Page 1

SINGLE/DOUBLE NEEDLE POST-BED COMPOUND FEED LOCKSTITCH

SEWING MACHINE WITH ROLLER

GC24618(SINGLE NEEDLE)

GC24618-l(DOUBLE NEEDLE)

INSTRUCTION

BOOK

. ' -

•

& PARTS CATALOG

Page 2

. POST-BED COMPOUND FEED

LOCKSTITCH SEWING MACHINE WITH

INSTRUCTION BOOK

Thank

machine with roller.

This

maintain the machine correctly wbile facilitate reference

In

accept safety operation guide from professionals.

lockstitch sewing machine

be

heavy duty

high-grade leather shoes, bags, gloves and other curvy leather products.

you for choosing Single I

·

is

an

instruction book &

order

to avoid trouble, please read this instruction book carefully before operation,

1.

freely adjusted, light

with

wheel

Double

parts

needle

catalog, which will help you to use machine

.Post-bed compound feed lockstitch sewing

of

parts.

BRIEF INTRODUCTION OF MACHINE

Single needle I Double needle post-bed compound

with

roller

is

and

feed

elegant

smooth

and

in

running with

driven roller presser

in

appearance, nice and even

ball

bearing

foot,

and

and

is

especially suitable

ROLLER

and

and

feed

in

stitches which can

needle bearing, excellent for

for

sewing

2.

MAIN SPECIFICATIONS

1)

Max. Sewing Speed:

2)

Stitch Length

Presser Foot Lift:

3)

4)

Needle

5) Needle:

6)

Hook:

7) Max.Thicliness to

Lubrication:

8)

9) Motor:

3.

PRECAUTION

a.

Though each machine

machine parts

installing & using the machine,

trouble

perform run-in operation.

for

rotating,

Bar

may

Stroke:

be

no

2500

1.3-7mm.

7mm.(by hand)

14mm(by knee)

41mm

DP

Vertical Hook

beSewn:

has

been

strictly inspected

loose

or deformed after long distance transportation

you

must

check

colliding,

no

abnonnal resistance and abnormal sound before you

and

it

carefully. Examine

6mm.

Manual

370w Clutch Motor

tested before leaving

X

rpm

5,

11#

..

it

and ensure there

20##

factory,

with

jolt.

the

So

before

is

no

1

Page 3

b.

The thread guide way

regulator

must clean

c.

After

oil.

d.

If special sewing material or spec

will affect clearance, please refer to the professionals.

you

assy.

etc. is apt to accumulate dust, which would affect sewing performance.

it

regularly.

clean

of

the parts such

the

machine, please lubricate

ial

as

rotating hook, feeding wheel and thread tension

all

thread is used, or

the

relevant points with sewing-machine

you

want

to replace those parts which

So

you

'

4. NEEDLE SETTING (Fig.l)

Please

Needle sho

nature of material to be sewn. When installing

needle, make

facing

insert the

of

screw

5.

and

between t

thread

Bobbin W

(C)

w

it can wind

lifted up.)

use

DP

X 5

the

II# -20

uld

be

selected

su

re the needle's long groove

the

operator's left side, then fully

needle

needle

finally.

shank

socket

and

# needle

as

per thread

up

to

tighten the clamp

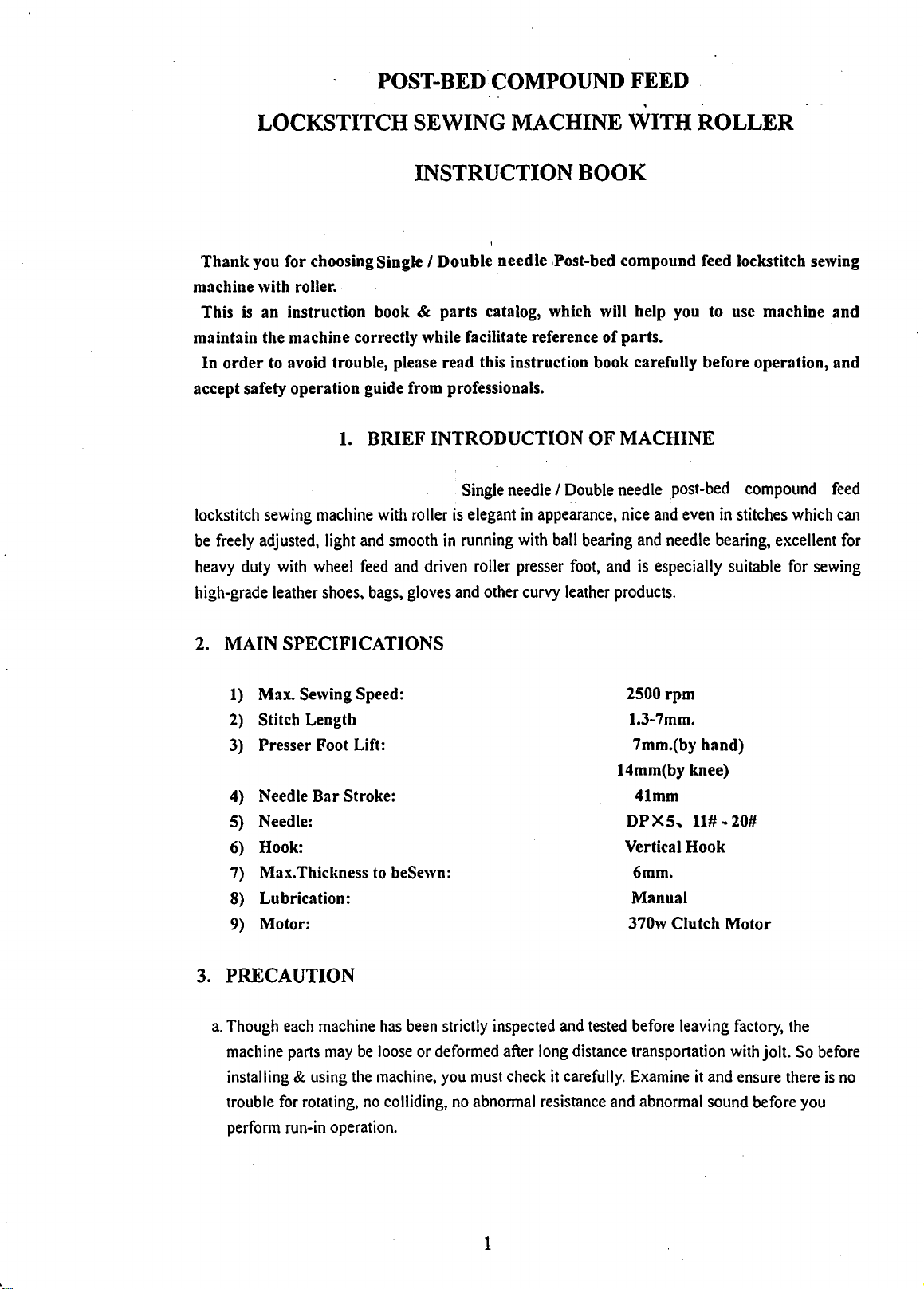

WIND THE BOBBIN (Fig. 2)

Put

Bobbin (B)

draw

on

up

to

ind

the

wo

bobbin automatically. W not sewing,

on

the bobbin winder spindle,

the

thread (A)

tensi

on

discs (E), then wind

Bobbin (B) several rounds, pull

ind

er Lever (D). press Spring Plate

Bobbin (B).

the bobb

in

from

When

sewing,

with the presser

the

spool

only.

and

(A)

bottom

and

the

up

it

will

foot

1

wi

ndin

g,

you

may

After

wi

nding

the

cutting blade

thread

and

pull

cut bobbin thread

two

rounds

it

off.

on

the

·by

thread

2

Page 4

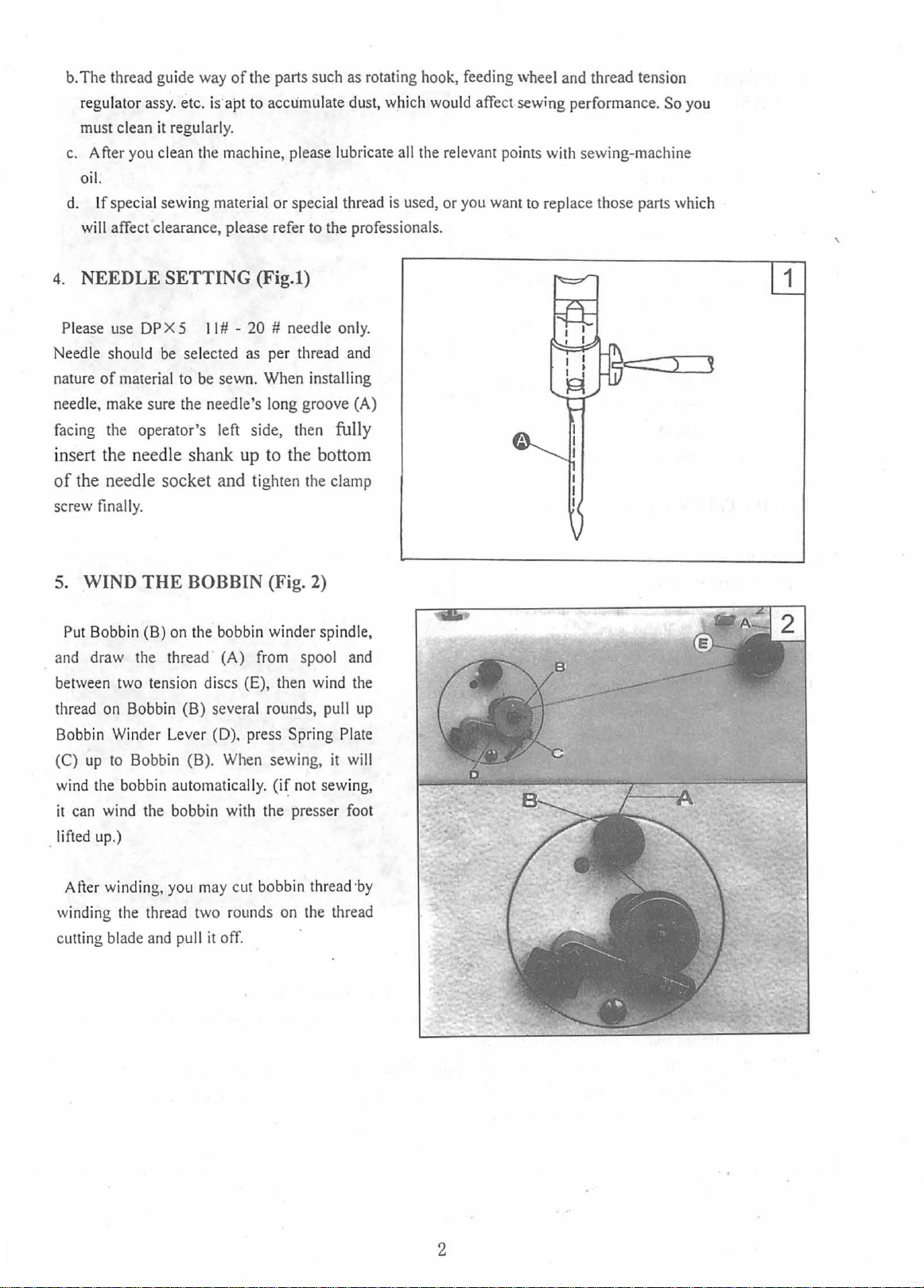

6.

INSTALL BOBBIN &

CASE

7.

THRAEDING.

(Fig. 3) ·

a.

Open Cover (A).

b. Lift

c.

d.

e. Press down Bobbin Latch (B).

f.

g.

up

Bobbin Latch (B).

Pull bobbin thre

50mm, then draw the end

thread throu

case.

Put the bobbin case into the

rotating

Whi

by

wheel

the bobbin thread.

Close Cover (A) again.

hook.

le taking the needle thread

left hand, rotate the balance

by right

(Fig. 4)

gh

ad

the slot

hand

BOBBIN

out about

of

of

bobbin

to

draw

up

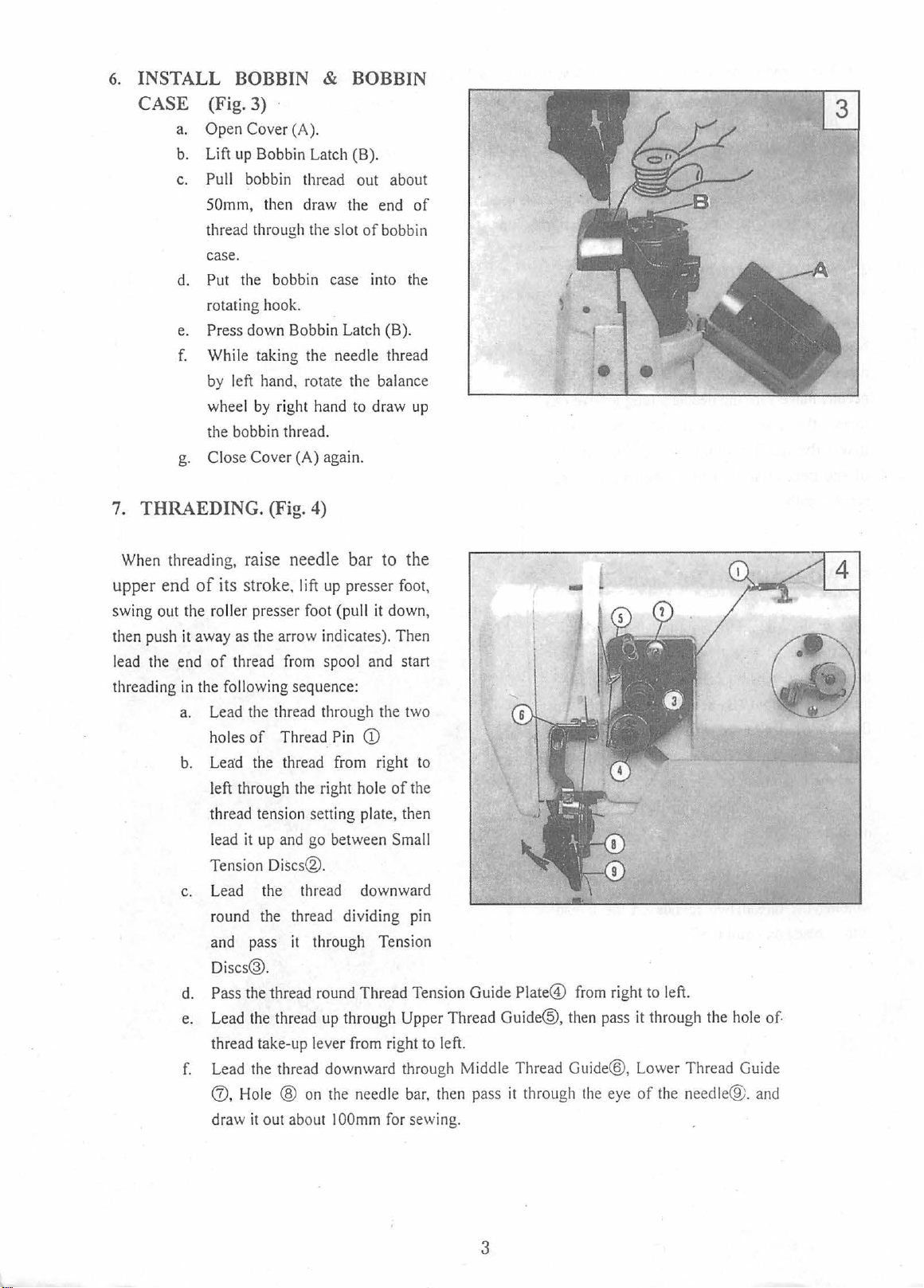

When

threading, raise needle bar

upper end

swing out the

then push

lead

threading

it

away

the end

in

a.

b.

c.

d. Pass the thread round Thread Tension Guide Plate®

e. Lead the thread

f.

to

of

its

stroke. lift

roller presser foot (pu

as

the arrow indicates). Then

of

thread

the following sequence:

Lead

the thr

holes

of

Lea:d

the thread from right to

left through

thread tension setting plate, then

lead

it

up

Tension

Lead

round the thread dividing pin

and pass

Di

thread take-up l

Lead the thre

d), Hole @

draw

Discs®.

the thread downward

scs®.

it

out about I

up

presser foot,

ll

it

down,

from

spool

and

ead

through the

Thread P

and

it throu

in

CD

the

right hole

go between Small

up

eve

r from right to left.

ad

downward through Middle Thread Gui

on

the needle

OOm

of

gh Tensi

through Upper Thread Guide@,

m for sewing.

the

start

two

the

on

bar,

then pass

it

through

-

from

then

the

right

to

left.

pass

it

through the

de®,

Lower Thread Guide

eye

of

the needle® .

hole

of.

and

3

Page 5

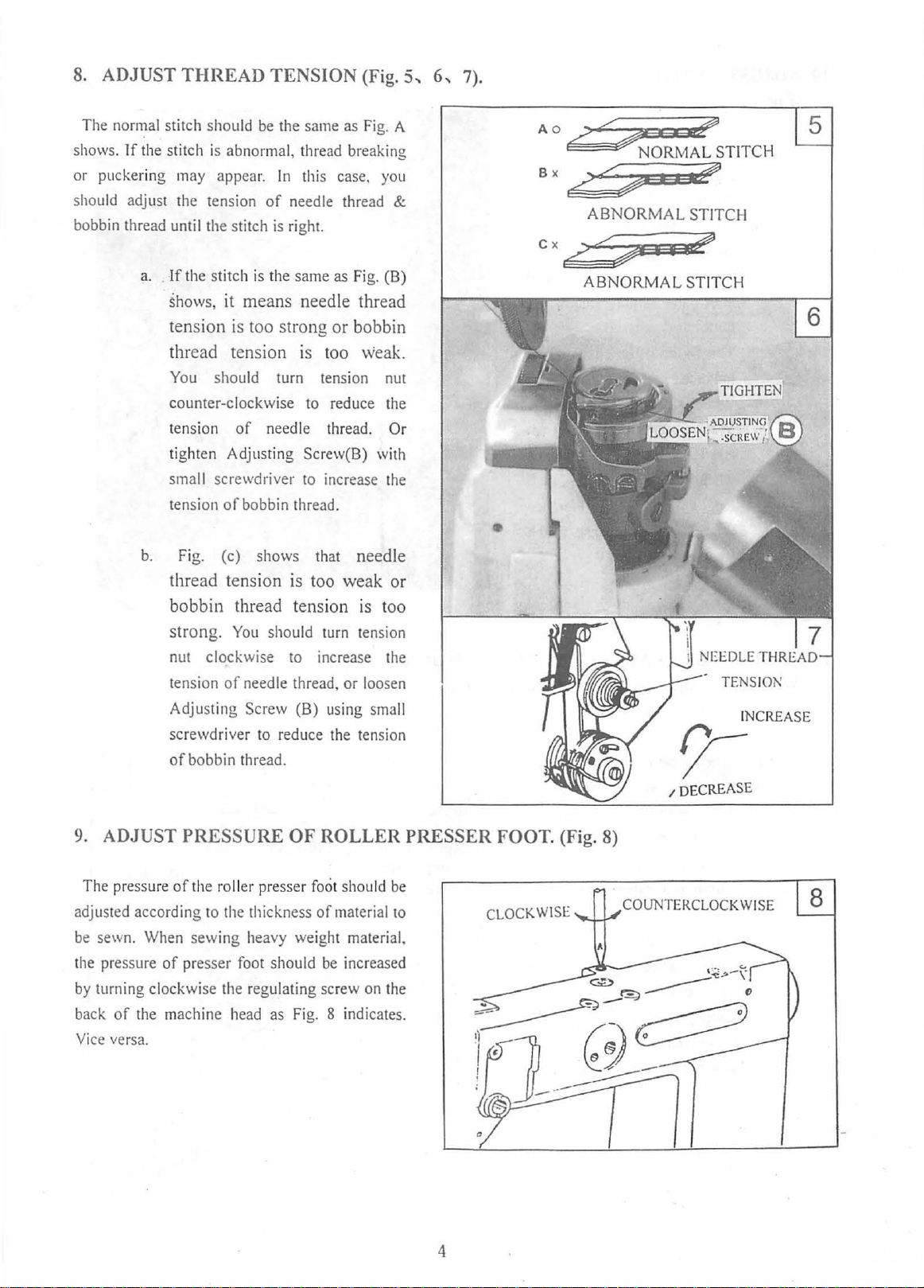

8. ADJUST

THREAD

TENSION (Fig.

5,

6,

7).

The normal stitch should

shows.

or puckeri

should adjust the tension

bobbin thread until the stitch

If

the stitch

ng

a.

. If the stitch is the same

is

abnor

may appear.

shows, it means needle thread

is

tension

too strong or bobbin

thread tension is

You

should turn tension nut

counter-clockwise to reduce the

tension

tighten Adjusti

small screwdriver to increase the

tension

b.

Fig.

th

read tension is

of

of

bobbin thread.

(c) shows that needle

bobbin thread tensi

strong.

nut clockwise to increase the

tension

Adjusting

screwdriver

of

You

of

needle thread, or loosen

Screw (B) using small

bobbin thread.

be

the same as

mal,

thread breaki

In

this case.

of

needle thread &

is

right.

needle thread. Or

ng

Screw(B)

too

should turn tension

to

reduce the tension

as

too

on

Fig.

Fig.

weak.

weak

is

you

with

too

A

ng

(B)

or

Ao/::::

Bx

Cx6,)=¢ii

•

<S~~Q;?

~~ORMAL

STITCH

~7••~

ABNORMAL STITCH

I I

,if!J

ABNORMAL STITCH

TENSION

INCREASE

r;-

/DECREASE

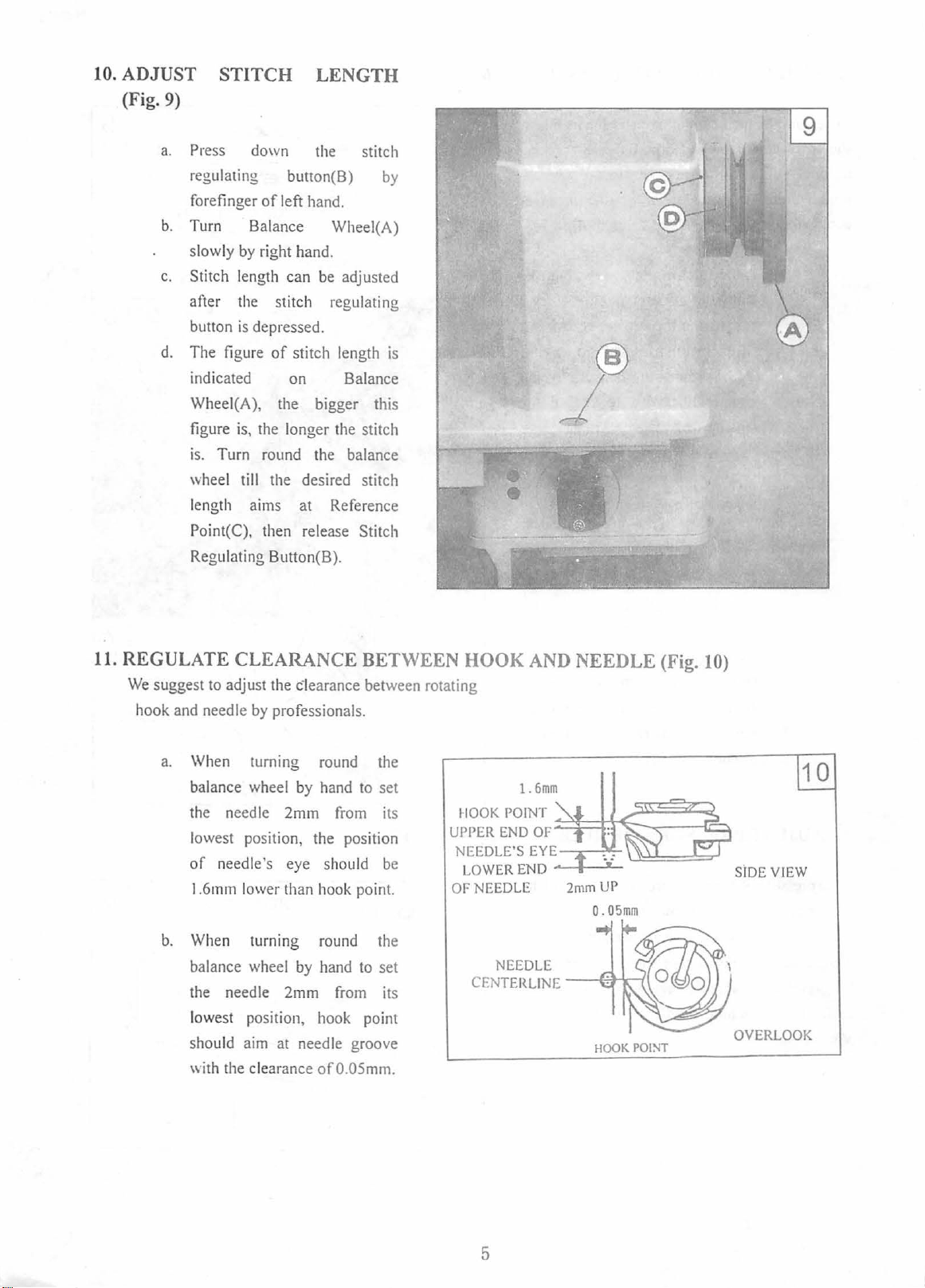

9. ADJUST

The pressure

adjusted according

be

sewn. When sewing heavy weight material,

the pressure

by

turning clockwise the regulating screw on the

back

of

Vice

versa.

PRESSURE

of

the roll

of

presser

the machine head

er presser

to

the thickness

foot

OF

should

as

Fig.

ROLLER PRESSER

foot

should

of

material to

be

8 indicates.

be

increased

FOOT

CLOCKWISE

. (Fig. 8)

4

Page 6

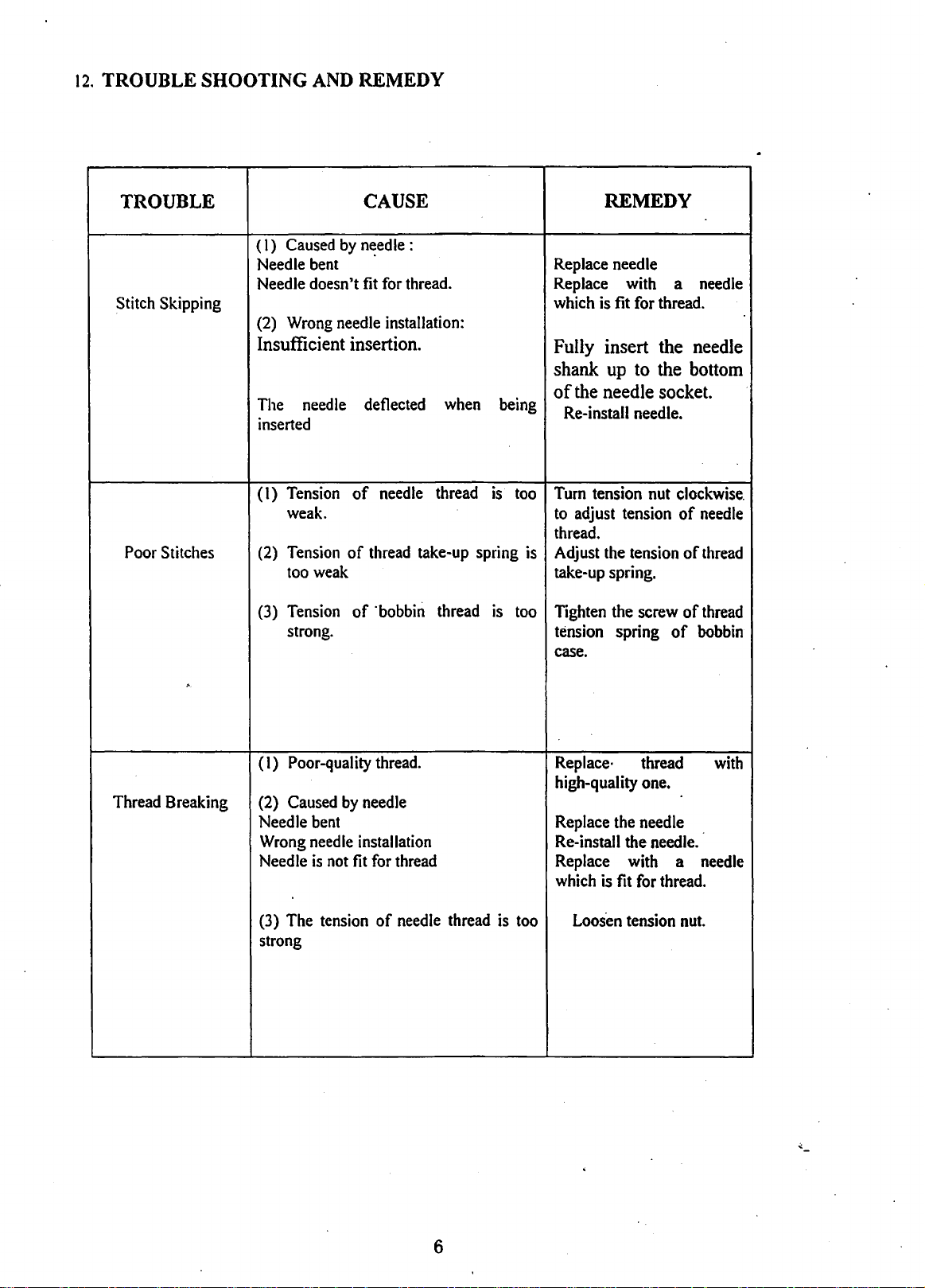

10. ADJUST STITCH LENGTH

(Fig. 9)

a.

Pre

ss down the stitch

regulating

forefinger

b.

Turn Balance Wheei(A)

slowly

c.

Stitch length can

after

button

d. The figure

indicated

Wheei(A), the bigger this

figure

is.

wheel till the desired stitch

length aims at Reference

Point(C), then release Stitch

Regulating Button(B

by

the

is

is,

Turn round the balance

bun on(

of

left hand.

right hand.

stitch regulating

depressed.

of

on Balance

the longer the stitch

B)

be

adjusted

stitch length is

).

by

®

_/

11. REGULATE CLEARANCE BETWEEN HOOK AND NEEDLE (Fig. 10)

We

suggest

hook

to

adjust the clearance between rotating

and

needle

a.

When turning round the

balance wheel

the needle 2mm

lowest position, the position

of

1.6mm

b.

When turning round the

balance wheel

the needle 2mm

lo

west position, hook point

sho

with

by

professionals.

by

hand to set

needle's eye should

lower than hook point.

by

hand

uld

aim

at

needle groove

the clearance

of0

from

to set

from

.05mm.

its

be

its

HOOK

UPPER

END

NEEDLE'S

LOWER

OF

NEEDLE

NEEDLE

CEN

TERLINE

1.6mm

POINT

~t=~~--..,..---€~

OF

EYE~.--.;JII;...

END...._....____..__

2mmUP

---<-;.t;rll

u::!=::~=-

0.05mm

HOOK

POI!'-IT

SiDE

VIEW

OVERLOOK

5

Page 7

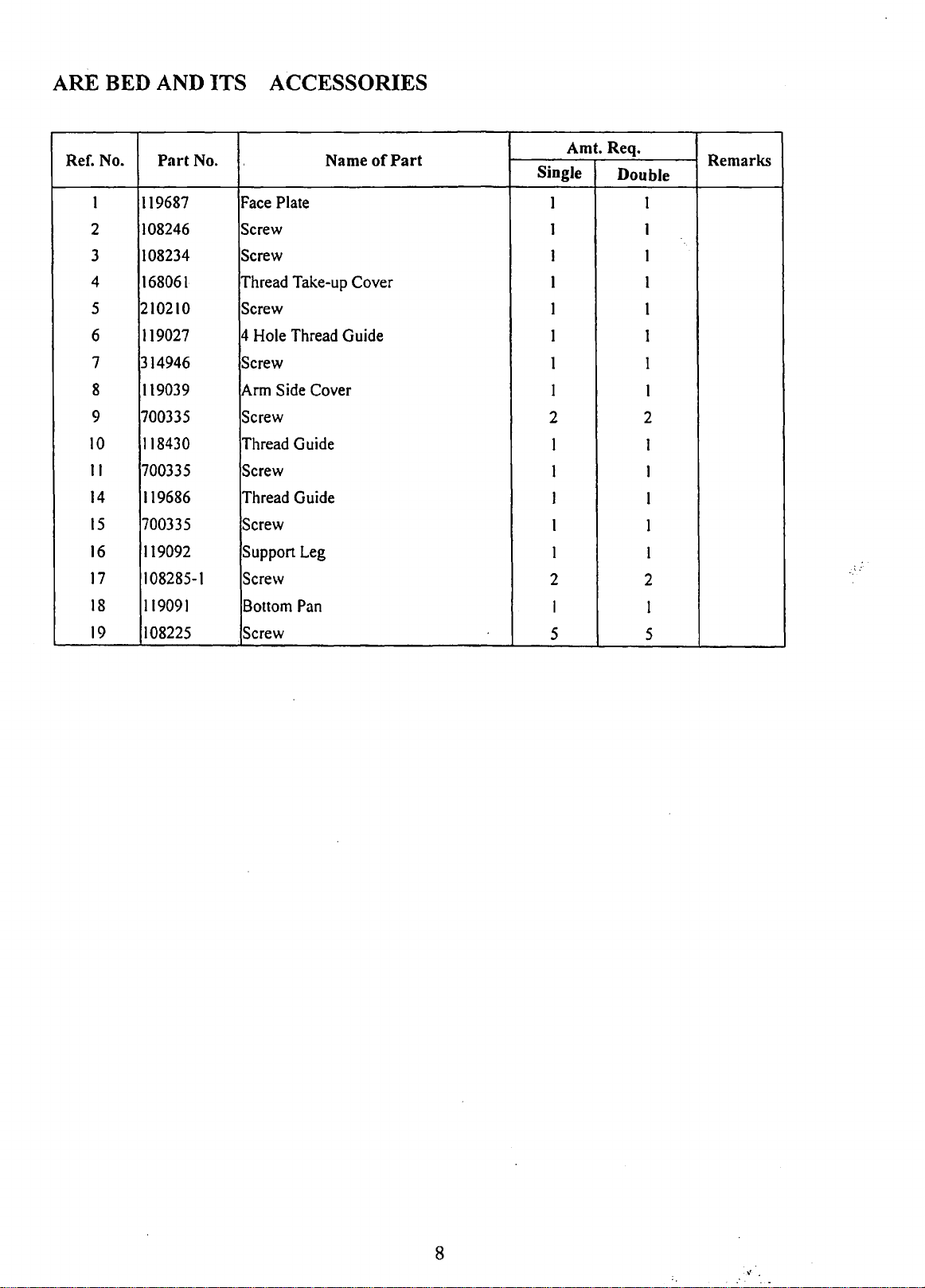

12.

TROUBLE

SHOOTING

AND REMEDY

TROUBLE

Stitch Skipping

Poor

Stitches

(

1)

Caused

Needle

Needle doesn't

(2)

Wrong

by

bent

needle

CAUSE

needle

·

fit

for

thread.

installation:

:

Replace

Replace

which

REMEDY

needle

with a

is

fit

for

thread.

needle

Insufficient insertion. Fully insert the needle

shank up to the bottom

of

The

needle

inserted

(I)

Tension

weak.

(2)

Tension

too

weak

(3)

Tension

strong. tension spring

deflected

of

needle

of

thread

of

·bobbin

when

thread

take-up spring

thread

being

is

is

too

too

the needle socket.

Re-install needle.

Turn

tension

to

adjust tension

thread.

is

Adjust

take-up spring.

Tighten

case.

the

nut

clockwise.

of

tension

the screw of

of

of

needle

thread

thread

bobbin

Thread

Breaking

(I) Poor-quality

(2)

Caused

Needle

Wrong

Needle

(3)

The

strong

by

bent

needle

is

not

tension

installation

fit

thread.

needle

for

thread

of

needle

thread

is

Replace·

high-quality

Replace

Re-install the

Replace

which

too

the

is

fit

Loos.en

thread

one.

needle

needle.

with

for

thread.

tension

a

nut.

with

needle

..:._

6

Page 8

ARE BED

AND

ITS ACCESSORIES

i

I

i

;

I

~

9

---~

I

-8

1

10-~

··~

/

11

7

Page 9

ARE BED

AND

ITS ACCESSORIES

Ref. No.

I

2

3

4

5

6

7

8

9

10

11

14

15

16

17

18

19

Part

No. Name

119687

108246

108234

168061

210210 Screw

119027

314946 Screw

119039

700335

118430

700335

119686

700335

119092

108285-1

119091

108225

Face

Screw I

Screw

Thread Take-up Cover

4 Hole Thread Guide

Arm

Screw

Thread Guide

Screw

Thread Guide

Screw

Support

Screw

Bottom

Screw

Plate

Side Cover

Leg

Pan

of

Part

Amt. Req.

Single

I I

I I

1 1

I

I

I 1

1

2

1 1

I 1

I

I

1

2

I

Double

5

Remarks

1

I

I

1

2

I

1

I

2

1

5

8

Page 10

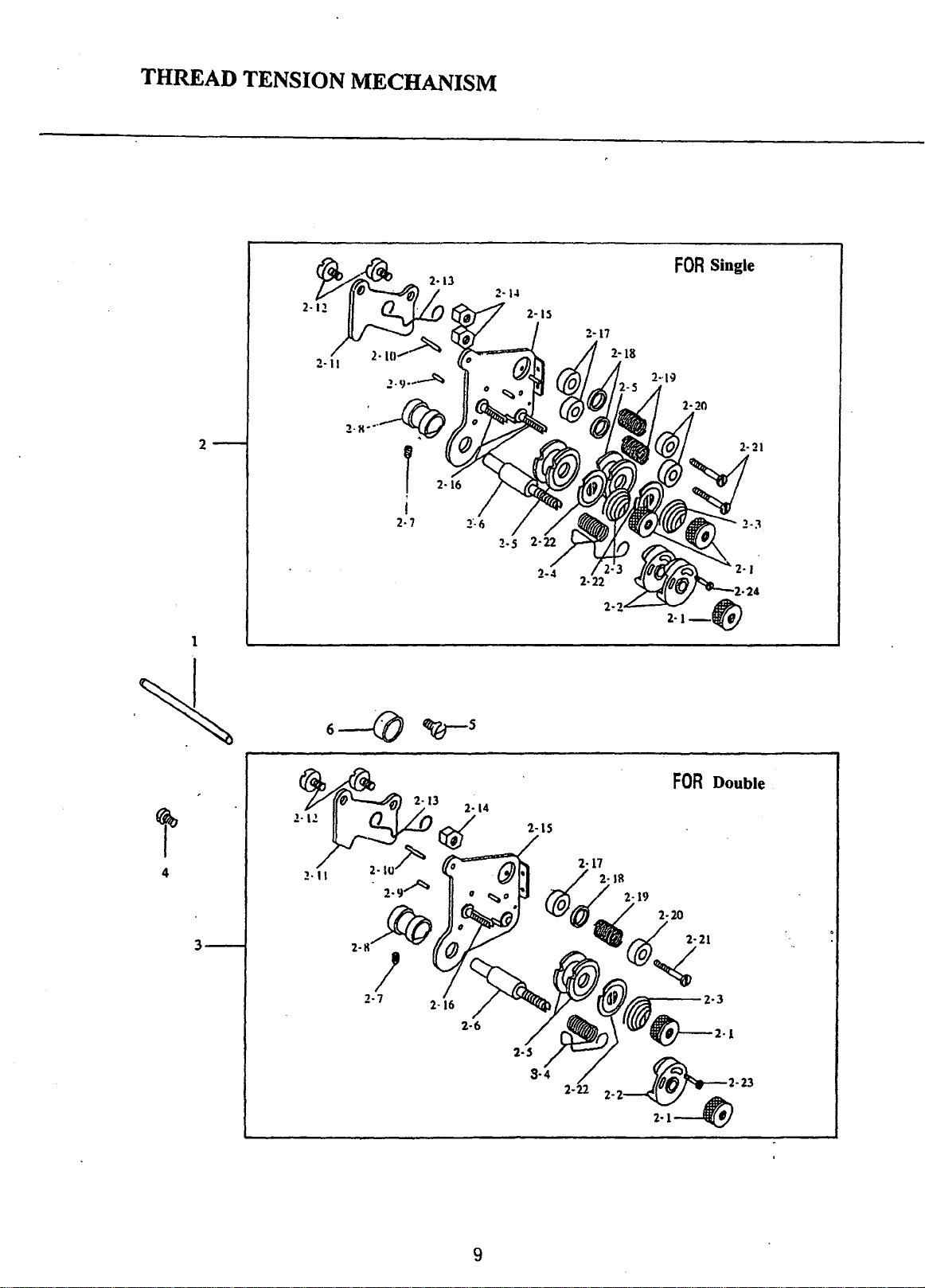

THREAD TENSION MECHANISM

z .• :

•.

~

2

1

I

2·7

2-1~

FOR

Single

1

6----0

4

3

~5

2·15

FOR

Double

9

Page 11

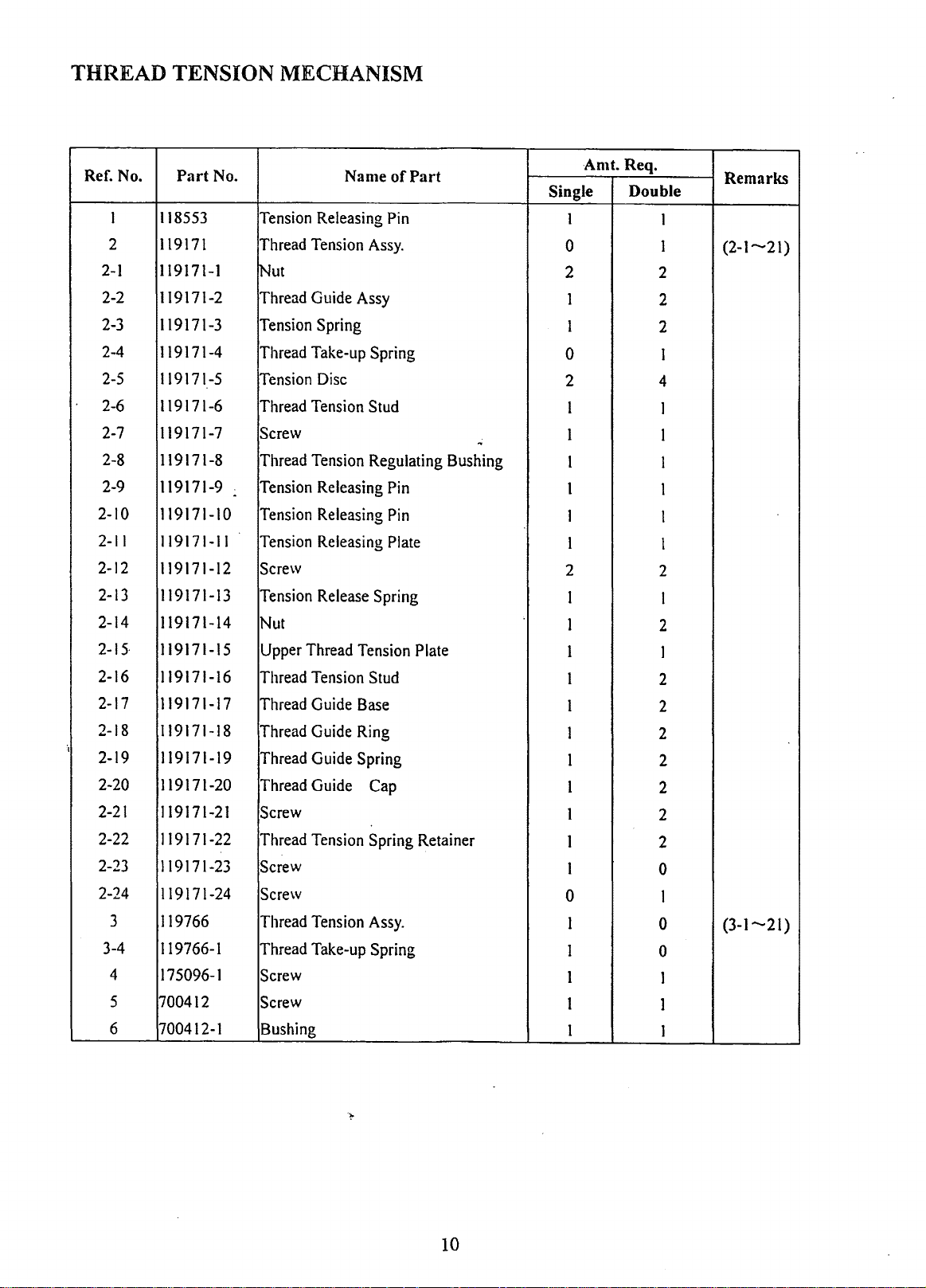

THREAD TENSION MECHANISM

·,

Ref.

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15·

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-23

2-24

3-4

1

2

3

4

5

6

No.

Part

No.

118553

119171

119171-1

119171-2

119171-3

119171-4

119171-5

119171-6

119171-7

119171-8

119171-9

119171-10

119171-11

119171-12

119171-13

119171-14

119171-15

119171-16

119171-17

119171-18

119171-19

119171-20

119171-21

119171-22

119171-23

119171-24

119766

119766-1

175096-1

700412

700412-1

.

Tension

Thread

~ut

Thread

Tension

Thread

Tension

Thread

Screw

Thread

Tension

Tension

Tension

Screw

Tension

Nut

Upper

Thread

Thread

Thread

Thread

Thread

Screw

Thread

Screw

Screw

Thread

Thread

Screw

Screw

Bushing

Name

Releasing

Tension

Guide

Spring

Take-up

Disc

Tension

Tension

Releasing

Releasing

Releasing

Release

Thread

Tension

Guide

Guide

Guide

Guide

Tension

Tension

Take-up

of

Part

Pin

Assy.

Assy

Spring

Stud

Regulating

Pin

Pin

Plate

Spring

Tension

Plate

Stud

Base

Ring

Spring

Cap

Spring Retainer

Assy.

Spring

...

Bushing

Amt. Req.

Single

1

0

2

1

1

0

2

1

1

1

1

1

I

2

I

1

I

I

I

I

I

I

1

I

1

0

I

1

I

1

I

Double

1

1

2

2

2

1

4

1

1

1

1

I

I

2

I

2

1

2

2

2

2

2

2

2

0

I

0

0

1

I

1

Remarks

(2-1-21)

(3-1-21)

""{>

10

Page 12

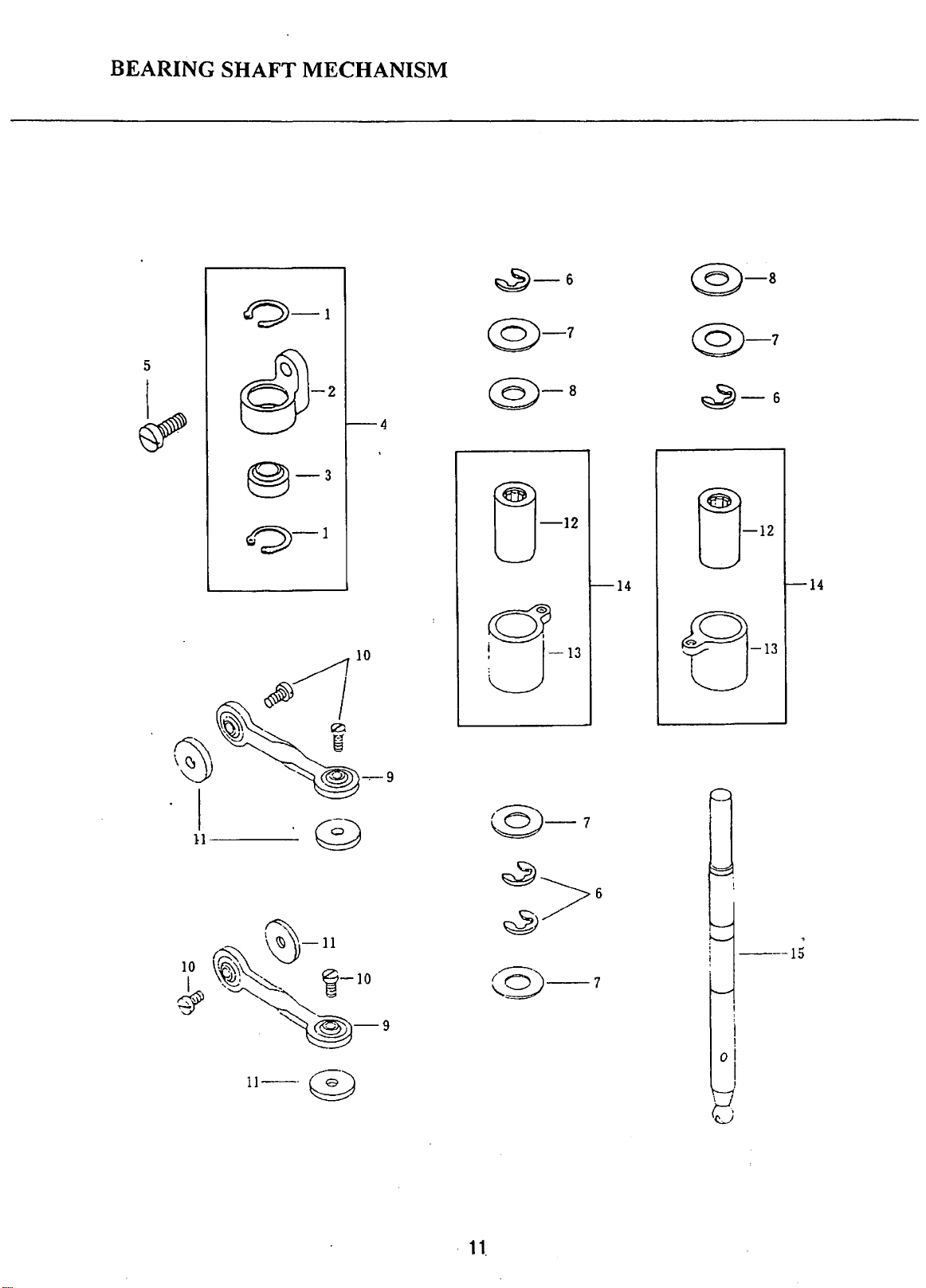

BEARING SHAFT MECHANISM

0-1

5

SJ-2

~

@3-3

o-1

f---4

~-6

@-7

@-a

u-12

;...___

14

d

o-13

@)-s

@-7

~-6

-12

u

-

14

e-13

11---

11-~

~

rg)-7

\..._

'

11.

---15

Page 13

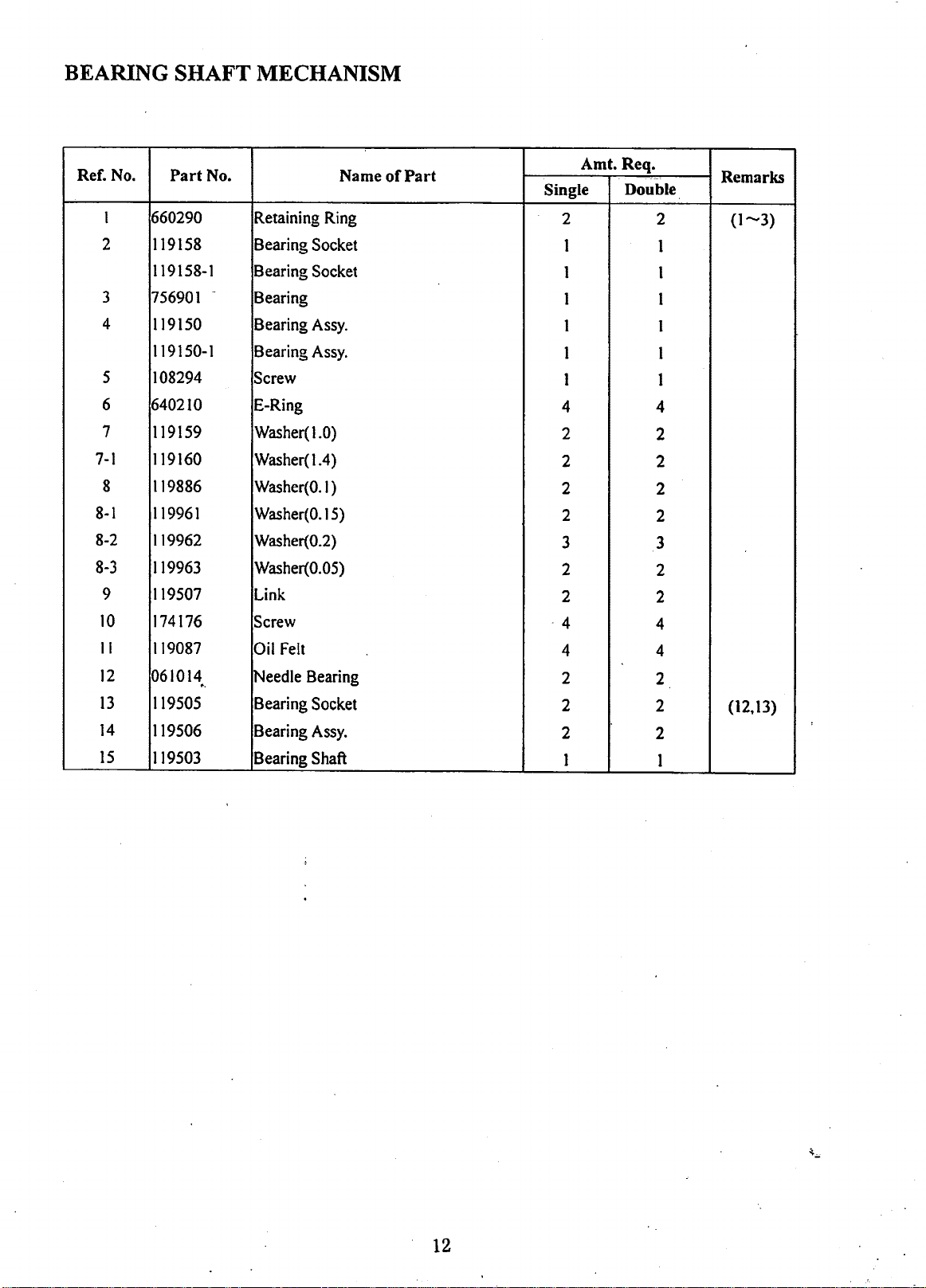

BEARING SHAFT MECHANISM

Ref.

No.

1 660290

2

3

4

5

6

7

7-1

8

8-1

8-2

8-3

9

10

II

12

13

14

15

Part

I19158

119158-1

75690I

119150

119150-1

108294

640210

119159

1I9160

119886

119961

119962

119963

119507

174176

119087

061014

..

119505

II9506

119503

No.

-

Name

Retaining

Bearing

Bearing Socket

Bearing

Bearing

Bearing

Screw

E-Ring

Washer(

Washer(1.4)

Washer(O.I)

Washer(0.15)

Washer(0.2)

Washer(O.OS)

Link

Screw

Oil

!Needle

Bearing Socket

Bearing

Bearing Shaft

Ring

Socket

Assy.

Assy.

1.0)

Felt

Bearing

Assy.

of

Part

Amt. Req.

Single

2

1

1 1

I

I

I

I

4 4

2

2

2

2

3

2

2

·4

4 4

2

2

2

1

Double

2

I

1

I

I

1

2

2

2

2

3

2

2

4

2

2

2

I

Remarks

(1-3)

(12,

13)

12

Page 14

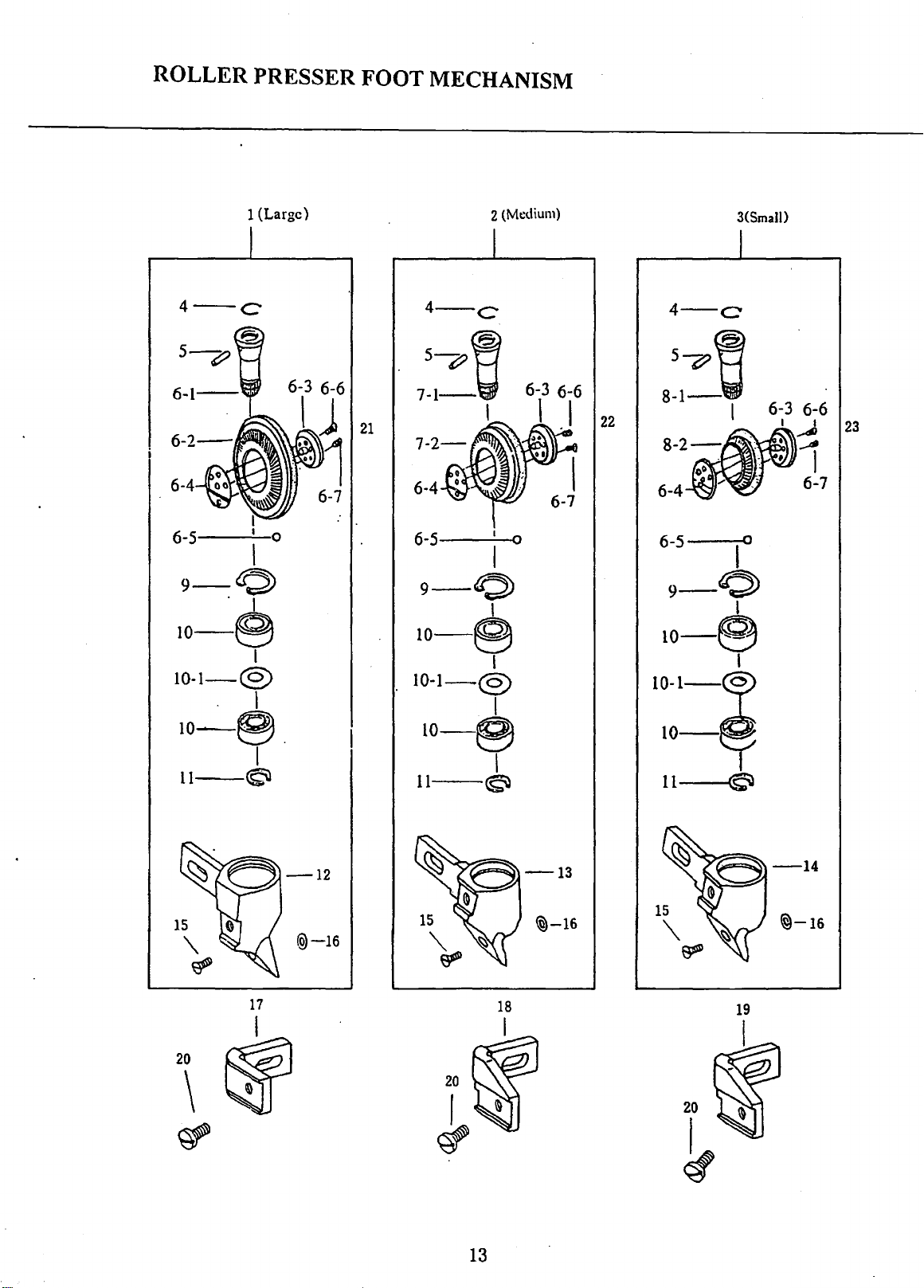

ROLLER PRESSER FOOT MECHANISM

1 (Large)

4-c

6-4

6-5

9-0

. I

Io-(9

10-1-@

. l

10-S.

11--©

1\

I

I 0

'

I

I

6-7

2 (Medium)

6-4

6-5 I 0

I

9-0

I

10-e

I

10-1-@

I

10-e

I

11--©

6-7

22

3(SmaJI)

6-5

10

9-0

I

10-e

I

11~

15

~

"

20

\

@-16

17

2

~

~-16

18

rtf

~

~

13

15

'\

~

19

20

f

~

~-16

Page 15

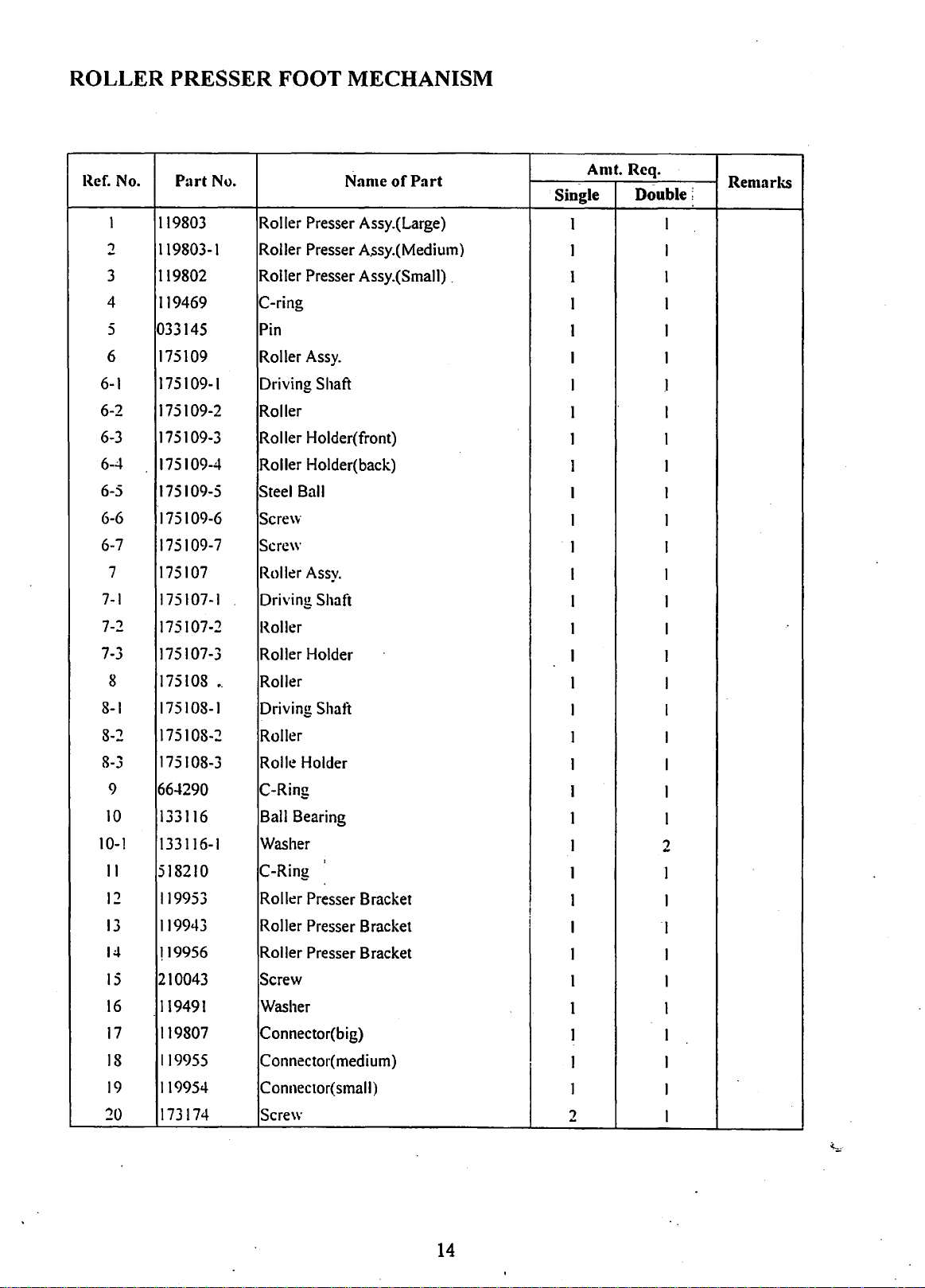

ROLLER PRESSER FOOT MECHANISM

Ref.

10-1

1

2

3

4

5

6

6-1

6-2

6-3

6-4

6-5

6-6

6-7

7

7-1

7-2

7-3

8

8-1

8-2

8-3

9

10

II

12

13

14

15

16

17

18

19

20

No.

Part

No.

119803

119803-1

119802

119469

033145

175109

175109-1

175109-2

175109-3

175109-4

175109-5

175109-6

175109-7

175107

175107-1

175107-2

175107-3

175108

175108-1

175108-2

175108-3

664290

133116

133116-1

518210

119953

119943

f19956 Roller Presser Bracket

210043

119491

119807

119955

119954

173174

Roller Presser Assy.(Large)

Roller Presser

Roller Presser Assy.(Small) .

C-ring

Pin

Roller

Assy.

Driving Shaft

Roller

Roller Holder( front)

Roller Holder(back)

Steel

Ball

Scre\v

Screw

Roller

Assy.

Driving Shaft

Roller

Roller Holder

•.

Roller

Driving Shaft

Roller

Rolle

Holder

C-Ring

Ball

Bearing

Washer

C-Ring

Roller Presser Bracket

Roller Presser Bracket

Screw

Washer

Connector(big)

Connector(

Connector( small)

Screw

Name

A.ssy.(Medium)

'

medium)

of

Part

Single

I

I I

1 I

1 I

1 I

I 1

I

1 I

1 I

1 1

I

I

1

I 1

I

I

I

1

I

1

I

I

1

1

1

1

I

i

I

I

1

1 I

1

I I

I

2

Amt. Rcq.

Double;

Remarks

I

.1

1

1

I

I

I

I

I

I

I

I

I

1

2

I

I

I

1

1

I

1

1

14

Page 16

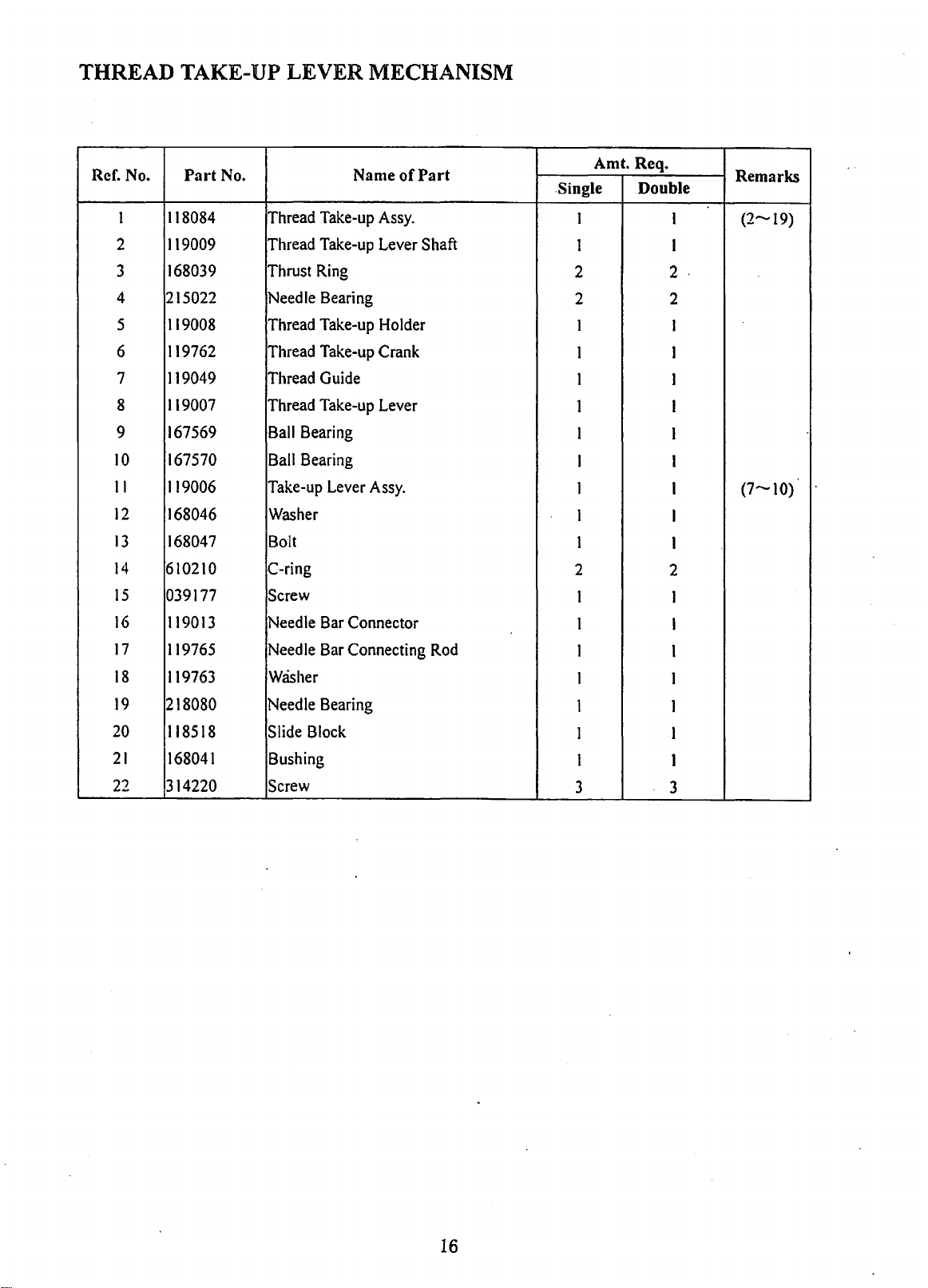

THREAD TAKE-UP LEVER MECHANISM

-22

1

I

I

22

~~

21-~

14-~

4 3

~

~

,~~

t~a

15

14

17

1,8

6

19

~

16

0

I I

®~

15

~

I

I

20

Page 17

THREAD TAKE-UP LEVER MECHANISM

Ref. No.

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

Part

118084

119009

168039

215022

119008

119762

119049

119007

167569

167570

119006

168046

168047

610210

039177

119013

1

19765

119763

218080

118518

168041

314220

No. Name

Thread

Thread

Thrust

!Needle

Thread

Thread

Thread

Thread

Ball

Ball

Take-up

Take-up

Take-up

Ring

Bearing

Take-up

Take-up

Guide

Take-up

Bearing

Bearing

Lever

Assy.

Lever

Holder

Crank

Lever

Assy.

Washer

Bolt

C-ring

Screw

Needle

Needle

Bar

Connector

Bar

Connecting

Washer

Needle Bearing

Slide

Block

Bushing

Screw

of

Part

Shaft

Rod

Amt. Req.

.Single

1

1

2

2 2

1

I

1

1

1

I

1

1

1

2

1

1

I

I

1

I

1

3

Double

1

1

2

1

1

1

1

I

I

I

I

1

2

1

I

I

I

1

I

1

3

Remarks

(2-19)

.

(7-10)

16

Page 18

UPPER

~~

SHAFTE MECHANISM

1

2 I

I·~

i-4

7

13

I

FOR MODEL Single

16

I

~

~q

15

I

14

18

17

Page 19

UPPER

SHAFTE MECHANISM

Ref.

I

2

...

.)

4

5

6

7

8

9

10

II

I:!

13

1-t

15

16

17

18

19

No.

Part

119164

108177

119163

108225

119085

119511

118600

215124

133283

118504

118503

610370

119042-2

215028

175150

242810

119042

108225-2

130224

No.

Adapter

Screw

Connector

Screw

Washer

Upper Shaft

Bushing

Needle Bearing

Washer

Collar

Screw

C-Ring

Link

Needle Bearing

Pin

Needle

Eccentric

Screw

Screw

Name

of

B~aring

Cam

Part

Single

I

I

I

I

I

I

2

2

2

1

1

l

I

I

I

I

I

I

1

Amt. Rcq.

Double

2

2

2

0

0

0

0

0

I

I

I

I

I

I

1

I

l

l

Remarks

I

(

11)

18

Page 20

NEEDLE

BAR

1\tlECHANISM

11

10

I

~t1)

13

14

n

I i

~I

i

6

118195(2.8)

118195-1 (2.4)

118195-2(3.2)

'9

29-1=-~

~off/

.

26

31

I I

~

28

~-27

@--19

~--20

1

S~ngle

·

19

Page 21

NEEDLE BAR MECHANISM

Ref. No.

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

29-1

30

31

Part

No.

118197

118196

108174-1

700868

700868-1

118195

118195-1

118195-2

175096

174173

175096-2

175150

215028

169137

305305

024191

118612

119718

030310

119046

119525-2

119718-2

118858

108285

118857

118543

118544

Needle Bar

~eedle

Screw

Screw

Screw

Needle Holder (2.8)

Needle Holder (2.4)

!Needle

Needle Bar

Screw

Thread Guide

Pin(

short)

Needle Bearing

Washer

Screw

Nut

...

Pin(

long)

Presser Lifting Shaft

Pin

Connecting

Washer

C-ring

Fitting Plate

Screw

Spring

Crank

Pin

II8543A Crank

640150 E-Ring

020490

130224

130224-1

134356

II8545

~pring

Screw

Screw

Needle

Washer

Name

Bar Clamp

Holder (3.2)

Rod

~

Assy.

Plate

of

Part

Amt:

Req~

Single

0

0

0

Double :

0

0

0

0 1

0

1

1

1

1

2

2

2 2

2

I

1

1 I

I

I I

1 1

1 I

1

1

1

1

I

I 1

I I

·2

I 1

1

I I

Remarks

I

1

I

I

I

1

(4,5)

(4,5)

1

0

0

0

1

2

2

2

I

I

I

I

1

I

I (24,25)

")

2

I

20

Page 22

:

·::.

NEEDLEB

ARFEEDING

. 3 2 I

MECHANISM

1 2 I

1

6

3

~~

~

b~~

~·([)

8

5

I

4

11

I

22

9~:00

Ej-14

12

17

16

21

Page 23

NEEDLE BAR FEEDING MECHANISM

Ref. No.

I

2

3

4

5

6

8

9

10

II

12

13

14

15

16

17

18

19

20

21

..,..,

Part

118600

215124

133283

118610

118285-1

130224

118594

100355

119014

119015

706196

119940

119940-5

119940-4

118521

108219

118520

314286

118520-1

118503

118504

No.

...

Bushing

Needle

Washer

Crank

Screw

Screw

Guide

Screw

Bracket

Fitting

·Screw

Needle

Needle

Needle

Fitting

Screw

Bushing

Screw

Bushing

Screw

Collar

Name

Bearing

Trough

plate

Bar

Holder

Bar

Bushing(

Bar

Bushing(lower)

plate

Assy.

of

Part

upper)

Amt. Req.

;

~(pgle.

2

2

4

1

.1

I

I

2

1

,.

3

2

I

I

I

0

0

·o

0

0

I

I

Double.

0

0

0

(}

0

0

1

2

1

3

2

I

I

I

1

I

I

I

1

1

)

Remari<S

(2

1)

22

J

...

:

..

;,.

Page 24

PRESSER

BAR

MECHANISM

~

~

·~

3-1

~-1

0

11

16

I

??

@o

~

I

15

<.i-15

24-~~

20-~

IU\[-23

t5

21

~f

22

35

I

~.~

10

-9

~11

~-12

~

1

13

1.-

~

049657 3/32"

049657-1 1/16"

29

~0

l I

25

26

27

~-28

23

Page 25

PRESSER BAR MECHANISM

I

I

!

Ref.

3-1

No.

1

2

~

..)

4

5

6

7

8

9

10

II

12

13

1-l

15

16

17

IS

19

20

21

22

..,~

....

..>

2-t

..,-

-=>

26

27

28

29

30

31

"'")

J-

~~

_)..)

34

:35

Part

119019

700785

119018

119018-1

118530

700510

19019-1

I

700510-1

119165-1

119165

173174

025874

05-l876

130187

175135

700335

069079

317950

119004

118577

100331

118535

343901

118105

IJI.t286

700017

119016

049657

049657-1

108171

118542

I

18536

118536-1

118539

640150

I

18536A

,

....

,r'90"'

IJ

..>

-

No.

Name

Presser Bar Bushing(upper)

Screw

Presser

Bar

Pin

Presser

Bar

Holder

Screw

Presser Bar Bushing(lower)

Screw

Roller Presser Retainer(upper)

Roller Presser Retainer(lower)

Screw

Spring

Bracket

Screw

Cover

Plate

Screw

Foot

Presser

Lifter

Screw

Bushing

Foot

Lifter Shaft

Screw

Spring

Plate

Screw

Guide Stud

Screw

Screw

Spring

Presser

Presser

Foot

Foot

Screw

Knee

Lifter Connecting

Lifting

Lever

Pin

Bushing

E-ring

Lifting

Lever

Assy.

!l3ushing

of

Part

Rod

Amt. Req.

Single

Double :

I

I

1

I

1

.,

I

-

I

I

I

1

I

I

1

I

I

.,

-

I

I

I

I

I

I

I

I

I I

I I

I

0

0

0

I 1

I

I

I I

)

I

1

1

I

1

1 .

1

2

I

1

1

1

I

I

I

I

I

2

I

I

I

1

I

1

I

I

1

I

)

I

1

I

I

I

I

Remarks

I

I

I

(30--33)

24

Page 26

TIMING

2

BELT

DRIVING

. . MECHANISM

6

I

\)

11

8

;1

6

~~~

·

..

~·j

;~

~

I

i !

13.

...

I

10

i

t~

\

.

.:

5

I

8

I

~~~

~

:.

~··

: \ \ . i

\

\..6'

\

@

I

i

I

9

~\

r~

I .

·I,

'\~·

I

:

!

1

25

Page 27

TIMING

BELT DRIVING

MECHANISM

Ref. No.

I

2

3 018624

4

5

6

7

8

9

10

II

12

13

Part

119097

610300

119707

335902-l

335902

119121

700689

018613

119708

069161

069161-1

119706

118726

No.

Cover 2

C-ring

Ball Bearing

Timing Belt

Screw

Screw

Collar( left)

Screw

Ball Bearing 1

Timing Belt

Timing Belt 1

Timing Belt l

Shaft

Collar( right)

Name

Wheel

Wheel

of

Part

Amt. Req ..

Single

I I

2

1 1

2 2

2

1 1

4

1

1

1

Double

2·

2·

2

4

1

1

1

l

I

l

Remarl<S

I

I

I

26

Page 28

STITCH

REGULA.

TORMECHA

6

NISl\'1

~--13

7-fi

II

L

~

~~-10

9

{1-u

~-12

3

27

Page 29

STITCH REGULATOR MECHANISM

Ref.

No.

1 175038

2

I

"\

.)

4

5

6 165356

7

8 I65356-8

9 165356-5

10

II

12

13

14

14-1

14-2

14-3

14-4

14-5

14-6

14-7

14-8

14-9

14-10

14-11

14-.12

14-13

Part

No.

~onnecting

Ball

6906

175038A

215028

118612

Bearing

~onnecting

!Needle

Bearing

Pin

Stitch Adjusting Plate

165356-1

Screw

!Nut

Spring

165356-7 E-ring

165356-6 Spring

165356-2

165356-3

175029

175029-1

175029-2

175029-3

Pin

Screw

Cam

Assy.

Stitch Regulating Slide

~Stitch

Regulating Block

IStud

175029-4 Screw

175029-5

Nut

175029-6 Presser Plate

175029-7

Screw

175029-8 Screw

175029-9

175029-10

175029-11

Stud

1

E . C

·

cccntru.:

Spring

175029-12 Collar

175029-13 Screw

Name

Rod

Rod

am

of

Assy.

Part

Amt. Req.

Single

1

1

D'otible

1

1

Remarks

1 1 ( 1 ,2)

1

I

I 1

I

1

I

1

1

I

I

I

I 1

I 1

I

1

I I

I 1

1 1

I I

I I

1

1

1 1

1

1

1 I

1 I

I 1

I

I I

1

1 I

2 2

28

Page 30

FEED

MECHANISM

l

Q)

~-6

,~J

·.~ . ·~\

·~

~~·

)'J

~1---'·

!

~~-9

~-7

10

__-J--~

f~~

. ' . .

-------

,~:

- ! /

--------------

---------

i

~

-----~·

\l

-------------------

::...-------

-

17

I I I

,.L.,.

4 3

c-~r/·'

{(\

8

-----------·

'

.

Q__)·~~}

18

13

14

13

29

Page 31

FEED

1.\'IECHANISM

Ref.

1

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

No.

Part

No.

610280

119085

133283

215124

118600

119163

108225

119164

108177

119084

11860

I Bushing

119521

130224

!335902-1

It

19521-l

700689

118603

119893

C-ring

Washer

Cap

Needle

Bearing

Bushing

Connector

Screw

Connector

Screw

Feed

Rock

Crank

Screw

Screw

Crank

Screw

Bushing

Collar

Name

Shaft

of

Part

Aint. Req.

Single

1

1

6

""

.J

1

1

1

1

1

1

1

1

""

.J

2

l

3

1

I

Double

1

1

6

3

1·

I

1

1

1

1

1

1

""

.J

2

1

3

I

I

Remarks

(16)

30

Page 32

CLUTCI-1

MECHA

2

NISM

7-7

I

4

5

7·6

7

31

Page 33

CLUTCH MECHANISM

I

!

I

I

I

I

I

I

Ref.

7-10

7-11

7-12

7-13

7-14

I

2

~

.)

...

5

6

7

7-1

7-2

7-3

7--l

7-5

7-6

7-7

7-X

7-9

No.

Part

I75025

518250

119711

1750I9

341901

133I09

II908IA

7005IO

172263

013153

173261

009-lOS

1/3264

065052

640150

175023

640I30

1)13076

()09037

1)09343

175126

No.

Shaft

C-ring

Shaft( short)

Shaft Coupler(left)

Screw

Connecting Plate

Safty Clutch

Scre\v

Safty Clutch Block

Spring

Latch

Hinge Stud

Shatt Coupler(

Pin

E-ring

Stud

E-ring

Pin

\Vash~r

Spring

Set Screw

Name

Assy.

right)

of

Part

Amt. Req.

Single

I

I

I

I

1

...

1

2

I

2

I I

I I

I

.,

-

I

2

I

I

I

I

I

Double

1

I

1

I

1

4

I

2

I

2

I

2

I

2

I

I

I

I

I

Renutri<S

I

I

(7-I-7-14)

I

I

I

I

I

I

!

l

I

32

Page 34

CENTRAL

POST

BED

MECHANISM

FOR

SINGLE

17

NEEDLE

2-~

1-

0

5

11------e

~

I

·~

4

~

16

058436(2.0)

058436-1 (1.6)

~!

ll

l 2

9

II@

,,

I'

II

~~

1

~

!

~-15

I

13

J !

~~

14

I

\

\

33

I

2

Page 35

CENTRAL POST

Ref. No.

I

2

...

.>

4

5

6

7

8

9

10

II

12

13

1-t

15

16

17

P;lrt

119145

250084

119721

119144

130224

18:!451

119725

317170

168351

305174

135292

I I 9 I

21

700689

016120

305144

05S-t36

05S436-I

210168

No.

BED

l\tlECHANISM FOR SINGLE NEEDLE

Cover Plate

Screw

Post

Washer

Screw

Screw

Stud

Pin

Screw

Plug

Washer

Bolt

Collar

Screw

Ball

Bearing

Cover Plate

Needle

Needle

Screw

Platet~.O

Plate(

Name

1

1.61

of

P;1rt

Amt.

Rcq.

Single Double

4

2

2

4

4

2

2

I

I

I

I

I

I

I

1

I

I

I

I

I

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Remarks

34

Page 36

ARMSH

.

AFTMECH

ANISM

7-1

~-3r-

~-fj

I .

4

9

l-5

________

-L--------------~

u---------------

~-2

12

I u

14

I

~

@)

~

•

I

13

13

15

I

I

~

ol)

G

I

13

----::r

@:]

I

8

10-·

STEEL

FIBRE

220xL

WIRE220xL

35

Page 37

ARM

SHAFT MECHANISM

Ref.

No.

I I19702-2

2

3 1I9702-3

4

5

6

7

7-1

8

9

10

I

0-1

II

12

13

14

15

16

17

18

19

20

21

22

130224

I19702-4

700510 Screw

119702-5

119702-1

119702A

119702-6

018643

069160 Timing

069160-1

119707

335902

335902-1

016153

119705

069746

168480

210265

175048

170913

341902

210287 Screw

Part

No.

Cam

Screw

Screw

Screw

Bushing

Arm

Shaft

Arm

Shaft

Bushing

Ball

Bearing

Timing

Timing

Screw

Screw

Ball

Bearing

Arm

Shaft Bushing

Bushing

Washer

Screw

Stitch

Ring

Balance

Screw

Assy

Belt

Belt

Belt

Wheel

Name

Wheel

of

Part

Amt. Req

Single

1

2

1

I

1

1

1

I

0

I

1

. 1

2

2

6

2

2

1

2

1

I

I

2

1

•.

Double

I

2

I

1

1

1

1

1

I

1

1

1

2

2

6

2

2

I

2

I

I

1

2

I

Remarks

'

36

Page 38

GEAR

DRIVING

MECHANISM

6

FOR

SINGLE

NEEDLE

2-3~

2-1--

1-3

9

1-l 1-5

~-GYLH

!

1-4

~----11

9

~12-1

7----i

10---1

I

7-~

I

~~---15

9

~~15

4 I

----®

4-1__,/

4-1

~

5-~

37

1\

I

'13

·/

14-~

/.

~15

15

Page 39

GEAR DRIVING MECHANISM

FOR

SINGLE NEEDLE

Ref. No.

I

1-1

1-2

1-3

1-4

1-5

2

2-1

2-2

__

_,

"')

"'

3

3-1

3-2

4

4-1

5

6

7

s

C)

10

II

11-1

12

13

14

15

16

Part

No.

119795

119795-1

119795-2

119795-3

119795-4

119795-5

119737

119737-1

119737-2.

119737-3

119723

119723-l

119723-2

119670

119670-1

11

<>7:!4

119723-A

119535

119534

119535-l

119535A

119532

119535-1

119533

5045

5046

700689

175113

Name

Gear Shaft

Assy.

Gear Shaft (upper)

Gear Shaft(lower)

Screw

Screw

Steel Ball

Bevel Gear

Ass~.

Bevel Gear Shaft

Bevel Gear

Feed

Wheel

Gear Bracket

Screw

Screw

Collar

Screw

!Bushing

Bevel Gear Driving

Shaft Coupler

Joint

Screw

Shaft Coupler

Assy.

Central Post Shaft

Screw

~Bushing

Bevel Gear(small)

jBevel

Gear(medium)

IS

crew

Central Bevel Gear

of

Part

Assy.

Assy.

Amt. Req.

Single

1

I

1

1

1

24

I

1

1

I

1

I

2

I

2

1

1

2

I

4

I

1

2

I

I

I

4

1

Double

0

0

0

0

0

0

0

I

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 (13--15)

0

Remarks

(1-5)

(7-9)

38

Page 40

LEFT

AND

MIDDLE

fl

.;

I

,:!

f

!!

,,

POST

BED

MECHANISM

17

FOR

TWO

NEEDLE

3~1/

2--i,

'51

L (/

;/

"

6-~:.

I o -

ii

II

,,

II

lj

!;

li

..

··

!

. :

a_/

18--~

21--11

058325(2.4)

Jl

I

'I

.

b~~

·~·f

)

IJ_...

39

Page 41

LEFT AND MIDDLE POST BED MECHANISM FOR TWO NEEDLE

Ref.

l

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

IS

19

20

21

22

No.

Part

No.

119976

119499

250084

119695

168351

135292

305174

016120

119121

700689

175318

119143

108093

119138

119136

108174-1

119140

108093

058325

058325-1

058325-2 Needle

100296

119296

108174-1

Name

Side Bracket(left)

Cover Plate

Screw

Cover Plate

Plug

Screw

Washer

Ball

Bearing

Collar

Screw

Stud

Spring Plate

Screw

Fitting

Feed

Screw

Post

Screw

Needle

Needle

Screw

Central Support

Screw

Plate

Wheel

Cap

Assy.

Plate(2A)

PlateJ

Plate(2.0)

1.6)

of

Part

Amt. Req.

Single

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 1

0

0

0

0

0 1

0

0

0

0

Double

Remarks

1

1

4

1

1

4

4

1

I

2

1

1

1

1

2

2

2

I

1

2

1

8

40

Page 42

LEFT

POST

1\lECHANISM

FOR

SINGLE

NEEDLE

2-l···o~

~

'---____.;;~

2

I

,.

~~

·~

r;)

~

1-9

r'v

'~

3

~·~

1

·

-?

~

l-

4~

,

1-3

1-5

0

'

1-9

...

o"l-6

-4

-1

~-15

I

~

~····1-10

~-17

~-1-7

5

I

'f

':o

:·\

(/I~

\\~

~~6

.;:--

1-

8

13

°

.......

.:~

0

l ( 0

.;-.

N

~·t,..

. 0

-~·

'!.{"'

8

•

0

•••• ~ .. 0 :--

•

'0'14

S"-"""

1· s

0-20

-19

e-23

0-24

8-25

..

·~~)-29

\.

:.:.,

..

·

~-18

'\.)-11

'

. (

'-....

0~~--12

41

Page 43

LEFT POST MECHANISM FOR SINGLE NEEDLE

Ref.

1-10

2-1

9-1

21-1

(.

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

2

"\

.)

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

..,

...

_

_,

24

No.

Part

119716A

000390

000928

010166

119487

175136

119377

000219

100529

119376

010079

0100158

100205

119716

119129

108093

119494

1700689

694ZZ

119106-1

119106

108177

119105

119128

119127

119525-1

119525

215031

215028

119108

125010

119104

119108-1

141710

119979

664390

No.

Rotating

Screw

Screw

Spring

Bobbin Case

Hook Gib

Needle Guard

Screw

Screw

Rotating

Bobbin

Bobbin Case

Screw

Bobbin Case

Rotating

Screw

Gear

Screw

'Ball Bearing

Holder

Opener Holder

Screw

Washer

Oil

Felt

Hook Opener Bracket

Hook Socket

Hook Shaft

Needle Bearing

Needle Bearing

Bushing

Washer

Out Bushing

Washer

Needle Bearing

Bushing

iC-ring

Name

Hook

Hook

Hook

Assy.

Assy.

Opener

Assy.

of

Part

Amt. Req.

Single

Double

0

0

0

0

0

0

0 I

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 1

0

·o

0

0 I

2

2

2

2

3

8

1

1

I

1

1

1

1

1

1

1

1

l

1

1

1

1

I

I

I

I

I

I

I

I

I

I

I

Remarks

1-1--10

(9)

42

Page 44

25

26

27

28

29

29-1

29-2

29-3

29-4

30

31

32

~

...

.).)

33-1

33-2

~~

.).)-.)

34

35

36

37

38

~

175138

119107

341901

119950

119947

119957

119958

119959

119960

119109-1

119109-2

119108

125010

122718

125008

125009

119133-1

119133-2

341901-1

119133

123778

Bushing

Collar

Screw

Screw

Washer(0.2)

Washer(0.1)

Washer(O.I5)

· Washer(0.5)

Washer(2.0)

Bevel

Gear(large)

Bevel

Gear(small)

Bevel

Gear

Washer(O.S)

Washer(

0.

1)

Washer(0.15)

Washer(0.2)

Bevel

Gear(small)

Bevel

Gear(large)

Screw

Bevel

Gear

Collar

Assy.

Assy.

0 I

0 I

0

2

0

0 I

0 2

0

0

0

0

0

0

0

2

0

0

0

0

0

0

2

0

0

I

1

I

1

I

1

I

I

1

I

1

I

I

1

(8.30,31)

(8.34-36)

43

..

Page 45

RIGHT POST BED MECHANISM

FOR MODEL Single

~

I

.2

8

1

0

0

0

2

(;

2-~

3

~m-.6

5

7

~

8-1

~8-2

~

0

I

0

2

~-

1

9

. \

{)

44

17-

18-

~

I

2

Page 46

RIGHT

POST BED MECHANISM

Ref. No.

I

2

3

4

5

6

7

7-1

8

9

10

11

12

13

14

15

16

17

18

Part

119695

250084

175267

700336

175318

330217

175324

119168

119436

108093

119143

108093

135292

305174

016120

119121

700689

175234

119499

No.

Cover

Screw

Cover

Screw

Stud

Screw

Side Bracket(right)

Side Bracket(right)

Post

Screw

Spring

Screw

Screw

Washer

Ball

Collar

Screw

Cover

Cover

Plate

Plate

Cap

Assy.

Plate

Bearing

Plate

Plate

Name

of

Part

I

Amt. Req.

Single

0

4

1

2

1

I

1

0

1

2

1

1

4

4

1

I

2

1

0

Double

-

1

4

0

0

I

1

0

1

0

0

1

I

4

4

I

I

..,

0

I

Remarks

45

Page 47

BEARING

DRIVIN

GMECHANISM

~

3

2-~~l

~

1

~lrf'

6

(Left)

0--j

'VY

4 5

ij)O~

I I

8 9

~--13

11

13--~

12

-

46

Page 48

BEARING DRIVING MECHANISM

Name

of

Ref. No.

I

2

3

4 06I014 Needle Bearing 2

5

6

7

8

9

10

II

12

13

14

Part

119507

119087

174176

119115-1

119112

119115

012555

664350

1731.74

119111

119216

108174

119115-3

No.

Link

Oil

Felt 2

Screw

Bearing Socket

Bearing Assy.(left)

Bearing Assy.(right)

Ball

Bearing

C-ring

Screw

Bearing Shaft

Cover Plate

Screw

Screw

Part

Amt.

Req.

Single

I

2

4

2

1

I I

2 2

2

1

1

I

4

0

Double

I

1

2

2

2

1 (4,5)

2

I

I

I

4

1

Remarks

(4.5)

~

I

47

Page 49

RIGHT POST

2

I

BED

DRIVING

-MECHANISM

@

3

I

~

l-9

1'1

',~··~-1-6

...

~

,.

1-9

~-13

~+10

~-15

~-1-7

1-

8

--.g

!·---

1-

8

-14

--17

18--B

19--0

20-8

25-@

Ref.

©-12

No.

I

1-2

1-3

1-4

1-5

1-6

1-7

Part

No.

119716A

,QQ0390

1000928

'010166

119487

175136

lt19377 Needle Guard

Rotating

Screw

Screw

Spring

Bobbin Case

Hook

Hook

Gib

~

I

16

Name

of

Assy.

Part

48

28-~

31--;':2}JJ~

30

I

28

Amt. Req.

Single

1

1

I

1 1

I

I

I I

Double

..

1

1

1

1

1

Remarks

(1-1-8)

Page 50

RIGHT POST BED DRIVING MECHANISM

1-8

1-9

1-10

2 010079

2-1

3

4

5

6

7

8

9

9-t

10

II

12

.

13

.

14

15

16

17

18

19

20

21

22

_

_,

")"'

24

25

25-1

25-2

25-3

26

27

28

29

30

31

000219 Screw

100529

119376

Screw

Rotating

Bobbin

010158

100205

119716

119128

119127

119129

108093

694ZZ

119106-1

119106

108177

119105

119525-1

119525

215031

215028

119524

119979

664390

175138

II9I07

119950

341901

131088

1250IO

122718

125008

125009

119133-1

1I9133-2

700689

341901-1

119I33

123778

Bobbin Cap

Screw

Bobbin

Oil

Felt

Hook

Rotating

Screw

Ball

Opener Holder

Opener Holder

Screw

Washer

Hook

Hook

Needle Bearing

Needle

Bushing

Bushing

C-ring

Bushing

Collar

Screw

Screw

Collar

Washer(0.5)

Washer(0.1)

Washer(O.IS)

Washer(0.2)

Bevel

Bevel

Screw

Screw

Bevel

Collar

Hook

Cap

Assy.

Opener Bracket

Hook

Opener

Bearing

Assy.

Socket

Shaft

Bc!aring

Gear(small)

Gear(large)

Gear

Assy.

2

..)

"'

2

4

4

2

2

I

1

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

I

1

I

I

I

I

I

I

I

I

2

6

2

2

2

4

2

4

2

I

I

1

I

1

1

I

I

I

I

I

I

I

1

I

1

I

I

1

I

I

I

I

I

I

I

1

(9)

I

I

(26-29)

49

Page 51

ACCESSORIES(l)

11-i

;~

\..

__

1-

~

3

~

4

>

_8

-~

"-....

....

___

...

~-10

'-

12--~:

~

~

14

,-·

.-....

~-

...

--?

.

~/

~~--

-·;_-,-·

..;•"'

__

15

50

16

Page 52

ACCESSORIES( I)

Ref.

I

2 029836

..,

.)

4

5 029946

6

7 134356

8

9

10

I

II

I

12

13

14

15

16

No.

Part

No.

123456

800

II 0 Spanner

129915

029007

029394

119089-1

100355

I

!032808

010079

259431

119026

FPL2

!FPL3

Name

of

Accessory Bag

Vinyl

Cover

Screw Driver(small)

Screw. Driver( medium)

Screw Driver(large)

Needle

Oiler

Stitch Length Indicator

Screw

IRubber

Cushion.

Bobbin

Bobbin Winder

Thread Guide

Pin

Thread Stand(2-pin)

Thread Stand(3-pin)

Part

Amt. Rcq.

Single

I

I

I I

I

r

1

10

1 1

1

I

2

4

I

I

I

0

Double

1

1

1

1

I

10

1

1

2

4

1

I

0

I

Remarks

i

I

51

Page 53

ACCESSORIES(2)

1-1

~

2

y

4

3

(\J

1 I

\ ;

·..

/

,~,

6-·1

.

,-···::?

-·'.

r~

QJ

-·,,

..

.

/l-6

.

·0

..

-·

//

~

)

I

,.'

''<V~

.

l"'l

~

;;!x"'.

5

11-·

"

..............

. !

; .

I

_/

A

12-u

1

52

Page 54

ACCESSO.RIES(2)

Ref.

.

13-1

14-1

I

2

3

4

5

6

7

8

9

·10

II

12

13

14

No.

Part

171543

171542

171413

171412

171411

029934

.

030341

029450

118636

460157

032717

032717-1

119078

11908<}-2

119088

119078-1

No.

Name

of

Part

Spring

Knee

Lifter Coupling 1

Knee

Knee

Knee

Hinge

Lifting

Lifter

Lifting

Assy.

Socket

Rod

Lever

Assy.

Pin

Hinge

Pin

Oil

Pan

Screw

Machine

Rest

Pin

Belt·

Cover(

large)

Screw

Belt

Cover(

small)

Screw

Single

;

· Amt. Req.

1

1

1

1

2

2

2

1

6

1

I

I

2

I

2

Double·~.

1

1

1

1

1

2

2

2

I

6

1

1

Remarks

(2-4)

1

2

I

2

53

Page 55

PRESSE'R FOOT.

FO~DOl.JBl.IE

NEE~LE

!

5 6

10

11

2

7 9

3

4

12

GAUGE

54

Loading...

Loading...