Highlead GC24518-1, GC24518-2 User Manual

®

Purchasing

Copy

Dept

HIGH

LEAD

GC24518-1/GC24518-2

Single-Needle.Double-Needle Post Bed Needle Feed

Lockstitch Sewing Machine

Instruction Manual

Parts

SHANGHAI HUIGONG

N0.3

Catalog

SEWING MACHINE FACTORY

---

CONTENTS

---

Instruction

1,

Precautions

2,

How

to

Attach

3,

How

to

Wind

4,

Lead

the

Upper

5,

Adjustment

6,

Adjust

7,

Adjust

8,

How

9,

How

10,

How

L

Ad

1

12, Adjustment

13,

Adjusting

14,

Lubrication

to

to

jus

the

the

place

lead

to

tmen t

adjust

Manual

before

the

of

thread

pressure

the

the

of

of

thread

staring

Needle

Lower

Thread

stitch

the

upper

the

........................................................................

length

guide

of

bobbin

lower

lower

thread

thread

take-up

operation

................................................................

Thread

...............................................................

presser

thread

......................................................

and

.............................................................

foot

into

the

........................................................

thread

........................................................

tension

spring

................................................

reverse

hook

.....................................................

....................................................

sewing

.................................................

...............................................

...................................................

..........

oc•

••••••••••••••••••••••••••

,.

1

2

2

2

2

3

3

3

3

4

4

4

4

5

15,

Installation

Parts Catalog

A,

ARM

BED

AND

B,

THREAD

C,

UPPER

D,

THRED

L

STICH

F,

LOWER

G,

HOOK

H,

OIL

I,

ACCESSORIES

OTHER

TENSION

SHAFT & PRESSER

TAKE-UP

REGULATOR

SHAFT & FEED

SADDLE

LUBRICATION

REPLACEMENT

of

belt

cover

ITS

ACCESSORIES

REGULATOR

FOOT

LEVER & NEEDLE

MECHANISM

ROCK

MECHANISM

MECHANISM

.........................................................................

PARTS

..............................................................

...............................................................

.........................................................

.........................................................

MECHANISM

MECHANISM

BAR

..........................................................

SHAFT

.....................................................

...................................................

...............................................

MECHANISM

MECHANISM

.........................................

............................................

:

....

5

6

8

11

14

16

18

21

24

27

30

l.Precautions before staring operation

1)

Safety precautions:

(

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

(2) Power must

(3) Power must

the machine, or when replacing.

4)

Avoid placing fingers, hairs, bars etc., near the pulley,

(

the machine is in operation.

be

turned offwhen the machine is not in use, or when the operator leaves the seat.

be

turned

off

when tilting the machine head, installing or removing the

"V"

belt, adjusting

"V"

belt, bobbin winder pulley, or motor when

(5) Do not insert fingers into the thread take-up cover, under/around the

is

in operation.

(

6)

If

a belt cover, finger guard, eye guard are installed,

devices.

2)

Precautions before starting operation:

(

1)

If

the machine's oil

If

the machine is lubricated

(2)

(3) When a new sewing machine is first turned on, verify the rotational direction

power

on.

(The pulley should rotate counterclockwise when viewed from the pulley)

(4) Verify the voltage and (single or three) phase with those given

pan

has an oil sump, never operate the machine before filling it.

by

a drop oiler, never operate the machine before lubricating.

do

not operate the machine without these safetv

ll..eedle,

on

the machine nameplate.

3) Precautions for operating conditions:

1)

Avoid using the machine at abnormally high temperatures C 3 5

lower)

2)

Avoid using the machine in dusty conditions.

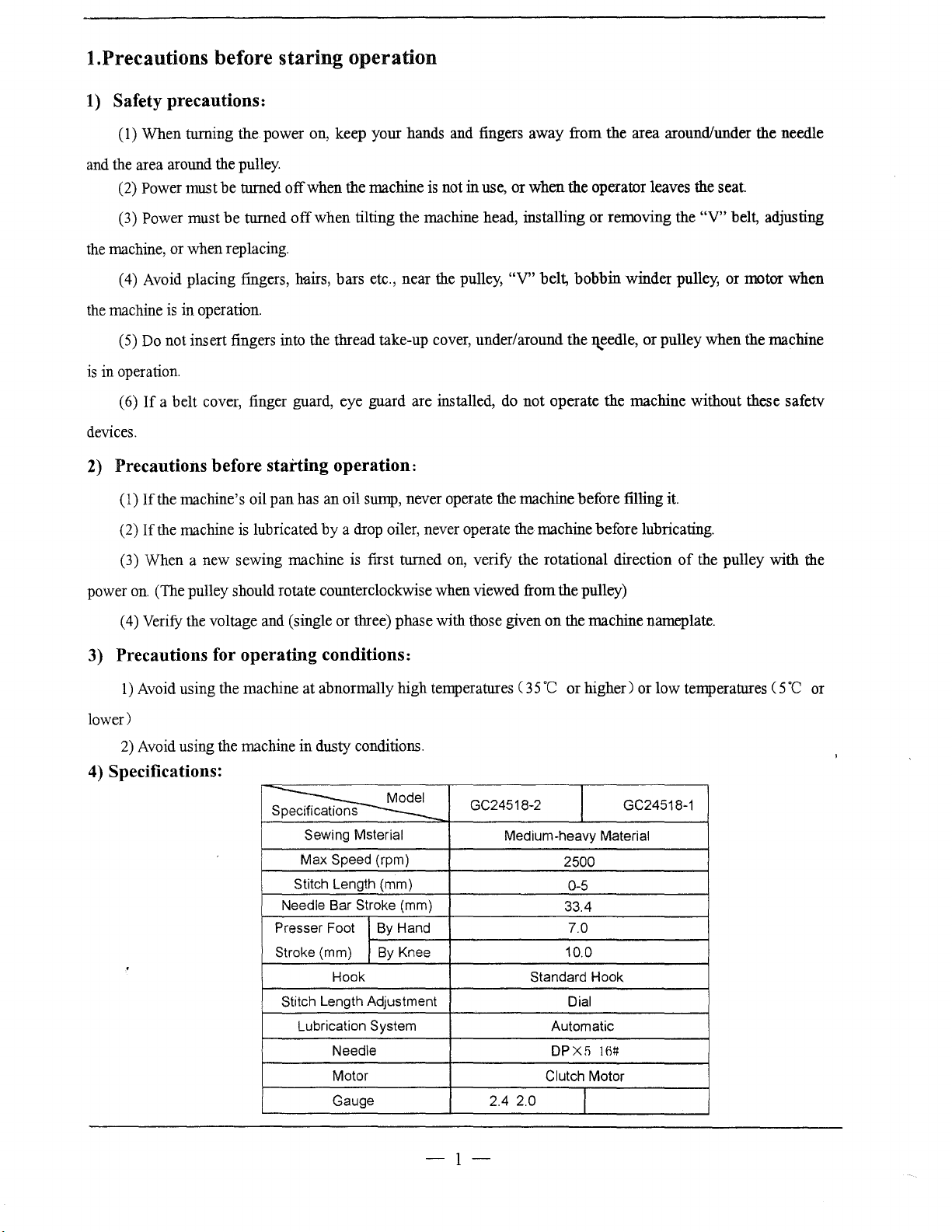

4)

Specifications:

·c

or higher) or low temperatures C 5

or pulley when the machine

of

the pulley with the

·c

or

s

~

Sewing Msterial

Max Speed (rpm)

Stitch

length

Needle Bar Stroke (mm)

Presser Foot By Hand

Stroke (mm)

Hook

Stitch

length

Lubrication

Needle

Motor

Gauge

(mm)

By

Knee

Adjustment

System

GC24518-2

Medium-heavy

Standard

2.0

2.4

Automatic

DPXfi

Clutch Motor

-1-

I

2500

0-5

33.4

7.0

10.0

Dial

I

GC24518-1

Material

Hook

Hi#

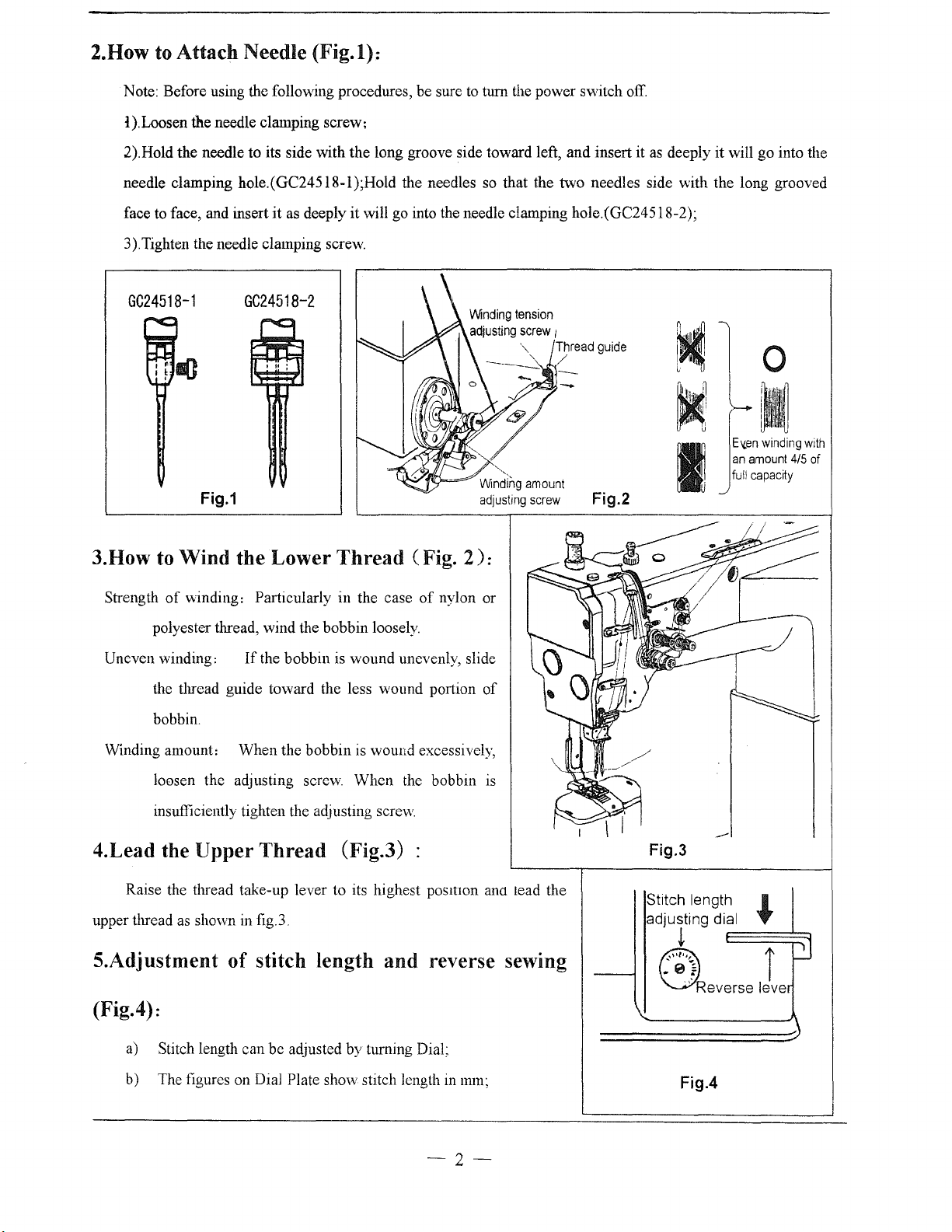

2.How to Attach Needle

(Fig.l):

Note: Before using the following procedures, be sure

l).Loosen the needle clamping screw;

2).Hold the needle to its side with the long groove side toward left, and insert it

needle clamping hole.(GC24518-l);Hold the needles so that the two needles side with the long grooved

to

face

3).Tighten the needle clamping screw.

face, and insert

GC24518-1

it

as

deeply

GC24518-2

it

will go into the needle clamping hole.(GC24518-2);

to

turn the power switch

Winding

tension

adjusting

screw

1

Thread

/

guide

off.

as

deeply it will go into the

.li~1

~~t~t.~

E'{en

'w1nd1ng

w1th

an

amount

4/5

of

Fig.1

-

-

'····:.

Wind1ng

adjusting

amount

screw

Fig.2

j

full

capac1ty

3.How to Wind the Lower

Strength

Uneven winding:

Winding amount: When the bobbin is wound excessively,

4.Lead the

upper thread

5.Adjustment

of

winding: Particularly in the case

polyester thread, wind the bobbin loosely.

If

the bobbin is wound unevenly, slide

the thread guide toward the less wound portion of

bobbin.

loosen the adjusting screw. When

insufficiently tighten

Upper

Raise the thread take-up lever to its highest posmon

as

shovm in fig.3.

Thread

of

stitch length

Thread

the

adjusting screw.

(Fig.3) :

(Fig.

of

nylon or

the

bobbin

and

reverse sewmg

2):

is

anct

lead the

Fig.3

Stitch length I

adjusting dial •

-

aeveEr:::se:::l:::l:=e:$r~:::l

(Fig.4):

a)

Stitch length can be aqjusted by turning Dial;

b)

The figures on Dial Plate show stitch length

in

mm;

-2-

'"'----------'_'\

Fig.4

c)

Reverse feeding starts when Reverse Feed Lever is depressed, and the machine will feed forward again

if

Reverse Feed Lever

1s

released.

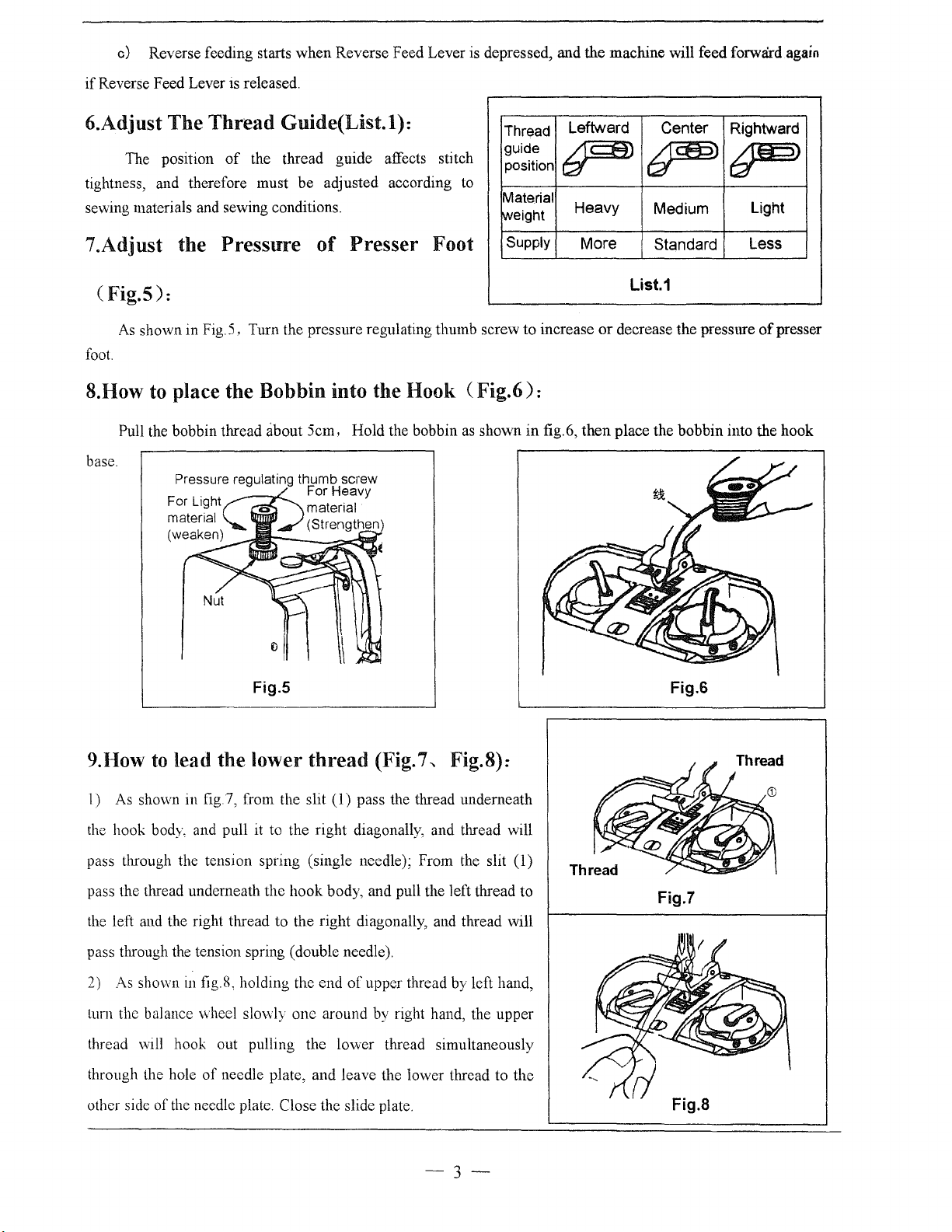

6.Adjust The

The position

tightness, and therefore must be adjusted according

sewing materials and sewing conditions.

7.Adjust the Pressure

Thread

of

Guide(List.l):

the thread guide affects stitch

of

Presser

Foot

C Fig.5):

As

shown in Fig.5, Turn the pressure regulating thumb screw to increase

foot.

8.How

base.

to

place the Bobbin into the Hook ( Fig.6):

Pull the bobbin thread about 5cm, Hold the bobbin

to

as

Thread

guide

position

Material

weight

Supply

sho·wn

in

Leftward

p

Heavy

More

or

fig.

6,

then place the bobbin into the hook

Center

p

Medium

Standard

List.1

decrease the pressure

Rightward

~

Light

Less

of

presser

Fig.5

9.How

1)

the

pass through the tension spring (single needle); From

pass the thread underneath the hook body, and pull the left thread to

the

pass through the tension spring (double needle).

2)

tum the balance

thread will hook out pulling the lower thread simultaneously

through the hole

other side of

to

lead the lower

As

shmvn in

hook body, and pull it to the right diagonally, and thread will

left and the right thread to the right diagonally, and thread will

As

shown

fig.

7, from the slit (1) pass the thread underneath

in

fig.

8,

holding the end

\-\heel slowly one around by right hand, the upper

of

needle plate, and leave the lower thread to the

the

needle plate. Close the slide plate.

thread

of

(Fig.

7,

Fig.8):

the

slit (1)

upper thread by left hand,

Fig.6

Fig.7

-3-

1

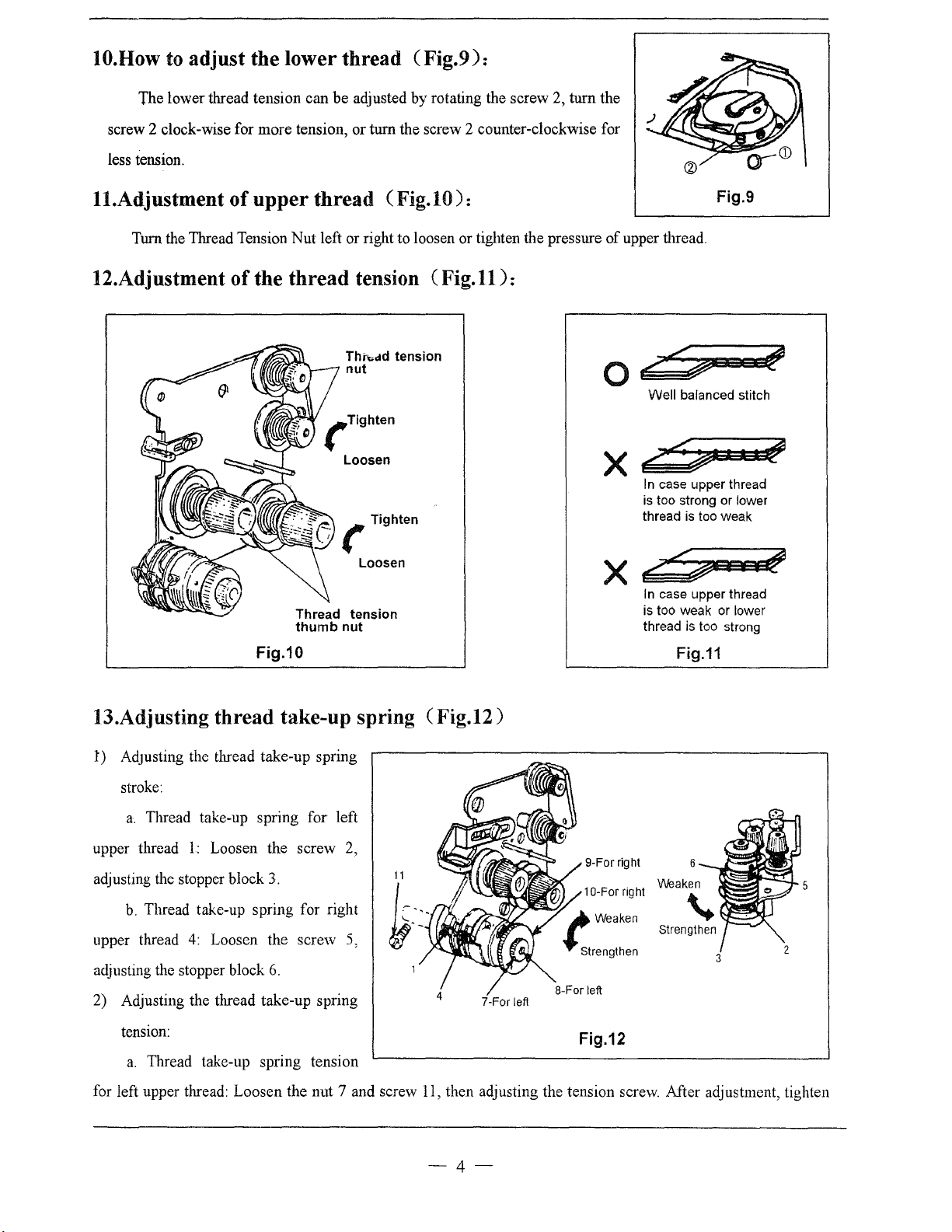

O.How

to adjust the lower

thread

( Fig.9):

The lower thread tension can

screw 2 clock-wise for more tension,

less tension.

ll.Adjustment

Turn the Thread Tension Nut left or right to loosen or tighten the pressure

12.Adjustment

of

upper

of

the

be

thread

thread

(Tighten

adjusted

or

by

rota6ng the screw 2, turn the

turn the screw 2 counter-clockwise for

(Fig.lO):

tension (

Tht-..:~d

nut

tension

Fig.ll):

of

upper thread.

Well balanced stitch

X

6~

In

case upper thread

is

too strong or lower

thread is too weak

Fig.9

.,if

Loosen

Fig.10

13.Adjusting thread take-up spring ( Fig.12)

1) AdJusting the thread take-up spring

stroke:

a.

Thread take-up

1:

upper thread

adjusting the stopper block 3.

b.

Thread take-up spring for right

Loosen the screw 2,

spnng

for left

11

~···

4:

upper thread

adjusting the stopper block

2) Adjusting the thread take-up spring

Loosen the screw

6.

5,

x~J

In

case upper thread

is too weak or

thread is too strong

Fig.11

9-For right

10-For right

lower

5

3

tension:

a.

Thread take-up

for left upper thread: Loosen the nut 7 and screw

spnng

tension

11,

then adjusting the tension screw. After adjustment, tighten

-4-

Fig.12

the nut 7 and screw

b.

Thread take-up spring tension for right upper thread: Loosen the screw 9, adjusting the nut

adjustment, tighten screw 9

11.

10.

After

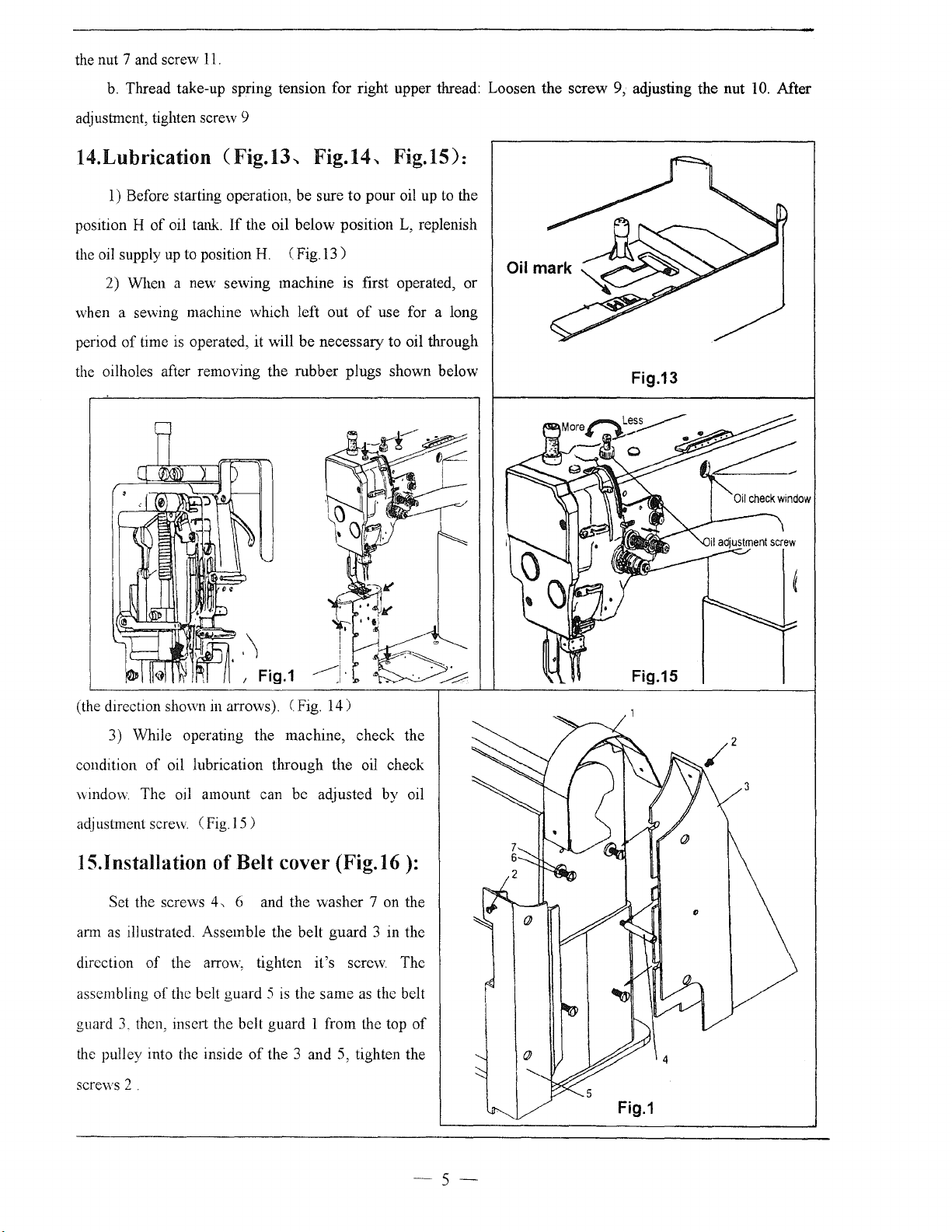

14.Lubrication

l)

Before starting operation, be sure to pour oil up to the

position H

the oil supply

when a

period

the oilholes after removing the rubber plugs shown below

of

oil tank.

up

2) When a new se\ving machine is first operated, or

sevving

of

time

is

CFig.13-.

If

the oil below position

to position

machine which left out

operated, it will

H.

Fig.l4,

( Fig.13)

be

necessary to oil through

Fig.15):

L,

replenish

of

use for a long

Fig.13

(the direction

3) While operating the machine, check the

condition

windovv.

adjustment screw (Fig.

15.Installation of Belt cover (Fig.16

Set the screws

arm as illustrated. Assemble the belt guard 3 in the

direction

assembling

guard

3.

the pulley into the inside

screw·s

sho\Yn

in

arrows). (Fig.

of

oil lubrication through the oil check

The oil amount can be adjusted by oil

IS)

4,

6 and the washer 7 on the

of

the arrow, tighten it's screw The

of

the belt guard S

then, insert the belt guard 1 from the top

2.

is

of

the 3 and 5, tighten the

14)

the same

as

the belt

):

of

Fig.15

-5-

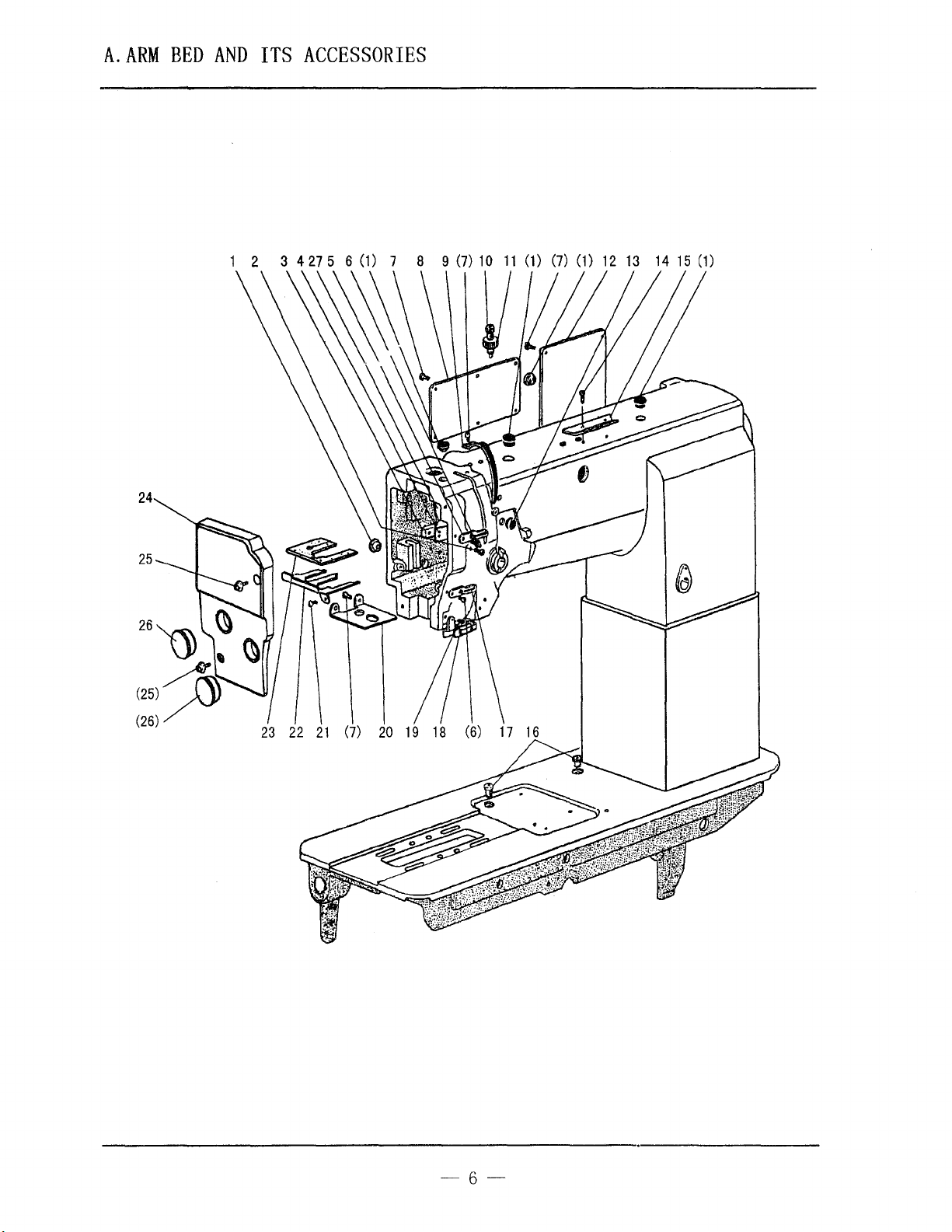

A.ARM

BED

24

AND

1 2

ITS

ACCESSORIES

14

15

(1)

25

23

22

1 (7)

18

(6)

17

16

-6-

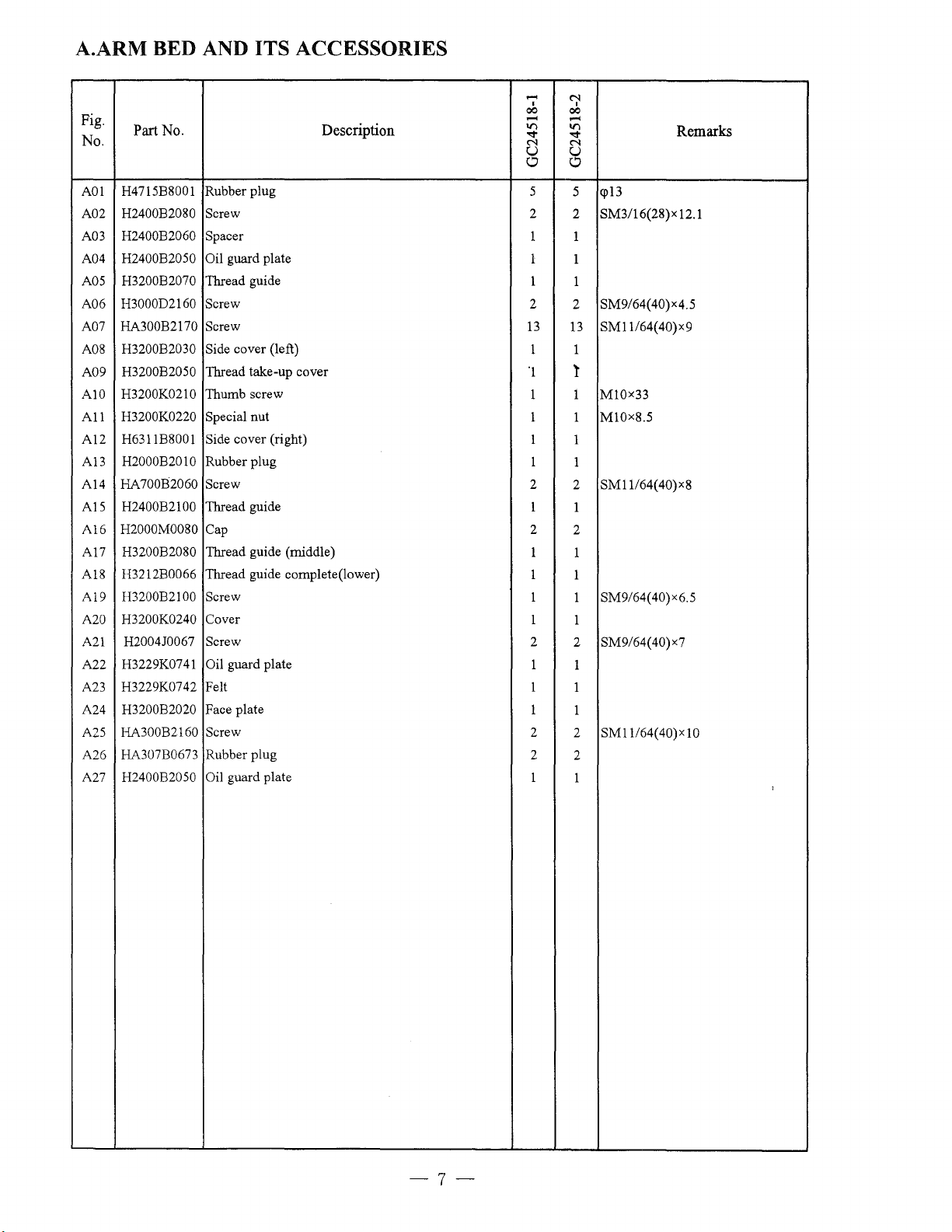

A.ARM BED AND ITS ACCESSORIES

Fig.

No.

Part

No.

Description

......

I I

00

......

tr)

'<t

C'l C'l

u

0

C'l

00

......

tr)

'<t

u

0

Remarks

H4715B8001 Rubber plug

AOl

H2400B2080 Screw

A02

H2400B2060

A03

H2400B2050 Oil

A04

H3200B2070 1bread

A05

A06 H3000D2160 Screw

A07 HA300B2170

H3200B2030 Side

A08

H3200B2050 1bread

A09

H3200K0210

AlO

H3200K0220 Special nut

All

H6311B8001

A12

H2000B2010 Rubber plug

A13

HA700B2060 Screw

A14

Al5

H2400B2100

H2000M0080

Al6

H3200B2080 1bread guide (middle)

A17

H3212B0066

A18

Ai9

H3200B2100

A20 H3200K0240

H2004J0067 Screw

A21

H3229K0741

A22

H3229K0742 Felt

A23

H3200B2020 Face plate

A24

HA300B2160 Screw

A25

A26 HA307B0673

H2400B2050

A27

Spacer

guard plate

Screw

cover (left)

Thumb screw

Side cover (right)

1bread

Cap 2

1bread guide complete(lower)

Screw

Cover

Oil guard plate

Rubber plug

guard plate

Oil

guide

take-up cover

guide

5

2

1 1

1

1

2

13

1 1

'1

1 1

1 1

1

1

2

1

1

1

1

1

2

1

1

1

2

2

1

5

q>13

2

SM3/16(28)x 12.1

1

1

SM9/64( 40)x4.5

2

SMll/64(

13

t

M10X33

MIOx8.5

1

1

SM11/64(40)x8

2

1

2

1

1

SM9/64(40)x6.5

1

1

SM9/64(40)x7

2

1

1

1

2

SM11/64(40)x10

2

1

40)x9

'

-7-

Loading...

Loading...