Page 1

GC24698-25L/-25R

Long Arm Post Bed Compound Feed Split

Lockstitch Sewing Machine

Instruction Manual

Parts Catalog

SHANGHAI HUIGONG NO.3 SEWING MACHINE FACTORY

Page 2

----- CONTENTS -----

Preparation for operation···············································································································1

1. Safety precautions ·································································································································1

2. Precaution before Starting Operation ·································································································1

3. Precaution for Operating Conditions ··································································································1

Cautions on use········································································································································· 1

1. Lubrication ············································································································································1

2. Cautions on operation ··························································································································2

Operation ·····················································································································································2

1. How to attach needle ·····························································································································2

2. How to wind the lower thread ··············································································································2

3. Selection of Thread ····························································································································· 2

4. How to route the upper thread ············································································································3

5. Adjustment of stitch length and reverse sewing ·················································································3

6. Balance of thread tension ·····················································································································3

7. Upper thread tension ····························································································································4

8. Adjustment of pressure of presser f oot ·······························································································4

9. Timing between rotating hook motion and needle motion ································································4

10. Adjustment of Feed dog height ············································································································4

11. Walking foot and presser foot vertical stroke adjustment ································································5

12. Safety clutch device ·······························································································································5

Specifications ················································································································································6

PARTS LIST ·················································································································································7

A. ARM BED MECHANISM ···················································································································7

B. THREAD TENSION REGULATOR MECHANISM ·······································································9

C. ARM SHAFT MECHANISM ············································································································11

D. PRESSER FOOT MECHANISM ·····································································································13

E. THRED TAKE-UP LEVER & NEEDLE BAR MECHANISM ·····················································16

F. STICH REGULATOR MECHANISM ·····························································································19

G. LOWER AND FEEDING SHAFT MECHANISM ··········································································21

H. FEED BAR MECHANISM ················································································································24

I. HOOK SADDLE MECHANISM ···································································································· 26

J. OIL LUBRICATION MECHANISM ·······························································································28

K. ACCESSORIES ··································································································································30

L. PNEUMATIC CONTROL UNIT ······································································································33

Page 3

Preparation for operation:

1. Safety precautions:

1) When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

2) Power must be turned off when the machine is not in use, or when the operator leaves the seat.

3) Power must be turned off when tilting the machine head, installing or removing the “V” belt, adjusting

the machine, or when replacing.

4) Avoid placing fingers, hairs, bars etc. near the pulley, “V” belt, bobbin winder pulley, or motor when the

machine is in operation.

5) Do not insert fingers into the thread take-up cover, under/around the needle, or pulley when the machine

is in operation.

6) If a belt cover, finger guard, eye guard are installed, do not operate the machine without these safety

devices.

2. Precautions before starting operation:

power on.

1) Never operate the machine before filling the machine’s oil pan.

2) When a new sewing machine is first turned on, verify the rotational direction of the pulley with the

3) Verify the voltage and phase (single or three) with those given on the machine nameplate.

3. Precautions for operating conditions:

1) Avoid using the machine at abnormally high temperatures(35℃ or higher)or low temperatures(5℃ or

lower).

2) Avoid using the machine in dusty conditions.

Cautions on use:

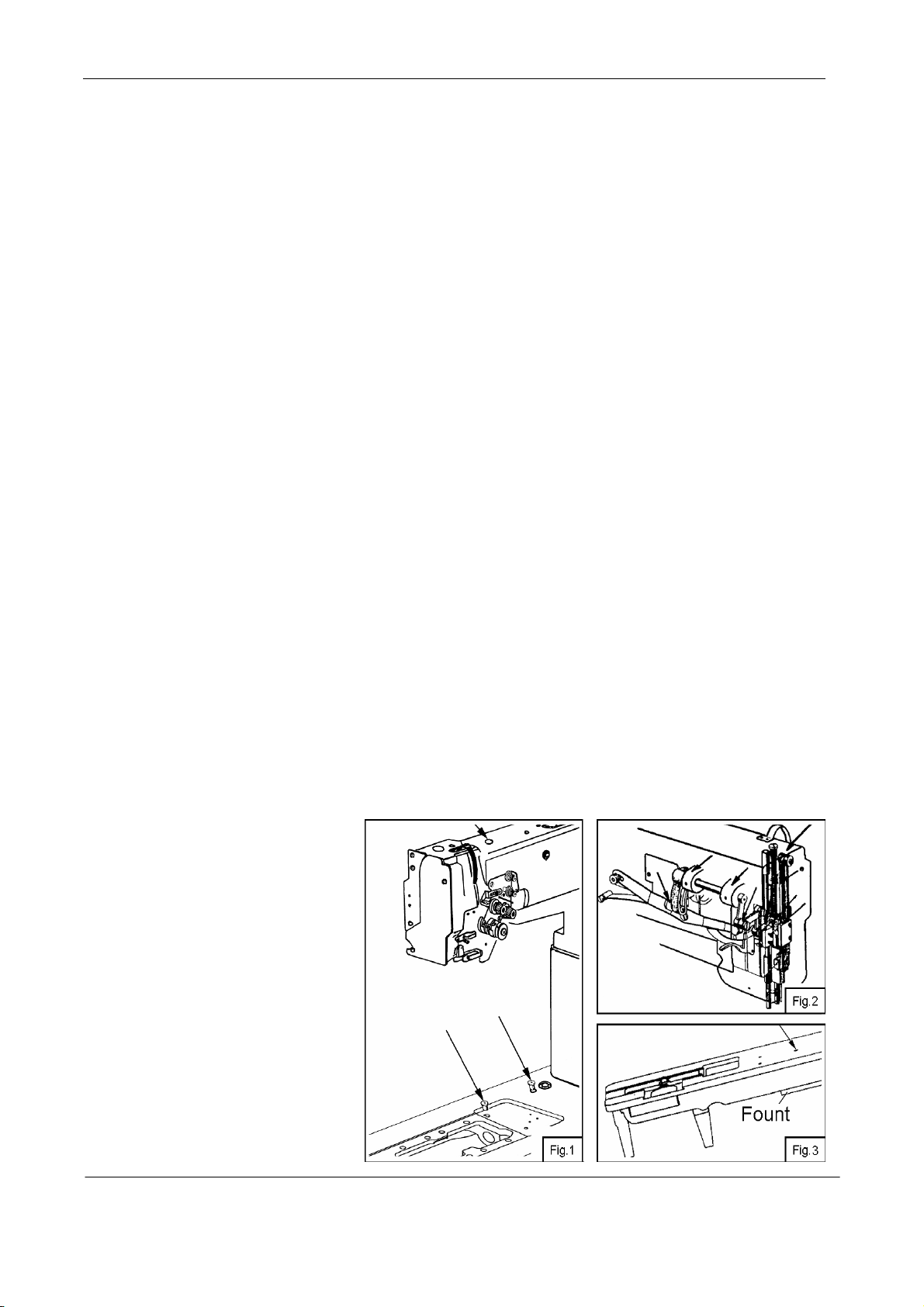

1. Lubrication (Fig.1, Fig.2)

When a new sewing machine is

used for the first time, or sewing

machine left out of use for a long time is

used again, replenish a suitable amount

of oil to the portions indicated by arrow

in the fig.

Note: Filling the oil to the fount

timely (Fig.3). Use white spindle oil.

— 1 —

Page 4

2. Cautions on operation

1) When the power is turned on or off, keep foot away from the pedal.

2) It should be noted that the brake might not work when the power is interrupted or power failure

occurs during sewing machine operation.

3) Periodically

clean the machine.

Operation

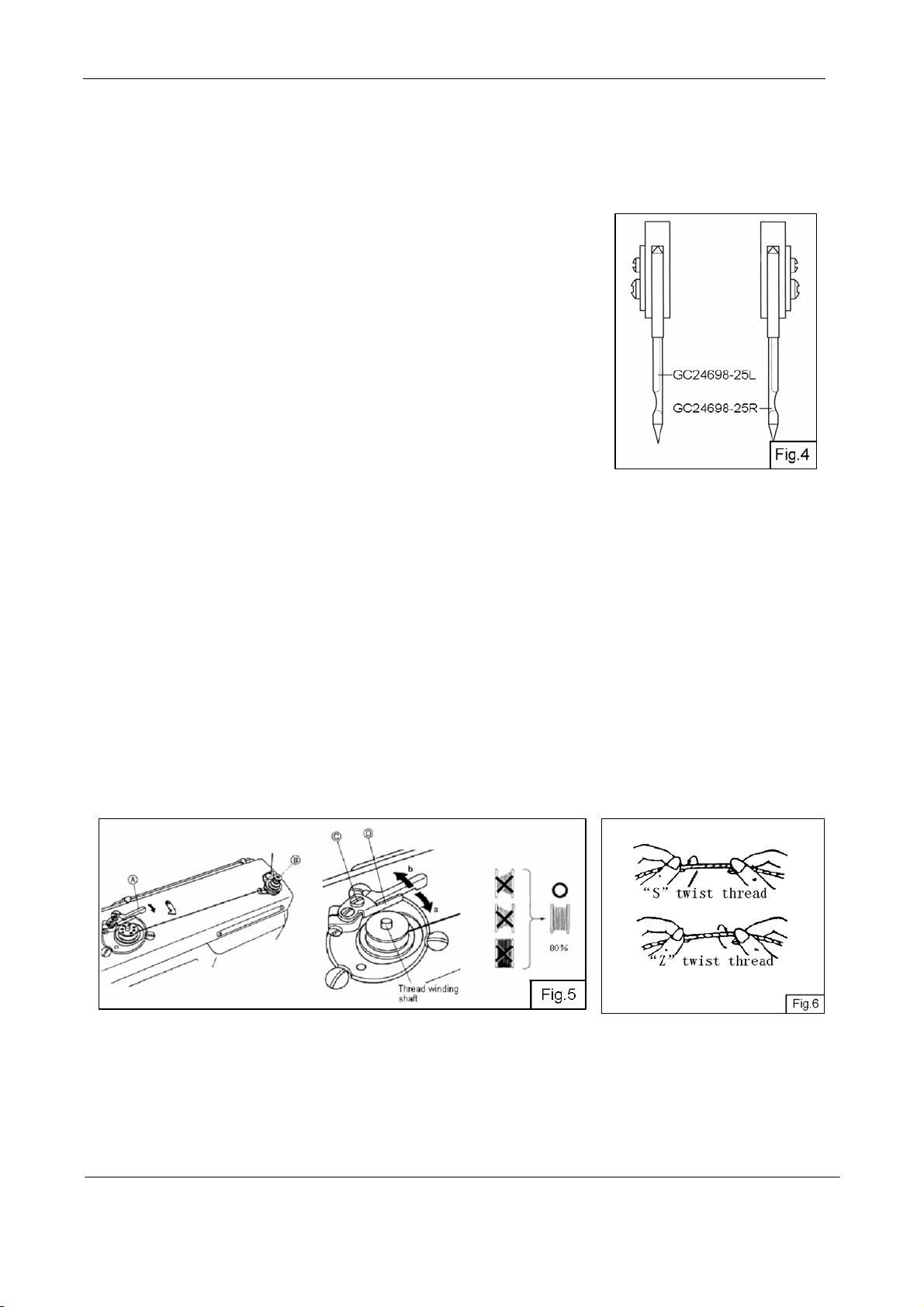

1. How to attach needle (Fig.4):

Note: Before attach needle, be sure to turn off the power.

Loosen the needle clamping screw;Hold the needles so that the two

needles side with the long grooved (faces each other), and insert it as deeply as

it will go into the needle clamping holes, tighten screws.

2. How to wind the lower thread (Fig.5):

Strength of winding:Particularly in the case of nylon or polyester thread, wind the bobbin loosely.

(1) Press the bobbin onto the thread winding shaft.

(2) Pass the thread for winding thread as shown in the figure, and wind the end of the thread clockwise

around the bobbin several times, then wind the thread on the thread adjuster side counter-clock wise several

times.

(3) Press lever A in the direction of the arrow, and start the sewing machine.

(4) The operation will automatically stop when winding is completed.

(5) Adjustment of thread winding strength, Adjust with the thread adjuster nut B.

(6)Adjustment of thread winding amount, Adjust by loosening screw C and moving the adjustment plate D

a. The thread winding amount will decrease when moved in the direction of a.

b. The thread winding amount will increase when moved in the direction of b.

3. Selection of Thread(Fig.6):

It is recommended to use “S” twist thread in the left needle (Viewed from front), and “Z” twist thread in the

right needle.

When discriminate use of needle thread is impossible, use “Z” twist thread in the needle. For bobbin thread,

“S” twist thread as well as “Z” twist thread can be used.

— 2 —

Page 5

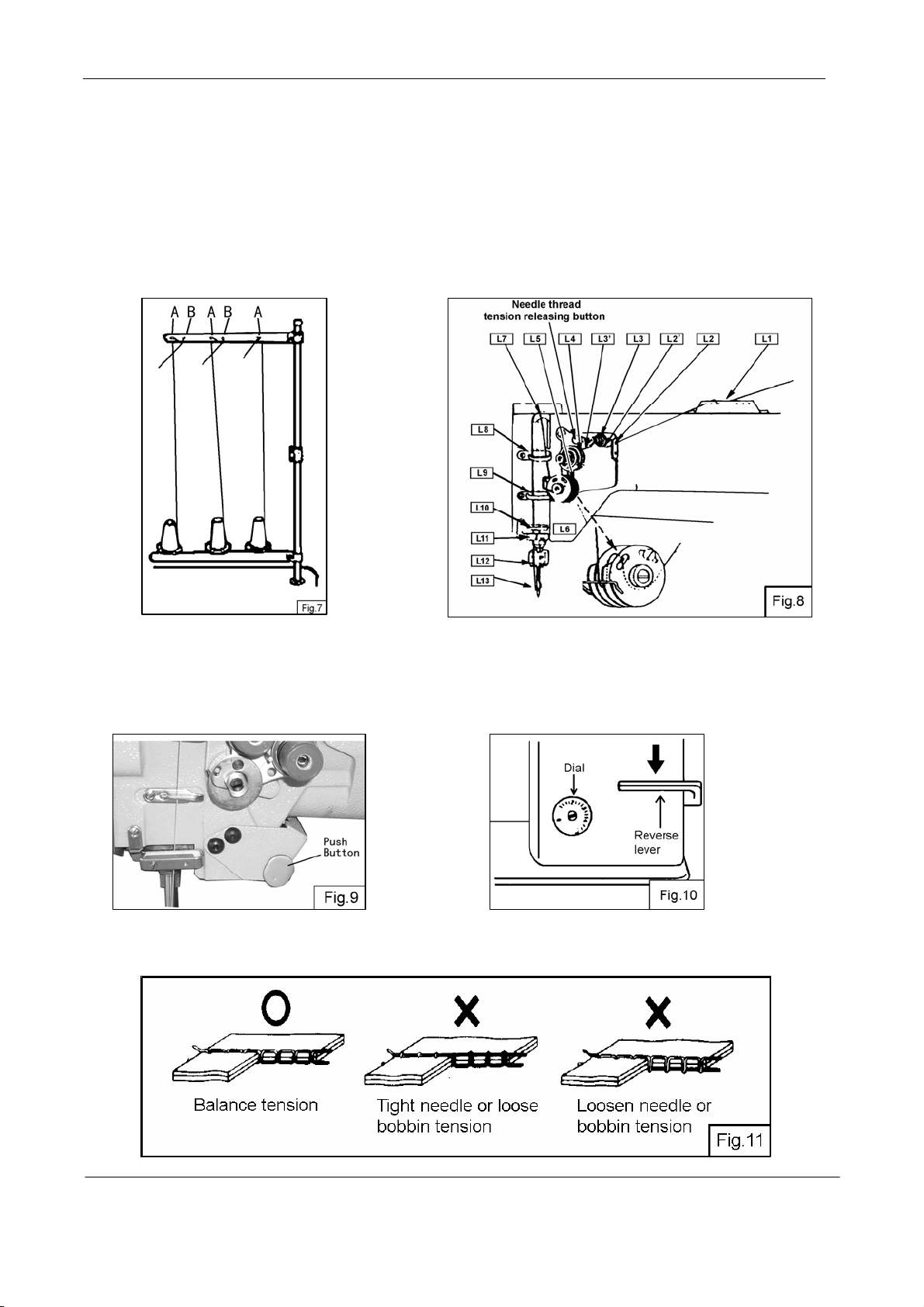

4. How to route the upper thread (Fig.7, Fig.8):

1) Pass each upper thread through thread guide A

Note: when thin slippery thread (polyester thread for example) is used pass the thread through thread

guide B as show in Fig.7

2) With the take-up lever located at the upper most position, pass each thread in the order in Fig.8.

Note: Pressing the upper thread loosening button, the upper

thread can be pulled out easily.

Adjustment of stitch length and reverse sewing

5.

1) Rotate the stitch length adjusting dial to change the stitch length

2) If the reverse lever/push-button is depressed, reverse sewing will take place.

(Fig.9 Fig.10):

6. Balance of thread tension (Fig.11):

— 3 —

Page 6

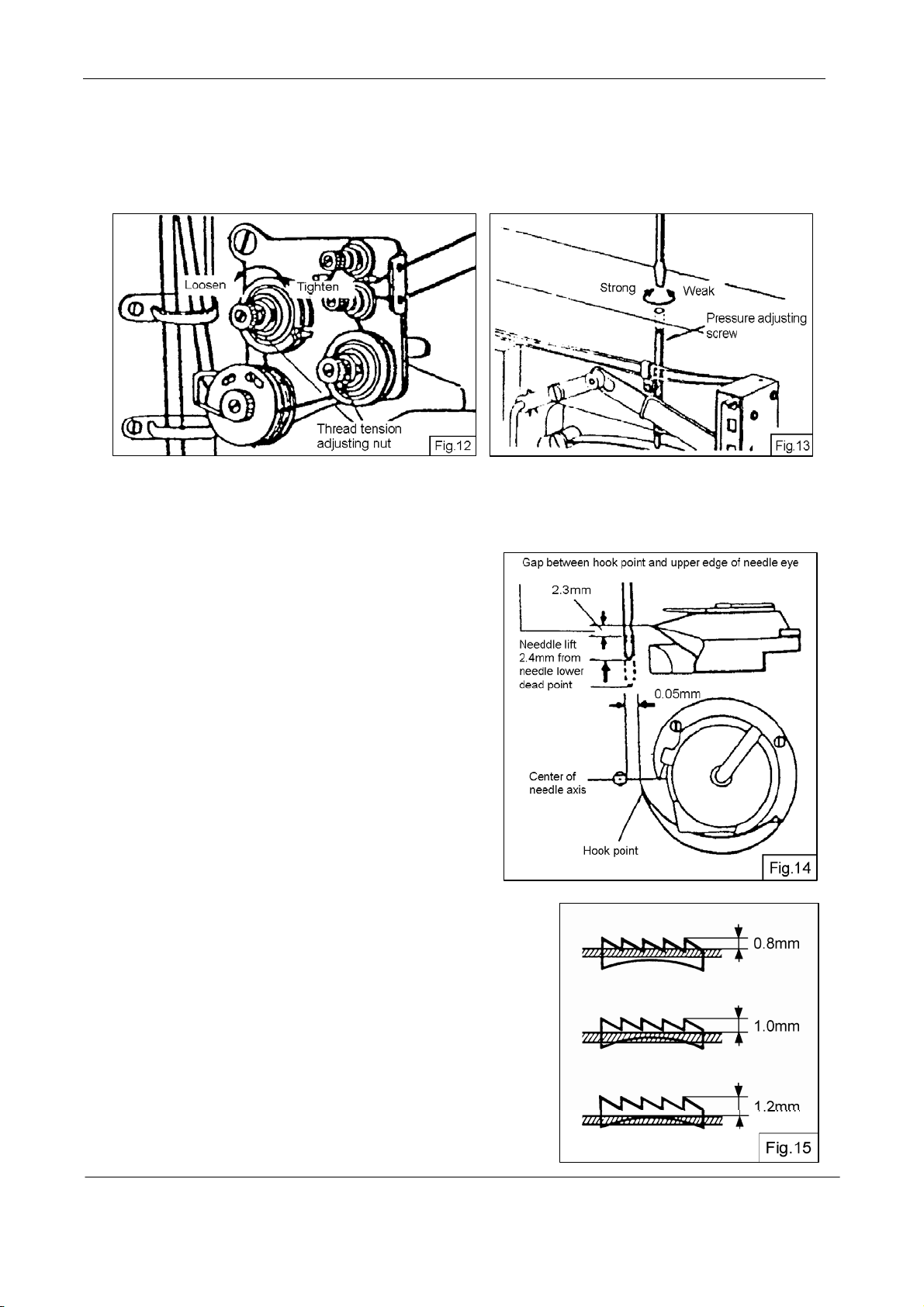

7、Upper thread tension (Fig.12):

1) The upper thread can be adjusted based on the lower thread tension.

2) Adjustment can be done by rotating the thread tension nut.

8. Adjustment of pressur

1) Pressure should be adjusted according to the material

to be sewn.

2) Turning the pressure adjusting screw to adjust the

pressure of presser foot

e of presser foot (Fig.13):

9. Timing between rotating hook motion

and needle motion (Fig.14):

1) Set stitch length to “6”;

2) When needle is lifted 2.4mm from the lower dead

point, the following position relationship should be

maintained:

·The upp

the hook point

·The hook point should be located at the center of

needle axis.

· Gap between

be 0.05 mm

er edge of needle eye should be 2.3mm below

the hook point and the side face of needle should

10. Adjustment of Feed dog height (Fig.15):

Height of feed dog should be adjusted for individual fabrics with the

following cautions:

1) Fabric will be damaged if the feed dog extends too high or

pressure of presser foot is too large

2) Even stitch length cannot be assured if the feed dog is too low

or pressure of presser foot is too small

— 4 —

Page 7

3) Feed dog height should be measur ed at the point wher e the needle

is at the top position.

For light fabric: Approx 0.8mm

For usual fabric: Approx 1.0mm

For heavy fabric: Approx 1.2mm

Adjustment procedure:

1) Lay down the machine bed toward the other side;

2) Turn the balance wheel by hand stop when the feed dog is raise to its highest position from the surface of

needle place;

3) Loosen the Screw and adjust the height of the feed dog;

4) After adjusted, tighten the screw.

The feed dog height is factory-adjusted to 1.2mm

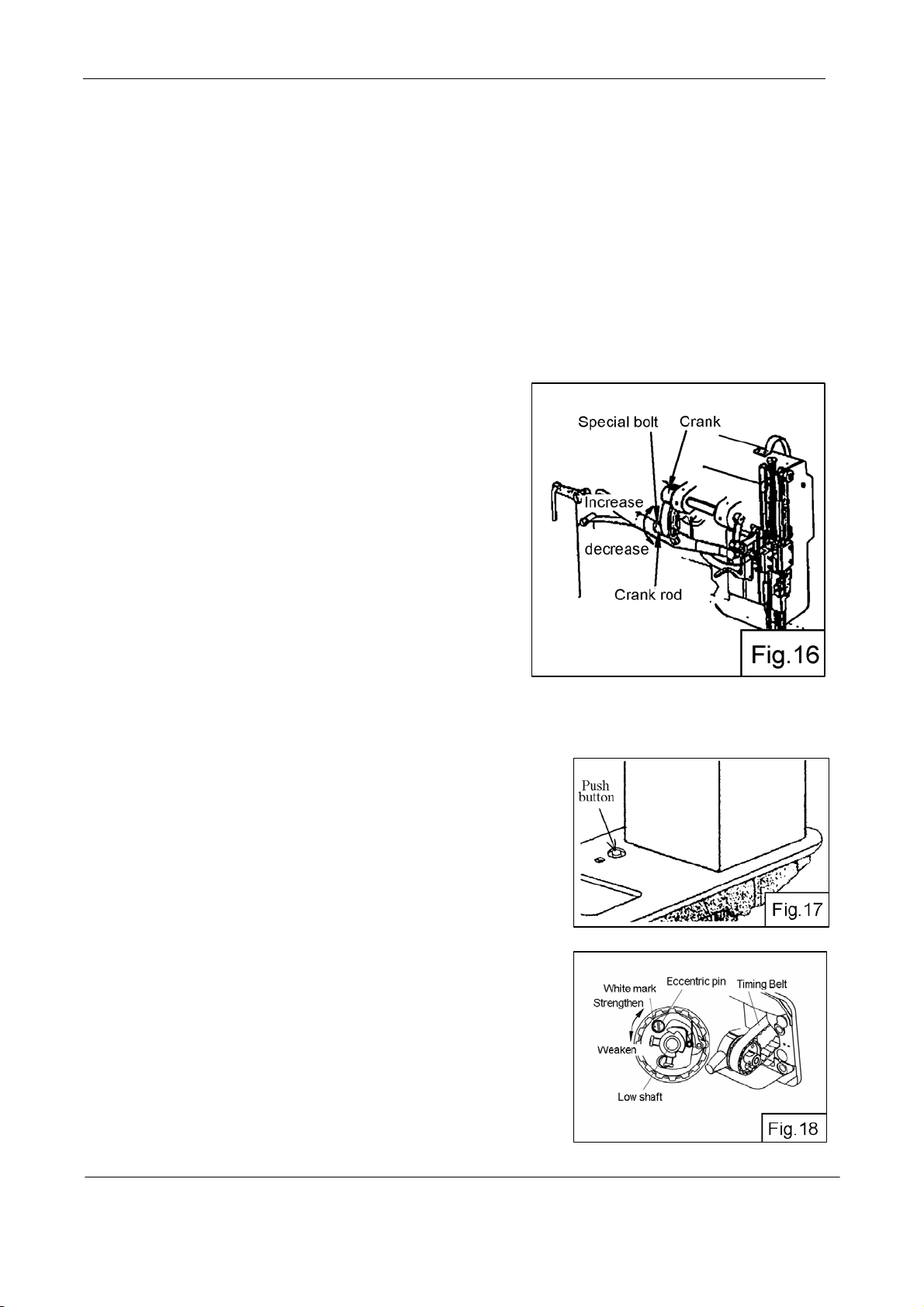

11. Walking foot and presser foot vertical

stroke adjustment (Fig.16):

When fabric with l

arge elasticity is sewn, or when thickness

of fabric changes, the vertical stroke (movable range) of the

presser feet should be adjusted as follows:

1) Loosen the special bolt;

2) The vertical strokes of presser feet become minimum

when the crank rod is moved downward and set;

3) The vertical strokes of presser feet become minimum

when the crank rod is moved upward and set;

4) After the adjustment, tighten the special nut.

The vertical strokes of presser feet can be adjusted within a range from 2mm to 6mm.

12. Safety clutch device (Fig.17, Fig.18)

Safety clutch device is installed to prevent the hook and cog belt

from damage in case the thread is caught into the hook when the

machine is loaded abnormally operation.

1) Function of safety clutch:

A. When the safety clutch acts, the cog belt pulley will be unloaded.

Then the rotation of hook shaft will stop. The arm shaft only will

rotate. Stop the operation of machine.

B. Clean t

C. Turn the cog belt hub by hand, and check whether the hook

shaft rotates lightly and properly, place the clutch device as follows.

2) How to set the safety clutch (Fig.18)

A. While pressing down the push button on the opposite side of

bed by left hand, turn the balance wheel slowly by right hand away

from you;

B. The ba

balance wheel more firmly;

he thread thoroughly which is caught into the hook.

lance wheel will stop by the gear plate, but turn the

— 5 —

Page 8

C. Release the push button, the safety clutch device is set.

3) Force applied to the safety clutch (Fig.18)

A. The force applied to the safety clutch is the smallest when the mark of eccentric pin faces the center of

the lower shaft. The force proportionally increases as the mark faces the outside;

B. To adjust the force slide the timing belt, loosen the set screw, and turn the eccentric pin;

C. After the adjustment, tighten the set screw.

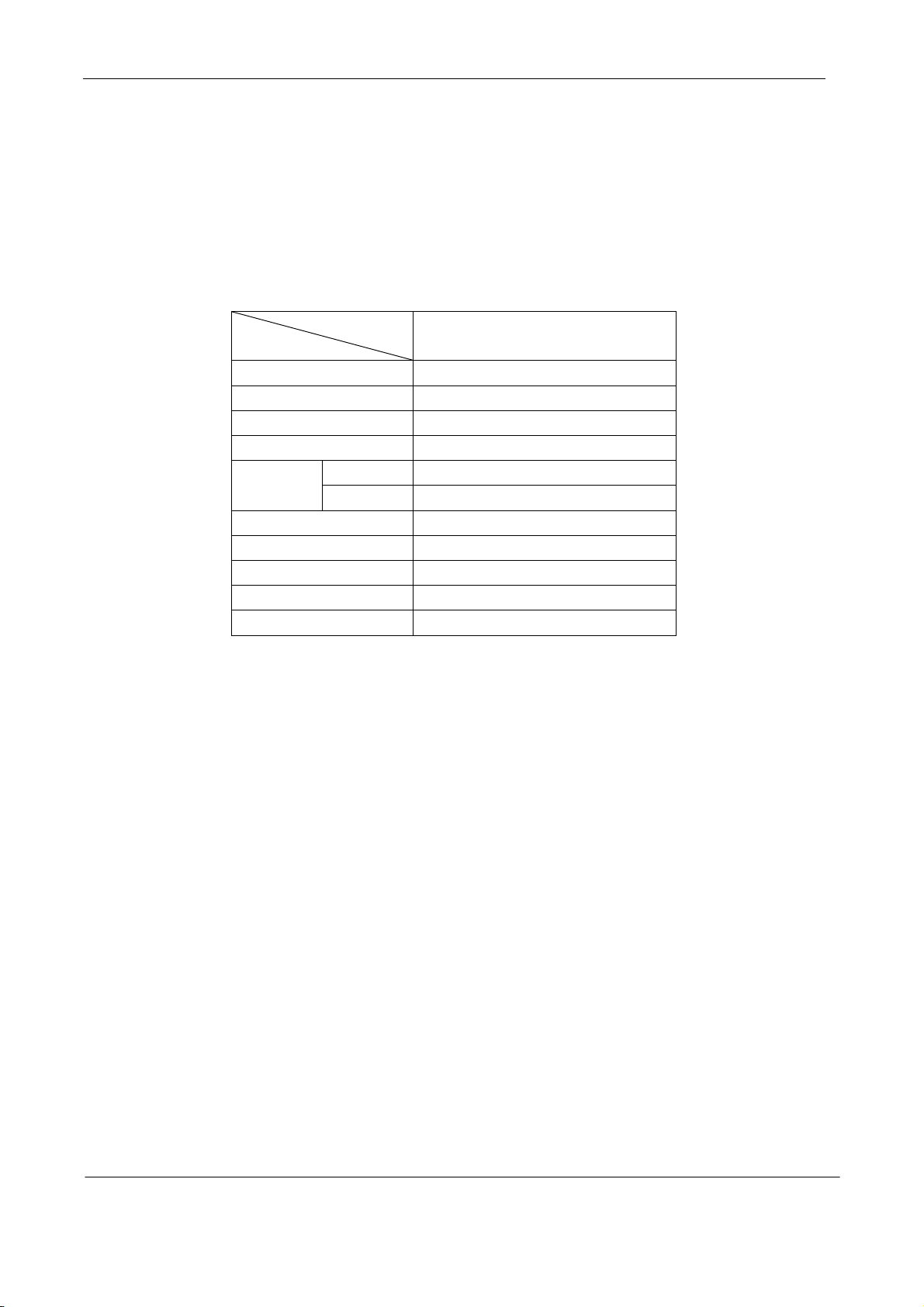

Specifications:

Model

Spec

Material weight Medium Heavy material

Max. sewing speed 1200rpm

Stitch length 0-7mm

Needle bar stroke 33.4mm

By hand 8mm Presser

foot stroke

By knee 16mm

Alternating movement 2-6mm

Stitch-length adjusting Dial type

Alternating movement Automatic

Needle DP×17(22#--24#)

Motor Servo Motor 550W

GC24698-25R/GC24698-25L

— 6 —

Page 9

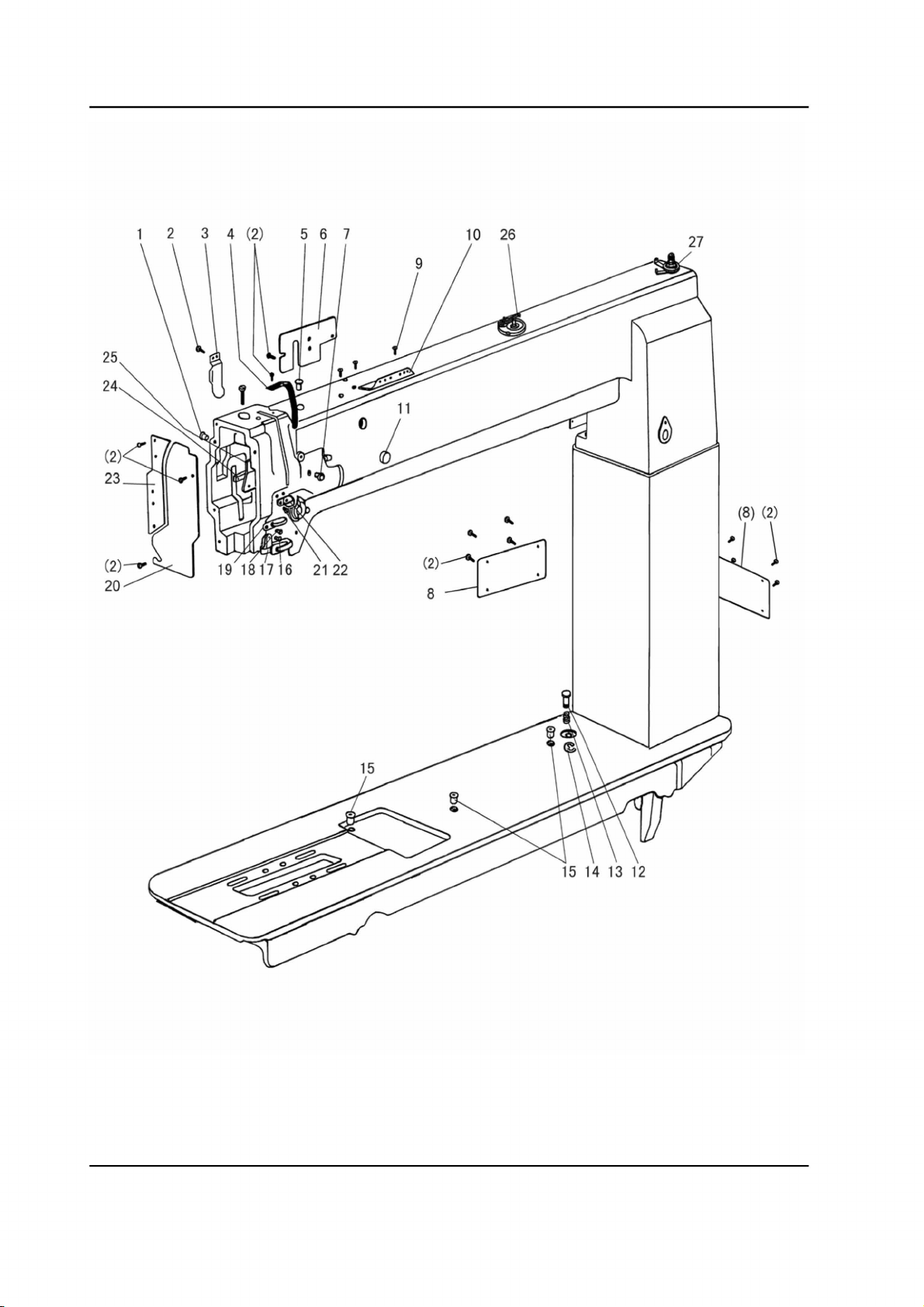

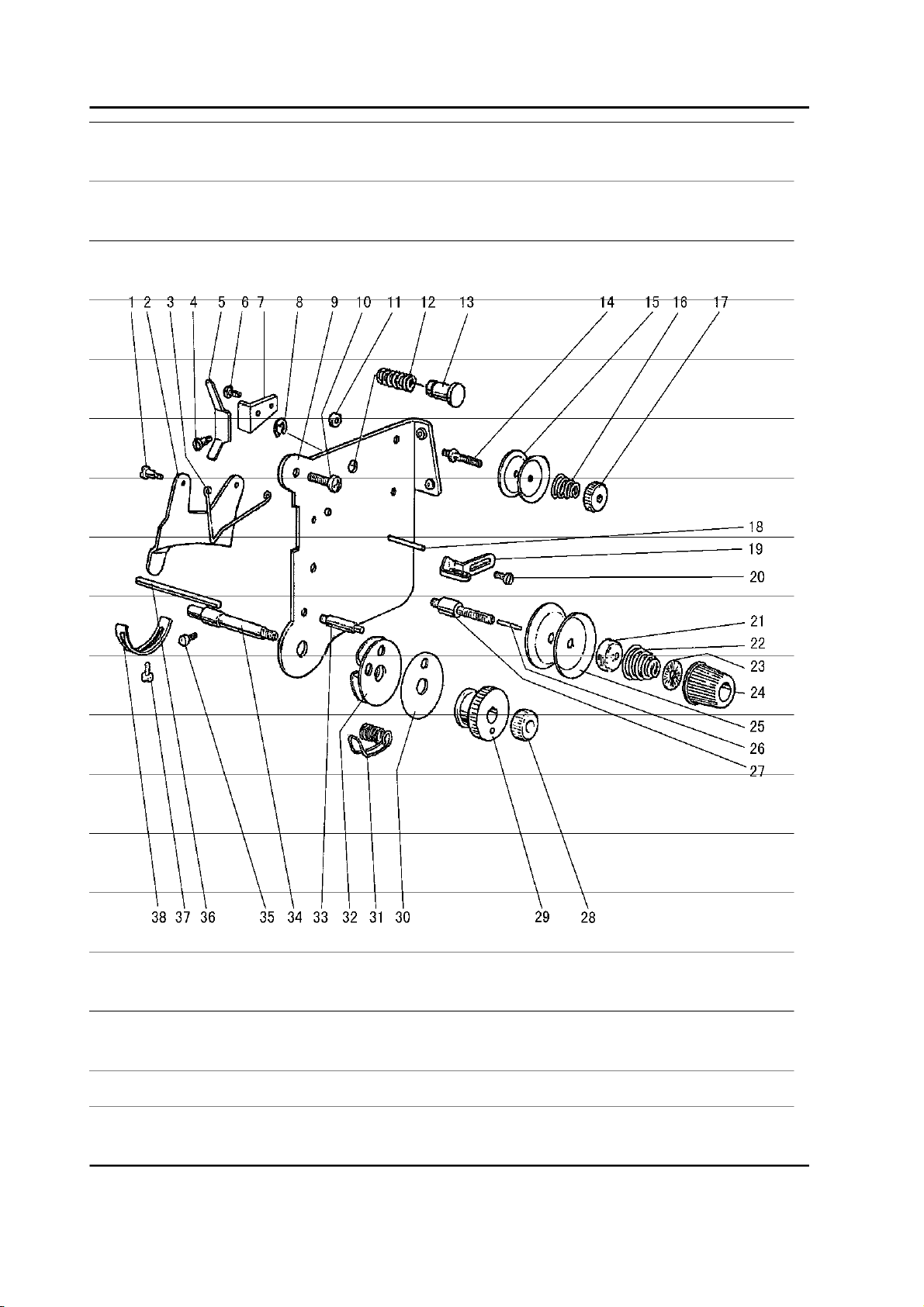

A. ARM BED MECHANISM

25

2.4

2 3 4

(2)

21

2.2

10

'

'

(2l

-'~

.·.

·

.....

8~

(8}

(2)

:

\

— 7 —

Page 10

A. ARM BED MECHANISM

Fig.

No.

A01 HA300B2090

A02 HA300B2170

A03 H4716B8001

A04 H4717B8001

A05 H4715B8001

A06 H4718B8001

A07 H2000B2010

A08 H7117B8001

A09 HA700B2060

A10 H2400B2100

A11 HA307B0673

A12 H4715H8001

A13 H4714H8001

A14 H007013050

A15 H2000M0090

A16 H3200B2100

A17 H3212B0066

A18 H3000D2160

A19 H4726B8001

A20 H4727B8001

A21 H2400B2080

A22 H2400B2070

A23 H4730B8001

A24 H2400B2060

A25 H3200B2060

A26 H7007D7101

A27 H7014D7101

Part No. Description

Rubber plug

Screw

Oil guide plate

Thread take-up cover

Rubber plug

Arm side cover (left)

Rubber plug

Arm side cover

Screw

Thread guide

Rubber plug

Push button

Spring

E-type ring

Cap

Screw

Thread guide

Screw

Thread guide

Face plate

Screw

Thread guide

Guide mounting plate

Spacer

Oil guide plate

Bobbin winder

Down-lead complete

Remarks

GC24698-25L

GC24698-25R

22

15 15 SM11/64(40)×9

11

11

11

11

11

22

2 2 SM11/64(40)×8

11

11

11

11

11

33

11

11

11

11

11

22

11

11

11

11

11

11

SM9/64(40)×6.5

SM9/64(40)×4.5

SM3/16(28)×12.1

— 8 —

Page 11

B. THREAD TENSION REGULATOR MECHANISM

— 9 —

Page 12

B. THREAD TENSION REGULATOR MECHANISM

Fig.

No.

B01 H2504C6510

B02 H3221B3142

B03 H3221B6812

B04 H4705C8001

B05 H4706C8001

B06 HA7311C306

B07 H4707C8001

B08 H007013050

B09 H3221B6820

B10 HA300C2030

B11 H3221B6810

B12 H4708C8001

B13 H4709C8001

B14 H3221B0683

B15 HA112B0693

B16 H3221B0684

B17 HA710B0671

B18 H3221B0682

B20 HA106B0676

B19 H3306B0661

B21 HA310B0702

B22 H4710C8001

B23 HA115B7010

B24 HA310B0701

B25 HA310B0705

B26 H3221B6817

B27 H3221B0686

B28 H32481B721

B29 H32481B621

B30 H32481BE21

B31 H4713C8001

B32 H32481BD21

B33 H4804C8001

B34 H4805C8001

B35 H3230K0751

B36 H3221B6817

B37 H4769E8001

B38 H3200B2100

B39 H3221B6819

Part No. Description

Screw

Tension releasing plate

Tension releasing spring

Screw

Lever

Screw

Mounting plate

E-type ring

Mounting plate

Screw

Nut

Spring

Push button

Thread tension stud

Thread tension disc

Spring

Thumb nut

Pin

Screw

Thread guide

Tension releasing disc

Spring

Thumb nut revolution stopper

Thumb nut

Thread tension disc

Pin

Thread tension stud

Thumb nut

Take-up spring guide

Plate complete

Thread take-up spring

Plate complete

Thread tension stud

Thread tension stud

Screw

Pin

Pin

Screw

Stopper

Remarks

GC24698-25L

GC24698-25R

2 2 9/64(40)×3

11

11

11

11

1 1 9/64(40)×7

11

1 1 GB/T896 5

11

2 2 11/64(40)×8

22

11

11

1 1 11/64(40)×14

22

11

11

22

1 1 9/64(40)×6

11

11

11

11

11

22

11

1 1 1/4(40)×23

11

11

11

11

11

1 1 9/64(40)×2.9

1 1 1/4(40)×14.5

1 1 11/64(40)×10

11

11

1 1 9/64(40)×6.5

11

— 10 —

Page 13

C. UPPER SHAFT MECHANISM

t------18

(10)

31

30

29

28 27 26

— 11 —

Page 14

C. UPPER SHAFT MECHANISM

Fig.

No.

C01 HA307C0662

C02 H33111C104

C03 HA105D0662

C04 HA100C2060

C05 HA100C2070

C06 H4708D8001

C07 H32111B104

C08 H32111B204

C09 H7004D8001

C10 H3205C0661

C11 HA113F0684

C12 H3205C1021

C13 HA100F2130

C18 H7104D8001

C19 HA104F0654

C20 H4713D8001

C21 H4714D8001

C22 H4716D8001

C23 H007013025

C24 H4717D8001

C25 H4718D8001

C26 H4719D8001

C27 H4715D8001

C28 H4720D8001

C29 H4721D8001

C30 H4722D8001

C31 H4723D8001

C32 H007009300

C33 HA700R0060

C34 HA700R0050

C35 HA700R0040

C36 H4928L8001

C37 HA700R0030

C38 H4930L8001

C39 HA110D0672

C40 H4931L8001

C41 HA703R0067

C42 HA703R0065

B39 H3221B6819

Part No. Description

Set screw

Crank

Set screw

Screw

Screw

Set screw

Felt

Arm shaft bushing (left)

Arm shaft

Spring flange

Screw

Pulley

Screw

Cog belt

Screw

Link

Pin

Spring

E-type ring

Link

Pin

Link

Pin

Bushing

Screw

Pulley

Screw

Retaining ring C-type

Washer

Support spring

Spacer B

Speed command disk F20 (up)

Spacer A

Speed command disk F11 (down)

Screw

Pulley (complete)

Washer

Detector bracket (complete)

Stopper

Remarks

GC24698-25L

GC24698-25R

11

11

11

11

11

1 1 SM1/4(24)×13

11

11

11

33

33

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

22

1 1 GB/T894.1 30

11

11

11

11

22

11

22

11

11

11

11

SM1/4(40)×6

SM1/4(40)×4

SM9/32(28)×13

SM9/32(28)×14

SM15/64(28)×8.5

SM15/64(28)×14.5

SM15/64(28)×10

SM15/64(28)×10.5

SM15/64(28)×4.5

SM15/64(28)×12

— 12 —

Page 15

D. PRESSER FOOT MECHANISM

— 13 —

Page 16

D. PRESSER FOOT MECHANISM

Fig.

No.

D01 H4705E8001

D02 H4707E8001

D03 H0030580608

D04 H4706E8001

D05 H4709E8001

D06 H3115F0671

D07 H2013J0065

D08 H2014J0066

D09 H2000J2100

D10 H4713E8001

D11 H20111C106

D12 H007009250

D13 H4714E8001

D14 HA307C0662

D21 H3100G2170

D22 H4730E8001

D23 H4729E8001

D24 H4727E8001

D25 H4728E8001

D26 H3100G2130

D27 H4726E8001

D28 H4725E8001

D29 HA111G0683

D30 H4723E8001

D31 H4754E8001

D32 H4744E8001

D33 H3200E2020

D34 H4746E8001

D35 H4768E8001

D36 H2404I0034

D37 H4748E8001

D38 H4767E8001

D39 H4752E8001

D40 H4749E8001

D41 H0207E8001

D42 H2004J0655

D43 H4717E8001

D44 H4718E8001

D45 H2004J0662

D46 H4719E8001

D47 HA100E2150

D48 H4722E8001

D49 H4721E8001

Part No. Description

Feed lifting rock shaft

Bushing

Nut

Set screw

Crank

Screw

Washer

Connecting rod

Screw

Oil wick

Holder

C-type ring

Eccentric

Screw

Screw

Lever spring

Screw

Twist spring

Knee lifting lever

Screw

Nut

Screw

Screw

Guide

Presser bar

Bushing

Screw

Spring bracket

Thread releasing plate

Screw

Lift lever

Spring

Bracket

Screw

Bell crank

Screw

Roller

Screw

Screw

Link

Screw

Washer

Bell crank guide

Remarks

GC24698-25L

GC24698-25R

11

22

1 1 (M6×0.75)

2 2 SM1/4(24)×7

11

11

11

11

1 1 M6(0.75)×24

11

11

11

11

22

1 1 SM1/4(24)×17

11

11

11

11

1 1 SM1/4(24)×7

11

11

2 2 SM11/64(40)×12

11

11

11

1 1 SM1/8(44)×9

11

11

11

11

11

11

1 1 SM11/64(40)×8.5

11

11

11

11

1 1 SM1/4(40)×5

11

22

22

11

SM1/4(28)×16

SM1/4(40)×6

SM15/64(28)×79

SM1/4(24)×19

SM9/64(40)×8.5

SM3/16(28)×10

SM11/64(32)×6

SM11/64(40)×10

— 14 —

Page 17

D. PRESSER FOOT MECHANISM

Fig.

No.

D50 H4753E8001

D51 H4708D8001

D52 H7905E8001

D52 H7105E8001

D53 HE204I8001

Part No. Description

Screw

Set screw

Lifting presser

Lifting presser

Finger gusrd

Remarks

GC24698-25L

GC24698-25R

1 1 SM11/64(40)×17.5

2 2 SM1/4(24)×13

1

1

11

— 15 —

Page 18

E. THRED TAKE-UP LEVER & NEEDLE BAR MECHANISM

2 3 4

56

7 8 9

10

11

12

13

48

47

31

32

— 16 —

Page 19

E. THRED TAKE-UP LEVER & NEEDLE BAR MECHANISM

Fig.

No.

E01 H24211DN05

E02 H4706F8001

E03 H4707F8001

E04

E05

E06

E07

E08

E09

E10

E11

E12

E13

E14

E15

E16

E17

E18

E19

E20

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E32

E33

E34

E35

E36

E37

E38

E39

E40

E41

E42

E43

Part No. Description

HA100C2020

H24211DN05

H24211DM05

H3504B0651

H2405D1112

HA110D0672

H24211D405

H24211D305

H2405D0662

H4716F8001

H4717F8001

H4719F8001

H32111D304

H4721F8001

H3204D6513

H4722F8001

H32111D604

H4806F8001

H4725F8001

H3400C2020

H3200I2030

H3400C2010

H4726F8001

H4753E8001

H4728F8001

H4729F8001

H4730F8001

H3410C301P

H3406C0671

H3406C0672

H4734F8001

H3204B0652

H602040240

H7004F8001

H7107F8001

H2012N0652

H7108F8001

H32311D406

H7104F8001

H7105F8001

Oil wick

Needle bar guide bracket stud

Screw

Set screw

Oil wick

Thread take-up lever support stud

Thread take-up lever

Thread take-up slide brock

Screw

Oil wick

Plug

Needle bar crank pin

Oil wick

Needle bar connecting link

Needle bar rock frame

Screw

Washer

Felt

Needle bar connecting stud

Screw

Needle bar

Vibrating presser bar

Bolt

Washer

Needle bar guide

Vibrating presser bar link

Screw

Vibrating presser bar guide

Spring

Vibrating presser spring guide

Square block

Screw

Needle bar vibrating crank(left)

Washer

Bushing

Taper pin

Needle bar vibrating shaft

Nut

Screw

Screw

Oil wick

Needle bar vibrating crank(right)

Connecting link

Remarks

GC24698-25L

GC24698-25R

11

11

1 1 5/16(28)×10.4

1

1

15/64(28)×10

1

1

1

1

1

1

1

1

1

1

15/64(28)×12

1

1

1

1

1

1

1

1

1

1

1

1

6

6

3/32(56)×4

2

2

1

1

1

1

1

1

9/64(40)×8.5

1

1

1

1

121

11

11

11

2 11/64(40)×17.5

1

1

1

1

1

1

1

1

1

1

15/64(28)×10

1

1

1

1

2

2

1

1 GB/T117 4×24

11

11

1

1 1/4(24)×16

1

1 5/16(24)×5

1

1

1

1

1

1

— 17 —

Page 20

E. THRED TAKE-UP LEVER & NEEDLE BAR MECHANISM

Fig.

No.

E44 H3129F0693

E45 HA100C2170

E46 H3129F0691

E47 H7106F8001

E48 HA700F2100

Part No. Description

Thread guide

Screw

Screw

Vibrating presser foot

Screw

Remarks

GC24698-25L

GC24698-25R

11

1 1 1/8(44)×4.5

1 1 3/32(56)×2.5

11

1 1 11/64(40)×7

— 18 —

Page 21

F. STICH REGULATOR MECHANISM

2 3 4 5 6 7 8

34

33 32

31

30

29 28 26

25 24 23 22

21

20

19 18

13

~16

~17

— 19 —

Page 22

F. STICH REGULATOR MECHANISM

Fig.

No.

F01 H4706G8001

F02 HA113F0684

F03 H3200F2020

F04 H7104G8001

F05 HA100G2070

F06 HF30G78001

F07 HA720F0687

F08 HA700F2030

F09 HF30G58001

F10 HA800F2020

F11 H3207F0672

F12 HA100F2110

F13 H7105G8001

F14 H4906G8001

F15 H4710G8001

F16 H3200F2050

F17 HA300C2030

F18 HA109F0673

F19 HA720F0685

F20 H7107G8001

F21 HA7421F120

F22 HA720F0683

F23 HA720F0687

F24 HA109F0674

F25 HA109F0671

F26 H3206F0662

F27 H415050200

F28 H428050060

F29 H4714G8001

F30 H4715G7101

F31 HA3411D308

F32 H4719G8001

F33 H4720G8001

F34 H4721G8001

F35 H4722G8001

F36 H4723G8001

F37 HA300C2030

F38 HA113F0684

F40 H4936L8001

F41 H4938L8001

F42 H4937L8001

F43 H4939L8001

Part No. Description

Feed regulator

Screw

Screw

Link

Eccentric shaft

Reverse stitch shaft

Spring

Stopper pin

Reverse stitch crank

Screw

Screw

Washer

Spring hook

Feed reversing lever

Spring

Bracket for spring

Screw

Screw

bush

Face plate

Dial

Plate

Spring

O-ring

Screw bar

Pin

Screw

Screw

Reverse sewing crank

Collar

Screw

Felt

Rverse block

Felt

Square block

Guide plate

Screw

Screw

block

rubber band

Screw

Spring

Remarks

GC24698-25L

GC24698-25R

11

22

11

11

11

11

11

11

11

1 1 15/64(28)×13.5

1 1 11/64(40)×8.5

11

11

11

11

11

44

11

11

11

11

11

11

11

11

11

1 1 GB/T70.1 M5×20

2 2 GB/T77 M5×6

11

11

2 2 SM15/64(28)×7

11

11

11

22

22

44

22

11

11

11

11

15/64(28)×8.5

15/64(28)×12

11/64(40)×8

3/16(28)×8.6

T7/16(8)×54.3

SM11/64(40)×8

M5×6

— 20 —

Page 23

G. LOWER AND FEEDING SHAFT MECHANISM

— 21 —

Page 24

G. LOWER AND FEEDING SHAFT MECHANISM

Fig.

No.

G01

G02

G03

G04

G05

G06

G07

G11

G12

G13

G14

G15

G16

G17

G18

G19

G20

G21

G22

G23

G24

G25

G26

G27

G28

G29

G30

G31

G32

G33

G34

G35

G36

G37

G38

G39

G40

G41

G42

G43

G44

G45

G46

Part No. Description

H4706H8001

H4707H8001

H7004H8001

H4710H8001

H3205H0654

H4712H8001

H4713H8001

H2405D0664

H4717H8001

H4719H8001

H4718H8001

H007009260

H4720H8001

H4721H8001

H7006H7101

H4724H7101

HA105D0662

H3205H0654

H4723H8001

H4727H8001

HA7311C306

H4728H8001

H4729H8001

H0030580608

H7105H8001

H2012N0652

HA100G2120

H4708D8001

HA108G0661

HA105D0662

H2012N0652

H4736H8001

H4737H8001

H007013050

H4738H8001

H4739H8001

H7005H8001

H4740H8001

H3204G0031

H3200G2030

HA104G0012

H3205G1032

H32243G205

Lower shaft bushing (left)

Oil wick

Lower shaft

Feed eccentric cam

Screw

Lower shaft bushing (right)

Oil wick

Screw

Feed eccentric

Needle bearing

Feed connecting rod

C-type stop ring

Oil wick

Shaft

Lower shaft bushing complete (middle)

Bushing

Screw

Screw

Ball bearing

Bearing holder

Screw

Washer

Screw

Nut

Feed connection crank (right)

Screw

Feed rock shaft bushing

Screw

Collar

Screw

Screw

Feed connection crank (middle)

Link

E-type stop ring

Pin

Oil wick

Feed rock shaft

Felt

Oil wick

Clip

Screw

Feed connection crank (left)

Feed bar shaft

GC24698-25L

GC24698-25R

1

1

1

1

1

1

1

1

1

1

SM1/4(40)×5

1

1

1

1

2

2

SM15/64(28)×14

1

1

1

1

1

1

1

1

GB/T894.1 26

1

1

1

1

11

11

11

1

11

11

33

11

11M6

1

11

1

222

22

4

1

11

121

11

11

11

22

1

1

2

11

11

SM1/4(40)×4

1 SM1/4(40)×5

SM9/64(40)×7

1 GB52008 M6

1 SM1/4(24)×16

2 SM1/4(24)×13

4 1/4(40)×4

1 SM1/4(24)×16

2 GB/T896 5

1

1

SM3/16(28)×12

2

Remarks

— 22 —

Page 25

G. LOWER AND FEEDING SHAFT MECHANISM

Fig.

No.

G47 H3205G0662

G49 H429050050

G50 H7106H8001

G51 H3200H2040

G52 H2013J0065

G55 H3205H0653

G56 H3205H0652

G57 H4743H8001

G59 H007009070

Part No. Description

Oil wick

Bolt

Feed bar

Screw

Washer

Screw

Felt

Feed bar forked connection

C-type stop ring

Remarks

GC24698-25L

GC24698-25R

11

1 1 GB/T78 M5×5

11

1 1 SM15/64(28)×17

11

11

11

11

11

SM1/8(44)×4

— 23 —

Page 26

H.FEED BAR MECHANISM

— 24 —

Page 27

H.FEED BAR MECHANISM

Fig.

No.

H01 H7107I8002

H01 H7904I8001

H02 H7108I8001

H03 H7104I8001

H04 H7105I8001

H05 H7106I8001

H06 H7113I8001

H07 H3208G0675

H08 HA300B2160

H09 H7109I8001

Part No. Description

Feed dog

Feed dog

Screw

Feed bar

Square block

Screw

Screw

Nut

Screw

Cover plate

Remarks

GC24698-25L

GC24698-25R

1

1

11

11

11

11

11

11

4 4 11/64(40)×10

11

— 25 —

Page 28

I. HOOK SADDLE MECHANISM

j22

21

,,

,,

~'

2

'

3

wj

17,/'

18

20

13

4

5

'i©

l,

1~

{;:8

~~g

'

11

14

6

10

— 26 —

Page 29

I. HOOK SADDLE MECHANISM

Fig.

No.

I01 H7124J8001

I02 H7123J8001

I03 H7109J8001

I04 H5337D8001

I05 H2400I2020

I06 H7127J7101

I07 H7125J8001

I08 H41622D216

I09 H410270D16

I10 H7115J8001

I11 HA105D0662

I12 H2204C0651

I13 H7106J8001

I14 H7104J8002

I15 H3210F0681

I16 H7122J8001

I17 H3204D6511

I18 H7113J8001

I19 H415080200

I20 H005004080

I21 H7904J8001

I21 H7116J8001

I22 H2000H2020

I23 H7121J8001

I24 H4705I8001

I25 HA105D0662

I26 H4706I8001

I27 H4707I8001

I28 HA307C0662

Part No. Description

Screw

Slide plate

Hook saddle

Screw

Bobbin

Hook

Opener

Square block

Pin

Cover plate

Screw

Screw

Collar

Hook shaft

Screw

Spring

Screw

Hook saddle post bed

Screw

Washer

supporter

supporter

Screw

Bushing

Gear (small)

Screw

Gear (Big)

Screw

Screw

Remarks

GC24698-25L

GC24698-25R

11

11

11

3 3 9/64(36)×30

11

11

11

44

11

11

1 1 1/4(40)×4

1 1 9/64(40)×6.5

11

11

1 1 M5×6

11

1 1 1/8(44)×3.5

11

4 4 GB/T70.1 M8×20

4 4 GB/T848 8

1

1

1 1 15/64(28)×14

11

11

3 3 1/4(40)×4

11

1 1 1/4(40)×6.5

1 1 1/4(40)×6

— 27 —

Page 30

J. OIL LUBRICATION MECHANISM

— 28 —

Page 31

J. OIL LUBRICATION MECHANISM

Fig.

No.

J01 H32175B304

J02 H4705J7101

J03 H3204K0011

J04 H411040160

J05 H4707J8001

J06 H7005J8001

J07 H7007J7101

J08 H32311D606

J09 HA106B0676

J10 H3200K0170

J11 H3200K0160

J12 H3200K0180

J13 H7020J8001

J14 H7021J8001

J15 H2000M0180

J16 H2000M0190

J17 H2000M0200

J18 H3107G0661

Part No. Description

Felt

Oil pipe complete

Oil reservoir complete

Screw

Holder

Felt

Oil pipe complete

Holder

Screw

Holder

Holder

Oil wick Ф2.5×35

Pressing plate

Sealed cushion

The oil amount observes window

Sealed cushion

Pressing plate

Screw

Remarks

GC24698-25L

GC24698-25R

11

11

11

2 2 GB/T819.1 M4×16

11

11

66

44

10 10

44

22

33

11

11

11

11

11

66

SM9/64(40)×4.5

— 29 —

Page 32

K. ACCESSORIES (I)

25

23

<:>

I

17

— 30 —

Page 33

K. ACCESSORIES (II)

27

28

(28)

— 31 —

Page 34

K. ACCESSORIES

Fig.

No.

K01

K02 HB01001025

K03 HB01001030

K04 HB01001015

K05 H2400I2020

K06 HA300J2230

K07 H801045200

K08 H2004O0065

K09 H2004O0066

K10 H2404K0654

K11 H2404K0655

K12 H2404K0656

K13 H802080350

K14 730

K15 H7013K8001

K16 H7014K8001

K17 H7009K8001

K18 HA300J2210

K19 HA300J2200

K20 HA300J2070

K21 HA704S0654

K22 H3207L0065

K23 H3200L0130

K24 H3200L0120

K25 HA100J2110

K26 H7112L8001

K27 H2008O0068

K28 HA300B2170

K29 H7115L8001

K30 H7123L8001

K31 H7124L8001

Part No. Description

JZDP1700P23

Needle DP×17-23

Socket wrench

Socket wrench

Socket wrench

Bobbin

Washer

Screw

Vibration preventing rubber

Vibration preventing rubber

Hinge complete

Hinge complete

Screw

Screw

O-type belt

Oil check

Oil check

Vinyl cover

Screw driver (small)

Screw driver (middle)

Screw driver (large)

Adjusting plate for speed command disk

Thread a needle kit

Oil box

Knee lift shaft

Oiler

Cotton stand pipe

Belt cover (upper)

Screw

Belt cover

Belt cover stand

Supporter

Remarks

GC24698-25L

GC24698-25R

6 6 DP×17-23

11

11

11

4 4 B0-B872(A)

22

4 4 GB/T99 4.5×20

22

22

22

22

44

4 4 GB/T100 8×35

11

11

11

11

11

11

11

11

11

11

11

11

11

11

10 10

11

11

11

— 32 —

Page 35

L. PNEUMATIC CONTROL UNIT

— 33 —

Page 36

L. PNEUMATIC CONTROL UNIT

Fig.

No.

L01 H4915B8001

L02 H4919B8001

L03 HA300B2170

L04 H005008100

L05 H415060200

L06 H4914G8001

L07 H4913G8001

L08 H4916G8001

L09 H415050450

L10 H0607N8001

L11 H415060200

L12 H005008060

L13 H0605N8001

L14 H0606N8001

L15 H4916G8001

L16 H0608N8001

L17 HF106L7101

Part No. Description

Air cylinder

Plate

Screw

Washer

Screw

Pole

Feeler

Joint

Screw

Air cylinder

Screw

Washer

Plate

Block

Joint

Valve

Touth switch complete

GC24698-25L

GC24698-25R

11

11

44

44

44

11

11

22

44

11

22

22

11

11

11

11

11

Remarks

— 34 —

Page 37

SHANGHAI HUIGONG NO.3 SEWING MACHINE FACTORY

ADD: 1418, Yishan Road, Shanghai, China

Zip Code: 201103

Overseas Business: TEL: 86-21-64853303 FAX: 86-21-64854304

E-mail:highlead@online.sh.cn http://www.highlead.com.cn

The description covered in this manual is subject to change for improvement of the commodity without notice

2010.5. Printed

Loading...

Loading...