Purchasing

Copy

Dept

HIGH

LEAD

GC24698-1L/GC24698-1R

Super

Post Bed Compound Feed Lockstitch Sewing Machine

Instruction Manual

Parts

SHANGHAI HUIGONG

N0.3

Catalog

SEWING MACHINE FACTORY

Instruction Manual

--- CONTENTS ---

• Preparation for operation

1 , Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2,

Precautions before starting operation

3,

Precautions for operating conditions

• Cautions on use

1 , Lubrication ( 1)

2,

Lubrication (2)

3,

Oiling condition

4,

Cautions on operation

Operation

1,

Installation

2,

Winding ofbobbin thread

~,

Selection

4,

Threading

...............................................................................

of

......................................................................

........................................................................

.......................................

.......................................................................

of

needles

thread

of

needle threads

..............................................................

.......................................................

.......................................................

,

................................

..................................................................

................................................................

.............................................................

...................................................................

...........................................................

2

2

2

2

2

2

3

3

~

1

1

1

2

5, Adjustment

6,

Balance

7,

Needle thread tension

8,

Adjustment ofpresser foot pressure

9,

Timing between rotating hook motion and needle motion

1

o,

Adjustment

11, Relationship between rotating hook motion and take-up lever motion

12, Relationship between needle motion and feed dog motion

13, Safety clutch device

14,

Upper feed adjustment

15, Outside presser foot and inside presser vetiical stroke adjustment

16,

Adjustment

16, Installation

of

stitch length and reverse sewing

of

thread tension

.............................................................

.........................................

.................................................................

....................................................

of

feed dog height

.......................................................

.................................................................

..............................................................

........................................................................

of

Belt cover

............................................................

.................................

...............................

........................

Parts Catalog

.....................

:~

3

4

4

4

4

5

5

6

6

6

7

7

A,

ARM

BED AND

8,

THREAD TENSION REGULATOR MECHANISM

ITS

ACCESSORIES

.....................................................

.........................................

8

10

C,

ARM SHAFT MECHANISM

D,

UPPER SHAFT & PRESSER FOOT MECHANISM

E,

TAKE-UP THREAD AND ARM SHAFT MECHANISM

F,

STITCH REGULATOR MECHANISM

G,

LOWER

H,

FEED BAR MECHANISM

SHAFT & FEED ROCK SHAFT MECHANISM

............................................................

...................................................

............................................................

.........................................

.....................................

....................................

12

14

17

20

22

25

L HOOK SADDLE MECHANISM

J,

OIL LUBRICATION MECHANISM

K,

ACCESSORIES

.....................................................................

.........................................................

......................................................

27

29

:11

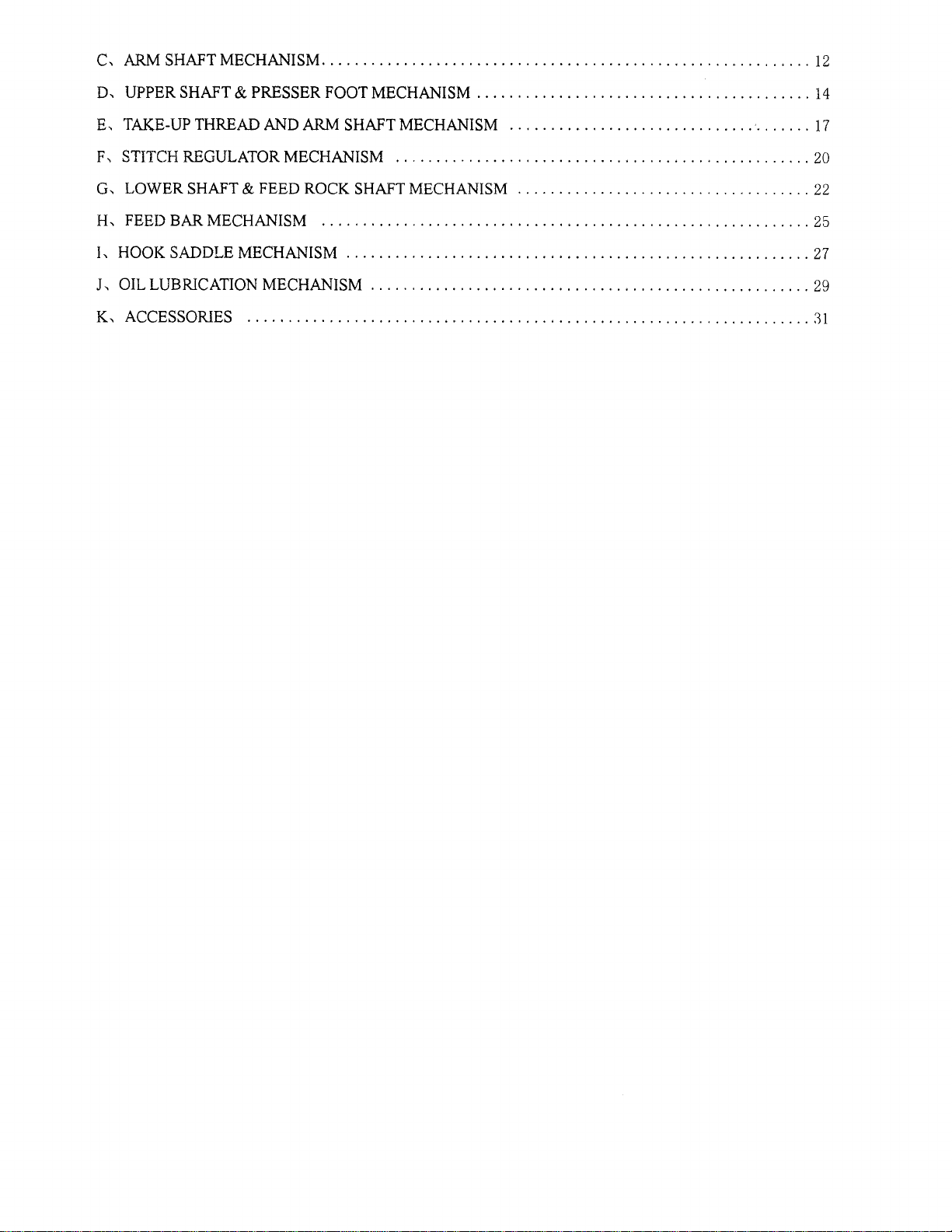

• Preparation for operation:

1.

Safety

1 ) When turning the power on, keep your hands and fingers away from the area around/under the needle

and

2)

3)

the machine, or when replacing.

4)

the machine

5)

machine is in operation.

6)

these

2.

Precautions before starting operation:

1 ) Never operate the machine before filling the machine's oil pan.

2)

pcwer

3)

prec~utions:

the area around the pulley.

Power must be turned off when the machine is not

Power must be turned off when tilting the machine head, installing

Avoid placing fingers, hairs, bars etc. near the pulley,

is

in operation.

Do not insert fingers into the thread take-up

I'f

a

belt

cover,

safety

When a new sewing machine is first turned on, verify the rotational direction

en.

Verify the voltage and phase (single or three) with those given on the machine nameplate.

finger

devices.

guard,

eye

guard

in

use, or when the operator leaves the seat.

or

removing the

"V"

belt, bobbin winder pulley, or motor when

covo~.r,

are

under/around the needle, or pulley when the

installed,

do

not

operate

"V"

belt, adjusting

the

machine

of

the pulley with the

without

3. Precautions for operating conditions:

I ) Avoid using the machine at abnormally high temperatures (

or lower)

2)

Avoid using the machir:e

Overall view

of

assembled sewing

in

dusty conditions.

machine

35

·c

or higher) or low temperatures ( 5

Balance wheel

·c

-I-

• Cautions

1.

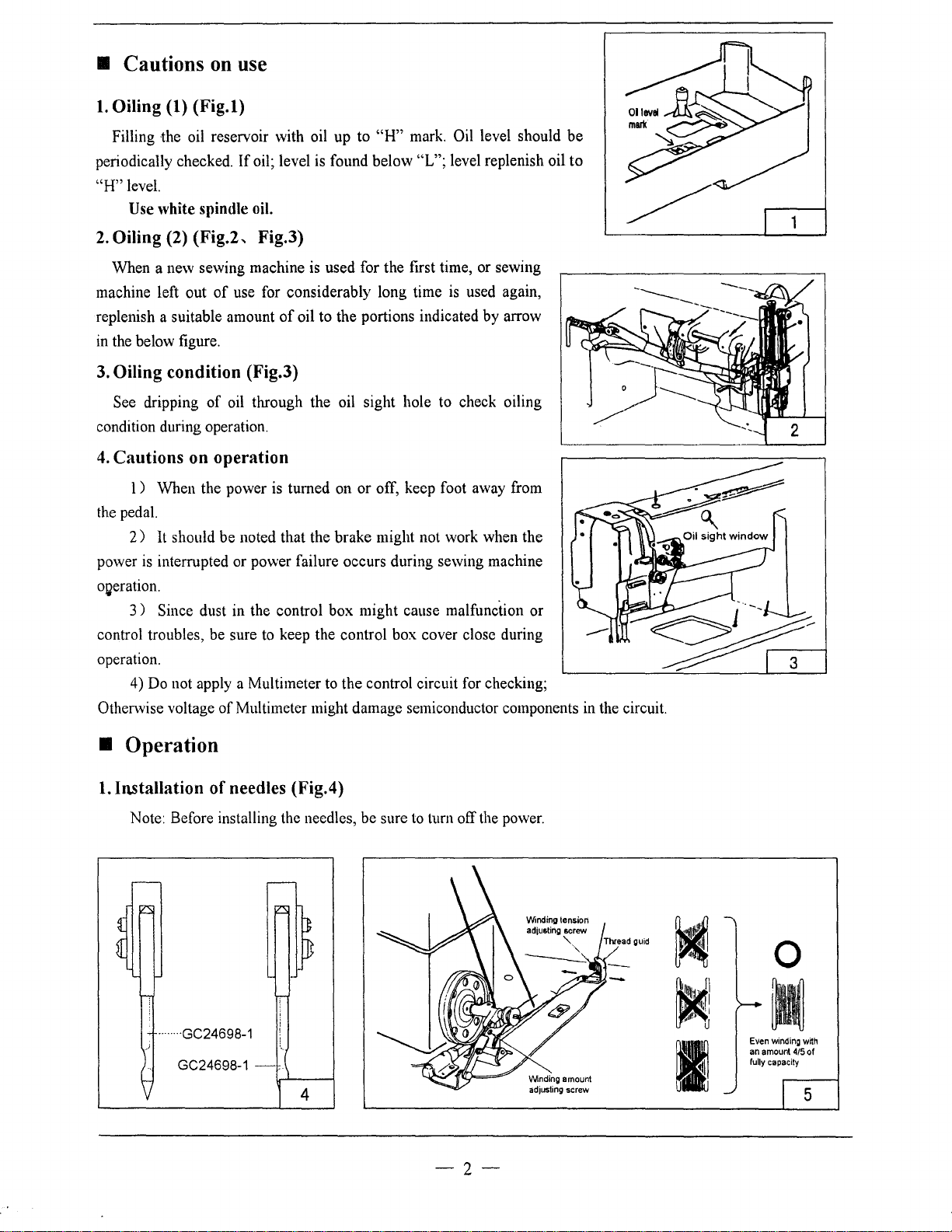

Oiling (1)

(Fig.l)

on

use

Filling the oil reservoir with oil up to

periodically checked.

"H"

level.

Use

white

2.

Oiling (2) (Fig.2, Fig.3)

When a new sewing machine is used for the first time, or sewing

machine left out

replenish a suitable amount

in the below figure.

If

oil; level is found below "L"; level replenish oil

spindle

oil.

of

use for considerably long time

of

oil to the portions indicated by arrow

"H"

mark. Oil level should

is

used again,

3. Oiling condition (Fig.3)

See dripping

condition during operation.

4.

Cautions on operation

l ) When the power is turned on or off, keep foot away from

the pedal.

2)

It should be noted that the brake might not work when the

power

is

interrupted or power failure occurs during sewing machine

OQeration.

3)

Since dust in the control box might cause malfunction or

control troubles, be sure to keep the control box cover close during

operation.

4) Do not apply a Multimeter to the control circuit for checking;

Otherwise voltage

of

oil through the oil sight hole to check oiling

of

Multimeter might damage semiconductor components in the circuit.

be

to

------

• Operation

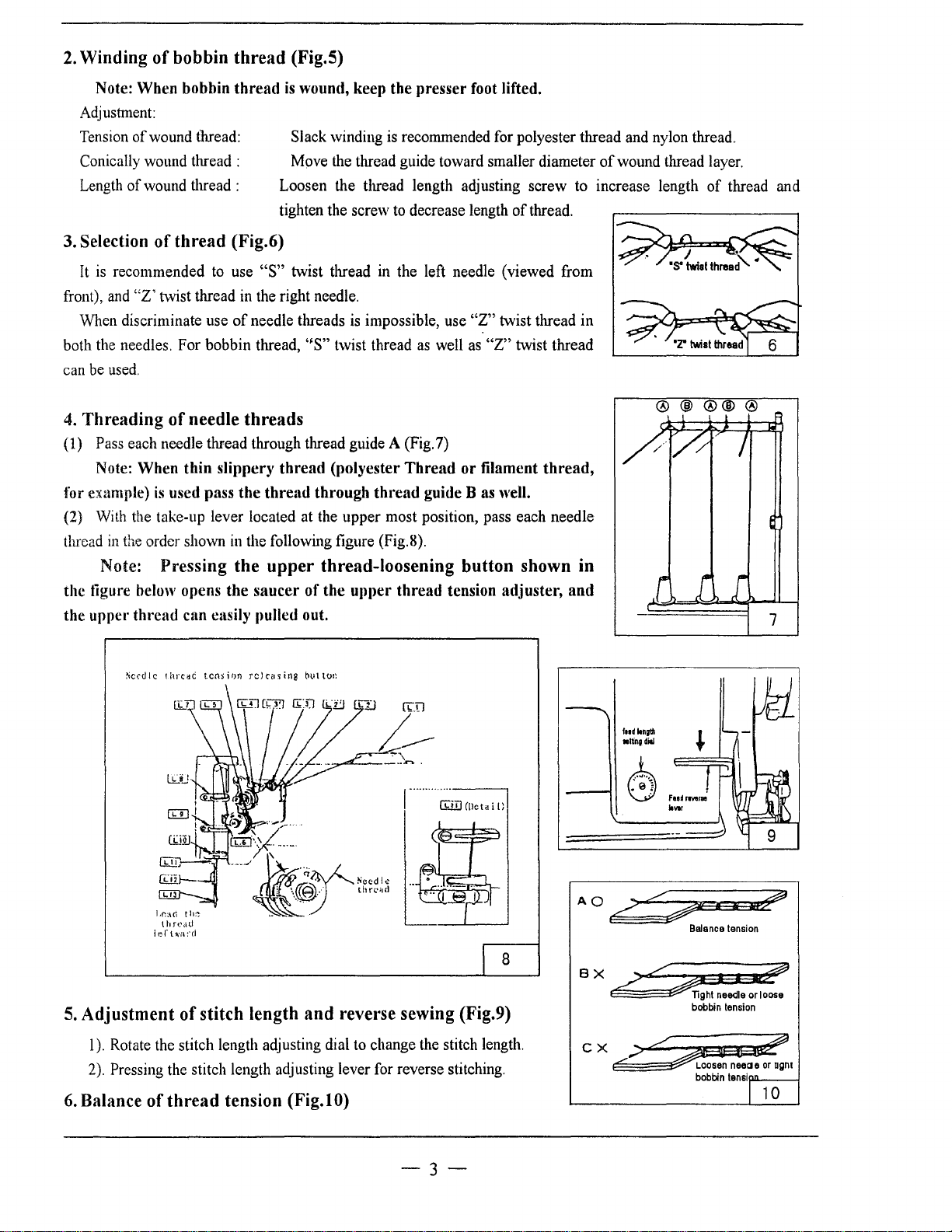

1.

Installation

Note: Before installing the needles, be sure to turn off the power.

... ·GC24698-1

of

needles (Fig.4)

GC24698-1 -

..

4

-2-

Wnding

adjusting

amount

screw

~

Even

an

amount

fully

I

0

winding

capacity

415

wrth

of

5

2.

Winding

of

bobbin

thread

(Fig.5)

Note: When bobbin thread

Adjustment:

Tension

Conically wound thread :

Length

3.

Selection

It

front), and

When discriminate use

both the needles. For bobbin thread,

can be used.

4.

Threading of needle threads

(1) Pass each needle thread through thread guide A (Fig.7)

of

wound thread:

of

wound thread :

of

thread (Fig.6)

is recommended to use

"Z'

twist thread

of

Note: When thin slippery thread (polyester Thread

for example)

(2) With the take-up lever located at the upper most position, pass each needle

thread

is

used pass the thread through thread guide

in

the order shown

in

Note: Pressing the

is

wound, keep the presser foot lifted.

Slack winding is recommended for polyester thread and nylon thread.

Move the thread guide toward smaller diameter

Loosen the thread length adjusting screw to increase length

tighten the screw to decrease length

"S"

twist thread in the left needle (viewed from

in

the right needle.

needle threads

the following figure (Fig.8).

upper

is

impossible, use

''S"

twist thread

as

thread-loosening button shown in

well

or

of

"Z"

twist thread in

as

"Z"

twist thread

filament

Bas

well.

thread.

thread,

the tigure below opens the saucer of the upper thread tension adjuster, and

the upper

thread can easily pulled out.

of

wound thread layer.

@@

of

thread and

@@@

7

~cedlc

thrti::IC

tension

releasing

Lr.:H\ th:-:

l

hft.'Jtl

1

e.r

t·"·j\

:·cJ

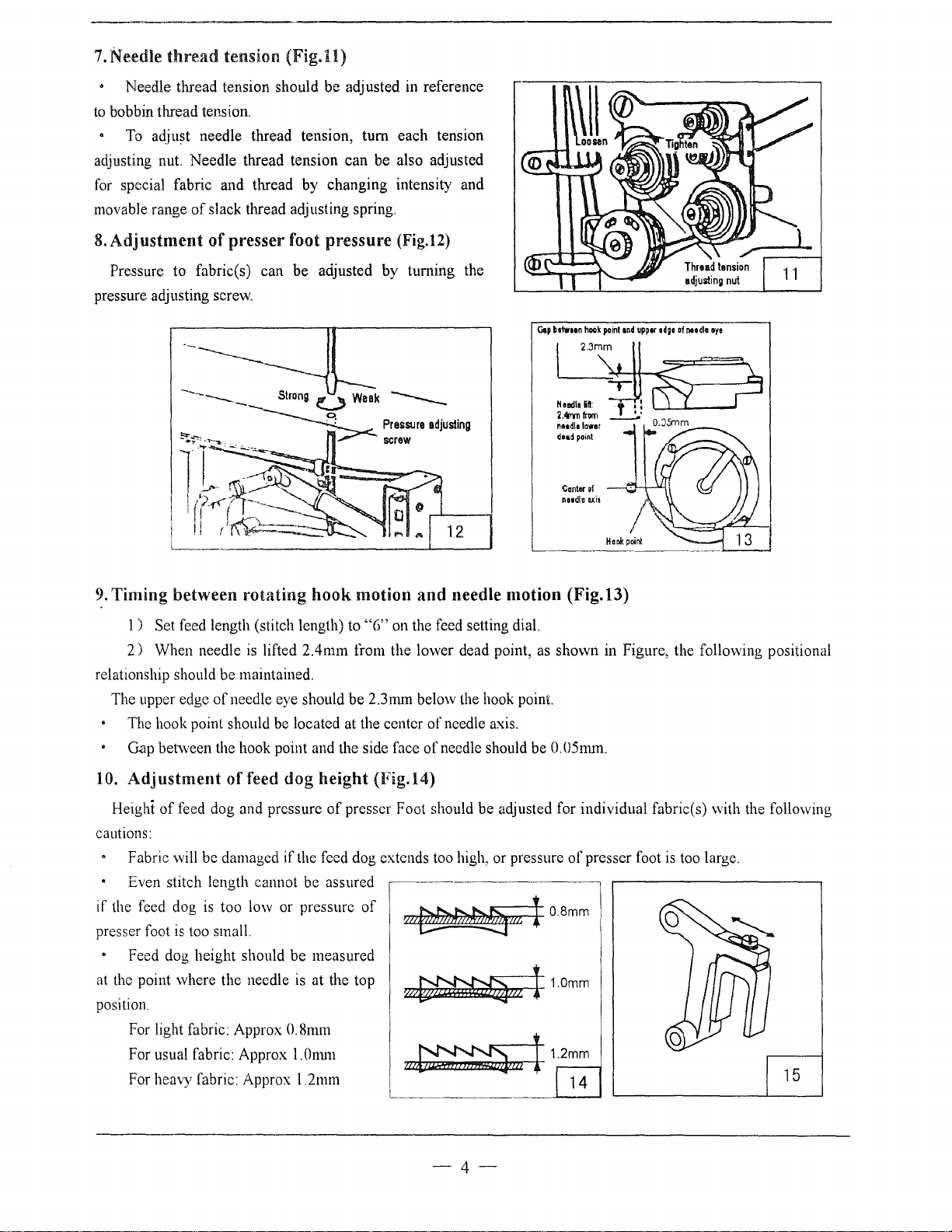

5.

Adjustment

I). Rotate the stitch length adjusting dial to change the stitch length.

2).

Pressing the stitch length adjusting lever for reverse stitching.

6.

Balance

of

thread

of

stitch length

tension (Fig.l

buttot~

and

reverse sewing (Fig.9)

0)

CiJlJ

((leta

ftodltnilfl 1

•ltingdill

'f

~

i

{)

~

te

....

r

AOc7-• &E7

Balance tension

8

BX

~

16::::-

CX,;>~

,.....-

~eaeoragm

I i

,.,;t?

TI9ht needle or loose

bobbin tension

bobbin tenslnfW''"-----l

I 1 o

-3-

7.

Needle

to bobbin thread tension.

adjusting nut. Needle thread tension can be also adjusted

for special fabric and thread

movable range

8.

Adjustment

Pressure to fabric(s) can be adjusted by turning the

pressure adjusting screw.

thread

Needle thread tension should be adjusted in reference

To

adjust needle thread tension, turn each tension

tension

of

slack thread adjusting spring.

of

presser foot pressure (Fig.12)

(Fig.ll)

by

changing intensity and

Gop

btiwtan

naedlelcwar

d••~

point

Center

nndle

hook

of

axis

point

and

uppor

odgo

of

noodle

oye

12

]

9.

Timing between rotating hook motion and needle motion (Fig.13)

1)

Set feed length (stitch length) to "G" on the feed setting dial.

2)

When needle is lifted 2.4mm from the lower dead point, as shown in Figure, the following positional

relationship should be maintained.

of

The upper edge

The hook point should be located at the center

Gap between the hook point and the side face

10.

Adjustment of feed dog height (Fig.l4)

Height

cautions:

if the feed dog

presser foot

at the point where the needle

position.

of

feed dog and pressure

Fabric will be damaged

Even stitch length cannot be assured

is

Feed dog height should be measured

For light fabric: Approx

For usual fabric: Approx l.Onun

For heavy fabric: Approx l.2mm

needle eye should be 2.3mm below the hook point.

of

needle axis.

of

needle should be 0.05mm.

of

presser Foot should be adjusted for individual fabric(s) with the following

if

the feed dog extends too high, or pressure

I

is

too low or pressure

too small.

is

at the top

of

\

nz~m

~ml

0.8mm

I

~~~11m

of

presser foot

1 0.8mm

1.0mm

_1

~1.2_~:__.

is

too large.

15

-4-

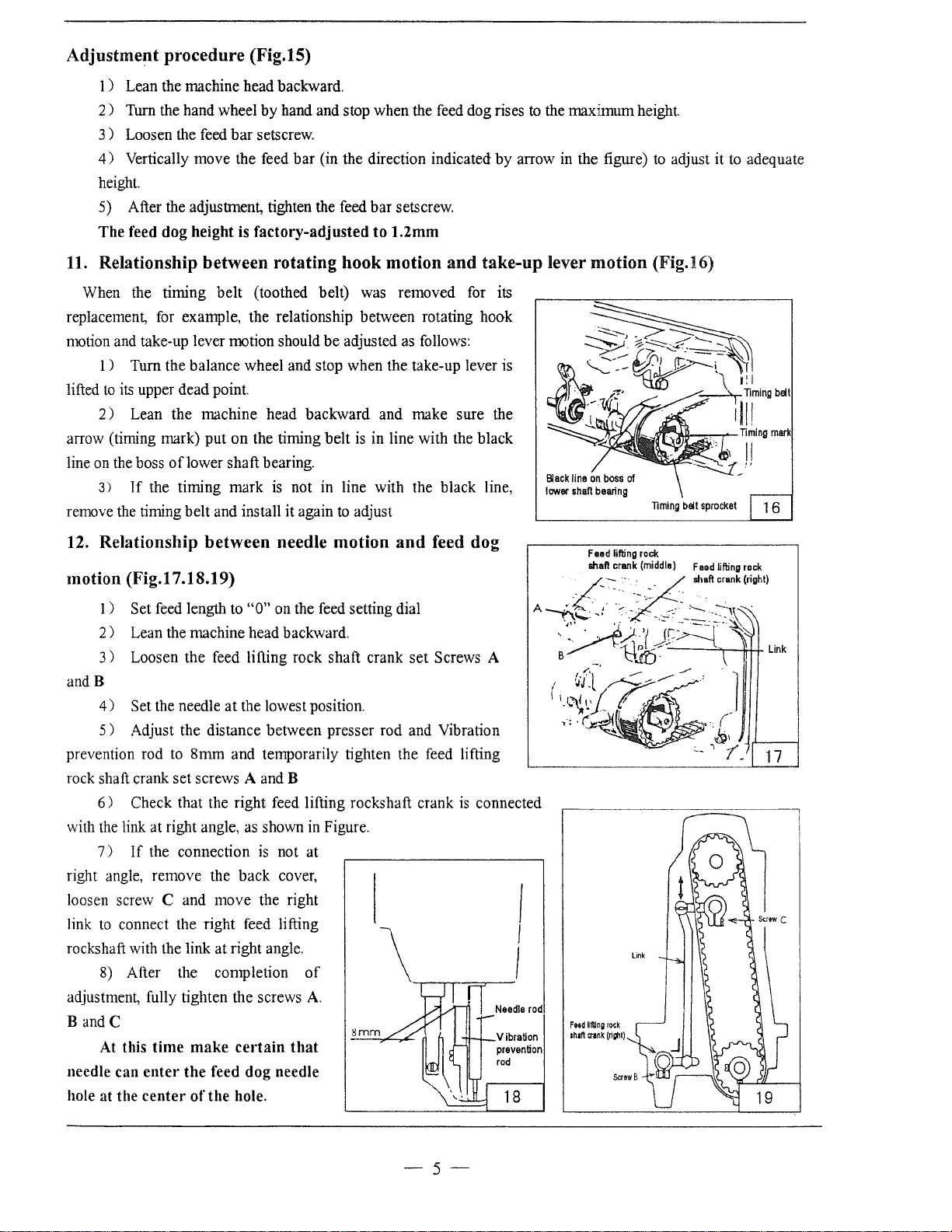

Adjustment

1 ) Lean the machine head backward.

2)

3)

4)

height.

5) After the adjustment, tighten the feed bar setscrew.

The

11.

Relationship between rotating hook motion

procedure

Turn the hand wheel by hand and stop when the feed dog rises

Loosen the feed

Vertically move the feed

feed dog height is

(Fig.15)

bar

setscrew.

bar

factory-adjusted

(in the direction indicated by arrow in the figure)

to

1.2mm

and

take-up lever

to

the maximum height.

motion

to

adjust it

(Fig.16)

to

adequate

When the timing

replacement, for example, the relationship between rotating hook

motion and take-up lever motion should be adjusted

1) Turn the balance wheel and stop when the take-up lever is

to

its

lifted

arrow (timing mark) put

line on the boss

remove the timing belt and install it again

12.

upper dead point.

2 ) Lean the machine head backward and make sure the

oflower

3)

If

the timing mark

Relationship between needle motion

belt

(toothed belt) was removed for its

as

follows:

on

the timing belt

shaft bearing.

is

not in line with the black line,

is

in line with the black

to

adjust

and

feed dog

motion (Fig.17.18.19)

1 ) Set feed length

2)

Lean the machine head backward.

3)

Loosen the feed lifting rock shaft crank set Screws A

andB

4)

Set the needle

5)

Adjust the distance between presser rod and Vibration

prevention rod

rock shaft crank set screws A and B

6)

the

with

right angle, remove the back cover,

loosen screw C and move the right

link

rockshaft with the link at right angle.

adjustment, fully tighten the screws

B

needle can

hole at the

link at right angle,

7)

to

connect the right feed lifting

8)

andC

At this

to

Check that the right feed lifting rocks haft crank

If

the connection

After the completion

time

enter

center

to

"0"

on the feed setting dial

at

the lowest position.

8mm and temporarily tighten the feed lifting

is

connected

as

shown in Figure.

is

not at

of

A.

8mm

make

certain

the

feed dog needle

of

the

hole.

that

Needle

Vibration

prevention

rod

18

Black

line

on

boss

lower

shan

-;("'

A -+I: ' - -.

-.....

,·0?-J)!=~-~

B

'

~·J l ~-

,~

of

bearing

Feed

shall

" -~ ··-

-.

Timing

filling

rock

crank

(middle)

--=.

-

:/1-

'B.lf)

~

bell

----

...---

~

sprocket

Feed

shaft

'--

.

1 6

lifting

rock

crank

(right)

.

:-\\~

\

I!

1J

L1nk

'':~;~/.~_

17

rod

F

.. d lifting

rock

shafl

crank

(nghl)

-5-

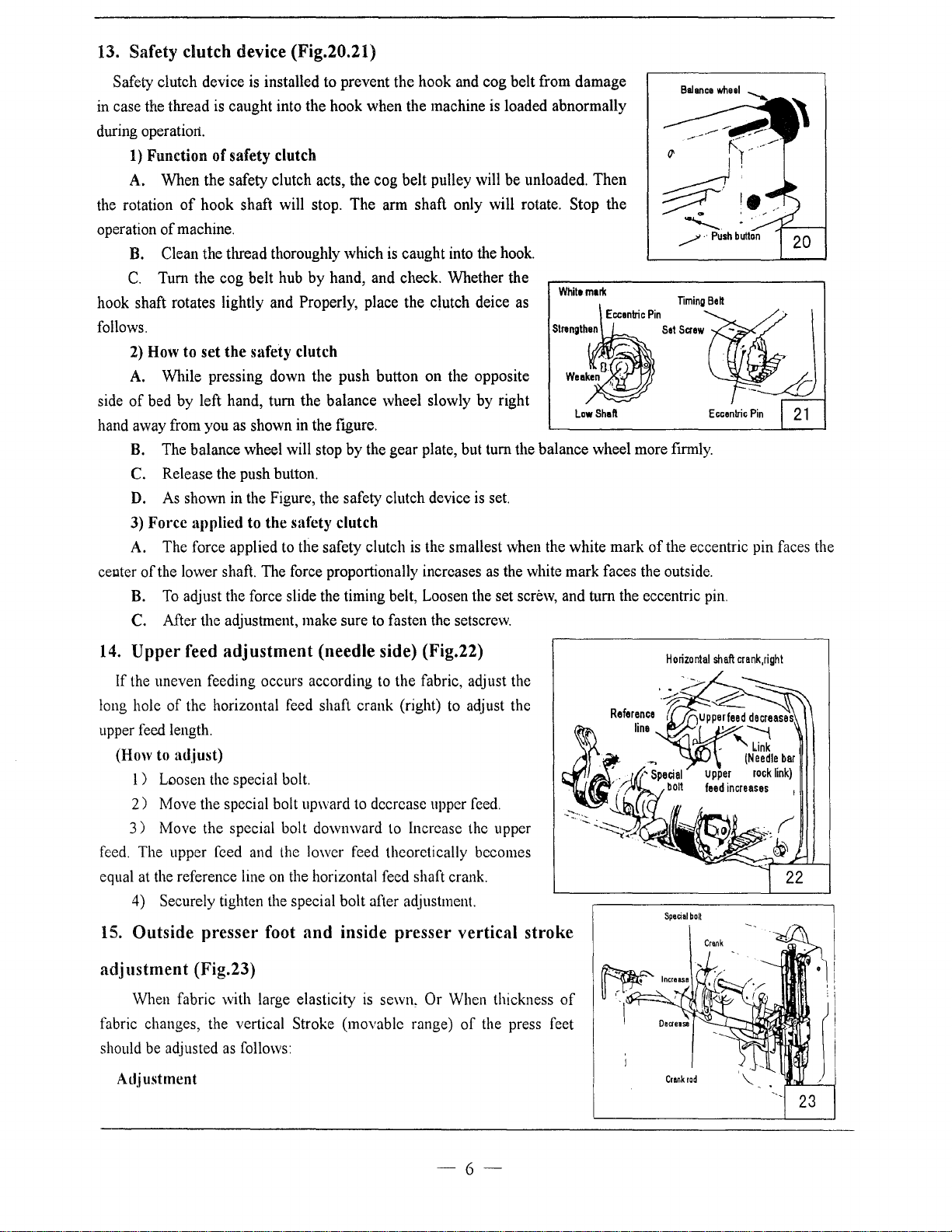

13. Safety clutch device (Fig.20.21)

Safety clutch device

in case the thread

during operatiort.

1)

Function

A. When the safety clutch acts, the cog belt pulley will be unloaded. Then

the rotation

operation

B. Clean the thread thoroughly which is caught into the hook.

C.

hook shaft rotates lightly and Properly, place the clutch deice as

follows.

2)

A.

side

of

hand away from you as shown

B.

C.

D.

3)

A. The force applied to the safety clutch

center

B.

C.

of

hook shaft will stop. The arm shaft only will rotate. Stop the

of

machine.

Tum the cog belt hub by hand, and check. Whether the

How to

bed by left hand,

Force

of

set

While pressing down the push button on the opposite

The balance wheel will stop by the gear plate, but tum the balance wheel more ftrmly.

Release the push button.

As

shown

applied to

the lower shaft. The force proportionally increases as the white mark faces the outside.

To

adjust the force slide the timing belt, Loosen the set screw, and turn the eccentric pin.

After the adjustment, make sure to fasten the setscrew.

is

installed to prevent the hook and cog belt from damage

is

caught into the hook when the machine is loaded abnormally

of

safety clutch

the

safety clutch

tum

the balance wheel slowly by right

in

the ftgure.

in

the Figure, the safety clutch device

the

safety clutch

is

the smallest when the white mark

is

set.

White

Law

mark

Shaft

~

....,__

/·Push

of

the eccentric pin faces the

14.

Upper

If the uneven feeding occurs according to the fabric, adjust the

long hole

upper feed length.

(How to

l ) Loosen the special bolt.

2)

3)

feed.

The upper feed and the lower feed theoretically becomes

equal at the reference line

4) Securely tighten the special bolt after adjustment.

15.

Outside

adjustment

When fabric with large elasticity

fabric changes, the vertical Stroke (movable range)

should be adjusted

Adjustment

feed

adjustment

of

the horizontal feed shaft crank (right) to adjust the

adjust)

Move the special bolt upward to decrease upper feed.

Move the special bolt downward to Increase the upper

on

presser

foot

(needle side) (Fig.22)

the horizontal feed shaft crank.

and

inside

presser

vertical

(Fig.23)

is

sewn, Or When thickness

of

the press feet

as

follows:

stroke

of

Horizontal

Spe~al

boll

shaft

crank,right

-

23

-6-

1 ) Loosen the special bolt.

2)

The vertical strokes

set.

3 ) The vertical strokes become minimum when the nut

4) After the adjustment,

The vertical strokes of the presser feet can be adjusted within· a range from 6mm to 2mm.

16.

Adjustment

of

the presser feet become maximum when the crank rod

is

moved downward and set.

fully

tighten the special bolt.

is

moved upward and

Screwing the pin that connects the link

the tolerance

otherwise, the stitch

17. Installation

1)

2)

3)

of

Fixed 1 to the

Fixed 3 to 1 with screws

Fixed 4

of

back sewing with the crank

between the stitches. Screwing the pin in clockwise can increase the stitch

of

back sewing will be increased.

of

Belt cover:

ann

with screws

to

3 and

ann

with screws

2 (2)

ofback

sewing (down) can adjust

..

v

(2)

3

of

forward sewing;

I

i

I

I

l

-7-

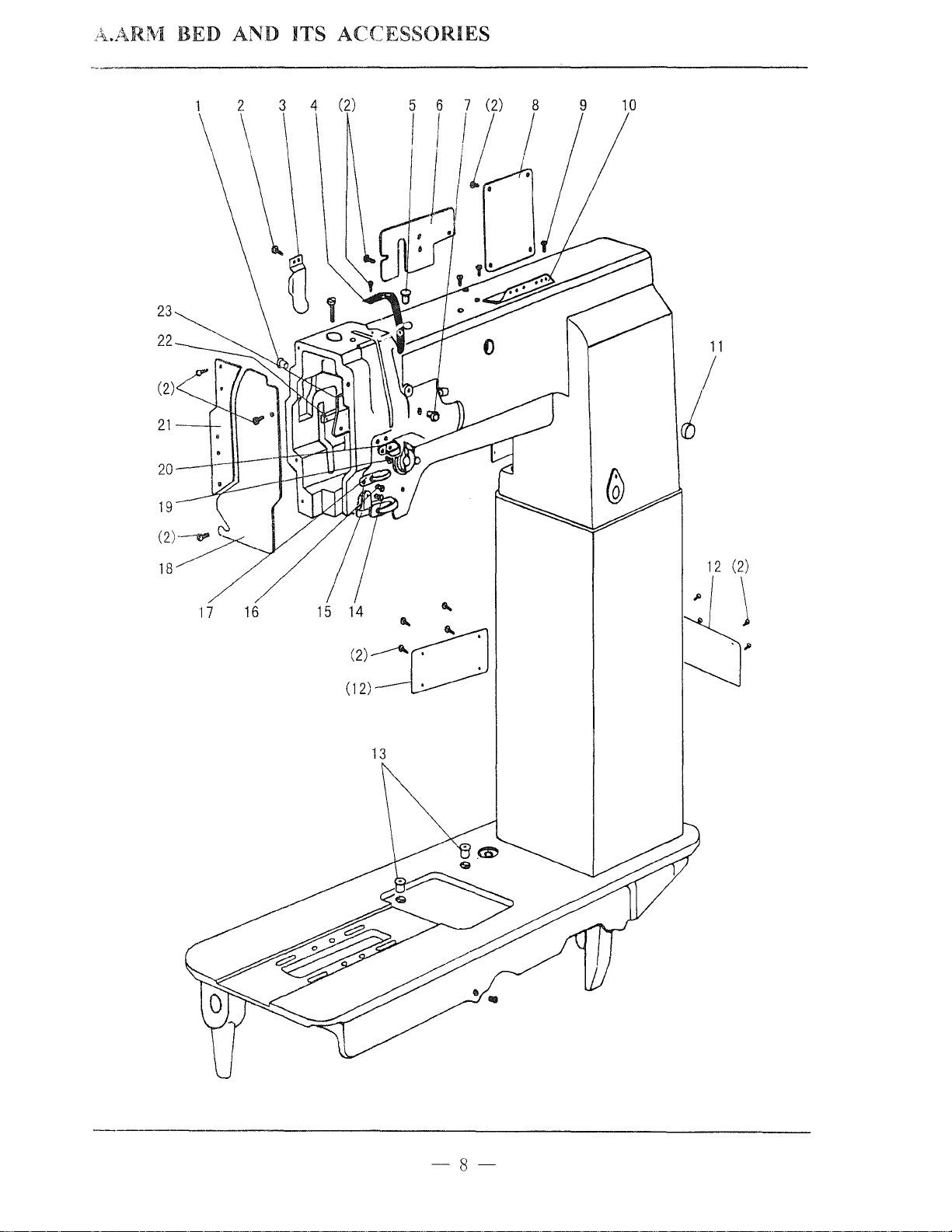

A

..

ARIVI

BED AND ITS

ACCESSORIES

1 2 3 4 (2)

\ \

\ \

. \

\

(2)

21

20

19

9

10

11

I

18

17

16

14

'

' '

(2)

------'~

(12)~

13

12

(2)

\

-8-

Loading...

Loading...