Page 1

I

HIGH

LEAD

GC24698-5RI-5L/-6

l

Post-bed

lockstitch

Instruction

heavy

sewing

duty

Parts

compound

machine

Manual

Catalog

feed

(20)

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

Page 2

----- CONTENTS-----

!.OPERATING INSTRUCTION ......................

UP

THE

2.SETTING

3.CAUTION BEFORE STARTING

4.0ILING········

S.NEEDLE··········· ........

6.THREAD···········"·······

?.WINDING

THE

MACHINE .....................................

THE

······

···

· ..........................................

.........

......

.....................

..

······

..

············································

LOWER

THREAD

ON

OPERATION·· .. ········· .......................................................................... 1

..........

.............

..........

...

..............................

...

........................................................................................................... 2

..

··· ...................................................................................... 3

THE

BOBBIN ................................................................................... 3

...

..................

............................................................................... 1

...

....................................................................... 2

........................................................ 1

. . .

8.THREADING

9.

Iill

GULATING

10. ADJUSTMENT

11

. ADJUSTMENT

12

.REVERSE STITCHING ........................................................................................................................................ 5

13.IillLATIVE POSITION

NEEDLE

14.

ADJUSTMENT

15. TIMING

THE

NEEDLE .....................................................

TilE

TH:READ TENSIONS···

OF

OF

THE

AND

THE

THE

BET'\VEEN

THE

STITCH

PRESSURE

OF

NEEDLE

HEIGHT

THE

HOOK

··

................................................................................................... 4

LENGTH

.............

VIBRATING AND

HOLE

OF

THE

AND

OF

FEED

THE

..............

..............

THE

FEEDER .............

DOG .....

NEEDLE ................

......

...................................................................... 3

..................................................................................... 4

...

. ::···

·· .........

....

..........

.......

............

LIFfiNG

............................................................................... 6

PRESSER

....

.........................................................

....

............................................................ 6

BAR, ALSO,

....

.........

...................

OF

THE

...

5

6

16.ADJUSTMENT

17.ADJUSTMENT

18.TIMING

19

.ADJUSTMENT

20.ADJUSTMENT

21.REPLACEMENT

22.TO

OFTHE

RE-ENGAGE

PARTS CATAL

A.ARM BED

B.

ARM SHAFT MECHANISM ..............................................................

C.PRESSER

.S

TITCH REGULATOR AND

D

E.HOOK SADDLE MECHANISM(GC24698-6)··

F.HOOK SADDLE MECHANISM(GC24698-SL)·········· ..

GHOOK

H. THREAD

SADDLE MECHANISM(G·C24698-SR) ............................................................................................... 29

TENSION REGULATOR MECHANISM ..........

OF

OF

VffiRATINGAND LIFTING PRESSER

OF

OFTHE

OF

THE

OG

AA'D IT'S

FOOT

MECHANISM .......................

BOBBIN CASE OPENER ................................................................................................. 7

THE

HEIGHT

THE

CLEARANCE

THREAD

THE

CONNECTION BELT ........................................................................................ 10

SAFETY CLUT

ACCESSORIES·····-·· ...................................................................................................... 12

OF

CONTROLLER

FEED

ROCKING MECHANISM ................................................................. 20

THE

PRESSER

FOR

THE

CH

.....................................................................................................

...

........................

......................

FEET

VIBRATING AND

SPRING ................................................................... 10

··

.. ····· ........................................................................... 26

..................................................................... 8

FEET

............................................................... 8

LIFTING

....

............................................................. 14

......

................................................................ 17

...

....................

......

.......................................................

...

...................

PRESSER

,.

.............

...............

FEET· ... 9

11

...

........... 23

32

!.SPECIAL PARTS

J.SPECIAL PARTS F

K.ACCESSORIES······ ................................................................................................................................................ 38

FOR

GC24698-5L/5R······· .................................................................................................

OR

GC24698-6 ......................................

...

....................................................................

...

.......

.. 35

37

Page 3

l.OP

ERATING INSTRUCTIONS

HIGHL

EAD GC24698-5L, GC24698-5R, GC24698-6

SERIES MODEL

This

is

a guide to use

high speed for heavy-duty materials sewing machine with compound feed and walk i

under the best condition.

Pl

ease read this guide

of

H!GHLEAD GC24698-5L, GC24698-

thor

oughly so

that

you may expect good

5R,

GC24698-6 series model long-arm

perform

Specifications

SING

LE

NEEDLE

GC

24698-5LI5R

MAX.

SPEED

MAX.

STITCI-

PRESSER FOO

CLEAI?i\~CE

N

EEDL

E

13013BIN

W

ORKING

13ED

DIMENSION

!'OWER

M

OTOR PULLE

(s.p.m.) 1,

1 (

rnm

)

S

IZE

SPACE

ll

EQU 1

T !land L

P

(mm)

(mm)

RED

Y

DIA

cda

(W)

.

iJ

l 1

(mm

)

.i

ter

ft

(rnm)

er (mm

)

DY

<I>

70

I

~>

60

(50 I 60H

200

10

20

28

X 3

(sanda

508 X 15

846

X

75

0\V SERVO MOTOR

z)

rd

No.

230

<I>

ng

foot feeding mechanism,

ance.

T

WO

NEEDLE

GC24698

24-26)

-6

3

70

I

cl>

60

(50 I 60

Hz)

USE

FOR

Tent, Sailcloth, Rubberized,

Lea

ther, Etc.

2.SETTING UP

Setting up the machine on the table after removed two pieces

supporting bolts ( A ) under the bed.

3.CAUTION

THE

MACHINE CFig.l

BEFORE

Fabr

ics, Heavy Synthetic, Heavy Upholstery Materials, Fiber Plate,

)

STARTING

THE

OPERATION

I)

Do not operate the machine, even

idling, unless it has been properly oiled

reservoir required lubrication.

During pract i

2)

The

niachine pulley turns toward to the operator.

3) Do not operate the machine at maximum.speed

ce

period.

th

~

if

only for testing and

at

every

spot

n

ew

machine should be oiled more frequ ency.

of

or

and

1,200 s.p.m., for starting

of

± -

ope

ration.

To

take practi

Fig. I

ce

operati.on at speed

materials in case by case.

of700

s.p.m., but operating speed are to

be

changed to

- 1

proper

conditionsuitable for the

Page 4

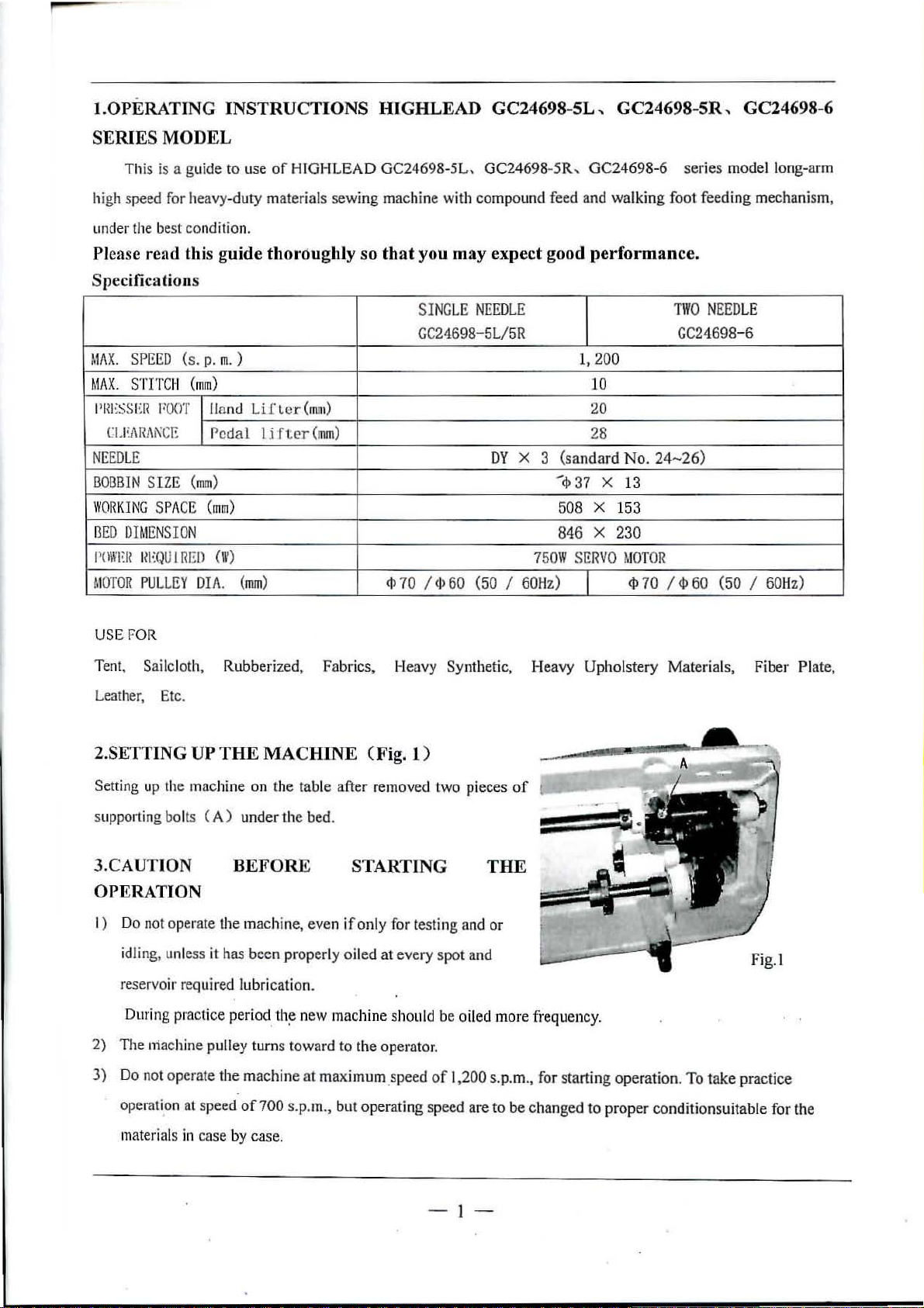

4.0ILING ·(Figs.

2,

3,

4, 5&6 )

I) Oil should be applied

Fig.2

at

each

ofthe

place designated by arrows in Figs.

2,

Fig.3

3,

4,

5&6

Fig.4

Fig.6

2) When

in

continuous use,

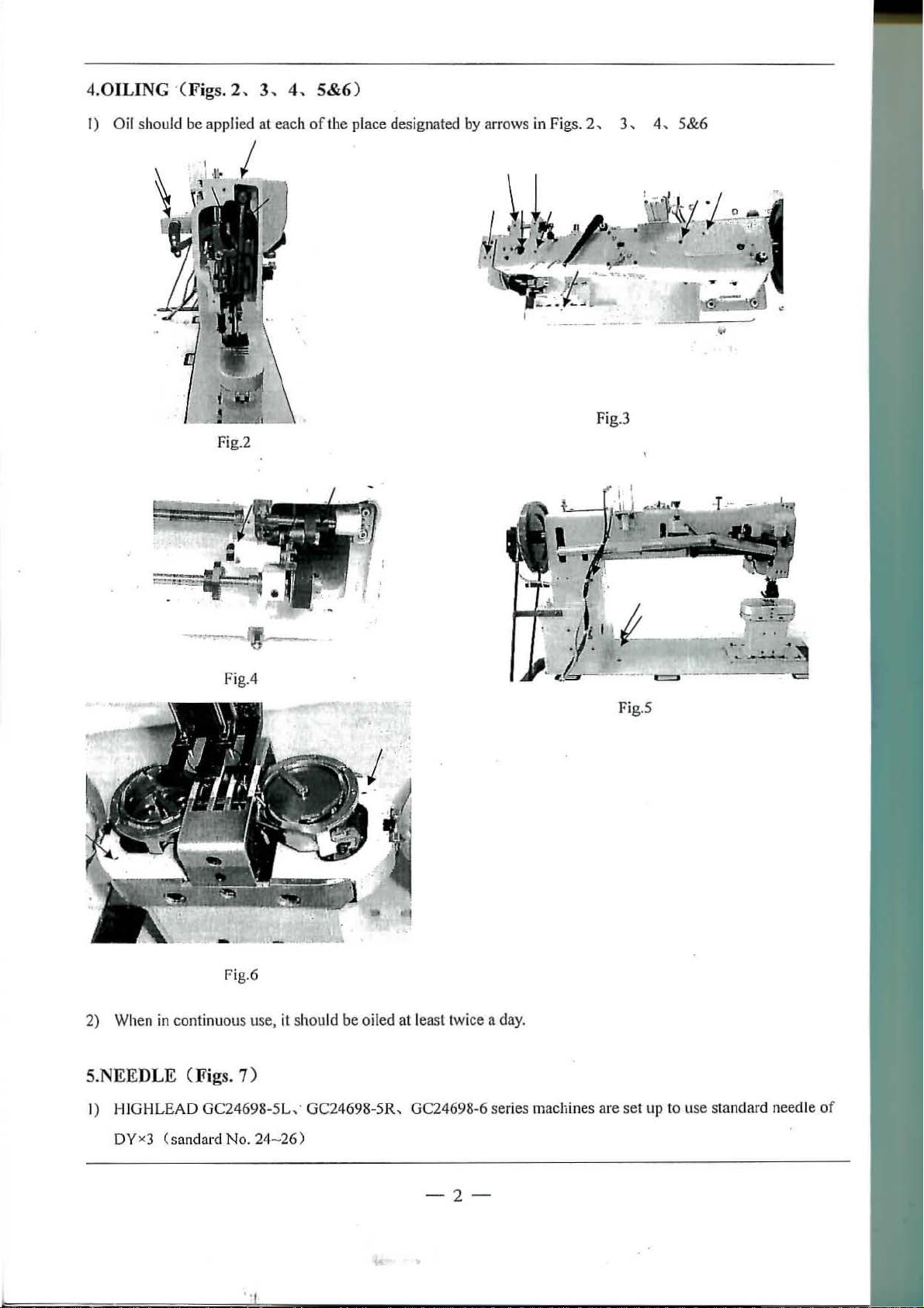

S.NEEDLE (Figs. 7)

it

should be oiled

at

least twice a day.

Fig.S

c=:~~

-·--

..

.

I • •

.-

~

..~

~

I)

HIGHLEAD

DYxJ

GC24698-5L,

(sandard No. 24-

· GC24698-

26)

5R,

GC24698-6

ser

ies machines are

-2-

set

up to use standard needle

of

Page 5

. . ..

.

.·#

~

"'

· '

.:

·

..

...

.-

--

~:-

2) The size

materials.

3)

To

toward you until the needle bar moves up to its highest

point, put the needle

it

outside.

4) Tighten the needle

of

needle to be used shou

insert the needle, turn the machine pulley over

up

into the needle b3r as deeply as

will go, with the long groove

set

screw secu;·ely.

ld

be' determined

of

the needle faced

by

the size

of

thread, type and thickn·ess

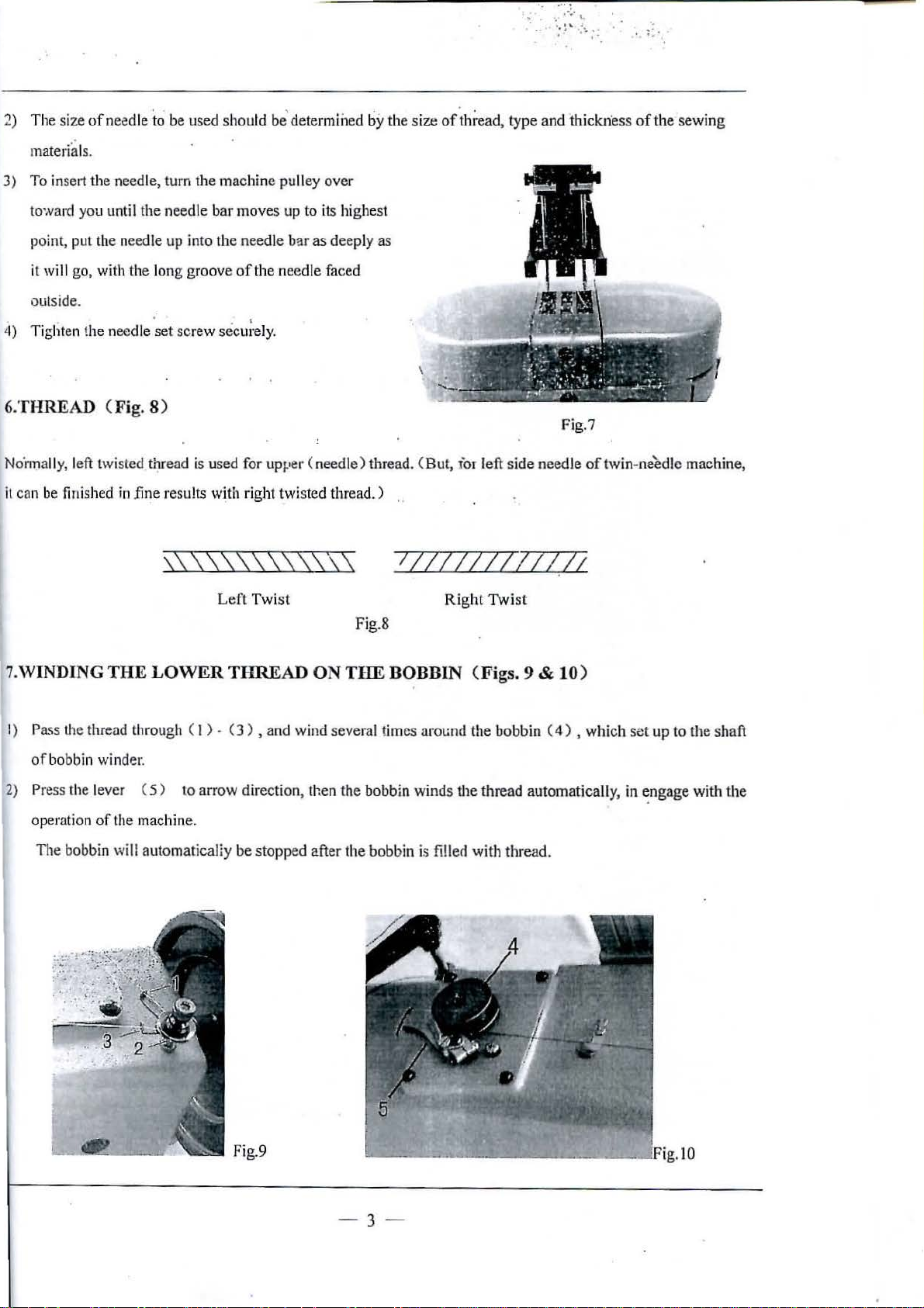

6.THREAD (Fig. 8)

Fig.7

No'rmally, left twisted thread is used for upper (needle) thread. (But, for left side needle

it

can be finished

in

fine results w!th right twisted thread.) .

\\\\\\\\\\\\\

1//IIZZZIZ(I;

of

the

sewing

of twin-ne'ectlc machine,

Left

Twist

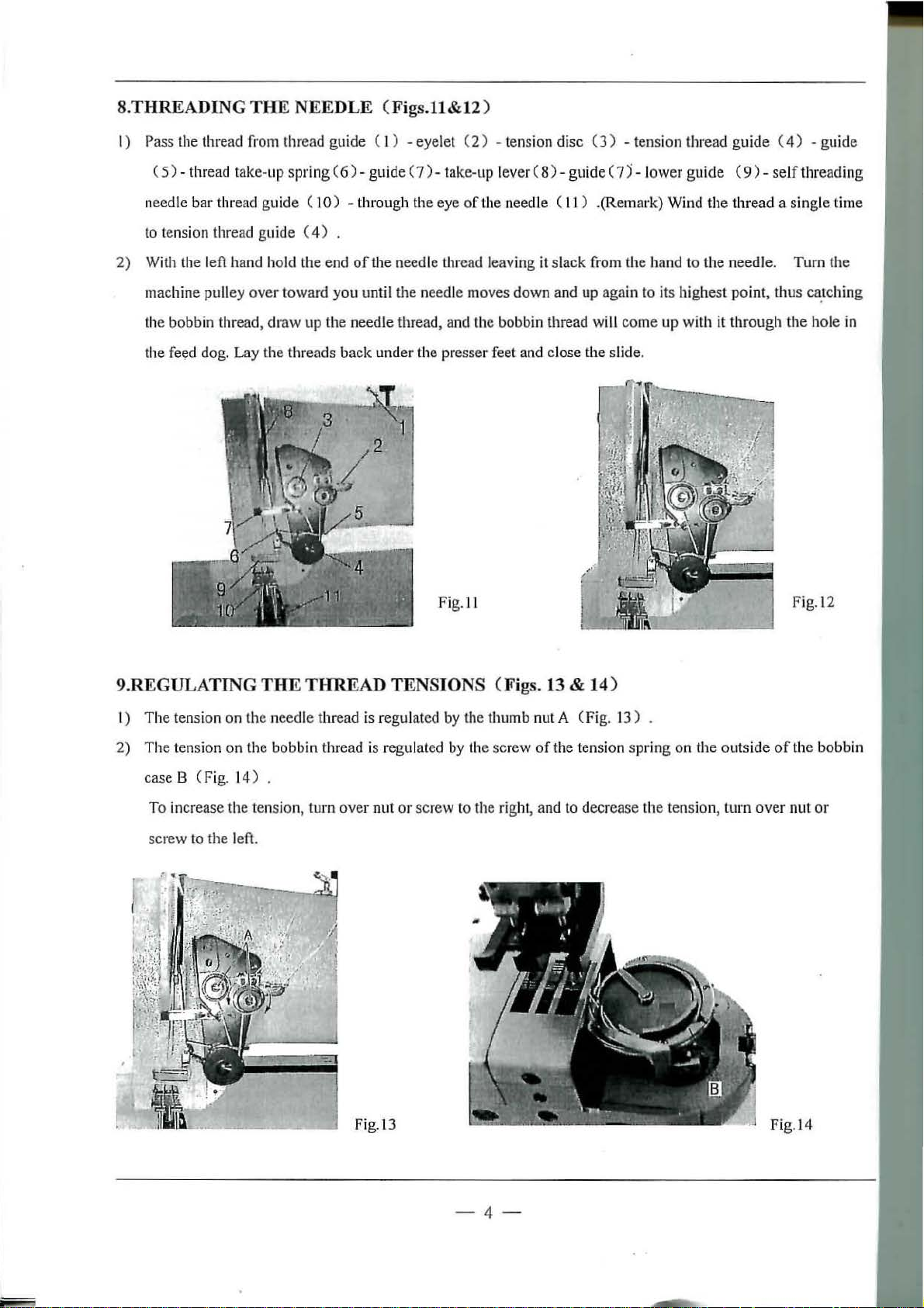

7.WINDING THE LOWER

I)

Pass the thread through ( I ) - ( 3 ) , and wind several times

of

bobbin winder.

2)

Press the lever (

operation

TI1e

of

bobbin will automaticaliy

5)

the machine.

THREAD

to arrow direction, then the bobbin winds the thread automaticall

be

stopped after the bobbin is fillecl with thread.

ON THE BOBBIN (Figs. 9 & 10)

Fig.8

Right

Twist

aro~..;nd

the bobbin (

4)

, which set

y,

in

up

to the shaft

~ngage

with the

Fig.9

-3

-

.10

Page 6

B.

THREADING

THE

NEEDLE (Figs.11&12 )

I) Pass the thread from thread guide ( I ) - eyelet (

( 5)- thread take- up spri

need le

to tension thread guide (

2) Wi

machine

the bobbin thread,

the feed dog. Lay

bar

thread guide ( 1

th

the left hand hold

pulley

over

the

ng

(

6)-

gu

ide (

7)-

take-up lever (

0)

- thro

ug

h the

eye

4)

.

the

end

of

the needle U1read leaving it

toward you until

draw

up the needle thread, and the bobbin thread will

threads

back

the

needle moves down and up again to its high

under the presser feet and close the slide.

-

~

1

2)

- tension disc (

8)-

of the needle (

slack

3)

- tension thread

guide (

7)-

l

ower guide

11

) .(Remark) Wind

from

the

hand

come

guide

(

9)-

se

the

thr

ead a sing

to

the

needle. Turn the

est

point, U

up with it through

(

4)

- guide

lf threading

le time

ms ca.rching

the

hole in

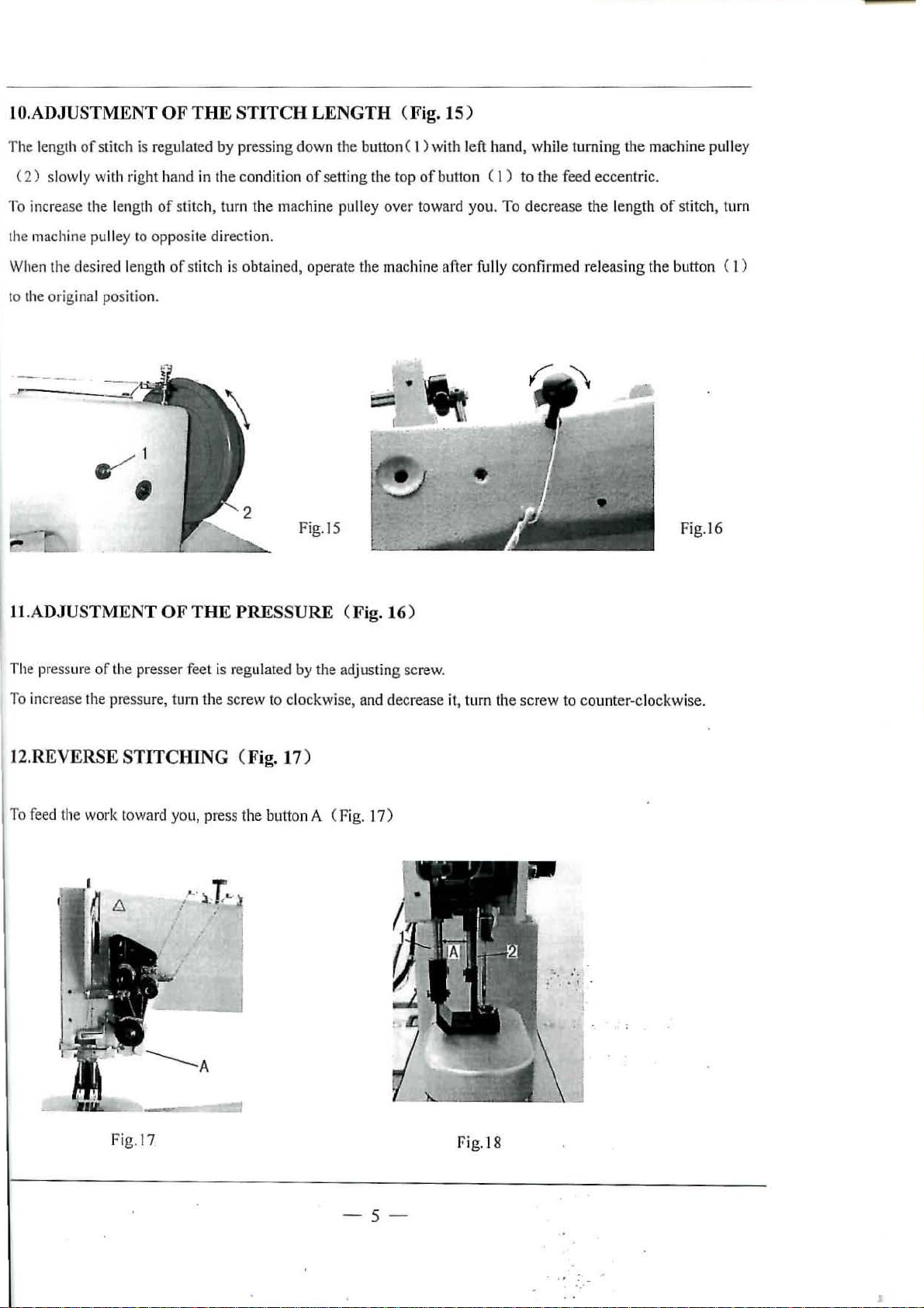

9.REGULATING

I)

The

tension on the needle thread is

2)

The

tension on the bobbin thread is regulated by the screw

case B ( Fig. 1

To increase the tension, turn

screw to the left.

THE

4)

Fig.

ll

THREAD TENSIONS (Figs. 13 & 14 )

reg

ulated by the thumb nut A

.

over out

or

screw to the right, and

(Fig.

13)

of

the tension spring on the

to

decr

ease the tension, turn

outs

ide

over

Fig.l2

of

the bobbin

nut

or

Fig

.l3

-4-

Fi

g.l4

Page 7

lO.ADJUSTMENT OF

Th

e length of stitch is re

(

2)

slow

ly with ri

gulated

ght

hand in the cond ition

THE

STITCH LENGTH (Fig.

by

pressing

down

the

of

setting the top

15)

button ( I ) with l

of

button ( 1 )

eft

hand,

while

to

the

turning

feed

ecce

the

machine pull

ntric.

ey

To incre

the machine pu

When the desired l

to the original position.

ase

the l

ll

~

ength of

ey to opp

ength of

1

stitc

h, turn the

osite direct

stitch

is

ion.

obta

machine

ined,

operate

pulley

over tow

the machine

•

Fig.

IS

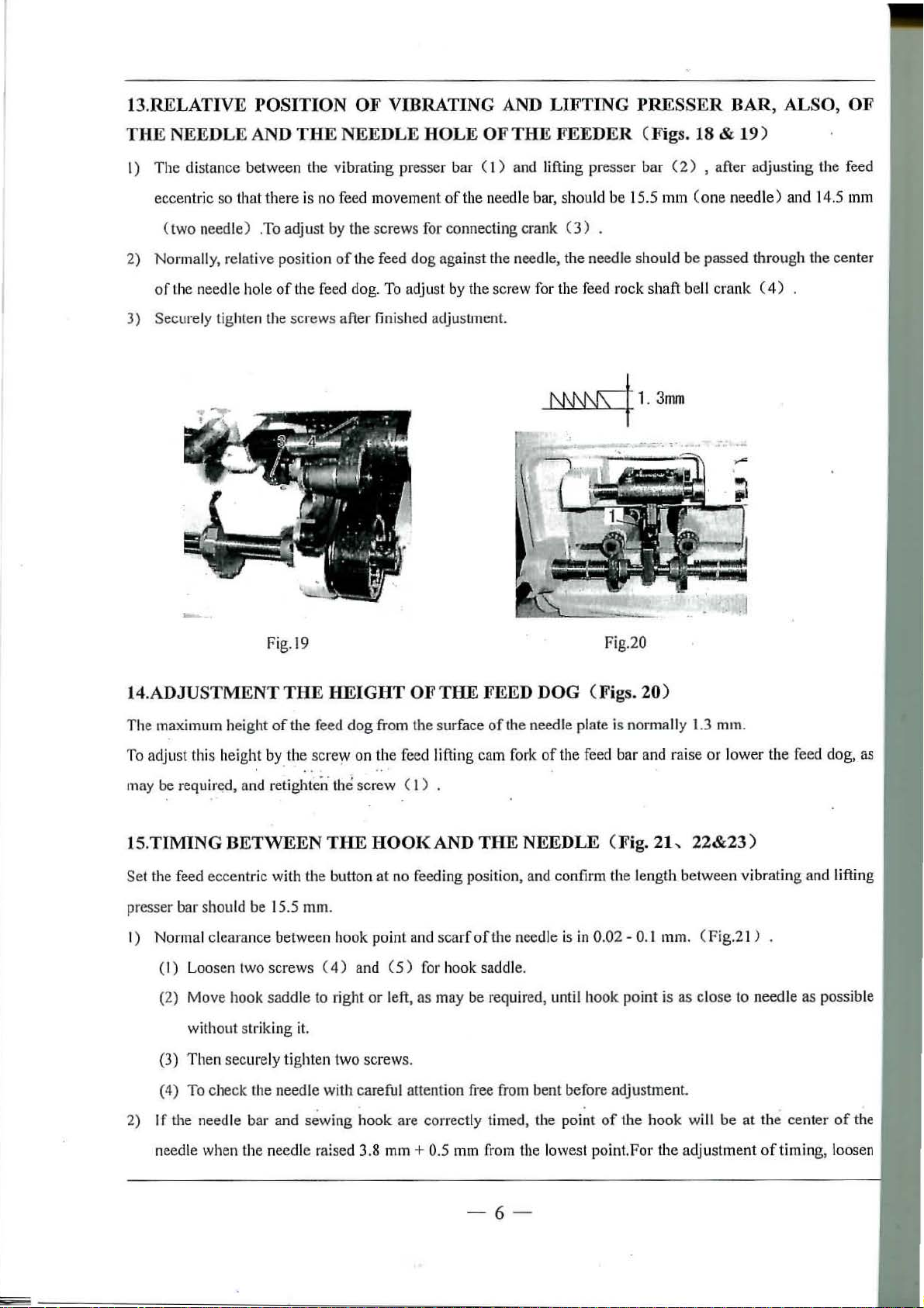

ll.ADJUSTMENT OF THE PRESSURE (Fig.16)

ard you.

after fully con

To

decrease

firmed r

the l

ength of stitch, turn

eleasi

ng the

button

Fig

( I )

.l6

The pressure

To increase rhe pressure, tum the

12.REVERSE

To feed the work t

of

the

presser

STITCHING (

owa

rd

you,

fee

t is regulat

press t

..

...

.

~

r

ed

by

screw

to

clockwise, and

Fig.17

he

button A (Fig. 17 )

..

j

the

adjusting screw.

)

decrease

it,

turn the

screw

to coun

ter-cl

ockwise.

Fig.l7

-5

-

f.'ig

.18

~

. . . -

·.·

J

Page 8

13.RELATIVE POSITION OF VIDRATING AND LIFTING PRESSER BAR, ALSO, OF

THE NEEDLE AND THE NEEDLE HOLE OF THE FEEDER (Figs. 18 & 19)

l)

The

distance between the vibrating presser

ecce

ntric

so

th at

there

is no feed movement

(two

needle ) .To adjust by

2)

Normally, relative position

of

Lh

e needle hole

3)

Securely tighten the screws after finished adjustment.

of

the feed

the

screws for connecting crank

of

the feed

dog

. To adjust by the screw for the feed rock shaft be

bar

( 1) and lifting presser

of

the n

eed

le bar, should be 15.5 mm

(3)

dog

against the needle, the needle should be passed through the center

bar

(2)

, after adjusting

(one

needle)

.

ll crank

and

(

4)

U1e

14.

feed

5 mm

~

Fig.l9

Fig.20

1

.3

14.ADJUSTMENT THE HEIGHT OF THE FEED DOG (Figs. 20)

Th

e maximum height

To adjust this height by the screw on

may be

requirc:<d

of

the feed

, and retighten· the screw ( l )

dog

• 0 • • •

from the surface

the

feed lifti

ng

cam fork

of

the

needle plate is normally 1.3 m

of

the feed

bar

and raise

IS.TIMING BETWEEN THE HOOK AND THE NEEDLE (Fig. 21

mm

m.

or lowe

-.

22&23)

r the feed dog, as

Set

the feed

presser

I)

Norma

(I)

(2) Move hook

(3) Then

(4) To check the needle with careful attention free from bent before adjustment.

eccent

ric with the button

bar

should be 15.5 mm.

l clearance between

Loosen two screws (

saddle

without

str

iking it.

sec

urely tighten

hook

4)

and

to

right

two screws.

at

no feeding position, and confirm the length

point

and

scarf

of

the needle is in 0.02 - 0.1 mm. ( Fig.21 ) .

(5)

for h

ooksaddle.

or

left, as may be required, until

. .

2)

If

the needle

needle when the n

bar

and

sewing

eedle

hook

are

cor

rectly timed, the point

raised 3.8 mm + 0.5 mm from the lowest point.For

- 6 -

hook

of

point

the

is

hook

the

between

as close

vibrat

to needle

will

be

at

adjustment

ing and lifting

as

possible

the

center

ofti

ming, loosen

of

the

Page 9

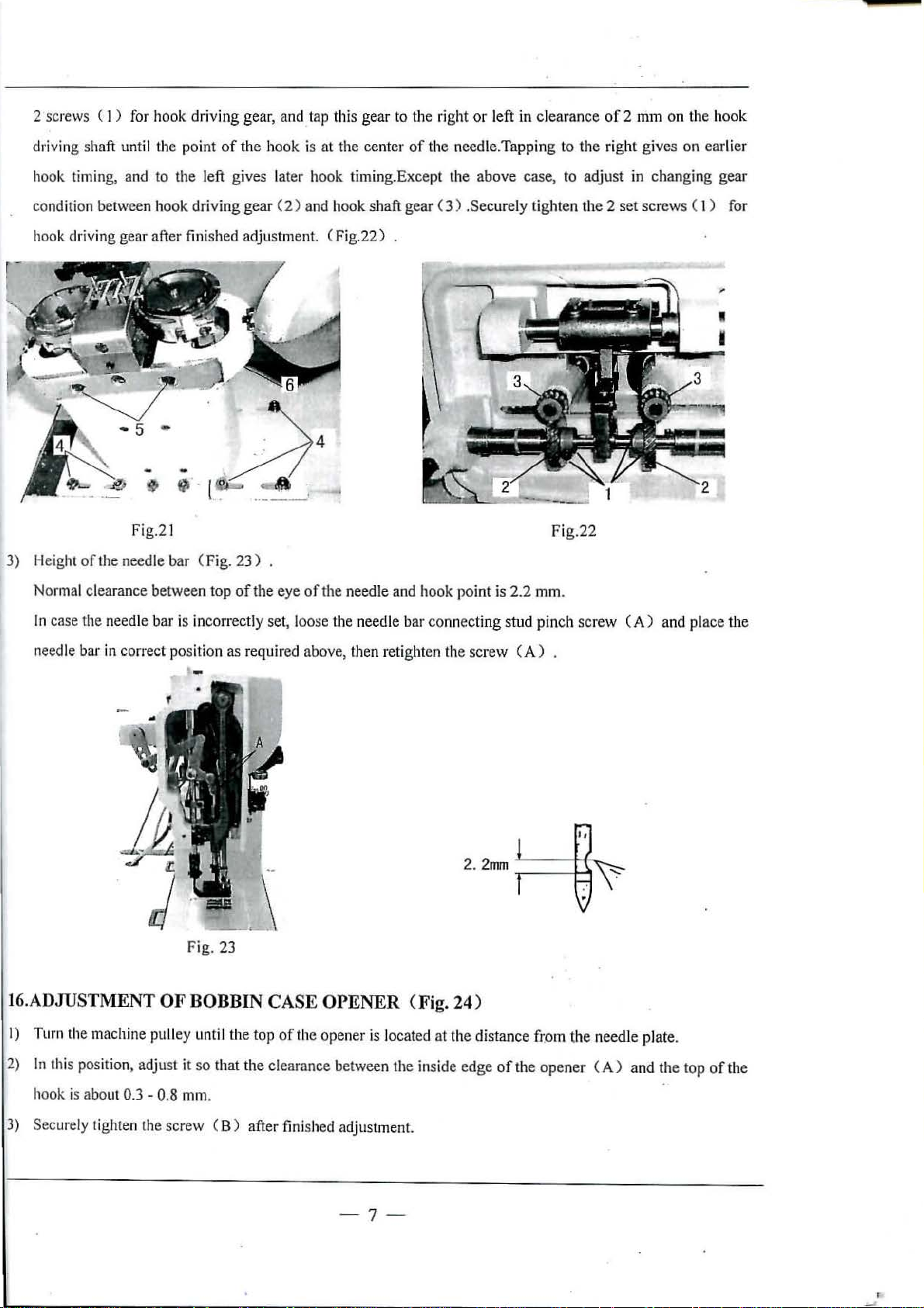

2 screws ( I ) for hook driving gear, and . tap this gear to the right

or

left in clearance

of

2 mm on the hook

driving shaft until the point

hook timing, and to the left gives later hook timing.Except the above case, to adjust in changing

condition between hook driving gear (

hook dr

3) Height

Normal clearance between top

ivin

g gear after finished adjustment. ( Fig.22)

Fig.21

of

the needle bar ( Fig.

of

the hook is at the center

2)

and hook shaft gear (

23)

of

the eye

of

the needle and hook point is

of

the needle.Tapping to the right gives on earlier

3)

.Securely tighten the 2

Fi

g.22

2.2

mm.

set

screws ( 1 ) for

gea

r

In

case the need le bar is incorrect

needle

bar

in

con·ect position

ly

set, loose the needle bar conn

as

required above, then retighten

ecti

th

e

sc

-

__

Fig. 23

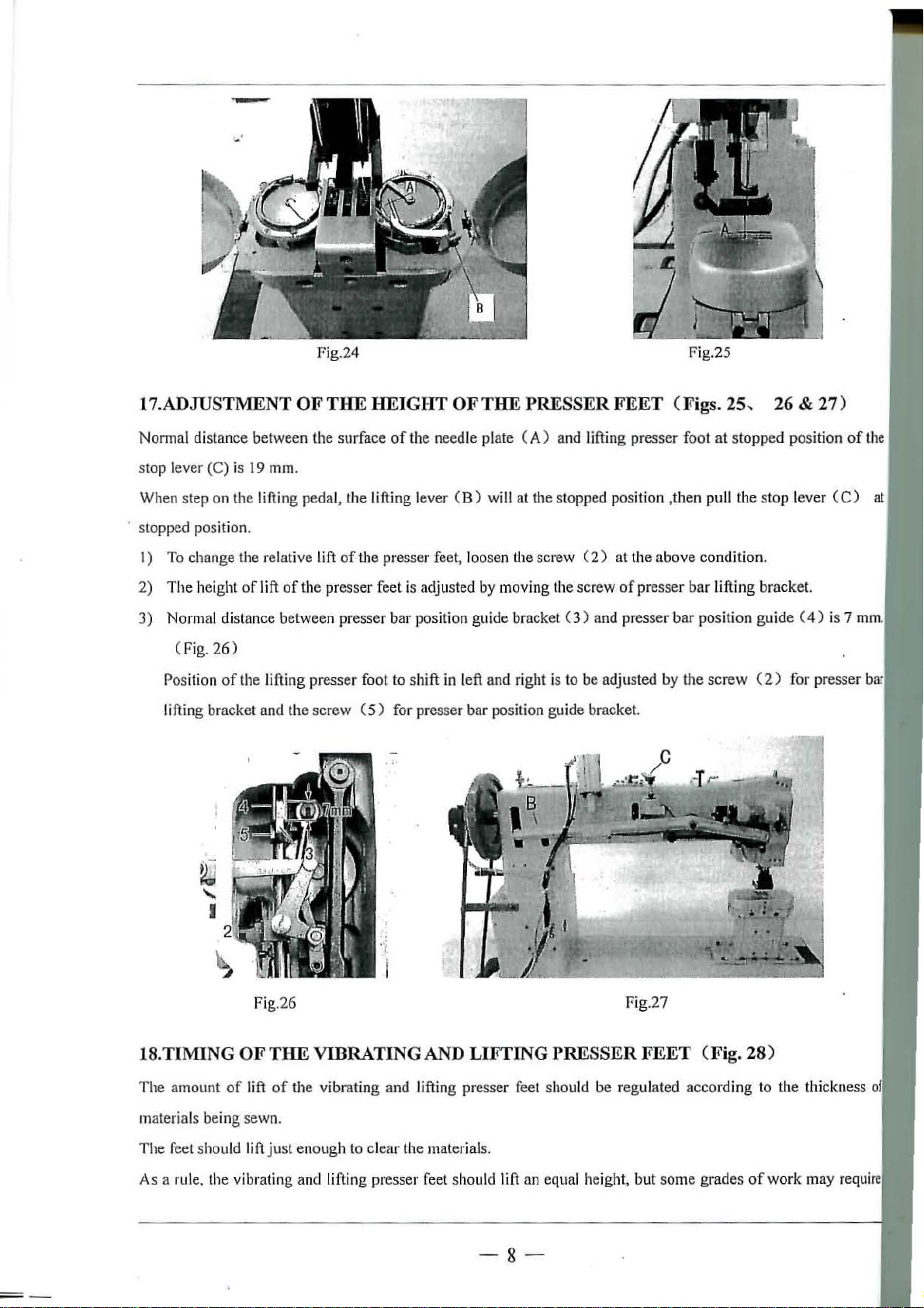

16.ADJUSTMENT OF BOBBIN CASE OPENER (Fig. 24 )

I) Turn the machine pulley unt

2)

In

this position, adjust it so that the clearance between the inside edge

il

the top

\

of

the opener is located

at

the distance

ng

stud pinch scr

rew

(A)

fr.om

of

the opener

ew

(A)

and place the

.

the

neecU

e plate.

(A)

and the top

of

the

hook is abo

3) Securely tighten the screw

ut

0.3 - 0.8 mm.

(B)

after finished adjustment.

-7-

Page 10

Fig.24 Fig.25

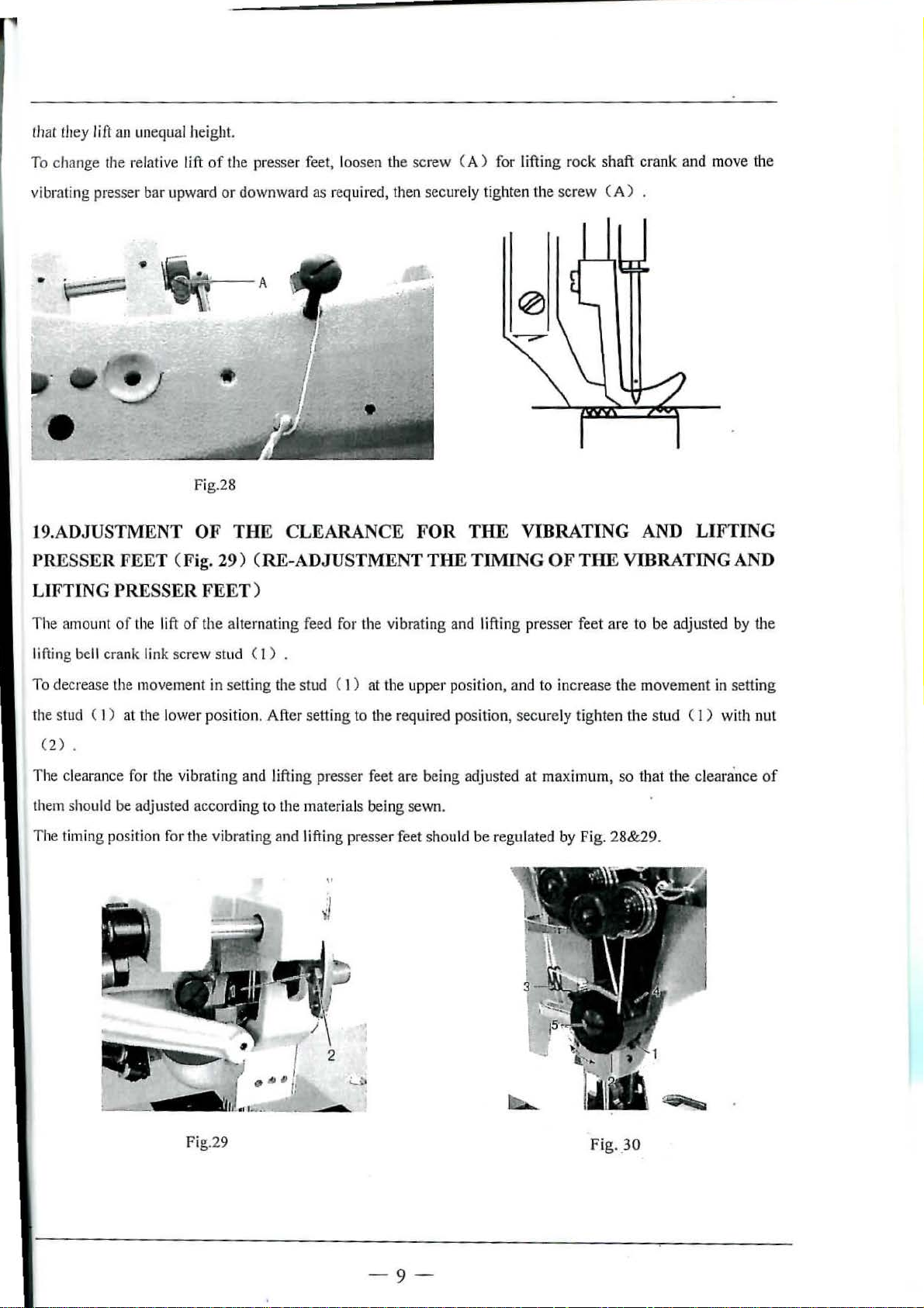

17.ADJUSTMENT OF THE HEIGHT OF THE PRESSER FEET (Figs. 25 , 26 & 27)

Normal distance between the surface

stop lever (C) is 19 mm.

When step on

stopped position.

I)

To change the relative

2)

The

the lifting pedal, the

height

of

lift

of

Lift

of

the presser feet is adj usted by moving the screw

3) Normal distance between presser bar position guide bracket

of

the needle plate ( A) and lifting presser

li

fti

ng

lever (

B)

will at the stopped position ,t

the presser feet, loosen the screw ( 2 )

C3)

and presser

foot

hen

at

the above condition.

of

presser bar lifting bracket.

bar

position

(Fig. 26)

Position of the lifting presser foot to shift in left and right is to be adjusted by the screw (

lifting bracket and the

screw

( 5 )

for

presser bar position guide bracke

t.

at stopped positio n

pull the

stop

guide

2)

lev

er

(4)

for presser

of

U

1e

(C)

at

is 7 mm.

Fig.26 Fig.

18

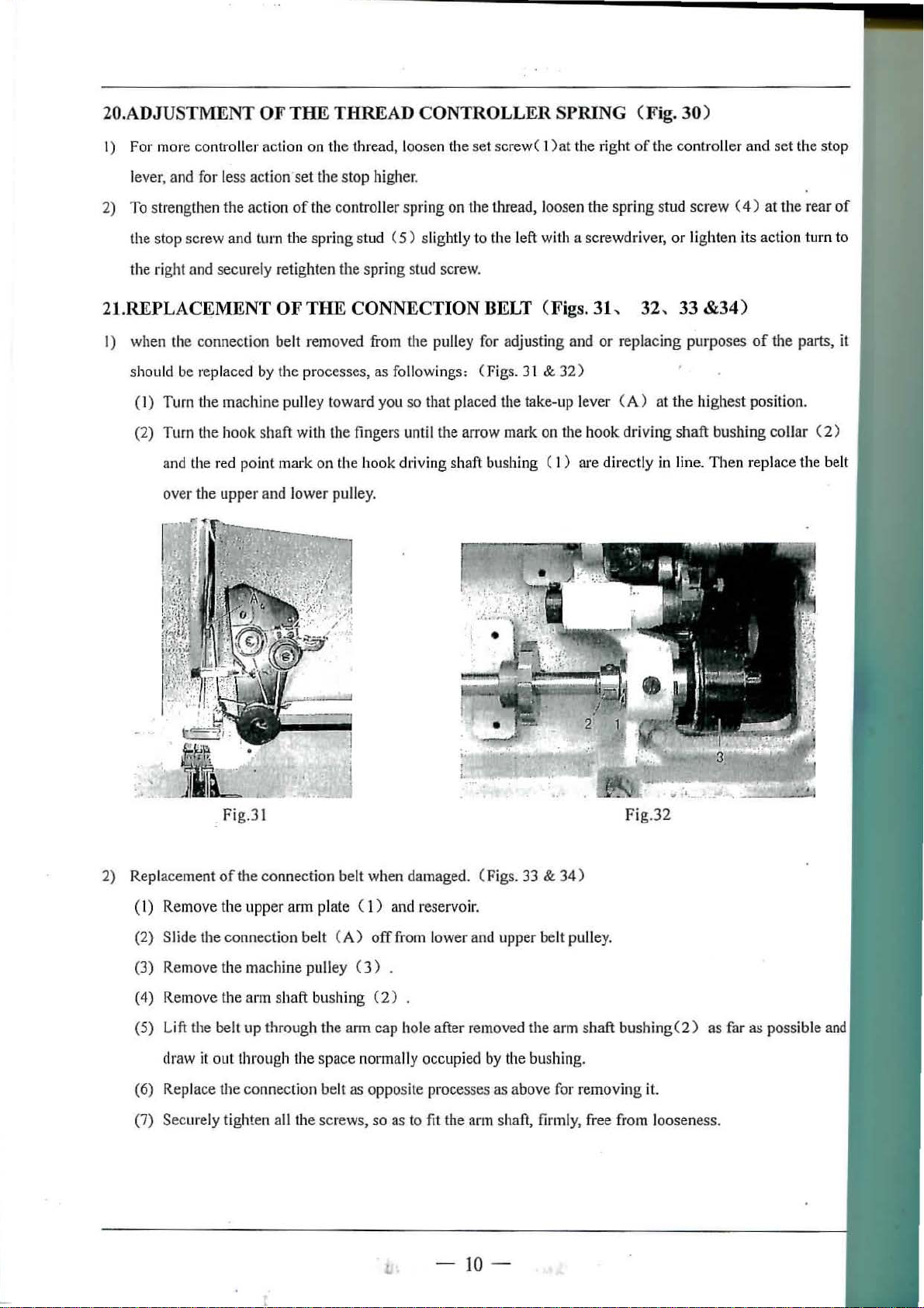

.TIMING OF THE VIBRATING AND LIFTING PRESSER FEET (Fig. 28)

The

amount

materials being

The

feet should lift

As a rule, the vibrating and lifting presser

of

lift

sew

just enou

of

the vibrating and lifting presser feet should be regul

n.

gh to clear the materials.

fe

el should lift an equa l height, but some grades

-8-

27

ated according to the thi ckness

of

work may

require

Page 11

that

they

/i

ft

an une

qual

heig

ht.

To change the relative lift

vibrating presser bar upward

of

•

Fig.28

19.ADJUSTMENT

PRE

SSE

R FEET (Fig. 29) (RE-ADJUSTMENT THE TIMING

LIFTING

PRESSER FEET)

OF

the presser feet, loosen the screw (A ) for lifting r

or

downward as required, then securely

tighten the screw

ock

shaft crank and move the

(A)

.

THE CLEARANCE FOR THE VIBRATING AND LIFTING

OF

THE VIBRATING AND

The amount

lifting be

To decrease the movement in setting the stud (

the stud (

(2)

The clearance for the vibrating and lifting presser feet are being adjusted

them should be adjusted according to the materials being sewn.

The timing position for the vibrating and lifti

of

the lift

ll

crank link screw stud ( 1) .

I ) at the l

.

of

the alternati ng feed for the vibrating and lifting presser feet are to be adjusted by the

ower

position. After setting to the required position, s

I )

at

the upp

ng

presser feet shou

er

position, and to increase the

ld

be regulated

,,

mov

ement in setti ng

ecur

ely tighten the stud ( l ) with nut

at

maximum,

by

Fig. 2

so

that

8&29

the clearan

.

ce

of

Fig

.29

-

9-

Fig._30

Page 12

20.ADJUSTMENT OF THE THREAD CONTROLLER SPRING (Fig. 30)

I) For more controller

lever, and for less

2) To strengthen the action

the stop screw and turn the

the right

and

action on

action·

secu

rely retighten

the

thread, loosen the set screw( 1

set

the

stop

of

the contro ller

spring

the

higher.

stud

spring

spr

ing

(5)

slightly

stud screw.

)at

the right

on the thread, loosen

to

the left with a screwdriver, or light

the

21.REPLACEMENT OF THE CONNECTION BELT (Figs. 31,

I)

when

the

connection belt removed from the pulley for adjusting and

should be replaced by

the

processes,

(1) Turn the machine pulley toward

(2) Turn the hook

and the red

over

the upper and lower pulley.

shaft

point

with the fingers until the arrow mark on the

mark

on the hook driving shaft bushing ( I )

as

followings: (Figs. 31 &

you

so

that plac

ed

the take-up l

or replacing

32)

ever (A)

book

are

directly in line.

of

spring

32,

drivi ng

the

controller

stud

33 &34)

purposes

at

the high

shaft

screw

bushing

Then

and

set

the stop

(

4)

at

the

en

its action turn to

of

the parts,

est

position.

collar

repl

ace

the belt

rear

(2)

of

it

Fig.31

2)

Replacement

( I) Remove

(2) Slide

(3) Remove the machine pulley (

(4) Remove the

(5)

Lift

draw it out through the space n

(6) Replace

(7)

Secmely

ofthe

connection belt when damaged. (Figs. 33 &

the

upper arm plate ( 1 ) and reservoir.

the

connection belt

ann

shaft bushing

the be

lt

up through the

the

connection belt

tighten all the screws,

(A)

offfrom

3)

(2)

ann

cap

ormally occupied by the bushing.

as

opposite processes

so

low

er

and upper belt pulley.

.

hole after removed the arm shaft bushin

as

above for r

as to

fit

the arm shaft, firmly, free fi·om looseness.

-10-

34)

emoving

Fig.32

it.

g(2)

as

far

as

possible

and

Page 13

1

2 3

'•

'

•

Fig.33 Fig.34

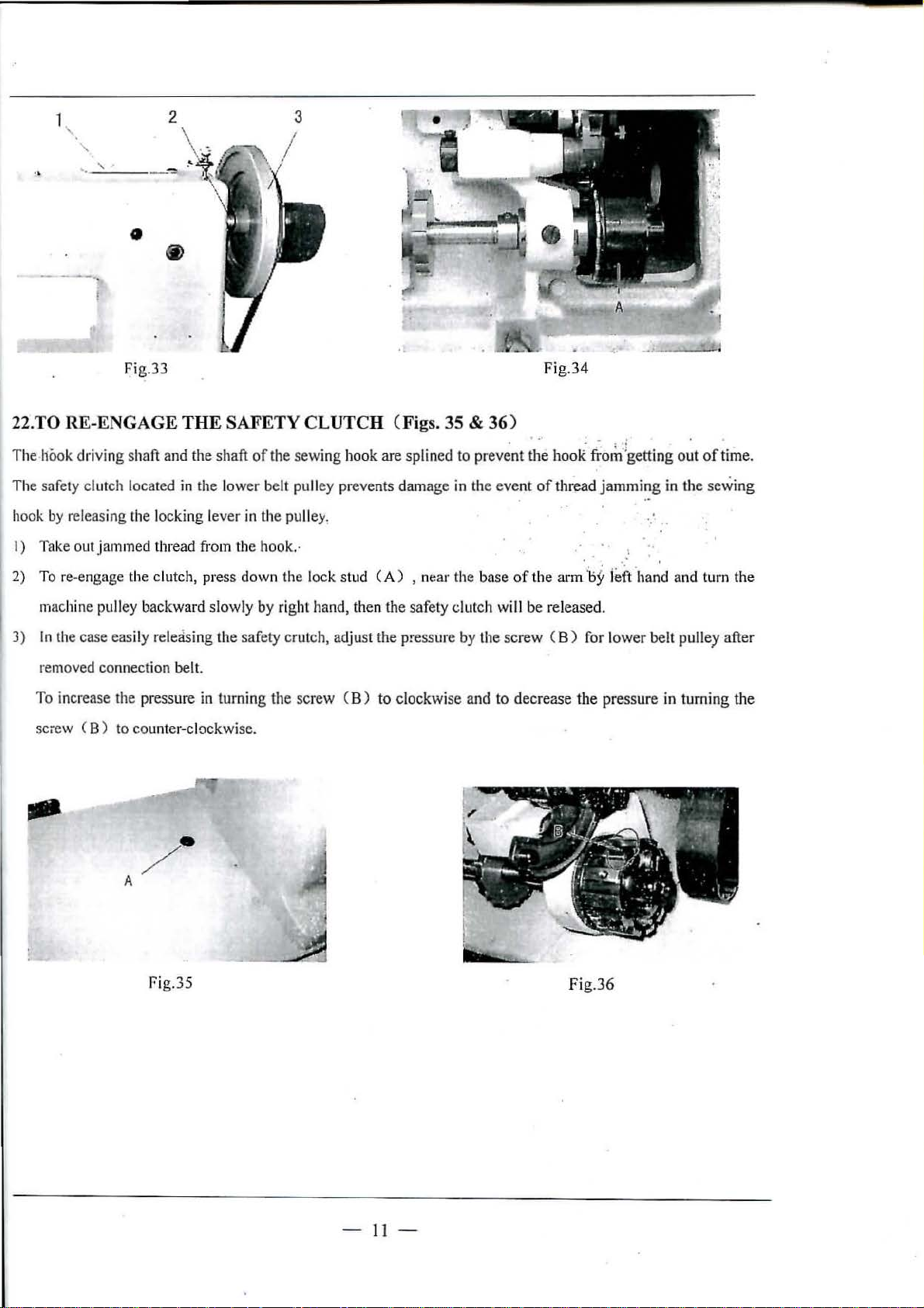

22.TO RE-ENGAGE THE SAFETY CLUTCH (Figs. 35 &

The

hook driving shaft and the shaft

The

safety clutch located in the low

hook

by

releasing the locking lever in the pulley,

Take out jammed thread from the hook.·

I)

2) To re-engage

machine pulley backward slowly by right hand, then the safe

3)

In

the case easily releasing the safety crutch, adjust

removed conn

To increase the pressure in turning the screw ( B) to clockwi

sciew

(B)

th

e clutch, press down the l

ect

ion belt.

to counter-clockwise.

of

the sewing hook are splined

er

belt pulley prevents damage in the

ock stud (A) , n

the pressure by the screw ( B ) for l

ear

ty

se

to

the ba

clutch wi

and to decrease

36)

prevent the bo

eve

nt

of

thread

se

of

the

arm

ll

be released.

oR

t'rorh :igetting

jamming

. . '

:

1:>~

l

eft

ower

the

pres

out

of

time.

in the sewing

band and turn the

belt pulley after

sure

in turning

the

rig.3s

-11-

Fig

.36

Page 14

A.

ARM

BED

AND

ITS

ACCESSORIES

39-

2

33

I

10

~

15

15

er1s~

~16

I)

38~

37'

-12

-

Page 15

A.ARM

Fig. Part s.

BED

Nos Nos

AOI

IIE924B710l Foo

lli\10062110

A02

A03

IIE913B800

117214HBOOL

A04

i\05

HE9L5B

B001

1\0

6 .

HE916B8001

1\07 11Al00C2170

1\0B

IIE

9L7B8001

1\09

HF

410B8001

1\10

IIE919D80

1\11

IIE

1\13

II

F4lll3800 1 Foot

i\14

IIE04808001

~IE020B800

A15

i\

16

IIE021B8001

Al7

1132

AlB

HE969B7101

i\19

116756138001

i\20

HA500C2070

i\21

HE045D8001 Washer

i\22

I

IE927B800 I Screw

i\23

HE928B8001

A21

HEI

i\25

IIE9

i\26

HE9

i\27

HE

i\28

~IE93208001

i\29

IIE933B

i\30

IIE9

i\31

11

73270800

i\32

IIE93708001

1\33

HE938B800I

i\34

IIE939B8001

i\35

IIE025C8001

A36

HG01B37101

A37

HD808B7101

i\38

11415050140

A39

H0313L8001

J\10

IIF41508001

i\41

1

1415060

J\42

IIEOlOMBOOI

A43

HF41

M4

J

12oomwo9o

M5

II

E956ll8001

01

9200800 I Foot

12li304

L1F8001

29138001

30B800

93Hl800

800

34ll800 L Arm

150

6B800l

AND

IT'S

t lift

er

Screw

I Collar(upper)

Screw

Foot

lifter

Colladlower)

Screw

Foot 1 i

Foot

fte1·

1 i

fter lift

Pin

lHter

lifter

Screw

L

Thread

guide

Nut

Washer

Thread

tension

Thread cutter

Screw

Lubricating oil

Set

screw

Oil

pad

L Oil wick

1

Vinly

tube

Oil

wick

L

Vinly

tube

oil

cap

I

Arm

oil

plug

Face

plate

Face

plate

Thread

guideOower)

Screw

Touch

switch assy.

1

ens1on1ng

Screw

Cylinder

Cylinder bracket

Screw

Screw

Cylinder

Ball

joint

oil

Supporting bolt

ACCESSORIES

Descrip

lifting

lifting

lifting

lifting

lifting

thumb

wnee

tion

lever latch

lever

lever latch shaft

ing lever

lever hinge stud

lever spring

mechanism

cap

screw

1 assy.

latc

hand

h spring

....l 0:::

<.0

1.(}

I

co

en

<.0

c-1

""'

u

c.:>

le 1

I I

co co

en

<.0

('.)

""'

u u

c.:> c.:>

1

3 3 3

1 1

1

1 1 l

1 1 1

1 1 1

1 1 1 S

1 l 1

1 1 1

1

l

1 1 1

1 1

1 1 1

1

1

1 1

1 1

1 1 1

I

1

2

2

1 1

1

1 1 1 SM3/16

1 1 1

1 L

1 1

1 1

1 1

1 1

l 1 l

1

1 l

1 1 1

l 1 1

1 L 1

1 1 1

2

2 2

1 1 1

l l 1

2 2 2

1

1 1

1 L 1

4 4

2

2 2 S

1 1

5

5 5

3

3 3

1.(}

en

<.0

N

""'

1

SMll/64

(40) X 6.

SM11/64(40) X4.

Ml/8(44)

X4. 5

1

1

SM17

/64(24) X 8

2

SM?/32(32)

2

1

1

2 SM9/64 (40) X 8

(28) X 6.

SMl/8

(44)

1

1

1

1

X 7

1

SM13/64

SMl/8

SDA32X50

4

1

ML7/

(32)

(40) X 3.

-B

64(24)

No

X 7

X8

tes

5

5

5

3

-1

3-

.

..

Page 16

B.ARM

SHAFT

MECHANISM

1

- 14 -

Page 17

B.

ARM

SHAFT

MECHANISM

Fig.

Nos

001

002

130:3

llOiJ

1305

1306

B07 IIE

008

009

010 IIE910C800

811

013

014 1131

13

1316

017

IllS I lE

13

020

13

1322

1323

1324

025

13

13

1328

B29

Parts. a>

Nos

HP40

4C8001 1\

HE

905C8001 Thread

II

E906

C800 1 Th

HE907C800

IIE020C800

I lA L00

1321

l Oil

I Set

50

908C800 1 Th

f

ii!

035C8001

HE909C

8001

1 Needle

IIA100C2070

IIA100C2060

OOC207

0

15

IIE041C8001

llfl0139J001

IIE9IIC800

19

IIE912C8001

O

1 Set

11

CSCO I Washer

IIE010G8001

21

I~

EO

14C800

1 Oil

IIE020C800l

HE914C8001

HE023C800l

HE916C8001

26

HE014C8001

27

H

E020C8C01

I

!E939G8001

H6623C8001

1331 HE026C8001

1332

ll3205C0G61

13

33 HE006

634

8:.15

B36

037

1338

1339 flfll

BiJO

041

1342 IIE007C8\l0

1343

0114 114l07

1345

D8001

I

~Eo:l0C8001

IIE

028C80

0l

HE9L7C800

1

113205]0662

UF405C8001

OOC2

020

IIF'407C8001 Machine pulley

HE038E8001

I

HE92IC800l

00672

IJE922C8001

tO

13

I

l

co

0)

tO

'<t' '<t'

c:-:1

(.)

c.=> c.=>

I 1 l

rm sh

aft

Descrip

tio

n

co

tO

'<t'

c:-:1

g

take-up lever I 1 l

read take-up lever hinge stud 1 1 I

wick

screw

Rub

ber plug

read take-up

slide

block 1 l 1

Oil wick

Needle

Pos

Set

Needle bar c

Oil

ition

screw

wick

l.lar

connecting

l.lar

crank 1 1 1

lin

k 1

screw

onn

ecting li

nk

stud 1 1

Set screw L

screw

I

1 1

2 2

2

2 2 2

l 1

1 1

L

1 1

1 1

1 1 1

1 1 S

1

1 1

l 1 1

1\rm

shaft

bushing

Oil

wicl<

pad

Set

screw

P

eed dri

Set

ving eccen

screw

Arrn shaft cente1·

Oil

pad

Set screw

Pulley

Screw

Oelt pulley(

Spring flange

Sot

screw

Checl< screw

Position

screw

Connection belt

Bearing

Ann

sh

aft bu.shing (right)

Screw

Set screw

Machine pull

l

~ok

dr iving shaft l

Spring

Shaft l

JUs

hing

uppe

ey

(left)

tric

busf.ing

r)

adjusti

ock stud.

ng

scr

ew

l l 1

I 1 1

1 1

]

1

1

1

2 2

I

1

1 1

l

1 1

! 1

2 2 2

L 1 1

2 2

1 l 1

1

1 l

l

1

1

l 1

I 1

]

1

2 2

1

1 1

2 2

1

1 1

1 1 1

! 1

1

l 1

g::

ln

l

co

0">

tO

N

(.)

1

1

1

M1

3~117/64

1

SM17/64(24)

1

1

2

1

1

1

M1X8

2

L

1

1

SMt5/6

2

2

l

Note

7/64 (24) X 6.

(2

4} X 3.

X20

4(28}

s

5

5

-1

5 -

.

..

Page 18

B.

ARM

SH

AFT MEC

Pig.

Parts.

Nos Nos

646

li6010l6100

HE9

1347

ll48

049

650

851

852

[!53

54

6

B55

B56

[!57

B58

B59

B60

23C8001

11E035G8001

IIE034G8001

HE9

24C800

11320

5C066

HF408

C80

HE022G8001 Screw

l

iE925C8001 Long

HE926C8001

HE927C8001

HE0281!8001

H

E028G8001

IIE029G800l

1!6010

1205

B61 HE027G8001

1362

H

E026G800l

11

B63

E031C8001

HAN1SM

Descrip

stud

Hook

driving

shaft

Set screw

Pos

iti

on

screw

Be

1

l t pulley(

lowe

L pring flange

01

Lower

shaft

lever

for

Set

scre

w

Pin

Set screw 2

Shor

t lever for pulley

0 pin

tio

n

loci<

ratchet. 1

r) 1 1

pulley 1 1

....:I

(0

Ln

I

00

O'l

(0

..qt

C':l

u

t.:>

I I

00 00

O'l

(0

'Q' 'Q'

C':l

u u

t.:> t.:>

1 1

1

1 1

1 1 1

.2

2

l 1

1 1 1

2

1 l

e:5

O'l

(0

C':l

1

1

2

1

2

1

SM5/32

Notes

(40) X 3.

6

-

16

-

Page 19

C.PRESSER

4

I

lj

FOOT

MECHANISM

32

28 \ .

'0

~

-33

51

10

~

64

57_n

~

55"-~b

@~

53

67

\

68

. I 54

c.

56-

-17

'f;9

f&;

-

Page 20

C.

PRE

SSER

Fig,. Parts.

N

os

No

s

FOOT

MECHANISM

Description

<0

I

00

en

<0

'<!'

C'-.1

u

<:.:>

.....) p::

In

'f

I

00 00

en en

<0

<0

'<!' '<!'

~

(.!)

~

No

tes

COl

HE90408001

C02

HE905

08001

C03

HE035C8001

CG4

llE009G8001

111::90708001

C05

C06

IIE041C8001

C07 JiE119E8001

II

09

IO

ll

E90808001

HE9

0908001

Hl!910D80P

IIE9ll08001

l

cos

C

C

C

Cl2 HE022K800l

Cl3

HE912D8001

HE0060800l

C14

HE0070

HE0

8001

0608001

C15

Cl6

C17 HE913D8001

CIS

HE00

908001

Cl9

C20

HE914D800

H3107G0661

1

C21 HE91508001

C22

C23

HE916D800

HE00706001

1 Set screw 1

C24 HE91808001

C25 HE919D8001

ILE

C26

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C40

C41

C42

C43

920D8001

HE92108001 reed lifti

HE024D8001

HE02508001

IIE035C8001

H3112F0662

HE922D8001

IIE0

38E8001

HE

92308001

HE9211D8001

11

3l07G0662

HE92508001

11E92608001

HE927D8001

HE035C8001

IIE92808001

H

E92908001

H

l'4040710

1 N

Needle

Needle

Oil

bar guide bracket

bar guide bracket stud

wick

1 1

1

Set screw 1

Need

le b

ar

connection stud 1 1

Oi 1 wick

Set screw

Needle

bar(3/4

N)

1

2 2 2

1

Needle 2 1

Needle

set

screw

2

Position bracket l

Screw 1

Presser bar position guide

Set screw

Presser bar bushing

(uppc1·}

l

1 1

1 1

Set screw 2 2

Presser bar pos

Set scr

Presser

ew

bar l

itio

ifting

n guide lev

er

bracket 1

Set screw 1

P1·esser bar spring bracket 1 1

Presser bar bushing(lower)

Presser bar 1

Lifti

ng presser foot(3/4H)

Set

scr

ew

ng

rock

shaft

Lifting

Screw

Oil

Nut

stud

wick

roclt

shaft

bushing 2 2 2

1 1

1 1

1

Lifting eccentric

Position sc

rew

Lifting eccentric connection

Lifti

ng

bell

crank 1

Set

scr

ew

Lifting

Link

Vibrating

Oil

Vibrating pres

Set

eed

bell

crank link

pr!l"sser

wick

ser

sc1·ew

le

bar vibratin cra

1

bar 1

1 1

foot(3/4H) l

1 1

nk shaft

1

1 1

1

1

1

1

1

1

.l

SM5/32 (40)

OY

X3

SM3/l6(32)

SMll/64(32) X9

1

1

2

1

1

1

1

SMO.

1339(36) X 16.

1

1

1

1

1

SM1l/64

1

1

1

1

11/64(40) X7. 5

1

#25

(40)

(32)

(40)

X 9

X5.

5

X6. 5

X 13.5

7

-18

Page 21

C.PRESSER

Fig.

Parts.

FOOT

Nos Nos

MECHANISM

Descriptio

n

~

co

m

<0

..,.

N

u

<.:1

.....l

In In

I

co

co

m

N N

u u

*

<.:1

0::

I

m

<0

..,.

<.:1

Notes

113100r2270

C44

HE027E8001

C15

C46

HE0

28E800

1 Set

C4

7 IIE933

C18

D8001

IIE038E800

1

C49

cso

HE035C8001

C5l

HE

935D8001

C52 HE93608001

IIE937D8001

C53

C54

111!93808001

IIE926E8001

C55

IIE0

38E800

C56

C57

~

W20

C58

HF'304D8001

C59

H£93908001 Vinyl

I

IF20908001

C60

C61

HE044

C62

IIE940D8001

C63

IIE94108001

1 Stop

7D8001

J8001 Washe

C64 HD611B8001

J-1007009100

C65

C66 II

C67

C68 IIY

D71

114310

1101800

2F800

400

l

40

1

C69 HY10D9800l

C70

C71

11431060

HY

1W0800 l Connecti

Needle

Screw

bar ro

ck frame

slide block

stud 1 1 1

screw

Needle bar vibrating crank(right) 1

Set screw

Co

nnection

Oil

wick

lin

k

Hinge screw

Nu

t

Peed conn

Feed conn

ecting

ecti

ng

screw stud

crank

(left)

Nut

screw

Vibrati

Lif

ng

presser foot

tin

g presser foot

tube

Vibrati

ng

presser bar(single needle)

r

Nut

Dushing

Bushing

St

op ring

Collar

Screw

Shaft

Cran

l<

Screw

ng

rod

1

1

1

l l 1

1 1

1 1 1

1 l 1

1 l 1

1 1

I 1

1

3 1 1

3 1 1

1 1

l 1

1

1

l 1

1 1 1

1 1

1 1

1 1 1

1 1 1

2

2 2

1 1 1

1

1 1

2 2

1

1

1

1 1 1

1

1

1

1 1

1

1 S

1 S

1

1

1

1

M17

MO.

S~

IO.

/64(24)

309

(20)

1339

(36) X 16.

7

-1

9-

Page 22

D.STITCH

REGULATOR

AND

FEED

ROCKING

MECHANISM

27

I

~

fiJ

I

26

-22

13

55

-

1~®

ll

' .

56

5

'i

I

j

18

r--19

-17

-

20-

Page 23

D.STITCH REGULATOR

Fi

g.

Parts.

No

Nos

s

AND

FEE

D RO

Description

CKING

MECHANIS

lO

I

00

0'>

<.0

'<11

C'l

u

~

M

-l

1.0

I I

00 00

0'> 0'>

lO lO

'<11 '<11

N

u

~ ~

13

~

N

otes

DOl

I

IE9

46E80

IJ

02 HE905E80

003

IIE906E8001

00

•1

HE907E800

005 IIE908E8001

II

006

00

D

009

010 H

Dll

01

013

014

E909E800

I

lA I

7

OS

OOB2l10

HE910

~IE911E800

E912E8

I

IE03

5G800

2

HE023C8001 Set scr

IIE913E8001

IIE914E800!

015 BE915

016

11601015100

017

HY10E68001

01

8

D19

0

20

7G0661

H3l0

HE035C800!

reed driving eccentric 1 1 1

01

Flan

01

S

et

1 Set

fo'ri

St

l

Set s

Pee

E80

01

Spring

1

00!

Coll

I Position sc

Feed

Spring

E8001

Bushing

Snap

Feed

Pin

Oil

021

22 11Y10E8800! l'ee

0

023

IIE920E80Dl

0211

112013]0065 Washer

025

IIE02211800!

026

IIE

02011800

027 IIE025B8

001

Feed

Screw

1 Oil

Screw

028 BE92IE8001 re

029

IIE922

E80

01

Set

O

:lO

IIE9

23E80

01

l'eecl

031 IIE131E8001 Nut

0

32 I IF104E8001

033

111!

033118

034

IIE034H800

0

35 IIE033

036

D37

0

38

039

040

04

1 I

042

043 IIE9

1 18

HE03411800i

IIE943E710

IIE928E800 1

IIE929E800

IIEOl2

E800

JE930E8001

IIE035C800!

26E800

Feed

00

1

reed d

1

Set

001

Feed

S

1

Feed

reed

l Collar

J Set

Binge

O

1

Nut

et

il

ge

screw

scr

ew

cti

on

plate

op

screw

crew

d driving eccentric adjusting

ar

rew

ew

reg

ulating

stud

disc

1 1 1

1 1 1

1 1 1

1 1 1

2 2

2 2

1 L

1

1 1 1

1 L L

1 1 1

2 2 2

1 1

1

1 1 1

1 1 1

pin

driv ing

connect

ion

l 1

1

1 1 1

ch screw 1 1 l

wick

d bar

bar forked

pad

ed

bar cra

nk

screw

bar hinge screw

driving rock sha

riving

scr

rock shaft stop coll

ew

driving rock

scr

ew

reversi

reversi

scr

ew

scr

ng lever

ng

ew

wick

connect

shaft

lever

ft

bu

ion

stop

shing

ar(lef

collar(r

igh

t)

t)

1 1 1

l L

1

1 1 1

1 1 1

1 1 1

1 1 1

1 1

1 1 1

2 2 2 S

1 1 1

1 1 1

1

1

1

1

2 2 2

1 1 l

2 2 2

1 1 1

1 1 1

l 1 1

1

I 1

1 1

l 1 1

1 1

SM3/ 16

(32)

SM3/16(32) X 10. 5

2 S

M3/16(40) X 11.

2

l

M17/64"(

1

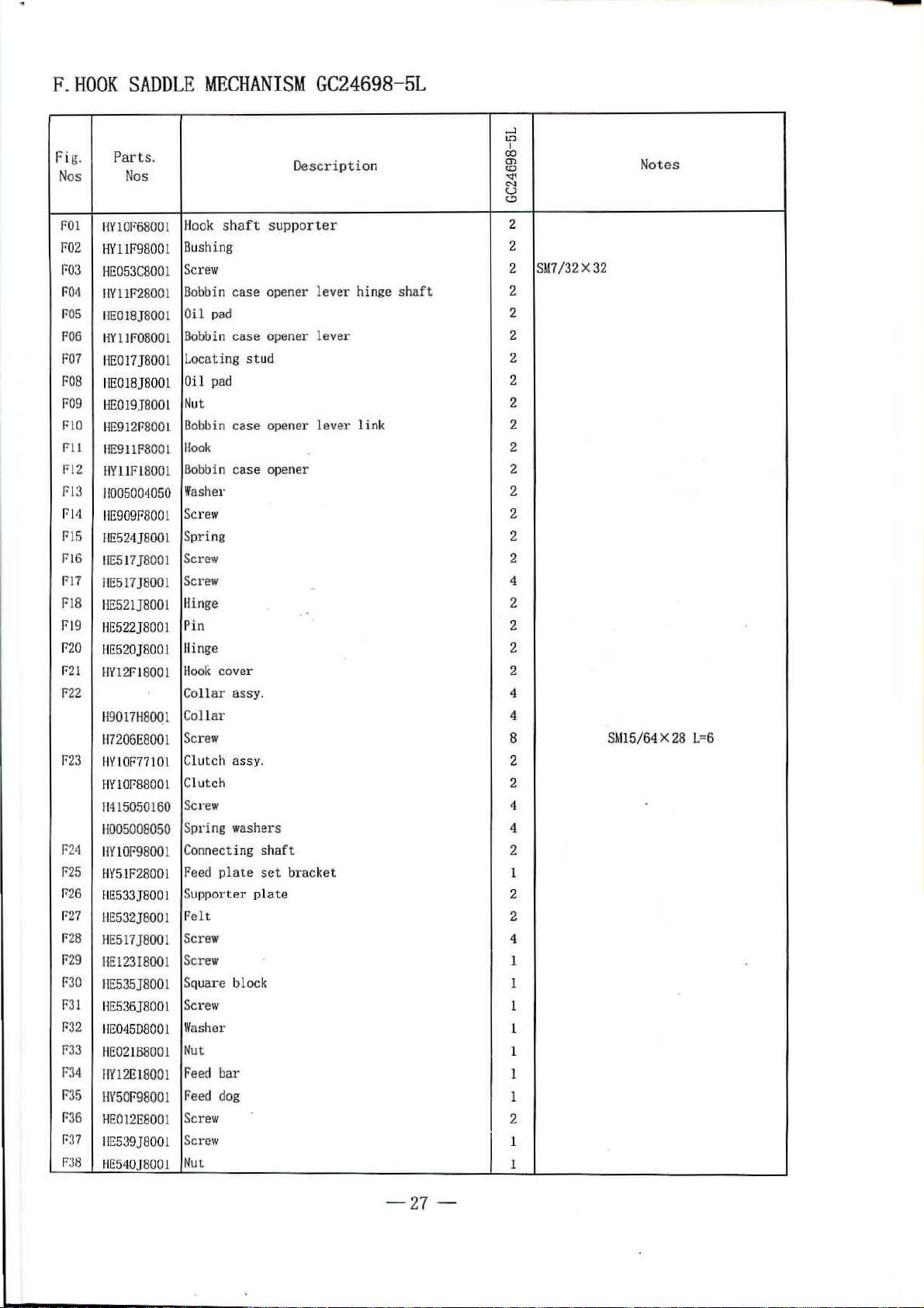

1

I

1

X 10. 5

21)

X7. 7

5

-21-

Page 24

n·.

Fig

Nos

STI

TCH REGULATOR

.

Parts.

Nos

AND

Descr

F

EED

iptio

ROCKI

n

NG

ME

CHANISM

-l

tO

Ln

I

00

en

tO

~

t'\1

u

~

I

00 00

en en

tO

~

t'\1

u u

~ ~

fP

t'\1

*

Notes

044

BE931E8001

045

IIE932E8001

II

E933

046

047

048

1)49

050

051

052

053

054

055

056

057

058

059

E800l

IIY12E68001

HE935E8001

HE936E8001

BE937E800

~IE035C8001

HE926E8001

liE938E8001

111!

939E8001

I-IY12E88001 Feed

UE940E800

BE941E8

HE942E8001 Washer 2 2

H005010080

Stop

screw

Feed

Set

Feed

Spring and

Hi

nge

1 llin

ge

Oil

reversi ng lever

scre

'N

reversing link

treadle

screw nut

screw

wicl~

sli

de

block 1

connecting link 1 1

Nut

fo'

ecd 1·eversing crank

Set screw 2 2 2

reversing lever s

1 t screw

001

Nut

Spring washer 1 1

(rig

ht) 1

lide

block sprin

2 2 2

1

1

1 1

1 1 1

1

1

SM3/16(32)

1

1

1

1

1

2

X4

(24) X 17.

(

24)

5

-22-

Page 25

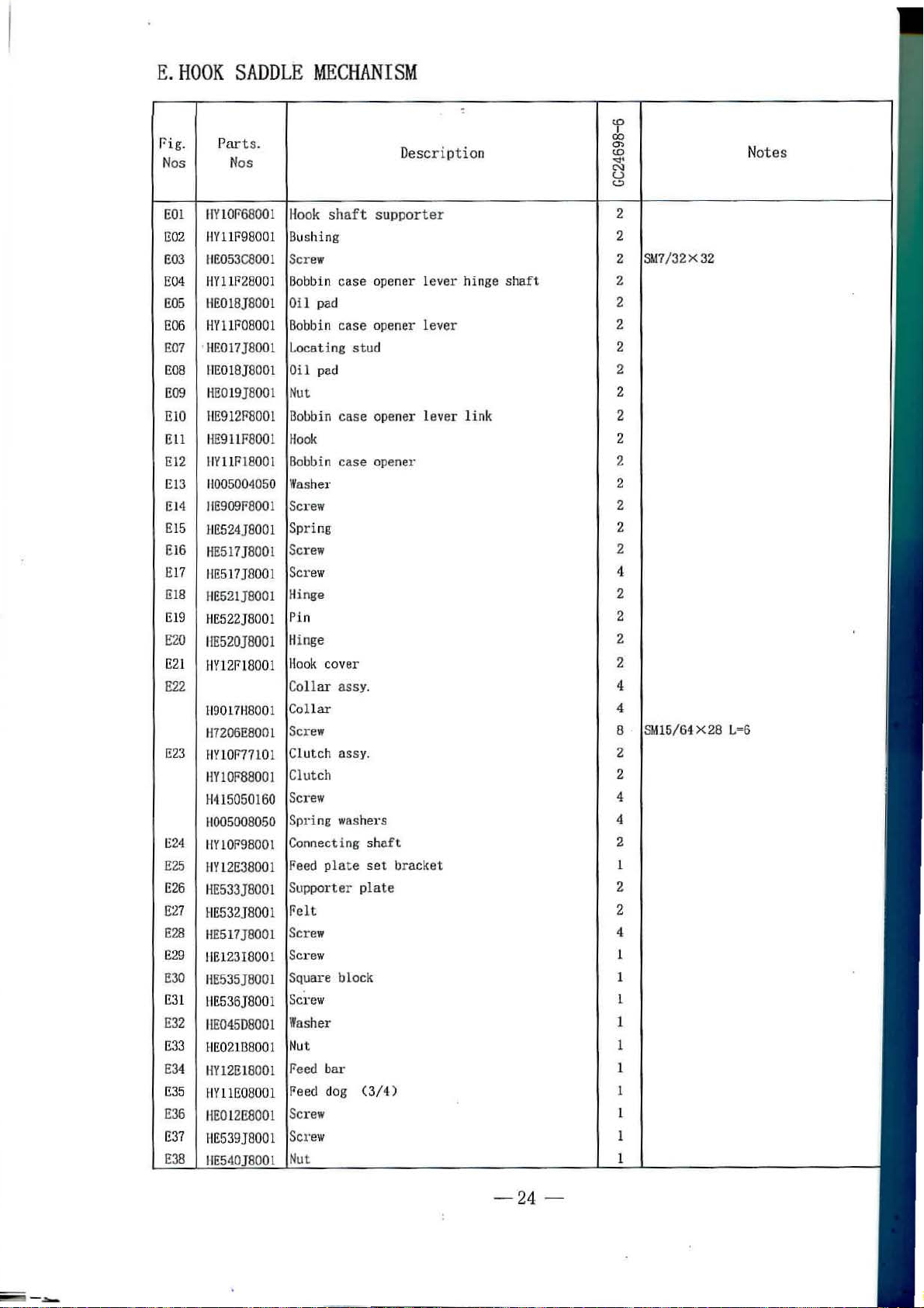

E.

HOOK SADDL

E

MECHANISM

0

0

a~

46

~

4

7/

)8

~

_.!-/

49

__

___

_.cs:-

-

__

----n

23-

45

Page 26

E

.HOOK

SAD

DLE

MECHANISM

Fig.

Parts.

Nos Nos

1!01 IIY10fo68001 Hook

E02

IIY11F9800

E03 IIE053C8001

1!04 I·IY11F28001

E05

HE018J8001

HY11F08001 Bob

1!06

E07

HE017J8001

E08

~

IE01

8J800

HE019J8001 Nut

E09

IIE912F8001

ElO

Ell HE

1!12

E13

El4

El5

El6

El7

El8

El9

E20

E21

911F

IIY11Fl8001

H005004050 Washer 2

IIE909P8001

111!52

4]800

HE517J8001

IIE517J800l

111!521]8001

HE522J8001

II

E520]8001

HY12Pl80

E22

U9

017H8001

H7206E800

E23

IIY1

0F77101

HY10F88001

H415050160

H005008050

E24

IIY10F9800t

E25

HYl2E3800l

1!26

HE533]8001

1!2

7

HE532J8001

E28

HE517]800l

E29

IIIH23I8001

E30

IIE535J8001

1!31

IIE536J8001

E32

IIE04508001

E33

IIE021D

E3

4

HY12El8001

1!35

~IV

11

1!0

E36

HE0121!8001

1!37

ILE539J800l

E38

Bushing 2

1

Scr

Bobbin

Oil

Locating stud

Oil

1

Bobbin

8001

Hook

Bobbin

Screw

Spri

1

Screw

Screw

Hinge

Pin

Hinge

H

ook

01

Co

Screw

1

Clutch nssy. 2

Clutch

Screw

Spring washers

Con

Feed

Square block 1

Sci·

lfns

Nut

B001

reed bar

Feed dog

800

l

Screw

Screw

Nut

Descr

ipt

shaft

supporter

ew

case opener lever hinge sha

pad

bin case opener l ever

pad

case opener lever link

case opener

ng

cover

llar

ass

y.

l

lar

necting sh

pla

aft

te

set bracket

ew

her

(3/4)

~

ion

ft

<0

I

00

m

<0

oq<

N

(.)

<..:l

2

S

lf7

2

2

2

2

2

2

2

2

2

2

2

2

2

4

2

2

2

2

4

4

SM15/64X28

8

2

4

4

2

1

2

2

4

1

1

/32X32

L=6

Not

es

-24-

__

Page 27

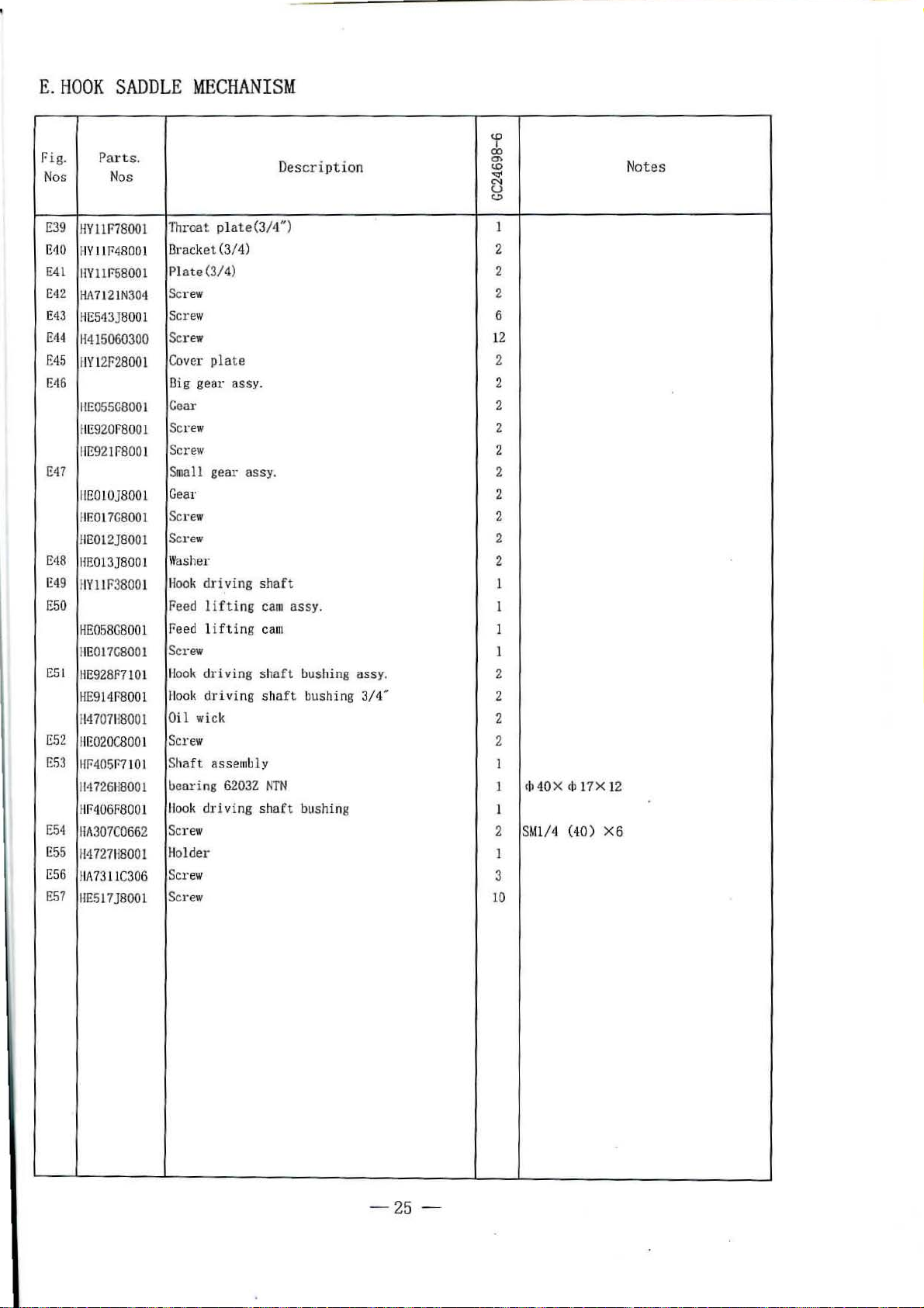

E.

HOOK

fig.

Nos

SADDLE

Parts.

Nos

MECHANISM

Description

tD

l

00

m

tD

q<

('.1

u

c:.:>

Notes

E39

HYllr78001

E1

0

HY

11F48001

E4l

IIYll

f-5800

E<12

Hi\7121N304

E

43

~IE513J8001

Et\4

H415060300

E45

HY12F2

8001

E16

HE055G8001

BE

920

fo80

IIE921F8001

E47

IIIlO

10]800 1

HE017G8001

~IE012]800l

E48

H

E013

}80

E49

IIY

ll

F3800

ESO

HE0

58G8001

IIE017G8001

ESI

HE928F7l0l

HE

914

1'800

114707H8001

E52

IIE

020C800

E53

HI'405F7101

114726H8001

Hfo40

6F800

E54

IIA307C066

E55

114727118001

E56

fiA7311

C306

E57

HE517J800

Throat plate(3/4N) 1

Bracket (3/4) 2

Plate (3/4) 2

l

Screw

Scr

ew

Screw

Cover

plate 2

Big

gear assy.

Gear

Screw

01

Screw

Small

gear assy. 2

Gear

Screw

Scr

ew

Washer

01

Hook

Feed

Feed

driving

lifting

lifting

1

shaft

cam

cam

assy.

Screw

ll

ook

!l

1

Oi 1

Screw

1

Shaf t asse

uear i

!look

1

Screw

2

driving sh

ook driv

wick

ng

dri

6203Z

ving

aft

ing shaft

111b

ly

NTN

shaft

bushing assy.

bushing 3/4N

bushing

Holder

Screw

Screw

l

2

6

12

2

2

2

2

2

2

2

2

1

1

1

1

2

2

2

2

1

1

1

2 S

1

3

10

cb

40

M1/4

X

cb

(40

17

X 12

) X 6

-

25-

Page 28

E.HOOK SADDLE

Fig.

No

E39

E40

E4

E42

E43

Et14

Et15

E46

E47

E48

E49

ESO

ESI

E52

E53

E54

E55

E56

ES7

Parts.

s

JI

Y I L

Nos

F7800

!lVI LF480

1

HYllF58001

IIA7121N304

HM43J8001

11415060300

I-IY1

2F280

I

IE055G80

I

IE920F800

IIE9211'800

IIEO

10]800

IIE017G8001

IIE012J8001

IIE013]8001

IWIL

F3800

II

E058G800

~

lEO

17G800

IIE928F710

IIE9L4F8001

li

4707118001

IIE020C800l

HF40

5F710

11<172611800

II

F406F800

IIA307C0662

H4727H800l

HA7311

I!E5 L 7]800

I

01

01

0 1

1

1

1

1

I

1

I

1

1

1

C306

1

MECHANI

Thro

at

Bracket(3/4)

Plate (3/4) 2

Screw

Screw

Screw

Cover

Big gear assy. 2

Gear

Screw

Screw

Small

Gear 2

Screw 2

Screw

Washer

Hook dri

reed

Feed

Screw

Hook

Hook

Oil

wick

Screw

Shaft

be

aring 620

Ho

ok

Screw

Ho

lder

Screw

Screw

SM

D

escriptio

plate(3/4H) I

plate 2

gear assy.

ving sh

lifting

lifting

dTi

ving

driving

aft

cam assy.

cam

shaft

bushing assy.

shaft

bushing

assembly

3Z

NTN

driving shaft bushing

n

3/4.

'f

co

en

lO

"""

E3

(.!)

2

2

6

12

2

2

2

2

2

2

1

1

L

L

2

2

2

2

1

d

>40Xc~17

L

1

2 SMl/4

L

3

10

(40)

X12

X6

N

otes

-

25-

Page 29

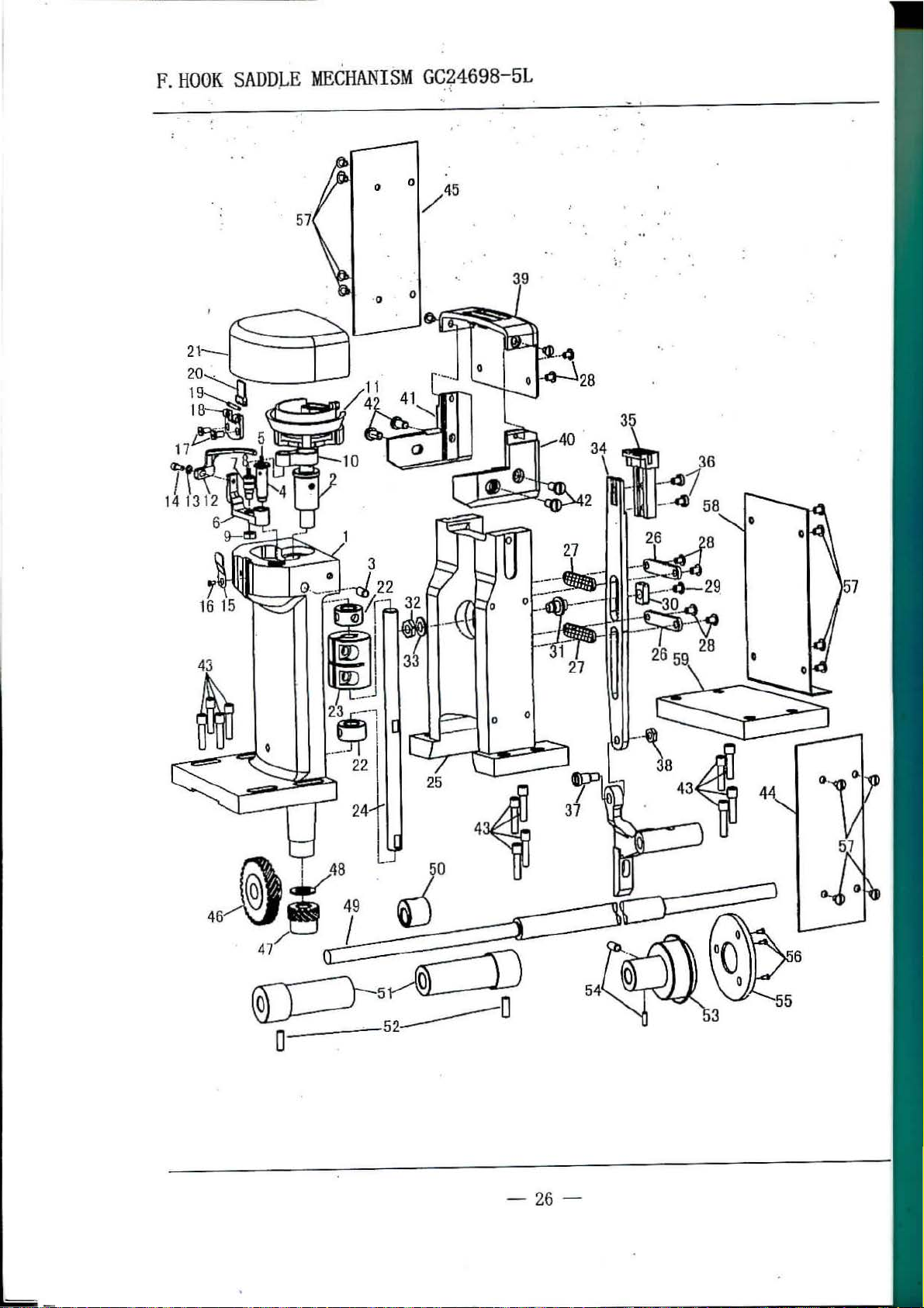

F.

HOOK

.

DLE

SAD

MECHAN

· . . - .-

ISM

0

0

/

GC~4698-5L

...

45

.

-26-

53

Page 30

F.

Fig.

Nos

HO

OK S

ADDLE MECHANI

Parts

.

Nos

SM

Des

GC2

4698-5L

cri

ption

...-1

tn

I

00

en

<.0

~

""

u

t,!)

Notes

F01

F02

t:'03

FO<I

t:'05

F06

t:'07

FOB

[:'09

FlO

Fll

F12

F13

f.'

I

ii

f-'15

f-'

16

f-'17

F18

f-'

19

F20

F21

F22

P23

P211

P25

P26

P

27

P

28

f29

F30

F31

P32

P33

f-'34

r-35

P

36

t:'

37

F38

HY101'68001

HY11F98001

HE053

C8001

IIY11F2800

IIE018J8

HY11F0800

HE017J800

IIE0

HE019

HE912fl8001

IIE911F8001

IIY11F18001

11005004050

I

IE909F800

IIE524JB00l

IIE517JBOOI

I

IE517JB0

IIE5

I'IE522J8001

B£

520]8001

HY12FI8001

H9017H80Q

H7

206E8001

HYIOF7710

H

YlOP8800l

11415050

H005008050

IIY10F9800

fi

Y5lF28001

HE533J

H£53

H£517}8001

IIEl23IBOOl

IIE535J8001

HE536J800

H£0<15

H£02188001

IIY12El800

HY50F98001

HE012E8001

H£539]8001

HE540J800

001

18JB0

01

J80

01

01

21J8001

160

BOOI

2}8001

0800

1

1

1

1

1

1

1

1

1

1

1

Hook

shaft

supp

orter

Dushing

Screw

Dobbin

Oil p

Bobbi

Lo

Oil

Nu

Oobbin

Hook

Bobbin

Washer 2

Screw

Spri

Screw

Screw

Hinge

Pin

ll

ll

Collar

Collar

Screw

Cl

Clutch

Sc

Spring washers

Con

Peed

Su

f

Screw

Screw

Sq

Screw

Wash

case opener lever hinge sha

ad

n case

cat

ing stud

pad

t

ng

opene

r lever 2

case opener l ever

case opener 2

link

ft

-

..

inge 2

ooJ<

cov

er

assy. 4

utch assy. 2

rew

necting shaf t

plate

set

bracket

pporter plate

el

t

uare bl

ock

er

Nut

Fee

d bar

Feed dog

Screw

Screw

Nu

t

2

2

SM7

/32 X

2

2

2

2

2

2

2

2

2

2

2

4

2

2

2

4

8

2

4

4

2

l

2

2

4

1

I

1

1

1

1

1

2

1

1

32

SM15/64 X

28 L=6

-27-

Page 31

r

F.

HOOK

Fig.

Nos

SADDLE

Parts.

Nos

MECHANISM

GC24698-5L

Description

.....l

lD

00

m

<0

"<t'

C';)

u

(.!)

I

Notes

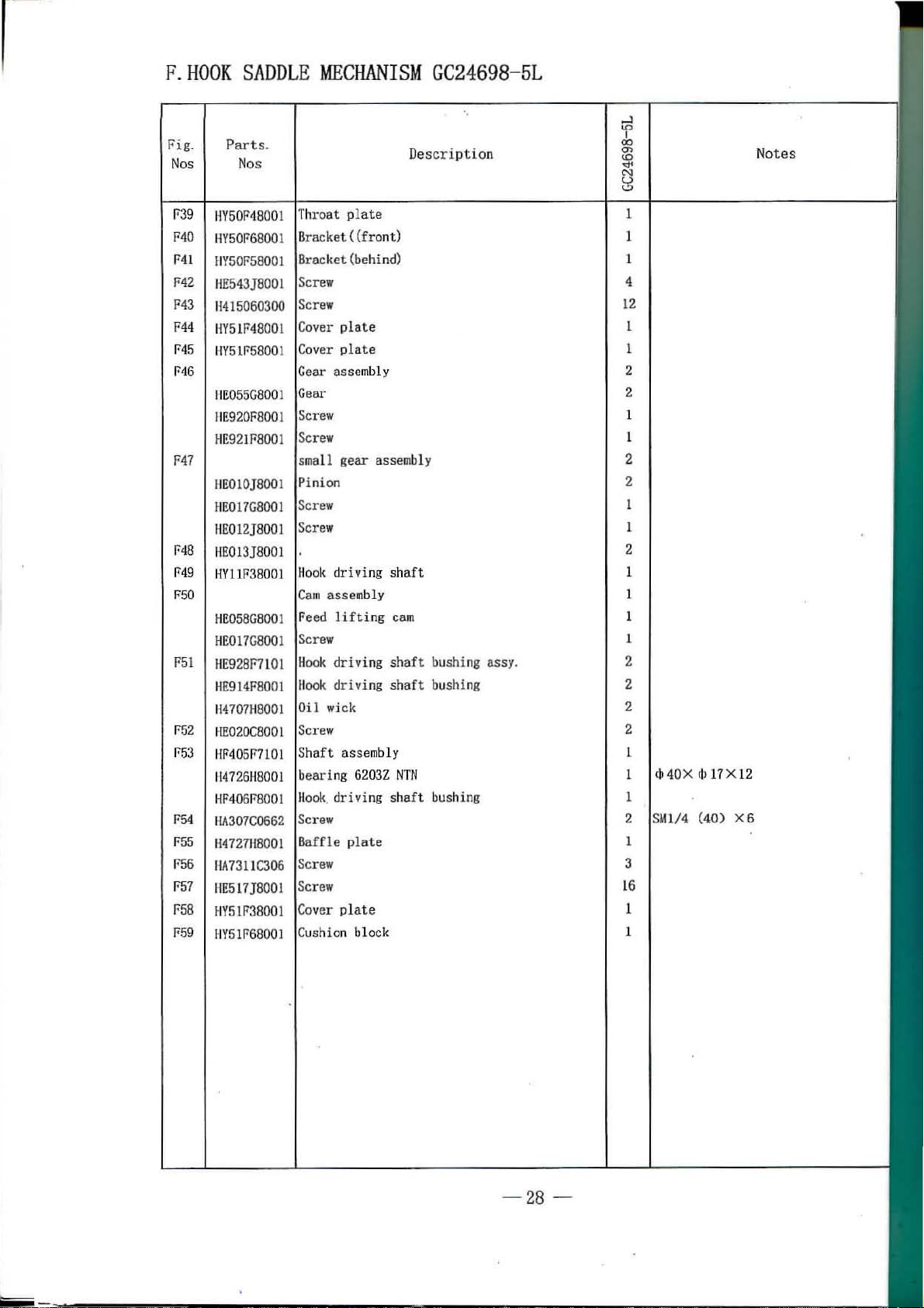

1'39

F40

F41

fo42

F43

F44

F45

F46

F47

F48

F49

F50

F51

F52

P

53

F54

1755

F56

F57

F58

J759

11V50F'4800

IW50F6

HY50F5800l

HE543]8001

H415060300

HY51F48001

HY51F58001

IIE055

I I

E920F800

HE92IF8001

IIE010]8001

HE017G8001

HE012]8001

HE013J8001

HY11

HE058G8001

HE017G8001

HE928F710l

HE914F8001

H4707H8001

HE020C800

H

F40517710l

H4

726H8001

HF40617

IIA30

H4727118001

IIA7311C306

IIE517J8001

HY51F38001

HY

51F68001

1

8001

G8001

I

F38001

1

8001

7C0662

Throat

Bracket ((front) 1

sma

Pinion

Screw

Screw

Hool<

Cam

Feed

Hook

Oil

Screw

Shaft asse

bearing 62032

Hool<. driving shaft

Screw

Baffle p

Screw

Screw

Cover

C

plate

(behind) 1

ll gear

assembly

wick

ush

ion block

assemb

ly

driving

lifting

driving

driving

plate

shaft

cam

shaft

bushing assy.

shaft

bushing 2

mbl

y

NTN

bushing 1

lat

e 1

1

4

12

1

1

2

2

1

2

2

1

2

1

1

1

1

2

2

2

cb40X dll7Xl2

1

SMl/4

2

3

16

1

1

(40)

X6

-28

-

Page 32

G.HOOK

SADDLE

0 0

57

MECHANISM

,...A4

GC24698-5R

j

46

-29-

·~

57

Page 33

G.

HOOK SADDLE MECHANISM

P

art

N

os

s.

Description

Fi~.

N

os

GC24698-5R

e:3

I

00

Ol

tO

-.:1'

N

u

(.!)

N

otes

GO

. I

C02

G03

G04

G05

GOG

G07

GOB

G09

GlO

Gll

Gl2

G13

Cl4

GIS

G16

Gl7

Gl8

CI9

G20

G21

G22

G23

G2

4

G25

G26

G27

G28

G29

G30

G3

1

G32

G33

G34

G35

G36

G37

C38

11

Yl0F68001

HYllr98001

t1E053C80

IIY

HE0

IIY

0l

llF2800 1

18J8001

11

FOB

OO

1

IIE017J8001

IIE018J8001

HE019J8001

HE912F800

HE911F800

1

1

HYllrl8001

H

005004050

HE909F8001

HE524J8001

HE517]8001

HE517J800l

H

E521]8

001

IIE522]8001

HE

520J8

001

HY12F18001

H9017H800l

H720

6E800l

HYl

OF7

7101

HY10F88001

1141

5050160

H00

500

8050

IIY10F

98001

HY5

1F28001

HE533J8C01

IIE532J8001

HE517]8001

HE12318001

I-JE

535J8

001

IIE53

6]8001

HE045D800l

IIE0

21B800l

HYl2EL8001

HY

60P

48001

Hook shaft

supporter

Bushing

Screw

Dobbin

Oil

case opener lever hinge sha

pad

ft

Bobbin case opener level'

Locating stud 2

Oil

pad

Nut

Dobbin

!l

Dobbin

Washe

case opener lever link

ook

case opener

r

Screw

Sp~

ing

Scr

ew

Sc

rew

Hin

ge

Pin

Hinge

Hook

cover

Collar assy.

Collar

Screw

Clutch assy.

Clutch

Screw

Spring

Co

Fee

Supporter

washe

nnec

ting

d plate

rs

sha

set

plate

ft

bracket

Felt

Screw

Screw

Sq

uare block

Sc

rew

Washer

Nut

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

4

2

2

2

2

4

4

8

2

2

4

4

2

1

2

2

4

1

1

1

l

1

l

1

l

/32X32

15/64X28

L=6

-3

0 -

Page 34

G.

HOOK

Fig.

Nos

SADDLE

Parts.

Nos

MECHANISM

GC24698-5R

Descri ption

0:::

I

""

00

m

<D

-.:r<

N

u

<.!)

Notes

G39

G40

G41

G42

G43

G44

G45

G46

G47

G4

8

G4

9

GS

O

GS

l

52

G

GS:l

C54

G55

G56

G57

G58

G5

9

HY50F48001

IIY50F

6800

1

HY50F58001

HE54

3J8

001

~It!

15

060300

IW51F48001

HY51F

5800

l

HE05

5G800

1

HE920F

800

1

IIE921F8001

IIEOlOJ

8001

HE017G

800

1

HE012]8001

HE01

3J800

l

IWllF

3BOO

t

HE058G

8001

IIE017G8001

IIE

928F

7101

BA

7311

C30

6

H470711800l

IIE02

0C80

01

IIF40

5F7101

H47261l8001

HF406F8001

I

IA307

C0662

11472711

800

1

IIA7311

C30

6

IIE517]800!

IIY51F3

8001

HY51F

6800

l

Throat

pla

te

£lracket ((fron t) 1

Bra

cket (behind) 1

Screw

Screw

Cover

plate 1

Cover

plate

Gea

r ass

embly

Gear

Screw

Scr

ew

small gear assembly 2

Pinion 2

ew

Scr

Scr

ew

washer

llook

driving

Cam

assembly l

Feed

lift

sha

ft

ing cam 1

Screw

Ho

ok dri

ving sh

Hook driv

aft

bushing assy.

ing shaft bushing 2

Oil wick

Screw

Shaft

assemb

ly

bearing

Hook

6203Z

drivi

ng

NTN

sha

ft bus

hing

Screw

Baffle

plate

Screw

Screw

Cover plate

Cushion

block

l

4

12

1

2

2

1

1

1

1

2

1

1

2

2

2

1

1

1

2

I

3

16

1

1

(jJ

40

S

Ml/4

X

<h

17 X 12

(40) X6

-31-

.

Page 35

H.

THREAD

TENSION

REGULATOR

5

i

HANISM

MEC

28

4

~

~

3~

29 44.55

I

17~8

9

18~~7

14~~~

~~~22

19~

31~

.J

~/AS

0.

~

47~~

,

~

48

I 49

6>

~u

~24

o--

20

21

23

~~):j

58

. '

36-

cJ

59 i ..

c

~

30

~

33

)

"F

40~3839

o.Y? I

7"

~~1i

46

~

~

41

~

37

[!

, 43

60

=-=~-

1~

~

62

~

I

50·

'

1

~@

-~

51

I

~

~

42.56~

~

63

-32

-

Page 36

H.

THREAD

fo"ig.

P

Nos

TENSION

arts.

Nos

REGULATOR

MECHAN1SM

Description

<0

cb

en

<0

~

C'\1

u

t.:>

,....l

1.0

I I

00

00

en m

<0

<0

~

~

t.:>

cz::

1.0

~

C'\1

u

t.:>

No

tes

110

1 B

E904G8001

1102

HE905G8001

11005006080

11

03

H

OI!

HE

907G8001 Screw

I

I()[.

HE908G8001

H

106

08

E0480800

H

E934G800

II

E935G8001

II

E936G800

II

E937G800

II

E938G8001 Hol

l

1166

1

H07

11

~10 9

lllO

!HI

lll

1113 116651

1 Screw 1 1 l

L

l

1 Shaft

5688001

0800 I Lever

IIIII Jl11310300'10

1115

11664988001

1116

114090110080

1

117

H431040010

1118

1119

H6650B800

H6657B8001

1

H20

1121

H

22 116653B8001

23

H

1166558

8001 Spri

11

21 H6658B8001

II

11

11

1127 I lEO l9K8

11

1129

1130

H

1132

H33

1131

H35

E924G7101

25

26 IIE910G8001

00

28

IIE

912G800

IIE913G800

HE046C8001

31

HEOI2E8001

IIE914G8001

HE915G800

HE916G8001

HE018H8001

1

L Thread releasi

L Thread contro

1

1136 IIE931G8001

11

37

HE046C8001

1138

llr

205G8001

H

39 HE917G800

1140

HE022K8001

1141

HE

918G800

1

1 Thread contr

1142 HE919G8001

11

113

IIE

920G800

I Screw

Presser

oar

spri

ng (fl

at)

1 1 1

Presser bar spring (auxiliary) 1 l

Washer

I 1 1

1 1 1

Screw

Ca

m 1 1 1

Hold plate

ve

r 1 1 1

Le

d plate I

Washer

Screw

Shaft

Screw

Screw

Pin

Thread winder

wheel

1 I

I

1

1 1

l

1

1

I

1 1

1

1

4

4

1 1

2 2

2 2

1 I

1

l 1 1

4

2

2

Pin I 1 1

Pin

Spring

ng

2 2

2

1 1 1

I 1

Tire 1 1 l

Mounting

Thread tesion

Screw

Stop

Stop

Thread guide

Screw

Thread guide

Nut

Stopper

Screw

TJu

·ead ta.

Thread controller

Set.

Thr

plate 1

releas

ing discs

ng

pinOong)

ller

covering pl

ate

screw

screw

ke-up

spr

ing

spring stud

screw

oller

disc

ead controll

er

stud

1

2 2 2

I 1 I

I 1 1

1

l I

2 2 2

1 1 1

2 2 2

1

1 I

I

l

1

1 l

I 1

1

1

1 1 1

1 l

l I 1

1

1 1 S

1

S

M17

SM17

1

1

1

1

dJ

<IJ

l

SM1l/64 (32)

SMO. 1339

l

1

l

1

Mll

/64 (24) X 13

/64

(24)

2.

5X8

2.5Xl2

(36) X 3.

/64

(32)

X 8

X 6. 5

5

X 4

-33-

Page 37

H.

THREAD

Fig

.

Part

Nos Nos

TENSION

REGULATOR

s.

Descripti

MECHANISM

'f

00

0>

on

w

-.d'

N

u

(.!)

.....J

0::

1D

lD

I

00

00

0> 0>

w

<0

...,.

'<f'

N N

u u

(.!) (.!)

'

N

ote

s

H44

IIE921G

800

l

HE915G8001

H45

H46 HE922G8001

H47

lli!923G8001

l

lt\

31

H48

H49

H50 I 12

H51 HA3

H52

1~

53

1154

1155 I!F

H

56

H57

115

8 H

1159 H31

01307 05

HA310B0702

206130671

10B070l

HF206G7

101

HF208G8001

HF

209

G800

1

2lOG800l

HF211G80

01

HE033B8001

E03

2B8001

0880692

H60 H1!929GB001

II

H61

H62

E930G7101

HA30CC2030

TI1read

guide 1

2 2 2

1 1 1

releasing pin (long) l 1 1

4 2

tension releasing discs 2

2 1

2 1

1

Tension release lever 1

Thread

guide

Thread guide(lower)

Scr

ew

Oil

pad 1 1

Thread take-

up spri

ng

Stopper

Scr

ew

1 1

1 1 1

1 1

1

1

4 4

1

2

1

1

1

1

4

-34

-

Page 38

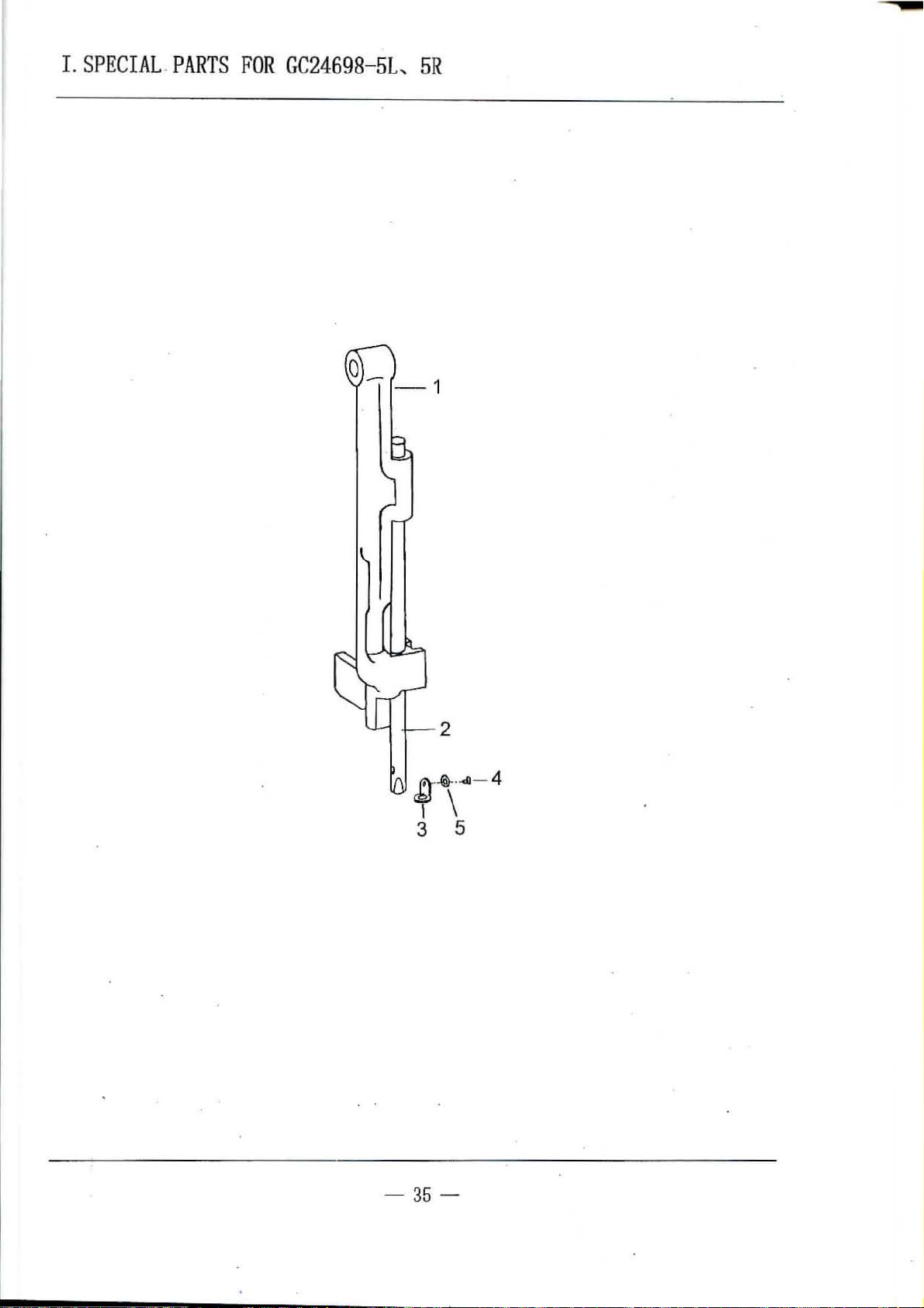

I

.SPECI

AL.PARTS

FOR

GC24698-5L,

5R

2

cD·-fr·.cG

I \

3 5

- 4

-

35-

Page 39

I.SPECIAL

Fig.

Nos

P

arts.

No

s

PARTS

FOR

GC24698-5L,

Descrip

tio

n

5R

....l

lf:) lf:)

I

00

0'>

lD lD

(';!

""

u u

<..::>

0:::

I '

00

0'>

N

""

<..::>

Notes

101

I02

103

!

04

T05

HF204D8001

llfo'205D

8001

llfo206D800

1 Needle bar

H4915J8001

ll005001025

Needle

Needle

et

scr

b8l·

bar

ew

Flat washer

guide bracket 1 1

l 1

threa

d guide

1 1

1

1

1

-

36-

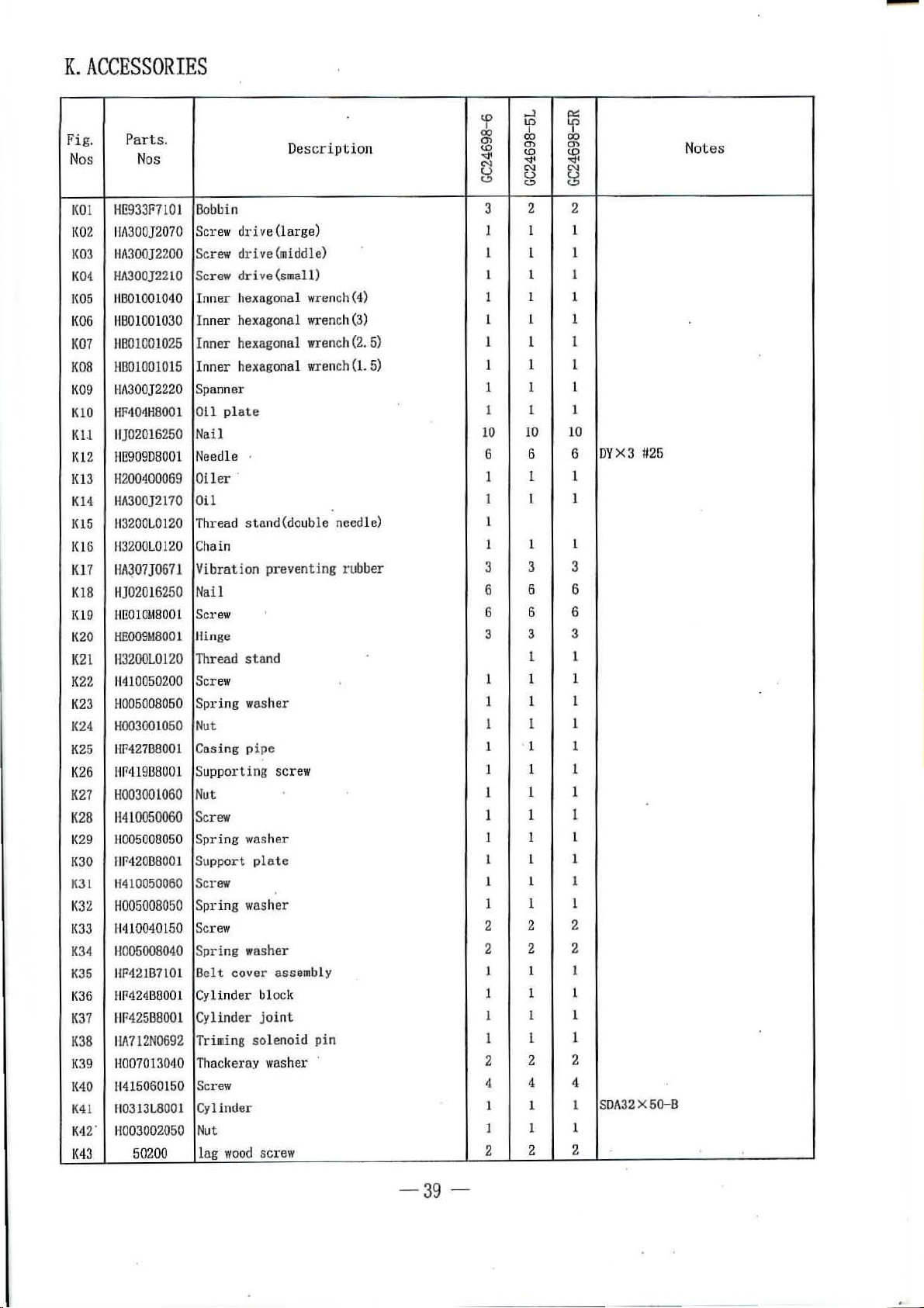

Page 40

w

sp

ecifications

l/4

"'

3/8*

l/2"'

7/8*

3/4H

1'

1

1/4'

1 1/2"'·

1 3/4"'

-;)

Needle bar

(C08)

HE970D8001

HE971D8001

HE97208001

HE97308001

HE9080800

HE97408001

HE975D8001

HE976D8001

HE977D8001

1

.

Needle

plate

(E39)

HY12F48001

HY12F58001

HY12F68001

HY12F78001

HYllF78001

HY12F88001

HY

12F

98001

HY13F08001

HY13F18001

Vibrat ing

pres

ser

foot

(C41)

HE962D8001

HE96308001

HE964-D800

HE965D8001

HE928D8001

HE966D8001

HE96708001

HE9680

800

HE969D8001

1

1

Lifting

presser

(C25)

HE95408001

HE95508001

HE956D8001

HE95708001

HE91908001

HE958D8001

HE95908001

HE96008001

HE961D8001

foot

Feed

dog

(E35)

HY13El8001

HY13E2800

HY13E380

1

01

HY13E48001

HY11E08001

HY13E58001

HY13E68001

HY13E78001

HY13E8800

1

Bracket

(E40)

HY13F2800l

HY

13F38001

HY13F48001

HY13F58001

HY11F48001

HY13F68001

HY13F7800l

HY

13F88001

HY13F9

8001

Plate

(E41)

HY14F08001

HY14F18001

HY14F28001

HY14F38001