Page 1

I

HIGH

LEAD

GC24518-1LD/1RD/2D

I

Single

feed

needle/twin-needle

lockstitcher

with

post-bed

auto

trimmer

needle

Instruction Manual

Parts Catalog

bar

SHANGHAI

HUIGO~G

N0.3

SEWING MACHINE

FACTORY

Page 2

!.Preparation

for

operation

1 ) Safety precautions

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the

needle and the area around the pulley.

(2)

Power must be turned

off

when the machine is not in use,

or

when the operator leaves the seat.

(3) Power must be turned

adjusting the machine,

(4}

Avoid placing fingers, hairs, bars etc. near the pulley,

when the machine is in operation.

(

5)

Do

not insert fingers into the thread take-up cover, under/around the needle,

machine

(6)

If

safety devices.

2)

Precautions before

(

1)

Never operate the machine before filling the machine's oil pan.

(2) When a new sewing machine is first turned on, verify the rotational direction

the power on.

(3) Verify the voltage and phase (single

3)

Precautions for

(I)

Avoid using the machine at abnormally high temperatures (35"C

is

in operation.

a belt cover, finger guard, eye guard are insta1led, do not operate the machine without these

operating

off

when tilting the machine head, installing

or

when replacing.

starting

conditions

operation

or

three) with those given on the machine

"V"

belt, bobbin winder pulley,

or

or

removing the

higher)

"V"

belt,

or

motor

or

pulley when the

of

the pulley with

namepl~te.

or

low temperatures

(5"C

or

lower) .

(2) Avoid using the machine in dusty conditions.

4)

Specifications

Model

Max. sewing speed 2000rpm

Stitch length

Needle bar stroke 33.4mm

Presser foot

stroke

Needle

Needle gauge

Lubrication Semi-auto lubricated

Hook

Motor

By

hand

By

knee IOmm

GC24518-1LD/IRD

l.6times hook

DPXS

220V550W Servo motor

-I-

I

o-smm

7mm

(14#-18#)

I

GC24518-2D

8mm

Page 3

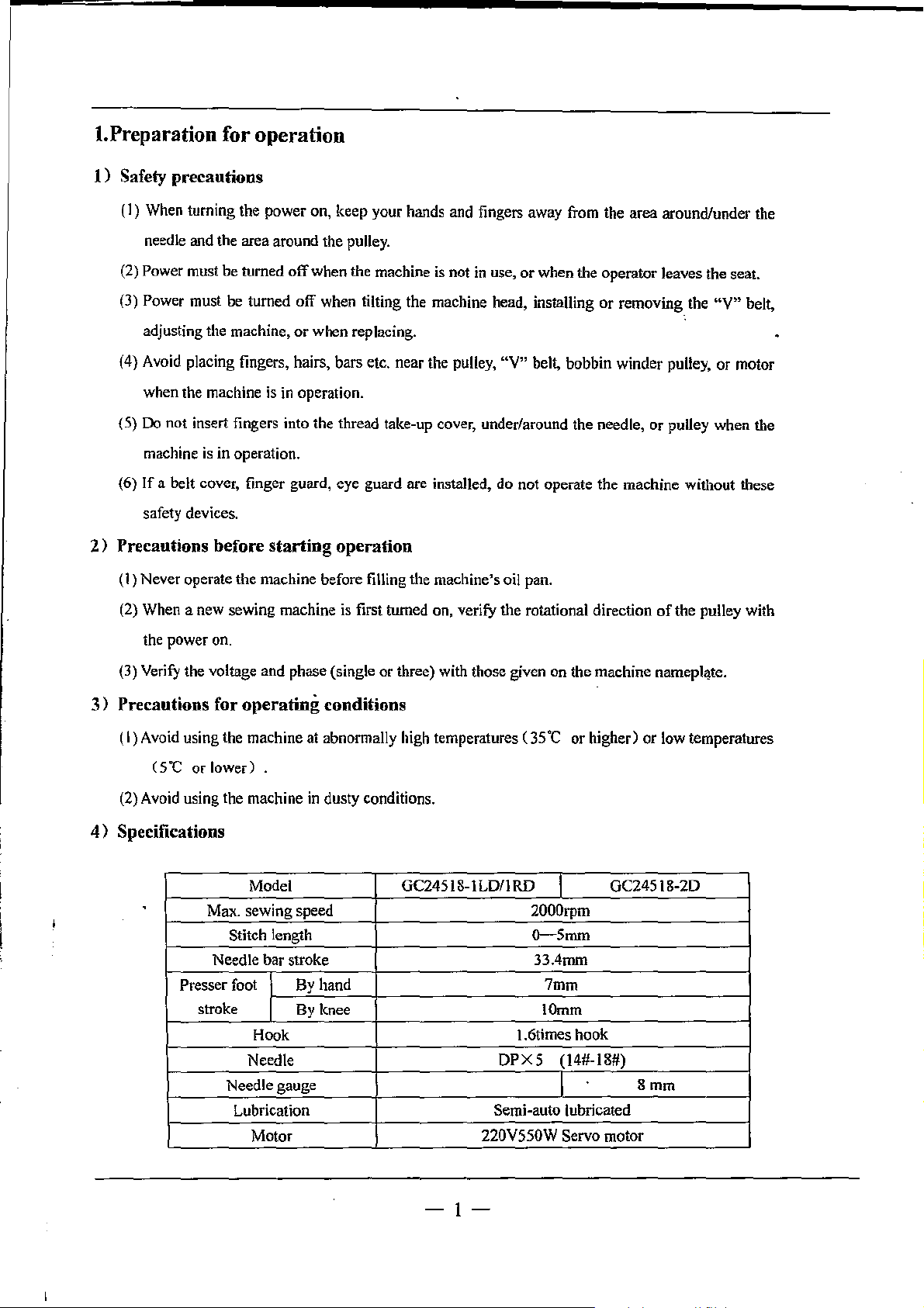

2.Lubrication

(Fig.l,

Fig.2,

Fig.3)

I) Before starting operation, be sure to pour oil up to the position H

position

2) When a new sewing machine is first operated,

a sewing machine which left out

period

through the oilholes after removing

shown below(the derection shown in arrows). (Fig.

3) While operating

The oil

L, replenish the oil supply up to position H. (Fig.])

or

when

of

use

for a long

of

time

is

amount

operated,

the

machine,

can

be

it

will be necessary to oil

the

rubber plugs

2)

check

the condition

adjusted by oil adjustment screw.(Fig. 3)

of

oil lubrication through the oil

of

oil tank.

If

the oil below

check

window.

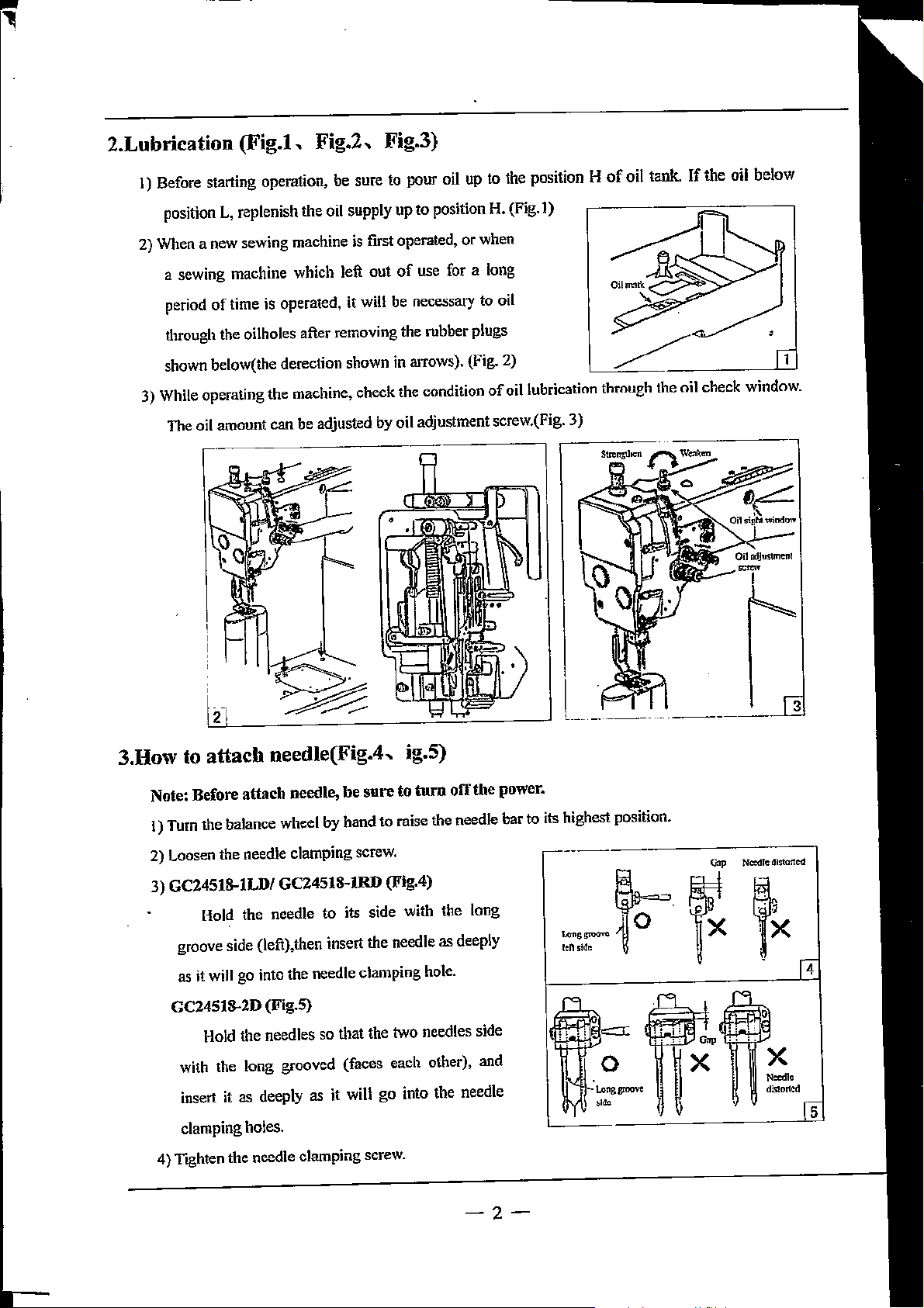

3.How to

Note: Before

1) Turn

2) Loosen

3)

GC245!S.ILDI

groove side (left),then insert

as it

GC2451S.2D (Fig.S)

with the long grooved (faces each other), and

insert

clamping holes.

4)

Tighten

attach

the

the

Hold the needle to

will

Hold the needles so that the two needles side

needle(Fig.4, ig.S)

attach

balance wheel by

go into the needle clamping hole.

it

as deeply as it

the

needle,

needle

clamping

GC24518-IRD

needle

clamping

be

sure

to

turn

hand

to raise the needle

screw.

(Fig.4)

its side with the long

the

needle

will

go into the needle

screw.

off

as

the

deeply

power.

bar

to

its highest position.

!eh

""''"""

s!de

0 X

X

-2-

Page 4

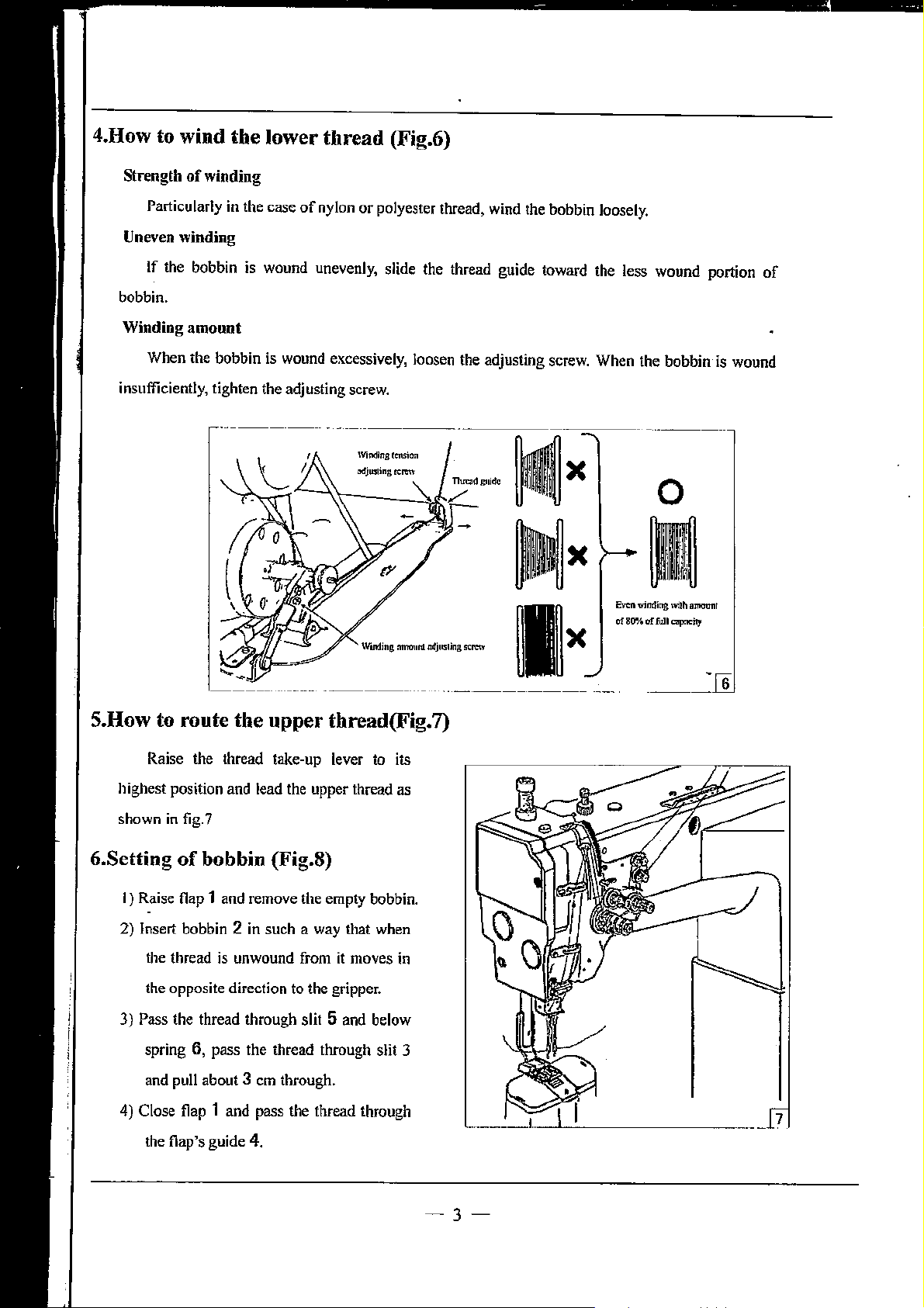

4.How to wind

the

lower

thread

(Fig.6)

Strength

Uneven

bobbin.

Winding

insufficiently, tighten the adjusting screw.

of

winding

Particularly in the

winding

If the bobbin

amount

When

the bobbin is wound excessively, loosen the adjusting screw.

case

of

nylon

or

polyester thread, wind the bobbin loosely.

is

wound unevenly, slide the thread guide toward the less wound portion

Wonding

:nnonnl

odjusling

SCI'Oif

X

X

When

Even winding

of

80%

the

bobbin

0

I

1¥i!h

a!

full~

ammmr

is

wound

of

S.How to route

Raise the thread take-up lever to its

highest position and lead the upper thread as

shown in fig. 7

6.Setting

I) Raise flap 1 and remove the empty bobbin.

2) Insert bobbin 2

3) Pass the thread through slit 5 and below

4) Close flap 1 and pass the thread through

of

the thread is unwound from

the opposite direction to the gripper.

spring 6, pass the thread through slit 3

and pull about 3

the

upper

bobbin (Fig.8)

in

such a way that when

em

through.

thread(Fig.7)

it

6

moves in

the flap's guide 4.

-3-

Page 5

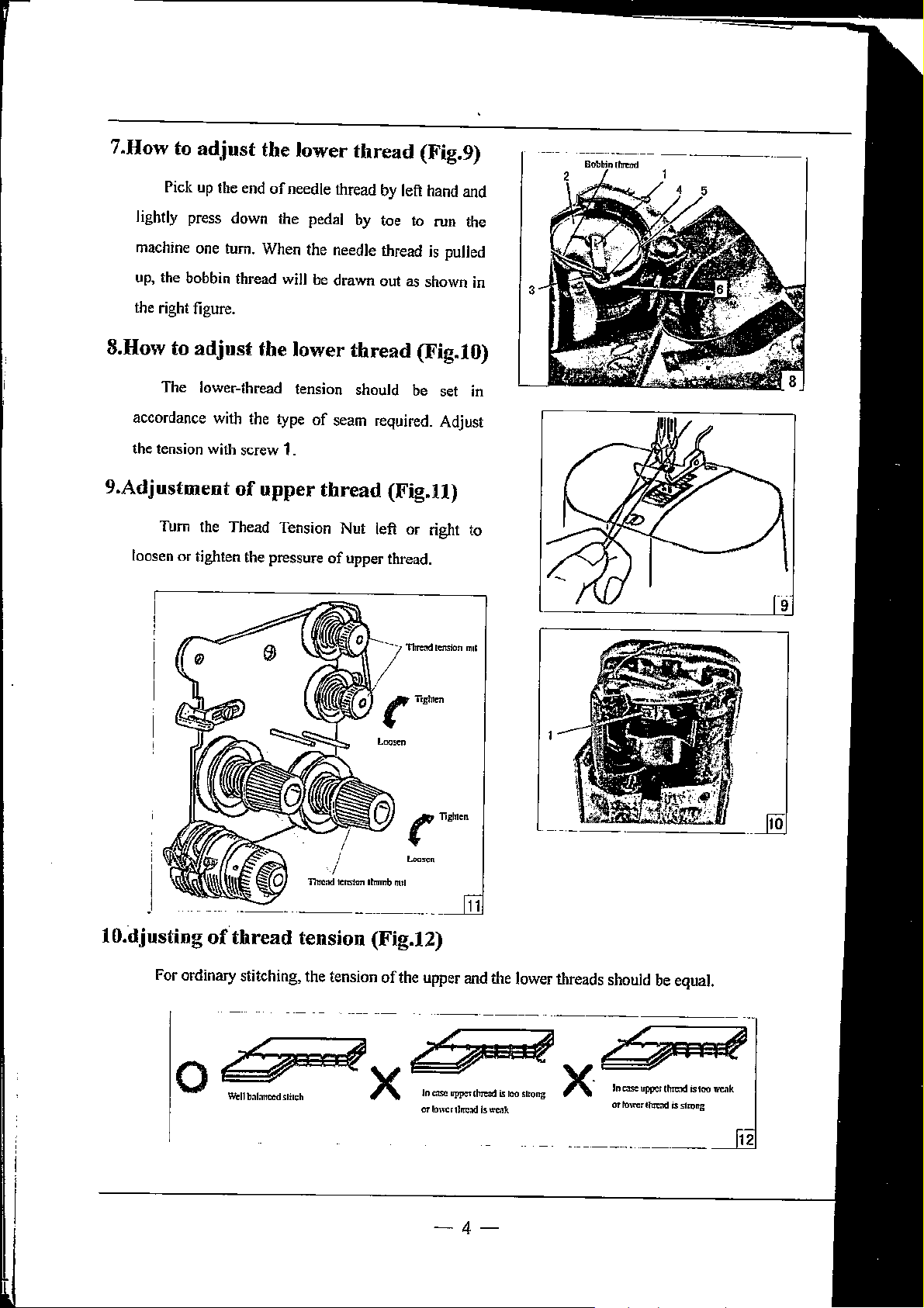

7.How to ad.just the lower

Pick

up

the end

of

needle thread

thread

by

left hand and

(Fig.9)

lightly

machine one tum. When the needle thread

up,

the right figure.

8.How to

accordance with the type

the tension with screw 1.

9.Adjustment

loosen or tighten the pressure

press down the pedal

the bobbin thread

adjust

The lower-thread tension should be set

of

Tum

the

Thead Tension Nut left or right to

will

be

drawn out as shown

the lower

of

seam required. Adjust

upper

thread

of

thread

upper thread.

by

toe

to

run the

is

pulled

(Fig.lO)

(Fig.U)

11!1'etld

ternjon

in

in

mol

'

.1

lO.djusting

For ordinary stitching, the tension

··-·--

of

thread

( llghlen

~=

tension (Fig.12)

of

the upper

-4-

and

the lower threads should be equal.

12

Page 6

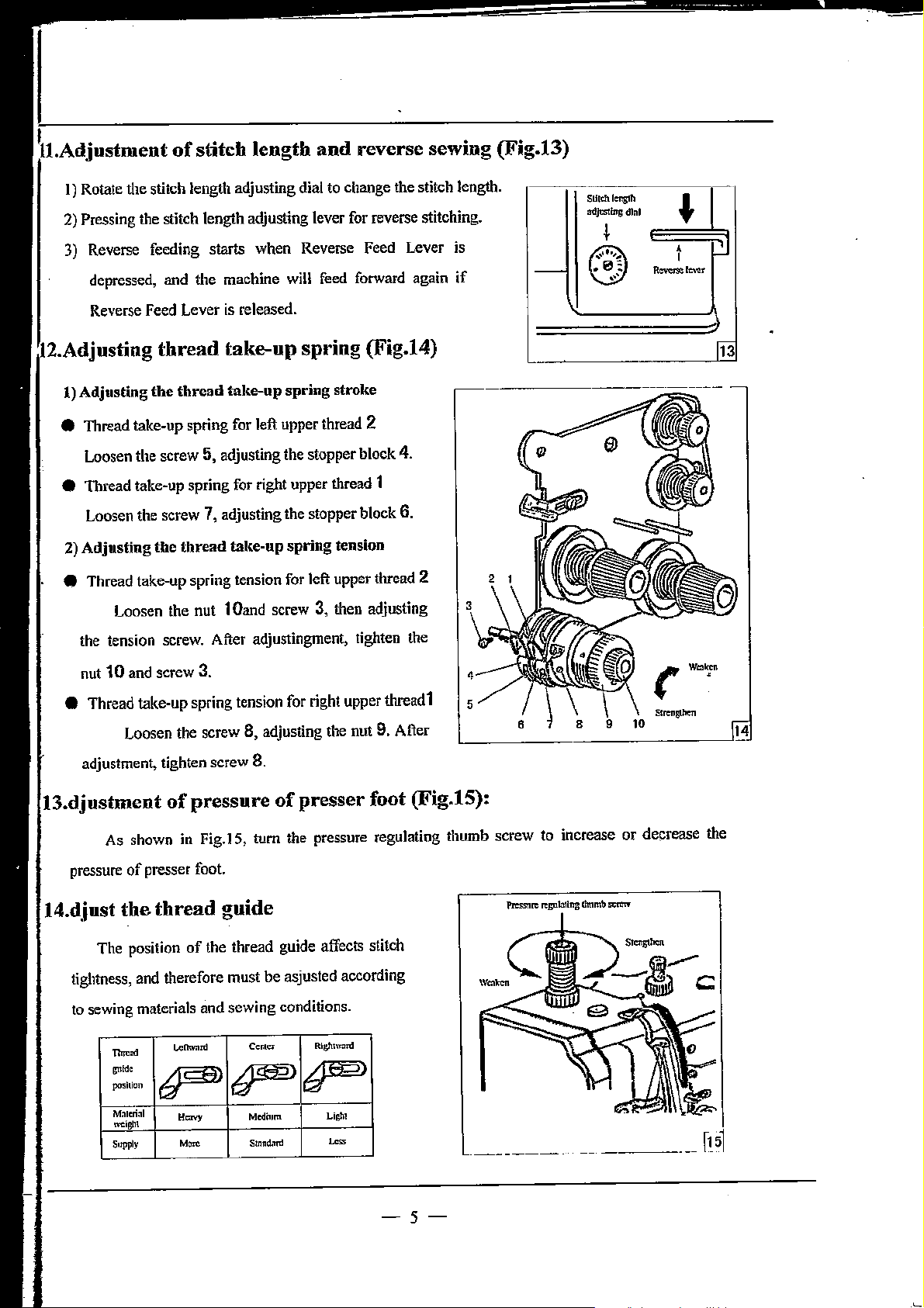

;n.Adju•:tm.eut

of

stitch length

and

reverse sewing (Fig.13)

I) Rotate the stitch length adjusting dial to change the stitch length.

2)

Pressing the stitch length adjusting lever for reverse stitching.

3)

Reverse feeding starts when Reverse

depressed, and the machine

Reverse Feed Lever

;12.Ad.jus1ting

l)

Adjusting the thread take-up spring stroke

thread

is

released.

take-up

will

spring (Fig.14)

Feed

Lever

feed forward again if

e Thread take-up spring for left upper thread 2

Loosen the screw 5, adjusting the stopper block 4.

e Thread take-up spring for right upper thread 1

Loosen the screw 7, adjusting the stopper block 6.

2) Adjusting

• Thread take-up spring tension for left upper thread 2

the

thread

Loosen the nut 1

take-up

Oand

spring

screw 3, then adjusting

tension

is

1-

-------------

···-

SU!dt

lenglh

adJns!lns

l

0

dlnl

t-

I

R~lowr

-'l

[13

the tension screw. After adjustingment, tighten the

nut 10 and screw 3.

e Thread take-up spring tension for right upper thread1

Loosen the screw 8, adjusting the nut 9. After

adjustment, tighten screw 8.

(l3.dj1ost1ment

As shown

pressure

l4.d,iust

The position

tightness,

to

sewing materials and sewing conditions.

-·

~"

pcr.;iticn

f-=;

Moteriol

m::iglll

Supply

of

presser foot.

the

thread

and

therefore must

p

of

pressure

in

Fig.

IS, tum the pressure regulating thumb screw to increase or decrease the

of

presser foot (Fig.15):

guide

of

the thread guide affects stitch

be

asjusted according

L<:llw:lrd

"""

-~

CenlCI"

p>

Medilom

Stnnd.ml

Rlglnw:m:l

F

LiGht

~

5

-5-

Page 7

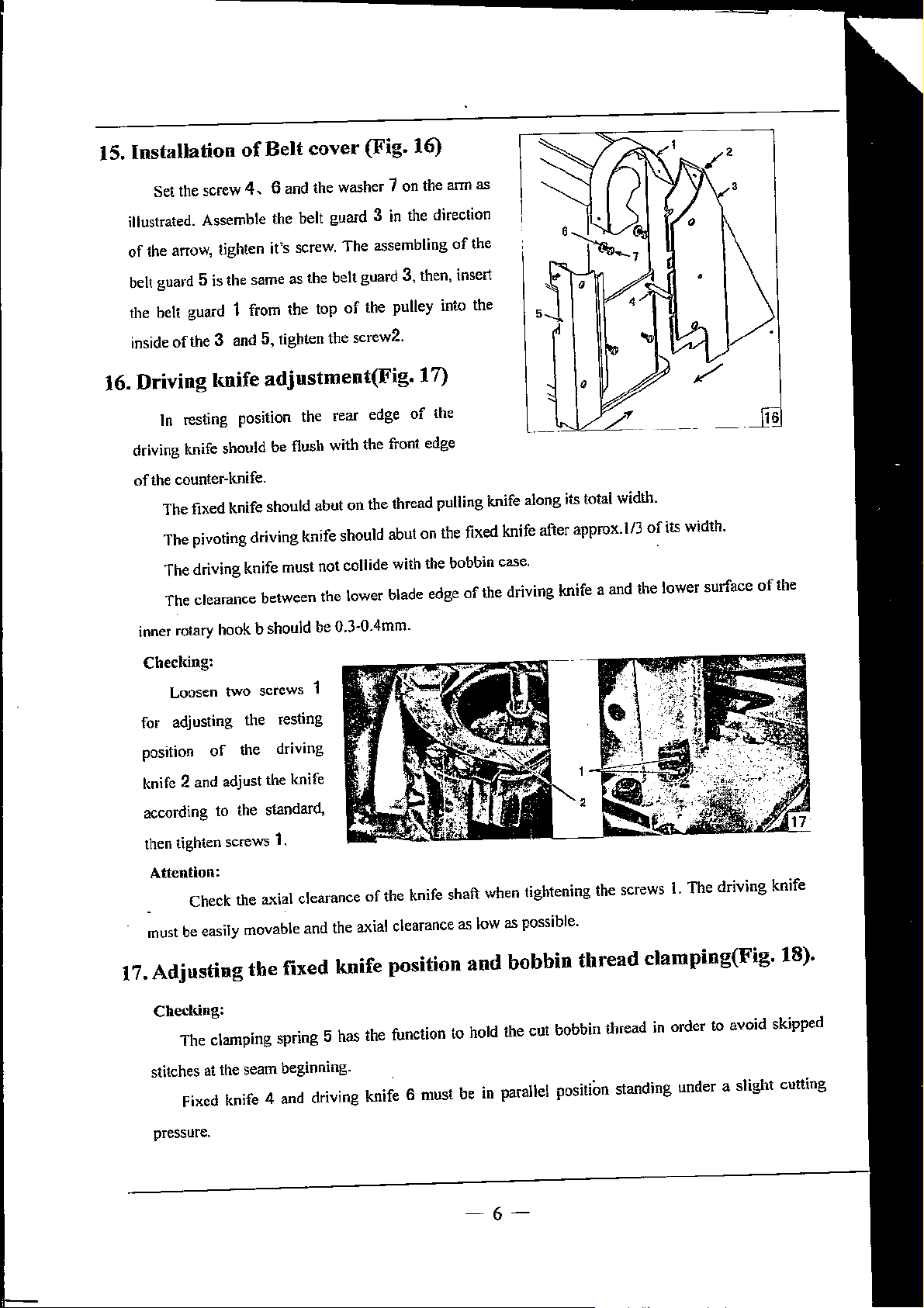

15. Installation

of

Belt cover (Fig. 16)

Set the screw

illustrated. Assemble the belt guard 3 in the direction

of

the arrow, tighten it's screw. The assembling

belt guard 5

the belt guard 1 from the top

inside

of

the 3 and

4,

6 and the washer 7 on the arm as

is

the same as the belt guard

of

5,

tighten the screw2.

3,

then, insert

the pulley into the

16. Driving knife adjustment(Fig. 17)

In

resting position the rear edge

driving knife should be flush with the front edge

of

the counter-knife.

The fixed knife should

The pivoting driving knife should abut on the fixed knife after approx.

The driving knife must not collide with the bobbin case.

The clearance between the lower blade edge

inner rotary hook

b should be

abut

on

0.3~0.4mm.

of

the

the thread pulling knife along its total width.

of

the

'

•

---

1/3

of

its width.

of

the driving knife a and the lower surface

- _ji6

of

the

Checlring:

Loosen two screws 1

for adjusting the resting

position

knife

according to the standard,

then tighten screws

Attention:

must

17. Adjusting

Checking:

stitches at the seam beginning.

of

the driving

2 and adjust the knife

1.

Check the

be

easily movable and the axial clearance as low as possible.

The clamping spring 5 has the function to hold the cut bobbin thread

Fixed knife 4 and driving knife 6 must be

ax.ial

the

fixed knife position

clearance

of

the knife shaft when tightening the screws

and

hohhin

in

parallel positiOn standing under a slight cutting

thread

1.

The driving knife

clamping(Fig. 18).

in

order to avoid skipped

pressure.

-6-

Page 8

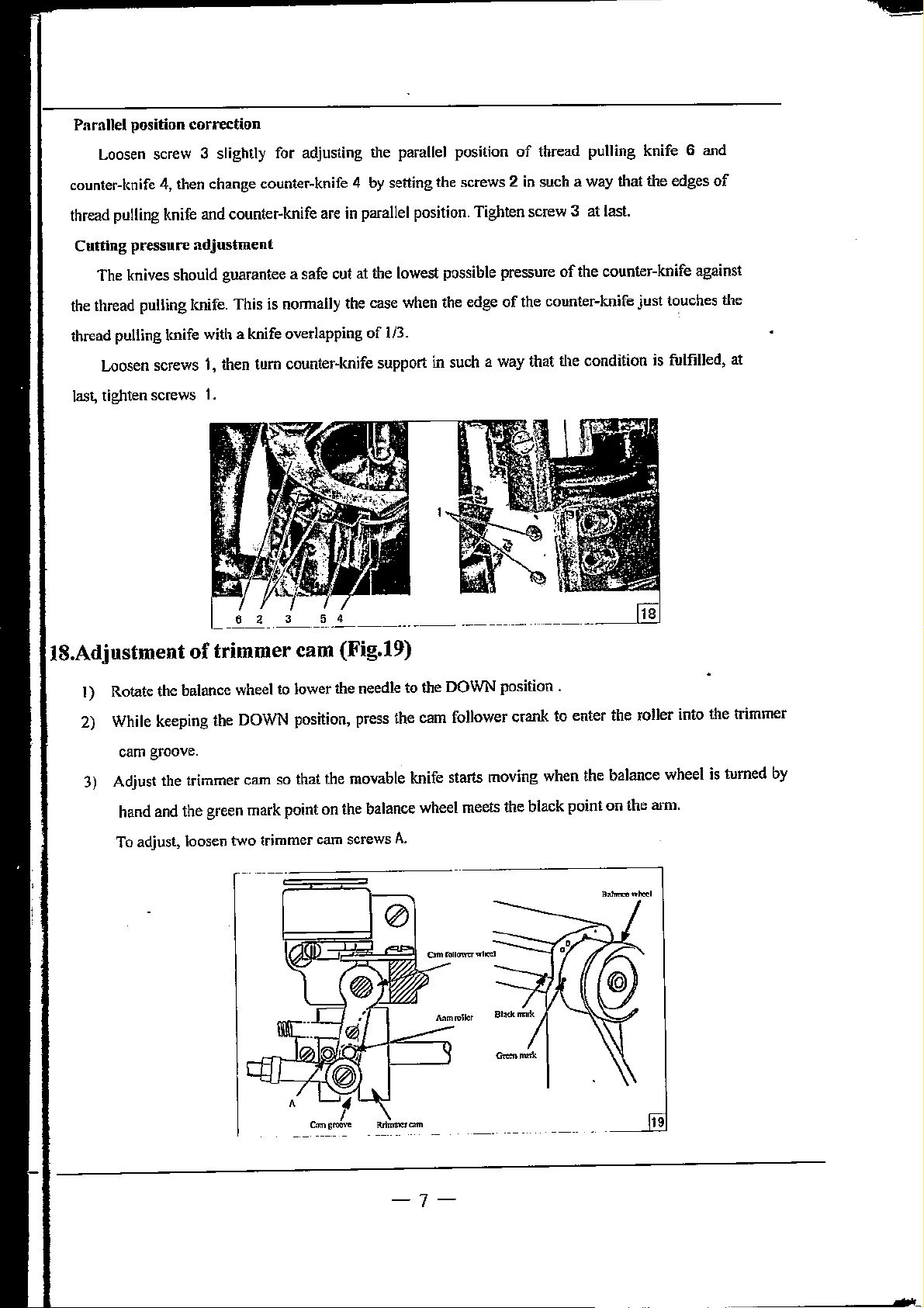

Parallel position correction

Loosen screw 3 slightly for adjusting the

counter-knife 4, then change counter-knife 4

thread pulling knife and counter-knife are

in

parallel position

by

setting the screws 2

parallel position. Tighten screw 3 at last.

of

thread pulling knife 6 and

in

such a way that the edges

Cutting pressure adjustment

The knives should guarantee a safe cut at the lowest possible pressure

the thread

thread pulling knife with a knife overlapping

last, tighten screws

pulling knife. This

Loosen screws 1, then tum counter-knife support in such a way that the condition is fulfilled, at

1.

is

nonnally the case when the edge

of

l/3.

of

of

the counter-knife against

the counter-lmife just touches the

of

1)

Rotate the balance wheel

2) While keeping the DOWN position, press the cam follower crank

cam

groove.

3)

Adjust the trimmer cam so that the movable knife starts moving when the balance wheel is turned

hand and the green mark point on the balance wheel meets the black point on the arm.

To

adjust, loosen two trimmer cam screws

to

lower the needle to the DOWN position .

A.

to

enter the roller into the trimmer

19

by

-7-

Page 9

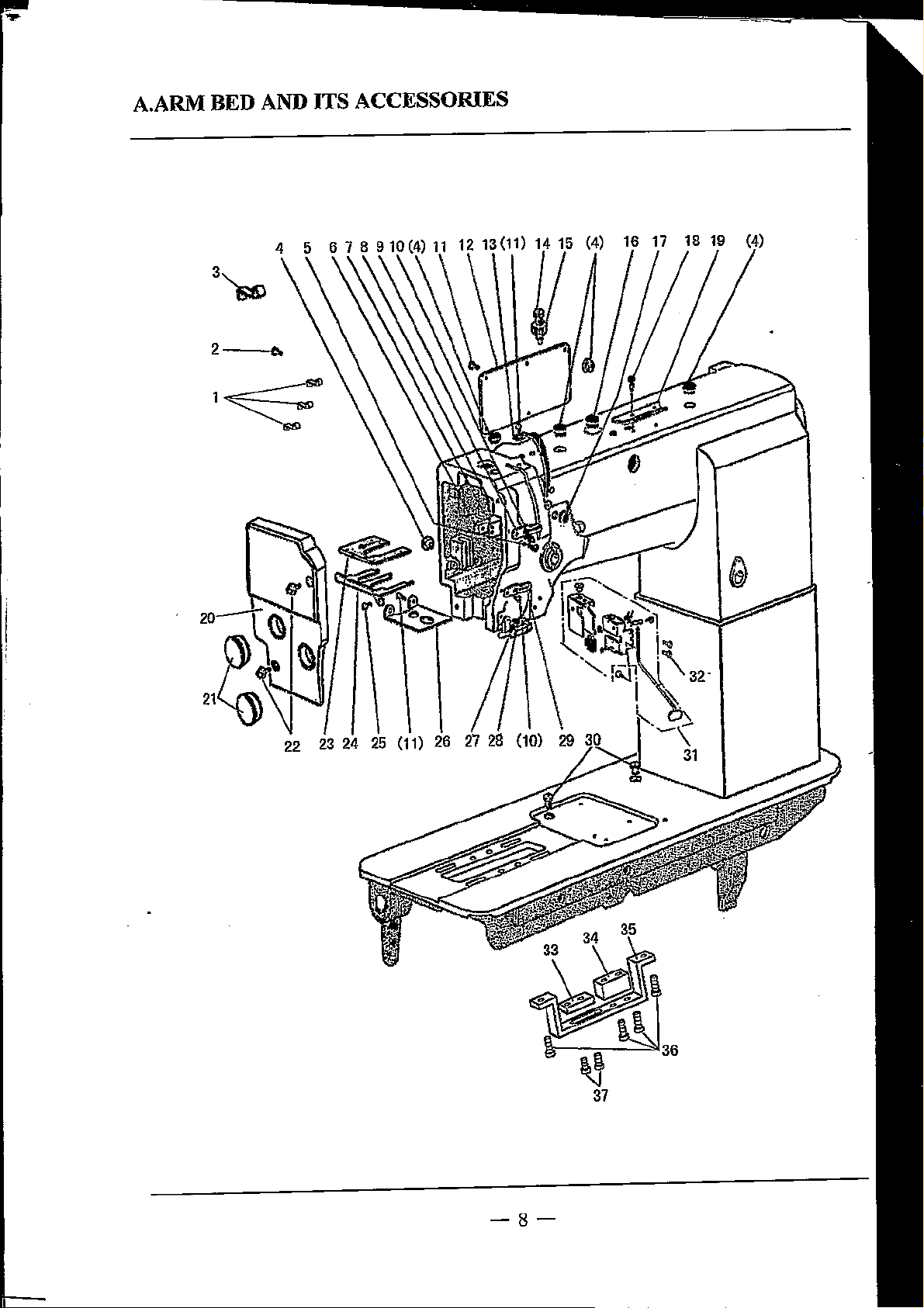

A.ARIVI

BED AND

3~

ITS

ACCESSORIES

2

..

22

(11)

-8-

Page 10

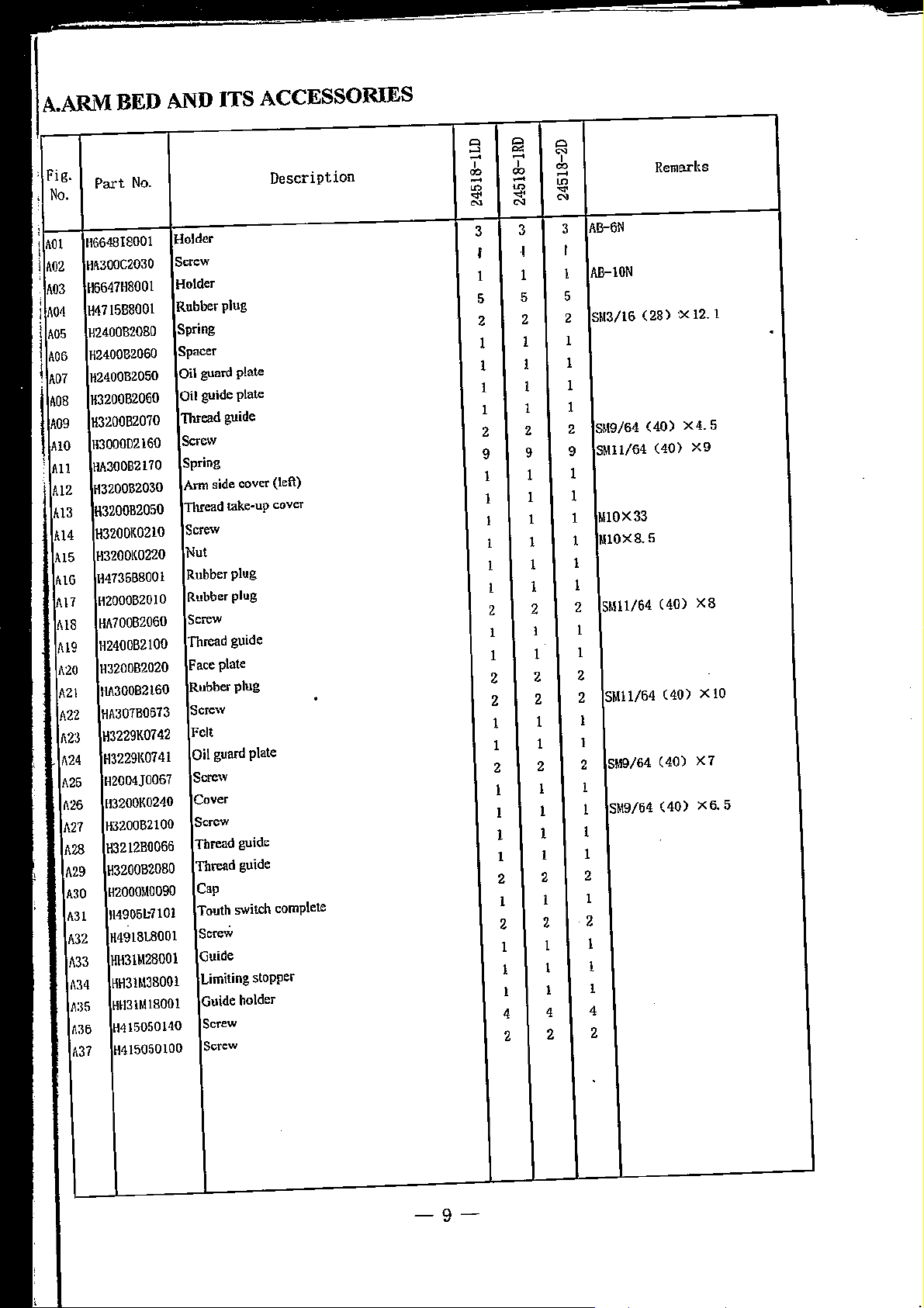

A.AR\VI

BED

AND

ITS ACCESSORIES

Part

No.

Description

complete

0

~

-

~

' '

~

-

..

N

3

1

5

2

1

1

1

1

2

9

1

1

1

1

1

2

1

1

2

2

1

1

2

1

1

1

2

1

2

1

1

4

2

iii

-

~

-

~

N

3

1

5

2

1

1

1

1

2

9

1

0

'i'

~

~

-

..

N

3

1

5

2

1

1

1

1

2

9

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

2

2

2

1

1

1

2

2

1

1

1

1

1

1

1

2

2

1

1

2

2

1

1

1

1

1

4

4

2

2

Remarks

(28)

'Xl2.1

(40)

(40)

(40)

(40)

(40)

(40)

X4.

X9

X8

X7

5

XlO

X6.5

-9-

Page 11

I

I

I

'

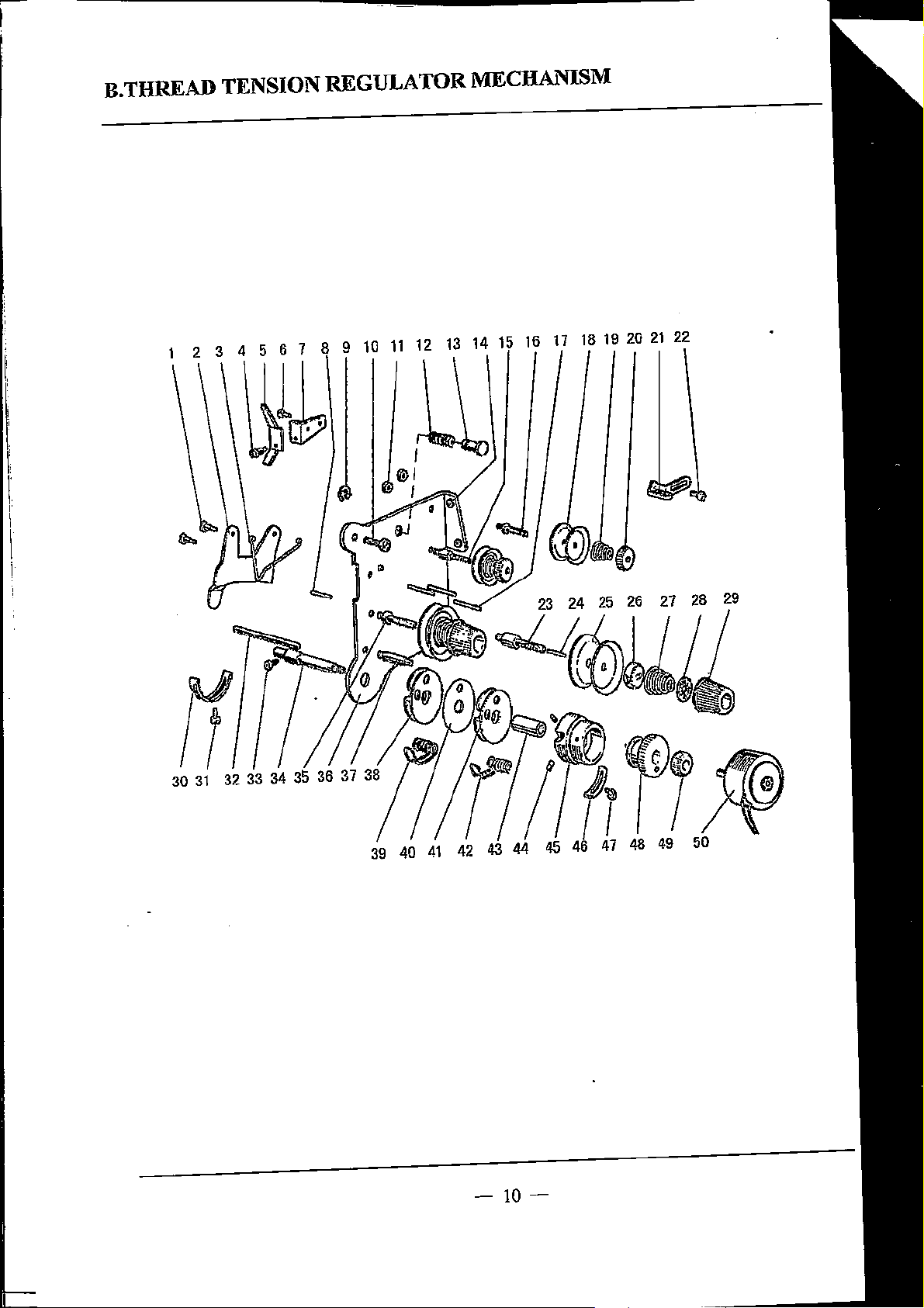

B.

THREAD

1 2 3 4 5 6 7 8 9

TENSION REGULATOR

10

11

12

13

.lb

MECHANISM

17

18

14

16

19

20

21

22

I

30

31

32 34

-10-

Page 12

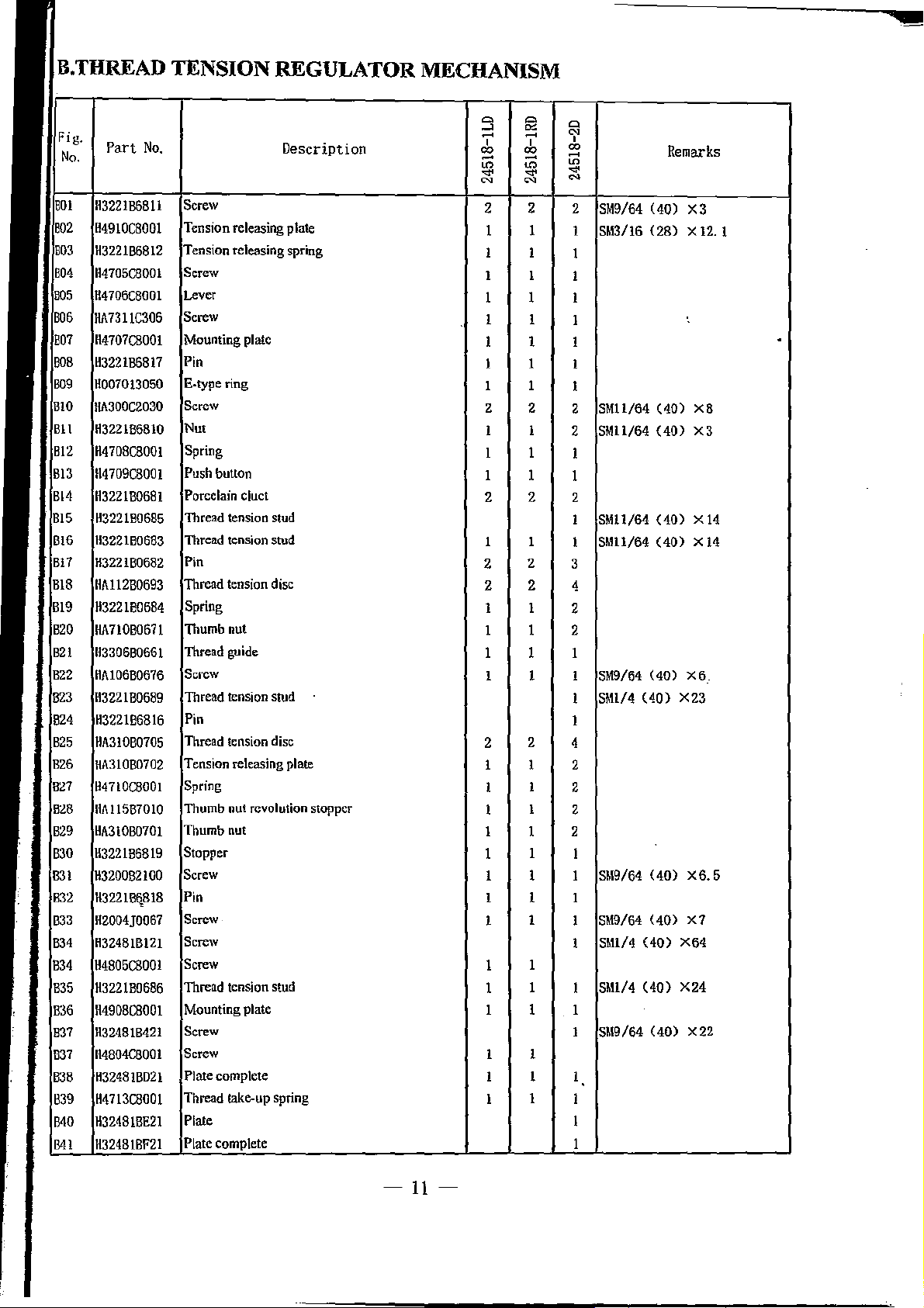

THREAD

TENSION

REGULATOR

MECHANISM

Part

No.

Description

spring

c\uct

tension stud

tension stud

uut

guide

tension stud

tension disc

nut revolution stopper

uut

tension stud

complete

take-up spring

Q

fi!

~

- -

ro ro

' '

~

~

-

-

~ ~

~

~

2 2 2

1 1 1

1 1

1 1 1

1 1

1 1 1

1

1 1

2 2

1

1

1 1

2 2 2

1 1

2

2

2 2

1 1

1 1 2

1 1 1

1 1 1

2

2

1 1 2

1 1 2

1

1

1 1 1

1 1 1

1

1

1

1

1

1

1 1 1

1 1

1 1

1

Q

~

ro

~

-

~

~

2

2

1

3

4

2

1

4

2

2

'

1

1

1

1

1

1

1

1

1

1

1

(40)

(28)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

Remarks

X3

X 12. 1

XB

X3

Xl4

Xl4

X6_

X23

X6.5

X7

X64

X24

X22

-11-

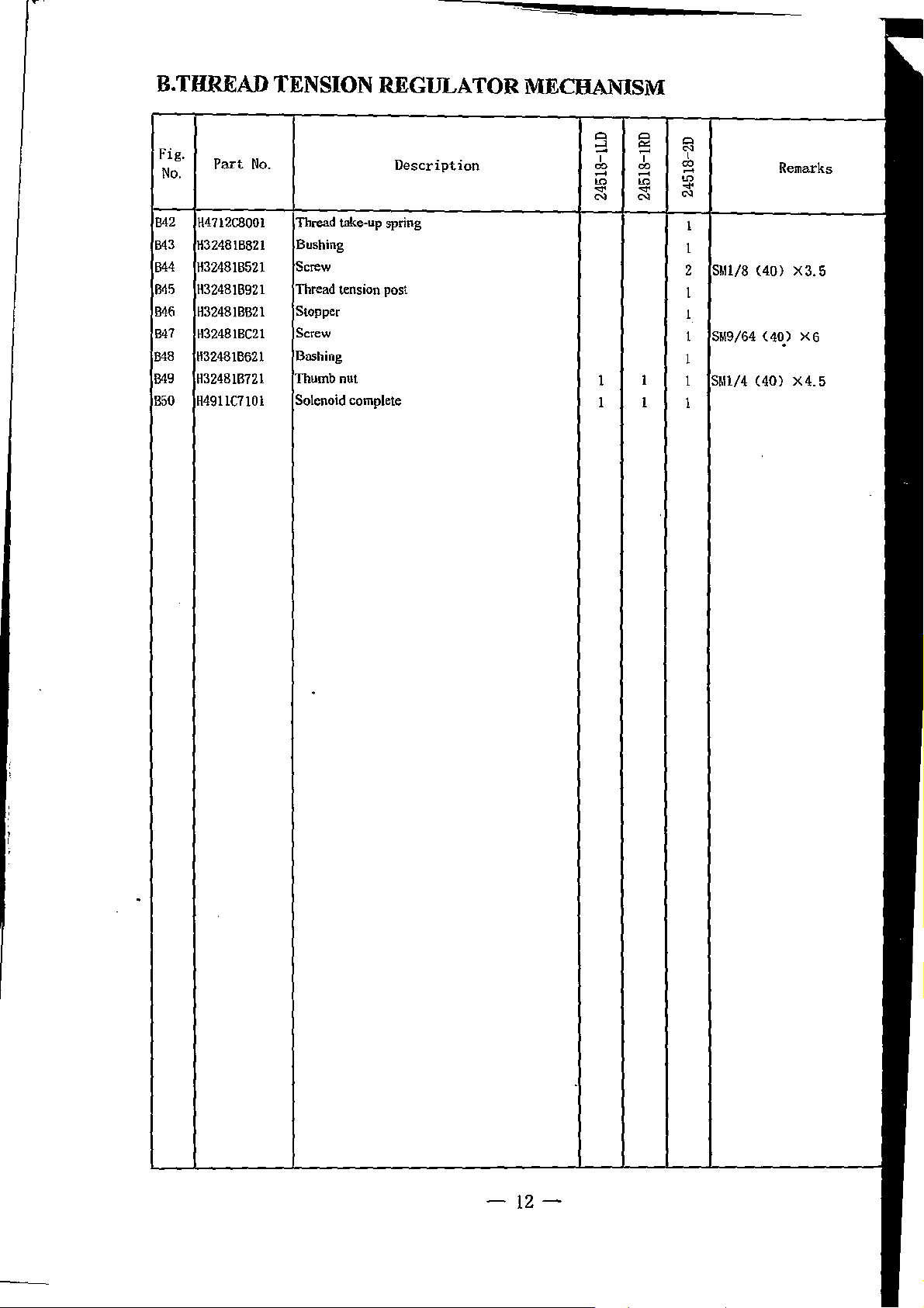

Page 13

B.

THREAD

TENSION

REGULATOR

MECHANISM

Fig.

No.

Part

No.

spring

complete

Description

0 0

~

~

-

-

ro ro

' '

~

~

-

-

..

..

N N

1 1

1 1

0

N

ro

'

~

-

..

N

1

1

2

1

1

1

1

1

Remarks

(40)

(40_)

(40)

X3.

X6

X4.

5

5

-12-

Page 14

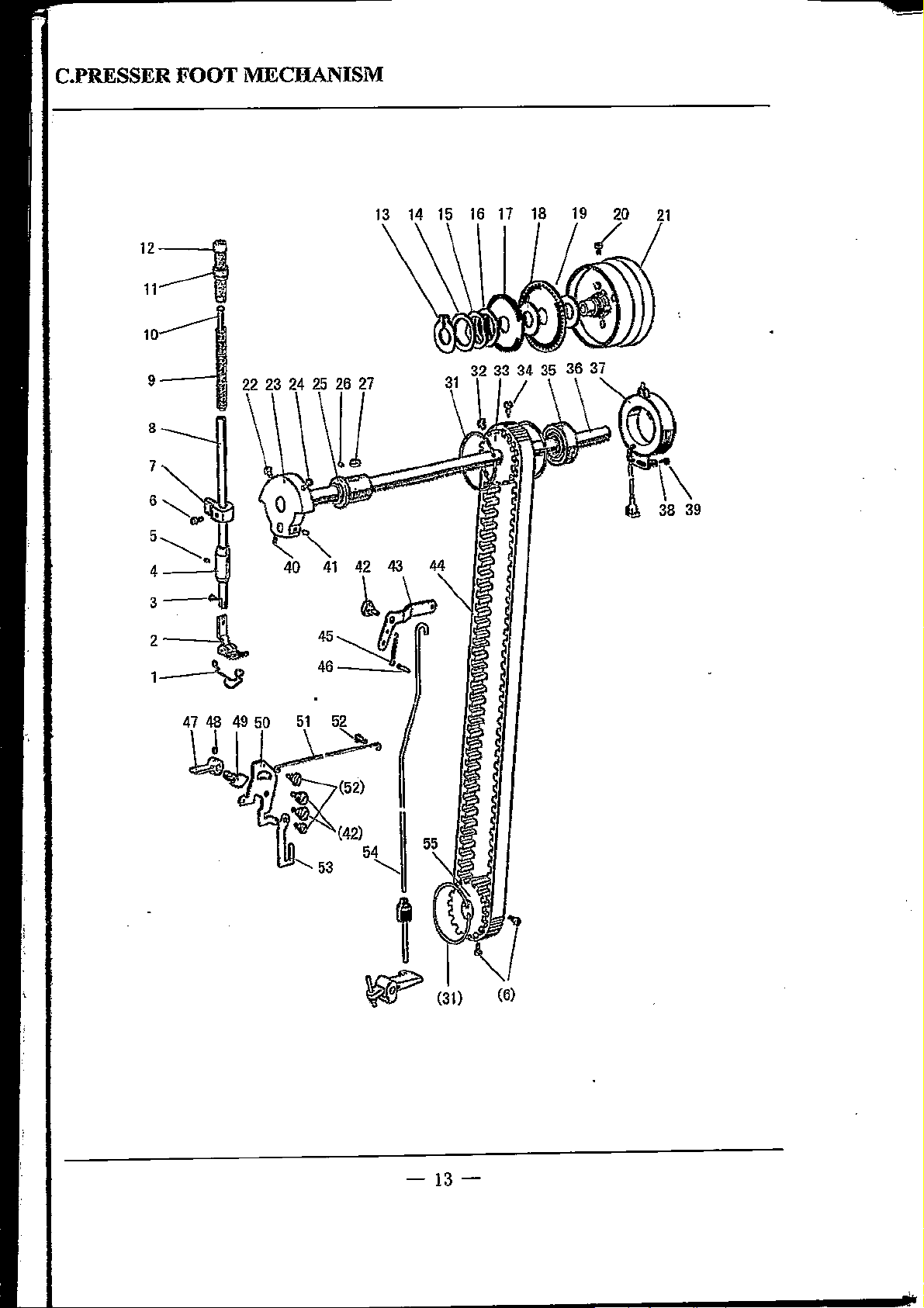

C.PRESSER FOOT MECHANISM

13

10

9

8

7

6""'-

.,

5~

4---'!"1

3-

R

2-l

1----\P

47 48 49

~

22

41

45~

46

50

51

52

.....

..-->

42

43

~_b

"'

54

53

"-._

1

~

(31) (6)

-13-

Page 15

---

C.PRESSER FOOT MECHANISM

Fig.

No.

Part

No.

foot complete

bar guide bracket

Description

foot

spring guide

command disk F20 (up)

command

"""'

disk

Fll

(down)

bracket (complete)

~

"'

-

00

'

~

-

~

N

1

~

N

"'

"'

-

00

00

~

-

~

N

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

3

'

'

~

-

~

N

1

1

1

1

1

1

1

1

1

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

1

1

1

1

1

Remarks

(44)

't28)

(28)

(28)

(28)

(28)

(40)

(40)

X9

(28)

(28)

(28)

Xl4

X10

Xl2

X13

X10

Xl4

X4

XB

X12

X6.

7

-14-

Page 16

C.PRESSER

FOOT

MECHANISM

Fig.

No.

C46

•17

COB

C49

C50

C51

C52

5.1

C54

C55

Part

No.

H3200E2090

H3208E0067

HAIOOBZllO

H3200E2060

H32JOE0682

H32\0E068!

HA107H0662

H32IOE0683

H6307E800!

H3207C067l

Description

Pin type

Presser har lifter

Screw

Eccentric

Knee lifter lever left

Knee lifter rod

Screw

Operation plate

Operation rod

Pulley

Q Q

~ ~

-

-

00

-

~ ~

f f

N

'

00

'

-

N

I I I

I

I I

2

2

I I

1 1

1 1 1

3

3

1 1 1

1

1 1

I 1 1

Q

N

00

'

-

~

f

N

SMll/64

2

I

1

S~\3/16

3

SM9/64

Remarks

(40}

(28)

(40)

X5. 5

.

xz. 5

X6

.

-

15-

Page 17

D.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

17

16

14

1-----,1'1

-16-

Page 18

D.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

Part

No.

Description

bar connecting stud

pulley

lever

Q

§l

~

- -

~ ~

'

~ ~

- -

~ ~

N N

1 1

1

1 1

2

4

1

4

2 2

1

1 1

1

1

1 1

1

3

1

1

1

1

1

1

2

2

1 1

1

1

2

1 1

1

1

Q

N

~

'

~

-

~

N

1 1

2 2

4 4

1

4 4

1

1

1

1

3 3

1

1

1 1

1

1

1

1

2 2

2

1 1

1

1

1

2

1

1

1

1

1

'

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

.1

1

1

Remarks

#18

(56)

(40)

(44)

(28)

(40)

(28)

(24)

(44)

(24)

(24)

X4

X8.5

X3.

X 12

X6

Xl5

X4. 8

X5. 5

X26.2

5

X7

-17-

Page 19

D.NEEDLE BAR AND THREAD TAKE-UP MECHANISM

Q

Fig.

No.

Part

No.

Description

Q

~

-

~

'

~

-

...

N

1

"'

-

~

'

~

-

...

N

1

1

Q

N

~

'

~

-

...

N

Remarks

(44)

X4.5

-18-

Page 20

E.STITCH REGULATOR MECHANISM

.262728

30

16 17

18 19

20

\x~~

1\

36 37 38 (31) 39

40

-19-

41

42

(31)

Page 21

E.STITCH REGULATOR MECHANISM

Fig.

No.

Part

No.

I"''"'"

pin

stitch

Description

shaft

(upper)

Q

~

00

m

N

~

Q

Q

N

"'

-

00

'

2

1

m

N

~

m

-

~

N

2

2

IS>lll/" ( 40)

1

1

'

00

'

Remarks

(28)

X8. 5

X

(28)

(28) X 12

12

X 8. 5

(28) X 12

xs.

5

(28)

X8.5

(28)

X7

1

(28)

X6

1

-20-

Page 22

F.LOWER SHAFT AND FEED ROCK SHAFT MECHANISM

1 2 3 4 6

22

23

24

25

26

~

-21-

Page 23

F.LOWER SHAFT AND

Fig.

No.

Part

No.

shaft bushing (left:)

shaft bushing (right)

shaft bushing complete (middle)

bearing

bearing

connecting fork

;

ring C-type

flange

shaft bushing

shaft

shaft crank(right)

FEED

ROCK

Description

(left)

SHAFT

Q

~

-

00

~

~

N

MECHANISM

Q

Q

~

N

00

'

00

'

'

~

-

~

-

~

~

N

N

1

1

1

1

1 1

3 3 3

1

1

1 1

1 1

1 1

3 3 3

2

2 2

1 1

1 1 1

1 1

3 3

1

1 1

1

1

1

1

1

1

1

1

1

1

1

1 1

3

1

2 2 2

2 2 2

2 2 2

2 2 2

2 2 2

Remarks

(40)

X5

(28) X 14

(28)

(24)

X4

(28)

X7

(44)

X4

(24)

X22

(24)

X3.5

(28)

(28) X 12

Xl4

Xl8

-22-

Page 24

F.LOWER

Fig.

No.

F44

F45

F46

H7

F-IH

F49

F50

F~l

F52

Part

HAIOOG2120

HA105D0652

HA106G0661

fl:l208G0676

H:l208G0673

H3206D0674

H2012N0652

H32311D306

H32311D406

SHAFT

No.

AND

Bushing

Screw

Collar

Screw

Connecting rod crank( middle)

N"t I

Screw

Screw

Oil wick

FEED

Description

ROCK

SHAFT

N

MECHANISM

Q

~

-

m

-

~

N

4

Q

N

ro

'

'

-

m

~

N

I

I

SMI/4

4

2

2

I

I

I

SM15/64 C28) X

I

I

SMS/16

I

SMI/4

I

I

SMS/16 C24) X26. 2

I

9

-

ro ro

'

-

m

~

I

4

2

I

I I

I I

I I

I

(24)

(24)

(24)

Remarks

X4

14

.

X5

XIS

.

-23-

Page 25

G.HOOK SADDLE MECHANISM GC24518-1LD (

1)

4 5 6 7 8

~

18

19

20

••

•

0 0

13

~

.,

..

•

-24-

Page 26

G.HOOK SADDLE MECHANISM

GC245l8-lLD

(2)

46 47 48

~~

::~

43

""'

42'\~-

41

51

52

53

54

55

56 57 58 59

49

50

11

60

61

62

l~/(40)

I·~

I

'!

63

64

(38)

66

67

-25-

Page 27

G.HOOK SADDLE MECHANISM GC24518-ILD

Q

Q

_,

Fig.

No.

l'art

No.

Description

-

'

~

~

-

.,.

~

~

00

~

.,.

~

Q

~

00

'

'

~

..

~

Remarks

complete

I

I

2

2

2

('>4\0.0)

5X4

X 5

3

6

8

2

8

4

-26-

ll/4\4WX6.5

(40)

X6

Page 28

G.HOOK SADDLE MECHANISM GC24518-1LD

Fig.

(',.14

G4.'i

G4fi

G47

G48

G-1\l

GSO

(;51

Gfi2

GS:l

G54

G55

G56

{;57

G58

G59

GUO

GGI

Gfi2

G63

GG4

Gfi!i

(;(,()

Gfi7

Ghli

(;(i9

Part.

No.

H40I030060

HG171]8001 Spring

No.

HG164J7101

HHIOI58001

HD726G8001

HHIOI68001

HGI77JBOOI

!f(jQ4020 180 Taper pin

HGJHZJBOOJ

HG!Bi]BOOI

H427040060

HG90]7BOOI

H415040370

H007013060

HGJ56]800I

HGI55]8001 Pin

1-11-131118001

HG91]88001

H428050080

H003008050

HG91}98001

Hfi31Jl8001

H'2000MOI'20

HG9l]58001

H41.'i060250 Screw

Hll31

I2800i

Screw

Cover

Needle plate

Screw

Feed

dog

Screw

Screw

Adjust cover

Screw

Transp.column

Screw

E-type

ring

Square block

Transp.lever

Cover

plate

Screw

Nut

Cover

Screw

Nut

Plate Holder

Plate

Description

Q Q

~

~

-

-

00 00

'

~ ~

- -

~ ~

~ ~

l

l

l

l

2

l

l

l

2

2

l

l

l

l

l

l

l

l

l

l

l

l

l

l

4

l

Q

~

'

00

'

~

-

f

~

Remarks

.

.

-27-

Page 29

H.HOOK SADDLE MECHANISM GC245l8-lRD (

l)

11

12

13

14

15

16

Y------31

~32

•

iJ_-30

~

~35

.._________

17

.-4----18

! 19

33

34

36

-28-

Page 30

H.HOOK SADDLE MECHANISM GC24518-1RD

52

53

47

48 49

50

51

54

(2)

55

56

57

58

42

39

38

37

59 60

\\

0

61

64 65

(44)

· .

66

(43) (50)

~

~

1!9l..

.., E ..

(49)

67

J

,---~

[f-,-,-1,

• I

..

I···

• I '

•II

'·

•

--~

·:

~

1

~~

II

·1K-1:

•J

1 tf

r·l·

:

I

~

••

1 r. I 1

~

.

·~

...........

69

68

;I:

1:

:~t,sl

II

I!

,.

~

..,

~.

<r

..

-·

..

(65)

..

-29-

Page 31

H.HOOK SADDLE MECHANISM GC24Sl8-lRD

~

"

Fig.

No.

Part

No.

Description

complete

"

-

00

'

~

-

~

"

"'

-

00

'

~

-

~

"

1

2

2

1

1

2

1

1

1

1

1

1

1

1

~

"

00

~

-

~

"

'

Remarks

5)X5

-30-

ll/4(4.0)

3

1

1

8

8

1

1

(40)

X6.

5

X6

Page 32

H.HOOK

Fig.

No.

Part

SADDLE

No.

MECHANISM

Description

GC24Sl8-lRD

Q

~

"'

"'

-

-

'

~

~

~

- -

..

N N

'

~

..

Q

N

~

'

~

-

..

N

Remarks

HG182}8001

H44

H45

HD726GBOOi

Hl-l20I58001

H46

H47

HGI77jBOOJ

HH20I6800l

H48

HGJ9Ij8001 Sorew

H49

H50

HG163J8001

H!il

HG91J58001

HG2

H415040370

Hf/:l

HG90j78001

H427040060 Sorew

H54

H!i5 HG164J7IOI

H50

H604020180

H57

HG171JBOOl

H40!030060 Snew

H58

H6311IBOOI

H59

Hl-13Jl!BOOI

HfiO

H2000MOI20

H61

HGi55JB00! Pin

Hfi2

H!i3

HGI56JB001

H007013060

H64

H65

H005001060

HliG

H415060250

Hli7

tll-l3ll2800I

HG90)88001

HliB

Hfi9

HG!JIJ4800I

Screw

Sorew

Needle plate

Screw

Feed dog

Sorew

Plate Holder

Screw

Transp.coiUitU1

Cover

Taper pin

Spring

Screw

Transp.lever

Nut

Square

block

E-type

ring

Washer

Sorew

Plate

Cover

plate

Plate Holder

I

2

I

I

I

2

4

I

I

I

I

I

I

I

I

I

I

I

I

I

I

6

4

I

2

I

.

.

-31-

Page 33

I.HOOK SADDLE MECHANISM GC24518-2D (

@ (1)

~

~--~

I

1._

I

~~r-

j~

L~(3)

1)

!

-----

i

(2)

~"'

18 •

19

20

~

0 0

,.

.

•

FJ-(30)

Y-------(31)

~(32)

0

~

~(35)

..._______ (36)

(33)

(34)

-32-

Page 34

I.HOOK SADDLE MECHAi'IISM GC24518-2D

(2)

44

43

40

39

--o::=::;,,"l--iP!f:,=?.:l---11

38--+

37~:

I

-~

46 47 48 49

::,.6~

~·

(64)

50

51

52 53

54

(1)

55

(43)

__......-(40)

rv---'(42)

IJ

...___

(41)

(37)

(38)

(63)

56 (55) (37) 57 58 59

-33-

60

61

62

63

64 65

Page 35

I.HOOK SADDLE MECHANISM GC245l8-2D

~

Fig.

No.

!•art

No.

Description

"

-

00

'

~

-

.,.

~

"

"'

-

00

'

~

-

~

""

~

"

00

'

~

-

~

""

2

2

2

4

••

2

2

4

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

6

2

2

2

8

2

2

2

2

2

2

(0. 5)

5X4

Jl/4\0UJ

(40)

Remarks

X5

X6.

5

X6

-34-

Page 36

!.HOOK SADDLE MECHANISM GC245l8-2D

Fig.

!44 HH3JI6800l Needle plate

!45

146

!47

l4H

149 HH31I58001

150 H415040370

IfJ

152 HGI50J800I

lfJJ

154

155

IS!i

!57 Hfi3III800I Screw

!58 HH3lli8001

!59

160

!61

!62

IG3

!64

Ifi5

I fi!i

Hi7

Part

No.

HGJ75J8001

HGI8l]8001 Adjust cover

HG!82J8001

HGJ77J800l

I

HG169]8001 Guide plate

H427040060

HGI91]8001

HG162J800l

HG163JBOOI

HG155J8001

H2000M0120

HGJ56J800!

H007013060

No.

H00500I060

H4l5060l60

H401035080

H415060250

HH31

128001

Screw

Sorew

Screw

Feed

dog

Screw

Transp.column

Screw

Screw

Cover

pJate(left)

Screw

Transp.lever

Pin

Nul

Square block

E-type ring

Washer

Sorew

Screw

Screw

Plate

Description

Q

§

~

- -

00 00

' '

~ ~

- -

.. ..

N

N

Q

N

00

'

~

-

..

N

I

2

2

2

I

I

I

I

1

1

2

2

8

1

I

1

I

1

1

8

8

2

4

1

Remarks

-

-

-35-

Page 37

J.OIL LUBRICATION MECHANISM

1 2 3

(1)

10

11

12

H/----+--24

......,,CC--

'

)

373635 34 33

......,-(23)

'---

28

(1

0)

(1)

27

-36-

....

Page 38

J.OIL LUBRICATION MECHANISM

Fig.

No.

Part

No.

Description

@

~

"

-

-

~ ~

~

-

.. ..

~ ~

'

'

~

-

~

"

~

'

~

-

..

~

Remarks

)01

HA300C2030

)02

H3200K0050

)03

H32422C208

)04

~32175B304

)05

H3204K0032

H3204K0043

J06

.J07

H3204K00ll

)OR

H4ll040160

JO!l

H3200K0030

)10

HA300B2170

)II

H3200K0040

112

H3209K0065

H3200K0180

J

13

H3216K0070

Jl4

)15

H323IID606

jl6

H3200K0160

)17

H3218K0072

)18

H3217K007I

)19

H3200K0170

)20

HA300B2130

)21

HAIOOE2l50

.}22

H3200K0250

)23

H3200K0190

H6304K800l

.J24

J25

H6305K800l

j2(i

H3200K0200

H3230K075I

J27

H3230K0752

J28

J29 H32I5K0696

)30

Hll0012070

)31

HI

10012080

)32

HllOOI2llO

.J33

H3204D6510

)34

H3215K0693

)35

H3215K0692

)36

H3215K0694

)37

H3215K40ll

H32151<0695

.J38

]39

HAl0680676

Sorew

Ho1deo-

Rubber

Felt

Oil pipe complete

Oil pipe complete

Oil pipe complete

Screw

Holder

Spring

Holder

Oil

Oil

Oil

Holder

Holder

Oil pipe complete

Oil pipe complete

Holder

Sorew

Screw

Holding plat

Holder

Oil pipe

Oil pipe

Holder

Screw

Bushing

Oil

Pm

Spring

-

Spring_

Screw 1 1 1

Screw 1 1

Filter

Screw 1 1 1

Mounting

Holder 1 1 1

Screw

plug

pipe complete

wick

pipe complete

pipe

holder

plate

complete

4 4 4

I I I

I

I I

2 2 2

I

1 I

I I

1 1 1

2 2 2

1 1 1

2 2 2

1 1 1

1

1 1

3 3 3

1 1

1 1 1

3 3

1

1 1

1 1 1

1 1

5 5 5

2 2 2

I

1 1

2 2 2

1 1 1

1 1 1

1 1 I

2 2 2

1 I I

1 1

I I I

1 I 1

1 1 1

1 1

1 1

1

1 1 1

•.

1

1

3

1

1

1

I

-

.

-37-

Page 39

"

1

..

-)"

,,

'

t

l

K.KNIFE

MECHANISM

678910

11

12

13

14

.

15

16

1 2

~v

. -

"'

\

17

3 4

....

/J

18

19

...

(17)

22 23 24

25

32

\

(21)

I

L

____

27

28

29

30--~'

31

(20)

•

26

l

I

38

39

-38-

40

41

42

43

44

45

Page 40

K.KNJFE MECHANISM

Fig.

No.

KOl

K02

K03

K04

K05

K05

K05

K07

KOB

K09

KlO

Kll

Kl2

Kl3

Kl4

Kl5

Kl5

Kl7

Kl8

Kl9

K20

1{21

K22

K23

K24

K24

K25

K26

K27

K28

K29

K30

K3l

K32

K33

K34

K35

K35

K37

K38

K39

K40

K4l

Part

No.

H4907K8001

H73!4G8001

HH3IM5800I

HH30M4800l

H4909K8001

HHIOM58001

HH30M58001

H4913K8001

H003002050

HH30M8710l

H4945K8001

HA113F0684

H6904]8001

HA710E0692

HH3Hl6800l

H431050050

H4934K8001

H4905K8001

H005001050

H4911K8001

H4936K8001

H3405D0663

~160

17H800

I

HH32Ml800I

H3405D0661

HHIOM68001

H4963K8001

H431050050

H4ll050160

H4965K8001

H2012N0652

H4983K8001

H49671\8001

H4973K8001

H4974K8001

H4977K8001

H498IK8001

H4979K8002

H003008050

HAIIIG0683

BA7111N304

H4972K800I

H4971K8001

0

~

IE

- -

00

Description

Screw

Washer

Ann

Link

Link

Ann

A~

Screw

N"t

Vibrating crank complete

Spring

Screw

Bushing

Screw

Crun

Screw

C•m l

Screw

Washer

Bolt

Screw

Link

Spring

Mounting plate

Screw

bar

Screw bar

Sboft

Screw

Screw

Set plate

Screw

Screw

Screw

Pin l l

Ann

Mounting plate

Holder

Solenoid complete

Nut 2 2 2

Screw

N"t

Screw l l

Lever l l I

00

'

~

-

~

N

'

~

-

~

N

l

l

l l

2 2

l l

l l

2

2 2

l l

2

2 2

l

l l

2

2 2

l l

2 2 2

2 2

l l

l l l

l l

l

l

l l

2 2 2

2

2 2

l

l l

l

l l

l

l l

2 2

l l l

l l l

l l l

l l

l l l

l l l

0

N

00

~

-

~

N

'

2

l

2

l

2

2

2

2

2

Remarks

l

l

l

l

.

l

l

l

M5X5

.

l

M5X5

M5X16

l

l

l

-39-

Page 41

K.KNIFE MECHANISM

Fig.

No.

Part

No.

Description

0

~

iii

~

~

J,

ro

~

~

~ ~

..,.

..

N N

1 1

1

1 1

1 1

0

N

ro

'

~

~

..,.

N

1 1

'

1

1

1

Remarks

-40-

Page 42

L.ACCESSORJES (

11

10~

g---~

1)

..----------

14

p:___--15

16

7

d~17

.--18

4

3

19

20

t--21

-11-

Page 43

L.ACCESSORIES

(2)

•

26 27

28

29

31

32

-42-

33

Page 44

L.ACCESSORIES

Fig.

No.

LOI

H801045200

L02

HA300J2230

L03

HA706S0067

L04

HAIOOJ2I80

L05

HA704S0654

L06

Hfi300]22IO

L07

HA300J2200

LOB

HA300J2070

L09

HBOIOOI015

LIO

HB0100l025

Lll

HBOlOOl030

LIZ

JZDP5000G1803

Ll3

HGl87J800l

Ll4

HAIOOJ2120

H3207L0065

Ll5

Ll6

H4705K800l

Ll7

H4706K800l

LIB

HA307J0067

Ll9

HAIOOJ2ll0

L20

H3200L0120

L20

HA200J2030

L21

HA120]8001

L22

H63IOL8001

L23

H0208L800I

L24

H6722N800l

L25

H0207L8001

L26

H6307L800l

L27

tl200000360

LZB

H6309L8001

L29

HA104J0652

HA104J0653

1.30

1.31

H32)3L0664

L32

HA104J0657

L33

H32l3l.0662

1.34

H3214l.0067

1.35

H3214l.20ll

1.36

Hfll04J6510

L37

HA300J2180

L38

HAI04J0659

L39

H007013090

L40

HH30l.5800l

L41

H2400K0080

Part

No.

Vibration preventing rubber

Washer

Bobbin winder

Vinyl cover

Adjusting plate for speed command disk

Screw driver (small)

Screw driver (middle)

Screw driver (large)

Sock!

wrench

Sockt wrench

Sockt wrench

Needle

Bobbin

Magnet

block

Thread a needle kit

Vibration preventing rubber

Vibration preventing rubber

Hinge complete

Oiler

Cotton stand

Cotton stand

Oil can

Belt cover (left)

Screw

Washer

Screw

Belt cover

Screw

Belt cover (right)

Screw

Washer

Knee

lifter crank

Spring

Knee

lift shaft

Small

parts

Knee

lifter pin

Description

for

reservoir

N"'

Screw

Screw

E-type ring

Oil

reservoir

V-belt

0 0

~

~

-

-

ro ro

'

~

~

- -

..

..

N N

2 2

2 2

1 1

1 I

I I

I

I I

I I

I

1 1

I 1

3 3

2

1 1

I 1

2

2

2 2

2 2

1 1

1 1

I I

I I

I

2

2

4 4

1 1

2 2

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

2 2

1 1

2 2

1 1

1 1

1 1

0

N

ro

'

'

~

-

..

N

2

2

I

I

I

I

1

I

I

I

I

I

1

DPX5

6

4

2

1

I

2

2

2

I

1

Remarks

-

#!B

.

1

1

I

1

2

4

1

2

1

I

1

I

1

1

1

1

2

1

2

1

1

1

h

I

'

-43-

Page 45

M.PNEUMATIC CONTROL UNIT

4 5 6 7

-44-

Page 46

M.

PNEUMATIC

Fig.

No.

Mill

M02

M03

M04

M05

M06

M07

M08

Part

H49J.'i~OOI

I!H30B88001

HA300B2170

H005008060

11415060200

H4914G8001

H4913G8001

H4916G8001

No.

CONTROL

Air cylinder

Arm

side cover (right)

Screw

Spring flange

Screw

"oin pole

Feeler

Windpipe joint

UNIT

Description

0

0

~

~

-

-

'

00

00

'

-

~

-

~

~

~

N

N

I I I

I

I I

4

4

4

4

4 4 4

I

1 I

I

I I

2 2 2

0

N

00

~

-

~

N

'

4

4

Remarks

.

-45-

...

Loading...

Loading...