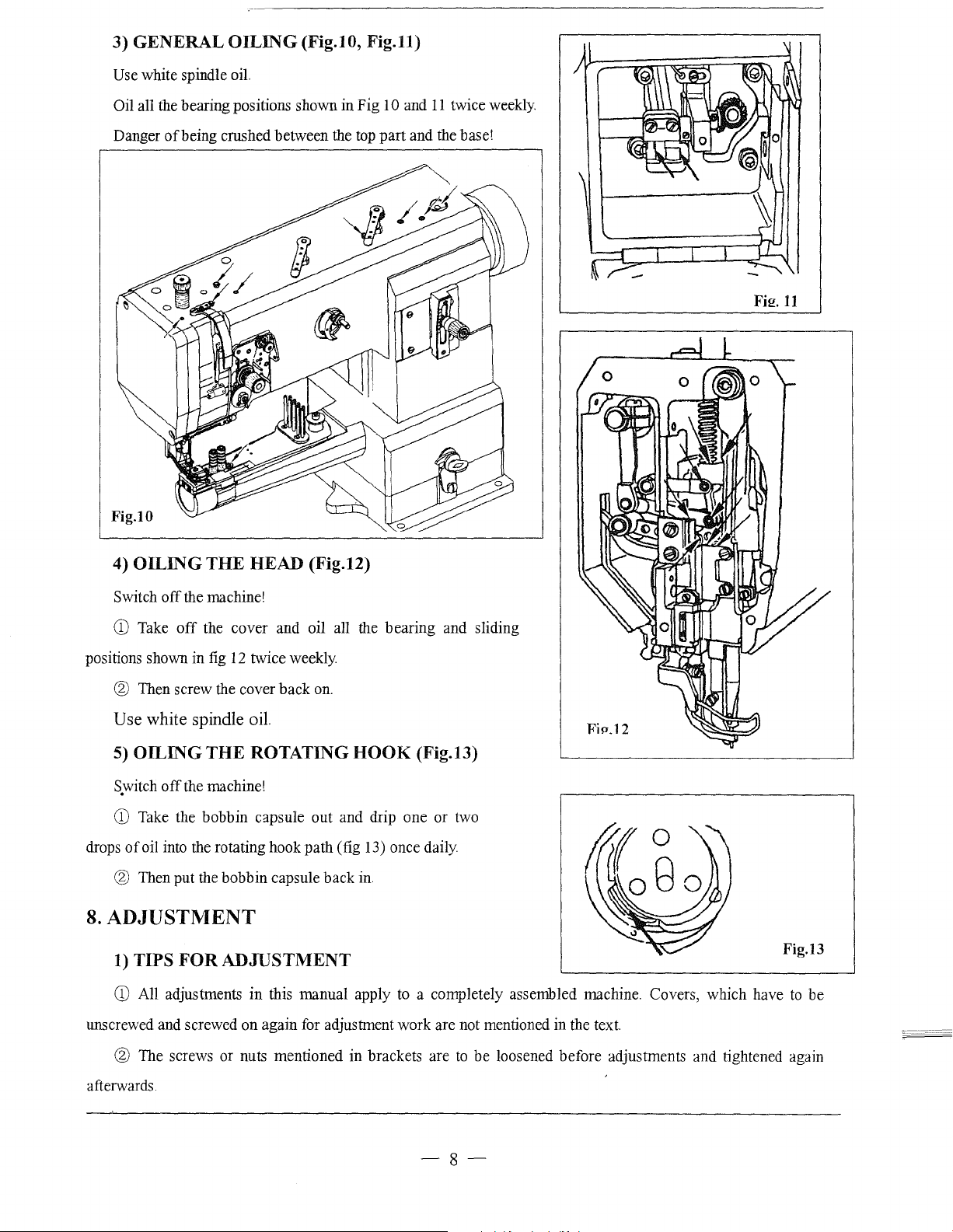

(2) Lower

Lower thread tension can

screw"A".

thread

tension (Fig. 8)

be

adjusted

by

rotating

6.

STITCH

1)

Adjust length

2)

Reverse Sewing

Push the knurl nut 1 up as far

7.

MAINTENANCE &

1)

MAINTENANCE AND CARE INTERVALS

CD

Cleaning - daily, more often with constant use.

LENGTH

of

stitches

® General oiling - twice weekly.

® Oiling

@ Oiling

2)

CLEANING

Switch

of

the head - twice weekly.

of

the rotating hook - daily.

off

the machine!

Fig.8

ADJUSTING

by

turning the knurl nut 1

as

it

will

go

(position R)

CARE

LEVER I REVERSE

Fig.9

SEWING

(Fig.9)

CD

Clean the rotating hook and rotating hook area daily, more often with constant use.

® Bring the needle

bar

to its highest position and remove the free arm cap.

® Take out the bobbin capsule and bobbin.

@ Unscrew capsule holder piece.

@ Take out screw and lift up the rotating hook handle.

@ Turn the balance wheel until point stands at the same height

(!) Take out the lower capsule and clean the rotating hook path with petroleum

® Put it back together

holder piece meshes with groove.

® Unscrew rotating hook handle and

@)

Draw back the free arm cap.

in

reverse order

of

the above. Make sure that the nose

put

in

the bobbin capsule with bobbin.

as

rotating hook point .

-7-

on

the

back

of

the capsule

Page 12

3) GENERAL

Use white spindle oil.

OILING

(Fig.lO,

Fig.ll)

Oil all the bearing positions shown in Fig 10 and

Danger ofbeing crushed between the top part and the base!

Fig.IO

11

twice weekly.

Fi!!.

11

4)

OILING

Switch off the machine!

CD

Take

positions shown in fig

@ Then screw the cover back

THE

HEAD (Fig.12)

off

the cover and oil all the bearing and sliding

12

twice weekly.

Use white spindle oil.

5)

OILING

s.witch

CD

Take the bobbin capsule out and drip one or two

drops

of

oil into the rotating hook path (fig 13) once daily.

@ Then put the bobbin capsule back

8.

ADJUSTMENT

1)

TIPS

CD

All adjustments

THE

off

the machine!

FOR

ROTATING

ADJUSTMENT

in

this manual apply

on.

HOOK

in.

to

(Fig.l3)

a completely assembled machine. Covers, which have

Fig.13

to

be

unscrewed and screwed on again for adjustment work are not mentioned in the text.

@ The screws or nuts mentioned in brackets are

afterwards.

to

be loosened before adjustments and tightened again

-8-

Page 13

2)

ABBREVIATIONS

UD-

Upper deadlock

LD

- Lower deadlock

3) POSITION

(1) Positioning

The

feed dog 1 should

Move the feed dog 1 (screws 2) according

OF

the

THE

FEED

feed dog

be

the same distance right and left from the needle plate.

at

DOG

an

angle to

to

the above rule.

the

direction

of

sewing (Fig.14)

(2) Positioning

The feed dog 5 should keep the same distance in front and behind the needle plate when moving

backwards and forwards when adjusting the maximum stitch-length.

CD

Adjust the maximum stitch-length.

@ Push the crank 1 (screws 2)

be on the crank-area.

the

feed dog

in

the direction

as

far

as

possible

of

sewing (Fig.15 Fig16)

to

the left on the crank-area

3.

The left screw must still

® Loosen screws 4

@ Move the feed dog 5 according

® Tighten screws

4.

to

the rule.

-9-

Fig.16

Page 14

4)

NEEDLE

(Fig.17)

HEIGH

---·---

(PRK·ADJUSTMENT)

When the needle

distance between the needle

plate should

Move needle

rule above without turning it

be

5) NEEDLE

STITCHING

With the length

pierce exactly in the middle

CD

Unscrew the presser foot 1 and the walking foot

@ Adjust the stitch-length

bar

is

in lower position the

bar

15mm.

bar

1 (screw 2) according to the

to

the side.

IN

THE

MIDDLE

WHOLE

of

(Fig.18)

the stitch at

of

the needle plate hole.

to

® Insert a new needle, loosen screws

@)

Bring the needle irrnnediately over the feed dog

@ Move the needle

bar

7 according

and the needle

OF

THE

'0'

the needle should

'0'

and bring the needle

3,

4,

5 &

to

the rule.

Fig.l 7

2.

bar

to

upper position.

6.

by

turning the balance wheel.

15mr

® Tighten screws

(J)

Bring stop 8 up

Note: The needle

3,

4 &

5.

to

the needle

bar

7 in guide 9 and the needle rock frame should move easily.

bar

area 7 and tighten screw

6.

-10-

Fig.18

Page 15

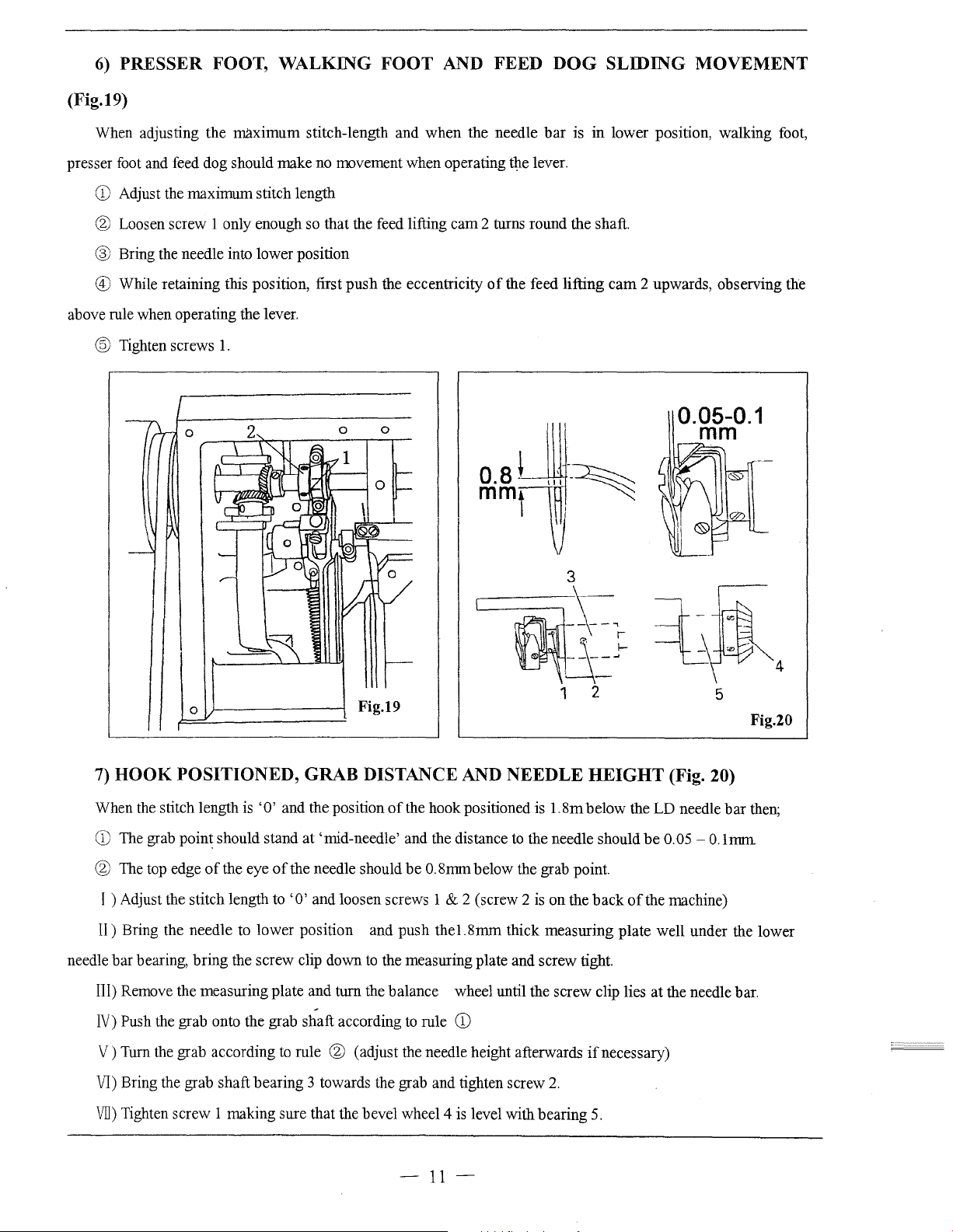

6)

(Fig.19)

PRESSER FOOT,

WALKING

FOOT

AND

FEED

DOG

SLIDING

MOVEMENT

When adjusting the

presser foot and feed

CD

Adjust the

® Loosen

screw

® Bring the needle into

maximum

dog

should

maximum

stitch length

1 only enough so

lower

make

@ While retaining this position, first

above rule

when

operating the lever.

@ Tighten screws

1.

stitch-length

no

movement

that

the feed lifting

position

push

and

when

the

when

operating the lever.

cam

the eccentricity

needle

2 turns

of

the feed

bar

round

is

in

the shaft.

lifting

3

lower

position,

cam

2 upwards, observing the

walking

0.05-0.1

mm

foot,

0

7)

HOOK

When

CD

The grab

® The top edge

POSITIONED,

the stitch length is

point

of

I ) Adjust the stitch length to

II)

Bring the

needle

bar

III) Remove the

IV)

Push the grab onto the grab

V)

Turn the grab according to

bearing,

needle

bring

measuring

'0'

and the position

should stand

the eye

to

the

of

the needle should

'0'

lower

screw

plate

=&~--~

Fig.19

GRAB DISTANCE AND

of

the

hook

at

'mid-needle'

and

loosen screws 1 & 2 (screw 2 is

position

clip

down

and

turn the

shaft

according to

rule

® (adjust the needle height afterwards

and the distance to the needle should

be

0.8mm

and

push

the1.8mm

to the measuring plate

balance

wheel until the

rule

CD

NEEDLE

positioned is

below

thick

=:}-~

~\-;-

1 2 5

HEIGHT

1.8m

below

the grab point.

on

the

back

measuring

and

screw

tight.

screw

clip lies

if

necessary)

--L~4

(Fig. 20)

the

LD

needle

be

0.05-

0.1mm

of

the machine)

plate

well

under

at

the needle bar.

bar

the

Fig.20

then;

lower

VI) Bring the grab

VII)

Tighten

screw 1 making

bearing

3 towards the grab

sure

that the

bevel

and

tighten

wheel 4 is level

-

11-

screw

with

2.

bearing

shaft

5.

Page 16

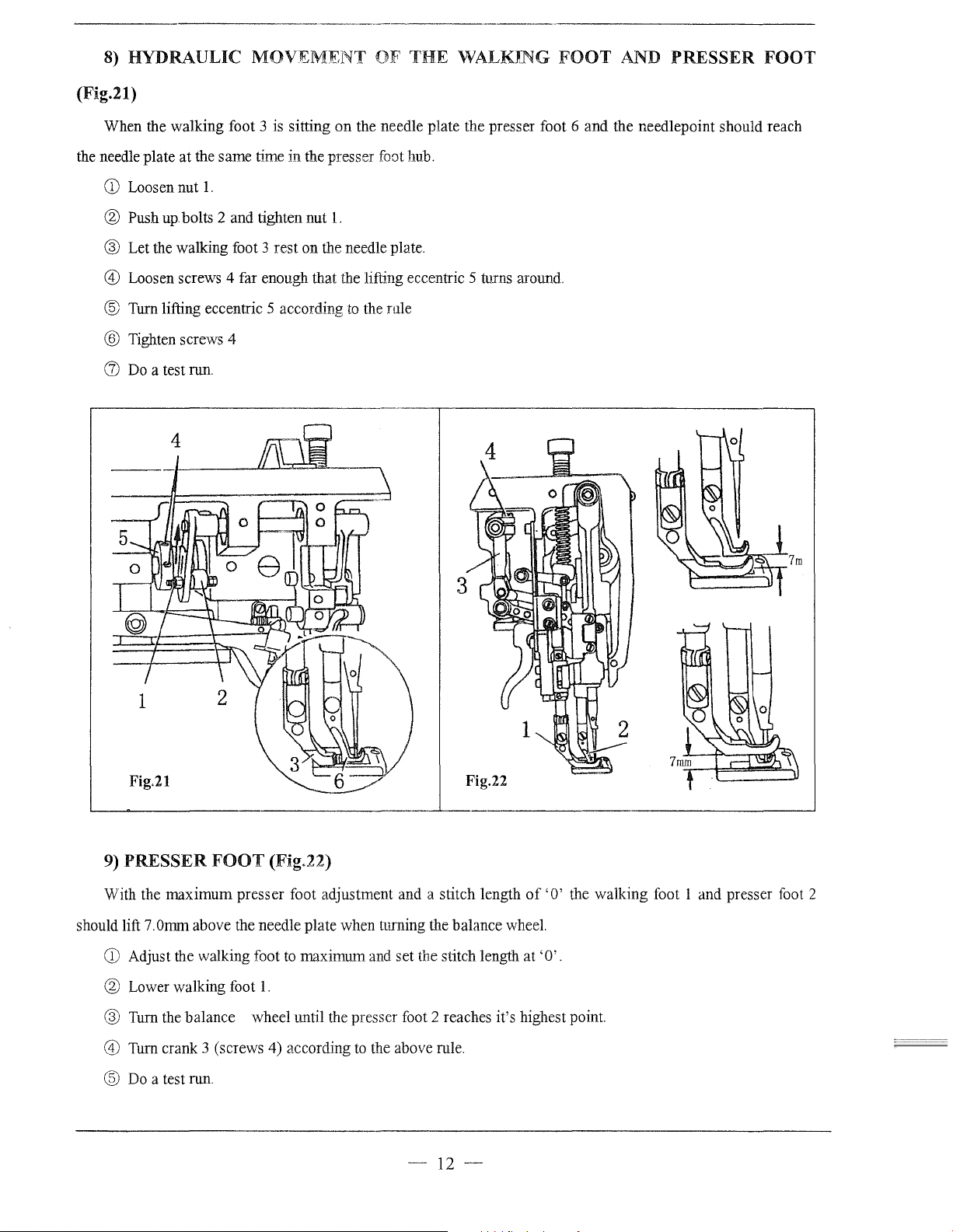

8)

(Fig.21)

HYDRAULIC

MOVEMENT

OF

THE

WALKING

FOOT

AND

PRESSER

FOOT

When the walking foot 3 is sitting

the needle plate at the same time in the presser foot hub.

CD

Loosen nut

® Push

1.

up

bolts 2 and tighten nut

on

the needle plate the presser foot 6 and the needlepoint should reach

1.

® Let the walking foot 3 rest on the needle plate.

@)

Loosen screws 4 far enough that the lifting eccentric 5 turns around.

@ Turn lifting eccentric 5 according

@ Tighten screws 4

([)

Do

a test run.

r-------------------·-,---------------------,

to

the rule

4

Fig.22

9)

PRESSER

With the maximum presser foot adjustment and a stitch length

should lift 7.0mm above the needle plate when turning the balance wheel.

CD

Adjust the walking foot

® Lower walking foot

FOOT

(Fig.22)

to

maximum and set the stitch length at

1.

of

'0'

'0'.

® Turn the balance wheel until the presser foot 2 reaches it's highest point.

@)

Turn crank 3 (screws 4) according

@

Do

a test run.

to

the above rule.

-12-

the walking foot 1 and presser foot 2

Page 17

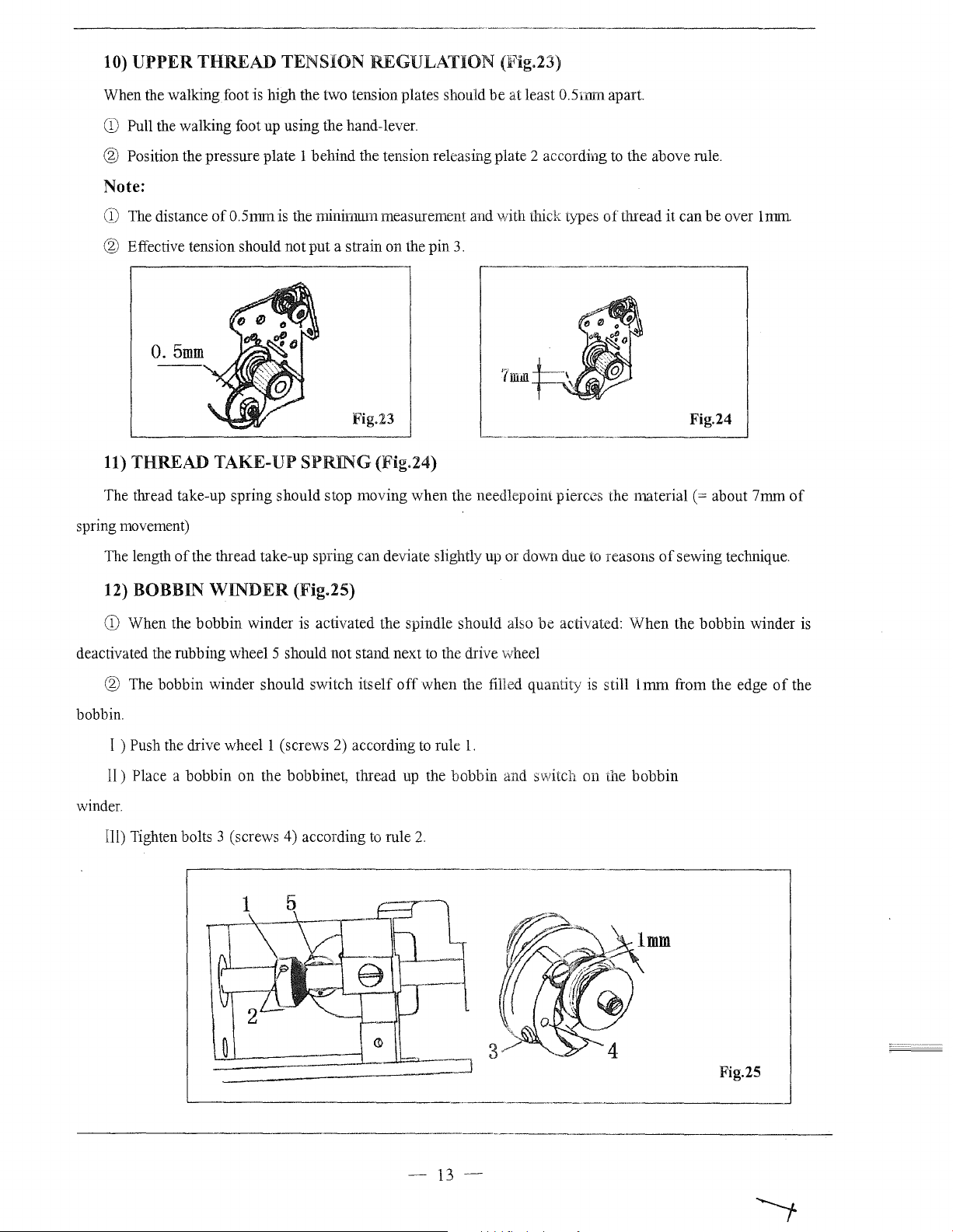

10)

UPPER

THREAD

TENSION

REGULATION

(Fig.23)

When the walking foot is high the two tension plates should

CD

Pull the walking foot up using the hand-lever.

be

at least 0.5mm apart.

® Position the pressure plate 1 behind the tension releasing plate 2 according

Note:

CD

The

distance

® Effective tension should not put a strain on the pin

of0.5mmis

the minimum measurement and 'Nith thick types

3.

0.5mm

'7mlll

Fig.23

11)

THREAD

The thread take-up spring should stop moving when the needlepoint pierces the

spring movement)

TAKE-UP

SPRING

(Fig.24)

to

the above rule.

of

thread

material(=

it

can be over

Fig.24

about 7mm

lnnn

of

of

The length

12) BOBBIN

CD

When the bobbin winder is activated the spindle should also

deactivated the rubbing wheel 5 should not stand next

® The bobbin winder should switch itself

bobbin.

I )

Push

II)

Place a bobbin on the bobbinet, thread

winder.

Ill) Tighten bolts 3 (screws 4) according

the thread take-up spring can deviate slightly up or down due

WINDER

the

drive

wheell

,-----------------------------··----------·-,

(Fig.25)

off

(screws 2) according

up

to

rule

to

reasons

be

activated: When the bobbin winder

to

the drive wheel

when the filled quantity is still 1

to

rule

l.

the bobbin and switch on the bobbin

2.

mm

of

sewing technique.

from the edge

of

is

the

'---·----------·------------------------------'

-13-

Fig.25

Page 18

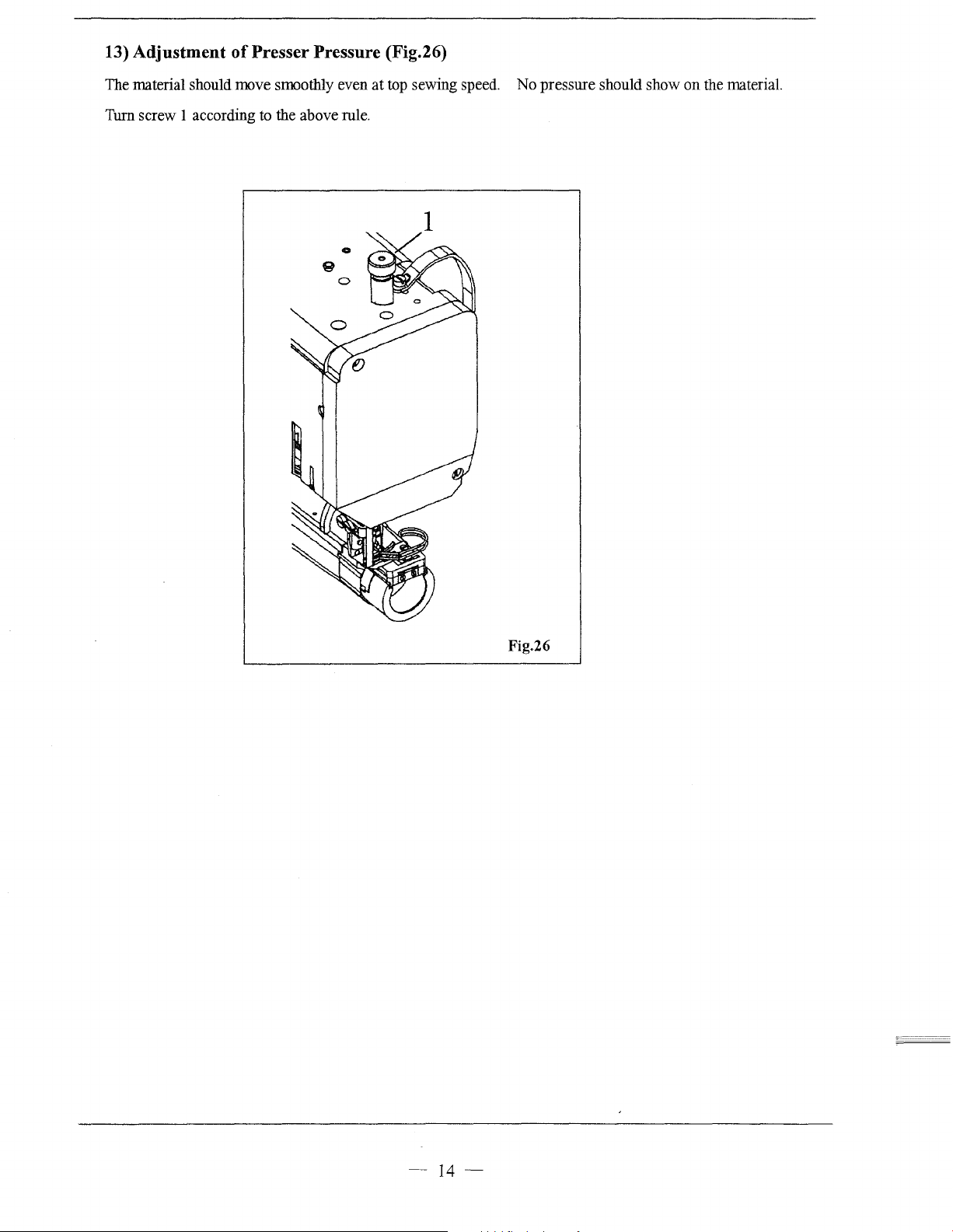

13) Adjustment

of

Presser Pressure (Fig.26)

The material should move smoothly even

Turn screw 1 according to the above rule.

at

top sewing speed. No pressure should show on the material.

1

Fig.26

-

14-

Page 19

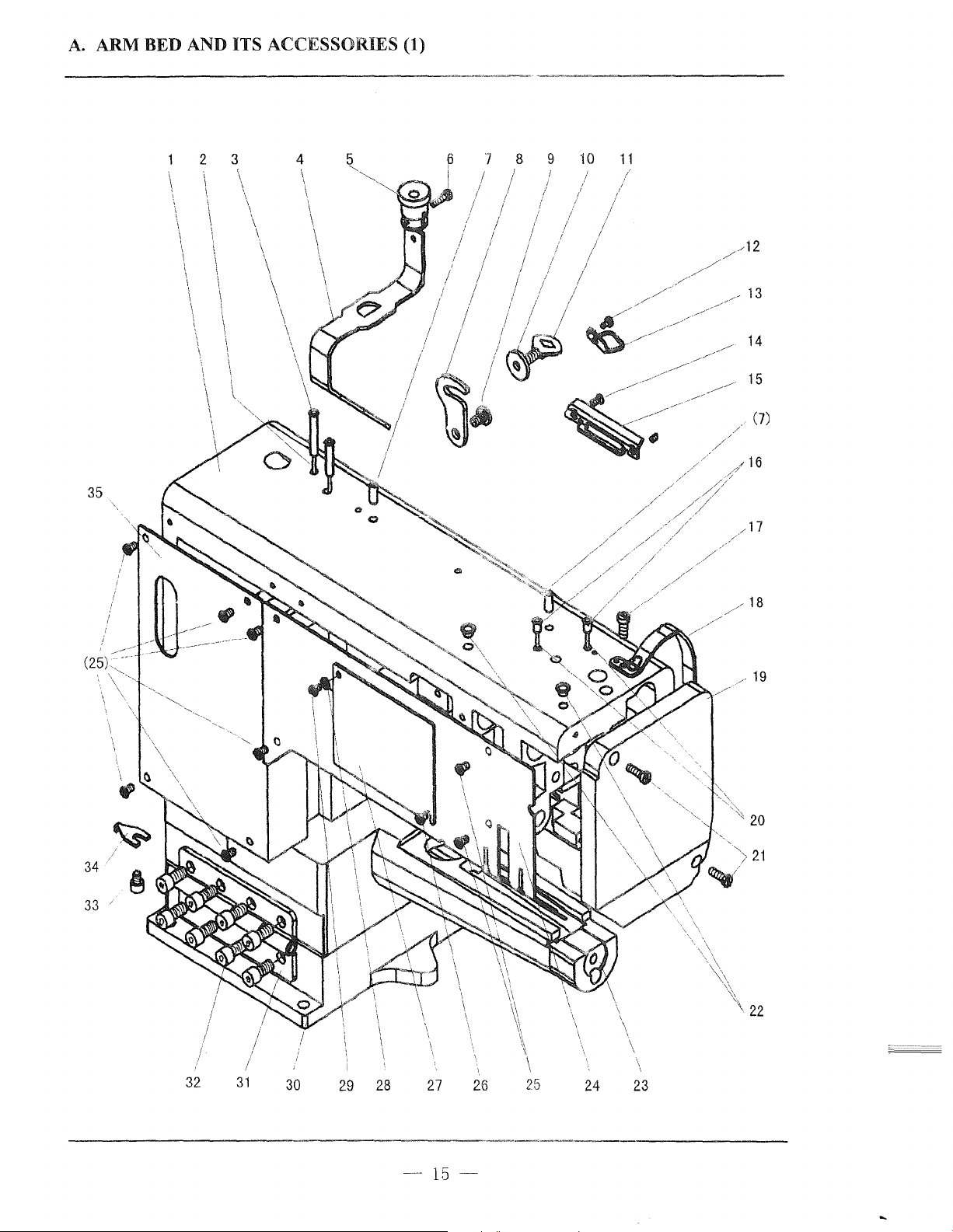

A.

ARM BED AND ITS ACCESSORIES (1)

3 4

2

6 7 8 9

/ / /

/ /

I / I

I / 1/

I

/ / I

/ I / /

' / /

I I / '

I

/1~

I

~~

1/

10

11

1/

35

34

~~

(7)

/

19

20

33

/

32

31

30

29

28

-15-

27

26

25

24

\

\

\

23

22

Page 20

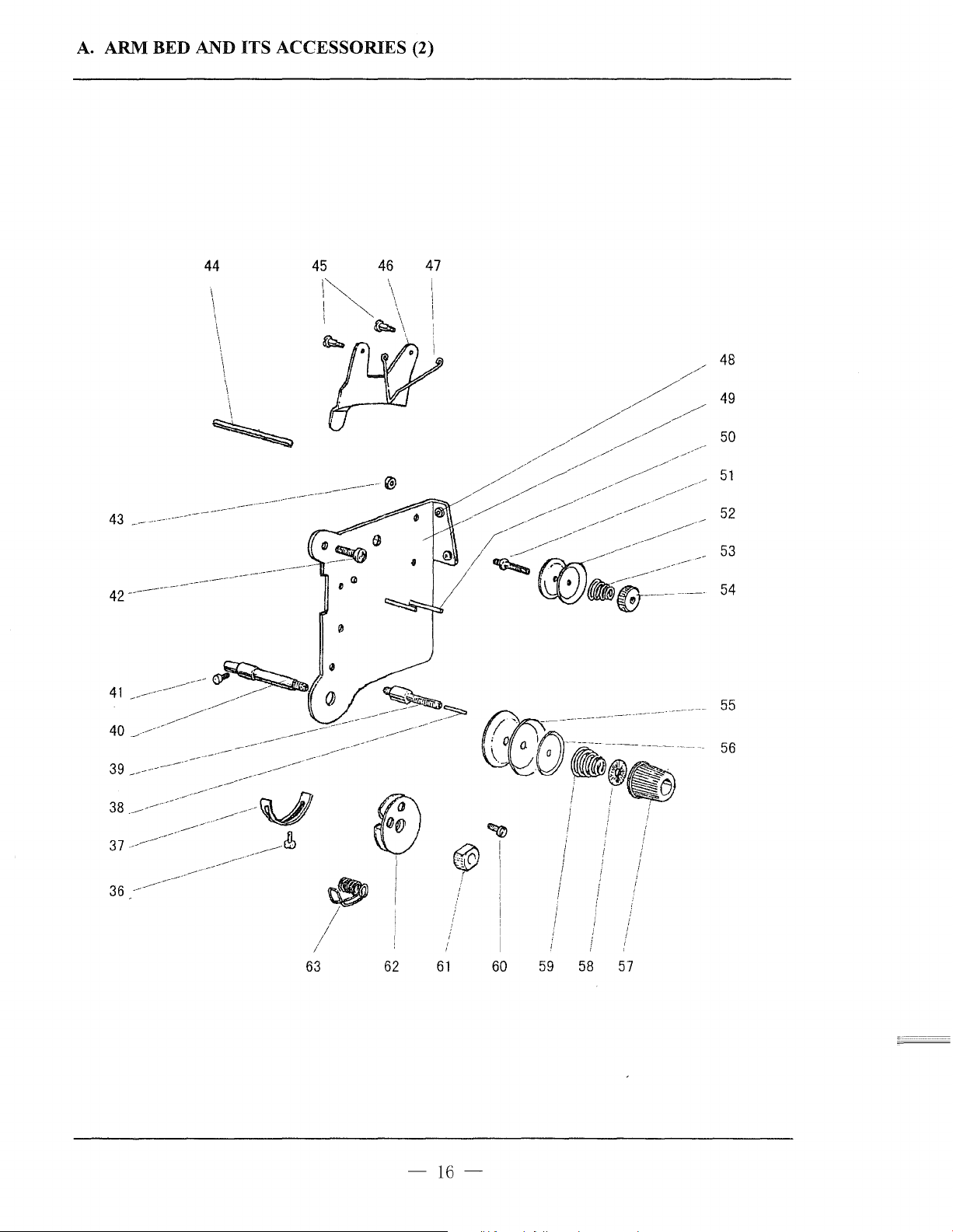

A.ARM

BED AND

ACCESSORIES (2)

_

IT_.S~------~

43

42---

41

44

I

\

\

\

\

-----

------

--~----

------

~~

~-

-------

~-----

45 46

1"'--

I""-~

!

I \

\

I

\

'~\

----@

'~

47

I

!

!

I

48

49

50

51

52

53

54

37--

~-·

63

I

I

/

fi)

~

I

62

I

I

I

i

61

-

16-

60

59 58

57

Page 21

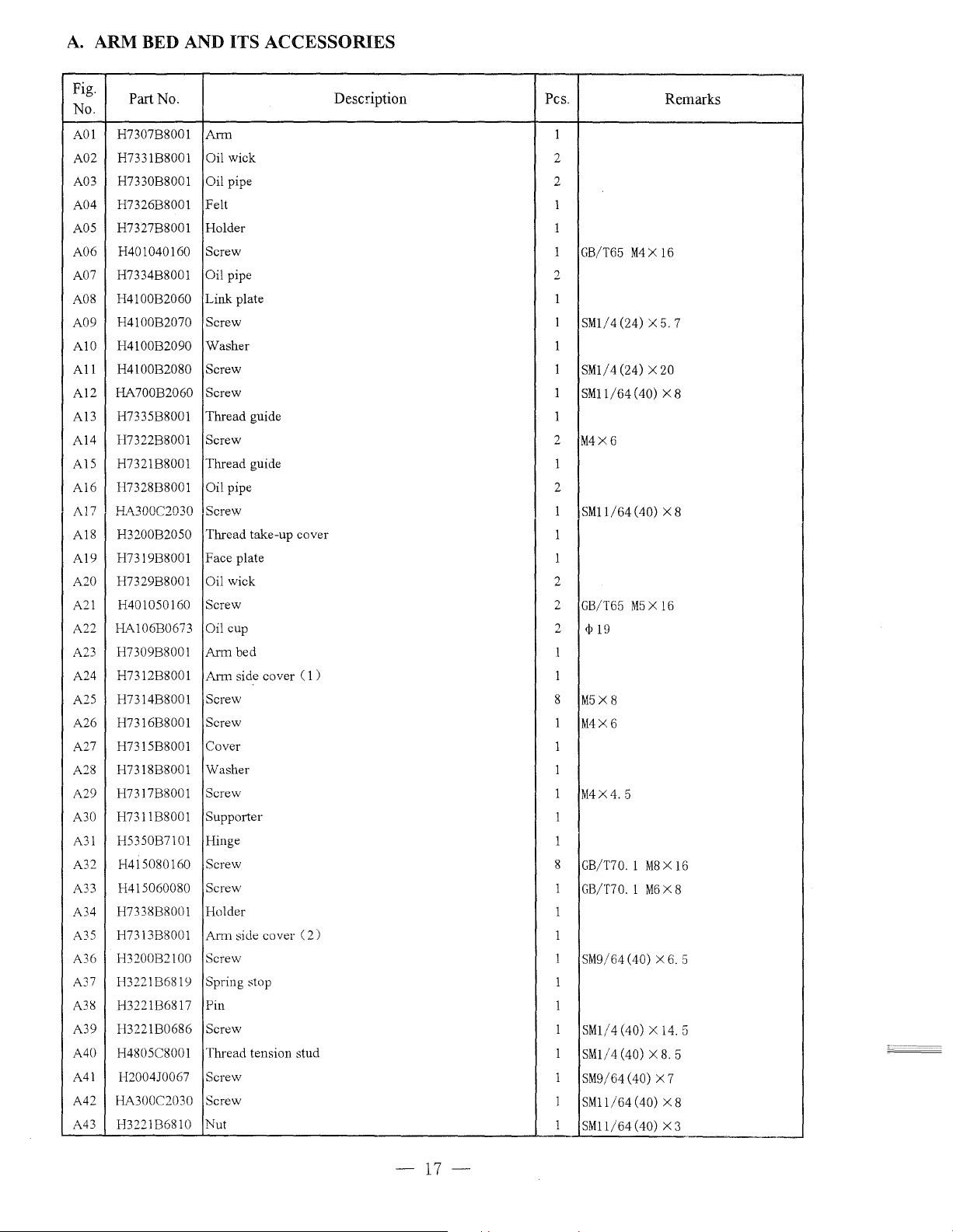

A.

ARM BED AND ITS ACCESSORIES

Fig.

No.

A01 H7307B8001

A02 H7331B8001

A03 H7330B8001

A04 H7326B8001 Felt 1

AOS

A06

A07 H7334B8001 Oil pipe 2

A08

A09

A10

All

Al2

Al3

A14

AlS

Al6

A,17

Al8

A19 H7319B8001 Face plate

A20 H7329B8001

A21

A22 HA106B0673

A23 H7309B8001

A24

A25 H7314B8001

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A38 H3221B6817 Pin

A39 H3221B0686

A40 H4805C8001 Thread tension stud

A41

A42

A43 H3221B6810 Nut

Part No.

Arm

Oil wick

Oil pipe 2

H7327B8001

H401040160 Screw

H4100B2060

H4100B2070 Screw

H4100B2090

H4100B2080

HA700B2060

H7335B8001 Thread guide 1

H7322B8001

H7321B8001

H7328B8001 Oil pipe

HA300C2030 Screw

~'

H3200B2050 Thread take-up cover

H401050160 Screw

H7312B8001

H7316B8001

H7315B8001 Cover

H7318B8001

H7317B8001

H7311B8001 Supporter

H5350B7101 Hinge

H415080160

H415060080 Screw

H7338B8001 Holder

H73\3B8001

H3200B2100 Screw

H3221B6819 Spring stop

H2004J0067 Screw

HA300C2030

Holder

Link

plate 1

Washer

Screw

Screw

Screw

Thread guide

Oil wick

Oil cup

Arm

bed

Arm

side cover (

Screw

Screw

Washer

Screw

Screw

Arm

side cover (

Screw

Screw

Description

1)

2)

Pes.

1

2

1

1

GB/T65

1

SMl/4(24)

1

1

SMl/4(24)

1

SMll/64

2

M4X6

1

2

1

SMll/64(40)

1

1

2

2

GB/T65

2

<P

19

1

1

8

M5X8

1

M4X6

1

1

1

M4X4. 5

1

1

8

GB/T70. 1

1

GB/T70. 1

1

1

1

SM9/64 (40) X

1

1

1

SMl/4(40) X 14.5

1

SMl/4(40)

1

SM9/64 (40) X 7

1

SMll/64(40)

1

SMll/64(40)

M4 X 16

X5.

X20

(40) X 8

X 8

M5 X 16

MSX

M6

X 8

XS. 5

XS

X3

Remarks

7

16

6.

5

--

-

17-

Page 22

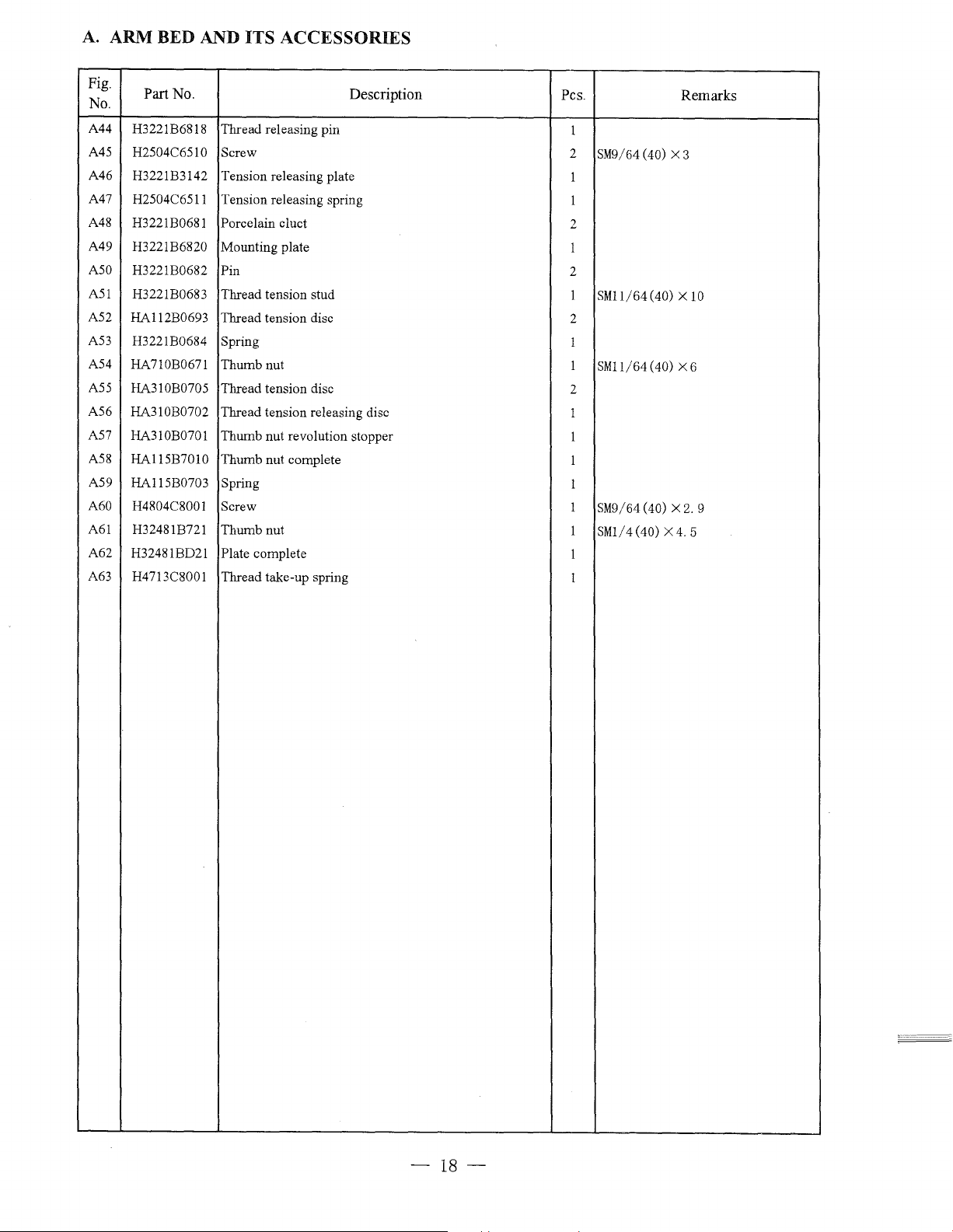

A.

ARM BED AND ITS ACCESSORIES

Fig.

No.

A44

A45

A46 H3221B3142

A47

A48

A49

A50

A51

A52

A53

A54

A55

A56

A57

A58

A59 HA115B0703

A60

A61

A62

A63

Part

No.

H3221B6818

H2504C6510

H2504C6511

H3221B0681

H3221B6820

H3221B0682

H3221B0683

HA112B0693

H3221B0684

HA710B0671

HA310B0705

HA310B0702

HA310B0701

HA115B7010

H4804C8001

H32481B721

H32481BD21

H4713C8001

Description

Thread releasing pin

Screw

Tension releasing plate

Tension releasing spring

Porcelain cluct

Mounting plate

Pin

Thread tension stud

Thread tension disc

Spring

Thumb nut

Thread tension disc

Thread tension releasing disc

Thumb nut revolution stopper

Thumb nut complete

Spring

Screw

Thumb nut

Plate complete

Thread take-up spring

Pes.

1

2

SM9/64

1

1

2

1

2

1

SM11/64(40) X

2

1

1

SM1l/64(40)

2

1

1

1

1

1

SM9/64

l

SMl/ 4

1

1

(40) X 3

(40) X

(40) X

Remarks

10

X6

2.

9

4.

5

-18-

Page 23

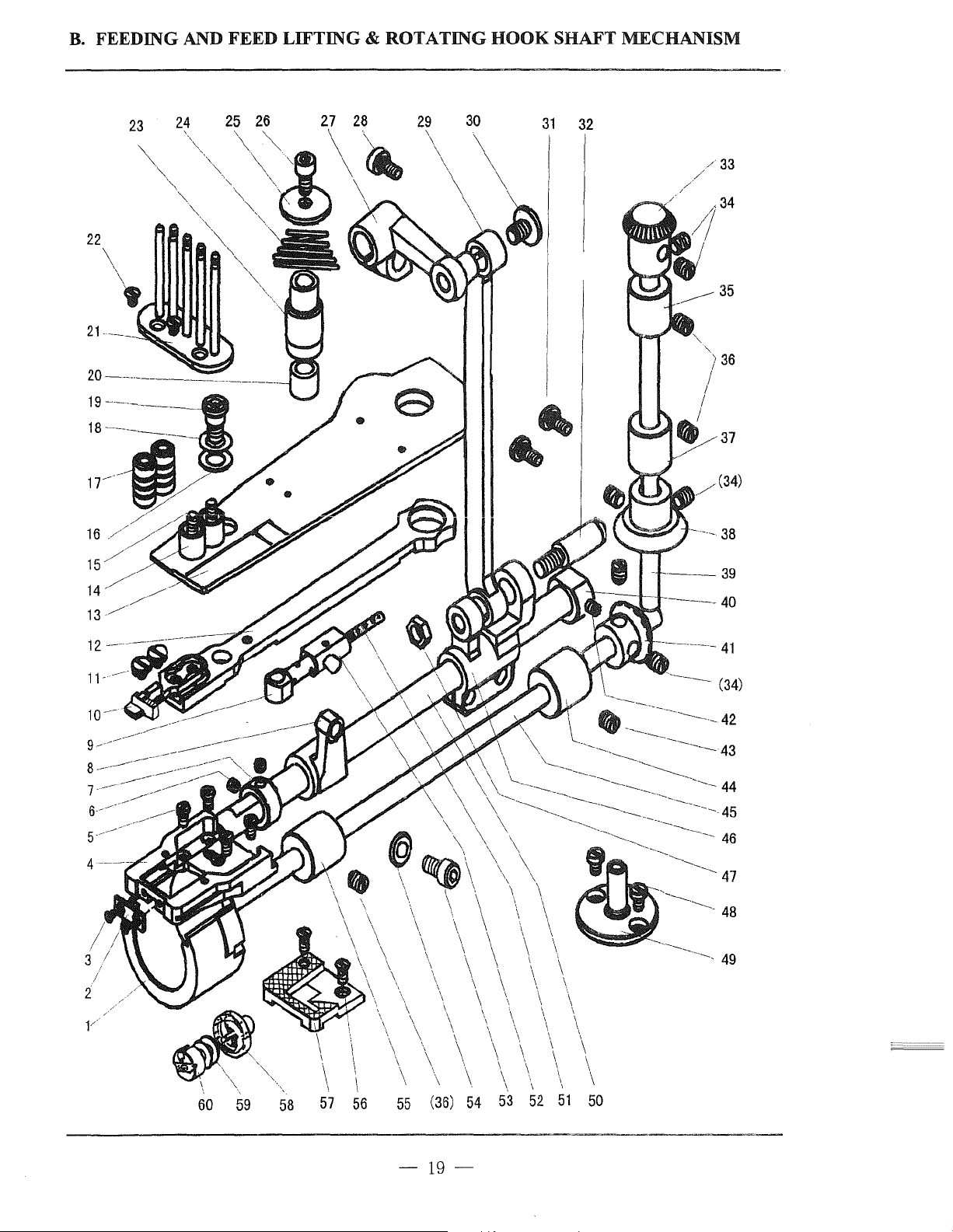

B.

FEEDING

AND

FEED LIFTING & ROTATING

HOOK

SHAFT MECHANISM

23

28

"

29

31

32

r--=--+-+------

-r-----

34

35

37

(34)

38

39

40

12

11-

3

2

-----

-----=--------::;;.7.

I

I

\

\

\

\

\

\

\

\

\

\

\

53

\

\

\

\

\

\

\

\

\

I \

\

\

\

52

~~

\ I

\

\

\

\

\ \

\

\

\

\

\

\

\

\

\

\

\

\

\

\

\

\

\

\

\

(36)

\

54

~'',

60

59 58

I

57 56

55

41

(34)

~-

-------45

46

---...._______

---------

48

\

\

\

I

\

--------

49

\

\

\

\

I

\

\

I

\

\

51

50

-19-

Page 24

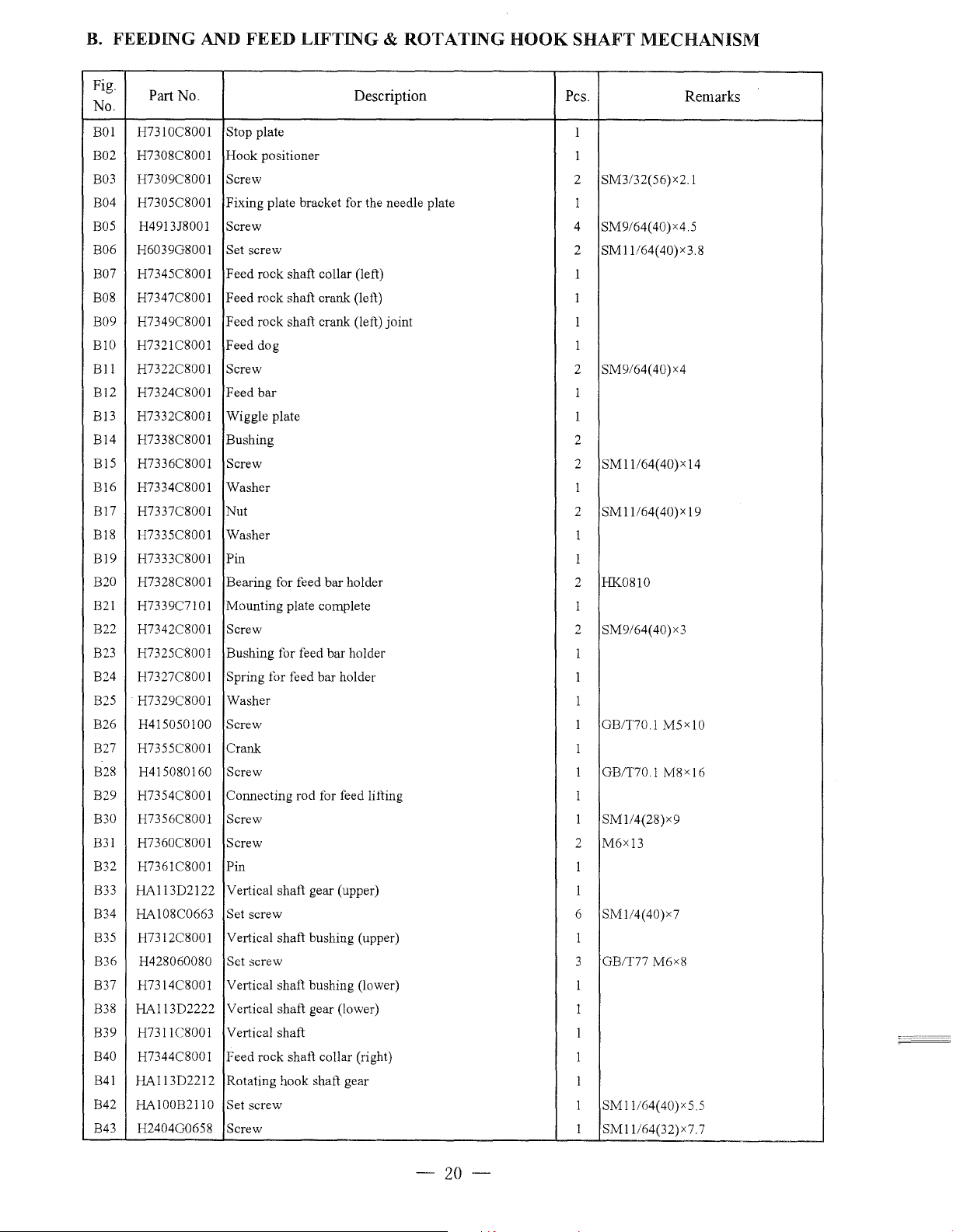

B.

FEEDING AND FEED

LIFTING

& ROTATING

HOOK

SHAFT MECHANISM

Fig.

No.

BOI

B02 H7308C800!

B03

B04 H7305C8001

B05

B06 H6039G800!

B07 H7345C8001 Feed rock shaft collar (left)

B08 H7347C8001 Feed rock shaft crank (left)

B09 H7349C800! Feed rock shaft crank (left) joint

BIO H732!C8001 Feed dog

Ell

B12 H7324C800! Feed

Bl3

B14 H7338C8001

Bl5

B!6

Bl7

Bl8

Bl9

B20

B21

B22 H7342C800!

B23

B24 H7327C8001

825

B26 H415050100

827

B28 H415080160

B29 H7354C8001 Connecting rod for feed lining

B30 H7356C8001

B31

832

B33 HAI13D2122 Vertical shaft gear (upper)

834

835 H7312C8001

B36

B37 H7314C8001 Vertical shaft bushing (lower)

B38

839

B40 H7344C8001 Feed rock shaft collar (right)

841 HA113D2212 Rotating hook shaft gear

B42

B43 H2404G0658

Part No.

H7310C8001 Stop plate

Hook

positioner

H7309C8001

H4913J8001

H7322C8001

H7332C8001

H7336C8001

H7334C8001 Washer

H7337C8001 Nut

H7335C8001 Washer

H7333C8001

H7328C8001 Bearing for feed bar holder

H7339C7101 Mounting plate complete

H7325C8001 Bushing for feed bar holder

H7329C8001 Washer

H7355C8001 Crank

H7360C8001 Screw

H7361C8001

HA108C0663 Set screw 6 SM!I4(40)x7

H428060080

HA113D2222 Vertical shaft gear (lower)

H73l!C8001

HAJOOB2110 Set screw

Screw

Fixing plate bracket for the needle plate

Screw

Set screw

Screw

bar

Wiggle plate I

Bushing

Screw 2 SM11/64(40)x14

Pin

Screw

Spring for feed bar holder

Screw

Screw

Screw 1 SM!I4(28)x9

Pin

Vertical shaft bushing (upper) I

Set

screw

Vertical shaft

Screw

Description Pes.

I

1

2

I

4 SM9/64(40)x4.5

2

1

I

I

I

2 SM9/64(40)x4

I

2

I

2

1

I

2 HK0810

1

2 SM9/64(40)x3

1

I

I

1 GB/T70.1

I

I GB/T70.1

I

2

I

I

3 GB/T77 M6x8

I

1

I

I

1

I

1

Remarks

SM3/32(56)x2.1

SM!l/64(40)x3.8

SM1!164(40)x19

M5x10

M8xJ6

M6x13

SMJ!I64(40)x5.5

SM11164(32)x7. 7

-20-

Page 25

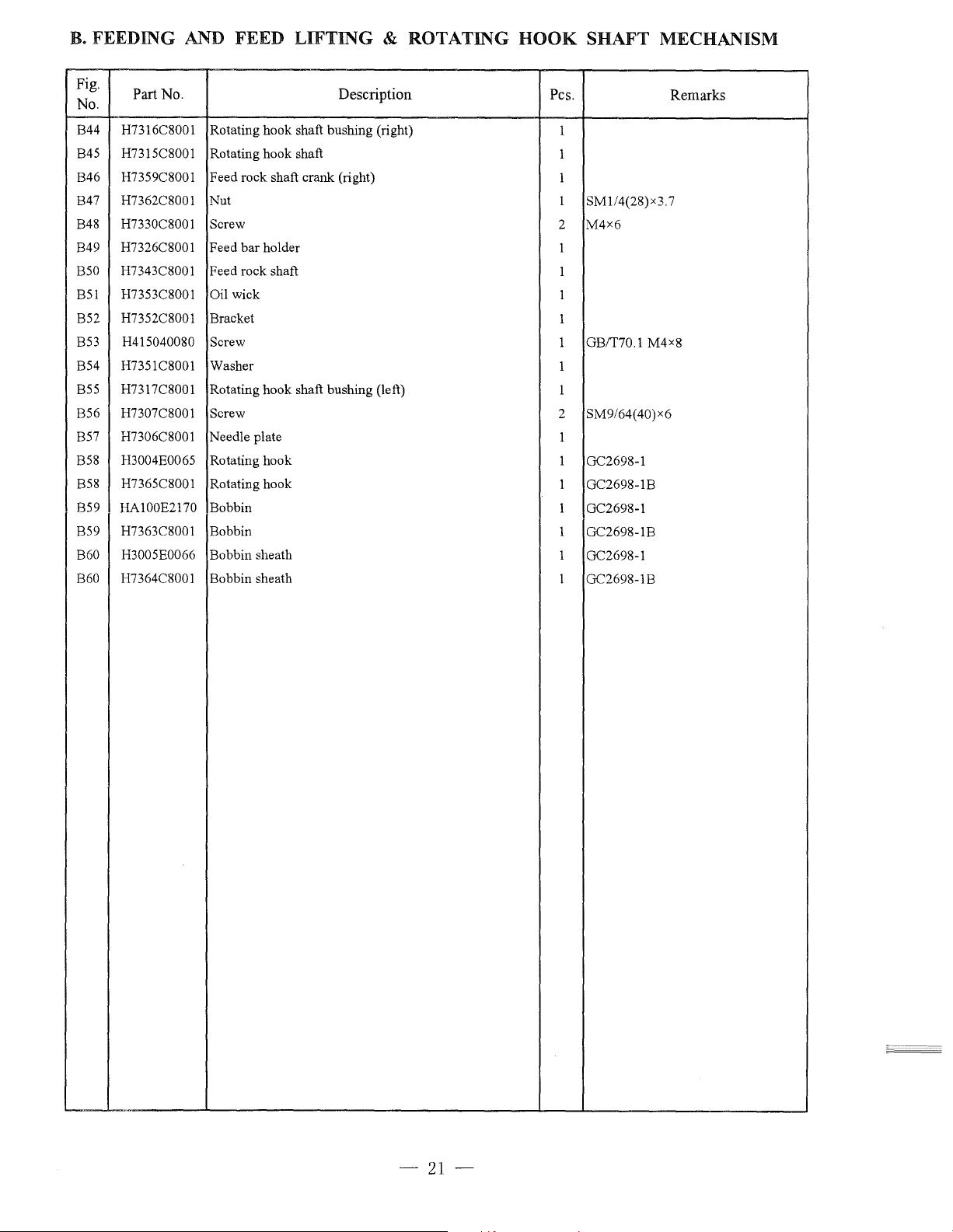

B.

FEEDING AND FEED

LIFTING

& ROTATING

HOOK

SHAFT MECHANISM

Fig.

No.

B44 H7316C8001 Rotating hook shaft bushing (right)

B45 H7315C8001 Rotating hook shaft

B46 H7359C8001 Feed rock shaft crank (right)

B47 H7362C8001 Nut

B48 H7330C8001

B49 H7326C8001 Feed bar holder

B50 H7343C8001

B51

B52

B53 H415040080

B54 H7351C8001 Washer

B55 H7317C8001

B56 H7307C8001

B57 H7306C8001 Needle plate

B58 H3004E0065 Rotating hook

B58 H7365C8001 Rotating hook

B59

B59 H7363C8001 Bobbin

B60 H3005E0066 Bobbin sheath

B60 H7364C8001 Bobbin sheath

Part No. Description

Screw

Feed rock shaft

H7353C8001 Oil wick

H7352C8001 Bracket

Screw

Rotating hook shaft bushing

Screw

HA100E2170 Bobbin

(left)

Pes.

1

1

1

1

SM1/4(28)x3.7

M4x6

2

1

1

1

1

1 GB!T70.1 M4x8

1

1

2 SM9/64(40)x6

1

1

GC2698-1

1 GC2698-1B

1 GC2698-1

1 GC2698-1B

1

GC2698-1

1 GC2698-1B

Remarks

'"

-21-

Page 26

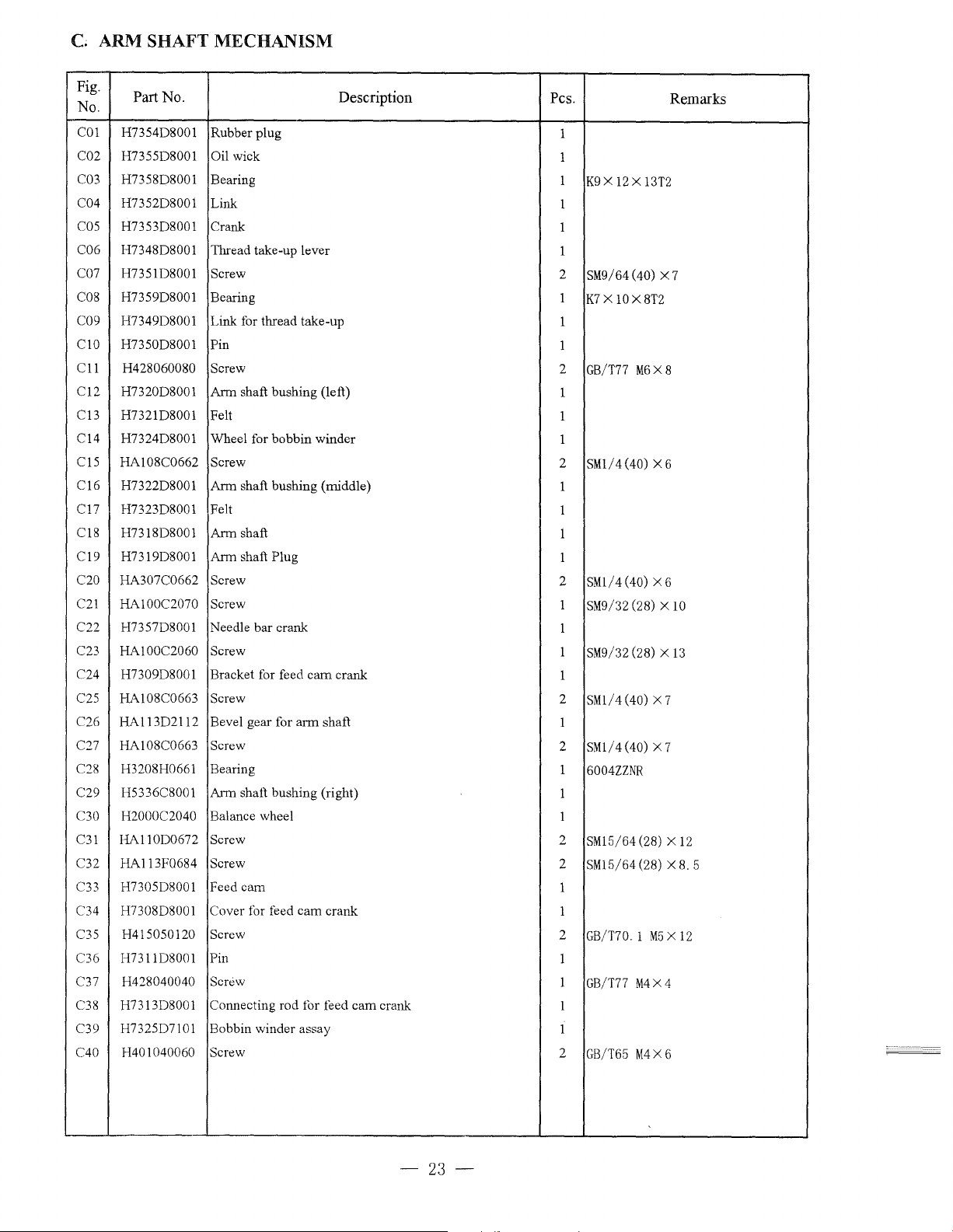

C. ARM SHAFT

MECHANISM

20 -

19

16

15

14

22

23

\

\

I

i

24

'·

25

26

27

I

!

28

I

29

30

10---~~

9

---

----,(_,__...._

(7) //\i!

//

---------

8/

--------~1

----------

7

_/"

I

6

I

~-~

---~----

-----

.......

_

....._

__

35

_

36

37

---

------·----------

////

I

i

I

-------

- -

- 38

I

5

4

3

2

-22-

Page 27

C ARM SHAFT

MECHANISM

Fig.

No.

COl H7354D8001

C02 H7355D8001 Oil wick

C03 H7358D8001 Bearing

C04 H7352D8001

cos

C06 H7348D8001

C07 H7351D8001

C08 H7359D8001 Bearing

C09

ClO H7350D8001 Pin

C11

C12

C13

C14

C15

C16

Cl7

C18

Cl9

C20

C21

C22 H7357D8001 Needle bar crank

C23

C24

C25

C26 HA113D2112 Bevel gear for

C27

C28 H3208H0661 Bearing

C29

C30 H2000C2040 Balance wheel

C31

C32 HA113F0684 Screw

C33

C34

C35

C36 H7311D8001 Pin

C37

C38

C39

C40

Part

No.

Rubber plug

Link

H7353D8001 Crank

Thread take-up lever

Screw

H7349D8001

H428060080 Screw

H7320D8001

H7321D8001 Felt

H7324D8001 Wheel for bobbin winder

HA108C0662

H7322D8001

H7323D8001 Felt

H7318D8001

H7319D8001

HA307C0662 Screw

HA100C2070 Screw

HA100C2060 Screw

H7309D8001

HA108C0663 Screw

HA108C0663 Screw

H5336C8001

HA110D0672 Screw

H7305D8001 Feed

H7308D8001 Cover for feed

H415050120 Screw

H428040040

H7313D8001

H7325D7101

H401040060

Link for thread take-up

Arm

shaft bushing (left)

Screw

Arm

shaft bushing (middle)

Arm shaft

Arm

shaft Plug

Bracket for feed

arm

Arm shaft bushing (right)

cam

cam

Screw

Connecting rod for feed

Bobbin winder assay

Screw

Description

cam

crank

shaft

crank

cam

crank

Pes.

1

1

1

K9X12Xl3T2

1

1

1

2

SM9/64 (40) X 7

1

K7 X 10X8T2

1

1

2

GB/T77

1

1

1

2

SMl/ 4 (40) X 6

1

1

1

1

2

SMl/ 4 (40) X 6

1

SM9/32 (28) X

1

1

SM9/32 (28) X

1

2

SMl/ 4 (40) X 7

1

2

SMl/ 4 (40) X 7

1

6004ZZNR

1

1

2

SM15/64 (28) X

2

SM15/64 (28) X

1

1

2

GB/T70. 1

1

1

GB/T77

1

1

2

GB/T65

M6X8

M5 X 12

M4X4

M4X

Remarks

10

13

12

8.

5

6

-23-

Page 28

D.

STITCH REGULATOR MECHANISM

------

---- 2

---

----4

- 5

---- 6

3

17 16

15

14

13

12

8

------~----

--------

---------

------

9

1 0

_11

-24-

Page 29

D. STITCH REGULATOR MECHANISM

Fig.

No.

DOl

Part No.

Description Pes.

H7305E8001 Bracket for stitch length plate

D02 H7307E8001 Stitch length plate

H415060160

D03

D04

DOS

H7315E8001

H7313E8001

Screw 2

Guide bushing

Spring

D06 H7310E7101 Stitch length regulating nut assay

D07 H7314E8001

H7312E8001

D08

Washer 1

Stud

D09 H4100F2070 Screw

DlO H7325E8001 Cover

H7326E8001 Screw

Dll

Dl2

H7316E8001 Feed regulator screw bar

D13

H7323E8001

Dl4

H7318E8001 Setting frame

H7324E8001

Dl5

Dl6

H7322E8001 Screw 1

H7319E7101

D17

Spring

Guide bushing 1

Pin 1

1

1

GB/T70. 1

1

1

1

1

M6X60

2

SM9/64

(40) X 7

1

2

M5 X 7.

5

1

1

1

SM15/64(40) X7. 5

Remarks

M6 X 16

-25-

-""-~"--

~

--------

----------

Page 30

E.

PRESSER

FOOT

MECHANISM

2 3 4 5

6

7

i

I

I

23 22

21

19 18

--

-

/12

/

/

/

/

/

Q/

//13

~

~------

-

///15

t

rrf}

~

17

..

//

11

J4

16

-26-

Page 31

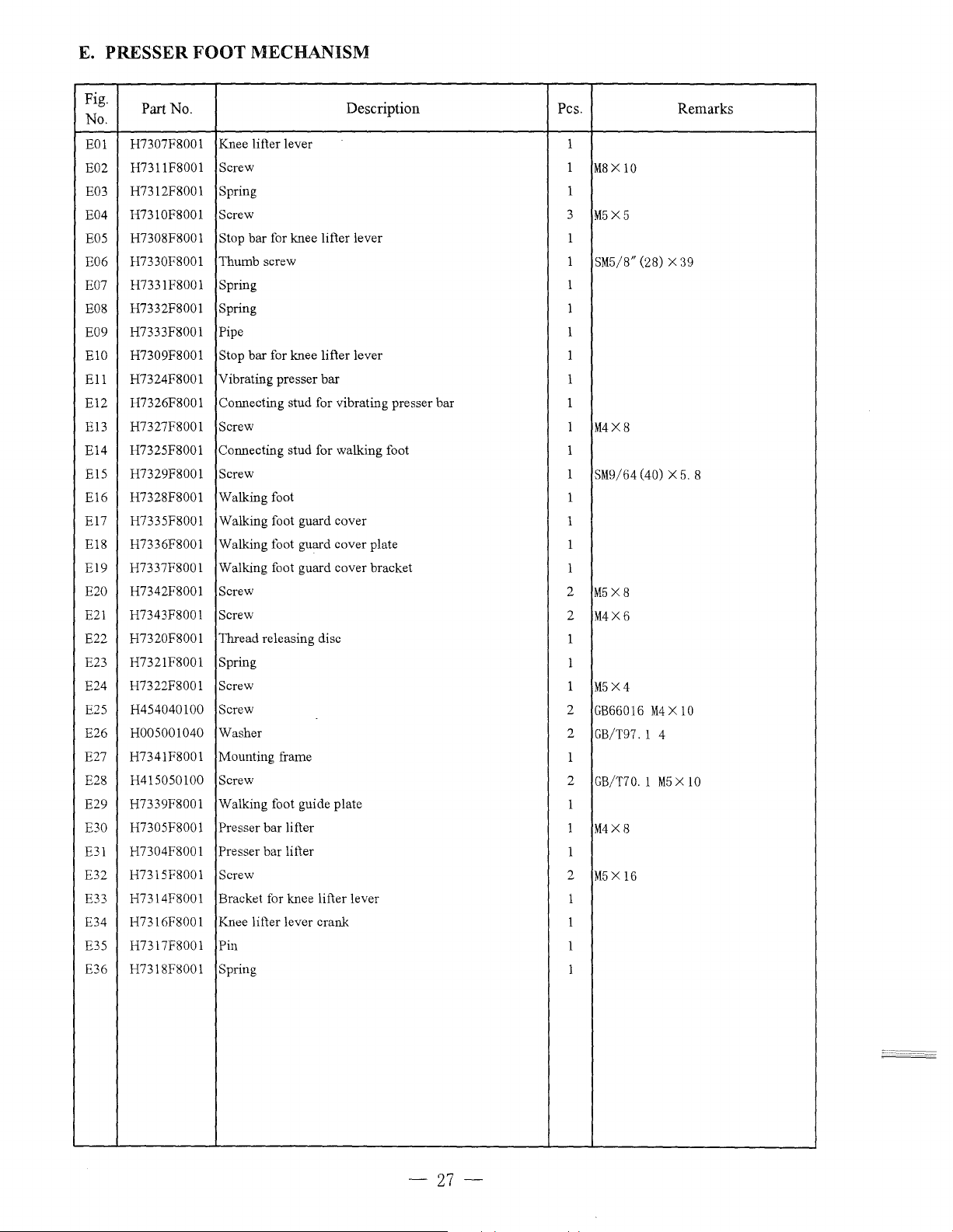

E.

PRESSER FOOT MECHANISM

Fig.

No.

EOl

E02 H7311F8001

E03

E04

E05

E06

E07

E08

E09

ElO

Ell

El2

El3

El4

El5

El6

El7

El8

E19 H7337F8001 Walking foot guard cover bracket

E20

E21

E22

E23

E24

E25

E26 H005001040 Washer

E27 H7341F8001 Mounting frame

E28

E29 H7339F8001 Walking foot guide plate

E30

E31

E32

E33

E34

E35

E36

Part No. Description Pes. Remarks

H7307F8001

H7312F8001

H7310F8001

H7308F8001

H7330F8001

H7331F8001

H7332F8001 Spring

H7333F8001 Pipe

H7309F8001

H7324F8001 Vibrating presser

H7326F8001

H7327F8001 Screw

H7325F8001 Connecting stud for walking foot

H7329F8001 Screw

H7328F8001

H7335F8001 Walking foot guard cover

H7336F8001 Walking foot guard cover plate

H7342F8001 Screw

H7343F8001 Screw

H7320F8001 Thread releasing disc

H7321F8001 Spring

H7322F8001 Screw

H454040100

H415050100

H7305F8001 Presser

H7304F8001 Presser bar lifter

H7315F8001 Screw

H7314F8001 Bracket for knee lifter lever

H7316F8001 Knee lifter lever crank

H7317F8001 Pin

H7318F8001

Knee lifter lever 1

Screw 1

Spring

Screw 3

Stop bar for knee lifter lever 1

Thumb screw

Spring

Stop

bar

for knee lifter lever

bar

Connecting stud for vibrating presser bar

Walking foot

Screw

Screw

bar

lifter

Spring

M8X

10

1

M5X5

1

SM5/8" (28) X 39

1

1

1

1

1

1

1

M4X8

1

1

SM9/64 (40) X

1

1

1

1

2

M5X8

2

M4X6

1

1

1

M5X4

2

GB66016

2

GB/T97. 1 4

1

2

GB/T70. 1

1

1

M4X8

1

2

M5X

16

1

1

1

1

5.

M4 X 10

M5 X 10

8

-27-

Page 32

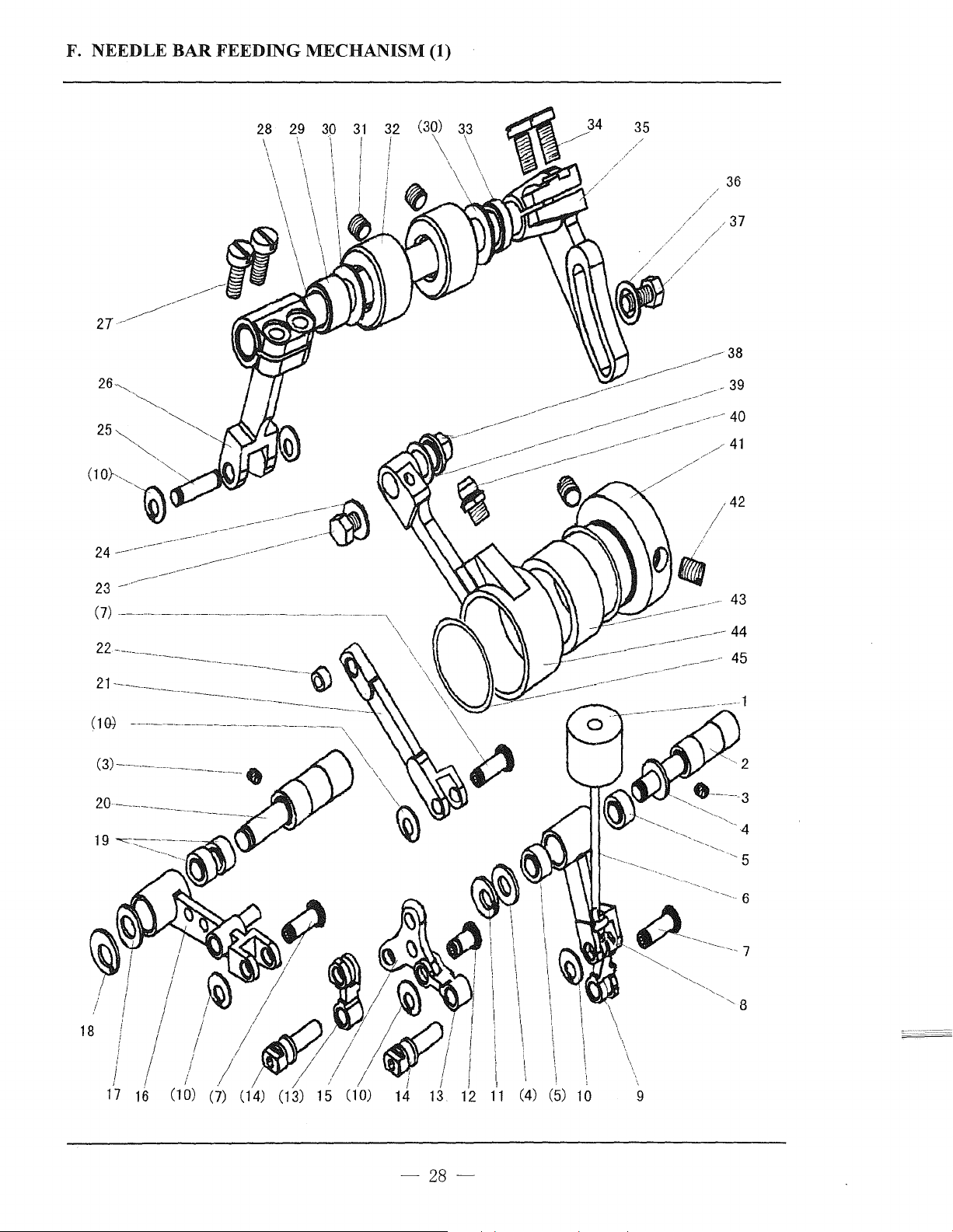

F. NEEDLE BAR

FEEDING

MECHANISM (1)

28 29 30

32

I

I

(30) 33

\ \

\ \

\ \

31

'!

I I

35

-~

/------38

---

-----

----~

-~-

-

---

/41

36

- 39

40

/42

( 1

Qj --------

(3)-------------------.

20

~-----

i

I

I

;

I

I

18

I

I I

I

I

I

I

I

16

-----------

~---

-----------------------------,

I

I

----

-6)

--------

I

/

15

\\_

\

\

\)

12

I

I

!

I,

11

(5) 10

43

45

5

9

-28-

Page 33

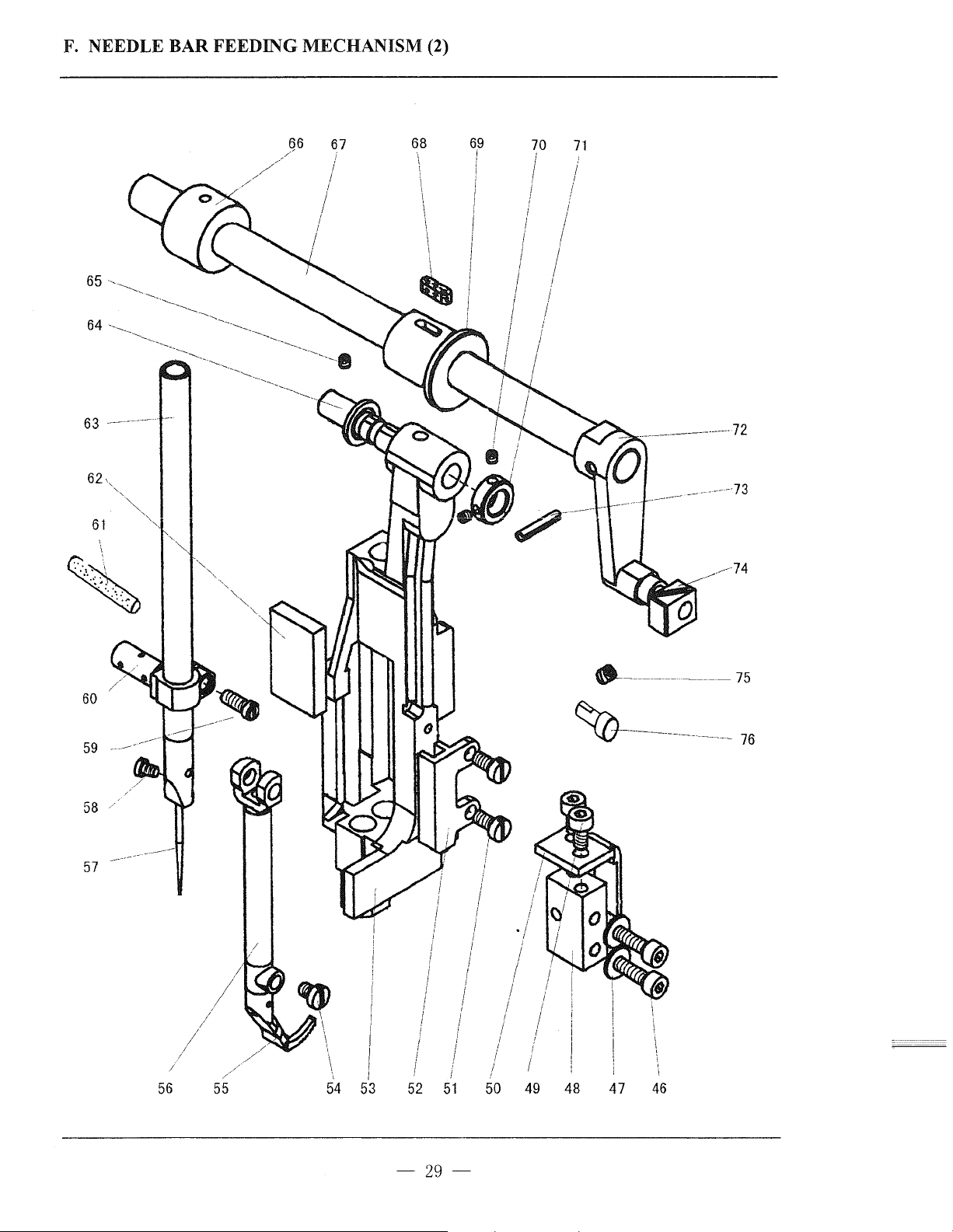

F. NEEDLE BAR FEEDING MECHANISM (2)

63

.\

65

62

61

----------

------

'

'

66

/

/

/

/

/

--

67

68

I

69

i

I

I

'

\

\

I

I

I

I

!

!

70

71

-----------------

-------73

---

____

72

.------74

'

60

59

57

-

----

56

52

51

50

49

·-------------

~-------------------

I

\

'

'

·,

48 4 7

46

75

76

-29-

Page 34

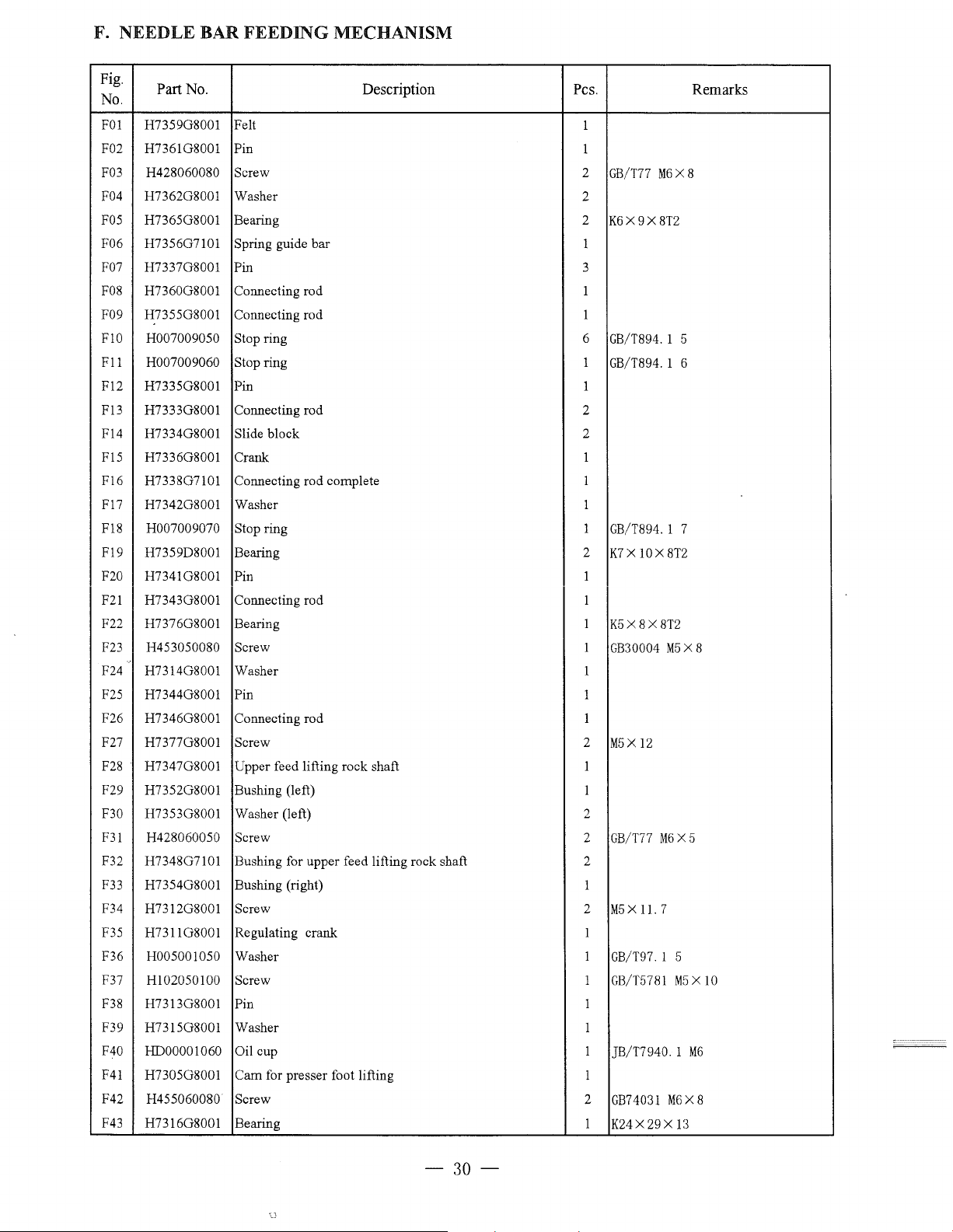

F. NEEDLE BAR

FEEDING

MECHANISM

Fig.

No.

FOI

F02 H7361G8001

F03

F04 H7362G8001 Washer

FOS

F06 H7356G7101 Spring guide bar

F07 H7337G8001

F08

F09 H7355G8001 Connecting rod 1

FlO H007009050 Stop ring 6

Fll

F12 H7335G8001

F13

F14 H7334G8001 Slide block 2

F15

F16 H7338G7101 Connecting rod complete 1

F17

F18

F19

F20 H7341G8001

F21

F22

F23 H453050080 Screw 1

F24 H7314G8001 Washer

F25 H7344G8001

F26 H7346G8001 Connecting rod 1

F27 H7377G8001 Screw 2

F28 ·

F29

F30

F31

F32 H7348G7101 Bushing for upper feed lifting rock shaft 2

F33

F34

F35

F36

F37

F38 H7313G8001

F39

F40 HD00001060 Oil cup 1

F4l

F42 H455060080

F43

Part No.

H7359G8001 Felt

Pin

H428060080 Screw

H7365G8001 Bearing 2

Pin

H7360G8001 Connecting rod 1

H007009060 Stop ring 1

Pin

H7333G8001 Connecting rod 2

H7336G8001

H7342G8001 Washer 1

H007009070 Stop ring 1

H7359D8001 Bearing 2

H7343G8001 Connecting rod 1

H7376G8001 Bearing 1

'"

H7347G8001 Upper

H7352G8001 Bushing (left) 1

H7353G8001 Washer (left) 2

H428060050 Screw

H7354G8001

H7312G8001 Screw

H7311G8001 Regulating crank 1

H005001050 Washer 1

Hl02050100 Screw 1

H7315G8001 Washer

H7305G8001 Cam for presser foot lifting

H7316G8001

Crank

Pin

Pin 1

feed lifting rock shaft 1

Bushing (right) 1

Pin

Screw

Bearing

Description Pes.

1

1

2

GB/T77

2

K6X 9X8T2

1

3

GB/T894. 1 5

GB/T894. 1 6

1

1

GB/T894. 1 7

K7

X lOX

1

K5X8X8T2

GB30004

1

M5X

2

GB/T77

2

M5

X 1 L 7

GB/T97.

GB/T5781

1

1

JB/T7940. l

1

2

GB7403l M6X8

1

K24X29Xl3

12

M6X

8T2

M5

M6X5

1 5

M5X

Remarks

8

X 8

10

M6

-30-

\_}

Page 35

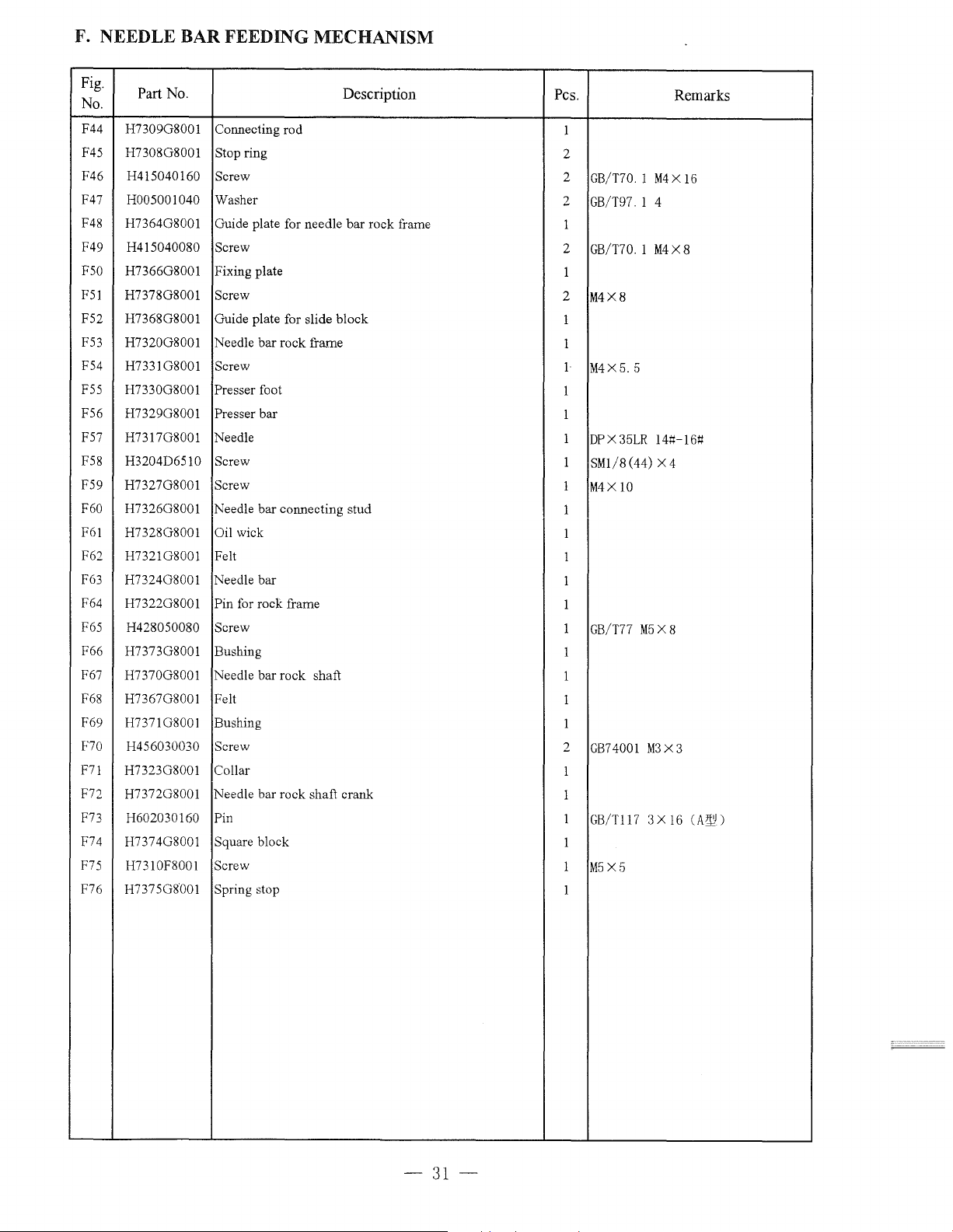

F. NEEDLE BAR FEEDING MECHANISM

Fig.

No.

F44 H7309G8001

F45

F46

F47

F48

F49

FSO

F51

F52 H7368G8001

F53

F54

FSS

F56

F57

F58

F59 H7327G8001

F60 H7326G8001

F61 H7328G8001

F62

F63

F64

F65

F66

F67

F68

F69

F70 H456030030 Screw

F7!

F72

F73

F74

F75

F76

Part

No.

Connecting rod

H7308G8001

H415040160

H005001040 Washer

H7364G8001

H415040080 Screw

H7366G8001 Fixing plate

H7378G8001 Screw

H7320G8001 Needle bar rock frame

H7331G8001

H7330G8001

H7329G8001

H7317G8001 Needle

H3204D6510

H7321G8001 Felt

H7324G8001

H7322G8001

H428050080 Screw

H7373G8001 Bushing

H7370G8001 Needle bar rock shaft

H7367G8001

H7371G8001 Bushing

H7323G8001

H7372G8001 Needle bar rock shaft crank

H602030160 Pin

H7374G8001 Square block

H7310F8001 Screw

H7375G8001 Spring stop

ring

Stop

Screw

Guide plate for needle

Guide plate for slide block

Screw

foot

Presser

Presser bar

Screw

Screw

Needle bar connecting stud

Oil wick

Needle bar

Pin for rock frame

Felt

Collar

Description

bar

rock frame

Pes.

1

2

2

GB/T70. 1

2

GB/T97. 1 4

1

2

GB/T70.1 M4X8

1

2

M4X8

1

1

1

M4X5. 5

1

1

1

DP

X 3

1

SM1/8 (44) X 4

1

M4X

1

1

1

1

1

1

GB/T77

1

1

1

1

2

GB7

1

1

1

GB/Tl1 7 3 X

1

1

M5X5

I

5LR

10

4001

M5

M3

Remarks

M4X

141:1-1

X 8

X 3

16

16

61:1

(A~

)

-31-

Page 36

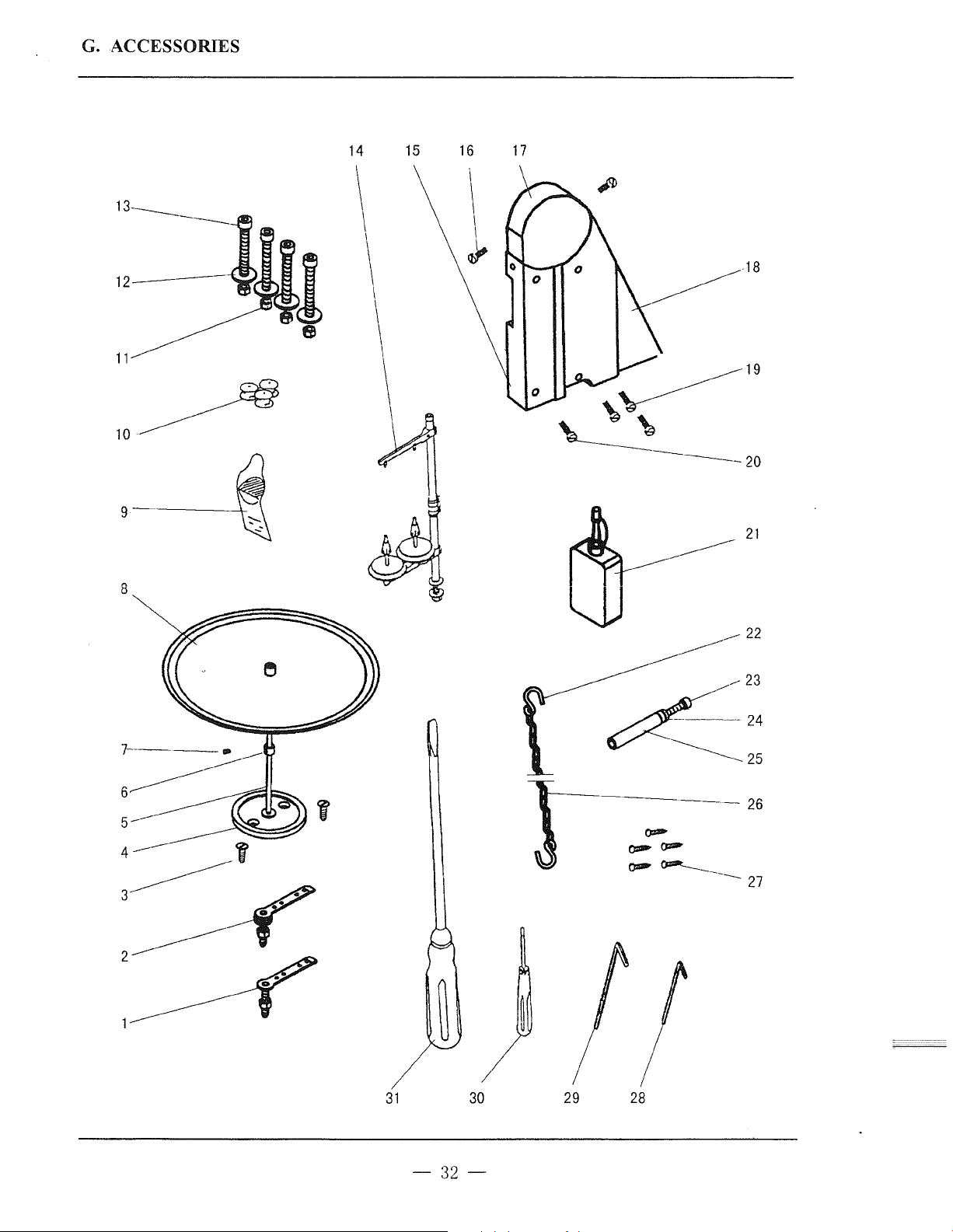

G.

A

CCESSORIES

g-

8

14

15

16

17

18

~

2-----------

31

30

----23

__...--

24

25

-r--~-:rs-

J -

29

28

___

--------

26

27

:::_

-----=--

--

-32-

Page 37

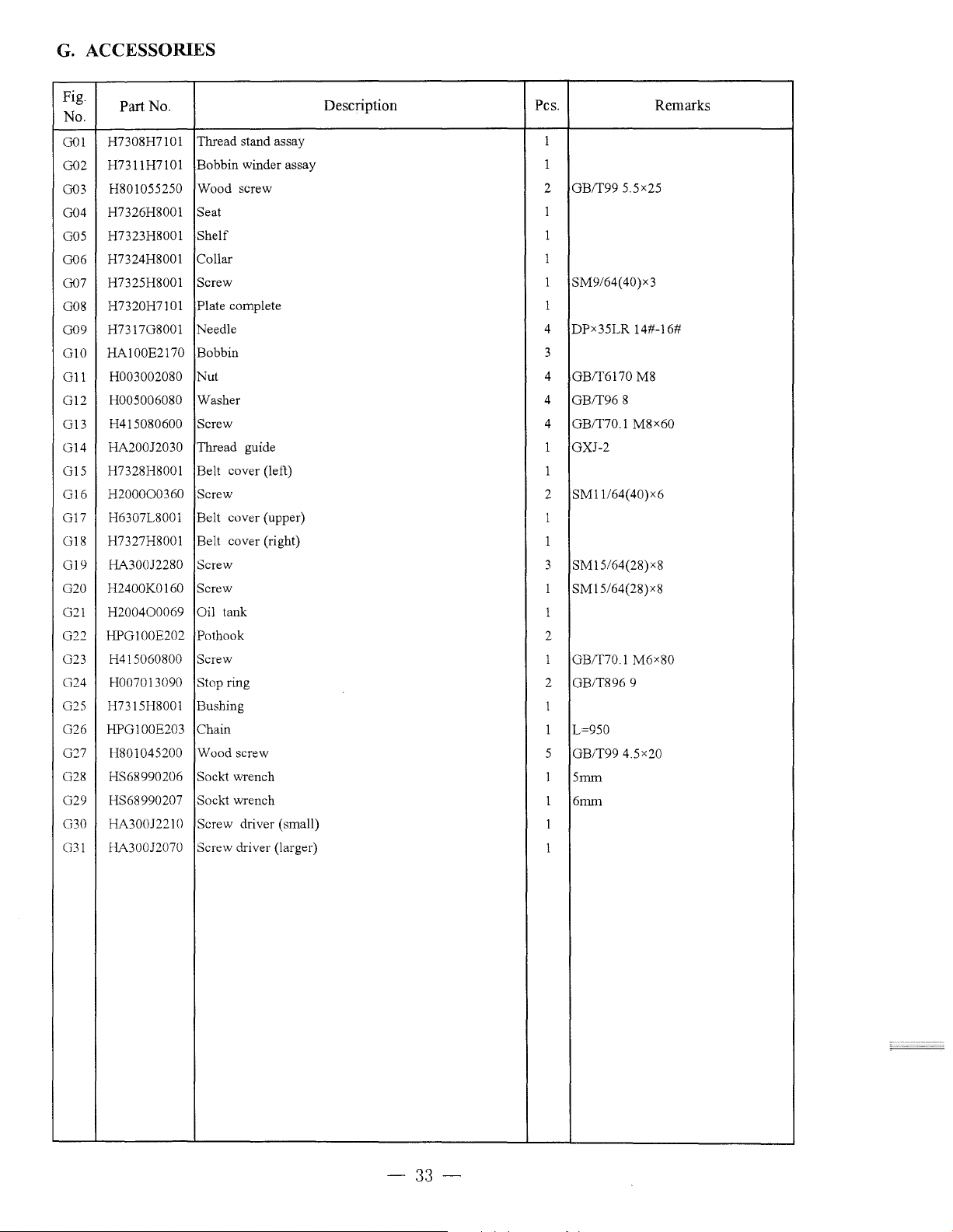

G.

ACCESSORIES

Fig.

No.

001

002

003

004

005

006

007

008

009

GlO

G11

G12

013

G14

015

016

G17 H6307L8001 Belt cover (upper)

G18

019

020

021

022

023

024

025

026

027

028

029

030

G31

Part No.

H7308H7101

H7311H7101

H801055250

H7326H8001 Seat

H7323H8001

H7324H8001

H7325H8001 Screw

H7320H7101

H731708001

HA100E2170 Bobbin

H003002080 Nut 4 OB/T6170 M8

H005006080 Washer

H415080600

HA200J2030 Thread guide 1 OXJ-2

H7328H8001

H200000360 Screw

H7327H8001 Belt cover (right)

HA300J2280 Screw

H2400K0160

H200400069 Oil tank

HP0100E202

H415060800 Screw

H007013090 Stop ring

H7315H8001 Bushing

HP0100E203 Chain

H801045200

HS68990206 Sockt wrench

HS68990207 Sockt wrench

HA300J2210 Screw driver (small)

HA300J2070 Screw driver (larger)

Thread stand assay

Bobbin winder assay

Wood screw 2

Shelf

Collar 1

Plate

complete 1

Needle 4 DPx35LR 14#-16#

Screw

Belt cover (left)

Screw

Pothook

Wood screw

Description

Pes. Remarks

1

1

1

1

1 SM9/64(40)x3

3

4

4

1

2

1

1

3 SM15/64(28)x8

1 SM15/64(28)x8

1

2

1 OB/T70.1 M6x8Q

2

1

1

5

1

1

1

1

OB/T99 5.5x25

OB/T96 8

OB/T70.1 M8x6Q

SM11/64(40)x6

OB/T896 9

L=950

OB/T99 4.5x20

5mm

6mm

-33-

Page 38

Page 39

Page 40

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

ADD: 1418,

Yishan

Road,

Shanghai,

China

Zip Code: 201103

Overseas

Business:

TEL:

86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The

description

covered

in

this

manual

is

subject

to

change

for

improvement

of

the

commodity

without

2003.12.

notice

Printed

Loading...

Loading...