Page 1

HIGH

GC2268

LEAD

CYLINDER-BED UNISON

Instruction

Parts Catalog

FEED

Manual

SEWING

MACHINE

SHANGHAI HUIGONG

N0.3

SEWING MACHINE FACTORY

Page 2

PRECAUTIONS

1. Safety precautions

1)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

2)

Power must

Power must be turned off when tilting the machine head, installing or removing the ''V" belt, adjusting

3)

the machine, or when replacing.

4)

Avoid placing fingers, hairs, bars etc., near the pulley, "V" belt, bobbin winder pulley, or motor

be

BEFORE

turned off when the machine

STARTING OPERATION

is

not

in

use,

or

when the operator leaves the seat.

when

the machine

5)

Do

not insert fingers into the thread take-up cover, under/around the needle, or pulley

machine

2.

Precautions before

1)

Do

not operate the machine before lubricating

2)

When a new sewing machine

power on (the pulley should rotate counterclockwise when viewed from pulley) .

3)

Verify

3.

Precautions

1)

Avoid

or lower)

2)

Avoid

is

in

operation.

is

in

operation.

starting

the voltage and

for

operating

using the machine at abnormally high temperatures (

using the machine

operation

is

(s·ingle

or three) phase with those given on the machine nameplate.

conditions

in

dusty conditions.

first turned on, verify the rotational direction

CAUTIONS ON USE:

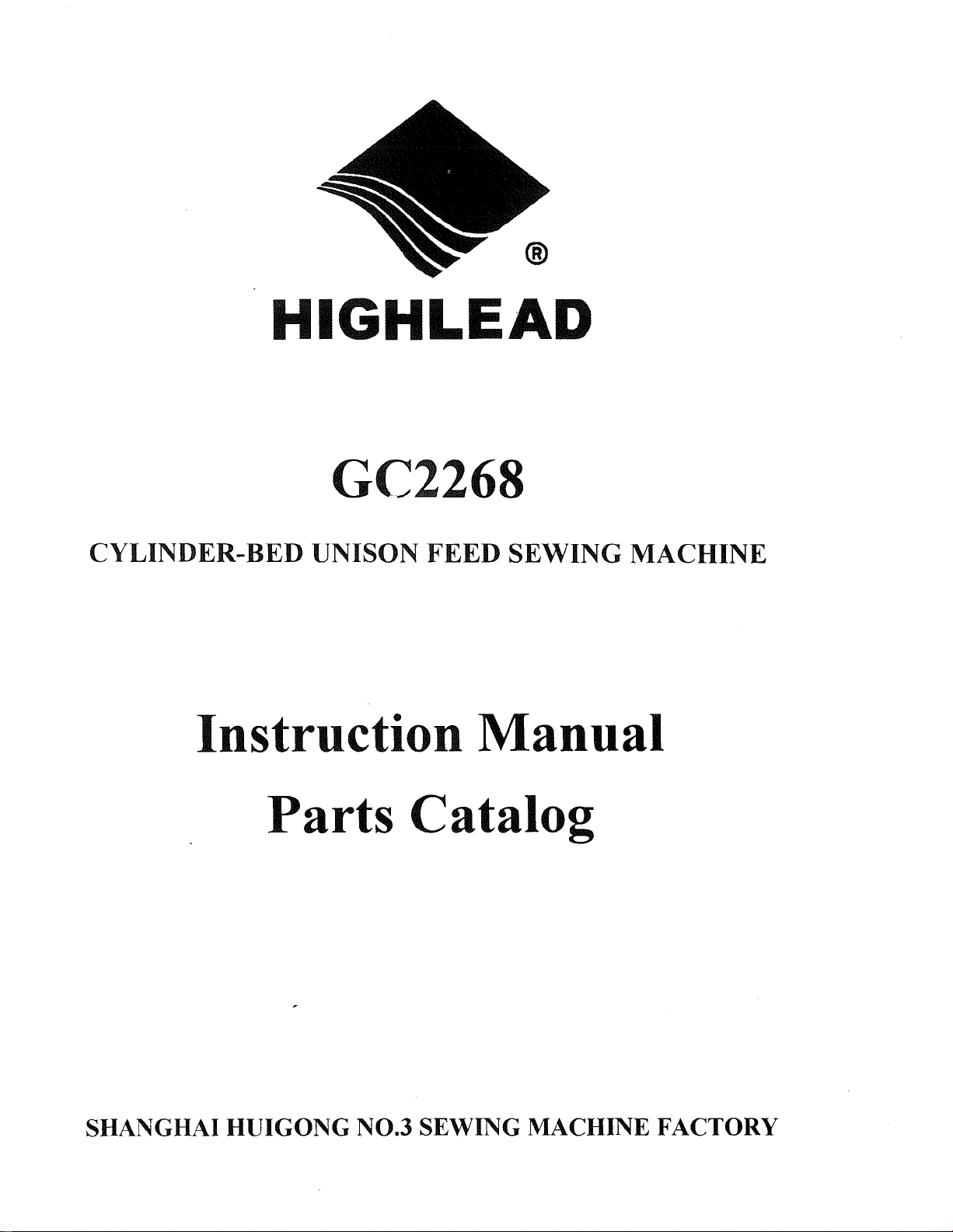

1.

LUBRICATION CFig.L Fig.2, Fig.3)

it.

35

"C

or higher) or

of

the

pulley

low

temperatures ( 5

when

with

the

the

"C

1)

Before

Prior to operation, apply adequate amount

to

the points marked with the arrows.

2)

Lubricating

Shift the slide plate, and apply two or three drops

of

oil

And

fore

with

the

3)

Lubricating

Prior

to

the

fail.

Starting

every day

of

five drops

arrow

to

operation, apply two or three drops

holes shown with the arrows

the

Sewing Machine

the

hook

and

hook

to

the hole shown with the arrow

oil

every day

B.

the

feed

bar

shaft

to

the felt shown

C,

D and E without

of

saddle

of

-1-

oil

A.

oil

Page 3

2

3

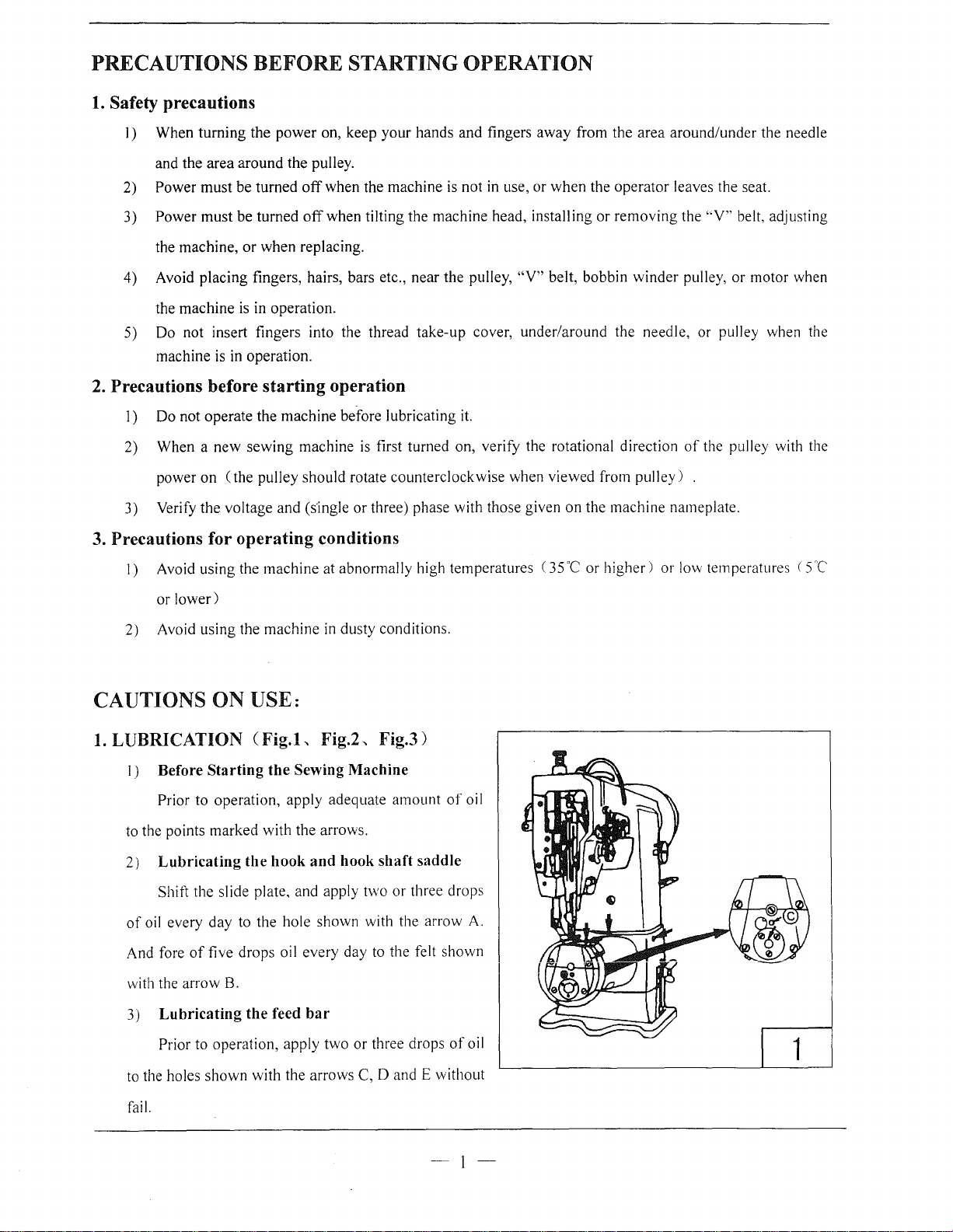

2. ATTACHING

Turn

OFF

I)

Turn the

2) Loosen needle

3) Insert the needle into the needle

further.

4)

Securely tighten

THE

NEEDLE

the power to the motor.

handwheel

clamp

the

to

needle

CD

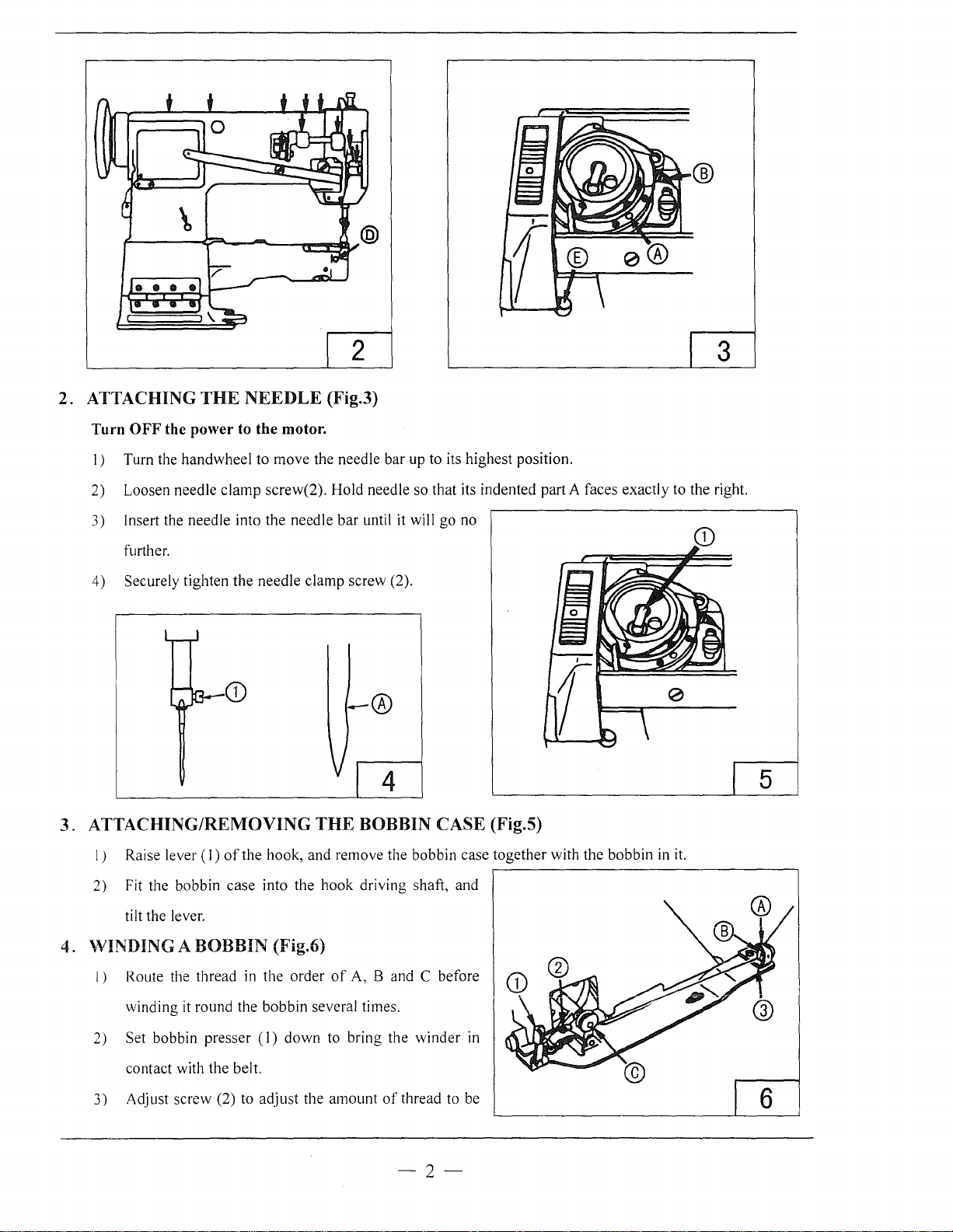

3.

ATTACHING/REMOVING

(Fig.3)

move

the needle bar up to its highest position.

screw(2). Hold needle so that its indented part A faces exactly to the right.

bar

clamp

until it will

screw (2).

go

no

-®

4

THE

BOBBIN CASE (Fig.5)

5

I) Raise lever

2) Fit the bobbin

tilt the lever.

(I)

of

the

hook, and remove the bobbin case

case

into

the

hook

driving shaft, and

together

with the bobbin in

4. WINDING A BOBBIN (Fig.6)

I) Route the thread in the

it

winding

2) Set bobbin

contact with

3) Adjust screw (2) to

round the bobbin several times.

presser

the

belt.

(I)

down

adjust

order

the

of

A, 8 and C before

to bring

amount

the

winder

of

thread to be

in

-2-

it.

6

Page 4

would round the bobbin so that the bobbin

is

wound with

thread

about

80%

of

its capacity. Turn the

screw clockwise to increase the amount

If

4)

5) The moment the bobbin has been wound up, the bobbin presser is released, and the bobbin winder will

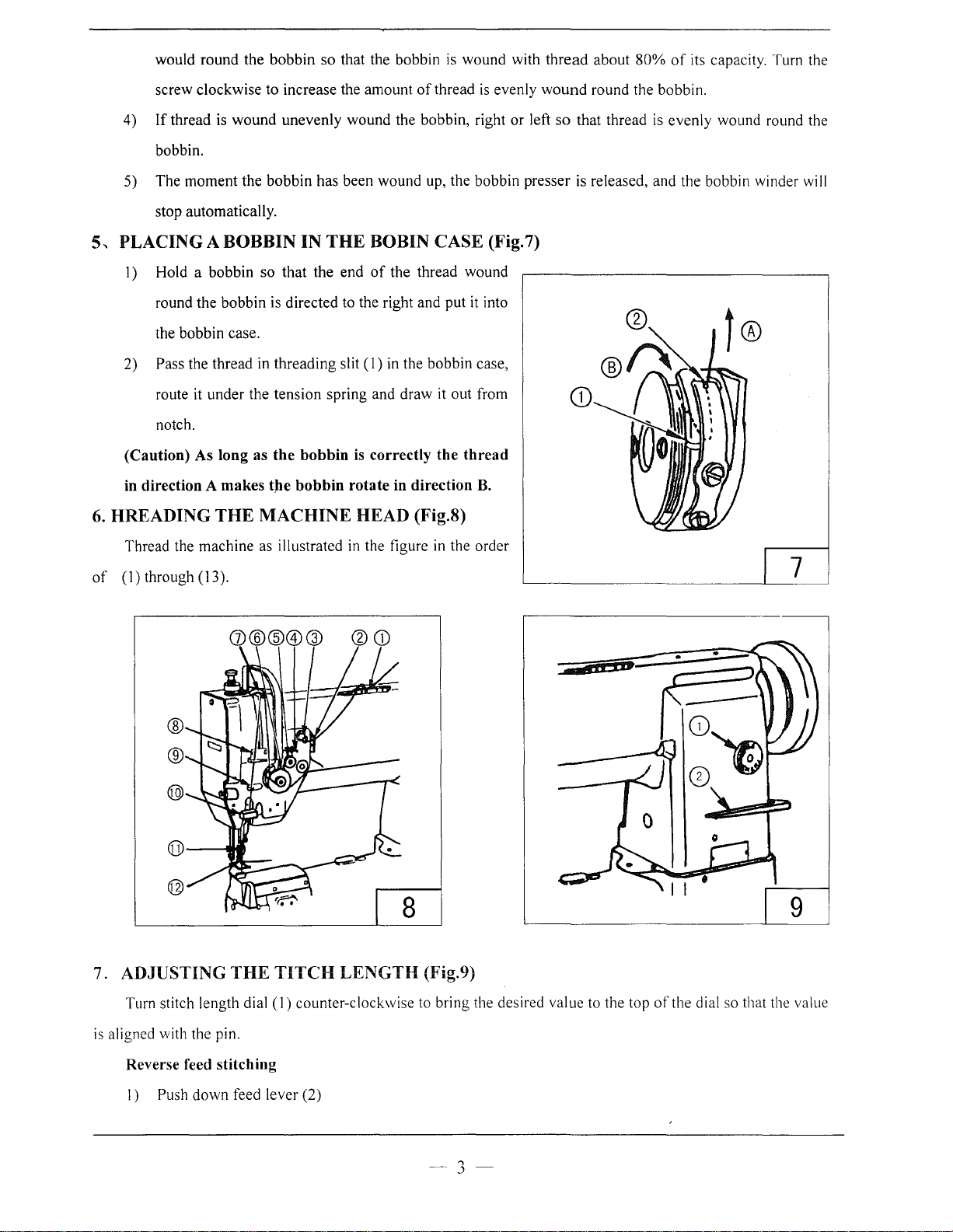

5,

PLACING A BOBBIN IN

2) Pass the thread in threading slit (1) in the bobbin case,

(Caution) As long as

6.

HREADING

thread is

bobbin.

stop automatically.

1)

Hold a bobbin so that the end

round the bobbin is directed to the right and put

the bobbin case.

route it under the tension spring and draw

notch.

in

direction A makes

wound

unevenly wound the bobbin, right or left

THE

the

bobbin

t,he

bobbin rotate in direction

THE

MACHINE HEAD (Fig.8)

is

BOBIN CASE (Fig.7)

of

correctly the

of

thread

is

evenly

the thread wound

it

into

it

out from

thread

B.

wound

so

that thread

round the bobbin.

is

evenly wound round the

Thread the machine as illustrated

of

(1)through(13).

G)@@®@

@

®

@

7. ADJUSTING

THE

TITCH

in

the figure

in

the order

8

LENGTH (Fig.9)

;p

7

AD-=

9

Turn stitch length dial (

is

aligned with the pin.

Reverse feed stitching

I) Push down feed lever (2)

1)

counter-clockwise to bring the desired value to the top

3

of

the dial so that the value

Page 5

2) The machine performs reverse feed stitching as long as the lever

3) The moment you release the lever, the machine resumed the normal stitching mode.

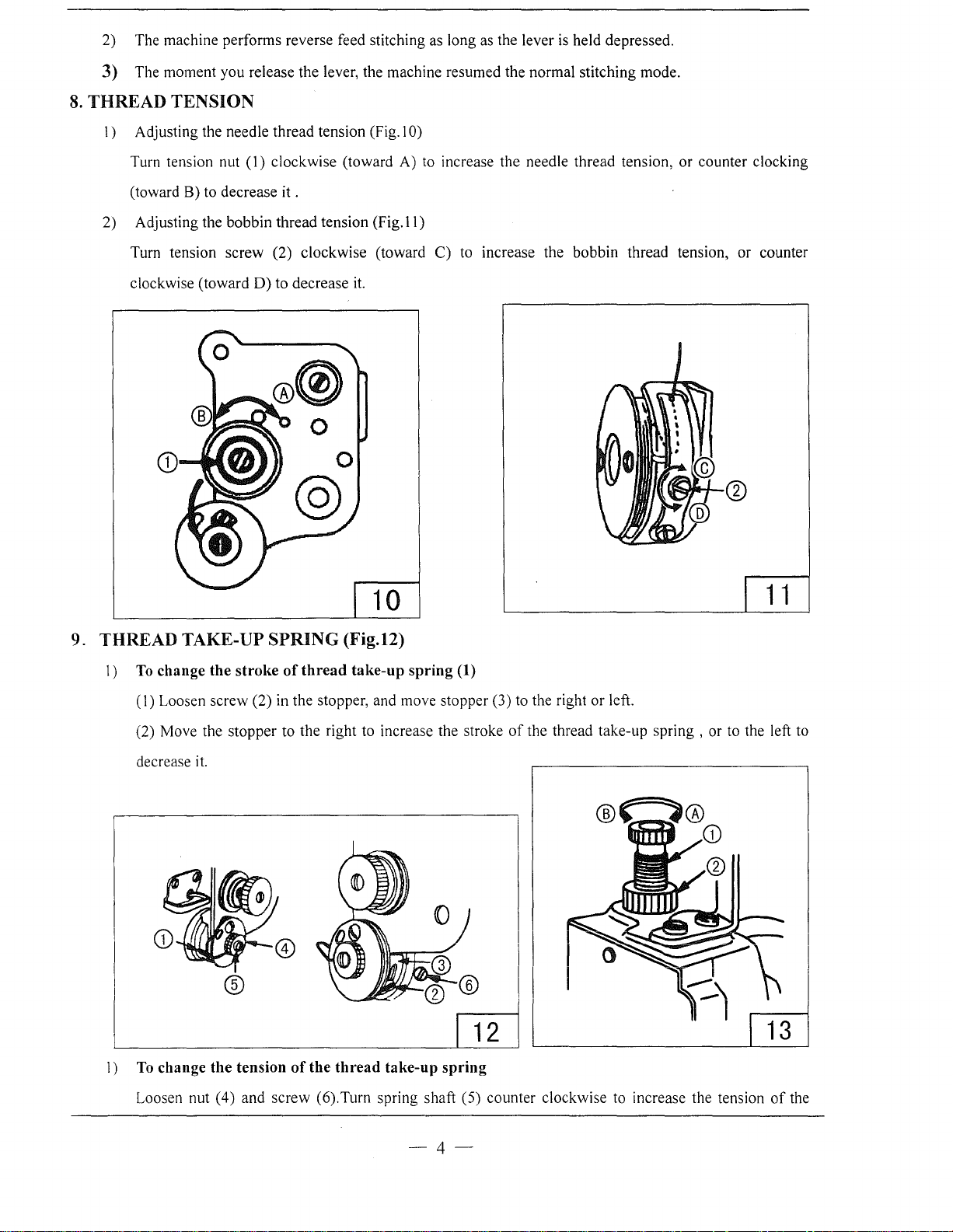

8.

THREAD TENSION

1)

Adjusting the needle thread tension (Fig. I 0)

is

held depressed.

Turn tension nut

(toward B) to decrease

2) Adjusting the bobbin thread tension (Fig.

Turn tension screw (2) clockwise (toward C) to increase the bobbin thread tension, or counter

clockwise (toward D) to decrease

(I)

clockwise (toward A) to increase the needle thread tension, or counter clocking

it.

II)

it.

10

1 1

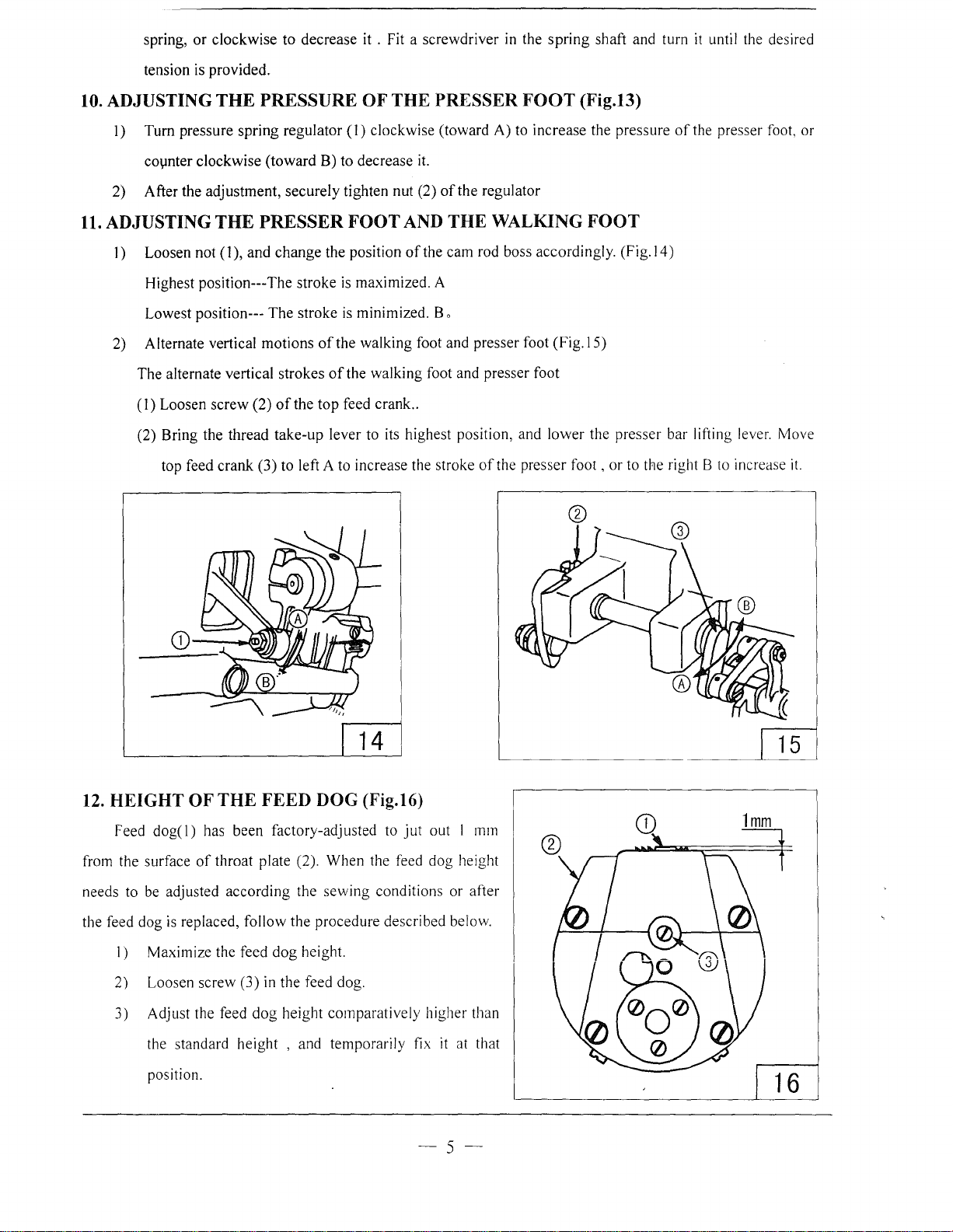

9. THREAD TAKE-UP SPRING (Fig.12)

1)

To

change the stroke

(I)

Loosen screw (2) in the stopper, and move stopper (3) to the right or left.

(2) Move the stopper to the right to increase the stroke

decrease

it.

of

thread

take-up spring (1)

®

'------------'-------'1

1)

To

change the tension

of

the

thread

take-up

spring

of

the thread take-up spring , or to the left to

I I

I I

II

L---1

_

____,__

Loosen nut (4) and screw (6).Turn spring shaft (5) counter clockwise to increase the tension

-4-

of

the

Page 6

spring,

tension is provided.

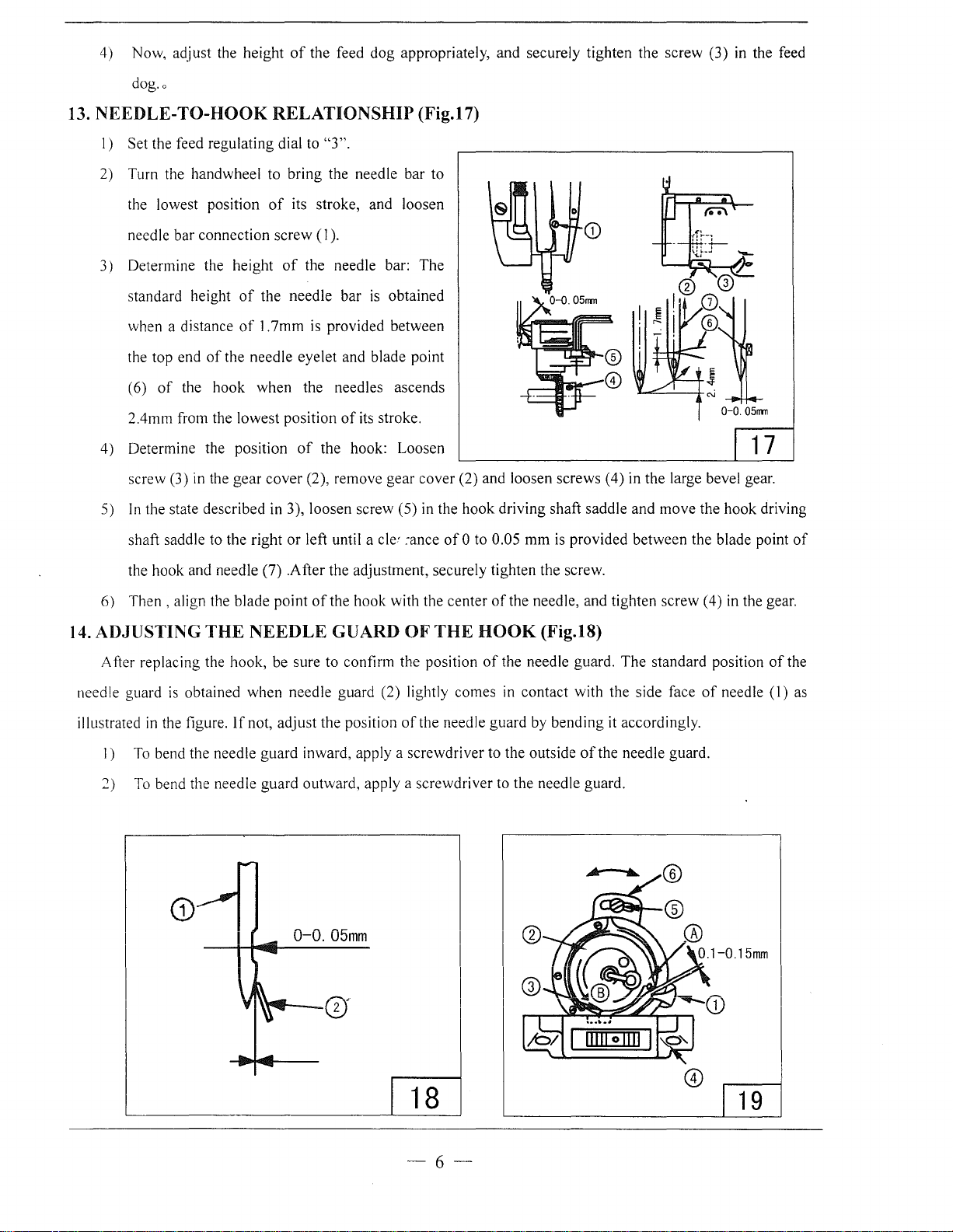

10.

ADJUSTING

or

clockwise to decrease

THE

PRESSURE

it

. Fit a screwdriver

OF

THE PRESSER

in

the

FOOT

spring

(Fig.13)

shaft and turn

it

until the desired

I) Turn pressure spring

co\.)nter clockwise (toward B) to decrease

2) After the adjustment, securely tighten nut (2)

11.

ADJUSTING

I) Loosen not

Highest position---The stroke

Lowest position--- The stroke

2) Alternate vertical motions

The alternate vertical strokes

(1) Loosen screw (2)

(2) Bring the thread take-up lever to its highest position, and lower the presser bar lifting lever. Move

top feed crank (3) to left A to increase the stroke

THE

(1

), and change the position

regulator(!)

PRESSER FOOT

is

maximized. A

is

minimized. B o

of

the walking foot and presser foot (Fig.15)

of

the walking foot and presser foot

of

the

top

feed crank

clockwise (toward A) to increase the pressure

it.

of

the regulator

AND

THE WALKING

of

the cam rod boss accordingly.

..

of

the presser

FOOT

(Fig.l4)

foot,

or to the right B to increase

of

the presser foot, or

it.

14

12.

HEIGHT OF

Feed

dog(!)

from the surface

needs to be adjusted according the sewing conditions or after

the feed dog

I) Maximize the feed

2) Loosen screw (3)

3) Adjust the feed

is

the standard height , and temporarily fix

position.

THE

FEED DOG (Fig.16)

has been factory-adjusted to

of

throat plate (2). When the feed dog height

replaced, follow the procedure described below.

dog

height.

in

the feed dog.

dog

height comparatively higher than

jut

out I mm

it

at that

-5-

Page 7

4) Now, adjust the height

dog.o

of

the feed

dog

appropriately, and securely tighten the screw (3)

in

the feed

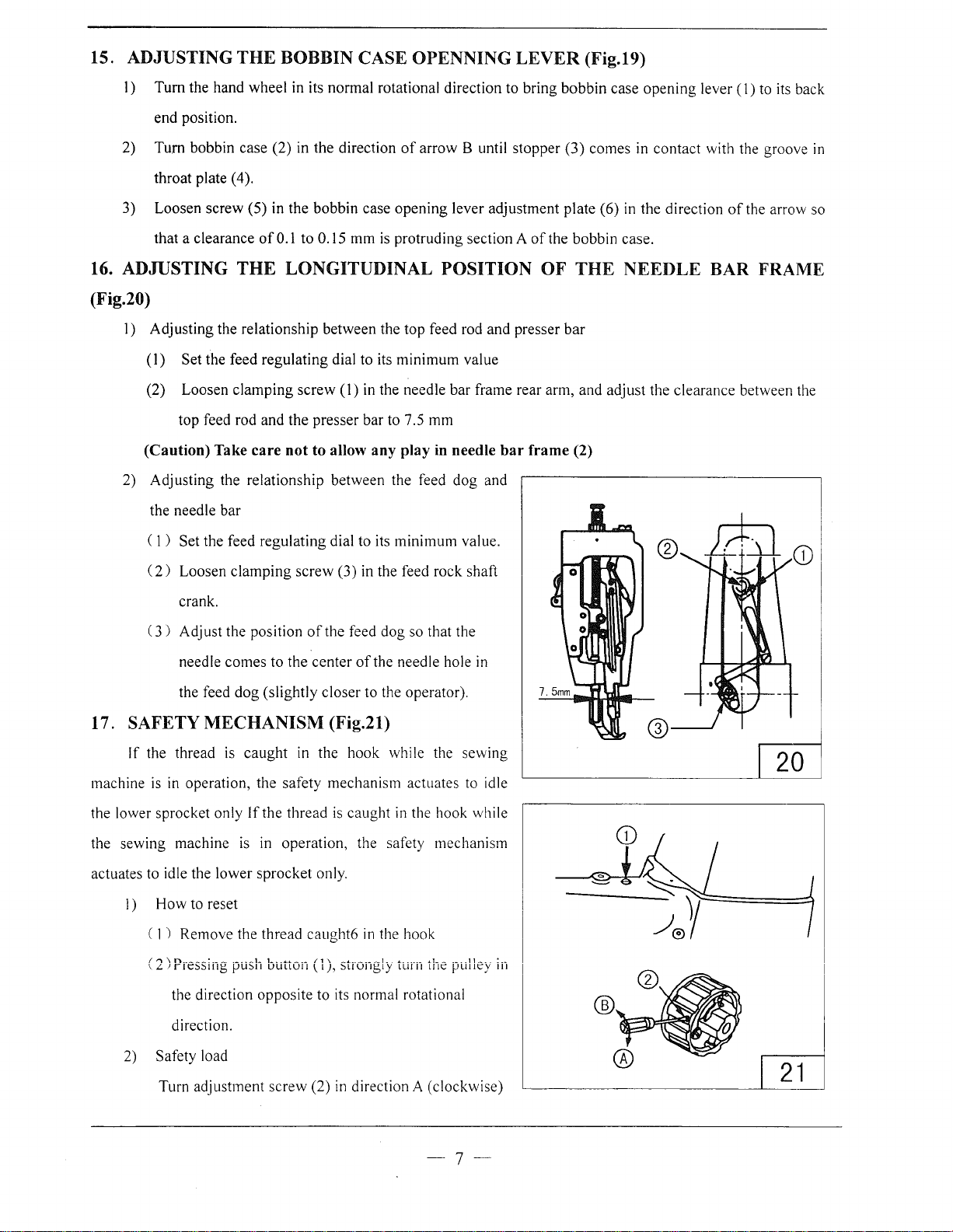

13. NEEDLE-

I)

Set the feed regulating dial to

2) Turn the handwheel to bring the needle bar to

the lowest position

needle bar connection

3) Determine the height

standard height

when a distance

the top end

(6)

2.4mm from the lowest position

4) Determine the position

screw (3) in the

In

5)

shaft saddle to the right

TO-HOOK

of

the needle eyelet and blade point

of

the hook

the state described in 3), loosen screw (5) in the

RELATIONSHIP (Fig.17)

"3".

of

its stroke, and loosen

screw

(I).

of

the needle bar:

of

the needle bar

of

1.7mm is provided between

when

gear

the needles ascends

of

the hook: Loosen 1 7

cover

(2), remove gear cover (2) and loosen screws (4) in the large bevel gear.

or

left until a

is

of

its stroke.

The

obtained

cle~

:ance

hook

of

0 to 0.05

driving shaft saddle

mm

is provided between the blade point

and

move

0-0.0511T11

the

hook

driving

of

the hook and needle (7) .After the adjustment, securely tighten the screw.

Then,

6)

14. ADJUSTING

After replacing the hook, be sure to confirm the position

needle guard

illustrated

I)

2)

align the blade point

THE

NEEDLE

is

obtained when needle guard (2) lightly comes in contact with the side face

in

the figure.

To bend the needle guard inward, apply a screwdriver to the outside

To

bend the needle guard outward, apply a screwdriver to the needle guard.

If

not, adjust the position

of

0-0.

the

hook

GUARD

05mm

with the center

OF

of

of

the needle, and tighten screw (4) in the gear.

THE

HOOK

of

the needle guard.

the needle guard by

(Fig.18)

bending

of

The

standard position

it accordingly.

the needle guard.

of

needle

of

(I)

the

as

18

-6-

19

Page 8

15. ADJUSTING

I)

Tum

the hand wheel in its

end position.

Tum

2)

bobbin case (2) in

throat plate ( 4 ).

THE

BOBBIN CASE OPENNING

nonnal

the

rotational direction to bring

direction

of

arrow

B until stopper

LEVER

bobbin

(3)

(Fig.19)

case

opening

comes in contact with the groove

lever (1) to its back

in

3) Loosen screw (5) in the bobbin case

of

THE

0.1 to 0.15

LONGITUDINAL POSITION

that a clearance

16. ADJUSTING

opening

mm

is

protruding section A

lever adjustment plate (6) in

(Fig.20)

I) Adjusting the relationship between the top feed rod and presser

(I)

Set the feed regulating dial to its

(2) Loosen

top feed rod and

(Caution) Take

2) Adjusting the relationship between the feed

the needle bar

(I)

Set the feed regulating dial to its minimum value.

(

2)

Loosen

crank.

(3)

Adjust the position

clamping

care

clamping

screw

(I)

the

presser

not

to allow any play

screw

(3) in the feed rock shaft

of

the feed

minimum

in the needle

bar

to 7.5 mm

in

dog

so that the

value

bar

frame rear arm, and adjust the clearance between the

needle

dog

and

bar

of

the bobbin case.

OF

THE

bar

frame (2)

the

direction

of

the arrow so

NEEDLE BAR FRAME

comes

to

the

center

of

needle

the feed

dog

(slightly closer to the operator).

the needle hole

17. SAFETY MECHANISM (Fig.21)

If

the thread

machine

the lower sprocket only

the sewing machine

actuates to idle the lower

is

in operation, the safety mechanism actuates to idle

How

I)

) Remove the thread

( 1

(2)Pressing push button (1), strongly turn the pulley

the direction opposite to its normal rotational

direction.

2) Safety load

Turn adjustment

is

to reset

caught

If

is

in the hook while the sewing

the thread

in operation, the safety mechanism

sprocket

screw

is

caught

only.

caught6

(2)

in

the hook

in

direction A (clockwise)

in

the hook while

in

20

in

21

-7-

Page 9

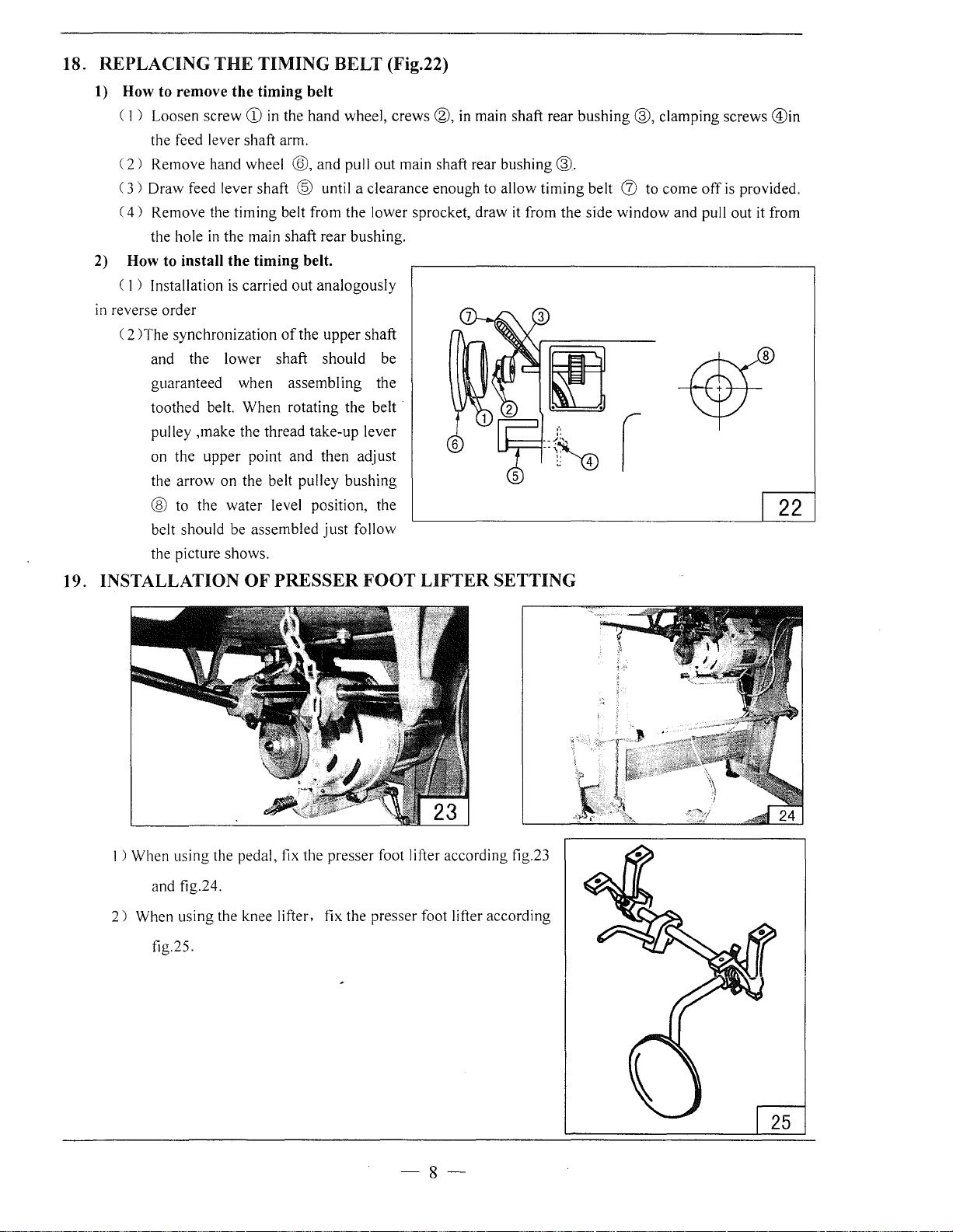

18. REPLACING

1)

How to remove the timing belt

( 1 ) Loosen screw

the feed lever shaft arm.

(

2)

Remove hand wheel ®, and pull

(

3)

Draw feed lever shaft @ until a clearance enough to allow

(

4)

Remove the timing belt from the lower sprocket, draw it from the side

the hole

2)

How to install the timing belt.

(

1)

Installation

in

reverse order

( 2

)The

synchronization

and the lower shaft should be

guaranteed when assembling the

toothed belt.

pulley ,make the thread take-up lever

on the

the

arrow

® to the water level position, the

belt should be assembled

the picture shows.

THE

TIMING BELT (Fig.22)

CD

in the hand wheel, crews ®, in main shaft rear

in

the main shaft rear bushing.

is

carried

When

upper

on

the belt pulley

out

analogously

of

the

upper

rotating the belt

point and then adjust

bushing

just

follow

out

main shaft rear

shaft

bushing®.

timing

bushing

belt

(J)

window

®,

clamping screws

to come

off

and pull out it from

is

provided.

@in

22

19. INSTALLATION

1 ) When using the pedal, fix the presser foot lifter according fig.23

and fig.24.

2)

When using the knee lifter, fix the presser foot lifter according

fig.25.

OF

PRESSER

FOOT

LIFTER

SETTING

-8-

Page 10

A.A

RM

BED

01

AND

ITS

ACCESSORIES__

04------.:..::::~~~

----

-----

05

11

37

Page 11

A.ARM BED

AND

ITS ACCESSORIES

Fig.

No.

AOI

A02

l\03

r\04

A05

A06

,\07

A08

.'\09

AIO

;\I I

A12

t\13

A14

Al5

Al6

A17

Al8

Al9

i\20

i\21

A22

A23

A24

i\25

A26

:\

27

.\

28

1\29

A30

i\31

1132

i\:33

•\:H

t\35

:

\:!6

:\:\7

Part No.

1-1

0209

88001

H3100F2360 Scr

1-1533508001

H

A73

11CH

1-124008206

IIA

307B06 74 Rubber plug

1-14717

88001 Thread take-up lever cover

HA80

0F2020 Screw

H5316B8001 Side plate

HA107Hl013 Screw

1-1

410082060 Hook

H4 100B2090 Washer

H4l00B2080 Wing bolt

H41

00B2070 Hinge screw

1-1

240082070 Frame thread guide upper

1-1472688

1-1240

082080 Screw

1132128

H3200B2l00 Screw

1102 108800 I

1-1533388

1-1

534088001 Throat plate

1-1

5341

B8001

1-15

3378800 I

H5339B8001

1-15334871

11

53388800 I

11

533

18800 I Lo\\er shaft

1-1533288001

1-1200082010

I-IA307B0673

115350B71

114

1 5080 160 Scr

11

2400132100 Thread guide

HA70082060 Screw

1-153

118800 1 Machine bast

1153548800 I

plate

Side

ew

Oil

guard plate

Sere\\

06

0 Spacer

001 Frame thread guide middle

0066 Thread guide

Throat plate base

Screw

001

frame

Screw

Bed

slide side plate left

Sere"

01

Bed slide

Bed slide

side pla

te

right

front metal

ScrC\\

Rubber plug

Rubber plug

0 l Hinge

ew

Fel

t

Description

Pes.

1

9/64

2

(40) X 7

I

9/64

2

(40) X8

I

1

<!>

1

1.8

1

15/64 (28) X

2

I

3 11/64 (40) X

I

1

1/4(2

1/

4(24)X5

4) X20

1

1

1

1

2 3/ 16(28) X

1

I 9/64 (40) X

l

2 11/64(40) X

1

2 11/64(40) X

1

4 9/64(40) X4

1

1

1

11/64

~)

13

<I>

19

(40) X 4

3

1

3

1

8

GB/1'70. 1 M8 X 16

I

2 11/64

I

1

(40) X 8

Remarks

13.

5

6.

5

.7

13

6.

5

18

15

-10-

Page 12

B.

THREAD

TENSION

REGULATOR

08 09

MECHANISM

1 0

11

1 2

13

14

15 16 17

36

35

34

33

32

31

30

29

Jl

__

------------------=18

~------------------19

~

20

25

26

27

28

-11-

Page 13

B.THREAD TENSION REGULATOR MECHANISM

Fig.

No.

801

802

803

804

805

806

H07

808

809

810

811

812

BI:J

814

815

816

817

1318

1319

820

B21

822

1323

824

825

826

H27

B28

1329

830

831

832

B33

H:l4

ll:l5

1336

Part

H2504C6510

H322183142

H322186812

H4705C8001

H4706C8001

HA7311C306

H4707C800 I

H007013050

H322186820

HA300C2030

H322186810

H4708C8001

H4709C8001

H322180683

HA11280693

H330082040

HA71080671

11322180682

HAI0680676

H3306B0661

HA31080702

H4710C8001

HAI1587010

HA31080701

HA31080705

H322180686

H32481 8721

H4713C8001

H324818D21

H4804C8001

H4805C8001

H3230K0751 Screw

H322186817

HG204C8001

H320082100

H322186819

No.

Description

Screw

Tension releasing plate

Tension releasing spring

Screw

Lever

Screw

Mounting plate

E-type ring

Mounting plate

Screw

Nut

Spring

button

Push

Thread tension stud

Thread tension disc

Spring

Thumb nut

Pin

Screw

Thread guide

Tension releasing disc

Spring

Thumb nut revolution stopper

Thumb nut

Thread tension disc

Thread tension stud

Thumb nut

Thread take-up spring

Plate complete

Thread tension stud

Thread tension stud

Pin

Pin

Screw

I

!stopper

I

Pes.

2

9/64(40)

1

1

1

1

1

9/64(40)

1

1

1

1

11/64(40)

2

1

1

1

11/64

2

1

1

2

9/64(40)X6

1

1

1

1

1

1

2

1

1/4(40)

1

1

1

1

9/64(40)

1

1/4(40) X 14.5

1

ll/64

1

1

1

9/64

(40) X

X23

(40) X

(40) X

X3

xs.

X8

X9

6.

Remarks

5

14

10

5

I

-12-

Page 14

C.TAKE-UP THREAD AND

ARM

SHAFT

01

MECHANISM

41

~~

40

14

45

4

51

4~

~

50

54

-

13

--

Page 15

C.

TAKE-UP THREAD AND ARM SHAFT MECHANISM

Fig.

No.

C:OI

COL

C03

C04

CO.'l

C06

C07

C08

(()l)

ClO

Cll

Cl2

C:l3

I

I

(

I

('JH

1'1'1

1~11

I

~'

I

I

~:

I~

I.,'

__

l':'li

('~-~

I

~K

I

~lJ

('',()

I

·:1

I

('.')')

c·;·;

('.j!

(

·:-;:1

l·:Hi

\

t''\N

I

I

(II

I

Part No.

H3100C2060

113 I OOC2050

H3100C2040 Thread take-up link

H0209F8001 Pin

H5305C8001

HAIOOC2020 Set screw

H5306C8001 Holder

HAI05D0662 Screw

IIA307C0662 Screw

H5310C8001

H53JIC8001 Pin

f-1240500663 Oil

HAIOOC2060 Screw

IIA I

II

I)

:r,J

II

OOC2070

115315CSOOI

11531

6CSOO

1153

17C800 I

I-IAIOOC2020

J!Ci204DSOOI

li;\307C0662

11Ci205D8001

I

,.,

11201410068 Oil

.~

112000C2030 Felt retainer

l

1153140\011 I

I

c

.)

115J26C800 I Arm sha!i bushing (middle)

115327C800 I

115332C8001 Feed cam (right)

Jl;\307C0662

115329C8001

115330U\OO

1120JIICJ06

110070

I 0260 Stop ring

113205C0661 Spring stop ring

. '

I Ll205C0661 Stop ring

!!A! !3!068·1

115337C800 I

I

L>\

I 00121.10

I

)/-

ll53J(J(

113208110661

IJ;\JI3F0684

\'J

1141

10

I~

OOC2040

Jl;\

II

OD06

11533RCSOOI

Needle bar connecting link

Oil wick

Thread take-up lever

Needle bar crank

wick

Scre11

Arm shaft bushing

I

!'cit

Felt

Screw

Feed cam

Scre1v

Upper feed driving rod

kit

Arm

shaft

Felt

Screw

Connecting

I Felt

lloldcr

SCt'C\\

l'ulky

(upper)

I

~crew,

·~oo

i

/\rill

..

snail ousnmg (nglltl

Needle bearing

Scrc11

72

Balance

Screw

11

Cog belt

(left)

(kli)

rod for upper

, , . . . .

heel

Description

ked

Pes.

1

1

1

1

1

15/64

1

1

1/4(40)

1

1/4(40)

1

1

1

1

9/32

1

9/32

1

1

1

1

15/64

1

1

1/4(40)X6

2

I

I

1

1

1

I

1

1/4(40)X6

2

I

1

1

I

2

1

l.l

bH;!KJ X k.

I

I

I

I

I

115/64

6004ZZNR/5K

2 15/64 (28) X

2 l.'i/61 (28) X

(28) X

X4

X6

(28) X

(28) X

(28) X

(21-l)

Remarks

10

13

10

10

X 8

8.

12

:]

I

5

Page 16

C.TAKE-UP THREAD AND ARM SHAFT MECHANISM

Fig.

No.

C43

C44

C45

C46

C47 H4714D800l Pin

C48

C49

C50 H007013025 E-type stop ring

C51

C52

C53

C54 H471708001 Lever for pulley

C55

Part

No.

H5334D800l

H5333D800l

HAI04F0654

H4721D8001 Screw

H471808001 Pin

H47160800l

H4719D8001 Short lever for pulley

H471308001 Long lever for pulley

H471508001 Pin

H472308001 Screw

Pulley

Shaft for pulley

Screw

Spring for pulley

Description

Pes.

l

I

I 15/64(28)x I

l5/64(28)x8.5

I

I

I

I

I GB/T896 2.5

I

I

I

1

15/64(28)x4 5

2

Remarks

0

-15-

Page 17

D.NEEDLE BAR AND

04

ROTATING

05 06

HOOK

SHAFT

MECHANISM

~

22

24---l

50

51

56

57

47

-

16-

Page 18

D.NEEDLE BAR AND ROTATING HOOK SHAFT MECHANISM

Fig.

No.

DOl

002

003

004

005

006

007

008

009

010

011 H5319H8001

012

013

014

015

016

017

018

019

020

021 HA7311C006

022

023

024

025

026

.

027

028

029

030

031 H410268016

032

033

034

035

036

037

038

039

040

041

042

043

Part

No.

H5325F8001

H5324F8001

H602040260

H5316F8001

H5319F8001

H5320F8001 Felt clip

H5328F8001

H5327F8001 Needle bar rock shaft bushing (left)

H5326F8001 Washer

H5320H8001

H5316H8001

H5317H8001

H2010J0066

H5314H8001

HA700F2100 Screw

HA800F2020

H3129F0692

H4722F8001

H320406513 Felt

H5322F8001 Thread guide for needle bar

H3129F0691 Screw

H4740F8001

HAIOOC2170 Screw

H532007101 Rotating hook

HIIOOE2010

H533708001 Screw

H532308001

H416220216 Guide plate slide block

H532908001

H532608001 Felt

H532708001 Oil wick

H2204C0651

H425050120 Screw

H005004050 Washer

H532508001

HG208E8001 Bushing

HG209E8001 Bushing

HG210E8001

HG211E8001

H530408001

Description

Needle bar rock shaft

Slide block

Pin

Needle bar rock frame

Felt

Needle bar rock shaft bushing (right)

Screw

Link

Link

Screw

Nut

Crank

Screw

Needle bar

Needle bar connecting stud

Screw

Needle

Bobbin

Rotating position guide

Guide plate pin

Guide plate

Screw

Rotating hook bracket

Washer

Bevel gear for hook shaft

Rotating hook shaft

Pes.

I

I

I A4x26

I

I

I

I

I

I

I J5/64(28)x23.5

I

I

9/32(28)x 13.3

2

9/32(28)x3.6

2

I

IJ/64(40))x

I

I J5/64(28)xJ3.5

I

I

I

I 9/64(40)x8.5

I

I 3/32(56)x2.5

I

OPxl7

I l/8(44)x4.5

I

KRT341NR

I

BO-PF541

9/64(40)x!O

I

I

I

I

I

I

I

I 9/64(40)x5

!V!5x!2

2

2

I

I

I

I

I

#23

I

Remarks

10

-17-

Page 19

D.NEEDLE

BAR

AND

ROTATING

HOOK

SHAFT

MECHANISM

Fig.

No.

044

045

[)46

047

048

[)49

050

051

052

053

D54

[)55

D56

[)57

D58

[)59

D60

D(J

D62

Part

No.

H5306E8001 Feed eccentric

HA305E0662

HG212E8001

HAI08C0663

1-!531508001

1-!531608001

1-!530808001

HA3411D308

H4107D0671

1-!41

0700672

H530908001

H609020120

HG206E8001

HE051C8001

HG205E8001

11531908001

l!A34ll

I

HA

0308

1!5314f800

700F2l

I

00

Set screw

Bevel

gear

for hook shaft

Set

screw

Rotating

Oil

Recessed

Set

Safe clutch

Safe

Safe

Safe clutch shaft pin

Rotating

Screw

Rotating

Oil wick

Screw

Guide

Screw

hook

wick

wheel

screw

bushing

clutch

spring

clutch

shaft

hook shaft

hook

for slide block

shaft

shaft

Description

bushing

collar

bushing

(left)

(right)

Pes.

I

2

I

3

I

I

2

I

I

I

I

I

2

I

I

I

2

15/64(28)x4.5

I/4(40)x7

15/64(28

A2xl2

SM

15/64(28)x7

ll/64(40)x7

)x 7

l/4"(40)x5.5

Remarks

I

I

I

I

I

I

-18-

I

Page 20

E.PRESSER

FOOT

FEEDING MECHANISM

16 15 14

~

32

33

re----50

~51

40

39

30

48

-19-

Page 21

E.PRESSER FOOT FEEDING MECHANISM

Fig.

No.

EO!

E02

E03

E04

E05

E06

E07 HG211F8001

E08

E09

EIO

Ell

El2

El3

E14

LIS

Ll6

17

I

I I X

El9

I

20

I

21

I

22

123

1:24

I

25

126

127

12X

I

29

uo

I

31 I 15331

U2

1-.33

I ).J

L35

IJ6

137

J]X

UlJ

40

I

141

142

143

Part No.

H4754E8001 Presser bar

HG204F8001

HAIOOC2020

H3200E2020 Screw

H5331G8001

1-!200012030

HG205F8001

H2400G2140

HAII7H0692

HG206F8001

H3100G2070

HG207F8001

1-!31

OOG221

HE04008001 Screw

I 1609025 I 80 Pin

f-13

107G066 I

HG208F8001

f-1200410655

I

13 I OOG2050

I

13 I 09CI0651

I

IG209FXOO

113IOOG2130

II!\

I

OOC2190

1Ki2 I OF800

I 15318G800 I

115314G800 I

1!4727E8001

11Ci212F800

113 I OOF2070

FXOO

I

131

OOF2

I 00 Bushing

113112F0663

I

1.:\

IOOB2110

113112F0661

113100F2010

1131

001"2020

113100F2030

115332F7101

11200012120

113115F0672

113100F2150

H3100F2130

Presser bar lower bushing

Screw

Presser foot aeey

Connecting pim roller

Presser bar bracket guide

Guide plate base

Presser spring regulator

Nut

Presser spring

Hand lifter

Hand lifter pin

0

Lifting bracket guide block

Screw

Presser

lifting lever base

Guide shaft hinge screw

Thread release spring

Thn:ad release guide assy

I

Presser bar

Hinge screw

Screw

I Screw

Hanging rod

Screw

Twist spring

I

Screw

Walking bar

I

Walking foot

Upper

Sere\\

Screw

Upper feed

L shaped link

Walking bar driving link

Walking bar spring

Walking bar spring

Upper feed

Connecting stud

Hinge screw

litting lever

feed

driving shati

'tud

dconnecting link

spring rod

Description

Pes.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I 3116(28)

I

I

I

I

2

2

I

I

I

I

I

I

2

I

2

I

I

I

I

I

I

I

I

I

I

Remarks

15/64(28)x I 0

1/8( 44 )x4

112(28)

17/64(24)xJ7.5

ll/64(40)x

t/i'ili'!31H6-00483

l/4(24)x7

11/64(40)x8

15/64(28)x I

3/16(28)x4.5

ll/64(40)x5

1/4(28)

7/32(32)

14

0

5

-20-

Page 22

E.PRESSER

FOOT

FEEDING MECHANISM

Fig.

No.

E44 HE045D8001

E45

E46

E47

E48

E49

E50 H5334F8001

ESI H2004J0067

E52 H5315F8001

E53 HG213F8001 Felt

Part

No.

Washer

H4728H8001 Washer

H3100F2160

H3112F0662

HAIOOC2040

H3115F0671 Screw

Nut

Nut

Screw

Walking bar retaining plate

Screw

Walking bar guide roller

Description

Pes.

I

I

I 7/32(32)

I 1/4(28)

ll/64(40)x5

I

J/4(28)xJ6

I

I

9/64(

2

I

I

Remarks

5

40)x7

0

I

-21-

Page 23

F.STITCH

---

REG

ULATOR

MECHANISM

-22-

Page 24

F.STITCH

REGULATOR

MECHANISM

Fig.

No.

FOI

F02

F03 H5305H8001

F04

F05 H5306H8001 Feed driving rocker shaft

F06 H5307H8001 Bushing

F07 HA3411D308 Screw

F08

F09 HA711B0681 Screw

FlO H5309H8001

Fll

F12 H5311H8001

F13

F14 HA720F0681

F15 HA7421F120 Stitch dial assy

F16 HA720F0686 Screw

F17 HA700F2030 Pin

F18

F19 H5339H8001 Reverse feed lever shaft

F20

F21

F22

F23 H5323H8001 Control lever crank link A

F24

F25

F26 H5322H8001 Feed driving rocker shaft arm

F27

F28 H5325H8001

F29

F30 H5329H8001 Hinge screw

F31

F32

F33

F34 H41111E204 Oil felt

F35 H5304E8001 Feed dog

F3n

F37

F38 H5315E8001 Hinge screw

F39

F40 H5309E8001

F41

F42

F43

Part

No.

H5308H8001

HAIOOC2020

HAIOOF2130

H5315H8001 Feed rocker shaft crank pin

H5313H8001

H5334H8001

HAIOOF2090 Spring

H5327H8001 Control lever crank

H5343H8001

HA34110308

H5333H8001

H5324H8001 Hinge screw

HA104G0012

HG207G8001 Tension spring

H5330H8001 Suspension hook

H200012050

HG205G8001 Feed bar crank

HA700F2100

H5307E8001 Feed bar support

H5308E8001 Feed bar support plate

H5314E8001 Screw

H5312E8001

HAIOOC2020

Feed driving rocker hinge pin

Screw

Feed driving rocker

Screw

Slide block

Feed driving rocker arm

Slide block shaft

Feed regulator

Needle feed regulating spring.

Screw

Screw

Hinge screw

Screw

Nut

Screw

Screw

Screw

Feed bar link

Screw

Description

Pes.

I

1 15/64(28)x

1

15/64(28)

1

I

I

)5/64(28)

1

I

9/64( 40)x4.5

2

2

1

I

I

I

I

3/16(28)x

I

1

I

I

I

3/64(32)x

I

15/64(28)x7

I

I

3/16(32)x8 5

3

3/16(32)x

I

I

3/16(28)x

I

3/16(32)

I

I

9/64( 40)x4

I

I

9/64( 40)x8

I

I

I

I

ll/64(40)x7

I

I

I

I

1/4( 4Q)x9

2

I

l/8(44)x6.3

4

IJ/64(40)x7.5

I

I

15/64(28)x I 0

I

10

X 7

12

16

13

12

Remarks

5

-23-

Page 25

F.STITCH REGULATOR MECHANISM

Fig.

No.

F44

F45

F46

F47

F48

F49

I

50

F51

F52

F53

F54

F55

t·sc,

I

57

F58

F59

F60

F6l H5312H8001

162

F63

F64

Part No.

H5313E8001

H5320E8001

H5316E8001 Nut

H5317E8001

H5319E8001 Thrust coolar

H6039G8001

H5321E8001 Bushing rear

HAIOOC2020 Screw

HAIOOF2130 Screw

H5332H8001

H5338H8001

H5335H8001 Hinge pin

ll5342H800 I Feed lever

llA34ll

HAII3F0683 Screw

D308

H5336H8001 Screw

Hi\

113

F0684 Screw

H53IOE800l Feed bar support

HI::ll4E8001 Screw

llEll5E800l

Description

Feed rocker link shaft

Bushing front

Feed rocker shaft

Screw

Feed lever connecting link B

Feed regulator bushing

Screw

Oil

wick

Stop ring

Pes.

I

I

2

I

I

2

I

I

I

I

I

I

I

I

I

I

2

I

I

I

I

1/4

(40)

II/64(4Q)x3.8

15/64(28)x I 0

15/64(28)

15/64(28)x 7

15/64(28)x

3/16(28)x6.5

15/64(28)x8.5

ll/64(40)x4

14.3

Remarks

I

I

-24-

I

Page 26

G.ACCESSORIES

~19

20

21

~22

~-ri

09

10

26--®

27-@

® @ ®

® ® ®

24

?

37

17

18

(

~

12

02

04

13

-25-

Page 27

G.ACCESSORIES

I

Fig.

No.

GO!

G02

G03

G04

G05

G06

C:i07

CJ08

G09

GIO

Gil

Gl2

Cil3

(i

(i

Ci

Cil7

Ci

(Jil)

Ci20

(i21

Ci22

(i2J

Ci24

(i25

(i2!J

Ci27

Ci28

Ci2l!

( ,.)()

(

i31

i32

(

(i33

i34

(

(

i35

(i36

(

i3

CJ3X

(i39

(i40

Part No.

H6307L8001 Belt cover (upper)

1-15311

I800I

1-1200000360 Screw

1-153

I21800I Belt cover (left)

H6722N8001

H0207L8001

H0206L8001

HA

706S0067 Bobbin winder assy

1-1801045200

HA30012230 Washer

HA20012030 Thread stand assy

HA

I

0610668

HAI0610665 Knee lifter plate

14

I-IAI06J0666 Knee I ifter bracket

15

HAI0610667 Screw

HA

I

I('

I X

7

0610662

HPGIOOE203

I lPG I

OOE202

114740f800I Needle

lli\30012070

fli\300.12200

lli\300J221 0 Screw driver (small)

IIIIOOE2010

11200400069 Oil assy

11403080750 Screw

1100500 I 080 Washer

11003002080 Nut

11201500065 Knee lilier

11802045250 Wood screw

1120 I 50006 7 Sl:t

lli\300J2180

11201500069

11201500066 Knee lilicr shali

1120

1600070 Coil spring

11531318001

II

130000

11120418001

lli\10012180 Vinyl covcr I

11G2081-1800

1131041-10651

Belt cover (right)

Washer

Screw

Washer

Wood screw

Knee lifter cover

Knee lifter shaft

Chain

S shaped hook

driver (large)

Screw

driver (middle)

Screw

Bobbin

blore

Scre1~

Knee lilier shalt

!Connector

I 060 Socket wrench

I Finger gusrd

I Lever I

Knee lifter shaft

Description

Pes.

I

I

I

I

2

I

I

I 5/64(28)x8

4

2

I

4.5x20

2

2

5

I

I

I

I

I

I

I

2

DPxi7

2

I

I

I

2

I

M8x75

4

4

4 M8

2

4.5x25

4

I

5

I

I

I

I

1

6mm

I

I

1

l

1164(

Remarks

40) X 6

23#

I

I

-26-

Page 28

SHANGHAI HUIGONG

N0.3

SEWING

MACHINE

FACTORY

ADD: 1418, Yishan

Zip

Code: 201103

Overseas

I

Business:

Road,

TEL:

Shanghai,

China

86-21-64853303 FAX: 86-21-64854304

E-mail: highlead@online.sh.cn http://www .highlead.com.cn

The

description covered

in

this

manual

is subject

to

change

for

improvement

of

the conunodity without notice

2008.2. Printed

Loading...

Loading...