Page 1

iii.

® HIGHLEAD

GC22618-1B

Cylinder-Bed Unison Feed

Sewing Machine

INSTRUCTION MANUAL

CATALOG

Page 2

1.

Safety precautions:

1)

When turning the power on, keep your hands and fingers away from the

area around/under the needle and the area around the pulley.

off

2) Power must be turned

operator leaves the seat.

3) Power must be turned

removing the

4) Avoid placing fingers, hairs, bars etc., near the pulley,

winder pulley, or motor when the machine is in operation.

5) Do not insert fingers into the thread take-up cover, under/around the

needle,

"V"

belt, adjusting the machine, or when replacing.

or

pulley when the machine is

when the machine is not in use, or when the

off

when tilting the machine head, installing

"V"

belt, bobbin

in

operation.

2. Precautions before starting operation:

1)

When a new sewing machine

of

direction

machine nameplate.

the pulley with the power on.

2) Verify the voltage and phase (single or three) with those given on the

is

first turned on, verify the rotational

3. Precautions for operating conditions:

1)

Avoid using the machine at abnormally high temperatures (35°C or

or

higher)

low temperatures ( 5

2) Avoid using the machine in dusty conditions.

OC

or

lower) .

or

4. Specifications:

Max. Sewing Speed

Needle

Needle Bar Stroke (mm)

Thread Take-up Lever

Max.Stitch Length (mm)

Presser Foot Stroke

Alternating Movement (mm) 2.0-6.0

(rpm)

~troke

(mm) 72.1

Byhand(mm)

By knee (mm)

1

2,200

DPX17

34.2

6

8

14

22#

Page 3

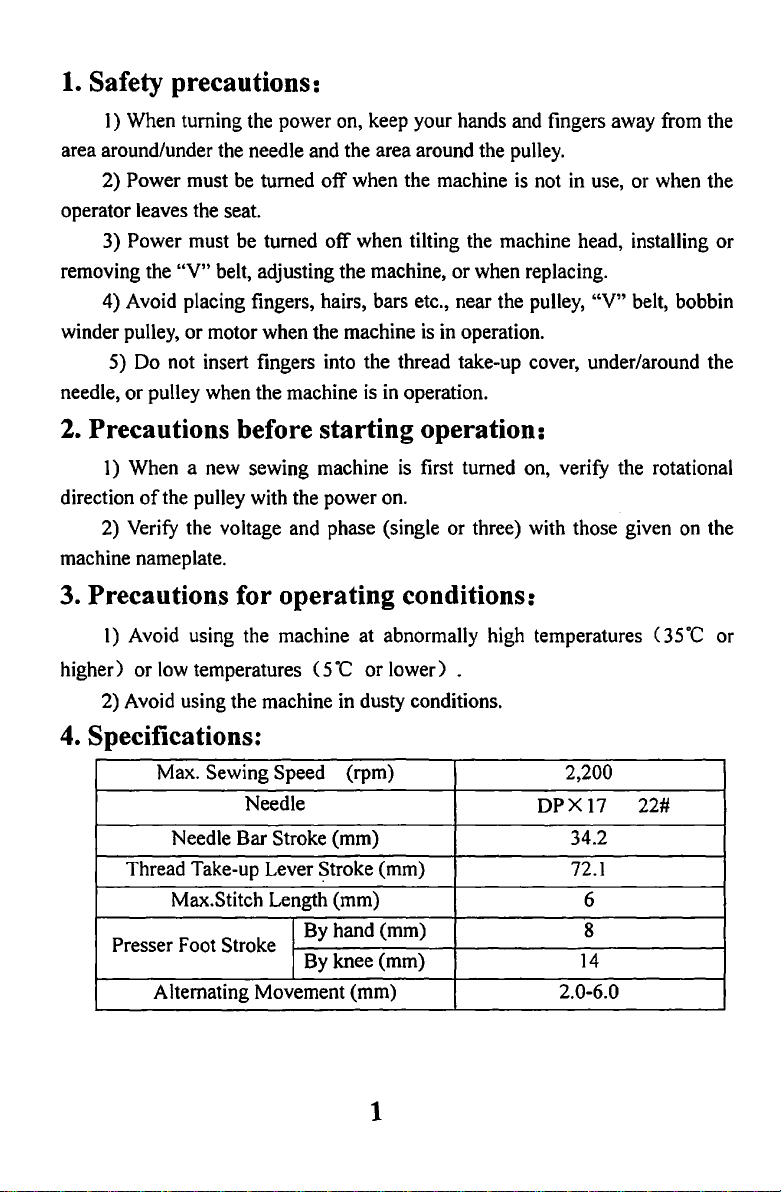

5.

Preparation

1)

CleaniDg 1he

Before leaving

rust-preventive

during stoJage

1)

Examination

Though

factory, the machine parts

banspotlalion.

cleaning

evay

the

before

machine

the

grease,

and

shipment. This grease must

machine is

~

joiL A thorough examination must

machine..

starting

factory,

which

Tmn

may

inspeded

may

the balance wheel

obsbuclion, parts collision, uneven

adjuslmcot

use

for

wbich

material.

must

3)

Lubrication

When

a

new

a long time is

anowheads

Please

Please

use~

ap6ft

be

made

machine

to

~need

spindle

pnsser

accordingly before run-in operation.

begins

to

be

used

to

be

oil

foot

operation:

the

machine

be

hardened

be

and tested slricdy before leaving the

be

loose

or

resislance

be

again,

lubricated.Fig.l)

wheo

used

it

the

or

or

an

must

machine

parts

are

coated with

and

c:ontamioated

removed with gasoline.

deformed

to

abnormal noise.

old

be

lubricated fully.

after long distance

be

performed after

see

if

there is running

If

these

machine which left

(fhe

is

operated without

by

dust

exist,

out

spots

of

Fig.

I

2

Page 4

4)

Run-in

A

new

being lubricated sufficiently, each

increasing speed

done.

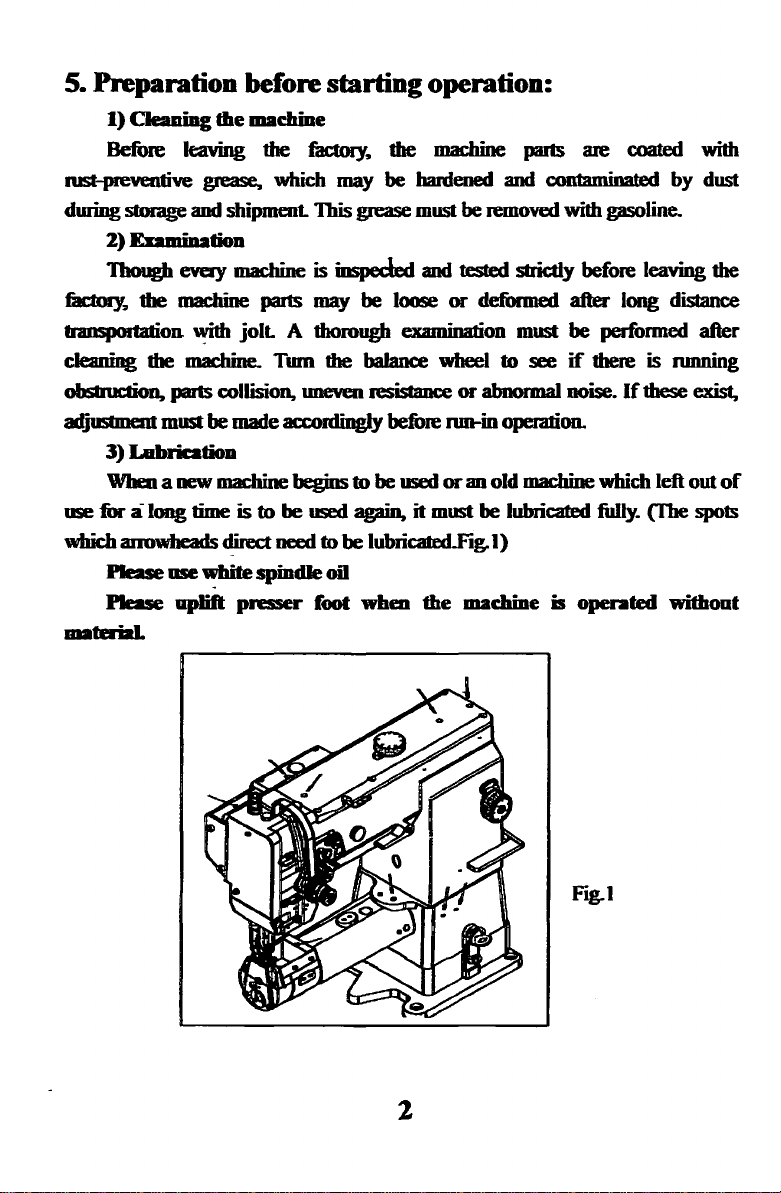

6.

How

Note:

This machine

according to the thread rightly. (Thread

freely.)

Insert

tighten

groove

operation

machine runs

to

the maximmn according

to

attach

Before attach the needle, be

's

the

needle

the

screw keeping

in

the

needle

Long groove

facing

to

the

left

.

at

a low speed ( 1600rpm)

a needle (Fig.2):

needle size is DPX17

until

it

boaoms.

facing

to

the

1he

and

lang

left:.

of

for

about a month after

parts will achieve its best state. Then

to

sure

need

the natme

to

tmn the

#122.

Needle

to

pass

X

power

size

the

pinhole

of

the work

switch

must

musl

ofi.

be selected

of

the needle

X

he

Fig..2

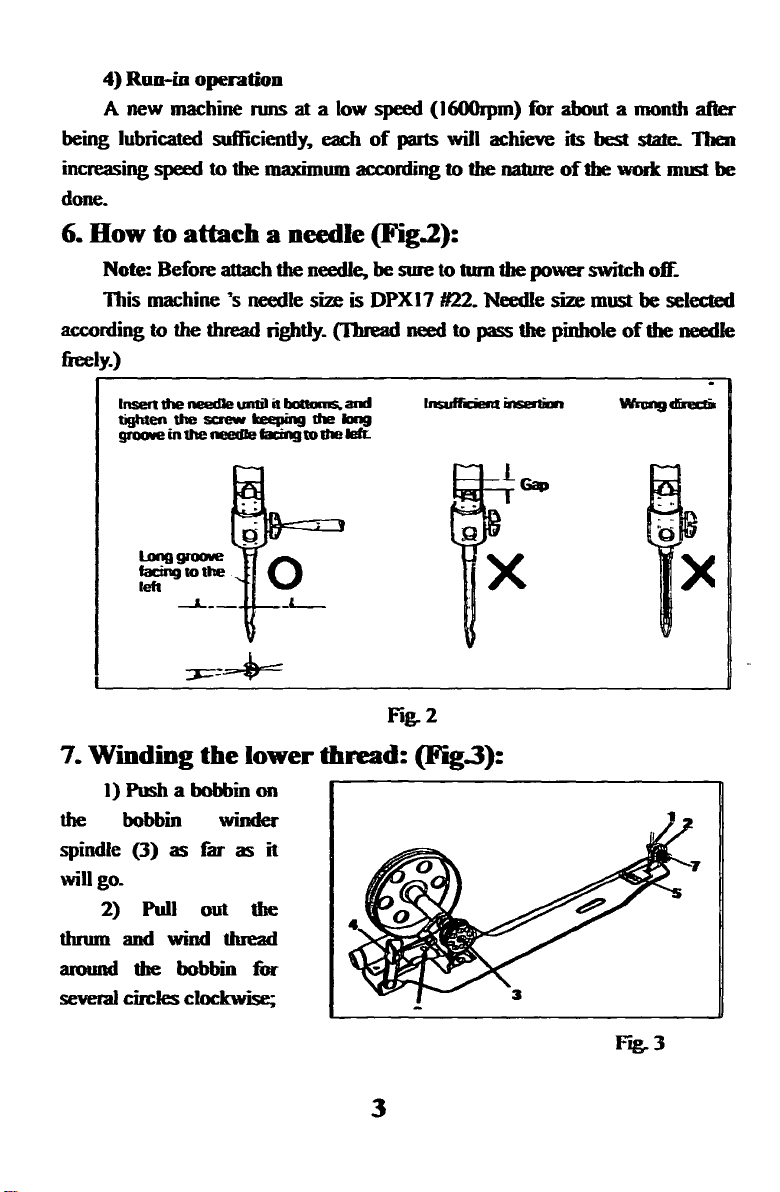

7.

Winding

1) Push a bobbin on

the

spindle

will go.

bobbin

(3)

2)

Pull

as

the

winder

far

out

lower

as

it

the

thn2d:

(Fig.3):

r--------------.,.

thnnn and wind thread

around the bobbin

several

circles clockwise;

for

F"rg..

3

3

Page 5

-----

3) Push the lever 4 backward so that the wheel

"V" belt, then start the machine.

4) The pulley will separate from the "V" belt automatically after the

bobbin is filled with thread.

8. Adjustment

I)

In case

Loosen the screw

right or to the left as may

2) Adjustment

Adjusting screw

screw will increase the amount, otherwise the amount

decrease.

3) Winding strength

Adjusting the nut

Adjusting screw 6 can adjust the amount

screw will increase the amount, otherwise the amount

decrease.

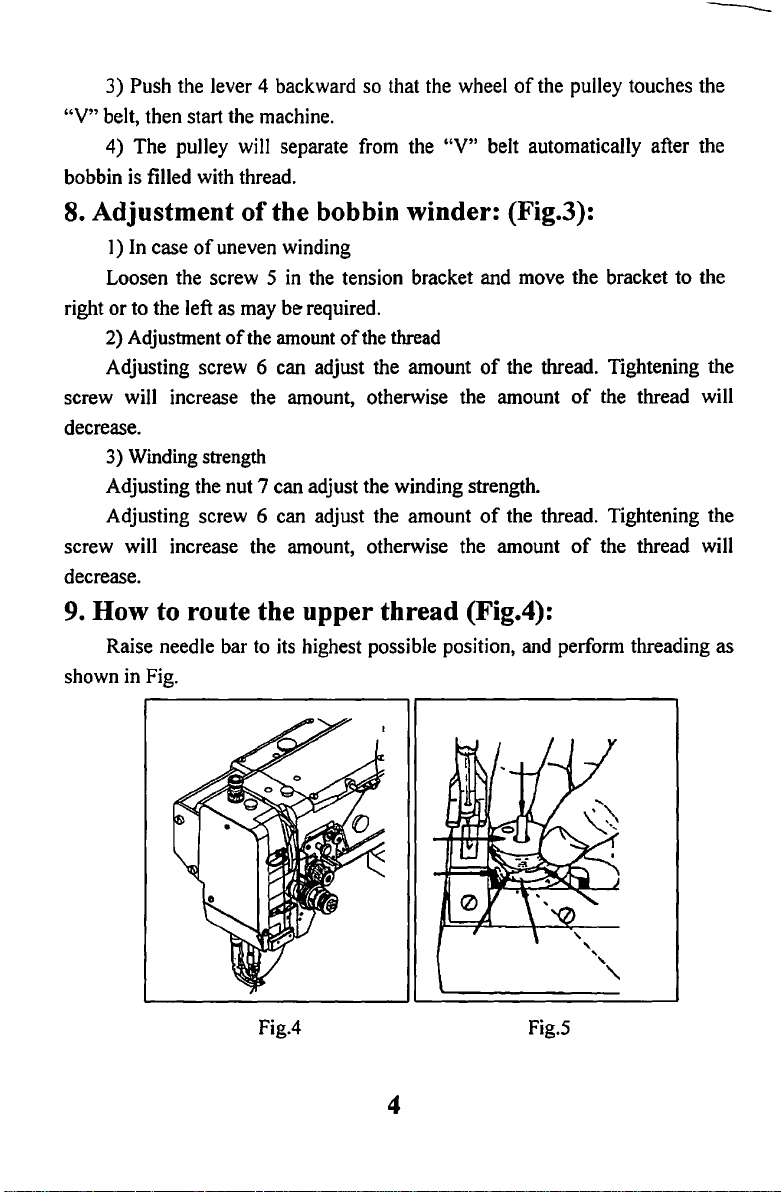

9.

How

shown in Fig.

to route the upper thread (Fig.4):

Raise needle bar to its highest possible position, and perform threading as

of

the bobbin winder: (Fig.3):

of

uneven winding

5

in

be

of

the

amount ofthe thread

6 can adjust the amount

7 can adjust the winding strength.

the tension bracket and move the bracket to the

required.

of

the pulley touches the

of

the thread. Tightening the

of

the thread will

of

the thread. Tightening the

of

the thread will

Fig.4 Fig.S

4

Page 6

10. Removing and inserting the bobbin (Fig.5):

1)

Taking out the bobbin: open the cover, take out the bobbin.

2) Inserting the bobbin: replace the bobbin into the shuttle bobbin case,

shutdown the cover. Be sure to make the bobbin rotate counterclockwise and

pull out the thrum.

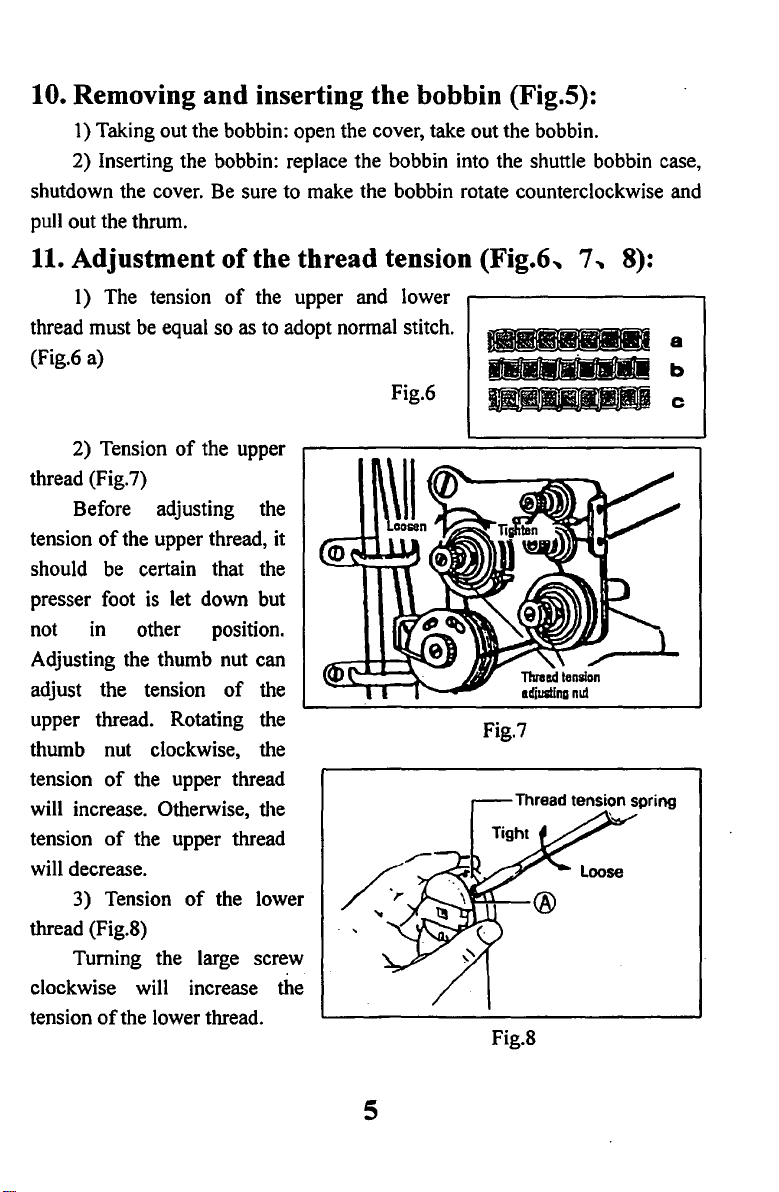

11.

Adjustment

1)

The tension

thread must be equal so as to adopt normal stitch.

(Fig.6 a)

of

the thread tension (Fig.6,

of

the upper and lower

:.

Fig.6

7,

8):

T]cJCJif:fOC!CJ-

a

b

c

2) Tension

thread (Fig.7)

Before adjusting the

tension

should be certain that the

presser foot

not in other position.

Adjusting the thumb nut can

adjust the tension

upper thread. Rotating the

thumb nut clockwise, the

tension

will increase. Otherwise, the

tension

will decrease.

thread (Fig.S)

clockwise will increase the

tension

of

of

of

3) Tension

Turning the large screw

of

of

the upper

the upper thread, it

is

let down but

of

the

the upper thread

the upper thread

of

the lower

the lower thread.

Fig.7

Fig.S

5

Page 7

Otherwise, the tension

of

the lower thread will decrease.

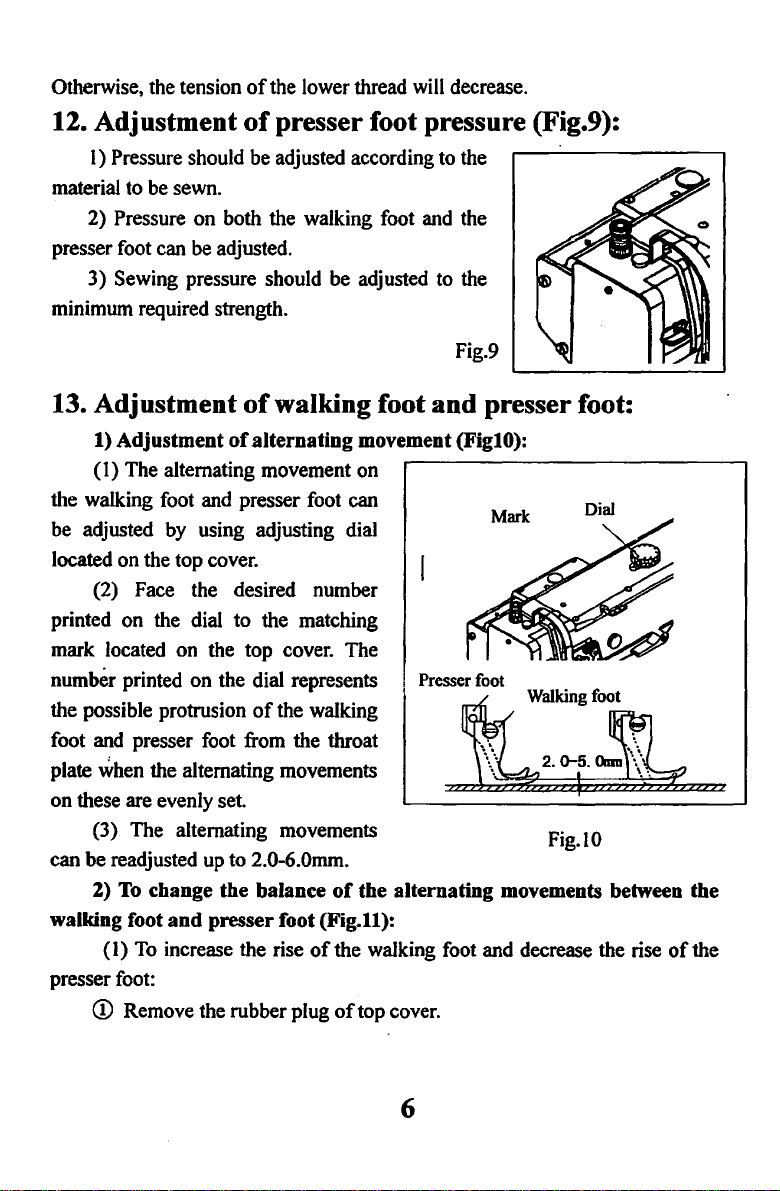

12. Adjustment

I)

Pressure should be adjusted according to the

material to be sewn.

2) Pressure on both the walking foot and the

presser foot can be adjusted.

3)

Sewing pressure should be adjusted to the

minimum required strength.

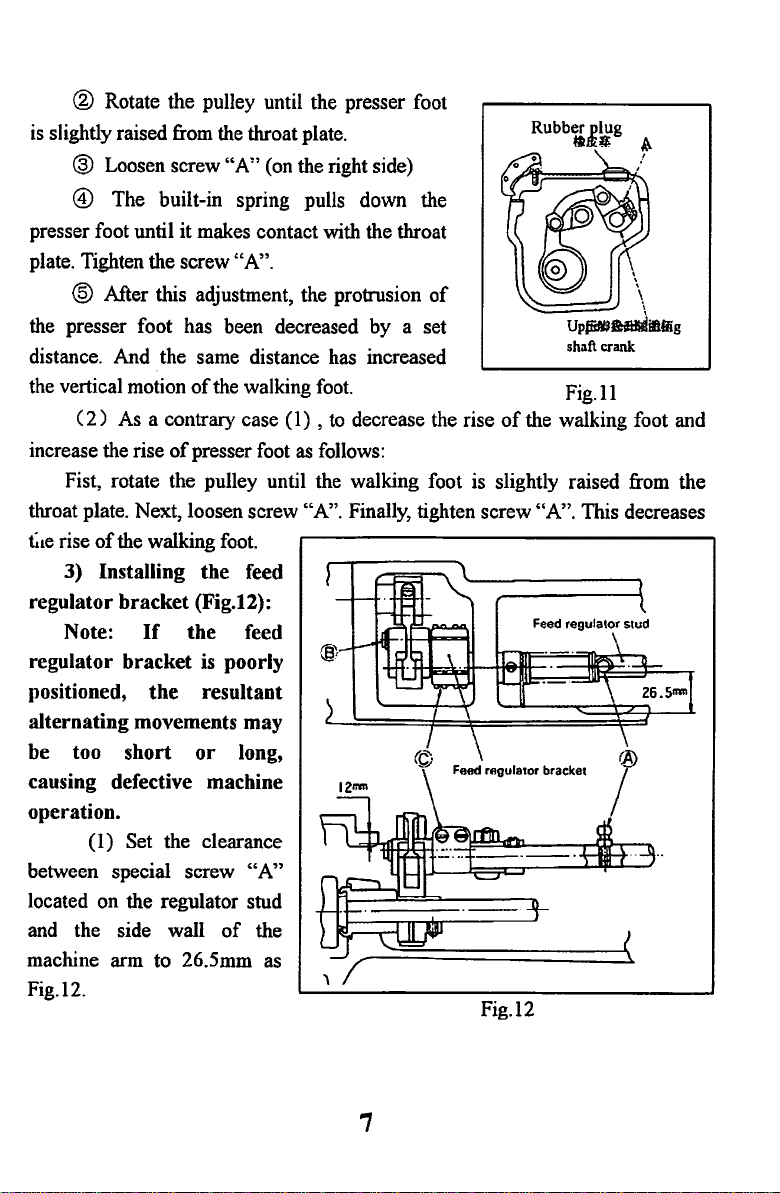

13. Adjustment

1) Adjustment

(I)

The alternating movement on

the walking foot and presser foot can

be adjusted by using adjusting dial

located on the top cover.

(2) Face the desired number

printed on the dial to the matching

mark located on the top cover. The

number printed on the dial represents

the possible protrusion

foot and presser foot from the throat

when the alternating movements

plate

on these are evenly set.

(3) The alternating movements

can be readjusted

2)

To

change the balance

walking foot and presser foot (Fig.ll ):

(I)

To

increase the rise

presser foot:

CD

Remove the rubber plug

of

presser foot pressure (Fig.9):

of

walking foot

of

alternating movement (FiglO):

of

the walking

up

to 2.0-6.0mm.

of

the alternating movements between the

of

the walking foot and decrease the rise

of

top cover.

Fig.9

and

presser foot:

...---------------.....,

Presser foot

~Walking

kto-5.~

Fig.IO

Dial

h

foot

of

?????

the

6

Page 8

® Rotate the pulley until the presser foot

is

slightly raised from the throat plate.

@ Loosen screw

"A"

(on the right side)

@ The built-in spring pulls down the

presser foot until it makes contact with the throat

plate. Tighten the screw

@ After this adjustment, the protrusion

the presser foot has been decreased by a set

distance. And the same distance has increased

the vertical motion

( 2 ) As a contrary case (1) ,

increase the rise

Fist, rotate the pulley until the walking foot is slightly raised from the

throat plate. Next, loosen screw "A". Finally, tighten screw "A". This decreases

Lte

rise

of

of

the walking

"A".

of

the walking

presser foot as follows:

foot.

foot.

to

decrease the rise

of

3) Installing the feed

regulator

regulator bracket

positioned,

Note:

bracket

If

the

(Fig.12):

the feed

is

poorly

resultant

alternating movements may

be too short

or

long,

causing defective machine

operation.

(1) Set the clearance

of

"A"

the

between special screw

located on the regulator stud

and the side wall

arm

machine

Fig.12.

to 26.5mm as

Rubber plug

•&I;

shaft crank

Fig.

II

of

the walking foot and

Fig.l2

t

7

Page 9

(2) With the feed regulator stud held as explained is step (1) above,

adjust the feed regulator bracket. This adjustment should insure a clearance

12mm between the periphery

and the top cover mounting face located on the arm. Tighten screw

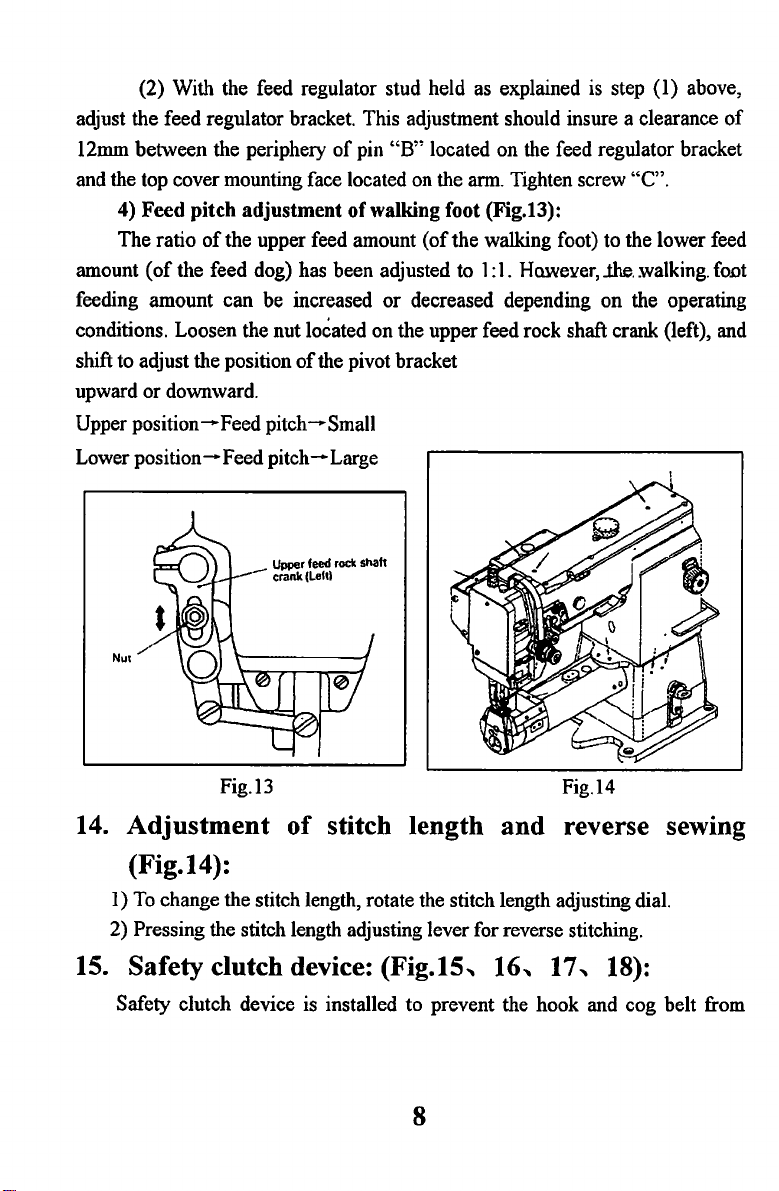

4)

Feed

pitch

adjustment

The ratio

amount

feeding amount can be increased

conditions. Loosen the nut located on the upper feed rock shaft crank (left), and

shift to adjust the position

upward

Upper

position-Feed

Lower

position-

of

the upper feed amount

(of

the feed dog) has been adjusted to 1 :1. Hawe¥er, lhe . .walking.

or

downward.

pitch-Small

Feed

pitch-

of

pin

"B"

of

walking foot (Fig.13):

or

of

the pivot bracket

Large

located on the feed regulator bracket

"C".

(of

the

walking foot) to the lower feed

decreased depending

on

the operating

of

fo.ot

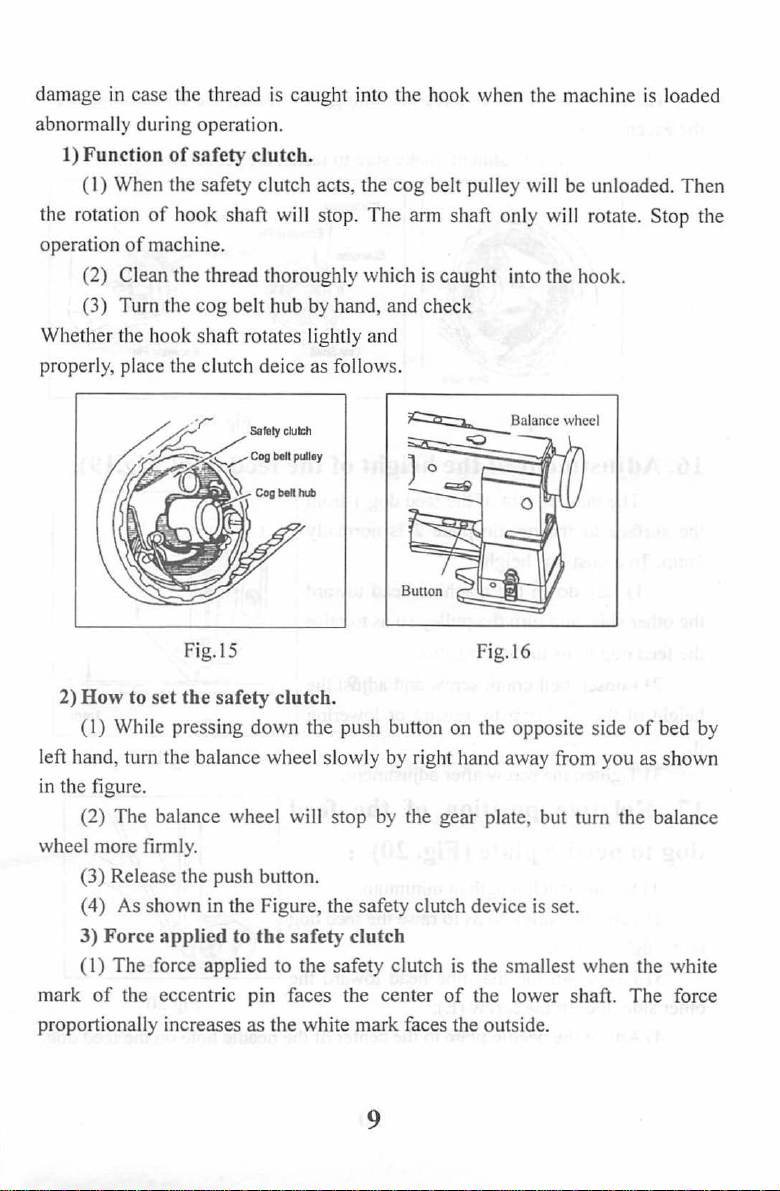

14.

Adjustment

Fig.l3

of

stitch length

and

Fig.l4

reverse sewing

(Fig.14):

I)

To

change the stitch length, rotate the stitch length adjusting dial.

2) Pressing the stitch length adjusting lever for reverse stitching.

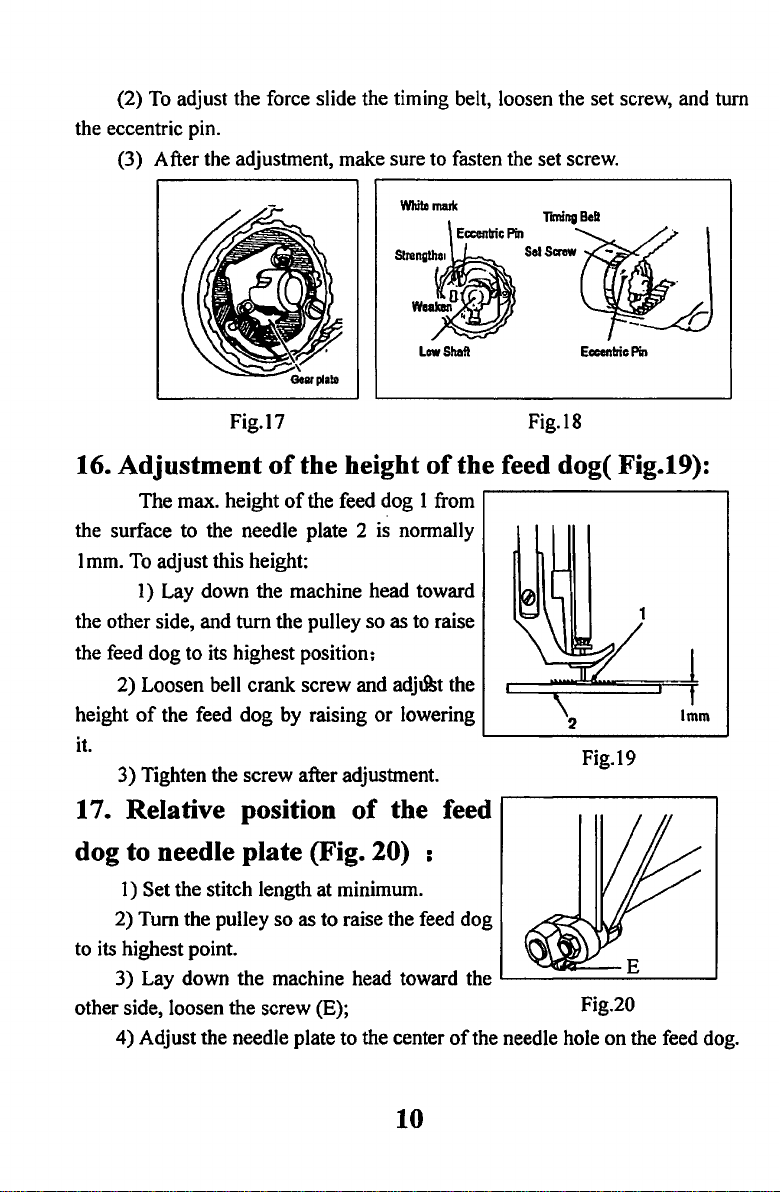

15. Safety clutch device: (Fig.15,

Safety clutch device is installed to prevent the hook and cog belt from

16, 17,

18):

8

Page 10

damage in case the thread is caught into the hook when the ma chine is loaded

abn

ormally durin g operation.

1) Function

(I)

the rotation

ope

ration

(2) Clean the thread thoroughly

(3) Turn the

Whether the hook shaft r

properly, place the clutch dei

of

safety clutch.

When the safety clutch acts, the

of hook

of

machine.

shaft wi

cog

belt hub by hand, and check

Fig.

IS

ll

stop.

which

otates lightly and

ce

as follows.

The arm

cog

belt pull

is

ey

will

shaft only wi

caug

ht into the hook.

Fig. l6

be

unloaded.

ll

rotate. Stop the

Then

2) How to

( I) While pressing down

left hand, turn the balance wh

fi

in the

(2)

wheel more firml

(3)

(4) As shown in the Figu re, the safety clutch device is set.

3) Force applied to

(I)

mark

proportiona

set

the

safety clutch.

the

push button on the opposite side

ee

l slowly by right hand away from you as shown

gure.

The balance wheel will stop by

y.

Relea

se

the push button.

the

safety clutch

The

force

applied

of

the eccentric pin faces th e center

ll

y increases

to the safety clutch is the smallest

as

the white mark faces the outsid

the

gear plate, but

of

the

tum

when

lower shaft.

e.

of

bed by

the

balance

the white

The

force

9

Page 11

(2) To adjust

the eccentric pin.

(3) After the adjustment, make sure to fasten the set screw.

the

force slide the timing belt, loosen the set screw, and turn

Low

Shaft

Eccentric

Pin

Fig.17 Fig.

16. Adjustment

The

max. height

the surface

to

the needle plate 2 is normally

of

the height

of

the feed

I mm. To adjust this height:

I)

Lay

down

the machine head toward

tum

the

the other side, and

the feed

height

it.

dog

to

its highest position;

2)

Loosen bell

of

the

feed

3)

Tighten the screw after adjustment.

crank

dog

pulley

screw and

by

raising

17. Relative position

dog to needle plate (Fig.

I)

Set the stitch length at minimum.

2)

Tum

the

pulley

so

as

to

raise the feed

to

its highest point.

3)

Lay

down

the machine head toward the

other side, loosen

4)

Adjust the needle plate

the

screw (E); Fig.20

to

dog

so

as to raise

adj&t

or

lowering

of

the feed

20) :

the center

IS

of

the feed dog( Fig.19):

1 from

the

2

Fig.I9

dog

L-----------'

of

the needle hole

on

the feed dog.

10

Page 12

5) Tighten the screw.

18.

Adjustment

When

the needle bar

position, normally the measurement between

the surface

end

adjust this at its lowest position.

normally the measurement between the

surface

of

the needle eye is

loosen screw (B.fig.3), and raise or lower

the needle bars may be required. Then

tighten the screw.

19.

1)

lifting cam are illustrated to Fig.22

2)

position.

(3) The eccentric feed cam can also be adjusted by removing the rubber

plug located on the top cover. In the latter case, however, the built-in bevel gear

is when adjusting.

of

the needle plate and the upper

of

the needle eye

of

the needle plate and the upper end

Adjustment

The standard position

Open the top cover, properly slide the eccentric ring to adjust the

of

the height

is

at

is

22.3mm.

11

mm.

To

of

feed

of

of

the needle

its

highest

You

can

In

this case,

adjust this,

timing

the eccentric feed cam and eccentric feed

(Fig.22):

c:::=:::~~===--,_j_

bar

Fig.21

(Fig.21):

22.lmtn

1

st

screw Upper shaft

Upper eccentric feed

lifting cam

Fig.22

Eccentric

feed cam

11

Page 13

A,

ARM

11

..::::::::--

BED

• •

AND

2

IT'S

ACCESSORIES

89

90

Page 14

A,

ARM

BED

AND

IT'S

ACCESSORIES

No.

AOI

A02

A03

A04

A05

A06

A07

AOB

A09

AIO

All

AI2

AI3

AI4

Al5

AI6

AI7

AlB

AI9

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

Ref.

No.

H5301001

H5301002

H5301003

H5301004

H5301005

H5301006

H530I007

H5301008

H5301009

H530IOIO

H5301011

H5301012

H5301013

H530I014

H5301015

H5301016

H5301017

H5301018

H5301019

H5301020

H5301021

H5301022

H5301023

H5301024

H5301025

H5301026

H5301027

H5301028

H5301029

H5301030

H5301031

H5301032

H5301033

H5301034

H5301035

H5301036

Description

Screw

Arm

side

cover 1

Rubber

plug

Screw

Set screw 2

Screw

Spring 1

Pin 1

Dial

for

upper feed

Oil guard

Face

plate

Rubber

plug

Thread take-up cover

Screw

Three hole thread guide I

Upper

feed

lifting

Oil

box

Screw

Top

cover

Screw

Screw

Slide

block

Face

plate

screw 2

Screw

Thread guide I

Thread guide

Screw I

Screw 1

Thread guide I

needle guide

Needle

plate

Set screw 2

Stop

plate

Screw

Bushing 1

Screw 3

plate

lifting

regulator

(right)

cam

Pes.

3

2

6

I

I

I

I

4

I

I

I

I

3

I

2

2

I

I

I

I

1

1

2

Page 15

A,

ARM

BED

AND

IT'S

ACCESSORIES

No.

A37

A38

A39

A40

A41

A42

A43

A44

A4S

A46

A47

A48

A49

ASO

A51

A52

AS3

AS4

ASS

AS6

AS7

A

58

AS9

A60

A61

A62

A63

A64

A65

A66

A67

A68

A69

A70

A71

A72

Ref.

No.

H5301037

H5301038

H5301039

H5301040

H5301041

H5301042

H5301043

HS301044

HS30104S

H5301046

H5301047

H5301048

HS301049

HS3010SO

HS301051

HS301052

HS301053

HS3010S4

H53010SS

H5301056

H5301057

H5301058

H5301059

HS301060

H5301061

H5301062

H5301063

H5301064

H5301065

H5301066

H5301067

HS301068

H5301069

H5301070

H5301071

HS301072

Description

Set screw

Hinge screw

Arm

bed hinge

Slide

plate

needle guide

Oil guard

Oil guard

Screw

Screw

Tension

Tension

Stopper

Screw

Thread take-up

Lever

Screw

Stop

Screw

Thread

Screw

Screw

Plate

Plate

Plate

Screw

Stopper

Screw 1

Thumb

Take-up

Thread

Bush

'screw

Mounting

Nut

Mounting

Pin

plate

plate

releasing

releasing

ring

tension

complete 1

complete

nut 1

spring

tension

plate

plate

plate

block

spring

stud

guard

post

(left)

plate

spring

Pes.

4

8

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

2

1

2

Page 16

A,

ARM

BED

AND

IT'S

ACCESSORIES

No.

A73

A74

A75

A76

A77

A78

A79

ABO

A81

A82

A83

A84

ASS

A86

A87

ASS

i\89

A90

A91

A92

A93

A94

A95

No.

Ref.

H5301073

H5301074

H5301075

H5301076

H5301077

H5301078

H5301079

H5301080

H5301081

H5301082

H5301083

H5301084

H5301085

H5301086

H5301087

H5301088

H5301089

H5301090

H5301091

H5301092

H5301093

H5301094

H5301095

Description

Thread tension

Pin

Spring

Push

button

Thread tension

Thread tension

Spring

Thumb

nut complete

Thumb

nut

Thread tension

Thread tension

Spring 1

Thumb

nut

Thread guide

Screw

Thread

releasing

Arm

Arm

bed

Supporter

Screw

Screw

Washer

Link

plate

stud

disc

releasing

revolution

stud

disc

pin

disc

stopper 1

Pes.

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

Page 17

Page 18

B,

ARM

SHAFT

MECHANISM

No.

B01

B03

B04

B05

B06

B07

BOB

B09

B10

Bll

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

832

B33

B35

B36

B37

B38

No.

Ref.

H5302001

H5302002

H5302003

H5302004

H5302005

H5302006

H5302007

H5302008

H5302009

H5302010

H5302011

H5302012

H5302013

H5302014

H5302015

H5302016

H5302017

H5302018

H5302019

H5302020

H5302021

H5302022

H5302023

H5302024

H5302025

H5302026

H5302027

H5302028

H5302029

H5302030

H5302031

H5302032

H5302033

H5302034

H5302035

H5302036

Description

Pin

Oil wick

Screw

Needle

bar

crank

Screw

Screw

Screw

Felt

F~lt

ring

(left)

for

upper feed

(right)

Arm

shaft

bushing

Screw

Screw

Feed

Screw

Oil guard

Feed

Balance

Screw

Felt

Arm

Screw

Arm

Feed

Screw

Holder

Felt

Stop

Connecting rod

Pulley (upper)

Screw 1

Spring

Screw

Arm

Arm

Screw

Balance wheel

(left)

cam

plate

cam

crank 1

wheel

shaft

bushing (middle)

shaft

collar

(right)

cam

ring

stop

shaft

bushing

shaft

Pes.

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

2

1

1

2

1

1

1

1

1

2

1

1

1

2

1

Page 19

B...

ARM

SHAFT

MECHANISM

No.

839

840

841

842

843

844

845

846

Ref.

No.

H5302037

H5302038

H5302039

H5302040

H5302041

H5302042

H5302043

H5302044

Description

Cog

belt

Oil wick

Set screw

Pin 1

Thread take-up

Thread take-up

Oi

1 wick

Needle bar connecting

lever

link

link

Pes.

1

1

1

1

1

1

1

Page 20

Page 21

C,

ROTATING

HOOK

SHAFT

MECHANISM

No.

COl

C02

C03

C04

cos

C06

C07

cos

C09

C10

Cll

C12

C13

C14

CIS

CI6

Cl7

CIS

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

Ref.

No.

H5303001

H5303002

H5303003

H5303004

H5303005

H5303006

H5303007

H5303008

H5303009

H5303010

H5303011

H5303012

H5303013

H53030I4

H5303015

H53030I6 Lever

H5303017

H53030I8

H5303019

H5303020

H5303021

H5303022

H5303023

H5303024

H5303025

H5303026

H5303027

H5303028

H5303029

H5303030

H5303031

H5303032

H5303033

H5303034

H5303035

H5303036

Guide

Guide

Guide

Screw

Bushing

Washer

Felt

Screw

Oil wick

Rotating

Bushing

Bevel gear for

Stop

Pulley 1

Screw

Pin I

Long

Short

Pin 1

Pin

Screw

Shaft

Spring

E-type stop

Screw

Bevel gear

Set

Oil wick

Rotating

Screw

Rotating

Set

Recessed

Safe

Safe

plate

plate

plate

ring

for

lever

lever

for

for

screw

screw

clutch

clutch

pin

slide

hook

pulley

for

for

pulley

pulley

ring

for

hook

hook

wheel

shaft

spring

Description

block

bracket

hook

shaft

pulley

pulley

hook

shaft

shaft

bushing

shaft

collar

pin 1

(left)

Pes.

1

1

1

1

1

2

1

2

1

I

1

I

1

2

1

1

1

I

1

1

1

1

1

1

3

1

2

1

2

1

1

Page 22

C,

ROTATING

HOOK

SHAFT

MECHANISM

No.

C37

C38

C39

C40

C41

Ref.

No.

H5303037

H5303038

H5303039

H5303040

H5303041

Safe

clutch

Safe

clutch

Rotating

Oil wick

Rotating

shaft

bushing

hook

hook

Description

shaft

shaft

bushing

(right)

Pes.

1

1

1

1

Page 23

15

~

J

"'%2

~

~

~

"'%2

~

~

t""4

1---4

~

1---4

~

I

1---4

(/l

Is::

Page 24

D,

No.

DOl

D02

D03

D04

DOS

D06

D07

DOS

D09

DID

Dll

D12

D13

D14

D15

D16

D17

DIS

D19

D20

D21

FEED

Ref.

H5304001

H5304002

H5304003

H5304004

H5304005

H5304006

H5304007

H530400S

H5304009

H5304010

H5304011

H5304012

H5304013

H5304014

H5304015

H5304016

H5304017

H530401S

H5304019

H5304020

H5304021

AND

No.

FEED

LIFTING

Feed

dog

Connecting screw

Feed rock

Set

screw

Feed

eccentric

Screw

Screw 2

Screw

Guide

plate

Guide

plate

Feed rock

Screw

Pin 1

Link

Nut

Feed rock

Feed rock

Collar

for

Set

screw

Feed rock

Set screw

MECHANISM

Description

for

feed

lifting

shaft

shaft

shaft

shaft

shaft

(left)

(right)

crank

bushing

feed rock

bushing

shaft

dog

crank 1

(left)

(right)

Pes.

1

1

2

1

2

2

1

1

1

1

1

2

1

1

1

2

1

2

Page 25

2

33

6 --.s-

~

\

7

36

28

35

t%2

~

~

~

~

~

~

~

1-1

~

~

n

~

1-1

rJl

a::

Page 26

E,

NEEDLE

BAR

FEEDING

MECHANISM

No.

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

Ell

E12

E13

E14

E15

E16

E17

El8

El9

E20

E21

E22

E23

E24

E25

E26

E27

E28

E29

E30

E31

E32

E33

E34

E35

E36

-

Ref.

No.

H5305001

H5305002

H5305003

H5305004

H5305005

H5305006

H5305007

H5305008

H5305009

H5305010

H5305011

H5305012

H5305013

H5305014

H5305015

H5305016

H53050.17

H5305018

H5305019

H5305020

H5305021

H5305022

H5305023

H5305024

H5305025

H5305026

H5305027

H5305028

H5305029

H5305030

H5305031

H5305032

H5305033

H5305034

H5305035

H5305036

Description

Needle bar rock

Needle bar rock

Needle bar rock

Washer

Pin

Felt

clip

Felt

Needle bar rock frame 1

Bracket

Screw

Needle bar 1

Oil wick

Slide

block I

Needle bar connecting

Screw

Screw

Screw

Thread guide

Spring guide bar complete

Spring 1

Presser

Presser

Screw

Presser

Slide

Guide

Screw

Bushing

Cam

Upper

Spring

Set screw 2

Collar

Set screw

Lifting

Screw

bar

bar 1

foot

block 1

for

for

follower 1

feed

rock

shaft

shaft

shaft

for

connecting

slide

block

upper feed

regulator

shaft

bushing

bushing

stud

needle

shaft

bracket

(right)

(left)

bar

link

shaft

Pes.

1

1

1

1

1

I

1

1

2

1

I

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

4

Page 27

E,

NEEDLE

BAR

FEEDING

MECHANISM

No.

E37

E38

E39

E40

E41

E42

E43

E44

E45

E46

E47

E48

E49

E50

E51

E52

E53

E54

E55

E56

E57

E58

Ref.

No.

H5305037

H5305038

H5305039

H5305040

H5305041

H5305042

H5305043

H5305044

H5305045

H5305046

H5305047

H5305048

H5305049

H5305050

H5305051

H5305052

H5305053

H5305054

H5305055

H5305056

H5305057

H5305058

Description

for

Shaft

Stop

Screw

Link 1

Set screw

Pin

Oil wick 1

Crank

Pin 1

Oil wick

Oil wick 1

Bushing

Set screw

Bushing

Lifting

Bell crank

Link

Screw

Screw

Bell

Bell crank guide bracket block

Lifting

ring

for

lifting

for

for

rock

for

feed

crank guide pin

lifting

lifting

shaft

lifting

rock

rock

rock

rock

shaft

shaft

rock

shaft

shaft

shaft

bracket

bracket

(right)

(left)

Pes.

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

Page 28

F,

PRESSER

1-~2

FOOT

MECHANISM

5

11

30

27

21

29

38

20~

_l

,

....

37

Page 29

F,

PRESSER

FOOT

MECHANISM

No.

F01

F02

F03

F04

F05

F06

F07

FOB

F09

FlO

Fll

F12

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F32

F33

F34

F35

F36

Ref.

No.

H5306001

H5306002

H5306003

H5306004

H5306005

H5306006

H5306007

H5306008

H5306009

H5306010

H5306011

H5306012

H5306013

H5306014

H5306015

H5306016

H5306017

H5306018

H5306019

H5306020

H5306021

H5306022

H5306023

H5306024

H5306025

H5306026

H5306027

H5306028

H5306029

H5306030

H5306031

H5306032

H5306033

H5306034

H5306035

H5306036

Description

Nut

Thumb

screw

Presser

Presser

Screw

Presser

Set

Bushing

Screw

Walking

Presser

Set

Spring

Presser

Presser

Set

Collar

Set

Tension

Screw

Seal

Screw

Screw

Knee

Pin 1

Knee

Pin

Spring 1

Knee

Screw

Guide block

Stop.

Knee

Screw

Knee

Knee

bar

bar

guide

bracket

bar

spring

screw

for

presser

foot

bar

lifter

screw

lifting

bar

lifting

bar

screw 1

screw

releasing

1

ifter

rod 1

lever

lifter

lifter

connecting rod 1

ring

lifter

connecting rod

lifter

connecting rod

lifter

connecting rod

cam

bar

shaft

cam

shaft

crank 1

shaft

crank 1

shaft

Pes.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

4

2

3

2

1

1

1

1

2

2

1

Page 30

F,

PRESSER

FOOT

MECHANISM

No.

F37

F38

No.

Ref.

H5306037

H5306038

Mounting

Screw

plate

Description

Pes.

1

2

Page 31

19

18

-

L/25

20

Page 32

G,

STITCH

LENGTH

REGULATING

MECHANISM

No.

G01

G02

G03

G04

G05

G06

G07

GOB

G09

GlO

Gll

G12

G13

G14

G15

G16

G17

GIS

Gl9

G20

G21

G22

G23

G24

G26

G26

G27

G28

G29

G30

G31

G32

G33

G34

G36

G36

Ref.

No.

H5307001

H530700~

H5307003

H5307004

H5307005

H5307006

H5307007

H5307008

H5307009

H5307010

H5307011

H5307012

H5307013

H5307014

H5307015

H5307016

H6307017

H6307018

H5307019

H5307020

H5307021

H6307022

H5307023

H6307024

H5307025

H6307026

H5307027

H6307028

H5307029

H5307030

H5307031

H6307032

H5307033

H5307034

H5307035

H5307036

Description

Screw

Bushing

Plate

for

stitch

length

Dial

Stopper

Spring

Stopper

Coil

Screw bar

Seal

Feed

Set

Pin 1

Screw 1

Washer

Feed

Feed

Set

Screw 1

Spring 1

Screw 1

Washer

Spring

Screw

Screw 1

Screw

Feed

Set screw

Feed

Link

Screw

Reverse block

Screw

Nut

Screw

Link

pin

releasing

for

stopper pin

pin

spring

regulator

screw 1

reversing

reversing

screw 2

retainer

reversing

reversing

for

reversing

shaft

crank

lever

lever

lever

lever

lever

shaft

shaft

shaft

block

crank

crank 1

link

shaft

crank

Pes.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Page 33

No.

G37

G38

G39

G40

G41

G42

G43

G44

G45

G46

G47

G48

G49

G50

G51

G52

G53

G54

G55

G56

Ref.

No.

H5307037

H5307038

H5307039

H5307040

H5307041

H5307042

H5307043

H5307044

H5307045

H5307046

H5307047

H5307048

H5307049

H5307050

H5307051

H5307052

H5307053

H5307054

H5307055

H5307056

Description

Pes.

Nut

Link

Screw 2

Crank

Screw 1

Screw

Crank

shaft

Link

for

reversing

block

slide

block

Set screw 2

Shaft

for

reversing

block

slide

block 1

Oil wick

Slide

block

Reverse block

Bushing

Set

screw

for

shaft

reverse

block

shaft

Reverse block

Reverse block

shaft

Set screw 1

Screw

Set

screw

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

Page 34

B,

ACCESSORIES

j

T

2 3

@--s

~-

6

~-7

~-8

fl"'-

--11

~18

19/

10

~15

16

0~

. \ 21

20

-9

Page 35

H....

ACCESSORIES

No.

H06

H08

H09

mo

811

812

813

ms 85308015

B16

ID7

ms

819

H20

1121

Ref.

No.

HOI

H02

H03

H04

H05

H07

W4 85308014 Washer 4

115308001

85308002

85308003

85308004 Bobbin winder

115308005

85308006 Supporter

115308007

85308008 Bobbin 1

85308009

85308010 Screw 4

85308011

85308012

115308013

115308016

115308017

115308018

115308019

115308020

115308021

Oiler

Wood

screw

Nail

Washer

Needle 1

Thread

stand

Nut

Knee

1 i

fter

Screw 2

Knee

I i

fter

Knee

I i

fter

Screw

driver

Screw

driver

Knee

I i

fter

Knee

I i

fter

Screw 1

Description

assay

assay

driving

shaft

bracket

cover 1

plate

crank

(larger)

(aiddle)

Pes.

1

4

15

1

2

1

1

4

1

1

1

1

1

1

Page 36

SHANGHAI HUIGONG SEWING MACHINE

ADD:

1418,

Zip

Code:

TEL:

(021)64061284

FAX:

(021)64853208

Yishan

201103

Road,

Shanghai, China

64852138

N0.3

FACTORY

Loading...

Loading...